Price $7.95 inc GST Feb/Mar 10 Price $9.95 inc GST AUG/SEP 2022 AUGUST / SEPTEMBER 2022 CASE STUDIES: CORPS AND WESTRAC ALLWORKS AND CJD EQUIPMENT HIREWORKS DARWIN AND KOBELCO INNOVATIVE PRODUCTS EYE ON THE INDUSTRY INDUSTRY EVENTS VERSACE CONCRETE SOLUTIONS AND WACKER NEUSON

Join our free Smart Construction Webinar series Don’t miss out! Register now 1300 566 287 | komatsu.com.au

We’ve cast the EEM net over a wide area for this issue, that’s for sure.

Kicking off with Versace Concrete Solutions in Sydney and the inspirational rags-to-riches story of company founder and director Giovanni Versace, we’ve also blasted across the Nullarbor for a couple of interesting case studies.

Allworks WA Pty Ltd, and husbandand-wife directors Robin and Angelo Sarich, have a head office in Perth, but the company has work going on all over Australia and at the moment is running something like 50 wheel loaders. It’s a fleet built up over time – as has been the company’s association with CJD Equipment. That’s a great testament to Allworks’ high regard for its equipment supplier.

Also in WA is Corps, a family-owned and run civil-construction company which, based in the Pilbara, runs Caterpillar machinery, serviced and maintained through WesTrac. The Corps family takes special measures to cope with the distance and difficulties of running heavy machinery in the remote Kimberley and Pilbara regions, and it’s an absorbing study.

Hireworks in Darwin is the focus of another case study, and another instance of an earthmoving outfit enjoying growth and success in line with a long-term association with a particular brand and dealer – in this case Kobelco equipment from Forecast Machinery. Hireworks’ Managing Director Allan Gillett’s story on his time with the company has plenty of good examples for others to follow and is a very interesting and instructive narrative. And we wouldn’t want anyone to think we weren’t paying any attention to our Queensland readers.

EEM trekked north to get the good info on the first Hastings Deering Global Operator Challenge at Toowoomba in July, and to see 27 machine operators go head-to-head. The three challenges were all hard-fought, and Aiden Lee from Queensland Electrical Solutions was a worthy winner. Aiden will head off to Japan to compete against other top-flight performers from the Pacific region. We wish him the best of luck.

You can read more about that, and a stack of other industry-related stories, as you work your way through the magazine.

So, as usual, we’ve been at full throttle getting this issue whipped into shape and ready for your inspection.

Don’t just sit there. Get reading!

Tom Foster Contributing Editor

GET IN TOUCH

EEM an email at tom@maynemedia.com.au

We’re keen to get your thoughts.

Do you have something you’d like to share with the industry? Send

FROM THE CONTRIBUTING EDITOR

4 WWW.EARTHMOVERS-MAGAZINE.COM.AU

Experience the Hidromek H4-Series range for yourself. Available now for test-drives. Guaranteed Trade-Back, Rent-To-Buy options & free demonstrations available. T&Cs apply. Contact Onetrak today to learn more or visit www.onetrak.com.au. Andy Griffiths, St Helens Quarries MACHINE: HMK 310 LC The Hidromeks are quiet, comfortable and enjoyable to operate. They’re as good as anything else on the market if not better. They’re built extremely solid with reinforced steel components that I have not seen on any other excavators. “ ONETRAK - 1300 727 520 WWW.ONETRAK.COM.AU

Jamie Gray

Jamie has been a professional photographer in Sydney for over two decades. He is the owner of Camera, Hammer and Tong, who provides digital content for small businesses in and around the construction industry. He is also a photo journalist & the product feature editor for What Tradies Want Magazine. But he’s just as comfortable with a hammer in his hand as a camera and pen. Undertaking a mature age carpentry apprenticeship in his 40s and still gets the nail bag on when he can.

Martin Kovacs

Martin

10. On the Cover 18. Meet the Expert 26. Industry Leaders 28. Industry Auction 32. Business and Finance 34. Machine Control Technology CONTENTS AUGUST / SEPTEMBER 2022 CONTRIBUTORS

business,

and

print

business and

issues

importance

digital technology developments

industry continues to adapt and evolve

the rollout

new technologies. 38. Industry Insurance 40. Industry Training 42. Marketing and PR 44. Dealer Profile 50. Case Studies 74. Service, Maintenance and Parts Feature SYDNEYDRAGWAY, EASTERNCREEK 21-23 APRIL 2023 6 WWW.EARTHMOVERS-MAGAZINE.COM.AU

Kovacs is a journalist with experience covering the

technology

energy sectors. Over the past 10 years, Martin has covered a wide range of subjects across both

and digital media, broadly encompassing

technology trends, focusing on

of

for industry. Martin takes a particular interest in

and the manner in which

amid

of

Scott Lidster

Scott is the Director of Australian Earth Training, a niche operator proficiency training organisation who work across the globe. He has over 25 years’ experience in heavy equipment operation and was an accredited Caterpillar Dealer Instructor (CDI) Trainer-Demonstrator. Scott’s unique skill set enables him to operate and train on a broad range of machines across the mining, construction, quarrying and waste industries, helping his customers to boost their productivity while lowering their owning and operating costs.

Ian Edwards

Ian Edwards is a Civil Construction Teacher and Assessor, who holds a Certificate IV in Civil Construction Supervision and Operations, a Certificate III in Civil Construction – Plant Operations, and a Certificate III in Civil Construction – Pipe Laying along with numerous Certificate III Civil Construction qualifications.

Ian has been involved in the Earthmoving industry for nearly 50 years, operating his own excavations company since 1972 and life member of the Golden Bucket. He has been operating excavators, backhoes, front end loaders, skid-steer loaders, and all associated attachments throughout his career.

GST inc GST AUGUST SEPTEMBER 2022 CASE STUDIES: CORPS AND WESTRAC ALLWORKS AND CJD EQUIPMENT HIREWORKS DARWIN AND KOBELCO INNOVATIVE PRODUCTS EYE ON THE INDUSTRY INDUSTRY EVENTS VERSACE CONCRETE SOLUTIONS AND WACKER NEUSON CAT® Global Operator Challenge Victoria Finals 2022 at Dig Deep Event!

Earthmoving Equipment Magazine is Published Bi-Monthly by Mayne Media Group Pty Ltd Publisher Kurt M. Quambusch Contributing Editor Tom Foster tom@maynemedia.com.au Features Editor Jamie Gray jamie@maynemedia.com.au Group Sales Manager KahChi Liew kahchi@maynemedia.com.au (02) 9452 4517 Production Manager Michelle Alder production2@maynemedia.com.au Design Ryan Turner art@maynemedia.com.au Subscriptions subscriptions@maynemedia.com.au 1300 764 688 ISSN 1835-2634 ACN 130 678 812 ABN 27 130 678 812 Subscribe: www.earthmovers-magazine.com.au Enquiries: Phone: 1300 76 4688 Int.ph: +612 9452 4517 Fax: (02) 9452 5319 Int.fax: +612 9452 5319 Copyright 2021. Mayne Media Group Pty Ltd. Material may not be reproduced or photocopied in any form without the written permission of the publisher. Mayne Media Group Pty Ltd believes that all material is correct at the time of printing CIRCULATION: 14,718 Last audit: September 2020 CIRCULATION (SEPTEMBER 2020) 14,718 PROUDLY PRINTED IN AUSTRALIA ON THE COVER: VERSACE CONCRETE SOLUTIONS AND WACKER NEUSON 82. Innovative Products 108. Eye on the Industry 124. Industry Events 132. Civil Contractors Federation 134. Association News 136. Subscribe Now WWW.EARTHMOVERS-MAGAZINE.COM.AU 7

TM

TM

VERSACE CONCRETE SOLUTIONS AND WACKER NEUSON

Running a small business is filled with unique challenges, dealing with the ever-moving goal posts that business operators face requires a great team and reliable equipment, staff and suppliers; not to mention unwavering motivation. For Giovanni Versace, Director of Versace Concrete Solutions, there’s a proud Italian heritage coming from a long line of concreters. Giovanni doesn’t have to look hard for inspiration – his young family is his motivation and wife Brooke is the backbone of the business. With their great relationship with Jackson Equipment Sales and Wacker Neuson, the future has never looked brighter for Giovanni and his team who are going from strength to strength.

Giovanni has been in the construction industry since the age of 14, working for both larger companies and subcontracting to smaller ones. About five years ago, Giovanni realised it was time to stop breaking his back working for other companies and instead start his own business and build a future for his family. “Coming from a long line of Italian concreters, it’s in my blood. I’ve had an interest in machinery and trucks from a young age like most little boys do. I was a boy who came from housing commission in western Sydney, and having my mother (a single mother with four boys all aged four and under) work three jobs just to keep food on the table, to now having everything I have today is a huge deal for me. I’m able to give my children more than I ever had,” said Giovanni.

