VOLUME 115/11 | DECEMBER 2023

PROSPECT AWARDS

CRITICAL MINERALS

VOLUME 115/11 | DECEMBER 2023

PROSPECT AWARDS

CRITICAL MINERALS

United. Inspired.

With Epiroc’s Rig Control System (RCS), the Pit Viper series can be configured with scalable Automation features such as AutoDrill and AutoLevel. It can be run with the operator off the drill, as well with the optional BenchREMOTE package, enabling one operator to run one or multiple units. RCS provides the foundation to add new functionality and options later without a major rebuild of the machine and autonomous drilling can be implemented with almost no human interaction with the drill.

TOM PARKER

tom.parker@primecreative.com.au

The International Mining and Resources Conference (IMARC) celebrated its 10th iteration in late 2023, bringing together professionals from all corners of the global mining sector to network and share ideas.

IMARC also gave mining equipment, technology and services (METS) companies a platform to showcase their offerings, with an expansive exhibition hall filled with decision-makers looking for solutions to their mining quandaries and inconveniences.

Australian Mining caught up with several major METS players at IMARC 2023 to chat about their offerings and takeaways from the conference.

ABB – a leading mining technology player – highlighted how collaboration will be critical in achieving electrification outcomes, while Epiroc showcased collaboration in action, with its Roy Hill autonomous haulage system (AHS) project on full display at the conference.

The Brokk 500 demolition robot turned heads in the IMARC exhibition hall, while SafeGauge unveiled the MultiTool Pro to audiences for the first time.

And when METS companies weren’t showcasing innovations to make mining a safer, more productive and sustainable industry, there were panel discussions and networking events happening around the clock.

For a mining professional, this really was the place to be.

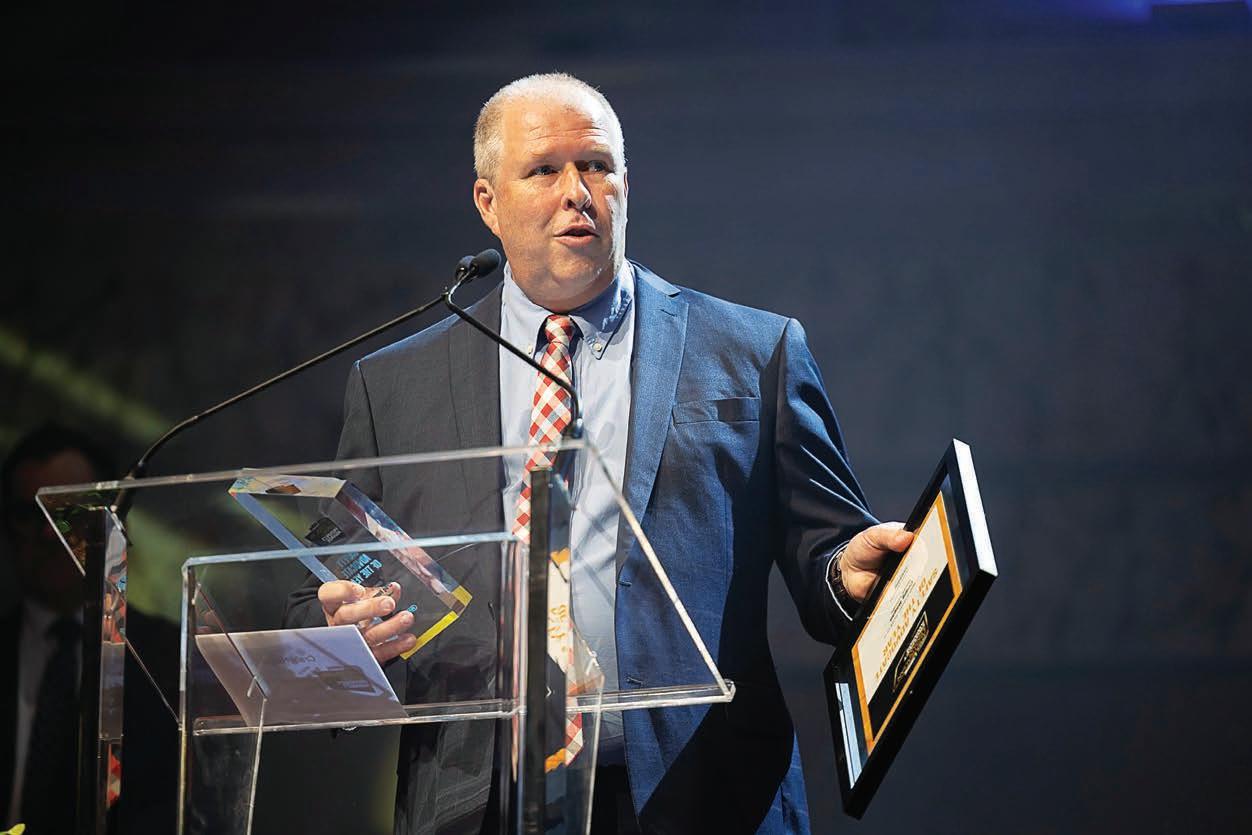

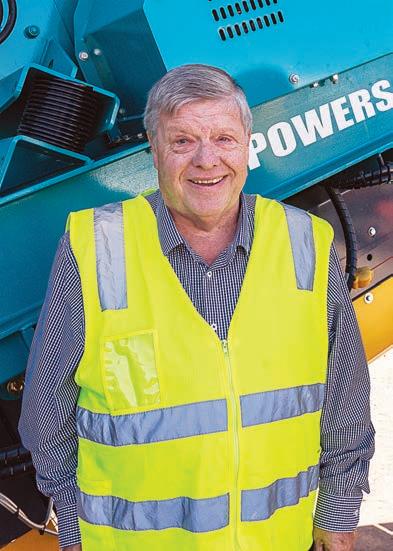

A week on from IMARC, the Australian Mining Prospect Awards took place in Brisbane, providing the opportunity for the best and brightest in the resources sector to be recognised for their excellence.

This edition celebrates all the winners from the night, with some notable honourees including the Roy Hill operation in Western Australia as Australian Mine of the Year, Roy Watterson as winner of the Lifetime Achievement Award, and MMG’s Rosebery mine as Mine Project Success of the Year. Head to page 34 for the full wrap.

Being the final issue of 2023, Australian Mining also tapped a number of major figures within the resources industry to discuss their achievements from the year just gone and forecast what’s ahead for 2024.

The likes of FLSmidth, Epiroc, Liebherr and Dendra provide their perspectives, exploring everything from the decarbonisation opportunities within mineral processing, the future of automation, and the growing importance of progressive mine rehabilitation.

KELSIE TIBBEN

CHIEF EXECUTIVE OFFICER

JOHN MURPHY

CHIEF OPERATING OFFICER

CHRISTINE CLANCY

MANAGING EDITOR PAUL HAYES

EDITOR

TOM PARKER

Email: tom.parker@primecreative.com.au

ASSISTANT EDITOR

ALEXANDRA EASTWOOD

Email: alexandra.eastwood@primecreative.com.au

JOURNALISTS

OLIVIA THOMSON

Email: olivia.thomson@primecreative.com.au

Tom Parker Editor

Email: kelsie.tibben@primecreative.com.au

CLIENT SUCCESS MANAGER

JANINE CLEMENTS

Tel: (02) 9439 7227

Email: janine.clements@primecreative.com.au

SALES MANAGER

JONATHAN DUCKETT

Tel: (02) 9439 7227 Mob: 0498 091 027

Email: jonathan.duckett@primecreative.com.au

DESIGN PRODUCTION MANAGER

MICHELLE WESTON

michelle.weston@primecreative.com.au

ART DIRECTOR BLAKE STOREY

blake.storey@primecreative.com.au

significantly in recent years as industries like mining acquaint themselves with the company’s approach to ecosystem restoration. This year has been particularly noteworthy, with Dendra advancing a major project in the United Arab Emirates while continuing to extend its offerings to mining operations across Australia. In fact, co-founder and CEO Susan Graham called 2023 a record year for several of its Australian customers – something made possible by the company’s unique RestorationOS platform. Dendra’s growth strategy is to build scale into whatever work it does. Technology improvements have enabled Dendra to achieve scale improvements by a multiple of 10, including scale improvements by a multiple of four in 2023.

Cover image: Dendra

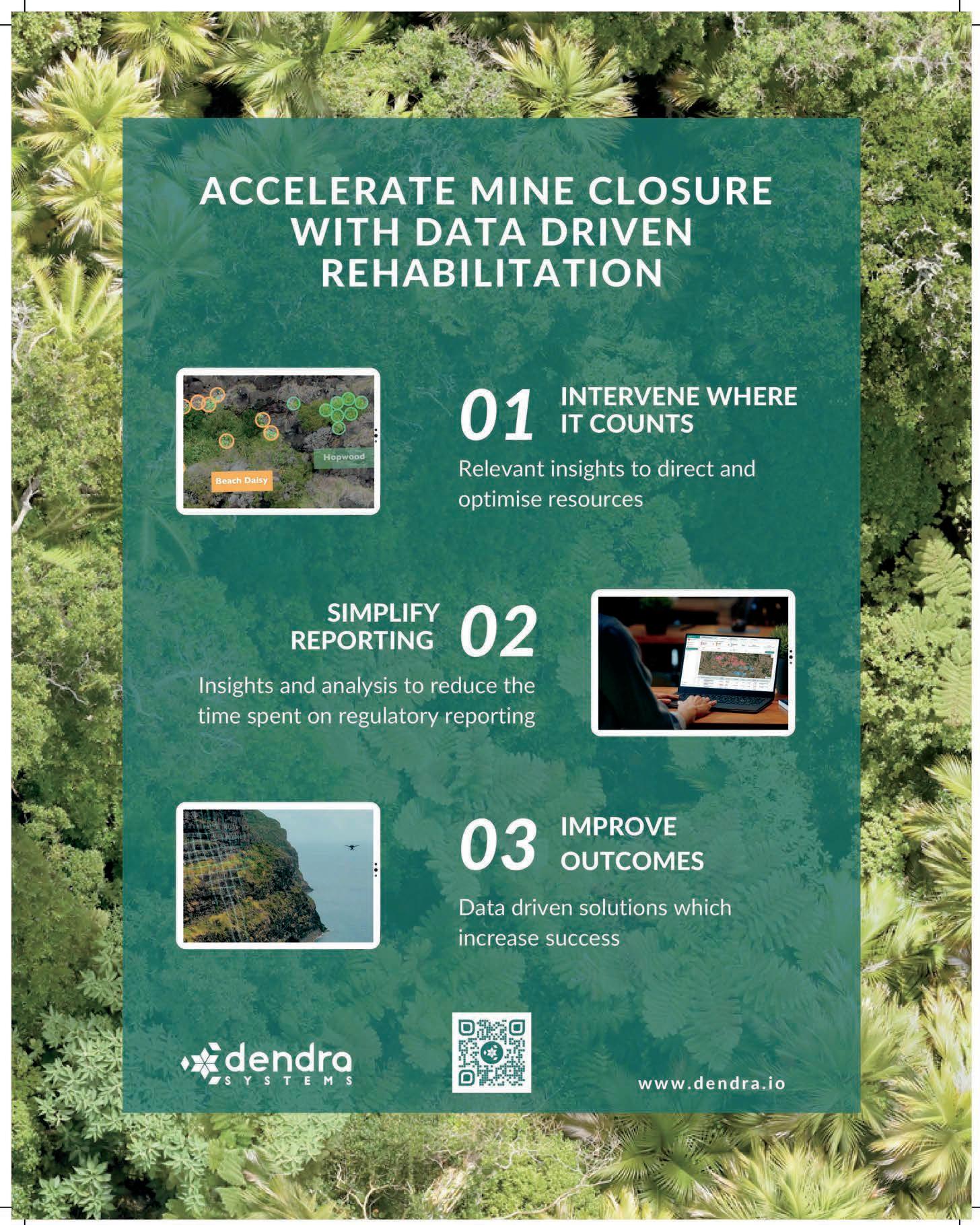

Overcoming a critical conundrum

When industry leaders came together in Sydney for IMARC 2023, the Australian critical minerals sector was a major topic of discussion.

