Building on the knowledge of the past. Innovating for the future.

1300 182 182 erizon.com.au

VOLUME 114/11 | DECEMBER 2022 CONNECTIVITY INDUSTRY OUTLOOK

ROBOTICS

Guaranteed Results 1300 182 182 REVEGETATION EROSION CONTROL erizon.com.au FIND OUT MORE DUST SUPPRESSION

PRINT POST APPROVED PP100008185 OFFICIAL MEDIA PARTNERS SERVING THE MINING INDUSTRY SINCE 1908 CRITICAL MINERALS ARE KEY TO AUSTRALIAN MINING IN 2023 A CRITICAL FUTURE VOLUME 114/11 | DECEMBER 2022 CONNECTIVITY INDUSTRY OUTLOOK ROBOTICS

Fleet Management Cyber Security FMS Integration & Interoperability Surface Underground Planning & Short Interval Control Standardisation Data Analytics Epiroc Regional Application Centre Mining Technology Solutions United. Inspired. Performance to succeed today. Technology to lead tomorrow. We believe that innovative mining technologies such as automation, interoperability and digitalisation tools are the future of our industries. And at Epiroc, the future of smart mining is already here with a full suite of complimentary products and services. epiroc.com/en-au

PAUL HAYES

paul.hayes@primecreative.com.au

Looking to the future can sometimes be a risky proposition. The uncertainty of asking “what if …?” can produce a certain level of anxiety that isn’t always welcome or productive.

After the difficulty of the last few years, however, considering the future has provided many of us with a certain level of hope and, dare I say, confidence. And with what was a relatively successful and positive 2022 largely in the books, looking ahead to 2023 doesn’t seem so risky.

It’s thus fitting that in this issue of Australian Mining, the final one for 2022, we take a sweeping look at what lies ahead for the resources sector in the coming 12 months.

First up, we take a deep dive into an Ernst & Young report that looks at the greatest business risk/opportunities facing the global mining and metals sector in 2023. In what will likely be a surprise to very few of us, environmental, social and governance (ESG) came in at the top of the list.

ESG only continues to grow in stature and importance in the global mining sector, with each of the three pillars increasingly influencing investor sentiment and the overarching financial prosperity of the industry.

ESG spans so many different considerations and variables that it is difficult to condense; however, mining companies that don’t take it seriously risk being left out in the cold.

We also examine the Australian Government’s final Resources and energy quarterly: September 2022, which underlined the role critical minerals will play in the future of the resources sector.

The report found that despite weakening iron ore prices, the surging global demand for critical minerals necessary for new low-emissions technologies is expected to deliver a record windfall of $450 billion for Australia’s 2021–22 resources and energy exports.

We also sit down with Austmine CEO Christine Gibbs Stewart to discuss some of the key aspects of the mining sector’s future, including decarbonisation and the different ways the industry can attract younger people to help address the ongoing skills shortage.

Amid all of this looking ahead, we also reflect on what was a bumper year for National Group, which celebrated its 25th anniversary and further evolved an already renowned mining services company into new activities and new regions of Australia.

But it’s not all looking forward and looking back. This issue includes all of the usual industry updates, product spotlights and informative content that usually appear in the pages of Australian Mining

As the year draws to a close, on behalf of the entire team I’d like to say thank you for a great year and we all look forward to an even stronger 2023.

Email: alexandra.eastwood@primecreative.com.au

Paul Hayes Managing Editor

Email: ashley.perry@primecreative.com.au

CLIENT SUCCESS MANAGER

JANINE CLEMENTS

Tel: (02) 9439 7227 Email: janine.clements@primecreative.com.au

SALES MANAGER

JONATHAN DUCKETT

Tel: (02) 9439 7227 Mob: 0498 091 027 Email: jonathan.duckett@primecreative.com.au

SALES ADMINISTRATOR EMMA JAMES

Tel: (02) 9439 7227 Mob: 0414 217 190 Email: emma.james@primecreative.com.au

DESIGN PRODUCTION MANAGER MICHELLE WESTON michelle.weston@primecreative.com.au

COMMENT

CHIEF EXECUTIVE OFFICER JOHN MURPHY CHIEF OPERATING OFFICER CHRISTINE CLANCY EDITOR PAUL HAYES

ALEXANDRA EASTWOOD

Email: paul.hayes@primecreative.com.au JOURNALISTS

TOM PARKER Email: tom.parker@primecreative.com.au LEWIS CROSS Email: lewis.cross@primecreative.com.au

ASHLEY PERRY

ART DIRECTOR BLAKE STOREY blake.storey@primecreative.com.au GRAPHIC DESIGNERS KERRY PERT, LOUIS ROMERO SUBSCRIPTION RATES Australia (surface mail) $120.00 (incl GST) Overseas A$149.00 For subscriptions enquiries please contact (03) 9690 8766 subscriptions@primecreative.com.au PRIME CREATIVE MEDIA Suite 303, 1-9 Chandos Street Saint Leonards NSW 2065, Australia

© Copyright Prime Creative Media, 2016 All rights reserved. No part of the publication may be reproduced or copied in any form or by any means without the written permission of the publisher. PRINTED BY MANARK PRINTING 28 Dingley Ave Dandenong VIC 3175 Ph: (03) 9794 8337 Published 12 issues a year

OF

INSIGHTS

YEAR.

www.primecreative.com.au

AS 2022 COMES TO A CLOSE, THE MINING CRYSTAL BALL HAS PROVIDED A NUMBER

INTERESTING

AHEAD OF A NEW

LOOKING AHEAD

AUSTRALIANMINING 5 DECEMBER 2022

18 IN DUSTRY OUTLOOK

T he risks and opportunities facing the mining sector in 2023

Australian Mining sat down with Ernst & Young and Accenture to explore the global resource industry’s outlook for 2023 and beyond.

22 IN DUSTRY OUTLOOK

C ritical minerals driving future growth

T he Australian Government’s latest Resources and energy quarterly for 2022 has underlined the central role critical minerals will play in the future of the resources sector.

26 IN DUSTRY OUTLOOK

Austmine’s leading role in next generation smart mining Australian Mining spoke with Austmine CEO Christine Gibbs Stewart to discuss some key aspects of the sector’s future.

28 IN DUSTRY OUTLOOK

From strength to strength: National Group’s bumper 2022 W ith a strong presence in Western

Australia and Queensland, 2022 saw National Group expand its presence in New South Wales, including a new contract with Moolarben Coal.

34 M INING EQUIPMENT

A n expanding global powerhouse

E xpansion into the Western Australian mining market has given Ritchie Bros. customers access to global reach and multi-channel solutions.

42 I NDUSTRY EVENTS

N etworking opportunities galore at WA Mining Conference

T he 2022 WA Mining Conference and Exhibition was the perfect setting for networking and connection.

48 M INE CONNECTIVITY

M icro data centres are transforming mining

T he resources sector is increasingly relying on advanced technologies to connect intelligent systems – and Zella DC’s data centres are at the forefront of turning traditional operations into smart mines.

52 M INE MANAGEMENT

E ffective environmental solutions for mine management

Erizon is dedicated to developing and deploying tailored solutions for the environmental management of largescale revegetation, rehabilitation, dust suppression, and erosion control projects.

60 IN DUSTRY OUTLOOK

T he electric future of mining

Vehicle electrification is a key step in the plan for mining to reach its net-zero targets. In response, Shell has launched a consortium to speed up the process.

IN THIS ISSUE

18 60 58 REGULARS 5 COMMENT 8 NEWS 68 PRODUCTS 70 EVENTS 28 AUSTRALIANMINING 6 DECEMBER 2022

THINK LAYFLAT HOSE

Compactly stored: Takes less than 1/10 of the space compared to poly pipe

two days

truck

layflat hose vs 10 trucks

poly pipe

required, only forklift ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ ✓ No Welding workforce or machinery required

joins

the pipeline

pumping volume Contact us today on +61 3 9720 1100 or email sales@crusaderhose.com.au to learn more or request a quote! www.crusaderhose.com.au • For rapid, high-volume & high-pressure applications • Ideal for long pipelines of 4-5 km • Abrasion-resistant flexible heavy-duty layflat hose • Comes in a range of diameters from 40 mm (1.5”) up to 305 mm (12”), capable of achieving over 500 litres per second • Shorter lengths also available for pump to rigid pipeline applications • Fast, compact and easy to use • Effortlessly deploys & handles large diameter hose • Heavy-duty frame certified to carry up to 200 m of 12” hose • Quick-connect hydraulic couplings for fast machine attachment Waterlord® Reeling System Waterlord® Layflat Hose Our Mine Dewatering Solutions • Compact, easy to use • High-tensile strength for very large submersible pumps • Secure couplings Flexibore® Layflat Hose Learn more about Waterlord products Learn more about Flexibore Layflat Hose Think Outside the Circle LEARN MORE

Many benefits of using Layflat Hose for Mine Dewatering.

