#1 SINCE 1996 JUNE/JULY 2024 + FORESTRY EQUIPMENT + EWPs + Chippers & clean-up options + Association news + Forestry equipment + Eye on the industry + Technical features Saws and log splitters! FEATURED: Husqvarna’s world first A BATTERY CHAINSAW WITH A CLUTCH! SUBSCRIBE AND WIN A HUSQVARNA CLIMBING GEAR HARNESS AND SIX CARABINERS RRP $1030.90!

PROFESSIONAL

PERFORMANCE

SUPERCHARGE YOUR KIT THIS TAX TIME WITH A FREE PRO BATTERY

UPGRADE YOUR PRO TOOLS Tax time

ƒ

Brilliantly engineered to withstand heavy workloads, STIHL AP battery-powered tools deliver the high-performance pros expect - day in, day out. Powering 35+ high-performance tools, all AP batteries are interchangeable across every AP tool.

Stay charged for the entire job with 2 x AP 300 S batteries and the AL 500 Super Charger. Work with one while you charge the other and swap them in and out as needed.

*Promotion valid from 1.6.24 to 31.8.24. While stocks last. Visit stihl.com.au for full T&Cs. ④Run time based on 100% charge. NO DOWNTIME ƒ GET A FREE PRO Battery* – SAVE $329 – visit stihl.com.au to learn more

MSA 220 C-B Run time 48 Mins④ Charge Time 30 MINS AP 300 S Battery 2 Charge Time 30 MINS AP 300 S Battery 1 80% 80% ONE BATTERY SYSTEM. 35+ TOOLS. ƒ

VIEW THE FULL AP BATTERY SYSTEM

The federal budget can seem very complex, but it’s worth working through at least the broad headings. Image: kemaltaner/Stock.adobe.com

Time honoured

As I write this, business and financial analysts around the country are trying to make clear the good and bad of the 202425 federal budget.

It’s not easy.

Aside from the sheer complexity of the thing, the budget itself seems to be presented to the public with slogans designed to appeal to what everyone wants to see.

That may be true, but even so, $22.7 billion committed to ‘facilitating privatesector investment, creating new jobs and opportunities’ can only be a good thing for the arbor sector, which is mostly made up of small, privately owned outfits. Let’s keep our fingers crossed the promised financial boost offers the support to the businesses which want and need to make use of it.

Alongside that commitment is $1.6

billion over five years to ‘reform the tertiary education system and deliver a future workforce’ and $641.4million in ‘targeted support for small business’. Wouldn’t it be awesome if the promised financial support did give rise to an increase in up-and-coming arboriculturalists?

Over the past few years the associations around the country have been working hard to promote the advantages and joys of tree work to secondary and tertiary level students in the hope they’ll consider what can be an extremely rewarding career. But that promotion has been done mostly through the greatheartedness of volunteers and at the expense of the associations themselves and their industry supporters. Perhaps there’ll be a few dollars available here and there to help the

associations further that work. It’d be a big, ongoing boost for the industry which would show benefit well into the future…possibly for generations to come.

As we all try and sort out the wheat from the chaff with the budget, the end of the tax year is creeping up on us fast as well, and according to the business press, we’re all in for a bit of a windfall there, too. There are tax cuts forecast which look set to benefit both individuals and small businesses.

So overall, It looks like the next few years may offer significant opportunities for arborists and tree workers to make the most of a supportive financial situation from the federal government Don’t let those opportunities pass you by.

4 THE AUSTRALIAN ARBOR AGE

Welcome

The Australian Arbor Age is published bimonthly by Prime Creative Media Pty Ltd.

CEO John Murphy

COO

Christine Clancy

Sales Director

Bradley Buchanan

Editor

Tom Foster tom.foster@primecreative.com.au

National Advertising Manager

Arron Reed arron.reed@primecreative.com.au

Phone: 0466 923 194

Client Success Manager

Arianna Lucini

arianna.lucini@primecreative.com.au

Design Cat Zappia

Subscriptions

P. +61 3 9690 8766 subscriptions@primecreative.com.au Website arborage.com.au

Husqvarna’s

Copyright

The Australian Arbor Age magazine is owned by Prime Creative Media and published by John Murphy. All material in The Australian Arbor Age magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical, including information and retrieval systems) without written permission of the publisher. The editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions, or for any consequences arising from reliance on information published.

The opinions expressed in The Australian Arbor Age magazine are not necessarily the opinions of, or endorsed by, the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2024

Articles All articles submitted for publication become the property of the publisher. The editor reserves the right to adjust any article to conform with the magazine format.

Head Office

379 Docklands Dr, Docklands VIC 3008

P: +61 3 9690 8766 enquiries@primecreative.com.au www.primecreative.com.au

Sydney Office Suite 3.06, 1-9 Chandos Street Saint Leonards NSW 2065, Australia

P: +61 2 9439 7227

6 THE AUSTRALIAN ARBOR AGE

#1 SINCE 1996 JUNE/JULY 2024 + FORESTRY EQUIPMENT + EWPs + Chippers & clean-up options + Association news + Forestry equipment + Eye on the industry + Technical features Saws and log splitters! FEATURED: Husqvarna’s world first A BATTERY CHAINSAW WITH A CLUTCH! SUBSCRIBE AND WIN A HUSQVARNA CLIMBING GEAR HARNESS AND SIX CARABINERS RRP $1030.90! 10 On the cover

battery-

chainsaw with a clutch has arborists smiling. #1 SINCE 1996 Events like these provide an exciting spectacle for spectators, pushing the boundaries of what climbers can achieve in their sport. “ ”

Page 36

powered

–

Cassian Humphreys

Cassian is an exMerristwoodian (NCH-arb 1991, bridged into the UK Diploma ’92), Qualified to the AQF L5 (AUS Dip) in ’09, upgraded in currency in 2017. He commenced his career after graduating in Horticulture (’85), transitioning into Arb (’89). Experienced in all aspects of arboriculture, having worked in Germany, Australia, Britain, PNG and Vanuatu, Cassian has been writing for AAA since 1999, with over 40 articles to his name. His core specialisation involves conservation arboriculture, education and tree-health-care.

Jim McArdle

B.Ed. Sc (Sydney), Dip. Arb. (Ryde), VTRA@QTRA qualifications. Director at McArdle Arboricultural Consultancy and TCAA

President, Jim’s career spans across almost 40 years and focuses on consulting and reporting in tree risk protection and management plans, and tree impact assessments.

08. SIGNIFICANT TREES

10. ON THE COVER

Kiah Martin gives Husqvarna’s T542i XP® and 542i XP® a workout

66. TECHNICAL FEATURE

Plant more native trees to reduce landslide risk

68. TECHNICAL FEATURE

Ascension and the analogy of the tree to illustrate the human condition by Cassian Humphreys

Dave Crispin

A professional consulting arborist at Treeswest Australia, certified to AQF level 5 (Diploma), international coach, speaker and presenter.

THE AUSTRALIAN ARBOR AGE 7

04. WELCOME LETTER 14. FORESTRY EQUIPMENT 16. SAWS & LOG SPLITTERS 26. CHIPPERS & CLEAN-UP OPTIONS 36. ASSOCIATION NEWS 48. EWPs 54. SUBSCRIBE AND WIN 56. EYE ON THE INDUSTRY 64. CLIMBING

Contributors Features Regulars

Balga – a significant tree?

The balga trunk may grow over three metres tall, and banding allows the age of the plant to be determined. Image:Chris/Adobe.stock.com

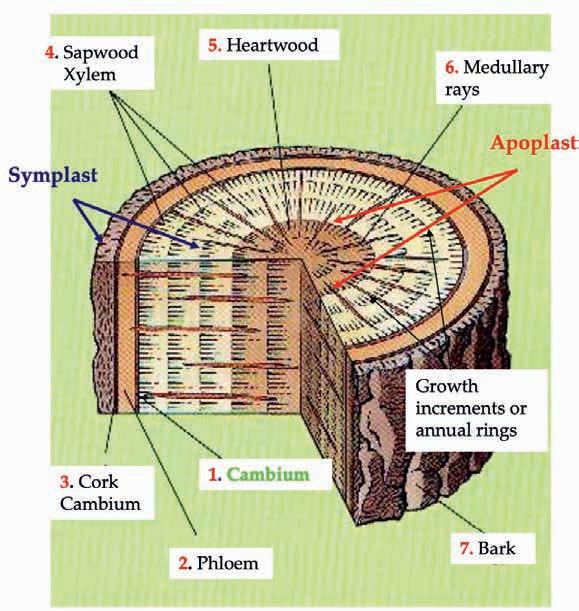

Balga (Xanthorrhoea preissii), not technically a tree, is a widespread species of perennial monocot found in southwest Australia, and is significant as a supplier of bush medicine.

Often colloquially known as The Grass Tree, the name ‘balga’ is derived from the Nyungar language, and the appearance of the plant was seen by early settlers of the region as resembling a native inhabitant holding a spear. It’s found in all types of soil throughout coastal plains, near watercourses, and in inland forest regions extending from the Western Australian coast to Albany in WA’s southwest.

What looks like a trunk is actually

made up of a ring of accumulated leaf bases which provide structural support but no nutrient transport. Nutrient transport is achieved via aerial roots which run down the hollow centre.

Balga was important to the Noongar people, who used the gum it contained as glue, and when burned, inhaled the smoke for relief from respiratory ailments. The spikes were used for fish spears, and the bardi grub which colonised the plant as a source of food.

