Price $7.95 inc GST Feb/Mar 10 Price $9.95 inc GST DEC/JAN 22-23 DECEMBER 2022 / JANUARY 2023 CASE STUDY: DEA AND CJD EQUIPMENT CAT ® GLOBAL OPERATOR CHALLENGE AP FINALS EXCAVATORS DUMP TRUCKS / SITE DUMPERS INNOVATIVE PRODUCTS ROKON AND BA EQUIPMENT GROUP

WELCOME

The team at EEM likes to end the year with a bang to celebrate Christmas and start it by letting our partners know the goodies we have in store for them in 2023!

Since the start of 2022, things have picked up across the earthmoving industry, and for the publication – including finding a new home with Prime Creative Media. Back in 2020, when the COVID-19 pandemic first hit, industrial events and client-based open demonstrations were put on hold indefinitely. While many of our partners have found great ways within their businesses to keep their customers happy, in many heavy machinery industries, as the saying goes – seeing is believing.

And so, eventually, normality or the new ‘normal’ took shape, with major events like DDT earlier this year, and open-day demonstrations by major dealers in the industry. The response has been unprecedented.

EEM was onsite for the Cat® Global Operator Challenge – Asia Pacific Finals and boy, not only was it an exciting trip to meet all the best operators from Japan, Indonesia, India, and the Philippines, there were also five of Australia’s finest on show. There, competitors got to operate Cat’s Next Gen Cat 320 with 2D GRADE technology, the Cat 950M Z and the Cat Next Gen 303CR. It was a hard fight between the best of the best, but the Japanese came out tops, and a couple of our Aussie lads came in second and third, and earned a spot at the Cat Global Operator Challenge being held in March 2023 at CON EXPO in Las Vegas! Well done to those guys, and what

EEM team enjoying themselves at the Cat® Global Operator Challenge – AP Finals in Japan.

a great opportunity to interact with the Cat team and learn about the partnerships it has with their customers.

Speaking of opportunities and partnerships, EEM also spoke to Rebecca Lincoln from Rokon and learned more about its commitment to delivery and it’s ‘client-first’ approach. These guys provide earthworks on various projects located in several different areas around Melbourne, and their high standards and commitment to sustainability and preserving the environment is shown in their partnership with BAEG.

Serving the big boys in the Tier 1 sector is no joke, as EEM found out from Sean Costello at DEA. Sean started off as a one-person, one-machine operation, but a few machines later, he realised with the game changing fast for his business back then, a reliable partner was needed when it got big. He talks about the value of trust proven and earned with CJD Equipment and his journey of support

and reliability with them. Read all about it in this issue.

Last, but not least, before we let you folks off to enjoy the magazine and holidays, we would like to remind you that we now have the ‘Excavators’ and ‘Dump Trucks/Site Dumpers’ segments. You will find all the best in the business featured there.

Syed Shah Managing Editor

THE EDITOR

FROM

Syed Shah, Managing Editor, EEM.

GET

Do you have something you’d like to share with the industry? Send EEM an email at syed.shah@primecreative.com.au We’re keen to get your thoughts.

EEM on site and in action with Rokon and BA Equipment Group.

IN TOUCH

4 WWW.EARTHMOVERS-MAGAZINE.COM.AU

The EEM production and PCM team.

CONTRIBUTORS

Jamie Gray

Jamie has been a professional photographer in Sydney for over two decades. He is the owner of Camera, Hammer and Tong, who provides digital content for small businesses in and around the construction industry. He is also a photo journalist & the product feature editor for What Tradies Want Magazine. But he’s just as comfortable with a hammer in his hand as a camera and pen. Undertaking a mature age carpentry apprenticeship in his 40s and still gets the nail bag on when he can.

Martin Kovacs

Martin Kovacs is a journalist with experience covering the business, technology and energy sectors. Over the past 10 years, Martin has covered a wide range of subjects across both print and digital media, broadly encompassing business and technology trends, focusing on issues of importance for industry. Martin takes a particular interest in digital technology developments and the manner in which industry continues to adapt and evolve amid the rollout of new technologies.

Mark O’Donoghue

Mark O’Donoghue is the CEO and founder of Finlease. Financing over $700mil p/a in equipment finance for private business owners in Civil and related industries. A family business with a nationwide network, Finlease has a 30-year track record of establishing long term relationships with clients, finding them the best finance solutions to support their business growth. The company’s goal is to make the finance process simpler for businesses so they can focus on what they’re good at.

10. On The Cover 16. Industry Leaders 18. Industry Auctions 20. Meet the Expert 26. Business and Finance 28. Machine Control Technology 32. Industry Insurance 34. Industry Training 36. PR and Marketing 40. Dealer Profile 42. Industry Events 50. Case Study 58. Skid Steers / Track Loaders 68. Excavators Feature 74. Dump Trucks / Site Dumpers Feature 78. Innovative Products 110. Eye on the Industry 120. Industry Events 126. Civil Contractors Federation 128. Association News Price $7.95 inc GST Feb/Mar 10 Price $9.95 inc GST DEC/JAN 22-23 DECEMBER 2022 JANUARY 2023 CASE STUDY: DEA AND CJD EQUIPMENT CAT® GLOBAL OPERATOR CHALLENGE AP FINALS EXCAVATORS DUMP TRUCKS / SITE DUMPERS INNOVATIVE PRODUCTS ROKON AND BA EQUIPMENT GROUP CONTENTS DECEMBER 2022 / JANUARY 2023

SYDNEYDRAGWAY, EASTERNCREEK 21-23 APRIL 2023 6 WWW.EARTHMOVERS-MAGAZINE.COM.AU

ON THE COVER: EPIROC HB 10000

Scott Lidster

Scott is the Director of Australian Earth Training, a niche operator proficiency training organisation who work across the globe. He has over 25 years’ experience in heavy equipment operation and was an accredited Caterpillar Dealer Instructor (CDI) Trainer-Demonstrator. Scott’s unique skill set enables him to operate and train on a broad range of machines across the mining, construction, quarrying and waste industries, helping his customers to boost their productivity while lowering their owning and operating costs.

Detailed Excavations Australia’s

Ann Callaghan

Volvo EC250E.

Ann has been the Manager of Allied Earthmovers Association for the past 19 years bringing many years’ experience into the role. After gaining business qualifications and managing a retail shopping centre in Sydney CBD, Ann first started her career in earthmoving when she joined the long-established family business in Penrith, which specialised in Caterpillar graders and dozers. Working in a male-dominated industry, Ann brings a different aspect to the Association. She has met many people in the industry and knows what the owner operator needs, from the importance of paperwork to machine availability. It’s an industry she respects and is proud to be a part of.

42 74 82

CEO John Murphy COO Christine Clancy Sales Director Bradley Buchanan Managing Editor Syed Shah Journalist Alexandra Cooper Brand Manager KahChi Liew kahchi.liew@primecreative.com.au 0421 474 407 Production Editor Michelle Alder michelle.alder@primecreative.com.au Design Ryan Turner Subscriptions subscriptions@primecreative.com.au (03) 9690 8766 Copyright Earthmoving Equipment

owned by Prime Creative

and published

John Murphy.

in Earthmoving Equipment

is

retrieval

Articles

articles

Head Office 11-15 Buckhurst St South Melbourne VIC 3205 P: +61 3 9690 8766 enquiries@primecreative.com.au www.primecreative.com.au

Office Suite 3.06, 1-9 Chandos

Saint

WWW.EARTHMOVERS-MAGAZINE.COM.AU 7

Magazine is

Media

by

All material

Magazine

copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and

systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Earthmoving Equipment Magazine are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated. © Copyright Prime Creative Media, 2022

All

submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Sydney

Street

Leonards NSW 2065, Australia P: +61 2 9439 7227

NSW

CAPITAL CONSTRUCTION EQUIPMENT

535 Dallinger Road, Lavington NSW, 2641. 02 6025 0444. www.capitalconstruction.com.au

FRANKS SERVICE CENTRE 186 Wakaden Street, Griffith, 2680, NSW 02 6962 6073. www.fscforklifts.com.au/

NORTH WEST FARM MACHINERY 22-26 Whittaker Street, Quirindi, 2343, NSW. 02 6746 3300. www.nwfm.com.au

STM EQUIPMENT Unit 3, 28 Dunn Rd, Smeaton Grange, NSW 2567 02 4728 7500 www.stmequipment.com.au

THREE RIVERS MACHINERY

25 Zora Street, Warren NSW, 2824 02 6847 3111. www.3rm.com.au

SCTM (Canberra)

1/45 Bayldon Road, Queanbeyan, NSW, 2620 02 6299 1500. www.sctm.com.au

SCTM (Wollongong) 6 Mineral Road, Oak Flats, NSW, 2529 024257 1500. www.sctm.com.au

EARTHMOVING EQUIPMENT AUSTRALIA (EEA) 99 Glenwood Drive, Thornton, NSW, 2322. 02 9671 1000. www.eeaustralia.com.au

QLD

EARTHMOVING EQUIPMENT AUSTRALIA (EEA) 123 Cobalt Street, Carole Park, QLD, 4300. 1300 753 332. www.eeaustralia.com.au

MCINTOSH & SON (DALBY) 17563 Warrefo Highwyay, Dalby, QLD, 4550. 07 4662 2288. www.mcintoshandson.com.au

MILNE BROS EQUIPMENT (BILOELA) 61-67 Dawson Highway, Biloela, QLD, 4715. 07 4992 1099. www.milnebros.com.au

MILNE

BROS EQUIPMENT (EMERALD) 67 Macauley Road, Emerald, QLD, 4720. 07 4982 4824. www.milnebros.com.au

SA LARWOOD AG SERVICES 38 Moonta

08

ROCKY RIVER AG 62

08

SA TRACTORS 12/160

TAS DLM MACHINERY 17/19-21 Killafaddy Road,

03

DEALER LIST

MILNE BROS EQUIPMENT (ROCKHAMPTON) Gladstone Road & Derby Street, Rockhampton, QLD, 4700. 07 4930 0300. www.milnebros.com.au SQMH 10 Bain Court, Toowoomba, QLD, 4350. 07 4634 2744. www.sqmh.com.au

Road, Kadina, SA, 5554.

