9 771837 971009 02 Price: $7.95 inc GST MAR/APR 2022 THE LATEST IN FEATURES + MEET FRANK LOWNDES + SMART SOLUTIONS + INNOVATIVE PRODUCTS + PERFORMANCE PRODUCTS + WORKSHOP EQUIPMENT + ASSOCIATION NEWS MAR/APR E-MAG WITH COMPLIMENTS FROM SUBSCRIBE TO AUSTRALIAN CAR MECHANIC MAGAZINE! SEE PAGE 89

here’d be very few fans of Australian automotive racing who didn’t know the name Craig Lowndes. Lowndsie’s been almost as big a favourite of the Australian public as Fords, Holdens and V8 Supercars.

But what not so many might know is Craig’s not the first generation of Aussie icons in motor racing from the Lowndes family. His father, Frank, was a much sought-after and justly admired tech icon in the heady days of the Monaro and GTHO Phase 1.

They were heady days indeed, and Frank had considerable success looking after cars for drivers like Colin Bond.

Of course, being a father to Craig would be a fair claim to fame as well.

Iain Curry spent time with Frank Lowndes as he shared some incredible stories of Bathurst and racing in the late 1960s and ’70s. Better still, Iain was given a close look into Frank Lowndes’ love of one particular car. I won’t spoil it. Work your way through the issue and see for yourself.

Elsewhere we have our second instalment of the VACC’s OurAuto Tech Talk column, reminding us all that while the print version does a great job of keeping industry techs up to date, the on-line version is an excellent service tool as well as a comprehensive archive.

On the cover we’ve underlined the challenge facing energy storage in modern cars, and how the move to electronics, especially start-stop technology, is placing ever-increasing demands on automotive

batteries. VARTA is a company clearly at the leading edge of battery technology for all kinds of vehicles, from passenger compacts through to the largest commercials and heavy vehicles, and the company’s advanced energy-storage solutions are more than keeping pace with auto energy demands. In fact, in some areas VARTA is leading the way. The company was ready for start-stop technology 20 years ago. Imagine what kinds of things are in development there now.

There’s plenty more going on in this issue. Peter Blanshard, IAME Group CEO, offers s few thoughts on performance during the COVID era, there’s a couple of Focus Features, some tech info on diesel particulate filters and air filters, the usual

Smart Solutions, Innovative Products, Eye On The Industry and Business and Finance sections, and in a glorious celebration of all kinds of motoring endeavours, Summernats 34 is back, and we celebrate the event’s return.

It’s all there. All you have to do is turn the page and get started.

Tom Foster Editor ACM

Clarios, the global Battery manufacturer behind the VARTA brand estimates that by now every third car that enters a workshop will be equipped with star-stop technology. Find out more on page 8.

www.mechanics-mag.com.au | AUSTRALIAN CAR MECHANIC 3

Magazine Deadlines May/Jun 2022 Deadline Apr 1, 2022 Jul/Aug 2022 Deadline Jun 1, 2022 Sep/Oct 2022 Deadline Aug 1, 2022 ON THE COVER

vehicle battery best practice starts with

stay.

M THE LATEST IN INNOVATIVE PRODUCTS + ONLINE SERVICES + ENGINE LIGHTINGMANAGEMENT & BATTERIES SUBSCRIBETOAUSTRALIAN CAR MECHANIC MAGAZINE! SEE PAGE 85 Readinside APGtheadvantage PartnersAuthorised have TOOLTEST M1 M TW E H APG“LIGHTTRUCKPARTS. ISHERETOSHAKEUPTHEINDUSTRY” JAN/FEB E-MAGWITH COMPLIMENTS FROM BURSON THE LATEST IN NEW FEATURES 771837 Price:JAN/FEB + CASE STUDY + INNOVATIVE PRODUCTS + FUEL CONTAMINATION + 4X4ANDTOWING + BATTERIESANDELECTRICAL + SMART SOLUTIONS SUBSCRIBETOAUSTRALIAN CAR MECHANIC MAGAZINE! SEE PAGE 89 PRECISION AUTOMOTIVE EQUIPMENT CELEBRATES 25 YEARS SupplyingWorldLeadingWorkshop,DiagnosticAndWheelServiceEquipmentSince1997 JAN/FEB E-MAG WITH COMPLIMENTS FROM BURSON SUBSCRIBE TO AUSTRALIAN CAR MECHANIC MAGAZINE! SEE PAGE 89 THE LATEST IN FEATURES + MEET FRANK LOWNDES + SMART SOLUTIONS + INNOVATIVE PRODUCTS + PERFORMANCE PRODUCTS WORKSHOP EQUIPMENT + ASSOCIATION NEWS T WELCOME

FROM ICONS TO NEW TECH CHALLENGES

odern

VARTA. Start-stop technology is here to

JUMPSTART YOUR WORKSHOP

Tackle any heavy duty task in your workshop with the Milwaukee® 218 Piece Automotive Starter Toolkit A1. The A1 is the must-have collection of Milwaukee Tool’s latest automotive innovation. Unlike other tool kits, the A1 combines durable hand tools and accessories with the portable productivity of M12™ cordless power tools—including two REDLITHIUM™-ION battery packs and charger. It’s the ultimate launchpad into the M12™ network of over 90 cordless solutions. Keep your tools secure in the 40" Steel Top Mobile Work Bench with lockable 45kg soft close drawers, while the built-in power centre will help you stay charged. Be workshop ready with this definitive Milwaukee® Automotive Starter Toolkit.

milwaukeetool.com.au/jss REQUEST A WORKSHOP VISIT FROM THE TRANSPORTATION SPECIALIST TEAM

WRENCHES • Ratcheting Combination Wrench Set – 15 Piece (Metric) (48229516) • Combination Wrench Set –15 Piece (Metric) (48229515) • 305mm (12") Adjustable Wrench (48227412) • 254mm (10") Adjustable Wrench (48227410) RATCHETS AND SOCKETS • 3⁄8" Drive Ratchet & Socket Set –56 Piece (SAE & Metric) (48229008) • 1⁄2" Drive Ratchet & Socket Set –47 Piece (SAE & Metric) (48229010) STEEL STORAGE • 40" Mobile Work Bench Steel Top (48228538) POWER TOOLS • M12 FUEL™ 1⁄2" Stubby Impact Wrench Kit (M12FIWF12-202B) • M12 FUEL™ 3⁄8" Ratchet (Tool Only) (M12FIR38) PLIERS • Diagonal Pliers 200mm (8") (48226108) • Long Nose Pliers 200mm (8") (48226101) • Combination Wire Pliers (48223079) • Torque Lock Curved Jaw Durable Grip 254mm (10") (48223410) • V-Jaw Multigrip 250mm (10") (48226210) SCREWDRIVERS • 10 Piece Screwdriver Kit (48222714) OTHER • Pry Bar Set – 4 Piece (48229214) • Hook and Pick Set – 4 Piece (48229215) • SHOCKWAVE™ Impact Driver Set –50 Piece (48324024) • Wide Blade Tape Measure 8m (48220208) • Fastback Flip Utility Knife with Storage (48221502) • SHOCKWAVE™ Automotive Impact Socket Set – 3 Piece (4932451568) TOOLKIT INCLUDES • • ARN-2261 218 PIECE AUTOMOTIVE STARTER TOOLKIT A1

Editor Tom Foster tom@maynemedia.com.au

CONTRIBUTORS

IAIN CURRY has been a specialist motoring writer and photographer for 15 years, working for a variety of magazines in Australia, United Kingdom, USA, Germany and Sweden. He is former editor of Performance BMW magazine and features writer for GT Porsche magazine, and has been fortunate enough to photograph Formula 1, the Le Mans 24 Hours, World Touring Cars, V8 Supercars and a range of adventure sports.

ADAM WATKINS is a full-time teacher of automotive technology at The Northern Sydney Institute Northern Beaches campus in Brookvale. Adam works on marques such as Mercedes Benz and BMW and spends time at the racetrack. Adam brought this knowledge into the classroom to train new generations of modern automotive apprentices.

is a professional photographer who, after 20 years in the field, started a carpentry apprenticeship. With a recently found love for purring V8s, Jamie is documenting the transformation of his stock Crewman. When he’s not writing, taking photos or practicing his wood work skills, you can catch him surfing at Turimetta Beach.

Publisher Kurt M. Quambusch

PO Box 489 DEE WHY

6 AUSTRALIAN CAR MECHANIC |

Production Manager Arianna Lucini arianna@maynemedia.com.au Group Sales Manager KahChi Liew kahchi@maynemedia.com.au 1300 764 688 Advertising Sales Manager Melvin Tay melvin@maynemedia.com.au 1300 764 688 Subscriptions Arlette Kouch (02) 8355 6841 (02) 9452 4517 arlette@maynemedia.com.au Design Peter Cartledge art@maynemedia.com.au ISSN 1837-9710 Australian Car Mechanic is Published Bi-Monthly by Mayne Media Group Pty Ltd ACN 130 678 812 ABN 27 130 678 812 Postal

NSW 2099 Australia Ph: 1300 76 4688 Int Ph: + 612 9452 4517 Int Fax: + 612 9452 5319 www.mechanics-mag.com.au Copyright 2022. Mayne Media Group Pty Ltd. Material may not be reproduced or photocopied in any form without the written permission of the publisher. Mayne Media Group Pty Ltd believes that all material is correct at the time of printing and will not be held liable for any incorrect information supplied within.

www.mechanics-mag.com.au

ON THE COVER: VARTA www.mechanics-mag.com.au | AUSTRALIAN CAR MECHANIC 7 CONTENTS JAN/FEB E-MAG WITH COMPLIMENTS FROM BURSON SUBSCRIBE TO AUSTRALIAN CAR MECHANIC MAGAZINE! SEE PAGE 89 9 771837 971009 02 Price: $7.95 inc GST MAR/APR 2022 THE LATEST IN FEATURES + MEET FRANK LOWNDES + SMART SOLUTIONS + INNOVATIVE PRODUCTS + PERFORMANCE PRODUCTS + WORKSHOP EQUIPMENT + ASSOCIATION NEWS Mechanic checks and adjusts the

car lighting system. 08. On The Cover 12. IAME Segment 14. OurAuto Powered by VACC 16. Apprentice Competition 18. Smart Solutions 28. Technical Feature 30. Motorsport News 34. Special Event 36. Performance Products 44. Workshop Equipment and Vehicle Hoists 56. Technical Feature 58. Industry Legends 61. Workplace Health and Safety 62. Technical Feature 64. Business Development 66. Innovative Products 75. Eye on the industry 79. Business and Finance 82. Classic Cars 87. Workshop Profile 89. Subscribe Now

headlights of a

MODERN VEHICLE BATTERY BEST PRACTICE STARTS WITH VARTA

Start-Stop technology is here to stay. Clarios, the global battery manufacturer behind the VARTA brand estimates that by now every third car that enters a workshop will be equipped with star-stop technology.

This technology transition is supporting the reduction of fuel consumption and is therefore welcomed by drivers and consumers, however it does present workshops with a new challenge when it comes to battery replacement.

BACKED BY THE GLOBAL MARKET LEADER: CLARIOS

VARTA automotive batteries are powered by Clarios, a world leader in advanced energy storage solutions. VARTA partner with their customers to meet increasing market demand for smarter applications, on a global scale. Their 16,000 employees develop, manufacture and distribute a

suite of evolving battery technologies for virtually every type of vehicle. Their technologies deliver uniquely sustainable, next-generation performance, and bring reliability, safety and comfort to everyday lives. VARTA add value at every link in the supply chain, contributing to the progress of the communities they serve and the planet we all share.

THE CHALLENGES OF A CHANGING MARKET

Within the next few years, around 90 per cent of all newly manufactured cars will have built-in start-stop technology, which reduces fuel consumption and emissions by switching off idle engines. But supporting

Pre 2005 2015+

8 AUSTRALIAN CAR MECHANIC | www.mechanics-mag.com.au ON THE COVER

start-stop technology is just one of the tasks of the battery. As cars are equipped with more and more power-consuming items – such as satnav, DVD screen and Smartphone interface, a robust energy supply has to be in place. And that’s a task conventional SLI batteries are simply not able to fulfill.