Rapid Deployment: Up to 4 km in

Easy Transport: One

can fit 3500 m of 300 mm

for

Easy Handling: No cranes

Continuous lengths of up to 200 m: No

required along

Flexible nature adapts to varying terrain Tough and robust Swells under pressure: Less energy and more

THE LATEST MINING AND SAFETY NEWS

RIO TINTO TURNS TO MINING MOSQUITO FLEET

Mining giant Rio Tinto will downsize mining trucks to deliver environmental and productivity gains. The move will also help in the eventual electrification of its mining fleet.

This new approach will see the large mining trucks at Rio’s Pilbara iron ore mines replaced with a relative mosquito fleet.

The small trucks can carry a 40-tonne payload, as opposed to the

larger trucks which carry from 220 tonnes up to nearly 300.

There are hopes that the smaller, autonomous trucks will act as conveyor belts out of the mining pits as they can move faster and more frequently.

Rio has calculated that the smaller truck usage will result in capital and operating cost savings, and lower greenhouse gas emissions, further

helping the company reduce its mining footprint.

The mining giant is also targeting fleet electrification, with the smaller trucks making recharging and replacing batteries easier.

Rio is working on the trucking transformation with Scania under a long-term research and development collaboration agreement.

The work has so far focused on advancing autonomous technology at the Channar mine in Western Australia and includes the option for transition to electric power.

Trials on Scania’s 40-tonne autonomous trucks started in April 2022, and Rio flagged that the use of “right-sized trucks” can improve resource recovery by three per cent, reduce strip ration and mine footprint by 10 per cent and deliver big capital expenditure savings.

Rio group technical managing director Santi Pal said the company’s climate action plan included phasing out the purchase of new diesel haul trucks by 2030.

“Partnering with industry leaders such as Scania across a range of fields is an important step towards achieving that,” he said.

AUSTRALIAN MINING GETS

THE LATEST NEWS EVERY DAY, PROVIDING MINING PROFESSIONALS WITH UP-TO-THE-MINUTE INFORMATION ON SAFETY, NEWS AND TECHNOLOGY FOR THE AUSTRALIAN MINING AND RESOURCES INDUSTRY.

“As well as the potential decarbonisation benefits, this partnership provides a path to potential productivity improvements.”

Scania vice president and head of autonomous solutions Peter Hafmar said Rio was its Swedish-based commercial vehicle manufacturer’s first customer as it looked to mining on a pathway to net zero emissions.

“This is a major step towards the goals of a sustainable autonomous mining solution, and builds on our already fruitful long-term collaboration,” Hafmar said.

BHP has announced an industry-first initiative to construct 140 flat-pack iron ore cars in the next four years.

The initiative will see BHP partner with UGL and QRRS, with additional state government support.

BHP has shipped ore car components from QRRS’s factory in China to UGL’s Bassendean facility as flat-packs, where the UGL team has assembled, welded and commissioned the cars before delivering them to BHP’s Pilbara operations.

Iron ore cars have traditionally been built offshore for over a decade. BHP orders an average of several hundred each year.

To date, five iron ore cars have been completed and delivered to the Pilbara. A further 15 are due to be built and delivered by February 2023.

At least 12 UGL jobs have been sustained through the project.

“BHP makes a significant contribution to the WA economy, and we want to keep building and strengthening that contribution through more local manufacturing,” BHP asset president WA Iron Ore Brandon Craig said.

“We are taking the first important step by working together with the expert teams at UGL and QRRS to build ore cars right here in WA.

“Through this investment we will support the WA manufacturing sector to strengthen its capability and create new opportunities for business growth and local employment.

“This is a terrific initiative that we’ve been able to develop with our partners and the West Australian Government, and we thank them for their support.”

Following the trial’s early success, BHP has committed to constructing an additional 120 cars over the next four years in WA, with the potential to create dozens more local jobs.

“I’m pleased to see BHP, QRRS and UGL collaborate on this industry-

first initiative and look forward to seeing its capability build into a sustainable and long-term project,” Western Australia Premier Mark McGowan said.

“We look forward to continuing this program with BHP and creating a strong and sustainable ore car assembly capability in the state,” UGL managing director Doug Moss said.

“We are proud to be the only Australian manufacturer of freight locomotives and we’re pleased to extend this capability through the reintroduction of rail ore car assembly into Australia, and particularly in Western Australia.”

AUSTRALIANMINING 8 DECEMBER 2022 NEWS

MINING PRESENTS THE LATEST NEWS FROM THE BOARDROOM TO THE MINE AND EVERYWHERE IN BETWEEN. VISIT

AU TO KEEP UP TO DATE WITH WHAT IS HAPPENING.

AUSTRALIAN

WWW.AUSTRALIANMINING.COM.

PILBARA GETS A BOOST WITH FLAT-PACK IRON ORE CARS THE DOWNSIZING OF TRUCKS WILL HELP IN THE EVENTUAL ELECTRIFICATION OF ITS MINING FLEET.

INDUSTRY MOURNS DEATH OF PETER BRADFORD

The leader who guided IGO through its transformation into a battery metals player has died at 64.

IGO has paid tribute to managing director Peter Bradford, who passed away suddenly on Saturday, October 15.

“Peter was an inspirational leader, an innovative and strategic thinker and a compassionate mentor who transformed IGO into the company that it is today – a globally recognised,

ASX100 listed company focused on creating a better planet,” a company statement read.

“His passion for mining and resources, and his personal drive to raise the bar across the industry, was unparalleled.

“Peter was passionate about climate change and the role our industry can play in the transition to a clean energy future, and was equally passionate in engaging others on these important

FORTESCUE POSTS RECORD FIRST QUARTER PERFORMANCE

Fortescue recorded iron ore shipments of 47.5 million tonnes in the first quarter of the 2022–23 financial year (FY23), which represents four per cent increase on the prior comparable period and a record for a first quarter.

But increased iron ore production was offset by surging costs over the past year.

The stronger results were driven by increased production at the company’s key operations in Western Australia. However, rising prices of diesel and labour pushed Fortescue’s direct costs 16 per cent higher year-on-year to

$17.69 per wet metric tonne. That price represents a three per cent increase on the previous quarter.

Iron ore prices have also taken a hit over the past year, dropping from $US119.65 per tonne in October 2021 to $US87.80 in October this year.

Fortescue has maintained its fullyear guidance of shipping between 187 million and 192 million tonnes of ore in FY23.

“Against this backdrop of a strong performance for the first quarter, we are well positioned to meet our guidance, execute on our strategy and ensure all

issues. He was adamant that he and the team at IGO could make a difference — locally, nationally, and globally.”

The Western Australian mining sector is mourning the loss, with Bradford often championing the industry in the state. He was the president of the Association of Mining and Exploration Company (AMEC), an active mentor for Women in Mining WA, and a former WA Mining Club

committee member and vice-president.

IGO non-executive chair Michael Nossal said Bradford was admired not only for his vision and commitment to delivering on the company’s purpose, but also for his endearing humility and enormous humanity.

The board has appointed Matt Dusci to the role of acting chief executive, effective immediately, while its conducts a formal search process for a permanent replacement.

our stakeholders continue to benefit from Fortescue’s success,” Fortescue executive chairman Andrew Forrest said.

The company also used its latest quarterly report to highlight its decarbonisation efforts, with $US6.2 billion ($9.55 billion) in capital investment planned by 2030 to eliminate fossil fuel risks, which it said would save an estimated $US3 billion and rise to annual savings of $US818 million ($1.26 billion) once fully implemented.

“Guided by our unique culture and values, Fortescue is leading

the green energy transition and setting record-breaking industry benchmarks,” Forrest said.

“We are establishing the building blocks of a new, global renewable energy value-chain-spanning technology, manufacturing, green energy generation and distribution which will deliver significant returns to our shareholders.”

Fortescue recently announced its formal commitment to exit fossil fuels by 2030, with plans to avoid three million tonnes of CO2 equivalent emissions per year and supply a carbon-free iron ore product.

AUSTRALIANMINING 10 DECEMBER 2022

NEWS

PETER BRADFORD GUIDED IGO TO BECOME A BATTERY METALS PLAYER.

A SMALL STEP ON OUR PATH TO CHANGE

AUSTRALIANMINING 11 DECEMBER 2022

ALL

PRODUCTS WE SELL

ARE COMMITTED TO CARBON NEUTRALITY IN ACCORDANCE WITH

**

MORE

in accordance with PAS 2060, see www.castrol.com/cneutral for more information. ** The

emissions are calculated in accordance with the Greenhouse Gas Protocol’s Product Life Cycle Standard and includes life cycle emissions. The

of carbon neutrality will be assured by an Independent

certified

specification. See

for more information.