8821 1999. www.larwoods.com.au

Wongabirrie Road, Crystal Brook, SA, 5523

8636 2772. www.rockyriverag.com.au

Churchill Road North, Cavan, SA, 5094. 08 8349 7500. www.satractors.com.au

St Leonards, TAS, 7250.

6339 1550. www.dlmmachinery.com

VIC

BALLARAT TRACTORS

155 Learmonth Street, Ballarat, VIC, 3350. 03 5334 2444. www.ballarattractors.com.au

KV EQUIPMENT

221 Midland Highway, Epsom, VIC, 3551 03 5445 6999. www.kvequipment.com.au

MELBOURNE TRACTORS 110 Hume Highway, Somerton, VIC, 3062. 03 9303 5777. www.melbournetractors.com.au

MELTRAC MACHINERY

6703 Princes Highway, Terang, VIC, 3264 03 5536 0222. www.meltrac.com.au

PRIMTEC TRACTORS

698 Benetook Ave, Mildura, VIC, 3502. 03 5022 1004. www.primtectractors.com.au

RAISING EXPECTATIONS

WA

FORKWEST

68 McCombe Road, Bunbury, WA, 6230 08 97254970. www.forkwest.com.au

GEOFF PERKINS MACHINERY

Lot 24 Stewart Street, Narrogin, WA, 6312. 08 9881 2222. www.perkinsmachinery.com.au

MCINTOSH & SON (ALBANY)

189 Chester Pass Road, Albany, WA, 6330 08 9847 4255. www.mcintoshandson.com.au

MCINTOSH & SON (ESPERANCE)

25 Norseman Road, Esperance, WA, 6450. 08 9071 1155. www.mcintoshandson.com.au

MCINTOSH & SON (GERALDTON)

160 Flores Road, Geraldton, WA, 6530. 08 99605500. www.mcintoshandson.com.au

MCINTOSH & SON (KATANNING)

Lot 4 Nyabing Road, Katanning, WA, 6317. 08 9821 7000. www.mcintoshandson.com.au

MCINTOSH & SON (KULIN) 294 Pump Road, Kulin, WA, 6365 08 9880 2556. www.mcintoshandson.com.au

MCINTOSH & SON (MERREDIN) 52 Mitchell Street, Merredin, WA, 6415 08 9041 1099. www.mcintoshandson.com.au

MCINTOSH & SON (PERTH)

547 Great Eastern Highway Redcliffe, WA, 6104 08 9475 1600. www.mcintoshandson.com.au

SOURCE MACHINERY

6 Reggio Rd Kewdale, Kewdale/Karratha, WA, 6105. 08 9358 3389. www.sourcemachinery.com.au

ACCESS SERVICE AUSTRALIA 26 Kilto Crescent, Glendenning, NSW, 2761. 02 9832 9990. www.accessservice.com.au 71 Bradman Street, Acacia Ridge, QLD, 4110. 07 3219 5130. www.accessservice.com.au 32 Healey Road, Dandenong South, VIC, 3175. 03 9768 2155. www.accessservice.com.au

MOTION MACHINERY

1/10 Dickens Place Armadale, WA, 6112. www.motionmachinery.com.au

SERVICE

ROKON AND BA EQUIPMENT GROUP

EEM uncovers how Rokon has grown over several decades to become one of Melbourne’s leading civil works contractors and the trusted partnerships that have contributed to this success.

From humble beginnings, Rokon has over the course of more than two decades of operations grown to become one of Melbourne’s leading civil works contractors.

During this time it has built an extensive portfolio of projects around Melbourne, and attributes its success to the long-standing and trusted partnerships it has formed with both its clients and the community.

Rebecca Lincoln, Rokon Plant Manager, told EEM that Rokon – which provides civil construction services for both minor and major projects – was founded in 1999 by Jim Thomas and his business partner, initially comprising a workforce of just 10.

“In 2014, Steve Traicevski joined Rokon as General Manager and is now fulfilling the Executive Director Commercial role,” Rebecca said. “Jim and Steve continued to grow the company after Jim’s partner departed in 2017. Under their leadership, the company has tripled in size in the last eight years.

“Today, as the preferred contractor for many of Victoria’s largest developers, Rokon is

ON THE COVER

Rokon’s fleet now includes the Hitachi ZX890 paired with the Epiroc HB 10000 hydraulic breaker, one of Melbourne's largest rock-breaking excavator combinations.

10 WWW.EARTHMOVERS-MAGAZINE.COM.AU

Rokon Founder, Jim Thomas and Executive Director Commercial, Steve Traicevski.

experienced in all types of civil projects, ranging from residential subdivisions, to medium density/retirement developments, wetlands developments, industrial subdivisions, remediation works, and infrastructure and structural works.”

Rebecca – who has a background in civil engineering design and over 15 years’ experience in the earthmoving industry, having pursued a career path that has seen her follow in her father’s footsteps – explained that the Rokon fleet now includes a broad range of equipment.

“Our fleet ranges from mini excavators to large scrapers dedicated to cut and fill for major bulk earthworks,” she said. “Our machines are all designed to deliver projects with excellent fuel economy, paired with state-of-the-art GPS technology and heavy-duty hydraulic breaking attachments.”

CONSTANTLY STRIVING TO IMPROVE OPERATIONS AND SERVICE DELIVERY

As one of the largest civil contractors in Victoria, Rokon’s core values include a commitment to delivery and a focus on positive client partnerships. Rebecca explained that Rokon’s client-first approach sees it constantly focused on seeking new ways to improve its operations, service delivery and in-house skills.

Rokon is committed to continuously growing and enhancing its equipment fleet.

Rokon is committed to continuously growing and enhancing its equipment fleet.

WWW.EARTHMOVERS-MAGAZINE.COM.AU 11

A strong relationship with BA Equipment Group has meant access to the biggest and best range of hydraulic attachments.

“From minor works to major projects, we have the skills, the knowledge, the equipment and the team to see a project through, whether it’s a vast greenfield site, a complex brownfield site, or a tricky urban infill,” she said.

“Our standing as the preferred contractor for many of Victoria’s leading developers has been built on a strong history of service to our clients, an appetite for knowledge, the technology we invest in, the talent we employ, and a determination to exceed the expectations of those we partner with.”

Rokon is also notably committed to continuously growing and enhancing its equipment fleet, while working with its network of providers across the metropolitan area

The HB 10000 has a lower environmental impact, as the operator is able to perform more precise breakout.

means it can efficiently bring together equipment for a diverse range of projects.

Drawing on its significant resources, Rokon is currently busy working on various projects located in a number of different areas around Melbourne.

This includes undertaking earthworks, residential subdivision and roadworks at sites such as Windermere Estate in Mambourin for Risland Australia, and bulk earthworks, sewer, drainage, water, gas, electrical and communication service installation at Ooranya Estate in Beveridge for TCG Construction Services.

Rokon has also been providing earthworks, gas, water, electrical, sewer, roadworks,

concrete footpath and laneway services at Aurora Estate in Wollert for Lendlease, and earthworks, residential subdivision and roadworks at Burwood Brickworks in Burwood for Frasers Property Australia.

EPIROC

BIO CHISEL

PASTE DELIVERS ENVIRONMENTAL BENEFITS

Rebecca told EEM that Rokon maintains a focus on sustainability and minimising its environmental impact, with it having recently begun integrating Epiroc’s Bio chisel paste across its workflows.

Approved by the European Commission for usage in environmentally sensitive applications, the Bio chisel paste formulation is based on special synthetic esters that are easily biodegradable, and it is also suitable for underwater applications.

It is specially made for hydraulic breakers, lubricating the wear bushings to avoid both wear and working tool breakage (reducing operation costs), and is capable of performing at a very high temperature, with an operating temperature range of -30°C up to 1100°C.

