WWW.IRO.NL /MEMBERS 2023

Why Breman Machinery? DISCOVER THE SECRET OF OUR EQUIPMENT!

If you need critical steel components of extreme weight and huge dimensions, either a single piece or a small series, we at Breman Machinery get excited. It makes us happy to develop and deliver these components using extreme precision to ensure that they can withstand the heaviest loads imaginable. It enthuses us to steadfastly take on challenges that stagger others. The more complex the question, the more interesting we find it.

IF IT TAKES EXTREME PRECISION! Write to us: Postbus 135, 8280 AC Genemuiden, NL Give us a call: +31 (0)88 273 62 00 Send us an e-mail: info@breman-machinery.nl

IRO THE ASSOCIATION OF DUTCH SUPPLIERS IN THE OFFSHORE ENERGY INDUSTRY

The association IRO is an independent non-profit organisation that supports and promotes the interests of its 400 member companies. Acting as the gateway to Dutch suppliers in the offshore energy industry, the IRO mission is ultimately aimed at maintaining and strengthening the position of the Dutch Offshore Energy industry by creating a level playing field for its members.

The IRO members consist of a wide variety of both multinationals and SMEs. They represent the entire supply chain within the Oil, Gas, Offshore Renewable and Marine Energy industry, with activities covering: Engineering & Consultancy, Construction & Fabrication, Plant & Equipment Supply, Contracting & Installation, Exploration & Production and Personnel & HSE, both for offshore upstream oil & gas

and offshore renewables (wind, marine, tidal and floating solar energy). The range of services that IRO provides to its members varies from maintaining government & NGO relations and facilitating networking opportunities within the IRO community to participating in international trade missions and exhibitions as well as providing Business Intelligence and training courses.

CONTENTS

Advertisers Index 2 Company Index 3 Preface 5 Offshore Energy Transition 6 Design, engineering, research & consultancy 46 Construction, fabrication, shipbuilding & repair 52 Contracting, installation & transport 60 Equipment & materials supply 66

Personnel, training & education 76 Products & Services 78

IRO Members & their Activities 84

1 2023 NETHERLANDS SUPPLIERS CATALOGUE

ADVERTISERS INDEX

Alleima 59

AncoferWaldram Steelplates B.V. Back Cover

Breman Machinery B.V. Inside Front Cover BRIDGES2000 B.V. 9 DEKC Maritime 51 EY 4

Fugro 15 IRM Europe BV Inside Back Cover M Restart BV 75 Offshore Energy 75 PAT-Kruger 51 Quercus Technical Services 75 Sif Netherlands B.V. 29

Siri Marine 51 Vroon Offshore Services B.V. 35 Yellow & Finch Publishers 50

ADVERTISERS & COMPANY INDEX 2 NETHERLANDS SUPPLIERS CATALOGUE 2023

COMPANY INDEX

Abuco B.V. 53

Allseas Engineering B.V. 61

AncoferWaldram Steelplates B.V. 67

Assai Software Services B.V. 47

Atlas Copco Rental Nederland 67

Bayards Helidecks B.V. 53

BigLift Shipping / Spliethoff 61

Blue Offshore 74

Bluewater Energy Services B.V. 47

Boskalis 62

Breman Machinery B.V. 58

Bridges2000 54

Broekman Logistics 65

Combifloat Systems BV 65

Combifloat Systems BV 68

Damen Shipyards Group 54

DBR BV 68

De Haan Special Equipment BV 69

DEME Offshore 65

EQUANS 55

Fluiconnecto B.V. 69

Fugro N.V. 48

Geomil Equipment B.V. 70

Glomar Offshore B.V. 58

Gouda Holland BV 70

GustoMSC 48

Helder Infra B.V. 77

HSM Offshore Energy BV 55

Huisman 56

Iv-Offshore & Energy B.V. 49 Jumbo Offshore 62

Konutherm BV 74

Machinefabriek Heerbaart B.V. 56

Mokveld Valves 71

Mooreast Europe BV 71

M Restart BV 77

Multraship Ocean Towage B.V. 65

N-Sea 65

Offshore Marine Contractors BV 63

Orga BV 74

Phoenix Mecano B.V. 72

RBES B.V. 65

Saltwater Engineering B.V. 50 SDC Verifier 49

Sinus Jevi Electric Heating B.V. 74 Smitsvonk Holland B.V. 72

SMST 57

Smulders 57

Solidd Steel Structures B.V. 58 Taxand Netherlands 50

TrustLube B.V. 74

United Offshore Services C.V. 74

VandeGrijp IGS BV 58

Van Leusden B.V. 73

Van Meeuwen Lubrication 73

Van Oord Offshore B.V. 63

Vroon Offshore Services B.V. 64 Wagenborg Foxdrill 64

3 2023 NETHERLANDS SUPPLIERS CATALOGUE

How EY’s Offshore Energy team can help you

Decarbonization, digitization, cost pressures and geopolitical uncertainty are just some of the forces transforming the energy and resources industry. Oil and gas companies face a challenge: how to marry short-term commercial pressures with the need to reshape their businesses for the future. Companies must reshape to thrive in this new energy world. But how do you balance the immediate cost and regulatory pressures of “now” with investment in what comes “next?” EY’s Offshore Energy team brings together the breadth of experience and talent needed to approach the entire transformation process. By considering four key pillars of change — structure and culture, customers, technology, and skills and capabilities — we can help you adapt for today and reap the opportunities of tomorrow. And together we can build a better working.

Bruno Jelgerhuis Swildens bruno.jelgerhuis.swildens@nl.ey.com www.ey.com

© 2023 EYGM Limited. All Rights Reserved. ED None.

PREFACE CHALLENGING TIMES AHEAD FOR THE OFFSHORE ENERGY INDUSTRY

Due to geopolitical developments the international goals for lowering hazardous emissions to slow down the climate change are under siege. As a result many countries face inflation and economic downturn partly due to high and volatile costs for energy.

The Offshore Energy Industry plays a crucial role in the energy transition process. It can support a controllable transition process: it provides security of supply of the required energy, builds wind energy farms and supports new innovative renewable energy sources.

The Offshore Energy Industry can help countries to be more self sufficient in oil and gas supplies in order to support smooth next steps in the energy transition process. Many countries are still depending on oil and gas for their energy supply.

Although we still rely on conventional energy sources we must realise that investors are stepping away from conventional energy faster and more massively under social pressure and responsibility to make their portfolio more sustainable. A difficult position since we still rely on conventional energy sources to offer security of energy supply worldwide. Nonetheless, our members have faced many challenging situations and always found a way to rise the challenge.

The Dutch offshore industry has been one of the top five in the world for more than fifty years. This position is due to a strong cluster of suppliers. Innovative companies are commissioned by the major energy companies to build, transport, maintain and clean up platforms, transformer stations and wind turbines after use. They play already an important role in the current energy transition, which is largely being realised at sea.

IRO believes that the Dutch offshore industry will remain a major player in the global offshore market, in particular through the use of smart techniques and solutions for the many issues concerning the offshore energy transition.

Great opportunities and challenges lie in making processes more sustainable. Ships can sail cleaner, on LNG and later perhaps also methanol or hydrogen. In addition, platforms and activities at sea can be made even more efficient and environmentally friendly.

How do we see our future? The IRO members are flexible and seize the opportunities that arise. It doesn’t matter what needs to be done at sea, the IRO members will get it done.

Therefore we are proud to present to you the Netherlands Suppliers Catalogue 2023, which gives a clear overview of the activities, products and services of our innovative Dutch offshore energy suppliers. Our members look forward to working with you!

Sander Vergroesen Managing Director

IRO - The Association of Dutch Suppliers in the Offshore Energy Industry www.iro.nl

5 2023 NETHERLANDS SUPPLIERS CATALOGUE

INTERVIEW WITH THE NEW CHAIRMAN OF IRO: MARK HEINE

HIS VIEW ON THE STATE OF AFFAIRS, CHALLENGES AND FUTURE OF THE DUTCH OFFSHORE ENERGY INDUSTRY

The starting point is people, planet, profit (or, better still, prosperity). On many of the main climate conferences organised in the world, the often-heard catch phrase is: “If you want to go green, you have to go blue.” The marine environment isn’t just a source of energy, it also offers endless possibilities for transport, infrastructure, and food. The growth potential is enormous, and the Dutch offshore industry sits front row to help develop this next big frontier.

What is in your view the state of affairs of the offshore energy industry?

The offshore energy industry is a vibrant and innovative sector with a clear “we can do it” mentality. Operating strongly across borders, all sector players have to deal with international developments. We play a part in some of the major societal themes of our time, like energy security, development of renewable energy sources and climate change adaptation. The sector is well-equipped to drive positive change. Due to the awful war in Ukraine and geopolitical developments we face unprecedented impact on energy supply and security of energy supply. Both can’t be taken for granted anymore and will remain important themes in the upcoming years. The costs of energy will rise.

As a result, the world faces economic downturns, inflation and insecurity of energy supply. The IMF predicts that the global GDP will slow down from 6% to less than 3% in 2023. IMF also predicts that the inflation rate will be at least 9%, and in some countries (especially European countries) even more. Costs will rise and it will probably continue for some years. We have to deal with these challenges and speed up. Besides these global economic challenges there are challenges to reduce carbon emissions to stop climate change. The energy transition is one of the major initiatives to limit CO2 emissions.

The offshore energy industry is an important player in the energy transition. Offshore wind, hydrogen and tidal energy will be important renewable energy sources. Hydrogen and marine energy are in initial phases and not yet major energy suppliers as offshore wind farms already are. Wind at sea is the current star. The sector will grow from 2023 onwards with more than 20% per year! Hydrogen is currently a small market; globally 8-10 billion euro in investments. Experts expect that it will double in the upcoming years. So, the future is bright for the offshore energy industry. For sure when we consider that in 2050 more than 75% of the global renewable energy will be produced by renewable energy sources like wind at sea.

