automation

automation

United. Inspired.

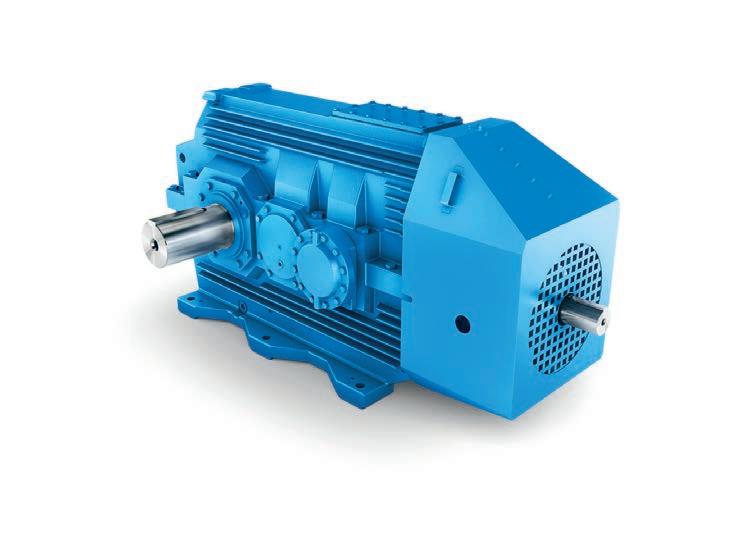

Without proactive maintenance, as your equipment ages there is a risk of unplanned repairs, early replacement and costly downtime. Midlife services from Epiroc is a flexible service solution that will prolong the lifespan of your asset. Replacing old with new components, returning your equipment to maximum productivity and operating efficiency at a fraction of the cost of a new machine.

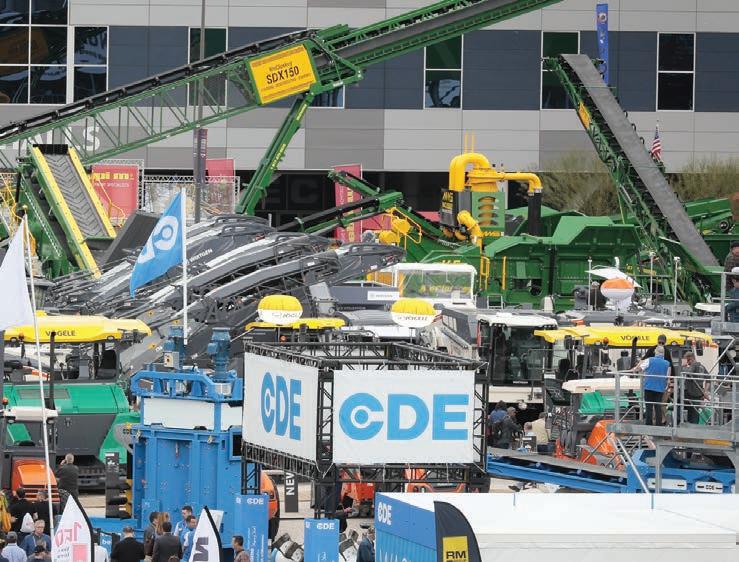

IMARC will allow global leaders and emerging gamechangers from the entire mining value chain the unique opportunity to come together under one roof.”

Those words are from IMARC director of conference content and strategy Sherene Asnasyous discussing this year’s International Mining and Resources Conference (IMARC), set to be held at the ICC Sydney November 2–4.

IMARC has always been where global mining leaders connect with technology, finance, and the future – and the 2022 iteration will be no different. That’s why this month’s issue of Australian Mining features an in-depth preview of the event.

With so many industry events having taken place in recent months, it’s especially exciting for IMARC, which has lain dormant since 2019, to be back on the calendar.

And if any further evidence was needed to confirm that events are back – and that Australian mining is as strong as ever – one need look no further that the fact this year’s IMARC has had to expand its exhibition floor by 40 per cent to accommodate an exhibitor list 85 per cent bigger than 2019.

While this year’s event will cover a huge range of topics, one of the biggest talking points is bound to be the skills shortage that continues to plague the mining industry.

This month’s Australian Mining also looks at the issue. We chat with a handful of industry

experts about how the country’s resources sector can recruit, train, and retain employees during what has been called “the worst skills crisis in a generation”.

Elsewhere, we take a deep dive into two of Australia’s most plentiful future-facing minerals – copper and nickel – looking at the current state of the market and why so many companies seem especially eager to get their hands on as much of these resources as possible.

Speaking of handling resources, this month’s issue also has a special focus on bulk material handling.

It can sometimes be easy to forget that mining is far more than digging previous ores and minerals from the ground. Those materials have to move from point A to point B (and beyond) and the process of getting them there involves a lot of technology and expertise.

We take a look at any and all aspects of bulk material handling, from conveyor guards to sustainable belts to workers’ safety and potential danger zones.

Founded in 1944, Martin Engineering has a global presence in 17 countries on six continents, with customers in dozens of industries.

The company’s engineers have been solving bulk material handling problems around the world for over 70 years and are available to provide expert advice and assistance for any issue, whether it’s material clogging the discharge port of a container or railcar, or a fugitive dust issue that can’t seem to be brought under control.

How Denmark is helping to drive sustainability in Australian mining T he likes of FLSmidth, Aalborg CSP, DHI, Advent Technologies and C.C. Jensen are among the Danish companies helping the Australian resources sector move into a more sustainable future.

E xplore, develop and invest at IMARC E xtraordinary demand has seen Australia’s largest mining and resources conference and expo significantly expand its floorplan in 2022.

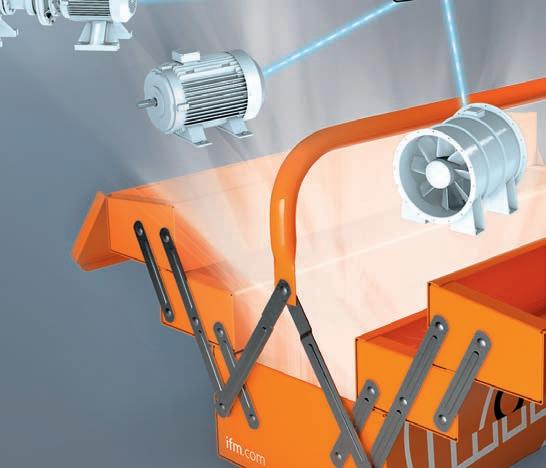

D riving efficiencies in material handling A stec Telestack’s mobile systems are providing Australian mining operations with a cost-efficient, flexible and reliable material handling and processing solution.

C opper and nickel: Pillars of the future?

A s the world continues its march to net-zero, the race is on for minerals essential to decarbonisation. Copper and nickel are at the top of the mining industry’s wish list.

T he world’s first battery-electric surface drill rig E piroc has teamed up with Swedish construction company Skanska to develop the first-ever battery-electric surface drill rig.

Filling the gap: Recruitment and the future of mining

A ustralian Mining speaks with industry experts about how the country’s resources sector can recruit, train, and retain employees during what has been called “the worst skills crisis in a generation”.

M itigating the long tail of dust

W hen it comes to tailings and other excess waste, miners need dustsuppression technology that can handle the size of their operation.

58

Transforming digital communications for mining N okia is engaged in developing innovative digital communications solutions for the resources sector, seeking to enhance operations, optimise safety, expand sustainability and drive efficiencies.

Due to the size and complexity of mining operations, most miners know (and expect) that inefficiencies and performance gaps exist across their mine value chain - particularly in load and haul circuit capacity.

Suboptimal haul routes, ineffective strategies, machine downtime, poor operator behaviour and inefficient processes are all some of the common problems that result in millions in lost production value every year. And with commodity prices climbing - masking true production and cost/ tonne output - potential profit losses could be closer to tens of millions annually.

Because of this, an increasing number of mining operators are turning to data and analytics to address poor productivity once and for all, closing the gap to best potential performance.

Decoda is a leading provider of Analytics as a Service, working with mine sites globally to achieve greater efficiency, mine plan compliance, and overall productive operations through delivering insights and improvements across the entire mine value chain.

Our intelligent, integrated Mining Operating System (iiMOS) uses real-time key performance insights, dynamic operational strategies, and remote haul road condition analysis to

help you drive efficiency and remove unpredictability across your load and haul circuits.

As your digital execution partner, Decoda provides an end-to-end service that allows you to develop strong alignment between your operational teams and the digital strategy underpinning your approach to data and analytics. This helps mine operators to:

• Achieve best potential operational excellence across the value chain

• Identify gaps in operator and machine performance to improve operational productivity

• Uncover millions in lost value opportunities

• Embed improvement strategies to improve mine site profitability

• Reduce variability and improve mine plan compliance.

Decoda brings together people, technology, and analytical methods to correct declining productivity and foster continuous, sustained improvement across mining value chains.

AUSTRALIAN MINING PRESENTS THE LATEST NEWS FROM THE BOARDROOM TO THE MINE AND EVERYWHERE IN BETWEEN. VISIT WWW.AUSTRALIANMINING.COM.AU TO KEEP UP TO DATE WITH WHAT IS HAPPENING.

Australia’s critical minerals will help drive the United States’ electric vehicle program following its move to grant preferred status to free trade agreement (FTA) partners. The US Inflation Reduction Act is expected to boost the Australian Government’s manufacturing agenda and help underpin the

demand for high quality Australian battery minerals.

Under the Act, a new electric vehicle will only be eligible for tax credits when at least 40 per cent of the battery’s critical minerals came from the US, an FTA partner such as Australia, Chile or Canada, or recycling in North America.

That could increase to 80 per cent by 2027.

The new law is a major milestone in the US’ transition from an economy long driven by fossil fuels to one that will be dominated by minerals such as lithium, nickel and aluminum.

Lithium share prices shot up when the ASX opened for the first time after the bill passed the House of Representatives. Companies such as Piedmont Lithium, Core Lithium, Sayona Mining, Allkem and Global Lithium Resources all surged.

Minerals Council of Australia chief executive Tania Constable said the development would strengthen the case for investment capital into mining.

“Australian mining needs about $20 billion per year to sustain current production,” she said.

