NEWS BRIEF

Never forget

PMMI, The Association for Packaging and Processing Technologies (Central Lobby), recognizes the significance of PACK EXPO Las Vegas 2023 opening on Sept. 11th. To honor the men and women who gave the ultimate sacrifice that day, PMMI will match donations up to $50,000 to the Tunnel to Towers Foundation. Built upon the mantra, “While we have time, LET US DO GOOD,” the Tunnel to Towers Foundation supports our nation’s fallen and catastrophically injured first responders, military heroes and their families. Donate at packexpolasvegas.com/T2T-donation. SD

sponsors hotel shuttle

Free transportation to the convention center is available daily from 7:00–11:00 a.m. and to show hotels from 2:00–6:00 p.m. on Monday and Tuesday and 2:00–4:00 p.m. on Wednesday. Buses to the hotels depart from outside the Central Hall. Shuttle buses are sponsored by Amicus Spend Management (Booth SU-7699A) SD

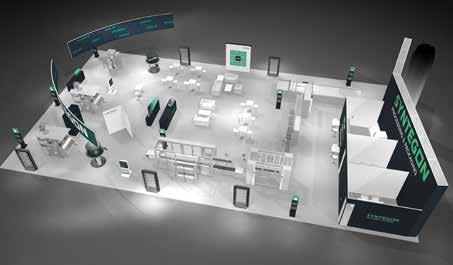

Match service to needs

Effective asset management improves performance and reliability, reduces unplanned downtime and minimizes adminstrative tasks. Service packages from Syntegon (Booth C-2800) provide support at seven levels so plans can be matched to needs. Fixed-rate plans decrease risk, simplify budgeting and scheduling and allow end users to focus attention on core business. SD

Events support students

The PMMI Foundation supports students preparing for careers in packaging and processing. Read in tomorrow’s PACK EXPO Show Daily about scholarship winners and yesterday’s fundraisers, the Golf Tournament at the Bali Hai Golf Club and a private PACK gives BACK™ performance of O™ by Cirque du Soleil®, sponsored by Rockwell Automation (Booth SL6127) SD

Welcome to Las Vegas!

Show breaks records as PMMI celebrates 90th year.

On behalf of PMMI, The Association for Packaging and Processing Technologies (Central Lobby), I welcome you to the 15th edition of PACK EXPO Las Vegas, the most comprehensive packaging and processing event in North America this year.

Now one of the largest trade shows in North America, the 2023 edition with more than 2,300 suppliers occupying nearly 1 million sq. ft. of floor space, shows how much this event has grown since its start in 1995 as PACK EXPO West with 532 exhibitors and just over 200,000 sq. ft. of floor space.

Due to the growth in our industry and listening to our industry’s concerns, we’ve expanded this show’s offerings and are proud to present the PACK EXPO Las Vegas debuts of Sustainability Central, the Logistics Pavilion and the Healthcare Packaging Pavilion. We also are excited to report substantial growth in the Processing Zone, which is 50% larger than in 2021

Two other debuts center on education, a ma-

Minhas speaks at PPWLN event

The annual Packaging & Processing Women’s Leadership Network (PPWLN) Breakfast will be held from 7:30–9 a.m. tomorrow (Tuesday, Sept. 12) in Room N-247. The event is free, but you must pre-register.

Attendees will have an opportunity to network with peers and gain inspiration from Manjit Minhas, an award-winning entrepreneur and Dragon’s Den judge, who will share how she transformed a simple idea into a massive beer empire and thrived in a male-dominated industry. A native of Calgary, Alberta, who started Minhas Breweries, Distilleries, and Wineries at the age of 19 alongside her brother,

(Continued on page 8)

jor aspect of all PACK EXPO trade shows. One is the Industry Speaks Stage (Booth C-1141)

(see schedule, p. 24), where experts from the PACK EXPO Partner Program, will discuss the latest hot topics and industry trends such as remote access, supply chain solutions, augmented reality and operational efficiency. The second is the Sustainability Stage (Booth N-9967) (see schedule, p. 14), part of Sustainability Central, where attendees will learn how to make their brands more sustainable.

Sustainability, a concern of PMMI, its partners, vendors, members and PACK EXPO exhibitors and attendees, assumes an even higher level of impor-

(Continued on page 8)

Vote now for TEA winners

Recognize PACK EXPO debuts by selecting winners in four categories.

Voting has opened to choose Technology Excellence Awards (TEA) for 2023. Showgoers may select winners in four categories: Food/ Beverage; General Packaging & Processing; Personal Care/Pharma; and Sustainability. Votes may be cast between now and noon on Tuesday, Sept. 12, on-site, online or on the official show mobile App.

“We encourage all attendees to take part in the voting process,” says Laura Thompson, vice president, trade shows at PMMI, who introduced the

(Continued on page 40)

It is time to experience

Case packer for gentle product handling

Bottom-loading via the Everest case packer from Schneider Packaging Equipment (Booth C-2223, SL-6604) means no machinery touches the top of your products. The machine—a conventional alternative to pick-and-place systems—is well-suited for rectangular or lay-flat cartons, delicate or sensitive products, gabletop cartons, shrink wrap or transparent film on top and industrial cans or bottles. SD

Heat-sealing basics

Heat Sealing-Art or Science? white paper written by Charles Trillich, co-founder of TOSS Machine Components (Booth SL6407), describes heat-sealing technologies and the evolution of precision heat-sealing. SD

Schubert founder passes away

Gerhard Schubert, founder and shareholder of Schubert North America (Booth SL-6820, SU-7654), passed away on July 4, 2023, at the age of 84. His vision of a modular, robot-assisted, top-loading packaging machine continues to influence today’s packaging technology. He began his career in 1953 with an apprenticeship as a mechanic and then spent about a decade gaining experience as a design engineer. In 1966, he founded Gerhard Schubert GmbH in Crailsheim, Germany, where it now anchors an international business with locations worldwide. SD

Inc. honors Packsize

Inc. magazine puts Packsize® International (Booth SU-7407) on its 2023 Best Workplaces list. The magazine also recognized the supplier of Right-Sized Packaging on Demand® systems in the Enduring Impact category, which recognizes high-scoring companies that have been in business for 15 or more years. “At Packsize, we have embraced a spirit of what we call ‘conscious cultivation’ to foster a work environment that is supportive, compassionate and socially responsible,” explains Sue Urses, chief human resources officer at Packsize. SD

PMMI publishes guide to standards

PMMI Business Intelligence, a division of PMMI, The Association for Packaging and Processing Technologies (Central Lobby), has published 2023 The Impact of Global and Local Standards on OEMs & Suppliers. The peer-reviewed guide serves as a resource for those who need to understand the importance of standards for good business, what core standards are relevant to packaging and processing and how to identify the standard(s) they need to follow. A free download is available at pmmi.org/report/2023-impact-global-and-local-standards-oems-suppliers. SD

Japanese beauty care brand Shokubutsu Monogatari is hitting all of the three Rs—Reduce, Reuse, Recycle—with a new 100% recyclable pouch construction for its shower cream refills in Thailand. Shokubutsu Monogatari is a brand of Lion, a Japanese multinational manufacturer of detergent, soap, medications, oral hygiene products and other toiletries, whose corporate commitment includes, “Supporting cleanliness, health and comfort, while protecting our global environment.”

“Lion has always been committed to developing sustainable projects and packaging,” says Lion (Thailand) SPC Business Executive Manager Somsak Srisaardrak. “This is in line with the shifting needs of consumers, as they become increasingly interested in environmentally friendly products.”

In 2019/2020, Lion asked Dow Thailand Group “to not only address consumer needs but also reduce greenhouse gas emissions and advance a circular economy in Thailand” by developing a recyclable pouch for its shower cream refills, says Kodak Xiao, Asia Pacific marketing director for Packaging Health & Hygiene, global market segment director for Food & Specialty Packaging and Specialty Plastics at Dow (Room S-116), the official Sustainability Partner for PACK EXPO Las Vegas.

Shokubutsu Monogatari had already entered the refillable/reusable packaging space with flexible refill pouches—a popular format in Thailand—but the packaging could not be recycled. According to Xiao, requirements for such a pouch include durability and high toughness to protect and ensure the quality of the product across its useful life as well as optics for shelf appeal. “Traditionally, such refill bags are made from multi-material packaging that typically involves different types of materials, such as polyethylene terephthalate (PET), nylon and polyethylene (PE),” he explains. “PET and nylon are used for printing purposes, while nylon can further strengthen the toughness of the packaging, and PE provides the function of heat seal.”

Dow was able to create a recyclable refill pouch with the required properties by using its INNATE™ TF Polyethylene Resins for Tenter Frame Biaxial Orientation (TF-BOPE) to replace the PET and nylon, resulting in an all-PE structure. According to Xiao, Dow is first to launch the TF-BOPE material globally, which is typically challenging to produce.

