The Australian Arbor Age magazine has been around for a while.

It’s no small thing for any business to be able to claim 28 years of continuous operation, and in the magazine publishing world it’s an outstanding achievement worthy of recognition.

But I had to adjust my perspective of this milestone when, for last issue, I sat with Jim McArdle of the Tree Contractors Association Australia and he ran through a few thoughts on how he’d like to mark the association’s 30th anniversary.

I’ve been around The Australian Arbor Age for a decade or so, writing bits and pieces here and there, and I was pretty happy when the new owners offered me the chance to work on the title full time. I reckoned it was fair to say I had some history with this mag.

But when I sat with Jim and started looking through the material he’d collected, my thoughts on what qualified as ‘history’ were very quickly reassessed.

Jim and his family have been involved in the timber industry and the arbor world across generations – long before the TCAA was even thought of – and Jim’s stories of boiling the billy to have morning tea ready for the crews working in the family timber yard when he was a youngster were a delight to me. His reminiscences of favourite chainsaws and equipment, humorous and colourful timber workers across the years, and some of the unlikely situations which confronted he and his brother during a day’s work made the short time we spent in discussion fly by all too quickly.

And most of that riveting storytelling covered his life with timber before the TCAA came into being.

My time with this magazine has been, by comparison, a very short chapter in a long and ongoing story.

A very great deal of Jim’s wealth of memories won’t make it into the pages of AAA unfortunately, but we’ve seen

some already, and I recommend to you the TCAA pages of last issue if you didn’t have a chance to read them. There’s a huge story between the lines of the short narrative relating the founding of the association and thoughts of past presidents and board members. The achievements of these people were, if anything, understated.

Jim’s a good bloke and we enjoy sharing a coffee and a yarn, and I hope he can be persuaded to share more of his past. We should all hope people like Jim, his family, and the TCAA – now the TCAAA – continue striving to improve the safety and professionalism of arboriculture.

Maybe you have a good story or two to tell from life in the trees?

Arbor Age would love to hear it, and would be very keen to help you share the story with its readers.

Shoot me an email and we’ll see what we can do: Tom.foster@ primecreative.com.au.

www.piranhachippers.com.au

CEO

John Murphy

COO

Christine Clancy

Sales Director

Bradley Buchanan

Editor

Tom Foster

tom.foster@primecreative.com.au

National Advertising Manager

Arron Reed arron.reed@primecreative.com.au

Phone: 0466 923 194

Client Success Manager

Arianna Lucini arianna.lucini@primecreative.com.au

Design

Cat Zappia

Subscriptions

P. +61 3 9690 8766 subscriptions@primecreative.com.au

Website arborage.com.au The

and tree impact assessments.

A professional consulting arborist at Treeswest Australia, certified to AQF level 5 (Diploma), international coach, speaker and presenter.

Believed to be 1500 years old, The Prison Tree – in the language of the indigenous people, ‘Kunumudj’ – has a history nearly as striking as its appearance.

Boasting a circumference of over 14 metres, the historically significant Adansonia gregorii sits just off the Derby Highway in Western Australia, about seven kilometres from the port of Derby itself.

The Baobab is a culturally significant site for the local Nyikina and Warrwa people, and figures in the history of the early settlement of Derby and the region’s pastoral industry. Stories from the early 1900s indicate the tree had

been in use by local Aboriginal people as either a resting or sacred place. Along with the nearby Myalls Bore, the tree was also the last overnight stop for local pastoralists droving cattle to the nearby port at Derby.

The Prison Tree is also said to have been used as a holding area for Aboriginal prisoners being transported long distances to the Derby gaol, and is now a registered Aboriginal site and on the WA State Heritage Register.

With a circumference of over 14 metres, the Adansonia gregorii is a registered Aboriginal site and on the WA State Heritage Register. Image: tolly65/Stock.adobe.com

On the cover

The MC-300 C-O battery-powered chainsaw makes light work of felling and cross cutting large trees. Images: STIHL

With the change in the weather and the end of the financial year fast approaching it’s time for eligible businesses and professionals to supercharge their kit and take advantage of a potential small-business tax break.

The STIHL range boasts a number of professional-grade battery-powered outdoor power tools to help commercial users complete their work safely and efficiently, no matter what the task. And for a limited time, commercial users can get two free professionalgrade batteries with selected STIHL battery tool bundles.

Here are STIHL’s top battery-powered tools for arborists and forestry professionals this Autumn.

Designed with professional users and arborists in mind, the new MSA 300 C-O sets a new benchmark in performance as the most powerful battery chainsaw in STIHL’s growing battery range, making light work of felling and cross-cutting large trees.

The power behind the MSA 300 C-O is the AP 500 S, which was designed

specifically to power the MSA 300 C-O. It’s the first battery in the AP System to use laminated battery cells capable of delivering an impressive highpower output of 3kW – comparable in performance to STIHL’s popular MS 261 C-M, one of STIHL’s all-rounder petrol chainsaws.

The MSA 300 C-O is the first batterypowered chainsaw to feature a full antivibration system, making it extremely comfortable to use. It has the lowest vibration figures across all STIHL’s battery and petrol-powered rear-handle chainsaws.

Launching in Autumn 2024 is the MSA 220 TC-O, STIHL’s high-powered battery top-handle chainsaw, designed specifically for trained professionals, which now features an oil sensor on an LED display. This innovative new added feature gives the user a warning when the chain-oil level is low.

With a compact and well-balanced design, the MSA 220 TC-O is easy to handle in awkward or outstretched positions. The intuitive trigger lockout system is simple to use, and the electronic unlock button is within easy reach of the thumb. The status LED will light up green when the chainsaw is ready for use, and the chain brake LED will light up red when the chain brake is engaged, so the operator can easily see when the tool is good to go.

Paired with the AP 300 S battery and the NEW 3/8 PS3 Pro chain, the MSA 220 TC-O’s output is comparable to that of STIHL’s popular petrol-powered MS 201 TC-M.

With a compact and well-balanced design, the MSA 220 TC-O is easy to handle in awkward or outstretched positions

Paired with the AP 300 S battery and the 3/8 PS3 Pro chain, the MSA 220 TC-0’s output is comparable to that of STIHL’s petrol-powered MS 201 TC-M.

On the cover

Get two free pro batteries with selected AP battery system tool bundles “ ”

The particularly rigid telescopic shaft for the HTA 135 enables quick length adjustment and exact positioning.

The HTA 135 battery powered pole pruner is the most powerful battery pole pruner in the AP Battery System. Reaching up to five metres in height, the HTA 135 allows professionals to complete their work safely from the ground rather than climbing the tree, saving plenty of time and reducing the risk of injury. The lightweight magnesium gearhead helps with maneuverability and balance, while the tough branch hook helps with the removal of loose cuttings from the tree itself.

The particularly rigid telescopic shaft of the HTA 135 enables quick length adjustment and exact positioning. allowing precise cutting of tall trees. The telescopic shaft can be extended up to a length of 405cm, with the total length of the tool ranging from 285cm to 405cm.

The HTA 135 allows professionals to reach a height of around five metres and can be used with 3/8"P and 1/4"P STIHL saw chains, ensuring maximum cutting performance.

The STIHL AL 301-4 is a gamechanger for professionals utilising STIHL’s commercial range of battery powered tools.

This mobile multi-battery charger allows professionals to charge up to four STIHL AP or AR batteries sequentially, meaning they’ll never be without a fully charged battery throughout their day.

The AL 301-4 is specifically designed for use in vehicles and on the go, therefore has a robust design as a result. The AL 301-4 is compatible with all AP batteries, and is also capable of charging STIHL’s AR backpack batteries with a connecting cable and STIHL AP adapter.

Charge through autumn with battery power by STIHL. For a limited time, get two free pro batteries with selected AP battery system tool bundles.

Visit your local STIHL dealer to learn more today. Find yours at stihldealers.com.au.

The HTA 135 battery-powered pole pruner is the most powerful pole pruner in the AP Battery System

100-per-cent Australian designed and made, Piranha chippers offer impressive performance. Images: Piranha Woodchippers

A brand new, Australian-designed and made commercial Woodchipper will be launched at The National Diesel Dirt and Turf Expo in April.

Piranha chippers are the latest kids on the block – a brand new commercial Woodchipper manufacturer focused on delivering world-class machinery.

100-per-cent Australian designed and made, Piranha chippers offer impressive performance and productivity capacities and are fully backed by an industryleading five-year structural warranty.

Built on 30 years of wood-chipper passion and design obsession – including three generations of timber-industry experience – Piranha is bringing a different approach to operator experience and work-site efficiencies. Piranha chippers continually give highperformance and yield the highest return-on-investment figures, ultimately increasing bottom-line dollars.

Starting with the best Piranha’s suppliers are top of the line in their businesses – the best brand names,

A brand new commercial Woodchipper manufacturer focused on delivering world-class machinery.

proven in their fields and supported locally.

Australia is renowned on the world stage for cutting-edge technologies in the aerospace, mining and automotive

industries, and Piranha has tapped into these top engineers and their resources to offer the most productive, efficient and modern woodchippers available on the market today.