“If we are going to increase the capacity of existing mines or open new mines – including in the commodities needed for our global transition to net zero emissions – capital investment will

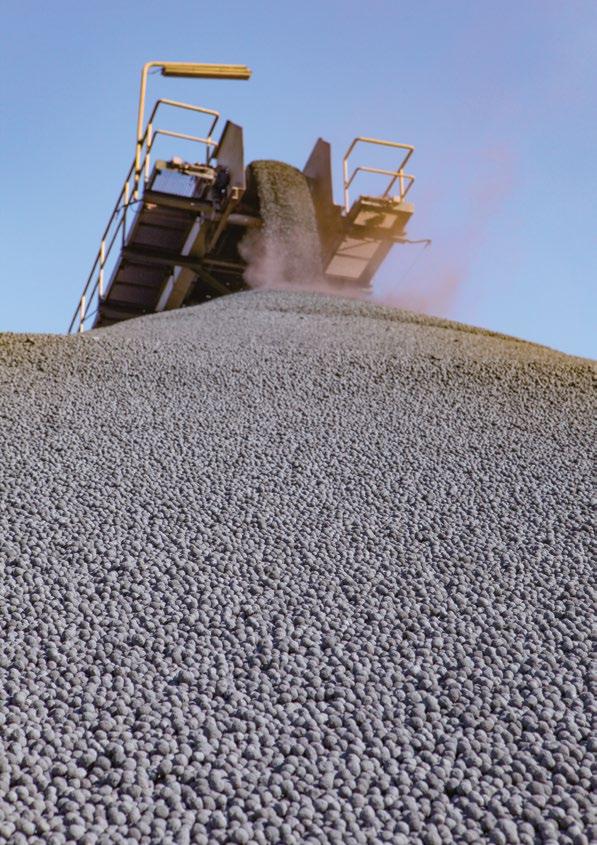

Mineral Resources (MinRes)’ transformational Onslow Iron project (formerly known as the Ashburton project) in Western Australia has commenced early works to support first ore on ship around December 2023.

Onslow Iron will unlock stranded deposits that would otherwise remain undeveloped in the West Pilbara region, using MinRes’ innovative and proprietary equipment designed to process and move bulk commodities at lower costs and with a reduced environmental footprint.

Following receipt of preliminary approvals, project preparations are on track and early construction activities, including bulk earthworks, have begun at the port of Ashburton, south of Onslow. At the nearby truck

maintenance facility, installation of the temporary construction village is underway, with first buildings to be installed from early September.

Mine development activities have also progressed at the Ken’s Bore Deposit, east of Onslow, with construction of the A320-capacity airport and the installation of two camps to support drilling and early construction works.

Recruitment for the construction phase of Onslow Iron is also well underway alongside a continued focus on community and stakeholder consultation.

In line with the project schedule, long-lead items have been ordered, including the first transhippers, which will be used to load capesize vessels that will be anchored offshore Ashburton port.

Each transhipper has a 20,000-tonne capacity, is fully enclosed to avoid dust pollution and has a significantly lower environmental footprint when compared to the major dredging activities that would be required to construct deepwater berths.

Onslow Iron will be one of the largest iron ore developments undertaken in WA and deliver substantial benefits to the state, including thousands of construction and operational jobs, billions of dollars of direct local investment through capital expenditure and billions of dollars of state and commonwealth royalties over the life of the project.

MinRes managing director Chris Ellison said the project would be the cornerstone of the company’s

AUSTRALIAN MINING GETS THE LATEST NEWS EVERY DAY, PROVIDING MINING PROFESSIONALS WITH UP-TOTHE-MINUTE INFORMATION ON SAFETY, NEWS AND TECHNOLOGY FOR THE AUSTRALIAN MINING AND RESOURCES INDUSTRY.

need to be increased by an order of magnitude.

“The Bank of America estimates that $US150 billion per year will be needed in global mining to produce the minerals needed to achieve the global transition to net-zero.

“Australia needs to position itself as a competitive destination for this capital in order to realise its full potential.”

iron ore strategy to deliver low-cost, long-life operations with project economics that are compelling through commodity price cycles.

“Importantly, our innovations will drive lower emissions across the project. Onslow Iron has been designed with a low environmental footprint and will be dust-free from pit to port,” he said.

“We’re also setting a new FIFO standard with our industry-first resort-style accommodation to ensure the physical and mental safety of our people, and to encourage more women and couples to live on site.

“It’s in our DNA to aim higher, push the boundaries and forge new paths, which is why Onslow Iron really represents a new paradigm for mining in WA.”

its underlying attributable profit had risen more than 40 per cent to $US23.8 billion ($33.89 billion) for the year to June 30.

“These strong results were due to safe and reliable operations, project delivery and capital discipline, which allowed us to capture the value of strong commodity prices,” BHP chief executive Mike Henry said.

bringing full-year dividends to $US3.25 a share.

The annual report also indicated an attributable profit of $US30.9 billion ($44 billion), net operating cash flow of $US29.3 billion ($1.73 billion) and record free cash flow of $US24.3 billion ($34.61 billion) for continuing operations.

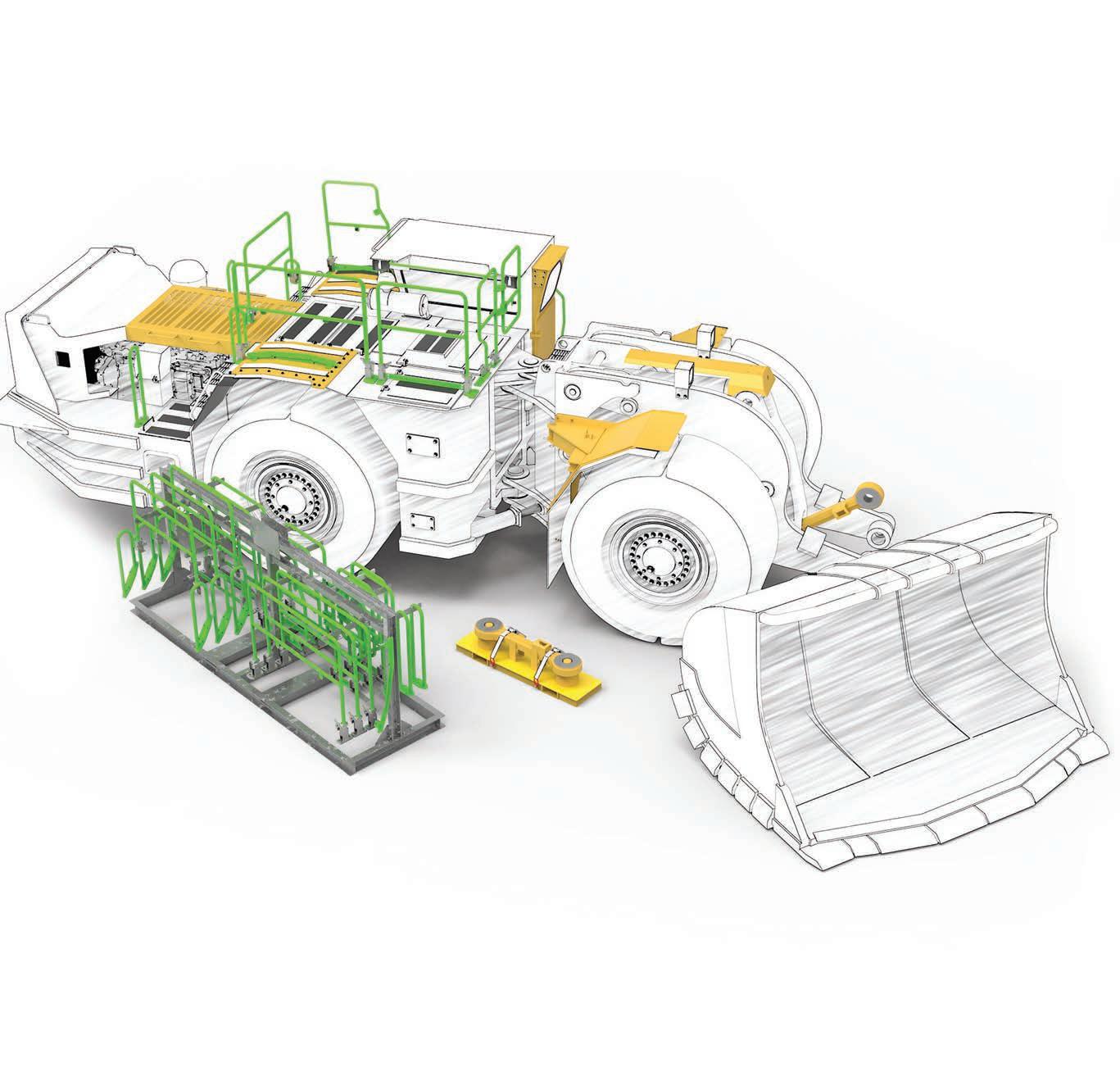

Leading Australian contract miner Byrnecut is set to bring in six Sandvik battery loaders for use at OZ Minerals’ operations in South Australia.

Under a deal with Sandvik Mining and Rock Solutions, Byrnecut will take delivery of the batteryelectric units in 2023 and 2024 for use at the Prominent Hill copper, gold and silver mine, southwest of Coober Pedy, and the Carrapateena copper and gold mine, north of Port Augusta.

Byrnecut has been engaged by OZ to provide underground mining services at the mines and it currently has a fleet of Sandvik LH621i loaders with automation operating on both sites.

Byrnecut asset manager Max Woods said the company was leading the way with battery-electric vehicles in Australia by putting the Sandvik loaders into service over the next two years.

“Not only will the use of electric vehicles significantly improve the working environment underground,

but it will also help our customers to work toward their emissions reduction goals – something that is increasingly important in the mining sector,” he said.

Woods said the purchase of the loaders, which will be equipped with Sandvik’s Automine automation system technology, was part of Byrnecut’s commitment to exploring and embracing new technologies that make its operations safer, more efficient and more sustainable.

“Eliminating emissions from loaders from the underground environment helps us create a better workplace, as does AutoMine technology that enables operators to work from comfortable remote control rooms,” he said.

Another major benefit to Byrnecut is the anticipated increased performance the new loaders could provide.

The company worked closely with Sandvik prior to purchase in order to model various application scenarios, including manual and automated operation.

Amid the record numbers, Henry said geopolitical factors would continue to affect the company in the near future.

“We expect China to emerge as a source of stability for commodity demand in the year ahead with policy support progressively taking hold,” he said.

“At the same time, we expect to see a slowdown in advanced economies as monetary policy tightens as well as ongoing geopolitical uncertainty and inflationary pressures.

“The direct and indirect impacts of Europe’s energy crisis are a particular point of concern.

“Tight labour markets will remain a challenge for global and local supply chains. Waves of COVID-19 infection continue to occur in the communities where we operate, and we are planning accordingly.”

BHP said its FY22 profit increase stemmed from higher coal and copper prices and a strong underlying operational performance, including record sales at its Western Australia Iron Ore operations (WAIO) and near record concentrator throughput at its Escondida copper mine in Chile.

The miner said its result was partially offset by COVID restrictions and supply constraints, higher inflation affecting diesel, electricity and consumable prices, along with lower copper grades at Escondida and wet weather at its BHP Mitsubishi Alliance (BMA) coal operations in the Bowen Basin.

“We’re expecting the loaders to provide greater throughput in both manual and automated modes while delivering a similar total cost of ownership per tonne delivered to their predecessors,” Woods said.

The loaders are expected to bring major cost savings across their lifecycles. They are likely to require fewer replacement parts than their predecessors, and servicing is simpler and more efficient.