Inside the top of the tree is a pulp eaten to ease stomach upsets.

The trunk may grow over three metres tall, and after fires the remains of leaves and the annual regrowth produce banding, allowing the age of the plant to be determined.

Creamy or white flowers appear on an upright spike, 1.5m to 2.5m long, between June and December, and appear more profusely when stimulated by bushfire.

8 THE AUSTRALIAN ARBOR AGE

Significant Trees

The worlds first battery chainsaw with a clutch!

The

NEW T542i

XP

and 542i XP from Husqvarna.

With a passion for innovation, Husqvarna has recently introduced the world’s first battery chainsaw with a clutch: the top-handled T542i XP®, and its rear-handled sibling the 542i XP®. The saws have landed in Australia, and Husqvarna H-Team Ambassador and professional arborist at TreeStyle Pty Ltd, Kiah Martin, has put them through their paces.

T

hese two saws, new to the Australian market, have inherited the tried-and-tested features of their predecessors, including excellent in-tree (top-handled version) and on-ground (rear-handled version) manoeuvrability, spot on power-to-weight ratios, great ergonomics and balance, and an everefficient brushless motor.

But there is one quite significant change.

Move to battery power

There’s something so familiar with these new battery saws, different from their earlier counterparts, in that they really do feel more like the saws of old – the older petrol versions that is. And I’m confident it’s the addition of the centrifugal clutch and the kick-start energy and momentum this provides that’s fuelling this feeling in the cut.

To better understand this feeling, I

recently contacted my colleague Peter Vergote – a climbing arborist from Belgium – and he told me, “The little extra weight I take for granted when I have this power! Even for pruning work where I only use the chainsaw for a couple of cuts.

“Since I have a T542i XP®, I almost never use my other top-handle saws. And definitely no petrol top handle.”

Tree professionals still using 40cc

10 THE AUSTRALIAN ARBOR AGE

On the cover

petrol chainsaws might now decide to finally make the transition to battery with the launch of this new platform, as the control and throttle response of these units under load certainly feels like their petrol equivalents, but with all the benefits and convenience of the battery system.

Great features

The two new chainsaws have more torque and more power at lower RPM. In fact, it’s around 10 per cent more, allowing increased cutting capacity and productivity during the workday. Scott Forrest – New Zealand arborist and good friend – agreed to let me quote him saying, “Finally! I’ve found a battery saw that can keep up with my production: the T542i XP®”.

The T542i XP® just changed the game with battery saws “ ”

THE AUSTRALIAN ARBOR AGE 11

Professional arborist at TreeStyle Pty Ltd, and Husqvarna H-Team Ambassador, Kiah Martin.

The new chainsaws have more torque and more power at lower RPM than comparable petrol chainsaws. Images: Husqvarna

Finally! I’ve found a battery saw that can keep up with my production

Is it time to upgrade or augment your fleet to include the T542i XP®?

If you know Scotty, you’ll understand it takes a lot to keep up with his speed and stamina! He is a machine!

The new models support the Husqvarna X-CUT® SP21G chain and optional the X-CUT® SP33G chain. Both are robust, pre-stretched chains and the first of their kind to be developed, designed and manufactured in-house by Husqvarna, with semi chisel cutters to keep sharpness over time and a narrow kerf for enhanced cutting efficiency.

In test driving these tools, some of the main platform highlights for me were:

• The addition of a centrifugal clutch

• An updated magnesium sprocket cover for quick debris bale out

• An adjustable oil pump for customisable oil-flow control

• A rim sprocket simplifies changeovers

• A new digital oil sensor on the intuitive user interface giving a heads up to fill and heads up when there’s no flow

• An IPX4 weatherproof classification, and

• A new, improved snug-fit guide bar cover (I love it!).

• Some of my favourite features of the T540i XP® are still present:

• A belt eyelet (my favourite little bit)

• An unobstructed view through the hand guard

T540i XP® with X-PRECISION™ SP11G chain (1/4” mini) and 10” X-PRECISION™ guide bar, but now you can also

12 THE AUSTRALIAN ARBOR AGE

the cover

On

THE AUSTRALIAN ARBOR AGE 13 brandt.ca/au 1800 237 887

Forestry Equipment

New Cat® 255 and 265 Compact Track Loaders

Delivering industry-leading lift and tilt breakout forces, and with significantly increased torque.

The all-new, next-generation Cat® 255 and 265 Compact Track Loaders elevate Caterpillar’s loader reputation through improved engine performance, lift and tilt performance, stability, operator comfort and technology.

A new performance standard

The new 255 and 265 loaders are powered by Cat C2.8T and Cat C2.8TA engines respectively, which offer 74.3hp (55.4kW). The new engines maintain horsepower across a wider RPM range and boast significant torque increases for improved working performance, and a redesigned engine compartment mounts the engine and cooling package lower into the frame for improved stability.

“ ”

Improved engine performance, lift and tilt performance, stability, operator comfort and technology

Hydraulics

Standard hydraulic-system pressure is increased to 3500psi (24130kPa).

New for these next generation machines, the closed-centre auxiliary hydraulic system allows the 255 and 265 to operate all Cat Smart Attachments, including the Cat Smart Dozer Blade, with the standard auxiliary hydraulics provided, and the 255 loader offers a new 12.6” (320mm) bar-tread narrow-track option, ideal for work in confined areas.

Improved operator’s office

Both the Cat 255 and 265 Compact Track Loaders feature a larger cab design with more overall volume and additional foot space.

A range of new mechanical and air-ride suspension seat options are available for the 255 and 265 loaders, including a high-comfort seat that is both ventilated and heated.

14 THE AUSTRALIAN ARBOR AGE

The all-new, next generation Cat® 255 and 265 Compact Track Loaders are a ground-up redesign of the previous series, improving on the features that made the previous models so popular.

The new 255 loader delivers class-leading lift height. Images: Caterpillar

Both the Cat 255 and 265 Compact Track Loaders feature a larger cab design with 22 per cent more overall volume and 26 per cent additional foot space.

Rated

Hydraulic Pressure – standard, psi (kPa)

Hydraulic Flow – standard, gpm (lpm)

Hydraulic Pressure – SEA High Flow, psi (kPa)

Hydraulic Flow – SEA High Flow, gpm (lpm) 30 (113) 30 (113)

Hydraulic Pressure – High Flow XPS, psi (kPa)

Hydraulic

Next generation loaders are equipped with either a five-inch (127mm) standard LCD monitor or an eight-inch (203mm) advanced touchscreen monitor, depending on the technology package selected. The standard monitor features Bluetooth connectivity and supports functionality for rear-view camera feed, creep, job clock, and maintenance reminders.

The new advanced joysticks provide integrated control of the advanced touchscreen monitor so all machine function control and adjustments can be made without the operator removing their hands from the controls.

Advanced technologies

The new compact track loaders deliver the next level of integrating machines with technology. Both the standard and advanced monitors offer the ability to run Cat Smart Attachments, such as the dozer and grader blades and backhoe. The machine automatically recognizes the type of attachment and the required joystick pattern for controlling it.

The available Cat Product Link Elite system tracks machine hours, location, asset utilisation, provides fault code details and delivers advanced monitoring and machine health, and is remotely accessible via VisionLink®. In addition, Product Link Elite provides remote flash and troubleshooting capabilities and quickly enables the remote activation of the SEA High Flow feature.

For more information about the new next generation Cat 255 and 265 Compact

For more on the new Cat 255 and 265 Compact Track Loaders, contact a Cat dealer or visit cat.com.

New engines maintain horsepower across a wider RPM range and boast significant torque increases for improved working performance.

THE AUSTRALIAN ARBOR AGE 15 255 265 Engine: Cat C2.8T Cat C2.8TA Gross power, HP (kW) 74.3 (55.4)74.3 (55.4)

221

280

9628

10492

Engine Torque, ft-lb (Nm)

(300)

(380) Operating Weight, lb. (kg)

(4367)

(4759)

2499

2822

Operating Capacity @ 35%, lb. (kg)

(1134)

(1280)

3500

(24130)500 (24130)

23 (86) 23 (86)

3500 (24130)3500 (24130)

4061

(28000)4061 (28000)

Flow – High Flow XPS, gpm (lpm) 30 (113) 34 (129)

