AS troubling as the 2020 incidents were that led Peter Stoitse Transport (PST) back into court last month, it is not the same company that is operating today, stresses CEO Mike Munday.

PST was convicted and fined $110,000 in the Melbourne Magistrates’ Court on August 21 for workplace health and safety offences – and ordered to pay $6358 in costs –after two drivers were injured in separate milk tanker accidents in 2020.

The offending follows earlier convictions and a $490,000 fine against the family-owned and operated South Gippsland company in June 2022 after the 2018 death of tanker driver Rodney Lunson, 50, in an incident at Leongatha.

“All of its sad but I’m glad as a company we’re able to now start putting this behind us,” Munday told Big Rigs.

“This has been a cloud over us for a while. It was a tragedy what happened to Mr Lunson and these incidents were terrible on so many levels for the people impacted by them, as well as our other employees.

“Peter Stoitse Transport and the Stoitse family acknowledge

for our leadership team to training for our drivers to improved technology and equipment.

“We are very confident in how we operate and in all of our safety process and policies and procedures, and have a very strong focus on our employees and providing assistance to them for not only training, but also their mental health, and any other support that they may need.”

PST has pared back the operation and today focuses mostly on general freight. that there were errors in the way were operating and conducting business, and that led to significant changes.”

Munday said he doesn’t agree with the statement made by WorkSafe Victoria executive director of health and safety Narelle Beer that the company had not drawn lessons from its “previous failure” after the latest fines and charges.

He said the company simply grew too big too quickly, experiencing “unmanageable” growth for a number of years without the right people in place to manage that properly.

After the 2018 tragedy, he said changes were made but admits they weren’t as effective as

they could have been.

In the latest prosecution, the court heard that a truckie raised issues with a tanker he was to drive in February 2020, despite the vehicle being cleared by the local service provider and his supervisor.

While driving in Poowong East, the driver realised the brakes were faulty and, as he attempted to slow, the prime mover and trailers drifted in opposite directions and jackknifed. The driver was taken to hospital with soft tissue and finger issues.

A few months later, another worker was driving down Korumburra-Inverloch Rd when the trailer suddenly began to

sway and the truck lost control before rolling into a ditch. The driver was taken to hospital with bruising and swelling to his foreman.

Today, Munday said PTS is a completely different operation.

It’s divested its milk division, transferring the operations and equipment to McColl’s Transport, and pared back the fleet from 120 to 40 trucks focused almost solely on general freight.

Most importantly, it’s invested heavily in safety and compliance since the 2020 incidents, said Munday.

“Well over a million dollars in safety and compliance, anything from leadership training

Munday said that PST had been audited by WorkSafe [Victoria] since the 2020 incidents – in 2021 and 2022 – and received positive reviews for all of its improvements with no improvement notices, or comments.

“We’ve completely changed the business and these fines won’t impact our business, or deter us, because what we’re doing now is above the industry standard.

“From the Stoitse family perspective, after these incidences they could have closed the doors and moved on, but they decided to continue operating and reform the business and to evolve.

“They have made some significant changes, at a significant cost, in order to continue to be an employer in South Gippsland.”

BY JAMES GRAHAM

BY JAMES GRAHAM

A LEADING caravanners’ advocate has taken to his popular social media page to remind motorists to show truckies more respect at designated rest areas. Writing on his popular Truck Friendly – caravan road safety program Facebook site, administrator Ken Wilson was reacting to a picture

that truckie David Oxley first shared with the On the Pads Queensland Facebook group. Oxley also agreed to share the picture with Big Rigs.

In the shot, taken at bp Caboolture northbound on August 13, all the B-double slots on site are taken up by caravans.

“Couldn’t even get a park,” Oxley wrote. “No wonder caravans are not popular with truck-

ies – especially when it comes to us doing things right by the book to avoid fines.”

Oxley said he sent the same picture in an email to bp but has not heard back.

Wilson, meanwhile, told his 23,000 Facebook followers that if caravanners want respect, and to be treated with respect by other road users, they need to earn it.

He says the photo clearly shows the lack of “courtesy, respect and consideration” that some caravanners and motorhome drivers have for other road users.

“The selfish and inconsiderate behaviour of the drivers in the photo is unfortunately a very common problem,” Wilson said.

“With September school holidays only a few weeks away, please stay out of truck parking bays. Do not park in truck turning circles, as they need space to turn, so we can all hopefully have a good day and take a break from driving.”

Wilson also told his followers not to be surprised if someone leaves a note on their windscreen if they parked their caravan or motorhome in a bay designated for trucks.

“Don’t be surprised if a truck parks in front of you blocking you in.

“They may not legally be allowed to drive it for several hours, so may not be able to

The situation wasn’t much better for Oxley a week later at the Caltex in Traveston, Queensland. all to see your lack of consideration for others. These are all suggestions and actions taken from the comments to the article in ‘On The Pads’.

pure laziness and incompetence.”

move the truck once parked so you can be stuck there for some time.

“Do not be surprised if someone yells out in the roadhouse restaurant or over the PA asking the caravanners to move their vans and embarrassing you. You are in the wrong.

“Don’t be surprised if a frustrated truck driver posts a photo of your rig on social media for

“We all agree there are not enough parking and rest areas, and the governments and corporations need to do more, however it does not excuse bad behaviour.”

Oxley, who travels between Brisbane and Cairns on a weekly basis, told Big Rigs that the problem is by no means limited to bp Caboolture.

He also sent us a picture of his battle to find a spot at the Caltex (formerly Puma) at Traveston this weekend.

“There was a separate area for caravans at both bp Caboolture and the Caltex Traveston that was half-empty,” Oxley added.

“I just think it comes down to

Some followers of Truck Friendly – caravan road safety program pointed out that there needs to be more respect shown by all of those sharing the road.

“Parking is not behaving badly,” wrote Erika Vorlicek after we first shared the story at bigrigs.com.au.

“It is also necessary for caravan drivers to do so to take a legally required break. So where exactly are the alloted caravan parks?

“Also, as the daughter of a long list of truck interstate truck drivers, don’t get me started on truck drivers behaving badly stories! FGS!

“It’s posts like this that create animosity between road users. Shame on you.”

Big Rigs has approached bp and Caltex for comment.

THE SELFISH AND INCONSIDERATE BEHAVIOUR OF THE DRIVERS IN THE PHOTO IS UNFORTUNATELY A VERY COMMON PROBLEM.”

KEN WILSON

WA’s peak trucking body welcomes the fast-tracked 2023 review of the National Freight and Supply Chain Strategy but isn’t pinning its hopes on it for tangible fixes.

Rather than wait for results from the federal government’s review, now brought forward from the scheduled overhaul in 2024, Western Roads Federation CEO Cam Dumesny says the industry is now on the front foot in a bid to off-set potential issues.

As WA heads into another fire/wet season, Dumesny says transport is already operating with “one arm tied behind our backs”.

“The Perth to Darwin freight route will be in limp mode as we still don’t have a bridge and come the wet season the low-level [Fitzroy] crossing will be under water,” Dumesny said.

“We have a briefing session for industry next week on the upcoming risks for this season, so that companies can begin to work with WA clients to assess the risk and put plans in place.”

Dumesny believes that

the current national strategy, first hatched by the Coalition in consultation with state governments and industry, has delivered “nothing but a bright shiny brochure”.

“The assessment is welcome, and yes we need a logistics systems approach, but we are fast losing confidence in the review, given its lack of achievements.”

The review of the National Freight and Supply Chain Strategy has commenced, following agreement with state and territory infrastructure and transport ministers.

Federal Transport Minister Catherine King says the review will ensure the strategy remains “fit-for-purpose” for the Australian freight and supply chains industry.

“We know this industry has experienced unprecedented and compounding disruptions over the past four years including a global pandemic, extreme weather events, geo-political tensions, skills shortages and more,” King said in a statement.

“The review is a critical opportunity to take stock

of what has changed and what has been achieved since 2019. It will help build a more effective strategy that is better equipped to address Australia’s growing and changing freight task.”

The review will assess if there are gaps in the strategy’s goals and identify priorities for the next five-year National Action Plan.

“Stakeholder engagement will be an important part of identifying these gaps and priorities,” King added.

“The review will undertake stakeholder consultation and consider public submissions. In late August, I am looking forward to hosting a round table to hear directly from industry how the strategy can be strengthened.”

Ministers will consider the recommendations of the review by the end of this year.

To have your say, visit infrastructure.gov.au and search, Review of the National Freight and Supply Chain Strategy Underway.

Submissions close on September 29.

OVER the next 12 months, a total of 123 girders will each make the 400km journey from Newcastle to Dubbo for the construction of the $220.2 million new Dubbo Bridge.

