Solução de Economia Circular da Flex é o 1º ecossistema integrado e closed-loop no mercado de eletrônicos no Brasil.

O programa tem como propósito transformar plásticos de engenharia, como PSAI e ABS de produtos do pós-industrial e do pós-consumo, como impressoras e notebooks, em novos produtos eletrônicos.

Os materiais são submetidos à uma rigorosa triagem e reformulação, acompanhados por testes em laboratório e reprocessamento do plástico.

Ao aderir ao nosso programa, além de fechar o ciclo para plásticos de engenharia, você se torna um parceiro SINCTRONICS nesta jornada.

olímero

-

olume

e d I tor I al C ou NCI l

Antonio Aprigio S. Curvelo (USP/IQSC) - President m ember S

Ailton S. Gomes (UFRJ/IMA), Rio de Janeiro, RJ (in memoriam)

Alain Dufresne (Grenoble INP/Pagora)

Bluma G. Soares (UFRJ/IMA)

César Liberato Petzhold (UFRGS/IQ)

Cristina T. Andrade (UFRJ/IQ)

Edson R. Simielli (Simielli - Soluções em Polímeros)

Edvani Curti Muniz (UEM/DQI)

Elias Hage Jr. (UFSCar/DEMa)

José Alexandrino de Sousa (UFSCar/DEMa)

José António C. Gomes Covas (UMinho/IPC)

José Carlos C. S. Pinto (UFRJ/COPPE)

Júlio Harada (Harada Hajime Machado Consutoria Ltda)

Luiz Antonio Pessan (UFSCar/DEMa)

Luiz Henrique C. Mattoso (EMBRAPA)

Marcelo Silveira Rabello (UFCG/UAEMa)

Marco Aurelio De Paoli (UNICAMP/IQ)

Osvaldo N. Oliveira Jr. (USP/IFSC)

Paula Moldenaers (KU Leuven/CIT)

Raquel S. Mauler (UFRGS/IQ)

Regina Célia R. Nunes (UFRJ/IMA)

Richard G. Weiss (GU/DeptChemistry)

Rodrigo Lambert Oréfice (UFMG/DEMET)

Sebastião V. Canevarolo Jr. (UFSCar/DEMa)

Silvio Manrich (UFSCar/DEMa)

ISSN 0104-1428 (printed)

1678-5169

e d I tor I al C omm I ttee

Sebastião V. Canevarolo Jr. – Editor-in-Chief a SS o CI ate e d I tor S

Alain Dufresne Bluma G. Soares César Liberato Petzhold

José António C. Gomes Covas José Carlos C. S. Pinto

Paula Moldenaers

Richard G. Weiss Rodrigo Lambert Oréfice

d e S kto P P ubl IS h IN g

www.editoracubo.com.br

“Polímeros” is a publication of the Associação Brasileira de Polímeros São Paulo 994 St. São Carlos, SP, Brazil, 13560-340 Phone: +55 16 3374-3949 emails: abpol@abpol.org.br / revista@abpol.org.br http://www.abpol.org.br

Date of publication: July 2022

Available online at: www.scielo.br

Polímeros / Associação Brasileira de Polímeros. vol. 1, nº 1 (1991) -.- São Carlos: ABPol, 1991-

Quarterly v. 32, nº 3 (July/Sep 2022) ISSN 0104-1428 ISSN 1678-5169 (electronic version)

1. Polímeros. l. Associação Brasileira de Polímeros.

Website of the “Polímeros”: www.revistapolimeros.org.br

Tailoring sustainable compounds using eggshell membrane as biobased epoxy catalyst Janetty Jany Pereira Barros, Nichollas Guimarães Jaques, Ingridy Dayane dos Santos Silva, Ananda Karoline Camelo de Albuquerque, Amanda Meneses Araújo and Renate Maria Ramos Wellen ..................................................................................................................e2022025

Bioplastic composed of starch and micro-cellulose from waste mango: mechanical properties and biodegradation Rodolfo Rendón-Villalobos, Miguel Angel Lorenzo-Santiago, Roberto Olvera-Guerra and César Arnulfo Trujillo-Hernández e2022026

Polyurethane/single wall carbon nanotube/polymethylmethacrylate nanocomposite: PM3 semi-empirical method, Monte Carlo applied Juan Ramon Campos-Cruz, Norma Aurea Rangel-Vázquez, Rosa Elvira Zavala-Arce and Edgar Márquez-Brazon e2022027

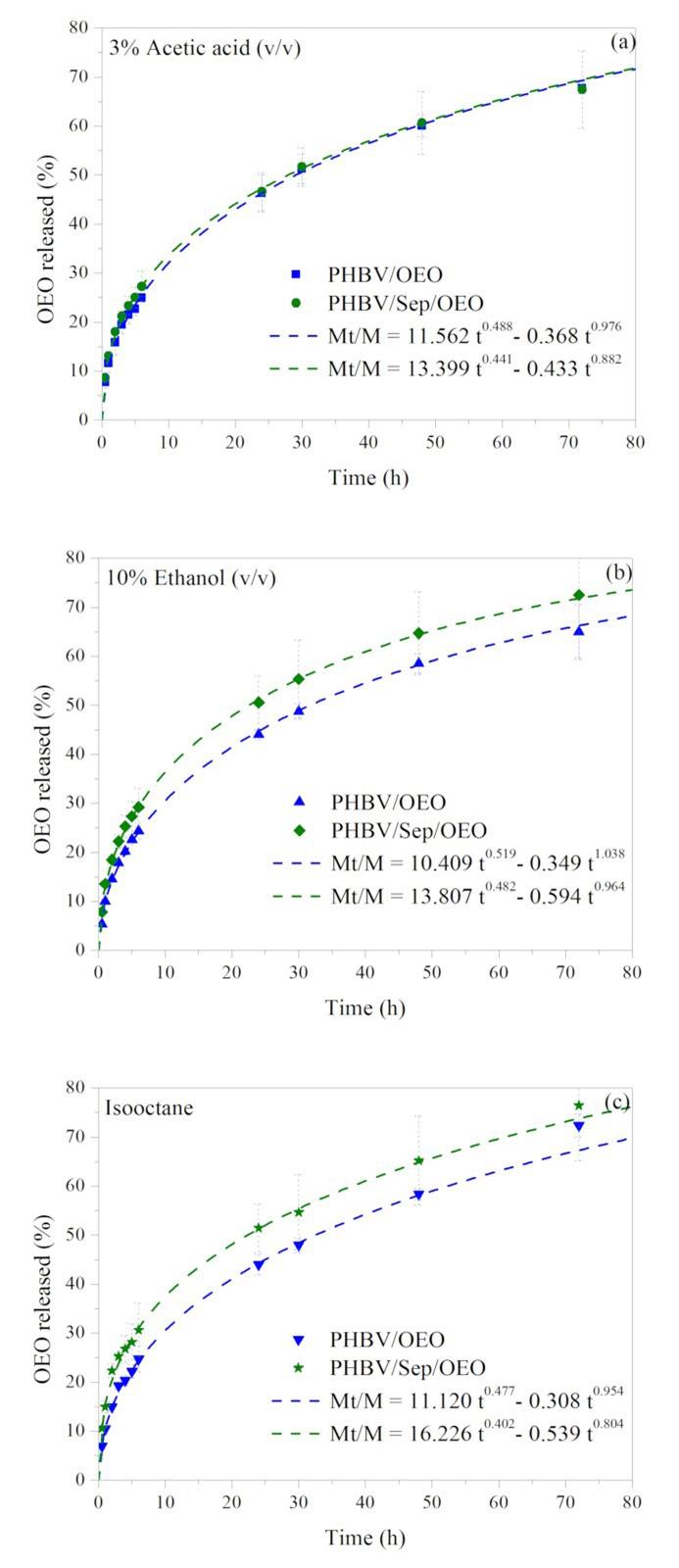

Release of oregano essential oil from PHBV films in simulated food conditionsa Renata Cerruti da Costa, Ana Paula Ineichen, Cristiano da Silva Teixeira, Ismael Casagrande Bellettini and Larissa Nardini Carli e2022028

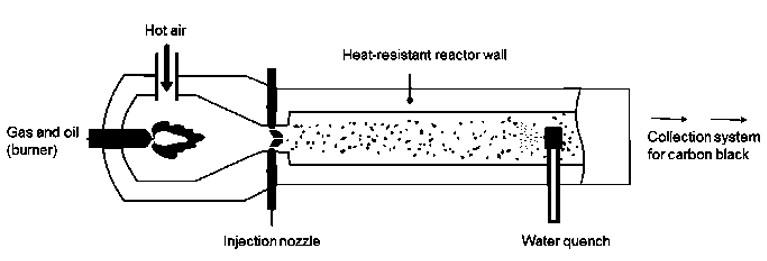

Influence of carbon black trimodal mixture on LDPE films properties: Part1 – DOE Juliano Martins Barbosa,, Cesar Augusto Gonçalves Beatrice and Luiz Antonio Pessan e2022029

Influence of carbon black trimodal mixture on LDPE films properties: Part2 – SME

Juliano Martins Barbosa , Cesar Augusto Gonçalves Beatrice and Luiz Antonio Pessan e2022030

Poly(methyl methacrylate) and silica nanocomposites as new materials for polymeric optical devices

Rafael Affonso Netto, Fabrícia Faria de Menezes, Rubens Maciel Filho and Julio Roberto Bartoli e2022031 Interactions of PP-PET blends modified by montmorillonite with different polarities Ariane Sarzi Porto, Jefferson Lopes Alves and Ana Rita Morales e2022032

Influence of processing parameters on mechanical and thermal behavior of PLA/PBAT blenda Virnna Cristhielle Santana Barbosa, Ana Maria Furtado de Sousa and Ana Lúcia Nazareth da Silva, e2022033 Poly(vinyl alcohol)/poly(glycerol) dendrimer hydrogel mediated green synthesis of silver nanoparticles Pollyana Marcondes, Gisela Helou Rosas, Maria Elena Leyva González, Alvaro Antonio Alencar de Queiroz and Paulo Sergio Marques e2022034

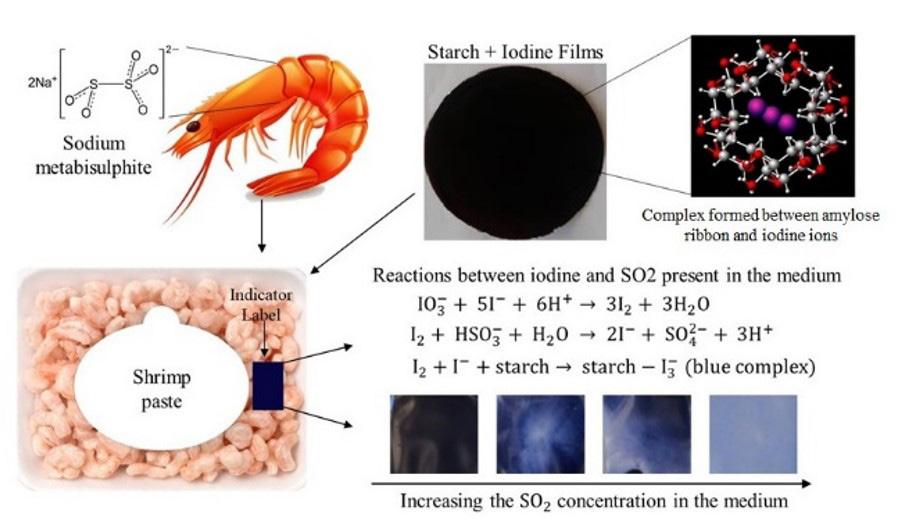

Development of an SO2 indicator label applied to shrimp Gleyca de Jesus Costa Fernandes, Karoline Ferreira Silva, Clara Suprani Marques, Luiza Zazini Benedito, Beatriz Ribeiro Cabral, Pedro Henrique Campelo, Soraia Vilela Borges, José Manoel Marconcini, Zuy Maria Magriotis, Pedro Ivo Cunha Claro and Marali Vilela Dias e2022035

Evaluation of lignin as stabilizer in vulcanized natural rubber formulations Gelsa Adriana Carpenedo , Nayrim Brizuela Guerra, Marcelo Giovanela, Marco Aurelio De Paoli and Janaina da Silva Crespo e2022036

Luran S polymer offers UV, heat, and chemical resistance coupled with durability.

Ineos Styrolution’s acrylonitrile styrene acrylate (ASA) polymer Luran S has been selected by sister company Ineos Automotive as the material of choice for the front grille of its upcoming Grenadier 4X4.

