RIVET Mining Services (RMS), one of the largest providers of bulk haulage and onsite services to mining companies in Western Australia, has gone into receivership.

In a preliminary statement, receivers FTI said that extreme weather events, project delays, labour shortages, and cost pressures had led to the company’s demise.

FTI added that its appointment related only to RMS, and not to the broader Rivet Group.

“All other entities of the Rivet Group will continue to trade in their usual manner and have the ongoing support of their senior secured lender to the group to do so to ensure that customers, suppliers and employees are not adversely impacted,” FTI said.

RMS was headed by Mark Rowsthorn, a co-founder and executive director of Toll Holdings and chief executive of Asciano as well running the McAleese Group that collapsed in August 2016.

RMS, which was part of McAleese, owed creditors almost $100m when it collapsed. Creditors later agreed to a deed of company arrangement.

According to its last nancial report lodged in 2017, RMS continued to be impacted by lower iron ore prices, signi cant weather events and

eet repairs and maintenance.

e Rivet Group emerged from the McAleese collapse in December 2016 with Rowsthorn at the helm.

It later emerged that investment house Varde Partners, which had acquired all of Rivet’s debt, were so concerned about the nancial health of Rivet Group that the distressed debt fund en-

gaged Ernst & Young to set out options in case the business collapsed – six months before it called in administrators.

e collapse of RMS comes months after Clough, a much larger WA contractor, called in administrators with $248 million owed to creditors including $88.7 million to the joint venture building

the Snowy 2.0 hydropower project for the federal government.

e TWU said it is working with RMS administrators to ensure workers are prioritised throughout this administration process.

TWU national assistant secretary Nick McIntosh said wafer-thin margins are unsustainable for any business,

but in transport they are the norm.

“We’re seeing hundreds of transport workers losing their jobs and supply chains plunged into chaos because operators are unable to survive the upsurge of operating costs like fuel, severe weather events, or project delays without regulatory support to recover those costs from wealthy clients,” he said.

“Driver shortages are the result of an industry in crisis. Truck driving used to be a career people were proud of, now it’s the cause of unrelenting stress and deadly pressure.”

Company collapses in March soared more than 20 per cent across Australia and Scott Taylor, a partner at law rm Taylor David, said the recent spate was only the “tip of the iceberg”.

“When you start seeing global banks getting anxious, being sold o or collapsing, it’s a clear indication of wider uncertainty, with more to come,” he told News Corp.

“What happens is that people become nervous and start selling down. Term deposits are generating a more certain yield than the stock market. Global markets have been struggling since the middle of last year, and they still have a long way to go. Consumer con dence has declined.”

A WODONGA-based heavy vehicle mechanic has had its ne increased following a fatal truck crash that claimed three lives in 2014, after the initial sentence was appealed.

Earlier this month, the Court of Appeal heard the $210,000 ne and conviction initially imposed on Heavy Mechanics Pty Ltd last year was manifestly inadequate.

It has now been increased to $350,000.

In June 2021 the Wodonga County Court found Heavy Mechanics guilty of a single

charge of failing to ensure, as far as reasonably practicable, that people other than employees were not exposed to risks to their health and safety.

e court heard that in August 2014, a petrol tanker serviced by the company de-coupled on the Wodonga-Yackandandah Road at Staghorn Flat.

e detached trailer crossed the road and struck two cars travelling in the opposite direction, killing all three occupants including a four-year-old child.

A WorkSafe investigation found the tow-eye coupling that connected the prime mover and trailer was excessively worn and had failed under load. At the time of the incident, it had been used for more than three years and 350,000km.

e court heard Heavy Mechanics had serviced the truck just days prior to the incident, including testing the tow-eye coupling, but that testing did not involve an accurate visual inspection or testing while the truck was detached from the

trailer, and that this had limited the ability to inspect the parts involved.

A jury found it was reasonably practicable for the company to have conducted more accurate testing and inspections, which would have revealed the wear and tear to the coupling.

WorkSafe executive director of Health and Safety Narelle Beer said WorkSafe would not hesitate to appeal sentences.

“ is horri c incident cost three lives, including a young child, and caused untold trauma to their loved ones and

community,” Dr Beer said.

“While no penalty can ever make up for this terrible loss of life, this sentence sends a strong message to duty holders using our roads that they must consider not only the potential risks to themselves and their workers, but also the potential catastrophic impacts on other road users or members of the public.”

Heavy Mechanics boss Keith Haire declined to comment at deadline for this issue, but told Big Rigs he would have more to say at a later date.

A SOON-to-be-hatched minimum standards’ body and its guiding legislation will not be a repeat of the ill-fated Road Safety Remuneration Tribunal (RSRT), assures Gary Mahon, CEO of the Queensland Trucking Association.

Mahon, who’s had a seat at all the early roundtables on the looming changes, was quick to dispel the commonly held myth that the RSRT was being resurrected by Labor, along with an updated version of its much-maligned 2016 Payment Order that profoundly disadvantaged owner-drivers.

“It is not a mechanism to introduce freight rates,” Mahon told attendees at the recent Trucking Australia conference in a session he co-helmed titled What Minimum Standards Look Like.

Although exact details are still to be hammered out, Mahon said that this time round the industry body would be a division of the Fair Work Commission – rather than a standalone entity – with perhaps two or three industry advisory groups appointed to assist commissioners with their decisions.

“What this process is look-

ing to try and do is bring some balance back into the equation, so you’ve got an opportunity to reasonably compete,” he said.

Mahon cited the example of contract negotiations as a prime area where a FWC body could assist in determining what’s reasonable, and what’s not.

“How many of you have been through a contract negotiation in which you have to meet the market?” he asked.

“How many have contracts with continuous improvement provisions in them so every 12 months you have to nd something between 3-5 per cent productivity improvement, and this is in an environment with 7 per cent in ation, on average?

“What about discretionary rate reviews? At the discretion of whom?”

Mahon told conference delegates that one large eet member had told him recently that a client demanded that the operation reduce rates by 3 per cent.

“He was told, ‘If you can, we’ll extend the contract by a year, if you can’t we’ll go back to the market’, and that’s not unusual.”

Mahon also said that it’s essential that every participant

who “exercises economic power” in the supply chain is captured by the new legislation. at includes freight forwarders and anyone else working in the rapidly emerging gig economy sector.

“ ere is no point to two or three players being captured by this legislation while the bigger end of town just sits and watches,” added Mahon.

“You’ve got the big end of town continually trying to lower the ceiling and the gig economy working away in competition. If we don’t act there is going to be collision in the middle and this industry is going to hurt a hell of a lot.

“Every day we are hearing more and more about how gigtype workers are inching their way into this industry.

“When this happens you’re going to have a competitive environment where you’re the one expected to be buying low carbon vehicles, the best PBS equipment for safety, you’re the one expected to apply all these standards, and employ people under a set of standards, and you’re going to be competing against a group who fundamentally don’t have to adhere to any

of those standards at all while running gear that is 12, 15, 20 years old.”

Mahon told the conference that he believes the minimum standards legislation could be tabled as early as late August, but he doesn’t expect it to come into play until well into next year.

Just a few days before the conference, Mahon joined a 30-strong delegation of truck drivers, rideshare drivers, food delivery riders, transport operators, employers and associations at Parliament House to meet with parliamentarians and call for the passing of transport reform.

Over two days, Mahon’s allies included Australian Road Transport Industrial Organisation secretary Peter Anderson, Western Roads Federation CEO Cam Dumesney, major transport operator ACFS CEO Arthur Tzaneros, and TEACHO chair Paul Ryan, along with truckies and and the Transport Workers’ Union. e delegation shared the urgency of passing “lifesaving reform” to set fair, safe and sustainable standards in transport.

TWU national secretary

Michael Kaine said it is important that politicians hear directly from workers and employers alike about the realities of working in an industry in “crisis”.

“Just this year, transport has su ered devastation after devastation,” said Kaine.

“ is year has also seen wealthy supply chain clients reaping enormous half-year pro ts. ese are pro ts reaped

from the razor-thin margins of transport operators, piling deadly pressure on workers and causing thousands to lose their jobs to administration.

Kaine said the transport industry needs safe, fair and sustainable standards to rebalance transport supply chains, ease the pressure and ensure trucking can thrive long into the future.

AFTER months of inexplicable delays – and a costly review – the rst draft of the new look Heavy Vehicle National Law (HVNL) should be coming together by the end of the year, promises Minister for Infrastructure, Transport, Regional Development and Local Government, Catherine King.

Speaking at Trucking Australia 2023, the Australian Trucking Association’s annual conference on the Sunshine Coast on March 31, King told attendees that Labor had made “real progress” on the reforms since coming to o ce 10 months ago.

With the National Transport Commission taking the lead – the same agency that ATA recently blasted for running a circus – King said a “comprehensive” Regulation Impact Statement has been prepared and is going to transport ministers this month for consideration.

“Our goal is a completely revised Heavy Vehicle National Law that is more exible, risk-based and that makes better use of new technology,” said King.

“ rough this process, governments have agreed to automate, as far as possible, the system through which heavy vehicle operators apply for restricted vehicles access on certain roads – and have begun work together

towards that end.”

King said Austroads is coordinating work towards a national, single seamless system for heavy vehicle access, while Victoria is leading work on cost-bene t modelling of providing as-of-right

access for high productivity freight vehicles.

“And the National Transport Commission and the National Heavy Vehicle Regulator are developing further detail of the new two-tiered system for managing driver

fatigue.

“We will be sharing a fuller update on all those actions shortly and – with many of these measures being considered out of session – it gives us time to talk to you but also to get on with our focus on large scale economic reform.”

In order to keep industry informed, King said she was also pleased to announce that heavy vehicle industry representatives will now be invited to attend select Steering Committee meetings to provide their views directly to senior decision makers on particular topics and to discuss progress.

“ ese reforms matter to you, so you should be involved.”

King also talked about how the Albanese government is already delivering on major freight infrastructure projects, including the Co s Harbour bypass, and additional funding for the Nowra Bridge, among others.

She also updated the conference on the new rest area steering committee and said that applications seeking a share of the $140 million will be invited in the rst

half of the year.

“Of course, though, none of these investments come cheap,” added King when discussing the proposed changes to the Road User Charge.

“ e reality is, road upgrades cost money.

“Governments across Australia are planning to spend around $33 billion on roads in the 2023-24 nancial year alone.

“In total, cost recovery from heavy vehicle operators is set to raise $3.8 billion over the next twelve months – with roughly 60 per cent of that coming through the road user charge.

“At the same time, the fuel tax credit – a measure the previous government put in jeopardy by not consulting with you when they dropped the fuel excise – sees $8 billion returned to the industry every year.”

King said any decision state and commonwealth ministers take on the RUC will be designed to lock in certainty over the next three years.

“We all want better roads – nobody more so than truck drivers – but we have to be

able to fund them. Particularly as we have the Victorian Farmers Federation, the Local Government Association and the Automobile Association calling for billions of dollars in additional funding, particularly on our regional roads.

“ at’s what responsible governments do – they listen, they deliberate and they take decisions in everyone’s interests.”

King also touched on the role industry is playing in helping to reduce greenhouse gas emissions.

She said transport is predicted to become Australia’s largest source of emissions by 2030.

“With our commitment to net-zero emissions we need to drive these down – whether it be through hydrogen highways, electric vehicles, or cleaner fuels.”

“ is ingenuity is why I am con dent that Euro 6 emis-

sions standards can be phased in for new trucks and buses, from November next year.

“ is will bring Australian noxious emissions standards closer to those already in place in the UK, Europe and elsewhere.”

In making this change, King said she’s conscious of the development costs faced by industry to meet steer axle mass and vehicle width limits when introducing low and zero emission heavy vehicles to their eets.

“ at’s why our government is working closely with the heavy vehicle industry through the National Transport Commission and the National Heavy Vehicle Regulator to settle any outstanding concerns before the implementation of Euro 6.

“We have to take these steps – even when they might be di cult – because the alternative is too damaging.”

MODERN roads must be funded by a system which secures road funding into the future, and is fair, transparent, and predictable.

at was one of the key takeaways from a wide-reaching snapshot of major industry issues, Trucking Australia: e Report, which was released by ATA CEO Michael Deegan at the recent Trucking Australia conference.

“A system which proposes 10 per cent tax increases each year for three years is broken,” said the report.

“ ere is no accountability about how funding is spent.

ere is no concern for the ability of business to pass on costs and survive.

e probe said road-related fuel excise revenue is eroding due to improvements in vehicle fuel e ciency, despite the increasing number of kilometres that Australian vehicles travel. Increasing numbers of electric and zero emission vehicles will only accelerate this trend.

“Our road user charging system is breaking down. Declining revenue will only increase the likelihood of extreme price hikes into the future.

“In the absence of national road user charges reform, the proliferation of state-based road user charges for electric vehicles will further undermine the goal of having a

SYDNEY

510 Victoria Street, Wetherill Park NSW 2164

Ph. 02 9756 6199, email: isri@isri.com.au, www.isri.com.au

BRISBANE

3/120 Gardens Drive, Willawong QLD 4110

transparent, sustainable and fair system for funding Australia’s road network.”

e ATA said Australia can’t a ord eight di erent taxes, with di erent rates and systems, on how Australians drive.

As an example, the report cited Victoria’s new EV tax which applies on Victorian vehicles even when they are not driving in Victoria.

“State-led road tax confusion will disadvantage the funding of roads in states with large road networks and smaller vehicle eets. We can’t a ord to make our regional and remote roads even worse.”

e solutions that the ATA is proposing include:

• A lower pathway for road user charge increases of zero per cent in 2023- 24 and then 2 .75 per cent in 202425 and 2025-26, instead of the increases of up to 10 per cent each year under consideration by governments.

• A lower road user charge for remote Australia, which would save remote area trucking operators and extra 13 .6 cents per litre on the cost of fuel.

• long-term reforms to the broken heavy vehicle cost base and road user charging system.

e report also highlighted the lack of progress on rest

areas for truckies, citing a government audit 15 years ago that found not a single route met rest area guidelines.

“ at audit should have led to this issue being xed in the 15 years which has now passed . “For too long the approach to xing rest areas has felt like governments have only been interested in applying Bandaids – with only a limited supply of Band-aids – rather than approach the issue with a comprehensive strategy.”

In recent years, the ATA said average annual federal funding under the dedicated program for rest area improvements was delivering well under $10 million annually for truck rest areas.

“Rest areas became an afterthought even in the dedicated

funding program designed to x them. Industry has warmly welcomed the Australian government’s commitment of an additional $80 million for rest areas over the next four years, with input from drivers and industry into the funding program. is is a strong downpayment on xing an issue which has been forgotten and ignored for too long.”

e ATA said it has campaigned for minimum rest area standards, which governments would then need to ensure are delivered.

“ ese standards should include the distance between rest areas, their design and a requirement that new rest areas on the national highway network be able to accommodate 53.5m combinations.”

Ph. 07 3275 2044, email: sales@isribrisbane.com.au, www.isribrisbane.com.au

MELBOURNE

Unit 1/569 Somerville Rd, Sunshine West VIC, 3020

Ph. 03 9311 5544, email: sales@isrisunshine.com.au, www.isri.com.au

MACKAY , Ph. 07 4952 1844, email: admin@isrimky.com.au, www.isriseatsmackay.com.au

PERTH R , WA 6106

Ph. 08 9362 6800, email: info@mmtisri.com.au, www.mmtisri.com.au

DARWIN

Mobile Sales and Service

Ph. 08 8927 0986, email: info@isridarwin.com.au, www.isridarwin.com.au

ADELAIDE

TAMDELE, 21 Hakkinen Road, Wingfield SA 5013

Ph. 08 8347 1222, email: sales@gitsham.com.au, www.gitsham.com.au

NEWCASTLE/HUNTER VALLEY

Unit 2/13 Hinkler Ave, Rutherford NSW 2320

Ph 02 4932 0600, email: sales@hvss.com.au www.isri.com.au

THE transport industry is all too aware of the critical skills shortage disrupting operations across Australia. Understandably, the shortage was a trending topic at Australian Trucking Association’s recent Trucking Australia conference.

Consistent with the 2023 conference’s tag line, “sparking solutions, powered by you”, conference delegates were invited to have their say on the matter in the Creating the Industry’s Workforce Strategy session.

After seeing the success of the Aged Care Workforce Strategy, CEO of the Western Roads Federation, Cam Dumesny, proposes and leads the creation of a similar national workforce strategy for the transport industry.