“Businesses must look at ways to reduce their environmental impact,” Rebecca observed. “If we are less dependent on natural resources, and have ways to deal with rising costs, we have a greater chance of long-term success.

“This is where products like Epiroc’s Bio chisel paste come into play. We are limiting our environmental impact by using renewable and recycled materials, reducing carbon emissions and implementing innovative, environmentally friendly practices.”

ON THE COVER

Rokon recently added an Epiroc HB 10000 hydraulic breaker to its fleet.

12 WWW.EARTHMOVERS-MAGAZINE.COM.AU

Rebecca told EEM that Rokon has also recently added an Epiroc HB 10000 hydraulic breaker to its fleet, with it having been deployed at the Melbourne Business Park industrial estate project in Truganina.

“We have increased our plant and equipment fleet to include the impressive Hitachi ZX890, paired with the Epiroc HB 10000 hydraulic breaker, one of Melbourne’s largest rockbreaking excavator combinations,” she said.

“The HB 10000 has the capability to provide a lower environmental impact, with the operator having the ability to perform more precise breakout, resulting in less fill product needed to go back into the ground when working on deep excavation and trenches.

“It has played a vital role in the development of a wetlands area for this project, and will be moving shortly to take on a major drainage project, where it will be excavating up to 70,000 cubic metres of fill and nearly 900m of drainage at 4 to 5m deep.”

BA EQUIPMENT GROUP GROWS NATIONWIDE PRESENCE WITH VICTORIA EXPANSION

Nathan Parziani, BAEG National Sales Manager, told EEM that BAEG’s acquisition of Breakthru Hammers earlier this year has seen it further strengthen its position in the Australian market, providing a presence in Victoria.

He said that this has created the largest hammer dealership in Australia, with BAEG focused on continuing to deliver its client base with the biggest and best range of hydraulic attachments at the best value, backed by exceptional customer service.

Nathan noted that BAEG has been servicing Rokon for a number of years, during which time they have formed a close working relationship, with BAEG providing Rokon with a broad range of products and services.

“We supply the entire Epiroc line-up of attachments, from breakers, to grapples, pulverisers, shears, combi cutters, compaction

plates, bucket crushers, bucket screeners and more,” he commented.

Rebecca said the knowledge and technical experience of BAEG has been a key component in delivering a superior service, describing it as having been “a welcome experience dealing with the BAEG team.”

“I’d like to mention Rob, Ben and Nathan in particular, who have been influential in the success of this business relationship,” she said.

“Also, after-sales service, including the HATCON monitoring system, is a valuable tool to ensure maintenance is effective and on time, and the ability to track utilisation and provide security with the location of the asset.

“These monitoring options are essential to a business to achieve longevity of the asset and parts, and also reduce servicing intervals to provide cost savings and improve productivity.”

As 2022 draws to a close, Nathan told EEM that it has been an extremely productive 12 months for BAEG, with this momentum poised to continue in the year ahead.

“Business in 2022 has been amazing, with exceptional growth and adding a Victorian branch along with many national roles,” he commented. “The 2023 outlook is exciting, with growth in many regions and departments forecast.”

Coming out of the pandemic and looking ahead to next year and beyond, Rebecca is similarly upbeat about what 2023 has in store, describing it as “an exciting time for Rokon.”

“Continued research into innovative opportunities with equipment, attachments, and efficient and environmentally responsible processes is a huge focus for the team,” she said.

“The future of renewable energy sources in construction is exciting, and continued efforts

at reducing our carbon footprint is a key factor in our future business development.”

EPIROC HB 10000 SPECS

Epiroc advises that its Heavy Breakers line is highly adapted for primary blast-free rock excavation and secondary rock breaking, along with primary demolition of massive reinforced concrete structures, with a robust design and high durability making the line suitable for the toughest jobs.

The HB 10000 weighs in at 10t (service weight), with it designed for use in conjunction with a carrier weight class of 85-140t, and (along with the rest of the Heavy Breakers line) features:

• ContiLube II – the automatic lubrication system optimises the lubrication procedure and reduces maintenance and standstills to a minimum

• Energy recovery – automatically utilises the piston recoil energy to reduce vibration levels and improve performance

• VibroSilenced Plus – non-metallic suspension of the percussion mechanism in the fully sealed box reduces noise and vibration levels

• DustProtector II – the optional active two-stage sealing system extends the service life of components and lowers grease consumption

• PowerAdapt – a built-in pressure cut-off valve prevents overloading

• AutoControl – the piston stroke length system automatically adjusts the output balance during operation, optimising performance

• Intelligent Protection System – the patented system automatically adjusts the start-up and shut-down behaviour during operation, combining easy positioning with maximum blank firing protection.

Rokon’s focus on sustainability has drawn the company to Epiroc’s Bio chisel paste.

WWW.EARTHMOVERS-MAGAZINE.COM.AU 13

The HB 10000 was deployed at the Melbourne Business Park industrial estate project in Truganina.

Right part, right price, right now.™

As an Australian family-owned company with global reach, Tilly’s is proud to stock over 43,000 new part lines for your earthmoving machinery. Tilly’s quality alternative undercarriage range extends from track groups to idlers, rollers, sprockets and track adjusters suitable for dozers up to D9 and excavators up to 30 tonne.

Tilly's are pleased to now offer a range of quality low-hour machines including General Construction Excavators and Loaders and D6-D8 ex-United States machines.

Tilly's is now offering account customers online ordering of over 30,000 parts for even quicker turnaround time, because we understand that down-time for your machines has a huge impact on your bottom line. That’s why we guarantee the quality of our new parts to ensure you are staying on track.

KOMATSU CONTINUES TO KICK GOALS WITH WESTERN SYDNEY WANDERERS

Global manufacturing and technological innovator, Komatsu Australia, has confirmed it will continue its sponsorship of the A-League Women’s football team Western Sydney Wanderers as part of its organisational focus on diversity and inclusion.

Western Sydney Wanderers are geographically placed in Sydney’s major construction corridor, making them an ideal match for Komatsu, which has its Australian head office located in Fairfield in Sydney’s west.

Sean Taylor, Managing Director and CEO of Komatsu Australia, said the company is excited

to enter the second year of its partnership with the team.

“We love what they stand for and see great synergies between our organisations,” he said. “Last year at our launch event, Komatsu staff were inspired by the Wanderers players and coaches at the club. There were some great stories that resonated about overcoming adversity as women in a male-dominated arena.

“There are strong links to some of the challenges women face in the workforce –specifically in our sector – and we really want

to bring these discussions to the forefront of our organisation.”

Komatsu has led the industry by putting diversity and inclusion on the agenda. The brand has won a range of awards in relation for its Say Again? program and industry leading training programs.

“Diversity presents a tremendous opportunity for our business. We are always looking for opportunities to highlight the benefits diversity can bring to our organisation and address the barriers that may hold us back,” Taylor said.

Komatsu has confirmed a second year sponsorship for the women’s Western Sydney Wanderers team.

INDUSTRY LEADERS

16 WWW.EARTHMOVERS-MAGAZINE.COM.AU

Like Komatsu, the Western Sydney Wanderers have been firmly focused on raising the profile of women.

“Unfortunately, Covid disrupted some of our plans last year so we are looking to leverage those opportunities to inspire our team.”

Like Komatsu within construction and mining, the Western Sydney Wanderers have been firmly focused on diversity and raising the profile of women in their sport.

Earlier this year, the club appointed Tom Sermanni as their first Head of Women’s Football. This leads the way in the Women’s A-League as the first football club to make such an appointment. The role forms part of The Wanderers Women’s

Football Program, which hopes to lay the foundations for future generations of women participating in the sport.

Additionally, this year’s newly appointed Head Coach, Kat Smith became one of 20 female coaches globally to be accepted into the FIFA Coach Mentorship Program.

“The strategies that the Wanderers are implementing echo our business strategies here at Komatsu. We are both focused on creating an environment that offers equality and opportunities for women because we understand and know the

unique value they can bring our workforce and teams.”

WHO DO WE SING FOR?

Komatsu employees, customers, family and friends can get 20% off seasonal memberships as an added benefit of the corporate sponsorship. Ask your Komastu representative for the discount code if you would like to take advantage of this limited time offer.

The Western Sydney Wanderers A-League Women’s season officially kicks off 26 November, when the team takes on the Newcastle Jets.

WWW.EARTHMOVERS-MAGAZINE.COM.AU 17

Sean Taylor, Managing Director and CEO of Komatsu Australia.

THE POWERFUL EFFECT OF AUSTRALIAN INDUSTRIAL BUSINESSES WORKING TOGETHER

Killard Group has maintained a long and prosperous relationship with Pickles.

Pickles and Killard Group have worked together across a range of different sales over the course of the last 20 years. The relationship has been so long and prosperous that neither party can quite remember the details of how the partnership began, only that collaboration has paved the way forward. It is due to several successful long-term business relationships such as with Killard Group, that Pickles is able to maintain Australia’s leading marketplace for used assets, selling over $672 million in gross sales of industrial equipment alone in FY22.