What are the challenges of the Offshore Energy Industry with regards to the energy transition? The energy transition has many challenges, offshore and onshore. For instance, the onshore energy grid needs to be expanded. Some 16,000 engineers are needed for that. Will we be able to attract and train enough qualified personnel? The Netherlands aims to generate 4.5 GW from offshore wind farms in 2023. In 2030 this should be expanded to 21 GW. Can we build these wind farms in fast-track mode? Yes, we can. But can the offshore wind energy be optimally used in the current grid on land? Not

6 NETHERLANDS SUPPLIERS CATALOGUE 2023

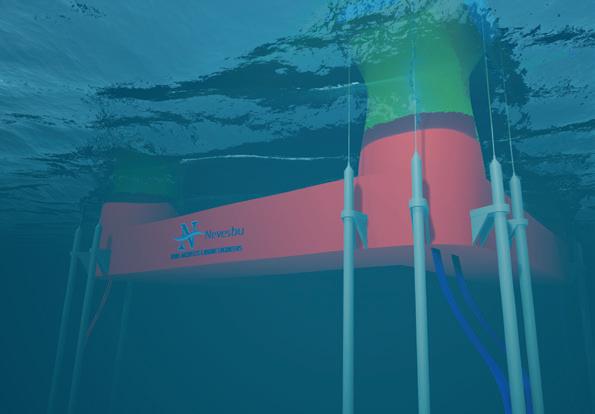

Mark Heine, IRO Chairman & CEO Fugro. Image courtesy of Fugro.

all already,

clear net zero

just yet, it seems. Furthermore, the new wind farms need to be maintained. We need extra qualified personnel for that. And the Netherlands is not the only country working on energy transition. For direct and daily import and export of energy many countries are intertwined. So, the energy transition is not just a national issue. It can’t be solved locally. We must cooperate. On national level and regionally between countries, and certainly between companies too. As many companies in the offshore energy industry operate internationally, we are used to collaborating with all kinds of partners. We love to bring in our expertise, knowledge, and international network.

A nice example is the current cooperation between Denmark, Germany, and the Netherlands to develop energy hubs to create a smart and efficient energy distribution system. Like many industries the offshore energy industry face a shortage of qualified technicians. By the way this counts for the whole maritime cluster. The offshore energy industry is changing rapidly. It is not only

oil and gas. It is much more. The offshore energy industry contains wind farms, hydrogen, solar energy, maritime energy but it also contains supply of critical raw materials for the purpose of the energy transition. Due to these developments the work in the offshore changes rapidly. To fulfil these great new challenges the sector needs qualified technicians. Newly educated technicians but also lateral inflow of technicians from other industries.

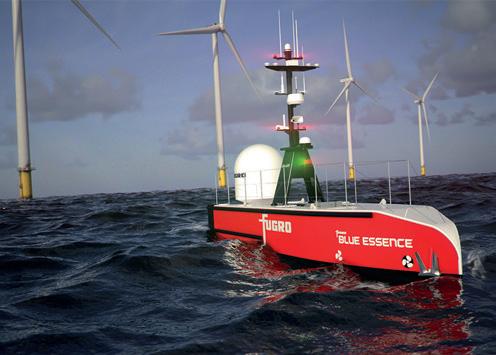

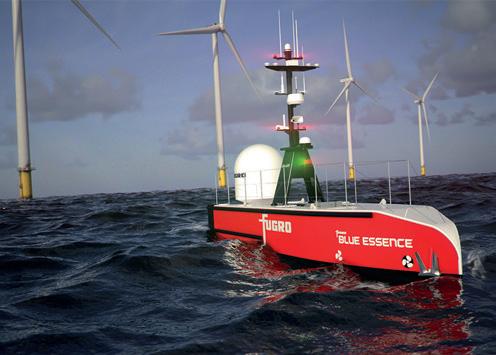

Another challenge is to expand and transform the fleet needed for the operations at sea. This transformation focuses on two main objectives: sustainability and cost efficiency. All our members are taking these two objectives constantly into account. My own company Fugro took uncrewed surface vessels in operation. These vessels don’t require personnel on board and can help to reduce carbon emissions by up to 95%. Another example: Van Oord ordered an offshore installation vessel that will be powered by methanol, so a lower CO2 footprint, and that, at the same time, can install huge 20 MW offshore wind turbines!

7 2023 NETHERLANDS SUPPLIERS CATALOGUE

Wind farms placed further out to sea demand efficient transport of energy over longer distances. Image courtesy of IV-Groep.

“Most of the companies in the industry, if not

have

ambitions. I’m certain we are going to achieve our goals. We must.”

What are the main opportunities of the offshore energy transition?

The price of oil rose more than 40% (Brent-price) compared with last year and gas almost two-thirds. This means that investing in offshore rigs is interesting again. We still need oil and gas. However, their role in energy supply will decrease. Other forms of energy supply like wind energy and hydrogen will increase as said. I already mentioned that the growth of the global wind energy business will be at least more than 20% annually. In the meantime, other offshore energy solutions will become part of the energy mix, like hydrogen and maritime energy. Currently wind farms are being placed further and further out to sea. This demands efficient transport of energy over longer distances. This is why energy hubs in sea will become crucial. As mentioned, Denmark, Germany and the Netherlands cooperate to develop such offshore energy hubs. Others are planning to follow. So not only building all necessary installations and infrastructure is good for the long-term perspective but also the rising demand for maintenance.

How would you describe the main characteristics of Dutch offshore energy industry?

I will use only four words to characterise the whole sector: sea, innovation, enterprising and cooperation. You will find these four characteristics in every company in the offshore energy industry. An ideal set of values to make things happen at sea. We’re entrepreneurial and continue

to join forces to innovate and tackle any challenge our clients have in marine environments. Many have forgotten that the IRO once started as the Industrial Council for Oceanology, an organisation that brought together in-depth knowledge of mining, coastal waters technology, fishery and oceanological technology. That knowledge still sits with our members and fits perfectly with the future.

How would you describe the ideal role of IRO in this current turbulent and complex environment? IRO has been there for more than 50 years. Over the decades it developed into a strong network organisation and an important export promoter for its members. I believe there’s an opportunity for the industry to increasingly become a conversation partner for the government, NGOs and other stakeholders. As the association of Dutch suppliers in the offshore energy industry IRO is the ideal interlocutor for the Dutch government and EU. IRO and all its members can be a source of knowledge and new ideas. Together, we can come up with good solutions for the energy transition, for infrastructure, for the protection of the natural environment and everything else for which we need the sea. The starting point is people, planet, profit (or, better still, prosperity). On many of the main climate conferences organised in the world, the often-heard catch phrase is: “If you want to go green, you have to go blue.” The marine environment isn’t just a source of energy, it also offers endless possibilities for transport, infrastructure, and food. The growth potential is enormous, and the Dutch offshore industry sits front row to help develop this next big frontier.

Sustainability is the future. What is in your view the future of the sector?

As I stated earlier the energy offshore industry is going through a transformation. All our members embrace sustainable development. They all work in their field of expertise and businesses to develop sustainable products and services. For instance, our sector is working together on sustainable propulsion systems for vessels, based for example on methanol. This will have a great impact on lowering carbon emissions. We will also further development of remote operations and more application of robotics. This will help to create faster and safer operations at sea, whilst at the same time reducing carbon emissions with lighter assets and less emission-heavy transport of people.

Most of the companies in the industry, if not all already, have clear net zero ambitions. I’m certain we are going to achieve our goals. We must. The future is bright.

8 NETHERLANDS SUPPLIERS CATALOGUE 2023

+31 (0)10-820 1770 - info@bridges2000.com FENDERS GANGWAYS MULTICATS INNOVATIONS PONTOONS BRIDGES -We deliver, fast, safe and fit for purpose -

safety

supplying

gangway connections. Connections

safe

they

today

Creating Connections Safe BO OFFSHORE GANGWAY FULL SERVICE: We do the engineering production and installation ourselves. This way the highest possible safety can be guaranteed. FAST DELIVERY: Need a solution quickly? We might even deliver in the same week. IN-HOUSE PRODUCTION: We produce fast, safe and always fit for purpose.

In a world constantly on the move,

at the highest level isn’t a luxury, but a necessity. Bridges2000 contributes to that safety by building and

reliable bridges and

that ensure people’s

movement from one world to another during their work. So that at the end of the day (shift)

can safely return to that important world of home. Solutions for

and tomorrow.

ENERGY TRANSITION TO GATHER PACE IN EUROPE WHILE THE REST OF THE WORLD LAGS, DNV FINDS

Europe, which can be regarded as the leader of the energy transition, will double down on renewables and energy efficiency to increase its energy independence, with the European gas consumption predicted to fall dramatically as a result of the war in Ukraine, DNV said in its latest energy transition outlook. Compared to last year’s forecast, DNV sees the continent consuming almost half the amount of natural gas in 2050. Gas will meet just 10% of Europe’s energy demand in 2050 compared with 25% today, according to the report. In contrast, lower-income countries, where cost is the main driver of energy policy, are predicted to see a different trend. High energy and food prices are reversing the coal-to-gas switch and putting a dampener on decarbonization investments, DNV finds. More broadly, inflationary pressures and supply chain disruption pose a short-term challenge to renewable growth, according to DNV.

Renewable energy production as driving force of energy transition

However, the impact of the current crisis on the overall energy transition is outweighed by the plunging costs of renewables and increased carbon costs in the longer term, DNV said. Growing and greening of electricity production remains the driving force of the transition, with renewables accounting for 83% of electricity production by 2050, DNV predicts. “The turbulence in the energy market does not

dramatically alter the decarbonization pathway towards midcentury,” said Remi Eriksen, president and CEO of DNV. “The strongest engine of the global energy transition is the rapidly reducing costs of solar and wind energy, which will outweigh the present short-term shocks to the energy system.”

Non-fossil energy to reach over 50% of the global energy mix

by 2050

For the first time, DNV’s forecast sees non-fossil energy nudge slightly above 50% of the global energy mix by 2050, mainly because of the growing and greening of electricity production.Electricity production will more than double and its share will grow from 19% to 36% of the global energy mix over the next 30 years. Solar PV and wind are already the cheapest form of electricity in most locations and by 2050 they will grow 20-fold and 10-fold respectively and will dominate electricity production with 38% and 31% shares, respectively, DNV predicts. Renewables expenditure is expected to double over the next 10 years to more than $1300 billion per year, and grid expenditure is likely to exceed $1000 billion per year in 2030.

Oil to start declining sharply from 2030 onwards Oil has been approaching a plateau for some years and it will start to decline sharply from 2030 onwards, according to DNV. As a consequence of the war in Ukraine, global gas consumption will also be lower than previously forecast. Before the war, DNV forecast natural gas would be the single largest energy source by the end of this decade, but this has been delayed to 2048. In addition, DNV has found that the short-term increase of coal consumption will not prevent it from rapidly exiting the energy mix with its peak back in 2014.

