THE 6X® - The radar level sensor that can handle any application, no matter if the medium to be measured is liquid, solid, hot, cold, hazardous or corrosive. www.vega.com/radar www.bulkhandlingreview.com VOLUME 29, ISSUE 3 | MAY/JUNE 2024

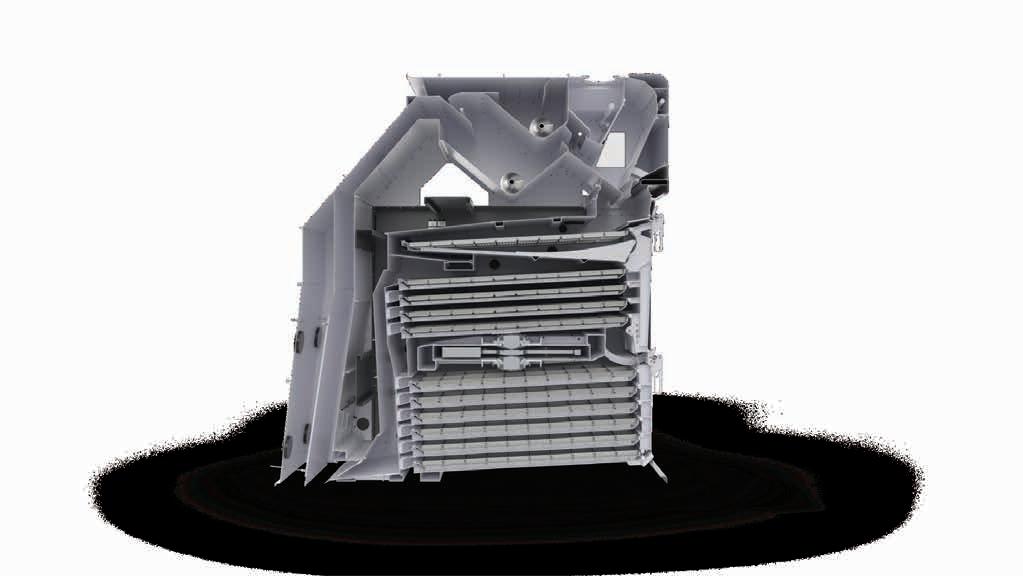

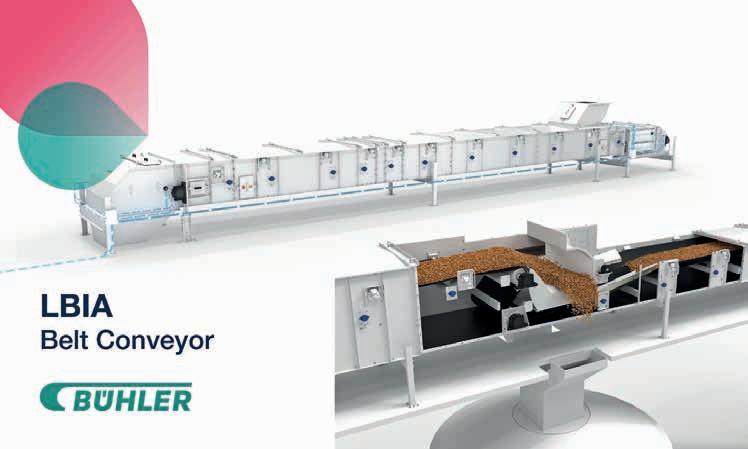

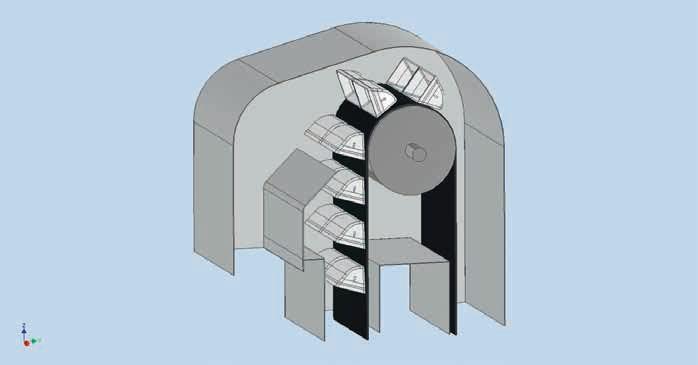

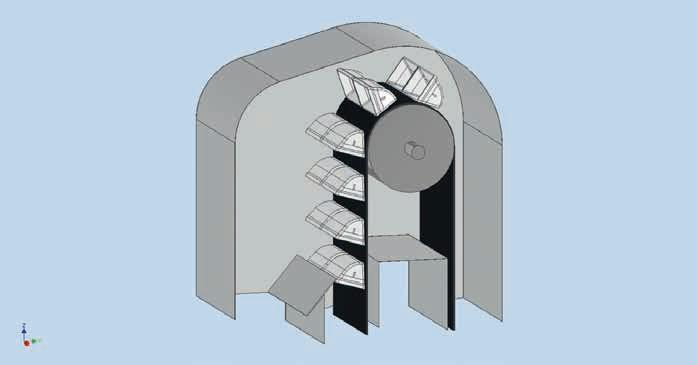

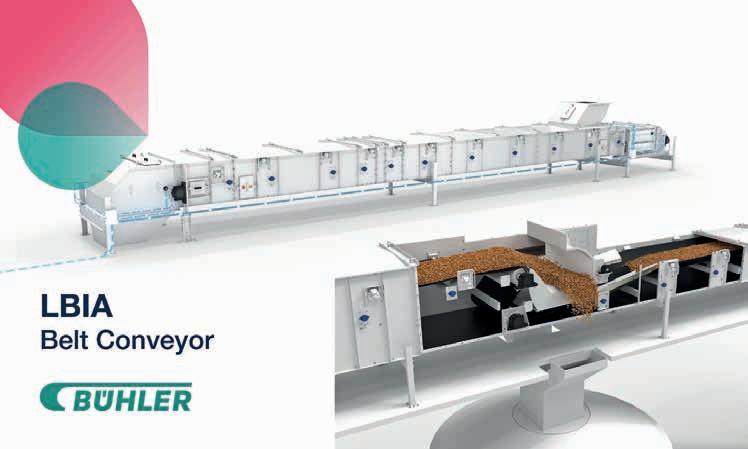

Bühler cutting-edge cleaning machine offers unparalleled uptime, user-friendly operation, and fully optimized yields for various grains.

Maintenance is a breeze, ensuring your operations maintain peak performance without interruption.

The sleek, accessible design streamlines cleaning processes and sieve replacement, significantly reducing downtime.

The TAS series boasts a diverse range of nine installation sizes to accommodate an extensive capacity spectrum:

Impressive throughput from 60t/h up to a commanding 250t/h. Screen area up to 48m

Contact Bühler Australia:

Phone: +61 3987 27906

Website: www.buhlergroup.com

Innovations for a better world.

Discover the pinnacle of grain cleaning technology with the Bühler TAS series.

Sales Manager adam.williamson@buhlergroup.com

Adam Williamson –

Satake buys WA silo business

Tylden silos stand the test of time

A silo’s best friend 62 Supporting farmers for more than 120 years

Australian Bulk Handling Review: May/June 2024 І 3 CONTENTS MAY/JUNE 2024 44 26 20 16 bulk bag per week or 20 per hour the lowest cost per bag model range, patented innovations and performance enhancements exact-match filler to your specific cost and capacity requirements length forklifting tubes positioning of this TWINby weight without in load cells and Every Flexicon filler offered with pneumatic (shown) or mechanical to interface with optional overhead Patented SWING-DOWN filler and swing-arm-mounted chute for automated filling and indexing REAR-POST FILLER with performance options retractable bag hooks, inflatable bag seal, dust containment vent, TIGHTEST BUDGETS lighter-duty version of the further still, yet has an inflatable bag spout seal and feed chute dust vent TWIN-CENTREPOST™ FILLER Two heavy-gauge, on-centre posts manual fill head height adjustment, and feed chute vent for displaced USDA acceptance. +61 (0)7 3879 4180 flexicon.com.au: Flexible Screw Conveyors, Tubular Cable Conveyors, Pneumatic onveying Systems, Bulk Bag Unloaders, THE 6X The radar level application, no matter if the medium to be measured is www.vega.com/radar www.bulkhandlingreview.com VOLUME 29, ISSUE MAY/JUNE 2024 COVER STORY: MEASUREMENT THAT WON’T FLAKE How do you measure a material too light, dry, and fluffy for ultrasonic sensors? Install a VEGA radar sensor. Find out how the VEGAPULS 6X can help with measurement. For the full story, see page 12 6 Industry news 12 Measurement that won’t flake 14 Critical performance 16 Pneumatically conveying wet, abrasive material 18 Covers kept simple 20 Remote transfer points: Monitoring and servicing long conveyors 24 European technology to revolutionise wrapping 26 Sugar hits the spot 28 Organic success 30 Turnkey triumph for Conveyor Industries 32 A better world 34 Powered up by POWERCELL® 36 Bonfiglioli’s gearbox growth 38 Redefining bulk handling efficiency 40 The Italian job 42 Australian tech for international trade 64 The wear of mining equipment Bucket elevators 44 Rise up with Alimark 46 Investing locally reaps Reliable rewards 48 Achieving maximum capacity for bucket elevators Silos 50 Reap

benefits 52

field 54

56

58

60

the

Stand out in the

Achieving effective fumigation

64 Ask an Engineer: How can I build a better silo?

Published by:

379 Docklands Drive

Docklands VIC 3008

T: 03 9690 8766

www.primecreativemedia.com.au

COO

Christine Clancy

E: christine.clancy@primecreative.com.au

Editor

William Arnott

E: william.arnott@primecreative.com.au

Journalist

Adam Daunt

E: adam.daunt@primecreative.com.au

Business Development Manager

Rob O’Bryan

E: rob.obryan@primecreative.com.au

Client Success Manager

Janine Clements

E: janine.clements@primecreative.com.au

Design Production Manager

Michelle Weston

E: michelle.weston@primecreative.com.au

Art Director

Blake Storey

Design

Michelle Weston

Subscriptions

T: 03 9690 8766

E: subscriptions@primecreative.com.au

www.bulkhandlingreview.com

The Publisher reserves the right to alter or omit any article or advertisement submitted and requires indemnity from the advertisers and contributors against damages or liabilities that may arise from material published.

© Copyright – No part of this publication may be reproduced, stored in a retrieval system or transmitted in any means electronic, mechanical, photocopying, recording or otherwise without the permission of the publisher.

Siloed solutions

Agriculture has been around for more than 10,000 years, ever since the first nomadic hunter gatherer humans decided to put down roots.

However, an age-old problem that farmers are still asking today is, ‘Where should I put all this grain?’

Grain storage is a vital part of the process for the agricultural industry – it doesn’t matter how big the harvest is if the crop spoils waiting to be processed or sold. Grain needs to be protected, not just from the elements, but from infestation. Leaving large piles of food around is also just ringing the dinner bell for rats and insects.

Silos are one solution to this problem, but not all are designed equally. Each farm or bulk handling site will have their own requirements and needs from their silo. For example, a farmer might be looking to expand their storage capacity to sell grain later when its more profitable. A grain port, on the other hand, will need much larger industrial silos that can handle hundreds of thousands of tonnes moving through its systems.

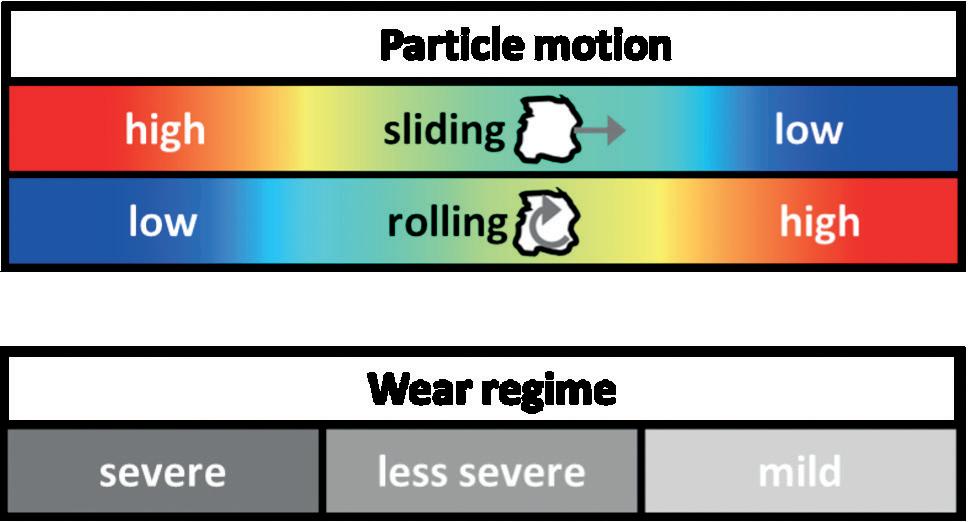

Silos also need to be properly filled and emptied. The first part is relatively straightforward – either through augurs, conveyors, or some other means of handling bulk grain. Getting the grain out is another story entirely.

Once inside a silo, some materials may become clogged, and not easily flow out. This could be due to moisture causing it to cake. The friction from the inner walls of the silo may slow the flow and cause particles to bind together, forming an arch or bridge above the outlet area, stopping flow entirely.

There is a simple way of fixing this – bang the side of the silo with a hammer. This puts someone at risk – swinging a heavy object is dangerous. The loud clangs aren’t good for the ears and the ergonomic concerns can do a number on a person’s back.

Not only that, but it could damage the silo, creating dents that material can get stuck on. Now, the flow issues are even worse.

This edition of ABHR highlights the vast range of organisations designing silos and the equipment that supports them. Read on to see how the industry is responding to the latest trends, technologies, and techniques.

4 І Australian Bulk Handling Review: May/June 2024

EDITORIAL

William Arnott Editor - ABHR

4B Australia Building 1, 41 Bellrick Street, Acacia Ridge, 4110, Queensland, Australia Tel: +61 (0)7 3216 9365 Email: 4b-australia@go4b.com www.go4b.com 4B DESIGNS AND MANUFACTURES COMPONENTS FOR BUCKET ELEVATORS AND CONVEYORS Engineering Solutions Since 1888 A Worldwide Manufacturer ELEVATOR BUCKETS ELEVATOR BOLTS BELTING & SPLICES PREVENTATIVE MAINTENANCE & HAZARD MONITORING SYSTEMS CONVEYOR CHAIN BEARING TEMPERATURE SENSORS SPEED SWITCHES BELT MISALIGNMENT SENSORS LEVEL & PLUG SWITCHES BULK2024: 18-19 September Melbourne Convention and Exhibition Centre - Booth 2332

Mining means business at BULK2024

Experts and decision makers in the mining sector are set to attend the upcoming Bulk Handling Expo. ABHR explains how the bulk handling industry can benefit.

AS AUSTRALIA GROWS, ITS DEMAND for minerals grows too. The country’s metals are needed to create vital infrastructure and manufacturing

Changes to technology are also having a major impact on mining and mining methods. The Minerals Council of Australia claims that by 2030, to meet the world’s demand for storage alone will require 50 new lithium mines, 60 new nickel mines and 17 new cobalt mines.

The council also expects mining investment is expected to increase by US$100 billion annually from current levels to produce the mineral commodities required for the world to achieve net-zero emissions by 2050.

It’s an important time for the industry, bringing about new challenges and lessons to be learned.

For this reason, the resources industry will play a major role at the upcoming Australian Bulk Handling Expo (BULK2024).

Located at the Melbourne Exhibition and Convention Centre, the event aims to help spread industrial knowledge, showcase the latest technologies and innovations, and provide an opportunity to network with like-minded peers.

BULK2024 show director Lauren Chartres said that while the event will bring all producers of bulk commodities together, there will be a special focus on how other sectors can learn from the resources industry.

“There is so much happening in the mining industry, and the scale of the technology that is used creates engineering challenges and solutions that could help other industries,” she said.

“Tapping into that wealth of knowledge and expertise can help businesses find an edge.”

BULK2024 is aimed at bulk commodity producers who are looking

to run their businesses more efficiently and keep one step ahead of the competition.

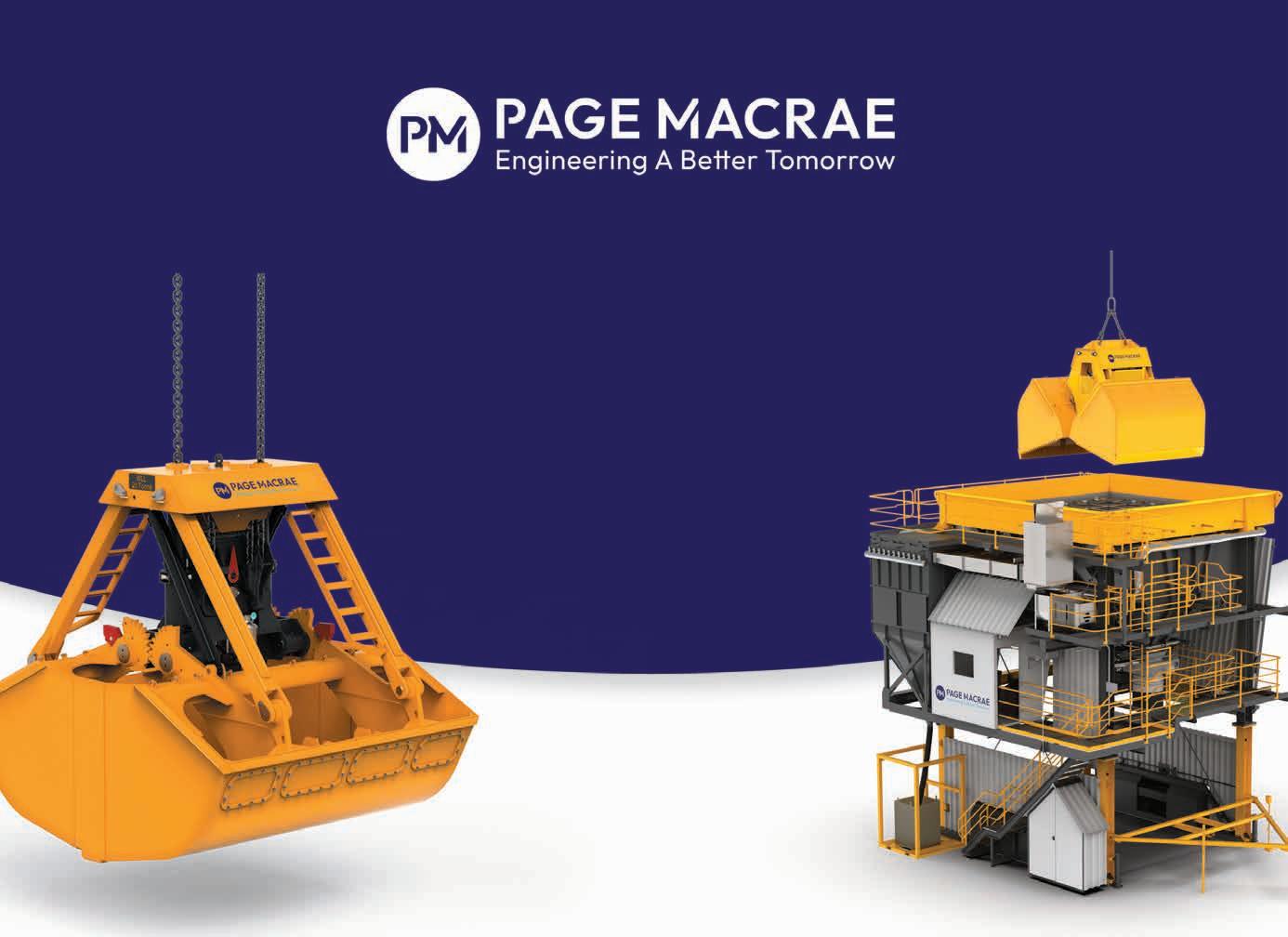

To ensure they can do that, the latest in equipment will be on display, including conveyors, silos, motors and drives, belt scrapers, container tipplers, dust control systems, and weighing or level measuring products.

“The mining industry is also embracing innovative new technology. Industry 4.0, automation, and artificial intelligence have the potential to radically change the way businesses operate,” Chartres said.

Attendees will have the chance to connect with industry leaders and innovators on the show floor and at various networking opportunities at the show.

It will also offer the opportunity to meet with new clients, learn about new markets and connect with customers

you might never have met elsewhere.

The expo will be held in conjunction with one of Australia’s biggest transport, logistics and supply chain events, MEGATRANS2020. The two events will be hosted over 30,000 square metres at the Melbourne Convention and Exhibition Centre, with one ticket entry for access to both exhibitions.

“We’re inviting everyone to be a part of this game-changing expo –from hands-on decision makers in the bulk handling industry to CEOs, COOs, regulatory bodies, and government at all levels,” Chartres said.

“We’ve seen how impactful bringing the industry together was at BULK2022 and are excited to see the industry continue to grow.”

BULK2024 will take place at the Melbourne Convention and Exhibition Centre from 18–19 September, 2024.

BULK2024 6 І Australian Bulk Handling Review: May/June 2024

C M Y CM MY CY CMY K

The resources industry will play a major role at the upcoming Australian Bulk Handling Expo.

artin manufactures energy-efficient electric vibrators that are ideal for screening, emptying hoppers and keeping material flowing. These rugged designs require minimal maintenance and are less expensive to operate than other power options.

Martin® Screen Vibrators are designed to serve as a direct retrofit for Derrick® shaker screens and require no modifications or adapters. Our sturdy construction delivers a long service life, easy maintenance and carries an industry-leading 3-year warranty.

Like our Screen Vibrators, the MM Series vibrators are constructed with only highest quality housings and internal components. They incorporate O-ring seals and precision machined surfaces for dust-tight, water-tight IP66 protection. Drives are interchangeable with other major manufacturers. Get shakin’ with Martin.

®

Electric Screen Vibrator

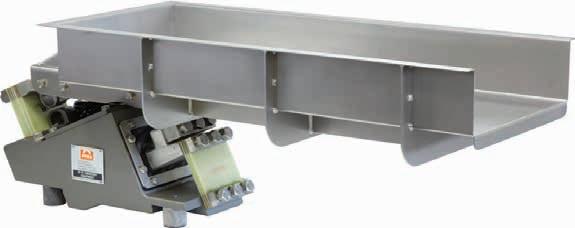

Thayer Scale low-profile cable scale for bucket elevators

THAYER SCALE’S LOW-PROFILE

Cable Scale is designed to work with conveyors used throughout the processing industry that cannot easily accommodate a conventional conveyor belt scale.

The mass-counterbalanced scale fits securely under a bucket elevator, a hinged plate conveyor, a cleated belt conveyor or another piece of material handling equipment and senses the load being transported providing realtime rate and totalisation information.

In addition, the low-profile cable scale requires little additional vertical headroom.

This unique solution will effectively convert your existing conveying equipment into a highly accurate weighing solution.

The low profile, masscounterbalanced scale has unique proportions to support entire conveyor structures. Dead loading of up to 2250kg can be accommodated on standard configurations without loss of net loading sensitivity.

The weigh platform effectively converts these conveyors into highly sensitive, mass-counterbalanced weighing platforms that allow you to manage and control weighingspecific process variables such as rate of flow, totalised material conveyed, and other variables.

Used in combination with Thayer Scale’s S52 line of instrumentation, the measurement of loading and speed can produce an accurate measurement of the totalised throughput and gravimetric flow rate. The precision instrument package facilitates reporting on conveying-specific metrics like flow rate in buckets/minute.

CSIRO launches survey into mining industry

AUSTRALIA’S NATIONAL SCIENCE agency, CSIRO, has invited Australians to participate in a survey that aims to shape the future of mining research.

CSIRO engaged Voconiq to conduct the survey that aims to explore the attitudes of Australians towards the mining industry today.

It follows previous surveys in 2014 and 2017, which produced insights on

Australians’ expectations for how mining is conducted.

“Mining plays a crucial role in producing the materials necessary for the transition to low emission technologies, global electrification and global development in general, and conversations generated from surveys like this will help shape the industry’s future, balancing its growth with community

expectations,” Rob Hough, CSIRO’s Director of Mineral Resources, said.

“Your insights will be instrumental in guiding our ongoing research.”

CSIRO will use the results from the survey to inform future mining related research initiatives that lead to public reports and academic publications.

The survey was conducted in March and April of 2024, and has now closed.

NEWS 8 І Australian Bulk Handling Review: May/June 2024

C M Y CM MY CY CMY K

Low-profile cable scale.

Image: Thayer Scale

PROVIDING SOLUTIONS

For over 45 years, Vortex has supplied dry material handling components to a global network of Original Equipment Manufacturers, Fortune 500 companies, and process engineering firms. Throughout the world, over 15,000 companies have utilized Vortex’s innovative slide gates, diverters, iris valves, loading solutions and custom engineered products to improve process efficiency.

With sales and service offices located in North America, Europe, Asia and Latin America, Vortex’s success comes from a philosophy, which includes focus on quality, timely customer service and dedication to adding value to our clients’ processes.

PROVIDING SOLUTIONS

Each Vortex component is appropriately selected to meet the demands in every application. With an in-house team of engineers, Vortex product designs can be completely customized for individual applications or special installations. Vortex understands the value of your process. Our team of application engineers have more than 150 years of combined dry material handling experience. Vortex’s knowledge of handling dry material characteristics in pneumatic, vacuum and gravity flow applications is unsurpassed. Vortex delivers intelligent, cost effective solutions for all dry bulk materials. No application is too large, too small or too difficult to handle.

INDUSTRIES SERVED

IN YOUR WORLD There’s no time for down time. That's why we make solids & bulk handling components that are made to perform. www.vortexglobal.com Learn more about Vortex Slide Gates, Diverters, Iris Valves & Loading Solutions at: Heavy Duty Slide Gates Aerated Conveying Engineered for handling everything from fine powder to abrasive aggregate Heav Duty Diverter Valves Loading Spouts

• Chemicals • Cement • Food & Grain • Fibers • Minerals • Petrochem • Pharmaceutical • Plastics • Rubber • Mining • Minerals • & Much more...

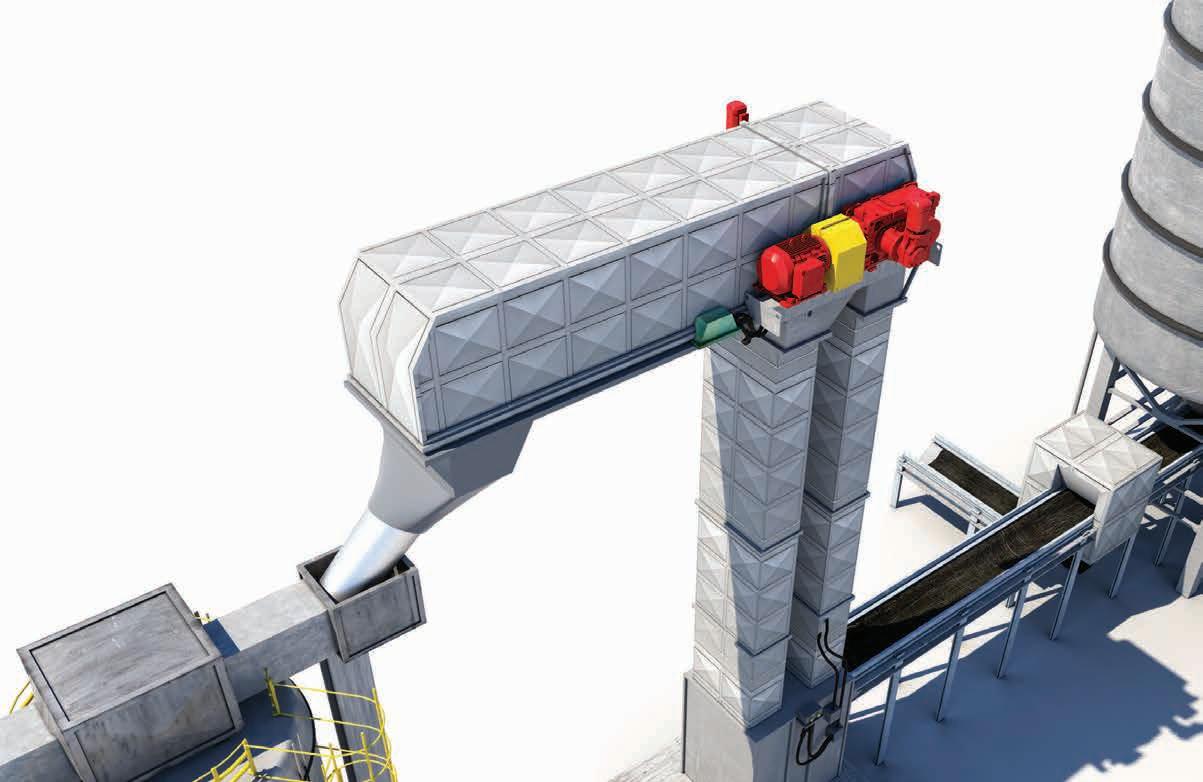

Fremantle Ports unveils unique storage dome

FREMANTLE PORTS HAS

revealed a new clinker circuit project that features a storage dome set to deliver ‘significant benefit’ to clinker users and importers.

The 40-metre-high storage dome and covered conveyor network will link directly to the adjacent Cockburn Cement Ltd plant and support BGC.

“The clinker dome holds the same amount of product as a conventional shed but has a much smaller ground footprint,” Fremantle Ports chief executive Michael Parker said.

“This is of significant benefit to future-proofing the Kwinana Bulk Terminal, as we can make space for other trades, sheds, and systems as we continue to develop and grow in the years to come.”

The dome storage solution was chosen instead of a conventional shed but has a much smaller footprint then the shed which is critical at the Kwinana Bulk Terminal.

The dome was constructed using a concrete ring beam, and then an airform membrane was inflated. A layer of foam was applied before steel and shotcrete were used to reinforce the structure.

“The instalment of the dome and the clinker import circuit facility is a very exciting investment, providing our customers faster cargo-handling, quicker ship turnaround times and more efficient landside operations,” Parker said.

“This project supports the construction industry in Western

Australia and is a key part of our long-term planning to facilitate trade through the Port of Fremantle.”

Parker said that clinker held an important place in the state’s resources and aggregates sector.

The Kwinana Bulk Terminal receives more than 1.1 million tonnes of imported clinker per year, which is used in domestic, commercial, and industrial projects. Indonesia accounts for around half of the annual amount, while Japan, Malaysia, the Philippines, and the United Arab Emirates make up the remainder.

“Without clinker, industry stops, and every tonne of the commodity entering Western Australia comes through the Kwinana Bulk Terminal,” he said.

10 І Australian Bulk Handling Review: May/June 2024 NEWS

The new storage dome at Kwinana Bulk Terminal.

Image:

Fremantle Ports

Bellevue Gold reopens WA gold mine

BELLEVUE GOLD HAS OFFICIALLY OPENED ITS $252 million gold project, which sees its mine reopen after sitting dormant for more than 20 years.

Located 35 kilometres north-west of Leinster, Bellevue Gold will employ about 230 workers, who will be housed in rooms 20 per cent larger than the industry standard.

The earliest production at the mine site dates back to the early 1900s. Operations restarted in 1986 before closing in 1996, at a time of historically low gold prices. The project lay dormant until Bellevue Gold recommenced exploration activities in 2017.

The company expects to produce more than 1.8 million ounces of gold over an initial 10-year mine life. With a mineral resource of 3.1 million ounces at 9.9 grams per tonne, the mine will be one of Australia’s highest-grade gold mines.

Bellevue Gold aims to be a net-zero emission site by 2026, with the lowest greenhouse gas intensity of any major Australian gold project. This will allow the company to market ‘green gold’, a product which has the potential to attract a price premium.

Wind and solar are expected to provide up to 80 per cent of the facility’s overall power needs.

WA Mines and Petroleum Minister David Michael congratulated Bellevue Gold on opening the gold mining project.

“I commend Bellevue Gold for working closely with the Tjiwarl Aboriginal Corporation to deliver mutually beneficial outcomes, and for committing to ongoing engagement,” he said.

“It is also encouraging to see the Bellevue Gold Project aim for net zero emissions as Western Australia’s resources sector will play a key role in the State’s transition to a low carbon economy.”

The WA Government’s Exploration Incentive Scheme (EIS) co-funded Bellevue Gold’s drilling activities in 2017 and 2019, and these results underpinned the mine’s reopening.

“The Exploration Incentive Scheme continues to encourage exploration in remote regions of WA, and it’s always pleasing to see the scheme deliver such outstanding outcomes,” Michael said.

“With record sales of $18.6 billion in 2022-23, gold will continue to play a significant role in WA’s economic future.”

Image: Phawat/stock.adobe.com

Measurement that won’t flake

wood core of the material, while the fines are used to create the surface.

As part of its production process, D&R Henderson, a particleboard producer, stored the very light, very dry powder in a 21-metre silo.

However, there was a problem. Because wood flour is so light, fluffy, and dry the traditional methods of measuring the level just simply didn’t work.

Sheeshendra Deo, Electrical Manager at D&R Henderson said finding a sensor fit for the job was a process of trial and error.

The company first tried using an ultrasonic sensor, which emits acoustic pulses to detect the level in a vessel. The light nature of the wood flour meant the pulse was being absorbed, which made the readings unreliable. On top of this,

“We tried a lot of sensors that just didn’t work,” he said. “The material had an extremely low dielectric, which meant it was a poor conductor of electric current.”

“Our product is also very dry. Normally these sensors depend on having some moisture there to find an accurate reading.”

Jim Curnow, a business development manager at VEGA Australia said radar systems need at least some conductivity to work.

“The wood flour had such a low dielectric, it was basically invisible to the sensor,” he said.

The company tried several sensors, but none of them were able to accurately detect the material. One potential solution was to install load cells, but that would be prohibitively expensive

the silo was vital for D&R Henderson. If the company didn’t know how much wood flour it had, it could lead to lost production while refilling the silo. Since the product supplements natural gas in the burners (which run the wood dryers), the gas cost can be huge.

Eventually, the manufacturer began testing the VEGAPULS 69, one of VEGA’s most advanced radar sensors. Wood flour was one of the materials VEGA claimed it could accurately measure.

Curnow said the 80 gigahertz radar was different to the others the customer had tried, as it has a much higher dynamic range, meaning that it was a lot more sensitive, enabling the unit to receive and process very small echoes from this type of material.

“The VEGAPULS69 has a dynamic range of 120 decibels. All of the other

COVER STORY 12 І Australian Bulk Handling Review: May/June 2024

Attaining an accurate reading in the silo was vital for D&R Henderson.

radars at the time were using around 85 decibels for measurement,” he said.

“The decibel scale is logarithmic. That means going from 85 to 120 isn’t just a 25 per cent increase – it’s over 1000 times more sensitive.

“That means the sensor can get a much better return signal from a low dielectric material and makes it for all intents and purposes immune to dust and buildup.”

One feature that helps protect the system from dust and buildup is the lack of a horn. Traditional Radar sensors often use a horn to focus the microwave beam into the right direction. The VEGAPULS 69 uses a lens antenna rather than a horn, removing an area where material could gather.

The sensors require no maintenance and can be set up and left alone. Integrated Bluetooth technology means the VEGAPULS69 can be programmed and integrated from the ground by site staff using their mobile phones, without the need to climb a 21-metre ladder with a laptop to make a program change.

Deo said VEGA made sure to take samples of the wood flour from the site to see if the sensors would work.

“They took various samples, and we were confident that it would work after seeing the results,” he said.

“We then began to replace all of the other sensors across the site with ones from VEGA and have close to 10 now installed.”

Curnow said the consistency of VEGA’s products is key to its success. This is why the company has released the VEGAPULS 6X, a radar sensor that can handle almost any application, no matter the medium.

This new radar level sensor VEGAPULS 6X now combines the best of the previous 80 GHz, 26 GHz and 6 GHz sensors VEGAPULS 61, 62, 63, 64, 65, 66, 67, 68 and VEGAPULS 69, in one device.

“They’re all German made to very high standards. I’ve been to the factory and seen the level of quality control that goes into every single step of the process,” Curnow said.

“It’s really high tech and impressive, and it means that everything we produce will operate as it should.”

Australian Bulk Handling Review: May/June 2024 І 13

Images: Vega

Wood flour is so light, fluffy, and dry that traditional methods of measuring the level didn’t work.

The VEGAPULS 69 uses a lens antenna rather than a horn.

Critical performance

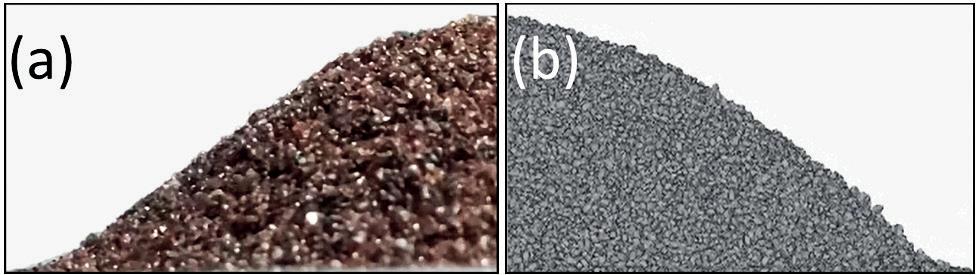

Critical minerals capabilities are in high demand in Australia and abroad. ABHR learns how Bulk Handling Technologies play a key role in this transition.

CRITICAL MINERALS ARE REQUIRED

to make the products of the future, but given its challenging handling characteristics, the sector requires specialised bulk material handling equipment, Bulk Handling Technologies (BHT) manager Paul Ingleson told ABHR

The Perth-based company, established in 2012, has developed a global client base for its specialised, heavy-duty screw feeders.

Syrah Resources, which operates the Balama Graphite Project, approached Bulk Handling Technologies to design and supply multiple heavy-duty twin-screw feeders due to its reputation for creating solutions for the critical minerals sector.

Located in the Cabo Delgado Province, the Balama Graphite Project is considered a ‘globally significant’ graphite project. The mine can produce 350 kilotonnes per annum and has an expected lifespan of 50-plus years. It has seen major industrial giants, including Korea’s Posco Future M, sign long-term contracts for graphite supply.

The investment has come because the growing demand needs to be

supported by specialised machinery, like the solutions created by Bulk Handling Technologies.

“Graphite filter cake, like many filter cakes, poses some difficult challenges for materials handling engineers and plant designers,” Ingleson said.

“With proper design, screw feeders can be one of the cleanest and most

reliable solutions for controlled feeding and discharge of filter cakes from storage hoppers.”

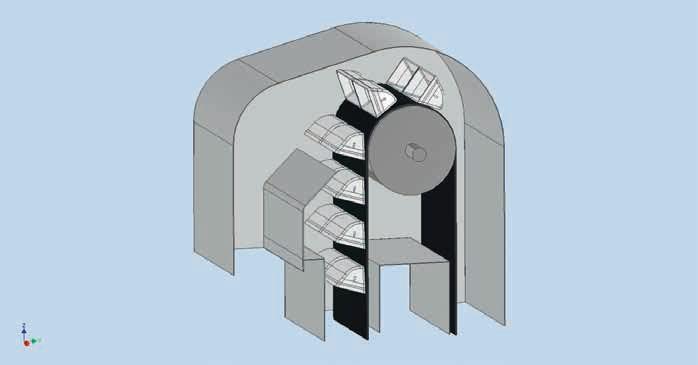

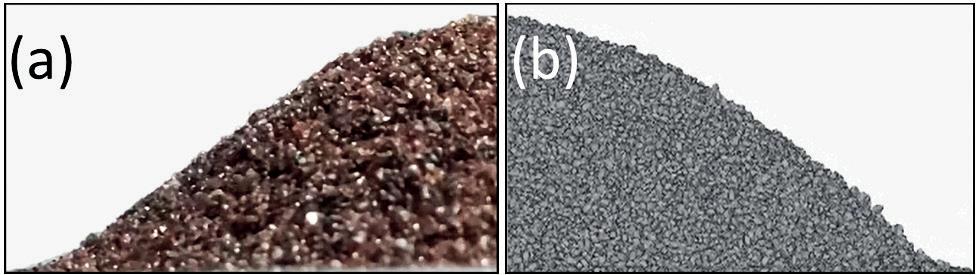

BHT designed the three heavyduty twin-screw feeders with specialty steels and surface treatments to handle graphite’s high nobility. The company carried out specialist material testing using a representative graphite sample to determine the flow properties and best solution for the client.

The testing determined the critical hopper dimensions, outlet size, and head load condition, which led to BHT recommending ribbon flight twin screw feeders.

The company manufactured, assembled, and tested the twin-screw feeders at its Perth headquarters.

VANADIUM ADVANCES

Each critical mineral presents a different logistical problem. For example, graphite filter cake is cohesive, whereas vanadium is highly abrasive.

A WA vanadium producer approached the BHT to support its operations with a tailored solution. The consultation process between the two saw BHT

MACHINERY 14 І Australian Bulk Handling Review: May/June 2024

Testing the design in a scale test rig with a sample of graphite filter cake.

The kiln feed screw installed on location.

Images:

Bulk Handling Technologies

construct a high-capacity cantilevered kiln feed screw which can feed abrasive magnetite to extract vanadium.

“High-capacity rotary kilns are often fed using screw feeders as the circular casing allows for a smaller kiln opening and optimum sealing at the inlet,” Ingleson said.

“The particular challenge with kiln feed screws is that you need to handle cohesive, moist product at the feed end while dealing with extreme temperatures and hard, baked product on the inside of the casing at the discharge end.”

Recently, BHT employed the flow material property data to determine the best solution for an operator working with betaa-spodumene, which is used to create lithium.

Like the graphite and vanadium contracts, alpha and beta-spodumene presents a unique challenge.

The material is extremely fine and highly abrasive, which can present problems for equipment.

BHT used the flow property data from the beta-spodumene testing to design and manufacture a storage feed bin as

screws to combat product aeration and reduce wear.

Ingleson said this testing helped assess important criteria that determined the best equipment for the graphite, vanadium and spodumene solutions.

“An important criterion for screw feeders is often the need to ensure uniform draw-down from the storage hopper above,” he said.

“Bridging, hang-up on sloped walls or ledges and insufficient extraction along the length of the outlet need

the first 50 orders

GET PREPARED FOR THIS YEAR AND INVEST IN YOUR ON-FARM STORAGE HESILOS.COM 1800 046 046 1-12 JONES STREET, FORBES NSW 2871 SILOS, FIELD BINS & FEEDERS 10 *For

delivery this harvest

for

Pneumatically conveying wet, abrasive material

A UK-based mica, also known as muscovite, producer has turned Flexicon to replace its pneumatic conveying system.

LKAB MINERALS HAS BEEN processing mica – a material used as a mineral filler in the agricultural, construction, polymers, and paint industries – at its Derby location since the 1950s.

One process involves moving large volumes of wet, abrasive mica powder from a wet process to a drying system on the floor above. To improve worker safety in the vicinity of the heated material and overcome abrasive wear, the company replaced mechanical conveyors with a pneumatic conveying system from Flexicon.

Processing muscovite

Mica received at the Derby Works as a fine powder in bulk bags undergoes one of six size reduction processes, depending on its end use. One of these is a wet process, in which water is added to create a hot, sand-like material with high moisture content ideal for use in paints and coatings.

The material was originally transported to a drying system on the floor above using a forklift and bucket elevator, and subsequently by a

mechanical conveyor and bucket elevator to distance workers from the material. However, components of both systems suffered abrasive wear.

Most alternate equipment evaluated either could not be routed as needed, move the moist material efficiently and/ or resist abrasive wear.

“We looked at a number of conveying systems, but most suppliers considered the material and the restricted routing as too much of a challenge,” Samantha Bucknall, UK group performance manager at LKAB said.

“Ultimately, only Flexicon was willing to take on the project and offer a viable solution.”

Pneumatic conveying of wet, abrasive material

“It was a new material for them,” Bucknall said. “We supplied a batch to the company’s test lab and worked with them to find the best solution.”

The resulting automated system is comprised of a 560l capacity floor hopper, which receives the mica from the wet process via mechanical conveyor. Pneumatic rather than mechanical

conveying permitted the most direct material transfer path.

A 30m long, 75mm diameter Pneumati-Con vacuum line propels the muscovite vertically 11m to the floor above and around two 90° bends to a 1220mm diameter filter receiver. The filter receiver separates the muscovite from the conveying air and is sized to hold 800l of material.

The dilute phase vacuum system is powered by a 15kW positive displacement vacuum pump, at 500 mbar pressure differential.

The filter receiver is sized to hold an entire wet mill batch, and includes a level sensor to signal the PLC when the full batch is accumulated and the next batch should be fed to the mill.

The filter receiver includes an automatic reverse-pulse jet cleaning

PNEUMATIC CONVEYING 16 І Australian Bulk Handling Review: May/June 2024

The hopper below the filter receiver receives the wet mica and discharges it to a drying system followed by separation by particle size.

LKAB Minerals have processed mica at their Derby facility since the 1950s.

Images: Flexicon

system, which dislodges material accumulated on the filter elements to maintain optimal conveying performance, and returns it to the batch to eliminate waste. Bag filters were selected over cartridge filters for more effective release of the sticky material.

Material is then transferred from the filter receiver to a drying system, then to any of three sieving stations for separating the product in two particle sizes. Due to greater customer demand for finer mica, two of the three sieving stations produce a 90 µm particle size, while the third produces a coarser 125 µm particle size.

LKAB supplies Mica under the trade name MicaFort in 25kg bags, 1 tonne bulk bags, or in bulk tankers.

Overcoming conveying challenges

“Installation of the new pneumatic system was difficult as it is located in a very tight space,” Bucknall said. “We

experienced a number of challenges during early operations, but Flexicon stayed with us to find solutions.”

One challenge stemmed from mica’s abrasiveness, which ate through one of the elbows within six weeks of operation.

“Flexicon suggested we replace the worn bend with a Smart Elbow deflection elbow from HammerTek Corporation. This gave us 12 months of operation, almost nine times longer, which we are very pleased with,” Bucknall said.

The deflection elbows are designed to minimise wear of the elbow wall. Unlike conventional elbows, which rely on material impact to change direction of material flow, the deflection elbow features a spherical chamber that protrudes just beyond the pathway of the material. A ball of suspended material rotates in the chamber, gently deflecting incoming material around the bend and preventing it from impacting the elbow wall.

Air-cushion

Air-cushion

Overall, the project represented a “leap of faith for us as we had not used a pneumatic transfer before and we were not sure how it would handle the wet mica,” Bucknall said. “We overcame

BELT CONVEYOR

CONVEYOR

Both belt and product are carried on a cushion of air

MONEY SAVING FEATURES:

• Low power consumption • Reliability

• Low wear and tear • Low maintenance

• High capacity • Light weight belt

• Steep angles of inclination • High belt speeds

• Dust tight • True belt tracking

• Complete settling of materials on belt

• Simple conversion from open to closed conveyor

Both belt and product are carried on a cushion of air BELT

CONTACT US FOR MORE INFORMATION Aerobelt Australia Pty Ltd Ph: 02 4631 2919 | Mob: 0419 279 566 | Fax: 02 4631 2915 info@aerobelt.com.au | aerobelt.com.au

Final milled muscovite material has gone through size reduction, pneumatic conveying, drying and sieving steps.

CONTACT US FOR MORE INFORMATION Aerobelt Australia Pty Ltd Ph: 02 4631 2919 | Mob: 0419 279 566 | Fax: 02 4631 2915 info@aerobelt.com.au | aerobelt.com.au

Covers kept simple

Kinder Australia’s K-MotorShield is a simple solution for keeping motors running in dusty environments.

MOTORS ARE PROBLEMATIC

places for dust to gather on a busy bulk handling site. They’re often close to the action and have plenty of places for dirt, debris, and dust to build up.

This can have disastrous effects on the motor’s lifespan. The fins that draw heat away from the internal components are not designed to be clogged with foreign material. Without proper airflow, temperatures can rise beyond a point that is safe for the motor and can damage the insulation in the motor windings.

This can result in short-circuiting, arcing, and other electrical faults, potentially causing serious damage to the motor.

Sean Kinder, business development manager at Kinder Australia, said protection is key to reducing the likelihood of failure.

“Covering the motor is an easy way to stop dust and debris from accumulating,” he told ABHR

“But sometimes sites will cover the motor with whatever they have lying around.

“Often, this is a piece of rubber –which helps stop the dust from getting into the motor but also acts as an insulator. Now you have a different problem, as the heat continues to build up and the same issues start occurring again.

“Kinder Australia provides a noninsulating cover that allows heat to escape and protects the motor from dust.”

The K-MotorShield motor cover is a durable, lightweight solution that can be quickly and easily installed on a motor.

Dirt and dust particles are pushed through the fins while heavy contaminants settle on top of the cover, not in the cooling fins.

This can improve airflow by 140 per cent and keep bearings, windings, and brushes on drive motors clean and dust free.

It is constructed from a corrosionresistant composite material, providing a long service life.

Kinder said the K-MotorShield is popular in Australian paper mills to protect the motors.

“There is a lot of water involved in paper processing and the resulting pulp is a sticky material. It can build up and turn into a large block for cooling fins if it reaches a motor,” he said.

“Mine sites also use the K-MotorShield, especially in areas where material spillage is a possibility.”

The K-MotorShield has a ‘snapon’ design, allowing it to fit easily on top of most motors. It is standardised for any NEMA and IEC frame size and can be customised to accommodate unique situations.

Kinder said the cover is a simple solution that keeps motors clean and extends their life.

“In bulk material handling operations, motors serve as the driving force behind essential machinery, making them invaluable assets. Protecting these assets from environmental debris ensures their prolonged lifespan, reduced downtime, and enhanced safety and compliance,” he said.

“It’s an effective and innovative solution. You can see the benefits immediately. Kinder staff will also visit the site to see the equipment after installation to ensure everything is working to our standards.”

FEATURE

18 І Australian Bulk Handling Review: May/June 2024

MOTORS

Dust that gathers on a motor can result in short-circuiting, arcing, and other electrical faults.

The K-MotorShield motor cover is a durable, lightweight solution that can be quickly and easily installed.

Images:

Kinder Australia

Remote transfer points: Monitoring and servicing long conveyors

John Barickman, senior product development engineer at Martin Engineering, explains the logistical and maintenance considerations required for kilometre-long conveyors.

WESTERN AUSTRALIA IS HOME to one of the longest continuous belt conveyor in the world, running between the Mount Saddleback mine and the Worsley refinery near Collie.

Travelling more than 50 kilometres during its winding journey through 22 tunnels and 10 bridges, the system transports around 2700 tonnes of bauxite ore for aluminium extraction.

Monitoring and servicing a system like this can be onerous, but the alternative is trucking. The reduction in cost for labour, fuel, vehicle maintenance, and road upkeep to retain that volume of production, including greatly improving workplace safety, justifies an extensive conveyor system.

However, since its construction in 1983, operators have found that one continuous belt may not be the greatest design decision.

Andrew Timmerman, engineering supervisor at Martin Engineering said a

drivers, trained mechanics, safe roads, and a lot of fuel.

“Long conveyor systems are designed to reduce some of the cost and safety issues. But like any solution, they have their challenges, too,” he said.

More and more, belt conveyors are being built that are kilometres long. They descend mountains and cross vast stretches of plains, forests, or jungles.

Built to compensate for expensive, slow, and potentially dangerous haulage by trucks, long conveyors travel at high speeds regardless of the weather.

Intersecting conveyors and system accessibility

Access to a transfer point by vehicle is recommended, if not critical, because of the nature of the most common maintenance tasks which could involve heavy lifting and work with power tools such as cutters and grinders.

Discharge and loading zones

quickly pile up and encapsulate the belt, causing dust emissions and idler fouling. Maintenance staff needs to access the area to make adjustments to remedy causes of carryback and spillage and clear away accumulation.

Properly engineered material transfer includes belt cleaning, sealing, chute clog prevention, impact management, tracking and monitoring to control the need for maintenance and unscheduled downtime. A goal should be to minimise the number of trips and address all issues in a single visit.

Transfer point maintenance

Transfer points can take some care to maintain. The most common ongoing transfer point maintenance tasks are:

• Primary and secondary belt cleaner blade replacement

Cleaner performance monitoring and tensioner adjustments

• Spillage cleanup sfer chute maintenance and clog mitigation

Having to frequently maintain a basic belt cleaner to make sure it is adequately tensioned and cleaning properly is costlier in labour over the long run than installing quality belt cleaning equipment upfront. This is known as Return on Performance (ROP), which differs from Return on Investment (ROI) in that it calculates the savings in labour for maintenance and equipment life over the long term, instead of merely the period in which the initial capital investment is recovered regardless of increased costs and replacements afterward. At a transfer point located miles away, having a reliable belt cleaner tensioning system that is self-adjusting and/or low maintenance drastically reduces the cost of operation.

CONVEYORS 20 І Australian Bulk Handling Review: May/June 2024

A long conveyor can transport bulk material faster and more consistently than vehicles. Images: Martin Engineering

Images: Martin Engineering

buildup due to material properties, lump/particle size, moisture content, temperature, abrasiveness and corrosiveness. When clogs happen, production stops and backflow fouls components in the discharge zone and spills over the edges of the system. Due to the distance and equipment needed on extended conveyor lengths, the

so calculating the ROP on low maintenance equipment may be a better metric than ROI.”

Equipment geared toward mitigating common transfer chute issues can include service-friendly primary and secondary cleaners, autonomous tensioners, belt alignment devices, self-adjusting skirting, vibration, and localised power generation.

Service-friendly primary and secondary cleaners are track-mounted components that pull away from the stringer for safe service outside of the system. After performing the proper lock-out/tag-out/block-out/test-out procedures, a single worker has easy access to safely service the blades using basic tools.

“Quality and durability are key elements for a sustainable remote transfer point,”

Low maintenance primary and secondary cleaners are tensioned upon installation and with no need for further adjustment. Positioned at an angle across the discharge pulley, it has a rubber strip constructed with tungsten carbide tips, requiring less maintenance

FOR EVERYTHING BELOW THE BELT At Kinder, we understand productivity. Our engineers

the

Increase

we

Unlock your productivity potential. Visit kinder.com.au

Safety and accessibility rules may require hand rails and grated walkways.

are experts in innovation with

ability to design bespoke solutions and provide products to suit all applications.

efficiency and reduce downtimeIf it’s above, around or below the belt,

have the answer.

the belt and the cargo remain centred, which is especially critical in loading and discharge zones. Standard OEM belt training devices impede the belt from drifting into the stringer but it is up to the operator to adjust the belt path through slight adjustments of the idlers down the system. On long conveyors, automatic belt training is essential both on the carrying side and the return side to mitigate mistracking from wind, shifting cargo, and various other causes.

Self-adjusting skirting rides the belt to create an effective seal automatically. Historically, skirting had to be adjusted when excessive dust and spillage escaped from the loading zone. Self-adjusting designs prevent spillage and equipment breakdown caused by fugitive material, creating a constant tight seal to the belt. The unit self-adjusts to rubber skirt wear, regardless of material volume and size diversity, delivering an adaptable and low-maintenance solution.

Monitoring and sensors

In addition to cameras that provide an overall view of conditions, sensors monitor operations and flow, delivering important data. One thing to keep in mind is the need to relay the information to a central control centre via Global System for Mobile Communications (GSM), which requires the proper equipment and power.

blade position and remaining service life, notifying operators when retensioning or blade replacement is required. A position indicator can be mounted anywhere from three to 800 metres from the cellular gateway, and the robust, sealed construction means it is virtually immune from damage.

Up to 50 units can be monitored by a single gateway connecting to the Internet, usually located at the highest point in the plant, where the cell signal is strongest. The system communicates via radio frequency from each sensor to the gateway.

Load sensors are specifically geared to communicate with automated tensioning systems so the unit can pull the blade away from the belt when there is no cargo. Running a cleaner on an empty belt can reduce blade life, degrade the belt face, and create potentially dangerous friction heat and static.

Flow indicators or “plugged chute detectors” can either alert operators to the need for maintenance or automatically activate flow devices like vibrators or air cannons to disrupt stuck material and commence flow without worker intervention.

Service and safety

Each piece of equipment requires a knowledgeable and trained technician for safe service. As a result, performing maintenance on a remote transfer point might involve

the most experienced technicians in the facility for long periods to inspect and maintain it. Additionally, it could require a fully equipped service truck with lifts and onboard power.

Many operators have turned to specialty service contractors who are trained and equipped to safely conduct regular inspections, provide maintenance, and offer recommendations. These highly trained and certified technicians can reduce replacement equipment lead times and perform maintenance tasks faster, minimising downtime.

To improve response time, many systems can be set up so technicians can be alerted through the GSM to issues at the same time as operators. Some service contractors can even maintain data logs on customers’ conveyors, recording system specifications, status details and service procedures performed. The collected information is helpful in scheduling preventive maintenance activities and in determining when outside resources should be utilised. This data can be used to better manage an operation’s equipment and budget.

Improving efficiency and operating costs

Due to power and logistical issues, not every conveyor is going to be as ambitious as the Mount Saddleback mine. Most, if not all, will have several transitions. Well-monitored autonomous equipment can make a remote transfer point much more cost-effective to operate. ROP-minded design and maintenance performed by trained service technicians can mitigate many of the disruptive issues and downtime associated with transfer points in general.

“Long conveyors with multiple transfer points have been around for several decades, and equipment designs for this unique environment have evolved in recent years,” Timmerman said.

“By focusing on safety, ease of service and reduced risk exposure, operators are realising that many of the most troubling issues can be effectively resolved.”

22 І Australian Bulk Handling Review: May/June 2024 CONVEYORS

A non-tensioning belt cleaner takes a unique approach to how the devices are designed.

CUSTOMISED APPLICATIONS SOLUTIONS FOR ALL Talk to a member of our team today 1800 810 420 | ahrensrural.com.au

European technology to revolutionise wrapping

Aurora Process Solutions has partnered with Robopac to supply high-end automated pallet wrapping technology in Australia and New Zealand.

WRAPPING PALLETS IS

indispensable to most companies that dispatch product as it protects and promotes the product during shipping. Manually wrapping pallets, however, isn’t ideal. Not only is it expensive, it puts workers in positions where they’re up close and personal with heavy machinery, day in and day out, it also depends on that person to get it right every time.

It’s a mundane task better suited to machinery than humans.

Any small slip up could lead to time, product and wrap going to waste. Braden Goddin, sales and marketing manager at Aurora Process Solutions, told ABHR that this wasteage is getting more focus now as companies are looking to become more productive and sustainable.

“We’re looking to lift the game

To do that, Aurora conducted a worldwide search to find new technologies to bring down under. Europe has been a particular market of interest for the company.

“European countries tend to use a lot of automation in their logistics sector,” Goddin said. “Their supply chains mean pallets could be handled multiple times across different types of freight, from trucks to, trains, ships and planes.”

“They need a high degree of load containment, and a lot of regulations have come into effect that require reductions in the amount of polyethylene used.

“They need technology that can deliver a more secure load while using less plastic film and less manual labour. That’s what Robopac delivers.”

Robopac is based in Bologna, which is known as the heart of the Italian packaging valley. From there, the company manufactures its advanced automated packaging systems to be used in systems around the world.

Aurora saw a lot of potential in helping to bring Robopac’s machinery to Australia. The country is large, and exports travel far and wide. Plus, Goddin said the Italian manufacturer has been taking the lead in pallet containment systems for decades.

Goddin said the agreement between the two companies allows Aurora to access a broader market than it has in the past, taking packaging technology to entirely new market segments.

“Pallet wrapping is used in all sorts of industries, from food and pharmaceuticals to the building industry,” he said.

“European companies are some of the first to innovate to meet new regulatory requirements, which takes a while to filter down to Australia and New Zealand.

“Robopac also has a niche capability in packaging system design. There are some innovative pallet wrapping methods and developments that are not used down in Australasia yet. So, we’re excited to let the locals take advantage of it.”

Aurora Process Solutions provides scaling technologies and processes to meet the needs of growing businesses. The company’s products help to semi and fully automate the packaging, conveying, conditioning, palletising, and hooding processes.

Aurora also provides technology that can quickly and easily scale up,

PACKAGING

Robopac also has a niche capability in packaging system design.

allowing curious customers to test the technology at a base level and see how it impacts their processes.

Goddin said one of the common concerns businesses have about installing automated technology is the technical expertise required.

“This may be the case with some highly complex, high-speed process applications but is not the case for general filling, closing, palletising operations,” he said.

“Product development has come a long way in regard to user experience and intuitive operation.

“Ease of use and simplicity has developed to the point where many of the machines can be considered plug-and-play. In a lot of applications, if you can operate a smartphone, then you have the capability.”

Robopac’s technology has been designed with this simplicity in mind. Goddin praised the company’s

engineering skills in simplifying the complex, as the product range remains easy to use and repair.

The company’s wide range means a tool can be found for almost any problem – whether it’s irregular loads with sharp edges, fragile and instable materials, or temperature concerns. This range also means options are available for sole traders, multinationals, and all businesses in between.

“Due to the sheer volume of equipment Robopac produces, spare parts and efficient service and support is easily available.”

Aurora plans to showcase the technology across the country, visiting clients and trade shows as well as working in conjunction with Robopac to build awareness.

ENJOY A BULK HANDLING REVIEW DISCOUNT OF 10% OFF ALL DRYERS FOCUSED ON THE FUTURE, CONTROL YOUR HARVEST! P: (07) 4631 4300 | E: sales@agridry.com.au W: www.agridry.com.au Mobile Grain Dryers: Predator & Kinetic Mixed Flow Grain Dryer: Tundra & Goliath Direct Silo Dryer: Tanami Aeration Systems for Drying & Cooling

Solutions

Images: Aurora Process

Sugar hits the spot

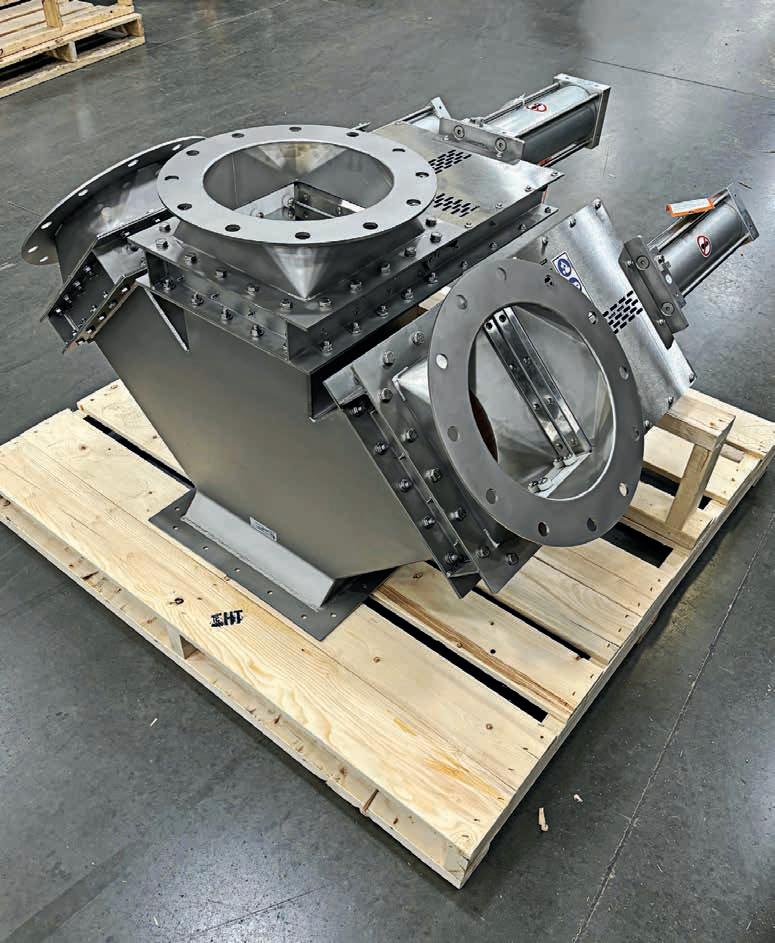

Vortex Global had partnered with a European company to keep its sugar high rolling.

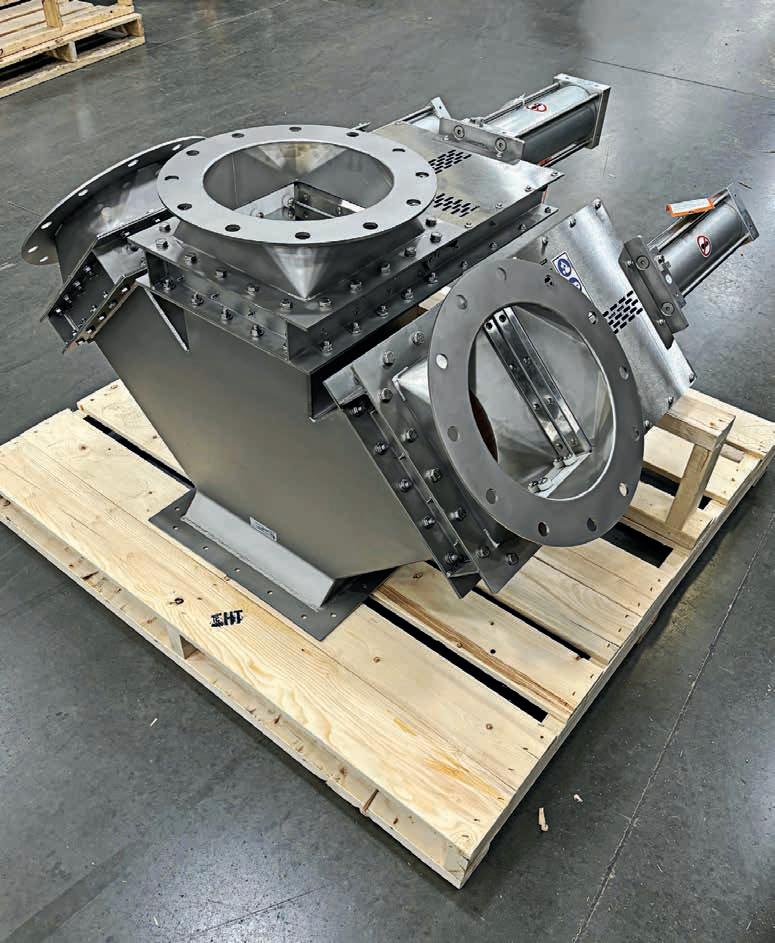

WHEN A FRENCH SUGAR PRODUCER

engaged Vortex Global to upgrade their site, the European company was clear two aspects were required.

The first was assurance that the new set-up would have a high level of dust tightness, while the second was a seamless material flow.

This led Vortex Global to design a customised solution that addressed these concerns.

“The customer’s requirement for dust tightness and the ability to feed any divert leg at will presented a unique challenge that called for a customised solution,” Vortex Global managing director Laurence Millington told ABHR

“Traditional gravity vee diverters were considered initially, but due to height constraints, an alternative approach was needed.”

France, especially Northern France, is one of Europe’s most critical sugarproducing regions, alongside the Netherlands, Belgium and Poland.

While the European Union is traditionally a net sugar importer, the region still produces around 18 million tonnes of sugar annually. According to recent data, it is the world’s leading producer of beet sugar.

The high production load meant the French site would be outfitted with a customised set-up and one that could handle significant volume.

After a thorough process, Vortex Global settled on using a tri-verter, which would use Vortex Roller Gates to divert the sugar.

Vortex had previously used the roller gates with its electropolished blades in another sugar-producing set-up successfully. The company incorporated three roller gates onto an inlet design

smoothly with minimal residual build up.

The three-way roller gate solution eliminated the need for a separate diverter, which reduced the French producer’s installation and maintenance costs. The roller gates will also minimise downtime and potential production loss by eliminating the extra machinery and transfer section.

Vortex Global designed the roller gate for material handling in gravityflow applications.

The company offers various customisable material options for rollers, end seals, bonnet seals, and side seals to suit the customer’s application.

The roller gate is available in various configurations, from rectangular sizes to custom hole patterns. The versatility of the roller gate enables Vortex Global to develop a tailored solution suited to the site and application of the customer.

Vortex’s bonnet and side seals, made from hard polymer, provide a strong dust-tight seal across the gate, reducing product dusting in the atmosphere.

Vortex Global’s roller gate seals have

Other additional features on the Vortex roller gate include no pinch points or exposed moving points and no internal cavities, which prevent material from being wedged and wasted.

This feature reduces the chance for material wedging in the machine, which has been shown to contribute to seal wear and material degradation.

Vortex has built the roller gate to ‘self-clean’ with the machine’s bonnet seals acting as a scraper to help remove material from the blade on the opening stroke and keep the material in the process line instead of the bonnet area.

Millington said the roller gate had various uses, from light applications to more abrasive powders, while modifications could be made for sticky and corrosive materials.

“Roller gates are renowned for their reliability and efficiency in handling bulk materials such as sugar,” he said.

“These gates are ideal for applications where a material like sugar may leave you in a sticky situation with a different piece of equipment.”

EQUIPMENT 26 І Australian Bulk Handling Review: May/June 2024

The three-way roller gate solution pixtured upside down.

Image: Vortex Global

Reliable - the specialist for all your Bucket Elevator needs

We have access to over 700 different bucket sizes, shapes and materials designed to give clients longer life, better reliability, and a lower total cost of ownership. We stock a range of Elevator buckets, conveyor belts, bolts, and Maxi Splice joiners.

As well as these key components, Reliable can offer new pulleys and a refurbishment service. With these offerings along with our expertise in new installations or existing system change outs, we are well positioned to offer a complete turnkey solution in Bucket Elevators.

ELEVATOR BUNDLES

• Buckets, Belting, Splices & Bolts

• Design and engineering support

• Single Solution: all-in-one order

• Pre-punched Belt matched to your Buckets

• Belt supplied to specifications

• Save time & money

• After sales support

TIGER TUFF BUCKET

Maxi-Lift revolutionised the industry with the release of the Tiger-Tuff, the first Maximum Duty Bucket. Today the success of the Tiger-Tuff guides the design for every bucket made. Tough, long lasting elevator buckets.

With 8 branches across Australia we offer our clients the support they require throughout the lifecycle of the system.

Locations:

• Reliable Conveyor Belt (NSW) – Newcastle, Gunnedah, Lithgow, Mudgee, Muswellbrook, Parkes

• Alliance Conveyor (QLD) – Mackay

• West Coast Conveyor Services (WA) – Perth

Contact details: 02 4928 5600 sales@reliable.com.au www.reliable.com.au

CONVEYOR SERVICES

Organic success

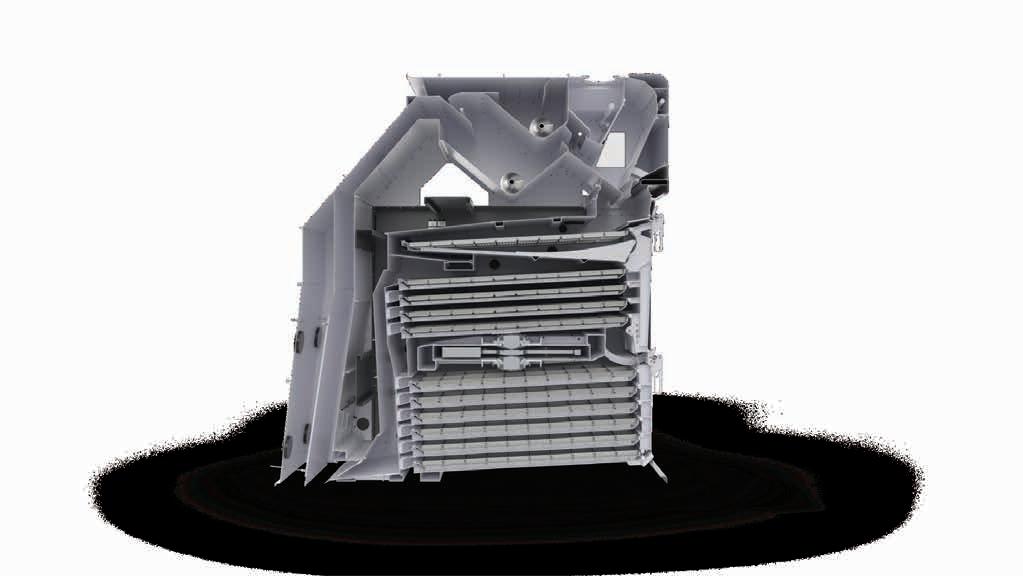

ABHR learns how Bühler supports the organic food sector in Germany through its partnership with Bio-regionale Genossenschaft Oberpfalz.

WHEN THE BIO-REGIONALE

Genossenschaft Oberpfalz, or BIregO eG for short, formed in 2014, its members shared a vision to promote organic food in the region.

The simple premise gained traction and grew from 60 members to more than 200, including producers, processors, and retailers in a cooperative.

“We want to expand organic farming and strengthen value chains here in the region,” BIregO eG board chairman Markus Schenk told ABHR

“Our project is already known far beyond the state’s borders.

“It’s unique and a beacon project for all those who aspire to a similar concept.”

The cooperative faced a major challenge in finding suitable grain storage, as the rules for organic food differ greatly from conventional storage.

The cooperative rented a warehouse nearby Thalmässing to house its wheat, barley, rye, spelt, oats, soybeans, sunflowers, millet and malting barley. It became apparent to everyone involved, including Schenk, that a new solution was needed.

The large disparity between the grain types, combined with BIregO eG’s work with smaller yield sizes and higher stocking requirements, necessitated a tailored storage solution.

BIregO eG required a reliable solution that met FDI standards and would require less maintenance than its rented set-up in Thalmässing. The new grain storage facility would need to be able to handle preparation and drying as well as possessing enough silo cells to store different crops in line with FDI standards.

After a thorough search, the cooperative engaged Bühler, the renowned grain storage manufacturer, to design its new solution. Schenk said Bühler’s pitch to be involved in the project was unique.

“We realised that Bühler wanted to do this project with us,” he said.

“We presented our plan, and they used their expertise to help develop it into a well-rounded concept.

“A company is only as good as its people – and you could feel that the project team was on fire for our plant project.”

Bühler took on the project and designed a grain storage solution from scratch, which included long-life wear parts and high-quality steel for less maintenance. The construction phase began in August 2019, and the plant was completed in 2022.

The storage solution was made up of four steel silo bins with a capacity of 6,900 tonnes and 52 silo cells in a cell block for differentiated storage.

The drying set-up included an STKL6-05/02 dryer with a capacity of 12 tonnes per hour based on its material handling of wheat and capable of eliminating 20 to 15 per cent moisture from the product.

Bühler designed the conveyor set-up as the backbone of the processing plant. The company has complete control over its conveyors as it designs and

builds chain conveyors, belt and bucket elevators, belt, and screw conveyors, as well as tubular push conveyors.

Bühler builds its conveyor solutions precisely to meet stringent requirements, including FDI standards.

It installed 24 chain and eight bucket elevator conveyors as part of BIregO eG’s conveyor set-up. The chain conveyors, comprised of three different models, could handle a capacity of 10-120 tonnes per hour, while the bucket elevator, consisting of two models, could handle 40-120 tonnes per hour.

The set-up enabled BIregO eG to increase its production efficiency and maximise the value and profit of its organic grain production.

“Bühler conveying systems are designed to meet the demanding requirements of material handling across a variety of industries,” Bühler grain quality sales manager Adam Williamson said.

“With a focus on innovation, efficiency, and sustainability, we have developed conveying solutions that facilitate the seamless transfer of goods, particularly in the processing of grains and other bulk materials.

Bühler consulted

MACHINERY 28 І Australian Bulk Handling Review: May/June 2024

BIregO eG on its grain-storage set-up.

Image: Bühler

“Bühler conveyors can handle any type of grain, feed or seed safely and gently.”

In the bulk handling industry, it is no secret that operator efficiency is linked to equipment uptime. When conveyor set-ups reliably provide uninterrupted service, they become indispensable to a bulk handling business.

Bühler understands the needs of its bulk handling customers, which is why it develops its conveyor systems with low maintenance requirements. Using this ethos, Bühler’s conveyor systems can achieve continuous productivity without impacting operators through downtime.

To achieve this, Bühler uses state-of-the-art technology with predictive maintenance capabilities. This enables operators to spot problems and address problems before they occur and create unscheduled maintenance or downtime.

Combined with Bühler’s high-quality products used during the manufacturing process, the conveyor systems can run with minimal maintenance and operator interference.

“This proactive approach to maintenance facilitates smoother operations and less unexpected intervention, allowing personnel to focus on productivity rather than troubleshooting,” Williamson said.

“This attention to maintenance efficiency underscores Bühler’s commitment to pushing the boundaries of what is possible in material handling and processing industries.”

When Bühler designs all its conveyor and grain silo solutions, including the one for BIregO eG, it uses premium parts and materials to manufacture the equipment. The materials are chosen in part for their resistance to corrosion and ability to clean.

The impact of the materials is two-fold: they reduce maintenance and address food safety and hygiene concerns. In Germany and worldwide, the grain processing industry has stringent standards for handling grain in accordance with food safety and hygiene standards.

“Bühler designs its equipment with safety and hygiene in mind, utilising high-quality steels that are not only durable but also less likely to harbour bacteria or contaminants,” Williamson said.

“This ensures that the grains handled by Bühler equipment are protected from contamination risks, enabling processors to maintain the highest levels of hygiene throughout their operations.”

After Schenk experienced the three-year project with Bühler, he was convinced that the cooperative could not have executed it without its partner.

“It’s important for us to develop the project together with Bühler in the future. I’m convinced that we are on the right track here – we can only pursue it together,” he said.

CONCETTI AUSTRALIA

HAVE YOU HEARD THE NEWS?

& NEW

IS NOW OPEN! AU.CONCETTI.COM COMPLETE BAG PACKAGING LINES FOR DRY POWDERS AND BULK SOLIDS

ZEALAND

Turnkey triumph for Conveyor Industries

Many businesses are looking for a one-stop shop for their silo manufacturing needs. ABHR learns how Conveyor Industries developed its reputation in this space.

NEW ZEALAND-BASED COMPANY

Conveyor Industries has developed a strong reputation for bulk material handling equipment and turnkey systems across both sides of the Tasman.

After many successful projects, especially in New Zealand, Conveyor Industries has become one of the leading deliverers of turnkey solutions for the bulk handling sector.

Simon Berkett, a business development manager for Conveyor Industries, told ABHR the key to the company’s approach was to work closely with the customer to tailor the solution as closely as possible.

This enables Conveyor Industries to ensure the equipment is the best fit for the customer’s application and increases the longevity of the equipment and its ability to fulfil the project requirements.

Berkett said that a one-stop shop for turnkey solutions provided peace of mind to customers as they dealt with them exclusively from conception to commissioning of the system.

Conveyor Industries was approached by a NZ-based mineral processor that wanted to increase its plant’s throughput and upgrade its intake system.

However, it would be a difficult upgrade as they would have to work around existing plants and buildings and ensure the new equipment worked perfectly with the existing set-up.

The mineral processor understood their project had technical difficulties that required a skilled approach. Conveyor Industries jumped at the challenge to provide a turnkey solution from project design to delivery and address the preexisting difficulties.

“We successfully delivered a comprehensive solution that exceeded

the client’s expectations by leveraging our expertise in bulk material handling and turnkey project management,” Berkett said.

“Despite the project’s complexities, our meticulous planning, collaborative approach, and attention to detail enabled us to overcome challenges and deliver the project on time and within budget.”

The Conveyor Industries team conducted a 3D scan and 3D modelling during the initial stages of the engineering and design phase. The intensive work enabled the team to understand the project’s scope and potential risks, saving time and mitigating them.

The 3D modelling encompassed the existing plant and equipment and the new equipment. This was a targeted plan from Conveyor Industries to meet the project requirements of a seamless integration between the old and new equipment. They had regular client meetings throughout the initial process to provide the customer with up-to-date project information.

handling sector. The team’s knowledge enables them to advise the best solutions for the customer’s application, including mineral processing.

“Regular meetings with the client ensured alignment and integration of their requirements throughout the design process and allowed for a more precise pricing estimation and reducing project uncertainties,” Berkett said.

The client was impressed by Conveyor Industries’ comprehensive approach to the design phase that it engaged them for the entire project delivery.

The large-scale project saw the Conveyor Industries team fully engage in its capability to conduct everything from below-ground, civils, mechanical supply, site installation and electrical works to project commissioning.

The company has been around for 25 years and has an experienced team

Mineral processing can be complex due to every different minerals’ unique characteristics, which can cause each material to handle and perform differently.

The NZ-based company used its in-house knowledge and international network of suppliers to design a new solution for the mineral processor.

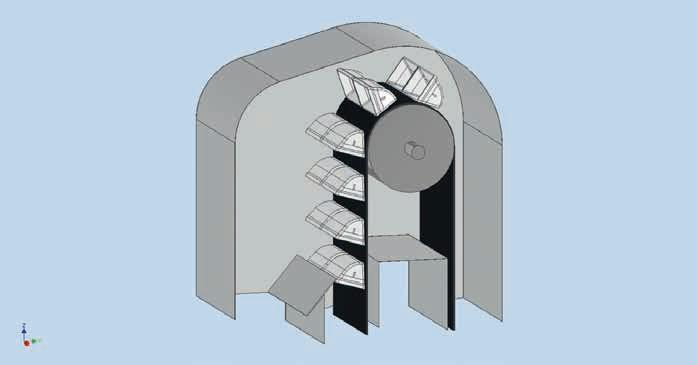

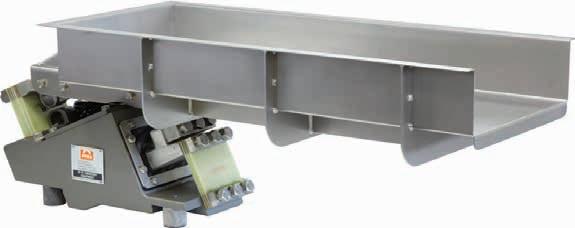

Conveyor Industries designed and supplied a bucket elevator, belt conveyors, silos, hammer mill, product conditioner, vibrating tube feeder as well as associated walkways, support structures, and chutes designed to the customer’s specifications.

Its specialised installing team was able to install all of the equipment on time while adhering to safety standards.

TURNKEY SOLUTIONS 30 І Australian Bulk Handling Review: May/June 2024

Conveyor Industries is a New Zealand-based company.

Image: Conveyor Industries.

After installation, Conveyor Industries tested and fine-tweaked all the equipment to ensure it was operational and suited the customer’s requirements.

Using Conveyor Industries’ project documentation system, the New Zealand company can supply spare parts and provide further technical support.

Berkett told ABHR that using one operator for a turnkey solution had distinct customer benefits.

“It’s easier for the client; instead of having to manage the entire process themselves and engaging multiple contractors, we can take care of it,” Berkett said.

“Instead of multiple parties on site, it’s the one supplier they know they can trust. Some businesses don’t have the internal resources to manage large projects and would need to hire an external project team.”

The company has found customers across several industries have approached

A major New Zealand fertiliser company, which operates regional dispatch plants for trucks and spreaders, wanted to upgrade its blending equipment.

Conveyor Industries successfully designed, engineered, and carried out the civil work, structural work and mechanical supply as well as the installation and commissioning of the equipment.

In another project, Conveyor Industries worked with a New Zealand rendering company to for a set-up using raw material storage hoppers and mechanical conveying equipment across several sites. Conveyor Industries delivered the initial layouts, civil design and supply and well as the mechanical supply phase. The company also successfully installed and commissioned the project.

Recently, a specialist fertiliser coating company was seeking to create the highly specialised NZ-based batch plants.

Conveyor Industries advised on a set-up using mechanical conveying and storage equipment as well as belt conveyors, elevators, hoppers.

Following a consult, Conveyor Industries was engaged to conduct the initial plant engineering and design as well as the detailed design and engineering.

The company also carried out the civil design phase, mechanical supply and completed the installation and commissioning.

Berkett said the company was proud of its ability to offer turnkey solutions to a wide range of industries.

“It highlights our ability to tackle complex projects and deliver tailored solutions that meet our clients’ needs,” he said.

“From initial concept to final commissioning, we remain committed to excellence, innovation, and customer satisfaction.”

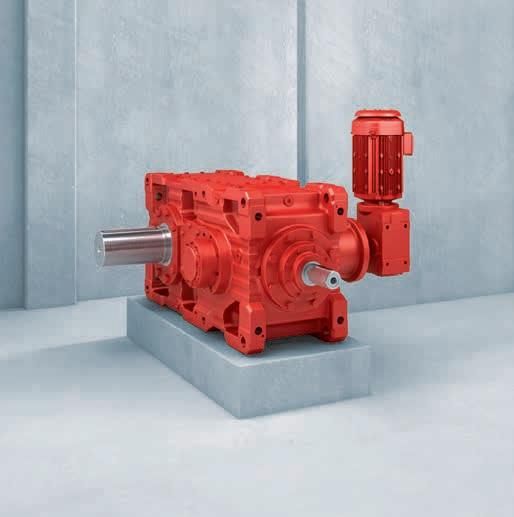

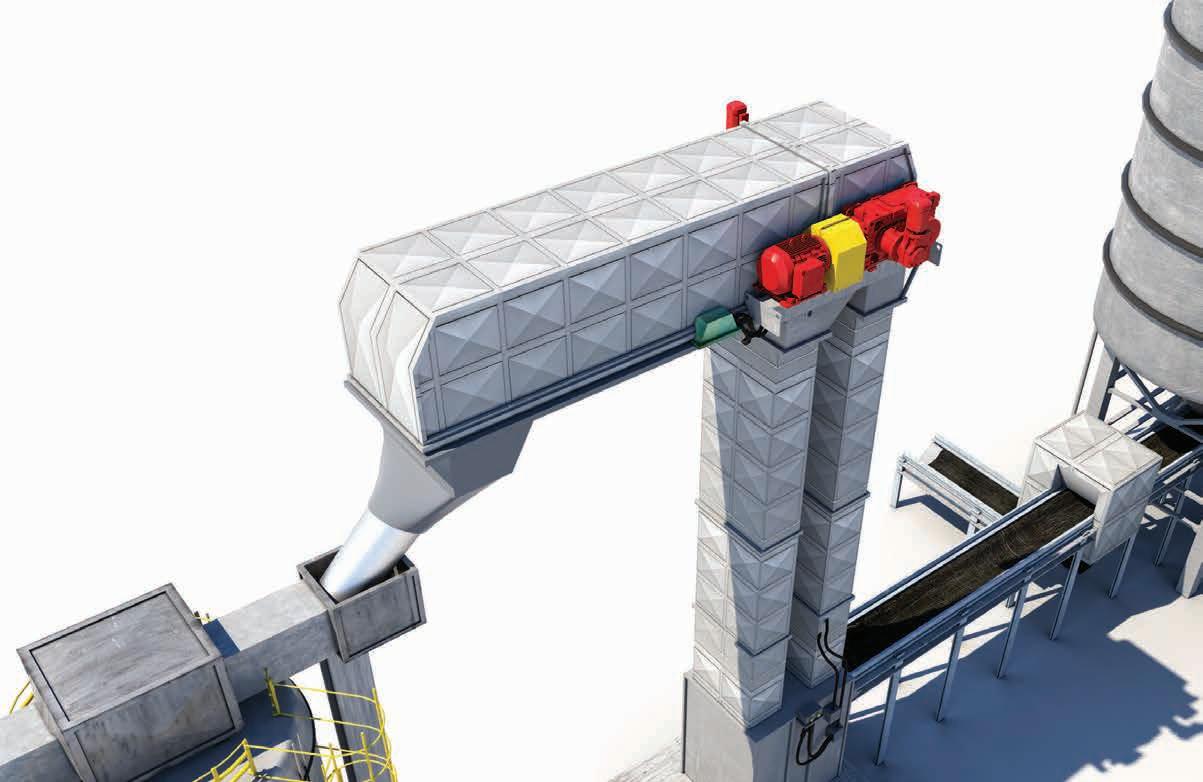

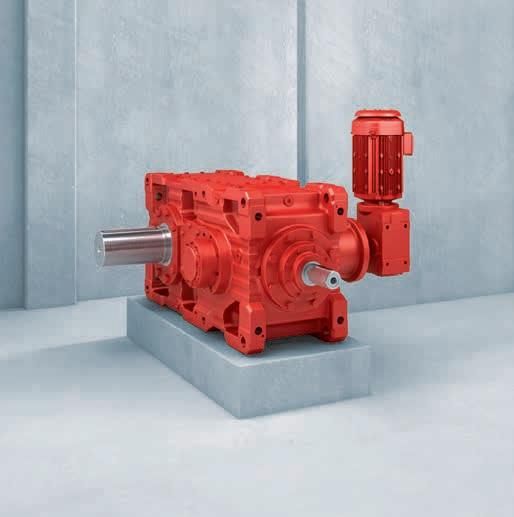

For high output torque, robust reliability and long operating life, choose Bonfiglioli

Our innovative mining portfolio - developed over more than 60 years, in collaboration with leading industry partners includes solutions for conveying, bulk materials handling, crushing, grinding, slurry

www.bonfiglioli.com/australia/en

www.bonfiglioli.com/new-zealand/en

A better world

For Haver & Boecker, sustainability is crucial to its day-to-day operations. ABHR examines how the concept defines the company’s technology, packing solutions, and dedicated Australian division.

SUSTAINABILITY IS THE NAME OF the game for many in the bulk handling industry, but for Haver & Boecker, the concept drives everything from product development to technical support.

When the company launched its Planet Blue campaign, it had a simple mission: offer smart solutions and technology to improve its clients’ sustainability and overall business efficiency and productivity.

“Whether you’re a producer of cement or other building products, chemicals or food, you will be looking for more sustainable solutions,” Haver & Boecker Australia sales engineer Alexandre Santi told ABHR

“We’re trying to improve the living conditions of humanity through our technologies and services as much as we can. This way of thinking is good for our customers as well if they want to become more efficient in their processes and help the environment.”

The company has made its reputation in developing tailored packing, storage, and palletising solutions for manufacturers of bulk handling powders globally. It also

creates dry mix solutions, including full dry mix plants. In Australia, Haver & Boecker’s dedicated local operations have been partnering with local businesses for more than ten years.

Its Planet Blue campaign has put an ongoing focus on key areas of Haver & Boecker’s product design. Minimising product loss by ensuring customers can process, pack, store and deliver goods safely, efficiently, and effectively minimises CO2 emissions and waste throughout the supply chain.

ADAMS technology

The company’s ADAMS originated from a Haver & Boecker client who needed a packing bag that could handle the UK’s weather conditions.

The resulting PE bag, designed by Haver & Boecker for durability and weather resistance, ensures that if the bagged product is stored in an unprotected area, it remains safe. By reducing loss and wastage, the product’s carbon footprint is minimised.

ADAMS technology combines form-fill-seal (FFS) technology with conventional filling technology. Tubular PE bags are fed via a roll into the

machine. The machine cuts, welds, and shapes the bag for maximum fill before feeding it to the filling spout. The clean filling process uses a vibrating lance and vibrating table to extract air from the bag before welding, delivering a completely sealed bag ready for compact transport and storage.

The bag’s corner seals and gusset design are easier to open and ensure all of the product can be removed from the bag.

Santi said ADAMS is ideal for bulkhandling companies working with dry-mix products. Research from Haver & Boecker revealed customers who used the ADAMS bags had up to four times better shelf life compared to other products. Company data also showed that ADAMS bags had the highest filling degree compared to competitors on the market.

Working to improve the circular economy, the Haver & Boecker Institute plays an important role towards more sustainable solutions. The world’s largest and most comprehensive technical institute for filling in the world works closely with bag manufacturers to develop more

SUSTAINABILITY 32 І Australian Bulk Handling Review: May/June 2024

The PE bag is designed for durability and weather resistance.

Image: Haver & Boecker

sustainable PE film, focusing on the use of recycled materials as much as possible. The bags themselves can also be recycled.

“We’re heavily invested in research and development and collaborate closely with bag manufacturers around the world to design and make the best, most eco-friendly bag we can,” Santi said.

SEAL technology

In bulk handling, your bag can effectively be your business card. It needs to look good, be compact, clean, and fully enclosed to ensure bulk material is handled safely with no loss of product.