Service agreements for underground and surface equipment

United. Inspired.

COP CARE

Service agreements for underground and surface equipment designed to keep productivity levels up and costs down. With COP CARE, our technicians are scheduled to come to you for regular servicing following the factory service intervals, which reduces the risk of unexpected breakdowns. Speak to us today to find out what service agreement is available for your machine model!

THE ENGINE ROOM

MINERAL PROCESSING INNOVATIONS ARE INCREASINGLY VITAL TO THE DECARBONISATION OF THE MINING INDUSTRY.

The mining industry couldn’t operate as it does today without a reliable mineral processing sector.

While mineral processing has long served as an inherent practice in the resources value chain, it is an industry that is growing in importance.

Increasing the efficiency of mineral processing machinery and technologies has the potential to significantly drive down carbon emissions, enabling mining companies to meet their growing environmental obligations.

One proponent of this is FLSmidth, which has a range of fixed plant equipment that enable mining companies and contractors to achieve more product for less CO2 per tonne.

This includes FLSmidth’s REFLUX technologies, comprising the REFLUX Classifier, REFLUX Concentrating Classifier and REFLUX Flotation Cell, alongside its crushing, milling and grinding solutions.

FLSmidth’s fixed plant equipment underpins the MissionZero mine, whereby the company is working with its mining customers on solutions that aim to achieve zero emissions, zero water waste and zero energy waste by 2030.

Another mineral processing innovator is Molycop, which provides grinding media to optimise milling, leaching and flotation circuits.

Recent years have also seen Molycop develop a presence in data technology, with the introduction of services such as process optimisation, online analysis, and data analytics and visualisation.

Such solutions are enabling mining companies and contractors to realise more value from their throughput, supporting a more intelligent and efficient mineral processing operation.

Elsewhere in this edition, Australian Mining showcases leading technology proponents such as Appian, Brennan, ifm, Vocus, Dendra and FLIR Systems, which are assisting their mining clients to enhance their processes through tech innovations such as artificial intelligence, machine learning and automation, to name a few.

We shine a light on the uranium revival and the Australian mining companies looking to capitalise on a soaring price.

There are also profile pieces on De Grey Mining and True North Copper, two near-term producers of gold and copper, respectively. In fact, De Grey is looking to deliver the Pilbara’s first Tier 1 gold mine through its Hemi project.

Rounding out the April edition are features on the Australian mining sector’s renewable energy efforts, and a rundown of the relief on offer for the country’s beleaguered nickel miners.

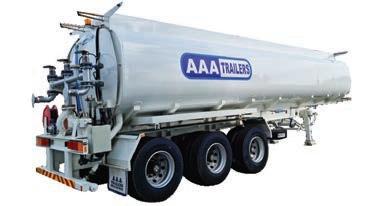

Founded in China in 1943, Xuzhou Construction Mining Group (XCMG) is one of the world’s leading manufacturers of mining and construction equipment. XCMG’s sales network extends into 184 countries, and the company is represented by 300 distributors worldwide. As it looks to grow its Australian presence, XCMG is offering the local mining sector a state-of-the-art range of mining trucks, excavators, loaders, graders, cranes, hydraulic parts, and rollers.

XCMG Australia mining trucks are designed for high transport efficiency and low maintenance costs, without compromising on operator comfort or safety.

Tom Parker EditorWith a national parts centre in Melbourne, XCMG Australia has plans to expand into Perth, while a research and development facility is also a possibility in the short term.

16 COMMODITY SPOTLIGHT

The future of Australian uranium Australian Mining showcases the projects underpinning a new generation of uranium mining in Australia.

20 INDUSTRY INSIGHT

Tracking a critical future

Deloitte’s annual Tracking the Trends report looks at the challenges and opportunities facing the mining industry in the year ahead.

22 MINING EQUIPMENT

Equipped for the future

XCMG Australia has plans to become a household name in the mining industry.

28 MINERAL PROCESSING

Solving the decarbonisation disconnect Australian Mining sat down with FLSmidth to discuss the decarbonisation challenges the Australian mining sector is facing today.

32 MINERAL

Molycop is transforming mine operations better than ever.

44 MINE TECHNOLOGY

A critical constellation

The Vocus Starlink satellite is opening Australia’s most remote mines to a new era of connectivity.

54 COMPANY PROFILE

A Pilbara treasure chest

De Grey Mining’s Hemi gold mine is set to become the first Tier 1 gold operation in WA’s famed Pilbara region.

66 COMPANY PROFILE

A new copper player emerges True North Copper is aiming to become a producer of copper sulphide ore at its Cloncurry project in northwest Queensland.

68 INDUSTRY DEVELOPMENTS

Remote facility, state-of-the-art services etso’s Karratha service centre in WA brings with it a suite of benefits for the Pilbara mining industry.

FOLLOW THE LEADERS: THE LATEST EXECUTIVE APPOINTMENTS

KEEP UP WITH THE LATEST EXECUTIVE MOVEMENTS ACROSS THE MINING SECTOR, FEATURING 29METALS, BHP AND RIO TINTO.

James Palmer has joined 29Metals as its new chief executive officer (CEO), with the former BHP leader to commence in the role on May 1.

leading ASX-listed copper-focused company, offering investors exposure to copper and other metals critical to the global energy transition – is compelling,” Palmer said.

The copper miner had been on the hunt for a new managing director and CEO since last December, when it was revealed that Peter Albert would retire on April 30, as part of the company’s new transition plan.

Palmer has more than 25 years’ experience across multiple commodities in various operational, technical, strategy and business development roles.

He joins 29Metals from BHP where he spent the past two decades in various leadership roles, most recently as BHP’s group performance and improvement officer.

“The board is delighted to appoint someone of James’ calibre and experience,” 29Metals chair of the board of directors Owen Hegarty said.

“James impressed us with his drive and energy, his deep operational and business improvement experience, and his track record of operational transformation and stakeholder engagement.

“The board extends our thanks to Peter, 29Metals’ foundation CEO, who has led 29Metals through its establishment, the IPO and the period since.”

Palmer said it was a privilege to step into this new role.

“The opportunity to take 29Metals forward to realise its vision – to be a

“I am very much looking forward to working with the board and the team across the business to drive safety and performance to realise the clear potential of 29Metals’ assets and people.”

BHP is welcoming a new nonexecutive director to its board.

Ross McEwan will join the team from April 3, bringing 30 years of executive experience with expertise in capital allocation, risk management and complex regulatory environments.

McEwan has held top jobs across the globe, including as CEO of NAB since 2019, and as group chief executive officer of the Royal Bank of Scotland from 2013 to 2019.

Prior to this, McEwan also held executive roles at the Commonwealth Bank of Australia, First NZ Capital Securities, and the National Mutual Life Association of Australasia.

“We are delighted to announce that Ross McEwan will join BHP,” BHP chair Ken MacKenzie said.

“Ross brings a strong focus on people and culture, technology and innovation and has deep experience in capital allocation and value creation. Ross has worked closely with a wide range of stakeholders, including customers, governments and regulators and brings a global perspective.

“He has a deep understanding of organisational transformation and brings a very strong focus on the customer and technology as a driver of change. We look forward to welcoming Ross to the board on April 3, 2024.”

McEwan’s appointment comes after BHP made sweeping changes to its executive team in December, with the appointment of a new chief financial officer, chief commercial officer, and chief technical officer.

This included Vandita Pant becoming chief financial officer, BHP president of Americas Rag Udd becoming chief commercial officer, and BHP chief development officer Johan van Jaarsveld being appointed as chief technical officer.

Rio Tinto announced that its nonexecutive director Simon McKeon will step down from his role on May 2.

“I am extremely grateful to Simon for his invaluable contribution,” Rio Tinto chair Dominic Barton said.

“Having regard for his roles as Rio Tinto Limited’s senior independent director and the designated director for workforce engagement, Simon has taken a particular interest in Rio Tinto’s revitalised approach to engagement with the broader Australian community as well as the company’s cultural reset.