Maritime sector needs to reduce emissions by 95% by 2050

Alongside the ‘best estimate’ forecast for the energy transition the outlook this year also includes the Pathway to Net Zero, which is DNV’s most feasible route to achieving net zero emissions by 2050 and limiting global warming

10 NETHERLANDS SUPPLIERS CATALOGUE 2023

The heightened focus on energy security and the rising cost of energy is reinforcing the difference in decarbonization speed between Europe and the rest of the world, according to the sixth edition of DNV’s Energy Transition Outlook.

Three World’s non-fossil energy forecast by source Image courtesy of DNV.

to 1.5°C. According to the pathway, reaching net zero globally in 2050 will require certain regions and sectors to go to net zero much faster. OECD regions must be net zero by 2043 and net negative thereafter; with carbon capture and removal enabling negative emissions. China needs to reduce emissions to zero by 2050 rather than the current goal of 2060, according to DNV. Some sectors like electricity production will need to reach net zero before 2050, while other sectors like cement and aviation will still have remaining emissions.

Crucially, DNV’s net zero pathway states that the maritime sector needs to reduce emissions by 95% by 2050. Also, no new oil and gas will be needed after 2024 in high income countries and after 2028 in middle- and lowincome countries, according to DNV’s Pathway to Net Zero. Investments in renewables and grid need to scale much faster; renewables investment needs to triple and grid investment must grow by more than 50% over the

next 10 years, DNV states. In addition, DNV’s Pathway to Net Zero points out the need for much greater policy intervention than we see today as the planet still remains on course to warm by 2.2°C by 2100, noting that global CO2 emissions reduction of 8% every year is necessary to reach net zero by 2050. The full policy toolbox must be unpacked, including: higher carbon taxes and subsidies, stronger mandates, bans and financial incentives to encourage renewables to replace fossil fuels, and smarter regulation and standards.

“With COP-27 approaching, it is important that policymakers recognize the huge opportunities inherent in decarbonizing the energy mix in light of the mounting costs of climate change impact. The technology exists to achieve net zero emissions by 2050, but for this to happen we must utilize the scope of the policy toolkit,” Eriksen concluded.

Source: www.offshore-energy.biz

11 2023 NETHERLANDS SUPPLIERS CATALOGUE

8 DNV Energy Transition Outlook 2022 9 Highlights 2015 2020 2025 2030 2035 2040 2045 2050 2036 Feedstock use of fossil fuel peaks 2033 Wind overtakes hydro 2040 Seaborne container trade exceeds crude oil trade 2044 Every third commercial vehicle on the road is electric 2034 Maritime energy demand peaks 2033 Half of all passenger vehicles sales electric 2014 Coal peaked 2025 Oil peaks Highlights of our forecast energy transition to 2050. The green slope represents the share of non-fossil energy sources in the energy mix. **Average primary energy used for production of H & derivatives. *Energy peaks not to scale relative to primary energy 2036 Natural gas peaks 2036 Primary energy supply peaks 2041 Final energy demand peaks 2.2ºC warming by 2100 2030 Transport energy demand peaks 2047 CCS captures 5% of global energy-related CO2 emissions 2038 Nuclear peaks 2020 COVID-19 drop-off, removing 6% of energy demand 2043 Half of world’s road vehicles electric 2044 Electricity use doubles relative to 2020 2050 Hydrogen 5% of energy demand 2041 Manufacturing energy demand peaks 2022 PV installations 1TW 2018 Energy demand for space heating peaked 2029 1.5 C carbon budget exceeded COP15 Paris Agreement 2056 2 C carbon budget exceeded Hydrogen Maritime non-fossil Maritime fossil Energy transitions sea Energy peaks Non-fossil share Energy milestones Energy transitions 20% of energy mix non-fossil 51% of energy mix non-fossil ENERGY TRANSITION TIMELINE -6% 2045 Solar PV 35% of power supply 2042 Wind 30% of power supply

“The strongest engine of the global energy transition is the rapidly reducing costs of solar and wind energy, which will outweigh the present short-term shocks to the energy system.”

DNV’s energy transition timeline. Image courtesy of DNV.

NEXSTEP FOR NEXSTEP COLLABORATION IS ONE OF THE GUIDING PRINCIPLES FOR OUR ACTIVITIES

Nexstep, the National Platform for Re-use & Decommissioning presented its fifth Re-use and Decommissioning report with the title “The power of collaboration” in July 2022. A title that fits the Nexstep concept so well since collaboration became the guiding principle for our activities within Nexstep.

And Nexstep has shaped that collaboration with the heavy lift contractors that led to the offshore installation portal, in the joint pilots for Through Tubing Cementation, in the joint search for the hydrogen pilot, in the collaboration with the pipeline operators NOGAT and NGT for the development of the comparative assessment et cetera.

After years of preparation the joint campaign contract for decommissioning of Mud Line Suspension wells was awarded in January 2022. This ‘Road to joint execution’ is not only a major achievement for Nexstep but also a breakthrough being the first project worldwide in which so many operators will jointly decommission wells. A perfect example of Nexstep’s role in facilitating and stimulating effective and good value decommissioning. This joint

campaign will not only lead to optimal opportunity for learning and improvements as well as major cost savings along the way.

As Nexstep continues to provide transparency to the service industry and the public on the decommissioning of wells, installations and pipelines our factsheet states that of the 34 platforms which have been removed, 15 were re-used for hydrocarbon production. In addition to re-using oil and gas platforms on other locations for the same purpose, infrastructure may be repurposed. It is estimated that some 10% of the infrastructure may be re-used/ repurposed. Some current repurposing projects: - PosHYdon pilot: productions and transportation of green hydrogen on Neptune Energy’s Q13a-A platform

12 NETHERLANDS SUPPLIERS CATALOGUE 2023

Image courtesy of Nexstep & Damen Shipyards Group.

- Storage of CO2: Porthos / Aramis

- GZI Next: NAM’s repurposing of onshore gas treatment installation to new energy hub in Emmen

Since the beginning of Nexstep we have organised shared learning sessions and the database now contains over 360 learnings. Shared learnings are valuable to the industry. Operators have embraced the shared learnings sessions during which the do’s and don’ts of executed projects are being discussed. In 2021, Nexstep launched a new initiative to promote collaboration for upcoming projects which resulted in the first Peer Assist that took place in

May 2021. Two Peer Assists have been held in 2022 on planned offshore projects and more will be scheduled.

The service industry is essential in developing new technology to improve the efficiency of decommissioning activities. Of special interest are innovative removal techniques for offshore installations, well decommissioning and pipeline cleaning and removal. As of 2020, IRO has been part of Nexstep’s Supervisory Board in the person of Sander Vergroesen as an observer.

More information at www.nexstep.nl

DUTCH MARINE ENERGY CENTRE

Marine energy provides a vast potential for supply contractors, offshore energy companies, utility operators as well as remote applications. For the majority of applications, the energy generated from waves, tidal streams or different levels of either salinity or temperature is complementary to other offshore energy sources.

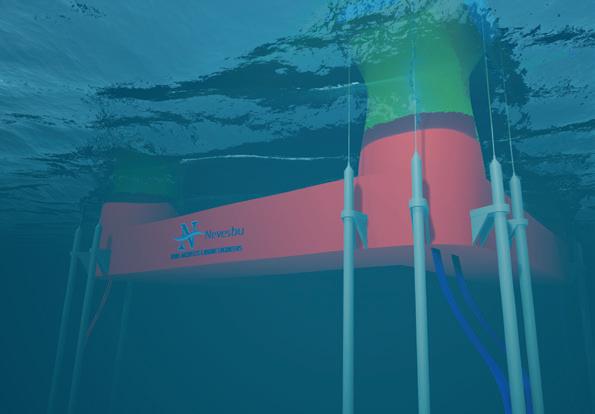

Moreover, additional benefits range from being predictable well in advance to being always available providing a constant power supply to offshore equipment offers collaboration opportunities with the oil & gas industries. The production of offshore hydrogen transforms renewable energy into a green energy carrier that can be used for chemical industry, as a fuel or stored and converted back into electricity. And finally, the co-location with offshore wind can not only increase the amount of energy harvested from marine space but also increase the capacity factor of cables and subsequently the base load of offshore renewable energy parks.

To realise solutions for all these applications, Dutch Marine Energy Centre (DMEC) is accelerating marine energy development in Europe and beyond. Our activities are focussing on managing technical innovation challenges, maturing investment readiness, exploring new markets and securing policy support. To offer broad expertise, our team collaborates with a large network of research institutes, test sites and engineering consultancies. In addition, we assist corporates in understanding the strategic position marine energy can have in their

13 2023 NETHERLANDS SUPPLIERS CATALOGUE

business, gain access to the key public and private actors in the sector and become a key player in the market. All these activities are bundled together in our Corporate Partnership Program.

Corporate Partnership Program

Within our Corporate Partnership Program, we enable companies to integrate marine energy in their business strategy by offering services including:

- Market entry to the sector, in which we provide the opportunity for you to: Engage with the Marine Energy Community; Work together with marine energy technology developers and corporations; Connect to offshore renewable testing facilities and public sector actors; Get invited to marine energy events throughout the year.

- Deepdive/feasibility study where we can use our extensive expertise in the sector to: Assess marine energy resources and identify locations for marine energy parks in a specific region; Analyse marine

energy electricity output, economics and spatial planning; Develop specialised market use case (oil & gas, aquaculture, islands); Identify top performing marine energy developers.

- Brand positioning, where we make our network available to you to: Communicate your company’s marine energy strategy; Release joint press statements and news posts; Communicate about your company’s involvement within the sector in our media outreach; Provide you with speaking opportunities at leading sector events.

Get in touch

For more information about the Corporate Partnership Program or to learn more about engagement opportunities with the marine energy sector please contact Yuki Esser, yuki@dutchmarineenergy.com or Koen Donkers, koen@dutchmarineenergy.com.

More information at www.dutchmarineenergy.com

RENEWABLE INVESTMENTS GROWS

OFFSHORE INDUSTRY FORMS DECARBONIZATION TIE-UPS, AS NEED FOR MORE RENEWABLE ENERGY INVESTMENTS GROWS

Despite the projections stating the global energy investments are to reach $2.4 trillion this year, much more is still needed to successfully tackle the issues of energy security and climate crises globally. On the other hand, the offshore industry – including energy and maritime sectors – is wasting no time waiting for favorable political action, but is increasingly entering into various collaborative projects to make the netzero ambition a reality for us all.

According to the International Energy Agency’s (IEA’s) report, the current levels of capital spending are still far from sufficient to tackle the energy and climate crises, which are currently permeating the world. Even though global energy investment is set to increase by 8% in 2022 to reach $2.4 trillion, with the anticipated rise focused mainly on clean energy, this is still expected to fall short of delivering solution to the multiple dimensions of today’s energy crisis. Fatih Birol, executive director of IEA, said: “We cannot afford to ignore either today’s global energy

crisis or the climate crisis, but the good news is that we do not need to choose between them – we can tackle both at the same time. A massive surge in investment to accelerate clean energy transitions is the only lasting solution.”

The same is true for Europe specifically, according to independent energy markets information provider S&P Global Platts, which forecasts the EU will need at least 150GW of renewable power to meet its green hydrogen goal, and to successfully phase out Russian fossil fuels and speed up the energy transition. Most of this additional renewable generation capacity will be wind and solar, S&P Global finds. Sector-specific associations have also warned that Europe needs to step up its efforts to increase its renewable energy-generating capacity, with the latest call coming from Ocean Energy Europe. Namely, the association deemed the implementation of EU’s Offshore Renewables Strategy as ‘sluggish’ to date, noting also that the secure, decarbonized and affordable energy is a top EU priority which should be reflected in the

14 NETHERLANDS SUPPLIERS CATALOGUE 2023

UNLOCKING INSIGHTS FROM GEO-DATA FOR A SAFE AND LIVEABLE WORLD For more information visit fugro.com

timely enactment of the strategy. Ocean Energy Europe has therefore created an action plan for EU institutions, designed mainly to streamline the funding available for ocean energy, and to ensure the EU meets its 100MW ocean energy deployment target by 2025.

Offshore wind to boost decarbonization of shipping and aviation sectors

Offshore wind is expected to be one of the major contributors of renewable energy to diversified future power grids, with the sector expanding into other clean energy areas. Namely, a new 2GW floating wind farm is planned to be developed offshore Ireland, that would produce green fuels such as hydrogen and ammonia. The project is proposed by the Killybegs Fishermen’s Organisation and Sinbad Marine Services, which have entered into collaboration with the Swedish floating wind developer and technology provider, Hexicon, to bring it to realization. The green fuels could be used to power the fishing fleet whilst also contributing to energy security for the port and local community, while the remaining energy produced by the floating wind farm would be connected to the national grid and contribute to Ireland’s target of 5GW from offshore energy by 2030.

Hydrogen-powered vessels will definitely play a major part of sustainable shipping industry of the future, but they will also be an important part of autonomous surveys and offshore monitoring operations. Just this week, the classification society Lloyd’s Register issued an approval in principle to clean maritime startup ACUA Ocean for what it’s said to be the world’s first zero-emission hydrogen-powered maritime autonomous surface ship. The vessel is powered by 6,000 liters of liquid hydrogen, which is expected to result in increased power, reliability and endurance and deliver on the UK Maritime Strategy climate change commitment to zero-emission propulsion by 2025. Sky is the limit for offshore wind, it appears, with the latest collaboration announced by Vattenfall and St1 who have joined forces to develop a fossil-free value chain for production of synthetic electro fuel from offshore wind. As part of the partnership, Vattenfall will develop an offshore wind power-based hydrogen supply infrastructure on the west coast of Sweden, while St1 plans to produce

one million cubic meters of electro fuels, primarily targeted for sustainable aviation fuel, using the green hydrogen. Such volumes equal, for example, the annual aviation fuel demand of Arlanda airport, Vattenfall said.

Carbon capture and storage as major part of energy transition puzzle

In pursuit of initiatives to reduce greenhouse gas emissions and accelerate the decarbonization, carbon capture and storage (CCS) has been identified as one of the ‘essential’ areas. The Netherlands is making great strides to exploit this space, as shown by the Netherlands Authority for Consumers and Markets (ACM) which gave an approval to competitors Shell and TotalEnergies to collaborate on CO2 storage in empty natural-gas fields in the North Sea. Shell and TotalEnergies plan to store CO2 on a large scale as part of the Aramis project, and in collaboration with the government entities Gasunie and Energie Beheer Nederland (EBN), build a high-capacity trunkline that connects to empty gas fields, among other activities.

Aramis is one of two planned carbon capture projects in the Netherlands, with the second being Porthos – Port of Rotterdam CO2 Transport Hub and Offshore Storage. Other European countries are not falling behind either, as Belgian LNG terminal operator Fluxys and Norwegian energy giant Equinor agree to develop a major CCS infrastructure project connecting Belgium to Norway. Even though it is still in the feasibility phase, with an investment decision expected by 2025, the project will allow the transport of captured CO2 from emitters to safe storage sites in the North Sea.

Norway has also been the focus of larger energy cooperation agreements with the EU this week, with the signing of a new deal set to deepen the long-term energy partnership between the parties. Norway and the EU pointed out the importance of the European energy market as ‘the main export market’ for the Norwegian oil and gas sector, and future potential for cooperation on offshore renewable energy, hydrogen, and CCS, driven by ambitious EU objectives under REPowerEU Plan.

Source: www.offshore-energy.biz

16 NETHERLANDS SUPPLIERS CATALOGUE 2023

“We cannot afford to ignore either today’s global energy crisis or the climate crisis, but the good news is that we do not need to choose between them – we can tackle both at the same time”

CHALLENGES AND POTENTIAL OF OFFSHORE SOLAR

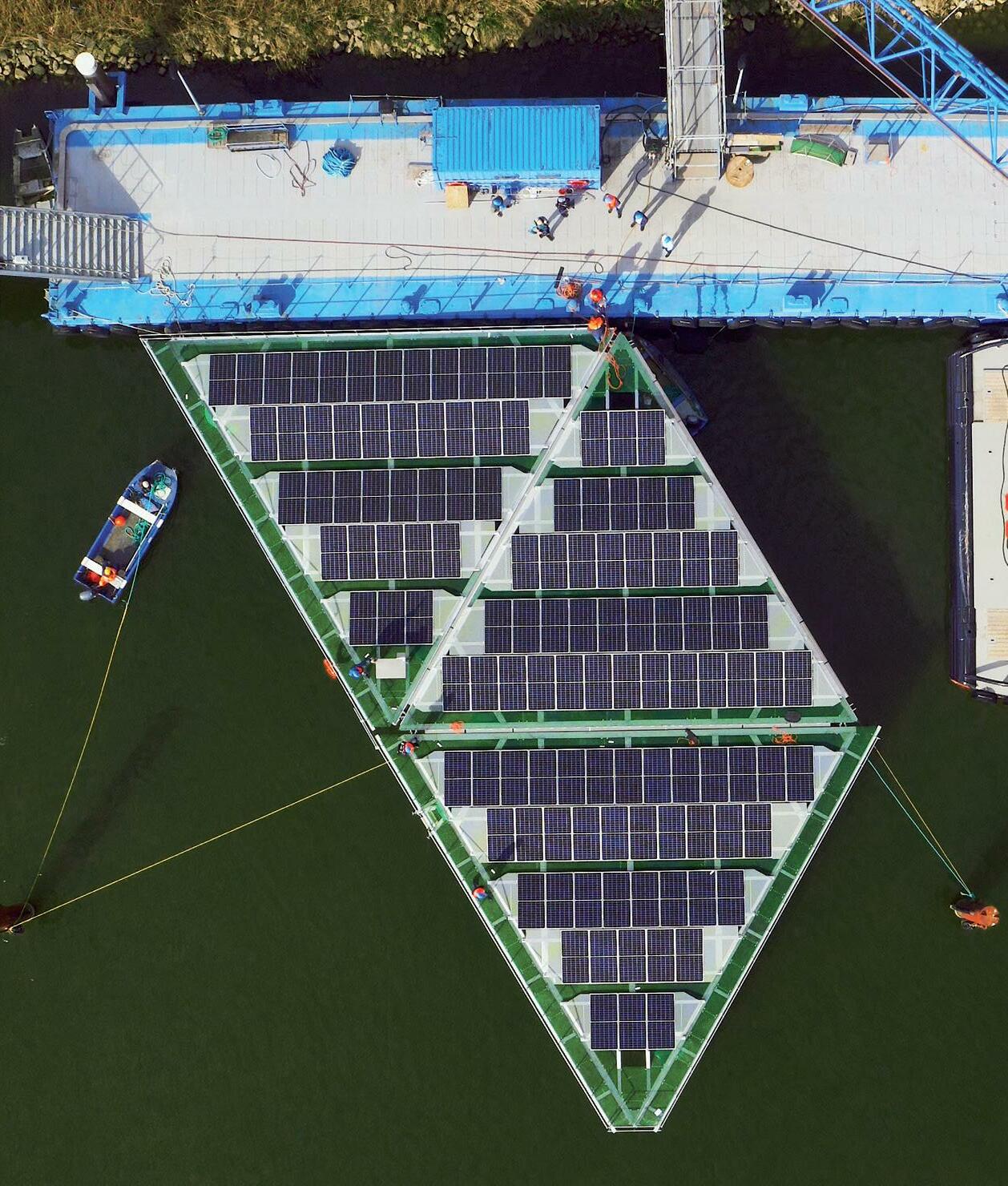

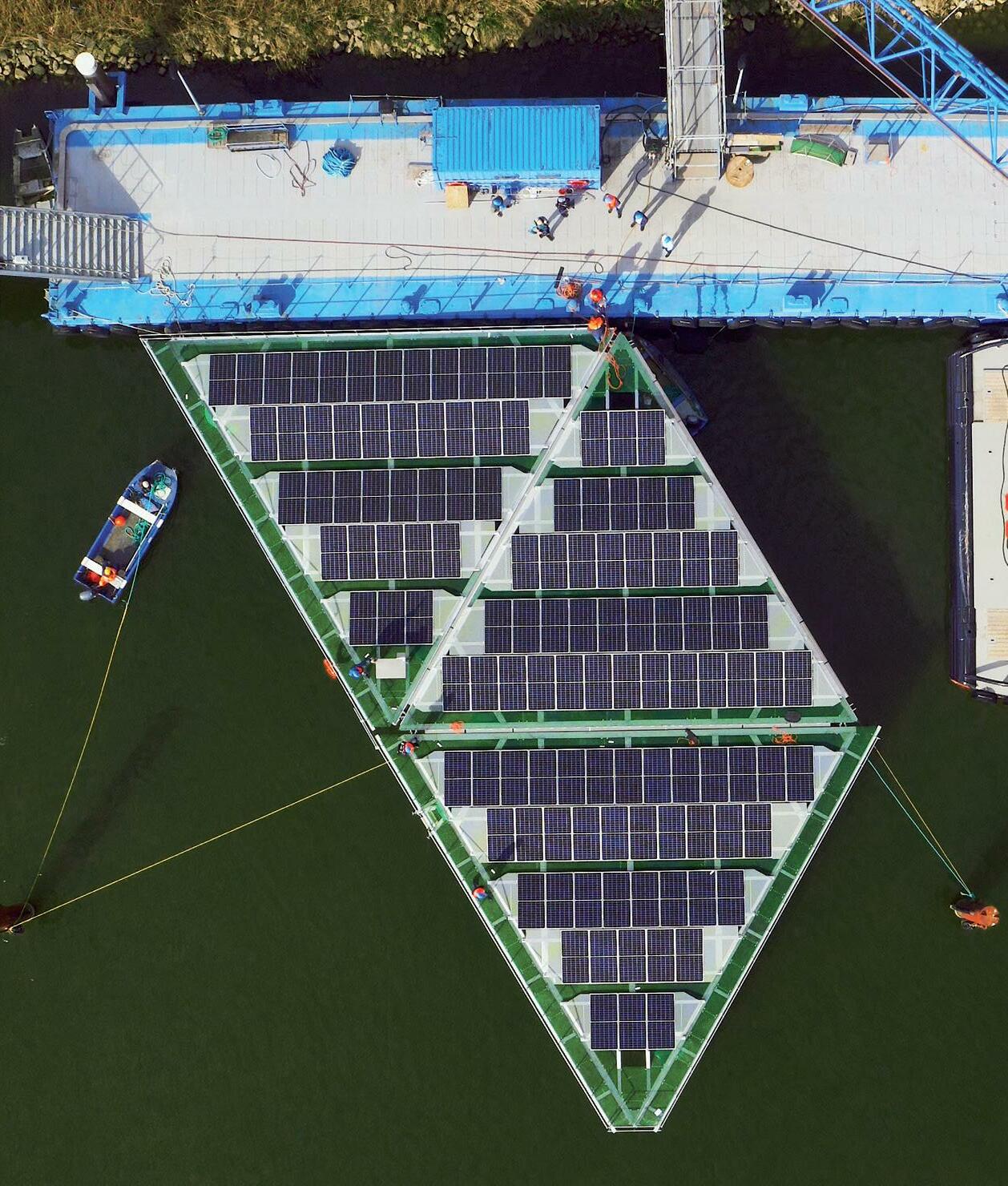

In the past few years, there has been an increasing interest in the development of offshore floating solar power plants. The technology has a very large power generation potential, in particular in the areas used by offshore wind farms.

In some scenarios, 45GWp solar power in the Dutch part of the North Sea has been projected in2050. The Dutch Roadmap Solar on Water concludes that in ten to twelve years, large scale application of offshore solar on the North Sea could offer possibilities, but it also expresses major concerns about the technical and economic challenges of offshore floating solar systems.

Perspective

Significant innovation in this field by commercial enterprises will only be undertaken if there is enough perspective for a profitable business case in a large market. This is only possible if are likely to be solved and costs can be decreased considerably. Nevertheless, several companies (especially in the Netherlands and in Norway) started investing in system developments that may lead to feasible and affordable solutions for offshore solar. Based on this, some smaller scale pilots have been established or are planned.

CO2 free

There are substantial technological challenges to build and operate floating solar systems in a harsh maritime environment, with wave heights up to 15m. At the same time, there are major challenges on system design, O&M schemes, grid connection and cost. The Dutch top sectors strengthen the economy through innovations that target to help solving important societal challenges such as the energy transition. In this approach the societal and economic goals go hand in hand. Recently, this has substantiated in so called missiondriven innovation. For the energy transition thirteen multiannual mission-oriented innovation programs (MMIP’s) have been formulated, and MMIP 1, titled ‘Renewable electricity at sea’, has the goal to contribute to the mission ‘A CO2 free electricity system in 2050’.

For the development of the MMIP 1 program, a further analysis of the challenges related to offshore floating solar

17 2023 NETHERLANDS SUPPLIERS CATALOGUE

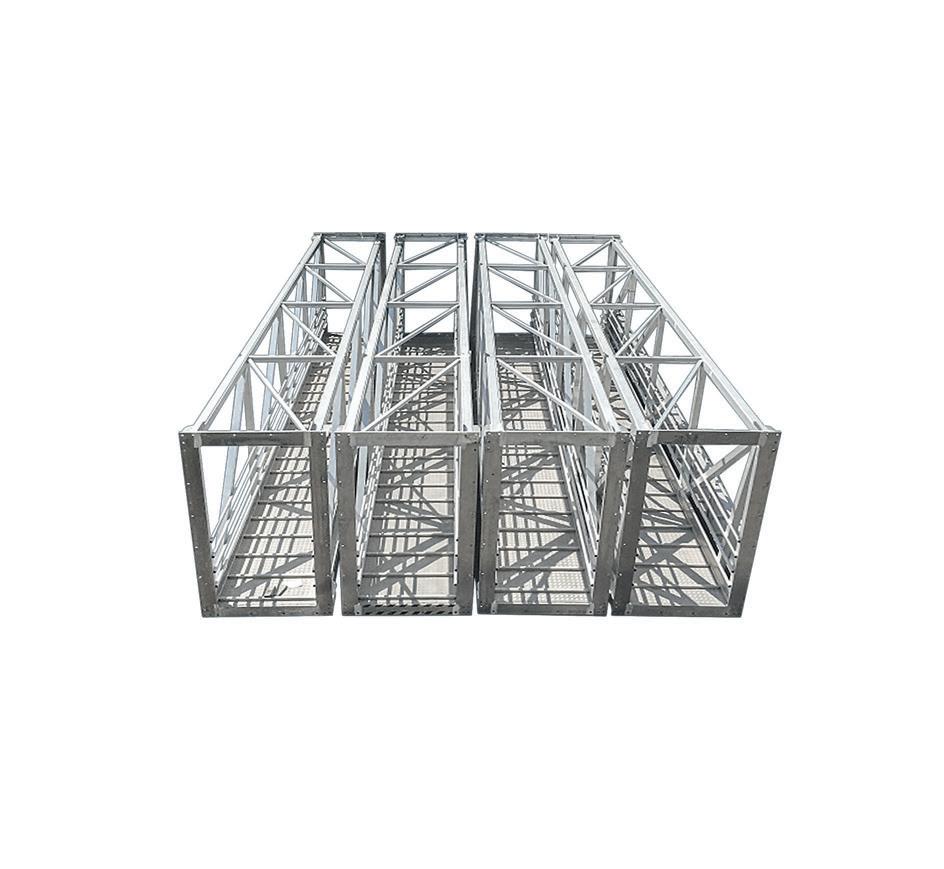

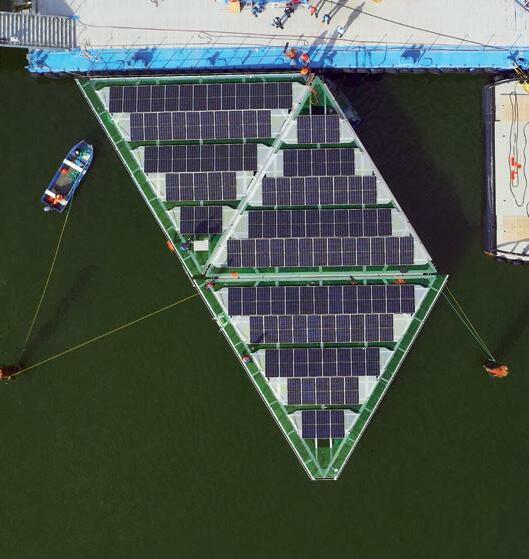

SolarDuck offshore solar truss concept. The platform is located on a certain height above the waterline. Waves can move underneath the truss structure. Image courtesy of SolarDuck.

was needed. For this, RVO (Netherlands Enterprise Agency) commissioned a report, requested by TKI Offshore Wind, based on an analysis conducted by TNO. Recently, the results of this report, called ‘Challenges and Potential for Offshore Solar’, was presented during a webinar.

According to Wiep Folkerts, Program Manager Solar at TNO, the Dutch energy system would need an additional 1,000km2 of space to develop solar power plants. “On shore, the Netherlands lack sufficient space to realise the ambitious solar energy goals”, he says. “At sea however, there still is ample space available in the Dutch Economic Zone. Offshore solar and offshore wind offer important synergies, for example because of the infrastructure that could be shared, such as cables and substations. Therefore, offshore wind farms seem to be ideal location for solar power plants. Another benefit of developing solar power plants at sea is that, because of the higher radiation of the sun at sea, the output of offshore of solar panels may be slightly higher compared to that of onshore panels.”

Various concepts

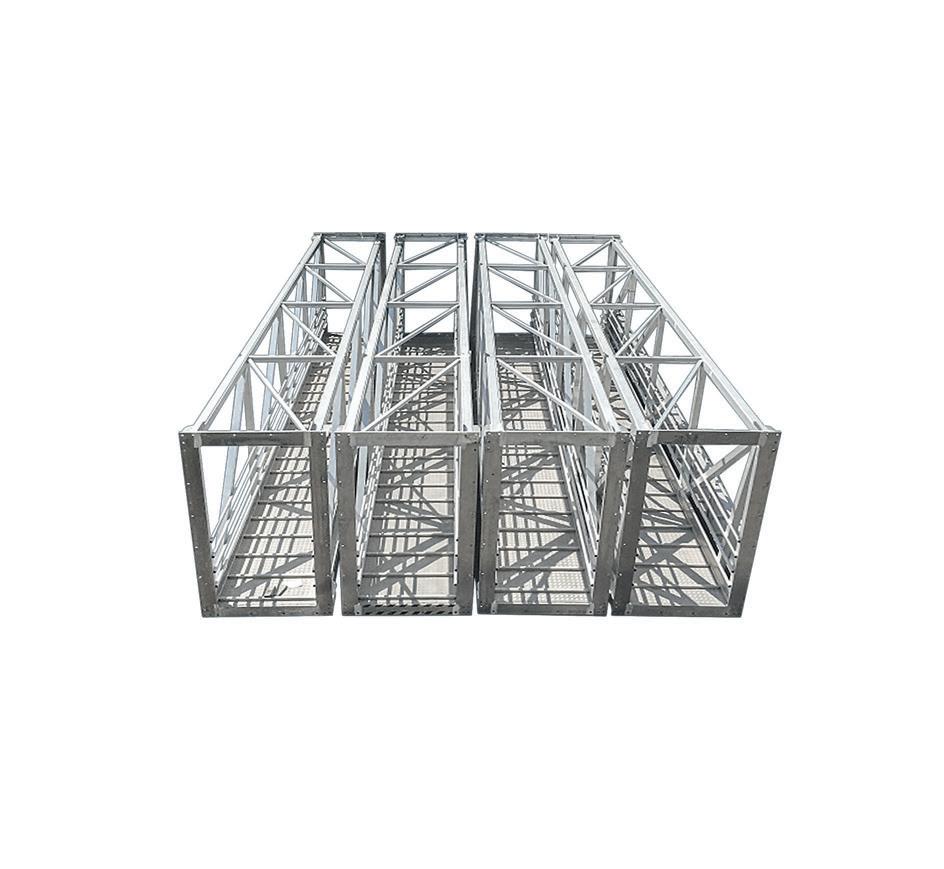

He continues, “Currently, in Europe, such as in the Netherlands and in Norway, there are already various concepts under development. The first concept is the so-called elevated truss concept. A truss structure is equipped with floaters and some kind of mooring system. A platform with solar panels is placed on the truss structure, supported by floating elements. The platform is located on a certain height above the waterline. Waves can move underneath the truss structure. The concept avoids the direct contact between (slamming) waves and the solar panels. This way, the mechanical load on the solar panels caused by waves will be less, and the fouling of the solar panels due to sea water residues on the panel surfaces may be smaller.

Companies

like SolarDuck and Tractebel are working with this concept. The second concept is a pontoon where the solar system is much closer to the water level. The pontoons are substructures that are mechanically coupled into a massively modular structure. The complete floating structure

18 NETHERLANDS SUPPLIERS CATALOGUE 2023

“Offshore solar and offshore wind offer important synergies, for example because of the infrastructure that could be shared, such as cables and substations.”

Oceans of Energy’s offshore solar energy pontoon installed at the North Sea. The pontoons are substructures that are mechanically coupled into a massively modular structure. Image courtesy of Oceans of Energy.

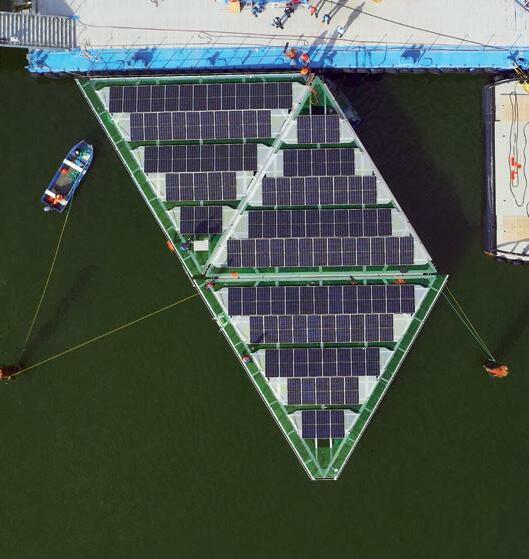

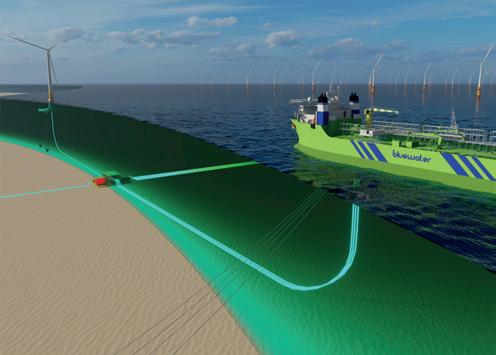

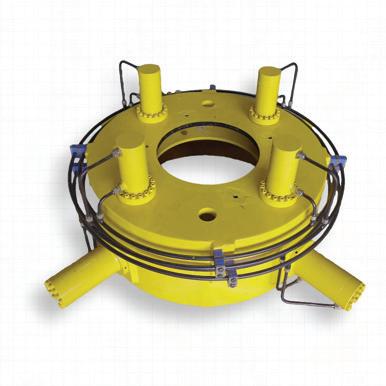

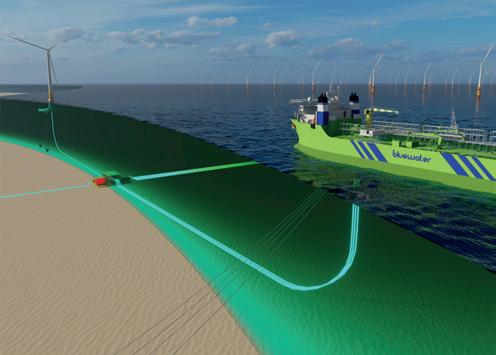

is moored. Solar panels are mounted on the pontoons, relatively close to the water level. The advantage is that the wind load on the panels and the structure is relatively low. Oceans of Energy, and Heliorec are some of the pioneers in developing this concept. Then you have the mattress-like soft and flex approach that fully moves with the waves. The basic idea of this concept is to let the floating structure move with the waves as much as possible. The transfer of mechanical energy from the waves to the structure will therefore be smaller, compared to for instance the pontoon concept, which results in reduced mooring forces. Because of this the structure needs less strength and may achieve lower costs. Solar panels are mounted on the floating body. During high waves, part of the structure may be overflown. Being near the water surface, it is less sensitive to wind loads. Bluewater/ Genap have embraced this concept. The final concept is based on the well-known technology of fish farms. Especially in Norway, with companies such as OceanSun and Inseanergy, there is expertise on this approach. A membrane is stabilised with a moored ring and on top of the membrane a solar power installation is installed.”

Challenges

The TNO report registered four main challenges for the development of offshore solar power plants. “When looking at constructing offshore solar power plants,” Mr Folkerts states, “the first challenge is how to design and construct a system that will survive the circumstances at sea, and also how to prove this survival. Relevant subjects in this are the connectors between the subsystems, the choice of materials used, the structural integrity and mooring, the dynamic power cable connection, and the calculation methodologies for prediction of hydrodynamic response. In fact, it is a matter of interaction between development of calculational methodologies and making the designs, do scale model testing for those designs, build pilots, see and measure how these models behave, give feedback to the methodologies, and thereby building up the knowledge on how to construct such floating structures in a cost- effective way.”

Operations & maintenance has its challenges too, and therefore there is work to be done and more knowledge to be built up over the coming years for this as well. Think for example of offshore resistant PV modules and electrical components. Not only is it important to find out for them how to survive at sea, but also how to make an effective maintenance schedule, for example for fouling prevention and fouling removal. For optimising O&M one could also look at digital twinning approaches.” The third

challenge lies in the power production and LCOE, and according to Mr Folkerts this actually is the key challenge. “All offshore solar projects are aimed at producing substantial volumes of power. It is important, for example for judging investment proposals, to make validated power yield models and reliable models for cost calculations and to show, how scale effects and other effects such as the combination of offshore wind and solar will affect the LCOE.” Societal acceptance is the fourth challenge described in the report. Relevant aspects in this are recycling and other elements of circularity, the ecological effects of offshore solar power plants, and the interaction with other uses of the sea. “All societal acceptance elements come together in permitting and permitting frames”, Mr Folkerts explains.

Solid solution

“Offshore solar is promising, so much is true”, Mr Folkerts concludes. “It can be the solution for the large-scale solar Ocean Sun Floater. The fish farm concept is based on the well-known technology of fish farms. Especially in Norway, there is expertise on this approach. A membrane is stabilised with a moored ring and on top of the membrane a solar power installation is installed. power production that we need. Still, it is a challenging development that needs innovation investments from the sector, which should work together with governments and knowledge institutes. There are different concepts in development and all those concepts have their specific advantages, values, and promises. Several pilots and demonstrators for accelerating the learning curve are underway, however more of them are needed towards scaling up and for winning the confidence of all stakeholders that offshore solar indeed is a solid solution.”

Source: Yellow & Finch Publishers

19 2023 NETHERLANDS SUPPLIERS CATALOGUE

Bluewater/Genap have embraced the soft and flex approach. Image courtesy of TNO.

Technically, larger turbines have no restrictions. Image courtesy of GE Renewable Energy.

OPTIMISING REVENUES

The world’s first offshore wind farm was commissioned in 1991. This Vindeby Offshore project, created by a group of Danish developers, consisted of eleven turbines that together generated 5MW. More than three decades later, a lot has changed.

The first offshore wind farms were constructed using technology with only slight adaptations compared to onshore wind turbines. In time, the turbines were designed, specifically for the harsh circumstances at sea. Also, at sea with no noise restrictions and plenty of room, operators started to look for larger turbines to reduce the cost of offshore power generation. At the beginning of the new century, the first 2MW offshore wind turbines were installed and increasingly more countries started to develop plans for the construction of offshore wind farms in order to reach their sustainability goals. Together with these plans, the industry continuously invested in further improving the efficiency and effectivity of the offshore turbines, resulting in turbines growing both in size as in power generation.

A handful

In Europe, currently the largest market except for China, the market for offshore turbines only knows a handful of companies that develop and produce offshore wind turbine generators. In the last few years, they together succeeded in further improving the power generation of offshore wind turbines. In February 2018, GE Renewable Energy announced their Haliade-X platform nameplated 12MW, and Vestas introduced the V164 10MW turbine. Soon after that, GE Renewable Energy and Siemens Gamesa launched their 14MW turbines, where the Siemens 14MW, making use of the Power Boost option, can even produce 15MW. Last year, Vestas introduced its 15MW prototype and the question arises where this race for power will end.

20 NETHERLANDS SUPPLIERS CATALOGUE 2023

Pioneer

According to Morten Rasmussen, Offshore CTO at Siemens Gamesa, this company has been operating in the offshore wind market since the very beginning. “For us, like many other companies in the offshore wind industry, it all started onshore with the supply of turbines for onshore wind farms, but as the supplier for the Vindeby project, we established ourselves as the offshore wind pioneer. Today, we estimate that over 50% of all turbines installed offshore, excluding China, are made by us.” He continues, “One of the most important differences between onshore and offshore wind is that installation onshore is much easier and therefore less expensive, for example because you only need a relatively simple concrete foundation, and no long-distance cabling is necessary to connect the onshore turbines to the grid, as onshore wind farms are usually close to the existing grid. On the other hand, the size of onshore turbines can be limited due to infrastructure and logistics, whereas offshore turbines have more freedom to increase in size.”

These two aforementioned differences also play a role in the upscaling of offshore wind farms and turbines. “Constructing the offshore wind power plants of today,” Mr Rasmussen says, “is expensive as they are huge projects, providing electricity to hundreds of thousands of households. They provide industrial power generation at price levels that are fully competitive with fossil fuel-based power plants. The most obvious solution to reduce the cost of electricity provided from offshore wind farms is to build farms with large and more powerful turbines. We are driven to develop more and more powerful turbines both by demand from the market demanding larger turbines and by our goal to remain ahead of competition.”

No technical limitations

The question arises where this upscaling of turbines will end. There are currently installation vessels under construction that will be ready for the installation of 20MW turbines, so contractors apparently expect larger turbines to be developed soon. According to Mr Rasmussen, the upscaling will not be hindered by technical limitations. “No one really knows where things will end as technically, there are no restrictions”, he says. “However, I think that it is important to listen to the market instead

of just looking at what is technically feasible. What do operators need? Look for example at the aircraft industry and the long-term lack of commercial success of the Airbus A-380. Technically it is an absolute masterpiece, though in the end it was a commercial disappointment, as the market was not ready for such a large aircraft.”

“This is one of the reasons why, in the development for more power and larger turbines, Siemens Gamesa has chosen a sound, stepwise approach to growth by taking just small steps at a time”, Apart from creating larger power generation, the industry has also been seeking other improvements. “While sizes and capacity are exponentially larger, the core concept “of the offshore wind turbine today is the same as it was for the Vindeby turbine”, Mr Rasmussen explains. “Naturally, we have always been looking for improvements, for example in the field of aerodynamics to improve the efficiency of the rotor blades. And today, our turbines use our patented Direct Drive technology instead of geared solutions, which

21 2023 NETHERLANDS SUPPLIERS CATALOGUE

“The most obvious solution to reduce the cost of electricity provided from offshore wind farms is to build farms with large and more powerful turbines.”

Morten Rasmussen, Offshore CTO at Siemens Gamesa. Image courtesy of Siemens Gamesa.

requires fewer components, and this saves money on construction and maintenance.”

Catapulted

GE Renewable Energy entered the onshore wind business in 2002 and with the acquisition of the power and grid business of Alstom in 2015, the company also became involved in offshore wind. With this acquisition, the company immediately gained a position in a highly competitive market. However, according to Vincent Schellings, Chief Technology Officer of GE’s offshore wind business, more was needed to keep a strong position amongst the market leaders.

“When we took over the Alstom power business, their largest offshore wind turbine generated 6MW and although the acquisition catapulted us into the market, we were convinced that we had to come up with something unique to help our customers drive down the cost of electricity. The first question our engineers were asked was to develop a rotor with a diameter of at least 220m, which was at that time a world-leading size. As bigger blades only make sense with bigger power generators, their next challenge was to develop a bigger power generator, which resulted in the 12MW Haliade-X. With the bigger turbines, we could meet demand from the operators that were looking for ways to reduce the cost of

electricity generated offshore. With bigger turbines, fewer turbines need to be installed per wind farm area, and fewer turbines also mean fewer subsea cables and less maintenance.” Rising costs Today, the Haliade-X turbine has been expanded to 14MW.

“Step by step,” Mr Schellings elaborates, “we increased the capacity of the Haliade-X prototype. It was certified in 2020 by DNV at 12MW and today it is also certified for up to 13.6MW, with the current prototype” running at 14MW and on its way to certification. The Haliade-X is therefore ready for the market, and we already have 7.4GW of customer commitments for this turbine. The first 14MW orders are noted, and production will start in 2023 for the Dogger Bank C offshore wind farm.” Mr Schellings admits that at some point the increase of power and turbine size might reach its limits. “Technically, larger turbines have no restrictions, and a decade ago I would not have thought that today’s offshore turbines would be possible. The aim of upscaling turbines is to reduce the cost of electricity.

However, without innovation at some point, the incremental cost of a larger turbine will exceed the incremental energy production, and hence drive the cost of electricity in the wrong direction. The cost here includes the turbine and the construction, as bigger turbines not only require more steel for the foundations and towers, but also bigger vessels for transport, larger cranes for installing, as well as larger marshalling yards. Logistical costs will increase, too. For this reason, GE Renewable Energy already has factories supporting its offshore business in port areas.”

Although upscaling might come to a halt someday, companies will keep on innovating to reduce costs. Mr Schellings explains, “One of the recent developments we think is worthwhile is 3D printing. Not necessary to produce components, but for example for the moulds needed to construct castings for turbine parts. The moulds presently require a lot of expensive manual labour, and a lot can be gained by 3D printing. Another aspect to mention in this matter is our Stay Ashore project with the Offshore Renewable Energy Catapult in the UK. This R&D project aims to find ways to reduce the time offshore for planned and unplanned maintenance. With this project, we focus on reliability of design, on how to make operations at sea more remote, and how to use robots in turbine maintenance.”

22 NETHERLANDS SUPPLIERS CATALOGUE 2023

Vincent Schelling is Chief Technology Officer of GE’s offshore wind business. Image courtesy of GE Renewable Energy.

“Without innovation at some point, the incremental cost of a larger turbine will exceed the incremental energy production, and hence drive the cost of electricity in the wrong direction.”

Continue to improve

In its Global Offshore Wind Report 2021, the Global Wind Energy Council predicts a total added capacity of offshore wind between 2021 and 2030 of 102.6GW. This figure shows the potential of this renewable source of energy for the industry.

Throughout these years, companies will continue to improve the entire supply chain in order to make the construction, installation, operations, and maintenance more efficient and cost effective. With this in mind, for the time being, the upscaling of turbines will have no technical limitations, but from a financial point of view, it is good to face reality. And we should not forget that apart from upscaling, there are more options for optimising the revenues from offshore wind.

Source: Yellow & Finch Publishers

Three decades later, a lot has changed. Image courtesy of oneworld.nl.

23 2023 NETHERLANDS SUPPLIERS CATALOGUE

GE Renewable Energy’s Haliade-X prototype has a capacity of 14MW and is ready for commercialisation. Image courtesy of GE Renewable Energy.

Old wind turbine blades. Image courtesy of Ørsted.

TNO INNOVATION OFFERS DISCARDED WIND TURBINE BLADES

A CIRCULAR FUTURE

Wind energy is gaining momentum. In Europe alone, there’ll be offshore wind turbines producing around 135 gigawatts of power by 2030. The downside is that blades are going to end up on the scrap heap at the end of their 25-year service life. In Europe, this results in some 4 million tonnes of waste every year. TNO has now taken a promising solution to an advanced stage.

‘It’s also badly needed,’ says Harald van der Mijle Meijer, Senior Consultant for Wind Energy Technology at TNO. ‘Not only do we need to get rid of the huge pile of turbine blades that are now being buried or incinerated, but governments are imposing increasingly stringent requirements on wind farm builders and owners. Companies bidding for tenders to build offshore wind farms in many countries must be able to demonstrate that the wind turbines are largely recyclable. Most components, such as the foundation and the tower, can already be recycled, but there’s no commercially attractive solution yet for the blades. That’s what we’re working on at TNO in collaboration with Brightlands Materials Center, an initiative of TNO and the Province of Limburg, which specialises in developing sustainable materials.’

Unique method

It involves a unique method for extracting the fibres from the turbine blade and reusing them in new products. Current blades are more than 50% glass and carbon fibre, which are in principle suitable for reuse. There are several sustainable options for the blades at the end of their service life. Mechanical or chemical recycling has drawbacks as regards quality and scaling up. The experts at TNO and Brightlands Materials Center have therefore focused on a thermochemical process involving pyrolysis, in which the material is heated to almost 500 oC without oxygen, releasing the fibres. They can then be processed into thermoplastic composite to be used in recyclable products. This method provides the best outcomes for reusing the recycled material again and again.

Two solutions for the price of one TNO Business Development Manager Richard Janssen works at Brightlands Materials Center: ‘We work here with a group of researchers on the development and innovation of polymeric materials, in this case thermoplastic composites. These consist of plastic and fibres, which makes them extra strong. You therefore see them in ever more products, from car parts to sporting goods. Wind turbine blades also consist

24 NETHERLANDS SUPPLIERS CATALOGUE 2023

of composites, but a different type: thermoset composites. They also contain fibres, but a different type of plastic that hardens during production and is very difficult to recycle. Pyrolysis is a solution to this problem, allowing the fibres to be recovered. We then use these fibres in the easier-torecycle thermoplastic composites, making it simpler to take them apart after use. Composite is as strong as metal but much lighter in weight. We develop technologies here not only to make thermoplastic composites, but also to recycle them. You want them to be circular and to be used in a variety of products for as long as possible. It provides two solutions for the price of one, as you solve a waste problem and also offer recycled material to manufacturers in a variety of sectors. They then don’t have to use raw materials for their products.’

Scaling up

Mariusz Cieplik, Senior Scientist Materials at TNO, specialising in pyrolysis: ‘This is an extension of a technology we developed previously to produce biochar, a soil improver that we make from biomass by means of pyrolysis. We’re now making that process suitable for recycling wind turbine blades. There are strong similarities between the two processes. In both cases, the aim is to separate fully what is released during pyrolysis from the solids that remain. The technology has since outgrown the lab. We now have a pilot plant that can make biochar on a scale of a few tonnes. And we’ve successfully replicated that process for turbine blade recycling. With TNO, we now have a perfect platform to build on. If we can scale this up to industrial level over the next few years, we’ll have a unique recycling process that will save a lot of waste and reduce the use of raw materials, because the material we recover will be given a new life in another, high-quality product.’

Bringing two worlds together Harald: ‘We make this attractive to all the parties in the supply chain. Manufacturers in various sectors, for example the automotive industry, are increasingly under legal obligations to use recycled materials in their products. And the wind energy industry has a waste problem. We bring those two worlds together. Our innovative process enables us to add value on two sides. The material we extract

the blades can be used in many high-value products, such as car parts, furniture, packaging, smartphones – too many to mention.’ Richard: ‘It could be a solution for both the material transition and the energy transition. During the production of wind turbine blades, manufacturers never properly considered the end of their service life. The blades had to make money, be strong and safe, and withstand extreme weather conditions. Recycling was never really on the agenda. Now we’re investigating how to keep the fibres from blades in use for as long as possible. If these fibres are no longer usable in one application, such as turbine blades, you process them again in the next application. That way, you delay incineration for as long as possible.’

Organising supply chains

In a few years’ time, blade recycling should be carried out at a number of locations around the country, preferably near major ports where the blades are brought in from sea or land. Hubs will then be set up there to turn the discarded blades into high-quality semi-finished or finished products. TNO is discussing this at European level with industry, governments, and knowledge partners, with the aim of organising it on a large scale.

Source: TNO

Source: TNO

25 2023 NETHERLANDS SUPPLIERS CATALOGUE

from

“Our innovative process enables us to add value on two sides. The material we extract from the blades can be used in many high-value products, such as car parts, furniture, packaging, smartphones – too many to mention.”

Cutting wind turbine blade in half provides two solutions for the price of one, as you solve a waste problem and also offer recycled material to manufacturers in a variety of sectors. Image courtesy of TNO.

INSPIRED BY NATURE COMPOSITE JOINT FOR OFFSHORE JACKETS

Monopiles and jackets are used for the foundation of bottom fixed offshore wind turbines. The steel welded TKY joints used for the assembly of jackets form a weak spot in the strength and durability of this type of construction. Start-up company Tree Composites has developed a joint made of composites that eliminates this weakness.

Maxim Segeren is Managing Director and Co-founder of the young company, and we talk with him about their innovative solution. He became involved in the offshore industry during his study at Delft University of Technology (TUD), where he earned his MSc degree in offshore engineering with a focus on offshore wind jackets, and a PhD degree in civil engineering with the slip joint connection for offshore wind turbines. After his PhD, he remained involved with the TUD. “After promoting,” he explains, “I stayed at the university where I became involved in forming consortia between the industry and science aiming at the development of innovations within offshore wind. One of those innovations was a wrapped composite joint that today is referred to as the TC Joint.”

TC Joints versus steel welded joints

According to Mr Segeren, a jacket has an excellent weight/ rigidity ratio and this is why they are technically the best foundation for offshore wind turbines. “Despite jackets being the better solution, monopiles are dominating the market, even when they are much heavier than jackets”, he states. “One of the reasons for this is the higher price of jackets and the longer production time caused by the complex welding of the multi-membered joints. The weld also causes local stress concentrations that can reduce the fatigue resistance by 10 to 100 times. To guarantee a lifespan of these complex welds of 25 “years or longer, the thickness of steel is increased locally in the order of 300%, which means extra use of steel.” Mr Segeren continues, “The improvement of our composite joint compared to welding steel joints is that the load is transferred through the surface of a dedicated composite wrap, and not through the smaller surface of the welds which is limited to the wall thickness.

The composite also protects the steel against corrosion. Our wrapped composite joint is made by the lamination of glass fibres on the individual steel tubes. The brace members (diagonals) are bonded to the chord members (legs) through a coupling formed by composite wrapping. This provides outstanding bonding strength and flawless quality. The composite wrap is tailored in length and thickness to deal with static and dynamic loads transferred by the joint. The optimised, nature-like shape of the composite wrap with increasing thickness towards the root of the joint reduces the stress concentration in the composite material and bonded interface, thereby solving issues in fatigue prone/driven design. As the lifespan of a jacket highly depends on that of the joints, the TC Joint makes the entire construction of the jacket longer lasting. Wrapped composite joints can also acquire higher dimensional tolerances than welds due to omission of distortions by welding heat input. Another advantage of the TC Joint is that it reduces the amount of steel used by 30% to 60% as a result of the increased fatigue resistance. The composite joint itself is lighter than

26 NETHERLANDS SUPPLIERS CATALOGUE 2023

Maxim Segeren, Managing Director of Tree Composites. Image courtesy of Tree Composites.

According to Mr Segeren, despite jackets being the better solution, monopiles are dominating the market, even when they are much heavier than jackets. Image courtesy of Ørsted.

steel ones and as no welding is needed, there is no need for thick local cans and overdesigned global thicknesses of the tubes. This steel reduction also helps to reduce CO2 emissions. Finally, the acceleration of jackets production by prefabrication of the joints is feasible by factor two to three, as the joint omits””complex welding activities onsite and does not require the application of an additional coating to protect the steel against corrosion.”

Old tree

With the first prototype built in 2017 at Versteden, a close collaboration with them followed with over 100 tests executed at TU Delft to perfect the technique. “When I heard about the composite joint, I was sceptical about the concept of a structural joint made by wrapping material around individual tubes, as I had tried to wrap a broken pencil myself in my younger years,” Mr Segeren admits, “however, seeing is believing. The successful laboratory tests created enthusiasm and a drive to further develop this innovative concept and its many advantages compared with steel joints

into a commercial product. Parties that could incorporate this innovation in their core business were non-existing, as this unique disruptive technique combines the two separate worlds of composites and steel structures. In other products such as aircraft wings and turbine blades, a combination of composite and steel is not uncommon, however the specific application and creation of a load transfer in a structural joint of offshore jackets by replacing traditional complex welds is a completely new concept.” In 2020, a dedicated company focussing on design and manufacturing of composite joints called Tree Composites was founded to develop the technique further. “We named the company Tree Composites after the inspiration by nature”, Mr Segeren elaborates. The inventor of the concept, Assistant Professor at TU Delft Marko Pavlovic, became inspired by an old tree in his hometown near Belgrade. The local community placed steel rods on branches of the tree to extend its lifetime. A tree reacts to the loads it is subjected to, and this tree can grow additional fibres at locations where they are needed. Mr Pavlovic noticed that the tree grew over and around the steel tubulars,

27 2023 NETHERLANDS SUPPLIERS CATALOGUE

“Next to this R&D project, we are preparing pilot projects and we hope that this will result in a full-scale offshore project soon.”

creating a structural connection. Based on this observation, he came up with the idea of the wrapped composite joint. At the end of 2020, just a few months after founding the company, DNV provided the statement of feasibility for the composite joints, marking an important milestone.”

WrapNode-I

In May 2021, the project WrapNode-I started with TU Delft as research partner and large parties joined the consortium such as HSM Offshore, Smulders, Siemens Gamesa, Shell, AOC, BuFA, Salzgitter Renewables, and Enersea. “The WrapNode-I project is part of GROW”, Mr Segeren voices. “GROW stands for Growth through Research, development & demonstration in Offshore Wind. It is a joint research programme in offshore wind that initiates research and accelerates innovations. The Netherland Enterprise Agency (RVO) financially backs the project through a subsidy. Aim of WrapNode-I is to test the effects of scale and other influences such as the offshore environment. So far with success, as in the combination of

steel and composite it is always the steel that shows failure or behaviour outside design limits. Next to this R&D project, we are preparing pilot projects and we hope that this will result in a full-scale offshore project soon. WrapNode-I will run until 2023 and will be followed by the next phase, WrapNode-II, in which a full-scale onshore demonstration jacket will be realised. After this, we aim to have a full-scale jacket offshore in 2025 as the first pilot project for offshore wind. The major challenge we face with the composite joint is not developing the technique, but introducing this gamechanger in the conservative offshore wind industry.”

Standardisation

“Today, the construction of jackets without using our TC Joints is still more expensive compared to that of steel monopiles,” Mr Segeren explains, “however, the construction of jackets using TC Joints will go much faster, and with the Dutch 2030 goals in mind for the realisation of offshore windfarms we need to speed things up. Time and production capacity will become an important item in realising these goals. What drives us is that we strongly believe we contribute to the acceleration of the energy transition with our joints. Our aim is to accelerate the production of the jacket by the introduction of the TC Joint from 1 to 2/3 jackets a week.

Achieving this will make it feasible to reach the renewable energy goals. In the Dutch wind industry, there are initiatives that are in favour of a restriction in size of the turbines and with a focus on standardisation and industrialisation. If that happens, an interesting idea arises to extend permits to 60 years and having a jacket foundation of a lifetime of 60 years that is feasible when using TC joints for a similar price. With lifetimes of current wind turbines of 25 to 30 years, a new turbine could replace the first after its lifetime without having to install a new foundation.” For Mr Segeren, the Tree Composites story has only just begun. According to him, once the concept has reached full adoption in the market, it can expand globally in dedicated production yards for jackets assembled with TCJs produced on the spot or prefabricated ones. “This sounds ambitious indeed and it will be challenging, but we believe in our solution. We are a motivated, passionate, and thorough team. We are eager to listen, learn, and improve, and hope to attract potential partners with our enthusiasm about the many pros of our solution”, Mr Segeren concludes.

Source: Yellow & Finch Publishers

28 NETHERLANDS SUPPLIERS CATALOGUE 2023

In the combination of steel and composite, it is always the steel that shows failure or behaviour outside design limits during testing.

Image courtesy of Tree Composites.

The foundation of offshore wind energy

Sif is leading in offshore foundations and delivers quality on time, safely and within the agreed budget. We make good on this promise because of our critical approach to the preliminary stage. Our dedicated specialists optimize each project on design, feasibility, coating and logistics. We want to ensure our production and the installation processes are efficient and cost optimal by working closely with our clients.

We also think beyond today’s projects. By considering tomorrow and keeping a close eye on market developments, we adapt to the changing needs of market participants. We use our knowledge, experience, and inventiveness for product development and innovation. This is how we actively help shaping the future of offshore wind energy.

Experience more on www.sif-group.com

MARIN built scale models of all three solutions and ran tests in its Offshore Basin on 17 and 18 March to see if the barriers could deflect a scale model comparable to the Julietta D in storm conditions. All images courtesy of MARIN.

MARITIME ‘CRASH BARRIERS’ TO AVERT COLLISIONS WITH WIND TURBINES

Dutch maritime research institute MARIN has tested three innovative barriers aimed at averting collisions between ships and wind turbines. The research was prompted by the incident involving the Julietta D on 31 January this year.

This drifting bulk carrier initially collided with a tanker before hitting a transformer platform and a turbine foundation for the Hollandse Kust Zuid wind farm currently under construction. A collision with an installed wind turbine carries a real risk of the turbine toppling onto the vessel, seriously endangering crew, passengers, the ship itself, and the environment.

Urgency