On a ROLL

A look at Aussie brakes

Repco filters are sourced from manufacturers who are world leaders in quality filtration and have an OEM pedigree utilising processes that ensure we maintain our ‘world’s best’ quality position.

Repco’s oil and air filter manufacturer has a world class quality engineering department and production line and a fully contained testing laboratory with QA processes managed by teams of highly qualified engineers. Our filter manufacturers are world recognised and sell to OEM and OES around the world.

Morning frost can be easily beaten these days, but sight of a frosty morning never fails to send a shiver down my spine.

It’s frosty outside. Early mornings are greeted with piping-hot coffee and the battle against seasonal depression is in full swing.

Each day a bursting schedule awaits all mechanics this time of year, as neglected problems come back to haunt customers. Maybe that fuel pump you told a customer they needed to replace finally seized in the cold. Or perhaps those old tyres finally had a car slipping into an unnecessary fender bender.

It’s hard to find a break between jobs, but you deserve a few relaxing reads to put your mind at ease.

Our contributor Iain Curry has written a couple of ripper pieces about an Aussie classic: the Torana. Both cars are based in sunny Queensland, the best place to be in an Aussie winter.

One’s a fantastic 1976 LX Torana and the other an immaculate 1973 LJ.

This edition of Australian Car Mechanic also features a couple of techs at different stages of their calling.

True-blue Aussie manufacturing and design is at the heart of Disc Brakes Australia.

The company has been a major player in the disc-brakes department for about 50 years, but its offerings have developed vastly across that time.

Australian Car Mechanic takes a look inside DBA’s Silverwater HQ in Sydney to learn how the brand delivers its quality selection to mechanics worldwide.

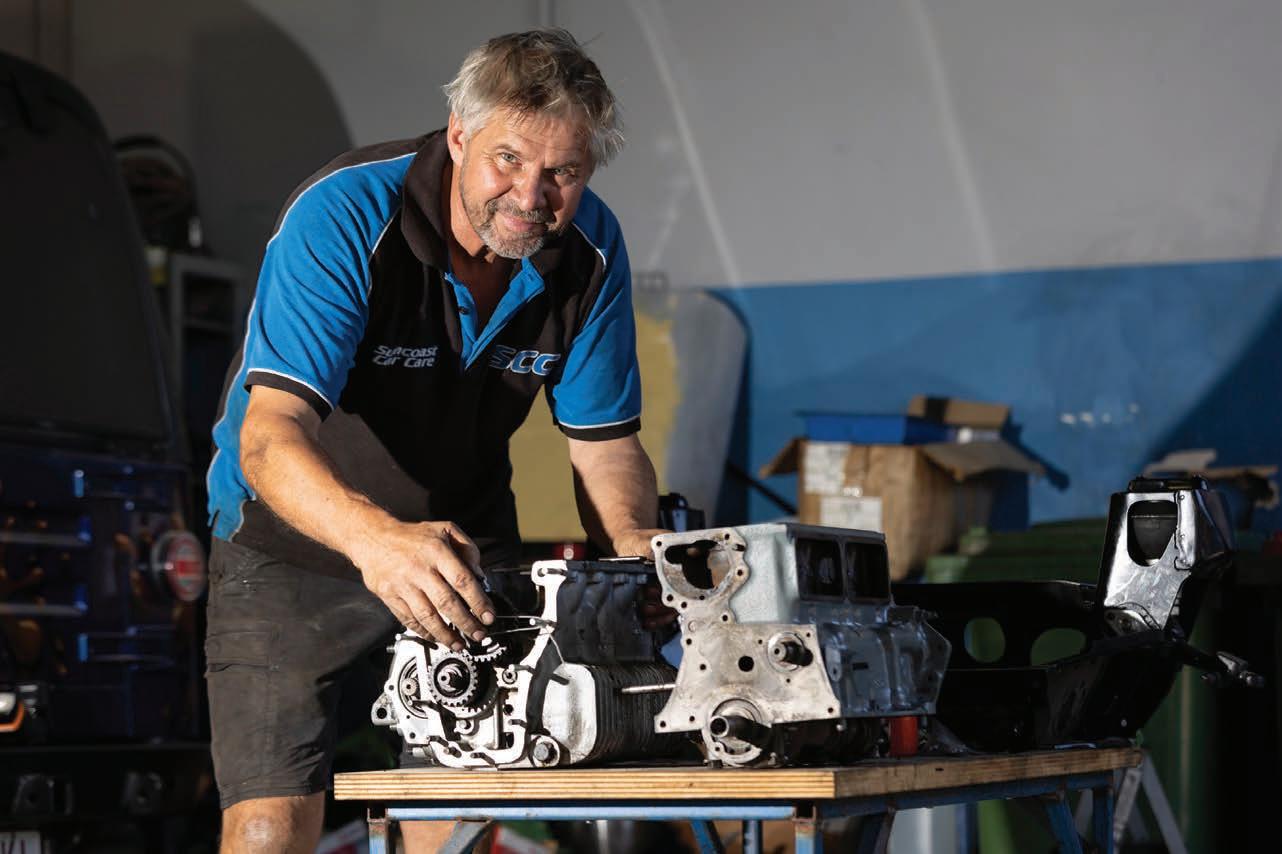

Ashley Beeby is based in Melbourne and in the early stages of her diesel-mechanic career. She killed it in high school with high marks, and then broke the mould by using those smarts for a career pursuing her passion for mechanics. Meanwhile on the Gold Coast, Julian Lock has been running Suncoast Car Care for more than a decade, accruing a tonne of workshop knowhow and sharing it with us in this edition.

Ensuring you have the best available options when it comes to steering, suspension and wheel components these days can be a headache. There’s a massive selection of brands and innovations abound. In this issue we look at a few brands and features from around the industry to keep you in the loop. What’s worse than a cracked gasket? An overworked mechanic. So ease up for a few minutes and take a gander at this edition of Australian Car Mechanic

Harry Murtough – EditorSep/Oct 2023

Deadline Aug 9, 2023

Nov/Dec 2023

Deadline Oct 11, 2023

Jan/Feb 2024

Deadline Nov 22, 2023

CEO

John Murphy

COO

Christine Clancy

Sales Director

Bradley Buchanan

Editor

Harry Murtough harry.murtough@primecreative.com.au

Customer Success

Arianna Lucini arianna.lucini@primecreative.com.au

National Advertising Manager

Rachael Kahui rachael.kahui@primecreative.com.au

M. 0481 181 334

Design

Blake Storey/Daz Woolley

Subscriptions

P. +61 3 9690 8766 subscriptions@primecreative.com.au

Website www.mechanics-mag.com.au

Copyright Australian Car Mechanic magazine is owned by Prime Creative Media and published by John Murphy. All material in Australian Car Mechanic magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronicor mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Australian Car Mechanic magazine are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2023

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Head Office

379 Docklands Dr, Docklands VIC 3008

P: +61 3 9690 8766 enquiries@primecreative.com.au www.primecreative.com.au

Sydney Office Suite 3.06, 1-9 Chandos Street St Leonards NSW 2065, Australia

P: +61 2 9439 7227

Australian manufacturing will always be at the core of what we do. It’s what’s made this company strong, it’s the foundation of what we stand on today, it’s how we continue to learn” says Phillip Joseph, General Manager Operations, as he stands at the end of an array of manufacturing machinery. A busy buzz fills the air, with trolleys of raw material, semifinished products and saleable items being whizzed around the factory.

Australian Car Mechanic visited the DBA Head Office in the Sydney suburb of Silverwater, which not only hosts their

administrative departments, but also its impressive Australian manufacturing and warehousing facilities.

“You always hear about Australian manufacturing struggling, being dead” Phillip added. “But that’s not generally true. If you have the right product, R&D and intellectual property, and the right cost structure to produce it, there definitely is a case for ‘made in Australia’. Especially since the pandemic, we are seeing a lot of interest in supporting local business, rather than importers that don’t provide the level of customer support we do.”

Manufacturing - we’re learning this morning - is more than machinery making parts though. DBA applies a holistic view to its manufacturing process, something that hasn’t changed since the foundation of the business nearly 50 years ago. “The market research, the engineering, the product design, all the way to the strategic sourcing of raw materials - which by the way are 100 per cent ethically sourced - the management of external partners along the supply chain, packaging and last but not least the marketing and sale of the product

well as being a leader in

and

Disc Brakes Australia has transformed from Australia’s leading brake rotor manufacturer into a premium brake solutions supplier.

from top to bottomAs brake rotor technology, you’ll also find DBA’s presence on the racetrack.

- we see these as integrated parts of the manufacturing process,” Phillip explained. The days of DBA solely making and selling brake rotors are gone. “We want to support customers in all their braking solutions,” Phillip said. “While we clearly see ourselves as the leader in rotor design and manufacturing, these days we aim to be a full-range supplier of brake components.” To achieve this, DBA’s design and engineering teams works closely with external partners who have built extensive knowledge in the production of brake pads, brake hydraulics and other, ancillary brake products. For all of them, the same wholistic view is applied. “Our brake pads, in fact all our braking products, are as impressive as our rotors in terms of design, manufacturing standards, quality, and performance,” Phillip said.

As we leave the manufacturing hall and head towards the warehouse across the driveway, we’re getting a sense of the scale of DBA’s business. Courier vehicles of various distributor brands continuously pull up to pick up same-day delivery orders. “Obviously, there’s a customer expectation of same-day delivery to most locations within the Sydney metro area, and it’s no different in the other capital cities. That’s why we operate out of seven distribution centres across ANZ,” Phillip explained. Then, there’s the international export business as well. “We have continued to establish the DBA brand name in the overseas markets and followed it up with a targeted expansion of our distribution structure,” Phillip added. “The world is quickly catching up on the superior quality at affordable prices that we offer, to a point where at times we have to stretch to meet the demand we’re seeing.”

Back in DBA’s offices, we’re given the overview of DBA’s impressive product range. “These days, we think in application categories more than product lines,” Phillip said. In DBA’s case, this means three product tiers, being OE replacement, Upgrade and Performance. “Essentially, we cover everything, from a daily driver to the motorsport application, following a ‘good, better, best philosophy’,” Phillip said. “STREET SERIES is our label for anything OE-replacement. Our internal benchmark is to meet OE specifications or, as is often the case, exceed them. We also pride ourselves on the most comprehensive vehicle coverage for the Australian car parc, including our ambition of being first-tomarket whenever a new car hits Australian roads and demand for replacement or upgrade parts sets in.” STREET SERIES

is also the most comprehensive range in terms of the products on offer - not only does it offer brake rotors/drums and pads/ shoes, but also brake calipers, hydraulic master and wheel cylinders, brake hoses, as well as brake wear sensors. “Anyone opting for a STREET SERIES product is guaranteed to be buying equal if not superior quality compared with the original part they’re replacing,” Phillip explained.

The next level up is what DBA calls its

Upgrade range, consisting of its 4000 SERIES brake rotors and the complementing SP and XP brake pads.

“The 4000 is our most versatile rotor and has proven its worth in countless 4WD, heavy towing, GVM upgrade, rally and track day applications, often under the most gruelling conditions that would send most vehicles equipped with inferior products heading for the hoist,” Phillip said.

