Christmas is done, New Year’s has been dealt with, Australia Day – or whatever you chose to celebrate on January 26 – was a raging success, Valentine’s Day swept by in an orgy of chocolate and love hearts, and here we now sit, catching our breath before bracing ourselves for Easter.

I sometimes wonder how we get any work done.

Even when there’s no public holidays for months, I wonder how Kah Chi and Jamie get any work done… or if they get any work done. Every time I get to look away from my computer screen, which is sometimes as often as twice a day, I see the pair practicing chip shots into the back of a ute in the parking lot. I had to go down there and threaten them with a written warning if they damaged the work vehicle, but they pointed out they weren’t using our ute, so everything was fine.

Do you have something you’d like to share with the industry? Send EEM an email at tom@maynemedia.com.au

We’re keen to get your thoughts.

I also had request they not set up a putting green in the tea room using old bits of carpet and items of office crockery. Aside from creating possible trip hazards and making use of the tea room difficult, I pointed out using their workmates cups as holes in the ‘green’ could end up with a lot of broken drinking receptacles. The pair claimed they made sure there was fluid in the cup to ‘slow and control ball deceleration’, but they did grab their bits and pieces and leave.

It’s tough being the bad guy sometimes. The sooner the Diesel Dirt & Turf golf day in late February is over, the better. Although, with DDT itself scheduled for just a few weeks later on April 8 and 9, there’s probably not a big likelihood those two will be seen much around the office between times.

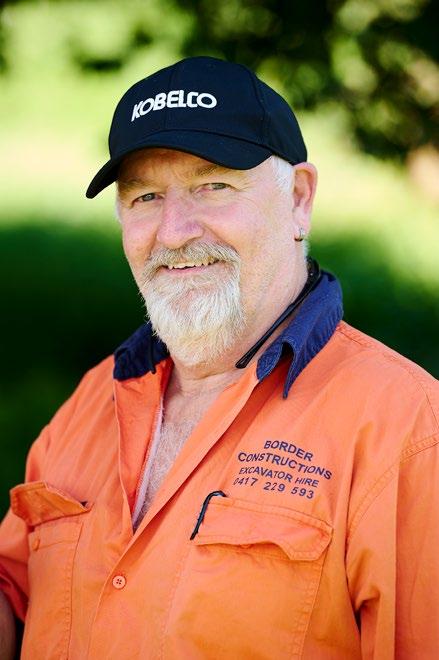

This issue is another pride-of-placer, with case studies on Border Constructions partnering

up with BrisVegas Machinery and Kobelco, Fenix Resources and Cat in West Aussie, and Marino Excavations and CJD Equipment in FNQ. We’re featuring skid steers and track loaders, and of course we’re jam-packed with industry news, products and excellent industry-focused advice.

In fact, as I work my way through the finished magazine, I’m surprised just how much firstclass writing and top-shelf photography we’ve managed to squeeze in. I guess Jamie and Kah Chi must’ve filed some bits and pieces while I was stuck at my desk. Maybe I’ve misjudged them.

I hope you all enjoy the issue, I’ll have to leave you to it. There seems to be a dimpled lump of something floating around in my coffee.

Tom Foster Contributing Editor

Jamie has been a professional photographer in Sydney for over two decades. He is the owner of Camera, Hammer and Tong, who provides digital content for small businesses in and around the construction industry. He is also a photo journalist & the product feature editor for What Tradies Want Magazine. But he’s just as comfortable with a hammer in his hand as a camera and pen. Undertaking a mature age carpentry apprenticeship in his 40s and still gets the nail bag on when he can.

Martin Kovacs is a journalist with experience covering the business, technology and energy sectors. Over the past 10 years, Martin has covered a wide range of subjects across both print and digital media, broadly encompassing business and technology trends, focusing on issues of importance for industry. Martin takes a particular interest in digital technology developments and the manner in which industry continues to adapt and evolve amid the rollout of new technologies.

Scott is the Director of Australian Earth Training, a niche operator proficiency training organisation who work across the globe. He has over 25 years’ experience in heavy equipment operation and was an accredited Caterpillar Dealer Instructor (CDI) Trainer-Demonstrator. Scott’s unique skill set enables him to operate and train on a broad range of machines across the mining, construction, quarrying and waste industries, helping his customers to boost their productivity while lowering their owning and operating costs.

NSW

CAPITAL CONSTRUCTION EQUIPMENT 535 Dallinger Road, Lavington NSW, 2641. 02 6025 0444. www.capitalconstruction.com.au

FRANKS SERVICE CENTRE 186 Wakaden Street, Griffith, 2680, NSW 02 6962 6073. www.fscforklifts.com.au/

NORTH WEST FARM MACHINERY 22-26 Whittaker Street, Quirindi, 2343, NSW. 02 6746 3300. www.nwfm.com.au

STM EQUIPMENT Unit 3, 28 Dunn Rd, Smeaton Grange, NSW 2567 02 4728 7500 www.stmequipment.com.au

THREE RIVERS MACHINERY 25 Zora Street, Warren NSW, 2824 02 6847 3111. www.3rm.com.au

WATSON TRACTORS 40 Vale Road Bathurst, NSW, 2795 02 6331 1978. www.watsontractors.com.au

SCTM (Canberra) 1/45 Bayldon Road, Queanbeyan, NSW ,2620 02 6299 1500. www.sctm.com.au

SCTM (Wollongong) 6 Mineral Road, Oak Flats, NSW, 2529 024257 1500. www.sctm.com.au

EARTHMOVING EQUIPMENT AUSTRALIA (EEA) 99 Glenwood Drive, Thornton, NSW, 2322. 02 9671 1000. www.eeaustralia.com.au

EARTHMOVING EQUIPMENT AUSTRALIA (EEA) 123 Cobalt Street, Carole Park, QLD, 4300. 1300 753 332. www.eeaustralia.com.au

MCINTOSH & SON (DALBY) 17563 Warrefo Highwyay, Dalby, QLD, 4550. 07 4662 2288. www.mcintoshandson.com.au

MILNE BROS EQUIPMENT (BILOELA) 61-67 Dawson Highway, Biloela, QLD, 4715. 07 4992 1099. www.milnebros.com.au

MILNE BROS EQUIPMENT (EMERALD) 67 Macauley Road, Emerald, QLD, 4720. 07 4982 4824. www.milnebros.com.au

MILNE BROS EQUIPMENT (ROCKHAMPTON) Gladstone Road & Derby Street, Rockhampton, QLD, 4700. 07 4930 0300. www.milnebros.com.au

SQMH 10 Bain Court, Toowoomba, QLD, 4350. 07 4634 2744. www.sqmh.com.au

LARWOOD AG SERVICES

38 Moonta Road, Kadina, SA, 5554. 08 8821 1999. www.larwoods.com.au

ROCKY RIVER AG 62 Wongabirrie Road, Crystal Brook, SA, 5523 08 8636 2772. www.rockyriverag.com.au

SA TRACTORS

12/160 Churchill Road North, Cavan, SA, 5094. 08 8349 7500. www.satractors.com.au

DLM MACHINERY

17/19-21 Killafaddy Road, St Leonards, TAS, 7250. 03 6339 1550. www.dlmmachinery.com

BALLARAT TRACTORS 155 Learmonth Street, Ballarat, VIC, 3350. 03 5334 2444. www.ballarattractors.com.au

GLENMAC SALES & SERVICE 85 BaldHill Road, Pakenham, VIC, 3810. 03 5941 5966. www.glenmac.com.au/

KV EQUIPMENT 221 Midland Highway, Epsom, VIC, 3551 03 5445 6999. www.kvequipment.com.au

MELBOURNE TRACTORS

110 Hume Highway, Somerton, VIC, 3062. 03 9303 5777. www.melbournetractors.com.au

MELTRAC MACHINERY 6703 Princes Highway, Terang, VIC, 3264 03 5536 0222. www.meltrac.com.au

PRIMTEC TRACTORS 698 Benetook Ave, Mildura, VIC, 3502. 03 5022 1004. www.primtectractors.com.au

FORKWEST

68 McCombe Road, Bunbury, WA, 6230 08 97254970. www.forkwest.com.au

GEOFF PERKINS MACHINERY Lot 24 Stewart Street, Narrogin, WA, 6312. 08 9881 2222. www.perkinsmachinery.com.au

MCINTOSH & SON (ALBANY) 189 Chester Pass Road, Albany, WA, 6330 08 9847 4255. www.mcintoshandson.com.au

MCINTOSH & SON (ESPERANCE) 25 Norseman Road, Esperance, WA, 6450. 08 9071 1155. www.mcintoshandson.com.au

MCINTOSH & SON (GERALDTON) 160 Flores Road, Geraldton, WA, 6530. 08 99605500. www.mcintoshandson.com.au

MCINTOSH & SON (KATANNING) Lot 4 Nyabing Road, Katanning, WA, 6317. 08 9821 7000. www.mcintoshandson.com.au

MCINTOSH & SON (KULIN) 294 Pump Road, Kulin, WA, 6365 08 9880 2556. www.mcintoshandson.com.au

MCINTOSH & SON (MERREDIN) 52 Mitchell Street, Merredin, WA, 6415 08 9041 1099. www.mcintoshandson.com.au

MCINTOSH & SON (PERTH) 547 Great Eastern Highway Redcliffe, WA, 6104 08 9475 1600. www.mcintoshandson.com.au

