t’s funny the things which sometimes trigger vivid, uncontrolled, split-second memories of incidents long past.

As I was working through the content for this issue I saw a piece on glow plugs and was instantly transported in my mind to the cab of an International Acco in the mid-1980s. I was sharing driving duties, and the other driver, older and more experienced than me, and was complaining about the truck owner chipping him for not letting the turbo wind down before shutting off the diesel.

Back then diesel engines weren’t popular for passenger or light-commercial vehicles, and in heavy vehicles diesel powerplants mostly worked hard. Keeping the oil circulating until the turbine had slowed, and wasn’t generating huge amounts of heat, before shutting off the motor had a huge effect on the turbo’s wear and lifespan.

But that wasn’t what struck me. I’d heard other drivers complain the recommended three-minute cool down was all in the owner’s mind – we had to fill out our log books anyway, so I didn’t see why it was a problem. No. The memory was so vivid because the other driver then went on to say the orange light on the dash at morning start-up was probably something that needed attention, but the owner hadn’t done anything about it, so he didn’t feel he should worry.

The light he was talking about was the glow-plug indicator light, and I was dumbfounded an experienced driver didn’t grasp its function or importance.

We’re lucky in Australia, especially driving along the east coast as I was at the time. We don’t see real extremes in temperature, and diesel motors can mostly generate the heat they need on their very early compression

strokes. But still, the good old glow plug, not much different today to the small heating element it was in my heavy-vehicle driving days, is a vital part of the diesel combustion system. Waiting that few seconds – and that’s all it is – for the orange light to go out can make the difference between a smooth start and no start at all in low temperatures, and I’m still astonished at how many owners of diesel-powered vehicles don’t understand the glow plug’s function. It’s good to see something every driver and tech should know outlined in a clear and sensible fashion.

There’s a mountain of great content in this issue, as always. Peter Blanshard of the Institute of Automotive Engineers highlights a few service issues which are often ignored

or taken for granted, the Focus Features include Brakes and Clutches and Steering and Suspension, we have a look at brake hoses, Iain Curry gets up close and personal with another superb classic, and we profile apprentice Tom Nilon and specialist workshop Automotion.

Of course we have a string of our usual columns and features as well.

Glow plugs, eh?

And what about how we used to have to crack the injectors and manually pump fuel through each cylinder if the system sucked air?

I’m not sounding old, am I?

Tom Foster, Editor ACM

IAIN CURRY has been a specialist motoring writer and photographer for 15 years, working for a variety of magazines in Australia, United Kingdom, USA, Germany and Sweden. He is former editor of Performance BMW magazine and features writer for GT Porsche magazine, and has been fortunate enough to photograph Formula 1, the Le Mans 24 Hours, World Touring Cars, V8 Supercars and a range of adventure sports.

ADAM WATKINS is a full-time teacher of automotive technology at The Northern Sydney Institute Northern Beaches campus in Brookvale. Adam works on marques such as Mercedes Benz and BMW and spends time at the racetrack. Adam brought this knowledge into the classroom to train new generations of modern automotive apprentices.

is a professional photographer who, after 20 years in the field, started a carpentry apprenticeship. With a recently found love for purring V8s, Jamie is documenting the transformation of his stock Crewman. When he’s not writing, taking photos or practicing his wood work skills, you can catch him surfing at Turimetta Beach.

Another big result at the world’s most prestigious enduro race marks over two decades of consecutive Garrett-supported teams on the top step of the podium.

TOYOTA GAZOO Racing’s Garrettboosted #8 GR010 Hybrid Hypercar piloted by Sébastien Buemi, Brendon Hartley and Ryō Hirakawa passed the chequered flag for a first-place finish at Le Mans 2022, marking the fifth straight year of the team’s dominance at the world’s most famous endurance race. The win also marks 23 consecutive years of Garrett-boosted Le Mans winners. Coming in second place was TOYOTA

GAZOO Racing’s #7 car, also turbocharged by Garrett, driven by Mike Conway, Kamui Kobayashi and José María López. The #7 and #8 cars are powered by Toyota’s 3.5L gasoline twin-turbo V6 hybrid powertrain, making 670hp (500 kW) per the LMH class. According to 24 Hours of Le Mans, TOYOTA GAZOO Racing has now surpassed Ford and Alfa Romeo and has become the fourth manufacturer to secure at least five consecutive victories after

Ferrari, Porsche and Audi. Driver Sébastien Buemi has joined Yannick Dalmas, Olivier Gendebien and Henri Pescarolo among four-time winners.

And coming in 3rd and 4th place, bringing Garrett-boosted teams to a full podium lockout, was team Scuderia Cameron Glickenhaus (SCG). Drivers Ryan Briscoe, Richard Westbrook and Franck Mailleux in the Pipo-engined #709 car, and drivers Olivier Pla, Romain Dumas,

Pipo Derani in the Pipo-engined #708 car finished 3rd and 4th place respectively.

The winning cars feature twin Garrett TR turbos with advanced ball-bearing technology, boosting engine performance and providing the acceleration needed to secure the team’s victory. The turbo system was designed from the groundup to withstand the unique operating environment created by such a gruelling 24-hour race. Garrett Motorsport engineers in Torrance, U.S. and Brno, Czech Republic, directly support the Le Mans racing teams.

For more than two decades, Garrett has supported every winning team at Le Mans with industry-leading technology and engineering expertise, continually evolving the strategy and enhancing products to meet ever-rising challenges that drivers face in this endurance event.

THE LIST OF WINNING TEAMS GARRETT HAS SUPPORTED AT LE MANS INCLUDES:

• TOYOTA GAZOO Racing (2018, 2019, 2020, 2021, 2022)

• Porsche LMP Team (2017)

• Porsche Team (2015, 2016)

• Audi Sport North America (2007, 2008, 2010)

• Peugeot Sport Total (2009)

• ADT Champion Racing (2005)

• Audi Sport Japan Team Goh (2004)

• Team Bentley (2003)

• Audi Sport Team Joest (2000, 2001, 2002, 2006, 2011, 2012, 2013, 2014)

To read more about the race standings and to see photos from the event, visit Le Mans’ official site.

GARRETT MOTION WINS 2021

The annual PACE (Premier Automotive Suppliers’ Contribution to Excellence) Awards recognize superior innovation, technological advancement, and business performance among automotive suppliers. The award winners were selected by an independent panel of judges and honoured at a virtual ceremony on September 30, 2021.

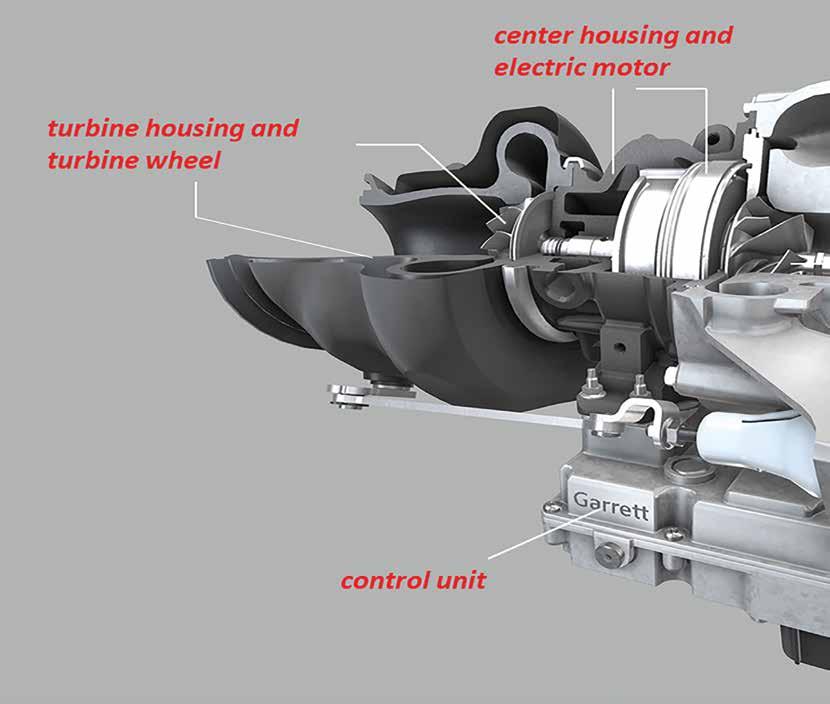

“We are thrilled to be recognized as an Automotive News PACE Awards winner for our innovative E-Turbo,” said Olivier Rabiller, Garrett President and Chief Executive Officer. “This prestigious PACE Award is our first in electrification and fourth overall in the past 10 years and is a testament of Garrett expertise to develop industry-first and highly differentiated technologies.

