Welcome back to The Australian Arbor Age. Our deepest sympathies go out to all Sydney arborists, families and business owners affected by the latest floods.

This issue in our Industry People section we have an introduction to the work of Canadian arborist Ryan Revers working in Toronto, Ontario. As well as having a very impressive body of his own unique work, Ryan has a dynamic history of working and presenting (ISA conferences) on repetitious light tree crown reductions, as a means to provide greater tree longevity, particularly in relation to wind and ice storms. Ryan is the father of new terms for arboriculture, in support of training amenity trees to be stronger than the wild ones. His input is based on observation of the alpha-trees, those rare trees in nature that naturally exhibit the greatest strength and resilience. Mimicking their success by training the non-alphas to achieve the same kinds of strength is – in his own words – to take the (abstract yet consistent) wild pattern of failure from the forest out of city trees. In the same way we want our buildings to stand up to environmental extremes, so we want that from our city trees. Whilst remembering lessons learned from the 2008 Brisbane

SuperCell storm, it is the alpha-trees that survived the wind spirals. In climate extremes it is the alpha-trees that save the built environment.

In this edition we have a new feature article and topic from me entitled ‘Time to Help The Trees To Stand Back Up’ - Part 1, I could have called this article ‘Time To Let The Trees Stand Back Up’ because this is their nature, but I see this process as a future arboricultural concern and service, so help stands. This article is the first part of a future series. This feature I have been planning for some time, as my body of work on Harp trees grows, so too does my passion and reason to write on a topic not yet covered by mainstream arb. This feature is a background to the topic and introduces four case studies. In Part 2 we will look at other case studies, as well as a field-based treatment exercise to help stimulate further harp/root production. In truth I am excited to expect a number of future articles on this classic arboricultural phenomenon.

Among out Technical Features we have a recap on the TCAA training day by Vice President Jim McArdle. This covers inputs from the guest speakers Dan McArdle and Bill Sullivan, with coverage on the Industry meeting and the new Executive Committee.

A Business Feature article by Peter

Dubiez and Phil Wheeler on All Round Tree & Garden Care introducing Glen Keedle, entitled ‘Business Growth - When Safety Means More Productivity’, how to go from a one-man business to a team of arborists.

QAA News this edition is also safety focussed with a drive to help establish safety codes of practice for the arboricultural industry. With sponsorship news, event recaps and upcoming events, Queensland arborists are kept informed.

This edition we also have TTIA news on a raise to the minimum wage, benefiting the tree industry from the Fair Work Commission.

We are also announcing the winner of the Husqvarna pole saw and the new prize for the coming year.

Whilst l have your attention, l would just like to include mention of our Production Editor Arianna Lucini. Running arboricultural articles involves a huge amount of very focussed and detailed work. l find this far harder than doing tree work which in comparison is effortless. l wish to take this moment to thank Arianna from the bottom of my heart. Her brilliant mind, attention to detail and rapid ability to support what is right (she puts me on the straight and narrow too) really helps to keep me writing.

Also, l wish to thank you Kurt Quambusch, thank God you took time out from publishing and worked as a Groundie, as well as asked if Arb’s had a mag all those years ago.

The time has come to announce our lucky winner of our 2021-2022 AA Subscription prize, jump to page 6 to see who is taking home the Husqvarna 530iPT5S battery Pole Saw (with battery and charger). Plus we are to be presenting our new 2022-2023 AA Subscription prize, the Husquvarna 525PT52S Pole Saw valued at $1599.

Regards, Cassian Rupert Humphreys AA Sub-Editor AA

OCT/NOV

DEC/JAN

FEB/MAR

Publisher Kurt M. Quambusch

National Advertising Manager Sue Janjic sue@maynemedia.com.au (02) 8287 0651

Group Sales Manager KahChi Liew kahchi@maynemedia.com.au (02) 9452 4517

Subscriptions subscriptions@maynemedia.com.au 1300 764 688

Design Peter Cartledge art@maynemedia.com.au

ISSN 1327 1784

The Australian Arbor Age is a Bi-Monthly magazine published by Mayne Media Group Pty Ltd.

ACN 130 678 812

ABN 27 130 678 812 Postal: PO Box 489 DEE WHY NSW 2099 Australia Ph: 1300 76 4688 Int Ph: + 612 9452 4517 Int Fax: + 612 9452 5319 www.arborage.com.au

Copyright 2022

Mayne Media Group Pty Ltd. Material may not be reproduced or photocopied in any form without the written permission of the publisher. Mayne Media Group Pty Ltd. believes that all material is correct at the time of printing and will not be held liable for any incorrect information supplied within.

Cassian is a Merrist-woodian graduate (NCH-arb - 1991) qualified to Diploma level in Australia (09), his career commenced in Horticulture (85) and transitioned into Arboriculture (89). An experienced tree climber, instructor, arboriculturist, consultant, educator and writer, he has 30 years of experience. He sees his work as making a contribution to the Australian arboricultural profession.

Guy is a Master Arborist and Utility and Municipal Specialist, facilitating the co-existence of trees and people for the past 46 years. His company HistoricTreeCare.com manages the risk in veteran and historic trees by installing lightning and support systems, root invigoration, pruning and community education. Guy writes for tree care publications and works with the ANSI A300 Tree Care Standards committee in the US. He studies the science of arboriculture around the world.

PETER DUBIEZ

Peter is the CEO of Sydneybased Enviro Frontier (EF). EF utilises over 250 Tree Companies across Australia in managing tree works on behalf of its clients in the Insurance, Government and Facilities Management sectors. All jobs are managed using its proprietary technology platform (TreeManager) making it the leading data provider for the insurance and facility management industry. The company also operates in NZ, UK and Spain.

For almost 45 years Graeme has been based in the Dandenong Ranges East of Melbourne and become world leader in large tree removals.

Working as a production faller for alpine logging operations for three decades, expert witness, Investigator for WHS incidents and Lead Auditor are a sound foundation for him to assist with improving industry safety.

Leigh is an expert climbing arborist with a passion for tree conservation. He is a graduate from Merrist Wood College with a Diploma in countryside and environment and sub-Diploma in Arboriculture. Climbing and leading crews in the south of England, his work/ travels have taken him to Brisbane where he has developed a true passion for adventure tree climbing.

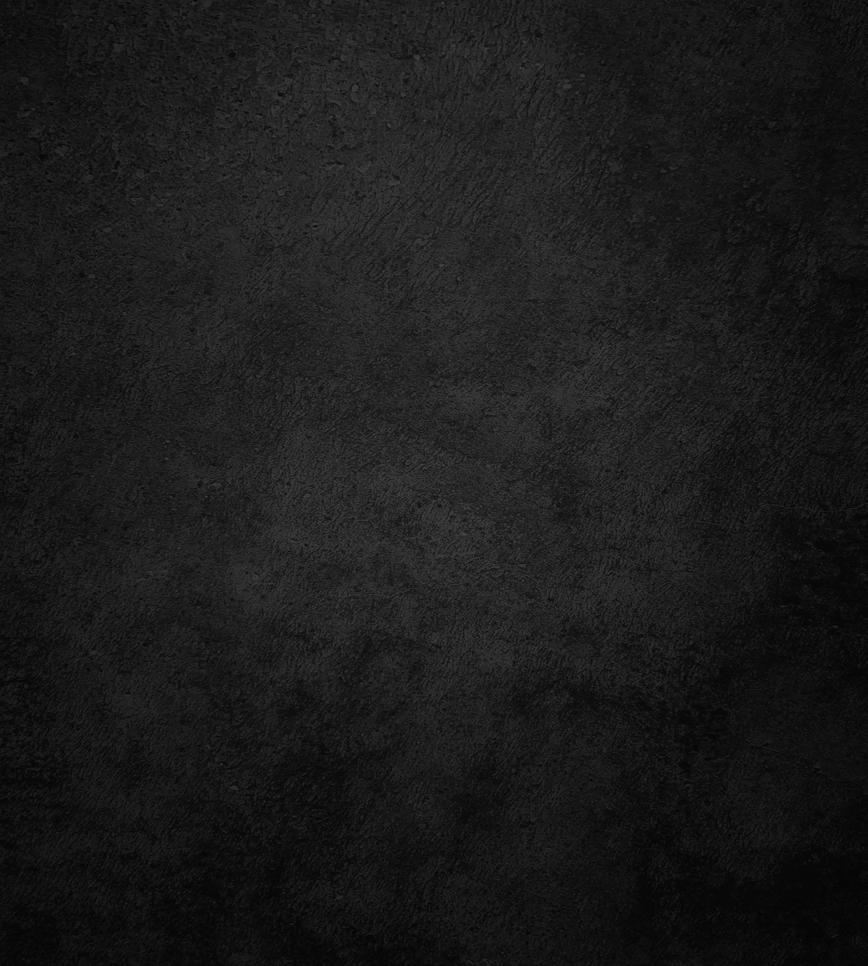

And the winner is… Peter Le Breton from Pillar Valley, NSW. When contacted about winning the prize, Peter said it put a smile on his face and reminded him that good things really happen. He sends a huge thanks to Husqvarna.