Ineos Automotive was established to meet demand for a rugged and uncompromising off-roader. The Ineos Grenadier, which is on track to begin series production in the fall, is designed to be a capable, durable, and reliable working tool, while also offering the comfort, refinement, and reliability expected of a modern vehicle, said Ineos Automotive. Luran S reportedly is up to the challenge. It offers superior UV, heat, and chemical resistance, according to the company. In addition, Luran S provides appropriate impact strength and dimensional stability to make it the best material for the job.

Donna Falconer, Head of Product at Ineos Automotive, said: “We have the highest expectations of the materials we use for the Grenadier. Luran S fulfills them all. Not only does it deliver superior performance in the harshest of environments, it also enables a high-quality finish and appearance.”

In a separate announcement, group company Ineos O&P Europe said it planned to invest €30 million in the conversion of its Lillo, Belgium, plant at the Port of Antwerp to enable capacity to produce either monomodal or bimodal grades of high-density polyethylene (HDPE). This will allow Ineos to meet strong demand for durable high-end applications such as cable ducts and pipes used to transport renewable power and hydrogen, while enabling the business to follow market trends as society turns away from single-use packaging.

Specific target applications include: Pressure pipe grids for transporting hydrogen; long-distance underground cable duct networks for wind farms and transportation of other forms of renewable power; electrification infrastructure; CO2 capture, transport, and storage processes.

Source: Plastic Today – plasticstoday.com

Flexible packaging business Eco Flexibles has worked with pet treat brand Lovimals to switch to new monopolymer packs.

The brand opted for a new digitally printed EcoFlow pouch with PE zipper. The move is designed to reduce overall production waste.

Simon Buswell, director at Eco Flexibles, said: “The pouch format has really taken off over the last couple of years due to its convenience-driven design, and that looks set to continue. Mordor Intelligence estimates a compound annual growth rate of over 5% to 2027, so we are expecting to see its popularity continue alongside the surging demand for sustainable, recyclable, and low carbon mono-polymer packaging designs.”

David Ryder, Company Director at Lovimals, added: “We were delighted to work with the Eco Flexibles team on this project, switching our pouch packaging designs to recyclable mono-polymer. Our subscription product range centres around pet health, and now with our redesigned packaging, we are playing our role in supporting the wellbeing of the planet too.

“By applying their expertise from the outset, the Eco Flexibles team made it simple, and the result speaks for itself. The reclose zipper and fantastic barrier strength gives practicality and performance for our customers and their four-legged friends, and the pack is now easily recyclable.”

Source: Packaging News –packagingnews.co.uk/news

POLY-CHAR 2023

Date: January 22-27, 2023

Location: Auckland, New Zealand Website: www.poly-char2023.org/ Polyethylene Films North America – 2023 Date: January 31 - February 2, 2023

Location: Orlando, United State of America Website: www.ami-events.com/o7ezmL?RefId=AMI+Website

Reinforced Thermoplastics - 2023

Date: February 7-8, 2023

Location: Cologne, Germany Website: www.ami-events.com/event/2e77454c-ae7f-43e7-bf4c108f6a44c89d/summary?RefId=Website_AMI

4th International Conference on Polymers and Plastics, Artificial Intelligence. Robotics, Smart Materials, Engineering & Information Technology (ICPPAI-FEB-2023) Date: February 18-19, 2023

Location: Shanghai, China Website: irnest.org/icppai-feb-2023/

Macrostruct23 — Macromolecular Structures – Interactive Meeting on Crystallisation, Fibrillation and Beyond

Date: March 1-3, 2023

Location: Leipzig, Germany Website: macrostruct23.de/ 4th World Expo on Biopolymers and Bioplastics

Date: March 6-7, 2023

Location: Berlin, Germany Website: biopolymers.materialsconferences.com/ 18th International Plastics and Petrochemicals Trade Exhibitions

Date: March 21-24, 2023 Location: Riyadh, Saudi Arabia Website: saudi-pppp.com/saudi-plastics-petrochem Plástico Brasil — International Plastic Exhibition Date: March 27-31, 2023

Location: São Paulo, São Paulo, Brazil Website: www.plasticobrasil.com.br/en

24th International Conference on Wear of Materials Date: April 16-20, 2023 Location: Banff, Alberta, Canada. Website: www.wearofmaterialsconference.com/ Polymers in Flooring Europe – 2023 Date: April 18-19, 2023

Location: Berlin, Germany Website: www.ami-events.com/N3NmxB?RefId=AMI_Website

38th International Conference of the Polymer Processing Society

Date: May 22-26, 2023

Location: St. Gallen, Switzerland Website: www.pps-38.org/ Polymer Sourcing & Distribution – 2023 Date: May 23-25, 2023

Location: Hamburg, Germany Website: www.ami-events.com/event/7e7d5b18-b87b-4167bbbe-ed4142955f44/summary

Frontiers in Polymer Science 2023 — Seventh International Symposium Frontiers in Polymer Science Date: May 30 – June 1, 2023

Location: Gothenburg, Sweden

Website: www.elsevier.com/events/conferences/frontiers-inpolymer-science June

Gordon Research Seminar — Polymers

Date: June 3-4, 2023

Location: South Hadley, Massachusetts, United State of America Website: www.grc.org/polymers-grs-conference/2023/ Gordon Research Conference — Polymers Date: June 4-9, 2023

Location: South Hadley, Massachusetts, United State of America Website: www.grc.org/polymers-conference/2023/ Polymer Testing World Expo Europe – 2023 Date: June 14-15, 2023

Location: Messe Essen, Germany Website: eu.polymertestingexpo.com/ Fluoropolymer 2023 Date: June 18-21, 2023

Location: Denver, Colorado, United State of America Website: www.polyacs.net/23fluoropolymer

Chemical Recycling - 2023

Date: June 26-28, 2023

Location: Frankfurt, Germany Website: www.ami-events.com/event/7aa8d789-efda-4178-bf363321aa5caca1/summary?RefId=AMI%20Website

MACRO2024 — 50th World Polymer Congress

Date: June 30 – July 4, 2023

Location: Coventry, United Kingdom Website: iupac.org/event/50th-world-polymer-congressmacro2024/

14th International Workshop on Polymer Reaction Engineering

Date: September 5-8, 2023

Location: Fraunhofer-IAP, Potsdam, Germany Website: dechema.de/en/PRE2023.html

Performance Polyamides Europe - 2023 Date: September 12-13, 2023

Location: Cologne, Germany Website: go.ami.international/pa-register-interest-2023/?_ ga=2.161659068.1873836536.16697322131689573348.1669732213

Polyolefin Additives - 2023 Date: October 3-4, 2023

Location: Barcelona, Spain Website: www.ami-events.com/event/3217a2fe-22bf-4751-b2415e15ad488df5/summary?RefId=Website_AMI

Plastics Recycling Technology

Date: October 10-12, 2023

Location: Vienna, Austria Website: www.ami-events.com/event/04194add-97e5-4a3b-a5a410e937775a9f/summary?RefId=Website_AMI

Sustainable Polymers

Date: October 15-18, 2023

Location: Safety Harbor, Florida, United State of America Website: www.polyacs.net/23sustainablepolymers

17th Brazilian Polymer Congress Date: October 29 - November 2, 2023

Location: Joinville, Brazil Website: www.cbpol.com.br/

Controlled Radical Polymerization Date: November 12-15, 2023

Location: Charleston, SC, United States Website: www.polyacs.net/crp2023

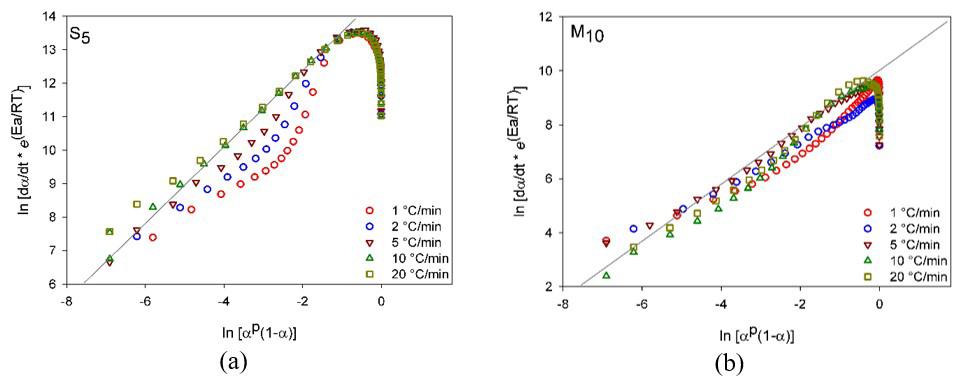

In this work eggshell membrane was added as biobased curing catalyst to epoxy (DGEBA), for comparison purposes the synthetic catalyst DEH 35 data was reported, the curing of compounds was followed through differential scanning calorimetry (DSC) under dynamic conditions and their kinetics were modeled using Kissinger, Friedman, Friedman model based and Málek approaches. From evaluated EA and lnA two steps of curing were verified, for the synthetic catalyst compound (S5) EA abruptly increased for the degree of conversion 0.7 α > the opposite trend was observed for the eggshell membrane compound (M10). It is supposed for S5 EA increases due to the competitive reactions leading to viscosity increase until reach the solid phase with decrease of the reactive groups availability, hampering the crosslinking, whereas for M10 EA decreases at 0.7 α > , hence invalidating the Kissinger model which assumes constant EA

Keywords: curing, eggshell membrane, epoxy, kinetics.

How to cite: Barros, J. J. P., Jaques, N. G., Silva, I. D. S, Albuquerque, A. K. C., Araújo, A. M., & Wellen, R. M. R. (2022). Tailoring sustainable compounds using eggshell membrane as biobased epoxy catalyst. Polímeros: Ciência e Tecnologia, 32(3), e2022025. https://doi.org/10.1590/0104-1428.20210088

Epoxy resins are thermosets and represent polymers whose properties are considered superior to the conventional ones, which provide them extensive applications, ranging from coatings, adhesives to composites for electronics, sporting goods, aerospace, for instance[1,2]. Epoxies properties are achieved through the cross-linking reactions, which occur between epoxy resin and hardening agent, promoting the reticulated network.

In resins which high performance is needed such as higher operating temperatures and greater mechanical strength, anhydrides as hardeners are conventionally added. However, the reactivity between epoxy and anhydride is low, resulting in longer times and temperatures for the curing end[3]; and as a result it may initiate the degradation processes, impairing the epoxy polymerization as well as its final properties, hence catalysts addition are commonly used to accelerate the cure making the process feasible[4,5]

The reaction of epoxides with cyclic anhydrides as the case of this paper, initiated by Lewis bases, proceeds through a chain wise polymerization, which comprises initiation, propagation, and termination or chain transfer steps[6]

Searching sustainable alternatives for epoxy curing, the eggshell membrane is a natural by-product, considered a waste with low commercial value, however it has great

potential to act as an catalyst, due to its biologically active compounds; chemically it has 90% protein, 2% glucose and 2% mineral phases[7]. Currently the membrane is used as biodiesel[8,9] and bio compounds catalyst[10,11]. Its potential to act in the curing is linked to its constituents, since the carboxylic functional groups, amino acids and sulfur present in structural proteins may act as curing catalysts[12]

Epoxy/eggshell biocomposites have already been produced with the purpose of mechanical and thermal properties optimization[13-15]. Saeb et al.[16] carried out a comparative study between the non-isothermal curing kinetics of epoxy/CaCO3 and epoxy/eggshell. The curing kinetics was investigated using Friedman, Ozawa, Kissinger - Akahira - Sunose and Málek models. Ozawa and KAS showed better agreement with the experimental data in relation to the Málek and Friedman ones. Nevertheless, using membrane as a catalyst is still scarcely explored. Jaques et al.[17] investigated the curing kinetics of epoxies adding eggshell (E) or membrane (M) as curing catalysts, it was applied Ozawa, Kissinger, Friedman isoconversional, Friedman model based and Málek to model the curing. The results showed that only the membrane presented potential application as cross-linking performer. Related to the kinetic models, Málek and Friedman presented the

1Unidade Acadêmica de Engenharia de Materiais, Universidade Federal de Campina Grande – UFCG, Campina Grande, PB, Brasil

2Departamento de Engenharia de Materiais, Universidade Federal da Paraíba – UFPB, João Pessoa, PB, Brasil *janetty_b@hotmail.com

best adjustments to describe the curing of synthetic and bio-based compounds.

Eggshell and eggshell membranes as potential enhancers for epoxy systems were previously investigated by our research group, the results showed that the membrane increased the curing rate, and may be used as a low-cost substitute for synthetic catalysts. Regarding the thermal properties, composites with natural catalysts showed less stability[18] Aware that the final properties of epoxies depend on their cross-linking process, and this process is influenced by the cross-linkers, the processing variables (time, temperature, pressure), and knowing the influence that using a natural catalyst may provide in the epoxy curing, it is essential to investigate their curing kinetics.

