Continental helps local Finders Distillery with purity solutions 1300 RUBBER www.continental-industry.com aus.ep@continental.com

1300

aus.ep@continental.com

RUBBER www.continental-industry.com

MARCH 2023 PLUS: Alternative Packaging | Food Safety | Ingredients runs in the

in coffee

family Excellence

CEO: John Murphy

COO: Christine Clancy

Managing Editor: Syed Shah

Editor: Adam McCleery

Ph: (02) 9439 7227

adam.mccleery@primecreative.com.au

Design Production Manager: Michelle Weston michelle.weston@primecreative.com.au

Art Director: Blake Storey

Design: Michelle Weston

Sales/Advertising: Stephanie Suzuki

Ph: +61 422 046 711 stephanie.suzuki@primecreative.com.au

Production Coordinator: Janine Clements

Ph: (02) 9439 7227 janine.clements@primecreative.com.au

Subscriptions AUS NZ O/S

1 year subscription 99 109 119

2 year subscription 189 199 209

For subscriptions enquiries please email subscriptions@primecreative.com.au

Food and beverage industry continues to champion innovation

Editor: Adam McCleery

Copyright

Food & Beverage Industry News is owned by Prime Creative Media and published by John Murphy. All material in Food & Beverage Industry News is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published.

The opinions expressed in Food & Beverage Industry News are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2019

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Head Office 11-15 Buckhurst St South Melbourne VIC 3205 Ph: +61 3 9690 8766 enquiries@primecreative.com.au http://www.primecreative.com.au

Sydney Office Suite 303, 1-9 Chandos Street

Saint Leonards NSW 2065, Australia Ph: (02) 9439 7227

The food and beverage industry plays a critical role in the very fabric of society. Advancements in food and beverage processing and manufacturing technologies impact on people’s day-to-day lives more than most other industries, for obvious reasons, we all need to eat and drink.

Because of this, sustainability and efficiency targets continue to carry extra weight for the industry.

The first major mile markers regarding more sustainable a nd efficient manufacturing in Australia are due in 2025, however, the last two years covering the industry have shown me that food and beverage manufacturers already have sustainability and efficiency at the forefront of their minds, leading to many reaching targets long before set dates.

The industry never stands still and as such manufacturers are constantly having to weigh up the merits of if, when, and why they will or wont adopt changing trends.

But what makes the industry so successful is the ability, and c apability, to respond to changing trends and demands from all areas of the market.

In this edition we speak to some key stakeholders in both the packaging and ingredients sectors who are seeing first hand the value of responding to market trends in a speedy, and efficient manner.

Ignoring the demands or obvious trends in the industry will rarely lead to success if a competitor is quick to the draw, consumers have become savvier and aren’t afraid to abandon one brand for another, making brand loyalty tricker than ever before but possibly more valuable.

is more precious than it has been for a long time and as such consumers are more likely to find a cheaper alternative, or any alternative for that matter, if they feel that brand or product better represents their views and hopes for the future of society.

Again, the food and beverage industry has a strong position within society as a whole, but that doesn’t guarantee success, only that the market share is there to be taken.

And this is why it’s so important for the industry to lead f rom the front, as it has already been doing, to help drive a move towards a far more circular economy.

Thankfully, the industry is well placed to make both small, and large, changes which directly result in a circular economy, particular around recyclable and alterative packaging.

Alternative packaging has continued to grow in popularity off the back of sustainability targets and consumer demands, along with governmental regulations around the use of plastic.

While challenging at first, it has become more and more clear over the years that the food and beverage industry is well placed to adopt alternative packaging, which in itself is having an impact on waste.

And on the topic of waste, food waste still constitutes a massive percentage of all land fill in Australia but packaging innovations, and manufacturing innovations, are all working towards reductions on that front.

Printed by: Manark Printing 28 Dingley Ave Dandenong VIC 3175 Ph: (03)

Long gone are the days of buying the same brand week in week out, rain, hail, and shine. The cost of living’s impact on consumer buying also can;t be understated. The dollar

Food and beverage manufacturing is going nowhere, people will always have to eat and drink. However, as the space becomes more competitive, the importance of adopting innovative new technologies has never been more important.

Until next month, happy reading!

WELCOME

9794 8337 4 Food &Beverage Industry News | March 2023 | www.foodmag.com.au

WHY 2023 IS THE YEAR TO DOUBLE DOWN ON TRUST

2023 will be an important year of transition and transformation for many companies in consumer product-related industries, increasing the stakes and importance of sustaining and growing trust with consumers, partners and employees.

Veeva is here to provide solutions that will help you achieve Food Safety, HACCP Compliance and Supply Chain Management, amongst many other requirements, with the aim of improving trust between your consumers and your products.

We have been working with Consumer Goods companies in US and Europe for over five years and are now bringing our industry knowledge to Australia.

Scan here to read about how Veeva works with leading market organisations to build and maintain consumer trust and loyalty.

8

16 MEET THE MANUFACTURER

The OG Group continues to ride popular trends to greater heights and its most recent marketing ploy us paying dividends already.

20 INDUSTRIAL HOSES

ContiTech’s PureOne industrial beverage hose turned out to be the perfect solution for a new and upcoming Sydney

22 PACKAGING

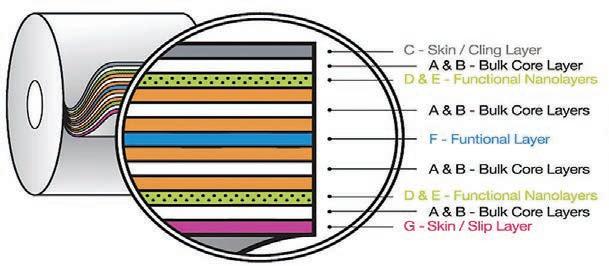

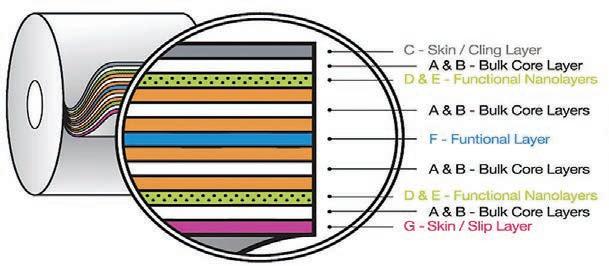

Favourite Packaging’s innovative new designs and methods are proving popular with the food and beverage industry, with the Nano33 stretch wrap presenting a great example.

24 INGREDIENTS

Foodfx has built a strong reputation for fine flavours and quality foods through the sourcing of local and premium ingredient

26 FOOD SAFETY

A product recall is every business and brand owner’s worst nightmare but Chr.Hansen can help guide companies on how to avoid or respond.

28 PACKAGING

Adarsh Fibre’s alternative packaging options have already been proven in other sectors and will now be rolled out across more food and beverage sectors.

Plasdene Glass-Pak is finding itself in an enviable position as the industry continues to trend away from plastic.

SOFTWARE SOLUTIONS

Veeva continues to provide the food and beverage industry with cutting edge software solutions.

34 COLD CHAIN LOGISTICS

Scully RSV is building a strong reputation as a specialist refrigerated truck and trailer company working right across Australia.

6 Food &Beverage Industry News | March 2023 | www.foodmag.com.au CONTENTS

NEWS

36 AIP 38 NEW PRODUCTS 16 34 24 32 30

World Class Facility Construction | Call: (02) 9746 9555 | Visit: totalconstruction.com.au Looking to build or expand a Ready Meals facility? Call Total Construction to see how we can help from concept to completion of your project.

Cutting costs and emissions in beef production

Aresearch team led by the University of Queensland has developed a tool to help the global beef industry simultaneously reduce costs and greenhouse gas emissions while meeting the demand for meat.

The team assessed the economic and emissions impacts of different cattle feeds at different locations around the globe to formulate a framework to guide and inform industry sustainability efforts.

Postdoctoral research fellow Adam C. Castonguay from UQ’s School of

Veterinary Science said the study showed that as much as 85 per cent of emissions could be cut without an overall economic hit to the beef sector.