Giovanni had a clear vision of the type of concreting business he wanted to run – to have as many elements as possible (if not all) fulfilled inhouse. Giovanni shared, “With the majority of our work being concrete works, I decided to buy all my own machinery/equipment so it was all inhouse and I wouldn’t need to subcontract out my work or pay to hire someone else’s machinery. For me, the whole experience of having my own business has been a series of challenges. Right when you think you’ve got everything down pat, something will come up just to throw a spanner in the works and test you, like covid. You never stop learning new things when you have your own business.”

In their day-to-day operations, Versace Concrete Solutions primarily use excavators and skid steers. After having varying levels of success with other brands of machines and suppliers, Giovanni and Brooke have settled in very nicely with the Wacker Neuson brand, which they purchase from Jim and Michael from Jackson Equipment Sales. “We have been dealing with Jim from Jacksons in Newcastle and Michael from Jacksons in Sydney. We had dealt with many others before coming over

ON THE COVER WORDS AND IMAGES // JAMIE GRAY

10 WWW.EARTHMOVERS-MAGAZINE.COM.AU

WWW.EARTHMOVERS-MAGAZINE.COM.AU 11

The Versace family.

to Jacksons and their customer service was second to none. They always provide constant updates and make casual phone call check ins to make sure we are happy with the product and getting the most out of it. It’s been so appreciated and they really know their stuff,” said Giovanni.

Giovanni continued, “Our very first machine was an old 4 tonne Yama with an open cab. During the last two years we have purchased our Wacker Neuson EZ17 Excavator, Ride on Trowel Machine, two Wacker Neuson walk behinds and we are now in the process of purchasing a 4 tonne excavator all from Jacksons.”

The Wacker Neuson brand is built off the back of great strengths such as reliability, fuel efficiency, breakout force and digging power. When I chatted to Giovanni and Brooke, it’s pretty clear that this has been their exact experience with their machines, but it was the Wacker Neuson EZ17 we were keen to hear more about. Giovanni happily shared, “Our machine is reliable and the boys have enjoyed the power and performance, which transfers directly over to efficient onsite performance. Plus, the quick hitch as a standard feature is what really got us over the line with the EZ17. Not having to break your back changing buckets and even just saving time is great. Being a smaller machine, the adjustable tracks help for tight access with a lot of our residential jobs, which have limited access between houses in newer estates.”

ON THE COVER

12 WWW.EARTHMOVERS-MAGAZINE.COM.AU

Left to right: Giovanni Versace; Jason Spiteri (top); Chris Brown; and Michael De Bono, Jacksons (front).

Having the right equipment that performs reliably and efficiently is only half the equation. The other part is having the relationship with your supplier and getting the service you need, when you need it. After struggling in this area in the past, both Brooke and Giovanni seem to embrace the importance of this with their relationship with Jacksons. They shared, “I believe we will always have a very fruitful relationship with Jim and Michael. I wouldn’t go anywhere other than Jacksons for advice and sales for our machinery because they have always gone above and beyond for us. One time I had a specific job that required an auger, and the wait time was going to be a few weeks, which wasn’t going to help me. However, Jim and Michael being the legends they are, had a spare one in the warehouse, which they gave to me to use until my new auger arrived. If that isn’t top-notch customer service and keeping your existing customers satisfied, I don’t know what is.”

Mike De Bono has only been with the team at Jacksons for four months but has an impressive history with Wacker Neuson of over 15 years, in which he has built up an extensive knowledge of all things Wacker. This experience places him in an excellent position with clients like Versace Concrete Solutions.

When I chatted with Mike on site while we filmed Giovanni and his team prepping for a slab, he shared, “My role is Sales Manager Sydney and I have been with Jackson Equipment Sales going on four months, however have been in a working relationship with Ben for four and a half years. This stems back to when I was the State Manager of

Wacker Neuson Sydney and my total time spent at Wacker Neuson was 15 years, with the last two years working for another company. Giovanni and Brooke have purchased the EZ17, various Wacker Neuson concreting trowel machines and are now in the process of finalising a new EZ36 cabin with VDS mini excavator to add to their fleet.”

WWW.EARTHMOVERS-MAGAZINE.COM.AU 13

Michael continued, “With its compact design the EZ17 offers good value with the way we order this machine in. It comes with a great list of features, including factory fitted hydraulic hitch as standard, long dipper stick providing the customer 2486mm digging depth and maximum dumping height of 2550mm, rear counterweight to counteract the long dipper, and powerful 18.2hp engine. The high thermal resistance, which means this machine can work in up to 45 degrees Celsius without loss of performance and optimally match hydraulics LUDV (load sensing pumps), ensures excellent digging power and sensitive control. Also included are steel grooved pins and bushes and retractable tracks 990mm to 1300mm with dozer blade extensions, which provide superior stability and optimal maintenance access.

ON THE COVER

14 WWW.EARTHMOVERS-MAGAZINE.COM.AU

“The EZ17 has such an impressive list of features that benefit the end user for concreters and other operators who regularly work in tight spaces, fitting through sub 1000mm openings, to drilling 600mm holes with the auger drive.

The canopy is also removable and it only takes undoing four bolts to fit funder garage doors. All this combines to create a perfect allrounder excavator.

“Our working relationship with the Versace team is only getting stronger because they make us part of their team and love discussing their growth opportunities with us, as we too make them part of our business by helping out. Whether it’s advising them on new attachments or new products that will benefit them, through to our service capabilities, both our relationships are built on trust,” said Michael.

WWW.EARTHMOVERS-MAGAZINE.COM.AU 15

Contact your local dealer for specific products and services for your landscaping or construction requirements. DESIGN & INNOVATION MEETS POWERFUL PERFORMANCE View the full range of Wacker Neuson products:

CAT® NEW LARGE HYDRAULIC EXCAVATORS LINEUP

Caterpillar offers a wide range of next generation large excavators, which comprise of performance models 336 to 395 featuring factory standard technology and the 336 GC and 345 GC standard models to suit applications like bulk earthworks or hammer use that don’t require the full suite of standard technology imbedded in the next generation performance range of excavators. “Our GC models provide solutions for operations where high reliability, faster return on investment and low cost per hour performance are the priorities, while our performance models are all about leveraging the integrated technology to achieve maximum productivity and lowest cost per tonne,” Teo adds.

The various configurations of the Cat ® engines in the large excavators can run on biodiesel up to B20 and by offering different emission choices like U.S EPA Tier 3 and U.S EPA Tier 4 Final options across most of the range, customers have more choice than ever.

HIGHER PERFORMANCE WITH LOWER FUEL CONSUMPTION

Teo said, “Our large excavators are designed with new features that help to lower the fuel consumption and increase fuel efficiency ranging from 5% to 25% while improving the machine performance and the productivity.”

Three engine modes of operation: Power, ECO and SMART modes are available to best match your performance and fuel efficiency expectations to your applications and to ensure the machines are always working in the most optimal settings for any job. It’s the next generation SMART mode however that automatically matches the engine RPM and hydraulic power to the actual

digging conditions to reduce fuel consumption and optimise performance in real time by sensing the load on the hydraulics that is a real game changer. Simply set the excavator in SMART mode and let it manage engine power when and where you need it with no further operator input.

A precise combination of lower engine speed and large hydraulic pump pressure and flow delivers more work per unit of fuel. “Cat pumps matched to Cat engines, with Cat hydraulics and Cat software means our systems are highly refined and tuned to work together,” explained Teo.

The cooling fans on next generation large excavators are mainly On-demand hydraulic fans with a couple of models using a hybrid system of electric and hydraulic fans. These variable speed fans ensure cooling is optimised and helps to save on fuel consumption when cooling (fan speed) requirement is low.

REDUCED MAINTENANCE

We wanted to help lower owner’s operating cost, so Caterpillar has reduced maintenance costs by up to 15 per cent based on 12,000 engine hours, Teo said. “We have gone further then we have ever before and extended and synchronised maintenance intervals on all models. Synchronised 1000-hour oil and fuel

filter service intervals reduce downtime and the extended intervals also means that on a 395 vs 390F, customers can save on 48 filters over 12,000 operating hours.”

The new hydraulic system no longer requires a pilot system, eliminating the need for a pilot filter, further reducing maintenance costs.

Other improvements like the advanced air intake filter with pre-cleaner has more dust holding capacity than the previous air intake filter for better engine protection. The new hydraulic oil filter provides improved filtration performance, anti-drain valves to keep oil clean when the filter is replaced, and longer life with a 3000-hour replacement interval, which is 50% longer than previous filter designs. The new high-efficiency hydraulic fan has an optional automatic reverse function to keep cores free from debris, eliminating the need for any operator interaction further lowering the maintenance costs.

