100+ PAGE

SEE THE VERY LATEST: Earthmoving machinery, earthmoving attachments, agricultural machinery, mowing equipment, trucks, boats, bikes, and more!

EVERYTHING IN ONE PLACE!

100+ PAGE

SEE THE VERY LATEST: Earthmoving machinery, earthmoving attachments, agricultural machinery, mowing equipment, trucks, boats, bikes, and more!

EVERYTHING IN ONE PLACE!

Built on decades of experience, Volvo’s range of E-Series excavators are the perfect combination of power and stability. Extremely versatile with superior digging force, quick cycle times and outstanding fuel efficiency, you can expect smooth operation and increased productivity in the toughest conditions.

Experience the Volvo difference in Volvo’s world class cab built with operator comfort and safety in mind.

Experience the Volvo difference in Volvo’s world class cab built with operator comfort and safety in mind.

Boasting superior visibility with slim cab pillars and a spacious environment with ample storage, Volvo’s renowned industryleading cab design offers a comfortable, low noise environment to allow operators to be more efficient and more productive than ever.

Boasting superior visibility with slim cab pillars and a spacious environment with ample storage, Volvo’s renowned industryleading cab design offers a comfortable, low noise environment to allow operators to be more efficient and more productive than ever.

Utilising the Volvo Co-Pilot in-cab interface, Dig Assist provides real-time guidance for operators to ensure job parameters are met more accurately with improved site safety.

Utilising the Volvo Co-Pilot in-cab interface, Dig Assist provides real-time guidance for operators to ensure job parameters are met more accurately with improved site safety.

Levelling sites, digging trenches, grading slopes, and creating site profiles has never been easier. The operator can visualise the bucket and the machine’s position with indicator guidelines for trenching.

Levelling sites, digging trenches, grading slopes, and creating site profiles has never been easier. The operator can visualise the bucket and the machine’s position with indicator guidelines for trenching.

A huge thank you to our Major Sponsors. It has been a pleasure working with you.

LOCATION

The Sydney Dragway, Ferrers Road, Eastern Creek New South Wales. How to get here: Via the M4 motorway or the Western Highway.

ENTRY FEE

$10.00 pr adult plus booking fee (children under 16 free).

DISABLED ACCESS

The majority of the Expo site is wheelchair friendly. Dragway site is level, fully paved and provides easy access for visiting all exhibitor sites.

ACCOMMODATION

There is a variety of accommodation options in the immediate area.

FOOD AND REFRESHMENTS

Food and drink vans are located throughout the site and there is a licensed bar and hospitality area.

LIVE ENTERTAINMENT

Live entertainment will run throughout the weekend.

TOILET FACILITIES

Toilet facilities are provided throughout the Expo site.

CAR PARKING

There is expansive free car parking facilities on site provided for visitors.

FIRST AID/EMERGENCY

Personnel are on hand to administer any first aid that may be required.

Komatsu will be the Gold Sponsor of the Diesel Dirt & Turf Expo again this year, with a big team presence planned to showcase its innovative range of Smart Construction technology. Located at Stand B1, Komatsu will have one of the largest displays of machinery and technology at the expo, and Chris Moroz, Komatsu’s Sales Manager – Central Region, says a big focus of its marquee will be Smart Construction, a suite of offerings that improve

productivity and safety in the construction, quarrying, and mining industries, through the application of unique technology and integrated products.

“The tools in our Smart Construction suite are designed to improve communication and connectivity between our customers, their machines, and their materials,” he says. “They cover unique solutions such as intelligent machine control, drone data collection to create

3D terrain maps, site dashboard visualisation and remote operator support.”

Komatsu will have three Intelligent Machine Control (iMC) machines on display: the PC360LCi-11 36-tonne excavator, the 23-tonne PC210LCi-11, and the D71PXi-24 and D65EXi-18 mid-sized dozers.

“iMC enables operators to program 3D design data directly into a machine, and delivers major productivity benefits for customers, from controlling cut depth while avoiding track shoe-slip on the dozers, to increased accuracy and automatic grading capabilities on the excavators,” Chris says.

Komatsu will also have its Retrofit Kit (RFK)

“We’re excited to have these machines onsite at DD&T and showcase Komatsu’s latest innovations for our construction customers.”The Komatsu team can be found at Stand B1 at the expo. Komatsu’s sales and support teams will be out in force to answer questions.

machinery to perform digital construction, using ICT features such as 3D machine guidance, payload management, and 3D construction data collection.

“RFKs can be fitted to a variety of machine sizes, makes and models, including older machines, making it an appealing addition for many of our customers,” he says.

Chris says Komatsu will also have a large presence from its sales and support teams from right across the business at DD&T.

“Visitors will be able to stop by and have a chat with representatives from our Smart Construction, recruitment, aftermarket, Komtrax, and Portal teams for any issues or questions on the machines and technology on display,” he says.

“They can also catch our PC138US-11 RFK and PC210LCi-11 in action across the three days at the demo site, and we’ll be running some exciting competitions where attendees can have the chance to win prizes, and take advantage of our show special offers.

“Diesel Dirt &Turf is a great opportunity for us to showcase our latest technology and innovations, and connect with customers and industry – the whole team looks forward to it each year. Come by Stand B1 to find out more about Komatsu, its products and services, and its people. We look forward to seeing you there.”

The Pickles team is dedicated to maximising the return on every asset. We have a highly trained team of international valuation experts who have the knowledge, deep experience and tools needed to provide accurate appraisals and specialist advice on how to enhance value. We stand by our valuations, providing sellers the assurance of protection in sale returns.

We understand that every situation is different. Our team brings hundreds of years’ experience in customising solutions that suit the unique needs of our clients. With expertise across multiple sales channels, we will recommend the most effective remarketing strategy based on our deep knowledge of industry trends, potential buyers, and current market conditions, to minimise any risk and maximise the value of every asset put to sale.

Talk to us today about partnering with Pickles.

For more information, contact Matt Blanch on 0428 163 083

Universal

1300apprentice

With more than 40 years of industry experience, XCMG has built a global reputation for innovation, reliability, and performance throughout its entire range of construction, agriculture, and industrial machinery.

XCMG’s mini excavator range is one of Australia’s newest and most impressive lineups of high-performance, value-for-money diggers. Starting with the compact yet powerful XE17U 1.7 tonner purpose-built for tight access work, up to the robust and powerful XE80U designed to dominate virtually any construction project, XCMG has you covered.

With premium engines from renowned manufacturers including Kubota and Yanmar, plus top-quality componentry by Kawasaki, Bosch-Rexroth, Eaton and Miller, XCMG mini excavators are built tough to perform, and durable to last.

XCMG heavy excavators are renowned worldwide for their exceptionally high power, excellent lifting capability, extensive reach, impressive operator comfort and overall maximum operator satisfaction.

Available in various excavator sizes from 10 to 50 tonne to cater for virtually any requirement or project, the entire range offers exceptional hydraulic performance, cycle times and breakout force. With premium Cummins and Isuzu engines, plus exceptional componentry by Kawasaki, Nabco and Miller, XCMG heavy excavators offer unmatched value for money. In addition, cabins are spacious and comfortable for even the longest days on the job, including sound dampening and state of the art controls. In addition, XCMG excavators are designed for efficient serviceability and minimal downtime, using only the most reliable components for premium longevity.

Simply, XCMG heavy excavators are a musthave for any owner who requires comfort, versatility, and performance at a competitive price.

XCMG’s impressive range of 11-20 tonne wheel loaders is fast becoming a key talking point in the Australian machinery marketplace. Impressively priced, XCMG loaders are uniquely powerful, rugged, energy efficient, safe, and comfortable – as well as being simple to service and operate.

From the 11 tonne XC938 model up to the 20 tonne XC958, XCMG loaders include premium features such as Cummins engines, automatic ZF transmissions, wet axles and brake systems, spacious and ergonomic cabs, and digital gauges displaying the loader’s vital functions and data.

XCMG loaders are designed from the ground up to work hard with reliability and efficiency, whilst also providing a premium operator experience in terms of comfort, control, safety, and serviceability.