COVID-19 proved disastrous for many civil construction companies at the turn of the decade and forced many businesses to pivot direction. Some accomplished being able to turn business around, while others were not able to move forward with much success. For the industrial businesses who weathered the storm, it became apparent that propping each other up and creating an industrial brotherhood was the only way to uphold the sector. Killard Group and Pickles have long known the value of these connections, with Managing Director, Jerry Daly, noting it as the only viable path to industry longevity.

“It’s all about relationships. We won’t survive without each other. It doesn’t matter who you deal with, you have to have respect for each other and prop each other up. It’s a big industry, but it’s always a close-knit one,” Daly said.

Daly is much respected among insiders of the Australian industrial sector. A salt-of-theearth man who began his career pipe laying, he launched Killard Group in 1999. The company has gone from strength to strength over the years as Daly capitalised on his industry knowledge and strong relationship management skills. Today, Killard is a frequent champion of private and government projects that revive water and infrastructure throughout Australia, predominantly along the east coast. Regional revival is a passion of Daly’s, who speaks proudly of the company’s commitment to upskill local workers for future management of infrastructure once fixed. This practice allows Killard to train rural workers with trade experience, who then have the ability to take over the maintenance of their local infrastructure. This method is strategic in the ongoing upkeep of rural spaces – areas that are not always easily accessible to city-based

INDUSTRY AUCTION – PICKLES

Killard Group’s Managing Director discusses a 20-year relationship with Pickles, and how

to

achieve longevity in the rapidly growing civil construction sector.

18 WWW.EARTHMOVERS-MAGAZINE.COM.AU

The expanding infrastructure of Australia’s major cities frequently calls for Killard’s services.

PARTNER WITH PICKLES

As Australia’s leading asset remarketer, Pickles provides a simple way to sell, with a personalised service and exposure to a national network of buyers. With 18 dedicated industrial locations nationally and a sales team that cover every regional and metropolitan city in Australia, Pickles takes the hard work out of selling your asset while making sure assets realise their maximum value.

Mildura

Dalby

Mildura

Dalby

For more information, contact

on 0428 163 083 or

Moranbah

Matt Blanch

Matthew.Blanch@pickles.com.au

For more information, contact Matt Blanch on 0428 163 083 or Matthew.Blanch@pickles.com.au SELL WITH US TODAY The Pickles team is dedicated to maximising the return on every asset. We have a highly trained team of international valuation experts who have the knowledge, deep experience and tools needed to provide accurate appraisals and specialist advice on how to enhance value. We stand by our valuations, providing sellers the assurance of protection in sale returns. We understand that every situation is different. Our team brings hundreds of years’ experience in customising solutions that suit the unique needs of our clients. With expertise across multiple sales channels, we will recommend the most effective remarketing strategy based on our deep knowledge of industry trends, potential buyers, and current market conditions, to minimise any risk and maximise the value of every asset put to sale. Talk to us today about partnering with Pickles. 10.5M+ WEBSITE USERS YEARLY 55+ SALES EXECUTIVES ACROSS AU LOCATIONS ACROSS AUSTRALIA 27 $671M+ INDUSTRIAL EQUIPMENT SOLD LAST FY

workers and sometimes lack the facilities to train local workers. To date, this resourceful move has resulted in over 150 locally employed tradespeople who are now in charge of maintaining their local infrastructure.

The expanding infrastructure of Australia’s major cities also frequently calls for Killard’s services. The boom in Sydney urban expansion alone will be enough to keep Killard busy well into the next decade, Daly said. The astonishing growth in cities has made a huge impact on civil construction businesses, who have witnessed a flood of requests for infrastructure building and repairs in the short period since COVID-19 restrictions eased.

This industry-wide boom impacts many businesses. For remarketing specialists like Pickles, the industry growth has created more opportunities to market and sell assets as Australia’s largest industrial marketplace. As many Australian businesses leveraged the value of their assets to free capital, a great deal of used assets were made available to Pickles to sell on behalf of various clients –assets which became invaluable resources in a time of slow international production, coinciding with huge growth demands.

By upholding a strong marketplace and maintaining solid partnerships within the sector, healthy industrial relationships played a critical role in creating and maintaining circularity to keep Australia in business.

Pickles continues to prioritise business relationships by providing expertise, flexibility and tailored solutions to partners. For a business like Killard Group, who have unique

asset needs, Pickles can meet their needs through offering the ability to purchase goods via multiple sales channels and providing access to a range of remarketing and valuations experts across Australia. Pickles has an excellent industry reputation for upholding partnerships thanks to this level of care, detail and service.

“Professional, transparent and trustworthy, Pickles always steers me in the right direction,” Daly said.

“It doesn’t matter who you deal with – or what department – Pickles always shows support to Killard in big and small actions. They will

host a BBQ to celebrate our success and show appreciation. Even for a big business, Pickles creates one-on-one familiarity.”

With business plans for both Killard and Pickles foreseeably expanding over the next decade, it is anticipated that the partnership will continue to grow. The future looks bright and the civil construction sector has never been stronger, thanks to businesses who know the value of working together to pave the way forward for a bigger and stronger Australia.

For more information on Pickles, head to pickles.com.au. For more on Killard Group, head to killard.com.au.

Through a successful relationship with Killard, Pickles can maintain Australia’s leading marketplace for used assets.

WWW.EARTHMOVERS-MAGAZINE.COM.AU 19

Killard champions private and government projects that revive water and infrastructure across Australia.

The

PERFORM UNDER PRESSURE

Your Cat ® hydraulic system is designed to withstand high pressures to meet the demands of your machine. Contamination and component damage can lead to reduced efficiency and unplanned downtime. That’s why a well-maintained hydraulic system is critical for achieving maximum performance and value for the life of your machine.

Every component in your hydraulic system is vital for the performance of your operation, and it all relies on the ability to perform under pressure.

“Genuine Cat parts are uniquely designed for enhanced performance, durability and seamless integration in a highly refined hydraulic system,” Caterpillar Hydraulic Component Application Specialist Fabrice Trolio said.

“That’s why it’s critical that you always use genuine Cat parts.”

There are three main component groups to consider: hoses and couplings, cylinders and rods, and pumps and motors.

CAT HOSES AND COUPLINGS

Designed for durability and corrosion resistance, genuine Cat hoses and couplings deliver industry-leading flexibility and can help increase machine reliability and safety. Cat hoses and couplings are tested together as a system to provide maximum performance in a wide range of applications.

Cat hoses and couplings deliver flexibility and help increase machine reliability and safety.

Protect your hydraulic system with genuine Cat® parts and achieve maximum performance throughout the life of the machine.

MEET THE EXPERT WORDS // CAT CISD

Cat hydraulic system can withstand high pressures to meet the demands of your machine.

20 WWW.EARTHMOVERS-MAGAZINE.COM.AU

CAT CYLINDERS AND RODS

Genuine Cat cylinders and rods help deliver the optimal balance of strength, surface finish and impact resistance. Cylinder seals are bore-skived and roller-burnished for superior sealing performance. The components work together to help ensure greater resistance to contaminants.

CAT PUMPS AND MOTORS

Genuine Cat pumps and motors are built to tight tolerances and are tested to match stringent Cat hydraulic system performance and endurance requirements. These

components are tuned to your machine’s unique controls and settings to help optimise performance and maximise equipment productivity.

DON’T WAIT FOR FAILURE

It’s so important to keep your eye on your hydraulic system efficiency. It can erode significantly before you notice a problem. That’s why it’s vital to help avoid failure by conducting proper maintenance – and relying on the support of your local Cat dealer. There are three key maintenance areas to consider: prevention, detection and inspection.

PREVENTION

• Conduct regular maintenance by changing and monitoring oil, performing daily inspections and looking for signs of wear and tear

• Learn the causes and effects of contamination

DETECTION

• Scheduled oil sampling (S•O•SSM) services are provided by your local Cat dealer to help detect hydraulic system issues

• Help improve your scheduling of downtime and budget management by predicting your machine’s repair needs

INSPECTION

• Check for leaks and don’t ignore excessive noise or vibration

• Inspect your machine for signs of damage, loose or missing hardware, and to help monitor hydraulic system cycle times and drift rates

Again, it’s always a good idea to listen to the advice of experts. On the benefits of repairing before failure, Trolio said, “It helps reduce costs for the customer. You’re able to plan downtime and avoid the high costs of repair after a failure has occurred. Dealers can provide a range of detection services to support the before-failure approach, such as S•O•S SM Services analysis.”

Hydraulics are the lifeblood of your business, and there’s almost no hydraulics issue that your Cat dealer hasn’t dealt with before. So make sure you make them your first port of call.

To find out more speak to your local Cat dealer, or visit cat.com/hydraulics-au

Cat pumps and motors are tested to match stringent the hydraulic system’s requirements.

