In this issue: Discussing dust Grain handling solutions New technologies www.bulkhandlingreview.com VOLUME 28, ISSUE 5 | SEPTEMBER/OCTOBER 2023 MATERIAL RECEPTION IN BULKTHE ORIGINAL LOW PROFILE FEEDER

Supplying equipment that meets legacy businesses’ needs while offering benefits for tomorrow’s industry is a tough task. Transmin has embraced this challenge, incorporating innovative concepts into its technological offering. ABHR sat down with the company’s director of capital sales and business development, Phil Gilbert, to discuss how its Low Profile Feeder (LPF)

modernised since it was first unveiled in 2009. For

Australian Bulk Handling Review: September/October 2023 І 3 CONTENTS SEPTEMBER/OCTOBER 2023 44 40 26 16 In this issue: Discussing dust Grain handling solutions New technologies VOLUME 28, ISSUE SEPTEMBER/OCTOBER 2023 MATERIAL RECEPTION IN BULKTHE ORIGINAL LOW PROFILE FEEDER

STORY: HYBRID HEROICS

COVER

been

the full story, see page 14 6 Industry news 14 Hybrid heroics 16 Netting 70 years of business 18 A royal exhibition 20 Collaboration delivers packaging success 22 Cushioned vibrators committed to quality 24 Tecweigh keeps bulk handling productive 26 Automated conveyors feed pharma powders 28 Family fights food shortages 30 Bulking up bags 32 No Croc: New belt cleaner technology unveiled 34 Smarter material handling through new technology 36 Keeping it clean pays off 40 Page Macrae Australia: Guiding industry 50 Rail clamp failure modes and maintenance 54 Leveraging unrealised value through characterisation 54 Industrial applications of numerical modelling in bulk materials handling 62 Member profile: Jacob Stecher Dust control 42 No longer gone with the wind 44 Don’t get lost in the fog 46 BULKtalk: Dealing with dust

has

Published by:

379 Docklands Drive Docklands VIC 3008

T: 03 9690 8766

www.primecreativemedia.com.au

COO

Christine Clancy

E: christine.clancy@primecreative.com.au

Editor William Arnott

E: william.arnott@primecreative.com.au

Journalist

Adam Daunt

E: adam.daunt@primecreative.com.au

Business Development Manager

Rob O’Bryan

E: rob.obryan@primecreative.com.au

Client Success Manager

Janine Clements

E: janine.clements@primecreative.com.au

Design Production Manager

Michelle Weston

E: michelle.weston@primecreative.com.au

Art Director

Blake Storey

Design

Michelle Weston

Subscriptions

T: 03 9690 8766

E: subscriptions@primecreative.com.au

www.bulkhandlingreview.com

The Publisher reserves the right to alter or omit any article or advertisement submitted and requires indemnity from the advertisers and contributors against damages or liabilities that may arise from material published.

© Copyright – No part of this publication may be reproduced, stored in a retrieval system or transmitted in any means electronic, mechanical, photocopying, recording or otherwise without the permission of the publisher.

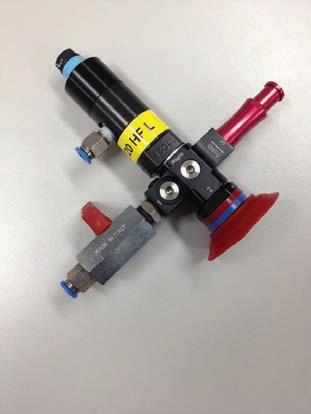

Defeating dust

Dust is an unfortunate by-product of the bulk handling process. Whenever most bulk materials are moved, fine particulates are lifted into the air, escaping into the nearby surroundings.

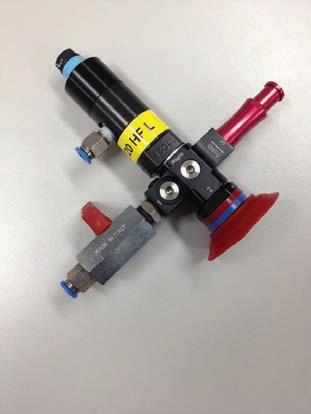

Different materials lead to different types of dust, which bring with them their own headaches. Grain dust, for example, can be highly flammable. When in an enclosed space, such as a silo, all it can take is a spark to create a catastrophic explosion.

When inhaled, dust from coal and stone can lead to a person developing several lung diseases. Over time, inhaling these dusts can lead to inflammation, which leads to the scarring of lung tissue, which can then cause difficulty breathing, and in extreme cases long term damage or death.

Dust also presents a problem for the local environment. Not only can it create a mess on site, building up around equipment and creating hazards to site staff and equipment, but it can also pollute nearby waterways. Due to the potential harm dust can cause, environmental protection authorities around Australia monitor air quality and dust emissions.

For all of these reasons and more, leaders in the bulk handling sector are working towards minimising their dust emissions.

In this month’s edition of ABHR, we are shining the spotlight on the organisations and individuals that are helping cut down on dust.

There is no magic bullet to solving dust emissions, especially because every site has its own needs and specifications that change what might work. Steve Davis uses his BULKtalk column to detail the many different options available for sites to address the problem.

Kinder Australia also showcases its special dust suppression system, the Essential Air Seal. The company uses its specialised equipment and engineering know-how to keep dust contained within a conveyor section. The next edition of ABHR will focus on conveyor maintenance. If you are involved in this vital part of the industry, please get in touch.

William Arnott Editor - ABHR

4 І Australian Bulk Handling Review: September/October 2023

EDITORIAL

1300 258 726 Sales I Service I Engineering Phone: 1300 258 726 Email: sales-australia@regalrexnord.com Altra Industrial Motion Australia Pty Ltd ABN 82 000 780 941 Sydney NSW Perth WA Mackay QLD Newcastle NSW Unit 1 Unit 14 Unit 1 11 Penny Pl 271 Great Eastern Hwy 20-34 Caterpillar Dr 18 Kinta Dr Arndell Park, NSW 2148 Belmont, WA 6104 Paget, QLD 4740 Beresfield, NSW 2322 Ph. 1300 258 726 Ph. 1300 358 26 Melbourne VIC Unit 1 24 Canterbury Rd Braeside, VIC 3195 Ph. 1300 258 726 Ph. 1300 258 726 Ph. 1300 258 726 www.regalrexnord.com www.altramotionaustralia.com

CBH signs major agreements to expand rail fleet

THE CBH GROUP HAS ENTERED into agreements with CRRC Meishan and Wabtec Corporation to expand the co-operative’s rail fleet.

Based in Sichuan province, CRRC Meishan is one of China’s leading manufacturers of quality rail equipment, specialising in the building and distribution of rail cars and grain hopper wagons worldwide.

It will supply CBH with 200 standard-gauge and 450 narrow gauge grain hopper wagons.

Due to the size of the order, the wagons will be delivered to CBH in seven tranches, beginning in September quarter of 2024, with the last tranche expected to be supplied and accepted by the June quarter of 2025.

Wabtec, a leading global provider of equipment, systems and digital solutions for the freight and transit rail sectors, will build 17 CM20ACi dualcab, diesel-electric locomotives for CBH.

The first tranche of five locomotives will arrive in Australia in the March quarter of 2026 and will be operational soon after. The following second tranche of 12 locomotives will be arriving in the June quarter of 2026.

CBH opened three competitive Request for Proposal (RFP) processes in 2022 for the purchase of standardgauge locomotives, narrow-gauge locomotives and wagons, to expand and strengthen its current rail fleet, which consists of 25 locomotives and 572 wagons.

CBH Chief Executive Officer Ben Macnamara said all three RFP processes have now been completed, marking a step to significantly expand the cooperative’s rail fleet.

“We are pleased to partner with CRRC Meishan, which is recognised internationally as a global leader in the design, manufacture and supply of quality grain hopper

wagons,” Macnamara said.

“Our rail fleet is a key asset for the co-operative and expanding our existing train sets is a strategic priority that is critical for us to achieve CBH’s ‘Path to 2033’ strategy that aims to lift our monthly export capacity to 3 million tonnes by 2033 or sooner.

“Expanding our wagon rolling stock, in conjunction with the expansion of our standard-gauge and narrow-gauge locomotive fleets, is a significant step to improve our outloading capability.

“By investing in our supply chain network, we are ensuring we can deliver tonnes to customers when needed and therefore return sustained value to Western Australian growers.”

CRRC Meishan Chairman of the Board Pan Shuping said the company was excited CBH had selected CRRC

Meishan for the expansion.

“The new hopper wagons will incorporate innovative designs to allow low wagon tare weight and quick discharge rate,” Pan said.

“CRRC Meishan is committed to working with CBH to bring reliable products for highly efficient operations.”

Wabtec President of Freight Equipment Rogerio Mendonca said the company was excited to be selected for the expansion of CBH’s narrow-gauge locomotive fleet.

“The CM20ACi is a perfect addition to CBH’s growing fleet,” Mendonca said.

“These locomotives will provide CBH with low operational costs, high availability and proven reliability needed to succeed in today’s competitive market.”

NEWS 6 І Australian Bulk Handling Review: September/October 2023

CBH opened three competitive Request for Proposal (RFP) processes in 2022.

decentraliseddrivesystems,plusengineeredsolutionsandafter-salestechnical

TheAustraliandivisionofSEW-EURODRIVEisheadquarteredinMelbourneand issupportedby networkofsales,serviceandassemblycentresinSydney, Brisbane,Mackay,AdelaideandPerth.Backedbyindustryleadingstockholdingand comprehensive24houremergencybreakdownserviceourproductrangeiseasily integratedintoindustrialmachines,formingthebackboneforvertical,horizontalor rotatingsystems.Thecompany’scustomerbaseincludeslarge-scalecorporations

OEM Benefits

• Simple, cataloged selections

• Drawings and 3D Models readily available

• Standardised Interface dimensions

• Ready-to-go solutions assembled from stocked components

End User Benefits

• Modular concept - easy to upgrade - reduced spares

• SEW Australian stock holding of all components - short delivery times

- SEW local aftermarket support

STANDARD DRIVE SOLUTION 5 Stocked Gearbox Base Sizes (Choose from 10 Gearbox Sizes) 72 FleXeDrive Configurations 6 Stocked Motor Platform Sizes (Choose from 17 Motor Sizes) Choose success - start a conversation for your future, today: MELBOURNE | SYDNEY | BRISBANE | MACKAY | NEWCASTLE | PERTH | ADELAIDE www.sew-eurodrive.com.au 1300 SEW AUS (1300 739 287) Scan the QR code to read the whitepaper or for more information: TECHNICAL ENQUIRIES: SEW-EURODRIVEPtyLtd 27BeverageDrive (POBox59) Tullamarine 3043 http://www.sew-eurodrive.com.au/ MrGuidoWagner National EngineeringandProjectsManagerPhone:+61(0)399331000 Fax:+61(0)399331067 guido.wagner@sew-eurodrive.com.au WWW.SEW-EURODRIVE.COM.AU Company background The SEW-EURODRIVEgroup aglobaldesigneranddeveloperof mechanical power transmission systems and motor control electronics, headquartered Bruchsal,Germany.Itsbroadspectrumofintegrated solutionsincludesgearedmotorsandgearunits,hightorqueindustrialgearunits, high-efficiencymotors,electronicfrequencyinvertersandservodrivesystems,

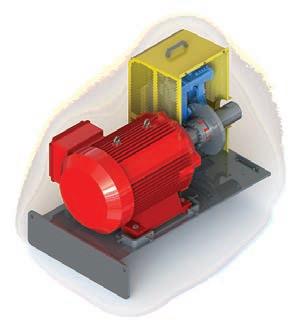

and smaller entrepreneurial enterprises acrossAustralia. Designed to be flexible Mounted a swing base, the FleXeDrive covers broad power range from 37 kW to 630 kW. gearbox base incorporates the gearbox itself, the gearbox cover, coupling, the guard and torque arm.The motor section has components such as coupling, brake discs and guards. However, there is flexibility around these configurations.Aside from the conventional options regarding size, power, speeds and ratios, users can also specify whether not to include a brake or coupling. With this flexibility comes simplicity. Wagner says that if users are familiar with traditional drive bases, they will certainly be able design solutions using FleXeDrive.“Everything at their fingertips, because parameters are standardised and predesigned.The dimensions and different models are all specified it’s easier to work with FleXeDrive than traditional drives, there’s no special training required,” he says. Nevertheless, SEW-EURODRIVE’s hotline support always available, around the clock, every day of year.“And of course, we are always open to having one-on-one discussions with customers to answer their questions and provide further information,” says Wagner. All the benefits of Generation X.e Included with FleXeDrive SEWEURODRIVE’s Generation X.e gearbox, which taken over from the series Tested and ready to go SEW-EURODRIVE has thoroughly tested the design elements and physical characteristics of the new drive solution. Using computer aided design and finite element analysis, the SEW-EURODRIVE has invested large stocks of FleXeDrive components. FleXeDrive is a new product, consisting robust, industrialscale motors and gearboxes available multitude of combinations. the name implies, FleXeDrive is all flexibility. Drawing from stock items, held for the purpose in Australia by SEW-EURODRIVE, OEMs end access to FleXeDrive solutions. The options cover: motor platform sizes; 17 motor sizes; stocked gearbox base sizes; and gearbox sizes. According to Guido Wagner, SEWEURODRIVE National IG, Engineering and Projects Manager, OEMs stand to benefit these simple, catalogued selections the wide range options to choose from. With drawings and 3D models readily available, standardised interface dimensions, is no waiting engineering design the work has already been Likewise, heavy-industry end in sectors such mining, bulk handling, and cement production enjoy short concept-to-production cycle. They receive benefits of EURODRIVE’s new-generation industrial gearbox, Generation X.e. Further, due to modular nature FleXeDrive, end users upgrade easily make savings reduced spares holdings. Stocked components The FleXeDrive range is backed short delivery, built-in quality and reliability, and support that SEW-EURODRIVE clients have expect, including helpline. “The main advantage FleXeDrive is time,” says Wagner. “Traditionally, 12 to 18 locally manufactured solution, with FleXeDrive, now looking delivery times of approximately four to six weeks.” addition to SEW-EURODRIVE’s investment Fast engineering Wagner says this saves customers a lot of time because they can engineer their solutions without having to for customised designs. “They only need from standard The components are ready he says. There also cost advantage because the components are manufactured and stocked in large quantities. added that users FleXeDrive need fewer spares. Because of the modularity and commonality of the new drive family, they can spare components between different FleXeDrive suitable for Australian conditions. saving time and setting new standards In a world that seems to be constantly speeding up, heavy industries like mining are subject to rapid fluctuations in commodity prices. When that happens, they need to quickly ramp up production to meet the changing demand. And that can mean acquiring new infrastructure to support their operations, just as fast. Responding to this kind of demand, SEW-EURODRIVE has introduced FleXeDrive, an industrial drive solution that sets new standards in drive technology, assembled and delivered in industry leading timeframes.

supportandtraining.

Schenck Process Mining to become Sandvik

THE NEXT STEP IN THE integration of SP Mining - the mining related business of Schenck Process acquired by global, high-tech engineering group Sandvik, will see SP mining entities change their names to reflect their new ownership.

On the 1st of October, Schenck Process Australia Pty Limited, which became a wholly owned subsidiary of Sandvik in November last year, will become Sandvik Rock Processing Australia Pty Limited.

The Australian entity is the largest part of SP Mining’s global

business, employing around 450 industry professionals.

Since the acquisition, Sandvik has been focussed on bringing together its expertise in crushing with the screening, feeding, weighing and loading know-how of Schenck Process Mining.

The company’s president of Asia Pacific, Terese Withington, said the move is part of an integration process which will eventually see SP Mining become a seamless part of Sandvik.

“In Australia, we are bringing together our sales and back-

office teams with those of Sandvik Rock Processing Solutions to allow our customers to access our combined expertise in crushing, screening, feeding, weighing and loading,” she said.

Together we aim to deliver even better digitalisation, sustainability, and productivity solutions to our industry.

“The end goal of our integration is to allow our customers to place combined crushing, screening, feeding, weighing and loading orders with our new legal entity.”

Withington said the scale of Sandvik’s operations and commercial reach will help to accelerate the combined innovation portfolio of Sandvik Rock Processing Solutions and SP Mining.

“We look forward to continuing to service the business needs of our customers and remain fully focused on the delivery of high-quality equipment, consumables, OEM spare parts and services to help them achieve their business objectives,” she said.

Frucor Suntory signs renewable energy deal

BEVERAGE MANUFACTURER

Frucor Suntory has signed an agreement with CleanCo to secure clean energy for its new beverage manufacturing facility at Swanbank, Queensland.

The facility will be powered by 11 GWh of publicly owned renewable energy as part of the deal.

Queensland Assistant Energy Minister Lance McCallum said the deal means more local jobs through clean energy as one of the world’s biggest companies delivers on their ambition for their new facility to be a

net zero operation.

“Frucor Suntory’s new factory at Swanbank will include beverage processing, packaging, warehousing, and distribution, and is expected to deliver around 450 construction and installation jobs while also creating 160 long-term roles when it starts operating in mid 2024.

“It’s Queensland’s clean energy that is enabling businesses to plan for future growth, and importantly, our investments are ensuring Queenslanders continue to own the energy assets that

will drive our renewable future.”

Frucor Suntory CEO Darren Fullerton said the company wants its new Swanbank facility to set a benchmark for sustainable investment.

“Working with partners like CleanCo is essential to helping us achieve that vision and will allow us to operate with 100 per cent Green Energy when the site goes live in mid-2024,” Fullerton said.

CleanCo CEO Tom Metcalfe said the publicly owned organisation is proud to provide its customers with sustainable retail products.

NEWS 8 І Australian Bulk Handling Review: September/October 2023

The move is part of an ongoing integration process.

Safeguard your operations

& reduce washdown splashback

HDPE Conveyor Guards

DYNA Engineering has developed a “chamfered mesh pattern”, designed to reduce washdown splash back and increase visibility through the guard panels.

This design feature is a major “point of difference” compared to standard HDPE mesh and will improve inspection and cleaning operations.

Washdown Mesh

• Up to 50% additional spray-through for washdown.

Increased Visibility

• Up to 25% additional viewing angle and see-through visability.

1800 801 558 dynaeng.com.au

ROBUST ✓ LIGHTWEIGHT ✓ ECONOMICAL ✓

Washdown Mesh Standard Mesh

A LANDMARK AGREEMENT

between the members of the Pilbara Industry Roundtable (PIR) has recognised the importance of increased use of renewable energy in the region.

“This agreement is a historic accord between Government and key industry players in the Pilbara, recognising that to reach our ambitious decarbonisation goals common use electrical infrastructure is key,” WA Energy Minister Bill Johnston said.

“This is a landmark agreement for our clean energy future and the economic development of the Pilbara and our State.

“The agreement recognises that electrical infrastructure development should empower local Aboriginal groups.”

Members of the Pilbara Industry Roundtable include Johnston and representatives from Rio Tinto, BHP, Fortescue, Roy Hill, Woodside Energy, Horizon Power, Alinta Energy, BP, TransAlta, Pilbara Independent System Operator Company, and the Chamber of Minerals and Energy of Western Australia.

The PIR met four times in the past year to oversee a works program modelling future electricity demand scenarios.

It assessed the current regulatory framework, examined land tenure arrangements, and explored social licence with a focus on empowering local Aboriginal people.

The PIR agreement recognises

Pilbara industry agrees to support renewable energy Preventing explosions with proactive maintenance

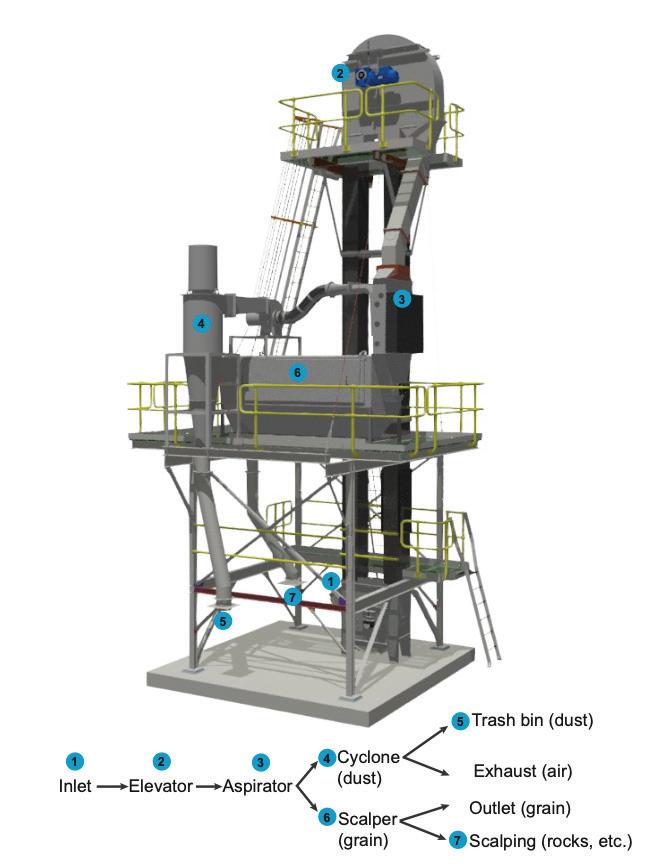

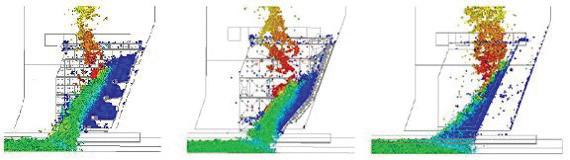

AT ONE OF LONDON’S LARGEST grain import/export terminals, there are more than 50 conveyors and elevators operating every day, running at high speeds.

The elevators are more than 65m above the ground and the largest conveyors run in both directions.

The grain terminal, which is more than a kilometre long, can store more than 250,000t of grain, and has more than 300 critical sensing points.

At this site, a collapsed bearing sparked a serious conveyor fire that spread to ancillary equipment and caused several hundred thousand pounds worth of damage.

Following the fire, the terminal needed a solution that was ATEX approved and industrial Internet of Things compliant to

ensure the investment was future proof and expandable.

The Port Authority began working with 4B’s in-house installation team, who delivered a full turnkey solution, training and ongoing support.

4B IoT solution Hazardmon.com was used as the framework of this project. The company’s proprietary HOTBUS communication platform was selected as a means of connecting all the sensors together and aggregating the data.

The sensors are continuously monitored, and the resulting data is analysed in the cloud enabling predictive analysis and smart reporting.

Management and operators quickly embraced the system benefits with information being readily available via web- enabled devices both on and off-site.

the challenges and opportunities that decarbonisation presents for industry and the region.

WA Climate Action Minister Reece Whitby said this is a significant step towards a clean energy future.

“It’s important we work together with major resources companies to reach our ambitious decarbonisation targets,” Whitby said.

“Our vision is for Western Australia to become a world leader in renewable energy. Our Government is committed to achieving net zero greenhouse gas emissions by 2050.

“Decarbonising WA’s economy to protect our environment for future generations is essential to the growth and diversification of our State.”

This solution was selected to be flexible, scalable and robust.

Since installing the system, it has prevented at least three explosive risk incidents. It has also reduced the number of belt misalignment conditions by a factor of 20 and improved operational safety by alerting staff of hazards immediately so that action can be taken.

NEWS 10 І Australian Bulk Handling Review: September/October 2023

A collapsed bearing sparked a serious conveyor fire that spread to ancillary equipment.