“On behalf of the board, I wish him well for the future.”

Whitehaven Coal appointed Mick McCormack as a non-executive director in February.

McCormack has more than 40 years’ experience working in the energy and

infrastructure industries in Australia, primarily within the oil and gas and renewable energy generation sectors.

He holds a Master of Business Administration and a Bachelor of Applied Science (Surveying) from the University of Queensland, and a Graduate Diploma of Engineering from Monash University.

McCormack previously worked at AGL Energy for 15 years and APA Group for 20 years, including serving as APA Group’s managing director and chief executive officer for 15 years.

He is also an experienced independent non-executive director who is currently on the boards of companies such as Origin Energy, Austal and Central Petroleum.

“I’m looking forward to making a contribution to the board of Whitehaven and working with the management team through what is set to be an exciting period of growth for the company,” McCormack said.

Whitehaven Coal chair Mark Vaile welcomed McCormack to the company’s board.

“We are pleased to expand the board and welcome Mick, who is a seasoned leader at both executive and director levels,” Vaile said.

“We look forward to his contribution including drawing on his deep knowledge of the energy sector and industry experience.”

The director appointment comes as Whitehaven is preparing to finalise its acquisition of BHP’s Daunia and Blackwater mines by April. AM

THE LATEST MINING

The extended and expanded agreement is set to bolster Pilbara Minerals’ lithium sales in the face of the recent price downturn.

Under an existing short-term agreement with Chengxin signed in 2023, Pilbara Minerals agreed to supply 70,000 tonnes of spodumene concentrate in the 2023–24 financial year (FY24) from its Pilgangoora operation in Western Australia.

over the next two years, with a deal to supply a further 300,000 tonnes of spodumene by the end of 2026.

“This amendment highlights the demand for Pilbara Minerals’ product and is a continuation of our strategy to expand our partnership with leading global lithium producers in the medium term while we progress the development of our long-term downstream partnership strategy,”

LIONTOWN ROARS INTO 2024

Liontown Resources has revealed a quarter of growth at its Kathleen Valley lithium project in Western Australia despite a drop in lithium prices.

The company bookmarked the December quarter with the milestone commencement of underground mining at Kathleen Valley.

Open pit mining also progressed to plan, with 1.4 million bulk cubic metres mined by the year’s end.

“The December quarter saw Kathleen Valley enter the peak

construction phase and achieve 72 per cent completion by year end,” Liontown managing director Tony Ottaviano said.

“The team has done an outstanding job in seamlessly mobilising to site, commencing six access portals, and achieving 352 total development metres in less than two months.”

Construction of crushing, screening and stockpiling infrastructure also advanced in the dry plant with commissioning targeted to commence early in the second quarter of 2024.

AUSTRALIAN MINING GETS

THE LATEST NEWS EVERY DAY, PROVIDING MINING PROFESSIONALS WITH UP-TO-THE-MINUTE INFORMATION ON SAFETY, NEWS AND TECHNOLOGY FOR THE AUSTRALIAN MINING AND RESOURCES INDUSTRY.

“This agreement further deepens our valued partnership with Pilbara Minerals and we look forward to supporting our global customers through the continued provision of high quality and cost-competitive lithium materials,” Chengxin chair

are committed to the energy transition and are focused on extending our respective positions as high quality, low-cost producers in the growing lithium battery materials market.” The deal stipulates that the spodumene concentrate be sold at the prevailing market price at the time, giving Pilbara Minerals room to see higher returns when lithium prices lift.

Pilbara Minerals also recently expanded its offtake agreement with Ganfeng Lithium Group for a further 310,000 tonnes through to the end of 2026.

The offtake expansions come at a time of increased production for Pilbara Minerals, with 176,000 tonnes of spodumene concentrate produced in the December quarter alone.

“We have around $515 million in the bank, which will see us through to first production at Kathleen Valley,” Ottaviano said.

Turning to 2024, Ottaviano said the company would be taking a measured approach to expansion in the light of the lithium price slump.

“We have commenced a review to examine the options of deferring the mine expansion from three to four million tonnes per annum until market conditions improve,” he said.

“The decision to undertake a review of the planned expansion and associated ramp-up of Kathleen Valley was based on short- to medium-term lithium price forecasts, which have materially declined in recent months.

“This will allow us to preserve capital and reduce the near-term funding requirements of the project as we seek to finalise a smaller, fitfor-purpose debt facility to see us through to first positive cash flows from Kathleen Valley.”

By utilising the latest technologies we provide an advanced combination of innovative solutions which optimise our customers mining operations performance, sustainability, availability and safety, around the globe. We supply:

• Wear parts and solutions for mineral processing, mobile and fixed plant operations

• Digital and equipment connectivity

• Asset condition and performance monitoring

• Design, engineering and manufacturing solutions

bradken.com

SCAN TO LEARN MORE

BHP LEADS THE WAY ON GENDER EQUALITY

BHP has demonstrated its commitment to achieving gender balance by becoming the first mining company to surpass over 40 per cent female representation in Chile.

The major miner extracts copper

the Escondida, Spence and Cerro Colorado mines.

The company’s female representation across its Chilean operations is more than double the national industry average, with 40.81

“We are proud of this achievement, but we are also aware that we have major challenges that go beyond gender balance. I hope our milestone will motivate the industry to continue bringing more women into mining.”

“To achieve this, BHP has implemented disruptive policies in the industry, such as making progress in addressing gender pay gaps, incorporating labour flexibility, strengthening training and talent

ALBEMARLE REPORTED $US9.6 BILLION IN NET SALES FOR 2023.

THE LATEST ROUND OF TRAINEES HAS GRADUATED FROM MINRES’ MC DRIVING TRAINING PROGRAM.

provide candidates with an existing multi-combination (MC) truck license with the skills and knowledge to drive 330-tonne quad road trains.

The program is tailored to each candidate’s experience, with training including vehicle pre-start inspections, daily safety checks, driving on the haul road, operating the side tipper trailers and radio communications.

“The program is a fantastic initiative to uptrain people who have little-to-no-experience in mining, with MinRes looking to fill more than 100 positions across our sites,” he said.

“The trainees are partnered up with experienced drivers to learn the ins and outs of operating quad road trains.

ARAFURA HITS THE GAS ON RARE EARTHS

Arafura Rare Earths has locked in a major gas supply agreement with New Zealand Oil & Gas (NZOG). The deal was struck between Arafura subsidiary Arafura Nolans Project and NZOG, who owns part of the Mereenie oil and gas field in the Northern Territory through a joint venture agreement.

Arafura’s neighbouring Nolans project has been tipped as a globally significant rare earth resource expected to become a major supplier of critical minerals.

The agreement will see NZOG supply up to 4.8 petajoules (PJ) of gas to Nolans over the next five years.

“Ensuring access to local natural gas is a positive step in the development of this major project, which will see critical rare earth minerals from the Northern Territory delivered to customers around the world in support of energy transition initiatives,” Arafura managing director Darryl Cuzzubbo said.

Gas supplied under the agreement will be aggregated with gas from other

to transition to a rewarding FIFO career with long-term prospects.”

Graduate trainee Jessica WilsonSmith successfully completed the program and is now based at MinRes’ Koolyanobbing iron ore mine site, driving Kenworth C509 and T909 trucks with up to five trailers.

“I spent six years in the New Zealand army as a combat driver

“MinRes offered a training program that didn’t require much mining or MC experience, which is great because it allows people to get their foot in the door and start a new career.”

To date, 40 trainees have taken part in the program, with graduates working at MinRes and CSI Mining Services mine sites across Western Australia.

Mereenie field joint venturers, Central Petroleum, Macquarie Mereenie and Cue Energy Resources, to supply up to 27.4PJ of gas to Arafura.

Central Petroleum will supply 6.85PJ of gas, aggregated with supply of 2.06PJ from Cue Energy and 13.7PJ from Macquarie Mereenie.

The agreement will kick off in 2026 for a three-year term, with a further two-year extension subject to gas reserves being available.

