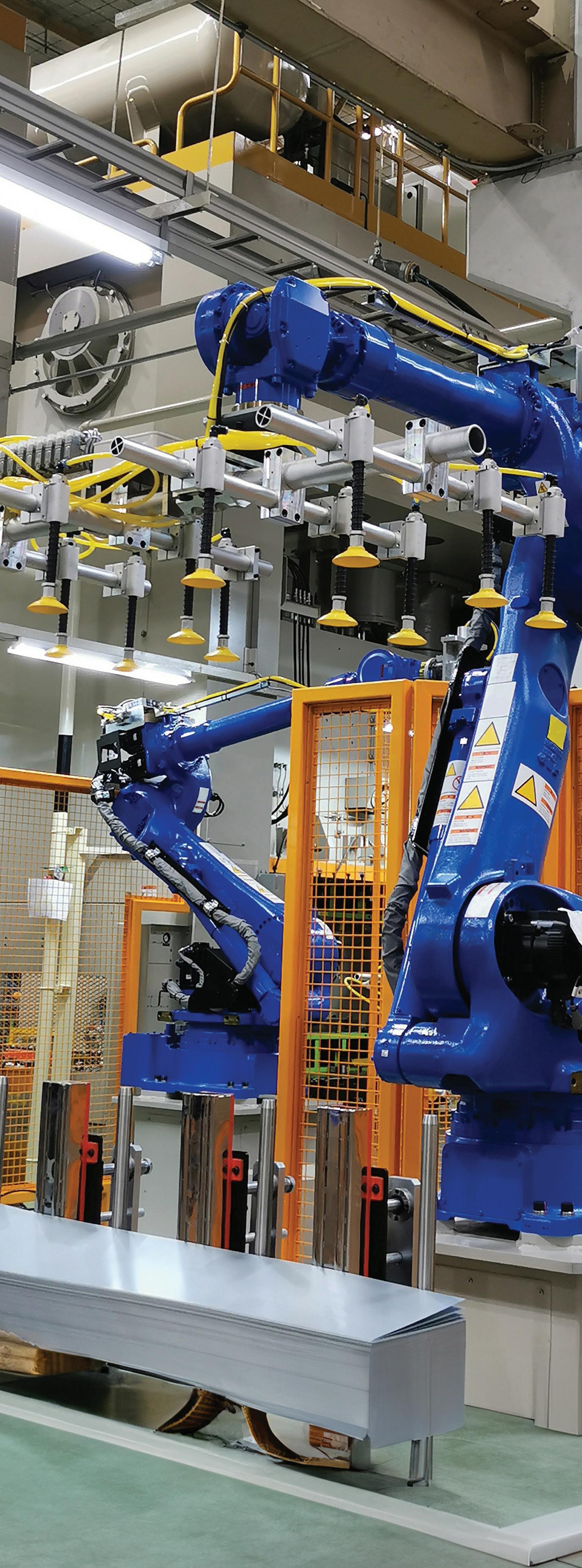

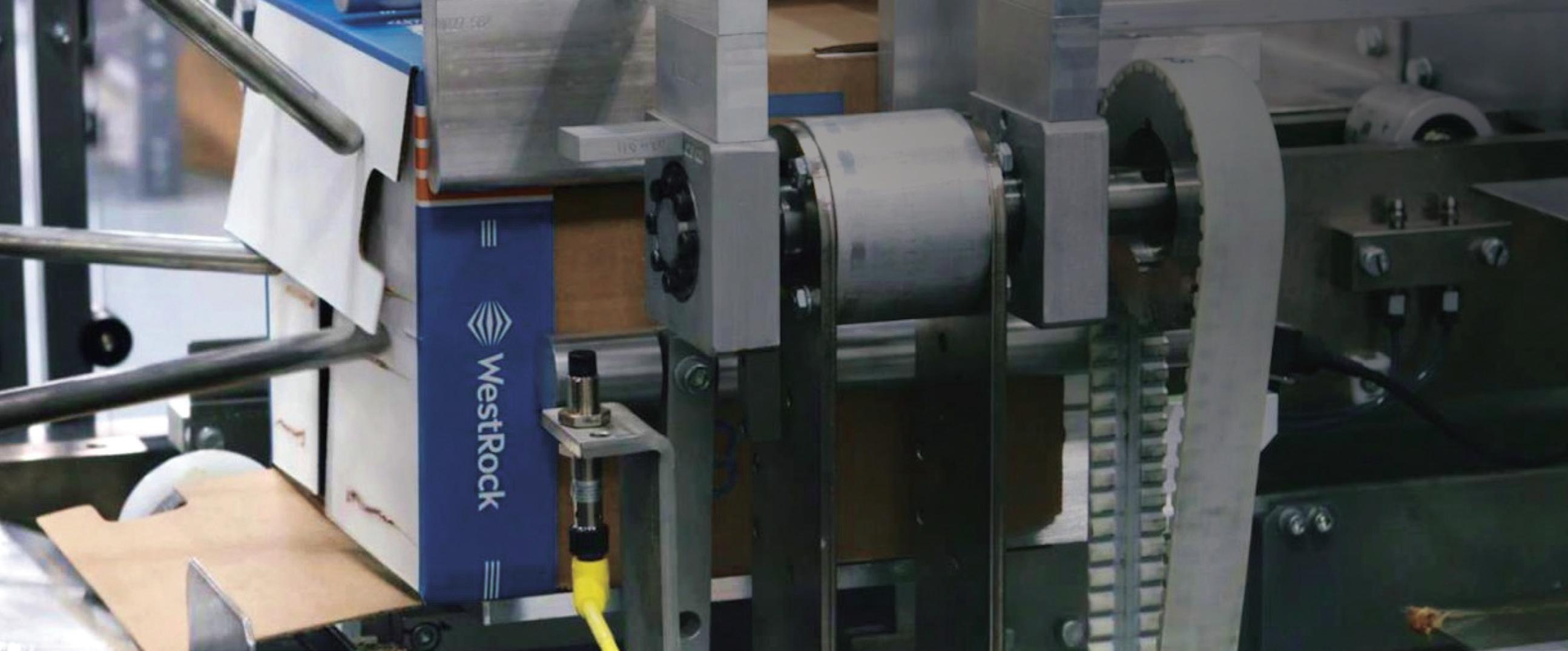

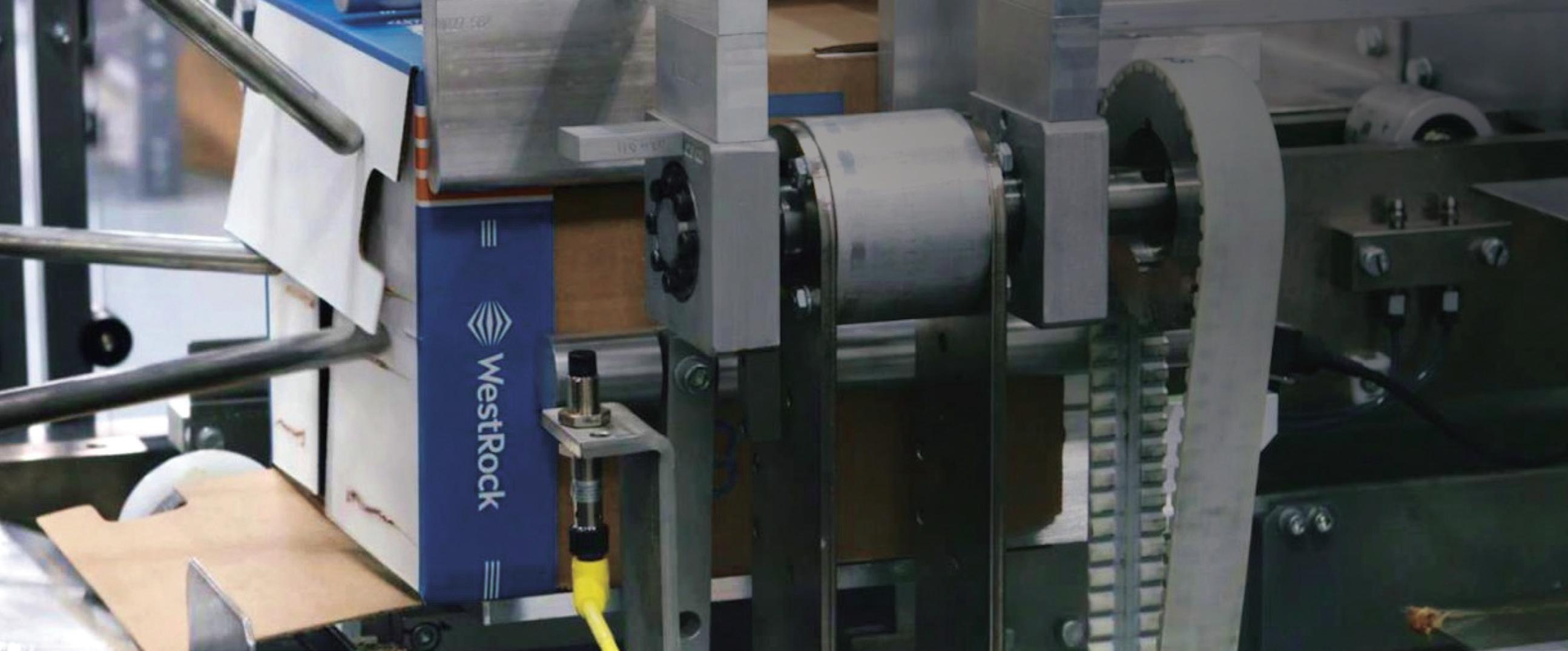

2024 MAY/JUN packworld.com 30 Compostable Packaging’s Ascendancy 52 Unilever Cuts Time-to-Market via 3D Printing 64 Club Coffee’s Recyclable, Paper-based Canister 72 Refresco’s Food-grade, Mono-material HDPE/rHDPE Aseptic Pack May Disrupt 10/104 P&G’s Tiles Part with Plastic Bottles, Drop Water Weight Precision case forming, better box performance –learn more at: westrock.com/ automation

w ©202 y an ogo ar y W y. s r v How do y h W s pr ound a This pr our pr hrough y our supply chain by r s. www.w

•

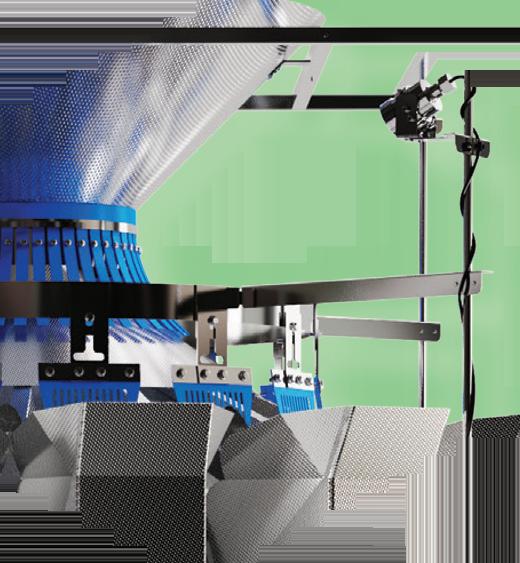

• Topload closing at speeds up to 200 cpm

• Endload cartoning at speeds up to 325 cpm

• Integrated product orientation and loading

•

Keeping The Promise For More Than 75 Years. Kliklok Cartoners

Topload forming in lock and glue formats

Scan to watch an awesome Kliklok video playlist! syntegon.com/2p

Standalone machines and complete lines

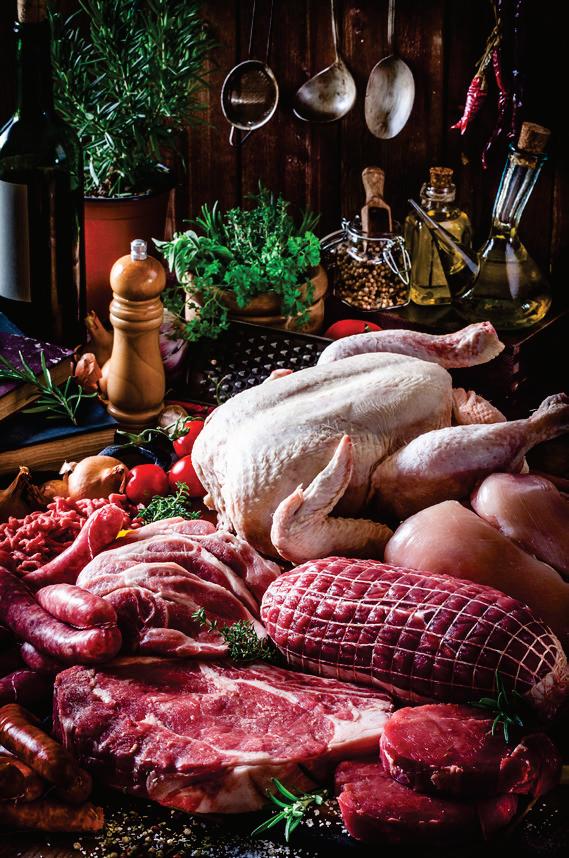

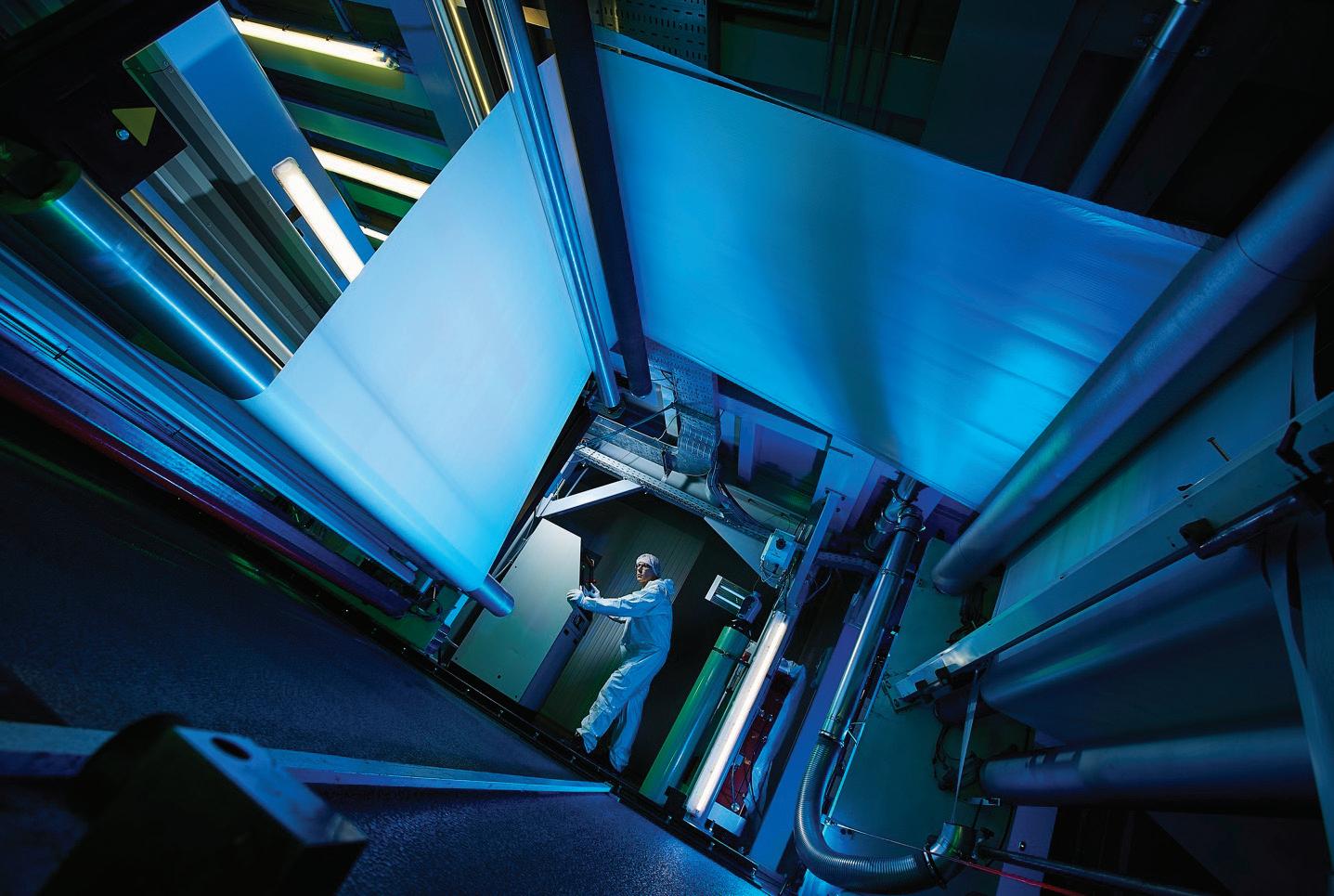

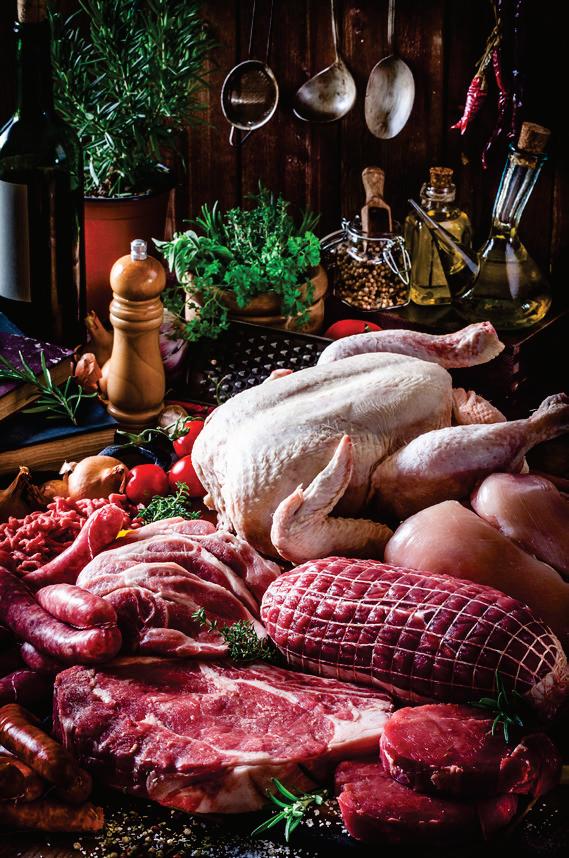

CM/CP Refresco’s monomaterial aseptic rigid carton is curbside recyclable. This product of microceullular foaming called reZorce binds layers of HDPE. Recycled content rHDPE inside the structure helps with PCR content regs. Virgin HDPE is used for food-contact layers and for standard or digitally reverse printed decoration layers.

FEATURES

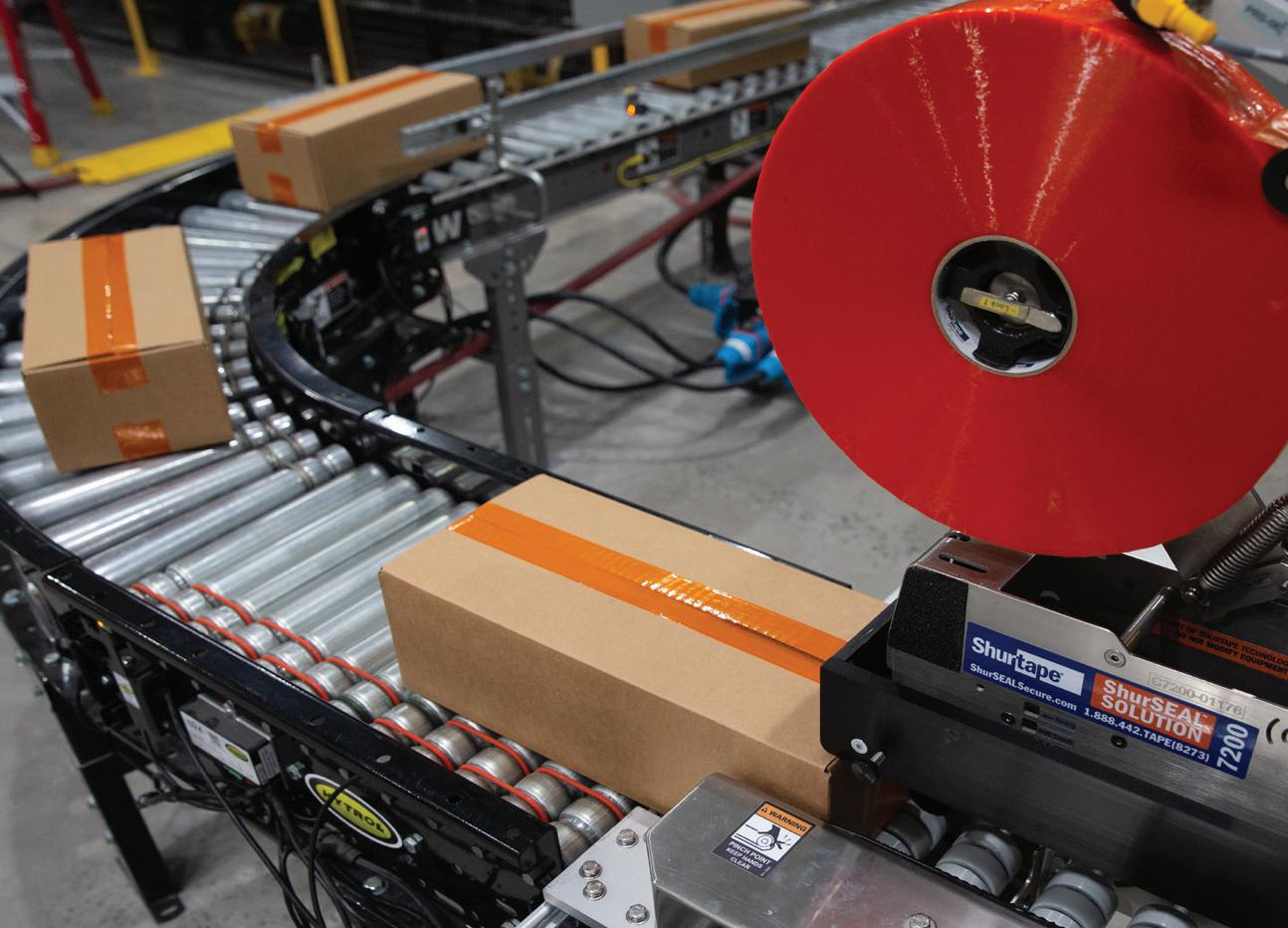

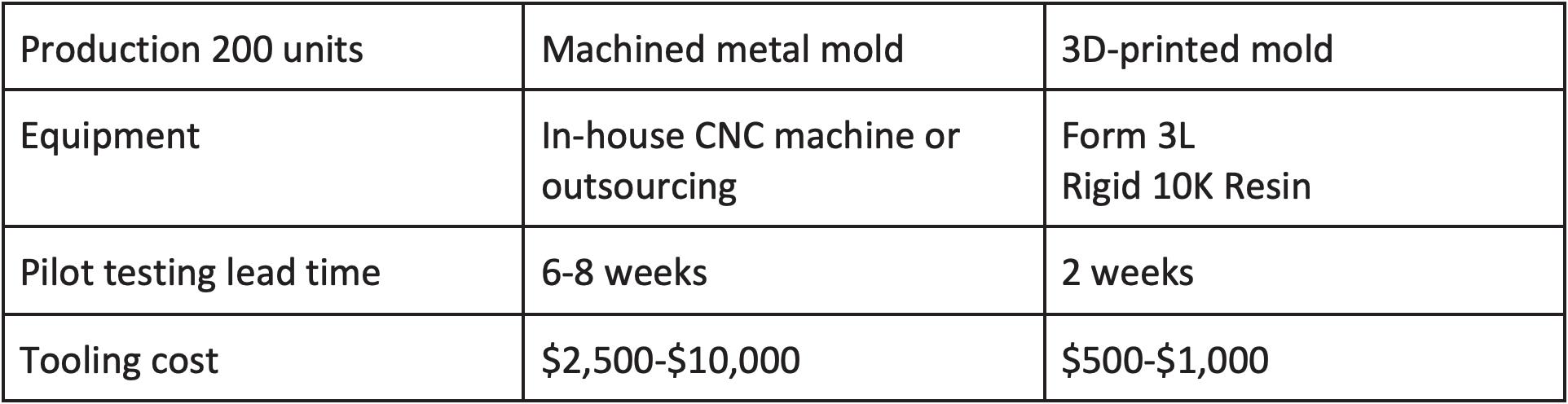

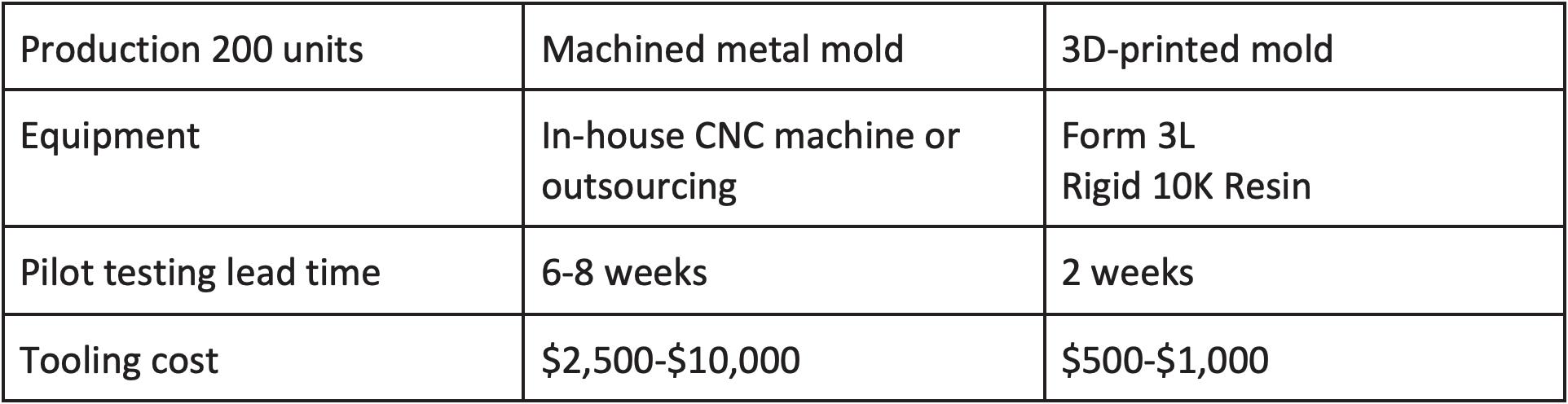

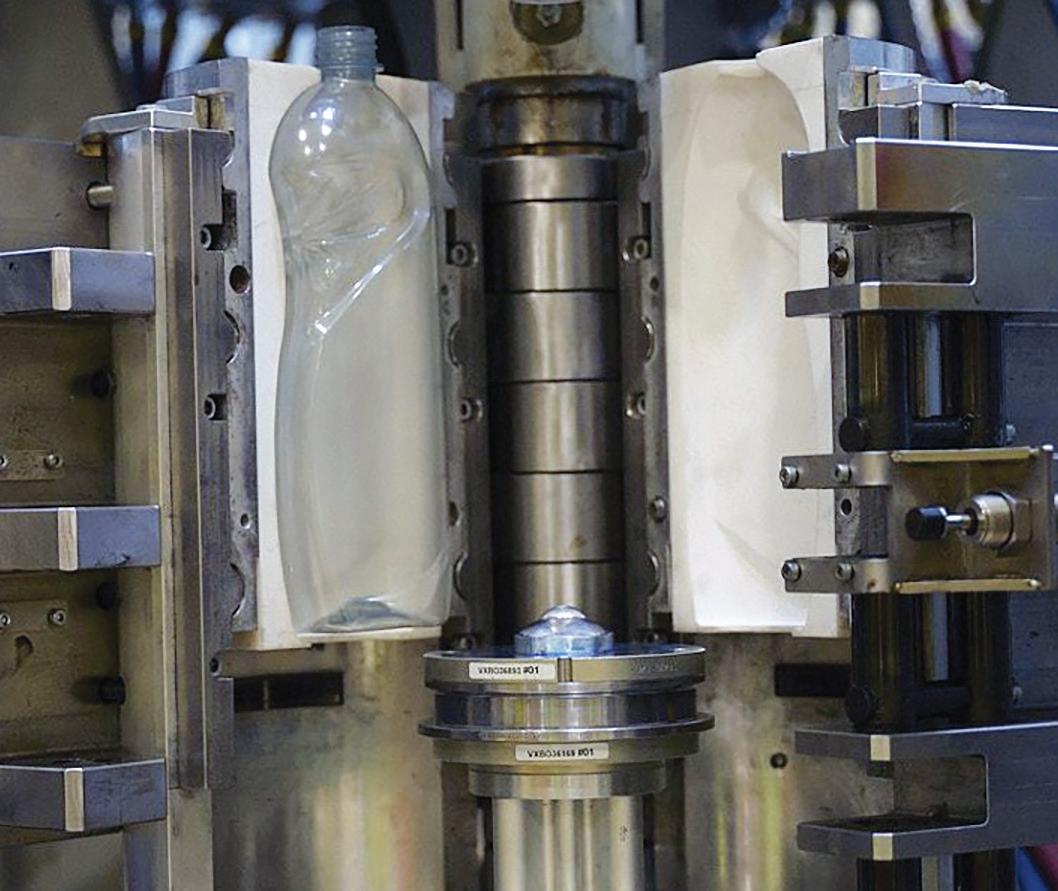

52 DIGITALIZATION

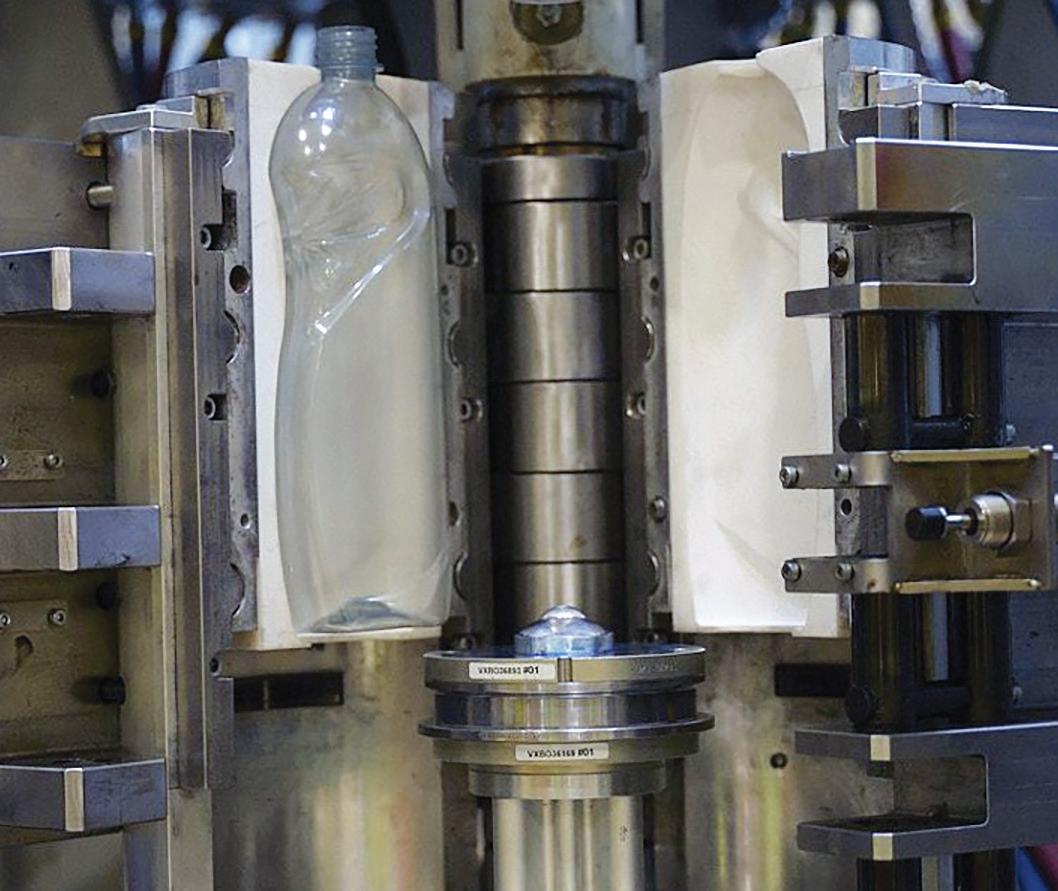

3D-Printed Molds Speed New Unilever Bottle Designs to Market

For Unilever, bottles that are stretch blow molded with a 3D-printed tool are nearly indistinguishable from the nal product produced through traditional metal tooling processes, and usher new formats to market more quickly.

64

Breakthrough in Recyclable Coffee Packaging

Club Coffee, one of Canada’s largest coffee roasters and packaging solutions providers to the ‘At Home’ segment, has burnished its sustainability offerings through its AromaPak family of sustainable and innovative packaging solutions for whole bean and ground coffee.

66

Dr. Bronner’s Paperboard

Cartons Re ll rPET Bottles to Ace LCA

Paperboard cartons get high LCA marks, but break down when wet. Meanwhile, 100% rPET bottles are circular, work great in the shower, and if they’re re lled, are not single-use. Dr. Bronner’s re llable carton leverages both formats’ strengths.

72

Refresco to Disrupt with Mono-material, Aseptic, FoodContact HDPE/rHDPE Carton

Expected to be on shelves by Q3 is a gamechanging new aseptic carton format. While brands swap plastic for paper, reZorce ips the script with circular, mono-material HDPE/ rHDPE for paper. Finishing validation, CM/CP Refresco will be rst to market.

76

SPE Foundation Offers Sustainable Packaging Patch for Girl Scouts

The new Girl Scout Gold Award SPE Foundation Grant is now available for eligible Girl Scouts who wish to make a positive impact on community recycling, sustainability, or diversity in STEM, helping fund Girl Scout troops interested in participating.

82

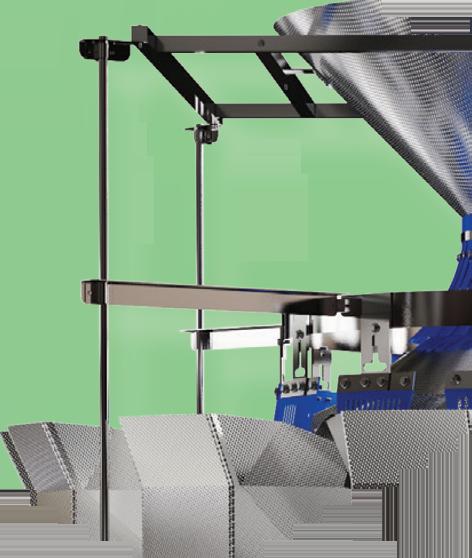

Gentle

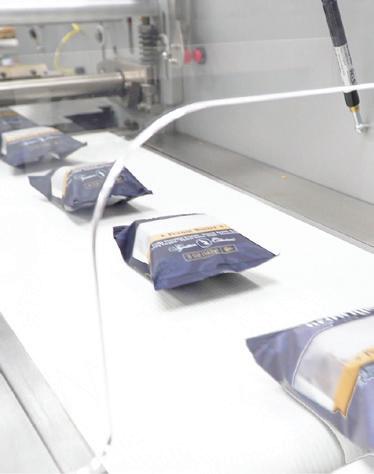

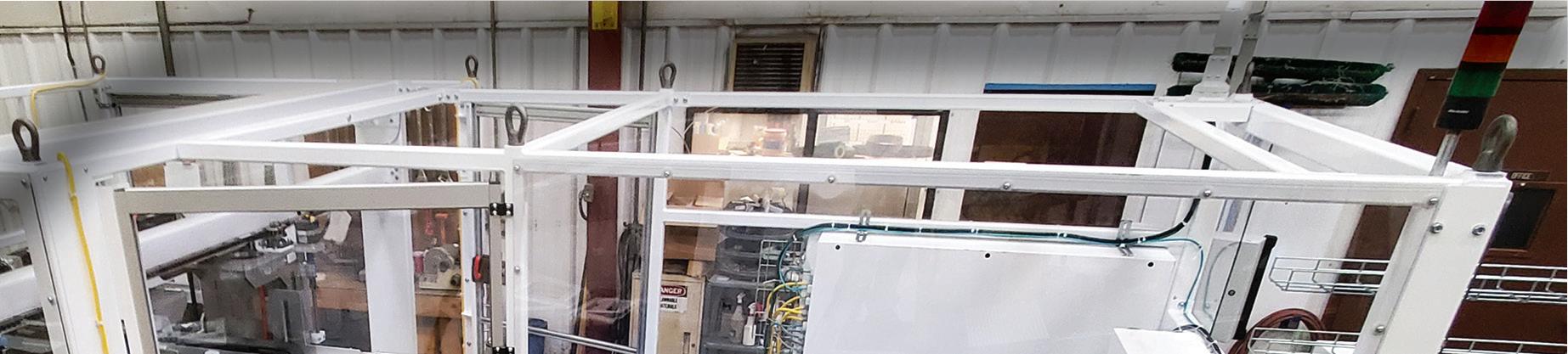

Case Packing Cures Broken Bottle Blues

The ascendancy of contract packaging means that once neglected bottling lines are coming back strong. Here’s how Yards Brewing switched drop pack operations to pick and place, reducing scrap to the bare minimum, both for its own and its contract customers’ craft brews.

2 PW MAY/JUN2024

VOL31 NO3

72 52 66 76

EDITORIAL ADVISORY BOARD

Aladin Alkhawam Supply Chain Security Director, Endo International plc

Jan Brücklmeier Technical Application Group Packaging Technology Expert, Nestlé

M. Shawn French Director – Innovation & Packaging Engineering (Beverage), Danone North America

Patrick Keenan R&D Packaging Engineer, General Mills/Annie’s Organic Snacks

Mike Marcinkowski Global R&D Officer, GPA Global & Hub Folding Box Co.

David Smith, PhD Principal, David S. Smith & Associates

Brian Stepowany Packaging R&D, Senior Manager, B&G Foods, Inc.

Jasmine Sutherland President, Texas Food Solutions; Vice President, Perfect Fit Meals

Expo, MRFs’ AI sortation informs brands pwgo.to/8292

Gamechanging, all-HDPE aseptic cartons are recyclable pwgo.to/8295

Recycling Conference registration open pwgo.to/8294

4 PW MAY/JUN2024 Packaging World® (ISSN # 1073-7367) is a registered trademark of PMMI, The Association for Packaging and Processing Technologies. Packaging World® is published seven times annually by PMMI with its publishing office, PMMI Media Group, located at 401 N. Michigan Avenue, Suite 1700, Chicago, IL 60611; 312.222.1010; Fax: 312.222.1310. Periodicals postage paid at Chicago, IL, and additional mailing offices. Copyright 2024 by PMMI. All rights reserved. Materials in this publication must not be reproduced in any form without written permission of the publisher. Applications for a free subscription may be made online at www.packworld.com/subscribe. Paid subscription rates per year are $254 in the U.S., $363 Canada and Mexico by surface mail; $605 Europe and South America; $907 Far East, Australia, and other countries by air mail. Single copy price in U.S. is $20. To subscribe or manage your subscription to Packaging World®, visit Packworld.com/subscribe. Free digital edition available to qualified individuals outside the United States. POSTMASTER; Send address changes to Packaging World®, 401 N. Michigan Avenue, Suite 1700, Chicago, IL 60611. PRINTED IN USA by Quad. The opinions expressed in articles are those of the authors and not necessarily those of PMMI. Comments, questions and letters to the editor are welcome and can be sent to: editors@packworld.com. Mailing List: We make a portion of our mailing list available to reputable firms. If you would prefer that we don’t include your name, please write us at the Chicago, IL address.

VIDEO 3D-printed

rush Unilever to market pwgo.to/8290 VIDEO Walk

line

Yards Brewing

EVENT COVERAGE From

REGISTRATION OPEN

packworld.com COLUMNS 7 Lead Off 44 The Legal Side 46 The Big Picture 48 Sustainable Packaging 50 Design Impact 104 The Insider NEWS/EVENTS 8 News 28 Quotables/By the Numbers 102 Industry Watch INTERVIEW 30 First Person PRODUCTS 96 Technology ADVERTISING 103 Advertiser Index Connect with a Leaders in Packaging supplier today! www.packworld.com/leaders 10 50

DEPARTMENTS

molds

the packaging

at

pwgo.to/8291

Waste

VIDEO

Packaging

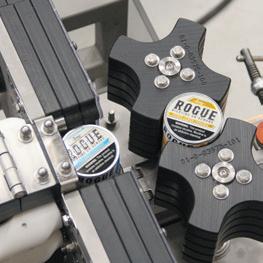

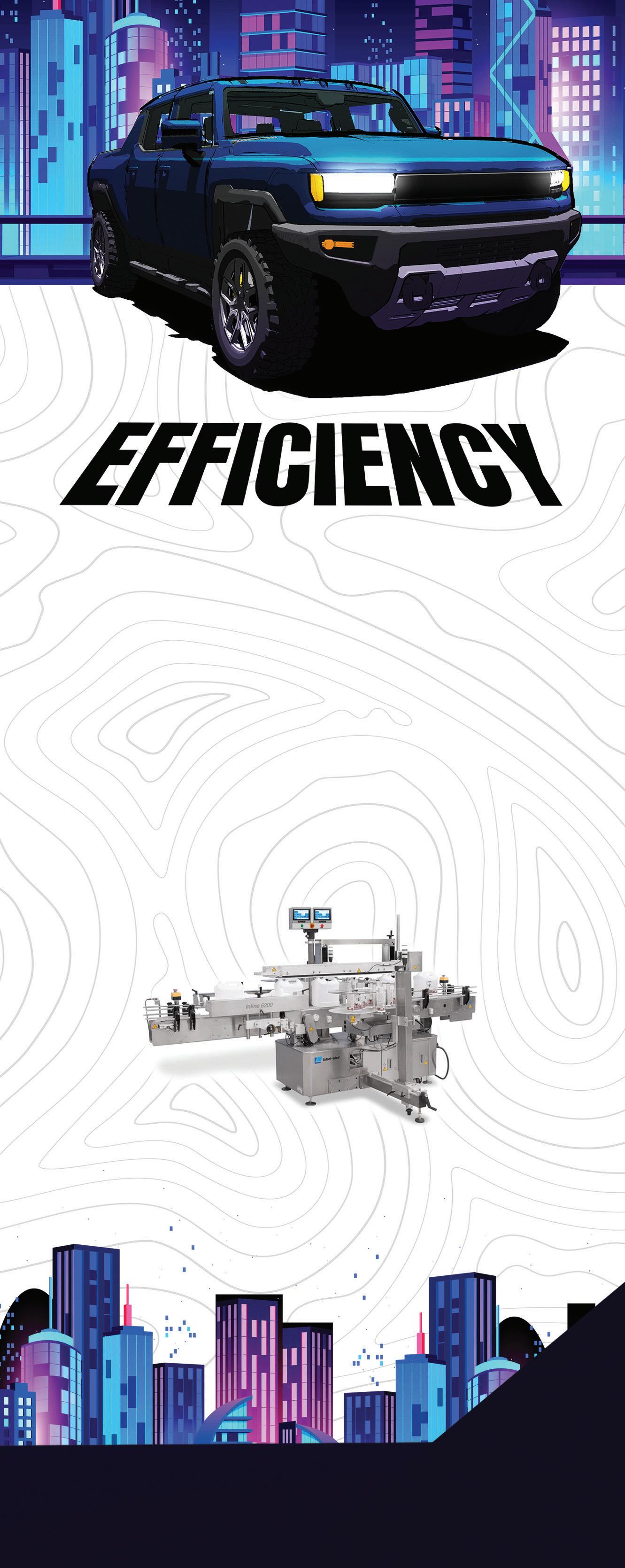

VISUALIZE MFLEX™ LABELING SYSTEMS IN MOTION

Flexibility is an essential component of the MFlex™ concept. The modular design allows for one design philosophy to be utilized for a wide range of applications by simply choosing the required modules from our extensive portfolio. Composed of a label applicator and integrated product handling solution, the MFlex™ precisely labels virtually any type of packaging shapes and product types while providing an easy and flexible platform to control and maintain.

SEE HOW THE MFLEX PRESSURE-SENSITIVE LABELING SYSTEM COMES TOGETHER

SELECT AN MFLEX™ CONFIGURATION

Go from modular components to a complete configuration by selecting from one of six available pressure-sensitive MFlex™ labeling systems.

SEE MFLEX™ LABELING IN MOTION

Preview a production line in motion and see how MFlex™ pressure-sensitive systems apply labels quickly and efficiently to various product types.

ADD ADDITIONAL COMPONENTS

Needing to add variable production codes to your label or package? No problem; simply select the appropriate coding technology for a complete integrated solution.

Visit us online at: www.epilabelers.com/products/mflex-inmotion-visualizer or scan the QR code to see how MFlex™ Pressure-Sensitive Labeling Systems can accommodate primary labeling and additional coding for virtually any type of product or packaging

EPI@ProMachBuilt.com | New Freedom, PA | 717-235-8345 | EPILabelers.com © 2023 ProMach Inc. INCREASE YOUR UPTIME AND LABELING EFFICIENCY CONTACT US TODAY AT EPI@PROMACHBUILT.COM

CONTENT

Matt Reynolds Chief Editor

Anne Marie Mohan Senior Editor

Sean Riley Senior News Director

Casey Flanagan Digital Editor

Pat Reynolds, Sterling Anthony, Eric F. Greenberg, Ben Miyares Contributing Editors

David Bacho Creative Director

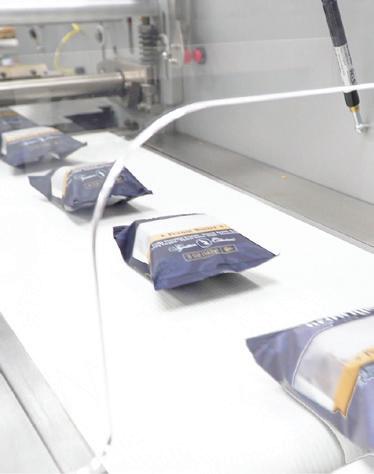

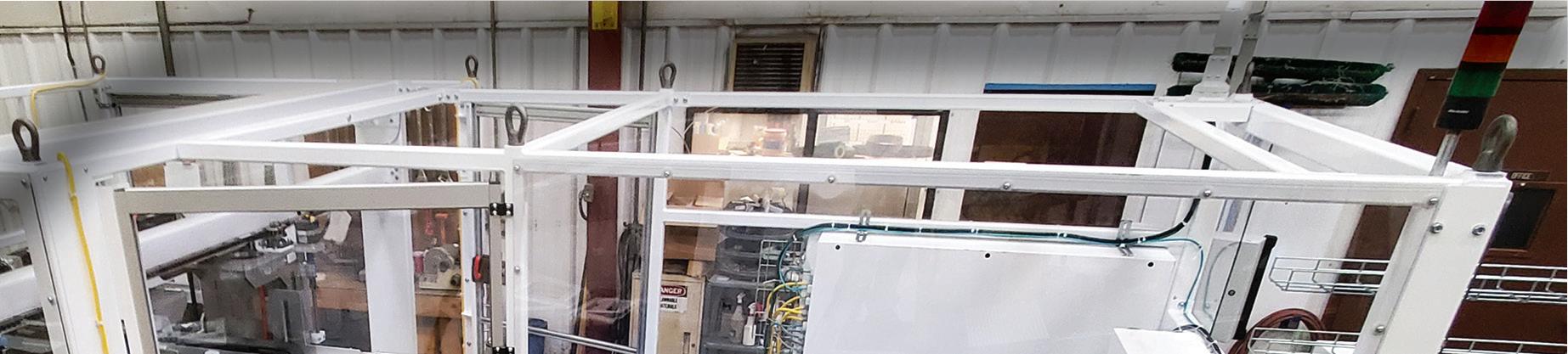

ADVERTISING

John Schrei Vice President, Sales jschrei@pmmimediagroup.com

Lara Krieger Senior Manager, Print Operations lkrieger@pmmimediagroup.com

Janet Fabiano Financial Services Manager jfabiano@pmmimediagroup.com

PMMI MEDIA GROUP

David Newcorn President

Elizabeth Kachoris Vice President, Digital

Kelly Greeby Senior Director, Media Operations

Jen Krepelka Director, Digital Media

Trey Smith Senior Director, Events

Joseph Angel Founding Partner and Executive Vice President, Industry Outreach, PMMI

Questions about your subscription or wish to renew? Contact circulation@pmmimediagroup.com.

PMMI Media Group

401 N. Michigan Ave., Suite 1700, Chicago, IL 60611

Fax: 312/222-1310 Web: www.pmmimediagroup.com

PMMI The Association for Packaging and Processing Technologies 12930 Worldgate Dr., Suite 200, Herndon VA, 20170

Phone: 571/612-3200 • Fax: 703/243-8556 • Web: www.pmmi.org

6 PW MAY/JUN2024 Follow us www.packworld.com

MRF’s Polymer Center Network to Expand Access to Recycled Plastic

There’s good news for brands struggling to source enough high-quality recycled PET, recycled high-density polyethylene, and recycled polypropylene to meet both EPR regulations and their internal packaging goals. Republic Services, the second largest provider of waste disposal services in North America, has launched a first-of-its-kind operation in the U.S.—one of at least four planned by the company—designed to sort and process plastic packaging waste to help meet the growing demand for recycled material. The new Polymer Center, located in Las Vegas, opened in December and is expected to produce more than 100 million pounds of recycled plastics each year, specifically PET flake and color-sorted HDPE and PP, for use in sustainable packaging and other applications.

and baling PP separately for a fifth grade. To sort further, or fractionate, additional grades or types of resins locally “just doesn’t make sense economically,” Keller says.

MRFs are also usually space constrained, he adds. “If you want to produce something different, you need to create another bunker, you need to create another storage area, you generally don’t want to ship those materials,” he says.

Another issue is the contamination of the resulting bales, which leads to inefficiencies and poor-quality recyclate. Currently, a typical PET bale sold by Republic comprises just 60% to 65% PET, with the rest consisting of contamination from labels, caps, and bottle rings. “It’s inefficient,” Keller says.

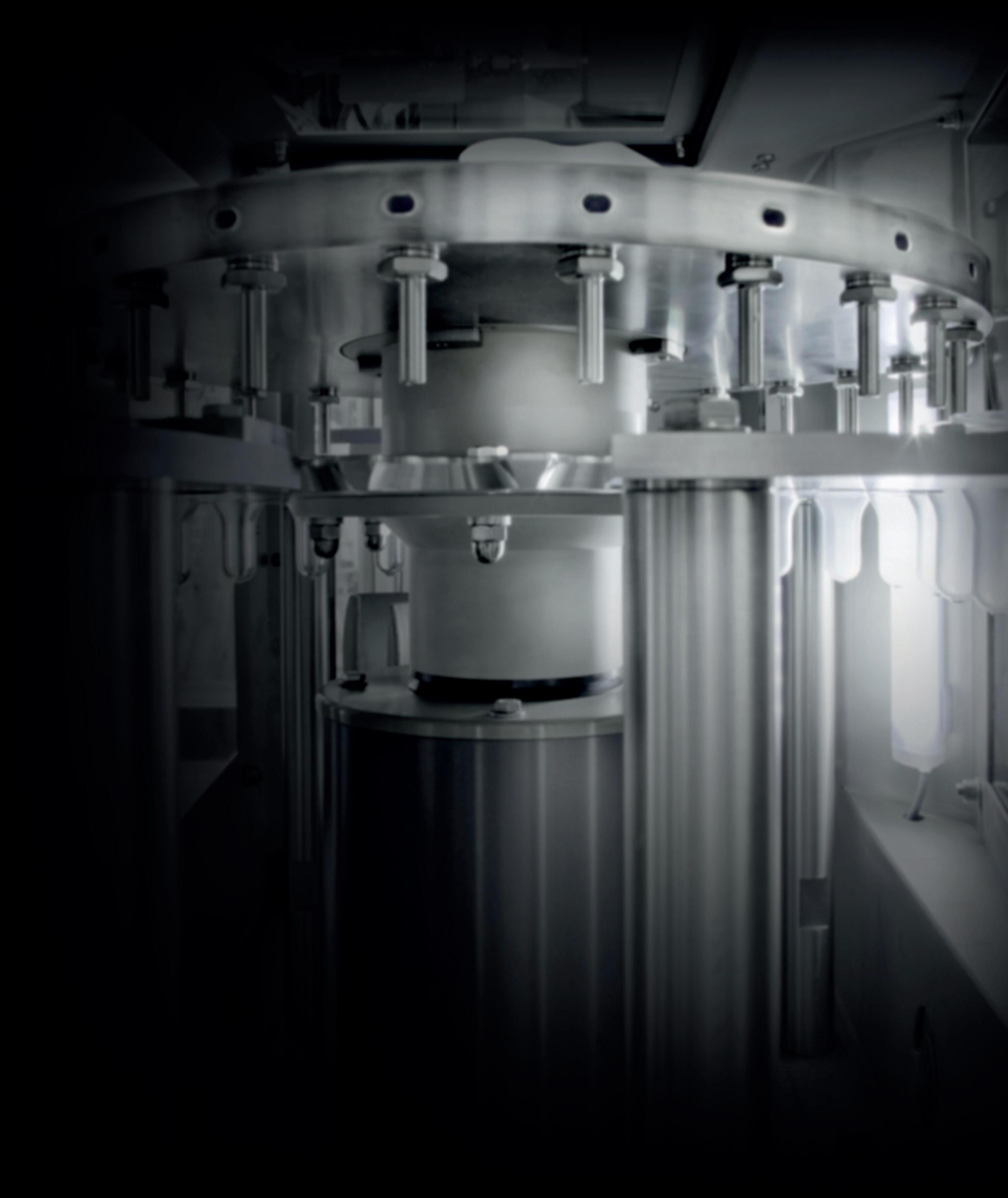

Republic’s new Las Vegas Polymer Center opened in December and is expected to produce more than 100 million lb of recycled plastics each year.

“In its simplest description, the Polymer Center provides secondary processing of recycled plastics to produce higher-quality materials for different end markets.” That’s according to Pete Keller, Republic Services’ vice president of recycling and sustainability, who shares that the regional hub-and-spoke model of the Polymer Center network enables Republic to send curbside-collected and baled plastics from a number of its regional MRFs (material recycling facilities) to a single center for further sortation and processing into multiple, high-quality grades of PET flake and HDPE and PP resins.

As Keller explains, the Polymer Center network addresses several barriers to circularity for plastics. Among them is the small percentage of plastics that make their way into a MRF versus the complexity and investment required to sort them. “On average, only 7% to 8% of the curbside recycling stream that Republic processes are plastics,” he says. “It’s a small percentage of what’s being processed overall. Seventy to 75% of what we make and sell is fiber-based, such as paper and cardboard. So the focal point of our operation is processing those materials.”

MRFs typically sort and bale four grades of plastic: PET, notably beverage bottles, natural or non-pigmented HDPE from milk jugs, pigmented or colored HDPE, which results in a bale of mixed colors, and “everything else,” i.e., PVC, LDPE, PP, PS, and “other.” Increasingly MRFs are sorting

“You’ve got upfront processing costs, transportation costs, yield-loss considerations, and potential disposal considerations.”

Most of these curbside PET bales are converted into textiles, such as carpet and clothing, which have limited end-of-life options. For HDPE, mixed-color bales can only be used to produce grey or black packaging, limiting end-market applications. By sending all baled materials to one facility, Republic can more efficiently deploy capital to further sort the grades of plastic. From natural and mixed-color bales of HDPE, Republic is producing natural and white grades, along with a red, orange, and yellow HDPE grade that can be used to produce orange HDPE packaging. PP is sorted into natural, white, and “other.” Polyolefins are further sorted into food and non-food end-use applications as well.

In the case of PET, Republic takes the PET bale “all the way to a clear, hot-wash flake that yields essentially 100% rPET,” shares Keller. This enables the material to go back into packaging applications, such as beverage bottles, and food packaging, including thermoforms. In late 2023, The Coca-Cola Company committed to purchasing a significant share of the PET flake from the Las Vegas facility.

For processing of color-sorted HDPE and PP into custom, drop-in resins, Republic formed a joint venture with polymer recycling company Ravago called Blue Polymers. By year-end 2026, Republic’s national network will include four Polymer Centers, the second of which is scheduled to be up and running by Q4-24/Q1-25 in Indianapolis, and three co-located Blue Polymers facilities. The first Blue Polymers plant is under construction in Indianapolis and is expected to begin production in Q1-25.

The network will serve 80 of Republic’s regional MRFs and has been designed with enough capacity to serve third-party volumes comprising plastic bales from other MRFs.

“The Polymer Center is really about enabling greater circularity,” says Keller. “It’s about keeping these materials in the marketplace longer, turning them over more times, and meeting a need. Most consumer packaged goods companies have pretty ambitious packaging goals as it relates to recycled content. So we think we’re addressing a real need in the marketplace by bringing these materials back into these circular solutions.”

—Anne Marie Mohan

NEWS 8 PW MAY/JUN2024

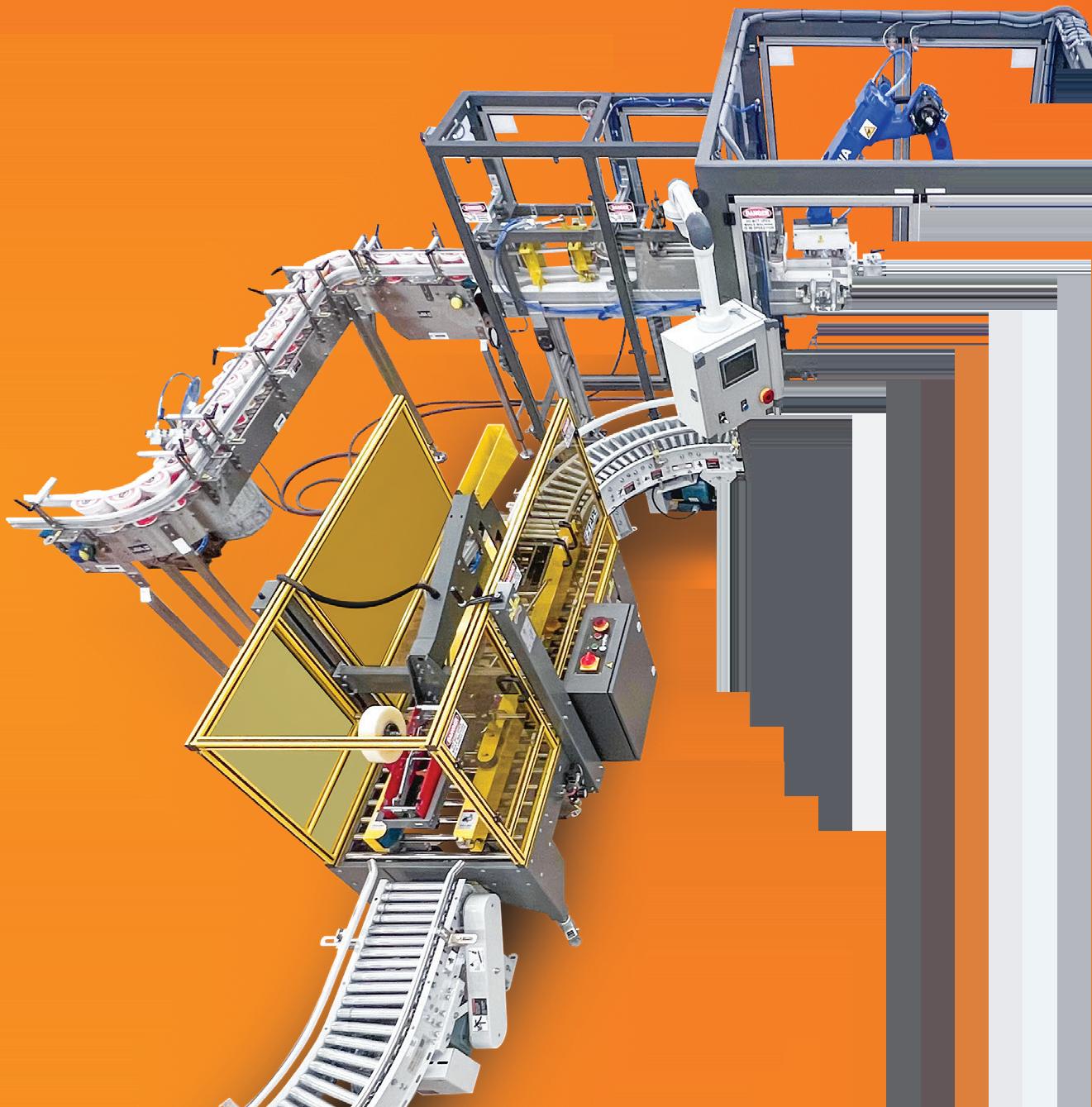

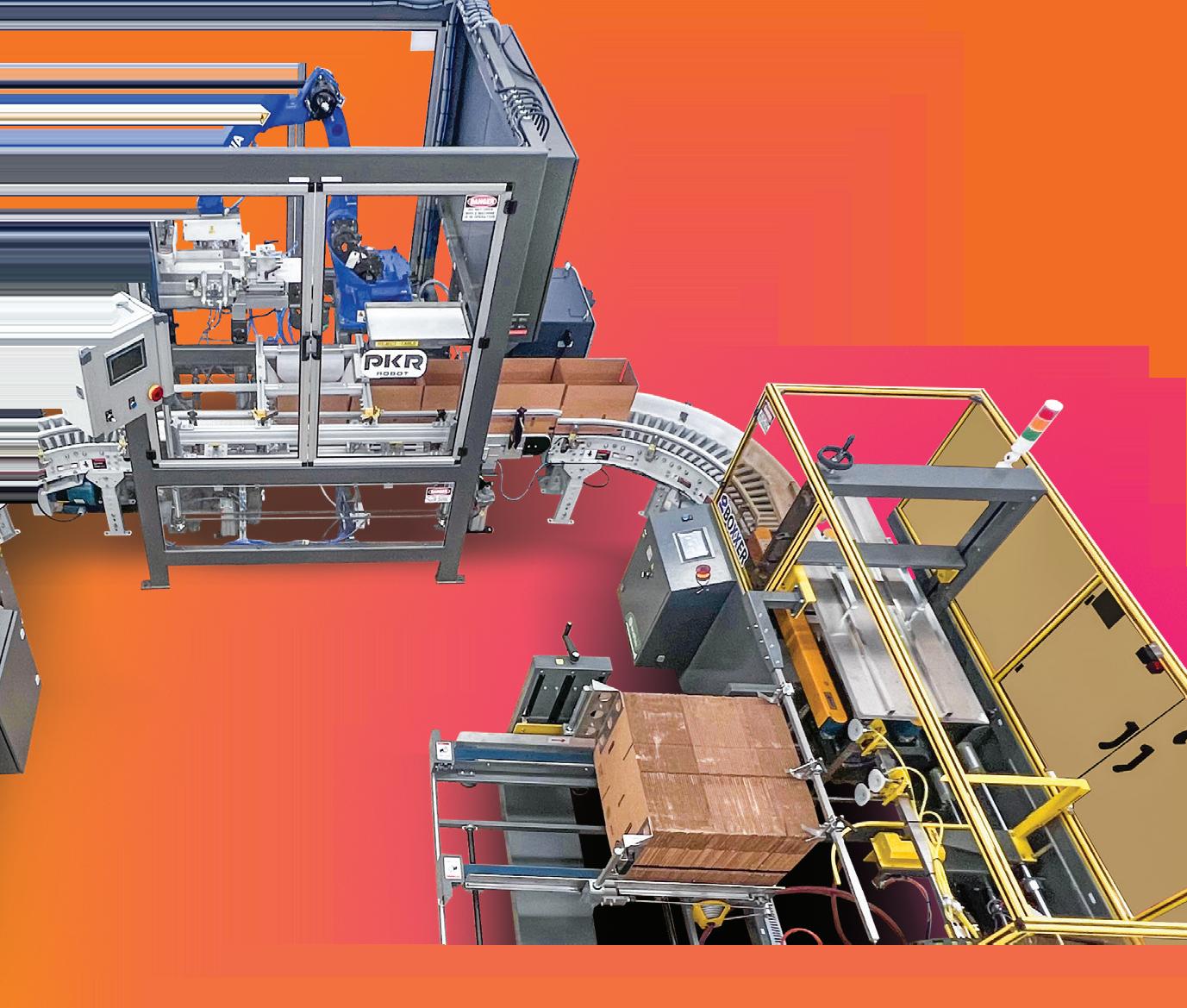

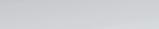

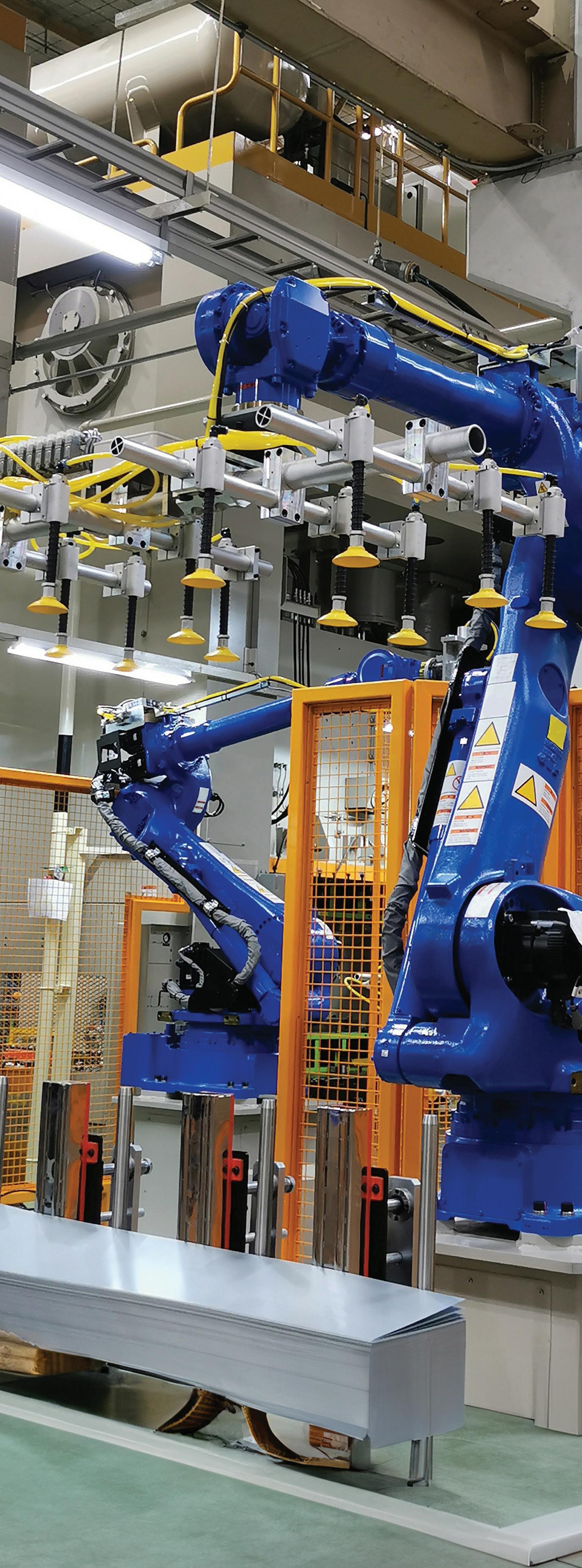

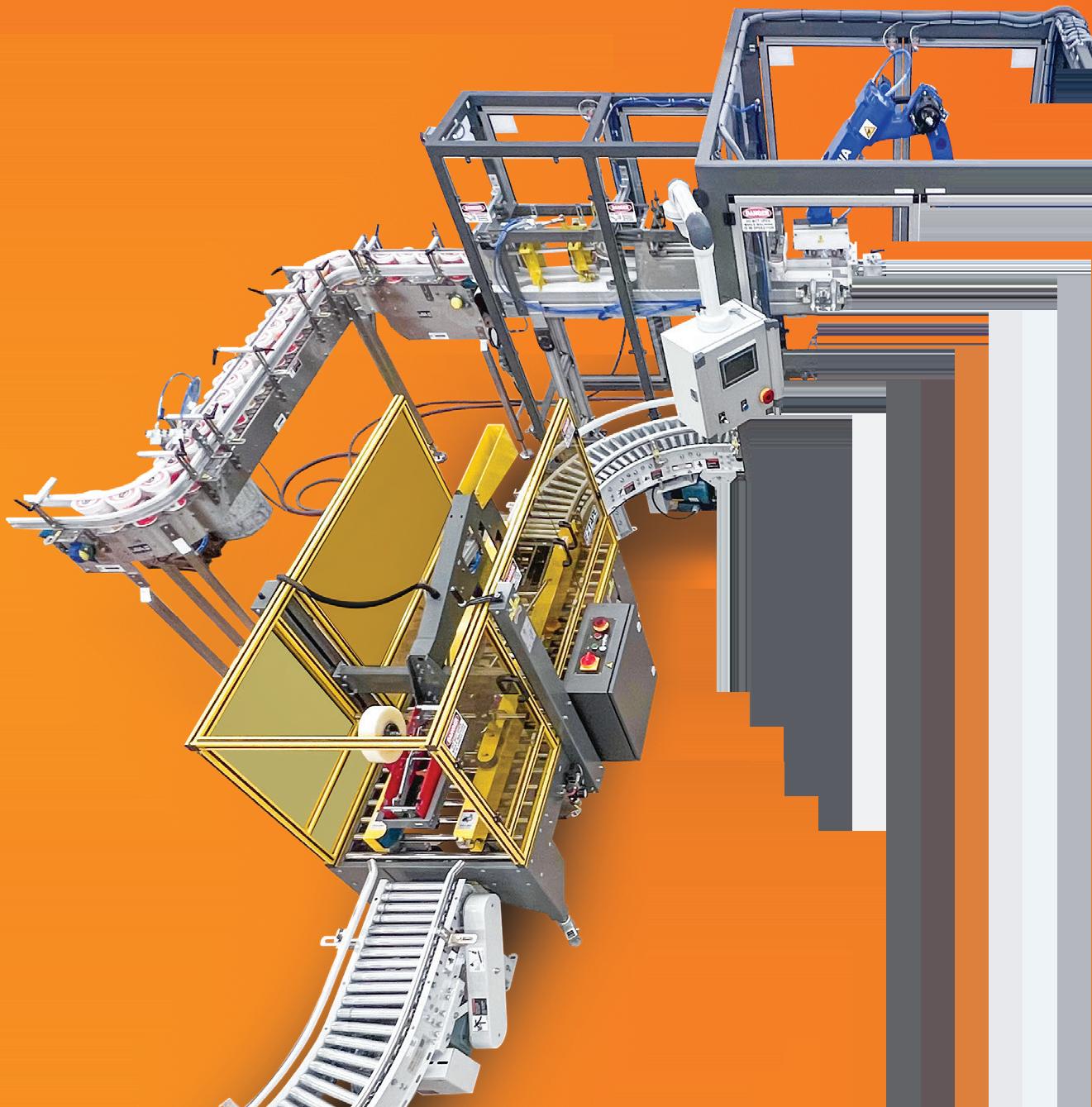

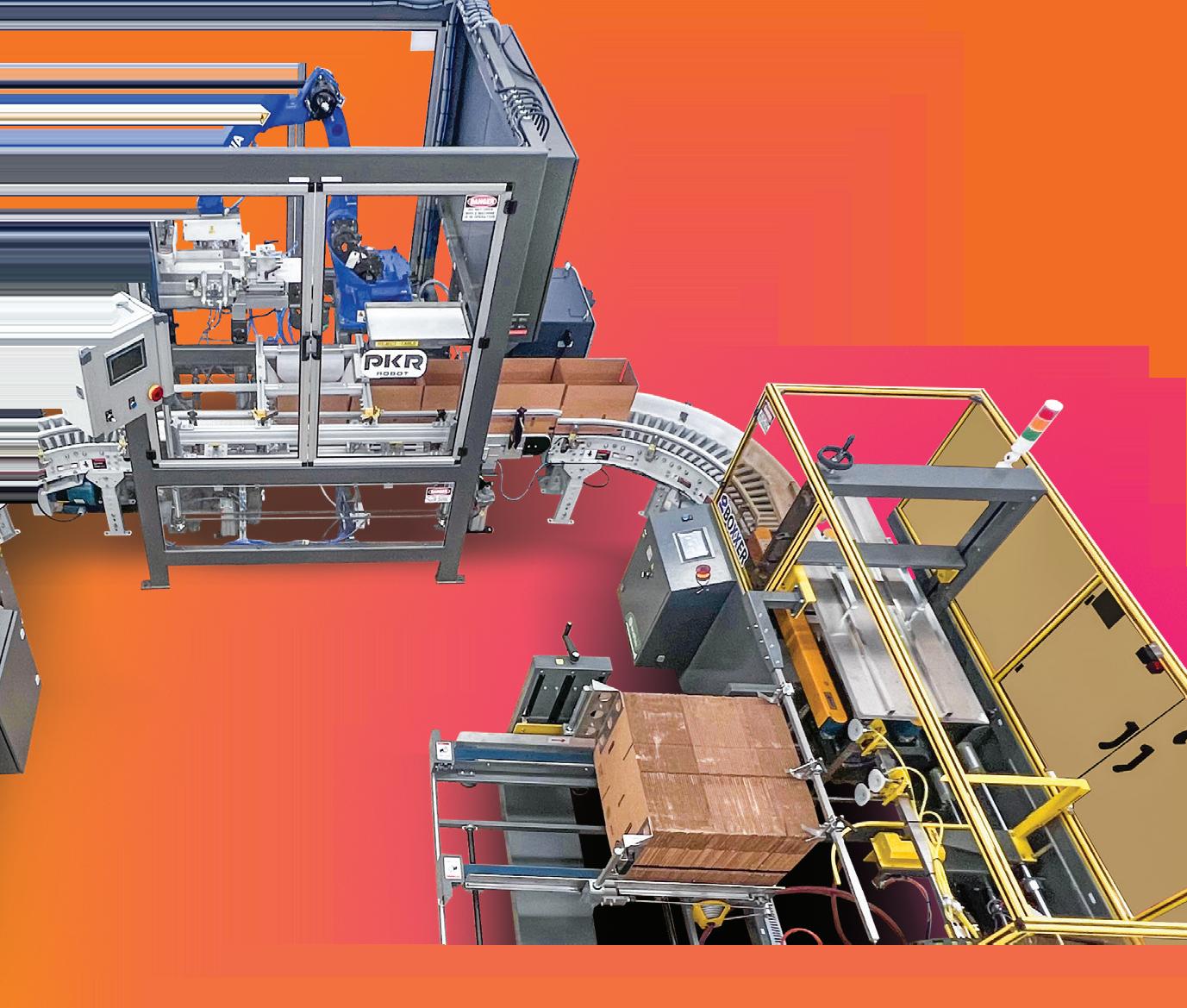

Packagers have long relied on A-B-C for hardworking machines that deliver top production with less wear and care. Today, our machines give you even more. Our advanced electronics give you total control at the operator station, for quick startup and rapid change-

over. All operating data is at your fingertips with full connectivity to your factory control station. Preventive maintenance notifications and remote service are designed to keep your line at top production...always. Today and tomorrow, we’re here to serve you.

Simple. Flexible. Reliable. Connected. End of line packaging solutions 800-237-5975 Since 1940, a tradition of innovation, quality & service 811 Live Oak Street, Tarpon Springs, FL 34689 - 727-937-5144

Depalletizers & Decasers Erectors & Sealers

Robot Packers

Palletizers

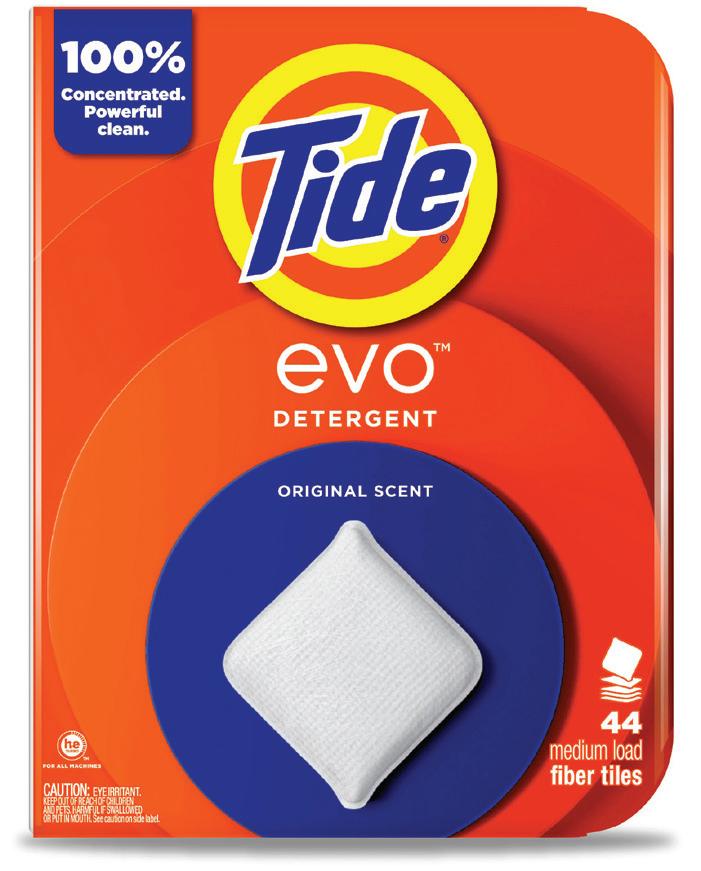

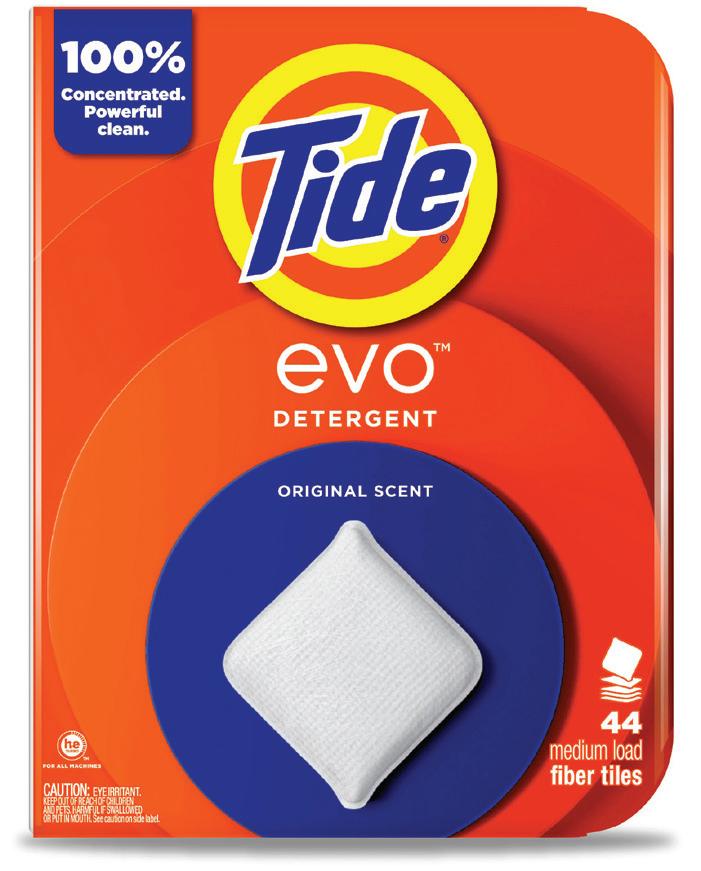

New Tide Detergent Tiles Eliminate Need for Plastic Packaging

Procter & Gamble (P&G) brand Tide has launched a new form of laundry detergent called Tide evo, which is a square-shaped, six-layer “tile” of concentrated ingredients woven together. The design of the thin, malleable fiber tile was driven by consumer insight and with sustainability in mind.

“Tide evo embodies over a decade of research and development, signifying a major advancement in how we approach cleanliness and efficiency in our daily lives,” says Sundar Raman, chief executive officer, P&G Fabric & Home Care.

P&G’s research found that consumers expect increasing levels of convenience. The company’s response was to develop the Tide evo fiber tiles, which are lighter, faster, and simpler than its other detergents. To be evermore environmentally conscious, the tiles are also designed using tens of thousands of miniscule fibers to create layers of soap without extra liquid and fillers while eliminating the need for plastic bottles. This new detergent dissolves upon contact with water.

The fiber tiles, measuring approximately 3.5 x 3.5 in., are packaged in a hinged-lid paperboard carton that is approximately 3.5 in. W x 5.7 in. D x 7.1 in. L. The carton is stored upright on the shelf and opens on the right side, after a perforated strip is removed. A click tab enables easy opening of the package for access to the tiles. It also allows the carton to be securely reclosed.

Inside is a specially designed tray with one partition that separate the tiles into two stacks. The trays provide structural support to the carton, so it maintains its shape from factory to consumer home, while simultaneously keeping the tiles securely stacked. The trays ensure the integrity of both the product and the package’s squareness, according to Marcello Puddu, senior director of Fabric Care Research & Development at P&G.

“The cartons are initially die-cut into 2D blanks and then partially assembled by our supplier. This partial assembly ensures a seamless process where the cartons are fully erected and filled with Tide evo tiles concurrently, streamlining production,” says Puddu.

NEWS 10 PW MAY/JUN2024

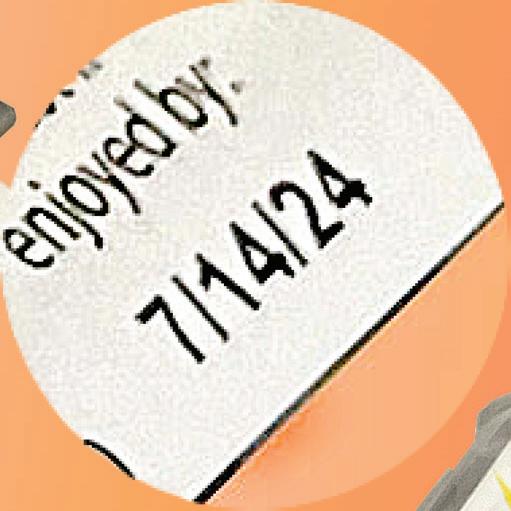

The inside of the carton lid features instructions for product use and a QR code for further information. The Tide evo carton is also printed using a standard offset process by a proprietary supplier and features Tide’s iconic blue and orange color palette.

The packaging underwent testing that simulates a range of environmental conditions, including shock, vibration, humidity, and temperature changes to ensure the package’s integrity and durability from manufacturing to disposal.

“The carton provides sufficient protection to delay moisture to migration into the package, preserving the integrity of the product,” says Puddu.

Supporting the company’s sustainable packaging goals, the fiber tiles are designed to be durable without the need for additional plastic packaging materials, such as shrink-wrap around the paperboard. In addition to minimizing materials, the Tide evo package also uses paperboard for the carton to the tray that is 100% Forest Stewardship Council certified and 100% recyclable.

Labeling strategies were also put into place to educate and encourage consumers to recycle the packaging. These include a How2Recycle label with clear recycling instructions and text that reads “Please Recycle Me.”

“During our product development journey, we had the pleasure of spending time with people who have told us they loved experiencing a ‘Tide clean’ in a new way,” says Puddu. “They fell in love with the convenience of a lightweight, waterless form in recyclable paper packaging. Their feedback makes us believe there are untapped ways to evolve this application beyond what we can imagine today. That’s why we’re excited about the opportunity continue learning alongside consumers as we expand the product’s availability.”

P&G launched Tide evo at retailers in Colorado in April and plans to expand distribution nationally later this year. The product is available in 16-, 22-, 30-, and 44-ct sizes in Original and Spring Blast scents. —Melissa Griffen

A single source with many solutions...

Sales, Service & Trials S : 5

11

Read more about a similar application on page 64.

Sustainable Pack for Coffee

Mississauga, Ontario-based Mother Parkers Tea & Coffee, one of North America’s leading coffee and tea companies and the largest supplier of private-label coffee and tea, has invested in new production capability to provide a new, more sustainable packaging option for coffee formats.

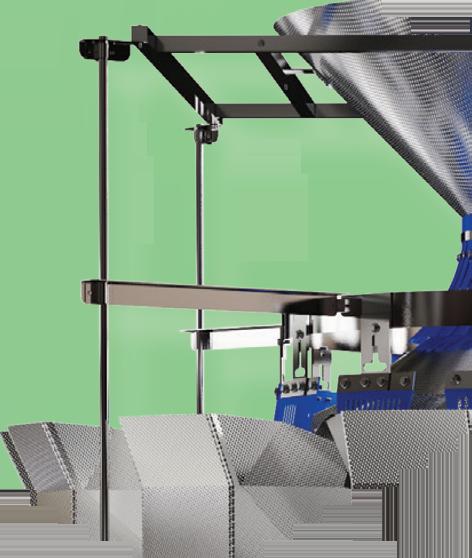

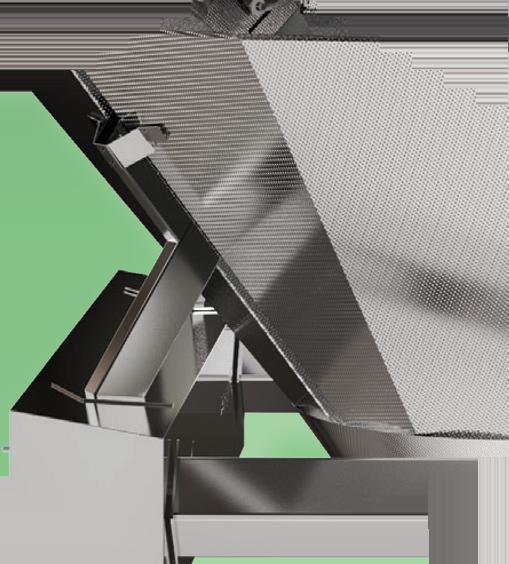

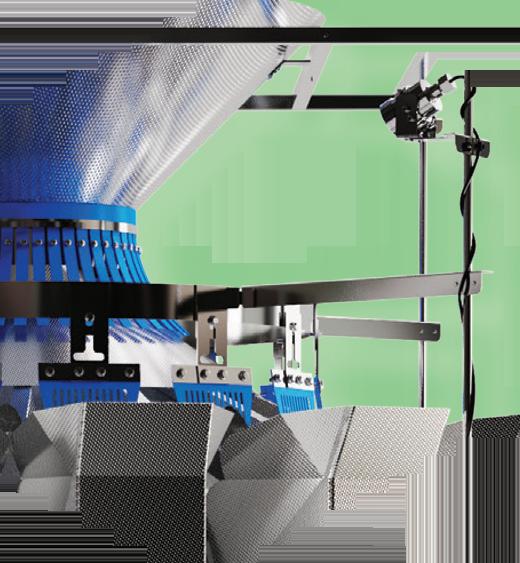

The Boardio paperboard canister, provided by Graphic Packaging International, provides an alternative to plastic, glass, and metal containers and delivers the same level of freshness and food safety with less waste. Essentially the material is a paper/foil lamination. Rolls of laminated material are cut into four flat blanks that are sent to customers like Mother Parkers, and there at the customer’s plant the canisters are formed and filled. Included is a one-way degassing valve that Graphic Packaging adds to the easy-peel membrane that is one of the four components the canister comprises. Presumably an auger filler of some kind will be part of this installation, but further details on whose filler are not available.

Mother Parkers cites recent research showing that consumers want packaging that is better for the environment, and many are willing to pay more for it. According to Mother Parkers, the consumers surveyed preferred Boardio packaging over current can and bag options that dominate today’s retail coffee market.

The new packaging delivers on sustainability, with:

• Increased transportation efficiency, as Boardio is delivered flat. Just three trucks are required for inbound packaging vs. 56 for pre-formed cans.

• A minimum of 50% less plastic versus Mother Parkers’ previous bag format.

• A minimum of 80% paperboard, which is FSC certified Boardio also carries the How2Recycle “widely accepted” certification.

“Mother Parkers provides our customers with a wide range of format options, including cans, bags, pre-measured portions for brewing a perfect pot of coffee, and single-serve capsules,” says Aico Konlin, director of category development for Mother Parkers. “We are always working on packaging innovation and the Boardio canister is a new format being added to our portfolio. We see it as a perfect solution across grocery, mass, and club channels, since we can offer it to our customers in sizes ranging from 10 oz to 48 oz.”

“Our new packaging solution is a win for the planet and for our customers and their consumers,” says Kim Cunningham, Mother Parkers’ chief commercial officer. “It offers a recyclable packaging option with less plastic, without sacrificing any of the freshness, consistency, or quality that Mother Parkers-produced coffee is known for. For retailers with private label coffee programs, it’s a way to show innovation, gain share, and drive shelf and transportation efficiencies, all while supporting sustainability objectives.”

The new packaging is the result of a partnership between Mother Parkers and Graphic Packaging to create a recyclable paperboard canister specifically tailored for coffee using Graphic Packaging’s Boardio technology.

“We’re committed to innovation, sustainability, and meeting the rapidly evolving demands of consumers,” said Johan Werme, Graphic Packaging’s head of sales for paperboard canister solutions. “By helping our customer Mother Parkers to transition from plastic into Boardio, we’re helping them make a world of difference to their customers, consumers—and to our planet.”

Mother Parkers will begin packing roast and ground coffee in Boardio from its Fort Worth, Texas, facility in late 2024. —Pat Reynolds

NEWS 12 PW MAY/JUN2024

Hello my name is

Rychiger

I’m sure many of us have experienced that initial encounter with someone whose name we can’t pronounce. We understand this scenario all too well since our transition from Nuspark. That’s why we have taken the initiative to provide assistance in mastering the pronunciation of our new name: RYCHIGER.

Learn how to pronounce our name with a scan

As part of the Rychiger Group we excel in delivering comprehensive solutions, from filling, and sealing, cartoning, case packing, tray loading, and palletizing equipment.

www.rychiger.com/pronunciation

Leader in packaging automation solutions

Make it smarter

Clemson Announces Spring 2024 Outstanding Packaging Science Senior Award Winners

Clemson University announced two Spring 2024 awards. Sarah Dumont was named the Robert Testin Outstanding Senior in Packaging Science winner, and Ezekiel Guevarra became the Packaging World Outstanding Packaging Science Senior.

Sarah

Dumont, Robert Testin

Outstanding Packaging Science Senior, Spring 2024

Sarah Dumont from Goose Creek, S.C. is a senior at Clemson University pursuing a Bachelor of Science in Packaging Science with an emphasis in Food and Healthcare Packaging.

Throughout her time at Clemson, she has been a proud member of Tiger Band, Phi Kappa Phi, and the Packaging Science Club, while also serving on the Dean’s Student Advisory Board for the Department of Food, Nutrition, and Packaging Sciences. Dumont has participated in creative inquiries focusing on zero-waste event planning and sustainable waste management. While working for Clemson’s Center for Flexible Packaging, she assisted in extensive film testing for industry partners as well as graduate research. Dumont’s co-op experience at Burt’s Bees developed her skills in innovative and sustainable packaging design. In recognition of her dedication to sustainability, she received the inaugural Printpack Sustainability Scholarship in 2023.

Ezekiel Guevarra, Packaging World Outstanding Packaging Science Senior, Spring 2024

Ezekiel Guevarra is a senior at Clemson University majoring in Packaging Science with a minor in Business Administration. Described as a hard-working student, Guevarra has frequented Clemson University’s Dean’s List and President’s List.

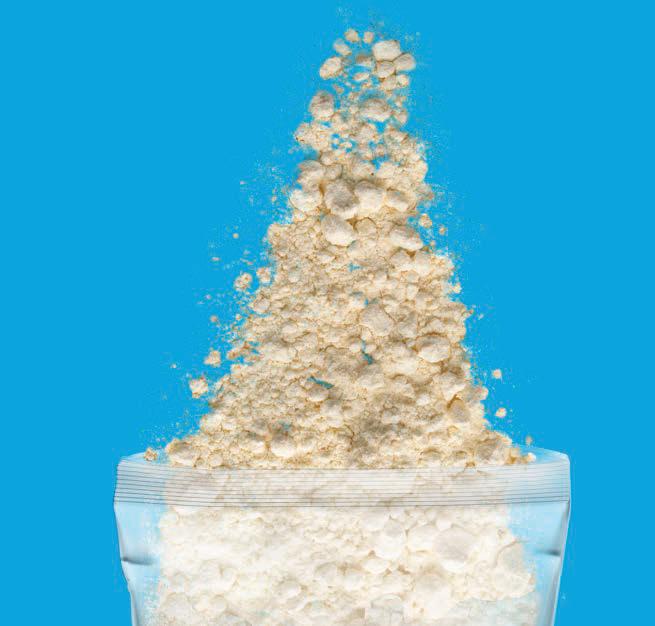

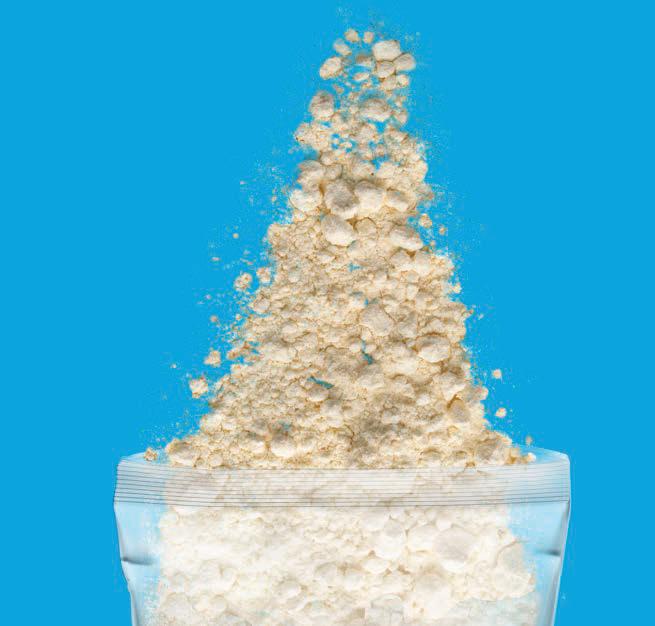

Throughout the duration of the Packaging Science Curriculum, he has completed a co-op rotation and an internship with Sonoco, developed a sustainable whey protein powder brand that markets to a broader market, and repackaged pancake mix into a package that promotes sustainability in his senior project. Guevarra is a member of the Clemson Packaging Science Club and intends to complete his Master of Science in Packaging Science under Dr. Duncan Darby.

—Matt Reynolds

NEWS 14 PW MAY/JUN2024 conveyor systems CLEAN-IN-PLACE CONVEYOR SYSTEMS • Quality

• In-House Fabrication • Extremely Fast Turn-Around • Smaller Footprint • Industry-BEST Value nerconconveyors.com

Engineering

Sarah Dumont

Ezekiel Guevarra

We believe every project we work on is a way to create a dynamic customer experience. That’s why we design customized packaging solutions to fit exactly what your customer needs.

To find out how we can help, visit us at mrpsolutions.com

We make possibilities. We We don’t just make caps.

AB InBev’s Four Peaks Takes the Guesswork Out of Recycling

Colliding opportunities in package design and sustainability have resulted in what Arizona AB InBev brewer Four Peaks Brewing calls a U.S. beverage-industry first.

Alongside a portfolio-wide packaging refresh, the Anheuser Busch craft partner announced in April a partnership with CIRT Inc. (Can I Recycle This?), making it the first U.S. beverage company to include CIRT’s digital, location-based recycling tool on its entire packaging portfolio, Anheuser Busch says.

“We’re incredibly excited for this partnership, as it was perfect timing to include on the new look of our entire portfolio,” Trevor Needle, Four Peaks marketing director, says. “This partnership offers our consumers a way to easily determine exactly where and how to recycle our products, promoting and increasing recycling one can at a time.”

The CIRT tool was created with backing from the 100+ Accelerator program, which is funded by AB Inbev, as well as Unilever, Coca-Cola, and Colgate-Palmolive. Launched in 2018, the program supports startups as they implement sustainable solutions.

Four Peaks learned about the connection between CIRT and its parent company as it was searching for ways to encourage recycling of its products. “Through that connection, it was serendipitous timing as Four

NEWS

16 PW MAY/JUN2024

Consumers can scan the CIRT QR code on the back of all Four Peaks packaging to access local recycling information.

Peaks was refreshing packaging for our entire portfolio, so we were able to design the labels to accommodate the CIT QR codes throughout,” Needle explains.

The CIRT tool on Four Peaks’ new packaging allows consumers to access local recycling instructions, from wherever they may be, by scanning a QR code on all of Four Peaks’ metal cans, glass bottles, and secondary packaging on cartons or cases.

By including this QR code on its entire portfolio, Four Peaks can provide local recycling information to over 21 million people across its market regions.

The brewer hopes to divert 3.5 million lb of material from landfills and offset over 5.1 million lb of CO2e[quivalent] emissions through the increased accessibility of recycling instructions.

Four Peaks is the second AB InBev craft brewer to partner with CIRT, after Wicked Weed Brewing in 2021, but it is the first to include the QR codes on its entire portfolio of 27 active beer brands and over 85 SKUs.

Four Peaks first set its sights on inclusion of CIRT technology in its packaging at the start of 2023, when it set out to redesign its entire visual brand identity.

Since the brewer’s previous packaging refresh in 2018, it had launched two on-trend beers with vibrant designs with its Wow Wheat and Hazy IPA products. Seeing the success of these new beers, Four Peaks hoped to tie the new brand equity to the rest of its portfolio.

“Our ultimate goals for this VBI refresh were to reinvigorate our established brands like Kilt Lifter and Hop Knot, create a cohesive and flexible system that allows for new brands to easily be added to our portfolio, and ensure consistency across all our current and future brands,” Needle says.

Four Peaks says it is the first beverage company to include the CIRT recycling tool on its entire packaging portfolio.

With the overhaul in the brand’s package design came an “amazing opportunity to really reassess our recycling messaging and make meaningful changes,” Needle explains.

That opportunity did come with some challenges. In ensuring that the QR codes were large enough to easily scan, Four Peaks had to change some messaging on its bottle labels to accommodate the addition.

After designing each packaging type to fit the CIRT code, Four Peaks turned to AB Inbev’s sustainability team to ensure it would include up-to-date recycling information and saw the opportunity to include CIRT’s tool on all its packaging.

“Over the next few months while finalizing our designs, we ensured we had the proper QR codes and recycling messaging for all of our different package types for the launch in 2024,” says Needle.

Four Peaks has already agreed to continue this partnership with CIRT for several years ahead, revamping both its brand image and the standard for recycling messaging within craft brewing. —Casey Flanagan

17

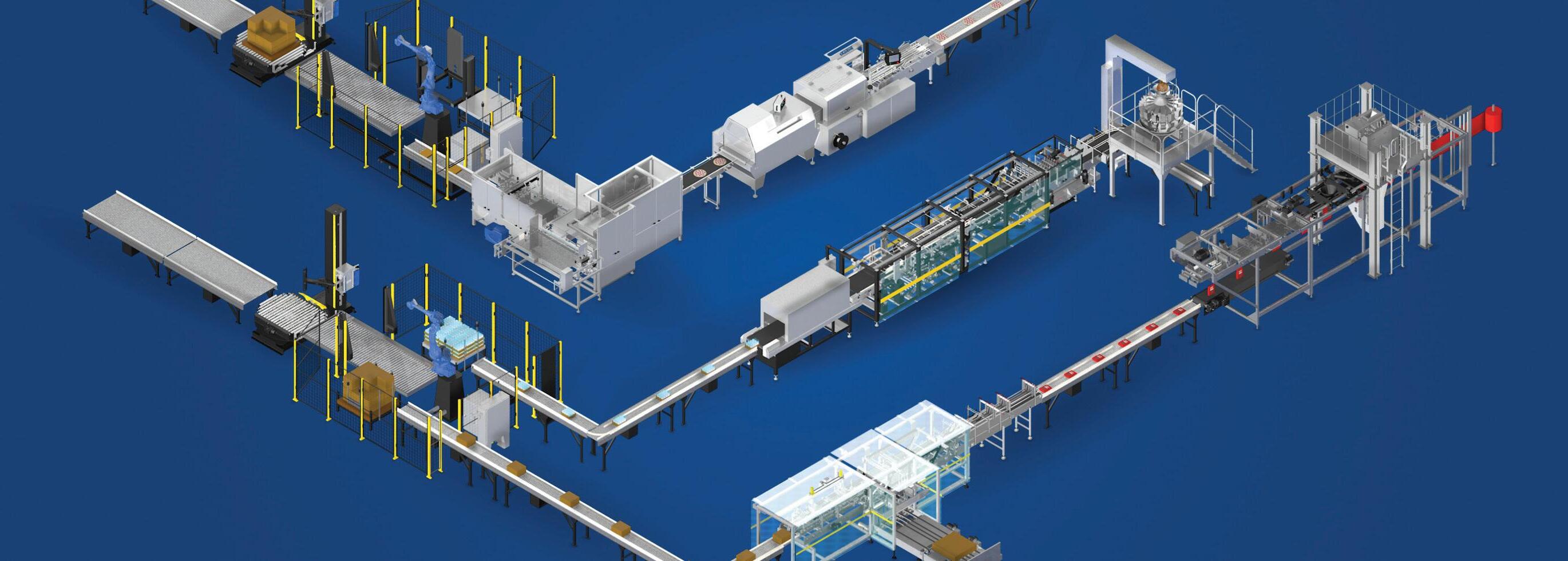

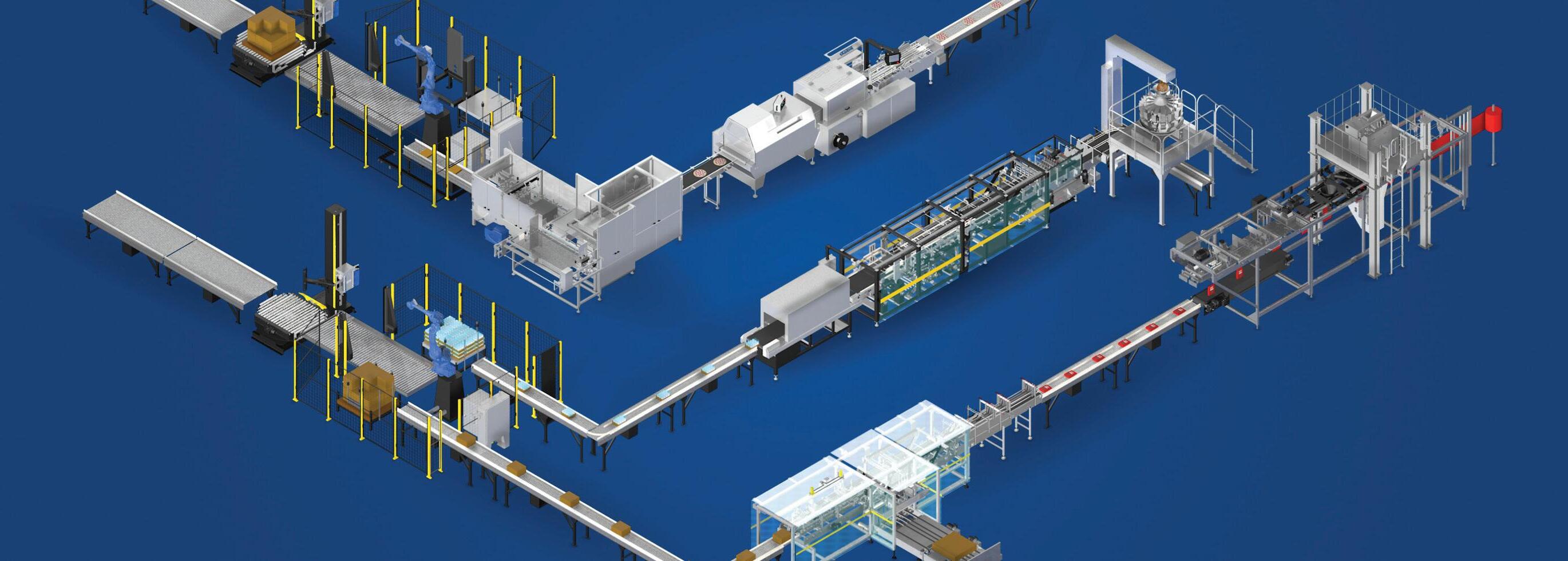

FlexLink is part of Coesia, a group of innovation-based industrial and packaging solutions companies operating globally, headquartered in Bologna, Italy. www.coesia.com�

Q-tips Moves into its Second Century with Brand Refresh

Iconic cotton swab brand Q-tips is moving into its second century with a fresh and modern look that puts the emphasis on the “Q” for quality in its name. Having achieved life hack-tool status second only to that of duct tape, the 101-yearold product has grown from its initial purpose as a ready-to-use cotton swab for baby care in 1923 to one used in applications as varied as pet care, beauty, arts and crafts, first aid, and more.

According to Olga Alpeter, associate brand director, Q-tips, Elida Beauty at Unilever, the new design was a year in the making and was done in collaboration with global brand agency 1HQ, which she describes as a “great partner in bringing the Q-tips design to life and balancing beautiful and modern elements with the brand’s deep equity in blue tones.”

Indeed, Q-tips is known for its blueand-white packaging—its core identity for the last 100 years. Retaining that equity was essential, meanwhile bringing the brand into a new century, with a look that highlighted Q-tips’ quality over other cotton swab brands.

“This refresh is an evolution of our look and feel, bringing our colors, fonts, and design elements into 2024

and beyond,” says Alpeter. “It was very important for us to continue to highlight shades of dark and light blue but also make it easier for people to find the swabs they are looking for at the store. Across all our products, you’ll see a unifying logo and messaging hierarchy with our ‘Q stands for Quality’ seal prominent on pack, which is at the core of what our brand stands for—it’s literally in the name!”

The redesign, which includes more than 10 products, uses colors such as pink, orange, and gold (in addition to the updated blue logo lockup) for its Precision Tips, Hygiene Shield, and Organic variants, respectively, to visually show the benefits of each, while making it easy for consumers to differentiate on-shelf. Q-tips Original retains the trademark blue color scheme.

The back panel of the packaging focuses on showing how Q-tips can be used for a range of applications. Says Alpeter, “It was important for us to show that Q-tips are for everyone and to update our examples to better represent the people who use them.”

The refreshed graphics for the Q-tips family of products launched in Sam’s Club in early April, along with a redesign to the outer paperboard packaging to reduce plastic film from the pack. The new visual identity continued its rollout in subsequent months to other retail outlets following its Sam’s Club introduction. —Anne Marie Mohan

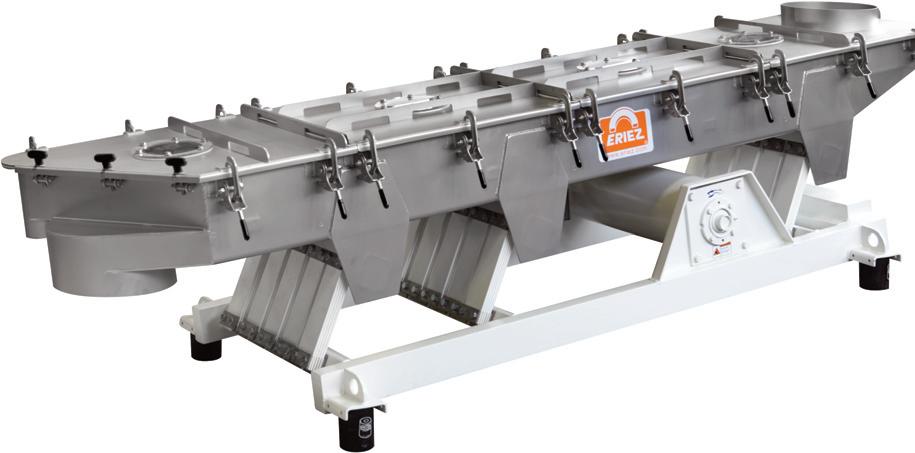

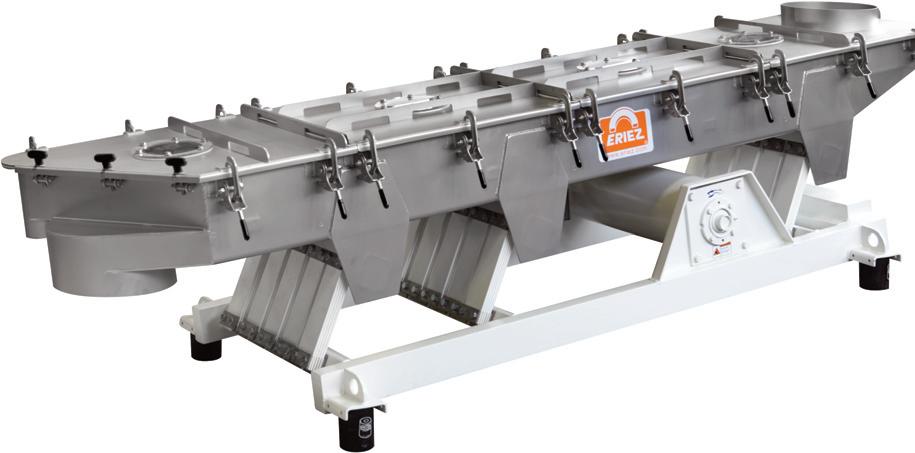

NEWS Mechanical & Electromagnetic Conveyors

•Models

Feeders & Conveyors Eriez.com | 814.835.6000 •Energy efficient electromagnetic drives •High Speed models for rapid On/Off cycling •High Deflection models for fine powders, leafy, and sticky products for Challenge Every ERIEZ_ FeedersConveryor1/3Pg_PW_6_23.qxp_Layout 1 5/12/23 5:45 PM Page 1 18 PW MAY/JUN2024

•Low profile models •Wide range of screener options

for every application

Paul Leibinger Inc. 2702 Buell Dr #2 . East Troy, WI 53120 . United States . +1 262 642 4030 . cs@leibingerusa.com “Smooth prints, seamless lines.” Explore our solutions at leibinger-group.com I LEIBINGER f b . No downtime T q zz . Precision printing, on demand G fl j G -b b . Low costs, lower environmental impact M z fi f -f f b . Unmatched performance, tailored solutions C f x b x b . F - ff - - 1 000 / (3 280 f / ) . M z fi MAXIMUM RELIABILITY, PERFECT PRINTING. WE ARE YOUR CODING & MARKING EXPERTS FOR PACKAGING.

Hotel Amenity Bottles Use 100% Ocean-Bound Plastic

According to the U.S. Plastics Pact, more than 1 million tons of plastic enter our oceans each year. Natural personal care brand LATHER has made a commitment to stop 5,500 pounds of that plastic from making its way there, beginning with its new Landscapes Collection for luxury hotels, which features high-density polyethylene packaging made from 100% ocean-bound plastic. Set for launch in June, the collection will provide hotel guests with “a perfect balance of luxury, wellness, and environmental consciousness,” the company says.

LATHER was founded in 1999 by Emilie Hoyt, whose mission to find relief from her debilitating migraines led to the discovery of the negative effects of synthetic fragrances on human health. LATHER operates several retail stores, sells direct-toconsumer, and can be found in spas, boutiques, hotels, and resorts. Its formulations are always synthetic fragrance-free and use locally sourced, natural ingredients from across the globe. Products include hair, face, body, and wellness products.

On the hotel/resort side, its products can be found in 550 properties, totaling 92,000 hotel rooms. Among its accolades, the brand has been named the Official Bath and Body Provider of Forbes Travel Guide. The new Landscape Collection includes shampoo, conditioner, moisturizer, hand wash, a cleansing bar, and face soap. Explains Kate Quaid, vice president of marketing for LATHER, “Each product in this collection focuses on a different landscape—mountain, forest, desert, and coast—and features unique skin and hair care ingredients and 100% natural fragrances that tie back to each landscape.”

To source the packaging material, LATHER worked closely with its proprietary bottle manufacturer, which supplied ocean-bound plastic reviewed and certified by a reputable third-party certifier. One challenge was the greyer color of the material versus the bright white of virgin plastic. “It can have a light grey hue and can have some small, dark flecks,” explains Quaid. “It can also be somewhat more brittle than virgin plastic.”

LATHER’s decision to source ocean-bound plastics for the collection is an extension of the brand’s commitment to using only natural and sustainable ingredients and “was a natural choice for a collection that is celebrating the wonders of our earth,” says Quaid.

In the plus column, in addition to preventing plastic found in coastal regions from reaching the ocean, the ocean bound plastic-based bottles help the hospitality industry address its sustainability goals. Says LATHER founder Hoyt, “Hotels are constantly seeking ways to enhance guest satisfaction while minimizing their environmental footprint. Our Landscapes Collection perfectly aligns with these goals, offering both an unparalleled guest experience and a commitment to sustainability.”

The material also supports local communities by providing economic opportunities, and according to the U.S. Plastics Pact, it requires 79% less energy during production versus virgin plastic.

The 100% ocean-bound plastic bottle in earth-tone colors with a black dispensing pump is being used for five Landscape Collection products: a shampoo, conditioner, body wash, moisturizer, and hand wash. The 12-oz bottles feature a viewing strip and an embossed 10-mL fill-level line on each side, making it easy for hospitality staff to monitor and replenish the products. The bottles are mounted in a new powder-coated steel bracket that features a concealed bottom shelf within the recessed bottle base, “creating a visually striking illusion of containers floating on the wall,” says the company.

LATHER is taking orders for the new line now, with the hotel collection launching in June and the consumer collection available in July.

—Anne Marie

Mohan

NEWS

0 0 -3 00 . W o ll- . W o ci s i , ll-s ol l s s s. W l s s c o o v s o sis. 20 PW MAY/JUN2024

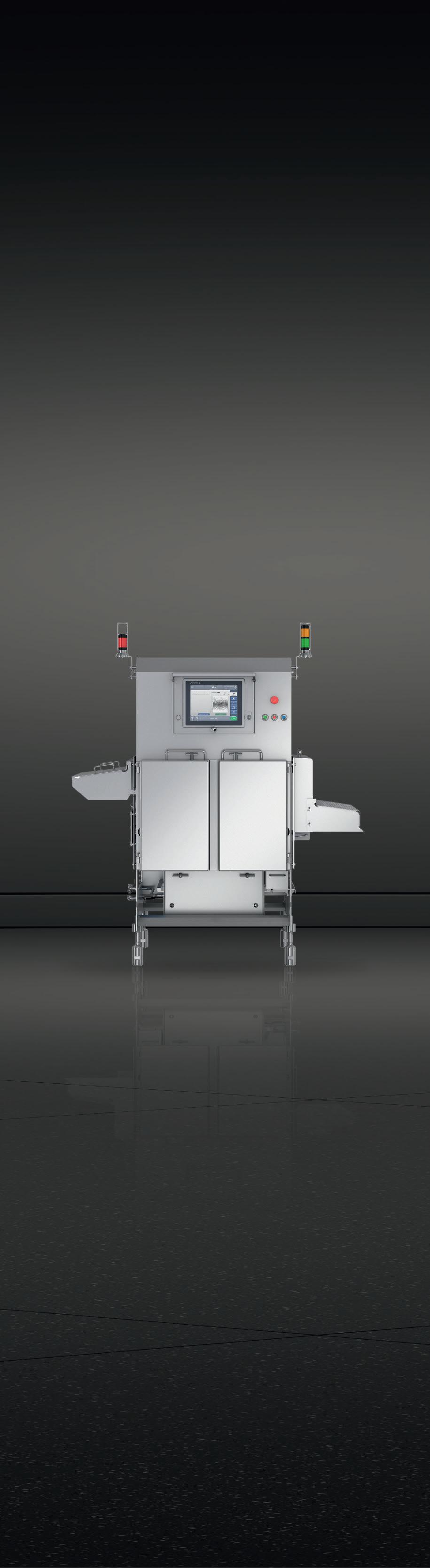

Delivering Results. With Heat and Control, you have a partner with the scale to support your success, the innovation to advance your operations, and a commitment to quality that will help you offer better products for consumers.

• Food processing systems

• On-machine and process area seasoning application

• Conveying and product handling

• Multihead/combination scale weighing and filling

• Snack bagmaking and case packing

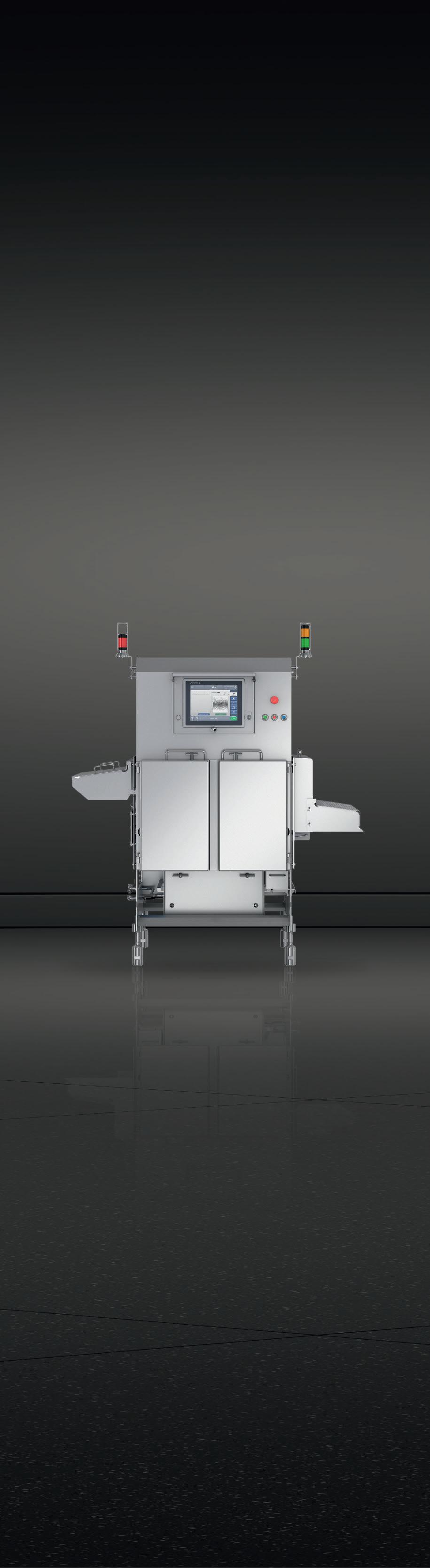

• Metal detection and x-ray

• Check weighing and seal checking

• Controls and information systems

We are successful when you are successful. That’s why we apply creativity, engineering excellence, and determined perseverance to every project to help our customers get the performance their business demands—whether measured by flavor, efficiencies, sustainability, improvement, or innovation.

92 98 34 108 94 116 17 20 107 33 32 99 36 26 42 0842 2 ~2~ ~2 26

PROCESSING AND PACKAGING SOLUTIONS

Helping

your best products to market.

you bring

LOOKING BACK. PRESSING FORWARD. ALWAYS INNOVATING. info@heatandcontrol.com | heatandcontrol.com Nov. 3-6, 2024

N-6106 McCormick Place Chicago, IL, USA

Booth

BUILT

FILL.

PALLETIZED TANDEM FILLER

Two is Better Than One

This design is similar to our most popular and efficient drum filling machine but with a modification. This application includes two scales for side by side loading and filling.

» User Friendly Benefits

» Improved Efficiencies & Accuracy

» Increase Production & Maximize Uptime

» Heavy-Duty & Long Lasting

This solution has a variety of product options available to meet your needs. To learn more, contact us by calling 833-467-3432.

We also provide installation, parts and field service 833-467-3432 www.specialtyequipment.com

Nesquik’s New Shrink-Sleeve Labels Make Packaging 100% Recyclable

In recent months, Nestlé has transitioned the full-body shrink-sleeve label for its Nesquik readyto-drink portfolio of flavored dairy beverages to a recyclable, yet still light-blocking, material. According to the company, the label is the first of its kind on-shelf and was engineered to address the recycling challenges associated with heavier-weight shrink-sleeve material, while providing product protection comparable to the label it replaces.

Traditionally, during the recycling process, shrink-sleeve labels sink to the bottom along with PET bottles in a float sink tank. This results in contamination of the rPET. Additionally, PETG label residue can cause clumping.

“With the former label, consumers could recycle Nesquik ready-to-drink bottles only after removing and disposing of the label sleeve, as communicated by the How2Recycle label included on the bottle sleeve,” explains Chastity McLeod, VP of Sustainability, Nestlé North America. “We’re transitioning to the recyclable label sleeve to help make it easier for the consumer to recycle the bottle and help increase the bottle’s ability to be sorted accurately at recycling facilities. With the new shrink sleeve, the entire Nesquik ready-to-drink bottle will be recyclable, meaning consumers can put the entire package—including cap, bottle, and shrink sleeve—into their recycling bin without needing to remove the sleeve.”

Before the transition, Nestlé was using a white PETG material with light-blocking properties—an essential feature as Nesquik’s milk-based beverage has attributes such as taste, color, and vitamin level that are susceptible to light. Finding a replacement that was both recyclable and provided the same light-blocking functionality involved multiple tests across all seven Nesquik flavors.

“This included light-transmittance tests across more than 20 candidate materials, product shelf-life studies, and the completion of plastics recyclability tests to ensure the new shrink sleeve and inks would remain compatible with the U.S. recycling system,” the company explains. Shares McLeod, Nestlé’s testing was in accordance with the Association of Plastic Recyclers’ (APR) industry standards for material recycling facilities (MRFs) in the U.S. and completed by an independent thirdparty laboratory.

Following this extensive R&D process, Nestlé selected crystallized PET, along with new washable inks. “Whether or not the sleeve comes off during the recycling process depends on what type of separation process a specific facility leverages,” McLeod explains. “If the sleeve remains on the bottle, then the inks are washed off so the sleeve material can be reincorporated with the plastic supply stream. The quality of the recycled plastic is not impacted, as the sleeve was designed so that it can be reincorporated with the plastic supply stream.”

The project was not complete though until Nestlé conducted factory trials to ensure the new sleeve would run effectively on its factory production lines. This included making adjustments to optimize both the shrink sleeve and existing equipment throughout the process. The team also trialed multiple different iterations of shrink-sleeve artwork and ink combinations to make sure the new sleeve maintained Nesquik’s authentic look and feel.

With the transition of all seven Nesquik varieties in June, Nestlé estimates that 4,500 metric tons of PET plastic will now be easier for consumers to recycle each year. Packaging for some Coffee mate and natural bliss creamer products will also use the new label, and Nestlé Sensations flavored milk products are expected to convert to the new sleeve in early fall. —Anne Marie Mohan

NEWS 22 PW MAY/JUN2024

TO

BUILT FOR LIFE. Just built better...

U.K. Chip Company’s

Recyclable Paper Chip Bag is a First for the Format

Snacking just took a turn for sustainability, thanks to The British Crisp Co.’s release of the first-ever recyclable paper chip bag.

Developed in partnership with packaging supplier Evopak, the chip bags use Aquapak’s Hydropol polymer as a plastic alternative, making them curbside recyclable, a British Crisp Co. release says.

“Brits consume over eight billion packets of crisps each year, the majority of which are not recyclable and end up in landfill or incinerators—that’s a lot of waste and a huge environmental problem,” Tom Lock, British Crisp Co. CEO, says in the release. “In partnership with Evopak and using exciting new polymer technology, we have created the first fully recyclable crisp packet.”

The Hydropol polymer behind these paper chip bags can be recycled, re-pulped, and composted, and can even break down in anaerobic environments.

The British Crisp Co. and Evopak add a thin layer of vacuum

deposited aluminum to ensure product freshness, but it doesn’t impact the recyclability of the chip bags. Consumers can add the bags to their curbside recycling bins alongside other recyclable paper items.

“We have developed a unique paper which has the potential to revolutionize packaging as we know it, thanks to the unique properties of Hydropol,” Daniel McAlister, Evopak Director of Business Operations, says in the release. “The paper can be used in a range of applications from snacks and confectionary, to pet care, dry foods, and cereals, and costs the same as existing materials.”

On-Pack Recycling Labels (OPRL), a U.K. evidence-based recycling labelling organization, has certified the packs as recyclable in standard paper recycling mills. This allows The British Crisp Co. to include a green “Recycle” logo and “I’m Paper, Recycle Me” label, notifying consumers that its packs can be added to curbside bins, unlike regular chip bags.

Hydropol is non-toxic, marine-safe, and does not break down into microplastics if disposed of improperly. It dissolves and subsequently biodegrades without leaving a trace if accidentally released into the natural environment.

The base plastic behind Hydropol is currently in use for applications including dishwasher tablets, ingestible pill casings, and soluble stitches. Hydropol expands on the base plastic’s current uses with its resistance to low temperature solubility and high barrier properties. The material is already in use in products including heat sealable paper mailer bags, dry pet food bags, and various blown film products.

“Today’s launch marks a significant milestone for Aquapak and our Hydropol technology, which can be commercialized at scale. This is a huge opportunity for brands and producers who now have a viable, functional, and recyclable alternative that enables full fiber recovery in a standard paper recycling process,” Mark Lapping, Aquapak CEO, says in the release.

The British Chip Co. says it plans to launch the new bags in coming months across shops, pubs, hotels, and coffee shops across the U.K. The launch will begin with the brand’s three most popular chip flavors: sea salt, salt and vinegar, and cheese and onion. —Casey Flanagan

NEWS 24 PW MAY/JUN2024

Dr. Pfleger Launches Recyclable Pastille Blister

Dr. Pfleger Arzneimittel GmbH is a Germany-based healthcare company that has operated for nearly 80 years with the motto that people are what counts.

They manufacture, develop, and distribute more than 60 medicinal products and medical devices in the fields of urology, dermatology, and gynecology, as well as home care medication for pain, hoarseness, and hair health.

“The work at Dr. Pfleger is always focused on the well-being of people. Because, for the company, it is people who count—yesterday, today, and in the future,” the company reports. “This focus on people applies down to the tiniest detail. Because Dr. Pfleger is well aware: It is not only the company’s own medicinal products themselves but also related topics, such as the packaging solutions used, that are an important contribution to future-oriented and sustainable actions. For the environment and thus for people.”

In March 2021, Dr. Pfleger approached ETIMEX Primary Packaging GmbH to develop a fully recyclable blister for their well-established ipalat throat pastilles as a sample. In addition to being offered in an aluminum can format, this initiative aimed to introduce sustainability to customers by providing product samples in a recyclable packaging variant using the PURELAY polypropylene (PP) monoblister.

Once they identified their packaging goal, they com menced development work. Dr. Pfleger, in collaboration with ETIMEX, embarked on a rigorous testing phase utiliz ing the new material. Dr. Pfleger received several small rolls of the mono PP to conduct numerous test runs on their own machinery. Having ETIMEX developers on-site was helpful for efficient testing—they were able to assist directly for machine conversion.

After successful testing, they produced an initial monoblister to check the new design for haptics and ease of push-through. The pharmaceutical industry faces unique challenges on the way to a new package: sam-

ple preparation times are typically long since specifications must be met as precisely as possible.

Despite these hurdles, after two years of development, they successfully validated the PURELAY blister. The monoblister is now available to consumers, allowing them the opportunity to sample products through individually removable pastilles.

The PURELAY PP monoblister from Etimex.

“This sustainable solution gives us the opportunity to have ipalat throat pastilles tested by our future customers. In this way, they can convince themselves of our product before they buy it,” says Corinna Spies, brand manager at Dr. Pfleger Arzneimittel.

As Dr. Pfleger highlights, the world needs future-oriented companies across all sectors, and with the long development and testing times that pharmaceutical companies face, there’s no time like the present to begin. Dr. Pfleger Arzneimittel’s commitment to people-centric innovation prioritizes forging new paths that positively impact both individuals and the environment. —Keren Sookne

The perfect choice for filling a variety of product types, sizes and packages Experience solutions without compromise, the Aurora Packaging Systems, Inc advantage!

Your single source approach to liquid packaging lines Juice and beverage, foods, home & personal care, petroleum and automotive; pharmaceutical, agricultural and specialty chemicals

716-955-0535 - www.aurorapackagingsystems.com info@aurorapackagingsystems.com

NEWS

26 PW MAY/JUN2024

Dr. Pfleger’s ipalat throat pastilles in Etimex’s recyclable PURELAY monoblister.

This cup will self destruct in 6 months

15 YEARS AGO, WE INVENTED BIODOLOMER. A bioplastic with limestone as the key ingredient. Biodolomer is fully compostable (certified by TÜV and BPI), and when decomposed, it will actually leave extra calcium from the limestone in the soil.

Biodolomer comes in granules that can be used for thermoforming, film blowing, extrusion coating, injection molding... you name it.

It does all the good stuff that plastic does. But not the bad.

It contains only ingredients that are approved by the FDA. It uses less energy in production and results in up to 80% less CO2 than traditional plastic.

You can even put it in your home compost and watch it disappear.

Biodolomer might just be the easiest way to make your brand more sustainable. For real.

Just like plastic. Is not. GAIA Biomaterials AB, Helsingborg, Sweden +46 (0)42 300 39 99 www.gaiabiomaterials.com

But no microplastics. At all. What so ever.

BY THE NUMBERS

How much more consumers are willing to pay for 1/8-oz of cannabis flower when it’s considered “something special,” which includes premium packaging that is collectible, giftable, or memorable, according to a report from Roland DGA

11 tons

The amount of non-recyclable packaging that will be eliminated annually by Aldi in the U.K. with its switch to a paper-based recyclable wrap for two of its own-brand blockbutter products

$50B

The anticipated total market revenue from chemical recycling companies around the world by 2030, rising at a CAGR of 30% between 2023 and 2030, according to Fairfield Market Research

65M

The number of e-commerce bags annually that have been affected by Walmart’s switch from single-use plastic to recyclable paper for the bags, resulting in a reduction of 2,000 tons of plastic

“A consumer may mistrust a brand if they see significant color variation on the shelves, leading them to question the quality of the actual product or possibly consider it an imitation of the original product. This could ultimately lead to a decline in sales. Today’s fast-paced consumers expect to find the same product and packaging look and feel no matter where they shop—be it at a mass merchant, a grocery store, or a drug store anyplace in the world.”

–Joyce Stempowski, product manager of graphics at Pantone, in an article from Packaging Gateway, “Interview: Pantone’s colourful role in the packaging industry”

“Technological innovations are guiding the barrier film market toward a revolutionary future. High-performance nanocomposite barrier films, infused with cutting-edge nanomaterials, are emerging as game-changers. This infusion elevates their barrier properties, fortifying product protection and extending shelf life. The packaging industry is about to remake itself as a result of an evolutionary move toward high-performance solutions.”

–Ismail Sutaria, lead consultant, Packaging and Materials, for Future Market Insights, Inc. (FMI), in a press release from the company, “Green Packaging Drives Barrier Film Market to Boom: $64.1 Billion by 2034”

“WWF has been clear on what a good treaty looks like—it must include global bans on the most harmful and avoidable high-risk plastic products, it must include global product design requirements that ensure the remaining products can be easily and safely reused and recycled, and there must be a strong financial mechanism in place to support a just transition. This is the treaty people and the planet need. I’m hopeful we can get there.”

–Erin Simon, vice president and head of Plastic Waste and Business at WWF, in an article from packagingeurope.com, “What to expect from INC-4”

“While the desire for retro products is high among American consumers, brands must strike a balance between nostalgia and sensory expectations of visual and taste experiences to keep consumers coming back and drive sales. They need to ensure that there is a right mix of novelty and nostalgia to entice consumers.”

–Meenakshi Haran, lead consumer analyst at GlobalData, in a press release from the consulting firm, “Brands tap into consumer desire for nostalgia with retro spin on product launches, says GlobalData”

QUOTABLES

26%

28 PW MAY/JUN2024

PEOPLE WHO CARE, SOLUTIONS THAT PERFORM.

ACCRAPLY | ANGELUS | ARCIL | BURT | DAIRY PACK | FLEETWOOD

GOLDCO | HAYSSEN | HEMA | MATEER | NIGRELLI | PNEUMATIC SCALE

SLEEVIT | STACT | SWF | SYMACH | THIELE | TRINE | ZEPF SOLUTIONS AND MORE...

Built upon 50 acquisitions of some of the world's most trusted OEM brands, BW Packaging is the industry's leading provider of people-focused packaging solutions. We are united by our desire to make a positive impact in the lives of our customers through:

SCAN HERE TO LEARN MORE ABOUT BW PACKAGING

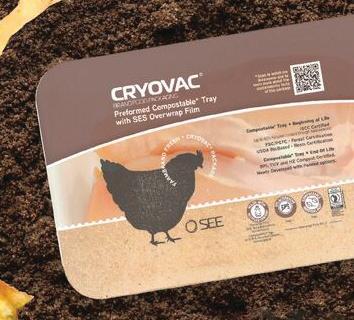

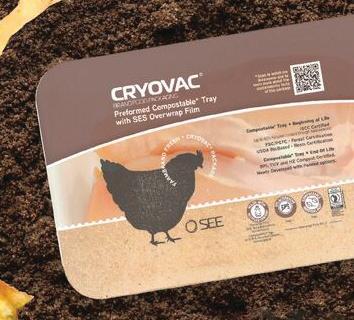

Navigating the Compostable Packaging Landscape

Packaging World:

With recent industry reports indicating compostable packaging is poised to grow at double-digit rates over the next decade and in light of a new report from the Biodegradable Products Institute and Closed Loop Partners’ Composting Consortium detailing the considerable consumer challenges related to composting, Packaging World sat down with BPI Executive Director Rhodes Yepsen to learn how the association is guiding the industry forward.

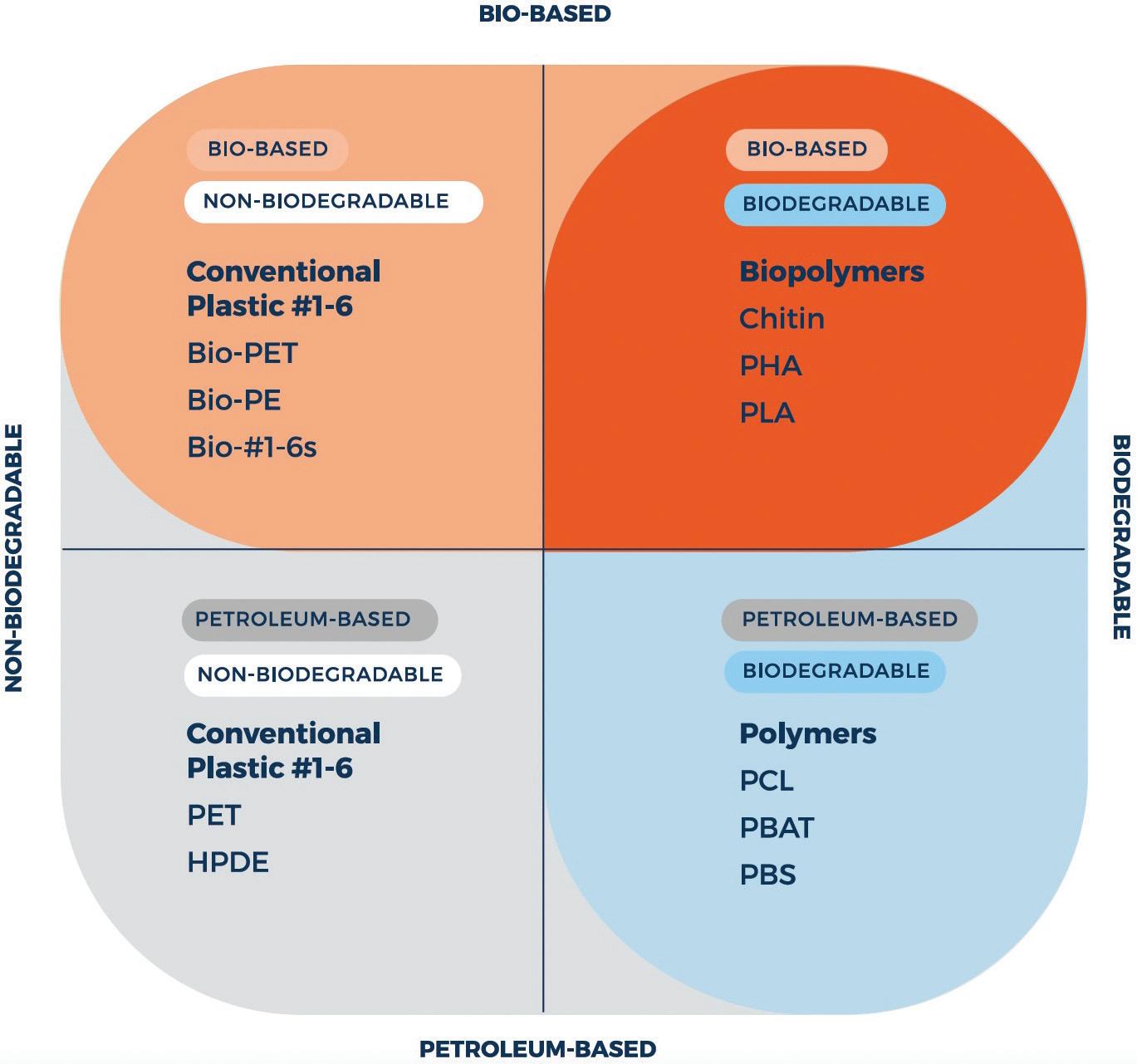

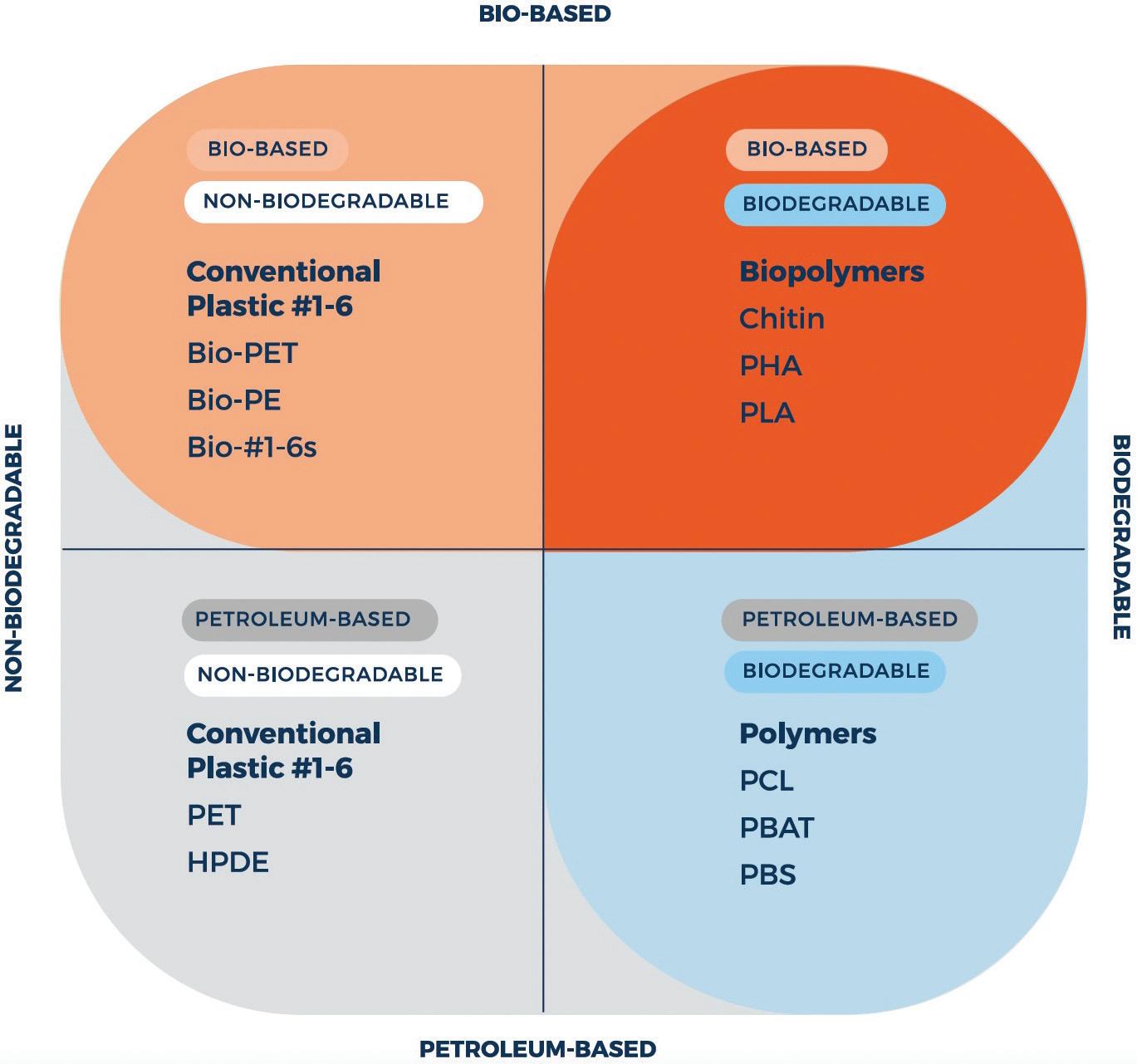

You probably get this question ad nauseum, but in order to level set, could you define biodegradable, compostable, and bio-based and explain how these characteristics sometimes overlap and how they differ?

Rhodes Yepsen:

Sure. So really these terms describe either the front of life or the end of life of products and materials. And as you indicated, sometimes they can have both of these attributes, and sometimes they are distinct. So starting with bio-based, bio-based refers to the origin of the raw material, meaning it was made with renewable feedstocks. This does not dictate whether the item is biodegradable, compostable, or even recyclable. Biodegradability and compostability, on the other hand, refer to the ability of the product or material to be processed through a biological pathway. Compostability is a specific environment, instead of conditions, in which biodegradation can occur. Composting is a controlled process and is one that we talk about a lot because that’s where we have a parallel to end of life with something like recycling, with organized collection and processing.

Biodegradation can also happen in uncontrolled environments if a product is leaked into the environment where there’s going to be a lot more variability in the rate of biodegradation. Because of that variability, because it’s not controlled, and we don’t want products leaking into the environment, that’s why you see laws popping up around the U.S., Canada, and Europe restricting the term

biodegradable, because we don’t want consumers to be confused and think they can litter an item. So yes, it’s really the front-of-life benefits, whether the item was made with a renewable feedstock or not, and then on the other side, the end of life, which, along with compostability or biodegradability, also includes recyclability, for instance, or reusability.

FIRST PERSON

30 PW MAY/JUN2024

Chart courtesy of Closed Loop Partners’ Composting Consortium

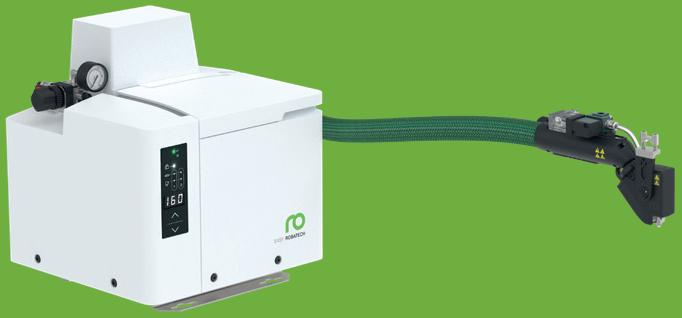

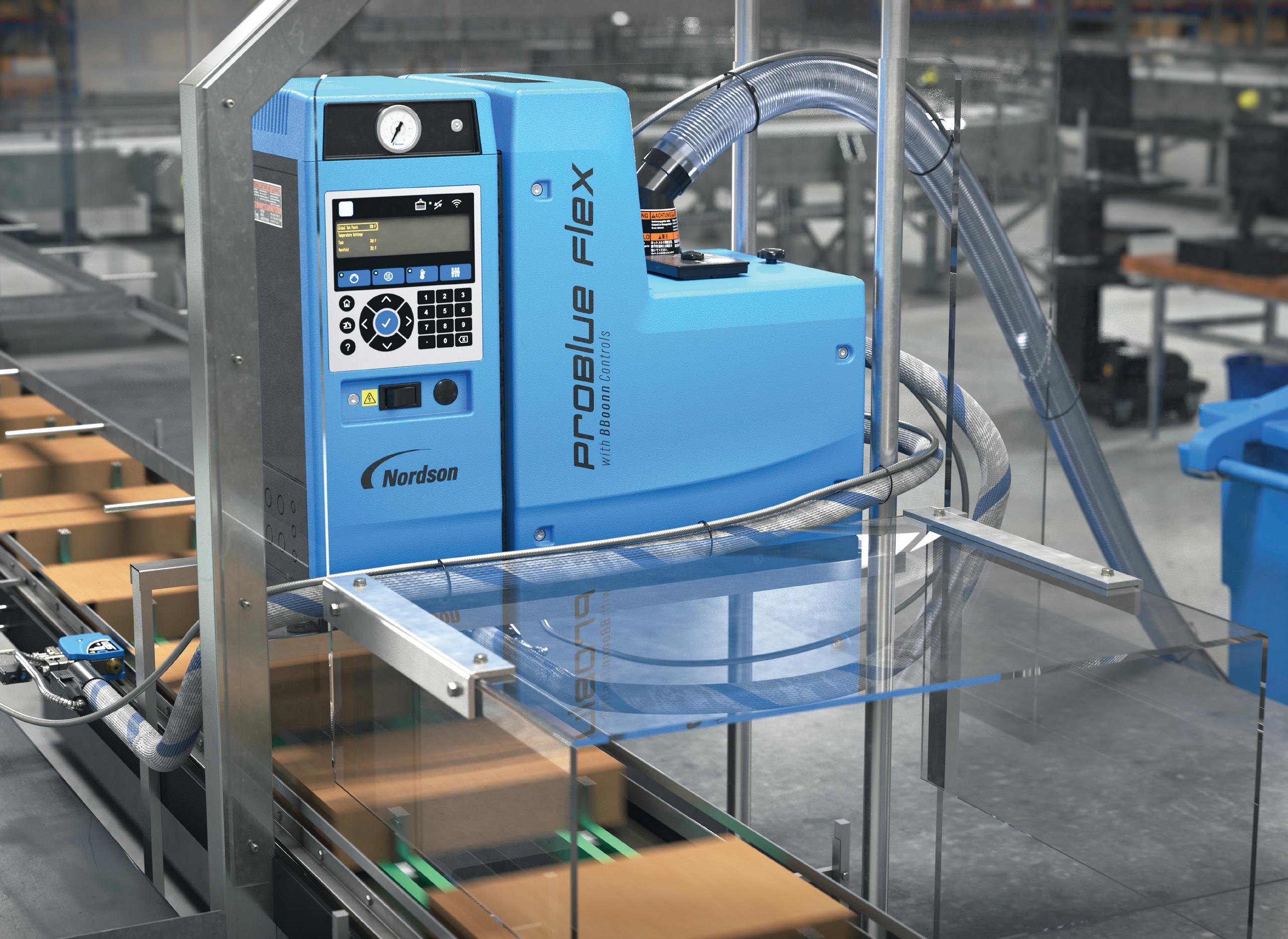

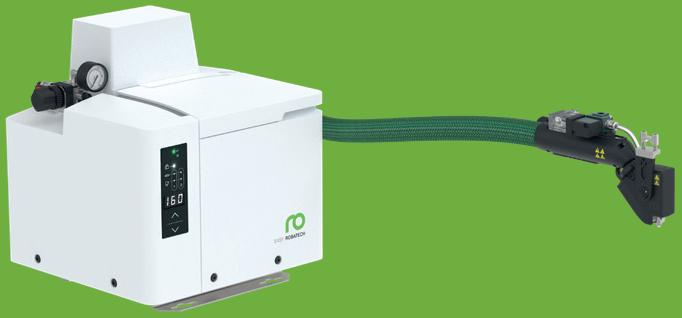

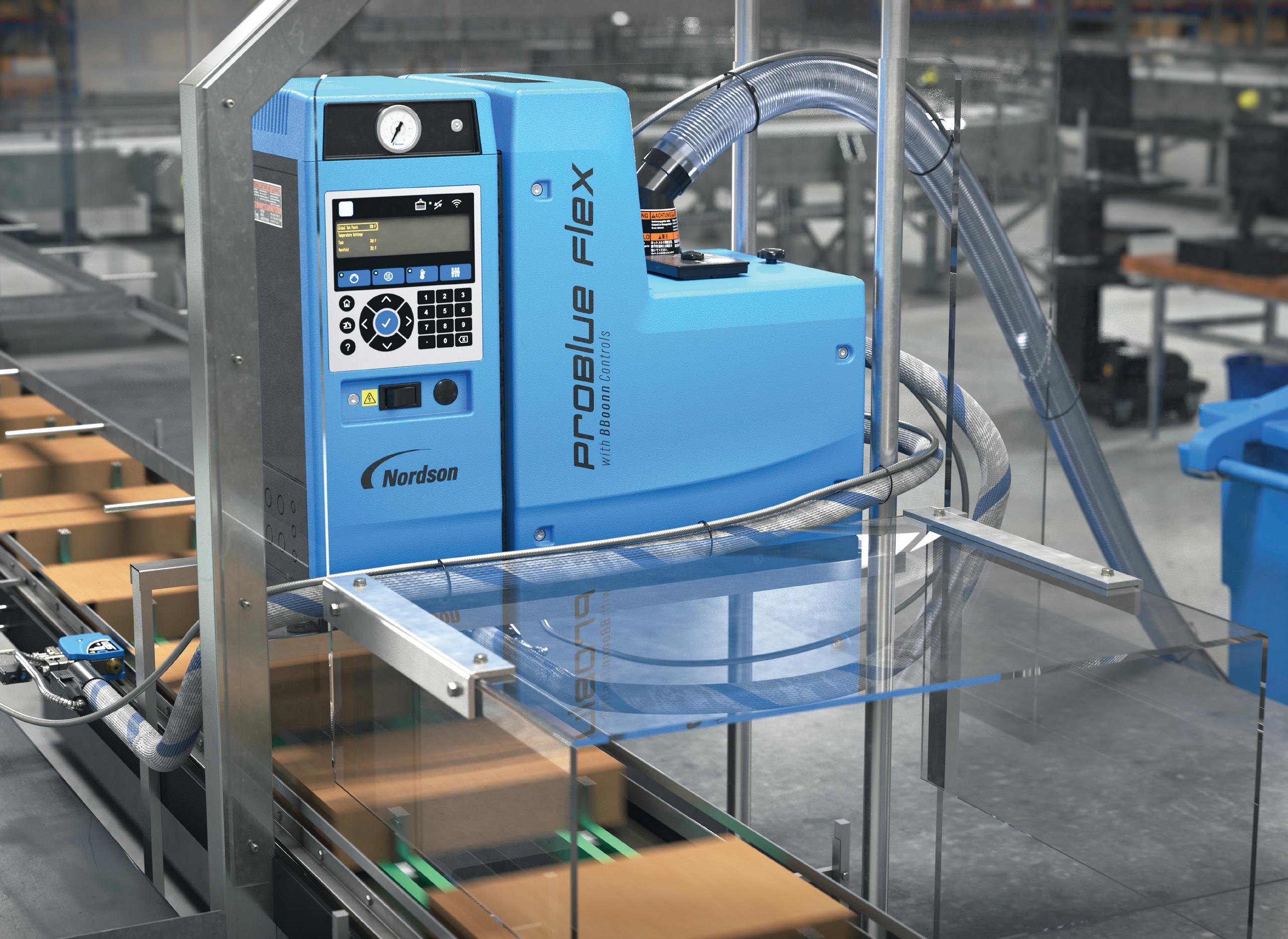

SHE’S NOT WORRIED ABOUT GLUING. NEITHER SHOULD YOU. Gluing made simple with the new EasyLine. Exclusively for applications requiring up to 2.5 l/h hot melt. Discover now easyline.robatech.com

Technology inspired by human talent

What are the main activities of the Biodegradable Products Institute?

We are a member-based association, and our core activities are around certification and claims, marketing and education, and policy. And through those different activities, we’re working to promote the production, use, and appropriate end of life for materials that can break down in these biologically active environments. Today that is primarily composting. That’s where the core of our history has been—working on materials and products, qualifying them for compostability, and making sure they’re designed with factors in mind to get them successfully collected and composted. We work with raw material producers, packaging converters, brands, retailers, municipalities, haulers, composters— everyone in the value chain is represented in our membership and our board of directors.

When it comes to policy, are you a lobbying group, or do you just report on policy for your members?

We do both. So we are a 501(c)(6) association, which allows us more latitude to be directly engaged in policy work than a 501(c) (3). Part of that involves informing members of things that are going on, with bill tracking and updates and status on things. But then we’re also engaged with amendments and meetings and direct outreach to influence policy. A lot of that is focused on the success of compostability claims, the things that are reinforced in our other work around labeling and standards, making sure claims are based on standards, and working on funding for infrastructure and composting. We’re very supportive of things such as extended producer responsibility [EPR] and are trying to make sure it’s inclusive of composting and not just focused on recycling. That’s been a big focus of ours—making sure that as policies evolve, they’re not calling for a blind replacement of all plastics with bioplastics on the one hand, but on the other hand, not wanting compostable products to be boxed out in the shadow of the bigger efforts around recycling.

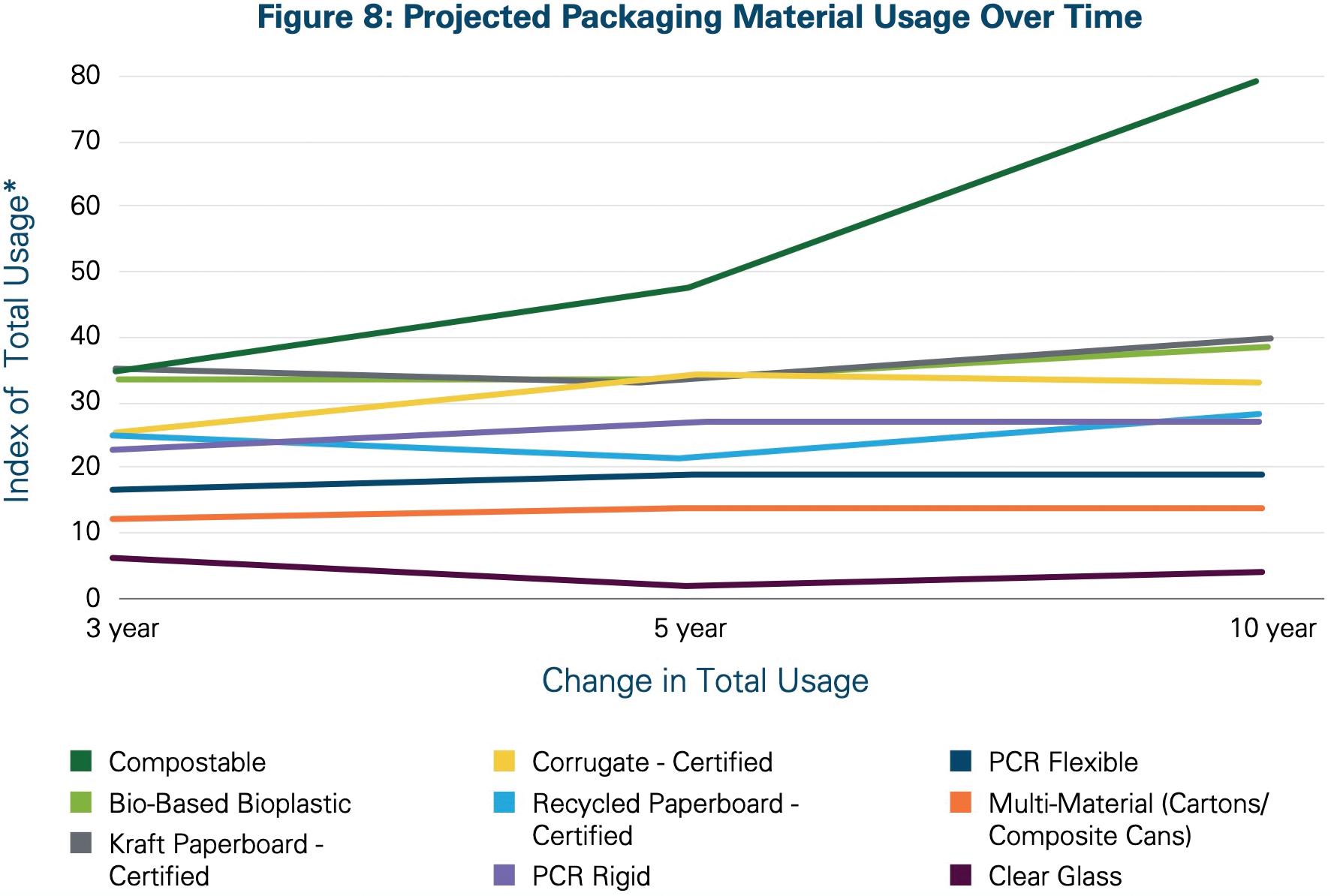

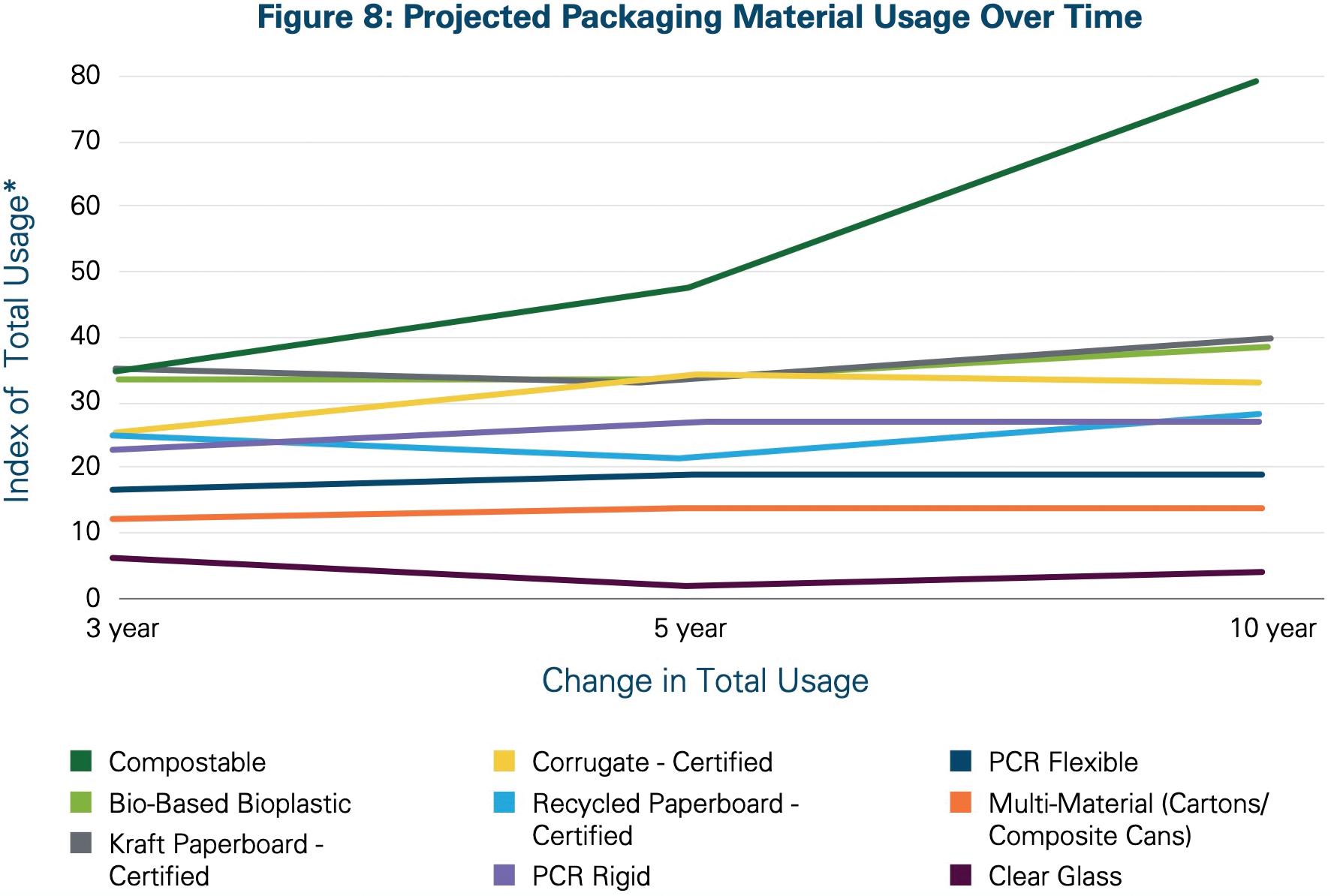

The 2023 Packaging Compass report (see pwgo.to/8268), from PMMI – The Association for Packaging and Processing Technologies and AMERIPEN, forecasts that compostable packaging will grow by a CAGR of 15% to 16% by 2027.

To what do you attribute this growth?

Last year, McKinsey did a survey of countries around the world and looked at the most sustainable attributes for packaging in consumers’ minds. Compostability was at the top in the majority of countries, followed by things like plant-based. So for sure, companies listen to consumer demands and read those reports as well. But it’s a combination of factors. Consumers want more options. They’re frustrated by all the reports of low recycling rates and the difficulties we’ve collectively had around the world with recycling, and they’re hungry for more options that will work. They’re also concerned about other factors such as chemicals in plastics and products. Certified compostable products don’t include things like PFAS with forever chemicals.

A lot of it is also being driven by corporate commitments and policy. Companies are making public commitments to do better

FIRST PERSON

32 PW MAY/JUN2024

C ama G roup is a leadin G supplier of advan C ed te C hnolo G y se C ondary pa C ka G in G systems , C ontinuously investin G in innovative solutions . Cama North ameriCa Buffalo Grove, il, uSa - 847-607-8797 /Company/Cama-north-ameriCa /user/Cama1spa CamaGroup Com Booth N-5152

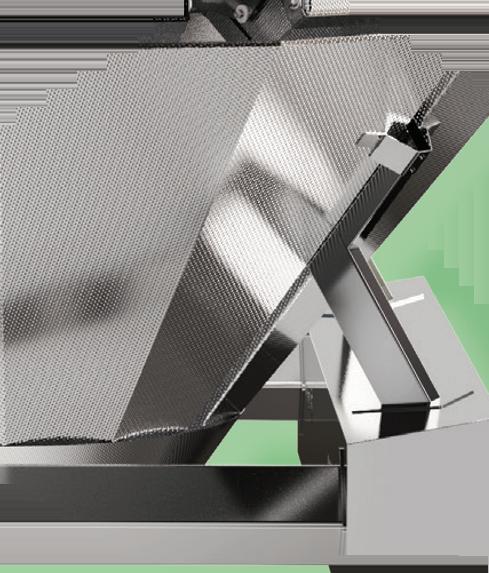

• Made at fixed angles of 30, 45, and 60 degrees

• Reduced footprint

• Eliminate changeover adjustments

• Low maintenance

• Accessibility layout for operator and fork truck traffic

in the face of the difficulties with packaging, and they’re setting targets to have all of their packaging be reusable, recyclable, or compostable. Similarly, policies around the world are trying to figure out where to reduce unnecessary packaging and how to collectively design packaging for recovery in a better way. For things like non-recyclable food-contact packaging, compostability has a great value proposition.

So I think it’s a combination of those things: Consumers being frustrated with the current options with the products they’re getting off the shelf, companies wanting to do better and making these public commitments, and then policies tying that all up and saying, “Well, we’re going to hold you to it.”

Despite the fact that compostable packaging is set to grow at such a rapid pace, it’s not the best packaging material for every application. From what I understand, foodservice packaging is one of the best uses because it delivers the nitrogen-rich food waste that composters need for their compost products. Does BPI consider the packaging application when certifying a compostable product?

That’s a great question and one that BPI has really taken a firm stance on over the years. So unlike some certifiers that are just certifying to a scientific standard, which involves tests to ensure the item will successfully compost, not create microplastics, not be toxic to plants in the soil—all of those are also in our certification—we’ve added in these other layers to help companies decide whether compostability is the right pathway for their item, rather than just saying, “Oh, well, consumers just want it to magically disappear.” That’s not how composting works. It’s not magic. It doesn’t disappear. And so we built in other criteria to our certification years ago that says you have to pass these other criteria or design of the end applications.

Once we get to that finished package phase when somebody’s applying, they have to demonstrate the product will be associated with desirable feedstocks that a composter is accepting—so making sure that the package is designed for the circular economy and the systems that will go to composting or anaerobic digestion. It can’t be a better fit for recycling, which is a difficult one to assess. In the public sector, that means items like beverage bottles, since that’s a really highly desirable recycling stream. And, it can’t require disassembly either, because we don’t want the risk of contamination if somebody isn’t taking the time to actually disassemble the package to get it composted.

It’s that first one that’s probably the hardest threshold to cut through. And what that means is things typically associated with food, so foodservice packaging, to-go items, bags

FIRST PERSON

34 PW MAY/JUN2024 844-293-2814

NEW

Draper Z Incline Conveyor

Contact Us for Details CONVEYOR EQUIPMENT IN 6 - 8 WEEKS

Image courtesy of PMMI and AMERIPEN from the “2023 Packaging Compass” report

to help people collect food scraps in the kitchen, both at home and in [commercial] kitchens, flexible food packaging, those multilayer packages around a snack bar or chips or other things like that. And then also common contaminants in the compost stream, things like produce stickers, which are not recyclable, tend not to be pulled off with fruit and go to the composting facility and are a tricky thing to screen out.

Do you discourage the use of compostable packaging for non-food applications like an electronics package, for example?

Well, it’s not the logical fit. I try to be cautious with saying something is never a good fit. It’s not a good fit for the general public for things that are going to be put into the curbside bin. So we do allow things not associated with food to get certified in specific scenarios where it’s maybe a closed-loop venue or they have a take-back program. So if you think about something like electronics or pharmaceuticals or apparel, all these industries are knocking on the door of compostability saying, “Why not? Why can’t we do it too?” And we say, “You can’t do it for the general public in something that’s going to go in the curbside bin, at least today, the way that those bins are set up. Maybe in the future, if the infrastructure is different, it could go into a curbside bin.”

Today, if a brand really wants to be involved in compostability, we say, “You just have to think this through. Is there a system to take those materials back? Is it packaging that’s business-to-business transport packaging where the facility can hold onto it, consolidate it,

Packaging Solutions That Work!

and bring it to a composter themselves? Then maybe compostability could still fit.” So it’s like we typically say, compostable packaging must be associated with desirable organic wastes for composters, with a little asterisk saying, except for these small instances where companies do have a system for take-back or a closed system.

As it exists today, the composting infrastructure is not really prepared for the kind of growth that’s expected for compostable packaging. Traditionally, who is investing in a composting facility? Is it a private company? Is it a government or municipality? How does that typically work?

There’s frequently a focus on there not being enough infrastructure to handle the compostable packaging. I’d say that’s the wrong question. The right question is around, do we have enough infrastructure for the primary feedstocks that need to be composted? So food is the number-one material going into landfills, and we don’t have enough infrastructure to handle all the food waste. First, we need to reduce the food waste, which organizations like ReFED are pioneering, but we’re still going to have a lot of food scraps and food waste that we’re not recovering. We’re barely scratching the surface of being able to capture that. And that’s where all the methane emissions are, that’s where all the nutrients we need to return to the soil for soil health come in.

And so the first question is, where’s the funding for the compost infrastructure for food, because that’s the bulk of the material that exists today, not the future growth in those projections for composta-

FIRST PERSON

’s v v s s d & b v , , s & s d d s d ! Ex d . . Ex d . . Cartoning | Top Load Systems | Tray Formers | Sleevers | Case Packers | Robotic Packaging 36 PW MAY/JUN2024

Diagraph Marking & Coding has been providing product identification solutions for 130 years that make it easy for manufacturers throughout the world to make the perfect mark — print after print after print. We focus on partnering with customers in every aspect of their coding and labeling operations to maximize efficiencies for our customers and drive tangible value throughout a long-term partnership.

TRAY PACK CODING CASE CODING CASE LABELING PALLET LABELING PACKAGE CODING PALLET PRIMARY SECONDARY 1 Research Park Drive St. Charles, MO 63304-5685 800.722.1125 diagraph.com • sales@diagraph.com Contact Diagraph today to discuss the best options for your operation. An ITW Company

ble packaging. It’s [food waste] here now, and it’s been going into landfills for a long time.

The funding is coming from a variety of means—private investment, grants, and loans. We need more things like the Compost Act, which we helped put together with a group of other associations. If it goes through, it would provide $2 billion over the next 10 years for grants and loans to private and public entities to increase access for food-scrap collection and composting. There are also some states that do cap and trade money to go to composters to help them with food scraps.

That’s probably where the biggest investment and change in infrastructure needs to happen, and then the packaging is the add-on, right? I think funding to handle the packaging is also becoming available now too with EPR bills. BPI successfully lobbied to change and modify the bills in Colorado and California so it would be baked in that the funding go to composters to help them with the extra cost of handling packaging and contamination. I think there also are grants available specific to packaging, too.

Are you seeing growth in the composting infrastructure in the U.S.?

Yes, there is growth. The US Compost Council, which is one of our key partners, has just exploded. I want to say it’s doubled in size over the last few years. Over a thousand people go to their conference every year. It’s become a real hub showcasing all the different levels where composting is happening.

The organization that tracks the growth in facilities the most is BioCycle. They recently put out a report that looks at large-scale facilities taking food scraps. The study is a bit tricky. It covers a number of facilities that reported, but I’d say there are probably more facilities than those that reported in the survey.

We’re seeing so many of these small, community composters pop up, that’s how they start. Sometimes they’re called bucket slingers, they start with bicycles and pickup trucks. And then within a few years, they’re not really community-scale composters anymore, now they’re mid-scale. And then the mid-scale ones, you talk to them later, and they’re like, “Oh, no, I cover the majority of the state of Michigan.” You’re like, okay, well that’s not really small or mid-scale. It’s one of those things that’s changing and growing so rapidly, it’s hard to keep track of.

There’s not really a lot of robust data out there, so another thing we’ve been pushing at the federal level is the Recycling and Composting Accountability Act. I had the honor of testifying to the Senate in support of that bill two years ago. The bill has languished, but we think the government needs to be helping with this. We need better data. It’s great that BioCycle has been tracking this for years. It’s great that we have organizations polling composters and recyclers, but it’s insane that we don’t have better recycling and composting data at the federal level. Why aren’t states required to report some baseline information about materials that are collected or not collected for recycling and composting and on their infrastructure for those materials? So yes, composting is growing, but can we show exactly how it has grown? That gets a little bit trickier.

FIRST PERSON

38 PW MAY/JUN2024

Let’s care together

+ INTEGRATED TECHNOLOGIES

+ IN TUNE WITH MARKET NEEDS

+ ALL-IN-ONE SOLUTIONS

+ PIONEERING SUSTAINABILITY

+ TOMORROW’S BENCHMARK

WE ARE IMA PERSONAL CARE.

Let’s Care is not just a commitment, it’s a guiding principle. IMA excels in cuttingedge technologies for processing and packaging a diverse range of personal care products, from cosmetics and perfumes to personal hygiene. In this journey, sustainability is prioritized with dedication. As a sole partner, our commitment goes beyond delivery, evolving into dedicated consultants and allies. Let’s Care is a call to action for customers to nurture their businesses by partnering with IMA.

ima.it/personalcare

What surprised you most about the results from the recent study BPI conducted with Closed Loop’s Composting Consortium (see pwgo. to/8269) on how consumers perceive different compostable packaging labels and designs?

While I expected consumers to not be able to sort out all of the variety of green marketing claims, I was surprised by the level of confusion that consumers have and just the massive level of education and policy work that’s going to be needed to sort out that confusion. Just the size and scale and gravity of that need was surprising.

What are some of the biggest challenges facing the compostable packaging industry that were identified by the report?

The study found consumers are confused about accurate identification and proper disposal of packaging. Ambiguous phrases and lack of consumer awareness contribute to compostable packaging being incorrectly placed in recycling bins, and vice versa, leading to contamination. While progress is being made on policies for compostable packaging, we need all non-compostable packaging to be identifiable too.

study between BPI and the Composting Consortium offered ‘first-of-its-kind,’

This is an area where more public policy is needed to help clarify how items are marketed and labeled. We’ve seen a big surge

in interest, probably because associations like ours are willing to make changes to compostable packaging. So part of that is on the compostable packaging itself. What are the elements needed to make an item readily identifiable for compostability? And the results focus on three basic elements that need to be there. These are a thirdparty certification mark, a prominent compostability claim—or that

FIRST PERSON

PACK BE NIMBLE. The newest addition to Standard-Knapp’s line of case packers is the Unipack 2.0, a robotic pick-and-place dynamo that can pack, unpack and repack. Designed for small to medium plants, this packer covers a small footprint, and is easily transported with an optional mobility kit. Compact, versatile, and modular. 63 Pickering Street, Portland, CT info@standard-knapp.com • (860) 342-1100 standard-knapp.com • eol.group Discover the Unipack 2.0 pick-and-place case packer from Standard-Knapp. standard-knapp.com/unipack 40 PW MAY/JUN2024

publicly available data on

The joint

U.S. consumer perceptions of compostable packaging.

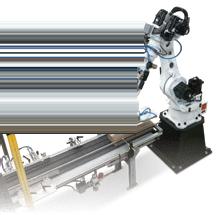

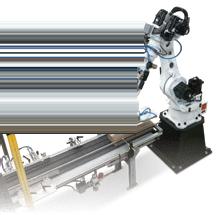

Compact & Affordable Robotic Automation

CASE/TRAY PACKING CARTON LOADING & ORIENTING PALLETIZING & DE-PALLETIZING ROBOTIC PRODUCT LOADING PKR Gantry for jars, cans, cartons & trays Z.ZAG Robotic Palletizer for pick & place cases / pallet / slip sheet PKR Delta for pouches & flexible packages PKR Robot with Articulated Arm pick & place in spaces with height limits PKR Scara for loading prerolls PKR Scara robotic loading for flow wrapping WATCH VIDEO WATCH VIDEO WATCH VIDEO L O WATCH VIDEO WATCH VIDEO WATCH VIDEO WATCH VIDEO ith Ready To Supercharge Your Production? Contact us now for ROI and take the step into the future of packaging automation. Call us at 702-450-0808 Visit paxiom.com/robotics info@paxiom.com PaxiomGroup PaxiomXperience Pre-roll Weighing Filling BaggingWrappingCappingSealingLabelingCartoningFormingPackingPalletizing LAS VEGAS • MIAMI • MONTREAL • SCHIO, ITALY Efficiency, speed, and precision in every pick & place Liberate your staff from repetitive and dangerous tasks Take advantage of the benefits offered by Industry 4.0 Visit our 50,000 sq ft System Integration & Xperience Center in Vegas

PKR Delta for bottles & tubes

word has to be big enough—and some element of color. That solves that core focus of where BPI is, but we also need public policy that addresses other types of packaging.

You can do all you want to change how compostable packaging is labeled and identified, but if conventional packaging doesn’t also have some rules, then consumers are still going to be confused because you’ll have these other leaf designs and green claims. The classic example we give is a drinking straw. If you tint that green because it’s compostable, but you also tint it green when it’s not compostable, how is a consumer ever going to know? So we need to be able to have sufficient claims and criteria for non-compostable items as well.

What are some of the actions the BPI/Composting Consortium report suggests to address labeling challenges? What role can BPI play in these initiatives?

To address the challenges outlined in the report, one potential solution is for brands to clearly indicate compostability on their packaging using two to three design elements, such as coloring, text size, etc., for better consumer understanding. Another solution is for municipalities to collaborate with various stakeholders to educate the public on proper disposal in recycling and organics bins, which is crucial for clean material streams. Implementing home composting certification standards would also help consumers identify items suitable for home composting. Policymakers, brands, and

retailers should collaborate to harmonize policies and regulations for packaging nationally, ensuring consistency across sectors and packaging types.