13 minute read

Bobst Vision K5 for Aditya

Aditya Flexipack becomes first Converter in India with BOBST AluBond

Kanpur based Aditya buys BOBST VISION K5 equipped with AluBond for production of High Barrier and High Adhesion CPP and BOPP Films.

Advertisement

Kanpur-based Aditya Flexipack, one of the leading flexible packaging products manufacturers in India, has purchased a VISION K5 1650mm which will be installed in their state of the art green field project focused on qualitative improvements & backward integration; the facility is spread across 19 acres and will be one of the largest converting facilities under one roof. The new metallizer is equipped with BOBST AluBond for the production of high barrier and high adhesion CPP/BOPP films and BOBST Hawkeye pinhole detector.

The VISION K5 will be the first metallizer for Aditya Flexipack after they decided to expand their business to bring the metallizing

process in-house. To meet the requirements of their customers, Aditya required a machine which could produce high barrier CPP and BOPP with high adhesion and high dyne level retention.

Established almost 20 years ago, Aditya Flexipack is known for their high quality, customer focused products and sustainable & safe working practices which have resulted in many long-term relationships with its valued customers.

The BOBST AluBond process which is fast becoming the standard metallizing process in the market for polyolefin based PP substrates was perfect for their requirements.

AluBond greatly increases metal adhesion on the most commonly used substrates; metal adhesion values of up to 5N/15mm can be achieved. In addition AluBond has been shown to significantly increase dyne level retention which translates in improved ink wettability during printing and may eliminate the need for an additional surface treatment boost i.e. corona refresh prior to converting.

Apart from providing excellent adhesion levels on all substrates, when AluBond is applied to CPP and BOPP films, it provides enhancement of oxygen (OTR) and water vapour (WVTR) barrier performance. AluBond is also starting to be used in the production of high barrier metallized CPP and BOPP mono-material laminates in response to the market’s demands for sustainable packaging films.

Commenting on the investment, Mr Raman Tandon, Director of Aditya Flexipack said, “Due to demand from our customers for metallized CPP/BOPP with high adhesion, high barrier and dyne level retention; we decided to bring the metallizing process inhouse. BOBST are well known in the industry for their machines’ ability to handle heat sensitive films such as CPP and we were very impressed with the AluBond process which will allow us to produce high quality film for our customers. We look forward to the machine being installed in our factory in the next couple of months”.

The whitepaper unveils the new four pillar approach to sustainability.

Flint Group Packaging Inks, one of the largest consumables suppliers to the global packaging industry, has identified four strategic pillars key to successfully achieving its sustainability ambitions.

Outlined in a new whitepaper published by Flint Group, the four pillars set out a programme of objectives and milestones that align with the company’s vision of realising a truly circular economy within the packaging industry.

Doug Aldred, President Global Packaging Inks said: “The new four pillar approach provides our Sustainability Task Force with clear areas of focus. Sustainability is a huge topic for the industry but there isn’t a single defined path that results in success. This is a journey that we share with our customers, suppliers and stakeholders and we encourage a shared commitment to bring about change. We are investing our time to focus on ways that we can support a circular economy in packaging and look forward to working with the wider industry on these efforts going forward.”

The four pillars include Ethical Management, Reduced Ecological Impact, Responsibly Built Products and Designing for Circularity.

Setting out a clear framework for global company-wide development, the Ethical Management pillar incorporates a range of audits and standards that Flint Group Packaging Inks has implemented for both the company and its suppliers to adhere to. In addition, it details new policies which are needed and that address human rights, antidiscrimination, green engineering and waste management, as well as anti-corruption and equal opportunities practices.

Reduced Ecological Impact includes a programme of targets for the business to meet in relation to energy consumption, greenhouse gas emissions, water consumption and landfill waste. It also outlines Flint Group Packaging Inks’ commitment to achieving ISO14001, the international standard for an effective environmental management system. The XtraMile programme, an initiative to help printers boost connectivity, reduce waste and drive operational efficiency, is also incorporated.

The third pillar of Flint Group Packaging Inks’ sustainability strategy, Responsibly Built Products, addresses the building blocks of ink formulation, regulatory compliance and the environmental impact associated with their use.

Mr. Paul Winstanley, Sr. Directory Technology & Innovation for Packaging Inks EMEA commented, “Our technical teams are developing sustainable ink formulations using non-fossil fuel based raw material sources that do not, for example, compete with food resources or contribute to deforestation. We have also commercialised a range of mono-solvent inks for gravure applications and have developed solutions for both flexo and gravure applications that are compliant with compostability standards to meet the increased demand for compostable packaging.”