“This can be achieved by opting for more efficient feeds and locations, and restoring forests in inefficient areas, without increasing global costs of production or reducing demand for beef,” Castonguay said.

“We have mapped out the most efficient locations around the world to produce beef and the maps change when factors are altered, such as how much

society values reducing emissions over reducing production costs.

“This has given us an unprecedented insight into the ‘what, where, and why’ of beef production at a global level and decisions about the future of the industry can be informed by inputting trade-offs and opportunities.”

The research group says the tool could be used by governments and industry to develop policies and strategies.

“There will be continued global demand for beef and there are a huge number of livelihoods associated with

it, so this research aims to find an appropriate balance to maintain the bottom line of the sector,” Castonguay explained.

“Further economic modelling and fine-tuning the data for specific locations would reveal the implications of any changes, including on beef prices for consumers.”

Castonguay said the optimisation method developed by the team using mapping technology overcame historic roadblocks to finding an environmentaleconomic balance. F

NEWS 8 Food &Beverage Industry News | March 2023 | www.foodmag.com.au

The optimisation method developed by the team using mapping technology overcame historic roadblocks.

New funding for Australian alternative proteins sector

University of Sydney researchers developing alternative proteins have received $2.2 million from the New South Wales Government in a new round of Tech Central funding announced last week.

An Alternative Protein Application Centre (APAC) has been granted funding to develop technology that supports a growing alternative protein manufacturing and processing industry.

According to the United Nations, an increase of 25 per cent in plant and animal proteins will be required by 2050, representing an opportunity for Australia’s agriculture and city-based food manufacturing sectors to supply domestic and global markets with highquality alternate proteins.

The Centre will be located within Tech Central Innovation District and led by the University of Sydney, will develop scalable designs and largevolume manufacturing.

The Centre will also conduct research and development on alternative protein production methods, including cellular engineering, precision fermentation, vertical farming, extraction and texturisation, all while training researchers and practitioners in the food and beverage industry.

Co-lead of APAC, Professor Fariba Dehghani, is an expert in food engineering from the School of Chemical and Biomolecular Engineering. She said she and her team were thrilled to receive funding for the Centre.

“It will further boost our capability for collaboration with the food

industry. It will also support our existing research collaboration with multiple industry partners for the development of alternative protein sources for manufacturing innovative and nutritional food products from Australian plants and other sources of protein.”

Central Research and Innovation Infrastructure Fund has granted $8 million towards projects at the University of Sydney, University of Technology Sydney and ARIA Research to advance research and development infrastructure at Tech Central. F

Coffee Cherry is now Upcycled Ingredient Certified

The Coffee Cherry Co. has officially achieved upcycled certification for its Coffee Cherry through the Upcycled Food Association (UFA)’s Upcycled Certified program demonstrating its commitment to preventing food waste by growing the upcycled economy.

“Being a verified Upcycled Certified Ingredient is a hard-earned milestone as we follow our mission to help better the lives of coffee farmers. It signals to our customers, consumers and the coffee communities we work with,

that upcycling coffee cherry pulp into an ingredient based on strict quality standards helps us deliver measurable sustainability, a new source of nutrition, and a role in breaking the cycle of food waste,” said Tom Clemente, CEO, The Coffee Cherry Co.

Since its inception, the organisation has provided a unique combination of nutrition and sustainability that empowers customers to change the future of food.

Working to reinvent not only

the coffee economy, but also inspire like-minded organisations to rethink their existing food production systems, Coffee Cherry is a powerful addition to the global menu.

Upcycled Certified products and ingredients like ours have undergone a rigorous, third-party certification by auditors who ensure that the product directly leads to measurable, falsifiable food waste prevention.

The Upcycled Certified Standard was created in alignment with the formal definition of “upcycled food”

developed by UFA, Harvard Law School, World Wildlife Fund, and others.

Upcycled food helps reduce food waste by creating new, high-quality products from otherwise wasted — but perfectly nutritious — ingredients.

Evidence shows strong consumer demand for upcycled foods, and more groups have predicted that upcycled foods will be a major trend. Whole Foods Market listed upcycled food as a top-ten trend in 2021 and continues as a trend in 2023 with upcycling of pulp. F

NEWS www.foodmag.com.au | March 2023 | Food &Beverage Industry News 9

The NSW Government has granted $8 million towards projects at the University of Sydney.

Marley Spoon Australia appoints new CMO

Marley Spoon, a leading direct-to-consumer brand company, today announced Mark Richardson will join the team as its new chief marketing and commercial officer, part of the Australian leadership team, starting on the 13th February.

With a wealth of experience working in marketing and commercial roles across retail, financial services and tech, his expertise in creating powerful campaigns, passionate customers, generating commercial success and strong challenger brands will be an asset to the Marley Spoon business and portfolio of brands, which includes Marley Spoon, Dinnerly, Chefgood and bezzie.

In his most recent position, where he was chief marketing officer at Aldi Australia for six years; Mark played an instrumental role in elevating the brand’s unique personality and propositions, where he’ll further bring these skills to life in his new role at

Marley Spoon.

“Food and wellbeing is at the heart of Marley Spoon and the Australian culture, where our brands add so much value and convenience to Aussie’s everyday life,” said Richardson.

“I’m proud to join the Marley Spoon team, where I can’t wait to get stuck in working with the talented team to create deep connections with consumers and customers across many touch points, while driving business goals and sales.

“Moving into an adjacent category opens so many exciting opportunities; I’m dedicated and focused on exploring new commercial avenues, revenue streams and growing the Marley Spoon portfolio customer base.”

“At a time when consumers have never been more focused on value and convenience, we’re delighted to welcome Mark to the team to accelerate business growth by elevating our customer retention and brands, making them top

of mind for Aussie’s across the country,” added Rolf Weber, CEO Australia and COO at Marley Spoon.

“His solid knowledge of the industry and creating disruptor brands will be

invaluable as we continue to enhance our offerings to help build a better everyday, just right, just for our customers.”

Richardson commenced his new role on the 13th February 2023. F

Adamantem to acquire majority stake in Retail Zoo

Retail Zoo, a leading multibrand food retail operator in Australia, including Boost Juice and Betty’s Burgers, today announced Adamantem Capital as its new investment partner.

Upon completion of the sale, ownership of Retail Zoo will change from Bain Capital to Adamantem, and will be held by Adamantem’s second mid-market buyout fund.

Adamantem will own a majority stake in the business and will partner with the existing management team led by Retail Zoo CEO, Nishad Alani.

The Retail Zoo founder Janine Allis will remain a shareholder and Board director.

This expands Adamantem’s investments in retail and consumer products, which includes processed

meats producer Hellers, professional sustainable haircare company NAK Hair, and horse feed and supplements manufacturer Hygain.

Retail Zoo is one of Australia’s market leaders in quick-service restaurants (QSR). Founded in 2000 with the iconic Australian brand, Boost Juice, the company now has more than 750 stores in Australia and overseas and has expanded into other brands including Betty’s Burgers which is now the fastest growing casual dining brand in Australia.

“Adamantem saw a unique opportunity to partner with Retail Zoo’s experienced management team with deep industry expertise,” said Adamantem’s Managing Director, Georgina Varley.

“We were attracted by Retail Zoo as a

strong platform in the food retail sector, with market leading brands in Boost and Betty’s.”

Retail Zoo’s brands are well positioned through cycles as an ‘affordable indulgence’ offering. The power of both brands is also fuelled by its strong internal teams and industry-

leading franchise relationships and business analytics.

“We look forward to supporting Retail Zoo’s management, franchisees and employees with further investment in the platform and expansion of the core brands across Australia and beyond,“ said Varley. F

NEWS 10 Food &Beverage Industry News | March 2023 | www.foodmag.com.au

Richardson commenced his new role on the 13th February 2023.