Along with Industry Skills Australia director of implementation and capability, Klausch Schmidt, and Ainsleigh Bilato of the National Road Transport Museum, Dumesny directed delegates to consider four key questions: How do we attract more people from di erent backgrounds into the indus-

try, how can we train our sta better, how can we retain sta in the industry and how can we improve the industry’s image?

Recognising that the ATA and its member associations do not have all the answers to inform a comprehensive solution, the responses and subsequent discussions of delegates were recorded for inclusion in the strategy.

Despite a 16 per cent increase in industry participation between 2021 and 2022, the demand for skilled workers continues to outweigh the current number of personnel active in the transport industry.

Attracting new personnel to tackle this gap is, therefore, a priority of the strategy. Schmidt suggested that the industry must be mindful of only addressing the shortterm de ciencies, noting that it needs to consider what skills employers will require in a one-, three- and ve-year timeframe.

For Schmidt, the answer to attracting new personnel lays in thinking outside the box, such as by exploring the opportunity for job sharing.

is was echoed by delegates who spoke of a changing transport industry in which exibility and a healthy work/ life balance is possible, opening the industry to parents and employees in the mining industry who are accustomed to a FIFO roster.

Targeting a younger demographic through school visits and informed career counselling was proposed, allowing the industry to show

school-leavers that a career can be found in transport, rather than an interim job.

E ective and ongoing training was recognised as a method of both attracting new personnel and retaining current personnel within the transport industry.

Western Australia’s Heavy Vehicle Driving Operations Skill Set was cited as a model that could be replicated by other states, in which trainees

undergo both theoretical and hands-on driving instruction training to obtain a HR, HC or MC licence to produce con dent and competent operators. Delegates indicated re-training and cross-training could aid in empowering and re-energising existing personnel.

While practical courses such as forklift and rst aid training were popular suggestions, courses that focus

on operator wellness were also proposed, such as nancial management and mental health awareness.

Delegates were asked to consider how we can improve the industry’s image to both internal and external stakeholders, including by emphasising its rich heritage. e outstanding technical developments in transport are most clear when juxtaposed against its rich history, telling the stories of the machines and operators that paved the way for those in the industry today.

Storytelling, from the contributions of transport operators to Australia’s most recognisable infrastructure to the role that migrants have long played in powering the industry, provides a channel through which the industry creates interest and pride in its work.

e use of social media to share these stories, particularly in a visual format, was recommended to reach a wider audience and, simultaneously, show the diversity that delegates have come to appreciate in the transport industry.

Fuel saving - e driver doesn’t need to use the truck to let the parking cooler work because VIESA Kompressor III works only with truck batteries

Longer battery life - e new automotive electronics reduce the charge/discharge cycles. is means that batteries have less stress and increase their life

The reliable, powerful parking cooler for a refreshing rest

e Viesa Internals and Platinums are designed for all trucks, 12 or 24 volt options ey are the same units but the Internal is tted to the external back wall of the sleeper cab and the Platinum is tted to the external roof of the sleeper cab.

• Cheap to t / run (water based)

•Supplied with a remote control

•6 to 8 hours usage time depending on truck batteries

•Quiet to run

•8 speed fan

•Annual servicing is required to keep it running to it’s full potential

•1 year warranty

Fitted Priced From $3,900.00 + GST

e Koolkat is designed for larger sleeper cabs.

e unit comes with 2 x auxiliary batteries and a charger which will charge as the truck is driving. It works exceptionally well in all weather conditions, dry or humid Colour matching extra

National Authorised Installers

Total weight 14 kgs Battery consumption 12.3ah Most efficient on the market

e Ecowind is a diesel powered unit designed for a range of truck types ere are a few di erent tment styles depending on your truck

•Side mount on chassis - Standard tment

•On top of chassis & Rear of chassis - Extra cost

JAMES GRAHAM

JAMES GRAHAM

WHAT an incredibly sad start to the year it has been for our truckies on the roads.

As I write this, according to numbers from the Transport Workers’ Union, 19 drivers had lost their lives.

That’s 19 too many. Everyone should turn up to work and expect to return home safely at the end of their shift. Yet trucking continues to live up to its unfortunate tag as the most dangerous occupation in Australia.

Why is that when we’ve made such incredible advancements in safety technology in recent times?

I don’t have any easy answers for you here, but it’s no wonder that momentum is gathering in Canberra for some kind of over-arching body to police standards across the board, particularly with the rise of the gig economy which isn’t subject to the same checks and balances as other sectors. If it saves one life, it’s worth trying.

DAVID Vile’s heart-warming yarn about a 1977 Dodge restored as a tribute to the busy newspaper trucks that used to ply the highways of Australia evoked plenty of fond memories from readers.

Wrote Peter Cross: “My first driving job was back in the early 1980s for AJ Bush at Rockdale delivering carton meat and smallgoods. I drove a similar Dodge with a 245 hemi six with a 4-speed from Rockdale to Campbelltown-Wollongong-Kiama, 5 days a week. Used to sit on

110km/h on the freeway coming home empty, the little 245 would be screaming its head off but it never gave up.”

John Stanford recalled driving for Wes Searle circa 1975 from Sydney to Dubbo with the Sunday papers in a 360 Dodge V8: “Used to get $43 for the trip.”

Jeffrey Dukes just finished 46 years in newspapers on the Darling Downs: “My dad delivered papers for 59 years before he had to give it up.”

Added Tony French: “I spent 11 years in paper trucks

THE clip we shared of a truckie’s dramatic escape from an apparent brake fail on Mt Victoria in the Blue Mountains, NSW, divided our online followers.

David Gaudron reckoned the driver did a great job to control the truck.

a lesson on how one; A: selects the appropriate gear prior to descending a steep hill, and B: locates the engine/exhaust brake switch.

Matthew

racing up and down the east coast. Mmmm…the good old days when we wrote our own rules. I had a ball.”

“I had exactly the same situation on Toowoomba range 30 odd years ago bloody terrifying situation. When you get to stop, you just don’t know how you manage to get to the bottom without incident. Good driving mate.”

Many others, such as Andrew Hetherington were not so sure. “Looks like someone needs

James Atkins doubted it would be mechanical failure: “That would be just a complete coincidence on Mt Vic…He rode the brakes too long simple as that.”

Bill Valentine also felt the driver may have been at fault: “I don’t understand how people lose their brakes down there if they drive appropriately, just because it is sign posted to 40km/h it doesn’t mean you can do that speed safely.”

Helen Gelling, however, was more concerned with the motorists caught up in the drama. “The numpty in the caravan wasn’t gonna budge for no one. Just move over and brake.”

PURCHASE A HELLA S SERIES WORK LAMP & GET A FREE POLO

The ultimate wheel finish, crafted without compromise.

ArmourBrite combines superior performance with long-lasting shine for a premium, easy-clean wheel finish. Championing durability, protection and style, ArmourBrite is exclusively created by Armoury Wheels, for wheels that go the distance.

CHOOSE ARMOURBRITE VISIT US AT THE BRISBANE TRUCK SHOW MAY 18 - 21

drop forged wheels value

resistant cleaning time gloss

BY JAMES GRAHAM

BY JAMES GRAHAM

VETERAN truckie Graeme Nicholson, 59, can recall the life-changing moment like it was yesterday.

He’d driven back from Adelaide to his Maclean depot on the NSW Mid-North Coast, and quietly taken himself o to bed as he’d done after countless other runs over the previous 32 years at the helm of Nicholson and Page Transport with wife Meredith Page, 57.

“I got up in the morning and said to Meredith, ‘I don’t feel real good and I had no indicators, nothing’,” recalled Nicholson of that fateful March, 2022, day.

“ e next thing the pressure on my chest was like an elephant standing on me and I just got worse and worse.

“Luckily we only live about two minutes from the hospital, so I said [to Meredith] I’ll get into the car if you can get me over there.”

After hooking Nicholson up to an ECG machine, it didn’t take long for the doctor to make a diagnosis.

“He told me, ‘You’ve just had a massive heart attack’. en I clocked o , they had to get the jumper leads on me and re me up.

“It’s pretty dark on the other side, very dark and quiet. Don’t let anyone tell you otherwise.

“When I woke up, I said to the doctor, “I think I had a little sleep’, and he said, ‘You had a lot more than that’.”

Nicholson’s heart had stopped for about 90 seconds, and he was quickly rushed north by helicopter to John Flynn Private Hospital on the Gold Coast Hospital for an emergency stent procedure.

Nicholson was soon back on his feet, however, with the positive lifestyle changes he’s made as a result of the scare still playing out to this day. Although he never considered himself unhealthy – he doesn’t smoke or drink excessively – Nicholson has upped the exercise and dropped 12kg since the heart attack to tip the scales at a relatively svelte 90kg.

He’s also made sure all his mates go and get their tickers checked out too.

But perhaps the biggest result of his cardiologist telling him to take the stress out of his life happens this month with half of the Nicholson and Page 10-strong eet going under the hammer in a Ritchies unreserved online auction on April 19-20.

With their two children Chloe, 27, and Harrison, 24, pursuing other interests and careers, Nicholson admits it was probably the hardest business decision he and his wife have ever had to make.

“Trucks have been a big part of our life, and there’s a lot of people who have relied on us over the years.

“Our drivers have had to move and nd other jobs and I’ve tried to help them in that way, and our customers that we’ve been loyal to and they’ve loyal

to us for many years, and we’re still trying to help them out but eventually they’re going to have to transition to someone else.”

e loyal sta includes longtime truckies such as Owen Weir, who has been there for nearly 10 years, and Danny Donegan and Roscoe Hooper who are approaching two decades of service.

“ ey’re part of the family, part of our DNA too I guess.”

From humble beginnings with a single Ford Louisville in 1991, Nicholson is proud of the way he and Page have built up the operation to be a regional powerhouse in the bulk haulage game today.

In all those years, the distinctive blue, green, white, and yellow livery has only ever been involved in two crashes, neither one serious.

“ e highlight has probably been a lot of the drivers,

they’ve been a lot of fun,” reected Nicholson.

“ ere’s been a lot of good times with the drivers. ey become part of the family, and that’s the hardest part [about winding down].

“Also, the service we give is another highlight for me, it’s second-to-none.

“People can take for granted the way we do the job, the way I expect the job to be done, and when we’re not

there and they’ve used someone else, and the service is sub-standard, they realise how good our drivers are at what they do.”

Sadly, Nicholson says it’s the driver shortage that is also contributing to his decision to start winding down toward retirement.

“In the last 12 months we’ve had three trucks parked in the yard, which I’ve never, ever had. I just said to my wife, this

a recent health scare, this revered NSW transport duo is reluctantly taking a step back after 32 years in business on the state’s Mid-North Coast.

is so hard. I’ve never seen it this bad.”

Nicholson believes the industry has, to a large extent, brought the crisis on itself by doing away with the age-old mentoring system that saw fathers have sons ride along every step of the way to learn the ropes.

If he has a message for other operators wanting to hang on to the truckies they have, it’s to treat drivers with respect and involve them in your everyday business decisions.

“I bounce everything o Dan-

ny and Roscoe. You need to involve the drivers and make them feel like part of the business and be prepared to stand up for them too.

“ e old saying that the customer is always right, isn’t necessarily always the case, because sometimes the drivers get accused of things and if I know they haven’t done the wrong thing, I’ll stand up for drivers all the time and argue with whoever.”

Nicholson believes it’s imperative to always back your drivers and give them your trust.

“I could leave a $100 note in any one of my trucks and in six months’ time that $100 note would still be in there.” ere are things, however, he won’t miss when he eventually does hook up the caravan or pack a bag to spend a few lazy days visiting his rst grandchild due in September.

“Compliance has done nothing for the industry – the NHVR is the greatest debacle I’ve ever come across,” he said. “I’ve tried and tried, been to several conferences with the NHVR and suggested ways

we could manage fatigue a bit better, but they aren’t interested in listening one little bit to the people from the coalface.” Nicholson says you only have to look at the Performance Based Standards system to see the divide at its most glaring. “I’ve got a 610 with drop deck trailers on and its 100ml over length. It’s 26.1m long and we got booked for being 100ml over, yet if I put an A-trailer on that combination so it’s got two A-trailers and a B-trailer and go to 35m I am legal to drive on that same road. It’s ridiculous.

“It’s so hard for us little blokes to break into that PBS system because we have to have our trucks versatile to do everything. We just can’t a ord that.

“I’ve got 40 years under my belt, I’ve almost done nine million kilometres myself and done everything in this industry except cart cattle and fuel, and I have these shiny-arsed people trying to tell me that I’m not compliant.

Don’t get Nicholson wrong, though. For all the many frustrations and challenges the

industry faces, he still thinks it’s a great time to be in road transport.

“If I was younger, I’d be diving into it head rst,” said Nicholson, whose best tip for newcomers is do your homework on how much it’s costing to run each kilometre.

“ ere’s a shortage of trucks, there’s a massive amount of freight about and you can negotiate a good rate.

“If you’re not making money out of trucks right now, you probably shouldn’t be in the game, it’s as simple as that.”

Krueger have opportunities in Heavy Vehicle Technicians, Fabrication, Sales and many more across our Manufacturing, Service and Spare Parts divisions in Melbourne, Sydney and Brisbane.

With immediate starts, job security and a great family business atmosphere, contact us for all available positions. Contact you nearest branch and discuss your opportunity today.

Expressions of interest for roles may be sent to recruitment_@krueger.com.au

RON Finemore was the recipient of the Don Watson Memorial Award at the Foundation Sponsor’s Gala Dinner held at the conclusion of the Trucking Australia 2023 conference on the Sunshine Coast late last month.

e Don Watson Memorial Award is presented to an individual in recognition of them having given conspicuous service to the Australian trucking industry.

Finemore is the executive chairman of Ron Finemore Transport and has over 60 years’ experience in the Australian trucking industry.

He was previously the executive chairman of Finemore Holdings, one of Australia’s leading transport logistics management companies. e business, which was sold to Toll Holdings in 2001, had been built from the ground up by Finemore and his people over the previous 40 years.

In 2004, Ron Finemore Transport was established by Finemore, following his acquisition of Wodonga-based company Lewington’s Transport. In 2005, Smith’s Transport in Orange was also purchased.

e company now operates with a eet of more than 290 prime movers, and over 700 pieces of trailing equipment, travelling over 70 million kilometres annually, and employs over 900 people.

e Don Watson Memorial Award recognises Finemore as a leading transport and logistics professional and also as a champion of industry professionalism, innovation and safety.

In his introduction to the announcement of the winner of the award, past-ATA chair Dennis Robertson spoke of the immeasurable time Finemore has given to help better the road transport industry as well as providing generalnancial support and the use of his sta and facilities.

“ ey always strive to nd the most e cient and safest way to do the job and are always developing new equipment which is acknowledged globally as world’s best,” said Robertson before inviting Finemore to the stage to receive his award from Lyndon Watson, the son of Don and Noelene Watson.

Added Finemore: “Every-

thing I’ve tried to do for the industry has been for the people, and the community.

“ e great people who work in the industry, and my passion has been to see people that have started in the industry with me in various categories, be successful.”

Finemore is particularly passionate about improving the efciency and e ectiveness of fatigue management policies and systems for the industry and was a presenter on that subject earlier in the conference.

“I wasn’t here at this conference other than to enhance the safety of the industry for the community of Australia,” he said.

“It’s a battle to try to get the bureaucrats to understand that people in our industry are only there for the good of the whole community.

“ e very large majority of our people are absolutely great people, as is the case in every part of society. Unfortunately, the trucking industry is not recognised for the job we do, even though for the last three years people have woken up to what we do. But most people would prefer not

The original Anti-Kink air coils

UV Resistant and Anti- Fade

Anti-Sag

Abrasive resistant

Excellent coil memory

High flexibility and superior cold weather operation

Longer service life and guaranteed improved performance

AVAILABLE IN A VARIETY OF LENGTHS TO SUIT ALL APPLICATIONS (2M-12M).

■ SUPPLIED WITH STANDARD ½” BSPT ENDS (¼” ALSO AVAILABLE)

■ ALTERNATIVE BLACK/YELLOW FOR AUXILLIARY PNUEMATIC SERVICES

■ COMPLETE SET UP WITH RED/BLUE TAPS AND QUICK COUPLERS!

to see the trucks on the road and unfortunately they can’t do without us.

“ e great job that everybody here does isn’t necessarily appreciated, but it is recognised.”

Known for his hands-on, down-to-earth approach by his sta and industry colleagues, Finemore and his team constantly strive to deliver improved safety, productivity, pro tability and return

on investment.

“I’ve been very, very lucky,” he concluded. “I’ve been in this industry 62 years, I had my rst truck before I had a licence, and I hope to be here for a few years more.”

A COMPLETE RANGE OF AIR COILS FIND

STEVE Broadbent, 62, reckons the secret to such a long life behind the wheel is pretty simply when you get down to brass tacks: he’s never lost the passion for the road, even after more than 40 years and six million kilometres.

He’s still just as fervent about the role today as he was when he rst started out, as a fresh-faced 19-year-old driving logging trucks for Gippsland legend Norman Blackwood.

“I just love it,” said Steve, still buzzing from his career highlight, winning the Professional Driver of the Year prize at the recent National Trucking Awards on the Sunshine Coast.

“People say it gets into your system, and it really does get under your skin. And the mates I’ve met up the road… it’s just a pleasure to go to work.”

For the past ve and a half years that’s been as a Melbourne-based interstate linehaul driver for Freestone’s Transport, more recently carting “time sensitive” parcel freight from Tullamarine to Sydney in a 2004 Peterbilt 379

Lowline in a single semi-trailer combination.

“She’s pretty forgiving and a pleasure to drive,” said Steve of one of the most revered rigs running the Hume today.

“She’s got all new running gear; a new CAT motor, 18-speed gearbox and been repainted not long ago so she looks the part.

“You get a bit of a big head because you listen to the UHF and people go, ‘Oh, look at that thing’, because there’s not many of them on the road, and it’s always clean and shiny.”

Wife Jodie Broadbent, nationally recognised for her work in the safety and compliance sector, can testify to just how fastidious her husband is when it comes to presentation, he’s been like that throughout his storied career. e cherished Lowline is washed at the end of each trip, without fail, she says.

“If it has been raining in Melbourne from Sunday to Tuesday, the truck is washed before he leaves on Tuesday night. If Steve is held over on Friday nights in Sydney, he will spend that afternoon

washing and polishing the old girl to the nth degree.

“Even when it rains, he dons his raincoat and washes and cleans the truck.”

e inside is no di erent, adds Jodie. A neat grey sheet on the doona and pillows complement the burgundy and cream interior and Steve even has a grey cable knit throw rug to adorn the bed.

“Steve has, at his own expense, purchased gold buttons for the dash and chrome nut covers for the exterior to show the truck o . He sees the presentation of the truck as a re ection of his professionalism.”

Jodie says that attitude extends beyond his job and customers to those he deals with outside of work.

He always makes time for non-industry people who are curious about what he does, and he’s become something of an unwitting social media star as a result of giving so many youngsters, and their parents, a tour through the Peterbilt at service centres along the Hume Highway.

“I’m always keen to get them to have a look at it, just

trying to get other people involved in the industry,” said Steve.

He believes there’s a myriad of issues contributing to the current driver shortage, from an unfair wage system and poor career image to the lack of correct training.

“I’m a rm believer that you’ve got to get them from a young age and teach them the right way, that’s how I was taught,” he said.

“Unfortunately, we don’t seem to be able to bridge that gap with the training at the moment.

“I don’t know whether it’s just in the too hard basket, or because of the dollars.”

He believes the burgeoning driver apprenticeship scheme is probably “not a bad thing”.

“When I rst started driving trucks, my rst thing was to get under the truck and adjust the brakes.

“Now I’m not sure you’re allowed to do that anymore, but you got your hands dirty straight away, and that to me is why an apprenticeship is probably a good thing – it teaches them from an early age how to drive a forklift, or be in

the yard, how to do things the right way.”

Steve has transported everything from livestock

tarps, tautliners, logging skels, drop-decks, at tops, vans and at-racks.

He has driven everything up to triple road trains and been all over Australia on all types of roads requiring him to drive to the conditions at all times.

At one stage that even included transporting delicate glass bottles from Penrith to Brisbane via the Putty Road, and Steve was renowned for never losing a bottle.

He’s also never been involved in an at-fault accident, in any vehicle, car or truck.

Although he prides himself on the way he’s embraced the many regulatory and technical changes over the years, Steve believes the general driving

standards aren’t what they used to be.

e ‘ y-by-nighters’ who think they can bend the rules to suit themselves, is a particular bugbear because everyone in the industry su ers as a result, laments Steve.

“If the public sees you doing the right thing they leave you alone, but they jump on you real quick if they see someone doing the wrong thing. Just education, a lot of education [that’s what we need].

“Back in the 80s and 90s before speed limits came in and trucks where quick there was a road etiquette that you lived by and that seems to have gone out the window.

“A lot of blokes my age are

THE other category winners at the 2023 National Trucking Industry Award on the Sunshine Coast on Friday, March 31, were: Outstanding Contribution to the Australian Trucking Industry: Jacquelene Brotherton (TWAL)

e chair of Transport Women Australia Limited (TWAL) – and popular columnist for Big Rigs and PR manager for Australian Truck Radio – has dedicated over 30 years to the transport industry across the livestock, general and refrigerated transport sectors.

careers in transport and logistics through a variety of initiatives including mentoring and scholarship programs.

“I am privileged to have made a 50-plus year career doing something I love. I have been blessed both in the opportunities I have been given and the people I have met and worked with through the years,” said Brotherton after her win.

try as a passionate advocate for the livestock transport sector. In 2016, she received an LRTAV Outstanding Industry Contribution Award for her contribution to the livestock transport industry.

keen to get out of the industry but I’m not quite that keen to nish up just yet.”

When he is ready to nally shelve the work diary, Steve concedes that he might just pivot into the auditing side of the industry.

With a gentle “push” from Jodie, he’s just completed a lead auditor course with PwC, covering quality, safety and environment.

“I’d like to go to that side of the business just to help companies do a better job, help them with their drivers, their procedures and their training.

“I still see a gap that’s still not quite there. I’m just passionate about the industry, always have been, I just love it.”

Her extensive experience includes everything from Chain of Responsibility compliance to eet management and warehousing.

She has also long advocated for women in non-traditional

“To be able to celebrate with them and share the joy was truly amazing. To have so many incredible women by my side who were even more excited than I was, was a humbling experience.”

National Trucking Industry

Woman of the Year: Alina Hawkins (LRTAV)

Alina Hawkins is known throughout the trucking indus-

Hawkins is admired for her in-depth knowledge of transport industry issues and the professionalism she demonstrates by her ability to research, consult, communicate e ectively and to operate e ciently to support the business, policies, goals and objectives of her colleagues in rural trucking.

National Training Excellence

Award: CMV Truck & Bus

CMV Truck & Bus is a Victorian based dealership group representing the Mack Trucks, UD Trucks and Volvo Truck and Bus brands.

TruckSafe John Kelly Memorial Award: SeaRoad Logistics Pty Ltd

e TruckSafe John Kelly Memorial Award recognises a TruckSafe accredited operator that has implemented and promoted the program in an exceptional fashion. is operator fosters a strong culture of safety in every part of their business.

SeaRoad’s road freight services provide integrated logistics services between mainland Australia and Tasmania. Its eet can provide a fully integrated service, including freight pickup, packing, container transport, unpacking and delivery.

IT was a Friday morning and I’ve hooked up Freightliner to cruise three hours from Melbourne to Horsham in Victoria’s central west to pick up the latest iteration of the Cascadia where it had been showing o at the Horsham Field Days.

is particular Cascadia is the 126 version with a 36-inch bunk, replete with the mandatory bull bar - if not by law, by common sense, if you want to keep your nose the right shape.

With this setup Freightliner have gone the ‘whole nine yards’, or more speci cally, the whole 26 metres to come up with a combination that makes the most e ective use of bonneted prime mover and trailer combo with a bunk that

will

t most drivers.

Whilst Cascadia can be ordered with up to a 60” sleeper, that iteration is going to severely test Australia’s 26-metre rule.

So, Freightliner came up with the perfect compromise. Let’s not forget that whilst we’d all like the most spacious prime mover our pockets will allow, it’s the cargo that makes the money.

More cargo, more dosh. Simples. Until the current laws catch up with sensibility, compromise is mandatory – which is why so many cab overs are out there pulling B-dubs.

But hey, there are some out there for whom nothing will do unless it’s got a bonnet on it. It’s called freedom

of choice, and it’s these folk to whom the 126/34 pallet Cascadia is aimed.

As mentioned, the bullbar is a necessary inclusion and there were a few internal doubts as to whether the combo would be possible, so Freightliner went to Krueger Trailers who said, “No problem.”

And here we are this Friday morning with the result.