“Tenter frame biaxial orientation is a mature film fabrication technology widely used in producing BOPP [biaxially oriented polypropylene], BOPET and BOPA [biaxially oriented polyamide] films,” says Xiao. “Traditionally, utilizing this technology to make BOPE is very difficult, as it is challenging to acquire a decent operation window on the industrial production lines due to the inherent property limitations of PE.”

To develop INNATE™ TF PE resins, Dow employed its proprietary catalyst and polymerization

technologies as well as its experience in the orientation film market. Notes Xiao, due to their unique molecular architecture, BOPE films can be smoothly fabricated on existing BOPP lines with high quality consistency and gauge evenness.

“Meanwhile,” he adds, “the high orientation applied in MD [machine direction] and TD [transverse direction] during the tenter frame process endows films with excellent mechanical properties, high stiffness and outstanding optical appearance, which represents a giant leap from the performance of traditional PE films and enables the substitution of traditional non-recyclable materials with all-PE designs for various packaging applications.

“The film also offers distinctive physical properties that can enable material substitution, film layer elimination and downgauging to reduce overall packaging materials.”

Joining Lion and Dow Thailand Group in developing the Shokubutsu Monogatari refill pouch were Dow’s Pack Studios Singapore and the distribution network of Asian petrochemical company SCG Chemicals (SCGC). “The recyclable refill bag for Shokubutsu Monogatari shower creams is an example of how more sustainable packaging can help to close the loop, through collaboration from business alliances, Dow’s recyclable packaging solution and support from SCGC,” says Lion’s Srisaardrak. “These made the development of Lion Thailand’s first recyclable refill bags possible while ensuring the quality of the product inside the packaging. This packaging also helps to reduce greenhouse gas emissions and advance a circular economy in the country.”

The Shokubutsu Monogatari shower cream refill pouch was introduced in September 2022 in two sizes, 200 and 500mL, across Thailand in department stores and supermarkets and “will eventually replace the older bags,” says the company.

For more info, visit dow.com. SD

Editor’s Note: The original version of this article was posted on March 1, 2023 by Packaging World.

Refill pouch ranks as 100% recyclable Resin technology enhances monomaterial properties.Monomaterial pouch provides performance attributes along with recyclability.

Secondary & End of line

When the choice is yours, why not choose more? A leading provider of primary, secondary, and end-of-line packaging machines, Paxiom has more than 30 years of industry expertise. Operating from seven global facilities, with a passionate and focused staff of professionals with the strongest national service presence, the ability to provide systems integration, and an installed base that included more than 7,000 machines across the world. Paxiom. Get more.

Ryson opens office in Mexico

New Ryson International (Booth C-4736) office in Mexico provides sales, service and support to customers in Latin America. Luis Lisandro Sanchez (right) is point of contact for sales. He has worked in the packaging industry in Latin America for 21 years and has experience in food/beverage and home and personal care products. Field Service Engineer Adrian Yescas Garcia (left) has been active in the Mexico and U.S. markets for more than six years. SD

Filler meets dairy standards

Hygienic rotary and straight-line machine from ATS Engineering (Booth SL-6238) fills liquid or viscous food products, seals containers and then applies overcaps. Machine, configured in up to eight lanes, offers easy changeover between cup sizes and no-cup/no-fill feature. Options include multi-fill capability, bottom-up fill and gas flushing. SD

Automate manual packing

Based on advanced mobile conveyors and robots, the BRIXX pick-and-place system from FlexLink Systems (Booth C-4400) automates manual operations for co-packers and eCommerce fulfillment operations, meeting consumer demand for higher differentiation and personalization. Modular, clickand-play design and intuitive software enable quick layout transformations to facilitate changeover. SD

NCA hosts lounge

The Candy Bar Lounge (Booth SU-7201), sponsored by Syntegon (Booth C-2800) and hosted by the National Confectioners Association (Booth SU-7201), provides a spot for confectionery industry attendees to network, gain insights and recharge during the show. SD

Machine loads 40 cartons/min.

Spartan cartoner from Econocorp (Booth C-4422) automates case/tray erecting and packing on beer lines. The rugged, mechanical, automatic horizontal cartoner operates at speeds of up to 40 cartons/minute. End-load cartons can be loaded manually or automatically. Closing options include tuck or sealing with hot melt or hot air. SD

Need project advice?

Industry veterans at the “Ask the Expert” Station (Central and South Lower Hall Lobbies) stand ready to answer packaging and processing questions. Attendees can stop by for guidance on narrowing their search for suppliers and navigating the show. SD

Virtual PLC optimizes workflows

Virtual nature enables operation independent of hardware.

The SIMATIC S7-1500V from Siemens Digital Industries (Booth SL-6351) is an entirely virtual PLC based on the functions and operation of the SIMATIC S7-1500 PLC but independent of its hardware.

The virtual controller S7-1500V is compatible with TIA (Totally Integrated Automation) Portal, also from Siemens, which provides a gateway to automation in the digital enterprise.

This integration allows you to use OT solutions previously employed in an IT environment and benefit from their advantages without giving up familiar structures. It also integrates into Industrial Edge, allowing users to operate applications centrally and automate process steps in a datacentric and software-based way. Thanks to IT mechanisms, you can even optimize entire workflows and costs with the SIMATIC S7-1500V PLC.

Key benefits include:

• Administration. Applying software updates to PLCs is easier because all software updates can be managed centrally with Industrial Edge Management system.

• Hardware Independent. The virtual PLC can be downloaded similarly to an App and integrated directly into the IT environment, enabling decoupling of hardware and software. The software runs on computers with Indus-

trial Edge Run Time in the factory while the hardware remains directly in the shop floor.

• IT-OT Convergence. The virtual PLC also plays an important role in IT-OT integration that helps customers make better data-driven decisions on performance, productivity, flexibility and sustainability.

For more info, visit siemens.com/global/en/products/ automation/systems/industrial/plc/simatic-s7-1500/ virtual-plc.html. SD

Publisher PMMI Media Group

Editorial Director

Hallie Forcinio

Associate Editors

Barbara Rook

Production Manager

Mary Thorne

Art Director

Debi Friedmann

IT/Production Support

Manny Dominguez

Photographers

Miles Boone and George Burns

Advertising Sales Management

Dave Newcorn, President, PMMI Media Group

John Schrei, Vice President, Sales, PMMI Media Group

tance this year. The new Sustainability Central will take an expansive look into packaging sustainability and what it means to brands, including expert speakers, interactive content and actionable sustainable solutions in manufacturing, materials, recovery, logistics, analytics and design. Dow (Room S-116), our official Sustainability Partner, will contribute its expertise in promoting sustainable practices by participating in Sustainability Central and the Sustainability Stage and sponsoring all the recycling on the show floor.

Our commitment to sustainability also includes the PACK EXPO Green program, which identifies exhibitors showcasing sustainable products and educational sessions focused on the topic. Another destination, the Reusable Packaging Pavilion, sponsored by the Reusable Packaging Association (Booth SU8000), along with its Reusable Packaging Learning Center (Booth SU-8000), addresses this aspect of sustainability.

To expedite your search, the PACK EXPO Sustainability Solutions Finder, curated by PMMI Media Group (Central Lobby), provides a targeted list of exhibitors to visit.

In our ongoing efforts to encourage the next generation of packaging and processing professionals, we are offering an array of events for emerging leaders and students, including

• The Young Professionals Networking Event, sponsored by Beckhoff (Booth SL-6335)

• The Future Innovators - Robotics Showcase (Booth N-9769), sponsored by Bastian (Booth N-10343) (see story, p. 29)

• The Amazing Packaging Race, a competition sponsored by Emerson Discrete Automation (Booth SL-6107) for teams from colleges, trade schools and universities

• The 2022 PACK Challenge (Booth N-9026), honoring the team from Waterford Union High School in Waterford, WI, builder of the winning filling machine for PACK EXPO International in 2022.

Speaking of PACK EXPO International, we are looking forward to welcoming you to Chicago next year (Nov. 3–6, 2024) and hope to see you earlier in 2024 at PACK EXPO East (March 18–20, 2024).

Please also make plans to participate in the newest member of the PACK EXPO family of trade shows, PACK EXPO Southeast. It will launch in 2025 in Atlanta (March 10–12).

Best wishes for a successful show, Jim

Pittas

Jim Pittas President & CEO, PMMI SDMinhas has built a company that ranks as the 10th largest brewery in North America, selling more than 8 billion pints of beer and generating revenue of $270 million last year.

Beyond her entrepreneurial prowess, Minhas has cemented her place as a renowned public speaker, mentor and host of the highly acclaimed Manjit Minhas Podcast. Through insightful interviews with top business leaders and CEOs, she extracts invaluable wisdom on achieving success. Discover how she triumphed over obstacles, defied the odds and thrived in the fiercely competitive beer and spirits arena.

The PPWLN Breakfast is sponsored by Emer son Discrete Automation (Booth SL-6107), Sep timatech Group (Booth C-2836), ID Technolo gy (Booth C-3414), BW Packaging (Booth C-1800), WestRock (Booth C-2023), SMC (Booth C-4839) Morrison Container Handling Solutions (Booth C-1651), Plexpack (Booth C-3036) and POWHER (ProMach Womens Resource Group).

For more info, visit pmmi.org/ppwln. SD

Vertical Conveying. Simplified.

Spiral Conveyors & Bucket Elevators

Unit Load Spirals convey cases, totes and packaged goods smoothly on our slat style belts and come in 9 standard slat widths ranging from 6” to 30”. Available in powder coated carbon steel, stainless steel, wet environment and freezer versions.

Mass Flow Spirals handle full and empty bottles, cans and jars in mass up to 2,000 units per minute. Available in 4 different slat widths ranging from 6” to 20”.

Narrow Trak Spirals are super compact and designed to handle smaller loads. Our 6” and 9” wide nesting slats can end-transfer small cartons and packages or side-transfer small bottles and containers in a single file or in mass at speeds in excess of 220 FPM.

Ryson’s Bucket Elevators combine vertical and horizontal transportation of bulk materials in one integral unit.

Our Bucket Elevators are designed for gentle handling and well-suited to transport a broad range of bulk products. They are completely enclosed with overlapping pivoting buckets, that prevent spillage and helps mitigate foreign debris.

They can be configured with multiple inlets or outlets that can be controlled individually. Available in three standard bucket sizes, yielding capacities up to 300, 700 or 1,800 cubic feet per hour. They can also be delivered in powder-coated carbon-steel, or stainless-steel for wet environments.

All Ryson equipment is modular and built to order. No matter the application, the Ryson team is up to the challenge of finding solutions for your conveying needs. For application assistance or more information, give us a call or visit www.ryson.com

Check out our running equipment at Pack Expo | Booth C-4736

www.ryson.com

(757) 898-1530

Ryson Spiral Conveyors need less floor space than conventional conveyors and are faster and more reliable than any elevator or lift.

pavilion

hotspots find targeted solutions

NORTH HALL

The Containers and Materials Pavilion

Find new sustainable materials, flexible packaging, printable films and more. Also see award winning packages at:

PACKage Printing Pavilion

Explore technology that makes customization, promotions, small runs, on-demand production and smart packaging cost effective.

The Logistics Pavilion

Find supply chain solutions including warehousing and dock equipment and systems, inventory management and control, distribution logistics services and transportation.

The Processing Zone

Find front-of-the-line solutions for food and beverage processing and discover ways to increase safety, improve efficiency and achieve total system integration.

SOUTH UPPER HALL

The Confectionery Pavilion

Uncover specialized equipment and integrated systems for your candy, chocolate, mints and gum production lines.

Sponsored by:

The Reusable Packaging Pavilion

Discover reusable assets that not only reduce waste but also provide more reliable protection for your production and can be part of a smart supply chain.

Sponsored by:

SOUTH LOWER HALL

The Healthcare Packaging Pavilion

A one stop shop for solutions targeted to pharmaceuticals, biologics, nutraceuticals, medical devices and more.

Serac expands operations

Acquires NFM/Doselec, opens offices in Mexico and India.

At Serac (Booth C-2423), operations are expanding via acquisition and the establishment of offices in Mexico and India.

On January 20, 2023, the Serac Group acquired NFM and its subsidiary Doselec, located in Falaise in the Normandy region of France.

The acquisition of Doselec takes place amid a strong global demand in the dairy products market and more generally in the market for food products in cups, which according to several studies is expected to grow by 16% by 2026.

Joining Serac Group, “will allow Doselec to . . . establish itself in places where it was difficult to go alone,” states Manuel Colasse, general manager of Doselec. Philippe Farrugia, Executive general manager of the Serac Group, explains, “Doselec’s expertise is a natural fit with the Serac Group’s core business in technical filling and consolidates our position in a fast-growing global market.”

NEW OFFICES

New offices in Mexico City and Pune, India, are building on Serac’s strong presence in Europe, the Middle East, Africa, Asia and North America. The new location in Mexico City, along with an existing subsidiary in Brazil, will enhance the company’s ability to provide faster and more efficient service to customers in Central and South America.

Serac MidAm offers a full range of services related to the installation, maintenance and upgrade of filling and capping machines designed and manufactured at Serac’s U.S. subsidiary in Carol Stream, IL. Mexico and the region are key market areas for packaging machinery, with a growing demand for high-quality and reliable equipment.

“We are excited to expand our global footprint with the opening of our new office in Mexico,” says Farrugia.

Rodrigo Melo Sanfuentes has been named general manager of Serac MidAm. “He brings a wealth of experience in the manufacturing industry and is excited about the opportunity to lead Serac’s efforts in the region,” says Nicolas Ricard, managing director Serac’s U.S. operations, who oversees business development in the North and Central Americas.

He adds, “I am confident that with our expertise and commitment to providing high-quality machines and services, we will be able to exceed our customers’ expectations and continue to grow our business in this region.”

The new office in Pune focuses on after-sales services and support of long-standing partners like Chitale Dairy and Castrol India.

“. . . having a unit here in Pune will only reduce our waiting time for spare parts and provide faster support and services,” says Sanket Shah, Castrol’s India engineering manager.

For more info, visit serac-group.com. SD

Kick back and dine for

Kick back and dine for leSS!

Open Daily Open Daily In North Hall

PACK EXPO Southeast debuts in 2025

in Atlanta

PMMI launches show to complement PACK EXPO East, better serve southern region.

The first edition of PACK EXPO Southeast, the newest show in the PACK EXPO portfolio, produced by PMMI, The Association for Packaging and Processing Technologies (Central Lobby), is scheduled to take place March 10–12, 2025, in Atlanta at the Georgia World Congress Center, the world’s largest LEED-certified convention center.

Located within driving distance of key manufacturing cities and a mere two-hour flight from 80% of the U.S. population, PACK EXPO Southeast will harness all the power of the PACK EXPO portfolio of trade shows for the robust southeast market.

Refuel Relax Return

South Upper Hall Room S-220

HOURS OF OPERATION:

Monday – Tuesday: 8:00 am – 5:00 pm

Wednesday: 8:00 am – 3:00

If

•

•

•

•

MONDAY,

8:30

TUESDAY,

1:30

WEDNESDAY,

8:30

“This show represents a big opportunity to bring the industry together in a region of the country that is not currently served by a trade show focused on packaging and processing,” explains Jim Pittas, president & CEO, PMMI. “PACK EXPO Southeast in Atlanta is the perfect location to focus on targeted opportunities in this robust market, which is home to some of the top manufacturing industries in the region.”

Like its sister shows, PACK EXPO Southeast will serve the packaging and processing needs of 40 vertical markets and deliver a depth and breadth of exhibits not provided by any other events in the region. It also will offer a strong educational component and networking events. PACK EXPO Southeast offers attendees an opportunity to:

• See new packaging and processing technology in action

• Gather crossover ideas from other industries

• Take advantage of the convenient location and bring a team of colleagues

• Foster new connections in the region via networking events and more intimate size

• Move projects forward faster by talking to experts and assessing options side-by-side.

Laura Thompson, vice president, PMMI, concludes, “PACK EXPO Southeast 2025 will provide a prime opportunity for exhibitors to reach a new, untapped customer base in this region. And attendees will have the chance to experience new kinds of machinery, materials and other innovations live and in-person, while forging critical relationships with their peers and suppliers.”

Exhibit booth sales have begun. Attendee registration will open in November 2024 during PACK EXPO International in Chicago.

Stop by the PMMI Booth located in the Central Lobby to learn more. For more info, visit packexposoutheast.com. SD

11, 2023

Sustainability Stage debuts

Anew show feature, Sustainability Central in the North Hall, houses the Sustainability Stage (Booth N-9967) where attendees will learn from more than a dozen industry experts about how to improve the environmental profile of their brands.

Topics include logistics, labeling, waste reduction, sustainable design and transitioning to more sustainable materials. with an opening presentation by Daniella Souza Miranda, global business director, Circular & Renewable Solutions at Dow (Room S-116), the show’s official Sustainability Partner.

Session descriptions, times and locations are listed on the following pages.

