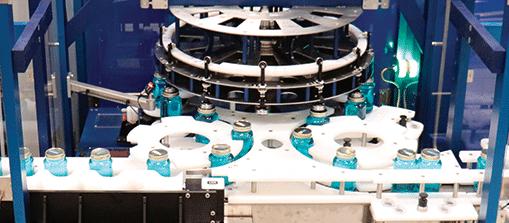

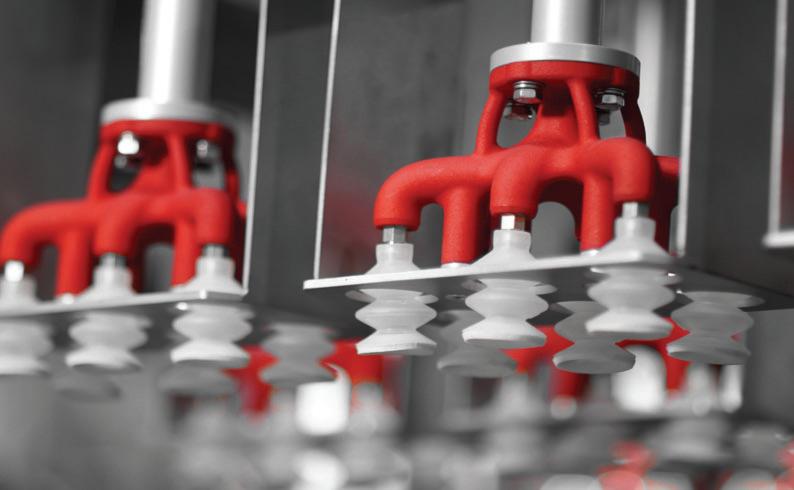

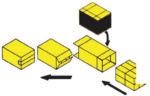

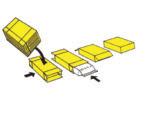

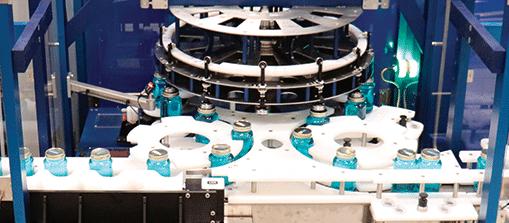

ProMach Pharma runs integrated line at show

ProMach Pharma Solutions (Booth W-17002) showcases its integration capabilities with a turnkey packaging line—from vial and syringe lling to case packing. e line, located in the Healthcare Packaging Pavilion, integrates equipment from ProMach Pharma brands—NJM, Pharmaworks, Serpa and WLS—plus systems from partners and third-party OEMs. A schedule of demonstration times is posted daily. SD

Welcome to PACK EXPO International 2022!

Industry connections abound at rst-time and familiar events. Emerging Brands Summit and Industry Speaks Stage debut.

Iwould like to be the rst to welcome you to Chicago . . . to McCormick Place . . . and to PACK EXPO International, the most comprehensive packaging and processing show in the world in 2022.

Styx plays at PACK gives BACK fundraiser

Doors open at 4:30 p.m. tomorrow (Monday, Oct. 24) for a networking reception prior to the PACK gives BACK concert by Styx, which begins at 5:30 p.m. in the West Ballroom, Level 3. Tickets can be purchased by logging into your PACK EXPO registration record. Tickets cost $95 each. Purchase nine tickets, and the 10th is free. All proceeds support the PMMI Foundation and its scholarship programs. SD

Print color labels on-demand

ColorWorks® printers from Epson America (Booth EB-71, N-5265, N-5363) deliver full-color labels at an a ordable price and help reduce label costs with lower inventories, less waste and increased operational e ciencies. Epson technologies connect people, things and information. SD

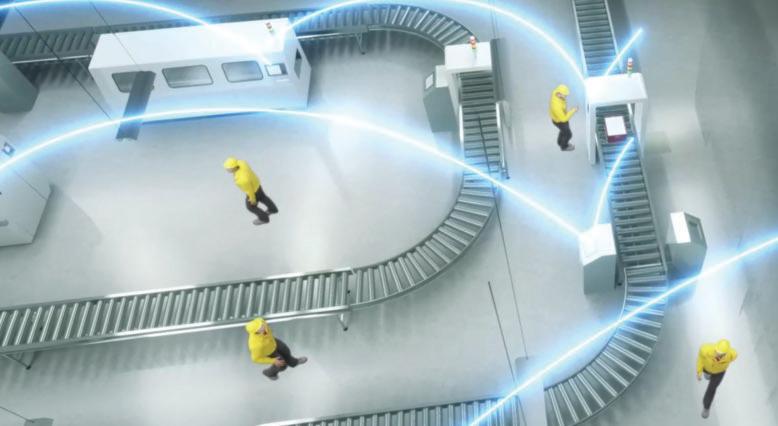

groninger expands

groninger (Booth W-18001) expands its Crailsheim, Germany, facilities with a new storage and logistics center, including a fully automated small parts and high-bay warehouse. e expandable high-bay warehouse provides 3,100 storage spaces, while the small-parts area was designed for 13,000 containers. SD

With it being four years since the last in-person PACK EXPO International, there is a lot of pent-up energy for this year’s event. As a result, the schedule is packed with new features as well as attendee favorites to help you forge the essential connections needed to advance your business and move the industry forward.

Emerging Brands Summit opens

The brand-new Emerging Brands Summit (Room S-100), produced by PMMI Media Group (Booth N-4550), takes place today.

e one-day event, sponsored by Frain Industries (Booth EB-35, S-1639), WestRock (Booth EB-43, S-2130, ),Domino Amjet (Booth EB-51, S-3506), Atlantic Packaging (Booth EB-37) and Syntegon Packaging Technology (Booth EB-15, S-3514), is designed for founders and leaders of startup manufacturing companies.

e schedule opens with breakfast and concludes with a reception. Event content is specifically designed for:

• Companies evaluating in-house and outsourced manufacturing and packaging solutions

As the show oor opens, the rst Emerging Brands Summit (Room S-100) brings together new brands with experts in manufacturing and packaging.

Aimed at founders and leaders of startups looking to scale production through in-house buildout or outsourced relationships with contract manufacturers and packagers, this new one-day event is happening today (see story below)

Other rsts for this edition of PACK EXPO International include the Healthcare Packaging Pavilion in the West Hall, the PACK to the Future Exhibit (Booth

PACK to the Future

Exhibit looks back and forward.

After a well-received introduction last year at PACK EXPO Las Vegas, the interactive PACK to the Future Exhibit (Booth W-20001) retains the curated historical display showing the evolution of packaging and packaging machines and explores key trends shaping the future in presentations on the PACK to the Future Stage (Booth W-20025) (see story, p. 22).

Topics include accelerating product development, advanced recycling, achieving net zero and a Circular Economy, increasing reusability and reducing waste.

NEWS BRIEF INDUSTRY SPEAKS P.14 | PACK TO THE FUTURE P.22 | INNOVATION STAGE P.28 | FORUM P.44

Come and see us in South Hall, Booth #3514 Syntegon_Corner_ad_ShowDaily_Chicago_2022.indd 1 SHOW DAILY SUNDAY, OCTOBER 23, 2022

(Continued on

page 4) (Continued on page 4)

Jim Pittas, president and CEO, PMMI.

SMT W packexpolasvegas.com join us for the next show DOWNLOAD THE MOBILE APP Scan to get the app: Search Access Your My Show Planner Navigate Get news Vote in the 2022 Technology Excellence Awards Sponsored by: Booth N-5534 Booth LU-8901 Sponsored by: Complimentary Wi-FI throughout McCormick Place (Continued on page 8)

.

This system WILL dramatically reduce operator touch-time, WILL speed up changeovers beyond your wildest dreams, and WILL eliminate costly downtime on your labeler. Our simple fix to your complex problems.

Nita is the original 100% Servo Labeler that WILL change your production universe forever.

www.NitaLabeling.com | sales@nita.ca | 1.855.668.NITA (6482) COME MEET YOUR NEW SUPER-EFFICIENT “EMPLOYEE” IN BOOTH S-3666. WE KNOW YOU WILL HIT IT OFF RIGHT AWAY.

MEET

YOUR NEW “BEST LABELER OPERATOR EVER” YES, THAT IS CORRECT. WE BUILT YOU A SKILLED WORKER RIGHT INTO THE LABELER . Introducing the ALL-NEW Nita Sentient Labeling Machine with ULTRA-PRECISE FULLY AUTOMATIC CHANGEOVERS.

THAT’S MORE LIKE IT.

the choice is yours,

not choose more? A leading provider of primary, secondary, and end-of-line

machines, Paxiom has more than 30 years of industry expertise. Operating from eight global facilities, with a passionate and focused staff of professionals, we also have a strong national service presence, the ability to provide systems integration, and an installed base that includes more than 7,000 machines across the world.

Get more.

When

why

packaging

Paxiom.

Visit us at Booth S-2153

Scan for the Paxiom Xperience™ Center virtual tour.

1.833.4PAXIOM | info@paxiom.com paxiom.com LAS VEGAS | MONTREAL | MIAMI | TORONTO | MILWAUKEE | SCHIO, ITALY WeighingPre-roll Filling BaggingWrappingCappingSealingLabelingCartoningFormingPackingPalletizing

PPWLN hosts breakfast

Dawn Hudson, former chief marketing o cer at the National Football League and CEO of Pepsi Cola North America, keynotes the Packaging & Processing Women’s Leadership Network (PPWLN) breakfast, 7:30–9:00 a.m. on Tuesday, Oct. 25, in Room S-100. e event is free to show attendees, but you must pre-register. SD ITP celebrates 50 years

Building on 50 years in the food sector, ITP (Booth W-21027) is focusing on experimentation, applied research and sustainability. A new production plant for fully recyclable packaging is slated for 2025. SD

Closing the gap

SpiralConnect unit, an option on most SpiralVeyors from AmbaFlex (Booth N-4941), can extend both infeed and outfeed tracks to the next machine in the line. is eliminates the need for transfers when a line upgrade causes a gap between conveyors. e exible nature of the slat technology allows belt length to be stretched in any three-dimensional direction for many meters. SD

Multi-lane augers adjust

Multiple spindle auger systems from All-Fill (Booth S-1706) dispense product across three to 12+ lanes on ll/seal, form/ ll/seal and strip/pouch machines. Servo drives enable independent adjustment of each auger. Mounting con gurations include baseplate, cantilever or overhead gantry. SD

Choose TEA winners

Vote now for your favorite nalists in the 2022 Technology Excellence Award (TEA) competition (see story, p. 54). Winners will be announced Tuesday afternoon (Oct. 25). Vote onsite at the Attendee Solutions Center in the North Hall Concourse or Lakeside Upper Hall Lobby; via the PACK EXPO International mobile App, sponsored by ProMach (Booth N-5534, N-5540); or online. SD

Protect from cyberattack

Automation hardware and software needs protection from cyberattack. A white paper from Siemens Digital Industries US (Booth N-5148), Cybersecurity for Automation Systems, describes the integration of protective techniques in new and aging automation infrastructures. SD

Hall of Fame welcomes 4

e late Jean-Jacques Gra n, Rebecca Oesterle, Pierre Pienaar and E. Je rey Rhodehamel, PhD, will be inducted into the Packaging & Processing Hall of Fame at 3:30 p.m. tomorrow (Monday, Oct. 24) in a ceremony at the Industry Speaks Stage (Booth N-4565) SD

( Welcome Continued from page 1) W-20001) and its PACK to the Future Stage (Booth W-20025) (see story, p. 1, p. 22), and the Industry Speaks Stage (Booth N-4565),where experts from PMMI Partner Associations present educational sessions on hot-button topics (see schedule, p. 14) e popular Innovation Stage (Booth N-4560, N-4580, N-4585) (see schedule, p. 28) returns and is joined by the Processing Innovation Stage (Booth LU-7130) on the upper level of Lakeside Center. is year, PACK EXPO’s annual bene t concert, PACK gives BACK, features the multi-mega million-selling rock band, Styx. A pre-show reception with refreshments and appetizers starts at 4:30 p.m. tomorrow (Monday, Oct. 24), followed by the performance at 5:30 p.m. Proceeds bene t the PMMI Foundation, which provides funds for scholarships and other educational programs.

