MAY 2023 PLUS: Industrial Hoses | Liquid Nitrogen Applications | Product Recalls Packaging for the future

CEO: John Murphy

COO: Christine Clancy

Managing Editor: Syed Shah

Editor: Adam McCleery

Ph: (02) 9439 7227

adam.mccleery@primecreative.com.au

Design Production Manager: Michelle Weston michelle.weston@primecreative.com.au

Art Director: Blake Storey

Design: Michelle Weston

Sales/Advertising: Stephanie Suzuki

Ph: +61 422 046 711 stephanie.suzuki@primecreative.com.au

Production Coordinator: Janine Clements

Ph: (02) 9439 7227 janine.clements@primecreative.com.au

Subscriptions AUS NZ O/S

1 year subscription 99 109 119

2 year subscription 189 199 209

For subscriptions enquiries please email subscriptions@primecreative.com.au

Packaging innovations are critical for the future

Copyright

Food & Beverage Industry News is owned by Prime Creative Media and published by John Murphy. All material in Food & Beverage Industry News is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published.

The opinions expressed in Food & Beverage Industry News are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2019

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Head Office

379 Docklands Drive Docklands VIC 3008

Ph: +61 3 9690 8766 enquiries@primecreative.com.au http://www.primecreative.com.au

Sydney Office Suite 303, 1-9 Chandos Street

Saint Leonards NSW 2065, Australia

Ph: (02) 9439 7227

Printed by: Manark Printing

28 Dingley Ave Dandenong VIC 3175

Ph: (03) 9794

Editor: Adam McCleery

Iused to give little thought to the packaging used in food and beverage manufacturing, beyond the cosmetic that is, until I started working within the industry.

Now, as I continue to cover the food and beverage packaging space, I have begun to look at things differently when I walk the supermarket aisles and I also start to wonder whether my brand loyalty to certain items was born from the look of the packaging or not. I do know that it had nothing to do with the make-up of the packaging.

However, I now consider these things and have realised, due in no small part to speaking with experts in the field, the massive impact overhauling the use of particular materials in packaging can have on the wider world.

Society continues to move towards a more sustainable future off the back of scientific data and the continued push from stakeholder groups, and governing bodies, around the need to reduce things like single use plastics.

Supermarkets getting rid of plastic bags is also an indicator of how consumer demands are helping to drive the change, the move would not appear wise if the companies didn’t think customers would support it, and they have.

As consumers we are seeing the changes in packaging happen, we are aware of the reasons why, but until recently many gave little thought to the machinations behind the changes and the positive impacts it will have going forward.

Advancements in packaging have several

advantages for the industry including mitigating the risk of food spoilage, breakage, and wastage, which goes a long way to helping reduce the millions of tonnes of food that end up in Australian landfills every year. Stronger plastic alternatives, better recycling programs, and completely new forms of packaging, are all playing a role.

The role consumers have played in the evolution of the packaging space can’t be understated. The consumer has become increasingly product savvy and wants to play a part in helping create a sustainable economy moving forward and when it comes to the food and beverage industry, they do that with what they choose to spend their money on.

Brand loyalty, as mentioned at the top, can be created among the adult consumer base through more sustainable practices, just as my brand loyalty as a child was likely based on the colour scheme of the product, a product I no doubt still consume today.

T his new approach to packaging has also brought some alternative packaging companies, and technologies to the fore. Fibre based packaging appears to be winning out in the race for plastic substitutes, while other stakeholders are investing in better recycling programs to generate a circular economy.

T his edition of the magazine will detail some of these new technologies and packaging options, giving insight into what the future holds. Happy reading!

WELCOME

8337 2 Food &Beverage Industry News | May 2023 | www.foodmag.com.au

see wh y food & beverage prefer to partner with Bü rkert Melbourne Convention & Exhibition Centre 20 23 FOODPRO 23-26 JULY

18 MEET THE MANUFACTURER

VinZero drinks are capturing a strong segment of the nonalcoholic drinks sector in Australia.