8 INDUSTRY OUTLOOK

A transformative year

As the Australian mining sector gears up for 2024, Australian Mining reflects on positive changes made in five key areas of the industry during 2023.

10 INDUSTRY OUTLOOK

Epiroc 2030

Epiroc is making mining operations safer through automation, fewer drill bit changes, and faster evacuation times.

14 INDUSTRY OUTLOOK

Dendra’s record year

Australian Mining sat down with Dendra Systems co-founder and CEO Susan Graham to chat about the company’s 2023 growth spurt.

28 INDUSTRY OUTLOOK

Tackling cybersecurity head on

As organisations across the globe battle the threat of cyber-attacks, Vocus is determined to ensure its customers can safely weather the storm.

31 INTERNATIONAL MINING

PNG into the spotlight

Now operating under new ownership, the PNG Industrial and Mining Resources Exhibition and Conference is set to take the Pacific nation by storm in July 2024.

32 IMARC

A sprawling mining celebration

Australian Mining caught up with several major players at IMARC 2023 to chat about their offerings and takeaways from the conference.

34 PROSPECT AWARDS

Going above and beyond for the industry

The Australian Mining Prospect Awards returned to Brisbane this year to celebrate the best and brightest of the country’s mining sector.

64 WATER MANAGEMENT

Driving success in underground dewatering

The Flygt Bartail range is Xylem’s new solution for the harshest underground dewatering applications.

REGULARS

3 COMMENT

98 EVENTS

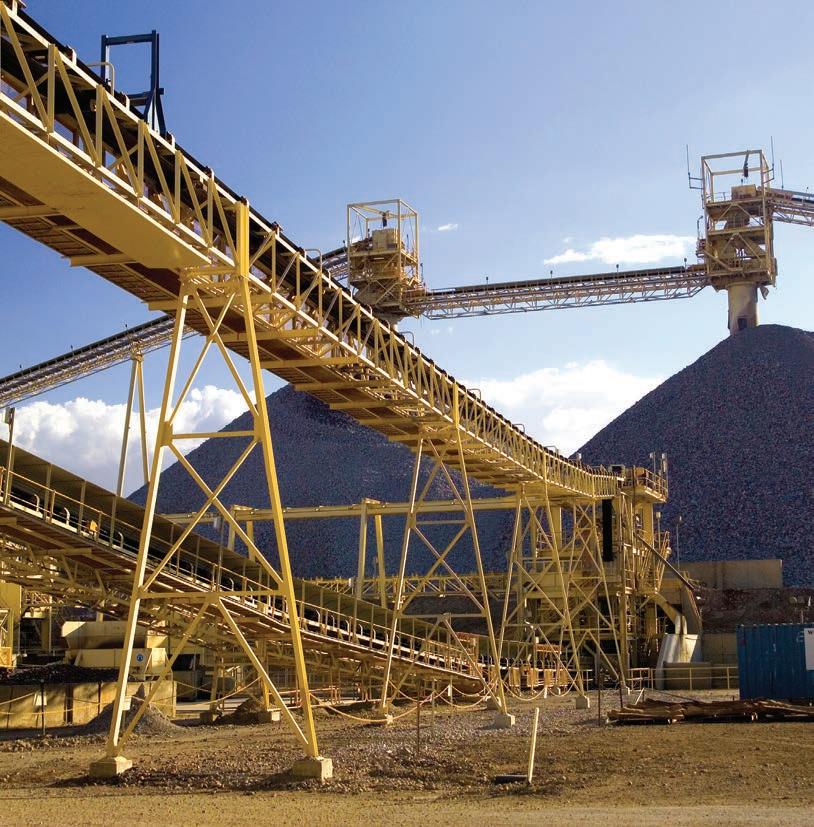

Australia is home to much of the world’s supply of critical minerals. These minerals, such as cobalt, lithium and tungsten, are hot commodities as they play a vital role when it comes to the clean energy transition.

But what is considered ‘critical’ varies between jurisdictions, even between states in Australia. Copper, for example, is considered a critical mineral in South Australia, but has not made the country’s national list.

Minerals added to the list enjoy favourable government policies and access to grants, such as the Federal Government’s newly boosted $4 billion Critical Minerals Facility.

Despite its importance, the Australian critical minerals sector has challenges to overcome, including the complexity and prolonged timelines associated with developing these projects, something many feel can be buoyed by government support.

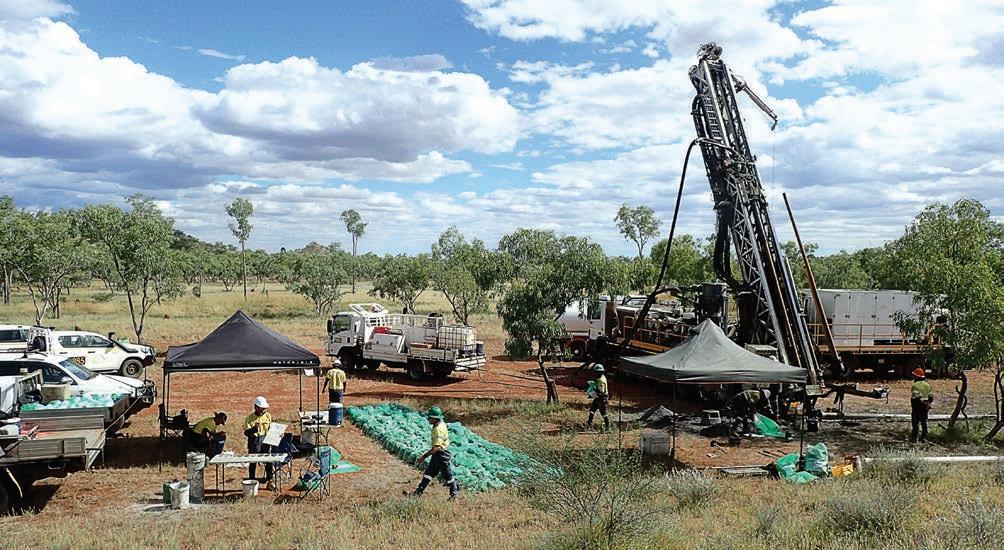

The 2023 International Mining and Resources Conference (IMARC) acted as an important platform for critical minerals discourse.

EXPEDITING ACCESS TO MINERAL TENEMENTS WILL ENSURE PROJECT TIMELINES ARE ACCELERATED.

SYDNEY TO DISCUSS THE AUSTRALIAN CRITICAL MINERALS SECTOR.

Australian Mining was on hand to document some of the discussions.

When asked what should define a critical mineral, Wyloo chief executive officer (CEO) Luca Giacovazzi said the answer had to do with utility.

“Just like the steam engine drove the industrial revolution, and the combustion engine sparked the development of the oil market into the multi-trillion-dollar industry it is today, I think we’re at the beginning stages of an energy metals revolution,” Giacovazzi said during a panel discussion at IMARC 2023.

“When we think about critical minerals, it’s about playing into that revolution – that shift towards decarbonisation and electrification that’s happening in the world – and asking what metals we need to actually support that shift.”

But Australian Strategic Materials managing director and

CEO Rowena Smith said there was more to the equation.

“I think that supply chain vulnerability is an important component of what constitutes a critical mineral,” she said during the same panel discussion. “The reality is there’s a long list of metals that are critical to modern technologies. If you added them all together, it would be a very long list, but some of those have already got very strong and established supply chains.

“And if we’re talking about government policy being focused on supporting critical minerals growth in Australia, I think it’s important that we’re disciplined about choosing the ones most in need of that support.”

When it comes to government support, miners have raised concerns about project timelines.

“Getting access to ground for exploration at the moment is a major roadblock in Australia,” IGO chair Michael Nossal said. “First you have to negotiate with the stakeholders involved in getting access to a site. Once you’ve been through that, there are traditional landowners and other community stakeholders involved.

“Then you have to find the mineral and work up to a resource before you get

“I think it would be very valuable for the government to look at ways to shorten the permitting timeframe.”

Resource Capital Funds Australia managing director Brett Beatty also shared his thoughts on the need to accelerate timelines for critical minerals

“A conventional copper mine takes nearly 20 years to develop from discovery through to full production,” Beatty said. “The reality is critical minerals are more

“They’re harder to finance because the pricing is opaque, and there’s a qualification period for some of these products that can take many years. It can be quite complicated and timeconsuming to break into a supply chain.

“I’m not surprised that people are frustrated that things aren’t happening quick enough, but I think the reality is this will take us some serious time and planning to work through these challenges.”

Smith agreed, adding her belief that it is also important for the government to support more advanced projects with

“Our critical minerals project in Dubbo, New South Wales, is 15 years in and has navigated a lot of these hurdles,” Smith said.

because the larger OEMs (original equipment manufacturers) have got very ambitious carbon net-zero targets.

“One of our major hurdles is: can we commit our operations to these zero-carbon deadlines in line with what the OEMs want? That’s why access to low-cost renewable power is critical for these projects.”

While critical minerals are essential components for modern technology, the process by which they are recovered is just as important.

Manufacturers – driven in part by customer sentiment – are more frequently looking to lower carbon emissions through their supply chains. This falls under the broader environmental, social and governance (ESG) umbrella, which is critically important to the modern market.

Transparent mining is a component of this situation, with customers wanting manufacturers to ensure the materials they use are responsibly sourced.

“People have been wondering if there is a way to prove the provenance of metals using blockchain and other technology, but it’s very difficult to do,” Giacovazzi said.

between the cost of going downstream in Australia versus the cost of going downstream internationally.

“It’s a difficult task, but there are clever ways of doing it. There are lots of different incentives, like production tax credits, that you can use.”

Given Australia has long been a raw material supplier, onshore processing has been a hot topic in the local sector in recent years. Nossal said downstream processing in Australia is not just a matter of cost, but expertise.

“If you look at something like downstream processing of lithium in Australia, there hasn’t been very much of it,” he said. “And what we’re finding is there’s not a lot of in-built expertise in the country around chemical processing.

“The skill base needed for processing is also another roadblock and something that the government can assist with in terms of immigration policy and skilled migration.”

The challenges associated with critical minerals are many and will require considered cooperation between the industry and government to address, both nationally and abroad. Despite the challenges, the potential payoff for the country is significant.

“Another way to accomplish this is for countries like Australia to go downstream and produce a finished product that you can then sell to an OEM who can then tell their customers that they’re using a very clean form of nickel.

“We have an opportunity to strengthen the midstream. We must play to that strength – and play fast.” AM AS

“We’re now at the point where we’re looking at offtake agreements and funding. That’s the point where infrastructure becomes really important

“Where we need government to play a big role is in balancing the scales

“This is the golden age for critical minerals,” Smith said. “It’s an opportunity that requires us to act. If we leave it for five years and think that we’re going to be able to establish ourselves in time, then we will have missed that opportunity.

THE AUSTRALIAN RESOURCES INDUSTRY HAS HAD A BUMPER YEAR. AS THE SECTOR GEARS UP FOR 2024, AUSTRALIAN MINING REFLECTS ON POSITIVE CHANGES MADE IN FIVE KEY AREAS DURING 2023. THE WORLD’S FIRST FULLY AUTONOMOUS ROAD TRAINS FROM HEXAGON WERE DEVELOPED FOR MINRES’ ONSLOW IRON

Throughout 2023, mining companies and governments introduced new legislation, technology, and safety measures to work towards implementing greater environmental, social and governance (ESG) efforts.

This trend was especially true in Australia, and is expected to continue into the new year.