With piling work progressing well for the 660m bridge, which will run across the Macquarie River and open to traffic in 2026, the precast beams to support the new bridge are being transported by road between now and August 2024 – the first of these have now been delivered on site.

The girders weigh 60 tonnes and are 34m long. Due to their size, only one girder fits on each truck and Goldsprings Heavy Haulage has been tasked with the moves.

Once a truck makes the

journey from Newcastle, travelling west along the Golden Highway before arriving in Dubbo, a crane is used to retrieve the girders from the trucks and place them into storage.

“There are several small bridges and tight turns to navigate along the route, including at Dunedoo where the pilot vehicle needs to stop traffic to coordinate getting the load around the tight corner safely,” said Transport for NSW regional director west Alistair Lunn.

Each convoy consists of a truck between 38-45m, accompanied by escort vehicles.

“At this stage, we expect to be placing the girders onto the bridge structure from late 2023, weather permitting,” added Lunn.

TRUCKIES have reacted to news of a NSW parliamentary inquiry into the pressures they’re under with a lukewarm response.

Writing on our Facebook page in response to the initial announcement, most were dubious about the upper house probe – chaired by Greens MP Cate Faehrmann – actually heading anywhere.

One reader also wondered why the NSW didn’t just read Senator Glenn Sterle’s detailed inquiry into the Importance of a viable, safe, sustainable and efficient road transport industry tabled in 2021.

“Didn’t Senator Sterle get all this covered in his inquiry. So why are people from other parties spending money on reinventing the wheel?” they wrote.

Faehrmann’s office did not return a call from Big Rigs for more comment.

According to a media release announcing the investigation, the inquiry will examine the extent, nature and impact of pressures on heavy vehicle driver practice

and how regulatory obligations are observed.

In particular, the committee will investigate how these pressures contribute to over-height vehicle incidents and the use of rest areas and other fatigue management practices, the statement said.

“The committee is also interested in exploring the impact, effectiveness and enforcement of current mechanisms to address the pressures on heavy vehicle drivers, including training and education requirements, penalties for overheight vehicle incidents, and the availability, suitability and accessibility of heavy vehicle rest areas in metropolitan Sydney and rural and regional New South Wales,” Faehrmann added.

“In addition, the committee will consider the capability for new and emerging technologies to assist in reducing pressures for heavy vehicle drivers.”

Simon O’Hara, CEO of Road Freight NSW, and a member of the NSW overheight taskforce, said he un-

derstands truckies’ frustrations and scepticism around what impact an inquiry will have.

But he urges drivers to use this unique opportunity to have their say.

He said this is the first inquiry of its kind in NSW in his eight years in his role.

“It’s time – freight deserves to get rest areas, just on the basis of the work they did during Covid,” O’Hara said.

“The community, particularly white-collar workers wouldn’t tolerate it, and neither should truckies.

“We can’t approach this from the position of cynicism. We have to be constructive; we need to get in there and put our submissions forward and ensure that our voice is heard.”

O’Hara acknowledged that Senator Sterle had done some “awesome work” in a similar vein with his 2021 report.

“But in NSW the focus hasn’t been on these sorts of issues, at least in my time. We need to approach this with a constructive attitude

SYDNEY

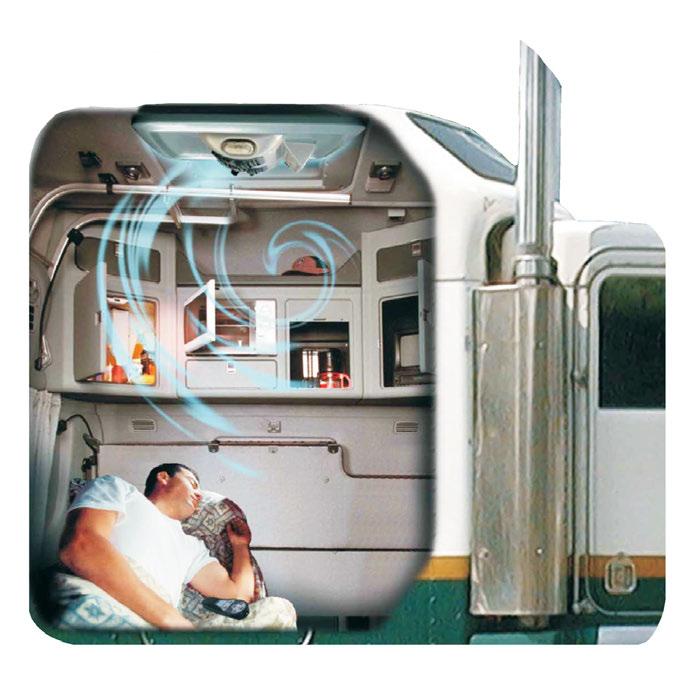

510 Victoria Street, Wetherill Park NSW 2164 Ph. 02 9756 6199, email: isri@isri.com.au, www.isri.com.au

BRISBANE

3/120 Gardens Drive, Willawong QLD 4110

because if we don’t, it may be another eight, 10, 15 years before we get the opportunity to try to address it again with the political class.”

The inquiry has stated it has a focus on the issue of over-height trucks, and how pressures may be contributing to the spate of recent breaches, and although O’Hara believes the inquiry is much broader than that, it’s essential this issue is addressed.

“The community is not going to tolerate it and we need to, as much as possible, get this issue to the forefront so we don’t have the [Ray] Hadleys of the world castigating truckies over what sometimes may, or may not be, an overheight truck.”

For a submission form, further information about the inquiry, including the terms of reference, visit parliament.nsw.gov.au/committees/inquiries/Pages/inquiry-details.aspx?pk=2980.

Submissions close on September 18.

“I’d encourage truck-

RFNSW urges drivers to use the parliamentary inquiry to have their voices heard.

ies and operators to either make submissions, or contact us and we’ll incorporate aspects of what they would like to raise,” O’Hara said.

“I think we’ve got to approach it holistically so that we encapsulate everything from industry and we don’t go off on our own niche areas, and we end up with points being raised from silos.

“It’s not about attributing blame, it’s about resolving these issues in a fundamentally constructive way.”

The others on the parliamentary committee are: Sam Farraway (Nationals), Mark Banasiak (Shooters, Fishers and Farmers Party) Anthony D’Adam (ALP), Dr Sarah Kaine (ALP), Bob Nanva (ALP) and Natalie Ward (Libs).

Ph. 07 3275 2044, email: sales@isribrisbane.com.au, www.isribrisbane.com.au

MELBOURNE

Unit 1/569 Somerville Rd, Sunshine West VIC, 3020

Ph. 03 9311 5544, email: sales@isrisunshine.com.au, www.isri.com.au

MACKAY , Ph. 07 4952 1844, email: admin@isrimky.com.au, www.isriseatsmackay.com.au

PERTH R , WA 6106

Ph. 08 9362 6800, email: info@mmtisri.com.au, www.mmtisri.com.au

DARWIN

Mobile Sales and Service

Ph. 08 8927 0986, email: info@isridarwin.com.au, www.isridarwin.com.au

ADELAIDE

TAMDELE, 21 Hakkinen Road, Wingfield SA 5013

Ph. 08 8347 1222, email: sales@gitsham.com.au, www.gitsham.com.au

NEWCASTLE/HUNTER VALLEY

Unit 2/13 Hinkler Ave, Rutherford NSW 2320

Ph 02 4932 0600, email: sales@hvss.com.au www.isri.com.au

ALMOST every day of the week Queensland pensioner Wes Walker still pulls into the Gatton hook-ups in his trusty black Chevy Silverado to police the parking and chat to truckies.

He’s no longer cleaning the two popular portaloos on site that he campaigned so tirelessly to get due to the prohibitive costs.

But more than a year on since they arrived in August 2022, Walker still wants one question answered by Queensland Transport Minister Mark Bailey: Where’s the permanent solution he promised to investigate at the time?

In a statement last year, Transport Minister Mark Bailey told Big Rigs – and all the other media that picked up on our story –that he thanked Senator Glenn Sterle for his advocacy and vowed to work on providing something grander in terms of facilities for truckies on site.

“I’m committed to working with Senator Sterle,

Transport and Main Roads and the heavy vehicle industry to find a permanent solution at the site, and have commenced discussions with my department on how best to do this,” Bailey told us.

When approached for a progress report this week, it seemed that the wind had gone out of Bailey’s sails. The Department of Transport and Main Roads (TMR) did not respond for comment when we asked for an update.

Walker is mystified as to why it all seems so hard for the state government. He’s aware of concerns around potential contamination to University of Queensland’s neighbouring agricultural fields, but isn’t buying that argument.