SOURCE MACHINERY 6 Reggio Rd Kewdale, Kewdale/Karratha, WA, 6105. 08 9358 3389. www.sourcemachinery.com.au

ACCESS SERVICE AUSTRALIA

ACCESS SERVICE AUSTRALIA 26 Kilto Crescent, Glendenning, NSW, 2761. 02 9832 9990. www.accessservice.com.au

71 Bradman Street, Acacia Ridge, QLD, 4110. 07 3219 5130. www.accessservice.com.au 32 Healey Road, Dandenong South, VIC, 3175. 03 9768 2155. www.accessservice.com.au

DC SERVICES 13 Carroll Street, Mount Louisa, QLD, 4814. 07 4774 2733. www.dcservicesnq.com

MOTION MACHINERY

1/10 Dickens Place Armadale, WA, 6112. www.motionmachinery.com.au

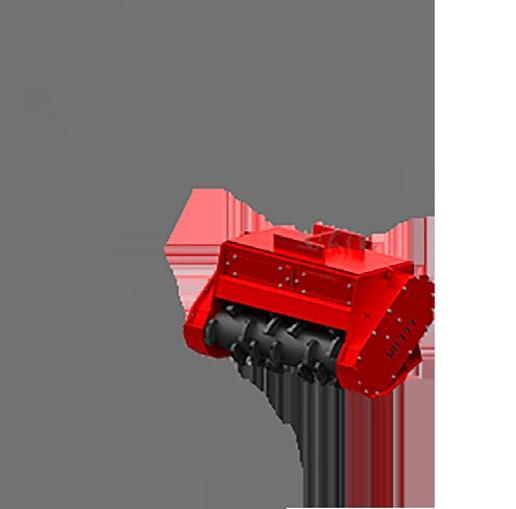

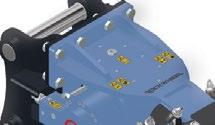

Epiroc company Erkat has thrown its support behind German-based research aimed at making mining, tunnelling and demolition operations more efficient, safer and environmentally friendly, adapting an ER 650 transverse drum cutter for the Technical University Bergakademie Freiberg’s RockFeel project.

RockFeel is designed to detect changes in rock strength, material differences, chisel blockage and wear during operation, with Erkat adapting the ER 650 for the project’s recently commissioned cutting test bench.

Erkat advised that the technology will, according to RockFeel, improve deposit yield, with waste material reduced by at least 10 per cent, while mining safety would be enhanced by the timely detection of caving risk, and an extended pick life would result in fewer pick change interruptions.

In addition to this, environmental benefits include significantly less water and energy consumption, fewer chemicals and no more

explosive gases, with RockFeel streamlining the process chain and paving the way for cheaper and greener lean mining.

The project’s opening day demonstration saw a tracked excavator and the ER 650 equipped with various sensors, allowing for the wireless transmission of data, with Erkat instructing the project team in the optimal handling of the cutter.

“Reliable real-time analysis of the rock would bring a whole range of advantages for our customers,” Erkat Managing Director Martina Schierholz said.

“We save time, improve yield, increase safety and contribute to our environmental protection efforts. We couldn’t ignore these many good arguments. We are following the progress of

the RockFeel project with great interest and hope that this innovation will be a milestone for our customers.”

ER transverse drum cutters can be put to use across rock or concrete wall and surface profiling, trenching, soft rock and frozen soil excavation and demolition applications, with the product line featuring:

• Extremely robust spur gears – for optimum energy transmission and reliability

• QuickSnap retaining system – for quick and easy pick changing (ER 600-3000)

• Large variety of cutting heads – for various applications

• Robust housing design – with HARDOX wear protection for higher uptime

• Underwater use – capable up to 30 m without additional installation or modification

• Mechanical 360° rotatable bracket – with central fixing bolt for easy positioning of the drum cutter (ER 50-3000)

• Adoptable high-torque gear motor – for higher productivity and motor lifetime

• High load-resistant output shaft bearing system – with lubrication-free slide ring seal system

• Pick sleeves – are replaceable (ER 1500-5500)

Epiroc’s HATCON (Hydraulic Attachment Tools Connectivity) remote monitoring solution is available with the ER transverse drum cutter range (ER 100-5500), with Epiroc advising it “enables next-level fleet management by monitoring operating hours, location and service intervals of your tools”.

“The data from HATCON provides a new level of control,” Epiroc states. “Making sure the utilisation is evenly distributed, optimising transport and increasing uptime with preplanned service stops has never been easier.”

HATCON works in conjunction with Epiroc’s cloud-based My Epiroc platform, with users able to log in via computer or smart device either in the office or the field, accessing their data and receiving notifications when it’s time for a service.

Epiroc states that My Epiroc is “a platform developed to be a workflow optimisation

partner, helping users keep track of productivity with relevant alerts and status updates”, with it highlighting the things that require immediate attention.

“Whenever support is needed, My Epiroc users are just a click or a swipe away from remote guided support, finding contacts, or to a transparent overview of all previously reported

inquiries,” Epiroc advises. “It is easy to manage tasks and actions related to the fleet in an efficient way and get the input needed in order to prepare for reporting.

“Data is securely stored in an encrypted cloud environment, which customers can also utilise to upload their own relevant content to create a safe digital fleet library over time.”

HATCON, available factory mounted or as a retrofit kit for premium range breakers and drum cutters, assists with:

• Fleet utilisation – make sure the utilisation of your fleet is evenly distributed, monitoring the position and operating hours of each tool

• Efficient servicing – connected tools mean when it’s time for a service, parts are already prepared to minimise downtime

• Keep track of tools – access the GPS position of every tool using your phone and My Epiroc

• Strengthen anti-theft – in addition to alerts about wear part status and service, the GPS function strengthens your anti-theft system

At Moody Kiddell & Partners, we see your success as our business.

For forty years, we have partnered with the earthmoving industry to provide finance and insurance solutions for your business.

From enquiry through to paid claim, we dig in with you every step of the way.

Call today to see how one of Moody Kiddell’s equipment finance and insurance experts can tailor solutions for your specific business needs.

What are partners for?

Moody

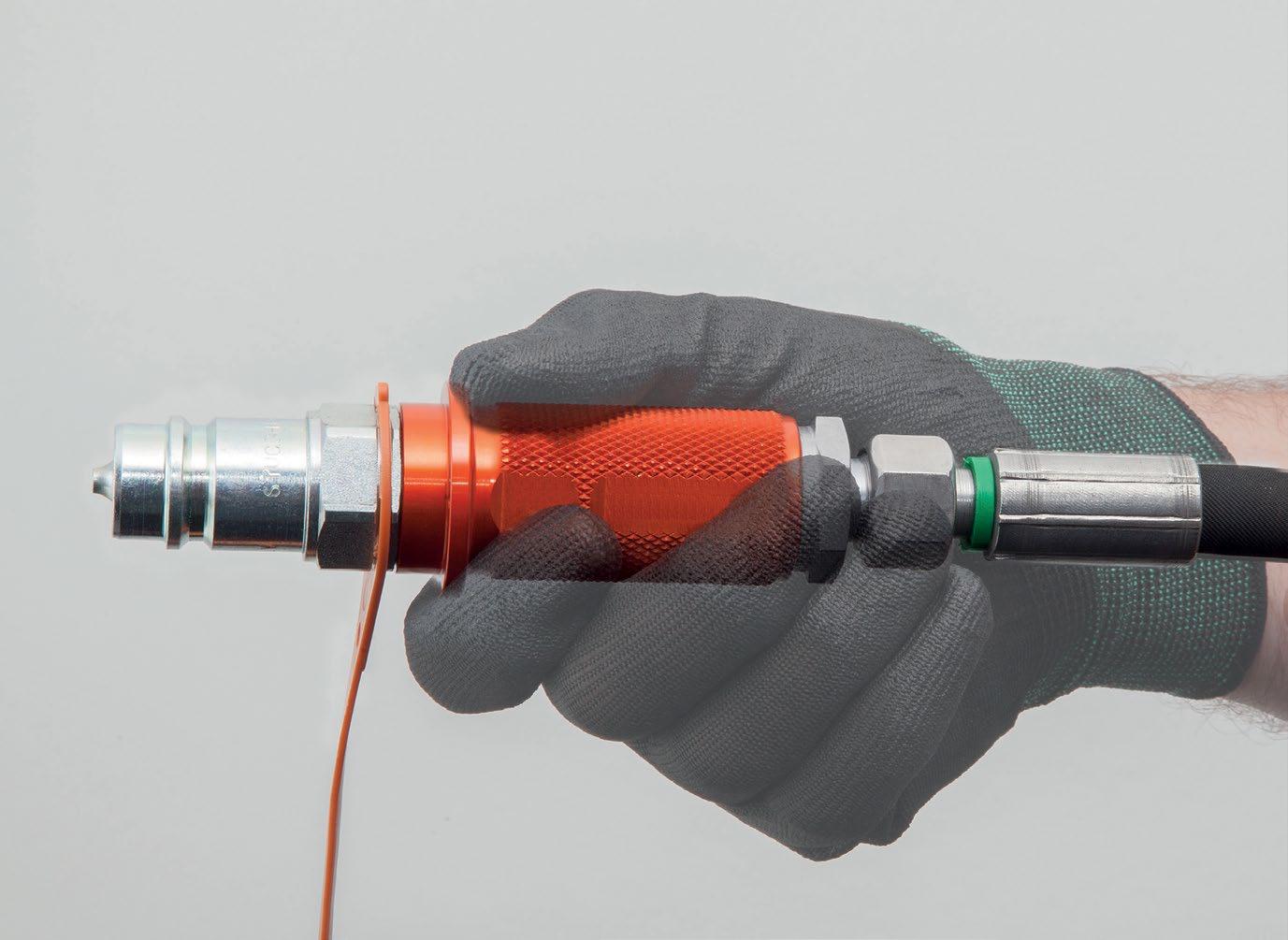

Founded in 1960, Stucchi is today one of the main producers of solutions for fluids connection and control. Stucchi quick couplings, operating up to pressures of 700 bar, are designed and produced in Italy to cover a wide range of applications, thanks to the use of different materials, the numerous sizes and configurations available.