Already favourites with various major mine sites throughout Australia, XCMG road graders and compaction rollers are competitively priced and offer high-power, heavy-duty work capability, impressive operator comfort and overall renowned satisfaction.

controllability, XCMG road machinery also offer premium reliability and heavy-duty work capability using only the finest componentry. Furthermore, XCMG machines are designed with safety and comfort of operation at the absolute forefront, with spacious ROPS / FOPS cabs, double emergency stops, reverse cameras, spacious cabins, ergonomic controls and much more.

XCMG elevated work platforms feature compact designs, easy transport, simple and smooth controls, tight turning radiuses, and reliable performance.

Australian Standards compliant, all models offer exceptional lift heights, working capacities and platform sizes, plus minimal maintenance and service requirements. Select models are also available in your choice of electric or hydraulic lift functionality, giving maximum flexibility and versatility to suit the requirements and preferences of owners and operators.

With dealerships and service agents throughout Australia, your investment in XCMG machinery not only delivers a premium machine, but also the peace of mind and minimal downtime that comes with unmatched after-sales support. XCMG’s primary focus is to ensure your complete satisfaction throughout your machine’s lifetime and beyond, by providing the best equipment, parts, service, and assistance available.

For more information about XCMG’s diverse range of construction, mining, and agriculture equipment, visit: www.xcmgmachinery.com.au

As the world’s third largest construction equipment manufacturer, XCMG delivers a machinery range that’s designed to perform, and built to last.XCMG machinery is supported by dealerships and service agents throughout Australia. XCMG’s mini excavator range balances powerful performance with premium value, exceptional reliability, and impressive build quality.

There will be a host of new equipment on display at WesTrac’s stand for the 2023 National Diesel Dirt & Turf Expo (DD&T), including something a bit removed from the expected yellow Cat® machines.

Alongside the extensive range of excavators, loaders, dozers, and paving equipment, the Cat-branded Ducati race bike of Australian Grand Prix motorcycle racer Jack Miller will be on show.

Miller, who rides for Red Bull KTM Factory Racing, used the bike in the 2022 ASBK MotoGP race in South Australia. Unlike the other equipment on display, the Ducati won’t be available for willing buyers to snap up, but given the popularity of the event last year, WesTrac expects a big number of visitors.

After taking out the award for Best Stand at the 2022 event, WesTrac has upped the ante for 2023 with more Cat equipment on display, a new Cat Attachments stage, a larger selection of Cat merchandise to purchase, and a dig pit that will be used for demonstrations, allowing visitors to test drive one of the Cat Next Gen Mini Excavators or Skid Steer Loaders.

WesTrac will have more than $5 million worth of new construction equipment on display, including 10 different Next Gen excavators that range from the sub-2-tonne Cat 301.5 Mini Excavator right up to the large Next Gen 349 3D Excavator.

According to WesTrac Retail Construction Business Manager James Konz, the Cat Next Gen range is proving highly popular with construction industry operators.

“From sole operators using one of the smaller

of the Next Gen machines are proving their worth,” James says.

“The amount of technology that comes standard with these machines is industry leading, with across-the-board benefits including improved safety, productivity, and efficiency as a result.

“When you add on some of the optional extras, it can take that performance to a whole new level.”

Alongside the ever-popular excavator range, WesTrac will also showcase some of its Cat Skid Steer loaders, Wheel and Compact

There will also be a range of paving equipment and a big display of the latest Cat attachments, which are key to increasing the versatility, productivity, and utility of Cat machines.

Some of these attachments will be showcased in live demonstrations, while WesTrac specialists will be on hand to talk to operators keen to understand the options available.

WesTrac also aims to use the event to showcase career and training opportunities. Through its WesTrac Institute, the company offers a range of training options including apprenticeships and trade upgrades.

James says WesTrac offers a significant number and diverse range of career choices to people.

“With rapid advances in equipment technology, the sorts of roles are a far cry from the ‘grease monkey’ mechanical trades of days gone by,” he says.

“Caterpillar® is a world leader in automation and operator assist technologies and that brings with it a vast range of career opportunities. Heavy diesel mechanics today are very much technicians and technologists with a broad cross-section of in-demand skills.

“While our display is designed to showcase Cat equipment, its other purpose is to inspire you – and hopefully your children – to explore exciting career options and opportunities in the construction industry and at WesTrac.”

For more information, visit: www.westrac.com.au

WesTrac returns to the Sydney Dragway in April 2023 for the National Diesel Dirt & Turf Expo (DD&T) - Australia’s largest construction industry expo and a great day out for earthmovers and their families.

The annual National Diesel Dirt & Turf (DD&T) Expo is fast approaching and YELLO Equipment is proud to announce the team will be joining in on the festivities and offering a first-hand look at their remarkable line up of SANY Earthmoving machines.

The three-day exhibition will give attendees the chance to explore and join in celebrations of the industry’s businesses, culture, and best of all – SANY excavators. Come and be a part of the action, with colleagues, family, friends, and the community!

To celebrate the biggest construction expo in Australia, YELLO Equipment have prepared a robust line up of machines that are ready to assist you on your next project. There will be a wide range of sizes and models on display, from mini, small, medium, and large excavators to wheel loaders and wheeled excavators.

Additionally, the ‘mighty mini’ SY16U will be on show and available for purchase in the popular ‘Tow & Go’ package, providing all the essentials you need to get work done efficiently in one incredible deal. The package includes:

• The SY16U – The compact 1.7-tonne excavator is perfect for the toughest jobs in the tightest spaces. The SY16U could quickly become your go-to for any earthmoving projects.

• A Sureweld SW2600 trailer – This fantastic trailer is a great option for transporting your new machine with an impressively low tare weight of 400kg and a carrying capacity of up to 2200kg.

Three Bucket Pack – These are quintessential

“DD&T provides a tremendous chance to not only showcase the quality of our machines, but to gather feedback and comments, while connecting with people in these communities who may not have previously had the opportunity to witness the phenomenal work of a SANY machine.” he says.

The YELLO Equipment team will be present and ready to answer any questions, provide walkarounds, and give attendees the opportunity to get up-close and personal with a wide range of machinery.

Whether you’re in the market for some new earthmoving equipment, are looking to upgrade your current machinery, or simply want to learn more about the latest industry trends – the YELLO Equipment team are there with you all the way.

The SANY Australia stand is truly a must-see for DD&T 2023. If you’re a fan of big, powerful machinery, join YELLO Equipment and SANY for an action-packed three days of people, food, and most importantly – extraordinary machinery.

Viva Energy is one of Australia’s leading energy companies, with more than 1350 Shell-branded service stations and 55 fuel import terminals and depots nationally. It also has a strong retail convenience offering, with the recent purchase of more than 700 Coles Express service stations, and the sole right to use the Shell brand in Australia for the sale of retail fuels.

It is also an exclusive macro distributor for Shell-branded lubricants, has a strategic relationship with Vitol for the supply of crude oil and imported products, and supplies 24 per cent of Australia’s fuel needs. Further, its Shell Fuel Card service is accepted at 1350 service stations across the country.

“We’re proud to be Australian, proud of our 120-year history, and extremely proud of our achievements,” said Renee Reilly, Viva Energy Sales and Marketing Manager – Lubricants. “We help Australians reach their destinations by making, importing, and delivering the fuels, lubricants, chemicals, and bitumen they need to get there. We play a major role in getting people and goods from A to B.”

Shell has a history of innovation in lubricants and was the first supplier to market cleaner, purer lubricants made from natural gas. Significant investment in research and development has led to technologically advanced products that are reliable in even the toughest Australian conditions, and across all industries including construction, quarrying, and mining.

“Shell invests significantly in technical collaboration and has over 350 product application specialists that work closely with OEMs and customers to develop innovative lubricant solutions,” says Silvana Farrugia, Technical Expert from Viva Energy. “Our lubricant products can deliver value but also improve business outcomes.”

“Our customer benefits include lower maintenance costs, longer equipment life and reduced energy consumption – these are some of the reasons that Shell has recently celebrated 16 consecutive years as number one global lubricants supplier,” Renee said.

With local expertise backed by a global brand, Viva Energy’s lubricant sales and technical team is well placed to identify and implement best in class lubrication solutions for customers.

“Online, on-site or over the phone, we are always available to resolve your lubrication questions, so you will know the right oil for any application fast,” Silvana said.

There are several helpful and convenient tools customers can use to assist with every aspect of product selection and lubrication management, including the Lubricants Online Store, Viva Energy Technical Help Desk, and Shell LubeMatch.

As lubricants, greases and coolants are critical machine components, Shell works with leading equipment manufacturers to make sure that their products meet the requirements of their equipment and the tough working environments that they operate. The Shell range of lubricants carries a wide range of industry and OEM approvals to meet and exceed the requirements of equipment manufacturers.

“At a local level, Viva Energy technical staff have a technical relationship with all key OEMs,” Silvana said. “This technical relationship enables consistent information flow between all parties, enabling us to work with customers to get the most out of their equipment.”

environments, with one of the most flexible and adaptable supply chains, including both local fuels refining and global sourcing. Viva Energy owns, leases, and operates a portfolio of established infrastructure assets complemented by third-party warehouse providers throughout Australia – including in some of the most remote parts of the country.

“Beyond refining and lubricants, we are also looking ahead to the future and aim to establish new energy projects which will transform the Geelong refinery site into a modern Energy Hub and meet the changing energy needs of all Australians,” Renee said.

“Our vision for the Geelong Energy Hub is focused on exploring opportunities in transition fuels (such as LNG), alternative fuels (such as biofuels and hydrogen), and renewable energy and emission reduction projects such as a solar energy farm at our Geelong Refinery.

“We know that it is critical for the sustainability of our business, but also our customers’ businesses that we understand the opportunities and risks associated with climate change, and incorporate these into our business strategy. All these initiatives help our customers to also reach their goals, and allow us to be a true business partner for all of their energy requirements.”

For more information, visit: www. vivaenergy.com.au/shoplubricants or contact Viva Energy’s Technical Helpdesk Monday to Friday, 8am to 6pm AES on 1300 134 205, or email technicalhelpdesk@ vivaenergy.com.au

Viva Energy is a locally operated Australian energy, retail, and industrial company, committed to providing dynamic and adaptable service.Viva Energy, the Shell Australia Licensee has been providing energy solutions to Australia for 120 years. Shop Shell Lubricants for your equipment at

More visibility brings insight, additional opportunities for growth and improvement, and new capabilities to proactively manage operations and enhance site safety and efficiency.

Reliable telematics systems and connected technologies are becoming an extremely valuable tool to ensure the day-to-day operations run as smoothly as possible for both site managers and operators. Having the knowledge of where equipment is located on site and how it is performing at any moment ensures maximum uptime, efficiency, and productivity.

Volvo Construction Equipment has developed Volvo Co-Pilot, your partner in the cab. An intelligently designed interactive display available as an option on select Volvo machinery, Volvo Co-Pilot offers real-time insights into work being performed to ensure

the highest standard of efficiency and accuracy in any application.

But Volvo Co-Pilot can’t do it alone. The interactive display works simultaneously with Volvo Assist, a suite of applications designed and developed exclusively by Volvo CE to unlock the full performance potential of both machine and operator. Volvo Assist includes Dig Assist for excavators, Load Assist for wheel loaders, and Haul Assist for articulated dump trucks, along with a suite of other connected technologies.

First released in 2016, Volvo Construction Equipment is continuously expanding the Co-Pilot’s functionalities, and is committed to ongoing future development of the system, focused on giving the operator and site manager all the tools and information they need to create and maintain a sustainable, highly

One such development is CareTrack, a state-of-the-art telematics system that is fitted as standard on general purpose articulated haulers, wheel loaders, and excavators, that provides access to a wide range of machine monitoring and tracking information. CareTrack provides customers with machine insights and quality connected solutions in the most efficient way possible.

Getting machines to do more – while both reducing fuel use and maximising safety –is one of the most important factors on a construction site. With CareTrack you can easily identify unnecessary machine idling and wasted time, along with fuel consumption, to optimise machine and operator performance. You can proactively manage your service and maintenance to maximise uptime, and gain crucial insight into your machine’s point in its life cycle to plan services, and even order space parts in advance to reduce unnecessary downtime.

“Customers now have unprecedented insights into the productivity of their machinery as CareTrack provides real-time insights into machine utilisation and fuel consumption, enables tracking, and simplifies maintenance to reduce downtime – it is a truly valuable resource,” explains Hayden Grant, National Product Manager at CJD Equipment, Volvo CE’s national distributor.

“Co-Pilot also helps operators use their machines efficiently. Not only can they learn about their machine’s fuel consumption and excessive idling, but they can also manage all operations with ease and customise functions to monitor their job progress with greater independence and confidence.”

The construction industry is experiencing a dynamic era of rapid innovation with new technologies changing how we work and communicate. As operations continue to grow in both size and scale, the shift towards strategic partnerships between manufacturers and customers is now more important than ever.Hayden says complete jobsite visibility helps ensure safety and improve communication. Volvo Co-Pilot offers real-time insights to ensure efficiency and accuracy on the jobsite.

Volvo Construction Equipment has also unveiled its latest Connected Map solution, a positioning service which provides a visual overview of all machines and vehicles on site, including non-Volvo equipment. Part of a portfolio of uptime services that utilises a telematics system, this innovative solution adds another layer of visibility.

Combined with Volvo’s successful CareTrack monitoring, the Connected Map solution aims to create more sustainable, connected, and efficient work sites. Connected Map works by extracting the positioning data from machines, either using the Co-Pilot touchscreen display or any other mobile device – providing it has a SIM Card and the Volvo Map App installed. This unique functionality also allows temporary site visitors to access the app in the same way.

“The Connected Map software is designed to work seamlessly and simultaneously with Volvo’s Co-Pilot,” Hayden says. “You can have a visual overview of the position of every

machine, vehicle, and visitor on your site –it’s a fantastic feature to have right at your fingertips.

“Users benefit from complete jobsite visibility, helping to make operations safer and more efficient. Connected Map also makes it easier operators and visitors to become familiar with the site and know where everyone and everything is.”

Volvo’s Connected Map solution allows for total visualisation of typical jobsite such as site facilities and landmarks, including roads to assist in site navigation around, loading zones, and dump zones. Site mangers can also communicate any changes to parameters on site to all users in an instant alert. Real-time updates to the map such as speed changes, one-way traffic, or alerting when visitors are on site through an online portal, can help to improve operational flow, increase productivity, and recognise safety incidents before they occur.

Volvo is renowned as one of the world’s best manufacturers of safe, high-quality, and technologically-advanced machinery. Telematics is just one step forward in the transformation towards strategic customer partnerships – with additional productivity services available.

Together, CJD Equipment and Volvo CE have provided a range of premium construction machinery suited to Australia’s unique industry requirements for decades. Volvo and CJD deliver a range of productivity, fuel efficiency, and safety solutions for a highly productive operation, ensuring machines are performing at their very best.

CJD Equipment has an extensive national support network in place to ensure you are well supported, no matter where or when.

For more information, contact your local CJD branch on 1300 139 804 or visit www.cjd.com.au

Connected Map provides a visual overview of all Volvo and non-Volvo machines and vehicles on site.

Volvo Assist includes Dig Assist for excavators, Load Assist for wheel loaders, and Haul Assist for articulated dump trucks.

Connected Map provides a visual overview of all Volvo and non-Volvo machines and vehicles on site.

Volvo Assist includes Dig Assist for excavators, Load Assist for wheel loaders, and Haul Assist for articulated dump trucks.

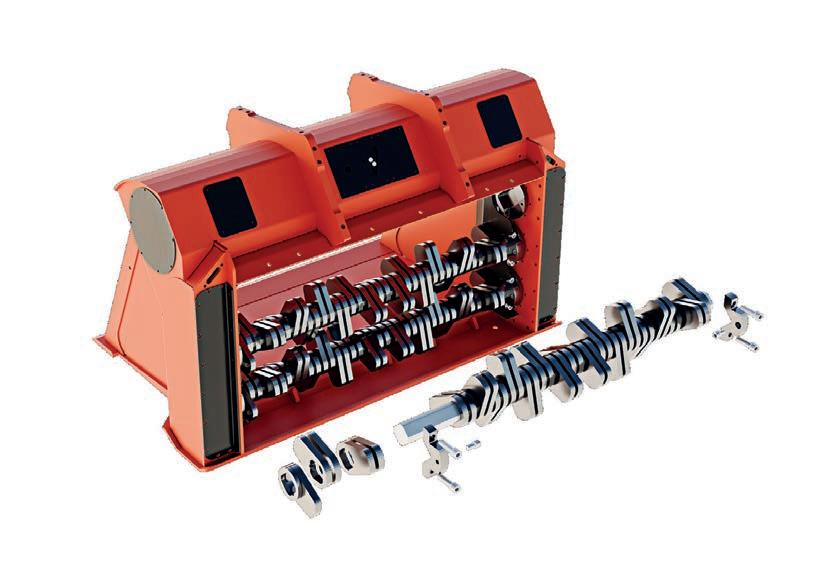

The Tigercat 6900 horizontal grinder is a heavy-duty upswing grinder designed for maximum production. The 6900 is built for extreme duty and long-life using only the highest quality components. It is made with the same build quality and components that Tigercat’s forestry range is renowned for.

The grinder outputs maximum mulch production thanks to its high processing capacity upswing motor. Feeding of both long and short material is easy and productive due to the adjustable in-feed angle.

The open discharge system includes a single discharge conveyor, and the open bottom

allows for clean operation and easy service.

Easy maintenance is always a focus area of Tigercat machines, and the 6900 grinder is no exception. A split hog box opens for full access to rotor and screens. Anvil and screens are also hydraulically retractable.

Operator controls include an easy to access electronic control system with colour LCD screen interface for machine monitoring and function adjustment. A radio remote control is used for primary machine operating functions. A convenient storage compartment for tools elevates to position for easy access.

Other standard equipment includes Tigercat’s

RemoteLog® telematics system and LogOn™ local WiFi machine monitoring system.

The 6900 grinder is extremely versatile with the bolt-on hog box and feed conveyor assembly. Metal can be effectively removed with optional large diameter magnetic head pulley and optional over band magnet.

Other options include a dolly system, three axle, air compressor kit and work lights.

Contact your local Tigercat dealer Onetrak to learn more about the Tigercat range.

Sydney-based electrical maintenance and repair specialist Allelec Services enlisted the help of Toyota Material Handling Australia’s (TMHA) range of Huski Construction Equipment to maximise its business operations.

Since its beginning three decades ago, Allelec Services has provided electric maintenance and repair to commercial businesses such as supermarkets and shopping centres.

Roughly 18 months ago, Allelec director Alan Borland needed to upgrade his miniexcavator to a bigger unit, and landed on the Huski M-38U mini-excavator with its 3.8-tonne capacity.

Borland reached out to the local TMHA team led by area sales manager Peter Bower, choosing Huski Construction Equipment due to its excellent reputation for reliability.

“We were happy to run with the purchase of the Huski excavator,” Alan said. “Then the opportunity came up with the scissor lift.”

The success of the Huski excavator led Alan to add a Huski SV08ENL scissor lift to Allelec fleet in early 2022.

“We had a smaller scissor lift but wanted the Huski one for the height – it’s a 26-footer – and its slimline design helps with accessing signage and the like while still being manoeuvrable without a monstrous deck on it,” he said.

“The scissor lift is very handy, it’s a narrow unit but with the extra height, it’s been very good.

“We used it for lighting upgrade works at Macquarie shopping centre and for a new signage installation at Chipping Norton, so it’s been very versatile as well.”

Alan said he enjoys owning his own equipment as it allows the business to be flexible and respond quickly to any issue, eliminating the need to find suitable contractors which can be costly and time-consuming.

TMHA prides itself on offering excellent customer service by developing real relationships with clients. Huski Construction Equipment area sales manager Peter Bower helped establish a strong relationship with Allelec Services early on by assisting with the purchase process.

“There were a couple of little questions at the start when understanding the machine so I rang Peter about it,” Alan said.

“Peter and his boss came straight out the following day and saw us straight away, helped us out and found out what the problem was and sorted it out. It was very immediate.”

Since becoming a TMHA customer in 2021, Alan has been satisfied with the products and service provided, saying he would be more than happy to continue his patronage in the future.

“I’ve been super happy, no problems at all,” he said. “I wouldn’t have any hesitation getting something else off them. They’ve always responded to us straight away.”

Alan said that he has even begun recommending Huski products to friends and colleagues due to their excellent performance.

“I’ve mentioned to a few people about the Huski excavator, that I’m very happy about it,” he said. “I’d have no hesitation in recommending it.”

He also said that Peter would be his first port of call if Allelec ever wanted to add more equipment to its stable, due to the performance of the existing machines and the service provided.

Allelec Services is based in Kings Park, Sydney, and has been servicing businesses across New South Wales for the last 30 years. Employing roughly 12 experts, the group specialises in maintenance and repair for large commercial operations such as supermarkets and shopping centre chains.

For more information, visit: www. huskiconstructionequipment.com.au or call 1800 425 438

For over thirty years Toyota Huski skid steer loaders have built a reputation on performance, driver comfort and legendary reliability. Toyota Material Handling proudly continue this outstanding pedigree with their range of built tough Huski mini excavators.

Stacked with operator features, the range consists of seven models including a 1.3-tonne short-radius machine and six zero tail swing models ranging from 1.6 to 6 tonne, plus famous Huski performance guaranteed to dig in and be productive on every job.

In today’s time-sensitive landscape, uptime and efficiency are vital to the success of any earthmoving enterprise.

Fortunately, ALLU’s range of Transformer processing buckets caters for just that, and more.

By having an ALLU Transformer bucket at the ready, civil workers wouldn’t have to move material offsite to be screened before hauling it back and reusing it. Instead, the processing bucket can screen the material right there.

“The push that we have here is into the civil construction and earthmoving industry, where they can repurpose material on site,” QLD Rock Breakers product specialist Craig Einam says.

“They don’t have to truck it off, truck it back, or bring fixed plant on, which is expensive. They can quickly repurpose material. They might only do a week’s work on one site and then they can move to the next site.”

Einam says contractors can save a lot of money by avoiding dump fees and transport costs, which can add up on today’s job sites.

“ALLU is the leading processing bucket in the world today, and stands out in a crowded processing market,” he says.

“ALLU has created a niche with their latest bucket technology, which puts them ahead of anything else.”

Save even more time

The latest ALLU innovation is Variable Drum (VD drum), which enables the operator to quickly replace fixed TS blades without the need to open the chain-box.

Enabling a variable drum setup means an individual drum or blades can be changed more quickly, saving time and money.

ALLU’s patented TS (top screen) construction and screening blades make it possible to screen materials even when they are wet or moist without fear of the structure getting clogged.

ALLU’s TS blades make it possible to screen wet materials without fear of the structure getting clogged.

With the TS structure, it is also possible to get three different fragment sizes from the same ALLU unit by rearranging the screening combs with no additional costs.

One step ahead with an extensive range of products

ALLU has been consistently one step ahead leading the industry for over 35 years, with truly mobile, compact screening buckets, which are the perfect attachment for compact base machines to screen and transform your materials.

The ALLU Transformer range is among the

widest spanning on the market, with units available to fit almost any base machine size – from the compact DL Series that suit excavators from four to 12 tonnes through to the M Series, which will fit excavators up to 160 tonnes and wheel loaders up to 90 tonnes.

ALLU New VD Drum is currently available for DN 3-12 TS and DN 3-17 TS models.

ALLU’s extensive range of products are distributed to over 30 countries around the world and are available across Australia throughout the authorised dealership network, which can also provide any maintenance required.

For more information contact the dealer in your state:

• QLD and NT: QLD Rockbreakers, www.rdw.com.au/qld-rock-breakers

• NSW: GroundTec, www.groundtec.com.au

• VIC, SA and TAS: Walkers Hammers, www.walkershammers.com.au

• WA: Total Rockbreaking Solutions: www.totalrockbreaking.com.au Or visit: www.attachmentspecialists.com.au/ALLU

ALLU Transformer buckets are purpose built for efficient material processing by turning waste material into profit by producing aggregates and reusable materials from bricks, concrete, metals, wood, cardboard, glass, asphalt, waste soil or just about anything. Wet or dry.