“The Nolans rare earth minerals project will deliver critical minerals

vital for the permanent magnets in wind turbines and EV motors – the marvellous machines that are the transition,” NZOG chief executive officer Andrew Jefferies said.

“The criticality of these materials is recognised by the Australian Federal and Northern Territory governments, and we are proud to be playing a key role in making it happen with our homegrown Northern Territory energy supply.

“Gas is a three-letter word for transition.”

CYLINDERS DESIGNED TO MAXIMISE EFFICIENCY

At MASPRO we have built our cylinders with quality in mind to increase lifespan which results in reduced downtime, unplanned maintenance and labour costs. When selecting a MASPRO cylinder, you can trust that no part has ever been repaired or refurbished, ensuring quality and reliability. This cost-effective solution provides peace of mind knowing that you are receiving a dependable product. Investing in MASPRO cylinders improves the productivity of your equipment, streamlines your operational efficiency, and lowers the overall cost of ownership of your drilling operations.

PORT PIRIE GETS A GREEN STEEL BOOST

Port Pirie Regional Council and Magnetite Mines (MGT) have signed a memorandum of understanding (MoU) to boost the development potential of the region as a future green iron production hub.

The MoU provides a framework for the South Australia-based council and MGT to engage State and Federal Governments on the development potential for green iron production, undertake preliminary planning for future production and assess other

partnerships that support a future green iron industry.

“On behalf of Port Pirie Regional Council, I am looking forward to the partnership with Magnetite Mines and accepting this significant opportunity to become more involved in green iron/steel production,” Port Pirie Regional Council Mayor Leon Stephens said.

“Port Pirie Regional Council has been exploring options to build upon our industrial strengths to attract alternative industry in order to diversify our local economy.”

THE LARGEST ASX MINING LISTING IN FIVE YEARS

Metals Acquisition (MAC) has become the largest ASX mining listing in five years, with big plans for Australian copper.

The company listed through a $325 million initial public offering (IPO), with the issue of 19,117,648 chess depositary interests (CDI) at $17 per CDI.

MAC’s foundational asset is the CSA copper mine near Cobar, New South Wales, which the company acquired from mining giant Glencore last year.

CSA is touted to be the highestgrade copper mine in Australia. The company will use the proceeds of its offer to further develop the mine and deliver a deferred payment to Glencore.

MAC now has a dual listing on the ASX and New York Stock Exchange, which the company said is part of its goal to acquire assets in high-quality, stable jurisdictions around the world that are critical in the electrification and decarbonisation of the global economy.

“We are very pleased to have

MGT chief executive officer Tim Dobson said the company is excited to be collaborating with the council.

“We see a once-in-a-generation, economy-changing opportunity for South Australia to take a leading role in global steel sector decarbonisation thanks to its expansive magnetite resources, green hydrogen and renewable energy,” he said.

“All major international steelmakers are committed to reducing their carbon footprints,

and need green iron to achieve that. It is clear to me that Port Pirie is a robust and logical location for South Australia’s second iron hub – processing and exporting Braemer iron ores for decades into the future.”

The MoU also provides a framework for cooperation on the development of supporting infrastructure for MGT’s Razorback iron ore project, including potential water supply elements and port development for the bulk export of magnetite products.

achieved an ASX listing and thank our new shareholders for their support for MAC,” MAC chief executive officer Mick McMullen said.

“An Australian IPO and listing will allow us to pursue a range of organic and inorganic growth opportunities in Australia and globally to continue building shareholder value.

“While we have made significant progress in improving overall operational performance at our CSA copper mine to date, our initial focus

will be to assess further exploration, development, and production improvement opportunities.”

MAC said its goal is to create a leading mid-tier, multi-asset producer of metals critical to the decarbonisation of the global economy.

“As we grow, we are focused on ESG stewardship and a firm commitment to the responsible and sustainable discovery, development, extraction, and use of mineral resources,” McMullen said.

Are you ready for a robust data transfer solution that can withstand extreme environments?

IO-Link is your home of reliable and efficient communications across the operation. A simple solution for complex industrial challenges.

Robust and ready for anything –Temperature, dust, vibration, moisture and corrosion are no match for IO-Link.

Efficient and productive – IO-Link empowers operations by providing real-time data from sensors and actuators.

Reduced downtime – Swiftly identify equipment issues to minimise the cost of malfunction and maintenance.

Scalable – Extend IO-Link across the operation at your own pace. ifm solutions grow with your business.

THE FUTURE OF AUSTRALIAN URANIUM

AUSTRALIAN MINING SPOKE WITH TWO COMPANIES ABOUT PROJECTS THAT ARE UNDERPINNING A NEW GENERATION OF URANIUM MINING IN AUSTRALIA.

The Australian mining industry certainly understands that resource commodity markets will regularly experience fluctuations.

A proliferation in cheaper nickel supplied countries with less stringent environmental, social and governance (ESG) standards has had a chilling effect on the Australian sector. And with many local nickel mines transitioning into care and maintenance in recent months, many eyes have turned to alternate minerals – and uranium is chief among the potential new players.

Uranium has gained popularity in jurisdictions that are looking to a future powered by less carbon-intensive fuels.

One of those is the European Union (EU), which has introduced a range of green energy targets in support of nuclear-powered ammonia and hydrogen production – a movement largely driven by France, which derives about 70 per cent of its electricity from nuclear energy.

Uranium is a key fuel in nuclear energy. Once mined, it goes through a conversion, enrichment and fuel fabrication process before being loaded into a nuclear power reactor.

Australia has long resisted getting on the nuclear bandwagon, despite holding 32 per cent of the world’s uranium resources, according to the ‘Australia’s Identified Mineral Resources 2022’ report.

The same report ranked Australia’s uranium production fourth globally, accounting for eight per cent of the world’s supply in 2021.

While Australian uranium production is lower relative to countries such as Kazakhstan, Canada and Namibia, the country has many exciting uranium projects in development.

And the timing could not be more perfect.

November 2023 saw the price of yellowcake – a type of uranium concentrate powder –skyrocket to $US80.25 per pound, its highest peak since March 2008. And the price continued to go up over the following months, with the commodity costing $US103.20 per pound in February.

Going deep

The jump in price has been especially welcome to Deep Yellow, a uranium developer operating in Africa and Australia, which has two major projects

underway – the Mulga Rock project in Western Australia and the Alligator River project in the Northern Territory.

Deep Yellow acquired Mulga Rock when its merger with Vimy Resources was finalised in August 2022. The previous definitive feasibility study (DFS) for the project, which was completed by Vimy in 2018, confirmed a potential annual production capacity of 3.5 million pounds (Mlbs) of uranium oxide over its 15-year mine life.

“We saw real bones in Mulga Rock from our due diligence,” Deep Yellow managing director and chief executive officer (CEO) John Borshoff told Australian Mining. “We believe we could build this project to more than what was stated in the 2018 DFS.

“The Mulga Rock East mining centre comprises the Ambassador and Princess deposits, and the Mulga Rock West mining centre comprises the Shogun and Emperor deposits. Everything that was announced in the 2018 DFS focused on the Eastern deposits, which are almost co-joined.

“Since Vimy merged with Deep Yellow, we’ve worked to redrill the project to substantiate its variability and to infill the large amount of

drilling that had already been done. This way we could get an indicated resource of uranium and the associated non-uranium minerals because the value uplift we were looking for was through the consideration of critical minerals in addition to the significant uranium component.

“Looking at these additional minerals in conjunction with the uranium was where we saw great value for our shareholders.”

Deep Yellow is currently preparing to commence a revised DFS that focuses on developing Mulga Rock into a polymetallic operation, extending its life beyond 15 years and delivering an increase in the project’s value and strategic importance. Recent metallurgical testing at Mulga Rock returned an overall uranium recovery of above 90 per cent and a critical minerals recovery of above 70 per cent.

Borshoff said the drilling undertaken was “significant”, particularly for the nonuranium minerals, where there hadn’t been a lot of previous test work done.