“The permanent solution is one massive portable one, not these part-time things,” Walker said.

Earlier research by Walker revealed that it would only cost $200,000 to have a larger unit delivered to the site, complete with a urinal, three toilets and a shower.

“They’re self-sufficient still, we just had to plug into power on the Gatton side of the bay for the hot water and lights.”

Meanwhile, Walker is happy to report that the hygiene of the two portaloos is at least being maintained at a pleasing level by the local crew that services them three times a week.

Carefully selected, TRAIL-LINK’s range of accessories will ensure safe and reliable complementary products for trucks and trailers:

Universal Plug catch

*NEW* Back up/Reverse alarms in 3 sound options (Beep/White-Noise/Beep with Auto-adjust for ambient noise)

Suzi hanger suspension springs

4-hole clamps

*NEW* Cab mount slider bars in 4 lengths

Pogo sticks

King Pin safety lock

“Everyone’s being very respectful of what they’ve got there, but we need to provide something better. There’s no reason why we can’t move forward to a bigger unit that has lighting at night, that’s the big thing.

“As we come into summer, sitting in a portaloo in the middle of a paddock ain’t going to be pleasant.”

BY SPY ON THE ROADTHE Fishery Falls rest area which is located 39km south of Cairns beside the Bruce Highway should be one of the best for truck drivers.

After all, it has two unisex toilets, tables and chairs and signs advising most parking areas are for heavy vehicles only.

Just across the road is the popular Fishery Falls Hotel where anybody who stops there can wander over for a meal or cold soft drink.

Despite all these facilities, the rest area is not a great place to stop for anybody wanting to answer a call of nature.

Because the toilets’ interiors are mostly dirty, they smell, and generally are swarming with blood sucking mosquitoes or

other disease carrying insects. It is because they are what truckies describe as “hole in the ground” toilets.

These are the ones with no flushing system and just a deep hole into which urine or waste drops into chemicals.

Most of the smell is a result of people, who stop there and not truckies, who leave the lid of the toilets open.

I have been there at least six times in the past year and it has always been the same.

It is such a shame considering many truckies tell me we need more rest areas and to find one which ticks most boxes, and has this problem is disappointing.

It certainly isn’t any fault of the poor people who have to clean the toilets.

I HOPE I’m wrong about the NSW parliamentary inquiry into the pressures on truckies.

Like many of you, I’m extremely sceptical about anything good coming out of it. The industry is drowning in expensive reports and reviews that go absolutely nowhere, so why is this going to be any different?

If a few unfortunate operators hadn’t had the misfortune to drive into Sydney tunnels over-height of late - and hold up angry commuters on their way to work - this inquiry wouldn’t have happened at all.

They don’t care about truckies. Look at the way they treated you during Covid. All they want to avoid is another serve on the Ray Hadley radio show and get re-elected. Answer? Hold an inquiry, fire out a few well-meaning media releases and stuff the results in the draw right next to Transport for NSW’s two recent ‘Have Your Says’ on where rest areas in the state should go.

Too cynical? It’s hard not to be from where I sit.

WOULD YOU LIKE TO CONTRIBUTE TO READER CORNER? EMAIL US AT EDITOR@BIGRIGS.COM.AU

OUR cover story in the last issue on safety crusader Rod Hannifey drew plenty of support for the loudest voice for truckies in Australia today.

Thank you Rod for all you do,” wrote Ken Wilson of the Truck Friendly – caravan road safety program. “You certainly

do not get paid enough for all the lives that you would have saved through you advocacy and hard work to help gain safer roads and facilities for the trucking industry drivers. Stay safe mate.”

Greg Jack Grabham added: “Great work Rod.”

TRUCKIE Trevor Warner’s suggestion of using the Derrimut Grassland Nature Conservation Reserve bordering the Western Ring Road to alleviate the chronic parking problem for Melbourne truckies was another hot topic online. Here’s an idea,” wrote Niell Graham, “Instead of towing

trucks, tow the cars that are left there for over 2 hours so when they knock off for the night, they will have to take their truck home and that way it will free up a truck space.”

“What a joke,” added Brad Simmonds. “It’s not BP or the local council’s responsibility to provide you with parking.”

The ultimate wheel finish, crafted without compromise.

ArmourBrite combines superior performance with long-lasting shine for a premium, easy-clean wheel finish. Championing durability, protection and style, ArmourBrite is exclusively created by Armoury Wheels, for wheels that go the distance.

CHOOSE ARMOURBRITE

IF YOU ARE LOOKING FOR:

Ultra-quality drop forged wheels value Water, stain and UV resistant cleaning time gloss

BY DANIELLE GULLACI

BY DANIELLE GULLACI

A RURAL NSW transport operator, who was recently fined $711 when he tried to avoid a town’s busy main centre in his B-double due to safety concerns, says he plans to take the matter further.

Brian Leihn runs a farm along with a transport business called Frontier Ag Solutions in the small town of Rugby in the Southern Tablelands region of NSW, where he’s been for the past nine years. He runs a fleet of three 26-metre B-doubles, which are used for livestock and tipper work.

He regularly travels through Boorowa, a picturesque little town about 26 kilometres from his base.

The town’s main centre runs along Marsden street and Pudman Street, with the latter being home to an IGA supermarket, chemist, coffee shop and various other businesses.

With nose to kerb angle parking along Pudman Street, decorative rose bushes running through the centre of the road and high pedestrian traffic, including people unloading trolleys behind their parked cars, Leihn thought he was doing the right thing by avoiding it while travelling in his B-double.

Interestingly though, this section of road is approved for B-double use. When Leihn was recently pulled up for travelling along a section of nearby Brial Street, he says the enforcement officer advised he should’ve been travelling through Pudman Street.

“The only B-double route

in 150km going east from our base is Brial Street. I’ve been running this business for nine years and have never travelled down Pudman Street once. Both the manager at IGA and at the chemist said they’ve never seen a B-double on this road,” said Leihn.

“It’s a narrow street which has been made narrow due to an island with roses and flowers, and the fact that people have to nose in to park.

IMAGINE A -METRE F LL LOADED B-DO BLE COMING DOWN THAT S A MA IM M OF A METRE TO A METRE AND A HALF AWA FROM PEOPLE EMPT ING THEIR TROLLE S BRIAN LEIHN

“For the last nine years that I’ve been in this district, I have always used Brial Street, which goes onto the B-double route – no truck in their right mind would use Pudman Street.

“Imagine a 26-metre fully loaded b-double coming down that’s a maximum of a metre to a metre and a half away from people emptying their trolleys. And they can’t see you coming until they get out in front of the truck.”

Big Rigs contacted the National Heavy Vehicle Regulator (NHVR) for further information about the route.

“The approved route for 25/26m B-double access

Alcoa®

through Boorowa is Pudman Street, Court Street, Brial Street and Long Street as per the NSW Restricted Access Vehicle (RAV) maps and lists,” said the regulator.

While B-doubles are able to travel through the town centre on Pudman Street, the section that follows, which is near a school, is not an approved B-double route.

On Brial Street, only part of the road is approved as a B-double route. “Brial Street is not an approved B-double route from Murringo Road to the intersection of Court Street as per the NSW RAV maps and lists,” advised the NHVR.

Leihn says he was pulled up recently. “They pulled me up on the side of the road and said, ‘Look I’m very sympathetic, I know the street, I’ll talk to my boss before I write this up.’ He goes back that night and talks to him. I asked if anything was going to be done about this road. He said you’re off route, go talk to the council, government or the NHVR.

“I explained why I don’t use Pudman Street – because it’s dangerous for pedestrians. You’ve got people getting in and out of cars, people backing out in front of trucks.

“They’re basically taking

955 191

us from a nice wide open street with no shopping centre or businesses there, and saying you now have to go down the main street past the IGA, straight through the heart of town.”

He continued, “I came through there last Friday afternoon and it’s really busy then. There was a lady standing at the back of her vehicle, she opened the boot

up and realised there was a truck coming past and had her mouth wide open in shock. It’s a 40km/h street and I was doing 10-15km/h. If anyone backs out in front of me, I can’t stop.”

Sue Corcoran is co-owner of the Boorowa Pharmacy on Pudman Street. She explained, “We have nose to curb angle parking along the street, so there’s

elderly people backing out with their cars. I can see why it wouldn’t be a good idea to have these bigger trucks going through here.

“I agree with Brian that it’s not great to be driving down here in a B-double during business hours. It’s quite narrow, there’s not a lot of room and the street is divided with rose gardens in the middle of it.”

Corcoran added, “I understand Brian’s annoyance at being fined. Boorowa is a small town and there’s really only two blocks in the town where there is significant traffic, so it is the right thing to support him.”