FROM 2021,

CASTROL

IN AUSTRALIA

PAS 2060

A SMALL STEP TOWARDS A

SUSTAINABLE FUTURE

C02e

demonstration

Third-Party and

to BSI’s PAS 2060 carbon neutral

www.castrol.com/cneutral

AUSTRALIA, JAPAN SIGN CRITICAL MINERALS PACT

Australia and Japan have signed a new partnership to help build secure supply chains for critical minerals.

The new Critical Minerals Partnership was signed by Federal Resources Minister Madeleine King and Japan’s Vice Minister for International Affairs, Ministry of Economy, Trade and Industry, Hirohide Hirai during the Australian visit of Japanese Prime Minister Fumio Kishida.

The partnership will establish a framework for building secure critical minerals supply chains between Australia and Japan, and promote opportunities for informationsharing and collaboration, including research, investment and commercial arrangements.

The partnership will support the further development of Australia’s critical minerals sector to ensure Japan has the supply of critical minerals required for its advanced manufacturing sector.

King said the new partnership underlined the ongoing strength of Australia’s deep ties and ongoing trade relationship with Japan and would build on existing trade supply chains.

“This new partnership will be a welcome boost to Australia’s critical minerals sector and will help Australia further develop its abundant reserves of critical minerals which will ultimately help both countries achieve their emissions

reductions targets,” she said.

“It will help to open up more foreign investment in our critical minerals sector and will increase collaboration between our two counties on the development of critical minerals.”

Australia has some of the world’s largest reserves of critical minerals, including rare earths, which are crucial components of clean energy technologies such as batteries, wind turbines, electric vehicles, solar panels and hydrogen electrolysers.

King said the partnership was a natural progression of Australia’s long-established role as a stable and reliable supplier of minerals and energy to Japan, and underlined Australia’s growing role as a global

supplier of critical minerals.

“The new partnership will help drive the development of Australia’s critical minerals sector and promote more foreign investment into crucial projects which will mine, develop and process these essential minerals,” she said.

“The Australian Government is working with our international partners, state and territory governments, and industry to position Australia as a world leader in exploration, extraction, production and processing of critical minerals.

“These resources not only support Australia’s standard of living, they will pave the way to a clean energy future for Australia, for Japan and for the world.”

MINERS HOPE FOR FOREIGN LABOUR HELP AS SKILLS SHORTAGE CONTINUES

As the skills shortage continues, large mining companies are hoping that foreign workers can help solve the problem.

Mining giants BHP and Whitehaven Coal have reported lower coal outputs over the past three months, while shipments through the Port of Newcastle were over 12 per cent lower in the past nine months. Both miners have cited labour shortages, absenteeism, wet weather and planned maintenance for the disruptions.

Whitehaven managing director Paul Flynn said there was no indication that labour availability was improving.

“It is not turning around in the way we would like it to,” he recently told investors.

“Trades are hard to find, there is no doubt about that, so we are looking at different roster patterns and including fly-in, fly-out arrangements.

“Even though we know the doors are open from our borders’

perspective, there is not the inflow of people we would expect from an expat perspective into the country.

“On that topic we are very much focusing on the higher skills areas in particular, offshore people coming in to fill many of the roles at a more senior, technical level across our mines.”

BHP’s chief operating officer Edgar Basto echoed this sentiment, saying that “expediting skilled migration” was one of the things needed to cure Australia’s labour shortage.

While a wetter than average season has also tampered production, Whitehaven said in August that it would moonlight as a property developer in the New South Wales Gunnedah basin to ease a housing shortage that was deterring prospective recruits.

The company also said it was preparing to transport workers to mine sites by helicopter if the flooding that has beset the region on multiple occasions over the past two years were to recur.

AUSTRALIANMINING 12 DECEMBER 2022

NEWS

AUSTRALIA AND JAPAN HAVE SIGNED A PARTNERSHIP TO HELP BUILD SECURE SUPPLY CHAINS FOR CRITICAL MINERALS.

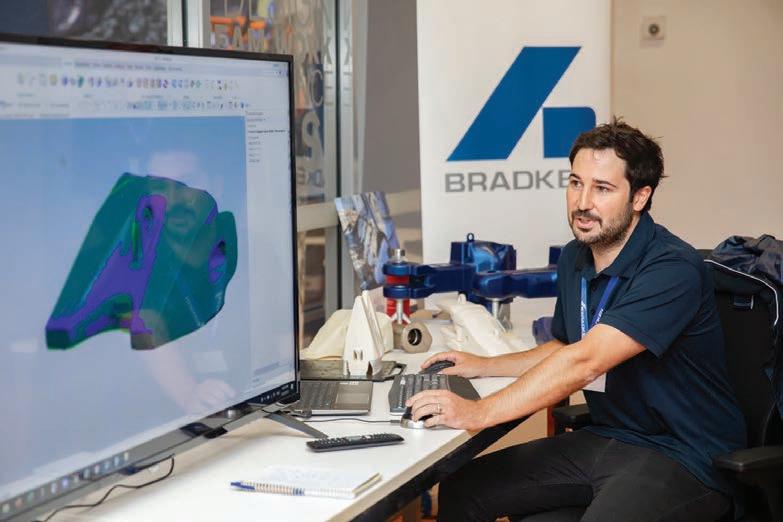

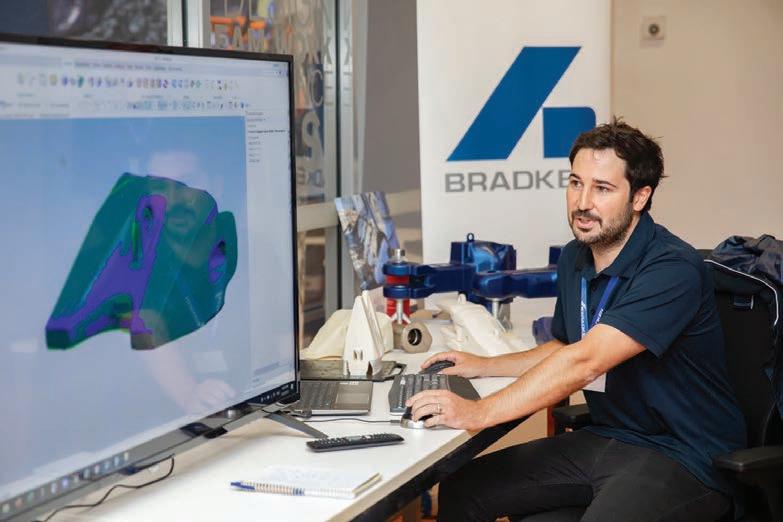

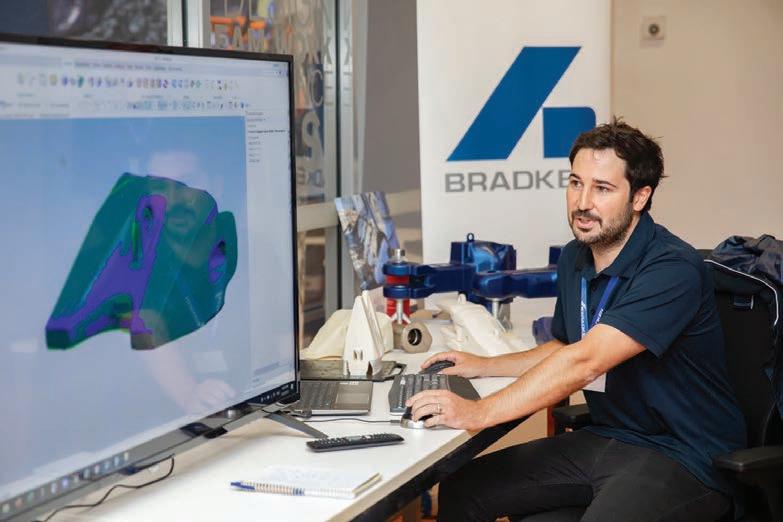

Innovating for the future

Bradken’s technology transformation is supporting the evolution of the mining industry.

•Innovative mining digital technology solutions

•Asset condition and performance monitoring solutions

•Design, engineering and manufacture

AUSTRALIANMINING 13 DECEMBER 2022

bradken.com

FORTESCUE MARKS FIRST ORE AT IRON BRIDGE MAGNETITE PROJECT

Fortescue Metals Group hit a significant milestone in late October, marking first ore feed into the processing plant at its Iron Bridge magnetite project in the Pilbara.

With first production anticipated in the March 2023 quarter, Iron Bridge will see Fortescue deliver an enhanced product range and, according to the company, create 900 new jobs. The project could also become one of Fortescue’s first fossilfuel-free sites.

Fortescue recently announced its formal commitment to exit fossil fuels by 2030, with plans to avoid three million tonnes of CO2 equivalent emissions per year and

supply a carbon-free iron ore product.