Peter has been operating as qualified Arborist from around 1980 after training at TAFE NSW - Pastow in Sydney.

Most of his work has been within National Parks, over a career spanning some 36 years, carrying out tree management assessments and works as required. Generally, evaluating defected trees within camping areas and reserves.

Most of his work these days has been within the Clarence Valley and the area north of Coffs Harbour with all aspects of the trade. Peter and his wife have taken on as much work as they can handle as Peter is about to turn 65 years old.

They recently purchased an Elevated Work Platform – a winner in Peter’s opinion! He also operates with a Hino 717, 300 series tipper, Red Roo stump grinders and a Brush Bandit 150 tree chipper – a “deadset beast” according to Peter. The Husqvarna is a welcome addition to his inventory and knows it will be put to good use by Le Breton Landscape Services, Trees and Stumps.

Thanks to the team at Husqvarna for their long-term support and we wish all our subscribers good luck for our next draw.

For more information regarding subscriptions, turn to page 72-73, call 1300 764 688 or subscribe online at www.arborage.com.au AA

Aerial Access Australia has been a major supplier of elevated work platforms (EWPs) throughout Australia more than 25 years.

Aerial Access Australia has been a major supplier of elevated work platforms (EWPs) throughout Australia for 25+ years. With a practical and operational understanding of their application, the team of passionate industry experts have set out to change the way this innovative equipment

and machinery is manufactured and distributed for Australian businesses.

What sets Aerial Access apart is their operational experience and knowledge to provide safe and innovative equipment to the industry. The motivation has always been to provide safe, cost effective, reliable and fit for purpose equipment to get the job done.

As the business has grown, their ability to invest in the development of technology has helped them establish long term relationships with industry leaders and grow their range of equipment.

Aerial Access is an Australian family owned and operated business. They are a group of people who have worked for

over 25 years in this industry to perfect and maintain extremely high levels of operational success. With a mission to support local communities, develop skills and training opportunities, and improve the safety of EWPs throughout Australia, Aerial Access is here to partner with businesses who want to elevate their operations with leading edge equipment.

Innovation is the core of this industry, and as Australia faces some very real environmental challenges over the coming years, the commitment of the Aerial Access team is to maintain a high level of investment in research and development, with a particular focus on environmental sustainability. From internal business policies to operational procedures that support the environmental and economic business objectives of their customers, Aerial Access sees the synergies between the operations and the requirement to protect and maintain the environment. Their equipment is designed to meet all industry standards and their sales commitment is to exceed expectations by understanding the

problem they are being expected to solve, while providing the best solutions for each individual customer.

The range is forever expanding as Aerial identify improvements and new technologies available within the industry, as well as develop their own, the speed to market of this controlled supply chain provides an unprecedented advantage to Australian consumers. The scale of Aerial Access and the ability to fast track and manage orders of varying sizes gives them the opportunity to respond quickly to market changes, ensuring they can meet budget and delivery timeframes for customers.

Aerial Access manager, Chris Sanderson, has the luxury of hands-on experience within this industry. While he acknowledges his start in the vegetation management business (on the tools) was a dynamic learning experience, he has seen it all and has always been interested in the technology available and the benefits EWPs provides stakeholders in every environment.

“We work on a significant scale, but our growth has been organic. It has taken 25 years of hands-on experience within this industry to really identify areas where our scale and size can make a difference to the EWP market to impact all Australians who risk their lives to keep us safe. By investing in new technology, by working alongside our R&D team and by increasing the safety and performance of this type of equipment, we can work with our customers to develop opportunities that enhance their operations.”

Chris is now responsible for working on the research and development of new equipment

that enhances the user experience, improves the operational performance, and delivers beyond minimum safety expectations and requirements. Based here in Australia, Chris and the Aerial Access team are on the ground with a service and parts division, working with each customer to determine the best outcomes and provide advice with the benefit of practical experience and backing from a highly motivated and skilled national team.

A safer way to do business impacts all Australians and our local communities. Aerial Access has a laser focus on safety and reliability that is prevalent throughout each stage of the manufacturing, sales and the aftersales journey.

To discuss your next build, get in touch with Chris, visit their websiteaerialaccess.com.au, or get in touch via email - sales@aerialaccess.com.au.

Alternatively, call the Aerial Access team on 1300 654 591.

For Spare Parts sales and enquiries email parts@aerialaccess.com.au

Aerial Access is currently looking for qualified diesel mechanics, heavy vehicle mechanics, auto-electricians and more. If you are interested in applying, please contact: apply@aerialaccess.com.au AA

Tree failure and the processing of fallen trees is a considerable career focus for most arborists. In this edition we look into the topic of fallen trees which, left unto their nature, literally stand back up.

We may never see the tree fall in the forest. With the minute percentage of trees failing in the cities, suburbs, or in the rural landscape, to illustrate this point we are very lucky to see a tree fail in the wild.

Though whilst bushwalking on a Bunya Mountains Forest path I was lucky enough to see the crown of a rainforest tree fail at around 20m in height.

Back in around 2004, on a still day, I was walking with my two sons, Euan and Fionn, (then aged 10 and 6), the head of the tree failed at around 1m in diameter, 15m long. This was preceded by three very loud cracks. We were around 60m away, after the first crack, I stopped dead in my tracks and told my boys to listen and watch. The second crack was around four seconds after the first, the third maybe two seconds after the second. The trunk exploded at the site of a cavity (based on later appraisal by binoculars, I reckoned the cavity was down to 10 per cent in wall thickness). I was not game to leave my kids alone on the path to assess the failure and approach closer due to the many live hangers. It’s one thing to risk self in natures rare ‘battle zones’,

another to leave our children on their own. When the cavity blew up shards of wood de-laminations, leaves and twigs rained down even to our feet, the head of the tree exploded and smashed through the forest like thunder. But the silence that followed made the experience all the more profound.

The closest I got to witnessing a whole tree failure involved a Black butt – Eucalyptus pilularis, whilst working the Energex VTA Program (proactive tree risk assessment) in around 2011. The tree had failed only hours before I arrived (due to Canker Syndrome), within 2m of ground level leaving a de-laminated 2m high ripped shard (Ref: AA past article of mine - 2012 - Canker Syndrome). This was for me an ominous experience, as I was appraising the tree, actually walking on the tree’s downed 1.5m trunk I received a phone call from a colleague, announcing the death of a very well loved and highly respected arborist, who had just died after being struck by a tree.

I have known and even witnessed arborists fall. In 1991 I saw a trainee climber (Merrist Wood College, UK) fall from 15m, almost on top of me (I leapt out of the way just in time), had I leapt to the right instead

of backwards, I could have caught his lifeline and arrested his fall. In 1996 I witnessed a past employee and friend take an 8m fall, bouncing around the tree’s crown, landing on his feet back to the trunk (his femur broke through his leg and trousers). Though when our time is not up, we are almost bullet proof, at times we humans are very fragile compared to trees.

I have never actually witnessed live a whole tree fail (root ball and all), with experience of the aftermath of a hurricane (Surrey UK 1989), cyclones in Queensland* and Vanuatu (Cyclone Pam 2015), as with many other arborists tree failure has been a considerable career focus.

“The 2008 Gap supercell storm and its effect on the Brisbane urban forest was recorded by me in a 2008 Energex report and 2009 AA article. It took experience of the Energex VTA program, appraising whole tree populations (central-west Brisbane to Tin Can Bay), as well as waking up to the QTRA drive (we now also have TRAQ and VALID) for recognising trees and tree failure in the context of risk (in a future article I will cover the negative on that), I take the tree failure story with an open mind. Moreover,

I recognise that tree failure is actually a rare event, it’s the mainstream media which dramatises/misleads true observation and experience, Covid-19, say no more.

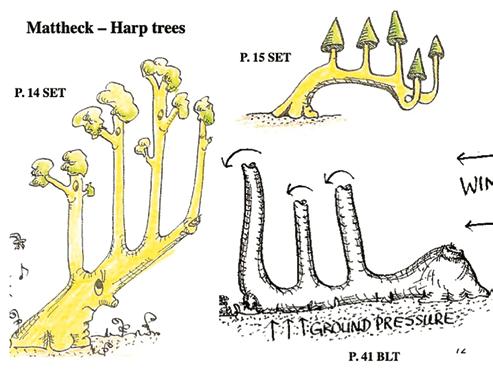

So what does this narrative have to do with trees standing up? Maybe the depth of value I have for trees is somewhat grandiose, but in the same way I value the fallen amongst humans (arborists, soldiers, firemen, nurses etc), I value the fallen amongst trees. It was my study of Mattheck’s Body Language of Trees and the development of my educational package (Tree Culture Course 2004-2012) as well as working the VTA program, that led me to awaken to the magic of the Harp Trees, studying tree populations on the Energex HV network enabled me to find a number of harp specimens in the field.

Indeed, many of our fallen tree brothers and sisters left unto their nature literally stand back up. This reality makes a perfect analogy of the fallen human, we all love the child and action hero/heroine that gets back up again,

not to mention the songs – an old Aussie footy favourite – ‘I get knocked down, but I get up again, you’re never going to keep me down’ (ref: Chumbawamba - UK band).

So why do we arborists race out with our chainsaws and chippers to process our fallen green mates? It’s like we think we’re the action heroes, saving the day from a downed tree? Surely, wouldn’t it be better to spend the energy in helping the tree to stand back up again. Certainly, in open space, in parks and in many private situations we can support and encourage trees to stand back up. With ‘carbon credits’ in mind it would be very worthy to value the body of standing trees to help give a dollar price on fallen ones, I suspect there is or should be a dollar rate per square inch of live sapwood (less for heartwood?) to help value the downed tree. We know well the body of the standing tree, the trunk generally central to the crown, with optimisation in mind ideally with a field pasture or paddock crown, all evenly balanced and conditioned for load. This is the vision we generally hold to, when we think of trees.

So in nature what happens when a tree falls following rootball failure?

To better understand the optimisation of downed trees lets first consider the process

“When the cavity blew up shards of wood de-laminations, leaves and twigs rained down even to our feet.”Fig. 2: Harp trees from ‘Stupsi Explains the Tree’ – Prof Claus Mattheck. Fig. 3: Crystal Waters, a classic harp tree.

The MHP line of trailer-mounted boom lifts offers three models built to suit a wide range of applications with maximum working heights of 12.6m to 14.8m and maximum platform capacities of 200kg to 227kg. These rugged and reliable machines are perfect for those who work at multiple jobsites and need the portability a trailer-mounted boom lift provides. Add to that the automatic self-leveling hydraulic stabilizers and these versatile boom lifts are the ideal machine for arboreal tasks.

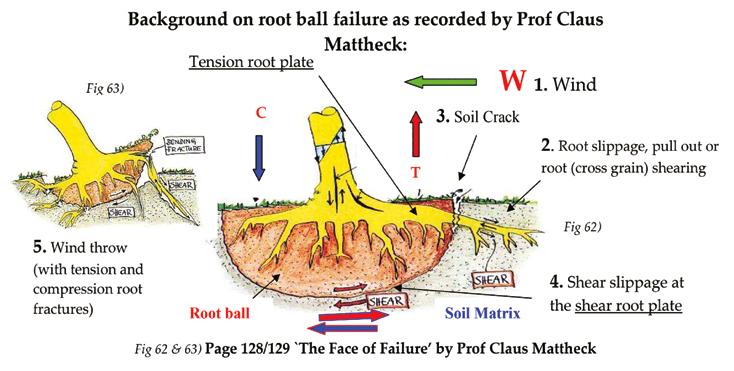

of rootball failure. To understand the rootball failure process as Mattheck describes it, I have found a no better considered perspective on this topic to explain what I have seen/see in nature. However, on Mattheck, I am aware of a current almost religious movement in arboriculture where mathematical impassioned rhetoric (the kind of rhetoric that distracts, confuses and belittles) is being used to disprove what I (and my brothers/sisters) see as natural truth (this is a hot topic within the five eyes of Arboriculture). Mattheck has very much been in the firing line on this, my attitude is –if I repetitively see a human hypothesis* be validated in nature, then for me it stands as

Fig. 4 ref: historically Figs. 62/63 (past AA article), Gap Storm Report /AA article 2008/2009. 1. Wind, 2. Tension root slippage or shearing, 3. Soil crack on the windward side, 4. Shear slippage at the root plate, 5. Wind throw.

Fig. 5: Flashforward to Ohio 2013, I can add that having seen the legend Ken James do a root crown excavation on a tree at Biomechanics week (Fig. 4), that in the same way trees step down force via oscillating their crowns, it is very likely that a form of oscillation is going on below ground too. Tree biomechanics has much to teach us. Ken’s sensors were picking up on considerable movement in the root-plate just from a person walking on the exposed roots.

the ultimate proof. I seldom seek permission to believe something from the collective (having heard Shigo’s call – I am not a sheep who stands in line based on say so). Regardless of the source, first I must see it for myself, if it makes sense on the level of the heart then I am a follower (I less trust mind which is often ego led). If we are honest, we own that good science is about observation which is effortlessly demonstrated in nature. *As captured in my 2008 Energex Gap Storm report turned 2009 AA article, I studied 85 root ball failures immediately after the supercell storm event (and reading The Face of Failure). I repetitively saw evidence of the process described by Matteck for myself.

The following was covered by Mattheck in his last 2004 Brisbane, Melbourne and Sydney conferences. Mattheck describes trees as having two distinct types of root plate, this is a reflection of the impact of compressive and tensile load on trees, largely caused by gravity and wind – the tension root plate and the shear root plate.

Fig. 4 ref: historically Figs. 62/63 (past AA article), with the following paragraph taken from my Gap Storm Report/AA article 2008/2009. Mattheck has detailed five general factors of failure which leads to root ball failure.

“The cause of root ball failure as with the cause of crown failure is seldom

Fig. 6: Another classic harp tree that I used to ride past every day in my time I worked as the Technical Officer for the Queensland Arboricultural Association in 2014. Going by the footprint of this tree, I would suggest that this Forest red gum – Eucalyptus tereticornis has been optimising in its fallen position for some years. On reflection, this is a tree I plan to return to, to measure. It would be interesting to measure the diameter of the original trunk, to measure the diameters of the optimised upright limbs (either optimised past lateral limbs, or epicormic shoots now endocormic in their nature – in my mind this amounts to the same with currency in mind), as well as measure the footprint of the now root crown. Not that I could bring myself to ‘fell’ such a survivor, but it would also be interesting to dissect such a specimen and count the rings of the original trunk in relation to the replacement ‘leaders’.

Fig. 7-9: I originally found this remarkable three stemmed harp tree in Highvale Qld whilst working the Energex VTA Program for ETS in around 2008. I actually went back to the region to try to find the tree for an update and to take some high-resolution pictures, having lost the originals off a dead hard drive, these pics I poached of a PowerPoint of mine, but the tree’s story has to be told.

Fig. 6

attributed to one factor; in a high wind event a structure will either transmute applied force through its body into the ground or it will fail. Trees as living structures are subject to considerable variation with their biomechanical status, this is based on environmental parameters which are as varied. We know via the science of Shigo and Mattheck that the threads of biochemistry run throughout the woody framework that is the tree, that successful mechanics (regardless of mechanical constraint or defect) are attributed to plant

vitality. Regarding trees with poor vitality, or in a storm event, failure occurs generally at the weakest link in a structure, or where the lever arm (height) is out of proportion in relation to the foundation. Often described as poor taper, or where hot spots leading to ‘whipping’ of canopies occurs. Whether a tree’s structure is upper crown to fork, or upper crown to root plate, or root ball, trees are most successful where there is even taper and an expansive root system, which has been unimpaired by hard landscape or development. The diagram above depicts the shear and tensile root plates. My experience and understanding of root plate failure and failed trees is based on and validated by Mattheck’s research. The failure mode can be a variety of factors which are determined by the individual root architecture of the tree.”

I personally saw Mattheck present on this in the Brisbane conference 2004 (his second downunder tour). Incidentally I was given a ticket of attendance to Mattheck’s first VTA tour of Australia 2000 by winning in the hot (tree) pix section of AA that year. My entry that won that year was a burl in a Poinciana so large (and dense, I could not climb through it) it took up the whole tree’s crown.

In my 2008 Gap Storm report I went on to give examples of a series of rootball failures as a comparison to the failure patterns discussed in Mattheck’s book ‘The Face of Failure’ – that past AA article can be seen via this link – https://tinyurl.com/ GapStormReport

Case Study 1 - A Highvale Gum TreeEnergex VTA Program - 2008

Fig. 8 Fig.

vitality of the upright ‘harp stems’ it seems highly implausible that these uprights are not drawing their own water from the ground. Regardless of the sustainability of this ‘downed’ tree, from a structural or biological perspective, this perhaps can be seen as a form of previously unrecorded optimisation in a harp tree.

Back in April 2013 there was the very major failure of a historic oak tree in Pontfadog Wales. The tree is recognised to have been between 1,200 and 1,600 years old, the short tree (retrenched by people and time) stood in a heavily compacted field and remnant hedgerow/dry stone wall.

This tree caught global attention amongst arborists, conservationists and tree enthusiasts, ancient trees an interest that had gained momentum post the mid-2000s. A movement that celebrates ancient trees. For us Aussies this movement started in 2008 with the ISAAC national conferences (ENSPEC Director and past President, Craig Hallum, I commend you for that line up). I attended the Brisbane conference and was gifted to have close contact with ancient tree enthusiasts and presenters, arborist Andrew Cowan, conservationist Jill Butler, ancient tree expert Ted Green (since knighted for his life’s work) and the legendary Dr. David Lonsdale.

Following the conference, I lined up country accommodation and took this merry band of tree lovers on a tour of trees in the D’Aguilar range S. E. Queensland.

Britain is regarded as having more remnant ancient trees than Europe, probably mostly Oak trees (Quercus spp), though the oldest, also native, are the coniferous Yew trees (comparable to our native Brown pine trees – Podocarpus elatus.

Back to the Pondfadog Oak tree – though since falling, a little too close to private property (the roof line of a home), perhaps for some, for I, a light pruning back from guttering would have sufficed as sufficient reason to (have at least tried to) keep the living chunk of ancient history. With consideration of the interest and support the Tree Hunter generated I believe that as a ‘phoenix’ the tree could have been supported (with funds raised) into living on.

Certainly, as an arboricultural project, the attempt would have been very worthy. Though my observations and suggestions were of no use to this ancient, they led Mr McBride to gain support to cover the root ball of another fallen old-timer. I still reference saving the Pontfadog Oak tree as an example of the capacity for modern arboriculture. For those serious students of Arboriculture, I encourage you to carefully study the posts on Rob McBrides FB pages, as an ancient tree conservationist he, like Jill Butler and Ted Green of the Ancient Tree

Forum, is worth following. Enthusiasts such as the Tree Hunter and those involved in the ATF are doing more for historic trees than most arboriculturists (though big name UK Arb’s are certainly involved).

We in arboriculture and the Land Care professions/industries (ref: ‘i-culture LandCare via Vegetation Management’ AA June/July 2022) are driven to fell and process downed trees, often without second consideration. Yet as Shigo states (ref: Modern Arboriculture, the cambium and parenchyma and the capacity of differentiation) through paying attention to trees (for ourselves), we can act on the capacity of trees via their cambium (parenchyma cells) to differentiate into a variety of growths, including roots. Many trees from all round the world grow roots into their own trunks, when it comes to ‘specialised’ optimisation down-under, rooting from the cambium back into inner decaying heartwood (part of the Magic of many Australian species that make up the family Myrtaceae) is well recognised.

So, what if we were to crawl inside the open cavity/root crown of fallen ancients like this and to treat the tree to produce roots. Expose the ‘internal’ cambium* via exposing pockets of decayed heart wood, to lightly abraid and treat the cambium with root hormone product (horticulture has many such products), then pack with moss, humus and leaf litter. I suspect we only need to set up a few ‘trigger points’ for root production, we may assist with a kick start, the trees

Fig. 10: The Pontfadog oak tree was, I believe, a classic example of a fallen tree that could have been saved with modern arboricultural support (or maybe more old school horticultural support). This conclusion is based on my study of the many pictures/posts of the tree visible via The UK Tree Hunters FB page Rob McBride is another ancient tree enthusiast - https://tinyurl.com/yckxnfr3

Principally via the study of the tree’s vitality (capacity to support new root growth due to energy reserves) I see a great opportunity for arboriculture or Conservation Arboriculture in action.

Fig. 11: The downed legend herself, the millennium plus old Pontfadog Oak tree - April 2013.

Fig. 12: When we consider the abundant production of wound wood (and burls?), we know that the cambium is being driven by good vitality, this means stored energy and solid energy production by the tree’s remnant crown.

will do the work. I know via study of the Tree Hunters page that there was only one major root (20cm diameter?) left, still attached to the tree. We could treat this the same way (as above) but also wrap it in a sock of hessian (a preventative practice for sunlight damage/ dehydration on transplant trees down under) and rebury it. In the case of top end support via the Soil Food Web Institute (AUS and NZ, they tried to establish a branch in the UK but I believe it failed) a compost tea irrigation system could be established to help keep up the essential associate microbiology and water to support root generation. *I have personally recorded the generation of callus/ woundwood on the inside of tree trunks and on the inside of wood splinters - Ref: ‘A voyage into the Symplast Part 1’ AA 2011. In truth I would be surprised if this Welsh ancient did not already have internal roots drawing on ‘humus’ from within.

Yes, a tree health care program would be necessary, to keep up the air, water and biologically active carbon (humus), but

considering the amount of support being generated for ancient trees I am sure funding to proactively help keep them alive is very viable. Proactive Arboriculture, now that’s a dream, the purpose of this article is to seed the passion for future arborists to make the change, though such will take better arb salesmen than I.

As part of my personal quest to help create the change, 10 years ago (close to the time of the Pontfadog ancient tree failure), I stood aside from mainstream Arboriculture and pursued the next level with SFI and Plant Health Care principles applied to organic food production (understandably there is more money set aside for food plants than trees). PHC or rather Tree Health Care is poorly supported in Australia. In parts of the United States and in Germany PHC is much better supported as a proactive form of arboriculture.

Bandit Mobile Service trucks are launching soon. All part of our promise to deliver outstanding customer support and backup across Australia. We’re here to support your success. More to come!

Fig.

To these ends in 2015 I partnered with a Social Justice organisation, with project proposals lined up in Vanuatu and Africa. Using my operational model there were many other project proposals I was not directly involved with lined up throughout the Pacific region (the Covid drama has stalled all such projects). It was on a business trip to Vanuatu in 2017 that I discovered this incredible specimen - The 1974 Cyclone Zoe Rain tree – Samanea saman formally Albizia. One of the most interesting arboricultural studies of my career.

Yet though flattened, rather than lie down to die she stood back up, making a full recovery. Going by this vitality (pictured 2017) I wonder if her lifespan has even been reduced.

Since my study of examples of harp trees, prompted by the failure/loss of the famous Welsh Pontfadog oak, I have been very

focussed on this topic and maintain that arborists could save many if not most trees that fail due to rootball failure, or worse, even shearing at the root crown (if sufficient roots are left connecting to ground). In my observation of fallen tree survivors, or harp trees, in the case of trees with good vigour and good vitality (Shigo’s definitions please), I believe that as little as 10 per cent of the tree’s root system remained attached to ground is enough to get a decked tree to stand back up. Especially if we cultivate the area of soil it is attached to, though in truth the cultivation of fallen trees to enable sufficient root ‘re’-generation, to help a tree to fully optimise on its downed situation (as discussed in case study #3) is to also involve horticultural grafting techniques.

This I intend to cover in Part Two of this article. But what we have to guide us on are legend tree survivors – such as the Cyclone Zoe Rain

Fig.

Fig. 13: Port Vila Market place Vanuatu 2017 - the 1974 Cyclone Zoe survivor - a classic Rain Tree, native to Central and South America. A popular introduction to Southeast Asia, Melanesia, the Pacific Islands and far North Australia. I personally gained a valuable insight to the robustness of this species consulting in New Guinea and Vanuatu, 2011 and 2017.

Fig. 14: This Port Vila - Vanuatu marketplace tree got felled 48 years ago by Cyclone Zoe. Yet here she is in all her glory, a tree that stood back up.

Fig. 15: Almost complete occlusion of her up-ended root plate, this body language to me is an indicator of shorn tension roots and a shorn root plate (indicative by the flatness of the root crown underside). Had this been a root ball failure I suspect we would have seen the remnant upended ‘hedgehog’ of roots, though perhaps in 40 years that evidence was compartmentalised.

Fig. 16: Shigo was the first to tell us that parenchyma tissue has the capacity to differentiate into a range of forms - callus (into wound wood), roots, shoots and even (in the case of cauliflorous tree species) flowers.

tree, that clearly have done this for themselves. This tree has almost completely occluded the underside of its upended root-plate (ref: Fig. 2), I had wanted to pull back the tarp, but did not wish to disturb the local marketeers, without the NiVan language (I was travelling alone at this point) the

last thing I wanted was to insult the locals. As with my experience of the people of Papua New Guinea, that is far from a good idea, respect for the locals is paramount.

Experience of excitingly photographing this tree (I could not contain myself) was enough to inspire the sensitive women of the marketplace. Seeing my love for the tree I was given a number of smiles of silent understanding, sometimes a lack of language is a great gift.

The Rain tree is very likely to have generated a new root system out of her old trunk at the point of touching the ground (ref: Fig. 17), this would be well validated by checking the ‘buttressing’ footprint (swelling and growth striations) at ground level where the resting trunk is ‘buried’. Not willing to impose on the locals I kept my

distance. In truth I have always intended to return on a non-market day. The fact that the tree occluded her exposed root plate/ root ball and in all likelihood grew roots out of her trunk is a testament to harp trees as consummate survivors. Though in my study of harp trees it’s only the trees with the really great guns – optimal vigour (genetic stock) and vitality (health) that achieve such goals. Even with the tarp obscuring the view I can see by the tree’s body language that she transitioned back up with as little as 10 per cent connectivity to mother earth.

Ref: Fig. 13-14, based on Visual Tree Assessment (Ref: Mattheck), it’s clear that after failing this tree reiterated/reorientated its crown by growing its existing horizontal branches into upright stems, as well as ‘folding’ its canopy back. The tree’s

Fig. 18

body was made up of two trunks (one now touching the ground) with a U-fork. Going by Fig. 17 the occluded top was either damaged at point of failure or removed (cut).

On the underside of the tree’s crown, I think it likely that new roots have generated from the trunk in contact with the soil, as well as the upended root crown. The brilliant truth of trees is that they never lie. Whereas we humans can and often do lie about our achievements, when it comes to trees their body language is the ultimate record.

original

“My call is that in the name of arboriculture (or maybe conservation arboriculture) we push past the limits of our arboricultural thinking (education) and help the trees to stand back up.”

From its unique doubly secure interlocking anchor bollard, to the highly efficient oversized ball bearings, this is a block with a difference.

– Compact, lightweight

– Double security at the anchor bollard

– Ideal for both everyday rigging and winch operations

– Hollow axle facilitates multiple configurations

– Hauling loop simplifies hauling, transfer and storage

– Fairleads flairs help maintain efficiency even in suboptimal set up

What validates such success is that this tree achieved such a feat on its own. I would think that this occurred before the area was a marketplace. How long this has been a marketplace I am uncertain, though I find it hard to imagine a tree achieving such adaption in such a heavily compacted and desertified area. It’s actually miracle-enough to see a tree sustaining such vitality in such a desert, especially when it was historically flattened. Imagine a human being beaten in the order of 80-90 per cent of his life and then unassisted getting up and walking away, I do not think so. Trees are far tougher.

In honour of this tree and as a symbol of the cyclone veterans of Vanuatu, that’s the people and trees, I have always wanted to carry out a future restoration project (this was a proposal to a Port Vila government minister) to improve the trees longevity, by restoring the heavily compacted soil. I had since had the idea to sponsor the building of a deck over the trees reconditioned root zone for the marketeers. Part of this as a

Fig. 20

project, is to involve investigation to gain a better idea of the trees’ optimisation below ground. As with consideration of the Pontfadog oak if trees such as the Rain tree are making this kind of adaptation with only two points of soil contact, imagine if we were to set up multiple points (via cambial abrasion, root hormone treatment and the establishment of bound moss patches to generate roots). I first awakened to this as an arboricultural strategy (via my earlier horticultural training) after doing exactly the above on a young, vandalised fig tree (I planted in a Brisbane park - 1991) back in 1993.

Though I see this Broad leaved Apple gum tree as a prime example of an optimising harp tree, as far as this discourse is concerned, I have already covered a solid chunk on the capacity of trees to stand back up. What is exciting for me with this specimen is the opportunity to experiment on a harp tree and to record my observations. This I will discuss in Part 2.

In a future article I will carry out some partially invasive works to uncover what is actually going on below ground.

Fig. 21

Fig. 22

Fig. 21-23: Looking at what was the upper crown on this tree when it was standing (the northernmost side) we can see a little under half the remnant crown remaining. It looks like the top was shorn off (probably at the time of failure) and has since occluded. Over time the lying trunk has thickened on the northern end of the tree and the ‘upper crown’ has likewise laid down wood. Going by the tree’s body language I am inclined to believe that the tree has rooted into the ground at this point. On the southern end only two roots have visibly kept going providing water and elements to help support the generation of wood (via photosynthesis from the remnant and replacement canopy) for what was the downed upper crown.

Fig. 23: Reading into the tree’s body language at this point and seeing the thickened now vertical limbs and the thickened ‘buttressed’ footprint at ground level, the likelihood of rooting at this point is high.

Fig. 24: Moving southwards down the fallen trunk we can see signs of epicormic/endocormic transition, particularly at the mid cluster of branches, the old horizontal limb has grown shoots, now thickening well optimised vertical stems since the tree fell. Though likewise two epi/endo limbs have grown as buds out of the tree’s trunk directly above the root crown.

Fig. 23

Fig. 24

You begin each day before dawn with a drive and determination to do more than the day before. When you move at this pace, you know to do more you need equipment that is made for more. That’s why our equipment is built from the ground up to meet your needs, delivering:

More Power and Production

Lower Operating Costs Ease of Maintenance Greater Longevity and Resale Value

If you’re ready to operate equipment that’s made to keep pace with you, then we invite you to contact the authorized dealer in your area of the world. To learn more about our equipment go to www.morbark.com

Morbark

NSW/VIC: Global Machinery Sales 1300 072 926 globalmachinerysales.com.au

QLD: Allclass Construction Equipment 1300 255 252 allclass.com.au

WA: Westco Equipment +61 (8) 9258 9333 westcoequipment.com.au

NZ: Commercial Outdoor Machinery 0800 26 66 88 commercialoutdoormachinery.co.nz

Boxer

NSW/VIC: Global Machinery Sales 1300 072 926 globalmachinerysales.com.au

QLD: Greenstar Equipment 1300767589 greenstarequip.com.au

WA: Westco Equipment +61 (8) 9258 9333 westcoequipment.com.au

NZ: Commercial Outdoor Machinery 0800 26 66 88 commercialoutdoormachinery.co.nz

NSW/VIC: Global Machinery Sales 1300 072 926 globalmachinerysales.com.au

QLD: Greenstar Equipment 1300767589 greenstarequip.com.au

Fig. 25: Study of the tree’s exposed root crown is of interest, as we can see that this was a root ball failure, the soil root ball has since been washed off, leaving the root plate exposed like a hedgehog. Likewise, we can determine that only 10-20 per cent of the tree’s root system has remained attached. Gum trees have evolved to deal with root loss and optimisation via erosion, though they rapidly die with root loss through being buried, this is the ‘development site’ curse.

Fig. 26: On the western side we can see the swelling in the tree’s trunk (growth striations with wood expansion) where the root is buttressing into the stem and expanding into the soil, going by the sizable footprint it’s likely that a number of roots have grown out of this remnant root. Also, we can consider an original root surviving in the same way, directly under the remnant failed root ball. I suggest that three roots would make up roughly 20 per cent of the tree’s original south facing root system.

Fig. 27: Likewise on the trees eastern side we can see a major root connecting the ground and buttress/trunk, this has grown significantly following the trees falling.

Fig. 28: Study of this photograph supports observation, measurements and some interesting information. I measured the base of the tree at 70cm diameter (red mark), the midpoint at 51cm diameter (blue mark) and the upper trunk at 69cm (red mark). Between the first adapted limb and root crown the tree has a steady taper heading north to the base of the said limb. At the midpoint the trunk drops down in diameter significantly, I suspect that the lower trunk has kept laying down wood, whereas the mid trunk is the same diameter at the time of failure. The diameter of the tree at the upper crown, the point I suspect roots were generated into earth is almost as great as the base. This validates the laying down of wood (akin to the remnant roots/ buttress), indicating two major attachment points to the soil. Note – I brush cut around the fallen tree to reveal the tree’s body for this case study.

For inspiring me in this – the Pontfadog oak - Wales I salute you. Incidentally, though I grew up in Devon, my surname Humphreys is Welsh. I come from a line of Welshmen I would have loved to have known.

In conclusion of this feature article, based on the established scientific record given us by Shigo and Mattheck, given us by the many examples of nature that a number of arborists (few scientists) see day in day out, my call is that in the name of arboriculture (or maybe conservation arboriculture) we push past the limits of our arboricultural thinking (education) and help the trees to stand back up. This I believe we can effortlessly do via the old school horticultural grafting

practises the oldest of us grew up with. With workshops in mind, grafting practises for root generation and cambial growth (i.e. ring barked trees) should be on the association bucket list. Also, with budget in mind consider the cost of destroying/processing a fallen tree by chainsaw/chipper and extend that financial investment to help a tree stand back up.

I had no idea when l committed to arboriculture aged 22, that l would find so much more in the field beyond my initial education, or that l would be destined to write. With thanks and praise to AA for giving me the platform.

Humphreys AAFig. 25

Fig. 26 Fig. 27

This issue we talk to Glen Keedle from All Round Tree & Garden Care about business growth – how to go from a one-man business to a team of arborists.

Can you share a little about your background prior to starting All Round Tree & Garden Care?

When I left school, I worked for many businesses general labouring and worked for several years for a local tree company. After some time I completed a Certificate IV in OHS and became a Workplace Health & Safety Officer for several years at a pipe manufacturing company. This was a very interesting and challenging position – writing and implementing SWMS and Risk Assessments.

What was it that lead you to the tree management industry?

When the Global Financial Crisis hit in 2008 I was made redundant from my role as a Workplace Health & Safety Officer. That’s when I went back to my Tree Care

qualifications. In 2009 I started my own tree removal business ‘All Round Tree & Garden Care’ in the Illawarra. I started off with one chainsaw, one ute and one trailer advertised in my local papers.

How long have you now been in the industry and how has your business changed in this time?

I have been in the industry for around 20 years and have owned my own business for 13 years. During this time, I have seen phenomenal changes in workplace safety. Having a safety background, it was just a matter of learning the industry and how to focus my knowledge on implementing and writing all my own safety material and, as we all know how dangerous this industry can be, making sure we all go home at the end of the day.

As my business grew, I had to update my equipment and keep up to date with the latest machinery and technology. This has helped with productivity, allowing us to take on more jobs. An example is lowering devices, when I first started there were only wraps around trees, we now have porta wraps, GRCS, and many friction devices.

Workplace safety has also changed over time. In my early days they only had prussic ropes for climbing and now there are many different options to climb with like rope runners, SRT, spider jacks and many more.

During this growth phase, myself and three other employees have obtained a Certificate III in Arboriculture. I also ensure employees have many other qualifications relevant to the industry such as operating chainsaws,

working at heights, first aid certificate, heavy vehicle license, etc.

One of the customers I purposely targeted was work with the Department of Education, due to the extent of the number of schools they manage. I have been a contractor for the Department of Education since 2014 and look after around 14 Schools in the Illawarra.

I am also a contractor for the State Emergency Services (SES) since 2015 this has enabled me to obtain emergency work. This has led to a great working relationship with Enviro Frontier, which has further increased my work opportunities.

What have been the biggest challenges for you in growing your business?

One main challenge in growing the business is being able to source skilled workers, which is why we place great emphasis on putting employees through training courses to increase their knowledge and skill levels in the arboriculture industry.

A second challenge is trying to foresee growth to be able to purchase new equipment which comes with financial risks.

What have you enjoyed most about the growth of your business?

I have taken an immense amount of pride watching my self-managed business grow and expand. I started this business by myself, with one chainsaw, ute and trailer within two years I saved up enough money

to purchase an old truck and chipper which allowed me to grow and slowly expand. Within the two years following I was able to purchase a new truck and Bandit chipper. Coming to 2022 we have currently two trucks, two chippers, a loader, a cherry picker and have on staff eight employees, three of those level 3 Arborist and one level 3 training arborist in his second year. We are also looking for our next candidate to undergo industry training.

The safety culture and professionalism we have formed over the years has been another enjoyable aspect of our business growth we have had over 13 years. We had four to five lost time injuries, which have been minor, and are currently around several thousand hours with no lost time injuries.

Is there anything you would do differently if you could do?

I don’t think there is a lot I would do differently.

What advice have you got for people starting a small business and wanting to grow?

You have to look at how far you want your business to go where you see yourself in two, three, four or five years, setting goals is essential. I set monthly, quarterly and yearly goals for my business growth and employees training and most goals I have met. If I have not met these goals, I look at why and then make changes and

improvements to achieve that goal.

An important goal which we have achieved for my business has been customer service and satisfaction, word of mouth has been a great attribute for our business reputation. Your business reputation can either help you grow your business or fold your business. I have made it a ritual that every day I return phone calls or messages from clients as every phone call could be a $200 job or a $5000 job.

During my interactions with the client about their job, I keep in communication around expected start and completion dates, how the tree will be removed, and vehicle access also taught my staff the importance of manners and respect to clients.

We are in the process of purchasing a new chipper from Bandit Industries, which will allow us to increase work productivity. As we are still growing, we have recently employed new staff that we will train and upskill.

We have recently diversified in other areas, including property maintenance for real estate companies, strata companies and a preferred contractor for the Land & Housing Contract (LAHC) on the South Coast for which we have employed another two employees.

Kind regards, Glen Keedle, All Round Tree & Garden Care. AA

“The safety culture and professionalism we have formed over the years has been another enjoyable aspect of our business growth.”

Vertical lift arms and a 40-hp (30kW) turbocharged Kohler KDI diesel engine gives the CTX100 exceptional lift and tipping capacities, coupled with the operator-centric features common to all Vermeer loaders. Grasp, lift and move brush and logs with ease and efficiency thanks to Vermeer’s Mini Skid Steer Loader range and the Rotating Log Grapple attachment with 360 degree rotation. Perfect for arborists doing the ground work and all tree care companies. Contact your local RDO Vermeer team today.

VERMEERAUSTRALIA.COM.AU | 1300 VERMEER

Vermeer and the Vermeer logo are trademarks of Vermeer Manufacturing Company in the United States and /or other countries. © 2022 RDO Equipment Pty Ltd (trading as Vermeer Australia). All Rights Reserved.

On the last weekend of May, the men and women of the TCAA gathered within the convention centre of St Joseph at Seven Hills. The cups of tea and greetings were amid voice overs of old colleagues and new friends coming together for the TCAA Training Day. Togetherness is tough after not physically meeting for two years as an association.

The first speaker of the day was introduced by Bruce Smith, who hails from Orange, inviting Dan McArdle to the podium. Dan professed the use of the Pre Climb Assessment and related this to AQF 3 outcomes from the Government Training Packages. Dan’s main thrust of In-House Training, due to labour skills shortages, focused on allowing PUCB (Persons undertaking and conducting business) and team leaders to instruct on best Industry practices within their own organisations; hierarchy (transits) of control and persisting with gear checks and quality tests, bringing what you know to a toolbox meeting.

The Safe Work approach utilising SWMS and JSA documents – including ALARP

and SOFARP – were readily defined by our guest speaker. ALARP is related to trees and risk where as SOFARP is related to all WH&S documentation in business by law.

Dan also reviewed safety issues:

• VTA

• Species

• Vigour

• Defects

• Exposure

• The Hierarchy of control

• Use of EWP as first option

• Where and when climbers are used if other areas of access are restricted due to safety factors

• The use of registered gear and logged gear

• The proper care including percentage of wear

• Dated materials

• Relegating old gear to the non-climbing bench

• Access methodology for difficult sites and the need for expert advice within the TCAA or TTIA - Timber Trades Industry Association on serious threats within the workplace.

The main event from Bill Sullivan progressed with tree risk and the usage of the vTRA system. Bill discussed the ‘Voo Doo’ Science of 154 tree risk systems used on the planet

from all aspects of the tree industry. He elaborated on the chocolate wheel probability and gave clear definitions of reasonable practice including risk, target, occupation descriptors, the assumption of consequence and the role of the TCAA arborist. Bill’s view of specific management on the Top End trees, like the African Mahogany and other boat brought immigrant trees that peppered the shallow soil profiles.

Bill also discussed:

• The need for educating tree workers, who require in-servicing or inducting

• The mentality of cutting tree roots to put down paving with cause and effect coming into play as well as windthrow of these affected trees

• The major issues of over pruning and the loss of the branches or decay of branches that fail from poor management practices.

Bill gave us an extract from Kenneth James and the issues of wind exposure on trees, a study dear to his heart. (Bill is from NT and closest city is Darwin – the Cyclone city).

Bill also alluded to the reasons plastic snakes were used as a deterrent for bats in the Botanical Gardens which can be still seen today. The tourism boost has significantly increased the gardens patronage.

Bill went on to address the Coroners’ reports regarding fatalities from falling tree branches. Bill was an expert witness for the court.

He also discussed the deaths in our society as well as the impacts on families and industry. All trees have risk and can be assessed from three levels by a competent arborist:

• Level 1: can be done by the general assistant or worker who has knowledge of the area to identify changes to a tree, or the arborist

• Level 2: can be done by the AQF 3 or AQF 5 – the VTA is a prelude to the check for issues and defects

• Level 3: can be done by the AQF 3 or AQF 5 but is when there are a variety of factors like exposure, species, variation and defects. Only a AQF level 5/6 Arborist can report on this level of inspection.

Bill has an AQF level 6 Arborist accreditation who’s motto is “know your tree before you give management advice”.

A TCAA general industry meeting followed, during which the president gave the 27th annual address “enthusiastically” keeping the association vision ‘Safety Experience Trust’. Lunch followed which was always going to be a gathering of what’s happening in the trenches over sandwiches and who’s voting in who.

Jim McArdle – Final address as President Jim McArdle gave an unveiling of the 2022 Tree Management Guidelines

He proceeded through the key points of the industry approved methods, highlighting the serious nature of current tree work incidents from Safe Work. He discussed the history and reasons the Tree Management Guidelines were produced from its inception in the 2008 Adelaide TCAA conference with Jeremy Barrell (UK Arborist) and the evolution of the document propagated after the tree deaths incidents in schools.

Best industry practices were defined and stated as being “the exercise of that highest degree of professional skill, diligence, prudence and foresight which would reasonably and ordinarily be expected from a skilled and experienced operator or assessor engaged in offering licensed services”.

It was discussed why TCAA arborists are the safer arborist with lower worker compensation rates and higher safety standards.

The afternoon gathered momentum with benchmarking of the senior level 3 and 5 arborists venturing through five common tree examples. The level 1, 2 and 3 risk assessment which ‘fit for purpose’ and assisted in conducting assessments in a reasonable decision-making proactive tree risk approach. A number of scenarios were reviewed and best management outcomes sort. Teams were arranged to engage on benchmarking the assessments of five

indigenous large trees – with the huge availability of hollows, bees and birds, targets and valued camellias being guarded and the group of arborists delegating responsibility to either duty holders or the assessor.

Most notable questions were:

• How do we come to the same conclusions? Outcome – Do a VTA and check occupation and target

• Do I have to increase the occupation rating if a seating arrangement is placed under a (dead) tree?

• What ecological values are found in an assessment?

• What other experts are needed if a court case ensues?

The feedback was unanimous and a Training Day for workers who could not attend will be prior to the next general meeting, ensuring all members are relicensed with this training module.

In summary, the issues of Access and Preclimb, having assessing arborists who are from the industry, assessing defects and health and structure of a tree and utilising hierarchy of controls within Safe Work, including our integrated “Code of practice”, found in The Tree Workers Guide underpins the best industry practices within the TCAA.

The industry women who attended, the AQF 3 and 5 arborists and those preparing for AQF 5 and guests, enjoyed the location and training.

For further information on the Tree Management Guidelines please contact admin@TCAA.com.au or call Jim McArdle on 0449 228 788.

The new executive was voted in:

• President - Carson Smith (Ned Kelly)

• Vice President - Jim McArdle

• Treasurer - Murray Boland

• Secretary - Bruce Smith

• Committee - Jeff Hunt, Brady Blaker, Dan McArdle

• Compliance - Dan McArdle

• Media representative - Robert McArdle

It is noted that the past three presidents were regional and the new metropolitan man who has won the presidency will take a new CRUNCH approach (with careful responsive understanding certifying harmony) with a vision for ‘All the Way with the TCAA’ to increase in training and safer work practices.

For Tree Contractors Association Australia membership enquiries, please go to www.tcaa.com.au/ membership/ or call 1300 660 379 or email admin@tcaa.com.au AA

Glenn and his team put thousands of hours into their old Bandit 150XP chipper, and they’ve just upgraded to another Bandit.

If you were looking for the toughest chippers in Queensland, it would be hard to beat Professional Tree Works’ Bandit 150XP, a machine that was the bedrock of the business for over 12 years.

Professional Tree Works is based on the Gold Coast, and director Glenn Dalton was rapt with the reliability of his old Bandit, before upgrading to the new Bandit 15XPC.

“We had it [the 150XP] for at least 12 years. They just last and last and last. We’re really happy with everything at Bandit,” says Glenn.

“Jason and the Bandit team’s customer service is outstanding. He always stays in contact with you direct, asking if you need anything and not to mention he cares about his customers for the long term after each sale.”

After upgrading to the 15XPC in 2021, Glenn and his team have already racked up 300 hours on the new unit and have been impressed with the Bandit woodchipper’s gutsy performance.

“We’re really happy with the 15XPC as well. It’s a fuel saver. And with the logs, it just

specialising in tree pruning, tree removal, stump removal and palm removal.

Glenn has a passion for all his clients making sure after each job is completed to a standard like no other. The business was awarded ‘Best Full-Time Arboriculture Business - Tree Trimming Gold Coast’ at the recent 2021 AI Global Media Corporate Vision Small Business Awards.

“We keep everything local. We’re lucky that we can do the five to ten-kilometre radius,” says Glenn.

chews straight through, there’s no problem that’s for sure,” says Glenn.

“I like that the chipper is compact, while still being extremely efficient. This size allows the chipper to be used on tight jobsites where other chippers may not fit.”

One of the great qualities of the 15XPC is its large engine, delivering the same power as its big brother, the Bandit 18XPC, in a smaller machine.

“The standout features are the chipper weight of 3,400kg, allowing to us keep our MR truck rather than investing in a larger truck,” says Glenn.

“Also, the Cat engine with a huge 624Nm of torque, and the infeed throat opening 495 x 381mm allows you to feed larger logs lying flat up to 17 inches.”

Other impressive specs of the Bandit 15XPC include:

• A CAT 142-horsepower diesel engine

• Easy manoeuvrability in a compact size

• 19" wide x 15" high drum style chipper

Glenn has been in the tree removal business for 30 years. Professional Tree Works primary customer base is located on the Gold Coast,

“We can do the tight access with our four stump grinders and handle the larger jobs as well. We always have a minimum of three staff on site, and keep up to date with ongoing training,”

“I got into tree game with my brother-in-law years ago. The first week that I was in it, I was pretty much lowering ropes all around me. I didn’t like it one bit. And then eventually, I stuck with it and I’ve been doing ever since then. It’s great and I enjoy it.”

For more info visit www.banditchippers.com.au and https://protreeworks.com.au AA

“Jason and the Bandit team’s customer service is outstanding. He always stays in contact with you direct, asking if you need anything and not to mention he cares about his customers for the long term after each sale.”

Chris Capsis, owner and lead Arborist of Outdoor Tree Service, is a multi-facetted guy, a marine mechanic by trade, surfer and arborist, who realised nearly a decade ago the increased speed, efficiency and safety of working from spider lifts and EWPs. With the 11-meter outreach of his CMC S18F, Chris and his team are safely and efficiently completing jobs in times that simply weren’t possible when only climbing.

ith 22 years as an arborist under his belt Chris has seen many changes in the industry over his time, some he is a fan of and others not so much. But one thing for sure, Chris and the Outdoor Tree Service team have fully embraced and love their CMC S18F.

Chris shared: “I started out with a lawn mowing business and I used to live with a mate that was in the tree business. After starting to do work with him and finding I was well suited to the industry and had a passion for it, it just evolved from there. Having a mechanical background allows me to do a lot of maintenance and repair work myself saving the company thousands in repair bills and reducing down time costs.”

A small but highly efficient team

Chris has gone through several incarnations of his business over the years with it at one stage involving three crews, and all the headaches that go with running a larger team. Today Chris has gone full circle deciding to run with a smaller and more efficient team. “I have given up on trying to please everyone all the time, instead today I focus on keeping our smaller team happy and productive, we run two 4x4 chipper trucks, 1590XP and 915XP Bandit chippers, Bandit and Rayco stump grinders, a 40ft truck mounted EWP, track CMC spider lift EWP and Stihl chainsaws. My first machine was a Bandit 9-inch chipper about 20 years ago. They have evolved a lot since then. My first stump grinder was a Rayco 1625 super junior stump grinder. Other equipment we have purchased includes an RG 50 4x4 super, an Angry Ant loader and recently the CMC spider lift.”

The CMC S18F excels in real world conditions

Chatting with Chris about the challenges of climbing, shoulder injuries and surgeries it highlights the massive advantages that the CMC S18F has bought to Chris’s business and how that directly translates to the significantly faster completion of jobs, added safety and reduction in work-related injuries onsite. “The ability of the CMC S18F to work in real world conditions is one of its best features – from the adjustable tracks which can reduce to narrow width of access of 770mm allowing it access into doorways and narrow gates, to its massive horizontal reach of 11m and 18m of height.

The basket can take two people and it’s an all-round reliable and stable machine and has been a great addition to the business. I’m proud that my hard work in the industry has paid off and I have been able to own my house and my machinery,” shared Chris.

The success of the CMC S18F comes down to a clever and reliable design. Chris has owned other similar equipment previously which just didn’t stand up to the type of work he and his team undertake. The S18F comes equipped with a single pantograph and two stage telescopic boom plus jib, mechanically adjustable tracks in height and width, with an impressive lateral outreach. This is a truly multipurpose aerial platform with amazing performance which is suited to both commercial use and rental companies.

Stuart Samson from Global Machinery Sales Chris has been purchasing equipment from Stuart Samson from Global Machinery Sales for more than eight years and the two have built a great relationship over that time. With both Chris and Stuart having a wealth of individual experience and industry knowledge, the two have worked together well on ensuring Chris has the best information and equipment on hand. “Stuart Samson has been a great asset as he has worked and knows the industry, he’s very easy to talk to and deal with. After sale

service and advice is paramount and Stuart has always provided this to a high level,” said Chris.

Stuart Samson himself has been the NSW State Manager at Global Machinery Sales for eight years now and has been working with Chris for that entire time. When asking Stuart about the relationship with Chris and the purchase of the CMC S18F, he shared: “It’s been a great opportunity to work with Chris and watch the business evolve to where it is today. Chris is a great example of clever business owner who embrace the philosophy of working smarter not harder. The S18F has been a great addition to the business to enable exactly that – with Chris now not taking on jobs, where he can’t use the S18F. It allows them to perform their job in a safe and efficient manner with its stability, narrow access and class leading outreach of 11 meters. Chris Capsis has been a great customer

over the years, with our relationship starting with Rayco stump grinders and now with CMC Aerial Platforms. The S18F has been such a good fit for Chris and so many other businesses. It’s no wonder CMC with their attention to detail, excellent service and innovative design have grown to the world’s largest tracked EWP manufacturer.”

CMC S18F

• Max work height: 17.78m

• Max reach (with 80kg): 11.15m

• Platform height: 15.78m

• Max load in basket: 230kg

• Min. track width: 0.77m

• Basket rotation: +/- 90 degree

For more information visit outdoortreeservice.com.au and globalmachinerysales.com.au AA

“The ability of the CMC S18F to work in real world conditions is one of its best features.”

Manufactured for the Australian market, the Snorkel line of trailer-mounted boom lifts features a range of capacities and lifting heights along with an array of features.

The portability of a trailer mount makes the Snorkel machines ideal for contractors who work at multiple jobsites.

The Snorkel MHP15HD is a heavyduty trailer-mounted boom lift that offers durable performance and precision on the jobsite. Rugged and reliable, the MHP15HD is ideal for general maintenance and construction. Automatic self-leveling capabilities enable safe and versatile work at height.

The MHP15HD’s durable two-man steel platform can lift a safe load of up to 200kg up to a working height of 14.8m. Additionally, a 600V AC rated wire platform allows operators to use power tools up high. The MHP15HD is also equipped with fully proportional speed controls for added flexibility. A versatile jib with 140° rotation delivers smooth and accurate precision, while enhanced side-to-side maneuverability provides better access to hard-to-reach places. Fitted with a superb 5hp engine, this trailer boom provides reliable performance, while optional bi-energy power offers clean and quiet operation in low-emission environments.

The Snorkel MHP13AT is a robust and reliable trailer-mounted boom lift that is ideal for tradespeople and facilities maintenance applications. With a working height of 12.9m and a platform capacity of 215kg, this model features the lowest total weight of the MHP line of trailer-mounted boom lifts at 1,360kg.

The articulating boom sections provide upand-over reach, making this model ideal for awkward working angles.

The Snorkel MHP13/35 features a maximum working height of 12.9m and the largest platform capacity in this line of trailer-mounted boom lifts at 227kg. The versatile jib boom and maximum reach of 5.6m make it ideal for a wide range of tree care, landscaping,

construction and maintenance applications.

All three of the MHP trailer-mounted boom lift models feature a rotating basket mount, automatic self-levelling hydraulic stabilizers, and a heavy-duty tow coupling.

For more information call the Ahern Australia team on 1300 900 700 or visit ahernaustralia.com.au

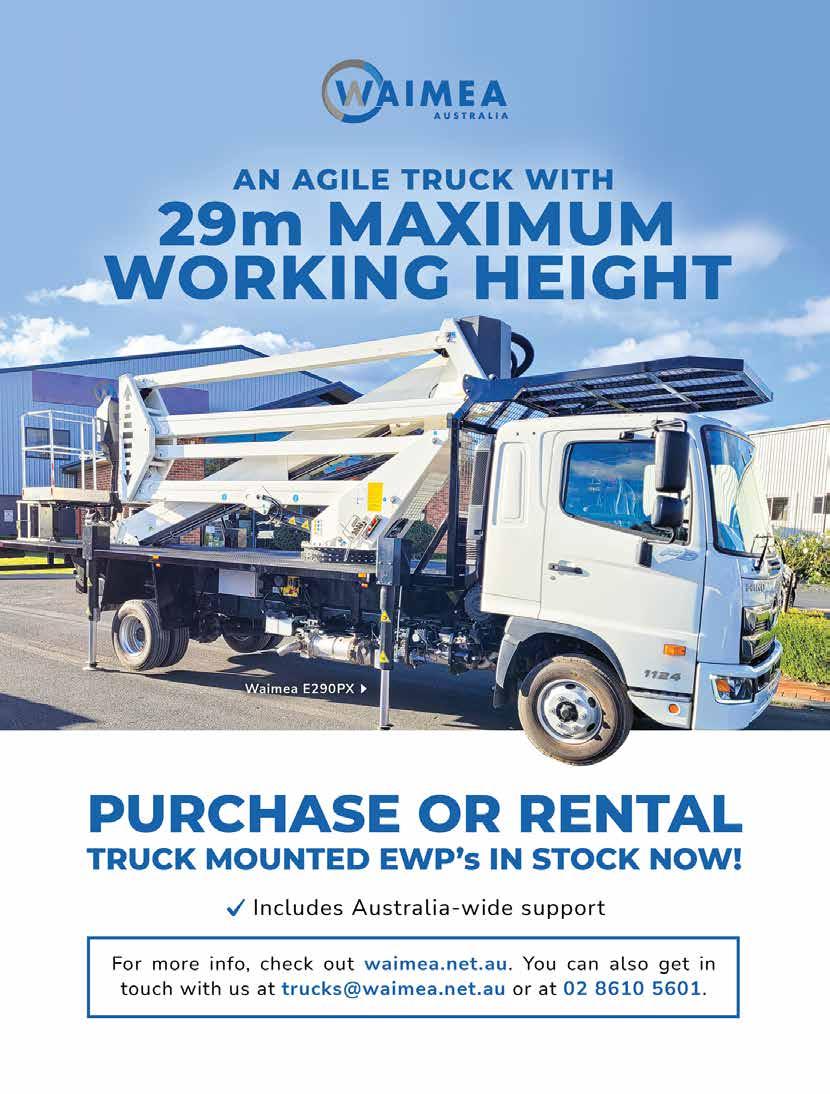

Waimea Australia, a division of Monitor Lifts, launched a 29m Truck Mounted EWP on an 11 ton GVM chassis.

This new Waimea unit is amazingly compact, with vertical outriggers and a large 250kg SWL with unrestricted outreach to 15.6m.

Truck mounted EWPs can be advantageous when doing multi-location, same day set-ups or projects requiring long distance travel. Especially being a registered road going vehicle, this can prevent any hassle with traffic management or permits. A unit such as the Waimea E290PX packs a real punch, with all the benefits of a medium size truck, with economical running costs.

Setting up is very fast; simply pull up, engage the PTO, climb out of the vehicle and level the chassis by lowering the stabiliser legs and you’re right to elevate.

The clever double-knuckle boom design of

the Waimea E290PX provides an excellent working area, from ground level right through to working height, with very minimal tail swing. The 2-man, 250kg SWL is available

throughout the entire envelope providing unrestricted outreach.

The four x vertical heavy duty stabiliser legs allow the truck to set up on all sorts of terrain and provide a very nice sturdy base to ensure excellent stability at height. The stabiliser legs do not protrude past the edge of the truck tray, allowing setup in very confined areas and within one lane width if doing street work.

Smooth proportional hydraulic controls allow very precise operation, and also provides for fast boom movements when required. Multiple functions can be made simultaneously. Platform rotation is standard and can assist when manoeuvring into tight areas.

Waimea Australia can even provide radio control options, automatic stabilisation / levelling, custom tool box design, roof and cab protection, etc. Step aboard and be ready to hit the road for the next project!

The Waimea Truck Mounted EWP designs are very compact, allowing for tight access and efficient operation. There are telescopic and knuckle models from 12m – 36m available to suit any requirement.

For more information on the Waimea Australia range, please call the friendly team today on (02) 8610 5601 or email trucks@waimea.net.au. Whether it’s sales or hire, or Hire 2 Own, Waimea Australia is sure to have an option to suit your needs.

The Monitor 2095 Spider Lift is becoming increasingly popular in the Arbor industry thanks to this machine’s incredible features and benefits.

With a big 250kg basket capacity, the Monitor 2095 has an incredible unrestricted horizontal outreach of 9.5m. Therefore, meaning that two men and saws can still achieve maximum outreach.

With a unique double-telescoping boom design, this provides the operator with superb up and over-reach which as you know is very important, especially when in your tight access, backyard applications.

All hydraulic hoses are routed inside the boom, removing the possibility of them being damaged by branches or other obstacles.

The Monitor 2095’s radio control provides smooth proportional functions and allows the operator to manoeuvre the machine comfortably into position, allowing them to move freely around each side of the machine.

Running a quality twin cylinder, air cooled,

Kubota Diesel Engine, the Monitor 2095 has the option of a 240-volt electric motor or onboard Lithium batteries therefore converting the machine into a Hybrid. This therefore provides you with the option to work quietly,

emissions free and efficiently if you’re wanting to make an early start. Now with the modern age battery chainsaws, you can get the job done without your customer even knowing you are there creating an excellent customer experience.

The Monitor 2095 spider lift features a fly-jib and basket rotation allowing you to have much greater manoeuvrability in the tree canopy. These two features are critical in helping you achieve complete your application to a high-quality standard.

Non-marking rubber tracks are an option for use on sensitive floors, and air and water lines are routed up to the basket to allow the use of pneumatic tools or a pressure washer. This therefore allows you to offer your services in not just Arbor work but also property maintenance such as roof and gutter cleaning.

The radio control is also used to operate the stabiliser legs which have the excellent ability to automatically level the spider up on uneven, slopping applications. Stowing to only 790mm wide thanks to an easily removable basket, 5140mmlong and 1990mm high, the Monitor 2095 has the amazing ability to navigate through a single doorway making this machine ideal for tight access applications.

Built to tackle rough terrain, the Monitor 2095’s tracks expand out and down to provide greater stability and excellent ground clearance. Two speed drive also allows the operator to move the machine very quickly from job to job.