According to business management consultants Ernst & Young, ESG will remain the greatest business risk and opportunity facing the global mining and metals sector in 2024 for the third year in a row.

Australian Mining takes a look at how the Australian mining sector has used 2023 to prepare itself to meet greater ESG transparency, among other trends.

The critical minerals boom reached new heights this year, most notably through the release of the Federal Government’s Critical Minerals Strategy.

Introduced in June, the Critical Minerals Strategy aims to grow Australia’s critical minerals wealth by providing a framework that the Federal

Government will use to guide future policy decisions.

“The new Critical Minerals Strategy outlines the enormous opportunity to develop the sector and new downstream industries which will support Australia’s economy and global efforts to lower emissions for decades to come,” Federal Resources Minister Madeleine King said.

“While the potential is great, so too are the challenges. The strategy makes it clear our natural minerals endowment provides a foot in the door, but we must do more to create Australian jobs and capitalise on this unique opportunity.”

To support the strategy, Australia’s critical minerals list is expected to expand in the new year.

With minerals such as lithium, tungsten and vanadium already on the list, King said minerals like bauxite, iron ore, coking coal, copper and nickel are Australian commodities that are crucial for the global energy transition. However, she didn’t confirm that these commodities would be added to the list.

“Our critical minerals list is different to some other nations. Other nations craft theirs on what they have, what’s scarce and what they can’t get, whereas we’ve got most of it. So it’s crafted on

another basis of what is of geostrategic importance for us and our neighbours,” King said at the Australian Financial Review Energy and Climate Summit.

“We also have to consider our region and our partners because they’re an important part of our prosperity. That’s always going to figure in it.”

While industrial relations reforms such as the ‘same job, same pay’ and ‘closing loopholes’ bills made a splash during 2023 – and will most likely continue to do so in 2024 – the Aboriginal Cultural Heritage Act 2021 reverting to the Aboriginal Heritage Act 1972 had a strong effect on the Western Australian mining sector.

The catalyst for the Bill change was the May 2020 Juukan Gorge incident, when Rio Tinto blasted two sacred rock shelters while exploring for iron ore.

To prevent similar incidents from happening in the future, the WA Government introduced the Aboriginal Cultural Heritage Act 2021 in December 2021. The Bill came into effect in July 2023.

Under the legislation, WA landowners were required to check if cultural

heritage sites were present on the land before undertaking anything which may compromise the sites.

However, following public workshops, education sessions, and consultation with key stakeholders, the WA Government decided to revert back to the Aboriginal Heritage Act 1972, with some key amendments.

The restored legislation’s amendments included the newly formed Aboriginal Cultural Heritage Council taking on the role of the committee that was established under the 1972 Act to make ministerial recommendations.

Proponents and native title parties were also given the same right of review for Section 18 decisions, with clear timelines and an ability for the WA Premier to call-in a decision of ‘state significance’ to act in the interests of all WA residents.

Section 18 refers to the part of the Act that states the minister must provide approval for every action undertaken at the site.

When a Section 18 has been approved, it is a requirement for the owner to notify the minister of any new information about an Aboriginal site.

“The Juukan Gorge tragedy was a global embarrassment, but our response was wrong, we took it too far, unintentionally causing stress, confusion and division in our community,” WA Premier Roger Cook said in August.

“The complicated regulations, the burden on landowners and the poor rollout of the new laws have been unworkable for all members of our community – and for that, I am sorry.

“The original intent of the legislative change nearly two years ago, was to prevent another Juukan Gorge – and (the WA) Government will deliver on that commitment.”

In September 2023, the amended legislation opened for public consultation.

This year has seen an emerging pattern of mergers and acquisitions (M&A) as ASX-listed mining companies fought to expand their portfolios.

Perhaps the two biggest mining acquisitions seen in 2023 were BHP’s takeover of OZ Minerals in May for $9.63 billion, and Newmont’s acquisition of Newcrest in November for $26.2 billion.

OZ Minerals and Newcrest are both Australian gold and copper mining companies that were taken over by major global miners. Copper notably has a variety of end uses in a green economy, whether it be through electricity distribution, electrical equipment and devices, industrial machinery, wind turbines, solar panels and, of course, powering electric vehicles.

BHP chief executive officer (CEO) Mike Henry said the takeover of OZ Minerals would provide growth opportunities around the world.

“This acquisition strengthens BHP’s portfolio in copper and nickel and is in line with our strategy to meet increasing demand for the critical minerals needed for electric vehicles, wind turbines and solar panels to support the energy transition,” he said.

“Combining our two organisations will provide options for growth, bring new talent and innovation to unlock these resources in a sustainable way.”

Newmont CEO Tom Palmer echoed similar sentiments regarding Newmont’s acquisition of Newcrest.

“This milestone represents a pivotal and historic moment in our strategy to create the world’s premier gold and copper company by consolidating Tier 1 assets in the world’s most favourable mining jurisdictions,” he said.

Sibanye-Stillwater acquiring New Century Resources for $120 million and Mineral Resources (MinRes) acquiring Norwest Energy for $497 million.

This year also saw Wyloo Metals acquire Mincor Resources for $760 million, with Ring of Fire Metals, Wyloo Metals and Mincor now unified under the brand name Wyloo.

equipped with an autonomous haulage solution provided by Hexagon.

The world’s first fully autonomous road trains were designed and developed for MinRes’ Onslow iron project in WA.

The trains are expected to help in removing the risk of driver fatigue, increasing fleet availability, lowering operating costs and reducing fuel use and emissions.

has these types of road trains operating 24–7, pulling this quantity of material on a 365-day basis.

“Hexagon couldn’t have achieved this successful milestone without MinRes and vice versa.”

As the end of 2023 approaches, so too has the deadline for mining companies to comply to the Respect at Work Act.

The Respect at Work Act was introduced in December 2022, and required employers to adopt proactive measures to prevent sexual harassment, sex-based discrimination and related victimisation. This covers not only the actions and behaviour of the employer, but also their employees and others who work for them.

Under previous laws, employers could be held vicariously liable for sexual harassment and discrimination where they failed to make all reasonable steps to prevent the behaviour from occurring.

While this is still the case, the new legislation enforces a positive duty on employers to take reasonable steps in eliminating sex-related discriminatory behaviours in the workplace.

This means employers need to proactively take action to prevent unacceptable behaviour relating to sexual harassment in their workplace, regardless of whether a complaint has been made.

“Once complete, our combined business will feature ten, Tier 1 operations supporting decades of safe, profitable, and responsible gold and copper production, with best-in-class sustainability performance.”

Other noteworthy transactions that took place in 2023 included

Many new innovations were created in 2023 to assist mining companies in meeting global climate goals, while simultaneously reducing maintenance and production costs and increasing workplace safety, productivity and efficiency.

A key example of this was MinRes’ agreement with Hexagon. In July, MinRes announced it would purchase a fleet of 120 fully autonomous road trains

“The ability to see a road train that’s pulling over 300 tonnes, three trailers over a 120km road, and to be able to take that from a mine site to port without having to put in any infrastructure like conveyors or rail ... is exciting,” Hexagon mining division chief technology officer Robert Daw told Australian Mining earlier this year.

“All of these solutions and expertise come together to create that world-first. We’re not aware of anywhere else that

As part of the changes, the Australian Human Rights Commission (AHRC) has been empowered with the ability to inquire into, and report on, issues of systemic unlawful discrimination or suspected systemic unlawful discrimination.

Owing to the gravity of the changes, employers have been given a oneyear grace period to demonstrate this positive duty of care. That door closes on December 13 this year, at which time the AHRC will commence its new responsibilities.

“Australia must take active steps to prevent unlawful workplace behaviour before it even begins,” AHRC president Rosalind Croucher said in August.

“With one in three Australians reporting they’ve been sexually harassed at work over the last five years, leaders of organisations and businesses play a pivotal role in setting the benchmark for best practice in preventing harassment and discrimination in Australian workplaces.

“This is a significant moment for leadership. Implementing the positive duty is an opportunity for Australia to change the places in which we work – to be safe, inclusive, gender-equal, and free from sexual harassment and discrimination.”

As the mining industry gears up for another big year in 2024, the progress of 2023 shows the sector is atoning for its shortcomings and growing as a result. AM

EPIROC IS MAKING MINING OPERATIONS SAFER THROUGH AUTOMATION, FEWER DRILL BIT CHANGES, AND FASTER EVACUATION TIMES.

The future of the mining industry lies in sustainable practices; but sustainability goes beyond reducing carbon footprint and adopting circular economic principles. A major of component of sustainability is safety.

In Deloitte’s ‘Tracking the Trends’ report for 2023, the consulting company identified safety as the foundation for a secure organisation.

“Generally speaking, fatality rates have been steadily declining across the industry as the mining sector places an increasing emphasis on physical safety,” the report stated.

“Mining and metals leaders who can seamlessly integrate and have genuine engagement, action and advocacy for all aspects of safety will lead their organisation towards a more sustainable, secure, resilient and prosperous future.”

Epiroc knows that ensuring workers get home safe is the most important part of any mining operation. That’s why the original equipment manufacturer (OEM) has set itself the 2030 target of zero injuries across its mining operations.

The path to achieving such a lofty goal is threefold, involving increased automation of hazardous machinery, fewer drill bit changes, and shortened evacuation times.

Automated machinery helps keep workers away from the frontlines of mining operations, minimising human contact with potentially hazardous equipment. Epiroc is a market leader in automated drilling, loading and hauling technologies.

When it comes to drilling operations, drill rod changes have been known to be hazardous, requiring operators and offsiders to work close to powerful machinery.

One of the latest tools in this space is Epiroc’s Explorac RC30 Smart drill rig, which automates the rod changeover component of drilling operations. While the drilling is still guided by an operator’s trained hand, automated rod

changeover allows workers to stay out of the line of fire.

“Operating a drill rig used to be a two-person operation, with the operator working in tandem with an offsider to sequence rod changes,” Epiroc global product manager – surface exploration David Benton told Australian Mining

“The Explorac RC30 Smart automates that process, allowing the machine to do a full rod changeover sequence with the push of a single button. This is a much safer way of doing things since there’s less opportunity for human error.”

Another example is Epiroc’s Pit Viper drill rig range for rotary drilling. Capable of completing an entire drill pattern autonomously without an operator on-board, the Pit Viper is 22 per cent more productive than a conventional drill rig system, with the added benefit of keeping workers safe in a control room.

Epiroc’s Boltec auto bolt reload (ABR) is another example of how the OEM is improving safety through automation.

The Boltec ABR is the first ever underground rock reinforcement drill rig of its type. Its main design feature is the fully mechanised bolt reloading system that automatically feeds bolts from a large carrier magazine to the feed magazine, all while the operator remains safe inside the cab.

Another angle of Epiroc’s 2030 zeroaccidents goal is improving safety by reducing drill bit changes.

One of the methods by which Epiroc achieves this goal is with the Powerbit X, a drill bit with a diamond protective layer that provides the drill bits longer

service life, meaning fewer changes and less exposure to hazards for operators.

And when it comes time to change drill bits, rigs such as the Pit Viper can perform this function automatically thanks to Epiroc’s automatic bit-changer technology, allowing operators to quickly make changes from the control room.

When working underground, ensuring miners are able to be reliably coordinated, especially in the case of an emergency evacuation, is a critical safety consideration.

Epiroc has revolutionised underground mine safety with Mobilaris Emergency Support, a real-time workforce safety toolbox that allows rescue leaders to better coordinate evacuations.

Mobilaris is a technology that visualises the live location of workers in a mine. The system can relay emergency messages through mine phones and related equipment such as the Mobilaris virtual tag and the Mobilaris cap lamp. Personnel can easily acknowledge emergency warnings with the click of a button, allowing rescue leaders to see who is aware of danger and who is not.

“Ensuring that evacuees are mobilising towards safety rather than the hazard and ensuring people are using the shortest possible routes to refuge chambers is heavily dependent on realtime information,” Epiroc product sales manager Andreas Prill said.