Visit us in Melbourne, Brisbane, Perth and on stucchigroup.com

Bristling with technology and performance features, the new Cat® D4 is the latest in the range of Next Generation track type tractors to reach Australian shores.

Succeeding the renowned Cat D6K2, Product Specialist Sean Ho says the D4 is the latest release to sport the new Cat nomenclature and deliver superior performance with a broad range of features, and options, to help owners extract maximum value.

“The Cat D4 (formerly D6K2) has long been a favourite because of its power, precision and optimised balance for smooth grading performance. The latest D4 takes the value up a level with improved sight lines, reduced operating costs, faster steering response and the broadest choice of easy-to-use technology features to improve machine productivity and efficiency,” Ho said.

“With the new, clear, size-based machine designations we have removed complexity for customers by aligning the D4 in the line-up of recently released machines that now includes the D1, D2, D3, D5, D6 and D11.”

The D4 is available in Standard or Low Ground Pressure (LGP) dedicated configurations.

“A Variable Pitch Angle Tilt (VPAT) blade is standard, with an option for a foldable VPAT blade to reduce transport width,” Ho

said. “This machine is loaded with performance features to ensure work is done quicker, more accurately and with more control.”

The D4 weighs in at 13,272 kg, with a net power of 130 hp (97 kW). D4 LGP has an operating weight of 14,008 kg.

Stable Blade works seamlessly with the operator’s blade movements to help produce a smoother surface, is a standard feature. From here, one can simply add to the D4 platform to best suit their needs.

“Select the optional Slope Assist as a GRADE feature that provides basic blade position assistance without a GPS signal making it ideal for operators needing to create a simple design on-the-go,” Ho added.

Ho said, “Customers can also further up-grade to have the D4 fitted out with a fully integrated, and factory installed, GRADE 3D

(GPS) for automatic blade control allowing to easily fulfill a range of complex designs. Interaction through a large 25cm (10 inch) touch screen display is easy to use – just like an Android OS smart phone.”

“What you will notice is there are no longer blade positioning cylinders used before,

but IMU’s mounted on mainframe and blade structures with antennas in cabin roof eliminating any risk of damage. It will also work seamlessly with blade mounted laser or UTS systems,” he added.

“What is new is the ability to benefit with Traction Control and AutoCarry™ with integrated GRADE 3D offering and work seamlessly with Slope Assist,” Ho said.

“Traction control saves time, fuel and track wear by temporarily reducing track power so the operator can adjust the blade load to limit any track slip. AutoCarry™ automating blade lift to help get more consistent blade loads with each pass,” he added.

“All these features link seamlessly with the hydrostatic transmission to offer the ideal ground speed for the work required.

“Technology smart, the D4 allows operators to be ‘best-in-class’ when working to site plans,” Ho said.

Ho pointed out that a key driver in the new D4 was to reduce maintenance costs by having longer service intervals.

“Customers can expect up to 7 per cent lower maintenance cost as the engine oil/engine oil filter service interval has been extended. Service intervals have also been extended on the air cleaner and Diesel Exhaust Fluid (DEF) pump filter. LED lights offer up to six times the life of halogen to save on parts cost.”

The Cat D4’s Eco modes optimise engine speed, while maintaining ground speed and power to help customers save fuel in lighter blade load applications like finish grading. Other efficiency features reduce engine speed when idling or shut the machine down after a specified time, which also helps to further save fuel and meet idling regulations.

The new cab is key to the customer experience. Inside the cabin, operators will enjoy a new large 25 cm (10 inch) display amongst a raft of features to not only set-up and overview the machines performance but provide some helpful operating tips.

The cab has integrated Roll Over Protection (ROPS) with 15 per cent more glass area and wider for comfort. Now with a steeper forward hood profile, there is 30 per cent better forward visibility to the blade and worksite.

Ho further explained, “A new wider air-suspension seat now has more adjustment settings available, additional storage spaces, new USB jack, 12V ports and combines beautifully with the new touch screen monitor allowing operators to not only keep a sharp eye on the machine’s performance, but work long shifts with reduced fatigue.

“This display also acts as extra eyes for a high-definition rearview camera display – with back-up lines to help guide you,” he added.

Interaction with the new D4 is also more seamless. A Cat App helps you manage the machine’s location hours but also delivers

critical maintenance alerts, while Cat Remote Services allows software updates to the machine wirelessly and with remote trouble shoot to perform remote diagnostics.

“The D4 is ready to maximise your versatility. All in all, this is an exciting new addition to the extensive Cat track type tractor line-up,” Ho said, adding it is “on-track for tough applications while having the ‘smarts’ to help you get the work done accurately and effectively.”

The D4 can also be ordered with specialised guarding to take on the challenges of forestry/ land clearing. In addition to machine protection against impacts and airborne debris, these specialty dozers can be ordered with an impactresistant cab featuring polycarbonate windows. For more information visit www.cat.com or contact the local Cat dealer.

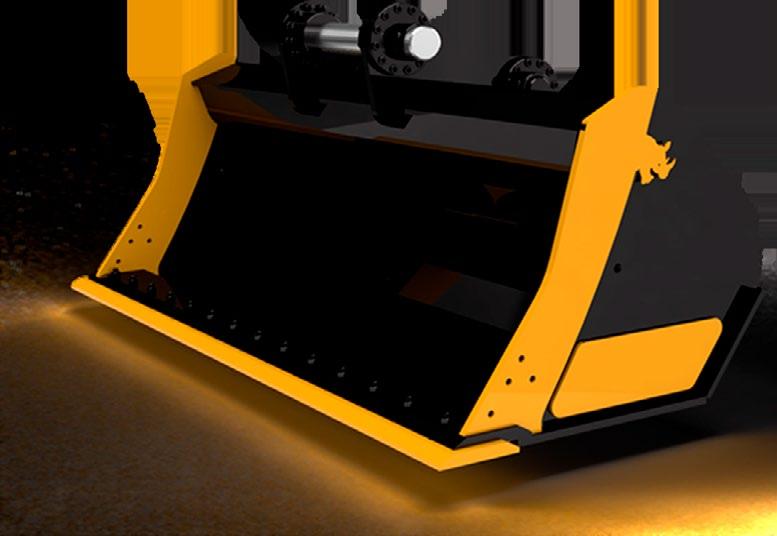

The job site is no place for equipment failure. Rhino Buckets are built to withstand more. Built with Bisalloy® steel, all welds exceed Australian Standards for guaranteed strength and longevity.

Rhino Excavator Attachments are built for the toughest job sites:

+ Rhino buckets were designed, tested and proven over years on the job in the punishing Pilbara. Thousands of kilometers from a replacement, our customers depend on Rhino delivering quality when and where it matters most.

+ Backed by a 2-year warranty and industry-best support - we don’t hide behind legal fine print.

+ Dual Radius Profile on digging buckets stops excess drag on the bucket and offers dramatic performance advantages

Why Gromac Quarries recently chose Cat® Certified Rebuilds for their 980 Wheel Loader and 345 Excavator.

Gromac Quarries is a family owned and operated business in Northern Queensland that specialises in the supply of quality quarry products. They produce concrete aggregates, sealing aggregates, crushed rock, sand and road base pavement materials. Registered with Queensland Main Roads, Gromac supplies and delivers to the Civil, Rail and Road construction industries. The Gromac fleet includes Cat® Wheel Loaders, Excavators and Articulated Trucks – 48 in total.

As the Operations Manager at Gromac, Paul Hooton recently made the decision to order Cat Certified Machine Component Rebuilds on one of their Cat 980 Wheel Loaders and a Cat 345 Excavator. There were many sound reasons for the choice to rebuild. In particular, Paul cites operator familiarity with the current machines as the deciding factor. For Gromac, buying a new machine would have meant additional training for the fitters or the need to bring in more highly trained technicians. As Paul says, “The quarry locations and the Tier 3 engines that we currently have

“We reduced our costs – and rebuilt our way.”

make it more flexible for our fitters to work in remote locations.”

Paul’s Customer Support Representative at Hastings Deering, Barry Searle, worked closely with Giro Samale, Caterpillar’s Aftermarket Service Representative to provide Paul with the optimal rebuild solution.