The town of Boorowa falls under the Hilltops Council, which Leihn has approached about the issue.

When contacted for comment, the council said, “We’ve taken notes of his concern. This is a route that’s been on the NHVR register for many years. We will have to look into this but it is a process.”

Leihn is now planning to start a petition in the hope of future change.

“I’m also taking that $711 fine to court. We’re going to make a video too of what it’s like to be standing at the back of your cars and have trucks coming down at you. Imagine a mother backing out with two little kids in the back seat. Who’s going to get hit first? And then there’s the trauma for the truck driver too. Imagine if they killed someone.”

A NEW project will see recycled plastics incorporated into asphalt as a performance enhancer at 10 sites across Victoria.

The RMIT University-led project is being supported by the Australian Research Council, Austroads and 10 Victorian councils.

The new roads will feature recycled plastic from consumer and industrial waste, including soft plastics.

According to RMIT, Australians generate 2.6 million tonnes of plastic waste each year and landfill space is expected to reach capacity by 2025. “This project is helping to address an urgent challenge.”

Project lead, RMIT associate professor Filippo Giustozzi, said the team will also produce best-practice guidelines on the use of recycled plastics in asphalt roads.

“These guidelines will enable local governments, which control 80 per cent of the nation’s roads, to begin widescale adoption of this innovative recycling solution,” he said.

The City of Melbourne and nine suburban and regional councils will each have sections of recycled road up to 900 metres long paved over coming months.

The 10 project sites will use an estimated 21,000kg of recycled plastic, but there

is the potential for this solution to be adopted more widely. “If Australia’s 537 local governments each used a small amount of recycled plastic in the many roads they resurface each year, then nationally we’ll have created a large end-market for recycled plastic,” he said.

RMIT has conducted extensive laboratory studies for Austroads on the viability of the recycled plastic asphalt mixture, which it says proves it is a mechanically, chemically and environmentally sound alternative.

“The performance of roads can actually be im-

proved with the additions of recycled material, such as plastic and rubber, to be more durable against traffic and resistant against ageing,” Giustozzi said.

The team’s latest study found the recycled plastic asphalt mixtures had 150 per cent less cracking and 85 per cent less deformation under pressure testing than conventional asphalt.

Local government areas involved in the project are City of Melbourne, Banyule, Bayside, Moonee Valley, Hobsons Bay, Baw Baw, Latrobe, Casey, Mornington Peninsula and Wyndham.

“I’LL go and stand at the back of the truck with my boot at the end of the trailer. All you do is use the arrow up and down on the wheel and when the green line on the mirror lines up with my foot, you go left to right and the other side will also be set.”

ese instructions came from Mercedes-Benz’s Noel Gri ths who is riding shotgun in the new M-B Actros 2663 GigaSpace.

He wants me to set up the second-generation MirrorCam so I know exactly where the back of the trailer(s) will be. Above this green line are three others in orange which indicate 30m, 50m and 100m behind the trailer.

Looking at the setup that green line looks like it’s halfway down the length of the trailer. “So, try it,” says Grifths. “Back up to the fence behind us.”

I do, and I put the trailer within six inches of that fence! And I’m being cautious. You can put a trailer (or two, or more) smack bang up against a loading dock all by yourself with this system. Ok, I’m convinced. More on this later.

e Actros GigaSpace

Driver Edition was on display at the Brisbane Truck Show in May and attracted a lot of attention. So much so that it was sold well before the show was over. Now M-B has invited me to take the truck for a spin.

Climbing up into the cab I’m surrounded by truck luxury. e two high resolution tablet screens – one

behind the stitched leather wheel and the other slanted toward the driver are familiar, having driven a number of Actros’s over the years.

Apart from looking like they’ve been lifted from an S-Class sedan (and they have – with software designed for a truck obviously) these screens are, to my eye, the best in the biz, both in looks and the way they operate.

Fact is, you don’t need 30 di erent dials staring you in the face when this system will tell you all you want to know at any time. Instead of regularly scanning all those dials you can keep your eyes on the road.

e dashboard is a mix of shades of grey and a swathe of beige, split with a tasteful strip of dark timber veneer (you have other choices here) and it looks luxurious, especially with the two supremely comfortable, quilted leather armchairs for driver and passenger.

All the trays are rubber-faced so no sliding around of odds and ends.

ere’s a phone recharge pad atop the dash, cup holders of various sizes galore, USB-C, 12- and 24volt sockets and a work/ dinner table that folds out of the dash in front of the passenger seat.

A drawer in the lower centre of the dash is perfect for the log book with another open space beneath it. Between the seats is a decent slide-out fridge and space for a second. Behind them is, of course the bunk and, in this case a second above it with plenty of headroom above that when folded out.

It’s Euro so you’re not going to get a queen-size bed, but it is supremely comfortable with plenty of room for my girth to constantly roll around on. Switches for lighting and reading lamp are also in the bunk area.

e cab is nished o with a skylight, side window shade blinds and a curtain running around the perimeter.

row the proximity key into a cubby, foot on the brake, press start and the 16-litre, 630hp, 3000Nm diesel purrs into life. I twist the right-hand wand into drive and the electronic park brake automatically disengages.

e truck knows that I haven’t moved yet so keeps some pressure in the system until I dab the accelerator, then the brakes automatically release and we’re on our way.

Now I’m using those MirrorCam screens placed on the A-pillars of the cab and the view is just brilliant in any direction as I peer through the glass. I can check the LH screen with barely a move of the head. Changing lanes, and those green and orange lines extend across the screen so I know that the truck behind me is more than 100mmetres away.

e cameras themselves are now 100mm closer to the cab, lessening the chance of damage. e advances over Gen-1 give a more normal view in the screens in that you see less of the trailer sides and still plenty of your surroundings – better than through glass mirrors in my humble opinion. ey’re heated of

course.

Active Driver Assist –level 2 automation – ‘drives’ the Actros for me, reading both lanes and keeping me in the middle.

Push a button on the wheel, slide your nger across the OK button and you can reset a little to the left or right depending on your needs. Otherwise, its leave the truck to its own devices for most of the time.

Take your hands o the wheel and the truck will warn you and if ignored pulls itself up, unlocks the doors and activates the hazards. I’m surprised it doesn’t apply paddles in the event you’ve had a heart episode!

It’s wonderful this steering, as is the ride, the quietness and most everything in this truck. Alongside every safety system you could think of there’s also Predictive Powertrain Control system, which uses topographical information to enable the truck to make the best and most economical choice of throttle application and gear selection. is includes saving fuel by coasting for long periods.

e whole lot drives through M-B’s excellent 12-speed AMT auto. e 3-step intarder will haul you up quickly and in the event of an emergency there’s ABA which will pull the whole rig up as safely as possible.

Cruising through the ‘burbs is a breeze with the truck, under certain conditions, able to stop and start at lights, for example, without having to touch brake or accelerator.

e GigaSpace cab is taller - like I can’t reach the sunroof, taller – and allows for three huge front-mounted and internally lit cabinets above the windscreen, the middle containing the microwave. Below these are another couple of storage cubbies.

Whilst this doesn’t sound like a big deal, the fact is that space is at a premium in the Euros so a few inches here or there and any advance in ergonomics is appreciated.

Previously the microwave was situated above the bunk which meant having to lean over said bed. e move and the extra height means plenty of room for a second bunk and more importantly for the person occupying it, they won’t feel like they’re in a co n.

Unless you place the GigaSpace next to another Actros, you probably won’t notice the changes, but once inside you will appreciate them.

All-in-all this is one magni cent truck. It rides, drives and handles brilliantly, and will do everything within its considerable power to keep you – and by extension other road users –safe.

If you’ve never driven an Actros, or you have but it’s an older model, I urge you to go and try one. You won’t be disappointed!

WOULD you believe it if somebody told you that a truck driver with 10 years of loyal service to a company –and who has earned long service leave – has never taken a sick day o work?

Probably not.

One who falls into this rare category is Martijn ‘Okie Dokie’ Dijkxhoorn who has been employed by Blenners for a decade as of last month and I would aptly describe him as the “employee from heaven”.

Before that, the now 51-year-old Okie Dokie was employed by several other companies for a total of another 10 years, and also never had a sickie.

I caught up with Okie Dokie after he had pulled up in his Kenworth 610 SAR at a Townsville roadhouse to fuel up and hook up a trailer.

“I am heading to Perth with bananas from Tully and really enjoy what I do,” he said.

So, what is the reason that Okie Dokie has been able to maintain such good health so that he has never taken a sickie?

“I try and eat healthy with lots of fruit and mostly buy food at supermarkets and have it whilst on fatigue breaks. I had the odd case of the u but the best place to be then was in the truck away from everybody and be by yourself. I did have all the vaccinations during the Covid outbreak to

abide by border movement laws but never got it. But I have a medical check-up every year and had one recently. Everything was ne including my blood pressure and other things,” he said.

Born in the village of Hummelo in Holland, Okie Dokie became interested in trucks as a youngster when a neighbour who lived nearby would take him for trips in his rig.

“Later I got my own licence and drove through Germany, France, Italy, Spain, the former Yugoslavia, to Russia including Moscow, Ukraine, to Britain and African countries such as Morocco and Algiers.

“I drove a Volvo FH-12 single drive amongst other trucks and hauled general and cows. It was well before the Ukraine war and the roads in Russia were generally long, I even went to Moscow,” he said.

When aged 31, Okie Dokie came to Australia as a backpacker and stayed at King’s Cross in Sydney.

“I bought a second hand 4WD and asked a bloke how I could get my Dutch truck driver’s licence converted to drive in Australia whilst I was here for a year and found out I had to have it translated into English and did so at the Department of Transport in Dubbo,” he said.

Okie Dokie saw an advertisement for truck driver jobs with a company at Cobram in Victoria and

soon was employed by Brian Hicks Transport.

“Brian Hicks organised all the necessary visa for me to work and live in Australia. I’m still very thankful for what Brian did for me,” he said. at is where he was given the nickname of Okie Dokie which has stuck like glue and is a slang term which means “okay”.

“When I was asked a question, I would just answer Okie Dokie and have had it [the nickname] ever since,” he said.

As I sat with Okie Dokie at the BP Cluden eatery recording his story, several truck drivers walked past and referred to him as Okie Dokie.

After the Cobram job, Okie Dokie started work with D&J Johnson which was at far away Tolga in the Atherton Tablelands region of north Queensland.

“I used to do Tolga to Brisbane carrying general freight in a Kenworth 950,” he said.

From there Okie Dokie moved on to start with Gillespie Transport at Jimboomba, carting portable buildings all over the country.

Okie Dokie got the job at Blenners from their Brisbane depot a decade ago and reckons it is the best move he ever made.

“I applied for the position on a Tuesday and started on Friday. And I drove from north to Sydney, Melbourne and Perth in a Volvo. ey really treat me well and I enjoy going to work every time,” he said.

Life has also been good to Okie Dokie whilst he has been in Australia. He married his wife Megan who he met

at a Cooper’s Plain service station.

“We have two children - a son Wesley aged 10 and a daughter Eleanor who is eight and we go camping all together whenever I get time o around the mountains,” he said.

A while back his father Aad, 83 years of age, visited from Holland and went on a marathon truck trip with him.

“Dad slept in the truck sleeper box and I was outside it snoozing under the stars in a swag. Dad has been and is always the boss. We went from Tully to Brisbane and onto Perth where I dropped him o and he caught a ight back to Holland. e entire trip took a week,” he said.

Okie Dokie is looking forward to holidays in December and will take his family back to his birth country.

“We will all be going as a family and I am so much looking forward to it,” he said.

Having travelled through every Australian state, Okie Dokie has been along many bad roads but which rates amongst the worst?

“ ey would have to be the ones between Bourke and Moree in NSW and the Goondiwindi to Millmerran road in Queensland,” he said.

As for roadhouses he rates well, the Nullarbor Roadhouse is right up at the top.

“ ey have a good kitchen, parking and showers,” he said.

Although Okie Dokie has been Down Under for two decades, he still maintains a Dutch accent.

His Blenners colleague Trevor Southern who tipped Big Rigs o about Okie Dokie’s achievement never to have taken a sickie described him as a top driver and bloke.

“Okie Dokie gets on well with everybody and is well liked,” Southern said.

Not many of Okie Dokie’s family and friends are aware he has been sick day free for so long but they will know once his story comes alive and is told on the pages of Big Rigs.

In all my years of snapping pics and doing stories for Big Rigs I have never come across anybody who has been sickie-free for so long.

As I left, I wished Okie Dokie a safe trip on his long journey to Perth and it was no surprise what his answer was.

“Okie Dokie” he said.

This indomitable truckie arrived in Australia from his native Holland as a backpacker more than 20 years ago - and hasn’t stopped working since.

WHEN I WAS ASKED A QUESTION, I WOULD JUST ANSWER OKIE DOKIE AND HAVE HAD IT THE NICKNAME E ER SINCEA neighbour in Holland sparked Okie Dokie’s interest in trucks when he was a kid. It was Okie Dokie’s colleague who got in touch with Big Rigs to nominate him for a story.

A TRUE veteran of the industry, Greg McDonald, 59, has quite literally been around trucks from the moment he was born.

Originally from New Zealand, Greg’s grandfather, Rod McDonald, ran a transport business there during the 1950s. en Greg’s parents, Graham and Nyra, bought some trucks and ran their own transport operation from the 1960s.

“I was driving trucks all my life. I was one of those kids who’d ride my bike to the yard every chance I could,” said Greg. “I grew up driving trucks around hay paddocks and the yard with no licence.

Once I left school, I went straight into transport. I wasn’t old enough to get my truck license yet, so was tarping loads, driving forklifts and that sort of thing.”

But as soon as he was old enough, Greg was straight behind the wheel – with his rst driving job being in a J5 Bedford. en by 23, he purchased his rst new truck, a Mack Superliner.

With such a strong family heritage in transport, it’s fair to say that trucking runs through Greg’s blood. “When I was a kid, you’d have family gatherings, and all the uncles would be there telling stories as they all had trucks as well.

My brother and sister also had their own trucks, my cousins were also in trucks. e whole family was in trucks,” he said.

Greg’s mother and father moved across the ditch to Brisbane in 1988, where they continued in the transport game through the 1990s and 2000s, eventually building up to a eet of 50 trucks. Greg moved over a few years later in 1991 and worked for his mum and dad.

When his father decided to sell o parts of his business, Greg and his wife Sharon bought one of the transport contracts from them. at sparked the beginning of Greg

McDonald Transport, which operated out of Yatala for close to 20 years, transporting freight locally and across the eastern seaboard.

“At the time, we had a T404 SAR Kenworth and tipper. Dad was selling out and the opportunity came to buy one of his jobs in 2006. We sold the tipper to my brother and bought two of dad’s trucks, and three new ones. Over the next 15 years, with that job, we grew from the ve trucks doing local to 18 doing local, interstate as well as tippers,” explained Greg.

By 2020, the company was operating a eet of 18 trucks. Following a strategic sale, the

couple sold all but one truck in February that year, just before Covid struck. From there, the eet grew back up to six trucks: two 2022 Kenworth T909s, a 2021 Kenworth T909 Diamond Edition, a 2019 Kenworth K200 Big Cab Aerodyne, and a 2013 Mack Super-Liner, ve of which were all put under the hammer at Ritchie Bros. Australian National Unreserved Auction, held on August 23-24.

ough there’s one special truck Greg didn’t want to part with. “I’ll still keep one truck, it’s a 2015 Kenworth T950 Legend – that’s one I’m never going to sell. I’ll keep it for truck shows and that sort of thing and might do some of the convoys too.”

e decision to walk away from the industry that has been such a big part of his life for so many years wasn’t an easy one, but Greg knew the time was right. “Retiring has been a hard decision. It’s hard to leave, I’ve never not worked, I’ve never not been around trucks. I’m third generation, I’ve never done anything else,” he said.

According to Greg, increasing levels of compliance are making it di cult for many transport operators, while also impacting the industry’s ability to attract new, young talent.

“ e transport industry has become relentless in its adherence to compliance, with regulatory hurdles that seem to multiply. Jumping through hoops and navigating this has become increasingly di cult and I believe it’s time to pass on the torch.

“I understand why com-

pliance is required but a fair amount of it is just plain ridiculous. I think what a lot of older people like myself nd quite hard is when we’ve done the job well for all these years and now all of a sudden we have all of this added compliance. As a kid I was always going into the yard on my pushbike. You can’t do that now. Kids can’t come anywhere near a depot.

“ ere are a lot of older people giving it away because of over-compliance, but then at the same time, we’re not getting the young people in.”

Greg says he’d like to see more done to attract young talent into trucking once they nish school. “I got into my rst big truck when I was 20 years old, but now insurance companies say people can’t get into them until they’re 25. We need to get kids into trucks when they come out the school gate. Send them to the workshop for a month, to the o ce for a month, tyre company, etc, show them how everything is done. If kids get out of school and there’s a labouring job paying $40 an hour, they’ll go and do that instead.”

While many transport operators have grappled with driver shortages, for Greg, he says that was never the case.

“I’ve been fortunate to have fair and loyal customers who’ve been instrumental in our journey, as well as some bloody good drivers who have been the backbone of our success.

“Good equipment attracts good drivers. I only ever advertised for a driver once and he only lasted a couple of weeks and was gone. When you put the good gear out there, pay a fair wage, treat drivers with a bit of respect, you’ll get good drivers.”

Now, as the curtains close on a career that’s spanned 43 years, Greg and Sharon are looking forward to a change of pace. “As I approach retirement, I’m looking forward to travelling and spending more time with my family. I’m hoping to travel overseas and maybe take a closer look around Australia too. I’ve been through all these towns, but never actually stopped to have a good look. It’s time for a new chapter,” he said.

the time was right to begin aGreg’s grandfather’s two Commers, which were driven by two of his uncles (pictured). This Mack Super-Liner is the first new truck Greg owned, purchased when he was 23. A 400hp Mitsubishi twin turbo from the 1980s. Greg’s parents ran their own transport operation from the 1960s. He worked for his parent’s transport company during the 1990s. The fleet there eventually grew to 50 trucks.

RETIRING HAS BEEN A HARD DECISION. IT’S HARD TO LEAVE, I’VE NEVER NOT WORKED, I’VE NEVER NOT BEEN AROUND TRUCKS. I’M THIRD GENERATION, I’VE NEVER DONE ANYTHING ELSE.”

GREG MCDONALD

AFTER almost 20 years in Tasmania, we recently made a short return road trip to South Australia and Victoria.

is entailed crossing from Devonport to the new purpose-built facilities at Geelong, aboard the Spirit of Tasmania. For those travelling to south or western Australia, Geelong is convenient, elsewhere not so much.

After many years away, it was reassuring to see the familiar liveries of K & S from Mount Gambier and John Collins still running, and gratifying to see some Tasmanian names on the road including Sea Road, Crips, and SRT.

Reassuringly we found the same friendly and positive attitudes in the drivers we spoke to as before, and it was refreshing to note the continuing support for Big Rigs.

Despite intermittent rain along the way we were fortunate to catch up with several trucks and drivers and here is what they had to tell us:

Loyal Big Rigs reader

Near Tailem Bend in South Australia, we caught up with Jason Vanderwel from Colac when he stopped over for a quick refreshment break.

He was driving a Shiell’s 2015 K200 with an X15 Cummins up front and towing

a B-double on his way from Port Adelaide to Mount Gambier to load up for wherever.

He told us he has been on the road for 20 years now, and has seen many changes over that time, but he said it was still a good job, though there is way too much “Go go!” these days, and though you may still want to catch up with your mates on the road, you rarely have the time to stop.

He added he counted himself lucky though to have a great boss who took care of both his men and his equipment, which makes all the difference.

“I started out doing local for the rst couple of years and have been doing Interstate with them ever since,” he said. He has been reading, and enjoying Big Rigs since he began driving.

Still a good job

Stopping over at Keith, the familiar bp Servo now having become Shell, but otherwise still a top spot and good friendly service, we caught up with Jason Mullenger from Kyneton.

He pulled in for lunch driving Bruton’s eye-catching 1995 T650 with a Gen 2 600 Cummins up front on his way from Murray Bridge to Stawell to pick up a load of sheep skins.

He told us he has been on

the road for approximately 30 years now, and he reckons it’s still a good job as he is fortunate to have an awesome boss who is strong on maintenance and easy to work for.

“Well, I reckon things have deteriorated a lot in the last 20 years, it was certainly a lot better in the ‘old days’, but just now I am not complaining, mainly because I still have a real truck!”

Whilst still at Keith, we were fortunate to catch up with Will Cassidy from Murray Bridge.

Originally from Christchurch, NZ, Cassidy rolled in driving an eye-catching Trans Australian Livestock’s 2021 T909 with a 580 Cummins up front and hauling a Bx2 stock crates.

He had just unloaded cattle from Queensland and was on his way to Adelaide for a load of sheep.

“I’ve been driving for 20 years now,” he told us, “15 years in Australia and the last 13 years with this company.

“So far, I’d have to say it’s all good, and I’m happy with the job, top out t, and gear which they look after, you can’t do

much better than that. I originally came over for a look around, then met my partner Harnah and we have a couple of kids, and the rest is history.”

Passing through Horsham we were fortunate to catch up with Michael Harris from Wagga Wagga when he stopped for a cuppa.

Driving a Hume’s FH Volvo, he was on his way from Adelaide to Oakleigh South and he told us he was a newcomer to the job, having been doing interstate for just a year, and prior to that doing local.

“So far, I’m loving it and it’s all good, and there’s nowhere I’d rather be! It’s usually Adelaide-Melbourne-Sydney and occasionally Brisbane.

“Love the Volvo, and Hume’s are a great family-based company who really look after their drivers and keep their gear well maintained, so I reckon I made the right choice!

Always looked after at SRT

Stopping at Little River for fuel we were happy to catch up with Josh Gardner from Melbourne driving a Tasmanian SRT Logistics 450 Iveco Stralis towing a fridge pan.

He was also on his way to catch the Spirit of Tasmania

at Geelong.

“I’ve been on the road now for 15 years all up and I reckon it is a top job. For the last ve years I have been working here for SRT.

“ ey have great management and have always looked after me, hence this is my longest job, and I am truly happy here. I reckon the move to Geelong was a good one, as unless you have to go into Melbourne, or maybe Eastern Victoria, it saves all the hassle of city tra c. I was here on day one of the move from Station Pier to Geelong, in fact I rolled up with the second truck to load.”

Rocke solid roles for this pair

It was also good to catch up with David “Butch” Butcher from Geelong, and William Cockerell, also from Geelong, at Little River grabbing a quick cuppa on their way from Melbourne home.

ey were driving a Rocke Brother’s 2016 FH500 Volvo and Butcher told us he has been on the road for 20 years all up, and Cockerell for ve years, but new to this job, just one week, and still learning the ropes.

ey both reckon it’s a great job and a top out t, and a regular run which gets them home daily. We noted that Butch barracks for Carlton, and William for Richmond.

RETIRED truckie Col

‘Snow’ Lovett, 74, fell into trucking almost by accident. Originally from NSW’s north coast, he headed to Camden in 1969 for a holiday and worked bailing hay on Camden Park Estate before getting a job in 1970 as a truck driver at TRN Haulage (now TRN Group) – and so he stayed there until he retired 37 years later in 2007.

He moved back to Kyogle to enjoy a slower paced, semi-retired lifestyle –though he continued to work on the road, this time

driving a school bus, and occasional runs delivering trucks around the country.

A few years into his job at TRN, Col was handed the keys to ‘Snow’s White’, a 1978 model White Road Commander.

His son Andrew Lovett recalls countless trips travelling in the truck as a kid, while sitting in the passenger seat, particularly during school holidays. He was six years old when Col started driving the Road Commander.

“ at was a big truck for the day. It was put to work subbing for Mitchell Brothers, running between NSW, Victoria, South Australia and Queensland, as well as the coal mines around the Burragorang Valley and NSW south coast,” explained Andrew; adding that his father was also one of the drivers of the successful Shell Volvo race truck back in the day.

Col was in the Road Commander until it was upgraded to a V8 Mack Superliner, but that truck always held a special place in

his heart – possibly because it was a step up from sleeping across the seats or over the steering wheel.

White manufactured the Road Commander between 1972 and 1983. e one Col drove was powered by a 290 Cummins engine – and so a few years ago, Col and Andrew set about nding a truck based on the same specs that they could complete together as a restoration project. As luck would have it, they located one in Naracoorte, SA, in 2015. “After a few phone calls, the deal was done,” said Andrew. “We had to get it trucked over. e truck was still running, but not in good enough condition to drive it that far. e guy who owned it actually had it working up until a few years

before he sold it. We don’t know the VIN of the original but this one is the exact same spec.” e father and son team soon got to work making the truck look as good as the original Road Commander driven by Col – and TRN was happy to help. ough Col retired from the company nearly a decade ago, Andrew is em-

ployed at TRN Group as its chief nancial o cer. “I fell into driving coal trucks for TRN back when I was 19 as a way of paying the bills while I was at uni doing a Bachelor of Commerce,” he said.

Following that he spent time working as an accountant for an engineering company and driving coal trucks on weekends. “It’s an odd combination I know, but it’s one that worked,” added Andrew.

“After a stint working in nance for Guinness in London, he came home and, sick of wearing a suit, jumped back into driving for TRN for about six months before moving into the o ce.”

ough he continued to drive on weekends or nights when he was needed, he stepped away from full-time driving in 1997. But 26 years later, he’s still at the company which now employs 360 people, albeit in a very di erent role.