One ALLU can produce multiple fragment sizes, with various blade and drum configurations.

LESS TRANSPORTATION OF MATERIALS

LESS LANDFILL

LESS FUEL CONSUMPTION

ALLU at DDT Expo, site A10

Processing times, cycle times and processed tonnes can be viewed and analysed via ALLU app.

For excavators and loaders from 8t to 160t.

ALLU Transformer above is processing plasterboard onsite for reuse instead of sending it to landfill.

Smaller-to-medium-sized earthmoving businesses have always been the base for Semco’s growth strategy. Reflecting on the company’s growth in the past 25 years, Semco CEO Satch Santilli said, “Our philosophy always was and remains, providing the best brands of equipment to satisfy the needs of smaller businesses.

“We value our loyal customer base that relies on us to keep them informed and supported as their businesses grow. By delivering on what we promise, customers trust us because we have helped them grow their bottom line through a genuine and helpful partnership, backed by advanced parts and maintenance support and knowledgeable technical staff.

“Together with our suppliers, we watch market developments and structure our equipment ranges to always have the most innovative, efficient, safe and productive equipment in the market. The National Diesel Dirt & Turf Expo is a unique opportunity for us to catch up with existing and potential new customers and to keep everyone briefed on the latest releases,” Satch said.

All new Morooka crawler carrier

The Morooka MST110C replaces the previous model MST2200VD. Featuring a new cabin

layout, Stage V Engine, joystick control and updated cooling arrangement, the MST110C delivers improved ergonomics, reduced engine emissions and fuel economy, improved serviceability and durability.

A major advance is the single lever electro-

hydraulic joystick that replaces the conventional two-lever pilot control system. This upgrade significantly improves operator control while reducing fatigue, being used for drive and dump functions. The joystick is connected via CAN to the engine and display monitor for easier troubleshooting for improved servicing.

The MST110C also has a decel function that reduces engine revs, reducing unnecessary fuel consumption. Engineering quality is outstanding, with the improved design of the dump body manufactured using HARDOX material that provides longer life and improved material retention.

With many construction sites presenting limited access, mini dumpers have become an essential tool on sites with a space challenge.

Many contractors who typically have an excavator and a truck are now adding laboursaving mini dumpers to their fleet because of the efficiency these provide, often enabling them to provide additional services within the scope of their business.

Semco’s range of Messersi and Yamaguchi mini dumpers has helped revolutionise the handling of construction site spoil removal on smaller city renovation sites. With a range

comprising diesel and electric models in a range of capacities, the Messersi mini dumpers effortlessly carry great payloads.

The Messersi TC50-e electric powered track mini-dumper operates in any environment. Powered by a LiFePO4 (Lithium-Iron-Phosphate) battery pack that delivers nominal power of 6.9kW, a single full charge of the TC50-e electric mini dumper is plenty for a shift of five to six hours with up to 2.5 hours of continuous travel when the dumper is fully loaded.

“Our experience in distributing and supporting quality Japanese-made equipment like our Takeuchi excavator and compact loader range has given us a clear preference for selling Japanese manufactured earthmoving equipment,” Satch Santilli said.

Excavators from Takeuchi

New from Takeuchi are its excavator models TB325R, TB335R and TB350R. These are ruggedly engineered mid-range capacity excavators and importantly, they carry the respected Takeuchi pedigree for reliability and performance.

Minimal tail swing design allows operators to focus more on their work and worry less about rear swing impacts. All models have excellent manoeuvrability and accessibility at confined worksites without sacrificing stability.

Yamaguchi tracked mini dumpers

“Yamaguchi’s reputation for quality engineering meets our need to supply high-quality, reliable equipment to demanding customers such as the rental market, where we see the major potential for these versatile machines.

“These mini tracked dumpers are ideal on sites where it is not efficient or practical to use an excavator or a compact track loader to move material off site. With their narrow width and functionality more akin to a wheelbarrow, they can be safely driven through very tight alleyways and other spaces often encountered by contractors working on high density innercity redevelopment or basement sites,” Satch added.

More models from Toro

Due for release is the all-new Toro Dingo TX 700 tracked digger, an affordable, compact, robust and highly reliable mini machine with heaps of power to do the toughest jobs. Featuring patented Dingo traction controls and a dedicated stand-on platform, the Dingo TX 700 is easy-to-use and offers increased operator comfort and improved visibility. It’s the ideal machine for both rental companies and contractors working within the confines of tight spaces.

The Dingo TX 700 is also compatible with dozens of attachments, meaning the machine can be used for a wide range of jobs.

Attachments include buckets, adjustable forks, grapples, levellers, utility blades and more.

With a focus on providing efficient tools, Semco can show excavator owners the latest releases in engcon tiltrotators, safe quick hitches and the range of high-productivity tools. Working with a tiltrotator saves time, cuts fuel consumption,

reduces machine wear and manpower while reducing waste material and delivering highprecision results.

Adding further versatility and productivity

EC-Oil enables the changing of hydraulic attachments without leaving the cab. Durable connectors allow tool connection at full system pressure and drip free couplings lower environmental impact and reduces problems with manual connections.

“By satisfying the needs of small to midrange contractors with ever improving tools to make their business more efficient, we have established long-term customers whose success is driving our rapidly growing sales.

Semco customers always have the assurance that they will be fully supported, regardless of whether they want to upgrade to new models or just want to keep their machines running as productively as possible through regular maintenance programmes and parts supply,” Satch added.

Visit the Semco stand B5 to check out these equipment innovations. Further information at www.semcogroup.com.au

TL6R

Approx operating weight 3,530kg

Features radial lift

Engine power 47.9 kW

Tipping load 2,390 kg

TL8R-2

Approx operating weight 4,165kg

Features radial lift

Engine power 54.6 kW

Tipping load 2,740 kg

TL10V-2

Approx operating weight 4,660kg

Features vertical lift

Engine power 54.6 kW

Tipping load 3,270 kg

TL12R-2

Approx operating weight 5,710kg

Features radial lift

Engine power 81.8 kW

Tipping load 3,915 kg

TL12V-2

Approx operating weight 5,835kg

Features vertical lift

Engine power 81.8 kW

Tipping load 5,325 kg

Quick couplings manufacturer Stucchi’s DP and GR multi-coupling series are paving the way for quick simultaneous connect and disconnect operations of multiple hydraulic lines. In addition to efficiency gains, the series have also been designed with a strong focus on providing high safety standards.

Drawing on over 60 years of manufacturing knowledge, the Italian company has devised a variety of multi-coupling solutions that cater for the needs of industry, allowing earthmoving operators to efficiently and effectively power on through across a range of tasks.

Stucchi’s multi-coupling series utilise its quick coupling system – offering performance advantages where lines need frequent connection and disconnection – and incorporate a range of specially designed components that allow for the connection and disconnection of multiple lines.

As Stucchi advises, a fixed plate accommodates all the males of the circuit, while a mobile plate is used for the females, with a mechanical lever bringing the two plates together, enabling multiple connections and disconnections with one simple movement.

Stucchi’s DP and GR multi-coupling series are particularly suited for earthmoving applications, featuring a design that combines a cam mechanism with flat-faced valves and special seals to avoid dirt inclusion, meaning attachment changes can be undertaken without leakage or contamination.

The design allows for the locking of the plates, maintaining a tight and secure connection, preventing brinelling, while it is possible to perform connection and disconnection even in the presence of residual pressure in the circuit.

The connection is made through the lever, enabling coupling and decoupling between

the plates, simultaneously connecting all the hydraulic lines, removing the risk of mistakenly connecting different hydraulic lines.

The DP and GR multi-coupling series respectively provide for:

• DP multi-coupling series – the quick connection and disconnection of up to six hydraulic, electrical, and pneumatic lines GR multi-coupling series – the quick connection and disconnection of up to 10 hydraulic, electrical, and pneumatic lines

The lines for both the DP and GR series can all have the same size, or each line can be different according to the application, while both series have been designed for easy installation on a pre-existing system. Stucchi’s multi-coupling systems include the following key features:

Lever system – reduces the force required to connect multiple lines (also in the presence of residual pressure in the circuit)

• Cam system – includes a safety lock, allowing for secure connections and disconnections

• Safety system – avoids falling during the disconnection

• Minimal fluid leakage risk – in the surrounding environment, minimising dirt inclusion

• Electric lines – can potentially be inserted for the transmission of electricity to the tool

• Couplings – mounted on the plates with threaded rings or seeger rings, facilitating installation and replacement

• Design – compact dimensions do not create bulk when undertaking operations

The multi-coupling series feature a mechanical lever that brings two plates together, enabling multiple connections and disconnections.