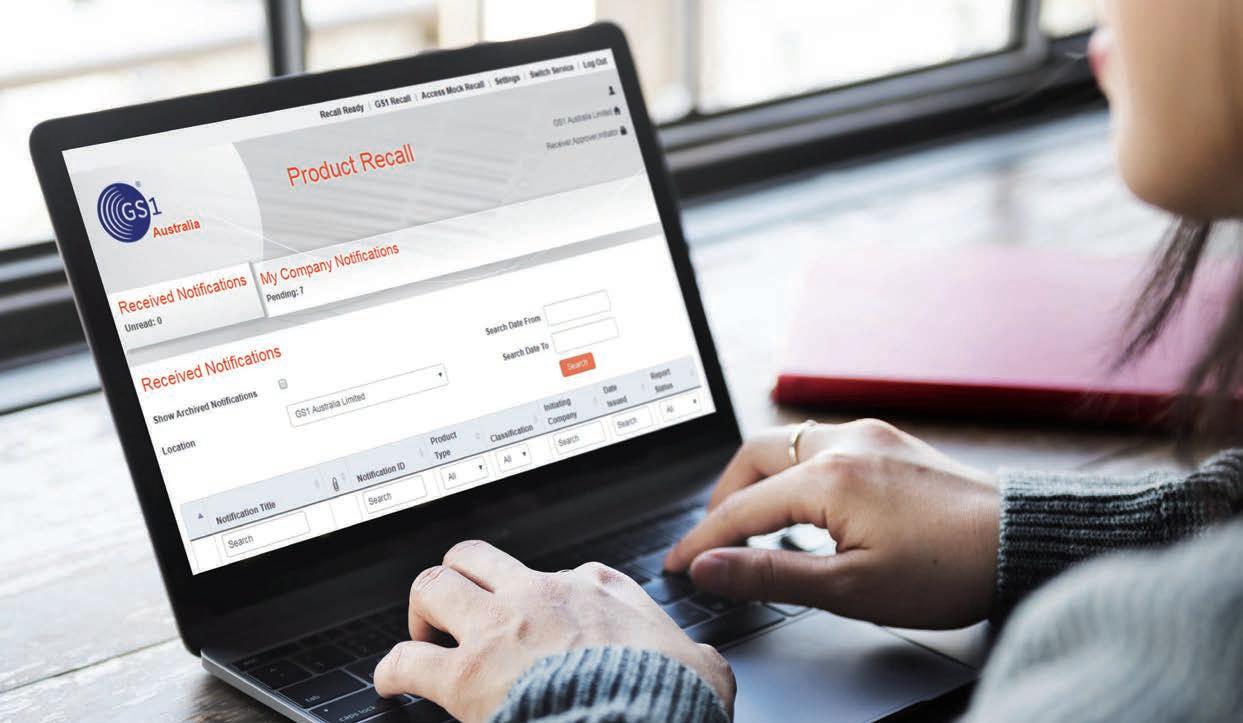

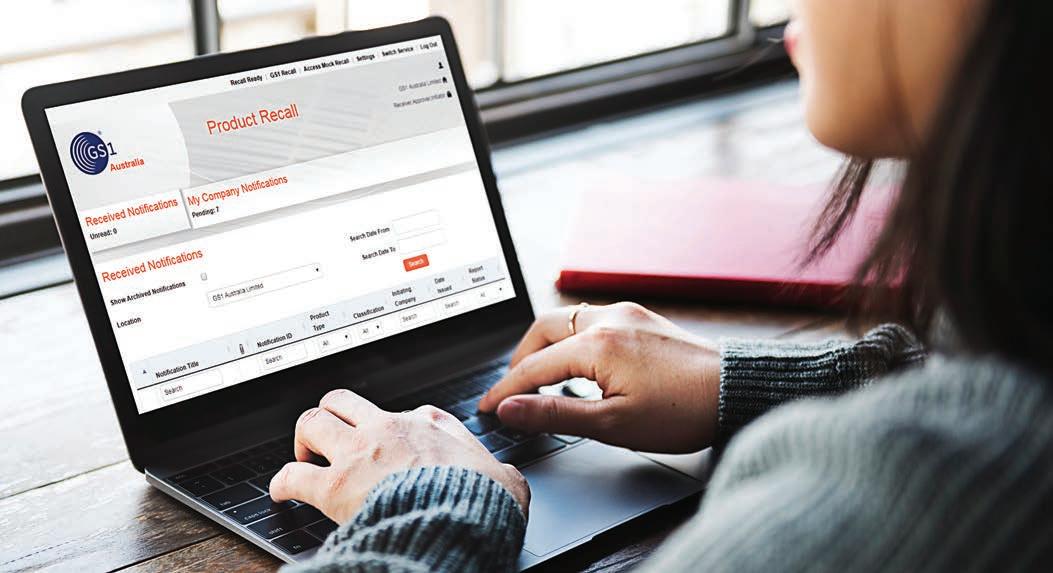

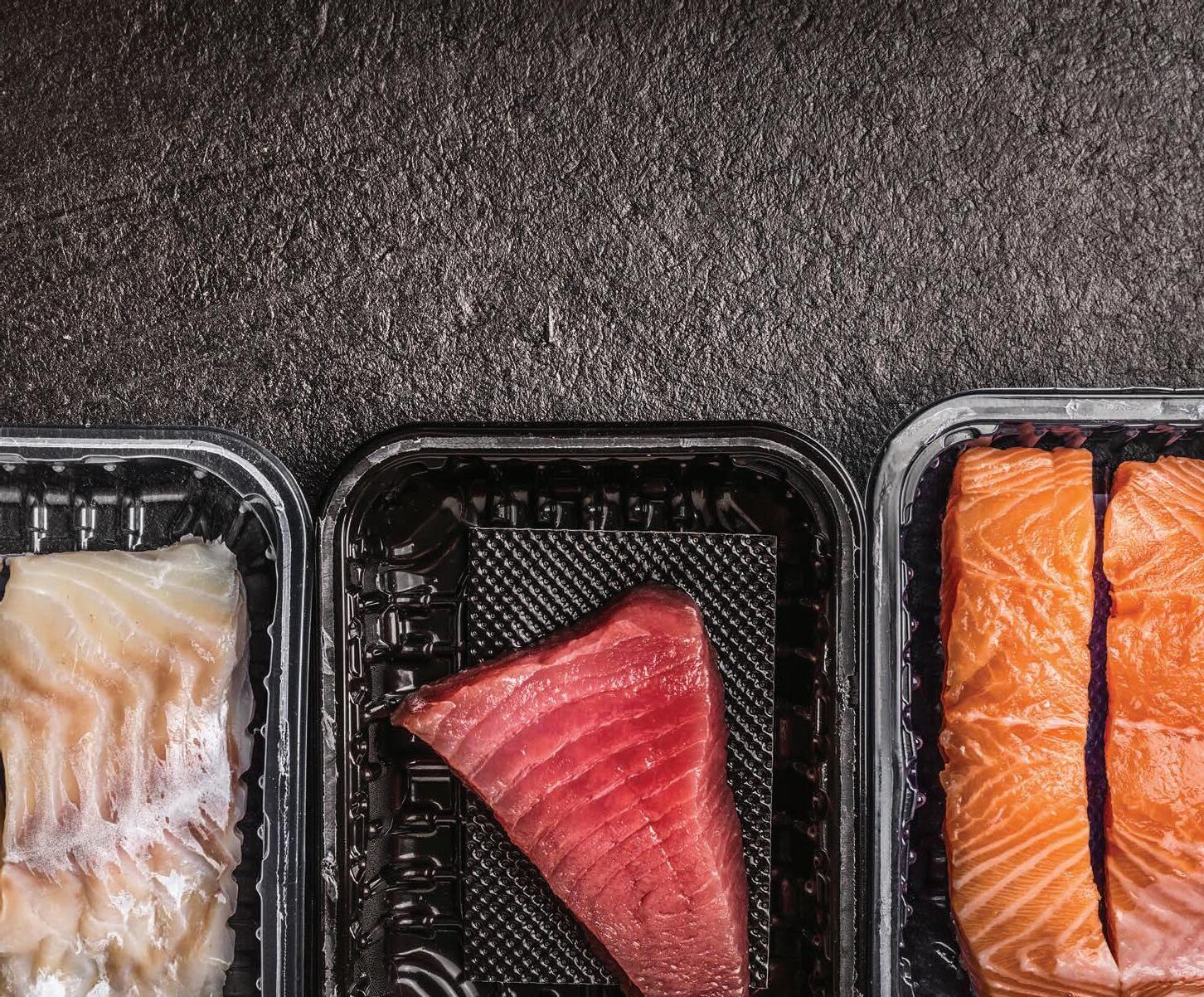

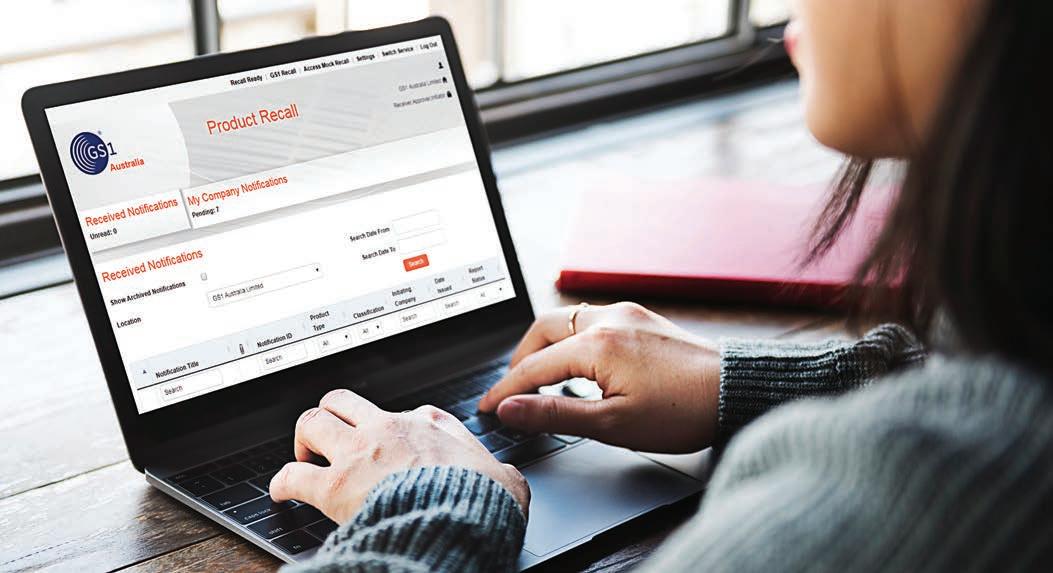

22 TRACEABILITY

GS1 Australia’s Recall Platform presents a great software solution to strengthen a company’s recall process.

COMPRESSED AIR

Bürkert is helping the industry lessen its air which can have positive benefits.

PACKAGING

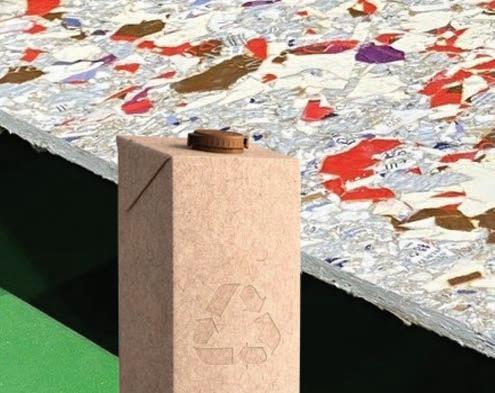

Tetra Pak’s partnership with saveBOARD has led to a first of its kind facility in Australia.

INDUSTRIAL GAS

Liquid Nitrogen Services, a subsidiary of Supagas, is set to expand its services further across Australia.

30 INDUSTRIAL MOTORS

Ifm moneo can help you protect your industrial motors with advanced vibration analysis.

32 PACKAGING

Favourite Packaging brings new packaging products to the market that are mono-structured and easier to recycle.

34 PACKAGING

COPAR is getting set to open the first wheat straw packaging facility in Australia, with prototypes ready for the market.

36 AIP

The winners of the Australasian Packaging Innovation & Design Awards have been announced.

CONTENTS 6 NEWS

38 NEW PRODUCTS 22 32 38 34 40

World Class Facility Construction | Call: (02) 9746 9555 | Visit: totalconstruction.com.au Looking to build or expand a Ready Meals facility? Call Total Construction to see how we can help from concept to completion of your project.

Dr Michele Allan, AO, has stepped down as Chair from the Food and Agribusiness Growth Centre (trading as FIAL) after serving four years as Chair and three years as a non-executive director on the Board.

One of Dr Allan’s legacies at FIAL is the inception and delivery of Project 2030 – the A$200 billion opportunity for the Australian food and agribusiness sector.

FIAL recognised the support, guidance, and leadership Dr Allan has offered FIAL and wishes her the very best in her future endeavours.

Dr Allan will be replaced by Emeritus Professor Roy Green, highly regarded for his leadership in innovation, manufacturing and regional growth and diversification.

With Professor Green’s strong track record in business-university

collaboration, particularly around science, technology and innovation, and the development of competitive and dynamic entrepreneurial ecosystems, he is well placed to support FIAL’s transition to the next phase of continuing to drive sector growth.

A particular focus will be on leveraging the cluster ecosystem to unlock the potential of Project 2030 for the Food and Agribusiness Sector.

“I am delighted to be appointed Chair of FIAL during the company’s transition into the next phase of growth,” said Professor Green.

“My background and understanding of competitive ecosystems will help support FIAL as they leverage the cluster ecosystem to unlock the potential of Project 2030, and drive export growth for the sector.” F

Change of Leadership for Food Innovation Australia Limited Metcash appoints Food Division CEO

Metcash announced the appointment of Grant Ramage as chief executive officer of the company’s Food pillar, with effect from 1 May 2023.

The appointment follows the completion of a global search due to the resignation of Scott Marshall early this year.

Ramage is currently executive general manager Merchandise in Metcash’s Food pillar, a position he has held for the past four years. Prior to this role he was State general manager, Supermarkets, Western Australia, after joining Metcash in 2015.

As leader of the Food merchandise team and a member of the Food leadership group, Ramage has been a key contributor to the very strong performance of both the Food pillar and the IGA network in recent years.

Ramage passionately believes that ‘independents are worth fighting for’ and has played a key role in supporting the significant improvement in the competitiveness of the IGA network.

In addition to increased value for shoppers, including competitive prices, he helped to navigate the prolonged and severe supply chain challenges of recent years, ensuring the IGA retail network continued to be well stocked and able to serve local communities.

In his previous state general manager role, Ramage delivered significant and sustained improvement in the state’s logistics operations and built the requisite resilience to help address increased competition, deregulation of trading hours, and recession.

Importantly, Ramage is highly regarded by both Metcash’s independent retailers and suppliers and has built

strong relationships and trust with these key partners.

Prior to joining Metcash, Ramage had a long and successful career at Coles

NEWS 6 Food &Beverage Industry News | May 2023 | www.foodmag.com.au

Liquor, where he held several roles across merchandise, marketing, operational leadership, business development, critical projects, and exclusive brands.

F

Prior to joining Metcash, Ramage had a long and successful career at Coles Liquor.