Mobilaris can highlight and prioritise individual personnel for rescue efforts where necessary, such as if they are unaware of the emergency, injured or trapped. The technology can even guide rescue personnel remotely in real-time.

“You can’t improve what you can’t measure, and you can’t measure what you can’t see,” Prill said.

“Real-time data allows for the removal of uncertainties and variables. This means mine sites can stabilise and then optimise operations, benefitting not just their ability to ensure safety but also the productivity of the mines.

“Knowing what is working and what isn’t in real-time is how safety and productivity is improved.”

With its Mobilaris Emergency Support, Epiroc is able to shorten evacuation times by 25–50 per cent.

And through its threefold approach to mine safety, Epiroc is paving the way for safe practices in the mining industry in pursuit of its 2030 zero-accidents goal. AM

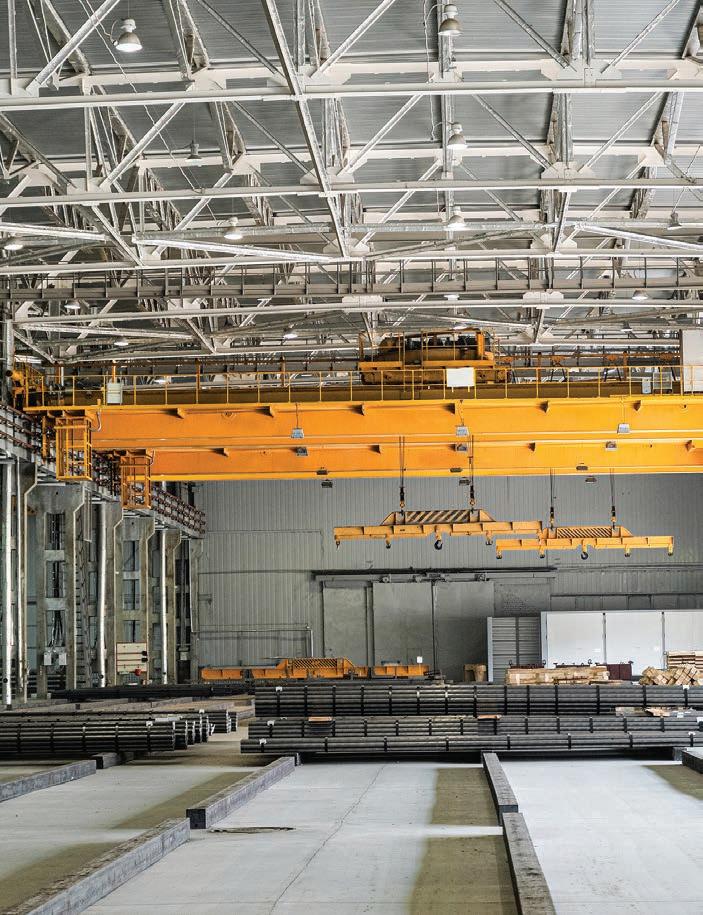

Prior to last year, Sparrows Group was widely known as a crane and lifting equipment contractor that specialised in Australia’s offshore oil and gas sector, while Altrad was one of Australia’s largest industrial service providers with a major presence in the global mining industry.

Altrad was previously unrepresented in the cranes and lifting space, but that all changed when it acquired Sparrows Group in 2022.

The merged entity, known as Altrad Sparrows, wants to bring its combined capabilities to the Australian mining industry.

“The Sparrows acquisition was largely a vertical integration strategic move that was designed to incorporate aspects of the business that Altrad hasn’t worked within, but compliments and supports Altrad’s existing capability,”

Altrad Sparrows cranes and lifting manager Australia Matthew Byles told Australian Mining

“Altrad has a heavy footprint in the WA mining industry, with significant contracts with many major miners. That experience, expertise and performance

in the mining industry will provide a pipeline to Sparrows, while adopting the new brand of Altrad Sparrows.

“We’re effectively combining Altrad’s reputation and mining footprint with Sparrows’ expertise in cranes and lifting.”

More specifically, Altrad Sparrows is looking to move into the overhead crane sector.

“We’re looking to apply our offshore record and expertise in project management, asset management, compliance and maintenance inspections, and the processes that come along with that,” Byles said.

“It’s very challenging for a company like Altrad Sparrows to get a large crane maintenance contract with a major miner because we haven’t had that presence until now. But providing turn-key solutions for new cranes, crane modernisations and overhauls, and endof-life assessments is where we have a high level of expertise and experience.”

Altrad Sparrows’ departments such as safety, quality and contract management are based in key areas of regional Western Australia, making maintenance easier for clients.

“Altrad has existing warehouse and maintenance facilities throughout the Pilbara, such as in Newman, Karratha and Port Hedland,” Byles said.

“That is a differentiator between us and the rest of the market because no other crane company in WA has multiple physical facilities anywhere in the Pilbara.

“This is important because mining clients prefer to have stock for things like spares on hand. For example, they might need to bring a hoist down off a crane and then to do an overhaul locally, as opposed to bringing it to Perth, which would incur significant more cost.

“We’re leveraging Altrad’s capability and their existing footprint in the mining industry with Sparrows’ capability, engineering, inspectors and technicians that we’ve currently got available in order to focus on high-end projects.”

Altrad Sparrows’ main objective for 2024 is to gain awareness and conduct the delivery of new crane projects, along with crane overhauls, compliance inspections, and project and asset management.

“We’ve already demonstrated these capabilities offshore with a reputation for world-class delivery, and we’d like to bring them onshore,” Byles said.

“Another differentiation is Altrad Sparrows’ consultative approach. Crane maintenance service providers should be an asset manager and advisor for their clients, not just a guy on the ground in boots and hi-vis who carries out maintenance every three months.

“The way that preventive and predictive maintenance has matured in industrial equipment, especially in mining industries, is you need to have someone who’s a consultant and adviser to the client, who can provide advice around end-of-life decisions, modernisations, and maintaining the equipment and ensuring it’s compliant.

“Altrad Sparrows has a large team of crane technicians and engineers readily available to deliver all aspects of crane maintenance.

“We want to bring that capability and transfer it to the mining industry.” AM

By utilising the latest technologies we provide an advanced combination of innovative solutions which optimise our customers mining operations performance, sustainability, availability and safety, around the globe.

• Wear parts and solutions for mineral processing, mobile and fixed plant operations

• Digital and equipment connectivity

• Asset condition and performance monitoring

• Design, engineering and manufacturing solutions

bradken.com We supply:

AUSTRALIAN MINING SAT DOWN WITH DENDRA SYSTEMS CO-FOUNDER AND CEO SUSAN GRAHAM TO CHAT ABOUT THE COMPANY’S 2023 GROWTH SPURT.

Founded in 2014, Dendra Systems has grown its footprint significantly in recent years as industries such as mining acquaint themselves with the company’s inspired approach to ecosystem restoration.

This has Dendra co-founder and chief executive officer (CEO) Susan Graham excited not only for the company’s future but also the future of sustainable mining worldwide.

“It’s been a record year for a number of customers joining us in Australia and benefiting from our unique RestorationOS approach,” Graham told Australian Mining.

“This is a reflection on our customers championing us and telling colleagues across the industry about how our approach has been able to help transform the way that they operate, and for them to achieve their own targets.”

Dendra’s RestorationOS combines ecology, data science, machine learning, and automation to restore biodiverse ecosystems at scale.

Within the Australian mining sector, this means harnessing Dendra’s drone

DENDRA’S SEEDING DRONES ENABLE AERIAL SEEDING FOR BIODIVERSITY AT SCALE.

technology, seeding solutions, endto-end digital platform, and domain expertise to progressively rehabilitate and restore mining operations.

Graham said technology improvements over the last nine years have enabled Dendra to achieve scale improvements by a multiple of 10. In 2023 alone, the company has achieved scale improvements by a multiple of four.

“This techno-economic curve that we’re driving, where we’re able to continually increase the scale capacity that we can operate, allows our customers to operate over much larger areas and restore larger areas more effectively,” Graham said.

“As part of our restoration operating system, we’re collecting data, we’re analysing it using the best ecology insights, including AI (artificial intelligence), to then provide actionable insights.

“Whether it’s actioning with Dendra drones that go out and do the seeding, or its actioning with the weed-spraying contractors, the erosion managers or the biodiversity specialists, there’s so many people involved in restoring an ecosystem, that

providing our RestorationOS platform enables the coordination of this very complex environment.”

Understanding that effective biodiversity management begins in the pre-mining phase, Liontown Resources recently engaged Dendra to monitor and survey a 2700-hectare area within its Kathleen Valley lithium project in Western Australia.

Dendra deployed its drone fleet to conduct a series of targeted surveys over existing and proposed land disturbance areas. By mapping and monitoring two priority flora species – Grevillea inconspicua and Hemingenia exilis –Dendra enabled Liontown to understand species’ abundance across the Kathleen Valley tenement.

CO-FOUNDER AND CHIEF EXECUTIVE OFFICER

Four weed species were also surveyed, alongside areas of erosion, habitat features, and legacy infrastructure.

“The drones collect high-resolution data, which is then processed through the Dendra platform, allowing us to determine not only current baseline data, but will also help us in the future to quickly identify any changes to Jones Creek, a culturally significant seasonal waterway and a Tjiwarl

songline,” Liontown said in its 2023 ESG (environmental, social and governance) report. “The technology will enable us to identify groundwaterdependent flora and reliant terrestrial fauna species, surface water movement, and monitor soil and sediment.”

Liontown has also gained important safety insights into its Kathleen Valley tenement, with high-resolution imagery identifying legacy infrastructure that may pose safety risks; for example, uncapped drill holes from previous

DENDRA HAS BECOME A KEY ENVIRONMENTAL TECHNOLOGY PARTNER FOR THE AUSTRALIAN MINING INDUSTRY.

future critical infrastructure such as determining a wind farm location based on biodiversity parameters like tree height classification.

Liontown credited Dendra’s ability to broaden and expedite ecological management.

“Traditional on-ground approaches to ecological surveys are slow and require a substantial amount of time to capture a small area of land,” Liontown said.

“Dendra’s platform and ecology-aware

characteristics of the entire Kathleen Valley project site, but also provide continuous monitoring so that we can see changes in the landform over time.”

Liontown has extended its use of Dendra’s technology to its Buldania lithium project in the Eastern Goldfields of WA.

Looking ahead to 2024, as Dendra evolves its RestorationOS platform, the company will continue to expand its mining customer base.

“We’re really excited about the new

“We’re opening up in two other major mining geographies, and we’ll be releasing some new platform features as part of our RestorationOS, which will mean customers will have new capabilities in terms of their experience.”

Dendra is also globalising, with a major contract in the United Arab Emirates (UAE) seeing the company redefine mangrove restoration, with a goal to restore 27 million mangroves within five years.

“We have just completed planting of a mangrove area that is more efficient than anybody has ever been able to plant before in the history of all mangrove restoration,” Graham said.

“We’ve established a Centre of Excellence for land restoration in the UAE, covering both large-scale arid and mangrove restoration projects. That will be used as a hub to export globally and allow us to restore mangrove ecosystems at a much larger scale than anybody else has been able to imagine.

“(The year) 2024 will be busy, and it will be a year of significant impact because of the scale we’re operating at and the number of people who are adopting this technology.”

As Dendra grows its footprint, Graham is seeing an Australian mining industry embracing ecosystem restoration more than ever, with increased regulation playing an important role.

“There are more than 50,000 abandoned mines in Australia, which

is because regulation hasn’t always supported industry best practice,” Graham said. “But what we’re seeing now is we’ve got increasing regulation and expectations from the regulator and community to improve practices.

“Then there are global expectations around ESG reporting and requirements where shareholders and their customers – in many cases the end consumer of these materials –have increased expectations around how land is rehabilitated and is reported on.

