NOV2022 packworld.com 38 Starbucks Elevates Whole Bean Bag Graphics 42 AGVs Cede Territory To AMRs 44 Dispenser Wows Whipped Cream Lovers 48 PepsiCo, Gatorade’s Gx Smart Bottle 52 Planter’s NutShaped Jar Saves Plastic 30 Has Circular Film-to-Film Recycling Arrived? Packworld.com has a new look. CHECK IT OUT! REPACK AGING THE FUTURE. Sustainable. Automated. Connected.

w ©2022 W y ogo ar y W y s r v 98% UPTIME? YES, IT’S THAT GOOD. and bo h a 98% v , you s and pr gins. o , allow hr our v oviding incr branding oppor Meta’s high-speed precision equipment sets a new standard in container strength, sustainability

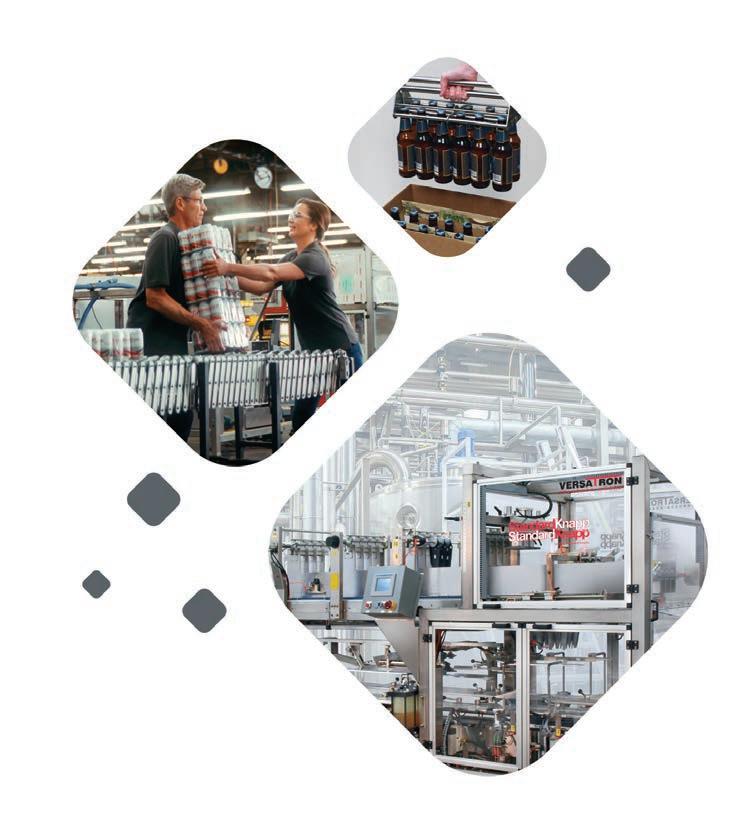

Many players, one team. www.syntegon.com Synergizing automation in�EDJ�PDNLQJ��KRUL]RQWDO�ÁRZ� wrapping, robotics, product handling, cartoning, FDVH�SDFNLQJ��V\VWHP�VROXWLRQV��OLTXLG�ÀOOLQJ�� jelly production, bag sealing, coffee, and service for you.

Packaging World designers and editors had fun mapping out Minnesota to illustrates the new MBOLD coalition, which is taking square aim at a truly circular recycling system for lms, both consumer and agricultural. The project is still in its infancy, but it is getting all the correct stakeholders involved— CPGs, retailers, MRFs, converters, and agricultural entities—to increase the amount of PCR lm for use both in back-of-house operations, to primary packaging, and eventually, in foodcontact applications.

30 COVER STORY

Circular Economy for Flexible Films Aspires to Food-Grade Film-to-Film ‘Holy Grail’

The MBOLD coalition catalyzes a new ecosystem of stakeholders to support a circular economy for exible packaging and lms in the Upper Midwest.

38

Starbucks Elevates Coffee Art with New Bag Graphics

In the rst new packaging design for its core whole-bean coffee roasts in a decade, Starbucks takes its storytelling strategy to new heights, with evocative artwork that richly conveys each variety’s heritage, distinctive avor, and quality.

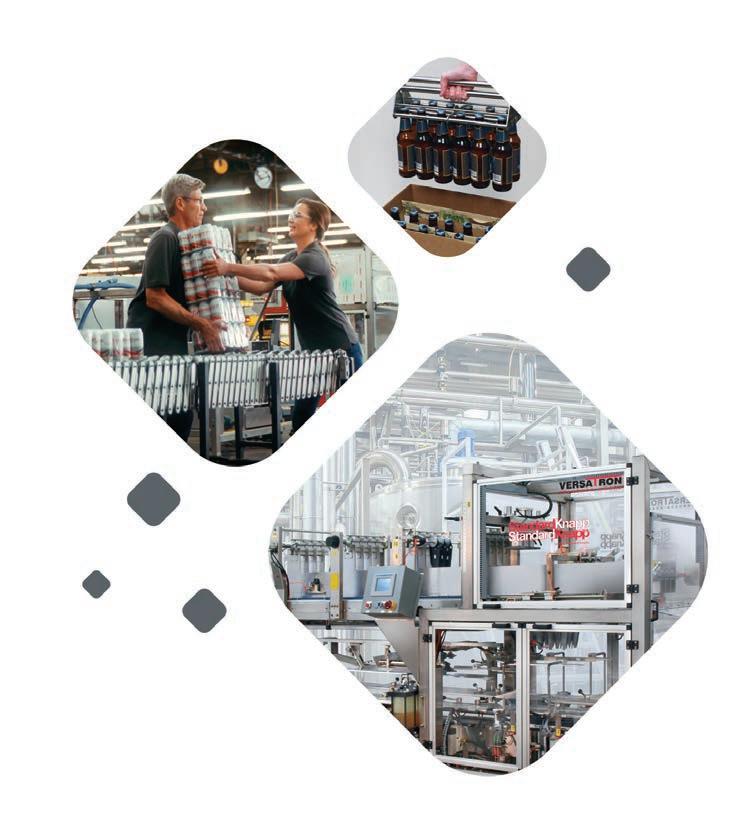

42 AUTOMATION Long-Charge AMRs Safely Plug Labor Drain

Mauser Packaging improved operator safety conditions and automated out hard-to- nd labor, all the while improving throughput to the tune of 600% in one location, thanks to the new AMRs’ fast and long-lasting charge.

44 EMERGING BRANDS

New Nozzle Technology Creates a ‘Whipnotic’ Experience

Whipped cream topping gets ipped on its can with new Whipnotic dairy topping that features a patented aerosol can nozzle that swirls fresh fruit juices and avor essences into the product during dispensing.

48

App Keeps Athletes Hydrated via Wearable Sensor, Smart Bottle, & Re ll Pod System

PepsiCo’s Gatorade Brand unveiled a new smart hydration system for health and tness consumers that features a durable bottle, a recyclable re ll pod, a wearable patch, an LED closure, and a smartphone app to interact with the athlete.

2 PW NOV2022 VOL29 NO11 FEATURES 30

38 44 48

Illustration by E.J. Luden

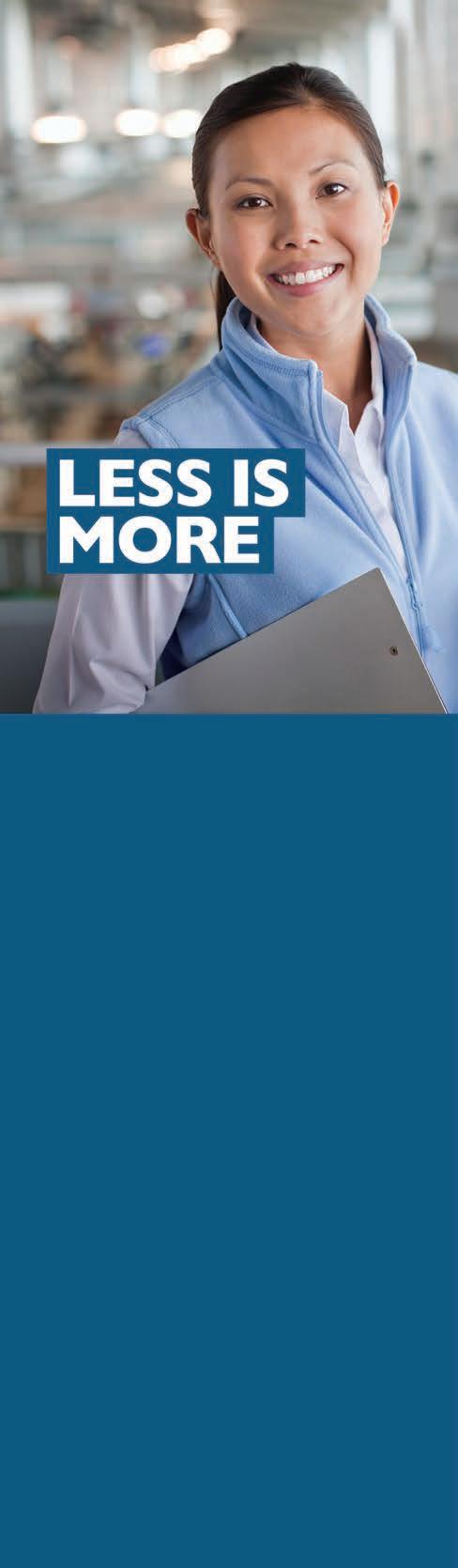

We don’t need many words to introduce our new Volta electric hot melt application head. For us, dots and lines are enough. That’s exactly what Volta does. Super reliable and super economical. What does the Morse code adhesive line say? Of course, it’s Volta ! LESS IS MORE DISCOVER VOLTA

4 PW NOV2022 Packaging World® (ISSN # 1073-7367) is a registered trademark of PMMI, The Association for Packaging and Processing Technologies. Packaging World® is published monthly by PMMI with its publishing of ce, PMMI Media Group, located at 401 N. Michigan Avenue, Suite 1700, Chicago, IL 60611; 312.222.1010; Fax: 312.222.1310. Periodicals postage paid at Chicago, IL, and additional mailing of ces. Copyright 2022 by PMMI. All rights reserved. Materials in this publication must not be reproduced in any form without written permission of the publisher. Applications for a free subscription may be made online at www.packworld.com/subscribe. Paid subscription rates per year are $254 in the U.S., $363 Canada and Mexico by surface mail; $605 Europe and South America; $907 Far East, Australia, and other countries by air mail. Single copy price in U.S. is $20. To subscribe or manage your subscription to Packaging World, visit Packworld.com/subscribe. Free digital edition available to quali ed individuals outside the United States. POSTMASTER; Send address changes to Packaging World®, 401 N. Michigan Avenue, Suite 1700, Chicago, IL 60611. PRINTED IN USA by Quad. The opinions expressed in articles are those of the authors and not necessarily those of PMMI. Comments, questions and letters to the editor are welcome and can be sent to: editors@packworld.com. Mailing List: We make a portion of our mailing list available to reputable rms. If you would prefer that we don’t include your name, please write us at the Chicago, IL address. DEPARTMENTS Connect with us: VIDEO Film-to-Film Circular Food-Grade Recycling pwgo.to/7749 VIDEO PepsiCo’s Gatorade Gx Smart Bottle System pwgo.to/7750 VIDEO Long-Charge AMRs Prompt 600% Improvement pwgo.to/7748 FREE DOWNLOAD Counterintuitive McKinsey Report on Plastics, GHGs pwgo.to/7747 packworld.com COLUMNS 7 Lead Off 22 The Legal Side 24 The Big Picture 26 Sustainable Packaging 52 Shelf Impact! 56 Professional Perspective NEWS/EVENTS 8 News 16 Quotables/By the Numbers 55 Industry Watch INTERVIEW 18 First Person PRODUCTS 53 Technology ADVERTISING 28 Leaders in Packaging Product Directory 55 Advertiser Index Connect with a Leaders in Packaging supplier and support packaging education! www.packworld.com/leaders 15 52 EDITORIAL ADVISORY BOARD Aladin Alkhawam Director, Packaging Operations, Par Pharmaceutical Jan Brücklmeier Technical Application Group Packaging Technology Expert, Nestlé M. Shawn French Director – Innovation & Packaging Engineering (Beverage), Danone North America Patrick Keenan R&D Packaging Engineer, General Mills/Annie’s Organic Snacks Mike Marcinkowski Global R&D Of cer, GPA Global & Hub Folding Box Co. Paul Schaum Chief Operations Of cer, Pretzels Inc. David Smith, PhD Principal, David S. Smith & Associates Brian Stepowany Packaging R&D, Senior Manager, B&G Foods, Inc. Jasmine Sutherland President, Texas Food Solutions; Vice President, Perfect Fit Meals