With the Cascadia’s obsession with aerodynamics, the shape of the truck is very di erent to its predecessor, the Coronado, and Daimler admit that they lost a few customers that they’d have liked to have brought along with the changes.

at said, the truck has been adopted by a pile of

new customers, who’ve never had a Cascadia before and in many cases not been with the Freightliner brand at all.

at they love the Cascadia is re ected in the high proportion of buyers who tip their toe in the water, buying one truck and then returning to buy more.

at Cascadia is the biggest selling truck in America – the land of massive wheelbased, blunt-nosed behemoths – should also not go unnoticed.

Why is it so? ‘FUEL ECONOMY,’ he shouts in capital letters.

Work all you like on producing better engines that use less fuel – and Freightliner have done just that with their excellent 16-litre DD16 Detroit engine putting out 600hp and 2800Nmm mated

to an also excellent Detroit DT12, 12-speed AMT gearbox – but you’ve got to push all that metal through the air at 100km/h, and a big blunt nose is going to drink fuel like a drunken sailor does rum.

e Cascadia runs parabolic springs on the steer axle and airbags on the drive.

ere’s a full suite of safety systems on board with Adaptive Cruise Control, Lane Departure Warning and all the other acronyms you can think of.

Side Guard Assist, which lets you ‘see’ down the lefthand side of the truck, is an option that is becoming more popular, especially with eets.

Sitting in the background as another part of the safety pack is Active Brake Assist or ABA.

e Cascadia’s radar is looking ahead all the time as

is the camera, and if there is a potential collision the truck will warn the driver.

If the driver doesn’t intervene by changing lanes or applying the brakes, the truck will continue to warn them and if nothing eventuates it will go into a partial brake mode followed by full autonomous emergency braking. e truck will be doing its best to prevent nasty outcomes.

No one can prevent an accident completely but it is all about mitigation. at’s why Freightliner use the term mitigation rather than prevention. e fact is, it’s not a perfect science but it will do its best to mitigate an outcome that could otherwise be an absolute disaster. As well as Active Brake Assist there is also ABS sitting in the background.

Continued on page 18

From page 16

THE view over the sloping bonnet is excellent. As mentioned earlier, it’s to aid the aerodynamics but it is also fairly short so you can place the truck on the road very easily.

You’re not going to lose sight of a car, or even a small child under this bonnet.

Freightliner achieved this by splaying the chassis rails and dropping the engine down some 3 inches, which comes with the side bene t of placing the ‘daily check’ items within easier reach.

e side mirrors, sitting on a single stalk aren’t big but they work as well as any others I’ve come across with great vision and the bene t of being

able to see over them.

You’ll see some Cascadia’s with additional mirrors halfway down the bonnet – a bit like British cars of the ‘50s.

ey look a little strange but Freightliner tell me that those who’ve optioned them swear by them.

at 12-speed ‘box can change gears manually by icking the column mounted stalk up or down.

You may use it once or twice as I did at rst, but the ‘e ort’ soon becomes too

much and it becomes apparent that it is best left to its own devices.

ere’s a three-stage engine brake that works a treat.

Darryl Fourter, Freightliner’s southern region eld service manager, tells me that the brake lights are required by ADR to come on when it is used, something I’d never thought of before.

Press the ‘check light function’ on the key fob and the all the trucks lights will ash until you deactivate the function.

You have no excuse of not knowing of a failed light. Climbing up into the cab and I’m greeted with the latest dashboard, nicked straight out of the Cascadia’s European half-brother, the Mercedes Ac-

tros. e two digital screens, to me at least, look aesthetically much better than the dials in the faux wood panelling of the earlier model – although I believe that can still be had for the diehards.

So, I’ve navigated the exit gate from the Horsham Field Days with those 44 pallets and Fourter starts to relax as I head down the tarmac. It’s not my rst time in a B-double but I forgot to mention that to him.

e trip back to Melbourne is a mixture of B road and highway driving, so I get to experience the worst of Victorian roads along with the occasional smooth stretches of tarmac. e Cascadia handles itself with aplomb, requiring minimal input to the steer-

ing to keep the truck on the straight and often narrow. I pride myself on not setting the lane departure warning o at all on the ride.

With some 60-tonnes of ballast on board the truck hauls up hills with ease and the engine brake pulls it up smoothly and quickly when required. I reckon the cab is a little noisier than the similarly powered Actros but is by no means invasive, and Fourter and I can chat amiably on the trip without raised voices.

Where Freightliner has excelled is in reducing noise, vibration and harshness, particularly in the cabin. e old Argosy used to rattle around a bit, something Freightliner admit they can’t worm their

way out of. e company spent a fortune in design to ensure that the Cascadia RH drive models would be world class in this area, and they have succeeded.

Fourter tells me of one he recently drove which had over 800,000km on the clock and was as tight as Lycra on an overweight pushbike rider.

But what is most important with this combination is that there’s space behind me for those 34 pallets and that’s money to the bottom line. And no NHVR lackey can relieve me of any of that extra pro t for being over length.

If you want a bonneted truck and wish to haul the maximum payload you should look into the Cascadia.

YOU’RE NOT GOING TO LOSE SIGHT OF A CAR, OR EVEN A SMALL CHILD UNDER THIS BONNET.”

BY ALF WILSON

BY ALF WILSON

ROAD transport operators who deliver freight and food to remote communities in the far north of Queensland are sceptical about seeing any of the $64 million freight funding package from the state government.

e money is designated to the Northern Peninsula Area (NPA), Torres Strait, Cape York and Gulf of Carpentaria regions over the next ve years in a bid to assist with the rising cost of living.

e price of groceries, fuel and other essentials in the region are amongst the highest in Australia because of freight costs.

In a statement, the state government said funding will start from the 2023/24 nancial year and be directed toward targeted subsidies for multi-modal freight services, the appointment of freight coordinators to manage complex supply chains and the development of com-

munity infrastructure such as cold storage.

When Big Rigs approached the government for more clarity on whether the smaller trans-

port operators who service the areas will see any of the $64 million we got the below response from a spokesperson for Transport and Main Roads.

“Following initial consultation at the recent Cost of Living Summit on ursday Island, we will lead engagement with government agencies and key stakeholders to identify sustainable implementation options,” the statement said.

“ is engagement is vital to ensure solutions are designed to maximise community bene ts. Further details will be communicated as implementation options are further re ned over coming months.”

Veteran 76-year-old small eet operator Dennis Dent, who is based at Mareeba, has four trucks which deliver a variety of freight to Cape York and the Gulf of Carpentaria and doubts that any road transport companies will receive any subsidies.

“I understand what the government is saying but where will it help us? If we drop our rates the government won’t subsidise us. It will bene t sea transport operators,” Dent told Big Rigs.

Dent said that the mostly

red dirt and corrugated roads up to the cape and gulf were closed on average for four months each year.

“Road transport overall is cheaper than by sea. I put in a quote to deliver freight up that way for $2000 and we couldn’t go because the roads were cut.

“ e person had to use a sea barge and showed me the price which was $7000.”

Simon Tuxworth runs the family company Tuxworth and Woods which has depots at Cairns, Mareeba, Cooktown, Weipa and Normanton as well as agents located at Mount Garnet, Georgetown, Croydon and Karumba.

e company was started by his now retired father Norm in 1972.

Tuxworth said that whilst he was praiseworthy of the package, he said that $20 million of the money would go to Cape York and the Gulf of Carpentaria and the rest to the Torres Strait.

“I thought they could have given a bit more to the cape and

gulf and it costs a lot to do a refrigerated load into the remote communities. I hope the money goes towards fresh food supplies in these communities. It is all about the health of the people. ere is a lot of soft drink and things like lollies going up there,” Tuxworth said.

Tuxworth and Woods has 13 road trains in total and six or seven of them do regular runs to Cape York and the gulf every week during the dry season. Most are Western Stars and the company employs between 45 and 50 people.

“As soon as the roads are open Woolies get onto us. We can deliver mostly overnight to these places whilst it can take ve days by barge,” he said.

Tuxworth said that savings could be made on freight if fresh fruit and vegetables which were grown around Cairns and the Atherton Tablelands didn’t go to Brisbane initially.

“ en it is sent back up here by road,” he said.

Continued on page 22

AFTER 290,000KM WE CAN SAY THE CASCADIA IS CLEARLY

KEVIN MUTTON, KRESKAS BRO

From page 20 GAVAN Roy, the operations manager for Weipa-based Rob Roy Earthmoving, said the funding will be widely accepted.

“ ere’s no doubt about that. e wet season especially can be a challenge for families and businesses up here on mainland Cape York, where barging is the only option for freight to be delivered, as the roads are generally closed due to rain and ooding for up to ve months.

“ e cost di erence between road freight and sea freight can be quite signi cant, which undoubtedly can place a huge burden on household budgets, and when there is only one dominating supplier for sea freight in the FNQ area, the ball is in their court.

“Being a transport operator, I understand there is a need to pass on the extra costs associated with providing transport services, and that just gets handballed down the line which in some instances ends up with the consumer having to cop hefty increases in goods by the time it reaches the shelves,” Roy said.

Roy told Big Rigs the injec-

tion of $64 million over ve years will be a welcome relief for residents and consumers in FNQ.

“But what’s the plan after the ve years, will we be paying through the nose again? is ongoing issue needs to be addressed and plans implemented moving forward, or at the very least provide transport operators with some relief from fuel prices, registration and insurance costs. Not to mention the cost of nes, which can make drivers lives miserable over a simple mistake in a work diary for example.

“ e transport industry –road, sea and air – in this country is majorly lacking respect and recognition particularly by governing bodies. is needs to addressed country wide because at the end of the day, the consumer is the one su ering.”

ursday Island is 39km across the sea from mainland Australia and there are many other islands in the Torres Strait which are serviced by barges.

On TI, which is the business centre of the Torres Strait, there is a big Seaswift depot where freight is unloaded from barges

and taken to the various businesses by trucks.

Other islands also have barges arriving and freight and goods are towed to their des-

tination on trailers mostly by tractors or light trucks.

Former long-time ursday Island resident Mark Bousen who owned papers there and at Weipa, Cooktown and Mossman campaigned for many years about the high cost of living due to freight costs.

Bousen, who moved to the Torres Strait in 2002, said the cost of living then was outrageous and continued to be increase during his 10 years on the island.

A journalist for more than 50 years, his family moved to the Torres Strait when they bought the Torres News. ey subsequently went on to buy the newspapers in Weipa, Cooktown, Port Douglas and Nhulunbuy in the Northern Territory, there by covering the entire Cape York and the Torres Strait regions.

“Our newspapers campaigned vigorously about the exorbitant cost of living in the region and the urgent need for freight subsidies. It was an on-going issue with us,” Bousen said.

“Nothing was forthcoming from successive federal and state governments of all political persuasions. I’m delighted action nally, nally is in the pipeline, albeit decades overdue. at should reduce the cost of living to more sustainable levels, one would hope. e freight costs a ect everything that comes to the region – food, building materials, furniture – anything and everything.”

Bousen said the dormant irony reposed with this issue is that freight subsidies were in place for Tasmania – far closer to the capital cities than the Torres Strait.

“ at didn’t cut ice with anyone – but there are far more votes and seats in Tasmania than in the wide, open spaces of Cape York and the Torres Strait.

“It was, and is, blatant political hypocrisy at its most blatant and never ceased to be sore point with me and our newspapers’ readers,” he said.

Queensland Premier Annastacia Palaszczuk said that during last year’s Torres Strait Community Cabinet, the local

community made it clear that one of the biggest challenges for the region was freight.

“We listened to the community. We’re delivering this funding package to tackle that challenge head on. By subsiding some of the freight costs to the Northern Peninsula, Torres Strait, Cape York and Gulf regions, we can ease pressure on local suppliers, and reduce one of the major factors making things like food, and clothing more expensive,” Premier Palaszczuk said.

Transport and Main Roads Minister Mark Bailey said that in 2022 his department conducted a review into remote community freight systems which identi ed the need for a more targeted, sustainable approach to managing freight disadvantage across the state.

“ is funding will target the high price of freight that is fuelling cost-of-living pressures, delivering on a package of work that addresses the unique challenges of transporting essential goods to these remote regions,” Bailey said.

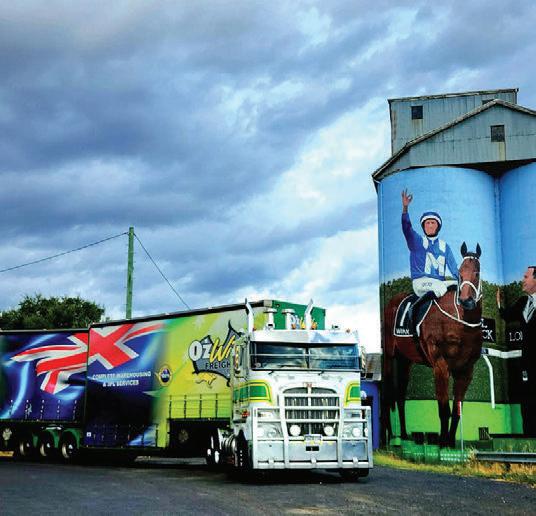

‘A MODERN Classic’ would probably be an apt term to describe the 1976 Kenworth which is owned and operated by Matt and Courtney Hambridge.

e 47-year-old Kenworth’s iconic SAR styling is straight out of the 1970s, coupled up to a current era engine and driveline.

Based just south of Sydney at Yerrinbool, Matt and Courtney operate MCH Heavy Haulage, with a eet of predominantly cabover Kenworths, joined last year by the SAR, which has taken pride of place as both a agship vehicle for the business and one which will be part of the Hambridge operation for many years to come.

Coupled up to a Drake quad oat and loaded with a Caterpillar PM620 pro ler, the couple had the Kenworth on display in late February at the Gundagai Tractor Pull and Swap Meet.

With the truck having recently once again become a fully working truck as opposed to an historic one, Matt gave a background to both the unique speci cations of the SAR and its new home as part of the MCH eet.

“It has the features of a modern truck in an older truck. It actually has a Series 60 Detroit in it and all the running gear out of a K104 Kenworth with an 18-speed ‘box and an airbag rear end,” explained Matt.

“ e 14-litre Detroit is rated at a little over 600 horsepower, so it has no problem getting over the hills! It is a bit of a toy, I just wanted something that I could do up so we got a hold of it and started tinkering.”

Having been on the lookout for an older SAR and having just missed out on another example, a ick through the classi eds on Gumtree late in 2022 soon had Courtney on a plane to Western Australia to check out the truck.

“Courtney found it on

IT ACTUALLY HAS A SERIES 60 DETROIT IN IT AND ALL THE RUNNING GEAR OUT OF A K104 KENWORTH WITH AN EE O AN AN A A EA EN

Gumtree and went straight over to Perth that afternoon to look at it, she came back and got a bank cheque and we went back over and drove it home,” said Matt.

“It has been converted with all the newer gear over there and the fella needed to buy a set of grain tippers for the harvest season and needed to sell it.

“We were a bit lucky; the truck had been sitting in his shed for four years, and he had only had it on Gumtree for two days.

“We bob-tailed her homeI am a bit time poor so didn’t have time to get a trailer sorted - there was a bit of hopping and carrying on but with the airbags it wasn’t too bad.”

Having planned to take a couple of his restored GM-powered Dodges on a trailer to Gundagai behind the SAR, Matt’s plans soon changed when one of his clients needed the pro ler picked up out of Wagga to go back to Sydney.

With the truck having been put back on full registration the week before it was an opportunity for the Kenworth to start earning its keep.

“It’s the rst week on the road as a working truck. It had been on vintage plates prior.

“I said to Courtney that it’s a bit of a waste having it sit in the shed and not being utilised so we got it spec’d to 75-tonne and got it back on full rego.

“Coming down here it was a perfect opportunity to take it for a run and still utilise it in the business. We took the weekend o for the show but this will save two trips.

Continued on page 26

A quick ick through the classi eds on Gumtree opened up a whole new world for this Yerrinbool couple.

Did you know that the paper packed into a Genuine Volvo Air Filter is nearly 40 meters long? That’s the length of a Patagotitan, the longest dinosaur that ever lived. All to trap as many impurities as possible and keep your engine clean.

The air filter traps harmful particles and keeps the intake air clean so your engine can perform at its best. The more paper there is, the better the performance.Genuine Volvo Air Filters have a high dirt-retention capacity and are leak-proof under normal operating conditions. Just as important,they are made from strong materials that are built to withstand the grueling engine environment.

• Made of strong materials – service interval as long as 24 months.

• Leak-proof under normal operating conditions.

• High dirt-retention capacity.

• Easy to install – no special tools or training required.

Keep rolling with Genuine Volvo Parts

Find out more by contacting your nearest Volvo Trucks dealership or visit volvotrucks.com.au

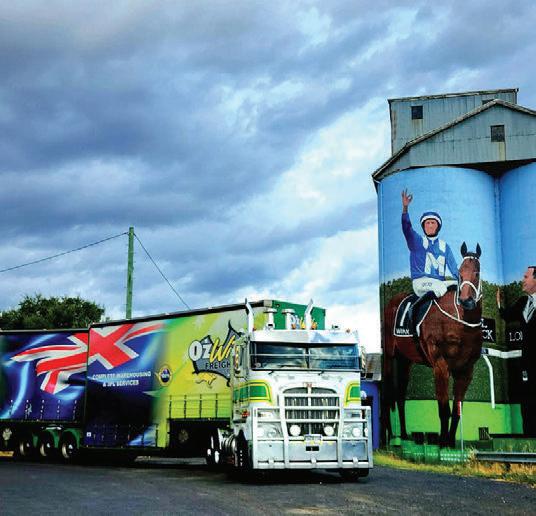

SHELL Rimula has partnered with Big Rigs in a big way – so there’s even more reasons to send in your best truck shots.

Each month, the Big Rigs team will choose a #PicOfTheMonth, with the lucky winner receiving a $500 Shell Coles Express Gift Card.

Keep an eye out for our regular posts on the Big Rigs National Road Transport Newspaper Facebook page, calling

for your best truck photos and add yours in the comments, or email them to editor@bigrigs. com.au.

Don’t forget to include a brief note about the truck and where the photo was taken. We’ll feature some of the best photos in each edition of Big Rigs Newspaper, with one winner announced each month. Keep those amazing truck pics coming!

Ryan Taylor enjoyed this cracker morning sunrise at the Victoria/NSW border.

Hugh Peachey snapped this great shot at the Fenix-Newhaul Geraldton depot at sunset.

Ian Paddy Patterson takes a morning break at the Mungle Creek rest area.

Jayden Perry stops by the Little Topar Roadhouse to admire the view, while on the way to Adelaide.

James Hadley snapped this stunner while unloading in Melbourne after an evening wash.

Jason C Biggs snapped this sunset shot at Marjimmy, NSW, as a big storm was rolling in.

Ryan Taylor enjoyed this cracker morning sunrise at the Victoria/NSW border.

Hugh Peachey snapped this great shot at the Fenix-Newhaul Geraldton depot at sunset.

Ian Paddy Patterson takes a morning break at the Mungle Creek rest area.

Jayden Perry stops by the Little Topar Roadhouse to admire the view, while on the way to Adelaide.

James Hadley snapped this stunner while unloading in Melbourne after an evening wash.

Jason C Biggs snapped this sunset shot at Marjimmy, NSW, as a big storm was rolling in.

Luke Selvage, snapped this great shot, coming out of the forest with a load of pulp at Burraga, NSW.

Brad Shiels snapped this Mangan Haulage rig, while stopped in Cowra, NSW.

Aaron Fuller, shared this great shot, reflecting before a load out of the mill at Maldon.

Tom Charlton stopped for a quick photo at Dunedoo, NSW, while on the way to Sydney.

A ripper shot from Michael Roels, snapped while running out through the pines at Orange, NSW.

Luke Moylan captured this great pic of a Frasers Livestock truck, with six decks on.

Paul Freeth captured this ripper sunset near Mataranka, NT.

Luke Selvage, snapped this great shot, coming out of the forest with a load of pulp at Burraga, NSW.

Brad Shiels snapped this Mangan Haulage rig, while stopped in Cowra, NSW.

Aaron Fuller, shared this great shot, reflecting before a load out of the mill at Maldon.

Tom Charlton stopped for a quick photo at Dunedoo, NSW, while on the way to Sydney.

A ripper shot from Michael Roels, snapped while running out through the pines at Orange, NSW.

Luke Moylan captured this great pic of a Frasers Livestock truck, with six decks on.

Paul Freeth captured this ripper sunset near Mataranka, NT.

When the going gets tough, truckies keep everyone going

Having relied on the Mack Trident since 2014, waste and recycling business Remondis is now progressively replacing them with the new Mack Anthem for its south-east Queensland operation.

Remondis Australia is the Australian operation of one of the world’s largest recycling, service and water companies. It has been in operation down under since 1982 and now operates from 39 locations, with a eet of over 560 heavy vehicles.

At the south-east Queensland division, there are currently sixteen 2014 Mack Tridents, along with two 2021 Mack Anthems. Another ve Anthems are scheduled for delivery in 2023.

“ ey’ve been the backbone of our local eet for nine years but we work them pretty hard, so we’ve decided to start replacing them with Anthems before we wear them out,” explained Sarah Collins, resource recovery manager at the Remondis Swanbank Renewable Energy and Waste Management Facility.

According to vice president of Mack Trucks Australia, Tom Chapman, the Mack Anthem is a natural progression for Remondis in renewing and improving the e ciencies of their eet.

“ e Mack Anthem has built a strong reputation for itself in terms of fuel-e ciency. Paired with mDRIVE-HD with deep reduction gears, the

bene ts are compounding in applications such as this one where controlled manoeuvrability on sometimes uneven, steep or low traction surfaces is critical,” Chapman said.

“For us, success is really forged in the strong relationships we build with our customers. Remondis perform the waste removal functions of both our factory and head ofce operations at Volvo Group Australia, so there’s great trust in the partnership and it swings both ways.”

e trucks travel between the Swanbank site and transfer stations at Rocklea and Northgate, making up to six trips a day, ve-and-a-half days a week. Averaging about 60,000 kilometres a year, the Macks are hauling single trailer and B-double payloads in side-tippers, carrying close to 36 tonnes.

“ e eet is NHVAS Mass and Maintenance Accredited and is enrolled in IAP so that we can operate Higher Mass Limits (HML), so we’re maximising our payloads on every trip,” said Collins Commercial customers bring loads of waste to the transfer stations, where they’re compacted and loaded onto the trucks.

“At the transfer stations the trucks drive into the loading tunnel at the end of the pit, and we drop the compacted waste into the tippers. We have a weighbridge in the tunnel and another on the way

out to ensure our loads comply with approved axle mass limits.” is kind of e ciency in loading is matched at the other end at Swanbank, where the Macks manoeuvre to the edge of the land ll to unload,” Collins explained.

“ e side tippers just open up like a big mouth, it’s very cool, and they’ve made a huge improvement in our productivity. We used to use trailers with walking oors, but the side-tippers are signi cantly

faster to unload,” Collins added.

As the trucks do most of their travelling on the motorway, the real issue is getting the trailers up to the top of the disposal site.

Collins added, “It’s a steep slope, and if the weather is bad it can take a lot of lowend torque to get the load up there. e Anthems don’t have any trouble at all. e mDRIVE-HD with an extended range of deep reduction gears, is ideally con g-

ured to climb steep slopes – a key safety consideration for us – so they’re more than up to the task. ey’ve also proven to be fuel-e cient, which is increasingly important to the business.”

e new Anthems are tted out with Mack’s Full Safety Pack. “Our drivers spend a lot of time in them, and VGA delivered a complete product, fully out tted. Our drivers are really chu ed with the new Anthems and are happy we’re buying more of them,” said

Collins.

With ve scheduled for delivery in 2023, the Mack Anthems will soon be a familiar sight on the highway.

“We’ve been using Volvo Group products in south-east Queensland for over 20 years now,” said Collins. “And they’ve proven to be reliable and an ideal t for the task. We’re looking forward to bringing the rest of the new Anthems into the local eet and enjoying the continued support of Volvo Group Australia.”

ACFS Port Logistics has added 10 new Fuso Shogun prime movers to its eet.

e new models, which include six 460 Shoguns and four 510 Shoguns, join a large number of Mercedes-Benz Trucks Actros models in the ACFS stable.

Daimler Truck touts Fuso’s Shogun 510 as the “hardest-hitting” Japanese truck in Australia, with more power (510hp) and torque (2500Nm) than its rivals.

ACFS Port Logistics moves 1.2 million TEU (Twenty Foot Equivalent Units) every year and operates 15 warehouses around the country. It is the largest privately-owned container logistics operator in Australia. e company has put the Shoguns to work in single, B-double and side-loader applications.

All Shoguns feature advanced engines that meet the Euro 6 emission standard and produce dramatically less particulate matter and nitrogen oxide than equivalent Euro 5 rated engines.