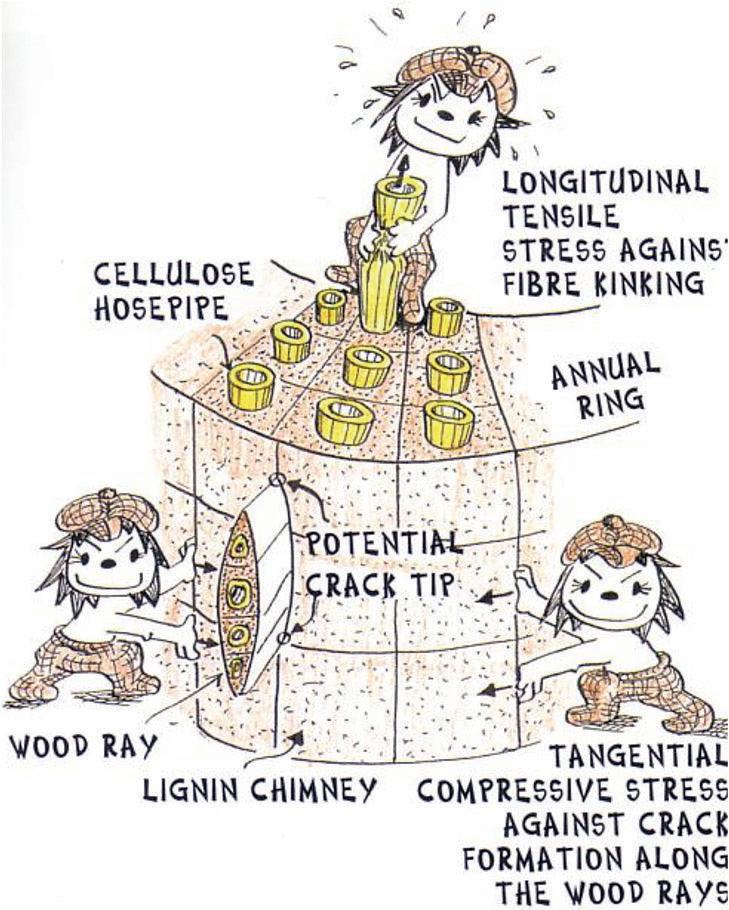

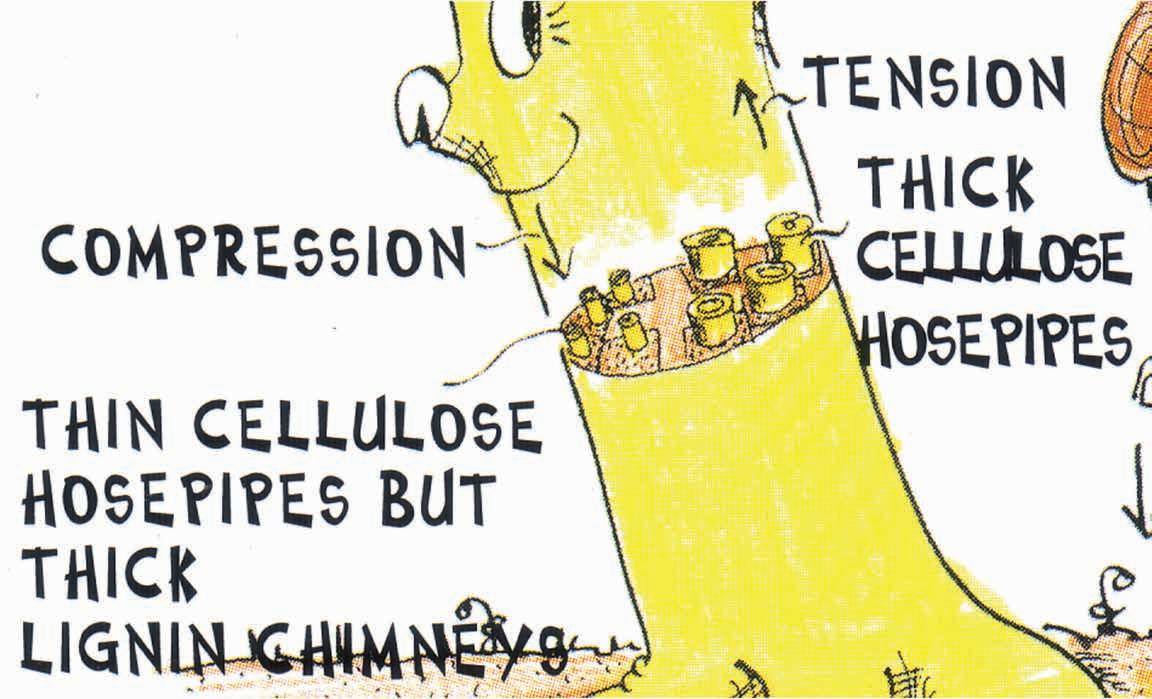

The TITAN 40/20 Premium Firewood Processor a compact, reliable and mobile solution built for processing larger quantities of firewood.

Revolutionise your firewood production with the eco-friendly Titan 40/20 Premium Firewood Processor

The Titan 40/20 Premium Firewood Processor stands out as a must-have tool for professional firewood producers looking to scale up operations while minimising environmental impact.

Australian firewood producers need a professional machine, and the 40/20 Premium Firewood Processor is ideal for the most demanding firewood producers. Thanks to features like a Ø100cm Widia Carbide circular saw and 200kN of splitting force and mechanical-hydraulic operation, long service life and minimum maintenance are ensured.

Environmentally friendly

The TITAN 40/20 Premium cuts logs with a WIDIA circular saw with cemented, carbide-tipped teeth, resilient to foreign materials, that cuts logs in the shortest time possible. It requires no lubrication with oil that could be dispersed in

the environment, and because of its completely mechanical operations, the firewood processor can also be used in more demanding conditions.

A telescopic hydraulic lifting table for logs up to 4.0m is available for easier work, and can be driven via PTO, electric motor, or a combination of both.

BoomSpeed function (standard equipment)

BoomSpeed shortens the splitting cycle by up to 60 per cent compared to the base model, with the same splitting force (20t). A specially built cylinder and the additional valves enable a better oil flow and a greater splitting speed.

Invest in efficiency and sustainability

Choosing the Titan 40/20 Premium Firewood Processor is not just a purchase; it’s an investment in efficiency, sustainability, and futureproofing for any firewood production business.

With its robust design, eco-friendly features, and powerful performance, this processor is ideally suited to meet the challenges of the Australian market and beyond.

To learn more of the Titan 40/20 Premium Firewood Processor, log on to grapples.com.au.

16 THE AUSTRALIAN ARBOR AGE

Saws and log splitters

FIREWOOD PROCESSOR TITAN 40/20 PREMIUM sales@grapples.com.au 0436 028 643 www.grapples.com.au ECO FRIENDLY GRAPPLES Cuts with a carbide tipped circular saw. Cut and split at the same time. Also see our larger 53/40 model! CALL NOW

Superaxe ticks all the boxes Saws and log splitters

>

>

Whitlands Engineering is one of the last remaining local wood-splitter manufacturers, prioritising local jobs, strict quality control and the pride that comes with being Australian owned and Australian made.

The Whitlands Engineering story started when head designer and CEO David Burder designed and built the first vertical hydraulic log splitter on the market – the now legendary Superaxe.

Safe, local product

Thirty-one years later Whitlands Engineering is considered one of Australia’s leading manufacturers of hydraulic wood splitters. All machines are built on site in the country Victorian workshop and shipped direct to buyers all over Australia and New Zealand.

A core focus of the Whitlands Engineering approach to product development is safety. Although not as widely publicised as other farm accidents, injuries from hydraulic wood splitters are common, and often very serious. In response to concerns, Whitlands Engineering has developed a two-handed control system used on the Superaxe which keeps the operators hands away from the cycling blade. This simple system has been applauded by hire companies, business owners and machinery operators as it maximises operator safety and reduces potential liability.

The range

Available in three different models ranging from smaller domestic machines right through to the powerful WS4150, all Superaxe models feature log lifters, heavy-duty construction, top quality Honda power packs, and a two-year manufacturing warranty.

Over 30 years the company has earned an unrivalled reputation for building ergonomic, tough, productive and efficient machinery. David said, “We’ve been providing machines to the farm and forestry sectors and arbor industry for many years – the durability, ease of use and speed of all our machines means they are the first choice for many companies seeking to exploit the profit potential in tree waste and plantation timber.”

There is a machine to suit all requirements – large or small. Furthermore, as a small company, Whitlands Engineering can also accommodate custom additions.

To see more of Superaxe and Whitlands Engineering, log on to superaxe.com.au.

Over 30 years the staff at Whitlands Engineering has earned an unrivalled reputation for building ergonomic,

18 THE AUSTRALIAN ARBOR AGE

Safe,

tough and efficient.

all Superaxes feature log lifters, heavy-duty construction, top quality Honda power packs, and a two-year manufacturing warranty.

Available in three different models,

tough, productive

efficient

WHITLANDS ENGINEERING: INDUSTRY LEADERS IN FIREWOOD MACHINERY WWW.SUPERAXE.COM.AU 1800 702 701 TURN

TIMBER

PROFIT

THIS RANGE OF MACHINERY WS3150 SUPERAXE SHOWN HERE > SUPERAXE WOODSPLITTERS

REX FIREWOOD PROCESSORS

REX LOG SAWS

THE REX LOG BUSTER

and

machinery.

EXCESS

INTO

WITH

>

>

>

WOOD CLEANING TROMMELS

INFEED

OUTFEED ELEVATORS WS150 SUPERAXE SHOWN HERE

HOPPERS >

Lucas Mill 30th anniversary

Lucas Mill reached a major milestone in March 2024 when the Australian family-owned company celebrated its 30th anniversary.

Lucas Mill had its debut at Warragul Farm World in March of 1994 and has been an amazing success story since that time.

The company’s original business plan was to sell 50 Lucas Mills in its first 12 months, and was blown away by its instant success, receiving orders for 50 Lucas mills in its first six weeks alone.

Passing the test of time

Three decades later the Victorian business has gone beyond the family’s initial dream of selling 50 mills a year, with the company boasting sales of over 23,000 mills sold into over 100 countries. Lucas Mill has international distributors in all major countries, some who have been with the company almost since its inception.

Lucas Mill continues to enjoy success both in Australian and international markets, and currently over threequarters of its sales export to a huge diversity of markets, from the jungles of Papua New Guinea to the Alaskan wilderness and the Lakes District in England.