“ e owners of TRN were on board with the restoration which was a good thing,” said Andrew, admitting that while he can drive a truck and is a whizz with numbers, his experience at xing and restoring a truck is very limited.

“ is gave us a place to store the truck during the process as well as the use of some great mechanics during their down time. Fortunately, the truck was mechanically sound. It was a credit to the previous owner who had spent a bit on it. Until a few years before it was purchased it had still been doing Nhill changeovers. After giving it a thorough check, Ben Rose started the process of stripping the cab down for restoration.

“It took about a year to get it back on the road. Because we were going back to the old TRN set-up, it was great to have TRN carrying out most of the work.”

Continued on page 24

This beautifully restored White Road Commander isn’t just a reminder of times gone by, it’s also an ode to this retired truckie’s long career – and a home on wheels.The original Road Commander tipping gypsum near Boggabilla, NSW, in the late 1970s. The restored Road Commander and mobile home is an impressive sight. Photo: Diesel Fumes Photography Three Generations: Kaden, Andrew and Col Lovett.

FORTUNATELY, THE TRUCK WAS MECHANICALLY SOUND. IT WAS A CREDIT TO THE PREVIOUS OWNER WHO HAD SPENT A BIT ON IT.” ANDREW LOVETTThis is how the truck looked at purchase in 2015, prior to the restoration. The original truck parked outside the family home in Camden, NSW (circa 1978). (l-r): Andrew with his children Addison, Kaden and Georgia, and wife Dannielle Lovett.

With the shortest bumper-to-back-of-cab dimension in the 13L conventional market, it doesn’t get more versatile than the all-new Western Star 47X. Offering tremendous visibility and jam-packed with innovative Detroit Assurance safety features, truck occupants can rest assured that they’re in the safest hands.

Designed from the ground up, the 47X is available with either the automated manual Detroit DT12, manual Eaton Fuller, or fully automatic Allison transmission. With either Detroit’s new 525hp DD13 Gen 5 engine or Cummins 380hp L9 engine under the bonnet, the 47X delivers superior efficiency, power, and reliability.

Working on a job site or hauling on the highway, the 47X punches above its weight.

From page 22 ANDREW explained the restoration process from beginning to end. To start, he said the chassis was sandblasted. “ en the truck went to the Adco Trailers workshop where some space was o ered for a spray painter to work out of. Jason Gibson stepped up to the challenge of repairing the cab and bringing it up to the look we were after. e doors were rusted out and needed to be re-skinned. e biggest repair was to the passenger side of the sleeper where it needed to be re-sheeted.”

He continued, “Over the next few months as time permitted, repairs were done, rivets and huck bolts

replaced and the cab was ready for paint. Denis from Signs Lines ‘n Scrolls then worked his magic with some old school signwriting. Alex and the boys from Adco Trailers did some fabrication work, including the checker plate and everything was starting to take shape.

“A few nishing touches like new mud aps from Dutchy’s Mud aps and new mud guards, and a little over a year from when it was purchased, the restored White rolled out the door in 2016.” at was the same year that TRN celebrated its 50th anniversary. e old White, adorned in TRN’s traditional colours, served as a centrepiece during a special celebration, sitting

alongside one of the company’s late model Kenworth cab-overs.

ough it sat pretty for that event, Andrew added that his Road Commander “isn’t just a show pony”.

“It travels up and down the east coast to shows, attending events from Queensland to Victoria,” he said.

With the truck looking as good as the day it rolled o the production line, the next step was nding a suitable trailer. And this is where the metamorphosis from truck to mobile home took shape.

“We needed to put a trailer on it because it was too rough on the road. We had a at top for it, and

then a cheap furniture van came up, so we tted it out,” Andrew explained.

While Col travels the show circuit, the trailer serves as a home away from home.

“My nephew Harrison is a chippy so he helped out with the conversion. e nished product provides some comfortable beds, a toilet, shower, kitchen and room to put the car in the back. It can be hooked up to mains or run o a generator or the batteries that are kept topped up with solar panels.”

It’s the perfect set-up for Col and his wife Heather to travel around the truck show circuit and enjoy their retirement.

ough the initial plan was for the truck to spend half the year with Col in Kyogle and half at Andrew’s in Camden, it spends much more time up north.

“With Dad being retired now, he uses it much more than me, so the majority of the time, it’s up there in Kyogle. He loves it and uses it at least every couple of months. He just spent two weeks away in it doing a few shows. I usually bring it down here for a few months each year,” said Andrew.

So far this year the truck has been to truck shows in Gundagai, Lockhart, Clunes, Kyabram, Rocklea, Gundagai, Wauchope and the Casino Truck Show, which took place on Saturday August 5.

Whilst it missed this year’s Haulin’ the Hume due to other commitments, it is a regular at the event, as well as Crawlin’ the Hume.

NO COMPROMISE

@ 1,800 RPM

1,850-2,050

lb-ft @ 975RPM

Extreme duty and heavy hauling for your biggest jobs

Detroit’s most powerful truck engine ever, the DD16 boasts up to 600 horsepower and 2,050 lb-ft of torque. The big bore workhorse provides efficient and dependable power and performance without compromise.

15.6L INLINE 6

DIESEL ENGINE

Detroit’s advanced technology also means emissions requirements are met through innovative fuel efficiency.

This power, performance, and efficiency are backed by the most comprehensive warranty and extended coverage packages, ensuring the highest level of support for our customers.

When you buy a Detroit product, you’re buying billions of miles of engineering excellence. Tried and true, Detroit engines that are built to ride the roughest roads.

With Detroit, there’s no compromise.

detroitaustralia.com.au

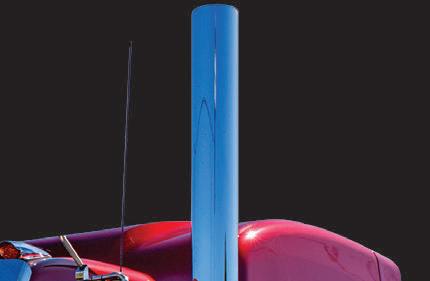

THINK of a classic American trucking icon of the 1970s and the cabover International Transtar would have to be a contender with its imposing size, trapezoidal grill and trim styling carrying from the front of the cab around the sides.

While a number of these units were put to work in Australia, today they are somewhat of a rarity, and to nd one painted up in the colours of another iconic American brand makes for a unique truck.

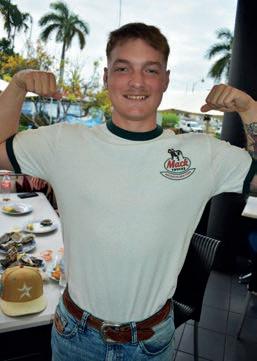

Such is the case with the ‘Bud Express’, Jason Huet’s bright red 1974 CO-4070, which is decked out with Budweiser Beer signage, and is a familiar sight at historic vehicle shows and events around the Brisbane area.

e big Transtar previously wore the colours of SCT Logistics before being painted up in the ‘Bud’ paint schemes it was used as a tow unit for a Budweiser drag-bike racing team based out of Brisbane, with the truck having stuck in Jason’s mind from a young age.

“I remember seeing this as a kid, and when I set out to buy something, I wanted something that I could drive around and have some fun with,” Jason explained.

“I was after a Ford LTL, but I said to my dad Des, ‘Something like the old Budweiser Transtar would be good’. Lo and behold about two weeks after that conversation he rang and said, ‘I know where it is!’ and he dragged me out to show me.

“He had already made an o er with my money, but it all

worked out well. e biggest hurdle was trying to convince my wife Karly to take it on. In the end I said, ‘Well, it’s going to be a truck or a Harley’ and she said, ‘You’re not getting a bike!’ so a truck it was!”

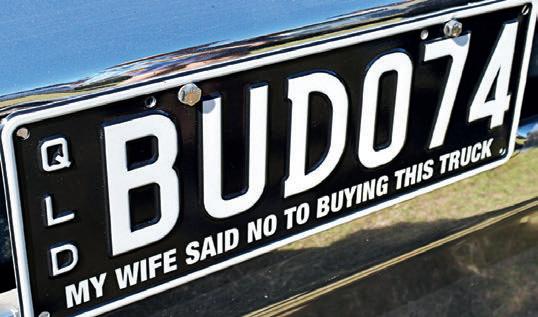

However, it seemed Karly had the last laugh when it came time to getting the International registered, having a bit of input to the personalised number plates.

“She ordered the number plates for it; she thought it was rather amusing. It’s amazing the number of people who notice that,” Jason said with a grin.

With father Des, a truck driver for a number of years, there is a bit of diesel in Jason’s blood, and he currently operates a variety of tip trucks including a Hino truck and dog carting landscaping supplies.

With the Transtar in his possession he was able to put his trade skills as a mechanic and auto-electrician to good use giving the truck an overhaul.

“We have just done a lot of tidying up - especially with the wiring and so forth and have put a lot of elbow grease in pol-

ishing it - the paint was done in 2004, it was parked out in a yard for a few years, but the paint has stood up to it pretty well. I have had the Budweiser stickers re-made but other than that it is what it is, it’s pretty good inside as upholstery had been done previously,” he said.

Sitting between the chassis rails is a Detroit Diesel 8/71 which has been turbocharged and is married up to a 15-speed Roadranger. Despite the Detroit’s having a reputation for being somewhat rowdy it doesn’t appear the bother Jason’s neighbours.

“It goes very well and it’s a fun truck to drive, I love driving it up over the Gateway Bridge from time to time to give it a good run. e plan is to keep working away at it, and I have

been toying putting on it on a rolling dyno just to give it a real good run under load. I have a classic Falcon at home as well as this and the neighbours reckon this isn’t as loud as that!” he explained with a smile.

With its bright colour and imposing presence, the Transtar is somewhat of a magnet whenever Jason has the truck either in the driveway at home, or out and about at some of the automotive gatherings around Brisbane.

“I can be out the front cleaning it up and it’s amazing the number of conversations I have with people just walking up and down the street.

“I have taken it to a few car club shows. e promoters love it because it draws people to it. We have also run it in the

Brisbane Convoy for Kids the last two years, and I really love doing that as it’s such a great event.”

Overall, the Transtar has been a worthwhile project for Jason to take on, and it is something that is worth preserving as a both a ful lling hobby along with maintaining a link to one of the highway haulers of times past.

“I really enjoy it. is is our hobby, and this is something you can see.

“You could buy a jet ski, which would cost more to maintain and own than this thing. I love the classic American ‘Big Truck’ styling of that 70s-era and it attracts a lot of attention - whether it’s a young kid or and older person it always gets the thumbs up from them.”

This stunning tribute to the 1970s big American truck era is the toast of Aussie fans whenever his besotted owner takes it for a run.Jason Huet with his project truck at Rocklea. The ‘Bud Express’ – Jason Huet’s Transtar is a 1970s-era classic. Jason’s wife Karly had the last laugh when she organised the number plates.

Versatility is what distinguishes the DAF range from other trucks in its class. So you need a tipper built to cope with the toughest conditions? There’s a DAF for that!

Whether your needs are long-distance haulage, city distribution, construction transportation, bulk or tank transport, the versatility of DAF keeps you moving, and that’s good for business.

SEE DAF VERSATILITY IN ACTION

SHELL Rimula has partnered with Big Rigs in a big way – so there’s even more reasons to send in your best truck shots.

Each month, the Big Rigs team will choose a #PicOfTheMonth, with the lucky winner receiving a $500 Shell Coles Express Gift Card.

Keep an eye out for our regular posts on the Big Rigs National Road Transport Newspaper Facebook page, calling

for your best truck photos and add yours in the comments, or email them to editor@bigrigs. com.au.

Don’t forget to include a brief note about the truck and where the photo was taken. We’ll feature some of the best photos in each edition of Big Rigs Newspaper, with one winner announced each month. Keep those amazing truck pics coming!

When the going gets tough, truckies keep everyone goingJason Pin captured this great photo of a morning sunrise at Fyshwick, ACT, just before jumping in the bunk. Owen M Weir snapped this photo, before heading to the recent Casino Truck Show, where he says a wonderful time was had by all. Ben Rice took this great shot while heading out of a forest south of Adelaide. Aaron Broz shared a great shot of Acacia Transport’s new Kenworth Legend SAR, “Sitting pretty outside the yard before its first official day on the road,” he said. Dale Clark shared this shot of this Mibus Bros 2019 Kenworth T659 and Drake trailer carrying a Terex Finlay I-130 crusher. Joe Watts captured this amazing pic of the super quad loaded with 195 tonne of iron ore at Marble Bar Rd, WA – bound for Port Hedland. Michael Roels captured the spectacular view of the sunrise at Tumut, NSW.

A Western Australian truckie who had a record of being spot on with information he passes onto Spy has slammed the state of the Barrier Highway which runs through parts of SA and NSW.

In particular he said the 49km section between Broken Hill and Cockburn was in urgent need of work.

“It is winding in places and has broken edges and some are very deep. If the second trailer of a road train got caught in one it could go over. You would think that with all the mining royalties from Broken Hill that it would be in top shape,” he said.

The long time truckie said when repairs are done they just “patch it up”.

This driver does a lot of interstate travel and said the roads in WA are very good when compared to many others around the country.

“We are very lucky in WA to have good roads,” he said. When interstate he likes stopping at the Little Topar Roadhouse.

Old Ford a highlight

An old but beautifully restored 1921 TT model Ford created plenty of interest when it was on display at the recent Townsville Show. It has a 22hp four stroke motor and was in a hall with other vehicles as part of the Vintage and Historic Motor Club display. Member George Sellen said it was restored by a club member and lots of people checked it out when they visited the hall.

In previous years it had been displayed at a historical museum run by the Townsville City Council at the park near the West End cemetery.

The club is based in Townsville and was started in 1968, and has members in Ingham, the Burdekin (Ayr and Home Hill) and Charters Towers.

Its objectives are to encourage the preservation, restoration and use of veteran, vintage and historic vehicles.

Cyclone like winds in Tassie

Strong winds and wet weather in Tasmania have been causing havoc on major highways travelled on by many truckies.

One told Spy that 43 trees had been blown down across or close to the Lyell Highway.

“That is on the west coast road between Tarraleah and Strahan, making some sections hazardous. Part of it is through the west coast range,” he said.

One of my best sub agents who lives along the north coast near the Bass Highway sent Spy an email detailing a spate of bad weather down there.

He lived in the North Queensland tropics for decades and moved to the Apple Isle a few years ago and has never experienced anything like it.

“It defies belief. There’s no end to this idiocy. We’ve been copping a battering for two days from strong winds and it’s still going. Lost power at 4am and still out. Outages right across the state. Winds over 100km/h. One place was 173km/h on west coast. Just no lights etc but got torches, candles, lanterns and it’s like an FNQ cyclone,” he said.

Several truck drivers have told Spy they were outraged to be told that a hamburger with

the lot would cost $25 at a remote roadhouse.

They realise that the business would have heavy freight costs for supplies but thought that was over the top.

Neither complained about the service or food standard but said they wouldn’t pay that even if they won first division in lotto.

Both doubt that the establishment will sell many of the burgers.

Dead animals appear

Carcasses of dead animals along the Cobar to Griffiths road have been a problem for truckies according to one veteran Deniliquin driver.

“There are many of them and some are in the middle of the highway. Truckies can’t just pull over and remove them,” he said.

The driver has appealed to the local council to have road workers remove them on a more regular basis.

“When I have been interstate I often see workers holding big sticks with a hook on the end doing the job,” he said.

He is not the first truckie I have spoken to with a similar gripe.

Truckies realise it is a dirty and smelly job but somebody has to do it.

Whilst on many trips in north Queensland one of the places I always stop at is the rest area just north of Innisfail at the junction of the Bruce and Palmerston Highways.

At busy times of the year there has always been a Driver Reviver site there where motorists stop for a break, free cuppa and a biscuit.

It is run by loyal volunteers including Innisfail Police liaison officer Michael Sands.

The rest area has toilets and trucks can park around the back next to a scenic view of a cane field.

The Driver Reviver is one of many that the Queensland Government has closed during 2023.

When I stopped there in early August I saw Sands and another PLO picking up material from the Driver Reviver building.

“It is finally closing,” he said.

On the positive side, Spy hears that there may be another rest area planned for nearby which will accommodate a Driver Reviver.

Having worked at the Cardwell Puma Roadhouse for seven years, Lilian Bosun has become well known to visitors including many truck drivers who have told Spy she is a very courteous employee.

The roadhouse is along the main street of Cardwell which is beside the sea and 160km north of Townsville and 190km south of Cairns.

Bosun is a renowned friendly worker who has been praised by many patrons at the roadhouse for her courteous and efficient manner.

Every day scores of truck drivers stop there and either

park across from the roadhouse if space is available or in the street beside it.

I stopped there in early August and was served by Bosun who was very friendly.

The roadhouse has clean toilets and a good selection of takeaway food and plenty of seating inside and outside.

You can also pick up a copy of Big Rigs – which lots of truckies do.

“I have been here for seven years and get to meet a lot of people every day including locals and many others passing though,” she said.