800.835.2526 or 316-284-2020 Newton@BuntingMagnetics.com BUNTINGMAGNETICS.COM Bunting’s large bag metal detector, the meTRON™����&,�FRLO�ZLWK�%XON�6HQVH�.LW��FDQ�HƬHFWLYHO\� GHWHFW�VWDLQOHVV�VWHHO�PHWDO�FRQWDPLQDWLRQ�DV�VPDOO�DV�����PP��DQG�FDQ�KDQGOH�EDJV�RI�GU\�SURGXFW� between 50-100 lbs. Features: • Detects ferrous and non-ferrous metal as small as 1.5mm. • Detects 316 stainless steel as small as 2.0mm. ��r�,GHDO�IRU�KDQGOLQJ�ODUJH�EDJV�RI�EXON�GU\�SURGXFWV��VXFK�DV�ưRXU�DQG�FKHPLFDO�SRZGHUV� ��r�([FOXVLYH�FRQVWUXFWLRQ�VKLHOGV�WKH�VHDUFK�KHDG�IURP�RXWVLGH�LQWHUIHUHQFH�DQG�GHOLYHUV�� ���WKH�VPDOOHVW�PHWDO�IUHH�]RQH�SRVVLEOH� ��r�&XVWRP�DSHUWXUH�VL]HV�HQVXUH�PHWDO�GHWHFWRU�LV�WKH�SHUIHFW�ƮW�IRU�\RXU�DSSOLFDWLRQ� Bunting’s “Big Bag Detector” Gives You Big Results For more information call 800.835.2526 RU�YLVLW�buntingmagnetics.com

EDITORIAL

Matt Reynolds Chief Editor

Iris Zavala Managing Editor

Anne Marie Mohan Senior Editor

Sean Riley Senior News Director

Mike Prokopeak Senior Director, Content & Brand Growth Pat Reynolds, Sterling Anthony, Eric F. Greenberg, Ben Miyares Contributing Editors

ART

David Bacho Creative Director

AUDIENCE & DIGITAL

Elizabeth Kachoris Senior Director,

ADVERTISING

Wendy Sawtell Vice President, Sales

Lara Krieger Production Manager

and

wsawtell@pmmimediagroup.com

lkrieger@pmmimediagroup.com

Kelly Greeby Senior Director, Client Success & Media Operations

Krepelka Director, Digital

PMMI MEDIA GROUP

David Newcorn President, PMMI Media Group

Sharon Taylor Director, Marketing Amber Miller Senior Marketing Manager Janet Fabiano Financial Services Manager

Joseph Angel Founding Partner and Executive Vice President, Industry Outreach, PMMI Lloyd Ferguson Founding Partner

Packaging World • PMMI Media Group 401 N. Michigan Ave., Suite 1700, Chicago, IL 60611 Phone: 312/222-1010

Fax: 312/222-1310 E-Mail: info@packworld.com

Web: www.packworld.com

PMMI The Association for Packaging and Processing Technologies 12930 Worldgate Dr., Suite 200, Herndon VA, 20170 Phone: 571/612-3200

Fax: 703/243-8556

Web: www.pmmi.org

Staff at PMMI Media Group can be contacted at info@pmmimediagroup.com

•

•

•

•

@PackagingTrends

Digital

Data

•

•

Jen

Media

6 PW NOV2022 Follow us on twitter @PackagingWorld

Parallel Trends Overlap, Intertwine at PACK EXPO

After a four-year, pandemic-induced hiatus, PACK EXPO International was back in Chicago in late October, 2022, and the top trends weren’t hard to spot. Sustainability, e-commerce, and robotics/automation as a means to stand-in for hard-to-find labor, could be found everywhere on the show floor.

But these trends are increasingly overlapping. I can’t so easily distinguish a sustainability-minded product launch from an e-commerce or fulfillment center-aimed piece of tech. They’re often one in the same these days, pulling double duty, or at least display attributes of both. Case in point: curbside recyclable padded paper mailers as part of on-demand semi-automatic bagger solutions serve two masters in sustainability and e-comm. Entries from PAC Machinery via its Fiber Flex preopened mailer and Rollerbag R-3200 automatic bagger, Pregis and its Sharp Max-Pro 18 bagger with Evertec padded paper mailers, and Sealed Air Autobag machines with paper mailers made from post-consumer fiber, are three examples I saw.

Speaking of paper, I’ve found myself spilling quite a bit of ink in recent months on a transition from plastic to paper(board) packaging wherever the application—and price point—would allow it. But flexible film materials suppliers and converters are among those exhibitors that have made the greatest strides since we saw them last in Chicago. There are too many to name, but I saw advancements from the likes of ProAmpac, Amcor Flexibles, Berry Global, Clysar, Pregis, and others, all demonstrating new, more sustainable entries into the films and flexible packaging categories. With a few notable exceptions around compostability, bio-based plastics, and oceanbound plastics, the lion’s share of these advancements came within one (or both) of two categories. The transition from multilayer coextrusions or laminations to monomaterial structures was one key area of advance, with the goal of achieving recycle-ready status or even true recyclability through How2Recycle. The other was the usage of higher and higher PCR contents as more and more feed stock slowly but surely comes available.

Four years ago, advanced (then typically called chemical) recycling was a hopeful but distant silver bullet/magic wand technology. Yet evidence of its progress was more apparent than ever at PACK EXPO International. Once again blending the lines between different parallel trends, UBM Raflatac was demonstrating a nifty application that it says is “the world’s first certified label material to fight ocean-bound plastic pollution” (plastic materials certified to have been recovered and recycled from rivers or coasts prior to their transition to ocean microplastics). These materials tend to be highly degraded and difficult to recycle, at least by traditional mechanical methods. But advanced recycling from category specialist SABIC was used in this application, resulting in either 85% or 90% (depending on transparent vs. opaque) ISCC PLUS-certified chemically recycled material on mass balance approach. Another pet-food pouch collaboration between Printpack, ExxonMobile, and Pregis was made using advanced recycled materials, exemplifying continued progress in this category.

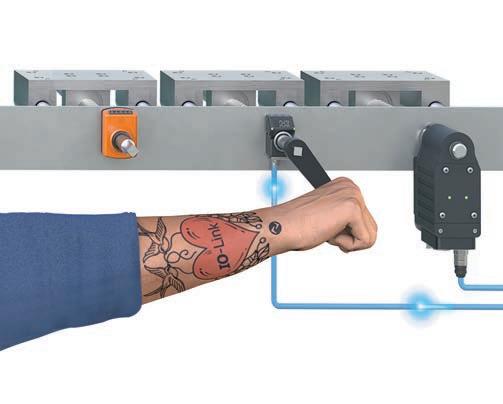

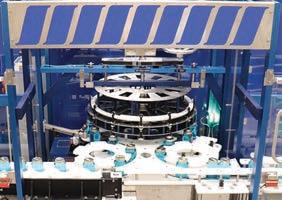

Switching from materials to automation, independent movers or pucks using linear-servos, usually on looping, track-style systems, could be found both in their supplier’s booths and on equipment in several OEM’s booths. One all-new entry in this category (not exactly in the continuous track system mold, but related) was Syntegon’s splashy new IDH (Independent Direct Handling) system. From an infeed, it gently collates and tray-packs variably placed products like biscuits or cookies, either on-edge in a slug or stacked in-line, via independent, parallel pickers with vacuum EoaTs. It’s more easily viewed in 10 seconds than described and contemplated in text, so check it out at pwgo.to/7751

And even more overlapping trends could be found at the intersection of e-commerce and workforce. Pick-and-place robots with vision systems capable of handling high-mix, variable product environments, previously the realm of human labor, were the name of the game here. Targeting e-commerce and fulfillment in pharma, electronics, and CPG markets, among others, one example from ABB and Banner, and Osaro, Cognex, and Fanuc were decidedly on-trend(s). PW

mreynolds@pmmimediagroup.com

BUILT TO PERFORM

7 847-437-1427 | pmikyoto.com Learn More | Watch Videos STILL

COMPACT OMPAC NEW

At only 6 inches in length and capacity of 240 products per/min, this cartoner is the perfect choice for a factory in need of powerful yet compact solutions.