Garrett’s E-Turbo draws upon our in-house advanced capabilities in high-speed motor, high-power density motor, high current and switching frequency inverter and motor control software. Our world-class

“WE ARE THRILLED TO BE RECOGNIZED AS AN AUTOMOTIVE NEWS

FOR OUR INNOVATIVE E-TURBO.”

engineers successfully overcame the many challenges in thermal management, energy recovery, compact packaging and highvolume and low-cost design to develop this breakthrough E-Turbo.

“Garrett is well positioned to support the future of electrification including hybrids, fuel cell and any other applications requiring a new approach to problem solving the most pressing needs of the industry.”

Garrett’s E-Turbo utilizes a high-speed electric motor positioned on the turbo shaft to spool the compressor more rapidly and eliminate lag, dramatically improving transient engine performance and lowend engine torque. The new technology

provides more power and faster response while further enabling engine efficiency.

Additionally, the E-Turbo can recuperate otherwise wasted energy as an electrical generator to power the hybrid motor directly or recharge the battery in certain driving situations, allowing automakers greater flexibility in the design of hybrid powertrains.

Craig Balis, Garrett Vice President and Chief Technology Officer, stated, “The utilization of our 48-volt or 400volt hardware on electrified hybrid powertrains, the fastest growing segment in the global auto industry, is an effective solution for OEM to address strict environmental standards and set new benchmarks in vehicle performance. By integrating our internally developed highspeed electric motor running at more than 200,000rpm only inches away from exhaust temperatures exceeding 1,000°C, we are able to deliver electrically assisted boosting under extreme conditions while providing energy recuperation to the vehicle’s electrical system.”

As previously announced, Garrett plans to begin serial production of its E-Turbo on a new state-of-the-art, fully dedicated and automated production line beginning in the fourth quarter of 2021. The technology is expected to be introduced next year for the first time at scale in MercedesAMG premium hybrid vehicles. Garrett is engaged in multiple other electrification projects with customers worldwide for both passenger and commercial vehicles. ACM

In

edition

As you are aware with good training and a good kit such as Launch, Bosch or Hella etc. calibration can be adequately affected on a lot of vehicles, however – and it’s the biggest however – if your preparation is poor, your result won’t be as accurate as you may want. For argument’s sake, certain calibration manufacturers combined with OEM specifications demand a certain radius of clean space around a car before you can complete your calibration. It may be 20 metres, it could be 50 metres, and this cleared space includes concrete or steel pylons which hold up the roof of your building. So why discard that instruction?

Most require a flat level surface, yet I have seen one area where the concrete floor had failed, and the front wheel was sitting in almost a pothole. Some manufacturers demand that a wheel alignment be done, including tyre pressure to be set and this too is an area that some technicians report they don’t have to do. Again, if we have the car properly setup you will have an opportunity

of getting a more accurate calibration. Do not discount any steps that either the manufacturer or the kit manufacturer asks that you complete and then, for God’s sake, don’t whine that you can’t get calibrations swiftly completed.

It now leads me to a second area of concern – one of which I thought we covered many years ago, and this is with the use of E10 fuel. As today’s fuel prices continue to skyrocket to never seen before price levels, the average consumer is looking for the cheapest alternative in fuel and those with modern cars and E10 compatible stickers all over them are now feeding their car this E10 product as fuel prices hurt. The concern that I have is that we have technicians that are telling clients not to use E10 in cars that have been specifically manufactured to burn this product. Sure, we are not going to put it into your 1967 HR Holden, nor a high compression 351 GTHO Ford but the 2020 Mazda, Honda, Nissan etc. can quite

this

I will be providing a few reminders following some interesting and factual conversations recently had with key industry experts about a few areas of concern.

happily burn E10 and consumer should not be steered away from using this product in their cars.

You are the professional. You should be able to buy the right oil, use the right quality oil filter, use the correct quality air and fuel cleaner, make the right choice on heat range of spark plug, all of which to allow your customer the ability to buy the cheaper fuel which currently is E10. They look to you for correct advice, not a blanket, “no, it should never be used” because there are a lot of mechanical engineers who specialise in metallurgy, fuel injection, computer programming which all lead to this vehicle’s sticker that states that it can quite adequately burn E10 fuel, regardless of your love or hate of the fuel. In times of crisis where even E10 is toppling $2.25 a litre, please assist your client with proper advice, not the good old gut feel or prejudice against ethanol.

I feel that in this edition I am on my soap box so I might as well continue. Yesterday I had a great conversation with a major oil company in Australia who have gone out of their way to educate the consumer on the correct grade of oil that should be used in their car. The problem they have is that the consumer now knows more about this than their local workshop. They report to me that they have small to medium enterprises that only wish to buy two or three grades of oil because “she’ll be right mate, the car runs on this without a problem”. This may be true, but for how long? What is our fuel efficiency like? In my last few paragraphs, I talk about the need of giving the correct advice so that people who wish to use E10 can successfully do so. We now have hybrid vehicles with small engines, incredibly high compression and are chasing every bit of fuel efficiency that they can find. After all, it is a hybrid and it is expected to return ultra-low emissions and ultra-high fuel efficiency, but no, we will just pick and choose whatever oil we think should go in the vehicle because “hey, it runs alright”.

If we want to retain customers, we must do a better job than the three examples that I have given in this edition. It’s not common that I write in such a forceful manner but lately I’ve truly had some conversations on topics that I thought we had put to bed many years ago.

If you would like any form of assistance, please don’t hesitate to contact your IAME and we can continue these conversations, so you are delivering the best advice to your customers.

The best way to reintroduce yourself to what’s new is to consider an apprentice that will assist you with some of the more up-to-date competencies and trends

in automotive services. Just because you’re an apprentice and are learner the underpinning knowledge for yourself, it does not mean that through their RTO they are not picking up on the super important issues such as the correct oil usage in a hybrid’s fuel motor and reinforcing that with you when you pick up the wrong drum to tip into the car. Their learning is threefold, history and underpinning knowledge, current knowledge, and their domain experience. That’s what makes a solid apprentice/mechanic.

The IAME has an excellent relationship with Apprenticeships Are Us and can supply you with an apprentice anywhere in Australia. Please, don’t hesitate to contact your IAME or Apprenticeships Are Us directly on (02) 9891 6900.

Let’s look to the future and run a highly professional, modern, profitable business. We are all here to assist.

For further information call IAME on (02) 9782 1100, visit www.iame.com.au or follow us on social media – www.facebook.com/iame.online ACM

The heart of these vehicles is battery technology and it’s moving fast. Thankfully so are the aftermarket solutions available to keep these vehicles on the road and your customers happy.

In February 2020, the Injectronics’ hybrid battery remanufacturing exchange program was announced, delivering Australia’s first scalable component re-use and resource recovery program of retired battery packs from hybrid-electric vehicles.

Part of IM Group, Injectronics is Australasia’s leading supplier of quality new and remanufactured automotive electronic components, as well as the preferred repairer of electronic and mechatronic parts.

I spy a Japanese giant, a pioneer, a cup, a speedy racer, bottle of ‘go fast’, a quad cam V8, a legendary cap, a need for speed, and a love letter to a beast.

Last year, in September 2021 the website hybrid.injectronics.com.au launched, and sales of newly re-manufactured Prius and Camry 40/50 series batteries began.

Fast forward to June 2022 and the solutions from Injectronics have progressed significantly with re-manufactured batteries and an option for a new aftermarket hybrid battery. The range now covers 11 models commonly found on Australian roads.

Propulsion, or drive batteries work best when operating in a stable environment. If the cells become too hot or too cold, their life span is reduced significantly. OE manufacturers carry out heat management of their battery packs in different ways with the option of forced air-cooling using ECM controlled fans the most popular.

One of the problems encountered by OE manufacturers of traditional prismatic cells (commonly found across the Toyota Hybrid range of vehicles), is the ability to keep them cool while performing charge and discharge cycles. This is due to the lack of airflow around the closely assembled cell packs.

The very clever engineers at Injectronics use cylindrical cells in their new aftermarket hybrid batteries. These cells carry the same capacity as their predecessors but due to their shape and size, allow even airflow and therefore heat transfer away from the pack.

If you have tried to purchase an OE battery in our global economic state, you will no doubt be aware that these are in very short supply. Injectronics – a local Australian business, has genuine alternative battery solutions for your customers vehicle.

As Australia’s first large-scale hybrid remanufacturing program, Injectronics can provide a cost-effective and sustainable solution. Giving hybrid batteries a second life, NiMH batteries can be remanufactured to provide exceptional battery performance and efficiency.

All Injectronics hybrid batteries whether remanufactured or new aftermarket are true “Plug and Play” components. This simply means the pack comes fully assembled. No extra purchases, no extra time, no confusion, and no hassle – its Plug ‘n’ Play.

Injectronics has a high standard when it comes to environmental sustainability. This is evident right down at the packaging and shipping level where each battery pack is delivered in a purpose-built case which is used to return the core for remanufacturing.

The Circular Economy is at the heart of this program, whereby waste is minimised or eliminated from landfill and handled in the safest possible way.

Injectronics is currently offering

replacement battery packs for Gen 2, Gen 3 and C model Toyota Prius, Toyota Camry 40 and 50 Series, ZWE186 Corolla, Estima, and LEXUS vehicles including GS450H, RX400H and RX450H.

With access Australia-wide, Injectronics hybrid battery packs are a convenient option for automotive technicians. They provide a cheaper repair solution for your customers, along with a vastly reduced environmental impact.

For more information, visit hybrid.injectronics.com.au, or call 1300 30 80 60.

“THE VERY CLEVER ENGINEERS AT INJECTRONICS USE CYLINDRICAL CELLS IN THEIR NEW GENUINE AFTERMARKET HYBRID BATTERIES.”

Milwaukee Tool understands the day-to-day challenges automotive professionals face in their workshops. The company is committed to delivering a cordless, hose-free future by developing strong alternatives to pneumatic tools. Cordless solutions improve safety and eliminate the mess associated with cords and hoses being out on the shop floor.

To support mechanics, the Milwaukee Job Site Solutions (JSS) team of experienced transportation specialists, bring the best advice and the best range of cordless power tools, hand tools, storage and accessories directly to your workshop. During the JSS visit, a transportation specialist will assess the way your workshop runs. From the job at hand, to your existing inventory, the JSS team learns where your pain points are, then recommends the most appropriate

product solutions; offers training and advice on how to optimise your processes; and helps you take advantage of Milwaukee’s cross-platform, cordless innovation across your workshop.

You will be able to test drive the latest Milwaukee products, including the new M18 FUEL™ Compact and Mid-Torque 1/2" Impact Wrenches. Experience first-hand how Milwaukee Tool has engineered these cordless wrenches to improve accessibility, designed to reach stubborn fasteners in tight spaces where larger impact wrenches can’t fit. The M18 FUEL™ 1/2" Compact Impact Wrench with Friction Ring (M18FIW2F12-0) measures only 124.5mm in length and delivers up to 339Nm of nut-busting torque, while the M18 FUEL™ Mid-Torque 1/2" Impact Wrench with Friction Ring (M18FMTIW2F12-0) packs

up to 881Nm of nut-busting torque while weighing only 1.58kg.

Both impact wrenches have 4-mode DRIVE CONTROL which offers greater precision with a range of preset RPM and IPM levels. AUTO SHUT-OFF mode applies the right level of torque for handtight fastening applications, without overtightening. Bolt Removal mode delivers full torque output, then decreases RPMs once the bolt is loosened to prevent fastener drops. For increased visibility in confined, low-light workspaces, these wrenches are designed with tri-LEDs that deliver bright light with less shadows.

Milwaukee products are Nothing but HEAVY DUTY™, made to withstand the harshest, most demanding jobs in modern workshops. Working closely with the Australian transportation industry,

Experience the Milwaukee ® difference with Job Site Solutions specialists who will help improve your workshop productivity, efficiency and safety.

“WORKING CLOSELY WITH THE AUSTRALIAN TRANSPORTATION INDUSTRY, MILWAUKEE TOOL HAS MANAGED TO REMAIN ONE STEP AHEAD OF THE EVERCHANGING DEMANDS PLACED ON MECHANICS.”

Celebrating 50 years in Australia.

Thanks to our team, both past and present, and our c u stomers for their s up port throughout the years.

Here's to the next 50 !

Milwaukee Tool has managed to remain one step ahead of the ever-changing demands placed on mechanics. This connection means that Milwaukee solutions are efficient, more productive, safer to use and, most importantly, geared for mechanics. Whether it’s repairs, maintenance or body work, the JSS team ensures that the tools you have on hand, your ways of working and your workshop’s safety and efficiency are maximised.

From cordless impact wrenches to under hood lighting, Milwaukee Tool has developed the power tools, hand tools, and accessories to help every mechanic build, repair and maintain any vehicle. Milwaukee Tool offers complete workshop solutions that maximise safety and efficiency –from the M12™, M18™ and the high performance M12 FUEL™ and M18 FUEL™ platforms, to their growing range of hand tools, accessories and the expanding PACKOUT™ modular storage system.

Experience the Milwaukee difference by booking a test drive with the Job Site Solutions team: www.milwaukeetool.com.au/jobsite-solutions/

discussions around new technologies, the future of the automotive landscape and how these will affect workshops,” continued Matthew.

“The events are also a networking platform for fellow automotive professionals to connect with one other, to share knowledge, as well as ensuring they remain up to date with new technologies to prepare for the future of the industry.

“Technology is always evolving and CoolDrive wants to ensure it is supporting its valuable workshop partners through regular training sessions, as well as constantly reviewing and expanding our product and service offerings.”

As part of this ongoing commitment to workshops, CoolDrive has also recently launched the ultimate information resource – CoolData, which is available for its customers to purchase as a subscription service.

Featured within CoolData are detailed technical drawings, a unique electronics data module and intelligent diagnostics tools to enable workshops to diagnose, repair and maintain vehicles quickly and accurately.

Many different topics are covered by the CoolData system, including Identification Data, Adjustment Data, Vehicle Maintenance, Repair Offerings, and Electronics and Engine Management.

At May’s Bathurst 12 Hour, CoolDrive hosted a training event for workshop technicians and owners, providing attendees the opportunity to hone their skills and learn new vehicle system technology from the industry’s leading trainers and experts.

Across three days, attendees underwent seven training courses with ‘future-focused’ topics, – DPF Diagnostics, CAN BUS Diagnostics, Modern EV Servicing, AC Diagnostics, Engine Management Sensor Diagnostic Training, EV Accessory fitment and Diagnosing Smart Charging Systems –not to mention they also experienced the best racing action and hospitality Mount Panorama had to offer.

“The Bathurst 12 Hour Specialised Training Event was a resounding success this year with positive feedback received from all attendees,” Matthew Douglass,

Category Manager – Tools and Equipment at CoolDrive Auto Parts said.

“Participants found the training programs on offer to be incredibly helpful and took away a lot of learnings that can be applied in their day-to-day running of their businesses.

“Hosting it at the Bathurst 12 Hour also made this event unique; with the informative and educational sessions held in and around the surrounds of Australia’s most famous racing circuit, while also seeing some of the fastest and most luxurious GTs in the world.”

The success of 2022’s training event has seen CoolDrive confirm its intent to hold more events at different locations across Australia in the near future.

“Our Specialised Training events cover a wide range of topics, giving attendees the chance to tighten up on their existing skill-sets as well as broaden them with

CoolData is available in packages for Cars and/or Trucks, with each subscription containing four unique user logins.

Each CoolData Car or Truck annual subscription includes access to Haynes Manuals AllAccess, which covers over 700 online manuals for car and motorcycle maintenance and repair.

Complementing CoolData and the specialised training events is CoolDrive’s expanded tools and equipment offering, to ensure workshops are equipped with the latest products to safely service both current and future technologies.

The offering at CoolDrive includes an exceptional range of air-conditioning tools and equipment, the renowned Autologic diagnostic range, and its partnership with SP Tools has brought its quality products direct to CoolDrive branches.

CoolDrive Auto Parts continues to build upon its reputation as a trusted partner to automotive workshops, following the success of its Specialised Training Event.

Professional repairers are also provided for at CoolDrive with the latest from Bosch and its diagnostic and ADAS tools as well as CPS Motorvac’s workshop specialist service equipment.

Additionally, CoolDrive’s new relationship with GYS sees the brand’s Battery Chargers/ Battery Support Units and Powerduction Induction Heat Tool products available through its extensive branch network.

The very latest circuit testers are also available from CoolDrive, including Power Probe’s full range of individual units and kits, plus Prologics Ultra Probe, Voltage Reference Probe and CAN Box Tester.

Also new to CoolDrive and an essential unit for any auto electrician is the N2 Neuron digital multimeter from Curien, the industry’s first compact two channel Bluetooth graphing multimeter which provides electrical testing accuracy and versatility in the palm of a hand.

Get your workshop equipped for the future of the automotive landscape with CoolDrive! For further information www.cooldrive.com.au.

ROLLER CABINET DRAWER SIZE:

• 1 Drawers 937 x 410 x 123mm, Max Load 38kg each

• 5 Drawers 570 x 410 x 75mm, Max Load 25kg each

• 1 Drawers 570 x 410 x 154mm, Max Load 30kg each

ICH-8D TOOL CHEST

• Professional quality 8 drawer tool chest

• Industrial duty ball bearing slides

• Double row bearing slides for addition strength on bottom drawers

• Rolled drawer edges for extra strength

• Protective drawer liners and heavy-duty side handles

• Sturdily built to last with durable powder coated finish • Top Lid has 2 x gas struts • Smooth, silent drawers and secure locks • Great selection of drawer sizes

IRC-7D ROLLER CABINET • Professional quality 7 drawers roller cabinet • Industrial duty ball bearing slides • Double row bearing slides for addition strength on bottom and top drawers • Push handles located either side of roller cabinet • Sturdily built to last with durable powder coated finish

Protective drawer liners • 1 lockable door with two shelves • 2 lockable and 2 fixed rubber wheels with cast iron hubs • Smooth, silent drawers and secure locks

Smooth running, strong wheels for mobility • Great selection of drawer sizes • Ideal for home hobbyist or tradesmen

The new ICRLC 24 Drawers Industrial Series Tool Box consists of a professional 7 drawer roller cabinet and 8 drawer tool chest cabinet which features a top quality lockable drawer system – just what’s needed to keep all those spanners, screwdrivers, sockets, files, pliers and other equipment in a neat and tidy arrangement – ideal for the workshop, garage, truck or ute. Well built, but not overly heavy (until you load them up), fitted with smooth ball bearing drawer runners and a soft drawer closure system to prevent accidental opening when manoeuvring around, with a wide selection of drawer, the ICRLC24D makes for a very versatile combination.

Give your tools the “Professional Garage Look” and keep them all neat and tidy and be proud to show them off.

TOOL CHEST DRAWER SIZES:

• 3 Drawers 570 x 410 x 74.5mm, Max Load 25kg each

• 1 Drawers 570 x 410 x 153.5mm, Max Load 30kg each

• 3 Drawers 313 x 410 x 74.5mm, Max Load 22kg each

• 1 Drawers 313 x 410 x 153.5mm, Max Load 28kg each

• Professional quality 7 drawer side cabinet • Industrial duty ball bearing slides • Double row bearing slides for addition strength on bottom drawers • Sturdily built to last with durable powder coated finish • Protective drawer liners • Smooth, silent drawers and secure locks • Ideal for home hobbyist or tradesmen

• Professional quality 2 drawers and shelf side locker • Industrial duty ball bearing slides • Double row bearing slides for addition strength on bottom drawer • 2 Drawers with industrial duty ball bearing slides • Sturdily built to last with durable powder coated finish • 1 adjustable height shelf • Smooth, silent drawers with protective drawer liners and secure locks • Ideal for home hobbyist or tradesmen.

For more information visit www.machineryhouse.com.au/K005B

Increasingly, well known and unknown brands are launching a range of Lithium products to gain market share in this rapidly growing product segment.

As Lithium is a relatively new automotive and recreational product category, it can be difficult to navigate the market and locate the products that are

both high quality and reliable.

Federal Batteries has responded to the market demand for Lithium technologies with the launch of their new REMCO Smart Lithium Deep Cycle battery. The new battery range boasts all the most attractive benefits of Lithium: lighter weight, longer lifespan, higher power density and faster charging. The new Smart Battery Management

System (BMS) is an outstanding feature of REMCO Lithium batteries. The BMS is built into the battery and is paired with a mobile phone app, so battery owners can monitor and manage their battery’s condition and performance in real-time.

Over the past 30 years, REMCO has become a reputable aftermarket brand, known for being reliable, superbly built and trusted by leading Australian OEMs and resellers. REMCO is supported by the Federal Batteries’ team of product experts who are involved in every aspect of the product development and production process. Each battery is designed to suit Australia’s unique environment.

REMCO has always strived to provide customers with an all-encompassing energy solution. The addition of the new Lithium range has increased REMCO’s SKU offering to more than 50, ensuring that customers have access to the right batteries to fit their specific applications. These applications may range from camping and caravanning, 4x4 touring and marine to industrial uses such as UPS systems, solar and mobility.

Staying true to the brand’s new tagline ‘Energy Anywhere’, the REMCO Lithium range will be available to consumers from Autobarn and Opposite Lock stores Nationwide, whilst the entire REMCO battery range is available to the trade via Bapcor’s Trade networks such as Federal Batteries and JAS Oceania.

“More than two years of research and development has been invested in the Lithium range to ensure that this new generation of REMCO batteries perform to the standards expected by our customers,” stated Anthony Trigona, Product Manager.

For further information, technical support, instructional videos and more, visit www.remcoenergy.com.au

It is hard to ignore the market’s growing desire for

Did you know that automated payment solutions can help businesses to reduce their invoice processing time by up to 74 per cent? Spenda helps businesses to manage their payments with ease and provides auto workshops with smart digital tools and systems that simplify the way your business handles invoices.

By using Spenda, along with easy integration into your accounting system, you can benefit from:

• Access to extended payment terms: Pay by credit card, even if your supplier does not accept cards and take advantage of extended payment terms and rewards programs (subject to the terms offered by your card provider)

• Pay multiple suppliers in one place: Conveniently view and pay suppliers from one easy-to-use dashboard. Track, group and batch-pay outstanding invoices and, at a glance, gain visibility on your outgoing payments

• Reduce human error and improve accuracy: Benefit from fewer hours needed to process invoices. Reduce the likelihood of data-entry errors, remove duplicated payments and enable better transparency, collaboration and costsavings across your business.

Ready to supercharge your invoice management processes? Get started with a free, no-obligation 30-day trial.

Give Spenda a call on 1300 682 521 or visit www.spenda.co/automotive ACM

www.mechanics-mag.com.au

Shane Olive is the driver of the fire breathing, 11,000 horsepower Burson Auto Parts Top Fuel Dragster that made its 2022 season debut at Sydney Dragway in January.

It has been a long way to the top of his craft for Shane, who continues a family tradition following in the well-worn skid tracks of his father, Phil Olive, who enjoyed great drag racing success during the ‘70s and ‘80s.

Since gaining his road driving licence, Shane has successfully competed in just about every junior and professional drag racing category along his 30-year journey to the world’s ultimate drag racing class, Top Fuel. Being attracted to a Championship winning team in Lamattina Racing and piloting the first ever Burson Auto Parts sponsored Top Fuel Dragster has made a lifelong dream a reality for the highly talented 47-year-old racer.

Shane doesn’t just drive the fastest Burson Auto Parts racing machine of them all, he also handles all of the engine maintenance and dragster preparation work

between each race event, ensuring that the Lamattina Racing Dragsters are in their best possible shape.

While he is an all-round motorsports fan, Shane has only ever competed in drag racing, his first and only motor racing passion, having grown up in it across his entire life.

“Being able to do what I love and to have a major Australian company wanting to have their name on the car as I compete at the highest level is just incredible,” Shane said.

“I can’t begin to tell you what a privilege it is to race with the support of the Burson

Auto Parts national store network. The feedback that we have received from fans about the car has been phenomenal – and the season has only just begun,” he added.

The opening round of the 2022 Burson Auto Parts Australian Top Fuel Championship at Sydney Dragway on January 21 and 22 saw Shane achieve his dream of competing at the sport’s premier level and it proved to be a baptism of fire. His first ever Top Fuel race saw him lined up against double American Top Fuel Champion Larry Dixon – and despite his debut race nerves, Shane won the drag race.

Having christened the Burson Auto Parts Top Fuel Dragster with its first win and having qualified strongly in the six car Top Fuel field, the dream run unravelled in the final with a blower failure.

“While the weekend didn’t end the way we wanted it to, it was a strong debut and a great Top Fuel start for me and Burson Auto Parts. We have a strong car and a great team – I’m looking forward to the rest of the season,” Shane said.

Shane is based in Sydney and is married with three daughters, one of them works on the Lamattina Racing Team crew, one of them at a motor racing venue and the third works outside of the sport.

To keep tabs on the Burson Auto Parts Australian Top Fuel Championship, visit the series’ Facebook page or the Lamattina Racing Team website – www.thecarrotkings.com.au ACM

As 2020 and 2021 well and truly demonstrated, sometimes the unexpected can happen, and it is important that businesses are prepared to deal with the impacts of events that may not be completely within their control, and have supportive risk management practices in place.

The bushfires in many regions of the country, followed by the COVID-19 pandemic, saw operations across a range of industries completed upended, and it was necessary for businesses to adapt to the new reality and restructure their operations where required.

Fortunately for workshops, disruptions to business activities in 2020 were not of the scale experienced by some other industries, however the lessons learned can be incorporated into business practices going forward.

Businesses will typically need to navigate a diverse range of risks across the scope of their operations, from health and safety risks, through to financial risks, along with various other economic risks, and preparedness can go a long way to promoting business resilience.

Of course, mechanics and workshop owners face a range of risks over the course of their daily operations, and health and safety risks are a key consideration for industry.

As advised via the business.gov.au website, businesses should identify, analyse and evaluate risks in seeking to both work out the range of risks they face and determine which risks are most urgent.

Among the steps businesses can take in developing a risk management plan, business.gov.au advises:

• Pinpoint the areas that matter most –determine which areas of your business a risk management plan will apply to, such as hazard-based risks

• Stakeholder consultation – specific feedback from stakeholders, such as clients and employees, can add detail to a risk management plan, helping to determine what is high and low risk

• Risk identification – consider what

could potentially go wrong, and how and why – this can involve drawing on past events and risks, and looking to the future, assessing the impact changes to your business environment could have on your business

• Risk analysis – determining which risks are most urgent, looking at the potential damage a risk could cause and the likelihood of it happening, using a rating system for damage and likelihood to work out the level of risk (risk level = damage x likelihood)

• Risk evaluation – set risk criteria, stating the level and nature of risks that are acceptable and unacceptable, comparing the level of risk for various events against this criteria, checking if existing risk management methods are enough to accept the risk

• Treat risks – develop a plan to treat risks, including risk types and the level of risk, along with strategies, timeframes, who’s responsible, the resources required and future action to be taken

• Reduce risks – committing to quality risk management can help promote

business stability, and preparedness for unexpected events, with open communication, defined roles and feedback important factors.

Further information can be found at the business.gov.au website.

In seeking to minimise the impact of unexpected events on your business, it is important to remain flexible in your operations, to ensure that the right policies and procedures are in place, and to balance short and long-term considerations.

As previously looked at in this series, writing a business plan can help to articulate the step-by-step processes and strategies required to grow your business, and risk management should be an inherent component of this type of planning.

Of course, the future will likely throw up all sorts of challenges, and while not every challenge can be predicted, in-built business resilience will go a long way to ensuring these challenges can be successful navigated. ACM

Preparing for the unexpected – seven points to consider.

“RISK MANAGEMENT SHOULD BE AN INHERENT COMPONENT OF THIS TYPE OF PLANNING.”

Faulty glow plugs can make it difficult if not impossible to start a diesel engine on a cold morning.

As you need to remove the glow plug to test it – this is often when you run into trouble.

The glow plugs are exposed to extreme heat, pressures, vibrations, and corrosive agents which develop during the combustion process. They may become seized in cylinder head recess thread due to moisture or debris entering via the thread. This can cause the glow plug to break at various points on the body when the plug is removed or alternately, the glow plug electrode (Tip) can on occasion swell over time and become stuck in the head and break off when the glow plug is removed, leaving the electrode in the cylinder head.

It can be helpful at times to try to unscrew the glow plug while the engine is still warm in preparation for removal.

Often just accessing the glow plugs to remove them for inspection and testing can be daunting – and this is where specialised tools come into their own. Specialist Tools Australia can assist you with selecting a kit that best suits your job.

SA-1331K and SA-1332K have extra-long universal jointed glow plug sockets with a specialised puller and drills that suits most Japanese, Korean and European Diesel Engines. These special sockets enable

access to difficult to reach glow plugs and the puller is fantastic for grabbing onto the glow plug in difficult to access places.

When testing glow plugs it is important that the test tool applies current load on the element, which is required to accurately check for faults. A multimeter will show correct continuity, but the current may break down when load is applied, giving an incorrect diagnosis of the glow plug.

MULTI VOLTAGE GLOW PLUG TESTER TOOL – SA-1053

This tool quickly and accurately test glow plugs, applying a current load on the element during testing ensuring a correct result.

The length and style of glow plug will often determine the type of tools you require with long thin glow plugs often causing the greatest issues.

In cold weather, often diesel engines can be difficult to start because the mass of the cylinder block and cylinder head absorb the heat of compression, preventing ignition, the glow plug is used to compensate for this heat loss.

When confronted with a broken or stuck glow plug, it is important to use the correct tool for removal, otherwise the issue can easily escalate, requiring the removal of the cylinder head or risk damage to other engine components. Glow plugs typically break at the head nut or at the tip which becomes brittle and distorted due to the heating as shown opposite.

Often you will unscrew the glow plug only to find that it is still stuck fast either on the body, thread, or the tip, depending on the style and length of the glow plug. Using a glow plug extracting tool (different styles found in a number of our Glow Plug removal kits) allows you to get a good strong hold on the head, or if that has broken off – the electrode may protrude –this will take a bit of force with some kits containing a slide hammer to give a good

straight force reducing further breakage. If this doesn’t succeed you may need to drill out the broken plug down to where the threaded portion begins.

Drill out the glow plug body using a step drill – using a new plug to measure the depth required to drill out the old thread ensuring that all swarf is removed as you go. Then you can tap a thread into the inside of the glow plug body and using a cone extractor which is available in a number of our kits and shown in the SA-4296 kit. The cone style forcing nut enables easy extraction of the stuck glow plug.

This kit removes 8mm and 10mm glow plugs found in many vehicles. The high-

quality ratchet T-bar drill holding adaptor shows the superior quality of this kit compared to similar kits. The puller force screw with force nut taps into the glow plug for removal. It also has dual-size hightensile step drills m8 and m10 and pilot drill centring sleeves.

The set includes all tools required for drilling, centring and pulling glow plugs for efficient removal.

During this process you should continuously remove any metal shavings or carbon that is loosened so that it doesn’t become lodged in the glow plug recess or worse, the cylinder. To assist in this process, Specialist Tools Australia uses the Govoni insulated magnet shown in the universal kit and the Govoni dummy injector which blows air into the cylinder and out through the glow plug hole ensuring no rubbish is left in the cylinder. The glow plug recess should be thoroughly cleaned of all carbon, rust and metal shavings before a new plug is fitted or the element end can be damaged.

This is a comprehensive kit for the complete removal of glow plugs stuck or broken at various points and includes an amazing, insulated magnet to assist with the removal of metal shavings as well as a heavily weighted slide hammer arrangement.

ACM Parts stocks a range of leading aftermarket parts and accessories for those looking for for an alternative to Genuine. Our Aftermarket range includes Radiators, Intercoolers, Condensers and Headlights.

Aftermarket Cooling Range: BorgWarner is a global product leader in clean and efficient technology solutions for combustion, hybrid and electric vehicles. Their expanding range currently consists of radiators, condensers and intercoolers to suit a wide range of makes and models.

Aftermarket Lighting Range: ACM Parts has partnered with Hella and Valeo to offer an extensive range of aftermarket lighting options. The range focuses on headlights to suit many European makes and models including Audi, Volkswagen, Mercedes, BMW and Renault.

Depending on the style of glow plug you have to remove, or the location of the glow plug in the head, you can look at more specialised removal kits that are suited to your job. Call the team at Specialist Tools Australia and they can assist you with selecting the correct tools for your job.

GOVONI UNIVERSAL BROKEN GLOW PLUG ELECTRODE REMOVAL KIT – G311188000 OR SA-3752

When extracting glow plugs, the glow plug tip (Electrode) may become seized in the electrode bore, and will often break at the point of the body and remain stuck in the cylinder head. The broken glow plug tips can be easily extracted with the help of this tool set which contains all of the tools needed to accurately tap resilient threads into the end of the glow plug.

Afterwards the glow plug tip will be extracted with the help of the extraction rod and a striking hammer. The drill will be guided precisely using the glow plug threading in the cylinder head. This will avoid any damage to the cylinder head. This set can be used with any current diesel motors using glow plug. thread sizes: M8x1, M9x1, M10x1 and M10x1.25, Govoni Universal Broken Glow Plug Electrode Removal Kit – G311188000 or SA-3752 Glow Plug Tip Removal Kit.

DUMMY INJECTOR AIR BLOWING ADAPTOR – GO509

This tool is used for blowing air into the cylinder during broken glow plug repair operations, used in conjunction with the broken glow plug repair and reaming tools. It is simply fit into the injector recess in the cylinder head and connected to the air supply, the air volume is adjusted via the tap as required.

G311109000 - Glow Plug Recess Cleaning Set.

GLOW PLUG RECESS CLEANING SET – G11109000

This is a universal reamer set with thread adaptors used to clean up the glow plug shaft area and the sealing seat in the cylinder head.

PROFESSIONAL COMPLETE GLOW PLUG AND SPARK PLUG THREAD REPAIR SET – G772004000

This kit is designed to repair/replace damaged glow plug or spark plug threads in the cylinder head using threaded inserts that are fitted into the head using the included tap guides for correct alignment.

G772004000 - Govoni Glow Plug Thread Repair Set.

For more information contact Specialist Tools Australia on (02) 6280 4334, visit www.specialisttools.com.au or email sales@responsiveengineering.com.au ACM

It’s not easy to keep up with advances in braking and braking systems, but that doesn’t mean it doesn’t need to be done.

One company which does stay well in touch with leading-edge braking technology is Disc Brakes Australia – DBA.

After 40 years in the braking business, DBA not only keeps up with technology, it’s fair to say the company sets the pace in many areas, especially rotors and drums.

That’s not all the company does of course, and as you read this there’s a stack of new gear in DBA’s product lines, including master cylinders, wheel cylinders, pads, calipers and sensors.

And if anyone knows the ins and outs of different brake fluids and their appropriate uses, it’s Bendix, Australia’s largest manufacturer of friction materials.

Based in Ballarat, Victoria, Bendix has a reputation for manufacturing, marketing and distributing quality products with high levels of customer service, and was happy to share some high-level expert knowledge on good ol’ Dot 4 – or Dot 3, Dot 5 and Dot 5.1 – and its application for both clutch and braking systems in passenger and commercial vehicles.

Are we going too fast for you?

Here’s a few products which might help slow things down.

With a comprehensive program of brake Master and Wheel Cylinders, Disc Brakes Australia (DBA) is launching the latest addition to its range of brake product lines.

Having enjoyed tremendous success with its new range of STREET SERIES brake pads since its market introduction in 2021, DBA is excited to announce the expansion of the STREET SERIES family of products into the hydraulic space. With a continuously increasing number of SKUs of brake calipers forming the base of the new hydraulics program, DBA is about to grow its offering even further by adding a comprehensive range of brake Master and Wheel Cylinders.

“We’re on track to becoming the number one brake solution supplier to the ANZ market, with our product range now comprising of the most complete market coverage for brake rotors/drums and friction products, and with hydraulic components catching up quickly,” explains Brian Johns, Head of Product, Innovation and R&D at Disc

Brakes Australia. “However, we’re not going to stop locally. With our export business becoming an increasingly important and fast-growing part of our business, the range will cover many applications found in markets around the globe.”

Available to the market from July is a range of over 900 SKUs. By the third quarter of 2022 this is expected to grow to over 1,200 SKUs, offering an estimated market coverage of up to two thirds of the Australian car park, thus supporting DBA’s market leading position for its rotor and friction lines.

All hydraulic products are easily identifiable by displaying the letters ‘dba’ on the cylinder body. Importantly, like all DBA parts, the new range has been meticulously catalogued on DBA’s online ‘Part Finder’ catalogue, accessible via their website dba.com.au. This includes a unique

database of competitor-to-DBA crossreferences to facilitate part identification.

Technically, DBA like with all its products makes no compromises when it comes to quality and durability of the new range. The hydraulic parts are manufactured to the highest available quality standards, conforming to TS 16949, the internationally recognised Quality Management System specification for the automotive industry.

Full traceability is integral to the success of the manufacturing process and ensures complete compliance at all stages of manufacturing from raw materials to the finished goods. As such, Disc Brakes Australia as a business is compliant to ISO 9001, guaranteeing all processes are continuously monitored. As part of its quality assurance process, DBA scans all OE products as a reference. All DBA sub-components and sub-assemblies are likewise measured and inspected at each stage to ensure the product is equal to or exceeds any OE specifications. Particularly, all plastic components and reservoirs are 1:1 re-engineered to OE specs to be impervious to the required fluids.

Prior to sign-off and shipping at completion of production, randomly selected parts are both performance-tested and environmentally tested. DBA ensures all parts go through a full durability test regime inclusive of ambient and high/ low temp testing. Internal checks are carried out for bore roundness, roughness and hardness. All reservoirs are pressure tested, as well as all springs and seals for completeness. Each product is also sealed prior to boxing, ensuring the product is free from particulate matter for direct use at the workshop straight from the box.

For peace of mind, all hydraulic components are covered by DBA’s product warranty of 12 months or 20,000km.

For further information head to dba.com.au or call 1800 730 039.

Brake fluid is a type of hydraulic fluid and serves several important purposes within modern braking systems.

The main task of brake fluid is to transfer force – when the brake pedal is pressed, it activates the brake master cylinder which pushes pressurised brake fluid through the brake lines and ultimately to the brake calipers which apply pad pressure to the disc brake rotors. Brake fluid is non compressible, ensuring that the pressure that’s applied at the pedal is maintained to deliver the necessary braking force to safely bring a vehicle to a standstill.

A secondary purpose of brake fluid is to lubricate all the moving parts within the braking system, helping to protect it against rust and other corrosion. It also helps dissipate heat within the system, leading to reliable and predictable braking performance.

Like most fluids and oils used in a vehicle, the brake fluid should be periodically changed to ensure it remains fresh and uncontaminated, which in turn ensures the braking system is operating at its full potential.

Although the braking system is classed as a closed system, over time it’s impossible to keep out small amounts of moisture which can be absorbed from the air through imperfect seals, microscopic holes in rubber hoses or even when the cap is left off the fluid reservoir for too long. Eventually the moisture mixes with the brake fluid increasing its water content; this reduces its ability to protect the braking system’s internals against corrosion, it also lessens the fluid’s boiling point which reduces performance.

Owners should consult their service manual to learn more about their vehicle’s brake fluid changeover schedule, or if they are experiencing a decline in braking performance, visit their local service centre or brake specialist who will properly diagnose the issue. In diagnosing a braking issue, the technician may perform a brake fluid test to learn if it’s still providing the necessary protection and performing as it should. To do this, the mechanic or technician will use an electronic brake fluid tester, dipping it into the brake fluid reservoir – the tool then analyses the quality of the fluid. More basic ‘strip’ tests are also available, which perform a similar function.

A technician tests the quality of the brake fluid to determine if it requires changing.

If the brake fluid does need replacing, your technician will specify a fluid that’s in keeping with the vehicle’s OEM parameters because not all brake fluids are the same. A visit through any automotive retail outlet reveals the wide selection of replacement brake fluids available on the market, and each will include a ‘DOT’ reference on the labels: DOT 3, DOT 4, DOT 5 and DOT 5.1.

DOT refers to Department of Transport, it’s a standard that sets the safety regulations that are acceptable for different brake fluids, and the DOT ratings given to a brake fluid are based on the fluid’s wet and dry boiling points. A reference point for dry boiling point is when the fluid is brand new, while wet boiling point is when the fluid is one to two years old and already has some moisture content. As an example, dry boiling temperature for a DOT 4 fluid would be over 230°C, while the wet boiling temp could be closer to 155°C. Generally speaking, the higher the DOT rating, the higher the boiling point and

Using a quality brake fluid is important to ensure the overall performance of the braking system.

longevity of the fluid. Before rushing off to buy the highest DOT fluid though, consult the vehicle owner’s manual because some brake fluids are incompatible with different brake lines and systems.

DOT 4 fluids are the most widely used

– Bendix offers both high performance Polyglycol DOT 3 and DOT 4 fluids, providing optimum performance in both hydraulic and conventional braking systems, meeting stringent Australian and U.S. specifications.

To learn about Bendix brake fluid visit www.bendix.com.au/product-range/brake-fluid

EV-Hybrid Disc Brake Pads are AASA Leafmark™ Certified which means they use organic brake friction materials for minimal environmental impact. In addition, low particle emissions deliver cleaner wheels and long disc life. Featuring Bendix’s exclusive Green Titanium Stripe, EV-Hybrid pads provide instant friction (no bedding-in required). Designed for quiet operation and low noise, EV-Hybrid pads are specifically engineered for EV and Hybrid Vehicles.

Low Dust, Low Noise

www.mechanics-mag.com.au

Filtration is more critical than it’s ever been. Where an oil-bath filter perched on top of a carby was ‘good enough’ for our grandfathers’ side-valve engines, performance increases and tightened emissions laws now place a heavy burden on filters to clear particulates and debris from moving fluids that would’ve seemed incredible a few decades ago.

Ensuring clean air entering an engine is probably one of the easier tasks for a filter. Providing the quality of oil

and fuel needed for modern motors, especially diesels, has become a highly specialised and crucial system in its own right. Maintaining the quality of oils, air and fuels not only massively decreases wear and tear, it also makes a major contribution to achieving emission levels required for safe and legal operation.

Of course, diesels are usually mated to turbos, and although they’re usually very robust and low-maintenance systems, there are a few common problems which can be

very difficult to deal with. Having the right tools means getting those jobs done quickly and efficiently, and that’s the aim of every pro workshop.

Those looking for big performance gains from petrol motors will often turn to turbos or supercharging as well, and that requires some specialised equipment.

Have a closer look at the products on these pages and you’ll be right up to date with the best fuel-injection and engine management systems available today.

The valve block is also involved in the release of excessive air pressure. If needed, the solenoid valve towards the air compressor is opened. The pressure is released through the pressure release valve on the compressor. In cases where a vehicle stays “locked” on a certain ride height, first check the function of the pressure release valve on the compressor before diagnosing a faulty valve block.

If an air compressor is no longer running, the usual suspect is often the compressor or a faulty relay. It might be the valve block. The air suspension pressure sensor is located inside the valve block, not in the compressor. If this sensor isn’t working correctly, the signal for activating the compressor stays out and pressure is no longer built up.

If the dryer no longer has the capacity to keep moisture out of the system, the valve block can corrode internally. Freezing temperatures can also cause the moisture inside the valve block to freeze and stop functioning.

Symptoms that seem to point to a leak in an air spring might indicate a defect in the valve block.

The valve block takes care of the distribution of pressurised air. The general objective is to use the pressurised air as efficiently as possible, so the compressor runs as little as possible. This prevents overheating and keeps energy consumption low.

Over time, the solenoid valves in the valve block can become sticky or blocked by small particles that circulate through the system during operation. For example, when an aging compressor breaks down, the valve block can become damaged too. Small metal particles can block the solenoid valves and disturb the air distribution causing the vehicle to be lower in one or more corners.

One last thing to keep in mind is normally the airline from the air compressor to the valve block is unpressurised if the compressor is not running. This allows the compressor to start easily. If for one of the above-mentioned reasons this airline stays pressurised, much more heat is built up each time the compressor is activated. This could lead to a burned-out compressor.

Even though it is small, this significant component of the air suspension system deserves some attention – especially after a compressor replacement.

For more information visit choosearnott.com

The valve block is a small but significant component of the air suspension system.

Australia’s leading supplier of automotive aftermarket steering and suspension components has embarked on a new brand marketing platform that captures the factors that make Roadsafe the country’s unparalleled leader for these integral automotive replacement products.

“Roadsafe - For The Road Ahead” signifies how this Australian steering and suspension component brand is always moving forward, constantly expanding the precision engineered Roadsafe range through suspension product innovation and development.

A brand new Roadsafe logo accompanies the new “For The Road Ahead” positioning statement, along with brand new product packaging, a new website (at www.roadsafe.

Roadsafe has been manufacturing and supplying Australia’s automotive trade with the widest range of replacement steering and suspension components for more than four decades.

ROADSAFE – ALWAYS READY TO INNOVATE FOR THE ROAD AHEADRoadsafe Steering and Suspension range.

com.au) and new marketing collateral across all of the Roadsafe product categories.

These categories include Roadsafe STR (Street and Passenger Vehicles), Roadsafe 4WD, Roadsafe HD (Heavy Duty) and Roadsafe CLS (Classic Vehicles). These product segments are boosted by new and innovative steering and suspension components engineered by Aussies

complete suitability and reliability in Australian conditions. This is particularly important and relevant for the Roadsafe 4WD product range.

Offering an unsurpassed range of chassis products in Australia, it is Roadsafe’s expertise that makes this Australia’s leading steering and suspension product supplier. The company’s own R&D and Innovation Centre is equipped with the most modern

The highest level of Roadsafe innovation and development is found across the entire Roadsafe steering and suspension product range, headed by the company’s precision engineered and solution oriented 4WD product range, designed by passionate four-wheel drivers for their fellow four wheel drivers.

Roadsafe makes 4WD steering and suspension enhancement easy through the company’s engineering experience, a major reason why this is also the destination for so many Australian 4WD Specialists for their suspension product replacement requirements.

for Aussies in order to best meet the demands of our specific driving conditions.

Moving forward for The Road Ahead also means that there is no compromise on product quality, with all Roadsafe steering and suspension components subject to stringent manufacturing standards and rigorous local testing. The company’s products have been tested vigorously including cyclic, FEA, destruction and drop testing, ensuring their

technology to custom design suspension components to best suit the Australian automotive aftermarket.

Highly experienced and attentive customer service is also integral to Roadsafe’s market leading success, with warehouse locations available across multiple states ensuring that high demand is met by strong national supply rates, supported by industry leading print and online cataloguing.

The unrivalled Roadsafe steering and suspension product range also includes specific vehicle application engineered ball joints, tie rod ends, rack ends, drag links, relay rods, track rods, idler / pitman arms, sway bar links and control arms.

To locate your nearest Roadsafe stockist, visit Roadsafe online at roadsafe.com.au or call (03) 8687 1700. ACM

Earlier this year The Australian Prudential Regulation Authority (APRA) released its Quarterly Superannuation Performance publication and the Quarterly MySuper Statistics report for the March 2022 quarter.

It revealed that superannuation assets totalled over $3.4 trillion at the end of the March 2022. This was a 9.7 per cent increase in the value of total super assets over the past year, reflecting strong investment performance and positive contributions growth due to COVID-19 fiscal stimulus received over the period.

However, the March 2022 quarter reflects contributions beginning to revert to long-term trends and weaker investment performance due to concerns over higher interest rates with rising inflation exacerbated by constrained supply chains as well as the uncertainty brought about by the conflict in Ukraine.

Contributions totalled $141.6 billion, an increase of 16.9 per cent for the year ending March 2022.

This contributions growth can be largely attributed to the increase in household savings during the onset of COVID-19, although member contribution levels have begun to revert back to longer term trends in the past two quarters.

For more information or copies of the publication visit: www.apra.gov.au/quarterly-superannuation-statistics

"IT IS ROADSAFE’S EXPERTISE THAT MAKES THIS AUSTRALIA’S LEADING STEERING AND SUSPENSION PRODUCT SUPPLIER."

Although brake hoses may not have the same prominence as other components such as brake pads, disc brake rotors, calipers or even the brake master cylinder, the humble brake hose is actually one of the most regulated components of a vehicle. This gives an indication of how critically important brake hoses are to the overall performance of a braking system.