VARTA HAS BEEN READY FOR START-STOP SINCE 2002

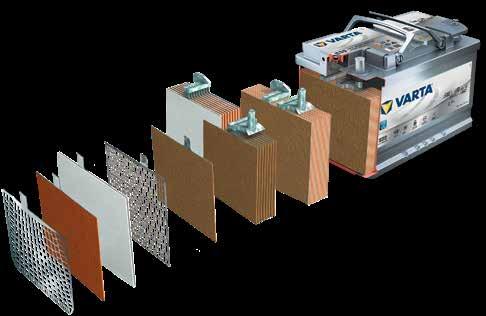

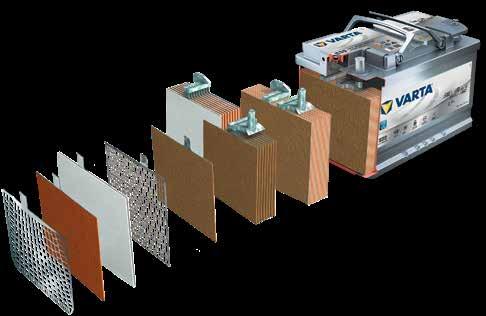

When VARTA started the AGM battery production in 2002, they didn’t just want to meet the demands of car manufacturers. They wanted a battery so powerful that it would become the benchmark in the startstop segment.

The result: VARTA® Silver Dynamic AGM. To guarantee the best quality, VARTA has put in place more than 100 process and product parameters and variables which are inspected and monitored during the production of the AGM batteries. This has made them the No. 1 battery supplier for the automotive industry. For cars with superior power needs, and for entry-level start-stop systems they recommend VARTA® Blue Dynamic EFB.

WHY EFB OR AGM?

Many drivers are surprised that when a replacement battery for their modern vehicle is required, the cost associated with the new battery is more than initially

www.mechanics-mag.com.au | AUSTRALIAN CAR MECHANIC 9 ON THE COVER

“IT´S A FACT, 7 OUT OF 10 NEWLY MANUFACTURED VEHICLES WITH START-STOP TECHNOLOGY EQUIPPED WITH AGM ARE FITTED WITH VARTA BATTERIES.”

VARTA E46 Blue Dynamic EFB.

VARTA E39 Silver AGM Dynamic.

expected. However, when you look at the power a battery is required to provide, it is understandable to see why a more robust battery is needed. Absorbent glass mat [AGM] and Enhanced Flooded Batteries [EFB] have been designed to cater for the increasing electrical demands (convenience, automatic and safety systems) and fitting a traditional flooded battery will not provide the power needed to accurately engage the Start-Stop function or other vital comfort and safety systems.

By choosing an AGM battery with the most advanced technology, you will get an outstanding battery that is capable of powering the most demanding vehicles and accessories. The innovative VARTA® AGM technology offers three times the endurance of conventional batteries, perfect for advanced start-stop systems in which the battery needs to be quickly recharged through the energy provided by the

SUPERIOR PERFORMANCE PowerFrame® Grid technology

Only with VARTA, do you get the patented PowerFrame® grid technology. This technology is stronger and longer-lasting than other grid designs.

Durable: PowerFrame grid technology is reliable and built to last. It’s nearly three times more corrosion resistant, making it more durable than other grid designs.

Performance: The PowerFrame grid technology pattern is optimised for full grid utilisation, providing more than 60 per cent* superior electrical flow for better connectivity. *Based on comparison to other grid designs in real world fleet testing.

Responsible: PowerFrame® manufacturing uses 20 per cent less energy and produces 20 per cent fewer greenhouse gases than other manufacturing methods. In short, it’s built for exceptional

CAR MANUFACTURERS CHOOSE THE BEST FOR THEIR CARS

Car manufacturers choose components that are the best fit for their cars. Besides quality, there are two other things car manufacturers look for when deciding on a battery. One is performance, the other is a very low fail rate. These factors are the reason car manufacturers choose VARTA batteries.

10 AUSTRALIAN CAR MECHANIC | www.mechanics-mag.com.au ON THE COVER

THE NO. 1 BATTERY SUPPLIER FOR THE AUTOMOTIVE INDUSTRY

It´s a fact, 7 out of 10 newly manufactured vehicles with start-stop technology equipped with AGM are fitted with VARTA batteries. This is because VARTA batteries stand for superior quality. The OE logo stands for “original spare part”. This means that nearly all VARTA batteries are parts that come from the same production line as the original equipment.

THE IMPORTANCE OF ORIGINAL SPARE PARTS

When you replace a battery with a VARTA battery, you can rest assured it was originally produced to run in a newly manufactured car. That’s what the OE logo stands for. What does that mean for you? VARTA original spare parts fulfill the highest quality requirements and are purpose-built for the highest performance –thanks to the patented PowerFrame® grid technology and more than 100 process and product parameters they measure during

“Manufactured with up to 20 per cent fewer emissions, they’ll reliably restart your car’s engine again and again, and effectively reduce your fuel consumption.”

THESE CAR MANUFACTURERS

BATTERIES

TRUST IN VARTA

Today, you’ll find VARTA’s products in millions of cars, powerboats, motorcycles and motorhomes. Their engineers put expertise and precision into each and every VARTA battery. VARTA batteries provide longer life, less corrosion and lower cost of ownership, qualities you’ll find in all their advanced start-stop automotive range. When you choose VARTA, you go for reliable precision technology that delivers best-inclass manufacturing quality.

INNOVATION WITH A PURPOSE

VARTA® batteries are the driving force behind fuel-saving innovations like start-stop engines. Manufactured with up to 20 per cent fewer emissions, they’ll reliably restart your car’s engine again and again, and effectively reduce your fuel consumption.

A PREMIUM EXPERIENCE

The VARTA Partner Portal gives workshops the tools to deliver a premium experience to its customers, supporting the trade and industry through business tools to support profitability and consumer experience.

A POWERFUL HISTORY

The VARTA® brand has a history going back more than 125 years. VARTA® batteries are factory-fitted by major carmakers and trusted by drivers globally.

Federal Batteries is the proud distributor of VARTA autmotive batteries and other Clarios brands. For more information visit www.varta-automotive.com/en-au ACM

www.mechanics-mag.com.au | AUSTRALIAN CAR MECHANIC 11 ON THE COVER

FIT VARTA

• Audi • Bentley • BMW • Chrysler • Chevrolet • Citroën • Ferrari • Fiat • Ford • General Motors • Honda • Hyundai • Jaguar • Land Rover • Kia • Maserati • Mercedes-Benz • Nissan • Opel • Peugeot • Renault • Seat • Škoda • Vauxhall • Volkswagen • Volvo

A POSITIVE START TO 2022

In some rural communities, the lack of transient consumers means a lack of break down services, which to some is their bread and butter.

But as the general rule of thumb goes, we have been well looked after in the automotive industry, there is always however, more work that now needs to be done. We may report that some shops have had buoyant time but, in the past, that would equal growth and expenditure in the shop. The shop may buy the new balancer that they have always wanted, invest in new apprentices, or invest in a new hoist. But we are not seeing that as much as we would like. Now is the time to invest that added income in that piece of equipment, staff or training you’ve always wanted. It is also not the time to be complacent and think that this wave of work will be there forever. Consumer confidence is not quite as strong as what Governments would like to see and there is already talk of breaking promises and lifting interest rates within these next 12 months.

We need to go back to basics and ensure every job is as good as we can make it and impress our customer, thus retain them. By way of example, the IAME does a lot of audits on independent shops

and some franchise groups. Silly little things such as wiper rubbers not cleaning screens effectively, tyre pressures left unchecked after a service and windscreen washers ill-aimed and no detergent. In the modern day car, these are the basics that a consumer judges a service quality on… yet, these are items that we find not attended to on some audits.

A consumer also likes to feel that they know you, the repairer. It’s therefore a good little trick when reporting what was done to the consumer’s car to actually use the mechanics name who worked on the motor vehicle within your storyline (debrief of service). People like to know that Bill or Jenny worked on their car, and this is their report to you. The consumer gets more buy-on and in fact, we have seen it where a consumer will return and enquire whether the service technician which was named before was still an employee and asks if he or she could work on their car as they did such a good job last time. A very cheap retention tool in just using the technicians name.

Another way of retaining consumer confidence in your business is to offer alternatives when jobs are required, for example, on a brake realignment, price up a standard realign and then enquire as to whether they are towing or driving at speed and offer a higher quality brake pad to suit their particular driving style. This again instills confidence that you have thought about the best alternative when it comes to offering advice on their service.

Tyre stores have perfected this for many years offering consumers many choices each with a different attribute of performance. We refer to the retention of the consumer here but in times, when we are on short supply of technicians, panel beaters or spray painters, it is good to offer them confidence in the way you run your business. Consumers as well as staff are all concerned about COVID and its variance. As a business owner, you need to be instilling in your staff, best practices not only for them but also for your customer.

I visited two shops this week where masks were not worn, hand sanitizer not used and no display to the consumer could be seen describing how these shops promote best practice for COVID reduction. Consumers want to know that you understand what is required and a blaze

12 AUSTRALIAN CAR MECHANIC | www.mechanics-mag.com.au

IAME SEGMENT

Peter Blanshard, IAME Group CEO.

As 2022 now opens up, we can measure the fallout from COVID and Omnicom with some shops reporting a booming 12 months while others, such as those in the panel industry, have shut their doors.

nature does not translate to tough and strong but more to ignorant and uncaring. When a consumer enters your shops, just like a staff member, they all want a safe working environment.

In the last edition I was concerned that Australia was going to have a problem with the supply of ad-blue due to a world shortage of urea. Thankfully, our Australian manufacturer ramped up production and a horrible shortage did not eventuate as predicted by so many. What we are seeing however, is phenomenally high fuel and diesel prices. This high cycle plays into the hands of the OEM that is bringing the next generation of cars into the country as hybrids or pure EVs. As I warned in previous editions, do not be negative towards this as the evolution is going to come and come quite quickly especially as fuel prices hit $2.10 a liter.

To be worried about charging stations for your EV, each state government is putting hundreds of millions of dollars on the table by way of government grants to

build and operate a fast-charging station which is supplied by totally renewable electricity. For example, New South Wales is trying to achieve a charging stations every 100km on rural roads and every 5km within major cities.

To the technician that has advised their clients not to buy EVs because of charging ports, it should now be the least of a consumers’ concern. To this, many governments are offering further advantages of making their next vehicle EV by way of the abolishment of stamp duty, thousands of dollars’ worth of rebates and bonuses and in the state of New South Wales, the use of single occupancy transit lanes.

With EVs and hybrids growing, so is our industry super fund which is now known as Spirit Super. I encourage all those in the motor trade to connect with Spirit Super to ensure your future is catered for with the latest investment skills and advice.

For further information visit www.iame.com.au or www.facebook.com/iame.online

www.mechanics-mag.com.au

| AUSTRALIAN CAR MECHANIC 13 IAME SEGMENT

ACM

“NOW IS THE TIME TO INVEST THAT ADDED INCOME IN THAT PIECE OF EQUIPMENT, STAFF OR TRAINING YOU’VE ALWAYS WANTED.”

VACC’S TECH TALK

VACC’s TechTalk first started as a part of the VACC’s Journal, then became its own publication in 1986 and has been in print ever since. The content in TechTalk has been used to keep VACC members up to date about emerging technologies that might enter the automotive industry. Also, to inform them of the operation of various new automotive systems and how to identify, service, diagnose and repair them efficiently.

The choice of articles is mostly based on feedback received from VACC’s Technical Advisory Service. If this team finds a pattern of commonly requested information, this gives us a clue that this is a common procedure or issue in the trade. This topic becomes the basis of an article. We will then contact members for more information about the problem and what solutions they found. This feedback from members and subscribers is greatly appreciated as it gives a more real-world solution that enhances the O.E based information in the articles.

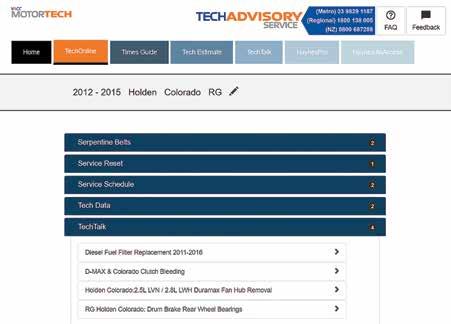

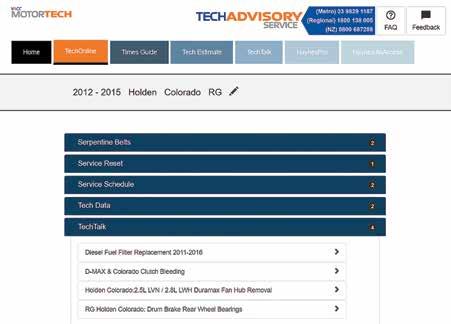

There are a few ways to access TechTalk articles via MotorTech. The first is to search for a vehicle make and model in the TechOnline section (See Diagram 1). This

will display all of the information developed by the VACC’s Technical Department in their separate modules. If there are any Tech Talk articles for that vehicle, they will be listed in the Tech Talk Module with the article’s title. The second way to find an article is to

look in the “Tech Talk Index”, which can be found in the TechTalk tab in MotorTech. This has all the articles listed under the vehicles make or under the categories of the topic. Then enter the article’s page number into the “Page Number” search box. MotorTech will then display the article as a PDF.

When I was an apprentice, I was encouraged to read all the past issues of Tech Talk with the intention of getting me up to speed faster. If you want your apprentice to do the same, within the Tech Talk tab, use the “Publication Years” search box to select the year, then use the “Publication Month” box to select the month. This will display the articles available for that issue as PDFs.

If you have any information or ideas for Tech Talk articles that would assist the trade, contact the VACC’s Technical Advisory Service or send an email to techtalk@vacc.com.au

Every TechTalk Magazine since the first issue in 1986 is available online via VACC’s MotorTech.

For more information about VACC’s MotorTech and Haynes Manuals AllAccess, go to motortech.com.au or call MotorTech Support on (03) 9829 1268. ACM

14 AUSTRALIAN CAR MECHANIC | www.mechanics-mag.com.au

VACC’s MotorTech has vastly increased the vehicle coverage and information depth available to subscribers. One of the multiple MotorTech sources is the online version.

OURAUTO POWERED BY VACC

Diagram 1: Select TechOnline. Use the search boxes to find the make model and series. Then click on the bar labelled “Tech Talk” to see the available articles.

An affordable scan tool for your business ourautoscantool.com.au Automotive information at your fingertips motortech.com.au Website and digital marketing solutions ourauto.com.au Phone 1300 687 288

CAPRICORN RISING STARS – APPRENTICE OF THE YEAR NOMINATIONS NOW OPEN

This is an opportunity for automotive workshops and repair centres to acknowledge apprentices for their ongoing effort and hard work. A nomination to Capricorn Rising Stars will not only benefit the individual, but the whole team, as it promotes and embeds a positive workshop culture, which rewards commitment and passion.

As Australasia’s largest automotive cooperative, Capricorn supports businesses to thrive and be sustainable in the automotive repair sector. Capricorn Group CEO, David Fraser said that the Capricorn Rising Stars program is an important program to help address the shortage of qualified repairers.

"Encouraging and acknowledging future leaders is an important part of growing and supporting the automotive industry. We at Capricorn wish to help Members strengthen their teams and believe recognition and reward will help businesses attract and retain the best talent," Mr Fraser stated.

The award prioritises acknowledging apprentices with a passion for automotive, a positive can-do attitude, and a strong commitment to forging a long career as a repairer. The competition is open to all types of workshops and disciplines; from panel and fabrication to auto electrical, general mechanical, heavy diesel and more.

Focusing on initiative, eagerness to learn and commitment to the auto repair industry means Capricorn Members are encouraged to nominate any star apprentices as they continue to develop their technical proficiency. Recognising an apprentice’s commitment will keep them engaged and excited about their promising careers ahead of them. Every apprentice

nominated will benefit by receiving a certificate sent to their workshop.

More than $20,000 in cash and prizes is up for grabs. The winning apprentice will score $5,000 to help support them in their apprenticeship. The Top five finalists (including the overall winner) will receive $1,000 cash, a $1000 Repco voucher and tickets to two Repco Masterclasses.

The nominating workshop of the overall winner will receive The Workshop Whisperer Service Advisor Pro online training (valued at $3,000 plus GST).

Capricorn thanks long-term program sponsors Castrol, Repco and the Workshop Whisperer who have donated these fantastic prizes.

Capricorn Members should nominate their star apprentices at cap.coop/stars. Entries close 30 April 2022.

16 AUSTRALIAN CAR MECHANIC | www.mechanics-mag.com.au APPRENTICE COMPETITIONS

Nominations are officially open for Capricorn Members to nominate their skilled apprentices as Capricorn Rising Stars.

To join Capricorn and benefit from membership in Australasia’s largest cooperative, visit capricorn.coop/join or call 1800 327 437 (AU) or 0800 401 444 (NZ). ACM

Capricorn Rising Stars, Apprentice of the Year 2021, Ben Brown and CWR Motorsport & Perform Team with Capricorn Area Manager.

Part Number 926-876

Upgrade your plastic Jeep oil filter housing now. This Dorman OE FIX filter housing is made entirely of aluminium for a more durable replacement. Don’t replace a leaking filter housing with another failure-prone design - truly fix it with this improved design Dorman product.

PROBLEM FIX

The factory oil filter adapter on certain vehicles leaks when its plastic material warps over time.

This Dorman OE FIX oil filter housing is made entirely of aluminum for a more durable replacement.

Engine Oil Cooler Gasket Set

This engine oil cooler gasket set is designed to match the original bolts required to repair and restore proper function to the oil cooler on specified vehicles

Valve Cover & Gasket

This replacement valve cover matches the fit and function of the original equipment part that may be damaged or warped. Made from quality materials for excellent fit and superior heat resistance.

Flexible Steering Coupler

This flexible steering coupler matches the fit and function of a cracked, worn or deteriorated original equipment coupler. Made of tough materials for durable, reliable performance, this part has undergone extensive testing to ensure a proper fit.

OE PRODUCT SOLUTIONS DORMAN PRODUCTS ARE PROUDLY DISTRIBUTED BY IM GROUP imdorman.com.au 1300 30 80 60 OTHER POPULAR OE SOLUTIONS FROM DORMAN Part number 917-191 Part number 264-920 Part number 926-990 Suits: Nissan Murano Z51, Elgrand E52, X-Trail T31 Suits: Holden Astra AH, Barina TM, Cruze JG / JH Suits: Hyundai (Various Models) 2005 onwards, Kia Cerato 2009 onward

JEEP UPGRADED OIL FILTER HOUSING SUITS: Chrysler 2012 - 2017, Dodge Journey 2012 - onward, Jeep Wranglers 2011 - onward

BOSCH CAR SERVICE 100 YEARS AND STRONGER THAN EVER

through the Bosch Service Excellence business program and once implemented into the workshop’s daily practices, have proven time after time to achieve extra growth within the network. There are also dedicated Bosch consultants always on hand to guide each Bosch Car Service workshop through their growth process.

After celebrating their milestone 100th year in 2021, the Bosch Car Service network is stronger than ever! Throughout the past century, the network has grown year on year and now boasts over 15,000 workshops who are all proud to leverage off the very familiar and trusted Bosch brand.

There is no stopping the growth of the largest network of independent workshops around the globe.

Leveraging off the brand is not the only reason why workshops belong to the Bosch Car Service network. Today, partnering with Bosch provides workshops with many

support features that may come as a surprise to most independent workshops.

Just to name a few, Bosch provides full branding support inclusive of internal and external signage, workwear, workshop and customer consumables. Each year, a full calendar of national marketing activities is organised for the network. This national marketing program is supported by digital marketing campaigns that actively attracts customers across Australia and New Zealand through to individual workshop locations hosted on the dedicated national Bosch Car Service website. New techniques and strategies are taught

The Bosch Autmotive Technical Training Program, comprising of face-to-face and online courses ensure that Bosch Car Service technicians are fully competent in the work they do. This is a key attribute to keeping the network’s customers safe and happy. Only qualified technicians become true experts at fast fault finding and confident repair work, ensuring vehicles don’t sit idle in the workshop for too long, costing the workshop time and money.

To assist further, a range of diagnostic equipment is available, direct access to Autodata and support from many other industry partners, such as Mechanic Desk and AAAA, all bringing great value to being part of the Bosch Car Service network.

Throughout the year, members are also treated to many social networking events, where not only industry ideas, issues and solutions are bounced off one another, but most importantly relationships are formed giving members a circle of friends that all speak the same language. The Bosch Car Service family is one that many members remain with until they’re ready to retire.

It’s now time to welcome new members into the network and on offer is a newly developed value proposition joining package.

For one special priced start-up fee, new members will receive everything required to transition into a Bosch Car Service workshop. The new value proposition joining package includes the following: Let Bosch Car Service welcome you to their family – to learn more about joining the world-class

18 AUSTRALIAN CAR MECHANIC | www.mechanics-mag.com.au

New value proposition now available for new Bosch Car Service members.

Bosch Car Service network, visit www.boschcarservice.com or contact the Bosch team direct via email at Bosch.ServiceNetwork@au.bosch.com

SMART SOLUTIONS

1800 226 727 CALL NOW FOR PARTS acmautoparts.com.au 150 THE MOST EXTENSIVE RANGE OF 150

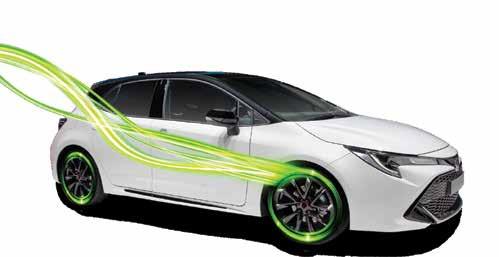

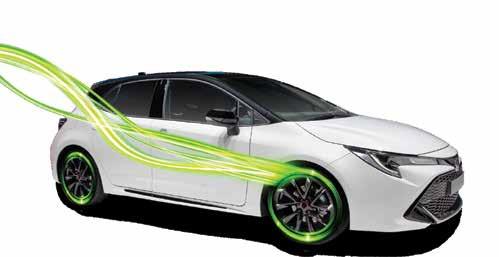

BODY CONTROL TO THE NEXT LEVEL

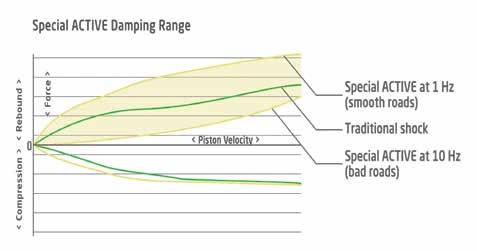

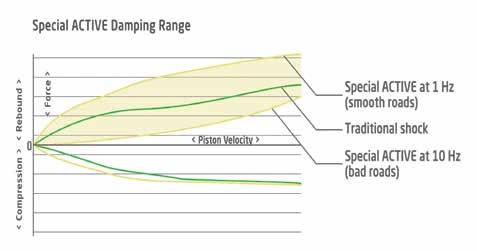

This revolutionary damping technique combines the benefits of both firm and comfortable suspension in a single, refined shock absorber. Firm for sporty driving on even road surfaces. Comfortable for a smooth ride on uneven road surfaces.

KONI’s engineering team sought to resolve two seemingly diametrically opposed concepts – comfort and handling. An obvious example is a Formula 1 racing car which offers the best possible roadholding but with minimal comfort. In a personal or sports car, one expects to experience the ultimate in comfort, combined with safe roadholding. Minimum damping is required for your comfort whilst strong damping is needed for safe and stable driving.

In general suspension terms, this conflict between comfort and handling can be split in two different frequency areas:

• For comfort, with the suspension moving in a high frequency area (± 10 Hz), it is necessary for low damping forces for the vehicle to remain comfortable

• For handling, with the suspension moving in a low frequency area (± 1 Hz), it is necessary for high damping forces for the vehicle to remain safe and in control

Conventional dampers are unable to solve the conflict in terms of comfort and handling, however if one could create a damper which can change the damping force level in relation to the frequency of

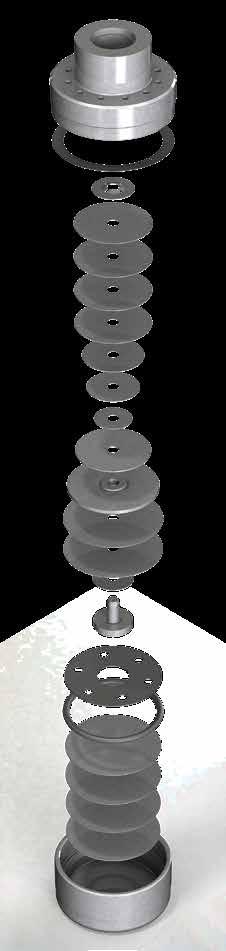

the movement, then this conflict would be resolved. The KONI FSD technology does just that, but how?

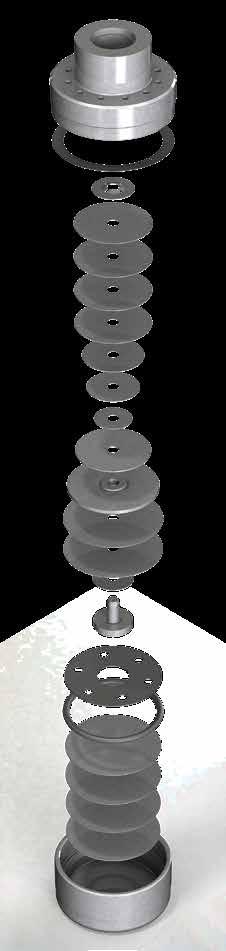

In standard shock absorbers, the main damping characteristic is defined by the

20 AUSTRALIAN CAR MECHANIC | www.mechanics-mag.com.au

KONI presents its Special Active range, equipped with Frequency Selective Damping (FSD), a world-first first shock absorber offering superior handling without compromising comfort.

SMART SOLUTIONS

“THE FSD FEATURE IS A HYDRAULIC AMPLIFIER THAT DELAYS THE BUILD-UP OF PRESSURE.”

oil flow going through the piston assembly. KONI added to this a special FSD valve, which controls the parallel oil flow next to the one going through the piston.

This parallel oil flow is closed by the FSD, giving a rise in damping force almost linear to the time that the piston is moving in one direction. Put simply: the FSD feature is a hydraulic amplifier that delays the build-up of pressure.

Since it is an integrated part of the hydraulic valve system inside the damper, no additional cables, sensors, or any other electronic devices are needed. In comparison with costly electronic systems with complex computerised technology and sensors, FSD is the simplest and most economical way to significantly improve the ride and driving characteristics of every car. Position-dependent shock absorbers will give you extra comfort, as they allow more movement of your car, but as a result the roadholding is inferior. Sudden bumps in the road will still be very unpleasant. Pneumatic shock absorbers may improve roadholding, but they are very expensive and time consuming to set up correctly.

KONI FSD technology combines the ultimate in comfort and roadholding. Being a purely mechanical technology, it removes any cost, reliability, or complexity problems which can arise from using electronically controlled suspension components.

KONI Special Active dampers with FSD has been proven on more than 1.5 million factory equipped vehicles and is available in Australia from Toperformance Products as an aftermarket upgrade for many modern European and Japanese vehicles. Visit www.toperformance.com.au

22 AUSTRALIAN CAR MECHANIC | www.mechanics-mag.com.au SMART SOLUTIONS

NASTY SURPRISE?

For 100% genuine DENSO parts always buy from authorised distributors. www.DENSO.com.au

To find your part and nearest distributor visit

Finding genuine DENSO parts has never been easier. The ‘Find my part’ function on our website will ensure you’re getting the right part for your vehicle and provide you with a list of local distributors and authorised resellers. When you buy from the correct channels, you’re always in good hands.

CONTACTLESS PAYMENTS

Few professions are more reliant on tools to carry out their jobs than mechanics. It’s what allows them to build and repair cars, provide an essential service and keep Australia moving. In a slightly different sense, tools are also essential in helping them keep their business moving too. Over the last two years, local businesses have adopted technology with a short-term survival mindset. Today it’s essential for them to adopt these ‘tools’ with a more future- and customer-focussed approach.

One of the most important technologies today – allowing mechanics to not only take control of their cash flow but provide the streamlined, modern and convenient services customers demand – is contactless, SMS payments. But what are contactless payments? Why are they essential? And how can mechanics seamlessly add them to their business tool box?

WHAT ARE CONTACTLESS PAYMENTS?

Cash payments – once the primary means of exchange between mechanics and customers – have been declining steadily for a decade. The transition has exploded recently as the pandemic emphasised the importance of safe and convenient payments. One of the fastest-growing short-term trends, and the future we’re so excited about, is contactless payments.

Rather than issuing a PDF or paper invoice via email or post when you’ve finished a service or repair – timeconsuming process that stagnates cash flow – a payment request is sent as an SMS directly to a customer’s smartphone with a one-click payment link. They don’t have to call up to issue payment on the phone or login to a separate app, they just have to click the secure link, enter their details and process the payment almost instantly with credit, debit, Google Pay or Apple Pay. Almost AUD$15bn in global transactions were processed through SMS contactless payments in 2020, and that figure is expected to almost double to over $25bn by 2025.

WHY ARE CONTACTLESS PAYMENTS ESSENTIAL?

Today, it’s essential for mechanics to understand their customers’ trends, habits and expectations, and find ways to cater to these needs. Podium research shows that almost nine in ten Aussies prioritise businesses that offer pandemic-friendly services, like contactless payments, while more than half would consider seeking a competitor if a local business didn’t offer this. Don’t let your mechanic business lose out to a competitor.

The more convenient and memorable a mechanic’s service, the easier it is to incentivise loyalty. The benefit isn’t just for the customer, but your business too. Contactless payments reduce admin, increase productivity and improve cash flow – all of which contribute to healthy and efficient businesses. Through Podium’s contactless payments, you can also see the status of every payment, invoice and transaction in one place. It

also enables you to forecast cash flow, automate follow-up reminders for overdue payments and even integrates with your accounting software to help when it comes to tax time.

HOW CAN MECHANICS ADOPT CONTACTLESS PAYMENTS?

First, ensure that your mechanic business number can send and receive texts. With Podium you can set up text messaging from your landline and control the entire process via computer, tablet or smartphone. Make this a default method of interacting with your customers and ensure your employees understand the process and feel comfortable answering questions, making sales and issuing payments via text. With the right software, the training will be minimal and the process as simple as sending a text.

Remember contactless is about convenience, so before you set up text payment, ensure you can accept a variety of payment types, including the essentials like debit and credit card, and Apple and Google Pay.

The easier it is for your customers, the more likely they’ll pay in a timely manner. Ensure they know in advance that you send text payments, though, so they don’t get suspicious and ignore your SMS.

24 AUSTRALIAN CAR MECHANIC | www.mechanics-mag.com.au $

Today SMS payments are an essential tool in the mechanic’s toolbox.

SMART SOLUTIONS WORDS l DAVE SCHIENE, PODIUM

Contactless payments aren’t yet a common form of payment in mechanics, so treat it as an opportunity to lead by example. And the sooner you issue a payment after completion of the work, the sooner it is they’re likely to pay.

Don’t wait until the end of the week; issue a payment as soon as they collect their keys, and you might find they pay as soon as they get home, or before they even start their vehicle.

As a local business owner today, it’s easy to think that standing out requires game changing tactics, but that’s not the case. Consumers want convenient experiences from businesses that understand and value them. Contactless, SMS-based payments are an opportune way to provide not only the services they’ll remember and recommend, but create business processes that drive productivity and boost cash flow.

As the industry continues to evolve, don’t be surprised if contactless payments become as essential to a mechanic as any other tool in their kit.

For more info visit podium.com.au

www.mechanics-mag.com.au | AUSTRALIAN CAR MECHANIC 25 $

SMART SOLUTIONS

“WITH THE RIGHT SOFTWARE, THE TRAINING WILL BE MINIMAL AND THE PROCESS AS SIMPLE AS SENDING A TEXT.”

s technology develops, more and more businesses are looking to embrace new software technology to digitise their core processes, and for good reason too; it’s estimated that businesses spend about 520 hours per year on accounting and tasks such as manually processing invoices, supplier enquiries, purchase order matching, onboarding suppliers, and payment reconciliation.

26 AUSTRALIAN CAR MECHANIC | www.mechanics-mag.com.au

SUPERCHARGE YOUR WORKSHOP’S EFFICIENCY WITH SPENDA’S SOLUTIONS Keep your focus on growing your business and have Spenda’s workshop management software streamline your daily activities.

SMART SOLUTIONS “THE ADOPTION OF DIGITAL TECHNOLOGY NOT ONLY HELPS SAVE TIME AND MONEY, BUT GIVES BUSINESSES A COMPETITIVE ADVANTAGE AGAINST MARKET RIVALS.”

A

The adoption of digital technology not only helps save time and money, but gives businesses a competitive advantage against market rivals still relying on inefficient manual processes.

By introducing digital tools such as Spenda’s workshop management software, you can supercharge your business’s efficiency and streamline daily tasks and operations. From online bookings and job management, through to purchasing spare parts and creating e-invoices, this software simplifies the front-end management of your business, while software integration with your accounting system on the back end ensures that your bookkeeping is covered too.

DIGITISE YOUR CORE PROCESSES

One of the fastest ways to save time, money and simplify the running of your business is by digitising your processes. This can include everything from allocating jobs and task management, through to creating an inventory of spare parts within the software and getting automatic alerts when your stock is low, and streamlining your invoicing and payments process.

With Spenda, you can spend more time growing your business and less time on admin and paperwork.

AUTOMATE CUSTOMER MANAGEMENT

Set the standard for customer experience by providing real-time automatic updates on the technician’s expected time of arrival and notification for any unexpected changes or delays. Better accuracy delivers a better customer experience, securing more repeat customers and referrals for your business.

STREAMLINED WORKFLOW

Their easy-to-use scheduling system simplifies both job management and the booking process. You can schedule appointments, track jobs, manage staff workloads, create invoices and more.

EASY INVOICING

Forget chasing unpaid invoices and get paid quickly with their innovative payments platform that integrates directly with your accounting system. Your technicians can easily close jobs, create invoices and take contactless card payments onsite or in the office using the iPad-based solution.

SET IT UP YOUR WAY

Easily create templates unique to your business for improved job management. Set up anything from pre-appointment questionnaires to feedback forms and quotes.

Ready to supercharge your workshop’s efficiency and boost cash flow? Give Spenda a call on 1300 682 521 (select ‘Option 2’) or visit www.spenda.co/automotive today. ACM

www.mechanics-mag.com.au

| AUSTRALIAN CAR MECHANIC 27

SMART SOLUTIONS

WHAT CAUSES BATTERY FAILURE?

What are the signs of battery failure that are a potential manufacturing defect?

• The failure would occur very early in the life of the battery (a matter of days or weeks)

• The battery would fail immediately, not gradually over time

• The battery would show a significant loss in voltage, as a cell would have stopped producing power. Each cell produces approximately 2.1V, so an immediate voltage loss of this kind very early in the battery’s lifetime could indicate a manufacturing defect in the cell (broken lead plate)

• The Cold Cranking Amps (CCA) reading would be significantly lower due to a cell failure; this will differ for each battery according to the quantity of plates within the battery.

The above points give various types of battery failure which are in fact very rare and would need to be individually investigated. Causes would potentially be an internal manufacturing fault and would therefore represent a physical fault within the production of the battery. These types of failures may typically be covered by the manufacturer’s warranty.

But, don’t these symptoms point to a flat battery? The answer is no

If a battery “fails” due to it becoming flat, the failure symptoms are different. This is something that is often misunderstood, as the battery presents simply as a “failed” unit. At this point, a frustrated customer will often return to their point of purchase and hope to claim a replacement under the manufacturer’s warranty. This type of failure has the following symptoms:

• The failure occurs gradually over time and might not be noticed by the driver when they see that the start-stop system (where fitted) is no longer working due to the battery being below 70% charge.

• It could also be perceived through a slower cranking speed and difficult engine firing – more so in diesel vehicles

• The battery may have a relatively good voltage, but the CCA reading is much lower and unable to provide power under load. The lights may illuminate, but the battery would not be able to crank the engine.

• The voltage of the battery may have been reducing gradually over time, and if so, it may be that the corresponding CCA reading will be extremely low.

• Recharging could possibly recover the battery in the short term, but failure will occur again.

Now that these two different sets of symptoms have been categorised, you must ask: Is it the battery itself that has failed, or rather the result of poor battery care and maintenance?

Many parts and accessories on vehicles are tested routinely during service or inspection, even the coolant strength is tested to make sure it can withstand the cold weather.

The battery on the other hand, is expected to be at its best for 365 days a year, often with no consideration of whether it’s in peak condition. Therefore, it’s no surprise that a customer is shocked when they are given the news that their vehicle battery has failed – especially when there has been no warning (through periodic testing at service intervals) that this might happen!

The only way to accurately assess the state of the battery is to carry out a battery testing using a good quality and up-to date battery tester.

VARTA automotive batteries are proudly distributed by Federal Batteries and are available at Burson and JAS Oceania. ACM

28 AUSTRALIAN CAR MECHANIC | www.mechanics-mag.com.au TECHNICAL FEATURE

When the car doesn’t start, often the first thought is… has the battery failed. However, it’s not always the battery itself that’s at fault.

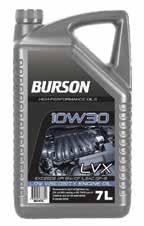

THE NUMBER ONE CHOICE FOR EUROPEAN VEHICLES 7 out of 10 newly manufactured vehicles with start-stop technology equipped with AGM are fitted with VARTA® batteries, used in brands like BMW, Mercedes, Audi, VW and Porsche. Engineered to the highest European (German) standards, VARTA® batteries deliver an unparalleled level of power and longevity. Idle Stop Start Battery – Silver Dynamic AGM Range Flooded Lead Acid – Silver Dynamic Range 42 Month Warranty 42 MONTHS German Engineered Performance PowerFrame ® Technology Superior Durable & Robust Suitable for EU Vehicles OE Spare Part 36 Month Warranty 36 MONTHS PowerFrame ® Technology 3x Longer Cycle Life Suitable for EU Vehicles OE Spare Part Made in Germany 1300 BURSON (1300 287 766)

BEN BARGWANNA AND BURSON AUTO PARTS RETURN TO TCR AUSTRALIA 2022

Burson Auto Parts

to

Bargwanna will again link up with Garry Rogers Motorsport, competing in one of the team’s race winning Peugeot 308 TCRs.

“Burson Auto Parts is very excited to continue our successful involvement in the TCR Australia Series in 2022 with one of the series’ most exciting young drivers.

“Given Ben’s pace in 2021 and ability to compete in the Burson Auto Parts Peugeot at the front of the field, we are confident that he will have a great year ahead. Add the support of GRM and Jason Bargwanna to the team and we are well positioned for a cracking season,” stated Anthony Hughes, General Manager – Marketing, Burson Auto Parts.

It follows a successful campaign last year where Bargwanna finished 10th and won the Michelin Cup as top placed rookie at the season’s conclusion.

Bargwanna scored his best result at the Bathurst finale, achieving his maiden TCR Australia pole position and podium in the opening race, finishing a narrow second to GRM teammate Aaron Cameron.

“I learnt a lot last year and as the season went on the results started to build. We set and achieved some clear goals for 2021, finishing races, podium results, rookie

of the year and then to get my first pole position at Bathurst was a real bonus. I love racing these TCR cars and challenging the best young drivers in the country, and some older experienced drivers as well.

“It was a real eye opener stepping up to this level of competition, but I have the confidence, a great team and partners, and we know we can hold our own in this field.

“For 2022 we want to challenge for regular top 5’s, take podiums and win races,” Ben said.

Bargwanna will lead the Burson Auto Parts attack on the TCR Australia Series, as his father Jason will step back from driving and take on a Team Manager role where he will fulfill a mentor role to Ben.

“The program has come together perfectly over the last two seasons with the support from our partners in Burson Auto Parts.

“Their continued commitment into the new season allows us to all move to the next stage and challenge for the title.

“I made the earlier statement that my fishing leave wasn’t far away, but I find that I am really enjoying this campaign. Ben has showed that he has improved and he became stronger during last season. His on track decision making and off track work ethic led to some great speed and strong results.

“I am extremely proud of his journey and I am excited to focus our attention and resources on Ben and allowing him to mount a truly competitive campaign. Who knows, should we get a co-driver race in TCR Australia, we already have one in stock!” explains Jason.

“I will still be heavily involved in the program both on and off the track. This year’s TCR championship looks to be the most competitive ever and the whole Burson Auto Parts race team is chomping at the bit and ready to rise to the challenge,” he added.

Burson Auto Parts Racing launched the car 71 livery in February, just prior to the opening round of the TCR Australia Series held at Tasmania’s Symmons Plains Raceway.

For more info visit burson.com.au

30 AUSTRALIAN CAR MECHANIC | www.mechanics-mag.com.au MOTORSPORT NEWS

Rising star Ben Bargwanna and

are playing

win this season.

“FOR 2022 WE WANT TO CHALLENGE FOR REGULAR TOP 5’S, TAKE PODIUMS AND WIN RACES.”

QUALITY TOOLS HISTORY OF PRECISION Australian owned since 1921 FOR FULL PRODUCT DETAILS VISIT WBTOOLS.COM.AU Use ACM2021 coupon code for 10% discount Prices and coupon valid until 30 June, 2022 (online orders only) SCRAPER RANGE P/N: 163304 $25.85 - $26.76 P/N: 163305-06 WB Tools new range of adjustable claw pry bars are available in five handy sizes, suitable for many applications. Featuring a double push lock that allows for easy angle selection the pry bars can be locked into twelve different positions, providing ultimate flexibility and usability. 4” $40.60 P/N: 163050 24” 8” & 16” $122.67 P/N: 163052 $109.36 P/N: 163051 PRY BAR RANGE The WB Precision Tools scraper range is made up of three types of premium scrapers. The Chisel Impact, Bend Impact and Quick Lock scrapers. Between these, WB Tools has you covered for any job. The scraper handles are specially designed to provide enhaned grip and comfort. Blades vary in thickness to provide improved strength depending on scraper design and use. Spare blades available. CHISEL IMPACT BEND IMPACT QUICK LOCK $19.00 - $20.60 P/N: 16300-03 33” $167.90 P/N: 163053

THE 2022 BURSON AUTO PARTS MOTORSPORT PROGRAM IS THEIR BIGGEST EVER

There is a form of motor racing to suit everyone from the craziest fan to the general motorsport enthusiast and everyone in between this year.

Already off and running is the earthshattering 2022 Burson Auto Parts Australian Top Fuel Championship, which made its flame throwing start in January. This is the world’s fastest and most powerful form of drag racing, with a total of six events being held across the country. Burson also has its own driver and team competing in this

series, exciting Top Fuel series debutant, Shane Olive with the championship winning Lamattina Racing Team.

Burson’s circuit racing action find them back in the TCR Australia series, this season supporting 2021 TCR Rookie of the Year Ben Bargwanna in his GRM Peugeot. After his breakthrough debut season, there is no doubt that Ben will be one of the major contenders this season.

This series will be contested across a planned seven rounds nationwide with the

first event held in Tasmania in February.

Burson Auto Parts has not forgotten the grass roots level of motorsport, playing its part in supporting the future stars of the sport in alliance with Motorsport Australia, the sports’ governing body. Burson Auto Parts continues to support junior motorsport awards and events, helping to unearth new and exciting motor racing talent.

To reach more mechanics and car enthusiasts across the country, Burson Auto Parts continues to support carsales.com editor in chief Mike Sinclair and young gun racer Anthony Molluso in their respective Excel Racing Series cars. This affordable and exciting racing category continues to grow in popularity and affordability for competitors.

Along with these exciting racing categories, Burson Auto Parts can also be seen during 2022 supporting racers and enthusiasts in the Victorian Historic Racing Register, Superkarts, V8 Jetboats, Speedway, Drifting along with smaller local motorsport and enthusiast events.

Along with all of these season-long motor racing involvements, you will also see their logo at the front of the pack during the 2022 Bathurst Six Hour enduro, emblazoning the Audi TT of Ben and Jude Bargwanna, who came so close to winning last year. This world renowned Production Car race will take place over the Easter weekend (April 15-17). With no fewer than 70 cars entered, this is sure to be another epic race at the majestic Mount Panorama circuit.

“The Burson Auto Parts message to the trade and all who need automotive parts, tools, equipment and accessories will no doubt be seen and heard across the country thanks to our exciting motorsport marketing program during 2022,” stated Burson Auto Parts General Manager –Marketing, Anthony Hughes.

For more information visit burson.com.au ACM

32 AUSTRALIAN CAR MECHANIC | www.mechanics-mag.com.au MOTORSPORT NEWS

Burson Auto Parts has developed a motorsport marketing program for 2022 that encompasses almost the entire spectrum of Aussie motor racing.

Ben and Jude Bargwanna will return to the Bathurst Six Hour enduro.

MORE THAN ROTORS MORE APPLICATIONS

While today DBA is so much more than brake rotors, THE DISC is what has made us what we are today. To celebrate our hero product and give it the praise it deserves, we have given it brand new wrapping!

Come and see our new packaging – and what’s inside – at the AAA Expo, Melbourne Convention Centre, 7 - 9 April 2022, stand L44.

Offering you the highest quality and best performance for your track and performance cars.

FOR MORE INFO VISIT DBA.COM.AU/AAAE_EXHIBITION

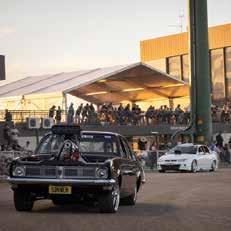

STREET MACHINE SUMMERNATS 34

e were all devastated when we had to cancel the 2021 event,” said Andy Lopez, co-owner of Summernats.

“But anyone there this year at EPIC in Canberra would agree that Summernats 34 was one to remember,” he said.

“2021 was a challenging year for everyone, but there is little doubt that the [more than] 80,000 punters who helped make this year’s event such a success really shook the dust off, proving just how resilient our community has become,” he added.

Running over four days in early January, attendees were treated to a true spectacle. As an Event Partner, Milwaukee Tool was on-hand to help fans celebrate their passion

for modified cars, with the help of Rob Starling and his small team of volunteers from the Laurie Starling Scholarship.

“We were so excited when Milwaukee [Tool] invited us to man their stand in the Rare Spares Pavilion at this year’s event,” said Starling.

“The response to Milwaukee® was amazing right across all four days.”

“Having the opportunity to get back faceto-face, well mask-to-mask in reality, with people again was a reminder of just how important it is for everyone to make new acquaintances and catch up with old friends.”

Starling and his volunteers spent their time on the Milwaukee stand talking to visitors, bench racing and sharing

lockdown stories. “What quickly became obvious was that a huge number of enthusiasts had spent many hours in the shed working on their projects during the lockdown,” he said.

“But what really knocked my socks off was how many had invested in new Milwaukee tools to help them get the job done.”

“These guys are passionate about tools and are passionate about Milwaukee,” he added.

Summernats marked the climax of a big year for Milwaukee Tool in the automotive industry. It brought together several activities that had been a focus for the company in 2021.

The winners of the Laurie Starling Scholarship, sponsored by Milwaukee Tool,

34 AUSTRALIAN CAR MECHANIC | www.mechanics-mag.com.au

After missing a year for the first time in this iconic event’s 34-year history, Summernats was back bigger and better than ever.

SPECIAL EVENT “ W

and the Milwaukee Street Machine Of The Year (SMOTY) were announced of this year’s Summernats.

Corey Scragg was presented with the Laurie Starling Scholarship, a highlight of the event for Rob Starling.

“It’s the culmination of 12 months of hard work,” he said.

“We were excited to ask Corey to join us on stage to accept the Scholarship and to say a few words.”

Simon Telford from Street Machine was on hand to award Milwaukee Street Machine of the Year to the winner, Chad Ribbons, whose low-buck, shed-build Holden HD ute was a fan favourite.

“Chad’s ute is amazing,” Starling said.

“Amongst what was a stellar line up of absolutely mind-blowing rides all competing for the coveted Street Machine of the Year prize, it was my pick.”

The Street Machine VIP Party signalled the start of what will be remembered as one of the most action-packed Summernats

on record. “As we watched the crowd pour through the gates on Friday, we knew it would be huge,” Starling explained.

With more than 2,000 entrants hitting the cruise route, nightly entertainment –including Timmy Trumpet, Hooligan Hefs and Kurser – along with burnouts, driffing and the unveiling of show-stopping new builds, there was something for everyone

at Summernats 34. “Andy and his team did an amazing job [pulling] off this event, and we were proud to be part of it again and represent Milwaukee,” Starling said.

“We can’t wait to get back to Canberra for Summernats 35,” he added.

To find out more about Summernats, visit summernats.com.au ACM

| AUSTRALIAN CAR MECHANIC 35

www.mechanics-mag.com.au

SPECIAL

EVENT

“WHAT REALLY KNOCKED MY SOCKS OFF WAS HOW MANY HAD INVESTED IN NEW MILWAUKEE TOOLS TO HELP THEM GET THE JOB DONE.”

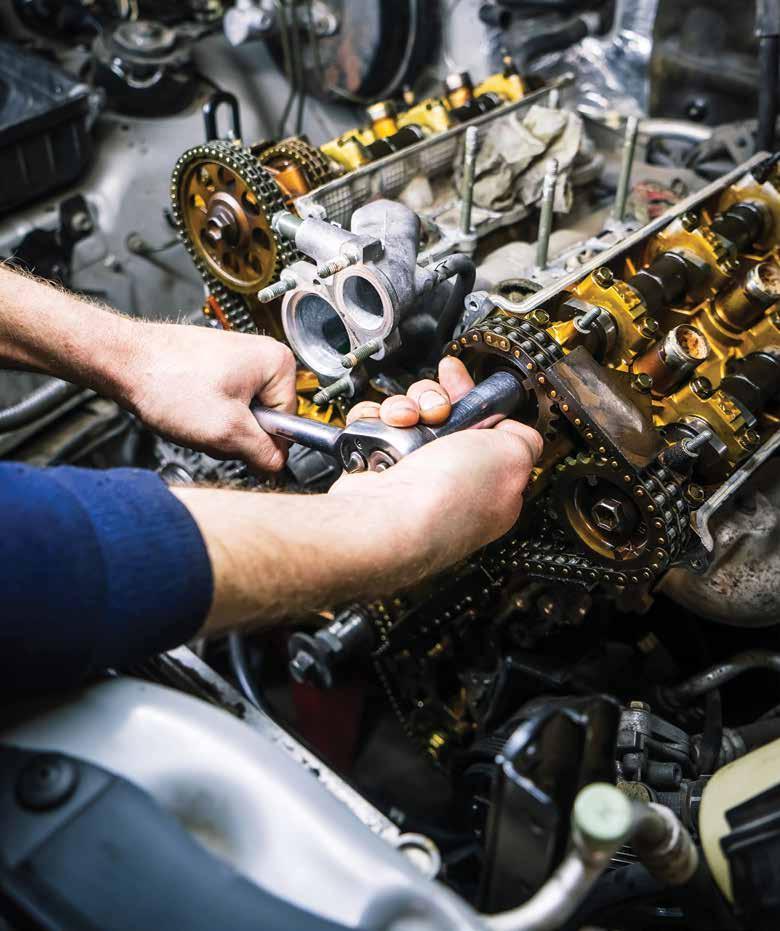

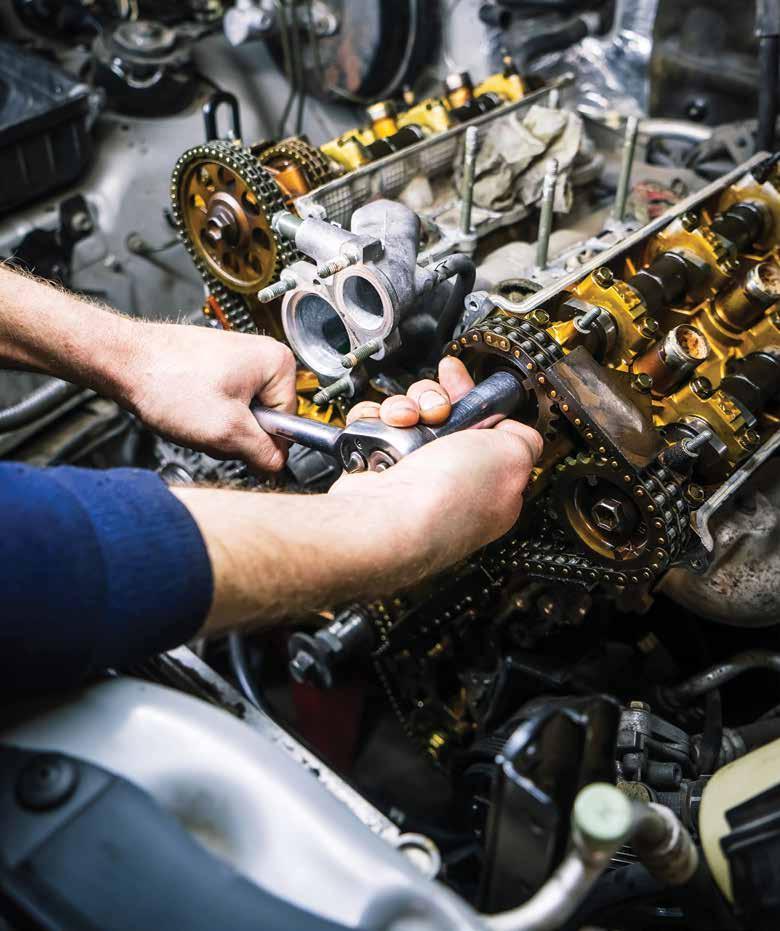

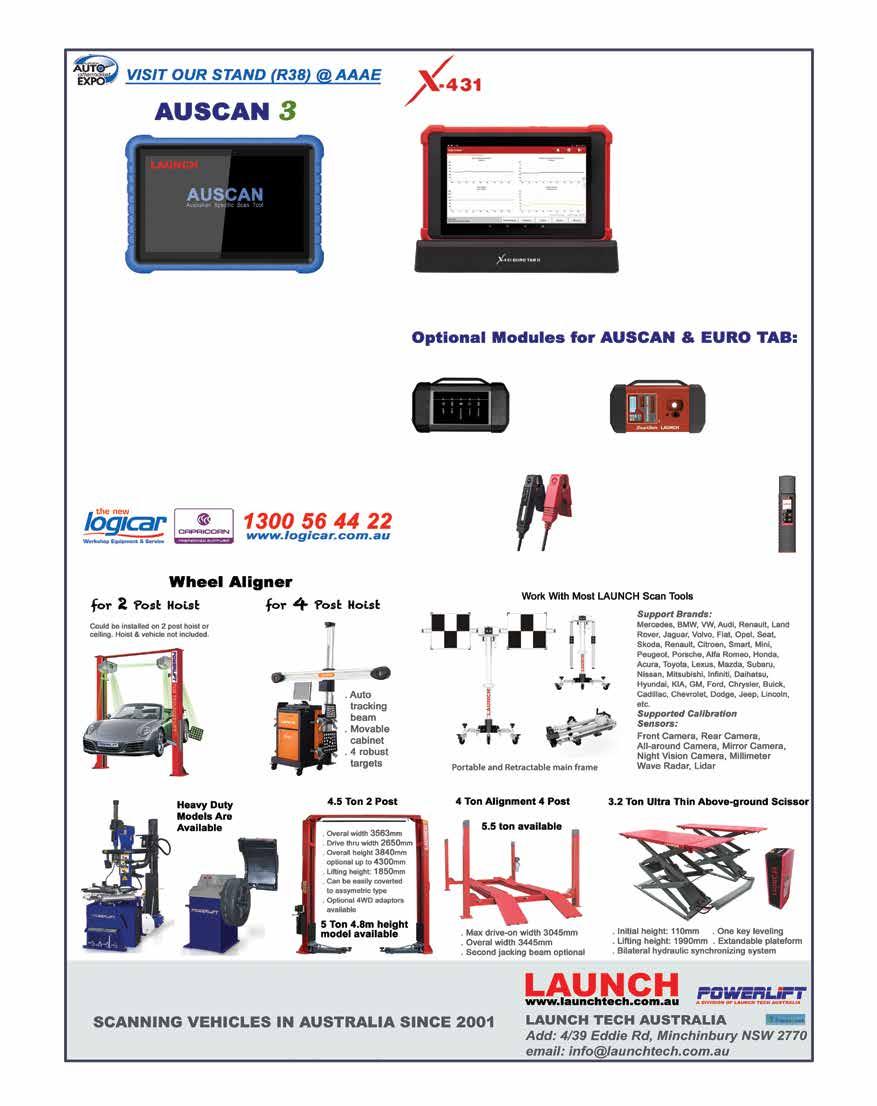

Getting the best performance from a small car, SUV, or commercial vehicle is a fine art requiring the very best and latest tools and equipment.

Assessing an engine’s performance is a science in itself, requiring the latest diagnostic hardware and software, and of course, suitably trained and familiarised technical staff.

But there’s a lot more to performance in a modern vehicle than just the engine’s

power output. Efficiency and minimum emissions are especially important in today’s environmentally aware world, and electronics are playing an increasingly bigger part in overall vehicle performance. That facet of a vehicle, from the smallest to the largest, needs to be included in any assessment and service schedule. Commercial vehicles call for carefully focussed and specific filter care and particulate control, and fuel-injection systems, while they can deliver spectacular economy

and incredibly efficient engine performance, need specialist care in proportion to their pivotal contribution to a vehicle’s drive train.

Even the mechanical aspects of modern vehicles, mostly controlled by electronics, rely on professional attention from wellequipped technicians to work at their best.

Here’s a handful of excellent products which will help any pro, well-run workshop or service centre manage some vital aspects of vehicle performance.

36 AUSTRALIAN CAR MECHANIC | www.mechanics-mag.com.au

FOCUS FEATURE PERFORMANCE PRODUCTS

Specialist Tools Australia, A division of Responsive Engineering Australia. 64 Kembla Street Fyshwick ACT 2609 P: 02-6280 4334 | E: sales@responsiveengineeing.com.au | W: www.specialisttools.com.au When only the best will doCheck our online catalogue - all tools in stock - in Australia www.specialisttools.com.au

XTREME CLUTCH SPRUNG STYLE TWIN PLATE ORGANIC UPGRADES

Xtreme Clutch have been expanding their range of sprung twin plate organic performance clutch kits, designed to suit high horsepower street driven vehicles.

Xtreme Clutch says the new range of upgrades are already proving very popular around the world and provides a great solution for vehicle owners looking for a driveable clutch that also offers dampening for reduced noise and vibration over traditional rigid hub multi-plates.

Xtreme Clutch is a part of the Australian Clutch Services group of brands and incorporates the street performance and motorsport range of clutch kits. Including a large selection of performance clutch options for each application, the comprehensive range of upgrades are sold around the world and are popular with both professional race teams and performance car enthusiasts.

The Xtreme Clutch sprung twin plate organic kits are available in two sizes, a 230mm and 270mm. Both of these kits have their own performance attributes that make them well suited to different vehicle applications. The 270mm clutch options have been developed specifically for larger capacity engines and are popular in supercharged V8 and turbo 6-cylinder applications. The design includes a strap driven intermediate plate which minimises the “twin plate rattle” often heard in multi-plate clutch kits due to the floating

intermediate plate. “The 270mm clutch option allows for excellent performance in highly modified street vehicles that require a quiet solution”, explains Stewart Furze, Xtreme Clutch Senior Mechanical Engineer.

“We have been working hard to develop the most driveable twin plate solutions we can to help support the expanding tuning market. With so many groups now able to get huge horsepower and torque figures from their performance packages, it is critical we can provide a clutch solution that retains the excellent level of driveability that performance vehicle owners demand.”

For smaller capacity turbo charged engines, the 230mm clutch is well suited. These kits include a lightweight, motorsport inspired alloy pressure plate along with a 4140 chromoly flywheel. “Our 230mm range of upgrades are highly adaptable to different makes and models from around the world,” says Stewart. “In the past, we offered these with rigid centre organic discs for street applications, however these new sprung kits for select vehicles reduce shock loading on the transmission in comparison to the rigid style discs and are well suited to high performance street use.”

Both clutch designs are recommended for

street applications up to 1000Nm, however Xtreme Clutch also have an option for vehicles being used in motorsport. “We are also offering the 230mm sprung style multiplate kits with a ceramic friction material for higher heat capacity”, says Stewart. “These kits are recommended for motorsport applications where minimal shock-loading on the transmission is critical, such as race cars modified for increased power but still using the factory gearbox.”

Like all Xtreme Clutch upgrades, the new range of kits come complete with everything required for the installation such as release bearing or concentric slave cylinder (application specific), metal alignment tool, replacement bolts and spigot bearing as required. “We are always looking to provide everything the installer may require in the kit and this is something we put a significant amount of time and effort into,” says Colin Jevons, Australian Clutch Services Sales Manager.

“Whether it be for our Xtreme Clutch performance products or our ClutchPro standard replacement kits, we are looking to provide a kit with everything that is required for the installation process to help minimise the chances of installation delays and to ensure that critical components such as spigot bearings and release bearings are replaced at the same time as the clutch. We are even including spline grease in our kits and thread locking compound with our flywheel bolts.”

The Australian Clutch Services product range is available through a nationwide distributor network and the new range of sprung twin plate kits are available now. To check your application, please visit the Australian Clutch Services online catalogue at www.australianclutch.com.au.

For more information or for help selecting a performance clutch solution, please call 1800 CLUTCH.

38 AUSTRALIAN CAR MECHANIC | www.mechanics-mag.com.au FOCUS FEATURE PERFORMANCE PRODUCTS

Combining the highest quality components with extensive in-house engineering and real-world testing, Xtreme Clutch takes performance clutch upgrades to a new level. Designed specifically to deliver the ultimate clutch solution for the street or track, Xtreme Clutch provide attention to detail in the driving experience of your vehicle.

1 Hakkinen Road, Wingfield SA 5013 WWWAUSTRALIANCLUTCH.COM.AU CALL1800CLUTCH (258 824) OUTBACKCLUTCH PERFORMANCECLUTCH WWW.AUSTRALIANCLUTCH.COM.AU CALL1800 CLUTCH (258 824) ENGAGING PERFORMANCE PERFORMANCE UPGRADES FOR STREET & TRACK

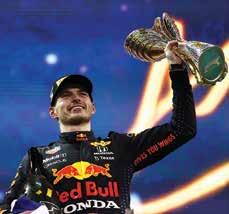

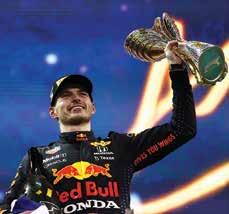

2021 WORLD CHAMPION PERFORMANCE

Red Bull Racing attacked the 2021 season all guns ablaze, with Max sweeping to victory in five of the first nine races! Red Bull had clearly stepped things and had the pace to take it to the all-conquering Silver Arrows.

Early in the 2021 season, a shellshocked Lewis Hamilton suggested on several occasions Red Bull may have introduced illegal engine upgrades.

However Red Bull’s Team Principle, Christian Horner, along with engine supplier Honda, acknowledged one of the keys to the RB16B’s championship-winning performance was the introduction of a revolutionary, new Mobil 1™ oil.

“We have a new oil from ExxonMobil,” stated Horner. “So, I think they can take all the credit for the fact that Lewis keeps pointing at our engines. The engines are the same specification.”

ExxonMobil’s Global Motorsport Technology Manager, Tomek Young added,

“ExxonMobil delivered a revolutionary new oil – that has helped push the team forwards. New components were incorporated as they were found to offer many benefits, including stronger interactions with metal surfaces and lower friction, helping deliver maximum power while offering protection and fuel efficiency. These benefits translate into an ability to run

the engine across a wider range of operating conditions and not be wound back.”

This is the advantage of Mobil 1 being a technical partner – not just a brand sponsor.

Same story for 2021 Repco Bathurst 1000 victors, Mostert and Holdsworth. They were blisteringly fast all weekend, and while this was a result of many, many factors coming together, as WAU’s lubricant supplier, Mobil 1 yet again played a critical role in the #25 WAU Commodore’s dominant victory in the ‘Great Race’.

Congratulations, Max Verstappen, Red Bull Racing, plus Chaz Mostert, Lee Holdsworth, WAU and every other Mobil 1 technical partner across the world of motorsport who visited victory lane in 2021. For 2022, things are only going to get better!

For Mobil 1 product details, along with distributor and stockist info, call MotorActive on 1800 350 622 or visit www.m1oils.com.au

40 AUSTRALIAN CAR MECHANIC | www.mechanics-mag.com.au FOCUS FEATURE PERFORMANCE PRODUCTS

Max Verstappen clinched the 2021 World Championship on the final lap, of the final race – what an epic victory!

2021

F1 WORLD CHAMPION

“We have a new oil from ExxonMobil. So, I think they can take all the credit for the fact that Lewis keeps pointing at our engines. The engines are the same specification.”

Mobil 1 MAX Performance

Stunned by Verstappen’s blistering pace during 2021, a shellshocked Lewis Hamilton took aim at Red Bull F1, suggesting they may have introduced illegal engine upgrades. However Red Bull’s Christian Horner, along with engine supplier, Honda, acknowledged that one of the keys to the RB16B’s championship-winning performance was the introduction of a revolutionary new oil by Mobil 1. Mobil’s advanced engine oil enabled the Honda 1.6-litre turbo/ hybrid power unit to run harder for longer – without affecting reliability. Max used this clear performance advantage to maximum effect, clinching the 2021 F1 World Championship.

Now that’s Max Performance – which is why Mobil 1 insists on being a technology partner – not just a brand sponsor.

m1oils.com.au/gomax Phone: 1800 350 622

Christian Horner Red Bull Racing Formula One Team Principal

Mobil 1™ is a trademark of Exxon Mobil Corporation and used under license by Ampol Australia Petroleum Pty Ltd

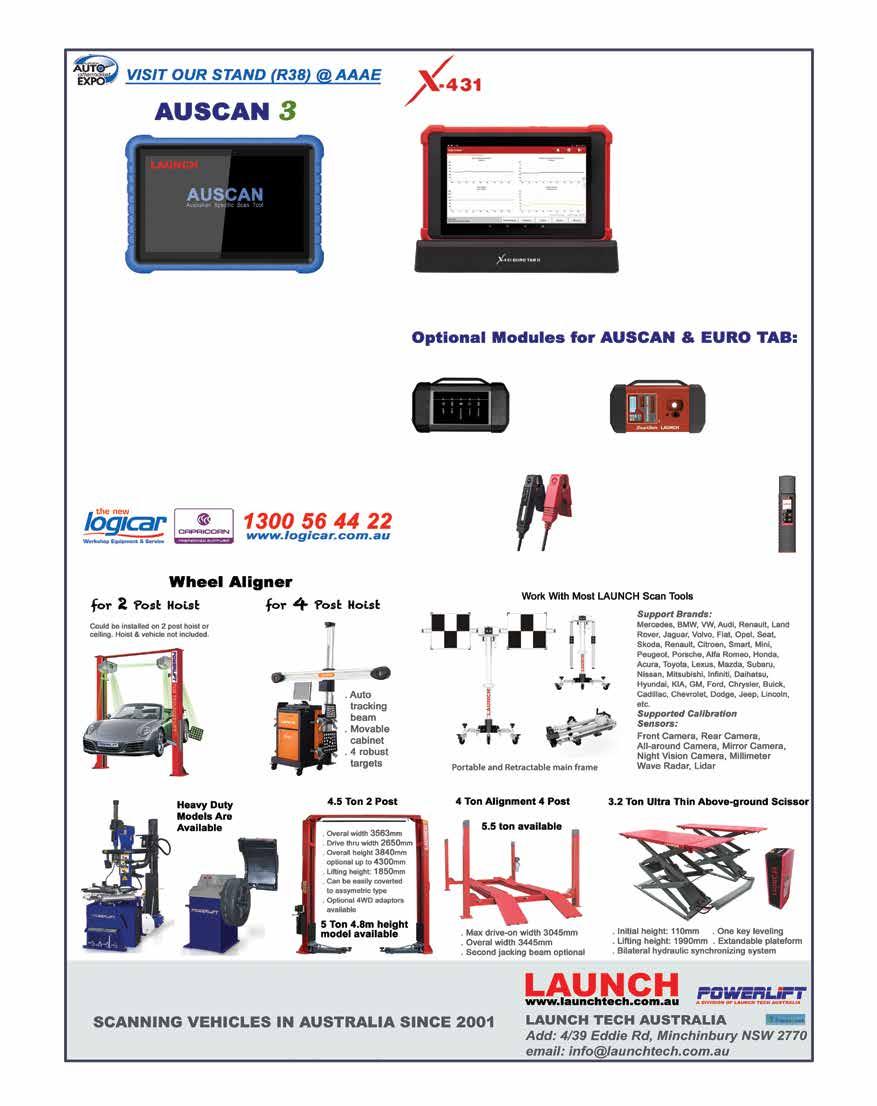

DENSO’S AFTERMARKET COMPONENT RANGE CONTINUES TO GROW

At DENSO every component has been designed with precision and subjected to rigorous safety and performance tests.

The OE-standard quality and reliability of DENSO aftermarket components add up to a tremendous value for their customers.

The range includes radiators, condensers, starters, alternators, spark plugs, sensors, air intake systems, diesel injectors, pumps and filters.

RELIABLE PERFORMANCE

DENSO’s radiator configurations, tanks, fin pitch, core dimensions and materials meet rigid standards and pass DENSO’s strict durability and function tests. Likewise, DENSO’s condensers are manufactured to allow the A/C system to operate at peak efficiency with minimal maintenance, assuring years of trouble-free service.

Constructed from premium aluminum

FOCUS FEATURE PERFORMANCE PRODUCTS

The team at DENSO have taken everything they have learned as an OE manufacturer and applied it to their aftermarket product.

42 AUSTRALIAN CAR MECHANIC | www.mechanics-mag.com.au

DENSO air intake solutions.

to resist corrosion, the condenser cores are specially designed to shed airborne material buildup.

EXCEPTIONAL DURABILITY

DENSO starter and alternators are lightweight, highly efficient and durable under the most grueling conditions. They exceed manufacturer standards, mount with a minimum of installation issues and provide years of reliable service – offering you real bang for your buck.

Highly durable components such as heavy duty ball bearings and impact limiters prevent internal damage resulting in products with the lowest return rates in the aftermarket.

SUPERIOR SPARK

DENSO offers a complete range of spark plugs, including:

Nickel TT – A unique twin tip electrode design to produce complete, efficient and cleaner combustion.

Iridium TT – Long life performance plugs are 6x harder and 8x stronger than platinum. They have the highest level of iridium content (90 per cent) giving them increased oxidation resistance, which allow these plugs to last 100,000km.

Iridium Power – High performance plugs with the world’s smallest iridium centre

DENSO complete range of spark plugs.

electrode. Their small electrode requires less voltage, reducing misfires.

Iridium Racing – The ultimate performance spark plug for the serious racer. Precision tuned for demands of high rev, high horsepower, high torque and high output engine applications under extreme endurance and competitive conditions.

REMARKABLE RESISTANCE

Oxygen sensors are among the most

DENSO injection common rail systems.

sensitive and critical components on your car’s engine, monitoring not only exhaust gas oxygen content but catalytic converter efficiency as well. In order to perform these functions properly, the sensors must adhere to OE standards within incredibly close tolerances.

Each DENSO oxygen sensor is constructed of the highest quality materials available; high-quality stainless steel, porous polytetrafluoroethylene (PTFE), fluorine rubber, aluminum oxide, high-grade platinum and ceramic. In head-to-head testing against the leading competitors, DENSO oxygen sensors were rated two times more resistant to silicone and lead poisoning.

ENGINEERING EXPERIENCE

Diesel engines combine excellent fuel economy and power, which is why we’ve seen an explosive growth in dieselpowered passenger and commercial vehicles on Australian roads. DENSO offers the world’s highest injection common rail system of 5 x injections per cycle, whilst retaining the ability to meet increasingly strict emission laws.

DENSO’s OE experience and knowhow is reflected in DENSO’s aftermarket product range to provide unmatched performance, reliability and fitment with real cost savings.

For more information and to find your part visit www.denso.com.au ACM

www.mechanics-mag.com.au | AUSTRALIAN CAR MECHANIC 43 FOCUS FEATURE

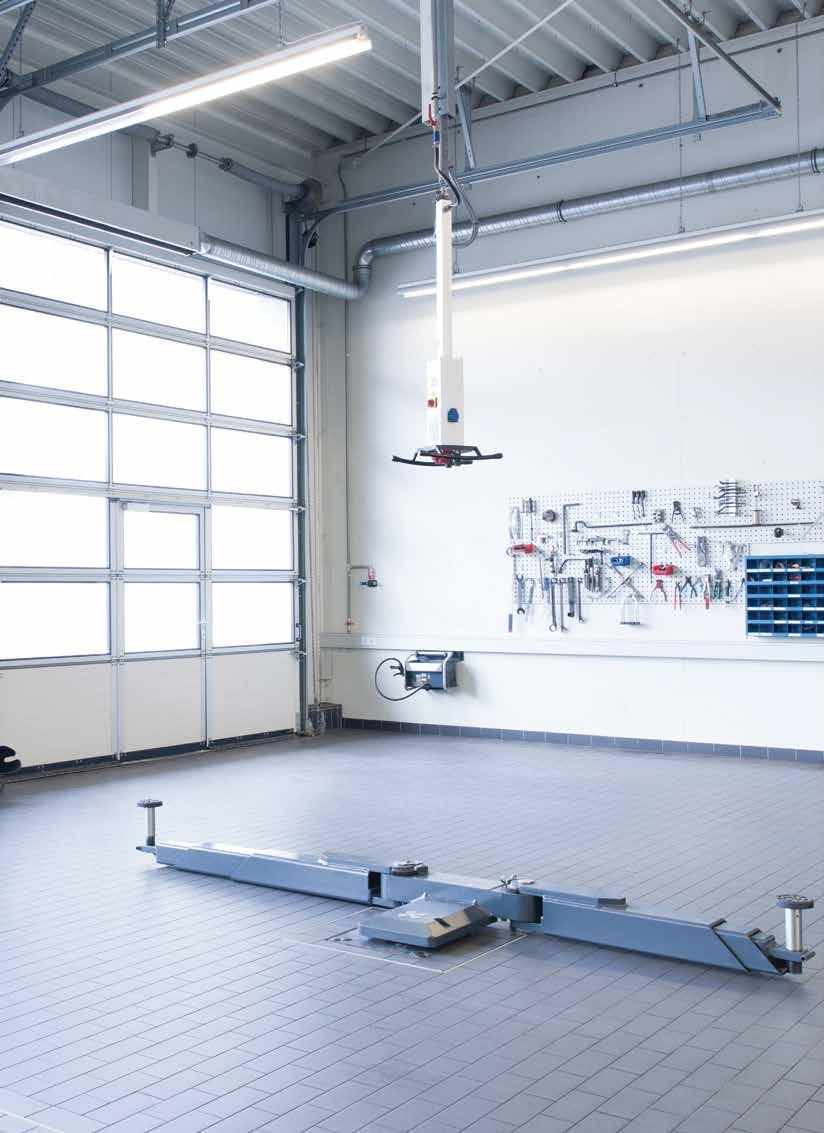

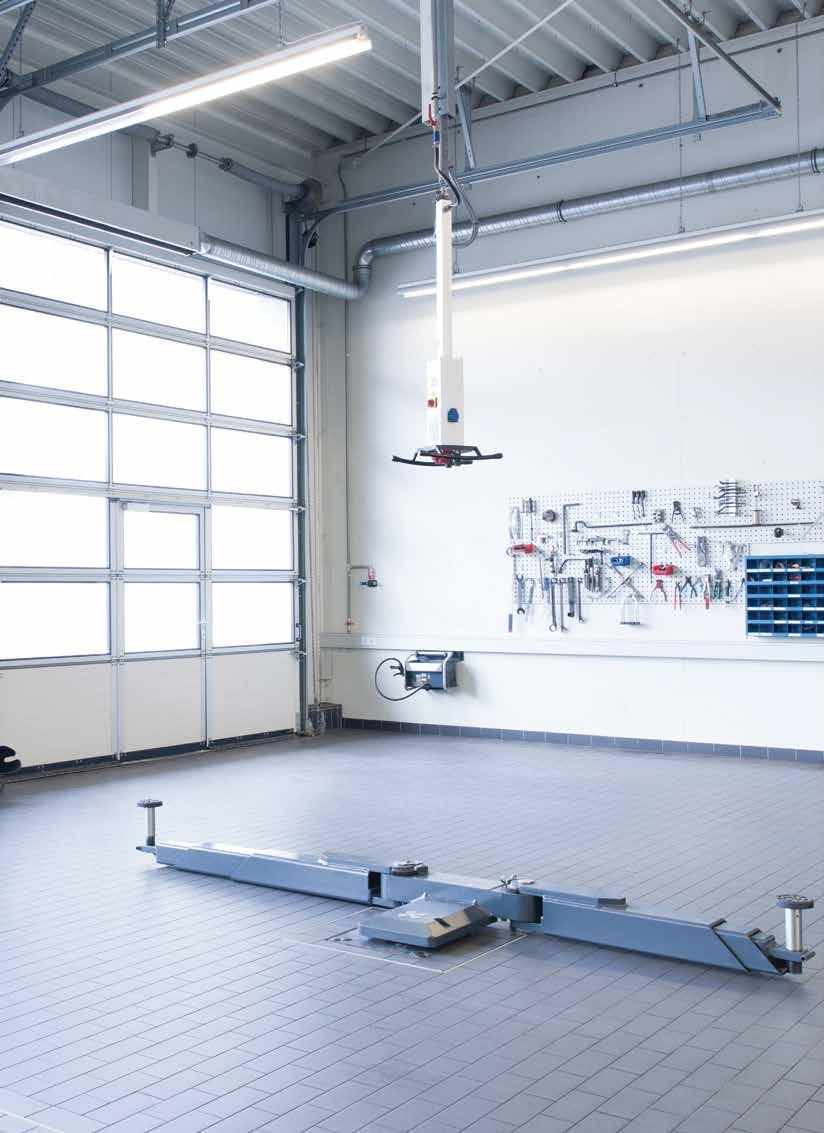

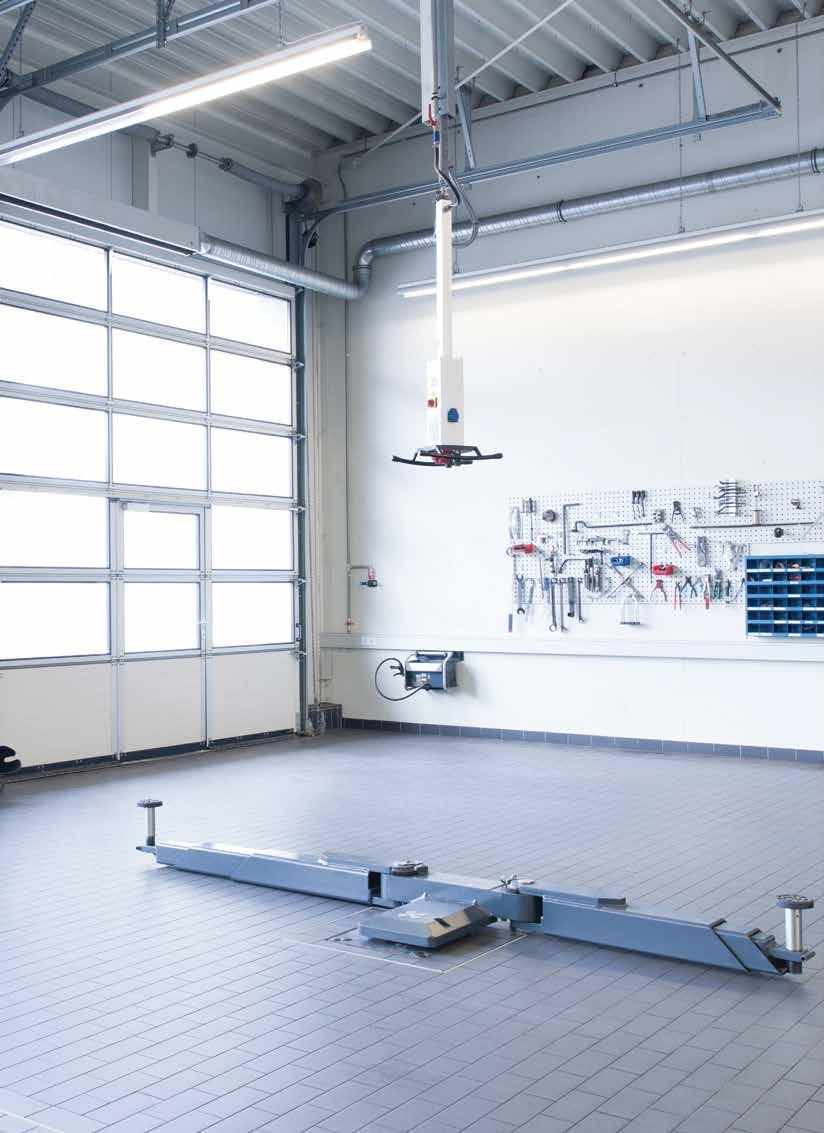

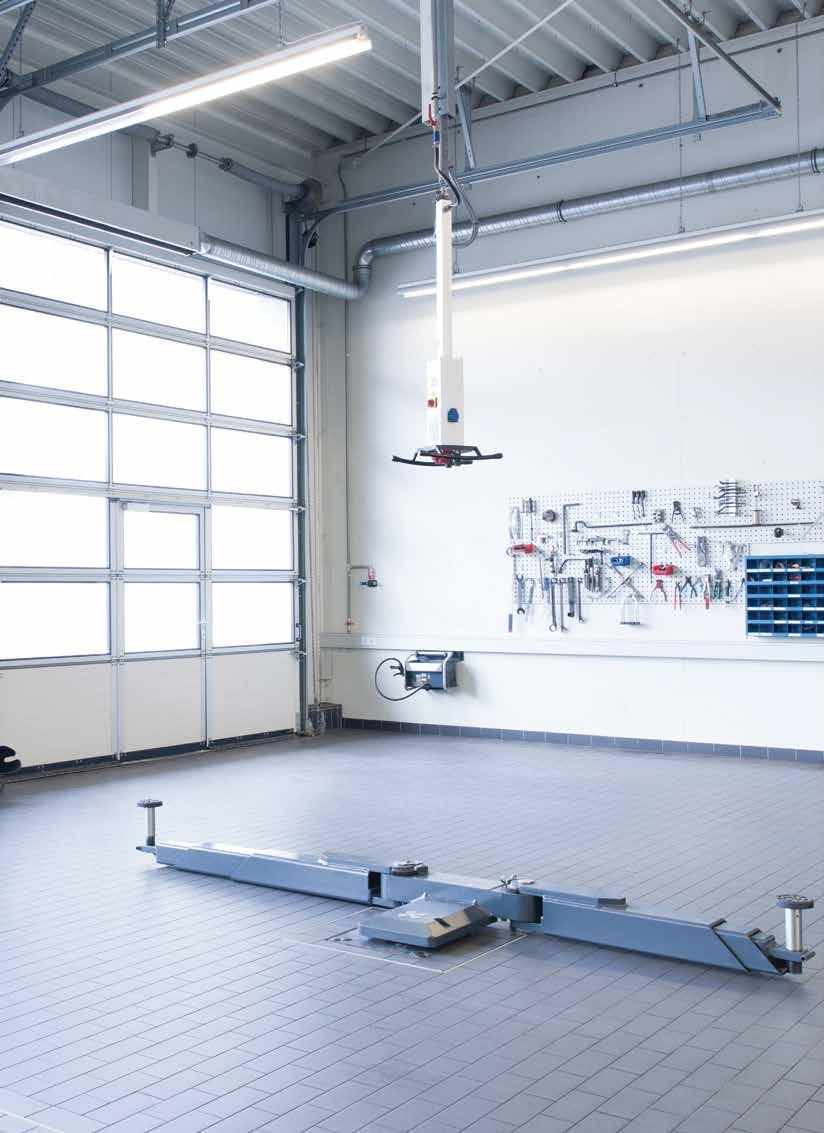

Nothing marks a workshop quite like a hoist. For generations, the hoist has been the symbol of service-station lube bays and a marker for the motoring public which said, “You can get help here.”

A modern hoist offers a great deal of user safety and fine adjustment which wasn’t available a few decades ago, but it’s still the marker of a professional workshop

to potential automotive customers.

There are quite a few technological improvements and innovations which may not be so obvious to those outside the auto trades, but which allow well-trained techs and tradesmen to meet the demands of a modern service bay. Software is obviously important, as is safety, but workflow management, training and even customer communication play a huge part

in reaching and maintaining the efficiency required to keep a workshop profitable.