Applying mathematical models to evaluate the curing kinetics helps to quantify the degree of conversion of epoxy compounds, in addition to providing reliable information such as identification of the curing mechanism, the activation energy (EA), collision rate among molecules (ln A). Additionally, from the comparison between theoretical and experimental data it is affordable to estimate the predictive power of the employed model, and afterwards its application in an industrial scale. Isoconversional models afford EA variable along with the curing progress whereas the conventional ones assume it constant[19-21]

Based on the above mentioned, this work aimed elucidating the curing kinetics of epoxy compounds (DGEBA)/eggshell membrane. The topic assumes great importance at both technological and scientific aspects since seldom works are focused on the membrane’s abilities into thermosetting compounds, as further presented a costless crosslinker. Additionally, the kinetics investigation was conducted using differential scanning calorimeter (DSC) under dynamic conditions and the curing modeling was performed applying Kissinger, Friedman, Friedman model based and Málek models which parameters may be used as control tools to reach the desired conversion for specific property and application.

Diglycidyl ether of bisphenol A (DER 383) with epoxide equivalent weight of 176–186 g/eq, anhydride methyl tetrahydrophthalic (MTHPA) and 2,4,6-tris (dimethylaminomethyl) phenol (DEH 35) were supplied by Olin Corporation (São Paulo, Brazil). Chicken eggshell was supplied by a local farm (Campina Grande-PB, Brazil).

Processing of membrane (M) was performed as an adapted methodology elsewhere proposed[22]. Eggshell was washed in sodium hypochlorite (NaClO) and afterwards immersed in water for 2 h to remove the membrane. M was oven dried at 100 °C for 24 h. Afterwards, M was ground in a coffee mill B55 Botini (Bilac, SP, Brazil) and sieved through #200 mesh.

Epoxy compounding at 100:87 (DER 383/MTHPAresin/hardener) with DEH 35 at concentrations 0 and 5 phr (parts per hundred) were mixed in a magnetic stirrer for 5 min at 800 rpm.

M in content of 10 phr was added into 100:87 (DER 383/ MTHPA). Afterwards, these compounds were mixed in a magnetic stirrer from Corning (Reynosa, Mexico) for 5 min at 800 rpm at ambient temperature (~23 °C). Compounds produced in this work are coded as presented in Table 1

The curing was followed up through differential scanning calorimetry (DSC) using a DSC Q20 from TA Instruments (New Castle, DE, USA). Samples of approximately 5 mg were tested in a standard closed aluminum pan, under a nitrogen gas flow of 50 mL/min. The samples were heated from 30 °C to 400 °C, at heating rates of 1, 2, 5, 10, and 20 °C/min. The theoretical background with the curing kinetics modeling information is presented in the Supplementary Material.

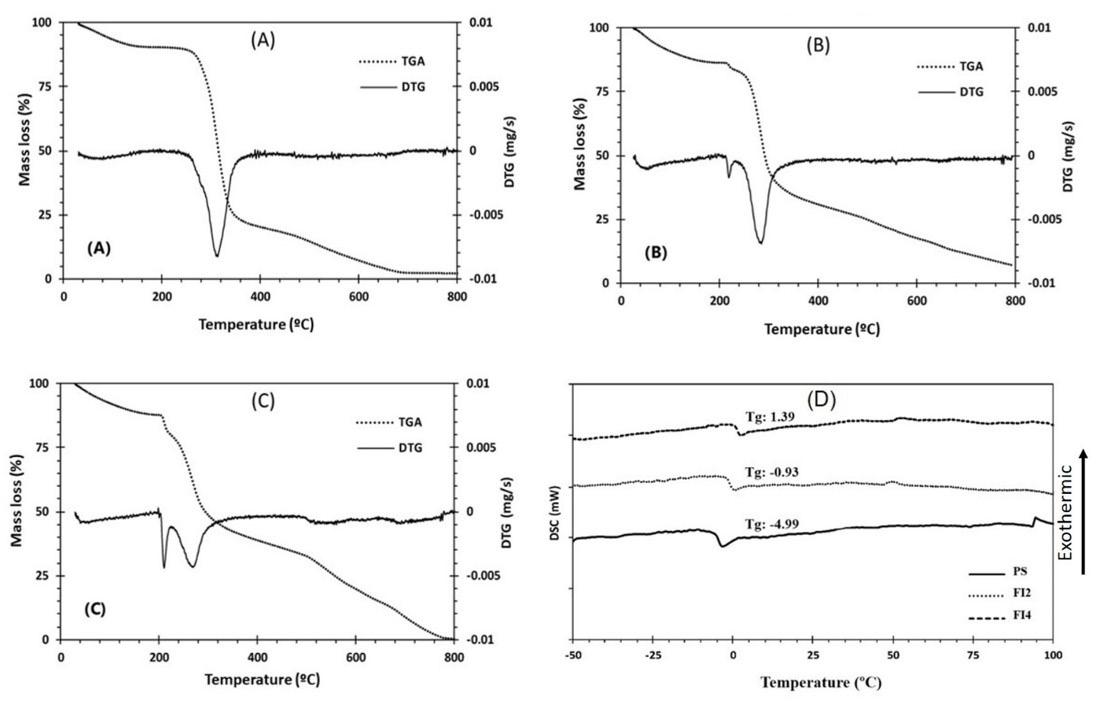

Figure 1 shows the DSC scans as time and temperature function for S0, S5 and M10 for the applied heating rates. During heating, an exothermic peak characteristic of the epoxy curing is observed. For S0, Figure 1a, at heating rates higher than 2 °C/min, the exothermic peak is verified on the half-way due to unfinished curing. Reports mention that the curing of DGEBA/Anhydride without catalysts takes place together with degradation reactions, usually at temperatures above 300 °C[5,23].

Additionally, to afore mentioned for the heating rates 5, 10 and 20 °C/min an endothermic peak is observed previously to the curing one (exothermic peak), which may be associated with the hardener (MTHPA) decomposition which starts at Ti = 120 °C and finishes at Tf = 275 °C, assuming nitrogen atmosphere and 10 °C/min as the heating rate, as reported elsewhere[18]. For S5 (synthetic catalyst added), Figure 1b, the curing presented a bell shape without discontinuities, indicating that for this system the reaction occurs through one mechanism, despite presenting lower time and temperature curing ranges[24-26]

Upon eggshell membrane addition as the catalyst, the epoxy curing proceeded at intermediate times and temperatures related to S0 and S5, Figure 1c-1d. Quantitatively in M10, there

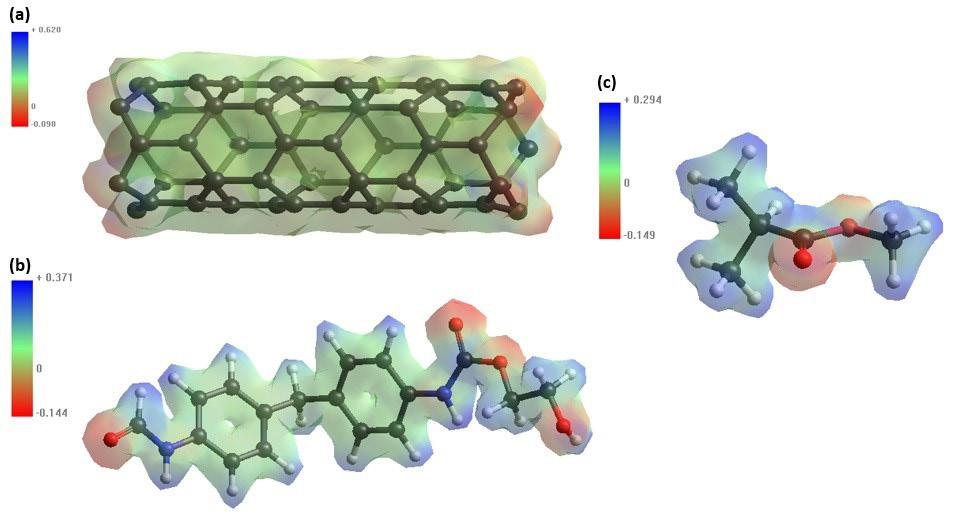

Polímeros, 32(3), e2022025,

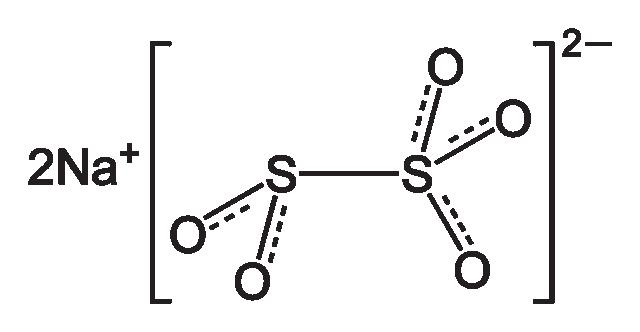

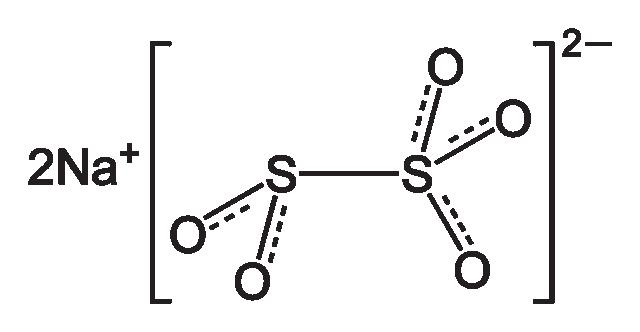

Barros, J. J. P., Jaques, N. G., Silva, I. D. S., Albuquerque, A. K. C., Araújo, A. M., & Wellen, R. M. R.is an increase of 65 °C of T0.01 related to S5 for the heating rate 10 °C/min (please see Table S1 of the Supplementary Material). Nevertheless, it is worth of mention adding the eggshell membrane the epoxy curing develops completely, occurs below 300 °C, and no degradation phenomena due to the MTHPA decomposition are verified. Therefore, may be assumed that the eggshell membrane properly acted as epoxy catalyst, as well as suggested that the curing initiation occurs through the amines and carboxyl present in the membrane proteins, as illustrated in Figure 2[17].

Figure 3a shows the relative degree of conversion as temperature function and Figure 3b the conversion rate as the degree of conversion function for S5 and M10 compositions.

Figure 3a illustrates epoxy compounds’ sigmoid as verified discontinuities are absents indicating that a sole process took place, this trend is typical of DGEBA curing under non-isothermal conditions, it may be suggested the curing occurred through the autocatalytic mechanism.

In general, the acquired sigmoid may be analyzed into three stages:

• In the first stage, 05% α ≤≤ , the curing rate is slow and gradually increases. In this stage the curing initiation through catalysis and formation of the first active centers take place, for the epoxy compounds produced in the

Polímeros, 32(3), e2022025, 2022

present work these phenomena may proceed by two mechanisms:

i) Esterification between the anhydride and the epoxy, whereas initially, the anhydride reacts with the epoxy’s hydroxyls and afterwards the produced carboxyl reacts with the epoxide ring. In S0 these processes would occur without initiator thus at longer times;

ii) Anhydride activation through the synthetic (DEH 35) or natural (membrane) initiator, followed by the oxirane ring opening.

• In the second stage, 590% α ≤≤ , the curing rate increases due to the reactive functional groups availability and easier molecular movement;

• In the third stage, 90100% α ≤≤ , the curing rate decreases due to the lower functional groups availability together with the viscosity increase resulted from the crosslinking[25-28]

Comparing Figure 3a-3b it may be observed that for S5 the curing proceeded at lower temperatures and higher rates than M10, which is resulted from the higher reactivity of synthetic catalyst (DEH 35). Nevertheless the membrane

Tailoring sustainable compounds using eggshell membrane as biobased epoxy catalyst

Tailoring sustainable compounds using eggshell membrane as biobased epoxy catalyst

Figure 2. Proposed reactions. (a) Oxirane ring opening by DEH35; (b) Oxirane ring opening by the eggshell membrane.

Figure 3. Degree of conversion (a); and Conversion rate (b) as temperature function. Heating rate 10 °C/min.

also promoted the curing through its main constituents such as glycine, alanine and uronic acid, once the amine and carbonyl groups in these constituents are potential catalysts[12,29]; the catalysis process occurs similarly to the synthetic one but slower. Figure 2 illustrates the proposed scheme for the epoxy curing under addition of synthetic (S5) and natural (M10) catalysts. The amino acid molecules attack the anhydride. Nevertheless, it must be considered that both the secondary amine and the hydroxyl group can also react with the oxirane ring.

Both curing reagents and process variables are the key controllers, aiming to understand and define the rational parameters the kinetic modeling is indispensable as bellow discussed.