“And what we’re also seeing is global frameworks being developed, which the mining industry is really paying attention to, such as the Taskforce on Nature-related Financial Disclosures (TNFD).

“So we’re seeing this combination of regulation, ESG requirements and shareholder pressure, as well as global frameworks like the TNFD, leading the mining industry to have better practices and adopt technology to achieve better ecological outcomes.”

Facing heightened ESG pressures and more environmental regulation than ever before, Australian mining companies have the opportunity to solidify themselves as responsible operators in the eyes of not only their stakeholders and shareholders but also society as a whole.

It’s a new revolution, and one that Dendra can help facilitate quickly and efficiently. AM

FLSMIDTH ASIA PACIFIC REGIONAL PRESIDENT JASON ELKS SPOKE TO AUSTRALIAN MINING ABOUT HOW THE RESOURCES INDUSTRY CAN BE A HARBINGER OF DECARBONISATION.

It’ll be transformational in 2024.”

When the Asia Pacific regional president of a multinational original equipment manufacturer (OEM) gives you a scoop, it’s worth taking it on-board.

Jason Elks, who is part of a team driving a new vision at FLSmidth, believes mining companies have a unique opportunity to lead the carbonneutral agenda and insulate themselves from the carbon tariffs underpinning the Australian Government’s Safeguard Mechanism.

Under the Safeguard Mechanism, companies that emit more than 100,000 tonnes of CO2-equivalent (CO2-e) per financial year will be required to buy Australian carbon credit units (ACCUs) to offset their carbon footprint.

In the 2023–24 financial year, ACCUs can be bought for $75 per tonne for every tonne a company goes above its 100,000-tonne CO2-e cap. This

FLSMIDTH HAS THE TECHNOLOGIES TO DRIVE A STEP CHANGE IN THE AUSTRALIAN MINING SECTOR.

increases annually with the consumer price index (CPI), plus two per cent.

For the mining industry, the best way of circumventing the Safeguard Mechanism isn’t just by introducing electrification in the pit, through new technologies such as battery-electric haul trucks and loaders, but also by scrutinising the efficiency of fixed plant.

“What we’re talking about is doing more for less – giving you more product for less CO2 per tonne,” Elks told Australian Mining. “We’re not saying we can eliminate CO2, but we can reduce the impact.

“The irony of that is if you look at the tariffs in Australia’s Safeguard Mechanism, it’s a per-tonne tax, and if you’re going to rank CO2 per tonne, fixed plant is the quickest and easiest way to give you a competitive advantage.

“And not many companies, bar a few companies we’re currently running trials with, are looking at it.

“It will be revolutionary.”

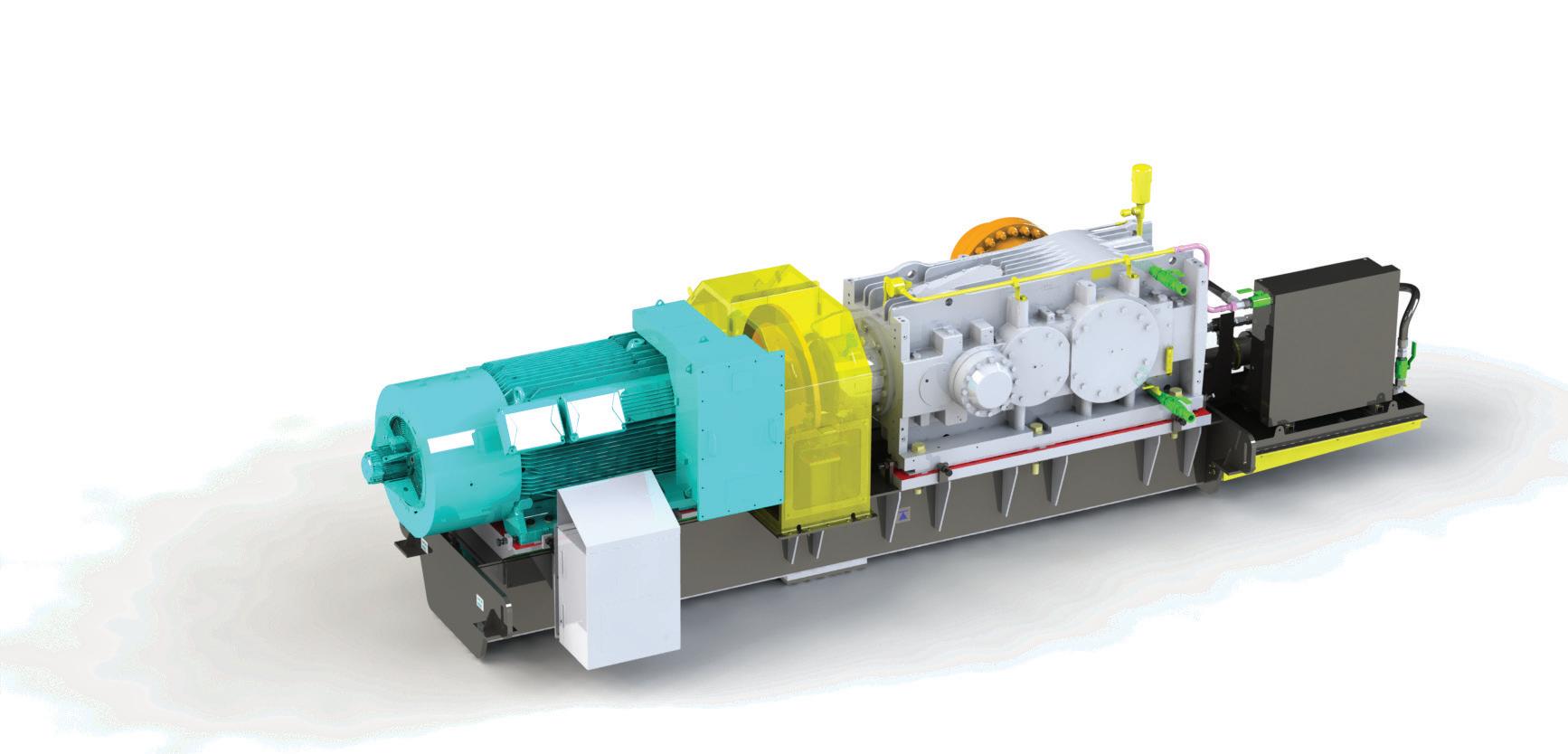

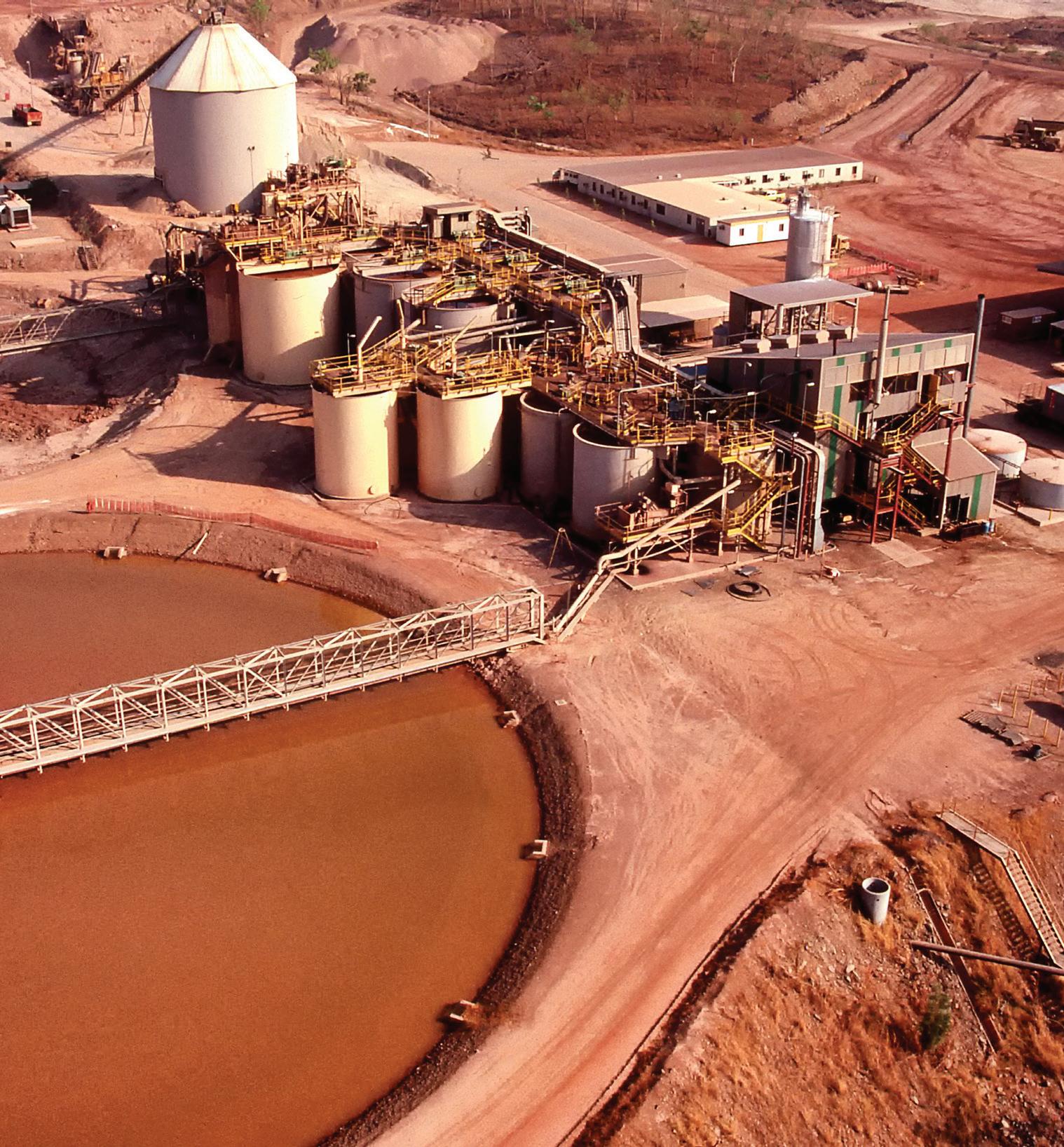

Esteemed for its mineral processing offerings, some of FLSmidth’s premium fixed plant include its REFLUX technologies, comprising the REFLUX Classifier (RC), REFLUX Concentrating Classifier (RCC) and REFLUX Flotation Cell (RFC), alongside its crushing, milling and grinding solutions.

The RC has become one of FLSmidth’s most advanced fineparticle, gravity-based separators, using minimal power and water to enable the recovery of more minerals more efficiently.

The product is core to FLSmidth’s broader MissionZero strategy, which is seeing the OEM work with mining customers on a partnership model to provide end-to-end solutions that aim to achieve zero emissions, zero water waste and zero energy waste by 2030.

“A primary focus of ours this year has been to work closer to the customer, move our inventory base closer to the customer, and de-risk their business,” Elks said.

FLSMIDTH’S REFLUX CONCENTRATING CLASSIFIER (RCC).

“So rather than selling a product to a customer, we’re more interested in being a part of the customer’s business and building their business.

“So if I say, ‘Do I want to sell you a crusher?’ No, I don’t. But if I say, ‘Do I want to help your company become a multi-billion-dollar business?’ Of course I do.

“We’re more focused on a partnership approach rather than product sales, and that’s what innovative customers demand.”

The partnership model sees FLSmidth meet with its mining partners monthly, brainstorming ways to optimise for today as well as the future.

“We work with customers on sixto-18-month rolling plans for supply and demand. We look at production schedules, we forecast needs, and we’re pre-empting what the customer base is looking for,” Elks said.

“This in turn allows us to bring our inventories closer to the customer, reduce lead times and therefore reduce risk.”

FLSmidth empowers its mining partners to work intelligently and proactively, considering the mediumand long-term opportunities rather than only operating in the now.