Designed as a non-handed, direct

replacement single piece rotor, cast from high-carbon alloyed iron and undergoing Thermal Stability Profiling (TSP) treatment, the 4000 SERIES metallurgy can handle the increased stress and heat generated under repeated, intense braking applications, according to DBA. With DBA’s Kangaroo Paw ventilation design of 144 diamond and teardrop patterned pillars, the unique pattern achieves an up to 30% increase in surface area and a 20% improvement in cooling efficiency as compared to a common straight-vane design used in many competitor products. Other DBA patents are the unique Thermographic Heat Paint (TGHP) stripes that change colour at certain temperature thresholds, thus aiding with the heat management of the brake system, and the optional, bi-directional T3 slot design, which enhances pedal feel and the consistency and effectiveness of every brake stop.

Sounds convincing. The 4000 SERIES rotor, we learned, is best complemented by the STREET PERFORMANCE (SP) or XTREME PERFORMANCE (XP) brake pads.

STREET PERFORMANCE is DBA’s most popular upgrade pad. It is aimed at drivers seeking notably improved braking characteristics over traditional OE brake pads. It was developed to provide an immediate and effective friction response to pedal application, using a copper-free, semi-metallic formulation and feature application-specific NVH shims, slots and chamfers for less vibration and noise. It also undergoes thermal scorching for extra durability.

Alternatively, drivers looking for extra bite and friction consistency from low to high temperatures might opt for XTREME PERFORMANCE. The range is best suited for performance cars and heavy-duty applications, where higher friction levels are required to safely brake under extreme conditions. Using a semi-metallic carbon fibre composition, these pads are likewise scorched for extra durability and feature application-specific slots and shims.

As we move through the range of products, Phillip points at the model of a rotor in front of him. “Our top-of-the-line, two-piece 5000 SERIES performance rotor, with aerospace-grade aluminium used to manufacture our extra lightweight hats, which help reduce the unsprung mass of the vehicle and provide superior steering and braking characteristics,” he said. “It obviously bears all the patents and hallmarks of the 4000 SERIES rotor. Another benefit is that customers who wear out their brakes by taking their cars to race events have the option of replacing the rings only and reuse the hats, making this one of the most cost-effective alternatives in the market.”

Finally, when it comes to pairing the 5000 SERIES rotors with the best suited bake pad, we realised once again that there is no black or white answer when it comes to braking solutions. “It depends,” Phillip said. “The XP pad as described earlier will be your choice if you need a serious performance upgrade while still using the car on road. If, however, you take your car track racing on the weekend, our brand-new RACE PERFORMANCE (RP) pad might be for you. It will happily sustain temperatures of between 250ºC and 750ºC for prolonged periods thanks to a carbon fibre infused friction formulation, making it the ideal track and endurance pad.” He then noted that due to its temperature requirements and ‘bite characteristics’, “it should never bee used when driving on public roads.” Good to know.

As our meeting draws to a close, we’re impressed with the DBA product line up, to say the least. Clearly DBA’s claim to be a full-range supplier rings true. And that is before Phillip even starts talking about the recently launched range of brake pads for electric vehicles, or the all-new range of Hybrid Composite brake rotors...

DBA can be contacted on 1800 730 039 or dba.com.au.

Australian Clutch Services (ACS) offer a tool hire program for their specialised Dual Clutch Transmission (DCT) and Self-Adjusting Clutch tools to help support workshops looking to expand into these markets. The tools are available for hire with the purchase of an associated ACS clutch kit through their distributor network.

The tool hire program has been developed to provide workshops with specialised tools that are often vehicle specific and required to complete these jobs, “With more workshops looking to take on DCT clutch replacement jobs, we are finding many are restricted by the specialised tools they require for the removal and installation process,” explains ACS Sales Manager Colin Jevons. “We offer a comprehensive range of these tools for hire with the purchase of the associated ACS clutch kit through our distributor network, meaning the workshop can take on these jobs without the significant investment in tools normally required.”

The tool hire program follows an easy process where the customer will order the clutch and associated tool through the ACS distributor, pay a deposit and small

service fee, and receive both the clutch kit and tool from the distributor. The tools are available for a seven-day hire and then the workshop can simply call ACS and organise a collection directly from their premises.

“We hold stock of the popular tools in our warehouses around Australia to help reduce transit time and ensure the workshop can have quick access to both the installation tool and the kit itself,” explains Colin. “We have been enhancing the program over the last couple of years and have already seen great results with many independent workshops being able to take on these jobs and expand their market opportunities.”

“With some of these tools being specific to certain model vehicles, this program then allows workshops to get into new markets and slowly develop these before purchasing the tools. We also offer the full range for purchase as well.”

With many modern vehicles utilising these types of transmissions and many of these vehicles now outside of factory warranty, ACS is experiencing increased demand for both the replacement clutch kits and also their tool range.

For more information on the ACS tool hire program, please visit www.australianclutch.com.au or your local ACS distributor.

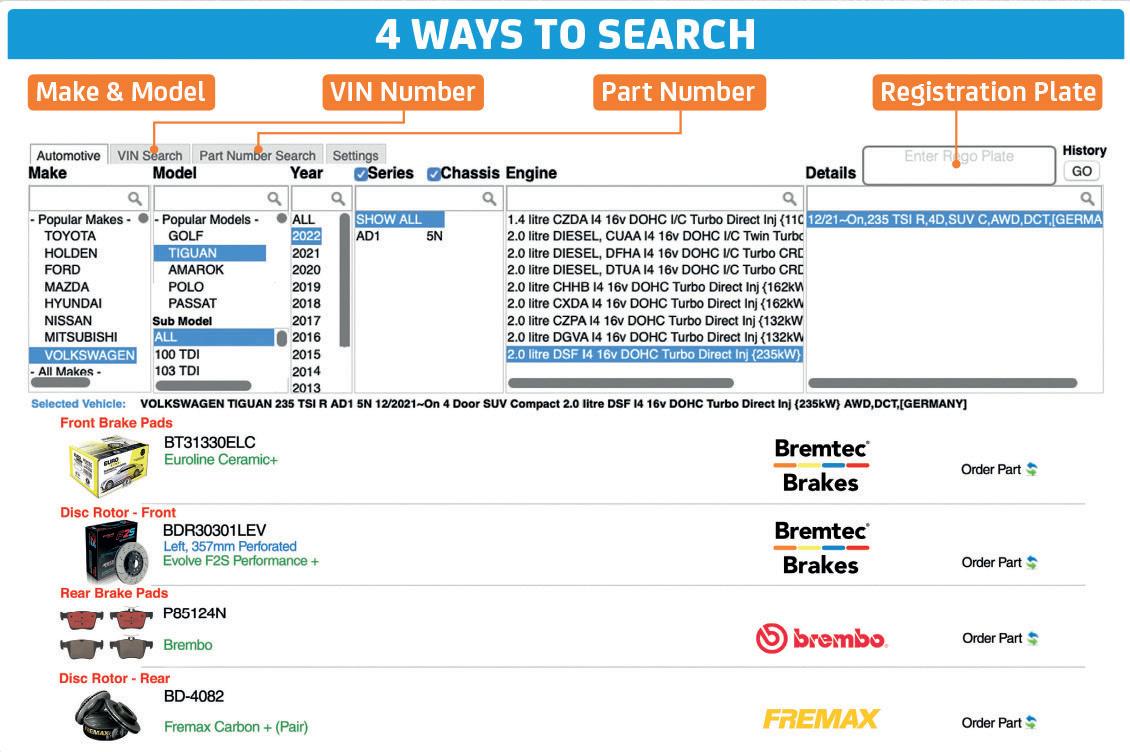

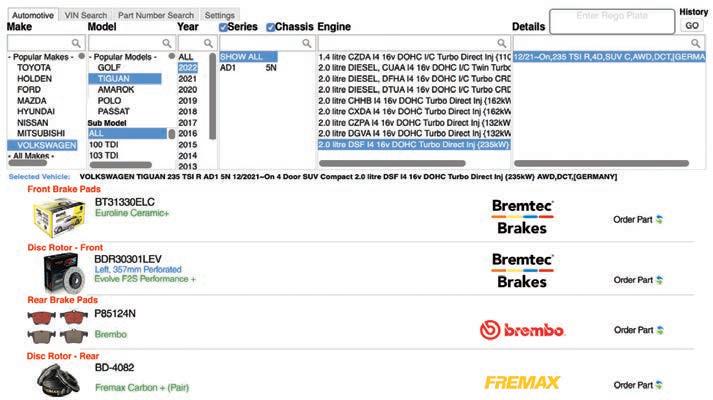

CoolDrive Auto Parts customers can cater for all of their braking needs thanks to the family-owned company’s exclusive digital braking catalogue, BrakeBook, and its impressive range of braking products and consumables.

One of the most accurate and comprehensive braking catalogues available in the market today, BrakeBook can be viewed as the pinnacle of fitment data for vehicles on Australasian roads with its strong depth of OE reference.

BrakeBook simplifies the searching for and ordering of replacement parts, with listings updated by the CoolDrive team in real-time.

Users are able to search for replacement parts in a variety of ways, including through vehicle make and model, a VIN search, rego search, or by part number.

BrakeBook covers CoolDrive’s entire braking product range which, following a large expansion in recent times, has seen CoolDrive become one of the market leaders in brakes in the local industry.

Headlining the braking range at CoolDrive are its exclusive offerings from leading global brands such as Bremtec Brakes, Fremax and Project Mu.

Bremtec Brakes is a world-class braking brand and a trusted solution for distributors, technicians, performance professionals and enthusiasts alike.

Bremtec offers a complete range of aftermarket brake products, manufactured to exceed original equipment specifications, and tested to the extreme to ensure an exceptional balance of performance, reliability and comfort.

Bremtec’s TRADE-LINE® brake pads contain the new advanced ceramic formulation, offering significantly less dust, reduced wear, while still offering the optimum balance of comfort, performance and durability.

The TRADE-LINE® disc rotors offer advanced metallurgy to reduce thermal judder for consistently quieter and dependable braking performance, complemented by the TRADE-LINE® ceramic brake shoes and brake drums.

PRO-LINE® Ceramic+ brake pads are engineered for optimum braking performance in heavy-duty conditions, formulated for increased stopping power and durability when fully loaded, or for drivers after an upgrade from standard or OE pads. Longwearing, PRO-LINE® brake pads produce significantly less brake dust.

EURO-LINE® brake pads are specific for

European vehicles and are engineered for increased stopping power but without the unwanted brake dust. Manufactured with the latest Ceramic+ formulation, EUROLINE® brake pads offer superior braking to be expected from a European brake system.

EURO-LINE® disc rotors are an OE quality brake disc rotor engineered with an OE internal vane design and a GeoZinc

coating to minimise rust corrosion and give a European look, with product benefits including a high resistance to cracking and a longer life.

Bremtec’s EVOLVE® Performance

Ceramic+ brake pads offer unrivalled braking when it comes to electric vehicles and spirited street driving.