The drilling also bolstered Mulga Rock’s total contained uranium, which now equals 71.2Mlb, up from 56.7Mlb at a 100 parts per million cut-off grade.

This means 86 per cent of the Mulga Rock uranium resource is now in the measured and indicated categories.

“This will be a key value-driver to include in the revised DFS, which we expect to commence by the middle of this year and to complete by mid next year,” Borshoff said.

While Mulga Rock is Deep Yellow’s flagship Australian uranium project, the company’s Alligator River project has also made significant progress.

The Alligator River project is the largest granted uranium exploration package in the Alligator River uranium province in the NT’s Arnhem Land. Like Mulga Rock, Deep Yellow acquired the project from Vimy.

“We’ve looked at these areas and have developed our search models to define the prospective corridors and properties that exist, and they’re going to be our focus areas for the targets we’re looking to set for the next four to five years,” Borshoff said. “At the moment, there are lots of targets that look isolated but could be knitted together within a structural geological framework.

“Starting mid-next year, we will begin methodically exploring, with drilling and investigative programs, these prospective corridors to identify new targets, and in parallel we will hunt known specific targets to see if they have resource potential.

“From there we hope to find either a nest of deposits that cumulatively come up or one big accumulation.”

Borshoff said the imbalance between uranium supply and demand remains huge, which means the industry must bring in the right people with the right expertise to manage it.

“I think the uranium-supply industry will battle because it’s unprepared and has been sitting passively on its haunches following events such as Chernobyl and Fukushima,” Borshoff said.

“Because of that, the industry has become unpractised in developing uranium mines.

“This is nobody’s fault. It’s the consequences of Chernobyl and Fukushima, oversupply from the first post-oil shock period, and the

large quantities of secondaries that developed allowing predatory uranium pricing to occur, to the point where utilities plundered and essentially destroyed the sector.

“Now the sector must be rebuilt, but you can’t rebuild a sector you’ve systematically destroyed over 12 years. This will take a long time … (and) we need huge exploration efforts to identify new deposits to meet new demand.

“I think Deep Yellow has a better chance of succeeding as we offer a pair of safe hands in this commodity, and stakeholders and governments need to be assured the supply industry can deliver what is needed.”

Taking a bite

Another aspiring Australian uranium producer, Alligator Energy, has been advancing its Samphire and Big Lake uranium projects in South Australia, and Nabarlek North project in the Alligator River Uranium Province of the NT.

“Alligator Energy began as a pure uranium exploration company in 2010 that specifically focused on uranium exploration in Arnhem Land in the Northern Territory,” Alligator Energy managing director and CEO Greg Hall told Australian Mining.

“All of our current uranium projects are in the Northern Territory or South Australia.

The dominant reason for this is both major political parties on a state and most notably through acquiring key uranium projects while the commodity

before the market took off,” Hall said. “Consequently, we’ve expanded quite a bit over the past two to three years. We’ve done this primarily through the acquisition of our flagship project –the in-situ recovery (ISR) Samphire uranium project – in October 2020.”

Alligator Energy is currently in the final stages of planning an ISR field recovery trial at Samphire, subject to regulatory approval. The trial project will consist of three producing wells and a containerised pilot plant.

“That will then lead straight into a feasibility study and then hopefully approval of the project itself,” Hall said.

“Samphire now has a resource of nearly 18 million pounds, with a large proportion being indicated, meaning you can use it for a study.

“We’ve also completed a second phase scoping study, which said Samphire will produce 12.3 million pounds over 12 years, at a production rate of 1.2 million pounds per annum.

“Now we are drilling beyond that initial resource and expanding it.”

Hall has built up an experienced ISR operations team and believes Samphire has many advantages that make it stand out from other uranium projects.

“The project is located about 20km from Whyalla (SA’s fourth-most populous city), which means we don’t need fly-in, fly-out workers and we don’t have to build an airstrip, power

lines and water lines over hundreds of kilometres, meaning cheaper capital costs,” he said.

“It’s also a shallow deposit, being only 80m deep compared to other insitu recovery mines that are over 100 metres deep. This means the drilling is cheaper.”

Alligator Energy is currently looking for ways to try to make Samphire a carbon-free operation.

“The South Australian Government has invested $600 million for a hydrogen hub to be established in Whyalla because there’s lots of renewable energy sources there,” Hall said.

“We’ve looked at this and said, ‘Samphire is only 20km from Whyalla. It’s an in-situ recovery project, meaning you’re not crushing or grinding the rock and you’ve got a very low power usage, so how can we operate this in a way where it has almost a near carbon-free footprint?’

“This is important, as we would be selling our future uranium to nuclear power utilities in Europe, North America, Korea and Japan.

“The European utilities in particular are very interested in the idea that we could provide uranium with a carbonfree footprint, so we’re going to see what we can do.”

It may be in its early stages, but Alligator Energy believes its Big Lake project in the Cooper Basin also has great potential.

“There has been uranium found at Big Lake from previous small programs of mineral drilling,” Hall said.

“We know there’s a lot of deep granite underneath that has lots of uranium, so we’re trying to see if there is a new in-situ recovery field there. There’s no economic uranium here yet, but we’re hoping to find some trapped in the upper sediments which overlay the Basin.

“We’ll be on the ground drilling in April or May this year.”

In 2020, Alligator Energy was also granted a new package of NT tenements called Nabarlek North. The company started work there 18 months ago and is set to begin a further targeted drilling program in July.

“We’re very excited because we’re trying to find similar structures and settings that formed the Ranger mine,” Hall said.

“If you can find something new that’s the same size as Ranger, that’s a real game-changer for the industry.”

Considering recent critical mineral downturns and the global energy transition, uranium may become a preferred source of power.

Lucky for Australia, the country is filled with strong uranium resources, many of which remain untapped. They are just waiting to be unearthed. AM

the Ultimate digging tool

The Volvo EC950E Excavator

With the big and powerful EC950E, no task is too tough. Increase profitability with superior digging force, quick cycle times and outstanding fuel efficiency for a maximum return on investment. The Volvo EC950E features a powerful 450kW Volvo D16 engine.

bigger machine, Bigger Results

Fully electro-hydraulic system

Protected components for longevity

Outstanding fuel efficiency

Machine monitoring programs maximises uptime

Big Enough to Trust, Small Enough to Care

Operator Comfort and safety

Proven safety systems

ROPS/FOPS-certified

Ergonomic machine interfaces

Spacious cab for ultimate comfort

CONTACT YOUR LOCAL BRANCH FOR MORE INFORMATION

TRACKING A CRITICAL FUTURE

DELOITTE’S ANNUAL ‘TRACKING THE TRENDS’ REPORT LOOKS AT THE CHALLENGES AND OPPORTUNITIES FACING THE MINING INDUSTRY IN THE YEAR AHEAD.

As 2024 rolls on, the resources sector is facing up to supply and skills shortages, environmental, social and governance (ESG) challenges, and a push to adopt emerging technologies.

An organisation that understands this well is professional services network Deloitte, whose its 16th annual ‘Tracking the Trends’ global report dissects these challenges.

‘Tracking the Trends’ has become a long-respected industry standard exploring key movements and issues facing mining and metals companies in the coming year. Australian Mining sat down with Western Australian-based Deloitte mining and metals leader Nicki Ivory to discuss the year ahead.

Future-proofing with purpose

The central trend for 2024 comes down to putting purpose at the heart of the resources industry and creating momentum to attract the next generation of miners.

“Technology is becoming ever more important as everything digitises, but we have skill shortages to contend with,” Ivory told

“The first way to address this is by attracting people with different skill sets that may not have considered a career in mining before. We need to create working environments where people can align themselves with the purpose of the company.”

In its report, Deloitte described how mining will only become more essential in the future.

And as the focus shifts to mining critical minerals for the coming energy transition, companies are presented with an opportunity to connect with the wider community in a partnership based on authenticity and the drive for a better future.