Sandvik 18-tonne battery loaders are among the most compact on the market. The powerful electric motors, innovative electric driveline, and the smaller tyres on the rear compared to the front result in small machine size, high payload with good visibility and impressive speeds.

Battery machines produce no underground exhaust emissions and significantly less heat than traditional diesel engines, supporting the mines to reach sustainability targets, through reduced carbon emissions.

Sandvik business line manager for load and haul Andrew Dawson said the first Sandvik battery-electric loaders began arriving in the country about a year ago, and interest has been extremely strong.

“We’re very pleased that Byrnecut and OZ Minerals see the benefits of this technology and are demonstrating it to the rest of the industry. We have always had an excellent working relationship with Byrnecut and look forward to cooperating with them throughout the roll-out and beyond,” he said.

Byrnecut is a renowned specialist underground mining contractor offering a unique range of services and depth of experience.

Sandvik’s AutoMine is an automation system for autonomous and tele-remote operation for a wide range of Sandvik loaders and trucks. The system is scaled from teleremote or autonomous operation of a single machine to multi-machine control and full fleet automation with automatic mission and traffic control capability.

idoba chief executive officer Sarah Coleman was a big winner at the recent Women in Industry Awards, taking out the Excellence in Mining award.

Fulton Hogan was also a major winner, coming out on top in multiple categories.

Fulton Hogan general manager Sarah Marshall was awarded the Excellence in Construction and Woman of the Year awards, while

Joanne Jeffs, Barbara Pitos and Nina McHardy were awarded the Social Leader of the Year award, Safety Advocacy award and Industry Advocacy award, respectively.

The Women in Industry Awards are held each year to recognise the exceptional work and dedication of the women in the industrials sector.

The awards are an invaluable opportunity to recognise not just the nominees and winners, but the hard

NRW Holdings made a higher pershare offer, but it had too many strings attached for MACA.

When MACA’s founding shareholders recently entered into written acceptance deeds allowing Thiess to secure 15.9 per cent of the mining services provider, it came after Thiess increased its off-market takeover bid from $1.025 cash per share to $1.075.

The boosted offer valued MACA at $367.3 million.

“Thiess’ increased offer is compelling and an attractive price representing a strong premium to recent trading prices prior to the

announcement of the initial Thiess offer,” MACA founding shareholder Geoff Baker said.

“My fellow founding shareholders and my fellow MACA director Rob Ryan have agreed to accept the revised offer price and have agreed not to withdraw those acceptances for the duration of the offer period.”

However, NRW, another WAbased mining contractor, had previously made a $1.085-pershare offer for MACA.

So why was the higher offer rejected?

According to the MACA board, NRW’s offer was inferior because

work and dedication of all women in industries such as mining, road transport, manufacturing, engineering, logistics, bulk handling, waste management, rail and infrastructure.

Marshall has been leading the Fulton Hogan team as general manager for over three years, while also serving as board director for the Australian Constructors Association. She has spent her career

spearheading positive change in the industry by driving sustainability, improving culture, and driving improvements in gender diversity.

The 2022 awards were sponsored by Atlas Copco, Weir Minerals, and Komatsu. Commenting on the awards, Komatsu expressed pride in its sponsorship.

“Komatsu is proud to once again be a sponsor of the Women in Industry Awards to celebrate the successes of the incredible women working in our industry,” the company said.

“All nominees and winners are making their workplaces and communities a better place for future generations, which closely aligns to our core values at Komatsu.”

The Excellence in Mining award, sponsored by Weir Minerals, went to idoba chief executive officer Sarah Coleman.

Coleman is a knowledgeable mining and management consulting executive with experience in operations, improvement, innovation, technology, and asset management. She founded leading business improvement company ImpRes in 2010, and now heads idoba as its CEO.

• S age Hahn– Business Development Success of the Year

• L ouise Adams– Excellence in Engineering

• Rebecca Healy– Excellence in Manufacturing

• Frances Ross– Excellence in Transport

• Danielle Bull– Mentor of the Year

• Helen Tower– Rising Star of the Year (sponsored by Atlas Copco)

only half of the proposal was in cash – NRW would have paid out a total of $188.6 million in cash, with the remainder to be paid in company stock.

It also came with several risks, including whether NRW could secure adequate financing.

“The NRW indicative proposal was a non-binding indicative proposal, was subject to conditions and there was no certainty that giving NRW (and its financiers) access to MACA to do due diligence would result in a binding offer or the execution of a scheme of arrangement implementation agreement,” MACA said in rejecting

the NRW offer earlier in August.

One MACA investor was more straightforward when suggesting NRW needed to make a firmer offer.

“NRW likely should put on their big boy pants and make a better offer with fewer strings attached,” the investor, who declined to be named, told the Australian Financial Review.

MACA’s boards ultimately determined the NRW offer was too great a risk and recommended shareholders accept the Thiess bid, which is waiting on approval from the Foreign Investment Review Board.

With Sandvik’s decades of experience designing mining equipment and unbeatable expertise with BEVs, we design our battery electric trucks and loaders to be the best choice for more sustainable mining. Minimum mine infrastructure needs, high payload capacity, fast and easy battery swap, purpose-built chemistry, and electric driveline with superior power; meet Sandvik battery electric trucks and loaders.

When Mineral Resources announced the second-best annual result in the company’s history, it highlighted lithium growth as one of its four key business pillars.

“MinRes began building a worldclass, long-life lithium business in Western Australia more than a decade ago,” MinRes managing director Chris Ellison said following the release of the company’s 2022 financial year report.

“Our foresight and investment are starting to bear fruit.

“Today we already are the largest ASX-listed spodumene concentrate producer and one of the first to derive earnings from lithium hydroxide.”

While MinRes’ 2022 underlying net profit of $400 million represented a 64 per cent drop on the previous year, the company said it experienced “a strong second half performance” due to record lithium prices.

Lithium carbonate and lithium hydroxide prices have held steady since April’s record high levels, with leading price reporting agency Benchmark Mineral Intelligence indicating both products are still trading more than 300 per cent higher than a year ago.

MinRes has also reported a big future in lithium growth.

“In lithium, MinRes and our JV (joint venture) partner

Ganfeng approved the next stage of expansion of Mt Marion to 900,000 tonnes per annum,” the company said. “We also delivered maiden earnings from lithium hydroxide production – a first for an ASX-listed company.

“Production resumed at Wodgina, one of the world’s largest hard-rock lithium mines, following the start-up of trains 1 and 2.

“The Kemerton lithium hydroxide plant, which like Wodgina is part of our MARBL JV with Albemarle, is in the final stages of pre-production activities.”

Paul Brown, MinRes chief executive – lithium, recently said upgrades at Mt Marion would further strengthen the company’s position as a “globally significant producer of lithium products”.

“Lithium is one of MinRes’ core commodities,” Brown said. “We’ve built a long-term business horizon that will guide us to expand and diversify our lithium portfolio in line with global demand.

“Doubling capacity at Mt Marion means this Tier 1 asset will become even more important to MinRes’ ongoing success, helping us continue making valuable contributions to the world’s renewable energy efforts.”

Global analysts like Goldman Sachs and Credit Suisse sent shockwaves through the sector in

June when they predicted a crash in lithium prices.

Goldman Sachs said there had been “a surge in investor capital into supply investment tied to the long-term EV (electronic vehicle) demand story, essentially trading a spot-driven commodity as a forwardlooking equity”.

“That fundamental mis-pricing has in turn generated an outsized supply response well ahead of the demand trend,” the company said.

That assessment was quickly rebutted, however, with Benchmark Mineral Intelligence highlighting several reasons it believed Goldman Sachs was wrong in its predictions.

More recently, a newly passed US law designed to drive EV production is likely to be a boon for Australian lithium producers.

Under the US Inflation Reduction Act, an new EV will only be eligible for tax credits when at least 40 per cent of the battery’s critical minerals came from the US, a free trade agreement partner such as Australia, Chile or Canada, or recycling in North America. That could increase to 80 per cent by 2027.

“Australian mining needs about $20 billion per year to sustain current production,” Minerals Council of Australia chief executive Tania Constable said of the new US law.

“If we are going to increase the capacity of existing mines, or open new mines – including in the commodities needed for our global transition to net-zero emissions –capital investment will need to be increased by an order of magnitude.

“The Bank of America estimates that $US150 billion per year will be needed in global mining to produce the minerals needed to achieve the global transition to net-zero.

“Australia needs to position itself as a competitive destination for this capital in order to realise its full potential.”

Goldman Sachs, for its part, may have changed its tune on the critical mineral.

Lithium – along with other futurefacing minerals such as nickel and copper – is a key ingredient in batteries and equipment needed in decarbonisation.

In a note to clients, Goldman Sachs said it expects “battery and hydrogen storage solutions to continue to receive greater attention from investors, who we believe have not yet fully appreciated their importance in mitigating market disruptions”.

“Globally, we see several regulatory initiatives that could provide tailwinds to accelerate solutions such as battery storage and hydrogen to alleviate energy reliability issues.”

Our industry has witnessed some crippling fires originating from the ignition of screening media. The source of these fires is linked to maintenance hot works and even equipment failure during normal operation. As well as posing a serious hazard to personnel, the cost of equipment damage and lost production can border on the incalculable.

Screen house fires can’t be prevented by operating procedures alone. The good news is that we can help you permanently eliminate this risk with our innovative Fire Resistant screening media.

See for yourself how easily these fires can occur and how Screenex®

Fire Resistant screening media can help to eliminate this hidden hazard

Rio is teaming up with its biggest customer – China Baowu Steel Group – to develop the Western Range iron ore project in the Pilbara.

Rio Tinto and Baowu announced in September they had agreed to enter into a joint venture on the project, with a total investment of $US2 billion ($2.96 billion).

Rio will invest $US1.3 billion ($1.92 billion) and hold a 54 per cent stake in Western Range, with Baowu paying $US700 million ($1.03 billion) for the remaining 46 per cent.

“This is a very significant milestone for both Rio Tinto and Baowu, our largest customer globally,” Rio Tinto Iron Ore chief executive

Simon Trott said. “The development of Western Range represents the commencement of the next significant phase of investment in our iron ore business, helping underpin future production of the Pilbara Blend, the market benchmark.”

Western Range’s annual production capacity of 25 million tonnes of iron ore will, according to Rio, help sustain production of its Pilbara Blend from the miner’s existing Paraburdoo hub.

The Western Range project includes construction of a primary crusher and an 18km conveyor system that will link it to the existing Paraburdoo

processing plant. Construction is expected to begin in early 2023, with first production anticipated in 2025.

Rio and Baowu also entered a sales agreement that will see Baowu buy up to 126.5 million tonnes of iron ore over approximately 13 years.

“The signing of the joint venture agreement for the Western Range project is a significant event in the history of cooperation between Baowu and Rio Tinto,” Baowu Resources chairman Shi Bing said.

“We fully appreciate the persistent efforts of both teams in accomplishing the important achievement.

South32 posted record profits of $US2.6 billion ($3.76 billion) in the 2021–22 financial year.

The windfall profits represent a 432 per cent jump from FY21 ($US489 million), along with a 156 per cent increase in underlying EBITDA (earnings before interest, taxes, depreciation, and amortisation) to $US4.76 billion ($6.87 billion).

a record $US1.3 billion ($1.88

billion) of returns in FY22, which is 10 per cent of the miner’s market capitalisation.

The Perth-based miner’s profits were driven largely by surging prices for metallurgical coal and aluminium, with South32 recording realised prices of $US1.54 billion from coal

exposure to metals critical for a lowcarbon future. Chief executive officer Graham Kerr said the company was aware of the need to move towards more future-facing minerals.

“We have repositioned our portfolio toward metals critical for a low-carbon future,” he said.

“We hope that the two parties will deepen the mutually beneficial and win–win partnership, continue to carry forward the spirit of sincere cooperation and further expand cooperation in more fields and aspects on the basis of working together to operate the project well.”

Rio’s Pilbara Blend products “are the world’s most recognised brand of iron ore and are known for their highgrade quality and consistency”.

“Our Pilbara Blend products make up approximately 70 per cent of our iron ore product portfolio. It is also the largest and most liquid iron in the market today,” the company said on its website.

an additional shareholding in the hydro-powered Mozal Aluminium smelter and the restart of our 100 per cent renewable powered Brazil Aluminium smelter.”

News of the record profits came days after South32 announced it had decided not to progress

artin provides the most innovative bulk material control com ponents in the industry. Self-adjusting skirting, wear liners and dust curtains effectively control fugitive material. Support cradles eliminate belt sagging and pinch points. Engineered chutes are designed for optimal dust containment and air flow management.

Our components reduce harmful conditions, decrease maintenance and insurance costs, and increase overall productivity. Got dirt? We’re ready to assist with all of your bulk material handling problems.

the first open-cut coal mine in Queensland to be fully rehabilitated and relinquished.

The Queensland Government has accepted surrender of New Hope Group’s environmental authority and mining leases for the site after critically assessing the project and concluding that all rehabilitation requirements had been met in full, deeming the site safe, stable, non-polluting, and able to support grazing.

Chief executive officer Rob Bishop said New Hope Group made the decision to backfill the voids, reshape and rehabilitate the area to meet community expectations.

“The extensive rehabilitation works were conducted between 2014 and 2017, with ongoing works undertaken over the past eight years,” he said.

“The Chuwar Coal Mine site demonstrates New Hope Group’s commitment to being a responsible operator and ensuring

Stanmore Resources fully acquired the former BHP Mitsui Coal, previously renamed to Stanmore SMC after the company bought BHP Minerals’ 80 per cent interest through the acquisition of all the shares in Dampier Coal.

The subsidiary entered into a definitive share sale agreement to take over the remaining 20 per cent interest in SMC held by Mitsui.

Stanmore chief executive officer Marcelo Matos said the transaction allowed the company to consolidate its position as a leading metallurgical coal miner in the Bowen Basin in Queensland.

“Having 100 per cent control of South Walker Creek and Poitrel, as well as Wards Well and other projects, allows Stanmore to

land use.”

New Hope Group has long championed one of Australia’s most ambitious and practical land management programs.

“Our progressive rehabilitation program at New Acland returns mined land to agricultural and conservation uses while contributing to the region’s agribusiness industry,” Bishop said.

“To date, more than 740ha of land has been rehabilitated at

recognised by the Queensland Government, who has formally ratified 349 hectares of progressively rehabilitated mined land.

“At the time of the Queensland Government’s announcement, it was the largest single area of certified rehabilitation for an open-cut coal mine in Queensland.

“To put the size of the area in context, the certified, rehabilitated land at New Acland covers about 300 Suncorp Stadiums.”

maximise value amongst our assets in the region” he said.

The purchase price upon completion is $US380 million, and will be reduced by any dividends paid to Mitsui by SMC prior to completion.

Based on current market conditions, Stanmore anticipates it will continue to have sufficient internal sources to meet all ongoing

cash requirements and fund the acquisition without the need to issue any new debt or raise capital.

Stanmore owns and operates the Isaac Plains Complex in the Bowen Basin region, which includes the Isaac Plains mine and processing facilities, the adjoining Isaac Plains East and Isaac Downs mining areas and the Isaac Plains underground project.

Australia’s third-largest iron ore miner reported a profit of $US6.2 billion ($9 billion) in the 2021–22 financial year (FY22), down from $US10.3 billion ($15 billion) in FY21.

While the profit was down 40 per cent year-on-year, it still represented the second-highest earnings result in Fortescue’s history.

The fact Fortescue recorded a reduced profit in the face of record shipments of 189 million tonnes or iron ore reflects a steep drop in price for the steel-making material amid an economic slowdown in China.

The price for iron ore has been hovering around $US108 per tonne after a high of almost $US160 per tonne in March 2022.

Fortescue said the 189 wet metrics million tonnes of iron ore it shipped in FY22 “exceeded the top end of guidance” and was a major contributor to the bottom line.

“Guided by our unique culture and values, the team has delivered another year of record operational performance for FY22, contributing to net profit after tax of $US6.2 billion, the second highest annual profit in Fortescue’s history,” Fortescue chief executive officer Elizabeth Gaines, who is stepping down from the role and into the company’s minerals division, said in the FY22 results announcement.

The profits also mean a windfall dividend for Fortescue shareholders, with chairman – and major shareholder – Andrew Forrest taking home $2.34 billion.

“Reflecting our ongoing commitment to delivering enhanced shareholder returns, the board has declared a fully franked final dividend of $1.21 per share, bringing total dividends declared for FY22 to $2.07 per share,” Gaines said.

“This represents a 75 per cent payout of full-year net profit after tax, consistent with our stated intent to target the upper end of our policy to payout a range of 50 to 80 per cent of NPAT (net profit after tax).”

While commodity process and mining companies have been hit a series of COVID-induced hard lockdowns in China, analysts believe Australian miners are set to benefit from the expected return of their biggest export customer.

According to a recdn t report from Ausbil Global Resources Fund, China is “likely to accelerate growth coming out of recent hard COVID lockdowns through significant stimulus”.

“Throughout 2022 … we have seen the government setting up for more aggressive stimulus, which we expect to play out during 2H 2022,” Ausbil co-portfolio managers Luke Smith and James Stewart write.

“While rolling lockdowns remain in place, the implementation of stimulus measures is likely to be somewhat constrained, but the building blocks are in place to accelerate economic activity.

“Given China represents at least 50 per cent of commodity demand, we believe commodities are likely to benefit from Chinese stimulus which is yet to hit the ground.

“Metal markets are currently tightly balanced in terms of supply and demand, with limited excess capacity available in any commodities following an extended period of underinvestment.

“Metals inventory remains low. Although demand may soften from the west, markets are tight and any acceleration from Chinese demand should underpin prices that are already stretched due to low inventories and underinvestment in supply.”

BHP has rejigged its executive leadership team, to take effect from October 1.

Edgar Basto will be appointed chief operating officer and Geraldine Slattery will assume the role of president, Australia.

In his new position, Basto will enable acceleration in safety and productivity improvement across the group. He will have accountability for the continued transformation of BHP through the embedment of the BHP operating system, and for BHP’s global performance and improvement and health, safety and environment functions.

Since May 2020, Basto has been BHP’s president minerals, Australia. He has more than 30 years of operating experience across BHP’s minerals, including overseeing the company’s two largest assets, Western Australia Iron Ore and Escondida, and leading the global health, safety and environment team.

Slattery will be responsible for BHP’s Australian operations. From March 2019 until the completion of the Woodside merger in June this year, she had been president petroleum and led BHP’s business, which included oil and gas interests and development and exploration programs in the US,

Australia, Trinidad and Tobago, Algeria, Mexico and Canada.

BHP chief executive officer Mike Henry said the appointments would enable the miner to build upon the strong performance delivered in recent years to drive even better safety and productivity outcomes.

As a result of these changes, the leadership team will comprise:

• Chief operating officer, Edgar Basto

• Chief legal, governance and external affairs officer, Caroline Cox

• Chief financial officer, David Lamont

• Chief commercial officer, Vandita Pant

• President, Australia, Geraldine Slattery

• Chief technical officer, Laura Tyler

• Pr esident, Americas, Ragnar Udd

• Chief development officer, Johan van Jaarsveld

• Chief people officer, Jad Vodopija.

Denmark has long been at the forefront of the global sustainability push –and with good reason.

“In the early 1970s, Denmark was 99 per cent dependent on fossil fuels,” Her Excellency Pernille Dahler Kardel, Denmark’s ambassador to Australia, told Australian Mining

“When the oil crisis hit, Danish citizens had difficulty heating their homes and everyone was forced to abandon their cars on Sundays.

“This crisis galvanised the nation to move away from its reliance on fossil fuels and sparked what some might say is a national obsession with becoming green – long before it became fashionable.”

Denmark’s hunger to become green permeates across the country’s policy and practice, and the nation has become a world leader in wind energy and waste, while its bike culture is certainly no joke.

So how is Denmark, a country not known for its mining, assisting the

Australian resources sector with its own sustainability objectives?

Kardel put it simply.

“While Denmark is not a mining nation, it is a nation that has long looked for solutions to reduce energy and water consumption,” she said.

“And many of those solutions can be applied across multiple industries, including the mining industry.”

