Price $7.95 inc GST Feb/Mar 10 Price $9.95 inc GST APR/MAY 2022 APRIL / MAY 2022 CASE STUDIES EYE ON THE INDUSTRY INNOVATIVE PRODUCTS TEST DRIVES INSIDE: 100+ PAGE DIESEL DIRT & TURF SUPPLEMENT SEE THE VERY LATEST: Earthmoving machinery, Earthmoving attachments, agricultural machinery, mowing equipment, trucks, boats, bikes & more! EVERYTHING IN ONE PLACE! GOLD SPONSOR EVENT PARTNER ® Friday 15th, Saturday 16th, Sunday 17th May 2020 AUSTRALIA’S LARGEST CONSTRUCTION EQUIPMENT EXPO Friday 8th, Saturday 9th, Sunday 10th April 2022 SYDNEY DRAGWAY FERRERS RD, EASTERN CREEK

MEET THE TEAM: EC140E 14,390 kg / 89 kW BIG ENOUGH TO TRUST Visit cjd.com.au for more information or call 1300 139 804 | enquiries@cjd.com.au precision digging EC220E 21,700 kg / 128 kW EC250E 26,460 kg / 159 kW

Volvo EC250E

Marino Excavations Volvo EC250E excavator paired with Volvo's Dig Assist makes light work of any job throughout Cairns and across the far North Queensland region.

Primed for productivity, the EC250E achieves precise and premium performance through a quality Stage V engine system and smart technology. Delivering the ultimate combination of high productivity and low fuel consumption.

CJD Equipment and Marino ExcavationsPartnering for the long haul.

Images are for illustration purposes only.

“Apart from being a very sleek machine, the smoothness of operation with the Volvo excavators is the best out there.”

- Grant Marino, Owner – Marino Excavations, Cairns

SMALL ENOUGH TO CARE Find us on Facebook, LinkedIn and Instagram

every time.

EC300E 26,460 kg / 159 kW

BIG ENOUGH TO TRUST SMALL ENOUGH TO CARE Visit cjd.com.au for more information or call 1300 139 804 enquiries@cjd.com.au | Find us on Facebook, LinkedIn and Instagram Bonus upgrade to 3 year/6000 hour warranty offer is valid for every new 14-30 tonne Volvo excavator purchased between 1st March 2022 and 31st August 2022. Offer available on Volvo excavator models EC140D, EC140EL, ECR145EL/ELD, EC200EL, EC200D, EC220D, EC220EL/ELD, ECR235EL/ELD, EC250D, EC250EL/ELD, EC300D, EC300EL/ ELD, EWR130E, EWR150E, EW160E, EWR170E, EW180E and EW240EMH. Machine must be delivered by 31st October 2022. Warranty is valid on component only. The warranty is limited to three years or 6000 operating hours, whichever occurs first, commencing from the date of delivery. Normal manufacturer’s warranty terms and conditions apply. Images are for illustration purposes only. CJD Equipment reserves the right to withdraw this offer at any time without notice. WARRANTY EXTENDED 3-YEAR/6000 HOUR Purchase a new 14 - 30 tonne Volvo excavator between the 1st of March and the 31st of August 2022 and receive extra peace of mind with an extended 3-year/6000 hour warranty. available now enjoy extra support

A huge thank you to our Major Sponsors .

It has been a pleasure working with you.

®

® AUSTRALIA’S LARGEST CONSTRUCTION EQUIPMENT EXPO DIESELDIRTANDTURF.COM.AU FRIDAY 8TH, SATURDAY 9TH & SUNDAY 10TH OF APRIL 2022 GOLD SPONSOR GOLD MEDIA SPONSOR OPERATOR CHALLENGES DEMO SITES LICENSED BAR & FOOD PICKLES AUCTION AT 1 PM, 9TH APRIL OVER 200 EXHIBITORS ® ® AUSTRALIA’S LARGEST CONSTRUCTION EQUIPMENT EXPO DIESELDIRTANDTURF.COM.AU FRIDAY 8TH, SATURDAY 9TH & SUNDAY 10TH OF APRIL 2022 GOLD SPONSOR GOLD MEDIA SPONSOR OPERATOR CHALLENGES DEMO SITES LICENSED BAR & FOOD PICKLES AUCTION AT 1 PM, 9TH APRIL OVER 200 EXHIBITORS ®

FUTURE-PROOF PERFORMANCE AND RELIABILITY.

TIER 4 FINAL, NO DPF!

The Doosan DX140LCR-5 machine builds on Doosan’s enviable reputation for hardworking, reliable and comfortable machines, with this next generation model offering an exceptionally powerful DPF-FREE TIER 4 FINAL engine.

By complying with US Tier 4 regulations, the Tier 4 Final DX140LCR-5 will have no issue operating on jobsites with Tier 4 emission standards - helping future-proof your investment. And with no DPF (Diesel Particulate Filter), you will avoid the maintenance issues experienced by other manufacturers - from time consuming regeneration cycles to expensive DPF servicing issues. This makes the Doosan DX140LCR-5 one of the most productive and reliable machines in its class.

www.doosan.clarkequipment.com.au | doosan@clarkequipment.com | T: 1300 736 848

*Tier 3 models still available.

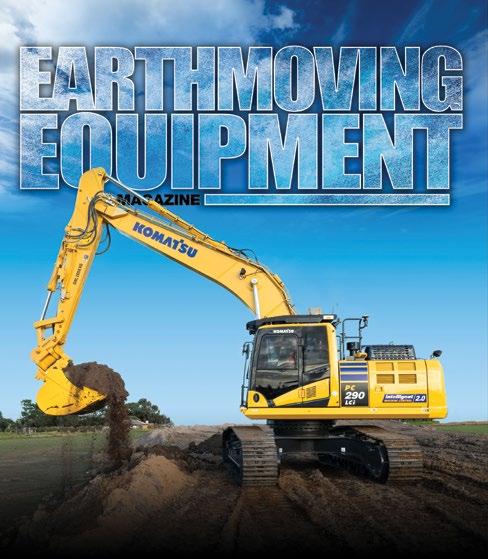

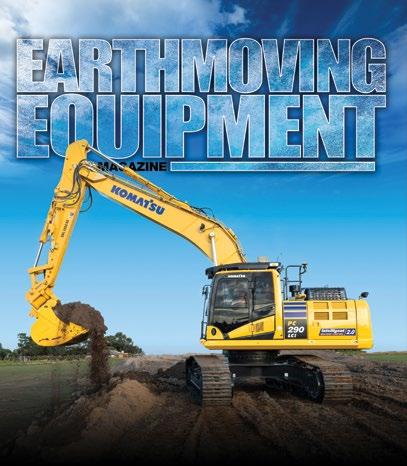

DD&T GOLD SPONSOR KOMATSU WILL AGAIN SHOWCASE ITS TECHNOLOGY ADVANTAGES

Komatsu will again be the Gold Sponsor of this year’s Diesel Dirt & Turf Expo, to be held from April 8-10 at the Sydney Dragway, Eastern Creek.

As Gold Sponsor, Komatsu is the primary earthmoving and construction equipment supplier supporting the Expo.

Located on Stand B1, Komatsu will have one of the largest displays at the DD&T Expo 2022, with a focus on its Smart Construction project management offering, a new protype cabless electric-powered excavator and its low emission technologies, said Chris Moroz, Komatsu’s Sales Manager – Central Region.

“We will also be highlighting our technical solutions that contribute to environmental best practice and sustainability in construction products, as well as our commitment to diversity and inclusion in our workforce.”

Moroz said this was the second year Komatsu has been the Gold Sponsor of DD&T Expo.

“We are excited to again be the Gold Sponsor of this national DD&T expo.

“For us, this is a great opportunity to be showcasing our latest technology and innovations, in addition to our general products and support capabilities, to a national audience for the broader civil construction industry.

“Our presence here also enables us to speak to and listen to people in the industry about their needs and challenges,” he said.

“We are back here again, because each year we have been the Gold Sponsor, we’ve had great feedback and sales success from customers.

“We see this as a unique opportunity to market our latest technologies, products and services on offer in a more personal way, directly to the industry.

“And, importantly, our DD&T Expo Gold Sponsorship is an opportunity for Komatsu to really show our commitment in supporting the industry and the businesses at its centre,” said Moroz.

UNIQUE CONCEPT ELECTRIC MINI EXCAVATOR

A highlight of the Komatsu stand at the DD&T Expo will be its prototype all-electric mini excavator. This unique excavator has no cab and is fully remote-controlled. It also introduces a completely new concept in how earthmoving operations are carried out.

“Designed to lay the foundations for the next generation of fully electric construction equipment, this 3-tonne mini-excavator harnesses Komatsu’s technological expertise in electric forklifts and mini excavators,” Moroz said.

8 WWW.EARTHMOVERS-MAGAZINE.COM.AU

“It incorporates never-before-seen technologies on mini excavators, including lithium-ion batteries and electric – not hydraulic – cylinders.

“And visitors to Komatsu’s DD&T Expo display will have an opportunity to view this unique new machine, and see it in operation for themselves,” he said.

LOW EMISSIONS TECHNOLOGY

Komatsu has been a leading provider of ultra-low emission Tier 4 Final powered machines in the past few years.

With this technology increasingly widely accepted, the company is looking at ways to lower costs for customers.

One recent initiative has been the opening of a diesel particulate filter (DPF) reman facility at its Fairfield head office.

This provides customers with the opportunity to further reduce their costs of operation by purchasing completely reconditioned, fully warranted replacement DPF units.

“Komatsu Reman DPFs are available through our service and parts departments and cost

approximately one-quarter to one-third the price of a new unit,” said Moroz.

“Changing over a DPF is a very straightforward process for our customers.

“We offer a fixed price, depending on the machine model, and it’s simply a matter of giving us the old DPF when we swap it out.”

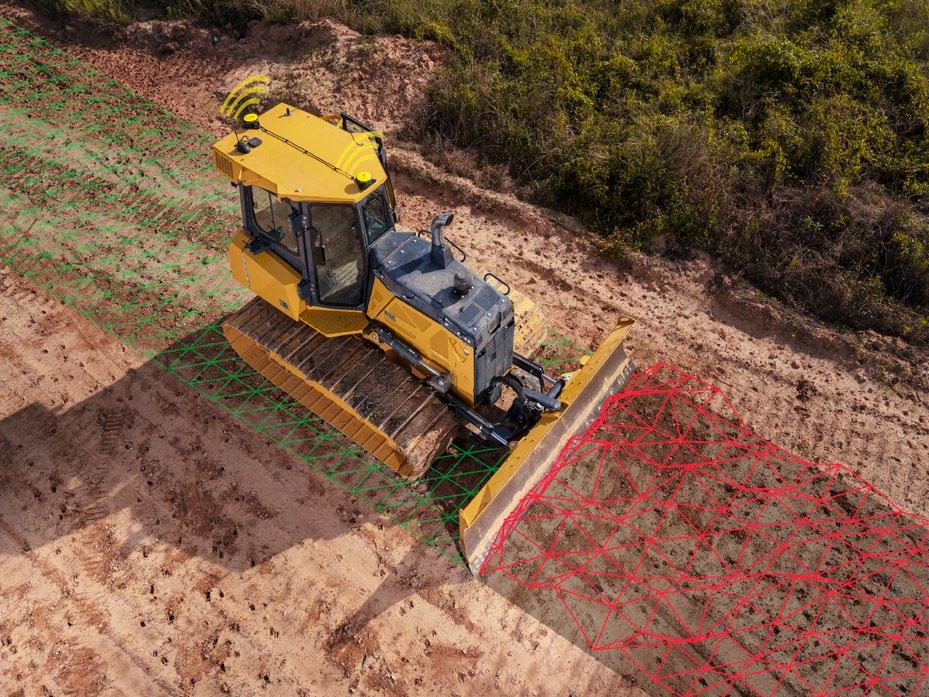

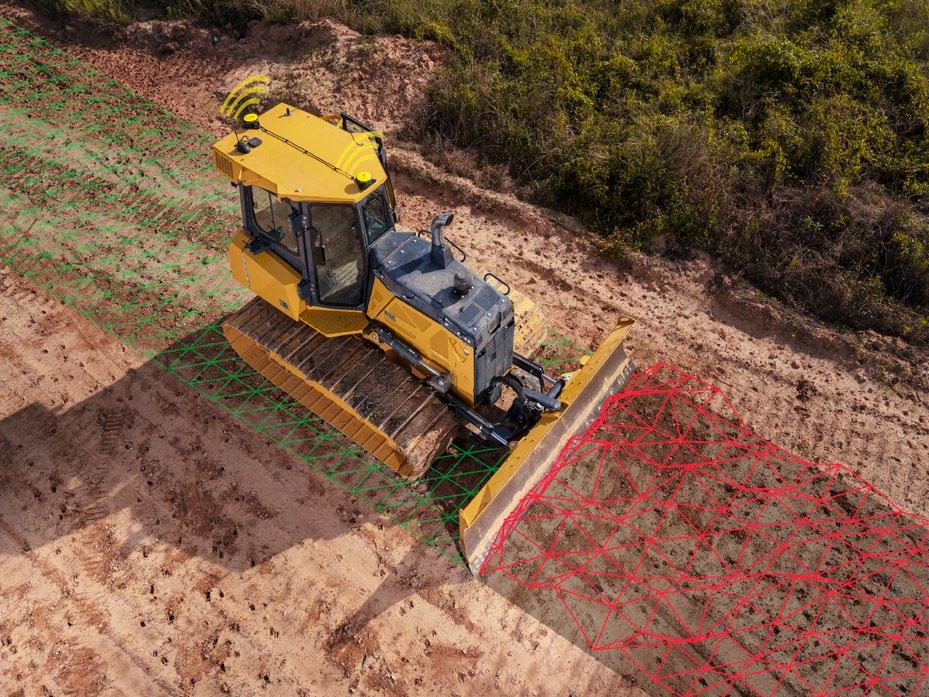

SMART CONSTRUCTION

Komatsu will use DD&T to showcase its Smart Construction suite of offerings that improve productivity and safety in the construction, quarrying and mining industries, through the application of unique technology and integrated products.

Developed to work across mixed-brand equipment fleets, Smart Construction provides a single ‘one-stop shop’ service and support solutions across all phases of a project’s lifecycle.

It captures information that can be used to solve problems or enhance operations and safety of a construction jobsite for customers and stakeholders.

A series of Smart Construction webinars for Komatsu customers across Australia and New Zealand will soon start monthly, running through to early 2023. These webinars will give users and potential users insights into what this technology can do for their operations and projects, and how to get the best from it.

“Representatives of our Smart Construction team will be onsite at DD&T, ready to talk to customers about how its application can deliver significant benefits to project and site safety, productivity, efficiency and the bottom line,” Moroz said.