Retail Zoo’s brands are well positioned through cycles as an ‘affordable indulgence’ offering.

internationalcoffeeexpo@primecreative.com.au Melbourne Convention and Exhibition Centre www.internationalcoffeeexpo.com Melbourne International Coffee Expo 2023 17—19 August 2023 CELEBRATING 10 YEARS OF EVERYTHING COFFEE Celebrating 10 years of packaging technology

Allied Pinnacle appoints new executives

Seasoned human resources expert Mofoluwaso Ilevbare will join Allied Pinnacle to help architect the future of the flour and bakery manufacturer’s workforce.

Ilevbare brings over two decades of exceptional experience and a wealth of knowledge of human resources strategy, leadership, culture, diversity and inclusion, and talent development to the newly appointed leadership role.

She has held senior HR positions across various sectors and categories within the fast-moving consumer goods and retail industries, having worked in esteemed companies such as Procter and Gamble and Woolworths Ltd.

Ilevbare has previously led the people and culture agenda in various roles across Europe, the U.S., India, the Middle East, Australia, and Africa.

Her 20+ years of multicultural experience has seen her recognised as one of the Global Top 100 HR Leaders, Global Top 501 Most Inspiring HR Leaders, Top 100

Leading Ladies Africa, Top 100 Career Women Nigeria, and Corporate Icon of the Year – Women in Africa, whilst also receiving a commendation letter from the state of Georgia for her commitment to empowering women.

Ilevbare will drive Allied Pinnacle’s People & Culture transformation, enabling the business to deliver on its 2026 vision and beyond. As part of the Executive team, her responsibilities will include overseeing all functions across human resources to align the organisation’s people and culture strategies with overall business and growth objectives.

Allied Pinnacle CEO David Pitt said, “Mofoluwaso is bringing her exceptional talents to Allied Pinnacle at an incredibly important moment as we enter a new phase of growth. We have a unique opportunity to reimagine how we manage, how we lead and how we organise.

“Mofoluwaso will play a key role in that, both for Allied Pinnacle and

Mofoluwaso Ilevbare joins Allied Pinnacle to help architect the future of the company’s workforce.

for our customers. I’m thrilled to have her leading the team as we deliver on our clear vision to be Australia’s Flour, Bakery Ingredients and Frozen Baked Goods business partner of choice.”

Ilevbare says, “I’m thrilled to join Allied Pinnacle at this juncture in the company’s growth. It’s an exciting time for the business and supporting

the team and prioritising a strong, inclusive culture is more important than ever.

“It also helps that I happen to have a healthy appetite for chocolate cake, a happy coincidence for a bakery and flour manufacturer. I’m excited to join the team and together build the future from flour.” F

Mars New Zealand appoints new general manager

Mars New Zealand has announced the appointment of Emily Dowling to the role of general manager.

As general manager, Dowling will oversee the growth and development of the Mars Petcare, Mars Snacking and Mars Food portfolios, including household favourites WHISKAS, M&M’s and MASTERFOODS while driving the company’s purpose: a better world tomorrow starts with how we do business today.

“Emily’s blend of commercial creativity and purpose-driven leadership will put her in great stead in New Zealand,” said Deri Watkins, Europe regional president, Mars Petcare.

“She has an exceptional record in partnering with customers for growth,

and driving the distinctiveness of our brands, and I look forward to seeing her impact on the New Zealand market.”

Dowling has more than 18 years of experience working in the FMCG industry across Australia and Europe. She joins the New Zealand Leadership Team from Mars Petcare Australia, where she has served as the Marketing Director since 2018.

During her tenure, she led the launch of the TEMPTATIONS brand (now the category leader in grocery cat treats); developed Mars Australia’s first Directto-Consumer (D2C) online store for the ADVANCE brand; and engineered the first consumer promotion for The Lion’s Share, a global fundraising initiative for the United Nations Development Programme.

In 2021 she was recognised as one of the top fifty chief marketing officers in Australia. “I’m thrilled to be joining Mars New Zealand,” said Dowling.

“The team here has always had an outsized impact on Mars’ business globally, particularly on the creative side with truly groundbreaking campaigns like My Hooman, our pet adoption platform.

“They’ve also demonstrated best in class agility in managing supply chain challenges in recent years, and I’m committed to driving that consistency for our retail partners and consumers.”

Dowling has relocated with her family and dog to Auckland. Her appointment follows the departure of Pete Simmons who has decided to leave Mars after 16 years with the business.

Rather than explore further overseas opportunities with Mars, Pete and his family have decided to stay locally in New Zealand. In his five years as general manager, Pete set about leading a program to refocus the business on growth priorities, partnering with customers across the different channels, establishing digital commerce in the business, and developing a strong talent offer – all whilst leading the business through COVID.

Pete has been a proud Mars employee, a passionate believer in our culture, and leaves behind an impressive legacy of business, brand, customer, and people development. Pete has been supporting Dowling with a smooth transition and will depart the business on 30 January 2023. F

NEWS 12 Food &Beverage Industry News | March 2023 | www.foodmag.com.au

World-first sustainable beef burger: Grill’d

Healthy burger restaurant chain Grill’d has rolled out a grass-fed beef burger made from black angus cattle that produces up to two-thirds lesser methane emissions than regular cattle.

In partnership with Sea Forest and validated by the University of New England NSW, Grill’d has developed an innovative way to feed its grass-fed cows Asparagopsis, a native and natural Tasmanian seaweed, to reduce ira methane emissions by up to 67 per cent, with ongoing live trials on the Grill’d farm targeting a 90 per cent reduction.

This world-first trial will revolutionise the grass fed-beef industry, leading the way for others and helping smash national targets signed by the Federal government to reduce methane emissions by 30 per cent by 2030.

In this momentous step on its journey to lower its carbon footprint,

Grill’d is empowering its guests to be the eco-friendly change they want to see, while still enjoying their grass-fed beef. And in good news for burger lovers, the new Gamechanger beef has the same delicious taste and is even better for the future of our planet.

“We’re really excited to see Gamechanger beef come to life. This is the future of beef – and we won’t stop at 61 restaurants. But for now, and for only an extra buck, guests can help the planet by choosing a low methane product, simply by upgrading their favourite beef burger,” says Grill’d founder Simon Crowe.

Grill’d’s burger patty production facility and 61 restaurants purchase 100 per cent Green Power to support renewable energy regeneration in the making of their burgers, and the freshest local ingredients (solarpowered lettuce, anyone?) are always used where possible. F

Grill’d has rolled out a grass-fed beef burger made from black angus cattle.

NEWS www.foodmag.com.au | March 2023 | Food &Beverage Industry News 13 Revolutionary New Stretch Wrap Thinner, stronger, more durable • Recyclable material • Nano ‘layered’ technology • Significant productivity and cost benefits • 30% less material • Reduce load shift in transit • Option for 30% recycled content E: info@favouritepackaging.com.au P: 02 4966 8582 favouritepackaging.com.au Contact us to discuss what it takes to be ahead of the National Packaging Targets and meet the latest consumer demands.

XXXX Brewery to produce solar powered beers to reduce footprint

XXXX Brewery will brew beer using 100 per cent renewable electricity after an agreement to power its Milton brewery with electricity from the Woolooga Solar Farm.

A new Power Purchase Agreement (PPA) was signed by XXXX Brewery through its owner Lion, to procure 100 per cent renewable electricity from the Lightsource bp solar farm.

Queensland deputy premier Steven Miles said the Queensland Energy and Jobs Plan gave businesses the confidence to invest in decarbonisation.

“An increasing number of companies want to decarbonise their operations and offer consumers low-emission products, made in Queensland,” Miles said.

“With the PPA in place, Lion has reached their target of 100 per cent purchased renewable electricity by 2025 in Australia, two years ahead of schedule. And they’re Australia’s first large-scale carbon neutral brewer.”

Lion sustainability director, Justin Merrell said in 2020 Lion became Australia’s first certified large-scale carbon-neutral brewer.

“The 144-year-old XXXX brewery at Milton is one of Brisbane’s most

historic landmarks, but this latest evolution to 100 percent renewable electricity proves this icon of Australian brewing, is still capable of moving with the times,” Merrell said.