LEAD OFF

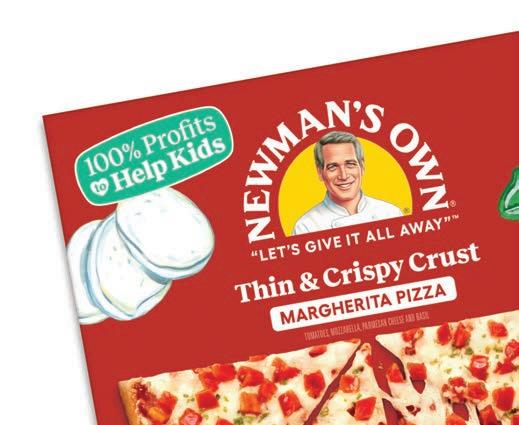

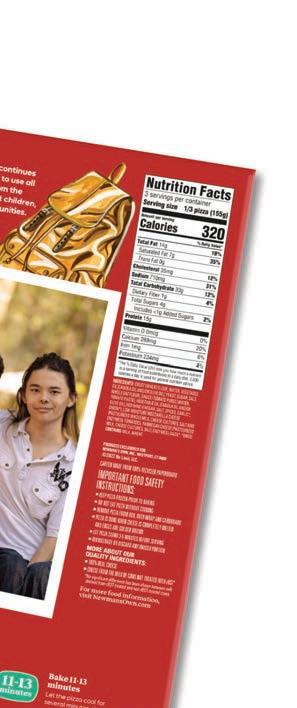

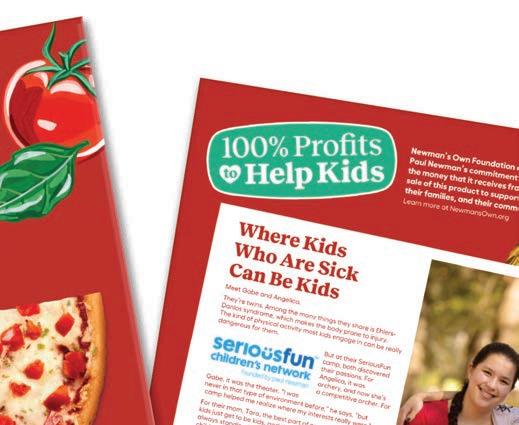

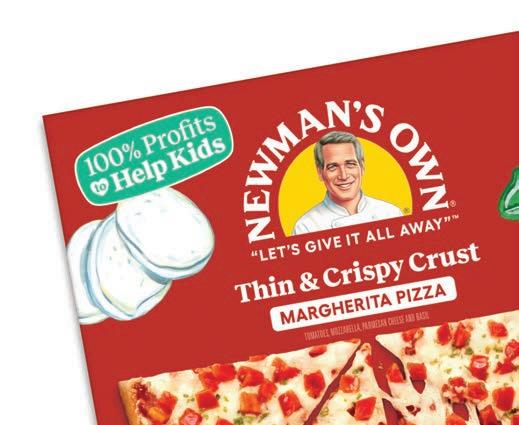

Newman’s Own Personalizes Pizza Boxes

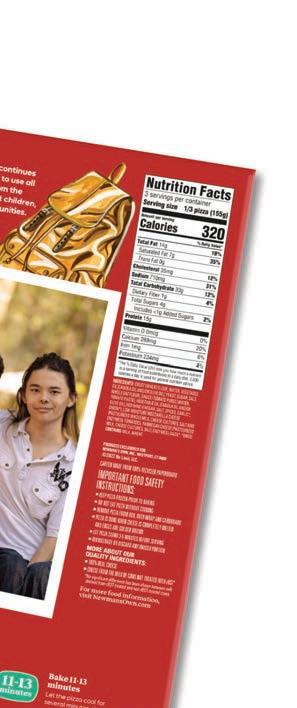

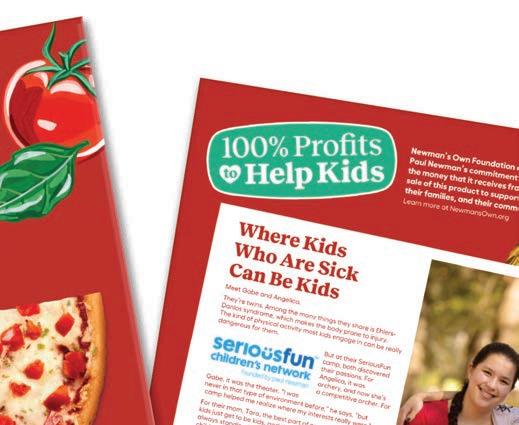

Newman’s Own food company, founded by beloved actor and racecar driver Paul Newman, is renowned for its philanthropy; 100% of its after-tax pro ts are donated to the Newman’s Own Foundation, a private non-pro t created to nourish and transform the lives of children facing adversity. Since 1982, when the company was launched, more than $570 million has been donated to children’s causes.

With its new packaging design, the rst examples of which debuted in September, Newman’s Own is bringing the impact of the brand to life by featuring pro les of some of the children who have bene tted from the company’s mission. Now included on the back of the packaging for four of its Thin & Crispy pizza varieties are photos and stories of six of the children who have attended Paul Newman’s SeriousFun Children’s Network (SeriousFun) camps, a community of adaptive summer camps for kids with serious illnesses.

“Newman’s Own does radically good work in its commitment to give away 100% of pro ts to help children who face adversity,” shares Nicole Malcolm-Manyara, chief marketing of cer of Newman’s Own. “The purpose of the new packaging, notably featuring the stories of kids it supports through its grantee partners, is to communicate the brand’s focus on helping kids and to help consumers better connect with the radically good impact they have when they purchase Newman’s Own products.”

The children highlighted include siblings Sarah and Akeem from New York, who appear on the box for Italian Sausage & Uncured Pepperoni Pizza; Clayton from North Carolina on the Uncured Pepperoni Pizza box; siblings Gabe and Angelica from Florida, on the Margherita Pizza box; and Sophie from Ohio on the packaging for Four Cheese Pizza. Accompanying each story is a QR code consumers can scan to access video interviews with the children featured on-pack. Through next summer, Newman’s Own will roll out the rest of its pizza packaging as well as packaging for other product categories, primarily lemonade, cookies, coffee, and dog treats, with more pro les, as space allows.

The personalized packaging is part of a larger initiative by Newman’s

Own that involved redesigning the packaging for its entire portfolio. According to Malcolm-Manyara, the company’s primary objective in changing the packaging was to modernize the brand and make it more relevant to shoppers in today’s retail environment. Working with Newman’s Own on the project was creative consulting agency Turner Duckworth and illustrators Helen Green, who refreshed the image of Newman in the brand logo, and Fanny Gentile, responsible for the ingredient imagery and backof-pack illustrations.

The new design has been updated with a primary color palette that is said by Malcolm-Manyara to be a bright, optimistic take on the original brand colors. “The teal on-pack is distinctive, unexpected, and fresh, complemented by a sunshine yellow to bring contrasting color into the primary palette,” she explains. “The secondary palette is fresh, vibrant, and expressive. It is inspired by natural ingredients and food to celebrate Newman’s Own delicious products. Its feel-good illustrations, inspired by ingredients in its food products and the passions of kids featured on the back of pack, provide additional interest, playfulness, and connection to both Newman’s Own delicious food and the children featured on pack.”

The typography has also been refreshed, with modern fonts that were selected to better resonate with younger consumers and stand out on shelves. “The two main fonts on packaging are Reckless and Fellix,” Malcolm-Manyara explains. “Reckless is a gregarious serif that brings friendliness and human-like warmth to type, while Fellix is a geometric sans font that complements Reckless and allows for harmony in applications.”

Since the pizza boxes were unveiled in September, Malcolm-Manyara says that consumer feedback to the new design has been very positive. “As a few examples, one consumer said ‘Your new branding is so fun! We (hear emoji) all your products!’ One even quipped, ‘Did Mr. Newman recently get super-hot, or do I need to get out more beyond the grocery store?,’” she shares. “Of course, we think everyone would agree Paul Newman was always very good looking, but we appreciate the sentiment in regards to the new logo.” —Anne Marie Mohan

PW NOV2022

NEWS

More PCR, Less Weight in Pantry-Sized Mars Candy Jars

Snack and treats leader Mars, Incorporated tapped Berry Global Group, Inc. to launch its popular pantry-sized treats in injection-stretch-blow-molded PET jars that have been optimized to be lighter weight and include 15% post-consumer resin (PCR). With the shared mission of creating more sustainable packaging solutions, Berry and Mars will launch the new jars for the M&M’s, Skittles, and Starburst brands later this month.

As part of Mars’ ongoing commitment to sustainability, the company is investing hundreds of millions of dollars to reimagine and redesign its packaging. “At Mars, we want to contribute to a circular economy where packaging material never becomes waste, but is recycled, reused or composted,” says Justin Comes, VP of R&D, Mars Wrigley North America. “We have set an aggressive, science-based strategy to innovate our packaging and this change to 15% PCR for these large-format jars is a signi cant step towards a more sustainable future.”

The easy-grip square jars are produced at Berry’s manufacturing facility using a single-pellet, food-grade resin to assure a clean, consistent substrate sourced from mechanical recycling. With a history of results in light-weighting, Berry approached Mars with the new concept including PCR. Berry brought its problem-solving and technical expertise to the table to help Mars make progress toward their sustainability goals. In addition to the inclusion of PCR, the jar is also widely recyclable.

“By leveraging our material science expertise and technical resources, we proactively created a solution for Mars without disruption to product performance. Through partnerships and creative thinking such as this, customers look to Berry for unique solutions to their sustainability challenges,” says Brian Hunt, an EVP and general manager for Berry Global’s Consumer Packaging North America Division.

The jars, which come in 60-, 81-, and 87-oz sizes, offer the same look and feel of their predecessors and will eliminate approximately 300 tons of virgin plastic per year, according to the company.

For the 81- and 87-oz jars, Berry reduced the weight by 10 g per jar, saving 374 metric tons of CO2 per the Association of Plastics Recyclers. According to the EPA’s Greenhouse Gas Equivalency Calculator, that’s equivalent to 42,084 gallons of gasoline consumed, 45,494,350 total smartphones charged, or 72.8 homes’ electricity use for one year.

Berry notes that the jar runs seamlessly through Mars’ existing production and distribution systems. —Matt Reynolds

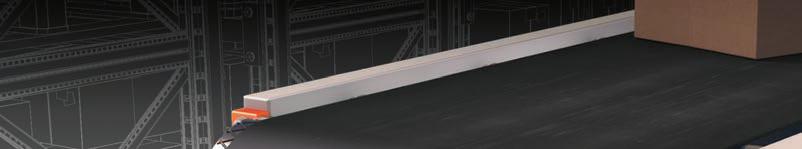

www.nerconconveyors.com 844-293-2814

9

48” Rotary Accumulation & Unscramble Table Contact Us for Details • 10 Business days delivery advantage • New streamlined design creating ÀH[LELOLW\�LQ�ÀRRUVSDFH�XVDJH • &DOO�IRU�QHZ�SULFLQJ�RI���´�URWDU\� DFFXPXODWLRQ�RU�XQVFUDPEOH�WDEOH 10 BUSINESS DAYS DELIVERY ADVANTAGE New Design & Faster Delivery Time

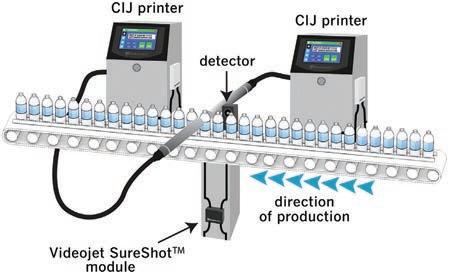

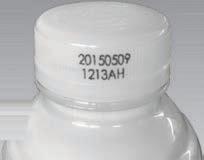

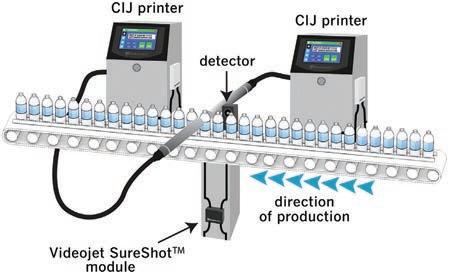

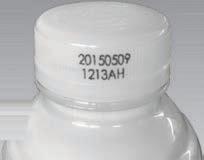

Anna is the proud owner of a thriving plant-based food company. To meet retailer demands, she needed traceability codes on flexible packaging but was unsure where to start. As demand for her product grew, Anna knew she needed the expertise to hit the ground running.

Anna discovered Domino’s effective lasers for flexible packaging, and now she relies on our understanding and experience. She also values working with a partner who understands how to support her sustainability goals. Anna came for the lasers to reduce the risk of coding errors while driving sustainability and left with peace of mind.

Redesign Differentiates Nestlé Drumsticks from Imitators

The Nestlé Drumstick brand of ice cream sundaes has been a household name for nearly 100 years, since 1928. But more recently, competitors—including many private labels— have been encroaching on the iconic brand’s turf, imitating the lineup and visual brand cues, and creating a homogenous sea of blue on the shelf, according to the company.

That’s why the brand team at Dreyer’s Grand Ice Cream, a wholly owned subsidiary of Nestlé, determined that it needed to redesign the entire portfolio. Its goals were to refresh the brand, bring its values and personality to life, drive differentiation, and tap into the strong emotional connection consumers have with the brand. They called on creative agency Chase Design Group to work with them on this icon in the ice cream category and leader in the $3.6 billion all-family snack category.

“Thanks to the redesign, our packaging now re ects a bolder personality that differentiates us from competitors and will be carried through on future innovations,” says Elmer Gonzalez, brand manager, Dreyer’s Grand Ice Cream.

Melinda Turner, senior account director at the Chase Design Group, says she looked for ways to break through the sea of blue by strengthening the assets the brand could own and focusing on its values: adventurous, original, and energetic. Unique pattern illustrations, customized for each avor/texture/coating, help highlight the adventurous eating experience.

“The iconic logo was maintained but positioned in an upward angle on the package to bring more energy to the brand,” Turner says. “Vibrant product photography, more authentic to the product experience and secondary typography were designed to reinforce the bolder appearance and enhance appetite appeal.”

Adds Jon Arriaza, senior design director, Chase Design Group, “While the blue background color was a critical part of the Drumstick brand and category cue, we moved beyond to differentiate it with photography, texture, patterns, and clever copywriting that de nes the unique aspects of the eating experience. To further distinguish the various avors, colorful, bold, simple repeat patterns that highlight the new cone illustrations were developed for the inner wraps. The new brand design system was then applied across the spectrum including merchandising and digital assets resulting in a fun, playful experience from shelf to consumption.”

All 23 SKUs are rolling out to major supermarkets and groceries nationally. —Matt Reynolds

10 PW NOV2022

Now Anna—with help from Domino—can achieve so much more. Meet Anna. LESS UNCERTAINTY. MORE COLLABORATION. Learn more about how Anna gained confidence with Domino. Experts in Traceability Codes Inkjet | Laser | Case Coding | Label Print & Apply NEWS

Connect with a Leaders in Packaging supplier and support packaging education! www.packworld.com/leaders

Loop Comes to Walmart InHome

Walmart Inc., and Loop, the circular reuse plat form developed by TerraCycle, announced that Loop has joined Walmart’s InHome gro cery delivery service in select cities. Customers in the metro areas of Bentonville and Rogers in Arkansas can purchase a limited assortment of products in re llable, reusable containers and have them delivered to their home through Walmart+ InHome.

“Identifying models that can make shop ping easy, convenient, affordable, and sus tainable is a core part of how we pursue our commitment to becoming a regenerative busi ness at Walmart. By leaning into reuse with Loop and so many of our brand partners, we see a unique opportunity to help our custom ers eliminate packaging and single use plastic from many of their regular purchases,” says Corey Bender, VP, merchandising for House hold Essentials, Walmart U.S.

The new Loop assortment includes a com bination of well-known food and household products from a range of brands, including Gillette, Clorox, Cascade, Kraft Heinz, Seventh

Generation, and Love Beauty and Planet, with more brands being added to the Loop product portfolio in the coming months.

Walmart+ InHome allows customers to have fresh groceries, everyday essentials, and more delivered to the location of their choice: from dropped off at their doorstop, to un packed directly into their kitchen or garage re frigerators, all done by highly trained Walmart associates. For customers looking to try out this ultra-convenient and highly personalized service—all while enjoying the added bene t of Loop—they can visit www.inhome.walmart. com to sign up for a 30-day free trial today.

Loop is one of the rst platforms to partner with brands and retailers to offer consumers a way to go from single-use packaging to one that is reusable. After consumers use the products, they place the empty containers in a designated spot inside or outside their home for a Walmart associate to retrieve them. From there, the con tainers are sent to Loop to be sanitized, then returned to participating brands to be re lled and returned to the store for future purchase.

“Loop was designed from the ground-up to reinvent the way we consume by learning from historic circular and sustainable models, while honoring the convenience afforded by our single-use consumption of today,” says Tom Szaky, founder and CEO of Loop and TerraCy cle. “Walmart and Loop have come together to create a simple and convenient way to enjoy a wide range of products, customized in brandspeci c reusable packaging, with the conve nience of in-home delivery.” —Matt Reynolds

Where formulations take ight.

45 years of expertise in contract lling sensitive formulations into unique, single-dose ampoule packaging.

CALL 908-362-9266 JAMES-ALEXANDER.COM

11

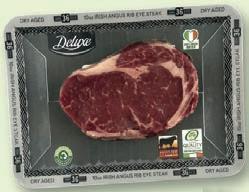

Monomaterial VSP

Retains Rustic Appeal, Helps Save Bacon

Austrian bacon producer Handl Tyrol switched to a new monomaterial polypropylene (PP) high-barrier packaging solution for bacon that retains the brand’s characteristic rustic wood appearance. The lm ensures safe vacuum packaging and offers excellent protection to extend shelf life and prevent food waste, the company says.

“This packaging is certainly eyecatching, while providing excellent product protection. It works with in existing recycling guidelines for retailers across Europe and is a great example of more sustainable packaging with no compromises: it still provides the highest level of food protection which of course is always our priority,” says Daniel Maier, head of pro curement, Handl Tyrol.

The new material for vacuum skin packing (VSP) replaces a multilayer lm based on PA,

and PE without barrier. This new monomaterial pack looks exactly the same as the incumbent. In fact, one of the main requirements of the project was that neither the look nor feel be sacri ced by switching to the new PP lm. Supplier Mondi was up to the task.

So why the change to a new material? “First and foremost is the qual ity of our product,” a Handl Tyrol spokesperson told Packaging World “Packaging is an important part of this. We always strive to make our packaging as environmentally friendly as possible and have found the combination that unites these goals in the provided PP lm.”

The product is vacuum-packed on an existing thermoformer, so no new equipment was re quired for the material change. The vacuum pack is labelled automatically with a thick, exible PP laminate. The backing, a roto gravure-printed rollstock that is also PP, is printed on both sides in sandwich. On the outside, a special lacquer is applied to create a haptic effect.

The new lm is recyclable in existing recycling streams in Europe for mixed polyole ns and keeps the bacon fresh, the company says, providing a “second skin” that seals securely with both a high-barrier top and bottom lm. The packaging has been de signed to look like a wooden chopping board, providing instant onshelf appeal and brand recognition.

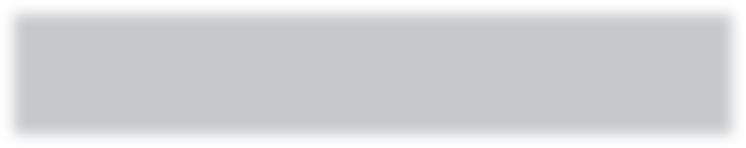

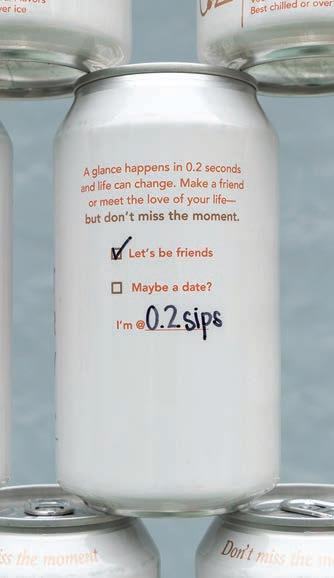

Interactive Can for RTC Cocktail Encourages Social Connections

California-based designer and entrepreneur Holly Riddel is on a mission to inspire people to look at one another with kindness, curiosity, and an open mind and heart. Integrating her passion for bringing people together with products designed to facilitate that connection, Riddel recently launched the 0.2 Meet Your Destiny brand, which includes a unisex fragrance that “evokes the emotional high of love and connection” and her most recent introduction, a ready-todrink cocktail with an interactive can that creates opportunities to connect.

According to Riddel, the 0.2 brand name, as well as the name of the company she founded to produce the products, 0.2 SIPS LLC, is re ective of her mission. “0.2 stands for the one- fth of a second that scientists say it takes to make an instant connection with another, to feel that rush of excitement, and to experience an instantaneous chemical reaction in the body and brain,” she explains. “Meet Your Destiny [canned cocktail] is meant to elicit that feeling, that sensory rush of pleasure, in a drink.”

Made with six-times-distilled vodka and allnatural ingredients, the RTD canned cocktail includes light notes of bergamot tea, mint, orange, fresh ginger, and a touch of pure honey. Differentiating Meet Your Destiny from other canned cocktails on the market, Riddel says, are its premium ingredients, no- zz drinking experience, and interactive packaging.

Meet Your Destiny comes in a 12-oz aluminum can from Ball; the generous, 12-oz serving size is meant for sharing. On the back of the can, copy reads, “A glance happens in 0.2 seconds and life can change. Make a friend or meet the love of your life—but don’t miss the moment.” Underneath that are two options, “Let’s be friends,” or “Maybe a date?” with checkboxes next to each. Beneath that, the can reads, “I’m @” along with an area to write-in contact information.

On the importance of personalized packaging to the Meet Your Destiny brand, Riddel says, “We are dedicated to bringing people together by inspiring interaction and excitement around the possibilities of connection. We are meant to be social. If

12 PW NOV2022 NEWS

Working closely with Handl Tyrol, Mondi employed its collaborative EcoSolutions approach to ensure the pack format was optimized for the manufacturer, product, end user, and environment. The monomaterial PP packaging was also shortlisted for the Green Packaging Star Award 2022.

“33% of the world’s food is lost or wasted every year, and this ac counts for 7% of GHG emissions,” says Jan-Mark Wilke, Mondi’s business development manager, Fresh Food for Consumer Flexibles. “Sustainable packaging can play a vital role in minimizing food waste. It reduces the environmental impact of the food industry by preventing food from spoiling before it reaches the table. With our monomaterial PP packaging for Handl Tyrol, we have been able to deliver another fresh food packag ing solution that protects the product effectively and can be recycled into existing recycling streams for mixed polyole ns. On top of that, it has an impactful design that incorporates the packaging and re ects the consumer use.” —Matt Reynolds

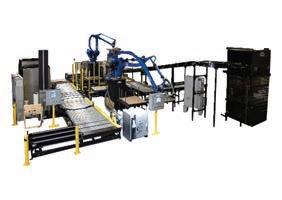

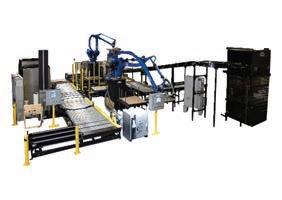

Time to rethink end of line palletizing

Introducing the RI20 palletizer, combining productivity, flexibility, and simplicity.

1. The RI20 control system focuses on usability and intuitiveness. The operator is in full control of the palletizer – for straightforward, easy installation and configuration.

2. A non-bolted installation allows for mobility, meeting the growing demand for flexibility in production.

someone is shy, our can and cocktail can help.”

The front of the can is noteworthy as well, with its evocative, eye-catching design. Created by a team in Japan, the design comprises a white background against which is a dynamic circle of pink, orange, and red colors overprinted with the brand name in metallic gold. Explains Riddel, “The circle is inclusive, and inside of it are two images to portray two souls coming together. The colors represent lust and love and are meant to be very sexy.”

Meet Your Destiny was launched at the end of Q1-22 and is available in California at retailers that include Total Wine & More, at hotels and resorts, including Loews Santa Monica and Rowan Hotel Palm Springs, and on-premise at a number of popular night spots.

—Anne Marie Mohan

3. Thanks to an advanced safety system and two pallet positions, the operator can exchange a full pallet without stopping the palletizing process.

Setting the standard for end-of-line robotics. Email us at info.us@ȋexlink.com or visit us at ȋexlink.com to find out more about the RI20.

13

Certi ed Cruelty-Free Biolage Adopts 100% PCR Bottles

Biolage Professional, a salon haircare stalwart since 1990, announced that its signature bottles (excluding the cap) are now made from 100% PCR (post-consumer resin) HDPE plastic, replacing the virgin HDPE used in the legacy bottle. The company says its new PCR white signature bottles, which are extrusion blow molded by bottle supplier Alpha, will save over 30 tons of virgin plastic every year.

Labels are applied to the bottles during lling at Biolage’s Florence, Ky. plant. Resource Label Group Canada supplies Biolage with the exographically printed labels. The front labels use three colors plus a satin varnish, with a single color printed via silkscreen. The back labels are printed in two colors plus a satin varnish.

The PP caps are the same composition and structure as the brand’s previous, they just use different colors.

Packaging is often the center of the sustainability story, but brands often look through an even wider lens, often called an ESG (environmental, social, governance) approach. Packaging is included here, but so are externalities like human rights, child labor, and legislation. That’s why it’s also important to note that, alongside the move to PCR bottles, Biolage’s product formulas will also be certi ed as cruelty free and vegan (no animal-derived

ingredients). The formulas were vegan to begin with, so they remain unchanged, only now they are certi ed as such.

The brand has also been given the Leaping Bunny stamp of approval by Cruelty Free International, a leading organization working to end animal testing. Leaping Bunny requires brands to forensically investigate their entire supply chain, including all raw materials and individual ingredients, for any cases of animal testing. Approval must be given to the brand’s entire portfolio— individual products or items cannot be approved in isolation. This was a stringent process and consumers can buy all Biolage products with complete con dence knowing that they meet the Leaping Bunny’s strict criteria.

“We are so excited to nally announce this brand renovation,” says Aurelie Croze, assistant vice president of Biolage Professional. “We’ve been working tirelessly to revamp our brand’s look and feel and to meet consumers needs in wanting vegan, cruelty-free, and sustainable beauty products. Receiving a Leaping Bunny certi cation from Cruelty Free International, one of the premier organizations leading the charge against animal testing throughout the supply chain, is such a proud moment for the brand. We can’t wait for the new era of Biolage Professional.”

Altogether, these packaging and social commitments are

Design.

Contact our product visionaries to customize a material handling system for your unique challenge. 269.673.2125 | MaterialTransfer.com/equipment Leverage our experience across thousands of applications to gain a custom bulk material handling solution. Drive process improvements, increase productivity, enhance safety and more. Imagine.

Deliver. Imagine how we can transform your operation! 14 PW NOV2022 NEWS

highlighted in the new sleeker look of the brand. The entire Biolage portfolio will also feature the Biolage AromaScience™ fragrance, made of a unique blend of fruits, owers, and spices that the brand is known for.

According to GlobalData, 35% of consumers actively look for cruelty-free claims on beauty products. Additionally, according

to the Global Cosmetic Industry and SurveyMonkey, 20% of consumers look for sustainable packaging, and more than one-third of consumers are willing to spend more for products that are better for the environment than cheaper, less eco-friendly options. Biolage Professional wanted to move in this direction with cruelty-free, vegan formulas and sustainable packaging because they know that more and more, consumers want to support a brand that commits to sustainability.

“I was so excited when the Biolage Professional team told me they were taking this huge leap,” says Biolage Professional Global Ambassador and Celebrity Stylist, Sunnie Brook. “I’ve been a fan of the brand’s unique portfolio for years, and I couldn’t be more excited for these iconic formulas to now of cially be certi ed vegan and cruelty-free and for the new sleek, professional-looking, and sustainable packaging. I know consumers and professionals alike are going to appreciate Biolage’s efforts to move the haircare industry toward a more responsible future.”

Biolage enacted its vegan, cruelty-free and 100% PCR claims as of August 1, 2022, and the updated packaging has begun to roll out across salons and retailers including ULTA Beauty, Amazon, JCPenney, Hair.com, with all new packaging being phased in by the end of 2022. —Matt Reynolds

INSPECTION SYSTEMS

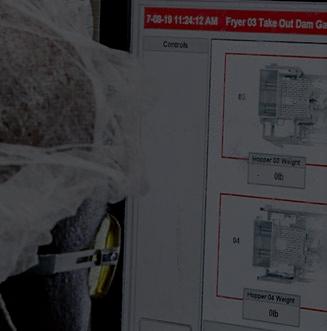

The Raptor is a highly accurate, fully integrated checkweighing system, specifically designed for high care food production environments.

The Raptor is employed to verify the weight of each product and reject non-conforming packs. The system has been designed, engineered, and constructed to the highest care/food grade engineering standards. It is capable of processing packaged products up to 8 kg.

Checkweighing System

888-220-8737 sales@fortresstechnology.com www.FortressTechnology.com

15

The number of jobs that will be lost when JBS shutters the corporate headquarters and manufacturing facility for its Planterra plant-based meat brand, effective Dec. 20

“The main purpose of our digital transformation is to help create superior solutions for daily problems of millions of consumers around the world, while generating growth and value for all stakeholders. We do that by leveraging data, AI, and automation with agility and scale across all dimensions of our business, accelerating innovation and increasing productivity in everything we do.”

–Vittorio Cretella, chief information of cer of Procter & Gamble, in an article from CIO, “P&G turns to AI to create digital manufacturing of the future”

“If this proposal moves forward, it will run directly counter to the administration’s environmental goals to reduce emissions. This proposal would not only cost taxpayers millions and millions of dollars, it would force the use of products and materials that will have a much larger environmental footprint than the plastic products the administration would be looking to phase out.”

The percentage of respondents to a study conducted by Blue Bite on consumer usage of QR codes and NFC tags who said they would be more likely to buy a product if they learned more by connecting with the packaging

–Matt Seaholm, president and chief executive of cer of the Plastics Industry Association (PLASTICS), in a release from the association, “PLASTICS Files Comment with General Services Administration, Opposes Rulemaking Banning Federal Purchase of Single Use Plastics”

The metric tons of chemically recycled plastic that 13 major brands are calling for by 2030, in a letter of intent from the members of the Consumer Goods Forum’s Coalition of Action on Plastic Waste

“We found that, for young adult drinkers in Scotland, alcohol packaging can capture attention, create appeal, and help shape perceptions of the product, drinker, and drinking experience. Five main themes emerged from our data: the ubiquity of alcohol packaging; its appeal and ability to catch attention; its association with particular occasions and activities; its ability to inform perceptions; and its engagement of both visual and non-visual senses—taste, touch, sound, and smell.”

–Daniel Jones, of the Institute for Social Marketing and Health (ISMH) at the University of Stirling in Scotland, in an article from BeverageDaily.com, “Study assesses in uence of alcohol packaging on young people”

2The number of enzymes discovered by Spanish researchers in worm drool that can be used to break down polyethylene, with one hour’s exposure to the saliva degrading the material as much as years of weathering

“The economic and environmental bene ts that a modern, highperforming nationwide deposit return delivers are well-documented: 188 billion additional containers recycled each year; more than 150,000 additional direct and indirect jobs created; and a carbon impact equivalent of removing 2.4 million cars from the road annually. These are only possible with a 90 percent collection rate and adhering to clear guiding principles. We at Reloop are committed to supporting responsible, effective policy, and efforts such as this bring us all one step closer to that objective.”

–Elizabeth Balkan, director at Reloop North America, in an article from Recycling Today, “Survey shows bipartisan support for recycling refund programs”

16 PW NOV2022 QUOTABLES BY THE NUMBERS 121

57%

800K

It’s Your Label.

Since your labels are the re ection of your product, make sure they are a true representation of your brand. They have to not only look great, but need to adhere in a variety of conditions and last for the life of your product.

Let Weber’s experience bring your label to life with creative solutions for economical materials, eye-catching nishes and amazing colors. Our digital label presses allow smaller minimums, incredible high-quality printing, and fast turn-around times.

Go to this link for a free packet of custom label examples and see the intense clarity and highquality of digital labels.

Or contact us at 1-800-843-4242 or info@weberpackaging.com for a free consultation with our experts about improving your labels.

Label Experts Chris & Wendy, 35+ Years combined

Label Experts Chris & Wendy, 35+ Years combined

Your Brand’s Best Ambassador? www.weberpackaging.com Locations Worldwide We Identify Your World

How General Mills Manages its CM/CP Suppliers on Sustainability, ESG

By Matt Reynolds, Chief Editor

Like most large brand owners, General Mills has made a variety of sustainability-minded commitments that it has pledged to meet within a speci c timeframe. It has done so both because it’s the right thing to do ethically, and for more practical reasons. After all, ecologically friendly operations translate into a sustainable business model that will remain pro table long into the future.

Climate change in particular threatens the long-term ability for General Mills to do business. That’s why decarbonization is a pillar of the company’s sustainability commitments. It has a 30% absolute goal to reduce its emissions end-to-end, scopes one through three, by 2030 from its baseline. It then aims to be net-zero on emissions across all of its value chain by 2050.

“Since our products are rooted in the Earth, we have a unique bond with Nature. Threats to Nature are threats to our business, threats to our existence as a food company,” Mark McCullough, Global Impact—director, operations integration, General Mills, said in an October F4SS supply chain conference that Packaging World attended. “We are taking the outputs of farming communities across the Earth and transforming those into something that’s delicious and convenient for consumers, then we market it to them. If the front end of the business, the upstream, agricultural part of our sector breaks down and the natural resources that we depend upon decline, we know that our business can be challenged. This is why General Mills, and its peers, are focusing on this.”

There’s also plenty of external pressure from ESG (environmental, social, and governance) sources that are shaping brands’ attitudes toward sustainability. Regional governments are rolling out EPR (extended producer responsibility) laws that will shape brand behavior. On the heels of massive investors like Blackrock saying that sustainability is a major factor in selecting where it will place its bets, investors are increasingly asking for companies’ sustainability bona fides. And we can’t forget consumer behavior; among General Mills companies, products that are marketed as more sustainable are growing at a rate that’s seven times faster than standard products.

“And the last one is retailers, the customers of our business,” McCullough said at the event. “Our retail customers have set lots of goals and they expect the players up the value chain to help them meet those, whether that’s on carbon emissions, regenerative

agriculture, or other things. As one example, Walmart has a 15 billionacre regenerative agriculture goal and they’re looking to companies like ours to help them meet it.”

Clearly, it’s in General Mills’ interest to proceed down a sustainable path. But while the company’s brands are the outwardfacing products that consumers deem responsible for carbonheavy value chains, what can the company do to impact sustainability, particularly decarbonization? Where it sits on the value chain, operations within the four walls of the Minneapolis-based company and its many facilities aren’t responsible for much of the carbon footprint that the overall value chain leaves. By its calculus, the company only directly contributes about 8% of greenhouse gasses in its value chain. That leaves more than 90% of the value chain’s emissions that come from scope three, which means emissions that General Mills does not directly have control over.

Most the carbon footprint of the value chain—61% of it in fact— comes from the upstream agribusiness that grows the crops and raises the livestock. And 22% of GHG emissions occur downstream from General Mills plants and facilities, such as in distribution, warehousing, and retail.

Naturally, the company has started with its own 8%, and in parallel has rolled out programs aiming to limit the 61% of value chain emissions upstream in its agricultural sourcing. And the downstream carbon emissions are being addressed in concert with retailers.

Interestingly, that leaves a small but significant sliver, a 9% swath of carbon emissions, in a unique part of the value chain. That’s in contract manufacturing and packaging (CM/CP).

“We are very invested in helping our partners reach their climate goals as well, in order to see the full decrease in our emissions we need to see to achieve our goals,” added Jessica Jubara, senior climate manager, General Mills, at the F4SS conference.

18 PW NOV2022 FIRST PERSON

Mark McCullough, Director, Global Impact - Operations Integration, spoke at the recent F4SS supply chain conference about comanufacture/co-packer management techniques related to his company’s stated sustainability and ESG goals.

Sustainability is an area of increasing importance and focus for General Mills. We are looking to our co-manufacturers to help us deliver our sustainability goals across our people and planet ambitions.

Packaging World caught up with McCullough after the event to see how his company strategically approaches sustainability and data reporting with its CM/CP suppliers.

Packaging World:

Roughly how much does General Mills work with contract packaging and packaging suppliers (CM/CP)?

Mark McCullough:

Roughly 25% of our nished product production comes from co-manufacturers, versus production at owned facilities.

Do you see any coming changes in the number/volume of upstream partners you work with for packaging operations? If a change, why?

As we work to scale our execution of our recyclable packaging commitment, we will continue working with existing suppliers and potentially need to engage new supply partners. In some cases, new technology will be needed and our access to this will be unlocked by working with new suppliers, particularly leveraging partnerships with suppliers further upstream ( lm producers, etc.)

What do your procurement or sourcing organizations look for in a CM/CP partner?

Our sourcing team seeks holistic value from co-manufacturers which spans cost, quality, service, capacity, innovation, and sustainability performance. Based on our diverse needs across many product platforms and food categories, we work with a broad set of co-manufacturers.

Does the sustainability profile of the CM/CP vendor factor in with the partnerships you choose? Could it be a differentiator?

Sustainability is an area of increasing importance and focus for General Mills. We are looking to our co-manufacturer and co-packager partners to help us deliver our sustainability goals across our people and planet ambitions.

Do you participate in programs that report, track, and over time, limit greenhouse gas emissions? Do you report this information to your retailer customers? How do your own, in-house packaging operations fit in to this reporting?

General Mills tracks and reports its scope one through three emissions in accordance with guidelines of the Greenhouse Gas Protocol. We report our emissions to CDP [formerly known as the Carbon Disclosure Project] and other raters and rankers, as well as directly to various customers through their bespoke reporting activities.

Do you ask your upstream CM/CP suppliers to participate in ESG programs that report, track, and over time, aim to limit greenhouse gas emissions?

Today, General Mills does not require co-manufacturers to participate in programs that report, track, and reduce their emissions over time. However, we support our suppliers in this and look to require these activities in the future.

Do you use platforms that help stakeholders track sustainability and emissions, such as EcoVedis, CDP, S-LoCT, or others?

General Mills reports on various elements of our climate ESG work and performance into CDP. We also sponsor select suppliers in a decarbonization training program called Supplier Leadership on Climate Transition (S-LoCT) that is managed by Guidehouse.

How do you differentiate between self-reported data and third-party audits?

Is one more valuable than the other?

We nd both methodologies valuable. We have General Mills audits for areas like food safely and regulatory compliance, and we use third-party audits for other elements such as Responsible Sourcing against SMETA [Sedex Members Ethical Trade Audit] protocol. We take into account internal expertise and resourcing in the decision to audit ourselves versus using third-party audits.

continued on page 20 19

4BZ�IFMMP�UP�UIF UIF�POMZ�DPCPU�XJUI�B� ��LH�QBZMPBE�BOE�B� ����NN�SFBDI� *UsT�UJNF�UP�NFFU�ZPVS� OFX�IFBWZ�EVUZ� CFTU�GSJFOE� )�4&3*&4�

continued from page 19

That’s a good segue to the next question. We often focus on the environmental (E) side of ESG, but there are also social (S) impact elements that are relevant to human rights abuses, child labor, etc.

Do these social elements come into play in your own packaging operations? How do you ensure your CM/CP suppliers meet the standards you hold yourself to?

General Mills has a Supplier Code of Conduct that lays out our expectations and requirements of suppliers on the topics of Human Rights, Health/Safety, Environment, and Business Integrity. The Supplier Code of Conduct applies to all our suppliers and their suppliers. Compliance to the Supplier Code of Conduct is mandatory and monitored via our Global Responsible Sourcing Program.

Do you use audits like SMETA to track your CM/CP partners’ performance in this arena, or any other platforms? Again, who pays for this?

As mentioned earlier, General Mills pays for these audits for our own facilities, and asks suppliers to pay for their own audits. Audit results can be shared with all customers and are good for three years.

What advice would you give to fellow brand owners and CPGs seeking to bring their upstream packaging partners closer in line with their sustainability goals?

Incorporate ESG performance into [your] purchasing decisions and set them as requirements for doing business with the organization. PW

20 PW NOV2022

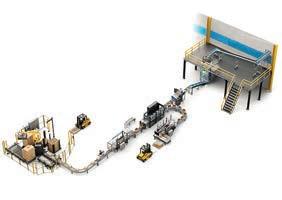

FIRST PERSON Automated End-of-Line Solutions Robotic Palletizers/Depalletizers Follow Us On Social Media Visit KES-USA.COM to view our Family of automation products Automated Case Packing Systems High-speed Robotic Picking/Placing Stretch Wrapping with Corner Board Options Transfer Cars & Conveyor Systems All Systems Custom Designed to Meet YOUR Needs

By Eric F. Greenberg, Attorney-at-law

By Eric F. Greenberg, Attorney-at-law

Oh, Those Wacky Food Labels

This month, we’ll look at two agencies’ efforts to update food labels: The U.S. Department of Agriculture’s “bioengineered” foods regulations (and the punch in the nose the agency got from a federal court about them), and the Food and Drug Administration’s proposal to update its de nition of foods that can claim to be “healthy.”

1. BIOENGINEERED RULES: Regulatory agencies sometimes go astray. For example, FDA recently posted an announcement titled, “FDA Releases Food Safety Prevention Strategies.” Now, lots of folks have a lot of opinions about what agencies do that’s right and wrong, but clearly, at a minimum, at least one of them need more grammar police.

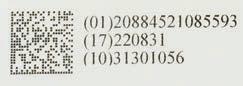

A more substantive example is the USDA, and how it went astray according to a federal court. Here Congress had passed a law that instructed USDA to make a batch of rules for when and how foods should reveal that they contained what used to be referred to as “genetically modified organisms,” and the rules USDA came up with allowed such disclosures to be made via an electronic or digital link— that is, a QR code—on a food label. Was that adequate disclosure?

No, said a federal court in California in September. The regulations were challenged in court by consumer advocacy groups. The court said many parts of them were valid, including their adoption of the relatively new terminology referring to these foods as “bioengineered” rather than the more familiar “genetically modified” or “genetically engineered.”

The regulations offered four options for how to make the disclosure that the food was bioengineered: text disclosure, use of a symbol, electronic or digital disclosure, or a text message. Specifically, part of the regulation allows companies to make the disclosure using an electronic or digital disclosure, such as a QR link, and to accompany it on the label with the statement “Scan here for more food information” or equivalent language, and a telephone number that a caller can use to obtain the bioengineered food disclosure.

Now, when regulatory agencies make regulations, they are supposed to follow Congress’ instructions, and courts will invalidate regulations that don’t. Here, the court said Congress told USDA to study “whether consumers would have access to the bioengineering disclosure through electronic or digital disclosure methods,” and USDA did that, but the court found that “access problems abounded.” That is, USDA’s study found that not everyone had smartphones or broadband to allow them to scan the codes. And in such a situation, Congress said USDA was supposed to provide “additional and comparable options,” like the alternative text message instructions, to the electronic disclosure. Instead, they just added another option, a text message option, as an alternative to the electronic or digital link. What’s more, the court said, Congress didn’t authorize USDA to

make a standalone text message disclosure option at all. On top of that, USDA’s “decision to provide a separate text message disclosure option did nothing to fix the problem of inaccessible electronic disclosures.”

So it’s back to the drawing board for USDA. Whatever they come up with, it’ll have to be something other than the QR code alone on a package label, maybe with more informative text accompanying it. In the meantime, though, the court said it won’t vacate the problematic regulations, so companies can keep using the QR code per the current regulation while we wait for USDA’s next move.

2. HEALTHY GETS AN UPDATE: Defining what is and isn’t “healthy” to eat is more difficult than you might at first expect. FDA has had a regulation articulating a definition of the term since the mid-1990s, and thinks that nutrition science has evolved since then in ways that make the current definition obsolete. So, it has proposed an updated definition that it thinks better reflects current nutrition science. The proposal appeared in the Federal Register for September 29, and public comments on it are due December 28.

FDA says that a labeling claim that a food is “healthy” is an implied claim of nutrient content, because it implies that the food contains good-for-you components and not too many less good-foryou components. Nutrient content claims are a type of claims that tout a food’s content of nutrients. Examples are low fat and high fiber.

And for years, FDA has had in place a big long part of a regulation, complete with a chart, that explains when foods can and can’t make the label claim that the food is healthy. Under the new proposal, FDA is adjusting its existing parameters, so that a food that wants to make the voluntary claim that it’s healthy “would need to contain a certain amount of food from at least one of the food groups or subgroups (e.g., fruit, vegetables, grains, dairy and protein foods)” that are recommended by the 2020-2025 edition of the Dietary Guidelines for Americans. Also, “The specific limits for added sugars, saturated fat and sodium would be based on a percentage of the Daily Value for these nutrients.” Raw whole fruits and vegetables would qualify to claim to be healthy “because of their nutrient profile and positive contribution to an overall healthy diet,” an FDA document explains.

The proposed regulation contains an informative explanation of these proposed criteria for the various food groups.

FDA also reminded folks that it’s in the process of collecting public input on ideas for an effective front-of-pack label symbol to indicate that a food is “healthy,” which, like the definition of the term, is a more complex adventure than at first appears. [Read my April 2022 column at pwgo.to/7746.] But I think I have the simple solution: The symbol for a healthy food should be a graphic of your mother smiling. The package could scan your retina to figure out who you are, and pick the correct graphic. It’ll be easy! PW

Eric Greenberg can be reached at greenberg@efg-law.com. Or visit his rm’s website at www.ericfgreenbergpc.com.

22 PW NOV2022

THE LEGAL SIDE INFORMATIONAL ONLY, NOT LEGAL ADVICE.

Our Multi-Head Combination Weighers deliver a high-quality build backed by our industry-leading customer service. High Tek USA knows that the food industry needs the best performance, with the best options all in one reliable and lasting solution. • 10.4” Color Touch Screen • Fully Enclosed Radial Feeders • Wash-down Models Available • Easy Access to Breaker for – Lock Out Tag Out • Achievable Speeds of up to 150 BPM • Load Cell Technology for ln-feed Detection • Available in 10, 14, 16, 20 & 24 Head Models • Easy Removal of All Parts for Cleaning • Optional Timing Hoppers & Diverting Hoppers Multi-Head Combination Weigher . Watch Our Weigher in Action!

By Sterling Anthony, CPP, Contributing Editor

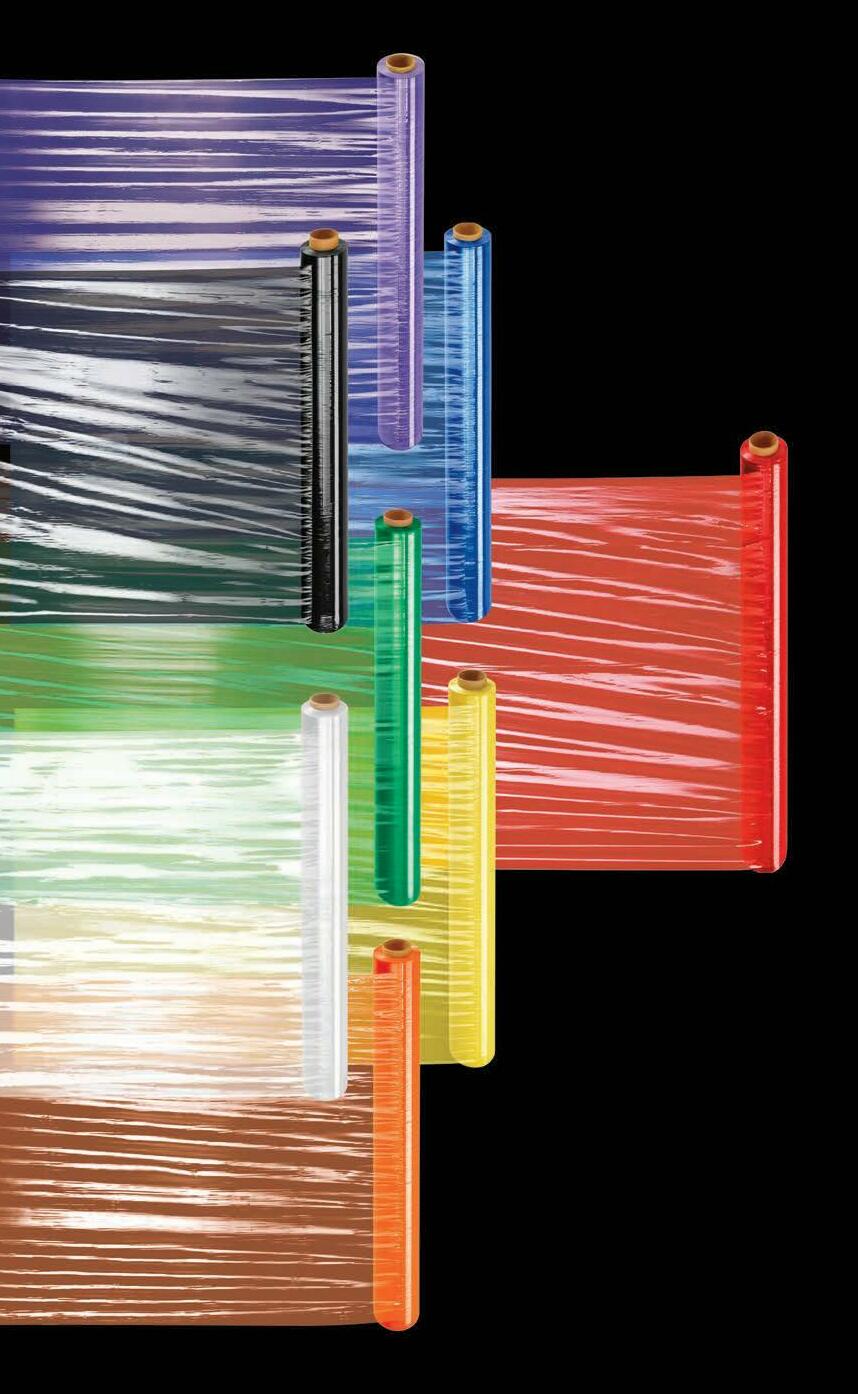

Film Criteria for Vertical Form/Fill/Seal Applications

As noted in last month’s column “Vertical Form/Fill/Seal 101: Key Considerations” (pwgo.to/7748), vf/f/s is a process where roll lm is formed into a tubular package, lled, and sealed, repeatedly, in a vertical orientation. It then stands to reason that the characteristics of the lm impact machine ef ciency and packaging quality.

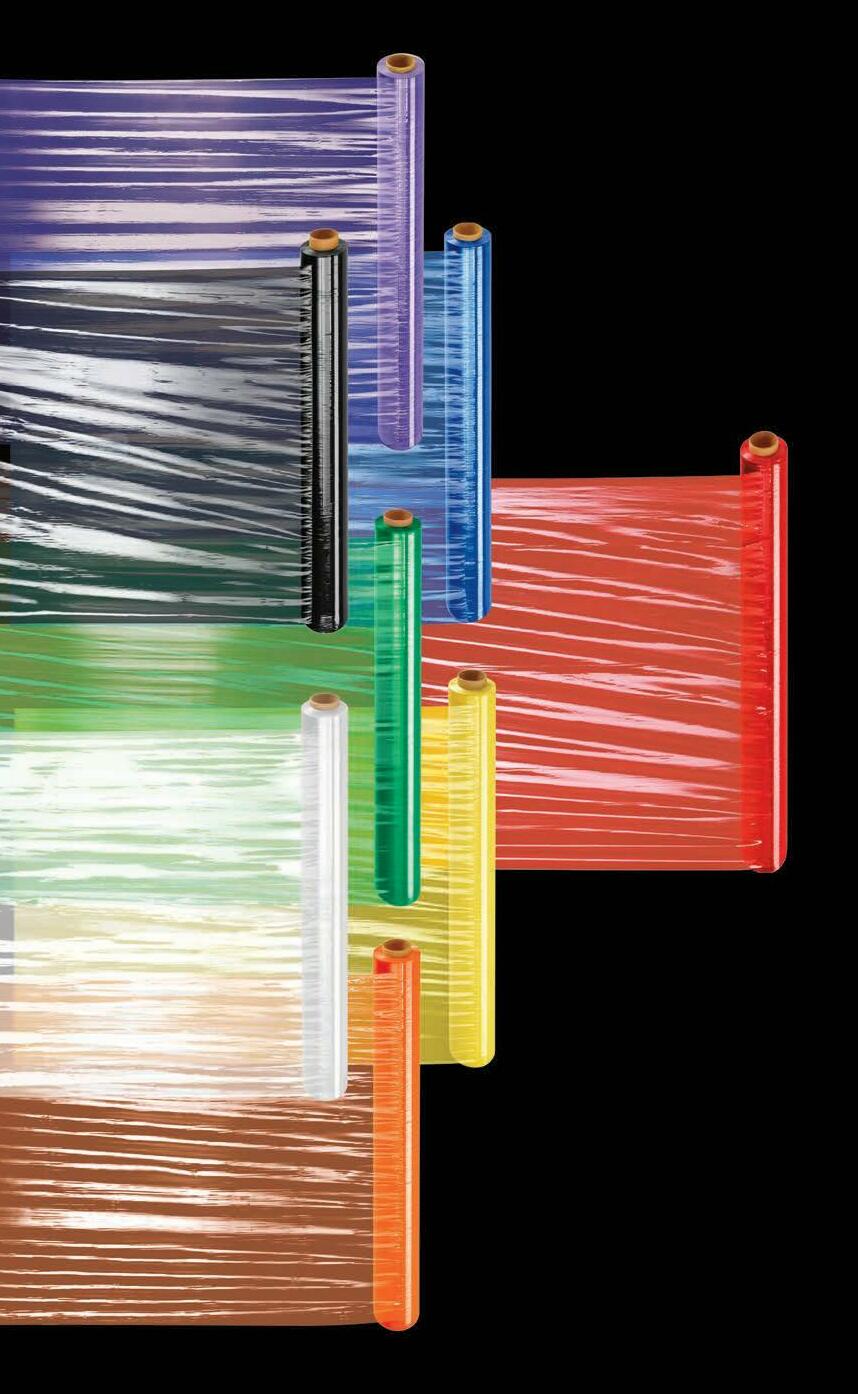

The term film herein is used to denote any vf/f/s substrate, includ ing those that incorporate coatings, foil, and metallizing. A film must meet product requirements (for example, barrier properties) when a decision-maker chooses among a monolayer, a coextrusion, or a lami nation. Optimal productivity and cost-effectiveness, however, can’t be achieved unless the film also meets machine requirements. Each of the three operations imposes requirements that set film criteria.

Form. A film requires stiffness to withstand enacted forces, starting with the tension exerted by the unwinding of the roll. Forces continue as the film is pulled upward, around, and over sets of rollers. A film also requires a sufficiently low coefficient of friction (COF), enabling it to slide over the forming collar and filling tube as it’s made into the desired shape. At the same time, the film requires pliability as it’s wrapped and folded around the collar and tube. Stiffness again comes into play as the formed package is pulled downward by driving belts. Also reasserting itself is the COF, this time needing to be low enough to accommodate the grip of the driving belts.

Lacking these properties, a film is subject to splitting, breaking, bunching, creasing, and sticking, among other undesirable effects. All of them can affect package registration, which refers to the package’s being in the proper orientation for a given purpose. It’s particularly important for pre-printed film; the graphics of which have to be properly aligned, typically with an electronic eye. It’s equally important for in-line coding, e.g., batch numbers, expiration dates, etc. Depending on package type, proper package registration also is essential for the location of features such as tear notches, zipper strips, and punched holes for display hanging.

Fill. Product flows down into the packages from fillers that weigh and dispense. However, the physical effects differ, in accordance with product properties, e.g., dry, granular, pellet, wet, liquid, etc. The package must be able to endure any imposed bulging, for example. A related concern is that the product’s shape, weight, and density may puncture the package. The film’s thickness plays a part, along with properties such as tensile strength, tear resistance, elongation, and

modulus of elasticity, among others.

Seal. Each of the three f/f/s operations are crucial. Still, it can be argued that this one is the most crucial. An imperfectly formed package, that’s under- (or over-) filled, is bad enough. But if it’s inadequately sealed, the game is over. The package can’t fulfill its first function, that of product protection and containment. Films are either inherently sealable (as are the polyolefins) or are made sealable with a coating. Either way, a film’s seal principally results from temperature, pressure, and dwell time.

Ideally, a film will require a low activation temperature and have a wide temperature range in which adequate seals can be achieved. When that’s the case, machine calibration, related to temperature setting and temperature maintenance, is simplified.

Pressure refers to the force with which the surfaces being sealed are held together. The sealing material will be in a softened state from the applied temperature and will exhibit flow properties. The pressure should achieve adequate contact between the surfaces and allow the proper flow for bonding. Pressure, however, should not be great enough to squeeze the sealing material outside and beyond the mated surfaces, making for sealing material that is too thin.