The fourth strategic pillar addresses the design of inks and coatings for the circular economy in support of the development of fully recyclable packaging solutions with minimal waste creation. By working closely with the recycling industry, the company is developing inks that are easier to recycle, including new water-based and low VOC inks.

The whitepaper is available to download from the Flint Group Packaging Inks’ website.

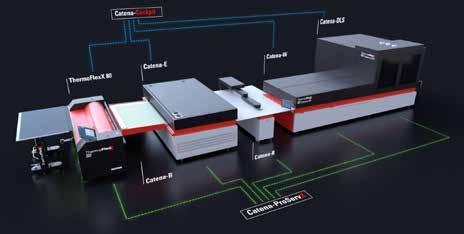

Flint Group announces ThermoFlexX Catena+

Fully automated flexographic plate processing equipment line minimizing operator intervention.

Flint Group has unveiled TermoFlexX Catena +, a fully automated plate processing line consisting of equipment modules which were announced earlier by the group; Catena - E (UV LED exposure), Catena - W(solvent plate processor), and Catena - DLS (dryer, light finisher and plate stacker combination with robotized plate transport).

Catena means “connected chain” and just as the name reveals, the Catena+ line is a modular system, which can join together for various levels of automation.

A Catena-DLS module can be connected to a Catena-W for automatic plate-processing. The Catena-DLS has 10 drying units, 7 stacking positions and a light finisher. Robotic movement ensures that plates are fully finished with no operator intervention after loading into the washer.

“We are proud to announce the CatenaDLS, the missing piece on our way to fully automated flexo plate processing. In combination with our ThermoFlexX imager, the recently released Catena-W and the Catena-E UV LED exposure, we provide a state-of-the-art, fully automated and integrated flexo plate processing system, which allows our customers to produce flexo plates at lowest total cost for every application,” explains Uwe Stebani, General Manager Xeikon Prepress. “And in combination with our groundbreaking Feldmuehle GmbH, manufacturer of label and flexible packaging papers, produces vegan paper. More and more consumers and manufacturers are refusing to buy products that contain animal ingredients. It is also an important subject for Feldmuehle – it is proved by the fact that all papers made by Feldmuehle are vegan. ThermoFlexX Woodpecker surface screening software and best-in-class Flint Group flexographic plates, we enable our customers to rival any other system in the market.”

Catena+ fully automated flexoplate making brings the whole chain together. Once the operator has removed the cover sheet the plate is automatically loaded into the imager, and is completely processed and fully finished with no further operator interventions needed, eliminating any damage caused by manual plate handling.

Designed as an open system, Catena+ allows easy loading of plates from other imagers into the Catena-E LED exposure

Feldmuehle produces vegan paper

unit. Plates from other exposure frames can No animal substances (such as protein or gelatine) are used in the production of Feldmuehle’s one-sided coated papers. Genetically modified raw materials are also not used in production. As an FSC certified company (FSC®C124501) it uses only materials that come from well-managed sources. Taking their responsibility towards society and the environment very seriously, the company attaches great importance to always being able to offer its customers ecologically and socially sound products.

also be easily loaded to take advantage of the highly productive WDLS.

The full line Catena+ also includes Catena Cockpit, which provides a highly visible status report on plate processing, progress and expected time of completion.

With Catena ProServX software, the machine health status of all modules is constantly monitored, thus, enabling a new level of pro-active support and maintenance. The need for physical service-interventions is minimized.

Feldmuehle GmbH develops and manufactures high-quality white coated label papers and packaging papers for the German and international market. In these two business areas, the company offers a broad product portfolio for the label and packaging industry, printing houses, brand owners and converters. Since June 2018, the company is part of a subsidiary of the Berlin-based Beteiligungsgesellschaft Kairos Industries AG. It is continuing the 100-year old tradition of paper production at the Uetersen site.

Holograms to secure global alcohol revenues

New tax stamp holograms welcomed in battle to secure alcohol excise revenues – Goa and Rajasthan to introduce holographic tax stamps.

Plans for new holographic tax stamps in Asia show the technology continues to be an effective device in the battle to secure global alcohol revenues, according to an international trade body.

The International Hologram Manufacturers Association (IHMA) was commenting on moves by Goa and Rajasthan in India to introduce a new excise policy for 2020-21, which will feature holographic tax stamps as a central plank of measures to protect alcohol revenues.

This would bring the total number of states in India adopting tax stamps to 25 as the country continues to fight the criminals who trade in illicit alcohol across the Asia subcontinent.

Excise duty on alcohol is a critical source of government revenue while providing way of controlling and limiting consumption, says the IHMA.