Ivory said the industry should be highlighting all of the good to come out of the sector in the last 20 years in an effort to drive recruitment.

“People are asking themselves how their work can tie in with their personal beliefs and purpose,” Ivory said.

“Miners can find an entire workforce waiting to be tapped that are looking for purpose-driven work.”

But authenticity is key, Ivory said. As geopolitical strains stack up and

uncertainty – Deloitte identified four key areas converging to create the current mining landscape: rising geopolitical tensions and global shifts in power; the rise of artificial intelligence (AI); a change in the availability and requirements of talent; and the urgent

VALUES.

organisation to respond to new threats, challenges, instability, and uncertainty. That’s really the key here.”

So how can operators build resistance to uncertainty? Ivory believes in a topdown approach.

“Building flexibility in your

to take a different kind of leadership than in stable times.”

That leadership is especially important if the workers entering the industry need reskilling or upskilling before they are ready for the demands of mining.

A technology-driven solution

According to the World Economic Forum, 50 per cent of all employees will need reskilling by 2025 as adoption of technology increases.

‘Tracking the Trends’ foresees the solution to this challenge lying with technology itself.

With the ability to use years of data collected across the Australian mining sector, Deloitte said AI algorithms could help to personalise training programs that build on workers’ existing skill sets to prepare them for future technologybased opportunities.

But a next-generation approach to data and AI doesn’t just have implications on an educational level. The ninth trend in Deloitte’s report emphasised an opportunity to harness a new level of agility in mining through data and AI.

“There are so many examples of where data and AI in combination can improve the entire sort of lifecycle and supply chain,” Ivory said.

She also cited a scope for increased efficiency, all the way from targeted drilling to predictive maintenance.

“Effectively harnessing generative AI will also help address energy security and improve profitability, generate operational efficiencies and resilience, and reduce emissions,” Ivory said.

If operators are going to meet the growing need for critical minerals, Deloitte is looking to data and AI to help companies determine which investments, scenarios or processes may deliver the best value.

Growing in a decarbonised future

An ongoing theme identified in Deliotte’s ‘Tracking the Trends’ report is the industry’s outlook of a net-zero future.

According to the London-based Energy Transitions Commission, there’s no fundamental shortage of raw materials needed to support the global transition to a net-zero economy.

The key issue is rather ramping up supply fast enough to decarbonise economies before crucial climate tipping points are exceeded, while also ensuring that mining is done in a sustainable and responsible way.

“Minerals underpin our way of life,” Ivory said. “And we all know that the green energy transition, here in Australia and around the world, is a mineralsintensive one.”

That’s why ‘Tracking the Trends’ emphasised the need for governments and operators to collaborate on projects and regulations through consultation to meet those critical supply needs.

According to S&P Global, the average mine takes 15.7 years to reach commercial production. Ivory said Australia’s red tape and regulations can be a key sticking point in reaching a decarbonised future.

“Miners must continue to advocate for the critical role minerals play in addressing climate change challenges

and lead the way to a sustainable future,” Ivory said.

“We have to find a way to expedite essential projects while still mining responsibly and meeting those decarbonisation goals.”

Research by the Deloitte Economics Institute has found that, if left unchecked, climate change could create $US178 trillion in global economic losses between 2021 and 2070.

But researchers found a coordinated effort in climate change mitigation could deliver an additional 300 million jobs by 2050 and boost the economy by more than $US43 trillion by 2070.

And opportunities for the sector to flourish are already in motion.

In October 2023, the Australian Government announced a $2 billion expansion in critical minerals financing, doubling the capacity to fund

Australian critical minerals mining and processing projects.

With nickel’s recent addition to Australia’s critical mineral list, more projects are able to access billions in funding and bolster the sector to weather downturns.

When it comes to tracking the trend of the industry’s overall health, Ivory remains optimistic in a strong future for the sector.

“Unlocking critical resources through permitting, addressing workforce challenges, and working with governments to re-think regulation are important issues facing Australian miners,” she said.

“Ultimately, understanding the challenges miners face and responding accordingly will help unlock opportunity and ensure they both capture and convey the value the sector generates.” AM

SOCIALLY-RESPONSIBLE MINING IS BECOMING INCREASINGLY KEY TO THE SECTOR’S FUTURE.

EQUIPPED FOR THE FUTURE

XCMG AUSTRALIA HAS PLANS TO BECOME A HOUSEHOLD NAME IN THE MINING INDUSTRY.

One of China’s oldest and largest construction and mining manufacturers has put down roots in Australia, with a mission to become the local industry’s number one.

XCMG Group’s journey to supplying high-quality equipment began in 1943. Since then, the company has risen to household-name status in its native China, and its products are now exported to more than 183 countries and regions via over 300 global distributors.

For over 30 years, XCMG has held the title of China’s leading mining and construction equipment manufacturer, the company said, and it is currently ranked third in the world. And it’s now bringing these years of expertise to local soil with XCMG Australia.

encompasses mining trucks, excavators, loaders, graders, cranes, hydraulic parts, and rollers decked out to thrive in the harshest of working environments.

are designed for high transport efficiency and low maintenance costs without compromising on operator comfort or safety.

Melbourne, XCMG Australia has plans to expand into Perth with another centre, while a research and development facility is a possibility looming on the horizon in the short term.

“We’re in major growth mode right now because we see the future in the Australian mining sector,” XCMG Australia general manager and director Roy Rossini told Australian Mining “We’ve been in this space overseas for several years, developing machines and growing and getting better and better.

“Companies are now recognising the fact that we are a true, committed player in the industry.”

Rossini emphasised the fact XCMG Australia is working with its customers in the resources sector to develop solutions based on the specific needs of Australian mine sites.

“We’re orientated around tapping into the local market with local knowledge,” he said.

“Our customers’ expertise and input are enabling us to build new models

Rossini described a situation in which XCMG Australia was recently able to adjust a machine to suit the needs of a major mining operation with the touch of a button.

“While we were standing there talking to the operator about their needs, we video called our manufacturing centre in China and made adjustments to the machine then and there,” he said. “We had componentry shipped to the site within 24 hours.”

XCMG Australia national business development manager Jason Keays believes this near-instant engineering and technical support is setting the company up to change the landscape of mining services in Australia.

“It drastically reduces lead times on heavy machinery like our mining trucks, putting us a cut above the competition,” he said. “A lot of original equipment manufacturers have a two- or threeyear lead time, but our manufacturing capabilities have us sitting at around eight months, or even earlier.”

XCMG Australia machinery is manufactured in China, and Keays stressed the fact that the providence of its high-quality parts is an essential aspect of the business.

“Our equipment is built with quality components from established companies with brand recognition in the Australian mining industry,” he said. “Customers can trust our quality and have confidence in the longevity of our

machines.

network of national dealerships is a vital link between its experts and the heart of our Australian customers.”

Each dealership is staffed by trained experts who understand the intricacies of the company’s machinery.

Team members can provide expert guidance and support to customers at any stage of their journey.

“All of our dealers have many years’ experience in capital equipment sales and support, and we have chosen partners that are capable of supplying our customers the after-sales service and back-up that exceeds their expectations,” Rossini said.

“We currently have around 17 outlets in Australia, with more coming in the next 12 months. Our reach in the Australian mining sector is growing every day.

“Whether it’s helping to identify the right parts for a specific repair or offering maintenance tips to prolong the lifespan of equipment, our dealership partners are dedicated to delivering exceptional service and support.”

As the mining sector grows and expands, the company is ramping up its own research and development capabilities to meet the industry at the forefront of innovation.

One pathway for which XCMG Australia is becoming known is its autonomous machinery, which is capable

of significantly increasing efficiency and decreasing carbon usage.

Australia is placing ever-increasing emphasis on sustainable mining practices as operators gear up to reach net-zero targets. Electric machinery is one way XCMG Australia is helping operators choose a greener alternative to traditional diesel-powered equipment.

By choosing electric machinery, operators can reduce emissions, lower carbon footprints, and meet environmental regulations.