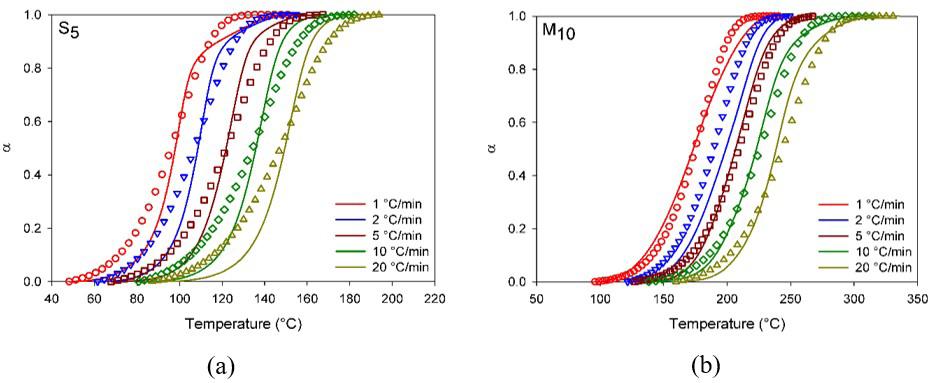

Plots in Figure 4 compare the experimental and theoretical degree of conversion as temperature function, and Figure S4 displays the discrepancy between these data estimated using the Kissinger model, which did not result in proper fits, being more evident for 00.5 α ≤≤ with

Polímeros, 32(3), e2022025,

Barros, J. J. P., Jaques, N. G., Silva, I. D. S., Albuquerque, A. K. C., Araújo, A. M., & Wellen, R. M. R.discrepancies higher than 10% for S5; whereas for M10 it was approximately 17% at 2 °C/min.

The Kissinger model estimates the global activation energy evaluated from the slope of linear regression ( ) 2 / p lnT β versus 1000/ p T (see Supplementary Material, Figure S9). However, it is feasible to consider E A as variable and increasing along with the curing, because upon higher α the reagents content and the active centers decrease, while the viscosity increases, translating in higher energy expenses to promote the curing.

Additionally, in Kissinger model p T is adopted to calculate the kinetics parameters; however E A in p T very likely differs between the initial and final stages[30]. It is believed, E A is function not only of temperature, but also of α, thus contributing to the discrepancy above verified and explaining the Kissinger inadequacy[26,27,31,32].

Alternatively, the Friedman Isoconversional model was applied aiming to evaluate EA along with α

Figure 5 displays the plots of E A and lnA as ( ) α function. Analyzing EA in the range 0.7 α > , S5 and M10 presented distinct trends while for S5 EA abruptly increases the reverse occurs with M10, the same trend is verified for lnA

It is suggested for S5 in the range 0.7 α > E A increases due to the competitive reactions leading to viscosity increase until reach the solid phase with decrease of the reactive groups availability, hampering the cross-linking.

Since, curing is followed by physical change of reaction medium. Initially, medium is a liquid composed of comonomers and newly formed oligomers. As the reaction progress, the oligomer/polymer’s molecular weight increases, as does the viscosity and glass transition temperature. Molecular mobility decreases. The most dramatic decrease in mobility is associated to the polymer chains crosslinking, whereas the medium changes from flowing liquid to solid that can be rubbery or glassy (gelling and vitrification). Cross-linked

Figure 4. Comparison between the experimental (lines) and theoretical (symbols) ,α, estimated using Kissinger model at indicated rates. (a) S5; and (b) M10.

Figure 5. Kinetics parameters of Friedman Isoconversional model. (a) E A versus α; and (b) lnA versus α

Polímeros, 32(3), e2022025, 2022

Tailoring sustainable compounds using eggshell membrane as biobased epoxy catalyst

Tailoring sustainable compounds using eggshell membrane as biobased epoxy catalyst

chains lose the ability to move over each other, providing greater molecular collision as seen in lnA[25-27,33]. Formation of glassy solid (i.e., vitrification) occurs when the glass transition temperature rises above the actual curing temperature. In both cases, dramatic decrease in molecular mobility affects the curing kinetics which becomes controlled by the reagents diffusion. This curing complexity leads to complex kinetic behavior that can be detected in EA changes with the curing progress. Free volume allowing only local movements of chain segments providing an increase in the overall EA[33-37]

For M10 EA increases in the range 0.10.7 α << due to reticulations processes as above mentioned. Nevertheless, for the range 0.7 α > it decreases, from literature database it is suggested, this fact implied the rate-determining step of the reaction generally changed from the reaction control to the diffusion limitation. The reason lied in that molecular chains mobility of reactive species became more limited due to the increased junction points and gradually elevated glass temperature, which greatly restricted configuration rearrangements and cooperative motions of the network chains, especially as the reaction system approached its glassy state[34,38]

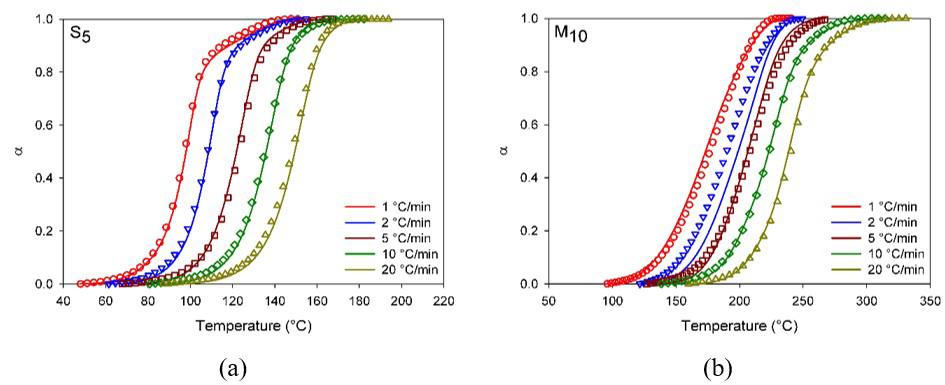

Figure 6 illustrates the theoretical and experimental plots of ( ) α as temperature function for S5 and M10, and Figure S5 (Supplementary Material) its discrepancies. Reasonable fits were gathered for both compounds with mean errors lower than 5%, exception is valid for M10 at 2 °C/min with deviation 13% that does not disqualify the model.

Investigation of the curing mechanisms was also performed through the linear regression of ( ) lnAf α versus ( ) 1 ln α , Equation 9, these plots are displayed in Figure 7. S5 and M10 presented an inflexion point on the conversion range of 0.4 and 0.23, respectively, this profile suggests compounds have similar curing mechanism, i.e., autocatalytic[16,24,25].

According to the literature, the autocatalytic mechanism best describes the curing of epoxy/anhydride due to OH formation that catalyzes the curing; these reactive functional

groups are generated by esterification, corroborating the sigmoid profiles as shown in Figure 4[39-41]

Aiming to effectively confirming the autocatalytic mechanism through the curing of S5 e M10 the kinetics parameters Ea, lnA and n were evaluated from the linear and angular coefficients of ( ) lnAf α versus ( ) 1 ln α , (linear zone) which range from -6 to 0.4. Based on these parameters theoretical plots were built for the autocatalytic Friedman model which are compared with the experimental ones in Figure 8 and their discrepancy is showed in Figure S6. Plots presented quite reasonable fits with errors lower than 10%, exception is valid for S5 and M10 at 1 °C/min with errors of 12% and 23%, respectively, due to higher deviation as verified at lower heating rates.

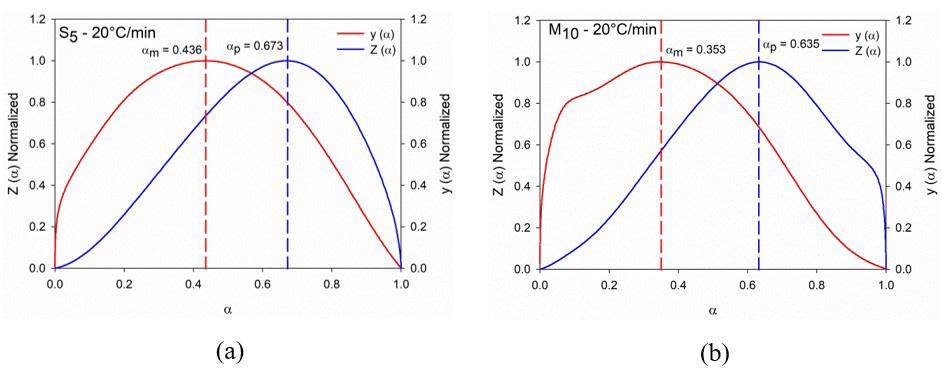

The functions of the Málek model ( ) y α and ( ) Z α as well as their maximum mα and pα were measured for S5 and M10 at the rate 20°C/min and are illustrated in Figure 9, (the other data are presented in Supplementary Material) both plots presented concave profile and agree with the criterion 0 0.632 mpαα <<≠ , indicating the curing is autocatalytic, as previously verified by autocatalytic Friedman model. From the parameter mα the linear regression ( ) / / . a ERT lndadte versus ( ) 1 p lnaa , Equation 14 was plotted afterwards the kinetics parameters lnA and nm + were estimated and are presented in Figure 10. As well as the autocatalytic Friedman linear regression the Málek regression displayed a roll with an inflection point indicating that the curing of S5 and M10 follows the autocatalytic mechanism, corroborating results already presented in Figure 9. Additionally, linear deviation was verified for the heating rates 1 °C/min and 2 °C/min, as also observed for the autocatalytic Friedman model.

As Málek model is unable to provide Ea the average EA evaluated based on the isoconversional Friedman model was applied to determine the kinetics parameters lnA, n and m through Equation 14. Afterwards, theoretical plots

Polímeros, 32(3), e2022025,

Barros, J. J. P., Jaques, N. G., Silva, I. D. S., Albuquerque, A. K. C., Araújo, A. M., & Wellen, R. M. R.Figure 7. Linear regression of Friedman ( ) lnAf α versus ( ) 1 ln α , Equation 9. (a) S5; and (b) M10

Figure 8. Experimental (lines) and theoretical (symbols) α evaluated using the autocatalytic Friedman model at the indicated heating rates. (a) S5; and (b) M10

Figure 9. Málek functions y (α) and Z (α) computed at 20 °C/min. (a) S5; and (b) M10

Polímeros, 32(3), e2022025, 2022

Tailoring sustainable compounds using eggshell membrane as biobased epoxy catalyst

Tailoring sustainable compounds using eggshell membrane as biobased epoxy catalyst

were built compared with the experimental ones as shown in Figure 11, their deviations are displayed in Figure S7. From Figure 11 proper correlation is verified for the Málek model in all applied heating rates for S5 and M10, which is corroborated by a maximum error of approximately 12%.

The kinetic parameters EA, lnA and nm + evaluated using the applied models in this work for S5 and M10 are shown in Table 2. Summing up EA displays distinct profile for S5 and M10 with a maximum difference of 29.85 kJ/mol through Friedman model based on the autocatalytic mechanism. Related to lnA, with exception of autocatalytic Friedman model, S5 resulted in higher values with maximum difference of 4.9 for Málek model when compared to M10, which suggests in S5 there are much molecular collision. These results indicate the curing reaction is more favorable for S5 than

for M10, corroborating the results of Figure 1 and Figure 3, confirming the greater reactivity of the synthetic initiator.

Regarding the parameter nm + for both compositions, it is higher than 1 confirming the complex curing profile and following the autocatalytic mechanism, which justifies EA variation along with the whole reaction, as also discussed in Figure 5. Additionally, these results are on line with those previously reported for curing in epoxy/anhydride resins[16,42].

In order to select the most appropriate model to describe the curing the theoretical and experimental plots of / ddt α are compared in Figure 12, and their discrepancies are in Figure S8. Applied models displayed proper fits with discrepancies lower than 5%, the exception was verified for Kissinger which was approximately 15%.

Isoconversion models by integration such as Kissinger are limited to determine Ea, since affords an overall Ea, which adds errors to the evaluation. However, it was observed for

Figure 11. Comparison between experimental (lines) and theoretical (symbols) α estimated using Málek model at indicated heating rates. (a) S5; and (b) M10

Polímeros, 32(3), e2022025,

Barros, J. J. P., Jaques, N. G., Silva, I. D. S., Albuquerque, A. K. C., Araújo, A. M., & Wellen, R. M. R.Table 2. Kinetics parameters of S5 and M10

Compounds

Kissinger Friedman Isoconversional Friedman Model Based* Málek

E a (kJ/mol) 69.9 ± 1.1 77.0 ± 3.81 66.7 77.0 ± 3.82 ln A (ln (1/s)) 15.6 ± 0.3 18.1 ± 0.31 15.7 15.0 ± 0.8 n+m - - 1.6 3.0 ± 1.1 R2 0.8716 0.9955 0.9979M10 E a (kJ/mol) 76.9 ± 20.3 96.6 ± 11.31 96.6 96.6 ± 11.32 ln A ln (1/s)) 13.2 ± 5.0 18.1 ± 2.81 18.9 10.1 ± 0.6 n+m - - 1.8 1.1 ± 0.4 R2 0.9329 0.9937 0.9928 -

S5

1Average EA and ln A based on Friedman Isoconversional model. 2Average EA based on Friedman Isoconversional for Málek model. *Presented data are without error/uncertainty range once the used software does not provide them.