See for yourself

Field days are the company’s shopfront and it attends 30 shows in Australia each year (a list of upcoming field days is available at lucasmill.com/Demonstrations/Field-Days), with two technical advisors onsite and demonstrating throughout the events. Ian Schulz has spent his entire career working with timber and was a trainer on the Lucas Mill when he worked at Creswick Forestry School, while Kyle Roberts has gained a vast range of knowledge with the Lucas Mill operation and the timber industry in general.

Still growing

Lucas Mill’s product range has expanded over time to include five Circular Blade Mills (with an electric option for Model 8 and Model 10), three dedicated Slabber Mills (including the Super Slabber which can slab up to 2.8m) and a large range of optional extras, from complete planer kits to weatherboard attachments.

Find out more about Lucas Mill and see the complete range of milling equipment at lucasmill.com.

THE AUSTRALIAN ARBOR AGE 19

Saws and log splitters

Lucas Mill owner with timber milled in Chile.

Dudley Keeble (retired) operating a Dedicated Slabber.

Saws and log splitters

KC330.9 : Superior performance. Images:

Kress Commercial OPE

Embracing sustainability in tree care.

In the world of arboriculture, sustainability isn’t just a buzzword –it’s a commitment to maintaining the health of trees and the future of the planet.

This commitment to sustainability is driving a shift in the industry, with more and more professionals and municipalities seeking to integrate sustainable practices into their operations. Among these, the Kress Commercial range of outdoor power equipment (OPE) stands out, offering a compelling solution for sustainable landscaping and tree care.

A leap forward

Unlock your tools’ true potential with the Kress 8-minute CyberSystem™, offering up to 10x battery life, 2x power output and zero downtime. Make the transition to zero-emissions today with market-leading commercial warranties – five years2 for tools and eight years for CyberPack™ batteries3 and the CyberTank™ Power Station4.

As sustainable practices are embraced in tree care, tools like those offered by Kress Commercial are leading the way. With their innovative design, high performance, and commitment to sustainability, they are setting a new standard for the industry. So, whether you’re trimming hedges, pruning trees, or cutting branches, choose Kress

Kress KC270.9 a game-changer for any arborist.

Commercial for equipment that works as hard as you do, while also working to preserve the planet for future generations.

With innovative designs and cuttingedge technology, these tools are revolutionising tree care.

Kress

Commercial

KC270.9 60V Brushless 55cm Long Shaft Pole Hedge Trimmer

The KC270.9 is a game-changer for any arborist. Its long shaft allows for easy reach of tall trees and hedges, reducing the need for lifts and ladders. This not only improves safety but also efficiency, as work can be done quicker and with less strain. The hedge trimmer offers the robust output of a 1kW motor, comparable to a traditional 25cc petrol trimmer. The 145° articulating head

Innovative designs and cutting-edge technology “

”

and 246cm shaft provide versatile cutting angles and a superior reach for complex tasks.

As part of the Kress Commercial CyberSystem™ OPE range, it delivers high-end performance with lower operating costs compared to petrol and other battery systems, making it a sustainable choice for environmentally conscious professionals.

20 THE AUSTRALIAN ARBOR AGE

Kress

With its combination of 2.8kW power, 24m/s chain speed, and an Oregon 0.325 lp chain, the KC300.9 outperforms traditional petrol-powered saws.

Kress Commercial KC330.9 60V

Brushless 12"/25cm Telescopic Pole Saw

Setting a new standard in productivity, the KC330.9 boasts an impressive reach of up to four metres.

With its 60V power supply, it competes head-to-head with its petrol-engine counterparts in terms of power and performance. Equipped with a two-point adjustment system, the pole saw offers superior manoeuvrability, allowing arborists to make precise cuts from various angles with ease.

Like the KC270.9 Hedge Trimmer, the KC330.9 delivers commercialgrade performance while significantly reducing operating costs compared to traditional petrol equipment.

Kress Commercial KC300.9 60V

Brushless 16"/40cm Chainsaw

Offering power and efficiency, this chainsaw outperforms traditional petrol-powered saws with its

The Kress KC330.9 offers an impressive reach of up to four metres.

combination of 2.8kW power, 24m/s chain speed, and an Oregon 0.325 lp chain. The CyberSystem™ battery and charging system, coupled with an IPX4 waterproof design, makes it an ideal choice for tree care and storm damage recovery. With an 8-minute1 charge time and a remarkable battery lifespan of 3000 charge cycles, this chainsaw is powerful, enduring, and well-balanced, allowing for comfort and longer periods of operation without fatigue.

Say goodbye to starting concerns that can come with intermittent use on petrol products. The Kress Commercial KC300.9 Chainsaw ensures smooth, fast, and efficient cutting.

A 145° articulating head and 246cm shaft on the KC270.9 give versatile cutting angles. A high chain speed ensures fast and efficient work.

1Charging time of the Kress Commercial 8-minute batteries when charged with the CyberTank charger in boost mode.

22 +3^ or 400 +6—hours of use (whichever comes first)

35 + 3 Years^ or 2000 + 1000 charging cycles (whichever comes first)

45 + 3 Years^ or 1200 + 800 charging cycles (whichever comes first)

^The additional warranty period applies only if customer registers their Kress products at www.kress.com/en-au/ within 30 days of purchase

THE AUSTRALIAN ARBOR AGE 21

Saws and log splitters

Peterson Portable Sawmills

Peterson Portable Sawmills’ commitment to optimising mill efficiency and maximising the potential of logs has led to forging strong partnerships with local woodturners and woodworking professionals. One such collaboration introduced the company to Pete.

For over three decades, Peterson Portable Sawmills have been the passion and livelihood of thousands of satisfied sawmillers worldwide.

With 25 years of experience in wood processing, Pete’s foray into woodturning commenced when he received a lathe from a local woodturners club as a gesture of gratitude for providing timber slabs used for countertops. Though the lathe initially sat idle in his shed for a year, Pete eventually embraced woodturning in 2014 and has since been dedicated to the craft, sourcing timber through working with Chris at Peterson’s.

“As soon as milled timber started coming off logs, I realised woodturners and woodworkers would utilise more of a log if it was milled instead of chopped up with a chainsaw,” remembered Chris. “Parts of the log previously used only for firewood could become saleable timber and slabs or turned into woodturning blanks – the firewood became the off product instead of the main selling piece.”

History

Pete’s association with Peterson’s traces back over two decades to when he delivered a large gum log – gifted by the local council – to the factory. It was unloaded with a 30ton crane and milled into garden sleepers – lots of them!

“Being portable is such a blessing!” said the craftsman. “Both woodworking and woodturning, you need wood, lots of wood.

“Sawmilling provides builders, joiners, cabinetmakers, woodworkers and woodturners with locally sourced timber, which I have.”

Since working with Peterson’s, Pete has been able to utilise test mills for processing logs and to deploy portable mills to access timber that cannot be transported to the factory. He actively participates in woodworking events like the New Zealand National Wood Skills Competition, where he not only demonstrates his woodworking prowess, but also champions Peterson’s mills.

“The yield from small or large logs is impressive,” he said. “Their speed and reliability, the training and aftersales service is world class. Assisting at their open days I have seen the interest and amazement people get from watching a Peterson in action, and what we are able to produce during the milling process.

“Woodturners who have experienced a Peterson in action often comment that they should have bought one years ago!”

Learn more

Pete’s story highlights the symbiotic relationship between woodturners and sawyers. For the staff at Peterson Portable Sawmills it’s a privilege to see Peterson mills transform ordinary logs into extraordinary works of art.

If you have any questions about how woodworkers and sawyers can work together, and to find out more about Peterson Portable Sawmills, log on to petersonsawmills.com.

22 THE AUSTRALIAN ARBOR AGE

The BVR line of brush chippers builds upon the legacy of Morbark’s innovation in the tree care industry through an updated modular design. The new configuration streamlines the equipment’s overall upkeep and maintenance routine, reducing customer downtime and increasing overall productivity.

The BVR brush chippers also feature Morbark’s proven and patented ZeroClutch®. Our ZeroClutch removes the anxiety of engaging the chipper drum, damaged drive belts, and burned clutch discs and elevates the customer’s operating experience. Customers will now simply start their brush chipper, throttle the machine to full RPMs, and engage the feed control bar.

The BVR brush chippers also feature a Reverse-Style Pivot Assembly, which contours the radius of the drum, reducing dead

space between the feed wheel and the drum. This gives the machine a mechanical advantage for increased down pressure, providing optimal chipping results when working with challenging materials.

Other notable innovations to the BVR line include:

• Infeed-Mounted Control Panel - Provides a more convenient access location for operators

• Side-Load Anvil - Four-sided, side-load anvil makes changing the anvil easier.

• 360-degree manual swivel discharge chute - Offers multiple locking positions for greater operator control over chip discharge, and a

• 3-position Electronic Control Bar with Dual Safety Pull Cables, designed to keep safety a top priority while working on a jobsite.

AUTHORISED DEALER NETWORK

For eqiupment availablity, request a demonstration or quote, contact your local Morbark dealer.

Monitor Industries - NSW/QLD/VIC

Ph: +61 1800 025 024

www.monitor.com.au

49-50 Cassola Pl, Penrith, NSW 2740

1/9 Brumby Street, Seven Hills, NSW 2147

143 Gunnedah Rd., Tamworth, NSW 2340

191 Magnesium Dr, Crestmead, QLD 4132

2/2 Alta Drive, Caboolture, QLD 4510

24-28 Williams Road, Dandenong South, VIC 3175

75 Willandra Drive, Epping, VIC 3076

Stevens Products - New Zealand +64 9 275 0443

www.stevensgroup.co.nz

293 Landing Drive, Mangere, Auckland, NZ

Scan the QRCode to learn more about Morbark’s new BVR Brush Chipper Line.

BVR10 BVR13 BVR16 BVR19 INTRODUCING MORBARK’S STARTING LINEUP OF BRUSH CHIPPERS

FUTURE OF CHIPPING BEGINS WITH MORBARK’S BVR BRUSH CHIPPERS

THE

Saws and log splitters

NEW Silky Super Accel 21cm Curved Professional

Get excited! The NEW Super Accel 21 is here.

It is not well known in Australia that Japanese companies have a term for constant and neverending improvement.

It is called Kaizen.

The team at Silky Saws Japan abides by the term Kaizen at their factory in Ono Japan where they collaborated to improve the Super Accel, attacking the challenge from two sides.

Silky is all about how the saw feels in the hand, and the strength of the tool, while keeping the saw as light as it can be! Silky Saws has reinvented the shape of the handle and a curved blade for a folding saw that is more ergonomic.

New scraper teeth and enhancements

The NEW Super Accel 21cm Curved Professional folding saw has a 21cm blade with the new GOKAI-ME scraper tooth at intervals along the blade. The new tooth is designed to clear sawdust from the cut, enhancing efficiency.

The cut starts with the handle closest to the branch and is pulled across it. The teeth immediately bite into the branch and start cutting. As the saw progresses through the pull stroke, more teeth join the party, making an aggressive incision in the branch.

At the same time, the scraper teeth at various intervals clear the sawdust from the cut.

The NEW Silky Super Accel 21cm Curved is fast and aggressive, with an increased efficiency in cutting live and large branches.

Features and benefits

• The scraper-shaped GOKAI-ME teeth are perfectly designed to remove the remaining sawdust and to make both rip-cuts, cross-cuts, and slant-cuts with great performance

• The NEW Super Accel features a 21cm curved blade crafted from highquality materials. This unique design ensures optimal cutting efficiency and manoeuvrability, making it the perfect tool for a variety of pruning tasks

• Whether you’re trimming branches, pruning bushes, or shaping shrubs, the NEW Silky Super Accel delivers unparalleled cutting precision. The curved blade enhances the saw’s ability to navigate through dense foliage with ease, providing clean and controlled cuts

• Weighing in with just the right balance of sturdiness and portability, the NEW Super Accel is a compact and lightweight hand saw, thanks to its rigid aluminium chassis

• The ergonomically designed handle ensures a comfortable and secure grip, reducing fatigue during extended use. The non-slip surface

adds an extra layer of control, allowing the user to tackle many pruning tasks with confidence and ease

• Electroless nickel plating coats the entire blade, giving stronger rust resistance, and

• The saw’s adaptability and efficient cutting make it an indispensable tool for both professionals and hobbyists alike.

For more info phone (07) 3823 1599, or log on to atcproducts.com.au.

24 THE AUSTRALIAN ARBOR AGE

Silky is all about how the saw feels in the hand.

The NEW Silky Super Accel 21cm Curved is fast and aggressive with an increased efficiency in cutting live and large branches.

The NEW Super Accel 21cm Curved Professional folding saw.

HUSQVARNA X-COM ACTIVE

Take communication to new heights

Experience X-COM Active, a robust, high-tech communication and hearing protection headset system designed for arborists and tree care professionals –making teamwork smoother and more efficient.

• Crystal Clear sound

• Advanced noise reduction

• Excellent hearing protection

• Up to 10 team mates across 3 channels FIND OUT MORE

Chippers and clean-up options

Enter: Vermeer’s largest stump grinder yet

For tree care professionals who have been searching for a commanding machine that can take down large stumps with ease and fit through tight jobsites that most stump grinders with this horsepower could not — your search is over.

The SC1052 stump grinder is the newest, most powerful machine in the Vermeer stump grinder line-up. While a large machine, the SC1052 can become compact when needed — allowing you to navigate through tight residential areas with ease.

For tree-care and landscape business owners, rental-fleet managers or anyone in between, the SC1052 is ideal at quickly taking down multiple small or mid-sized stumps or efficiently tackling robust, challenging stumps.

All-day performance

The SC1052 is backed by a 115hp (85.8kW) Origin 4.3L gas engine and an 18 gallon (68.5L) fuel tank – the choice of a gas engine made to simplify refuelling the machine.

“The Vermeer SC1052 stump grinder is the next generation of large stump grinders,” said Josh Vrieze, senior product manager at Vermeer Corporation.

With cutting capabilities up to 31” (78.4cm) above grade and 25” (63.5cm) below the surface, operators can

Ideal at quickly taking down multiple small or mid-sized stumps “ ”

26 THE AUSTRALIAN ARBOR AGE

The SC1052 is the newest, most powerful machine in the Vermeer stump grinder line-up. Images: RDO Equipment/Vermeer

Two-sided carbide V-profile teeth on the VCS not only help to optimise overall cutting performance, but also help extend the cutter wheel’s longevity “ ”

experience fewer interruptions due to repositioning while working. With a 72” (182.9cm) straight-line cutting width, the SC1052 tackles six-foot (2m) stumps with ease. The impressive cutting power behind the SC1052 makes it an ideal fit for operations that consistently remove bigger stumps or spend the majority of their time grinding stumps.

The cylinder-and-linkage bar design gives operators a wide cutting range and minimises the need to reposition. The design helps to position the cutter wheel out and away from the machine as the boom drops. Repositioning the machine less means more time spent doing important work — removing stumps efficiently.

Cutting-edge innovations

The SC1052 is equipped with innovative technology and design components to help your crew be more productive while working.

A notable feature on the SC1052, and all new Vermeer stump grinder offerings, is the Vermeer cutting system (VCS). This feature was developed to address many challenges associated with traditional cutting systems. Instead of using a bolt to secure teeth to the cutter wheel, the VCS is equipped with a mounting and retention structure. This design helps to keep teeth from shifting in the pocket and absorbs the shearing force while operating. Two-sided carbide V-profile teeth on the VCS not only help to optimise overall cutting performance, but also helps extend the cutter wheel’s longevity

due to maximised durability.

For operators looking for more productivity on the job, the SmartSweep™ control system can help reach daily grinding goals. The SmartSweep system provides constant feedback while monitoring the engine load, creating a smooth and consistent cutter-wheel sweep rate.

No matter where the work is done, jobsite safety should be a top priority for operators and crew members. That’s why the operator presence system, equipped on all Vermeer stump grinders, is crucial for your crew. This feature of the control handle is intuitive, disengaging the cutter wheel and bringing it to a stop within seconds if the operator’s hands leave the control.

Navigating jobsites with ease

At just 35” (89cm) wide without dual wheels, the SC1052 smoothly navigates through a standard 36” (91cm) residential gate. The SC1052 is equipped with a four-wheel drive system and differential lock that enables smooth travel over uneven or challenging jobsite terrain.

The Vermeer SC1052 stump grinder is not just a new stump grinder, but a machine that can maximise efficiency, power and productivity.

An optional feature to maximise manoeuvrability on the jobsite is the wireless remote control which allows operation of the stump grinder away from the operator’s station. Along with the enhanced visibility using a remote control can provide, it can also help the machine fit through tight gates or areas without the operator getting in the way.

Maintenance made simple

Engineered for efficiency, the SC1052 features access panels for hassle-free maintenance — no tools required. To make maintenance even more convenient, the machine is beltless, meaning operators no longer need to worry about replacing machine belts. The Vermeer SC1052 is not just a new stump grinder, but a machine that can maximise efficiency, power and productivity on each jobsite you encounter.

For more information on the SC1052 or other Vermeer tree-care, rental and landscape equipment, contact your local Vermeer Australia team at 1300 VERMEER or visit vermeeraustralia.com.au.

THE AUSTRALIAN ARBOR AGE 27

Chippers and clean-up options

Use of an AirSpade is the best way to minimise damage to the tree’s root system and the most efficient technique available.

AirSpade and AirVac

A

great combination for non-destructive digging.

AirSpades have become a preferred method for arborists on many jobs ranging from vertical mulching, bare rooting, radial trenching, and soil aeration. AirSpade’s proprietary supersonic nozzle turns compressed air into a high-speed, laser-like jet that dislodges soil in a fraction of a second without damaging roots.

Use of an AirSpade is the best way to minimise damage to the tree’s root system and the most efficient technique available.

A tree-service must-have

Over the past 30+ years, the AirSpade has become a must-have tool for treeservice companies providing tree-health management and site construction services.

Applications using the AirSpade are

safe for both trees and personnel on site. When paired with a standard 185cfm tow-behind air compressor, the AirSpade delivers exceptional performance for a range of applications at remote locations. Through ongoing engineering, research, and experimentation, AirSpade continues to develop new options, nozzle sizes, and

accessories in response to demand from arborists and other end users. Councils and shires in Australia are increasingly specifying non-destructive digging when requesting tenders, more often than not using AirSpade in their Tender Scope of Works.

Powered by a common, tow-behind air compressor, excavating with the AirSpade offers several advantages over conventional tools such as picks, shovels, and backhoes, and is two to three times faster than hand excavation and causes less worker fatigue. They eliminate sharp metal edges, and are therefore harmless to buried, solid objects such as utility lines, telecommunication cables, tree roots, hazardous-waste containers, or military ordnance.

Excavation Rates

Excavation rates for the AirSpade are a function of soil type and nozzle size (air flow). Hard, stiff soils will have lower excavation rates than soft, sandy soils. For any given soil, the lower the unconfined compressive strength, the faster the digging.

As shown in the table, six standard AirSpade supersonic nozzles, ranging in size from 25cfm to 330cfm, are available. As a rule of thumb, the quantity of soil that can be excavated in a given amount of time is rough.

Pairing AirSpade with AirVac

The next generation AirVac is the costeffective, mobile alternative to large, expensive vacuum-excavation trucks.

Engineered to be rugged and dependable, AirVac vacuums up to two cubic ft/min of dirt, sand, gravel, and muck. It safely uncovers underground utility lines, tree roots, or other buried facilities, and is ideal for trenching, potholing, and keyholing applications.

Soil is dislodged and driven airborne by the AirSpade, then vacuumed directly

The AirVac is the cost-effective, mobile alternative to large, expensive vacuumexcavation trucks.

28 THE AUSTRALIAN ARBOR AGE

Images: Knight Pneumatics

into the AirVac container. It’s ideal for small-diameter, deep excavation (potholing) where a hand shovel or backhoe bucket cannot be used. The recovered soil is easily replaced into the trench or hole.

Designed to run off a standard, 185cfm tow-behind air compressor, AirVac boasts a tank capacity of 11 cubic ft. (82 gallons) and an extra-wide dump door to facilitate emptying spoils for backfilling.

The powerful, multi-stage venturi vacuum engine is also detachable to provide ease of transport. Featuring all aluminium construction with heavyduty rear rails, loading the AirVac onto the bed of a vehicle is an easy task.

The tank lid is removable for access to the tank interior and is held in place with quick-release latches. Handles are provided on the AirVac for its lifting but are not intended to support the entire weight of the tank if full.

The AirVac has two wheels and

Non-Destructive Digging

AirSpade

rear handles for manual transportation. A wide dump door with quick-release latches is located at the front bottom of the tank so material can be easily removed or dumped back into the trench or hole.

For more information contact Andrew Knight on 0411 314 007, or email sales@knightpneumatics.com.au.

AVU16540KTA AirVac

AirSpade Vac Vacuum Excavator

• Durable, lightweight 373 litre aluminum tank with over .2 cubic meters of soil capacity.

• Dismantles for easy setup and transportation.

• Exhaust silencer for quiet operation.

• Rear handles for superior maneuverability.

• Wide tires for rugged and off-road traction.

• Wide opening dump-door with quick release latches for easy to empty operation.

AIR-SPADES® are in use in arboriculture, utility, construction, and industrial applications worldwide. AIR-SPADE is the tool of choice due to its fast, non-destructive method of excavation.

Flows from 25cfm to 330cfm.

• Ideal for Bare Rooting

• Radial Trenching

• Root Collar Excavation

• Vertical Mulching

AirSpade 2000 Series

Typical

Rates (CuFt/Min) Model Nozzle Size OSHA Cohesive Soil Type A OSHA Cohesive Soil Type C AirSpade 2000 25 0.4 0.9 60 0.7 1.1 105 0.9 1.5 150 1.2 1.8 225 1.7 2.3 AirSpade 3000 330 2.4 3.0

Excavation

5000 Series Utility AirSpade Kit Contact: Knight Pneumatics P/L sales@knightpneumatics.com.au Andrew Knight 0411 314 007 Call for more literature

Chippers and clean-up options

The BT300 will outperform any other 12" chipper in today’s market, and has more horsepower than most 18" chippers.

Piranha Chippers BT300

Designed from the ground up to excel at performance and serviceability, Piranha Chippers are 100 per cent designed and made in Melbourne, Australia.

The Piranha Chippers BT300 is powered by the 4HK Isuzu turbodiesel engine which produces a classleading 197hp. This power is sent to the 650mm diameter cutter drum which weighs 400kg with four staggered cutter knives and with a 390mmH X 500mmW (16” X 20”) direct opening into the cutterdrum housing (no step downs).

The BT300 will outperform any other 12" chipper available in today’s market, and indeed has more horsepower than most other 18" chippers currently sold. Being a state-of-the-art, electronically controlled common-rail direct-injection diesel motor, the 4HK provides amazing fuel economy and is also very quiet when running. The dual horizontal infeed wheels offer incredible pulling power, and, with the assistance of

the hydraulic winch (which quickly folds up out of the way when machine loading), difficult trees and branches are quickly dealt with, using minimal physical effort from the operators. Other features that ensure ease-of-use include the hydraulic auto-engage clutch, hydraulic discharge-chute swivel and the hydraulic tailgate-raise-and-lower functions.

Serviceability

The design team paid a lot of attention to the finer details of the BT300, and servicing of all required items has been designed to be able to be done quickly, easily and with minimum effort.

Starting at the front with the engine, the Isuzu 4HK service intervals are every 500 hours, which means you can work

for longer before doing the scheduled oil and filter changes, and with many operators already running Isuzu trucks in their fleets, the shared filters mean you can limit stockholdings of essential engine parts and spares.

When the front door of the engine compartment is opened, all filters and service points are right there in front of you, making the changing of filters and oil extremely easy. The remote oil-drain hose makes draining the old engine oil out of the sump quick and easy without making any messes, and the access door at the top of the engine cover ensures new oil is easily filled back into the motor. The work light mounted inside the engine bay ensures checking the essentials is easily done, even in dark conditions.

30 THE AUSTRALIAN ARBOR AGE

The other major service requirement for any chipper is attending to the chipper knives, and on a Piranha Chipper this is done with easy access via the side walk-way ramp, and then when the chipper housing hood is opened, the top part of the cutter drum is completely exposed, making changing the knives extremely easy and safe. Chipper blades are torqued up very tight as we know, and when you are required to reach down into a small access door, the job becomes very difficult. This has all been changed with the Piranha BT300.

Talk to Piranha

Piranha Chippers are 100 per cent Australian made and owned, and with a class leading five-year/3000-hour warranty. They’re your first choice if you are serious about chipping wood.

Contact the Piranha team today. They’d love to show you just how good the BT300 is in real life! Call 1300 406 171, or log on to piranhachippers.com.au.

THE AUSTRALIAN ARBOR AGE 31

When the chipper housing hood is opened, the top part of the cutter drum is completely exposed, making changing the knives extremely easy and safe.

The BT300 is powered by the 4HK Isuzu turbo-diesel engine which produces a class-leading 197hp. When the door of the engine compartment is opened, all filters and service points are easily accessible.

Attending to the chipper knives is easy, thanks to access via the side walk-way ramp.

Chippers and clean-up options

Chipper truck bodies – built to last

Shakanda Engineering has spent years developing a chipper truck body for the arborist market that exceeds the lifespan of any other in the market today.

With a superior, long-lasting body, protective-coating system and flexibility of design, coupled with a three-year structural warranty on all chipper bodies and a full and friendly back-up service, it’s easy to see why people are choosing Shakanda.

Key features include:

• Three-year structural-integrity warranty

• Fully sandblasted, 2-pack zinc-primed and 2-pack top coated

• Fully customised to customer requirements

• Many optional extras

• Quality and durability – Chipper Tippers are made to last! and

• After-sales service.

National

For over 20 years, wholly Australianmade and owned Shakanda Engineering has been engineering endurance into every one of its truck bodies, becoming a premier Vehicle Body Building Specialist, manufacturing innovative and tailor-made equipment to suit every requirement in the commercial-vehicle market.

Based in South Gippsland, Victoria,

its truck bodies are sold Australia-wide, with recent chipper bodies going to Cairns, Sydney, Canberra, Western Australia and the Northern Territory.

Quality and value

Shakanda’s chipper bodies are predominantly built in what’s called a monocoque construction. There is very little framework involved to keep the body together – yet it’s still strong. This reduces a lot of weight and decreases the potential corrosion areas where woodchips would otherwise sit and eat into the steel material. Coupled Shakanda’s superior protective-coating systems – resistant to the corrosive acid produced by woodchips – and Shakanda can offer the long-term lifespan that sets its chipper bodies apart from anything else in the market.

Backup service

Shakanda Engineering prides itself on back-up service. The highest standard of design and quality are built into every one of its projects and is backed up with a full three-year structural warranty on all manufactured vehicle bodies.

Shakanda Engineering is able to offer a long list of features on its chipper bodies.

For more information about Shakanda Engineering and any of its bodies, including chipper bodies and full custom builds, please call (03) 5662 3144 or visit shakandaaustralia.com.

32 THE AUSTRALIAN ARBOR AGE

Shakanda Engineering has produced a superior, longer-lasting chipper body.Images: Shakanda

Chippers and clean-up options

Morbark’s BVR line

The BVR line of brush chippers builds on the legacy of Morbark’s innovation in the tree-care industry through an updated modular design.

History of innovation

Morbark’s history of innovation with wood-chipping equipment goes back to the 1970s with the development of the world’s first whole-tree disc chipper.

The whole tree disc chipper, also known as the Total Chiparvestor, was developed in response to the challenge of disposing millions of trees affected by Dutch elm disease in the United States in 1972. Building upon the success of the Chiparvestor, Morbark introduced a towable, hand-fed brush chipper in 1980, known as the Eeger Beever, which featured the first hydraulically driven feed wheel and safety control bar, further revolutionising the industry and making operating a brush chipper safer.

BVR innovation

The complete line of BVR chippers includes the BVR 10, BVR 13, BVR 16, BVR 19, and BVR 22, and features chipping capacities from 12 inches to 20 inches. The new configuration of the brush

chipper line streamlines the equipment’s overall upkeep and maintenance routine, reducing customer downtime and increasing overall productivity.

The BVR brush chippers also feature Morbark’s proven and patented ZeroClutch.

The ZeroClutch removes the anxiety of engaging the chipper drum, damaged drive belts, and burned clutch discs, and elevates the customer’s operating experience. The ZeroClutch technology features an integrated drum-speed sensor that monitors the drum speed and will not allow the clutch to engage if material is lodged between the feed wheel and drum or if the discharge chute is plugged. Customers will now simply start their brush chipper, throttle the machine to full RPM, and engage the feed control bar.

BVR brush chippers also feature a reverse-style pivot assembly which contours the radius of the drum, reducing dead space between the feed wheel and the drum. This gives the machine

a mechanical advantage for increased down pressure, providing optimal chipping results when working with challenging materials.

Other notable innovations to the BVR line include the infeed-mounted control panel that provides a more convenient location for operators, a side-load anvil, a 360-degree manual swivel discharge chute which offers multiple locking positions for greater operator control over chip discharge, and a three-position electronic control bar with dual safety pull cables, further elevating industry safety standards.

Moving forward

Morbark transitioned from manufacturing its popular Eeger Beever brush chipper line to the BVR line in January 2024, and began delivering new BVR units in February 2024.

To see more on the BVR range, log on to morbark.com.

34 THE AUSTRALIAN ARBOR AGE

A 360-degree manual swivel discharge chute offers multiple locking positions for greater control over chip discharge. Image: Morbark

Morbark’s BVR line of brush chippers builds on the legacy of Morbark’s innovation in the tree-care industry through an updated modular design. Image: Morbark

THE AUSTRALIAN ARBOR AGE 35

WA Arbfest 2024

Dave Crispin, senior arborist at Treeswest Australia and Arboricultural Association of Western Australia (Arb West) committee member, was thrilled at the 2024 WA tree-climbing competition.

Buddy, that rocked!”

“Dude, this was GOAT!”

Those are some of the comments I heard at the end of the Western Australian Arbfest (Tree Climbing Competition), staged in early March this year. And if you, like me, are not across what ‘GOAT’ actually means (I had to look it up), for the uneducated: Greatest Of All Time.

Novices welcome

After 12 months of planning by the ArbWest committee the event finally came to fruition, and I can honestly say it was well worth the effort.

Partnering with the City of Bayswater and the Stihl Shop Osborne Park, it was decided at the outset that new, up-and-coming climbers and novices

should have the opportunity to compete against one another at a separate event. This meant the competition started on the Friday with the inaugural Novice Climbing Competition, and it proved to be a big success.

The venue

The venue was Claughton Reserve in the City of Bayswater.

Our requirements for the event, as you would expect, depended on the quality of the trees. We needed five or six mature trees with open canopies, minimal defects, and spaced far enough apart that we had separation from one climbing discipline to another, but not too far apart that climbers and their support had to walk any distance.

Other considerations included easy

access from a major arterial road, a large open area with plenty of car parking space, and a central location.

And of course, being Western Australia, plenty of shade trees for climbers and spectators.

Claughton Reserve delivered!

Sponsors and supporters

With thanks to our supporters and sponsors: Stihl Shop Osborne Park, Vermeer WA, TCM Tree Care Machinery, Daimler Trucks, Ahern, Multi One Loaders, Rosher, Uniforest, Rise Equipment, Digrite, Baileys, Husqvarna, Hayes Tree Care, LRV8 and Bioscience. Without them the event would not have been possible. Thank you!

ABC Radio Perth was the first live cross for the day, with ArbWest Committee

36 THE AUSTRALIAN ARBOR AGE Association news

“

Jordan Wong demonstrating his skills on his way to becoming the eventual winner in the inaugural Canopy Shootout. Images: Arb West

member Jolyon Elliott spruiking the event to a state-wide audience. The second live cross was on Channel 10, just before the national news in a segment called What’s on in Perth this weekend.

A great start

With a field of 47, a 68 per cent increase from the previous competition, the stage was set for a spectacular event.

The novice competition ran smoothly, with several climbers showing great potential and being asked to attend the following day.

Saturday was an early start with volunteers arriving from 6.00am, bleary-eyed from the previous day. With a coffee to start from one of our vendors at the event, it was go, go, go, throughout the whole day. If it wasn’t for the support of the volunteers the event would not have run as smoothly as it did. In recognition of this, we decided on a volunteer award, with the eventual recipient, Hayes Tree Care.

All stallholders were allocated a spot and all were marshalled in place on the Friday, ready for the following day.

The backdrop of the sun rising through a light mist sitting on the river set the stage for a glorious Perth Saturday and the buzz from sun-up was electric. All competitors were on time and ready for the pre-start briefing.

THE AUSTRALIAN ARBOR AGE 37

Riki Peterson competing in the Canopy Shootout.

Briar Waugh pruning a palm tree at Cable Beach..

Association news

During several head counts between 10.00am, and 3.00pm, conservative estimates were put at around 450-500 people at any one time: a great turnout by any account. All the hard work with our marketing strategy and advertising had paid off. The aim was to encourage the support crews, work colleagues and the public to attend, walk around visiting stallholders, and watch the event. Conversations with stall holders at the end of the day were very positive, with orders taken for both machinery and equipment. All vendors commented on how well the event ran, and they were excited to get involved next year, promising to be back bigger, and better.

Briar Waugh

Climbers came from interstate and intrastate, both male and female, vying for a chance to win big and compete in

the national climbing competition. Of the climbers qualified for the nationals, two, Briar Waugh and Riki Peterson, shared a quick chat.

In a previous life, Briar, 26, was a youth worker in New Zealand and travelled to Broome as part of a road trip around Australia. In search of work to fund the next leg of the trip she answered an advertisement for a tree worker. With her love of the outdoors, and an industry that prides itself on inclusion, she very quickly became an asset to the company.

I asked Briar, who works for Kimberley Tree care, how long she’d been climbing. To my surprise it was only one year. She’s 2.5 years into her three-year apprenticeship and climbs as much as she can. Asked what life was like as a climber in the Kimberley, Briar explained that no two days were the same. She’s

based in Broome, but may travel local, or out to a remote community, travel three hours to Fitzroy crossing, or two days to Kununurra. Briar is a champion of equal opportunities, and with temperatures reaching 42 degrees daily, and humidity at 85 per cent, she ‘holds her own’.

“We have to drink at least 10 litres of water a day, with electrolytes, to avoid dehydration,” she said. “We also have to take two sets of kit.”

“What type of trees do you work with?” I asked.

“Lots of palms,” she replied. “25m-30m Moringa trees (Moringa oleifera), and Baobab var. that smells like rotting faeces. You must be careful not to get it on your skin or clothes because you have to shower and change straight away, otherwise you ride home in the truck on your own.”

I asked if there were any challenges she faced coming from youth work.

“I had to train at the gym for a while to be able to start the big saws and build up my fitness, but that didn’t take long,” she said.

Gauging Briar’s enthusiasm, and her passion for the industry, I’m certain we’ll see more of her in years to come.

Riki Peterson

Riki Peterson and the Western Australian Tree Climbing Competition have a symbiotic relationship – they benefit from one another.

Riki draws a crowd. With his skill and speed usually unmatched, he consistently manages to place. The first time Riki stepped into a harness was back in 2010 in a climbing competition. Since then he’s gone on to qualify for five national events and two Red Bull events. This year was no exception, taking out first place in the aerial rescue, aerial ascent, and the work climb, and walking away with a tidy prize pool.

Other climbers who placed high included:

• Oliver Willmoth – first in the throwline and the speed climb

• Pa scal Oosterik,

• Aydyn Aagesen, and

• Luke Osborne.

Canopy Shootout

Another first for this year was the introduction of the ‘Canopy Shootout.’

Qualifiers competed for only five spots, with their placings considered throughout the day. A spot in the

38 THE AUSTRALIAN ARBOR AGE

Briar and crew taking a break on the Tanami Track.

shootout meant a chance at walking away with the $1,100.00 cash prize and an attractive looking trophy. The competition was fierce, with all climbers bringing their A game, but the eventual winner was Jordan Wong. Jordan’s speed and skill set him apart from the rest, and he was definitely a crowd favourite.

2025

Events like these provide an exciting spectacle for spectators, pushing the boundaries of what climbers can achieve in their sport. We look forward to welcoming back the interstate challengers again next year, who will be undoubtably eager to take away line honours and bragging rights at the next Canopy Shootout, part of the Western Australian ArbFest in 2025.

39 forestcentre Attachment solutions for safe and efficient pruning and removal of trees forestcentreau 02 6947 2833 forestcentre.com.au

The Kimberley Tree Care outfit driving back from Fitzroy crossing..

NSW Code of Practice for tree amenity

The TCAA’s compliance Officer, Dan McArdle, shares some history and views on the current review of the NSW Code of Practice for the arbor industry.

Once again, there is an arb-industry review and update of the NSW Code of Practice (COP) for tree amenity, which includes arborists and tree workers. The review is currently underway, with several meetings taking place in February, March and April, 2024.

It’s expected the selected panel of experts working on the latest draft will have completed its review by July 2024, and the resulting document will be released for public comment for a period of time.

Try again

The TCAA has, in the past, been active in the development of the COP and the team has once again made available expert advisers to work with SafeWork NSW.

The last extensive review and was completed in 2006-07, and revised the 1998 Code of Practice. However, the work completed on the 2006-07 document was not endorsed at the time, and all the hours of work and face-toface meetings spent revising the draft seemed to me to have been shelved.

Recently the industry stakeholders received the 1998 COP and were requested to put forward submissions

for change to update the version. This couldn’t go unchallenged, and the TCAA Compliance Committee promptly resubmitted the 2006-07 draft as a starting point – which has now been adopted as such.

Industry expertise

The development of the draft had input from some recognised members of the arboricultural industry, including:

• Tree Contractors Association

• Arboriculture Australia

• Total Height Safety

• Active Tree Services

• McArdle and Sons Pro Tree Service

• Energy groups

• TAFE NSW, and

• Others who supplied their exceptional and valuable volunteered time to create a working document with content relevant to the trade.

The most important facet of the contributions from these people and organisations was the information and suggestions being workable on day-today jobs. Trade associations have a direct input into industry-related matters of all sorts, including training, policy development, regulations, Australian standards, WH&S development, raw mulch, wood splitters, tree-

40 THE AUSTRALIAN ARBOR AGE Association news

Author and TCAA Compliance Officer, Dan McArdle (right), has been involved with shaping the NSW Code of Practice (COP) for tree amenity for more than 16 years.

The TCAAA has been active in the development of the COP.

management guidelines, risk assessment, tooling and minimum industry standards. The list is extensive.

Question need to be asked

Does this have impact on your business? Yes.

Ultimately, the objective is to reduce the risk of injury and/or fatalities.

Over my time as an employer, I have seen workerscompensation tariffs reduced from 17 per cent to the current rate of around 7.9 per cent. This reduction is a direct result of the efforts of industry groups to improve workplace safety procedures and training designed by the likes of TCAA, AA, QAA, WTG, VTG and NT associations, but also the willingness of Persons Conducting a Business or Undertaking (PCBU) to adapt to new methods and safety procedures.

When I’m at the table or Zoom meeting, I’ve learnt one very important fact: if you don’t get involved decisions will be made without you or your input.

For example, assume the standard distance in tree felling is 1.5m to twice the tree height in all directions. My question is, ‘Is this suitable in most of our working environments domestic or commercial work?’

The answer is ‘no’! In most cases it’s just not possible yet.

What about the ways to implement the hierarchy of control for working at heights? If a tree can be assessed as safe to be felled, it should be.

And crane work and regulation is not mentioned in either Draft 1998 or 2007 (inclusion is being discussed at this point).

Have your say

These are examples of the challenges the industry experts are addressing, offering the benefit of their wide experience and knowledge, in development of this document.

I encourage all industry stakeholders to take interest in the public-comment stage of the COP when it’s released later this year. I again remind everyone that, if you allow it, decisions will be made without you or your input. You have the opportunity to offer the benefit of hands-on industry experience, and any input will be welcome through the TCAA website or via email to tcaa.com.au.

Mark the subject line of the email: ‘Attention Compliance Officer: Dan McArdle’.

NEW ZUBAT ULTIMATE 330MM EXCEPTIONAL DESIGN SUPERIOR QUALITY 0418 231 549 www.atcproducts.com.au QTRA CALEND AR 202 4 For further information visit www qtra co uk Email: admin@qtra co uk QTRA Training (2 days) 2024 •09/10 September Adelaide 2024 • Melbourne 12/13 September 2024 • Sydney 25/26 September 2024 Using a traffic light system of colour -coded risks values, supported by skill, measurement and judgment, QTRA users can enable trees owners to make balanced and informed risk decisions qtra.co.uk Unacceptable if imposed on others Tolerable Broadly Acceptable Unacceptable •05/06 September Perth • 18/19 September 2024 Gold Coast T RAINING • Auckland 30 September/01 October 2024 The most important contributions come from industry professionals.

Association news

QAA news

More great competition, initiatives and advancement from the Queensland Arboricultural Association.

QAA invites volunteers, sponsors, and spectators to support the qualified arborists who will demonstrate their expertise in the trees in the QTCC 2024 at the scenic Tamborine Mountain showgrounds. Images: QAA

The QTCC 2024 is gearing up to be an exhilarating event at the scenic Tamborine Mountain showgrounds.

QAA invites volunteers, sponsors, and spectators to support the qualified arborists who will demonstrate their expertise in the trees on this exciting day. Your participation helps celebrate and encourage the art and skill of tree climbing. Save the date. Keep the weekend of September 6-8 free!!

QAA sponsorship opportunities: supporting the arboriculture community

The QAA is dedicated to advancing the arboriculture industry through pivotal education, training, and advocacy efforts. As sponsorship opportunities for the upcoming year are now open, businesses can align with the QAA to show their support for the industry. These partnerships not only offer significant exposure and networking possibilities, but also bolster initiatives

benefiting the entire arboriculture community.

Interested parties should act quickly to secure their sponsorship, available on a first-come-first-serve basis. For more details, please contact the QAA office.

Industry Meet & Mingle

May 24 saw the QAA host the first arborist Meet & Mingle.

This informal gathering is a great opportunity for QAA members, nonmembers, and industry suppliers to connect over a drink and some tasty nibbles. Whether you’re looking to share experiences, gain insights, or just enjoy good company, this event is the perfect setting to meet fellow arboriculture enthusiasts and professionals in a friendly atmosphere.

The Meet & Mingles will continue to run every two months in different locations around Brisbane, the Sunshine Coast and the Gold Coast. The QAA is looking forward to seeing everyone

at the next event on Friday, July 26. Keep an eye on the QAA website for an announcement on the venue.

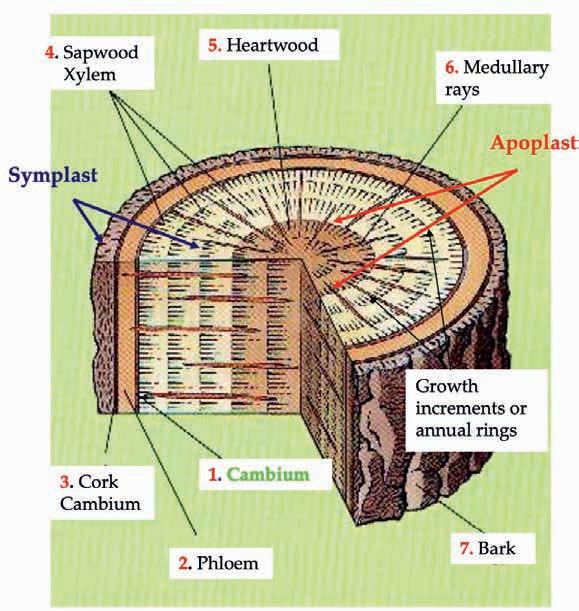

Celebrating educational success: Bryan Gould’s ARB101 series

A sincere thanks to Bryan Gould for a fantastic conclusion to the ARB101 workshop series.

Covering essential topics from Tree and Risk Assessment to Tree Biology, Physiology and more, these workshops have enhanced the skills of many aspiring and experienced arborists.

Bryan’s engaging and informative sessions have left participants enriched and eager for more. The QAA looks forward to future sessions that continue to support professional development in arboriculture.

Career Expos 2024

After last year’s success, QAA is excited to return to local high schools to inspire future arborists.

42 THE AUSTRALIAN ARBOR AGE

The Career Expos are a critical platform for addressing the skills shortage in the arboriculture industry and for businesses to connect with potential employees. The QAA needs your help to man its stall, engage with students, or offer them work experience. This can, in turn, significantly impact our community and positively support your business. Below are the dates and locations for the upcoming expos:

• Carmel College, Thornlands: June 4, 2024, 4.00pm – 7.00pm

• Morayfield State High School, Morayfield: June 4, 2024, 12.00pm – 3.00pm

• Sunnybank State High, Sunnybank: June 6, 2024, 8.30am – 2.45pm.

Tree Risk Assessment Qualification (TRAQ)

A special thank you to Mark Roberts and all participants in the upcoming TRAQ courses.

Please be reminded TRAQ will return in 2026. If your qualification expires before then, please contact Arboriculture Australia to enrol in a renewal course.

Upcoming workshops and educational opportunities

The QAA’s commitment to education continues with various workshops designed to enhance your skills and knowledge:

• Forest Biosecurity Awareness: June 19, 2024, with Janet McDonald from DAF, focusing on pest and disease damage. Additional Workshops include

Covering essential topics from Tree and Risk Assessment to Tree Biology, Physiology and more, the Bryan Gould ARB101 workshop series has enhanced the skills of many aspiring and experienced arborists.

Preparing Quotes and Tenders, Diagnosing Tree Diseases, and Practical Sessions on Woodchipper Operation and Stump Grinding.

Make sure to check to check the QAA events page regularly and register early to secure your spot as these workshops are in high demand.

Thank you for reading this far. The first person to contact the office noting they have read this article will receive a free copy of an MIS booklet of their choice.