For operators who aren’t ready to make the switch, XCMG Australia can supply high-quality diesel equipment with a decarbonisation pathway in place to convert to electric down the line.

XCMG Group signed a major partnership with Brazilian-based iron ore miner Vale in 2021 for zero-emission equipment and autonomous machinery. Keays said XCMG Australia is also determined to become a decarbonising player in the Australian mining sector.

“Again, our focus is on working with the customer on research and development and tying solutions into the future of mining,” he said.

“By increasing our skin in the game, we can give our customers more options for their own future.”

That type of forward-focus is part of XCMG Australia’s plan to grow with the local mining sector.

Though specifics are being kept under wraps, Keays and Rossini emphasised the fact the company is looking to the next 12 months and beyond with major development projects in the pipeline.

“We have huge plans to electrify equipment across our entire range,” Rossini said. “Prototypes are underway at our manufacturing facilities in China, so it’s an exciting time for the company.”

Thriving in a dynamic landscape like the mining industry can be tough, but XCMG Australia is determined to take the guesswork out of choosing

the right equipment by bringing its knowledge and expertise to mine sites across the country.

“Whether it’s providing top-quality machinery, offering expert guidance and support or ensuring prompt access to parts and components, we are dedicated to helping our customers succeed,” Rossini said.

“As we continue to grow and expand into the future, our commitment to excellence remains unwavering, and we look forward to serving the needs of our customers for many years to come.” AM

MINING EQUIPMENT MANUFACTURER MCLANAHAN HAS BEEN MEETING THE INDUSTRY’S MINERAL PROCESSING NEEDS FOR OVER A CENTURY.

McLanahan specialises in rotary equipment for a variety of washing, screening and crushing duties.

These machines have a reputation for being tough – able to handle large feed sizes and process high capacities.

McLanahan rotary scrubbers and screens are used in washing and classifying applications to remove excess clay and slime material from ore. Water is mixed with the material feed and fed into a drum, which contains internal lifters that continuously lift and roll the material to detach the clay particles.

“The rotary scrubbers are used extensively in iron ore operations in Western Australia, and we have a number of large operations there,” McLanahan director of global business development – mineral systems Richard Williams told Australian Mining McLanahan offers washing equipment with capacities from 20–8000 tonnes per hour, with customisable solutions for any washing application boasting less maintenance and lower operating costs. The use of steel trunnion rollers to support equipment provides high durability and easy operation.

In another critical element of the mineral processing chain, rotary breakers

are used in coal operations for crushing material and removing undesirable excess.

Like scrubbers, the breakers comprise a huge metal drum containing internal bars that continually lift and drop the material onto internal breaker plates as the drum rotates.

“Rotary breakers are a very useful technology to upgrade a deposit,” Williams said. “The softer rock, such as coal, is broken when tumbled through the breaker and passed through the screens to be collected, while harder (gangue) rock is discharged from the end of the machine.

“Rotary breakers therefore provide both size reduction and grade improvement.”

A variation of the rotary breaker is used in similar applications in nickel laterite operations, while McLanahan’s gravity discharge autogenous mill (GDAM) is used in the aluminium industry.

“GDAMs are preferred in aluminium applications, as they generate the least fines and dust from crushed material when compared to high-speed hammermills or air-swept mills,” Williams said.

“Clay-rich, difficult-to-process ores in the battery minerals space like lithium, vanadium, rare earths, nickel laterites and copper are all developing industries that have a need for rotary equipment,” he said.

“As an example, we work with a lithium-processing operation that is reprocessing old tailings to extract more spodumene concentrate from waste.

“Our team was able to customise equipment by combining features of a scrubber and an autogenous mill to break down the consolidated tailings agglomerates and separate undesirable waste, such as gangue rocks or vegetation that is introduced by the mining process.”

According to Williams, flexibility is the name of the game when it comes to major mining operations with their own unique needs.

“We have our standard range of equipment that we can tailor to any application,” he said.

“Our team of technicians and engineers are well equipped to work in consultation with an operation to get the best outcome possible.”

This is all part of McLanahan’s ongoing commitment to delivering quality personalised service to all of its customers.

“We have people in the field continually ensuring the equipment is the most up-to-date available,” Williams said. “We want to ensure our equipment stays on the cutting edge of the latest features and best operational performance we can provide.”

Williams emphasised McLanahan’s knowledge base and commitment to customers as key pillars in the company’s success.

“With most of our design work for mining and minerals processing done in Australia, our team are experts in Australian conditions with local knowledge and local design experience,” he said.

“We’re focused on providing a high level of customer experience and working with the customer throughout the design phase, the implementation phase, and especially the operational phase.

“What really defines value for us and our customers is the long life and efficient use you get out of our products.” AM

Bringing you our world of expertise

We are now better equipped than ever to help you to optimise your comminution and material handling operations for maximum performance, safety and efficiency.

Combining the industry leading screening, feeding and loading expertise of Schenck Process Mining with our mastery of crushing and wear protection, allows us to bring you an unrivalled equipment line-up. We underpin this unique offering with our expert process knowledge, full range of digital tools, high quality OEM spare parts, consumables and life-cycle services.

Scan the QR code to discover why we are the industry’s partner in eco-efficient mineral processing.

A COMPLETE PIPELINE

ACU-TECH PIPING SYSTEMS MODELS AND MANUFACTURES HDPE PIPING SOLUTIONS TO SUIT UNIQUE MINE SPECIFICATIONS.

Mineral processing requires robust infrastructure to handle the various fluids, slurries and chemicals involved.

A company that understands this is Acu-Tech Piping Systems, which manufactures high-density polyethylene (HDPE) pipes and fittings for a range of industries.

“Acu-Tech plays a pivotal role in mineral processing by providing reliable and durable piping solutions tailored to the unique needs of the mining industry,” Acu-Tech Piping Systems mining lead Cliff Mataseni told Australian Mining

“HDPE pipes have long been the preferred choice for various mining applications due to their unique characteristics and proven performance in rugged terrains, extreme climates, and changing site environments.”

Acu-Tech’s HDPE pipes have been designed for a wide range of mining applications such as slurry and tailings lines, above-ground pipelines, dewatering systems, process piping, leaching processes, remediation projects, and raw water supply, to name a few.

The pipes are designed to withstand aggressive substances commonly encountered in mineral processing plants.

“This durability minimises the risk of pipe and chemical degradation and failure, reducing the likelihood of leaks, spills, and unplanned downtime,” Mataseni said. “Our HDPE pipes are trusted for their flexibility and long-term reliability in demanding environments.”

To complement its HDPE piping solutions, Acu-Tech manufactures and imports a range of fittings that are available in various sizes, configurations and specifications.

“With our experienced operators and fully equipped plastic fabrication workshop, Acu-Tech offers custom fabrication services to meet the specific requirements of mineral processing facilities, optimising the efficiency and reliability of these precise systems,” Mataseni said.

“We fabricate spools, manifolds, and other components from HDPE pipes and sheets to ensure seamless integration into the processing infrastructure.”

Acu-Tech’s HDPE pipes are also made from recyclable material, boosting durability and environmental outcomes.

“HDPE is a recyclable material with a longer service life, reducing the need for frequent replacements and minimising

the environmental impact of mining activities,” Mataseni said.

“The pipes are manufactured through heat-fusion welding, creating seamless and leak-free joints, and eliminating the use of mechanical joints that are prone to leakage. This ensures a reliable and secure pipeline network that limits the risk of environmental contamination and costly repairs.

“HDPE pipes are also significantly lighter than traditional metal pipes, making them easier to handle and install, while their flexibility allows for seamless manoeuvring around obstacles and uneven terrain, reducing the risk of accidents and injuries during installation and maintenance activities.”

Acu-Tech has successfully supplied HDPE piping solutions to numerous mining projects across Australia, one being an iron ore mine in WA.

“The project required the manufacturing and delivery of 270km of bespoke-sized HDPE liner pipe, which was used as a sacrificial corrosion liner within a steel pipeline,” Mataseni said.