Figure 12. Comparison between experimental and theoretical / ddt α for applied models at the heating rate of 5 °C/min (a) S5; and (b) M10

Friedman Isoconversional, as shown in Figure 5, for S5 curing, Ea developed in two stages, in the almost constant followed by the second with an ascending profile at the curing end, such variation invalidates the curing assessment by Kissinger.

For M10 Ea also changed along with the curing, hence invalidating Kissinger model. Summing up, the isoconversional Friedman, Friedman model based and Málek models are suitable for describing the curing of S5 and M10 resins.

Epoxy compounds with eggshell membrane and DEH 35 were kinetically investigated in this work and their parameters were evaluated using Kissinger, Friedman, Friedman model based and Málek models. From the DSC scans in M10 the curing occurs through one mechanism, despite presenting higher time and temperature related to S5. Nevertheless, it is worth of mention adding the eggshell membrane the epoxy curing develops completely as verified on DSC scans. Therefore, may be assumed that the eggshell membrane properly acted as epoxy curing catalyst. Applied models displayed proper fits with discrepancies lower than 5%, the exception was verified for Kissinger which

Polímeros, 32(3), e2022025, 2022

was approximately 15% most due to the activation energy changes along with the curing.

• Conceptualization – Janetty Jany Pereira Barros; Nichollas Guimarães Jaques.

• Data curation – Janetty Jany Pereira Barros; Nichollas Guimarães Jaques; Ingridy Dayane dos Santos Silva; Ananda Karoline Camelo de Albuquerque; Amanda Meneses Araújo.

• Formal analysis – Janetty Jany Pereira Barros; Nichollas Guimarães Jaques.

• Investigation – Janetty Jany Pereira Barros; Nichollas Guimarães Jaques.

• Methodology – Nichollas Guimarães Jaques; Renate Maria Ramos Wellen.

• Project administration – Renate Maria Ramos Wellen.

• Resources – Renate Maria Ramos Wellen.

• Software – Nichollas Guimarães Jaques; Janetty Jany Pereira Barros.

• Supervision – Renate Maria Ramos Wellen.

Tailoring sustainable compounds using eggshell membrane as biobased epoxy catalystBarros, J. J. P., Jaques, N. G., Silva, I. D. S., Albuquerque, A. K. C., Araújo, A. M., & Wellen, R. M. R.

• Validation – Nichollas Guimarães Jaques; Janetty Jany Pereira Barros; Renate Maria Ramos Wellen.

• Visualization – Nichollas Guimarães Jaques; Janetty Jany Pereira Barros; Renate Maria Ramos Wellen.

• Writing – original draft – Janetty Jany Pereira Barros; Nichollas Guimarães Jaques; Ingridy Dayane dos Santos Silva; Renate Maria Ramos Wellen.

• Writing – review & editing – Janetty Jany Pereira Barros; Nichollas Guimarães Jaques; Renate Maria Ramos Wellen.

The authors would like to acknowledge the financial support from the Coordenação de Aperfeiçoamento de Pessoal de Nível Superior (CAPES), from Conselho Nacional de Desenvolvimento Científico e Tecnológico (CNPq) and Fundação de Apoio à Pesquisa do Estado da Paraíba (FAPESQ) (Concession term: 017/2019). Professor Renate Wellen is CNPq fellow (Number: 307488/2018-7). The authors would like to thank Olin Corporation (Brazil) for kindly supplying the reactants.

1 Qi, B., Zhang, Q. X., Bannister, M., & Mai, Y.-W. (2006). Investigation of the mechanical properties of DGEBA-based epoxy resin with nanoclay additives. Composite Structures, 75(1-4), 514-519. http://dx.doi.org/10.1016/j.compstruct.2006.04.032.

2 Tang, L., & Weder, C. (2010). Cellulose whisker/epoxy resin nanocomposites. ACS Applied Materials & Interfaces, 2(4), 10731080. http://dx.doi.org/10.1021/am900830h. PMid:20423128.

3. Uglea, C. V. (1998). Oligomer technology and applications. Boca Ratton: CRC Press http://dx.doi.org/10.1201/9780585392233

4. Criado, J. M., Málek, J., & Ortega, A. (1989). Applicability of the master plots in kinetic analysis of non-isothermal data. Thermochimica Acta, 147(2), 377-385 http://dx.doi. org/10.1016/0040-6031(89)85192-5

5 Montserrat, S., Flaqué, C., Calafell, M., Andreu, G., & Málek, J. (1995). Influence of the accelerator concentration on the curing reaction of an epoxy-anhydride system. Thermochimica Acta, 269-270, 213-229 http://dx.doi.org/10.1016/00406031(95)02362-3

6 Pascault, J.-P., Sautereau, H., Verdu, J., & Williams, R. J. J. (2002). Thermosetting polymers Boca Raton: CRC Press http://dx.doi.org/10.1201/9780203908402

7 Mine, Y. (2008). Egg bioscience and biotechnology New York: John Wiley & Sons http://dx.doi.org/10.1002/9780470181249

8 Sharma, Y. C., Singh, B., & Korstad, J. (2010). A application of an efficient nonconventional heterogeneous catalyst for biodiesel synthesis from Pongamia pinnata Oil. Energy & Fuels, 24(5), 3223-3231. http://dx.doi.org/10.1021/ef901514a.

9 Wei, Z., Xu, C., & Li, B. (2009). Application of waste eggshell as low-cost solid catalyst for biodiesel production. Bioresource Technology, 100(11), 2883-2885. http://dx.doi.org/10.1016/j. biortech.2008.12.039 PMid:19201602.

10 Mosaddegh, E. (2013). Ultrasonic-assisted preparation of nano eggshell powder: a novel catalyst in green and high efficient synthesis of 2-aminochromenes. Ultrasonics Sonochemistry, 20(6), 1436-1441 http://dx.doi.org/10.1016/j.ultsonch.2013.04.008 PMid:23684545.

11 Laca, A., Laca, A., & Díaz, M. (2017). Eggshell waste as catalyst: a review. Journal of Environmental Management, 197,

351-359 http://dx.doi.org/10.1016/j.jenvman.2017.03.088 PMid:28407598.

12 Ji, G., Zhu, H., Qi, C., & Zeng, M. (2009). Mechanism of interactions of eggshell microparticles with epoxy resins. Polymer Engineering and Science, 49(7), 1383-1388 http:// dx.doi.org/10.1002/pen.21339.

13 Xu, Z., Chu, Z., Yan, L., Chen, H., Jia, H., & Tang, W. (2019). Effect of chicken eggshell on the flame‐retardant and smoke suppression properties of an epoxy‐based traditional APP‐PER‐MEL system. Polymer Composites, 40(7), 2712-2723 http://dx.doi.org/10.1002/pc.25077

14. Hamdi, W. J., & Habubi, N. F. (2018). Preparation of epoxy chicken eggshell composite as thermal insulation. Journal of the Australian Ceramic Society, 54(2), 231-235 http://dx.doi. org/10.1007/s41779-017-0145-4

15 Azman, N. A. N., Islam, M. R., Parimalam, M., Rashidi, N. M., & Mupit, M. (2020). Mechanical, structural, thermal and morphological properties of epoxy composites filled with chicken eggshell and inorganic CaCO3 particles. Polymer Bulletin, 77(2), 805-821 http://dx.doi.org/10.1007/s00289019-02779-y

16. Saeb, M. R., Ghaffari, M., Rastin, H., Khonakdar, H. A., Simon, F., Najafi, F., Goodarzi, V., Vijayan, P. P., Puglia, D., Asl, F. H., & Formela, K. (2017). Biowaste chicken eggshell powder as a potential cure modifier for epoxy/anhydride systems: competitiveness with terpolymer-modified calcium carbonate at low loading levels. RSC Advances, 7(4), 2218-2230 http:// dx.doi.org/10.1039/C6RA24772E

17 Jaques, N. G., Souza, J. W. L., Popp, M., Kolbe, J., Fook, M. V. L., & Wellen, R. M. R. (2020). Kinetic investigation of eggshell powders as biobased epoxy catalyzer. Composites. Part B, Engineering, 183, 107651. http://dx.doi.org/10.1016/j. compositesb.2019.107651

18 Jaques, N. G., Barros, J. J. P., Silva, I. D. S., Popp, M., Kolbe, J., & Wellen, R. M. R. (2020). New approaches of curing and degradation on epoxy/eggshell composites. Composites. Part B, Engineering, 196, 108125 http://dx.doi.org/10.1016/j. compositesb.2020.108125

19 Vyazovkin, S. (2017). Isoconversional kinetics of polymers: the decade past. Macromolecular Rapid Communications, 38(3), 1600615 http://dx.doi.org/10.1002/marc.201600615 PMid:28009078.

20 Vyazovkin, S. (1997). Evaluation of activation energy of thermally stimulated solid‐state reactions under arbitrary variation of temperature. Journal of Computational Chemistry, 18 (3 ), 393 -402 http://dx.doi.org/10.1002/(SICI)1096987X(199702)18:3<393::AID-JCC9>3.0.CO;2-P

21. Ton‐That, M.-T., Ngo, T.-D., Ding, P., Fang, G., Cole, K. C., & Hoa, S. V. (2004). Epoxy nanocomposites: analysis and kinetics of cure. Polymer Engineering and Science, 44(6), 1132-1141 http://dx.doi.org/10.1002/pen.20106

22 Souza, J. W. L., Jaques, N. G., Popp, M., Kolbe, J., Fook, M. V. L., & Wellen, R. M. R. (2019). Optimization of epoxy resin: an investigation of eggshell as a synergic filler. Materials, 12(9), 1489 http://dx.doi.org/10.3390/ma12091489 PMid:31071924.

23 Galy, J., Sabra, A., & Pascault, J.-P. (1986). Characterization of epoxy thermosetting systems by differential scanning calorimetry. Polymer Engineering and Science, 26(21), 15141523 http://dx.doi.org/10.1002/pen.760262108

24 Shanmugharaj, A. M., & Ryu, S. H. (2012). Study on the effect of aminosilane functionalized nanoclay on the curing kinetics of epoxy nanocomposites. Thermochimica Acta, 546, 16-23 http://dx.doi.org/10.1016/j.tca.2012.07.026

25. Nonahal, M., Rastin, H., Saeb, M. R., Sari, M. G., Moghadam, M. H., Zarrintaj, P., & Ramezanzadeh, B. (2018). Epoxy/PAMAM dendrimer-modified graphene oxide nanocomposite coatings:

Polímeros, 32(3), e2022025,

nonisothermal cure kinetics study. Progress in Organic Coatings, 114, 233-243 http://dx.doi.org/10.1016/j.porgcoat.2017.10.023

26 Zhou, T., Gu, M., Jin, Y., & Wang, J. (2005). Studying on the curing kinetics of a DGEBA/EMI-2, 4/nano-sized carborundum system with two curing kinetic methods. Polymer, 46(16), 6174-6181 http://dx.doi.org/10.1016/j.polymer.2005.03.114

27 Li , L. , Zeng , Z. , Zou , H. , & Liang , M. (2015). Curing characteristics of an epoxy resin in the presence of functional graphite oxide with amine-rich surface. Thermochimica Acta, 614, 76-84 http://dx.doi.org/10.1016/j.tca.2015.06.006

28 Barros, J. J. P., Silva, I. D. S., Jaques, N. G., Fook, M. V. L., & Wellen, R. M. R. (2020). Influence of PCL on the epoxy workability, insights from thermal and spectroscopic analyses. Polymer Testing, 89, 106679 http://dx.doi.org/10.1016/j. polymertesting.2020.106679

29 Nakano, T., Ikawa, N., & Ozimek, L. (2003). Chemical composition of chicken eggshell and shell membranes. Poultry Science, 82(3), 510-514 http://dx.doi.org/10.1093/ps/82.3.510 PMid:12705414.