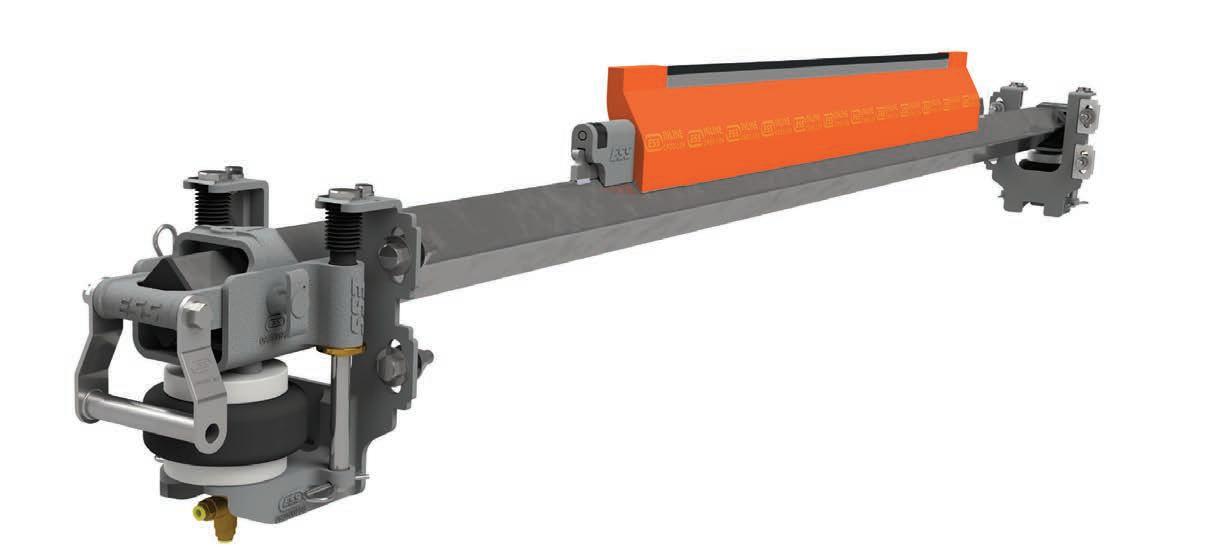

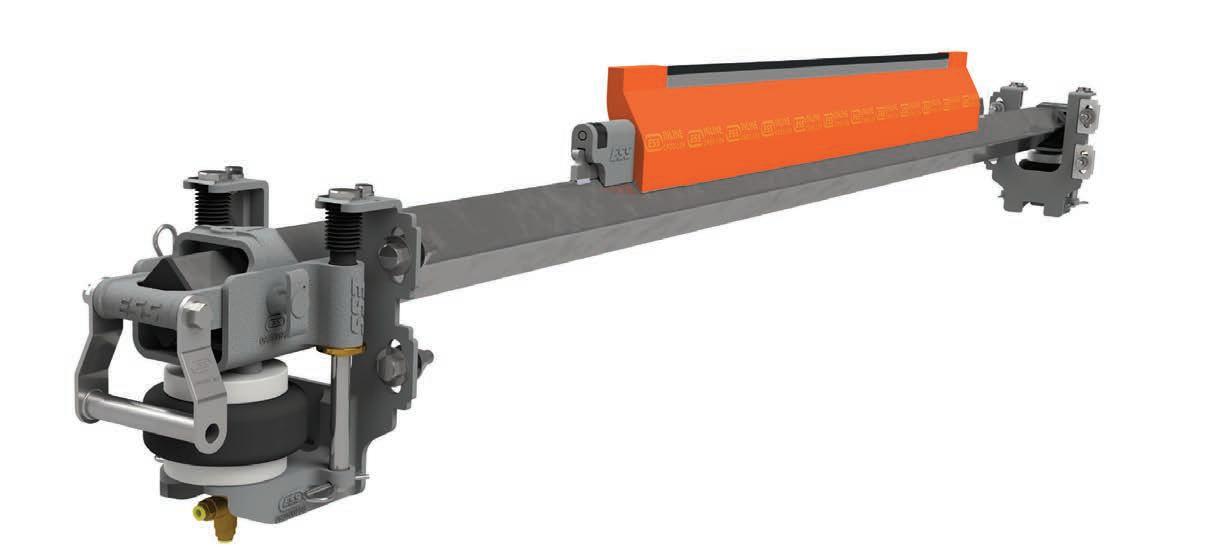

ESS CROC-LOCK

When carry-back is allowed to move past the transfer point and back along the return strand, it leads to decreased efficiency, increased maintenance costs, and potential environmental hazards.

Belt Cleaners are the standard solution to carry-back, ensuring smoother operations, reduced maintenance costs, and enhanced environmental responsibility. However, servicing belt cleaners pose their own challenges and manual handling safety risks.

ESS’ introduces its new generation of Secondary Belt cleaners - The ESS CROC-LOCK Secondary Cleaner!

With ESS’s 40 years of experience designing, manufacturing, installing and servicing belt cleaners, ESS’s new design seeks to improve the ability to service and lessen manual handling risk.

FEATURES AND BENEFITS OF ESS CROC-LOCK:

• Diamond Shaped Mainframe and Cartridge - Removes flat surfaces to minimise fines build up.

• Female blade covers the Male locking track - minimising the ingress of fines.

• Tapered Locking Mechanism - Makes it easier to disengage the blades from locking teeth for quicker maintenance.

• Blades self-lock together - Only one blade retaining lock is required.

• Blade has a curved profile - Minimises fines build-up

FOR MORE INFORMATION ABOUT ESS CROC-LOCK SECONDARY CLEANER VISIT: WWW.ESSENG.COM.AU

ENGINEERING SERVICES & SUPPLIES PTY LTD

Ph: 1800 074 446 www.esseng.com.au

Proudly Australian

Gala dinner to celebrate women in industry

The Women in Industry Awards will return in 2024, with winners to be announced on June 20 in Sydney.

FOLLOWING A RECORD-BREAKING event in 2023, the Women in Industry Awards are slated to return next year.

The awards recognise exceptional women who have achieved success through leadership and innovation across traditionally male-dominated industries like bulk handling.

It is an opportunity to highlight the women who are driving change in the industry, and to help break down barriers and create new possibilities. These may be women you work with, women whose achievements are inspiring you from afar, or women who are providing you with invaluable guidance and support.

The 2023 event had 160 nominations across 10 categories and a 95 per cent growth compared with 2022. The gala dinner sold out for the first time in the event’s history, with a 55 per cent increase in attendance on 2022.

Sponsorship opportunities for the 2024 Women in Industry edition are now available. The Women in Industry Awards provide a unique opportunity for progressive businesses to get

onboard and demonstrate their support of women in their workplace.

Four sponsors have already signed up to support the 2024 awards: Atlas Copco, SEW-Eurodrive, Fulton Hogan, and Paccar.

Nominations for the event will open close to the event. The categories are:

RISING STAR OF THE YEAR –Sponsored by Atlas Copco

Recognising an individual who has shown significant promise within their chosen industry or who has reached new goals at the start of their career.

BUSINESS DEVELOPMENT SUCCESS OF THE YEAR

Recognising an individual who has created new growth opportunities that has allowed their organisation to expand and generate greater revenue.

INDUSTRY ADVOCACY AWARD

Recognising an individual who has helped shape a positive view of their industry and/or helped to create a policy change that benefits those working in the sector.

MENTOR OF THE YEAR

Recognising an individual who has demonstrated a commitment to developing female talent within their organisation or wider industry.

SAFETY ADVOCACY AWARD

Recognising an individual working actively to improve safety for their industry.

EXCELLENCE IN MANUFACTURING –Sponsored

by PACCAR Australia

Recognising an individual who has thought ‘outside the box’ to implement an outstanding personal contribution to their manufacturing business and the wider manufacturing community.

EXCELLENCE IN TRANSPORT

Recognising an individual who has gone above and beyond to improve and positively impact the Australian transport industry.

EXCELLENCE IN ENGINEERING –Sponsored by SEW-EURODRIVE

Recognising an individual who has

12 І Australian Bulk Handling Review: September/October 2023

EVENTS

shown leadership in engineering, technological excellence and innovation.

EXCELLENCE IN MINING

Recognising an individual who has made a positive contribution to one of the many facets of the mining industry.

EXCELLENCE IN CONSTRUCTION

Recognising an individual who has made a positive contribution to one of the many facets of the construction industry.

WOMAN OF THE YEAR – Sponsored by Fulton Hogan

Woman of the Year is chosen from the winners of the other Awards categories.

THE WORLDWIDE LEADER IN VIBRATION TECHNOLOGY

FLOW AIDS

Any solution for your needs

OLI is the world’s top selling manufacturer of electric and pneumatic vibrators. The high level of customer service, guaranteed by 18 trading subsidiaries worldwide, and long-lasting and performing products make us always ahead.

The flow aids range of products offers any solution for your needs and helps you to increase the process efficiency and improve the plant safety.

OLI Vibrators Pty Ltd. 7 Jellico Drive, Scoresby Vic 3179, Australia - Phone: +61 3 9764 9988 - Mail: info@olivibrators.com.au - www.olivibrators.com.au

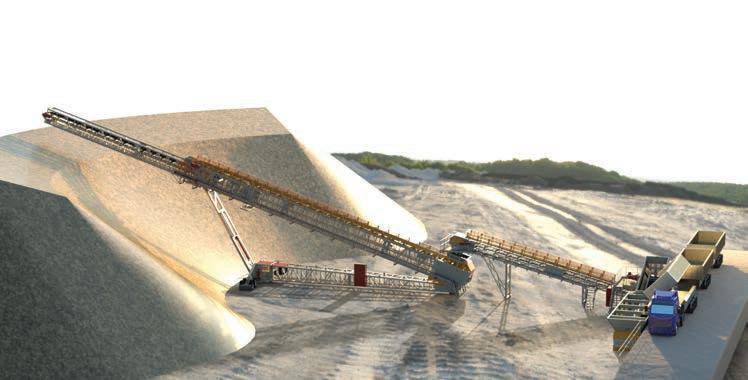

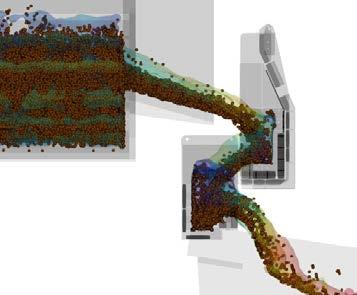

Hybrid heroics

Transmin has combined the best of apron and belt feeders to benefit businesses in legacy and emerging markets

SUPPLYING EQUIPMENT THAT

meets legacy businesses’ needs while offering benefits for tomorrow’s industry is a tough task.

Transmin has embraced this challenge, incorporating innovative concepts into its technological offering.

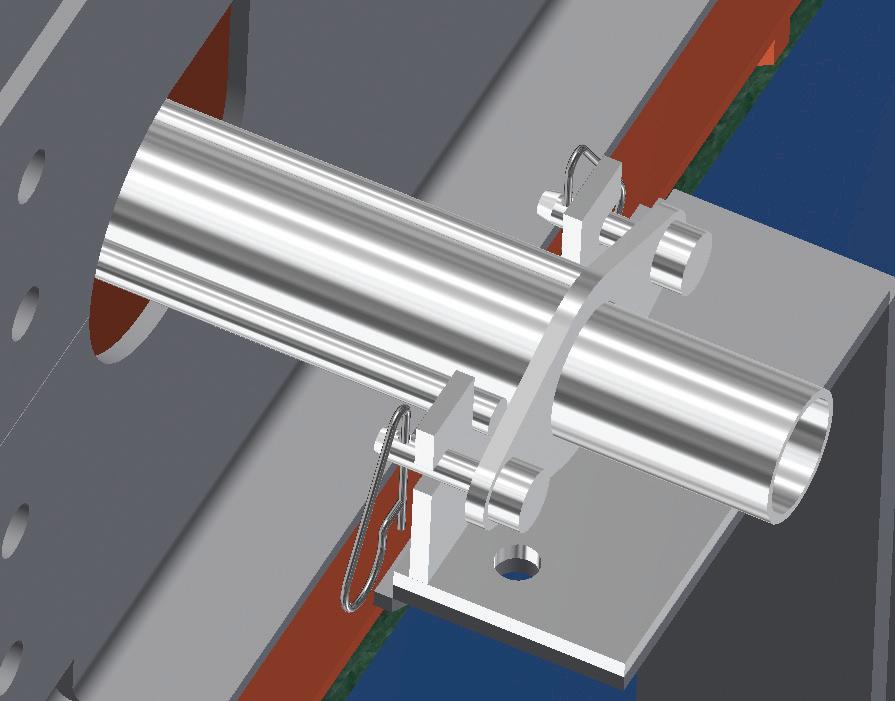

ABHR sat down with the company’s director of capital sales and business development, Phil Gilbert, to discuss how its Low Profile Feeder (LPF) has been modernised since it was first unveiled in 2009.

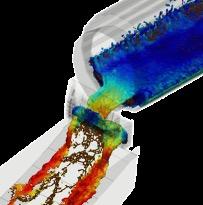

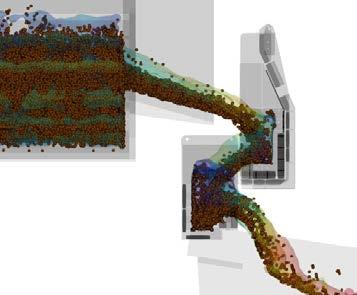

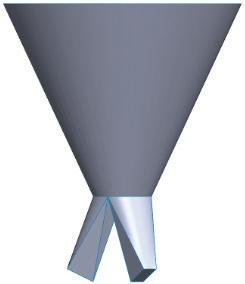

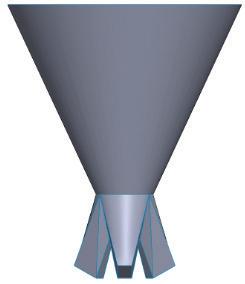

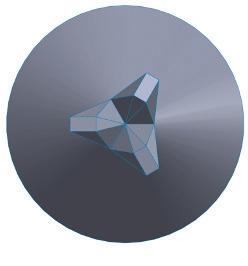

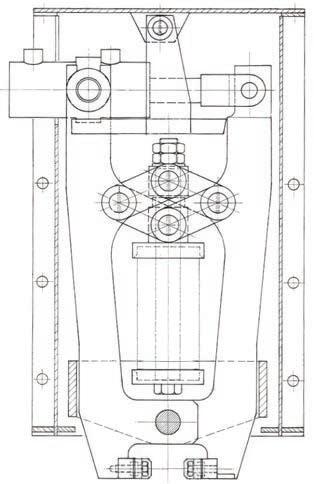

He said the LPF combines the best parts of an apron and belt feeder into a modern hybrid machine.

Slats secure the low-profile feeder belt, the whole assembly being positively driven by chains and sprockets, eliminating the issues of miss-tracking and wandering associated with wide belt feeders.

The belt of the low-profile feeder reduces spillage when compared

with an apron feeder, where the interlocking pans can be difficult to clean and lose valuable product as they return underneath.

“We have the benefits of both types of technology rolled into one design in the low-profile cleaner. It has proven extremely successful,” Gilbert said.

“The ability to change direction by the introduction of a special bend section is unique. Neither a belt nor apron cleaner can do that, but it is a benefit that has been attractive to our customers.

“So, while the feeder can do similar functions as an apron or belt feeder, it doesn’t come with some of the problems of those feeders and can save space, especially at the discharge end.”

The LPF can be made wider, units up to four metres wide and over 55m long have been installed. Customers can have trucks tip into the feeder without needing another service point, saving upfront costs.

The feeder’s ability to curve and change direction allows businesses to use the machine to move products to different areas on-site while saving on horizontal space.

“The ability to tip into the machine, have it go horizontal or extend upwards in one machine is unique to the feeder,” Gilbert said.

“In the case of rare earth operators, for instance, they’re bringing their product in on trucks so the low-profile feeder can be configured to suit a sidetipping truck or end-tipping truck to tip into the machine.”

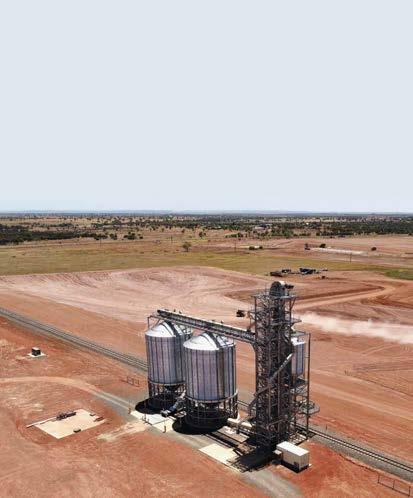

The versatility of the Low Profile Feeder has proven popular in Australia and overseas. Transmin has developed successful partnerships with customers in over 60 countries, including Brazil, South Africa, and Canada.

In one case, an Australian opencut gold mine struggled to extract its stockpiled product sufficiently.

COVER STORY 14 І Australian Bulk Handling Review: September/October 2023

Transmin has supplied companies across the world including Brazil, South Africa and Canada.

A secondary tunnel was expensive, while a front-end loader was too labour intensive.

The LPF could be set at a low height and incline, which meant it could be a feeder and conveyor to extract and carry from the stockpile. This simple setup enabled the mine to save on civil costs and space and achieve proper stockpile extraction.

The span of the low-profile feeder’s success has seen it venture into several industries, including agriculture, iron ore mining and critical mineral mining operations specialising in rare earth batteries.

Innovation is a crucial tenant of Transmin’s business to ensure its customers receive progressive machines like the low-profile feeder. Recently, the company employed an innovation manager to bolster its success in this space.

The company has a proven track record of matching its designs to customers’ briefs to maximise its operations. An iron ore operation in Newman, Western Australia, benefitted from the wider low profile feeder belt which matched the new generation of super wide screens in its processing facility.

Transmin built the LPF with a low vertical envelope to save the customer space while it operated one of the largest feeders on the market specifically made to suit iron ore.

This part of the company’s objective is to help businesses in other sectors, like agriculture or dry tailings, to enhance their operations with Transmin technology.

“We’ve recognised from a strategic sense that we need to develop and innovate for our customers,” Gilbert said.

“That’s why we’ve set up the innovation department for Transmin products to help develop them for new markets and applications and help them boost their business.”

The development is set to usher in an exciting era for the company. Transmin believes the low-profile feeder can have broader applications in more mining sectors, including the dry tailings space.

The company is developing fivemetre-plus wide machines to fit beneath the filter presses in modern dry tailings plants.

This innovation has overseas companies interested in how the LPF can be converted to suit the sector.

Australian Bulk Handling Review: September/October 2023 І 15

The Low Profile Feeder has proved applicable to several bulk handling industries including mining and rare minerals.

The Low Profile Feeder combines the best technology of the apron and belt feeders into a hybrid.

Netting 70 years of business

NetterVibration Germany is celebrating its 70th anniversary of concentrating exclusively on producing vibration technology.

JEAN

NETTER FOUNDED

NetterVibration in 1953 with a goal: serve industry with vibration.

Since then, the company has grown significantly, now with 120 employees in head office, expanding across Germany, and building six subsidiaries across the globe.

One of these subsidiaries is NetterVibration Australia. The subsidiary’s managing director, John Isherwood, told ABHR that the business originally supplied its products to Australia through an agent, but decided to change its strategy around four years ago.

“NetterVibration approached me with a proposal: lead a new subsidiary through a joint venture called NetterVibration Australia,” he said.

“We set up an office and a warehouse in Mandurah, south of Perth, and now sell directly to the customer.”

Whether it is moving pills from a two-litre hopper, to compacting the thousands of cubic metres of concrete required in a dam wall, NetterVibration has the right vibrators for the job.

It has a range of more than 3000 models in electric, hydraulic, and pneumatic drives. Many are held in stock in Australia, with frequent deliveries from the factory, depending upon demand.

Isherwood said the company has developed a solid reputation for quality. Manufacturing is done in Germany, with a few specialised models made under licence in Italy to strict quality control by Netter.

The majority of vibrator parts are now made in the same factory as assembly, with their previous machining sub-contractor integrated into the NetterGroup.

“The business has only ever focused on vibration and improving its products. It’s developed specialist expertise and understands what works and what doesn’t,” Isherwood said.

“There is no compromise in selection of the best vibrator most suited to the project. Factory trained technicians with hundreds of hours of experience will help every step, starting with the calculations, through the choice of best vibrator, the best position for best results and the best method of installation.”

When it comes to selecting the right tool for the job, Isherwood’s team helps customers by analysing the application the device will be used in. There is no ‘one size fits all’ option when it comes to this, so the team will look at drawings and data to narrow it down.

The company’s vibrators have been used in a vast array of applications,

from rail car unloading, to packaging, to assisting with silo flow.

“Anybody who has a storage bin –whether its flour, uranium or iron ore – will have to deal with hang-ups and blockages,” Isherwood said.

“The material properties can also change if there’s a change in moisture, or particle size. Our vibrators can be installed to handle almost any potential combination.

Isherwood said the company plans to continue expanding in Australia, following its rapid early growth.

“We’re working closely with clients to help them achieve the best outcomes for their processes.”

VIBRATORS

16 І Australian Bulk Handling Review: September/October 2023

NetterVibration has 120 employees located at its head office.

The company can deliver vibrators, large or small.

4B Australia Building 1, 41 Bellrick Street, Acacia Ridge, 4110, Queensland, Australia Tel: +61 (0)7 3216 9365 Email: 4b-australia@go4b.com www.go4b.com 4B DESIGNS AND MANUFACTURES COMPONENTS FOR BUCKET ELEVATORS AND CONVEYORS ELEVATOR BUCKETS ELEVATOR BOLTS BELTING & SPLICES PREVENTATIVE MAINTENANCE & HAZARD MONITORING SYSTEMS CONVEYOR CHAIN BEARING TEMPERATURE SENSORS SPEED SWITCHES BELT MISALIGNMENT SENSORS LEVEL & PLUG SWITCHES Engineering Solutions Since 1888 A Worldwide Manufacturer

A royal exhibition

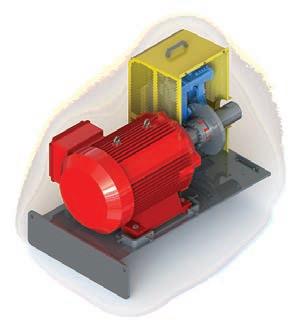

Regal Rexnord showcased some of its newest technologies at this year’s AIMEX event. ABHR spoke to Rex Sinclair to find out what was on display.

THE ASIA-PACIFIC’S

International Mining Exhibition (AIMEX) is one of the country’s longest running mining trade shows. The event provides a platform for suppliers to highlight their latest technological developments.

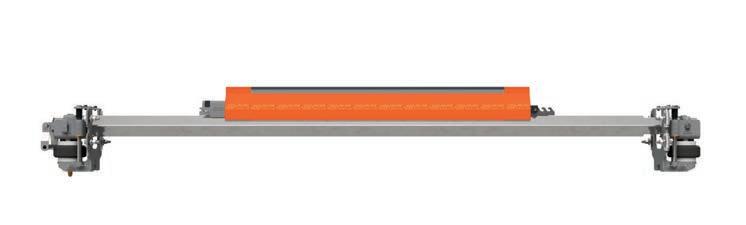

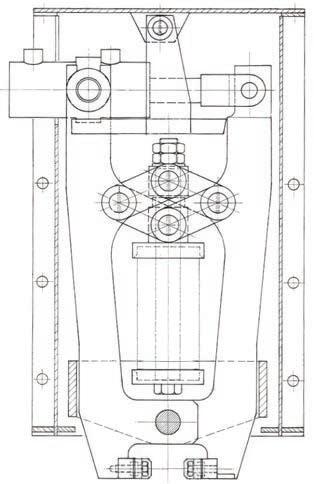

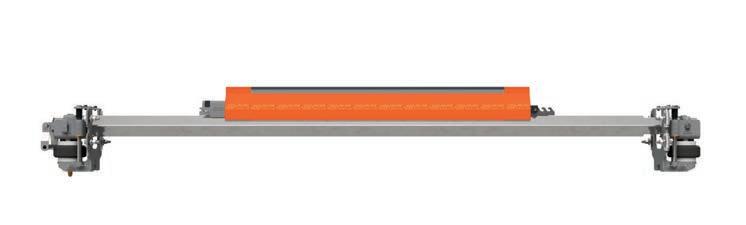

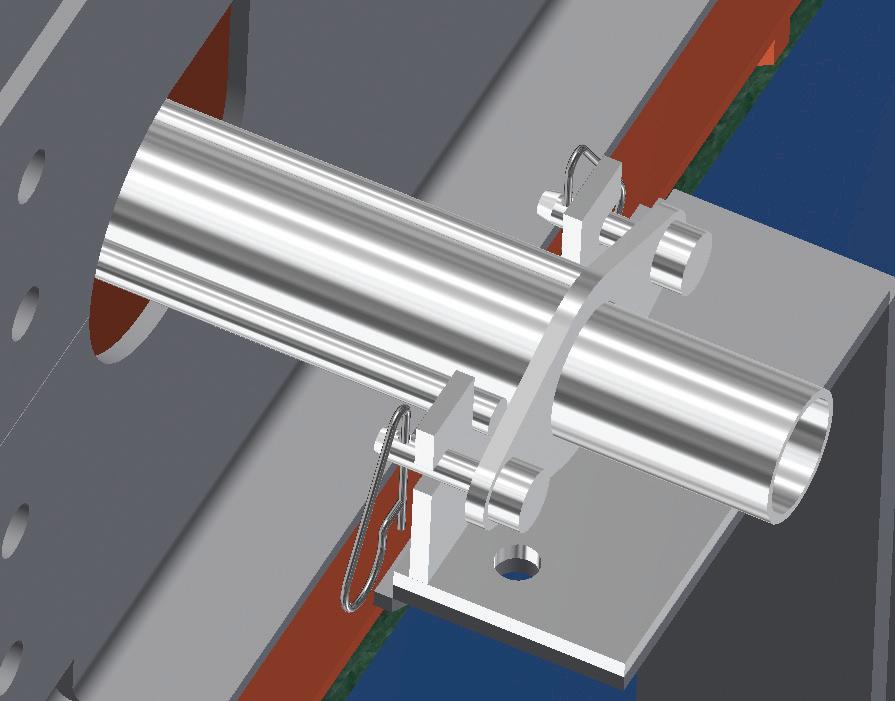

Regal Rexnord featured a range of advanced power transmission solutions in its stand, including Stieber torque limiting, releasable backstops. Primarily used on large inclined conveyor applications, these backstops are designed to be mounted onto the conveyor’s gearbox or directly onto the pulley shaft. Because they can operate in the reverse direction, it allows mines to run a conveyor in reverse for maintenance purposes.

Rex Sinclair, Regal Rexnord’s national sales manager, explained this unique backstop offering has significant safety benefits.

“The design includes bearings installed to support the backstop – almost no other backstop has that kind of functionality,” he told ABHR. “With a fixed backstop, belt clamps and chain blocks are needed to release tension on the belt – that’s not necessary with the Stieber resealable design.”

“It makes belt or roller changeouts a lot safer, quicker and easier.”

The torque-limiting, releasable design was based on meeting customer’s needs. Sales have increased steadily increased as more mine operators

understand the benefits. Much of backstop’s popularity is due to the efforts of the Regal Rexnord sales team as they continue to educate design engineers and bulk handling facility operators on the benefits of the product.

EMBRACING IOT

Svendborg Brakes IIoT (Industrial Internet of Things) system was also showcased at the Regal Rexnord stand. The system is designed to support predictive maintenance by filtering and analysing component performance data. Sinclair said this allows operators to be alerted of an issue before it becomes a problem.

“The whole idea is to prevent downtime,” he said. “Across the wider company, Regal Rexnord has a platform called Perceptive. It’s an IIoT system that spans across our brands and products.”

Visitors at the Regal Rexnord stand were also able to learn about Svendborg Brakes’ Universal Control (UC) Case, a unique portable IIoT solution. The UC Case is used as a tool for remote support and data visualisation during commissioning or servicing of Svendborg Brakes conveyor braking systems.

The unique case allows Regal Rexnord technicians to perform remote diagnostics on a brake system’s behaviour. This performance information allows the Regal Rexnord team to provide advice on which actions the mine operator needs to take to prevent a malfunction.

The case can be easily connected to the specific conveyor braking system in question. This can be done by following simple instructions provided - no training is required. The case sends the captured performance data to the cloud, where specialists can troubleshoot for potential faults.

Additional functionalities are being developed to help the UC Case work in environments where internet connections are unreliable.

Sinclair said that AIMEX provided customers with the chance to speak directly to the team of highly experienced Regal Rexnord application engineers at the stand. “It was an opportunity for us to help expand our customers understanding of the wide range of power transmission solutions and technologies we offer that are all designed to help improve their operation’s performance,” he said.

EVENTS 18 І Australian Bulk Handling Review: September/October 2023

Regal Rexnord has a range of advanced power transmission solutions.

“It makes belt or roller changeouts a lot safer, quicker and easier.”

If you need a better way to store dry bulk solids, Nelson can deliver it. Nelson are totally committed to innovative design and product development, and are now engineering silos with a proven 4-leg base design mounted on load cells. This unique Nelson design development ensures accurate weight measurement. For grain, legumes, sugar and flour, and plastic granules, Nelson 4-leg design silos are available in pre-painted steel. For flour, sugar, plc and industrial powder, Nelson are building fully welded stainless steel silos, also with the proven 4-leg design, mounted on load-cells.

With the Nelson CAD programme, we have the capacity to develop a cost effective design package to meet the needs of the industry. We can then engineer your order in our own complex - with a fixed price that will save you up to 50% of the cost of on-site construction.

And Nelson can deliver, install and commission purpose-built silos, with an absolute minimum of lead time.

For all your bulk storage problems, please call Nelson Silos, Rochester Victoria Toll Free on: 1800 801 966 Nelson Silos Suppliers to Australian Industry nationwide T: 03 5484 1577 F: 03 5484 1593 T: 02 6862 3688 info@nelsonsilos.com.au www.nelsonsilos.com.au Head Office NSW Email Website We have technical consultants based in Melbourne, Sydney, Brisbane and Auckland (NZ) Australia’s largest manufacturer of transportable silos.

SUGAR/FLOUR STAINLESS STEEL SILO, INSULATED AND CLAD WITH COLORBOND.

Collaboration delivers packaging success

One of Australia’s leading fertiliser producers has reaped the benefits of adding Italian innovation to its automatic packaging and palletising systems.

FERTILIZER AUSTRALIA HAS

revealed that 5.4m tonnes of fertiliser are sold in Australia each year, with about half of this manufactured domestically. In addition to domestic use, Fertilizer Australia’s data shows Australia exports between 200,000 and 400,000 tonnes of fertiliser each year. This is primarily from fertiliser manufacturer and distributor Incitec Pivot Fertiliser’s (IPF) ammonium phosphate plant in North Queensland. Greater than 90 per cent of the fertiliser used in Australia is sold in loose bulk, which does not require packaging. The remainder of the fertiliser is packed into bags and drums made from various plastics. This packaging protects solid and liquid fertiliser forms for transport, storage and use in smaller volumes.

A fair amount of the fertiliser packed in bags and exported comes from IPF. Its quality fertilisers, plant nutrition and soil health solutions help Australian farmers maximise crop productivity and achieve sustainable plant nutrition outcomes for their soils and farms.

IPF decided to renew its automatic packaging and palletising systems for granulated products a few years ago as part of a broader strategic project. After evaluating a range of international suppliers, among the most important in the world for this type of technology, the choice fell on the Italian manufacturer Concetti.

Concetti has supplied more than 200 fertiliser plants worldwide and acquired expertise in packaging solutions for harsh industrial environments and corrosive products. Concetti manufactured two complete automatic bag weighing, filling, closing and palletising lines at IPF’s Gibson Island (Brisbane) and Kooragang Island (Newcastle) Primary Distribution Centres (PDC). Each consists of a

gravity-fed net weighing system NET/G, a Concetti STARPACK bagging machine and a high-level push-type palletiser.

In addition, the Gibson Island PDC has an end-of-line system for hooding and stabilising full pallets, also supplied by Concetti.

The bags used are the most common type for the fertiliser market, 20-25 kg in woven PP with gussets or pillow-type bags, depending on the needs. Still, the challenges concern the variable density of the various packaged fertilisers, traceability, and how to fight corrosion.

Customised solutions require knowledge of the industry and customer needs

“Concetti is an Italian company that has been operating in Australia for more than 10 years with sales and technical assistance activities and is recognised by the market as a reliable and experienced partner for the supply of systems tailored to customer needs,” said Concetti sales manager Trevor Mitford.

The IPF and Concetti technical teams have been working side by side to set up the full packaging line according to the specific production needs of Incitec

Pivot and the characteristics of the packaged fertilisers.

Fertiliser production plants are complicated structures that operate at various temperatures and pressures, with many subjected to some highly corrosive and abrasive substances. Phosphate and nitrogenous fertilisers are particularly corrosive to steel.

Moisture in any quantity, unavoidable in the world’s temperate zones and particularly prevalent in coastal areas in winter, presents considerable challenges to fertiliser operations due to this everpresent risk of corrosion. Without detailed attention to mitigate it, any exposed surfaces are soon little more than rust.

“The Concetti lines operated by Incitec Pivot Fertilisers are manufactured with anti-corrosive and anti-abrasive construction and with extensive use of stainless steel, with special paints and with a range of protection systems to reduce damage to a minimum,” Mitford said.

This packaging line configuration contributes to efficient and longlasting operation, protecting economic investment.

The plants are also easily accessible

PACKAGING 20 І Australian Bulk Handling Review: September/October 2023

Concetti bag packaging system for fertiliser.

for cleaning and maintenance. However, designing systems to resist corrosion is only part of the solution. Good housekeeping and maintenance are essential.

Implementing a preventative maintenance plan

A 2022 study put the global cost of corrosion at $2.2 trillion per year. It reduces the useful life of equipment, raises maintenance costs and can lead to excessive downtime and even

environmental issues. Control, prevention and ongoing corrosion management have become an engineering discipline.

An in-depth training of the client machine’s operators on the use of systems and maintenance personnel is certainly a starting point. A rigorous routine is also required to inspect, control and clean the product contact or retention zones.

Cleaning, including basic sweeping and brushing down, is a necessary discipline. Plenty of quick-release and electrically interlocked access doors

are provided at key transfer points to allow inspection and cleaning between products. This removes any residues and prevents product build-up.

Fertiliser traceability

Traceability enables manufacturers, trade partners, consumers, and authorities to identify, authenticate and track goods throughout the supply chain.

Many countries worldwide are providing guidelines on the labelling of fertilisers.

Since 2018 there has been a National Code of Practice for Fertiliser Description and Labelling in Australia.

Regulations are evolving, and therefore broad flexibility in integrating different printing and labelling solutions and technologies is required. The Concetti lines are equipped with or were supplied predisposed for the later fitting of label applicators or ink-jet coders to apply date/time or batch coding information. Additionally, loaded pallets can also have a label applied.

WEIGH BELT FEEDERS Mild Steel Powder Coated for Quarry and Mine installations or Stainless Steel construction for the Food Industry or the Harshest Environments. Throughput up to 1,000 TPH CONVEYER BELT SCALES For Belt Widths between 450mm and 2,000 mm accuracies of +-0.5% for a single idler and +-0.25% for a dual idler VOLUMETRIC FEEDERS For Volumetric or Gravimetric Loss in Weight Applications. Auger Sizes up to 152mm diameter and 20,000 Litres per Hour Contact Tecweigh Website www.tecweigh.com.au Email sales@tecweigh.com.au VIC: 03 9775 0266 | NSW: 02 9159 9160 | QLD: 07 3184 0980 | WA: 08 6558 1936 CUSTOM ENGINEERED WEIGHTOMETERS & WEIGHING SOLUTIONS Manufacturer of conveyer belt scales (weightometers), weigh belt feeders and volumetric and gravimetric auger feeders all manufactured in australia

Concetti high level palletiser.

Cushioned vibrators committed to quality

Oli Vibrators has designed a range of vibrators that can handle some of the worst conditions in bulk handling.

THE BULK HANDLING SECTOR puts equipment through its paces – whether it’s the harsh, corrosive outdoor environments in heavy industry, or the strict hygiene requirements and precision required in the food industry.

That’s why Oli Vibrator’s range of pneumatic and electric equipment are built.

Mark Thompson, general manager of Oli Vibrators, said poorly designed and manufactured industrial vibrators run the risk of having inferior lifespans that end up costing more in the long term.

“As inferior vibrators start to wear, consistency of performance will drop, which has a flow-on effect to the rest of the operation. Imagine you are producing 10,000 bags of material a day, and then you find that you can’t get your product into the bags properly,” he said.

“You might need to pull two to three people off the line to deal with this, not only affecting productivity, but also creating an inefficient use of labour.”

Oli Vibrators manufactures its range of robust vibrators to European standards, which are then distributed around the world to its local branches.

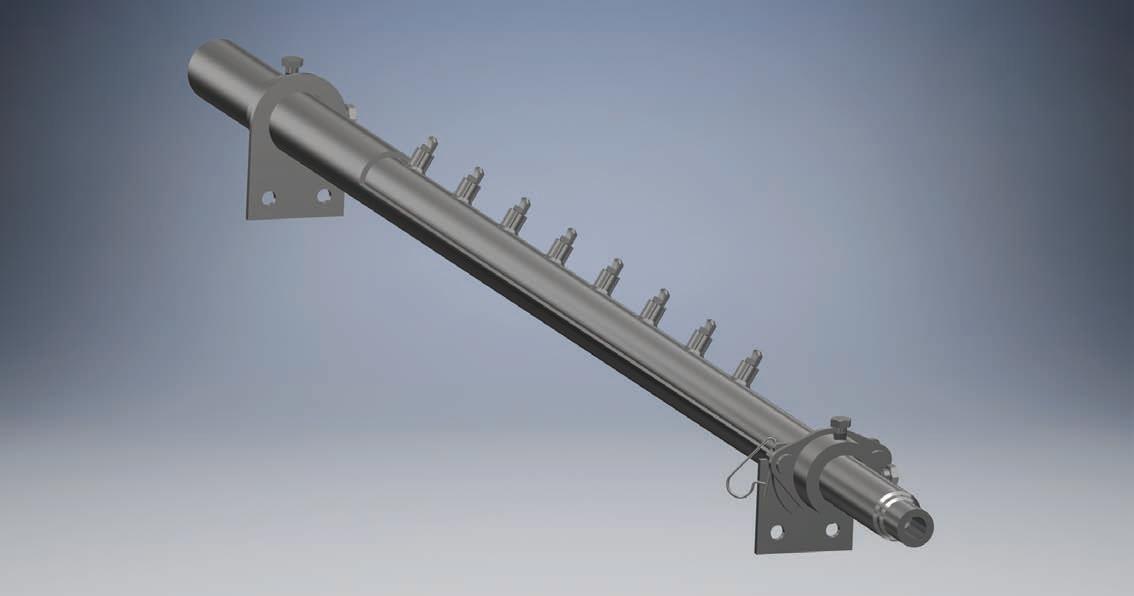

Thompson points to the K Type LF cushioned vibrators as an example of the company’s commitment to quality.

The range has been developed for use on hopper silos, vibrating feeders, compaction tables and channel lines. Its lightweight anodised aluminium body and lubrication-free design ensures longevity of performance in intense environments.

Its linear force gives comfort to detaching hygroscopic and granular materials as well as compaction

of the dustier products. With a working temperature range of -20°C up to 130 °C and an operating pressure of 2.0 Bar – 6.0 Bar, Thompson said the K Type linear vibrators are some of most versatile pneumatic vibrators.

“Whether its in a plastic, food, chemical or construction environment, the K Type linear vibrator will assist in getting your product moving,” he said.

“Its variable frequency and effective transference of the required fwworce together with its compact design and tight footprint make it suited to those often difficult and hard to get at applications.

“With efficient air consumption and five sizes to the range, the K type LF can be your answer to solving your compaction, flow or detaching problems while protecting your valuable asset.

Vibrators are tools that suit specific tasks and applications,

which is why Oli Vibrators Australia works closely with its customers to find the right one.

Its company mission of ‘when you need it, where you need it’ has led the business to focus on delivering the equipment to the client with minimal delay.

Each product also comes with a two-year warranty, which includes full replacement or repair of the product.

Thompson said fast after sales support is critical to many of its customers.

“The vibrator market is competitive, so we rely on our highquality products, technical expertise and the ability to provide all the specifications an engineer could possibly want,” Thompson said.

“We’ve got all that along with a global network to back us up and specialisation in vibratory equipment.”

VIBRATORS 22 І Australian Bulk Handling Review: September/October 2023

“As inferior vibrators start to wear, consistency of performance will drop, which has a flow-on effect to the rest of the operation.”

Oli Vibrators manufactures its range of robust vibrators to European standards.

The company works closely with its customers to find the right tool for the job.

Visit Melbourne’s leading construction and major infrastructure event Featuring: 15,000sqm of trade show, showcasing the latest innovations for the construction sector 150+ speakers across four stages discussing • health and safety • recruitment, careers and training • digital connectivity • construction productivity • sustainability • major projects insideconstructionexpo.com.au/register 20-21 SEPT 2023 | MELBOURNE CONVENTION AND EXHIBITION CENTRE GET YOUR FREE TICKET NOW SCAN HERE TO GET YOUR FREE TICKET CONFERENCE SPONSORS ASSOCIATION PARTNERS SUPPORTING SPONSOR

Tecweigh keeps bulk handling productive

Regarding bulk handling, nothing is more important than avoiding downtime.

WHILE MACHINERY CAN BREAK down in Australian conditions, the projects need to be able to continue, which depends on fast repairs, good after-hours service and highquality products.

The costs of downtime have been estimated at nearly $50 billion a year in the industrial manufacturing industry, according to Deloitte, which results in unhappy customers, lost revenue, and productivity.

To avoid these high costs, it can help to partner with a local company that makes its products for Australian conditions.

Tecweigh’s business development manager Barry Gamble said being a local manufacturer has allowed the company to keep costs down and ensure continued supply.

“We do all our manufacturing in Carrum Downs, Melbourne, which gives us a fast response time,” he said.

The Australian manufacturer has produced a range of conveyor belt scales, weigh belt feeders and

volumetric feeders for two decades from its Melbourne headquarters.

Being based in Australia means Tecweigh can also offer local aftersales support. The company maintains a significant stock inventory for its conveyor belt scales, volumetric feeders, and weigh belt feeders. It also provides field service support and spare parts supply.

This allows the company to offer strong support for clients after purchase.

Tecweigh works with its clients to maintain the custom weighing machinery and ensure it remains in top condition.

“Custom designs are our standard. Whether it is chemicals, crushed stone, sand, coal, or materials that are low density, sticky, or abrasive, we specialise in building the equipment needed to weigh it accurately,” Gamble said.

“Our products are also designed for heavy-duty work and have been proven over time to be accurate in some of the world’s harshest environments.”

With more than 100 years of industry experience collectively among

its employees, the company continues looking for innovations.

The team has been trained to deliver a tailored weighing solution and on-site service for complete support from the planning stages to project delivery.

From humble beginnings, Tecweigh has built its bespoke business to provide weighing-in-motion solutions for industries nationally.

To ensure its products are reliable in Australia’s rugged conditions and provide accurate information, Tecweigh uses stainless steel, hermetically sealed IP68 load cells designed to provide accuracies of ± 0.5 or ± 0.25 per cent with either Single idler or Dual Idler configuration for its weigh belt feeders and conveyer belt scales.

The weigh idler system has been designed to be easy to calibrate to provide consistent accuracy. Its volumetric feeders have a range of up to 32,000 litres per hour with single or dual drives for loss in weight or gain in weight applications.

The company has developed a presence in international markets, including China, the UK, Malaysia, Indonesia, and the Middle East, including Coal Loading Projects.

Gamble said the company is increasing its range with a new loss in weight/gain in weight controller alongside its leading range of products.

“It uses an Australian-designed and built signal conditioner circuit board, deployed at the heart of Tecweigh’s measuring and metering products,” he said.

“The loss in weight controller gives users greater accuracy for dispensing products and provides an extra layer of control over an ordinary volumetric feeder by using feedback from a scale.” Our aim is long-standing relationships,” Gamble said.

SENSORS 24 І Australian Bulk Handling Review: September/October 2023

Conveyer belt scales are designed for weighing in the quarry, mining, and food industries in all conditions.

DO YOU KNOW A DRIVER OF CHANGE?

WOMEN IN INDUSTRY NOMINATIONS ARE NOW OPEN. Now is your chance to nominate an industry leader who you believe is advocating for positive change and deserves to be recognised.

Thurs 20 June, 2024

The Women in Industry Awards recognise outstanding women leaders from across Australia’s industrials sector.

womeninindustry.com.au PROUDLY SUPPORTED BY Australia

MHD upply

PROUDLY PRESENTED BY

Automated conveyors feed pharma powders

When a pharmaceutical company needed to automate its packaging operations, it turned to Flexicon screw conveyors.

EPIC PHARMA DEVELOPS AND manufactures a range of generic pharmaceuticals for the treatment of pain, lipid disorders, hypertension, and infection. It also provides contract manufacturing services to some of the largest pharmaceutical companies in the world.

As part of this service, the company packages cholestyramine resin, a fine, dusty yellow powder that is hygroscopic and can be difficult to convey.

Originally, the company fed the resin to pouch filling machines by raising 100kg drums approximately 1.8m above the plant floor, requiring operators to manually scoop the material into each filler’s infeed hopper.

With three to four drums emptied per shift, the process proved awkward

and prone to dusting and product spillage, a problem that was rectified by installing four automated flexible screw conveyors from Flexicon Corporation.

The 396L capacity floor hopper of each conveyor fits within the limited space of the packaging suites and allows operators to dump the drums at floor level with less product spillage, dust, and risk of injury.

Frank Mellone, senior director packaging and distribution, said the flexible screw conveyors have brought a more efficient process as well as a cleaner and safer plant environment.

Each 114mm diameter polymer conveyor tube encloses a flexible stainless-steel screw that is driven by a 2.2Kw electric motor. As the screw rotates, it propels material through the

PACKAGING 26 І Australian Bulk Handling Review: September/October 2023

The flexible screw conveyor tube and spiral are disassembled and cleaned at regular intervals.

From the filling machine, operators assemble pouches of cholestyramine resin powder into cartons for shipment.

flexible downspouting into each pouch filler’s intake hopper. Each conveyor starts or stops in response to a signal from the pouch filler’s hopper, maintaining a consistent amount of product in the hopper.

“Each flexible screw conveyor is cleaned after five batches, which involves quickly disassembling the flexible screw and tube and washing each with water and an approved detergent,” Mellone said.

The pharmaceuticalgrade conveyors and hoppers have stainless steel product contact surfaces, are validated and comply with FDA Manufacturing Practices.

Mahboob Rahman, VP manufacturing and engineering, said, “The conveyor systems function problem-free, being engineered correct length, diameter and convey angle, and with a hopper that enables smooth flow.”

The conveyor screw is driven above the point of discharge, preventing material contact with bearings or seals.

FREECALL 1800 046 046 WWW.GRAINST.COM.AU 10 HIGH STREET BUTE, SA Friday 29th September From 11am GRAND OPENING IN SOUTH AUSTRALIA Specialising in Grain, Fertilsier and Feed storage OPEN DAY

Grain Storage Technology by HE Silos Forbes

Family fights food shortages

HE Silos Forbes is developing new grain technologies that aim to make Post Harvest grain storage easier and more accessible.

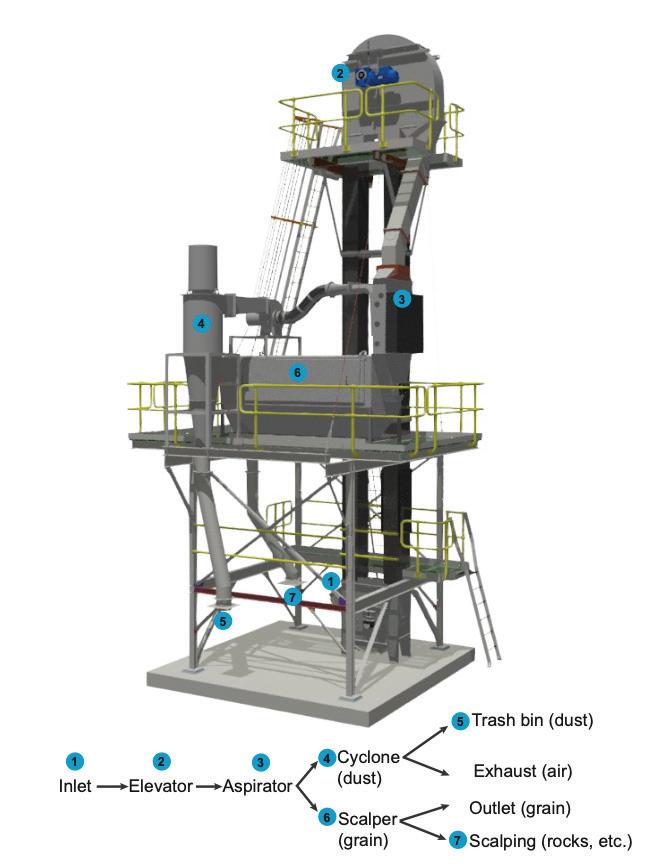

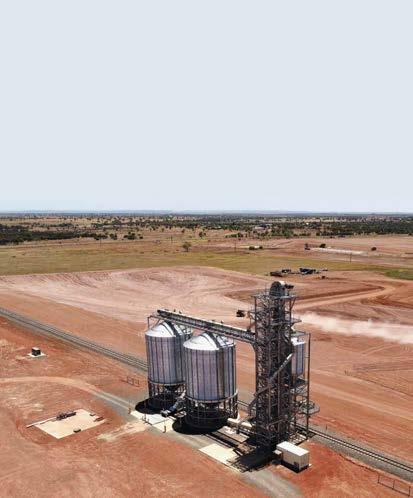

IMPROPER GRAIN STORAGE CAN wipe out vital crops. As the rates of droughts, floods and other unseasonable weather events increase, the threat of famine also increases.

HE Silos Forbes has made its mission to help fight this. StevieLeigh Morrison, the family business’s executive director, told ABHR that accessibility is the key.

“So many people go hungry around the world. If we were able to help save one per cent more grain through better storage practices, that means more people can be fed,” she said.

“India loses almost the same amount of grain from improper post harvest storage as Australia grows in a year.

“Most systems on the market that can monitor temperature and phosphine levels are between $5000 and $10,000. Smaller growers cannot afford that, so our contribution to food security needs to be accessible.”

To deliver on this, the company has partnered with the University of

Wollongong’s Smart Infrastructure Facility with Dr Cormac Fay heading the project as part of the CSIRO’s Innovation Connections grant program. The university is working closely with HE Silo’s Forbes development team to design and test a new type of silo venting system to improve grain quality.

The standalone unit will ideally suit all operations, adaptable to fit on any Silo storage system and work without requiring electricity. This will allow it to run all year round and ensure every grower can include it on their silos.

Morrison said that not everyone has access to power, but still need to protect their grain.

The concept was inspired by conversations between HE Silos Forbes and its customers, listening to the struggles they were facing when it comes to post-harvest storage.

“Being able to give farmers the ability to directly market their grain has never been more important,” Morrison said.

“Farmers with storage need to know the grain can be sold at the same level of quality when it was initially stored.

“The unit is still in the testing phases – the system is designed to reduce condensation, which is one of the causes of grain degradation during post harvest storage, and find ways to add value to the grain.

To support the development, HE Silos Forbes have provided the university with a miniature silo. The researchers have access to an atmosphere chamber enabling them to simulate any weather condition, to fine tune and ensure the system will work in any climatic condition.

“It’s important for us to continue supporting innovations through collaborations like these. We’ve seen the meteoric effect of what can happen when technology rapidly advances, and it’s a vital step to fight food shortages.”

The Morrison family has been involved in the agricultural industry

28 І Australian Bulk Handling Review: September/October 2023

GRAIN STORAGE

HE Silos manufactures its equipment in NSW.

for four generations and has plans to continue this growth. HE Silo’s Forbes sister company, Grain Storage Technology (GST), will begin distributing its products across South Australia’s Yorke Peninsula.

The silos will be manufactured in NSW and installed and serviced by GST’s staff locally.

Morrison said diversifying the markets HE Silos supports means it can enhance multiple regions.

“The moisture in the soil in the Yorke Peninsula is high right now, and its likely they’ll have a great growing season,” she said.

“In Southern NSW, it’s not looking as great – which is surprising due to the recent flooding. That means we can help take Grain Storage Technologies to the next level in other regions.”

To support its new distribution centre, the company will be hosting an open day.

Guests will be able to speak to industry leaders and get up close with the product.

HE Silos Forbes plans to have the whole family there, from the founder to the latest member – an 18-month year old.

Morrison said the day will be a great way to showcase the family values HE Silos Forbes holds.

“You can meet us and get to know the people who you’re buying from. You can get up close and touch, see and learn about our products.”

“We will be showcasing our current offering, along with a few new developments, built specifically for the South Australian market.”

“Family is everything for us. Nothing is more important than family, feeding the world, and sharing our passion for grain storage,” Morrison said.

World leaders with over 45 years’ experience in Bulk Materials Handling Research and Consulting

TUNRA Bulk Solids develops custom solutions to suit the individual needs of our clients.

Services:

Flow Properties and Materials Testing

Dust (environmental) Testing

Wear Testing (Impact, Abrasion and Erosion)

Conveyor Belt and Idler Roll Testing

Custom Numerical Simulation and Calibration Testing

Materials Handling Consultancy and Contracted Research

Bin and Stockpile Design

Pneumatic and Hydraulic Conveying

Technology and Knowledge Transfer

Site Visits

Professional Development Courses

www.bulksolids.com.au +61 2 4033 9055

Short Course: Storage, Feeding, Transfer and Belt Conveying 2023 Dates: 14th - 16th November (Perth)

2024 Dates: February (online), May (Brisbane) August (Newcastle) November (Perth) Enquiries to Danielle.Harris@newcastle.edu.au

To support the development, HE Silos Forbes have provided the university with a miniature silo.

Bulking up bags

Cost and time savings are making bulk bags an attractive packaging alternative. ABHR spoke with Packweigh to learn more.

OVER

THE PAST FEW YEARS, Packweigh Equipment has noticed a growing trend – more of its customers are looking to pack their product into bulk bags.

Rod Wilson, co-founder of the bagging equipment manufacturer, told ABHR there are several possible reasons for the upswing.

“There is an obvious cost savings when compared with filling 20kg to 25kg bags,” he said.

“Time is money, and it’s significantly faster to fill a one tonne bag instead of 50 20kg bags. The bags themselves also cost less in the long run.

“As with all products though, it depends on what exactly is being made. Bulk bags make sense when you’re selling to farms or other manufacturers – situations where the end users want to buy a one tonne bag.”

Packweigh has around five standard designs it uses for its bulk bagging systems and can customise them depending upon the situation.

The material being packaged plays a major role in this design process, along

with the type of bags the customer wants to use and the speed that is required.

A system was recently manufactured to fill 1000kg of lime and gypsum into bulk bags, including a pallet dispenser, automatic bag filling and release, plus full pallet accumulation. It used a different design to systems that mostly handle seed and grain, as powders are more complex to handle.

Wilson said due to the settling of the product, the surge hopper needed to be designed differently.

“You also need to account for bag inflation and an entirely different weighing system for powders,” he said.

“There is also the issue of product densification, to ensure the bag is stable when it is conveyed out. Dust can also become an issue which must be addressed.

“We will even program the system differently for certain powders to avoid potential issues those materials can create.”

Packweigh’s automatic bagging systems have also proven to be popular.

Wilson said even on smaller systems automation is becoming a common addition, due to the increasing cost and availability of labour. This is especially prominent in regional areas, which are feeling the sting when it comes to finding and retaining staff.

Because the company is an Australian manufacturer, it has the flexibility to design bulk bagging systems that can suit specific conditions and applications.

One customer had a requirement for no pallets to be involved in the bulk bagging system. Packweigh designed six systems that would release a bag onto a conveyor large enough to transport twotonne bags. From there, full bags were accumulated and then picked up from the straps by a forklift.

“Our equipment isn’t just being assembled in Australia – we use Australian suppliers wherever possible, designing the machines to use locally obtainable parts,” Wilson said.

“This means that if we ever don’t have something in stock, we can quickly get it from our supplier, minimising delays and downtime.

“When you rely on other stakeholders, there’s a chance there you can be let down. We didn’t want to let our customers down – so that meant having as much control over the manufacturing process as possible,” he said.

According to Wilson, Packweigh’s customers have been happy with the bulk bagging machines.

“They are getting the speeds they were looking for and have been reliable workhorses,” he said.

The company aims to create long term business partnerships instead of traditional customer relationships, which is why Packweigh values reliability. its machinery as reliable.

“We spend time with our customers, give them all the options up front,

30 І Australian Bulk Handling Review: September/October 2023

PACKAGING

Packweigh has around five standard designs it uses for its bulk bagging systems.

explain what everything does and don’t take anything for granted,” Wilson said.

“We discuss their needs and do all the layout, drawings, and planning to make sure they get the right tools for the job.”

The company manufactures its products at its Brisbane-based factory, where it can assemble an entire packaging line. Customers can even visit the factory to see the system in operation before it is installed.

Wilson said the Packweigh can also support its customers on site and over the phone.

“We can even provide remote diagnostics online, without needing to travel – cutting down on time and costs,” he said.

“Good quality service, reliable equipment and flexible designs are what the customer needs, and it’s what Packweigh delivers.”

Packweigh’s automatic bagging systems are popular among its customers.

No Croc: New belt cleaner technology unveiled

ESS has released the ESS Croc-Lock Secondary Cleaner, improving upon its previous designs to deliver increased efficiency and serviceability.

WHEN MATERIAL ADHERES TO THE belt beyond the discharge point of the head pulley, it becomes dislodged along the return run and builds up underneath the conveyor belt. In some cases, the build-up could be severe and look like an ant hill, which buries the conveyor belt structure and impacts a company’s bottom line and deadlines.

The time taken to rectify the issue can be expensive. Depending on the business, downtime can cost companies hundreds of thousands, if not close to millions, in overall expenses.

Belt Cleaners are integral to any bulk goods company’s maintenance strategy centred on long-term success in dealing with carry-back.

With an effective belt-cleaning strategy, companies can avoid increased downtime, maintenance, environmental contamination, and replacement purchases in the long term as machines break down from carryback. Given the high cost of downtime on a company’s bottom line, it’s essential to trust a knowledgeable operator when getting a belt-cleaning solution.

ESS Engineering has more than 40 years of experience designing, manufacturing, installing and maintaining belt cleaners nationwide, constantly aiming to improve both efficiency and serviceability of its products.

ESS’s accounts development manager, Ken Minch, has witnessed belt

cleaners evolve from a simple block of urethane bolted onto a carrier into cast polyurethane blades with cartridges. Now, ESS has released the ESS CrocLock Secondary Cleaner, improving the company’s previous designs to deliver increased efficiency and serviceability.

Minch says the new belt cleaner design delivers several upgrades to help solve several bulk handling headaches, including carry-back and downtime.

The Croc-Lock has a curved blade design and a diamond-shaped mainframe and cartridge. This removes flat surfaces from the belt cleaner, minimising fine build-up and carry-back that hamper cartridge removal during service.

“Previously, the cartridge was like a tray which we believed was increasing fines build-up,” Minch said, “The diamond design gives us nice, tapered edges everywhere, resulting in reduced material build-up.”

“We’ve changed the shape of

the blade, but we haven’t changed the pivot point or lost any of the flexibility of the blade.”

The new cleaner also features a high-level self-locking blade system. The tapered locking mechanism makes it easier to disengage blades from locking teeth, allowing for easier maintenance.

Minch said this was a vast improvement from the old ways of positioning workers underneath the conveyor belt to disengage blades or requiring a hammer and wedge to disengage hard-to-move blades.

The innovative tooth-locking design eliminates any ingress of fines, and each successive blade locks in place the former blade and only one blade retaining lock is required, the end stop, which holds everything in place for a secure secondary blade cleaner.

Minch states that the innovative locking mechanism reduces the time taken to perform maintenance of the blades.

“In typical servicing applications, we found that fines and moisture would work their way between the blades, and we’d have to hit it with a hammer to remove it,” he said.

“It’s not impossible, and we’re able to do a blade change in around 15 minutes with one person, but you’re

BELT CLEANERS 32 І Australian Bulk Handling Review: September/October 2023

The new design delivers increased efficiency and serviceability.

still swinging a hammer around and potentially using a wedge to break the binding of the fines.

“The testing we’ve done indicates this will be easier (with the Croc-Lock.)

“With the same installation as described above, only taking a time of around five minutes, and it is still possible to do while the belt is in operation”.

The new product will offer a choice of spring and air tensioning units. This will allow companies to retrofit the product to existing ESS IPS mounts and tensioners and service the belt cleaner while the belt is still running.

“It will also reduce the wear on the roller shell, which will increase the life of all the rolling stock. You’ll increase the life of the belt because it’s not being ground down around corners and bends,” Minch said.

For Minch, who has decades of experience in belt cleaning design, the Croc-Lock represents a significant step forward. “I helped build our first belt cleaner, and I’ve seen the changes, and we’ve been driven by the same question, ‘How can we do this better?” he said.

“We’re about making everything safer, faster without the need to climb underneath conveyors, and it’s been successful.”

BAG PACKAGING SYSTEMS FOR CORROSIVE PRODUCTS / HEAVY DUTY ENVIRONMENTS AU.CONCETTI.COM T. 04 1748 7367 sales@concetti.com FERTILIZER +200 lines SALT +50 lines CHEMICAL +100 lines CONCETTI

The Croc-Lock Secondary Cleaner can form part of an effective belt cleaning strategy.

Smarter material handling through new technology

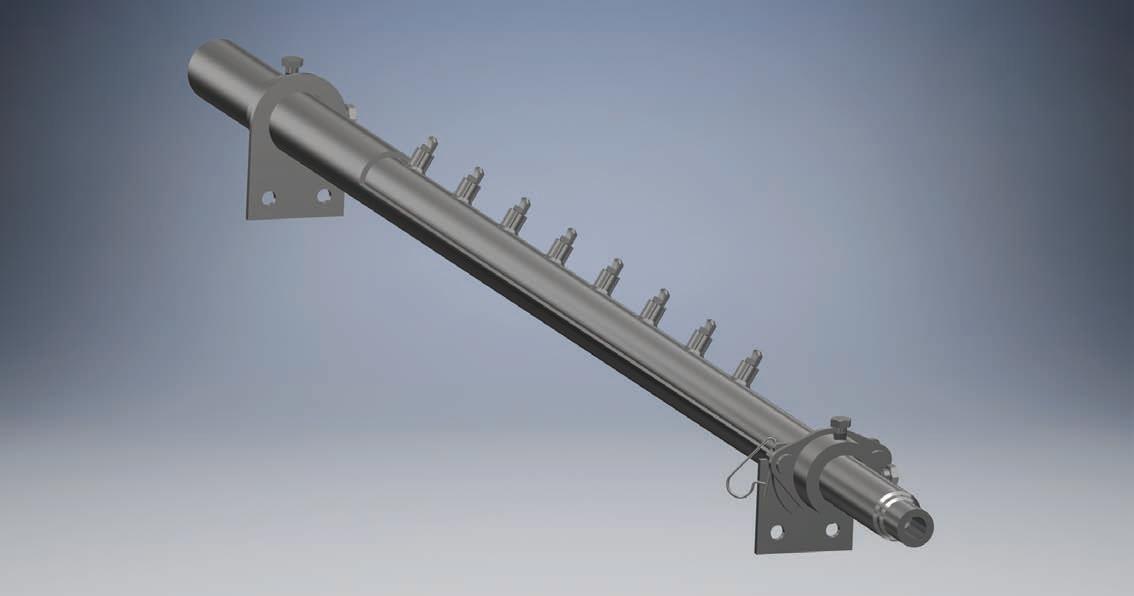

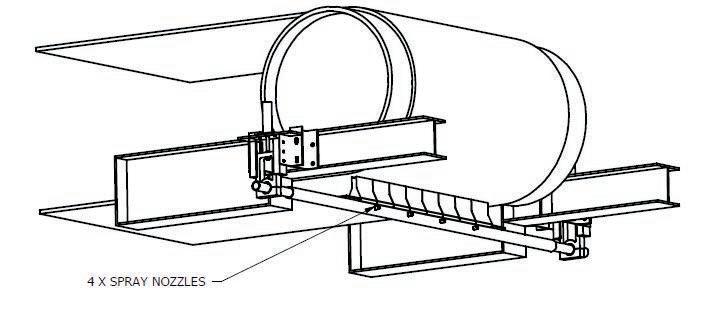

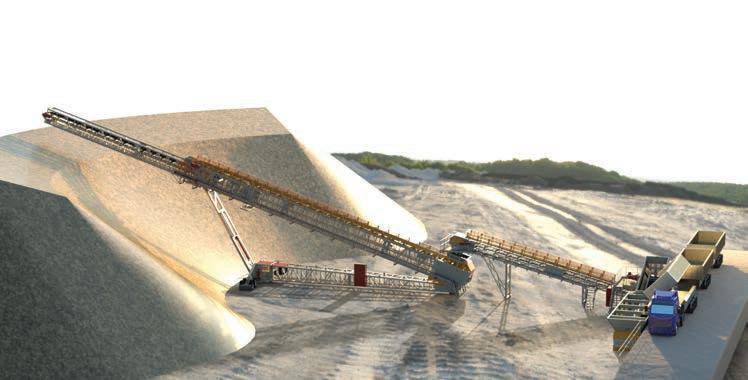

A new, semi-portable side tip feeder could be a game changer for reducing costs across several bulk handling industries.

TRADITIONAL TECHNOLOGY

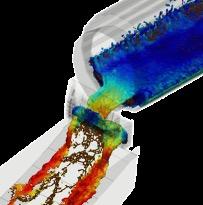

within the bulk handling sector has led to restricted choices for unloading site tipper trailers. However, OPS in collaboration with Telestack look to offer a new technology to give more options to material handlers.

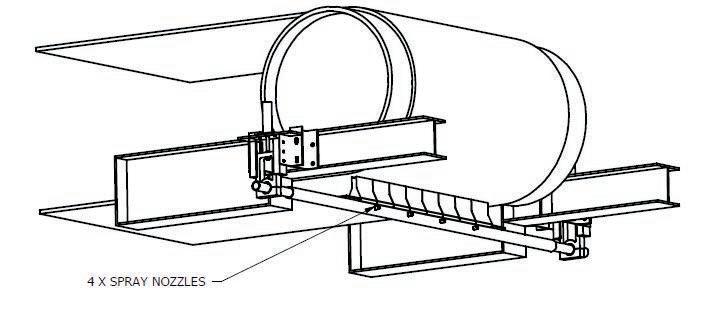

Telestrack’s Side Tipper Unloader promises to offer an alternative solution allowing side tippers to discharge directly into conveying systems.

ABHR spoke to OPS’ capital sales manager Gerry McGuigan, to take an in-depth look at the wide-ranging benefits of the Telestack Bulk Material’s Titan side tipper.

OPS, the Australian dealer of Telestack’s products, has supplied Telestack equipment to meet the needs of the bulk handling industry. The pair collaborated to produce the HF24T, a relocatable reclaim feeder that could handle up to 3000TPH (tonnes per hour) and CAT 992 or larger loaders.

“Our goal is to remove inefficiencies in bulk material handling processes. We see opportunities anywhere where

we can eliminate loaders or haul trucks, reduce labour requirements, or save fuel,” he said.

“Given the increased number of side tipper road trains in our operation and feedback from haulage providers, it was quite a natural material handling challenge for us to approach next.”

OPS Group identified a need to eliminate excess handling as more material from mines was moved by roads. With its unique side tipping set-up, the Side Tipper Unloader proved an ideal fit.

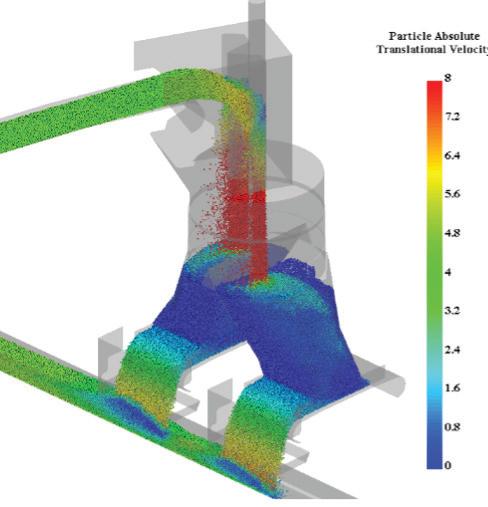

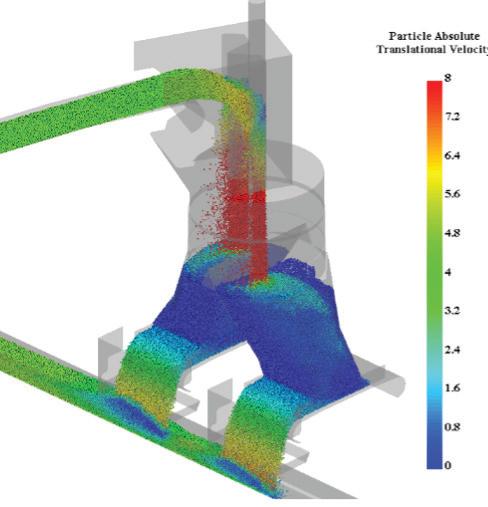

The Side Tipper Unloader is a surface feeder that accepts material from sidetipping trucks or road trains.