The new Cat 336 Hydraulic Excavator offers class-leading production and low-cost operation. Its powerful hydraulic system delivers strong digging forces and swing torque to boost production in the most demanding applications. The new Cat 340 Hydraulic Excavator features a more powerful engine, wider track gauge, and 7.5-tonne counterweight to increase productivit y

MEET THE EXPERT

“Caterpillar’s next generation excavators have revolutionised the excavator market,” Excavator Product Specialist, Yibin Teo, says adding, “A focus on the customer experience was central in the design of the new line of large excavators, which includes more models, more standard technologies and an even greater range of options and price points.”

18 WWW.EARTHMOVERS-MAGAZINE.COM.AU

by 10% over the 2020 model Cat 336. Its increased power and stability, combined with next generation electrohydraulic system efficiency, make it the best choice in the 40-tonne (45-tonne) class for moving tonnes per hour.

TECHNOLOGY

At the core of the Cat excavator range, simple, easy-to-use technology helps operators and owners get the most out of their machine. Cat GRADE with 2D provides real time guidance on bucket teeth position and helps the operator reach grade faster and boosts productivity.

The systems can be upgraded, or factory

optioned with 2D Advanced, which is able to provide in-field design or Cat GRADE with 3D which is able to track the bucket position through the Global Navigation Satellite System for high accuracy grade performance.

Grade Assist allows operators to stay on grade with the use of a single joystick input, automating the boom bucket and tilt commands. Grade Assist has been refined for use with heavier work tools and is now available on the 349 and 352.

Lift Assist is a new feature that is available on all performance models. The Lift Assist feature provides real time indication of load centre and mass and by calculating the weight of the actual load being lifted and comparing it to the excavator’s rated capability, visual and auditory alerts show and tell the operator where in the excavator operating range the load can be safely lifted.

Standard Product Link ™ makes the management of the customer jobsites easier by gathering data from the equipment. It provides location, machine hours, fuel usage, productivity, idle time, diagnostic codes, and grade control internet connectivity as well as remote flash and troubleshoot which can reduces downtime.

Cat PAYLOAD technology is a fully integrated system that delivers precise load targets with on-the-go weighing, which prevents over/underloading, and reduces load times and maximises efficiency.

OPERATOR ORIENTED CAB

The newly designed cabs with automatic climate control and wider seats raise the standard in comfort and productivity. The cabs are designed with advanced viscous mounts

that reduce cab vibration by up to 50% over previous excavator models.

All the controls and the joysticks are ergonomically designed to reduce operator effort and fatigue. The ROPS cabs with narrow front cab pillars along with other features like the standard rear-view camera, larger windows at the front, sides, and rear give excellent visibility to the operators in all the directions. The tilt-up left console allows the operators to enter and exit the cabs easily and safely.

Performance-enhancing features like the front-facing control panel, keyless pushbutton start, and large touchscreen monitor with jog dial keys come standard, which simplifies the operation. Convenience features like Bluetooth integrated radio, USB ports for charging and phone connectivity, cup, and bottle holders provide better access, connectivity, and storages, which further boost operator comfort.

Teo said the excavators set a new benchmark for the industry. “They are revolutionising how owners and operators utilise our machines to maximise performance, improve productivity and operator efficiency and reduce operating costs and help owners improve their job-site profitability. “Designed to deliver an unmatched customer experience,” Teo added. “The range has to be experienced to be believed – they have set a standard that enhances our segment leadership and paves our way forward.”

For more information about Cat large excavators, visit the local Cat dealer.

NSW/ACT WesTrac 1300 881 064

VIC/TAS William Adams 1300 923 267

Western Australia WesTrac 1300 881 064

QLD/NT Hastings Deering 131 228

South Australia Cavpower 08 8343 1600

NZ TERRA 0800 93 39 39

WWW.EARTHMOVERS-MAGAZINE.COM.AU 19

DOES YOUR BLADE MAKE THE GRADE?

CAT® MOTOR GRADER CUTTING EDGES

If you’re looking to help increase wear life and reduce costs, it’s important to choose the right cutting edges. In the long run, it’ll make a big difference to your motor grader’s performance and productivity.

Genuine Cat® motor grader cutting edges are built to deliver superior performance and long wear life. They’re designed for easy removal and installation too.

CHOOSING YOUR CUTTING EDGE

There are many factors that contribute to your choice of cutting edge. Consider your application environment – in particular, the level of impact, penetration and abrasion your edge needs to endure. It’s critical that your edge penetrates the material and doesn’t break during operation.

As Caterpillar Component Application Specialist Joe Clevenger knows, “Matching the correct edge to application allows for better machine performance and greater end results for your job. This can result in reduced operational and maintenance costs.”

The table (right) provides an overview of cutting edge options for a range of environments and applications.

GENERAL DUTY

• High Carbon Steel

• Available for 12’, 13’, 14’ and 16’ blades

• Offered in a curved profile shape in a variety of thicknesses

• Best suited for low to moderate impact and moderate to high abrasion.

HEAVY DUTY

• Thorough hardened DH-2 Steel

• Available for 12’, 13’, 14’, 16’ and 18’ blades

• Offered in a variety of thicknesses in curved, flat and serrated profile shapes

• Well suited to high impact and highly abrasive applications.

SPECIALTY

• Tungsten Carbide

• Available for 12’, 13’, 14’, 16’ and 18’ blades

• GraderBit2™ System, Rotating Bit System, Edges with Tungsten Carbide

• Best suited to low to moderate impact and moderate to high abrasion

NOTE: The Cat GraderBit2™ System installs without tools and adjusts to your grading conditions.

MEET THE EXPERT WORDS // CAT CISD

20 WWW.EARTHMOVERS-MAGAZINE.COM.AU

CUTTING EDGE SHAPES

Each of the options in the table is available in a variety of shapes and thicknesses to suit every application. As well as the large range of off-the-shelf options, you can also customise your cutting edges through the Made as Order (MAO) program.

Flat edges: These are suitable for heavy road maintenance and pioneering. Their strength and available wear material make them the best option for applications that require maximum abrasion and impact resistance.

Curved edges: Curved cutting edges are best suited to applications where you need superior penetration and rolling action. Curved edges are also useful for fine grading and finish work.

Flat serrated edges: When you need to penetrate packed gravel, a flat serrated edge can provide better penetration than a continuous edge. They provide greater down pressure per inch of edge contact.

Curved serrated edges: These loosen hard-to-penetrate materials quickly. Curved serrated cutting edges can penetrate better than a flat serrated cutting edge.

Caterpillar offers a wide range of cutting edges for motor graders, with each providing certain benefits when used in the appropriate application. Your Cat dealer can provide the expert advice you need.

It’s an important decision, so make sure your blade makes the grade. To learn more, scan the QR code below or visit cat.com/cuttingedge-au

WWW.EARTHMOVERS-MAGAZINE.COM.AU 21

Selecting the right genuine Cat motor grader cutting edge can help you maximise wear life, performance and reliability, while keeping operating costs to a minimum. Your Cat dealer can help you choose the right cutting edges to suit your application. Options include: - General Duty - Heavy Duty - Specialty, including the Cat GraderBit2™ System Make sure your blade makes the grade. Speak to your Cat dealer or visit cat.com/cuttingedge-au. DOES YOUR BLADE MAKE THE GRADE? CAT® MOTOR GRADER CUTTING EDGES. INCREASE WEAR LIFE. REDUCE COSTS. © 2022 Caterpillar. All Rights Reserved. CAT, CATERPILLAR, LET’S DO THE WORK, their respective logos, “Caterpillar Corporate Yellow”, the “Power Edge” and Cat “Modern Hex” trade dress as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission. NSW/ACT WesTrac 1300 881 064 VIC/TAS William Adams 1300 923 267 SA Cavpower 08 8343 1600 QLD/NT Hastings Deering 1300 952 701 WA WesTrac 1300 881 064 NZ TERRA 0800 93 39 39

1300 EquipU (378 478) www.equipmentspecialists.com.au NEW K SERIES • Larger cab • Cummins QSL engine • NO AdBlue, DPF, EGR • HYDROSTATIC models available

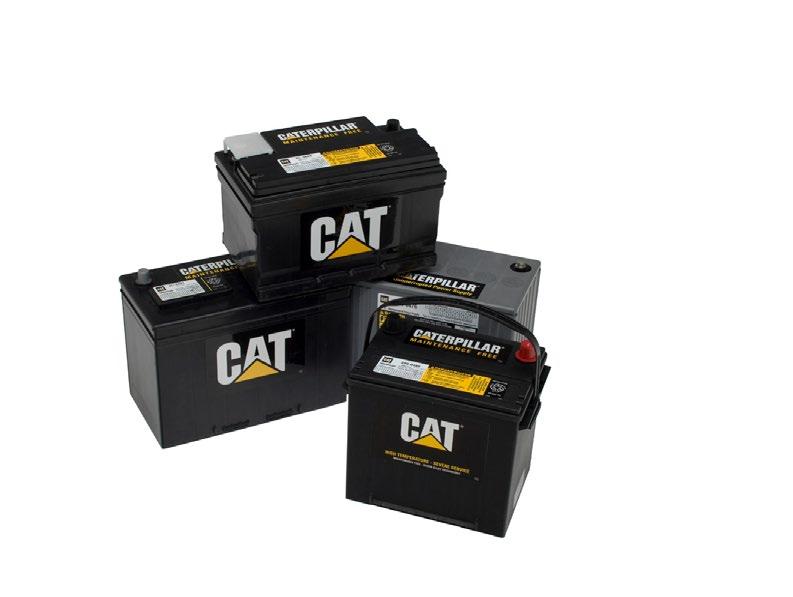

A RELIABLE MACHINE STARTS WITH A RELIABLE BATTERY GENUINE CAT® BATTERIES

Genuine Cat® batteries are built to withstand intense vibration that comes with your toughest jobs. They’re designed and tested to stringent specifications and rigorous tests. And of course, as a genuine Cat product, they’re also protected by Caterpillar’s comprehensive warranty program.