KOMTRAX UPDATES

Early in 2022, Komatsu’s remote monitoring system Komtrax underwent an upgrade, which is being included in new machines.

Key features and updates include a new Single Sign On capability for added convenience and security, increased machine status visibility, additional safety features, operator ID and machine idling statistics.

Komatsu’s specialist Komtrax team will be on hand at DD&T to discuss these latest features, and how this technology can help customers improve machine management, safety and operational efficiency.

In February this year Komatsu celebrated the sale of its 20,000th machine covered by Komtrax across Australia, New Zealand and New Caledonia.

“We were proud to deliver our 20,000th Komtrax-enabled machine to Sydneybased Cono Services in mid-February,” said Mary Jo O’Donovan, Komatsu’s Komtrax Systems Co-ordinator.

Cono Services took delivery of our latest model PC490LC-11, which incorporates Tier 4 Final emissions technology to significantly reduce the impact on our environment. And it features our latest generation of Komtrax, which lets us provide additional data for the benefit of our customers, such as seatbelt alerts and time-of-day idle information.”

Throughout DD&T, Komatsu staff and technical experts will be on hand to talk to visitors about all aspects of the company’s products and services, and to offer advice and assistance with any issues or questions.

“We’ll also be running competitions where visitors and their families will have the chance to win prizes, and take advantage of show special offers,” said Moroz.

“And we particularly welcome families to come and visit our stand, and find out more about Komatsu, its products and services, and its people.”

WWW.EARTHMOVERS-MAGAZINE.COM.AU 9

MULTI-MILLION DOLLAR QUARRY & CIVIL AUCTION PicklesLIVE auction Wednesday 27th April Assets located nationally.

For more information, contact Stewart Watt on 0434 601 999 Earthmoving & Crushing Equipment • 20+ Excavators (5-30T) • 3 x Cat Compactors • 7 x Wheel Loaders (15-40T) • 5 x Cat & Komatsu Dozers • 5 x Late-Model Mobile Crushers (Impact & Jaw) • 6 x Mobile Screens • 7 x Mobile Stackers • 7 x Artic Dump Trucks • 5 x Artic Rollers • 6 x Skid Steers Trucks & Trailers • 5 x Service Trucks • 7 x Tippers • 4 x Water & Fuel • 3 x Drake Floats *Asset listing is subject to change. Visit the website for final listing.

LOCATION

The Sydney Dragway, Ferrers Road, Eastern Creek New South Wales. How to get here: Via the M4 motorway or the Western Highway DISABLED ACCESS

The majority of the Expo site is wheelchair friendly. Dragway site is level, fully paved and provides easy access for visiting all exhibitor sites.

ACCOMMODATION

There is a variety of accommodation options in the immediate area.

FOOD AND REFRESHMENTS

Food and drink vendors are located throughout the site and there is a licensed bar and hospitality area (social distancing rules apply).

TOILET FACILITIES

Toilet facilities are provided throughout the Expo site.

CAR PARKING

There is expansive free car parking facilities on site provided for visitors.

FIRST AID/EMERGENCY

Personnel are on hand to administer any first aid that may be required.

www.dieseldirtandturf.com.au 8TH - 10TH APRIL 2022

OPENING HOURS FRIDAY 8TH APRIL 9.30AM 5PM SATURDAY 9TH APRIL 9.30AM 5PM SUNDAY 10TH APRIL 10AM 3PM GENERAL INFORMATION 12 WWW.EARTHMOVERS-MAGAZINE.COM.AU

As an Australian family owned company with global reach, Tilly’s is proud to stock over 43,000 new part lines for earthmoving machinery. The extensive range now includes the Maxiforce® range of small bore diesel engine parts.

From our base in Toowoomba, Queensland, we ship quality parts across Australia and around the world. See our friendly and knowledgeable team at Diesel Dirt & Turf!

