United. Inspired.

Epiroc’s Automatic Bit Changer (ABC) is the next future-ready advancement in autonomous drilling. ABC allows your operators to make or break joints, select drill bits, add them or remove them without leaving the cab, or from the comfort and safety of a control room. With the ability to change out four bits significantly faster than any single manual exchange, the Automatic Bit Changer eases your team’s workloads and ups drill times.

paul.hayes@primecreative.com.au

BREAKING THE SURFACE TENSION

The turn of phrase ‘scratch the surface’ might be apt when discussing surface mining, but not in a literal sense.

It takes a lot more than a scratch to remove the soil and rock that stands between miners and the precious mineral deposit underneath.

In this issue of Australian Mining, we look at some of the equipment, machines and technology that play their own vital parts in the process of surface mining.

From crushing and screen media to mobile processing units to dragline support to automation to conveyor systems to servicing and rebuilding excavators, dump trucks, wheel loaders, dozers and motor graders, there really is a lot happening on the minesite surface.

Elsewhere in the magazine, we look at different examples of mine rehabilitation. The life of a mine does not end when resources are exhausted and rehabilitation is a critical process of any such operation, especially in the context of companies maintaining their social license to operate.

When Dendra Systems recently hosted the first in a series of networking events exploring rehabilitation and the mining industry’s environmental future, Australian Mining was on hand to document the key takeaways.

We also shine a light on the role of women in the mining industry, examining new research undertaken that looks at innovative

ways employers in the resources sector can be encouraged to provide women with training and employment opportunities in rural areas of Australia.

This issue also features a big splash on the recent Women in Industry Awards, which acknowledge outstanding women across a range of industrials sectors, recognising those who are driving change within the industry. The awards are an opportunity highlight the exceptional work and dedication of the women in the resources industry.

Finally, Elon Musk makes a somewhat unexpected appearance in the pages of Australian Mining following Tesla’s recent announcement of plans to build its own lithium refinery.

Is this the way of the future? Is this kind of vertical integration a viable option for electric vehicle manufacturers? We look at these questions, as well as a few others, ahead of what could be a major shift in the world of critical minerals and their role in electrification and a carbon-free future.

Email: alexandra.eastwood@primecreative.com.au

TOM PARKER Email: tom.parker@primecreative.com.au

LEWIS CROSS Email: lewis.cross@primecreative.com.au

ASHLEY

STOREY blake.storey@primecreative.com.au GRAPHIC IT MIGHT SEEM TO SOME AS THOUGH ALL OF THE ACTION ON A MINE SITE TAKES PLACE UNDERGROUND, BUT THERE’S PLENTY HAPPENING ON THE SURFACE.

Email: ashley.perry@primecreative.com.au CLIENT

Tel: (02) 9439 7227 Email: janine.clements@primecreative.com.au

SALES

JONATHAN DUCKETT Tel: (02) 9439 7227 Mob: 0498 091 027 Email: jonathan.duckett@primecreative.com.au

SALES ADMINISTRATOR EMMA JAMES Tel: (02) 9439 7227 Mob: 0414 217 190 Email: emma.james@primecreative.com.au

SUBSCRIPTION

For

Cover

image: Bradken

ART All rights reserved. No part of the publication may be reproduced or copied in any form or by any means without the written permission of the publisher. PRINTED BY MANARK PRINTING 28 Dingley Ave Dandenong VIC 3175 Ph: (03) 9794 8337 Published 12 issues a year

W hen Dendra Systems hosted the first in a series of events exploring the mining industry’s environmental future, Australian Mining was on hand to document the key takeaways.

Vertically integrating lithium

R ecent news of Tesla planning to build its own lithium refinery in the US begs the question: Is this type of integration a viable option for electric vehicle manufacturers?

Boosting conveyor energy savings and sustainability

F enner Conveyors’ next generation of PowerSaver LRR conveyor belt compound creates further energy savings and reduces capital expenditure in the process.

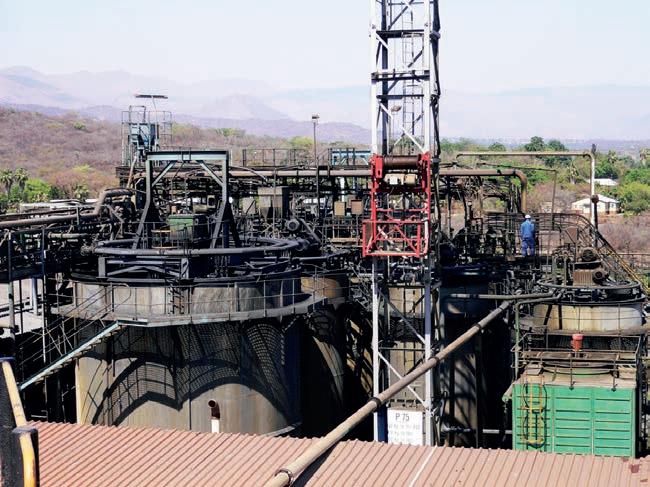

A n all-in-one surface mining solution

T he Easi-Miner, RITALKA’s continuous surface mining excavator, eliminates the

36

hardness grade.

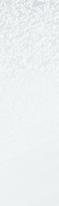

A ltra Motion limits dragline downtime

A ltra Motion occupies much of the dragline braking business in the Bowen Basin. The OEM is now looking to replicate the same success in the Hunter Valley.

I ncreasing productivity through automation solutions

T he capture and effective use of data has become an increasingly critical dimension of mining operations. It’s often dependent on tailored solutions like those provided by Position Partners.

R anger rehabilitation

44

Meet the winners of the 2022 Women in Industry Awards

T he awards acknowledge outstanding women across a range of industrials sectors, recognising those who are driving change.

T he rehabilitation process of the shuttered Ranger uranium mine recently marked a key milestone, but a report on a neighbouring deposit raised questions of continued mining versus environmental and social obligations.

48

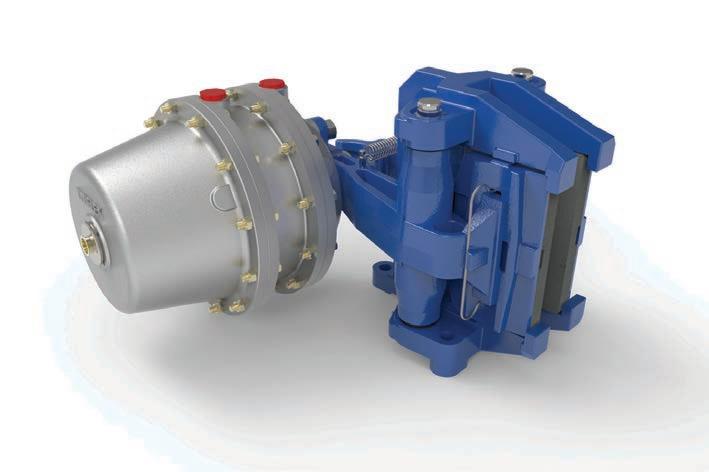

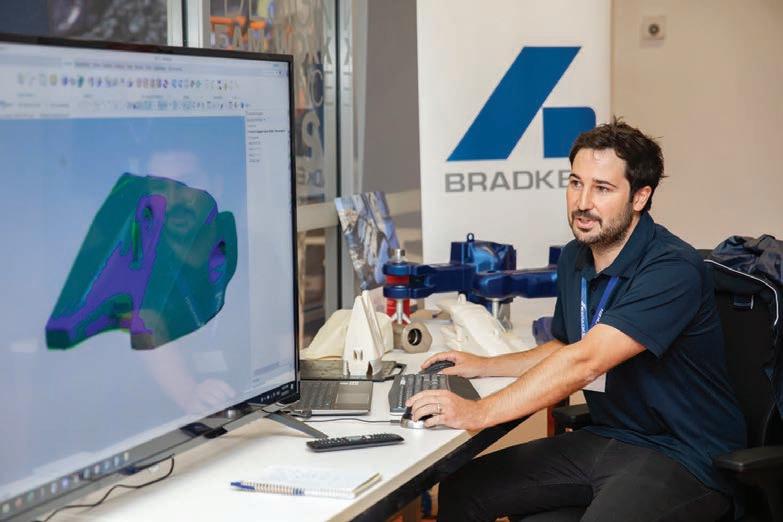

Fit-for-purpose solutions

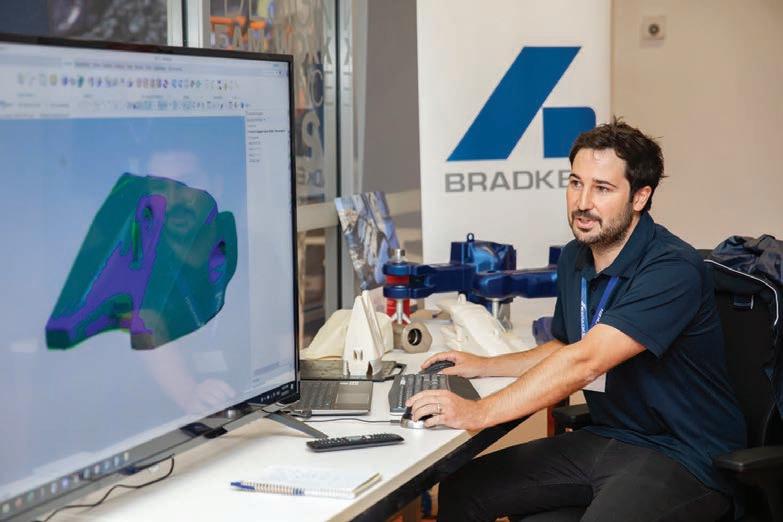

W ith a long history of supplying topof-the-line equipment solutions to mining companies across Australia, Bradken is continuing to improve its product line.

Bradken’s technology transformation is supporting the evolution of the mining industry.

•Innovative mining digital technology solutions

•Asset condition and performance monitoring solutions

•Design, engineering and manufacture

AUSTRALIAN

Terms have been agreed to recommission the Dartbrook coal mine in NSW, with an alliance between three of its many suitors.

The mine has been soughtafter because it is one of the few sanctioned and undeveloped coal assets in the country at a time when prices for the commodity have been driven to record highs.

Owner Australian Pacific Coal (AQC) said that after receiving an offer for a proposed alliance with M Resources for Dartbrook, its ongoing discussions with its largest shareholder Trepang Services, with respect to AQC’s outstanding debts and the receipt of a conditional non-binding indicative proposal from Tetra Resources and Javelin Private Capital Group, the company entered into a binding term sheet with each of Trepang, M Resources and Tetra Resources for a strategic partnership.