The OEM’s technologies enable miners to drive down emissions now, while orders can be made and processes put in place to decarbonise an entire flowsheet in the years to come.

“Decarbonisation is the answer, there’s no doubt about it,” Elks said.

“And we have to stop haul trucks from emitting diesel particulate – that’s one part of the puzzle. But that’s not going to happen until 2030–2035 when the battery technology catches up and capital equipment is changed out.

“Imagine if we could take 20 per cent off your CO2 footprint per tonne today. It’s not about what we’re innovating, we already have the technology available in some commodities now.”

With trials being conducted with some proactive mining companies,

FLSmidth’s vision for carbon-neutral mineral processing is coming to life.

Elks said the company is engaging miners operating in iron ore, manganese and coal before it builds out from there.

“We’re working with our mining partners to achieve greater beneficiation of their products, so less will go to waste, they’ll recover more, and they’ll ultimately have more saleable product,” he said.

“From studies we have conducted ourselves, supported by theoretical university papers, depending on the product and mine, we could recover up to 50 per cent of mine waste as saleable product.

“This would be revolutionary for a company’s footprint, their tailings requirements, and for reducing capital expenditure on the back end.

“It’s a multi-billion-dollar proposition for iron ore producers each year.”

To achieve a net-zero future, the Australian mining industry will need to ask itself some difficult questions.

Operational footprints will need to be cut significantly for Scope 1 emissions to be reduced, and measures such as the Safeguard Mechanism mean mining companies that don’t cooperate will be penalised.

The most effective decarbonisation plans will be implementing abatement measures now alongside medium- and long-term strategies.

This is where FLSmidth can help, with established beneficiation technologies that can drive down Scope 1 emissions per tonne now while converting mine waste into more saleable product.

industry is starting to have its ‘a-ha’ moment, but it’s going to take greater ambition if the sector is to grab its netzero imperative with both hands.

“This is my plug: between now and 2026, a transformation is going to happen in the Australian mining industry,” Elks said.

it will come from the suppliers, it will come from fixed plant, and it will come from mobile fleet manufacturers.

“We will transform the industry, but the miners have to come with us. They can’t just keep buying what they bought yesterday, or nothing will change.” AM

AS 2023 DRAWS TO A CLOSE, TOTALENERGIES TAKES A LOOK AT SOME OF ITS WINS THROUGHOUT THE YEAR, WHILE ALSO DETAILING WHAT 2024 MIGHT HAVE IN STORE.

Decarbonisation has long been a primary goal for TotalEnergies, and the company has found that 2023 events set the perfect stage to help get this message across.

“IMARC (International Mining and Resources Conference) 2023 was a great opportunity for us to showcase our multi-energy portfolio and our commitment to sustainable development,” TotalEnergies vice president – lubricants, specialties and B2B, Asia-Pacific Middle East, Vincent Minard told Australian Mining.

“We participated in speaking engagements and panel discussions, where we shared our insights and best practices.”

In Minard’s speech at IMARC’s Powering Mines with Renewable Energy Sources presentation, he said TotalEnergies is well-placed to help miners meet their net-zero goals.

“We have studied the various

decarbonisation roadmaps that the mining companies are developing and have noticed that they are not necessarily aligned in terms of products to be used, or the timing of when those products will be needed,” he said.

“At TotalEnergies we look at mining companies not as single entities, but as part of a local or regional eco-system, because we believe that by aligning the milestones on the roadmap we have the best chance of cost optimisation.”

TotalEnergies vice president – global mining, one B2B solutions, Dirk de Bruyn also spoke at the event.

As TotalEnergies continues to invest more in decarbonisation and mining, the company has seen its clients shift toward achieving operational excellence with low-carbon energies.

“We have a wide footprint and presence in over 130 countries, which enables us to transfer knowledge and expertise across different markets and sectors,” de Bruyn said.

“At TotalEnergies, we recognise the

challenges facing the mining industry today in understanding what roadmap they can follow to meet their net-zero objectives.”

With 2025 on the horizon, TotalEnergies is looking into what the mining industry needs and how the company can best support the journey to net-zero.

“There is a lot of work being done on battery-electric vehicles, full electric vehicles, hydrogen or natural gas, and everyone is wondering which new energy

TOTALENERGIES IS EXAMINING HOW IT CAN BEST SUPPORT THE MINING INDUSTRY’S JOURNEY TO NET-ZERO. TOTALENERGIES HAS SET ITSELF AMBITIOUS

will emerge as the winner in mining,” de Bruyn said.

“But we don’t believe that this a race where there will be only one winner.

“With the wide range of equipment in mining, coupled with a range of different life-of-mines and a mix of geographical locations, each with their own local policy and regulations, there is a likely to be a mix of solutions, and even this mix is likely to change as we transition through the options between now and 2050.” AM

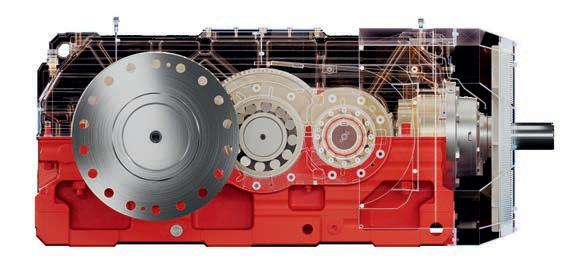

The global merger of Regal Rexnord and Altra Industrial Motion into Regal Rexnord IPS ushers in a new era in Industrial Powertrain Solutions. Renowned brands with world class powertrain products delivering end to end

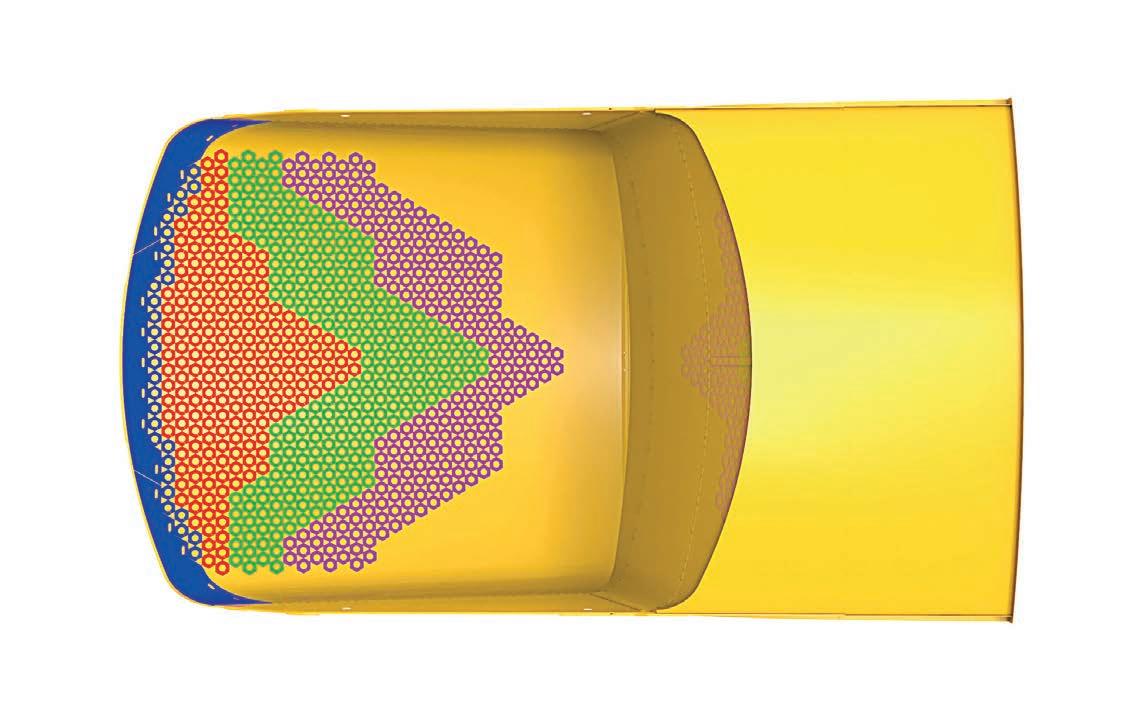

LIEBHERR HAS ALWAYS WORKED TO SUPPORT ITS CUSTOMERS WITH CUSTOMISED SOLUTIONS – AND THAT INCLUDES BUILDING THE BIGGEST EVER LIEBHERR BUCKET FOR THE BIGGEST LIEBHERR EXCAVATOR.

October 13 2023 saw the first of Yellow Iron Fleet’s Liebherr R 9800s roll off the build pad at Atlas Campaspe in central New South Wales, ready to go to work.

The mine, owned and operated by Tronox, has an approved life of 10 years with significant reserve upside. This consists of more than five million tonnes of heavy mineral, which will be processed and sent to Tronox’s pigment plants to produce high-quality titanium dioxide, a bright white pigment that adds brilliance and opacity to a range of everyday products.

In addition to being the first of its kind for Yellow Iron Fleet, this R 9800 is also a first of its kind for Liebherr.

The excavator comes fitted with a custom designed and built backhoe bucket, the largest Liebherr has ever built at 55m3 and the only Liebherr excavator bucket of this size.

The bucket was proudly designed and manufactured by Liebherr-Australia in collaboration with the customer Yellow Iron Fleet.

technical leader Martial Vicq explained the team designed the bucket, working

under certain constraints to ensure the best outcome for machine and customer.

“The overall design is based on the designs of the closest-sized bucket we have, beginning with the parametric design. Then we work with the customer to adapt the new bucket to their needs,” Vicq said.

“From start to finish, the design process, adapting all the dimensions and ensuring the bucket met all fabrication tolerances and ISO standards, took about two weeks.

“But in those two weeks there were many things we had to consider when designing a bucket this large. These include the machine this bucket was to go on, the weight of the bucket, and the physical build process in the fabrication workshop.”

The first consideration for Liebherr was the R 9800’s digging envelope.

“The standard R 9800 bucket, at 47.5m3, is already close to the upper limit of the R 9800’s digging envelope, and now we wanted to put an even larger bucket on it,” Vicq said.

“This meant we had to think of a way to increase the size while remaining

the inside bucket width from 4300mm to 5100mm, a boost of 18 per cent, meant the capacity of the bucket could be increased from 47.5m3 to 55m3, or 16 per cent.

Outside of this change on the fabrication floor, the final thing to consider was the weight of the bucket and what the machine could feasibly handle.

Each Liebherr machine is built to a specific rated suspended load (RSL), and going over the RSL limit could increase the risk of machine instability and reduced component lifetimes.

“We know the weights of various excavated materials and we know the weight that the machine can support,” Vicq said. “Using those bits of information, we were able to design the maximum-size bucket that would fit on the machine while still being productive.”

Increasing the bucket width meant it would be too wide for the standard twoplate bucket roll, which meant there had to be a change on the fabrication floor.

The bucket roll (or the rear roll section) on standard Liebherr buckets is

process for the R 9800 called for three plates rather than the standard two.

Day shift team leader Colby Jachmann from Liebherr-Australia’s fabrication team explained how the increased width impacted the build process.

“Of course, the main difference for this bucket, compared to the other buckets we build, is the sheer size of it,” Jachmann said.

“We have never built anything this big before, so it was a fun challenge for a lot of the team.

“When it comes to putting the bucket together, really the only change was just that we now had to weld three parts together to make the bucket roll. Having three plates does not compromise the strength or integrity of the bucket.”

The final designs came together and were sent to the fabrication workshop in Adelaide, where work began on putting together this mammoth bucket in early April.

Over the course of the build, the Adelaide fabrication teams put in over 2000 man-hours and used 975kg of welding wire. The finished bucket weighs in at around 47 tonnes,

LIEBHERR-AUSTRALIA’S LARGEST EXCAVATOR BUCKET, AT 55M³, FOR YELLOW IRON’S FIRST R 9800 AT TRONOX’S AUSTRALIAN MINERAL SANDS MINE.

In the realm of mining operations, bund walls serve as crucial safeguards against potential truck rollovers at the tip head. However if your bund wall isn’t compliant, it can instead slow productivity and heighten dangerous safety risks such as trucks traveling over exposed edges.

Decoda’s BundAware™ system utilises LiDAR technology to assess the angle, height, and proximity of bund walls - offering immediate in-cab notifications and enabling

drivers to proactively relocate to a more secure position near the bund wall.

The platform includes real-time heat map tracking analytics of non-complaint bund walls to facilitate prompt rectification and continuous improvement.

By building bund awareness, BundAware™ also builds mine site safety, compliance, productivity and profit.

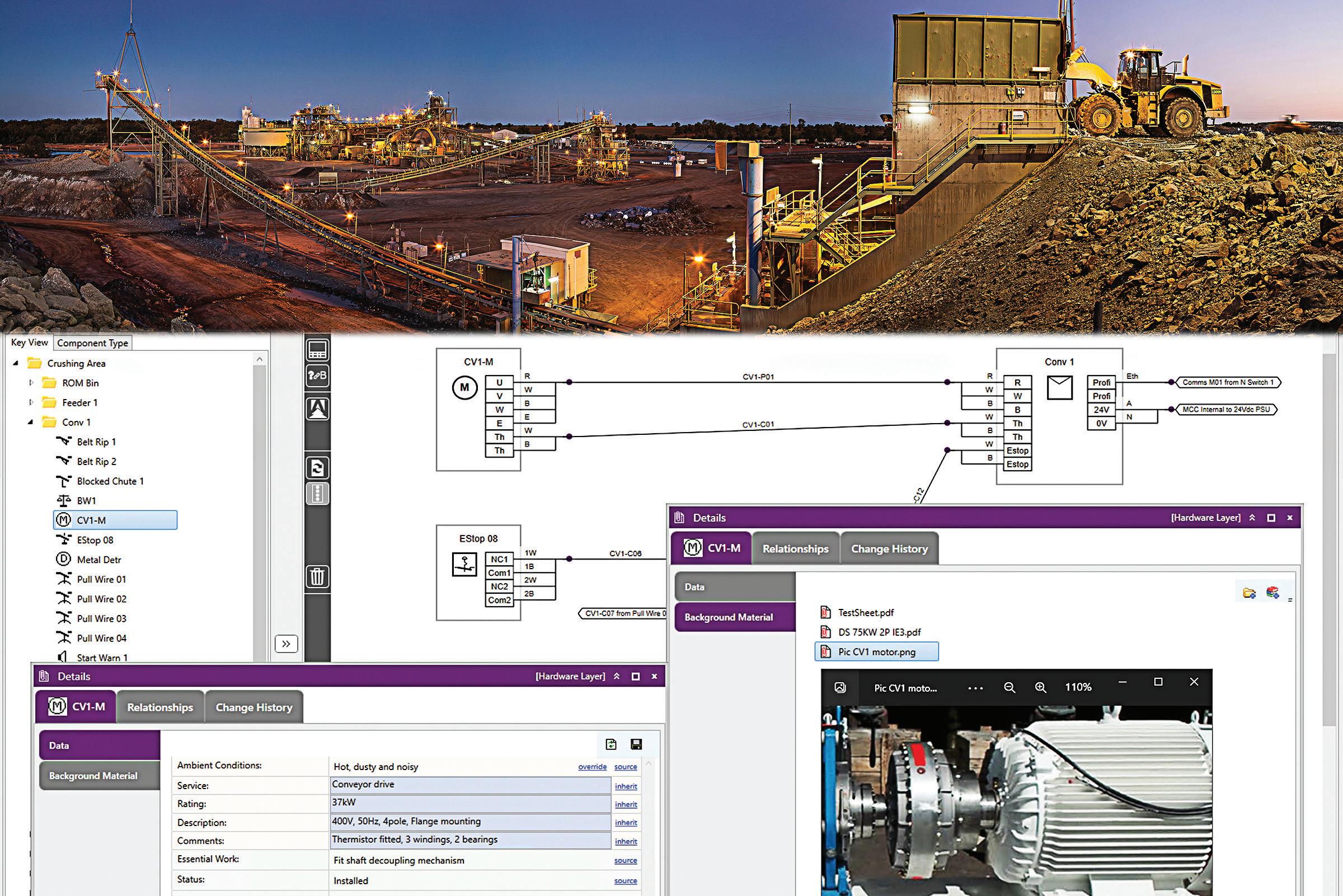

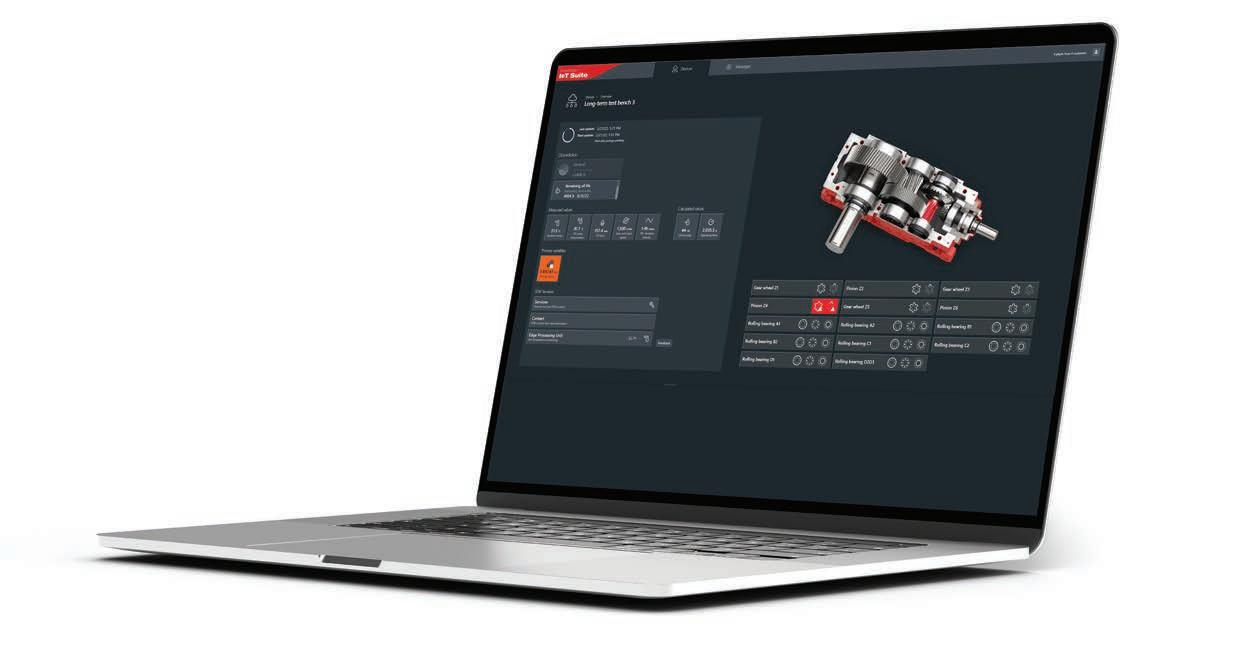

ASSET KNOWLEDGE OF CONNECTED SYSTEMS HAS BECOME MORE COMPLEX WITH THE RAPID RATE OF TECHNOLOGY ADVANCEMENT. DAD ENABLES THE TRANSITION TO A DIGITAL MODEL OF ASSETS.

As the owner of one of Australia’s leading electrical, control and safety system engineering companies, I&E Systems, Dermot Kennedy was no stranger to the world of documents and the time-consuming and costly work practices of his industry.

It became clear to Kennedy in the early 1990s that the design, delivery and management of complex systems could be done better.

“To invent a paradigm shift, you must have the technical engineering knowledge to do it,” DAD director of relationships Jim Stancombe told Australian Mining.

“The concept of DAD came to life on an electrical upgrade project in Western Australia. In the first instance, the asset owner had a severe blind spot when it came to their complex electrical and control systems.

“Errors in design documents left undiscovered will have exponential cost impacts the later they are found. In a digital model, errors are discovered much more rapidly due to the nature of collaborative and inherent self-checking.”

Seeing the asset owner’s problem as a potentially universal one, Kennedy conceived the software solution called DAD and in 1998 began to develop the tool.

Successfully utilised in over 200 projects, DAD has been used by some of the world’s leading companies on major projects across a range of industries. From small $50,000 projects to large billion-dollar undertakings, the DAD software solution reduces baseline costs by over 50 per cent.

But the DAD team aren’t content to stop there.

“The thinking behind how to detail the way systems work and how to manage asset information has rarely been challenged, yet technology has advanced significantly,” Stancombe said.

“The current document and asset management trends lean toward the digitisation of existing processes without consideration of why the processes exist and if they are still valid in a digital space. This is particularly the case in engineering and asset management.”

The team behind DAD is committed to transforming the way the resources industry works by disrupting the traditional supply chain.

As a transformational change to the fundamental capture and dissemination

DAD REPRESENTS THE COMPLEXITIES OF MODERN SYSTEMS IN A SIMPLE, DIGITAL WAY.

DAD EMBODIES ALL ASSET LIFECYCLES OF COMPLEX SYSTEMS, FROM DESIGN TO DECOMMISSIONING, AND CAN BE INTRODUCED AT ANY STAGE – THE EARLIER THE ADOPTION, THE MORE BENEFIT TO THE OWNER.”

of system information, from sets of drawings and documents to a digital model, DAD is not a like-for-like replacement.

“Our tagline is ‘it’s about time’ and this is where the significant savings come from, cutting time by working smarter than the current documentbased practices,” Stancombe said.

Traditionally, the supply chain is built around document-focused work practices between design, delivery and operations teams that work in silos.

These methods can be expensive and time-consuming and may result in information becoming more inaccurate and therefore less valuable as it’s passed

though the silos, meaning that what is delivered is not suitable to the needs of the downstream users.

“Our niche is disrupting the traditional supply chain to enable digital transformation in system engineering and asset management,” Stancombe said.

“DAD embodies all asset lifecycles of complex systems, from design to decommissioning, and can be introduced at any stage – the earlier the adoption, the more benefit to the owner.”

DAD improves engineering processes and associated management tasks between the separate-but-connected disciplines and lifecycle phases of a complex system by facilitating instantaneous information exchange through a system information model.

“DAD represents the complexities of modern systems in a simple way,” Stancombe said.

The DAD team is committed to working with its customers to ensure that they make the most of this powerful tool.

“If you’re doing a new project or an upgrade, we’ll help you do the system design and engineering for half the price.” Stancombe said. “We’re so confident in our system’s capability that we’re bringing further disruption to the supply chain by doing this work under a lump sum, fixed price agreement.”

“With a little understanding we can help clients establish the modelling method and support them to maximise their software experience.”

The DAD team recently enabled a major iron ore producer in the Pilbara to digitally transform their asset knowledge and work processes, saving them significant time and money. But this is just the tip of the iceberg.

“We have had our approach reviewed and supported by leading academics, researching errors and omissions on typical electrical drawings and the improvements in accuracy are staggering, particularly when you consider the excessive cost involved in reproducing drawings,” Stancombe said.

“Primitive methods are still being used on the latest and most complex systems. The same data is repeated numerous times across multiple drawings and each instance must be entered, checked and approved. Duplication of information across drawings and documents is an inherent problem eliminated by DAD.

“We want our clients to become leaders in the digital transformation of complex system lifecycles,” Stancombe said. “And the DAD team will ensure that they succeed.” AM

Demand for minerals combined with declining ore grades is creating new complications for the mining industry, especially when it comes to the environment. The amount of water and energy needed for extraction and processing is increasing, resulting in a growing environmental footprint.

With new sustainability-related challenges, such as increasing costs and risk, tighter regulations and your business needs and the new environmental demands are met.