They utilise the latest high-performance

Ceramic+ formulation, designed for maximum braking efficiencies, excellent initial cold bite stopping power, and a high resistance to

The EVOLVE®-specific “GG” friction class caters to the unique demands electric vehicles place on their braking systems, due to higher acceleration capabilities, heavier vehicle mass and lack of vehicle noise.

Engineered for extreme conditions, EVOLVE® High-Carbon rotors offer greater resistance to heat stress cracking and thermal judder.

Born from racing technology, EVOLVE F2S® High-Carbon rotors are engineered with unique HPC (Hyper Pillar Cooling) venting for improved airflow to resist cracking and metal fatigue, with a brake temperature paint applied to the edge of the rotor to easily monitor effects of driving styles. The rotors are also hyper-slotted for improved bite in high-performance vehicles and 4x4 applications.

Reinforcing CoolDrive’s braking credentials are Fremax brake discs and drums.

Fremax components offer an ideal combination of quality, innovation and safety, with all of its brake disc and drums manufactured with a high-carbon metal alloy to ensure better braking performance and a longer life.

An innovative paint is utilised across all Fremax products to offer increased protection against rust, while a unique protective oil does not contaminate the brake pads nor does it require cleaning, for a faster and secure application.

Furthermore, a patented concentric groove on the surface face ensures a faster bedding in process, to significantly reduce noise and vibrations.

Fremax has also recently launched its new Safety Check technology which indicates the right time to change brake discs, taking away any uncertainty for maximum safety.

CoolDrive is the national distributor for Project Mu’s high-end brakes and braking products.

Originating in Japan, Project Mu is a specialist manufacturer with a focus on providing the best quality braking products for applications including street performance, track days, club racing, drifting, and professional motorsport.

From OEM street replacement pads and discs, to performance brake upgrade kits, right through to world class motorsport pads, Project Mu’s focus is to provide the best quality product for specialised applications.

CoolDrive also has global distribution rights for all of the racing compounds (outside of Japan) and supply NASCAR, BTCC, Supercars and various other racing series worldwide.

Capping off the CoolDrive braking range are products from brands including Bosch, Brembo, ICER, HULK 4X4 and Stolz, which ensures a complete fitment offering with products available for street, performance, off-road and track usage.

CoolDrive also has available an extensive range of quality consumables that get the job done right, including brake fluids, cleaners, greases, and lubes, as well as a dedicated support team to help customers with any technical queries.

For further information on BrakeBook and CoolDrive’s braking range, visit www.cooldrive.com.au

sourcing these pieces can save thousands. Many recycled pieces can often go for as much as 50 per cent less than new prices, despite being barely used.

ACM Parts has handled recycled parts for the past 10 years, and offers thousands of parts for hundreds of models and makes.

The team at ACM Parts meticulously dismantle more than 10,000 vehicles every year. These pieces are handled with extreme care as they’re catalogued and distributed through one of four ACM Parts warehouses across Australia.

Thanks to this process, customers can secure high-quality, valuable parts, including engines and gearboxes, and smaller parts such as clutches, brakes, and steering and suspension components.

ACM Parts Reclaimed also deals in exterior pieces – body components, doors, headlights, and indicators.

Chances are if you need a component,

Not only are these options cost-effective,

You can learn more about ACM Parts’ Reclaimed range – as well as other offerings – by visiting acmparts.com.au.

• Clutches

• Brakes

• Suspension and steering

• Engines

• Gearboxes

• Alternators

• Ignition systems

• Sensors

• Heating and aircon

• Consoles

• Headlights, and

• More!

More than 800,000 vehicles are deregistered in Australia each year, and ACM Parts plays a key role in returning suitable components to market.

Specialist Tools Australia stocks the specialised tools that enable accurate diagnosis and fast repairs.

To achieve a satisfactory and costeffective repair, it is critical to initially obtain a proper diagnosis and identification of any faults before purchasing any parts or proceeding with repairs. This is true of almost anything not just motor vehicles.

The ECU will use the injectors to compensate for each other and for various engine discrepancies. For example, a four-cylinder engine with 0-5 range, compensations above two is an indication of a problem.

When removing injectors, the ultimate goal is to remove them without damaging them or other engine components. This allows the components to be tested independently of each other and saves a great deal of extra work, and ultimately the cost of the repair.

Removing injectors without destroying any components, including the injectors can be a simple and easy job with the right tools and an understanding of the system you are working with, although some presentations can be very daunting – especially if there is a build-up of material around leaking injectors or simply the structure of the engine and the injectors themselves.

Generally, finding the correct tool that will attach to the injector, followed by using a slide hammer, hydraulic ram or other pulling arrangement to extract the injectors with the least amount of impact or jarring ensures their safe removal. Then it is just a matter or ensuring the recess is clean and the injector seat is cut square to the perpendicular, ensuring they sit without leaking in the recess when reinserting the new or remanufactured injectors.

The ultimate seized injector extraction

kit for Denso, Delphi, Bosch and Siemens injectors is Govoni’s (GO405) for removing very stuck injectors, due to fouling caused by combustion leakage where the injector is locked in the recess and cannot be removed without the proper tools.

The universal supporting feet adjustment, screw into the fixing screws of the head, ensuring its use in different levels (l/r) as well as the possibility to adjust the slippage of the two side bars. The adjustment takes place both in height and width according to the conformity of the engine head. This kit can be used directly on the vehicle, with the engine mounted; its mechanical operation intact, and can be used in confined spaces or in the far back position near the passenger compartment which often causes difficulties if a slide hammer arrangement is the only tool you have. The versatility of setup provides a stable and strong platform where various methods of extraction can be used.

As vehicles become more technologically advanced, the necessity for specialist tools becomes more essential.

One of Specialist Tools Australia’s other favourite kits is the M9R injector removal kit used on Nissans, Renault and Opel engines which enables the extraction of broken injectors without completely dismantling the engine. The Govoni MultiStage injector removal kit (GO426) can attach to broken injectors at various common breakage points down to the extraction of the injector nozzle retaining nut. This is a very heavy-duty and robust kit.

Govoni Universal kit GO507 for injector removal, is equipped with slide hammer, pliers, articulated joint adapter and special socket that will fit around the head of the injector (Bosch style). This kit allows the technician various options for the removal different types of injectors in a variety of vehicles commonly found in Australia where they are not excessively stuck.

Govoni tools are extremely robust, high performing Italian tools designed for the professional automotive technician looking for many years of reliable service from their tools, with the flexibility of being able to adapt the tools to different styles of injectors and engines.

At Specialist Tools Australia the team go beyond just selling tools. Their vast automotive diagnostic knowledge, especially with diesels, assists them in ensuring you get the right tool for your job.

For more information contact Specialist Tools Australia on (02) 6280 4334, visit specialisttools.com.au or email sales@responsiveengineering.com.au

Quite a robust kit; the G0426 can attach to common breakage points on broken injectors.

From a proud heritage of automotive electrical and air conditioning Know How, we have diversified our range, knowledge and solutions as we look to the future. We see a growing demand for mechanical products in the automotive industry. From transmissions to braking systems to servicing parts, mechanical components are critical to a vehicle’s performance and safety.

We have expanded into these new ranges to offer a complete solution to you, our customers, and provide the widest product range for all your automotive parts needs.

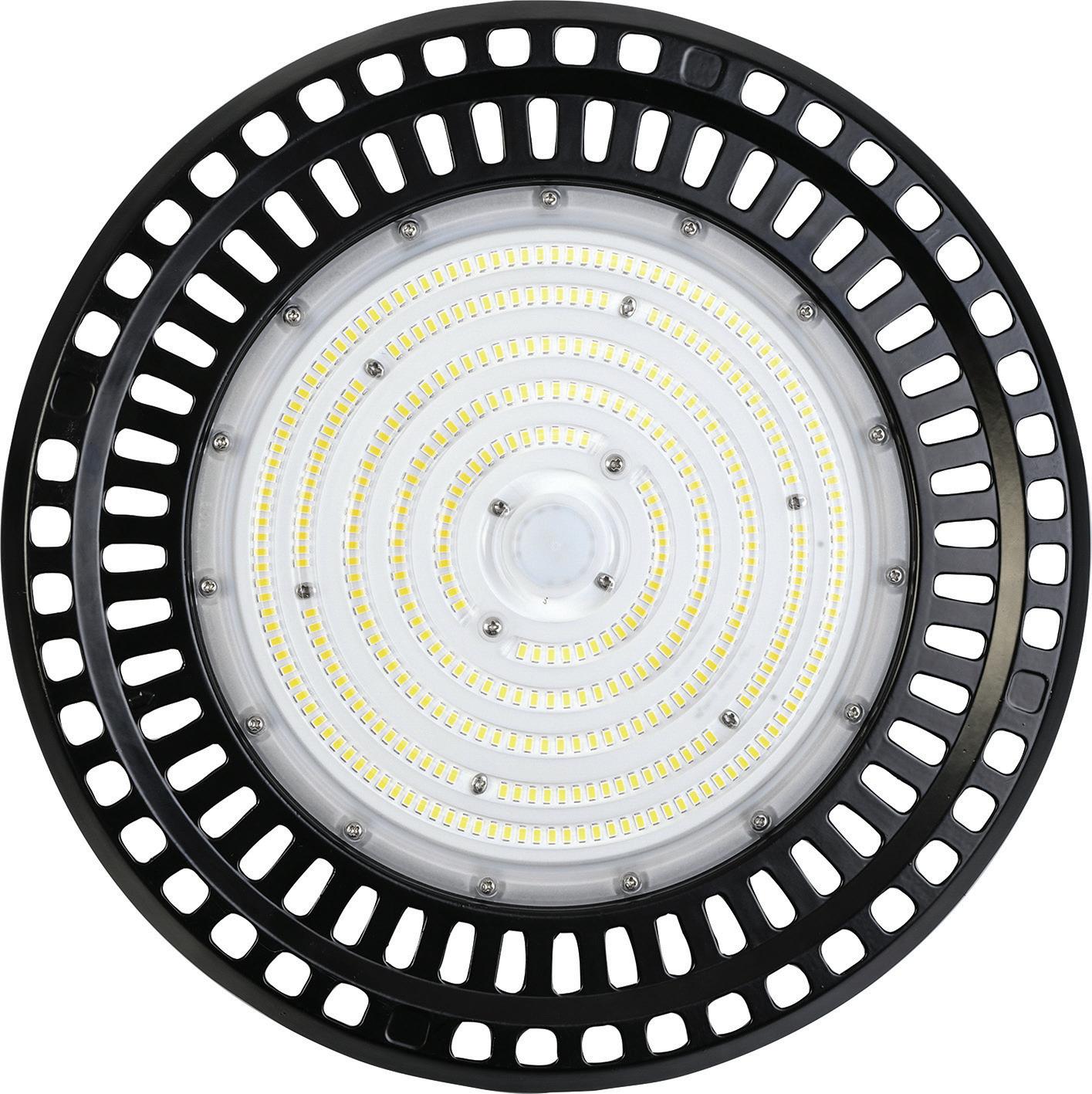

ow more than ever, businesses need to work smarter to ensure they are reducing costs where they can, to avoid passing on unwanted rate rises to customers. One easy solution OEX recommends is switching to LED lighting as it can be an extremely costeffective and a power-efficient solution. While many operators use halide or halogen lights, there are more costs and downtime involved in their use.

LEDs are far more efficient than halogen bulbs. While halogens generate a large amount of heat, the amount of heat created with LEDs is far smaller, helping save energy. LEDs tend to last much longer and are a more energy-efficient and less maintenance-intensive technology. Metal halides have long warm-up periods and a shorter lifespan. LEDs also emit a light that is whiter and brighter than most halogen options and

provide up to 50,000 hours of life. If operated for 60 hours per week, this equates to up to 16 years maintenance-free life for a single purchase.

The OEX 200W High Bay Workshop

Light is a simple plug-in replacement for 240V halogen or halide high bay lights. It delivers energy-efficient, crisp white LED lighting to the workshop while reducing energy consumption and lowering your electricity bill. The OEX High Bay light is a no-maintenance lighting solution. There is no need to replace globes or spare parts, and the robust die-cast aluminium housing is sealed to a weatherproof IP65 rating.

OEX High Bay lights provide a massive light output of 28,700 lumens, enough to illuminate a workshop or warehouse up to 15m high. Because they are much brighter than halide lights, less lights are required to fill a workshop space.

The OEX lights plug in to a standard 240V mains socket and come with an IP65 weatherproof rating – water-resistant and suitable for outdoor use with full protection against dust ingress. They offer a bright white 5,700K colour temperature, and come in a die-cast aluminium body for heat dissipation. They are also backed by a fiveyear warranty.

The complete OEX range is well stocked in both NAPA Auto Parts and Repco stores, so accessibility to the energy efficient range is convenient and local.

For more information on the OEX range and any of their market leading products, visit oex.com.au.

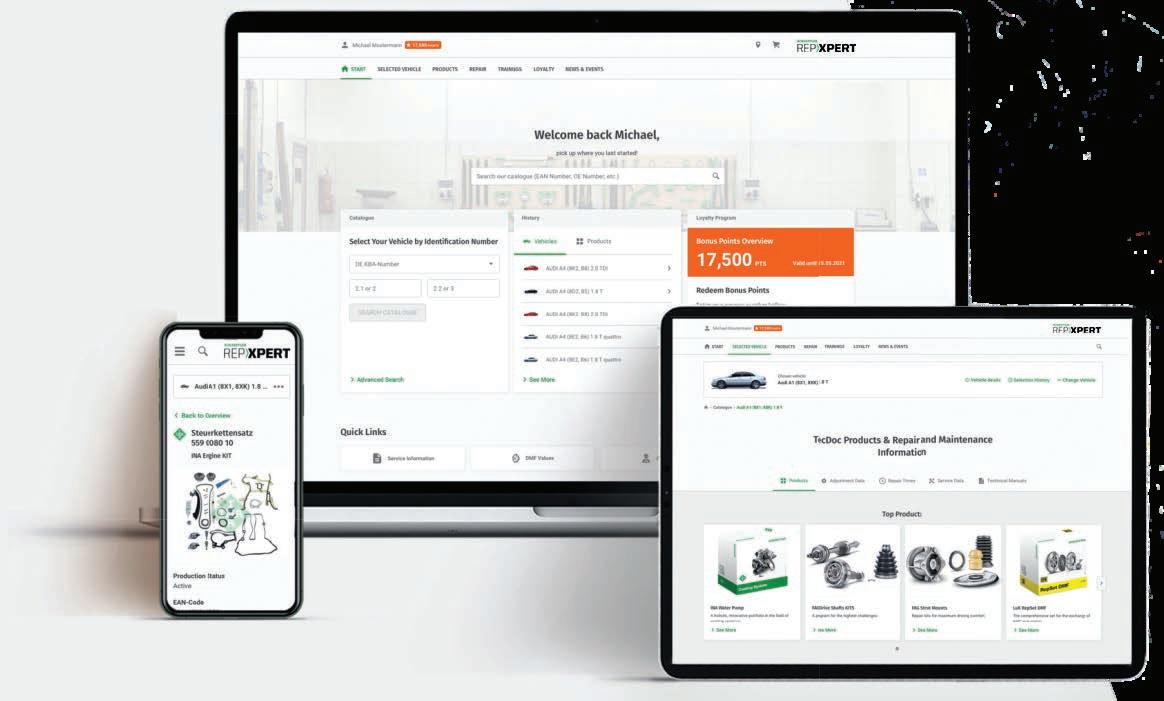

Want a chance to win 20,000 Capricorn preferred supplier bonus points?

Simply sign up to REPXPERT, and register your account between 1st May and 31st July for your chance to WIN!

www.repxpert.com.au

There were once again fantastic reports about the information and show and shine at the Brisbane Truck Show. This event is a showcase of the heavy-vehicle industry’s best of the best. Every time this event is held, it gets great acclaim and an even stronger following.

The IAME also had a brilliant seminar for our AATR (Australasian Automatic Transmission Rebuilders) Division.

This year was held at Crowne Plaza on the Gold Coast, which has been fully renovated and is an outstanding venue for a trade show and seminar. Our two American presenters have never failed our division, and each time they are invited they overwhelm the participants with their technical expertise and knowledge.

Our seminar has really changed, with a far bigger flavour around diagnostics and tips and tricks. To back up our US presenters we had Garrett Turbo and PJD Training discussing turbo diagnostics and EV hybrid insights. The whole two-day seminar really had depth for any workshop, not just those focused on transmission rebuilding. It’s a wealth of knowledge with over 860 pages of electronic notes and supporting documentation. As one US presenter said, “The value of the ticket was obtained just in the notes and the rest of the weekend’s tutorial and trade show was basically free.”

To impress US presenters who do this

week to week is quite a feather in the cap or AATR. For more information on our AATR Division and upcoming seminars visit aatr.com.au.

More details of the Mining and Automotive Skills Alliance have been announced. It’s an independent industry-led organization established by the Australian Government to provide industry with a stronger, more strategic voice in ensuring Australia’s Vocational Education and Training (VET). This organisation operates as a jobs and skills council and the Mining and Automotive Skills Alliance will have a Strategic Workforce Advisory Panel (SWAP), one for mining and one for automotive. In addition, there will be Technical Advisory Groups (TAG) established to support the recommendations made by the Strategic Workforce Advisory Panel.

In my time at the IAME I have seen Industry Skills Councils come and go in various forms. Where we originally operated under ATA, then moved under MSA and then segregated to create our own group known as ASA, followed by operating under PwC with Industry Reference Committees (IRC) through to now AUSMASA. I really hope that this new structure can keep pace with the ever-changing needs of our industry.

Since the beginning of May many associations and automotive groups have been hosting their trade shows and seminars. They’ve been a marvelous success for the tradesperson.WORDS: PETER BLANSHARD, CEO OF IAME. Electric vehicles are the latest to get the acronym treatment, so it’s important for mechanics to be in the loop.

I was discussing the visionary needs of a business owner or practitioner with a contact from a university in the UK. The feel for a well-educated, or in fact new, practitioner is that they need to possess the new skill set known as CASE.

The ‘C’ stands for ‘connectivity’.

Obviously we have vehicles today that communicate with the OEM and have telematics in times of accidents or distress. But this will grow. In the future, we will have vehicle-to-vehicle communications, vehicleto-infrastructure communications, and we will have basically vehicle-to-anything communications such as a connection via Bluetooth to a jogger or pedestrian waiting to cross the road.

The ‘A’ is basically for ‘Anonymous Drive’ for advanced driver aids, including ADAS and advanced driver fatigue sensoring, which is directly linked to the connectivity of a vehicle.

The ‘S’ is for sharing.

This may not be connected sharing of data, but the ability of a practitioner to share or download everything happening in a motor vehicle, store it, and then put it back in when the repair is complete.

The ‘E’ is the power source: ‘electrification’.

In my last article I wrote about hydrogen as a power source, but obviously all the electronic communication and sensors will require additional power over and above that of yesterday’s 12-volt battery, so even if the main power plant is a hydrogen-burning engine, we will still require electrification of the vehicle just to drive the onboard systems. I don’t think anybody really knows how long it will be before you must engage in complete knowledge of CASE systems, but it certainly isn’t too far away.

I have also learnt there is a whole new acronym for our OEM and car sales marketing: VUCA. VUCA basically doesn’t effect us very much in the RS&R market, but it refers to:

• ‘ Vulnerability’ which is economy drives effective car sales;

• ‘ Uncertainty’ which is created in a purchaser’s mind about a car’s technology (however, from am OEM’s return on investment, it’s about how long a certain facet of technology is going to be current for);

• Complexity. Everybody loves a high-tech motor vehicle, but it gets to the point where the complexity starts to worry the user. It’s probably also the driver of our need for CASE; and

• A mbiguity. Obviously, with things such as driver sensors, driver aids and mode of power plant, a consumer may not have total understanding. Therefore, there is ambiguity from one motor vehicle to

another because of the way we describe things is not generic. It’s quite individual and therefore hard to compare one vehicle directly to another.

It’s obvious there’s no guarantee any of these new-fangled acronyms will have a total bearing on our training needs or direction in the manufacture of a new car, but I can’t help but think there’s quite a bit of truth in what I have been advised. It’s also been just recently I’ve heard some EVs are not making enough noise at low speed in either forward or reverse. This is obviously an OH&S concern in our carparks and workshop environment. Some manufacturers go out of their way to ensure the audible noise is quite apparent where some vehicles don’t make any noise at all. I’m quite sure there is an opportunity to upsell a customer to a reversing beeper to ensure their vehicle offers the best pedestrian safety.

What would $15,000 buy you back in 2004? A shiny new Toyota Yaris if you wore your sensible hat, or how about one of these? A 1973 Holden Torana LJ XU-1 now worth over ten times that amount.

Gary Marriott snared himself this bargain XU-1 almost 20 years ago, and despite its subsequent stratospheric price rise, still uses it in the spirit of Peter Brock – the great man who piloted his Holden Dealer Team LJ XU-1 to 1972 Bathurst glory.

This low-mileage, three-owner classic is breathtaking in the metal. Its compact coupe body sits perfectly squat over tiny 13-inch Globe Sprintmaster alloys, and looks every inch the giant-killing minimuscle car that so captured Australian imaginations half a century ago.

“My first car was an LJ XU-1, bought when I was sixteen,” Gary says. “It was a 1972 and I paid $2500. I was already working by then, and even though I wouldn’t have my licence for another six months, I had the car. After three years I sold it for a panel van, but I always promised I’d buy another XU-1.”

Fast forward three decades and Gary made good on his word.

The original owner of the ’73 LJ bought it new in Melbourne, and in 1995 enlisted Tate Engines to rebuild the motor to 1973 Bathurst specifications.

“Ian Tate was Peter Brock’s engineer and a whizz with [Holden] Red motors,” says Gary. “It’s got the right gearbox [M21 close-ratio four-speed manual], the right diff, right engine, and the right head, which is pretty rare.

“The heads on these they’d throw away and put Yella Terras on because they thought there were better, but they weren’t. The XU-1 head was far better.”