Cat pumps and motors are tested to match stringent the hydraulic system’s requirements.

WWW.EARTHMOVERS-MAGAZINE.COM.AU 21

Cat cylinders and rods keep a balance between strength, surface finish and impact resistance.

THE PERFECT FIT FOR PEAK PERFORMANCE

Pins may be low on the priority list, but they’re high on the productivity list. It’s no secret that taking care of your machine helps improve your bottom line. That’s why inspections, maintenance and proper replacement using genuine Cat® linkage pins and bearings are vital to your operation.

Wherever rotation occurs on your machine, it’s the job of genuine Cat linkage pins to support the movement. Working together as a system, Cat linkage pins and bearings are specifically designed to deliver the performance you expect.

Why is it so important to choose genuine Cat linkage pins and bearings?

Caterpillar engineers work to tight tolerances, matching the parts’ dimensions, materials, heat treatment, surface treatments and finish. Genuine Cat linkage pins and bearings fit your machine perfectly, wearing effectively with all neighbouring and dependent parts.

With so much riding on your linkage pins and bearings, it’s a good idea to listen to

expert advice. Clarine Koh, Aftermarket Services Consultant for Caterpillar, understands the importance of keeping your machines running as planned.

“Cat linkage pins and bearings are designed specifically to fit Cat machine dimensions to ensure precise bucket control, leaving room for sufficient lubrication,” Koh said.

“Pins and bearings that are too big or small can cause sloppy bucket movements. This undermines productivity and can cause excessive wear.”

As you would expect, Genuine Cat linkage pins and bearings are also quality tested to ensure more time between replacement. That means less downtime and more savings in the long run.

MAINTENANCE IS VITAL

Poor maintenance can result in unplanned downtime so it’s critical to include Genuine Cat linkage pins and bearings in your maintenance schedule. The benefits are clear: • Maintain smooth bucket movement and accuracy when working.

• Maintain ability to take on high load conditions.

• Prevent wear to bigger components.

• Help avoid costly downtime due to unplanned repairs.

Help keep your machine running and your work precise. Choose only genuine Cat ® linkage pins and bearings.

Order online at parts.cat.com or contact your local Cat dealer.

Genuine Cat® linkage pins and bearings aid rotation on your machine to deliver the performance that is vital to your operation.

MEET THE EXPERT WORDS // CAT CISD

Genuine Cat linkage pins and bearings fit your machine perfectly and wear effectively.

22 WWW.EARTHMOVERS-MAGAZINE.COM.AU

Genuine Cat linkage pins and bearings are quality tested to lengthen the time between replacement.

SMALL PARTS. BIG PRIORITY. Every pin in your machine joints is designed for a perfect fit, to help improve productivity, increase wear life, and keep your bucket moving smoothly. Help keep your machine running and your work precise with genuine Cat ® linkage pins and bearings Order online at parts.cat.com or pick up from your local Cat dealer. © 2022 Caterpillar. All Rights Reserved. CAT, CATERPILLAR, LET’S DO THE WORK, their respective logos, “Caterpillar Corporate Yellow”, the “Power Edge” and Cat “Modern Hex” trade dress as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission. SCAN TO ORDER GENUINE CAT® LINKAGE PINS & BEARINGS THE PERFECT FIT FOR PEAK PERFORMANCE NSW/ACT WesTrac 1300 881 064 VIC/TAS William Adams 1300 923 267 SA Cavpower 08 8343 1600 QLD/NT Hastings Deering 1300 952 701 WA WesTrac 1300 881 064 NZ Terra 0800 93 39 39

Melbourne Convention and

Centre 20-21 Sept 2023 EXHIBITION SPACE NOW ON SALE

leading construction and major infrastructure event insideconstructionexpo.com.au

Exhibition

Melbourne’s

Introducing the new SK45SRX-7 and SK55SRX-7 mini excavators from Kobelco – delivering improved performance and class-leading next generation cabin design. With an extra spacious cabin, improved ergonomics and advanced technology, you’ll be able to make full use of the extra power and speed on offer, all day long. For uncompromising operator comfort and superior productivity, experience the new Kobelco SK45SRX-7 and SK55SRX-7 today –taking performance to the next level.

kobelco.com.au | 1300 562 352 @kobelcoaustralia

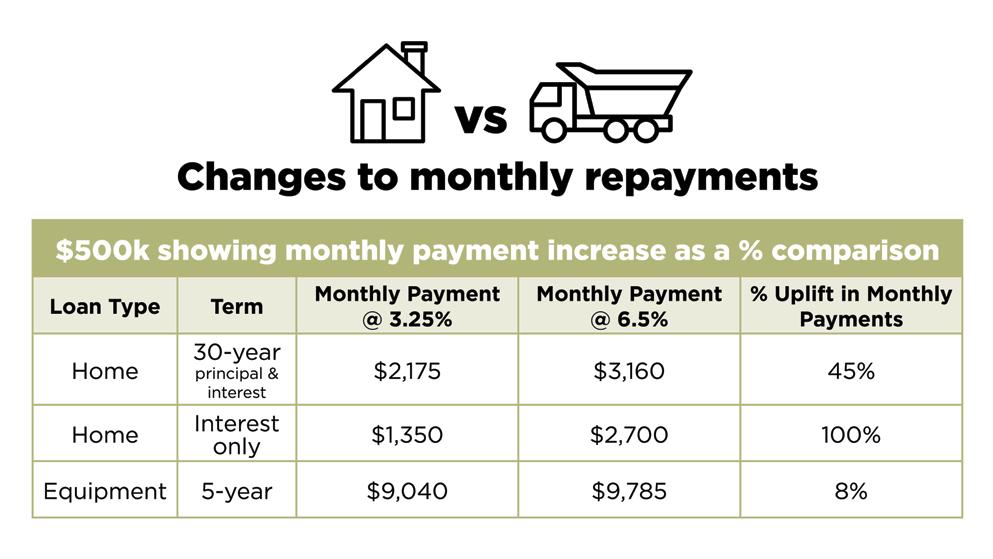

HOW INTEREST RATE INCREASES

IMPACT EQUIPMENT FINANCE

Finlease reports.

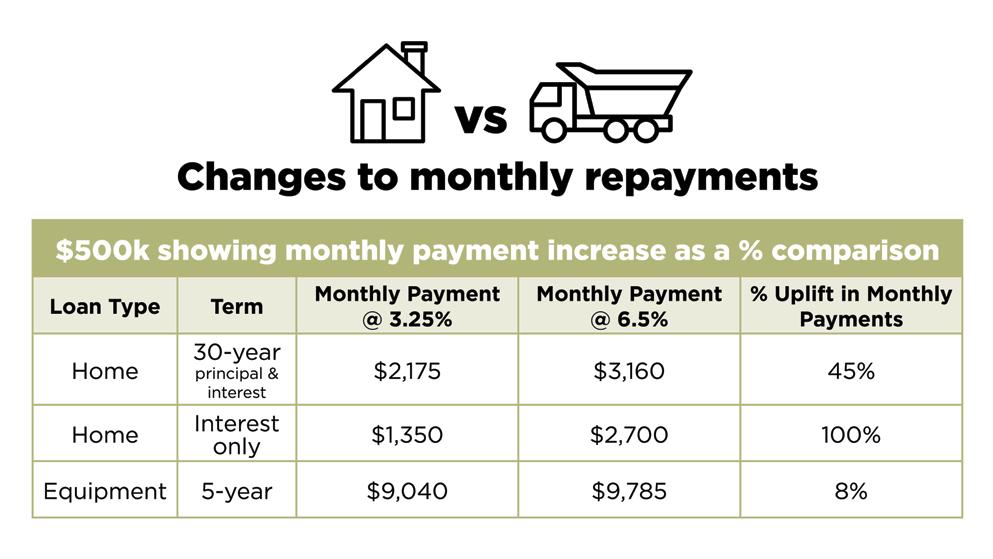

Where the five-year fixed home loan rates increased to around 6.5 per cent, it won’t be surprising that motor vehicle and equipment finance interest rates have also moved into the 7 per cent plus range.

As recently as one year ago, home loan rates, and equipment and motor vehicle finance rates were around 3 per cent or lower. So, what is the effect of these interest rate increases in real terms and how may this affect your business moving forward?

Unlike home loans where a doubling of the interest rate resulted in an increase of 45 per cent or 100 per cent in the monthly payment, the monthly payment effect on the equipment finance loan was much lower at around 8 per cent. This is simply due to the shorter term where the entire debt is fully paid off over five years.

In a world where businesses are seeing increased costs across the board in such areas as labour, materials, as well as the actual purchase cost of vehicles and machinery, debt (interest rates) is also one of these increasing costs.

To prepare, businesses today can:

• Access the Finlease calculator at finlease. com.au/equipment-finance-calculator to test payments on a range of interest rates

• Review your costs of doing business and adjust pricing accordingly.

How home loan rates compare to equipment finance loans.

• Utilise the expertise of a finance broker to seek out the most favourable equipment finance solutions.

