WORLD-LEADING SUSPENSION

WORLD-LEADING SUSPENSION

ARNOTT INC SETTING THE STANDARD

ARNOTT INC SETTING THE STANDARD

WORLD-LEADING SUSPENSION

WORLD-LEADING SUSPENSION

ARNOTT INC SETTING THE STANDARD

ARNOTT INC SETTING THE STANDARD

The truth is, everyone at Repco has an unexplainable bond with motoring. The journey’s been a ride but for a hundred years, we’ve been driven by passion.

For many, summer holidays are a great chance to unwind. But for a lot of us, they clog up an already stuffed exhaust, if you know what I mean. Upon returning to workshops, mechanics (much like other professions) found their pre-Christmas problems didn’t just evaporate somehow.

In fact, they seemingly grew, with a bevy of summer holiday calamities befalling many drivers and their vehicles. If you’ve made it to March, I commend you.

The post-holiday rush will have hopefully died down, and you’re well into gear for what will be a smooth drive for 2023 (touch wood). As a reward, take a breather and tune into this edition of Australian Car Mechanic

Being a mechanic is stressful enough, but have you imagined fixing an issue in half the time while a bloke with a notepad watches your every move?

Well, that’s what many technicians at Mazda do annually as part of their MazTech championship tournament.

Our contributing writer Iain Curry spoke to organisers and competitors about why they put themselves through the stressful, yet thrilling, competition year after year.

When it comes to making something

their own, painter Bella Turrise has a signature style. The recently graduated spray painter has already experienced plenty of success in her detailing career. However, as revealed in this edition, she has high-flying aspirations beyond her current accomplishments.

One word to describe the current issue of Australian Car Mechanic ? Performance.

From tips on keeping brakes in tip-top shape, to new innovations in clutches and shock absorbers – we’ve got you covered to make sure your car’s sporting the best!

Speaking of speed, you’re not likely to run into anything cuter than Brian Davies’ 1970 MG Midget anytime soon. The quaint, yet speedy little runner looks superb on the open road, and Iain’s chat with Brian revealed why he has a soft spot for MGs over other classic brands.

Our man on the tools – contributor Jamie Gray – has gotten among the mechanics this edition, with a field interview at a Bosch Car Service centre and a play around with a top notch trolley from JBS.

You’ve earned a break, so crack open a cold can and sink into this edition of Australian Car Mechanic

Harry Murtough – EditorArnott Inc is a world leader in suspension products. The family-founded business was established 35 years ago, and has expanded to offer more than 700 products across over 1000 applications. A relatively new player in the Australian market, we take a deep dive into Arnott’s history and how it’s grown to the global operation it is today.

May/Jun 2023

Deadline Apr 6, 2023 Jul/Aug 2023

Deadline Jun 7, 2023 Sep/Oct 2023

Deadline Aug 9, 2023

CEO John Murphy

COO

Christine Clancy

Sales Director

Bradley Buchanan Editor Harry Murtough harry.murtough@primecreative.com.au

Customer Success

Arianna Lucini arianna.lucini@primecreative.com.au

National Advertising Manager

Sineade Sullivan sineade.sullivan@primecreative.com.au

M. 0435 111 610

Design

Blake Storey

Subscriptions

P. +61 3 9690 8766 subscriptions@primecreative.com.au

Website www.mechanics-mag.com.au

Copyright Australian Car Mechanic magazine is owned by Prime Creative Media and published by John Murphy. All material in Australian Car Mechanic magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronicor mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Australian Car Mechanic magazine are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2023

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Head Office

379 Docklands Dr, Docklands VIC 3008

P: +61 3 9690 8766

enquiries@primecreative.com.au www.primecreative.com.au

Sydney Office Suite 3.06, 1-9 Chandos Street

Saint Leonards NSW 2065, Australia

P: +61 2 9439 7227

IAIN CURRY has been a specialist motoring writer and photographer for 15 years, working for a variety of magazines in Australia, United Kingdom, USA, Germany and Sweden. He is former editor of Performance BMW magazine and features writer for GT Porsche magazine, and has been fortunate enough to photograph Formula 1, the Le Mans 24 Hours, World Touring Cars, V8 Supercars and a range of adventure sports.

JAMIE GRAY is a professional photographer who, after 20 years in the field, started a carpentry apprenticeship. With a recently found love for purring V8s, Jamie is documenting the transformation of his stock Crewman. When he’s not writing, taking photos or practicing his wood work skills, you can catch him surfing at Turimetta Beach.

As the trusted global leader in the automotive-suspension aftermarket,Arnott shocks and struts are customtuned and heavily-tested in-house. With most coil spring conversion kits available from Arnott coming with an Electronic Bypass Module, comprehensive conversion is simple. Arnott has specially engineered their struts and shocks to produce maximum longevity.

With experience in engineering, designing and manufacturing high-quality suspension products for automobiles, trucks and SUVs, Arnott is the technical expert when it comes to replacement suspension products. Its ever-growing assortment consists of new and re-manufactured air struts/shocks, adaptive electronic struts/shocks, magnetic struts/shocks, air springs, air-suspension compressors, valve blocks, ride-height sensors, and coil-spring conversion kits.

began traveling throughout Florida repairing cars, often for little or no fee. Adam’s passion for cars, coupled with Donald’s selfless satisfaction in helping others, laid the foundation for what would become the most successful, advanced and innovative air-suspension products manufacturer in the world.

From their modest start, re-manufacturing air-suspension products and accessories

for a couple of Ford Motor Company vehicles, Adam and Donald dedicated themselves to offering the highest quality air-suspension products, along with worldclass service and support, at great prices. After years of local grassroots success, Adam and Donald developed a business plan, and named their venture ‘Arnott Incorporated’ as a tribute to the family values upon which their work, dedication, and service was based. Word of Arnott’s expertise traveled fast across Florida. A move to Orlando in 1994 put the team in a

Arnott’s latest innovation is engineering and manufacturing fully adaptive electronic shocks and struts in its US facility.

their name. They tirelessly researched and evaluated existing models of air-suspension products, and soon discovered that not only could they remanufacture the original equipment products, but they could improve upon existing suspension parts. Arnott Inc.’s new goal was to manufacture unique products that ensured the total satisfaction and safety of their customers. Soon, Arnott evolved into an international leader in the innovation and manufacture of air-suspension products and accessories.

In 2011 - thanks to continued growthArnott moved to its current, nearly 300,000 sq. ft, facility on a 21-acre campus in Merritt Island, Florida, just a few short miles from the Kennedy Space Center and Port Canaveral, offering the company an excellent gateway to global shipping and logistics. The facility includes a brand new 65,000 sq. ft. research-and-development centre with test equipment, multiple auto lifts, a video and photography studio, and its own Mazak multi-tasking CNC machine for creating and testing new parts. In addition, Arnott houses an air-conditioned production facility which includes multiple advanced and sophisticated five-axis CNC machines. These impressive, fully robotic machines eliminate multiple setups, improving and ensuring part integrity and efficiency. The expansion and the addition of the sophisticated new machine facility enabled Arnott to not only increase productivity, but also improve on already lofty quality-control standards.

The facility also has an expanded manufacturing area including smaller ‘focus’ factories for new builds, a remanufacturing center and paint shop, state-of-the-art shipping and distribution center, and a massive storage warehouse where raw materials and components are stockpiled and ready for assembly.

Arnott’s main offices house Arnott’s multi-lingual Customer Care and Call Centre.

Arnott’s European Union branch office, manufacturing facility and distribution centre, located in the Netherlands, provides sales and support throughout Europe, the Middle East and Asia. It ensures faster shipping, payment in local currencies and manufactures air springs and compressors.

Arnott has been awarded ISO 9001:2015

Management System Certification based on quality-management principles, including strong customer focus and continual improvement of robust, efficient processes. It is a standard developed to help businesses and organisations deliver consistently high-quality products and services, become more efficient and improve customer satisfaction. In addition to ISO 9001:2015 Certification, Arnott has also received TÜV Rheinland Product Safety and Quality Certification, assuring customers and partners in Europe that its products meet the highest safety and quality standards. The products also carry GOST ISO 9001-2011 Certification and the EurAsian Conformity (EAC) Mark for Arnott’s Quality Management System, required for export to Russia, Belarus, Kazakhstan, and Armenia.

Arnott’s latest innovation is engineering and manufacturing fully adaptive electronic shocks and struts in its US facility.

The addition of this important product category allows Arnott to successfully offer a full suite of suspension products to its customers. This addition prompted a small but important tag-line change to Arnott Suspension Products – reflecting the company’s depth in the replacement suspension market. Arnott is focused on producing the highest-quality products and is committed to continually improving the effectiveness of its Quality Management System. The fruits these efforts will include a more efficient company, increased customer satisfaction and an environment that motivates employees and promotes job satisfaction.

Over the years, Arnott has extended its list of supported luxury cars, trucks and SUVs from Ford-Lincoln-Mercury makes to General Motors, Land Rover, Lexus, Bentley, BMW, Jaguar, Porsche, Audi, MercedesBenz and more. Based on its success in automotive suspension, Arnott also has a performance line expanding on the AccuAir and JRi Shock brands for performance upgrades to Jeeps and other vehicles, and a motorcycle division that offers adjustable air-suspension kits for many leading makes, including Harley-Davidson, Honda, Indian, Suzuki and more.