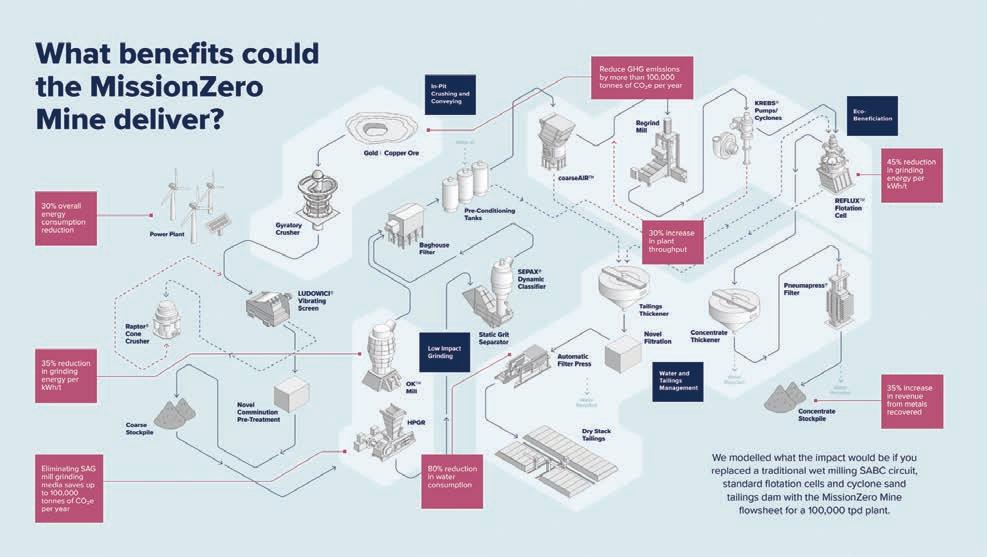

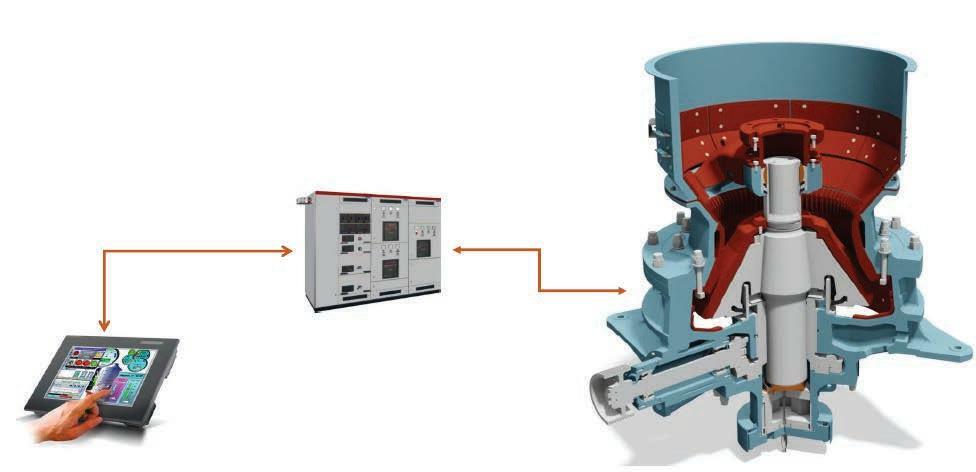

Danish original equipment manufacturer (OEM) FLSmidth has been supporting the sector for decades and has become a market leader for its pit-to-plant solutions spanning everything from crushing and milling, pumping, flotation and separation through to tailings management and beyond.

With a customer base brimming with the world’s leading mining companies across commodities such as iron ore, gold, copper, nickel and lithium, FLSmidth aims to achieve “sustainable productivity through innovation”, a vision embodied by the OEM’s MissionZero strategy.

MissionZero is centred around driving a paradigm shift of zero emissions, water waste, and energy waste in mining by 2030 not only for FLSmidth’s own operations, but also for its customers.

This ambition becomes possible when multiple technologies are combined. An example of this is FLSmidth’s MissionZero Mine.

“To achieve zero emissions, it’s not simply about electrifying the mine operation; it’s also about changing the flowsheet using different technology, to reduce the energy and water needed for production,” FLSmidth APAC mining president Tamer Eid told Australian Mining

FLSmidth found that if a mining company replaced a traditional wet milling SABC (SAG mill/ ball mill/pebble crusher) circuit, standard flotation cells and a cyclone sand tailings dam with the MissionZero Mine, the operation would realise a 30–45 per cent reduction in overall energy consumption, along with an 80 per cent reduction in water consumption.

The operation would also realise increased metals recovery.

“If we put in different technology together such as coarse flotation, REFLUX flotation, our market leading high-pressure grinding rolls (HPGRs) and dry stack tailings, you can actually change the flowsheet to reduce your energy and water demands significantly,” Eid said.

Comminution (making a big rock into a small rock) is estimated to use in the vicinity of 2–3 per cent of the world’s total energy.

“So when you have different technology that can change the game of comminution and reduce that energy consumption, that is significant,” Eid said.

FLSmidth’s OK Mill can use dry grinding instead of a waterbased method, saving on water and energy usage by 10–20 per cent kWh/t (kilowatt-hour per tonne) in the process.

HPGRs also use a dry grinding process and are therefore a more sustainable alternative than SAG mills and ball mills.

Miners will not only save energy with HPGRs, but they also achieve emissions reduction indirectly from the elimination of the steel grinding media needed inside SAG and ball mills.

Coarse flotation also reduces energy consumption.

“Coarse flotation enables miners to beneficiate with larger particle sizes, meaning they can grind less to liberate the ore, using up to 45 per cent less energy per kWh/t,” Eid said.

“With coarse flotation alone, you reduce the amount of energy needed and therefore the amount of energy generation required to deliver the same throughput, and it can be applied to existing circuits.”

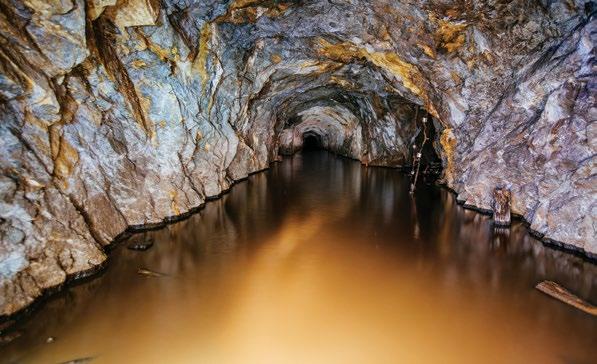

There are also opportunities in tailings management.

“Instead of having a tailings pond, you can have dry stack tailings, where tailings are stacked on top of one another,” Eid said.

“That means you can recover up to 95 per cent of valuable water, utilise it back in the process, and you don’t have big tailings dams and high-water usage.

“Especially in the drier places of the world, such as some of the mines in the north-west and Pilbara region of Western Australia, water is at a premium. For some new mines, companies need to have different dewatering and tailings arrangements to enable these mines to be viable.”

Eid said while each of these technologies is effective independently, they produce even greater results when combined.

“We work closely with customers to help integrate these different technologies – using our end-to-end flowsheet capability. This delivers extra value and supports not only

changing the NPV (net present value) of the mine itself, but also fulfilling their corporate social responsibility goals,” he said.

Aalborg CSP is another Danish company with sustainability solutions for the Australian mining industry.

The company’s technology – which supports solar, boilers, heat pumps and storage – replaces the energy derived from fossil fuels with energy generated from the sun, which can be stored and distributed to satisfy demand for electricity, heating and process steam production, cooling and desalination.

Via the company’s heat exchanger and heat pump solutions, excess electricity from wind and photovoltaic (PV) technology can be converted to heat or process steam to operating conditions of between 40°C and 565°C.

The thermal energy solution can be integrated with other renewable energy solutions and Aalborg CSP’s high- or low-temperature storage technologies to secure a constant supply of energy.

Andreas Zourellis, Aalborg CSP’s vice president of technical sales –international markets, said the Danish EPC’s (engineering, procurement, and construction) solutions are well suited to the dry terrains of the Australian mining landscape.

“What is intriguing and special about the Australian mining industry is some mine sites are very remote and decentralised and they are in locations where the sun is shining for most of the day,” he told Australian Mining

“By combining a solar thermal plant, whether it’s low-temperature or high-temperature, with thermal battery as grid-scale storage, we can offer a completely decentralised system generating green heat or

The 36MWth (megawatt-thermal) system generates 1700MWh (megawatt-hour) of electricity per year and 20,000MWh of heat per year, and desalinates 250,000 cubic metres of water per year.

Zourellis said that while this case study is relevant to the agriculture industry, a similar energy system could be used in the resources sector.

“The Australian mining industry uses extensive amounts of energy to desalinate water or treat water that can be used later for mining processes,” he said.

“We can power a desalination unit with solar power and then provide fresh water. This is already up and running in Port Augusta.”

With water scarcity a global issue and saline wastewater ever-present on a mine site, desalination is a costeffective way of reusing water. Other than providing emissions free heat and electricity, Aalborg CSP’s thermal energy solution gives a desalination unit the green tick.

“Our world is water.”

DHI has an expert understanding

tools that can be used to understand their water impacts and conduct forecasting. For example, DHI’s FEFLOW tool has been used for decades to model open-pit dewatering, with many Australian Tier 1 miners implementing this solution.

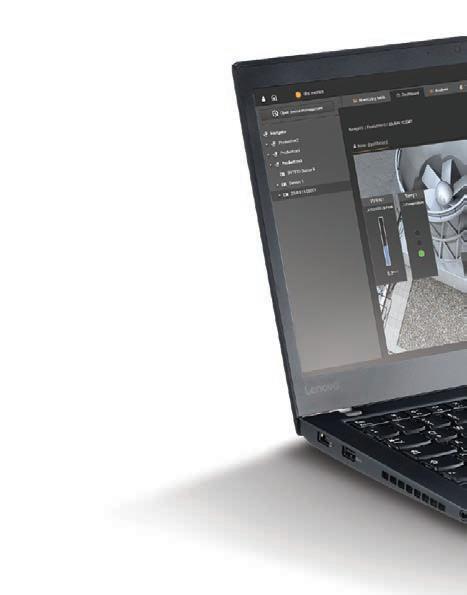

The company is now moving into the digital advisory space through its MIKE Mine solution, which provides real-time monitoring, forecasting, scenario-testing and reporting of water operations on a mine site.

MIKE Mine – which DHI calls a “decision-support system” – sees the company build a web-based browser for mining companies, combining operational data and planning data in the process.

DHI then brings in forecast models to understand the direction of the site’s water operations, before combining all available data to create a water action plan for the mining operation.

DHI executive vice president Stefan Szylkarski said the ultimate goal was to provide mining operations with a real-time, automated water management system.

“Instead of someone running it (water management) manually, we’ve

dewatering is progressing in real-time, how their water operations are going at any one point in time.”

Advent Technologies is becoming another vital piece of the mining industry’s renewable energy puzzle.

Holding the intellectual property for next-generation HT-PEM (high temperature-proton exchange membrane) technology, the company develops, manufactures, and assembles complete fuel cell systems and supplies customers with critical components for fuel cells in the renewable energy sector.

Advent fuel cells are multi-fuel capable, meaning they work on hydrogen as it comes in many different forms (methanol, e-methanol, e-fuels, natural gas), thus eliminating the need for complex hydrogen infrastructures.

The company was listed on NASDAQ in February 2021 and has already deployed over 1000 telecom fuel cell units worldwide.

Advent’s fuel cells can provide up to 100kW of critical power and have proven an essential back-up power source for the telecommunications

alongside renewable sources such as solar and wind.

Advent’s vice president of sales and marketing Alan Kneisz said the fuel cells are instrumental where the use of grid power is challenging or not possible, which can be the case in the remote expanses of the Australian mining industry.

Kneisz said that while Advent can’t yet compete with diesel from a price perspective, fuel cells will become increasingly important as their total cost of ownership decreases and the world nears the net-zero thresholds of 2030 and 2050.