The aim of the parties is to see Dartbrook rejuvenated as a coal-producing mine as soon as practicable.

Under the arrangement, M Resources and Tetra will earn a 20 per cent direct joint venture interest each in Dartbrook. In addition, Trepang – if it agrees to extend the existing AQC access and compensation agreement, various easement arrangements and term transfer of water rights on mutually agreeable commercial terms to allow underground mining operations to continue for the duration of mine life extension approvals – will earn a 10 per cent free-carried direct joint venture interest.

AQC will retain a 50 per cent direct joint venture interest in Dartbrook.

If M Resources and Tetra do not achieve production restart at Dartbrook within 27 months, M Resources and Tetra will relinquish their joint venture interest, which will revert to AQC.

M Resources will enter into an exclusive marketing services agreement to act as marketing agent of coal sales and an exclusive logistics services agreement for all coal types produced at Dartbrook. Tetra will be appointed as the operator of Dartbrook.

The partnership is conditional on AQC’s ongoing fully underwritten entitlement offer being completed successfully, and AQC obtaining all required authorisations (including any shareholder approval) with respect to the partnership within 120 days from the date of the binding term sheet.

M Resources will be entitled to appoint a director to the board of AQC, which is also currently

AUSTRALIAN MINING GETS THE LATEST NEWS EVERY DAY, PROVIDING MINING PROFESSIONALS WITH UP-TOTHE-MINUTE INFORMATION ON SAFETY, NEWS AND TECHNOLOGY FOR THE AUSTRALIAN MINING AND RESOURCES INDUSTRY.

negotiating with Trepang to have the right to nominate up to two directors to the board for so long as Trepang maintains a relevant interest of 20 per cent in AQC.

The development effectively scuppers the bid by former Australian coal baron Nathan Tinkler, which was three times the offer by M Resources.

A new nine-member consortium will create a pilot program of electrification solutions for mine sites. The consortium will see Skeleton, Microvast, Stäubli, Carnegie Robotics, Heliox, Spirae, Alliance Automation, Worley, and Shell come together to introduce Shell’s mining electrification solution for off-road vehicles.

Shell announced the consortium during an online press briefing held in October. The solution features an end-to-end electrification system that reduces emissions without compromising on efficiency or safety, while aiming to be cost-competitive versus diesel-powered operations.

By combining a high-powered battery solution with ultra-fast charging and a standardised microgrid energy system, Shell’s new

solution can be complemented with renewable electricity generation onsite or through the grid.

Electrification also offers off-road industries the immediate potential to shift away from a long-standing reliance on diesel.

This shift will be critical for hardto-abate sectors like mining, as mobile equipment comprises 40–50 per cent of mining’s CO2 emission.

“It is increasingly clear that no one single organisation can solve decarbonisation alone,”

Shell sectoral decarbonisation and innovation vice president Grischa Sauerberg said during the press briefing. “The need for a collaborative effort is particularly evident within carbon-intensive industries like mining, where the challenges are great but the

opportunities are even greater.

“To overcome these challenges and unlock these opportunities, Shell is helping to bring together some of the sector’s most innovative companies – with electrification proving an important first step towards the shaping of a clear decarbonisation pathway.”

Shell’s mining electrification solutions for off-road vehicles consists of: power provisioning and microgrids, with an aim to provide a consistent and reliable supply of renewable power in a safe and stable manner; ultra-fast charging, taking approximately 90 seconds via flexible, hard-wearing, and resilient on-site, ultra-fast charge points, which provide assets with continuous operations in the most challenging of environments; and in-vehicle energy

storage through a combination of advanced battery and capacitor technologies that aim to deliver long lifetimes, ultra-fast charging, and high performance.

“The challenge of decarbonisation is immense, but not impossible, providing collaboration and innovation go hand-in-hand at all times,” Sauerberg said.

“(This was) on show during the recent Charge On Innovation Challenge, which saw the Shellled consortium of equipment manufacturers, technology partners, industry experts and Shell Energy –our in-house supplier of renewable power – push the boundaries of what is possible for hard-to-abate sectors.

“Our winning solutions are proof of how together the industry can help power progress.”

MINING PRESENTS THE LATEST NEWS FROM THE BOARDROOM TO THE MINE AND EVERYWHERE IN BETWEEN. VISIT WWW.AUSTRALIANMINING.COM.AU TO KEEP UP TO DATE WITH WHAT IS HAPPENING.

A transformative piece of machinery named the Flora Restorer is facilitating world-class rehabilitation on a globally renowned area of native vegetation in WA.

The climate at Eneabba, where the Flora is used, is harsh, with average summer maximum temperatures hovering around 35°C and have been known to climb as high as 48°C.

The area sees as average of fewer than 30mm of rain across December, January and February, and winds regularly gust in the 30–40km/h range, making erosion of the sandy soils a constant problem.

Against that backdrop, mineral sands company Iluka Resources has successfully restored 18 square kilometres of Kwongan vegetation, to a point that only a carefully trained eye would notice the difference between established rehabilitated areas and untouched parts of the local environment.

It’s a journey Iluka has been on for many years, but one that’s been aided greatly since Flora Restorer was pressed into action in 2019.

Iluka principal rehabilitation scientist Mark Dobrowolski said the machine took “a whole bunch of individual rehabilitation techniques that were already being used and combines them in a onestop-shop”.

“Flora Restorer is a sort of a one-pass piece of equipment which spreads fertiliser, scarifies the ground preparing the ground surface, and places a diverse variety of seed in on that ground – anything from as big as my thumb to a tiny little dusty seed,” he said.

“And then it rolls a land imprinter over it, creating a dimpled surface, before it sprays an artificial soil crust of bitumen emulsion to hold those seeds in place until it rains.

“We combined all these processes together to improve our germination of the seed we collect so carefully and treat to break dormancy, and then spread out on the ground.

“We’re trying to make sure that we get the best value for germination from that seed that we can in our rehab.”

Native Kwongan is prized internationally for its diversity of species and resilience to the elements. But it’s also hard to generate from scratch due to the climatic extremes.

“Since we used Flora Restorer, we’ve been able to nearly triple the rate of germination of the seed we broadcast in rehabilitation – while using the same amount of seed,” Dobrowolski said.

“At the same time, by combining all the techniques in the one machine,

Australia’s largest independent regional and domestic airline, Rex, has announced plans to grow and transform its latest acquisition into Australia’s premier fly-in, fly-out (FIFO) operator.

The company has completed the purchase of National Jet Express (NJE), the regional services arm of Cobham Aviation Services Australia,

Kim Hai said he would like to pay tribute to the sellers, Advent

International, which had prepared the sale in “the most meticulous and professional way”.

He also paid tribute to the NJE executives and staff who ran the business successfully over the past two years despite the turbulence caused by the COVID pandemic.

“There is no better operator of air services in Australia than the

we can rehabilitate two or three times the area back to native vegetation, back to the Kwongan.

“So it’s a double whammy of increased area and increased quality of rehabilitation.”

While the efficiencies of Flora Restorer are certainly a selling point, Dobrowolski’s favourite piece of innovation on the machine is one that tackles the ever-present threat of erosion.

“Eneabba is regularly the hottest place in the state in summer – in the morning the wind blows from the east at 30km/h and then in the afternoon it blows from the southwest,” he said. “The poor little plant has to survive in that windy, dry environment. It doesn’t want to get sand-blown all its life and sand drifts everywhere, so you need to control that to get those tiny little seedlings to establish.

“My favourite innovation on Flora is a combination of two very old technologies. One is land imprinting to dimple the land. Combine that in our sandy-profiled soils with bitumen emulsion crust, it’s great because it stabilises the land and the little plants can pop up through it and grow.

“The water pools on that surface and it doesn’t erode and gets in the ground, allowing those plants to establish.”

Flora’s capabilities tie in neatly with Iluka’s rehabilitation ambitions to restore the Kwongan landscape to something like how it might have looked before mining started.

The process is also strongly assisted by the company’s painstaking approach to rehabilitating the “right way”.

“Mining, for Iluka, is relatively short term and we move site-to-site,” Dobrowolski said.

“Our reputation is only as good as our last mine and that’s part of my role at Iluka, to ensure we research and adopt the best practices possible for doing rehabilitation after mining.

“In 20 years’ time, people will hopefully look across this site and just see natural Kwongan and won’t be able to see the difference between the natural vegetation and what we’ve rehabilitated.

“We aim to put back a functioning ecosystem which can self-sustain and perpetuate through life.”

The Flora Restorer has already been able to attract wider attention. Last year it was one of three finalists in a hot field for the prestigious WA Government Golden Gecko Award, which recognises environmental excellence in the resources sector. And it’s in the running again this year.

economy has been shaken to the core by the global financial crisis and COVID, Rex has still managed to achieve a positive gross return of 2.9 per cent.

“Rex will overlay this financial and operational prowess on NJE’s core strengths to transform it to be Australia’s premier FIFO

for their FIFO needs instead of relying on 30-year-old Fokker 100 aircraft used predominantly by the other operators.

“In anticipation of the surge in demand for NJE’s services, we are looking to lease immediately another two De Havilland Canada Dash 8-400 NextGen (NG) aircraft to add to its fleet.

“We will continue to invest in new aircraft and technology to grow the business, especially in Queensland, where resource companies have been facing severe issues with capacity and reliability in recent times.”

In addition to the airline Rex, the Rex Group comprises wholly owned subsidiaries Pel-Air Aviation (air freight, aeromedical and charter operator), the Australian Airline Pilot Academy (which has campuses in Wagga Wagga, NSW, and Ballarat, Victoria), and propeller maintenance organisation Australian Aerospace Propeller Maintenance.

www.liebherr.com

By 2030, fossil fuel free solutions will be established.

Liebherr strives for long-term sustainable solutions, providing different modular options centred on environmental sustainability, safety, cost, flexibility, and maintainability including:

– 30 years experience in electric drive mining excavators with all machine models available ranging from 150t to 800t class

– Trolley Assist option available on all Liebherr mining trucks

– Liebherr combustion engine compliant with Hydrogenated Vegetable Oil (HVO) fuel

– Tier 4 Final certified engine available on trucks, excavators, and dozers

– Liebherr AC drive system on all truck models providing a modular platform for future powertrain technologies

Liebherr‘s roadmap includes batteries, combustion engines using green fuels, and hybrids.

