5 minute read

Digitizing Print

Digitizing Print: The latest launches by leading players of the Technology

“An update on the latest machines launched in the past six months by leading global digital printing machinery manufacturers.” - Jacob George

Advertisement

> Digital Printing innovations brave the

COVID holdup. Xeikon

CX300 replaces

CX3; HP Indigo upgrades 6K and 8K; Canon upgrades

LabelStream 4000 series. > Screen PacJet FL830 is a brand new technology scheduled to be released around

March 2021. > Miyakoshi develops

MJP30AXF; Memjet’s

DuraFlex combines speed, simplicity, affordability & durability. Despite it being a Covid infested world, the advances made by the digital printing machinery manufacturers have been interesting in the last six months. In fact the industry pundits had predicted 2020 to be an eventful year considering it was the Drupa year and

Kodak and Uteco have also returned to the market through the latest technology updates and upgrades in the flexible packaging market. They have further strengthened their partnership and launched the first flexible packaging printing machine Sapphire Evo W that uses Ultrastream continuous inkjet technology.

Key Notes :

many launches were expected as well. We try to look at the various options that have been made available by different manufacturers during the first 6 months of 2020.

Take Xeikon’s new CX300 as an example. It replaces the CX3 and provides the option to upgrade to the CX500. The CX300 is a 330mm format label printing machine and a single shift operation can provide over 50,000 square meters of production capacity per month. The full-colour printing press is equipped with five printing units, including CMYK and singlechannel opaque white. Based on the company’s Cheetah 2.0 technology, and other features include: printing speed up to 30m/min; printing format 220- 512mm; LED imaging head running at 1200x3600dpi, and providing image quality equivalent to offset and gravure printing, allows the operator to evaluate the status of the printing press remotely in addition to other features.

HP Indigo 6K and 8K have also been updated – upgrading the existing digital label printing technology. The new products launched in the HP Indigo stable are 6900 and 8000 models. The HP Indigo 6K digital printing press has been carefully designed to provide more applications, including high opacity white for shrink sleeves, and new brands including silver, fluorescent, invisible red and green for brand protection applications Inks, as well as brand-new glazing functions from industry partners that provide enhanced mechanical durability and improved performance, improve the characteristics of labels produced using the “package-ready” label ecosystem. The new and improved 8000 digital presses have added similar features, including increased productivity, reduced waste, and easier conversion between media types and jobs.

Canon has also upgraded its LabelStream 4000 series, adding optional orange channels, high-opacity white inks similar to screens, and enhanced usability to improve production efficiency. The new white ink channel can achieve an opacity of up to 80% at a speed of 36m/min in a single pass. The LabelStream

4000 Core unit provides an entry-level option that can be expanded to meet specific requirements.

Kodak and Uteco have also returned to the market through the latest technology updates and upgrades in the flexible packaging market. They have further strengthened their partnership and launched the first flexible packaging printing machine Sapphire Evo W that uses Ultrastream continuous inkjet technology to enter the market. The two companies previously collaborated on the development of Sapphire Evo, which includes Kodak Stream technology (predecessor of Ultrastream). The first system that uses Ultrastream technology and has a print format of 1250mm has been sold to the market. Based on water-based inks, Sapphire Evo W has a wide format and

provides a production speed comparable to traditional analog printers. It can print small to medium batch orders, achieving a price advantage comparable to flexo printing, and can be compared with traditional flexible packaging printing.

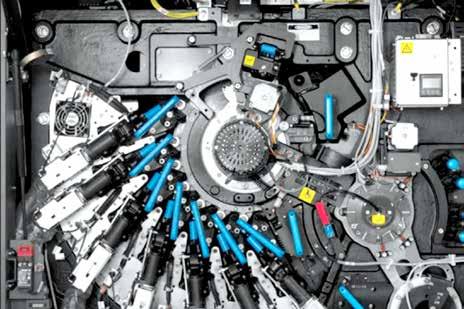

Screen’s PacJet FL830 is a brand new technology. It is an aqueous inkjet printing system for flexible packaging that can handle large-scale production applications. PacJet FL830 is currently scheduled to be released around March 2021. PacJet FL830 can process media up to 830mm at a speed of 75m/min. It can use CMYK and white waterbased inks that comply with relevant food safety regulations and print at a resolution of 1200dpi.

Japanese printer manufacturer Miyakoshi

developed MJP30AXF, another waterbased inkjet printer that prints on flexible packaging. Due to the use of water-based inkjet and its related advantages in food safety, the company has determined that MJP30AXF is particularly suitable for food packaging applications. In May 2020, the first MJP30AXF was installed in Beta customers in Japan. The MJP20W/30W model is a new UV inkjet digital printing system for flexible packaging applications. These objectives are based on Miyakoshi’s initial success with the MJP13LXV UV inkjet digital label printer.

Memjet’s technology is likely to be the basis of many inkjet digital flexible packaging printing systems, especially its DuraFlex platform. DuraFlex is a modular, single-pass printing system designed to combine speed, simplicity, and affordability with enhanced durability, A4 and A3 widened four-colour printheads, high-speed data paths, and modules that control all functions of the printhead. This will be the core of the nextgeneration MVZ printing machine of Italian printing machine manufacturer Rigoli, which has a higher printing speed and can be directly integrated into many new packaging lines.

It is generally expected that Landa will finally realize its commitment to the flexible packaging printing market in terms of printing speed and format, because many people predict that its 1000mm format W10 will become its cornerstone that supports 1050mm web size and can print 4-8 colours at high speed.

Well, to put it softly, there seems to be a whole lot of development that we can see in the arena considering the brakes that has been put on the industry by the Corona pandemic! As they rightly say, come what may, the show must go on.