Dr Michele Allan, AO, stepped down and is being replaced by Emeritus Professor Roy Green.

www.foodmag.com.au | May 2023 | Food &Beverage Industry News 7 environmental groups, sporting clubs in remote areas. F FOOD | FRESH PRODUCE | MEAT PACKAGING sales@copar.eco WWW.COPAR.ECO+61255656770 PROUDLY AUSTRALIAN-MADE & COMPOSTABLE. WHEAT STRAW PACKAGING WITH PURPOSE

CDS Vic will allow Victorians to return their used drink cans, bottles, and cartons for a 10-cent refund.

Woolworths to remove 15-cent shopping bags in final states

Woolworths stores in New South Wales, Victoria and Tasmania have begun to phase out their 15-cent reusable plastic shopping bags as part of the retailer’s commitment to stop selling the bags nationwide from June.

Over the coming weeks, the supermarket will gradually run down stock of the 15-cent reusable plastic shopping bags across New South Wales, Victoria and Tasmania, in a move that will see more than 9,000 tonnes of plastic removed from circulation annually across the country.

Eight in every ten Woolworths customers already bring their own bags when they shop, and the retailer is continuing to encourage customers to bring their own bags to boost sustainability, rather than buying them in store. Woolworths’ paper bags and other reusable bags will remain available to those who need them.

Woolworths has already removed these bags from stores across ACT, NT, SA, QLD and WA over the last 12 months, with customers responding well to the change.

Woolworths Supermarkets director of stores, Jeanette Fenske, said, “We’re

excited to have Victoria, New South Wales and Tasmania complete our national journey to remove the 15-cent

plastic shopping bag from all our stores nationwide.

“Having reusable bags on hand has become second nature for many shoppers, and so far we have seen our customers embrace this change with their usual eagerness to do good for the environment.

“Bringing your own bags is the very best outcome for the environment, and we encourage our customers to keep up the great work. Paper bags will continue to be available for those who forget to bring their own – but ultimately we want to sell less bags altogether.” F

$1M investment to find new citrus varieties

Hort Innovation is set to invest nearly $1M to assess new citrus varieties that are suited to Australian growing conditions.

Funded by Hort Innovation’s citrus levy, the $987,000 project will provide independent assessment of the horticultural performance of new citrus varieties under Australian conditions, as well as testing citrus varieties for ‘trueness-to-type’.

The assessments will take place in Dareton in New South Wales, as well as in Western Australia.

Hort Innovation CEO Brett Fifield said the project will build on previous citrus variety projects, with the aim of measuring tree attributes that are desirable for Australian growers and consumers both domestically and overseas.

“Independent assessment of new citrus varieties — under Australian conditions — means growers will be able to identify new varieties that might suit their production regions. It will also help growers be aware of key consumer and production traits of the varieties,” said Fifield.

The new project will build on the success of previous research in this area.

fruit size and sweetness, as well as assessing any issues producers might need to consider when growing the trees.”

and it will continue to benefit from valuable input from the Australian citrus industry along the way.

The new project is part of a suite

rootstock evaluation and breeding, that also complements biosecurityrelated projects to protect the citrus production base in Australia. F

NEWS 8 Food &Beverage Industry News | May 2023 | www.foodmag.com.au

Woolworths has already removed these bags from stores across ACT, NT, SA, QLD and WA.

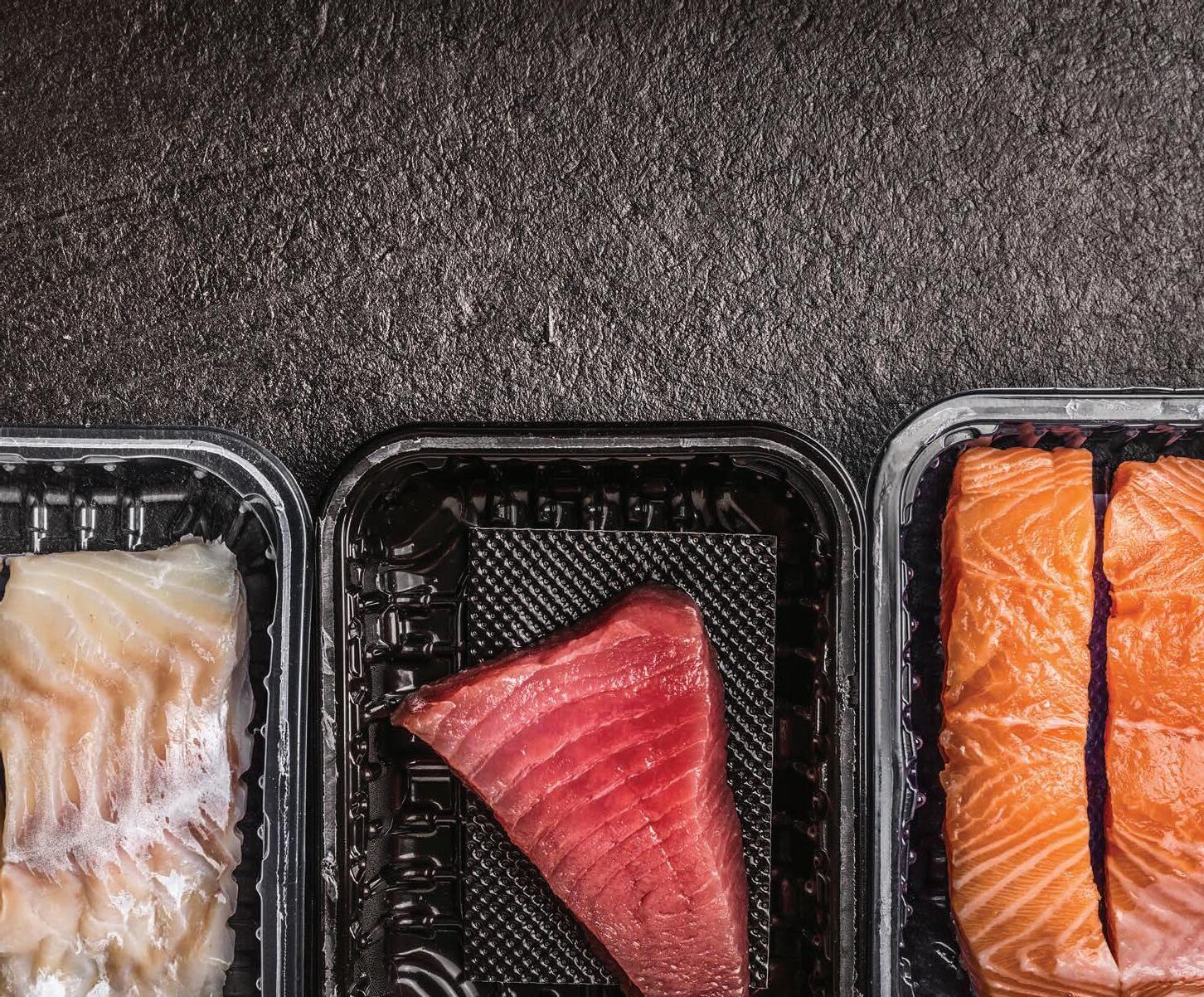

A Gas Partner that appreciates your craft MEAT & SEAFOOD PROCESSING au.airliquide.com Discover More.

Good Drinks awarded $750,000 in government funding

Good Drinks Australia (ASX: GDA) has been awarded $750,000 in State Government funding that will contribute toward improving the company’s operational efficiencies.

The grant will assist in funding civil works and site upgrades, including the installation of a new fermentation tank, and groundworks that will allow for the addition of seven additional tanks in the future.

This upgrade is a part of GDA’s existing continuous improvement program, maintaining our low-cost manufacturing advantage and improving production efficiencies.

“We welcome the WA State Government’s support and show of confidence in our business,” said Good Drinks Australia managing director John Hoedemaker.

“The grant helps fund the upgrade in our production capacity, with the

expansion delivering additional scale and production advantages to the business, preparing us for demand increases in the future.”

The current round of the Western Australian government’s Value Add Investment Grants have been awarded to ten dynamic local agrifood and beverage processing businesses.

With $6.3 million dollars granted, Good Drinks Australia received the highest tier of funding. WA State Government Agriculture and Food Minister Jackie Jarvis commented:

“This valuable grants program is supporting businesses to pursue goals and aspirations with confidence, creating jobs and flow-on benefits throughout the supply chain, and helping to diversify the WA economy,” said Hoedemaker.

Work on the brewery upgrades will begin immediately and is due to be completed in late 2024. F

Australian wineries bound for the US

Australian wineries seeking to enter the world’s largest wine market will have additional support following new investments from the South Australian Department for Trade and Investment, Wine Victoria and Wines of Western Australia into Wine Australia’s US Market Entry Program.

The US Market Entry Program is a highly effective business matching program for wineries, with Wine Australia’s team providing guidance on compliance, pricing, logistics and marketing, as well as assisting wineries in finding routes to market, either through importers, brokers or direct import orders with retailers.

Through the new investments, wineries in South Australia, Victoria and Western Australia may be able to recover 50 per cent of the

participation fee for the program. In the 2023–24 Market Entry Program, the Government of South Australia is funding 50 per cent of participation costs for 30 spots, Wine Victoria for 20 spots, and Wines of Western Australia for 5 spots.

Many former participants are now firmly established in the US and have used the program as a springboard to build their presence.

In 2022, Australian wine exports to the US increased by 13 per cent in volume to 140 million litres and it remains Australia’s largest export market by value, at AUD$390 million.

Wineries seeking to participate in the US Market Entry Program are encouraged to visit wineaustralia.com to review the costs and criteria and submit an expression of interest by 31 March 2023. F

NEWS 10 Food &Beverage Industry News | May 2023 | www.foodmag.com.au

Good Drinks Australia received the highest tier of funding.