Liebherr-Australia Pty Ltd. • 1 Dr. Willi Liebherr Drive • Para Hills West, South Australia 5096 • Phone (08) 8344 0200 info.las@liebherr.com • www.facebook.com/LiebherrMining • www.liebherr.com.au

Liebherr is a leader in proven low emission solutions, utilising grid electrification.

A new report has found that the Queensland Government severely underestimated the impact of higher royalty taxes on the state’s coal export sector.

The report by independent analysts Commodity Insights was commissioned by the Queensland Resources Council (QRC) to review the impact of the State Government’s decision to add three new coal tax tiers – with much higher royalty rates – to a previous regime.

According to the report, the royalty revenue forecasts from Treasury are based on “extremely conservative and unrealistic coal price forecasts”.

“As a result, they massively understate the revenue collection by the Government and the cost impost placed on the sector. The royalties also clearly reduce the competitiveness of the Queensland coal export sector relative to its competitors by sharply increasing the cost structure,” it said.

The analysis confirms Queensland is the outlier in the world in terms of coal royalty rates, with its new top rate of 40 per cent now 43 per

cent higher than the next nearest rate of 28 per cent, which is nearly four times higher than the average highest rate globally.

The report found the new top royalty rate for metallurgical coal, which is by far Queensland’s most valuable export, is now 2.7 times higher than the nearest competitor and almost five times the global average, confirming widespread industry alarm at the new tax rates.

QRC chief executive Ian Macfarlane said the Government’s move to double the amount of tax to be paid by coal producers this financial year compared to last year – from $7.3 billion to Commodity Insight’s $12.4 billion forecast for 2022–23 – has dramatically increased companies’ production costs and harmed the industry’s ability to compete internationally for customers.

“International commodity prices may be high right now, but as any exporter knows we need the good times to balance out the bad, when prices are low or even below the cost of production,” he said.

The pledge is part of a $9.2 billion plan to hit net-zero emissions, and to eliminate fossil fuel use entirely and not rely on carbon offsets by the end of the decade.

Fortescue said its decarbonisation strategy and associated investment, when fully implemented, will reduce annual operating costs by $US818 million ($1.21 billion), avoid three million tonnes of CO2 equivalent emissions per year, and supply a carbon-free iron ore product.

“We must accelerate our transition to the post-fossil-fuel era, driving global-scale industrial change as climate change continues to worsen,” Fortescue founder and chairman Andrew Forrest said at a CEO roundtable as part of US President Joe Biden’s First Movers Coalition and the United Nations Global Compact.

“It will also protect our cost base, enhance our margins and set an example that a post-fossilfuel era is good commercial, common sense.”

The company’s cumulative $US6.2 billion ($9.2 billion) investment will be made between

2024 and 2028 and include an additional 2–3 gigawatts of renewable energy generation and battery storage, as well as the estimated costs associated with a green mining fleet and locomotives.

Fortescue said it expects the investment to enable the displacement of approximately 700 million litres of diesel and 15 million gigajoules of gas per year by 2030, plus the associated reduction in CO2 emissions.

“There’s no doubt that the energy landscape has changed dramatically over the past two years and this change has accelerated since Russia invaded Ukraine,” Forrest said.

“We are already seeing direct benefits of the transition away from fossil fuels – we avoided 78 million litres of diesel usage at our Chichester Hub in FY22.

“Fortescue, FFI and FMG, is moving at speed to transition into a global green metals, minerals, energy and technology company, capable of delivering not just green iron ore but also the minerals, knowledge and technology critical to the energy transition.”

“It wasn’t that long ago, such as in 2020, that coal prices were below the cost of production and some miners were losing money.

“On top of that, regardless of where coal prices are on any given day, companies’ fixed costs like fuel, labour and other consumables are rising every year due to inflation, which is a challenge every business is facing.

“The new royalty regime is another cost impost that will need to be absorbed if Queensland companies are to remain internationally competitive, which means budget cuts will have to be made elsewhere.

“It’s pretty simple – resources companies paying higher tax bills have less money to spend on developing new projects or expanding operations, or on rehabilitation programs, upgrading plant and equipment, investing in low emissions technology or employing more people.

“The State Government’s cash grab to balance its own budget hurts local suppliers and

employment opportunities, and means companies will also have less money to support charities and sports clubs, which they do very generously.”

Macfarlane said he believes the move will hurt regional communities as well as people living in the city, and anyone whose jobs and businesses rely on the continuing prosperity of the state’s minerals and energy sector.

“BHP has already paused future investment in Queensland as a direct result of the royalty hike, which is shocking in itself,” he said.

“The Ambassador of Japan to Australia, Yamagami Shingo, has also spoken out about the damage the royalty hike has done to Japan’s long-standing trade relationship with Queensland –a concerning development which the Government continues to downplay.

“We know companies across the resources sector – not just coal companies – are now seriously considering their future investment options in Queensland.”

OZ Minerals has been given board approval to develop its fourth operating asset, the West Musgrave copper-nickel project in Western Australia, for direct capital investment of about $1.7 billion.

The go-ahead will unlock one of the largest undeveloped nickel projects in the world and, with expected lowest quartile costs, it is set to generate about $9.8 billion undiscounted cashflow over its 24year operating life.

OZ Minerals chief executive officer Andrew Cole said with all key regulatory approvals now in place, a number of relationship banks have provided credit approved commitment letters for a new $1.2 billion syndicated facility to support development of the project in addition to the existing facilities.

“We are also considering the option to sell down a minority interest in the project to a strategic partner building on the significant inbound interest we have received over the past six months,” he said.

“In addition to the 80 per cent renewable energy sourced from wind and solar for power generation, the

project scope includes a pathway to net-zero Scope 1 emissions by 2038, aligned with the potential transition to an electric haulage fleet at the first engine change out, together with exploring other initiatives to reduce diesel and the application of offsets.

“Our project execution strategy will enable us to mitigate industry-wide cost inflation being experienced globally. An increase in direct project capital to about $1.7 billion is offset by a substantial increase in project value and results in stronger cash flow generation of about $1.9b during the first five years of production.

“To further manage inflationary pressures, we have increased our contingency allowance to about $190 million and our construction schedule allows for first concentrate in H2 2025.”

OZ Minerals chair Rebecca McGrath said the board’s approval of West Musgrave was a fundamental step towards realising OZ Minerals’ strategy to evolve into a modern minerals producer set to supply global copper and nickel markets

carbonisation and electrification era.

“Key to the announcement is the support for the project by the Ngaanyatjarra People, with the signing of the Land Access Agreement after more than five years of collaboration to facilitate a productive long-term partnership,” she said.

“The board considered the value created for all stakeholders when making the final investment decision. We can see the enormous potential of this project for:

• our workforce in a modern flexible working environment

• t he local community in economic and wellbeing opportunities

• our shareholders in realising our growth potential

• governments in income from royalties, exports and jobs

• customers who we will assist in meeting demand for minerals critical to the electrification and decarbonisation era

• our suppliers who we look forward to working with to build a modern, low carbon emissions mine.”

Site mobilisation is set to

items have been secured, along with production slots, and contract partners have been identified for 80 per cent of the material contracts.

The processing plant will be delivered by GR Engineering Services.

LOESCHE GmbH is a key technology partner and provider of the vertical roller mills that support high energy efficiency and low operating costs at West Musgrave.

The vertical roller mills will deliver a paradigm shift in mineral processing with unique operational flexibility and high energy efficiency.

LOESCHE managing shareholder Thomas Loesche said it had been a vision of his to develop drycomminution technologies that enabled better sorting efficiencies, reduced power and consumables.

“We are very pleased to be involved in such an important project” he said. “OZ Minerals is breaking new ground and proving that sustainability does not stand in the way of project development, but rather makes

The Western Australian Government has outlined a wide range of actions to tackle sexual assault and sexual harassment in the state’s workplaces in response to a parliamentary inquiry into the fly-in, fly-out mining industry.

The State Government has supported plans to be implemented across key areas such as primary prevention, data and research, a refocused regulatory framework, and better support and advocacy for victims of workplace sexual harassment.

As part of the State Government’s response, a new code of practice will be developed to help improve security measures for workers staying at workplace accommodation.

This code will act as a minimum standard that employers must consider to ensure the safety of their workers living regionally or remotely.

WA Mines and Petroleum Minister Bill Johnston said the Government had also committed to funding a community legal and advocacy service centre to provide free guidance and advice to affected Western Australians.

“The State Government recognises the importance of providing victims of workplace sexual

harassment with the opportunity to share their experiences, receive psychological support and promote healing,” he said.

“In line with Recommendation 20, the Government has already committed to changing the law to bring WA’s definition of what constitutes sexual harassment in line with other Australian jurisdictions and to remove the ‘disadvantage test’ complainants.

“The Government aims to introduce these legislative reforms early next year.”

The WA Government also supports the recommendation to establish a culturally appropriate expert group within WorkSafe WA to investigate, assess and deal with reports of sexual harassment and assault offences in the sector. This work will be further enhanced by the findings of the regulatory review being undertaken by Elizabeth Shaw.

“These initiatives build upon a number of existing programs the Government has been progressing.” Johnston said. “This includes the $8.4 million Mental Awareness, Respect and Safety (MARS) program that boosts responses to mental health, workplace culture and

Thiess Group Investments has secured 51.83 per cent of the shares in MACA, giving the mining services company effective control.

The result is based on acceptances for Thiess’ unconditional cash takeover offer to acquire all of the ordinary shares of MACA for $1.075 per MACA share, and on market purchases made by Thiess.

The MACA directors have now recommended all remaining MACA shareholders to accept the bid prior to the end of the offer period to avoid the risks of becoming a minority shareholder in a Thiesscontrolled entity.

The offer was scheduled to close at 7.00pm Sydney time on Friday, October 7, unless extended by Thiess.

MACA co-founder Geoff Baker said with the offer having been made unconditional and control having passed to Thiess, remaining MACA shareholders should accept the offer before it closes.

mine safety in WA’s mining sector.

“The MARS program oversees a number of projects including the Respect in Mining pilot program, the Thrive at Work in Mining program and a landmark study into mental health, workplace culture and safety across WA’s mining sector.

“Conscious of the landmark study being conducted by the Centre for Transformative Work Design and the regulatory review, the Government will further report to Parliament before the end of 2022.

“We support, or in-principle support, all the report’s recommendations for Government and encourage industry to also consider how they can apply the report’s recommendations.”

WA Women’s Interests Minister Simone McGurk said everyone had a right to feel safe and supported at work.

“We have a vicious cycle, where women aren’t attracted to work in the industry, let alone stay in the industry, because of inappropriate behaviour and a disregard of women’s experiences,” she said.

“We need more women to work in this sector and we need them to be treated with respect. It’s imperative

the mining sector works with the State Government to lead cultural change and prioritise prevention and better supports for victim survivors.

“I would especially like to thank the women who spoke to the inquiry about their experiences – your courage will help make the industry safer for future generations.”

The Minerals Council of Australia said it was pleased the WA Government acknowledged and supported the adoption of all 55 recommendations and welcomed its commitment to working with all jurisdictions. MCA chief executive Tania Constable said the organisation was also working closely with the Chamber of Minerals and Energy of WA on appropriate actions to prevent perpetrators seeking alternative employment arrangements within industry.

The MCA urges the Government to consult the minerals industry on the design and implementation of the range of supported actions.

“It is important that all jurisdictions are consistent in the development and application of legislative and policy settings designed to prevent and respond to sexual harassment,” Constable said.

“Thiess’ offer is compelling, representing an attractive premium to trading prices prior to the announcement of the offer. My

he said.

EnviroSoil is a sprayable topsoil alternative for when you need to transform large areas of depleted soil into a nutrient-dense environment where vegetation can thrive. The combination of EnviroSoil and EnviroLoc Hydromulching BFM is a smarter way to reclaim your land, overcoming the need to import and spread truckloads of expensive topsoil.

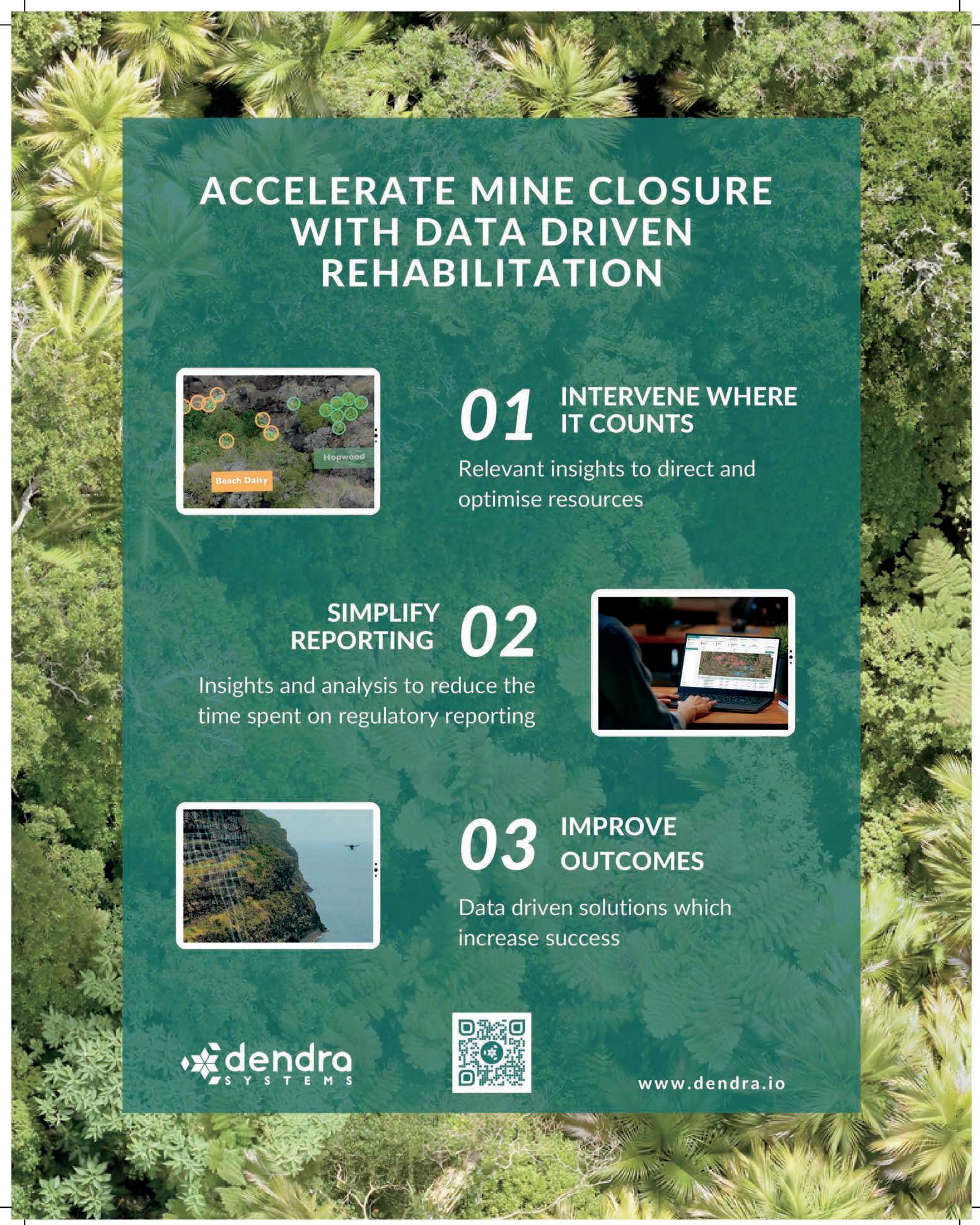

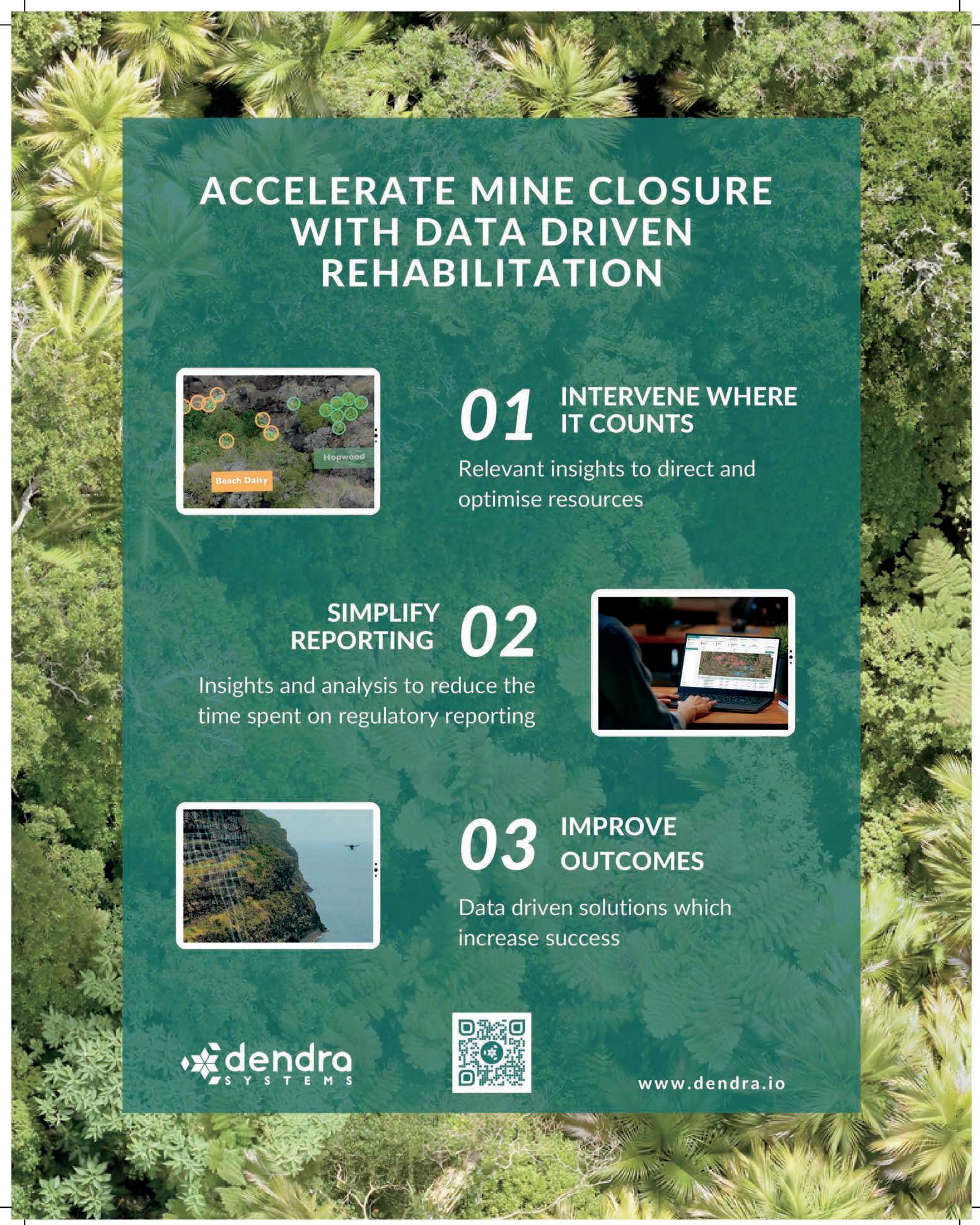

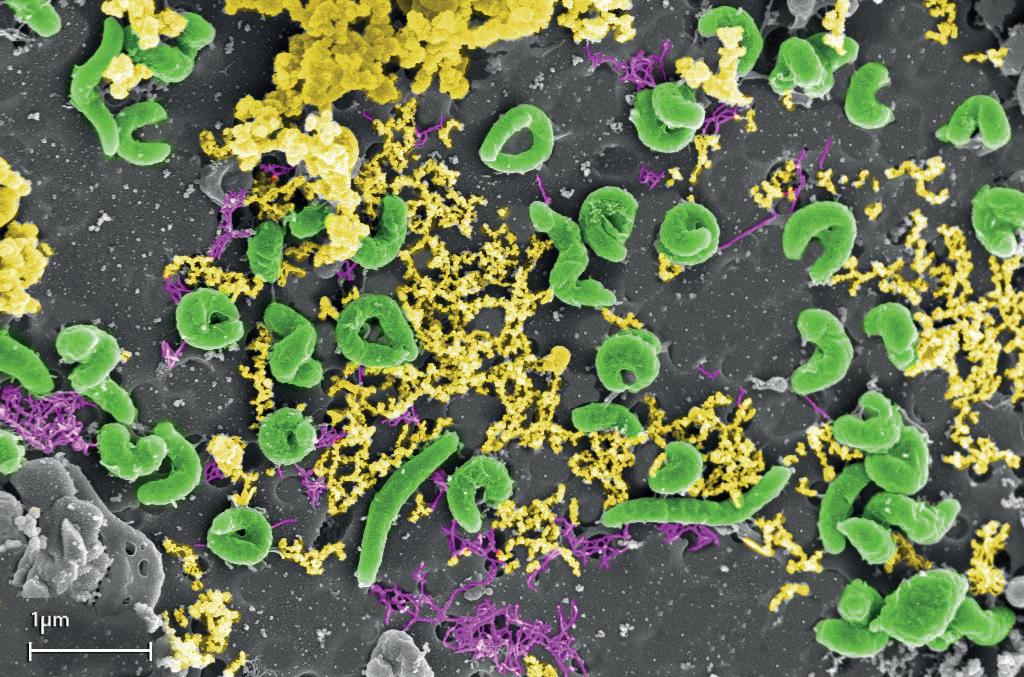

The concept of mine rehabilitation is taking on new meaning in the digital age, and one technology innovator is assisting miners to gain a greater understanding of their ecosystem, expediting environmental restoration in the process.

Dendra Systems provides a holistic view of ecosystem restoration and management, offering an end-to-end service to drive faster rehabilitation and environmental reporting.

This includes the market-leading myDendra Insights platform, which harnesses machine learning to provide a wide range of accurate, timely and actionable ecosystem insights at scale.

The company’s environmental management suite furthers myDendra Insights, translating data into decisions and enabling operators

to monitor rehabilitation progress and conduct transparent reporting.

Dendra places an emphasis on collaboration, so it’s fitting the company is hosting a series of networking events to facilitate discussion specific to the mining sector’s environmental future.

The first such event took place in Perth in September, where Australian Mining facilitated a panel with representatives from the likes of CRC TiME, Tranen Revegetation Systems and Contour Consulting to discuss the importance of technology in mine rehabilitation.

Bryan Maybee is a mineral economist and mine planning engineer with the WA School of Mines who leads the risk, evaluation and planning program at CRC TiME, which is a collaboration of more than 70 leading mining

entities, government and community groups addressing the complex challenges underpinning mine closure and relinquishment.

CRC TiME has initiated a portfolio of foundational projects to identify disconnects in knowledge, behaviour and stakeholders that inhibit orderly mine closure and rehabilitation.

Maybee said his work was less concerned with the implementation of technology than what that technology enables.

“When we think about restoration, rehabilitation and mine closure, what really excites me is the role technology can play in linking stakeholders who will be left with the land post-mining to the decisionmaking processes that happen across the mine life cycle,” he said during the panel discussion.

Maybee said it was important to support a partnership model,

in which different stakeholders can work together and leverage technology to achieve their postmining goals.

Richard Marver, a rangelands botanist, landscape ecologist and director of Contour Consulting, said with demand for rehabilitation increasing as more mines reach the end of their life, the sector must find ways to carry out restoration practices more efficiently.

By expediting information-sharing and decision-making processes –two capabilities Dendra champions itself – the importance of technology cannot be understated.

Maybee said increasing understanding of and interest in closure and rehabilitation outcomes is a key driver for CRC TiME research.

“(Interest) is coming from all stakeholders – some of which are the investment community – leading

to additional reporting requirements in the mining industry,” he said.

“(Mine closure and rehabilitation) is one of the things that’s being used to decide how a company does as far as its ESG (environmental, social and governance) performance.

“As part of that, what we’re doing at the CRC is looking at things like environmental economic accounting, where we’re undertaking a study to see how environmental economic accounting frameworks can be applied into the mining sector.”

Maybee said that while environmental economic accounting is not a specific technology application, technology will enable CRC TiME to carry out these studies.

“Creating these natural capital accounts is hugely data-intensive, so being able to use drones to monitor previously inaccessible areas – which are either too high-risk or perhaps too sensitive to go into – we are able to collect that data and populate those accounts,” he said.

While drones can improve the scope of data capture, technology will also assist in its management.

“When we consider the volume of data we will be processing, we need to start looking at database technologies and at different ways to manage, store,

collect and disseminate data, and being able to efficiently and effectively run reports needed for different reporting requirements,” Maybee said.

“For CRC TiME, technology is part of everything we do, whether it be an operational or mine-planning solution. It’s built into all the systems we look at.”

CRC TiME’s risk, evaluation and planning program is focused on promoting the importance of integrating closure and rehabilitation activities into mine planning.

“At CRC TiME, we are researching ways to make sure mine closure and rehabilitation is part of the original mine plan and decision process,” Maybee said.

“We make sure it’s part of how we strategically build our mindset.

“As part of that, we look at where we can use technology to change the way we think about rehabilitation.”

Maybee said there were two ways technology can support this process.

“We’ve got technology allowing us to plan the closure and rehabilitation activities as part of that early planning process in order to get our license and ensure we adhere to the relevant regulations,” he said.

“Once that’s in place and we can consider technologies – such as automated components, which allow us to do certain rehabilitation activities progressively in the same

location as mining is taking place – we can start to think differently about the way we plan the mine.

“So now, rather than thinking about closing a mine after it’s done, we can start to think about planning the mine for closure and consider that mining is just one use of that land; there will be another use afterwards.

“How do we transition to that post-mining use as part of the initial land use plan we devise right from the start?”

According to the panellists, transparency and regulation are two key drivers of technology innovation in the mining industry.

With transparency comes the need to communicate and provide stakeholders relevant information to demonstrate performance and accountability. This could be with community groups, investors or government entities.

Mining companies need to demonstrate they are operating in line with legislation, which Dendra field ecology lead Guy Smith said affects many of his customers.

“We’re often guided by regulations and commercials, and the initial discussions we have with customers consider what they are currently

doing to meet the requirements,” he said during the panel discussion.

“Then we step in and suggest how we can help them achieve the same, if not better, results with less effort and less time in the field, and essentially further streamline their current processes.”

Smith said technology innovation is a “moving beast”, with Dendra constantly evolving and changing to respond to industry drivers and through its own internal development.

“We could be flying one drone initially but exploring ways to

develop that into a swarm of drones, which will drive greater return on investment for customers,” Smith said.

As remote technologies advance and the capacity to complete off-site analyses improves, ecologists will spend fewer hours on mine sites in the future.

Damian Grose, founder and general manager of Tranen Revegetation Systems, said this would help to address the current skill shortages affecting the mining sector.

“What we do on the ground works – it needs bodies running around – but if there are better ways to do our work more efficiently at scale, then that’s only going to help,” he said during the panel discussion. “The more we can get done with technology and machinery, the better.”

For Tranen – which revegetates land through practices such as direct seeding – drones are starting to play an increasingly important role.

“If you look at the on-ground work we do, such as direct seeding large areas, these areas can be quite inaccessible … but drones can now direct seed for us. Drones can cover very large areas very quickly, where it’s very slow to do it

“And then remote sensing enables us to capture data and target where works need to happen very efficiently and monitor progress.”

However, while drones and remote technology are becoming more prevalent, Smith believes on-ground surveying “will never be fully replaced” due to quality control and the need to confirm remote analyses. He also sees potential for the environmental technology industry to combine different remote surveying techniques into a single package.

“There are a lot of technologies which work independently, such as remote cameras and ultrasonic bat recorders. How can we combine all of that into one central place and get a complete picture of an ecosystem with less field effort?” Smith said.

Gaining that complete picture is not only about optimising surveying processes and technologies, but it also concerns the operational approach and whether rehabilitation is incorporated into mine planning practices.

With environmental experts such as Dendra, CRC TiME, Contour Consulting and Tranen Revegetation Systems at its side, the Australian mining industry has the tools it needs to enhance its rehabilitation

where people, businesses and our planet thrive together. komatsu.jobs/

Scan for career opportunities

© 2022 Komatsu Ltd. or one of its subsidiaries. All rights reserved.

© 2022 Komatsu Ltd. or one of its subsidiaries. All rights reserved.

Elon Musk is not exactly known for thinking small. So no one should be surprised when the Tesla chief executive officer and world’s richest person floats the idea of buying a mining company to further aid the growth of his company.

The thinking goes that such a move would give Tesla, a leading electric vehicle (EV) manufacturer valued in excess of $US500 billion, more control over the critical minerals vital to the batteries at the heart of its vehicles.

“(Buying a mining company is) not out of the question,” Musk said when asked about the possibility earlier in this year.

“We will address whatever limitations are on accelerating the world’s transition to sustainable energy.

“It’s not that we wish to buy mining companies, but if that’s the only way to accelerate the transition, then we will do that.”

But it seems buying a mining company and controlling the critical minerals vital for EV manufacturing –lithium, nickel and the like – may not be the only way for Tesla to accelerate the renewable transition.

The US-based automotive company has told the Texas Comptroller’s Office that it is assessing the feasibility of building a battery-grade lithium hydroxide refining facility on the Gulf Coast of the state to support its production of EV batteries.

Tesla said the facility, which the company indicated would be the first of its kind in North America, will process “raw ore material into a usable state for battery production”.

If the plant is approved, Tesla said construction could begin as early as the December quarter of 2022, paving the way for first commercial production in the December quarter of 2024. The plan would see Tesla ship final product from the refinery by trucks and rail to various manufacturing sites to support the supply chain for largescale EV batteries.

Credit intelligence provider Fitch Solutions believes the proposed facility represents an “important shift” in EV manufacturers’ upstream strategy.

“We believe that the increasing popularity of the lithium-

iron-phosphate cell will drive further interest from other automakers to develop similar projects,” Fitch said in a recent report, ‘Tesla refining project embodies the future of EV supply chain’.

“This planned project … offers strong synergy potential for the local EV supply chain as the US, Canada and Mexico all look to increase lithium mining.”

“You can’t lose” Musk, for his part, has not been shy about his thoughts on the need to increase lithium refining as the world moves towards a future powered by renewables and driven by EVs.

“You can’t lose,” he said of lithium refining in Tesla’s second-quarter earnings call.

“It’s licensed to print money.”

However, the proposed refining facility is not without its risks.

Lithium supply continues to be an issue in the EV sector and there is a concern over Tesla’s ability to secure a cost-effective, long-term source of the mineral to support the plant. However, other EV manufacturers could also be getting in on the lithium-refining act.

“We expect to see additional automakers looking to vertically integrate their upstream operations in the EV supply chain by also onshoring or nearshoring refining facilities, particularly in North America and Europe, where refining capacity is low,” Fitch said in its report.