Additionally, all multi-couplings come with a QR code sticker, linking to the relevant page on the stucchigroup.com website, displaying technical information about the product.

Stucchi has steadily grown its presence in Australia over the past decade, having established its Australian branch, Stucchi FCP, in 2013, comprising a key component of its international operations, and providing a platform for it to further build its presence in the Oceania region.

Based out of Victoria, with offices in Queensland and Western Australia, Stucchi focuses on providing a premium and accessible service for its growing Australian customer base.

Michael Trevor, Hydrill Services Managing Director, said Hydrill has “developed a great partnership with Stucchi Australia”, and that Stucchi’s “dedication to customer service is the reason we continue to work with their team to provide the best service to our customers”.

“In our latest project, Hydrill assisted a leading CSG drilling company to prepare a rig for the field,” he said. “Stucchi delivered a solution to connect the drilling package to the HPU in the form of a multi-coupler system – a process that was previously time consuming and messy for the rig operator.

“From design to delivery, Stucchi was flawless in their service, delivering their proposed solution quickly and effectively. The multicoupling solution Stucchi provided exceeded the customer’s expectation, and has reduced rig moving time significantly. Service and quality product like this ensures our ongoing custom.”

Sydney-based civil contractor Ardee Civil draws on over two-and-a-half decades of experience in the water works sector, having built its reputation around providing topquality workmanship in undertaking often complex projects. Ardee has worked across a wide range of residential and commercial projects over the years, providing water main, wastewater, and stormwater services.

As Managing Director Mick O’Donovan told EEM, Ardee has Sydney Water major works constructor (wastewater) accreditation, with it having carried out a broad range of projects across different areas of Sydney for the utility.

Mick, who himself has been in the industry since 1994, said Ardee has primarily focused on this type of work in carving out a niche for itself as a specialist capable of taking on projects requiring a high degree of knowledge.

“We’ve mainly concentrated on the Sydney Water work,” he explained. “This spans lots of water mains, sewer mains, and stormwater projects, and a lot of the projects we work on are often in very tight spots.

“We’ve been around for a long time, and we maintain good relationships and look after our clients. Obviously, to do this you have to have the right equipment. So, we do like having good equipment around us as well.”

Ardee’s water main services include residential and commercial potable and recycled water work, from one lot up to 400 lots, with pipes ranging from 100mm up to 750mm in diameter,

while it also upgrades old water mains to new mains, including transferring fire and other services.

Its wastewater works span wastewater sidelines, concrete encasements, and subdivisions up to 400 lots, with construction of

1050mm or 1200mm diameter in-situ manholes, with its stormwater works ranging from 150mm up to 2100mm in diameter, with in-situ or precast pits.

Mick said Ardee has built a broad portfolio of projects for Sydney Water over the years, with it very much focused on delivering quality finished work.

“We’ve been doing Sydney Water work now for a long time,” he said. “We’ve got good staff and equipment, because with complex works you need machines that have the lifting power and the digging power.

“For instance, we’re working on some pump stations at the moment that are running up to 18m deep.”

Ardee’s project portfolio also includes a 300mm water main upgrade in Manly Vale, including all connections and road restorations, and installation of a gross pollutant trap in Bankstown, including all excavation, shoring, and backfilling.

In addition to this, it has carried out deviation of an 1800mm RCP pipe with pit chambers, sheet piling, and dewatering in Kensington, and deviation of a 300mm and 150mm wastewater pipe, including chambers, in Parramatta.

Mick has long been running Kobelco excavators – having bought his first Kobelco almost 25 years ago and utilising a number of different models in varying weight classes over the years – and recently added a 36t Kobelco SK380SRLC to his fleet.

He told EEM that the SK380SRLC’s powerful output, combined with a limited tail swing, was a key factor is his purchasing decision.

“It’s for the work we do in tight spots, which is usually complex works, and you need machines like that for the lifting power and the digging power,” he said.

“We’re actually using it on a job we’re doing at the moment, including 1800mm pipes, which is in a tight area.”

STM Trucks & Machinery North Sydney Area Manager Peter Moore said Mick had bought his first machine, a used Kobelco SK60-3, from him in November 1998, followed by a new Kobelco SK135SR in November 2002, with his latest machine, the SK380SRLC, delivered in November last year.

Mick said he has been dealing with STM for many years, noting STM supports its products with strong client services.

“There’s a relationship there and they have good service,” he said. “They look after the small guys and the big guys.”

The Kobelco SK380SRLC runs a 200kW Stage V Hino engine, with Kobelco advising the high-pressure common rail fuel injection system, variable-geometry turbocharger, and exhaust gas recirculation (EGR) system reduce particulate matter, while the large EGR cooler greatly reduces the formation of nitrogen oxide gases.

The SK380SRLC’s short radius design occupies only one highway lane, with it capable of operating effectively in narrow spaces.

Additionally, the SK380SRLC features:

• Operator comfort – an air-tight cabin features a spacious interior, with an airsuspension seat installed as standard, while air-conditioning vents are optimally positioned, directing air flow toward the operator’s neck and back

Powerful performance – a maximum digging depth of 6.99m and maximum digging reach of 10.93m, bucket digging force of 208kN and arm crowding force of 139kN (Power Boost provides more power instantly) Controls – a light-touch lever is designed to reduce fatigue over long working hours or continuous operations, an LCD multidisplay shows information including fuel consumption, the one-touch attachment mode switch converts the hydraulic circuit and flow amount to match attachments

• Safety – rear, left and right cameras allow the operator to confirm the safety of the worksite

• Maintenance – the LCD multi-display shows maintenance intervals, a lower access step near the engine simplifies maintenance, a handrail on the step side provides access to the maintenance port on the upper arm, and the FOPS guard can be tilted open for window cleaning.

For almost half a century, STM has made it possible for businesses across NSW to power up – supplying and servicing quality trucks and machinery to meet the demands of any job.

Starting out in a single shed in the 1970s, we know what it takes to build a business – and are passionate about helping you grow yours. Today, our family owned and operated enterprise is proud to offer a multi-site, modern service, with a team of more than 120. We care about giving every customer the best experience possible – with a wide range of trusted brands, flexible finance, spare parts, repairs and personal service.

We may have come a long way from that shed, but our family commitment to quality remains. Whatever your size, whatever your budget, STM is your one stop shop – with everything to keep your business moving.

Spitwater High Pressure Cleaners are an ideal choice for users of earth-moving equipment. With their hot water capability, versatility, ease of use, and durability, these machines are designed to tackle even the toughest cleaning jobs with ease. Whether you need to clean heavy machinery, vehicles, or handle site cleanup, Spitwater has a high-pressure cleaner to meet your needs. So why wait? Start exploring the range of Spitwater High Pressure Cleaners today and experience the benefits for yourself.

Spitwater High Pressure Cleaners offer high-pressure water jets that can remove dirt, grime, and other contaminants from a variety of surfaces. These cleaners are powered by electric motors, which means they are highly efficient and cost-effective to operate. Electric motors also produce fewer emissions than their petrol or diesel-powered counterparts, making them a more environmentally friendly option.

One of the main benefits of Spitwater High Pressure Cleaners is their hot water capability. These machines can heat water to temperatures of up to 95°C, which makes them highly effective at removing stubborn dirt. Hot water is also better at breaking down oil and grease, which are commonly found on earthmoving equipment. This means that users can get a more thorough clean in less time –especially important when working in timesensitive environments.

Spitwater’s cleaners come in a range of sizes and power levels, which means they can be used for a wide variety of applications. From smaller, wash bay installed cleaners to large, trailer-mounted units, Spitwater has a solution to meet any cleaning need. This makes them an ideal choice for earth-moving equipment users, who often need to clean a variety of trucks and equipment types.