Australian-made structural-grade steel is used in all components of Piranha’s chippers.

To ensure the highest quality workmanship Piranha’s professional welder tradespeople are independently tested and NATA certified to AS/NZS 1554.1 welding standards, ensuring Piranha’s peace-of-mind as it stands behind its industry-leading, five-year structural warranty. Australian-made structural-grade steel is used in all components of Piranha’s chippers, ensuring they are world-class and the best of the best.

Some of the leading features that set apart the BT300 Piranha chipper include:

• Twin axle trailer design – supplying double the braking power and twice the flotation over soft surfaces compared to single-axle units

• Load-sharing ‘Soft-Glide’ leaf-spring suspension provides a superior ride compared to a single-axle trailer and doesn’t send violent feedback through the drawbar into the tow vehicle, making towing the Piranha a safe and enjoyable experience, and

• Heavy-duty all-terrain tyres on tough steel rims ensure the BT300 will easily go anywhere the tow vehicle can.

Piranha’s ‘Posi-Arc’ infeed-arm pivot design means the large top infeed wheel aggressively climbs towards the incoming timber, up and on top of the trunks and brush, through the natural positively inclined arc the unique feedarm design provides. This makes for a very strong feeding action, allowing the Piranha to pull in difficult branches, twisty timber and whole trees with ease. The hydraulic lift and crush also aides in feeding difficult timber sections into the chipping drum if branches are particularly crotchety and difficult. The

350mm high x 500mm wide in-feed opening directly into the chipper drum housing ensures the Piranha saves as much time and effort as possible.

The unique staggered four-knife chipper drum – designed in-house by the Piranha team – with integrated high-velocity fans makes for a superior chipping action and a very strong chip discharge. Being 650mm in diameter ensures the chipping/cutting action is only done on the lower half of the circular arc, resulting in less vibration and fuel use. The replaceable blade-bolt blocks ensure the drum does not suffer integrity damage if the blades encounter foreign material fed into the machine and they can be easily replaced if ever required.

The chipper drum access hood completely exposes the top part of the drum when opened, making changing the knives very easy and practical.

All manufactured sheet-metal steel parts are individually primed and painted before assembly for superior, long-lasting corrosion protection,

ensuring the Piranha will continue to look good and perform flawlessly for decades.

Piranha chippers come standard with many features that work together to reduce the operator’s fatigue and stress, including:

• Hydraulic auto clutch

• Hydraulic winch

• Hydraulic tailgate raise and lower

• Hydraulic 360° discharge chute (continuous swivel)

• Twin (top and bottom) horizontal infeed wheels

• Central grease-station hub

• Full-sized spare wheel, and

• Bulletproof one-touch capacitive switches for quick and easy operation of all functions.

They’re all standard on the BT300.

The Piranha team is ready and waiting to answer any questions. Book your demo session today so you can see for yourself how well the BT300 performs.

Call 1300 406 171 or log on to piranhachippers.com.au.

Replaceable blade-bolt blocks ensure the drum does not suffer integrity damage if the blades encounter foreign material.

Hire companies across Australia and New Zealand have long had HANSA in the range, though one machine seems to be a staple – the HANSA C25.

Chippers get a hard time in the hire industry, being used by changing customers, different levels of skill and knowledge, and machines are pushed to their limits and beyond. It needs a strong product to perform under those circumstances.

That’s why hire companies choose HANSA.

“Like many of us, hire companies are businesses where reliability and performance is key to business continuity and success,” said John Lyon at HANSA Products Australia. “Our machines deliver that for them”.

There are some eye-watering stories of the condition in which some chippers have come back in after hire.

“Pasted with sand and salt from chipping mangroves all day,” recounted John. “That machine got a deep clean!”

Luckily for the hire companies mangroves are few and far between, and overall if the customer is inducted

on the machine correctly it should just be a matter of standard-use maintenance – like knife sharpening and a clean before the next hire.

Hansa has been in the hire game since

1996 and works with all the big names, like Kennards and Hirepool, while also providing machines to independent hire companies. The HANSA C25 is the go-to for the hire companies looking

Offering 160mm (six-inch) capacity on a small footprint and powered by the Honda GX690, the HANSA C25 is just the right size for the majority of the hire-market customers.

for a hydraulic-feed solution for their customers.

“We have great relationships with our hire customers. We know what they need and go the extra mile to ensure they have it” said Lyon.

HANSA has a bespoke training and onboarding procedure for hire outlets, ensuring when a new machine is despatched the hire team is fully trained and skilled on how to use and induct

customers on the machine.

“Ensuring the hire team is 100 per cent confident and capable is key to keeping the operator safe,” Lyon confirmed. HANSA even has a ‘Return From Hire’ checklist developed over the years with customers. This ensures when a machine is returned after hire, the correct checks and controls are done with the operator. It’s a catch-all system, making sure the machine is not damaged and the correct checks are complete before the next hire.

HANSA has lots of customers who have followed the ‘Hire it. Try it. Buy it’ route.

Purchasing a chipper is a significant investment, and hiring a machine before making the leap is a great way to get a feel for what capacity or type of machine is needed. Using the machine on your worksites, towing it behind various vehicles, using it in various crews and contracts, spending time going over the machine, looking at the service

The protective coating system on our chipper bodies means we can comfortably say we would expect no less than a 10 year lifespan from our chipper bodies.

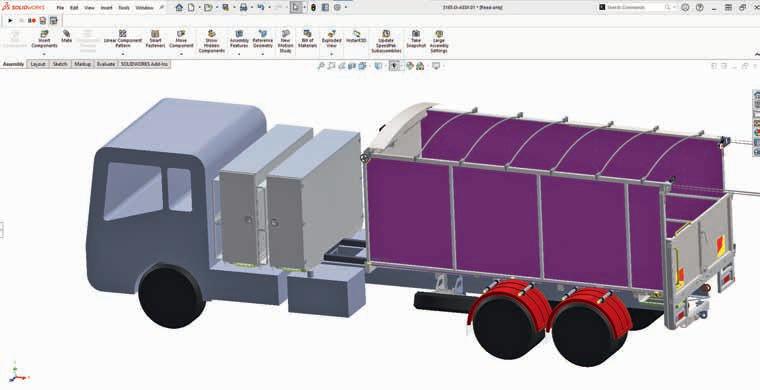

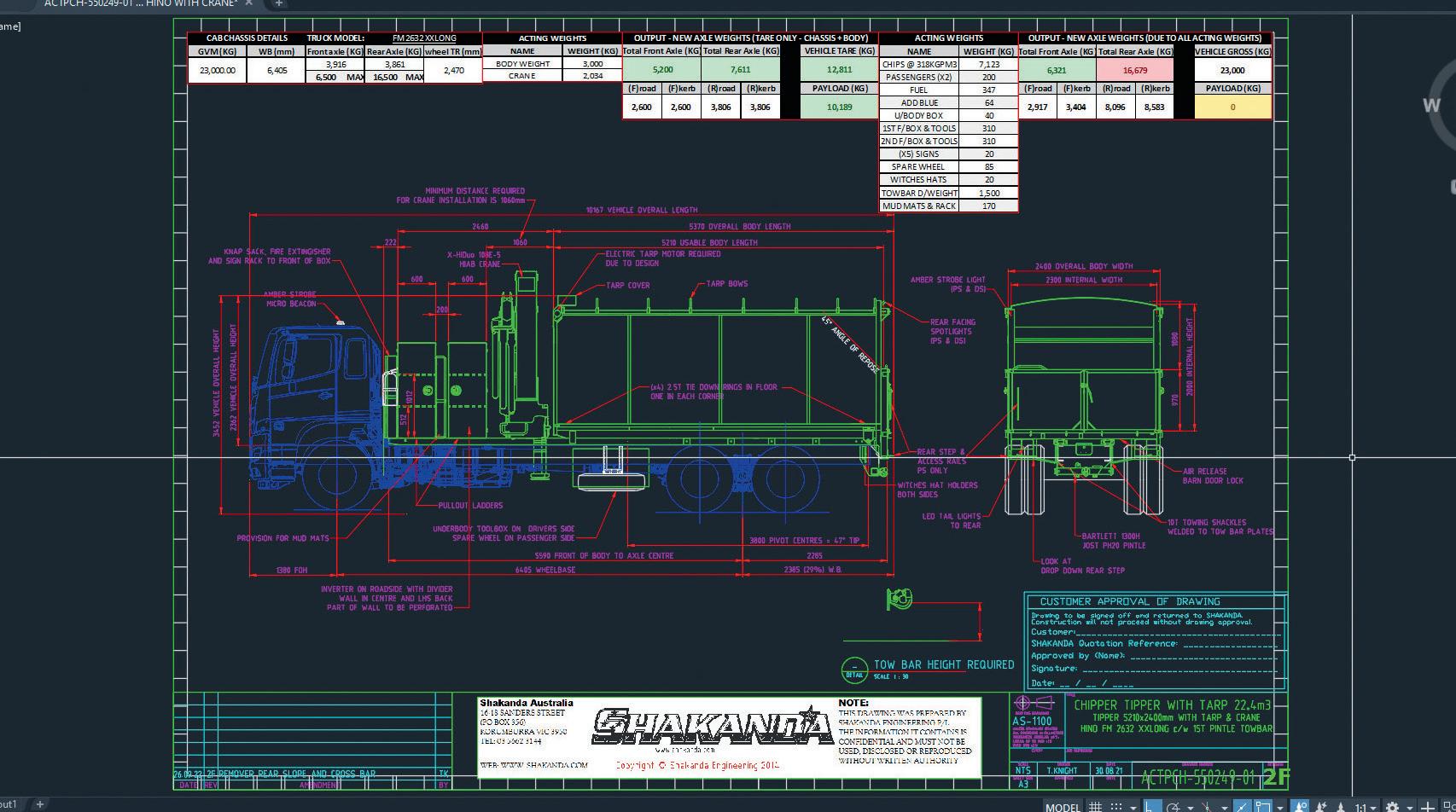

Shakanda Engineering is able to offer a long list of features on its chipper bodies. Customers can have two-way tailgates, barn doors, toolboxes in one or two sides of the body, ladder racks, pole-saw boxes, a variety of towbar options with pintle hooks or combination ball and pintle hooks, change the body size to increase the front toolbox, or change the overall dimensions of the body if they want to alter the capacities for a particular truck.