“We believe that the main concern underpinning Tesla’s refining project is to secure a cost-effective, long-term source of refined lithium … confirmed by the surge of lithium prices to record highs in September 2022.”

The demand for lithium is becoming ever stronger throughout the world.

The Australian Government’s Resources & Energy Quarterly for the September quarter of 2022 highlighted the insatiable demand for the battery

metal, which is being primarily driven by the EV sector.

“Despite faltering global economic growth in the June quarter, sales and production of electric vehicles continued their rapid growth trend,” the report said. “Global sales of all types of EVs increased 36 per cent in the year to June 2022 compared with the same period in 2021 – with Chinese sales up 110 per cent, European sales up 6 per cent, and North American sales up 27 per cent.

“In China, total EV sales have averaged almost half a million vehicles a month so far in 2022, reaching a peak of 650,000 vehicles in June.”

Fitch believes the recent passing of the Inflation Reduction Act in the US offers further support to automakers’ vertical integration plans.

“The US Inflation Reduction Act, passed in August 2022, has driven automakers to source EV battery metals from regionally-based producers and refiners,” Fitch said.

“This is because the bill has introduced a critical metals policy to its EV tax credit, requiring that 40 per cent of metals included in EV batteries must be extracted or processed in North America, or in a country that the US has a free trade agreement with.

“This project will also contribute to Tesla’s goal of reducing its battery price by creating a local, reliable source of refined lithium, and ensure that Tesla vehicles will qualify for US EV tax credits under the recently passed (Inflation Reduction Act) bill.”

As EV manufacturers build more cars to keep up with demand, the need for lithium has soared, sending prices to record levels.

The Resources & Energy Quarterly predicted prices for spodumene concentrate – a raw lithium material –to rise from an average of $US598 per tonne (t) in 2021 to $US2730/t in 2022 and $US3280/t in 2023, before pulling back to $US2490/t in 2024.

Prices for lithium hydroxide – a refined version of spodumene – are expected to lift from an average of $US17,370/t in 2021 to $US38,575/t in 2022 and $US51,510 in 2023, before cooling to $US37,650/t in 2024.

Looking at the lithium mining market more broadly, current production will fail to meet growth in demand for lithium-ion batteries that are needed for much of the world to meet global climate goals, according to Rio Tinto’s minerals chief Sinead Kaufman.

Scan the QR code and let’s work together for a carbon neutral future!

“We see, as others do, an enormous demand for lithium as a building stock for lithium-ion batteries,” Kaufman said at the Battery Gigafactories Asia Pacific conference in Perth in September. “Forecasts show that light electric vehicles will make up about 50 per cent of the light vehicles on the road by 2030.

“Which means that lithium consumption … needs to surge way above anything that’s currently been planned to be mined.

“With every project in the world that’s projected to come on, we’ll still

be short by 50 per cent of the amount of lithium that’s required to build the electric vehicles.”

While prices will continue their climb in the coming years, the Resources & Energy Quarterly expects Australian lithium production to increase from 247,000 tonnes of lithium carbonate equivalent (LCE) in the 2021–22 financial year (FY21) to 387,000 tonnes in FY23 and 469,000 tonnes of LCE in FY24.

Relative scarcity and booming prices, combined with a global push towards decarbonisation and hugely increased demand, may create the perfect storm that sees EV manufacturers like Tesla take steps to vertically integrate their production processes and invest in mining companies or, indeed, mineral refining facilities.

“Ultimately, lithium is one of the major limiting factors to how big that actual demand number ends up being,” Andrew Miller, chief operating officer of battery metals price reporting agency Benchmark Mineral Intelligence, said at the Battery Gigafactories Asia Pacific conference.

“Fundamentally, that demand is not going anywhere.”

“WE EXPECT TO SEE ADDITIONAL AUTOMAKERS LOOKING TO VERTICALLY INTEGRATE THEIR UPSTREAM OPERATIONS IN THE EV SUPPLY CHAIN BY ALSO ONSHORING OR NEARSHORING REFINING FACILITIES.”TESLA CEO ELON MUSK DESCRIBES LITHIUM REFINING AS BEING “LICENSED TO PRINT MONEY”.

As a world leader in air compressor development we know the importance of quality service and maintenance. We provide the best possible service for your compressed air system. We have compressed air service technicians located throughout Australia and have local knowledge of the conditions your business may face.

An easy way for miners to achieve CO2 reduction, is by upgrading inefficient lobe blowers located at your process plants. Our new ZS4, 5 VSD (variable speed drive) and VSD+ oil-free screw blowers are the latest market releases that help to reduce carbon emissions by upgrading old technology.

Atlas Copco’s Smartlink technology, gives you the ability to monitor your equipment via real time data. Depending on the chosen service plan, we can also monitor the equipment, allowing you to identify variations in operation and update maintenance schedules and visits to improve uptime and reliability.

3 ways you can reduce carbon emissions and have an energy efficient compressor room at the same time

Fenner Conveyors is placing a greater emphasis on conveyor research and development (R&D) than ever before, resulting in more efficient and more forward-thinking products.

The PowerSaver low rolling resistant (LRR) rubber conveyor belt compound is a clear example –a product that is helping operators simultaneously drive down costs and CO2 emissions.

Since the first generation was launched in 2018, Fenner has supplied more than 140km of the PowerSaver product to the market.

Fenner engineered conveyor solutions (ECS) manager Mike Finlen said PowerSaver answers the call for a more energy-efficient belt compound.

“Many mining projects typically have long, overland conveyors and, from a capital cost perspective, they’re interested in reducing power demand on those conveyors,” he told Australian Mining

“There’s also a growing focus on conveyor efficiency from an energyconsumption point of view, where

mining companies are trying to be greener. PowerSaver helps them achieve this.”

The PowerSaver compound is applied to the bottom cover of the conveyor belt. It achieves power savings by minimising cover indentation on the pulley cover, helping with easier flow over the idlers. This leads to less friction and more efficient conveying.

Finlen said PowerSaver’s ability to reduce operating tensions and drag on the conveyor means mining companies can downsize their drives and pulleys, reducing their capital expenditure (capex) in the process.

“When we’re talking about conveyors that could be over 20km long, there’s significant cost savings to be had,” Finlen said.

PowerSaver was developed specifically for the Australian market, mindful of the requirements of the major iron ore, bauxite and coal miners, who are the main operators of overload conveyor systems.

The flagship PowerSaver project was developed in collaboration with a major iron ore miner in Western Australia, with the

belt compound installed on a series of overland conveyors. The mining company put PowerSaver through extensive acceptance testing before Fenner was contracted. This involved sending the product to the US.

“Prior to finalising us as a supplier, the customer asked to have samples of PowerSaver sent to Conveyor Dynamics Inc. in the US to undergo a validation process,” Finlen said.

“Once the results came back and the performance of PowerSaver was proven, the customer had confidence that PowerSaver was a leading material and could achieve its power consumption targets.”

This first generation of PowerSaver was so successful it became a benchmark for low rolling resistant compound standards in Australia.

Fenner rubber R&D manager Upul Silva said while the first-generation PowerSaver can achieve up to a 20 per cent energy saving on a conveyor belt, the second-generation product can achieve a 40 per cent energy reduction.

PowerSaver 2.0 was launched in 2020 following extensive testing and analysis to ensure it complied with the relevant Australian Standards.

This began with a small-scale dynamic mechanical analysis (DMA) to characterise the development compounds before large-scale testing was conducted on an indentation rolling resistance test rig. This was done in partnership with the University of Newcastle Research Associates (TUNRA).

Silva said when the PowerSaver 2.0 was being developed it was the first LRR compound to be tested at TUNRA using the then-new Australian Standard 1334.13.

“The PowerSaver 2.0 compound was developed using specialty polymers, specialty carbon blacks and novel materials,” he told Australian Mining. “It also utilises new mixing techniques to get the optimum compound mix and performance so that we can deliver the best outcomes for our customers.

“There was a lot of work done in the laboratory and in production to try and get that final compound mix right, which has resulted in us developing the best performing compound possible.”

Finlen said that manufacturers previously had to trade-off between

achieving a reduction in indentation rolling resistance and maintaining the compound stiffness to ensure durability of the product.

But PowerSaver 2.0 has been designed to achieve both of these variables.

“In the past, when a more energyefficient product has been developed, there’s been reduction in material toughness,” Finlen said.

“One of the things we were very conscious of in developing PowerSaver 2.0 was to not have that level of compromise. We quantify this by a characteristic known as dynamic shear modulus at low strain.

“With PowerSaver 2.0, we achieved a 50 per cent higher dynamic shear modulus at low strain compared to previous compounds.”

Some of the inspiration behind the PowerSaver 2.0 has come from Fenner’s parent company, Michelin, which has global resources and places a particular emphasis on R&D.

“Since we joined the Michelin Group in 2018, we’ve been collaborating and sharing data with the company,” Silva said.

“Michelin has 3000 employees at its R&D centre in France, where it develops its own specialty polymers, and I’ve worked closely

with Michelin’s material and rolling resistance experts to develop PowerSaver.”

Having successfully launched the second generation of PowerSaver, Silva said Fenner and Michelin have been working on the third generation of the product for at least a year. The two companies hope to have PowerSaver 3.0 ready by late 2023.

“PowerSaver 3.0 will have further improvements to rolling resistance and the shear modulus,” Silva said.

“It’s important for us to continue driving the performance that our customers desire so we are not resting on this compound.”

Fenner and Michelin have also been experimenting with sustainable materials, which will underpin the development of all future Fenner compounds, including the PowerSaver.

As per Michelin’s sustainability goals, the company and its subsidiaries will need to be producing compounds made up of 100 per cent sustainable material by 2050.

While limiting capex is critical to insulate companies from the current inflationary environment, the mining industry cannot be lost on the broader net-zero imperatives.

Luckily enough, PowerSaver can achieve both goals. AM

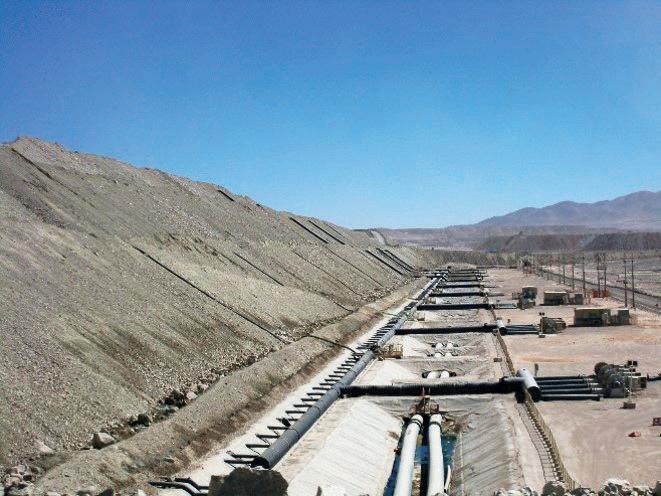

Mobile processing units (MPUs) are used in mining operations across Australia to manufacture or blend bulk explosives at the blast hole.

Operational efficiency and maximising productivity are key financial risks for mine operators. Dyno Nobel has sought to mitigate these concerns with its new MPU, the DYNOBULK Flex.

“As a mining services provider, it’s our job to help our customers reduce their costs and increase their productivity,” Dyno Nobel general manager business development Rebecca Landon told Australian Mining

“With the DYNOBULK Flex, we can provide this productivity increase with a more capable MPU.”

The DYNOBULK Flex is one of the most efficient MPUs, with features like dual-purpose bins and a high-speed product pump driving down operational cost and time.

The MPUs are currently being used by a large multinational coal miner in Queensland’s Bowen Basin, with more expected to be employed across the region.

The Bowen Basin contains the largest coal reserves in Australia, with some of the world’s largest miners taking up residence there to share in the natural deposits.

“The ultimate question that customers have after they use the DYNOBULK Flex is, ‘When can I have more?’” Northern operations and business improvement manager Ben Hyde said.

“So far the feedback has been excellent, and they’ve been really happy with the efficiency.”

With the DYNOBULK Flex, operators can rely on the MPU’s larger carrying capacity and dualpurpose bins to achieve maximum optimisation. This means miners

productivity gains through the use of an optimised bin configuration, according to Dyno Nobel.

The Flex has three bins, compared to two in a standard MPU. One of these bins is for ammonium nitrate, while operators can choose to use the other two bins in a way that suits them – either for more ammonium nitrate or, alternatively, TITAN emulsion.

“It’s all about flexibility and optimisation for the customer,” Hyde said.

The optimisation of the MPU has an additional safety benefit, as the user’s interaction with heavy mining equipment is reduced by the lower number of turnarounds needed to achieve the same volumes.

The DYNOBULK Flex MPU also minimises the assets and time traditionally needed to load a blast, further improving the safety of a site, with fewer trips between storage

Users can also optimise the payload for seasonal changes, with the MPU able to be configured for wet and dry conditions by changing the bin configuration. The truck is designed to enable these configuration changes on-site.

“There’s a lot of benefit in getting the product mix right,” Landon said.

“With the DYNOBULK Flex, operators can deliver the right type of product they need for that particular shot, no matter the season.”

One of the company’s largest clients has seen big improvements and benefits in a range of areas on their sites, and Dyno Nobel wants to encourage more mining operations to see the benefits of the DYNOBULK Flex MPU firsthand.

“Our customers are seeking innovative and practical technologies from us,” Landon said.

“And the DYNOBULK Flex

Minnesota-based Integral DX, a family owned and operated business with a straightforward vision – ‘embrace those who respect, honour and value relationships’ – is seeking to enter the Australian market with a highly mobile, flexible and reliable surface mining solution.

The founder and chief executive officer of RITALKA, the parent company of Integral DX, is Kevin Wald. The company’s unique name is derived from his children, Riley, Tallen and Kayla, who in the early days of the business were a constant motivation for the long hours of work.

The Easi-Miner was initially designed and manufactured in the 1970s by Huron Manufacturing in South Dakota, and has had multiple owners over the course of its operating life before RITALKA purchased intellectual property rights in 2019.

Over this extended period, the Easi-Miner successfully worked on many mine sites across the US, Canada and Mexico, with several EasiMiner units having been operating in the US for more than 50 years.

Since 2019, Wald has introduced new design features to the Easi-Miner with the aim of attracting interest in larger mining markets, Australia chief among them.

“Upon purchasing the designs for Easi-Miner, COVID hit and caused a significant delay in our ability to inform the Australian market about our machine,” Wald told Australian Mining

“We believe that Australia is the strongest market actively pursuing surface mining anywhere in the world, and that’s why we’re increasing both our visibility and presence.”

The Easi-Miner’s unique design incorporates a cutting head that rips and loads material onto a primary conveyor, eliminating the need for

primary crushers, while providing real-time updates via a sophisticated control system.

The machine is designed to handle high-volume output, with the primary and discharge conveyors operating at variable belt speeds up to 250m/min, providing a loading capability of approximately 900kg every two seconds.

With a swing arc of 180° (90° to each side) and a maximum ground discharge of approximately 9m, the Easi-Miner is incredibly flexible and able to load material directly into haul truck or trailer of any size.

The machine is designed with high spiral shoulders that allow material to be pushed into the drum centre and cutting teeth to properly size material so it can be loaded on a continuous basis.

“The machine doesn’t just break it out in various-sized chunks from the cut; rather it produces a uniform material size,” Wald said.

“By working in conjunction with the speed of the cut, the depth of the cut, and the teeth orientation on the cutter, you can ensure a material size is produced that meets the next stage of your operation’s value-add process.”

The Easi-Miner operates on a quadtrack crawler system that gives the ability to excavate within inches of a mine wall and extremely close to the thinnest bottom of a seam.

“The quad-track steering ability of the Easi-Miner means it is highly agile and manoeuvrable, especially in opencut mine sites,” Wald said.

“The Easi-Miner can adjust to various open-cut depths and overburdens, handle a 10 per cent grade, while operating at speeds of up to 3.5km/h at a ground pressure of 22 PSI (pounds per square inch).

“The other benefit of the quadtrack system is the ability to get a more consistent cut as the platform is incredibly stable, ensuring a consistent and accurate cutting depth.”

head can cover an area of up to approximately 4m across and 0.5m deep. The cutting head has been designed to extract the material in a downward motion, allowing it to cover distances in a more effective and efficient way.

The mined materials pass through the digging assembly and dual conveyor system only once before being transferred for transportation or to be windrowed directly behind the machine, eliminating any additional stress to Easi-Miner’s frame and tracks.

Additional production requirements, including the sizing of customised head patterns, pick types, and drum diameters, can be performed quickly, with the machine’s cutting teeth able to be configured to suit site-specific requirements.

The Easi-Miner is also an inherently safe piece of equipment.

“There are no requirements for people to be outside of the Easi-Miner in order to operate the machine, as it’s completely electronically-controlled and capable of storing operating data for future analysis,” Wald said.

clear view of all sides and features a sophisticated air filtration system, a fully adjustable seat, and mounted AC and DC lighting units. All up, the cab is home to more than 30 electronically controlled functions.

In addition, recent design innovations have resulted in greater operational efficiencies.

“Based upon the first 8000 hours of mining incorporating the new design, we have determined that the Easi-Miner operates at a much lower cost per hour than our initial forecasts,” Wald said.

primary crushers, bulky loaders and large haul trucks, the Easi-Miner eliminates the demand for additional attachments, rippers and vertical drills. By removing the doublehandling generally associated with more traditional methods of surface mining, Easi-Miner’s all-in-one design helps cost savings to be passed onto the customer.

Wald and his team believe they have a mobile, robust and innovative equipment solution that is primed for Australian surface mining operations. AM

henever a major machine upgrade is required, Cat® machine owners have the choice to replace, rebuild or repair.

There are many factors that influence this decision, including cashflow and the expected lifespan of the machine, but many operators in the mining industry choose one of the cost-effective rebuild options offered by Cat dealers. Advances in technology are also important, with so many new technologies available that support productivity gains and reduce operating costs.

As a business grows, its fleet must evolve with it and navigating the challenges of machinery management requires making the best use of existing machines, while also planning for future operations.

A machine or component rebuild offered by Cat dealers gives the peace of mind of a quality solution with a lower capital outlay. Plus, owners don’t have to buy a new machine to benefit from new technology and other improvements.

Rebuilding is an opportunity to add engineering upgrades and other advances that will help a fleet run smarter and smoother. In other words, operators enjoy many of the benefits of a new machine at a much lower cost.

WThe decision to rebuild also means avoiding the issue of training staff on completely new equipment, making it easier to get up and running and keep productivity on track. Even better, rebuilding can free up capital for other investments.

Cat dealers offer a broad range of rebuild solutions, including Cat Certified Powertrain, Cat Machine Component and Cat Full Machine Rebuilds.

All three solutions are available for a wide range of machines, including 336 excavators, 777 dump trucks, 988 wheel loaders, dozers and motor graders.

Whichever option you choose, participating Cat dealers offer an extended warranty*, performance and technology upgrades, and competitive low finance rates* for eligible machines.

A Certified Powertrain Rebuild covers radiator, engine, transmission, torque converter, final drive, and axle. Components are disassembled and all critical engineering updates incorporated. This option restores the powertrain to like-new performance. Cat ProductLink™ hardware is installed with all Cat Certified Powertrain Rebuilds, enabling

remote monitoring of machine efficiency and performance.

A Certified Machine Component Rebuild is designed to restore an engine or transmission, plus the torque converter, to deliver like-new performance for these components. Critical engineering updates are included with this option.

A Certified Full Machine Rebuild can help recover the performance of your original machine. You can also benefit from the latest engineering updates, and Cat ProductLink™ is installed on all Cat Certified Machine Rebuilds. AM

In addition to all of the Certified Rebuild options, your Cat dealer offers a range of non-certified dealer machine rebuilds, performed by a qualified technician with tailored financial solutions available.

Take advantage of current offers, including performance and technology upgrades, extended warranty* and competitive low finance rates* when you rebuild your 336 excavator, 777 dump truck, or 988 wheel loader. To find out more visit cat.com/rebuilds-au or contact your local Cat dealer.

* Terms and conditions apply. See cat. com/rebuilds-au for details.

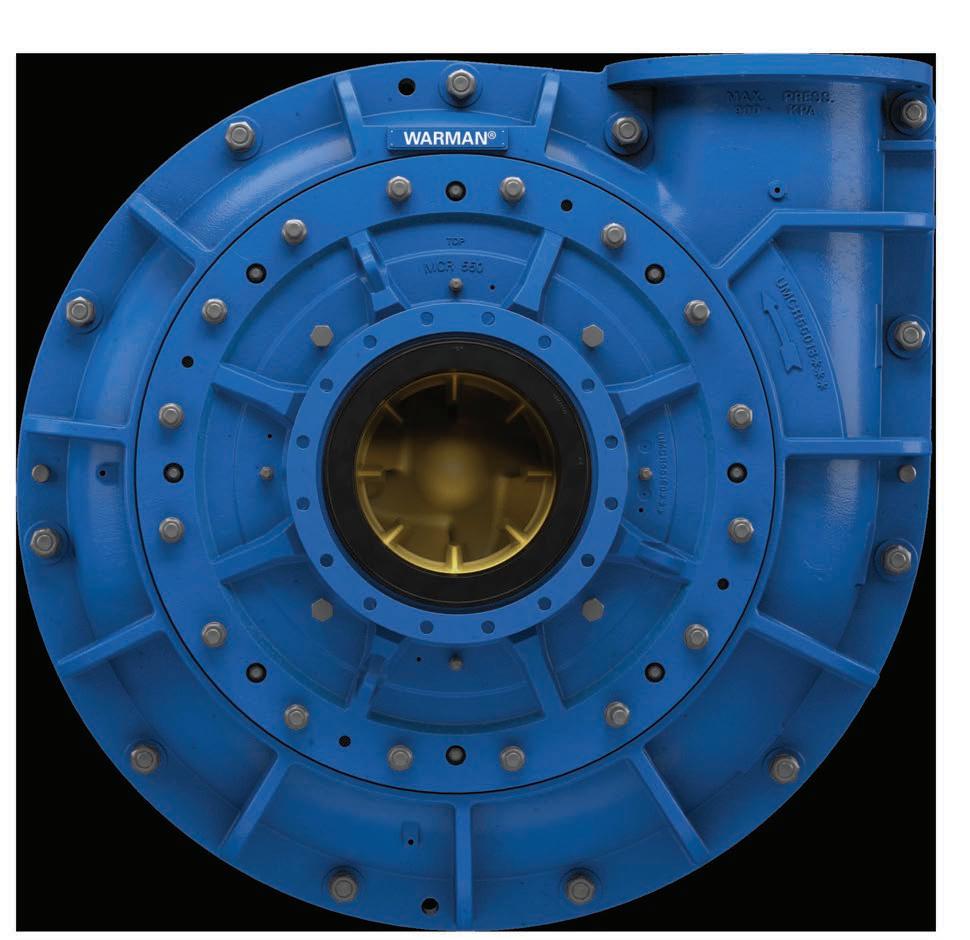

The proven, trusted industry leader for unrivalled performance and innovation – always. When it comes to specifying your next pump or pump upgrade, it’s not a question of whether you can afford Warman®, it’s whether you can afford not to. alwayswarman.weir

Australian mining is changing for the better.

BluVein, with the support of Austmine and leading mining companies, is supporting industry efforts with the development of a safe, standardised, and intelligent charging solution for battery-powered vehicles.

The benefits of mine site electrification are many. The most significant may be the removal of diesel (and subsequently diesel exhaust emissions), eliminating the harmful particles and chemicals associated with an increased risk of lung cancer, respiratory and cardiovascular disease in workers.

The move away from big dieselpowered machines towards fleets of electric-powered vehicles on mine sites means a technological solution for the rapid charging of batteries is critical.

According to a recent survey undertaken by the research platform

BluVein is the result of 12 years of research and development in electrified highways by Swedish technology company EVIAS, combined with 25 years of developing mining machinery, robotics and power systems by Brisbane-based Olitek.

BluVein’s guiding design principles include comprehensive safety systems, standardisation with flexible

The BlueVein1 technology is designed to electrify underground mining via a trolley charging architecture that encompasses no exposed high-voltage conductors. It can be integrated with all heavyduty battery-electric vehicles and is designed for ease of operation.

Electrical contacts are safely enclosed in the ingress-protection

technology embedded in BluVein1, offering a dynamic charging solution for heavy-duty mining fleets in openpit mining.

Capable of dynamically feeding power to mixed-OEM fleets, BluVeinXL enables the onboarding of smaller battery packs, leading to the ramping-up of faster vehicle haulage speeds, grid-load balancing and maximum fleet availability.

There is a significant ease of ownership with the BluVeinXL technology, as it remains completely machine-agnostic and capable of being deployed on any vehicle, at any mine.

The technology is safe, modular and near-to-ground, which offers easy installation and means it can be being deployed or relocated quickly.

In addition, the fact the BluVeinXL is side-mounted with no overhead vehicle integration eliminates the requirement for any overhead wires or infrastructure.

The BluVeinXL technology helps to ensure increased production, with vehicle fleets not required to frequently charge or swap batteries, along with significant reductions in total cost of ownership as a result of reduced onboard energy, lighter trucks, greater payloads, and faster and steeper haulage.

BluVein has an array of project partners, including Agnico Eagle, Anglo Gold Ashanti, BHP, Epiroc, Glencore, Newcrest, Northern Star, South 32, Vale and ReThink Mining (Canadian Mining Innovation Council), all of whom provide support and feedback to develop and deliver BluVein’s advanced electric solutions.

BluVein’s vision to support as fully electric mining industry is emblematic of the mining equipment, technology and services (METS) sector and its role as one of the most advanced, innovative, and internationalised sectors in Australia.

Austmine, Australian mining’s leading industry association, continues to support companies with an unrelenting drive towards the sustainable transformation of mining.

BluVein is electrifying mining with safe, flexible and troublefree technologies, enabling the industry to achieve its mission of decarbonisation by accelerating the shift to battery-electric fleets and a net-zero future.

AUSTMINEA SOLUTION FOR RAPID BATTERY CHARGING IS VITAL IN AN ELECTRIFIED MINING FUTURE.

BRAKING BUSINESS

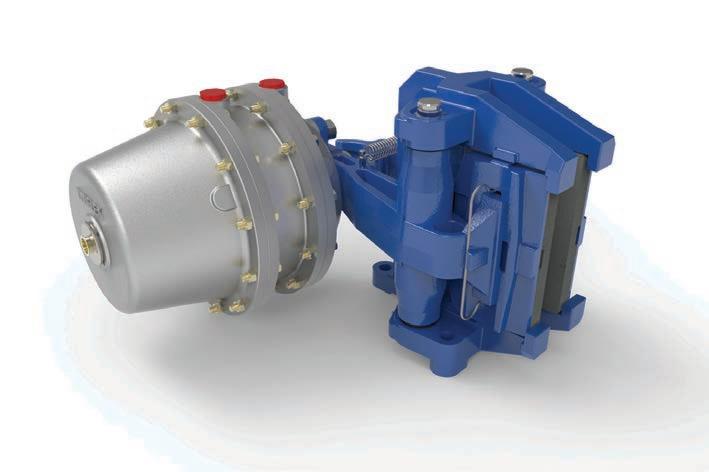

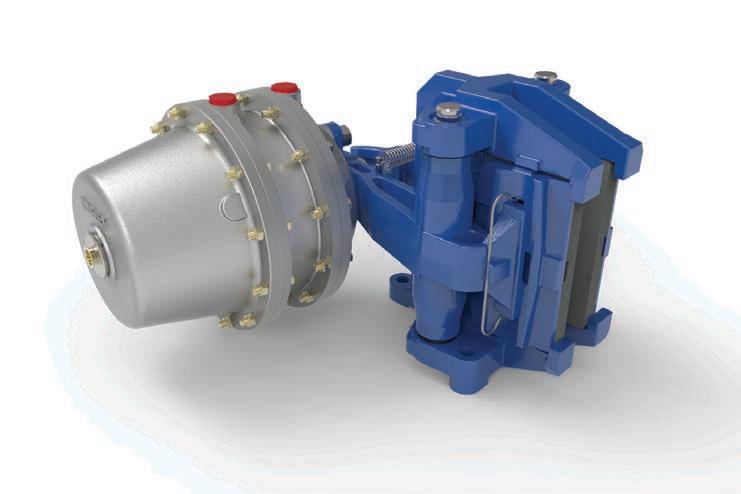

Founded in 1946, Altra Motion brand Twiflex is a global leader in innovative braking solutions for industrial applications.

concerns for companies across the Australian mining industry, with its caliper disc brakes a dragline game-changer.

Twiflex first supplied caliper disc brakes for draglines in the 1970s for Rapier 1000 and 2000 series machines, and today – through Altra Motion –has been providing the local dragline industry with market-leading brakes

braking business, and its credentials are equally applicable to the Hunter Valley region of New South Wales. Altra has launched a Newcastle service facility to support its NSW customers. It has the personnel to

BOWEN BASIN. AS A

Given Altra Motion is the OEM of Twiflex brakes, the company can communicate internationally with its factories if there are any specific product concerns.

“Being the OEM alleviates errors,”

ALTRA MOTION OCCUPIES MORE THAN 80 PER CENT OF THE DRAGLINE

IN THE

RESULT, THE OEM IS LOOKING TO REPLICATE THE SAME SUCCESS IN THE HUNTER VALLEY.

“This expedites the service process, replaces the need to go through a third party, and eliminates mistakes.”

Altra Motion NSW sales manager Daemon Flack said “things can get lost in translation” when multiple companies are involved in the service process.

With 26 brands under the Altra Motion name, the OEM can also call on the expertise of its many brands to answer service queries or resolve a product or mechanical engineering issue. This could include the likes of Svendborg, Marland or Ameridrives.

But this doesn’t take away from Twiflex’s capacity as an individual brand, one that offers the most extensive range of industrial caliper

Booyens told Australian Mining.

“If you look at what Altra Motion as a business brings – 20-plus brands with factories worldwide and the depth of support that comes with that. The factory training our technicians receive, it’s not just Twiflex; it’s also Svendborg, Marland and Amerigear, et cetera.

“The depth of training we receive as Altra Motion employees brings more than just Twiflex to the table as far as our customers are concerned and the workshop support and backup we can offer our customers.”

Booyens said the Australian dragline industry was in good hands through Twiflex’s brake offerings, with Altra Motion’s many other brands able to provide their unique perspectives, if needed.

“This is why we’ve been so successful in the Bowen Basin – the ability to provide that holistic, endto-end support from across the Altra Motion business,” he said.

The Twiflex caliper disc brakes can increase brake efficiency and reliability, with the ability to dissipate heat while simultaneously decreasing maintenance costs and improving braking capacity.

Booyens said the Twiflex brake range ticks many boxes.

“If I was a mining company, why would I use a Twiflex brake system? Working with mines for 12 years since I’ve been in Australia, they’ve got three parameters they work around,” he said.