“We are working with the mining industry on smaller applications and, as our technology develops and we have more partnerships, we aim to develop them into bigger applications such as larger scale power stations,” he told Australian Mining

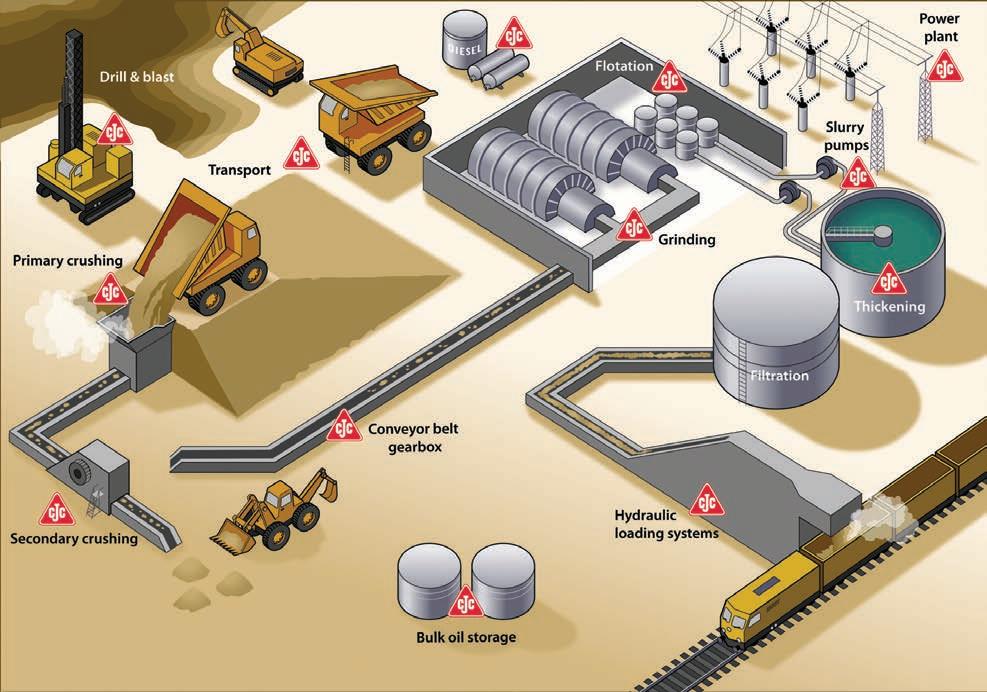

A global leader in oil maintenance, C.C. Jensen’s CJC offline oil filtration solutions reduce component wear and oil consumption on a mine site, in turn delivering major efficiency improvements.

C.C. Jensen provides solutions for various pieces equipment across a mining operation, whether it be a haul truck, crushing equipment, hydraulic loading systems, flotation and grinding applications in a processing plant, or one of many other options.

The filtration solutions can support diesel fuel, hydraulic oil and gear oil, enabling unique productivity and environmental outcomes for each application.

“With diesel, we want make sure that finer particles and water are not present,” C.C. Jensen’s business manager for mining in the Asia

Pacific Nicolaj Vestergaard Sandt told Australian Mining. “Water in diesel creates bacterial growth and will create rust in the bottom of the tank.”

Sandt said if contaminants get to the injectors or the fuel pump, they can get stuck in the fine tolerances and ruin the equipment.

“These are failures that have been common in the world for many years, but there is no need for those failures,” he said. “They shouldn’t be there if we remove the core reason why.”

C.C. Jensen can extend the lifetime of hydraulic systems by up to 95 per cent through oil filtration, Sandt

said, while the company’s gear oil solutions have significantly improved the efficiency of heavier applications such as crushers and mills, leading to a 60 per cent reduction in the use of spare parts.

C.C. Jensen has demonstrated its ability to avoid three out of four shutdowns, and one copper mine in Chile was even able to reduce shutdowns by 87 per cent by using the Danish company’s oil filtration solutions.

Despite almost daily in-line filter changes, the copper mine previously had to make oil changes every two

months as dirt and contamination accumulated in the oil.

Since installing offline oil filtration, however, the Chilean mine shuts down once a year for six hours for a single oil change, not only reducing downtime but limiting oil usage and the operation’s CO2 footprint.

As the Australian mining industry races towards a decarbonised future, there is going to be greater demand for environmental innovations. And as a global sustainability trailblazer, Denmark will continue to be an important part of the net-zero narrative. AM

The International Mining and Resources Conference (IMARC) will host more than 7500 attendees from over 100 countries at Sydney’s International Convention Centre from 2–4 November.

The conference, the largest of its kind in Australia, will provide the opportunity for domestic and international industry leaders to engage, learn, network and, most importantly, do business, while addressing the energy transition,

rising costs, skills shortages, social performance, and diversity within the resources sector.

IMARC is the most significant in-person gathering of Australian and international mining and resources representatives in almost three years and will be held under the one roof across a massive 17,000 square metres.

IMARC managing director Anita Richards said the response to this year’s event has been overwhelming.

“We’re welcoming a record number of delegates this year, representing 800 mining companies, and with IMARC

exhibitors increasing by 85 per cent since 2019, we’ve had to expand the expo floor by 40 per cent,” she said.

“The program will see over 450 speakers across six concurrent conferences covering global opportunities, industry collaboration, the energy transition, investment, innovation and more.”

A major networking and investment opportunity, IMARC is also the only event of its kind that uses enhanced and accurate networking technology to match delegates, allowing them to pinpoint new

business and investment opportunities and start crucial conversations.

“This is not just a conference and exhibition; real deals are closed on the IMARC floor,” Richards said.

The mining industry is facing more challenges than ever before, including supply-chain volatility, the rising cost of business, environmental, social and governance (ESG) pressures, navigating the energy transition, and growing social and investor expectations.

IMARC is a key forum that addresses these issues by gathering a wide cross-section of the mining value chain to share lessons and insights, and help each other navigate pathways to a sustainable and prosperous future, whether in exploration and investment, operational transformation, workforce growth or community engagement.

For example, IMARC’s Balance for Better, Next Gen programs and First Nations partnership initiatives aim to set the tone for a more diverse future, encouraging attendance from Indigenous delegates, providing opportunities for young people, and championing equality, with women in leadership positions, community roles and engineering a key focus.

The Next Gen program is for students, graduates, and future leaders. It provides an opportunity for the industry’s future workforce to network, learn and be inspired by leaders in mining, resources, and technology at Australia’s largest industry event.

Developed in partnership with the Victorian Government, the program is committed to promoting STEM (science, technology, engineering, mathematics) across the mining and resources industry.

Those in attendance at IMARC

Next Gen can expect to build relationships, learn about a diverse range of careers, gain insights from current leaders, meet over 470 companies representing all aspects of the mining value chain, and connect with mining C-suite executives, human resources managers, and key advocates for the future workforce.

Global mining leaders look to IMARC as a crucial opportunity to build on the progress the sector

is making towards sustainability, diversification and addressing the skills shortage facing the industry.

Fortescue chief financial officer Ian Wells will be speaking at IMARC. He believes talent needs to be a key focus across mining and resources.

“The mining sector is a great place to work with many opportunities, and while our sector is committed to training and developing Australians to be part of the workforce of the future, current acute skills shortages means

we must look beyond our borders for additional workers,” Wells said.

“As an industry, we must and can do more to build on our commitment to developing a diverse workforce that is reflective of society and to foster a workplace culture that truly embraces diversity and inclusiveness.

“We believe that diversity has been key to our success and we remain strongly committed to increasing female and Aboriginal employment across the business.”

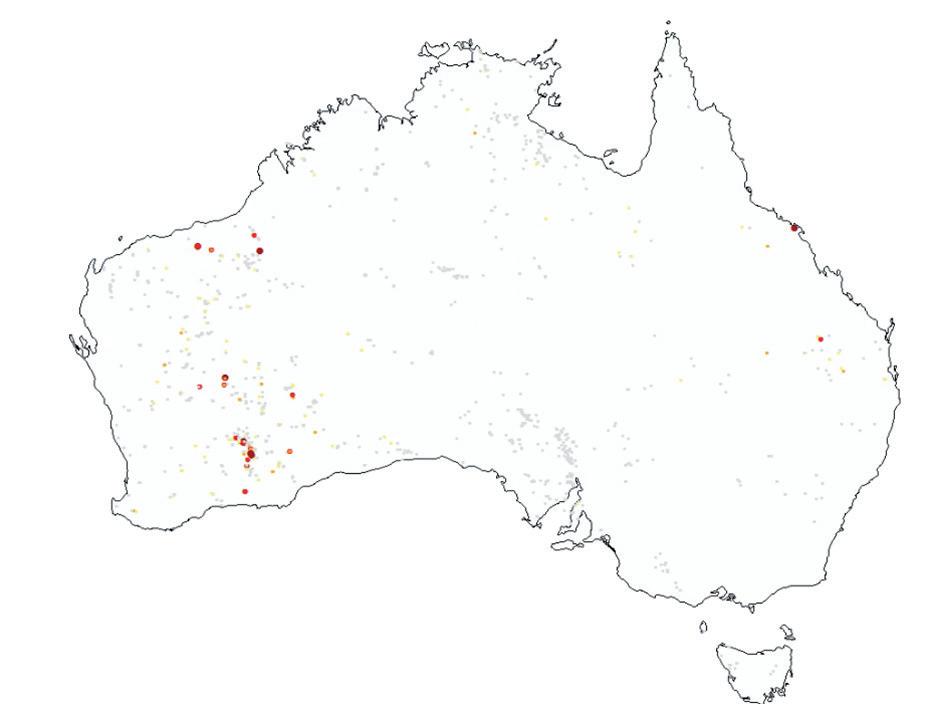

COMMODITIES FROM ACROSS AUSTRALIA WILL BE DISCUSSED AT THE CONFERENCE.

While looking internationally, Fortescue has also invested heavily in local talent, including through the Billion Opportunities program which has invested more than $4 billion into Aboriginal businesses since 2011.

IMARC director of conference content and strategy Sherene Asnasyous said the forum would provide a platform for conversations about the next steps towards an essential increase in recruitment and retention across the industry.

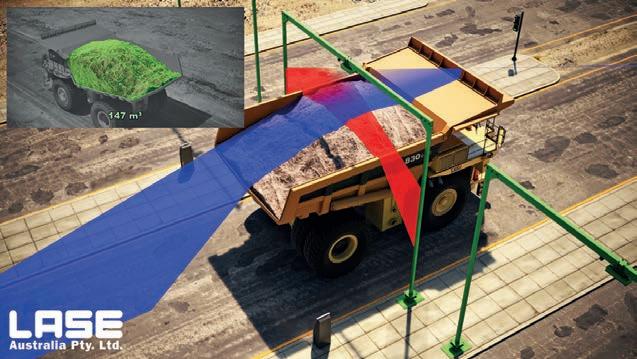

For more than 30 years, we have been the global contact for high-precision and robust laser measurement technology for industries. With our sensors and in-house developed applications, our systems stand for more safety and efficiency. Our goal is to drive the automation of industry with easily retrofittable solutions. With 30 partners worldwide, we are always at your side.

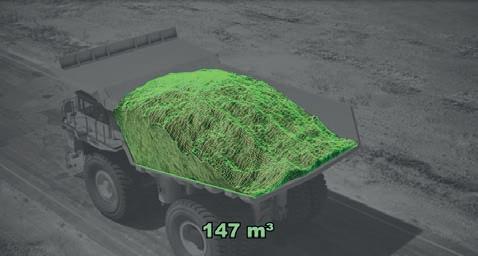

A highly accurate 3D laser measurement system for automatic and dynamic mea surement of truck-load volumes during a passage for various materials such as stones, sand, ore or wood products.

no conversion factors

exclusion of manipulation

easy and fast installation

“IMARC will allow global leaders and emerging game-changers from the entire mining value chain the unique opportunity to come together under one roof and tackle not only the skills shortage but other urgent challenges facing the industry right now,” Asnasyous said.

“This is including the energy transition, rising costs, social performance, and diversity within the resources sector.”

More than 250,000 people are employed across the Australian mining value chain, making it one of the largest employment industries in the country.

Another key theme this year is innovation and technology, with local start-ups and leading global brands showcasing their latest products and services across automation, communication, safety and sustainability to create better, faster, safer, and more profitable operations.

“This industry has seen so much change since the last in-person IMARC event, but this November global delegates will finally have the opportunity to connect face-toface in Sydney, build relationships,

forge partnerships and do business,” Richards said.

AspenTech vice president and general manager of metals and mining Jeannette McGill said it’s vital the sector comes together to discuss challenges – especially where technology is concerned.

“Industry collaboration enables critical debate to build consensus amongst movers and shakers of the industry. Hence, it is necessary to keep the conversation going and agree to disagree before the industry, as a whole, levels up,” McGill said.

Other themes at this year’s conference include:

• accelerating the energy transition

• embracing digital technology and mining innovation

• investing in exploration and project developments

• m inimising disruptions and building resilience

• progressing ESG and strengthening social value

• redesigning the mining workforce and culture.

The theme of accelerating the energy transition will be especially important as the global mining and

resources industry continues to make a serious and collaborative effort in responding to the threat of climate change.

Miners joining this conference will benefit from hearing what their peers are doing in terms of climate resilience and decarbonisation.

An array of presentations from climate change experts, as well as discussions from renewable and energy providers and technology showcases, will provide insights as to what options and capabilities are available to meet decarbonisation requirements.

The brand-new three-day conference on accelerating the energy transition will focus on:

• powering mines with renewable energy sources

• low-carbon, low-energy technologies

• electrification

• climate resilience and decarbonisation strategies

• critical and future facing minerals

• t he role of fossil fuels in the energy transition

• hydrogen production and export.

Attendees will hear from METS

Ignited national cluster development

manager Andrew Scott and Pilbara Minerals chief operating officer Dale Henderson, among others.Asnasyous added that with such a diverse cross-section of the mining and resources industry attending, the event is a unique opportunity for collaboration to address evolving challenges.

“IMARC will shine a spotlight on the role the METS (mining equipment, technology and services) sector is taking in driving the global energy transition, how it is bringing innovation to the exploration and development of new future-facing resources, and how it is helping balance the needs of the developed and the developing world, as well as local communities and environments, in the resource transition.

At its core, IMARC creates a global conversation and is all about the business of mining and resources.

It provides extensive opportunities for collaboration, knowledge-sharing and crosssector engagement to help drive a smarter, more productive industry of the future.

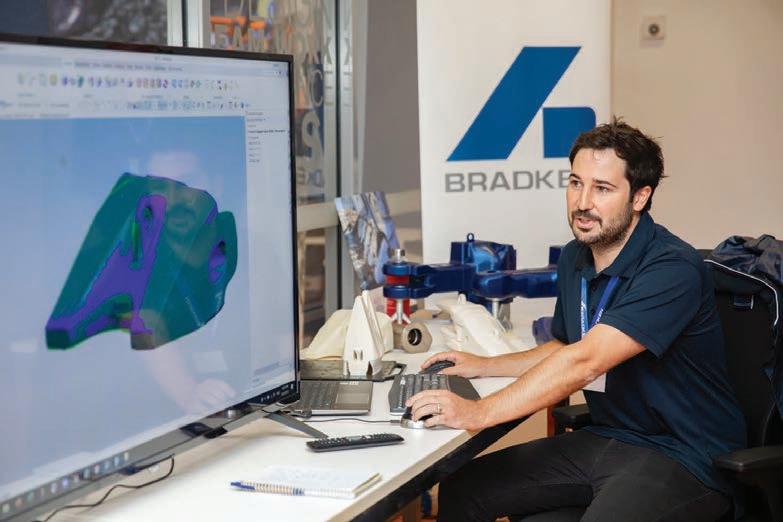

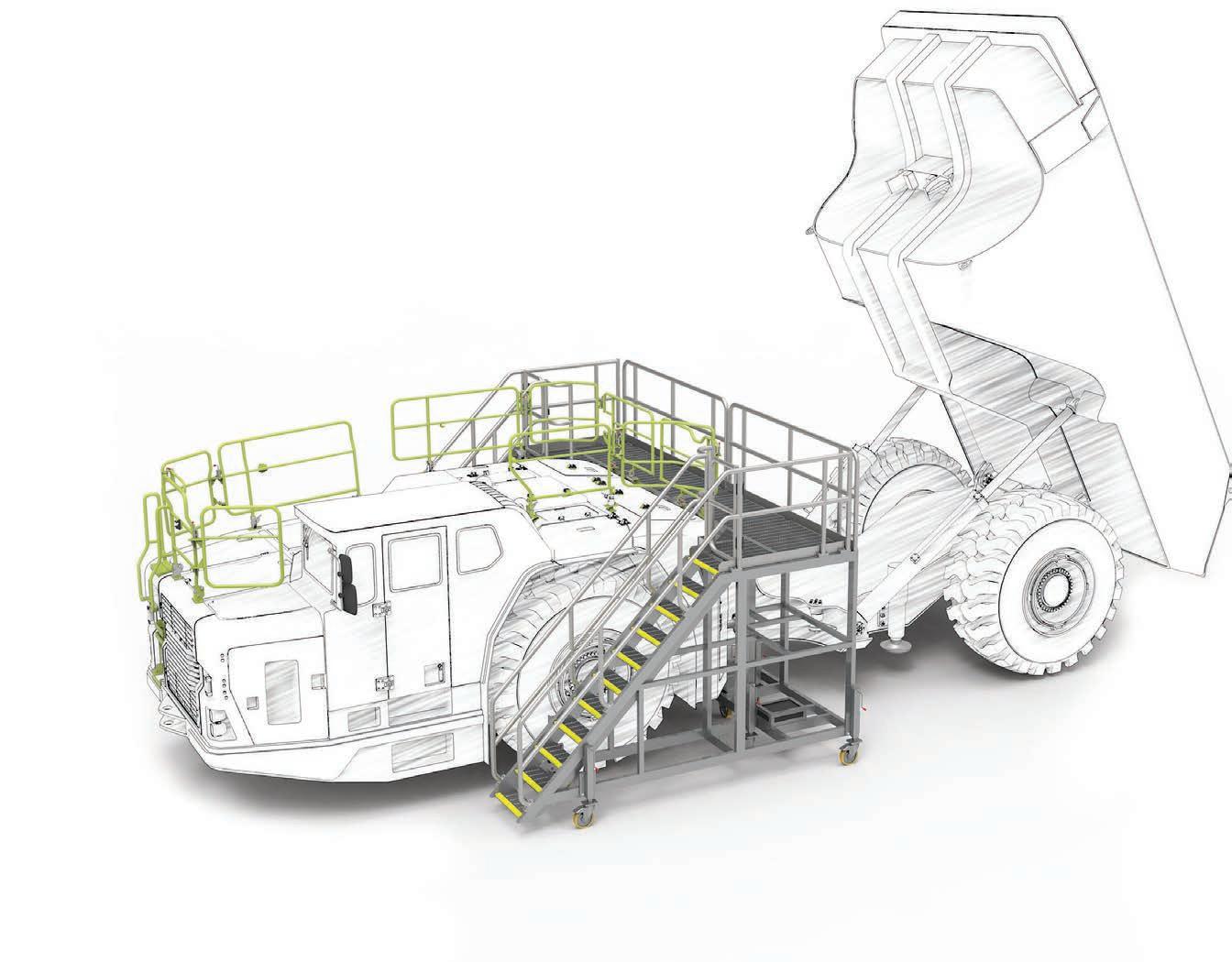

“We’re a company that can develop something exactly for what a customer needs for the exact purpose.

“What separates us is that total service of being able to design, engineer and fabricate a product all under the same roof.

“It’s been engineered, it’s been certified, and it’s gone through an extensive process to ensure it outperforms its use.”

Certification is critical to the design and engineering of any mining equipment, let alone material handling items, which navigate extreme weights to ensure goods are stored or transported safely and efficiently from one place to another.

“The industry’s understanding of why things need to be safe, why things need to be certified (is improving) and it also goes back to the method of use – having correct equipment that’s fit for purpose and engineered for purpose that’s being used in the correct manner,” he said.

“Yes, it’s about production, and yes, it’s about making money, but you don’t want people out there risking their lives to satisfy the bottom line.

“Sometimes it is more expensive and that’s the thing – you’ve got to think of cost and value. They’re two very different things.

As one of Australia’s leading mining services companies, Bend-tech Group offers a holistic approach to solution management, ensuring mining companies or contractors can access a product that’s been specially designed for them and their operation.

This is particularly true in the material handling sector, where Bend-tech not only has an extensive product offering but also the capacity to customise solutions to suit the intricacies of a specific operation.

“We can basically develop a material handling device or solution for almost anything,” Bend-tech marketing manager Rhys Werndly told Australian Mining

“We’ve got a team of on-site consultants, so we might get a request for a site visit that might be a material handling or equipment handling issue that is maybe being done manually or being done unsafely.”

Once Bend-tech receives the request, its team attends the site to better understand the situation, including the weight of the item, how it is lifted and where it needs to be placed, before developing a concept to make it safer and more efficient.

“Everything we do is engineered and certified to Australian Standards,” Werndly said.

“So you can be sure that if you have a two-tonne item, the material handling device or solution you’re using is designed, engineered and certified to handle six tonnes – it has to be certified to handle three times more than its loading limit.”

Once a material handling concept has been developed, it needs to be approved before progressing to engineering and into production. Bend-tech handles the process from initial consultation to manufacture, ensuring customers receive an end-to-

“If it’s not certified, then it hasn’t been proven to perform beyond its use,” Werndly said. “If someone’s just welded up some steel and is starting to lift stuff with it, who knows when it could break or fail?

“That’s why we get so much work, because our equipment is certified. It’s a requirement for Safe Work audits. Some of the engineering processes we need to go through to get one of our products on-site are extreme.

“Whether it’s an access platform or any other materials handling product, mining companies literally won’t use it if it’s not certified.”

Werndly said the Australian mining industry is moving in the right direction regarding the prioritisation

“Having something that might be more expensive on face value, the value that brings to your personnel, their peace of mind, their productivity, their efficiency in real-time because they know what they’re using is safe. That may not be measured and probably should be.”

To complement its holistic, end-toend approach to solution management, Bend-tech offers a comprehensive suite of products for the material handling sector.

This includes – but is certainly not limited to – lifting and handling equipment, maintenance tooling, storage benches, containers and racks, trestles and work stands.

Bend-tech’s emphasis on engineering and customising certified,

WHERE

MORE

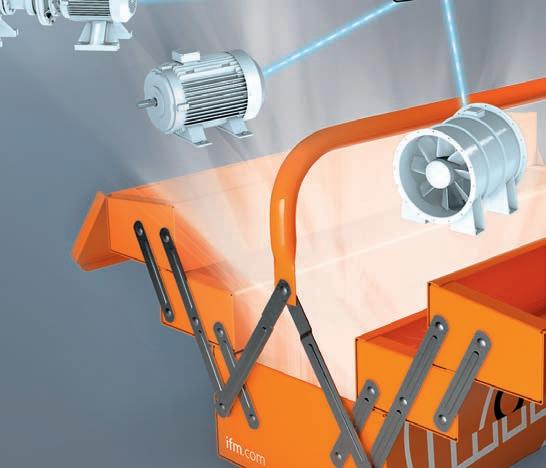

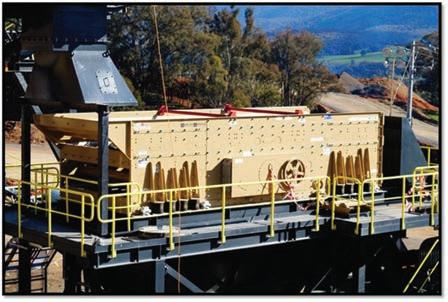

Mining companies are forever seeking new ways to lower production costs for material handling and processing applications.

In partnership with OPS Group, Astec Australia is doing just that.

OPS and Astec have maintained a strong and exclusive partnership since 2014, with OPS supplying the mining industry with technologically-advanced equipment from Northern-Ireland-based Astec subsidiary, Telestack.

Telestack continues to invest heavily in its Omagh facility as part of a long-term strategy to futureproof its capacity to support the development of an extensive range of world-class, innovative and quality products.

This includes its partnership with Astec Australia and OPS.

Astec Telestack specialises in the complete design, manufacture, installation and commissioning of mobile bulk material handling systems across a range of sectors, including mining.

And with more flexible stockyard system requirements and the push for greater cost efficiencies in the stockyard equipment space, the Astec Telestack range has become an important option for operators who require innovative equipment with custom-designed features and high build quality.

The equipment is robust and built to operate under difficult mining conditions.

“The Telestack equipment has many advantages; it’s made in a quality-assured factory in Northern

Ireland, by a global OEM (original equipment manufacturer), and the products are manufactured to a high quality,” OPS Group chief operating officer Ben Suda told Australian Mining

The Astec Telestack range has also become more popular with the re-emergence of heap leaching in the Australian mining sector. Heap leaching is an industrial mining process used to recover minerals from low-grade ore through a series of chemical reactions.

Suda said heap leaching enables mining operations to avoid more intricate ways of beneficiation.

While smaller heap leach stockpiles could be stacked by excavation equipment, when an operation chooses to build a larger heap leach pile it would be more appropriate to use a stacker.

This is where the Astec Telestack range comes to the fore.

The modular configuration of the product range results in lower capital expenditure and running costs, which is a distinct departure from traditional large and sometimes cumbersome stacking machinery. It is also more affordable than bespoke engineered solutions.

“Traditionally, sites often have a system designed specifically for their requirements, which requires significant engineering hours, and they’ll typically come up with a design that’s built for that particular application,” Suda said.

“But in addition to engineering hours, there’s also contingency applied and generally a large construction component specific to that installation must be entirely amortised over the one build.

“In my experience, you will see costs much greater with a site-specific engineered solution compared to utilising an existing Telestack product.”

Suda said there’s also less risk in opting for a modular solution such as the Astec Telestack range, because the customer knows exactly what they’re getting and can have confidence that it has a proven track record.

“The performance of the Telestack range is predictable and basically everything we manufacture is pre-assembled and tested in the plant,” he said.

When working with a customer, OPS will point to a similar case study to ensure they have a reference point and can see the application in play.

“Typically, we’ll be able to find an application we’ve already installed that is similar to what we’re supplying, so the customer can see how that’s working, possibly get a reference from that site or, in some instances, even visit that application,” Suda said.

“That gives them more peace of mind that what they’re seeing is what they’re getting.”

Telestack stacking systems offer automatic stockpiling capability, eliminating material compaction and resulting in a process that reduces costs per tonne and increases the capacity and quality of the material.

The system is also designed to be easy to transport.

“Our Telestack equipment is modular, in many cases easily containerised and able to be moved by standard road-going trucks,” Suda said.

“This supports our remote clients such as remote Australian mine

sites and other remote markets such as Indonesia. Here, you sometimes don’t have the transport corridors you might have in more centralised locations.

“Because these machines can be containerised, you can break them down into assignments easily and load them into trucks, so you can get them on-site and then reassemble them in modules. So you’re not building the plan from scratch.”

With transport practicality comes build practicality and Suda said once the Telestack machine arrives to the mine, it can easily be assembled by the on-site team without the need for specialist support.

“Once you’re on-site you don’t require the contingency of a construction team completing significant site preparation or months of engineering to configure the equipment, because our products have already been pre-assembled and tested prior to being modularised for transporting.

“Our customers place an order and we start building the Telestack machinery immediately, which substantially reduces time and costs.

“In some instances, where flexibility allows, we may offer an alternative solution based on existing stock availability to reduce lead time further.”

The OPS team works very closely with end-users, ensuring the Astec Telestack equipment is tailored to specific on-site conditions.

“Customisation is an important aspect of our service delivery,” Suda said.

“Depending on the site location, there may be a requirement to meet specific safety standards, including the positioning of walkways and access points, and other key operating processes and procedures.

“Our standard mobile units can still be customised to meet certain customer requirements, including the ability to modify belt widths, install additional guarding and other key components, including roller changes, depending on the type of material being transported.”

The Astec Telestack range covers all facets of moving and processing material, capable of capacities in excess of 3000 tonnes per hour.

“Because our products are mobile, they are hugely flexible, and if the

mining operation has a relatively short life, then the equipment can easily be redeployed to another location or re-sold,” Suda said.

“Our products can possess strong residual value, which isn’t always the case with a site-specific engineered solution.”

OPS has invested in branches across Australia as the group expands and diversifies, supporting specific mining regions with capital equipment – either for sale, hire or demonstration purposes – as well as full service and parts support capability.

The company offers process engineering, on-site commissioning, training and maintenance, with a team committed to delivering quality and value through its ‘whole of life’ equipment service offering.

OPS Group and Astec Australia also have a parallel agreement through OPS subsidiary Mineral Processing Solutions (MPS), providing another pathway for Astec’s bulk material handling equipment.

MPS distributes Astec’s Kodiak cone crushers to the Australian mining sector, including sites across

Western Australia, South Australia and the Northern Territory.

MPS managing director Shane Czerkasow said reliability is a key that sets Astec equipment apart.

“The Kodiak 350+ cone crusher is fit-for-purpose. It’s been designed and built for use in the rugged Australian mining environment,” Czerkasow said. “That’s Kodiak’s competitive advantage.

“In the case of the 350+, decades of experience and innovative design have combined to produce a highlyreliable, low-maintenance, operatorfriendly crushing unit.”

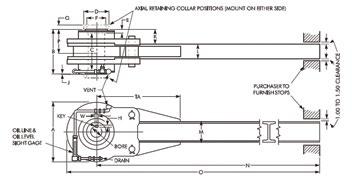

The Kodiak incorporates a unique roller bearing design that, according to Astec, increases energy efficiency and reduces operating costs by up to 50 per cent. In addition, the crusher is equipped with the Kodiak control system (KCS) ,which allows for continuous monitoring and on-thefly adjustments.

Whether it’s an Astec Telestack stacker, a Kodiak cone crusher, or any other bulk material handling machinery, the Australian mining industry is better for Astec and OPS Group’s long-term partnership. AM

THE TELESTACK EQUIPMENT HAS MANY ADVANTAGES; IT’S MADE IN A QUALITYASSURED FACTORY IN NORTHERN IRELAND, BY A GLOBAL OEM, AND THE PRODUCTS ARE MANUFACTURED TO A HIGH QUALITY.”

Remote, real-time monitoring of belt cleaners from an intuitive digital dashboard, Flexco Elevate is the first-of-its-kind technology that delivers predictive data-driven insights to manage belt cleaner performance. Move from reaction to prediction and optimise belt maintenance for your operation.

Scan to learn more.

“That’s the thing about DYNA; we’re always developing new and improved versions of our HDPE guards, listening to customers when they express, as a priority, the need for greater visibility or increased spraythrough capability,” Greaves said.

“We respond to their feedback and, through iteration, go about designing, developing and manufacturing a new and improved version of the HDPE guard.”

The improved guards are versatile and able to be configured for access platforms, conveyor pull wires, retractable idler roller frames, metal detectors, and belt change stations, while maintaining strong chemical resistance.

“If you’re dealing with a product that is corrosive, HDPE guards tend to resist pretty much most common chemical products or by-products that are found on mine sites,” Greaves said.

The sustainability benefits of the HDPE plastic guards are significant, and within the mining industry DYNA Engineering is at the forefront of the circular economy by making its panel components infinitely usable.

After designing, manufacturing, and distributing a new conveyor guard system for mining operations across Australia, DYNA Engineering listened to customer feedback and has undertaken further modifications to its high-density polyethylene (HDPE) plastic guards.

“Since releasing our HDPE guards in 2019, there have been requests from customers to see greater capability for the use of high-pressure hoses in order to more easily spray water beyond the panels, as well as a need for increased visibility in the configuration of the guards,” DYNA Engineering general manager Thomas Greaves told Australian Mining.

“The mesh size for HDPE guards is a lot thicker than steel mesh, so recently we have developed a different type of mesh. It’s triangular in shape, creating increased viewing

angles, addressing our customers’ visibility requirements.

“We have also developed a solution for high-pressure hose use, which is superior to our original squareshaped guards.”

Using DYNA Engineering’s HDPE plastic conveyor guards rather than more traditional steel mesh guards comes with some significant benefits. Chief among them is the fact the lightweight HDPE guards eliminate the stress of heavy lifting, while still being robust and easy to install.

“In terms of safety, when lifting them on and off conveyor systems workers are exposed to less repetitivestrain injuries,” Greaves said.

Installing and removing the HDPE plastics guards takes only minutes, limiting the amount of time spent around the conveyor and reducing the risk of accidents occurring during periods of maintenance.