MONDAY, SEPTEMBER 11, 2023

RESHUFFLING THE DECK: A NEW PERSPECTIVE ON THE TAKEMAKE SYSTEM

10:00-10:30 AM

As the demand for sustainable products and practices grows, we’re taking a deeper look at how we manage resources, leverage new technology, make and use products and handle the materials afterward. Join us to hear how a materials ecosystem approach can unlock the value from plastic and agricultural waste.

Daniella Souza Miranda Global Business Dir, Circular & Renewable SolutionsDow

UNLOCKING THE POWER OF SUSTAINABILITY IN LOGISTICS

11:00-11:30 AM

Using Flock Freight’s solution—shared truckload— as proof of concept, learn how companies can meet sustainability goals without sacrificing profitability. Dive into how sustainability lies at the core of Flock Freight’s business model and has played a pivotal role in building enterprise value. Hear an expert debunk the misconception that sustainable strategies are at odds with creating value and the need for better models to turn sustainability from an added expense to a key ingredient for growth.

Oren Zaslansky Founder & CEOFlock Freight

INCREASING PACKAGING EFFICIENCY WITHOUT DECREASING QUALITY

12:00-12:30 PM

Lovevery’s goal is to help parents feel confident they’re giving their children the best start in life. Fun, simple and engaging, our award-winning play products are thoughtfully crafted and rigorously tested for quality and safety. Our play essentials are made with sustainable, organic and natural materials that are good for the planet. We call this The Lovevery Commitment, which is grounded in our commitment to families to preserve what we’ve been given and pass it down to our children. As part of this commitment, we are

Sustainability STAGE

Updated schedules may be found on the show website or via the show App, sponsored by ProMach (Booth C-3222)

Other free educational opportunities on the show floor include the new Industry Speaks Stage (Booth C-1141) (see schedule, p. 24), the Innovation Stage (Booths C-2051, C-2058, C-2151) and the Processing Innovation Stage (Booth N-10511) (see schedule, p. 30), plus The Forum—An Industry Knowledge Exchange (Booth C-2158) (see schedule, p. 58)

Schedule as of August 23, 2023.

For more info, visit packexpolasvegas.com. SD

working to reduce carbon output across our supply chain. Our packaging design practices are playing a key role by focusing on reducing the amount of material, volume and weight we use to deliver our products. We’re also finding new ways to introduce reusable packaging and educate families on how to recycle.

AJ Piejko Brown Packaging Design Engineer LoveveryLEVERAGING SUSTAINABLE PACKAGING TO ENGAGE CONSUMERS

1:00-1:30 PM

Now more than ever, consumers are asking more of brands and retailers when it comes to packaging. They want it to be recyclable, affordable, have a low impact and ultimately be sustainable. Understanding consumer sentiment can be difficult while balancing other aspects of packaging design. This session will help navigate the challenges of consumer engagement around innovative sustainable packaging while proving that it is beneficial for the planet and your wallet.

Mikey Pasciuto Co-FounderScrAPP

INJECTING INNOVATION INTO SUSTAINABLE PACKAGING

2:00-2:30 PM

Every process has pros and cons depending on what you want to achieve at a brand level. Explore the manufacturing process of injection molding with sustainable materials, including strengths, weaknesses, capabilities and limitations. Learn if an injection-molded process is right for you.

Dustin Wills

VP, North American Sales Paperfoam

THROWN AWAY: ONE MAN’S TRASH IS ANOTHER MAN’S TREASURE

3:00-3:30 PM

Recovery has become more than traditional curbside pickup. Learn about innovation in recovery for hard-to-recycle materials and back to the basics in traditional recycling. This panel discussion will bring class to trash.

Brent Lindberg - Moderator

Founder & Head of Curiosity

Fuseneo

Dylan Layfield

VP, Material Sales & Recycling

Terracycle

Tamsin Ettefagh

Chief Sustainability & EVP, Commercial

Purecycle

Lon Pschigoda

GM, WMU Paper Pilot Plants

Western Michigan University

Steve Lyons

Dir, Strategic Environmental Analysis

Sabacci Consulting Group

PACKAGING LABELS: CHASING THE RIGHT MARKS, WORDS AND MESSAGES

4:00-4:30 PM

Do you know what you can and cannot say on your packaging? Do you know when new state requirements take effect and how they will impact your organization’s compliance? Hear industry-leading experts break down new regulatory requirements and restrictions. Discuss the rapidly changing regulatory landscape and how you can be prepared.

Dan Felton Exec Dir

AMERIPEN

TUESDAY, SEPTEMBER

12, 2023 STYLE THAT FITS: BUILDING YOUR PACKAGING

10:00-10:30 AM

WARDROBE

Building the perfect wardrobe goes beyond mere chance; it requires the expertise to choose the best silhouette, fabrics and accessories. Step onto the fashion runway and hear insider style secrets, empowering you to curate a well-coordinated packaging wardrobe considering materials, shapes, textures and colors that will bring your packaging to life.

Brent Lindberg

Founder & Head of Curiosity

Fuseneo ∆

OxyStar barrier material utilizes a multilayer PET with an oxygen scavenging agent. PET has a naturally low oxygen transmission rate (OTR) and this construction slows down the flow of oxygen molecules through the package from the outside. Once the scavenger agent finds an oxygen molecule, it a aches to it and binds the oxygen within the sidewall of the package to keep your product fresh and lasting longer.

TUESDAY, SEPTEMBER 12, 2023 (CONT’D)

NEW BOTTLE, SAME SPRITE

11:00-11:30 AM

Sprite’s status as one of the biggest and most recognized brands in the world can largely be attributed to its crisp lemon-lime taste and iconic green bottle. As of 2022, Sprite, Seagram’s, Fresca and Mellow Yellow have transitioned from a green to a clear polyethylene terephthalate (PET) bottle in North America. This move marks Coca-Cola’s commitment to a World Without Waste by making it easier to recycle PET packaging into new bottles, thus supporting a circular economy. For Sprite, this was no easy feat as the brand is associated with predominately green packaging. Coca-Cola was able to make the switch to a more sustainable package through technical expertise and by understanding the consumer mindset.

Noah

WigingtonGlobal Packaging Development & Innovation Lead

Coca-Cola

ALTERNATIVE SUSTAINABLE MATERIALS: THE FUTURE OF PACKAGING

12:00-12:30 PM

As alternative materials enter the packaging landscape, it is critical that they are designed and engineered to provide relief from their problematic predecessor and function and protect as a replacement. Manufacturers are demanding alternatives but need a level of confidence not always accessible within the framework of a startup. Collaborations like that of Atlantic Packaging and Cruz Foam promote innovation and application ingenuity. Hear how a great idea can turn into a viable replacement when validated through industry standards and endorsed by a sustainable leader like Atlantic Packaging.

Kyle Pischel Dir, Packaging Solution Center Atlantic PackagingToby

Corey Exec Chairman & COOCruz

FoamBEYOND SUSTAINABILITY: LEAD THE SHIFT TO CIRCULAR PACKAGING

1:00-1:30 PM

An estimated 11 billion kg of plastic pour into our waterways and devastate our oceans. Rather than seeing plastic as waste, we need a way to reveal its inherent value and recognize its true worth in changing our lives. Plastic Bank, founded in 2013, is a social enterprise that provides an opportunity for the world to collect and exchange plastic as a currency. This idea has spurred a global Social Recycling movement that has stopped 80 million kg of plastic waste from entering the ocean, while empowering collection communities in vulnerable coastal areas of Southeast Asia, Latin America and Africa to find a path out of poverty. Learn how recycling can be socialized by being part of a greater purpose-driven movement—for individuals and institutions alike. Plastic pollution endangers more than 800 species, including us. Hear how you can become part of the solution.

David Katz

Founder & ChairmanPlastic Bank

LIKE, SUBSCRIBE AND FOLLOW THE MOST SUSTAINABLE SOLUTIONS AT PACK EXPO

2:00-2:30 PM

This foursome plus moderator will provide a “CliffsNotes” version of can’t-miss innovations at the show and provide colorful commentary about sustainability developments. Learn what these innovations mean for the packaging industry and how they might be helpful to your own organization.

Brent Lindberg - Moderator

Founder & Head of Curiosity

Fuseneo

Cory Connors Dir, Sustainable Packaging

Landsberg Portland

Adam Peek

Sr VP, Sales Meyers

Evelio Mattos

Creative Dir, Packaging

International Direct Packaging

Jonathan Quinn Dir, Mkt Development & Sustainability

Pregis

CLOSING THE PACKAGING LOOP: ADVANCING THE CIRCULAR ECONOMY

3:00-3:30 PM

Explore successful examples and challenges associated with advancing circular economy practices. From sourcing renewable key inputs, energy considerations and decarbonization to recycling and recovery, companies are considering how to minimize waste and keep materials in circulation while regenerating nature. With billions of packages in circulation around the world daily, this session considers the significant potential impact of packaging and provides tactics for driving progress toward a more sustainable future.

Christopher Davidson

VP, Sustainability

WestRock

COLGATE-PALMOLIVE’S SUSTAINABILITY & SOCIAL IMPACT STRATEGY

4:00-4:30 PM

At Colgate-Palmolive, we are really proud that Colgate is in more homes than any other, so we can and we will create a healthier, more sustainable future for all. To achieve this mission, Colgate has developed a Sustainability and Social Impact Strategy with 11 actions ranging from Accelerating Action on Climate Change to Designing Sustainable Products. This session will cover the strategy, actions and examples of how Colgate is embedding sustainability across its value chain.

Cecilia Coates

Mgr, Global Sustainability

Colgate-Palmolive

WEDNESDAY, SEPTEMBER 13, 2023

LEVERAGING SUSTAINABILITY IN PACKAGING COST OPTIMIZATION

10:00-10:30 AM

As the consumer goods and packaging industry faces several headwinds coming out of COVID, including an uncertain economic situation, softening demand, supply chain challenges that haven’t fully been resolved, etc., sustainability often takes a back seat to cost optimization and other performance improvement levers. There are, however, ways to incorporate sustainability into these initiatives to continue to make progress toward goals and commitments without sacrificing either objective. Learn how to incorporate sustainability thinking into cost optimization and provide examples of its value creation.

Rebecca Marciniak

Principal

Dilhani de Silva

Partner

Roland Berger

ALL TOGETHER NOW: UNLOCKING PACKAGING’S CIRCULAR FUTURE

11:00-11:30 AM

It’s time to go beyond broad recyclability claims and design packaging that is actually being recycled into valuable post-consumer recycled material. But how can brands transform from passive producers of waste to active participants in a circular economy? By embracing a systems approach that engages materials suppliers, reprocessors, materials recovery facilities and machinery makers to shed light on all the links of the circular supply chain. From advanced recycling to reuse and refill and monolayer materials, we’ll explore the ways stakeholders can take their recyclability claims from promise to reality.

Matt Reynolds

Chief Editor, Packaging World

Anne Marie Mohan

Senior Editor, Packaging World

Sean Riley

News Editor, Packaging World PMMI Media Group

INTENTIONAL DESIGN FOR SUSTAINABLE AND RECYCLABLE PACKAGING STRUCTURES

12:00-12:30 PM

To meet the combination of growing consumer demand and an escalating regulatory environment, Michelman helps customers transition to more sustainable solutions for their packaging needs. Discuss how to transition from film-based to fiber-based substrates that will enable improved end-of-life options for final structures in existing recycling streams—all while maintaining excellent barrier performance!

Talia Collins

Mgr, Global Research & Development

Michelman

Toby Corey

Exec Chairman & COO

Cruz Foam SD

MAKE IT SMARTER AT PACK EXPO 2023

BOOTH C-5033

PRIMARY

CASEPACKING

TRAYPACKING

CARTONING PALLETIZING

PRIMARY

CASEPACKING

TRAYPACKING

CARTONING PALLETIZING

Brewery shifts to fiber-based handles

Automated applicator applies paperboard can handles.

Ska Brewing, a craft brewery in Durango, CO, is the first craft brewery in North America to install an automated paperboard can handle applicator from WestRock (Booth C-2023). The new machine allows the company to transition all of its beer offerings from plastic carriers to a fiber-based multipack product wrap.

“The installation of the CanCollar Corsair is one of Ska’s ongoing, never-finished efforts to build a more sustainable future,” says brewery co-founder & CEO Dave Thibodeau. “We saw the opportunity to implement this fiber-based CanCollar, and we’re jumping on it. We hope it will become the industry standard moving forward.”

The craft brewery, which has never been keen on plastic packaging, identified WestRock’s Can Collar as an alternative that supports its sustainability goals. The company’s CanCollar Corsair machine automatically applies various CanCollar paperboard-based multipack formats to 24-pack trays of product, which allows Ska to package all of its canned brand offerings—including four packs and six packs—using a solution that reduces plastics consumption by up to 95% when compared to alternative plastic multipack options.

“The CanCollar, which promotes circularity, will immediately reduce the amount of plastic Ska contributes to the environment by approximately 4 tons/year,” says Ska Brewing COO Steve Breezley. “This contributes to a reduction in overall waste and the carbon footprint associated with the shipping and storage of our products.

The innovation, ethos and ethics behind this solution are what we’re all about.” For more info, visit westrock.com. SD

Editor’s Note: The original version of this article was posted by Packaging World on April 12, 2023.

Wherever you are and whatever your industry, there’s a PACK EXPO event to provide solutions you need today and the inspiration for tomorrow.

March 18-20, 2024

Philadelphia, USA

June 4-7, 2024

Mexico City, Mex.

Nov. 3-6, 2024

Chicago, USA

March

June

Sept.

Partners bring knowledge to show Partner

Program links attendees to wide array of organizations.

Approximately 30 organizations are partnering with show organizer PMMI, The Association for Packaging and Processing Technologies (Central Lobby), for PACK EXPO Las Vegas, connecting attendees to leading associations from all segments of packaging and processing.

“The Partner Program is one reason why PACK EXPO Las Vegas is the most comprehensive packaging and processing event in North America in 2023,” says Jim Pittas, president & CEO, PMMI. “These organizations bring targeted knowledge to the show floor and give attendees actionable information to improve their operations.”

Participants in the PACK EXPO Partner Program exhibit in the Partner Pavilion or elsewhere on the show floor.

New this year, the PACK EXPO Las Vegas Partner Plus Program gives groups the opportunity to present sessions on the Industry Speaks Stage (Booth C-1141) (see schedule, p. 24) or to co-locate meetings with the show under the banner, Industry Meets. For example, the Cold Pressure Council (Booth C-1153) has scheduled its Annual Conference on Tuesday, Sept. 12, 2023, at the Las Vegas Convention Center and a Board of Directors meeting the next day. Other Industry Meets participants include: the International Bottled Water Association (offsite);

MHI Automation Industry Groups; Composite Can & Tube Institute (Booth C-1350); Contract Packaging Association (Booth C-1256); Institute of Packaging Professionals (Booth C-1154); and OMAC - The Organization for Machine Automation and Control (Booth C-1255). The latter plans a public General Session and a Workgroup meeting at 10:00 a.m. and 11:00 a.m., respectively, on Tuesday, Sept. 12.

The Industry Speaks Stage, another first for PACK EXPO Las Vegas, offers an opportunity to hear experts representing Partner Program participants discuss hot topics and trends including automation, high-pressure pasteurization, digital transformation, contract manufacturing/packaging, flexible packaging, modern warehousing and logistics, machinery standards and sustainability.

“As part of the PACK EXPO Partner Program, we are looking forward to seeing our members and meeting potential members while talking to brand owners, packaging designers, label printers, molders and others who are learning more about the advantages of in-mold labeling and decorating technology,” says Dianna Brodine, managing director at the In-Mold Decorating Association (Booth C-1347). “In addition, we are releasing white papers about the sustainability and recyclability of in-mold labeling/dec-

INDUSTRY MEETS

Cold Pressure Council (Booth C-1153)

Composite Can & Tube Institute (Booth C-1350)

Contract Packaging Association (Booth C-1256)

Institute of Packaging Professionals (Booth C-1154)

International Bottled Water Association

MHI Automation Industry Groups

OMAC - The Organization for Machine Automation and Control (Booth C-1255)

orating processes and presenting an Industry Speaks session on the subject [4:30 p.m., Monday, Sept. 11].”

For up-to-date schedules and Partner Program Pavilion details, check the PACK EXPO Las Vegas mobile App, sponsored by ProMach (Booth C-3222), or the show website.

For more info, visit packexpolasvegas.com, promach.com. SD

PARTNER PROGRAM PARTICIPANTS

3-A Sanitary Standards (Booth C-1353)

AIM (Booth SU-8306)

AMERIPEN (Booth C-1151)

Anuga FoodTec Family (Booth C-1158)

ASD Turkish Packaging Manufacturers (Booth C-1145)

Association for Roll-to-Roll Converters (Booth C-1351)

Association of Plastic Recyclers (Booth C-1157)

Australian Packaging and Processing Machinery Association (Booth C-1150)

CANAINCA

Cold Pressure Council (Booth C-1153)

Composite Can and Tube Institute (Booth C-1350)

Consumer Brands Association (Booth C-1248)

Contract Packaging Association (Booth C-1256)

Flexible Packaging Association* (Booth C-1348)

Foil & Specialty Effects Association* (Booth C-1346)

Foundation for Supply Solutions (Booth C-1152)

International Bottled Water Association

In-Mold Decorating Association* (Booth C-1347)

Institute of Packaging Professionals* (Booth C-1154)

Instituto Argentino del Envase (Booth SU-8135)

International Society of Beverage Technologists (Booth C-1354)

MHI Automation Industry Groups

National Confectioner’s Association (Booth SU-7201)

OMAC – The Organization for Machine Automation and Control (Booth C-1255)

OPC Foundation (Booth C-1250)

PLCopen (Booth C-1253)

Reusable Packaging Association* (Booth SU-8000)

SNAC International (Booth C-1146)

The Tube Council of North America*

UCIMA – Italian Packaging Machinery Manufacturers Association (Booth C-1149)

U.S. Department of Commerce (Booth C-1159)

World Packaging Organisation* (Booth C-1246)

Engineered for reliability and longevity, VDG Drum Motors are designed for 80,000 hours of continuous operation before maintenance, reducing operational and maintenance costs and increasing throughput.

Showcase displays award winners

Visit The Showcase of Packaging Innovations®, sponsored by WestRock.

The Showcase of Packaging Innovations® (Booth N-9550), sponsored exclusively by WestRock (Booth C-2023), features award-winning packages from competitions around the world.

“The Showcase of Packaging Innovations is a traditional and treasured component of PACK EXPO,” says Jim Pittas, president & CEO of PMMI, The Association for Packaging and Processing Technologies (Central Lobby), the show organizer. “We are most grateful to WestRock for sponsoring this facet of the show once again. Being able to view an array of innovative packaging in one place is inspiring and gives attendees ideas to take home and adopt to make their packaging more environmentally-friendly and consumer-friendly.”

Ten organizations are participating in this year‘s

Showcase, which is located in the North Hall straddling the boundary between the Containers and Materials Pavlion and the PACKage Printing Pavilion.

Sustainability plays a role in many of the award winners. A judge for the Flexible Packaging Association competition, Gary Borges, associate professor, University of Wisconsin-Stout, explains, “Sustainability is growing tremendously . . . Post-consumer recycling is a trend that we saw. And we’re seeing an increase in paper structures that . . . we can send to our paper waste streams at home. So, we’re seeing all of these innovations taking place. It is pretty impressive.”

For more info, visit packexpolasvegas.com, westrock. com, dow.com, flexpack.org, fsea.com, imdassociation. com, iopp.org, profoodworld.com, reusables.org, tube.org, worldpackaging.org. SD

At the Flexible Packaging Association, the RESCUE!® Outdoor Disposable Fly Trap earned the Highest Achievement Award. It also won a Packaging Excellence Gold Award, a Technical Innovation Silver Award and an Expanding the Use of Flexible Packaging Award. The flexible packaging, produced by Glenroy for Sterling International, is easy to use: Cut along the dotted line at the top to expose the trap entrance, add water and hang. The pouch construction protects the consumer from the powerful attractant inside. Once the trap is full (collecting up to 20,000 flies), the consumer simply discards it.

In the ninth annual Sustainability Excellence in Manufacturing Awards, organized by ProFood World, a PMMI Media Group (Central Lobby) publication, First Place in the Program Category honors a certified carbon-neutral brand made in a zero-waste Conagra Brands facility in Fayetteville, AR.

PARTICIPANTS

Dow (Room S-116)

Dow Packaging Innovation Awards

Flexible Packaging Association (Booth C-1348)

Foil and Specialty Effects Association (Booth C-1346)

In-Mold Decorating Association (Booth C-1347)

Institute of Packaging Professionals (Booth C-1154)

ProFood World (Central Lobby)

Sustainability Excellence in Manufacturing Awards

Reusable Packaging Association (Booth SU-8000)

The Tube Council of North Ameria WestRock (Booth C-2023)

World Packaging Organisation (Booth C-1246)

In a competition sponsored by the In-Mold Decorating Association, label supplier MCC Verstraete and molder Jokey Group were honored with the Best In-Mold Label Award for an interactive in-mold label with a digital watermark. Designed for De Dames van Akkkerlust, a new ice cream brand, the intelligent feature adds value in the packaging journey—from tracking and authenticating products to boosting customer engagement to digitally sorting the package for recycling. The sustainable packaging is designed to reflect the nature of the ice cream, which is made on a sustainable farm from 100% organic milk.

The Best of Show Award in the 2023 AmeriStar competition, sponsored by the Institute of Packaging Professionals, revolutionizes single-use packaging with a focus on sustainability and consumer satisfaction. Annie’s certified industrially-ompostable molded fiber cup offers functionality equal to a plastic thermoform and broadens the use of molded fiber into shelf-stable products. The packaging offers a 45% reduction in carbon footprint and is direct-printed via a flexographic process. A spray coating made from a renewable formula offers grease and water protection. Improved convenience and warmth retention enhance the consumer experience. The package also won an AmeriStar Award in the Sustainable Packaging category.

The top prize in the Dow Packaging Innovation Awards, the Diamond Award, went to Procter & Gamble for its G ECOCLIC® box for liquid laundry capsules. The patent-pending cardboard packaging scores for sustainability and child safety. The carton consists of FSC-certified materials with a minimum of 70% recycled fibers, and its dimensions and design fit 50% more packs per pallet. The certified child-resistant design also is easy to open even for people with dexterity limitations and sight or cognitive impairments. A reassuringly loud ‘one click’ closure signals the pack is closed.

Demo shows integrated line

Immersive holographics showcase other machines.

Afully integrated packaging line Syntegon (Booth C-2800) shows multiple systems running with the DCG compact pullnose distribution system at the forefront. Ideally suited for goods such as sticky bars or baked products, the DCG system discharges up to 32 rows of product/min. On the PACK EXPO line, it gently discharges 400 products onto the downstream packaging leg at 18 cycles/min.

Then the FIT inline module continuously feeds products to the hygienic Doboy Pack 403 horizontal form/fill/seal machine. Linear motors ensure gentle handling while preventing products from sticking together or accumulating along the way.

The single-wrapped products continue at a rapid and steady pace to an RPP robotic pick-and-place system, where delta robots softly pick, group and deposit products in batches of four into the infeed of the final machine, a Klikok MEC mid-range end-load cartoner. The cartoner, with its patented rotary carton feeder, packs foursomes of products into each carton at rates of up to 170 cartons/min. Alongside the live machines, visitors can view two immersive holograms showing other technologies in the company’s portfolio: Osgood liquid-filling machines and Elematic case packers.

For filling, the Osgood LFS model is the next generation in clean and ultra-clean applications for preformed cups and tubs. The Elematic 1001TL topload case packer, a North American favorite, combines a small footprint with a large format range and quick changeovers. The holograms’ educational visuals and voiceovers show viewers all that the machines have to offer. For more info, visit syntegon.com. SD

Industry Speaks Stage features PACK EXPO Partners

Anewcomer to the free educational programming at PACK EXPO Las Vegas, the Industry Speaks Stage (Booth C-1141) in the Central Hall, draws experts from the PACK EXPO Partner Program.

The 30-min. presentations focus on topics such as automation, standards, developments in high-pressure processing, sustainability, flexible packaging, contract man-

IMPROVING EFFICIENCY IN PROGRAMMING: INDUSTRIAL AUTOMATION

10:30-11:00 AM

Do you want to be more efficient in developing your application software? Check what PLCopen and its members can provide. Topics include ways to a structured approach, development of application-specific libraries of reusable components, object orientation also for motion control and software quality issues.

Eelco van der Wal Managing DirPLCopen

THE STATE OF SNACKING: AN INNOVATION ERUPTION

11:30-12:00 PM

With the snack and snacking adjacent category generating 27% of all food and beverage sales in the U.S., take a look at why snacking is a central component of our daily lives and how the market is evolving to reflect consumer preferences.

David WalshVP, Membership & Communications

SNAC International

MACHINERY STANDARDS UPDATES INCREASE BUSINESS OPPORTUNITIES

12:30-1:00 PM

Learn the latest updates made in the newly published ANSI/PMMI B155.1 Safety Requirements for Packaging and Processing Machinery and their impact on business opportunities. Both machine builders and end users need to know the latest requirements and how to apply them as these influence the design and operation of packaging and processing machinery.

Bruce

Pres

Maindesign safety engineering, inc.

AUTOMATION JOURNEY FROM AN END USER PERSPECTIVE

1:30-2:00 PM

The world of robotics and automation for intralogistics is advancing quickly. Suppliers are pushing into new frontiers as technical barriers fall and innovations come to market. Warehouse operators and solution designers are combining technologies in new ways. With a focus on mobile robotics, piecing, picking and learning systems,

ufacturing/packaging, warehouse automation, in-mold labeling/decorating, metallic labels/cartons, automatic identification and data capture, beverages and snack food.

Session descriptions, times and locations are listed on the following pages. Updated schedules may be found on the show website or via the show App, sponsored by ProMach (Booth C-3222)

Other free educational opportunities on the show

participants will gain insight into cutting-edge applications from a panel of industry experts.

Brent Barcey

VP, Sales & Business Development

TRG Member: Plus One Robotics

INNOVATION FOR CONSUMER TRUST AND INDUSTRY GOALS

2:30-3:00 PM

Industry collaboration leads to innovation that increases consumer trust, achieves industry goals and aids navigation of complex regulatory landscapes by examining SmartLabel.

John Hewitt

VP, Packaging & Sustainability

Consumer Brands Association

HPP DELIVERS FOOD SUSTAINABILITY AND NEW SKINCARE SUCCESSES

3:30-4:00 PM

Discover the untapped potential of high-pressure processing (HPP) in adding value to food waste streams by enhancing protein functionality, extracting bioactive compounds, fast freezing and more.

Mary-Grace C. DanaoResearch Associate Professor

University of Nebraska-Lincoln

Joyce Longfield Board Member

Cold Pressure Council

SUSTAINABILITY & RECYCLABILITY: IN-MOLD LABELING/DECORATING

4:30-5:00 PM

In-mold technologies offer advantages in both sustainability and recyclability for brand owners, molders and decorators of plastic products. The in-mold application of a film label renders packaging and containers recyclable in the normal workflow of a recycling facility without requiring the removal of the label material. Production and operational efficiencies result in sustainable creation of durable goods for markets such as automotive, medical and appliance. Learn more about in-mold technologies and their advantages described in white papers to be released at PACK EXPO Las Vegas.

Dianna Brodine Managing Dirfloor include the new Sustainability Stage (Booth N-9967) (see schedule, p. 14), the Innovation Stage (Booths C-2051, C-2058, C-2151)/Processing Innovation Stage (Booth N-10511) (see schedule, p. 30), plus The Forum—An Industry Knowledge Exchange (Booth C-2158) (see schedule, p. 58)

Schedule as of August 23, 2023.

For more info, visit packexpolasvegas.com. SD

DIGITAL TRANSFORMATION SUCCESS USING OPC STANDARDS

10:30-11:00 AM

Real-world examples from end users highlighting their digital transformation journey when using OPC technologies.

Mike Clark Dir

OPC Foundation North America

THE CONTINUING PATH OF HPP INNOVATION

11:30-12:00 PM

The current widespread use of HPP technology has been a journey driven by innovation. Join us to learn more about the foundations of its current success and the expanding opportunities that lie ahead.

Rick Marshall

Dir, Business Development

Shape Process Automation

ADVANCING THE PACKAGING INDUSTRY WITH AIDC TECHNOLOGY

12:30-1:00 PM

By embracing automatic identification and data capture (AIDC) technologies, the packaging industry is witnessing significant advancements in traceability, data management, quality control and consumer engagement. These technologies empower businesses to optimize operations, streamline supply chains, enhance customer experiences and maximize competitiveness in a rapidly evolving market. Hear an overview of the technologies changing the market and learn about the role AIM plays in helping advance the packaging and AIDC industry.

Michael Allen

Business Development Dir

AIM North America

FLEXIBLE PACKAGING INDUSTRY: POLICY DRIVING INNOVATION

1:30-2:00 PM

Hear about the current state of the flexible packaging industry and discuss legislative, regulatory and other factors driving innovation in the space, the second fastest growing segment of the packaging industry in the U.S.

Alison Keane Pres & CEOFlexible Packaging Association ∆

NEVER BEEN SO EASY

SEE US AT BOOTH SU-7412

TOTALLY AMERICAN WITH AN ITALIAN HEART

Ronchi America proudly presents the SIRIO/S capper, built in Atlanta, GA. This SIRIO/S capper includes all of the Ronchi features and is FAT ready within 12 weeks or less. The SIRIO/S capper is also capable of being synchronized with the US built Ronchi EXACTA/R 18 filler.

DYNAMIC GROWTH: CONTRACT PACKAGING AND MANUFACTURING INDUSTRY

2:30-3:00 PM

Viewing data from the Contract Packaging Association’s State of the Industry Report, member feedback and its Request for Quote platform, dive into the changing demands of this dynamically growing industry. These essential providers of capabilities and services address the needs of emerging and legacy brands launching food and retail products. Explore how CoMans and CoPacks add value as consumerand market-driven needs impact the packaged goods supply chain. Understand how brands are adapting to meet new challenges with strategic CoMan and CoPack partnerships and accelerating time to market.

Ron Puvak Exec DirContract Packaging Association

SUSTAINABILITY AND METALLIC DECORATING FOR CARTONS AND LABELS

3:30-4:00 PM

Sustainability as it relates to decorative metallics is on the forefront of the minds of brand owners and others in the print and packaging industries. The Foil & Specialty Effects Association (FSEA) has taken important steps to generate pertinent, accurate information about metallic transfer-decorating technologies and sustainability. Discuss recent FSEA studies on the repulpability/recyclability of metallic-transfer decorating on paper/board.

Jeff Peterson Exec DirFoil & Specialty Effects Association

END-TO-END AUTOMATION IN MODERN WAREHOUSING AND LOGISTICS

4:30-5:00 PM

This comprehensive overview of the automation journey starts at initial strategy and design, moves to the implementation of automation technologies and ends with the continuous monitoring and optimization of these systems. Take an in-depth look at the challenges and opportunities presented by end-to-end automation in warehousing and logistics, focusing on the significance of strategic planning and meticulous design in the successful implementation. View a blueprint for a successful transition toward automated operations. Then, navigate toward the nuts and bolts of logistics automation, showcasing technologies that enhance productivity, reduce errors and contribute to overall business growth. Lastly, highlight the indispensable role of sensor intelligence in ensuring operational efficiency and safety in automated systems. Examples of intelligent sensor systems demonstrate how these technologies provide crucial data, support real-time decision making and empower businesses to remain agile and responsive in the face of changing market dynamics. Lastly, the presentation will highlight the indispensable role of sensor intelligence in ensuring

both operational efficiency and safety in automated systems. This segment features examples of intelligent sensors, demonstrates how these technologies provide crucial data, support real-time decision making and empower businesses to remain agile and responsive to changing market dynamics.

Chris York

Chief Technology OfficerSlate River Systems

Nils Hart

Exec Dir, Business Development

Murata Machinery USA

Susan Nangle

Consulting & Digital Solutions SICK

WEDNESDAY, SEPTEMBER 13, 2023

THE PACKAGING POLICY PRECIPICE— CHALLENGES OR OPPORTUNITIES

10:30-11:00 AM

The U.S. remains at a critical precipice on packaging and environment policy with significant new laws continuing to be passed and implemented on packaging producer responsibility, labeling, recycled-content mandates and more. Join a fast-paced discussion about what’s happening and how to engage with the ensuing challenges and opportunities.

Dan Felton Exec Dir AMERIPENSUSTAINABILITY INTO PACKAGING AND PROCESSING MACHINERY

11:30-12:00 PM

Examine the global and regional perspectives of sustainability and circular design, showcasing initiatives, programs, regulations and roadmaps from Italian packaging machinery manufacturers.

Riccardo CavannaPres

UCIMA - Italian Packaging Machinery

Manufacturers’ Association

WHAT CAN THE ISBT OFFER YOU, THE PROFESSIONAL IN THE BEVERAGE INDUSTRY?

12:30-1:00 PM

The vision of the International Society of Beverage Technologists (ISBT) is to be the premier global beverage industry technical association, which drives sustainable growth, resolves challenges and leads productivity innovations. ISBT offers the global industry a platform to network and help the industry thrive. Come learn what this 75-year-old society offers its members and their companies in a global format.

Ron Puvak Mktg Committee ChairInt’l Society of Beverage Technologists SD

UnPACKed discusses standards

Host Sean Riley sits down with Bruce Main, PMMI machinery safety expert and technical advisor, for a wide-ranging discussion about standards and regulations. To access the interview, search for unPACKed with PMMI on Apple Podcast, Spotify or wherever you listen to podcasts or click on pmmi.org/podcast/episode-121-managing-risk-pmmi-ansi-standard.

During this podcast, Main clarifies misconceptions about machinery standards, discusses PMMI’s latest standard update and recommends a new white paper as a resource to OEMs. Main starts by describing the difference between legal regulations such as from Occupational Safety and Health Administration or the E.U. and voluntary industry standards like ANSI/PMMI B155.1 Safety Requirements for Packaging and Processing Machinery

He emphasizes that machinery builders and users need to pay attention to the ANSI B155.1 standard since it outlines the required risk assessment process.

To round out the podcast, Main recommends that both OEMs and their customers use the white paper, 2023 The Impact of Global and Local Standards on OEMs & Suppliers, to learn more about current standards and their subsequent impact.

For more info, visit pmmi.org/podcast/episode-121-managing-risk-pmmi-ansi-standard. SD

ORBIS (BOOTH SU-8001) AND SPECRIGHT (BOOTH SU-7670) FOR SPONSORING THE PACK EXPO LAS VEGAS LANYARDS.

Shift to more responsible packaging

Portfolio offers recyclable, renewable, recycled-content options.

Many brand owners attend PACK EXPO to find technologies that minimize their environmental impact and meet their sustainability goals, but different products have different performance requirements. So, there is no single “best” packaging type.

This poses immediate challenges along the sustainability pathway. Consumers are demanding products and packaging that are better for the planet. But it can be hard to know where to start. For example, when considering more recycled content, producers are working to understand rapidly changing regulations and a wide spectrum of municipal recycling standards.

Amcor Flexibles North America and Amcor Rigid Packaging (Booth SU-7244, SU-7254) offer more sustainable options for all products, with on-demand, measurable and reportable data for 130 packaging comparisons to support sustainability goals and reporting. Attendees can take a deep dive into more responsible flexible and rigid packaging and find actionable steps to move forward. Its portfolio includes products that deliver recyclability for complex applications, new fiber packaging and higher recycled content across all packaging formats.

“While some materials have clear benefits, they may not be the right choice when you consider the full life cycle of the product,” says John Wilson, sus-

tainability director at Amcor. “Our R&D teams can help brands to design the best solutions for their packaging application.” To address sustainability needs, Amcor is exhibiting samples from its AmPrima™, AmFiber™ and AmSky™ portfolios:

• AmPrima recycle-ready substrates are designed to be recycled—if clean and dry—through existing store drop-offs or curbside, where available, and can include recycled content.

• AmFiber paper-based packaging is curb-

Flexible Automation TO IMPROVE YOUR THROUGHPUT SOLUTIONS

side-recyclable and meets the needs of dry mixes, confections and bars and is an alternative to polyethylene (PE) overwraps.

• AmSky recycle-ready thermoform blister packs are polyvinyl chloride- and aluminum-free, meet the Association of Plastic Recyclers (APR) Critical Guidance Recognition for the PE recycle stream and pass the APR high-density PE rigid recycle stream testing. For more info, visit amcor.com/afna. SD

Protect product quality

Inspection systems ensure only good products go out the door.

Fortress Technology (Booth C-4303) is presenting nine contaminant detection and inspection concepts so attendees can compare performance attributes, size and layout options. Applications include a wide range of food categories, such as bakery, bulk, meats, dairy, snacks, fresh produce, prepared foods and confectionery, as well

as ingredients, raw materials, pharmaceuticals and packaged items.

The company is introducing an x-ray system designed specifically for North American facilities. One of this year’s highlights, the Icon x-ray machine, is designed for high-care food production environments with advanced detection algorithms, superior

The PMMI Foundation would like to thank those who kicked off the show at PACK gives BACK

The money raised helped provide academic scholarships to six students pursuing careers in the packaging and processing industry.

THANK YOU TO OUR SPONSORS

TITLE SPONSOR:

BRONZE SPONSOR:

hygiene standards and multiple Industry 4.0 networking and data integration options.

Another notable machine, the Stealth large bag metal detector, is integrated with the new Fortress Raptor XL checkweigher. This combination helps eliminate costly returns and recalls for bulk manufacturers, suppliers and ingredient buyers.

To optimize factory floor space and accommodate faster upstream equipment, Fortress offers the three-lane Multi-Aperture metal detector. This unit is suitable for production facilities that release multiple products.

The Raptor checkweigher, which easily integrates with existing metal detection equipment, delivers dynamic weight monitoring to meet legislative weight rules with minimal customization on existing product feed and packing lines.

Fortress also is showcasing a side-by-side Interceptor metal detector configuration, offering an alternative approach to maintaining compliance with hazard analysis and critical control points requirements without installing two separate inspection lines. This configuration caters to bakery, dairy and meat producers and provides enhanced metal detection capabilities while addressing product and orientation effects simultaneously.

For more info, visit fortresstechnology.com. SD

Editor’s Note: The original version of the article was posted by Packaging World on July 6, 2023.

Lenze sponsors lounges

Once again, Lenze Americas (Booth C-4803) is sponsoring lounges for exhibitors and PMMI members at PACK EXPO Las Vegas. The lounges provide meeting space, seating, refreshments and a chance to take a break away from the busy show floor.

The Exhibitor Lounges are located in rooms S-215 and N-114. The two PMMI Member Lounges are located in rooms S-222 and N-101.

“Lenze Americas understands the significance of providing members and exhibitors with a dedicated space to rejuvenate amidst networking with attend ees at their booths. We take pride in our continued sponsorship of these lounges this year,” says Paul O’Connor, Lenze Americas.

“We are grateful to Lenze Americas for support ing this resource again,” says Jim Pittas, president & CEO, Processing Technologies (Central Lobby) nizer of the PACK EXPO family of trade shows.

Future Innovators

He explains, “This year’s industry growth and numerous new features at PACK EXPO Las Vegas will make the show floor incredibly busy. As a result, these lounges will be highly sought after by exhibitors and PMMI members as a valuable space to relax and network.”

The respite space will be especially welcome this year as the PACK EXPO Las Vegas show floor is expected to be extra busy with 30,000 attendees touring nearly 1 million sq. ft. of floor space to visit more than 2,300 exhibitors.

For more info, visit packexpolasvegas.com, lenze.com. SD

Students demo self-built robots

THE ‘BOTS ARE TAKING OVER PACK EXPO Las Vegas! SHOWCASE

Robotics teams from Las Vegas-area high schools are demonstrating the robots they have built along with design, engineering, assembly and troubleshooting skills at The Future Innovators - Robotics Showcase (Booth N-9769), sponsored by Bastian Solutions (Booth N-10343)

Demos are scheduled throughout each day of the show. Stop by to see what these teams have built, watch their robot in action, ask questions and tell the students about career opportunities in manufacturing and engineering.

Monday - Tuesday | 9:00 am - 5:00 pm

Located in the North Hall in Booth N-9769

Wednesday | 9:00 am - 3:00 pm

This annual event is designed to open doors for a new generation of packaging professionals and encourage participation in STEM studies. It’s one of many student-based activities at PACK EXPO Las Vegas, which also includes the winners of the 2022 PACK Challenge (Booth N-9026) from Waterford Union High School and the Amazing Packaging Race, which is sponsored by Emerson Discrete Automation (Booth SL-6107) and occurs on the final day of the show.

For more information about supporting student programs, visit the PMMI U booth at N-9000.

Produced by:

For more info, visit packexpolasvegas.com, bastiansolutions.com, emerson.com/en-us/industries/automation/ food-beverage. SD

35% metsagroup.com/metsaboard Come see Vegas-area high school students showcase their “bot skills”. Interact with the bright minds of the future and ask questions about their innovative robot designs.

Innovation Stages offer free educational sessions

The always-popular Innovation Stage program returns to PACK EXPO Las Vegas with four platforms: the Processing Innovation Stage (Booth N-10511) in the North Hall, plus three Innovation Stages (Booth C-2051, C-2058, C-2151) in the Central Hall. Exhibitors and subject matter experts will present more than 60, 30-min. sessions about the latest technology breakthroughs and best practices.

Topics range from automation, digitalization, artificial intelligence (AI) and cybersecurity to food safety, workforce challenges, sustainability and technology innovations. Highlights include sessions by WestRock (Booth C-2023) (sustainability), Syntegon Packaging Technology (Booth C-2800) (gloveless fill/ finish), Siemens Digital Industries (Booth SL-6351) (digital twins), Delkor

THE RISE OF POINTLESS AUTOMATION: FINDING VALUE IN ROBOTICS

10:00–10:30 AM

Innovation Stage 2 | C-2151

Robotic equipment is fascinating and exciting to watch but does not bring any value to your production processes unless it can run continuously in an unforgiving manufacturing environment. Learn how innovative robotic technology is improving automation aptitude of real manufacturing lines.

Bob BurkhardtRobotics Portfolio Mgr

R.A Jones, a Coesia company

MEET MARKEM-IMAJE’S SUPER PIEZO INKJET

10:00–10:30 AM

Innovation Stage 3 | C-2058

Super Piezo Inkjet guarantees a high level of coding excellence across different substrates while ensuring compliance with the strictest traceability regulations. Reproduce high-quality 2D barcodes at speeds up to 120m/min.