Giro outlined Paul’s options, in particular the main benefits of a Cat Certified Machine Component Rebuild. As Giro said, “It’s done

Whatever your situation, there is a Cat rebuild solution to suit your business needs and give your Cat machine a new lease on life. For a fraction of the cost of a new machine, a Cat rebuild can return your end-of-life machines, systems and components to like-new condition. You’ll also enjoy the peace of mind of an extended warranty^ with ongoing support from your Cat dealer. The financing options are attractive too, with interest as low as 0% and secured financing for 24 months* for Cat Certified Rebuilds. That’s Aftermarket Smarts.

by the dealership using skilled technicians using the most updated Cat technology with only Cat genuine parts. It incorporates all the latest engineering upgrades that are available to that machine. And you have a factory standard option for extended protection that covers both parts and labour for the duration that you choose.”

Paul couldn’t be happier with the outcome of the machine component rebuilds.

They certainly won’t be the last Cat rebuilds that Gromac undertakes. As he says, “Based on our previous Cat Certified Rebuilds, we’re in talks with our dealer to get component rebuilds done on two 980H Wheel Loaders, and a full rebuild on a 980H Wheel Loader.”

Scan the QR code or speak to your local Cat dealer to discuss a Cat rebuild solution that best fits your equipment and business needs.

*^Terms and conditions apply. See cat.com/rebuilds-au for details.

Komatsu has released a significant update to its intelligent Machine Control (iMC) technology, known as iMC 2.0, that delivers major productivity, efficiency and cost saving advantages to its latest model “intelligent” dozers and excavators.

The new technology is available on the justreleased D71EXi/PXi-24 and D61EXi/PXi-24, D65EXi/PXi-18 and the D85EXi-18 dozers and the PC210LCi-11, PC290LCi-11 and PC360LCi-11 excavators.

iMC 2.0 further advances the automation capabilities of these new machines, with factory integrated enhancements including two multiconstellation GNSS antennas.

These advances significantly enhance iMC dozer operations on slopes, while new-generation iMC excavator hydraulic cylinders incorporate the latest Komatsu stroke sensing technology with a new factory IMU (inertial monitoring unit) sensor attached to the tilting attachment, automating the tilting function.

In addition, iMC 2.0 features all-new “intelligent” high resolution touchscreen monitors, purpose designed for each machine type, that provide accurate displays of machine operating conditions, and the jobsite design.

Operators can customise split-screen views to give themselves the optimum views of what they want to focus on, while an easy-to-use multi-touch navigation system provides realtime information on bulk earthmoving, grading, digging and finishing.

All these combine to ensure greater accuracy and increased response speeds, according

to Aaron Marsh, Komatsu’s National Product & Solution Manager with its SmartConstruction & Integrated Machine Control Division.

“Our new iMC 2.0 products, services and digital solutions incorporate a host of advanced machine technologies – some exclusive to Komatsu – allowing users to integrate sophisticated productivity-enhancing automation and cutting-edge jobsite design into their operations,” he said.

“By applying Komatsu dantotsu (unique and unrivalled) principles, this latest technology

delivers distinct benefits with automated and semi-automated dozer and excavator operations.”

Available initially on Komatsu’s new D71EXi/ PXi-24 and D61EXi/PXi-24, D65EXi/PXi-18 and the D85EXi-18 dozers, iMC 2.0 automatically controls the blade so that it closely follows the target surface, controlling cut depth while avoiding track shoe-slip.

Exclusive features of iMC 2.0 on dozers include Lift Layer Control, and Tilt Steering Control.

With Lift Layer Control, the dozer automatically spreads fill material from existing areas of the worksite with just the press of a button, then measures the terrain it’s tracking over –and using that data to plan the next pass.

“This feature allows the design surface to be created from as-built data, and can cover lift work,” said Marsh.

“Compared with conventional dozing practices, production rates are doubled, plus – because it’s 100 per cent automatic while automatics are engaged – each layer is completely consistent and accurate.”

The one-touch Tilt Steering Control feature frees the operator from having to steer the dozer to maintain a straight heading, by

continuously and automatically tilting the blade as required to maintain straight-line travel.

“This results in greatly reduced operator fatigue and increased comfort, because operator input is reduced by up to 80 per cent compared with a conventional dozer,” Marsh said.

“And straight-line travel guarantees a cleaner cut, along with increased productivity.”

Other features of iMC 2.0 on Komatsu’s latest dozers includes:

Quick surface creation, letting the operator create a temporary design service at the press of a button, allowing the machine to begin spreading or stripping using automatic modes while awaiting finish-grade designs. The operator simply needs to set the elevation, fall and cross-fall, and get to work.

Proactive dozing control, allowing the dozer to perform dozing and carrying tasks by using the as-built data the machine has collected in previous passes – creating a target blade trajectory by offsetting its collected as-built data. This allows the machine to minimise undulations and under-cutting, with work carried out as smoothly and efficiently as if it were being done by a highly experienced operator.

Manual co-ordination control, enabling the operator to manually adjust blade tilt or lift in cases where the actual surface and the design surface don’t match; automatic operations resume once the steering lever is set back to neutral. The system is designed to be flexible enough that the operator can adjust the work/blade positions as required by jobsite conditions.

Faster blade response on grade breaks, letting the operator temporarily increase blade reactivity in transitions between different grade angles, to avoid over or under digging, and maintain high levels of accuracy.

“In addition to these new features, our iMC 2.0 dozers include two integrated GNSS antennas, which are able to receive location signals from GPS, GLONASS, Galileo, BeiDoun and QZSS satellites,” said Marsh.

“They also include a new GNSS receiver control box, incorporating an LTE modem for remote access, and a digital transceiver for GNSS correction information.

“These all combine to ensure higher positioning accuracy due to greatly increased satellite availability, and the ability to work

continuously and accurately regardless of how remote the site is, or where there’s vegetation or in hilly or mountainous terrain.

“Through our automatic dozing capabilities, Komatsu machines equipped with iMC 2.0 technology help make every pass count, from bulk cutting out to final trim work.

“This assists customers to achieve superior production rates and lower construction costs compared with traditional aftermarket machine control systems,” he said.

IMC 2.0 EXCAVATOR

Komatsu’s new PC210LCi-11, PC290LCi-11 and PC360LCi-11 now include iMC 2.0 to ensure even greater productivity gains for end-users.

“The renowned accuracy and automatic grading capabilities of our existing iMC machines has been enhanced with new features that increase ease of operation and finish quality, while significantly reducing cycle times,” said Marsh.

“New automatic features, such as Auto Grade Assist, and Auto Tilt Control let the operator relax and focus on productivity, without having to worry about overdigging.

“These two new features keep the bucket edge precisely on-grade, while increasing bucket fill factors,” he said.

iMC 2.0’s Auto Tilt automatically tilts the bucket to design, then returns it to horizontal to unload, so that achieving final grade is significantly quicker and easier.

“This greatly increases ease of operation on slope and ditch work, automatically limiting

under-digging and increasing bucket fill –making delivering final grade quicker and easier,” Marsh said.

“It’s ideal to use with tilting buckets, particularly when working on slopes, ditches and complex designs.”

The Auto Grade Assist function includes a bucket angle hold feature, which lets the operator select the desired bucket angle, then the system automatically holds this angle through the grading pass.

“This makes final grading and trimming work much much easier, while allowing the operator to manually intervene at any time just by operating the bucket lever function.”

According to Marsh, this feature is ideal for final grading, trimming multi-plane surfaces and detailed sealing applications.

“Komatsu iMC 2.0 builds on our unique sensor technology, incorporating strokesensing hydraulic cylinders and IMU sensors, meaning operators no longer need to worry about over digging,” he said.

“When the bucket hits the target surface, the control function automatically limits and maintains grade with real-time bucket edge positioning, ensuring precise and accurate surfaces that exactly match the design, first time, every time.

“This latest excavator dantotsu technology from Komatsu lets us deliver increased productivity, efficiency and finished quality across a wide range of earthmoving, construction and production applications,” Marsh said.

Komatsu develops and supplies technologies, equipment and services for the construction, mining, forklift, industrial and forestry markets. For a century, the company has been creating value for its customers through manufacturing and technology innovation, partnering with others to empower a sustainable future where people, business and the planet thrive together. Front-line industries worldwide use Komatsu solutions to develop modern infrastructure, extract fundamental minerals, maintain forests and create consumer products. The company’s global service and distributor networks support customer operations to enhance safety and productivity while optimising performance.

Compact machines have been experiencing a major resurgence in Australia over the last 12 months. The demand for used bobcats, skid steers and diggers under 5 tonnes have lifted sales of these assets to close-to-record highs.

At Pickles Industrial they thought this interesting trend required further investigation. They wanted to find out what was driving this demand, and how the current market was reacting to the lack of supply.

A common theme within many Australian industries is supply chain issues. These problems, in part, are a result of the COVID-19 pandemic, which has slowed, and in some circumstances stopped, the progress and productivity of economies. These economies are largely responsible for the production and manufacturing of materials, goods and parts for new machines.

Shipping has been a main contributor to the shortages of parts and machinery, as well as one of the key reasons for the rising costs of goods.

The global shipping container shortage is one reason why many original equipment manufacturers (OEMs), such as Caterpillar and Kubota, are struggling to get their compact machines on board ships for export. This was due to orders for new containers being cancelled during the pandemic, with market recoveries beating expectations.

Port issues in both the US and China have also been slowing trade routes and delaying the availability of ships to move cargo to their necessary destinations. Other incidents, such as the 2021 Suez Canal accident, created a lasting ripple effect, which caused delays and schedule setbacks.