In addition to their hot water capability and versatility, Spitwater High Pressure Washers are also designed for ease of use. They come with a range of features that make them simple and intuitive to operate – even for new users. All Spitwater models have a range of standard and optional accessories, which allow users to tailor the cleaner’s output to the specific task at hand.

Finally, Spitwater High Pressure Washers are built to last. These machines are constructed from high-quality materials and are designed to withstand the rigors of daily use. They also come with a range of safety features, such as automatic shut-off systems, which help to protect users and prevent damage to the washer. This means that users can rely on their Spitwater High Pressure Washer to provide consistent, high-quality cleaning performance for years to come.

Spitwater’s range of High Pressure Cleaners provides solutions for owners of earthmoving equipment, or anybody with stubborn dirt and grime to remove.Spitwater products are available in a range of sizes and power levels, making them suitable for a wide variety of applications.

Careful fleet planning plays a major role in the success of any business that relies on any machinery that is required to work non-stop, every day.

Machinery based businesses that focus on bottom line profitability always consider minimising operating costs such as scheduled maintenance, spare parts inventory, technical support, and any other factors that will minimise machinery and labour downtime.

When Director Nick Conroy established SureGreen, he fully recognised the benefits of taking this approach which has guided his decision to use Toro mowing equipment throughout the business.

“We have grown rapidly and operate throughout New South Wales, working on public space management and maintenance of expansive turfed sites such as parks and reserves, educational campuses, retirement villages, commercial developments, and other public space applications,” he said. “In this landscaping environment, our customers have high expectations of quality and performance, as well as demanding adherence to meeting contracted maintenance schedules.”

“From our early days, our priority was to find equipment that would best suit our needs and decided on Toro mowers supplied by Semco Equipment Sales,” Nick said. “Since then, our experience with Semco has validated that decision as they have demonstrated their ability to supply parts and service backup to ensure our business achieves its goals.

“There is no doubt that the close relationship with the knowledgeable and obliging Semco staff supporting the Toro mowers has been a key part of the SureGreen success and growth.

“We have 52 full time staff including horticulturalists, greenkeepers and landscapers, together with 13 apprentices, all deployed across multiple work sites. We can’t afford any downtime therefore equipment reliability is a key issue for us. The Semco and Toro teams help us to achieve this.”

“Using Toro mowers exclusively gives us the ability to minimise our inventory of common parts which ensures a very rapid changeover of any worn parts,” Nick added. “Another benefit is

that our team is familiar with all the features of the mowers, adding to efficiency.

“In our view, Toro is the undisputed market leader in mowers and are proven performers, producing the best cut on the market, while the support from Semco in supplying the mowers, parts and service has been a critical part of our success.”

When visiting the 2023 National Diesel Dirt & Turf Expo, you can check out the complete range of the latest Toro mowers and other

equipment that will ensure your business stays efficient and competitive in today’s tough market.

Visit the Semco/Toro stand H1 opposite the food court for your chance to win Toro lawnmowers and over $10,000 worth of giveaways. You can also talk to Semco’s Toro specialist Albert Martin on 0419 468 594 or call the Semco hotline on 1800 685 525.

VISIT SEMCO/TORO

AT STAND H1 OPPOSITE THE FOODCOURT FOR YOUR CHANCE TO WIN TORO LAWNMOWERS AND OVER $10,000 WORTH OF GIVEAWAYS. CHECK OUT OUR WIDE RANGE OF RESIDENTIAL & COMMERCIAL MOWERS AND CONSTRUCTION & TREE CARE PRODUCTS

VISIT SEMCO/TORO

AT STAND H1 OPPOSITE THE FOODCOURT FOR YOUR CHANCE TO WIN TORO LAWNMOWERS AND OVER $10,000 WORTH OF GIVEAWAYS. CHECK OUT OUR WIDE RANGE OF RESIDENTIAL & COMMERCIAL MOWERS AND CONSTRUCTION & TREE CARE PRODUCTS

TX1000

VISIT SEMCO/TORO AT STAND H1 OPPOSITE THE FOODCOURT FOR YOUR CHANCE TO WIN TORO LAWNMOWERS AND OVER $10,000 WORTH OF GIVEAWAYS. CHECK OUT OUR WIDE RANGE OF RESIDENTIAL & COMMERCIAL MOWERS AND CONSTRUCTION & TREE CARE PRODUCTS

With a focus on Fleet Management, Truck and Bus, Equipment and Vehicle Hire, Civil and Earthmoving, Repco Commercial has established itself as a leader in providing comprehensive solutions for businesses across Australia.

Repco Commercial offers a broad range of products and services, including parts, consumables, workshop tooling and equipment, and tailored solutions to meet the unique needs of each business. With a strong commitment to quality, Repco Commercial partners with market-leading brands to provide customers with the best products and solutions available.

With more than 315 distribution points across Australia, Repco Commercial streamlines the ordering process, reducing the time and effort required to manage fleet parts and consumables.

Repco Commercial offers the widest range of vehicle parts, solutions, and accessories for trucks, 4WDs, and cars – from filtration and braking to steering and suspension, drivetrain,

electrical, engine management, and fuel systems.

A comprehensive range of tools, heavy equipment, and workshop consumables is also available – including specialty tools, air tools, jacks and heavy lifting equipment, heavy-duty pressure cleaners, welding solutions, wheel and brake service, KVA generator sets, lubricants and equipment, diagnostic equipment, compressor solutions over 1100lpm, and personal protective equipment.

Repco Commercial has a team of experienced professionals who can help businesses select the best products and services to meet their specific needs. The team has the knowledge and expertise to provide guidance on everything from product selection and installation to ongoing maintenance and support. Repco also supports your warranty Australia wide.

For more information, visit: www. repcotrade.com.au

Repco Commercial offers a broad range of parts, consumables, and tailored solutions to suit your business needs.

R H Davies is a civil contracting business based in Moree in Moree Plains Shire in Northern New South Wales. It is located on the banks of the Mehi River, in the centre of the rich blacksoil plains.

The company works in roadworks, construction projects, and undertakes a lot of work for the local shire.

R H Davies was founded by Howard Davies in 1990 when Howard moved from England to Australia and decided to start his own business.

“I bought my first machine – a skidsteer – and started taking on work for the local farmers in the area,” Howard says. “My second machine was an excavator, which led to work in civil construction.”

After receiving a contract at the local council, Howard started getting more work in the civil space. Two machines turned into three, and a few trucks were added to the business to enable it to float its own machinery to and from work sites.

The fleet now consists of four trucks and around 15 machines, including skidsteers, graders, excavators, rollers, and trucks.

Ten years ago, Howard’s son Harrison started working for the family business.

“After school I jumped into one of the trucks and then progressed to operating machinery,” Harrison explains.

“Recently we were looking to upgrade to a grader after having used skidsteers with grader blades. We had not heard much about Hidromek, but came across the Hidromek HMK600MG grader when we were doing some online research. Onetrak had it in stock, so we headed to the Onetrak yard to have a closer

look at the Hidromek rollers and excavators. They all impressed with their build quality.”

Shortly after viewing the machines Howard and Harrison decided to purchase a HMK110CS roller, followed by a HMK145LCSR excavator.

“The HMK145LCSR excavator has an operating weight of 16.8 tonnes so it’s a bit heavier than other similar machines,” Harrison says. “It’s well-built with reinforced components on the boom and undercarriage. The excavator is super powerful and operates really well with the tilt hitch, posthole digger and breaker. It’s also very fuel-efficient which helps keep costs down.

“The HMK600MG grader has outstanding visibility thanks to how they have designed the cabin. We opted to have ours fitted with Topcon

wide cab angles.”

Howard adds: “Some general stand-outs of the Hidromeks for us are: aircon – we are definitely putting it to the test as Moree gets very hot. The machine cabs remain nice and cool thanks to the efficient aircon systems.

“The Hidromeks are also very smooth to operate, and cabins are very spacious and comfortable – which is important when you’re doing big days. In short, they’re designed well and presented nicely.

“Onetrak has been very good to deal with. Nathan from the New South Wales team is our main contact, and he has been super helpful. If he doesn’t have the answer, he will find out and gets back to us straight away.”

Howard says the aftersales support has been impressive.