“Despite challenges such as deviations in pipe wall thicknesses and a doubling of the initial tendered scope, AcuTech delivered the HDPE pipes to the project site through over 900 truck and trailer movements within a compressed timeframe.

“Acu-Tech also manufactured bespoke liners for on-site welding machines and

mobilised extra machinery support. The project scope was completed on-time, showcasing Acu-Tech’s commitment to excellence.”

Acu-Tech’s involvement in mineral processing extends beyond HDPE pipe supply and installation.

“We provide comprehensive technical support and expertise to mining operators throughout the project lifecycle, from initial design and

material selection to installation and maintenance,” Mataseni said.

“We also offer training programs to educate mining personnel on proper handling, installation, and maintenance practices for HDPE piping systems.

“By empowering operators with the necessary skills and knowledge, we contribute to a safer work environment and mitigate the risk of accidents and incidents.” AM

REFLUX™ Classifier

Gravity-based separation with maximum efficiency

The REFLUX Classifier is our advanced fine particle, gravity-based separator, offering significant advantages in capacity, adaptability and efficiency

Key

benefits

■ Improved efficiency produces higher recoveries

■ Compact design delivers high throughput

■ Low OPEX

■ Decreased environmental impact

Introducing the REFLUX™ Classifying Concentrator (RCC™) a new variation of the established REFLUX™ Classifier (RC™) specifically designed for low grade, high value ores.

The RCC™ builds upon the success of our original REFLUX™ Classifier, by optimizing bed formation and split fluidization utilising gravity-based separation techniques to tackle the recovery challenges associated with low-grade minerals.

Read more at flsmidth.eco/3RE7pqo

SOLVING THE DECARBONISATION DISCONNECT

AUSTRALIAN MINING SAT DOWN WITH FLSMIDTH TO DISCUSS THE DECARBONISATION CHALLENGES THE AUSTRALIAN MINING SECTOR IS FACING TODAY.

One of the most costeffective ways for a mining company or contractor to reduce their carbon footprint is by improving the efficiency of their fixed plant, something in which FLSmidth specialises.

The esteemed original equipment manufacturer (OEM) has a range of fixed plant equipment that can drive down total site emissions per tonne.

This includes FLSmidth’s REFLUX technologies, comprising the REFLUX Classifier (RC), REFLUX Concentrating Classifier (RCC) and REFLUX Flotation Cell (RFC), alongside its crushing, milling and grinding solutions.

“What we’re talking about is doing more for less – giving you more product for less CO2 per tonne,” FLSmidth APAC regional president Jason Elks told Australian Mining. “We’re not saying we can eliminate CO2, but we can reduce the impact.”

The RC has become one of FLSmidth’s most advanced fine-particle, gravity-based separators, using minimal power and water to enable the recovery of more minerals more efficiently.

The product underpins FLSmidth’s MissionZero strategy, whereby the OEM is working with its mining customers on a partnership model to provide end-to-end solutions that aim to achieve zero emissions, zero water waste and zero energy waste by 2030.

Elks said FLSmidth will be working with several leading mining customers this year to support the installation of its REFLUX technologies.

“The REFLUX technologies will help our customers maximise optimisation in fixed plant, giving greater tonnages and reducing their overall CO2 inputs to the production of commodities such as coal, iron ore and manganese,” he said.

FLSmidth’s digital prowess goes hand-in-hand with the REFLUX range, with the OEM not only able to provide the machinery to process the minerals but also the digital

infrastructure to monitor production levels and asset health.

“FLSmidth’s digital optimisation technologies are really starting to gain traction globally,” Elks said.

“This includes LoadIQ, our smart sensor technology that accurately measures volumetric filling and ore trajectory of your mill, as well as our SmartCyclone technology.”

FLSmidth’s SmartCyclone offering is a process-control solution that monitors cyclone parameters and identifies early warning signs that could lead to failure, ensuring the proactive maintenance and continuous operation of a grinding circuit.

“Our digital offerings are really starting to pay dividends for our customers,” Elks said. “We’ve had multiple successful trials and we’re across many sites globally, so we are seeing really strong uptake of optimisation through FLSmidth’s digital agenda.

“Our digital technologies enable customers to operate their equipment at optimal efficiency. While being able to realise peak efficiencies and equipment life, customers are also able to increase production, so it’s a win-win.”

Installing FLSmidth’s digital infrastructure enables mining companies and contractors to be firing on all cylinders, all day and every day, with the benefits of avoiding plant shutdowns just as critical to profitability as realising optimal efficiency.

And with efficiency comes better sustainability, with the opportunity for miners and contractors to quickly drive down emissions as the Safeguard Mechanism becomes more restrictive in the coming years.

Elks said that while proponents such as FLSmidth are charting a path for the Australian mining industry to decarbonise, there is still an operational disconnect regarding the decarbonisation imperative.

“We’re all talking about decarbonising, and we’re all talking

THE REFLUX TECHNOLOGIES WILL HELP OUR CUSTOMERS MAXIMISE OPTIMISATION IN FIXED PLANT, GIVING GREATER TONNAGES AND REDUCING THEIR OVERALL CO ₂ INPUTS TO THE PRODUCTION OF COMMODITIES

SUCH AS COAL, IRON ORE AND MANGANESE.”

about this impending or current crisis that we need to address,” he said.

“We can talk about that at a board and executive level, but then at an operational level we have KPIs and production outputs that are diametrically opposed to a company taking a chance and trialling technologies that are necessary to fully decarbonise.

“There’s are two things that are holding this back. One is risk; risk in regards to current operations and throughput. And the second one is trust; trust as to whether this transformation can deliver the outcome.

“I don’t think we’ve defined that journey yet. I think everyone’s looking

for a silver bullet, and the bit that’s missing is we have to accept this war will be won through multiple iterations.”

Elks spoke about the combined role of technology, suggesting that no single carbon-neutral solution can drive down emissions alone.

“It’s not about battery technology, it’s not about solar, it’s not about wind, it’s not about greater efficiencies, and it’s not about digitalisation. It’s all of those plus more,” he said.

“If we’re sitting back in operations, whether we’re a junior, mid-tier or major miner, and saying, ‘We’ll wait till somebody comes and puts this bolton technology that will transform my operations and give me the necessary sustainability outcome’, it’s never coming. It’s not there.

“It’s going to take multiple iterations and we have to accept that.

“We have to trust, we have to start the journey, we have to change our KPIs at the local level, and we have to allow operations to trial and embed new technology to transform. Only then can the mining industry put itself in the best position to decarbonise and meet the necessary net-zero requirements.”

While there are inevitably laggards, Elks said more and more mining and mining equipment, technology and services (METS) companies are starting to understand the parameters of the journey ahead.

“I (recently) had an engaging conversation with an executive of a major engineering firm and it was really pleasing to hear the journey they’re on,” Elks said. “We were talking about trust and innovation and how it’s not about the technology. Before you can even pitch the technology, before you can even define the burning platform, there

needs to be a willingness for change and change management.”

In a world with greater levels of environmental obligation and legislation, change will be mandatory rather than optional, and mining companies and contractors without adequate change management processes in place risk being left behind. AM

ALL IN ON MINERAL PROCESSING

HAZEMAG ALLMINERAL’S MINERAL PROCESSING TECHNOLOGIES ARE HELPING MINING COMPANIES REACH HIGH EFFICIENCY ACROSS A RANGE OF COMMODITIES.

With 500 employees across 11 countries, Hazemag remains strong after 180 years in business.

“We started in the aggregate recycling business, where we recycled rubble from World War II by crushing, recycling and separating the materials to retrieve the wood and iron from the aggregates, and then reused those aggregates,” Hazemag allmineral Australia managing director Teddy Craies told Australian Mining

“As the business grew, it also acquired other companies like allmineral.”

Hazemag allmineral has two aspects to it: aggregate and mining in the Australian quarry, iron ore and coal sectors.

“The crushing and mineral process are two separate functions, so we’re covering both areas, providing solutions from a single source,” Craies said.

“Crushing reduces the product size and then (the mineral) is separated through other processing mediums, but there are some materials that are very hard to separate.”

This is where allmineral’s allair and allflux systems can help.

The allflux is a wet mineral processing solution suited to a wide range of commodities and materials, including

iron ore, coal, heavy mineral sands and slag.

The allflux has three separation levels for the material to pass through and uses fluidised bed technology with autonomous heavy media for the separation and hydraulic classification of slurried fines.

“The allflux was an idea that originated in 1988 and was continuously developed,” Craies said. “It can now deliver up to 2000 cubic metres per hour in volume production.”

The allflux is unique in its ability to create two product streams – one coarse and one fine – from a singular feed source, reducing the need for further downstream processing, saving cost and infrastructure footprint.

In the coarse sand space, the feed sludge creates an upflow causing light, fine particles to rise and heavy particles to sink and be drawn off.

In the fine sand chamber, the fine particles enter with the light material and form an autogenous fluidised bed to allow the light material to float and overflow with the upflow water.

The discharge of coarse material out of the central hopper is automatically controlled by an analogue system.

“The allflux allows companies to optimise their extraction system because it helps extract as much material as

the allflux comprises three separations in one unit: two product streams and a waste.

“You have a coarses section, a middlings section and the waste that comes with this,” Botha told Australian Mining. “This three-step process

a dry mineral processing solution from allmineral best suited to the coal and recycling sectors.

“The allair is a jigging machine,” Craies said. “Its particle size ranges from 1mm to 50mm, and its throughput rates ranges from 20 to 100 tonnes per hour per machine.

“It’s a compact, mobile unit that can be easily transported from site to site, whereas the allflux is a fixed system with more infrastructure.”

Craies described the allflux and allair as “niche” products requiring little maintenance.

“Generating two products from the one unit, the allflux is mirroring what the customer needs in terms of power consumption and costs, enabling customers to save on capex (capital expenditure) and opex (operational expenditure),” Craies said.

“Both of the products are environmentally friendly. While the allflux reuses water during its process, the allair mobile solution requires no water.

“Parts are also refurbished so there’s minimal waste, while there is reduced need for consumables, making the cost of operation far more economical.” AM

REVOLUTIONISING MINERAL PROCESSING

AS ONE OF THE WORLD’S OLDEST AND MOST EXPERIENCED GRINDING MEDIA COMPANIES, MOLYCOP IS TRANSFORMING MINE OPERATIONS.

Many mining processes consist of breaking rocks before grinding finely them to recover valuable minerals. The key to efficient mineral processing is reliable grinding media, and that’s where Molycop comes in.

Founded as Commonwealth Steel in 1918, Molycop spun off into its own entity in 2016. It was acquired then by private equity company American Industrial Partners a year later.

“Molycop has been growing for more than a century and is now one of the world’s biggest grinding media suppliers,” Molycop technologies president Darren O’Connell told Australian Mining

“Molycop helps mining companies stabilise and optimise milling circuits, as well as with leaching, flotation and other mineral extraction processes.

“We do this by providing more real-time data from innovative measurement equipment.”

Recent years have seen Molycop develop a presence in the digital data technology sector of the mining industry. The company stepped into the space through the acquisition of Digital Control Lab, a mill monitoring solutions-provider based in Florida, US.

Following the acquisition, Molycop introduced services such as process optimisation, online analysis, and data analytics and visualisation.

“The digital data technologies area of our business helps mines increase their

productivity while having a lower carbon footprint,” O’Connell said.

“Making decisions in real-time and controlling plants to optimal levels means mining companies not only get maximum return from their capital investment; they reduce their energy and reagent consumption while increasing recovery.

“This means mines can be both more profitable and sustainable.”

Process optimisation

Molycop’s process optimisation solutions aim to reduce variability and increase throughput while maximising mineral recovery.

“We deliver many milling optimisation solutions consisting of measurement, control and optimisation

management, which significantly increase throughput rate while also decreasing planned downtime for relining,” O’Connell said.

One of these solutions is MillROC (Milling Remote Optimisation Consulting and Coaching), a data platform that remotely monitors and models circuits and processing plants.

“MillROC was developed in collaboration with our joint venture partner, Orway Mineral Consultants,” O’Connell said.

“MillROC provides live key performance data for the circuit and features focus applications that offer deeper insight into what operators can immediately do to address specific problems or identify opportunities for improvement.

“MillROC is supported by remote real-time assistance from world-leading mineral processing consultants who can view the circuit’s live performance dashboards and provide immediate advice and coaching.

“The ultimate objective of the MillROC team is to establish an embedded system of continuous improvement that delivers higher levels of performance, lower costs and healthier profit by maximising throughput, increasing power efficiency, reducing wear and promoting longer liner life.”

Another notable Molycop process optimisation solution is MillSlicer VIP, which combines MillSlicer with the Value Invention Process (VIP) Platform.

MillSlicer consists of vibration sensors mounted on the mill shell that measure angular impact intensity, maximum impact angle and centroid of the impacts. This information can be used to achieve enhanced efficiency and productivity.

The VIP Platform is equipped with features such as enterprise-wide data integration and reporting, efficient and secure storage for operational data and live analyses of that data, and simple and intuitive dashboards, graphs and key performance indicators.

When combined, MillSlicer VIP improves the throughput and efficiency of semi-autogenous grinding (SAG) and autogenous (AG) mills by measuring volume, steel charge per cent, toe angle and liner impacts. The solution features more accurate and precise mill fill level measurements, which helps to enable better mill feed control.

When a gold mining company installed MillSlicer VIP alongside associated Molycop control and optimisation services, it was able to reduce its planned shutdowns by 25 per cent, carrying out three shutdowns a year instead of the usual four at its operations in West Africa.

“With the cost of shutting down a mill estimated at approximately $100,000 an hour, and a typical shutdown lasting two or more days, installation of MillSlicer VIP resulted in significant payback for the customer,” O’Connell said.

“Other Molycop customers have experienced similar benefits by applying Molycop digital tools to their comminution circuits, including improvements of between five and 20 per cent in throughput through milling optimisation and a reduction in grinding media consumption by five to 10 per cent.”

Data and analytics

Molycop delivers a broad range of analytics to help mining companies reduce variability and deliver improved outcomes by leveraging efficient data capture, visualisation and analysis.

Molycop Tools is a suite of Microsoft Excel-based programs that support plant

consists of 63 accessible spreadsheets designed to help users characterise and evaluate the operating efficiency of any given grinding circuit by following standardised methodologies and widely accepted evaluation criteria.

Molycop Tools incorporates a full set of digital simulators for conventional and SAG applications alongside corresponding mass balance and parameter estimation routines.

“Molycop has further developed and enhanced these tools based on fundamental models with empirical artificial intelligence and machinelearning techniques,” O’Connell said.

Alongside its uses within MillSlicer VIP, the VIP Platform collects, archives and visualises data from hundreds of mining companies.

“This not only helps with day-today decision-making and support, but can also be used for longer-term optimisation,” O’Connell said.

“MillROC was built on the VIP Platform. Both solutions provide real-time data and insights into circuit performance, helping companies make decisions on the way they operate circuits to remove constraints.”

Molycop also offers mill optimisation services designed to build in-house capability to optimise mineral processing operations, including milling circuit flow analysis, grinding media sizing, ore sampling and ore abrasion analysis, and more.

Advance controls

In partnership with Mintek, South Africa’s national mineral research organisation, Molycop designs, commissions and implements advanced control systems to deliver improved outcomes for mineral processing operations.

technology and advanced process control, StarCS was developed as an adaptable and operator-friendly control system that advances process stabilisation and optimisation control while improving productivity.

StarCS integrates all of Molycop’s control systems including MillStar, which offers a comprehensive suite of control strategies that can be applied to almost any milling circuit configuration.

MillStar can also improve particle size distribution and reduce downtime and maintenance costs, in turn leading to greater efficiency.