30 Blaine, R. L., & Kissinger, H. E. (2012). Homer Kissinger and the Kissinger equation. Thermochimica Acta, 540, 1-6 http:// dx.doi.org/10.1016/j.tca.2012.04.008

31 Criado, J. M., Sánchez-Jiménez, P. E., & Pérez-Maqueda, L. A. (2008). Critical study of the isoconversional methods of kinetic analysis. Journal of Thermal Analysis and Calorimetry, 92(1), 199-203. http://dx.doi.org/10.1007/s10973-007-8763-7.

32 Šimon, P. (2004). Isoconversional methods. Journal of Thermal Analysis and Calorimetry, 76(1), 123-132 http://dx.doi. org/10.1023/B:JTAN.0000027811.80036.6c.

33 Vyazovkin, S., & Sbirrazzuoli, N. (2006). Isoconversional kinetic analysis of thermally stimulated processes in polymers. Macromolecular Rapid Communications, 27(18), 1515-1532. http://dx.doi.org/10.1002/marc.200600404

34 Wu, F., Zhou, X., & Yu, X. (2018). Reaction mechanism, cure behavior and properties of a multifunctional epoxy resin, TGDDM, with latent curing agent dicyandiamide. RSC Advances, 8(15), 8248-8258 http://dx.doi.org/10.1039/ C7RA13233F PMid:35542009.

35 Kamran-Pirzaman, A., Rostamian, Y., & Babatabar, S. (2020). Surface improvement effect of silica nanoparticles on epoxy

nanocomposites mechanical and physical properties, and curing kinetic. Journal of Polymer Research, 27(1), 13 http://dx.doi. org/10.1007/s10965-019-1918-y.

36 Achilias, D. S., Karabela, M. M., Varkopoulou, E. A., & Sideridou, I. D. (2012). Cure kinetics study of two epoxy systems with Fourier Tranform Infrared Spectroscopy (FTIR) and Differential Scanning Calorimetry (DSC). Journal of Macromolecular Science, Part A, 49(8), 630-638 http://dx.doi. org/10.1080/10601325.2012.696995

37 Li, C., Bu, Z., Sun, J., Fan, H., Wan, J., & Li, B. (2013). New insights into high-ortho phenolic novolac: elucidating dependence between molecular structure, curing kinetics and thermal stability. Thermochimica Acta, 557, 77-86 http:// dx.doi.org/10.1016/j.tca.2013.01.004

38 Roudsari, G. M., Mohanty, A. K., & Misra, M. (2014). Study of the curing kinetics of epoxy resins with biobased hardener and epoxidized soybean oil. ACS Sustainable Chemistry & Engineering, 2(9), 2111-2116 http://dx.doi.org/10.1021/ sc500176z

39 Erdoğan, B., Seyhan, A. T., Ocak, Y., Tanoğlu, M., Balköse, D., & Ülkü, S. (2008). Cure kinetics of epoxy resin-natural zeolite composites. Journal of Thermal Analysis and Calorimetry, 94(3), 743-747 http://dx.doi.org/10.1007/s10973-008-9366-7

40. Paramarta, A., & Webster, D. C. (2017). Curing kinetics of bio-based epoxy-anhydride thermosets with zinc catalyst. Journal of Thermal Analysis and Calorimetry, 130(3), 21332144 http://dx.doi.org/10.1007/s10973-017-6704-7

41 Montserrat, S., Flaqué, C., Pagès, P., & Málek, J. (1995). Effect of the crosslinking degree on curing kinetics of an epoxy–anhydride system. Journal of Applied Polymer Science, 56(11), 1413-1421. http://dx.doi.org/10.1002/app.1995.070561104.

42 Sun, G., Sun, H., Liu, Y., Zhao, B., Zhu, N., & Hu, K. (2007). Comparative study on the curing kinetics and mechanism of a lignin-based-epoxy/anhydride resin system. Polymer, 48(1), 330-337 http://dx.doi.org/10.1016/j.polymer.2006.10.047

Received: Dec. 09, 2021

Revised: July 16, 2022

Accepted: Aug. 01, 2022

Polímeros, 32(3), e2022025, 2022

Tailoring sustainable compounds using eggshell membrane as biobased epoxy catalystSupplementary material accompanies this paper.

Table S1. Curing parameters computed from DSC scans.

Figure S1. DSC scans for the investigated compounds at indicated heating rates. Effect of DEH 35 and eggshell membrane content.

Figure S2. Degree of conversion for S5 and M10 at indicated heating rates.

Figure S3. Curing rate (min -1) for S5 and M10 at indicated heating rates.

Figure S4. Discrepancy between theoretical and experimental α using the Kissinger model at indicated heating rates. (a) S5; and (b) M10

Figure S5. Discrepancy between theoretical and experimental α for Friedman isoconversional model at indicated heating rates. (a) S5; and (b) M10

Figure S6. Discrepancy between theoretical and experimental α computed using the autocatalytic Friedman model. (a) S5; and (b) M10

Figure S7. Discrepancy between theoretical and experimental α estimated using Málek model (a) S5; and (b) M10

Figure S8. Discrepancy between theoretical and experimental α at 5 °C/min. Applied models indicated. (a) S5; and (b) M10

Figure S9. Kissinger linear regression ( ) 2 / p lnT β versus 1000/ p T for S5 and M10 compounds.

Figure S10. Comparison between experimental and theoretical / ddt α estimated using Kissinger model at indicated rates. (a) S5; and (b) M10

Figure S11. Friedman isoconversional linear regression ( ) / lnddt α versus 1000/ p T for S5 and M10 compounds.

Figure S12. Comparison between experimental and theoretical / ddt α estimated using Friedman isoconversional model at indicated rates. (a) S5; and (b) M10.

Figure S13. Comparison between experimental and theoretical / ddt α estimated using Friedman model based model at indicated rates. (a) S5; and (b) M10

Figure S14. Málek functions y (α) e Z (α) for S5 at indicated heating rates.

Figure S15. Málek functions y (α) e Z (α) for M10 at indicated heating rates.

Figure S16. Comparison between experimental and theoretical / ddt α estimated using Málek model at indicated rates. (a) S5; and (b) M10.

This material is available as part of the online article from https://doi.org/10.1590/0104-1428.20210088

Polímeros, 32(3), e2022025,

Barros, J. J. P., Jaques, N. G., Silva, I. D. S., Albuquerque, A. K. C., Araújo, A. M., & Wellen, R. M. R.Rodolfo Rendón-Villalobos1* , Miguel Angel Lorenzo-Santiago2 , Roberto Olvera-Guerra1 and César Arnulfo Trujillo-Hernández2

1Centro de Desarrollo de Productos Bióticos, Instituto Politécnico Nacional, Yautepec, Morelos, México 2Centro de Ciencias de Desarrollo Regional, Universidad Autónoma de Guerrero, Acapulco, Guerrero, México *rrendon@ipn.mx

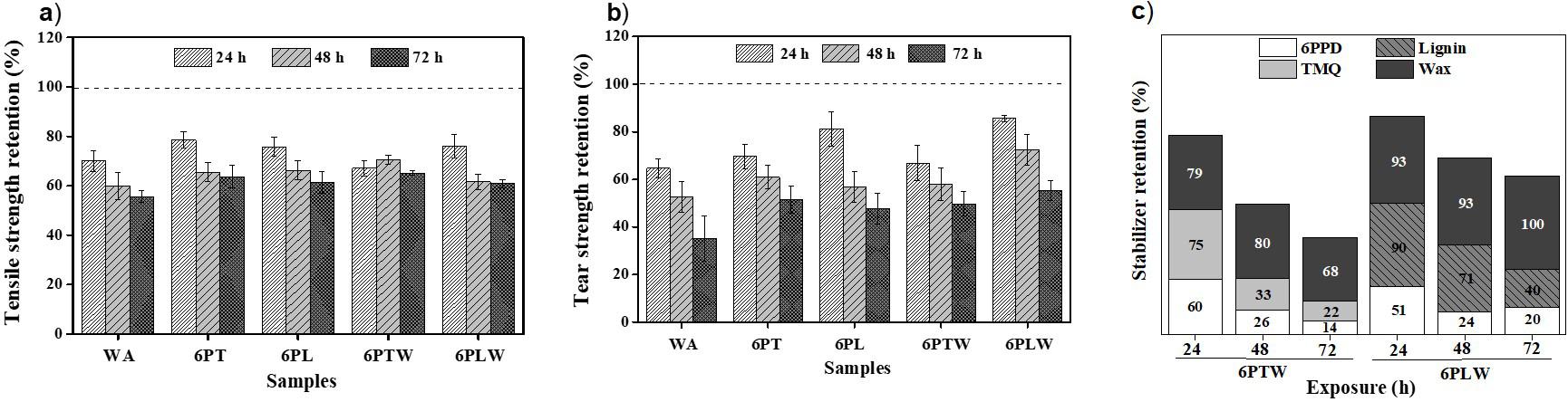

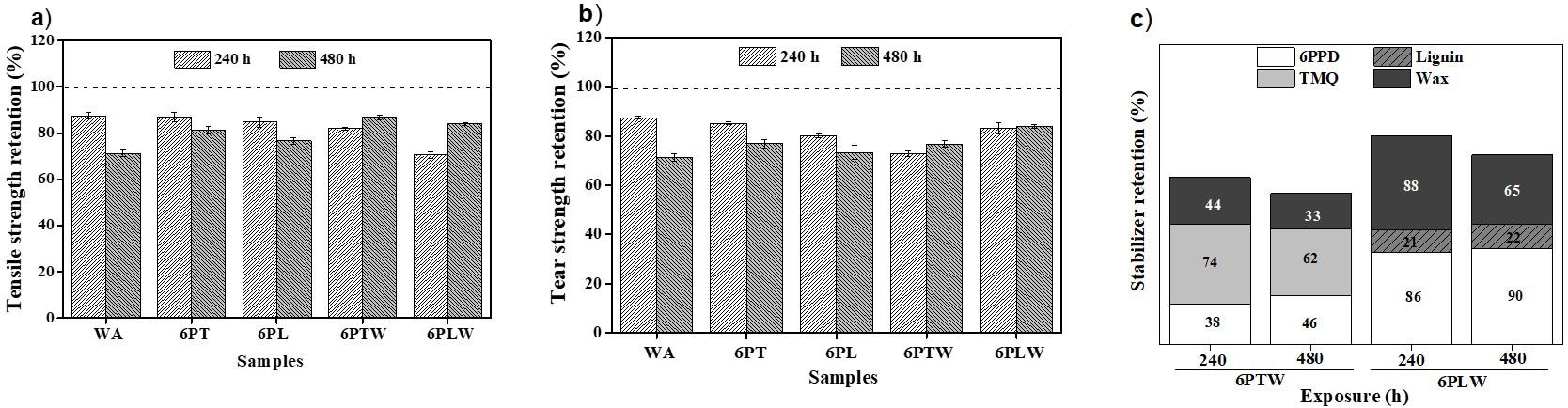

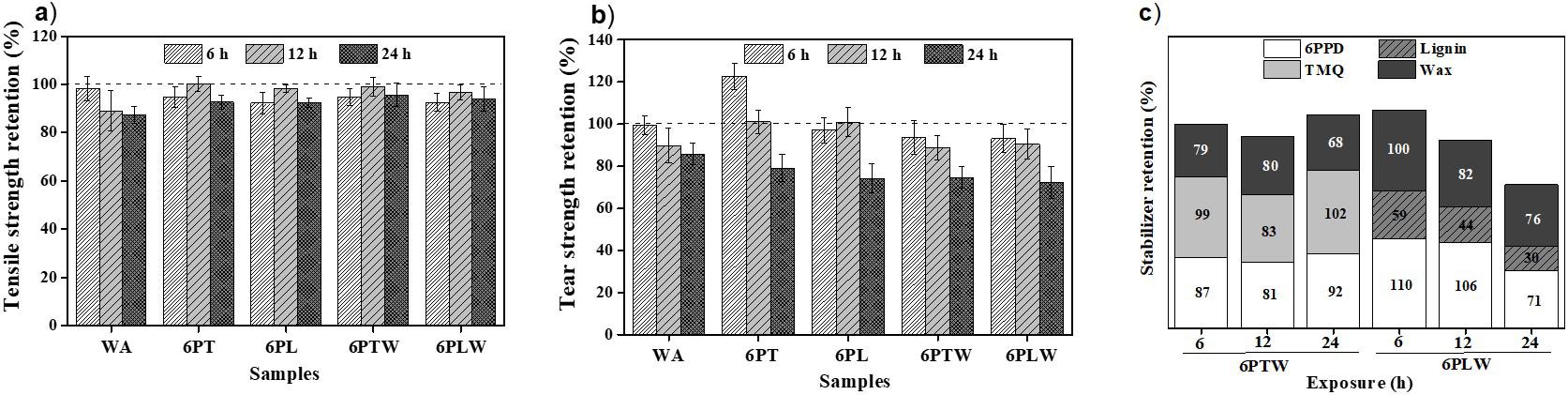

Waste mango was used to obtain starch and micro-cellulose for the production of bioplastic. Three different formulations were made: positive control or cotyledon starch/glycerol; SC1 or cotyledon starch/glycerol and cellulose at 0.1% and SC5 or cotyledon starch/glycerol and cellulose at 0.5% w/w. The bioplastics were mechanically analyzed (tensile strength, elongation and Young´s modulus) and, aerobic biodegradation analysis was realized with a standard test method based on the amount of material carbon converted to CO2. The mechanical tests indicated that with the addition of cellulose, the bioplastics improved their mechanical properties. The biodegradation at 30 days showed 93 and 94% for SC1 and SC5. Therefore, the biodegradation of bioplastics depends on both, the addition of cellulose and the environment where they are placed (e.g., soil characteristics: pH level, C:N ratio, moisture). These bioplastics offer new opportunities for fast degrading biomaterials in agricultural applications (padding and protection bags).