For more information about the plethora of products on offer from Arnott Inc. visit arnottindustries.com.

Arnott’s Florida headquarters at Merritt Island is placed in a logistically sound location, as well as being surrounded by American staples of innovation such as the Kennedy Space Centre.

Arnott’s Florida headquarters at Merritt Island is placed in a logistically sound location, as well as being surrounded by American staples of innovation such as the Kennedy Space Centre.

Busy Aussie mechanics under the pump and bumper-to-bumper with jobs need diagnostic tools that can adapt as quickly as they do.

A tool that can be seamlessly hooked up to almost any vehicle and identifying issues in no time to have clients’ cars out of your workshop asap.

Enter the AUSCAN 4 - Launch’s latest scan tool that’s been tailor-made with Australian mechanics in mind.

The newest iteration is more powerful in every way than the previous AUSCAN 3, sporting a Quad-Core 2GHz processor, 4G of memory and 64G in storage.

The AUSCAN 4 has OEM level access to more than 110 vehicle manufacturers from across Australia, Asia (including China), USA and Europe.

For those specialising in Audi and VWs, it goes the extra mile with more than 30,000 guided functions supported.

When you’re hooked up via cable or connected wirelessly, the AUSCAN 4 is immensely efficient with its ability to automatically identify VINs for intelligent diagnosis.

Its one-stop Info Centre makes accessing repair information and diagnostic report history a breeze with an easy-to-use touch screen interface.

If you specialise in trucks, EVs, Motorcycles, ADAS, agricultural or other machinery the AUSCAN 4 has your back with optional software support available.

If you somehow get stuck with a

particular issue, the AUSCAN 4 has training videos and repair information builtin for easy access.

You can even get help or give it to your fellow mechanic via remote diagnostic functions, which allow you to communicate with other workshops*. Mechanics will also get the most out of

✔ 10.1 inch high-resolution (1280x800) screen, sunlight readable gorilla glass screen

✔ 2.4GHz/5GHz wifi connection support

✔ Quad-core 2GHz processor, 4G memory, 64g storage and open Android OS (V10.0)

✔ Diagnostic VCI connector DBSCAR VII supports more communication protocols including CAN, CAN FD, DOIP (extra DOIP cable required) and others

*Conditions apply

the AUSCAN 4, with the first three years of updates provided for free.

As well as standard diagnostic tool functions including window calibration, electric throttle relearn, air/fuel, brake and oil maintenance resets the AUSCAN 4 also boasts a number of special functions.

These include:

• Injection quality adjustment

• Injector coding

• DPF regeneration

• Reset pressure differential sensor

• VGT electronic actuator installation and calibration

• And more!

As if the AUSCAN 4 wasn’t already the Aussie mechanic’s best friend, you can get a free Launch VSP-800 Endoscope valued at $225.50!

The VSP-800 gives mechanics access to otherwise unreachable parts of a vehicle, allowing the user to view, record and save images/videos with ease.

This limited time offer will end on April 30 2023

Launch brings the best in diagnostic tools with the AUSCAN 4.The AUSCAN 4 features OEM level access to more than 110 car manufacturers right out of the box.

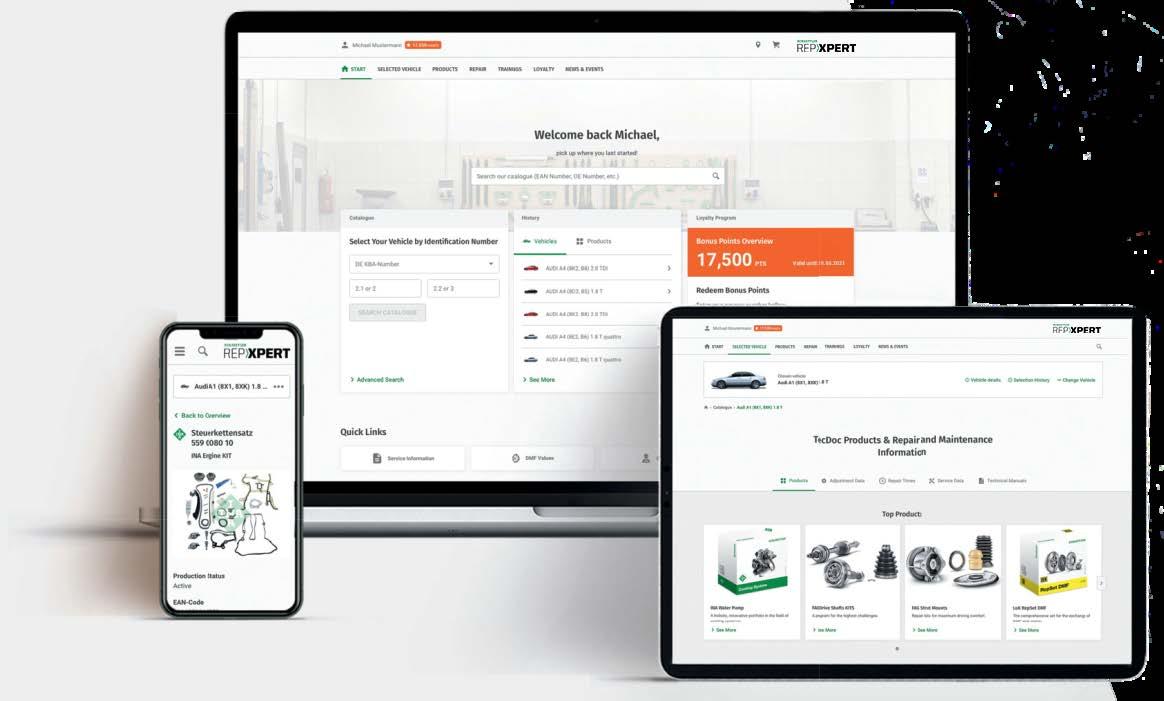

Schaeffler has reorganised its REPXPERT garage-oriented services portal to deliver the vast amount of information it contains more effectively.

Around 200,000 users access REPXPERT through 36 country portals in 16 languages. To structure this amount of information more clearly and ensure a user-friendly experience, Schaeffler has updated the garage portal and raised it to a new level.

“Through REPXPERT, garages and technicians have an easy-to-use portal that quickly guides them to the information they are searching for and offers more technical content than ever before as part of the free service,” said Schaeffler Head of Automotive for Australia and New Zealand, Warren Barnett.

Schaeffler has implemented a personalized dashboard. It makes extensive technical information, repair data, training courses, news and events more accessible to every website visitor. Users with registered accounts have even more functions available.

They can access the complete aftermarket parts catalogue, manufacturer data and see

products or vehicles.

A revised navigation menu and new global search function within the catalogue quickly take users to the desired REPXPERT content. Garages also have access to the bonus program where they can accumulate points found in LuK, INA and FAG product boxes and exchange them for specialty tools and other useful items. Other additional features include a complete range of repair data and vehicle-specific

repair and maintenance information (RMI) from TecAlliance, as well as the ability to register for training courses.

“We listened to the feedback we received from garages worldwide and have implemented those changes into REPXPERT which now offer our users an even better experience that includes more technical information than ever,” Warren said.

The integrated parts catalogue offers the entire product range of all represented aftermarket manufacturers as well as allowing easier access to extensive repair and maintenance information (RMI).

Schaeffler product data gets updated daily.

REPXPERT users will also find numerous courses with extensive theoretical and practical knowledge. Classroom training courses, online training courses and e-learning courses can either be accessed directly or booked via an integrated calendar with online registration. Additionally, the in-depth technical information is continuously expanded in installation videos, step-by-step instructions, garage tips and help with typical fitting errors.

n our series of technical expert advice, we take a look at common problems around a passenger-car braking system: how to diagnose and to resolve them correctly.

It is important to remind customers of the importance of regular brake inspections. Many vehicle owners will only have their brakes inspected when they run into a problem; hence many rotors, pads and other components are kept beyond their proper and safe useby dates. Regular inspection provides greater safety for motorists, greater replacement trade for workshops, and ultimately the opportunity to offer a quality brake upgrade to the customer.

While checking a vehicle’s brakes, keep an eye out for the following, common brake issues:

Low brake fluid

Usually indicates a leak in the brake system, which poses a serious safety hazard. The calipers, wheel cylinders, brake hoses, brake lines, and master cylinder all need to be inspected. If a leak is found, the defective component must be replaced. The vehicle should not

be driven until the repairs can be made because a leak may lead to brake failure.

Low brake pedal

Can result if shoe adjusters on drum brakes stick and fail to compensate for normal friction-material wear. Adjusting them may restore a full pedal, but unless the adjusters are cleaned or replaced the problem will return as the friction linings wear. Other causes include worn friction material or a fluid leak.

Means there’s air in the brake system due to improper bleeding, fluid loss or a very low fluid level. The cure is to bleed the brakes using the sequence recommended for the specific vehicle. Another possible cause is a rubber brake hose that is ‘ballooning’ when the brakes are applied.

Excessive pedal travel

Possible causes include worn friction material, misadjusted drum brakes, and air in the brake lines. Potentially dangerous because the system may run out of pedal before the vehicle can be safely stopped.

A dangerous condition caused by worn internal rubber seals in the master cylinder or a leak in the hydraulic system which prevents brakes holding pressure.

A jerking or pulsing brake pedal indicates DTV (disc thickness variation), and the brake rotor needs to be resurfaced or replaced. The faces of a rotor must be parallel (within 0.0005”/ 0.0127mm on most cars) and flat (no more than about 0.002” or 0.050 mm of runout). Don’t forget the wheel bearings (if serviceable) – they will need to be cleaned, inspected, and repacked with grease. New grease

Indicates a torque variation in the brakes. This is commonly associated with friction material deposits on the brake rotors causing a grab and release motion. The intermittent torque from left to right pulls

on the steering rack and transfers to the steering wheel. Steering wheel vibration can also indicate DTV (disc thickness variation) when combined with a pedal pulsation. Check for friction material deposits (dark patches) first.

Vibrations and noise through the brake pedal and/or steering wheel under braking. Commonly caused by rotors having been incorrectly machined.

Usually indicates metal-to-metal contact and the need for a long overdue brake job. Drum and rotor replacements will likely be needed in addition to new pads and/or shoes and potentially new brake hardware. Some older generation brake pads have mechanical wear indicators which give out a screeching sound. Newer pads use electronic wear sensors to alert the driver via a fault light/ sound when the friction material needs replacing.

Commonly caused by vibrations between the brake pads and caliper, which may be cured by resurfacing or replacing the rotors, installing new pads and pad shims, or applying brake grease or noise compound to the back of the pads.

Oil, grease or brake fluid on the friction surface will cause them to grab. The cure is to identify and eliminate the source of contamination, and then replace the linings. Badly scored drums or rotors can also grab. Resurfacing or replacement may be needed.

May create a steering pull and/or increased fuel consumption. Caused by weak or broken retracting springs on drum brakes, a jammed or corroded caliper piston or a floating caliper with badly corroded mounting pins or bushings. Brake calipers should be overhauled or replaced every 60,000km. Dragging brakes cause extreme wear and excessive temperature, which can mean lower performance in emergencies.

Can be caused by contaminated friction surfaces, misadjusted brakes, a bad wheel cylinder or caliper, dragging brakes on one side, or loose wheel bearings. Can also be caused by a side-to-side mismatch of friction materials on the front brakes, or differences in rotor thickness, type or condition.

Lack of power assist may be due to low engine vacuum, a leaky vacuum hose or a defective booster. Sometimes a faulty check valve will allow air to enter the vacuum in the booster, causing a hard pedal when the brakes are applied. This condition can be diagnosed by letting the vacuum out of the system while the engine is switched off, then start the engine while the brake pedal is depressed. If there is a sinking feeling when the engine has started, the power assist booster is working. After trying this, if there is no pedal drop, the power-assist booster may need attention, or there may be a blocked vacuum hose, or a new check valve is needed.

Brake fluid

Is hydroscopic, which means it absorbs

Many people only get their brakes checked when a problem arises, however it’s prudent to get them inspected regularly.

moisture. If this happens, the boiling point of the brake fluid drops dramatically, which causes the fluid to boil, resulting in a loss of braking. Fluid should be replaced every two years or 60,000km. When flushing new brake fluid through the system, make sure the master cylinder reservoir has been cleaned so not to flush any contamination through the brake system.

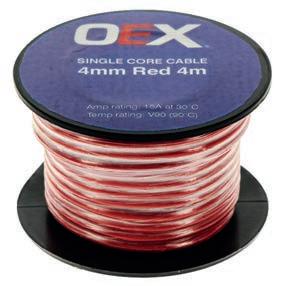

OEX has earned a reputation among Australia and New Zealand’s auto electrical and thermal specialists for OE quality products at the right price.

With a comprehensive and ever evolving range including alternators, starter motors, air conditioning components, radiators, lighting and automotive accessories, OEX has the right parts for your vehicle application.

DBA is Australia’s leading brake-rotor manufacturer and a distributor of complete braking solutions. As part of its commitment to outstanding customer service, DBA regularly shares technical expert advice via its website and other public and industry sites.

For more information visit dba.com.au/ resources, or call 1800 730 039.

Within the last month I wrote CEO News for the IAME’s Member Newsletter, and I am afraid to say that I was so passionate about what I wrote I will be covering some of the same subjects in this issue.

I believe the first point is the word PASSION – we as an industry should enjoy what we do and at the same time make money out of it. I have also mentioned in nearly every CEO News that to stem our skills shortage we have to take on apprentices and retain them. This retention, and an apprentice assisting by encouraging friends and family to follow suit in apprenticeships, starts with their enjoyment of, and passion for, their work and ends with their remuneration.

I was in a shop last month, and the business owner met me within the workshop and I opened my enquiry asking “how was business?”. He exclaimed he had a ‘yard full of pigs’ and therefore work was ‘absolutely crap’. This wonderful

declaration was in clear earshot of a newly inducted apprentice… how good would he feel going home after his third week of work and telling mum and dad his shop was ‘full of pigs’ and ‘work was crap’? If he’d ever wanted to stifle a young person’s enthusiasm, this employer had excelled.

The next point I would like to make regarding retention is the financial rewards to an apprentice while learning his or her craft. These young people live in the same cities as we do, and their modes of transport cost the same to register and ensure. They put fuel in their cars at the same price as we all do. They buy food at the same shops as we do, and they possibly entertain themselves in the same licensed establishments we do. The major difference is a qualified mechanic is often paid twice the award wage. The poor apprentice receives nothing but award wage – the lowest in all apprenticeship trades. As an industry we need to fight for a better basic award wage for our

Passion is the key for the automotive industry, and in some regards we are lacking.A lack of a decent income may be one reason the industry is suffering a skills shortage.

apprentices. Technology advances each and every day, but an apprentice wage is less than can be earned flipping hamburgers or packing boxes. It is disgraceful to expect an 18-year-old apprentice to survive on $13.62 per hour. I honestly believe the clue to acquiring and retaining apprentices is that we need to speak more of the opportunities within our industry and pay a realistic wage for their endeavours.

Speaking of technology changing, there is now a real flurry to achieve the next milestone in road fatality. We certainly had our safety cells with high-strength steels. We had our introduction of autonomous emergency braking, lane-departure warning and other ADAS features, so our new chapter is going to be around driver monitoring for driver fatigue. The two systems are known as DMS (Driver Monitoring Systems) and DSS (Driver State Sensoring). You wouldn’t be wrong to know that some vehicles already have an introductory to these programs in the cars we drive today. However, what is planned by 2031 is absolutely mindblowing, and I believe we have upwards of 17 major companies pursuing the manufacture of sensors to achieve this goal of eliminating driver fatigue.

On a different note, but on a similar circumstance in that I have discussed this

before, the question of servicing a vehicle to best operate using E10 fuel is back on the political horizon.

I recently had the opportunity to address the federal government crossbench with regards to ethanol-enriched fuels and how they could add to not only jobs in Australia, but also assist with environmental concerns, as the majority of cars today are built with the ECU mapping firmly aligned to E10 fuels. In the rest of the world where these globalised cars operate, there will be no option but to burn E10. Therefore, their mapping is more defined around the 10 per cent ethanol mixture and RON. You would be doing yourself an

injustice by trying to talk the consumer out of servicing their new car with burning E10 in mind. In October 2022, Standards Australia produced the workings of the Australian industry on a foundation of EV electric work. I was lucky to chair the subcommittee on the RS&R sector and, proudly, all our recommendations were well received and are now published. Working on EVs, as we all know, is perfectly safe when done the right way and when the vehicle has no faults. It is when something has gone wrong, such as a motor vehicle collision or when safeguards have not been properly engaged with that risk increases.

I am horrified to say I have spoken with many people in the automotive industry who tell me they have attended training courses that have either lacked substance or quality. More so, the information our practitioners hold is effectively no different to when they walked into the classroom. This is a blatant waste of time and money, but more importantly it will get someone killed. As an industry we must stop utilising the services of these training providers who have no idea and are training purely for milking a source of revenue. There were many items discussed around best practice when we were building the information bank for the Australian standards, and how we can now have a training course that doesn’t touch upon some of the safety prerequisites is beyond me. I ask each and every one of you that, if you attend a course that has been poorly written or delivered, you report to ASQA so immediate action be taken against the RTO delivering this potentially lethal lack of information.

Visiting Denmark to represent her nation wasn’t exactly what Bella had envisioned when she went into TAFE, but she’ll take it.

She placed sixth out of 15 spray painters from across the globe, finishing in the top 40 per cent in terms of marks.

In addition to her Scandinavian success, Bella was also awarded Apprentice of the Year Western Sydney during the NSW Regional Training Awards.

“I didn’t think it would happen, I was just doing my job like everyone else. I must’ve impressed a few people so that was pretty cool,” she said.

Her former teacher, Carl Tinsley, said Bella was a fitting role model during her studies in a complex field.

“It’s a very technology-heavy industry now,” he said. “We have ultraviolet primers and use gas-fired infrared which can dry a car’s paint in under 10 minutes.

“Also, modern cars are using advanced materials so it’s an exciting and high-tech industry to be in.

“For example, modern cars have loads of sensors for safety and parking. There’s a lot of skill required to be able to paint over them without interfering with their operation.”

She may only be 23, but Bella Turrise has accomplished a lot in pursuit of her passion for spray painting vehicles. It all started at an early age, but really struck another gear in high school.

“I restored a car in high school as part of a HSE subject,” Bella said. “I brought a car in and did some work on it, and that got me interested.” The car she worked on? Her granddad’s old 1984 Suzuki hatch.

“It couldn’t be driven, there were no electrics whatsoever, all it had was an 800cc engine,” Bella joked.

Like many, Bella went to university, but missed scratching her artistic itch.

She enrolled with TAFE NSW’s Campbelltown campus, undertaking a fouryear Certificate III in Automotive Refinishing Technology.

“We’d be doing something different almost every lesson, we’d get a run-through and theory lesson before going to the workshop and putting it into practice,” Bella said.

It was during her time at TAFE that Bella got the call-up to represent Australia as a Skillaroo in the WorldSkills Competition

Bella graduated mid-2022, and took her talents to AMA Group to work on trucks at Wales Trucks Repairs at Smithfield.

A bit of a change-up from painting cars, but a welcome one for Bella who said she enjoyed the bigger projects.

“I love the change, it’s just so different and exciting,” she said.

“We’re normally painting everyday with spray guns, normally we’re working with a lot more paint than we would in a car shop.

“I used to only mix up 50ml for some things with cars, but here I’ll never mix up anything less than 200ml.

“I like being able to set myself on a job and work on it for a while, so it’s good to be working on truck.”

The paint work for commercial trucks has Bella satisfied for now, but she certainly has big plans for the future.

When she’s not on the floor at Smithfield, Bella said she loved doing her own custom jobs on vehicle parts.

Whether it’s badass flames, or unique racing stripes, she loves expressing her creative flair in her free time.

Bella said she hopes to do more custom work in the future, but that’s not all.

Vehicle finisher and spray painter Bella Turrise talks about her already flourishing career.Bella’s Certificate III in Automotive Refinishing Technology course lasted four years, and included plenty of time on the tools.

“I’ve always loved the custom side of things – the fancy paints, the fine lines and metallics,” she said.

“I’d love to get into working on custom designed motorbikes. But I also really want to go and paint some planes as well.

“I actually considered joining the Air Force when I first started. I wanted to play with the jets, I thought that would be pretty cool.

“If I had an opportunity to paint something that flies, I think that would be awesome.”

With plenty of success already, and massive ambitions for the future, it’s going to be hard to keep Bella on the ground.

A Skillaroo, much like a Socceroo or Hockeyroo, is a member of the Australian WorldSkills team that represents the nation at international competitions.

After deciding university wasn’t for her, Bella

Skillaroos can come from a number of industries, including cooking, cyber security and carpentry.

hopped over to TAFE to pursue her love for painting. In 2022, Bella’s talents in painting led her to be named to the Skillaroo team bound for the WorldSkills Competition 2022 in Denmark.Affordable roadsters are depressingly rare these days. In decades past a young chap (or young miss) could reasonably expect to afford a new or near-new drop-top sporting car to get their kicks. And how about the choice? Think MG B, Triumph Spitfire, Alfa and Fiat Spiders, Austin Healey Sprite and the Lotus Elan. Top down, wind in the hair, manual gearbox, rear-wheel drive. Golden times indeed.

Today, your affordable new roadster list begins and ends with the Mazda MX-5. Even then, the cheapest one is over $40k to drive-away. Regardless, young folk of today with such disposable tend to buy a dual-cab ute, not a sportscar. With diesel engine, auto gearbox and cornering ability of a whale, they truly don’t know what they’re missing out on.

Let 81-year-old Brian Davies be your inspiration. As a kid and then teenager in Timaru on New Zealand’s South Island, he

was beguiled by his cousin’s MG TF and then MG B.

“When you look at brands like MG and Jaguar, for me it brings back the glory days of motor racing,” he says.

Still smitten by these old Brits, Brian’s days are filled with tinkering and driving the gorgeous little 1970 MG Midget he bought a few years ago.

Here, there, everywhere

It’s a truly tiny two-door roadster – shorter than a modern-day Fiat 500 – and not one you’d normally expect an octogenarian to enjoy getting in and out from.

“I have to shoehorn myself in, but this inconvenience is short lived by the time you hit the highway,” he explains.

“It’s a car that puts a smile on my face every time I put the key in the ignition. Its power-to-weight ratio is phenomenal, and while its ride and handling’s quite abrupt,

it’s like driving a motorised skateboard.”

The Midget has seen Brian’s life with cars come almost full circle. His first was a Morris Minor 850cc OHV, then a Standard Vanguard, before moving to Australia in 1964 and buying and restoring a 1954 MG TF. “I was good mechanically, but I needed help from a cabinet maker friend to fabricate up new framework where the wood suffered from dry rot,” he says. By this stage he’d developed quite the affinity for BMC products, and moved on to an Austin A40 Farina. Brian was working for distributors of BMC spare parts, making his hobby easier.

His motorsport enthusiasm saw him become the go-to man for BMC’s sports division, looking after Austin Healey, MG and Mini Cooper.

He relocated to Papua New Guinea and did up a Hillman Minx and a “mouldy Mk2 Ford Zephyr,” before a return to New

Brian Davies has treated himself to an MG Midget for tinkering and weekend drives, revisiting a model he bought new as a young man.

Zealand saw him buy his first new car: a British Racing Green MG Midget 1100cc, optioned with luxuries such as wire wheels, a heater and a radio.

“I’d lusted after an MG B, but the Midget was far more affordable,” he explains. “But after owning it for six months, I was contacted by a solicitor whose wife hated their new MG B and wanted to swap it for my Midget plus a bit of cash. I put myself into debt, but there I was with a near-new

MG B in Tartan red with leather upholstery, wire wheels and overdrive. Back then, the stuff that a young man’s dreams were built on.”

He ultimately returned to New Guinea, working across the country establishing and managing Toyota dealerships. Compared to the British cars he was used to, “Toyotas were far better made,” says Brian. “The Japanese had that pride-ofwork ethic.”

Even so, when he settled in Australia it was his passion for classic Brits that proved stronger. He restored a rubbernose MG B in the 1980s, but it wasn’t until recently he decided to revisit his love for the very first new MG he bought. “I found this 1970 Midget Mk3 that had only had two owners, both from the same family,” Brian says. “The nephew, who I bought it from, had given it a full rotisserie restoration.”

It’s one of the 1184 Midgets assembled in Zetland, Sydney, between 1967 and 1971 as complete knock-down (CKD) packs. Brian’s is a later facelifted version, of which just 396 we made. Locally produced electrics and paint were used, with this car originally painted in Australia-only Camino gold. As you can now see, the restoration involved a switch to the more popular Tartan-red hue.

These MkIII Midgets used the highly tuneable 1275cc engine - as found on the Mini Cooper S – but were detuned versions good for only 48kW and 98Nm.

The car’s original engine remains, but has been bored out to 1300cc and had a camshaft grind, and after sampling this thing in action, I can report it’s got ample shove to

haul along such a lightweight roadster.

“On the open highway at 110kph it certainly wants more,” says Brian. “I’ve had it up to 140kph, and believe it could easily accomplish 160kph, just like an MG B. It’s easy to drive and reliable. The previous owner would do 1100km round trips in it, and I’d happily hop in it, throw luggage in the boot and drive from Queensland to Sydney without hesitation. I know it’d get back again too.”

While there was the expected overhaul of the gearbox, diff, brakes and wiring, it was also gifted a series of smart upgrades better suited to modern driving. There’s a brake booster kit on account of the increased performance; an oil cooler’s been fitted, it has 14-inch wire wheels from an MG B replacing

the original 13s, while an alternator replaces the antique generator.

Even so, this is a 1970s offering that has elements taken from immediately postwar. The suspension features semi-elliptic leaf springs, while there’s no synchromesh on first gear. “When I start it, the normal procedure is push it into second, then you

the rag top roof folded there’s no sense of claustrophobia. But with the tiny front screen and wafer-thin doors, you wouldn’t much fancy your chances in an accident.

There’s space behind the low-set seats (you really feel you’re sitting on the road) and enough space in the boot for a couple of weekender soft bags. The Smiths

with this car,” Brian explains. “If I bought something new like a Mazda MX-5, there’s things I can’t even look at. But for the MG I have a tune-up kit to adjust the fuel mixture on the twin carburettors, and have a vacuum gauge to balance them. I couldn’t do that on a modern car.”

‘traditional’ MG is all about. Upkeep’s also easy. “Spare, and even new, parts are plentiful from Moss of England, while eBay is always helpful. Parts are no dearer than what you’d pay for a Toyota or Kia.”

The Midget may be one of the tiniest things on the road, but the fun and attention it brings are mighty. As for Brian, he’s still smitten with classic MGs, even after a lifetime owning them. “I’d say to anyone thinking about a weekend fun toy, don’t think too long. We’re only here for a short time, and it should be a fun time.”

The MG 1970 Midget has a 1275cc engine like a Mini Cooper, but runs at 48kW and 98Nm.It’s a car that puts a smile on my face every time I put the key in the ignition.Brian’s MG Midget’s engine has been bored out to 1300cc, and he reckons it would hit 160km/h if the winds are in his favour.

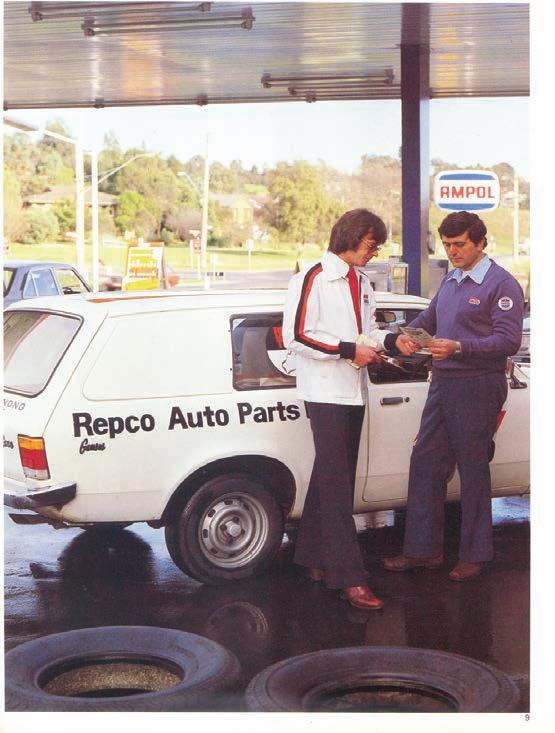

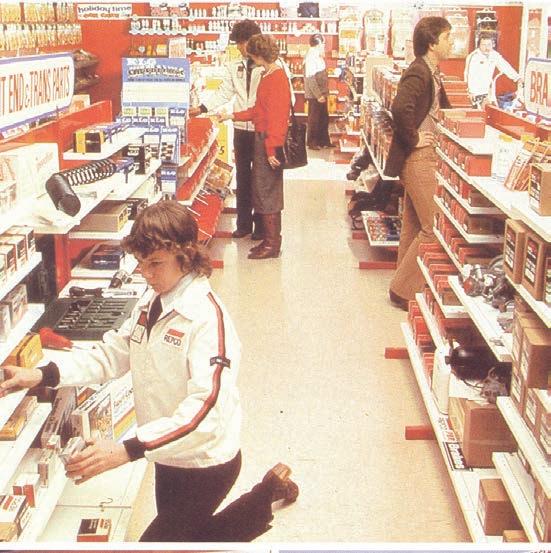

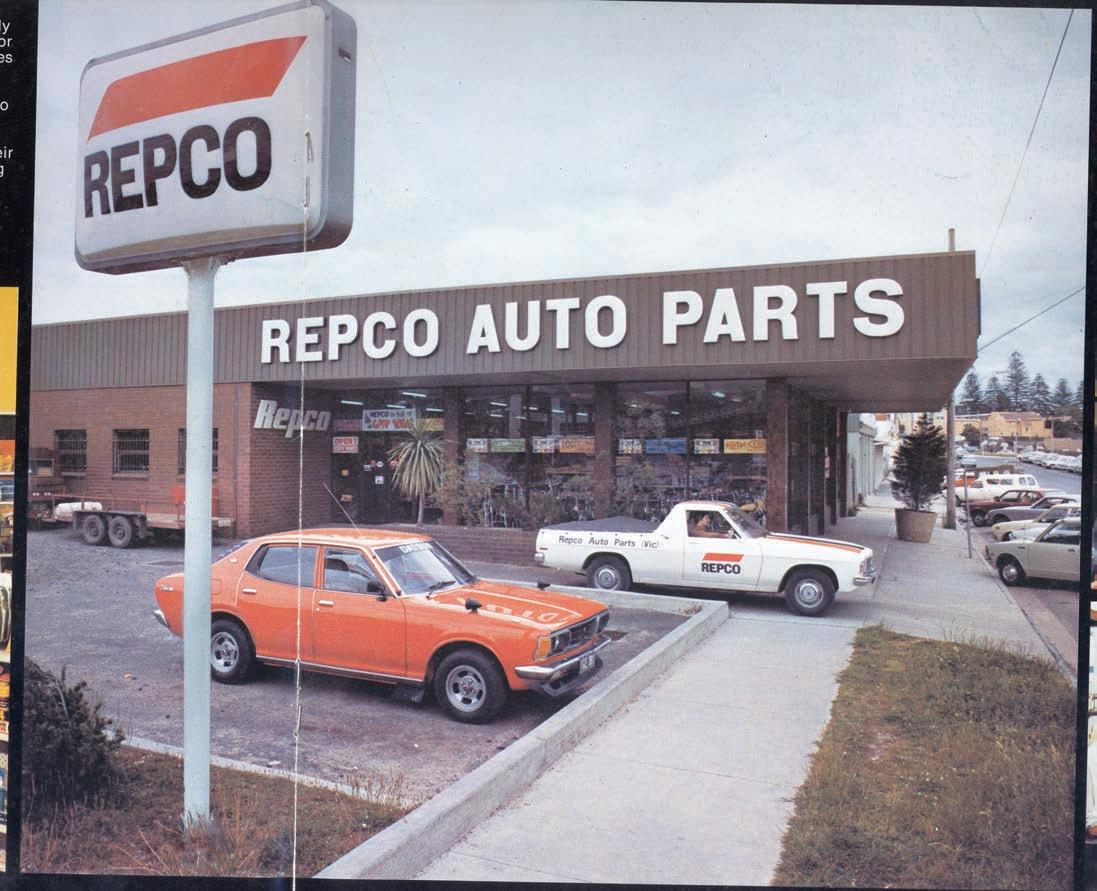

Repco icon Malcolm Dunning marks an historic 45 years with the company.

Whether it was the haircuts or lack of the internet, a lot has changed during Mal’s time with Repco.

The way Repco does business has evolved massively with the times.

This was your average Repco store exterior when Mal first started working with the company. It certainly was another era!

To be with one company for a lifetime can seem daunting to some, but for Malcolm ‘Mal’ Dunning, there’s nowhere he’d rather be than Repco. The trade sales manager has been with the company for an impressive four-and-a-half decades after joining in 1977.

Through the many hats he’s worn and workplaces he’s worked in Mal has served as a witness to Repco’s evolution and the changes in the auto industry as a whole.

A fine motor Mal’s appreciation for the auto industry started early in life, and it was the driving factor behind him joining Repco.

“I had a passion for anything mechanical and loved tinkering with cars and motorbikes, plus my father told me Repco would make an excellent business to work for as they had a great reputation even back then,” he said.

After notching the Top Sales Cadet Award in his first year at Repco’s Brisbane office, Mal progressed through numerous sales roles before being transferred to manage a struggling store in Taringa, Queensland.

It didn’t take long before Mal’s can-do attitude had reversed the store’s downward trend. Within six years, the business had become one of the most profitable in Queensland.

“We offered great service and treated our customers like our friends,” Mal said. “Service and relationships are the two keys to success.”

After a total of 11 years with the Taringa outlet Mal was promoted to Regional Manager, taking charge of 23 stores in south-east Queensland. He then pivoted to the role of State Sales Manager in the Queensland Equipment department, a position he held for another 11 years, before landing the massive role of Queensland State Sales Manager.

“I always wanted to be a Repco Sales Manager and have been lucky enough to have held that role for 20 years,” he said.

Of course, Mal’s many positions and success he’s experienced with Repco came with plenty of recognition. This included being named Innovator of the Year 2011 and Zone Leadership Team Member of the Year 2014.

Mal’s an early riser, with his morning email to his sales team going out no later than 5.30am each day. As well as his commitment to sales, Mal’s passion for tinkering has him heavily invested in ways to improve and expand customer service

few wise words.

“I have learnt that if you treat all staff and customers with respect, and try to help them be successful in their career or business, they will return the favour,” he said.

As Mal’s climbed the Repco ladder, the company itself evolved with the auto climate to adapt with the demands of consumers and companies alike in terms of the products they provide.

“Repco has grown from being a predominantly trade-based business to a true dual-format business servicing trade and retail customers with goods and services,” Mal said. “Our stock range has

grown to cover a wide range of customers.”

Not only were there changes in Repco’s business, but how it did that business as well.

“When I started with Repco there were no computers and every invoice was handwritten and priced, so technology has certainly improved since then,” Mal added. “Our award-winning online B2B and B2C platforms have transformed the way we do business so our trade and retail customers can view products and order online 24/7.”

Repco’s evolution culminated in its 100th anniversary late in 2022. Having been involved for nearly half of that lifespan, Mal said it was a special occasion indeed for not just Repco, but the Aussie auto industry as a whole.

“It was absolutely a great experience to celebrate Repco’s 100-year anniversary with all current and many retired staff members who were invited to attend along with our valued suppliers,” he said.

As well as Repco’s centenary, Mal’s storied career is bursting with highlights, including attending the GPC-NAPA Expo in 2015 in Las Vegas, which featured more than 14,000 participants. But arguably the pinnacle of Mal’s time with Repco was his induction into the Repco Hall of Fame in 2016.

“It was a tremendous honour to be called out on the night to accept the award, and I felt truly humbled by the experience,” he said.

countryside, including trips to the historic Shelsley Walsh Hill Climb. It was at this time his passion for cars and bikes flourished, and he set out to learn how they worked and how they could better perform.

the additive industry which was becoming an important part of lubricant production.

The Dymond family-owned Lane 88 Auto Museum opened on the 18th of June 2022 on the site of Penrite Oil’s previous headquarters and blending plant at 88 Lewis Road Wantirna South. The museum houses a small private collection of vehicles owned by John ‘JD’ and Margaret Dymond, and celebrates the Dymond

At 16, JD joined Vauxhall Motors where he served a seven-year apprenticeship. While at Vauxhall, JD obtained a mechanical engineering degree at night school, and it was during these years he met Margaret. She lived locally and had family who worked at the Vauxhall plant. They relocated to Melbourne in 1958, where JD took up a position with BP

In 1979, JD’s passions of classic cars and mechanical improvement collided when he and Margaret took the opportunity to the purchase Penrite Oil Company.

JD’s 20 years’ experience in both the oil industry and the additive market gave him the background and knowledge needed to take up the challenge of his own company, along with the nine children he and Margaret would welcome into their lives.

Through the 1980s and 1990s, several Penrite product developments, including the HPR and 10 Tenths engine-oil ranges, were the direct result of industry demands the Dymond family discovered through their involvement in racing.

Although JD is no longer with us, Margaret and the family still enjoy, and actively participate in, motoring events across Australia and New Zealand.

JD and Margaret bought many cars over the years, but always had a soft spot for Vauxhalls and European touring cars. Consequently, the collection features examples from Mercedes Benz, BMW, Bugatti, and Riley, alongside historic racing cars (list of notable vehicles below). The museum is fortunate to also have several short-term loan vehicles and is home to the newly purchased Erebus Motorsport Mercedes-Benz E63 AMG, acquired by Penrite Oil in December 2022. The vehicle was sponsored by Penrite at the 2015 Bathurst 1000, and was Penrite’s first major

The Dymond family detours into the past with the Lane 88 Auto Museum.John ‘JD’ Dymond and his family have a strong and historic connection to the Aussie motor community. As well as hosting its own collection of classic cars, Lane 88 also serves as a venue for Penrite-backed meet-ups such as the VIC Mazda MX-5 Club.

sponsorship involvement in the Australian Supercars Championship, an important milestone in the company’s history.

In the blending plant at the rear of the site, much of the equipment and base-oil tanks were retained to capture the charm of Penrite’s history, and to tell the Penrite Oil Company story. The museum is also home to the John Dymond Library, the collection of his personal technical and automotive books. The library has been catalogued and is an accessible resource for future generations of automotive-engineering students and carclub historians.

The Lane 88 Auto Museum hosts Penritebacked club functions, meetings, media events, and invite -only open days. Recent events have included the Penrite Oil Sandown SuperSprint launch attended by Penrite Racing drivers Dave Reynolds and Lee Holdsworth, and meetings for Vauxhall, Ford Zephyr, Rover and Triumph clubs, VIC Mazda MX-5 club, River City Cooper Roadster Club, and others. The museum will host the Penrite Racing Gen 3 Fan Open Day on Saturday, 4th of March, a chance for fans to see the new Gen 3 cars before they hit the track, and to meet the Penrite Racing drivers.

540K Mercedes – originally owned by German aviation Designer Ernst Heinkel

1938 BMW type 328

1969 DBS Vantage

1983 Cheetah MK 8 – The first car to be sponsored by Penrite in ’84

1951 Cooper Jap Mk 5 - Winner

1952 Australian Hill Climb Championship

1955 Vauxhall Velox ute – The first ute made in Australia

DB4 Aston Martin

Petty Manx race bike

Vauxhall 30/98 OE

WITH THE VDE-CERTIFIED TOOLS FROM WIHA.

WORK IN A PERFECTED PROTECTED WAYLane 88 is home to many great and charming historical vehicles, including this lovely Holden HR. You don’t see many 1936 Rileys in as good condition as this!

There’s a fair bit of pressure when your boss – or worse yet, a customer – leans over your shoulder while you work on a car. They watch, they assess, they critique. They may even make a little noise that could translate as ‘good job’ or ‘why’s he done that?’ Now imagine you’re working on a tricky problem, the clock’s ticking, and there’s a chap right in your face dissecting your every move. When you’re done, he silently and secretly writes down your score.

This is the pressure cooker of MazTech, where Australia’s best Mazda technicians compete against each other and the clock to detect and correct faults on vehicles and components. For one competitor – this year it was Luke Carabott from Ryde Mazda – the ultimate prize is being crowned the best Mazda technician in the country. To win you need experience, coolness under pressure and the ability to think and work fast.

The MazTech event usually takes place in over 50 countries, but has been disrupted by COVID in recent years. Two winning master technicians from each country – from as far afield as Colombia, USA and Italy – then go to compete in Horishima, Japan, in the MazTech World Final. It was last held in 2019, and, we can say with pride, Team Australia is reigning

champion. Not bad going when you consider more than 22,000 global Mazda technicians were entered in the first round of testing.

It’s not known when the next World Final would be, but for 2022, Mazda

Australia ensured its national assessment continued. Mark Oldis runs our event and explained every Mazda Master Technician in the country had to enter the first round, an online exam. “To qualify for the state round, they needed a certain score and be selected by their dealership to compete; they had to be the best of the best at their

They say competition improves the breed, and what better way for technicians to properly test themselves than in the heat of battle?WORDS AND IMAGES: IAIN CURRY MazTech competitors undertake various repair tasks, from broken fobs to low power concerns.

place of work,” he said.

You’re then up against the winners in each state, where the challenge was working on six different on-vehicle and on-bench tests. “You get 20 minutes to diagnose a vehicle fault or complete a repair test on an engine or electrically (what does this mean?),” Mark said. “From there we take the top two from QLD/NT, NSW and VIC/TAS, plus one from SA and WA for the national final.”

So, what sort of issues and problems do the technicians need to work out in double-quick time? Mazda brought many of its current vehicle range, from the popular CX-5 SUV to the BT-50 ute (co-developed with Isuzu) and a CX-30 featuring the brand’s complex Skyactiv-x engine: a petrol four-cylinder with innovative sparkcontrolled compression ignition.

The BT-50 was presented with low power concern (we all jokingly blamed Isuzu for that); the CX-30’s key fob wouldn’t work and the CX-5’s windscreen wipers refused to return to their park position. “The technicians are judged on time, obviously, but also on best practice, best procedure and not damaging the vehicle,” said Mark. “In our training we have six diagnostic steps we use, such as verifying the fault and accessing the right part of the workshop manual, and there’s a specific judging criteria for each.”

Luke Carabott went through from NSW to the Australian final, where he and others were presented with eight stations to complete – just as they would at the World Final. They had a BT-50’s auto gearbox that wouldn’t shift smoothly, a noncranking CX-8, a cranking but non-starting CX-30, busted headlight in a CX-5 and a Mazda6 requiring a cylinder leakdown test.

“It’s pretty full on,” said Luke after his victory. “It’s just you and the guy assessing at that station, so it’s head down and try your best. At the end of it all I had the biggest headache; we were all exhausted. It’s not the physical side, it’s the mental.”

Luke had competed a few years before and thought his prior experience helped his win. There’s the well-earned glory, but it’s also no bad thing to go back to your workplace and remind co-workers you’re the best Mazda tech in the land. Luke said he encountered faults most would rarely see, and even ones he’d not had during his eight years with Mazda, so took many learnings from the event. And, from a professional point of view, he’s further upskilled and has been able to share this knowledge with his team in Ryde.

The joy of competition aside, striving for higher technical expertise at manufacturer workshops is a noble cause. “For me,

who writes the tests, it’s also a skills-gap analysis,” Mark said. “As they’re competing I can see where they might need extra training.”

Many car brands do similar events to MazTech, suggesting there are key benefits to bringing a competitive element to diagnosis and repair. The likes of Jaguar/ Land Rover, Nissan and Volkswagen all have their own contests, while Hyundai has the brilliantly-named World Skill Olympics.

So, I know you’re thinking it: what are the prizes?

Across the industry it’s been known for technicians to win a new car or global holidays for being best in the world, but Mazda sticks to trophies and glory. “For Luke to be the elite technician in his state, and then to be the best of a very select group in Australia, is a pretty big achievement,” said Mark.

Luke snared a $500 travel voucher for winning the Australian round, but sadly missed out on the all-expenses trip to Japan to compete against winners from other countries, again due to COVID. “I need to push for automatic entry for the next World Championships!” he joked. That, or he’s just going to have to go out and win it all over again next year.

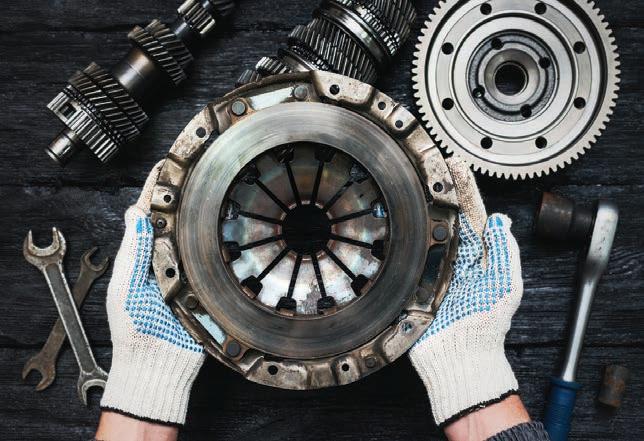

For many drivers, this is the first thing that pops into their head when ‘performance’ is raised…

Performance products are all about one basic thing: making a vehicle better.

It might sound simple, but as we all know, it’s far from it. Many consumers are content with running their car out of the showroom and saying sayonara to any thought of swapping out pieces for better ones.

But when mechanics and technicians are called up to the plate, they want to be well-equipped to take a customer’s vehicle to another level. In your head you might be thinking something along the lines of Pimp My Ride when it comes to making absurd alterations to a car to make it look like something from an early Fast and Furious. However, improving a car’s performance can be as subtle as a new clutch, filter or shock absorbers.

They might not be as flashy as a dualexhaust, but they’re arguably more effective in improving a vehicle’s overall performance, and more importantly, its shelf life.

Understanding and appreciating these crucial pieces is the crux of many mechanics’ business.

In this section of Australian Car Mechanic, we present a few products geared towards helping customers and mechanics get the most out of their vehicles

ACM Genuine Parts are replacement parts sourced through our independent supply chain directly from the manufacturer of the original part and guaranteed to fit the original equipment manufacturer’s specifications.

Because failure is not an option, our genuine range of products are subjected to rigorous safety and performance testing.

Our genuine parts are branded with the original manufacturer’s logo, including traceable OEM part numbers, guaranteeing the highest quality available, without the excessive mark ups.

From a proud heritage of automotive electrical and air conditioning know-how, NAPA Auto Parts has diversified its range, knowledge and specialist solutions to keep your workshop moving. The auto industry is a constantly evolving and dynamic market, and NAPA Auto Parts knows as well as you do, that it is crucial to stay ahead of the curve and adapt to changing customer demands and industry trends. NAPA Auto Parts has always delivered high-quality brands and range, but has recognised the need to expand the offering.

A look towards the future shows a growing demand for mechanical products in the auto industry. From transmissions to braking systems and servicing parts, these mechanical components are critical to a vehicle’s performance and safety. Napa Auto Parts has expanded into these new ranges to offer a complete solution to you, and provide the widest product range for all your auto part needs. Steering and suspension components are two of the most important systems in any vehicle, particularly in 4x4s designed for off-road use. The steering system must be precise,

responsive, and durable. The suspension system is responsible for providing a smooth ride by absorbing shock and vibrations from the road surface. It also helps to maintain the tyre contact with the road, improving handling and stability.

These systems are particularly important for 4x4s, as they must handle the added weight and strain of off-road use. Heavyduty components must be used to ensure the vehicle can navigate rough terrain without causing damage to the steering or suspension systems.

Whether you’re crossing the Simpson or tackling a weekend away, NAPA Auto Parts has the 4x4 components you’ll need, backed by its own widely popular Drivetech4x4 range of steering and suspension products. It includes heavy-duty suspension lift kits, heavy-duty and extra heavy-duty coil and leaf springs, power-steering repair kits and components, rack and pump assemblies and shock absorbers. The range also expands into steering components, including tie rod ends, drag links, idler arms, ball joints and more.

Drivetech4x4 provides three different

strut designs – Enduro, Enduro Pro and Foam Cell. In addition to this, Drivetech4x4 has multiple spring combinations offered, being a ‘H’ or ‘J’ series. The suffix in the part number determines which type of spring is in the kit. The first letter is the front spring and the second being the rear. The third letter relates to the series of dampers used. An ‘H’ spring is designed to give approximately 40-50mm lift, with a slight increase in load of approximately 50-100kg. The ‘J’ series is also designed to give approximately a 40-50mm lift, with an approximate additional weightcarrying capacity of 350kg – however, these springs require the vehicle to have a constant load applied of approximately 150-200kg. It is imperative when using the ‘J’ springs that this additional weight is applied, as failure to do so will result in a harsh ride experience.

For more information about the NAPA Auto Parts and its wide range of leading automotive specialist and mechanical brands for your workshop, speak with your local NAPA Auto Parts team. Visit napaparts.com.au/locations for your

Combining the highest quality components with extensive in-house engineering and real-world testing, Xtreme Clutch takes performance clutch upgrades to a new level. Designed specifically to deliver the ultimate clutch solution for the street or track, Xtreme Clutch provide attention to detail in the driving experience of your vehicle.

The Xtreme Clutch range of twinplate sprung organic upgrades has proven popular in both the domestic and export markets, with the innovative design offering the ideal solution for driveability in high-powered street applications.

The sprung multi-plate range has evolved over the past two years as Xtreme Performance Clutch continues to incorporate these options into new applications. The kits were developed in-house at Australian Clutch Services in Adelaide, the home of the Xtreme Clutch brand, and have been extensively tested throughout Australia, Europe and the US. Performance upgrades are available in two sizes: 230mm and 270mm, and both have been specifically developed to suit a variety of vehicle applications and uses.

The 230mm clutch is a race inspired design with lightweight alloy pressure plate available with a flat or rolled tip diaphragm, casting, intermediate plate and chromoly flywheel. This design is available with sprung organic friction discs and floating intermediate plate and is ideally suited to vehicles with limited bellhousing space

such as 4-cylinder turbo applications. The 270mm clutch is perfectly suitable for high-powered V8 applications and incorporates a pressed metal, heavyduty pressure plate, strap-driven

cylinder or release bearing, pilot bearing, alignment tool and bolts as required.

“The sprung organic range of upgrades has already proven very popular with performance tuning groups and our distributor base around the world,” Australian Clutch Services Sales Manager Colin Jevons said. “The sprung version of these twin plates helps to improve dampening and is ideally suited to daily driven street cars that have far exceeded the capabilities of a single plate upgrade. With a 1000Nm torque capacity and exceptional driveability, these kits are becoming the go-to for many of our performance customers around the world.”

Xtreme Clutch also offers a sprung ceramic 230mm twin-plate upgrade for those using the vehicle for motorsport applications and require a clutch with improved dampening characteristics over traditional, rigid, twin-plate clutch upgrades.

intermediate plate (to minimise noise) and a performance flywheel.

Each kit includes all necessary components for each specific vehicle application, such as concentric slave

For more information please contact Australian Clutch Services on 1800 CLUTCH or visit the Xtreme Clutch website xtremeclutch.com.au

“The sprung organic range of upgrades has already proven very popular with performance tuning groups and our distributor base around the world.”

As a world leading manufacturer of original equipment thermal system products, DENSO’s aftermarket range offers unique advantages to our customers.

Our premium quality range includes A/C compressors, A/C condensers, receiver driers, expansion valves and pressure switches.

The Protex Ultra Performance range is the ultimate upgraded braking solution for drivers and enthusiasts with a focus on performance.

Protex’s Ultra Performance Disc Rotor is made from high-carbon cast-iron material and offers better thermal stability,

quieter braking, and high performance in challenging driving conditions. Slotted, drilled, and various vane configurations are available for better cooling in hightemperature braking situations.

Outstanding features of the Ultra Performance Disc Rotor include:

• Protex’s Ultracoat Z360* exclusive anticorrosion coating for faster fitting and longer life.

• A high carbon formulation with six directional slots and a innovative vane design for optimised heat dissipation.

• Quieter, responsive, and a smoother pedal feel

• Quicker fitting reduces labour costs and cleaning time.

• Protex Ultra Ceramic Plus pads deliver ultra-quiet, stable stopping power.

• Protex is committed to minimising environmental impact, from production methods through to materials. Protex’s Ultra Ceramic Plus Brake Pads contain zero copper, providing less environmental impact without compromising performance.

With over 30 years in the industry, Protex offers everything needed to service the entire braking system.

*To find out more about the Protex range, including pads, rotors and hydraulics and many more Protex products that offer full braking solutions, log on to protexparts.com.au

Protex Ultra Performance – the ultimate braking upgrade.

ROADSAFE, Australia’s leader in automotive steering and suspension parts, brings the company’s passion and suspensioncomponent expertise to a new high in the form of a quality shock-absorber program delivered to the aftermarket. The new program consists of OE-replacement or enhancement options.

The ROADAFE STR and 4WD Shock A bsorber ranges form integral parts of the ROADSAFE automotive aftermarket product range which is competitively priced and delivers quality to repairers and suspension specialists nationwide.

ROADSAFE STR covers replacement shock absorbers for passenger vehicles and daily drives, while the ROADSAFE 4WD is a performance enhancement for 4WDs and suited up to a 50mm lift. ROADSAFE STR and 4WD shock absorbers are locally tested to specifically suit Australian conditions. All ROADSAFE product testing is conducted in a dedicated research-anddesign facility located in Victoria, where shock absorbers are assessed using a very stringent testing process which includes visual inspections, shock dyno tests, vehicle fitment and on-road testing. Its quality is backed by a comprehensive three-year/100,000km warranty.

ROADSAFE STR replacement shock absorbers are nitrogen-gas charged to provide precise and consistent valving. They also feature high-quality, hardchromed finished shafts to eliminate wear, chipping and drag. Finely tuned valving to suit each specific vehicle application ensures improved vehicle comfort, control, steering response and reduced emergency-stopping distances. High-quality piston-rod guides ensure smooth operation with superior strength against side loading.

Each ROADSAFE STR Shock Absorber pressure tube is seamless, ensuring they are 100 per cent cylindrical, with highburst pressures, resulting in consistent

performance and reliability. High-quality rubber mounting bushings reduce noise, vibrations and harshness, while also ensuring stable mounting.

The ROADSAFE STR Shock Absorber range is available in sealed-strut, telescopic and spring-seated designs as determined by vehicle specifications, ensuring repairers have easy access to an extensive range of shock absorbers to suit a vast array of vehicle makes and models. ROADSAFE 4WD Shock Absorbers feature a larger surface area for optimum heat dissipation and excellent dampeningcontrol properties. The ROADSAFE 4WD big bore design ensures greater oil capacity and temperature control under extreme four-wheel-driving conditions.

Additional features include a largediameter, high-quality, chrome-finished

shock absorbers also feature a large surface piston-rod guide to support increased side load and heavy bump impacts. The ROADSAFE 4WD Shock Absorber range also benefits from highquality upper-shaft seals to handle the demands of rugged terrain, along with heavy-duty, double-welded mounting points for increased stability and strength.

ROADSAFE 4WD direct-fit shock absorbers are available in nitrogen-gas (up to 35mm bore) and foam-cell (up to 40mm bore) configurations to ensure reduced fade, aeration and cavitation control.

The ROADSAFE STR and 4WD replacement shock absorber range is available from Burson Auto Parts and other quality independent auto parts resellers nationwide. To find out more call

steering and suspension leaders bring roadsafe shock absorbers to the aftermarket.ROADSAFE STR Shock Absorber range is nitrogen-gas charged, meaning pinpoint precision and endurance.

t DENSO every component has been designed with precision and subjected to rigorous safety and performance tests. The OE-standard quality and reliability of DENSO aftermarket components add up to tremendous value for its customers.

DENSO offers a complete range of spark plugs, delivering world-leading technology. The range includes:

Nickel TT – A unique twin-tip electrode design to produce complete, efficient and cleaner combustion.

Iridium TT – Long-life performance plugs are 6x harder and 8x stronger than platinum. They have the highest level of iridium content (90 per cent) giving them increased oxidation resistance and allowing them to last 100,000km.

Iridium Power – High-performance plugs with the world’s smallest iridium centre electrode. Their small electrode requires less voltage, reducing misfires.

Iridium Racing – The ultimate performance spark plug for the serious racer. Precision tuned for the demands of high-rev,

high-horsepower, high-torque and highoutput engine applications under extreme endurance and competitive conditions.

DENSO spark plugs have a number of unique features that set them apart from the competition, like using a 1.5mm diameter nickel alloy in the Nickel TT plugs that reduces spark wear by up to 40 per cent compared to standard nickel.

Another unique component is the 1.1mm diameter platinum electrodes which can withstand incredibly high temperatures.

DENSO’s high-purity iridium alloy can handle the highest of temperatures and is the hardest material used for spark plugs. Iridium tips ranging between 0.4mm, 0.55mm and 0.7mm are laser-welded to the centre electrode.

DENSO uses four different terminal types:

• Thread (no terminal nut, mainly for motorbikes and older cars)

• Solid (solid terminal for car applications, cannot be removed)

• Terminal (easy to unscrew, thread with nut)

• Crimped (thread with crimped nut, better connection between nut and thread, nut can be removed)

DENSO specialises in a number of OE products, such as radiators, condensers, starters, alternators, spark plugs, sensors, air-intake systems, diesel injectors, pumps and filters. DENSO’s oxygen sensors are constructed from the highest-quality materials available; high-quality stainless steel, porous polytetrafluoroethylene (PTFE), fluorine rubber, aluminium oxide, high-grade platinum and ceramic.

Denso oxygen sensors are resistant to silicone and lead poisoning that make it as highly sought after OE-parts by workshops. DENSO’s radiator configurations – tanks, fin pitch, core dimensions and materialsmeet rigid standards and pass DENSO’s strict durability and function tests. Likewise,

DENSO’s condensers are manufactured to allow the A/C system to operate at peak efficiency with minimal maintenance, assuring years of trouble-free service.

Denso’s starters and alternators perform to manufacturer standards, mount with a minimum of installation issues and provide years of reliable service.

Highly durable components such as heavy-duty ball bearings and impact limiters prevent internal damage, resulting in products with the lowest return rates in the aftermarket.

There’s been an explosive growth in dieselpowered passenger and commercial vehicles on Australian roads. DENSO offers the world’s highest injection common-rail system of 5x injections per cycle, while retaining the ability to meet increasingly strict emission laws.

DENSO’s OE experience and know-how is reflected in its aftermarket product range providing unmatched performance, reliability and fitment with real cost savings.

For more information and to find your part visit denso.com.au

Deflecting beam torque wrenches work by applying torque to a deflecting beam rather than a coil spring. With no wearing parts, the unique design ensures accuracy of +/- 2% throughout the range of the wrench.

The torque setting can easily be set via a sliding scale which displays the torque units. The dual signal feature allows the users to see, feel, and hear when the selected torque has been reached. When working in a noisy environment the operator can see the signal mechanism release without relying solely on an audible notification.

• Deflecting beam mechanism (no spring)

• Dual signal (see and hear when the wrench has reached the selected torque)

• Torque units displayed in ft.lbs, Nm & kg-cm

• Left & right-hand operation

• Rigidity - all steel construction (Made in Australia)

• Repeatability - accurate to +/-2%

• Durability - no wearing parts

• Meets or exceeds international standards

• Certificate of calibration can be provided on request

• Lifetime warranty on deflection bar

Of all the places an Aussie mechanic could end up, how does stranded in the Sahara without any petrol sound? Ian Steele’s passion and expertise for Citroens has seen him wander through the desert hunting for fuel, competing in and helping win gruelling rallies, and working in countries where language barriers were overcome with spannering skills.

Now aged 72, Ian runs his Just Cits business with the panoramic views of Queensland’s Sunshine Coast hinterland for company. He’s the go-to expert for anything Citroen, from the Traction Avants, DS, and 2CV icons through to modern C5s. With ample space at his property, numerous sheds house rare and collectible classics, while his grounds are littered with younger cars – mainly Xantias – for parts or possible future fix-ups.

Like a fine wine

But why Citroen? “I started my apprenticeship with Holden in Gympie when

I was 15,” Ian explained. “Dad had a Peugeot, and it was a far superior car to the GM stuff I worked on – Holdens, Pontiacs, Chevs. Then my brother bought a Citroen Light 15 and I remember how well it handled. I wanted one.”

Brisbane’s Citroen dealer was Maxim Motors, run by Jim Reddiex – more on him shortly. “When I was eventually offered a job there I handed in my notice to my workshop’s boss,” Ian said. “He told me ‘there’s no future in Citroens’ and if I stayed he’d make me foreman. I told him I didn’t want to stay and work on Holdens, Fords and the Pommie crap.” That was 1972, and he’s still working on the Citroens today, over half a century later.

At this stage Ian had bought a 1927 Citroen, a couple of Light 15s and an ID – the less expensive DS variant. In case you’re not aware of these French executive cars, built from 1955 to 1975, they look like spaceships thanks to a breathtaking Bertoni design, and ride like magic carpets due to their hydropneumatic suspension. In short, it’s of

great benefit to be experienced and expert if working on Citroens.

Ian clearly had the right stuff. Maxim boss Jim Reddiex was to be part of an Australian privateer crew heading to Europe to compete a Citroen DS23 in the 1974 London-SaharaMunich (UDT) World Cup Rally. One of those mad events that went between the English and German cities via Nigeria (not the most direct route), across the desert and covering a total of 19,300km. It would snake through Spain, Morocco, Algeria, Tunisia, Turkey and more.

Ian was picked for the crew to drive another DS23 – a former Group 2 rally car – as service car. Ahead of the event, Ian, Jim and driver Ken Tubman (winner of the inaugural 1953 Redex Trial) recce’d the course through North Africa. It was here they got stuck in the Sahara when they exhausted fuel supplies. “Jim and I walked 32km across the desert to Arlit (in Niger) where there was

From the deserts of Africa and the Northern Territory to workshops across Europe, Ian Steele’s life with Citroens is a proper adventure story.

a uranium mine,” Ian said. “We though the walk was only going to be 5km, and we’d left Tubby with the car. By the time we got back the next day in a Kombi with fuel, Tubby had re-written his will and was in tears he was so glad to see us.”

There’s a happy ending. The Australian team won the rally in a Citroen DS23, the carburettored five-speed giant triumphing by over 28 hours. The arduous route and navigation dramas saw time penalties galore, and only 19 of the 70 cars that started made the finish line. Stirling Moss, for one, never made it in his Mercedes-Benz. And

Ian has been working on all kinds of cars since he was a young teen from Gympie, Queensland.

From the Sahara to Munich, Ian’s seen a wide variety of roads and tracks through his Citroen fixation.

Ian has been working on all kinds of cars since he was a young teen from Gympie, Queensland.

From the Sahara to Munich, Ian’s seen a wide variety of roads and tracks through his Citroen fixation.