Right part, right price, right now.™

EXHIBITORS’ LIST

OUTDOOR EXHIBITORS

Adjusta Mattress L1

AEG Powertools c5

AEI Insurance Brokers A23

Ag - Pride A13

Air Radiators pty ltd G5

Alemlube A24

All Lift Equipment Sales Pty Ltd D7

Allied Earthmovers Association A30

Arrow Machinery F10

Aspel Cleaning Equipment C8

Atlantic Oil B3

Attach2 R2

Auger Torque D8

Austas Hammers A14

Austramac Australia Pty Ltd A25

Bongaree Forks and Mini Loaders L4

Boss Attachments F2

Caltex J3

Cappro Pacific A18

Carter Wesco f10

CEA U1

CEG Sales and Service C4

Challenge Implements J2

CJD EQUIPMENT D11

CJ & LH Wiesner Pty Ltd Q3

Cleaner Cutting Systems R8

Clark Equipment B7

Colbrook industries R1

Continental U5

CR KENNEDY G1

Crosschem A20

Cub Cadet A15

Dean Trailers C7

Delta A9

Dennis , Sisis P6

Digga Australia A17

Diggerlid H4

Divalls Earthmoving and Bulk Haulage J5

Doherty Couplers and attachments

D9

Earthmoving Attachments Australia E7

Ei Engineering E4

Elite Attachments H6

Engcon J1

FAE Australia Pacific PTY LTD C1

Fernland Q6

Finer Hydraulics G6

Flip Screen Australia D1

Free 247 Lifestyle G2 G E T A2

Graysonline L3

Groundtec Equipment A10

Hatz Diesel Australia H2

Hitachi Construction Machinery Australia P7

Horsley Park RFS

Hogan Engineering F7

Indeco Australia Pty Ltd N2

international Greenkeepers Association Q2 Inlon Pty Ltd A5

ITR BEVRAGE CART SPONSORSHIP

ITR Pacific L2

Kanga Loaders B2

KOMATSU B1

Land HQ P1

Lark Utvs H5

Liebherr c2

Liugong D3

Longwall Hydraulics A22

Lucas Mill Pty Ltd Q5

Machine Control Australia G8

Makinex A11

Manitou Australia C6

Marxgold A8

Mecalac a25

Merimbula’s Sweet n Sour Lolly Shop

Miller Australia

Moody Kiddell and Partners E1

14 WWW.EARTHMOVERS-MAGAZINE.COM.AU

EXHIBITORS’ LIST

LANEWAY BOOTHS

Nepean Motor Group A26

Norm Engineering F1

NTI LIMITED E6

Onetrak D4

Orange Hire A6

Pickles M1

Porter Group B4

Position Partners D2

Prolube Lubricants A30

Record time A19

REPCO COMMERCIAL H1

RodRadar LDR J5

ROO ATTACHMENTS B6

Saliba Ag F5

SBA EARTHMOVING ATTACHMENTS A16

Selectweld Pty Ltd

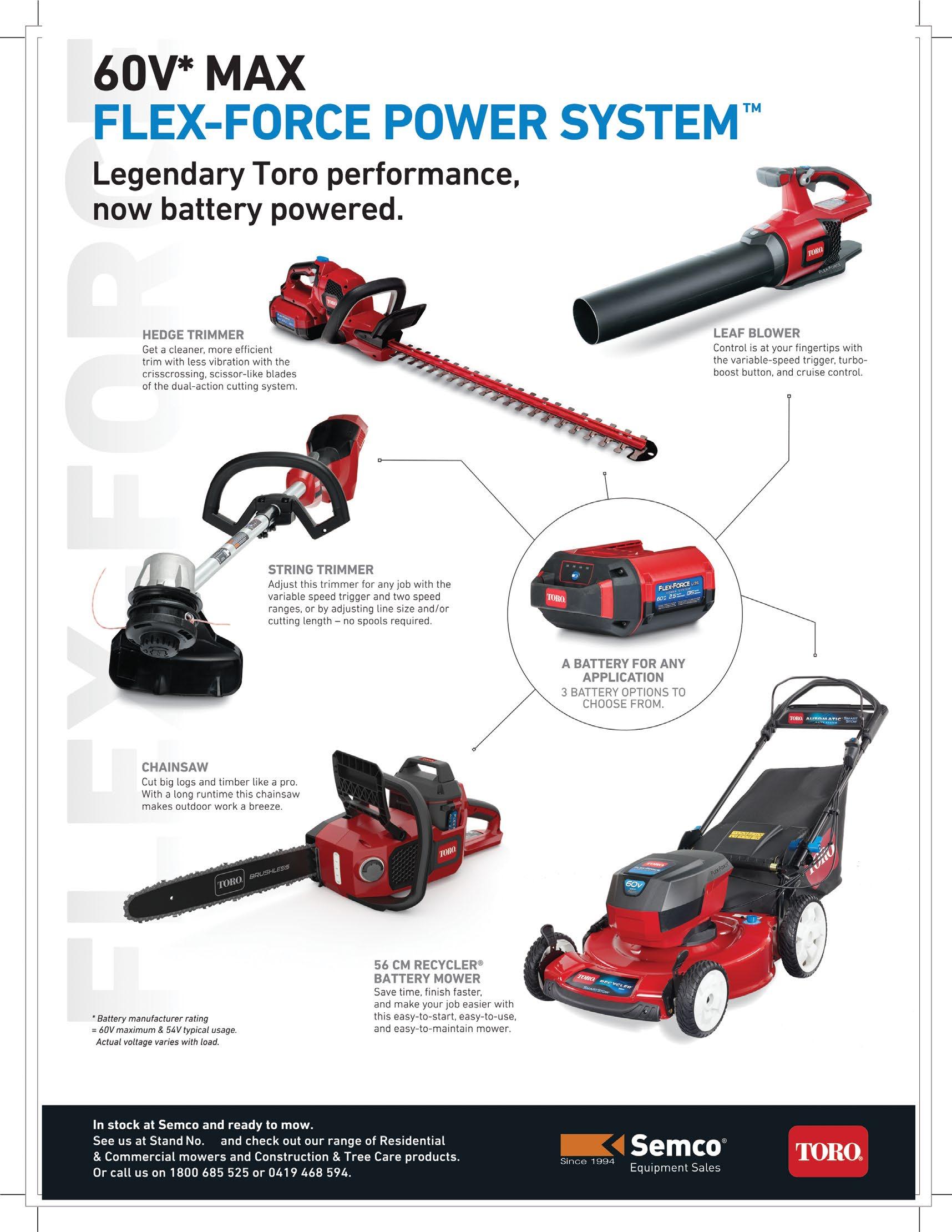

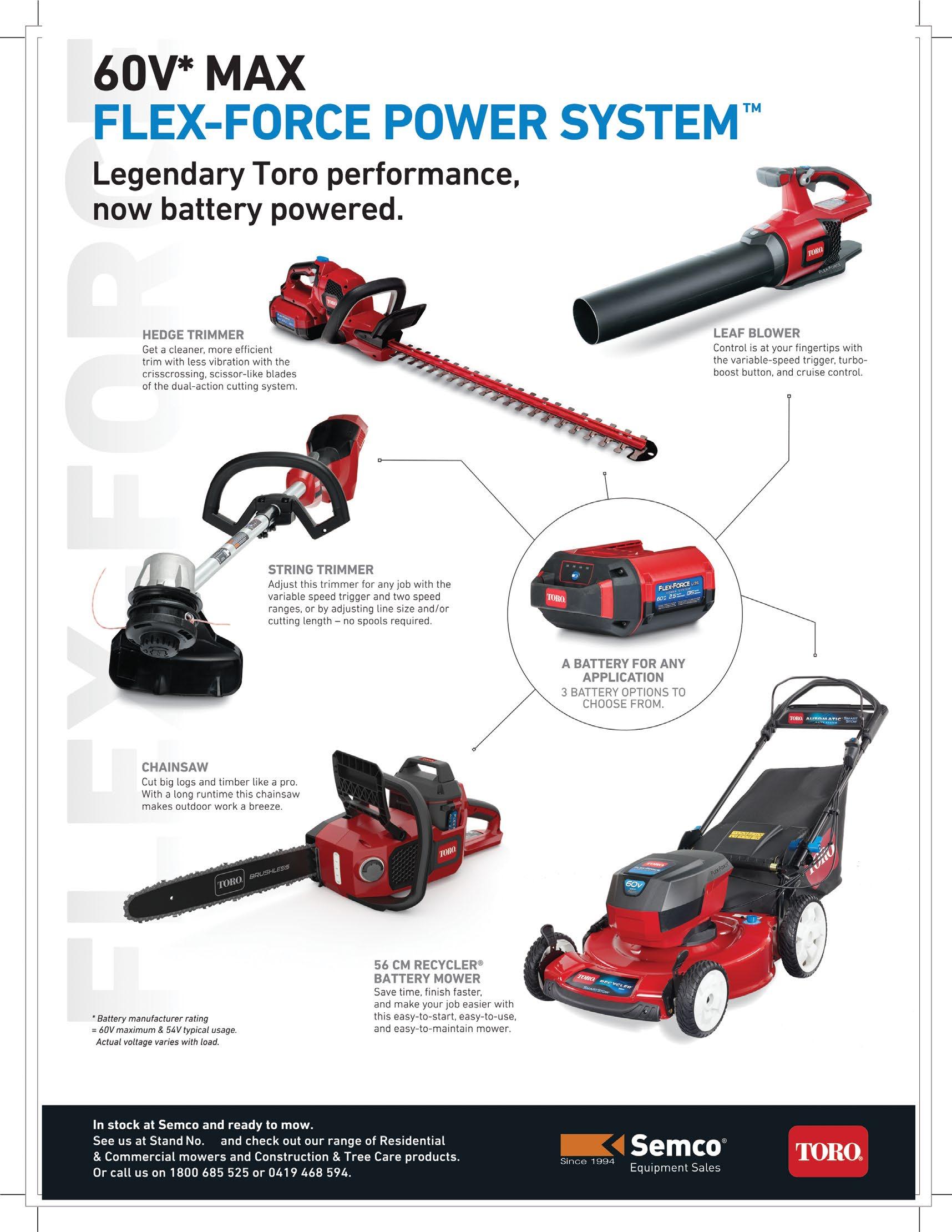

Semco Equipment Sales B5 Showbag warehouse

Sleeptime F3

SMA MOTORS / CITY HINO P2

Spitwater A7

Steelwrist C3

Sureweld E5

Sydney Trucks & Machinery D3 TFI E2

Tillys Crawler Parts H8

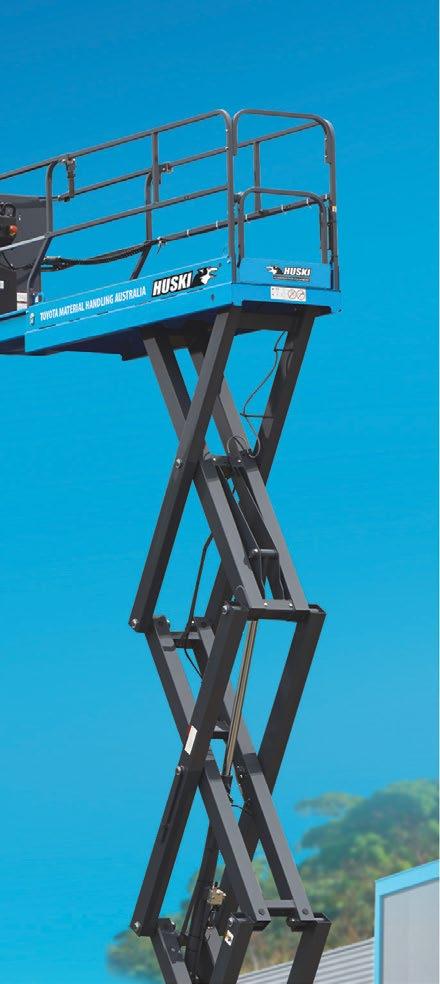

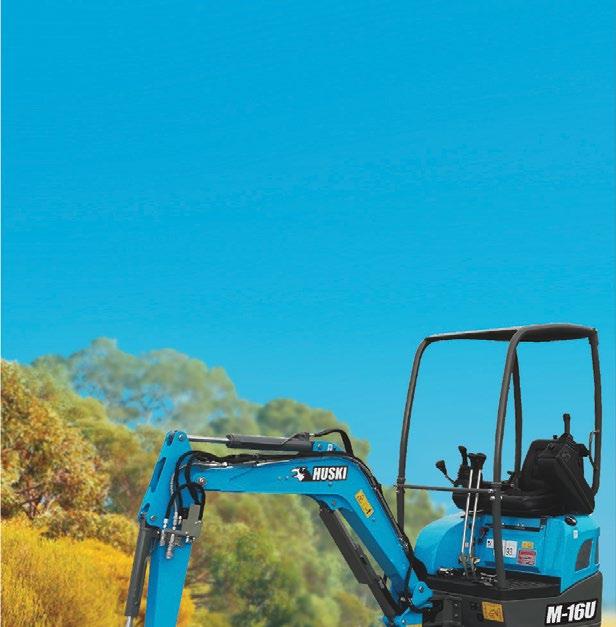

Toyota Material Handling A1

Trucks N Toys J4

Tutt Bryant Equipment F6

Ventrac Australia P4

Veermer Australia / RDO Equipment K1

VIVA ENERGY AUSTRALIA A4

Weedtechnics A12

West-Trans Equipment K4

WesTrac u10

What-a-Hide G3

XCMG MINING EQUIPMENT AUSTRALIA V1

Yello Equipment D10

1300 Apprentice 91

Anglo Design Pty Ltd 55

Beilby Downing Teal 40

Credit One Finance 52,53

DEMO AREA FOR EDDIE Dial Before You Dig 12,13

DKG INSURANCE AND RISK EXPERTS 8 Finlease 71,72,73

Gaam Emergency Products 60 Harrison Barratt Group Pty Ltd 18

Hydraulink 32 Mayne Media Group 92,93

Power Transmission Technology 74

PRIME CREATIVE 1

REPCO

Safe Gauge 35

Shannons insurance 49,50 SOILBOND Pty Ltd 28

Stucchi Australia Pty Ltd 21, 21A

Trade Earthmovers/Earthmovers & Excavators 1

SYDNEYDRAGWAY,

8-10 APRIL 2022 WWW.EARTHMOVERS-MAGAZINE.COM.AU 15

EASTERNCREEK

SEMCO EQUIPMENT SA SITE B5 1250m2 12 5m NTI T RUCK ASS ST SITE E6 250m2 2 0m 0m 1 5m 2 1 MOODY & KIDDELL SITE E1 250m2 SURE WELD SITE E5 200m2 0 m 20 m 4 0m VACANT SITE F9 200m2 GRAYS ON LINE SITE L3 150m2 1 0m 15m 25m ADJUSTA MATTRESS SITE L1 300m2 2 0m 15m 37 5m 2 0m INDECO SITE N2 200m2 25m WEST TRANS SITE K4 250m2 25m 1 0m 1 0m 20m 20m 25m CHALLENGE IMPLEMENTS SITE J2 250m2 VACANT SITE xx 250m2 27 5m 2 0m SMA SITE P2 550m2 LAND HQ SITE P1 250m2 15m 40m 15m 20m VACANT SITE XX 200m2 INTERNATIONAL GREEN KEEPERS SITE Q2 - 400m2 10m 31m 4 0m 10m 27 5m 0m VACANT SITE S1 275m2 82 5m 2 0m FOOD & SEATING AREA HOGAN ENGINEERING SITE F7 350m2 N O R M E N G N E E R I N G S T E F 1 40 0 m 2 VACANT SITE F4 250m2 1 0m 2 0m 20m 20m RDO EQUIPMENT VERMEER AUSTRALIA SITE K1 750m2 CALTEX S TE J3 125m2 12 5m DIVALLS SITE 7 120m2 ALEMLUBE SITE A24 150m2 15m ALLIFTS SITE D7 500m2 L S 1 NEW CARPARK 40m F E RR E R S R O A D EXHI BI TOR CAR PARK AUGER TORQUE SITE D8 250m2 DOHERTY SITE D9 250m2 SANY SITE D10 500m2 20m ONE SIT 50 25m 22 5m 17 5m 10m 20m SLEEP TIME SITE F3 400m2 JCB SITE U1 500m2 2 2 5 m 20m 10m 20m 20m 25m HATZ S TE H2 75m2 7 5 m 10m 35m REPCO SITE H1 435m2 7m D GGER LID SITE H4 70m2 UTV S TE H5 70m2 15m VACANT SITE XX 150m2 2 0m WESTRAC SITE U10 1600m2 10m TFI SITE E2 200m2 PICKLES SITE M1 800m2 2 0m 1 2 5 m 5m 1 0m 10m CJD SITE D11 500m2 E I ENG NEERING S TE E4 250m2 TRUCK N TOYS S TE J4 100m2 A E S T E A 2 50 m 2 10m 12m 2 0m 60m VACANT SITE XX 100m2 0m VACANT S TE J6 200m2 VACANT SITE XX 150m2 0m 0m 7m V A C A N T S I T E S 2 20 0 m 2 10m VACANT SITE XX 100m2 VACANT S TE XX 100m2 10m 2 0m V ACANT SITE D5 500m2 15m T LLYS S TE H3 75m2 15m 10m CAST M NI LOADERS S TE L4 100m2 10m VENTRAC SITE P4 250m2 3 0m VACANT SITE XX 275m2 0m T O L E T S T O L E T S T O L E T S EMERGENCY EVACUATION POINT EAA SITE E7 250m2 BOSS ATT ACHMENTS SITE F2 500m2 25m 25m 12 5m VACANT SITE U6 1200m2 VACANT SITE XX 100m2 VACANT SITE XX 100m2 10m - BAR AREA10m 25m FOOD VAN FOOD VAN FOOD VAN A G E R R I S 10m LITTLE BIG RIGS 400m2 40m 1 0m 20m ITR SITE L2 250m2 SALIBA AG SITE F5 250m2 FAE SITE C1 400m2 TUTTS BRYANT SITE F6 450m2 FERN LAND SITE Q6 100m2 LUCAS MILL SITE Q5 150m2 DENN S S SIS SITE P6 150m2 2 0m HITACHI SITE P7 375m2 FREESTY LE KINGS 12 5m 89m XCMG SITE V1 1300m2 65m 2 0m 2 0m 82 5m 4 5m 25m VACANT SITE XX XXXm2 L VACANT SITE XX 250m2 VACANT S TE XX 250m2 10m EL TE ATTACHMENTS S TE H6 110m2 SEMCO SITE Q1 300m2 15m CARTER WESCO SITE F10 200m2 C R KENNEDY SITE G1 250m2 2 0m T O I L E T 85m 2 0m CONT NENTAL SITE U5 150m2 1 0m 37 5m VACANT S TE XX 35m2 5m 7 m 7 m 7m SELECT WELD S TE G10 35m2 A R RADIATORS S TE G5 55m2 F NER HYDRAUL CS S TE G6 90m2 DARCY SITE G8 145m2 5m 5m 15m VACANT SITE K3 300m2 8 m 12 m 80m 2 0m 15m WEISNER SITE Q3 150m2 COLBROOK INDUSTRIES S TE R1 200m2 ROD RADAR 100m2 10m VARD GROUP SITE S3 145m2 WHAT-A-H D S TE G2 50m2 FREE 247 LIFESTYLE Blue Eye Wear 50m2 S TE G3 50m2 5 m 10m 10m GATE 'A' G A T E ' D ' F O R S P E C T A T O R S VACANT SITE XX 100m2 VACANT SITE XX 100m2 VACANT SITE XX 100m2 ADTRAIL SITE R5 CLEANER CUTTING 100m2 100m2 DEMO MOWING AREA 1 1650m2 DEMO MOWING AREA 2 1650m2 SYDNEYDRAGWAY, EASTERNCREEK 8-10 APRIL 2022 AS OF 22.03.2022 *THIS MAP IS SUBJECT TO CHANGE Please visit www.dieseldirtandturf.com.au/exhibitors-list-2022/

TOYOTA MATERIAL HANDLING S TE A1 600m2 WEED TECHNICS S TE A12 100m2 M AK NEX SITE A11 150m2 AGPRIDE S TE A13 150m2 AUSTAS HAMMERS SITE A14 100m2 ALES AEG SITE C5 175m2 50m 17 5m 2 5m 15m 25m 1 1 4 m SALMON BUCKETS SITE A16 500m2 CROSS CHEM SITE A20 70m2 STEELWRIST SITE C3 400m2 20m 30m 10m 7m GROUNDTECH SITE A10 100m2 AVANT SITE A9 100m2 PORTERS SITE B4 500m2 ROO ATTACHMENTS SITE B6 500m2 SPIDER WORKS SITE A21 150m2 15m ONGWALL ITE A22 100m2 0m CUB CADET SITE A15 100m2 10m 2 0 m 20 m C E GROUP SITE C4 380m2 19m 12 5m KOMAT SU SITE B1 1000m2 15m 25m 35m TRAK E D4 0m2 ATLANTIC O L SITE B3 300m2 5m 1 5m 1 0m 1 10m 10m 10m 2 0m 30m 14m FLIP SCREEN SITE D1 500m2 20m VACANT 10m MARXGOLD 1SITEA8 20m2 G E T SITE A2 125m2 NEPEANMOTORGROUPSITEA26100m2 ASPEL CLEANING S TE C8 100m2 8 m 1 2 m LANE WAY BOOTHS 10m 10m 1 2 5 m 12m 30m 20m 1 0m ORANGE HIRE SITE A6 200m2 TO LETS AUSTRAMAC SITE A25 250m2 24m STM SITE D3 600m2 MAN TOU SITE C6 175m2 0m 1 0m V VA ENERGY S TE A4 90m2 12 5m 7 m INLON S TE A5 70m2 6m RECORD T ME S TE A19 60m2 T O L E T B L O C K M O W I N G D E M O A R E A ENGCON SITE J1 400m2 2 8 6 m 10m 15m 0m 30m D E M O A R E A E N T R Y KANGA SITE B2 300m2 DIGGA SITE A17 300m2 DEAN TRAILERS SITE C7 150m2 POSITION PARTNERS SITE D2 350m2 SPITWATER SITE A7 100m2 CLARK EQUIPMENT SITE B7 600m2 CAPPRO SITE A18 100m2 1 0m EBHERR SITE C2 400m2 E XIT ATTACH 2 SITE R2 150m2 15m T O I L E T B L O C K CONCRETE STAIRS DEMO AREA DEMO AREA DEMO AREA DEMO AREA DEMO AREA DEMOAREA PRO LUBE SITE A30 100m2 1300 APPRENT CE GOLD SPONSOR GOLD MEDIA SPONSORS INDOOR LIST: 1300 Apprentice 91 Anglo Design Pty Ltd 55 Beilby Downing Teal 40 Credit One Finance 52,53 DEMO AREA FOR EDDIE Dial Before You Dig 12,13 DKG INSURANCE AND RISK EXPERTS 8 Finlease 71,72,73 Gaam Emergency Products 60 Harrison Barratt Group Pty Ltd 18 Hydraulink 32 Mayne Media Group 92,93 Power Transmission Technology 74 PRIME CREATIVE 1 REPCO Safe Gauge 35 Shannons insurance 49,50 SOILBOND Pty Ltd 28 Stucchi Australia Pty Ltd 21, 21A Trade Earthmovers/Earthmovers & Excavators 1

18V 6.0AH 6 PIECE FUSION HEAVY MACHINERY KIT BSB18FB662AG $1,549 RRP 18V 450G 2-SPEED GREASE GUN SKIN BGG18-0 $519 RRP AEG Onsite will be attending the DDT Event at Stand C5. We’ll have tool demos and exclusive event offers. Come and meet our AEG Onsite team and check out our ‘shop on wheels’. Why use AEG Onsite? • We bring the tool shop to you • Transact onsite • A dedicated account manager DEAL 1 DEAL 2 18V 1/2" BRUSHLESS SUB COMPACT 4-MODE IMPACT WRENCH SKIN BSS18S12BL0 18V 2.0AH FORCE BATTERY A18FB2 18V COMPACT CHARGER BL18S 18V FUSION RECIP SAW SKIN A18FRS0 18V 12" BRUSHLESS CHAINSAW SKIN ACS18B Present this ad the AEG Stand (C5) at the event and get a 4.0Ah FORCE heavy-duty battery valued at $159 for free when you spend $1000 or more.

18V ½" FUSION 6 MODE HIGH TORQUE IMPACT WRENCH SKIN BSS18HTF12B6-0 + 18V 6.0AH FORCE BATTERY L1860R-X5 FOR $688 RRP 18V ½" FUSION 6 MODE HIGH TORQUE IMPACT WRENCH SKIN BSS18HTF12B6-0 + 18V 12" BRUSHLESS CHAINSAW SKIN ACS18B FOR $828 RRP DEAL 3 DEAL 4 18V 4.0AH FORCE BATTERY & 18V SMART CHARGER COMBO KIT A18OSK14 18V 4.0AH FORCE BATTERY & 18V SMART CHARGER COMBO KIT A18OSK14 18V HIGH PRESSURE INFLATOR SKIN A18HPI0

ASV MAX-SERIES POSI-TRACK LOADERS – THE NEW INDUSTRY BENCHMARK

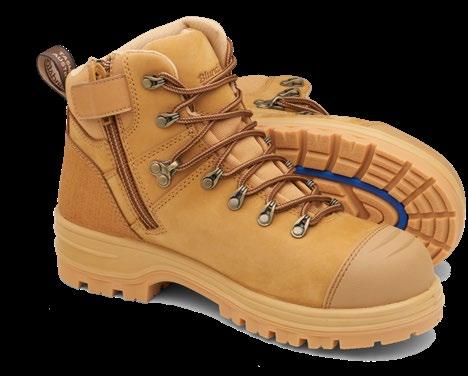

ASV Posi-Track Compact Track Loaders have been a construction industry staple in Australia throughout the past decade. Already packed with exceptional and unique innovations, ASV Posi-Track Loaders are now even more impressive, with the addition of the new MAX-Series operator cabs.

Featured as standard on all ASV Posi-Track models sized 65 horsepower and above – including the all-new 132 horsepower RT-135 – MAX-Series cabs offer unmatched comfort, control, visibility, safety and reliability.

COMFORT

A primary focus of ASV’s redesigned MAX-Series cab is the maximum comfort of the operator, even on the longest and hottest days in the seat. Up to 30 per cent more head, shoulder and leg room, plus a fully adjustable suspension seat with four-way armrests, ensures operators of any size are comfortable and relaxed. In addition, the fully insulated cab with improved air conditioning and climate control stays cool and comfortable on hot summer days.

In addition, the unique suspension system found only in ASV Posi-Track undercarriages – including double torsion axles, heavy duty rubber wheels and, on the larger models, independently moving wheels –ensures that shock vibrations felt in the cab are significantly minimised, reducing operator fatigue and discomfort.

CONTROL

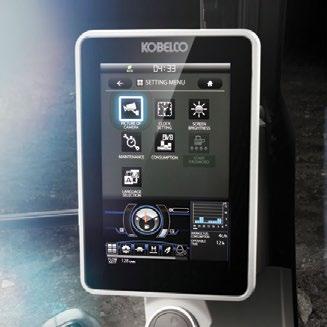

One of the first new features operators will notice when they climb in the new MAX-Series cab is the 7-inch colour touchscreen display. This innovative addition conveniently displays all vital machine information, offers a highquality view of the reversing camera, provides easily accessible service history and comprehensive maintenance schedules.

This gives operators a better understanding of their machine performance and condition, ensuring service and maintenance requirements are met and, subsequently, the machine performs to its brilliant best throughout a longer lifetime.

In addition, the overall layout and positioning of key controls, such as the joysticks and

throttle, has been updated to deliver a more ergonomic and operator-friendly experience. The machines are now easier and smoother to control than ever, and set a new industry benchmark for operator satisfaction.

Furthermore, not only has the machine control been improved dramatically, but so too has the operator’s ability to control their work environment. Bluetooth radio, high fidelity speakers, phone connectivity and device control are all new additions to allow operators to better enjoy their work day.

VISIBILITY

Working with various major blind spots is no longer a concern for MAX-Series operators –the new panoramic all-clear window designs offer 360-degree visibility and unobstructed views all around the machine; in fact, up to 52 per cent more visibility than previous models of ASV Posi-Tracks.

Plus, MAX-Series cabs include the industry’s first roof escape hatch for added operator safety and offer an optional heavy gauge Falling Object Protective Structure (FOPS) level 2 cab, for unmatched cab impact resistance.

Furthermore, the high quality 7-inch display screen offers a premium view of the rear of the machine via the reverse camera to ensure maximum safety for both the operator and also bystanders, and also reduces the likelihood of reversing into hazards and causing damage to the machine or surrounding environment.

SAFETY AND RELIABILITY

As noted above, the MAX-Series range of Posi-Track Loaders from ASV are packed with many crucial safety features often unavailable on alternate brands of Compact Track Loaders.

The new roof escape hatch is an industry-first for added operator safety, the unobstructed panorama views and high-quality reverse camera offers excellent visibility all around the machine, and the optional level 2 cab guarding enhances falling object impact resistance.

In addition, the renowned ASV Posi-Track undercarriage remains as stable, reliable and easy to service as ever. With its unique torsion axle suspension, rubber track system and open wheel design, ground shock is significantly reduced, and dirt and debris are easily ejected from the undercarriage, meaning less wear and tear on the machine and a longer service life. Furthermore, the new MAX-Series cabs include fully sealed watertight fuse panels.

CUSTOMER SUPPORT

In addition to a premium nationwide service and parts network and 25 local dealers throughout Australia, ASV also offers an industry-leading 2-year bumper-to-bumper warranty on all Posi-Track Loaders, plus comprehensive operational support from our expert product representatives throughout the machine’s entire life.

To learn more about ASV’s range of Posi-Track Loaders, including the new MAX-Series models, visit www.asvaus.com.

20 WWW.EARTHMOVERS-MAGAZINE.COM.AU

TM TM

The products

this promotion are sold by Caterpillar’s

dealers, which are independent businesses, on prices, and terms and conditions, and such other offers, as determined independently by each

dealer. Available from participating Caterpillar dealers in Australia and New Zealand, while stocks last. References to specific offerings available from participating dealers are provided as a guide only, and based on non-binding feedback provided by various Caterpillar dealers. Planned maintenance kit contents vary according to machine type and maintenance interval. Additional tools may be required. The information contained herein represents results obtained under specific conditions and maintenance practices. Caterpillar implies nothing further, and no one should infer that using the Cat products described herein will result in the same or similar benefits as defined in this

© 2022 Caterpillar. All Rights Reserved. CAT, CATERPILLAR, LET’S DO THE WORK, their respective logos, “Caterpillar Corporate Yellow”, the “Power Edge” and Cat “Modern Hex” \trade dress as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission. MAKING THINGS EASIER FOR YOU IS ALL PART OF THE PARTNERSHIP All the genuine Cat ® parts you need for your machine’s specific maintenance interval are boxed up in a Cat planned maintenance kit – parts like filters, fluids, gaskets, and seals. You’ll save time and get the right parts when you need them, so you can focus on getting the job done. Order online at parts.cat.com or pick up from your local Cat dealer. MAXIMISE YOUR WORK TIME WITH A CAT ® PLANNED MAINTENANCE KIT

subject to

authorised

Caterpillar

document.

NSW/ACT WesTrac 1300 881 064 SA Cavpower 08 8343 1600 VIC/TAS William Adams 1300 923 267 WA WesTrac 1300 881 064 QLD/NT Hastings Deering 1300 952 701 NZ Terra 0800 93 39 39 SCAN TO ORDER MAKE THE JOB EASY WITH A CAT® PLANNED MAINTENANCE KIT DO YOUR OWN MAINTENANCE Regular maintenance can help your components last longer, and can help maintain efficiency and extend repair intervals. With a Cat ® planned maintenance (PM) kit you can choose all the genuine Cat parts you need. They’re customisable and convenient too. Plus, if you’re doing your own repairs, it’s easy to order Cat Self-Service Options on parts.cat.com. NOW HERE'S THE EASY PART ORDERING YOUR PM KIT FROM PARTS.CAT.COM Already have an account? Scan the QR code to order your PM kit New to parts.cat.com? Order your PM kit by following the instructions below Register your account Add your serial number to the ‘Add Equipment’ list Navigate to the PM kit section on your equipment page Choose the PM kit you need Build your PM kit Add it to your cart and check out NEW

MAREEBA SANDS BOOSTED BY EXCAVATOR UPGRADE

“About 12 years ago we kicked off the business,” Petersen said. “I used to work for other quarries nearby and I was doing a job in the area we are now when I noticed there was plenty of sand lying about. So, I made an offer to the landowner saying we should be selling this stuff. He and I went into business; started off quite shakily and we progressed from there.”

The small business has cemented itself as a stalwart of the community, treating each customer like a friend or neighbour.

Petersen said his local reputation of more than three decades was a great help in getting the business off the ground at first, but the struggles of small business didn’t avoid Mareeba Sands.

“Because I’ve been working in earthmoving and quarrying for a long time in the area, people already knew who I was when I entered this business,” Petersen said.

Mareeba Sands has been working away in far north Queensland for 12 years, sourcing sand and hauling it across the region. But as owner Ron Petersen told Quarry, a quality service like Mareeba relies on quality products from CJD Equipment.

Mareeba Sands owner, Ron Petersen and CJD Equipment Mackay regional sales manager, Jarrad Bennett.

24 WWW.EARTHMOVERS-MAGAZINE.COM.AU

The economical EC220D uses 14 to 16 litres of fuel per hour.

“But the biggest challenge was still trying to win everybody over, even though people knew me and what I’d done. Also, with all our permits, managing the landscape was another challenge as we tried to work within the guidelines.”

The Mareeba Sands site covers four different blocks, an hour west of Cairns, varying from 12 hectares (ha) up to 40ha.

Digging no further than three and a half metres deep, Mareeba Sands has been able to supply washed coarse sand, fill sand, fine sand, clay, and concrete pre-mix to customers across the region.

Using Petersen’s own truck and dog combo, plus some “subby” fleets on bigger jobs, Mareeba Sands has proudly developed a portfolio of happy customers.

“The biggest, most constant job would be sand for the previously done sewerage works for the Mareeba Shire Council. That was quite an extensive job for them,” Petersen said.

Other Mareeba Sands jobs have been in Chillagoe and Georgetown, up to 400 kilometres away.

Of course, none of this would have been possible without the service and support

of CJD Equipment, of which Petersen couldn’t speak highly enough.

“It’s been good dealing with CJD,” Petersen said. “When you first start with ordering something, you change your mind, you go home, you change your mind again. But the financing with CJD was brilliant, professional, and super quick to deal with. We changed our mind on something at lunchtime and got an email back in the afternoon saying we were good to go – try that with a bank!”

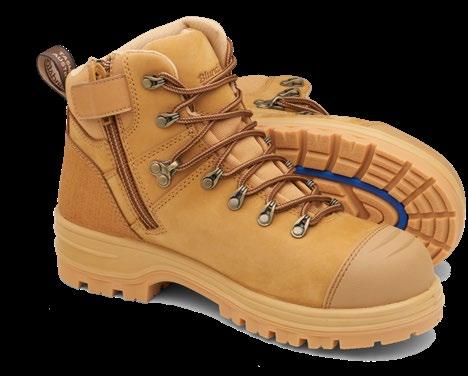

Petersen had been running an older Volvo EC210 excavator for about eight years at Mareeba Sands. The machine had totalled nearly 11,500 hours of operation.

After a more than serviceable stint from the old machine, Petersen decided it would be more cost-effective to look into an upgrade, instead of forking out more cash on repairs.

So, in rolled the EC220D excavator and Petersen couldn’t have been happier with his decision.

“The EC210 was a reliable machine with brilliant fuel economy. We were extremely happy with its stability and performance. But the new EC220D is even better,” Petersen said.

The EC220D comes with a range of extras on the previous model which pleasantly surprised Petersen. They included an auto-greaser, seat covers, UHF radio, flashing light, windscreen guards, fall protection guards, handrails, reversing camera and a heavier counterweight.

In effect, Mareeba Sands has been allowed to run at full throttle, while saving a bit of cash on repairs and fuel.

“It’s doing everything I expected of it and that’s why I went with a Volvo once again,” Petersen said.

“The other reason is their fuel economy is like no other machine I’ve used. It would average between 14 and 16 litres per hour, depending on the application.”

And while all the trimmings can help a small business like Mareeba to excel for its community, sometimes a little bit of extra care and respect is all that’s needed to maintain a strong partnership.

Petersen attested to this and praised CJD Equipment and Volvo Construction Equipment for their ability to treat “little old Mareeba” as an equal.

“I was pretty impressed because, being a small operator, you’d think they’d hardly even see you,” Petersen said.

“You can imagine, they’ve got clients who’ve got 30 or 40 machines. So, for them to look after a small operator so well is something they can take their hat off to.”

Learn more about the great range of Volvo excavators at The National Diesel, Dirt & Turf Expo from Friday 8th April to Sunday 10th April. Visit CJD Equipment at site number D11 for more information on how these versatile machines can work for you. Contact CJD Equipment on 1300 139 804 or visit www.cjd.com.au.

WWW.EARTHMOVERS-MAGAZINE.COM.AU 25

Mareeba Sands uses the Volvo EC220D excavator to make light work of its resource.

C.R. KENNEDY: TAILORED EARTHMOVING SOLUTIONS

C.R. Kennedy is the sole and exclusive distributor for Leica Geosystems in Australia, with it focused on harnessing the innovative and industry-leading iCON product portfolio to deliver tailored machine control solutions for the earthmoving industry, supported by its comprehensive national after-sales network.

The iCON range spans a variety of different technologies, comprising integrated hardware and software solutions, which can be deployed across different aspects of earthmoving operations, enabling greater efficiency when applied to both individual applications and as a component of wider workflows.

Among the Leica Geosystems range, the iCON iGG3 grader, iCON iGD3 dozer and iCON iXE3 excavator systems provide operators the tools required to get the job done faster and deliver an enhanced level of control, with each of these systems having been designed to speed up operations across a range of applications.

The iGG3 optimises material usage, bringing design surfaces and alignments virtually in the cab, breaking operators free from stakes or hubs, with it delivering millimetreaccurate control of the blade, making it ideal for all fine-grading applications.

Similarly, the iGD3 can dramatically increase machine utilisation and productivity by optimising material usage on earthmoving and fine-grading contracts, with it capable of being used with a wide range of sensors, combining ease of use with flexibility and a powerful and intuitive user interface.

Meanwhile, the iXE3 guides the operator using reference models and GNSS in 3D, with design information and real-time cut/fill indications displayed in the cab on the control panel, allowing operators to rapidly excavate to the reference design.

Software is a key component of the iCON portfolio, with the iCON site software providing users smart, customised positioning solutions for road construction and civil engineering

applications, having been designed to improve speed, performance and accuracy.

iCON site comprises an innovative and straightforward software design, featuring an easy-to-understand and intuitive interface, with it providing for seamless integration into all iCONstruct sensors and controllers.

In addition to this, iCON site provides for smooth data integration into the iCONtrol machine control portfolio and workflows, and a customisable solution to increase productivity by focusing on site-relevant tasks.

Paving the way for real-time monitoring, Leica Geosystems ConX cloud-based collaboration tool allows operators to efficiently manage all their connected construction projects and to share job-related data with all stakeholders.

ConX additionally enables visualisation and validation of localised reference models, along with survey data and constructed data with powerful analysis tools for monitoring and reporting site productivity.

Based out of Port Melbourne, C.R. Kennedy’s national network includes major state offices in Brisbane, Adelaide, Sydney and Perth, along

with regional offices in Cairns, with its workforce comprising over 250 staff, including product specialists, qualified surveyors, support staff and factory-trained service technicians.

Having been appointed the distributor for Leica Geosystems in Australia in 2001, C.R. Kennedy works under Leica Geosystems guidelines, with its service departments fully authorised by Leica Geosystems and departments located around the country.

An important component of C.R. Kennedy’s offering is its national after-sales service network, which includes training, service and repairs, along with technical support.

26 WWW.EARTHMOVERS-MAGAZINE.COM.AU

Stock is available. Enquire today.

Distributed in Australia from Nimac Pacific For further information,visit www.nimacpacific.com.au or call 0415 559 897 and 0411 488 116

Sydney | Newcastle | Canberra | Melbourne |Adelaide | Hobart | Launceston | Perth | Brisbane

W H E N VO L U M E M AT T E R S D12

Stock is available. Enquire today. Sydney | Newcastle | Canberra | Melbour ne |Adelaide | Hobart | Launceston | Perth | Brisbane Distributed in Australia from Nimac Pacific For further infor mation,visit www.nimacpacific.com.au or call 0415 559 897 and 0411 488 116 B y

DIGGER LID LAUNCHES DIGGERSHIELD KIT: NEXT-LEVEL WEATHER PROTECTION

Aussie company Digger Lid has been steadily building its reputation as a provider of simple, yet highly effective machine and operator weather protection products in recent years, and has recently added to its growing portfolio with the introduction of its top-of-the-line DiggerShield kit.

Digger Lid, the brainchild of brothers Joel and Luke Pfitzner, started out with the basic premise of keeping digger seats dry in the wet weather, and has since grown to sell thousands of specialised enclosures, Digger Lids, both in Australia and around the world.

The heavy-duty line of Digger Lids have been designed to withstand extreme weather conditions, not only providing weather protection, but also allowing operators to keep on working through in the wet, with the rapidly growing range now fitting over 60 machines.

Now, with the introduction of the DiggerShield kit, Digger Lid has developed a product for canopy machine owners and operators that places a priority on comfort and versatility, and which will provide protection in a range of conditions, including heat, rain and wind.

DIGGERSHIELD KIT: SUPER-TOUGH PANELS PROVIDE PROTECTION

The Australian-made-and-designed DiggerShield kit comprises super-tough 6mm polycarbonate sheets, available in a clear or tint option (the pricing is the same), which Digger Lid laser cuts and folds to the machine model’s specific canopy profile. The DiggerShield – which has been designed as a semi-permanent and longer lasting

offering to Digger Lid’s standard enclosures –consists of two to three panels per machine, spanning a rear, right-side and half panel on the entry side where compatible.

In addition to this, the DiggerShield, which is designed for DIY installation, features:

• No drilling or modifications – with the DiggerShield featuring various external brackets, designed to clamp to the machine’s canopy, and only then bolt to your screen’s pre-drilled holes.

• Machine float and transportation – the DiggerShield can be towed and transported (customers should refer to the Digger Lid website for specific information).

• Maximum visibility – the DiggerShield has been designed to deliver machine operators an unhindered line of sight.

• Canopy removal – is still possible with the DiggerShield installed, paving the way for ultimate versatility and machine access.

• Convenient machine access – the DiggerShield is designed to allow full access to a machine’s fuel refilling, engine bay and other assorted components.

• Everything included – all required panels, hardware and accessories are included for installation (with the DiggerShield supplied as a complete kit).

DIGGERSHIELD COMPLEMENTS

EVOLVING PRODUCT PORTFOLIO

The DiggerShield is suitable for the following excavator models: Kubota U17-3, Yanmar ViO17 Kobelco SK17SR (four

post canopy), Bobcat E20, Bobcat E17z and Wacker Neuson EZ17, with Digger Lid advising that its products are made to order on a weekly cycle.

Digger Lid states that the DiggerShield is perfect to pair with its compact and lightweight Quicky cover, designed to provide a universal fit for excavator, tracked loader and skid steer seats/controls, with it allowing for quick and easy coverage in wet weather.

The Digger Lid portfolio also includes its Original Excavator Cover, a PVC tarpaulin soft cabin enclosure, designed to provide the comforts of an enclosed cab machine, available in four universal sizes that fit over 60 different machines.

In addition to this, Digger Lid ranges: universal engine covers, skid steer loader covers, mini loader covers, micro excavator covers, and a variety of accessories and apparel.

Further information on both the DiggerShield and wider Digger Lid portfolio can be found at: https://www.diggerlid.com.au/

30 WWW.EARTHMOVERS-MAGAZINE.COM.AU

ONATDISPLAY STANDDDT#H4 6MM POLYCARBONATE (250 X IMPACT RESISTANCE OF GLASS) STAINLESS STEEL, RUBBER LINED CLAMPING SYSTEM CANOPY REMAINS REMOVABLE WITH SCREENS IN PLACE AVAILABLE IN CLEAR OR TIMTED info@diggerlid.com 1300 661 881 www.diggerlid.com.au

DITCH WITCH CEA MAXIMISING PROFIT AND PERFORMANCE

Horizontal Directional Drilling is a demanding industry and having the best equipment on the market has been an essential part in the success of Bench Direction Drilling and Civil. Bench Civil purchased its first Direction Drill in 2010, the JT2020. Twelve years later and several machines on, Barry is still a proud and loyal Ditch Witch customer maximising on profit and performance.

“When looking for a machine in the civil and construction industry you need to take a range of factors into account, such as longevity, service and durability, so when seeing what Ditch Witch had to offer, it was a pretty simple choice,” Barry explains.

“The longevity of the Ditch Witch machine is second to none. They are built tough to last through the long and often difficult days in the civil industry.”

The JT20 Directional Drill is packed with plenty of power in a compact size, and the JT20 helps you work faster so you can tackle more jobs. The JT20 has a turbocharged 74hp engine that produces less noise for the operator. It’s among the quietest in its class –while its slim yet durable profile allows you to tackle more jobs in tight places.

“We need machines we can rely on and people who understand the machines, allowing us to maximise results day in, day out. When working in the industry you understand how important it is,” Pringle says.

“For over 12 years, Ditch Witch CEA have been able provide great aftersales service, manufacturers backup and service/parts availability.”

The JT20 Directional Drill has an advanced cooling system that uses five fewer gallons

of fluid than competitive systems offering exceptional efficiency and less environmental impact, while an industry-best cruise control system simplifies drilling and back reaming.

“We have a range of Ditch Witch machines that have been purchased over time. Our collection has grown into eight various machines, which all allow us to make difficult days easier, not to mention one of the main advantages is the training of the machines with purchase,” Barry says.

Bench Direction Drilling and Civil are located in Adelaide and have proudly provided Directional Drilling and Civil works for over 12 years in partnership with Ditch Witch CEA. If you are interested in how Ditch Witch CEA can assist your next civil or construction project get in contact with them today.

Visit: www.ditchwitchcea.com.au

Ditch Witch CEA has been maximising profit and performance for Bench Directional Drilling and Civil since 2010 with a range of machines. Barry Pringle, Director of Bench Directional Drilling and Civil explains.

32 WWW.EARTHMOVERS-MAGAZINE.COM.AU

Designed for small-scale landscape and irrigation jobs, the Ditch Witch range of mini skid steers have a narrow frame for better maneuverability in tight, compact spaces. Built for heavy-duty operation, the construction-grade design improves machine durability and longevity and overall machine ROI.

WITCH

STEERS

operator comfort and convenience for working on and off the machine. SMALL ON SIZE BIG ON POWER. ditchwitchcea.com.au Contact your nearest branch today 1300 788 757 Compatible with an array of attachments for more versatility Customer-driven control placement optimizes operator comfort and reduces fatigue. Diesel engine delivers maximum power to the attachment for greater productivity. Smaller, narrower frame is perfect for YOUR JOB JUST GOT A WHOLE LOT EASIER

BRISBANE SYDNEY MELBOURNE ADELAIDE PERTH

DITCH

MINI SKID

Best-in-class operator platform design improves

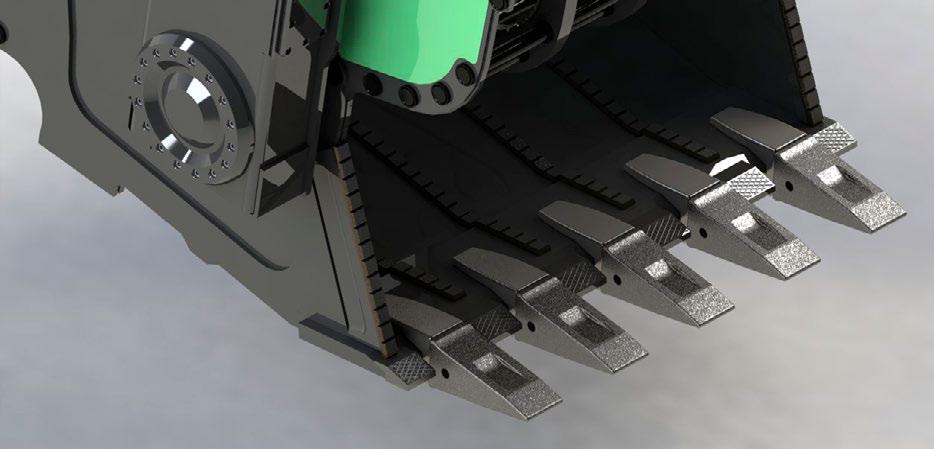

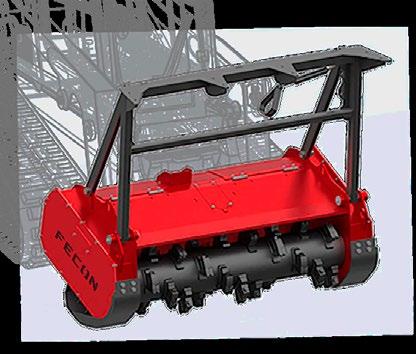

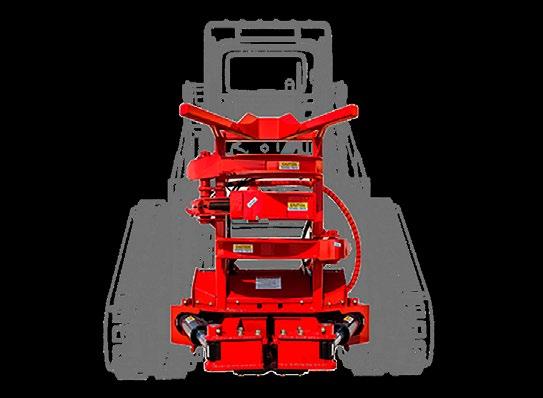

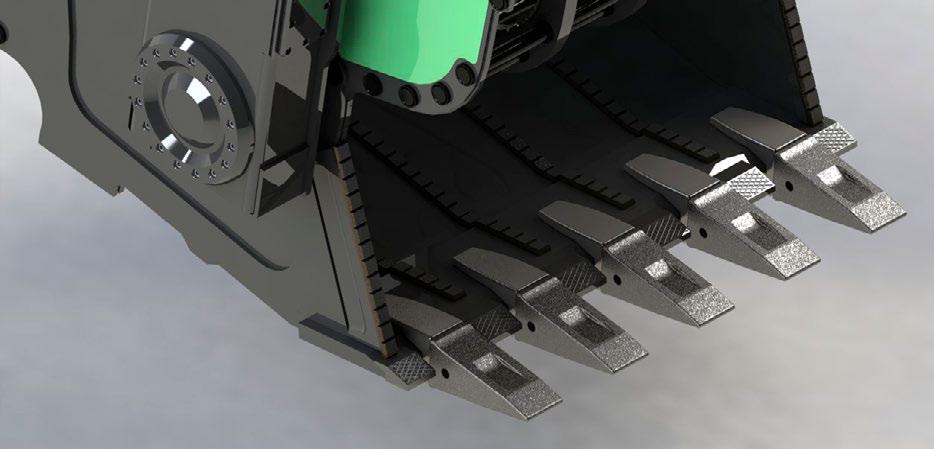

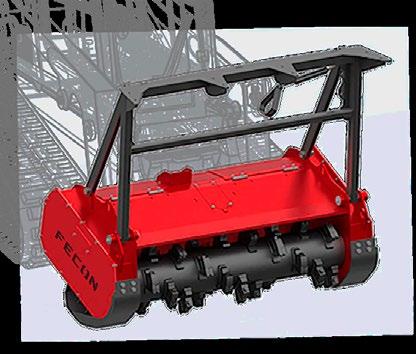

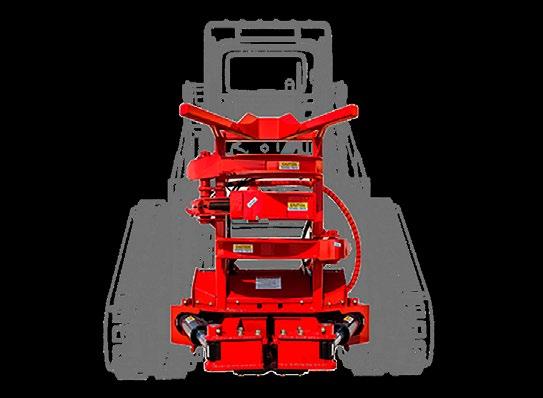

FECON FORESTRY EQUIPMENT: BUILT TOUGH FOR AUSTRALIAN CONDITIONS

Fecon is one of the world’s premier manufacturers of forestry attachments and machines, globally renowned for building the toughest attachments in the industry.

Made in the USA using premium quality steel, Fecon products are engineered and constructed with unmatched durability and power to tackle any Australian timber. Furthermore, with Fecon Australia – your national supplier of the full range of Fecon forestry equipment – customers throughout Australia receive world-famous forestry machines backed by only the best local service, support, parts and sales.

Perhaps the most legendary member of Fecon Australia’s attachment family is the iconic ‘Bull Hog’ mulching head. Designed to be powerful and versatile, Fecon Bull Hog mulchers are perfectly engineered to suit a wide variety of track and skid steer loaders offering anywhere from 53 up to 191 LPM of hydraulic flow, plus mini and large excavators sized from 5 tonne and above.

Fecon Bull Hogs satisfy the three key requirements in a forestry mulcher: durability, performance, and value for money. Innovative engineering, premium quality steel throughout, reinforced rotors and mulching teeth and exceptional welding processes combine to deliver strength and longevity. Variable motor speeds also maximise the overall performance of Fecon mulchers. For lighter material loads, higher RPM means more bites per second and finer material sizing – whereas with heavier material, the Bull Hog delivers more rotor torque keeping the rotor turning when other heads may stall.

In addition, now available is Fecon Australia’s all-new FTX200 mulching tractor. Engineered as a tough, formidable and versatile tractor

running high flow hydraulics, the FTX200 can tackle many different tasks including mulching, tree felling, bucket work, grappling, asphalt grinding, mowing, stump grinding and so much more.

With 200hp under the bonnet, 303 LPM of hydraulic flow, optional winch, steel tracks and a robust D3 undercarriage with its massive 457mm of ground clearance, the FTX200 is a perfect solution for many industries needing a supremely powerful and versatile forestry tractor.

Equally impressive is the comfort and control offered by the FTX200 – within its extremely spacious, ergonomic and climate-controlled cab are easy-to-use joystick controls and a 7-inch

touchscreen IQAN controller, allowing operators to control everything from air conditioning, to the intelligent Fecon Power Management System, and machine troubleshooting. Quite simply, you may never find a more comfortable and efficient operator cab on a track loader or dedicated forestry tractor.

Fecon Australia also offers a diverse range of vegetation management attachments, including the revolutionary low RPM Stumpex for skid steers, track loaders and excavators; an auger-style stump grinder that uses slower, yet more efficient, grind rotations to minimise mess and deliver a clean end-product. Furthermore, Fecon’s innovative tree shears are perfectly designed and constructed to nimbly shear, lift, bunch and carry multiple trees with a single attachment, also compatible with CTLs, SSLs and excavators.

Fecon Australia also offer a nationwide parts, service, sales and support network for all machines and attachments, ensuring that any scheduled or unplanned downtime is resolved quickly and easily. Don’t wait weeks for replacement parts or service requests as is standard for many forestry equipment suppliers in Australia – Fecon Australia will have your support needs catered to swiftly and efficiently.

For more information about Fecon Australia’s range of forestry machines and attachments, visit www.fecon.net.au or call the national information line on 1300 332 661.

34 WWW.EARTHMOVERS-MAGAZINE.COM.AU

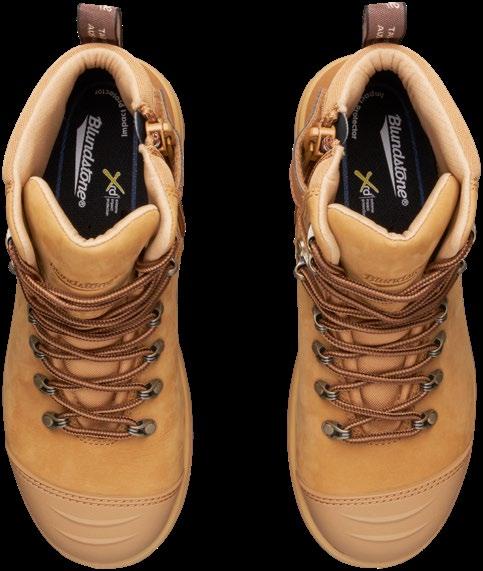

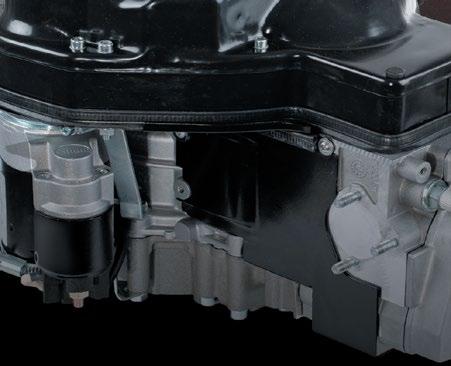

HATZ fiPMG OFFERS COMPACT SOLUTION FOR DC POWER GENERATION

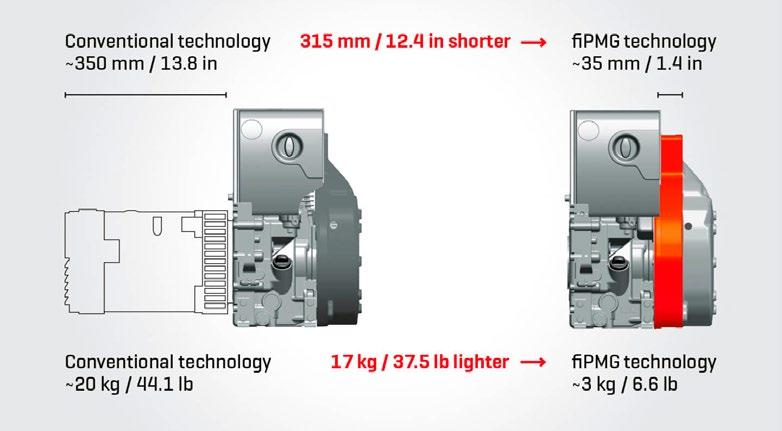

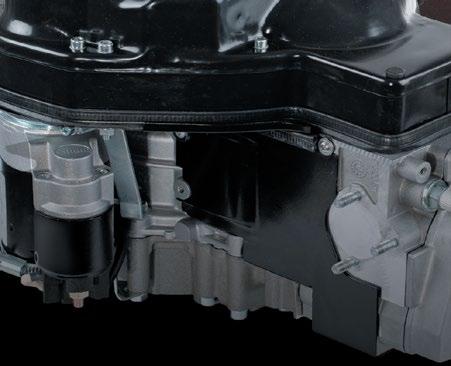

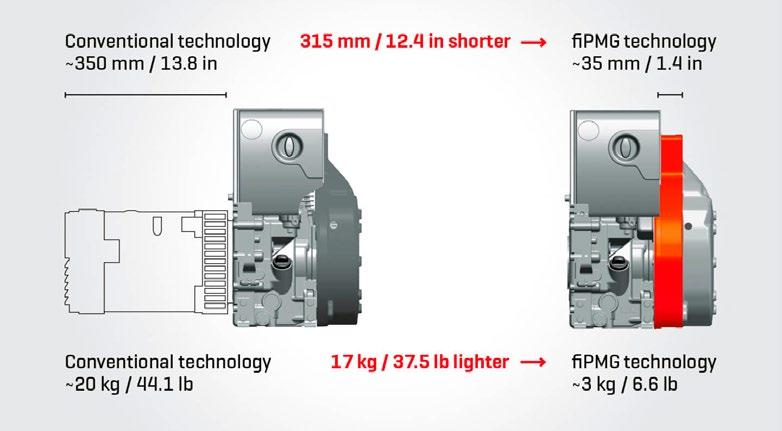

The Hatz fiPMG generator is opening the way for more product developments that will result in compact power units not thought possible for such performance and reliability previously. This is because the Hatz fiPMG generator can be integrated into an engine design, and this gives it a big advantage over a conventional or mounted design because the fiPMG generator reduces the space it requires by 90 per cent and is also 85 per cent lighter in weight.

The Hatz fiPMG generator is the ideal option moving forward to ensure the operation of critical applications in hybrid systems, as a power outage backup or by providing a continuous power supply.

Hatz’s new flywheel integrated permanent magnet generator is an exciting product gaining a great deal of attention with customers worldwide. In fact, it won the Diesel Progress Summit 2020 award for “New Power Technology”.

The fiPMG is a unique concept that combines the Hatz E1 technology, the worldfirst electronically controlled single cylinder diesel engine, with a PMG generator installed where you expect to find the engine flywheel. It’s this design combination that results in a much lighter and more compact generator package, which can operate at variable speeds based on the load required. Another well though-out advantage of the fiPMG and is available in both AC and DC at multiple voltages. The result of this overall design makes this the ideal solution for battery charging and any hybrid applications.

The fiPMG technology that Hatz has developed will quickly accelerate technologies into a new direction over the next few years into a growing interest in electrification and hybridisation of current standard equipment.

The scope of electrification/hybridisation available with fiPMG technology includes a wide range of products and will in some cases include making changes from a typical diesel engine to full electric or hybrid units.

Hatz fiPMG technology can extend the range and battery life while keeping weight and physical size in compact dimensions. The application has the potential to reduce the cost of electrical components keeping product releases profitable and affordable.

The Hatz fiPMG is already being installed into power units that require extremely reliable performance such as 5G Smart Towers, mobile light towers, solar and conventional mobile road signal equipment, mobile communications infrastructure, electrical lifts, motor homes, battery driven equipment and

Conventional vs. permanent magnet. Compared to the conventional design of the engine/generator unit, the flywheel-integrated permanent magnet design is 315mm shorter and 17kg lighter.

auxiliary power units in construction equipment or on-highway truck applications.

With the Hatz fiPMG, instead of converting from a diesel engine application to fully electric, you can use a very small diesel engine

as a battery charger that can increase your range while also reducing the size of your battery pack to compact.

To see more about Hatz’s fiPMG technology visit www.hatz-diesel.com/en/fipmg/

The Hatz fiPMG flywheel-integrated Permanent Magnet Generator when integrated into an engine takes up less space and weight than conventional designs.

36 WWW.EARTHMOVERS-MAGAZINE.COM.AU

Your Efficient Hybrid Solution.

Hatz Flywheel-Integrated Permanent Magnet Generator (fiPMG)

An extremely compact solution for hybrid power generation. Numerous applications will benefit from the advantages of the Hatz fiPMG.

Efficient and reliable ¬ Hybrid systems eliminate the range anxiety of an all electric solution while offering a lower total cost of ownership than conventional generators.

Critical size and weight

¬ Reduced dimensions and weight up to 90% compared to a conventional generator.

Highly sensitive electronics

¬ Consistent clean power for sensative electronic equipment and enables variable speed based on load.

Reduced total cost of ownership

¬ Reduced run times and engine speeds reduces fuel consumption and maintenance cost.

E1 engine technology

¬ Full electronic engine control allows for integration with battery management systems and connectivity to telematics and IoT.

Critical Applications (but not limited to) Light Towers Mini Wheel Loader Skid Steer Mini Excavator Scissor Lift Hatz Diesel Australia Tel : 1300 796 900 engines@hatz.com.au hatz.com.au

NO COMPROMISE ON RELIABILITY

Engineered to deliver greater power and productivity.

Packed with features, the Hitachi Wheel Loader range is big on Operator Comfort, Safety, Fuel Efficiency, Productivity and Reliability. Ask for a machine demonstration on your site and compare the performance today. Contact your local branch or visit www.hcma.com.au

NO PLACE FOR THE SECOND RATE – INDUSTRY LEADER

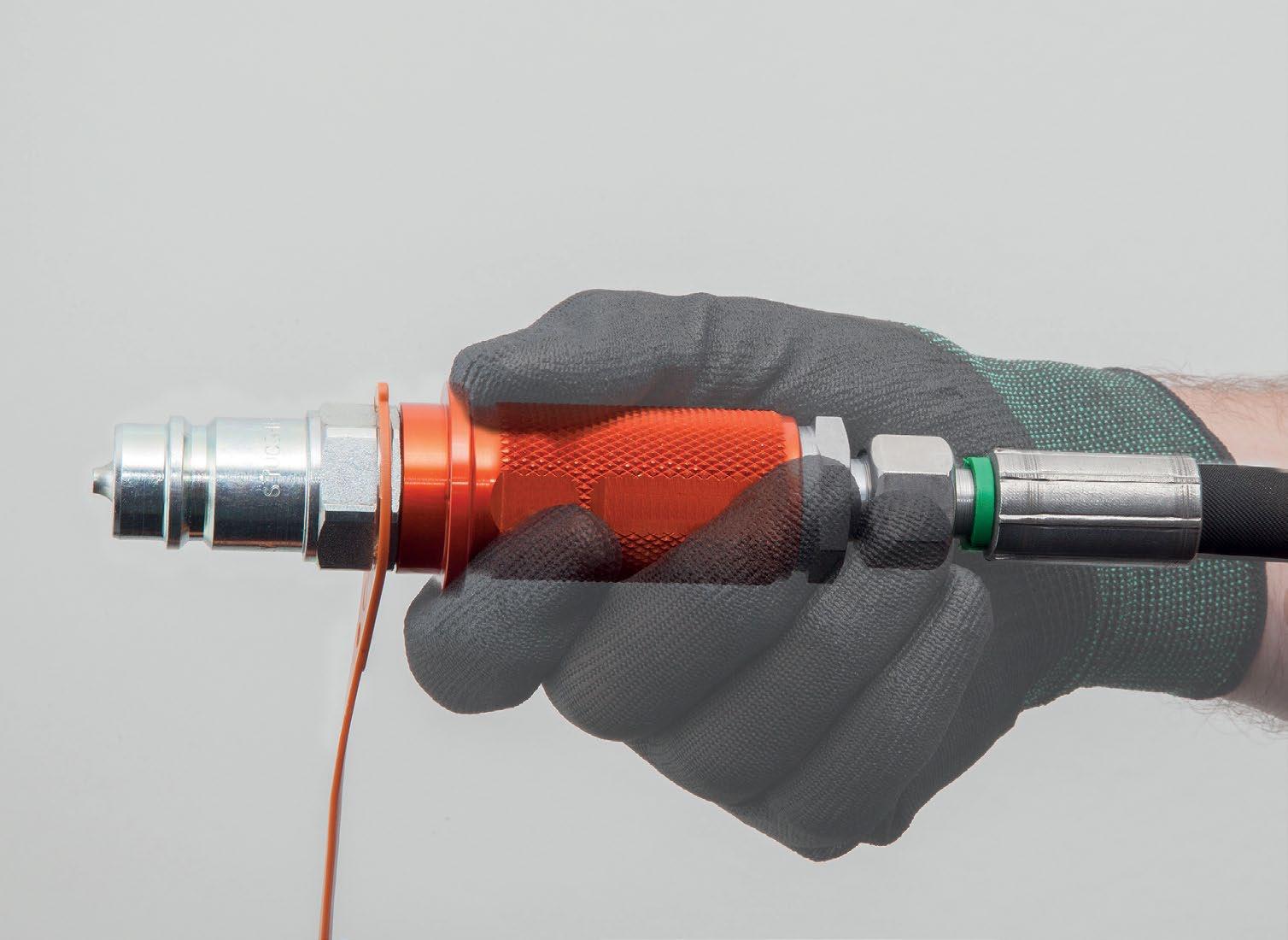

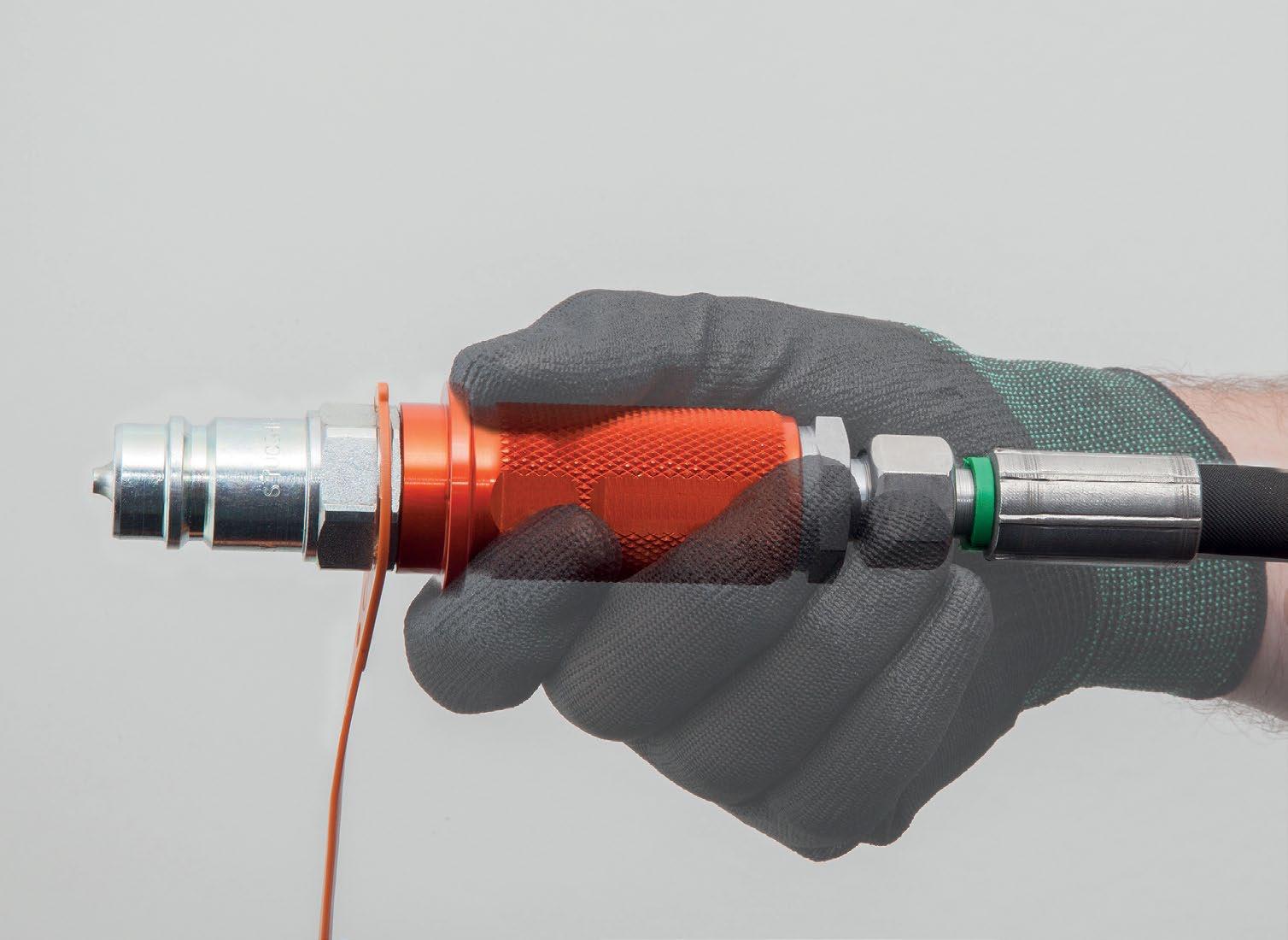

HYDRAULINK’S GUIDE FOR TOP OPERATORS INSISTING ON TOP SERVICING TO STAY THE DISTANCE

The performance, sophistication and operating pressures upon hydraulic equipment have increased significantly over recent years, and the price of earthmoving equipment has moved ever upwards as it gets better and more capable.

With individual items of earthmoving equipment costing well into six figures – and the biggest items and fleets into the multi-millions – it makes simple economic sense to maintain the expanded capabilities of this advanced technology to ensure safety, efficiency and uptime on the job.

“Servicing top equipment is a job for top hydraulic service technicians – why would you risk first-rate equipment with second-rate servicing?” says Hydraulink Hose and Fittings General Manager of Contracts and Major Projects, Ian Morris.

“After conducting industry research, we’ve found that people managing earthmoving equipment and other hydraulically actuated machinery are seeking key attributes from a hydraulic supplier, to maximise uptime and safety,” says Mr Morris.

These attributes include:

1. Proven top standards of training, safety and WH&S, as well as accreditation exceeding ISO and SAE standards. To foster a culture of safety, Hydraulink has developed its own in-house training program and facility – the Hydraulink Academy, which ensures all Hydraulink technicians, plus distributors and customers, are well-prepared, confident and up to date with all of the latest safety, environmental, and best practice processes, including several Nationally Recognised units.

2. A strong and expanding mobile fleet with hundreds of locations Australia-wide. Hydraulink’s 24/7 Mobile HSST (Hydraulink Sales and Service Technicians) fleet provides prompt service to save machinery downtime. The Hydraulink model includes a 24/7 call centre that can dispatch a technician (with a fully stocked vehicle) quickly from any one of the hundreds of locations throughout Australia.

3. The resources and backing of a successful national network. The Hydraulink network is a team of dedicated and loyal people with a depth of expertise built from scrupulous staff, franchise, and leadership selection policies.

4. Familiarity with customer sites and diverse machinery. Typically, a skilled technician familiar with multiple machinery in an industry

With hydraulically actuated machinery costing typically from hundreds of thousands to more than 2 million each, servicing is no place for penny pinching today to produce big problems tomorrow.

can do a better job in less than half the time taken by a less skilled or DIY operator.

5. A robust and reliable supply chain. Hydraulink was able to manage the recent pandemic disruptions with proven supply chain strategies – including industry-best forecasting, purchasing, stocking, warehousing, and logistics performance.

6. Cost-efficient prices. Along with consistency of work, pricing consistency is always a top priority in competitive industries like earthmoving. No one wants cost surprises at the end of a job, or different prices for the same job.

7. Top standards of predictive maintenance to help obviate unexpected downtime. An ability to anticipate the unexpected, ingrained by long years of experience and delivering deep value might never appear on an invoice, but it does on the profit and loss sheet. Hydraulink provides machine health checks and has a HydraTag value add service available that can note and store all of a machine’s hydraulic hose and fitting products data. This allows for the quick and easy look up, replication and replacement of vital parts in the event it’s needed.

8. A positive, can-do attitude. Hydraulink has been in the industry since 1945 and believes that a model focused on safety and quality is much better than half measures or quick fixes that ultimately cost more than they are worth and push the risk of bigger trouble just a little further down the timeline.

9. Proven, locally focused and owner-operator and franchise business models. Hydraulink’s franchise, distributor and branch model delivers specialised skills required by industry, particularly in areas where there is a locally specific type of industry that uses specialised and expensive machinery.

“Overall, Hydraulink’s main aim and purpose is to keep industry, equipment and valued customers working – minimising the cost of downtime and maximising lifespan and uptime for expensive machinery,” says Mr Morris. No race to the bottom

“One of the interesting things to emerge from the feedback was that customers were typically not interested in a race to the bottom, focused solely on the cheapest job. Sure, they wanted competitive pricing, but not at the expense of sustainable machinery performance. They were highly focused on having the reassurance of a partner that would be there with the right skills when they were needed,” says Mr Morris.

“Getting the best out of machinery is a deep value equation, not hit-or-miss, or DIY, to save a dollar today for a big risk tomorrow. Why would you do that, risk a fortune to save a dollar? Why would you spend your time doing a job someone else can do better, faster and with greater certainty? You may quickly discover that, if something sounds too good to be true, it usually is.”

Hydraulink Australia 1300 36 37 34.

Hydraulink New Zealand 0800 80 66 66.

40 WWW.EARTHMOVERS-MAGAZINE.COM.AU

WHAT IS THE HYDRAULINK DIFFERENCE? Premium Quality Hose & Fittings Exceeding SAE and ISO Standards Hydraulink Academy Trained Industry Leading Technicians Fast, Reliable, 24/7 Mobile Service Australia-Wide » Respond promptly - 24/7 mobile service and over 140 Hydraulink locations, Australia-wide » Minimise downtime and keep your machinery working » Have a team of highly skilled, experienced and trained technicians » Supply high quality hydraulic hose and fittings » Be a reliable, capable and trusted business partner OVER 140 LOCATIONS NATIONWIDE YOU CAN COUNT ON HYDRAULINK TO: www.hydraulink.com.au Discover the Hydraulink Difference 1300 36 37 34 Phone

JOHN DEERE EXPANDS UPON PRECISION TECHNOLOGY SUITE WITH SMARTGRADE

REMOTE SUPPORT

John Deere is pleased to offer SmartGrade Remote Support on its newest SmartGrade dozers, motor graders and compact track loaders. SmartGrade Remote Support, which includes both Remote Display Access (RDA) and Wireless Data Transfer (WDT), will be available on most SmartGrade products for six years from the factory invoice date.

Currently available on the 700L/750L/850L SmartGrade dozers, the SmartGrade motor graders and the compact track loaders, these features enable dealers and customers to work together to remotely transfer project files to machines and troubleshoot any grade control-related issues. This is important for more efficient management of large GPS equipment fleets. Real-time remote visibility and management of important grade control parameters can save valuable troubleshooting time and keep machines up and running.

Dealers can also use the latest technology for operator training and troubleshooting.

“Offering real time support to our customers is key, especially when it comes to the Precision Construction lineup. By incorporating technology like SmartGrade in our dozer lineup, we are helping to boost job site productivity and efficiency while enhancing the capabilities of our operators,” said Sean Mairet, product manager grade control, John Deere Construction & Forestry. “There isn’t always a one-size-fits-all solution, and contractors need options to pair the right technology with their business needs. This is where customers really benefit from the flexibility of our grade management path.”

SmartGrade Remote Support is crucial in providing customers with the most efficient method of troubleshooting and increasing uptime and enables the dealer to remotely

monitor and support the machine from miles away. Wireless Data Transfer provides the ability to remotely send updated design files to the machine, saving trips to the job site. Any user with a MyJohnDeere.com account paired with the machine can utilise remote support.

To learn more about SmartGrade Remote Support, as well as the full range of John Deere Precision Construction technology solutions, scan the QR code.

John Deere adds SmartGrade Remote Support to precision technology suite.

John Deere adds SmartGrade Remote Support to precision technology suite.

™

42 WWW.EARTHMOVERS-MAGAZINE.COM.AU

A

NEW DAY.

UNEARTH A NEW LEVEL OF PERFORMANCE.

A NEW DEERE.

Renowned worldwide for their outstanding quality and reliability, John Deere mid-sized excavators are designed and built using state-of-the-art tools, techniques and components by a quality-conscious workforce in a John Deere manufacturing plant. Loaded with operator friendly features such as a 7” touch-screen monitor, Intelligent Hydraulic system and PowerTech™ Plus engine, these machines deliver impressive performance with smooth, low-effort control. And with our expert dealers in more locations across Australia than ever before, you’ll get the support needed to ensure your operation is running at maximum productivity.

It’s a New Day and a New Deere.

TRACTA_J64793_CONSTRUCTION_AU_EEM

JohnDeere.com.au/ANewDay

EARTHMOVING MACHINERY PARTS MANUFACTURED

AND DISTRIBUTED BY ITR, DIRECT TO YOU

ITR Pacific is part of the USCO ITR Group – the world’s largest aftermarket supplier of earthmoving machinery parts.

With an extensive geographical footprint of warehousing and workshops in the Australian market and industry experts in each region, ITR Pacific can offer a superior customer experience across a full range of Undercarriage Parts, Rubber Tracks and Pads, Ground Engaging Tools, Repair Parts, Tyres and more.

The unparalleled range held locally, and support from the Group, means ITR Pacific can confidently sell into all sectors of the Australian market, including Mining, Construction, Plant Hire, Agricultural and Forestry Industries.

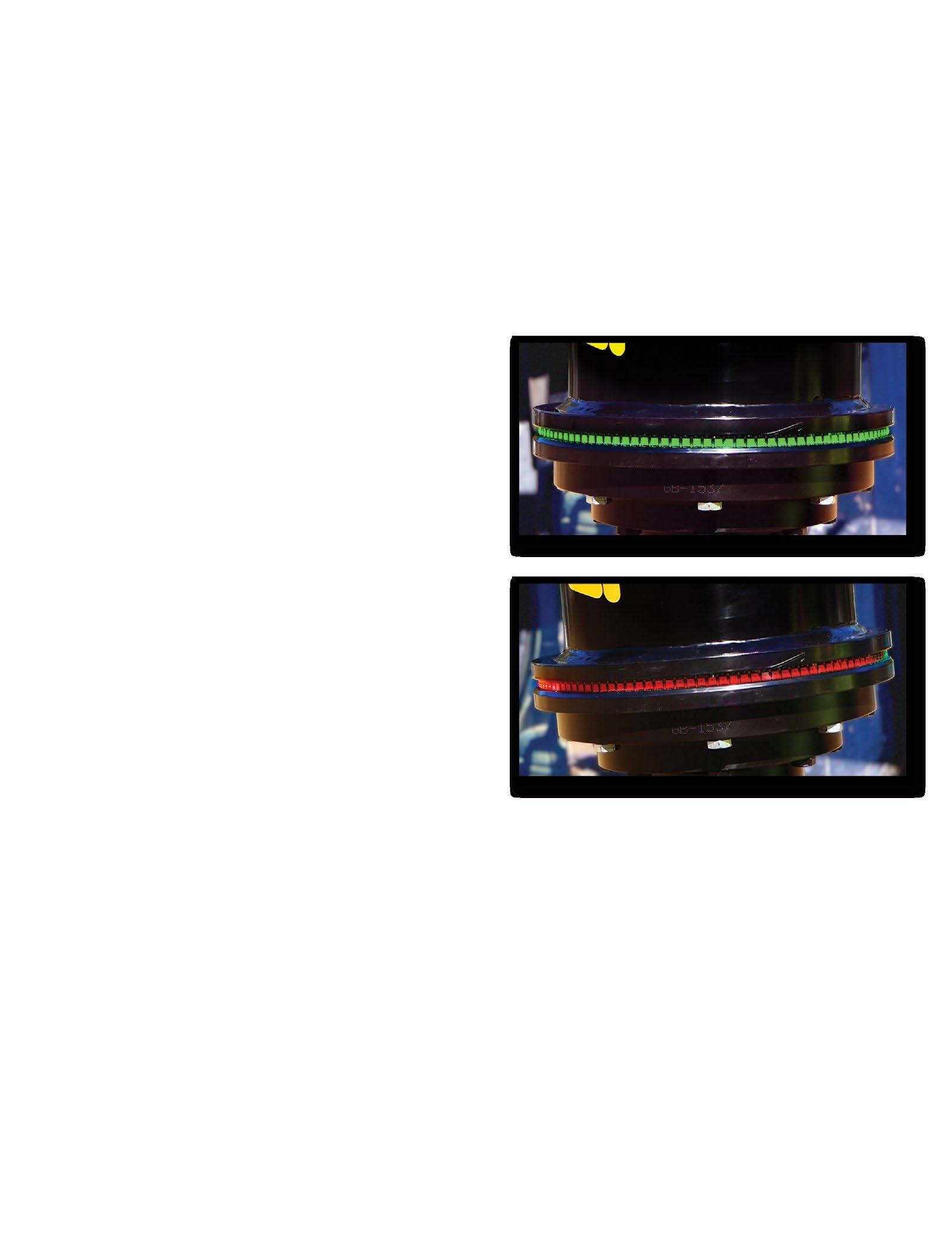

UNDERCARRIAGE

ITR has one of the most complete undercarriage ranges on the market, covering components such as track chains, shoes, rollers, sprockets, idlers, and segments, which are manufactured within the group’s Asian manufacturing facilities. A fundamental characteristic of the ITR Undercarriage product line is that its production is entirely managed in-house: from the component design to the choice of material through to production. Numerous quality controls throughout the manufacturing process are carried out to ensure all products meet O.E.M standards.

an excellent quality level and the necessary confidence to brand the product ITR. ITR can today confidently say that they carry one of the most complete product ranges for Mini Undercarriage.

GROUND ENGAGING TOOLS

ITR Pacific stocks a full range, covering most makes of Ground Engaging Tools. The product line comprises all the necessary wear parts for manufacturing, reconditioning, and maintenance of bulldozers, excavators, loaders, and graders. The heterogeneous mix consists of teeth and adapters, cutting edges and end-bits, single and double bevel edges,

RUBBER TRACKS AND PADS

Rubber Tracks and Pads have recorded strong and steady growth since first introduced into the group in the 1990s. ITR Rubber Tracks are the fruit of a long road of design studies and tests in the field, which has achieved

44 WWW.EARTHMOVERS-MAGAZINE.COM.AU

blades, fasteners, and all other components necessary for excavation or levelling, such as rippers and blades for graders.

MACHINERY REPAIR PARTS

Thanks to careful design, technological innovation, and strict process controls, ITR Repair Parts have always been synonymous with high quality. This product range is continuously developing, not only by building up a strong distribution network but also through acquisitions that have helped expand their product offering to cover engine, hydraulic, transmission and frame parts.

OTHER PRODUCTS

ITR has developed a range of smaller product lines to meet the market demand. ITR Radial tyres are the best in their class for the mining industry, heavy-duty construction, and industrial applications. Alongside tyres, there is hydraulic hammers, aluminium loading ramps, portable track presses and fuel tanks, buckets for excavators and loaders, and much more.

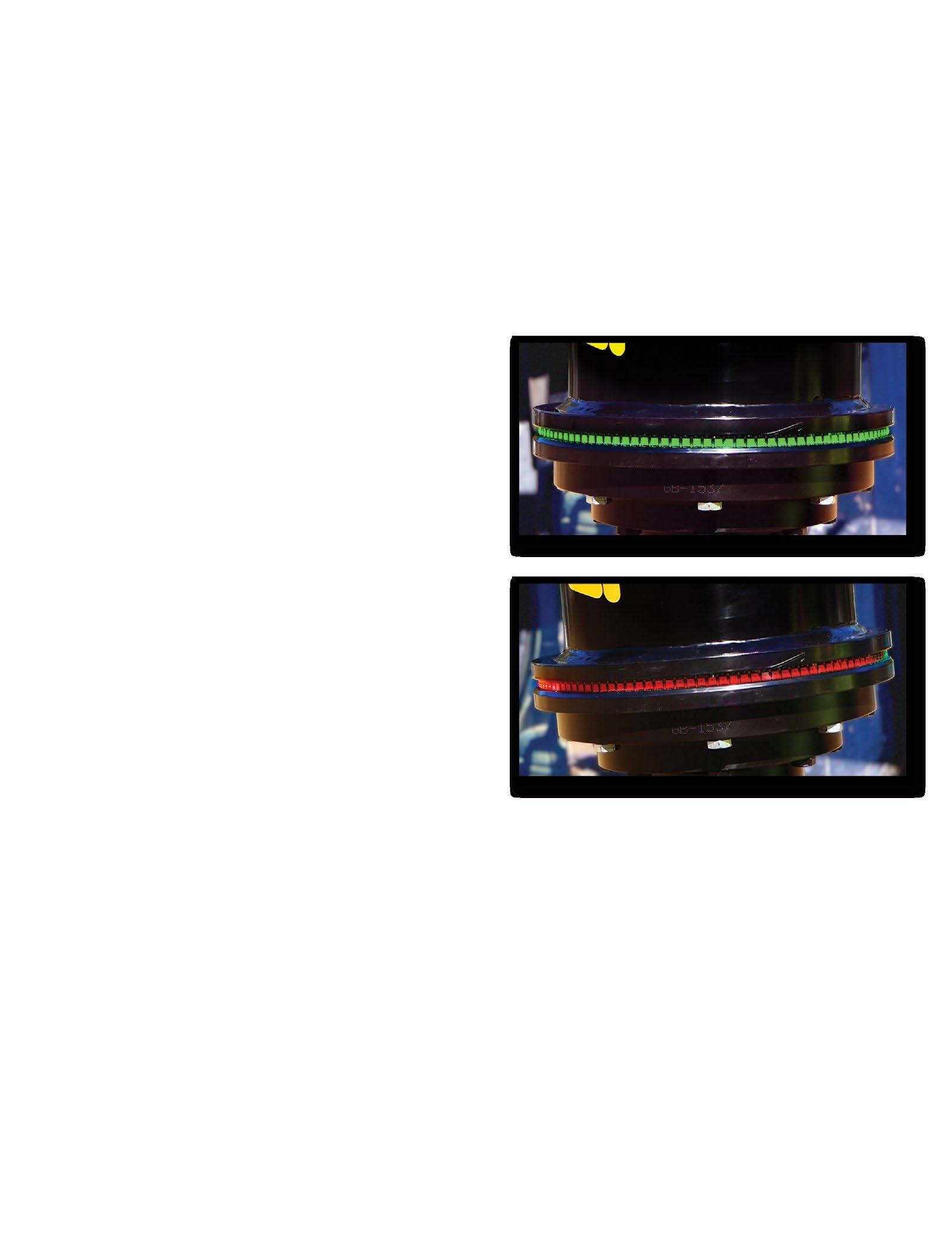

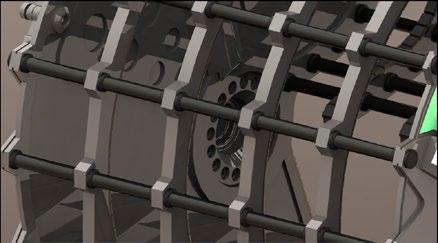

FULLY EQUIPPED TRACK SHOPS

Expanding passed just the parts, ITR Pacific is targeting a new opportunity with the introduction of two new Undercarriage, Workshop facilities into both their QLD and NSW operations. This new development will allow ITR to use all their knowledge and expertise to ensure the process of track lengthening, shortening, new link assembly bolts ups, and pin and bush turns are streamlined and efficient for a quick turnaround time. As ITR does not compromise on the quality of the parts, they have certainly not compromised on the quality of their Track Workshop Equipment, ensuring that each job can be carried out professionally and exceed their customers’ expectations.

ON-SITE UNDERCARRIAGE INSPECTIONS

ITR Pacific knows that a large percentage of the cost in owning and operating a track-type machine is related to its Undercarriage, therefore it is recommended to be proactive and have your Undercarriage inspected regularly to get the most life from your asset.

ITR Pacific offer professional Undercarriage Wear Inspections and detailed reports using the ITR WearTek Plus reporting system, allowing customers full access to their track reports through a mobile app and online web portal.

RUBBER TRACK INSTALLATION

With the acquisition of DTN Equipment in July 2020, ITR Pacific expanded their sales and service arm to include the fitment of excavator and skid-steer loader Rubber Tracks, along with other Undercarriage Parts such as Rubber Pads and Sprockets. The ITR Mini Undercarriage installation team currently consists of two service vehicles that operate in Southeast Queensland, with plans to expand this service to their Sydney, Melbourne, and Perth branches. With over 53 years of invaluable industry experience and qualified specialists, ITR will use the successful and well-known DTN model when establishing its fitment services Australia-wide.

The substantial growth ITR has seen over the last 12 months is nothing more than a reflection on the Australian Earthmoving Industry and the services and parts that it is demanding. To find out more about ITR’s full product offering and services, give them a call on 1300 820 214 or visit their website

For more info visit www.itrpacific.com.au

WWW.EARTHMOVERS-MAGAZINE.COM.AU 45

ITR Pacific offers a complete range of aftermarket Earthmoving Machinery Parts for most makes & models of Loaders, Graders, Dozers, Excavators, Scrapers & more.

Your 1st Choice for Earthmoving Machinery Parts The manufacturers’ names, numbers, symbols and descriptions are used for reference purposes only and it is in no way implied that any part listed is the product of the manufacturer. BRISBANE MELBOURNE SYDNEY PERTH KALGOORLIE 2 Lions Park Dr Yatala QLD 4207 07 3807 9188 info@itrpacific.com.au 177 Northcorp Bvd Broadmeadows VIC 3047 03 8301 9500 info@itrvic.com.au 7 Narang Pl St Marys NSW 2760 02 8608 1144 info@itrnsw.com.au 499 Great Eastern Hwy Redcliffe WA 6104 08 9479 4800 info@itrwa.com.au 23 Darcy Ln Kalgoorlie WA 6430 08 9035 6600 info@itrwa.com.au www.itrpacific.com.au 1300 820 214 PREMIUM UNDERCARRIAGE Track Chains Rollers Idlers Track Shoes Sprockets Track Hardware REPAIR PARTS Engine Parts Transmission Parts Hydraulic Parts Final Drives Frame & Body Components Miscellaneous Parts MINI UNDERCARRIAGE Excavator Rubber Tracks CTL Rubber Tracks ASV Posi Tracks Rubber Pads Steel Track Groups Rollers Sprockets Idlers GROUND ENGAGING TOOLS Teeth & Adapters Cutting Edges & End Bits Grader Blades Bucket Protection Double & Single Bevel Edges Half Arrow Blades Plow Bolts & Nuts SITE L2

24-TONNE JCB 467 ZX WHEEL LOADER

There are many reasons to choose the top-of-the-range 24-tonne JCB 467 ZX loading shovel. It’s productive, efficient, easy to maintain and extremely durable.

For ultimate reliability JCB constructed their wheel loaders using only the very best componentry, including a Cummins Engine, ZF driveline, Bosch Rexroth pumps and Parker Valve block.

The whole of the 467 ZX front loader went through an extensive development program to ensure its durability, including 1.2 million test cycles.

Computer-aided finite element structural analysis to make these wheel loaders last longer – the front-end loaders are used in every corner of the globe – JCB tested the 467 ZX to ensure optimum operation in climates ranging from -20°C to 50°C.

The 467 ZX front loader has a large diameter loader and articulation pins; bushes have secondary seals, which block dirt. Operating 467 ZX front-end loaders is ergonomic. Forward/reverse direction control is a fingertip away, and electro-hydraulic servo controls make loader end handling easy. Return-to-dig, arm height limitation and float functions are always at hand. Disabling these aids is easy too.

This wheel loader’s ZX geometry means that shovel corners are highly visible for excellent manoeuvrability. In fact, visibility is excellent all-round on this front loader, with a threepiece laminated front screen, heated exterior mirrors and a sloping rear bonnet design.

The spacious 3m 3 cab on the 467 ZX front-end loader is fitted with a full-colour LCD dash display with analogue dials. The 467 ZX’s cab is isolator mounted for quietness and it’s positively pressurised to keep out dust. JCB’s smooth ride suspension system reduces shock loadings and spillages.

The JCB 467 ZX front loader’s 216kW Cummins engine is mated to a 4-speed ZF fully automatic powershift transmission and standard-fit limited slip differentials for stepless gear changes and smooth operation.

For the ultimate in precise, efficient control, the JCB 467 ZX front loader’s innovative variable displacement pumps feed a load-sensing valve block, only consuming power on demand. They can provide 395 l/min hydraulic flow for maximum multifunctioning performance.

Clever electronic management can control progressive clutch cut-off on the 467 ZX front loader. This equates to efficient, productive loader control. The feature automatically diverts maximum power to the loader hydraulics for optimal truck/hopper loading duties.

Unloaded spool valves lower the 467 ZX’s loader arms lower under gravitational – not hydraulic – force. Meanwhile, wheel speed braking means brakes rotate at wheel speed

for heat and drag reduction, as well as improved fuel economy.

The 467 ZX loading shovel’s axles use planetary drive with cylindrical roller bearings for minimal power and heat loss. Meanwhile, wheel speed braking and a low drag coefficient provide maximum power with low fuel use.

467 ZX front loaders have class-leading service and maintenance access, and long 500-hour service intervals. A side bay offers easy access to pressure test points, transmission filters, emergency steer pump, batteries and isolator.

Greasing is convenient from ground level and wide-opening gullwing doors provide easy access to this wheel loader’s engine bay and cooling pack areas.

The 467 ZX front-end loader has a variable speed hydraulic cooling fan that automatically reacts to ambient temperatures and adjusts the fan speed for maximum economy. A single-faced wide core radiator helps to maintain the optimum operating temperature.

JCB’s Electronic Management System controls tractive effort via the front loader’s transmission to reduce service brake wear and fuel consumption.

Auto-idle technology automatically reduces the engine speed of the JCB 467 ZX wheel loader when not in use, which helps reduce fuel consumption and prolong engine life.

For more information call 1300 522 232 or visit www.jcbcea.com.au/machines/wheel-loaders/ 467-zx-wheel-loader/

48 WWW.EARTHMOVERS-MAGAZINE.COM.AU

MINIMUM SWING

MAXIMUM SPACE

Introducing our latest addition to the X Series. At just 1,720mm, the new 245XR has a 40% shorter tailswing than the conventional 220X, making it ideal for work in confined urban sites and highways. Despite having reduced tail swing, the 245XR still boasts one of the biggest, most comfortable, quiet and easy to operate cabs on the market, while our proven Tier 4 Final DIESELMAX engine and selectable swing smoothing as standard provide optimum performance in any application.

NEW 245XR EXCAVATOR

your local dealer today 1300 522 232

Contact

www.jcbcea.com.au

EXCAVATOR ATTACHMENTS

Tried. Tested. Trusted.

The job site is no place for equipment failure. Rhino Buckets are built to withstand more. Built with Bisalloy® steel, all welds exceed Australian Standards for guaranteed strength and longevity.

Rhino Excavator Attachments are built for the toughest job sites:

+ Rhino buckets were designed, tested and proven over years on the job in the punishing Pilbara. Thousands of kilometers from a replacement, our customers depend on Rhino delivering quality when and where it matters most.

+ Backed by a 2-year warranty and industry-best support - we don’t hide behind legal fine print.

+ Dual Radius Profile on digging buckets stops excess drag on the bucket and offers dramatic performance advantages

Done right, with Rhino

+ 1800 818 079 + kerfab.com.au + sales@kerfab.com

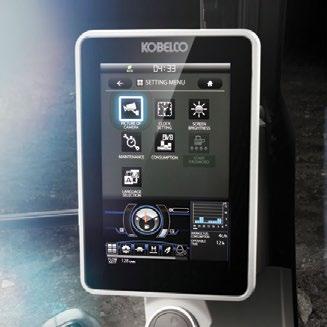

KOBELCO SK850LC-10 DELIVERS SUPERIOR POWER AND PERFORMANCE FOR HEAVY-DUTY JOBS