In a nutshell, brake hoses are responsible for carrying brake fluid from a vehicle’s brake lines – which are fixed to the car or truck’s underbody – on the last part of the fluid’s journey to the brake calipers which of course are located at the wheels. The fact that there’s wheel movement going on as part of the suspension assembly as well as for steering, means that brake hoses need to flexible yet tough.

Another reason they need to be robust is because the brake fluid travels through under high pressure once the brake is applied and brake master cylinder comes

When thinking about braking systems, hoses are likely to be well down the list in terms of the components that immediately come to mind for most people.

COMPONENT WITH A BIG JOB

into play. Brake fluid is non compressible, so the pressure that’s generated at the pedal is maintained to deliver the necessary braking force to safely bring a vehicle to a standstill. In order to maintain this pressure, the hose must retain its original shape.

It’s no surprise then that the regulations and testing that govern the manufacture of brake hoses is strict, with testing benchmarks set that are unlikely to ever be replicated in real world driving conditions.

To meet governing DOT and SAE J1401 standards, brake hoses must pass the following tests:

• Burst pressures. Must withstand water pressure of 4,000 psi for two minutes

• Whip testing. Must endure being continually bent for 35 hours under pressure

• Tensile testing. Hose assembly must withstand a pull of approx. 147kg without separating from its end fittings in a ‘slow pull’ test and approx. 168kg in a ‘fast pull’ test

• Cold resistance. Hose is chilled to -45°C for 70 hours and must not show visible cracks when bent around a cylindrical shape

• Chemical resistance. Hose is subjected to 120°C for 70 hours while filled with an SAE ‘compatibility fluid’; afterwards the hose is subjected to a 4000-psi burst test

• Ozone resistance. Hose assembly is exposed to ozone for 72 hours at 40°C and then inspected for cracks under magnification

• Fitting corrosion resistance. Hose assembly is exposed to salt spray for 24 hours and must show no base metal corrosion to the end fitting surface.

Most OEMs don’t have set schedules for replacing brake hoses, so they should be inspected during vehicle servicing, both visually and by feeling the hoses with the hands to pick-up any potential cracks or deformities that are out of sight.

If any of the following flaws are detected during an inspection, the brake hoses should be replaced:

• Cracks – even if very small, there’s a risk they’ll grow leading to possible bursting

• Bubbles or other deformities – the hose should not change shape under braking pressure (have someone pump the brake pedal during this test)

• Leaks and stains – a leak or stain is not normal and will allow air and moisture into the braking system – this means reduced braking force and an increase in corrosion within the system

• Corrosion – while brake hose fittings are plated to resist corrosion, when this protection wears away, corrosion will occur faster, potentially compromising the fitting.

Bendix offers Ultimate 4WD Brake Hose Kits for standard height vehicles as well as in longer lengths for those four-wheeldrives equipped with raised suspensions – all meet the SAE J1401 standards as described earlier as a minimum.

To ensure high levels of performance and durability, the Bendix brake hoses are constructed from PTFE (Teflon®) tubing which is then covered by woven stainless steel 304 braid, and finished with the Bendix blue protective layer that further safeguards the braid from dirt, dust and grime.

While steel braiding isn’t required under SAE J1401, this added component helps to deliver a more consistent and firmer brake pedal feel and prevents over expansion of the hose under high braking pressures.

For additional performance, the Ultimate 4WD Brake Hoses are terminated with 12L14 steel and chrome plated; they also feature a rubber over-moulding designed to minimise coupling-to-hose fatigue which provides a longer life in tough environments.

offers a new level of underfoot safety. A unique pivot pad has been incorporated into the sole, allowing freedom of movement, and reducing ankle twist injuries.

This world-leading biomechanical design is a result of years of research and development into the needs of workers in the trades, mining and construction industries. The airportfriendly range includes four unisex styles and two women’s-specific styles crafted for the ever-growing female market.

All six styles feature a water-resistant upper, lightweight, compression-resistant composite toe cap, and an all-new zoned airflow footbed to activate ventilation and provide moisture control - no more sweaty feet.

Biomechanics come to the forefront with all the features and design principles applied to the new GripTek® soling system. From larger cleats and tracks which deter dirt build-up to a broader sole surface of the heel area and carefully moulded TPU to assist in preventing ankle injuries, GripTek®

The overarching comfort system, SoftCell® utilises a combination of specialist materials and a unique biomechanical foot-cradling design to increase stability, balance, comfort and manoeuvrability, while reducing ankle slip risk and fatigue.

Every single component used in the construction of the RotoFlex range has been researched, tested and trialled to ensure Blundstone deliver truly innovative, better-performing safety footwear. Their dedicated design team looked at multiple options for each element and selected the best performing, most appropriate product - and if they couldn’t find the perfect piece, they created it.

Launching in September 2022, RotoFlex delivers a strong foundation from the ground up, providing unbeatable fit and unrivalled comfort - perfect from day one. Put their innovation to work at the link below.

www.blundstone.com.au/rotoflex

Iconic Australian footwear brand Blundstone, continues to be at the forefront of safety footwear, with the launch of their new RotoFlex® Range.

series turbochargers feature the latest innovations in turbocharger technology. Advanced compressor and turbine aero provide a wide range of performance boosting solutions for 3.0L - 12.0L engine platforms. Offered in standard rotation, with seven compressor inducer options and a variety of V-Band and T6 inlet turbine housing configurations making it easy to select the right turbocharger for your application.

NEXT Tech Equipment makes the process transparent and easy via their informative website. What makes this unique? Often, companies will provide so much information about their products that the customer is confronted with the problem that they have more questions after they have done their research rather than be confident and content with what they have seen.

NEXT Tech Equipment is conscious about avoiding exactly that problem by providing concise information videos, highlighting the benefits and features of the vehicle hoists that are on offer. That way, what you see and hear from those videos is exactly what you will receive and you won’t be left with any doubt.

NEXT N-45 (4.5t) HOIST

Starting with the solid, one-piece post that is re-enforced with internal brackets that are attached to an industry leading 20mm

thick baseplate, the N-45 is structurally robust and the evidence is proven in the 970kg weight of the vehicle hoist itself.

The small details are as important as the big details when it comes to a great design and NEXT hoist range has those covered with smart innovations when it comes to protecting the vehicle.

Each post has two rubber pads to avoid an inadvertent bump from a car door that is opening. Each lift arm has an additional, easily removed and replaceable rubber protection pad to again protect the vehicle doors when opening.

With a tool tray securely fitted to each lifting arm, you will have somewhere to place wheel nuts and tools as you are working. No more misplacing nuts, bolts or your spanners… And yes… They come standard with every NEXT two-post hoist.

To complete the package, NEXT Tech has added the 80mm and 180mm pad

extensions to ensure you can lift passenger vehicles, four-wheel drive vehicles and commercial vans safely and securely.

With a NEXT two-post vehicle hoist, the team at NEXT Tech have ensured that not only you are protected and safe, but the vehicle is protected and safe as well.

NEXT N-55 (5.5t) HOIST

Want to lift big? NEXT also has you covered with the New Generation NEXT N-55. With 5.5t lifting capacity the hoist also standard comes with a 600mm height extension (optional 1200mm extension is also available) to enable the user to lift taller vehicles. All the design and safety protocols are manufactured into this vehicle hoist as safety is their number one priority.

With a NEXT N-55 vehicle hoist, you get four extra-long, triple expanding arms. This allows you to position a dual cab ute so that it is always placed with the centre of

There’s a lot to consider when setting up your new workshop or upgrading your existing equipment.

gravity in line with the centre of the hoist, irrespective of whether it is fully loaded or entirely empty.

NEXT Tech Equipment is an Australian owned company that specialises in vehicle hoists and wheel service equipment. The three Directors have extensive knowledge and experience in the garage workshop, dealership and tyre store market.

With that expertise, Don McEvoy (Product Technical Director) explains: “We have the perfect combination of knowledge and history within the industry to understand what the customer requires. Through this experience we knew we could only utilise iconic manufacturers with an extensive footprint within the global market. We also wanted our products to have strong aesthetics and colour continuity within the range so new mechanical workshops can capitilise on the image projected from such a vision.”

For more information visit nexttechequipment.com.au or email enquiries@nexttechequipment.com.au

The X431 EuroTab II from Launch is a high-end comprehensive diagnostics tool with docking station. Developed around Android 7.1 technology, the X431 TAB II inherits all the excellent functions of the previous generation tool: wide-vehicle model coverage, powerful diagnostic function