With MissionZero, our ambition is to deliver innovative and digital solutions to the mining industry that support zero water waste, zero emissions and zero energy waste by 2030.

AQURA TECHNOLOGIES MATCHED TALISON LITHIUM WITH THE MOST SUITABLE PRIVATE WIRELESS NETWORK BY ASKING A SIMPLE QUESTION.

The first 4G private network in the global resources industry was born in Western Australia at a Rio Tinto mine.

Aqura Technologies managing director Alan Seery experienced it when he worked as Rio Tinto’s infrastructure and communications strategy principal.

“We first went live in 2013,” Seery told Australian Mining. “Now there’s about 60-plus private networks in Australia. It’s been quite a decade.”

Since July 2017, Seery has worked for Aqura Technologies in a variety of roles, most notably as its managing director since June 2022.

After collaborating with a range of miners and enterprises to introduce private 4G and 5G across Australia, Aqura Technologies is turning its focus to support the broader mining sector on its digitisation journey.

“The complexity and cost of private 4G and 5G technology has come down significantly as the ecosystem matures and there’s more vendors in the market. This, and the vastly expanded number of supported use cases, is making it more cost effective for miners to implement,” Seery said.

this is Talison Lithium, which engaged Aqura Technologies in October 2022 to support a significant private wireless network uplift and application integrations for its Greenbushes lithium operation in WA.

Talison saw a need to invest in a major connectivity upgrade as Greenbushes’ mobile mining fleet was planned for a significant expansion and remote drilling operations were on the horizon.

“Aqura is currently delivering a site wireless network using a mix of private 4G, point-to-point, and point-to-multipoint technologies,”

Talison Lithium operational technology manager Adam Radics told Australian Mining

“We are currently working towards the second phase of the project that adds some additional capacity and coverage. Aqura has been organised and disciplined in their process, following a well-engineered delivery methodology, while also being flexible and agile enough to cope with change.”

Talison’s new private wireless network was made fit for purpose and was designed for current and future requirement and use cases. Seery said this was made possible by asking questions outside the technology.

“After introductions via a partner

“We also asked Talison about their vision, where they are currently, and where they would like to be. That was the key conversation.”

While Aqura and Talison are in the early stages of their partnership, benefits are already standing out for the lithium miner.

“Talison has set some significant production expansion targets, and we are confident our new communications infrastructure, and the systems it enables, will support us to meet those targets,” Radics said.

“There are further systems and improvements that have, until now, not progressed as they weren’t technically feasible nor financially viable. This new shared private 4G infrastructure is an enabler for those projects to now come to reality.”

The success of the project so far

what Talison’s business needs were, before then translating that into a technology solution.

“One of the biggest challenges our industry has is defining reliability,” Seery said. “When you don’t know, you install two of everything because, in theory, if one goes down, at least you’re still operating. But that just blows out the budget and the specification around what you need.”

This is where companies with extensive experience like Aqura can help.

“Through nearly a decade working in this space, we know what works and what doesn’t, so we can deliver a very fitfor-purpose network that’s considerably more affordable and effective than what they originally thought they would need,” Seery said.

“Better matching outcomes with the technology is where we excel. That’s

WORLD-CLASS FACILITIES IN CENTRAL QUEENSLAND ARE SUPPORTING THE FUTURE TRAINING NEEDS OF THE STATE’S RESOURCE SECTOR.

Mtraining, workforce and research needs of the Queensland resources sector.

Rockhampton’s School of Mining and Gladstone’s School of Manufacturing are each delivering world-class facilities to support the skills needs of future workforces in central Queensland that are directly and indirectly involved within the resources sector.

The Australian Government provided $30 million towards the cost of the CQUniversity Mining and Manufacturing project, which includes the two purpose-built facilities.

Federal Assistant Minister for Education Anthony Chisholm said the facilities represent a major coup for the people of central Queensland.

“The Albanese Government is committed to delivering high-quality education, regardless of where people might live,” Chisholm said.

“These amazing facilities enable CQUniversity to train students in emerging areas such as automation and drone operations, and provide tailored spaces for the delivery of upskilling and professional development.”

The facilities provide state ofthe-art equipment to support skills training, education and research to ensure a pipeline of highly skilled and qualified workers to meet skills

demands across the region and into the future.

CQUniversity vice-chancellor and president Professor Nick Klomp said the university was committed to the development of its regional campuses, and the facilities provide enormous future benefit to the local community.

“Mining directly and indirectly supports thousands of jobs in the region and, in the longer term, these facilities in Rockhampton and Gladstone will further support regional Queenslanders to undertake the training they need for the jobs of the future within the resources sector,” Klomp said.

Klomp also explained how the development of the new facilities was a direct result of CQUniversity’s close engagement with community and industry.

“Through our work with industry and community, we developed a deep understanding of the region’s needs when it came to industry development, skills training and regional growth, and using this knowledge we worked with the Government to outline those needs and secure the required funding,” he said.

“These projects help to boost local economies and communities in the short-term while also supporting long-

term industry growth and regional development outcomes.”

Gladstone’s School of Manufacturing not only includes advanced training and research resources and equipment, but is also home to the Gladstone Hydrogen Hub, which supports the delivery of hydrogen training and research delivery.

The School of Mining and School of Manufacturing have sparked interested from industry players across Queensland, with collaborations developed to utilise the spaces and train the next generation of mining and manufacturing workers, including with resource and infrastructure training organisation MyneSite.

A resource and infrastructure training organisation, MyneSight provides teaching and assessment services to the open-cut and underground mining sectors.

The collaboration is designed to boost opportunities for students in the region by increasing the mining-related training available.

MyneSight general manager Larnie Mackay said collaborating with CQUniversity allowed the organisation to provide a seamless pathway for central Queensland residents to obtain quality surface and underground mining skills, from inexperienced entrants to future graduates to those wanting to maintain skills and those wanting to advance in their chosen field.

Hardox® 500 Tuf is the latest grade of Hardox® wear plate. It combines the hardness of Hardox® 500 with the toughness of Hardox® 450. The wear resistance of Hardox® 500 Tuf makes it possible to increase the load capacity by using a thinner plate and still have the same outstanding service life. Or stay with the same thickness and increase service life by 30% or more.

Hardox® 500 Tuf can also double as a structural steel. Its high yield strength and toughness allow for lighter mining bodies that are resistant to dents and can take impact loads with less supporting structures.

Get the full story of Hardox® 500 Tuf at www.hardox.com

LIGHTER MINING TRUCK BODY

HIGHER LOAD CAPACITY

EXTENDED SERVICE LIFE

LESS FUEL ON EMPTY RUNS

AS ORGANISATIONS ACROSS THE GLOBE BATTLE A BARRAGE OF CYBER-ATTACKS, VOCUS IS DETERMINED TO ENSURE ITS CUSTOMERS CAN WEATHER THE STORM WITH RESILIENCE.

Many wouldn’t associate mining with internet cybersecurity systems.

But they are as critical as the cybersecurity systems of any company in any industry.

A mine’s cybersecurity systems help guard against threats such as phishing, ransomware and data theft before they can cause harm to the business.

While a mine might not seem like a cyber attacker’s usual target, Vocus cyber specialist Stephen Mullaney says any company has the potential to become the focus of an attack.

“There are a lot of bad actors out there who deploy ransomware to disrupt other companies’ operations as their day-to-day business,” Mullaney told Australian Mining. “They don’t really care what industry it is as long as they can get in and put a company in a compromised position.”

Vocus state manager WA and national lead Simon Head said mines had traditionally implemented security to standard parameters, such as firewalls

that protect their systems from the outside world.

But criminals are getting much smarter about bypassing standard security barriers and cybersecurity systems need to be multilayered and resilient to yet-to-be-discovered forms of intrusion.

“Vocus runs highly secure networks and we have done so for decades,” Head told Australian Mining. “As the technologies evolve, and as organisations have looked to implement stronger, more robust security policies, we’ve evolved with the market.

“We have also established a number of partnerships with many of the leading security players in the market that complement what we already do from a network security perspective.”

Vocus has seen key mining players implement stronger solutions to help combat the threat of cyber-attacks to help ensure nothing can get to their employee data or safety measures.

“Some of the most forward-thinking miners have implemented things like network segmentation, which means that even if a bad actor were to break

into their internal network, they couldn’t go far,” Mullaney said.

“It also pays to separate your IT (information technology) and OT (operational technology) systems because if someone were to get into an IT system like HR or employee information, they can’t then jump to your OT system and mess with the autonomous vehicles or tailings dams monitoring systems. And vice-versa.”

Head said the challenges for miners lies in promoting cyber resiliency.

“Most organisations now understand that cybersecurity is necessary even if they haven’t previously experienced a cyber-attack on their systems,” he said.

“Vocus is helping these organisations stay resilient, stay online and ensure every part of their business is resilient to any form of attack.”

According to Vocus, cyber resiliency is the future of cyber-attack protection and should replace the traditional “throw money at it and hope it works” mindset.

“With a mine, so much of its information, monitoring and processes are there to ensure worker safety, so

mines are now starting to take cyber resiliency very seriously as a result,” Mullaney said.

“The cybersecurity landscape has changed dramatically over the last three to five years, so much so that it will be one of the first things a board will discuss when they meet.”

While cybersecurity may be the topic at board meetings, Head said all employees in a workplace have a responsibility to report anything suspicious going on.

“Vocus has an internal mantra of ‘see something, say something’, and we aim to help our customers’ organisations achieve a similar level of awareness when it comes to cybersecurity,” he said.

For Head, being part of a customer’s cybersecurity journey is something of which he and Vocus are especially proud.

“Vocus has decades of experience, and we want to share that with these companies,” Head said. “We’re happy to talk to any organisation in the industry, both now and in the future, about how we can help them build cybersecurity resilience, rather than being reactive to an attack when it happens.” AM

Stuck in the old way of doing things? Transform your system engineering and asset knowledge practices with DAD, a powerful software tool.

Discover how you can design and engineer systems at half

It’s about time.

NOW OPERATING UNDER NEW OWNERSHIP, THE PNG INDUSTRIAL AND MINING RESOURCES

EXHIBITION AND CONFERENCE IS SET TO TAKE THE PACIFIC NATION BY STORM IN JULY 2024.

Just 12 months after acquiring the PNG Industrial and Mining Exhibition and Conference, Prime Creative Media will showcase the redeveloped event in July 2024.

The premier event brings together Papua New Guinea’s industrial, mining and resources industries in one location, with over 100 displays of equipment and stands on show, while the conference will showcase experts from across the resources sector presenting on challenges and opportunities for the local industry.

“We are excited to bring our extensive knowledge and expertise to PNG Industrial and Mining Resources Exhibition and Conference,” Prime Creative Media chief executive officer John Murphy said.

“Our goal is to take the event to the next level through professional delivery and utilising our media communications channels and industry relationships to grow the conference and its attendance.”

The conference offers an opportunity to hear from experts in areas such as government, mining, energy and infrastructure presenting on topics like productivity, safety, sustainability, and innovation in technology and equipment.

Information sessions will focus on a variety of topics and feature

presentations followed by an engaging panel discussion with the audience.

PNG Mining, Prime Creative Media’s new magazine and the event’s official publication, also launched this year, focusing on the mining industry in Papua New Guinea and the surrounding region.

Murphy travelled to PNG in October to officially launch the publication.

“It was great to connect with industry leaders and officials to launch PNG Mining,” he said. “We had great feedback from these meetings and are looking forward to working closely together in the future.

“This publication will be a champion for the entire Papua New Guinea resources sector, so it was important that we meet with professionals and decisionmakers from across the local industry.”

With 2024 shaping up to be a bumper year for the Papua New Guinea resources industry, there is little doubt discussions at the event will be lively.

Some of the biggest news to come out of the Pacific region in 2023 was Newmont’s $26.2 billion acquisition of Newcrest, a process that has spanned the better part of a year.