PMMI is committed to providing educational and networking opportunities for students. It also nurtures young packaging professionals via its Emerging Leaders Network. Student events include

the new PACK Challenge (Booth W-17000), a machine-building competition sponsored by PepsiCo, as well as past favorites such as the Amazing Packaging Race, Future Innovators - Robotics Showcase (Booth W-21028) and CareerLink LIVE.

At 7:30 a.m. on Tuesday, Oct. 25, the Packaging & Processing Women’s Leadership Network will host its annual breakfast with keynote speaker Dawn Hudson, former chief marketing o cer at the National Football League, and CEO of Pepsi Cola North America.

As you visit the 2,000+ exhibitors spread across 1.2 million net sq. ft. of oor space, don’t miss the awarding-winning packages in the Showcase of Packaging Innovations® (Booth W-20052), sponsored by WestRock (Booth EB-43, S-2130), and make sure to cast your votes in the Technology Excellence Awards competition (see story, p. 54)

Enjoy the show!

Jim Pittas President and CEO, PMMI SD

Highlights of the PACK to the Future Exhibit include machines dating from the 1890s to the 1990s.

New this year is an interactive display of past, present and future sustainability e orts. Its centerpiece is a Corrugated Car of the Future Virtual Reality (VR) Experience, sponsored by e Paper and Packaging Board. To participate in the time-traveling sportscar experience, attendees sit in the futuristic replica and use a VR headset to learn about sustainable packaging and the industry’s Box to Nature program, an initiative to educate consumers about the importance of recycling corrugated materials and boxes.

Other highlights include an area dedicated to women in packaging and processing, an interactive audio tour revealing interesting facts and historical details and fun quizzes that test attendees’ knowledge of the industry.

is area of the show oor also features the Showcase of Packaging Innovations® (Booth W-20052), sponsored by WestRock (Booth EB-43, S-2130) (see story, p. 26), and the Future Innovators - Robotics Showcase (Booth W-21028), where teams from local high schools demonstrate their robots and answer questions about their work.

For more info, visit www.PACKEXPOinternational.com. SD

Students show o robots

Robotic teams represent area high schools.

Students from several Chicago-area high schools are visiting PACK EXPO International this week.

e high-school robotics teams are displaying their creations along with their design, engineering, assembly and troubleshooting skills at e Future Innovators - Robotics Showcase (Booth W-21028)

Demos are scheduled throughout the day, each

day of the show. Stop by to see what these teams have built, watch their robot in action, ask questions and tell them about career opportunities in manufacturing and engineering.

e event is designed to encourage participation in STEM studies and activities and open doors for a new generation of packaging professionals.

For more info, visit www.PACKEXPOinternational.com. SD

NEWS BRIEF PACK EXPO International 2022 SHOW DAILY OCTOBER 23, 2022 4

NEWS BRIEF

(PACK to the Future Continued from page 1)

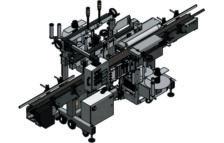

The Model 86MLX Pony Label Rite® labeler (shown in a 33% scale model) from NJM Packaging (Booth W-17002, N-5650) applied a microfine coating

of adhesive

to

the

label

and precisely applied it. The thin coating prevented glue from oozing around the sides of the label and eliminated the need to manually inspect the finished product. The full-size machine featured a one-piece, cast-iron frame, measured 41 in. long by 30 in. deep and weighed 975 lb. The original selling price was $500. Source: NJM Packaging

New Solutions VF 1200 Continuous Motion Bagger Up to 180 / minute Hygienic model on display Accurate to 0.01g WeightCheQ 0-250 High Precision Check Weigher PKR Delta Robot Case & Tray Packer BI 600 + BU 600 Bag Inserter & Bag Uncuffer System 1g 1.833.4PAXIOM PaxiomGroup PaxiomXperience Learn more at paxiom.com WeighingPre-roll Filling BaggingWrappingCappingSealingLabelingCartoningFormingPackingPalletizing NEW NEW NEW NEW I Booth S-2153

Stand-up pouch system cuts changeover time

e high-e ciency 760-SUP stand-up pouch system from CMD (Booth LU-8118) cuts setup and changeover time, while simplifying operation and process stability for consistent, veriable product quality. e system boasts 25% less material waste and addresses changing needs for speed, exibility and new sustainable materials. SD

Emerging Brands Alliance forms

Online community o ers many resources.

The Emerging Brands Alliance, a new online community organized by PMMI Media Group (Booth N-4550) for founders and leaders of start-up consumer packaged goods (CPG) companies, provides year-round education, resources and growth opportunities for brands looking to scale their manufacturing operations. Membership is free.

e community provides a forum where member brand owners can ask questions, network with each other, nd educational content and news and access an array of resources that can help build their brand.

A total of three $20,000 grants are being awarded today, one each in the following categories:

• Certi ed minority or women-owned company

• Self-manufacturing company

Cartoner handles multiple formats

Using manual or automatic feeding, the Cariba C221 intermittent-motion horizontal cartoner from MG America (Booth W-15003) accommodates most primary pharmaceutical, nutraceutical and cosmetics packaging formats, including blister packs, round/shaped glass and plastic bottles, jars, soft tubes and ow packs at up to 120 cartons/min. SD

Sullair marks 5 years as part of Hitachi

Sullair (Booth S-3752) recently commemorated its ve-year anniversary as part of Hitachi Group with a company picnic and tree planting. Hitachi acquired Sullair to complement its existing compressed-air capabilities and gain a larger footprint in North and South America. Since the acquisition, Hitachi has invested more than $45 million in Sullair, including a large manufacturing process expansion that created more than two dozen full-time jobs. SD

Inspect cased product

e PRO Series Case system from Teledyne TapTone (Booth S-4126) is designed for noncontact, nondestructive, 100% automatic container inspection through a sealed corrugated and/ or shrink-wrapped case. Acoustic or proximity technology inspects glass jars with metal closures or metal cans for pressure or vacuum. In many applications, the system will detect other aws such as missing or damaged containers or lids. SD

Need project advice?

Industry veterans at the “Ask the Experts” Station in the Attendee Solutions Center (Booth N-4552, LU-7000) stand ready to answer packaging and processing questions. Attendees can stop by for guidance on narrowing their search for suppliers and navigating the show. SD

Featured resources include:

• Emerging Brands Summit (see story, p. 1)

• Educational video series custom-made for brand owners, including the rst release “Package is”

• Ask an Expert Forum—a free service for members!

• Contract manufacturing and packaging quote requests

• Online supplier directory

• Emerging Brands Alliance page on LinkedIn

• Emerging Brands Grants.

e Emerging Brands Grants program is designed to help growing CPG companies scale their operations by providing funds for operational expenses.

• Any eligible company. e rst three grant recipients, chosen from a eld of more than 460 requests, will be announced today at the Emerging Brands Summit.

“Now more than ever, brands need support and adequate resources to keep up with the rapidly growing demands they are facing,” says Kim Overstreet, director, Emerging Brands Alliance.

Grants can be used to enable a variety of projects and resources, such as prototype creation, market research, legal and consultant services, creation of pitch materials for investors, exhibiting fees and custom packaging for eCommerce.

For more info, visit www.PACKEXPOinternational. com, www.emergingbrandssummit.com, www.emergingbrandsalliance.org. SD

SHOW DAILY

PACK EXPO International 2022

Publisher PMMI Media Group Editorial Director Hallie Forcinio

Associate Editors Kari Moosmann and Barbara Rook

Production Manager Mary orne

Art Director

Debi Friedmann

IT/Production Support

Manny Dominguez

Photographers

Miles Boone and George Burns

Advertising Sales Management

Dave Newcorn, President, PMMI Media Group

Wendy Sawtell, Vice President, Sales, PMMI Media Group

PACK EXPO International 2022 SHOW DAILY OCTOBER 23, 2022 6

NEWS BRIEF

Bagging

rapping

&

1.833.4PAXIOM PaxiomGroup PaxiomXperience WeighingPre-roll Filling BaggingWrappingCappingSealingLabelingCartoningFormingPackingPalletizing Swifty Bagger 3600 Premade Pouch Bagger Sleek F40 Compact Flow Wrapper Sleek i65 Inverted Flow Wrapper Sleek F65 High-speed Flow Wrapper Learn more at paxiom.com VerTek Vertical Form, Fill & Seal Bagger NEW VF 1200 Continuous Motion Bagger Booth S-2153

Exhibitor

(Booth S-2442)57

Exhibitor

Tuesday:

(Booth N-4511)

N-4518)

(Booth S-1656)47

(Booth S-3500)

(Booth S-2153)

(Booth S-3374)

S-2450)

(Booth S-2422)

(Booth LU-8205)

(Booth S-3506)

(Booth N-5725)

Specialty Materials (Booth LU-6704)44

(Booth S-1630)

Epson America (Booth N-5265, N-5363)71

Finance Institute

Frain Industries (Booth S-1639)

Packaging (Booth S-3448, S-3449)

Tek USA (Booth LU-7258)

Ilapak - Delta Systems & Automation (Booth S-2514)

Inland Packaging (Booth

(Booth

(Booth S-3653)

(Booth

S-2022)

S-3514)

Whiting-Turner

(Booth

(Booth

(Booth S-1700)19

(Booth

• Founders of high-growth emerging brands looking to scale operations

• Leaders of product development, operations, or finance.

The agenda combines educational sessions and an Emerging Brands Marketplace with 50 tabletop exhibitors, including suppliers of processing equipment, packaging machinery, packaging materials and containers and contract manufacturing and packaging services, as well as Expert Advisors, who bring decades of consumer packaged goods (CPG) experience working for major brands, and are available for one-on-one consultations to provide personalized advice.

“With so much change in the industry over the last few years and the increase in eCommerce and consumer demand in every industry vertical, we felt that it was important to launch a program that can serve as a roadmap to help companies take their operations to the next level,” says Kim Overstreet, director, Emerging Brands Alliance, a new online resouce for the emerging brands community. “Now more than ever, brands need support and adequate resources to keep up with the rapidly growing demands they are facing.”

“The Emerging Brands Summit could not have come at a better time for our industry, and PACK EXPO International offers the perfect platform to launch this critical program,” says Jim Pittas, president and CEO, PMMI, The Association for Packaging & Processing Technologies (Booth N-4550), the producer of the PACK EXPO family of trade shows.

Registrants to the Emerging Brands Summit have free access to Braindate, a web-based meeting platform that facilitates knowledge sharing between attendees and/or solution providers by enabling scheduling of in-person conversations.

Emerging Brands Summit attendees may display a sample or prototype of their product on the Product + Solution Showcase on Braindate. The Showcase is a destination for sharing product details with peers, solution providers and experts, who can help solve processing and packaging challenges.

“Frain Industries is honored to be a Platinum Sponsor of the new Emerging Brands Summit!” says Clair Frain, marketing manager at Frain Industries. It “promises exceptional educational and networking opportunities for professionals who are ready to take their operations to the next level.”

For more info, visit www.PACKEXPOinternational.com, www.emergingbrandssummit.com, www.emergingbrandsalliance.org. SD

SHOW DAILY OCTOBER 23, 2022 8 PACK EXPO International 2022 New to the Show? If your badge says “ First-Time Attendee ” stop by and you can: ¤ Ask questions of show staff ¤ Access product locators ¤ Participate in sessions Sponsored by: Booth N-5534 You’re invited to the FIRST-TIMERS LOUNGE! South Building, Level 1, Room S-102 Near the South shuttle bus area Sunday –

11:00 am – 3:00 pm Happy hour: 3:00 pm – 5:00 pm Wednesday: 11:00 am – 3:00 pm Open DailyOpen Daily Lakeside Center, Level 2 back of the show floor Sponsored by: Booth LU-8758 Delicious lunch options for under $10 a meal . Enjoy fun backyard style games and happy hours. Kick back and dine for leSS!Kick back and dine for leSS!

(Emerging Brands Summit Continued from

page 1)

Table ADCO Manufacturing

Atlantic Packaging 37 BMSI Packaging 33 Brandjectory 80 Breedlove Center For Entrepreneurship77 Cavanna Packaging USA

Chicagoland Food & Beverage Network

76 Contract Packaging Association (Booth

75 CSI - Central States International 41 Della Toffola USA

31 Domino Amjet

51 Dorner

67 Duraco

Econocorp

17 ePac 29

Food

79

35 Harpak-ULMA

13 High

65 IMA

25

S-4040) 16 Jones Nonwovens 36 Klöckner Pentaplast GroupKlöckner Pentaplast of America (Booth W-16018, W-24022) 59 KUKA Robotics

N-6236) 52

Table Medical Packaging (Booth W-14004)63 Morrison Container Handling Solutions (Booth N-4906) 55 Nutra-Pack Systems 39 Pacteon Group

69 Paxiom

53 Plan IT Packaging Systems

49 Plexpack

21 PMI KYOTO Packaging Systems (Booth

45 Power Central

LL-9910) 12 QC Conveyors

23 Septimatech Group

N-5934)27 Specialty Food Process Technology 28 Spee-Dee Packaging Machinery (Booth

11 Syntegon Packaging Technology (Booth

15 The Austin Company

LU-7633)56 The

Contracting Company 61 Triangle Package Machinery

United Flex 20 WestRock

S-2130) 43 Expert Advisors Table Butler, Scott - LeanFoodBiz 3 Green, Mark - Mark Green & Associates (MGA) 2 Greenburg, Eric - Eric F. Greenburg, P.C.6 Valenti-Jordan, Jamie - Catapult Commercialization Services 1 Vandenoever, Tony 4 Wolf, Diane 5

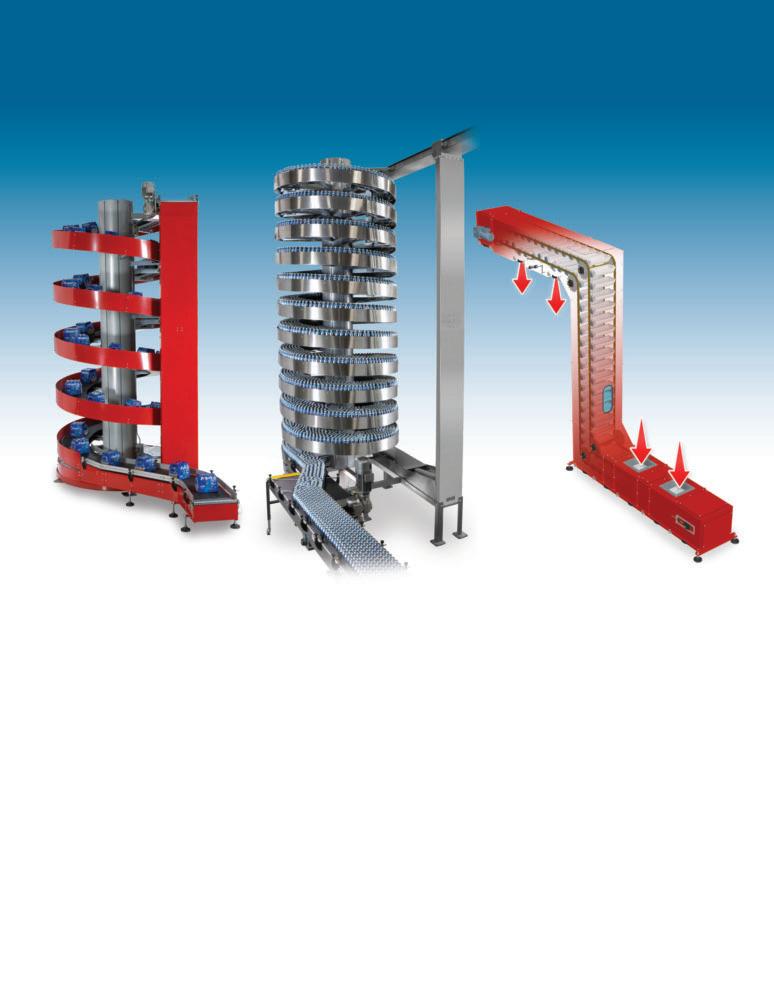

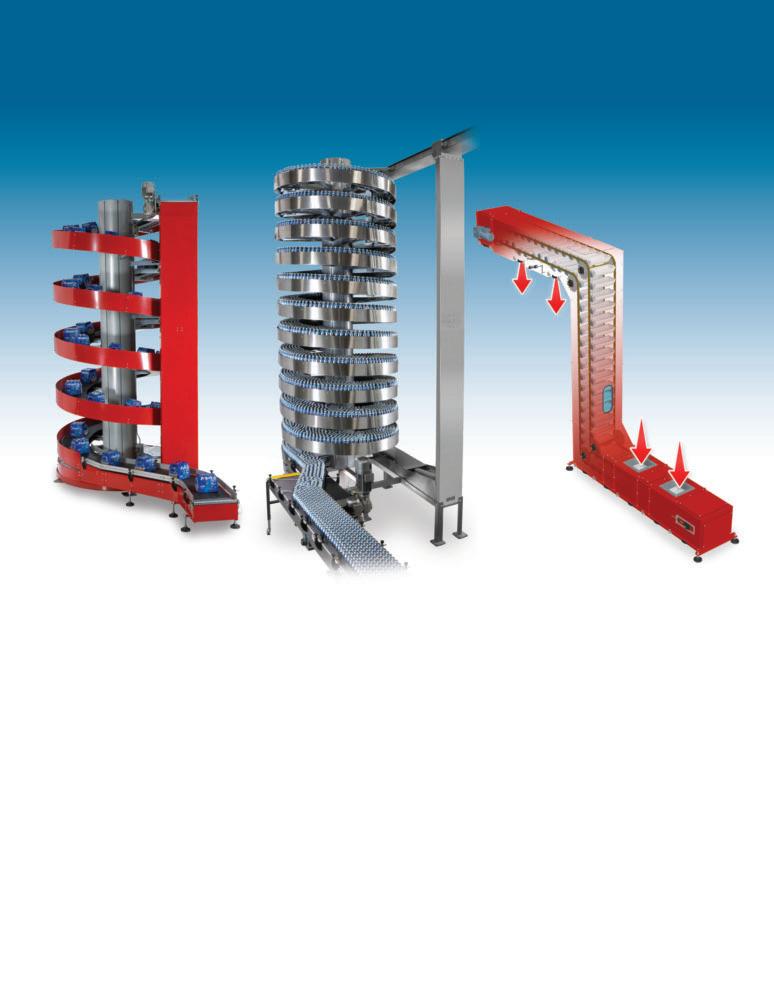

Ryson Vertical Conveying Solutions

Spiral Conveyors & Bucket Elevators

Ryson Spiral Conveyors need less floor space than conventional conveyors and are faster and more reliable than any elevator or lift.

Unit Load Spirals convey cases, totes and packaged goods smoothly on our slat style belts and come in 9 standard slat widths ranging from 6” to 30”. Available in powder coated carbon steel, stainless steel, wet environment and freezer versions.

Mass Flow Spirals handle full and empty bottles, cans and jars in mass up to 2000 units per minute. Available in 4 different slat widths ranging from 6” to 20”.

Narrow Trak Spirals are super compact and designed to handle your smaller loads. Our 6” and 9” wide nesting slats can end-transfer small cartons and packages or side-transfer small bottles and containers in a single file or in mass at speeds in excess of 200 FPM.

Ryson’s Bucket Elevators combine vertical and horizontal transportation of bulk materials in one integral unit.

Ryson Bucket Elevators are designed for gentle handling and well-suited to transport a broad range of bulk products. Our signature feature is that they are completely enclosed with overlapping pivoting buckets, that prevent spillage and helps mitigate foreign debris.

Their modular design enables us to customize with ease. They can be configured with multiple inlets or outlets that can be controlled individually. The design makes them easy to install and modify. Available in three standard bucket sizes, yielding capacities up to 300, 700 or 1,800 cubic feet per hour. They can also be delivered in powder-coated carbon-steel, stainless-steel or wet environment versions.

www.ryson.com

Watch our detailed Bucket Elevator Video

Watch our detailed Bucket Elevator Video

All Ryson equipment is modular and built to order. No matter the application, the Ryson team is up to the challenge of finding solutions for your conveying needs. For application assistance or more information, give us a call or visit

. 300 Newsome Drive • Yorktown, VA 23692 • Phone: (757) 898 1530 • Fax: (757) 898 1580 RYSON INTERNATIONAL, INC. MEMBER OF ROYAL APOLLO GROUP www.ryson.com See our equipment run in the North Hall - Booth N - 5945

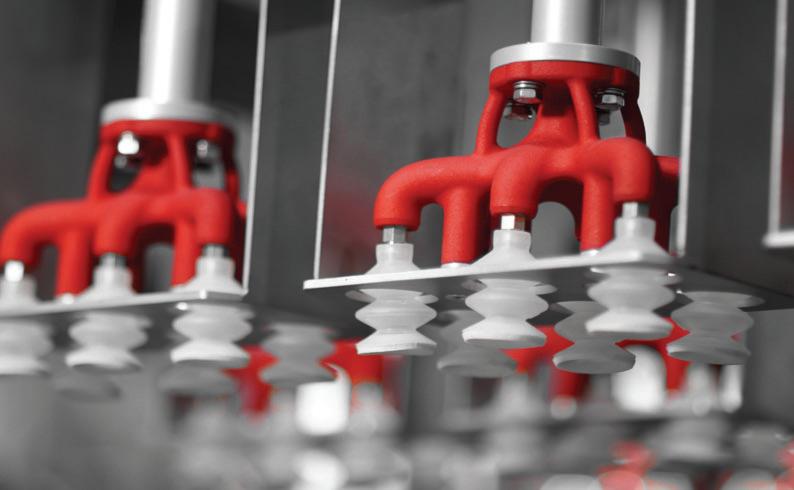

Syntegon wins packaging

For the third year in a row, the German Packaging Institute (Deutsches Verpackungsinstitut) has honored Syntegon (Booth EB-15, S-3514) with the German Packaging Award. This year’s judging panel recognized the development of the Versynta microBatch cell in the Packaging Machines category.

The highly flexible and fully automated production cell with gloveless isolator fills and closes the

smallest batches of pharmaceuticals and biopharmaceuticals safely and with virtually no product loss.

“We are very happy that such an important innovation for the pharmaceutical industry has received the award,” says Dr. Alexander Giehl, head of the Pharma Liquid & Inspection business cluster at Syntegon.

He notes, “Pharmaceutical and biotech companies require more flexible equipment for new and highly effective drugs for ever smaller patient groups.

Maximum product yield and fast batch changeovers are crucial for the smallest batches. We not only answer this trend with Versynta microBatch—we are actively shaping the future of pharmaceutical fill/ finish operations, in line with our mission ‘processing and packaging for a better life.’

“Our Versynta portfolio combines 40 years of isolator know-how and 70 years of expertise in pharmaceutical fill/finish processes. Our production isolators feature the fastest cycle times on the market. Pharmaceutical manufacturers, development labs and biotech startups alike can benefit from this achievement.”

HIGHEST ROBOTICS EXPERTISE IN SMALLEST FOOTPRINT

The fully automated and highly flexible production cell is designed to fill and close a variety of containers with pharmaceutical liquids and enables a complete batch-to-batch changeover in less than 2 hr. Syringes, cartridges and vials, made of glass or plastic, can be filled with virtually no product loss. The gloveless isolator with integrated air treatment significantly reduces the risk of contamination since it eliminates manual intervention. Fully automated filling and 100% in-process control ensure continuously high quality. The GMP-compliant system sets new standards in small batch filling with an output of 120 to 500 containers/hr.

THIRD CONSECUTIVE AWARD

Recognition of the Versynta microBatch cell follows awards for the TPU1000 paper-forming machine for sustainable food portion packs in 2020 and the paper alternative “Blister Meets Paper” for tablet packaging in 2021.

The Versynta microBatch cell has received other honors: In October 2021, the Parental Drug Association (PDA) presented Syntegon and its development partner Vetter, an international pharmaceutical service provider for injectable drugs, with the PDA Drug Delivery Innovation Award in the “Partnership Innovation” category.

For more info, visit www.syntegon.com. SD

SHOW DAILY OCTOBER 23, 2022 10 PACK EXPO International 2022

Title Sponsor: Bronze Sponors: Proceeds benefit the Booth S-1660 A NETWORKING EVENT THAT ROCKS! MONDAY, OCTOBER 24 WEST BALLROOM, LEVEL 3 Reception: 4:30 pm Performance: 5:30 pm Tickets: $95 (Purchase in Registration)

award German Packaging Institute honors Versynta microBatch cell.

The Versynta microBatch cell is a highly flexible, fully automated pro duction cell for filling and closing liquid biopharmaceuticals.

Syntegon has been awarded the German Packaging Award in the Packaging Machines category for its Versynta microBatch cell.

Hear about ‘Must See’ Technology & Trends

PMG editors ferret out most intriguing exhibits.

After

scouring the show oor all day, the editors of PMMI Media Group (PMG) (Booth N-4550, W-20052) share the buzzworthy technologies they’ve discovered.

Meet at Innovation Stage 3 (Booth N-4585) at 3:30 each day for a 30-min. brie ng moderated by Sean Riley, senior news director, PMG. Hear about the latest innovations in automation, packaging, healthcare packaging, processing and machinery from these leading editors:

(Booth

SATURDAY, OCT. 22

• Michael Costa

Senior Editor, ProFood World

• Matt Reynolds Editor, Packaging World

SUNDAY, OCT. 23

• David Green eld

Director of Content, Automation World

• Anne Marie Mohan Senior Editor, Packaging World

MONDAY, OCT. 24

• Keren Sookne Director of Editorial Content Healthcare Packaging

• Lilian Robayo Paez

PMMI Media Director for Latin America

PMMI

TUESDAY, OCT. 25

• Aaron Hand

Editor-in-Chief, ProFood World

• Stephanie Neil Editor-in-Chief, OEM Magazine e editors also eld questions from the audience. Each session is recorded for presentation the next day on PE Express.

For more info, visit www.PACKEXPOinternational.com.

SHOW DAILY OCTOBER 23, 2022 12 PACK EXPO International 2022

MUNDO

SD

David Greenfield Director of Content Automation World Anne Marie Mohan Senior Editor Packaging World

Michael Costa Senior Editor ProFood World Matt Reynolds Editor Packaging World

Lilian Robayo Paez PMMI Media Director for Latin America MUNDO PMMI

Keren Sookne Director of Editorial Content Healthcare Packaging

Aaron Hand Editor-in-Chief ProFood World Stephanie Neil Editor-in-Chief OEM Magazine

Sean Riley, senior news director, PMG, moderates the

‘Must

See’ Technology & Trends session

at

3:30 each day

on

Innovation Stage

3

N-4585). J Y P CK P C SS An Interactive Show Floor Must-See! Take a tour through this curated exhibit spanning 250 years of historical equipment, materials and photographs. Get a glimpse into the future and attend over 20 free sessions presented on the PACK to the Future Stage exploring: 〉 The circular economy 〉 Smart packaging & Innovative sustainability initiatives 〉 The evolution of pharmaceutical packaging ALSO FEATURED: A corrugated car of the future VR Experience produced by Paper + Packaging Board. Join us in the West Building, Booth W-20001

F T. E Y. ECYCL BLE. F , S n ac ion a CK EX O In na ional, Oc ob 3-26, boo S-2130. w s roc .com/pac xpo ©2022 W s c ompany. WEST OCK, W s c nd D sign, an h W s c ogo ar ra mar s own d by W s c ompany ll righ s r s rv d.

SUNDAY, OCTOBER 23, 2022

1:30-2:00 PM

COLD PRESSURE COUNCIL LET’S TALK ABOUT HPP— GROWTH, THE HPC® MARK AND INDUSTRY APPLICATIONS

High-pressure pasteurization (HPP) is cold pasteurization in pure water; it uses ultra-high pressure purified water to keep packaged food pathogen-free to stay fresh longer. Very high pressures inactivate bacteria such as Listeria, E. coli and Salmonella. Foods using HPP include ready-to-eat and ready-to-cook meats, ready-meals, fruits and vegetables, juices and smoothies, soups and sauces, wet salads and dips, dairy products, pet food, baby food, seafood and shellfish. HPP helps producers increase food safety and extend shelf-life while providing consumers with nutritious, natural, flavorful food.

Ryan Pereira President, HPP & Fresh JBT

2:30-3:00 PM

ISO & ANSI STANDARDS UPDATES TO THE MACHINERY DIRECTIVE AND ISO & ANSI STANDARDS

This overview shares the latest updates on changes to the Machinery Directive in the EU, the ISO and ANSI machinery safety standards, and how PMMI is assisting member companies to keep abreast of the changes and impacts to machinery and processes.

Bruce Main President Design Safety Engineering

MONDAY, OCTOBER 24, 2022

10:30-11:00 AM

OMAC - THE ORGANIZATION FOR MACHINE AUTOMATION AND CONTROL

INTRO TO PACKML-2022, UPDATE TO ANSI/ISA-TR88.00.02 FOR DISCRETE MACHINE CONTROL

A team from the OMAC Packaging Workgroup has won approval from ISA on several updates to ANSI/ ISA-TR88.00.02-2015 that improve the PackML State Model and expand/clarify the associated PackTags and data types for greater accessibility and supervisory control across a variety of vendor platforms.

Doug Meyer Sr Mgr, Motion Yaskawa America

11:30-12:00 PM

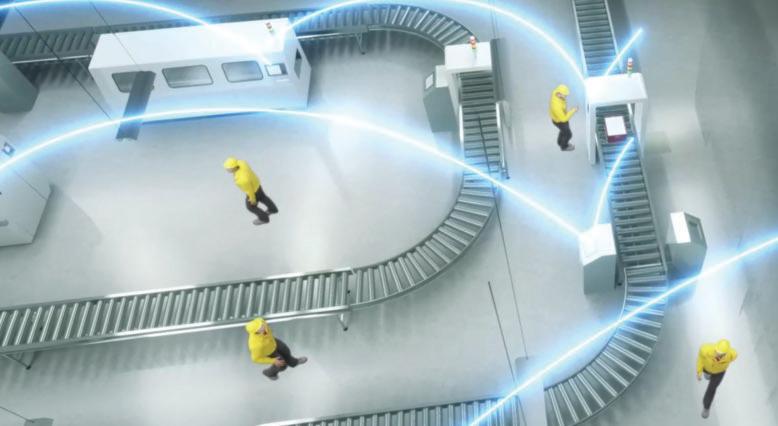

MHI CONVEYOR & SORTATION SYSTEMS INDUSTRY GROUP

2022 DELOITTE/MATERIAL HANDLING INDUSTRY ANNUAL REPORT

This is your opportunity to have access to the latest report on trends and digital technologies that are transforming supply chains. MHI’s Conveyor and Sortation Systems (CSS) Industry Group will present the report findings, how this will affect the packaging industry as a whole and how specific packaging automation technologies will aid in the future of the industry. CSS is a 50-year-old industry group under the MHI umbrella with a collective deep understanding of the market. Come for the presentation and stay for the Q&A. Bring your own challenges and application curiosities for this energized group to address. Key takeaways: a review of the digital technologies transforming the supply chain; the latest data around material handling market growth; potential threats and opportunities within the packaging industry.

Mike Drolet Development Mgr

Murrelektronik

Allison Meyers Marketing & Communications Mgr Fives Intralogistics

12:30-1:00 PM

MHI’S SLAM INDUSTRY GROUP ECOMMERCE FULFILLMENT— BUSINESS CASE FOR A SLAM SOLUTION

MHI’s SLAM Industry Group is made up of the companies that provide the software, hardware and integrated solutions that go into the last 100 ft. Together, these companies collaborate to provide thought leadership and education on best practices in this critical area of your operation. Key takeaways: What is a SLAM system? (It stands for scan, label, apply and manifest, but it is so much more); core components of SLAM (what you see and what you don’t); and how to mitigate risk in your fulfillment operation.

Gina Barrieau

Banding Sales Mgr, eCommerce Felins

Greg Berguig

VP, Sales and Marketing PAC Machinery

Justin Garski

Packaging OEM Mgr Rockwell Automation

1:30-2:00 PM

SNAC INTERNATIONAL STATE OF SNACKING

As consumers turned to snacking as a source of fun and comfort during the pandemic, they became increasingly focused on holistic health and wellness goals. With the return to more active lifestyles, shoppers continue to look for value-added benefits beyond nutrition in the snacks they choose. During the next year, innovation is set to explode in a snack category that continues to grow by providing healthful and tasty options, while reaching consumers faster through eCommerce. Learn which snack categories are growing, why they are growing, and how snack makers are capturing opportunities in one of the fastest-growing CPG categories.

David Walsh

VP, Membership and Communications SNAC International

2:30-3:00 PM

INTERNATIONAL SOCIETY OF BEVERAGE TECHNOLOGISTS

EVOLUTION, TRENDS AND ISSUES FOR BEVERAGES

As new technologies became available, beverages evolved to the point where more than 20,000 foods and beverages are introduced each year. Technology advances and consumer preference can change the beverage world rapidly. Trends in total market, beverage groups and emerging markets can be identified. Changing markets, industry challenges and world events can create issues for the beverage industry. COVID-19, The Great Disruption (supply chain problems), sustainability, green, legalized cannabis and other issues have impacted the industry.

Tom Reimer Dir of Education

International Society of Beverage Technologists

TUESDAY, OCTOBER 25, 2022

10:30-11:00 AM

DIGITAL TWIN CONSORTIUM APPLICATIONS OF DIGITAL TWIN

Learn about digital-twin technologies and pilot projects in the packaging field. Learn how using digital-twin technologies, both in real time and offline, improve the efficiency and effectiveness of the traditional process, in terms of cost, quality, time, OEE and improving ESG (environmental, social and governance) factors.

Dan Isaacs

Chief Technology Officer Giuseppe Padula

Regional Branch Organizer Digital Twin Consortium ∆

SHOW DAILY OCTOBER 23, 2022 14 PACK EXPO International 2022

The Industry Speaks Stage (Booth N-4565) offers educational sessions led by experts from PACK EXPO Partner Associations and focused on hot-button topics and industry trends across multiple industry verticals.

OxyStar barrier material utilizes a multilayer PET with an oxygen scavenging agent. PET has a naturally low oxygen transmission rate (OTR) and this construction slows down the flow of oxygen molecules through the package from the outside. Once the scavenger agent finds an oxygen molecule, it attaches to it and binds the oxygen within the sidewall of the package to keep your product fresh and lasting longer.

RECYCLABLE BARRIER MATERIAL FIRST OF ITS KIND DIRECT FOOD CONTACT FDA COMPLIANT INCREASED SHELF LIFE BLOCKS OXYGEN WATCH OUR PRESENTATION AT THE INNOVATION STAGE WEDNESDAY @ 11AM TO HEAR ABOUT IT

11:30-12:00 PM

INTERNATIONAL SOCIETY OF BEVERAGE TECHNOLOGISTS

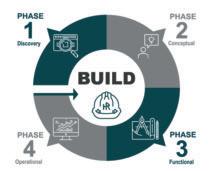

WHAT IS THE PROCESS TO CREATE A PRODUCT?

New product innovation (NPI) is creating, producing, selling and delivering a product to the consumer. The three-phase process includes ideation (concept or creation), design (development) and execution (commercialization). Each phase has a series of gates to complete before moving to the next phase. Learn about the NPI process and the roles of different departmental functions. Understand where your function fits and what is needed to ensure a successful product launch.

Brian Stegman Exec Dir

International Society of Beverage Technologists

2:30-3:00 PM

AMERIPEN

PACKAGING POLICY NOW AND FOR THE FUTURE

The U.S. is standing at a critical precipice on packaging and environment policy proposals and implementation, with new laws coming at us on packaging producer responsibility, labeling and recycled-content mandates. Discuss what’s happening and how it will impact the entire packaging value chain now and in the future.

Dan Felton Exec Dir

AMERIPEN - American Institute for Packaging and the Environment

3:30-4:15 PM

CHICAGOLAND FOOD & BEVERAGE NETWORK

FOOD MANUFACTURING FACILITY OF THE FUTURE

The last two years have transformed our lives and businesses. How has it changed what is needed in a food manufacturing facility? How are supply-chain disruptions, labor challenges, including the Great Resignation, and evolving customer and consumer expectations changing how we manufacture food and beverage? How have food and beverage industry expectations changed? And how will we adjust our manufacturing processes, strategies, tactics and teams to best meet these evolving expectations? Learn how our panel of experts is adjusting to deal with today’s business realities and what they see as the implications for imagining and creating the food manufacturing facility of the future.

Alan Reed - Moderator Exec Dir

Chicagoland Food & Beverage Network

WEDNESDAY, OCTOBER 26, 2002

10:30-11:00 AM

CONTRACT PACKAGING ASSOCIATION

WHAT IS DRIVING INTEREST IN CONTRACT PACKAGING AND MANUFACTURING?

Using data from our State of the Industry Report, member feedback and our RFQ platform, we look at the changing demands of this dynamically growing industry. Often a confusing and frustrating segment, these essential service providers address the needs of emerging and legacy brands launching retail food and CPG products. Explore how CoMans and CoPacks are adding value as consumer and market-driven needs shift. Learn how the newest innovative products have become key opportunities for CoMans. Understand how brands are adapting to meet challenges with strategic CoMan and CoPack partnerships and accelerate time to market.

Carl Melville President Melville group on behalf of CPA Ron Puvak Exec Dir

Contract Packaging Association (CPA) SD

SHOW DAILY OCTOBER 23, 2022 16 PACK EXPO International 2022 WEST HALL | Booth W-20052 Next to the Containers and Materials Pavilion Get inspired by award-winning packaging from around the world—the next great idea for your brand might be on display! Sponsored by: FEATURING ENTRIES FROM: ■ ABRE —Brazilian Packaging Association ■ AIMCAL —Association of International Metallizers, Coaters and Laminators ■ DOW —Packaging Innovation Awards ■ FPA —Flexible Packaging Association ■ FSEA —Foil and Specialty Effects Association ■ IAE —Instituto Argentino del Envase ■ IMDA —In-Mold Decorating Association ■ IoPP —Institute of Packaging Professionals ■ ProFood World’s Sustainability Excellence in Manufacturing Awards ■ RPA —Reusable Packaging Association ■ The Tube Council ■ WPO —World Packaging Organisation

Wherever you are and whatever your industry, there’s a PACK EXPO event to provide solutions you need today and the inspiration for tomorrow.

June 13-15, 2023 Guadalajara, Mex.

Sept. 11-13, 2023 Las Vegas, USA

March 18-20, 2024 Philadelphia, USA

June 11-14, 2024 Mexico City, Mex.

Nov. 3-6, 2024 Chicago, USA

®

Visit packexpo.com

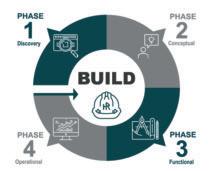

OpX updates FAT guidance

The revised “One Voice Factory Acceptance Tests – Protocols for Capital Equipment in the CPG Industry” work product improves the factory acceptance test (FAT) process. Developed by the OpX Leadership Network (Booth N-4550), the Factory Acceptance Tests work

product is designed to resolve FAT criteria, expectations and miscommunications that often result in unbudgeted travel and material costs, increased timelines and overall confusion for consumer packaged goods (CPG) companies and original equipment manufacturers (OEMs).

is update includes new leadership guidance, additional review of responsibilities for OEMs and end users, and the integration of the Virtual FAT work product as an appendix rather than a standalone product.

“When conducting an e ective FAT, clear communication between all parties is critical,” says Bryan Gri en, senior director, industry services at PMMI, e Association for Packaging and Processing Technologies (Booth N-4550), convener of the OpX Leadership Network. “ is latest update helps streamline that communication and facilitate a more productive FAT, regardless of whether it is virtual or in-person.”

e OpX Leadership Network was founded in 2011 by PMMI to ensure CPG companies and OEMs are connected and well-prepared to solve common operational challenges, make smarter decisions and achieve operational excellence.

e revised FAT work product and other operational resources are available for free by downloading at opxleadershipnetwork.org/projects/download.

For more info, visit www.opxleadershipnetwork.org. SD

Reinventing the Rules of the Game

breakfast at PACK EXPO will feature Dawn Hudson, former President and CEO of

Cola North America and former Chief Marketing Officer of the National Football League. Drawing on her diverse

will share winning business strategies, and

for

your professional game.

WHEN: Tuesday, October 25; 7:30-9:00 am

Room S-100

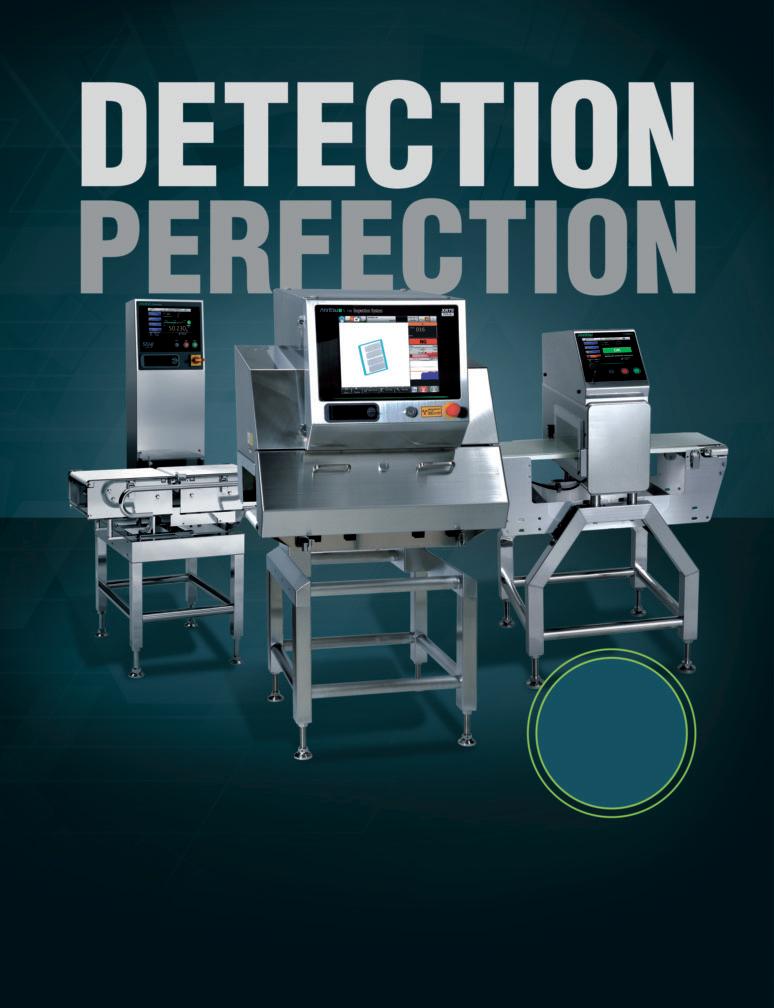

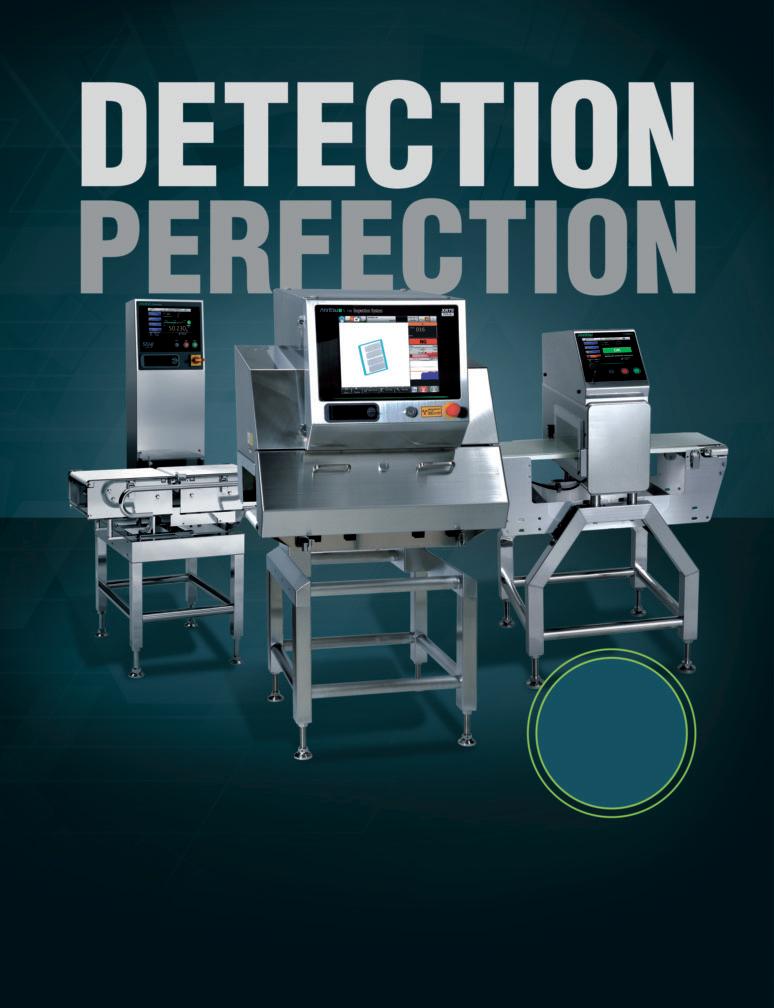

Anritsu ranks as best workplace

Anritsu - Product Inspection & Detection (Booth N-4730) was named one of the “Best Places to Work in Illinois” for 2022 by e Daily Herald newspaper. Honored for the third consecutive year, Anritsu improved its ranking, moving up to 22 among 46 honorees in the small business category.

Company President Erik Brainard praised its employees, saying, “Our team at Anritsu is unique in so many ways. We are made up of people from very di erent walks of life, and we value the diverse perspective that everyone has to o er. What is impressive is how well this team comes together and works as a unit. We share the same goals and visions for this company, and every one of you is the reason why we are one of the Best Places to Work.”

e awards program identi es, recognizes and honors the best places of employment in Illinois, bene ting the state’s economy, workforce and businesses. Companies from across the state participate. Approximately 25% of the score is based on an evaluation of each workplace’s policies, practices and demographics. An employee survey measures the employee experience and provides the remaining 75% of the score.

e combined total determines the nal ranking.

For more info, visit www.anritsu.com/in vis. SD

SHOW DAILY OCTOBER 23, 2022 18 PACK EXPO International 2022

The Packaging & Processing

Women’s Leadership

Network (PPWLN) serves to recruit, retain and advance women’s careers by bringing established leaders and young professionals together to expand the presence and influence of women in the industry. Vist pmmi.org/ppwln and join the PPWLN LinkedIn group to stay connected. Thank You to Our Event Sponsors

The PPWLN

Pepsi

experiences, Hudson

tips

elevating

WHERE:

Complete

BOOTH: S-3634

Automation Solutions Filling & Sealing Automation End-of-Line Packaging Automation

Association Partner Program grows

Learn, network at Industry Meets and Industry Speaks.

The PACK EXPO Association Partner Program connects attendees to leading associations from all segments of packaging and processing. This year’s program, the largest in PACK EXPO history, offers an unparalleled breadth and depth of industry knowledge to attendees.

The Association Partner Pavilion, in the North Hall, provides a central location for attendees to access these resources. Participants in the 2022 PACK EXPO International Association Partner Program are listed at the bottom of this page.

New this year is the Association Partner Plus designation and Industry Meets schedule of ancillary events and meetings hosted by groups listed in the far right column. Events include a hygienic equipment design seminar, design for recycling training, a fluid power forum and Fundamentals of Medical Device Packaging course. Check the PACK EXPO International App or show website for the latest schedule and pre-registration requirements.

“We are thrilled with the positive response to the Association Partner Program and newly launched Industry Meets Program,” says Laura Thompson, vice president of Trade Shows at show producer PMMI, The Association for Packaging and Processing Technologies (Booth N-4550). “PACK EXPO International is making a triumphant return to Chicago after four years away, and it is only possible with the strong support of these prestigious associations.”

Another new feature, the Industry Speaks Stage (Booth N-4565), offers educational sessions led by experts from PACK EXPO Partner Associations and focused on hot-button topics and industry

trends across multiple industry verticals. A schedule of sessions may be found on p. 14 or on the PACK EXPO International App or show website.

In addition to the Association Partner Program, PMMI has partnered with industry associations from

PAVILION HOSTS

CCPIT - China Council for the Promotion of International Trade

CFPMA - China Food and Packaging Machinery Industry Association

Confederation of the Danish Industry (LU-7560)

Fundacion Argentina para la Promocion de Inversiones y Comercio Internacional (Booth LU-8755)

INP – Brazilian Plastic Institute/Think Plastic Brazil (Booth W-25011)

Italian Trade Agency (Booth LU-8541)

Korean Packaging Machinery Association

Mouvement Des Enterprises De France International (Booth N-5564)

Switzerland Global Enterprise

UCIMA – Italian Packaging Machinery Manufacturers Association (Booth N-6002)

VDMA – Food Processing and Packaging Machinery Association

across the globe to host pavilions on the show floor. International Pavilion Organizer Partners include the 11 organizations listed under Pavilion Hosts. For more info, visit www.PACKEXPOinternational.com. SD

INDUSTRY MEETS

3-A Sanitary Standards (Booth N-5901)

Active & Intelligent Packaging Industry Association (Booth N-5802)

Cold Pressure Council (Booth N-4525)

Contract Packaging Association (Booth EB-75, N-4518)

Flexible Packaging Association (Booth N-4533)

Institute of Packaging Professionals (Booth N-4523)

International Bottled Water Association

MHI Automation Industry Groups (Booth N-5701)

National Fluid Power Association

OMAC – The Organization for Machine Automation and Control (Booth N-5100)

The Association of Plastic Recyclers (Booth N-5902)

INTERNATIONAL PARTNER PROGRAM

AIM (Booth N-5000)

AIMCAL - The Association of International Metallizers, Coaters and Laminators (Booth N-4527)

Asociacion Mexicana de Envase y Embalaje

ASD Turkish Packaging Manufacturers Association (Booth N-4900)

Australian Institute of Packaging

ABRE – Brazilian Packaging Association (Booth N-6003)

CANAINCA

Chicagoland Food & Beverage Network (N-4511)

Composite Can and Tube Institute (Booth N-4512)

Digital Twin Consortium (Booth N-6102)

Foil & Specialty Effects Association (Booth N-4536)

F4SS – Foundation for Supply Solutions

Flexographic Technical Association (Booth N-4510)

In-Mold Decorating Association (Booth N-4534)

IAE - Instituto Argentino del Envase (Booth N-6101)

International Society of Beverage Technologists (Booth N-5702)

ISTA - International Safe Transit Association (Booth N-4537)

Midwest Food Products Association National Confectioners Association (Candy Bar Lounge, Booth S-2583)

OPC Foundation (Booth N-5001)

PLCopen (Booth N-5002)

Reusable Packaging Association (Booth LU-6737)

SNAC International (Booth N-5801)

The Anuga FoodTec Family

The Australian Packaging and Processing Machinery Association

The Paper and Packaging Board

The Tube Council of North America (Booth W-20052)

UCIMA – Italian Packaging Machinery Manufacturers Association (Booth N-6002)

U.S. Department of Commerce (Booth N-4901)

World Packaging Organisation (Booth N-4902)

SHOW DAILY OCTOBER 23, 2022 20 PACK EXPO International 2022

READY

THE BEST SOLUTION

TO BE

Ronchi America has started producing an 18 head EXACTA stand-alone fille r that can be easily integrated into new and existing lines. It is proudly and entirely built in Atlanta, Georgia and available in 12 weeks or less. TOTALLY AMERICAN WITH AN ITALIAN HEART www.ronchipackaging.com SEE US AT BOOTH N-6228

PACK to the Future arrives

Historical exhibit serves as foundation for advancements.

The interactive PACK to the Future Exhibit (Booth W-20001) celebrates the role of packaging and processing throughout history and the impact it is poised to have on the future. The exhibit follows the evolution of modern packaging and processing over 250 years to the present and shifts to explore key trends shaping the future in daily live sessions on the PACK to the Future Stage (Booth W-20025)

Launched in 2021 at PACK EXPO Las Vegas, the curated, interactive PACK to the Future exhibit tells the story of packaging and people who saw a better way, solved challenges and provided the foundation for today’s—and tomorrow’s—innovations.

The exhibit includes:

• 30 historial packaging machines and replicas dating back to the 1800s

• Timeline walls displaying 250 years of history

SUNDAY, OCTOBER 23, 2022

ADVOCATING ON THE SUSTAINABILITY OF FLEXIBLE PACKAGING

12:30-1:00 PM

Flexible packaging has many needed sustainability benefits, but full circularity is a challenge: Opportunities for collection and reprocessing are limited, and requirements for food- and medical-grade packaging— the predominate market for flexibles—are complex. This session speaks to how the Flexible Packaging Association is advocating for the industry and solutions to close the loop on this important packaging type.

Alison Keane

President & CEO

Flexible Packaging Association GUIDING TRENDS IN MANUFACTURING

1:30-2:00 PM

This session highlights the top industry and machine trends steering the course of the manufacturing industry. Learn how labor challenges, sustainability and the rise of eCommerce are influencing the manufacturing decisions of tomorrow. The presentation also explores how machine integration, robots and artificial intelligence are transforming operations and propelling manufacturing to new heights of efficiency. Learn how the manufacturing industry is preparing for the challenges of the future by addressing the trends of today.

Donna Ritson President DDR Communications

• An area dedicated to women in packaging and processing

• An interactive display of past, present and future sustainability efforts, including a Corrugated Car of the Future Virtual Reality (VR) Experience. Sponsored by The Paper and Packaging Board, the experience allows attendees to sit in a replica of a futuristic car and use a VR headset to learn about sustainable packaging and the industry’s Box to Nature program, an initiative to educate consumers about the importance of recycling corrugated materials and boxes

• An interactive audio tour revealing interesting facts and historical details

• Fun quizzes that test attendees’ knowledge of the industry.

Each day on the PACK to the Future Stage, in-

A CORRUGATED REVOLUTION— THE NEW RETURNABLE

2:30-3:00 PM

Learn how Yanfeng Automotive Interiors successfully employed P2 Packaging as a semi-returnable option for shipping automotive parts.

David Colclough

Sr Buyer - North America Packaging Yanfeng Automotive Interiors

THE ROAD TO PACKAGING INNOVATION

3:30-4:00 PM

This session highlights some of the packaging innovations launched by Mars Wrigley Confectionery and what it took to get there.

William A. Singleton III Global Packaging Dir Mars

MONDAY, OCTOBER 24, 2022

CONCEPT TO MANUFACTURING IN 5 DAYS: UTILIZING ADVANCED CAPABILITIES

9:30-10:00 AM

By leveraging advanced capabilities, such as Virtual Analysis and Advanced Rapid Prototyping, PepsiCo is aiming to dramatically accelerate the time required to go from concept to final product, within five days.

Max Rodriguez

Sr Mgr, Global Beverages R&D

Thangthip Tekanil

R&D Packaging Engineer

PepsiCo

dustry experts provide 30-minute presentations on cutting-edge advancements in sustainability, circularity, net-zero goals, returnables and manufacturing trends.

The session schedule is outlined below. PACK EXPO International offers many other free educational opportunities, including the long-running Innovation Stage (N-4560, N-4580, N-4585) plus the new Processing Innovation Stage (Booth LU-7130) (see schedule, p. 28), The Forum at PACK EXPO (Booth N-4543) (see schedule, p. 44) the new Industry Speaks (Booth N-4565) (see schedule, p. 14). The Reusable Packaging Learning Center (Booth LU6737) also will present educational sessions.

Updated schedules may be found on the PACK EXPO International App or the show website.

For more info, visit www.PACKEXPOinternational.com. SD

THE EVOLUTION OF PHARMACEUTICAL PACKAGING

10:30-11:00 AM

An examination of the future of pharmaceutical packaging as it becomes more sustainable and meets the needs for greater convenience, self-administered drugs, reduced hospital stays and serving patients at home. The session also looks at how past and present innovations, focused on meeting patient and product needs, offer a path for the future.

Ron Yakubison Exec Dir, Global Technology Packaging Merck

ROBUST ADVANCED RECYCLING MAKES ALL PLASTIC PACKAGING TRULY CIRCULAR

11:30-12:00 PM

No material is inherently sustainable. To achieve true Circular Economy sustainability for plastic packaging, we must capture all plastic packaging without having to sort. Regenerative Robust Gasification is uniquely capable of accepting all plastic packaging, including metallized, multilayer, chlorine, foils, fitments, filth, etc. New plastic resins can be made via the syngas-methanol-plastics route, which already exists commercially. By co-locating at landfills, using renewable process power and simplifying collection and sorting, GWP is favorable relative to traditional virgin plastics. The Consortium for Waste Circularity is organizing Robust Advanced Recycling projects in which packaging industry stakeholders can participate.

Bruce Welt Professor University of Florida - Packaging Engineering

SHOW DAILY OCTOBER 23, 2022 22 PACK EXPO International 2022

∆

Pharmaceutical Packaging Manufacturing & Integration 800-811-6990 NJMPackaging.com 727-232-8200 Pharmaworks.com 800-348-5453 SerpaPackaging.com 856-273-3377 WeilerLS.com •Tablet, powder & liquid filling •Manufacturing, distribution & integration •Capping •Labeling •Serialization •Unscrambling Four Brands – One Company – Total Pharma Solutions •Blister machines •Rebuilds & upgrades •Product handling & feeding equipment •Tooling & change parts •Cartoners •Horizontal, vertical, top load & intermittent motion cartoners •Top load, side load & bottom load case packers •Automatic palletizers & auxiliary equipment •Full line integration •98% uptime, guaranteed •Vial, syringe, device & bottle labeling •Serialized label coding & inspection •Vial coding & inspection •Digital label printing •High-speed applications Complete Turnkey Line Integration Cartoning, Case Packaging and Robotic Palletizing with Line Integration Blister Machines, Feeding, Inspection and Cartoning High-Speed Pressure Sensitive Labeling Solutions BOOTH #W-17002 BOOTH #N-5650 ProMach Pharma Solutions is in TWO BOOTHS at PACK EXPO! Healthcare Packaging Pavilion & North Hall... October 23-26, 2022 McCormick Place Chicago, Illinois USA ASEPTIC FILL FINISH BLISTER PACKAGING BLISTER TOOLING CAPPING CARTONING CASE/TRAY PACKING CODING COLD FORMING COTTONING COUNTING FEEDING FILLING INSERT FEEDING ISOLATION TECHNOLOGY LABEL PRINTING LABELING LINE INTEGRATION REBUILDS/UPGRADES ROBOTIC PALLETIZING SERIALIZATION STERILIZATION THERMOFORMING UNSCRAMBLING VISION INSPECTION WASHING

THE SCIENCE OF CIRCULARITY— HOW MATERIAL INNOVATIONS CREATE NEW OPPORTUNITIES TO CATALYZE A CIRCULAR VALUE CHAIN

12:30-1:00 PM

Brands are making ambitious sustainable packaging goals that are driving demand for material innovations to reduce the use of virgin plastic, improve environmental impact and increase recyclability to enable package circularity. Procter & Gamble (P&G) and Eastman are innovation leaders in sustainable packaging, which brings challenges beyond materials and packaging design. The infrastructure needs to increase collection, improve sortation and recycle a wider range of plastic waste, presenting opportunities for innovation and collaboration around the circular value chain.

In this session, P&G and Eastman representatives share experiences bringing sustainable materials to the market. Both are founding members of the newly launched PET Recycling Coalition, an initiative of The Recycling Partnership, which is working to create scalable solutions to improve the circularity of PET packaging through a more robust recycling system. Learn about the PET Coalition’s goals and approach and how to get involved.

Matt Storey Segment Mgr, Circular Packaging Eastman John M. Layman, Ph.D. Sr Dir, Corporate R&D Proctor & Gamble

RACE TO NET-ZERO: HOW TO DRIVE ESG IN A FRAGILE WORLD

1:30-2:00 PM

How to drive ESG in a fragile world. Michael Okoroafor, Ph.D. Chief Sustainability Officer McCormick

THE 10-YEAR PACKAGING MATERIALS AND SUSTAINABILITY COMPASS

2:30-3:00 PM

PMMI, producer of the PACK EXPO portfolio of trade shows, has partnered with AMERIPEN, the American Institute for Packaging and the Environment, to create the 10-Year Packaging Materials and Sustainability Compass, a collaboration report on the future of materials usage and replacement for CPG companies, OEMs, materials suppliers and recovery professionals. Research behind this report seeks to uncover what materials are projected to be replaced or remain unchanged, what new packaging materials are on the horizon and how the legislative landscape will be shaped in the next decade. Findings will provide comprehensive guidance to packaging value-chain professionals on the direction of: materials usage for the next three, five and 10 years; expected changes to sustainability legislation, including extended producer responsibility, and key drivers of those changes. The project scope includes

quantitative data captured from producer and recovery groups in the packaging value chain and qualitative interviews from senior key players in each segment. The informative, actionable session presents highlights from the 10-Year Packaging Materials and Sustainability Compass.

Rebecca Marquez

Mgr, PMMI Business Intelligence

Dan Felton Exec Dir

AMERIPEN

DESIGNING BREAKTHROUGH PACKAGING WITH SUSTAINABILITY IN MIND

3:30-4:00 PM

This session touches on P&G’s sustainability goals and how it brings those to life in designing new-to-theworld packaging for its products.

Ken McGuire Research Fellow

Procter & Gamble

TUESDAY, OCTOBER 25, 2022

LIVING CARBON SMART

9:30-10:00 AM

To achieve climate goals, we need a systems-level view and solutions that can draw on multiple sources of waste carbon. Advances in technology and a global momentum to avert the deepening climate crisis have brought us to the cusp of a new industrial era. Recycled CO₂ will be the feedstock, and clean electricity the energy source, to produce the climate-safe materials and fuels that are today made from oil. Hear about examples of carbon recycling and the opportunities to establish a new carbon economy and create materials for consumer goods, from packaging to textiles.

Dr. Sean Simpson

Chief Science Officer & Founder

LanzaTech

PACKAGING – FRIEND OR FOE. THE CHALLENGES AND DEMANDS OF A GLOBAL FOOTPRINT

10:30-11:00 AM

There are many parameters to be taken into consideration when choosing the right packaging for the job, including product needs and legislative, investment and consumer considerations. This session touches on some of the elements that make this such a topical, challenging and interesting field, including where focus could be spent in the future.

Graeme Smith

Global Sustainable Packaging Dir Mars Petcare

BEYOND PEAK PLASTIC: ENGINEERING A HIGHPERFORMANCE FUTURE WE CAN AFFORD

11:30-12:00 PM

According to McKinsey, more than 75% of millennials say they think about sustainability when they make their purchases. The packaging industry has long accepted ubiquitous plastic use; however, changing consumer preferences no longer make unsustainable materials a viable option for long-term business strategy. Zume CEO Alex Garden discusses how plastic alternatives like molded fiber can be an economically viable solution to help brands and packaging manufacturers reach their sustainability commitments.

Alex Garden Chairman & CEO Zume

THE RETURNITY PACKAGE DEAL: LESS WASTE, LOWER COSTS

12:30-1:00 PM

With 100 billion global parcel deliveries a year, and over 200 billion by 2026, the environmental impact is undeniable. U.S. packaging alone can pave a milewide cardboard road from New York City to Los Angeles and back—three times over. Returnity replaces single-use shipping and delivery packaging by designing, manufacturing and implementing cost-effective reusable packaging and circular logistics systems for companies like Walmart, Estée Lauder, New Balance and Rent the Runway. Its packaging is now used for more than 2 million shipments and deliveries a month. Returnity identifies high-return-rate opportunities for clients and is especially passionate about educating businesses and consumers on the value of the package return rate. Rates below 75% are actually worse for the planet. The average Returnity bag or box can be used for 20 customer shipment cycles (40 total) with a 95.5% return rate.

Mike Newman CEO Returnity

INNOVATING PACKAGE PORTFOLIOS THROUGH A POSTPANDEMIC DEMAND

1:30-2:00 PM

Learn about innovating package portfolios through a post-pandemic demand via holistic packaging design and engineering approach.

Kory Nook VP, Packaging R&I DANONE

PET PACKAGING TRENDS AND COMPARATIVE LCA RESULTS

2:30-3:00 PM

Polyethylene terephthalate (PET) is the perfect material for numerous applications and achieves legislative and brand commitments. This session on all things PET covers trends, debunks myths and describes a new comparative life cycle analysis (LCA) that evaluates environmental impacts for several widely used types and sizes of containers.

Laura Stewart Dir, Operations

National Association for PET Container Resources (NAPCOR)

SHOW DAILY OCTOBER 23, 2022 24 PACK EXPO International 2022

LOOP’S ROLE IN THE FUTURE OF REUSABLE PACKAGING

3:30-4:00 PM

This session focuses on the evolution of the Loop platform and how Loop works with CPG brands, retailers and quick-serve restaurants to build a network of reusability. We will discuss: approaches to reusable packaging including design, material type, labeling and dispensers/closures; Loop as a “pre-fill” platform; and Loop’s growth from mid-2019 to present

Tony Rossi

EVP, Business Development TerraCycle

WEDNESDAY, OCTOBER 26, 2022

DEVELOPING PRODUCTS AND SOLUTIONS TO SUPPORT A CIRCULAR ECONOMY

9:30-10:00 AM

Urgent focus is being directed at climate change, greener transportation, fresh food, personal care, clean water, Circular Economy, plastic waste and renewable feedstocks. This presentation addresses these challenges, relays them through the UN Sustainability Development Goals, and outlines a portfolio of solutions to support downstream customers as they set their sustainability and Circular Economy goals.

Matthew Marks Leader, Circular Economy, Americas

SABIC

HEADWINDS, TAILWINDS AND REALISTIC EXPECTATIONS FOR PET RECYCLING IN 2025

10:30-11:00 AM

PET recycling is at a crossroads as the industry drives towards 2025 goals. Brands, consumers, regulatory agencies and NGOs support systemic improvements, while known limitations restrain success. We will consider what is reasonably possible for increased PET recycling, what changes are needed, and what the rPET industry might look like in 2025.

Steve Lyons Dir of Strategic Environmental Analysis SBAcci Consulting Group

THE EVOLUTION OF PHARMACEUTICAL PACKAGING

11:30-12:00 PM

An examination of the future of pharmaceutical packaging as it becomes more sustainable and meets the needs for greater convenience, self-administered drugs, reduced hospital stays and serving patients at home. We also will look at how past and present innovations, focused on meeting patient and product needs, offer a path for the future.

Ron Yakubison

Exec Dir, Global Technology Packaging Merck

IMPROVING RESIDENTIAL RECYCLING WITH BOX TO NATURE!

12:30-1:00 PM

The paper industry, partnering with the Paper and Packaging Board, is introducing a residential recycling shipping box messaging initiative called Box to Nature. The partnership is working with customers and large brands to educate consumers about the box with easy instructions on recycling right, every time. Learn about how you can become part of this important initiative.

Mary Anne Hansan

President

Paper and Packaging Board SD

SHOW DAILY OCTOBER 23, 2022 25 PACK EXPO International 2022 Find your scale at YamatoAmericas.com Always the best way to weigh. WEIGHING & FILLING SOLUTIONS NEW Yama

Tray Filling for Leafy Greens

Commercial

Scales

High Speed Bulk Weighing

• From napkin drawing to operational equipment • Maximizing productivity, minimizing floor space • OEM communications ... we’ll connect the dots • Immediate solutions designed for future expansion • Agency compliance built directly into your conveyor Accumulate, Rotate, Elevate, Integrate, Lift-gate, Incline, Combine, Decline, Alpine, In-line, Grip, Flip, Split, Invert, Divert, Merge, Twist, Turn, Curves, Transfer, Push, Stack, Hand pack, What’s that?, Serpentine, Sanitary. m to Multi-Conveyor ... your best, conveyed better. www.multi-conveyor.com But your secret is always safe!

WestRock sponsors Showcase

Exhibit displays award-winning packages from around globe.

WestRock (Booth EB-43, S-2130) presents winning entries from worldwide packaging competitions as the exclusive sponsor of this year’s Showcase of Packaging Innovations® (Booth W-20052).

“At WestRock, we are focused on delivering bold innovation to solve our customers’ biggest challenges,” says Margaret Herndon, the company’s chief marketing o cer. “ e Showcase displays the best the industry has to o er in packaging innovation, and we are excited to be part of a program that engages customers and generates new thinking and new solutions.”

Show producer, PMMI, e Association for Packaging and Processing Technologies (Booth N-4550), is pleased to partner with WestRock on this initiative.

“ e Showcase of Packaging Innovations has come to be a show oor favorite at PACK EXPO,” says Jim Pittas, president and CEO, PMMI. “We are thankful for companies like WestRock who seek to inspire the future of our industry and motivate package designers by showcasing packaging that is functional, innovative and sustainable.”

is year’s Showcase participants include 13 organizations from around the world. A sampling of the award winners on display is pictured here.

For more info, visit www.PACKEXPOinternational.com, www.westrock. com, www.abre.org.br, www.aimcal.org, www.dow.com, www. expack.org, www.fsea.com, www.imdassociation. com, www.packaging.com.ar, www.iopp.org, www.profoodworld.com, https://paperbox.org/, www.reusables.org, www.tube.org, www.worldpackaging.org. SD

The Best in Show package in IoPP’s AmeriStar competition, Blue Buffalo Tastefuls Spoonless Singles from General Mills and Product Ventures, provides a perfectly portioned split cup with a built-in chopper. The recyclable polypropylene split cup separates easily, reducing the need to store opened containers in the refrigerator.

PARTICIPANTS

ABRE - Brazilian Packaging Association (Booth N-6003)

AIMCAL - Association of International Metallizers, Coaters and Laminators (Booth N-4527)

Dow (Booth W-22017) Dow Packaging Innovation Awards

Flexible Packaging Association (Booth N-4533)

Foil & Specialty Effects Association (Booth N-4536)

In-Mold Decorating Association (Booth N-4534)

IAE - Instituto Argentino del Envase (Booth N-6101)

Institute of Packaging Professionals (IoPP) (Booth N-4523)

PMMI Media Group (Booth N-4550) ProFood World’s 2021 Sustainability Excellence in Manufacturing Awards

Paperboard Packaging Council (Booth W-20052)

Reusable Packaging Association (Booth LU-6737)

Tube Council of North America (Booth W-20052)

World Packaging Organisation (WPO) (Booth N-4902)

Last year, ABRE honored this canister for ease-of-use and ergonomics. Package features waisted silhouette and onepiece, flip-top closure with an induction seal. A pull ring ensures complete removal of the seal.

SHOW DAILY OCTOBER 23, 2022 26 PACK EXPO International 2022

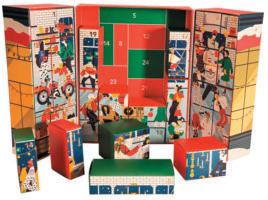

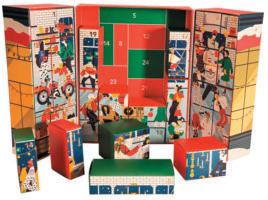

The Package of the Year Award winner in the 2021 North American Paperboard Packaging Competition, the 2020 edition of Kiehl’s Advent Calendar produced by Johnsbyrne, features a storybook display design to deliver a premium unboxing experience while eliminating the use of plastic. A 100% paper-based rigid outer box houses 24 snuggly packed straight-tuck folding cartons containing product.

A capsule dispenser from Germany’s PACKSYS earned a President’s Award in the WPO’s WorldStar competition. Designed for people with limited motor function, the dispenser releases

one

capsule

at a

time via an easy-topress, lockable actuator.

The Diamond Award, the top prize in the Dow Packaging Innovation Awards, considers three criteria: sustainability, technological innovation and enhanced user experience. The Brookfarm Roll ‘n’ Recycle curbside-recyclable, high-barrier stand-up pouch from Australia’s OF Packaging earns top honors on each point.

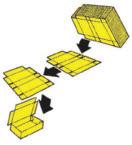

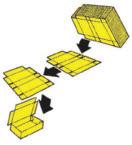

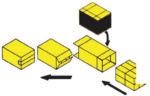

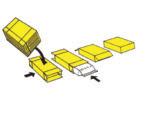

The lightline machines from Schubert can be delivered quickly and are exceptionally attractive in terms of price . With the preconfi gured machines, customers can adapt more fl exibly to market trends and signifi cantly shorten their time-to-market.

The LIGH LI C CK consists of a single compact machine frame, and packs boxes, cans, bags or bottles into cartons and trays with or without a lid, wrap-around cartons and RSC cartons. It offers an affordable and space-saving possibility to automate packaging processes with the most effi cient technology on the market while ensuring the highest availability and packaging quality.

The world’s leading FMCG and private label manufacturers rely on Schubert. www.schubert.group

WH

WH

Y

F C H LD I B

?

WH W LD Y LIK CK?

D CI I IC . H LIGH LI C CK

CK

X

CHIC

G OCTOBER 23 – 26, 2022 BOOTH # 8730

WELCOME

Innovation Stage hosts 60+ sessions

Processing Innovation Stage makes Chicago debut.

Anattendee favorite, the Innovation Stage, returns to PACK EXPO International with more than 50 informative sessions. e free, 30-minute presentations occur throughout each day on three stages (Booths N-4560, N-4580 and N-4585) in the concourse of the North Building near Starbucks.

Topics include sustainability and eCommerce, building a resilient supply chain, automating minimal material operations, cyber resilience, robotics, upgrading from heat sealing to ultrasonic sealing, brand protection and smart sensors.

New this year, after a successful launch at PACK EXPO Las Vegas, the Processing Innovation Stage(Booth LU-7130) in the Lakeside Center concourse will feature sessions on Sunday, Monday and Tuesday focused on high-pressure pasteurization, product handling, batching and blending, clean-out-of-place parts washers and sanitary drainage system design.

Innovation Stage presenters rank as subject matter experts and represent a cross-section of exhibitors, including Syntegon Packaging Technology (EB-15, S-3514), Amcor Rigid Packaging (S-3705, S-3814), Placon

(W-24033), SMAC Moving Coil Actuators (N-5774), Michigan State University (W-20044), Siemens Digital Industries (N-5148), WestRock (EB-43, S-2130), Amcor Flexibles North America (S-3705, S-3814), Brenton, a ProMach product brand (N-5546), Emerson (N-4736), Soft Robotics (N-5230) and JBT-Avure (LU-7118)

e full Innovation Stage schedule is listed on the following pages. Check the PACK EXPO International App or the show website for the latest updates.

PACK EXPO International o ers many other educational opportunities, including PACK to the Future (Booth W-20025) (see program on p. 22), e Forum at PACK EXPO (Booth N-4543) (see program on p. 44), and the new Industry Speaks (Booth N-4565) (see schedule, p. 14). e Reusable Packaging Learning Center (Booth LU-6737) also is hosting daily educational sessions.

Updated schedules may be found on the PACK EXPO International App or the show website.

For more info, visit www.PACKEXPOinternational.com. SD

SUNDAY, OCTOBER 23, 2022

THE FUTURE OF RECYCLED FOOD PACKAGING AND CLOSING THE LOOP

12:00-12:30 PM

Innovation Stage 1|N-4560

Creating a closed loop for food packaging has never been more critical. is session will cover the factors driving this need and discuss what it will take to get to a closed loop for a more sustainable future in food packaging.

Yui Kamikawa VP, Sustainability

Klöckner Pentaplast

BAKING SUSTAINABILITY INTO YOUR OPERATIONS

12:00-12:30 PM

Innovation Stage 2|N-4580

During this session, you’ll gain tips and best practices from our experience working with real customers and how you can take the rst crucial steps on your own sustainability journey.

Tam Osentowski

Principal Sustainability Consultant

Schneider Electric

DIGITAL DOUBLE LIFE: THE INTERSECTION OF TECH & BUSINESS

12:00-12:30 PM

Innovation Stage 3|N-4585

Most of us are living a digital double life. We use smart devices for everyday tasks in our personal lives and legacy systems and processes at work to tackle today’s biggest challenges. In this session, learn the secret to easily connecting your supply chain without uprooting your current tech stack.

Matthew Wright

Founder & CEO Specright

ELECTRIC ACTUATOR BEATS PNEUMATIC—PRICE, SPEED AND LIFE

12:00-12:30 PM

Processing Innovation Stage|LU-7130