“All of our beer produced here – up to 250 million litres annually

– is now made using 100 per cent renewable electricity. This agreement will stop around 138,000 tonnes of carbon emissions from entering the atmosphere. That’s the equivalent of taking 45,000 cars off the road.

“XXXX is encouraging all

Australians to ‘Give a XXXX’ about the planet for the benefit of our environment, and for beer. Today’s announcement is another great example of how we’re investing in climate solutions to reduce our footprint.” F

Opal and JBS Australia win WorldStar global packaging award

Opal and JBS Australia have won a 2023 WorldStar global packaging award in the transit category for their innovative corrugated cardboard dunnage solution.

The dunnage was previously awarded Gold in both the Sustainable Packaging Design of the Year Industrial sub-category and Outside of the Box Design of the Year at the Australasian Packaging Innovation & Design Awards in 2022.

Opal developed the innovative dunnage solution in collaboration with

JBS to limit product movement during transportation, which can result in costly damage and food waste.

Dunnage is usually constructed from expanded polystyrene (EPS), which can’t be easily recycled and ends up in landfill.

Opal’s dunnage is a column-like corrugated structure, and a sustainable, 100 per cent recyclable cardboard alternative to non-recyclable EPS.

The dunnage also provides enhanced transportation and distribution efficiency for JBS Australia as it accommodates 1,800 boxes per pallet compared to

traditional EPS dunnage, which enables only 200 boxes packed per pallet.

Importantly, the sustainable dunnage supports the phase out of problematic and unnecessary singleuse plastic packaging under Australia’s 2025 National Packaging Targets by substituting EPS dunnage with recyclable cardboard packaging.

According to Sam Churchill, group manager sustainability for JBS Australia, the Opal Dunnage Solution aligns with JBS Australia’s Sustainability commitment to reduce its packaging

footprint, by working with its customers and supply chain partners to increase recycled content and recyclability of its packaging and reducing packaging material use and waste within its operations.

“This innovative product has resulted in tangible cost savings and operational efficiencies. By reducing our packaging footprint we are meeting our sustainability objectives for the benefit of our business and customers, and providing positive environmental outcomes,” said Churchill. F

NEWS 14 Food &Beverage Industry News | March 2023 | www.foodmag.com.au

A new Power Purchase Agreement (PPA) was signed by XXXX Brewery through its owner Lion.

1800 728 559 www.scullyrsv.com.au Info@scullyrsv.com.au AUSTRALIA WIDE Australia’s Largest Dedicated Fleet of Refrigerated Transport Solutions

Scully RSV provides top-quality refrigerated truck and trailer solutions for delivering produce to regional businesses across Australia. From short and long-term hire options, new and ex-fleet sales, and customisation services, all backed by cutting-edge technology and dedicated customer service to help your business thrive. QUALITY RELIABILITYFLEXIBILITY SERVICETECHNOLOGY Temperature Monitoring System GPS Tracking

.

Automation and innovation in coffee

The OG Group is an Australianowned coffee brand manufacturer with ties to both the manufacturing and hospitality sides of the industry, and in the last two decades its brands have seen rapid growth, innovation and change.

Oasis Coffee, Griffiths Bros. Coffee Roasters, Coffee Lab, Double Shot Coffee and partner brand DHUWA, make-up the OG Group’s brand portfolio.

The family’s longstanding relationship with the coffee industry started in the late 70s when

Patisteas’ father and uncle bought a little coffee manufacturing business called Oasis. At the time the coffee sector was only small and in no way reconcilable with the one Australia enjoys today.

“Oasis only had two offerings, a pulverised coffee product, the quintessential backbone of the business, plus a small amount of food service to cafes and restaurants,” said Patisteas.

“My father and uncle grew the food service side of the business, which became a dominating force in the 80s.”

In the early 80s the Oasis company

acquired the Griffiths Bros Coffee Roasters. Established in 1879 in Melbourne, Griffiths Bros is one of the pioneers of coffee manufacturing in Australia and has helped fuel our nation’s love affair with coffee for more than 140 years.

The OG Group derives its name from the unification of Oasis and Griffiths Bros.

“Being a manufacturer is a rare component these days and I think we underestimated the joy you get out of manufacturing a product, particularly coffee, which gives many people joy,”

said Patisteas.

This drove Patisteas to move back to Australia from the United Kingdom in 2000 and partner with Togias.

The duo, who acquired he business through family succession, were determined to grow its offerings but quickly leant the expenses involved in manufacturing, especially a specialty product such as coffee.

“Peter and I came to a position where we had taken over the business with antiquated equipment. Things were at the point where we felt automation was the right next step, so we reached out to

16 Food &Beverage Industry News | March 2023 | www.foodmag.com.au MEET THE MANUFACTURER

After taking over the family business, brother-in-law Peter Patisteas and Chris Togias, managing directors of the Oasis Griffiths (OG) Group, have seen first-hand the evolution of the coffee sector.

our Italian and German colleagues who assisted us in that journey,” said Togias.

Once that issue was solved, the pair needed to address inputs and outputs.

“Inputs and outputs also needed an incredible amount of machinery changes and Australia really stepped up in terms of local engineers and manufacturers that we could contact and work with,” he said.

“People that we could invite in and then they could help.”

Through this approach the OG Group has built up and retained an extensive and specialised network in their production and supply chain, which helped grow the quality of their product and the output.

“We’ve always had an appetite for

are critical. It’s been generational change as well as significant investment.”

Togias said the exponential and rapid growth of the coffee sector in Australia over the last two decades has resulted in growth for the company.

“Back in the 1980s coffee in Australia was mostly just instant,” he said. “Whereas now the method of making coffee has become more technical for the consumer.”

Changing consumer trends have, and

coffee,” said Togias.

“So as a business we get that feedback, and we evolve. We are proud of what we do and if you don’t respect the consumer, you pay the price.

“That is backed up by the home market growing, it’s moving at a high rate and is now one of the largest segments. It’s been interesting to see the demographic change.”

Supply of green beans, the OG Group’s base ingredient, is impacted by

biggest hurdle now, in terms of volume and price point,” Patisteas said.

“Green beans which have been our core input, have been too low for too long,” said Patisteas.

“Industry groups actively trying to support farmers is helping that. As far as supply chain goes it is constantly changing and becoming harder and harder.

“Climate change is always creating problem around the growing. We have

www.foodmag.com.au | March 2023 | Food &Beverage Industry News 17

Brothers-in-law Peter Patisteas and Chris Togias head up the Oasis Griffiths (OG) Group.

After taking over the company the pair decided to diversify into manufacturing coffee.

“I have to say the problems have diminished over the years, notwithstanding we lose some expertise around changing requirements for employment, and things like automation,” said Togias.

Togias reiterated how important the role of evolving automation has helped the company not just succeed but to grow its production output.

“When we took over the business there were approximately 12 people on the production floor. Today this number has halved and we’ve doubled our output, this is a result of our investment in equipment,” he said.

“It’s not about cutting jobs but about raising efficiency, which gives us the chance to make the remaining staff more multi-skilled.”

Sustainability is also another area which has always been of key focus to the OG Group, so new APCO standards and other regulations evolving around sustainable production is one both men have welcomed.

“My dad used to go through the dumpster at the end of the week to determine why we are creating waste and where is it coming from,” said Patisteas.

“There’s a natural tendency for a lot of business owners to look at sustainability as different, but it’s not,

motors to reduce energy loads,” he said.

“Those are the easy moves, but the harder ones are putting time and money into resourcing how to add or contribute to a sustainable process.”

And another key area where the company can continue to reduce waste, and contribute to a circular and more sustainable economy, is through its own production by-product.

“Our production has husk as a by-product of the roasting process. We create enormous volumes of it,” said Togias.

“At the moment we give some away to growers and landscapers and the rest goes to landfill.

“But we have started looking at reducing our footprint in the first instance and then creating a fuel that can be converted into energy. From our perspective it’s about stepping up and investing to initiate that change.

“We are proud with what we are doing to help achieve sustainable goals and we don’t manufacture any of our products without sustainability at the front of our mind,” Togias concluded.

The OG Group aims to continue its journey towards more sustainable and high-quality coffee products for the Australian market, helping to meet the growing obsession the consumer market has with the product. F

18 Food &Beverage Industry News | March 2023 | www.foodmag.com.au

The OG Group has found success in the coffee manufacturing space.

The OG Group roastery continues to put out quality product for the market.

Introducing... Introducing... NEW 15KG MAYO LESS WASTAGE EASIER TO LIFT & STORE MORE VERSATILITY FOR YOUR MENU For more information visit www.foodfx.com.au facebook.com/batchno.5 @batch_no5 Phone 1300 003 663

Protect your brand and products with the right industrial hoses

Sydney based distiller, Finders Distillery, has had continued success with ContiTech’s hoses after initially discovering issues with its initial choice of hose. Adam McCleery writes.

Distilling, among others, has proven fertile ground for the Continental’s hoses.

Distilleries rely on robust and highquality industrial hoses to mitigate the risks of process failures, to ensure product purity at all stages of production, and to ensure hygienic and reliable transportation of fluids.

When Finder Distillery, a Sydney based producer of gin and vodka, first launched operations a handful of years ago it quickly discovered issues with its choice of industrial hoses.

While testing the hoses with water the company discovered it was tainted and discoloured at the output end, prompting them to contact Continental to help identify the issues and come up with a viable solution.

“You could get flaking of the tube, the rubber could impart taste onto the product, which we call leaching.”

The impacts of contamination can be felt right across the company, meaning the right choice of solution is critical, no matter the cost.

“If you’re not using the right hose those things can have huge financial and operation impacts. The risk to the overall brand is there too,” said Brown.

“People choose cheaper alternatives because they look at the front-end cost and only see the savings but at the end of the day paying the extra to source and use a quality product is going to have long term positive impacts on your business and product.”

The flexibility and light weight of the Continental product, plus the capability

“We have a commitment and desire for producing only the highest quality products at Finders,” said Kyle Ford, distiller at Finders.

Clayton Brown, area sales manager for Continental, worked with Finders Distillery to achieve those exact goals.

“We recommended our PureOne Hose which handles up to 98 per cent alcohol. They’ve been using it ever since and with no complaints, it also rectified that initial issue they had,” said Brown.

Continental’s Granby hand-built distillery hose is used to transfer base spirit from main storage tanks to a 300L copper still where the distillation process can begin. The base spirit which is raw product measures 98% ABV.

“It’s super important that you use the right hose with the right rubber compound,” said Brown.

“If they use a rubber compound that can’t handle the high alcohol content it’ll break down the tube lining of the hose quickly, which will have adverse impacts on their product.

to handle high-proof alcohol as necessity to not taint product made the Granby hand-built hose ideal.

“The hose tube is what is super critical in this high proof alcohol application because it needs to be able to handle that high concentration,” said Brown.

“The PureOne hose uses a specific compound to handle that, and the construction is corrugated, which means that it’s super flexible and light weight making it easy to handle.

“Because it has a steal helix in the reinforcement is can also handle full vacuum and it’s capable of doing 200psi, which is more than enough with the pumps that distilleries use to transfer their product through the process.”

The hose is also able to handle being dragged around a facility because of its high abrasion resistance, helping to extend the life cycle of the product even more.

T he flexibility of the hose also makes it a perfect solution for smaller distillers.

“It’s important to point out a lot of

INDUSTRIAL HOSES

As demonstrated by Finders Distillery, the PureOne hose is an ideal solution for the beverage sector.

"We recommended our PureOne Hose which handles up to 98 per cent alcohol. They’ve been using it ever since and with no complaints, it also rectified that initial issue they had."

distillers are micro and operating in very small spaces so having a super light wight, and flexible, hose is super important,” said Brown.

Scott Weston, national business manager for Continental, said some cost implications can also depend on where in the production system the hoses are installed and used.

“You may have to also clean out filters and pumps, and there are added costs that come with those replacements,” said Weston.

“And that isn’t just time but also physical assets. Most Australian distilleries are producing spirits in batches. A faulty hose can taint the entire batch, meaning a loss of hundreds of bottles on the market.”

In summary, the PureOne hose is perfect for distillers and other beverage manufacturers. It’s suitable e for suction and discharge service, and it can also

The SafePro® solution

Protecting food, including some of the finest smoked salmon, with cultures to suppress growth of pathogenic and spoilage bacteria.

Hear from Adam Harris, Owner & CEO of Harris Smokehouse about his choice

Pure One handles high-proof alcohol and is flexible and light weight.

Nano33 is being touted as the next generation of stretch film.

Use less plastic stretch wrap without compromising on strength

Nano33 is the thinnest pallet film on the market but promises equal, or better, outcomes than more traditional offerings. Adam McCleery writes.

Advancements in stretch wrapping is resulting in cost savings for manufacturers and producers through a reduction in the amount of stretch film needed per pallet.

And with the world slowly moving away from non-essential plastics, reducing its use will benefit a company, its customers, and the greater community.

This is where Favourite Packaging steps in with a viable solution to over wrapping and pallet stability, with a touch of recyclability on top.

Nano33 is being touted as the next generation of stretch films, getting its name from its 33-layer design. Having 33 layers and still being considered ‘nano’ should indicate how thin the wrap is.

Justin Yates, Favourite Packaging managing director, said the progress in stretch film material is remarkable.

“A standard stretch wrap may have been between 20 to 25 microns thick and that used to be a standard for

anything that was used,” said Yates.

“By coming down thinner, to 13 or 15 microns, they can still get the same strength using those thinner gauges as the 20 to 23.”

Despite it being far thinner than traditional pallet wraps, Nano33 promises to match, and even exceed, more traditional solutions, with less plastic use.

Another indication of Nano33’s toughness is the fact that even though the price per kilogram may be a bit more, through its ability to provide durability and stability the product still saves money for its user.

Nano 33 also touts excellent puncture and tearing resistance like that of the ‘plywood effect’, creating strength through layering.

Justin Yates, Favourite Packaging managing director, said there were to key drivers behind the development of the Nano33 stretch wrap.

“One is the obvious one, it uses less plastic per pallet wrap,”

he said.

“And the second driver, Australia is expecting regulation like Europe to be introduced in relation to stricter, more secure and safer loads. Such regulations require more effective pallet load control in transit.

“With a stronger stretch wrap like Nano33, pallet loads in transit will be more secure and will have less ‘sway’ at the top.”

Engineered specifically for securing safer pallets while using less material,

Nano33 can perform at higher wrapping speeds with ease and has excellent load retention which leads to a more stable and secured shipping.

This significantly reduces the risk of load damages under normal shipping conditions. Nano33 is also superbly suitable for products like bottled water, soft drinks, and any other beverages type.

The Nano33 will also meet the APCO guidelines for sustainable packaging which includes ‘design for

PACKAGING 22 Food&Beverage Industry News | March 2023 | www.foodmag.com.au

Nano33 stretch wrap is the thinnest pallet film on the market

recover’, ‘optimise material efficiency’, ‘design to reduce product waste’, and ‘design for transport efficiency’.

“Stretch wrap has always had the multi-layer process but it started as a three layer before a seven or nine layer became the standard,” said Yates.

“That has since been blown out of the water and with Nano33, it goes to 33 layers.

“They can play around with different materials in each layer to produce a different result in how it stretches and the yield curve, which gives a lot of flexibility to customise how the film will perform.

“It’s not just better materials, but by using them in different layer combinations it can make the film do things it never used to be able to do.”

Apart from the Nano33 stretch film being recyclable, Favourite Packaging also offers a Nano33 variant made from 30 per cent recycled material.

While the recycled Nano33 doesn’t offer exactly the same features as the main Nano33, it still provides the stability and durability needed.

And while the cost of Nano33 might be a little greater per kilogram than traditional wraps, that cost is covered

through its innovative design resulting in up to 30 per cent less material being required per pallet.

“Because they are standardised pallets, customers can customise the tensioning on the system so while heavy pallets would normally be a standard 23 microns, coming down to 13 microns in some cases creates savings you don’t see on alternative solutions,” said Yates.

“For lightweight you can usually get away with something thin, this comes into its own with the heavier pallets.”

Taking on a thinner stretch wrap is also an easy way for Australian manufacturers and producers to help meet, or exceed, sustainability targets set, as per the National Packaging Targets 2025.

“If you can get a 30 per cent reduction on pallets you wrap it will certainly make it easy to achieve or beat targets,” said Yates.

There is also a flexibility of approach offered by Favourite Packaging in terms of what a customer needs, however Yates said it would require very large volumes of product for a customisation of the Nano33, but the option is there.

“There are two main types that are used,” he said.

“Within those two the heavier products would use one type and the lighter products another. But if you have large volumes and need some customisation then you can play around with the layers and material to do that, but you would need decent volume to do that.”

And for manufacturers and producers looking at an even greater level of sustainability, Favourite Packaging also offers Nano Green, which is made up of 30 per cent recycled plastic.

“When making all plastic products in a factory a lot of scrap is created, being clean scrap it’s not post-consumer scrap,” said Yates.

“We can then put that back in at a rate of 30 per cent into the Nano stretch. It doesn’t give you the same stretch

characteristic because there is a trade-off to using recycled material, but most people wrap with a machine wrapper can use the recycled version.

“It’s 30 per cent now but looking to go higher as we improve the technology on that.”

Favourite Packaging will continue to innovate and improve on packaging technology and the Nano33 is a great example of how packaging i nnovations can help shape the future of the food and beverage industry.

“Any organisation that wraps pallets in the hundreds every week is likely to benefit economically from using Nano33, in costs, compliance and in brand strengthening,” Yates concluded.

“We offer an analysis and study so that a business case and design profile can be concluded and considered. F

PACKAGING www.foodmag.com.au | March 2023 | Food&Beverage Industry News 23

Nano33 Stretch Wrap has 30 per cent less material, is stronger, and more durable.

Experienced, innovative, and committed to quality

Foodfx has built a strong reputation for fine flavours and quality foods through the sourcing of local and premium ingredients. Food & Beverage Industry News reports.

Established in 1986 as a food manufacturer specialising in recipe creation and customisation, Foodfx is a leading partner for National QSRs, food service and further manufacturing (B2B) for professional chefs across all types of cuisine.

“Our speciality is to enhance customer’s experience with our premium and diverse offering of condiments for their menu range,” said Foodfx Australia general manager, Mohamed AbouElkheir.

The Foodfx recipe list includes an extensive range of mayonnaises, sauces, and prepared meal bases. All made from an essential base of being fresh and innovative.

“Our vision is to be the preferred culinary partner for all of our customers, whilst also going the extra mile to understand our customers’ requirements ensuring we create a flavour that exceeds their expectations.”

Foodfx’s portfolio of brands includes Port Mahon, which uses premium Australian ingredients and free range, whole eggs to create creamy mayonnaises that are superior in quality and consistency.

Batch No.5 is the youngest brand

in the portfolio and offers customers accessible superior mayonnaises, sauces and relishes to compliment all styles of menus.

Herman’s Homemade is another brand within the Foodfx portfolio, offering high quality meal bases for customers to replicate meals that feel homemade.

“Foodfx works with QSR’s to develop and create custom offerings developed by our expert chefs within prompt timelines and with quality sourced ingredients,” said AbouElkheir.

AbouElkheir said the string of external factors which have impacted the food and beverage industry in recent years also highlighted the importance of being able to adapt and overcome.

“The past couple of years has seen enormous change within the industry due to price increases across multiple ingredients, transportation costs, staff shortages and flavour trends,” he said.

“It is critical to the business success to listen to our customers and understand the market trends. For example, changes in flavour profiles, healthy trends, whilst also looking to experiment with international flavours that reflect our diversity as a nation.

“The shifting of the market seeking

alternative food options vs. traditional recipes, such as plant-based, whilst not compromising on a premium culinary experience has also been quite exciting to see.”

And as the industry continues to move more towards alternative and more sustainable packaging, Foodfx is there to help clients with the transition.

“Sustainability around packaging and options to reduce waste has seen a major shift, ensuring Foodfx continues to work with our customers and suppliers on solutions and options to achieve our joint objectives,” said AbouElkheir.

“ This assists our partners in achieving their sustainability targets, whilst also benefiting from more efficient and cost-effective manufacturing.

“This has become even more crucial within the current domestic economic situation and soaring operational costs.”

The impact of the COVID-19 pandemic, along with changes in consumer and market demands, also continues to be felt across the industry today.

“COVID-19 has placed a massive strain on the industry across the complete supply chain, from Foodfx as a

manufacturer, all the way to our end customers.

“Across COVID lock downs and ongoing restrictions, the volatility in supply time lines and varying demand requirements has tested the whole hospitality industry,” said AbouElkheir.

“Foodfx has worked very closely with our partners, suppliers and customers, to adapt to this new environment. Working across menu rationalisation, pack format efficiencies, MOQ flexibility, shorter delivery times, scheduling flexibility, etc.

“Our objective to maintain a consistent level of service and quality to our valued customers during these difficult times.

“Based on broad customer feedback, we are proud to say that we have been successful in achieving this goal.”

And the renewed focus on Australian sourced and manufactured goods during, and in the wake of the

INGREDIENTS 24 Food &Beverage Industry News | March 2023 | www.foodmag.com.au

batch 5 is the youngest brand in the Foodfx portfolio.

pandemic, allowed Foodfx to tap into its expertise to help the industry and clients.

“We proudly stand as Australianowned for Australian made premium condiment manufacturing, using only the highest quality local Ingredients,” said AbouElkheir.

“This was a challenge for many Australian manufacturers, at Foodfx we are always look at opportunities rather than challenges.

“Foodfx strategy has always been to

prioritise local sourcing and hence that became a strength for us in the COVID and post COVID environment.

Foodfx’s ‘customer first’ approach has also kept the company in a great position to help customers and clients evolve and grow with the industry.

“As we ensure we work with a ‘customer first’ mentality, our decisions are always based on the customers’ requirements,” said AbouElkheir.

“Cost impacts have meant we need to innovate our pack sizes and work

harder on securing long term supply partners to ensure customers have sustained value. In doing so, we also need to ensure that Foodfx continues to benefit as a company to withstand these external factors and maintain our own development and longevity.”

Foodfx’s extensive network of suppliers has also helped the company remain consistent in meeting both customer and market needs.

“We have a very strong local base of suppliers at a national level for the majority of our supply requirements,” said AbouElkheir.

“We always work with a partnership mind set, putting honesty, and respect first as one of our core values in dealing with our long-standing suppliers.

AbouElkheir said sticking true to the core values of Foodfx ensured the company could present a ‘win-win’ scenario both parties.

“Our business has seen growth because of our ability to adapt and respond to our customer’s needs,” he added.

“As such we are continually developing our products to ensure sustainability, clean ingredients, and dietary requirements, such as vegan, plant based, and gluten free.

“Ethically sourced ingredients is one of our prerequisites for internal approval of suppliers, domestic and local, and hence we have managed minimal disruptions for our customers and consumers regarding their requirements.”

The company’s commitment to developing innovative flavours for their customer’s menus also remains at the heart of Foodfx’s approach.

“And Foodfx is always looking into trends in the industry and the latest innovations across ingredients, recipes, process, and equipment,” said AbouElkheir.

“Listening to the customer and understanding the needs of the end user is a key to delivering value, which eventually ensures growth and sustainability for the business and for our stakeholders.”

And as 2023 rolls on, FoodFx will continue to emphasise its ability to offer value to customers.

“Batch No.5 will also be a focus brand of ours in 2023, particularly given the current economic pressures facing our customers and all of the industry batch No.5 gives accessibility to our customers who are after a quality product but may not require our premium brand Port Mahon.”

INGREDIENTS www.foodmag.com.au | March 2023 | Food &Beverage Industry News 25

F

Foodfx’s strategy is to prioritise local sourcing.

“Batch No.5 is the youngest brand in the portfolio and offers customers accessible superior mayonnaises, sauces and relishes to compliment all styles of menus."

What a national recall can teach you

A product recall is every business and brand owner’s worst nightmare. The impact can be devastating. Financial loss due to recovering stock and lost future sales, damage to brand reputation and risking the health and safety of consumers.

Adam Harris, from Harris Smokehouse, a fourth generation, family-owned business, and manufacturer of high quality seafoods walked this path in August 2022.

Listeria monocytogenes, a pathogenic bacteria, was discovered during routine testing of their product.

Fortunately for Harris, his business is now back, stronger and better, with improved safety hurdles, whilst retaining the natural product positioning, integral to his brand and expected by consumers of smoked salmon.

Pivotal to Harris’ recovery and success, was hard work, diligence and partnership with a supplier who could step him through the process to keeping his smoked salmon safe from listeria and his labels free from artificial additives or preservatives.

Hear more about Harris’ story and

the supplier who helped him through here, or read more below, Harris Smokehouse is known for their premium quality, delicious smoked seafoods, steeped in the tradition of 60 years of heritage.

Now owned by Harris and based in the Adelaide Hills, his business is based on the core values of Ethical, Sustainable and Natural.

When listeria was picked up during routine testing, two national recalls ensued.

In Harris’ words, it was a horrific experience.

SA Health supported Harris and the business, providing them with three choices – try to continue to eliminate listeria as they had previously been doing, to add a chemical preservative or to find a natural solution.

The first two choices were not real options for Harris, the experience

of the recall had been the worst time in his life and the thought of adding chemical preservatives would go against his promise to consumers for the product to be transparent, honest and clear.

Harris chose the third option and decided to work with Chr. Hansen, a global biosciences company, with expertise in fermentation and the science and supply of good bacteria.

“We basically now have a team of good bacteria working for us, and we don’t pay them. We are fighting the bad guys with good guys”, said Harris.

Carlo Mason, business manager for Chr. Hansen in Australia explains further,

“By putting specially selected cultures, our good bacteria, on the surface of the food in really high numbers they are able to outcompete spoilage or pathogenic bacteria and

reliance on food acids, chemicals and preservatives and help keep food fresh and safe for longer.

“Chr. Hansen were able to provide a natural solution that wouldn’t alienate our consumers, they had the scientific data and back-up, they had done all of the hard work and were respected for their science, and it was trusted,” said Harris.

“They steered us out of our troubles.

“You don’t know what you don’t know. I don’t want anyone to go through this experience (a product recall).

“If I could take lessons from this and share, it would be - just take this proactive and preventative approach. Now we have learnt this, learn from us.

“You feel very alone when you go through this, you feel very overwhelmed.

“When you engage with people who do not feel overwhelmed because they have the knowledge and understanding, it is very comforting, and it is confidence inspiring.

“The team at Chr. Hansen were our knights in shining armour.” F

FOOD SAFETY 26 Food &Beverage Industry News | March 2023 | www.foodmag.com.au

Chr.Hansen was able to help Harris Smokehouse combat listeria.

Chr. Hansen continues to help the industry with its expert knowledge.

We’re the brand, behind the brands you know, and love.

As experts in sourcing, handling and packaging supply, we’ve helped thousands of large and small clients build their brands, for more than 30 years. We deliver worldclass packaging solutions together with service excellence. Let us do the same for you.

Sydney (02) 9774 6600 Brisbane (07) 3903 9900 Perth (08) 9232 5200 Melbourne (03) 9930 4999 Hobart (03) 6277 1500 Adelaide (08) 8402 1600 Hunter Valley (02) 4035 9500

plasdene.com.au | plasdene@plasdene.com.au EXTENSIVE STOCK RANGE GLOBAL SOURCING INVENTORY MANAGEMENT CUSTOM PACKAGING NEW PRODUCT DEVELOPMENT NATIONAL WAREHOUSING & DISTRIBUTION QUALITY ASSURANCE AUSTRALIAN FAMILY OWNED & OPERATED TOTAL PACKAGING SOLUTIONS

Pulp packaging offers viable packaging alternative

As new packaging targets come into view, with many set for 2025, changes to the way Australia creates, collects, and recovers product packaging are front of mind for many primary producers.

Adarsh Fibre, located in Western Australia, specialises in sustainable pulp packaging and medical products, and is seeing a strong rise in the popularity of sustainable alternatives to plastic packaging.

The company takes pride in offering a range of products designed to minimize environmental impact and reduce waste, and is currently constructing a new, state-of-theart facility to further its goals in the Australian food and beverage packaging sector.

Adarsh Fibre sources its material from local organisations who are looking to reduce their waste, lessening pollution from transportation and enhancing the circular economy. Faz Pollard, director of Adarsh Fibre explains how the manufacturing process works.

“Wastepaper and cardboard are dissolved in a water bath, creating the raw material known as pulp,” he said.

“High pressure and temperature are then applied in the desired shape, resulting in a very robust material perfect for high-quality, dimensional stable packaging.”

As pulp packaging can use pre-consumer and post-consumer paper and cardboard, the quality of product is as reliable as traditional packaging.

The advantage that Adarsh Fibre has over other companies entering the alternative packaging space was made evident when speaking to Dave Magill, project lead.

“Adarsh Fibre has a strong background in local manufacturing, which has given us the necessary experience to develop modern and

robust production facilities and processes,” he said.

“This experience is a key factor in our decision to enter the food and beverage packaging market.

“Our advantage is being a local, experienced manufacturer with largescale facilities.” Adarsh Fibre will continue its market research and welcomes new connections from other manufacturers who would like to supply off-cuts of paper and cardboard or who may have packaging requirements of their own.

The food industry in Australia is the primary user of packaging materials, accounting for a 38.8 per cent share in 2021, with the paper and board packaging category to record the highest growth at a CAGR of 3.4 per cent.

Zach Riordan, marketing officer for Adarsh Fibre said the company has a key focus on providing alternative packaging solutions to the food and beverage industry in Australia.

“We aim to offer a new opportunity to producers, suppliers, and retailers with our newly built facility,” he said.

“As an Australianowned and operated company, we are able to meet the increasing demand for locally produced and high-quality products such as egg cartons, fruit trays, and coffee cup holders.”

Adarsh Fibre’s facility is capable of processing approximately 3000 tonnes of wastepaper and cardboard annually.

To source the material needed, Adarsh Fibre continues to build a strong network with others who are working towards net zero.

Riordan remarked “our director already has many established

connections in the Perth area, and we are trying to expand our network even further.”

products first, and helps rethink packaging design, functionality, and material composition toward a sustainable outcome. Their research and development teams are currently working with multiple industry sectors

PACKAGING 28 Food &Beverage Industry News | March 2023 | www.foodmag.com.au

Adarsh Fibre are specialists in sustainable pulp packaging and medical suppliers and the company is seeing first-hand the rise in popularity of alternative and sustainable packaging.

Adarsh Fibre specialises in sustainable pulp packaging.

DO YOU KNOW A DRIVER OF CHANGE?

WOMEN IN INDUSTRY NOMINATIONS ARE NOW OPEN. Now is your chance to nominate an industry leader who you believe is advocating for positive change and deserves to be recognised.

WOMENININDUSTRY.COM.AU

THURS 8 JUNE 2023

The Women in Industry Awards recognise outstanding women leaders from across Australia’s industrials sector.

MHD Supply Chain Solutions

PROUDLY PRESENTED BY

SPONSORED BY Australia

Traditional glass packaging shapes forge new drinks category success

Since its founding in 1987, Plasdene Glass-Pak has climbed to the forefront of the packaging distribution space in Australia.

The company has remained in the Pearson family ever since its inception, and no matter the changes across packaging in the last three decades Plasdene Glass-Pak has kept abreast of them.

Plasdene Glass-Pak general manager, Jayne Pearson, said the company prides itself on having the agility to respond rapidly to changing market needs, and a “Make It Happen” hustle and heart attitude towards delivering business solutions, ensuring the ability to meet the needs of any customer.

“We are a major importer and distributor of a vast range of rigid packaging products. Many core product lines stocked and supplied nationally are from our own mould investments across a multitude of manufacturing platforms,” said Pearson.

“In doing so, we deliver competitive, total value to the customer, with our buying power scale, supply continuity through investment in inventory, quality assurance, sourcing expertise and unparalleled choice for B2B clients.”

With a seven-branch distribution network in Australia in all capital cities and in the Hunter region in NSW,

Plasdene works with all scale clients sourcing and supplying both off the shelf product lines, and completely customised packaging solutions, such as decorated items and new mould development for completely bespoke containers, managed by a dedicated project management on-staff team.

“We manage large scale supply to multinational clients and many reputable brands, but we also offer choice and flexibility for our smaller customers too. Across our 10,000 SKU product range, many product lines are supplied in both bulk pallet and small pack format, ensuring the best packaging shapes globally, are accessible to all. This helps niche brands grow without vast financial outlay, and is ideal for established brands to launch new products, conduct trials or grow revenue with limited edition product lines. This supply flexibility removes barriers, helps customers differentiate in the market, and supports customer growth capabilities,” said Pearson.

“And on top of that is the one-stop, total pack solution. Our supply capabilities extend beyond bottles and jars, to closures, cartons, dividers and bulk storage solutions, meaning clients can take complete package dry good deliveries together in batch quantities only as required on a Just In Time model,

and all from one place,” added Pearson.

“Being a private, family-owned business means we can make quick decisions that are mutually beneficial to both our business, and the many thousands of businesses we support, through our supply expertise and service excellence model. Dad started the business in 1987, with himself as sole employee and without a single customer, selling plastic bags and record cover sleeves from the boot of his car. Starting from scratch, he had absolutely no experience selling packaging, but with two kids to feed and a fledgling company to support, the learning curve was by necessity, very swift!”

Fast forward to 2023, Plasdene Glass-Pak is now considered professional experts in packaging handling, sourcing and supply, such that some of the largest and best global brands rely on Plasdene to deliver world class packaging, to literally keep their lines running and product on the shelves.

“We’re so very proud to have helped literally hundreds of thousands of businesses build their brands through our genuine service factor, many of whom are long term clients. Our “Partner with Us and Grow” brand purpose represents our business as a start-up more than three decades ago, and our desire to nurture customer growth, fostering genuine,

enduring partnerships with our clients and staff, alike. That customer loyalty and trust in our business capability and our people, is never taken for granted.”

Any potential issues can be resolved, and strategic decisions made with immediacy, within the context of a tightknit family-owned Australian business, ensuring speed to market responses minus the bureaucracy, and a service provider that does business with family values and the genuine “care factor”.

“A big advantage for our clients is our ability to manage the sourcing, inventory planning, production scheduling, logistics and secure storage under 35,000 square metres of warehouse space, nationally. Our aim is to deliver supply continuity and service excellence, and much of what we do is mitigating risk and solving problems, before the client even knew there was one!”

As Pearson explains, “following Covid-19 global supply chain disruption, Australian industry has had a significant evolution, as businesses scrambled to secure reliable, supply continuity arrangements. Where once packaging was often an afterthought in the product innovation funnel and generally sourced within a “Just In Time” model, since the global pandemic a risk-mitigation focus shift is now apparent. Warehousing capability and long-range safety stock

PACKAGING 30 Food &Beverage Industry News | March 2023 | www.foodmag.com.au

Plasdene Glass-Pak is finding itself in an enviable position as the industry continues to trend away from plastic, and functional health beverages grow in popularity. Adam McCleery writes.

requirements are now a critical part of any business continuity plan, but these are added and unnecessary costs. Most businesses have recognised that if you don’t have packaging, you don’t have product on the shelves. It’s that simple. We’re well-placed to respond to this need.”

T he business is particularly wellestablished as a market leader in pharmaceutical and healthcare glass packaging, with well-established and quality-led supply lines.

“We’ve been supplying pharmaceutical glass into the Australian market for more than three decades. Our sophisticated supply lines, discerning high quality standards and expertise in glass handling ensures we’re in a good space to respond to customers looking to launch new products, or scale up.

Our 7-branch distribution network and extensive warehousing capability allows customers to draw down stock only as required. With inventory on hand locally and warehousing inventory nearby to customers, and further supporting with the extension of trading terms allows clients to stay cash flow positive when they need to run lean, but also need to grow,” Pearson added.

Being at the forefront of packaging trends, Plasdene Glass-Pak has therefore been well-placed to respond to the burgeoning new market segment, for

fill this new functional drinks category, for the likes of gut health, immunity and detox-style elixirs and tonics.

“Whilst we do supply plastic containers (including rPET options), the majority of brands in this space are in glass, in capacity of 100mls or less. It’s largely positioned as “throw down” single serve sizing, geared for “on-the-go” one shot convenience,” said Pearson.

“It really exploded during Covid when people put a renewed focus on health and wellness, and building immunity. It’s now a legitimate supermarket category.”

And as the category continues to gain a stronger foothold in the market, Plasdene Glass-Pak continues to offer well proven, pharmaceutical grade bottles to suit the job.

“It’s incredible to see how perceptions of certain packaging formats and potential uses change over time, aligned to new trends. Bottles with a tamper evident finish traditionally used to pack cough medicine, are now being used for drinks that purportedly help you feel better,” said Pearson.

“Together with a readily accessible container, we have clients that are able to differentiate their brand with specific colour or custom printed closures to suit. In so many different colour variants and print designs, they look fantastic on the shelves.”

“Unconventional uses for packaging

and regular glass food jars traditionally used for packing jams and pickles, now commonly holding takeaway cold press juices.”

“It’s an interesting trend where the new market category has aligned to the pharmaceutical containers, which adds weight and credibility to the market pitch around health and wellness. And of course, glass is often a preferred material for health-related products, being completely non-reactive and pure, preserving the flavour and keeping the contents fresh. Glass is also made of natural raw materials (soda ash, sand and lime) and can be completely and infinitely recycled, presenting excellent sustainability credentials.

“Additionally, glass packaging leverages a premium positioning, whilst the pharma-style shape is a unique look for beverage packaging, which helps the product stand out on the shelf.”

This changing trend in functional health drinks has presented a clear opportunity to Plasdene Glass-Pak, which retains a strong supply of the right sort of bottles.

“ We are very well placed to respond to changes around consumer demand, such as in the gut health beverage space. And we have inventory on hand ready to support supply, which is also a benefit,” said Pearson.

“Where we are seeing interest is with existing beverage manufacturers of various types looking to diversify or de-risk channelled through this new category, together with some exciting new players entering the market.”

As well as the rise in the use of pharmaceutical bottles in the single shot functional drinks space, changes around the use of plastic is also having an impact on demand for glass packaging.

With many industries reducing the use of plastic due to problematic consumer perception and complexity of

sustainability properties, the beverage sector is ideally placed to adopt more glass.

“Because glass is well established as a sustainable choice of packaging and its inert, you won’t get taint and it’s also fully recyclable. Glass containers are generally produced with a reasonable percentage of recycled content, with targets on recycled content improving all the time,” said Pearson.

“There’s a space for both glass and plastic containers in Australia, and we’re fortunate to be able to offer clients this choice. Various resin containers, such as HDPE and PET present many packer and consumer benefits too, but for sure, many people want that pure and natural sense that glass brings, particularly for a single shot consumable beverage product.”

A nd with seven facilities around the country, in each major city and the Hunter Region of NSW, Plasdene Glass-Pak are able to work closely with manufacturers and producers right across Australia and respond in rapid time.