HOW LONG CAN WE EXPECT THESE INCREASES BEFORE WE REACH THE PEAK?

The reality is that the harder you hit the brakes, the sooner you slow down the inflation, however if you hit the brakes too hard, you risk stalling the economy, which can lead to a recession.

The RBA will need to closely monitor this to get the balance right.

The best intel we can see at this stage, is around 12-18 months, or when inflation returns to the 2 to 3 per cent band required by the RBA to stabilise inflation to an acceptable level. Once this band is achieved, we can expect interest rates to remain at the level required.

However, if inflation drops below this desired band, we can reasonably expect to see some reduction in those interest rates to ensure Australia has a soft landing and avoids a recession.

Our advice is to also utilise the expertise of your finance partner or accountant. Businesses should also be planning their truck or vehicle purchases to take advantage of the government tax incentives that are ending June 30, 2023. This incentive is available for new and used (including private sales) for any company with a turnover of less than $50 million.

To find out more, please visit finlease.com.au

BUSINESS AND FINANCE

With so much press focusing on the significant increases in home loan rates and interest rates in general, it is timely to have a look at what this means for businesses,

Finlease evaluates how rising interest rates

are affecting Australian businesses.

26 WWW.EARTHMOVERS-MAGAZINE.COM.AU

C.R. KENNEDY INTRODUCES LEICA ICON SITE EXCAVATOR

Machine

control technology for compact excavators.

C.R. Kennedy is proud to announce the release of Leica Geosystems’ new iCON site excavator system. The versatile machine control solution is designed for compact excavators – a single solution to increase the efficiency and accuracy of small-scale trenching, grading, and earthmoving operations – for the Australian market.

The iCON site excavator system, builds upon the powerful iCON Site platform, allows compact excavator operators to dig to designs easily and precisely, and is available for use both as a standalone option or as an add-on to an existing iCON site GNSS smart rover.

The iCON site excavator introduces three new components to the existing iCON suite, the iCON Excavator application itself, a dual GNSS receiver (the Leica iCON gps 100) and an optional communication device for GNSS corrections (the Leica iCON CR50), encompassing a setup that delivers versatility in tackling a range of applications.

The Leica iCON site excavator system supports compact excavator with swing boom, tiltrotator and tilt bucket functions.

MACHINE CONTROL TECHNOLOGY

Measure an area and create a design using a field controller unit with a smart antenna.

28 WWW.EARTHMOVERS-MAGAZINE.COM.AU

With iCON Site Excavator used as an add-on, it integrates seamlessly with existing iCON site applications, paving the way for benefits from new workflows that combine measuring, stakeout, excavating and reporting.

LEICA ICON SITE EXCAVATOR FEATURES: OPTIMISING EARTHMOVING TASKS

The Leica iCON site excavator system supports compact excavators with swing boom, tiltrotator and tilt bucket functions. Across its assorted on and off-machine applications, iCON site with iCON site Excavator is designed for simple setup and ease of use.

Ultimately, this provides greater flexibility and underpins efficient and effective equipment and personnel deployment through enabling operators to optimise earthmoving tasks, with versatility of on machine and off machine options incorporated in a single software.

For instance, across various stages of the workflow, it allows operators to:

• Measure an area – and create a design (using a field controller unit with a smart antenna)

• Directly dig – according to the design (using the same field controller in the excavator cab)

• As-built checks – once completed, use the same system to perform these checks.

Other features include:

• Map-driven – selection and navigation

• Traffic-light – indication of work results

• Split-screen functionality – allows different viewing perspectives

The iCON site excavator can be used in conjunction with a range of iCON field controllers.

• Digital designs – using the same designs as the big machines in the project ecosystem

• Leica ConX – integration ensures seamless communication of design updates

The iCON site excavator can be used in conjunction with a range of iCON field controllers.

The iCON site excavator can be used in conjunction with a range of iCON field controllers, while the new GNSS receiver and communication device are designed specifically for compact machines, allowing greater flexibility to adjust to different sites and project requirements.

C.R. KENNEDY BACKS PRODUCT PORTFOLIO WITH NATIONWIDE SERVICES SUPPORT

C.R. Kennedy, the sole and exclusive distributor for Leica Geosystems in Australia, is focused on providing high-quality products and tailored solutions for industry, supported by its comprehensive national after-sales network, including training, service and repairs, technical support, hire equipment and customer care agreements.

Based out of Port Melbourne, C.R. Kennedy’s national network spans major state offices in Brisbane, Adelaide, Sydney, Hobart, Perth, and Cairns with its workforce comprising over 260 staff, including product specialists, qualified surveyors, support staff and factory-trained service technicians.

MACHINE CONTROL TECHNOLOGY

30 WWW.EARTHMOVERS-MAGAZINE.COM.AU

© 2022 Caterpillar. All Rights Reserved. CAT, CATERPILLAR, LET’S DO THE WORK, their respective logos, “Caterpillar Corporate Yellow”, the “Power Edge” and Cat “Modern Hex” trade dress as well as corporate and product identity used herein, are trademarks of Caterpillar and may not be used without permission. NSW/ACT WesTrac 1300 881 064 SA Cavpower 08 8343 1600 QLD/NT Hastings Deering 1300 952 701 WA WesTrac 1300 881 064 VIC/TAS William Adams 1300 923 267 NZ Terra 0800 93 39 39 UNDER PROTECT YOUR HYDRAULIC SYSTEM WITH GENUINE CAT ® PARTS. Your Cat ® hydraulic system is designed to withstand high pressures to meet the demands of your machine. Contamination or component damage can lead to reduced efficiency and unplanned downtime due to failure. A well-maintained hydraulic system is critical for achieving maximum performance and value for the life of your machine. Your Cat dealer has all the expertise you need to help keep your hydraulic system running at its best. To find out more speak to your Cat dealer or visit cat.com/hydraulics-au SCAN HERE

PERFORM PRESSURE

WHAT YOU NEED TO KNOW ABOUT OFFERING MOBILE PLANT AND EQUIPMENT FOR HIRE

NTI has reported a transport, urban and civil infrastructure boom in Australia, with considerable activity in the mining and general construction sectors. With this massive pipeline of projects, businesses are making the most of their opportunities. But there’s a snag: mobile plant and equipment (MPE) is in short supply.

This environment of MPE shortages and increased demand is music to the plant hire industry’s ears. At the same time, companies with surplus MPE can generate revenue from assets that would otherwise be sitting idle.

Therefore, it’s essential to understand hire arrangements and insurance. If you get them wrong you may end up with a customer conflict, or worse, an uninsured financial loss. Obtaining the right expertise is essential.

Here we explore the key considerations when hiring out your MPE.

OBTAIN QUALITY LEGAL ADVICE

Hire agreements are central to any hire business and a critical risk management tool. Engage a lawyer experienced in preparing hire agreements for the mobile plant industry to draft an agreement tailored to you.

The one-off (and tax deductible) expense is negligible compared to the risk exposure from a contract that’s poorly worded or doesn’t cover the relevant risks and conditions.

“This is critical,” NTI’s National Strategic Underwriter – MPE Gary Woodhams said. “Don’t take shortcuts – if you don’t obtain good legal advice, you’re guaranteed very poor results when things go wrong.”

Crafting a good quality hire agreement will provide years of contract certainty and clarity of obligations for all parties.

Conversely, a poorly crafted hire agreement – or one without legal input – invites complications. You’ll most likely experience problems obtaining adequate insurance ,

conflicts around who is responsible for damage and insurance, accusations of unfair contract terms and delayed or declined insurance claims.

UNDERSTANDING BUSINESS OBJECTIVES AND HIRE PROFILE

Before drafting a hire agreement, your lawyer will need to understand some critical facts about your business to establish the hire profile and needs, including:

• Will you be offering wet or dry hire – or both?

• What’s your target market?

• Which items will you offer?

• What hire periods will you offer?

• Who holds risk in the equipment, how will it work, is it clear and fair?

CRAFTING THE HIRE AGREEMENT

Preparing your hire schedule with transparent terms and conditions is a critical step you must work through with your lawyer.

“There is so much to consider, and you need that legal expertise to craft a hire agreement that will serve you and your customers well into the future,” Woodhams said. “Critically, you want to deliver positive customer experiences. They’ll protect your reputation and boost your brand, leading to repeat business, referrals and a steady revenue stream.”

The goal is clarity of obligations to protect both owner and hirer.

DAMAGE WAIVERS

Damage waivers are not insurance policies; they are conditions or clauses in a hire agreement

that limit the hirer’s liability or responsibility for certain types of damage to the equipment. Damage outside the damage waiver’s scope remains the hirer’s responsibility.

If poorly constructed, damage waivers have the potential for disputes and other difficulties.

Communication and clarity on what the damage waiver does and does not cover is critical so the hirer can identify and make suitable arrangements to deal with any gaps, including opting out of the damage waiver and insuring themselves if they prefer.