Dwell time is the duration in which the film surfaces are held clamped between the sealing jaws. An associated property is hot tack. It refers to bond strength immediately after a seal is made but before it cures. Hot tack needs to be strong enough to resist the weight of the filled product.

One more criterium that a film might have to meet is the ability to seal through the product, in those applications in which product is likely to get into the sealing area.

All of the preceding discussions apply to vf/f/s machines, regardless of make and model. Their relevance, however, increases along two continuums. One is type of motion: intermittent vs. continuous. The other is maximum machine speeds. In all instances, what’s sought is operations that run smoothly in fulfillment of the machine’s designed capabilities. When operations fall short, some aesthetic failings are notable by visual inspection. Other failings, such as poor bond strength, are better determined by instrumentation.

For film suppliers, it all translates to having to develop offerings that meet their clients’ dual requirements for marketing and production. For economies-of-scale and to be able to be priced attractively, those offerings should have wide applicability across a variety of vf/f/s machines. PW

24 PW NOV2022

THE BIG PICTURE

A lm must meet product requirements when a decisionmaker chooses among a monolayer, a coextrusion, or a lamination. Optimal productivity and cost-effectiveness, however, can’t be achieved unless the lm also meets machine requirements.

The most reliable and complete online directory of packaging and processing technology suppliers in North America – designed from the buyer’s perspective. Features include: You’re looking for... Are you looking for packaging or processing solutions and you don’t know where to start? • Plain-language lters so it’s easy to nd what you need. • Type-ahead keyword search. • Visual navigation by machine or desired package type. • Packaging-speci c lters that are tailored to each product category. ProSource.org

By Anne Marie Mohan, Senior Editor

Plastic Packaging May Not Be So Bad, After All

Amidst the ongoing demonization of singleuse plastic packaging, global consulting rm McKinsey & Co. has published a thought-provoking report on the “Climate Impacts of Plastics,” and the conclusions may surprise you. When examining the total greenhouse gas (GHG) contribution of plastics versus its alternatives, including product lifecycle (cradle to grave) and impact of use, it found that among those applications for which non-plastic alternatives are used at scale, the plastics examined in the report offer a lower total GHG contribution compared with alternatives in 13 of 14 cases, including both direct and indirect valuechain emissions. These GHG savings ranged from 10% to 90%, considering both product lifecycle and impact of use.

Furthermore, the report noted, when indirect impacts were excluded, such as lower food spoilage in the case of food packaging, and only direct lifecycle emissions, including production, retail transport, and end-of-life disposition, were considered, plastics had the lowest GHG impact in nine of the 14 applications.

“Plastics are ubiquitous across the global economy and the subject of frequent debate, from their impact on marine pollution to their recyclability,” says McKinsey. “However, their role in enhancing use efficiencies, such as decreasing food spoilage and reducing greenhouse gas emissions, is often overlooked. Rather, plastics are frequently maligned across topics such as leakage to the environment, toxicity, use of resources, production emissions, and ocean pollution. Although these important considerations need to be addressed, an opportunity exists for a more balanced, science-based perspective on plastics versus alternative materials.”

The 30-page document includes information on the markets selected— packaging, building and construction, automotive, textiles, and consumer durables, which represent around 90%

of plastics volume—the methodology used, and in-depth details on several of the applications studied. McKinsey’s analysis was based on the U.S. market in 2020, with additional sensitivities to illustrate the impact in other regions and how results will change as the global environment moves toward a “decarbonized world” in 2050.

Among the findings of the report related to packaging in the U.S.:

• When high-density polyethylene grocery bags are compared with the next-best alternative, paper bags, HDPE packaging is found to have 80% fewer total GHGs.

• Wet pet-food packaging in PET and polypropylene versus aluminum or steel packaging has 70% fewer emissions.

• PET soft drink containers emit 50% fewer GHGs than aluminum bottles.

• Fresh meat packaging made from expanded polystyrene or polyvinyl chloride has a 35% smaller GHG footprint compared to fresh meat packaging made from paper.

• When compared with glass soap containers, HDPE soap containers have 15% fewer GHGs.

• Industrial drums made of HDPE emit 30% more GHGs than those made from steel.

• When comparing plastics versus plastics-enabled mixed materials, McKinsey found that HDPE milk containers have 5% greater GHG emissions than paper, while the GHG emissions of EPS water cups and paper cups are on par.

One of the applications chosen for a deep-dive analysis in the report is soft drink containers. McKinsey explains that it based its analysis on a comparison of 20-oz PET bottles with 12-oz aluminum cans and 12-oz glass bottles, selected because they represent the most common beverage container sizes for their respective material substrates. According to the LCA, PET bottles have the lowest emissions of all the materials, due to their

26 PW NOV2022 SUSTAINABLE PACKAGING

Getting Started with Sustainable Packaging

Looking for information on how to get started with sustainable packaging? This Packaging World primer provides an overview on what sustainable packaging is, what’s driving the push for more sustainable packaging, and how to reduce the environmental impact of packaging. It also includes links to resources. Download this free PDF today at pwgo.to/7345.

lightweight properties and the low amount of energy required to produce them. “By contrast, aluminum cans have two times the emissions of PET bottles, and emissions from glass bottles are three times higher,” shares the report.

While the PET bottle has the lowest production emissions, the lifecycle analysis found that it has the least favorable GHG emissions for its end-of-life disposition. “PET has the lowest recycling rate and credits from avoided virgin production among the three materials. It also has the highest emissions from waste-to-energy. PET releases CO2 when burned, whereas aluminum and glass do not,” explains the report. “However, the GHG impact of production emissions is more significant than end-of-life disposition emissions, resulting in PET having the lowest GHG impact.”

In its study, McKinsey also found that the indirect value-chain impacts of plastics can be quite substantial, particularly in the case of plastic used in food packaging. “There are few at-scale alternatives to plastic in food packaging across a broad range of applications, driven primarily by reduced food spoilage when using plastics,” says the report.

Your Responsive Experts

MOTION CONTROL

In evaluating 20 common food categories, McKinsey found that plastic packaging is used in more than 90% of products sold in six categories, including fresh and frozen meat, breakfast cereal, yogurt, cheese, still bottled water, and frozen food. In another eight categories—milk, edible oil, chocolate, nut and seed mixes, cookies, packaged bread, juice, and rice—plastic is present in the packaging of more than 50% of the products sold. Notes the report, “These figures translate to a significant but unquantified GHG benefit from plastics.”

Through its analysis of different product categories and applications, McKinsey successfully conveys that a multitude of factors must be weighed and balanced in order to select the most environmentally friendly material. The trick, it advises, is to know how much the positives outweigh the negatives.

PW 1-800-366-5412 · encoder.com

IN

EPC encoders provide reliable motor feedback in compact housings designed for long duty cycles in harsh conditions, and are manufactured in Idaho, USA. Contact EPC TO LEARN MORE 27 For a copy of the complete report, visit pwgo.to/7747

Business Drivers

E-COMMERCE

The

while making it

and

When

are

automation

do

movers

do. Choose

The following companies are leading suppliers of contract packaging, e-commerce, package design, packaging line integration, software, and sustainability solutions. To see all product categories, please visit Packworld.com/leaders The MX suction cup can work across an array of applications such as bin picking, order fulfillment, box depalletizing, and parcel sorting. Gone are the days where you need to change gripper or suction cup for each individual product in the application. The #1 item picker: Piab MX suction cup family E-COMMERCE

BEL 5150E with Smart Select calculates the optimal case size for every order. Designed especially for e-commerce, the system minimizes shipping, corrugated and product damage costs

easier

quicker for operators to pack boxes. Optimize Every Case on Your E-Commerce Form, Pack & Seal System

With expertise in a vast range of packaging technologies, BW Packaging Systems can recommend single-machine solutions and fully integrated packaging lines for food, beverage, pharmaceutical, personal care, household and several other industries. Your Trusted Partners for Reliable Packaging Solutions PACKAGING LINE INTEGRATION

you

looking for

equipment to give you a performance edge,

what the other global producers and

of high-demand goods in food processing, packaging and material handling

Duravant. Your Line Deserves Duravant - www.duravant.com PACKAGING LINE INTEGRATION Increase throughput, create line efficiencies, & reduce changeover time with our: Timing Screws, Drive Units, Auto Adjust Rails, Change Parts, Can Openers, Down Bottle Reject Systems, Custom Designed Machines, Automated Container Handling Equipment. Expertly Designed & Innovative Container Handling Solutions PACKAGING LINE INTEGRATION MULTIVAC is one of the world’s leading suppli ers of packaging solutions for a wide variety of products including meat, poultry, seafood, fresh produce, medical/pharmaceutical and consumer products. Visit us at Booth #N-4745 and in the Medical Pavilion at #W-18002. Industry Leading Fully Automated Packaging Solutions PACKAGING LINE INTEGRATION nVenia, headquartered in Wood Dale, IL, designs and manufactures primary, secondary and end-of-line packaging equipment, featuring the product brands of ARPAC, FISCHBEIN, HAMER and OHLSON. Next-level Packaging Equipment, Integration and Innovation PACKAGING LINE INTEGRATION Ryson Spirals have a much smaller footprint than conventional incline conveyors and are faster and more reliable than any elevator or lift. Ryson makes a full line of spirals that satisfy most vertical conveying needs. Find out more at www.ryson.com Save Space and Increase Throughput with Ryson Spiral Conveyors. PACKAGING LINE INTEGRATION

Business Drivers

SUSTAINABILITY

Our

fit-to-size

of

boost fulfillment. These auto-

systems

and pack every order

the smallest box necessary for

efficiency and cost

Robotics

The following companies are leading suppliers of Robotics.

Our holistic approach: partner with suppliers to develop materials AND machinery at the same time. The results: entirely sustainable packaging solutions for flow wraps, bags, cartons, and cases — and even paper-based pods, blisters, cups, and trays!

see all product categories, please visit Packworld.com/leaders

ROBOTICS

The LSP Series Case Packer can pack pouches

large bags into deep cases at speeds up to 180 products per minute. This newly developed loader can place a variety of pouches

multiple types of cases seamlessly.

ROBOTICS

Looking to Solve Your Labor Crunch?

FANUC and our team of Authorized System Integrators are ready to make your plant or fulfillment center more efficient. We offer the largest variety of easy-to-use and reliable robots and cobots to pick, pack, fulfill or palletize any product.

ROBOTICS

The RPP’s

products

or

into

wrapper and

infeeds, and directly into topload trays and cartons – while moving or stationary. Stainless steel IP65 construction keeps your line hygienic and safe.

These market-leading companies participating in Packaging World’s 2022 Leaders in Packaging Program are named sponsors of PW’s Future Leaders in Packaging scholarship. This year’s recipient is Alexandria Technical & Community College, Mechatronics program. We appreciate the support of all participants on behalf of packaging education.

To

. Sparck Technologies is the global leader

advanced,

automated packaging solutions to

boxing

create

on demand in

total

savings. Right-size automated packaging for labor savings and efficiency PACKAGING LINE INTEGRATION

Vision: Intelligent & Sustainable Packaging Solutions for Everyone

and

into

Advanced Robotic Case Packers

Solving workforce challenges with automated picking solutions combining soft grasping, 3D vision and artificial intelligence enabling machine builders and end users to solve the hardest automation problems in the food and consumer goods industries. High-Speed Automation Solutions Solve Labor Shortages ROBOTICS

delta robots can load

flat, stacked,