Yella Terras were a popular aftermarket head upgrade offering a decent power gain for a reasonable price. Holden even enlisted its creator Dave Bennett to modify heads for the 202cu in ‘Bathurst’ GTR XU-1 cars.

Gary’s XU-1 isn’t one of these 200 ‘Bathurst Specials’ of 1972 or the 150 ‘Bathurst’ XU-1s of 1973, but Tate’s engine upgrades replicate them.

Peter Brock took his first Bathurst crown at the wheel of a Holden LJ Torana XU-1. Little

road-going versions are so highly sought after.Gary’s first car was an XU-1 he bought for $2500 in ‘72. Imagine how much that’d be worth now.

Under the bonnet is the 3.3-litre straightsix – first seen in Holden’s HQ – with uprated camshaft and higher compression ratio. A trio of Zenith-Stromberg CD-175 carburettors dominate the right-hand side of the engine bay, and do their part in offering a deliciously racy bark on start up.

“They haven’t got a lot of horsepower, it’s all about power-to-weight,” Gary says.

Factory rating was 142kW at 5600rpm, but weighing just 1048kg, the XU-1s would seriously shift.

“It’s not like a Ford 351 engine with lots of horsepower, but the XU-1’s just so small and light, it feels far more powerful than the numbers,” he says.

Gary says his 86,000 mile XU-1 was in good, tidy condition when he bought it, although the previous owner had added bonnet pins and the paint was showing its age. He treated his new toy to a full repaint, and almost two decades later it still sparkles under sunny Queensland skies.

The current owner is perfect custodian for this slice of Australian history. When he was a kid, Gary’s parents both raced speedway, and they were always working on cars together in the back yard in Strathpine, north of Brisbane.

Initially a Ford nut, when he first saw a Warwick Yellow HK GTS Monaro he

The XU-1 is no stranger to the roads, with Gary preferring to take it out for a spin than let it gather dust.

developed a Holden affliction too, cemented when the XU-1s hit the scene.

Gary’s current home workshop in rural Queensland is to die for.

The mighty space has a hoist, an engine stand holding a Ford 351, tools galore, Holden and Ford memorabilia hanging from walls, and a TV showing supercars. There’s even a wood burning stove and air conditioning to ensure it’s operational yearround.

The XU-1 is up on the hoist as I arrive. I’d forgotten how tiny these Toranas are – hard to believe they roughed up the mighty V8 Falcon GT-HOs back in the day – but then that Brock fella wasn’t bad at working miracles. The Torana’s underside is beautifully preserved, albeit with some telltale stone chips.

“It’s a car that gets driven,” Gary says. “If you don’t want stone chips, leave it at home. But that’s no fun.” Too true.

We check out the brakes – the same as used in HT/HK Monaros – which look meaty enough for an XU-1 of this size and weight.

A new set of Koni shocks have been fitted, replacing worn Bilsteins, while Gary’s just put in a new front end and steering rack.

“It still had original GMH ball joints, about fifty years old, so it’s been well looked after,” he says.

The Sprintmaster wheels may be buttonsized by today’s standards, but they’re certainly fat and help give this XU-1 a truly sexy stance.

They’re nine inches wide out back and seven inches up front, replacing six-inchwide originals, which he keeps in a box.

“These wheels were moulded off the ones raced at Bathurst in 1973,” Gary says. “They were magnesium and break down with age, so there was no choice but to make moulds.”

The cabin mirrors the outside appearance – very well cared for but not trying to hide age or use. The seats feature Willans harnesses and look suitably period with houndstooth inserts.

“The first owner had these put in,” Gary says.

“Colin Bond used to race XU-1s with cloth seats as he didn’t slide around as much during cornering. They were a factory option, as was the radio.”

The simple AM radio is a true survivor. While most will have been ripped out for more flash aftermarket units, this one lives

on. There’s even a mummified fly behind the plastic. If only it could talk, it would reveal some of the fun that’s been had in this hot Torana over the years.

The dash dials are classic 70s sportscar: simple black and white speedo, tacho, and vitals with orange needles – which are all a driver really needs.

Driving? That’s exactly what Gary does.

“I took it down to Sydney a couple of years ago, it went to Albury last year, and I’m taking it to Eastern Creek this December,” he says. A fair few thousand added to the odo there.

“You know you’ve driven a distance in it,” Gary says. “It’s not really comfy. But they were built to race, not to be comfortable. On track it handles beautifully – it’s not overpowered and it’s just lovely to drive.”

Another bonus is the XU-1’s sheer simplicity. Gary reports very little has gone wrong during his 20-year custodianship.

“The distributor played up once on the highway, but I carry spares and I got going

in half an hour,” he says. “Beyond that, it’s mainly servicing and regular oil changes.”

His mate Glenn Smith is always keen to help with upkeep, and Gary says he’s a master of the dying art of stripping down and rebuilding carburettors.

“I’ve only ever done the carbies once,” he says. “People say these carbies are a handful, but they’re a good basic carbie –easy to work on and easy to tune. Once tuned, they don’t go out.”

He opens the bottom drawer of his tool cabinet, and there’s the decades-old balancing gear close to hand. Such rarities are imperative when running a car like this.

Neither Gary nor the XU-1 show signs of slowing down. He’s a regular at Torana club runs, and says if his mates plan any sort of distance trip, he’s straight in.

But when you fall in love with a car as a teenager, it can keep a grip on you for life. And Gary’s clear that this desirable, valuable Holden is one car he won’t sell for any price.

“It wouldn’t matter if it was $400,000,” he says. “I’m keeping it.”

BALL JOINTS

TIE ROD ENDS

STEERING RACK ENDS

KYB has over 60 years’ experience in designing and manufacturing critical steering components for OE customers. With this experience, KYB has commenced the global release of ‘in-demand’ replacement steering components to the aftermarket.

STABILIZER LINKS

CONTROL ARMS

Just like KYB’s suspension products, the new Steering range is also vehicle specific, making each part ideal for its corresponding make and model. First fit first time, every time!

• Anti-Corrosion Protection: Ultracoat Z360, our proprietary and exclusive coating ensures a fast fit and longer-lasting protection against corrosion.

• Optimal Heat Dissipation: High carbon formulation with 6 directional slots and innovative pillar design ensures maximum heat dissipation.

• Quiet Braking: Experience a responsive and smoother pedal feel with less noise.

comfortable pedal feel with our ceramic friction pads.

• Quick Fitting: No bedding-in process is required, making fitting quicker and easier.

Like many of us in high school, Ashley hadn’t given too much thought to her career. She signed herself up for work experience with a mechanic, for quite the intriguing reason.

“I signed up for it for work experience with my only real knowledge of the industry being based off Megan Fox in Transformers,” Ashley said.

“She looked cool, and maybe I could look cool and earn some popularity points in school.”

But there was no motorbike polishing to be had after Ashley realised she’d be doing work experience with a diesel mechanic.

“I signed up on a whim, and when I found out I’d be working on trucks, I had no intention of attending,” she said.

After some convincing from her parents, Ashley decided to begrudgingly give it a go. It was a good thing too, because Ashley ended up falling in love with the industry from then on.

“In hindsight, the biggest reason for me getting hooked was because I was curious,” she said.

“There’s so much to learn, my first engagement with the industry was with an engine company and they were all about assembling these massive, detailed engines.

“There was so much precision required and a level of understanding and knowledge.

“There was all this information I had no idea existed – it sparked my curiosity which drove me more than anything.”

High school continued, but Ashley’s fascination with mechanics remained.

Then she entered that most pivotal of stages: year 12.

With a coveted ATAR of 95, you would think Ashley was destined for a career in medicine or law.

Without even knowing it, however, Ashley had subconsciously made her mind up on the career she wanted to pursue long before graduation.

It was a mechanic’s life for her.

“I had decided unconsciously before I decided consciously,” Ashley said.

“I was really fortunate in that sense because I had spent so much time in the industry and I got to compare that to doing exam revisions for a full day in university auditoriums. It was very clear to me which way I was gonna go.”

Ashley, now 24, has been a certified diesel mechanic for two years. She works for Australian civil infrastructure company BildGroup, operating both at its

workshop in Campbellfield and across the greater Melbourne area. Diesel vehicles and machinery are part and parcel to BildGroup’s business, and it’s Ashley’s business with the workshop team to keep them running as smooth as possible.

“I’m not only working on trucks, I’m also working on construction equipment whether that’s diggers, bulldozers or generators,” she said.

“Sometimes, I’ll even be working on road maintenance equipment like road profilers and asphalt pavers.”

The inner workings of heavy machinery remain a constant source of

Ashley Beeby’s pursuit of diesel mechanics was about as straightforward as dissecting a truck engine. But the journey has Ashley cruising along in her dream profession.

“There was so much precision required and a level of understanding and knowledge. There was all this information I had no idea existed – it sparked my curiosity which drove me more than anything.”

curiosity for Ashley; everyday there’s something new to learn.

While it’s not as ‘life-or-death’ or gory as being a doctor or surgeon, diagnosing and repairing issues with heavy machinery is all about meticulousness.

“There definitely are similarities in that you have to test your own understanding and the situation before you can make a decision,” Ashley added.

“When you’re going to pull something apart, you don’t want to pull something apart then find you were wrong or overlooked something.

“There’s an attention to detail and knowing how even the smallest piece works.”

This methodical approach has kept Ashley invested in the industry long past her work experience as a teen.

“You really get into the flow of what you’re doing because there’s steps when you’re diagnosing something,” she said.

“If it’s an internal hydraulic leak, you can’t see it on the outside but maybe machine functions don’t have the power or speed they should.

“It’s those moments in the job where I’m really in the mix of using my brain and being challenged while growing my understanding of the field.”

Ashley not only proves more than capable in the workshop – she also helps to grow the industry as a whole.

Ashley regularly participates in the Victorian Department of Education’s VET Champions initiative, which promotes highachieving professionals from vocational training backgrounds.

As trades become more diverse –particularly in terms of the percentage of women – Ashley said she’s noticed the process taking longer than many might have expected.

However, she said as long as women realise the opportunities in these industries at a young age, interest can only grow.

“Even if the options are there in year 12, I feel like it’s already too late. The lowest I’ve engaged with has been year 9 with VET Champions,” she said.

“I feel like the space is shifting, but we keep having to have those conversations, it might take three years and feel like we’re still not gaining traction.

“Then it will be like ‘wow! Where did they all come from?’. We’re not really seeing the flowers grow from the seeds we’ve sewn quite yet.”

There’s no denying, for Ashley at least,

The OEX 200W High Bay Workshop Light is a simple plug in replacement for halogen or hallide highbay lights. It delivers energy efficient, crisp white LED lighting to the workshop while reducing energy consumption and lowering your electricity bill.

Features:

• 28,700 Lumens output

• Two brightness settings

• Plugs in to standard 240V sockets

• Water resistant IP65 rating

• 2 year warranty

these pathways.

“Don’t worry about what your ATAR was because you can have those smarts in any environment … it will all be an asset to you in the real world.”

Schaeffler’s Automotive Aftermarket division has recently made significant changes to its chassis repair portfolio. As part of these changes, the division has expanded its range of products under the FAG brand, specifically focusing on steering and suspension parts, drive shafts, and strut mountings. By complementing their existing wheel bearing program, Schaeffler now offers a comprehensive and market-leading portfolio for professional chassis repair under the FAG brand.

This strategic move is a direct result of Schaeffler’s commitment to quality across its entire range of spare parts. The company’s wide-ranging quality strategy encompasses material selection, development, assembly, and tailored repair solutions. To ensure consistent high quality, Schaeffler employs durable and performance-enhancing coating and sealing technologies in their products.

Schaeffler Automotive Aftermarket Product Management and R&D President Dr. Robert Felger emphasised that every component, no matter how small, is developed and tested according to Schaeffler’s stringent quality standards. In fact, Schaeffler’s extensive experience in developing and producing components and advanced chassis modules for originalequipment manufacturers spans more than 130 years under the FAG brand. This rich heritage demonstrates their expertise

and dedication to delivering high-quality products. Schaeffler is also committed to developing future-oriented chassis technologies.

Furthermore, Schaeffler’s quality concept extends beyond the products themselves. They aim to enable garages to perform efficient and dependable repairs. With a specific emphasis on common chassis applications within the European car parc, the Schaeffler division has expanded its portfolio to include numerous accessory parts. This expansion is in direct response to the demands of garages seeking comprehensive solutions. The FAG repair solutions provided by Schaeffler encompass all necessary components and accessories, including nuts and bolts. Importantly, these accessories maintain the same high quality as the replacement parts. As a result, garage customers can trust in consistently receiving superior quality for repairs, particularly for safety-relevant chassis components.

Overall, Schaeffler’s Automotive Aftermarket division has restructured its chassis repair portfolio, introducing a broader range of products under the FAG brand. This strategic decision aligns with Schaeffler’s commitment to quality and customer satisfaction, as evidenced by their rigorous development and testing processes. By enabling efficient and dependable repairs, Schaeffler supports garages in delivering reliable and highquality services to their customers within the local Australian car parc.

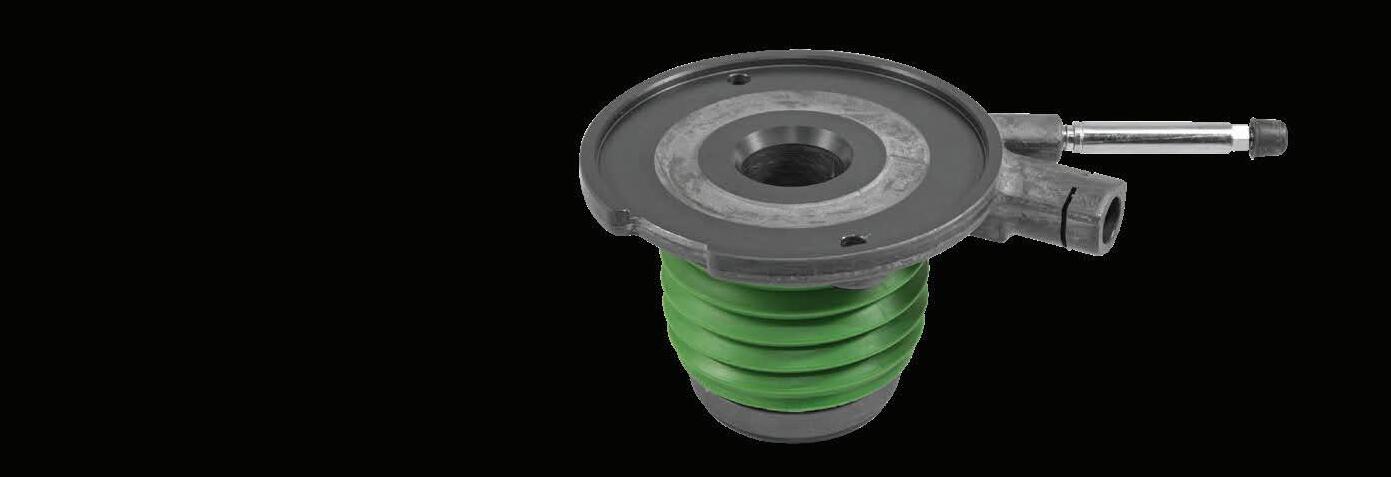

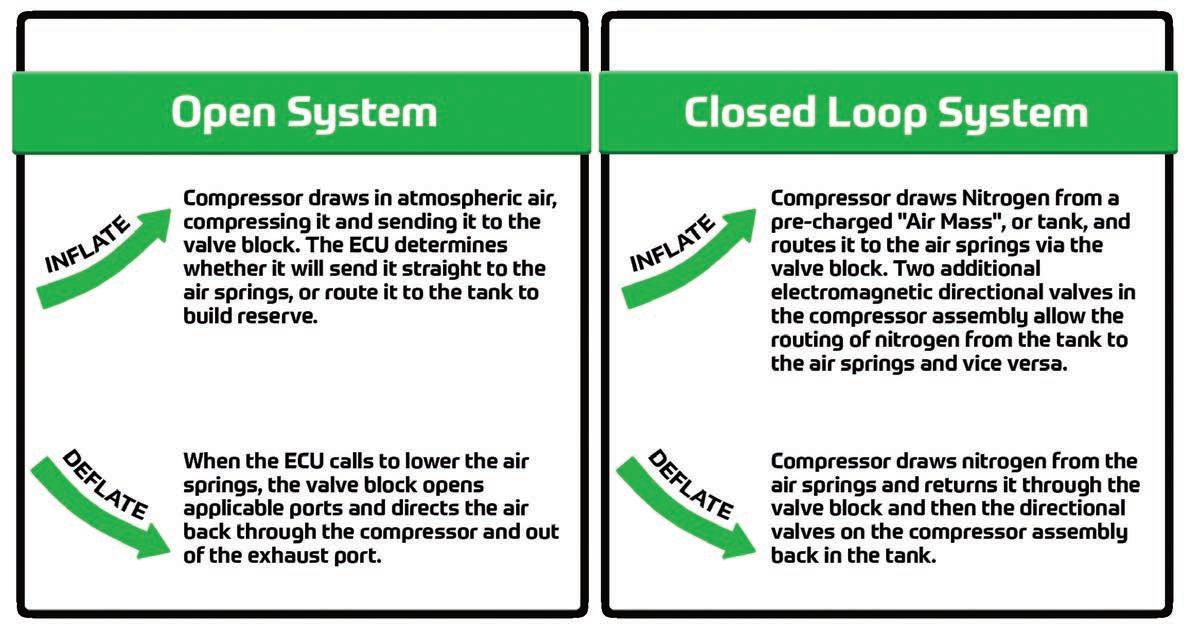

un fact: not all automotive air suspension systems use the same working principles. Therefore, it is important for a professional workshop to know which system they are working on: a conventional open system or an alternative “closed loop” air suspension system.

Properly diagnosing possible system errors or defects, ensuring the correct working procedures are followed, correctly installing new air suspension components, and checking the system and making it operational again after an air spring leak is different from the conventional open air suspension system. In this article, Arnott will provide more insight into the alternative closed loop system.

Now that we know that specific technical knowledge and understanding is required, let’s look at the general differences between the two systems’ working principles before diving deeper into the subject.

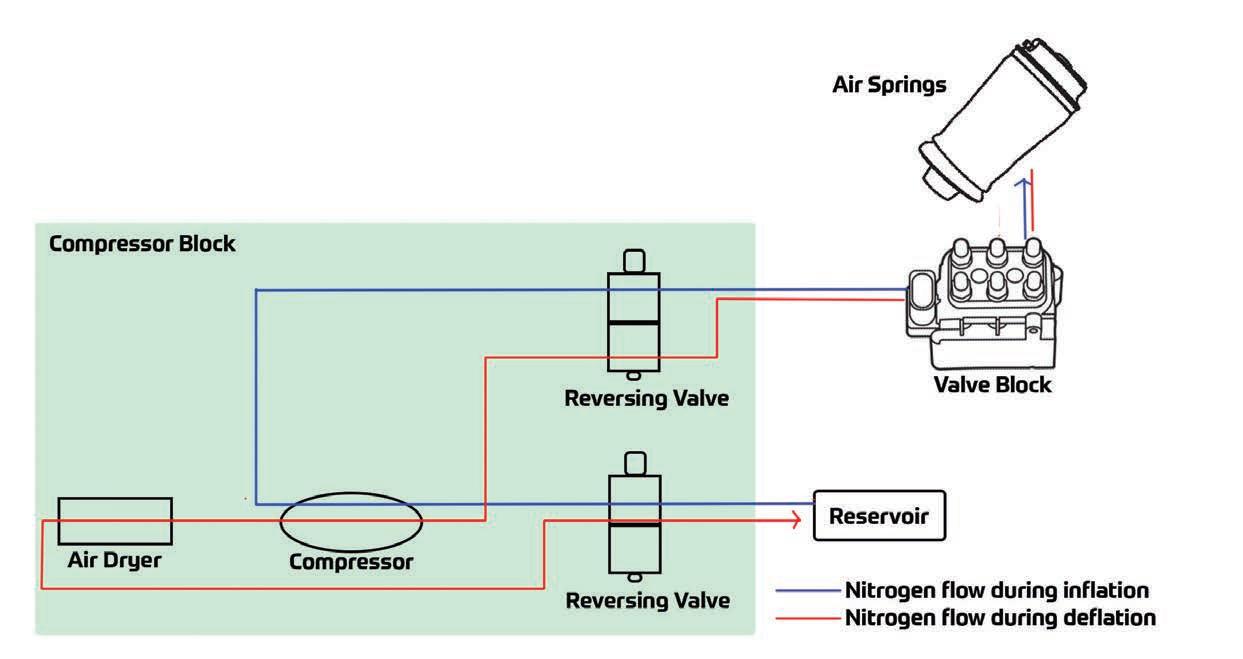

Looking at the graphic above, it shows that the workings of the compressor are quite different in a closed loop system. Where in an open system the compressor compresses ambient air to fill the reservoir and/or air bellows, in a closed loop system the compressor uses the pressurised

nitrogen that is already in the system. Additionally, in a traditional air suspension system (open system) excessive air is released into the open but in a closed loop system the nitrogen stays inside the system and excessive pressure is led back to the reservoir. It is important to keep this operating difference in mind when working on the closed loop system.

For inflation/additional pressure, the closed loop system uses two reversing valves that will open towards the valve block. Then the solenoid valve for the appropriate air spring opens and the additional pressure is transferred. When deflating, the excessive pressure is not discarded but cleverly routed back to the reservoir by opening the two reversing valves in the other direction. The excessive pressure is now transferred back into the reservoir. The pressure flow diagram below gives an indication of how the pressurized nitrogen is routed when an air spring is inflated or deflated.

Although it is called a ‘closed loop’ system and the diagram above shows how the compressed nitrogen is transferred from one area to another to inflate/deflate the system, don’t be fooled. A closed loop system does

have the capability to make up for small amounts of nitrogen loss by drawing in and compressing atmospheric air. When the system has a leak, it will try to retain its required operating pressure by opening the (ambient) air intake. However, it can only compensate for a small loss of nitrogen and when the compressed nitrogen mass gets too low the system will stop functioning.

Just like a conventional air suspension system, the system pressure will gradually drop when there is a big air leak present. Therefore, a symptom of an under-charged system is when it ceases to operate. In a closed loop system, however, the ECU (Electronic Control Unit) continuously calculates the “nitrogen mass” as an indication of normal operation. If too low, error messages like “max payload exceeded” might appear on the dashboard (depending on the car manufacturer).

An indicator of an overcharged system is the audible discharging of excess pressure. This only occurs when a mechanic has not followed the correct procedure when recharging the system after a leak repair. An overcharged system can lead to damaged and defective components, along with serious safety consequences.

Now that Arnott has explained some of the basic working principles of a closed loop air suspension system, we would like to leave you with some key guidelines to follow when a vehicle needs repair or replacement on a closed loop air suspension system:

• The air springs/struts must be replaced if the vehicle has been driven/moved with one or more empty air bellows.

• The appropriate car manufacturer’s installation instructions must always be followed. If the instructions and specifications are not followed correctly, the system will continue to produce errors and malfunction.

• A vehicle raised with an empty air suspension system may not be lowered onto its wheels or be driven. When the air springs/struts are empty and the vehicle is lifted, a vacuum is created in the air bellows. If the vehicle is then lowered afterwards, creases might develop in the bellows resulting in premature failure of the part.

• Follow the correct inflation procedure. Failure to adhere to these procedures could lead to shearing of the electrical connection, or other additional damage to the part. Not following the correct inflation process can even cause the air spring to explode due to pressure in the wrong component or over pressurizing a component part.

• The nitrogen used to pressurize the air springs needs to be inside the system for the compressor to do its job. A closed loop compressor can only partially compensate for a pressure difference. If the system pressure gets below a certain

value, the system needs to be recharged.

• In general, the output pressure in the system must be 17 bar after replacement of any spare part like air spring, air strut, compressor, and valve. Verify the manufacturer’s specification for the exact output pressure needed and

always follow the recharging procedure as described by the manufacturer. Not following the correct inflation and recharging process can cause the air bellow to explode due to excessive pressure in the wrong component or over pressurizing a component part.

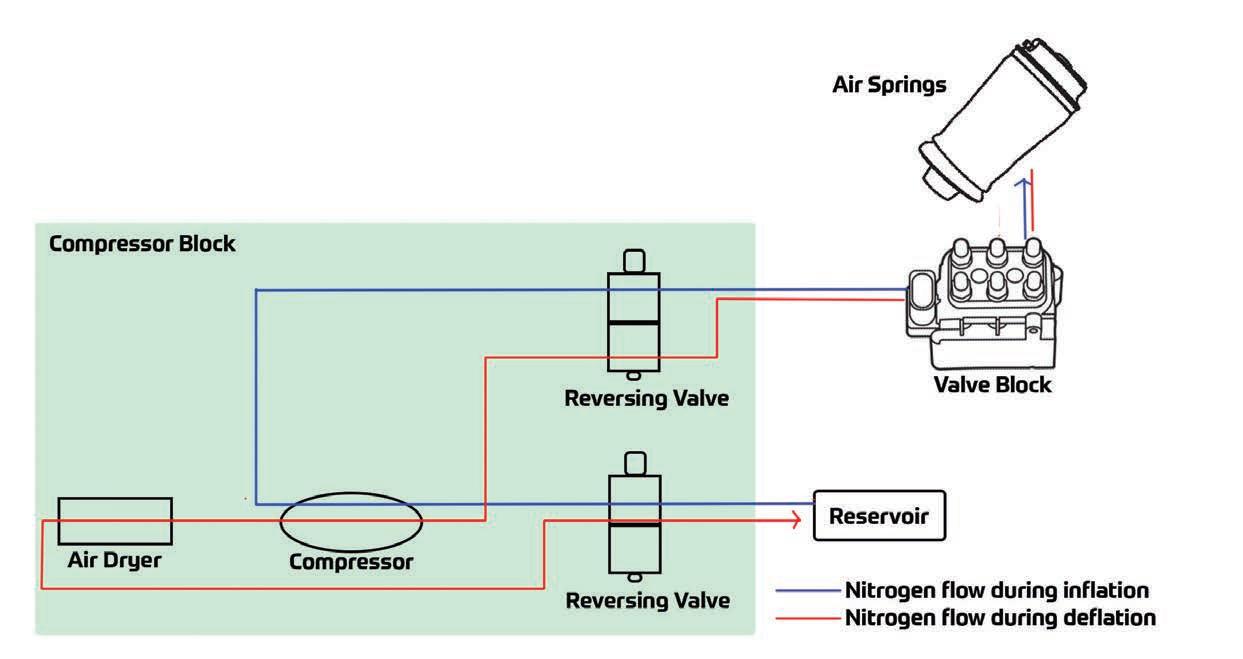

The Ultima shock absorber range is one of the most comprehensive and up-to-date in Australia when it comes to vehicle coverage.

Ultima shock absorbers have been trialled and tested in Australia for 25 years and are subject to ongoing innovation and development.

They are exported to more than 80 countries across the globe.

The extensive Ultima range is shown above, and also offers assembled front struts/ quick struts/ ready struts for

most popular 4WD dual-cab and SUV applications.

Ultima shock absorbers are designed to deliver quality, performance and longevity and include the following key features:

• OE quality, NOK multi-lip oil seals.

• SV-3 anti-foaming fluid.

• Induction-hardened and micro-polished piston rods.

• Seamless eye rings.

• Rubber mounting brushes.

• Unique vehicle-specific vale code.

• Fitting kits.

• Bump stops and dust boots (most applications).

Ultima also offers assembled front struts/ quick struts/ ready struts for most popular 4WD dual-cab and SUV applications. The Ultima range is covered by a threeyear/100,000km warranty is available throughout Australia from all specialist resellers and suspension specialists.

For more information, email: info@ ultimashockabsorbers.com.au or visit ultimashockabsorbers.com.au.

In automotive repairs, precision, and reliability are paramount. This is especially the case when dealing with components such as hubs, wheels, brakes, clutches, steering and suspension systems. Among the multitude of tools available to mechanics, one stands out as a true icon in the Australian automotive industry—the Warren and Brown Deflecting Beam Torque Wrench. Renowned for its unmatched accuracy and durability, this tool has proven to be indispensable for serious mechanics across the country.

The Warren and Brown Deflecting Beam Torque Wrench differentiates itself from its counterparts by employing a deflecting beam instead of a coil spring mechanism. This unique design ensures an unparalleled accuracy of +/- 2 per cent throughout its range, setting a new standard for torque wrench precision. The absence of wearing parts further enhances its reliability, making it a trusted companion for mechanics dealing with delicate systems including wheels and suspension.

When it comes to brakes and clutches, precision is crucial for the optimal performance and safety of vehicles. The Warren and Brown Deflecting Beam Torque Wrench guarantees that the correct torque is applied to critical fasteners, preventing overtightening or under-tightening, which can lead to brake or clutch failures. With its exceptional accuracy, mechanics can confidently tighten bolts and nuts, ensuring the integrity of these vital systems.

The steering system is responsible for the control and manoeuvrability of a vehicle. Properly torqued steering components are essential to maintain the stability and responsiveness of the system. The Deflecting Beam Torque Wrench allows mechanics to achieve precise torque application on steering components, minimising the risk of loose connections, or overtightening that could compromise the steering’s effectiveness. With this tool in hand, mechanics can confidently service and maintain steering systems, guaranteeing optimal performance and safety.

A vehicle’s suspension system plays a pivotal role in providing a smooth and comfortable ride while ensuring optimal handling and stability. The Warren and

Brown Deflecting Beam Torque Wrench enables mechanics to accurately tighten suspension bolts, ensuring proper alignment and secure attachment of various suspension components. This level of precision ensures that the suspension system operates as intended, enhancing vehicle performance and driver comfort.

In addition to its remarkable accuracy, the Warren and Brown Deflecting Beam Torque Wrench has withstood the test of time due to its exceptional durability. Designed to withstand the demands of a professional automotive environment, this tool can endure rigorous use and remain reliable throughout its lifespan. Mechanics can rely on its consistent performance,

accurate torque readings even after prolonged use.

For automotive professionals who demand precision, reliability, and durability, the Warren and Brown Deflecting Beam Torque Wrench is a staple in their toolbox. With its unrivalled accuracy of +/- 2 per cent and robust construction, it has become an essential tool for working on critical components such as brakes, clutches, steering, and suspension systems. When it comes to ensuring the safety and performance of vehicles, the Warren and Brown Deflecting Beam Torque Wrench sets the standard for excellence in the Australian automotive industry.

The Warren and Brown Deflecting Beam Torque Wrench: Uncompromising accuracy for brake, clutch, steering, and suspension systems.

When it comes to car parts, there are a few that are essential for smooth driving. Two of these parts are GMB hubs and universal joints.

GMB Hubs

GMB hubs are made with high-quality materials, including GCR15 steel and G-10 resin. The hubs are responsible for keeping your wheels rotating smoothly and supporting the weight of your car. They’re built with precision and engineered to withstand heavy loads, so you can be sure they’ll keep your wheels in good working order even in harsh conditions.

One of the best things about GMB hubs is their excellent sealing capabilities. This means that they do a great job of keeping contaminants like dirt, water, and debris out of the bearings. This helps to prevent premature wear and tear, which can extend the lifespan of your hubs.

Universal Joints

Universal joints are another important part of the drivetrain system. They allow for smooth power transfer between different components, even when there are varying angles and movements. This is essential in

quality materials and built with precision. This means that they’re able to handle high stress and torque loads without any problems. This results in a smoother driving experience and reduced wear on other drivetrain components.

So, why GMB?

GMB hubs and universal joints are the perfect match for optimal vehicle performance. They’re built to last and offer exceptional quality and reliability. If you’re looking for peace of mind and a smooth driving experience, GMB is the way to go.

To find your nearest authorised GMB stockist, call 1300 007 132 or visit gmb-

GMB’s Hubs sport the best in sealing capabilities, which provides the ultimate protection against things such as dirt.

GMB’s Hubs sport the best in sealing capabilities, which provides the ultimate protection against things such as dirt.

Errol Smith and his twin brother have taken a humble 1976 LX Torana and restored it into a jawdropping SL/R 5000 L34 tribute. Not bad for some old bush mechanics.

Few cars speak to 1970s Aussie excess quite like a Holden Torana SL/R 5000 L34 sedan. Bolt-on flares, fat tyres, aggressive rear wing, and a shiny drop tank feeding a thirsty, rumbling V8.

Fifty years since its introduction as an option pack on the already venerable SL/R 5000, the L34 – of which only 268 were produced – was the homologation special to wow petrolheads and impressionable kids alike.

One such teenager was Errol Smith, now 65 years old and talking to me beside his incredibly clean SL/R 5000 L34 tribute. No,

it’s not a real one. But when these Torana muscle cars are fetching $250,000 it’s little wonder they’ve become the prize of collectors or die-hard enthusiasts that got in early when prices were sensible.

Either way, good luck spotting one carving up the street or race track as its designers intended. I remember there were a few driven hard on weekends near my Sydney unit back in the late 90s, but now I can’t recall the last time I’ve seen one on the road. Shame.

“When I was a young fella and they brought these out, my job didn’t allow me enough money to buy one,” Errol says. “I

worked through the years and ended up in the mines driving a dump truck, and the mining money meant I could afford this car to turn into an SL/R 5000.”

B1 and B2

He has a twin brother, Glenn, and the pair have worked together to restore, rebuild, and modify this 1976 LX Torana, stickered up to look like the earlier LH cars. Errol talks about their teamwork for the build, and modestly hands most credit to his twin.

“We work together alright,” he says. “He yells at me, and I listen! We have our disagreements but we’re still mates

afterwards. He used to hate it when we’d work on the car and I’d get something right and he’d have got it wrong.”

There’s strong mechanical history in the family. Glenn has built an SL/R 5000 L34 tribute too, his in a more flamboyant Barbados green. He’s also got an HDT VC Brock Commodore – bought new by the twins’ uncle – which is another homegrown special that’s easily moved into the six-figure value category.

Growing up, the family had a dairy farm near Gympie in rural Queensland, where bush mechanics was alive and well.

“Dad had an old FJ panel van as a farm

If you’ve got the mindset, and the patience, they’re pretty simple mechanically. But you’ve got to want to work on cars like this.The Smith twins got rid of the Torana’s original engine in favour of a 308 V8 they built.

truck, and we were always pulling the gearbox out of the thing and fixing the brakes,” Errol says. “Driving up and down those hills every day was hard on it.”

There wasn’t the luxury of towing it back to the workshop, either.

“We had a big wire rope we’d throw over a limb on a Moreton Bay fig tree,” Errol says. “We’d pull it up with a tractor and put a 44-gallon drum under it. Those were our jacks and ramps.”

Health and safety? Wasn’t so much of a thing in the early 1970s.

Despite promising he’d never rebuild another car after previously completing an XD Falcon, Errol was committed to his Torana dream. He bought this car in Ballina in 2010 for $10,000. The previous owner had added bolt-on arches, hinting at its future transformation.

“I’d always liked the square shape of the Torana, but the SL/R 5000 with the V8 was way more appealing than the six-cylinder jobs,” Errol says.

It still had the original motor installed, which the twins ditched in favour of a 308 V8 from a Commodore.

“We built it, put a bigger cam in and fitted it into the Torana’s bay,” Errol says. “It still had the banjo diff in so it could snap at any time. My brother shortened a 10-bolt Salisbury diff from an HQ tonner, we added a Commodore rear axle, and the gearbox is the M21 four-speed.”

Prior to this they’d stripped down the Torana and tagged all the parts in boxes. There was rust in the usual spots – bonnet hinges, under the windscreen, and around the back window – which was cleaned ahead of sandblasting to bare metal.

Errol opted for a subtle Polaris white finish with SL/R black bonnet, contrasting with the less-than-subtle new bolt-on replica L34 flares and alloy drop tank hanging below the gloriously aggressive rear end. It was built locally to original Brown Davis specifications, handily provided by the Torana Club.

The 14-inch-deep dish alloys are a striking 10-inch fat in the rear (and eight inches up front), while the stance looks so good due to lower, stiffer springs and adjustable shocks. Rear brakes are from a Commodore with an HQ stud pattern, while inside the cabin has been retrimmed in black with houndstooth seat inserts.

Everywhere you look, the finish and style are first class, and when fired up, that V8 doesn’t half sound good too.

When you’ve got a minute… Errol says maintenance isn’t hard at all –just the usual fluid changes and greasing. He suggests for mechanics bored with their day job, tackling a build like his Torana can be very rewarding.

“If you’ve got the mindset, and the patience, they’re pretty simple mechanically,” he says. “But you’ve got to want to work on cars like this. Go and see an old bloke first and pick his brains before doing anything. You’ve got to have the mechanical knowledge.”

When results look this good, it’s an appealing thought. With this Torana’s bulging bonnet up, seeing the space there is to work in the engine bay makes even the lowest-spec modern Toyota Corolla look like a stuffed maze of plastics, wiring, lines, hoses, and bottles.

The antidote? Grab yourself a classic like this and revel in a time when Aussies created enviably impressive muscle cars.

Launch has a quality selection of hoists to suit a massive range of needs for mechanics. Whether it’s a two-post, four-post, or scissor hoist you need, Launch has you covered.

TLT245AT

Launch’s 4500kg TLT245AT two-post hoist is simple and safe to operate. The model comes with a single-side manual safety lock and lowering device.

It features dual hydraulic cylinder drives which allow for stable and smooth lifting without a chain.

The hoist has wire rope equalisation systems that ensure synchronous movement between two carriages, keeping the vehicle from tilting.

The TLT245AT also comes with hose burst protection valves which reduce the risk of damage or injury in case of hose failure. It is also available in asymmetric installation with optional kits.

It includes door rubber pads to avoid damaging vehicles while in use.

Multiple lifting pads means the TLT245AT meets the requirements for light trucks and SUVs. It also passed 115 per cent dynamic loading test and 150 per cent static loading test.

Launch’s 4000kg TLT440W wheel alignment four-post hoist comes in blue or red and is ideal for handling small-to-medium vehicles weighing 4 tonnes or below.

The four force-synchronised steel cables prevent the vehicle from sloping when being elevated or lowered. This synchronised system has a horizontal precision of 1mm.

The positioning level is adjustable, as is the distance between platforms and wheel base – within a certain scope – making this hoist very accommodating.

To ensure the safety of both user and vehicle, the TLT440W has a cable rupture safety system which prevents the vehicle from overturning.

The hoist also features a CE-STOP function that sounds an alarm to warn users to keep a safe distance when the hoist lowers below 250mm from the ground.

Offering peak performance in compact packaging, both Launch’s 4000kg

TLT840WAF and 3500kg TLT635AF scissor hoists provide unparalleled convenience. Both come with separate low-voltage control boxes to allow for easy and safe raising and lowering of their hidden scissor structures.

The hoists come with a manual lowering mechanism in case of power outage. A double security design on both hoists features hydraulic locks as well as a mechanical tooth safety claw which ensures the load is safe.

The TLT840WAF comes with a protection mechanism which provides pipe-explosion proofing – preventing the hoist from collapsing instantly – and overload safety valve protection. This provides an extra layer of protection in the case of hydraulic failure or a burst oil pipe.

The TLT840WAF also offers pin-point horizontal adjusting accuracy making it suitable for four-wheel alignment detection. Its sliding block is water-resistant and oilfree.

For more information on Launch’s hoist range, visit: www.launchtech.com.au

Head over to wbtools.com.au, enter code “ACM23” at the checkout to receive 10% off your next order.

This is why for more than 100 years, Warren and Brown have been leading the charge when it comes to adjusting and gauging torque, providing innovative and high-quality tools to professionals in a variety of industries.

In the world of hand tools and machinery, torque is a critical aspect of ensuring that work is done safely and efficiently.

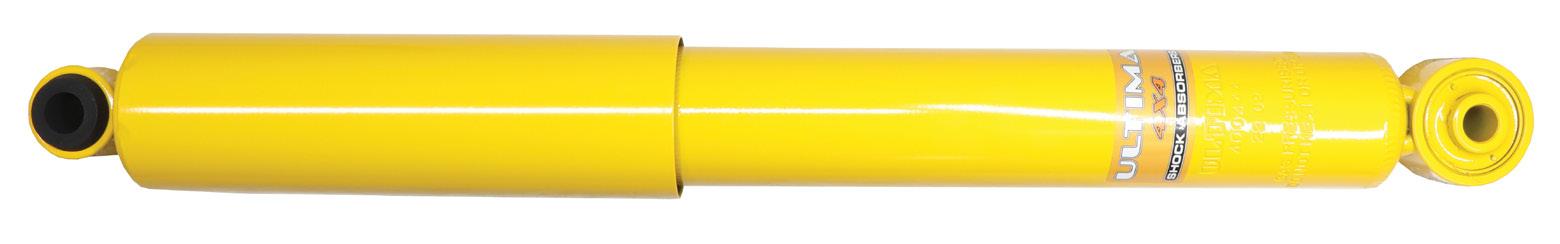

If you hadn’t already heard, Hot Devil has the hottest blow torches in town. And the HD600 Trade Map Super Flame Turbo Torch is yet another great example!

This torch kit includes a solid metal assembly, and an oversize burner tube specifically designed to give you the ability to braze, silver solder, pre-heat metals for welding and other heat-based work, all at an incredibly fast heat transfer rate.

A quick glance at the solid metal build on the hand piece and you know this torch has been built tough for the trades, and features an easy-start auto ignition, which incorporates a clever ignition lock switch and adjustable gas flow valve. And what does all this mean? Yep, you guessed it, using this torch makes any job a breeze.

The simple durability of the design, accompanied by the super turbo flame which can transfer heat up to 25 per cent faster than leading competitors blow torches, leading to a product that not only lasts longer, but also allows you to spend less time on the tools!

For more information on the HD600 Trade Map Super Flame Turbo Torch and all other quality gas torches and soldering irons brought to you by Hot Devil phone (03) 9775 0713 Email: sales@lnmarketing.com.au Or visit www.hotdevil.com.au.

THE PREFERRED PARTNER OF THE WORLD’S LEADING VEHICLE MANUFACTURERS: Alfa Romeo, Audi, BMW, Chrysler, Citroen, Ferrari, FIAT, Ford, Jaguar, Jeep, Lamborghini, Land Rover, Lancia, Maserati, Mazda, Mitsubishi, Mercedes-Benz, Nissan, Peugeot, Porsche, Renault, Saab, Seat, Skoda, Suzuki, Toyota, Volvo, Volkswagen, VauxhaII, OpeI, GM and Isuzu.

There’s a disarming honesty to Julian Lock, owner of Suncoast Car Care in Maroochydore, Queensland. He’s not shy in calling out some of the darker, dodgier sides of the mechanical trade, and that’s pleasingly refreshing. Be it dishonest workshop owners, price gouging mechanics, under-skilled workers or customers paying for jobs that haven’t been done, Julian’s seen it all.

It makes him worth listening to. We can’t pretend all who work in the mechanical trade are bright beacons of honesty.

Julian himself doesn’t profess to being in line for a sainthood, but he does preach integrity.

“My ethos is when you become a mechanic, you’re there to help people,” he

says. “You’re in the service industry and helping people should be what floats your boat.”

He’s quick to point out this doesn’t always work in his favour. “I’m too much of a yes man,” he continues. “People ring me up in a fluster and I know I’ll end up working on the weekend. A guy rang yesterday as his turbo blew on the ute he needs for work. I’ll probably be putting the new one in on Saturday morning.”

All in a day’s work

Julian took over Suncoast in 2011 having previously been its workshop manager. “Twelve years later and here we are with an enviable customer base, priding ourselves on fixing vehicles that others