Alternatively, you can comprehensively insure the equipment yourself while in the hirer’s possession and use. You can attach conditions, such as hirer responsible for an elevated (i.e. not extreme) level of excess to force their skin in the game, and other appropriate and reasonable terms to ensure accountability.

SPEAK TO YOUR INSURANCE BROKER Your hire agreement must clearly describe what insurance you’re providing and the risks the hirer must manage or cover. Woodhams’ recommendation is to work with your broker.

“Brokers are experts and your appointed risk advisors,” he said. “Be directed by their advice. The insurance side needs careful professional attention. If you are providing a damage waiver or full insurance, that is increased risk.

“Your broker’s input on how insurance arrangements comply with hire agreement requirements is invaluable. Your goal is to avoid uninsured losses for you or your customer. You want to be sure your hirers understand their liabilities and have a positive experience.”

It is essential to understand that your insurer is legally entitled to follow and deal with any insurance claims per the hire agreement terms, conditions, exclusions and limitations, including making recoveries (i.e. suing) directly off the hirer (i.e. your customer).

Hiring out your MPE can be a great way to generate revenue from all your assets. If you’re thinking of hiring out some of your MPE, it’s so important to obtain the right advice and insurance. Speak to your lawyer and insurance broker.

If you’d like to learn more about risk management and how to protect your business, contact your insurance broker or NTI today. Visit NTI’s Yellow Cover at www. yellowcover.com.au

32 WWW.EARTHMOVERS-MAGAZINE.COM.AU INDUSTRY INSURANCE WORDS: NTI NATIONAL STRATEGIC UNDERWRITER – MOBILE PLANT & EQUIPMENT, GARY WOODHAMS

BAUMA 2022 INNOVATION AWARD FINALIST FOR OPERATOR TRAINING

Well, I finally ticked off a bucket list item when I recently attended the largest trade exhibition in the world, Bauma 2022 in Munich, Germany.

Along with checking out the latest and greatest from just about every OEM on planet, I was keen to get amongst all things training when I arrived at Bauma’s Messe Munchen exhibition grounds.

BAUER GROUP

There were a few exhibitors who had some real neat simulators, Virtual Reality (VR) and Augmented Reality (AR) solutions. But the company that caught my eye was the Bauer Group, a world renowned foundation contractor and builder of the finest foundation equipment.

Now I’m going to be honest, I’d never heard of Bauer and I know squat about the foundation sector. So you could imagine my surprise when I rounded the corner to their site to see a bunch of crazy looking foundation equipment! For a second, I thought of just bailing and heading off to find something in my lane (earthmoving). But I’m glad I walked inside and introduced myself to Brigitte Niemann, Bauer Training and Development Consultant, who graciously walked me through some of their training solutions.

Brigitte went on to tell me that Bauer has purpose-built facilities all around the globe, the closet to our neck of the woods being in Singapore, Malaysia. At these facilities you can tick off all your traditional delivered training requirements, like operator training for drill rigs, pile drivers and duty cycle for cranes, training for mechanics and service personnel.

And the real intriguing one for me, operator training for process technologies/mixing and separation technology, which drills into the art of soil mixing (pun intended)! Super important to know, as it improves the capability of the equipment and the quality of work carried out.

NEXT LEVEL OPERATOR TRAINING

As cool as all of Bauer’s traditional training methods are, it wasn’t until Brigitte shifted gears and started to tell me about their “Next Level Operator Training” that harnesses AR capabilities, that I started to get excited. This product came about during the pandemic, when travelling to a customer’s sites pretty much ceased. Products still needed to be supported and operators still needed training, right?

So, what did Bauer do? They got together with one their partners – Usaneers GmbH –and developed this super neat, innovative training solution.

There are two training options for the construction sector. The only prerequisites are a stable internet connection and the AR glasses, which will be shipped out to you prior to the training event, along with a specially designed hard hat that accommodates the VR glasses (safety first!) all in a tough-as-nails travel case.

OPTION ONE

The trainee wears the AR glasses, and the trainer is connected virtually from where in the world, providing live guidance in the application. In this way, the trainee is presented with a worksite under real conditions, but also receives the necessary support to manage the task as well as the required theory.

The visual field of the glasses is transmitted in a web application and enables the trainer to interact via video and audio from any

location. The versatile tools of the AR application make it possible to highlight objects in the working environment, display images, videos or technical documents in the visual field or also work together on the shared screen. The entire time, the trainee has their hands free to carry out the required activities.

OPTION TWO

The trainer wears the glasses and is on the equipment or on the site. The trainee follows the activity remotely. This option is particularly suited for groups, as multiple participants can follow the training from their own end device or together in the training centre.

So there we have it, a snapshot of how training can be completed differently and remotely. Needless to say, I’m a fan.

INDUSTRY TRAINING WORDS // SCOTT LIDSTER

At Bauma 2022, Scott Lidster visited the Bauer Group’s exhibition for its insight on operator training.

The Bauer Group’s booth at Bauma 2022 in Munich.

34 WWW.EARTHMOVERS-MAGAZINE.COM.AU

Bauer’s hard hat and VR glasses, presented in a tough-as-nails travel case.

*T&CS APPLY. VISIT ONETRAK.COM.AU FOR FULL DETAILS

FINDING THE STORY

There’s a saying that content producers love to share, and that is “Everyone has a story.”

When you’re talking about individual human beings, that’s fairly easy to believe.

But what about when you’re talking about businesses? Some of them are just not that interesting, right? How do you make good content – great stories – about dry topics?

The answer is that you do it the same way you create any other story. You ask questions. You look for the point of interest. You find the things that will resonate with audiences. You talk about the people, not just the product. There are people on both sides of every business transaction and the audiences consuming your content are people, too. People are interesting!

One of the most fascinating content pieces I have ever written was about a business that makes yellow plastic tubes. The product, on the surface, doesn’t seem very exciting. When we went to visit the production site it was not much more than a shed on the outskirts of Perth.

What made it fascinating content was the story behind the business. The founder was a true entrepreneur who was dry and funny and very clever. His team was a mixed bag of interesting personalities. And his product was transforming an entire industry sector.

Everybody has a story and every business has a story. Give your audiences good content by finding those stories.

Here are five tips for creating inspiring content

you can use:

1. Align it with your business goals and position – Are you all about innovation? Focus on that. If you’re all about reliability, make that the heart of your stories.

2. Talk about people – People use products and services. Tell their stories to tell yours.

3. Make it warm – A good story is not a product brochure or a technical lecture.

4. Include great images.

5. Go in with an open mind – You know what the key messages are that you need to hit. Let the rest of the story reveal itself through deep conversations and real listening.

If you need help finding those good stories, get in touch with Hardman Communications and we will show you how via hello@hc.net.au

MARKETING AND PR WORDS // ALEXANDRA WILLIAMS

Hardman Communications gives earthmoving businesses a rundown on how “finding the story” can help when it comes to PR and marketing.

36 WWW.EARTHMOVERS-MAGAZINE.COM.AU

Everybody has a story and every business has a story, Hardman Communications says.

1300 EquipU (378 478) www.equipmentspecialists.com.au NEW K SERIES • Larger cab • Cummins QSL engine • NO AdBlue, DPF, EGR • HYDROSTATIC models available

The SK135SR-7 perfectly demonstrates the commitment Kobelco has to designing and manufacturing the most capable excavators available, built with Japanese quality for legendary reliability.

As the #1 selling machine in the 14 tonne class, the SK135SR-7 combines unbeatable performance, fuel efficiency and reliability with a premium operator station and modern machine design.

And now Australia’s most popular short radius heavy excavator is available with a proven Isuzu Tier 3 engine, with no DPF and no AdBlue required, reducing operating costs and increasing convenience.

kobelco.com.au | 1300 562 352 @kobelcoaustralia

YOUR ONE STOP SHOP

STM FOR MACHINERY

For almost half a century, STM has made it possible for businesses across NSW to power up – supplying and servicing quality trucks and machinery to meet the demands of any job.

Starting out in a single shed in the 1970s, we know what it takes to build a business – and are passionate about helping you grow yours. Today, our family owned and operated enterprise is proud to offer a multi-site, modern service, with a team of more than 120. We care about giving every customer the best experience possible – with a wide range of trusted brands, flexible finance, spare parts, repairs and personal service.

We may have come a long way from that shed, but our family commitment to quality remains. Whatever your size, whatever your budget, STM is your one stop shop – with everything to keep your business moving.

SYDNEY / WOLLONGONG / CANBERRA WWW.STM.COM.AU 1300 305 420

SOUTH QUEENSLAND LIME AND EQUIPMENT SPECIALISTS AUSTRALIA

South Queensland Lime (SQL) has over the course of its two-plus decades of operations forged a strong reputation as an independent supplier of calcium carbonate (limestone) products for the agricultural, industrial and mining sectors.

The wholly Australian-owned company has in recent years significantly expanded the scope of its activities, making substantial investments in its facilities and in turn bringing new products to market.

As explained by SQL SSE Mine Manager Mick Williams, located in the rural Queensland town of Gore, the SQL site draws on a long history dating back over 100 years, with its operations having originally been linked to a Brisbanebased cement works.

SQL itself was founded in 2000, acquiring an additional lease over the area, with a change of ownership in 2020 underscoring the wholly Australian-owned company’s long-term outlook and paving the way for further expansion in the mining and manufacturing industries.

Williams – who draws on 25 years of experience in the mining industry, nine of which have been at SQL – told EEM that SQL’s hands-on approach distinguishes its service offering, with a firm emphasis on both reliability and regular communication with its client base.

“Limestone is a very versatile mineral and is used in many aspects of our daily lives, from paints and glass all the way through to animal feeds, supplements and soil conditioners that treat acids and help improve the soils our foods grow in,” Williams explained.

“We have a high-quality limestone resource, with reserves of more than 20 years. Our large

product sizing range spans from superfine through to large filter stone and flood rock, and every opportunity is on the table.”

QUALITY A KEY FOCUS ACROSS A WIDE PRODUCT RANGE

Backed by a strong focus on quality control, SQL produces a number of products for the mining industry, with its high-quality ground calcium carbonate stone dust

used for explosion prevention in underground coal mines, acid sulphate soil treatment and pH water treatment.

In addition to this, it produces lime products for glass manufacturing, industrial and functional fillers, and water and soil treatments, and provides the agricultural sector fertiliser elements, animal and poultry feeds, feedlot supplements and soil conditioning products.

“We supply products to livestock feed producers, agricultural resellers, feedlots, mining companies and the wider manufacturing industry across Queensland and interstate,” Williams said. “While not as large as some miners, we still move hundreds of thousands of materials annually.”

Williams noted that SQL has navigated a number of challenges in recent times, singling out severe weather conditions as being an unpredictable element that can have a significant effect on both production processes and market requirements.

“The main challenge we face would be weather and the extreme impacts it often has on our operations and our customers,” he told EEM.

“We’ve dealt with droughts and unprecedented animal feed demand in 2019, through to the challenges of managing Covid, and then right into the wettest year on

DEALER PROFILE

South Queensland Lime supplies high-quality limestone, from superfine to large filter stone and flood rock.

40 WWW.EARTHMOVERS-MAGAZINE.COM.AU

Earlier this year, SQL added a Lovol FL966H wheel loader to its fleet.

record in 2022. Rain presents a challenge as powdered limestone needs to be kept dry at all times during the production process.”

In line with this, Williams noted that SQL has taken significant steps in recent years towards enhancing its production processes, moisture-proofing its production line, bolstering its capability and consistency.

LOVOL FL966H WHEEL LOADER DELIVERS UNCOMPLICATED AND RELIABLE OPERATIONS

Earlier this year, SQL added a Lovol FL966H wheel loader to its fleet, with Williams explaining that the main reason the company opted for the FL966H, supplied by Toowoombabased earthmoving and transport operator Equipment Specialists Australia (ESA), was “its simple mechanical operation”.

“We wanted a loader that delivered reliable operation, and was simple to maintain and manage, including its simple hydraulics and drive system,” he said.

“Local support was also a big factor given our remote location, and with the simplicity of the unit it meant that the price was very competitive at the time compared to other brands of machinery.”

The FL966H has thus far been working mainly on SQL’s mobile screen plant, which Williams noted supports it “in improving our yield and volumes.”

“It also supports other areas of the site when needed,” Williams told EEM . “It has good lifting capabilities and steady footing. Reports back from the operators also complement its good vision from the drive position and its smooth operation.”

The 22 tonne (operational weight) FL966H has a 6 tonne rated load capacity and runs a 192kW Deutz Weichai engine with a

mechanical fuel pump (meaning no engine control unit), while limited electrically controlled functions eliminate problematic items.

It is equipped with a ZF powershift transmission (4F/3R with fast kick-down), Lovol axles and air-over-hydraulic disc brakes for superior stopping (a wet brake option is available), and additional features:

• A ROPs and FOPs-certified lined and sealed cab, lessening noise and vibration, with air-conditioning and an air-suspension seat

• A 4cbm GP bucket (with a choice of GP, rock, coal, grain and bulk buckets); 4.39m bucket lift height; boom lifting time of 5.7 seconds

• A pilot joystick with float position

• A Danfoss steering valve; hydraulic pressure of 3000 psi; fuel tank capacity of 180 litres; travel speed of 38km/h

• A one-piece fully opening side engine cover, enabling ample access (with no bolted covers to remove); patented composite reinforced pivot structure and bushings; radiator air flow is not obstructed by any items for industry-leading cooling

• Dimensions: 8.54m (length), 2.925m (width) and 3.4m (height).

EQUIPMENT SPECIALISTS AUSTRALIA PROVIDES COMPREHENSIVE SERVICE SUPPORT

Williams said that ESA had delivered strong support across the sales process, assisting initially with gaining an understanding of the FL966H’s capabilities, which has in turn paved the way for its smooth integration into SQL’s operations.

“The before and after-sales service has been good, and in order to understand the machine in the early stages we were given a unit to test,” he said.

“They are easy to contact and parts are easily sourced. The relationship is only relatively new and there haven’t been any issues, and we expect this to continue based on what we have seen so far.”

This has helped SQL focus on its day-to-day operations, with Williams noting that business has been particularly busy over the last 12 months despite the challenges that many organisations are facing at present.

“Business has been on the rise for the last couple of years as agriculture and industry continue to learn the benefits of our products and the critical role they play in sustainable agriculture,” he said.

“Looking forward, I don’t think that’s going to change any time soon as the population grows and the world continues to focus on sustainability and improved soil health.”

The

FL966H

mainly supports SQL’s mobile screen plant to improve yield and volume.

WWW.EARTHMOVERS-MAGAZINE.COM.AU 41

Severe weather conditions have had a significant effect on production processes and market requirements.

CAT® GLOBAL OPERATOR CHALLENGE – ASIA PACIFIC FINALS

Life is all about making the most of opportunities. The five Australian finalists, who just competed in the Asia Pacific Finals of Global Operator Challenge, were treated to a life-changing week long experience in Tokyo where they went up against the best operators from Japan, Indonesia, India, and Philippines. When the dust settled, two Australians stood tall as the best operators in the Asia Pacific region. They qualified to compete in the Global Finals in March in Las Vegas at the 2023 CONEXPO.

Checking in at the Sydney International Airport, I knew there would be some great adventures in the week ahead. Not having been to Japan before, I knew it was going to be a bit of a culture shock. But what I wasn’t prepared for was the friendly, welcoming and helpful Japanese people that would go out of their way to help you – from the team at the Caterpillar D-Tech centre in Chichibu, to complete strangers that would regularly go out of their way to help when you inevitably got lost on the Japanese Rail System (JR). Or others who helped navigate an automated food ordering system.

Before I delve into the competition itself, let me just say I’ve been lucky enough to attend some significant events before in my time as a photo-journalist and digital creator. But the level of attention to detail that the Cat team went to in making this a world-class event was awe-inspiring. Several Australian competitors hadn’t been overseas before, so the bar has been set pretty high for them. But for

INDUSTRY EVENTS

Nick Thompson, Masato Imai and Patrick Doheny receiving their awards at the Cat Global Operator Challenge.

42 WWW.EARTHMOVERS-MAGAZINE.COM.AU

The Finals centred on three challenges, and the competitors were scored based on time, safety and quality of work.

THE AUSTRALIAN TEAM

As per the Australian state qualifying events, the Asia Pacific Finals revolved around three challenges, which the competitors were scored based on time, quality of work and safety. With the competition spread over two days and no leader board scores displayed, it was anyone’s guess right up to the presentation who had performed the best in the eyes of the judges. As it turned out, it was speed and time that the judges were most focused on. Time penalties were added to the competitor’s overall score for any indiscretions or mistakes made along the way.

The Australian team consisted of a great bunch of characters that did a fantastic job of representing their state and dealer. Jake Myers from WA shone as a standout performer. He has stepped into a different role at his work and hasn’t been operating machines for a year or so. I couldn’t help but imagine how well he would have gone had he been spending his days in a machine recently. Jake was awarded the prize for safety and performance,

work.

Jack Dival was the NSW finalist, who put in three impressive performances across the competition and missed out on making it to make the top three. Aiden Lee from QLD

Australian competitors Patrick Doheny (VIC) and Nick Thompson (SA), the adventure is set to continue in Las Vegas after placing first and second runner-up, respectively.

which truly showed the quality of his

INDUSTRY EVENTS

rounded out the Australian five finalists, and if it weren’t for a couple of penalties on his first challenge on the first day, where a few nerves just got the better of him, he also would have been a real candidate for the top three.

The second challenge was the “Load & Go” Medium Wheel Loader Challenge.

WWW.EARTHMOVERS-MAGAZINE.COM.AU 43

Nick Thompson (SA) and Patrick Doheny (VIC) are off to Las Vegas Conexpo for the Global Finals.

THE CHALLENGES