WHY CHOOSE GENUINE CAT BATTERIES?

As Caterpillar Aftermarket Services Consultant Clarine Koh highlights, “Cat Heavy Duty batteries are manufactured exclusively for Caterpillar so you can’t find the same batteries anywhere else. Our heavy duty batteries are uniquely designed from the inside out to resist vibration, which is one of the top reasons why batteries fail in off-road battery applications. Our batteries have anchored full frame grids and a reinforced casing that ensures they can withstand vibration without suffering mechanical damage and loss of capacity while maintaining structural integrity.”

Every battery in the Cat portfolio is designed to work in the most extreme conditions.

Cat Heavy Duty Batteries

o Factory fitted on all Cat equipment and generator sets. These provide maximum vibration resistance and higher starting power.

o Uniquely designed from the inside out to resist vibration, one of the main cause of battery failure in off-road battery applications. Vibration resistance is well above industry standard.

o Thicker posts, thicker paste and thicker connectors for better reliability.

o Positive and negative plates are anchored to the container and locked at the top. The heavy duty grid design helps prevent short circuits, out gassing and water loss, which may extend battery life.

Cat General Duty Batteries

o Designed for optimal performance in moderate to light applications.

o Caterpillar offers a variety of lead-acid, gel and absorbed glass mat (AGM) batteries that can be used for automotive and light truck, bus, RV, marine, industrial, agricultural, stationary power and recreational usage.

FAST REPLACEMENT

When you need a replacement battery fast, you’ll usually find that your Cat dealer has heavy duty and general duty batteries in stock and ready to install. Or you can easily order anytime, anywhere from parts.cat.com.

EXCELLENT WARRANTY

Speak to your local Cat dealer for more information on the replacement and warranty program.

Are your batteries due for replacement? Make sure you’re prepared for a battery failure. Scan the QR code to order online at parts.cat.com or contact your local Cat dealer for more information.

A dead battery means equipment downtime, lost productivity and reduced profits. Genuine Cat batteries can provide reliable starting power and the proven performance you need from your equipment.

MEET THE EXPERT WORDS // CAT CISD 24 WWW.EARTHMOVERS-MAGAZINE.COM.AU

CAT ® BATTERIES RELIABLE BATTERIES FOR THE TOUGHEST JOBS POWER AND PROVEN

A dead battery means equipment downtime, lost productivity and reduced profits. Genuine Cat ® batteries are designed to withstand intense vibration and tested to stringent specifications and rigorous tests. Plus, we have both high performance heavy duty and general duty batteries that suit a wide range of applications and are backed by our comprehensive warranty program. Order online at parts.cat.com or contact your local Cat dealer. © 2022 Caterpillar. All Rights Reserved. CAT, CATERPILLAR, LET’S DO THE WORK, their respective logos, “Caterpillar Corporate Yellow”, the “Power Edge” and Cat “Modern Hex” trade dress as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission. SCAN TO ORDER

PERFORMANCE

KOMATSU SMART CONSTRUCTION WEBINAR SERIES

This is an introductory overview to Komatsu’s iMC (intelligent Machine Control) machines and technology, tailored specifically for those new to the concept, before looking at the capabilities of the latest iMC 2.0 machines/ technology, and their potential for today’s worksites and projects.

What you will learn: As a result of participating in this webinar, you will understand the latest developments in machine control technology – where precision control capabilities are built into Komatsu’s iMC machines at factory level – provide unmatched efficiency, productivity, accuracy and jobsite

safety across all aspects of earthmoving and excavation, from initial bulk works to final trim. Why you should attend: If you are looking to take your project efficiencies and productivity

Integrated Machine Control (iMC) – where does the value start and end?

REGISTER NOW!

INDUSTRY LEADERS 26 WWW.EARTHMOVERS-MAGAZINE.COM.AU

potential to the next level, this webinar will show you how. Whether you’re involved in small-scale earthworks, large infrastructure projects, resource extraction or primary production, iMC technology can deliver unprecedented benefits in terms of accuracy, productivity, speed of delivery, jobsite safety and client satisfaction. It empowers a single machine to carry out many aspects of earthmoving and material placement that previously would have required two or more additional machines, with all stages of a project’s earthworks accurately captured to provide detailed as-built results to clients, surveyors and government agencies.

Presenter: Matthew Fleming, Technology Advisor, Australia & New Zealand.

Scan the QR code to register now! WWW.EARTHMOVERS-MAGAZINE.COM.AU 27

EARTHMOVING AND CONSTRUCTION ASSET PRICES ARE PREDICTED TO CONTINUE TO RISE IN

After 12 months of arguably the most fortuitous market conditions in Australian history, the 21/22 financial year ended with a bang. Industrial equipment sales had been consistently achieving new records and there was no slowing down in sight. Highly successful sales were now the norm, even while businesses continued to regain capital on their used or decommissioned items.

Remarketing services, too, saw an influx of growth in FY 21/22. Australian businesses still recovering from the repercussions of the COVID-19 pandemic used Pickles’ remarketing services to retain fleets of assets now valued much higher than they had been previously.

The interest in the Australian earthmoving and construction industry sparks a new conversation about consistency of the market. Will this demand for Australian assets continue? Or will this bubble burst?

THE ASSET BUBBLE

Predictions on what the market can look forward to next are varied between forecasters, particularly surrounding large items. The backlog of orders that has transpired due to the pandemic suggests that this high demand for assets can only extend for a long as the shortages remain. The reality, however, is that the delays are likely to roll well into FY 22/23, and possibly the year or years that follow.

Manufacturers across the globe continue to push back expected delivery times of assets due to raw material shortages, production delays and international shipping issues. While the Australian asset bubble remains contingent on new shipments, there is often no telling when these orders might arrive. On top of that, as new waves and mutations of COVID wash over societies across the

world, new issues – such as extensive staff shortages – make for further delays. With no clear end to this new normal in sight, manufacturers continue to snowball through cycles of orders and delays. Consequently, Australian items continue to permeate the market thanks to their accessibility.

While the bubble is expected to deflate once the influx of new assets finally reaches Australian shores, it will likely take several years for the market to level out. When this happens, the price of assets will likely level out, but the market is only expected to grow in years to come. Market information from Mordor Intelligence suggests that machinery digitisation and emission-focused production will only drive up the industry.

Some experts have expressed concerns about the market swinging drastically in the other direction once this levelling begins,

market conditions to maximise returns on industry equipment is

the norm for businesses across

INDUSTRY AUCTION – PICKLES AUCTION 28 WWW.EARTHMOVERS-MAGAZINE.COM.AU

FY 22/23 Leveraging

becoming

Australia.

and this could effectively reduce the worth of used assets substantially and start a cycle of low returns until the market plateaus. These market downturns, however, are not a given. If they do occur, they are not predicted to affect Australian businesses for another couple of years. This does leave businesses with a potential deadline for offloading assets while asset values are still at record highs.

THE STRENGTH OF THE MARKET

The last calendar year has provided optimum opportunities for businesses looking to capitalise on remarketing services for their used or decommissioned assets. A large number of industrial and construction companies took advantage of the well-timed opportunities to close up businesses and move on comfortably. Other businesses were simply forced to transition into closure, as liquidation became the only viable process to recoup capital. Regardless of the circumstances, a large pool of Australian businesses came to rely on Pickles’ valuations and remarketing services as a way to circumvent loss of cash flow or asset value retention. It can be challenging to fully understand the true value of company assets, so these services extend a helping hand to businesses in need to obtain the highest possible value for their used assets.

Pickles hosted a large number of successful sales for businesses across Australia, with the Norris Group Liquidation Auction one of the most successful sales across the board. Thousands of assets were sold over multiple events over the month of May with a total of over $22.5M in sales obtained for the Norris Group. All parties involved were exceedingly happy with the result.