In 2022, Australian wine exports to the US increased by 13 per cent in volume.

Industrial Fluid Solutions Worldwide. World-class. World-changing. 1300 RUBBER aus.ep@continental.com Continental is a world leader in industrial rubber and plastic products and has the largest global footprint of any rubber products manufacturer. Our knowledge and expertise in hydraulic hose manufacturing and quality products on the market. Plus, our extensive problem-solving experience across multiple industries and applications enable us to share innovations over our entire product offering. Which means we can deliver unexpected solutions and advanced improvements in situations where others can’t. We push the boundaries of what is possible, and we are constantly solving tomorrow’s most challenging problems – today and every day. continental-industry.com Hydraulic Hose & Fittings Industrial Hose & Fittings

New managing director at Eriez-Europe

Eriez has announced the promotion of Gareth Meese to managing director of EriezEurope.

In this key leadership role within the company’s global group, Meese will be responsible for driving the growth and development of Eriez-Europe, ensuring that its plans align with the organisation’s worldwide corporate strategies.

Meese began his career with Eriez as an Export Sales Engineer at the company’s Cardiff operations. Over time, he progressed to various other roles within Eriez and served most recently as regional sales director—EMEA, where he led Eriez’ strategic sales efforts for Europe, the Middle East, India, and Northern Africa.

According to Eric Nelson, Eriez vice

president, International Operations and Business Development, Meese will take on many new challenges as managing director of Eriez-Europe.

“Gareth will focus on critical initiatives related to people development, process improvements, technology advancements, and the continued advancement of Eriez as a global solutions provider,” he said.

“Gareth’s exceptional ability to grow sales, combined with his proven expertise in motivating and mentoring his team, will be vital to the ongoing success of Eriez-Europe.”

Established in 1942, Eriez is a global leader in separation technologies.

Our commitment to innovation has positioned us as a driving market force in several key technology areas, including magnetic separation, flotation,

metal detection and material handling equipment.

The company’s 900+ employees provide trusted technical solutions to the mining, food, recycling, packaging, aggregate and other processing

industries.

Headquartered in Erie, Pennsylvania, USA, Eriez designs, manufactures, and markets on six continents through 12 owned international subsidiaries and an extensive sales representative network. F

Magic Valley introducing cultivated pork without harming animals

The global cultivated meat market is set to reach $630 billion by 2040.

ustralian agrifood startup Magic Valley today announces the launch of its cultivated pork

The milestone comes off the back of launching its cultivated lamb product last year, with both meats completely free of slaughter or any inhumane treatment of animals in the production process, making them ethical and sustainable

Cultivated pork is made from skin cells humanely taken from a living pig, which are then cultivated into stem cells using a mixture of amino acids and other nutrients used as food for cell growth.

Using its signature breakthrough technology, Magic Valley uses no further animal byproducts such as foetal bovine serum (FBS) in the production process.

The cells are able to grow infinitely,

The process means that the initial skin scraping is all that is required to continue making unlimited quantities of

the desired meat and is more stable and faster than competing technologies.

Magic Valley’s technology is scalable across all different types of meats, not just pork and lamb.

Magic Valley’s mission-driven founder and CEO, Paul Bevan, is eager to see more positive global change and views this milestone as a key driver in cementing Australia’s footprint in the alternative protein industry to support the UN with its goals.

“The global need for alternative proteins to meet the demands of the growing population is imperative as we take that journey to achieving net-zero, steering clear of traditional ways of consuming meat for ethical and environmental reasons,” said Bevan.

The global cultivated meat market is set to reach $630 billion by 2040, giving Australia enormous opportunity to contribute to this burgeoning industry that is aligned with the UN’s Sustainable Development Goals. F

NEWS 12 Food &Beverage Industry News | May 2023 | www.foodmag.com.au

Eriez has announced the promotion of Gareth Meese to managing director of Eriez-Europe.

Asahi Beverages and NRL toast partnership renewal

The National Rugby League (NRL) today announced a multi-year extension of its partnership with Australia’s leading drinks company, Asahi Beverages.

The renewal consolidates existing sponsorships with Asahi Beverages’ business divisions – Carlton & United Breweries and Asahi Lifestyle Beverages – into one agreement.

The deal locks in Asahi Beverages as the official beer, cider and non-alcohol beverage sponsor of the NRL.

Asahi Beverages’ portfolio includes some of Australia’s most-loved drinks with something for every NRL fan to enjoy, whether they’re at the ground or cheering on their team at home with friends and family.

The lead brands for the partnership will be Victoria Bitter, as the official Beer of the NRL, and Solo, the official non-alcohol beverage of the league.

Both brands will leverage in-stadium activations, social and digital campaigns and retail footprint executions to engage fans, including with non-sugar option Solo Zero.

In addition, Asahi Beverages drinks, including Gatorade and Cool Ridge

Saputo set to sell two fresh milk processing facilities

Saputo Dairy Australia (SDA) has announced its intention to further optimise its operating model by entering into a definitive agreement with Coles Group Limited to sell its fresh milk manufacturing sites at Laverton North (Victoria) and Erskine Park (NSW).

The transaction is subject to customary conditions, including clearance from the Australian Competition and Consumer Commission (ACCC), and is expected to close in the second half of calendar 2023.

Fresh milk products remain an important part of SDA’s business and as part of the sale agreement with Coles

Group Limited, SDA will continue to have fresh milk products processed at these two manufacturing facilities.

SDA will work closely with its customers through the transition to ensure these changes have minimal impact and intends for its loyal consumers to continue enjoying its diverse range of dairy products.

There will also be no changes to its valued farmer relationships, with suppliers’ milk continuing to be collected and processed throughout Victoria, New South Wales and Tasmania.

“As the Australian dairy industry landscape continues to evolve, this proactive measure aims to further adapt

SDA’s manufacturing network and is designed to strengthen our market competitiveness,” said Leanne Cutts, Saputo Inc.’s President and COO (International and Europe).

“We’re continually working to

water, will be supplied to NRL Elite Teams such as the Kangaroos and Indigenous All Stars before, during and

“We are excited to bring together a long-term partner in Carlton & United Breweries and our more recent relationship with Asahi Lifestyle Beverages into one agreement under Asahi Beverages,” said NRL CEO Andrew Abdo.

“The renewal will enhance our existing partnership and continue to offer unique benefits and great product choice to fans during our major events.”

Asahi Beverages Group CEO Robert Iervasi said the company was thrilled with the announcement.

“Asahi Beverages is thrilled to continue our multi-beverage partnership with the NRL,” he said.

“The NRL is a major passion of so many of our consumers and through this partnership we will be able to reach people wherever they choose to enjoy our great range of beverages.’’ F

ensure we have the right manufacturing enhance our position as a high-quality, low-cost processor,” said Lino A. Saputo, Saputo Inc.’s Chair of the Board, president and CEO. F

NEWS www.foodmag.com.au | May 2023 | Food &Beverage Industry News 13

The lead brands for the partnership are Victoria Bitter and Solo.

The transaction is subject to customary conditions.

Aussie cherry industry sets 40 per cent of production export target

Australia’s cherry growers are redoubling their trade efforts through a new $1.2M export program that will boost support for existing and aspiring exporters amid plans to send 40 per cent of production overseas by 2025.

The initiative is being delivered through Hort Innovation using industry levies and funds from the Australian Government and led by Cherry Growers Australia with industry partners.

The initiative will include more than 50 activities that will build export capability among Australian cherry growers, minimise trade risks during supply chain disruptions and other challenges and grow Australia’s reputation for delivering quality cherries.

Cherry Growers Australia’s chief

operating officer, Andrea Magiafoglou said the nation’s cherry industry, made up of some 200 producers, is poised for growth as it enters a new phase of export development.

“Industry has set an ambitious target of exporting 40 per cent of production by 2025 and this dedicated export program, with support being tailored to each region, will help us reach that,” she said.

“With many cherry growers being export ready, we are now in a position where we can build on our success to be an export-focussed industry.”

Magiafoglou said there is a strong willingness for industry to work together to share data and intelligence to preserve premium export prices in the face of increasing global competition; and thereby manage this risk.

More than $26M in research and development activities, from pest and disease management efforts to

educational events to market access preparation work, underpins the Cherry Export Strategy. F

Allied Pinnacle announces exclusive rights to CSIRO developed High Fibre Wheat

Australia.

High Fibre Wheat is high in amylose, meaning the resulting flour contains 6 times more fibre than standard wheat flour, without any compromise on taste.

The natural alternative will enter the Australian market in 2023, available exclusively through Allied Pinnacle. Currently grown by wheat farmers across Australia, this innovative High Fibre Wheat is the result of 20 years of global research and development.

In a first of its kind, High Fibre Wheat delivers benefits for consumers relating to both the amount of fibre and also the type of fibre.

with a host of benefits to consumers.

Allied Pinnacle CEO David Pitt says,

“We are investing in the future of Australia by bringing the CSIROdeveloped High Fibre Wheat to Australians,” he said.

“Unlike other wheat flours, High Fibre Wheat and the resulting flour it yields, looks, tastes and bakes like regular flour, answering consumer demand for products that don’t require any new eating habits. It’s a true grain to table solution that we’re proud to provide.”

AHigh Fibre Wheat in Australia.

The Australian partnership is with Arista Cereals, a joint venture

cooperative, Limagrain.