Keywords: bioplastic, cellulose, cotyledon starch, biodegradation, mechanical tests.

How to cite: Rendón-Villalobos, R., Lorenzo-Santiago, M. A., Olvera-Guerra, R., & Trujillo-Hernández, C. A. (2022). Bioplastic composed of starch and micro-cellulose from waste mango: mechanical properties and biodegradation. Polímeros: Ciência e Tecnologia, 32(3), e2022026. https://doi.org/10.1590/0104-1428.20210031

Since the appearance of synthetic plastics in the past century from the refining of petroleum, synthetic plastics have become the most commonly used materials in different industrial sectors, mainly due to their low cost, lightweight and durable materials with adequate mechanical and chemical properties[1,2]. The heterogeneity of synthetic polymers as well as the variability in their properties have allowed for their use in generating a wide range of products that have several benefits in the medical and technological sectors[2,3] However, pollution from plastic waste has developed to become a great threat to ecosystems, especially aquifers with the oceans been the most affected[4,5]. An estimated 8.3 billion metric tons of plastic are produced worldwide, and only 9% of used plastic has been recycled, 12% are incinerated and 79% accumulated in landfills or natural environment as litter[6,7]. In recent years, interest in the development and applications of degradable plastic (i.e., plastics produced from fossil materials) or bio-based plastics and fillers (i.e., plastics synthesized from biomass or polymers from renewable resources) with functionalities and processabilities comparable to traditional petrochemical-based plastic has attracted increasing attention[8].

Biodegradable polymers based on natural polysaccharides, such as starch and cellulose, are used as raw material to develop biodegradable films since they have the capability

of forming a continuous matrix and they are a renewable and abundant resource[9-12]. Starch is one of the most promising natural polymers because of its inherent biodegradability, overwhelming abundance and annual renewability[12-14] In addition to its status as a renewable resource, starches offer very attractive features: its low energy consumption involved in its production, its potential to add value to by-products from other industries, its characteristic biodegradability, among others[14,15]. Starch is essentially composed of a mixture of polysaccharides: amylose, amylopectin and a minor fraction (1% to 2%) of non-glycosidic conformation[16]. Amylose is avowed as linear polymer (poly-α-1,4-D-glucopyranoside) mainly distributed in the starch granule amorphous part and, a branched polymer amylopectin (poly-��-1,4-Dglucopyranoside and ��-1,6-D-glucopyranoside), that gives place to the crystalline domains[17]. In many native or normal starches, around 70 – 80% of the mass of starch granule contains amylopectin and about 20 - 30% amylose[16,17]. The studies of Mali et al.[18] and Bae et al.[19] reported that starches with high amylose content (~30%) have great filmforming properties in comparison with other starches with lower amylose content. Taking into consideration mango starch which can be used as raw material for the manufacture of biodegradable films, since the concentration of mango starch amylose is high enough (31.4%)[20], and is assumed

to be the basis for good biodegradable films. In this sense, it is important to point out that in Mexico the mango is one of the fruit crops with the highest production, reporting in 2019 a production of 2 089 000 tons[21], however, the low opening in the national and international markets have generated an increase in the generation of post-harvest waste. The waste mango currently it is not widely used and which represents an environmental problem due to the followings: lack of distribution channels of mango, inadequate management of the large volumes of residues that are generated, and environmental policies that regulate the deposition of post-harvest mango residues. Therefore, this waste mango can be used as raw material to obtain starch to develop bioplastic film.

Biodegradable plastic can be degraded by naturally occurring microorganisms such as bacteria, fungi, and algae to yield water (H2O), carbon dioxide (CO2) and/or methane (CH4), biomass, and inorganic compounds[22,23]. Therefore, the study of the biodegradability of biodegradable plastic plays a significant role in the development of biopolymers. For a bioplastic to be considered biodegradable, there must be a significant change in the chemical structure and also 90% of the substance is converted to carbon dioxide in less than six months[24]

As for cellulose, this polysaccharide is considered the most abundant natural polymer in the world with the characteristic of being renewable and biodegradable. In the same way it has also been a classic example of a biopolymer used as matrix[25,26]. Cellulose is commonly found in the primary cell wall of green plants; however, it is also produced by some bacteria[27]. It is completely a linear polymer whose basic unit is D-glucose which is successively linked through a glycosidic bond in configuration β (1-4) to form cellobiose molecules. Cellulose chains are arranged in microfibrils of polysaccharides which aids in the stability of plant structures which also suggests that cellulose is a biomaterial with high strength and other superior mechanical properties[23,24]. However, the native fibers of cellulose are rigid mainly due to the components that form them (Lignin, cellulose and hemicellulose), being lignin, the only component made up by aromatic organic units which gives it a high rigidity that allows it act as adhesive of the other two. Therefore, it became necessary to carry out series of chemical and thermal treatments to remove them from the fibers without damaging the structure of the cellulose microfibers[28]

For all of the above, many researchers have seen the development of biodegradable plastic as a promising solution in reducing the negative influence of plastic waste on the environment since they are environmentally-friendly and are also made from renewable resources and not from fossil fuels.

Regarding these concepts, the work aimed to evaluate the effect of the incorporation of micro-cellulose in the mechanical properties and biodegradation in soil of bioplastics prepared from cotyledon starch/glycerol/micro-cellulose.

Ataulfo mango waste (Mangifera caesia Jack ex Wall) were supplied by a regional mango producer in El Arenal,

Guerrero, Mexico. Sodium hydroxide, sulfuric acid, hydrogen peroxide, citric acid, ethanol, sodium chlorite, hydrochloric acid, glycerol, phenolphthalein and distilled water were supplied by Merck-Millipore™. Benzene, acetylacetone, dioxane and potassium hydroxide were purchased from Sigma-Aldrich™. All chemicals were used as supplied by the manufacturer.

The mango cotyledons were cut into 2 cm pieces and placed in a container kept in a continuous flow oven for 24 h at 40 °C. The cotyledons were ground for 5 min using a semi-industrial mixer with distilled water and citric acid 3% (w/v) solution[29]. The material obtained was passed through 60, 80 and 100 mesh sieves respectively, and the resulting mixture was centrifuged at 7000 x g for 5 min at 4 °C. Finally, the starch obtained was kept in a continuous airflow oven at 40 °C for 24 h, pulverized in a mortar, passed through 100 mesh sieve and stored in double click bags[30].

The apparent amylose content was determined according to the method suggested by Gilbert and Spragg[31], potato starch was used as standard. 0.1 g dry starch sample was weighed and 1 mL ethanol (95%) was added followed by 9 mL of 1 M NaOH solution. The sample was kept for 10 min in a shaking water bath at 85 ± 0.2 °C. The starch solution was cooled and transferred into a volumetric flask and the volume made up to 100 mL mark with distilled water. 2.5 mL of starch solution was taken into 50 mL standard flask; 0.5 mL of 1 M acetic acid was added followed by 1 mL of stock iodine (0.2 g I2 / 2.0 g KI/ 100 mL) and the solution made up to the 50 mL mark with distilled water. A sample was taken from this solution and transferred to a Perkin-Elmer Lambda 3B double beam UV/ visible spectrophotometer to obtain the absorbance of the sample at a wavelength of 600 nm. The blue value was calculated using the formula[31]:

The fibrous endocarp was cut and sieved with a 100mesh sieve. The bagasse was washed with distilled water for 20 min with stirring and at room temperature. It was filtered using filter paper, and the samples were dried in a continuous flow oven at 40 °C for 24 h[32]

The dried fibrous endocarp was subjected to alkaline treatment[30] using a 2% (w/v) sodium hydroxide solution in a ratio of 1:20 (fiber: solution), keeping it stirred for 2 hours at 80 °C (Figure 1a). The samples were oven-dried in continuous flow oven at 40 °C for 24 h, and ground using an E3303.00 mini cutting mill (Eberbach Corp.) The fibers were bleached (Figure 1a) in a 1:20 ratio (fiber: solution) in a solution composed of H2O2 (v/v) and 4% NaOH (w/v),

Polímeros, 32(3), e2022026,

Rendón-Villalobos, R., Lorenzo-Santiago, M. A., Olvera-Guerra, R., & Trujillo-Hernández, C. A.Figure 1. Illustrate kind steps of: (a) chemical (alkaline, bleached and acid hydrolysis) and thermal treatments (sonication) applied to cellulose to obtain micro-cellulose and (b) bioplastic preparation (from cotyledon starch and micro-cellulose).

stirred for 2 h at 50 °C and washed with distilled water and dried at 40 °C for 24 h[33]

2.3.2.

Cellulose fibers were prepared by acid hydrolysis (Figure 1a), using the method proposed by Cordeiro et al. [30] with some adaptations. Acid hydrolysis was carried out using H2SO4 solutions at 52% (w/w) in a 1:20 ratio (fiber: solution), with hydrolysis time of 2 h at 45 °C. The sample was centrifuged at 6300 x g for 10 min at 10 °C and, the

Polímeros, 32(3), e2022026, 2022

resulting suspension was sonicated for 5 min at a power of 99 W using a Branson™ 2510MT ultrasonic cleaner, according to the modified techniques of Szymańska-Chargot et al.[34] and Kasuga et al.[35]

The lignin content was determined using ethanolbenzene solvent for 5 h[36]. The mixture was washed with distilled water and dried in an oven at 103 °C for 1 h, then treated with 72% H2SO4 for 2 h while stirring at 37 °C.

Bioplastic composed of starch and micro-cellulose from waste mango: mechanical properties and biodegradationThe material was diluted to 3% H2SO4 and stirred at 80 °C for 4 h; finally, the sample was dried at 105 °C for 1 h and placed in a desiccator for cooling until a constant weight was obtained. The lignin content was calculated using Equation 1, where: A is the weight of lignin and W is the oven-dry weight of the test specimen[37]

A100 Lignin % W = (2)

Holocellulose was measured by treating dry fibers with an acidified aqueous sodium chlorite solution in an acid medium at 75 °C for 1 h[38] until the fibres were bleached. The determination of cellulose in fiber was carried out employing a process with aqueous solutions of acetylacetone, dioxane, and hydrochloric acid[39]. The hemicellulose content was theoretically calculated from the difference in the holocellulose and cellulose contents.

Bioplastic were prepared from cotyledon starch and micro-cellulose using the method described by Pranoto et al. [40] (Figure 1b). The solution was prepared from cotyledon starch (4% starch, w/v) with the addition of micro-cellulose (0.1 and 0.5%, w/v) and glycerol (0.9%, w/v) used as a plasticizer. The solution was prepared in a beaker with 95 mL distilled water at ambient temperature, then the cotyledon starch was added and stirred for 10 min at 30 °C. Thereafter, the solutions were kept at 60 °C for 10 min. Glycerol and micro-cellulose were then added and the solutions were made up to 100 mL with distilled water and heating was applied until it reaches 75 °C. The filmogenic solution was cast onto the glass plates (30 cm x 20 cm) and dried at 40 °C for 12 h in a continuous airflow oven (Barnstead International™, Model Imperial V). The films obtained were peeled off and stored in a desiccator at 25 °C with relative humidity (RH) of 57% provided by a saturated solution of NaBr.

The test was carried out based on the ASTM D598812 standard[41]; which establishes the test method to determine the degree and rate of aerobic biodegradation of materials in contact with soil. The soil had the following characteristics: pH 8.1, carbon 9.64%, nitrogen 0.19%, humidity 6.80%, C:N ratio (16:1). The desiccator was conditioned with layers of soil on the bottom on which were placed the bioplastics and polymer plastic. Inside the desiccator, 20 mL of 0.5 N potassium hydroxide (KOH) solution were placed in a 100 mL beaker, as well as another beaker with 50 mL of distilled water. The desiccator was sealed, and placed in a dark place at 21 ± 2 °C with a humidity of 50%. The carbon dioxide (CO2) produced was trapped by the KOH solution. In addition, a positive control desiccator was included; no biodegradable film sample. Periodically, the amount of CO2 produced by the microorganisms present in the soil was determined. The CO2 released from the system was fixed in the 0.5 N KOH solution and titrated with 0.25 N HCl, using phenolphthalein as an indicator. The percentage of biodegradation was calculated according to the following equation[41]:

mg of CO produced % Biodegradation 100 mg of theoretical CO = × ₂ ₂ (3)

The samples were cut obtaining an area of 4 cm2 and placed on the surface of the Petri dish containing the soil. The weight loss evaluation was determined gravimetrically, the samples were weighed before and after 5, 10, 15, 20 and 30 days of degradation. A polymer plastic bag (Low-density polyethylene, LDPE) was used as a reference[42]. The samples were carefully cleaned, then washed with distilled water, until all traces of soil were removed. Then, the samples were dried for 24 h at 60 °C. Finally, the films were weighed and the final weight was recorded. The calculation of the loss in weight was carried out using Equation 4 and photographic monitoring and analysis by SEM were carried out.

starting weightfinal weight % weight loss 100 starting weight = × (4)

To detect changes in the structure of fibers with alkaline treatment as well as chemical and structural analysis of starch, Fourier-transform infrared (FT-IR) spectra were performed on a Perkin Elmer Spectrum (100/100 N model, Shelton, CT, USA) in the range of 4000-650 cm-1 in the transmittance mode, with a resolution of 16 cm-1 and 8 scans[43]. Scanning electron microscopy (Carl Zeiss EVO LS 10) was used to observe the morphology of the samples at an accelerating voltage of 25 kV, with a resolution of 3-10 nm; spot size of 2 was used to image the samples[44].

The mechanical properties of the bioplastics were determined using TAXT2i texturing equipment (Stable Micro Systems™, Surrey, UK), equipped with a 25 Kg load cell. The bioplastics were studied following the ASTM method D-882-02[45]; the bioplastic samples were cut into rectangles that were 10.0 cm long and 1.0 cm wide. The tensile strength (TS), elongation (%E) and Young´s modulus, were determined using a deformation rate of 1 mm/min.

3.1

3.1.1

Cotyledon starch granules presented an oval and elliptical morphology, a size from 2 to 17 μm, with an average of 9.2 μm. This size is similar to that reported by cotyledon starch of five mango varieties grown in India, where the granules presented intervals of 1.5 to 28 μm in diameter[46] . The resulting starch composition showed a significant amylose content of 29.19%; nevertheless, it was lower than the amylose content of 30.45% and 32.0% found in seeds from Tommy Atkins an Alphonso varieties mango[47,48] Morrison and Azudin[49] and Gao et al.[50] have reported that the amylose content may vary due to environmental effects and cultural conditions. In general, it has been reported that

Polímeros, 32(3), e2022026,

Rendón-Villalobos, R., Lorenzo-Santiago, M. A., Olvera-Guerra, R., & Trujillo-Hernández, C. A.the amylose content present in native starches is between the values of 18 and 30% and 70 to 82% for amylopectin content, in addition to the presence of other constituents such as lipids, proteins and minerals[51,52]. The lower the amount of these other constituents and the higher the amount of amylose, the better the film and coating formation as amylose is directly linked to the chemical and physical characteristics of the film[53]

On the other hand, since what is sought in a fiber with hydrophobic properties, that can help and avoid deterioration due to high humidity conditions, it is necessary to perform a chemical and thermal treatment, that can help to remove glue from the fibers without damaging the structure of the micro-cellulose fibers.After chemical and thermal treatment the fibers showed a uniform surface and rectangular shape with sizes ranging from 40 to 400 μm in length, in comparison with the values of 200 to 250 μm that presents the native fiber (without chemical and thermal treatment). Likewise, the application of the fibers is desired for reinforcement in polymer blends, it is desirable to remove amorphous constituents (hemicellulose and lignin) and increase the content of cellulose, which is the crystalline phase of the fiber[32,34]. The decrease in contents of lignin and hemicelluloses was recorded for sample modified in NaOH and H2SO4 solutions. The results of lignin were 10.03 wt % for native fiber and 0.72 wt % for fiber subjected to a modified acid-alkaline treatment; this result showed that the lignin determined by the Klason method, was partially removed in cellulose fibers. The calculated hemicellulose decreased from 28.63 wt % to 1.49 wt % for native and modified fiber, respectively. Based on the results, the lignin content from this study (10.03 wt %) is close to the value of 9.0 wt % reported by Guzmán et al.[53]. However, different values are obtained given that the food-processing industry method was employed which is similar to the Klason lignin extraction process, with the variant that a final step of 1 h calcination at 550 ° C is done. A major difference was observed in the lignin results in relation to the values of 5.76 wt % and 6.97 wt % of lignin in mango peel and mango by-products, respectively[54,55]. On the other hand, the hemicellulose content of 29.75 wt % obtained in this study was lower than those of mango peel (32.5 wt %) and mango by-products (31.75 wt %)[53,56]. A possible explanation is the fact that hemicellulose was not completely removed by the neutral detergent solution used for determining the Neutral Detergent Fibre in the food-processing industry method, as such this method was not used for this study. In addition, the acid concentration (52% w/w) used in the hydrolysis process allowed the destruction of both the amorphous and crystalline regions of cellulose and the decrease in contents of lignin and hemicelluloses[57-59].

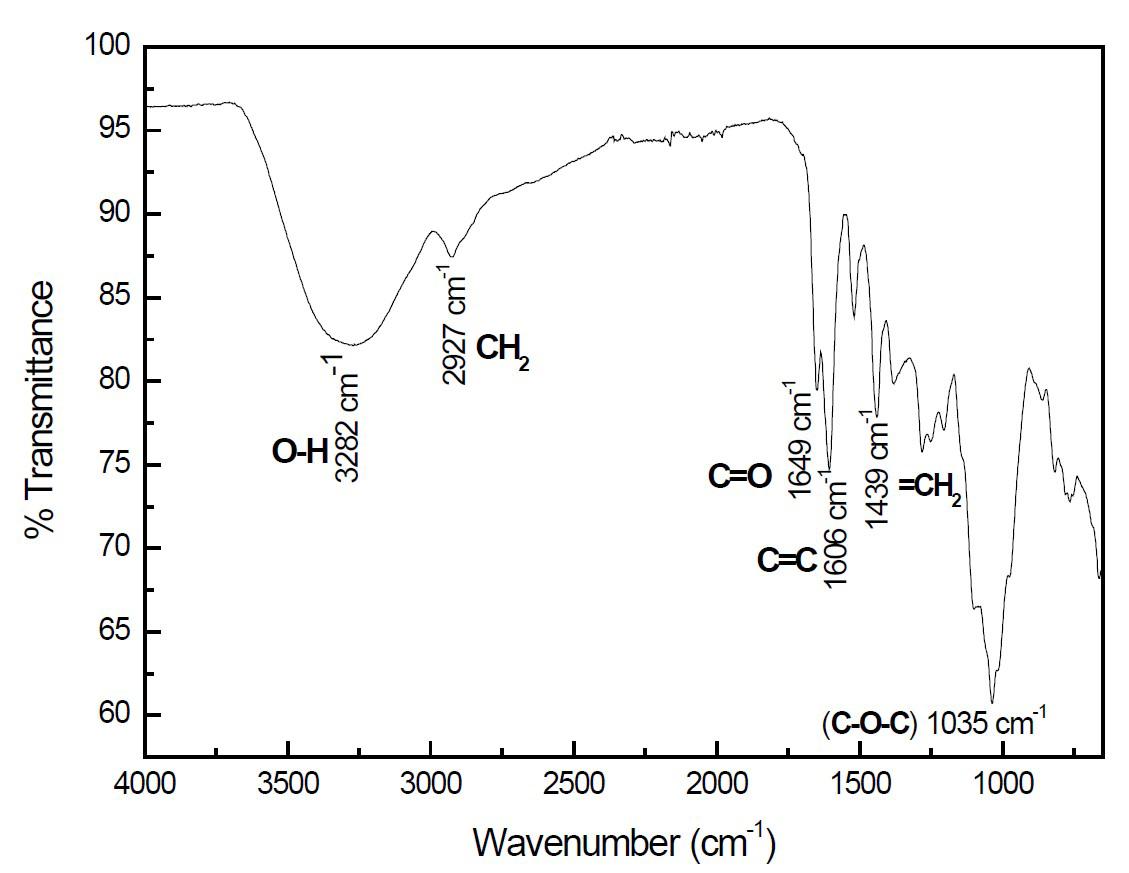

Through acid-alkaline treatments, hemicellulose and lignin were removed, as this also improves the thermal stability and tensile strength of the fibers, an essential property necessary for the elaboration of bioplastics. Typical bands assigned to cellulose were observed in the region of 1745 - 900 cm−1 , where the signal at 1635 cm−1 correspond to vibration of water

Polímeros, 32(3), e2022026, 2022

molecules absorbed in cellulose and starch. The absorption bands at 1420, 1366, 1334, 1027 cm−1 and 896 cm−1 belong to stretching and bending vibrations of CH2 and CH, OH and C-O bonds in cellulose. The native and micro cellulose fibre infrared spectrum subjected to chemical treatment showed a peak at 894 cm-1 (Figure 2), signal was found in the polysaccharide absorbing region (950-700 cm-1) which is associated with the anomeric carbon present in cellulose and which also reveals the component structures of ß-glucans[60]. The stretching of C-O-C bonds of the alkyl-aryl ether (at 1232 cm-1), a compound that belongs to the structure of lignin can be observed only in the native sample since this signal disappears after chemical treatments confirming lignin removal. The 1745 cm-1 peak corresponds to the stretching of the C=O groups linked to aliphatic carboxylic acid and ketone and the residue of hemicellulose or the ester links of the carboxyl group in the ferulic and p-coumaric acids of lignin and hemicellulose[61,62]. This signal decreased when the sample is subjected to acid treatment, which made it possible to verify the removal of lignin and hemicellulose. The bands within 2922-2854 cm-1 are ascribed to the aliphatic materials such as cutin, waxes and cutan present in hemicellulose and lignin[63].

The band at 2876 cm−1 is attributed to CH stretching vibration of all hydrocarbon constituent in polysaccharides. The FTIR spectra of the fibre samples under study provided evidence that the fibers subjected to a chemical treatment has featured the removal of lignin and hemicellulose. A significant decrease is noted in the infrared spectrum when the sample was subjected to an acid-base treatment due to the removal of these components[64]

In the case of native cotyledon starch, the FTIR spectra provided information about the presence or absence of specific functional groups and can give an even deeper insight into the granule starch structure. In the region within the spectrum of 1700 – 800 cm-1 the fingerprint was found, the region where the characteristic peaks in polysaccharides occur. In the region between 3000-2800 cm-1 the C-H stretching was found and finally the region between 3600-3000 cm-1 the O-H stretch region was found. The band in 930 cm-1 is attributed to the α-1,4 glycosidic bonds, (C-O-C) in starches. The peak at 1163 cm-1 is attributed to C-O coupling modes and C-C stretching of the polysaccharide structure[65]. A signal was observed at 2920 cm-1 which is related to the amount of amylose and amylopectin present in the starch granules. A peak appears at 2850 cm-1 which is related to the alkyl

Bioplastic composed of starch and micro-cellulose from waste mango: mechanical properties and biodegradation

Bioplastic composed of starch and micro-cellulose from waste mango: mechanical properties and biodegradation

and aliphatic groups (H-C-H) present in hemicelluloses and lignin[64]. The presence of this peak is attributed to a thin filament composed of fiber that covers the cotyledon. The maximum absorption was found at 3280 cm-1, which is considered due to the vibrational tension stresses associated with the free, intermolecular and intramolecular bonds of the hydroxyl groups of starch[66]. Infrared spectroscopy showed direct information on chemical changes that occur during chemical and thermal treatments applied to cellulose, in the same way FTIR allowed to observe the presence of different functional groups in the isolated samples (e. g. starch).

Mechanical properties of starch/micro-cellulose-based bioplastics and conventional plastic (low-density polyethylene, LDPE) are shown in Table 1

The tensile strength (TS), Elongation (%E) and Young´s modulus of the starch bioplastic sample (positive control) was lower when compared with other samples. However, samples with cellulose presented higher values. These results suggest that at higher cellulose content, mechanical properties of the material tends to increase, since the interaction between the reinforcing material and the polymeric matrix determines the mechanical properties, in terms of stress, elongation and Young’s modulus[67]