The Norris Group Liquidation Auction consisted of 12 live and online auctions to showcase the volume and quality of the equipment on offer. The sale event featured

trucks, trailers, vehicles, earthmoving and waste equipment, and a range of smaller parts and accessories. The most successful asset class was earthmoving and waste, where large, niche assets received $13.7M in total sales. Of the assets taken to market, 96% were sold during the auctions, with the recouped monies used by liquidators to work with financiers and creditors on behalf of the Norris Group. While it was the smallest earning class of the auctions, parts and accessories fetched $2.3M in sales. This success highlighted the need for all types of assets in the current market. The marketing campaign that preceded the sale event was highly successful in attracting the right clientele. All up, $2.2M+ impressions, 200K+ page views, and 43K users on the event landing page were recorded, which indicated that there was a lot of interest. A proactive marketing approach, national anticipation, and the amount and quality of assets on offer all contributed to the high interest, and consequently the supreme sales results.

HOW BUSINESSES LEVERAGE MARKET CONDITIONS

Australian business owners are capitalising on the current booming market to offload assets for optimum prices. The outlook for Australia’s industrial market in 2022 looks strong, and decision-makers are jumping in to access liquidity or to wrap-up their business offerings while the market is hot.

Although international production is kicking back into gear, it’s predicted that it will still take a number of years for the market to level out. At the same time, infrastructure development will continue to drive the demand in the sector, and used assets are predicted to continue to sell at premium prices.

For businesses navigating this new normal, Pickles’ valuations and remarketing services offer a way to start new – to leverage assets, to recuperate capital – to start afresh, or retire to a new way of living. Whatever the reasons behind a fleet sale, Pickles will get you on the right path.

WWW.EARTHMOVERS-MAGAZINE.COM.AU 29

To buy or sell assets, visit pickles.com.au NORRIS GROUP LIQUIDATION AUCTIONS $22.5M TOTAL SALES 96% CLEARANCE RATE 1,284 ASSETS OFFERED 3,303 BIDDERS $4.6M TOTAL SALES TRUCKS & TRAILERS $1.9M TOTAL SALES VEHICLES $13.7M TOTAL SALES EARTHMOVING & WASTE $2.3M TOTAL SALES PARTS & EQUIPMENT

2018 Hammbreaker Max 800 VZ950 2017 Keestrack R6 Impact Crusher 2019 Caterpillar 140 Articulated Grader 2020 Drake Quad Axle Low Loader 2021 Isuzu FYJ 300-350 8x4 Hook Bin 2019 Komatsu WA480-6 Wheel Loader 2017 Komatsu PC210LCI-10 Excavator 2020 Komatsu PC138US-11 Excavator 2019 Bomag BW 213 D-5 Roller $104,000 2020 Caterpillar 259D3 Skid Steer 2019 Isuzu NPR 45-155 4 x 2 Tipper 2019 Komatsu PC18MR-3 Excavator A selection of items from this auction: $55,000 $34,000 $150,000 $195,000 $215,000 $265,000 $325,000 $335,000 $700,000 $585,000 $420,000

MKP INSIGHTS SOLUTIONS FOR YOUR BUSINESS

Rising interest rates, a downturn in the housing market and increasing pressures on wages and the cost of living have left many business owners uncertain about the state of the economy. But there are reasons to remain positive, and with the right planning and processes in place, businesses can safeguard cash flows and continue to capture opportunities when they arise.

It has been a turbulent time for Australian businesses, with increased pressures throughout the economy forcing many within the earthmoving and construction sector to evaluate their growth strategies. But it’s not all bad news. At Moody Kiddell & Partners, we’ve identified four key considerations that businesses should factor into their planning to ensure their cash flows remain robust and they can continue to capture growth opportunities.

1. EQUIPMENT FINANCE INTEREST RATES HAVE RETURNED TO NORMAL LEVELS

Equipment Finance interest rates reached historical lows of under 4% back in early 2021. This period of historic lows helped businesses navigate out of the COVID-economy by reducing interest costs and improving financial ratios which enhanced access to additional balance sheet debt. However, these historic lows were always going to be unsustainable. While interest rates have risen, they have only risen to more balanced levels in the high single digits. Returning to this normal priced environment is more sustainable, offering rates that remain affordable and allow business owners to maintain a profitable bottom line. Remember, businesses have operated at normal interest rate levels during many previous economic cycles. To put the current rate rise into perspective, a 1% increase on a $100,000 purchase financed over a 5 year term translates to a $10 increase in repayments per week.

2. AUSTRALIAN BUSINESSES AND INDIVIDUALS REMAIN WEALTHY

The recent downturn in the housing market has seen house prices fall from historical highs. Even with this small reduction, equity positions remain strong: house prices have still maintained a significant valuation uplift in comparison to most of their original purchase prices (particularly for properties acquired more than 4-5 years ago). Those who purchased properties in the last year will

unfortunately experience some valuation pressure, however, used equipment values have improved significantly due to supply chain delays, resulting in an uplift in business balance sheet equity. The net wealth of the average Australian has improved considerably throughout this period.

3. HAVE A SOUND DEBTOR COLLECTION PROCESS IN PLACE

Pressure on business credit facilities will see a slowing of businesses paying their creditors and suppliers. Before supplying any goods or services, business owners should be meticulous when engaging new customers with their due diligence to ensure the customer’s ability to pay is evident. Businesses under pressure will seek out new relationships as prior relationships are fragile and under strain, usually due to non-performance or non-payment. A detailed and planned

collection process will safeguard a business’s cash flow now and into the future.

To further mitigate risk, businesses can take out an MKP Credit Insurance policy. Trade Credit Insurance can protect your business in the event that a customer or client is unable to pay, by insuring receivables, safeguarding hard-earned revenues, providing an additional layer of due diligence on new clients whilst also providing quick access to replacement capital. Trade Credit Insurance transfers the risk of non-payment to an insurer, to protect your cash flows while giving you the confidence to pursue new opportunities.

4. SETTLE ANY OUTSTANDING DEBTS WITH THE ATO

After two years of minimal action, the ATO is becoming increasingly proactive in their recovery activity, using disclosure of outstanding debts to credit reporting agencies and Director’s Notice of Demand to collect outstanding taxes. Removing this priority creditor is key and should be a focus for all business owners.

Tailored specifically for business owners, an MKP Home Loan can help pay off your tax bill.

With an MKP Home Loan you get access to more of the equity in your home so you can strengthen cash flows, restructure or consolidate loans and refinance business debts, including tax debts.

Opportunities for growth within Australia’s earthmoving and construction sector remain. Partner with Moody Kiddell & Partners today to see how we can help position your business to best capture them. Call 1300 000 657 or visit www.mkpgroup.com.au

Since 1981, Moody Kiddell has partnered with Australian businesses, providing finance, insurance and advisory solutions. With four decades of multi-industry experience, we offer businesses the tailored service business owners need to achieve their vision and safeguard its legacy.

BUSINESS AND FINANCE WORDS // MOODY KIDDELL & PARTNERS

32 WWW.EARTHMOVERS-MAGAZINE.COM.AU

We Dig Deep

At Moody Kiddell & Partners, we see your success as our business.

For forty years, we have partnered with the earthmoving industry to provide finance and insurance solutions for your business.

From enquiry through to paid claim, we dig in with you every step of the way.

Call today to see how one of Moody Kiddell’s equipment finance and insurance experts can tailor solutions for your specific business needs.

What are partners for?

Moody Kiddell. Partners With You

Moody Kiddell & Partners Unit Trust ABN 28 187 241 830 Australian Credit Licence 388771 Moody Kiddell & Partners (Insurance) Pty Ltd ABN 48 071 572 828 AFSL 512898

1300 000 657 mkpgroup.com.au

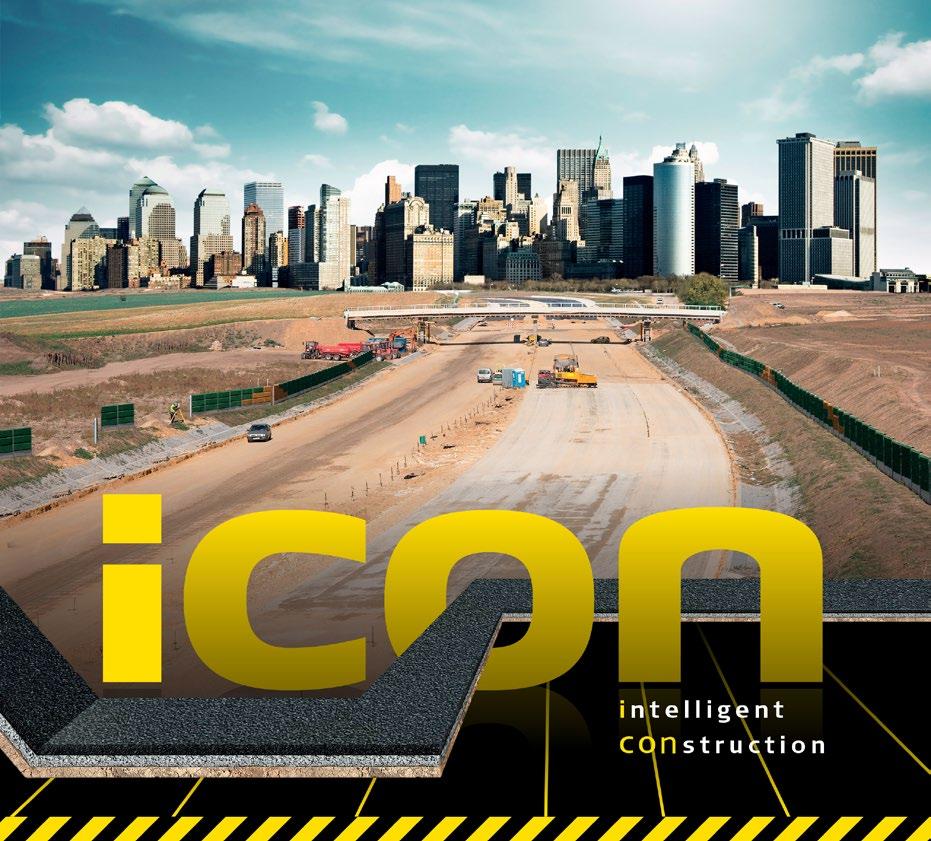

LEICA GEOSYSTEMS INTRODUCES LEICA ICON FIELD SOFTWARE VERSION 6.0

Leica Geosystems has introduced its latest software for the building construction industry, releasing its Leica iCON field software version 6.0 towards the end of last year, which has seen the introduction of a number of new features, providing enhanced functionality in catering to the different needs of industry.

Leica states that the Leica iCON field v6.0 software is designed to meet the needs of general and concrete contractors, the MEP and HVAC trades, and BIM/VDC departments, with it comprising “simple, trustworthy and easy to implement technology that enables the verification of built parts in a building construction project”.

“Leica iCON field v6.0 is packed full of improvements designed to meet the needs of and answer big challenges for the building construction industry by providing fast, precise, real-time verification of just-constructed parts in a building project,” Leica advises.

LEICA ICON FIELD V6.0: NEW FEATURES

The Leica iCON field v6.0 software sports a refreshed user interface, designed to deliver a more modern look and feel, with the home menu having been rearranged to provide additional information for the active project and job, while a new colour scheme is employed in the different applications and menus, improving visibility.

In addition to this, the user interface groups connection to all cloud services under a new ‘Clouds’ option, while projects and jobs handling is enhanced via the introduction of 2D thumbnail view and user-defined sorting (with the view capable of being configured to list view or thumbnail view).

Among the new features introduced by Leica iCON field v6.0 are:

• Map screen (Perspective View) – data visualisation has been enhanced with the introduction of Perspective View, offering better data realisation and improving the navigation on site, with operators able to zoom in and out, rotate, pan and adjust the perspective camera height from the enhanced map controls.

• Grid and Scan data capture – quick grid and precise grid scan support is provided

for Robotic Total Stations with a new quick data camera option for motorised sensors, with the Quick Grid function capturing reflectorless measurements quickly within an area, while Precise Grid Scan more accurately measures a defined grid.

Using the MS60 MultiStation, scanning support is provided via rectangular scan definition and polygonal scan definition, with 1000, 2000, 4000 and 8000 pts scan speeds, three predefined resolutions for quick scans and user-defined resolution for full flexibility (along with Quick Grid

and Precise Grid Scan support, the same as for all Robotic Total Stations).

Leica iCON build The complete solution for all positioning and measuring tasks on site

• Quick coding – Quick Codes, a new tool to quickly assign different codes to the measured points, can be activated from ‘View’ options in the map handler, with the screen splitting automatically to a 50:50 ratio once the tool has been enabled, showing the active code list on the left-hand side (this functionality is available in all measuring applications except the Draw/Sketching, Checks and Verification applications).

MACHINE CONTROL TECHNOLOGY

Sketching Volumes Checks Points & MEP Layout As-Built Verification Layout Lines ntelligent CO n struction 34 WWW.EARTHMOVERS-MAGAZINE.COM.AU

VERIFICATION FEATURES

Leica iCON field v6.0’s verification features provide operators a number of options, with Leica Senior Product Engineer Shane O’Regan noting upon the software’s release that for customers “fast, accurate verification in building construction is a significant concern”.

“The new Leica iCON field v6.0 and Verification app allow contractors to extend their possibilities using multiple integrated sensors, allowing for easier, more complete and real-time verification on site,” O’Regan commented.

“Out of tolerance areas are immediately available for layout, for quick decision making and corrective measures to reduce unnecessary rework at later stages of the project.”

In Leica iCON field v6.0 the following verification use cases are provided:

• Use case 1 (best fit plane, horizontal or vertical) – if no design data is available, operators can verify captured data against a best fit plane

• Use case 2 (data to reference) – a BIMrelated use case to compare the as-built construction with the digital design

• Use case 3 (quick verify) – it is also possible to quickly verify real-time measurements against a reference with the new Verification application

C.R. KENNEDY

As the sole and exclusive distributor for Leica Geosystems in Australia, C.R. Kennedy is focused on harnessing the innovative and industry-leading Leica iCON product portfolio

to deliver tailored solutions for the earthmoving industry, supported by its comprehensive national after-sales network.

The iCON range encompasses a variety of different technologies, included integrated hardware and software solutions, which can be deployed across different aspects of earthmoving operations, designed to deliver greater efficiency and cost savings.

C.R. Kennedy’s head office is in Port Melbourne, with its national network encompassing major state offices in Brisbane, Adelaide, Sydney and Perth, along with a regional office in Cairns.

MACHINE CONTROL TECHNOLOGY 36 WWW.EARTHMOVERS-MAGAZINE.COM.AU

DEMAND FOR MOBILE PLANT AND EQUIPMENT IN THE CURRENT ECONOMY

Demand for mobile plant and equipment (MPE) will increase considerably over the next three to five years. But there’s a complication: disrupted global supply chains.

Demand for mobile plant and equipment (MPE) will increase considerably over the next three to five years. But there’s a complication: disrupted global supply chains.

NTI’s National Strategic Underwriter –Mobile Plant & Equipment, Gary Woodhams, explains,“Before COVID, there was a lot of transport, urban and civil infrastructure expected to be delivered. But as governments have needed to stimulate their economies, many projects have been brought forward.”

By 2024, some $49 billion of work will be under construction in the transport infrastructure sector alone. There is also considerable activity happening in the mining space. These projects create many opportunities for companies and contractors but also present challenges.

TOO MANY JOBS, NOT ENOUGH EQUIPMENT

Typically, businesses source MPE from overseas. But governments worldwide are supporting their own economies through this period, meaning there is little MPE available.

In short, equipment is scarce and we’re seeing an upsurge in equipment hire, meaning hire or operational businesses with underutilised assets can benefit from opportunities to provide MPE to other companies.

MPE OPPORTUNITIES AND CHALLENGES

Operational businesses can take advantage of infrastructure pipelines to tender and win more work. The challenge is access to MPE, and if hiring – fair rates and fair hire contract conditions.

For hiring businesses, there’s an opportunity to generate income from their assets. The challenge is ensuring they can supply those assets correctly valued and adequately protected.

In both cases, the hire agreement is the critical document. It must make commercial sense for both parties, offering good value to the hirer and fair returns to the owner.

The insurance component is crucial. A good agreement will clarify who is responsible for the insurance; or, if there is a damage waiver, the types of damage or incidents covered by the owner and what must be covered by the hirer.

For the owner, retaining a lawyer to draft a standard hire agreement will be money well spent.

For the hirer, reading the agreement carefully and asking the owner directly what’s covered and what’s not is prudent. It’s also essential to understand the terms and shop around if you’re not comfortable.

KNOW YOUR TERMS: DAMAGE WAIVERS AREN’T INSURANCE POLICIES

Hire businesses commonly include damage waivers in their hire agreements. However, hirers need to know that a damage waiver is not an insurance policy. It’s a clause that releases the hirer from the cost of repairing or replacing damaged equipment.

However, these clauses can be restrictive by limiting the damage waiver benefit ‘to or excluding certain events’ with additional restrictions or requirements. These can be onerous and very easily expose the person hiring the equipment to an expensive uninsured financial loss, as Gary explains: “We sometimes see clients who think a damage waiver is insurance. I’ll give an example: a client hires in a conditionally registered excavator for five days. They pay an extra $700 for a damage waiver.

“The excavator is tracking on the road and slews around. The dipper arm comes to a stop

inside a passing BMW. The damage waiver covers any damage to the excavator – but not to the car.”

That’s why if you are hiring mobile plant and equipment, it’s essential to know your terms and be sure you understand what your hire agreement covers.

“For the owner, hiring is a great way to expand your business’s capabilities or generate extra revenue,” Gary says.

“However, not spending the money to have a lawyer experienced in crafting hire agreements for the mobile plant hire industry is a false economy.

“Not obtaining the correct insurance cover and extensions is also a false economy.

“The cost means nothing compared to what a claim or prolonged dispute could be worth.”

As always, it’s worthwhile for both owners and hirers to obtain the right advice and the right insurance. Speak to your lawyer and your insurance broker. Contact us today if you’d like to know more.

Want more insight from Australia’s leader in heavy vehicle, mobile plant and equipment insurance?

Visit NTI’s Yellow Cover at www.yellowcover.com.au.

38 WWW.EARTHMOVERS-MAGAZINE.COM.AU INDUSTRY INSURANCE WORDS: NTI NATIONAL STRATEGIC UNDERWRITER – MOBILE PLANT & EQUIPMENT, GARY WOODHAMS

TRUCKS, TRUCKS AND MORE TRUCKS

Truck operators – whether it be a rigid truck, an articulated truck or a body truck – are without a doubt the unsung heroes of the earthmoving game. They are integral to any project that they are utilised on.

When you’ve got a bunch of handy truckies, the material moves consistently, safely and stress free. When you don’t have switched-on truckies, those three points are flipped on the head.

The thing with trucks though, is it’s usually one of the first machines that a new to industry person starts their dirt moving career on, which can be problematic for a range of reasons including safety and productivity.

Here are five tips to becoming a better truck operator:

1. CONSISTENCY IS KING

Some operators think that the secret to running trucks is to run them full tilt, flat to the boards, screaming eagle style everywhere – it’s not. There is no benefit flying around like a lunatic and arriving back at the loading unit and waiting for it to finish loading the truck. Read the play a little, the trick is to arrive just in time (last pass). That way you’re not flogging the truck unnecessarily and you’re not knocking yourself around either.

2. MINIMISE YOUR TRUCK EXCHANGE TIME

Truck exchange time (or spot time) is the elapsed time from when loaded truck receives last loading pass until next truck receives its first loading pass. Working on lowering your exchange time at the loading unit and at the dump will give you the best opportunity at lowering your overall cycle times, guaranteed. Of course, you need to be going from A to B at reasonable speed to the conditions. But at no stage should you be running the truck outside of it’s safe operating window.

3. TYRE PRESERVATION

There’s a crazy statistic in our industry that says 80 per cent of large tyres fail before they wear out! That’s a massive amount of cash and lost opportunity sent to the scrap heap. The two biggest killers to a truck tyre are impact damage and cut damage. Two items that we as operators can influence through our decision making and actions.

If there’s spillage on the haul road or floor, don’t choose to drive over it, drive around it. Then call up to have it removed by the grader or another machine in the area. Be super mindful not to spin the tyres. Spinning the tyres is a sure-fire way to cut a tyre. Place water into the equation and I’ll guarantee that your tyres will look like Edward Scissorhands has been running his mitts over your tyres!

4. STAY PRESENT

Don’t be one of those scoundrels who jumps in their truck in the morning, turns the two-way

down, turns the stereo up, and drifts off into their own world for 10 hours. Most people get into strife when they haven’t been tuning into what’s going on around them. Whether they’ve missed a call on the two-way or they’re just not watching what’s happening around them.

It’s your responsibility to ensure that you’re across what position the digger operator wants you in when you get back to the cut. Do they want you coming in at 45°or 90°? What’s happening at the dump? Are we paddock dumping, running to the dozer or have we changed to a new fill area?

Stay present!

5. UNDERSTAND YOUR BRAKING CAPACITY

Trucks in our world, gross operating weight, can range from around 40 tonne on a civil job up to 600 tonne in the mining space. An off-highway truck can lull people into a false sense of security once you overcome the sheer size of them. Generally speaking, they drive very similar to an automatic car.

What’s not the same though is their braking system. Most off-highway trucks run wet pack brakes (bathed in oil). When they’re operated in line with the manufacturer’s guidelines, they work fine. However, when they’re not and the brake oil gets excessively hot, premature failure can occur.

Another factor to consider is the surface that you’re operating on. It’s mostly going to be dirt, mud, clay or even a combination of them all – not the best surfaces to try and pull a fully loaded truck up on in a hurry.

INDUSTRY TRAINING WORDS // SCOTT LIDSTER

40 WWW.EARTHMOVERS-MAGAZINE.COM.AU

For almost half a century, STM has made it possible for businesses across NSW to power up – supplying and servicing quality trucks and machinery to meet the demands of any job.

Starting out in a single shed in the 1970s, we know what it takes to build a business – and are passionate about helping you grow yours. Today, our family owned and operated enterprise is proud to offer a multi-site, modern service, with a team of more than 120. We care about giving every customer the best experience possible – with a wide range of trusted brands, flexible finance, spare parts, repairs and personal service.

We may have come a long way from that shed, but our family commitment to quality remains. Whatever your size, whatever your budget, STM is your one stop shop – with everything to keep your business moving.

STM FOR MACHINERY SYDNEY / WOLLONGONG / CANBERRA WWW.STM.COM.AU 02 4647 4488

YOUR ONE STOP SHOP

STARTING A NEW FINANCIAL YEAR OFF RIGHT

Here’s a few of our top tips:

1. REFLECT, REDIRECT AND COURSE CORRECT

Interrogate your data and get a good understanding of what worked well last year. Be honest about what was a flop. Was there anything that, if done better, might be worth trying again?

2. SHARE THE VISION

Bring your team along for the ride. Employees want to feel connected to a business’s strategy and like their work matters. You don’t need to bog them down in the details, but clearly and effectively communicating your high-level objectives and how you plan to get there should be a bare minimum. Ensure your senior leaders and anyone managing staff understand how and where their team fits into the picture. Incorporate an employee engagement plan to provide ongoing updates about how the business is tracking towards these goals so staff don’t feel like they are operating in a vacuum.

3. SCAN THE MARKET

Alongside reflecting on what you should stop, start, and continue, take some time to look at your competitors (direct and adjacent) and see if there’s any trends you may have missed. Is there something they did well, or lessons you can learn from mistakes they made? Did you lose any key clients to

a competitor and do you understand why? Are there vertical markets that are already being overcrowded by competition? If you followed a similar strategy, be honest about who did it better and break down why.

4. CUSTOMER DEMANDS AND OPPORTUNITIES

Next look at your top clients. Are there any emerging needs you should prepare for? Are there opportunities presenting themselves? Has your client mix diversified since last financial year? What industries and sectors are you focusing on and what are the emerging themes and issues keeping them up at night? Make sure you understand their landscape.

5. INVEST TO SET YOUR TEAM UP FOR SUCCESS

Now that the stress of EOFY has (almost) passed look at investing in some new or

refresher training that will get bang for buck with your team. Topics common with our clients are:

• Media training – refresher training for boards and executives or middle management that are subject matter experts on a path to leadership roles. If PR/media engagement and thought leadership is a core element of your FY23 marketing strategy, this is a great investment to consider and also an excellent professional development tool that everyone should regularly undergo refresher training on.

• Content workshops – social media is a staple to most business strategies. Collecting quality content is often a marketing teams greatest challenge! Equipping field staff with the knowledge of how to easily gather content that can be utilised by a marketing team is a great investment. We often help educate teams on how to take photos, grab soundbites, video clips or identify valuable content that should be shared with the business.

• LinkedIn masterclasses – if you’re a B2B business and your team are not using LinkedIn, you’re missing out. There have been so many new features released for company pages, but also personal profiles. The potential is huge, and staff just need to understand how to use and apply it.

6. KEEP THINGS FRESH

New financial year is a great time to launch any new tools or templates the team might find helpful. Keeping fresh doesn’t need to mean a brand overhaul. Don’t underestimate the power of a new look and feel PowerPoint template, an updated proposal template or capabilities statement, visual tweaks to social media, new e-newsletter templates or even a revised email signature. It’s also a nice way to re-engage your team and get them excited about your brand and share your brand story.

It’s never too late to review your strategy and even doing one of the above is better than none. If you’d like some help kickstarting this financial year, reach out and ask us about our strategic shakedown service, internal training or even help with a brand refresh.

Contact us here: hello@hc.net.au

MARKETING AND PR WORDS // ALEXANDRA WILLIAMS

42 WWW.EARTHMOVERS-MAGAZINE.COM.AU

We all start a new year and a new financial year off with the best of intentions but can quickly get sucked into the execution of the plan and business as usual tasks. Investing some time in reflecting on the previous year and looking forward to ensure things are on track is critical to success. It can seem overwhelming, but it doesn’t need to be.

W H E N VO L U M E M AT T E R S D12

Stock is available. Enquire today. Sydney | Newcastle | Canberra | Melbour ne |Adelaide | Hobart | Launceston | Perth | Brisbane Distributed in Australia from Nimac Pacific For further infor mation,visit www.nimacpacific.com.au or call 0415 559 897 and 0411 488 116 B y

RAM EQUIPMENT BOOSTS PRODUCT

TRUCK

Dry hire earthmoving equipment specialist RAM Equipment is focused on ensuring its customers have access to the most effective equipment for the job at hand, with the Adelaide-based business having recently bolstered its product portfolio by adding the D’Avino D12 high-volume, rear-tipping dump truck to its line-up.