High Fibre Wheat is a new natural grown wheat, developed and farmed in

The naturally high fibre content is delivered through conventional breeding to provide more resistant starch, a prebiotic fibre, than traditional wheat,

The Australian Dietary Guidelines recommend Australians enjoy a wide variety of nutritious foods from the five food groups including Grain (cereal) foods, mostly wholegrain and/or high cereal fibre varieties. F

NEWS 14 Food &Beverage Industry News | May 2023 | www.foodmag.com.au

More than $26M in research and development underpins the Cherry Export Strategy.

High Fibre Wheat is a new natural grown wheat.

Mars Wrigley Asia appoints new general manager for Asia

Mars Wrigley, a global leader in the treats and snacks category and a business division of Mars Incorporated, has announced the appointment of Kalpesh Parmar as general manager (GM) for Mars Wrigley Asia.

Parmar succeeds Patrick Gantier who, following a 15-year career with Mars, has left the organisation to pursue other opportunities.

Parmar was most recently the GM of Mars Wrigley India and brings with him more than two decades of experience in the FMCG industry, working across multiple geographies in Asia, Middle East and Africa.

Since joining Mars Wrigley India in January 2020, Parmar has leveraged his experience in business strategy and brand building to drive growth while focusing on talent development and engagement.

In his new role, Parmar will oversee 20 diverse markets in the Mars Wrigley

Asia portfolio.

He will lead business operations of the chocolate, gum and fruity confections segments across all Asia markets, as well as the pet nutrition segment in South Korea, Taiwan and Hong Kong.

“I am humbled to take on this role and continue my career at a company that is truly purpose-led. We have an amazing team and we make fantastic products that are loved by many across Asia,” said Parmar.

Parmar has worked in both matured and emerging markets including South Korea, Singapore, Dubai, Turkey, Nigeria and India, holding senior positions across business development, brand building, distribution and e-commerce.

Prior to joining Mars Wrigley in 2020, Parmar was with Unilever for over 12 years where his last role was CEO for South Korea, Pacific Islands and Mongolia. F

NEWS www.foodmag.com.au | May 2023 | Food &Beverage Industry News 15

Prior to joining Mars Wrigley in 2020, Parmar was with Unilever for over 12 years.

Research pays off in India avocado trade deal

The Australian Government’s Hass avocado market access agreement with India is underpinned by a $3M investment into research to support the export of the fruit.

Delivered through Hort Innovation using industry levies and funds from the Australian Government, some of Australia’s top scientists partnered with the avocado industry to develop phytosanitary data that shows the health and safety of Australian Hass avocados is in line with India’s import requirements.

Hort Innovation chief executive Brett Fifield said in-market consumer insights gathering, inbound trade missions and strategic planning through a targeted export strategy have also been a focus for the industry.

“Getting to the point the Australian Government has with India today is no small feat,” he said.

“As well as significant work by the Government, this trade agreement, which is enacted after 10 successful shipments, has been informed by hundreds of hours of research.

“That includes developing novel phytosanitary measures for the fruit, with partners such as the Department of Agriculture and Fisheries QLD. That involves rigorously applying treatments to our avocados to prove they are pest and disease free with no impact on quality.”

Mr Fifield said the phytosanitary risk science Hort Innovation delivers with agencies, such as the CSIRO, contributes to international research in this field.

“As an isolated continent, Australia has a reputation for taking the risks of spreading pests and pathogens that harm crops and natural environments seriously. That is why our produce is considered premium-quality and is highly sought after all over the world.” F

STA welcomes National Reconstruction Fund

The nation’s peak body representing 115,000 Australian scientists and technologists welcomes Australia’s National Reconstruction Fund as a powerful new investment in the country’s future.

The $15 billion National Reconstruction Fund legislation passed the Senate last night, and secured final passage through the House of Representatives at lunchtime today.

The bill establishes the National Reconstruction Fund Corporation to administer the fund.

The NRF will invest in Australian next-generation materials development, value-adding and advanced manufacturing among its seven priority areas.

Its remit includes clean energy and green technologies, mining science technologies, medical manufacturing,

critical technologies, advanced manufacturing and value-adding in agriculture and food.

Science & Technology Australia

CEO Misha Schubert said it would give Australia a powerful new vehicle to “spur and scale” the nation’s economic development and diversification.

“The creation of the new National Reconstruction Fund will be a transformative investment in our country’s future economic security powered by home-grown science,” she said.

“It will help to deepen Australia’s scientific and technological innovation – which is key to strengthening our national prosperity, creating jobs and securing new income streams.

“This significantly boosts Australia’s pool of investment capital for nextgeneration materials development, value-

adding and advanced manufacturing – the foundations of a strong, modern economy. This will help turbo-charge sovereign capability and economic complexity.”

NEWS 16 Food &Beverage Industry News | May 2023 | www.foodmag.com.au

On behalf of its 139 member organisations, Science & Technology Australia made a submission in February on the NRF’s design and implementation. F

The Government’s Hass avocado market access agreement with India is underpinned by a $3M investment into research.

C M Y CM MY CY CMY K

The bill establishes the National Reconstruction Fund Corporation to administer the fund.

Turning passion into a successful business

The founders of non-alcoholic drinks company VinZero are capitalising on the growth of the sector as consumers continue to seek out more non-alcoholic drinks options. Adam McCleery writes.

18 Food &Beverage Industry News | May 2023 | www.foodmag.com.au MEET THE MANUFACTURER

What started as a side hustle for Paul Legaz and Amanda Gabriel has turned into a successful business.

Paul Legaz and Amanda Gabriel founded VinZero, a non-alcoholic drinks company, shortly after Legaz decided to give up alcohol himself and it didn’t take long before they discovered they had stumbled upon a fast-growing sector.

“After the release of Heineken’s non-alcoholic beer, I realised you can have a full bodied beer and still do other things like pick up the kids from training or go for a surf,” said Legaz.

“There was, and still is to some extent, a stigma around going out and not socialising with a drink. But the non-alcoholic sector is really helping with that.”

Legaz was in Spain with Gabriel a short time later when he first stumbled across non-alcoholic wines and spirits, which again opened the pair’s eyes to the business possibilities of a product which was addressing an issue.

“We realised in Europe the non-alcoholic sector was really popular, the trend had already begun,” said Legaz.

But upon the pair’s return to

Australia, they were sadly disappointed with their options here.

“We found one, tasted it, and realised there was a gulf in quality between the European and the local product,” said Legaz.

“The brand from Spain turned out to be the pioneers. Of non-alcoholic. The first in the world to do it.

“From there we got excited about the existing market and started by tasting air freight samples, before discovering the wider world of non-alcoholic drinks.”

“From bringing in samples we realised there was a business here, so we pursued it as a side hustle before being introduced to key stakeholder who started showing interest. It was great timing.”

After some key lessons from stakeholders in the beverage and non-alcoholic beverage markets, Legaz and Gabriel had a business.

The pair started by importing international products, brands which were well established in the European market, with an eye towards manufacturing their own.

www.foodmag.com.au | May 2023 | Food &Beverage Industry News 19 MEET THE MANUFACTURER

Paul Legaz and Amanda Gabriel are helping supply Australians with non-alcoholic beverages.

VinZero produces its own product and imports other non-alcoholic beverages for the Australian market.

“At the time I learned there was another importer with one brand,” said Legaz.

“But we had done the research and realised this was a movement and it would be taken up in Australia we got excited and made the right business moves to land excellent brands with amazing reputations with many international awards.

“The timing was crucial.”

VinZero drinks made sure to source the highest quality brands it could, to help achieve its first main goal of educating the local market about the benefits, and quality, of non-alcoholic drinks.

By doing so, VinZero build a strong portfolio of high-quality overseas products to bring to the Australian market.

“We believe in our products, and they generally get good reviews and get well endorsed. It’s important that someone who hasn’t tried non-alcohol before try a good product first. First impressions are important,” said Legaz.

“You must invest in making them quality products.”

Legaz and Gabriel’s own product, Nocktail, non-alcoholic cocktails, was the pair’s first move into producing their own product on top of distributing.

“We bought Nocktail from the original owner and now we make it here in Australia,” said Gabriel.

“We work with amazing people that Paul and I have become close with that help with taste profiles and helping us to adapt and optimise our cocktails for the market.

“It’s important to adapt to the market trends and the flavours the consumers are seeking. We aim to get that flavour profile spot on.”

Helping VinZero perfect its own product, is working with the brands they distribute here in Australia.

we work with overseas are purely non-alcohol brands because the market is big over there, the technology overseas is on point. Recreating that here will make things much easier,” said Gabriel.

And with this partnership came the benefit of critical advice from key stakeholders in the sector.

“One of the things we were told when we were introduced to stakeholders was that if you get ranged you can’t run out of stock,” said Legaz.

“At times we’ve had excess stock or caught short, those were unknowns, and it was a challenge to work out, along with working out the shipping logistics.”

Australia when they started was more of an afterthought.

“Whereas here in Australia the market is sort of tacked on to the normal alcoholic beverages,” she said.

Both Gabriel and Legaz credit Dan Murphy’s with helping VinZero reach a position where it could continue to import and distribute, while also moving into producing its own local product.

“Dan Murphy’s contacted us to see what we were importing and after that our passion for this grew very quickly because we could see we were onto something. And on top of that, this is something that’s close to us, to be part of a movement about health and wellbeing,” said Legaz.

“It’s not about telling people not to drink alcohol. It’s mainly there for people who can’t drink, but it’s also about giving people options and allowing them to moderate and feel inclusive.

“If they decide they don’t want to drink that night they can still go to an establishment, socialise and grab their keys and go home safely.”

Gabriel said both her and Legaz felt lucky to have started the Dan Murphy’s partnership.

“To have them embrace the trend is great for the category itself, it has been amazing,” she said.

we face is availability and people understanding there is quality out there.

“It’s also a challenge for us going forward to help educate the consumer base about our quality products in the space and to give it a go.”

One of the next steps for VinZero is a strong focus on the hospitality sector before potentially moving into brewing its own non-alcoholic beer in Australia.

“This year is a big focus on hospitality for us too, we are looking at getting in restaurants and other venues. That is another great way to get the word out,” said Legaz.

And the support of some of its existing portfolio brands will play a key role in the roll out of a VinZero non-alcoholic beer of its own.

“The brands we already have are open to us doing local brewing too and that is something we are looking towards,” said Gabriel.

“We will look at brewing a beer here we just have to make sure the flavours and ingredients are here.

“We also aim to lower the costs by manufacturing locally.”

Key to everything Legaz and Gabriel do with VinZero can’t be overlooked, a company which desires to educate the market about health and wellbeing while also providing premium products to support that message. F

20 Food &Beverage Industry News | May 2023 | www.foodmag.com.au MEET THE MANUFACTURER

VinZero praised its partnership with Dan Murphy’s for its growth.

VinZero imports premium products from overseas markets with strong non-alcoholic beverage markets.

Melbourne International Coffee Expo 2023 17—19 August 2023 CELEBRATING 10 YEARS OF EVERYTHING COFFEE Discover the lastest innovations in sustainable packaging solutions Visit the Southern Hemisphere’s largest dedicated coffee trade show. Early bird tickets are currently available. Get yours now to save! internationalcoffeeexpo@primecreative.com.au Melbourne Convention and Exhibition Centre www.internationalcoffeeexpo.com

Better recalls through communication

Mark Blitenthall, manager of service engagement at GS1 Australia, speaks about the challenges still being faced by supply chain disruptions that continue to bring into focus the need for traceability and transparency, especially around product recalls.

“As careful as organisations are to prevent and avoid adverse events, there will, on occasion, be risks that ultimately require management through a product recall,” he said.

“Because of globalisation and the growing complexity of supply chains it is becoming increasingly necessary for organisations to be prepared so they can manage a product recall as a routine process.”

GS1 Australia’s Recall platform is an online system that is used by hundreds of companies across the country to enable the fast and efficient removal of unsafe products from the supply chain.

As with other services provided by GS1 Australia, the Recall system was

developed after close consultation with key stakeholders.

“It’s something we have developed in consultation with industry, like a lot of services we create and provide,” said Blitenthall.

“GS1 Australia Recall is a standardised industry driven communication tool that enables organisations of any size to efficiently share product recall and withdrawal notifications with regulators and their trading partners, enabling the fast and efficient removal of products throughout the supply chain to minimise the impact of these events.

“The platform supports them through the entire process from identifying a problem, alerting the relevant regulator, such as FSANZ, through to the notification of trading partners and reporting the withdrawal of product from the market.”

The platform integrates to other GS1 platforms like the National Product Catalogue product registry

and the Smart Media digital asset management solution, to make the process of managing recalls as efficiently as possible.

“If the user has their product information in the registry, Recall will pull the product data from there and automatically populate the product information, ensuring there are less keystrokes and fewer errors,” said Blitenthall.

“If they have images in Smart Media, Recall will pull them down to provide further, visual information about the product that is being recalled or withdrawn.

“Having a solid and well-rehearsed recall process and system is foundational for managing risk. GS1 Australia Recall supports and encourages that.”

The platform provides critical information from details about the product, why it was recalled, along with images of the product.

“This is so that the trading partner can easily identify the product to remove

it from their shelves,” said Blitenthall.

“And then there is a status reporting capability that displays the progress of all actions taken by receivers of the recall notice in real time, allowing the issuer of the notification to receive instant updates and monitor progress in the Recall system.

“Whilst the platform supports the management of the recall process, it’s also important that the user has a plan and process in place to manage product recalls.

“The platform provides a tool for enhancing this process through its communication and reporting workflow. It is also well supported,” said Blitenthall.

“We have a support team that provides assistance in the form of training and help with using the platform to conduct recalls and mock recalls, guiding users step-bystep through a recall, withdrawal or alert, from notice creation to communication and follow up

“We also encourage users to a current Recall Ready status in the system to assure their trading partners that they are ‘ready’ to submit a detailed recall notification, should the need arise. Initiators can maintain their Recall Ready status by issuing a mock or live notification every 12 months.

“A recall is a high-pressure situation, you want to be confident you can manage it internally, or have the option to reach out to someone who can support you in that,” said Blitenthall.

The Year in Review report is an extension of the Recall Bootcamps that have been run over the past couple of years. The Bootcamps aim to leverage the expertise of leading industry experts to share best practice with a community of like-minded individuals and organisations.” Participants are educated through a series of workshops to help users better understand the recall process.

“We did four boot camps in 2021

TRACEABILITY 22 Food &Beverage Industry News | May 2023 | www.foodmag.com.au

GS1 Australia has released the 2022 Recall: Year in Review report. Key findings inform the reader of the continuing risks to product safety and the necessity to plan for the occurrence of product recalls in Australia and how to better prepare for, and even avoid, food safety incidents. Food & Beverage Industry News reports.

GS1 Australia’s Recall platform is already used by hundreds of companies to enable fast and efficient recalls from the supply chain.

and two in 2022,” said Blitenthall.

“It’s about creating a forum where people who are involved in the recall space can come and benefit from the knowledge and experience of industry experts who provide thought leadership and advice through a webinar.

“It’s about sharing insights with people in the recall space who are looking for advice and support.

“The boot camps facilitate this, and then we make information availablefrom recordings of the sessions to other take away points to implement within your own operations.”

The boot camps provide an important resource for users of the Recall platform. They also give rise to enhancements to the platform from feedback captured during discussions.

“It’s about creating the community to support anyone in the recall space to have access to training and informal learning in addition to a platform that supports their recall process,” said Blitenthall.

“We get a lot of insight from those sessions and that is where we came up with the idea for a Recall Year in Review report.

“We’ve collected a lot of useful information and being able to compile it into a report to share helps learning

occur as widely as we can get the information out.”

One new feature to come from the extensive consultation and feedback gathering is the introduction of an Action Centre, designed to consolidate outstanding actions. Another is the Recall Ready tab, which allows users to quickly view recall status. There is also a Feedback Button for users to share comments and findings along the way.

The community is the foundation for a lot of the work and development GS1 Australia does, seeing the benefits of collaboration around key areas such as recalls.

“It’s a foundation to everything we do as a not-for-profit organisation, and we see it as our role to help facilitate collaboration within industry and create forums to facilitate this,” said Blitenthall.

“We also provide advisory groups around the use of our standards and services, which allow us to develop and evolve tools in conjunction with industry.

“It’s critical we do everything we can to engage industry stakeholders and get feedback and facilitate information sharing between members of the user community.”

Blitenthall said recalls are an

THE FUTURE OF TASTE, FOOD & BEVERAGE BEGINS HERE

area which benefits greatly from the collaboration provided by a platform such as GS1 Australia’s.

“In support of knowledge-sharing and upskilling of all stakeholders in the quality management space, GS1 Australia continues to create a space where conversations about recall best practice can occur and be accessed by everyone,” he added.

Feedback from users also helps inform the continued evolution and development of the recall platform.

“We take feedback through the platform, suggestions of improvement for example. We are always collecting that and making changes where they are needed. This gives rise to new features which strengthens the platform even further,” said Blitenthall.

“It makes sense to collect this feedback and implement those changes that have the potential to improve the user experience for significant sections of the user community.

This point highlights the value of the community and collaboration created through GS1 platforms and services.

“Training is one of the primary ways in which we support the user community,” Blitenthall added.

“We talk users through the platform

and encourage users to reflect on their usage of the platform in the context of their own recall process to ensure that they understand what the steps are for a recall process.

“It’s a broader thing than just using the platform, which is where we try to use the boot camps to educate users around the broader considerations regarding preparing for and managing product recalls and withdrawals

GS1 Australia’s Recall platform is also HACCP certified as effective and suitable for businesses that operate a HACCP based food safety program, which adds yet another element to the benefits the service provides users.

GS1 Recall was first evaluated for HACCP International certification in 2016. The evaluation determined that GS1 Recall system meets the requirements and expectations of the food industry.

HACCP International certification of GS1 Recall gives their customers assurance they will meet the requirements of a recall system.

GS1 Australia Recall platform will continue to incorporate industry feedback to ensure it can meet the needs of its users and evolve with the technology. And 2023 is expected to be another great year for the service. F

Learn more: www.iff.com

TRACEABILITY www.foodmag.com.au | May 2023 | Food &Beverage Industry News 23

At IFF we are transforming our industry through the design of better products, building on our heritage of creating sense experiences with the addition of world changing scientific expertise and R&D.

We are your partner for essential solutions, guided by a customer-centric approach in everything we do. Applying science and creativity for a better world. It’s time to discover the IFF difference.

Copyright © 2023 by International Flavors & Fragrances Inc. IFF is a Registered Trademark. All Rights Reserved.

Time to move away from compressed air?

The food and beverage industry faces mounting pressures to meet new standards in line with embracing reports.

Bürkert’s high-precision electromotive drives provide highly intelligent and diverse opportunity for process optimisation and cost savings

To future proof their brands within the marketplace, conscientious manufacturers are addressing retailer and consumer demands for clear messaging and assurances that they’re keeping up their end of the bargain in securing a carbon zero future. In this instance, the cost of upgrading and evolving to ensure the manufacturing processes are optimised, addressing waste, and carbon emission reduction, all whilst maintaining safety, quality and consistency is the only way forward, whether you’re ready or not.

The use of compressed air in the food and beverage industry can present certain challenges and concerns due to potential issues related to air quality, contamination, food safety and energy usage.

According to Chicago Pneumatic, “compressed air is eight-times more expensive than electricity. It takes a large amount of energy to compress air and most of that energy disperses as heat.” If the heat produced isn’t repurposed via a heat recovery system, this just ends up being dead energy and emissions into the atmosphere.

Electromotive valves, also known as electrically operated valves, are often considered better than pneumatic valves in certain applications due to several advantages they offer:

Faster Response Time

Electromotive valves typically have faster response times compared to pneumatic valves. They can open and close quicker, allowing for more precise control and

faster actuation, which is particularly beneficial in applications where rapid response and precise control are critical.

Higher Precision

Electromotive valves can provide higher precision and accuracy in controlling flow rates and pressures. They are capable of fine-tuning and modulating the flow or pressure with greater precision, making them suitable for applications that require precise control, such as in medical equipment or industrial processes.

Lower Energy Consumption

Electromotive valves typically consume less energy compared to pneumatic valves. Pneumatic valves require compressed air, which can

be energy-intensive to generate, whereas electromotive valves operate on electricity, which can be more efficient and cost-effective, especially in applications where energy consumption is a concern.

Greater Flexibility

Electromotive valves offer greater flexibility in terms of control options. They can be controlled remotely using electrical signals, making them compatible with various control systems, including computer-based automation, PLCs (Programmable Logic Controllers), and IoT (Internet of Things) systems. This allows for seamless integration into modern automated systems for improved efficiency and control.

SUSTAINABILITY 24 Food &Beverage Industry News | May 2023 | www.foodmag.com.au

associated costs.

Quieter Operation

Electromotive valves generally operate more quietly compared to pneumatic valves, which can produce noise due to the compressed air being released or vented. Quieter operation can be beneficial in applications where noise reduction is important, such as in medical or laboratory settings.

Cleaner Operation

Electromotive valves do not require compressed air, which can introduce contaminants into the system, whereas pneumatic valves require compressed air that may contain impurities or moisture. This makes electromotive valves more suitable for applications that require a clean environment, such as food processing, pharmaceuticals, or semiconductor manufacturing.

While electromotive valves have several advantages over pneumatic

intelligent and diverse opportunity for process optimisation and cost savings for the food and beverage industry. This on/off valve suite of electrically driven shut-off operations provide an advantage to manufacturers with their fully integrated automation, digitalised systems.

Bürkert’s process valve product range now makes it possible to switch systems entirely to electromotive actuators. The two on/off valve types feature convincing efficiency that is equal to that of pneumatic actuators.

And the electric actuator uses the same time-proven valves of the Bürkert ELEMENT product family.

This means that the actuators are also interchangeable. Electromotive

A mechanical position indicator with a 360° LED clearly indicates the position and status of the valve at all times.

I n addition, the possibility of a manual override also exists.

The closing speed is adjustable to protect field devices and pipes against pressure shocks. The electromotive on/ off valves respond instantaneously to process signals to guarantee fast shutoff of the flow within 3-4 seconds, if necessary.

Hygienic, high-quality and durable

The field bus capable shut-off valves consist entirely of high-quality components.

Reducing energy consumption benefits both the company and the environment.

closed design. This makes it ideal for use

Other uses include heating and cooling circuits for heat exchangers, mobile or decentralised drinking water treatment systems or large-scale systems in which the supply of compressed air is impractical due to the long distances. Electromotive valves are especially suitable for processes where compressed air is not desired.

Technological diversity –typical Bürkert

The Bürkert electromotive shut-off valves are offered as an angle seat valve (Type 3320) and as a globe valve (Type 3321), as well as the highly sought-after diaphragm valve for those hygienic or aggressive environmental conditions.

Each of the valves can be used for diverse media – including gases and water, alcohols, oils and alkaline solutions, saline solutions and steam –with temperatures from -10 to 185 °C, at ambient temperatures up to 65 °C. F

www.foodmag.com.au | May 2023 | Food &Beverage Industry News 25

Bürkert’s high-precision electromotive drives provide highly intelligent and diverse opportunity for process optimisation and cost savings for the food and beverage industry.

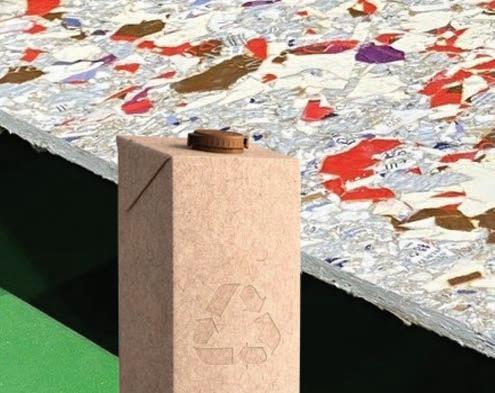

Beverage cartons find second life in construction

Apartnership between Tetra Pak, a food processing and packaging solutions company, and saveBOARD, manufacturers of sustainable building materials, is a prime example of how recycling packaging for a secondary use or market can help drive a circular economy.

Recently, the first saveBOARD facility in Australia was opened as a result of the collaboration. Located in Warragamba, Sydney’s southwest, the new $5.5 million facility has the capacity to process up to 4,000 tonnes of beverage cartons annually and employ up to twelve local staff to operate the plant.

The facility’s construction was supported by the Australian Government’s Recycling Modernisation Fund and the NSW Government’s ‘Waste Less, Recycle More’ initiative.

The facility is the first of its kind in Australia to manufacture construction panels from beverage cartons that would otherwise go overseas to paper recyclers in Asia.

The panels are a one-for-one alternative to conventional plywood, oriented strand board (OSB) or chipboard and are 100 per cent recyclable The fact that they use no chemicals or adhesives like formaldehyde, no water and have the lowest carbon footprint of comparable building products means they can be used for green star certified buildings, was a key factor behind Tetra Pak’s support.

The industry-led project is the first

collaboration in Australia under the umbrella of the Alliance for Beverage Cartons and the Environment (ACE) and is a joint initiative with saveBOARD and its partners Freightways and Closed Loop.

Vikas Ahuja, Tetra Pak’s sustainability director Oceania, said the work being done with saveBOARD aligns perfectly with the company’s sustainability goals.

“We commit to making food safe and available, everywhere. This is our purpose and why we come to work every day. We aim to provide safe nutrition as widely as possible,” he said.

“We believe a package should save more than its costs. An LCA study of food and beverage packaging in Australia and New Zealand conducted by thinkstep-ANZ showed that cartons have the lowest carbon footprint compared to other beverage packaging formats including glass, PET and recycled PET”

“If you think about carbon footprint of a milk carton, the packaging is about two per cent of that product’s total footprint. Based on some of those numbers, we are saving more than 50 times the environmental impact of the carton itself by preserving milk for more than two years without requiring refrigeration.

Ahuja said Tetra Pak launched its collaboration with saveBOARD after recognising that the Australian market was well suited to both a growth in paper-based packaging and demand for timber replacement construction

materials, much like it is in the United States and other large international markets.

“It fits very well with Australian market conditions,” he said.

“There are other ways of recycling beverage cartons in Europe and most of Asia, where the demand for fibre is high and cartons are already re-pulped back into paper.

“For Australia, it was important for us to find a market appropriate technology. We are already oversupplied with recovered paper, so finding a solution better suited to our market than re-pulping was important for us”

The success of saveBOARD technology, which has been in use in USA for more than 15 years, also meant the risks of applying it in Australia were minimised. In an interesting twist, the very origin of this technology was linked with liquids, and beverages, in a couple of ways.

“The originator of this technology was trying to make building products that were more water resistant, and he realised that milk comes in a paper carton and is water resistant, so why can’t a wall do the same,” said Ahuja.

“That is how this product started. Its origins are completely interlinked with beverage cartons.”

Knowing that Australia has a high demand for construction panels was another tick in the positive column for Tetra Pak.

“When looking for what to bring into the local market, they knew they were picking a successful product,” said Ahuja.

“It has a significantly lower carbon footprint because it is made from recycled materials, and it’s fit for purpose when you compare its performance to those existing materials.

“By delivering a one for one replacement into a large existing market, it was a simpler and safer commercial proposition.”

The booming demand for paperbased, renewable packaging, is another key driver behind the facilities construction.

“Demand for paper-based packaging is growing, and we don’t see that backing off,” said Ahuja.

“As the shift towards more paper-based packaging grows, the opportunities to reuse it again in different products becomes important. People looking at packaging made from natural, renewable, plant-based materials like paper are positioning themselves well for a growing market.”

The government funding from the Australian, NSW, QLD and VIC governments for all three saveBOARD plants was also another strong indication that the future of recycling, particularly paper-based packaging is expected to continue to grow in Australia, towards meeting the packaging and recycling targets.

PACKAGING 26 Food&Beverage Industry News | May 2023 | www.foodmag.com.au

The reality of a circular economy around packaging continues to strengthen as companies further improve, or adopt, emerging innovations. Adam McCleery writes.

Tetra Pak and saveBOARD are helping strengthen the circular economy.

to support these projects, means investors see a ratification of things like the technology, but also feedstock availability, and potential support for things like planning consents, that all help these projects land and succeed.

“The packaging targets have engendered a lot of cross-sector collaboration that includes not just the brands selling packaged products, but the collectors, sorters and recyclers and is a key reason why the targets and funding have helped drive work in this space.”

The first saveBOARD project came about because of a collaboration between Tetra Pak, a large local dairy company, two waste management companies and a large logistics and information management company.

In terms of processing saveBOARD, “it’s a simple process where beverage cartons are shredded and then pressed between two hot plates at a high temperature. That’s it,” said Ahuja.