The cost of shipping goods has also increased dramatically. When you combine shortages, price spikes, travel delays, and throw in a rebounding world economy that is hungry to get back to pre-pandemic consumption, the result is a surge in demand with reduced supply. In some scenarios, this has resulted in shipping costs being 25% to 50% higher compared to the same time last year, with shipping between the US and China up an astronomical 350% in some cases.

Due to the exorbitant shipping costs that global trade is experiencing, the prices of new compact machinery have increased

significantly. Dealers are seeing ongoing inventory shortages due to delays from OEMS. For those receiving any stock at all, OEMS have had to increase their prices by 4% to 22% to dealers. For some buyers, this has priced them out of the new machinery market and instead, veered their attention to the used market.

Due to the shortage of new compact machinery and subsequent price increases, the used machinery market has become increasingly turbulent. Auction data from Pickles Industrial shows how prices have changed in the last year alone for near identical compact machinery.

A comparison of Kubota SVL75 Skid

demonstrates how demand is outstripping supply and potentially creating a price bubble.

In September of 2020, for instance, a Kubota SVL75 Skid Steer with 852 hours on the clock sold for $60,000. Fast forward to September 2021, the same model, with 835 hours, sold for $66,000 – a 10% increase. Incredibly, a model sold in November 2021 for $76,500, albeit with only 548 hours on the clock. Nonetheless, sales like these are only pushing the price ceiling further.

The recent sales of Kubota 5T Excavators are another example of the exploding used

machinery market. In August of 2020, an excavator sold for $48,000 with a total operational use of 2759 hours. Six months later, the same model with 50 additional operational hours sold for $52,000.

Chip (or semiconductor) shortages have been plaguing many industries globally. The compact machine market has been unable to avoid the problem with manufacturers like Kubota and Caterpillar warning customers of compact machine supply shortfalls. Materials, too, are adding to the strain of compact machine manufacturing as the price of steel and other raw materials continue to surge. A lot of this is to do with mining outfits getting back to 100% production capacity and catching up with demand due to COVID-19 closures.

Equipment hire companies are one of the industries experiencing the effects of compact machinery shortages.

One business that has experienced the disadvantages of machinery shortages is Orange Hire. The Brisbane-based equipment hire company has a compact machinery fleet size of around 140 5 tonne or smaller excavators and 95 track loaders, most of which are Kubota’s. This makes Orange Hire one of the largest owners of Kubota

machines in Australia. A big part of Orange Hire’s asset goals is to maintain one of Australia’s youngest fleets. This is achieved by selling machinery around the 4-year mark, only retaining assets between 2 to 3 years of age.

This makes Orange Hire an interesting study of the effects current market conditions have on enterprises, both experiencing and contributing to these market variances.

Asset & Disposal Specialist at Orange Hire, Jacob Webber, outlined the company’s 2022 outlook when considering the extreme delays of new equipment.

“As our goal is to keep our fleet young and reliable, the importance of acquiring new equipment as we dispose of older equipment is crucial. However, with OEM’s giving us delivery timelines of between 6 to12 months, we are finding it difficult to align this crossover.”

Jacob spoke of how offloading assets is becoming a tricky situation with such a strong used market currently at play.

“We are finding that the second-hand market is exceptionally positive where we are selling assets for a larger percentage of original cost than what we have experienced over the last 12 to 18 months. I see this as the used equipment market moving in line with the new equipment market, whereby the new price is increasing and that is dragging the used equipment price up with it.”

Due to the demand for hire equipment, buying used machinery has become a part of Orange Hires new strategy, as mentioned by Jacob.

“If we identify a compact machine like a skid steer or bobcat with a short usage life, we’ll look to acquire this asset as we know it will have a high rate of hire. Under usual market conditions this wouldn’t even be a consideration, but as we’ve seen, one must take advantage of the excellent hire demand we’re experiencing.”

The higher costs of new compact machinery have significantly impacted the future direction of the company. As Jacob details: “The costs of new machinery have certainly increased, but this is something we just have to accept. We understand that shipping costs have exploded recently, as have shortages of chips and other components which all contribute to the overall price point. A worry for us, however, is what the second-hand market will look like in 18 to 24 months. Will prices remain strong for us to recoup capital investment? Or will it have come off a great deal once more assets enter the market and demand wanes?”

The compact machinery market has become an increasingly interesting market to follow and one worthy of monitoring over time. Pickles Industrial predicts that the trend for higher priced assets will continue and stabilise well into 2022, due to a fluctuating market that has to deal with chip shortages and shipping constraints..

As an Australian family-owned company with global reach, Tilly’s is proud to stock over 43,000 new part lines for your earthmoving machinery. Tilly’s quality alternative undercarriage range extends from track groups to idlers, rollers, sprockets and track adjusters suitable for dozers up to D9 and excavators up to 30 tonne.

Tilly's are pleased to now offer a range of quality low-hour machines including General Construction Excavators and Loaders and D6-D8 ex-United States machines.

Tilly's is now offering account customers online ordering of over 30,000 parts for even quicker turnaround time, because we understand that down-time for your machines has a huge impact on your bottom line. That’s why we guarantee the quality of our new parts to ensure you are staying on track.

Finance is essential for the success of any business. As a new calendar year approaches, the finance specialists at Moody Kiddell & Partners have drawn up a checklist of key factors you should consider while planning to achieve your growth aspirations for 2022.

Financial expertise and product planning can give your business the flexibility it needs to plan and generally expect growth, with the right foundations. Whether you are looking to grow your business or to continue to fund current operations, it’s always good practice to have additional finance approvals available to capture new opportunities and cover your working capital. This knowledge will allow you to bid with confidence for machinery that allows you to tender for the larger job contracts. Reach the stronger position of a planned growth mindset to explore capital purchases before the opportunities occur, rather than rushing with a reactive approach.

Have you looked at an excavator with a specific attachment or needed to place a large stock order for pipes but been unsure of the cashflow required? Asking ‘what do I need to facilitate those orders to happen seamlessly?’ is a question better asked sooner rather than later. Finance foundations allow you to know what you can do to achieve your growth aspirations and goals. Have the figures sorted so that you can engage with the opportunities in the market as well as having the peace of mind to tackle them with your team.

Every business is different, and it is important that the finance you obtain is suited to your specific circumstances. At Moody Kiddell & Partners, they tailor their financial products so that you can access the finance your business needs to achieve its growth aspirations. They do this by working efficiently through these key factors:

• Debt horsepower or diversity with current lending partners

• Pre-approval of your financed amount

• Funding and debt requirements

• Knowledge of the balance sheet

• Borrowing capacity

• Key financial trends relevant to your business

• Financial ratios (interest cover, leverage, debt)

A detailed evaluation of your business’s financial position will give you a clearer picture of your financing needs, including your appetite for risk, opportunities for appropriate leverage and capital expenditure.

Your business may be capable of expanding faster than you originally expected after gaining accurate financing limits and pre-approvals.

MKP EQUIPMENT LINE: PUTTING YOUR EXISTING EQUIPMENT TO WORK

MKP Equipment Line is their financing tool tailored to the needs of clients for products including earthmoving, truck buckets and more. By aligning your existing plant and equipment closer to their true effective life, MKP Equipment Line can strengthen cash flows, build opportunities for growth, and uncouple your personal assets from your business.

MKP Equipment Line borrows against the true working value of your assets to unlock additional equity in your business. This results in lower monthly financing payments, allowing you to purchase new equipment and fund business improvements, while giving you the flexibility and peace of mind that stronger cash flows provide.

MKP Equipment Line also gives you the confidence to tender for new and larger contracts and finance business critical items including:

• Light commercial vehicles

• Trucks and trailers

• Earthmoving and mining equipment

• Arbor and woodworking equipment

Earthmoving Contractor boosted cash flow by using existing equity in plant and equipment.

A well-established (15yrs+) civil earthmoving contractor required finance of $1,050,000 over 48 months. MKP assisted with the goal to provide working capital, secured against business plant and equipment to allow a much larger pipeline of work. Their client was seeking a facility from a financier who understood the true value of the equity in their well-maintained earthmoving equipment, including excavators, bulldozers, graders, water trucks and wheel loaders.

“It’s been my pleasure to build such a strong partnership with Moody Kiddell & Partners since 2001. I call it a “partnership” because it feels like they have been there every step of the way. They are a “One Stop Shop” that every business needs to service all their financing requirements. The systems, processes and most importantly THE PEOPLE make the whole experience SIMPLE and EFFECTIVE.”

K Kassira | Director, KK Civil EngineeringAs is the case with many earthmoving contractors, the largest asset in this client’s business is the equity in their plant and equipment, and they were looking to leverage this equity to reinvest back into the business. Cash flow mismatch is a common challenge facing many civil and earthmoving contractors when commencing new projects. It is magnified for contractors by the requirement that they also pay bank guarantees and retentions up front. Traditionally, contractors have established and utilised facilities such as an overdraft to plug this working capital gap. Mainstream financiers will typically secure such a facility with a GSA (general security agreement) over the trading and asset holding entities within a group structure, in addition to obtaining mortgages over the residential and commercial properties held by company directors.

MKP have developed a credit product that recognises the true equity in a contractor’s plant and equipment. Leveraging against this value, they were able to create working capital to help the business grow, while giving the customer the flexibility of stronger cash flow and peace of mind by

uncoupling owners’ and directors’ personal assets from the business. The payout figure for these assets was $550,000, and when evaluating this against day one, 80 per cent advance of orderly liquidation value, MKP Finance was able to provide the directors with a working capital

payment of $500,000 into their business bank account. The amount financed was $1,050,000 ($550,000 payout to financiers and $500,000 paid to the business as working capital). The loan term was 48 months, with no end-of-term balloon. In this new finance facility, the client’s monthly payments were equal to their repayments on their existing facilities, with the added benefit of having $500,000 of working capital available in their bank account.

At Moody Kiddell & Partners, they pride themselves on building long term partnerships with their clients. Your success is their business, and in every step of the relationship MKP invest their core values of Integrity, Service and Performance.

Make sure your business has sufficient working capital over the holiday break or secure your project pipeline with access to the right finance facilities to meet your business goals.

Expert knowledge. Immovable support. That’s what it means to be Partners with you.

Get in touch today for a no obligation discussion to finance your next purchase by calling 1300 000 657.

Since 1981, Moody Kiddell has partnered with Australian businesses, providing finance, insurance and advisory solutions. With four decades of multi-industry experience, we offer businesses the tailored service business owners need to achieve their vision and safeguard its legacy.

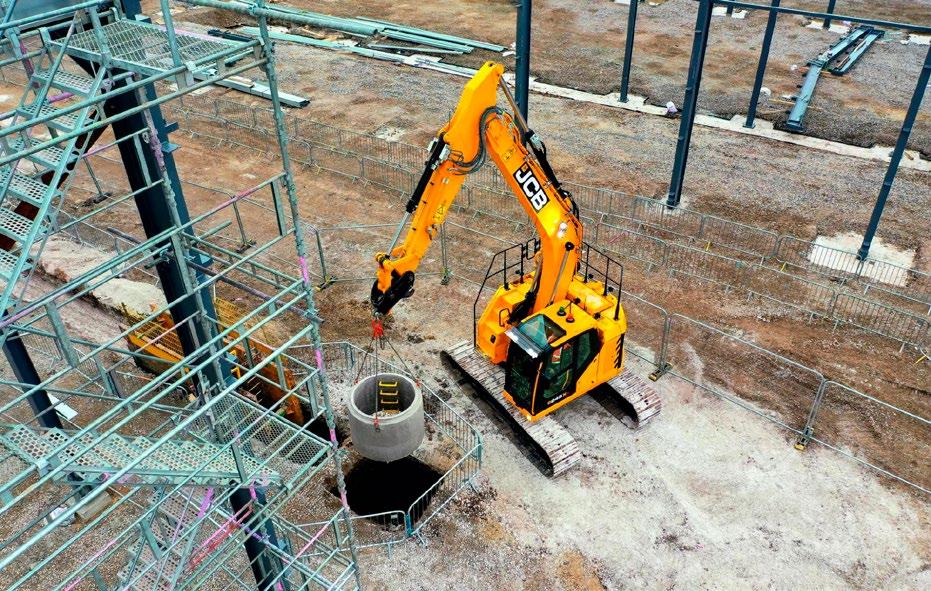

Civil and electrical infrastructure company TOBCO has enjoyed significant growth since its establishment a little under a decade ago, with the New South Wales-based business – which has a particular expertise in utility infrastructure, and which prides itself on being a hands-on, self-performing contractor – operating across New South Wales, Queensland and Victoria.

Civil engineers Glen O’Brien and Sam Turnbull started the business in 2013, drawing on a combined 40-plus years’ experience in the industry (with both having held senior positions for tier one construction companies), and have since presided over the expansion of its operations, with TOBCO undertaking small-to-medium-sized construction projects of up to $50 million in value.

TOBCO Civil Construction Manager Ruan van der Merwe told EEM that TOBCO – which is an ASP and RMS pre-qualified principal contractor for the New South Wales electricity distribution network – currently has five main capabilities that it operates in, encompassing the civil, utilities, maintenance, traffic lights and renewables sectors.

Ruan, who as a civil engineer has been working in the construction sector in South Africa and Australia for the last 13 years, said that TOBCO “possesses the experience, staff, accreditations, equipment and reliable contacts necessary to provide a complete EPC contractor service”.

“TOBCO’s fleet comprises over 150 heavy earthmoving plant, specialist civil construction equipment, vehicles and field staff,” he explained. “Owning their own plant

and operators allows TOBCO to control time-delayed risk to ensure the successful completion of client projects.

“In particular, TOBCO undertakes electrical works on over-ground and underground electricity cables, communications installations, electrical power transmission and distribution infrastructure and substations, street and highway lighting, gas supply, water

supply, wastewater, sewerage and storm drain infrastructure.”

Ruan emphasised that TOBCO’s capacity to self-perform most aspects of a project, meaning it does not have to subcontract the majority of its work, helps it to stand out in the market, with it having a range of resources to draw on, along with diverse construction industry experience across both public and private project delivery.

With this foundation in place, TOBCO has been actively involved with varying civil engineering, electrical infrastructure, construction and maintenance works, and is currently undertaking a number of projects.

Among these projects, TOBCO is engaged as the principal contractor for the Namoi River Crossing Project, in Manilla, New South Wales, being undertaken for Tamworth Regional Council, involving the design and construction of a new bridge located approximately 450m upstream from the existing heritage-listed Manilla Bridge.

TOBCO is also working on the New England Solar Farm roadworks, in the Uralla Shire, New South Wales, constructing all access roads for the facility, along with working on various bridges for the Walcha Council, Armidale Regional Council and Tamworth Regional Council.

In addition to this, TOBCO has been undertaking ASP works for several clients in and around Sydney, and overhead electrical works for several councils in New South Wales.

“We have been extremely busy this year, especially in the civil business,” Ruan told EEM. “We have a great order book, and enough work to keep our resources busy until at least the end of the year.”

Assisting its operations, TOBCO has recently installed a number of Leica iCON systems across its fleet of graders, dozers and excavators, utilising the services of C.R. Kennedy, the sole Leica Geosystems distributor in Australia.

“TOBCO are currently using two Leica iCON iGG3 grader systems, a Leica iCON iGD3 dozer system and also a Leica iCON iXE3 excavator system,” C.R. Kennedy Sales Representative, Joshua Smith said.

“They also have an iCG70T tilt GPS rover, which is being used as a foreman’s kit (mounted to the vehicle) and as a rover on a pole, and are utilising an iCG60 base station

with a high-powered UHF radio to achieve GNSS corrections for millimetre accuracy.”

The iGG3 grader system brings design surfaces and alignments virtually inside the cab, providing millimetre-accurate control of the blade, making it ideal for fine-grading applications, with it featuring:

• Auto/manual information directly on the screen

• Fully customisable 3D views of the machine and jobsite

• Design and actual slope always displayed

• Multiple run screens to choose from

The iGD3 dozer system also brings design surfaces and alignments inside the cab, allowing operators to work independently and accurately anywhere on the project design, guided by GNSS or a total station, featuring:

• User-selectable views (e.g. Plan View, Cut & Fill View)

• Visible display screen, even in sunlight

• Remembers all your settings

• Scalable from 2D to full 3D capability

• Create a reference surface with up to four slopes

The iXE3 excavator system is designed to guide the operator using reference models and GNSS in 3D, with design information and real-time cut/fill indications displayed in the cab on the control panel, with it:

• Allowing the operator to rapidly excavate to the reference design, ensuring more uptime and operator satisfaction, while increasing safety and productivity

• Work with a wide range of popular data formats, including the LandXML, DXF, GEO, KOF, L3D, LMD, LIN, MBS and TRM formats

• The operator can use the function “Create Model” to make even complex models directly on the panel without leaving the cab and without the assistance of a surveying engineer

Ruan told EEM that “so far, the products have been great and user-friendly”, noting that one of the primary reasons TOBCO had chosen to utilise C.R. Kennedy is due to the level of service support provided.

In addition to technical support and training, helping businesses to unlock the full potential of their equipment, C.R. Kennedy’s national after-sales service network includes service and repairs support, hire equipment and customer care agreements.

Joshua said that TOBCO’s investment in the Leica range of solutions marks the beginning of the two companies working together, with C.R. Kennedy at the ready to provide the product support required as TOBCO taps into the various benefits of the range.

“Our relationship is only new, around three months old,” he commented. “But they have invested heavily in Leica machine control and are expanding rapidly.”

The key to keeping your plant and equipment in good working order is an effective maintenance schedule. Good maintenance has plenty of benefits. It maximises capital expenditure and return on investment (ROI). It saves time and money by minimising downtime and ensuring reliable service to staff, customers and consumers.

NTI’s Mobile Plant & Equipment Risk Engineer, Hayden Reed, says “maximising ROI depends strongly on good maintenance. If a vehicle or other equipment is unusable, it can’t generate revenue; it’s a cost.”

“Maintenance is a way to maintain a certain function of an asset whilst also maximising the residual value of the asset. It’s essentially just a mixture of those two functions.”

Maintenance is an investment, not a cost. Skimping on maintenance can lead to unpredictable failures and revenue losses.

Costs are incurred as the equipment wears. Resetting to a ‘cost per hour’ format enables

Clean

• Is your equipment cleaned regularly?

you to have a deeper understanding.

Managing maintenance costs is vital to your long-term success. Trying to minimise maintenance costs will most likely result in higher Total cost in Ownership (TCO). Aiming to achieve the lowest cost per hour over the entire life of the asset should enable you to make a long term view of expenditure.

• Is this cleaning done within enclosures as well as externally?

• If not, what would you have to implement to achieve this?

• Does your usage create further risks e.g. in forestry or coal handling?

Lubricate

• Are you using the lubricants recommended by the manufacturer for your operating environment or climate?

• Does your equipment get lubricated sufficiently?

• Does your application require more frequent attention than the OEM baseline?

Adjust

• Is your schedule for adjusting equipment frequent enough to identify problems before they cause damage?

• Are the staff conducting these tasks trained and competent in what to look for and how to adjust?

• Are the specifications used aligned with OEM guidelines?

Inspect

• Do you have a schedule of different inspections performed by trained and competent people?

• Is your daily pre-start inspection specific to the exact equipment (e.g. model and specification) used?

• Are your people empowered to identify and raise issues during inspections?

Repair

• Do suitably experienced and qualified persons undertake your repairs?

• Have you discussed your equipment requirements and maintenance strategy with my maintenance provider?

• Do you have a process to identify and repair all faults before breakdown?

Clean: it’s easier to identify potential faults on clean equipment (and it’s less likely to catch fire or break down. It’s a simple, low-cost practice that also presents your business to clients in a positive light.

Lubricate: most modern equipment no longer requires continuous lubrication. However, it remains critical to keeping your equipment in good condition. If lubrication is inadequate, damage will be almost instantaneous, and it can dramatically reduce the equipment’s operating life.

Adjust: it’s vital to maintain adjustment of components within manufacturer specifications. Doing so will prolong service life and reduce running costs

Inspect: inspections (by experienced and observant personnel) can prevent breakdowns. Arguably the most important of these is the equipment operator’s daily pre-start inspection. Further inspections are best carried out by skilled maintenance personnel at scheduled services to identify any pending issues.

Repair: repairs are best undertaken by experienced maintenance personnel with a thorough knowledge of the equipment, as they will be able to advise the most cost-effective solutions. A structured repair process ensures that all maintenance issues raised are planned and completed before the machine breaks down and further damage is done.

Want more from Australia’s leader in mobile plant and equipment insurance? Visit www.nti.com.au/yellowcover for more information.

Simulators aren’t new to the training world. The first time I had a crack at one was 20 years ago at a mine site in the Hunter Valley, it was pretty cool. Simulators are a tremendous tool for introducing industry operators to a new piece of equipment in a safe, stress-free environment, without impacting production. The evolution of simulators now sees them having the ability to benchmark experienced operators against recommended OEM techniques with the intended outcome of not only having a productive operator, but also one that’s exercising machine health.

One of the most exciting training aids that has dropped onto the scene in recent years is Virtual Reality (VR). To have the ability to totally immerse an operator into a world where everything feels like it’s at their fingertips, still blows my mind. VR by far is a technology that I think will pave the way for operator training into the future.

I recently caught up with Chris Nolan, Account Manager and Design Specialist at Simformotion, the licensee for Cat® Simulators for Caterpillar Inc. for over 13 years, making them Caterpillar’s oldest heavy equipment simulator licensee.

With models for mining, construction and forestry, the product line is vast with more in development. Full simulators feature convertible controls on the same base unit, motion systems, cab seat with working seatbelt, and multi-screen configurations. Save space or cross train with conversions. Compact models are also available for socially distanced stations. Both set-ups include authentic Cat controls and the option for VR edition.

According to Chris, what sets Cat Simulators apart from other brands are the authentic Cat controls and other Cat differences. By using the same genuine controls as found in the actual machine, the operator can make a seamless transition to the field. Each simulator is developed with Caterpillar operator experts, so applications match those found on the real machines. Learners will experience consistent training in the safety of the virtual environment, knowing they are learning “the Cat way”.

Besides working with Cat experts during simulator development, Simformotion also provides training and support for customers. Trainers will work with customers via live stream or arrive onsite. Technical support is available 24x7. Plus, Cat Simulators offers SimScholars™, an online curriculum for a blended learning program in the classroom or for remote learning.

Keen to find out more of what Simformotion can offer your business? Head on over to their website –www.simformotion.com or check out www.catsimulators.com

The Doosan DX140LCR-5 machine builds on Doosan’s enviable reputation for hardworking, reliable and comfortable machines, with this next generation model offering an exceptionally powerful DPF-FREE TIER 4 FINAL engine.

By complying with US Tier 4 regulations, the Tier 4 Final DX140LCR-5 will have no issue operating on jobsites with Tier 4 emission standards - helping future-proof your investment. And with no DPF (Diesel Particulate Filter), you will avoid the maintenance issues experienced by other manufacturers - from time consuming regeneration cycles to expensive DPF servicing issues. This makes the Doosan DX140LCR-5 one of the most productive and reliable machines in its class.

Hosted and presented by International Greenkeepers. Sydney Dragway, Ferrers Road Eastern Creek.

Plenty of free parking, refreshments and lunch included. Seminar starts 7:30 am finishes at 1:00 pm, followed by guided visit to exhibitors at the 2022 National Diesel Dirt & Turf Expo. If you work in public space or grounds maintenance planning or construction, you can’t affor to miss this free seminar. Learn about the latest techniques, processes and equipment from some of the industry’s leading professionals.

Register now at www.dieseldirtandturf.com.au/free-training-seminar/

Key Speakers include:

Peter Kirby: Industrial herbicide options in the current climate. Peter has worked within the turf and ornamental industry in both commercial and technical roles for 19 years, holding positions with Nuturf, NUfarm, Bayer and Adama.

Steven Jacobson: Will present a session on solving slope and grounds maintenance problems. Steve has previously been a golf course greenkeeper and superintendent.

Toby Clarke: International sales director for Dennis mowers and Sisis equipment. Vertical action aerators, hyrdraulic driven scarifiers, self propelled scarifier and de-thatcher and drum aerators.

Albie Legget: from Australian Lawn Care speaking on disease management. Albie has 30 years sports turf industry experience, He is a qualified greenkeeper and golf course superintedent, holding a master’s degree in agriculture from the University of Sydney and involved in technical research

Ben Gibson: Building a great safety culture through effective leadership. Ben appears on industry podcasts and national Turf Association magazines and a speaker turf industry events in Australia, Asia, New Zealand and the US.

and James Evins of John Deere: Will speak about advances in smart technology and business lessons from the age of coronavirus.

Other program presenters include Matt Goodbun and Michael Parsons on the topic of top dressing and line marking, Bob Paddison from Turf Drain Australia, Weed Technics, Repco, and International Greenkeepers.

Seminar enquiries: Daryl Davidson 0406 942 363 or Damien Curtis on 0475 514 279 or email internationalgreenkeepersfh@gmail.com

Stephen Foster

Nepean Mini Excavations (NME) has been providing excavation and earthmoving services around western Sydney for the better part of seven years, with Managing Director Dale Warwick stating that while the locally owned and operated business started out small, it has since carved out a strong niche for itself in the area.

Dale told EEM he had originally started with a small truck and a mini-excavator, and has steadily built his fleet as the business, which primarily provides excavations for concrete and fibre glass swimming pools, has grown over the years.

Dale, whose experience in earthmoving and excavation stretches back 15 years, said he had long harboured an ambition to start his own business.

“I knew that that’s what I wanted to do,” he commented. “I started working for some old bosses and contacts that I had, and then things really just snowballed from there.

“I bought an additional excavator, and a small posi-track, and then after that I bought another excavator and another posi-track. I now run four trucks, four excavators, two posi-tracks, four mini-dumpers, and every attachment you can think of pretty much.”

Dale told EEM that in addition to pool excavations, NME provides a range of earthmoving services, working on jobs both big and small, with it currently undertaking a sandstone block retaining wall project worth $300,000.

When it comes to his approach to work and ensuring customer satisfaction, he said he prides himself on being a perfectionist, and won’t sign off on a project until it has been completed right down to the smallest detail.

“I am the fussiest human I know, you ask the boys who work for me,” he commented. “If it’s not perfect, it’s not good enough. Every job needs to be done as if I was doing my own backyard at home. If it’s not to that standard, then the job’s not finished.”

Machines that are robust and reliable are needed to both power through jobs efficiently and help maintain high work standards on site, with NME having recently added a couple of C&F Traker T60HT mini-dumpers to its fleet.

Dale described them as being no-frills, wellconstructed machines, which can be relied upon to get the job done.

“They seem to be significantly more robust than the competitors’ machines,” he commented. “Like they’re stronger and should last longer because they look and feel like they are better built, with stronger parts.”

Dale said the main motivation behind the purchase of the T60HTs is his relationship with Sydney Trucks & Machinery (STM), which offers a range of new and used trucks and machinery, along with an extensive inventory of spare parts.

Family-owned-and-operated STM has provided Dale with a range of equipment since he started NME, complemented by after-sales services when required.

“I’ve bought multiple machines and trucks through STM over the last six-and-a-half years,” he said. “Nothing’s ever a problem, and if there is an issue they sort it out. If I need something they make it happen straight away.

“To be perfectly honest, the reason I bought those T60HTs is because STM are close to my area, and I know them and get on with them very well,

and if something goes wrong, they’ll fix it on the spot.”

In addition to this, Dale’s fleet also includes a number of Kobelco excavators, also purchased from STM over the years.

“I love the Kobelcos because their warranty is as good as anybody else’s, and they never, ever question anything, as far as the warranty goes, if something was to go wrong,” he commented.

“I’ve never had anything, any major failures in six-and-a-half years. They’re quieter than most other machines, and they are better on fuel than most other machines, and they’ve got more than adequate power to get the job done.”

Dale told EEM that “business has been fantastic” over the past year, with NME having been kept busy throughout 2021 working on a range of projects, with there being no signs of things slowing down any time soon.

In fact, building on the momentum of the previous 12 months, he noted that 2022 is also shaping up to be a busy one, with around 60 per cent

of NME’s work made up of excavations for concrete and fibre glass swimming pools.

“With COVID and people not being able to go overseas or away on holidays, a lot of people are spending money at home, renovating and putting pools in, so they can swim at home over the summers,” he said.

“The year ahead is also looking like it’s going to be fantastic. Work and the business is going as well as it ever has.”

Designed for construction, landscaping, agriculture and gardening applications, the T60HT has two electric starter engine options (a 6.3 kW Honda GX270 petrol engine, or 4.9 kW Yanmar L70N diesel engine), and can carry loads up to 550 kg.

Weighing in at 510 kg (empty weight), it additionally features:

• Versatile high-tip system – a maximum tipping height of 1.42 m

• Hydrostatic transmission – 4 km/h travel speed, dual lever direction control

• Hydraulic system – three-stage hydraulic power

• Narrow undercarriage for easy site access – The undercarriage is 680mm which allows the mini dumper to operate in tight access operations along with 180mm rubber tracks with tensioner, and three rollers with smooth drive rocking system

• Operator platform – folds out for use

C&F TRAKER T85HT MINI-DUMPER FEATURES

The T85HT can be put to use across heavy duty applications, with it having two electric starter engine options (an 8.7 kW Honda GX390 petrol engine, or 7.4 kW Yanmar L100 diesel engine), and is capable of carrying loads up to 700 kg.

Weighing in at 600 kg (empty weight), it also features:

• Versatile high-tip system – a maximum tipping height of 1.42 m

• Hydrostatic transmission – 5 km/h travel speed, mono-joystick direction control

• Hydraulic system – three-stage hydraulic power

• Narrow undercarriage for easy site access – The undercarriage is 780mm which allows the mini dumper to operate in tight access operations along with 180mm rubber tracks with tensioner, and three rollers with smooth drive rocking system

• Operator platform – folds out for use

For almost half a century, STM has made it possible for businesses across NSW to power up – supplying and servicing quality trucks and machinery to meet the demands of any job.

Starting out in a single shed in the 1970s, we know what it takes to build a business – and are passionate about helping you grow yours. Today, our family owned and operated enterprise is proud to offer a multi-site, modern service, with a team of more than 120. We care about giving every customer the best experience possible – with a wide range of trusted brands, flexible finance, spare parts, repairs and personal service.

We may have come a long way from that shed, but our family commitment to quality remains. Whatever your size, whatever your budget, STM is your one stop shop – with everything to keep your business moving.

Starting, building and reporting on your communications plan is a critical part of any marketing strategy, but many businesses, large and small, forget to take the right steps in order to get the right plan in place for your communications activities.

To get started on your comms plan, there are three main steps to take to set you up for success:

Take some time to sit back and get really clear on what you want to achieve. All of the activities you ultimately build into your plan should work towards achieving that goal. The goal could be to launch a new machine, build brand awareness, advocate for a government change of policy, generate more sales leads etc. It could be quite broad (build brand awareness) – or quite specific (launch X product on X date). But most of all, remember to make your goal SMART– Specific, Measurable, Achievable, Realistic and Time Bound.

Complete your due diligence. Gather all the insights and resources you can. In particular you want to be really clear on who your customer is and what you want to communicate to them. It might help to ponder these questions:

• Who is my target audience?

• Who influences my target audience?

• What channels do I have access to?

• What are my competitors doing?

• What communications activities have worked well (or not) in the past?

• What connections, events, expos, field days, sponsorships and other communications related activities can I build on/leverage?

You have to be brave enough to actually own your results. Don’t just put things out there in the world and then forget about them, or worse, hide from any poor results. Right at the start you should be thinking about what success will look like and how you will measure

it when the work is complete – finding clear benchmarks and setting achievable KPIs will set you up for success.

Stuck on pulling together your comms plan? Don’t worry, get in touch with us today and we’ll help you on your communications journey –hello@hc.net.au

Whether you’re digging deep or aiming high improved Castrol RX SUPER has always got your back. Upgraded CJ-4 specification combats soot and gives critical moving parts a tougher protective layer. New DuraShield BoostersTM giving up to 40% better protection against wear*. Improved Castrol RX SUPER - the versatility that always gets the job done.

When Western Australian iron ore miner Fenix Resources was looking to improve efficiency and productivity at its material handling and ship loading facilities, the Cat 982 Next Generation Wheel Loader proved to be a smart investment.

Fenix Resources does things a bit differently to the major iron ore miners in Western Australia.

For one, the company’s Iron Ridge mine is “boutique” compared to other, larger mines. But what Fenix doesn’t have in quantity, it makes up for in quality, with Iron Ridge hosting the second highest grade iron ore resource in Australia. That allows the company to export DSO (direct ship ore) product without significant processing requirements.

Iron Ridge is also one of the only operating mines in the Weld Range, located in the Murchison region or WA’s Midwest. That means transport infrastructure is limited to roads, requiring Fenix Resources to truck its ore 490km to the nearest port at Geraldton, which is managed by the company’s joint venture transport operator, Fenix Newhaul.

Once the ore reaches Geraldton, it is offloaded at Fenix’s dedicated materials handling and port storage shed before being loaded on to ships every 14 to 18 days.

Fenix Resources also helped establish and engage the services of Schwarze Brothers, an indigenous-owned and run materials handling company to manage material handling at the port. The company is run by four brothers, all loader operators, who are members of the Wajarri Yamatji community, Traditional Owners of the Weld Range region in which Fenix operates.

According to Fenix Resources Managing Director Rob Brierley, the ship loading activity becomes quite frantic, with each ship carrying some 60,000 tonnes of ore.

“It’s a continuous cycle of mining and trucking 24 hours a day, seven days a week,” Rob says.

“When a ship comes in, we operate continuously over about a two-day period with wheel loaders in our storage shed loading material into hoppers that go out to a series of conveyors and on to the ship.”

Part of Fenix’s commitment to Schwarze Brothers was to supply equipment, with an agreement to transition machine ownership to the fledgling company over a three-year period.

After consultation with WesTrac, which has a regional branch and major workshop in Geraldton, Fenix and Schwarze Brothers settled on the Cat 982 Next Gen Wheel Loader as the model of choice and placed an order for three machines.

While delivery was anticipated to be quick, COVID-led shipping delays resulted in a two-month delay.

“We let WesTrac know about the urgency to deliver the machines and they were as frustrated as us about the delays,” Rob said.

“But they helped us to source hire loaders and did their best to expedite the delivery of our new loaders in as timely a fashion as they could.

“They arrived in November and were put straight to work at the Port.”

According to Schwarze Brothers co-owner and operator Matchum Schwarze, the wait was worthwhile.

“These are the best machines we’ve been in,” Matchum said. “They are easily the smoothest and they’ve got the power we need to get through the work.”

That includes running the three loaders almost consistently for 30 to 40 hours while ships are in port, with the four brothers rotating shifts until loading is complete and potentially running each machine for up to six hours without stopping.

Features on the new Cat 982 are evident across all areas of efficiency, productivity and operator comfort.

“The first thing you notice is the space when you get into the cab,” Matchum said. “And it’s a lovely, smooth ride.”

Joint owner and operator Dwight Schwarze says the auto set tyres function provides a considerable benefit.

“When you enter the pile, the machine automatically provides a lift bucket command in a split second which stops the tyres spinning,” Dwight says. “It keeps the floor clean, helps with the digging and saves the tyres.”

The brothers also say dust ingress into the cab is eliminated, which is an important factor when working inside the shed.

Rob admits that fast loading is one of Fenix Resources’ top priorities and the Cat 982 Next Gen Wheel Loaders, coupled with the Schwarze Brothers’ operational skills, are ensuring that is occurring.

“When a ship comes in, I like to see it leave as soon as possible,” he says. “These guys are really hard workers and their primary objective is to work safely and efficiently, but quickly, so they couldn’t be happier because they get to spend hours and hours in these brand new, exceptionally productive and efficient machines.”

The Cat 982 Next Gen Wheel Loader also incorporates a range of innovative fuel efficiency and safety technologies, while maintenance times and costs are reduced

thanks to extended fluid and filter change intervals, convenient access to hydraulic and electrical service centres and the ability for dealers to run remote troubleshooting to help diagnose problems quickly.

Fenix hit a major milestone in November 2021, shipping its one millionth tonne of ore from more than 1.2 million tonnes mined. With an expected mine life of six years, and the iron ore price recovering from recent lows, the Cat 982 Next Gen Wheel Loaders undoubtedly have many hours of hard work ahead.

But neither Fenix Resources nor Schwarze Brothers are concerned, because that’s what these productive, efficient and intuitive machines are built for.

For more information on Cat Next Gen Wheel Loaders, visit westrac.com.au