We pride ourselves on back up service if anything goes wrong. The highest standard of design and quality are built into every one of our projects, backed up with a full Three Year Structural Warranty on all manufactured vehicle bodies.

procedures, maintenance and overall build of the machine in your own time and with your team really helps you make an informed decision.

Offering 160mm (six-inch) capacity on a small footprint and powered by the Honda GX690, the HANSA C25 is just the right size for the majority of the hire-market customers.

Commercial arborists and landscapers, looking to hire a chipper to cover extra work loads or a brokendown chipper, can get the cover they need with this reliable machine. The towing weight of 885kg (fully spec’d) makes it easy to incorporate into a fleet and teams at short notice.

Boasting a powerful 81kg cutting disc, the machine makes good use of its extra wide infeed of 330mm x 178mm.

This extra-large in-feed increases productivity by allowing the operator to feed in larger volumes of branches at one time.

The HANSA soft-start technology is also on the C25.

After starting the machine the operator engages the cutting disc by winding in the engagement handle. This brings the drive-belts under tension, and once fully engaged the machine is brought up to full-revs and is ready to begin chipping. From here the electronic control system does all the thinking for you.

The adjustable auto-feed system allows adjusting the auto-reverse based on the material being processed. This ensures the engine is always running at the optimum

and keeps engine recovery time to a minimum to maximise output.

Coupled with the directly activated hydraulic variable speed feed roller, the operator can make fine adjustments based on the material binging processed. This allows even more performance out this six-inch chipper.

Where?

Where can you find a HANSA for hire?

Just visit hansaproducts.com and navigate to the hire menu and to find your closest hire outlet.

Maybe you will be the next Hire it. Try it. Buy it story.

Interested in buying a C25 outright?

Visit treecaremach.com.au for more info and to book a demo.

Caterpillar is pleased to introduce a new mulcher, HM6015, to fit Cat® excavators and wheeled-excavator machines.

The HM6015 delivers the reliability to meet customer needs in tough forestry applications.

The new Cat HM6015 Forestry Mulcher is purpose-built for use in land-management applications such as clearing right of way, roadside maintenance, removal of invasive

species, vegetation management, and many more. The HM6015 model is the latest addition to Caterpillar’s current offering of mulchers on excavators customers are already accustomed to. This model is a new solution for HEX and WHEX machines in the 27-ton to 36-ton class at a market-based price, and is supplied with a bite-limiter rotor.

For machine compatibility, bolt-on brackets, hydraulic connecting lines, case drain lines, and a wiring harness

Purpose-built for use in land-management applications such as clearing right of way, roadside maintenance, removal of invasive species, vegetation management, and many more. Images: Caterpillar

will be offered as separate line items to an order. This provides the flexibility dealers and customers need to fit multiple machine models.

The mulcher head includes a hydraulic door designed to minimise debris throw and improve material refinement, as well as a staggered tooth design for high productivity, minimising stalling the head.

Additional features include replaceable counter blades, bolton replaceable skids, replaceable protection chains, bolt-on replaceable

applications.

carbide teeth cutters, multiple service access panels, and a replaceable poly chain belt.

With its easy-to-maintain design, the HM6015 incorporates a number of safety features to protect both workers and equipment at the jobsite.

With the addition of the new Cat HM6015 model, Caterpillar now offers a mulcher attachment for Cat frontreach machines from 11 tons to 36 tons (10 tonnes to 32.7 tonnes) and longreach front machines from 40 tons to 52 tons (36.3 to 47.2 tonnes).

Key components on this mulcher contributing to its consistent, reliable performance include:

• The variable torque hydraulic piston motor shifts between high speed/low torque and low speed/high torque to deliver speed when it’s needed and power when it counts, and

• Hardened counter blades mounted inside the housing help break down the finished material, which can increase the rate of composting.

Maintaining the HM6015 mulcher is fast and simple. Multiple service panels on the machine provide easy access for quick adjustments, and internal components can be easily removed in the field through the access panels, further simplifying maintenance and reducing downtime. The poly chain belt-drive transmission eliminates slippage on startup, increasing

reliability and reducing maintenance costs, and most of the wear parts are made to be field-replaceable to keep the HM6015 working at peak efficiency.

The ability to adjust the hydraulic mulching door allows the operator to control the material throw, which also increases operating safety, especially critical on roadsideclearing applications or when working near powerlines. Groundlevel primary grease points make daily maintenance easier and safer.

Learn more

A complete list of mulchers, listed by region, is available from the local Cat dealer or by visiting cat.com.

Earthmoving Equipment Australia (EEA) is a huge company representing some very big machinery brands. One of EEA’s owners, Chris Newton, has some great memories of the company’s growth. He’s also very optimistic about the company’s future, especially for Merlo in the arbor sector.

Chris Newton and business partner Michael Smith started the EEA business 12 years ago with a single brand, Thwaites, an English manufacturer of site dumpers.

“We created a market,” remembered owner and director, Chris Newton.

Chris and Mike wanted to grow into mainline construction equipment and were fortunate in picking up a Case dealership, which obviously suited their plans and combined talents. With hard work and good decisions EEA became the number-one Case dealership in Australia and quickly grew its area in NSW. A move into south-east Queensland soon followed.

“From there we continued to grow our range and business,” said the justifiably proud Newton. “We now have eight different divisions and 180 staff, so it’s been a busy 12 years.”

The tree-care machinery division includes Bandit, Hansa and Castloaders, all represented in the 12 EEA dealerships Australiawide.

The inclusion of Merlo came when, as EEA continued to grow interstate, Chris and Mike were looking after the Newcastle area for Merlo, the pair’s first area of representation for the brand.

Previously the Merlo business had been rental, and there wasn’t much information around ownership warranties or client ownership, so EEA began to put in place a marketing plan and sales strategy.

“We began growing the market share through Newcastle and all the way up through to south-east Queensland and Bundaberg,” said Newton. “We rebuilt the brand and started picking up more retail-based customers.

“It wasn’t the easiest time when we first started,” he reflected. “We had Covid issues, stock issues and so much more, and that held us back quite a bit. But growth with Merlo has been

Merlo roto telehandlers have really changed the game “ ”

fantastic. Sales have increased yearon-year.

“The dealer conference in Italy last year gave us an insight into the company. There was never any doubt about Merlo’s commitment to quality and safety, especially automated safety, but at the conference we saw the passion behind the brand from the owners of Merlo.

“It was fantastic for us.”

After 12 hard and successful years in the machinery business it seems unlikely there’d be anything much to get Chris excited, but he still glows when he sees revolutionary new equipment.

“The introduction of Merlo’s Cingo range is a really exciting prospect for us,” he beamed.

“They’ve taken an existing product – the smaller tracked carriers and dumpers – and really revolutionised those products into a multi-use, multidimensional asset.

“That’s really exciting! It’s very unique to this market.

“There’s been a lot of issues with the existing players and their tracked carriers. Merlo’s horsepower and resources have really revolutionised that area of the marketplace.”

“The future for EEA is basically continuing to communicate effectively that safety is the number one thing,” said Newton with some intensity. “Safety in all different industries, not just construction or arbor any one area.

“Some areas in the past have taken equipment – telehandlers are a good example – which are very basic, and

from a safety perspective they didn’t have the level technology Merlo offers. As we grow we’re looking forward to educating those industries about considering the importance of safety.

“A lot of people are working in remote locations, and there are important safety features available which will help protect them. We’re keen to educate people in those markets so they can find good solutions for not only production, but for their safety as well.

And EEA’s plans for Merlo?

“Let’s talk about the Merlo roto telehandler, for instance,” said the company director, clearly enthusiastic at the direction of the conversation. “It’s unique to the market.

“Obviously EEA’s arbor experience is pretty big with the Bandit brand, and Merlo’s roto telehandler is increasing OH&S for the arbor industry to levels that haven’t been seen before. You’ve got skilled climbers going up into trees and you’ve got skilled groundies controlling heavy, slung loads, quite often in densely populated areas. And as skilled and as gentle as they can be, Nature has a way of throwing little surprises into the workplace. Unexpected things happen and people are put at risk.

“Merlo roto telehandlers have really changed the game there. Those risks are being reduced by that machine to a great extent. The roto telehandler can mean climbers won’t have to face the risks of being in the tree, and it can handle larger loads, do it safely, and remove the limb or tree with greater efficiency and productivity.”

To learn more of EEA and Merlo, log on to eeaustralia.com.au.

Merlo’s roto telehandler is increasing OH&S for the arbour industry to levels that haven’t been seen before.

Images: Merlo

Maintaining green areas often requires the use of several machines. Magni’s Tree cutting attachment was designed to reduce – to one –the number of tools required to maximise efficiency and time.

Magni’s Tree cutting is the result of in-depth research in the field of tree care. Every component maintains perfect harmony between all its elements and meets the needs of this sector, guaranteeing performance and efficiency.

The Tree cutting consists of a grip saw that allows cutting and handling the log in total safety. Manufactured from high-tensile, low-wear Hardox® steel, this attachment is extremely light, allowing all cutting and handling operations to be carried out with great ease.

The gripper is designed to ensure a firm grip and can handle a cutting diameter up to 75cm. Thanks to the Power Tiltator, the gripper ensures 360° rotation, allowing gripping the branch or tree to be cut from any position or angle.

Highly rugged and durable, the springmounted saw box prevents the saw blade bending due to force acting on it. The cutting mechanism consists of a hightensile blade that is easily accessible for

maintenance and is little susceptible to dirt. This minimises maintenance and wear, saves time and maximises productivity.

Since work is not just performed at ground level, the chain is lubricated with grease. Compared to oil lubrication, this avoids oil misting, which would spoil the working area and the cab windscreen. The grease stays on the chain much longer, minimising wear and maintenance.

Thanks to the automatic chain tensioner, the chain always has the right tension, regardless of whether the machine has just been started up or has been in operation for several hours. This means that the working process is not interrupted by a chain coming off.

Available for the RTH range, this kit is designed specifically to make the work of the operator simple and efficient. Because of its features, it is used to maintain roadsides, trails and paths on all kinds of flat and steep terrain.

For this forestry kit Magni TH developed a special remote control which allows controlling all normal cab operations and specific movements of the attachment, making the job safer and more efficient. The colour display shows all boom geometric data to the user on the ground, greatly increasing operator safety.

Moreover, the Italian company created two dedicated options to use this attachment to its full potential…

• Pre arrangement for the Tree cutting device consisting of a series of special cab equipment: protection grid on the windshield, additional rollers on the joysticks for tree cutting operations, cameras with protections and a dedicated HD screen in the cab, front and rear cab working lights and a special filter featuring F7 filter class (CEN EN 779), and

• Boom protection for the Tree cutting device in dusty environments protects the boom and its sections thanks to a metal plate mounted into each of the boom hollows, and additional gaskets at the end of every boom section. This prevents sawdust and debris from entering the boom sections.

Magni’s Tree cutting has been designed with detailed knowledge of the needs of this sector and is thus the ideal all-in-one solution for green maintenance.

Find out more about the Magni Tree cutting at allliftforklifts.com.au

Climbing gear

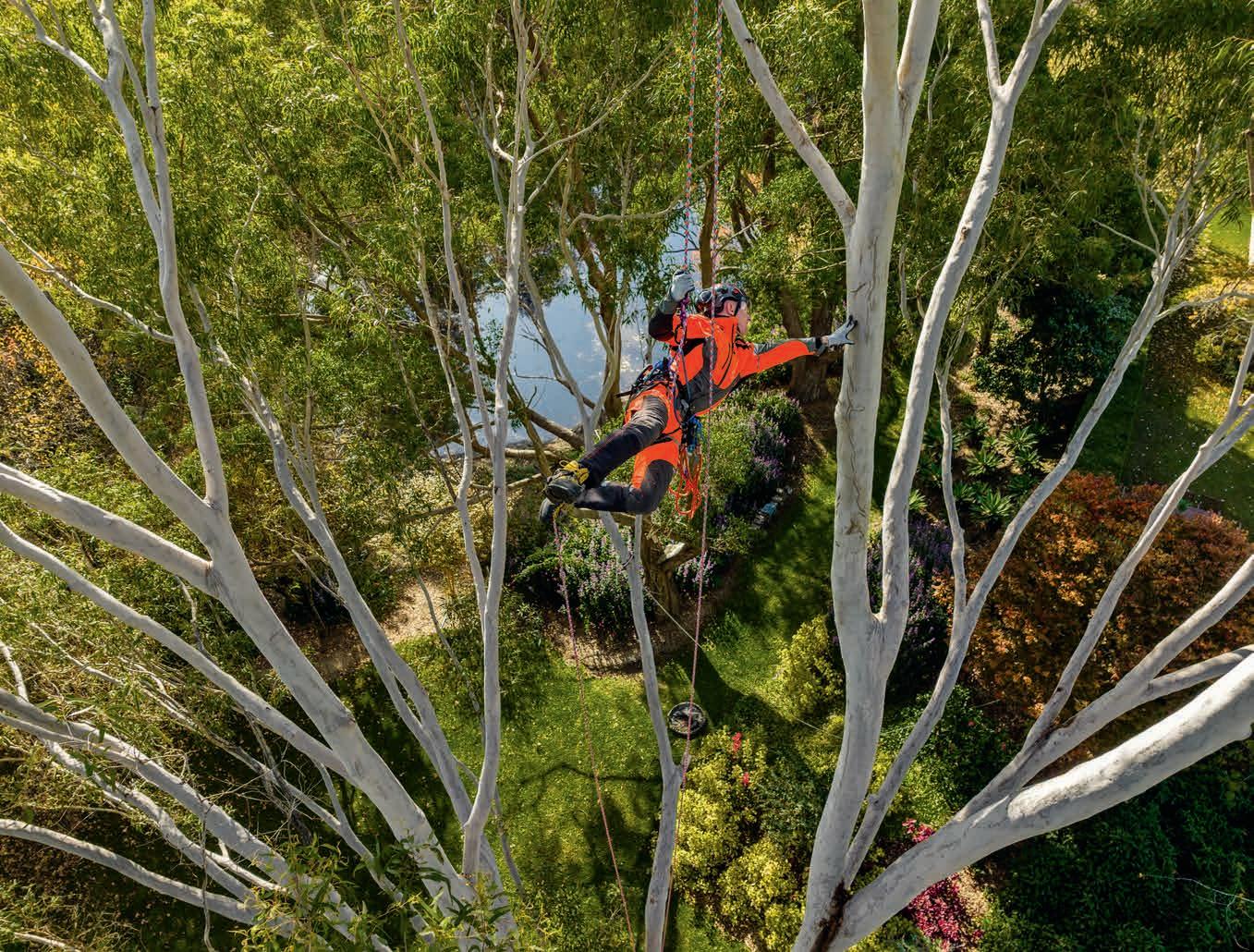

Husqvarna offers a selection of climbing and rigging equipment to make life in the treetops easier.

Images: Husqvarna

Husqvarna’s range of climbing gear has been specifically designed for arborists and tree-care professionals.

Husqvarna’s climbing gear range includes a climbing harness and ropes designed in partnership with Teufelberger, a world leader in climbing equipment, and Husqvarna has added a storage bag that makes it easy to organise the equipment and take it wherever it’s needed.

Pro standard and harness

Already an industry leader in chainsaws and cutting equipment, Husqvarna has introduced an adjustable, robust and extremely comfortable harness for climbers who spend many hours

In addition to climbing ropes, harness and bag, Husqvarnan also offers a selection of other climbing and rigging equipment.

up in the trees. The harness provides world-class mobility and comfort while helping reduce the risk of injuries and physical stress when working long hours aloft.

“The new climbing gear is fantastic!” said H-Team ambassador Jamie Boston.

“Husqvarna has absolutely top-notch quality gear, and the climbing harness is the hero of the range.”

A wide range of settings allows climbers to customise the harness to different climbing styles and jobs.

“It allows you to have all the attachments and tools you need to go through your day-to-day work,” said Jamie.

To complement the harness, Husqvarna also offers two sets of high-quality climbing ropes which meet both CE and ANSI standards, adding versatility for different rope techniques and super smooth running during both ascent and descent.

Husqvarna has also introduced a gear bag for storing, organising and protecting the climbing and rigging gear. The user-friendly and durable 70-litre gear bag is made of high-quality fabric and includes a reinforced bottom, a helmet storage lid at the top, and side zips, allowing users to have easy access to all their gear, no matter the conditions, making work both easier and more efficient.

In addition to the climbing ropes, harness and bag, Husqvarna also offers a selection of other climbing and rigging equipment to make life in the treetops easier. This includes a chainsaw lanyard with an anti-shock feature that reduces the impact if the chainsaw gets caught in a falling branch or other object. Plus, the range also includes:

• A sling

• A work positioning lanyard

• Rigging rope

• Prusik

• A friction saver, and

• Accessory carabiners (none PPE). Husqvarna’s arborist equipment is made of the highest quality materials and covers the many needs of climbing and rigging, and will soon include a range of purpose-made ropes with dimensions and colours to suit a broad group of professionals.

“I’ve used other products in the past,” said H-Team ambassador Kiah Martin, “and my preference is for Husqvarna.”

“The reason for that is quality product and quality people, and really good research and development. If we can keep developing products to make them safer, more functional, more durable, to reduce the fatigue on the user, and that the user has been involved in helping develop…it’s a beautiful collaboration.

“It doesn’t matter what industry you’re from, that can only be a good thing.”

Husqvarna’s long-term goal is to offer revolutionary equipment for arborists and tree care professionals.

To see the entire range log on to husqvarna.com/au, and the Husqvarna Autumn Catalogue is out now!

Sam Lucas kicked off his life in arboriculture as an 18-year-old. Over the years he’s developed a hard-working outfit, and Sam’s happy association with Monitor goes back more than decade.

Lucas Tree Services specialises in tree removal, pruning and maintenance throughout Victoria, and owner Sam’s pride in his company’s success is mixed with a happy outlook and easy manner.

“I started the business when I was 18,” he said with a grin. “I feel a bit old saying that now, but basically I got into it as a job, started a career path with my wife, and we’ve just excelled from that point.”

Since the earliest days using Rayco machinery, Sam and Lucas Tree Services has enjoyed an excellent relationship with Monitor.

“From when I started as one-man band with one stump grinder and one wood chipper, and was struggling to get a business going, Monitor has been great,” related Sam. “The respect and support

The business Sam and his wife built has been a successful one. Case

they gave us at a business level was amazing – whenever we had a breakdown they supplied us with machines – they’re quick on servicing, and very friendly,” he recalled. “Even now, Monitor respects all our staff and gives us the same level of service they gave us 10 and 12 years ago when we were starting out.

“It’s been a great working relationship. We’ve been able to build a business with the backing of Monitor and I couldn’t speak highly enough of them.

“At the moment we’re running up to seven crews a day with our current fleet,” said Sam. “Most of our work is for local government and power authorities throughout metropolitan Melbourne. We’re currently active for over 10 councils and one power provider, and all our equipment runs pretty much daily on those sorts of works.”

The equipment Sam’s talking about includes CMC lifts, a couple of Först chippers, Rayco grinders and no less than five Morbark woodchippers, all from Monitor.

“The machines are always compliant and we’ve never had an issue with them,” said Sam. “They’re reliable, meet all our current emissions standards and environmental policies and, yeah, they’re doing great.”

The latest addition to the Lucas Tree Services’ fleet is a Morbark Beever 1821 heavy-duty industrial woodchipper.

With its high-capacity and lighterweight design, the 1821 compact chipper is an ideal unit for residential

A dual-sided, chambered air-impeller system increases chip-throwing velocity and reduces dust and material blowback out the infeed to pack more into the chip truck.

The wide infeed opening with dual infeed rollers, and an oversized 18" diameter top-feed wheel with straight flow-through infeed, easily climbs over material, reduces drag and increases chipping efficiency.

tree services, utility line clearing, vegetation management, maintenance contractors and municipalities. The dual-sided, chambered air-impeller system increases chip-throwing velocity and reduces dust and material blowback out the infeed to pack more into the chip truck, increasing efficiency.

The powerful TorqMax™ top-feed wheel-compression system generates more than 5060kg/m of material-pulling force and the wide infeed opening with dual infeed rollers, and an oversized 18" diameter top-feed wheel with straight flow-through infeed, easily climbs over material, reduces drag and increases chipping efficiency. A full-length channel chassis with cross bracing increases structural strength while maintaining low unit weight, and a full 360° hydraulic chute with swivel discharge and adjustable height puts chips right where needed without removing the Beever from the tow vehicle.

It’s a long-lasting, durable machine backed by a world-class parts and service support team at Monitor.

Other highlights include:

• Dual infeed wheel with TorqMax™

top feed wheel compression system, hydraulic lift assist, spring assisted down pressure and manually applied hydraulic down pressure at the valve handle

• A reversing automatic feed system

• Enclosed engine with gauge panel, radiator fines screen and slide rails for belt adjustment

• Fuel tank sight gauge, drain plug and shutoff valve, and

• Hydraulic tank shut-off valve, drain plug and clean-out cover.

Sam’s total satisfaction with the 1821 is on par with his customer satisfaction when dealing with Monitor.

“We bought the 1821 mainly to upgrade our fleet a few years ago,” he told us. “It was one of the first Morbark machines we actually bought. Since then we’ve ended up buying five of them and all the guys have pretty much converted.

“We’re lovin’ the good infeed, plenty of power, the lift and crush is perfect, it’s very user friendly and very low maintenance.”

“It’s a great machine.”

Tyres

Hitch

pintle ring

Scan the QR code to check out the latest deals from Husqvarna!

Are you in search of a chainsaw that can handle even the toughest jobs? Husqvarna’s lineup of professional chainsaws are expertly crafted to tackle the demands of all-day cutting, felling, and pruning with ease. With unbeatable power, exceptional performance, and superior design quality, our professional range is built to help you get the job done right. Try one for yourself and experience the Husqvarna difference. Learn more at husqvarna.com BONUS!

Receive a bonus SPIRE Arborist Helmet valued at $209 with the purchase of a T525 or T540 XPII Chainsaw

Injury reporting or notification to WorkCover/ WorkSafe is only required in the case of notifiable incidents. Image: Shining Pro/Stock.adobe.com

The Federal Government continues its campaign targeting employers who underpay employees according to the relevant employment legislation. Brian Beecroft of the Timber Trade Industrial Association highlights some important changes in legislation.

Commencing January 1, 2025, intentional underpayments of wages by a business will be a criminal offence.

Employers may commit an offence if they owe money to an employee under the Fair Work Act or an industrial instrument (like an award or an enterprise agreement), and intentionally engage in conduct that results in a failure to pay on or before the money is due. This can include failure to make required superannuation contributions.

A Voluntary Small Business Wage Compliance Code will be established before the changes take effect, and compliance with this code means a small business won’t be prosecuted if it underpays its employees.

TTIA will ensure members defined as small businesses will have some support through this compliance code.

Companies prosecuted face penalties three times the amount of the underpayment if a court can determine it, or $7.825 million, whichever is greater. If the court can’t determine the underpayment, the maximum penalty is $7.825 million.

Individuals can be imprisoned for up to 10 years, be fined either three times the amount of the underpayment if the court can determine it, or up to $1.565 million, whichever is greater; or be both fined and imprisoned.

While the new laws arguably seem to be quite heavy handed, particularly in relation to imprisonment, the Fair Work Ombudsman has attempted to reassure employers these laws don’t apply to those who unintentionally underpay their employees, or inadvertently pay the wrong amount due to an error.

That remains to be seen, and as an association, TTIA will put the spotlight on any future prosecutions.

In summary, the Fair Work Ombudsman will, once the offence takes effect in 2025, investigate suspected criminal underpayment offences.

These developments once again highlight the absolute importance of TTIA members arranging an appointment with our Legal Officer for an up-to-date TTIA wage audit of all wages, policies, and templates. Contact our office on (02) 9264 0011, or Janet Gilbert on 0414 557 235, to arrange an appointment.

Members often ask the TTIA’s National Timber Employers Hotline the question, “How serious does an injury need to be

Brian Beecroft TTIA CEO.

Brian Beecroft TTIA CEO.

before there is a requirement to record it?”

For instance, if an employee suffers a minor cut at work that only requires a band-aid, should the incident be recorded?

Minor cuts that can be fixed with a band-aid are not explicitly mentioned in relevant legislation or in the Workplace Injuries and Disease Recording Standard – AS 1885.1-1990 which sets out good practice regarding injury recording. The wording of relevant workers compensation legislation and the Standard do imply, however, that even minor cuts should be recorded.

The Standard recommends all occurrences should be recorded, including ‘no lost-time’ workplace injuries or diseases – that is, those for which first aid and/or medical treatment was administered. Applying a Band-Aid would be considered providing first aid, so the Standard’s recommendation would be to record such injuries, including while working at home.

Workers compensation legislation contains the relevant legislative requirements. In New South Wales, for example, workers compensation legislation requires employers to keep a register of injuries that is readily accessible in the workplace. The register is a record of any injuries suffered by workers, whether they result in compensation claims or not. This, too, implies minor injuries are not excluded from recording requirements. Employers can draw up their own injury register; however, it must include:

• The name of the injured worker

• The worker’s address

• The worker’s age at the time of injury

• The worker’s occupation at the time of injury

• The industry in which the worker was engaged at the time of injury

• The time and date of injury

• The nature of the injury, and

• The cause of the injury.

Recording minor injuries may help draw attention – and prompt remedial

action – regarding sources of injuries. Members should note that even minor cuts can become infected, especially in environments where workers may be exposed to blood-borne pathogens or other contamination.

Reporting of injuries is a different matter from recording them.

Injury reporting or notification to WorkCover/WorkSafe is only required in the case of notifiable incidents –those resulting in death or serious injury, or dangerous incidents such as uncontrolled spills, leaks, or explosions. Minor cuts don’t need to be reported unless your organisation requires those incidents to be reported within its own internal safety-management system.

TTIA operates a fully functioning, in-house WHS unit. If you have any further enquiries regarding workplace injury reporting obligations, please contact our WHS Manager, Ken Hocking, on 0418 280 335, or the TTIA Hotline on (02) 9264 0011.

Dave Crispin, senior arborist at Treeswest Australia and Arboricultural Association of Western Australia (Arb West) committee member, highlights some of the effects and management of high temperatures.

It’s so hot even the ice-cream truck melted.

Jokes aside, Western Australia is experiencing one its hottest Februarys on record.

I hate to use the word ‘unprecedented’ – it became part of our lexicon during Covid (and there’s another one – ‘Covid’) and like most people I’m over Covid and anything else that is associated with it –but unfortunately, it looks like it’s here to stay, just like our severe heatwave here in Western Australia.

Temperatures in and around Perth in January and February were averaging between 40 ºC and 45 ºC, and it seems to be happening more frequently as our climate changes.

How do trees cope in the intense heat?

Unlike us they cannot uproot and hide under the shade of one of their own.

At a recent lecture the theme was, ‘Action - Reaction = Consequence’.

Over the preceding weeks I’ve seen this play out on several occasions, manifesting as canopy decline due to sun scorch.

Like most consultants, I’m asked to look at many trees, and one occasion recently I was asked to look at a stand of Celtis australis (European hackberry). Several of the trees had recently been crown thinned, (Action) at the client’s behest, resulting in minimal foliage in the upper crown, which ordinarily would protect it from the midday sun. The tree had tried to respond, (Reaction) but it was too little too late. Consequence –all the main extended lateral branches radiating out from the trunk, exposed to the intense sunlight, had suffered major sun damage. As a result, the upper side of the branches had delaminated, peeling back to reveal the xylem tissue. The periderm (outer bark) was peeling off in sheets.

We can cover up, trees cannot.

Consider this: when the ambient temperature on Perth streets reaches

around 35 ºC, and the direct sunlight hits the bitumen road surface, it’s not uncommon for the road to heat up to 50 ºC and beyond. The impact this has on the root zone, especially the lower order roots, can be disastrous. Many shallow-rooted trees like the humble Corymbia calophylla (Marri) have been lost recently.

Various trees have different tolerance levels to heat. Some cope better than others.

When Sydney had its record-breaking heatwave in 2020, 12 days over 40ºC, some trees died, while others coped

very well. Thinking that native trees would fare better than exotics was not the case. Both exotics and natives took a hit. Trees that had a low heat tolerance and died included the Acer rubrum (red maple), Liriodendron tulipifera (Tulip poplar), surprisingly, Banksia integrifolia (Coastal banksia), and Tristaniopsis laurina (Watergum). Others suffered severe heat stress, and eventually had to be removed.

Trees that were more resilient, and seemed to cope better, were the Ulmus parvifolia (Chinese elm), Fraxinus excelsior (European ash), Callistemon

viminalis (Weeping bottlebrush), and the Brachychiton populeneus (Kurrajong).

The info came from Misha Ketchell’s 2023 We need urban trees more than ever, published on theconversation.com.

Heat stress on trees in the urban environment is more prevalent given the retained and reflected heat from buildings and infrastructure, more so than in a rural environment. Heat stress reduces the tree’s ability to photosynthesise and increases photooxidative stress (chloroplasts are damaged inhibiting photosynthesis). If prolonged, this can lead to premature leaf abscission, leaf chlorosis, and decreased growth.

Extended periods of intense heat like those we’ve been experiencing, coupled with drought-like conditions due to declining rainfall, are a major cause for concern, especially for our local amenity trees. Residential trees can be given supplemental water by the property owner. Street trees, not so much.

In future, local government will have to invest more time in planting heat- and drought-tolerant tree species, and allocate more funds towards tree watering to reduce heat stress and tree mortality during the hottest periods of the Western Australian summer.

Looking after our own Arboriculture, and horticulture, are outside professions, it is part of the allure when talking with young people ready to sign up for what I consider to be one of the most rewarding professions there is. And summer is typically a favourite time of the year for working outside, but it does come with its challenges. Heat exhaustion (when your body loses excessive amounts of water and salt), is a real threat, and one that must be taken seriously. Plenty of hydration and electrolyte replacement is as essential as sunscreen and long sleeves when working outside on high-temperature days.

Every surface exposed to the sun has the potential to give first- or seconddegree burns, so gloves are an essential part of PPE (Personal Protective Equipment).

First-degree burns affect the outer layer of skin – the epidermis. They are painful, are usually accompanied with swelling and redness.

Second-degree burns affect the outer and underlying layer of skin, epidermis

and dermis. Second-degree burns cause pain, redness, swelling and blistering, and the person should seek medical advice.

CPD Trees, run by Mick Byrne, operates in Perth Hills, an area of dense forest.

Mick is a long-standing Arb West member and has had to stand down his team on a number of occasions this year due to Harvest and Vehicle Movement Bans (HVMB). HVMB’s are the responsibility of the local government authority, and as a rule they’re only issued on the actual morning. I asked Mick how he managed to find work for the guys when there was a work ban in place.

“After ringing the clients and cancelling the work for the day, I have to do a quick ring around and try and find work where there isn’t a ban in place,” he explained. “If not, I must stand the guys down.”

He mentioned on high fire risk days when they can work, when the appropriate measures are put in place, electrical saws are used, regulation

fire extinguishers are taken out, and the guys are rotated to take regular hydration breaks.

All being said, you can’t beat working outside in this beautiful state, whatever the weather has to offer. Arriving back at the yard on 40 ºC day to be greeted with ice-cold icypoles, and iced-watermelon makes it all worth it.

The Polyphagos Shot Hole Borer (PSHB) continues to cut a destructive path through Perth’s urban tree population. In a recent press release it was reported a number of Perth’s famous landmarks had reported infestations, and a number of culturally significant and historic trees would have to be removed –or at the least be heavily pruned.

Locations such as Hyde Park, established by European settlers in 1897 under the name ‘Third Swamp’, has a rich tree history, with records of Ficus and Platanus being planted in 1897, and Pinus sp. and Jacaranda planted in 1912 and 1921 respectively, 100-year-old trees –and some even older – have become infected.

Driving past Hyde Park recently I noticed one of our Arb West members, Morin & Sons, had two crews at the park removing a large Ficus macrophylla var. hillii. Such a magnificent tree meeting an untimely end! Speaking with Alex Morin, the business owner, he mentioned this was only one of many trees he had recently removed for the Department of Primary Industries and Regional Development.

One of Perth’s most notable landmarks, Kings Park, so named in 1901 to mark the ascension to the throne of King Edward VII, and sitting on approximately 400 hectares, has a host of trees favoured by the borer. Unfortunately, there are now a number that have to be removed.

The thought of losing so many of our historically significant trees, part of our Western Australian heritage, is devastating.

Take note: as an association, it is incumbent on Arb West to disseminate current, factual, practical advice to our industry, members or not, to try and contain the spread of PSHB. I suggest other associations in other Australian states watch this space!

To learn more of Arb West and its membership, log on to arbwest.com.au.

The TCAAA’s Jim McArdle points out there’s a phenomenon that eludes most arborists when discussing big leans in trees.

Most lay people, non-arborists, would say a tree with a lean is a common threat of failure.

This would only be the case in a solitary tree in moist or saturated ground, or a tree facing the prevailing wind. Some trees lean due to the removal of adjacent trees causing them to compensate a new foraging and support system in order to remain viable.

Why don’t trees lean toward the equator?

With age some do, like Araucaria columnaris (Cook pine). Phototropism is the cellular response to light. For example, most indoor plants on windows to grow toward the sun. Trees have many cells that are opportunistic towards the light, often the sun, or at least towards a gap where they’re exposed to light. The exception is roots which grow away from light (skototropism).

Can a leaning tree be retained?

It would be wise to retain a leaning tree unless it’s hazardous, and the AQF level 3 or level 5 arborist can best ascertain this through testing the roots at the SRZ distance or interface from structural to woody feeder roots. A table of SRZ calculations is given in AS4970 2009.

Key areas of concern when assessing or doing a pre-climb questionnaire would be observing a weight-to-balance ratio deficit, slenderness, lift of root plate, root rot, or fracture in the lower or mid stem within the tree, and whether the tree is naturally grown or from a pot, having no tap root; one way of addressing these issues is root test investigation.

We were called to a local job where a

tree was moving and the lean toward a house was raising concerns. Within the hierarchy of control there was limited access, so we couldn’t use an EWP, crane or helicopters, and stabilising the tree was a challenge. After tying the tree to an anchoring point and two large and stable trees nearby, the weight-tobalance ratio was corrected and the moving tree was dismantled.

Basal root rot and decay can easily displace a tree and cause it to lean and fail. If saturated for long periods, moisture under the soil tends to move mycelium to up the tree’s vessels towards branches. Unfortunately, it can cause branch failure or lead to root loss and failure or leaning.

Root tests can offer some hope of identifying, root vigor (energy), vibrance (appearance) and vivacity (root tenacity or tendency to spread rootlets and colonise) in the area of support. The

A safer, more productive and innovative way to handle any type of tree work: remote control

Canopy Lift Knuckle Boom Crane with Mecanil SG200 remote rotating grapple saw is a ground-breaking solution which is revolutionising the tree industry. Available for hire nationwide, it allows the operator to access any type of tree work via remote control, in a safe and productive way. No direct tree access or climbing is required.

• Emergency tree removal

• Storm-damage tree removal

• General tree removal

• Available for hire in NSW and interstate

• Crane reach 26m – lift 1.25 tonnes

• Crane reach 29m – suitable to access trees up to 35m

• Crane lift at 4m – 11,400kg on hook and chains

Hire a licensed Canopy Lift knuckle boom crane with grapple saw attachment and operator for tree-care work now!

Trees like the Santalum acuminatum (Quandong), have been utilised as grand walking vistas and entrances. Image: ssmalomuzh/Stock.Adobe.com

issue with identifying species or types of trees is when a vivacious root system overcrowds or outcompetes with a support which could be established as typical or atypical habit. The arborist must know their species and where the zone of rapid taper is located.

Root-plate lift can be established by utilising a foot mallet or probe first, then reviewing the area around the structural root zone.

The foot mallet is simply sounding the ground with the feet or a mallet and determining if any air pockets are found, indicated by lower resonance of the mallet effect. A probe can also be utilised when checking the root zone area for consistency and density in the soil medium, or whether resistance is freely given in the areas of the mallet test – ‘pockets of air’. The structural root zone is the interface of stability and trees would either be windthrown commonly – but not always – at this distance.

When determining compaction, a probe may utilised, but make sure it’s insulated.

Hard-surface areas, drainage and moisture collection areas (pools) are examined for their impact on the system and whether they are positive or negative contributors to support. Negative contributors will act like constraining forces on the root system, reducing root-plate support. Positive contributors like other enmeshing tree

roots of a similar species will act as increasing support.

Contaminated soils may have a pedal structure and high compaction rate which allow for surface-dwelling roots and poor root-plate adhesion. This is a negative contributor and can cause windthrow or failure.

Competing species in root systems can have a negative contribution on the leaning tree if the roots of the adjacent tree area are invasive and highly charged with opportunistic features. Trees like Celtis sp. (Hackberry), Ficus sp (Strangler Fig), Ficus elastica (Rubber), Ligustrum sp. (Privet) and Erythrinas sp. (Coral), and Ailanthus altissima (Tree of Heaven) are key tree species which will outcompete native vegetation. Native trees which may contribute to competing are Eucalyptus robusta (Swamp Mahogany), Ficus watkinsiana (Nipple Fig) and Casuarina glauca (Swamp Oak).

Where leaning trees are the result of two separate trees competing for root stability on the same point in the landscape, the issue is affectation by the constraining forces. If the tree which is leaning is not the feature tree, then it could be removed. But if it is the feature tree, it would need root-test investigation to maintain the status and to possibly engineer a solution to retain the tree. One simple way of restraining a leaning tree with susceptible root attachment is to buffet the stem against the lean with a stay. The load presses

into the timber and the ground may be battened for additional support, particularly in sandy soil or wet soil.

Other options may include engineered cabling with secured anchorage rated to the appropriate tonnage of tension.

Any system introduced would be ideal in increasing support.

On review of the draft AS4790 20024 standards, no additional information is given in the sphere and arborists can change the TPZ to a more subtle oval shape with roots biased towards the lean or away from the lean (note the TPZ is usually a circle and can also be moved if conditions onsite warrant it, including having a cliff one side but still inside a measured TPZ, having a rock platform in the TPZ, or a slab without roots underneath).Major encroachments must have root investigations as per AS4970 2009 by the arborist.

Where the tree roots are leaning with the prevailing wind, the tree has most commonly adapted to the wind force and the windsail area reduces during wind force from weather events on the prevailing wind. Where the lean is into or against the prevailing wind there could be an issue of increasing the wind force in extreme weather and the windsail increases instead of diminishing. The lean has bearing on whether the tree has additional force it can either dissipate or not, hence failure or possible windthrow.

Trees generally weather storms and can lean over to the direction of the prevailing wind, making themselves a smaller target to windforce.

Ken James has an excellent article on wind dynamics and his table indicates typical effects of winds at different speeds on trees.

Note the uprooting of trees at between 89kph and 100kph.

Tree effect Wind speed

Leaves rustle 6kph-11kph

Whole trees in motion 51kph-61kph

Twigs break 63kph-74kph

Branches break 76kph-87kph

Trees break or uproot 89kph-100kph

Hurricane 117kph or greater

The BVR line of brush chippers builds upon the legacy of Morbark’s innovation in the tree care industry through an updated modular design. The new configuration streamlines the equipment’s overall upkeep and maintenance routine, reducing customer downtime and increasing overall productivity.

The BVR brush chippers also feature Morbark’s proven and patented ZeroClutch®. Our ZeroClutch removes the anxiety of engaging the chipper drum, damaged drive belts, and burned clutch discs and elevates the customer’s operating experience. Customers will now simply start their brush chipper, throttle the machine to full RPMs, and engage the feed control bar.

The BVR brush chippers also feature a Reverse-Style Pivot Assembly, which contours the radius of the drum, reducing dead space between the feed wheel and the drum. This gives the machine a

mechanical advantage for increased down pressure, providing optimal chipping results when working with challenging materials.

Other notable innovations to the BVR line include:

• Infeed-Mounted Control Panel - Provides a more convenient access location for operators

• Side-Load Anvil - Four-sided, side-load anvil makes changing the anvil easier.

• 360-degree manual swivel discharge chute - Offers multiple locking positions for greater operator control over chip discharge, and a

• 3-position Electronic Control Bar with Dual Safety Pull Cables, designed to keep safety a top priority while working on a jobsite.

For eqiupment availablity, request a demonstration or quote, contact your local Morbark dealer.

Monitor Industries - NSW/QLD/VIC

Ph: +61 1800 025 024

www.monitor.com.au

49-50 Cassola Pl, Penrith, NSW 2740

1/9 Brumby Street, Seven Hills, NSW 2147

143 Gunnedah Rd., Tamworth, NSW 2340

191 Magnesium Dr, Crestmead, QLD 4132

2/2 Alta Drive, Caboolture, QLD 4510

24-28 Williams Road, Dandenong South, VIC 3175

75 Willandra Drive, Epping, VIC 3076

Stevens Products - New Zealand

+64 9 275 0443

www.stevensgroup.co.nz

293 Landing Drive, Mangere, Auckland, NZ

Scan the QRCode to learn more about Morbark’s new BVR Brush Chipper Line.

BVR10 BVR13 BVR16 BVR19Leaning trees within a patch would be typical as they are searching for light, and phototropism can produce artistic leaders and interesting canopies.

One typical large leaning Ironbark tree I’ve observed ever since I was a young child has always leaned extensively north next to my bustop and toward the road.

When investigating the site, the road is on the north with the swale approximately 3.5 metres from the stem, and the south is a field and biodiversity area on the nature-strip curtilage.

From the edge of the patch trees are subjected to additional loading and therefore there is a propensity to take on an increased load which may influence the rootplate and a lean.

Species, such as the Araucaria columnaris (Cook Pine), are known to lean toward the north. Large trees are known to lean with different soil-profile densities.

Trees leaning in protected areas are usually acceptable to be retained. Large trees which have shifted from natural conditions may have greater difficulty

in re-establishing their position and stabilising. Trees with larger buttress roots are difficult to move, but over time increasing force can shift. Trees on moving soil, slip areas or glacial movements, riverbeds, cliff faces and next to highways where vibration is constant can have difficulty in remaining upright. When trees lean their root system may be exposed, or if they’re supported against a fence or another tree, it may be a case of condemning and replenishing the tree.

In most coastal areas where prevailing salt in the air and constant moisture move a tree in inclement weather, trees can adapt to the conditions or salt injury can take effect on windward side. Some adaptions which are considerable feats include additional ribbing of response wood, additional stem support from advantageous roots, pneumatophores (Mangrove roots) and new epicormic stems which grow vertical and input large reserves of sugars back into the stem.

Historically the hanging tree at Parramatta had a substantial lean and was utilised in hanging convicts. I have to admit that’s one tree I am glad to see a cultural disposition of loss.

Trees leaning into spirituality listed in the Bible include the Acacia, Almond, Almugwood, Balsam tree, Broom tree, Cedar, Cypress tree, Fig, Juniper, Myrtle

tree, Oak, Olive trees, Palm, Pine and Aleppo – that’s besides the symbolic trees, including the Tree of Life and the Tree of Knowledge.

The Budda sat under a Ficus religiosa (Bohdi tree) and other trees like the Anandabodhi tree. Birthing trees have similar role in that they present a featured, protected area, usually in their root buttress, allowing for birth to be semi-protected.

The dying stockman from Henry Lawson lay under the shade of a coolabah tree. And it’s thought the Kelly gang had their last stand at Stringybark Creek in Toombullup State Forest near Benalla laid under the Stringybark tree.

The national tree of Australia is the Acacia pycnantha (Golden wattle) but it’s hard to find one flowering at our historic government buildings. It’s also known that Acacia aneura (Mulga wattle) are the most common in Australia, with incredibly dense, heavy and supportive roots. The Ginko biloba (Ginko) is a dinosaur tree that generally leans with a deep taproot and has medicinal qualities improving circulation and keeping memory sharp for the brain, making the nervous system more focussed and synapses responsive. It’s ideal for HSC students with the disclaimer of use for epileptics, heart conditions if pregnant, and so forth.

Designing environments with Australian trees like the Callistemon sp (Bottlebrush), Corymbia ficifolia

(Western Red) and Santalum acuminatum (Quandong), where we survey the natural environment for inspiration including trees leaning, or trained to lean into another, to create an avenue, have been utilised as grand walking vistas and entrances.

Although most of The Leaning Trees scattered in the Greenough area are located on private property, they can’t be overlooked by anyone driving along the Brand Highway. The tree trunks lie horizontal to the ground and have become somewhat of an icon, a bizarre natural phenomenon caused by airborne salt blown in off the Indian Ocean.

Bonsai has also given the preference of leaning – on a microscale – to present a unique artistry in tree habit. The lean is always a feature that can mimic age as some aged and weathered trees can, in difficult environments, have excessive leans.

Trees which have failed and which are lying on the ground are not leaning.

Leaning trees within a plantation are not usual as they are difficult to harvest. Monocultures are used in harvesting, although promoting a species can be difficult to control with infectious diseases.

As a child we had a ‘horse’ tree which was over a cliff and we would gladly ‘ride’ it with a brother or playmate. It was anchored into a crevice and would be very difficult to dislodge. This type of tree, although a feature, should be constantly assessed if left in a public school or facility. If removing trees like this on the basis of a leaning tree, it can leave us with less budding climbing arborists.

A common issue is children who like to climb trees find the tree they want to climb the most is close to the school fence, offering a sense of freedom or a joyous escape. Even as a child I was scolded for climbing trees and sent to the principal’s office, and that was after the principal told the school not to climb trees!

A tree with a lean is a commonly seen as threatening failure. Sometimes it’s true, but not always.

The Queensland Arboricultural Association continues to watch over and advance arboriculture in Australia’s north.

The recent cyclone that swept through parts of Queensland left a trail of destruction in its wake, particularly impacting Cairns and Southern QLD. As the winds subsided and the rains ceased, arborists rolled up their sleeves to tackle the monumental task of restoring the urban landscape.

The clean-up efforts have been nothing short of extraordinary, with arborists working tirelessly to remove fallen trees, clear debris, and assess damage to green spaces. Their dedication and expertise have been instrumental in rejuvenating communities and restoring a sense of normality amidst the chaos.

However, as the clean up continues, it’s crucial for arborists to prioritise their own well-being. The physical and emotional toll of such intense work can be draining, making self-care essential to prevent burnout. Regular breaks, hydration, effective time management, balanced nutrition, and adequate rest are not just luxuries but necessities in this demanding profession.

QAA sponsorship opportunities: supporting the aboriculture community

At the heart of the arboriculture community lies the Queensland Arboricultural Association (QAA), a not-for-profit organisation dedicated to advancing the industry through education, training, and advocacy. Central to the QAA’s success are its sponsors, whose support enables the association to fulfill its mission and empower arborists across the state.

With sponsorship sales now open for the upcoming year, businesses have the opportunity to align themselves with the QAA and demonstrate their commitment to the industry. These partnerships provide valuable exposure and networking opportunities while supporting initiatives that benefit the entire arboriculture community.

Interested parties are encouraged to secure their sponsorship packages promptly, as opportunities are sold on a first-come basis. For more information

on becoming a QAA sponsor, interested parties can request a Sponsorship Package by emailing office@qaa.net.au or calling the office 07 3821 1488.

Event recap: Empowering Arborists Through Education

Education lies at the core of professional growth in arboriculture, and recent workshops hosted by the QAA have provided invaluable opportunities for arborists to enhance their skills and knowledge.

Bryan Gould’s workshop Managing Trees – adopting a selective approach, emphasised key aspects: selecting trees as landscape anchors; understanding

design requirements; biological tolerances; and functional survival.

Attendees gained deep insights into meaningful tree selection and enhancing urban treescapes. Thanks to all participants for their exceptional dedication to learning.

Craig Reid concluded the Aerial Rescue workshops on the Sunshine Coast.

Rooted in the Minimum Industry Standard MIS304 Aerial Rescue, these sessions covered a spectrum of rescue scenarios and techniques, offering invaluable insights for competitive climbers. Topics included pre-rescue planning, emergency response strategies, access methods, casualty

care, and equipment configuration. Special thanks to Jamie Boston for his assistance with this workshop.

Mark Hartley’s An Irreverent look at Tree Protection on Development Sites workshop returned to Brisbane in March, receiving positive feedback. The QTRA training has also been successful and will be offered again soon. Contact the QAA for training or refreshers.

As we look ahead, the QAA remains committed to providing arborists with opportunities for growth, learning, and collaboration. Upcoming workshops on Objective Writing, Pest, Disease & Damage, Introduction to Mycology & TRAQ promise to further expand arborists’ knowledge base and skillset. Additionally, exciting events such as the Freestyle Comp and the Queensland Tree Climbing Championship (QTCC) offer platforms for arborists to showcase their talents, connect with

peers, and celebrate their passion for the profession. These events not only foster camaraderie within the arboriculture community, but also inspire excellence and innovation in tree-care practices.

Through ongoing education, support, and collaboration, the QAA remains steadfast in its commitment to empowering arborists and promoting excellence in arboriculture across Queensland and beyond. To find

out more and to book in to any of the upcoming events or workshops, visit the Events page on the QAA website.

QAA Executive

For info call QAA on (07) 3821 1488, email office@qaa.net.au, or visit qaa. net.au. Follow the QAA on Facebook (QueenslandArboriculturalAssociation), Instagram (qaa_arborist), or LinkedIn (queensland-arboriculturalassociation).

Elevated work platforms

The CMC S18FR-D has an incredible 11.5m of horizontal outreach and 230kg basket capacity, combined with a 14hp Kubota diesel engine and a radio-controlled remote, to proved simple, easy operation.

With an incredible 11.15m of horizontal outreach and a 230kg basket capacity, the S18F is an ideal machine for arbor work, property maintenance, painting and more.

With a user-friendly design, the S18FR-D is towable on a 3.5T GVM trailer thanks to a weight of only 2580kg, and yet still has the ability to fit through a standard doorway, making it an ideal machine size for many industries.

Having a radio-controlled remote, auto-leveling outriggers and two-

speed drive just adds a whole new dimension for the operator, allowing them to view each side of the machine when operating and making a huge improvement in overall safety.

Also, thanks to a powerful 14HP Kubota diesel, the S18FR-D allows operating up to three functions at one time.

Monitor

To find out more about the CMC S18FR-D spider lift, the CMC range, and Monitor’s other great brands and products, log on to monitor.net.au.

• Two-speed drive

• Auto-level stabiliser legs

• Kubota diesel engine

• Remote control

• Closed LxH 5.15mx 2.28m

CMC S18FR-D specifications

• 14HP Kubota diesel engine and 240V electric motor

• Maximum working height 17.7m

• Maximum outreach 11.15m

• Basket size 1.4m x 0.7m x 1.1m

• Basket maximum load 230kg

• Turret rotation ± 178° (356° non continuous)

• Basket rotation ± 90°

• Machine weight: 2580kg

The S18FR-D is towable on a 3.5T GVM trailer “ ”

A robust and versatile trailer-mounted access platform. Images: Niftylift

210

With a 21-metre working height and 12-metre outreach, the Nifty 210 has one of the largest unrestricted working envelopes in its class.

The Nifty 210 is a robust and versatile trailer-mounted access platform with a special boom design which allows the cage to be moved vertically in a straight line using a single control, making it ideal for working near walls or buildings.

The dimensions and vast working envelope of the machine make it suited to a vast range of environments and ideally suited to the arbor industry.

A road-towable chassis and reverse overrun brakes mean the Nifty 210 can be towed from site to site by a commercial vehicle or suitable 4X4, helping reduce transportation costs and giving the user more flexibility when moving the machine.

Once the Nifty 210 is onsite, a traction-drive system operated from the cage allows effortless positioning. Hydraulically powered drums turn the road wheels and one operator can unhitch and manoeuvre from one location to another in a safe and controlled manner, even on softer ground like gravel and grass.

The Niftylift 210 comes with a versatile combination of diesel and mains power.

The Nifty 210 comes with a versatile combination of diesel and mains power, giving the benefits of the electric and engine power options on the same machine.

The Nifty 210’s cage will accommodate up to two people and their tools and will elevate them to a position anywhere in its class-leading, unrestricted working envelope.