This process also allows variations of the product which are well suited to different applications in construction.

“There is one with a layer of fibreglass that can be used for roofing,” said Ahuja.

“Another with a layer of craft paper so you can use it to replace interior plasterboard, skim it and paint it. “The one that gets the most interest, is the ‘exposed board’ because it tells its own story, you can see the pieces of recycled Tetra Pak cartons in the board, and people recognize the brands they buy.”

material which is a great replacement for plywood used for site hoardings, and boxing for pouring concrete. Thanks to the product’s history overseas, it had already proven to be up to building standards and certifications.

Ahuja, and Tetra Pak, expect the market for saveBOARD products to grow because of the sustainability and cost benefits of using saveBOARD’s products for future construction projects.

The demand for sustainable products with hefty premiums is relatively small. “Critically, for new recycling ventures to succeed, you must find something that is commercially viable in its own right, like the saveBOARD product,” he said.

“The great thing with saveBOARD is that it’s price competitive when compared to standard building materials like plywood and OSB.

“saveBOARD are giving builders a great choice, they can have a recycled, sustainable, almost zero carbon material, and save money with that choice. Some major Australian brands readying projects for launch, using saveBOARD products.

“It doesn’t end there. We are now investing in sorting equipment in Material Recovery Facilities (MRFs) across Australia. We have just invested in Australia’s first AI-robot for sorting beverage cartons for saveBOARD. And we are interested in partnering with other MRF operators, but also brands which have an interest in having their packaging sorted at MRFs for local recycling.” F

www.foodmag.com.au | May 2023 | Food &Beverage Industry News 27 PACKAGING

liquidnitrogenservices.com.au 03 9782 2646 1300 Nitrogen The Gas Professionals! For Your Liquid Nitrogen and Dry Ice Needs

The beverage cartons are broken down before being pressed into viable building materials akin to plywood.

Supagas’s future growth for LNS

Since the introduction of Liquid Nitrogen Services to the Supagas brand the combined offerings from both Adam McCleery writes.

“What we do with Liquid Nitrogen and Dry Ice is more about show. It’s something these businesses use to promote their food, for example, they might use Liquid Nitrogen on cocktails or Dry Ice to create a fog effect for desserts,” he said.

“And fine dining restaurants might use them in some of their dishes. It’s something that creates a wow factor.

“When we talk food and beverages, in terms of restaurants, that’s where Supagas and LNS align. Supagas were already working in the cylinder side of things, for example pub gas cylinders. And we, at LNS compliment that with our products, along with our strong presence in the hospitality sector.

their gas needs, whether small or large orders. Supagas and LNS work together, strengthening supplier and customer relations, with LNS as a key touch point in the Liquid Nitrogen space.

The services LNS provides vary from Liquid Nitrogen deliveries, cryogenic equipment, Dry Ice, accessories and more.

“It is a very niche business, the Liquid Nitrogen side, there aren’t a lot of people in this industry so to get the experience and knowledge from us, with an already established gas supplier in the market brings with it lots of advantages,” said Filliponi.

“At LNS, we retain that family business sense, at the same time LNS has grown and changed from where we initially began, which we really like. It is about remaining true to our customers to continue to provide them with quality products and exceptional service.

“Being a part of Supagas there have been few changes; in terms of the day to day running of LNS, things remain the same, which is a true testament of how well LNS continues to do, aligned with Supagas strategy.”

“And it has definitely extended our growth potential.”

“Supagas was largely involved with craft breweries, distilleries and more. Now, LNS has come together with the Supagas brand to deliver to the market, helping to cover the gas needs and requirements of businesses in the Food and Beverage industry.”

As a result, Filliponi said, Supagas and LNS provide the ‘whole package’.

“You won’t see many companies without LNS or Supagas involved in some shape or form,” he said.

The future of LNS and Supagas Supagas and LNS, as brands cater to various customer segments based on

“As a result, we are in and amongst it with the likes of head chefs, who rely on us. We take calls at all hours, happily. They can rely on us for a lot of stuff, and we take pride in that.”

LNS continues to grow with potential to further expand, building on the business foundation and striving to supply and service current and future customers.

LNS, the gas professionals are here to assist customers with their gas and equipment requirements’.

To find out more about Liquid Nitrogen Services products and services contact 03 9782 2646 or liquidnitrogenservices.com.au. F

started back in 1992. As the familyowned business continued to grow, in November 2018 Supagas and my parents saw great potential for LNS to join the Supagas family. And now LNS is a sub-division of Supagas,” he said.

“The company built up a strong name in Melbourne over more than two decades, and for its service especially. Supagas wanted to keep that name recognition and personal touch in providing exceptional service and quality products to customers in Melbourne.”

LNS and Supagas, two brands align LNS as a sub-division of Supagas, works closely with the hospitality sector, as the LNS team continues to grow the market.

Filliponi said the food and beverage scene in Melbourne assists in the growth potential of LNS immensely.

Liquid nitrogen is routinely being used in hospitality and food manufacturing.

INDUSTRIAL GAS 28 Food&Beverage Industry News | May 2023 | www.foodmag.com.au

Liquid Nitrogen Services are a subdivision of Supagas and will expand across Australia.

3 NOMINATIONS NOW! OPEN AUSTRALIA’S LEADING MANUFACTURING AWARDS endeavourawards.com.au IN PARTNERSHIP WITH

Motor protection made easy with moneo wizard

Protect your industrial motors with advanced vibration analysis from ifm moneo. Food and Beverage Industry News reports.

Imagine having Gandalf protect your industrial motors. It would be a formidable force to reckon with. Well, according to Freddie Coertze, the ifm moneo Data Science Toolbox has a wizard that can provide just that type of protection – by predicting motor issues through the use of advanced vibration analysis (AVA).

“A unique aspect of moneo is that this wizard can help users determine the vibration limits of their motor and predict failure well in advance, so there is enough time to act,” said Coertze, the national IoT business development manager for ifm Australia.

“It’s a great way for an industrial business of any size to start implementing a predictive maintenance plan – without the fuss and complexity that is often associated with this process. Because you’re starting just with the motor monitoring.”

Unlike other condition monitoring

solutions, moneo has been designed for ease-of-use. It is a self-service IIoT platform where the hardware, software, and smarts – which are predictive formulas created by artificial intelligence (AI) – come in the one package.

The AVA wizard is a tool that comes with moneo and can be used as a simple way to start monitoring and protecting motors.

“It’s very easy to set up. Basically, the wizard tool will talk you through the steps so you can do everything yourself without the need for an IT or analytics expert,” said Coertze.

“It’s a matter of connecting your sensor, dragging and dropping that into the moneo dashboard, selecting the motor configuration, and then moneo has an inbuilt AI tool that will create baselines for you in regard to what the acceptable limits of motor vibration will be for that configuration.”

Users can then start seeing the vibration levels of their motor installation on the dashboard.

The set limits suggested by moneo appear as red and yellow dots to indicate if the motor is running outside of its determined limits.

“If vibration levels exceed the yellow, you have early notification that your motor needs attention and if it reaches red, it goes into alarm,” explained Coertze.

“It’s the difference between having a warning that something is about to fail and having early notification that is predicting a failure later.

“Essentially, this wizard gives you time to fix motor issues before they become bigger problems. As we say, to protect, you need to predict, and this wizard helps you do that.”

Importantly, moneo has been designed to keep it simple for users, but also to expand as requirements change.

“You can extend on this form of motor protection by adding a device that provides a more intensive vibration and into other aspects of predictive maintenance as well,” said Coertze.

“But if we think about businesses just wanting a starting point, this is a great way to begin. You might have an asset such as a conveyor where if it breaks down due to a motor failure the whole production of a facility might come to a halt.

“So having this tool will let you know in advance if the motor has issues such as if it’s misaligned or it’s out of specification, and you can save it before any event like that occurs.” F

INDUSTRIAL MOTORS 30 Food &Beverage Industry News | May 2023 | www.foodmag.com.au

The ifm moneo Data Science Toolbox helps to predict motor issues through the use of advanced vibration analysis.

ifm moneo are experts at helping companies protect industrial engines.

Recognising excellence across the waste, resource recovery and recycling sectors. 2023 NOMINATIONS ARE NOW OPEN www.wasteawards.com.au/nominations To nominate visit 25 OCTOBER 2023 SPONSORS HELD IN CONJUNCTION WITH

Recyclable pouches for food, coffee and other perishables

Research shows that consumers are now making purchasing decisions based on ethics and/or sustainability, which is impacting, among other aspects, packaging design

As the 2025 National Packaging Targets get ever closer, the move towards sustainable flexible packaging continues to intensify. Favourite Packaging, a company that specialises in food, pet food, and industrial flexible packaging, through their membership of APCO, have cooperatively sourced and now released new recyclable flexible packaging options, including Recyclable Pouches.

Favourite Packaging’s Pouches, over the last decade have become more and more popular for a wide variety of foods, perishables, coffee, powders, liquids, pet foods and now Favourite Packaging can supply a recyclable option that have the

same or improved features.

Favourite Packaging managing director Justin Yates said these innovative Pouches finally provide the right protection to preserve shelf life, meet the criteria for recyclable flexible packaging while contributing to improving your brand image.

“Our aim was to come up with something that fits in with the 2025 National Packaging Targets while meeting the technical requirements for food and perishables,” said Yates.

“The big thing was getting away from packaging using PET for its barrier. That’s been the go-to material for many years, and it has been easy to work with but not feasible to recycle.”

“We had to come up with something else that was a mono-polymer and fit in with APCO guidelines which would then allow it to be considered recyclable

in the new guidelines.”