FEATURES:

FEATURES:

With a new factory designed 5.5m3 bucket, in addition to new heavy duty axles,brake cooling package, larger counterweight, auto digging system and advanced joystick steering system (AJSS) as standard, Komatsu’s new WA480-8 continues the long tradition of being the industry’s ideal yard loader.

With a new factory designed 5.5m3 bucket, in addition to new heavy duty axles,brake cooling package, larger counterweight, auto digging system and advanced joystick steering system (AJSS) as standard, Komatsu’s new WA480-8 continues the long tradition of being the industry’s ideal yard loader.

As with all our wheel loaders, key components are manufactured by Komatsu to work together in an integrated package. The WA480-8 comes standard with our Komtrax remote monitoring and location system, backed by our Australia-wide service and support.

As with all our wheel loaders, key components are manufactured by Komatsu to work together in an integrated package. The WA480-8 comes standard with our Komtrax remote monitoring and location system, backed by our Australia-wide service and support.

Call us today on 1300 566 287 to find out more.

Call us today on 1300 566 287 to find out more.

Look, I know I’m preaching to the choir when I say the earthmoving industry is a massive, foundational pillar of Australian society as we know it. Maybe I’m going a touch overboard to suggest that without the tireless efforts of our hard-working contractors, operators, engineers – and everybody in between – our society wouldn’t be much of a society at all. After all, what good is life without the homes we live in? The thousands of kilometres of roads and bridges across which glorious fresh produce is transported from paddock to table? Or the thunderous, packed stadiums where we watch some of the world’s greatest athletes collide every week for our amusement?

Leon Cranswick EditorOkay, that might be a tad on the dramatic side, but it’s still true. Earthmoving is critical to almost everything we do. And that’s a big part of why I’m so proud to have been handed the reins of Earthmoving Equipment Magazine as its new editor.

Compared to you, valued reader, I’m pretty new to the game. I’ve written about heavy machinery of all shapes and sizes for just over a year, but it’s only since joining Team EEM I’ve had the opportunity to really get amongst it

This made my first ever visit to The National Diesel Dirt & Turf Expo in April all the more exciting – even with the event’s unofficial mascot KahChi running me off my feet.

At DD&T, with so many earthmoving pros and industry legends crammed into one place, the extraordinary energy and enthusiasm of the industry was cranked to 11. It’s an enthusiasm more contagious than anything you

can swab. And let me tell you, the 150+ pages of EEM June/July is bursting with that same brand of enthusiasm from cover to cover.

I don’t think anybody loves running an earthmoving business more than the stars of our cover story, Jim and Trevor from Mad Cat Group in Warragul, Victoria. And their tough-as-nails, heavy-duty Kobelco SK380XDLC-10 excavator is making their (and their operators’) jobs that much more satisfying.

Elsewhere in Victoria, O’Connor Contracts has built a productive relationship with earthmoving attachments specialists Miller | NGDF. We find out what Miller’s manufacturing and repair services can offer contractors, and how the business is set to expand in the coming years.

Further north in Sydney, we chat to two businesses that are happily putting new Cat® excavators to work: Access Tec with an efficient Cat 309 and HM210 mulcher package, and Chalouhi with a powerful Cat 340 – the latest in a huge existing Cat fleet. We also hear from Gold Coast civil construction business Sniffers Group about the 20+ years of solid service Komatsu machinery has provided.

Lastly, we touch base with Patrick Doheny and Nick Thompson, who proudly represented Australia in Las Vegas at the Cat Global Operator Challenge finals in March.

Happy digging!

Leon Cranswick Editor

Ann has been the Manager of Allied Earthmovers Association for the past 19 years bringing many years’ experience into the role. After gaining business qualifications and managing a retail shopping centre in Sydney CBD, Ann first started her career in earthmoving when she joined the long-established family business in Penrith, which specialised in Caterpillar graders and dozers. Working in a male-dominated industry, Ann brings a different aspect to the Association. She has met many people in the industry and knows what the owner operator needs, from the importance of paperwork to machine availability. It’s an industry she respects and is proud to be a part of.

Earthmoving Equipment Magazine is published bimonthly by Prime Creative Media Pty Ltd.

CEO

John Murphy

COO

Christine Clancy

Sales Director

Bradley Buchanan

Editor Leon Cranswick leon.cranswick@primecreative.com.au

Brand Manager

KahChi Liew kahchi.liew@primecreative.com.au 0421 474 407

Production Editor Michelle Alder michelle.alder@primecreative.com.au

Art Director/Design Daz Woolley

Subscriptions

P. +61 3 9690 8766 subscriptions@primecreative.com.au

Website www.earthmovers-magazine.com.au

Copyright Earthmoving Equipment Magazine is owned by Prime Creative Media and published by John Murphy. All material in Earthmoving Equipment Magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical, including information and retrieval systems) without written permission of the publisher. The editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions, or for any consequences arising from reliance on information published.

The opinions expressed in Earthmoving Equipment Magazine are not necessarily the opinions of, or endorsed by, the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2023

Articles

All articles submitted for publication become the property of the publisher. The editor reserves the right to adjust any article to conform with the magazine format.

Head Office 379 Docklands Dr, Docklands VIC 3008

P: +61 3 9690 8766 enquiries@primecreative.com.au www.primecreative.com.au

Sydney Office Suite 3.06, 1-9 Chandos Street Saint Leonards NSW 2065, Australia

P: +61 2 9439 7227

OTR Australia supply earthmover, agricultural, truck, bus and light vehicle tyres and rims from 6” through to 63” in diameter, to blue chip mining, civil contracting, road transport companies, agricultural dealerships and end users.

We maintain a healthy inventory of new and used earthmover tyres of critical sizes and have the ability to custom manufacture Australian Made wheels in 1 of our 10 locations Australia wide.

SALES PHONE 1300 791 672

For any enquiries please visit www.otraustralia.com

is tough enough for quarry sites, and perfect for the range of demands the Mad Cat Constructions team throws at it.

Jim Knight and Trevor Reynolds are Mad Cat by name, but when it comes to their earthmoving game, they take their work very seriously. Team EEM recently dropped into one of their job sites in Warragul, Victoria, to learn what they were all about – and see a couple of their latest Kobelco excavators in action.

of construction cowboys with a taste for chaos and diesel coursing through their veins?

In speaking with Mad Cat Co-Directors

Jim Knight and Trevor Reynolds, one sliver of that hyperbole rings true – they are deeply passionate about their work, and the people and machinery that make it possible.

“I love earthmoving,” Jim says. “I genuinely love machinery, technology, and efficiency –anything that goes fast.

“We mainly work on greenfield sites and do subdivisions from start to finish. That includes retaining walls, roads, curbs, all the sewer and stormwater – the whole package.”

Despite the Mad Cat name, Jim (who manages daily operations) will tell you he and Trevor (who handles all construction administration) run a pretty tight ship, whether it’s ensuring their machinery is treated and operated with care and respect, or simply keeping the site toilets in order.

But Jim and Trevor are also passionate about training employees to go about things the right way – for the sake of their own growth and development, not just for the business.

“I honestly love watching people develop into proper operators, not just truck loaders,” Jim says. “We’ll take them through all aspects: reading plans, how to set up lasers, and then move into the GPS stuff. And over that time, they’ll become a full operator, and then they can pass that knowledge onto other staff members.”

For Jim, this also means building mutual trust, ensuring that he’s not required to supervise all his operators 24/7.

“Everyone takes ownership in the job, and they feel more rewarded – and happy to be part of the team,” he says.

“Our staff is our business,” adds Trevor. “Obviously, the work that we’re doing, Jim and I couldn’t do it all ourselves.”

Jim and Trevor originally ran their own smaller earthmoving businesses, which came together when they decided to price a job for VicRoads 18 years ago.

“From that, we became business partners and started Mad Cat Constructions,” Jim says. “And it just grew from there.”

Jim’s original business was called Mad Cat Bobcat and Tipper Hire, a name that ended up carrying through to the current business.

“Everyone thought I was a bit mad in the way

I did things, and I was also mad about Bobcats – and pretty handy in a Bobcat too,” he says. “That’s how the name Mad Cat came about, and it sort of stuck.”

Jim says in the past he and Trevor have pondered changing the name – concerned that it could give the wrong impression – but they’re now happy to let their reputation do the talking. In fact, Jim and Trevor have recently doubled down on the name, with the business in the process of transitioning into Mad Cat Group as operations expand into new areas.

The Mad Cat name might be stuck for good, but Jim and Trevor have recently made one important change to their operations: swapping from yellow to Kobelco blue for Mad Cat’s primary workhorse excavators.

This was driven in part by the need to have their excavators seamlessly integrate with their trusted Trimble Earthworks automation package – something other brands couldn’t offer. Jim says the Trimble system is critical to how the Mad Cat fleet operates.

“Our machines wouldn’t operate without it,” he says. “That’s the main attachment that makes everything else work, and what enables us to be not as hands-on.”

Another factor was Mad Cat’s relationship with the team at local Kobelco dealer Melbourne Tractors. Jim says he originally called Tim Hanson at Melbourne Tractors to discuss an auger, and ended up purchasing two new Kobelco excavators: a 35t SK330, and a 38t SK380XD.

The XD series: Extreme duty

The SK380XD is the latest in Kobelco’s line of extra-heavy-duty excavators, designed to deliver massive power in the harshest conditions.

“The SK380XD is a market leader with regards to its build, its undercarriage, its strength, its hydraulic power, and its 244kN breakout force,” says Tim. “The machine is a real heavy hitter when it comes to earthmoving in general.”

Based on the range of tasks Mad Cat had been undertaking at its current Warragul site, Tim knew the XD would provide the power and versatility the job demanded.

“It involved a really broad spectrum of earthworks, and I thought that machine was going to be best suited to what Jim and Mad Cat needed here,” he says.

Jim was initially reluctant when Tim recommended the SK380XD.

“I was concerned about the weight,” Jim says. “But when we got the machine and actually put it to work, we realised we should have gotten two, not just one. It’s that good of a machine. Its breakout, its speed, its stability – everything is very impressive.”

with his operators.

they have the option, the SK380XD is always the first machine to leave,” he says. “They’re

hold its weight, especially when you’re reaching

Mad Cat Constructions’ Kobelco excavators have been a hit with operators.

Jim says Melbourne Tractors took care of all Mad Cat’s custom requests without trouble.

Mad Cat Constructions’ Kobelco excavators have been a hit with operators.

Jim says Melbourne Tractors took care of all Mad Cat’s custom requests without trouble.

vibration. I’ve spent a lot of time in it myself, and I’m extremely happy with it.”

Trevor says what sold them on a quarry spec SK380XD was that it gave them power and versatility to tackle work in a wide range of environments – and they even had it customfitted with wide tracks to enable better tracking in softer wetland areas.

“It’s obviously heavy duty, it’s designed for rock and that type of stuff,” he says. “We’re in West Gippsland, where you get a lot of very solid red clay, which we’re constantly digging, turning over, and compacting. So, in this environment, it works very well.”

But all that power doesn’t mean the SK380XD lacks for accuracy.

“Even though it’s a quarry-spec machine, it’s expected to dig within a 10mm tolerance –and it actually does,” Jim says. “It’s extremely precise.”

He says the combination of the precision and breakout power of the SK380XD allows them to achieve with one pass of a large mud bucket what once would have required additional passes.

“The fuel efficiency is exceptional because we are moving so much more dirt than we were, and our numbers haven’t changed that much,” he says. “We’re very happy.”

Jim says the service delivered by Melbourne Tractors has been equally impressive.

“When it was time to fit these machines

out with the scales, the GPS, the tilt hitches, the wide tracks, and big buckets, Melbourne Tractors were straight on top of it, straight away,” he says. “They got the project started, completed, and delivered very efficiently.”

Trevor says he and Jim won’t hesitate to reach out to Tim and the Melbourne Tractors team when another purchase is on the cards – and will be confident in the back-up support available to them.

“With other machines we’ve purchased over the past few years, we’re still having trouble getting support and follow up on those,” Trevor says. “So, you can’t compare the two. Without a doubt, Tim from Melbourne Tractors will get the first phone call.”

The new XD Series is engineered for the most demanding applications. Built on Kobelco’s rock-solid reputation for quality and reliability, these extreme duty machines feature a rugged machine body with comprehensive additional reinforcement where it matters most. These machines take strength and durability to an all new level – delivering increased performance across even the harshest work sites. Built for power. Built for reliability. Built to last. The new Kobelco XD Series.

Right part, right price, right now.™

As an Australian family-owned company with global reach, Tilly’s is proud to stock over 43,000 new part lines for your earthmoving machinery. Tilly’s quality alternative undercarriage range extends from track groups to idlers, rollers, sprockets and track adjusters suitable for dozers up to D9 and excavators up to 30 tonne.

Tilly's are pleased to now offer a range of quality low-hour machines including General Construction Excavators and Loaders and D6-D8 ex-United States machines.

Tilly's is now offering account customers online ordering of over 30,000 parts for even quicker turnaround time, because we understand that down-time for your machines has a huge impact on your bottom line. That’s why we guarantee the quality of our new parts to ensure you are staying on track.

Southern

Southern Hemisphere Proving Grounds (SHPG) is a global leader in winter testing facilities for automotive, component, and tyre manufacturers. So, the team knows a thing or two about tough conditions for motor graders.

Located in Wanaka, on the South Island of New Zealand, it’s fair to say that lives depend on SHPG’s work, and the quality and performance of its machines.

“During the snow season, we run a 24/7 operation, maintaining snow and ice test circuits for vehicle testing,” says John Weir, Machinery Maintenance Supervisor at SHPG. “The snow flats are graded up to three times every 24 hours and the snow/ice test tracks twice every 24 hours.”

SHPG’s fleet is predominantly Cat® equipment, with three 140 graders, a 938K and 980 wheel loader, 312 and 330 excavators, a D400 dump truck, and a range of Cat gensets.

The Cat GraderBit2™ System adds extra bite to a grader’s cutting edge board. And it’s

perfect for the unforgiving conditions you’d find at a place like SHPG. It’s a snap ring system, so bits are installed and replaced effortlessly with no tools required, thanks to the pull-ring pin that inserts into the shaft and locks over the bit.

Standard Ground Engaging Tools (GETs) are comprised of large, hardened steel cutting edges, and in harsh conditions, they can wear down quicker which means more costs in terms of product, labour, and downtime.

But the Cat GraderBit2 System can add to the potency and performance of these machines, which made it an attractive option for SHPG.

“We liked the look of the product and wanted to try a more penetration focused grader bit,” Weir says. “Also, having Terra Cat as a one-stop shop had huge appeal. The bits last longer, and are quicker and easier to change out.

“They also give us a better result, as the product penetrates better, and reconstitutes the dislodged material back onto the road surface more efficiently than the other system.”

In terms of the benefits to SHPG’s business, Weir continues: “We are seeing less maintenance downtime, and less fuel burn due to the product cutting better and easier. These factors combine to give us a lower cost per hour.”

SHPG will consider converting other machines in its fleet to the GraderBit2 system especially for maintaining the access and onside roading network, due to how well the product performs in the harder applications. And, for SHPG, the benefits of GraderBit2 extend beyond the performance of the system itself. Weir is also a big advocate of SHPG’s Cat

There are seven bit designs that can form two continuous edge systems or 10 different serration patterns. These options allow pass through of 15mm to 60mm aggregate and can be adjusted depending on your grading conditions.

The Cat GraderBit2 system is built to be rebuilt. Overlay channels and replaceable

an offset design that makes sure that bolted joint strength is optimised and bit placement is always consistent.

You may never have to face the conditions that SHPG faces. But one thing is for sure. The team not only tests cars and tyres on their proving grounds. They’re testing GraderBit2 as well. And it’s passing with

Performance is maximised at any cast angle thanks to angling plates that keep the bits facing the right way. SHPG is considering coverting other machines to the GraderBit2 system.

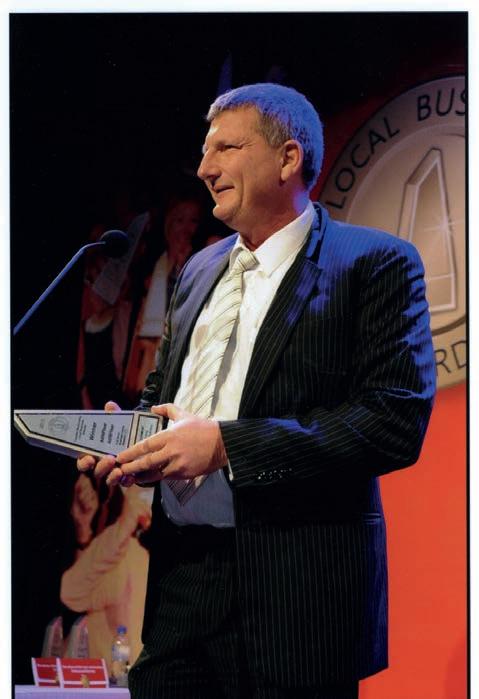

The annual charity auction at The National Diesel Dirt & Turf Expo 2023 raised thousands for The Children’s Hospital at Westmead.

The National Diesel Dirt & Turf Expo (DD&T) is Australia’s largest construction expo and draws huge crowds who come to learn about a range of industry vendors and events. The Pickles team eagerly awaits the show each year and hosts the crowning event of the weekend — a live charity auction.

The Clancy Ward

The highly anticipated auction brings industry insiders together to witness Pickles remarketing roughly 60 to 80 pieces of civilconstruction and earthmoving assets, and kicks off with a select number of items auctioned off to raise funds for charity.

For the 2023 event, Pickles and Semco Equipment Sales teamed up, with Semco providing assets and Pickles hosting and providing auctioneering services. All funds raised were for The Children’s Hospital at Westmead, specifically for improvements to the Clancy Ward, a department that cares for children with a range of health issues, including liver and kidney problems, diabetes, blood disorders, and those awaiting organ transplants. The ward goes above and beyond to care for sick Aussie kids in their time of need and relies on charitable donations to support the excellent care and treatment the kids there receive.

The event sale drew a large crowd, thanks to both the cause and the great range of assets on offer. The brand-new items donated by Semco included a Toro riding lawn mower valued at $4500, a Toro push mower valued at $2000, a $2500 Honda generator and a $2500 Dynavac compaction plate. The assets were on display at the front of the Pickles exhibit, drawing in hundreds of passers-by throughout the day.

Charity auctions are usually highly regarded events, with plenty of enthusiasm from all those involved. Pickles’ industry-leading team of auctioneers and specialists is always eager to contribute to such important events, and to drive that enthusiasm to even greater heights with auction theatrics. DD&T 2023 turned out to be a spectacular event, with an animated crowd in attendance to watch as all four assets were sold – three to in-person bidders and one via an online bid.

The event resulted in thousands of dollars in donations, all of which will be provided directly to The Children’s Hospital at Westmead. While the funds raised are the most important goal of the event, it also serves to promote the recipients.

“Pickles is extremely pleased to be involved with raising funds for this wonderful facility, whose staff perform an amazing and valuable community health service,” said NSW State Sales Manager, Matt Blanch.

While the charity auction served as a key event, the three-day expo was jam-packed with an array of other highlights. A large display area was manned by Pickles sales executives, and new, refreshed, Powered by Pickles marketing materials on show kept the weekend both busy and inspiring.

Crowds filtered through for the duration of the expo, with guests keen for the opportunity to explore without any restrictions. The atmosphere was lively, and a sense of renewal and reconnection was in the air. While there were many familiar and long-time supporters at the event, there was also a large number of young families in attendance which created a cheerful mood among the crowds. The Pickles stand in particular drew in the younger crowd, who were keen to get their hands on a range of Pickles merchandise, including hats, foam footballs and stubby coolers for mums and dads. Some of those who picked up footballs played impromptu football games on the grass surrounding the display, adding to the festive feel.

construction machinery. The most popular Pickles assets during the event were:

• A 2019 Volvo L150H wheel loader which made $172,500

• A 2018 IMS PM1050 Pugmill which made $285,000, and

• A 1999 Caterpillar 933 track loader which made $45,000.

DD&T 2023 was an extremely successful occasion, with many repeat attendees noting how the event had gone from strength to strength over the last few years. An impressive amount of quality exhibitors, high attendee numbers, and successful networking opportunities all contributed to the huge success of the event. Pickles’ executives were especially impressed with

The Pickles team is dedicated to maximising the return on every asset. We have a highly trained team of international valuation experts who have the knowledge, deep experience and tools needed to provide accurate appraisals and specialist advice on how to enhance value. We stand by our valuations, providing sellers the assurance of protection in sale returns.

We understand that every situation is different. Our team brings hundreds of years’ experience in customising solutions that suit the unique needs of our clients. With expertise across multiple sales channels, we will recommend the most effective remarketing strategy based on our extensive knowledge of industry trends, potential buyers, and current market conditions, to minimise any risk and maximise the value of every asset put to sale.

Talk to us today about partnering with Pickles.

For more information, contact Matt Blanch on 0428 163 083

As companies put a stronger focus on ESG practices, Komatsu Australia says that hybrid machines are shaping up as marquee additions to many of its customers’ fleets.

Komatsu has been the market leader in hybrid machinery for 15 years, following the introduction of the world’s first hybrid hydraulic excavator, the HB205-1, in 2008 in response to climbing fuel prices – and the brand says hybrid equipment maintains an important position in the equipment line up of Australian companies, alongside other emerging technologies.

Dean Gaedtke, Komatsu Australia’s General Manager for Construction, says that there is still a strong appetite for hybrid machines on worksites, with 190 now operating in the country, and more than 5000 units globally.

“The Komatsu hybrid machine performs just as well as our conventional excavator,” Dean says. “It has similar high production outputs and power, while saving anywhere from 20–40 per cent on fuel consumption depending on the application.

“That’s why we’re seeing a lot of interest from our construction customers, especially those working on Tier 1 projects, looking to invest in hybrids for their fleets. The Komatsu hybrids are highly productive and reliable while helping our customers with ESG alignment to the construction sites or contract sustainability requirements. Plus, the value recovery on the Komatsu hybrid compared to conventional excavators is greatly improved. The Hybrid system is designed to give you more fuel savings the harder it works. For example, the more you dig and slew, the more fuel can be saved per tonne.

“Hybrid technology significantly reduces the impact of equipment on the environment, without adversely impacting the economic feasibility of a project. It’s a simple equation: less fuel, less emissions, less carbon.

“Hybrids have been strongly established in the automotive market now for many years, and now it’s the construction industry’s turn to realise their full potential as a strong addition to any fleet.”

Dean says Komatsu’s strong focus and long experience in electrification is what sets them apart from competitors when customers are looking to invest in hybrid machinery.

“Komatsu, locally and globally, has been leading the electrification journey for over 30 years. Our experience in Smart Construction, digitisation, and electrification spans across many years with reliable and innovative machinery,” he says.

“Our ESG strategy has us aiming to reduce CO2 emissions by 50 per cent by 2030, and be completely net-zero by 2050. It’s a big feat but with the introduction of flagship machines like the PC210E all-electric hydraulic excavator, which we previewed at Bauma last year, we’re on a good path to meet those targets.

“And it’s not just our machinery, it’s the technology that is applied with it. Komatsu’s

technology offerings like Komatsu iSite (Productivity & Fleet Management), Smart Construction and iMC – Intelligent Machine Control, are making it easier to reduce your carbon footprint onsite, through capturing accurate machine productivity data. This helps our customers to manage their machines and the efficiency of their operation and minimise their fuel wastage.”

The two hybrids currently available in Australia are the HB215LC-3 and the HB365LC-3 excavator. The 24-tonne HB215LC-3 comes with 110kW/148hp of engine power and nearly 1m3 of bucket capacity, and the larger 38-tonne HB365LC-3 operates with a 201kW/269hp engine power and 1.8m bucket capacity.

Both deliver the same performance as a conventional excavator, but with fuel savings of up to 40 per cent through the innovative UltraCapacitor system, and come standard with the Komtrax remote monitoring and location system, backed by Komatsu’s Australia-wide service and support network.

Dean says there is peace of mind in knowing that Komatsu is the one distributor for the entire country.

“No matter which state or territory you are in you are dealing with Komatsu Australia,” he says. “We have around 3000 employees

across 55 locations in our region to support our customers.”

Dean says that while hybrids and electrification are a strong focus, Komatsu’s R&D team is continuously looking at what’s next for the brand and the industry as it works towards a net-zero future.

“Komatsu invests close to $1 billion AUD annually in R&D, and we’re constantly looking at ways to innovate our machinery and services,” Dean says. “As we look past hybrids and electrification, hydrogen fuel and hydrogen fuel cells are on our radar as possible solutions where high demand power is required over long working days. Artificial intelligence, integrated machinery digitally connected into site designs and site management tools, are also no longer a vision of the future. We are working in this realm today.

“Of course, all the great technology and development means nothing if it doesn’t improve safety, productivity, and profitability for our customers. These are some of the core outcomes we strive for in our products and services.”

For more information on Komatsu’s Hybrid machine offering, visit: www.komatsu.com. au/innovation/komatsu-hybrid-excavators

Komatsu has been a market leader in hybrid machinery for 15 years.

First and foremost, brokers can offer the benefits of a long-term relationship, which can be particularly important in a world where bank and account managers frequently change. Business owners appreciate working with someone who understands their business and can represent them to the market without having to repeat their story multiple times.

In addition, brokers offer a service that works around the clock. Because much of the administrative work is done outside of normal business hours, it’s essential to be able to speak with a broker or banker when it’s convenient for you.

A good broker will also manage the entire project, taking care of everything from arranging invoices and insurance to signing documentation and ultimate settlement.

Brokers can also help businesses spread their debt over several competitive underwriting financiers, which provides a broader base for expansion and some competition to ensure the best interest rates and commercial conditions. Brokers deliver a competitive facility, in a painfree manner, that feels like a breath of fresh air compared to the banks.

Another benefit of working with a broker is advocacy. Many business owners are experts in their specific industries but may not be as knowledgeable about financing equipment. A broker will ensure that any approval is most closely aligned with the client’s needs, not

just what the bank wants. A capable broker will have the experience, knowledge, skill, and influence to negotiate the best outcome for the client.

It’s worth noting that the market for equipment and vehicle financing is changing rapidly. With the increasing popularity of behavioural lending, many underwriters now offer automatic ‘low doc’ competitive finance approvals for selected equipment and vehicle financing up to $150,000 and $500,000 for replacement equipment, trucks, and trailers. Brokers can provide some wonderful alternatives for business owners.

However, as with any industry, there are good operators and not-so-good ones. To find the right broker, it’s essential to look at what existing clients are saying and ask other business owners who they use and why. The best referral is a happy customer.

Get in touch with the Finlease team at www.finlease.com.au to learn more about how a broker can assist your business today.

C.R. Kennedy’s Nick Leith breaks down the features of the new Leica iCON GPS 160 Smart Antenna, and how it can help boost productivity for contractors large and small.

Backed by more than 200 years of history, Leica Geosystems is one of the world’s leading suppliers of sensor technology – one trusted by the mining, infrastructure, and construction industries across Australia and beyond. Like all smart technology, global navigation satellite system (GNSS) technology continues to evolve and mature, and C.R. Kennedy –Australia’s sole distributor for Leica Geosystems – is keeping Australia up to date with the latest solutions available.

The unit’s high-precision dualfrequency GPS receiver provides highly accurate positioning data, even in areas with limited satellite coverage.

technologically advanced antenna product in the market right now.”

Some of the technology packed into the GPS 160 includes:

• An integrated global modem

• A colour display with an intuitive interface

• The latest real-time kinematic (RTK) positioning technology, ensuring quick initialisation and reliability

• SmartLink Fill to bridge RTK signal interruptions for up to 10 minutes.

The unit is also optionally available with calibration-free tilt compensation functionality, which allows users to lean the pole at angles up 20 degrees. This enables faster readings in awkward places, such as up against walls.

Nick says the GPS 160’s multitude of uses also means it has something to offer almost anybody in the construction industry.

“It’s what is commonly referred to as a ‘foreman solution’, or a ‘site-supervisor solution’, which means anybody in the construction field can pick it up and go to work with it very quickly,” he says. “It’s very intuitive and easy to use.

“It’s designed to be used by owner operators all the way through to tier one contractors. And it’s especially well-suited to the big state government joint ventures.”

What’s more, the GPS 160’s durable IP66/IP67 certified aluminium housing means the unit can withstand even the toughest conditions.

“Australia offers some of the harshest conditions in the world,” Nick says. “From the freezing cold of Tasmania to 45- to 50-degree temperatures out

in the middle of the Kimberleys, or the deserts of the Northern Territory.

“It’s essentially limitless in terms of where you can use it and what you can do with it.”

Nick says C.R. Kennedy is committed to providing not only the quality products and tailored solutions for customers, but also the very best after-sales support – from technical support and service to training.

“All of our products come with TeamViewer pre-installed and free-of-charge for the life of the product,” Nick says. “TeamViewer allows us to provide our customers with remote support or

training – potentially anywhere in the world.

“The GPS 160 also has the ability to connect to Leica ConX, Leica’s cloud-based monitoring and management tool.”

C.R. Kennedy is based in Port Melbourne, with a national network of more than 260 staff across branches in Melbourne, Brisbane, Adelaide, Sydney, Hobart, Perth, and Cairns.

As an introductory offer, C.R. Kennedy is offering 18 months of SmartNet for the price of 12 months, or a two-year iCON site CCP with the purchase of an iCG160 or iCG160 Tilt. For further information, visit www.survey.crkennedy.com.au

As is the case year after year, April’s Diesel Dirt & Turf Expo was packed from end to end with some of the most impressive construction machinery the world has to offer. From some of Europe’s finest and most innovative attachments, to the latest towering dump trucks and excavators out of Japan – there was something cool to see everywhere you looked.

But one of the most unique and eye-catching vehicles on display didn’t come courtesy of any of the many heavy-hitting equipment manufacturers – it was proudly displayed at the stand of specialist equipment insurer NTI.

That vehicle, a striking orange 1954 Chevrolet pickup truck, was first spotted on a farm in the United States and brought to Australia, where it is set to become the latest vehicle to be restored and raffled to raise funds for Motor Neurone Disease (MND) research.

NTI has raffled in support of the MND and Me

Foundation. Over five years, NTI has raised more than $1.5 million for MND research.

“Daphne is a ‘hot lava orange’ pickup truck, built with a 1954 Chevrolet Cab Over Engine body on a 1969 Chevrolet C-20 Pickup chassis,” said NTI CEO Tony Clark. “While the truck might be mid-century, she’s got modern features, including a 460hp LT1 Chevrolet Performance engine.

“Daphne was found on a farm in the USA and purchased by a young Australian working there. Its original owner was supportive of the re-sell once she’d heard about how it would be restored and raffled for the MND cause.

“Our commitment to raising funds for MND research comes after NTI’s former CEO Wayne Patterson lost his battle with the disease in 2018. We established the official NTI MND Research Grant to help fund research into

possible by generous donations, and General Manager Marketing for GM Australia and New Zealand Chris Payne said they were excited to be teaming up with NTI and Matt Stone Racing on a vehicle for a fantastic cause.

“For many years Chevrolet Performance LS crate engines have been the logical choice for builders of special project vehicles like this one,” he said. “This project truck is a terrific example of how the latest generation LT engines can now be used to provide big horsepower and incredible reliability, and really make it a special prize to help bring attention to MND research.”

Matt Stone of Matt Stone Racing said it was an added bonus that such a fun project was for a good cause.

“Our biggest contributing factor has been the time and the effort that’s gone into getting the work done and getting the truck built, juggling that with our busy racing schedule,” he said.

“It’s a great project to be involved in, with a lot of work in a short amount of time, but thankfully we come from a motorsport background so that’s something we’re used to. Partnering with the NTI crew who are very passionate about both the cause and the project meant that it was something exciting to be involved in.”

Daphne has made her journey from The National Diesel Dirt & Turf Expo in April, to MotorEx and the 2023 Brisbane Truck Show in May; with her next stop set for the Cooly Rocks On Festival from 7-11 June on the Gold Coast. The raffle will be drawn at the NTI Supercars Round in Townsville in July.

For more information, scan the QR code.

Cat® Command remote control technologies remove operators from potentially hazardous applications and still stay productive, day after day.

For almost half a century, STM has made it possible for businesses across NSW to power up – supplying and servicing quality trucks and machinery to meet the demands of any job.

Starting out in a single shed in the 1970s, we know what it takes to build a business – and are passionate about helping you grow yours. Today, our family owned and operated enterprise is proud to offer a multi-site, modern service, with a team of more than 120. We care about giving every customer the best experience possible – with a wide range of trusted brands, flexible finance, spare parts, repairs and personal service.

We may have come a long way from that shed, but our family commitment to quality remains. Whatever your size, whatever your budget, STM is your one stop shop – with everything to keep your business moving.

Well, CONEXPO-CON/AGG 2023 rolled around back in March, and I was fortunate enough to have attended North America’s largest construction trade show. And what a show it was!

While the EEM team was swanning about CONEXPO’s VIP circuit, I was out and about getting amongst the punters and exhibitors checking out all the latest and greatest on offer to the industry.

One company that I’ve been watching for a little while is CM Labs out of Montreal, Canada. They’ve been designing and developing training simulators for more than two decades. In that time, they’ve positioned themselves as the leading vendor for simulation-based training in the construction and ports industries.

The centrepiece of their award-winning simulators is their Vortex Studio. Developed by in-house PhD physicists, engineers, and mathematicians, Vortex Studio is the industry’s leading platform for building and deploying real-time, interactive simulations of mechanisms, heavy equipment, and vehicles.

They’re bringing three simulator solutions to the market – Vortex Edge Plus, Vortex Edge Max, and their mac daddy offering the Vortex Advantage.

A quick break down on each offering:

Vortex Edge Plus: Designed for maximum portability and simple set up, the desktop Vortex Edge Plus makes it easy and affordable for organisations to run CM Labs’ full catalogue of construction and forestry equipment training modules anytime, anywhere.

Vortex Edge Max: Training for operator skill development makes it simple for organisations to leverage the latest in innovative technology. Easy to transport and set up, they are ideal for organisations looking to explore simulation for the first time.

Vortex Advantage: Designed to provide the most immersive simulator training available today. The Vortex Advantage is a full-immersion training simulator that develops transferable operator skills. It’s designed for extended training, including mastering advanced skills. With OEM hot-swappable controls sets and pedals, and options for different screen configurations, the Vortex Advantage delivers high-quality training and flexibility.

I’d arranged to catch up with Gary James, CM Labs Subject Matter Expert and SIM Guide to talk a little deeper about their products. Gary’s background positions himself well to wax lyrical about CM’s simulators.

The Florida native started in the earthmoving

game young at 17 years of age as a labourer. After three years of hard work and dedication, Gary got his break landing a position on an ADT. From there he picked up further skills, eventually becoming a foreman with the same outfit.

In later years, Gary and his family found themselves in Colorado, which was where he was introduced to simulators. Here, he landed a job with Next Gen Equipment Training, where he was able to pass on years of industry knowledge and experience.

When it comes to simulators and knowledge sharing, Gary’s one of the most passionate people you are ever likely to meet.

I asked Gary what he loves most about CM Labs offerings.

“Their dedication to realism puts them

Australian Earth Training’s Scott Lidster shares what he learned about Canadian training simulator business CM Labs, and its Vortex range at CONEXPO-CON/AGG 2023.

ChatGPT has been a hot topic the past few months. If you haven’t heard of it, it’s an AI-driven chatbot that can produce extremely sophisticated content. It is capable of generating human-like responses to a wide range of prompts, including questions, statements, and even images.

ChatGPT in action

If you haven’t already, try it out – it’s the best way to understand what it does. Basically, ask it a question and BING, it gives you an answer that sounds like it came from a human with subject-matter expertise. The system is being touted as a great alternative (or enhancement) to online customer enquiry services, and as a great way to generate marketing content. From blog posts to essays to medical licensing exam papers, ChatGPT is knocking it out of the park. Kind of.

Because although it’s shockingly adept for what is essentially an algorithm, it also lacks the nuance and strategic insight of a real human.

And here’s the thing. There’s always been change. ChatGPT is not going anywhere, and

others are coming up behind it. We just need to work out how best to use it.

Don’t take our word for it though. We asked ChatGPT to list some pros and cons of using it to create content, and this is what it came back with:

Pros:

Timesaving: ChatGPT can generate marketing content quickly, which can save time and resources for businesses. This is particularly useful for businesses with limited marketing budgets or small marketing teams.

Diverse content: ChatGPT can generate a diverse range of marketing content, including blog posts, social media posts, and product descriptions. This can help businesses create a consistent and varied marketing strategy across multiple channels.

SEO: ChatGPT can generate content that is optimised for search engines, which can improve a business’s search engine rankings and increase website traffic.

Cons:

Lack of creativity: ChatGPT’s responses can lack creativity and originality, which may make the content less engaging for customers. This can result in lower engagement rates and

reduced customer interest in a business’s products or services.

Inconsistent tone: ChatGPT’s tone may not always align with a business’s brand or messaging, which can result in inconsistent marketing content. This can harm a business’s reputation and make it difficult to build a loyal customer base.

Limited understanding of business goals: ChatGPT’s responses are based on the input it receives, which may not always align with a business’s marketing goals or strategies. This can result in content that is off-topic or irrelevant to the business’s needs.

Ultimately, ChatGPT is a tool like any other. It’s great for:

• Developing a first draft to help you clarify your ideas

• As an ‘unbiased reviewer’ to give you some feedback on your own draft

• To explain complex concepts in a way they can be understood.

So, take a look and see what you think. And be quick – when we first signed up late last year it was entirely free. There’s already a paid option now, and it’s only going to get more expensive.

The AI revolution has begun – but just how revolutionary is it? The Hardman Communications team breaks it down.

• Standard with 4/5 heavy duty tynes (removable) - other options available.

• Ideal for that stubborn material.

• Customisable to fit your machine, installation of hydraulics and fitting options available.

• Kits available for domestic and international orders.

• Front Rippers are also a great addition to any Skid Steer or Track Loader.

Norm Engineering Hydraulic Rear Rippers are designed to excavate the toughest material and are custom made to suit different machines. Easily replaceable tynes are fitted with heavy duty ripper teeth and can be removed to suit individual tasks and requirements.

Available in kit form or can be custom fit to your machine. The weight, width, length, height, number of tynes and ripping depth all depend on the machine that the rippers are being fitted to.

Please contact the team at Norm Engineering or your closest dealer for the exact specifications to suit your machine.

4-in-1 tilt control bucket 4-in-1 bucket broom

concrete batching bucket

Cat® Steer Assist for Dozers can automate steering functions to help make operation easier and increase productivity with less effort, resulting in greater efficiency and higher quality work. Product expert Chris Barrett explains.

Caterpillar® has always accelerated the pace of innovation, adding new and improved technology – all designed to improve job site safety and machine productivity. Here, Product Application Specialist for Technology, Chris Barrett explains the latest technology, the Steer Assist on Cat medium-sized dozers.

“Programmable electronic hydraulic valves, smart sensors, electronics, and GNSS (Global Satellite Navigation Systems) systems are at the heart of our Next Gen Machines’ DNA,” Chris says. “This enables an infinite number of solutions to meet modern job-site requirements.”

Steer Assist has been developed based off local customer feedback and was field tested locally. This feature is an example of an Annual Product Update that enables new customerdriven features and software enhancements to be uploaded without adding new hardware to the machines.

Steer Assist can be used with the base Slope Assist technology, or Cat Grade with 3D.

Slope Assist helps operators reach a target slope by automatically maintaining the blade slope and main fall angles.

Slope Assist is perfect for site preparation and clean-ups, spreading as well as simple design

plans or areas where a GNSS signal may be lost or not available.

In Steer Assist mode, Steer Assist automatically keeps the dozer tracking in a straight line. This is especially useful when working on side slopes such as dam walls or a batter where Steer Assist can keep the dozer tracking straight without any input. Without this feature, the operator would need to make constant adjustments to the steering to maintain a straight heading.

Steer Assist can control the differential steering or use Tilt Steering for production dozing or when the blade is under heavier loads.

According to Chris, not many civil projects are completed these days without the use of 3D machine control and a digital job site plan.

“Cat Grade with 3D’s automatic grade control eliminates the need for continual grade staking and checking, and the productivity gains are well proven compared with traditional methods,” he says.

With Steer Assist 3D, the operator simply selects a 3D or horizonal line in the digital design plan on the Cat Grade display. Once a

line is selected, the operator simply engages the auto button on the blade control joystick and the dozer then will automate the blade and automate the steering.

This is particularly useful in applications such as following a curb line or an alignment for cutting in roads or spreading material evenly across a large area.

“Just start your pass and watch the technology do the rest,” Chris says. “It really makes work a lot easier for operators.

“Whether it’s on flat ground or on slopes, or a design with tight curves, the accuracy is very impressive even at higher speeds.”

Based off local operator feedback, the Steer Assist system can be set to the operators preference.

Steer Assist can be selected to work in forward only mode, or forward and reverse, and the activation range and blade overlap between passes can be adjusted to suit the job at hand.

The Steer Assist 3D reduces the number of passes when spreading with precise pass-topass overlap.

“The Steer Assist 3D works well with other dozer Assist technology features to help increase productivity, such as AutoCarry and Traction Control,” Chris says. “It is also

compatible with the new Cat Command Remote Control technology.”

Operators can also take manual control of the machine steering or blade to temporarily override the Steer Assist. When the operator is no longer inputting a command manually, control is given back to Steer Assist.

Having the automatic blade and steering control working seamlessly together enables the dozer to operate with a high degree of accuracy.

Steer Assist is standard on new Next Gen Dozers equipped with Slope Assist or Cat Grade with 3D.

Additionally, Cat Steer Assist is also available to retrofit on Next Gen D5, D6* and D7 machines in the field.

The on-board mobile technology Product Link™ can provide RTK GNSS corrections from Virtual Reference Stations (VRS), Internet Base Stations Solutions (IBSS).

In addition, the new VisionLink Productivity application can be used to send design files over the air from the office as well as enable remote support of the Grade display.

As-built production data from the Grade with 3D system is displayed to show work remaining, work completed, and on grade performance.

VisionLink Productivity has expanded its capability to bring payload, cycle segmentation, and now Cat Grade with 3D data to an application that can help customers analyse jobsite performance and improve productivity based on actionable information. It is scalable to any size operation, regardless of asset brand, and can be accessed anywhere via mobile, tablet, or desktop.

Chris says the new, easy to use Steer Assist technology will result in confidence, speed, and accuracy for all operators.

“Operators will see better production and a higher quality of work, and have more confidence when working around curbs and defined site boundaries,” he says.

“It is a great feature that allows simple jobs to be finished quicker with better surface quality and with less operator input required. And that helps lower fatigue and improve productivity.

“Our dealer machine sales and technology specialists have received in-field training, meaning customers will stay abreast of the latest product developments. Learn about Cat Steer Assist technology on Cat Next Generation Dozers from your local Cat dealer.”

For more information online, check out: www.cat.com/en_IN/products/new/ technology/assist.html

Sydney’s FCG Ground Control is a business built on strong industry relationships. Founder Pascal Mouawad discusses his business, and how the above-and-beyond support from STM Trucks & Machinery made him and his team Kobelco excavator converts.

Over more than 30 years the in earthmoving and demolition industries, Pascal Mouawad has seen it all – the highs, the lows, the good, bad, and ugly.

But as the founder of Sydney-based contractor FCG Ground Control, Pascal seems to have found a sweet spot in the industry – a business big enough to take on some serious demolition work, but small enough to ensure that it still feels and works like a tight-knit

Decades of experience has taught Pascal to value strong relationships, both in business and life. And for FCG, one of the relationships most crucial to the business is with Sydney equipment dealer STM Trucks & Machinery.

“We all love STM – we’ve developed a beautiful relationship with them over the last few years,” Pascal says.

Pascal says a friendship with Mark Morris

when they were both employed elsewhere. And when, in the early days of FCG, Pascal found the backup support for his once-preferred excavator brand had become unsatisfactory, Mark encouraged him to try Kobelco.

Pascal took the plunge, adding multiple Kobelco excavators to FCG’s fleet and, ever since, he’s been thrilled with the support provided by Mark and the STM team.

“Mark’s a big-hearted man, and he always goes out of his way for me,” Pascal says. “If I ever need anything, he’ll deliver it for me. That’s a big deal for any company.

“That’s what separates STM for me. The fact that I have that true personal friendship, as well as a dealership that supports my business.

“And we’ll go out of our way to let people know – we’ll always include them on our social media posts. When you’re good to your dealers, they’ll be good back.”

FCG Ground Control is a business built on a strong foundation of extensive industry experience and connections.

“We deliver all types of works,” Pascal says. “Any earthmoving and trucking works for demolition, excavation, remedial groundworks – and more.

“We run a 10-15-man company – nothing too big, nothing too small. That includes a full-time

Homes. Another example of why he takes relationship building so seriously.

“We do essentially all the demolition work for their Northern Beaches sector,” he says. “I’ve been doing their work for 15 years non-stop, and we’ve become their preferred demolisher.”

As well as demolition and tipping, FCG’s offering also extends to hook bins.

“We’ve got two units that facilitate hook bin services around the region, for both residential and commercial projects,” Pascal says.

Both demolition and hook bin teams were called into service on a recent FCG project – the demolition of a massive old factory in Sydney’s inner south.

“It’s the old pipework factory at Alexandria,” Pascal says. “It was a four-week project with full remedial control plans that we needed to meet, involving asbestos waste and lead dust waste – a lot of highly contaminated materials. And we managed to clean it all up, execute it in accordance with the plan, and complete the job successfully.”

Pascal says it was an interesting and intricate job – one that required some very specific demolition knowledge and expertise.

“The front façade of the whole building had to be retained, so we had to do all the provisions and groundworks for that,” he says.

“There were also some serious safety requirements, because it was a big steel structure that would rock and shake if you touched it. There was even a more than 100-year-old overhead crane that we had to retain under heritage order. We were able to recover it safely, and it’s going to be reused as a feature in the construction of the new building.

“It wasn’t a project for everyone – definitely not your standard demolition job.”

While Pascal’s experienced team was the brains behind this complex operation, two Kobelco excavators from STM brought the

team at STM was readily available to provide any support necessary for FCG’s excavators and attachments – something he says demonstrates a dealer willing to do whatever it takes to support his business.

relationship stays this way for a long time.

“Because right now, when it comes time to buy another piece of gear, I wouldn’t even bother looking anywhere else. STM’s the

“They’re great people at STM , and they’re definitely on the rise.”

Lovol’s range of wheel loaders includes models featuring Danfoss hydrostatic drive, including the FL980K (26-tonne weight with eight-tonne payload).

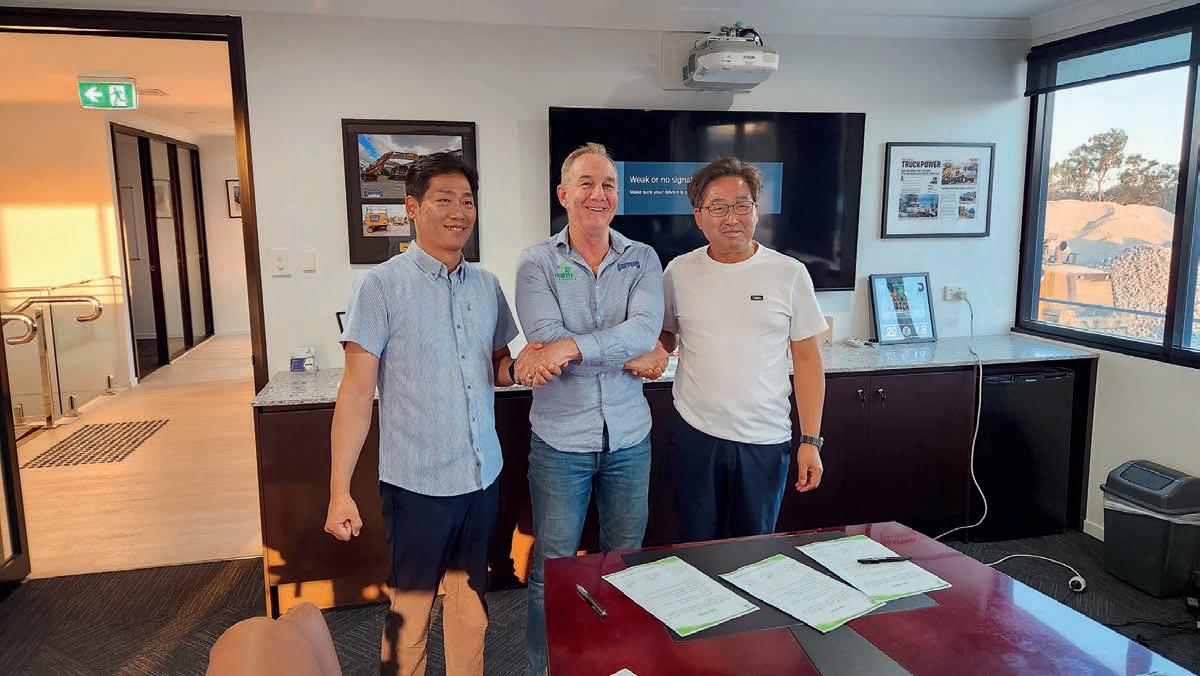

Lovol Construction Machinery, a Chinese manufacturer with a rich history, has been making waves in the Australian earthmoving equipment market. Equipment Specialists Australia (ESA) – the authorised distributor for Lovol equipment in Australia – has recently expanded its range of Lovol excavators and wheel loaders, bringing a high-quality yet affordable alternative to the industry.

The wheel loader range includes models with Danfoss hydrostatic drive and Cummins engines, designed for the mining, quarry, and construction sectors. The range also offers models with ZF Powershift Transmission and Cummins engines for all types of construction work. There are models featuring noncomputerised Deutz Weichai engines, perfect for smaller businesses and the farming sector.

As for the excavator line up, Lovol offers an extensive range of options, from the zeroswing range, ideal for tight spaces, to the limited swing and conventional swing models for various applications. With a total of 34 models available ranging from 1.8 tonnes to 100 tonnes, including long reach and material handlers, end-users can find the perfect excavator for their needs.

Lawrence Perkins, Operations Manager at ESA, explains that the company’s offerings have bridged the gap between high-priced big brand names and cheaper, low-quality alternatives.

“In the past Lovol has primarily targeted mainland Asian and European countries that want lower spec but high-quality machinery,” he says. “Lovol has now shifted its focus to compete with the big brands in terms of modern design, operator comfort, high

performance features, all while keeping the toughness and reliability at the highest level.”

For smaller businesses like garden centres needing smaller loaders, Lawrence says they’ve historically been stuck either with $200,000+ big brand name machines that are beyond

their budget, or much lower quality budget alternatives.

“Lovol’s filling that in-between market with comparable quality to the big name brands with luxury comforts, high performance, and features across the full K series range,” he says.

EEM gets the inside scoop on the latest Lovol equipment available from Equipment Specialists Australia.

Lawrence says that Lovol’s new machines have been receiving positive feedback from customers.

“Everyone who’s got them has been absolutely loving it, and just rapt that they’ve purchased them compared to spending huge amounts more just to get a brand name sticker,” he says.

Lawrence says Lovol’s collaboration with top-tier component suppliers is another aspect that sets it apart from competitors now with five years warranty on some models.

“They have many loader models already now available that are in line with high-end brands in regard to having a full hydrostatic drive train made by Danfoss,” Lawrence says.

Despite the stigma associated with Chinese products, Lawrence believes that Lovol’s commitment to quality, innovative features, and competitive pricing will change the perception of the brand. He says other Chinese top tier brands have been working hard to do the same also and now being considered more seriously.

“Lovol’s got a high-quality product that sits a little bit above other top tier Chinese manufacturers in terms of setting the standard for quality, features, performance, and more,” Lawrence says. “But compared to the budget priced machines – they are worlds apart.”

The overwhelmingly positive feedback received for Lovol’s machinery has attracted the attention of new sectors, including the mining industry. Lawrence explains that this interest is unprecedented, as the mining sector has traditionally never considered Chinese products before.

“The mining industry now wants to get involved with Lovol products,” he says. “It’s going to be the first Chinese brand to break into the underground mining sector, which proves the quality of the machines.

“Lovol has matched and surpassed the

features of some of the big OEMs, with the hydrostatic drive being a key example. It’s kind of caught some of the big brand manufacturers by surprise, as they’re still trying to develop and catch up.”

In terms of machine availability, Lawrence says that ESA hasn’t faced any significant issues with supply, and China has been quick to deliver. But the demand for Lovol machines has been so high that they are often sold before they even make it to Australian shores.

“That’s our biggest issue for us right now – machines being sold before they arrive,” Lawrence says. “But people won’t be having to wait six to eight months, it’s typically a couple of months maximum.”

To meet this growing demand, ESA has been increasing its orders for Lovol machinery, with shipments arriving every few weeks. Lawrence says as demand continues to rise, ESA will have more opportunities to forecast and meet the market’s needs.

“Right now, we’ve got a shipment of 12 wheel loaders and another 12 excavators arriving,” Lawrence says. “And we’re ordering more every few weeks now.”

Lawrence says ESA has a solid and evergrowing network of dealers across Australia, and is looking to continue that expansion to meet demand.

“We already have a great backbone established for the business, particularly with our maintenance and field service,” he says. “So, we’re actively building on our dealer network to ensure we can offer full coverage Australia-wide. After sales service is extremely important to us – it’s our number-one focus.”

For more information, visit www.equipmentspecialists.com.au or phone 1300 378 478

ESA’s current Lovol range includes:

• Wheel loaders, including: the 6-tonne weight, 1.8-tonne rated FL918K; the 15-tonne weight, 4.5-tonne rated FL948K, the 20-tonne weight, 6-tonne rated FL962K; and the 26-tonne weight, 8-tonne rated FL980K – all featuring Danfoss Hydrostatic (HST) Drive and Cummins engines suitable for the mining, quarry, and high-end construction sector

• The wheel loader range also includes: the 18-tonne weight, 5.5-tonne rated FL958K, the 22-tonne weight, 6-tonne rated FL966K; and the 24-tonne weight, 7-tonne rated FL976K – all with ZF Powershift Transmission and Cummins engines suitable for all types of construction work

• And rounding out the wheel loader range is the 10-tonne weight, 3-tonne rated FL936H; 12-tonne weight, and 3.5-tonne rated FL938H – with Powershift Transmissions and non-computerised Deutz Weichai engines suitable for small businesses and the farming sector

• The excavator range includes 1.8-tonne, 3.6-tonne, 5.5-tonne, and soon-to-arrive 13-tonne zero-swing models; the 22-tonne, 70-tonne, and 80-tonne limited-swing range

• L astly, a wide range of conventional-swing machines, for a total of 34 models available, including long-reach and material handlers.

JETLAND is a leading supplier of high strength & heavy duty Aluminium loading ramps in Australia. High quality raw material and safety testing systems ensure a safe and reliable product.

No manufacturing delays, all ramps listed online are in stock at our warehouse in Mordialloc, Victoria.

We can also supply Custom built ramps - made to your specifications for your particular needs.

Free Delivery

Australia wide.

As one of the world’s premier locations for disconnecting with reality and living life by the seat of your pants, Las Vegas is never short on excitement.

But every three years, a very specific kind of excitement descends on the sparkling desert city, as earthmoving and construction enthusiasts from around the world gather for North America’s largest construction machinery event, CONEXPO/CON-AGG.

This past March, the 2023 event spread its wide range of equipment out across a massive 64 acres, as manufacturers showed off the latest and greatest gear.

But nowhere was the atmosphere more electric than at the huge arena purpose built for the Cat® Global Operator Challenge, where onlookers were treated to a demonstration of the very best heavy machinery operators the world has to offer.

The prestigious Cat Global Operator Challenge is a competition that tests the skills of operators on a range of Cat equipment. The competition featured finalists from around the world, who had qualified through regional and semi-final competitions.

The final featured the world’s nine best operators, who competed in a series of challenges designed to test their knowledge and skills across three machines: an excavator, a wheel loader, and a backhoe loader.

This year, Australia was proud to get behind two local heroes: Victoria’s Patrick Doheny,

and South Australia’s Nick Thompson who, along with Masato Imai from Japan, topped the competition at the Asia Pacific Finals in Tokyo last October.

For Nick, the whole journey was like nothing

Nick says the journey marked the first time he’d ever left Australia, and that it was fascinating to get a taste of how the construction industry worked in other countries. As for CONEXPO, he says photos and videos –

set-up before everyone else did – we were just walking around going ‘wow’,” Nick says. “Just the sheer scope of it all. You see the photos, but you can’t really piece it all together until you’re there.”

But for each finalist, any sense of wonderment had to be quickly contained so they could focus on the task at hand: battling it out to determine the world’s best operator. And with the world looking on, in person and over livestream, all nine operators put up a tough fight.

But only one operator could emerge as the world champion. And this time, that operator was Patrick Doheny.

Patrick emerged victorious with an overall completion time of 26 minutes and 49 seconds, proudly cheered on by supporters from both Australia and his homeland of Ireland. Second and third places were claimed by the United States’ Matt Ferris, and Poland’s Łukasz Mokrzyński respectively.

Patrick also claimed top spot in the wheel loader challenge with a time of eight minutes, 45 seconds.

“I was obviously over the moon,” Patrick says. “It was great just to get that far, and to finish it off winning the title in Las Vegas was pretty special.”

Patrick is Co-Director of Melbourne civil construction business CRE Group where, these days, he mostly stays off the tools.

“I haven’t really spent much time on a machine since around 2009,” he says. “It’s really just been in the two years leading up to the event.”

Despite this, Patrick’s muscle memory held strong, and his 25 years of earthmoving experience shone through.

“I obviously still have a massive interest in

earthmoving equipment though – hence, why we set up the Dig Deep event in Melbourne,” he says.

Patrick and his business partner Michael Harding founded Dig Deep to raise awareness for mental health in construction. The inaugural event, held in May 2022, donated all its profits to Beyond Blue. It was also home to the local heats of the Global Operator Challenge – hosted by Victorian Cat dealer William Adams – where Patrick himself emerged victorious and punched his ticket to Tokyo.

Patrick and Nick grew up on opposite sides of the world, and their respective paths to Las Vegas have been quite distinct as a result. But the common thread in their stories is a big one – they were both born into the earthmoving game.

Patrick grew up in Ireland, where he was immersed in a world of machinery from an early age.

“My father has a plant hire business back in Ireland,” he says. “So, I’ve been around machinery since I was a child.”

Finalists demonstrated their skill and precision through a range of challenges.

While this kindled his passion for earthmoving equipment, Patrick eventually took a break from operating machinery to pursue a degree in civil engineering – a path that led him to his current role.

Nick also describes a deep-rooted connection to the earthmoving industry.

“It all started when I was a little kid,” he says. “My dad used to work for his best mate, doing moss rock retaining walls with skid steers and a truck. I’d sit on his lap while he drove us around on the skid steer. And I loved it, I was just like a pig in mud.”

Nick soon followed his father’s footsteps into a construction career, where he has remained ever since. Today, he’s a full-time operator for South Australia’s Modcon Civil.

Of course, Patrick and Nick were not alone on their journey. Both men were fortunate for the support from their families, friends, employers, and dealers alike.

Patrick says the support he received from both Caterpillar and Victorian dealer William Adams played a pivotal role in his journey –from the Dig Deep event all the way through to Las Vegas.

“We were all blown away by the support that Caterpillar and William Adams gave us in Vegas, Japan, and in the lead-up – they

unbelievable. I really couldn’t speak highly enough of them.”

Patrick says this level of support is indicative of how William Adams does business.

“William Adams has a massive footprint here in Victoria, and for them to still be able to operate under the same kind of culture as a family business is pretty unique,” he says. “We deal

Nick also expressed gratitude for the support he received, particularly from his employer Modcon Civil, and subcontractor Bardavcol.

“For my boss – and friend – Jake HamiltonModerate to go out of his way, and throw in a lot of money towards us getting over there was just amazing,” Nick says. “Jake’s a great boss and great friend.”

Nick says South Australian Cat dealer Cavpower also played a crucial role in preparing him for the competition. “

“Cavpower did a lot to help get me up to standard,” he says. “They got me trained up on the on the loader and mini excavators – the machines that I don’t usually spend a lot of time on. Big ups to the Cavpower team.”

With the 2023 winner’s trophy secured, Patrick says he is content to take a step back from operating machinery once again to focus on running his business. But he says the experience has served to reinforce his love for the industry.

“Through all the events, from Dig Deep to Tokyo and Vegas, I’ve been reminded that there’s a lot of lot of really good people in the earthmoving and construction industry,” he says. “From dealers to sales reps to all the other business owners we met, as well as the other contestants – every one of them was a legend, and everyone was cheering each other

Nick says the experience has also taught him a great deal about the industry, and his place

“For a while I’d been wondering whether I wasn’t as good as I thought I was,” he says. “But I’ve come to the realisation that I have a lot of skills and experience and not to sell myself short.

“Even though I came seventh, that’s still seventh in the world. Plus, I was second in the excavator challenge and third in the loader challenge. So, I’m rapt with my effort all around, as well as everyone else that was involved.

“I’ll definitely be returning to have a crack at number one.”

Lifting capacities 5000kg

Reach 26 metres

Continuous rotation of the turret

ASCS security system with 10.1’’ display Tilting cab with inclination up to 20°

Multi-position stabilisers

125 kW/170 hp engine

Hydrostatic transmission with management system

After five jam-packed days of innovative product launches, major company announcements, enlightening education sessions and countless networking opportunities, CONEXPO-CON/AGG and IFPE 2023 came to a close in Las Vegas – but not before taking the construction industry to the next level.

The show crushed expected attendance numbers, drawing more than 139,000 construction and fluid-power professionals from 133 countries, making it the largest trade show in North America with more than 2400 exhibitors from 36 countries spread out over almost 280,000 square metres of exhibition space.

CONEXPO-CON/AGG show chair. “Live events in the construction industry are very important because you can see, touch, and experience the products. That value was reaffirmed this past week across the show floor.”

The 2023 show emphasised how the construction industry is evolving in many ways to adapt to sustainable technologies, products, and practices. Show attendees were treated to sustainability in action, from electric- and hydrogen-powered construction equipment to more recyclable materials and waste-reduction opportunities.

Across the show floor, sustainable technologies, products and practices included Volvo

Caterpillar® featured four battery electric machines, as well as a series of prototype batteries for off-road equipment ranging from 48-600 volts. Additionally, a Cat® Command display provided attendees with a look at the possibilities of remote operation.

Electric machinery was also an area of focus for LiuGong, which was proudly displaying its 856H electric wheel loader, as well as a 9027FE electric mini excavator.

In addition, attendees found:

Aerial work-platform specialist Skyjack had its new SJ120 E on hand, a zero-emissions mast lift with a 30-per-cent improvement in duty cycle

• Asphalt-recycling equipment from Pavement Recyclers LLC and VSS Macropaver, who use different processes to keeping asphalt out of landfills. Concrete contractors also got in on the green trend when they checked out Holcim’s ECOPact concrete that can eliminate carbon emissions entirely in some

CONEXPO-CON/AGG and IFPE 2023 by the numbers

• Over three-million net square feet of exhibits (10.5 per cent larger than 2020)

• More than 139,000 registered attendees (six per cent increase over 2020)

• More than 2400 exhibitors from 36 countries, including 603 new-to-theshow exhibitors

• More than 24,000 international registered attendees from 133 countries

• 91,000 scans of badges to access the 190 education sessions

• 6 00 global media from 33 countries.

instances. Holcim was also the winner of the inaugural Contractors’ Choice for the Next Level Awards

• Construction pros wanting to maximise energy efficiency explored Kubota’s V3307 Micro-Hybrid engine for installation in their existing equipment, saving fuel with attachments like Rototilt’s Rototilt Control system

• Contractors in disaster recovery will be able to save up to 600 sand bags per barrier (and not worrying about disposal should it become contaminated) with Rapid Barrier Systems’ water-inflatable barriers

• Demolition contractors will also be reducing waste and preserving still-usable material with Aquajet’s Hydrodemolition robots, seen at the Brokk booth, that can help remove damaged concrete while leaving still-good concrete and rebar reinforcement intact

• Wacker Neuson showed compaction is another place where low-efficiency engines can be replaced with battery-operated equipment, showcasing several electric tools, including battery-powered, reversible plates

• Small-engine specialists Briggs & Stratton brought its Vanguard brand’s swappable lithium-ion batteries for attendees to test out, and Redline Detection showcased its battery coolant and leak detector

• B3C Fuel Solutions brought products to help contractors eliminate waste by restoring emulsified/damaged oil, and make sure lubricant that does find its way to the environment is non-toxic and biodegradable

• Waste2Water brought solutions to help equipment operators keep waste and

chemical-laden water out of the environment

• AT&T’s Equipment and Machinery Solutions team brought a solution to help track its actual Scope 1 emissions versus its targets.

The Arbor Day Foundation partnership

One of the biggest sustainability efforts on the

a forest of greatest need. Additionally, exhibitors, attendees, and fans of the show can contribute to the Arbor Day Foundation’s funds, allowing it to further the goal of planting, nurturing, and celebrating trees around the globe.

Educational opportunities

CONEXPO-CON/AGG & IFPE also featured a wide range of educational opportunities, including 190 expert-led sessions on topics such as construction safety, equipment technology, and sustainable building practices.

“The success of CONEXPO-CON/AGG & IFPE 2023 is a testament to the resilience and strength of the construction and fluid-power industries, which has continued to adapt and innovate despite the challenges of the past three years,” said Marcia Klein, Treasurer of Casappa Corp, and show chair of IFPE. “We’re proud to have provided a platform for industry professionals from around the world to connect, learn, and discover new solutions for improving their businesses and the world we build.”