“At Fortescue, we take pride in the fact that we consistently deliver what we say we will, and Iron Bridge is no different,” Fortescue’s executive chairman Andrew Forrest.

“Building on our track record of safely and successfully developing and operating iron ore projects in the Pilbara, Iron Bridge will lead the way for magnetite operations in Western Australia.”

Located 145km south of Port Hedland, Iron Bridge will deliver 22 million tonnes of high-grade 67 per cent Fe magnetite concentrate per year. This product, Fortescue said, will enable the company to enter the

PLANS TO ACCELERATE CRITICAL MINERALS HUNT

The Federal Government is accelerating the growth of the critical minerals sector and supporting clean-energy technologies through new initiatives as part of efforts to reach net-zero.

A new National Critical Minerals Strategy is being developed in consultation with industry and community stakeholders, including Traditional Owners.

Prime Minister Anthony Albanese said the country had some of the world’s largest reserves of critical minerals and the strategy would set out a clear vision for the sector.

It will complement other Government initiatives, including the National Battery Strategy and the Electric Vehicle Strategy.

The National Reconstruction Fund will include the $1 billion Value Adding in Resources Fund which will work alongside the $2 billion Critical Minerals Facility.

“These initiatives will expand Australia’s mining science technology capability, diversify supply chains, create local jobs and help drive growth in the critical minerals sector including rare earths – a key component of low-emissions technologies, such as batteries, electric vehicles and solar panels,” Albanese said.

“Additionally, (the Federal) Budget will include $50.5 million over four years to establish the Australian Critical Minerals Research and Development Hub to help unlock our

high-iron-ore-grade market segment by providing an enhanced product range while also increasing annual production and shipping capacity.

“The Iron Bridge high-grade magnetite product is a significant differentiator for Fortescue, and led by the highly experienced project team I am incredibly pleased with the significant progress made to achieve first ore feed into the processing plant,” Fortescue chief operating officer iron ore Dino Otranto said.

“This is a project that has been delivered during a challenging environment, and despite a global pandemic, rising inflationary pressures and a tight labour market,

nation’s critical minerals potential.

“The hub will combine expertise from Geoscience Australia, the CSIRO and the Australian Nuclear Science and Technology Organisation to work with Australian industry to address technical challenges and support international research and development collaborations.

“The Government will also allocate $50 million over three years to the Critical Minerals Development Program for competitive grants to support early and mid-stage critical minerals projects, building on the $50m recently committed to six key projects across Australia.

“The International Energy Agency projects mineral demand for use

the Fortescue values have risen to the forefront and demonstrated our ability to continue delivering this groundbreaking project.”

According to Fortescue, the nature of the Iron Bridge ore bodies and the company’s use of a dry crushing and grinding circuit contribute to the project’s operational efficiency across energy, water use and cost.

Low-cost power will be delivered to Iron Bridge through Fortescue’s investment in the Pilbara Energy Connect project, which includes energy transmission line infrastructure, solar gas hybrid generation and associated battery storage solution.

in electric vehicles and battery storage could grow at least 30 times to 2040.”

Albanese said Australia was the world’s largest lithium producer, and latest figures forecast the value of lithium exports are due to increase more than 10-fold over two years, from $1.1 billion in 2020–21 to almost $14 billion in 2022–23, with continued growth over future years.

“The development of a battery industry could contribute $7.4 billion annually to our economy and support 34,700 jobs by 2030,” he said.

Information about the National Critical Minerals Strategy consultation is available on the Department of Industry, Science and Resources consultation website.

AUSTRALIANMINING 14 DECEMBER 2022

NEWS

FORTESCUE HAS MARKED FIRST ORE FEED INTO THE PROCESSING PLANT AT ITS IRON BRIDGE MAGNETITE PROJECT.

Hard work Made Easy

We know that safety and productivity partly is the result of a satisfied operator. The spacious ROPS/FOPS certified cab provides a comfortable operating enviroment with ergonomically placed controls, ample storage space and a comfortable seat with three point seat belt warning. With low internal noice levels and vibration protection, operators will experience a productive work shift.

Visit cjd.com.au for more information or call 1300 139 804

STAGGERING PILBARA MINERALS WINDFALL FROM LITHIUM DEMAND

Increased production and sales have generated a significant $783.7 million contribution towards a cash balance of $1.375 billion for Pilbara Minerals in the September quarter.

The company lifted spodumene concentrate production and sales from the Pilgangoora project in Western Australia to take advantage of positive lithium raw material demand.

Production of 147,105 dry metric tonnes of concentrate was achieved, representing a 16 per cent increase over the June 2022 quarter, with the Ngungaju plant achieving nameplate capacity of 180,000–200,000 tonnes per annum.

The performance reflects solid operating strategy and represents

In response to increasing customer demand and strong lithium raw materials pricing, Pilbara Minerals has continued to adjust production by lowering its targeted product grade to optimise product yield, thereby maximising sales volumes to take advantage of current market

from three Battery Material Exchange (BMX) sale auctions, with one auction achieving a realised price of $US6988/dmt SC5.5 basis (FOB Port Hedland), which equates to $US7708/dmt on an SC6.0 equivalent basis (CIF China).

The P680 Project was also commenced, with bulk earthworks

and Northfleet at the Australasia Bus and Coach Expo in Sydney in early October.

Why a bus in the mining industry? The answer lies in the ongoing electrification of vehicles across the sector.

The 57-seat coach will operate out of Covalent’s Mt Holland Mine in Western Australia, using its 450km range to transport mine site personnel daily to and from work.

The long-range sustainable transport solution comes in response to Covalent’s commitment to reducing its carbon impact.

“Once operational, our project will be providing 50,000 tonnes of lithium hydroxide per year –enabling the production of 1.1 million electric vehicles annually,”

Lithium Project will be a fully integrated operation, overseeing the end-to-end production of batteryquality lithium hydroxide. This includes a refinery in Kwinana along with a mine and concentrator at its Mt Holland Project.

“The need to work with our clients to offer carbon-neutral transport solutions has never been more important,” Northfleet managing director Toby Hagen said.

There is a burgeoning demand for clean energy alternatives within the resources sector.

Mining is responsible for 4–7 per cent of global glasshouse gas (GHG) emissions; however, the industry plays a vital role in the decarbonisation solution as it provides the raw materials needed

targets, sustainable methods are imperative in order to accelerate production and operation without increasing emissions.

Electrification within the industry, such as projects like Covalent Lithium’s electric bus, is a viable emission-reduction tactic. Diesel fuel mining trucks, for example, require a large amount of torque to pull the weight that they do, burning 350L per hour on average and comprising 30–50 per cent of their mines’ total energy consumption.

Launched in 2021, the Charge On Innovation Challenge sought the global contribution of advanced technological concepts to assist in the electrification of extensive haul truck systems. The challenge concluded in May

founding benefactors – BHP, Rio Tinto and Vale – the finalists will collaborate with interested mining companies, original equipment manufacturers (OEMs), and investors in order to speed up the development of the technology needed to enable the eventual introduction of zero-emission fleets.

“With this group of innovators, we’re taking another step in the right direction towards changing the way haul truck systems operate in the mining sector,” Rio Tinto chief technical officer Mark Davies said.

“Through collaborations like this, where we all come together to create change, we can drive longterm benefits for our industry and the environment.”

AUSTRALIANMINING 16 DECEMBER 2022

NEWS

IN RESPONSE TO INCREASING CUSTOMER DEMAND AND STRONG LITHIUM RAW MATERIALS PRICING, PILBARA MINERALS HAS CONTINUED TO ADJUST PRODUCTION.

WARMAN®

The proven, trusted industry leader for unrivalled performance and innovation – always. When it comes to specifying your next pump or pump upgrade, it’s not a question of whether you can afford Warman®, it’s whether you can afford not to. alwayswarman.weir

Copyright© 2022, Weir Minerals Australia. All rights reserved.

THE RISKS AND OPPORTUNITIES FACING THE MINING SECTOR IN 2023

AUSTRALIAN MINING SAT DOWN WITH ERNST & YOUNG AND ACCENTURE TO EXPLORE THE GLOBAL RESOURCE INDUSTRY’S OUTLOOK FOR 2023 AND BEYOND.

The Australian mining industry has weathered many challenges in 2022, with societal disruptions affecting global equilibriums, leading to geopolitical, economic and environmental uncertainty.

Miners have had to adapt to higher capital and operational costs due to rising global inflation, while La Niña-induced wet weather has quelled production across the country.

Supply-chain disruptions, seemingly the new normal, are another upshot of inflation and the sustained presence of COVID, among other levers.

And never has it been more important for end users to assure supply diversity and security amid growing global geopolitics, heightened by events such as Russia’s invasion of Ukraine.

According to Ernst & Young (EY), environmental, social and governance (ESG) remains the greatest business risk/opportunity facing the global mining and metals sector in 2023.

EY releases a report each year considering the top 10 business risks/ opportunities facing the mining and metals sector, and ESG was on top for the second year in a row. This was followed by geopolitics in second spot, then by climate change at three, license to operate at four, and costs and productivity at five.

Rounding out the top 10 were supplychain disruption at six, workforce at seven, capital at eight, digital and innovation at nine, and new business models at 10.

In preparing the report, EY surveyed global mining and metals executives between June and August 2022, with most respondents from the C-suite.

The heightening stresses of geopolitics, climate change, license to operate and costs and productivity begs the question: why is ESG again considered the key business risk/ opportunity facing the global mining and metals sector in 2023?

“ESG-related issues made up the entire top three risks of last year’s report – each with a significant, distinctive impact that made it impossible to treat them as one risk,” EY consulting partner Michael Rundus told

“ESG is now inherent in every single risk this year, which created a real challenge for our team writing the report but I think truly highlights a risk that has further broadened with stakeholders and cannot be ignored.”

ESG continues to grow in stature and importance in the global mining sector, with each of the three pillars increasingly influencing investor sentiment and the overarching financial prosperity of the industry.

“Good governance is always going to be a top trend, but investors and analysts are smarter,” a senior mining executive in EY’s report said. “It’s no longer a ‘check the box’ exercise.”

ESG spans so many different considerations and variables that it is difficult to condense; however, mining companies that don’t take it seriously risk being left out in the cold.

“Miners need to take a holistic approach to ESG – a focus on one area isn’t enough,” Rundus said. “Integration of ESG into corporate strategy is key to success; it impacts all areas of the business and so cannot be left to a small department to solve.

“The goal needs to be net-zero in all aspects of ESG and miners need to be able to report effectively on this.”

Global professional services company Accenture is supporting the global mining sector on its ESG journey, providing the consultancy, technology and digital expertise to set miners up for success from pit to port and beyond.

Accenture Australia and New Zealand mining lead Eric Croeser said the company’s ESG support begins with identifying improvement opportunities within a miner’s carbon value chain, where it is critical to be able to accurately measure and analyse the current state of play before footprints can be limited.

In April, Accenture released a report, ‘How investors view mining’s new role as a champion of decarbonisation’, which

saw the company survey decision-makers at 200 public and private institutional investment firms with Tier 1 mining clients in their portfolio.

The report found that while the mining industry was long considered a problem in environmental sustainability, it is now seen as a critical part of the solution.

“Investors and consumers alike are beginning to recognise the industry as not only the first source of emissions in the value chain, but a necessary provider of critical raw materials needed for the global energy transition,” the report said.

Croeser said the world is going to need more ‘future-facing’ minerals to

AUSTRALIANMINING 18 DECEMBER 2022 INDUSTRY OUTLOOK

EY CONSULTING PARTNER MICHAEL RUNDUS.

enable the renewable energy transition going forward. This is a key part of Accenture’s dialogue.

Accenture helps its mining clients evaluate the ‘S’ and ‘G’ in ESG and how mining companies are engaging and supporting the local communities around them. The firm is also focused on improving supply-chain inefficiencies in the mining sector.

“We consider supply-chain disruptions and supply-chain efficiencies, with a bit of a cost inflation component in there,” Croeser told Australian Mining.

“Here we’re helping our clients transition into lower-cost options in their supply chain and building in supply-chain resilience around getting visibility across the supply chain and understanding what some of those efficiencies are.”

Above all, Accenture is focused on developing a connected mine, where the firm – together with its clients –explores the wealth of data across the entire value chain to provide integrated, end-to-end situational awareness and systemic management.

Rising from fourth to second on EY’s list of the top 10 business risks/ opportunities facing the global mining and metals sector, issues of geopolitics were amplified by Russia’s invasion of Ukraine in February. The conflict sent commodity markets into a spin, with countries and jurisdictions moving to impose sanctions on Russia.

Russia’s trade was hamstrung, restricting imports from one of the globe’s primary suppliers of crude oil, natural gas and coal.

The European Union (EU), which is particularly reliant on Russian fossil

fuels for power generation, was severely affected at a time when sweltering summer conditions swept across the continent.

This sent coal prices through the roof.

“The main driver of high thermal coal prices since Russia’s invasion of Ukraine in February 2022 has been a rapid diversification of European energy demand away from Russian gas and coal, with a resulting increase in

demand for gas and coal from other suppliers,” Fitch Solutions said in an August report.

EY said government changes have also influenced global geopolitics.

“Changing governments in key mining regions such Australia, Peru, the US and Chile mean miners are waiting to see what new policies and taxes will emerge,” Rundus said. “Many miners are fearful of the re-

emergence of resource nationalism – 72 per cent of miners we surveyed were anticipating some form of resource nationalism to recoup debt incurred during the pandemic.

“We have already seen this in Queensland with coal royalties and we may see use of other instruments such as windfall taxes.”

In June, the Queensland Government introduced a new system for coal

AUSTRALIANMINING 19 DECEMBER 2022 INDUSTRY OUTLOOK

SUPPLY-CHAIN INEFFICIENCIES CONTINUE TO PRESENT A MAJOR ISSUE IN THE MINING SECTOR.

EY NAMED ESG AS THE GREATEST BUSINESS RISK/ OPPORTUNITY FACING THE MINING SECTOR IN 2023.

royalties in response to record coal prices. This significant change came after a 10-year royalty freeze on the sector.

Under the new three-tiered system, the royalty rates are 20 per cent for coal prices above $175 per tonne, 30 per cent for prices above $225 per tonne, and a 40 per cent tier that would apply when prices exceed $300 tonne.

Miners such as BHP, Coronado Global Resources, Anglo American and Bowen Coking Coal – all of which have coal assets in Queensland – expressed concerns over the new royalties, particularly considering the lack of

engagement from the State Government prior to the royalties being introduced.

Costs and productivity rose from 10th to fifth on EY’s list of the top 10 business risks/opportunities, something Rundus said was coming to light even before Russia’s invasion of Ukraine.

“Energy costs have been rising since before the Ukraine war, and given these costs constitute around one-third of mining operating costs, that is clearly having a huge impact,” he said.

“All input costs have increased steadily since the COVID-19 pandemic and, given the talent shortage, wages are on the up as well.

“As interest rates rise with the intent of taming inflation, the cost of borrowing will increase as well, forcing buyers to evaluate their purchasing strategy going forward.”

EY said that any cost reduction exercises should be focused on value and avoid affecting ESG commitments.

To limit the impact of rising costs, operators also need to understand their productivity challenges.

“Mining companies are maintaining a focus on productivity and cost management and, despite current challenges, only 17 per cent and 24 per cent of our respondents have experienced

a decline in asset or labour productivity (respectively),” EY said in its report.

While the global mining industry is facing challenges from all angles, EY said the overarching outlook remains strong in light of the sector’s role in the renewable energy transition.

“The energy transition will begin and end with mining and metals, so I think we can remain bullish on the outlook,” Rundus said. “The shockwaves of the Ukraine war have led to an acceleration of the energy transition.

“There is so much capital being invested into technology solutions, renewables, hydrogen and green metals, and this is likely to accelerate at a rate the sector is not prepared for, particularly as countries take energy security into their own hands.”

This comes with the caveat that the global mining industry needs to work to improve its image, otherwise it may not have the personnel or investment to realise future growth opportunities.

“Miners have a long way to go in building trusted relationships with local Indigenous communities,” Rundus said.

“They need to move beyond doing just what’s required by regulation and instead fully commit to furthering truth and reconciliation and creating longterm value for these communities.”

Rundus said this also concerns social inclusion.

“Bullying and harassment are endemic in the mining sector and tied to ongoing issues around a lack of diversity, inclusion and respect,” he said.

“Mining and metals companies need to manage workforce culture or face significant risks in attracting the next generation of workers, and in sustaining their businesses into the future.” AM

INDUSTRY OUTLOOK

GEOPOLITICAL ISSUES, INCLUDING RUSSIA’S INVASION OF UKRAINE, HAVE HAD MAJOR KNOCK-ON EFFECTS ON GLOBAL RESOURCES.

INVESTORS SEE MINING AS A NECESSARY PROVIDER OF CRITICAL MATERIALS NEEDED FOR THE GLOBAL ENERGY TRANSITION.

Does your connectivity help you attract and keep the best people?

High-speed and reliable connectivity is a key part of any plan to attract skilled employees and to look after their health and wellbeing when working away from home.

Vocus’ fibre network and integrated satellite services provide secure, reliable, and resilient high-speed connectivity to some of the biggest names in the resources industry.

To learn more about what our high-performance fibre network can deliver for your business, visit vocus.com.au or call 1300 88 99 88.

vocus.com.au

CRITICAL MINERALS DRIVING FUTURE GROWTH

The Australian mining industry has long ridden on the back of a handful of key resources, but few have matched the outsized influence iron ore has had for much of the 21st century.

As the country’s largest source of export revenue, iron or has poured hundreds of billions into Australia’s coffers.

And while the key steelmaking ingredient is not going away any time soon, its spot at the top of the Australian mining food chain won’t last forever.

minerals vital to achieving rapidly approaching net-zero targets – lithium, copper, nickel, et al – is only going to grow. This growth was underlined in the Australian Government’s recent Resources and energy quarterly for September 2022.

Produced by the Department of Industry, Science and Resources, the report found that despite weakening iron ore prices, the surging global demand for critical minerals necessary for new low-emissions technologies is expected to deliver a record windfall of $450 billion for Australia’s 2021–22 resources and energy exports.

for Australia’s ongoing economic wellbeing and shows the outlook for Australian resources and energy remains strong,” Federal Minister for Resources and Northern Australia Madeleine King said.

The record forecast follows last year’s $422 billion result. Resources earnings are then forecast to fall to $375 billion in 2023–24, which would still represent the third highest ever), as world supply responds to high prices amid a backdrop of softer demand.

The increased forecast is also being driven by the search for alternative sources of energy following Russia’s

King believes Australia is experiencing strong growth in demand and prices for minerals that are crucial for low-emissions technology due to growing demand for electric vehicles (EVs), batteries and cleaner energy.

“The Australian Government is strongly backing our critical minerals sector, which provides the crucial minerals needed to help Australia and the world meet our net-zero commitments,” she said.

It should be noted, however, that iron ore is still pulling its weight, although export earnings are forecast to ease from $119 billion in 2022–23 to $95 billion in

AUSTRALIANMINING 22 DECEMBER 2022 INDUSTRY OUTLOOK

AUSTRALIAN GOVERNMENT’S RESOURCES AND ENERGY

CRITICAL MINERALS WILL PLAY IN THE

AUSTRALIAN NICKEL EXPORT VOLUMES ARE ESTIMATED TO RISE TO MORE THAN 20,000 TONNES IN

(IMAGE:

THE

QUARTERLY: SEPTEMBER 2022 UNDERLINED THE CENTRAL ROLE

FUTURE OF THE RESOURCES SECTOR.

2023–24.

BHP)

INDUSTRY OUTLOOK

The Resources and energy quarterly attributes lower iron ore prices to slowing global growth and weakness in China’s housing sector. Iron ore prices are expected to ease further, as world supply grows faster than demand.

Australian Mining takes a look at some of the key resources in the latest report.

Lithium

Australia’s lithium production is forecast to grow from 247,000 tonnes of lithium carbonate equivalent (LCE) in 2020–21 to 387,000 tonnes in 2022–23 and 469,000 tonnes of LCE in 2023–24.

And the country’s lithium export earnings are forecast to increase more than 10-fold in just two years, from $1.1 billion in 2020–21 to $13.8 billion in 2022–23, before easing to $12.9 billion by 2023–24.

Global lithium demand has continued to grow, driven by rising demand for EV batteries.

“Despite faltering global economic growth in the June quarter, sales and production of EVs continued their rapid growth trend,” the Resources and energy

tonnes of LCE in 2021 to 724,000 tonnes in 2022. Over the following two years, demand is forecast to rise by over 40 per cent, reaching 1,058,000 tonnes by 2024.”

“Asia remains the major source of demand for lithium, despite the spread of new battery-manufacturing capacity into Europe and the US.”

Copper

According to the Resources and energy quarterly, copper prices are forecast to fall by 4.9 per cent per cent to below $US8900/t in 2022, as COVID containment measures and high energy prices weigh on demand. Prices are forecast to fall to $US8300/t in 2024 as mine production grows.

“Australia’s copper exports fell to 802,000 tonnes in 2021–22 as scheduled maintenance reduced production,” the report stated. “Copper exports are expected to grow to 977,000 tonnes by 2023–24 as production from new mines and mine expansions come online.

“As output and export volumes grow, Australia’s copper export earnings are projected to lift from $12.3 billion in 2021–22 to $13.9 billion in 2023–24.”

As with other critical minerals, much of copper’s growth will be driven by decarbonisation, though other factors will likely play out in the short term.

“Over the longer term, the global energy transition is set to bolster the demand for copper, due to its relatively heavy use in renewable energy technologies, battery storage and EVs,” the report stated.

“Uncertainty in traditional energy markets resulting from Russia’s invasion of Ukraine is providing incentive for countries to accelerate this energy transition. This could see the increase in copper demand brought forward.”

Nickel

Nickel prices are expected to average $US24,900 a tonne in 2022, evidence of another resource boosted by the fallout from Russia’s invasion of Ukraine.

Prices are expected to ease over the outlook period, however, as a result of increased Indonesian production and improving liquidity in the LME nickel market.

“Recent high prices have boosted Australia’s nickel export earnings, which reached $4.4 billion in 2021–22,” the Resources and energy quarterly stated.

“Export earnings are forecast to rise to $5.1 billion in 2022–23, before easing to $4.6 billion in 2023–24.

“Australia’s export volumes are estimated to rise from 157,000 tonnes in 2021–22 to 202,000 tonnes in 2023–24, supported by the need for Australian nickel for the transition to lowemissions technologies.”

While nickel sits squarely in the pool of critical minerals vital for the world’s energy transition, the report found that “soft economic conditions create a short term drag on nickel demand”.

“Global headwinds and a price spike have seen nickel consumption weaken over the past year,” it stated. “In the June quarter 2022, global nickel consumption rose 0.8 per cent on the March quarter, but was 3.8 per cent lower than in the June quarter 2021.”

It is not all gloom and doom for nickel, however.

“Global nickel consumption is expected to exhibit stronger growth over the rest of the outlook period,” the Resources and energy quarterly stated.

“Nickel demand is forecast to be 3.3 per cent higher year-on-year, at almost 2.9 million tonnes in 2022.

Nickel consumption is subsequently expected to grow strongly over the next two years, increasing by 5.3 per cent in 2023 and by 4.2 per cent in 2024, when consumption will be three million tonnes and 3.1 million tonnes, respectively.”

Iron ore

Prices for Australia’s workhorse fell around 20 per cent in the September quarter.

A combination of growing global recessionary fears, new COVID outbreaks and weakness in China’s housing sector has dampened world steel and iron ore demand in recent months.

But Australian exports have remained steady.

“Australian export volumes were 0.9 per cent higher year-on-year in the first half of 2022, with new greenfield supply starting to come online from major producers,” the Resources and energy quarterly stated.

“Exports are forecast to increase by 3.1 per cent in 2022–23 to reach 903 million tonnes and rise by 3.8 per cent to 937 million tonnes in 2023–24.

“Lower prices over the outlook are expected to see Australia’s iron ore export earnings ease from $134 billion in 2021–22 to $119 billion in 2022–23, and then to $95 billion in 2023–24.”

Overall, weaker demand and grater levels of supply are expected to push the price of iron ore, which averaged around $US100/t in the September quarter, down further.

“From a forecast average price of around $US110 per tonne in 2022,” the report stated, “the benchmark iron ore price is projected to average $US90 per tonne in 2023 and around $US70 per tonne in 2024.”

AUSTRALIANMINING 23 DECEMBER 2022

AM

CRITICAL MINERALS ARE A KEY INGREDIENT IN THE MANUFACTURE OF ELECTRIC VEHICLES.

From the telephone to early computer networks to the internet and beyond, connectivity technologies have passed through many eras of evolution.

And while business has become increasingly interconnected over time, the traditional trade-off between service availability and performance has been a residual characteristic of the technology.

Today, however, we’ve arrived at an era in which network communications technologies have matured to the point where ubiquitous connectivity is a reality and organisations no longer need to make compromises.

This new era has been labelled Connectivity 4.0, and the Australian mining industry is at the forefront of driving a wave of advanced technology solutions with network providers

such as Nokia, Vocus and Challenge Networks, alongside mining contractors like MACA, supporting their datahungry needs.

A suite of network technologies at the heart of Connectivity 4.0 includes terrestrial and sub-sea fibre, regional 4G and 5G mobile services, low-earthorbiting (LEO) satellite coverage and private long-term evolution (LTE) networks. These are especially useful for mining operations that require reliable and secure communications to operate autonomous vehicle fleets, along with machinery often reliant on the transmission of large packets of data.

Beyond the connectivity requirements to service mission-critical systems on a mine site, there is an increasing desire to enhance employee experience and achieve environment, social and governance (ESG) objectives.

Connectivity 4.0 unlocks new levels of pervasive connectivity, enabling mining organisations to reimagine what’s possible like never before.

“Nokia is a company that is striving to bring digitalisation to mining,” Nokia’s head of sales and business development, mining, oil and gas – Oceania Brendan Conroy told Australian Mining

“Historically, communications connectivity was focused on operational requirements, the need for missioncritical networks to run autonomous vehicle fleets, trains, and precision drills on mine sites. Now we’re seeing expansion beyond these operational benefits to also unlock the benefits of connectivity for the health, safety and wellbeing of the workforce.

“The rapid development of connectivity across the Australian mining sector holds significant potential

for the adoption of a range of digital services for the mining workforce, including the ability to access important health data and wellbeing services, electronic banking, the streaming of entertainment and sports and the ability to connect seamlessly with loved ones.”

What was once a difficult technological proposition has becoming significantly easier, with companies such as Nokia, Vocus and Challenge Networks providing the network infrastructure, data strategies and digital solutions for mining operations regardless of size, location and requirements.

“The development and provision of high-speed data connectivity over LTE to mines, whether it be for heavy mining equipment, the connectivity of the workforce, or the requirement to provide mobile technology and data solutions

AUSTRALIANMINING 24 DECEMBER 2022

AUSTRALIAN TELECOMMUNICATION AND TECHNOLOGY COMPANIES ARE AT THE VANGUARD OF PROVIDING NEXT-GENERATION CONNECTIVITY SOLUTIONS TO THE MINING INDUSTRY, SUPPLYING HIGH-SPEED, LOW-LATENCY, ULTRA-RELIABLE NETWORKS. INDUSTRY OUTLOOK

critically important and increasing multifaceted,” MACA general manager strategy and growth, Shane Clark told Australian Mining

“Today, on-site LTE is really enabling deep connectivity for the mining workforce, and fly-in, fly-out (FIFO) workers are benefiting from the ability to connect with family and friends to relieve the incidents of stress and drive better mental health outcomes.

“We have a new generation of mining employees that demand digital connectivity, never having experienced anything other than the ability to communicate with their loved ones and the outside world.

“So when friends, family or themselves are working on a remote mine site, the expectation is that they can continually reach out and communicate without disruption, and that is very important for us, ensuring our staff are able to maintain those important social links.”

This wave of digital transformation is greatly improving agility and driving

efficiencies through automation and other related digital processes.

But there are many technological hurdles still to be cleared, and companies like Vocus are firmly focused on meeting their mining clients’ requirements for fast, reliable, and lowlatency network delivery.

“There are many key drivers around network speed and capacity, and through the implementation of multiple technology solutions we are meeting the challenge to provide this vitally important communications infrastructure to our clients,” Vocus account director, natural resources Benedict Boylson told Australian Mining “Connectivity to the cloud, and a movement towards cloud-first applications as well as the adoption of software-defined wide area networks (SD-WAN) rollouts, is a significant driver of capacity, as well as the ability to provide mine site workers and nearby communities with a fast and robust connectivity equivalent to those achieved in metro areas .”

Connectivity 4.0 is a holistic, flexible and scalable approach to connecting the many apps, systems and platforms on which mining companies depend as they transform into a digitalised operating environment.

Where mines were once built around singular legacy and ageing connection fabrics, contemporary connectivity approaches are shifting communications traffic over several technologies, including improved multiplexed high-

The biggest challenge has been the ability to provide capacity to remote mine sites, and for a company like Vocus the requirement to employ various technological approaches and techniques is critical.

For example, Vocus rolls out fibre from a mine site to its fibre backhaul –an extensive network that passes through many of the major mining areas – or via its strategic partners utilise fixed IP wireless from a mine site back into the core network.

Connectivity is also being provided through the employment of LEO satellite technology, the equivalent of low-latency fibre-like capacity.

“LEO network connectivity is very easy to enable through just a simple satellite ground terminal, and that’s going to be significant technological advancement in terms of being able to establish internet connections anywhere and basically provide mines and exploration teams with network access,” Boylson said.

Although a significant part of Connectivity 4.0 relates to the technologies of which it is comprised, the transformation it enables is not just about connecting things. Indeed, one of the most significant benefits of the Connectivity 4.0 mindset is its ability to solve the challenges around remote workforces.

Beyond the ability to effectively enable collaboration between workmates, enhanced connectivity is also proving to be a critical way of supporting employee wellbeing and

wellbeing by providing connectivity to family and friends.

“The labour market is just so tight now and so there’s just an expectation to have good-quality internet available in the living quarters at mine sites,” Clark said. “We provide services across 16 different mine sites and they’re at various stages of their lifecycles, so quite often we’ll establish early services and satellite technology provides internet connectivity because it’s hard to actually create and grow a workforce if you don’t have fast and reliable systems up and running quickly.”

The broad adoption of Connectivity 4.0 will normalise the ability for seamless collaboration – allowing employees to build everyday communities across sites and communities – without having to think about the technology underlying it. Companies will be able to design nextgeneration employee experiences around the ubiquitous, reliable connectivity that makes collaboration possible.

There is much more to employee retention than just higher salaries, it seems. People want to be engaged in new challenges.

Mining companies can support this with investment in modern, scalable connectivity technologies that make their workplaces more attractive to potential recruits.

“The ability to scale through the different network technologies has improved significantly, where 10 years ago, or even more recently, there just wasn’t that many options available,”

AUSTRALIANMINING 25 DECEMBER 2022

INTERNET CONNECTIVITY IS CRUCIAL FOR MINING COMPANIES ATTEMPTING TO MEET SOCIAL GOALS.

OUTLOOK

DIGITAL TRANSFORMATION OCCURRING ACROSS AUSTRALIA’S MINE SITES IS IMPROVING THEIR AGILITY.

INDUSTRY

AUSTMINE’S LEADING ROLE IN NEXT GENERATION SMART MINING

AUSTRALIAN MINING SPOKE WITH AUSTMINE CEO CHRISTINE GIBBS STEWART TO DISCUSS SOME OF THE KEY ASPECTS OF THE SECTOR’S FUTURE.

There’s a lot of work being done in Australia on battery technologies, on charging solutions, and on the electric vehicles (EVs) themselves. Mining companies with light and heavy vehicles are looking at EV technology, both for underground and open-pit mines, and some of the technologies and solutions that are being produced are being led by Australian companies. It’s exciting.

original equipment manufacturers (OEMs) and investors to accelerate the technology development to support the future rollout of zeroemissions fleets. ESG performance is a critical dimension to effective mining operations, how do companies effectively meet their obligations under this framework?

records and just making it easier for employers to manage their workforce, which has a heavy wellbeing aspect to it because the more organised you are around that area, the happier your workforce is going to be.

In the lead-up to Austmine’s mining innovation conference and exhibition, to be held in Adelaide from May 9–11 May 2023, chief executive officer Christine Gibbs Stewart outlined her organisation’s focus, and that of the broader mining equipment, technology and services (METS) sector, on supporting the ways in which the Australian mining industry can meet the expectations of a new-generation workforce and provide a leading role towards a more sustainable future.

What is the role of Austmine?

Our purpose is to champion the Australian METS sector to continue to be the best in the world.

We do that by connecting people to opportunities, insights and each other; promoting the global advancement of innovation and technology and mining; promoting the global advancement of innovation and technology and mining; promoting the great services and solutions that our members provide; and driving industry collaboration.

We seek to connect organisations within the METS sector to miners, so they better understand each other and build a stronger mining industry.

How is the mining industry engaged in decarbonisation?

The METS sector is really focusing on decarbonisation and electrification.

Mining companies and suppliers are looking at every aspect of what’s happening in mining. They’re looking at energy consumption, renewables, environmental concerns, water management, water recycling. They’re also looking at community issues, which of course fits in that ESG (environmental, social and governance) space.

Sustainability and ESG is not quarantined to one area – it’s now a layer across every mining organisation in looking at how they can do things in a more sustainable manner. It’s become really a key strategic focus.

And if you look at mining companies and what they’re doing from a strategy point of view, ESG is the headline and everything really falls out of that.

Can you outline the recent Charge On Innovation Challenge?

The Charge On Innovation Challenge was facilitated by Austmine with Rio Tinto, Vale, and BHP as the key patrons.

An additional 16 other mining companies were involved, seeking to accelerate commercialisation of interoperable solutions that can safely deliver electricity to large battery-electric offroad haul trucks –reducing emissions while enhancing mine productivity.

There is an emerging market for these solutions in mining with eight innovators selected, including ABB, Ampcontrol and Tritium (Australia), BluVein XL, DB Engineering & Consulting with Echion Technologies, Hitachi Energy, Shell Consortium, Siemens Off-board power supply, and 3ME Technology.

The winners are collaborating with interested mining companies,

What does health, safety and wellbeing look like in the modern mining industry?

More broadly, automation is removing workers from harm. And so a large driver for automation is not only productivity, but helping with that, particularly if you think about it in the underground mining situation.

If you don’t have people in precarious

AUSTRALIANMINING 26 DECEMBER 2022 INDUSTRY OUTLOOK

AUSTMINE CEO CHRISTINE GIBBS STEWART.

GIBBS STEWART HAS SEEN A GREATER FOCUS ON MINING EMPLOYEES’ HEALTH AND WELLBEING.

There’s a shortage of skills in certain areas and on the digital side of things, including computer science, data analytics, automation.

There are some organisations that are looking at those areas, including the Australian Minerals and Energy Skills Alliance, as well as the Queensland Future Skills Partnership.

Both those organisations are looking at credentialing, designing strategies and programs as to how the industry can fast track those skills that are needed, particularly through vocational education and the TAFE system.

You must enable young people

these students in a mining career, but through a completely different lens than what’s traditionally been looked at. It’s exciting in that regard.

Can you outline the Austmine conference set for May 2023? The title of the conference is Transforming Our Future and it’s really future-focused.

We’re looking at where we want to be as an industry in the future and then talking about how we’re going to get there. There’s a discussion around legacy, innovation and what that really entails.

We think we’re open but if you scratch below the surface, we’re not as open as some of us would like to think.

The conference will focus on

INDUSTRY OUTLOOK

What does the industry need to do to encourage young people to consider a career in mining?

AUSTMINE WANTS COMPANIES TO BETTER CONNECT TO BUILD A STRONGER MINING INDUSTRY.

FROM STRENGTH TO STRENGTH: NATIONAL GROUP’S BUMPER 2022

Nalready renowned mining services company into new activities and new regions of Australia.

“National Group’s gone from strength to strength in 2022, with new contracts beginning such as our contract with Anglo American,” National Group managing director and chief executive officer Mark Ackroyd told Australian Mining

That new contract commenced in February and involves the supply of heavy earthmoving equipment to Anglo American Australia’s open-cut coal mines at its Capcoal operation in Queensland’s Bowen Basin.

Having supplied the Capcoal operation for three years, the latest contract doubled the amount of equipment National Group delivers to the Lake Lindsay and Oak Park mines.

Up to 30 National Group maintenance staff members have

in mining.

National Group has also boosted its New South Wales presence, with a new three-year contract with Yancoal subsidiary Moolarben Coal awarded in 2022.

The company’s contract-mining arm – National Mining Services – is providing works including the safe prestripping of up to 15 million bank cubic metres of overburden each year at the Moolarben coal mine.

National Mining Services has used National Group’s ultra-class mining equipment on the contract, including Liebherr R9800 excavators, Liebherr T282 dump trucks and other ancillary equipment.

The Moolarben contract came after National Group was awarded a surface mining contract at Newcrest Mining’s Cadia gold mine in central NSW in 2021. This involved the supply of equipment such as Caterpillar

Ackroyd said his company’s work at Cadia continues to grow, with the

underground mine, which is one of the largest gold and copper deposits in the

AUSTRALIANMINING 28 DECEMBER 2022 INDUSTRY OUTLOOK

WITH A STRONG PRESENCE IN WESTERN AUSTRALIA AND QUEENSLAND, 2022 SAW NATIONAL GROUP EXPAND ITS

PRESENCE

IN NEW SOUTH WALES, INCLUDING A NEW CONTRACT WITH MOOLARBEN COAL.

NATIONAL GROUP SUPPLIES CATERPILLAR EQUIPMENT ALL OVER AUSTRALIA.

NATIONAL GROUP MANAGING DIRECTOR AND CHIEF EXECUTIVE OFFICER MARK ACKROYD.

world – returned to National Group to work on the Cadia contract.

The recent commodity boom has bolstered National Group’s order book, with miners looking to boost their production to take advantage of the conditions. Ackroyd said this has resulted in greater demand for the business’ services.

“For miners to increase their output, it requires more people, more equipment and better performance to do so, which rolls back into companies like us at National Group that have more opportunities to supply the necessary equipment,” he said.

“For anyone in this space at the moment, the market is very buoyant and very busy. Whether it’s labour, equipment or maintenance supply, no matter what it is, the whole industry is very active.”

While National Group is one of the biggest, most distinguished mining services companies in Australia – if not the globe – its employees are not just numbers on a spreadsheet.

As National Group head of marketing and partnerships Kain Ford puts it, “everyone knows Mark, is part of the team, and is treated equally”.

A 100 per cent privately-owned outfit, National Group has big company experience but a familyowned feel that focuses on the customer.

“For National Group, it’s always been our understanding of customers’ needs and being responsive,” Ackroyd told Australian Mining earlier this year.

“We’ve worked hard to find the right balance between systems that help control and minimise risk, while maintaining the entrepreneurial dynamism of a private company.”

Diversification is a key focus, not just in business, commodity and location, but also in personnel.

This forms part of National Group’s environmental, social and governance (ESG) policy.

“We aim to drive sustainability throughout our organisation, which to us means reducing our impact on our environment, ensuring our people and communities are supported, and that our governance decisions align to our sustainability goals,” Ackroyd said.

“We believe we can contribute to improving the sustainability of Australia’s mining sector, an industry that will remain critical in facilitating the renewable transition globally while providing safe and gainful employment for local communities for decades to come.”

National Group recognises there is more to do to improve the mining sector’s ESG performance in line with internal, customer and societal expectations. But through the company’s diversification focus and

accessible environment, it’s quickly becoming one of the most passionate ESG proponents in the Australian mining sector.

When Australian Mining spoke with Ackroyd about National Group’s 25th anniversary earlier in the year, he reflected on the growth of staff; the teamwork, camaraderie and organisation culture; and the longterm client relationships that have been forged over the years.

As one of Australia’s top 300 privately-owned companies in terms of revenue, National Group is an entrepreneurial success story.

But you won’t hear Ackroyd talking about his personal achievements. He is especially proud of National Group’s expanding focus on corporate social responsibility. Helping the local footy club in a mining town, for example, is about the company supporting communities in which its people live.

For Ackroyd, business is simple. It starts with having good people who understand what clients want, and who will work harder, smarter and faster to deliver it. He wants people of high integrity who are there for the long haul, and who are genuinely customer-centric.

With a simplified corporate structure that has a direct line of contact and no middle management, National Group has the agility to match miners’ dynamic, ever-evolving schedules. This enables swift decisions and the ability to quickly respond to clients’ urgent needs.

Going into 2023, National Group will continue to increase its presence in the Australian mining industry, finding new opportunities, new regions and new commodities to explore.

The company has a particular focus on boosting its already-strong order book of Tier 1 miners and expanding its fleet in preference of larger machines.

As the world further realises its green future, mining services companies such as National Group, which have the flexibility, reach and reputation to quickly capitalise on new opportunities and apply expertise in new ways, will become increasingly critical.

“Our job is to supply the most energy-efficient equipment,” Ackroyd said. “We’ve done that for a long time because we buy the latest equipment from the top manufacturers. Having a young, state-of-the-art fleet is better for the environment.”

Whatever the future holds, there is one area in which National Group will always maintain its focus.

“I want National Group to remain a highly customer-focused company, from the most junior employee to my job and the board,” Ackroyd said. “I want everybody to stay on the same page about the need to always put customers first.” AM

AUSTRALIANMINING 29 DECEMBER 2022 INDUSTRY OUTLOOK

NATIONAL GROUP’S MOOLARBEN CONTRACT INCLUDES THE SUPPLY OF EQUIPMENT SUCH AS CATERPILLAR 793 DUMP TRUCKS.

NATIONAL MINING SERVICES HAS USED NATIONAL GROUP’S ULTRA-CLASS MINING EQUIPMENT, INCLUDING LIEBHERR EXCAVATORS AND DUMP TRUCKS.

FLSMIDTH STRENGTHENS POSITION AS LEADING MINING SUPPLIER

TECHNOLOGY

The acquisition, which was announced early 2022, will allow FLSmidth to increase its geographical footprint and competencies to serve its customers across multiple technologies.

It will also allow for a more robust customer approach in service and aftermarket, as well as an increase of resources and investment in research and development (R&D), digital and innovation.

T he acquisition supports FLSmidth’s central ambition to bring sustainable technology to the mining market that will increase customer productivity

and profitability while reducing its environmental footprint.

FLSmidth identified the thyssenkrupp mining offering as an ideal fit with its MissionZero sustainability ambition and its digitalisation agenda, and can now combine the two companies’ competencies, offerings and expertise.

FLSmidth sees mining heading into a growth phase, and this acquisition will place the company in an even better position to meet customer needs.

thyssenkrupp’s mining equipment offering consisted of open-pit mining equipment and systems, mineral processing solutions, and material handling solutions. It was primarily

involved in crushing, conveying, grinding and processing, areas that are broadly complementary to FLSmidth’s offering.

The two companies have some overlap of technologies, but overall, FLSmidth sees a clear complementary offering –especially in the areas of sustainability and digitalisation.