However, illicit smuggling and counterfeiting cost treasuries billions of dollars a year in lost revenue. And the cost is not just a financial one affecting governments - drinks manufacturers can see brands tarnished, revenues tumble and market capitalisation dented through the counterfeiting of their products.

In Goa, which currently has no alcohol tax stamps, liquor prices have risen 50% since April 2020, as have excise duties on Indian foreign liquor sales. There, officials are finalising proposals to introduce a holographic tax stamp, which will be applied to each bottle of alcohol to assist in authentication.

In North West India, Rajasthan state is planning to re-introduce alcohol excise stamps after a 10 year absence in a move to tackle concerns over increases in inter-state smuggling and sales of illicit liquor.

Tax stamps serve two purposes according to the IHMA. One is to provide a record of payment of tax while the other is to provide evidence that the stamp - and hence the product to which it is affixed - is genuine.

Dr Paul Dunn, chair of the global trade body, said it’s clear that the news from India shows that governments and agencies around the world continue to rely on and value holograms as an effective, reliable and dynamic security solution.

Dr Paul Dunn, chair of the IHMA, and an example of a holographic tax stamp on a bottle of alcohol

“It’s apparent that the benefits of holographic-based tax stamp programmes are welcomed by both suppliers of components, products and systems to the drinks sector and officials with responsibility for securing tax revenues,” he said.

“While holographic tax stamps are widely accepted and effective authentication devices, there is no better opportunity during the current pandemic for governments and treasuries to act decisively to secure alcohol excise revenues by continuing to use the technology as an integral part of their strategies.”

The use of well-designed and properly deployed authentication solutions, as advocated by the ISO12931 standard, enables examiners to verify the authenticity of a legitimate product, differentiating it from fake products coming from counterfeiting hot spots in Asia and eastern Europe. Even those that carry a ‘fake’ authentication feature can be distinguished from the genuine item if that item carries a carefully thought-out authentication solution.

The tax stamp standard ISO22282, which assists tax authorities to improve compliance with excise tax regulations by providing guidance on tax stamp procurement, construction, security, issuance and examination, references the uses of holograms for tax stamp.

IHMA represents more than 90 of the world’s leading hologram companies. Members include the leading producers and converters of holograms for banknote security, anticounterfeiting, brand protection, packaging, graphics and other commercial applications around the world, and actively cooperate to maintain the highest professional, security and quality standards.

Highly efficient children books production with asterPRO Full Cycle

“Children’s literature is in big demand and we had the need to increase our productivity while maintaining the high quality of sewing of the aster machines”. – Mrs. Liu, Hongbo Haotian

Hongbo Haotian is a large-scale Chinese printing company, established in 2010 in Beijing with the goal of servicing the metropolitan area of the capital city where publishing houses are flourishing.

Hongbo’s main products are high-end art and photo albums and children’s books, the latter a strong and thriving market in China. The company, already a customer of Meccanotecnica since 2014 with an asterEVO book sewing machine, decided to increase its production capacity for thread sewn books with an asterPRO Full Cycle to meet the increasing market demand in this segment.

The children’s book segment in 2019 accounts for 26.5% of China’s total book retail market, according to Beijing-based OpenBook, a clearinghouse for publishing statistics. The segment expanded 18.5% compared to 2018, confirming a double-digit growth streak.

Whether this growth trajectory is due to the sheer number of people under 18 (about 370 million and counting) and newborns (14.65 million in 2019) or its rising middle class (around 400 million people) with higher disposable income to spend on education and reading, it is seemingly unstoppable. Challenge “In the last years we are witnessing a big growth for thread sewn children books,” says Mrs. Liu, Managing Director of Hongbo Haotian.

“Children’s literature is in big demand and we had the need to increase our productivity while maintaining the high quality of sewing of the aster machines”.

Solution Hongbo Haotian decided to invest in an aster- PRO with Full Cycle technology that allows the sewing of books without the blind/ lock stitch. The investment decision has been guided by 3 main reasons: 1. The Full Cycle Technology allows increasing production efficiency, saving costs and improving profitability, compared to traditional sewing machines. 2. This technology also improves the daily output, increasing productivity especially for books with a low number of signatures. 3. Aster machines are easy to use and having operators already trained in using them have also played its role in the decision.

Result “In only 5 months after installations, we have sewn 20 million signatures and produced millions of books”, says Mrs. Liu. “This proves the great reliability of the system that has fulfilled our expectations”.

Business benefits • Highly reliable binding (thread sewing) • Revenue increase (more productivity) • Cost savings (higher efficiency) • Ease-of-use (aster machines) • Sewing quality (no thermal fusion)