“We’ve been dealing mainly with Brad and he has also been brilliant,” he says. “We have received nothing but good service, which is what you want when you purchase a new machine.”

Harrison says having the Hidromeks on site has attracted a lot of curious onlookers.

“Like us they haven’t seen that many Hidromeks around, and when they do, they are very impressed with the quality,” he says.

“We’d definitely recommend Hidromek and Onetrak to anyone asking. The operators we have had working for us have been very happy with the performance and comfort of the machines, so it’s all positive from us.”

To find out more about Hidromek, contact Onetrak on 1300 727 520 or visit www.onetrak.com.au

New data from Australia’s leading specialist insurer, NTI reveals rigid trucks and mobile plant and equipment (MPE) under five tonnes are at greatest risk of theft.

Unsurprisingly, trucks, trailers and MPE in metropolitan areas, close to arterial roads, are most susceptible to being stolen – especially on Mondays, which ranks as the worst day of the week for larceny.

While insurance is a ‘must have’ to safeguard assets, experts suggest there are measures owners can take to protect their critical assets from increasingly sophisticated thieves – and avoid costly disruption to business operations.

1. Store equipment in a secure location

Firstly, NTI risk engineers advise owners to ensure equipment is stored in a secure place when parked.

“Most trucks and trailers are parked up on premises, so it’s more about the site security than the vehicle itself,” says Paul Bressan, NTI Heavy Motor Risk Engineer.

The team also suggests installing barbed-wire fencing around the perimeter of the property –ideally electrified – and bright lights or motion sensor lights, and signage to alert potential thieves that the property has security systems in place.

“It’s important to understand the property’s key entry and exit points and install obstacles such as drains at the key points to make it harder for thieves to get in and out,” Bressan says.

He also advises operators to install a CCTV

system – ideally one monitored remotely 24/7.

“We rarely see theft from larger carriers as they tend to have CCTV on site and after-hours security,” he says.

“Smaller carriers tend to rely on just fencing and maybe CCTV surveillance.”

Additionally, Bressan urges owners to store spare keys securely.

“A lot of carriers have a lock box on the side of the building for contractors coming in and out that can be easily accessed. They’re pretty easy for thieves to break into,” he says.

For MPE located off site, NTI Risk Engineers suggests investing in metal vandal covers, which are used to encase the MPE when not in use and inhibit entry.

2. Install tracking devices

Bressan also recommends owners fit antitheft devices, such as GPS tracking systems on trucks, trailers and MPE.

While newer equipment comes standard with fleet management software, older models will need a system retrofitted.

In addition to vehicle immobilisers such as wheel locks, shut-off systems, ignition locks and battery switches, Bressan suggests using lockout tags on trailers to protect cargo from theft.

“With larger trucks, thieves tend to break into the vehicle – there’s less chance of the actual vehicle being stolen, so the more security measures the better,” he says.

“If it means it takes longer to break into the vehicle, it can make a difference.”

3. Document what you’ve got Bressan believes asset registers are “a must”.

These list all company assets, as well as location, ownership, and condition information. They should also include information about maintenance and repair activities, inspection schedules, barcodes, models, and other relevant notes.

This information can be saved in a piece of software, a database, or a Word document; but it must be accurate and kept up-to-date to serve its purpose.

It’s also worth considering micro-dot asset identification systems, which mark each asset with a unique code recorded on a secure database and matched with other asset and ownership identifiers such as VINs (Vehicle Identification Numbers).

This helps law enforcement identify, trace, and return stolen equipment.

Lastly, owners should have robust checks and balances in place when hiring out MPE.

NTI has detected increasingly sophisticated crime gangs targeting MPE, especially around Sydney.

There’s evidence of people creating fake companies, hiring equipment, paying the first couple of invoices in cash, and then all of a sudden they immobilise the GPS tracking system and disappear.

NTI recommends owners ensure they have systems in place to check the legitimacy of those they’re hiring equipment to.

To learn more, contact your insurance broker, or NTI, today. Visit NTI’s Yellow Cover at www.yellowcover.com.au

Insurance is crucial to safeguard your assets, but experts suggest there are measures you can take to protect them from theft – and avoid unnecessary and costly disruption to business operations.

Since 1984, Norm Engineering has designed and built earthmoving attachments for tractors, mini loaders, skid steers, track loaders, excavators, backhoes, and telehandlers. As an Australian manufacturer, Norm Engineering understands the tough Aussie environment and have built buckets to withstand its harsh conditions. The year 2022 was big for Norm Engineering, celebrating 38 years of Moving The Earth For You!

Most may think Norm Pesch started Norm Engineering, but it was Norm’s father-in-law, Wally Acimovic, who began the business bearing his son-in-law’s name when Norm was in the Royal Australian Air Force. Norm, at the time, oversaw the engineering support section for the Black Hawk helicopters of RAAF No.9 Squadron. However Wally, former owner and founder of Roswal Trailers, clearly had a premonition that one day Norm would want to leave his job and work for him. Luckily for Wally, that gamble paid off. Like most of the greatest success stories, it started from very humble beginnings. Wally constructed the company’s inaugural bucket after being unhappy with the bucket that was on the front of his own skid steer. After going past a few tries, he made the perfect one, and the rest, as they say, is history. Norm Engineering has the reliability you can build your business around. Norm Buckets are proven to be one of the most durable and reliable Earthmoving attachments in Australia. Thousands of earthmoving contractors Australia-wide rely on Norm Engineering attachments. This is because Norm Engineering sets the new benchmark in the earthmoving attachment industry, with stronger materials, engineered for a longer life and enhanced reliability.

Backed by over 30 years’ experience, it

is not surprising that the Norm Tilt Control 4-in-1 Bucket remains Australia’s first choice in the earthmoving bucket range. The Norm Engineering Tilt Control utilises industry leading 4-in-1 bucket design with a tilting rear pickup.

The low maintenance and high strength design of the tilt control system coupled with a simple 12-volt solenoid operation puts this 4-in-1 light years ahead of the pack, giving the operator full radial control of the cutting angle.

This unique design means it is possible to continuously vary the cutting edge relative to the inclination of the loaders’ front wheels, particularly when working on an incline while trying to perform a straight cut.

The 4-in-1 bucket has optional extras to suit

individual needs, these extras include teeth and 3 x replaceable bolt-on edges to extend the life of the bucket. This versatile attachment is controlled from within the cab.

• The bucket can scoop and carry sand, gravel, small rocks, and debris

• The serrated edges allow a strong grip when clamping logs, small rocks, and debris

• The middle bolt-on edge allows back blading, the gravel then accumulates in the bucket ready to be dumped

• The dozer blade levels.

This attachment is ideally suited for clearing, levelling, scooping, carrying dirt and debris, therefore making this the perfect attachment for construction, industrial and agricultural work, roads, sidewalks and car parks. Norm Engineering has thought of everything, including the tiedown points on either side of the 4-in-1 buckets, ensuring you can transport this attachment safely.

Taking care of every fine detail, Norm Engineering has an extra option to customise your load guard with your company name etc. –just another one of those personal touches that make Norm Engineering attachments stand out from the crowd.

Norm Engineering’s goal is to manufacture quality buckets that are reliable, strong and built to last. Over the past 38 years, Norm Engineering has established strong and long-lasting relationships with many of our customers, if you’re serious about increasing your machine’s capabilities, contact us on 07 3376 3177 or visit us at www.normeng.com.au to see the full range of Australian hand-built attachments.

Suitable For:

• Council & Construction work

• Landscaping & Agricultural work

Best Suited To:

• Track Loaders, Mini Loaders & Skid Steers

• Tractors, Backhoes & Telehandlers

Features:

• Available in widths from 915mm - 2400mm

• Wide opening jaws & serrated edges

• Reversible bolt on edges & extra heavy duty flat floor

• Includes hoses, standard couplings & tie down points

Suitable For:

• Council & Construction work

• Landscaping & Agricultural work

Best Suited To:

• Track Loaders & Skid Steers

• Tractors, Backhoes & Telehandlers

Features:

• Available in size; 1600mm, 1800mm & 2100mm

• Optional poly, poly wire or gutter brush

• Includes 3 replaceable bolt on edges

• Optional motor & hoses fitted on either side

Suitable For: