JAN/FEB E-MAG WITH COMPLIMENTS FROM BURSON THE LATEST IN NEW FEATURES 9 771837 971009 01 Price: $7.95 inc GST JAN/FEB 2022 + CASE STUDY + INNOVATIVE PRODUCTS + FUEL CONTAMINATION + 4X4 AND TOWING + BATTERIES AND ELECTRICAL + SMART SOLUTIONS SUBSCRIBE TO AUSTRALIAN CAR MECHANIC MAGAZINE! SEE PAGE 89 PRECISION AUTOMOTIVE EQUIPMENT CELEBRATES 25 YEARS Supplying World Leading Workshop, Diagnostic And Wheel Service Equipment Since 1997

Combining the highest quality components with extensive in-house engineering and real-world testing, Xtreme Clutch takes performance clutch upgrades to a new level. Designed specifically to deliver the ultimate clutch solution for the street or track, Xtreme Clutch provide attention to detail in the driving experience of your vehicle.

1 Hakkinen Road, Wingfield SA 5013 WWWAUSTRALIANCLUTCH.COM.AU CALL1800CLUTCH (258 824) OUTBACKCLUTCH PERFORMANCECLUTCH WWW.AUSTRALIANCLUTCH.COM.AU CALL1800 CLUTCH (258 824) ENGAGING PERFORMANCE PERFORMANCE UPGRADES FOR STREET & TRACK

A GREAT START TO 2022

ey up! ACM is kicking off another huge year with a jam-packed issue. Starting at the front is the cover story: Precision Automotive Equipment is celebrating 25 years. That’s a big milestone well worth making a fuss over, and we’re right behind PAE as it forges on to a half century…all in good time, of course.

We’ve also embraced the new year with a new idea. On page 12 you’ll find a section called OurAuto Powered by VACC. Each issue we’ll have look at diagnosis and repair equipment and software, thanks to VACC Motortech, and it’s hard to imagine a faster-growing sector of auto service.

So that’s a great start to 2022.

But we haven’t forgotten all the bits and pieces which have made this magazine such a literary and industry giant, either.

The IAME report we started last year –and which has proven so informative and popular – kicks on, with IAME Group CEO Peter Blanshard giving us the rundown on the Australian Standards paper on hybrid and electric vehicles. The tech features are raging, of course. Specialist Tools Australia has some excellent equipment to help deal with diesel-fuel contamination and we’ve given that gear a thorough once over this issue. Iconic brand Mobil 1 also digs deep into the difference between ‘factory approval’ and ‘meets or exceeds expectations’ from a technical point of view. That’s something every professional technician and tradesman should be aware of.

The Focus Features underline some exciting new advances in 4X4, batteries and electrical, and of course, Iain Curry brings us one of his gorgeous Classic Cars. This time he’s found a sensational 1959 Plymouth Belvedere, and while American cars have never been especially close to my heart, there’s no denying the incredible condition of this one. It’s absolutely gorgeous.

Keith Wilson is our profiled mechanic, the Dore Bros Garage is the workshop profile,

and naturally Innovative Products and Eye On The Industry hold their usual pride of place.

So while it’s a new year with new ideas, we’re still, at heart, all about Australian car mechanics and professional auto technicians.

Thank goodness for that, eh?

Tom Foster Editor ACM

recision Automotive Equipment, one of Australia’s leading automotive workshop equipment suppliers, installation and service providers started from very humble beginnings. The core of Precision Automotive Equipment’s success is the fact that for the most part of its 25 year history it was a family business, with Rod’s wife Karen and son Brent actively involved. While now a part of Bapcor, this business culture and focus on customers has remained the same.

www.mechanics-mag.com.au | AUSTRALIAN CAR MECHANIC 3

.

Magazine Deadlines Mar/Apr 2022 Deadline Feb 1, 2022 May/Jun 2022 Deadline Apr 1, 2022 Jul/Aug 2022 Deadline Jun 1, 2022

ON THE COVER

P +WORKSHOP TOOLS + OILS AND ASSOCIATIONLUBRICANTS NEWS SPOTLIGHT INDUSTRY PEOPLE +TECH BULLETINS + INNOVATIVE PRODUCTS ANDHOWCASTROLIS OFTOTHEGROWINGWORLD HYBRIDVEHICLES… SAY FULLHYBRID PLUG-INHYBRID RANGE-EXTENDED ELECTRICVEHICLE NEW FEATURES SUBSCRIBETOAUSTRALIAN CAR MECHANIC MAGAZINE! SEE PAGE 81 771837 Price:NOV/DEC + SMART SOLUTIONS + SKILLS SHORTAGE + INNOVATIVE PRODUCTS + SUBSCRIBETOAUSTRALIAN CAR MECHANIC MAGAZINE! SEE PAGE 85 TOOL TEST IW U U MA WR CHE Supporting Independent Australian Businesses Introducing APG AuthorisedDistributor andWorkshopPrograms “LIGHTTRUCKPARTS. APGISHERETOSHAKE UPTHEINDUSTRY” JAN/FEB E-MAG WITH COMPLIMENTS FROM BURSON THE LATEST IN NEW FEATURES + CASE STUDY + INNOVATIVE PRODUCTS + FUEL CONTAMINATION + 4X4 AND TOWING BATTERIES AND ELECTRICAL + SMART SOLUTIONS SUBSCRIBE TO AUSTRALIAN CAR MECHANIC MAGAZINE! SEE PAGE 89 PRECISION AUTOMOTIVE EQUIPMENT CELEBRATES 25 YEARS Supplying World Leading Workshop, Diagnostic And Wheel Service Equipment Since 1997 H WELCOME

Publisher Kurt M. Quambusch Editor Tom Foster tom@maynemedia.com.au Production Manager Arianna Lucini

Group Sales Manager KahChi Liew kahchi@maynemedia.com.au 1300 764 688 Advertising Sales Manager Melvin Tay melvin@maynemedia.com.au 1300 764 688 Subscriptions Arlette Kouch (02) 8355 6841 (02) 9452 4517 arlette@maynemedia.com.au Design Peter Cartledge art@maynemedia.com.au ISSN 1837-9710 Australian Car Mechanic is Published Bi-Monthly by Mayne Media Group Pty Ltd ACN 130 678 812 ABN 27 130 678 812 Postal PO Box 489 DEE WHY NSW 2099 Australia Ph: 1300 76 4688 Int Ph: + 612 9452 4517 Int Fax: + 612 9452 5319 www.mechanics-mag.com.au Copyright 2022. Mayne Media Group Pty Ltd. Material may not be reproduced or photocopied in any form without the written permission of the publisher. Mayne Media Group Pty Ltd believes that all material is correct at the time of printing and will not be held liable for any incorrect information supplied within. 4 AUSTRALIAN CAR MECHANIC | www.mechanics-mag.com.au Dore Bros Garage, established in 1946, is thriving thanks to the family’s third generation and the ethos of their customer focus.

arianna@maynemedia.com.au

IAIN CURRY has been a specialist motoring writer and photographer for 15 years, working for a variety of magazines in Australia, United Kingdom, USA, Germany and Sweden. He is former editor of Performance BMW magazine and features writer for GT Porsche magazine, and has been fortunate enough to photograph Formula 1, the Le Mans 24 Hours, World Touring Cars, V8 Supercars and a range of adventure sports.

ADAM WATKINS is a full-time teacher of automotive technology at The Northern Sydney Institute Northern Beaches campus in Brookvale. Adam works on marques such as Mercedes Benz and BMW and spends time at the racetrack. Adam brought this knowledge into the classroom to train new generations of modern automotive apprentices.

is a professional photographer who, after 20 years in the field, started a carpentry apprenticeship. With a recently found love for purring V8s, Jamie is documenting the transformation of his stock Crewman. When he’s not writing, taking photos or practicing his wood work skills, you can catch him surfing at Turimetta Beach.

ON THE COVER: PRECISION AUTOMOTIVE EQUIPMENT www.mechanics-mag.com.au | AUSTRALIAN CAR MECHANIC 5 CONTENTS JAN/FEB E-MAG WITH COMPLIMENTS FROM BURSON THE LATEST IN NEW FEATURES 771837 971009 01 Price: $7.95 inc GST JAN/FEB 2022 + CASE STUDY + INNOVATIVE PRODUCTS + FUEL CONTAMINATION + 4X4 AND TOWING + BATTERIES AND ELECTRICAL + SMART SOLUTIONS SUBSCRIBE TO AUSTRALIAN CAR MECHANIC MAGAZINE! SEE PAGE 89 PRECISION AUTOMOTIVE EQUIPMENT CELEBRATES 25 YEARS Supplying World Leading Workshop, Diagnostic And Wheel Service Equipment Since 1997

CONTRIBUTORS

06. On The Cover 10. IAME Segment 12. OurAuto by VACC 14. Apprentice Competitions 16. Smart Solutions 26. Technical Features 32. Motorsport News 33. Feature Story/Snap-on 36. 4x4 and Towing 41. Business and Finance 42. Batteries and Electrical 58. Recruitment 60. Case Study 62. Innovative Products 77. Eye on the industry 80. Classic Cars 84. Workshop Profile 86. Mechanic Profile 88. WH&S 89. Subscribe Now

25 YEARS OF PRECISION AUTOMOTIVE EQUIPMENT AND QUALITY SOLUTIONS

Precision Automotive Equipment celebrates a major milestone in 2022, the Australian company’s 25th Anniversary.

One of Australia’s leading automotive workshop equipment suppliers, installation and service providers started from very humble beginnings.

With a longstanding history in the automotive industry, company founder Rod Wilkinson was working as a workshop equipment service technician, giving him a strong understanding of the problems that automotive workshop owners and operators were having with their equipment.

With many of his service customers asking him to source quality replacement workshop equipment, together with business partner Phil Atkins, Precision Automotive Equipment was born in Brisbane, initially operating from Rod’s

6 AUSTRALIAN CAR MECHANIC | www.mechanics-mag.com.au ON THE COVER

home garage and becoming a registered company in 1997.

While growing into a quality workshop equipment sales business, both Wilkinson and Atkins never lost sight of the emphasis on after sales service, something that didn’t seem as important to their competitors. This made Precision Automotive Equipment a popular choice for updating or establishing the smallest to the largest automotive workshops.

After sourcing equipment locally for several years, it was clear that Australian workshop demand for the best quality equipment required the sourcing of world leading product. In response to this, Precision enjoyed outstanding success

www.mechanics-mag.com.au | AUSTRALIAN CAR MECHANIC 7 ON THE COVER

“PRECISION ENJOYED OUTSTANDING SUCCESS WITH THEIR EXCLUSIVE POWERREX RANGE.”

with their exclusive Powerrex range, opening the gates to other world leading brands becoming exclusive to Precision Automotive Equipment including the globally renowned Hunter wheel service product range and the world number one Rotary Lift hoist range.

These distribution agreements were major highlights of the company’s history, as they provided a major vote of confidence from globally leading equipment manufacturers in the expertise and customer support provided by Precision Automotive Equipment for Australian automotive service and repair businesses.

Demand for premium quality workshop equipment and the company’s industry renowned expertise to re-design complete turn-key automotive workshops across the country saw Precision open new sales and

service branches in both Sydney (2012) and Melbourne (2014), giving repairers across the entire east coast of Australia access to Precision Automotive Equipment’s range and unparalleled after sales service.

This expansion led to significant business growth, bringing Precision Automotive Equipment to the attention of Australasia’s largest automotive aftermarket specialised company, Bapcor, which acquired the company in 2016.

The core of Precision Automotive Equipment’s success is the fact that for the most part of its 25 year history it was a family business, with Rod’s wife Karen and son Brent actively involved. While now a part of Bapcor, this business culture and focus on customers has remained the same.

For more information visit precisionautomotive.com.au or call 1300 366 252.

8 AUSTRALIAN CAR MECHANIC | www.mechanics-mag.com.au ON THE COVER

“IT WAS CLEAR THAT AUSTRALIAN WORKSHOP DEMAND FOR THE BEST QUALITY EQUIPMENT REQUIRED THE SOURCING OF WORLD LEADING PRODUCT.”

The Precision Automotive Equipment team celebrates 25 years of success in 2022, the national team is ready to help workshop owners and operators nationwide to modernise their equipment, diagnostic tools and more.

PRECISION AUTOMOTIVE EQUIPMENT OPENS BRAND NEW SA/NT BRANCH

Precision Automotive Equipment, one of Australia’s largest automotive workshop equipment suppliers and service providers, has become truly national with the opening of the company’s new South Australian branch.

Centrally located at 17A Birralee Road in Regency Park, this new Precision Automotive Equipment branch office includes a showroom and service centre, taking care of the automotive equipment requirements of customers located both in South Australia and in the Northern Territory.

This new branch office provides a hub for Precision Automotive Equipment’s South Australia based team of business development managers and service technicians, ensuring prompt and local service for their ever-growing customer base in that region.

Testament to Precision Automotive Equipment’s commitment to customer service is the appointment of a Rotary authorised and qualified hoist technician along with a wheel service equipment technician who are permanently based in this new South Australian branch. This complements the Australian company’s unparalleled network of authorised service

technicians located throughout Australia.

Former South Australian service technician, Mark Holloway, now leads the team as branch manager, overseeing the sales and service requirements of all Precision Automotive Equipment customers across South Australia and in

the Northern Territory.

An integral part of Bapcor Limited, Australasia’s largest automotive aftermarket specialised company, Precision Automotive Equipment now has a complete national footprint with branches located in Brisbane, Sydney, Melbourne, Adelaide, Hobart and Perth.

According to Precision Automotive Equipment General Manager, Peter Hewitt, “We are delighted to be truly national with the opening of our new South Australian branch. This enables us to continue providing the world’s highest quality workshop equipment along with a premium level of after sales service to our customers, no matter where they are located.”

Mark Holloway and his enthusiastic South Australian Precision Automotive Equipment team look forward to taking care of automotive workshop modernisations, completely new workshop design and fitment projects, along with specific equipment replacements and service requirements by calling 1300 366 252.

Visit precisionautomotive.com.au or call 1300 366 252 for more info. ACM

www.mechanics-mag.com.au | AUSTRALIAN CAR MECHANIC 9 ON THE COVER

WELCOME 2022

The first thing that comes of mind is parts supply and the increased cost through transport and customs. It doesn’t stop here, as only this week we have learnt there is a world shortage in Urea production. If you were a farmer, this could concern you as the product is used as a fertilizer. Additionally, it may concern you if you owned a laundromat but far more painfully, it is the core ingredient in AdBlue® (diesel exhaust fluid) which is used worldwide in our diesel to reduce particulate matter and emission control. A shortage in this product will lead to a shortage in road transport, thus, further delays in obtaining parts. Undoubtedly a shortage in this product will also affect its costs (cents per litre) and this added cost

will be passed on in your freight costs.

From a technical point of view the purity of this fluid is essential to the correct function of the AdBlue® with emission controls. With the potential of a huge shortage, we will undoubtedly have people trying to create their own with contamination being at the forefront of their creation (but I suppose that’s a good thing, more work for the industry).

By the time summer is over the Australian Standards should have out for public comment, their paper on Hybrid and Electric Vehicles. The one thing that I have learnt from this is that we are a long way from generic training and as one OEM said: “Just because you have done my training course today, it does not empower or skill

10 AUSTRALIAN CAR MECHANIC | www.mechanics-mag.com.au

IAME SEGMENT

Peter Blanshard, IAME Group CEO.

The turmoil of 2021 is now behind us and depending upon what state you are from, business concerns due to COVID shutdowns just varied in depth… at some stage everybody has been affected. In saying this, it now opens the door for 2022 being a further year of unrest and uncertainty.

“TAFE IN NEW SOUTH WALES AND VICTORIA HAVE BEEN WORKING WITH OEMS SO THAT THEY CAN TRAIN THE YOUNGER PERSON ON THE EXACT EV OR HYBRID.”

you to raise a bonnet on anything else than what I have shown you today”. These comments are truthful. TAFE in New South Wales and Victoria have been working with OEMs so that they can train the younger person on the exact EV or Hybrid. We really are at grass roots level and the generic blanket cannot be thrown from vehicle to vehicle. Each manufacturer is striving for better battery life, not to mention quicker ways of charging and/or integration with more advanced ADAS. With regards to ADAS, we have many new items to come such as speed reading headlights which could roll into production at any time.

The biggest concern with EV and Hybrid is safety and we encourage all practitioners that wish to work on an EV to do so with the utmost respect to their PPE and following OEM specification. There is no use in having the best gloves if you fail to wear eye protection and an arc is drawn straight through your eye.

Following with the EV and Hybrid topic, we have been made aware that people have been modifying charging plugs so that can get higher amperage into the battery pack for that faster charge. One of the main things you can create by doing this is an overheat of the battery and the potentiality of fire. It is when this occurs, you pray for what you do next. From what we have learnt, a thermal event with a lithium battery is almost impossible to put out. There was a recently a very good article by John Mellor with regards to a whole new set of “unique fire risks”, John stated that data from London indicated that EVs are catching fire at twice the rate of petrol or diesel vehicles which in themselves are far easier and faster to extinguish. It’s also ludicrous to note that on registration of these vehicles and exhaust test was required. Firstly, finding the exhaust

pipe would be a challenge but secondly, you don’t have to be Einstein to guess what some of the numbers would be for hydrocarbons etc.

Some of the common workplace safety hazards have been illustrated in this year’s Pro Visual wall chart and one of which has been unsafe shelving. Various state WorkCovers are inspecting workshops for unsafe homebuilt shelving as hazards that come from this are deadly. This stems from people placing heavy products above head height where manual handling strain injuries occur, down to the type of material

the shelf is made of being unsuitable for the goods it is carrying i.e. thin ply supporting perhaps used or recycled batteries. In this case, acid often leaks and a soft wood quickly deteriorates and the battery falls through. It now comes down to stacking of the shelves where people will invariably store 60 litre drum of flammable material low down and those batteries which have caused a problem, on the shelf above. We have a fire disaster waiting to happen. We have problems with shelving not being adhered to walls and floor correctly and in most places, we don’t list weight load of the shelving. It’s no wonder makeshift shelving has come under the attention of government authorities.

There is always a lot more to discuss and a lot is happening with automotive at the moment, however I would like to take this opportunity to wish every a safe holiday period and of course the happiest of new year celebrations. Your IAME will reopen on Tuesday 4th January 2022 for any of our tools, products or equipment that you may have missed prior to Christmas.

For further information visit www.iame.com.au or www.facebook.com/iame.online ACM

www.mechanics-mag.com.au

| AUSTRALIAN CAR MECHANIC 11 IAME SEGMENT

MOTORTECH: HAYNES MANUALS ALLACCESS

in the workshop and the corresponding manual being available is around six months. The actual writing takes a pair of technical authors about three months, of which roughly one month is spent in the workshop. Hundreds of photographs accompany each manual’s step-by-step instructions. These instructions cover many aspects of vehicle repair not found in other online systems, such as;

• Clutch and transmission replacement

• Steering and suspension servicing

• Exterior body parts replacement like bumpers and mirrors

• Interior trim removal like dashboards and door trims

• Chassis electrical such as audio systems, cruise control and lights

The images in Haynes Manuals AllAccess are high resolution and in colour, so you can zoom to clearly see fine details. Also, many of the manuals in the Haynes Manuals AllAccess system come with extra or updated content. Such as additional images and videos showing various processes.

One of these sources is Haynes Manuals AllAccess, which puts the entire portfolio of the famous Haynes Manuals at your fingertips, whenever you need them. Haynes Manuals are written from hands-on experience based on a complete vehicle tear-down. Haynes usually buys one or more project vehicles for every manual, and strip down

all relevant components. Then, put the cars back together again, renewing any worn parts. They have two highly skilled technicians in their project workshop who assist and advise the technical authors.

The interval between a vehicle arriving

Haynes Manuals AllAccess is available in all three of the levels of VACC MotorTech. After you have logged into the MotorTech website, click on the “Haynes AllAccess” tab on the top right (see the top of this page for an example). From there, select your make and model of the vehicle, and you will be presented with the manuals. Select the one you want and then navigate to the section you need.

For more information about VACC’s MotorTech and Haynes Manuals AllAccess, go to motortech.com.au or call MotorTech Support on (03) 9829 1268. ACM

12 AUSTRALIAN CAR MECHANIC | www.mechanics-mag.com.au

VACC’s MotorTech is growing in popularity with many members signing up to take advantage of the different sources of automotive diagnostic and repair information, that have been brought together under a single online platform.

OURAUTO POWERED BY VACC

An affordable scan tool for your business ourautoscantool.com.au Automotive information at your fingertips motortech.com.au Website and digital marketing solutions ourauto.com.au Phone 1300 687 288

CAPRICORN RISING STARS IS BACK

Why you need to consider nominating your apprentices in 2022.

Attracting and retaining apprentices in the automotive industry has never been more important. That’s why Capricorn Members are being encouraged to recognise and reward their hardworking apprentices with a Capricorn Rising Stars, Apprentice of the Year nomination.

We know being an apprentice and training an apprentice can be a great opportunity for both apprentice and employer. However, it is no easy undertaking. Not only does supporting an apprentice take time and effort, but it also takes a lot of passion, commitment and sacrifice from our apprentices to achieve their qualification.

The ‘Capricorn State of the Nation’ report showed 39 per cent of Capricorn’s 24,000 plus Member businesses currently employ an apprentice. So, there is a huge pool of talent waiting to be rewarded and recognised for their commitment to the future of the automotive industry.

Here are five important reasons you should nominate your apprentice:

1. KEEP YOUR APPRENTICE COMMITTED TO A CAREER IN AUTO

Learning a new trade is a big commitment and takes a lot of passion and dedication. Provide the ultimate encouragement to your apprentice with a Capricorn Rising Stars nomination and keep your apprentice engaged and passionate about their apprenticeship.

2. BUILD A POSITIVE WORKSHOP CULTURE, THROUGH ADVOCACY AND RECOGNITION

High performing teams often work well as they trust one another and reward each other for hard work. By nominating your apprentice, you’re not only rewarding them but letting them know that you’ve got their back, building trust as an advocate.

3. REWARDING OUTSTANDING PEOPLE, NO MATTER WHAT STAGE OF THE JOURNEY THEY ARE AT

Capricorn began the Capricorn Rising Stars awards to recognise aspiring auto repairers who demonstrate their

automotive passion, a positive can-do attitude and a strong commitment to forging a long and rewarding career in the service and repair industry.

This unique judging criteria creates a level playing field for first to fourth year apprentices across all automotive service and repair disciplines. This means Capricorn Members can nominate any of their apprentices who demonstrate

outstanding potential and character as they continue to learn their craft and display eagerness to develop their skills.

4. GREAT PRIZES TO BE WON

Everyone loves to be rewarded! The 2022 Capricorn Rising Stars prize pool has something for both the winning apprentices as well as the workshops that nominate them. These prizes are once again thanks to the generous support of our industry sponsors.

Keep an eye on capricorn.coop/ risingstars for announcements on all the prizes up for grabs.

5.

EVERYONE IS RECOGNISED!

Every nominee will be sent a certificate to formally recognise their accomplishment. With your apprentice’s permission, you can display the certificate in your reception area to let your customers know about the high-quality team you are nurturing in your workshop.

Nominations open soon, so keep up to date by visiting capricorn.coop/risingstars

14 AUSTRALIAN CAR MECHANIC | www.mechanics-mag.com.au APPRENTICE COMPETITIONS

ACM

THE NUMBER ONE CHOICE FOR EUROPEAN VEHICLES 7 out of 10 newly manufactured vehicles with start-stop technology equipped with AGM are fitted with VARTA® batteries, used in brands like BMW, Mercedes, Audi, VW and Porsche. Engineered to the highest European (German) standards, VARTA® batteries deliver an unparalleled level of power and longevity. Idle Stop Start Battery – Silver Dynamic AGM Range Flooded Lead Acid – Silver Dynamic Range 42 Month Warranty 42 MONTHS German Engineered Performance PowerFrame ® Technology Superior Durable & Robust Suitable for EU Vehicles OE Spare Part 36 Month Warranty 36 MONTHS PowerFrame ® Technology 3x Longer Cycle Life Suitable for EU Vehicles OE Spare Part Made in Germany 1300 BURSON (1300 287 766)

THE ACM DIFFERENCE

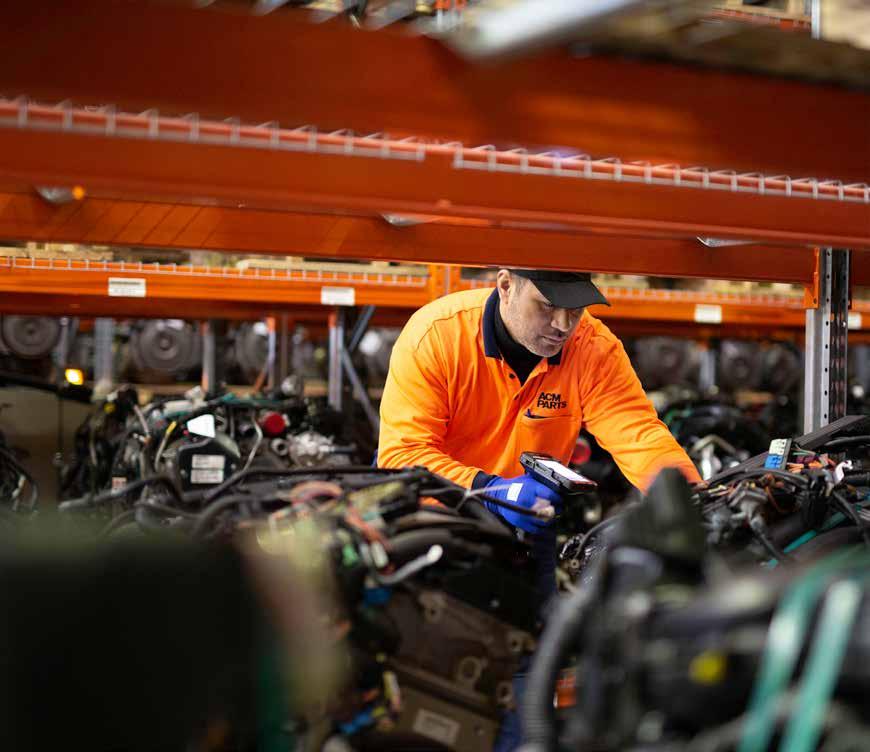

A new standard in recycled auto parts.

Traditional self-serve wrecking yards where the customer pulls their own parts off a vehicle are becoming something of the past. Modern wreckers can now be closer compared to a new parts retailer, many with full parts listing available online, knowledgeable dedicated sales staff and even delivery services.

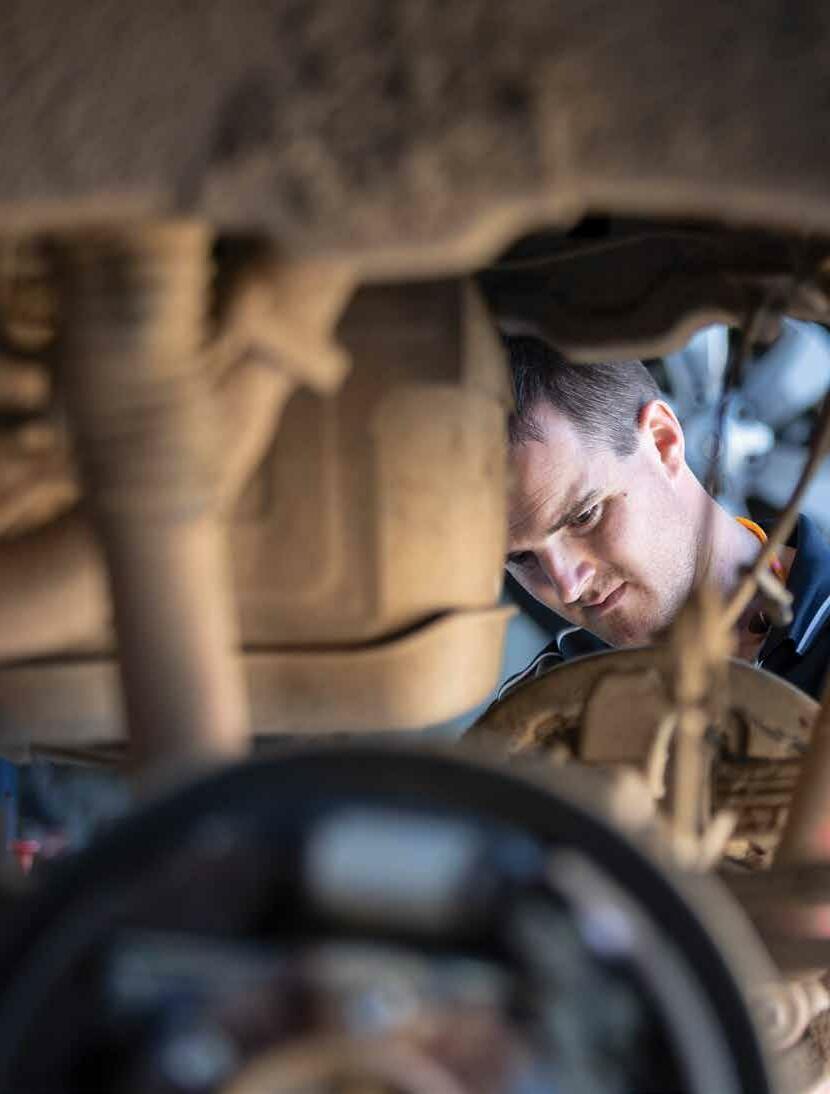

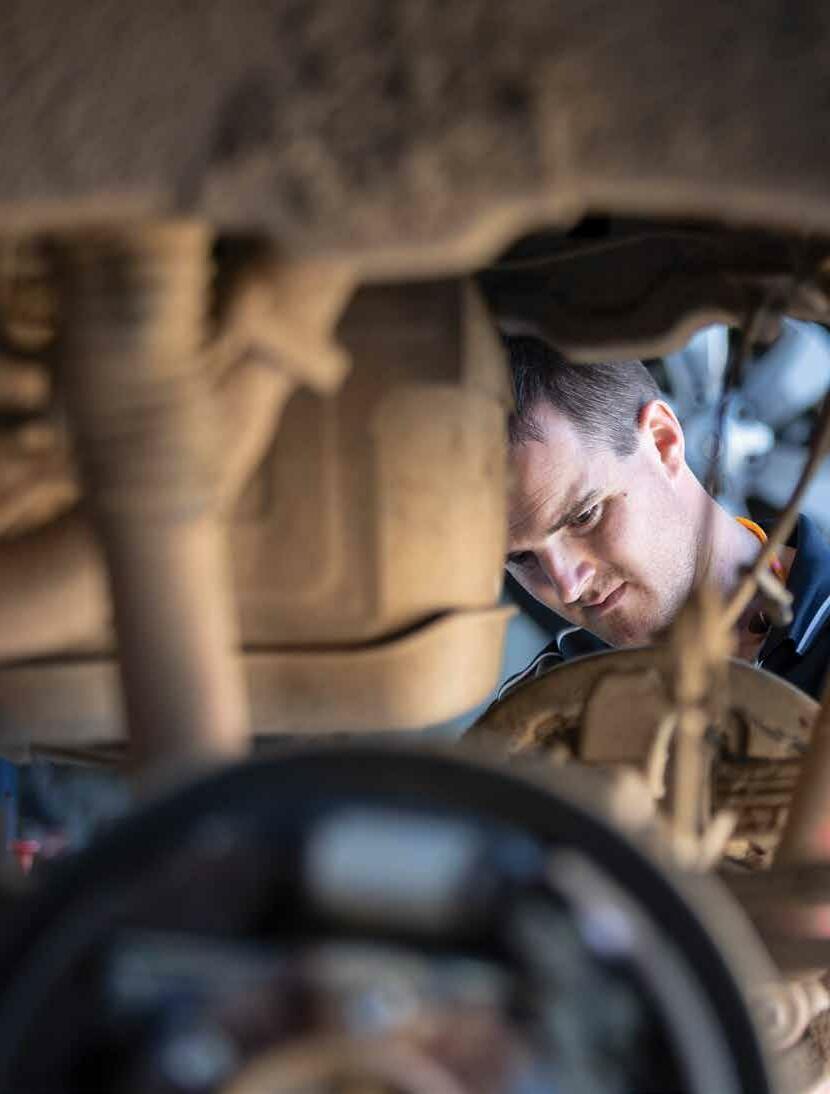

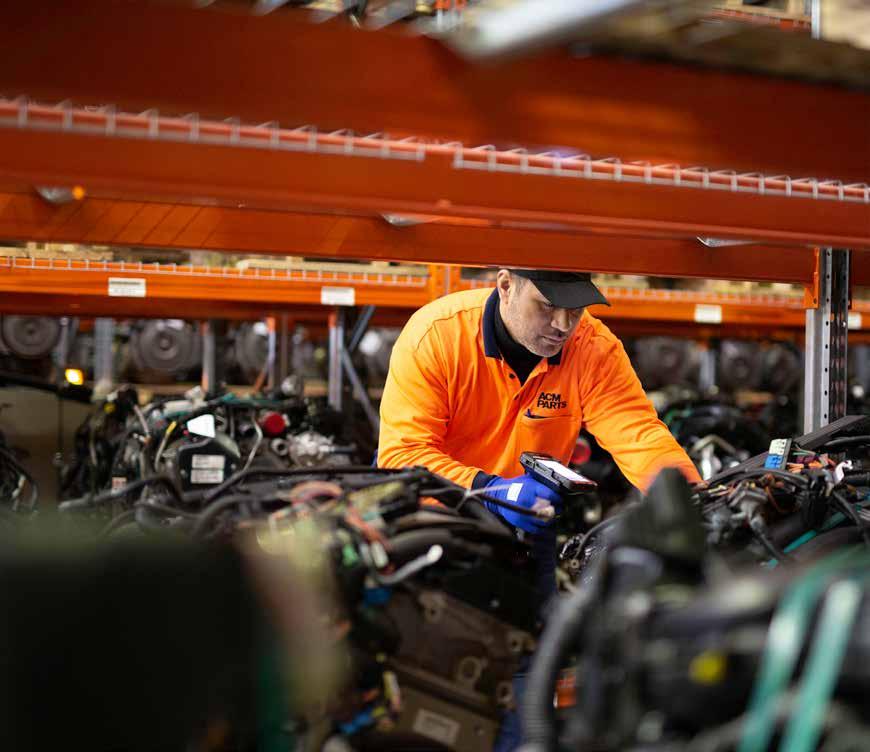

Since it first opened in 2014, ACM Auto Parts has set a new standard in recycled automotive parts, offering not only the most extensive range of recycled automotive parts in Australia, but a range of parts that are each quality controlled and given a standard six-month warranty – with warehouses in various locations across Australia and nationwide delivery.

EXTENSIVE RANGE OF QUALITY PARTS

Each vehicle that arrives at ACM Auto Parts is carefully dismantled by a team of professionals. Once dismantled each part is taken through an extensive quality control process. This includes condition assessment, testing (when possible), cleaning and then packaging.

ACM Auto Parts covers a wide range makes and models with more than 50 brands and hundreds of models, they specialise in mechanical and collision parts.

The mechanical range includes, but is not limited to, engines, driveline, suspension and brake components. Before dismantling each vehicle is drained of any fluids. Then each part is carefully removed, ensuring plugs are used to seal all water, oil and fuel leakage points. Each part is then washed, secured and transferred to one of ACM

warehouses where they are cataloged, itemised then taken through ACM’s Quality Control processes before being place on the shelf ready for purchase.

ACM Auto Parts also offers an extensive range of both new and recycled collision parts. The new or Parallel (OEM) collision range include panels, bumpers, headlamps and taillights. Each comes packaged, ready for installation. They also offer a range of high-quality recycled collision parts that are carefully dismantled and taken through ACM’s quality control process. After dismantling, each part is carefully transported to one of ACM’s warehouses. There they are assessed and graded for any minor damage. The part is then cleaned and polished. This is followed by photographs – which make it easy to reference by the sales team later. Finally, the part is carefully packaged and placed onto the shelf – ready for order.

CUSTOMER SERVICE

The range is backed by a team of knowledgeable sales staff, most with mechanical or automotive parts backgrounds. Each team member is technically trained to match the parts required and offer support both before and after purchase. With a range of more than 150,000 parts on the shelf at any one time, if something is not in currently stock the team are often able to arrange to get the part in for the customer and will go above and beyond to meet their needs.

INDUSTRY LEADING WARRANTY

Once purchased each part from ACM comes with a standard six month warranty, allowing for that extra piece of mind, something not always offered on recycled parts. They also have options to add an extended warranty to 12 months and include labour.

To get in touch with the team at ACM Auto Parts call 1800 226 727 or visit acmautoparts.com.au

16 AUSTRALIAN CAR MECHANIC | www.mechanics-mag.com.au

SMART SOLUTIONS

With multiple brands and over 150,000 parts in stock, ACM Auto Parts hold the largest range of high quality recycled mechanical parts in Australia. Plus new and recycled Collision Parts.

We pride ourselves on the quality of our parts and have a dedicated QC team that inspect, clean and package each part. Ensuring the parts received are as described.

Our internal sales consultants have extensive knowledge of automotive parts and are focused on providing exceptional customer service. Plus with sites all across Australia, getting your parts has never been easier.

Our industry leading warranty offers a 6 month guarantee on all parts purchased from ACM Auto Parts for private vehicle use.

RANGE QUALITY CONTROL BEST SERVICE LEADING WARRANTY

EXTENSIVE

1800 226 727 CALL NOW FOR PARTS acmautoparts.com.au DAILY METRO DELIVERY

DUAL ACTION MULTI-PURPOSE IMPACT SOCKETS – PERFECT FOR MECHANICS

sockets and a complete catalogue of the entire range. There is also a national store locator, to help find your nearest stockist where you can obtain expert advice to find the right impact sockets to suit you.

On the website you can also find all of the various socket sizes either individually or in sets. Each product has a unique page that provides the product’s specifications in both standard and deep configurations. You can also find a list of accessories that help you to get the most out of your Dual Action sockets.

ONE SET ONCE

The Dual Action range of impact sockets are the only sockets you should use on the equipment you value. Now there’s no need to buy one socket set for your power tool and another one for your hand tool, you can just invest in one set once.

Dual Action sockets were the first of their kind to be available in Australia. They are designed for the strength an impact tool demands and engineered for the precision a hand tool provides. Trusted by mechanics all over Australia, Dual Action gives you versatility in a single socket set, saving you time, money, and tool kit space.

MADE TOUGH

Perfect for mechanics, Dual Action impact sockets are made of chrome-molybdenum alloy steel, the perfect material to meet the extreme requirements that professional users require from their tools. A drop forge process is used to form the Impact Sockets, followed by precise heat and surface hardening treatments to deliver unsurpassed material strength, hardness and superior surface durability.

THE RANGE

Available individually and in sets, Dual Action sockets are a stand-alone product range, which users find particularly appealing as it enables them to replace two sockets with

one. The range is highly comprehensive in both sockets and sets with ¼" ⅜" and ½" drives in Metric, Imperial, standard and deep variants. All sets are available in 6 or 12 point.

Dual Action sets include not just a range of strong impact sockets, but also a ratchet with a quick release button, that is low profile to allow greater access to confined areas. The ⅜" and ½" sets also include a wobble extension which provides 15 degrees of deflection and can also be locked straight for normal use.

NEW WEBSITE

To find out more about these high-quality impact sockets, Dual Action has recently launched its new website which is a hub of useful information. There’s a video that provides you with a close-up look of the thin-walled design of the Dual Action

Specifically engineered for the needs of the professional technician, Dual Action’s thin-walled sockets and accessories provide unparalleled versatility that come with a lifetime warranty. So, when you’re ready to get serious about your tools, the best action you can take is Dual Action.

For more information or to find your nearest stockist please visit: dualaction.com.au

18 AUSTRALIAN CAR MECHANIC | www.mechanics-mag.com.au

Dual Action thin-walled socket products – have the dual benefit of working with an impact power tool and a hand tool.

SMART SOLUTIONS

DUAL ACTION

The best action you can take.

Dual Action sockets are truly multi-purpose, designed for the strength an impact tool demands, and engineered for the precision a hand tool provides. Trusted by tradies, loved by enthusiasts, Dual Action gives you versatility in a single socket set, saving you time, money, and tool kit space.

So when you’re ready to get serious about your tools, the best action you can take is Dual Action.

dualaction.com.au

TM

XTREME CLUTCH’S NEW KIT RANGE

Australian Clutch Services launches new performance products at SEMA Show.

Australian Clutch Services Marketing Manager. “The engineering team at ACS have been working hard to develop these products for launch at the show and we received great feedback throughout the event on both the new products and also our existing range of performance upgrades.”

The kits included a mix of products that would be suitable for the Australian market as well as US only applications.

“Several of these applications were developed specifically for the US market, however, we are expecting the upgrade for the GR Yaris and also our new performance concentric slave cylinders to be popular throughout Australia,” explains Hayden. “We are also offering these kits in a variety of configurations including organic and ceramic for street and motorsport use respectively. In addition, we also offer a range of clutch system accessories with these kits such as bearings, hydraulics, bolts and alignment tools as required.”

Australian Clutch Services (ACS) has recently launched a new range of performance upgrades at SEMA Show in Las Vegas. The new products will be offered under the Xtreme Clutch brand name in Australia but were launched under ACS’ US based performance division, XClutch.

Xtreme Clutch are specialists in performance clutch solutions for street and motorsport applications. As a division of Australian Clutch Services, Xtreme Clutch products are developed out of the ACS head office and R & D facility in Adelaide and are sold in Australia through an extensive network of distributors. The products have also seen great success overseas and are currently exported to Europe, the Middle East, Asia and New Zealand.

The XClutch brand was developed specifically for the US market, but based on the existing range of products by Xtreme Clutch. With an emphasis on performance and quality, the brand has quickly taken off in the US aftermarket. ACS say that SEMA Show 2021 was an ideal place to launch their latest range of performance products for both XClutch and Xtreme Clutch The new products were designed and

engineered in-house at ACS to suit various international markets. The four products include a 230mm triple plate carbon clutch for fifth generation Dodge Vipers, a twin plate organic clutch for S55 powered BMW M2, M3 and M4, a 240mm single plate organic upgrade to suit the Toyota GR Yaris, a heavy-duty upgrade for the 3.6L Jeep Gladiator and a new performance concentric slave cylinder for motorsport and custom clutch applications.

“SEMA Show 2021 provided the ideal opportunity for us to showcase these new products to the world,” says Hayden Jarrett,

Xtreme Clutch offers an exceptional range of performance upgrades to suit a wide range of vehicles including classic vehicles all the way through to the latest 2021 models. The range is also very broad in its variety of options for each application including different friction plate materials such as organic, ceramic and carbon and multi-plate options in different sizes and configurations, meaning customers can select a clutch that most closely suits their specific vehicle goals and use. Each kit is also developed to incorporate everything the installer may require such as release bearings, pilot bearings, hydraulics, bolts and alignment tools.

For more info on the Australian Clutch Services range of products visit australianclutch.com.au or any Australian Clutch Services distributor nationwide.

20 AUSTRALIAN CAR MECHANIC | www.mechanics-mag.com.au

SMART

SOLUTIONS

Xtreme Clutch performance upgrade to suit GR Yaris.

New Xtreme Clutch Universal CSC.

Xtreme Clutch twin plate to suit BMW M2, M3 and M4.

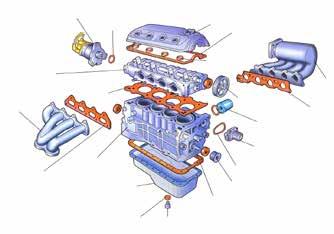

Keeping Engines Moving From OE to Aftermarket

THE PREFERRED PARTNER OF THE WORLD’S LEADING VEHICLE MANUFACTURERS: Alfa Romeo, Audi, BMW, Chrysler, Citroen, Ferrari, FIAT, Ford, Jaguar, Jeep, Lamborghini, Land Rover, Lancia, Maserati, Mazda, Mitsubishi, Mercedes-Benz, Nissan, Peugeot, Porsche, Renault, Saab, Seat, Skoda, Suzuki, Toyota, Volvo, Volkswagen, VauxhaII, OpeI, GM and Isuzu.

THE PREFERRED PARTNER OF THE WORLD’S LEADING VEHICLE MANUFACTURERS: Alfa Romeo, Audi, BMW, Chrysler, Citroen, Ferrari, FIAT, Ford, Jaguar, Jeep, Lamborghini, Land Rover, Lancia, Maserati, Mazda, Mitsubishi, Mercedes-Benz, Nissan, Peugeot, Porsche, Renault, Saab, Seat, Skoda, Suzuki, Toyota, Volvo, Volkswagen, VauxhaII, OpeI, GM and Isuzu.

FLUID TRANSFER

BOOK A MILWAUKEE® TEST DRIVE

Milwaukee Tool understands the day-to-day challenges automotive professionals face in their workshops. The company is committed to delivering a cordless, hose-free future by developing strong alternatives to pneumatic tools. Cordless solutions improve safety and eliminate the mess associated with cords and hoses being out on the shop floor.

To support mechanics, the Milwaukee Job Site Solutions (JSS) team of experienced transportation specialists, bring the best advice and the best range of cordless power tools, hand tools, storage and accessories directly to your workshop. During the JSS visit, a transportation specialist will assess the way your workshop runs. From the job at hand, to your existing inventory, the JSS team learns where your pain points are, then recommends the most appropriate product solutions; offers training and advice on how to optimise your processes; and helps you take advantage of Milwaukee’s cross-platform, cordless innovation across your workshop.

You will be able to test drive the latest Milwaukee products, including the new M18 FUEL™ Compact and Mid-Torque 1/2” Impact Wrenches. Experience firsthand how Milwaukee Tool has engineered these cordless wrenches to improve accessibility, designed to reach stubborn fasteners in tight spaces where larger impact wrenches can’t fit. The M18 FUEL™ 1/2” Compact Impact Wrench with Friction Ring (M18FIW2F12-0) measures only 124.5mm in length and delivers up to 339Nm of nut-busting torque, while the M18 FUEL™ Mid-Torque 1/2” Impact Wrench with Friction Ring (M18FMTIW2F12-0) packs up to 881Nm of nut-busting torque while weighing only 1.58kg.

Both impact wrenches have 4-mode DRIVE CONTROL which offers greater precision with a range of preset RPM and IPM levels. AUTO SHUT-OFF mode applies the right level of torque for hand-

tight fastening applications, without overtightening. Bolt Removal mode delivers full torque output, then decreases RPMs once the bolt is loosened to prevent fastener drops. For increased visibility in confined, low-light workspaces, these wrenches are designed with tri-LEDs that deliver bright light with less shadows. Milwaukee products are Nothing but HEAVY DUTY™, made to withstand the harshest, most demanding jobs in modern workshops. Working closely with the Australian transportation industry, Milwaukee Tool has managed to remain one step ahead of the ever-changing demands placed on mechanics. This connection means that Milwaukee solutions are efficient, more productive, safer to use and, most importantly, geared for mechanics. Whether it’s repairs, maintenance or body work, the JSS team ensures that the tools you have on hand, your ways of working and your workshop’s safety and efficiency are maximised.

From cordless impact wrenches to under hood lighting, Milwaukee Tool has developed

the power tools, hand tools, and accessories to help every mechanic build, repair and maintain any vehicle. Milwaukee Tool offers complete workshop solutions that maximise safety and efficiency – from the M12™, M18™ and the high performance M12 FUEL™ and M18 FUEL™ platforms, to their growing range of hand tools, accessories and the expanding PACKOUT™ modular storage system.

Book a test drive with the Job Site Solutions team at www.milwaukeetool. com.au/jobsite-solutions/

22 AUSTRALIAN CAR MECHANIC | www.mechanics-mag.com.au SMART SOLUTIONS

Experience the Milwaukee® difference with Job Site Solutions specialists who will not only help improve your workshop productivity, but also efficiency and safety.

KEEPS YOUR BUSINESS UNDER CONTROL alcius.com.au *Refer to www.alcius.com.au for terms & conditions. WITH OVER 50 YEARS INDUSTRY EXPERTISE AND AUSTRALIA’S LARGEST PARTS NETWORK, ALCIUS HAS THE CLIMATE CONTROL PARTS YOU NEED, WHEN YOU NEED THEM. DISCOVER THE ALCIUS ULTIMATE SUMMER SET UP OVER $37K WORTH OF PRIZES TO BE WON Alcius products are supported by the strength of the Bapcor network. 24M* SCAN THE QR CODE TO FIND OUT MORE

JOB DONE RIGHT, GET PAID ON TIME

Use smarter digital solutions to better manage your workshop.

Spenda’s auto workshop management software has been specially designed to support automotive businesses to help streamline daily operations while enabling your business to deliver a smoother customer experience.

Coupled with thier payments solution, it will enable you to speed up day-today tasks such as booking, allocating, completing and charging for jobs, while also reducing the time spent chasing unpaid invoices, so you can focus more

time on growing your business.

On top of this, their auto-workshop software helps your business reduce errors and speeds up reconciliation with payments integrated directly into your small business accounting software.

Take payments instantly via the portable iPad POS terminal or invoice jobs using the innovative ‘Pay Invoice By Link’ feature,

which gives your customers the convenience of paying their bill in just a few clicks. It’s easy – once a job is complete, simply email your customers a link with the invoice, which they can use to make the payment.

24 AUSTRALIAN CAR MECHANIC | www.mechanics-mag.com.au $

SMART SOLUTIONS

FINE-TUNE YOUR INVOICING AND PAYMENT PROCESS WITH SPENDA

SMART SOLUTIONS

HOW IT WORKS

1. Raise the job invoice via the POS terminal and select the option to email your customer a unique and secure payment link.

2. The customer then clicks the link on their phone or computer, views the invoice and enters their preferred payment method, either a credit card or bank account

There’s no need to enter credit card details over the phone, making it a secure payment method. Payment details are also saved to make future payments quick and easy.

3. Once the payment is processed, you’ll receive a notification and the payment is then sent to your nominated bank account. The transaction is also automatically posted to your accounting system.

Ready to supercharge your payments process and boost your cash flow? Give Spenda a call on 1300 682 521 (select ‘Option 2’) or visit www.spenda.co/ automotive today. ACM

www.mechanics-mag.com.au | AUSTRALIAN CAR MECHANIC 25 $

FACTORY APPROVAL VERSUS ‘MEETS OR EXCEEDS THE SPECIFICATION’

WHAT’S THE DIFFERENCE – AND WHY YOU SHOULD CARE

Many of these advancements are driven by the need to meet increasingly more stringent emissions standards, better fuel efficiency targets, longer and longer service intervals and consumers demanding, reliability expectations. It’s little wonder, Original Equipment Manufacturers (OEM) have each introduced a proliferation of exacting and extremely specific oil specifications – unique to themselves. The days of being able to get by just from using an oil of the right viscosity are long gone.

MEET THE MYTH

Whenever an OEM develops a new formulation in conjunction with their oil partner, they make the specifications available to the broader market so that independent oil blenders and manufactures can then formulate their own oil that meets the specification – that’s where ‘Meets or

Exceeds the specification’ comes from. However, aftermarket lubricant manufactures are not required to secure any explicit acknowledgment, sanction or approval from an OEM to make the claim their product “meets or exceeds” a particular standard. Nor is there any Australian standard, or peak

body that independently issues compliance verification. Once you understand what’s involved in verifying an oil meets the factory specification – you start to wonder, how are the independents actually testing each and every individual oil? How exactly are they verifying compliance?

26 AUSTRALIAN CAR MECHANIC | www.mechanics-mag.com.au

Vehicle manufactures spend many millions of dollars and countless hours of testing and validation in the development of ever more technologically advanced engines.

TECHNICAL FEATURE

“We have a new oil from ExxonMobil. So, I think they can take all the credit for the fact that Lewis keeps pointing at our engines. The engines are the same specification.”

Horner

MOBIL 1 MAX WON.

Lewis Hamilton recently suggested that Red Bull Racing may have introduced a few illegal engine upgrades to their F1™ cars, but he might want to take a closer look at the oil developed for the car rather than the engine itself.

Mobil 1™ has delivered a revolutionary new oil – that has helped give Red Bull Racing a clear performance advantage.

Oils are so much more than just viscosity and there’s no doubt Mobil 1™ road users will benefit from the same revolutionary advancements that have helped push Red Bull Racing Formula One to the front, go to m1oils.com.au/gomax to get the full story.

1800 350 622

The difference beween a brand sponsor and a technology partner.

m1oils.com.au/gomax Phone:

Christian

Red Bull Racing Formula One Team Principal

Ltd Mwerk001-ACM

Mobil 1™ is a trademark of Exxon Mobil Corporation and used under license by Ampol Australia Petroleum Pty

FACTORY APPROVED

With an increasing array of varying quality base stocks being introduced into the marketplace, many of the world’s carmakers have realised the need to run specific approval programs. The OEMs are inherently reluctant to officially endorse any product they haven’t properly tested and approved – especially something as finely engineered as an engine oil. That’s why securing an OEM Approval is a very expensive and laborious process – it’s a much tougher benchmark to meet. To gain approval, an oil is submitted to the individual OEM, who conducts an exhaustive certification process that includes extensive testing of wear-andtear, distribution on moving metal-to-metal parts, exhaust emissions, oxidation, fuel economy, heat stress stability, etc. All in all, about 600 gruelling hours of continued, real-world use, across multiple engines simultaneously – which is why it’s such an expensive process. There is no ‘blanket approval’ for a brand, this verification process is just for one specific oil, against one specific specification.

BUYER BEWARE

You will find many brands that have not secured OEM Approvals, will sometimes use clever, or misleading language and labelling practices that, at a glance, indicates their non-compliant lubricant has OEM Approval. Buyer beware, read the supplied information very carefully. Any lubricant that has OEM Approval is clearly marked in a very specific way.

WHY DOES IT MATTER?

Anybody who owns a new Ford Ranger and is not using the correct specification lubricants are likely to know first-hand why it matters. In this particular application, non-compliant oil has been traced back to a litany of issues, from oil pump damage, injector failure, problems with the EGR cooler as well as DPF operation. It’s all about the lubricant’s additives package, which can represent up to 30 per cent of an oil – and by far the oil’s most expensive component. How these additives interact with the increasingly complex systems found in modern engines is at the core of

any OEM specification. Even two lubricants from the same brand, of the same viscosity, both carrying very similar approvals from the same OEM, may be subtly different to the point that prevents them from being interchangeable. The risk is poor performance, increased emissions along with premature wear, increased maintenance costs and possibly engine damage.

The OEMs spend a lot of money and go to extraordinary lengths testing and developing specific lubricants and highly specialised specifications. After all, it’s their hard-earned reputation on the line. The only way to know the oil being poured into an engine will perform as necessary, is to use an oil the OEM has tested and approved. Using OEM Approved lubricants protects businesses and end users from purchasing lubricants with incorrect or misleading specification and performance claims.

Mobil 1 and Mobil Super are proud to carry more OEM Approvals than any other lubricant brand sold in Australia. The OEM Approvals for every Mobil lubricant sold in Australia are listed on the individual Product Data Sheet (PDS) which can be found here: (www.exxonmobil.com/en/ pds#f:Location=[Australia]).

Keep in mind, the manufacturer’s standard is the minimum specification, not the maximum. Premium products, such as Mobil 1 routinely far exceed any standard during independent, real-world testing.

28 AUSTRALIAN CAR MECHANIC | www.mechanics-mag.com.au

For more information go to m1oils.com.au or call the Mobil 1 team on 1800 350 622. ACM TECHNICAL FEATURE

DIESEL FUEL CONTAMINATION

hen fuel contamination is encountered it is most commonly due to water in the fuel supply but it can be from other contaminates such as debris, rust or algae growth in the fuel.

Earlier diesel engine fuel systems with their more forgiving tolerances were able to cope with fuel contamination better than the high tech finely engineered Common rail Systems we have these days. This doesn’t mean they are immune to contaminates in fuel such as water but modern Common Rail Systems are much less tolerant.

Water is by far the most prevalent and most damaging contaminate we encounter in modern Common rail diesel fuel systems, the main purpose of the fuel filter is to remove harmful particles from fuel. Although, some fuel filters have a water controlling coating on the filtration medium, water will still travel through fuel filters especially at the flow rates of Common Rail Fuel Systems.

Water causes catastrophic damage to supply pumps, rails, high pressure lines, injectors and many other components. Water does this firstly by causing a lack of lubrication and very quickly (sometimes within hours) causes components to rust. Rust is very abrasive and damages most of the components of the fuel system and

it will require all parts of the fuel system to be replaced. Rust particles can be submicron in size and therefore will travel through the best fuel filters.

The Common Rail Fuel System circulates fuel at a very high rate so as to help facilitate cooling of components and fuel. Flow rates are around 70 liters per hour, with the fuel cycling from the tank and through the fuel system and then back to the fuel tank. In the event of an issue, the debris from component damage is very quickly circulated through the whole fuel system, so when undertaking a repair, no damaged part or debris can be allowed to remain in the system as they will damage new components.

DIAGNOSING CONTAMINATION

It is important to first collect a fuel sample from an area where water and particles would be most likely to gather, for example the fuel filter base or fuel tank pick up canister.

The sample should be put into a small clear glass bottle 100ml approx. 25-30mm diameter. The sample can then be inspected visually, or tested with a test strip or paste.

Use a small high energy LED torch to enable metal particles to be seen as they will appear larger and become much

Fig. 1: Electronic diagnosis.

Fig. 2: Govoni Injector Removal tool, Bosch and Delphi - GO425.

Fig. 3: Injector leak off test using Common Rail Diesel Fuel Return Flow Kit SA-8392 with adapters for Bosch, Delphi, Denso and Siemens Injectors.

more visible to the naked eye with the LED light.

Darker red/orange particles may indicate rust from a rusty fuel tank found in earlier vehicles, or an aftermarket steel fuel tank that has been fitted where a poly tank was original or this rust could simply have been pumped in during a routine fill.

Note: Very small metal particles can travel through the fuel filter and once inside the fuel system it will continue to cause an increasing amount of abrasive debris to form.

www.mechanics-mag.com.au | AUSTRALIAN CAR MECHANIC 29 TECHNICAL FEATURE

When we encounter diesel vehicle running issues or an engine fault light, often this is related to fuel contamination.

WFig. 1 Fig. 2 Fig. 3

Fig. 4: Particles gathered together with the use of a small super strong Neodymium Rare Earth magnet.

Fig. 5: Fuel sample with water contamination. Responsive Engineering sells these Reagent bottles in both 150ml and 250ml.

Fig. 6: Damaged fuel pumps and rail from water contamination.

The bright shiny metal is from wear to components such as injector spindle or push rod, supply primary trochoid pump gear set and cam block.

The amount of this metal can indicate the amount of wear that has taken place up to now and how catastrophic the damage is.

In a 100ml bottle this can vary from 20-100 particles to many thousands, at this point we can gather together particles that can’t be seen even with the LED light using a small super strong Neodymium Rare Earth magnet.

Held against the side of the test bottle particles will quickly gather at the area around the end of the magnet, this will show to what extent the sample contains metal particles.

Diesel fuel is produced via the fractional distillation of crude oil between 200°C (392°F) and 350°C (662°F). These production temperatures mean that no significant water or biological contaminates are likely to originate from diesel fuel produced at refineries, the contamination could have occurred during haulage or storage, with the fuel becoming contaminated with water, rust and algae/ bacteria spores etc.

Cladosporium Resinae (algae) appears to be one of the more common growths found in Diesel, whilst biological growth can be a problem; the water itself is a bigger problem. A biological growth is often an indication of water within the tank. The algae will grow at the junction of diesel and water layer and will multiply very rapidly

Fig. 4

and this can block filters etc.

We can find other contaminates in the Diesel sample such as bitumen residue, carbon from the Diesel fuel – but in this primary inspection we are looking at introduced contaminates that may have damaged the fuel system.

Testing the vehicles Injector Return Volume allows us to inspect some aspects of Injector operation using either an injector

Fig. 5

return volume measuring kit for magnet valve injector types or Piezo injector test kit. Both kits are used to indicate injector damage via return volume or pressures. When we combine injector return leakage test, fuel sample results, injector compensation figures and system pressure control ability, this will give us confirmation that the system is contaminated and that repairs are required.

Fig. 6

30 AUSTRALIAN CAR MECHANIC | www.mechanics-mag.com.au

FEATURE

TECHNICAL

Water Watch installed.

FUEL SYSTEM REPAIR

Some specific tools may be required to repair the fuel system, these could include.

1. Injector removal tools (Govoni Master Injector Extractor Kit – GO405, Universal Bosch Injector Removal Kit SA-2074A and many other kits for specific vehicles)

2. Injector seat cutting/cleaning tool (Universal Injector Nozzle & Seat Cutter SA-3636L, Universal Injector Seat Cleaning and Milling set Bosch/ Delphi SA-8038)

3. Fuel supply pump removal tool (Supply Pump Removal Tool SA-8033, Bosch Injection Pump Socket Kit SA-5289A, Injection Pump gear removal tool SA-2911A)

4. Injector return line vacuum test tool (Common Rail Diesel Fuel Return Flow Injector Test kit –SA-8392, Cylinder leakage Tester SA-7384, Piezo Injector Return Flow Test Kit SA-2897K, Comprehensive Diesel Cylinder Leakage Test Kit SA-7191C).

Responsive Engineering says the most effective method used to protect a diesel fuel system is to have a Diesel Water Watch unit fitted. These systems detect very small amounts of water, typically between 5-10ml.

Diesel Water Watch has a visual and audible alarm which activates as soon as water is detected; prompting the driver to pull over and assess the level of contamination caught in the glass bowl and drain it.

This prevents the contamination from

entering the sensitive components of the Common Rail Fuel System.

If the warning alarm continues to reoccur you may need the fuel tank removed and cleaned.

The Diesel Water Watch system works by utilising an electronic probe suspended in the fuel. The unit removes water and debris heavier than the fuel using a diffuser system to help separate the debris and then retains both the water and particulates in the bottom of the glass bowl. The pressure of the fuel flowing rapidly through the Diesel Water Watch holds contamination particles below the flow of the fuel, where it can be easily removed.

No filters are used, so there is no additional restriction on fuel flow or pressure, and no ongoing maintenance. The Diesel Water Watch was not only invented in Australia, but is also made in Australia and comes with a lifetime warranty. Detailed fitting instructions and bracket kits are available for most of the popular diesel vehicle applications in Australia.

For more information visit www.specialisttools.com.au or call (02) 6280 4334. ACM

www.mechanics-mag.com.au

| AUSTRALIAN CAR MECHANIC 31

FEATURE

TECHNICAL

Water Watch How it works.

VICTORIOUS DEBUT

Car Series

Burson Auto Parts ambassador Ben Bargwanna has made a stunning NSW Production Car Series debut with three victories in all three races held at Sydney Motorsport Park over the weekend of November 6 and 7.

The TCR Australia rookie driver was competing for the first time in the Burson Auto Parts Audi TT RS, a car prepared meticulously by his father and highly accomplished racer and fellow Burson Auto Parts TCR Australia driver Jason Bargwanna.

Ben Bargwanna managed to maximise his two practice sessions in the car, to climb from 11th to 4th by the second practice session, gaining a strong understanding of the Audi’s performance characteristics on the 3.9 kilometre Sydney Motorsport Park circuit.

On just his second lap of qualifying, the 20 year old Burson Auto Parts racer set a lap time that saw him miss pole position by just 0.007s, firmly planting him on the front row for the Saturday’s opening race which was held in damp and tricky conditions.

After being challenged for the lead on a number of occasions, Bargwanna showed racing maturity beyond his years to remain calm, regain the lead and take his first victory of what was going to be a dominant debut event.

Bargwanna had to cope with changing track and weather conditions along with some speedy competition during the three Sydney races.

“It was an amazing weekend from the get-go!” Bargwanna said.

“During the first two races the rain came and the Audi came to life, I was able to pull

some good gaps until reaching the lapped traffic but I comfortably had the pace to extend the gap again.

“The final race was dry, this meant that I had to get a good start and maximise the strengths of the Audi which was its corner balance and corner exit drive. I was able to create a big enough gap by setting the fastest laps of the race which earned my third win in a row for the weekend,” he added.

This event was an excellent preview to what Ben Bargwanna and his younger cousin Jude Bargwanna can look forward to when the Burson Auto Parts Audi TT RS returns to the track for the 2022 Bathurst Six Hour Production Car enduro which will take place at Mount Panorama from April 15 to 17, 2022.

For more information visit burson.com.au ACM

32 AUSTRALIAN CAR MECHANIC | www.mechanics-mag.com.au MOTORSPORT NEWS

Burson racer makes it three wins out of three in production

debut.

Ben Bargwanna

BUILD RELATIONSHIPS AND STAND STRONG DURING COVID

19 TIMES

Starting as an apprentice in 1994, Simon Hall has extensive experience as both a customer of Snap-on tools and, most recently, a Company Store Manager. Picking up his first tools from Snap-on early in his career, Simon knew the premium brand well when he accepted a unique role with the Snap-on team. He commenced in early 2020, managing a company store servicing the Clayton, Springvale, and Huntingdale regions of Melbourne.

Simon operates the Snap-on owned mobile store while also offering support to Snap-on franchisees in the area. Though a company owned model, as Simon reflects, the day-to-day operations that lead to business success are the same.

“Go through your pre-list, plan your day. In this business, it’s very much about the schedule. Work out who you’re seeing and who you’ve been talking to about particular items or deals. Then always aim to stick with your call schedule. It may not result in a sale every time but our customers appreciate you being reliable and on a schedule.”

Simon’s first day with Snap-on saw him take part in the 2020 Snap-on Franchisee Conference, just days before the COVID-19 pandemic took hold and began to impact Australian businesses. While early 2020 restrictions in Melbourne did put limitations on getting in front of customers, the business was able to remain active and adapt. The conditions of 2021 also had an impact, with Simon being called off the road at times, while workshops were also challenged by time out of action.

But there is one thing that saw the business through – and that is relationships. Simon believes they are core to success for Snap-on and its franchisees.

“Getting through this has come down to Snap-on’s emphasis on building customer relationships,” Simon reflects. “You work hard to maintain those relationships

through the tough times. On top of getting the tools into peoples’ hands, if you build those relationships, the success follows.”

Despite an initially daunting time to start, Simon was able to establish and grow a strong customers base in the local area. One key aspect was remaining flexible but organised. Simon’s experience is testament that, even in an economic downturn or times of uncertainty, the Snap-on Tools business model can stand strong and be successful.

What does he recommend for building relationships with clients? It’s all about communication, staying in contact makes all the difference. “I always text if I’m going to be late or can’t make it,” Simon

www.mechanics-mag.com.au | AUSTRALIAN CAR MECHANIC 33

Simon Hall, Snap-on Tools Company Store Manager based in Melbourne, reflects on the last two years of working in the business during the global pandemic and economic downturn.

FEATURE STORY

“EMPLOYMENT IS COMING BACK FOR THOSE WORKSHOPS THAT HAD TO REDUCE HOURS AND THERE’S PLENTY OF WORK AROUND.”

advises. “Our customers are busy and don’t always want to pick up their phone. But they appreciate you getting in touch. Over time, with this approach, you tend to become their first port of call when they need a tool, and we work together between my store and other franchisees in the area to support those needs.”

Heading into 2022, Simon has noticed a return of growth in the industry, but with some shifts in both tool preferences and employment trends.

“I would say there are two shifts I’m noticing in terms of tools. The first is that battery-powered tools are becoming very popular, though there is still a strong place for pneumatic tools. The other is that the core products of Snap-on – the spanners, the sockets, ratchets and screwdrivers are always popular and consistently going into workshops.

“One of the single biggest factors to Snap-

on tools is putting the tool in the hands of your customer. I recently sold a high-quality Snap-on breaker bar. It’s a simple tool, but when you explain the features and benefits, and physically put it in your customers’ hands, it makes all the difference. If I hadn’t done that, I wouldn’t have sold it.”

“I also anticipate and can see the move towards intelligent diagnostics, now integrated into a range of Snap-on scan tools. There’s a lot of work in the background to get that data and make it available through the Snap-on cloud, for our scan tools to access. Snap-on has a team dedicated to this.

“Not every scan tool supplier can have that level of support, whereas Snap-on does. It’s impossible for a technician to know every expected outcome when testing and diagnosing. That’s why this data is so critical.”

During the pandemic, Simon also noticed an employment shift in the industry. Where he’d only see one or two people change jobs in a month prior to the pandemic, he lost track of how many mechanics were either changing jobs or moving between workshops.

“Overall, they’ve been successful after those moves,” says Simon. “Employment is coming back for those workshops that had to reduce hours and there’s plenty of work around. A lot of businesses I service are desperate for mechanics.”

Despite the challenges of the last two years, the Snap-on franchisees and customers have held strong and worked

34 AUSTRALIAN CAR MECHANIC | www.mechanics-mag.com.au

“YOU WORK HARD TO MAINTAIN THOSE RELATIONSHIPS THROUGH THE TOUGH TIMES.”

through the tough times. When considering a Snap-on franchise, Simon believes in the processes behind Snap-on’s business model. “Build those relationships and back it up with your belief in the quality product. People see your passion and confidence in the tools,” Simon noted.

“We’ve seen some tough operating conditions, but I believe in this brand and the outcomes show. Compared to other franchise businesses, you face smaller operating costs relative to your investment, and you can make a great living out of it. The Snap-on program sets you up for success and you make it work.”

Snap-on is a leading manufacturer of premium tool and equipment solutions. Its unique franchise model transports Snapon’s tool range direct from workshop to workshop via dedicated franchisees.

Join Snap-on and bring the world’s #1 tool brand mobile showroom to the customer. Learn how by visiting snaponfranchise.com.au or speak with the Snap-on team on 1800 810 581. ACM

www.mechanics-mag.com.au | AUSTRALIAN CAR MECHANIC 35 FEATURE STORY JOIN SNAP-ON AND BRING THE WORLD’S #1 TOOL BRAND MOBILE SHOWROOM TO THE CUSTOMER. DRIVE YOUR OWN SUCCESS TODAY! 2018 Top 10 2020 Top 10 SNAPONFRANCHISE.COM.AU | 1800 810 581

Adriver exploring Australia’s vast unpopulated regions places huge faith in his vehicle and the people who maintain it. The situation is especially marked because four-wheeldriving as a recreational pastime is usually family inclusive, meaning the vehicle owner has the welfare of the entire family to consider when making decisions on equipment and maintenance.

Braking is an aspect of performance which gets close scrutiny from drivers because if the vehicle won’t slow, stop, or allow its speed to be controlled, the driver knows instantly. There’s no need

for workshops and diagnostic software to see things aren’t right. It’s even more obvious when the vehicle’s towing, another favourite of the four-wheel-drive set. A camper, caravan or even a luggage or tool trailer would be a common accessory on most four-wheel drives, and the stress it can throw on braking and cooling systems is substantial. Everything from the tow vehicle’s radiator and coolant circulation through to the trailer’s hitch, electricals and suspension needs to be up to the tasks expected of it, and most owners will look to competent service people to help them assess and find what they need.

On a less technical level, but every bit as vital, is filter choice and care. Australian fourwheel-drivers love their desert and beach drives, and sometimes OEM filters just aren’t up to the task of dealing with Aussie extremes. Once again owners and drivers will look to those caring for their vehicles for advice and competent installation.

With everything from the Suzuki Jimny through to 200 series LandCruisers hitting far-flung Australian destinations, a busy workshop needs access to a vast range of information and parts.

ACM can help. Here’s a few towing and four-wheel-drive highlights.

36 AUSTRALIAN CAR MECHANIC | www.mechanics-mag.com.au

FOCUS FEATURE 4X4 AND TOWING

• Patented Kangaroo Paw ventilation design for up to 20% better heat dissipation • High-carbon alloyed iron for increased heat tolerance • Thermal Stability Profiling (TSP) treatment realigns iron microstructure for increased stability

• Unique thermographic heat paint (TGHP) assists with the monitoring of heat stress

• Available in various surface configurations, with the popular T3 slots facilitating dust and gas dissipation

BRAKE

PADS

• Scorched for optimal performance • Low-metallic, low copper friction material for superior performance across the full temperature spectrum • Application-specific NVH shims and slots facilitate low noise and maximum drive comfort

CALIPERS

Easy “bolt off, bolt on” in case caliper replacement is required

+100KG +80KG +150KG +150KG + 400KG +5KG +30KG +2,400KG FOR MORE INFO & WHERE TO BUY VISIT DBA.COM.AU THE PERFECT COMBO FOR ADVENTURE

BRAKE ROTORS

•

BRAKE

PUTTING ON WEIGHT THIS HOLIDAY SEASON?

Disc Brakes Australia’s range of upgrade brake

products can help. COPING WITH THE EXTRA KILOS?

Every tradesperson hauling equipment, tools, and building material in their vehicle knows it – additional weight can add up quickly! The same goes for 4WDs – bull bar, rear bar, tyre swing-out, rock sliders, roof rack, and other accessories all contribute to an increased Gross Vehicle Mass (GVM). Add to that the luggage in the boot and on the roof and a bunch of people, and before you know it you have almost put an extra tonne of weight on your vehicle (always make sure not to extend the legal GVM!). If you then decide to tow along an unbraked trailer, you are looking at another three quarters of a tonne. So the vehicle’s brakes are now dealing with an extra 50%+ of weight compared to the vehicle’s tare weight that need to be stopped.

Whilst most OE-fitted brakes will do a reasonable job with the extra load, there are two aspects that will help a mechanic determine whether to recommend a brake upgrade to their customer when the vehicle comes in for a service: (a) Are the brakes technically capable of handling the extra load, and (b) considering every metre counts, would shortening the vehicle’s stopping distance be of value?

Let’s start with the latter. In theory, a GVM increase should have no impact on the stopping distance, assuming all other conditions remain unchanged and the brakes can handle the extra weight. However, in reality the load sensitivity of most tires in their typical operating range is such that the friction coefficient decreases as the load increases, meaning less friction between the tyres and the road leads to a longer stopping distance. A brake upgrade can help compensate for this. Larger brake diameters, surface design (slotted, drilled, etc.) as well as the pad friction composition all increase braking performance, which will not only help you make up for the additional metres, but can even reduce the stopping distance compared with the original equipment.

Which brings us back to point one –are the brakes currently on the vehicle capable of handling the extra weight? With higher weights, higher thermal energy

is created during the braking process, which standard brakes might not be able to dissipate adequately, especially when brakes are applied over a prolonged period. The result will be brake fade and eventual brake failure.

This is where DBA has the upgrade ‘combo’ for a wide range of SUVs, utes and 4WDs. Its 4000 Series rotors offer superior braking performance under the heaviest conditions thanks to the patented Kangaroo Paw ventilation vane design, high carbon cast-iron material, Thermal Stability Profiling (TSP) treatment, and the unique thermo-graphic paint markings. 4000 Series rotors are available in various surface configurations, with the popular T3 tri-directional slots facilitating additional dust and gas dissipation.

The 4000 Series rotors are perfectly complemented by DBA’s range of Xtreme Performance brake pads. Scorched for optimal performance, this low-metallic, low copper friction material offers superior performance across the full temperature spectrum. Application-specific NVH shims and slots facilitate low noise and maximum drive comfort.

Complementing its range of 4WD and ute offerings, DBA has recently introduced an all-new range of brake calipers for direct replacement. Manufactured using state-of-the-art CNC machine and laser technology, these calipers offer the most convenient and time-efficient “bolt off, bolt on” solution for the mechanic.

For more information and to find the right upgrade parts for any vehicle, check out DBA’s electronic Part Finder at dba.com.au, contact DBA on Facebook or via email at sales@dba.com.au, or get in touch with the DBA team by calling 1800 730 039.

38 AUSTRALIAN CAR MECHANIC | www.mechanics-mag.com.au FOCUS FEATURE 4X4 AND TOWING

PROTECTING YOUR 4WD AIR FILTER

Most of the time, an engine’s air filter maintenance is relatively simple – replace the air filter at a pre-determined interval and set and forget until it is up for its next replacement.

However, replacement intervals set by the manufacturer only account for regular road use and when you start venturing off-road, things get a little bit more complicated. Your vehicle’s air filter acts as the lungs of the engine, filtering out any particles in the air that cause premature engine wear and damage. Once you’re dealing with things like sand and dusty roads, your air filter starts working a lot harder to keep your engine protected.

First and foremost, if your 4WD is seeing a lot of use off-road, the best thing you can do is give your air filter regular checks, especially after a hard day on a dusty track. It’s good practice to open up your intake airbox after every trip and monitor what’s going on inside. Across most 4WDs, this is a relatively simple process that should only take a couple of minutes. If it’s taken in enough dust, you’ll want to replace it with a fresh air filter. A clogged air filter chokes your engine of air and can lead to excessive fuel consumption and a lack of power. If it’s not up for replacement just yet, give the airbox a clean and remove any dust or debris.

It’s also important to make sure that your intake system is sealed properly. Rubber or plastic hosing ages over time and can become brittle and crack. Regularly check

your intake hoses for any splits or cracks and replace them where necessary. Ensure as well that your air filter is sealing properly inside the airbox. If you notice any dust on the clean side of the airbox, chances are it’s getting in around the filter as opposed to through the filter. Ensure that your air filter is installed correctly and that the seal isn’t twisted or damaged. You’ll also want to look out for the condition of your airbox. Make sure that the clips or screws holding it closed are tight and that the airbox doesn’t have any damage that could be letting in dust.

Another thing to consider is fitting your 4WD with an intake snorkel. Whilst these are usually associated with water crossings and keeping water from destroying your engine, they can also help preserve the life of your air filter. When you’re out on those dusty tracks, raising the intake height from the engine bay to your 4WD’s roof allows

the engine to breathe in much cleaner air from an area where far less dust is present. While you’re at it, fitting a snorkel sock is also a good preventative measure when you’re dealing with dust. These can be easily removed as well when it comes time for a replacement.