In this issue: 2023 Conveyor Showcase Highlighting local manufacturing Figuring out feed management www.bulkhandlingreview.com VOLUME 28, ISSUE 4 | JULY/AUGUST 2023

OVER 35 YEARS OF TRUSTED SOLUTIONS E: info@transmin.com.au | T: +61 (0)8 9270 8555 FOLLOW US ON: With highly innovative bulk materials handling solutions in over 60 countries, Transmin is a market leader providing quality equipment to the mining and processing industries. From plant to port, we service our diverse worldwide client base across mining operations handling Iron Ore, Gold, Copper, Lithium, Rare Earths and many other commodities. www.transmin.com.au WINNE R INNOVATION 2012 WINNE R C.Y O'CONNOR AWARD 2012 OUR AWARDS

COVER STORY: THE 2023 CONVEYOR SHOWCASE

The Conveyor Showcase highlights manufacturers and suppliers across a whole range of conveyor components and systems, in a comprehensive overview of the best of what the industry has to offer. For

CONTENTS JULY/AUGUST 2023 Australian Bulk Handling Review: July/August 2023 І 3 54 44 24 14 In this issue: 2023 Conveyor Showcase Australian made bulk equipment Figuring out feed management VOLUME 28, ISSUE JULY/AUGUST 2023

6 Industry news 14 Business as usual 16 What you don’t know can hurt you 18 Kitted out for transfer chutes 20 Five-minute blending going on four decades 22 Torque around town 24 Stress test with one of the best 26 Page Macrae crosses the Tasman 28 OPS support stacks up 30 ESS makes an impact with the cradle 32 Here to help 54 Automated CAD design to meet requirements 56 Managing conveyor feed 60 Good vibrations for mass flow 62 Optimising scrapers for improved belt performance: Addressing carryback issues 66 Dispelling the common myths about conveyor belt scales Australian manufacturing 34 Tecweigh’s local touch 36 Packed for success Conveyors 38 Finding new markets 40 Time for conveyor belts to be part of Australia’s circular economy 42 How low can Thor go? 44 Tough troughs 46 Conveying without a belt 48 Removing material from an operating conveyor belt 50 Analysing impact forces and overcoming issues in high-capacity belt support applications

the full story, see page 12.

Published by:

379 Docklands Drive

Docklands VIC 3008

T: 03 9690 8766

www.primecreativemedia.com.au

COO

Christine Clancy

E: christine.clancy@primecreative.com.au

Editor William Arnott

E: william.arnott@primecreative.com.au

Journalist

Adam Daunt

E: adam.daunt@primecreative.com.au

Business Development Manager

Rob O’Bryan

E: rob.obryan@primecreative.com.au

Client Success Manager

Janine Clements

E: janine.clements@primecreative.com.au

Design Production Manager

Michelle Weston

E: michelle.weston@primecreative.com.au

Art Director

Blake Storey

Design

Michelle Weston

Subscriptions

T: 03 9690 8766

E: subscriptions@primecreative.com.au

www.bulkhandlingreview.com

The Publisher reserves the right to alter or omit any article or advertisement submitted and requires indemnity from the advertisers and contributors against damages or liabilities that may arise from material published.

© Copyright – No part of this publication may be reproduced, stored in a retrieval system or transmitted in any means electronic, mechanical, photocopying, recording or otherwise without the permission of the publisher.

Keeping up with conveyors

Conveyors are the lifeblood of the bulk handling industry. Every day they move millions of tonnes of raw material from point A to point B. Without them, modern mines would not have anywhere close to their current throughputs, and the manufacturing industry would be almost unrecognisable.

Australia, as a major exporter of primary products, relies on conveyors of all kinds. Massive belt conveyors handle the heavy-duty iron ore, while screw conveyors feed sticky material in industrial production.

In this edition of Australian Bulk Handling Review (ABHR) we are highlighting the crucial conveyor sector, through the 2023 Conveyor Showcase. It includes several major organisations that operate within the industry and is a tool to help you navigate the different offerings available.

You can also learn about how to remove material from an operating conveyor belt, the latest in conveying equipment, a look at different kinds of conveyors, and find out how conveyor belts can be turned into new products.

Conveyors are also getting smarter, using new technologies to assist with maintenance, monitoring and logistics.

We are lucky to have several key conveyor manufacturers located on our shores. This has a variety of benefits, including reduced turnaround times, no language barriers, minimal timezone interruptions, the ability to use localised expertise and adherence to Australian Standards.

It also creates critical jobs and opportunities to develop skills locally. This has a massive flow on effect throughout the economy.

That’s why this edition also features several articles that highlight local manufacturers like Tecweigh and DYNA Engineering. Read on to find out about the benefits of buying from a local business.

Looking ahead, next month’s edition of the magazine will be featuring articles that dive into dust control, along with a deeper look at engineering services. If you’d like to get involved, please get in touch.

FEATURES

William Arnott Editor - ABHR

4 І Australian Bulk Handling Review: July/August 2023

EDITORIAL

RPM Monitoring FEATURES AND RPM FEATURESFEATURES Gateway O ce Shell Wear Detection Real-Time 24/7 Wireless Monitoring Acoustic Monitoring RPM Monitoring FEATURES AND BENEFITS header Gateway O ce Shell Wear Detection Real-Time 24/7 Wireless Monitoring Acoustic Monitoring RPM Monitoring FEATURES AND BENEFITS header Gateway O ce Shell Wear Detection Real-Time 24/7 Wireless Monitoring Acoustic Monitoring RPM Monitoring FEATURES AND BENEFITS header Gateway O ce Shell Wear Detection Real-Time 24/7 Wireless Monitoring Acoustic Monitoring RPM Monitoring FEATURES AND BENEFITS header Gateway O ce Shell Wear Detection Real-Time 24/7 Wireless Monitoring Acoustic Monitoring RPM Monitoring FEATURES AND BENEFITS header Gateway O ce Shell Wear Detection Real-Time 24/7 Wireless Monitoring Acoustic Monitoring RPM Monitoring FEATURES AND BENEFITS header Gateway O ce Shell Wear Detection Real-Time 24/7 Wireless Monitoring Acoustic Monitoring RPM Monitoring FEATURES AND BENEFITS header Gateway O ce Shell Wear Detection Real-Time 24/7 Wireless Monitoring Acoustic Monitoring RPM Monitoring FEATURES AND BENEFITS header

THE AUSTRALIAN RAIL TRACK Corporation (ARTC) has installed the first of two temporary steel girders for the Southern Cross Drive Bridge, as part of the ongoing Botany Rail Duplication project.

The steel girder was lifted into place by a 600-tonne crane and will allow new concrete girders to be poured in site, without closing the road below.

Each temporary girder spans 33 metres long and weighs 115 tonnes, the second girder will be lifted into place later this month, with the new bridge expected to be finished in late 2023.

ARTC general manager NSW projects, major construction projects, Julian

Richards said the Southern Cross Drive Bridge is one of five bridges the ARTC is constructing or modifying in the Botany Rail Duplication project, with major construction works for the project on track to be complete in 2024.

“Not only will this project increase freight capacity, it will also encourage more freight movements to be made by rail – helping to shift freight away from road transport and reduce truck movements and associated traffic congestion,” Richards said.

“Each extra freight train travelling on the Port Botany Rail Line will take up to 54 trucks off Sydney’s roads and that will be well received by local road users.

The $400 million project aims to deliver better access to global export markets via Port Botany and improve freight supply chains across NSW

The project will duplicate the remaining 2.9-kilometre section of single line track to Port Botany and construct a passing loop on the Southern Sydney Freight Line at Cabramatta to accommodate freight trains up to 1300 metres in length.

Preparations are also underway for major works in August, when the existing O’Riordan Street Bridge will be demolished, and a new double-track concrete bridge constructed during a fiveday rail shutdown.

Massive girders installed on Botany Rail Duplication Queensland sugarcane crush kicks off

THE 2023 SUGARCANE CRUSH is underway as growers, harvesting crews, and mills work to cut and crush Queensland’s 30 million tonnes of cane by the end of November.

Canegrowers Tableland Chairman Claude Santucci said the weather is spectacular for harvesting.

“We had a bit of a cold snap come through a few days ago, so that will help push up the sugar content a bit, although it will be a while before we start getting decent levels,” Santucci said.

“The early cut cane from last year is looking really nice…if we can keep

this weather and the mill has a good run, I’m hopeful we can have a pretty good 2023 season.”

Latest estimates put the crop at 30.55 million tonnes of cane, producing between 4 and 4.5 million tonnes of sugar, the majority of which will be exported to overseas markets in Japan, South Korea, and Indonesia.

With the world sugar price hitting record highs and forecasters predicting a drier winter this year, growers are optimistic that 2023 could be a bumper year for the industry, Canegrowers Chairman Owen Menkens said.

“Last year we were pretty optimistic going into the crush, with prices on the up and a great crop in the paddock, but unfortunately things didn’t pan out the way we wanted,” Menkens said.

“Poor weather, workforce shortages, and poor mill performance in some areas combined to cause major disruptions that ultimately led to the crush running through Christmas and well into the new year in some districts, and around one million tonnes of cane left unharvested.”

Menkens said there was a very positive feeling around the industry at the minute, with the industry on the verge of a transition to a range of new and growing opportunities in the bioeconomy that rely upon sugarcane for feedstock.

“The export of raw sugar will always be the foundation of our industry, but we know there are many other complimentary opportunities that are emerging for the industry and we hope that this coming season, combined with a strong price, will provide the basis for new and increased investment into these exciting projects.”

NEWS 6 І Australian Bulk Handling Review: July/August 2023

Work has begun across the QLD sugarcane growing regions.

• Integrated cooling DURAPLATE™

• Drop-in footprints via customisable mounting feet

• Local Engineering Expertise

• Australian stock and assembly

• Full Rebuild facilities on East and West coasts

• Full load testing to 1mW

DURAPLATE™

Integrated gearbox cooling system

NO external coolers required

NO external power or water required

Highly durable and damage resistant compared to alternate methods

Fully self contained

INDUSTRIAL POWERTRAIN SOLUTIONS

Newcastle 02 4962 8000 | Perth 08 94124100 | Sydney 02 4677 6000 | Melbourne 03 9736 6000 | sales.australia@regalrexnord.com

ENGINEERED FOR THE LONG HAUL

Winners of the Women in Industry awards announced

THE WINNERS of the 2023 Women in Industry Awards have been revealed. The awards recognise outstanding women from across a range of industrials sectors, including in mining, transport, manufacturing, engineering, logistics, bulk handling, waste management, rail and construction and infrastructure.

The 2023 Women in Industry Awards were held at Aerial South Wharf in Melbourne.

The 2023 winners:

Business Development Success of the Year

Stefanie Frawley from TMX Global.

Stefanie successfully identified a gap in the offerings available to TMX customers, and introduced a new Portfolio Management option. As a result, Stefanie has grown her team from one to seven employees, servicing more than 14 clients in this new offering, and increased revenue from her team by 1000 per cent in the past two years.

Industry Advocacy Award

Jemma Walshe from Fulton Hogan.

Jemma advocates to ensure time, energy and resources are dedicated to making a difference to the communities that Fulton Hogan works within and has been critical to the establishment and roll out of a number of positive community engagement outcomes.

Mentor of the Year

Teagan Dowler from The BCW.

Teagan has dedicated her career to supporting women in industry. Running online coaching sessions and a career development program, she is tireless in her passion for celebrating, supporting, and developing females in

industry and has positively impacted the careers of thousands of women in Australia and abroad.

Safety Advocacy Award – Sponsored by Komatsu

Giselle Phillips from Fredon QLD.

Giselle has been instrumental in pioneering change within the Fredon QLD business; driving the use of technology to streamline the compliance of training and competencies, as well as being proactive in delivering mental health and well-being initiatives.

Rising Star of the Year – Sponsored by Atlas Copco

Sophia Kurianski from Jinolo.

In 2021, Sophia founded Jinolo, a 3D collaboration start-up that helps industrial design and engineering teams save time and money when working on designs with external clients and suppliers. Jinolo has already garnered significant attention, with manufacturing, design, and engineering teams using Sophia’s software to collaborate on 3D files.

Excellence in Transport

Coralie Chapman from Humes Concrete Products.

Coralie has always had a passion for promoting the various roles in the transport and logistics industry as well as safety around heavy vehicles. She is passionate about encouraging women to choose transport as a career path and strongly advocates for diversity and inclusion for people pursuing “nontraditional” careers.

Excellence in Engineering –Sponsored by SEW Eurodrive

Elsa Antunes from James Cook University.

Elsa graduated her PhD in chemical engineering in 2018 and in the five years

since has shown ambitious leadership and innovation in the engineering sector. She has been promoted to Senior Lecturer, received over $1 million in grants and is instrumental in creating collaborations with industry and government across a range of topics.

Excellence in Manufacturing –Sponsored by PACCAR Australia

Kristi Riordan from Harvest B.

Kristi founded Harvest B. in 2020 to help address global protein needs and sustainability concerns in our food system. With capital support from Woolworth’s venture fund, W23, she has since opened Harvest B’s first factory and a dedicated lab facility to enable rapid cycles of R&D to commercial production.

Excellence in Construction –Sponsored by NAWIC

Trudy Grimshaw from Department of Finance, Western Australia.

Trudy found her passion for construction through a winding road of career choices. Currently the Senior Project Director on the Bunbury Hospital Redevelopment, Trudy in all respects demonstrates how women can take a leading role in the construction industry.

Excellence in Mining – Sponsored by Weir Minerals

Ashara Moore from BHP.

Ashara commenced her career as a Site Engineer, working on projects Australia-wide. Her ultimate goal is to encourage people from all backgrounds to be involved in the resources sector.

Ashara firmly believes that mining can be done better – and is determined to be a part of the solution.

Woman of the Year – Sponsored by Fulton Hogan Giselle Phillips from Fredon QLD.

NEWS 8 І Australian Bulk Handling Review: July/August 2023

C M Y CM MY CY CMY K

™

Inaugural Inside Construction Expo approaches

A BRAND NEW EXPO is set to help the construction and related industries “engineer the future” of Australia.

The Inside Construction Expo 2023 will be held on the 20-21 September 2023 at the Melbourne Convention and Exhibition Centre.

It will provide the ideal environment to present and discuss answers to the issues facing the construction industry.

Discussions regarding the skills shortage in the sector, the continuing digital transformation of the industry and safety will take place at the expo to highlight the way forward.

The conference will focus on major projects and civil construction, with the conference and world-class exhibition

providing a platform for construction equipment and companies, alongside industry leaders, to present ideas and equipment that are best suited to the current concerns in the industry.

Inside Construction Expo is backed by support from several valued organisations and media partners. Without this support, Winterbottom said, the event would not be possible.

“We’re pleased to partner with industry associations and peak bodies to bring Inside Construction Expo to life,” she said.

“Specialist in assembly and fastening materials, Wurth Australia has come on board as a supporting sponsor for the Expo.”

“We are thrilled to be part of the 2023 Inside Construction Expo, which promises to be a game-changer for the industry. This event will provide an unparalleled opportunity for us to showcase our latest products and innovations, as well as to connect with fellow professionals and share insights and expertise,” said Serge Oppedisano, CEO of Wurth Australia

Winterbottom also said positioning solutions provider Position Partners and manufacturer Komatsu have signed on as conference sponsors.

If you’d like to attend, exhibit, submit a presentation or become a sponsor visit insideconstructionexpo.com.au

NEWS 10 І Australian Bulk Handling Review: July/August 2023

The Expo will be held at the Melbourne Convention and Exhibition Centre.

Image credit: Nils Versemann / Shutterstock.com

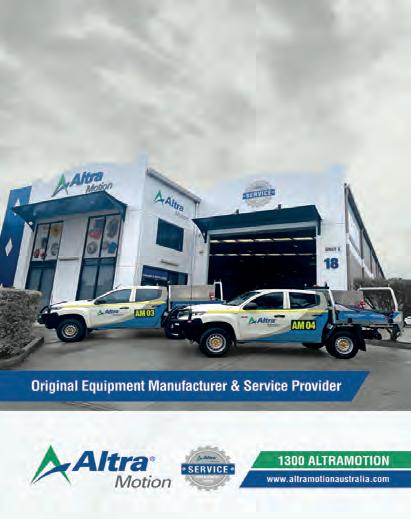

1300 258 726 Sales I Service I Engineering Phone: 1300 258 726 Email: sales-australia@regalrexnord.com Altra Industrial Motion Australia Pty Ltd ABN 82 000 780 941 Sydney NSW Perth WA Melbourne VIC Mackay QLD Newcastle NSW Unit 1 Suite 34 Unit 14 Unit 1 11 Penny Pl 271 Great Eastern Hwy 3 Albert Coates Lane 20-34 Caterpillar Dr 18 Kinta Dr Arndell Park, NSW 2148 Belmont, WA 6104 Melbourne, VIC 3000 Paget, QLD 4740 Beresfield, NSW 2322 Ph. 1300 258 726 Ph. 1300 358 26 Ph. 1300 258 726 Ph. 1300 258 726 Ph. 1300 258 726 www.regalrexnord.com www.altramotionaustralia.com

CONVEYOR SHOWCASE 12 І Australian Bulk Handling Review: July/August 2023 Business Details

type of conveyor do you manufacture? Company Name Company Email Address Company Phone Number Belt Screw Chain Pneumatic AGI apac@aggrowth.com (+61) 477 474 726 •••• BEUMER Group GmbH & Co. KG info@beumer.com (+61) 2 9450 0380 • • Bridgestone Mining Solutions Australia461 Dundas Road, Forrestfield, WA 6058(+61) 400 066 505 • Bruks Siwertell magnus.rundqwist@bruks-siwertell.com (+1) 770 849 0100 ••• Bulk Connections sifison@bulkconnections.com (+27) 3 1466 9618 •••• Continental Conveying Solutions www.continental-industry.com (+61) 03 9720 9428 • Conveyor Manufacturers Australia ajolly@cmacv.com (+61) 2 8358 8660 • CRP Industries sales@crpindustries.com.au (+61) 3 9768 2228 Diacon Australia reception2@cpeqld.com.au (+61) 7 4957 2472 Dos Santos International, LLC info@dossantosintl.com (+1) 770 423 9895 • DYNA Engineering dyna@dynaengineering.com.au (+61) 8 9473 4300 • Finlay Screening & Crushing ggrigson@finlay.com.au (+61) 7 388 81777 • Flexicon Corporation (Australia) PTY. LTD. sales@flexicon.com.au (+61) 7 3879 4180 • • Hyer Industries Inc desmond@thayerscale.com (+1) 7 8182 68101 JET Materials Handling Pty Ltd admin@jetmaterialshandling.com (+61) 4 2811 6368 •• KAUMAN kauman@kauman.com (+34) 6 7875 4615 • Kinder Australia Pty Ltd conveyorsolutions@kinder.com.au (+61) 3 8587 9111 Martin Engineering info@martin-eng.com (+1) 309 852 2384 • Nilos Australia Pty Ltd info@nilosaustralia.com (+61) 4 3908 2080 OREFLOW AUSTRALIA PTY LTD chrisc@oreflow.com.au (+61) 4 3999 3484 • Premron Pty Ltd sales@premron.com.au (+61) 7 4972 2982 ••• Promet info@promet.com.au (+61) 8 9249 8749 ProStack - A Terex Brand ProStack@terex.com 028 7122 3110 • Qetra admin@qetra.com.au (+61) 6209 7712 • R BRUNONE commercial.brunone@brunone.fr (+33)2 3264 2020 REMA TIP TOP communications@rema-tiptop.com.au (+61) 4 2360 8343 • RKM sales@rkmrollers.com.au (+61) 8 6558 1287 •• STMalnati S.a.s. info@stmalnati.com (+39) 02 8950 1730 • Tecweigh Pty Ltd barry@tecweigh.com.au (+61) 4 3016 6444 Thayer Scale Sales@ThayerScale.com 781 826 8101 •• Transmin ConveyorPro aftermarket@transmin.com.au (+61) 8 9270 8555 ••• TUNRA Bulk Solids enquiries@bulksolids.com.au (+61) 2 4033 9055 VAYERON info@vayeron.com.au 1800 404 160 • WA Belting Solutions david@wabelting.com.au 1300 651 320 • WAM AUSTRALIA alessandro.bini@wamgroup.com (+61) 3 9737 4700 •••

What

What type of conveyor components do you manufacture/distribute?

Australian Bulk Handling Review: July/August 2023 І 13

Idlers Rollers Scrapers Belts Pulleys Pulley Lagging Walkways Lacing Skirting Guards Impact Beds Wear Panels Consulting Testing Maintenance Belt Scales Dust Collectors ••••• •••• •••• •••••••••••• • ••••••••• •••••••••••• •••••• • • • •• • • ••• • •••••••••••• • • •••• •• • •••• ••••• •• • ••• •• •••• ••• ••••• • • • • •••••• • • • •• ••••••••• ••••• •••• •••••••••••• • •••••••••••••• • • ••• •••••• • ••••• •• •••••• •• • ••• •••••• •• ••••• •••••• ••••• •• •••• •• •••••• •• • ••• •

Business as usual

Regal Rexnord has acquired Altra Industrial Motion. ABHR learns what the move will mean for the Australian bulk handling industry.

in Australia right now is brakes and clutches,” he said. “It’s important as an organisation that we don’t lose that focus. As you get bigger, if you get too distracted by other things, you lose your focus.

“From a strategy point of view, Regal Rexnord has really left us to continue on our growth initiatives and ensuring that we keep supporting and our customers.

“Down the line, there’s obviously some synergies that we can work on with our sister companies; however, particularly for us, we’re very much business as usual and Regal Rexnord has really given us the autonomy to continue doing what we do best.”

Altra Motion designs and manufactures a wide range of highly engineered motion control, automation and power transmission solutions across its 26 brands, including Svendborg Brakes, Twiflex, Marland Clutch, Wichita Clutch, Industrial Clutch, and Stieber.

It also brings with it a strong Australian client base, with customers throughout the bulk handling sector.

Eltagonde said the culture of both Regal Rexnord and Altra Motion has a strong focus on respecting and supporting its people to ensure employees get the best out of themselves colleagues.

“Regal Rexnord’s focus right now is about promoting within, utilising our talents within the organisation and

ACQUISITION 14 І Australian Bulk Handling Review: July/August 2023

IN 1980, James L. Packard and Henry W. Knueppel joined an American tool service capability, technology content and domain expertise.

Altra Motion Australia has facilities across the country.

Altra Motion designs and manufactures a wide range of motion control, automation and power transmission solutions.

Designed for industrial sectors INDUSTRIAL VIBRATORS

OLI is the world’s top selling manufacturer of electric and pneumatic vibrators. The high level of customer service, guaranteed by 18 trading subsidiaries worldwide, and long-lasting and performing products make us always ahead.

Our vibrators are designed for industrial applications in all sectors, from the most extreme environments such as quarries, mines and foundries to the food and pharmaceutical.

OLI Vibrators Pty Ltd. 7 Jellico Drive, Scoresby Vic 3179, Australia - Phone: +61 3 9764 9988 - Mail: info@olivibrators.com.au - www.olivibrators.com.au

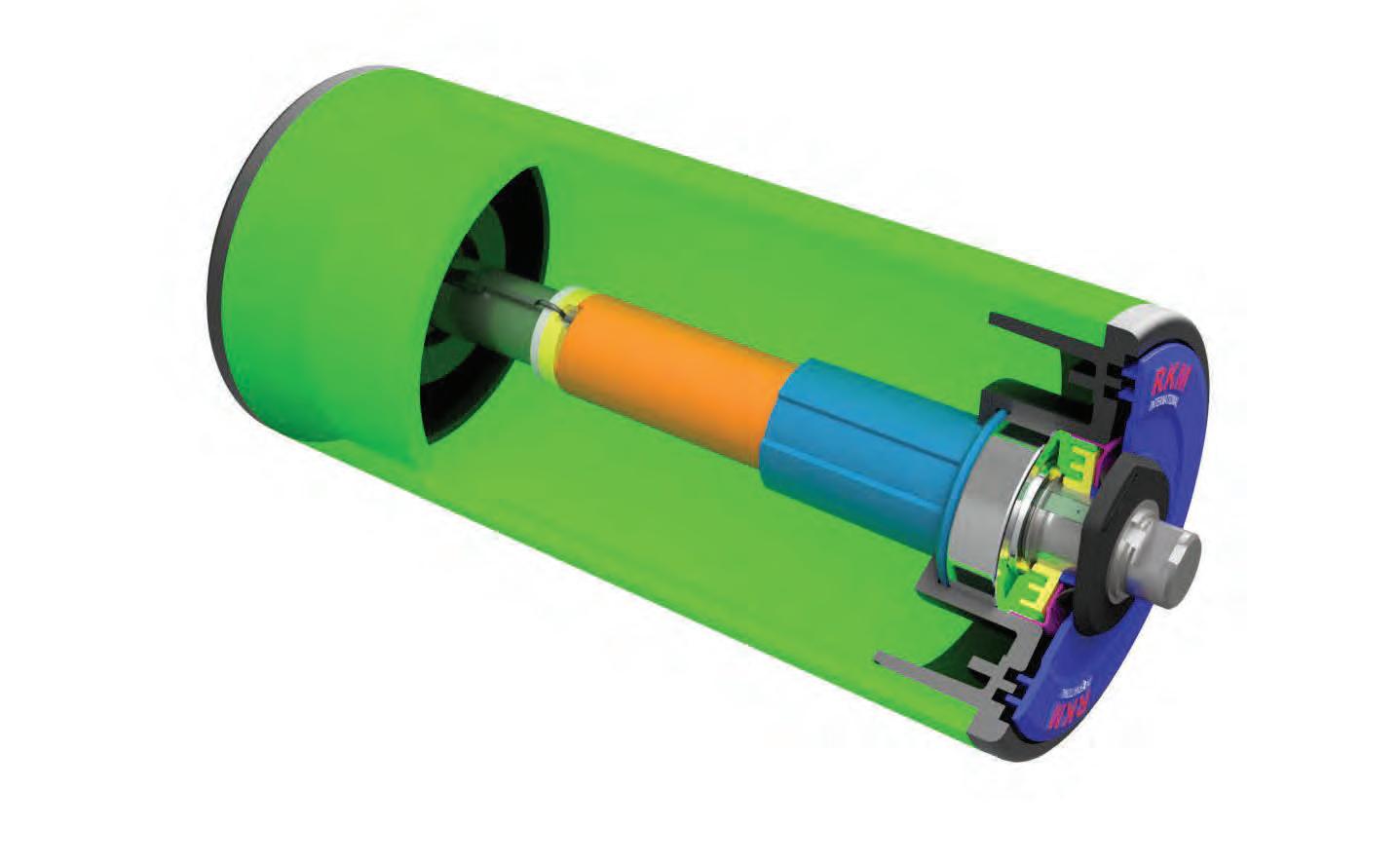

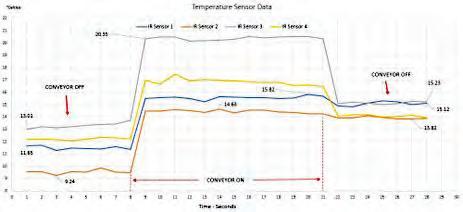

What you don’t know can hurt you

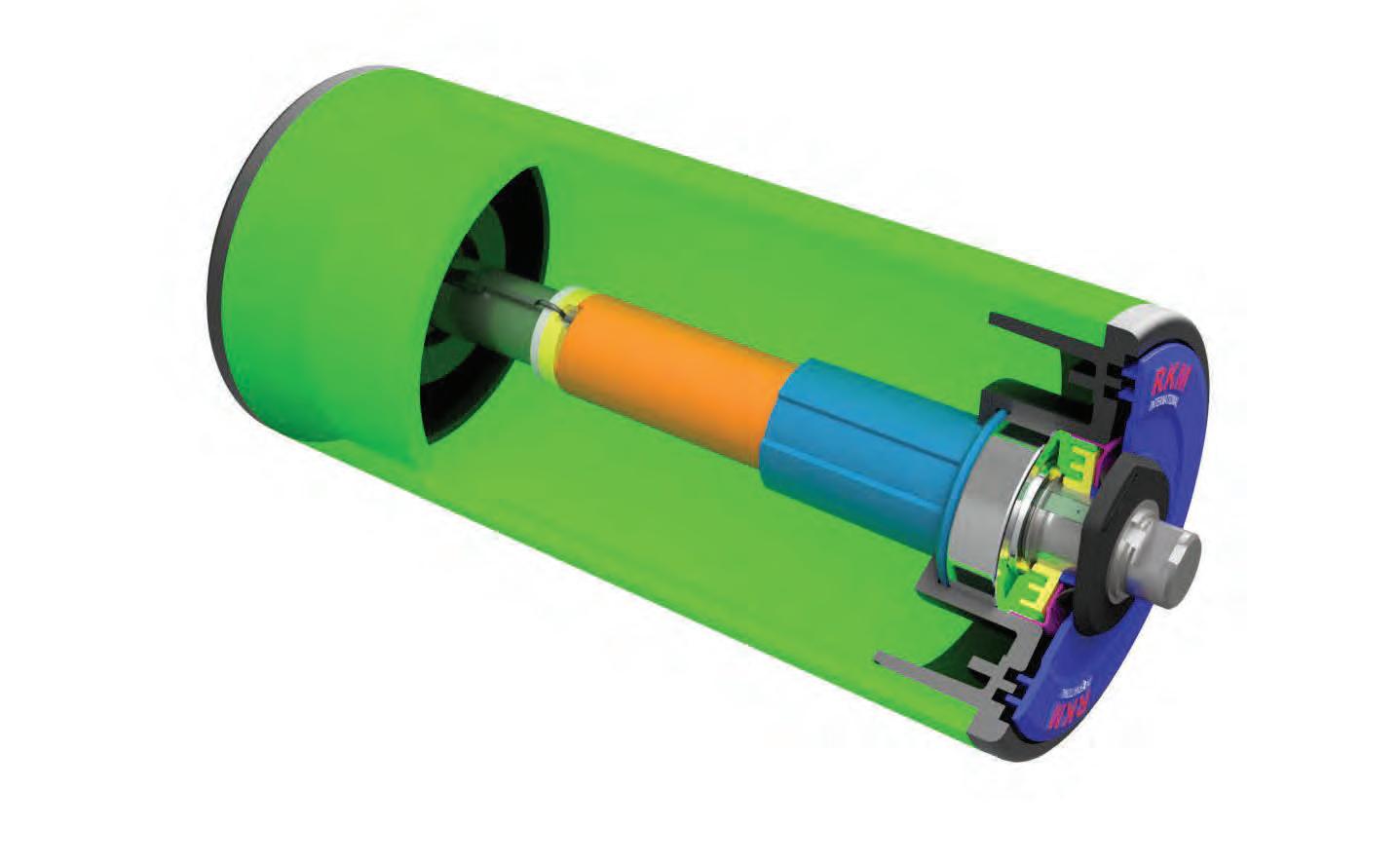

Rollers and idlers are often in locations that are difficult to inspect, but if they fail the costs can be catastrophic. Vayeron’s technology helps spot these issues well before they escalate.

ROLLERS PLAY A CRITICAL ROLE on mining sites and need to withstand exceptional punishment from the harsh Australian elements and massive throughputs.

However, they can be difficult to inspect properly. A proactive manual inspection regime can help spot carryback and defects, but is unlikely to eliminate them totally. There is only so much a person can see or access, and a lot happens within a roller that is almost undetectable.

Small problems inside these rollers can grow into major issues, and potentially catastrophic failure.

Ryan Norris, Vayeron’s co-founder and chief executive told ABHR about a shiploader that caught fire due to a malfunctioning roller. The resulting blaze took out a significant chunk of the port’s iron ore loading capacity and had a massive financial impact on more than just the miner.

“There was a butterfly effect – because the miner had reduced productivity, it had flow on effects on the iron ore spot market prices. Events like these don’t happen very often, but can cost hundreds of millions of dollars,” he said.

installed inside of a roller to ensure events like that never happen.

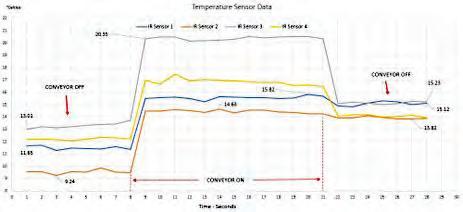

Harvesting the rotational energy of the roller, the maintenance-free device monitors the roller, including vibration, bearing temperature, shell wear and carryback build up.

Norris said the rollers allow for insights that previously weren’t possible.

“The smart sensors allows sites to monitor, predict the performance of, and optimise the rollers, rather than having to rely on adhoc replacements or bulk changeouts,” he said.

“It means you can treat each

the need for employees to get up close with heavy machinery to inspect them. On many mine sites, rollers can be in enclosed or elevated areas, making them risky to inspect.

The technology acquires data from the rollers, which can then be used in third party systems such as a control system or a digital twin. Elaborate analysis can be performed on the data, allowing mines to derive insights into the operation.

Norris said the industry is moving towards digital solutions and aims to anchor what is occurring in the physical world with the digital.

“Digital insights can support maintenance to allow for a leaner operation – an important thing to consider when you see the high turnover rate of staff in the mining industry,” he said.

“Our application programming interface allows other technology to use the data that has been gathered to create more effective insights.

“There’s an information gap that we are filling with our smart rollers. They can gather data from along the entirety of a conveyor and use that wealth of information to support the entire operation.”

CONVEYORS 16 І Australian Bulk Handling Review: July/August 2023

Vayeron’s technology can monitor vibration, the temperature of bearings, shell wear and carryback build up.

A monitoring cartridge can be installed inside of a roller to collect data.

Combined expertise

Schenck Process Mining has become part of Sandvik Rock Processing Solutions.

Combining the expertise and reach of our teams allows us to develop even better services to ensure that your equipment operates safely and at peak performance throughout its entire lifecycle.

We are now better positioned than ever, to develop innovative solutions to the challenges of our industry.

ROCKPROCESSING.SANDVIK

Watch this video to learn what this new parternship means to your business or visit our website:

Kitted out for transfer chutes

Martin Engineering has made difficult modifications and lost inventory a thing of the past with its new transfer chute kits.

MOST COMPANIES KNOW the pain of lost inventory all too well. They have ordered a new transfer chute but when it arrives, the parts do not arrive together and come in multiple boxes of various sizes.

With the best intentions, companies set aside inventory until the scheduled downtime when the chute can assembled. Some inventory vanishes and companies are left to deal with the headache.

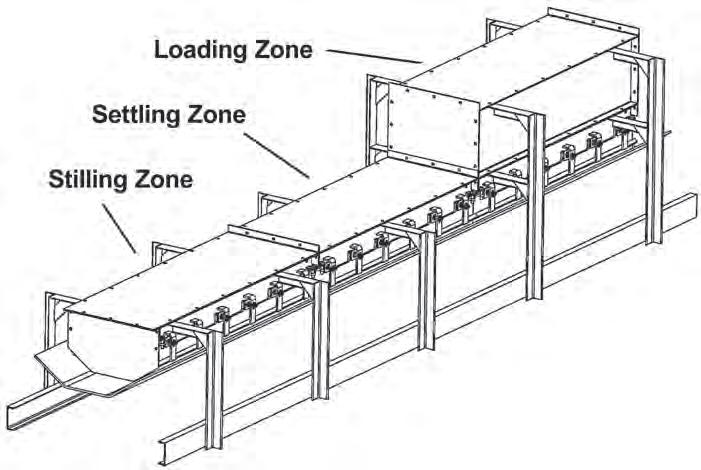

Martin Engineering has unveiled a transfer point kit designed to address three common issues the bulk handling industry faces: product loss, difficult assembly, and expensive retrofits.

The company knows product loss can lead to delays and has designed its new transfer point kit to be delivered in a single crate with all assembly parts included.

“This is a rugged one-kit solution designed to fit most standard conveyors and belt widths, regardless of what material is being transferred,” said Martin Engineering’s conveyor products manager, Dave Mueller.

“Our centre for innovation is constantly looking for ways to engineer equipment with safety and our customer’s bottom line in mind.

“That’s why the kit doesn’t just streamline labour, time and production, but it’s also a logistical solution by shipping it in one crate.”

While most new chutes need to be fabricated in downtime – which increases project budgets and extends production time – the transfer point kit takes a new approach. The kit can be assembled before shutdown and installation, easing the impact on the customer.

Complete with a fully modular design, the new product can be retrofit with future changes without the expensive cost seen with other transfer chutes.

If customers involve a Martin Engineering technician in the installation process, they will receive the company’s “Absolutely no excuses guarantee” which promises quality products and service to the customers’ satisfaction.

Muller said the company had received plenty of positive feedback from customers about its new and innovative product.

“After installation, Martin territory managers or partner distributors are available to offer support,” he said.

“The feedback for the kit has been excellent. Customers get the heavy-duty Martin quality they’ve come to expect in a more convenient, efficient and sustainable package.”

CHUTES 18 І Australian Bulk Handling Review: July/August 2023

An efficient transfer point starts with a modular enclosure but also has excellent belt support and sealing accessories.

Modular transfer point kit can be easily modified to adapt to changes in production.

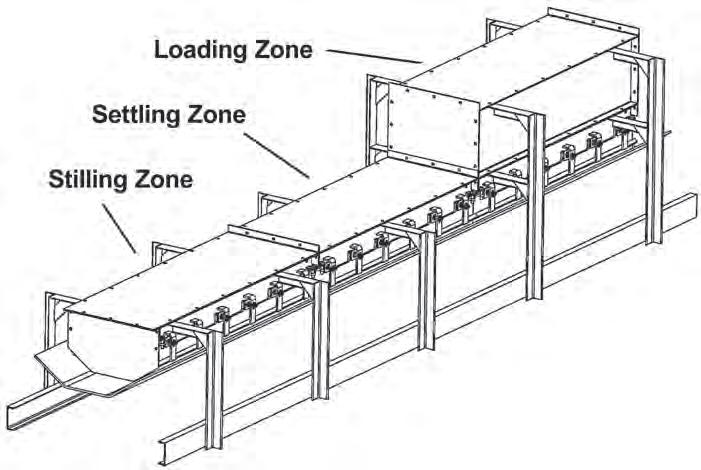

The kit features modular horizontal loading zone, settling zone, and stilling zone configurations, providing easier installation and a wider variety of chute options while facilitating future upgrades.

The skirt seal – the most frequently replaced wear part on transfer points - is sold separately as a single piece that runs the entire length of the chute.

Each kit is ordered as a loading zone, settling zone and stilling zone. Dustier applications may require a longer settling zone. The size of the kit is determined by the receiving belt’s speed and width –accommodating 450-1800 mm.

The taller loading zone controls air turbulence and connects to both the drop chute and settling zone. When cargo hits a belt with great velocity, fines and lumps splash up the sides of the belt.

Without a properly sealed enclosure, the material will spill underneath the conveyor, creating a hazard, restricting access and fouling other components.

The settling zone follows the loading zone and helps mitigate dust emissions.

filtered, or settled back into the cargo stream before leaving the stilling zone and continuing as a conventional conveyor.

weldment, wear liner assembly, wear liner plate, outer chute supports, top cover, tail panel/clamp/rubber sheet, installation hardware and an owner’s manual.

THOR TOWERSTACKER™

Telescopic Cable Mast Conveyor

• Versatile, affordable conveyor solution

• Quick and cost-effective installation

• It can be lowered to the ground to provide easy access for maintenance

• No head or tail undercarriage provides greater clearance under the conveyor

• Complies with all relevant Australian Standards, AS1170, AS4324.1 and RPEQ requirements

SALES | HIRE | SERVICE | PARTS 1800 182 888 | www.lincom.com.au | sales@lincom.com.au | OFFICE LOCATIONS | QLD | N QLD | HUNTER REGION | NSW | VIC | WA

We bring the world’s best material handling equipment to you.

REDUCE DOWNTIME. INCREASE PRODUCTIVITY.

Outer chute supports are provided in standard lengths and cut shorter or narrower on-site as needed.

Five-minute blending going on four decades

Two mixers installed 40 years ago have helped the US-based Plastics Engineering Company manufacture its range of custom-formulated moulding compounds and industrial resins.

A LARGE PORTION of the Plastics Engineering Company’s production is dedicated to novolac and resol thermoset moulding compounds—also known as phenolic resins.

These resins are highly adaptable and used across many applications. As a result, the company tailors its products to each customer’s requirements. That could

entail adjusting the molecular weight, moisture content, viscosity, pH, particle size, reactivity and other properties.

Immediately prior to packaging, the resins are blended with reinforcements, minerals, fillers and/or liquid additives, a task performed by two model 700-TSC180-MS Rotary Batch Mixers which have

Five-minute tumbling prevents degradation

The mixers have no agitators, internal shafts or related bearings or seals. Instead, a horizontally oriented vessel rotates on external trunnion rings located at each end. Ingredients flow into the vessel through a stationary inlet at one end and discharge through a stationary outlet at the other. Within the vessel are mixing flights, also called baffles or lifters, which create a gentle four-way tumble-turncut-fold mixing action that produces onspec blends in three to five minutes.

“We get a good, thorough blend without degrading the product,” Randy Block, a mechanical engineer at Plastics Engineering, said.

To fill the vessels, a pneumatic conveyor transports resins from compounding units to a holding hopper, which also separates out dust. When enough material accumulates in the hopper, it is discharged to one of the mixers as it slowly rotates.

After the mixer receives a dose of powdered additives from a loss-ofweight hopper above, a valve stops the flow and the mixer makes a preset number of revolutions. When called for, liquid additions are pumped through spray nozzles onto a wide bed of moving material within the mixing vessel. At the end of the batch cycle, the mixer’s discharge gate opens while the vessel is still rotating. This allows the mixing baffles to guide the batch toward and through the discharge gate with little or no residual.

“They do a good job of moving the material quickly and efficiently,” Block said. “If we’ve got a straight dry material, there isn’t much to clean out.”

The gentle mixing action is critical, Block said, because it preserves product quality.

BLENDING

To fill the vessels, a pneumatic conveyor transports resins from compounding units to a holding hopper.

“We get a good thorough blend but we don’t degrade the product. If we used a typical paddle mixer, we would grind the granules against each other and create dust. That doesn’t happen here.”

Continuous rotation of the drum during discharge prevents stratification of ingredients having disparate sizes, shapes and bulk densities, and empties the batch rapidly in a steady stream.

“That’s important because it minimises wait times at the packing stations,” Block said. “Because of that quick discharge, we are more efficient when packing bulk containers.”

“We’ve made the same product as a 2,268 kg order and as a 113,398 kg order. And blending is just as uniform on short runs as it is across larger ones.”

The mixing flights also create a dynamic bed of material, ideal for incorporating liquid additions.

“We get a good consistent dispersion. The product doesn’t get too wet in some parts and less wet in other parts,” Block said. “A typical paddle mixer would give us a less even coating.”

Since their installation in 1983, the mixers have rarely been idle. Over the last 12 years, one mixer has had 34 hours of downtime and the other just 4.5 hours.

“The longevity of the machines is a testament to my predecessors, who selected them,” Block said. “We’ve been pleased with the lack of downtime and maintenance costs.”

Services:

Flow Properties and Materials Testing

Dust (environmental) Testing

Wear Testing (Impact, Abrasion and Erosion)

Conveyor Belt and Idler Roll Testing

Custom Numerical Simulation and Calibration Testing

Materials Handling Consultancy and Contracted Research

Bin and Stockpile Design

Pneumatic and Hydraulic Conveying

Technology and Knowledge Transfer

Site Visits

Professional Development Courses

TUNRA Bulk Solids develops custom solutions to suit the individual needs of our clients.

World leaders with over 45 years’ experience in Bulk Materials Handling Research and Consulting

www.bulksolids.com.au +61 2 4033 9055 2023 Course Dates: Storage, Feeding, Transfer and Belt Conveying 14th - 16th November (Perth) In-house customised courses available on demand contact Danielle.Harris@newcastle.edu.au

The hinged access doors at either side of the vessel provide access to all material contact surfaces for cleaning and visual inspection.

Torque around town

All Torque Transmissions has expanded its operations across the east coast and are planning to grow even further.

CRAIG MIGHELL IS PASSIONATE about power transmission. He started working with the technology when he was just a 15-year-old and has built upon this lifelong dedication with his business – All Torque Transmissions.

First opening Friday 13th in 1996, he told ABHR about how he grew from the spare bedroom at home, into an east coast spanning business.

“I realised there was a distinct lack of specialist power transmission knowledge in Victoria and across the east coast,” he told ABHR

“A lot of companies try to sell a bit of everything. There’s a filtration that happens over time when not enough people are trained in certain areas. They leave the industry or change jobs, and then that knowledge is harder to access.

“We have homed in on power transmission, which is why our staff are educated to be specialists.”

All Torque Transmissions has grown from a one-man operation into a 26-person team, with staff members trained across multiple disciplines in the power transmission field. This means if someone is absent or is sick, there is always another teammate ready to fill in

Bonfiglioli, WEG, Baldor, Comintec, Warner Electric, KB Electronics, Flender, Dodge, and many more.

“I can’t think of a single power transmission supplier we don’t have access to or deal with. And because we’re an independent business, there are no conflicts of interests – we only find the right solution for the application,” he said.

“We pass on that support to our customers, and make sure they can ring any of our staff, at any time of the day. We offer 24/7 availability across all branches.”

The company operates out of four branches, two in Victoria in Braeside and Preston, one in NSW, in Queensland.

The QLD branch was set up following the acquisition in 2021 of Engineering Transmission Agencies (ETA) which operated similarly to the Victorian and NSW branches of All Torque.

Mighell said most existing ETA staff decided to stay on with management.

ETA, the branch has grown significantly in the past two years, with further potential, thanks to its in-house gearbox and geared motor assembly facility.

The plan is to continue that growth in the northern states and expand into the local market. The company will increase the amount of available stock, and expand its offering to the mining, grain handling and food and beverage sectors.

It is also now the national distributor for Flender’s shaft coupling range and has spent the past 18 months ensuring it had enough stock to roll it out to the industry.

Mighell said the timing is right for All Torque Transmissions, which has big ambitions for the future.

“We have a very good, Australia wide coverage for the whole gamut of power transmission equipment,” he said.

“Customers can also benefit from our wealth of information – if they have a question about a brand or component, it’s likely that one of our team will know the answer. That kind of expertise you just can’t get from a search engine.”

POWER TRANSMISSION 22 І Australian Bulk Handling Review: July/August 2023

The company has the backing of several key suppliers.

All Torque is the national distributor for Flender’s shaft coupling range.

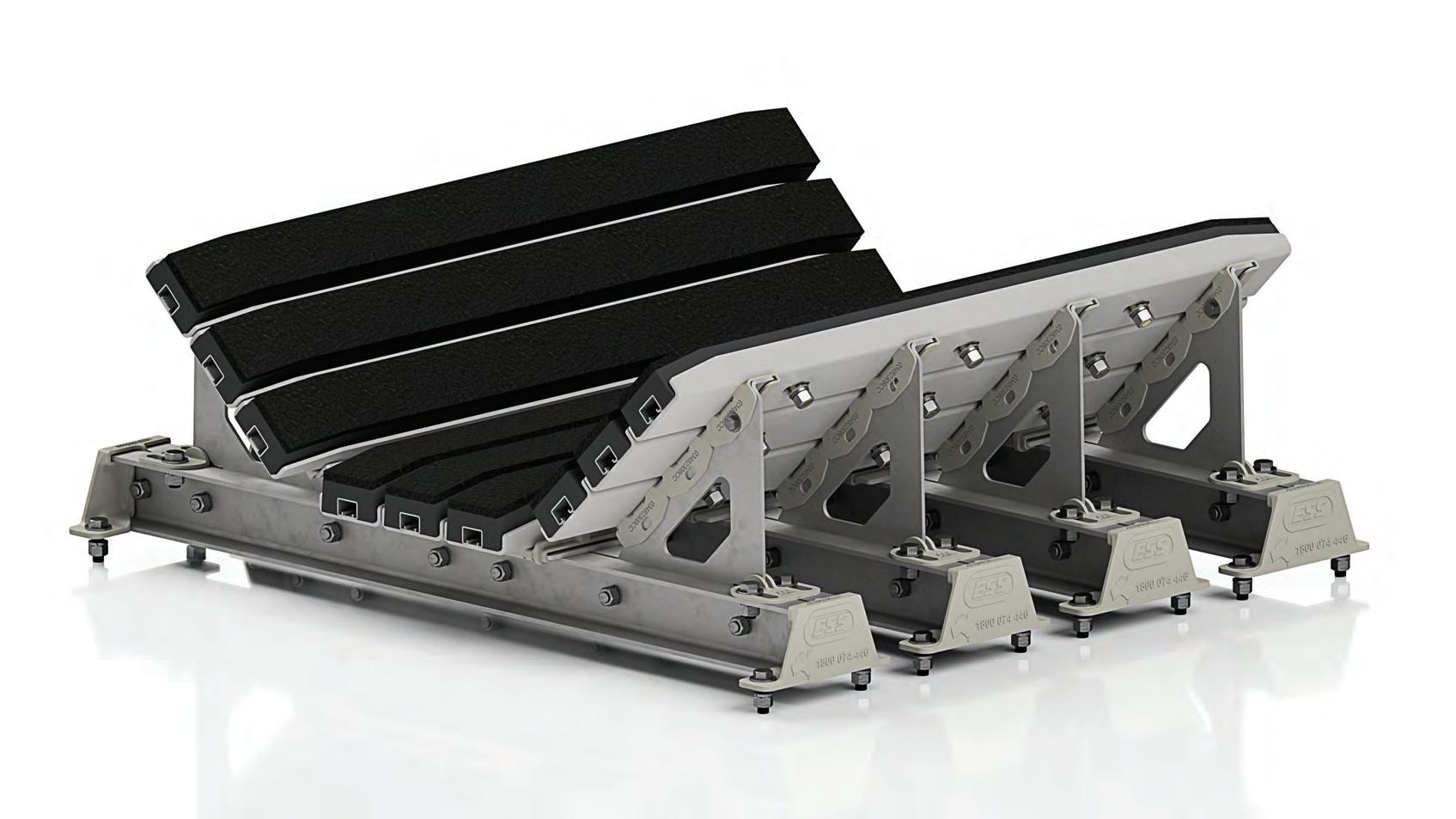

MODULAR IMPACT BEDS!

When large, sharp lumps strike the conveyor, belt damage occurs at load zones. This results in premature component failure through belt punctures, damage to idlers and structure, and decreased material

Installing impact beds at load zones reduces damage to the conveyor belt, surrounding structure and idlers. Other advantages include effective belt sealing, which reduces material spillage and reduced belt

ESS introduces a new modular impact bed design for medium and light-duty applications!

ESS Modular Impact Bed features include;

• Modular support frames for easy maintenance

• Polyethylene surface to reduce friction

• Rubber body to absorb impact

Benefits of the ESS Modular Impact Bed include;

• Shorter manufacturing & lead time

• Suitable for a wide range of conveyor belt applications

• Reduced downtime

• Reduced maintenance and repair costs

FOR MORE INFORMATION ABOUT ESS IMPACT CRADLES VISIT

WWW.ESSENG.COM.AU

SERVICES

Australian

ENGINEERING

& SUPPLIES PTY LTD Ph: 1800 074 446 www.esseng.com.au Proudly

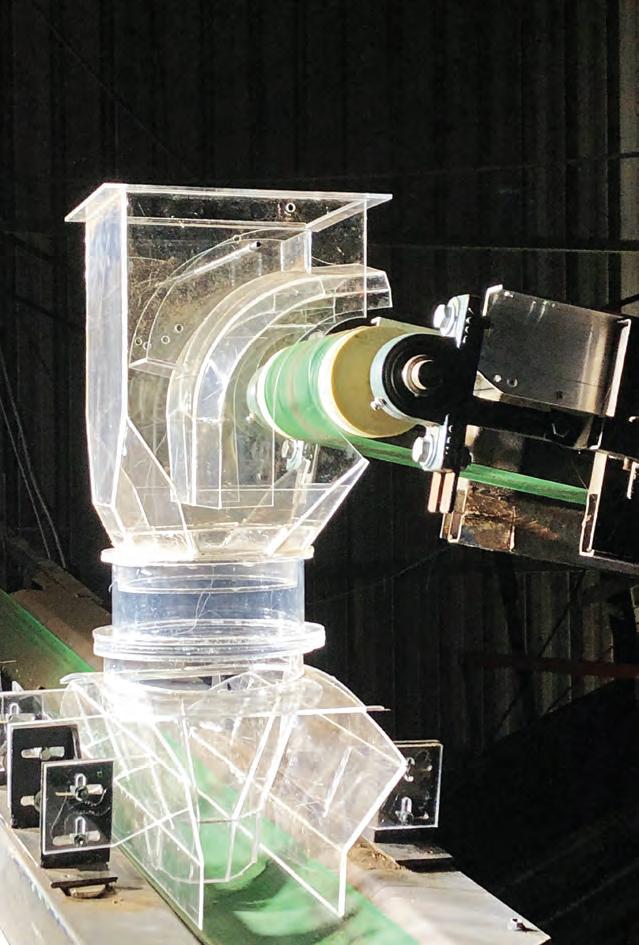

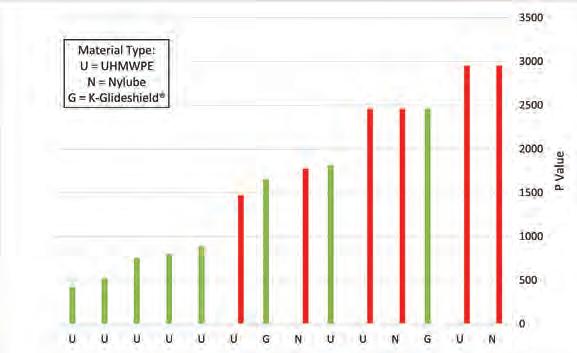

Stress test with one of the best

Bulk Solids Modelling is using a specific type of modelling to take away the stress when looking for the right bulk handling equipment.

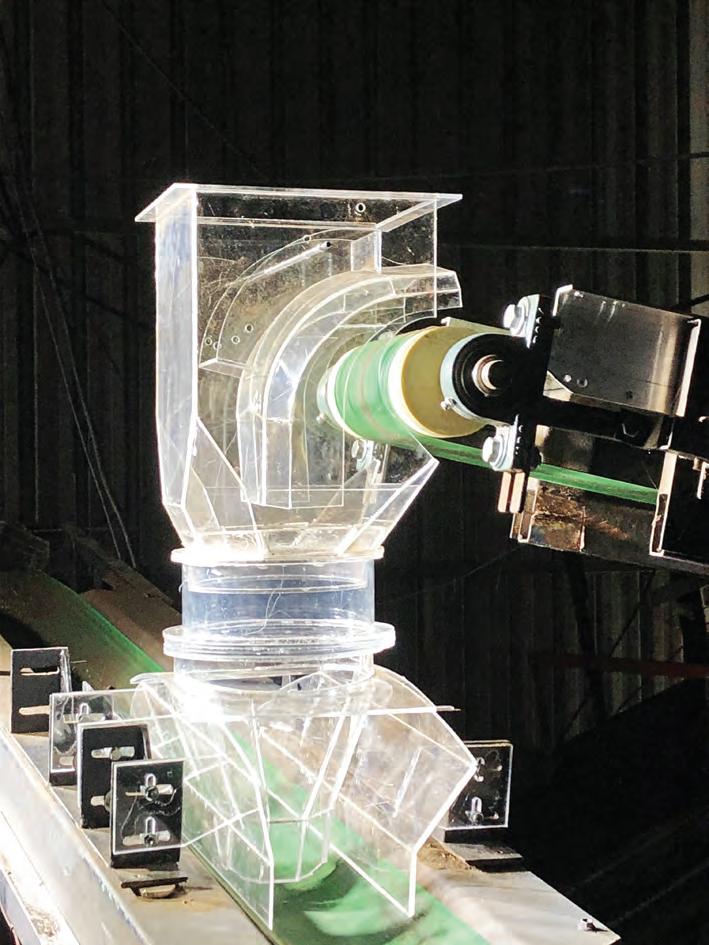

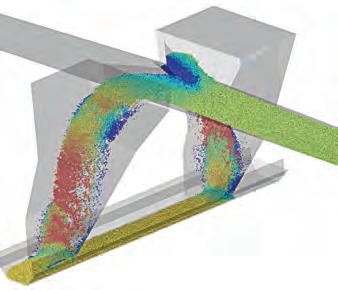

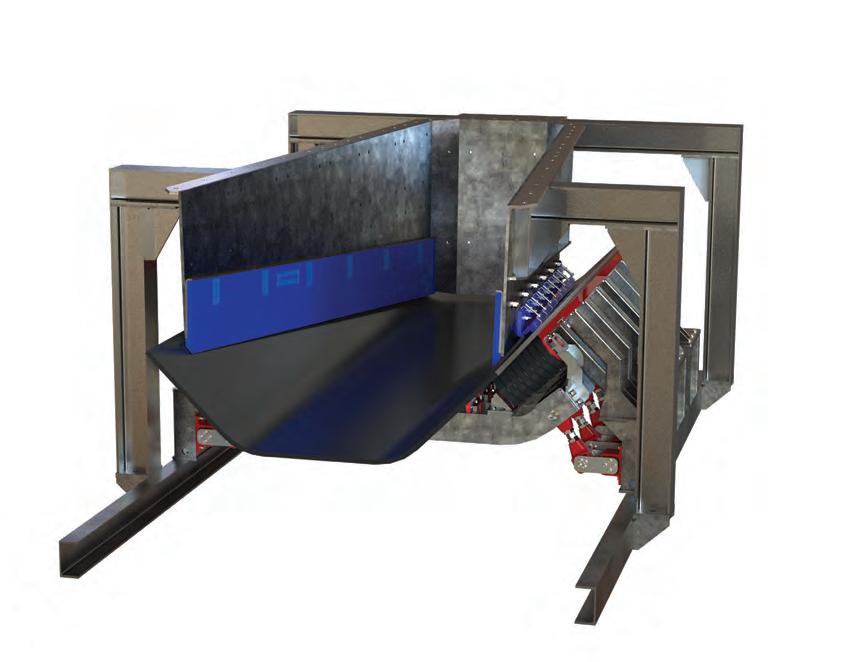

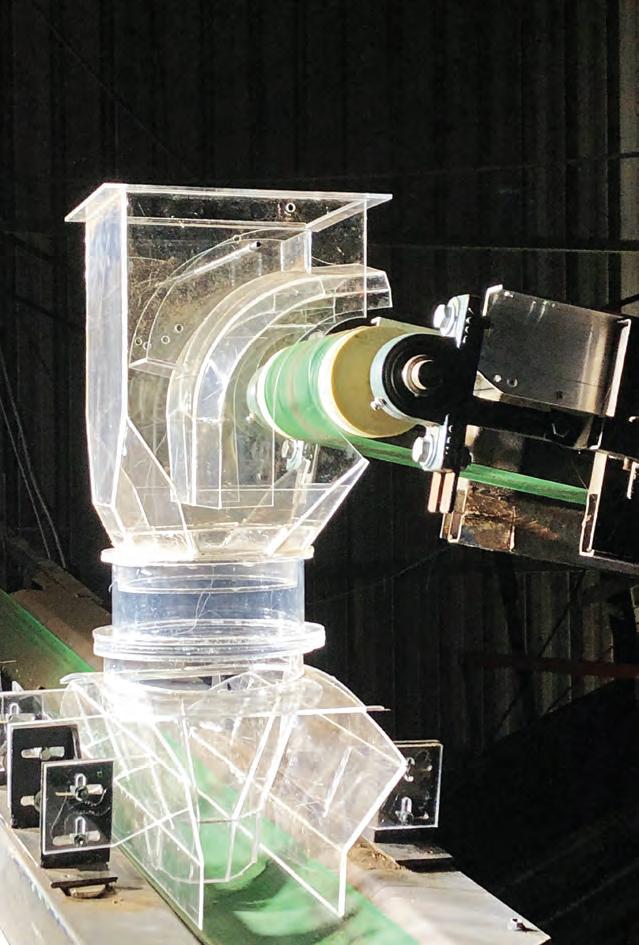

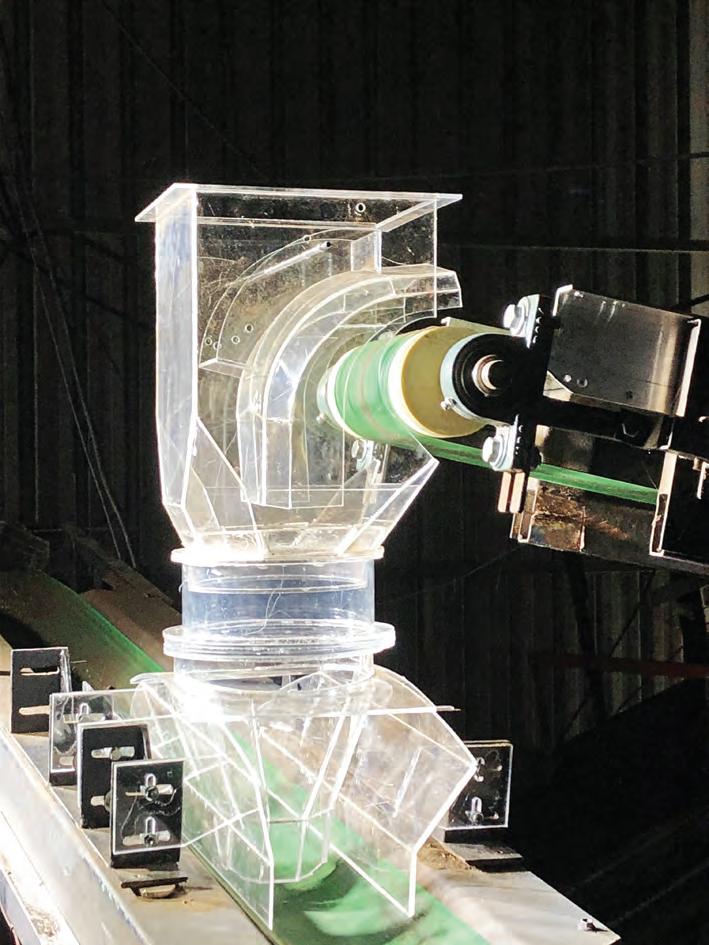

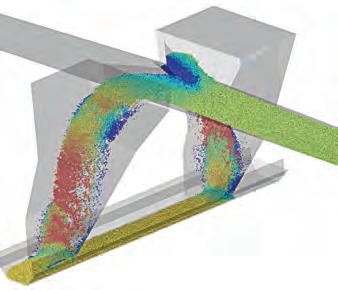

WHEN PETER DONECKER developed dynamic scale modelling (DSM), he knew it had potential. So much so that it eventually led to the creation of his company, Bulk Solids Modelling.

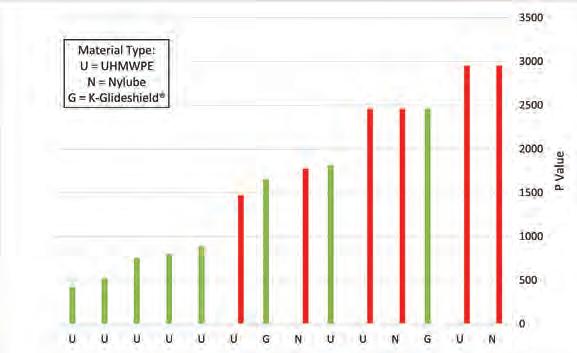

“We were looking at wear materials in mining operations in general and in the course of that we noticed that a very small change in the geometry of the chute had a massive effect on the wear behaviour,” he told ABHR

“That’s when the penny dropped that it is not just the materials but how the ore flows.

“We thought how we can do this in a lab and came up with the idea for scale modelling.”

There is a perception in the industry that it is necessary to use some form of scaled down version of the actual ore in a model, but Donecker has sought to change that.

He believes to run a fully accurate simulation, a material made specifically for the situation at hand needs to be used to replicate real-world usage.

The method has proven successful with Bulk Solids Modelling having worldwide reach after working with clients in Brazil, Canada, Africa and Asia.

“The first conceptual leap that people have to make is that density is not an issue… because we’re using Froude number scaling and the Froude number does not change with density, it is independent,” he said.

“The real issue is when you take a cohesive material, like a sample of iron ore, and create a material that is one-tenth the particle size, it will be extremely cohesive, but we want the cohesion to move in the other direction.”

For an accurate test and demonstration of a chute’s capabilities, the cohesive forces need to stay in the same proportion to other forces like the inertial force.

However, the finer cohesive material gets the more cohesive it gets. This can cause a material to agglomerate and

display much higher cohesive forces which impacts the testing results.

This is why Bulk Solids Modelling uses custom materials and moisture control in its testing to ensure consistent results.

“We’ve got material that does not agglomerate, and we can control the cohesion via the moisture content,” Donecker said.

“Because of this, we can explore a whole range of cohesive conditions (accurately), starting off with low moisture content and then increasing it.

“We can see what happens and sort of stress test the situation.”

Donecker’s method has revealed other significant advantages which could benefit the bulk handling industry.

Using DSM serves as a point of difference to validate DEM results and shines a light on previously unforeseen issues with chutes.

“The advantage of using scale modelling is that you can check the design that you have done in DEM with a completely different approach… that gives you the extra confidence you got it right,” Donecker said.

With nearly 30 years in the industry, Donecker has seen plenty of companies caught out with an ineffective chute.

If a transfer chute does not work as planned, it becomes a major headache worth significant sums of money. For example, if the chute is dispersing an uneven load the cost to fix the imbalance,

SIMULATION 24 І Australian Bulk Handling Review: July/August 2023

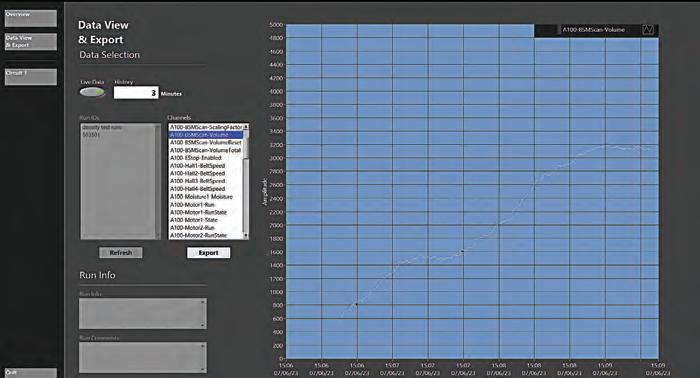

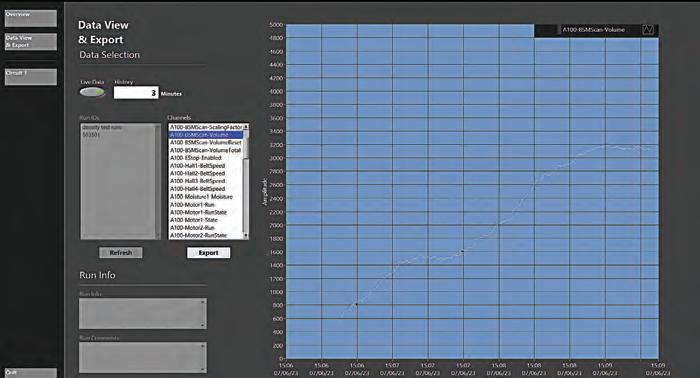

Screen capture of process monitor showing real-time throughput measurement.

View of the line from the laser scanner on the belt running simulated iron ore.

alongside the associated downtime and preparation time, brings in a hefty bill.

“You may have spent a million dollars for the chute which is one cost but if you can’t process your ore through it, it can cost many millions of dollars,” Donecker said.

“For example, if you’re processing 18,000 tonnes of ore per hour, every minute you can’t do that is worth a lot of money.

“It’s quite a big deal and you’ve lost all the production time while they’re fixing it and it may not (fix the problem).”

To avoid this crippling situation, Bulk Solids Modelling allows customers to try before they buy with scale models.

Peter and the team can make tweaks to a model using a laser cutter and Perspex, enabling companies to see the impact of the alteration in real-time.

“This way you’ve got everyone gathered together at the one time, looking at the model and everybody’s making suggestions in real-time, and out,”

The main reason Donecker and his team can deliver these changes in real-time is because the DSM method offers significant time-saving measures compared to alternatives.

With DEM, simulations can be run for 24 hours after the inputs are set before it must be run again to test another set of inputs. The result is timeconsuming and intensive.

The company’s fully instrumented system can process simulations in 20 minutes and run through a year’s worth of DEM simulations in a fraction of the time.

“This is one of the big advantages, a scale model runs faster than a full-scale chute because of the way time scales,” Donecker said.

“The analogue system is vastly faster than the digital systems.”

The Western Australian company is always looking to remain on the cutting edge and save its customers’ time.

of the most crucial factors is the

The ability to accurately assess throughput rate and peak capacity is vital in an industry built around delivering commodities into supply efficiently.

The downside is it can take significant time to measure the throughput with the need to crashstop the circuit and conduct a belt cut before emptying out the whole system and starting again.

Donecker estimated the process used to take a whole day’s work until the company developed a laser scanning system to tackle the issue.

“By using this real-time throughput measurement we’ve cut down what used to be a whole day to just a couple of hours, it is an absolutely huge improvement,” he said.

“I’ve had cases where the whole test program is completed is finished in two hours (because of this scanner).”

While these factors may sound simple, Bulk Solids Modelling has put in the work to ensure a fast and efficient

Scan me on your Phone for more information PHONE: 1300 400 MPS WWW.MPSAUS.COM.AU AVAILABLE IN: WA NT SA QLD NSW TAS VIC sales@mps.com.au ONE OF THE WORLD’S LARGEST STOCKS OF PREMIUM, TELESTACK BULK MATERIALS HANDLING EQUIPMENT

Page Macrae crosses the Tasman

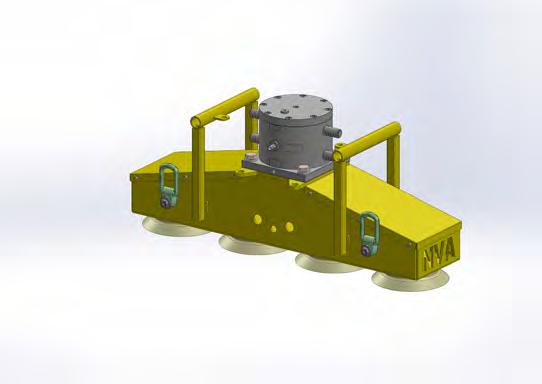

After supporting Australian ports for more than 10 years, Page Macrae Engineering is now expanding onto local shores. ABHR finds out why it is targeting local shores and how it will benefit bulk handlers.

NEW ZEALAND-BASED port equipment manufacturer Page Macrae Engineering, has been involved in the Australian market for more than a decade. Now, they have taken a major step to bridge the gap across the Tasman Sea, setting up in Victoria.

Pioneering this development is Charles Hennessy, who will oversee a streamlined spares distribution service and the development of the company in Australia.

GM of Sales and Marketing, Peter Swan told ABHR that Page Macrae Engineering are very proud to be employing their first in-country Aussie national and starting the journey of local Australian customer support.

“We believe that these first local support steps will eventually lead to a much larger comprehensive presence in Australia,” he said.

Stocking the right spare parts requires an understanding of our customer’s service cycles and what equipment is in each location. That’s why Hennessy has been spending time traveling around the country and visiting ports.

“We have been meeting with our customers to help understand their requirements for spare parts and learning what solutions they need,” he said.

“Keeping our customers happy is the main aim, and we’re using their feedback to build plans for growth.

“If customers have upcoming contracts they’re applying for, we want to make sure we’re giving

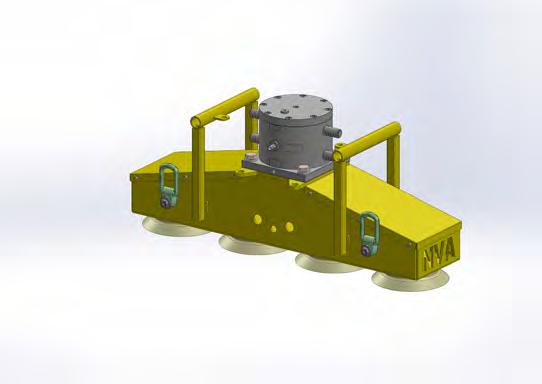

Page Macrae’s growth aspirations are not just in the parts and services side of the business. Business Development Manager – Product Solutions, Bruce Ennis talked with ABHR about developments in its new products funnel.

Ennis said Page Macrae Engineering is very excited about the range of new products ut will be bringing to its Australian customers, with a focus on new technology in bulk material ship unloading and log-handling equipment.

“We also hope to further develop our container loading and unloading products soon and Charles with his strong logistics background, will play a key role in bringing these products to market,” he said.

The new product funnel and service focus for Page Macrae Engineering comes after a time of business realignment for growth. New product designs are being driven by the day to day conversations they have with clients rather than a design team sitting in the office.

PORTS 26 І Australian Bulk Handling Review: July/August 2023

Page Macrae Engineering designs grabs for bulk handling and log handling applications.

New product designs are being driven by the day to day conversations with clients.

Safeguard your operations

& reduce washdown splashback

HDPE Conveyor Guards

ROBUST ✓ LIGHTWEIGHT ✓ ECONOMICAL ✓

DYNA Engineering has developed a “chamfered mesh pattern”, designed to reduce washdown splash back and increase visibility through the guard panels.

This design feature is a major “point of difference” compared to standard HDPE mesh and will improve inspection and cleaning operations.

Washdown Mesh

• Up to 50% additional spray-through for washdown.

Increased Visibility

• Up to 25% additional viewing angle and see-through viability.

1800 801 558 dynaeng.com.au

Washdown Mesh Standard Mesh

OPS support stacks up

Solving on-site issues can be a tricky task. ABHR learns how the OPS Group helps take the stress out of the process.

SOLVING ON-SITE ISSUES can be a tricky task. Oftentimes, customers are not aware of the simple solutions available within their industry. The OPS Group, however, is changing that by helping take the stress out of the process for bulk handling operators.

What seems like a small change could have unintended consequences or require expensive workarounds and downtime. In some cases, the plant team might find the task of changing things too daunting entirely.

Sean Burke, area manager at the OPS Group, told ABHR that often these seemingly complex engineering quandaries have a simple solution.

The problem, he said, is that operators are often not well versed in the equipment that’s out there.

“For example, we had a customer that needed to move material behind a retaining wall. There was limited space on the site, and they didn’t know how to do it,” Burke said.

“We were able to provide a solution with equipment we had in stock and available at the time.”

The first step in helping customers find a solution is discussing the problem. Once the OPS team understands the site’s struggles, they can generally find a machine fit for the purpose.

“I have encountered relatively few challenges that I would categorise as complex. If I encounter something unfamiliar, I can readily rely on the expertise of the factory personnel at Telestack or other OPS staff, who possess an exceptional understanding of the equipment and its capabilities,” Burke said.

In many cases, permanent equipment isn’t required. In fact, a permanent solution may exceed the capital expenditure budget of a site. That’s why OPS has equipment it can hire out to its customers who may only need it for a few weeks or months.

The OPS Group provides specialist processing equipment and portable solutions for the mining, quarrying, construction, and recycling industries. Its staff are made up of experienced industry professionals who know the

equipment and industry extensively.

Burke said customers are usually focused on the project not the equipment, so they often don’t know what solutions are even available.

“In many civil construction projects we assist, clients primarily engage with excavators and loaders, often unaware of the extensive array of equipment options available for rental,” he said.

Reliability is a key concern for the OPS Group’s customers. Breakdowns and downtime significantly eat into their profits. To address this, the OPS Group has chosen to provide Telestack’s range of equipment.

Burke said Telestack’s quality as what sets the brand apart from others on the market.

“They’re second to none when it comes to bulk handling. Due to their quality construction, you’ll see longer service lives and fewer disruptions.”

Part of what makes Telestack’s equipment such high-quality products is the workmanship and materials that go into each machine. The brand uses industry-recognised components to

STACKERS 28 І Australian Bulk Handling Review: July/August 2023

The OPS Group has access to Telestack’s complete range of equipment.

ensure each part performs properly.

The positive impact of Telestack’s equipment has already been felt by one of Burke’s clients, who recently acquired their first Telestack stacker. The stacker eliminated the need for manual labour and enhanced site organisation and safety. Previously, the client had to relocate their screening plant multiple times a day, but with the stacker, they were able to maintain a fixed position, resulting in improved efficiency.

The OPS Group has access to Telestack’s complete range of equipment, enabling it to cater to a wide spectrum of project requirements. Whether it is a small-scale job with a throughput of only 50 tonnes per hour or a massive undertaking necessitating throughputs in the thousands of tonnes, it is equipped to provide the appropriate stackers for the task at hand.

Burke said the bulk handlers also values flexibility and speed – and that is something the OPS Group can provide.

arises with immediate urgency. Bearing this in mind, we maintain substantial inventory distributed among multiple branches nationwide,” he said.

“At any given time, we have the capacity to service the majority of enquiries within a few days.”

The OPS Group has a footprint in QLD, VIC, SA, WA and the NT, as well as Indonesia. From these branches, the

Burke acknowledged that the industries served by the company generally operate continuously, prompting him to always guarantee accessibility to his clients.

“A simple phone call is usually sufficient to address any challenges our customers may encounter. We are committed to providing solutions and assisting them effectively,” he said.

Bulk solids storage and handling solutions generated in Australia for Australian Conditions

Walla Walla, NSW Toowoomba, QLD Perth, WA (07)4634 4622 info@kotzur.com www.kotzur.com (02)6029 4700 0475 294 701

The OPS Group provides specialist processing equipment and portable solutions.

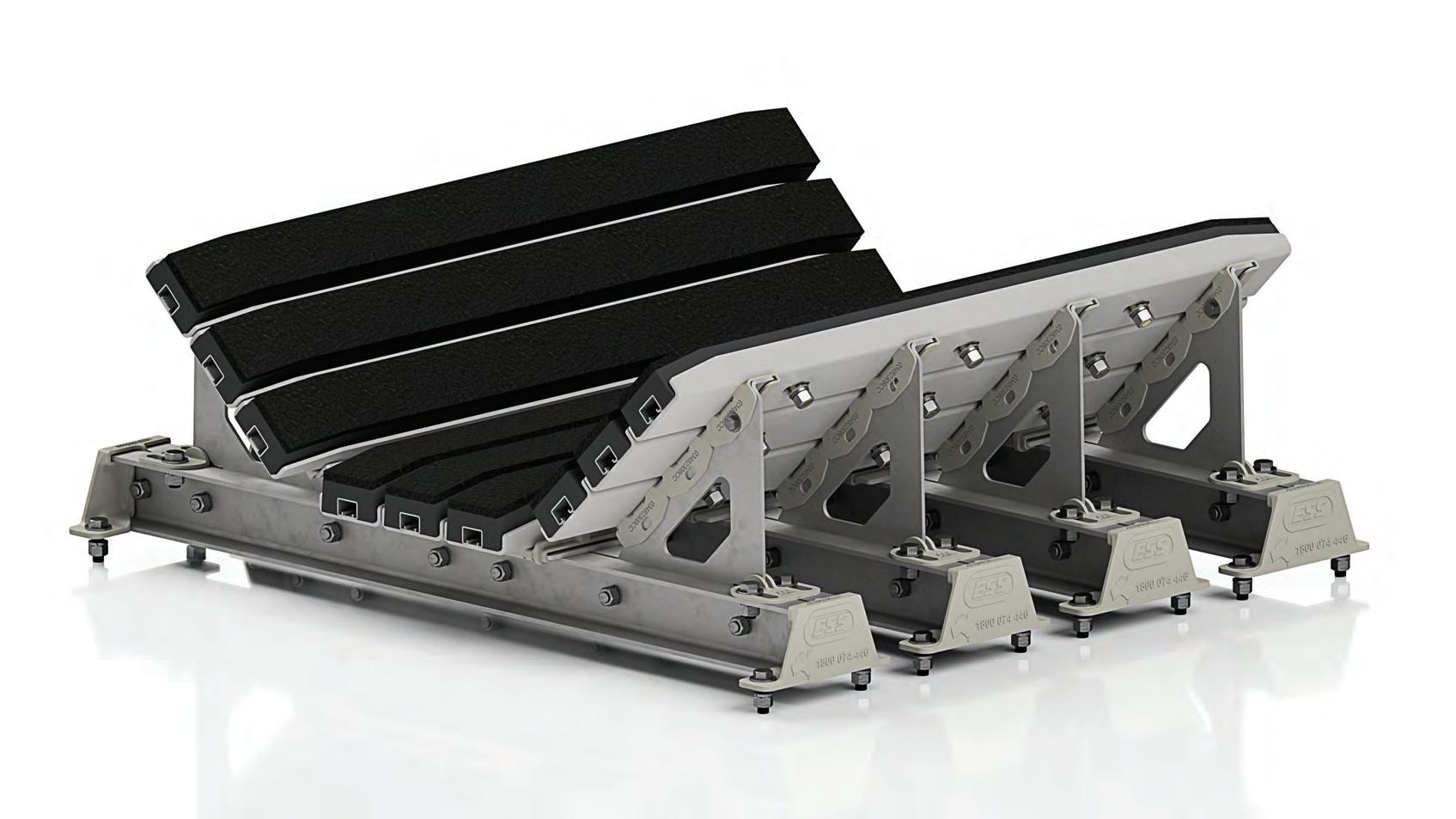

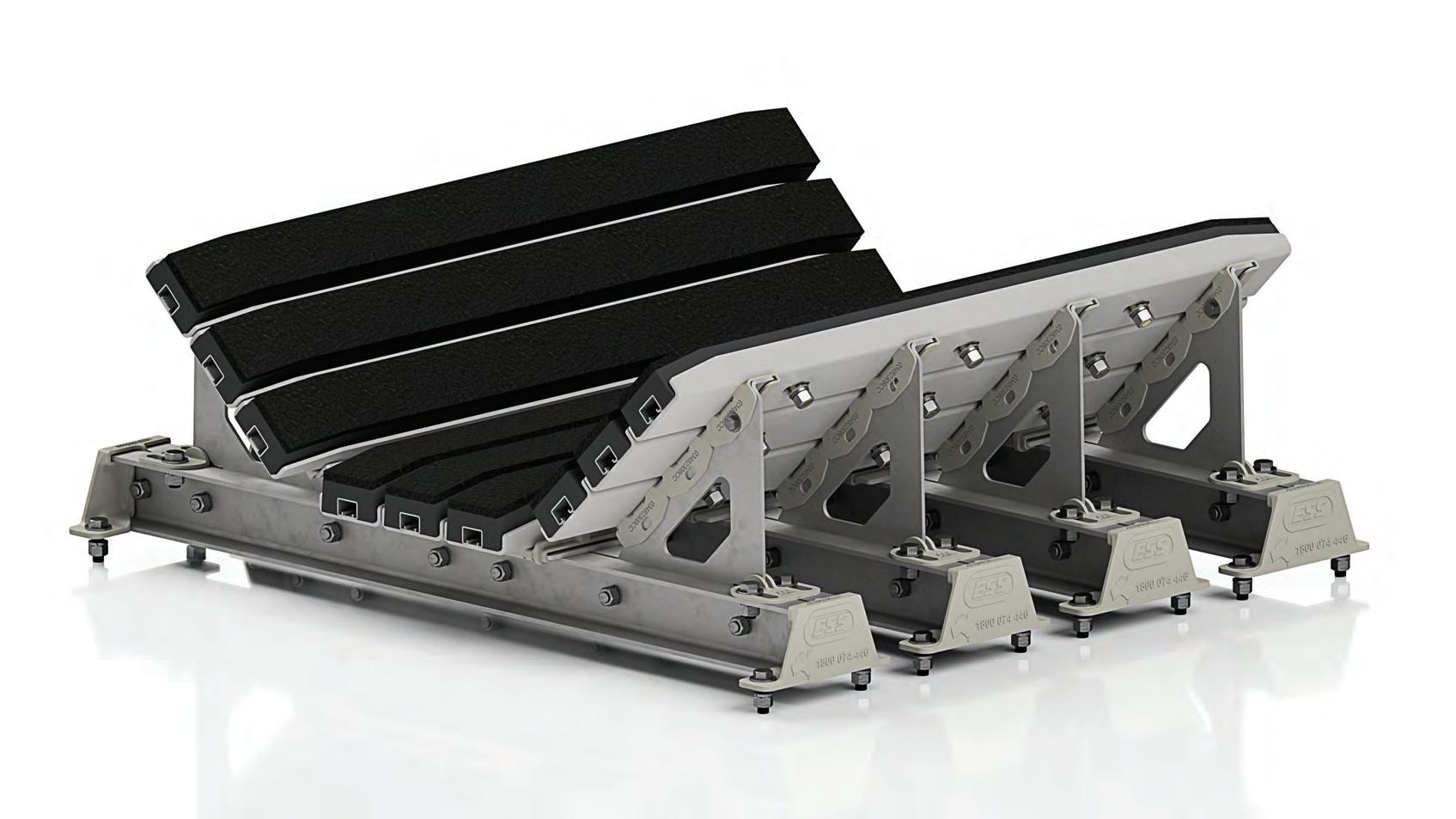

ESS Engineering makes an impact with the cradle

The conveyor belt is the most crucial component in efficient bulk materials movement and the single most expensive component in the conveyor belt system.

DAMAGE TO THE CONVEYOR BELT shortens its life and cuts into profits. While all conveyor belts will wear out over time, damage should be avoided where possible to ensure a reasonable return on investment. Bulk solids impacting the conveyor can cause accelerated damage to the idlers, structure and belt.

An impact bed is located underneath the belt at the impact zone, and it is designed to support the belt and helps absorb the impact of falling material. Impact beds also decrease the tendency of sharp edges of material piercing the belt.

These cradles usually comprise a set of individual impact-absorbing bars assembled into a steel support framework. The bars are made of durable elastomeric materials that combine a slick top surface, allowing the belt to skim over it, and sponge-like secondary layers to absorb the impact energy.

ESS has a long history of designing, manufacturing, installing, and maintaining ESS GAB Impact Cradles. However, the custom nature of these impact beds has meant that the price point was prohibitive to smaller operations and was generally supplied to heavy-duty applications where they saw the best return on investment for clients.

ESS now has a modular design for light-duty and medium-duty applications to make impact beds available to the broader market.

ESS research and development engineer Alex Adl said that the new impact cradle design would be close to 40 per cent cheaper than the previous module because the design was less labour-intensive and easier to produce.

ESS aimed to streamline the design process by creating a calculator that uses variables including material size,

belt speed, belt width and drop height to determine whether the application needs a medium or light-duty impact cradle.

The company focused on making a design suitable for a wide variety of medium and light-duty applications and reduced production time.

“The result was a design that uses independent modular support frames rather than interconnected and welded support frames to house the impact bars,” Adl said.

The modular impact beds are manufactured to provide consistent design and quality while ensuring a reduced lead time.

Adl said there are also on-site benefits to this module design.

“Scheduled downtime is common across all industries but none more so than those which consistently handle high degrees of bulk material,” he said.

MACHINERY 30 І Australian Bulk Handling Review: July/August 2023

The new modular bed is designed for light and medium-duty applications for the broader market.

“While inspection and preventative maintenance is always the best practice, many situations can leave companies

caught in reactive situations due to unexpected breakdowns in machinery.”

Load zones and transfer points are areas of high impact and throughput critical to the bulk material handling

is suitable for heavy-duty applications) but can be labour-intensive and costly to repair. ESS’ modular design for medium and light-duty applications means that downtime is reduced as only the parts that need to be repaired need to be removed.

Adl said that the modular design’s ease would allow on-site repairs and faster turnarounds for less downtime.

“If something happens on-site, you can just change the module rather than sending it all away (for repairs),” Adl said.

“You can just undo the bolt, replace (the module), and it is done.”

process. If these areas break down unexpectedly, the entire operation grinds to a halt. Therefore, it is essential to minimise downtime without sacrificing safety or quality.

Impact beds are in load zones, and the impact bars or frames inevitably need to be replaced because of the high impact. Traditionally, impact cradles are bolted together, which is beneficial for the product’s overall strength (which

This can constitute a significant cost reduction because only damaged modules must be replaced rather than the entire impact bed. This modular design also means that the impact bed can change with the application by adding and subtracting modules based on a site’s needs.

“You can add or change [the number of modules] depending on what you need, and most importantly, it can be changed on-site,” Adl said.

“While inspection and preventative maintenance is always the best practice, many situations can leave companies caught in reactive situations due to unexpected breakdowns in machinery.”

Here to help

Oli Vibrators has started expanding rapidly in NSW. ABHR sat down with the company’s sales manager responsible for growing the new market.

WHEN YOU NEED IT, where you need it. This strategy has led Italy-based Oli Vibrators to expand across the world, setting up dozens of trading subsidiaries – including in Australia.

The branch, located in the eastern suburbs of Melbourne, supplies a range of vibrators and flow aids for all manner of industries.

Oli is looking to grow. Costa Pegios has been tasked with establishing the company in New South Wales. With more than three years in the industry and extensive experience with the construction sector, Pegios said he is excited about the task.

“With the size of NSW and the amount of manufacturing that goes on in the state, it’s extremely important to have a presence here,” he told ABHR

“We’ve typically focused our time in Victoria. There’s a lot of potential here to make a real impact.”

Initially, Pegios met with existing clients in the region, along with his own contacts, letting them know Oli Vibrators is ready to help solve any flow problems they may be facing.

In many cases, the staff running a production line won’t have the in-depth knowledge and engineering skills to find the right solution. That’s why education has become an important first step.

One of the most common problems

Pegios found is hammer rash on the bases

of bins and hoppers. When flow stops or slows, one of the simplest solutions is to strike the equipment with a large hammer. This can get the material flowing again, but it comes at a serious cost. Constantly hitting expensive assets with a hammer causes damage to the system, leaving dents that can cause even worse hangups. In extreme cases, hammer rash can lead to catastrophic failure and puts workers at serious risks.

“I once had a customer that was coating popcorn kernels with salt. The problem was the salt came out of the bags in bricks. They had someone sitting at the base of hopper, smacking it with a mallet,” he said.

“A vibrator or flow aid saves people from thousands of dollars in terms of damaged assets, not including downtime for repairs.

“After installing our devices, the customer said they wanted to frame the hammer and never use it again.”

Pegios visits his client’s plants to spot the tell-tale signs of flow issues. If there are any, he discusses strategies with the customer before helping find a solution.

arise, and the ways to fix it. Quite often, the importance of flow aids isn’t front of mind for the company’s customers, which is why having a fresh pair of eyes on site is so important.

Pegios aims to establish an office and warehouse in Sydney. He is currently supported by the team in Melbourne, which have dozens of years in combined experience.

“Our general manager, Mark Thompson, is only a phone call away and has amazing knowledge about the industry,” he said.

“The journey in NSW has just begun. It’s been great to meet with our customers and to let them know we’re here to help.”

VIBRATORS 32 І Australian Bulk Handling Review: July/August 2023

A’SIA P TY LTD TRANSMISSIONS TORQUE ALL

Costa Pegios has been tasked with growing OLI in NSW.

Oli Vibrators supplies a range of vibrators and flow aids from Melbourne.

Servicing Australia Wide Contact us now for all your PT equipment requirements Bonfiglioli W, VF, C-A-F-S & Planetary gearboxes. VIC HEAD OFFICE 1/11-13 Lakewood Blvd, Braeside 3195. 03 9587 2212 sales@alltorque.com.au Large range of Flender N-Eupex, N-Bipex & Zapex couplings. Full

of Weg W21, W22, Mining Motors & inverters. Motor

80

Comintec Torque Limiters, roller & friction type. Dertec

gearboxes & motors for the food industry. Baldor DC & AC NEMA motors. KB Controllers for all DC & AC motors.Telcomec clutches & brakes. See the full range at www.alltorque.com.au VIC 6 Reserve Street, Preston 3072 03 9480 1566 preston@alltorque.com.au NSW 6/155 Glendenning Road, Glendenning 2761 02 9099 1149 nswsales@alltorque.com.au QLD 125 Balham Road, Rocklea 4106 07 3274 2677 sales@eta.com.au Power Transmission Specialists A’SIA P TY LTD TRANSMISSIONS TORQUE ALL

range

slide rails from frame size

to 355 in stock.

stainless steel

Tecweigh’s local touch

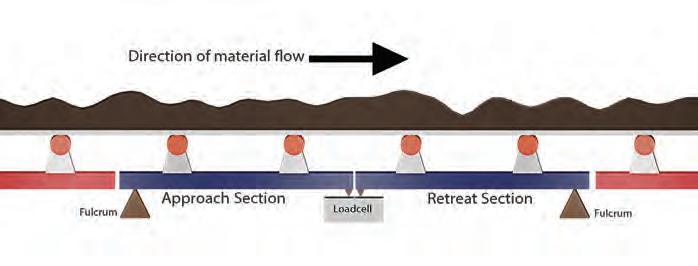

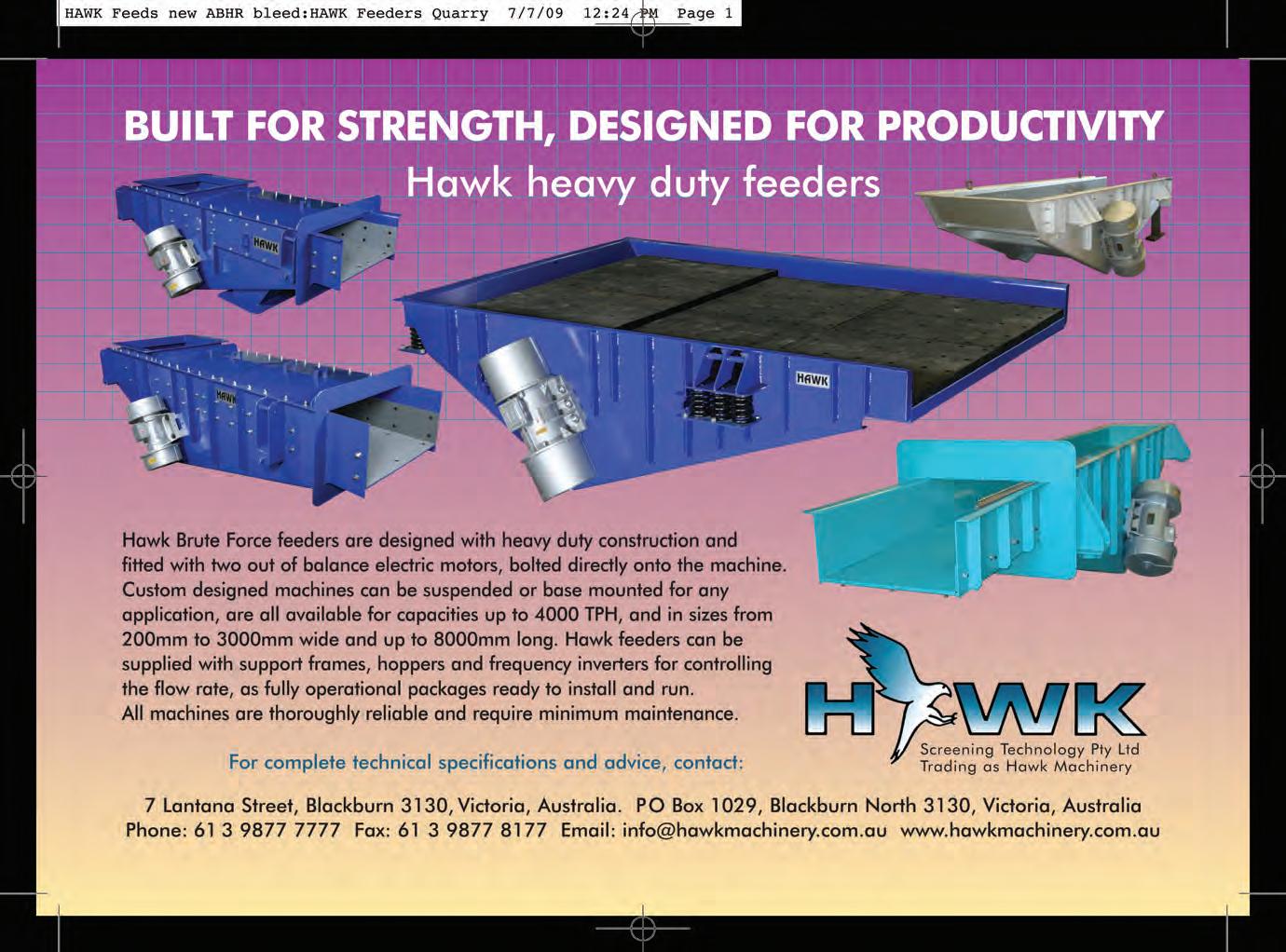

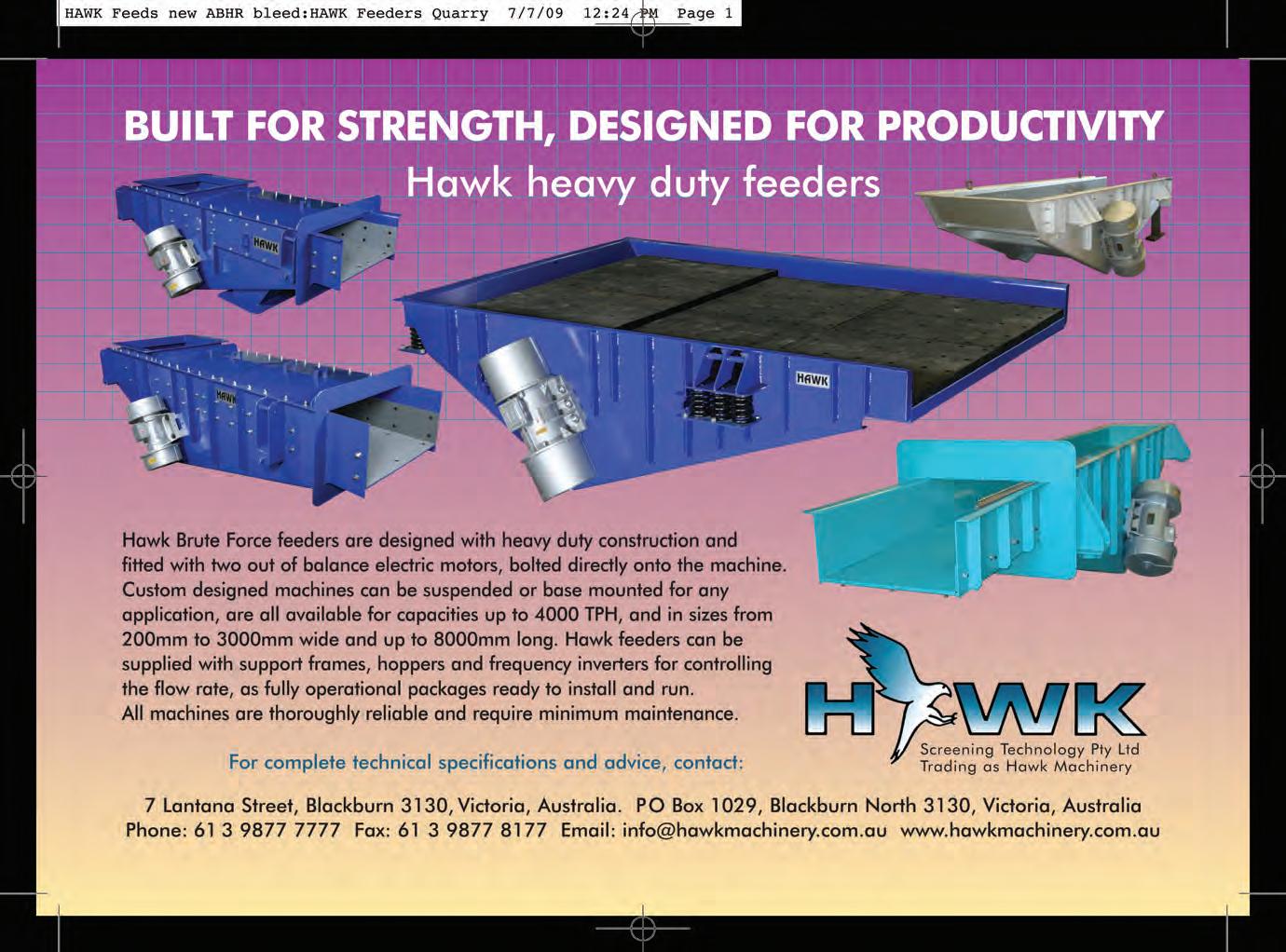

The Australian manufacturer’s latest conveyer belt scales are designed for weighing in the quarry, mining, and food industries in all conditions.

IN AN INDUSTRY that needs tailored solutions and quick turnarounds, Tecweigh’s Australian advantage has shone through for the customers in the bulk handling sector.

The Australian manufacturer has been producing a range of conveyor belt scales, weigh belt feeders and volumetric feeders for two decades from its Melbourne headquarters.

Being an Australian-made brand ensures Tecweigh’s custom-engineered products can perform dynamic measuring in the harshest of conditions.

Barry Gamble, Tecweigh’s business development manager, said being a local manufacturer has allowed the company to keep costs down and ensure continued supply.

“We do all our manufacturing in Carrum Downs, Melbourne, which gives us a fast response time,” he said.

“We can normally deliver what the client needs within seven to 10 days.”

Dynamic measuring is a key component in the quarrying, mining, food, and extractive industry which helps relay accurate information to customers.

Without accurate information, storage management and feed metering become incredibly difficult.

To ensure its products are reliable in Australia’s often-harsh conditions and provide accurate information, Tecweigh uses stainless steel, hermetically sealed IP68 load cells designed to provide accuracies of ± 0.5 or ± 0.25 per cent for its weigh belt feeders and conveyer belt scales.

The weigh idler system has been designed to be easy to calibrate to provide consistent accuracy. Its volumetric feeders have a range of up to 32,000 litres per hour with single or dual drives for loss in weight applications.

Its weigh belt feeders can also be manufactured to specific lengths and widths, using powdercoated mild steel or stainless steel, depending on the application.

“Custom designs are our standard. Whether it is chemicals, crushed stone, sand, coal, or materials that are low density, sticky, or abrasive, we specialise in building the equipment needed to accurately weigh it,” Gamble said.

“Our products are also designed for heavy-duty work and have been proven over time to be accurate in some of the world’s harshest environments.”

With more than 100 years of industry experience collectively among its

employees, the company is continuing to look for new innovations.

Gamble said that in addition to its main range of products, the company is increasing its range with a new loss in weight controller.

“It uses an Australian-designed and built signal conditioner circuit board, deployed at the heart of Tecweigh’s measuring and metering products,” he said.

“The loss in weight controller gives users greater accuracy for dispensing products and provides an extra layer of control over an ordinary volumetric feeder by using feedback from a scale.”

The fact it is based in Australia means Tecweigh can also offer local after-sales support. The company maintains a significant stock inventory for its conveyor belt scales, volumetric feeders, and weigh belt feeders. It also offers field service support and spare parts supply.

From humble beginnings, Tecweigh has built its bespoke business to provide weighing-in-motion solutions for industries nationally and Internationally.

The company has built a long-lasting relationship with its own local suppliers and aims to further grow in the industry.

AUSTRALIAN MADE 34 І Australian Bulk Handling Review: July/August 2023

Conveyer belt scales are designed for weighing in the quarry, mining, and food industries in all conditions.

Do you talk conveyor belts? Talk to us!

We are looking for people importing, using, recycling, and disposing of conveyor belts to join a working group to shape a better future for used conveyor belts.

Conveyor belts are highly specialised equipment, made using quality materials and technology. At the end of a conveyor belt’s life, they often end up in landfill or stockpiled onsite. It’s not without reason – we know there are barriers to recovering conveyor belts.

Tyre Stewardship Australia is on a mission to find better uses for end-of-life conveyors. And we need your knowledge and conveyor belt know-how to make it happen.

Express you interest to join our conveyor and rubber tracks working group

Email us your name, company, position, and experience with conveyor belts and rubber tracks, and why you want to join the conveyor belt and rubber track working group to getonboard@tyrestewardship.org.au by 30th August 2023.

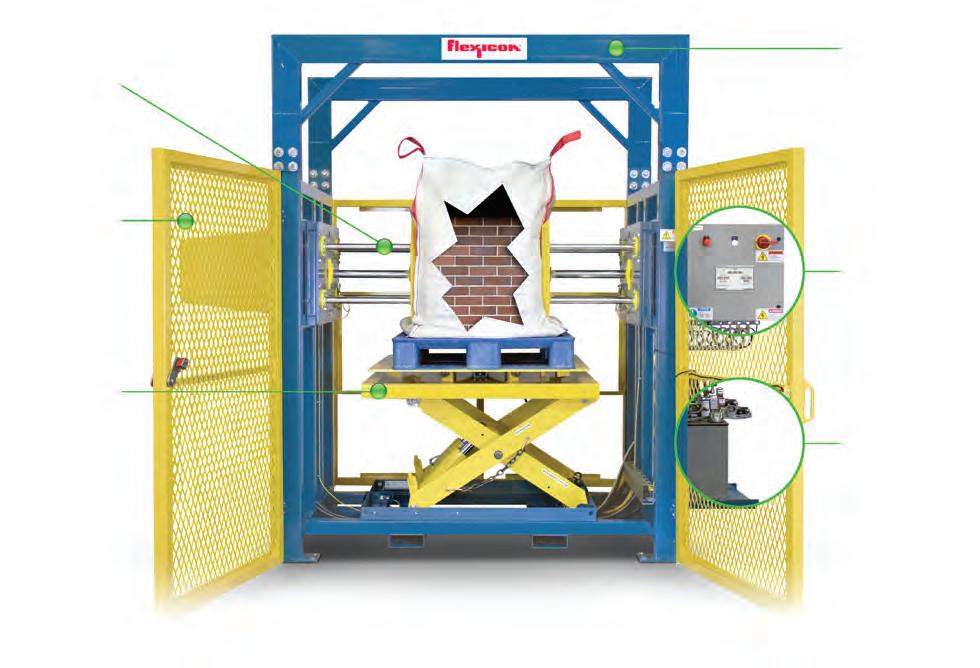

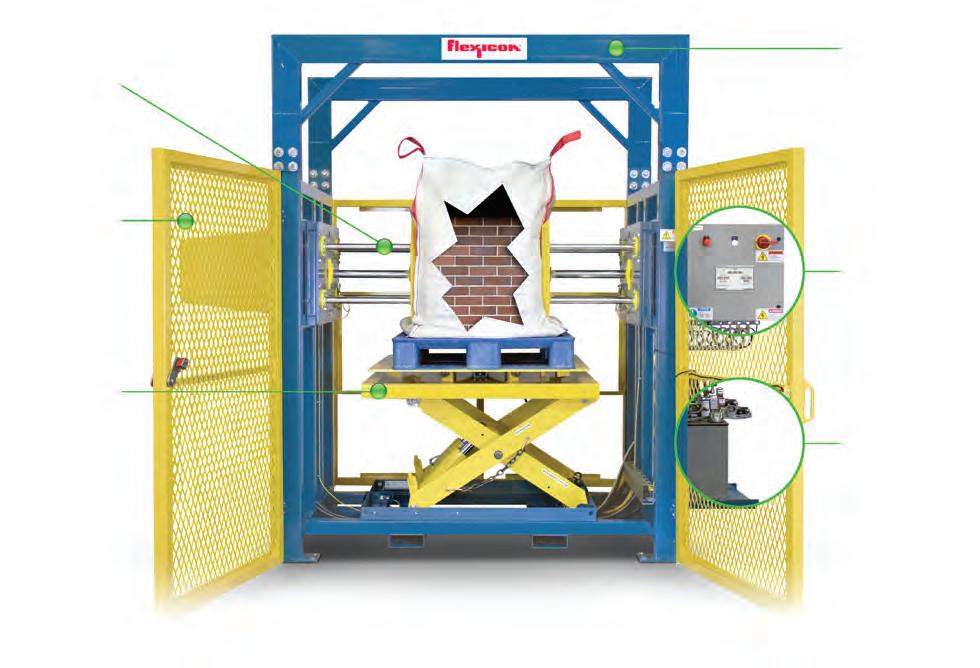

Packed for success

ABHR sat down with a co-founder of bulk bagging manufacturer Packweigh to learn how the company has grown.

ROD WILSON and his business partner Jim Nolan had found a gap in the Australian market.

The pair decided to take the plunge, launching a small business that supplied industrial sewing machines for bagging equipment.

Now, almost 20 years later, Packweigh Equipment has expanded its customer base, product range and physical size, becoming a major manufacturer of packaging equipment.

While the company originally focused on industrial sewing machines, it has since branched out to include weighing equipment, conveyors, and palletising systems.

Nolan worked as the company’s lead designer, coming up with many of the machines in the company’s product line,

while Wilson helped grow the businesses through sales and customer relationships.

A major motivator for the pair was quality. They had seen equipment in the industry that wasn’t up to their high standards. In fact, manufacturing reliable and long-lasting equipment is a core part of the company’s mission.

Wilson told ABHR that being the manufacturer means the company is more accountable for the quality of its products.

“When you rely on other stakeholders, there’s a chance there you can be let down. We didn’t want to let our customers down – so that meant having as much control over the manufacturing process as possible,” he said.

“Our equipment isn’t just being assembled in Australia – we use Australian suppliers wherever possible,

designing the machines to use locally obtainable parts.

“This means that if we ever don’t have something in stock, we can quickly get it from our supplier, minimising delays and downtime.”

The company aims to be a longterm business partner for its customers, which is why it works alongside them to find the equipment that is suited to their needs and budget.

Wilson said this customer service is what has led to Packweigh’s success.

“We spend time with our customers, give them all the options up front, explain what everything does and don’t take anything for granted,” he said.

“We discuss their needs and do all the layout, drawings, and planning to make sure they get the right tools for the job.”

AUSTRALIAN MADE 36 І Australian Bulk Handling Review: July/August 2023

The company manufactures and ships its products from its Brisbane-based factory.

“Everybody’s different, which is why we design to suit the customer’s needs.”

The process usually involves determining what the customer wants out of the packaging equipment. Wilson will then help design a potential solution that is iterated upon before being implemented.

Feedback from clients has been

positive, with some doubling their output with half of their staff, leading to returns on investment in as short as six months.

The company manufactures and ships its products from its Brisbanebased factory. There, it has the space to assemble full bagging lines and customers can even visit to see the equipment in operation.

The company moved two years ago to accommodate Packweigh’s growth.

“We’re building bigger machines now and can take advantage of the larger space,” Wilson said.

“It’s led us to gaining more market share, which has led to even more growth. We’re looking forward to continue expanding and supporting the Australian market.”

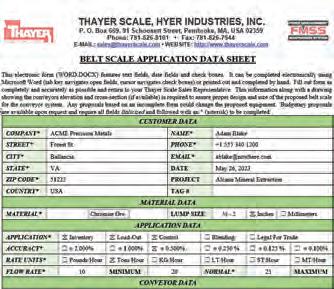

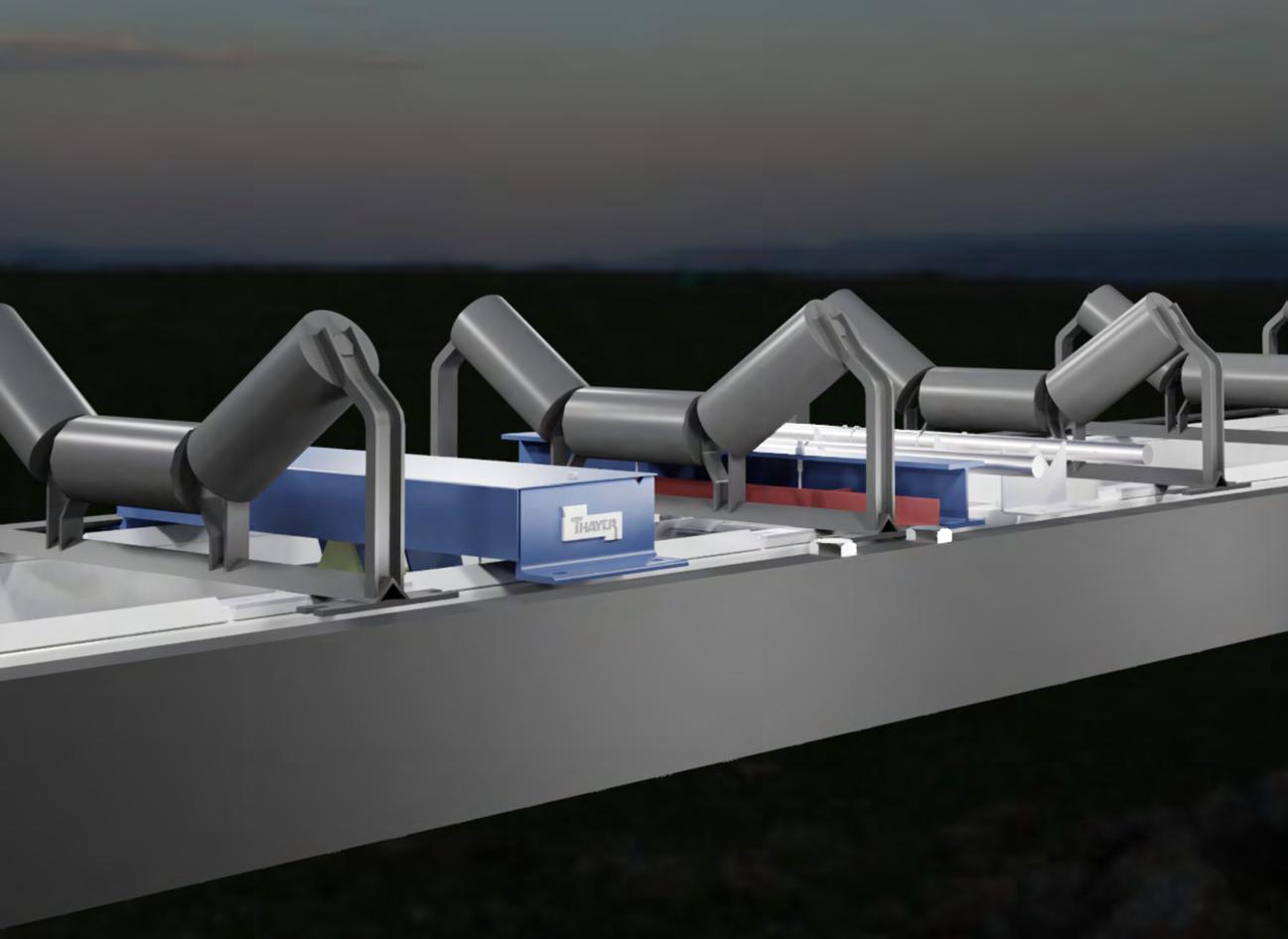

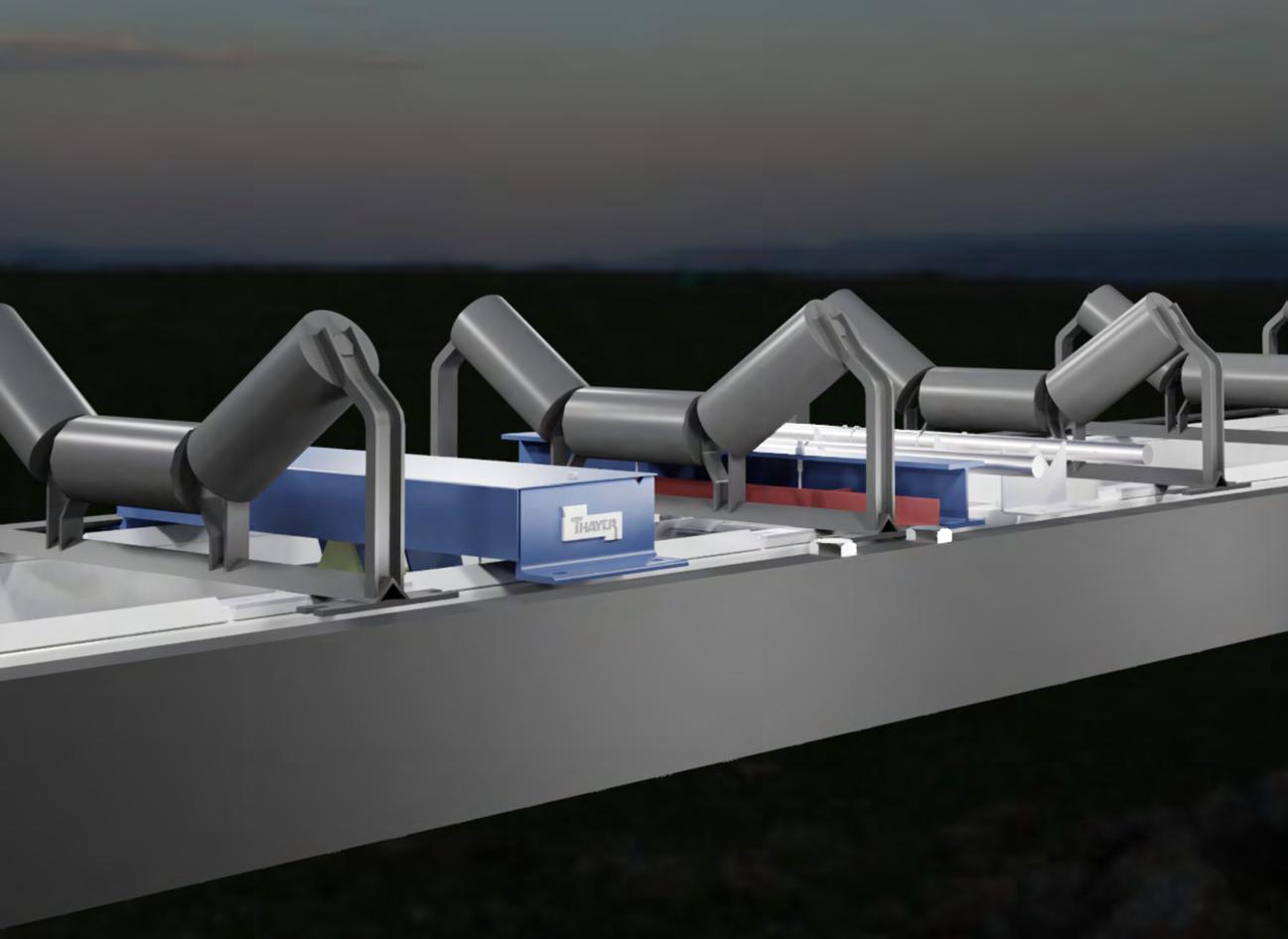

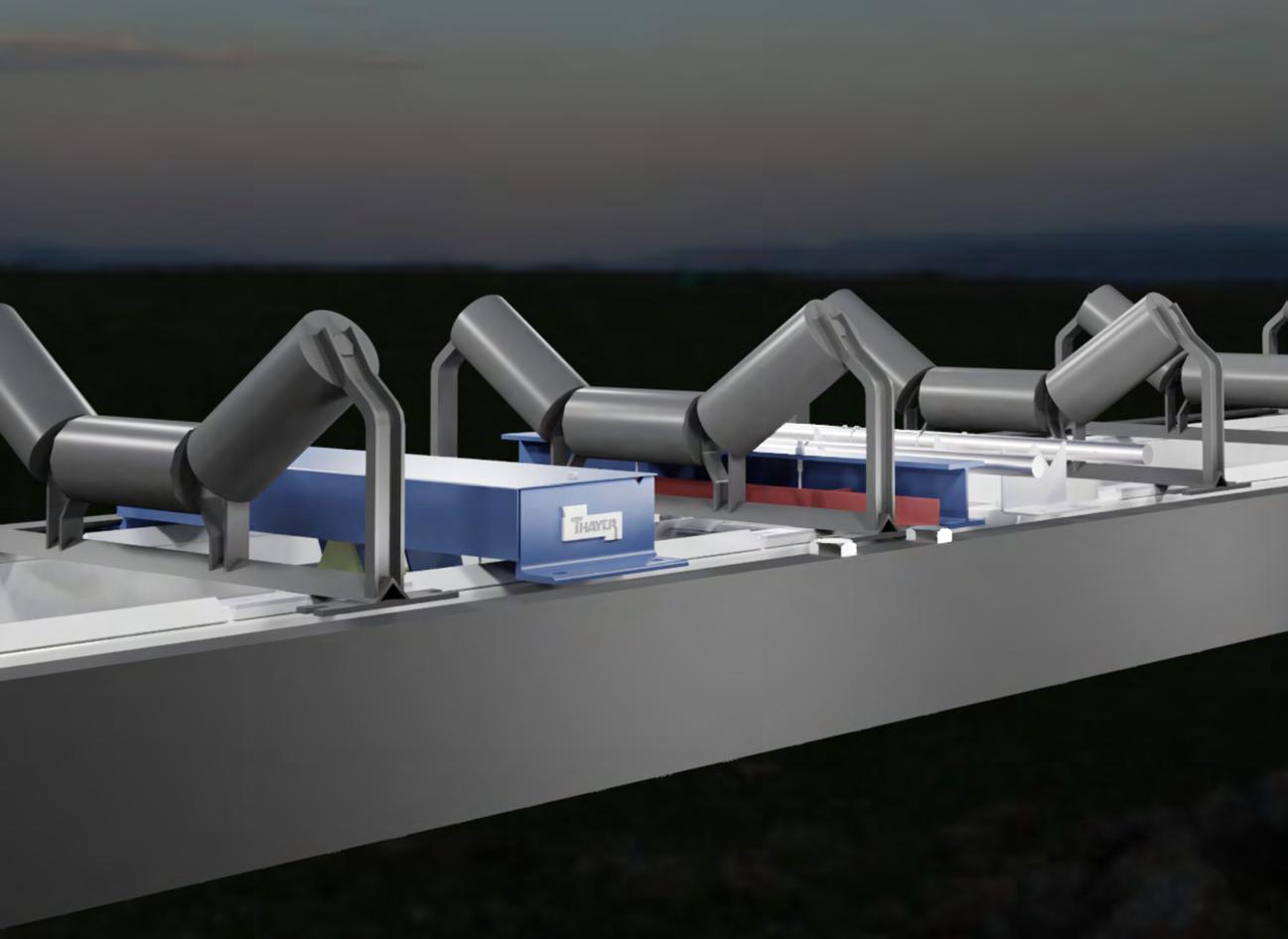

TheLeaderinBeltScale InnovationSince1964

ThayerScalehasmanufacturedhighaccuracyandcertified-for-trade beltscalesforover50years.Many,ifnotmostofthefeaturesinmost current-generationbeltscaledesignswereoriginallyintroducedby ThayerScale.Wecontinuetoleadthewayininnovationandexcellence.

TolearnhowThayerScaleachievesbetterthan+-0.1%accuracyon eventhemostextremebeltscaleapplications,contactustoday.

Thayerscale.com +1781.826.8101

Packweigh can assemble full bagging lines.

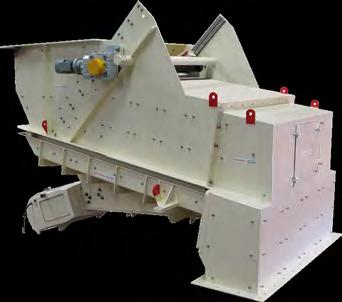

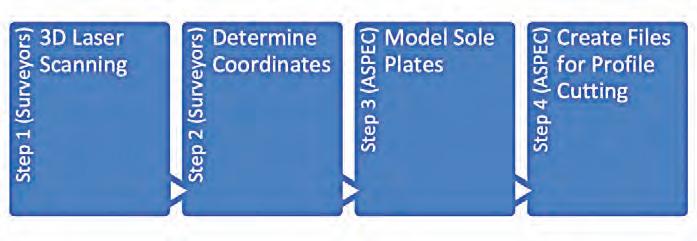

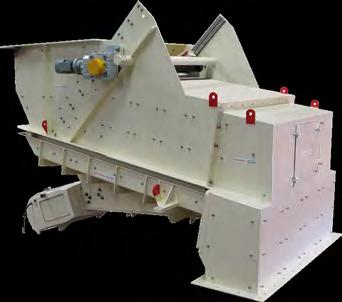

Finding new markets

SINCE INCEPTION IN 1987, Transmin has become a major player in bulk handling equipment for the mining and minerals processing sectors in Australia and overseas. The company has experienced significant growth in the last few years. To maintain that growth, several strategies are being implemented which include structural change, product development, innovation, supply chain growth and team building.

One of the products which has benefited greatly from recent changes is Transmin’s reagent plants, which play a core role in mineral processing. Reagents such as lime, flocculant, soda ash, guar, and other materials are used within mineral processing activities to control pH, clarify solutions or aid in the chemical reactions taking place during mineral extraction.

Reagent plants have always played a core role at the Western Australian manufacturer. In fact, reagent plants are where everything started for the company, when it commenced business supplying reagent preparation plants to the WA gold mining industry.

Phil Gilbert, director of capital sales and business development at Transmin, has been with the company for twenty years and has seen reagent plant business grow substantially alongside the mining industry. Other parts of the business including feeders, rockbreakers, bin isolation gates and grinding media handling systems also grew rapidly, especially during several mining booms.

He told ABHR that Transmin had grown significantly in the iron ore and hard rock sectors and is looking to grow further in other expanding industries both in Australia and overseas.

“For example, due to the growth in demand worldwide for battery technology, there’s a huge amount of activity in the rare earth minerals and lithium at the moment,” he said.

“A few years ago, most of our business was supporting the iron ore industry with feeders, rock breakers and gates. While we’re still very active in these areas, we’ve seen a major upsurge in the reagent side of the business.

“Since the start of the 2022 financial year, we’ve secured about 12 reagent projects for sectors such as lithium, water treatment, rare earth and gold, some of which are of a substantial size.”

To strengthen its offering and ability to deliver projects more effectively, Transmin has changed its structure to three ‘product vertical’ streams each focusing entirely upon a specific range .

Historically, equipment for the iron ore industry needs to be heavy duty to handle the intense loads and operating conditions they are exposed to. For other industries and mining sectors, Transmin has developed the design of its equipment to better suit the different materials and the conditions they will face.

For example, the company has designed a new range of feeders for the tailings reclamation projects.

It has also grown the capability of its team, training its staff to be experts on

their product lines. By turning its staff into specialists, Transmin can offer more detailed expertise.

Gilbert said that sourcing of new employees and employee retention can be a challenge at the moment.

“Mining companies and suppliers are all competing for the best talent in what is a fairly limited market, especially in Australia, we are all fishing in the same pool in terms of employees,” he said. “That can make things tricky as there is a shortage of qualified and experienced people.”

“We’ve had to be creative with our policies of employee engagement and retention which is working well.”

Transmin’s specialists work closely with its customers to determine what will work best for the specific project. Often, the company’s customers are looking

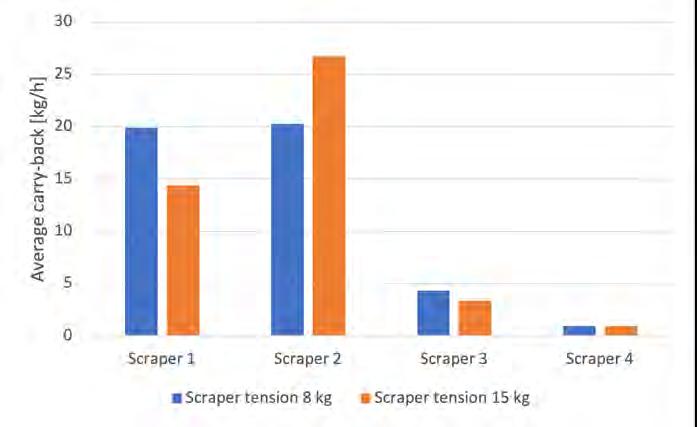

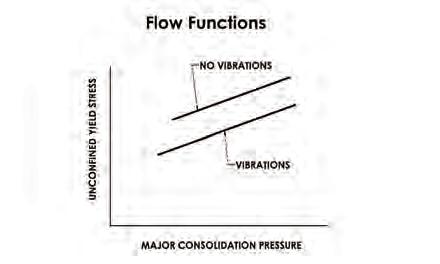

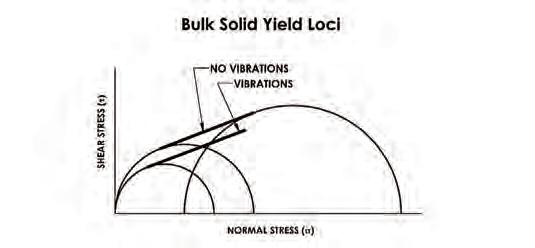

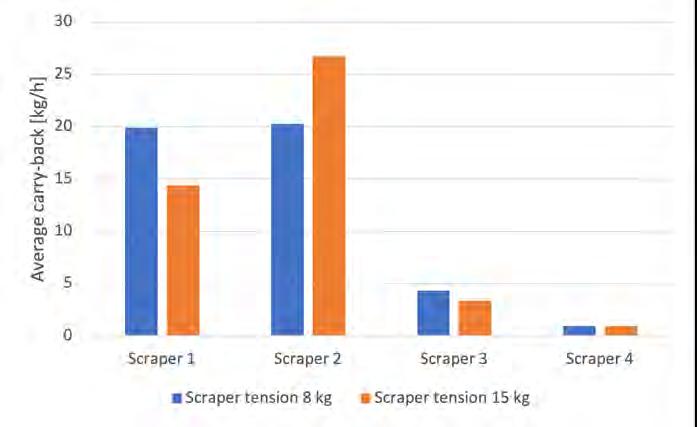

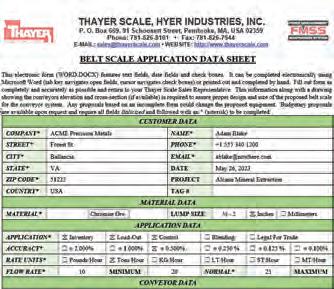

PROCESSING 38 І Australian Bulk Handling Review: July/August 2023