Established by Kevin and Michael Grace in 2014, RAM prides itself on providing its clients innovative service solutions, underpinned by an extensive, carefully selected range of equipment decked out with the latest technology and designed to deliver exceptional performance.

This sees RAM work closely with its clients to gain insight into their requirements on a project-by-project basis, assisting with the planning and execution of individual projects, and ultimately ensuring its clients

are equipped with the most efficient machines for the job.

“With 70-plus years of expertise, we understand what it takes to get the job done right,” Kevin told EEM . “That’s why we offer innovative dry hire solutions to the market.

“RAM has one of the largest fleets of construction equipment for dry hire in South Australia and supplies specialised attachments for excavators and skid steers within the industry.”

The D12 slots neatly into RAM’s selection of site dumpers, providing an all-rounder option for undertaking earthmoving operations, with it sporting the hallmark qualities that have come to be associated with the D’Avino range, having been both built to last and tackle demanding applications.

A GROWING FLEET SEES RAM SERVICE A WIDE RANGE OF INDUSTRIES

RAM’s product portfolio encompasses excavators, skid steers, site dumpers, compaction rollers, wheel loaders, dozers, graders and tipper trucks, along with a range of attachments, while it also offers attachments, accessories and ex-hire machinery for purchase.

“Our promise to our customers is to continuously improve our processes and make construction hire easy – when it matters,” Kevin commented. “Growing our fleet is an important aspect to servicing a wide range of industries, and with global supply chain issues we must take any opportunity we can.”

Kevin highlighted the value the D12 adds to RAM’s product portfolio, pointing to the impressive range of qualities it providers operators, enabling it to power on through and thrive in tough local conditions.

“The D’Avino D12 dumper is a great addition for medium-to-large-sized worksites as it has an impressive carrying capacity of 12,000kg thanks to its high-volume skip,” he told EEM.

“The most impressive aspect of the site dumper is its ability to change the steering modes, giving it crab steering, front and combine steering. This increases the machine manoeuvrability, and an impressive turning circle of 4650mm.”

DEALER PROFILE

44 WWW.EARTHMOVERS-MAGAZINE.COM.AU

PORTFOLIO WITH D’AVINO D12 DUMP

In addition to this, Kevin singled out a number of key features that strongly appeal to clients looking for an efficient and reliable dump truck option.

“For half the year, most clients want to utilise a site dumper that has an enclosed cabin for safety,” he observed. “Along with this, the D12 is equipped with a double steering axle, and a 4WD hydrostatic transmission, has a levelled carrying capacity of 6800 l and a heaped capacity of 8300 l.”

D’AVINO D12 DUMP TRUCK DELIVERS HIGH PERFORMANCE AND MANOEUVRABILITY

Weighing in at 6170kg (unladen weight), the D12 runs an 83 kW Perkins 1104 TA Tier IIIA engine and has a maximum driving speed of 35km/h, with it combining high performance and manoeuvrability with operator comfort and safety.

The D12’s key features include:

• High-performance drivetrain – the fourspeed, 4WD automotive hydrostatic transmission enables high torque and power output with constant traction to the wheels during speed shift, paving the way for the D12 to safely operate to a maximum gradient of 40% with a full load. Along with this, the machine’s independent inching control pedal aids the operator in completing tasks with maximum precision, and a front swivel axle and differentials lock system enable maximum traction and grip with any ground condition.

• Double steering axle and rigid chassis – the four wheels/three-mode steering system increases manoeuvrability in confined spaces, seeing a 25% reduction in the turning radius compared to conventional articulated machines in the same category. The system also comes with “crab steering mode”, enabling the operator to safely approach trenches and working areas on a single manoeuvre.

• Enclosed cabin – the wide enclosed cabin is designed to meet FOPS II and ROPS standards, with the automotive air-conditioning system and suspended seat providing the operator a comfortable and safe environment. In addition to this, the all-around wide surface of the windows offers enhanced levels of visibility.

• Certified Hardox body – the high-volume body is manufactured using Hardox 450 abrasion-resistant steel, setting a new benchmark in the industry, while optional bulkhead protection ensures operator safety in any condition.

NIMAC PACIFIC OVERSEES HIGHQUALITY PRODUCT PORTFOLIO

Distributor Nimac Pacific is focused on bringing quality machines to the local market, with its broader D’Avino range of trucks having

created a strong impression among business owners and machine operators.

As Nimac advises, the D’Avino machines are built in Italy, and are put together “following state-of-the-art manufacturing and quality control processes”.

“For over seven decades and three generations, the D’Avino family has been involved in the industry, building an incomparable know-how and experience on manufacturing machines which are focused on satisfying the customer needs,” Nimac states.

As noted by Nimac, D12 dump trucks provide a range of performance, robustness and reliability benefits, and have been chosen as a partner for private and public expeditions in extreme environments all over the world.

For more information please contact Nimac Pacific at www.NimacPacific.com.au

WWW.EARTHMOVERS-MAGAZINE.COM.AU 45

MERLO’S TOP-OF-THE-LINE ROTO 50.26SEE PLUS

Merlo Group Australia has expanded its local product line-up with the ROTO 50.26SEE PLUS rotating telehandler, sporting the full scope of features that have over the years come to be associated with its distinctive ROTO range, with a firm emphasis on productivity and versatility of use.

Established in Cuneo in 1964, Merlo draws on a long history of innovative product development, with the Italian manufacturer having brought its first ROTO model –distinguished by a revolving turret system capable of rotating 360°, meaning there is no need to reposition the machine – to market in 1991.

Catering to the evolving needs of its international customer base, Merlo has since steadily grown the ROTO product portfolio, which now comprises three separate product families: the Entry range, S-Classic range, and S-Plus range.

Across the wider ROTO range, Merlo has focused on developing machines that place a premium on ergonomics and ease of use, while its top-of-the-line S-Plus models have been designed to meet the needs of even the most demanding operators.

DEALER PROFILE

46 WWW.EARTHMOVERS-MAGAZINE.COM.AU

Belonging to the S-Plus line, the ROTO 50.26SEE PLUS is in turn decked out to deliver a premium operating experience, with it bringing together a finely tuned balance of technology and precision performance and incorporating a range of unique features.

• Axles – manufactured by Merlo in-house, feature dry disc brakes to maximise braking capacity and minimise the machine’s consumption levels

• Tilting cab – provides for greater comfort, improved ergonomics, and safety, with a dedicated button allowing operators to engage the system, tilting the cab vertically up to 20°

Safety Merlo’s patented ASCS is capable of recognising the attachment being used and measuring the magnitude of the load being handled, maximising the speed of the hydraulic movements without any risks to the operator’s safety.

At the same time, operators can check all operating parameters in real time, viewing at which point the safety system will intervene by slowing down and stopping any problematic movements.

Additional safety features include:

• Cab – is compliant with the ISO 3449 FOPS Level II and ISO 3471 ROPS standards

• Automatic parking brake management

– the system brakes the machine if the engine switches off, avoiding unintentional movements

ROTO 50.26SEE

PLUS FEATURES AND BENEFITS

The ROTO 50.26SEE PLUS weighs in at 17.3t, has a maximum capacity of 5t, a maximum lifting height of 25.9m, and provides for continuous turret rotation, with it running a 125kW FPT NEF45 Tier 2 engine and capable of reaching a top speed of 40km/h.

The telescopic boom consists of five sections, comprising a double C profile in high-strength steel with welds along the neutral bending axis, while hydraulic hoses and electrical wires are positioned inside the boom, protecting against any possible impacts.

Meanwhile, further bolstering durability and providing an added layer of protection, the machine’s frame features a steel belt around the outside made from a metal bar 70mm in diameter.

Performance

The ROTO 50.26SEE PLUS’s hydrostatic transmission has been carefully configured to pave the way for a smooth operating experience. It allows for millimetric variations in machine movements and load positioning, and with full-time four-wheel drive provides for excellent braking capacity, along with high levels of power and torque to the wheels.

In addition to this, performance benefits are delivered via:

• Suspension and levelling – the electronically controlled active suspension eliminates pitching, with locking of the axles providing for maximum stability, and levelling correction compensating for transverse and longitudinal slopes (lateral inclination: 12 per cent; frontal inclination: 4 per cent)

• Hydraulic system – offers two configurations: LS pump and flow-sharing distributor, up to three simultaneous movements, with an oil flow rate of up to 140L/min; double LS pump and flow-sharing distributor, up to four simultaneous movements, with a flow rate of up to 260L/min.

Comfort

The cab has been designed with comfort in mind, measuring in at 1.01m in width and providing substantial roominess, with vibration-damping silent blocks harnessed to reduce both noise and vibrations.

In addition to this, it incorporates a pressurisation system, preventing the entry of dust, while operator comfort is further improved via an air-suspension seat with a raised backrest.

The cab is also equipped with the following features: