Price $7.95 inc GST Feb/Mar 10 Price $9.95 inc GST JUNE/JULY 2022 JUNE / JULY 2022 CASE STUDIES: LEADER EARTHWORKS AND WESTRAC NT EXCAVATION & DEMOLITION AND CJD EQUIPMENT GLOBAL UTILITY CONSTRUCTION AND WESTRAC CAT ® INNOVATIVE PRODUCTS EYE ON THE INDUSTRY INDUSTRY EVENTS TEST DRIVE: UHI US40K SKID LOADER D&J's CIVIL UPGRADES TO KOBELCO XD SERIES AUSTRALIA'S LEADING MAGAZINE FOR THE EARTHMOVING INDUSTRY

Support you can rely on. Call us today on 1300 566 287 komatsu.com.au *Terms and conditions apply visit: https://komatsuweb.link/q1-2-dozerpromo-2022

4 years / 8,000 hours Komplimentary Maintenance and Premium Warranty * Komatsu Bulldozer Purchase a *

‘Mopping up’ is probably a fair description of the Diesel Dirt & Turf aftermath.

The worst run of wet weather NSW has seen since meteorological record-keeping started threatened to dampen not only spirits for the Expo, but to pretty much saturate the exhibitors and attendees as well.

Of course, it takes more than several months of torrential rain and flooding to a substantial proportion of NSW to slow down the Australian earthmoving industry, and as it happened over 70,000 people turned out to see the latest equipment, listen to experts and visionaries speak and to wander around Eastern Creek’s Sydney Dragway taking in what was truly an amazing and exciting atmosphere.

Keeping up with the theme of entrepreneurship, Jamie and KahChi set up a stand outside the front gate selling umbrellas. I gather it worked out okay, because I haven’t seen them since. They keep sending me postcards from somewhere called

GET IN TOUCH

Do you have something you’d like to share with the industry? Send EEM an email at tom@maynemedia.com.au We’re keen to get your thoughts.

Rosewood Baha Mar in the Bahamas asking if I could please let the local police know the pair were in the office at the time a large consignment of wet-weather gear was stolen from a warehouse in Paramatta.

As always, despite appearances, they must’ve done some work before they left. As I scan through the material for this issue I see it’s another blockbuster.

In addition to the DD&T wrap up, we’ve had an in-depth chat with Phil Immisch of Leader Earthworks and Morgan Rose of WesTrac. Phil’s story is an inspirational journey from being a sole owner-operator to being at the head of a thriving company with 40 staff and a fleet of machines in around eight years of hard work and smart decisions, one of which was to use Caterpillar equipment from WesTrac.

Similarly, Global Utility Construction started out small, grew fast, and is now a huge and growing concern, and principals Luke Maxwell and Aaron Wright are also very

happy with their company’s association with WesTrac. It’s another success story where the directors made smart decisions, but are also full of praise for a hard-working team and support from the equipment supplier.

We also have case studies on NT Excavations and CJD Equipment, and we took the UHI US40K Skid Loader for a ride on a work site and found it was a first-class piece of machinery.

So maybe Jamie and KahChi do deserve a break.

Still, there seem to be a lot of raincoats, wellington boots and waterproof pants in the storeroom. If they hadn’t sold all the umbrellas I doubt everything would fit in there.

They must be planning a story on rain apparel for next issue. They’re always thinking, those two.

Tom Foster Contributing Editor

FROM THE CONTRIBUTING EDITOR 4 WWW.EARTHMOVERS-MAGAZINE.COM.AU

YOUR ONE STOP SHOP

For almost half a century, STM has made it possible for businesses across NSW to power up – supplying and servicing quality trucks and machinery to meet the demands of any job.

Starting out in a single shed in the 1970s, we know what it takes to build a business – and are passionate about helping you grow yours. Today, our family owned and operated enterprise is proud to offer a multi-site, modern service, with a team of more than 120. We care about giving every customer the best experience possible – with a wide range of trusted brands, flexible finance, spare parts, repairs and personal service.

We may have come a long way from that shed, but our family commitment to quality remains. Whatever your size, whatever your budget, STM is your one stop shop – with everything to keep your business moving.

STM FOR MACHINERY SYDNEY / WOLLONGONG / CANBERRA WWW.STM.COM.AU 02 4647 4488

Jamie Gray

Jamie has been a professional photographer in Sydney for over two decades. He is the owner of Camera, Hammer and Tong, who provides digital content for small businesses in and around the construction industry. He is also a photo journalist & the product feature editor for What Tradies Want Magazine. But he’s just as comfortable with a hammer in his hand as a camera and pen. Undertaking a mature age carpentry apprenticeship in his 40s and still gets the nail bag on when he can.

Martin Kovacs

Martin Kovacs is a journalist with experience covering the business, technology and energy sectors. Over the past 10 years, Martin has covered a wide range of subjects across both print and digital media, broadly encompassing business and technology trends, focusing on issues of importance for industry. Martin takes a particular interest in digital technology developments and the manner in which industry continues to adapt and evolve amid the rollout of new technologies.

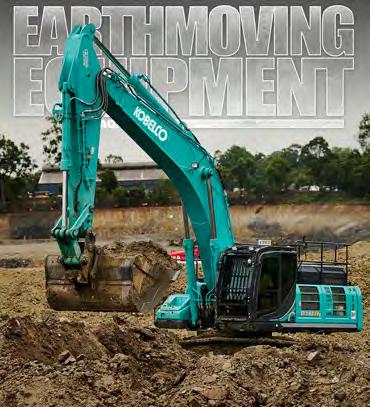

10. On the Cover 18. Meet the Expert 24. Industry Auctions 26. Industry Leaders 30. Business and Finance 32. Machine Control Technology 36. Industry Insurance 38. Industry Training 40. Marketing and PR 42. Dealer Profile 46. Test Drive 54. Case Study 76. Innovative Products 98. Eye on the Industry 118. Industry Events 126. Civil Contractors Federation Victoria 127. Subscribe Now Price $7.95 GST Feb/Mar 10 Price $9.95 inc GST JUNE/JULY JUNE JULY 2022 CASE STUDIES: LEADER EARTHWORKS AND WESTRAC NT EXCAVATION & DEMOLITION AND CJD EQUIPMENT GLOBAL UTILITY CONSTRUCTION AND WESTRAC CAT® INNOVATIVE PRODUCTS EYE ON THE INDUSTRY INDUSTRY EVENTS TEST DRIVE: UHI US40K SKID LOADER D&J's CIVIL UPGRADES TO KOBELCO XD SERIES AUSTRALIA'S LEADING MAGAZINE FOR THE EARTHMOVING INDUSTRY CONTENTS JUNE / JULY 2022 CONTRIBUTORS

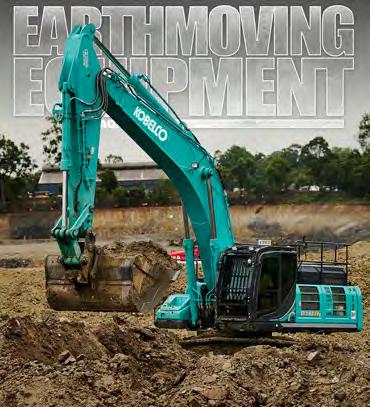

ON THE COVER: KOBELCO XD SERIES 6 WWW.EARTHMOVERS-MAGAZINE.COM.AU

Scott Lidster

Scott is the Director of Australian Earth Training, a niche operator proficiency training organisation who work across the globe. He has over 25 years’ experience in heavy equipment operation and was an accredited Caterpillar Dealer Instructor (CDI) Trainer-Demonstrator. Scott’s unique skill set enables him to operate and train on a broad range of machines across the mining, construction, quarrying and waste industries, helping his customers to boost their productivity while lowering their owning and operating costs.

Diesel Dirt & Turf Expo, Sydney Dragway, 2022.

Ian Edwards

Ian Edwards is a Civil Construction Teacher and Assessor, who holds a Certificate IV in Civil Construction Supervision and Operations, a Certificate III in Civil Construction – Plant Operations, and a Certificate III in Civil Construction – Pipe Laying along with numerous Certificate III Civil Construction qualifications.

Ian has been involved in the Earthmoving industry for nearly 50 years, operating his own excavations company since 1972 and life member of the Golden Bucket. He has been operating excavators, backhoes, front end loaders, skid-steer loaders, and all associated attachments throughout his career.

Earthmoving Equipment Magazine is Published Bi-Monthly by Mayne Media Group Pty Ltd Publisher Kurt M. Quambusch Contributing Editor Tom Foster tom@maynemedia.com.au Features Editor Jamie Gray jamie@maynemedia.com.au Group Sales Manager KahChi Liew kahchi@maynemedia.com.au 0421 474 407 Production Manager Natasha Spencer production2@maynemedia.com.au Design Ryan Turner art@maynemedia.com.au Subscriptions reception@maynemedia.com.au (02) 9452 4517 ISSN 1835-2634 ACN 130 678 812 ABN 27 130 678 812 Subscribe: www.earthmovers-magazine.com.au Enquiries: Phone: 1300 76 4688 Int.ph: +612 9452 4517 Fax: (02) 9452 5319 Int.fax: +612 9452 5319 Copyright 2021. Mayne Media Group Pty Ltd. Material may not be reproduced or photocopied in any form without the written permission of the publisher. Mayne Media Group Pty Ltd believes that all material is correct at the time of printing CIRCULATION: 14,718 Last audit: September 2020 CIRCULATION (SEPTEMBER 2020) 14,718 PROUDLY PRINTED IN AUSTRALIA WWW.EARTHMOVERS-MAGAZINE.COM.AU 7

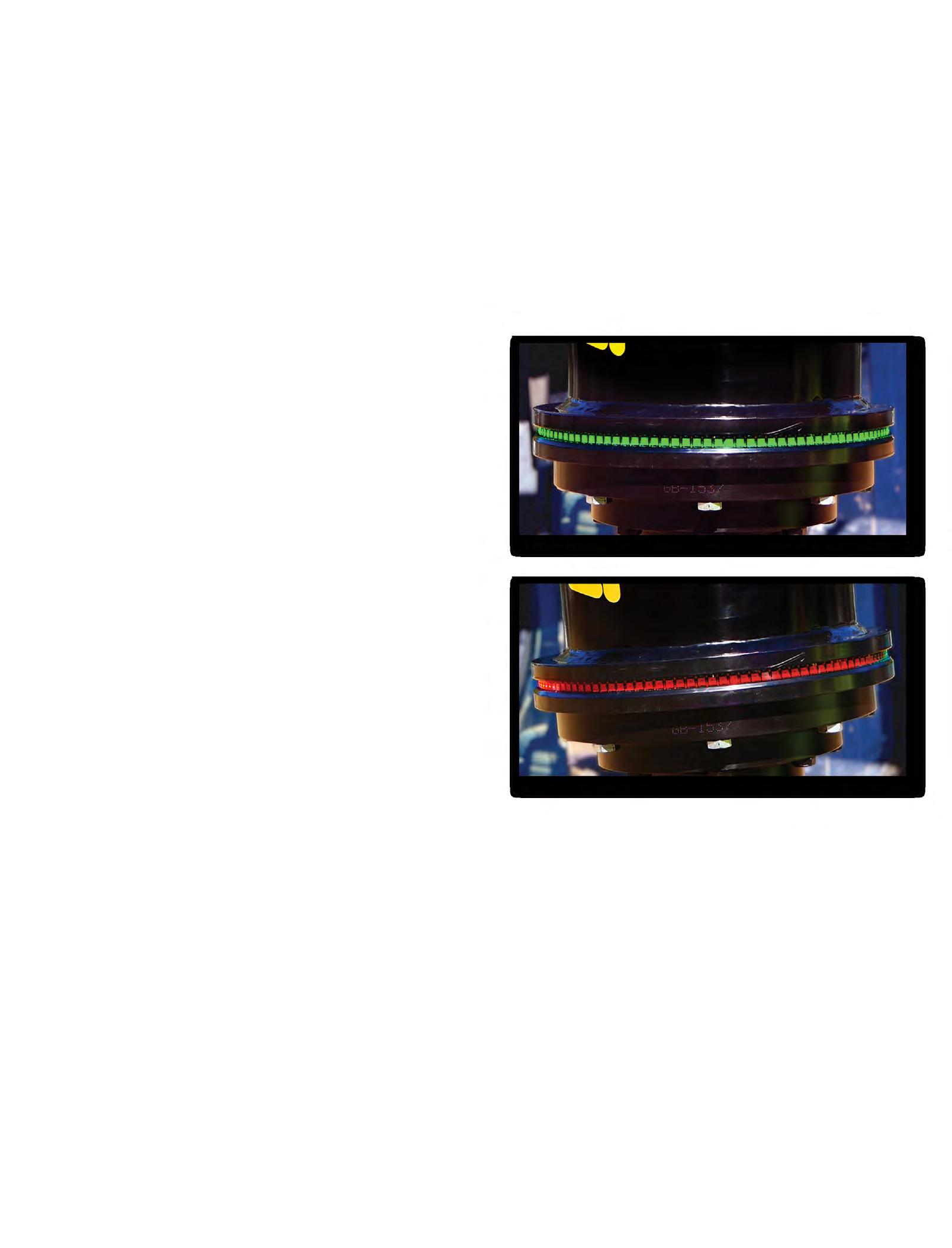

Contact your local dealer for specific products and services for your landscaping or construction requirements. DESIGN & INNOVATION MEETS POWERFUL PERFORMANCE View the full range of Wacker Neuson products:

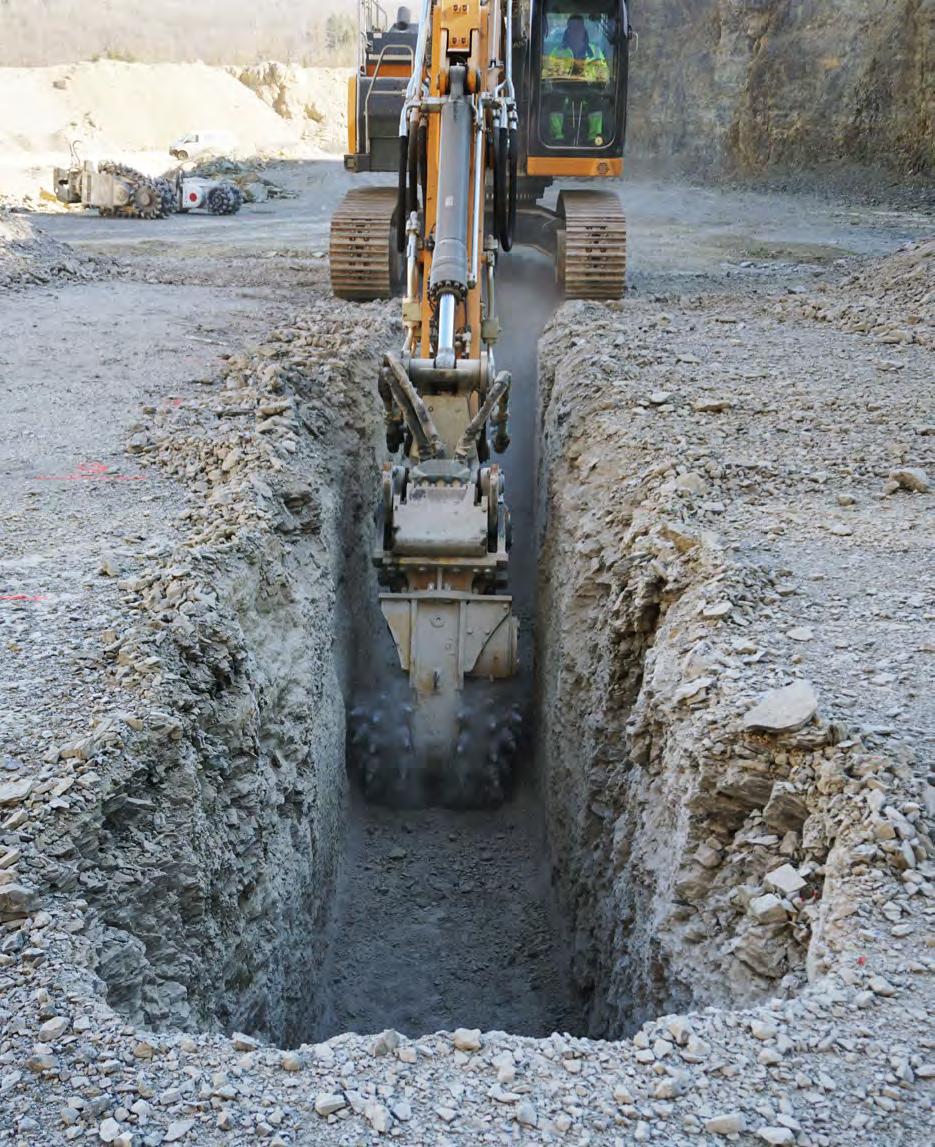

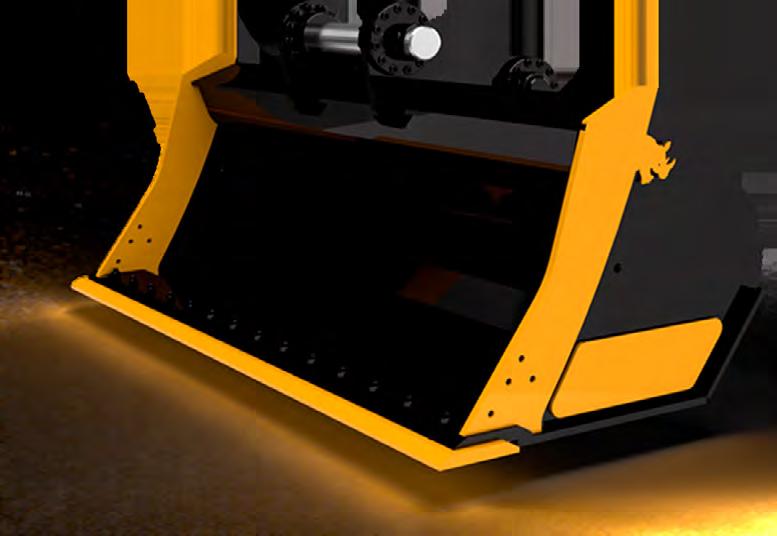

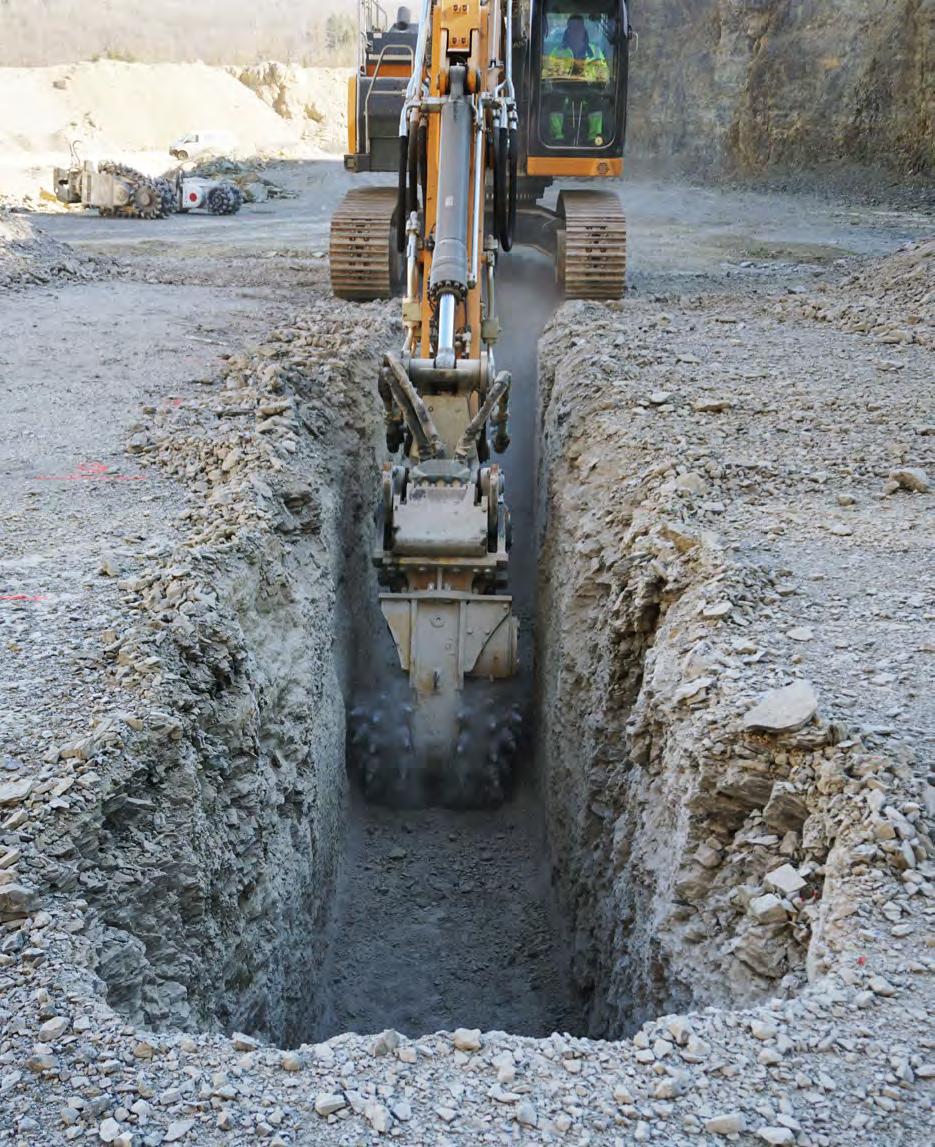

D&J’S CIVIL CONSTRUCTION AND KOBELCO

What do you get when you combine two hardworking Irishmen, over 40 years of industry experience and half a dozen Kobelco excavators? The answer is Darren and James – the two top characters behind D&J’s Civil Construction. These lads are a polished construction outfit working out of the greater Brisbane region, providing all aspects of sewer, storm and water pipeline construction; live connections; and concrete works on several civil projects across Queensland and northern NSW.

Darren O’Mahony and James Horgan are the company directors of D&J’s Civil Construction Pty Ltd. EEM had the opportunity to make an onsite visit to the D&J’s lads near Yatla in Queensland to check out their latest Kobelco machine in full flight and have a good chat about the growth of the business in recent years.

A PROVEN SITE MANAGEMENT AND SUPERVISORY TEAM

The D&J’s Civil Construction projects include residential and commercial subdivisions and high-rise developments. D&J’s has been working hard and developed an excellent proven site management and supervisory team, with an experienced workforce and

a reliable fleet of Kobelco plant and various other equipment. It’s been a willingness to provide innovative solutions to enable time and cost saving measures that has seen the D&J’s team rise and successfully undertake projects both on a large and small scale.

It was a wet and gloomy day for a site visit with plenty of mud dominating the site that was being prepared for a large industrial set up. Both Darren and James were ripping in, despite the conditions, and when watching them work around each other preparing the ground for pipe work and drainage, it was clear these boys have built up some impressive skills both in and out of their Kobelco machines.

ON THE COVER WORDS AND IMAGES // JAMIE GRAY

10 WWW.EARTHMOVERS-MAGAZINE.COM.AU

When chatting with the lads about the growth opportunity that has opened for D&J’s, they shared, “We are 100 per cent committed to maintaining the highest standards of quality and provide timely, honest and reliable service delivering better outcomes for all stakeholders and rewarding opportunities for our people. Our hard-working team of operators are at the heart of our operation. We are lucky to have operators with skills in the machines and knowledge of the industry, which contribute highly to the success of our projects.”

BRISVEGAS AND KOBELCO

The D&J’s Civil Construction team have been working with BrisVegas and Kobelco since 2020 and over that time has purchased six machines including 2 x SK140SRLC-7s, SK500XDLC, SK380SRLC, SK140SRLC-5 and an SK235SR-2 with a blade.

WWW.EARTHMOVERS-MAGAZINE.COM.AU 11

Darren O’Mahony and James Horgan, D&J’s Civil Construction.

When scratching the surface about the features that have seen the team’s appreciation and trust for the Kobelco product grow so substantially over this time, James said “The obvious features that jump out as business owners is the fuel efficiency and reliability. The Kobelco machines are very productive onsite. The fact that we also receive error

notifications in real time when our operators are hard at work is a big advantage because it gives us the opportunity to fix potential problems straight away to prevent major issues occurring. This peace of mind allows us to focus our energies and time to other aspects of our business. The Kobelco home screen remote manager is excellent and gives us the ability to

see many features of the machine when you are not physically on site.”

James continued, “From an operational perspective our fleet of Kobelcos have great breakout digging power, which given the varied types of work we undertake and the varied types of ground we work in is extremely important. Our operators love sitting in the Kobelco cabs – the

ON THE COVER

12 WWW.EARTHMOVERS-MAGAZINE.COM.AU

comfort of the combined elements of the cabin, from the seat to the low noise and vibration, to the AC on hot Queensland days all contribute to a very positive operator experience.”

POSITIVE RELATIONSHIPS

The two Irishmen’s relationship as directors seemed as well balanced, efficient and inspired as that of the BrisVegas and Kobelco

partnership. When the conversation moved to the relationship with BrisVegas and their sales rep Matt Thorne, Darren shared, “It’s been a positive relationship and experience with the BrisVegas team. They have always been very efficient in booking in services in a timely manner.

The services are completed around our working schedule to the best of their ability, which

WWW.EARTHMOVERS-MAGAZINE.COM.AU 13

helps us reduce downtime for the machine on site. This is a huge benefit for us and our productivity.

“Matt has been a pleasure to deal with. He is extremely knowledgeable about the product range and really understands what we as a company are seeking when investing in new equipment. Our ability to openly communicate our needs and Matt’s understanding of both

the industry and the Kobelco product range have been the backbone of our relationship.” It seems like James and Darren have their eyes and goals set on a bright future up there in Brisbane. Given the depth of their expertise and ever-growing Kobelco fleet, they are set to make the most out of every opportunity that presents itself and exceed their client expectations along the way.

ON THE COVER

14 WWW.EARTHMOVERS-MAGAZINE.COM.AU

The SK135SR-7 perfectly demonstrates the commitment Kobelco has to designing and manufacturing the most capable excavators available, built with Japanese quality for legendary reliability.

As the #1 selling machine in the 14 tonne class, the SK135SR-7 combines unbeatable performance, fuel efficiency and reliability with a premium operator station and modern machine design.

And now Australia’s most popular short radius heavy excavator is available with a proven Isuzu Tier 3 engine, with no DPF and no AdBlue required, reducing operating costs and increasing convenience.

kobelco.com.au | 1300 562 352 @kobelcoaustralia

NSW

CAPITAL CONSTRUCTION EQUIPMENT

535 Dallinger Road, Lavington NSW, 2641. 02 6025 0444. www.capitalconstruction.com.au

FRANKS SERVICE CENTRE 186 Wakaden Street, Griffith, 2680, NSW 02 6962 6073. www.fscforklifts.com.au/

NORTH WEST FARM MACHINERY 22-26 Whittaker Street, Quirindi, 2343, NSW. 02 6746 3300. www.nwfm.com.au

STM EQUIPMENT Unit 3, 28 Dunn Rd, Smeaton Grange, NSW 2567 02 4728 7500 www.stmequipment.com.au

THREE RIVERS MACHINERY

25 Zora Street, Warren NSW, 2824 02 6847 3111. www.3rm.com.au

SCTM (Canberra)

1/45 Bayldon Road, Queanbeyan, NSW, 2620 02 6299 1500. www.sctm.com.au

SCTM (Wollongong)

6 Mineral Road, Oak Flats, NSW, 2529 024257 1500. www.sctm.com.au

EARTHMOVING EQUIPMENT AUSTRALIA (EEA) 99 Glenwood Drive, Thornton, NSW, 2322. 02 9671 1000. www.eeaustralia.com.au

QLD

EARTHMOVING EQUIPMENT AUSTRALIA (EEA) 123 Cobalt Street, Carole Park, QLD, 4300. 1300 753 332. www.eeaustralia.com.au

MCINTOSH & SON (DALBY) 17563 Warrefo Highwyay, Dalby, QLD, 4550. 07 4662 2288. www.mcintoshandson.com.au

MILNE BROS EQUIPMENT (BILOELA) 61-67 Dawson Highway, Biloela, QLD, 4715. 07 4992 1099. www.milnebros.com.au

MILNE BROS EQUIPMENT (EMERALD) 67 Macauley Road, Emerald, QLD, 4720. 07 4982 4824. www.milnebros.com.au

MILNE BROS EQUIPMENT (ROCKHAMPTON) Gladstone Road & Derby Street, Rockhampton, QLD, 4700. 07 4930 0300. www.milnebros.com.au

LIST

SQMH 10 Bain Court, Toowoomba, QLD, 4350. 07 4634 2744. www.sqmh.com.au SA LARWOOD AG SERVICES 38 Moonta Road, Kadina, SA, 5554. 08 8821 1999. www.larwoods.com.au ROCKY RIVER AG 62 Wongabirrie Road, Crystal Brook, SA, 5523 08 8636 2772. www.rockyriverag.com.au SA TRACTORS 12/160 Churchill Road North, Cavan, SA, 5094. 08 8349 7500. www.satractors.com.au TAS DLM MACHINERY 17/19-21 Killafaddy Road, St Leonards, TAS, 7250. 03 6339 1550. www.dlmmachinery.com DEALER

VIC

BALLARAT TRACTORS

155 Learmonth Street, Ballarat, VIC, 3350. 03 5334 2444. www.ballarattractors.com.au

KV EQUIPMENT

221 Midland Highway, Epsom, VIC, 3551

03 5445 6999. www.kvequipment.com.au

MELBOURNE TRACTORS

110 Hume Highway, Somerton, VIC, 3062.

03 9303 5777. www.melbournetractors.com.au

MELTRAC MACHINERY

6703 Princes Highway, Terang, VIC, 3264

03 5536 0222. www.meltrac.com.au

PRIMTEC TRACTORS

698 Benetook Ave, Mildura, VIC, 3502. 03 5022 1004. www.primtectractors.com.au

RAISING EXPECTATIONS

WA

FORKWEST

68 McCombe Road, Bunbury, WA, 6230

08 97254970. www.forkwest.com.au

GEOFF PERKINS MACHINERY

Lot 24 Stewart Street, Narrogin, WA, 6312.

08 9881 2222. www.perkinsmachinery.com.au

MCINTOSH & SON (ALBANY)

189 Chester Pass Road, Albany, WA, 6330 08 9847 4255. www.mcintoshandson.com.au

MCINTOSH & SON (ESPERANCE)

25 Norseman Road, Esperance, WA, 6450.

08 9071 1155. www.mcintoshandson.com.au

MCINTOSH & SON (GERALDTON)

160 Flores Road, Geraldton, WA, 6530.

08 99605500. www.mcintoshandson.com.au

MCINTOSH & SON (KATANNING)

Lot 4 Nyabing Road, Katanning, WA, 6317. 08 9821 7000. www.mcintoshandson.com.au

MCINTOSH & SON (KULIN)

294 Pump Road, Kulin, WA, 6365 08 9880 2556. www.mcintoshandson.com.au

MCINTOSH & SON (MERREDIN) 52 Mitchell Street, Merredin, WA, 6415 08 9041 1099. www.mcintoshandson.com.au

MCINTOSH & SON (PERTH) 547 Great Eastern Highway Redcliffe, WA, 6104 08 9475 1600. www.mcintoshandson.com.au

SOURCE MACHINERY

6 Reggio Rd Kewdale, Kewdale/Karratha, WA, 6105. 08 9358 3389. www.sourcemachinery.com.au

ACCESS SERVICE AUSTRALIA 26 Kilto Crescent, Glendenning, NSW, 2761. 02 9832 9990. www.accessservice.com.au 71 Bradman Street, Acacia Ridge, QLD, 4110. 07 3219 5130. www.accessservice.com.au 32 Healey Road, Dandenong South, VIC, 3175. 03 9768 2155. www.accessservice.com.au

MOTION MACHINERY

1/10 Dickens Place Armadale, WA, 6112. www.motionmachinery.com.au

SERVICE

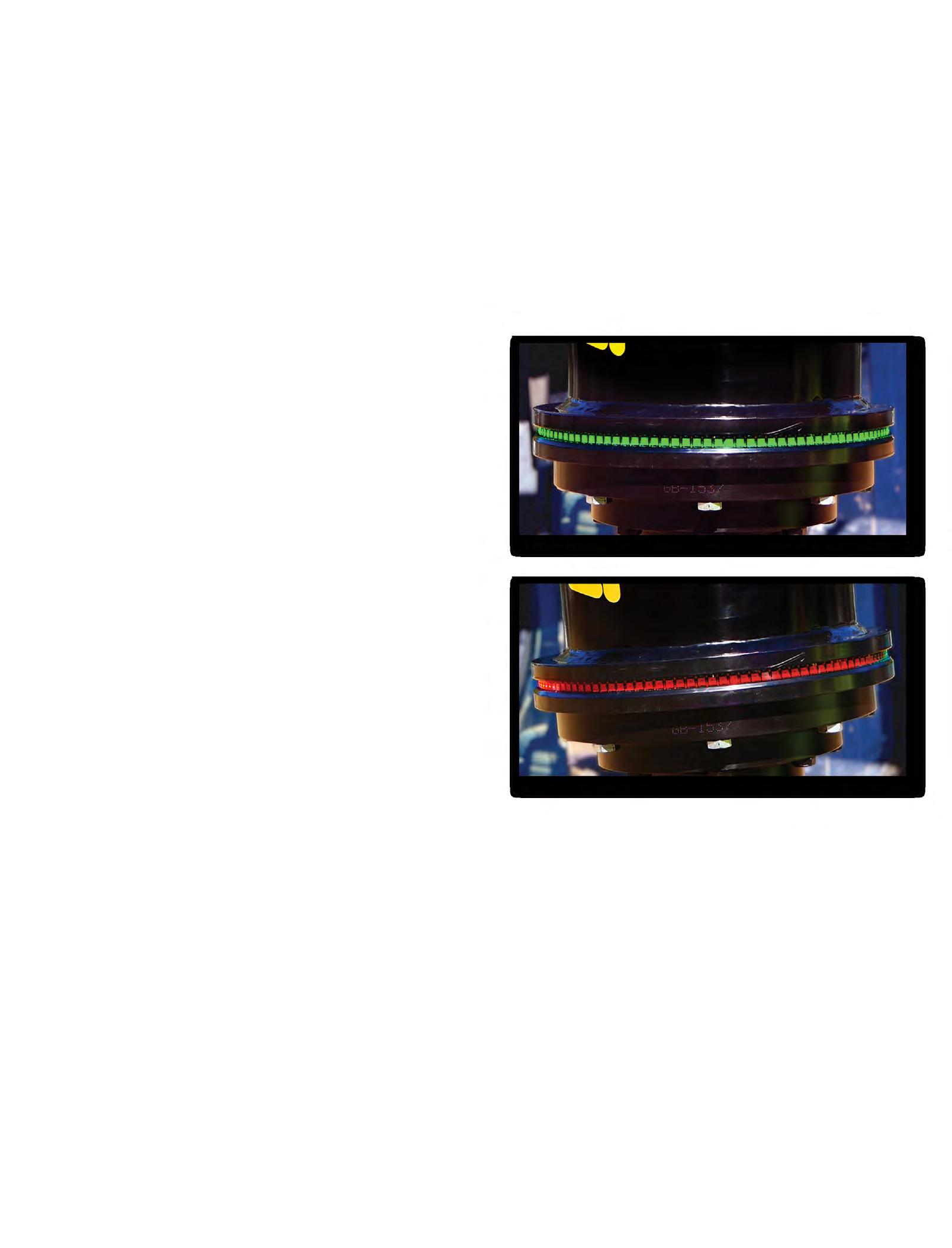

INTRODUCING NEW CAT® HAMMERS H190S AND H215S EASIER AND SAFER WITH ADVANCED TECHNOLOGY

Hydraulic hammers are one of the most versatile work tools available and able to extend the usefulness of skid steer loaders, backhoe loaders and excavators of all sizes in applications from civil construction, road building, earthmoving, quarrying and mining.

New hydraulic hammers H190S and H125S are now added to the Cat® hammer line-up which offers high levels of features and technology that delivers greater productivity at the jobsite. “The introduction of these hammer models expands the portfolio and supports our strategy of offering customers options at differing value points,” Cat Work Tools consultant Mr Jason Zhang stated. He also added that these new hammers cover Cat 349-395 excavators with carrier weight ranging from 45 tonne to 120 tonne fulfilling the hammer need for the large excavators like 374 and 395.

“These hammers are simple to operate and require less time on service, which in turn boosts the productivity at the job site. The hammer hits with consistent power and can be switched between blow frequency and power to best suit different applications and improve efficiency.”

KEY FEATURES AND BENEFITS

The Power Adjust feature on H190S and H215S hammers allows the operators to manually adjust the power of the breaker for different materials and applications. The long stroke has less piston frequency which results in higher impact power and productivity and it is best for harder materials and strenuous

applications, while the short stroke has higher piston frequency which results in less impact power and it is best for lighter applications.

“This allows the operators to determine the desired piston speed based on the materials and applications to increase the productivity and efficiency while lowering the fuel consumption,’’ Mr Zhang added.

The hammers also offer an overflow protection function. This function is performed by the Internal restrictor valve in the hammer, which detects the overflow of hydraulic oil from the excavator. It limits and adjusts the oil flow to the hammer. “This feature prevents the over speeding of the piston and avoids costly damages and rebuilds – reducing your operating costs,” he stated.

MEET THE EXPERT WORDS // JASON ZHANG, CAT WORK TOOLS CONSULTANT

18 WWW.EARTHMOVERS-MAGAZINE.COM.AU

The Automatic Shut Off (ASO) feature on H190S and H215S hammers offers protection against blank firing by stopping the piston from cycling internally when there is no material under the tool.

Mr Zhang said, “Eliminating blank firing helps protect the hammer from premature damage by reducing internal stresses and heat and this helps to lower overall hammer ownership and operating costs. Additionally, ASO will protect rental fleet hammers where operator skill level and expertise can vary.” This feature can be easily set to on or off in the field.

The hammers are protected by the Auto stop feature. This feature warns the operator when the hammer is hammering too long in one spot. A warning message will pop up on the screen after 15 second of permanent hammer activation and after exceeding 30 second, the hammer will automatically stop. Mr Zhang explained that “this feature helps prevent premature damage to the hammer and machine, even with an inexperienced operator”.

A hammer mounted auto lube system is a standard offering in these hammers. “This auto lube system provides continual greasing while the hammer runs – saving your time and protecting your investment,” he said.

Mr Zhang described that the hammers are also configured with the Oil-fired design to ensure less waste is generated in internal heat providing more power to the tool which delivers efficient operating cycle and consistent production over time.

EFFORTLESS MAINTENANCE

The maintenance is very easy in these new hammers, all the daily checks and routine service can be performed while the hammer is attached to the machine. “Easy and quick access to critical lubrication points and all other maintenance areas ensures the hammers are ready to operate at their peak and helps to reduce maintenance costs over the life of the tool,” Mr Zhang said. “Service of the lower bushing can be carried out in the field using simple hand tools and the bushing is rotatable to 90 degrees, which doubles the life reducing the overall service time and lowering the owning and operating costs,” he further added.

The hammers are designed to keep the gas pressure steady through the duration of the annual service interval eliminating

the need for constant checking of the gas charge. “You can also verify the gas charge of the hammer without removing it from the carrier,” Mr Zhang explained.

A buffer system fitted inside the hammer housing to protect the carrier from potentially damaging reflective forces. The system also helps to reduce vibration to the machine, improves noise suppression and aids hammer durability.

NEXT GEN EXCAVATOR TECHNOLOGY

CONFIGURED WITH H190 S AND 215 S

HAMMERS

Hammer Auto – Stop

Will give the operator an indicator in the cab when operating the hammer in one location at 15 seconds. Hammer will automatically stop after exceeding 30 seconds.

E – Fence

When operator hammer, dimension points for ceiling, floor, front can be programmed when needed.

PL161

Both hammer models will ship from the factory with PL 161 mounted on the hammer housing. Machine can receive the hammers ID and select appropriate settings (flows and pressure) automatically from the pre-loaded work tool list on the HEX by using information from the PL161 via Bluetooth communication.

Overall, the Cat hammer portfolio are configured to ensure that they prioritise safety and offer best choices that are suited for all customer needs while delivering efficient productivity and durability.

For more information about the Cat H190S and H215S hammers, visit the local Cat dealer.

NSW/ACT WesTrac 1300 881 064

VIC/TAS William Adams 1300 923 267

Western Australia WesTrac 1300 881 064

QLD/NT Hastings Deering 131 228

South Australia Cavpower 08 8343 1600

NZ TERRA 0800 93 39 39

WWW.EARTHMOVERS-MAGAZINE.COM.AU 19

KEEP IT ALL ON TRACK CAT® UNDERCARRIAGE WITH CUSTOM TRACK SERVICE AND TRACK ASSURANCE

Maximise your undercarriage life and reduce downtime.

When you buy a Cat® undercarriage or an eligible Cat machine from a participating Cat dealer you’ll be enrolled in Custom Track Service (CTS). CTS is a comprehensive program that includes free scheduled inspections ^ using advanced diagnostic equipment to help maintain your undercarriage. But that’s not all. With CTS you’ll also have access to Track Assurance#, providing extended undercarriage coverage on top of the standard Caterpillar parts warranty.

WHY IS CUSTOM TRACK SERVICE SO IMPORTANT?

As a Cat dealer undercarriage specialist, Nish Mohan knows the importance of a wellmaintained undercarriage. “An improperly managed undercarriage can account for more than half of your machine’s operating costs. That’s why a new Cat undercarriage with CTS is a strong business decision. CTS can help you manage your undercarriage system, control your costs and reduce downtime.”

HOW DOES IT WORK?

With Custom Track Service you qualify for free undercarriage inspections ^ from a trained technician who uses the latest technology to:

• Accurately monitor your undercarriage performance and predict wear rates

• Evaluate service options and plan your maintenance

• Gather data to tailor a service strategy to meet your equipment planning needs

• Help you make informed decisions about maintenance – and investigate any issues with your undercarriage before they become serious.

The benefits are huge. CTS can help you manage and maximise undercarriage life, enable more efficient planning for better availability, and use analysis to enhance maintenance and service strategies. All in all, it can help you maximise your uptime and keep your operating costs on track.

MEET THE EXPERT WORDS // CAT CISD 20 WWW.EARTHMOVERS-MAGAZINE.COM.AU

WHICH UNDERCARRIAGE IS RIGHT FOR YOUR MACHINE?

Your Cat dealer has the expertise to help choose the undercarriage option that’s right for you. Whether you need maximum durability for demanding terrain, or operate in low to moderate impact applications, choosing the right undercarriage will maximise uptime and performance. Here’s a summary of the Cat undercarriage options.

General Duty

Ideal for low to moderate impact applications, delivering the right balance of performance and value.

Heavy Duty

Provides the best results in high-impact, hard rock materials and applications where link wear or fatigue is the principal driver of end of life.

Heavy Duty Extended Life (HDXL)

Designed and engineered for maximum durability in the most demanding conditions. HDXL delivers up to 40% † more wear life. It’s got all the robustness you’ll need –and then some.

Cat Abrasion™

Delivers the lowest cost per hour in high abrasion, low to medium impact applications, resulting in up to 50%‡ lower cost per tonne.

COVERAGE PERIODS

Cat undercarriage consultant Rodney Irvine sums it up. “As part of the CTS program, Cat dealers use the most advanced diagnostic platforms and equipment available, with the ultimate goal of keeping their customers’ costs down and supporting them to protect their investment.”

TRACK ASSURANCE – FOR EVEN MORE PEACE OF MIND

Extended undercarriage coverage provides you with support beyond the standard new machine or parts warranties.

When your new Cat undercarriage is enrolled in the CTS program, you’re eligible for Track Assurance # . That means free extended undercarriage coverage beyond the standard parts warranty. The Track Assurance program covers all major moving undercarriage components on Cat TrackType Tractors, Track-Type Loaders and Hydraulic Excavators.

There’s so much riding on your undercarriage, so it’s important to keep it all on track. To find out more about Cat undercarriage options and Custom Track Service, or to book a free inspection^ , contact your local Cat dealer or visit cat.com/undercarriage-au

*^#†‡Terms and conditions apply. See cat.com/undercarriage-au for details.

FREE UNDERCARRIAGE INSPECTION^

Scan here to contact your local Cat dealer to organise a free inspection.

coverage ends at the stated years, hours or percentage worn – whichever comes first. Speak

Your

to your Cat dealer for full details.

WWW.EARTHMOVERS-MAGAZINE.COM.AU 21

To buy or sell assets, visit pickles.com.au NORRIS GROUP LIQUIDATION AUCTIONS $22.5M TOTAL SALES 96% CLEARANCE RATE 1,284 ASSETS OFFERED 3,303 BIDDERS $4.6M TOTAL SALES TRUCKS & TRAILERS $1.9M TOTAL SALES VEHICLES $13.7M TOTAL SALES EARTHMOVING & WASTE $2.3M TOTAL SALES PARTS & EQUIPMENT

2018 Hammbreaker Max 800 VZ950 2017 Keestrack R6 Impact Crusher 2019 Caterpillar 140 Articulated Grader 2020 Drake Quad Axle Low Loader 2021 Isuzu FYJ 300-350 8x4 Hook Bin 2019 Komatsu WA480-6 Wheel Loader 2017 Komatsu PC210LCI-10 Excavator 2020 Komatsu PC138US-11 Excavator 2019 Bomag BW 213 D-5 Roller $104,000 2020 Caterpillar 259D3 Skid Steer 2019 Isuzu NPR 45-155 4 x 2 Tipper 2019 Komatsu PC18MR-3 Excavator A selection of items from this auction: $55,000 $34,000 $150,000 $195,000 $215,000 $265,000 $325,000 $335,000 $700,000 $585,000 $420,000

THE HISTORY OF PICKLES

Pickles comes full circle with its return to the agricultural industry.

While most Australians know Pickles as an auctioneering powerhouse, few know of the humble beginning of the Pickles business as a stock-and-station agent in rural Moree over 50 years ago. In 1964 the Pickles family started the company as a way to buy and sell livestock, equipment and property in NSW. This business successfully provided an agricultural marketplace to the locals of Moree for over a decade, before expanding into auctioneering with a branch based in Newcastle. The valuations and agricultural aspects of the business’s first iterations still permeate the Pickles company as it stands today.

Pickles has transformed over the years to now boast billions in annual asset turnover and a range of subsidiary businesses. Pickles has long since exceeded expectations, and after years of developing the remarketing industry, is now returning to its roots with a newly-created department focused entirely on agricultural equipment, PicklesAg.

Pickles is well-known throughout Australia as a market leader in providing industrial equipment to clients around the country. PicklesAg is the natural continuation of their Industrial department, and brings the company full circle by providing a division that singularly supplies the Australian market with ag equipment.

This new division is a culmination of Pickles’ forward thinking business ventures and longstanding history in the agricultural heritage of Australia. PicklesAg can provide every fundamental service required of farm managers who need to expertly offload, update and manage agricultural equipment.

PicklesAg is a dedicated agricultural marketplace that connects equipment buyers and experts across Australia. The PicklesAg team provides specialist services across the country and offers a trusted way to access an array of easily accessible, used machinery.

24 WWW.EARTHMOVERS-MAGAZINE.COM.AU

INDUSTRY AUCTIONS

Buy & Sell with Pickles Ag Our Experience: Talk To A Local Expert Today $54M+ GROSS SALES TRACTORS 2,700+ TRACTORS SOLD $55M+ GROSS SALES HAY ASSETS 19,000+ HAY ASSETS SOLD $6.2M+ GROSS SALES SEEDING/TILLAGE 600+ SEEDING/TILLAGE ASSETS SOLD 200+ HARVEST EQUIPMENT SOLD $5.7M+ GROSS SALES HARVEST EQUIPMENT SINCE 2017 National Agricultural Equipment Auction June July Aug SeptOct Nov Dec Sat 18-22 Sat 23-27Sat 20-24 Sat 17-21 Sat 22-26 Sat 19-23Sat 10-14 Connor Brown Rodney Newton Sales Executive – Agriculture Northern, VIC Sales Executive – Agriculture North West, NSW Clay Redmond National Sales ManagerAgriculture Contact: 0427 986 032 Email: clay.redmond@pickles.com.au Aaron Wilson Sales Executive – Agriculture South East, QLD Contact: 0477 697 453 Email: aaron.wilson@pickles.com.au Contact: 0419 593 549 Email: connor.brown@pickles.com.au Contact: 0417 852 159 Email: rodney.newton@pickles.com.au

BULLDOZER REPLACES TRACTOR – A RIPPER IDEA

Dry earth farmer Kurt Mayne and specialist machinery operator Brendan King have joined resources to specify a combination rig of bulldozer, deep ripper, fertiliser and seeder to economically prepare and treat land in one comparatively swift pass.

The bold venture, with an investment of more than $1.5million in machinery alone, has prepared more than 10,000 hectares in two years and is now being used in a fight against a grass die-back disease, which has afflicted their region.

Mayne and King have worked closely with agronomists and soil scientists to repatriate pastures, which had been grazed out of nutrients and to restore fallow farming land to productivity.

Their CQ (for Central Queensland) Ag Earthworks business operates out of Emerald and works mainly in the Rolleston region, south of the town, where Mayne runs his thirdgeneration family property Broken Plains. Mayne has used the bulldozer to create just on 3000 hectares of farmland, previously used for finishing cattle and planted it with mung beans, chickpeas, wheat, and barley.

He is working on restoring an even greater area of pasture for more efficient preparation of his herd.

The success of the venture has meant more than half of all work for CQ Earthworks rig is now coming from neighboring properties,

keen to emulate their operation, and the partners are considering a second unit.

Mayne, 34, and King, 35, challenged earthmoving specialist Komatsu to equip a 337kW D275AX-5EO bulldozer to meet the requirements of their ambitious plan to outstrip the performance of the most efficient broadacre tractor.

“It had to be able to operate faultlessly at 6kmh in second gear at 85 per cent engine load in ambient temperatures above 40deg Celsius, while ripping to a depth of 450mm across unprepared ground,” Kurt Mayne said.

The target speed was up to 50 per cent greater than that averaged by conventional

Two Central Queensland business partners are successfully pioneering the replacement of a broad acre tractor with a bulldozer to achieve better productivity and help restore precious pastures to full strength.

INDUSTRY LEADERS 26 WWW.EARTHMOVERS-MAGAZINE.COM.AU

tractors and bulldozer competitors, according to Mayne, enabling a fuel saving alone of better than 20 per cent.

A purpose-built hydraulic system from the bulldozer would drive the air seeder towed behind the bulldozer and ripper rig, capable of spreading eight tonnes of seed and fertiliser at any desired rate per hectare.

Brendan King is the machinery operator of the partnership; he spends up to 10 hours each day on the D275 monitoring the refinements made by Komatsu.

“They placed high-capacity oil coolers behind the radiator working on the transmission and hydraulics, making space by moving the air conditioning condenser to the back of the cabin,” King said.

“I watch the gauges carefully and even in ambient temperatures above 40 degrees Celsius they operate comfortably in the 86-94 degrees Celsius range.”

Recognising the long hours he’d spend in operation, King specified a breathe-safe pressurised cabin and a scrub canopy to provide additional weather and environmental protection.

The D275 is fitted with auto steer and GPS guidance which enables King to spend his time in the cabin a little like an airplane pilot making calculations to maximise operational efficiency, in his case the ripper depth and optimising the seed drop, usually to an accuracy of just 20 grams.

Non-stop operation is an important component of the hire proposition, providing substantial benefit over tractor options.

“With a blade up front we can push through country that a tractor couldn’t handle and that keeps our average speed up,” King said.

A major contributing factor is the D275’s lock-up torque convertor, which reduces

ABOUT KOMATSU

operator stress especially when ploughing in harsh conditions.

“People have commented on how nimble it looks for a big machine – it feels like I’m driving a big skid steer loader,” he said.

According to Komtrax, Komatsu’s complimentary on-board GPS-based monitoring telemetry, the CQ Ag Earthworks bulldozer is returning 57 litres/hour operational efficiency, including idle time while Brendan King checks blades and replenishes seed and fertiliser.

“Fuel costs, paid for by the hirer, have been balanced by the high prices they’ve been achieving for cattle and crops, but as the cost of fuel rises, our economy will become an important consideration, even with off-road fuel subsidies,” King said.

Kurt Mayne and Brendan King are quick to point out the service they provide – both in hire and on Mayne’s property – is based on more than their ability to provide efficiency in machine operation.

“I’m a number’s man and I rely heavily on the advice of the soil scientists to tell me exactly how each paddock should be treated and what nutrients and crops we should be planting,” Mayne said.

The recent outbreak of grass die-back, a phenomenon which has agronomists puzzled, has meant farmers are looking to efficiently plant legume crops to restore soil integrity.

“Our big opportunity is to restore grazing land,” Mayne said.

“Cattle are eating the goodness out of the land and like farmland after cropping, it’s important to rejuvenate grazing land too.

“When we started, people down south thought it strange that we were tilling and fertilising so deep, but now they’re not only understanding but starting to follow us.”

Mayne and King met on the football field –

their sons play junior rugby league together – and their initial interest was spurred by Mayne’s desire to find a better way to plant and seed, and King’s desire to become a selfsufficient machinery operator.

They began their venture with seed money of just $60,000 each, funding the rest through Komatsu Finance, which saw value in their proposition and extended a repayment program over five years.

“Honestly money is so cheap at the moment, we had to give it a go,” Mayne said.

The partner’s D275, serviced on-site by Komatsu from its Emerald branch to minimise downtime, is approaching 3000 hours of operation and the partners say it will easily exceed 10,000 hours within its purchase period.

“We’re pretty much booked out for the next 12 months and we recently had to refuse a big job,” King said.

“We set out to keep things simple, but it looks like we may have to investigate a second machine.”

Komatsu develops and supplies technologies, equipment and services for the construction, mining, forklift, industrial and forestry markets. For a century, the company has been creating value for its customers through manufacturing and technology innovation, partnering with others to empower a sustainable future where people, business and the planet thrive together. Front-line industries worldwide use Komatsu solutions to develop modern infrastructure, extract fundamental minerals, maintain forests and create consumer products. The company’s global service and distributor networks support customer operations to enhance safety and productivity while optimising performance.

WWW.EARTHMOVERS-MAGAZINE.COM.AU 27

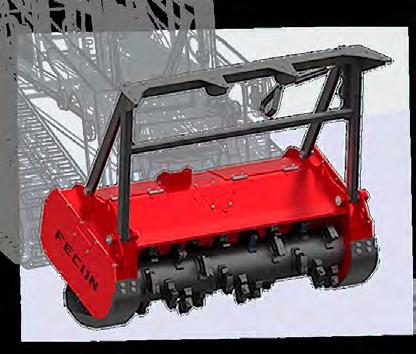

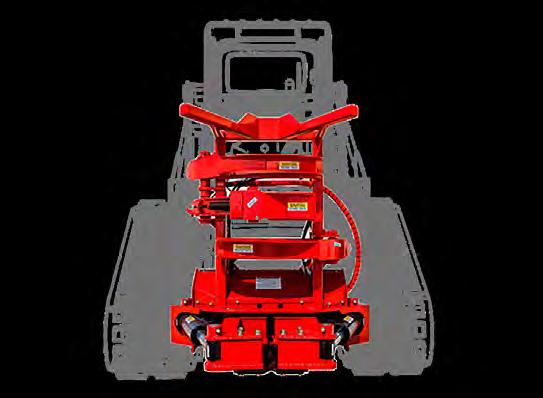

TM TM TM ASV EEM 2022 Artwork - Jan 2022 Outlines.indd 1 12/01/2022 11:23:47 AM Fecon

AM Fecon EEM 2022 Artwork - Jan 2022 Outlines.indd 1 12/01/2022 11:24:13 AM

TRADE CREDIT INSURANCE: HELPING SUBCONTRACTORS TRADE WITH CONFIDENCE

pressures within Australia’s construction industry have led to a rise in administrations throughout the sector. Trade Credit Insurance can play a vital role in protecting subcontractors from bad debts by insuring receivables, safeguarding hardearned revenues and providing quick access to replacement capital should clients default.

Over the past few months Australia has seen an increase in insolvencies across the construction sector, with increased pressures within the industry it is likely this number will continue to rise throughout 2022. This highlighted by one of the nation’s five largest construction companies, Probuild Group of Companies, falling into insolvency earlier this year and leaving over $300M in unsecured creditors.

The collapse of Probuild demonstrates counterparty risk cannot always be avoided, even when contracting to large, reputable firms. Subcontractors need to be aware of these risks as debtor defaults can significantly impact their businesses, causing cash flow instabilities and challenges to pay their own suppliers, creating a domino effect throughout the industry.

Despite an oversupply of work, builders are currently facing several sustained pressures on their margins. From rising costs of materials and wages to supply chain headaches and project delays. These pressures heighten the risk of debtor default for subcontractors.

Trade Credit Insurance is a vital tool that can be used by subcontractors to protect their businesses if a contractor is unable to pay, by insuring receivables.

WHAT IS TRADE CREDIT INSURANCE?

Trade Credit Insurance (also known as Debtors Insurance) protects businesses from bad debts. By transferring the risk of non-payment to an insurer, Trade Credit Insurance safeguards your cash flows while giving you the confidence to pursue new opportunities.

MKP Insight: For many businesses, their debtors’ portfolio is their largest asset.

HOW DOES TRADE CREDIT INSURANCE WORK?

When you sell your goods or services on credit to a customer, you place yourself at risk of non-payment. Trade Credit Insurance provides cover for your receivables in the event of buyer default. For many companies, a traditional Whole of Turnover policy is best, however, our solutions can be tailored to suit your business’s specific needs. These include insuring key accounts or key contracts; targeted cover of

major buyers above a certain dollar threshold; or replacing an existing bad debt reserve with an aggregate first loss policy or insuring a single account. A typical policy includes an excess and indemnifies the policyholder for up to 90% of the debt.

KEY BENEFITS:

Trade Credit Insurance is principally used to protect businesses in the event that a customer is unable to pay for goods or services rendered. With the right policy however, it can offer your business so much more than securing cash flows.

Swift access to replacement capital

In the event of insolvency or non-payment of a customer, Trade Credit Insurance provides you with swift access to replacement capital, protecting your cash flow and ensuring your business can continue to operate.

Protect hard earned profits

Trade Credit Insurance gives you peace of mind that the risk of non-payment has been transferred to an insurer, so you can be sure you are paid what you have earned.

Increase sales to existing and new clients

A Trade Credit policy can provide you with the support and confidence you need to extend larger credit limits, more favourable trading terms and alleviate buyer concentration risks, gaining a competitive advantage in the market.

Improve credit management

Get greater access to information about your potential debtors and the tools to get paid faster by defaulting clients.

Strengthen balance sheet and governance

By placing your bad debt provision with a credit insurance policy and inject funds back into the business as working capital you can strengthen your balance sheet. The Trade Credit Insurance premium is tax deductible. Funds are placed back into the business through a claim payment, rather than taking out unrecoverable money from a bad debt provision.

Recover pre-insolvency and postinsolvency costs

Recover costs associated with collecting an overdue debt and the ability to protect yourself against a preference claim, which can occur up to 3 years from time of insolvency.

Save time and money

By outsourcing certain credit management functions to the insurer, including covering the hard costs of collection and legal fees when chasing an overdue debt, you can save valuable time and money and focus on what you do best: running your business.

For a free assessment of your current debtors and options on product cover and costs, contact Moody Kiddell & Partners today on 1300 000 657.

Since 1981, Moody Kiddell has partnered with Australian businesses, providing finance, insurance and advisory solutions. With four decades of multi-industry experience, we offer businesses the tailored service business owners need to achieve their vision and safeguard its legacy.

BUSINESS AND FINANCE WORDS // MOODY KIDDELL & PARTNERS

Sustained

30 WWW.EARTHMOVERS-MAGAZINE.COM.AU

We Dig Deep

At Moody Kiddell & Partners, we see your success as our business.

For forty years, we have partnered with the earthmoving industry to provide finance and insurance solutions for your business.

From enquiry through to paid claim, we dig in with you every step of the way.

Call today to see how one of Moody Kiddell’s equipment finance and insurance experts can tailor solutions for your specific business needs.

What are partners for?

Moody

Moody Kiddell & Partners Unit Trust ABN 28 187 241 830 Australian Credit Licence 388771 Moody Kiddell & Partners (Insurance) Pty Ltd ABN 48 071 572 828 AFSL 512898

Kiddell. Partners With You

1300 000 657 mkpgroup.com.au

C.R. KENNEDY ADDS LEICA

AP20 AUTOPOLE TO LOCAL PORTFOLIO

Leica Geosystems describes its recently introduced Leica AP20 AutoPole as a “unique and productivity-boosting smart solution” for its robotic total stations, with the AP20 bringing together three smart features – tilt compensation, automatic pole height readings and unique target identification – to streamline workflows.

This contributes to effectively removing the remaining analogue steps in construction survey workflows, with the AP20 both saving time spent onsite and reducing the need for cumbersome post-processing corrections in the office.

As it stands, operators can face a range of challenges across workflows, including the total station locking to the wrong target, points being measured and stored with the wrong target heights, and the time, effort and skill required to ensure the pole is vertical while measuring and staking.

Designed to accommodate for dynamic and variable worksite conditions, the AP20 makes it easier to navigate these challenges by allowing measurements with a tilted pole, providing automatic height readings and enabling target search and locking.

Both the height and tilt of the pole can be adjusted to reach a hidden point, increasing efficiency by enabling users to quickly re-establish the line of sight and relock to the robotic total station, paving the way for high reliability, while minimising the requirements for rework and associated delays.

MACHINE CONTROL TECHNOLOGY 32 WWW.EARTHMOVERS-MAGAZINE.COM.AU

TILT COMPENSATION

Tilt Compensation removes the need to level the pole, effectively enabling users to measure and layout more points per day, while maintaining high job standards with control and clarity over the point quality.

It decreases measurement time and increases flexibility and safety onsite by allowing the measurement of points in locations that are inaccessible or which put the user at risk, even enabling upside-down and nearby hidden point measurements.

Benefits include:

• T ime and effort is saved for each measured and/or staked point.

• Users no longer need to focus on ensuring the pole is held vertically

• Hi dden points can be more easily and quickly measured.

• There is no longer the requirement to calibrate the pole level bubble.

• Auto-switch when using the pole inverted allows for maximum flexibility.

POLEHEIGHT

The PoleHeight functionality updates the height for users automatically as the pole height changes, paving the way for reliable and accurate measurements, helping to both save time and eliminate mistakes.

By updating the pole height automatically in the field software, the AP20 ensures that the height on record is always correct, removing the need to read, check and enter height changes, avoiding errors, time-consuming post-processing and the requirement to return to the field to remeasure.

Benefits include:

• T ime onsite is saved by no longer needing to read, communicate and enter the pole height.

• Measurements with wrong target heights are eliminated.

• Costs are saved in correcting measurements with wrong target heights.

• Less chance of additional requests for information and rework due to wrong target heights.

TARGETID

TargetID ensures the user’s instrument will always lock to the correct target, preventing locking to foreign targets and avoiding work interruptions.

It enables the total station or multistation to identify a target on the fly during search, with the prevention of locking onto other targets especially important when there are several surveyors working simultaneously at busy locations.

Benefits include:

• Users no longer have to keep checking that the total station is not fixed on the wrong object.

• T ime and effort is saved by not having to instruct the total station to find and lock onto the correct target.

• Risk of measuring wrong points by being locked to the wrong target is removed.

• Confidence when working in busy environments with multiple sensors and targets.

C.R. KENNEDY: NATIONAL NETWORK DELIVERS COMPREHENSIVE SUPPORT

C.R. Kennedy is the sole and exclusive distributor for Leica Geosystems in Australia, with it focused on providing tailored solutions for the earthmoving industry, supported by its comprehensive national after-sales network.

Based out of Port Melbourne, C.R. Kennedy’s national network includes major state offices in Brisbane, Adelaide, Sydney and Perth, with its workforce comprising over 250 staff, including product specialists, qualified surveyors, support staff and factory-trained service technicians.

WWW.EARTHMOVERS-MAGAZINE.COM.AU 33

No matter what sector of construction you’re in, you’ll leave CONEXPO-CON/AGG with new ideas, new relationships, and new opportunities to grow your business, and your place within the industry. This isn’t just North America’s largest construction trade show, it’s taking construction to the next level. LEARN MORE AT CONEXPOCONAGG.COM 2.7M square feet of exhibits / 130,000 attendees / 1,800 exhibitors / 150 education sessions TAKING CONSTRUCTION TO THE NEXT LEVEL. 2020 Attendee Britton Lawson, Veit and Company, Inc. MARCH 14-18 / 2023 / LAS VEGAS / NEVADA

REVIEWING YOUR SUM INSURED: DO YOU HAVE ENOUGH COVER FOR THE POST-COVID WORLD?

The COVID-19 pandemic has impacted businesses around the world in different ways. Here in Australia, the insurance industry – and the companies it protects –have seen new costs and challenges. Nick Dendrinos, NTI’s Head of Motor Portfolio, explains how the industry is travelling and how businesses can make sure they’re ready for the challenges ahead.

The most straightforward place to start is with business costs. Nick says that microchip shortages and fuel price increases have impacted businesses across the board.

“The cost of oil and fuel have a major impact on the production of raw materials, which in turn has an impact on things like the price of vehicle parts, building and construction parts.”

This uptick in prices coincided with a growing demand for vehicles and equipment, driven by many factors, including low interest rates and the instant asset tax write-off incentives.

“The huge explosion of e-commerce, wholesale goods market and the construction material markets have created a higher demand for freight movement,” he says.

“Which is fantastic, of course, but at the same time, that industry needs to move freight fast.”

The result is a significant backlog in new vehicle and equipment orders. Some original equipment manufacturers (OEMs) have closed their order books until 2023.

“The lack of availability of vehicles and equipment has put a hold on a lot of business’s plans,” he notes. “There’ll be patches of growth coming through when manufacturers start filling their orders.”

WHAT IT MEANS FOR INSURANCE

On the insurance side, the most important step any business can take is to review their policies and cover, with particular attention to their sums insured.

“At NTI we pay out the market value or the sum insured, whichever is the lesser,” Nick says. “The dynamic we have at the moment is that market values have in many cases surpassed the declared sums insured.

“At the same time, underlying inflation’s gone up as well. So the cost of repair is up too.

“The key message is for brokers and customers to work together to get their sums aligned to what their vehicles and equipment are worth now. We’ve seen 10 per cent increases,

but for some specialised items, we’ve seen 50, even 60 per cent increases.”

TOTAL LOSSES AND REPLACEMENT

Upwards pressure on vehicle and parts prices is just one complication. In the case of a total loss or a replacement, businesses can face significant delays.

“That’s another reason to review the sum insured,” Nick says, “because there’s a ratio of when an item is deemed repairable or not. With a higher sum insured, you have more flexibility regarding the viability of repairs.”

Business owners have to be realistic and work with their insurers to find the best option for their situation.

FINAL THOUGHTS

Now is the time to review your values and ensure your cover reflects your assets.

“This is a time for brokers and businesses to review those values upwards. You want to make sure that if you do have a loss, you’re compensated appropriately for what your vehicle is worth,” Nick says.

“Review that sum insured and let your insurer know right away if it needs to change. You don’t want to get caught short.”

Want more insight from Australia’s leader in heavy vehicle, mobile plant and equipment insurance? Visit NTI’s Yellow Cover at www.yellowcover.com.au.

NTI2131_Broker_Right 36 WWW.EARTHMOVERS-MAGAZINE.COM.AU INDUSTRY INSURANCE

Insurance products are provided by National Transport Insurance, a joint venture of the insurers Insurance Australia Limited trading as CGU Insurance ABN 11 000 016 722 AFSL 227681 and AAI Limited trading as Vero Insurance ABN 48 005 297 807 AFSL 230859 each holding a 50% share. National Transport Insurance is administered on behalf of the insurers by its manager NTI Limited ABN 84 000 746 109 AFSL 237246. NTI.M034.2.19072021 As Australia’s #1 plant and equipment insurer, you can trust YellowCover to provide the right insurance for your job. Specialist underwriting and claims teams are just the ticket to the game. You want an insurer that’s with you from the start of your claim and repair – not just reimbursing you at the end. That’s why we have: In-house tradequalified Repair Managers Unique trading accounts with manufacturers, dealers & distributors Talk to your broker or visit Yellowcover.com.au An in-house parts procurement team The right insurance for the job. NTI2131_Broker_Right Insurance_295x225_1.indd 2 20/9/21 1:46 pm

CAN YOU RECOMMEND A GOOD TRAINING MOB?

Well, don’t stress because this is your lucky day. I’m going to give you the good oil on the Hunter Valley-based operator training provider TRECK Industries.

TRECK Industries assists the civil, waste, quarrying and mining industries across Australia, meaning they can come to you. They specialise in customising plant training and assessment, operator training, up-skilling and machine familiarisation needs.

TRECK was founded by Ben (Swifty) and Debbie Swift in 2017, after identifying a gap in the market for not only training operators to obtain a qualification, but the need for trainees to gain a deeper understanding of the machine they’re learning, as well as the industry they are trying to enter. I don’t think I’d be talking out of school by saying that Debbie is the brains of the show. Swifty just does what he’s told!

Swifty brings a truck load of passion to his training though. He also brings 40 years of operating experience across a range of equipment over various applications, such as civil construction, agriculture, quarrying and mining.

His operating career started early in life, ripping around on his dad’s front-end loader, helping out with the family bulk fertilising business across New South Wales. He was a Certified Dealer Instructor at WesTrac CAT, before becoming Operations Manager at the Hunter Plant Operators Training School (HPOTS). He’s also currently an operator trainer/demonstrator for Hitachi Construction Machinery Australia.

Not only do TRECK Industries train and deliver nationally recognised RII qualifications on plant equipment, they also offer alternative training/services as well, like up-skilling, application training, machine/ manufacturer specific training and verification of competencies (VOC) on most earthmoving equipment.

They recognise the constant shift with modern machinery and technology, and the TRECK Industry crew are constantly researching the bits of iron hitting the market in the industries that they support, to ensure they’re delivering quality training time and time again.

Want to learn about TRECK Industries? Hit up their website at www.treckindustries.com or give them a call on 0456 000 968.

INDUSTRY TRAINING WORDS // SCOTT LIDSTER

38 WWW.EARTHMOVERS-MAGAZINE.COM.AU

I get asked this question often and what I generally respond with is, do your homework and find a provider who’s close to where you live. But sometimes people don’t have time to do the research, and sometimes there isn’t a provider in their area.

Experience the Hidromek H4-Series range for yourself. Available now for test-drives. Guaranteed Trade-Back, Rent-To-Buy options & free demonstrations available. T&Cs apply. Contact Onetrak today to learn more or visit www.onetrak.com.au. Andy Griffiths, St Helens Quarries MACHINE: HMK 310 LC The Hidromeks are quiet, comfortable and enjoyable to operate. They’re as good as anything else on the market if not better. They’re built extremely solid with reinforced steel components that I have not seen on any other excavators. “ ONETRAK - 1300 727 520 WWW.ONETRAK.COM.AU

QUICK TIPS FOR INTERNAL COMMS

Are you overlooking your best marketing tool?

No one knows your brand, your products, your services and your market like your own team – but plenty of organisations, big and small put internal communications way down the priority list when they are developing their strategies and plans. An engaged team can make a huge difference to your communications results. Here are five ways to do internal comms better:

1. DO IT FIRST, NOT LAST

Too many businesses make internal comms an afterthought. Don’t tell your people what your plans are after you have already rolled them out. Let them know what’s coming so they can optimise your programs by being prepared.

2. LEVERAGE THEIR NETWORKS

Want more engagement and more followers on social? Get your own team to promote your content. It is the quickest, easiest and

cheapest way to drastically boost your social results, yet a huge proportion of businesses either don’t do it at all, or don’t do it well. Doing it well means ensuring your team knows what to do, how to do it, and how it will support your company goals. Make it easy for them!

3. TRUST AND SHARE

Lots of brands talk about building partnerships with their customers. You need to build partnerships with your people, too. Don’t over-varnish your internal comms. Authenticity matters in and outside your office. When things are tough, be honest. If you tried an approach and it didn’t work, let your team know. You don’t want to be a party pooper, but you do want your team to feel like, well, a team. The caveat here is that internal comms could end up external, so do exercise a degree of caution.

4. MAKE SURE YOU REACH THEM

This might seem like a no-brainer, but a surprising amount of internal communications never reaches its intended audience. If you have a dealer network, or your staff mainly work in the workshop, on the road or factory environment, they’re probably not all seeing that email you send out each month. Think about other ways to engage. Is it a poster in the lunchroom? A dial-in call? A printed newsletter? SMS?

5. ASK FOR THEIR SUPPORT AND IDEAS

Ask for feedback and mean it. Collect ideas and show how you have used them. Ask your team to help you out. Research shows that people are more likely to do something for you if you’ve already asked them to do something before! People like to be appreciated, so ask, and be grateful.

Need help with internal comms? Get in touch hello@hc.net.au

MARKETING AND PR WORDS // ALEXANDRA WILLIAMS

40 WWW.EARTHMOVERS-MAGAZINE.COM.AU Earth_Moving_Single_Pg_T85Ht.indd

By

WHEN VOLUME MATTERS

D12 Stock is available. Enquire today. Sydney | Newcastle | Canberra | Melbourne |Adelaide | Hobart | Launceston | Perth | Brisbane Distributed in Australia from Nimac Pacific For further information,visit www.nimacpacific.com.au or call 0415 559 897 and 0411 488 116 Earth_Moving_Single_Pg_T85Ht.indd 1 7/05/2021 3:13:35 PM

XCMG SYDNEY DELIVERS ALL-ROUND PRODUCT AND SERVICE OFFERING

“This lead to partnering up with my cousins, Michael Bek and Mark Tadros, importing excavators, loaders and dumpers from the UK and USA in 2012 under the name Australian Equipment Wholesalers, which is the mother company,” he said.

“In 2020, we signed up to distribute and service rock saw manufacturer Austramac nationally, which put us on the mission to find an OEM earthmoving manufacturer to supply our customers with quality equipment, establishing us as a one-stop earthmoving supply and service centre.”

D&D Diesel Service General Manager David Kapahnke had put Sassin in touch

“Multiple meetings later, sharing the same vision we signed up, and are now one of the fastest growing, highest stockists of the third largest manufacturer in the world,” Sassin commented.

“That’s how XCMG Sydney started, and with many years of industry experience, a growing team and systems in place, we will continue to grow.”

DEALER PROFILE

XCMG Sydney has built its reputation around not only providing its clients high-quality equipment and industry-leading technologies, but also stocking a comprehensive range of attachments and accessories, underpinning a strong commitment to going above and beyond in developing efficient customised solutions.

Managing Director Sassin Bey draws on a broad range of experience in the earthmoving equipment industry, telling EEM that he had initially started out 15 years ago selling secondhand tools and equipment.

with XCMG Deputy General Manager for Australia Roy Rossini, ultimately leading to the partnership between the two companies.

42 WWW.EARTHMOVERS-MAGAZINE.COM.AU

XCMG SYDNEY RANGE FEATURES

LATEST TECHNOLOGY AND QUALITY COMPONENTS

Sassin told EEM that XCMG Sydney has since grown to oversee three locations – its Sydney Chullora head office, along with locations in Wollongong and Canberra – pointing to the varied benefits of the XCMG range when it comes to standing out in a competitive marketplace.

He also highlighted XCMG Sydney’s commitment to client-focused service support as providing strong additional value and peace of mind.

“Our XCMG range is extremely comprehensive, featuring the latest technology and quality components, along with the most compatible warranty, and best of all our service and pricing puts us a step ahead of our competitors,” he said.

“Our excavator range, from 1.7 to 50 t, is all in stock, all civil spec, highest safety spec (factory e-stops, beacons, anti-burst valves, ROPS/ FOPS, double-locking Miller hitches), and our turnaround time is the fastest in the industry.”

Among the XCMG Sydney range, the XE155ECR crawler excavator weighs in at an operating weight of 16.67 t and runs a 90 kW Cummins B4.5 engine, with it designed to get the job done across a range of tasks including excavation, loading, levelling, trenching, crushing, drilling, clamping and lifting.

Towards the larger end of the excavator range, the XE370D crawler excavator weighs in at 36.8 t, runs a 212 kW Isuzu GH-6 engine – and, like the XE155ECR, can be let loose on tasks including excavation, loading, levelling, trenching, crushing, drilling, clamping and lifting.

Both the XE155ECR and XE370D feature high-quality structural components, exceptional hydraulic capability, comfortable operation and excellent safety, and provide overall premium performance and reliability.

A COMPREHENSIVE RANGE OF ATTACHMENTS AND ACCESSORIES

Sassin emphasised that XCMG Sydney is focused on delivering its clients all-round assistance, beyond simply selling equipment, with it having put together its product and service offering around catering for a range of requirements.

This effectively allows XCMG Sydney to cater for diverse client needs, with it capable of developing highly productive customised solutions, decked out to tackle specific tasks and projects.

“At XCMG Sydney we don’t only supply the equipment and leave you pondering on

where to source attachments and accessories,” he said.

“We stock everything in-house, from Dozco hydraulic hammers to Austramac rock saws, the Auger Torque full auger range, Sureweld ramps, trailers and even accessories, such as diesel tanks, grease guns, lubricants and tool chests for maintenance.”

This focus on providing a one-stop shop service has led to the ongoing expansion of XCMG Sydney’s supply capabilities, with Sassin pointing to the comprehensive range of machinery and parts it now has at the ready for its clients.

“In less then 12 months, we’ve gone from stocking a dozen pieces of XCMG equipment to currently having over 10 million in stock,” he said.

In turn, XCMG Sydney has enjoyed strong growth in recent years, with it continuing to add new members to its workforce and evolve its service offering as it stakes out a strong position in the market.

Sassin told EEM that the outlook is bright moving forward, building on the back of both the quality XCMG machinery range and its client-focused service offering.

WWW.EARTHMOVERS-MAGAZINE.COM.AU 43

Right part, right price, right now.™

As an Australian family-owned company with global reach, Tilly’s is proud to stock over 43,000 new part lines for your earthmoving machinery. Tilly’s quality alternative undercarriage range extends from track groups to idlers, rollers, sprockets and track adjusters suitable for dozers up to D9 and excavators up to 30 tonne.

Tilly's are pleased to now offer a range of quality low-hour machines including General Construction Excavators and Loaders and D6-D8 ex-United States machines.

Tilly's is now offering account customers online ordering of over 30,000 parts for even quicker turnaround time, because we understand that down-time for your machines has a huge impact on your bottom line. That’s why we guarantee the quality of our new parts to ensure you are staying on track.

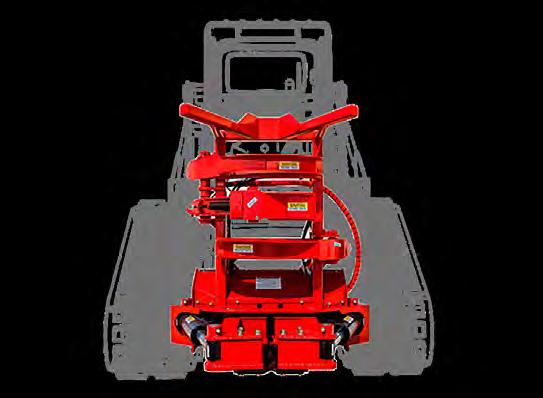

UHI US40K SKID LOADER

UHI Machinery might not be a brand that everyone has heard of, but they are producing solid machines with great specs, features, and most importantly price tag. EEM put the

Loader to the test with some very impressive results.

It’s worth mentioning that the UHI brand machines come out of the same factory as other more recognised brand name machines, with some serious specs and components like the Xinchai 4-cylinder 49hp engine (producing 36.8kW/2500 rpm). The hydraulic drive technology features stable drive and high efficiency with reliable performance – you will feel the power from the get-go! If you’re the type of operator looking to up the ante in the power department, the US40K is the machine for you.

TEST OPERATOR: MATT ALDER

For our review we teamed up with Matt Alder from DUAL Landscapes & Stonework. Matt and his team have been producing stunning work around Sydney’s Northern Beaches for almost 15 years. He has operated a wide range of machines during that time and was a great asset to have on hand for this test.

TEST OPERATOR // MATT ALDER

WORDS AND IMAGES // JAMIE GRAY

46 WWW.EARTHMOVERS-MAGAZINE.COM.AU

UHI US40K Skid

After putting the skid steer through its paces for a few hours, when I asked Matt for his first thoughts about the UHI US40K, he shared, “This machine has turned out to be a bit of a surprise package. I hadn’t heard the name UHI before and wasn’t too sure what to expect. The first thing I noticed was how smooth it was because other machines I’ve operated tend to really throw you around. The US40K had loads of power and plenty of room in the cab. It was a little different to what I am used to in terms of controls, with the left-hand joystick controlling the direction of the machine and the right-hand joystick controlling the bucket. The machine was fitted with a 4-in-1 bucket with easily changeable open and close speed, and after spending 20 minutes getting used to this configuration, I was off and away. Ease of use was impressive – the machine is intuitive so most people with a bit of experience will find it easy to operate.”

IMPRESSIVE 750KG LOAD RATING

Apart from the power and ease of use of the US40K, there are some great specs and components onboard, which contribute to the impressive performance of the US40K. With a load rated capacity of 750kg and an operating weight of 3140kg, the US40K is producing max breakout force of 18kN. This unit gets moving with a ground speed of 14.3 km/h. With four bar linkage, hydraulic flow rate of 62.5 litres/min and 200 bar of

UHI US40K SKID LOADER 4-cylinder 49hp engine Static hydraulic drive 750kg load capacity 14.3km/h max speed 62.5 litres/min hydraulic flow rate Reversing camera WWW.EARTHMOVERS-MAGAZINE.COM.AU 47

Matt Alder, test operator, DUAL Landscapes & Stonework

48 WWW.EARTHMOVERS-MAGAZINE.COM.AU

hydraulic pressure, you can easily run any attachment on this machine.

Other items that will impress are the reversing camera, rotating beacon, mechanical suspension seat and Permco working pump with Rexroth travel pump and motor.

I asked Matt about the physical performance of the US40K, “During testing we had various materials to move around and rip into, from freshly tipped tree lopping and branches to mulched material, rock and stone. The machine didn’t hesitate at any stage producing plenty of power, even when lifting heavy stone material, which I work with all the time. It felt solid on the ground and had a good amount of ground speed. I can see the US40K being a top machine for operators who need to move material. Operators like me who work with stone and heavier materials through to tradies who require other attachments will feel the quality of the machine’s frame. It’s a solid machine with dimensions of 3310mm x 1800mm x 1950mm – you can feel the firmness and build quality.”

The next step up from the US40K is the US50K, which with its Japanese Yanmar Engine at 68hp, rated load capacity of 900kg,

operating weight of 3200kg, and high flow rate up to 120l/min, would also be an ideal machine for operators like Matt who lift heavy material.

Another big feature of the UHI brand is its international, first-class quality hydraulic unit, which features reliable, energy-saving high

efficiency design and manufacture. What’s even more impressive is that the machine hydraulics are the same as other leading brands, so you have access to a large number of accessories and attachments – like augers and buckets – which will fit perfectly to your UHI machine.

WWW.EARTHMOVERS-MAGAZINE.COM.AU 49

THE WRAP-UP

With its 750kg lifting capacity, smooth controls and user-friendly operation, the UHI US40K is set to make solid inroads into the skid steer market. Operators who need to move material or level, the UHI US40K will do all of that and more with no fuss and impressive power and reliability.

When I asked Matt about his closing thoughts, he shared, “This machine is well worth a look. UHI has put the skid steer together with performance and ease of use as top priority. Even the 4-in-1 bucket moves a little slower than I originally expected, but once I was used to the feel of its operation, I actually preferred it. Other 4 in 1s I’ve operated have required precise timing with operation, but the US40K felt intuitive and accurate.

Now that I’ve given the UHI skid steer a run, I’m going to check out their mini excavator range to see if they’re as well put together as the US40K.

50 WWW.EARTHMOVERS-MAGAZINE.COM.AU

www.unitedheavyindustries.com.au Melbourne 2/94 Boundary Road, Sunshine West, VIC 3020 Sydney 1/323 Newbridge Road, Chipping Norton, NSW 2170 Brisbane 122 Ashover Road, Archerfield, QLD, 4108 Adelaide 27 Staite Street, Wingfield, SA 5013 Perth 302 Gnangara Road, Landsdale WA 6065 Townsville 5 Vennard Street Garbutt QLD 4814 Darwin 15 McKinnon Road Pinelands NT 0829 UWL807 ARTICULATED MINI LOADER WITH 4 ATTACHMENTS $24,990 GST Inc. UWL810T TELESCOPIC ARTICULATED MINI LOADER LOADER WITH 4 ATTACHMENTS $32,990 GST Inc. UWL280 2.8T LIFTING WHEEL LOADER WITH 3 ATTACHMENTS, 123HP $54,990 GST Inc. US40K SKID STEER LOADER WITH 4 IN 1 BUCKET $39,990 GST Inc. US50K SKID STEER LOADER WITH 4 IN 1 BUCKET $52,000 GST Inc. U50 ELECTRIC WHEEL LOADER WITH 3 ATTACHMENTS $15,990 GST Inc. 1800 000 844 CALL TODAY UWL350 3.5T LIFTING WHEEL LOADER WITH 3 ATTACHMENTS, 150HP $69,990 GST Inc.

Takeuchi’s huge range of excavators and light earthmoving equipment has you covered CALL US NOW 1800 685 525 www.semcogroup.com.au TB138FR, TB257FR, TB280FR 3,850kg, 5,840kg, 8,500kg TB219 1,945kg TB295W 9,425kg TB210R, TB215R, TB216 TB2150, TB2150R 16,000kg, 16,000kg TB217R 1,680kg www.takeuchi.com.au TB250-2, TB260, TB370, TB285 5,120kg, 6,020kg, 7,000kg, 8,500kg TB225, TB235-2 2,350kg, 3,550kg

www.takeuchi.com.au ® From World First to World Leader TAKEUCHI TL TRACK LOADERS TL8R-2 Approx operating weight 4,165kg Features radial lift Engine power 54.6 kW Tipping load 2,740 kg TL12V2 Approx operating weight 5,915kg Features vertical lift Engine power 81.8 kW Tipping load 5,325 kg TL10V2 Approx operating weight 4,660kg Features vertical lift Engine power 54.6 kW Tipping load 3,270 kg TL12R2 Approx operating weight 5,375kg Features radial lift Engine power 81.8 kW Tipping load 3,915 kg TL6R Approx operating weight 3,530kg Features radial lift Engine power 47.9 kW Tipping load 2,390 kg NSW SEMCO SYDNEY 55 - 63 Kurrajong Rd, North St Marys Tel: 0298 336 000 SEMCO NEWCASTLE 52 Sandringham Avenue, Thornton Tel: 0249 547 066 SEMCO QUEANBEYAN 96 Yass Rd, Queanbeyan Tel: 0262 972 755 SEMCO GOULBURN 1 Wayo Street, Goulburn Tel: 4822 9728 or Darren Browsowski 0419 468 598 VIC SEMCO MELBOURNE 74 East Derrimut Crescent, Derrimut Tel: 0393 037 777 QLD SEMCO BRISBANE 21 Machinery Street, Darra Tel: 0733 756 999 SA BPF EQUIPMENT 2 Duncan Road, Dry Creek Tel: 08 8262 1000 1800 685 525 www.semcogroup.com.au TAKEUCHI DEALERS SEE US AT STAND B5

CASE STUDY

LEADER EARTHWORKS AND WESTRAC

This impressive growth has seen Phil take the business from a one man, one machine operation in 2014 to a company with over 40 staff and 50 pieces of equipment in 2022.

Phil has placed Leader Earthworks as experts in the industry, with a clear goal to provide excellent first-class service in all projects. “When newer, modern equipment is released, we phase out the older versions rather than stubbornly sticking with them. As a result, our fleet of Caterpillars is among the most modern in South East Queensland and North East NSW. This ensures our machines are reliable and our service maintains high safety standards,” said Phil.

Leader Earthworks is a great example of what’s possible with the right machinery partner, a great team with a can-do attitude, and the right man at the helm. With his Caterpillar machines from WesTrac by his side, you get the feeling that anything is possible and Phil’s just the man for the job.

It’s been a massive eight years for owner and director of Leader Earthworks , Phil Immisch, who specialises in bulk earthworks and plant hire services in Queensland and NSW.

WORDS // IMAGES JAMIE GRAY

It’s been a massive eight years for owner and director of Leader Earthworks , Phil Immisch, who specialises in bulk earthworks and plant hire services in Queensland and NSW.

WORDS // IMAGES JAMIE GRAY

54 WWW.EARTHMOVERS-MAGAZINE.COM.AU

Phil Immisch, Director, Leader Earthworks.

Phil’s experience in the industry began in 2005 when he worked in civil construction and mining in NSW, Queensland and WA, before starting Leader Earthworks in 2014.

“I managed to gain a range of experience in my early years, which with hard work gave me the confidence to back myself later in my career,” said Phil.

PROVIDING PLANT HIRE AND BULK EARTHWORKS

Leader Earthworks provides plant hire and bulk earthworks contracting for civil construction, agriculture and mining projects. As a diverse, professional plant hire service

WWW.EARTHMOVERS-MAGAZINE.COM.AU 55