Stainless steel servo gearmotors

PSH..CM2H..

Hygienc. Modular. Flexible

PSH..CM2H..

Hygienc. Modular. Flexible

As stringent hygienic requirements become more relevant in the food, beverage and pharmaceutical industries, the PSH..CM2H.. series guarantees the highest level of cleanliness and protection against contamination.

Developed to withstand high-pressure cleaning, even at high temperatures and with chemical cleaning agents, this series is the ideal drive solution where hygiene is the priority.

Your Benefits:

• Faster cleaning times

• Compact design for your open machine concept

• Suitable for the food and pharmaceutical industry

• Precise and safe positioning

• Fast startup and optimum operation

CEO: John Murphy

COO: Christine Clancy

Managing Editor: Syed Shah

Editor: Adam McCleery

Ph: (02) 9439 7227

adam.mccleery@primecreative.com.au

Design Production Manager: Michelle Weston michelle.weston@primecreative.com.au

Art Director: Blake Storey

Design: Michelle Weston

Sales/Advertising: Stephanie Suzuki

Ph: +61 422 046 711 stephanie.suzuki@primecreative.com.au

Production Coordinator: Janine Clements

Ph: (02) 9439 7227 janine.clements@primecreative.com.au

Subscriptions AUS NZ O/S

1 year subscription 99 109 119

2 year subscription 189 199 209

For subscriptions enquiries please email subscriptions@primecreative.com.au

Copyright

Food & Beverage Industry News is owned by Prime Creative Media and published by John Murphy. All material in Food & Beverage Industry News is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published.

The opinions expressed in Food & Beverage Industry News are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

© Copyright Prime Creative Media, 2019

Articles

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Head Office

379 Docklands Drive

Docklands VIC 3008

Ph: +61 3 9690 8766 enquiries@primecreative.com.au http://www.primecreative.com.au

Sydney Office

Suite 303, 1-9 Chandos Street

Saint Leonards NSW 2065, Australia

Ph: (02) 9439 7227

Processing in the food and beverage industry continues to evolve at a rapid pace, and as a result the impact of new and emerging technologies are being keenly felt. Thankfully, the continued innovations in processing bring with them a string of benefits which are impacting the bottom line, output, and overall environmental impact, in positive ways.

As the June edition of Food & Beverage Industry News gives some insight into, processing solutions continue to improve upon products entering the market, thanks in large part to the over arching applications which processing solutions can be applied to.

Processing technology and solutions are entwined with every aspect of food and beverage manufacturing and its rapid advancement is coming at the exact right time.

As the world continues towards a more sustainable, and environmentally friendly future, the spotlight is being shone on the carbon footprint of critical industries, including food and beverage.

The industry is responding to the challenge being laid out by governing bodies, governments themselves, and consumer demands. All three clearly setting out expectations for improvement, as demonstrated by The Paris Agreement and the Federal Government’s Modern Manufacturing Initiative.

Australian industries have been set bold targets of Net Zero by the end of the century and to achieve this many companies are being encouraged to start the downward trend by 2030, or risk missing the Net Zero target altogether.

Foodpro is only one month away, making its return after the COVID-19 pandemic put a stop to the previous event. Melbourne will once again host the event and after an extended break the anticipation for the trade show is reaching its peak.

Because of the break, foodpro is expected to showcase many off the innovative changes alluded to above, among the other offerings a global trade show like foodpro has to offer.

Food & Beverage Industry News is the official show guide for foodpro 2023, which means we have been given some early insight into how jam packed the event will be with the best food and beverage manufacturers and producers from across Australia, and the world.

Foodpro will give the industry a clearer view of where it stands in the scheme of reaching Net Zero and highlight areas possibly still in need to advancement.

T he impact of changing consumer demands on the food and beverage industry has always been a key driver behind changes and innovation, and the current climate is no exception.

Consumers are demanding more environmentally friendly products, from how and where ingredients are sourced, to the packaging products come in.

It’s been proven consumers will vote with their dollars, encouraging food and beverage manufacturers and producers to become more environmentally friendly and sustainable.

Terms such as ‘circular economy’ come to mind, and thanks to innovative new ideas and products, these sorts of ideas have become easier to make a reality. Despite some hiccups along the way.

Printed by: Manark Printing

28 Dingley Ave Dandenong VIC 3175

Ph: (03) 9794

In this issue of Food & Beverage Industry News, we get some added insight into how processing specialists, among others, are adapting to the road map to Net Zero.

As a result, the future of the industry is likely to look very different to the now, which I for one find exciting.

Until next time. Happy reading!

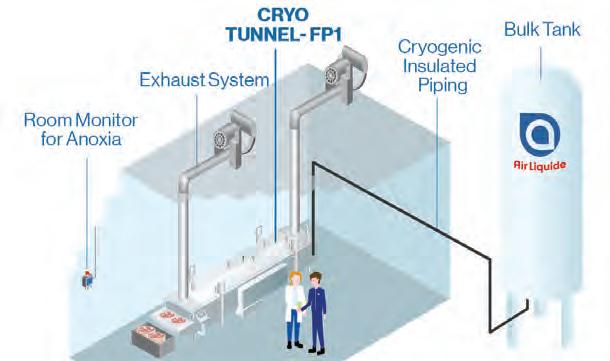

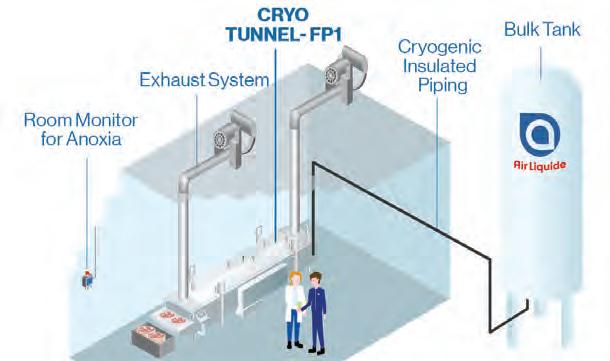

Air Liquide offers an ideal range of gas application equipment with excellent cryogen efficiency and improved sanitary design for food processors. With minimal capital investment required and low installation costs, as well as ease of operation and maintenance, Air Liquide can significantly improve your productivity and product quality.

01 Quality you can depend on

Food grade gases compliant with local regulations and follow HACCP methodology (CO 2 ) to guarantee quality and safety of our products.

02 Experts at your service

Air Liquide will provide you with the full support of our food application and technical experts for the design of your solution, its installation and start-up and the ongoing optimisation of your processes.

03 Flexible supply

Reliable, continuous supply, ALIGAL™ is available in various supply modes from cylinders up to bulk liquid.

18 MEET THE MANUFACTURER

A love of family, and heritage, helped give rise to Granddad Jack’s award-winning distillery.

22 PACKAGING

Favourite Packaging is helping the industry with alternative packaging options.

24 PROCESSING

How Krones is helping the industry address the changing tastes and demands of consumers.

26 PROCESSING

Tera Pack’s High Shear Mixer provides a flexible processing tool for food and beverage manufacturers.

28 CONSTRUCTION

Total Construction is seeing first-hand the impact the current economic climate is having on the industry.

30 NUTRITION

Angel Yeast is helping bring prominence to yeast extract as a new source of protein.

32 MANUFACTURING EQUIPMENT

SEW Eurodrive’s newest portfolio of stainless-steel gearmotors presents strong reliability and hygiene.

34 MACHINERY

Combilift’s pedestrian stackers provide a range of benefits including safer facilities for workers.

36 PROCESSING

Inox Australia’s Instantiser range is a great solution for the mixing, cooking, and cooling process.

38 CRYOGENIC FREEZING

Air Liquide’s cryogenic freezing solutions help product maintain freshness and saves of wastage and loss of commercial output.

40 INGREDIENTS

International Flavours & Fragrances combines creativity and science to create essential solutions for the industry.

42 NEW PRODUCTS

The modern plant needs more than condition monitoring to ensure assets are healthy and meeting production demands.

To support a successful predictive maintenance program you need realtime streaming analytics.

ifm’s moneo is an easy to use, self service software platform that simplifies the integration of Industry 4.0 concepts into existing systems.

The in-built DataScience Toolbox enables operators and engineers to leverage their knowledge of equipment with the benefits of AI-assisted predictive analytics and machine-learning techniques. This empowers businesses to identify and remedy anomalies before they become expensive, big problems.

Coles has said it will phase out soft-plastic shopping bags in-store and online by the end of next month as the supermarket strengthens its commitment to reduce unnecessary plastic packaging at the checkout.

T he remaining supply of softplastic bags will be run down in the coming weeks before Coles ceases the sale of all soft-plastic bags by the end of June, a move that will remove 230 million plastic bags from circulation in 1 year.

Coles Group chief operations and sustainability officer Matt Swindells says the decision to end the sale of soft-plastic bags nationwide, both in-store and online, was an important step in meeting the supermarket’s sustainability ambitions.

“Today’s decision to no longer

Anew partnership has been announced between Jakarta-based fine chocolate manufacturer Pipiltin Cocoa and Katalis, a business development program backed by the Australian and Indonesian governments.

Pipiltin Cocoa will serve as a point of contact with other interested premium cocoa businesses in Indonesia as the industry targets the Australian market, responding to Australia’s growing demand for a more diverse range of premium products.

The new partnership will provide important market insights for Indonesian exporters seeking to penetrate the Australian specialty chocolate market and beyond.

When announcing the exciting new partnership, Paul Bartlett, director, Katalis, said, “Katalis works to foster new economic partnerships, business sector engagement, and cooperation that leads to more integrated markets

offer soft-plastic bags at the checkout is proof of our commitment to reduce the amount of plastic used in our stores and online. This positive change will remove 230 million plastic bags from circulation in 1 year,” said Swindells.

“The most sustainable option is to bring your own reusable bag to the supermarket, but for those who forget, we will continue to sell 100% recycled paper bags that can be recycled kerbside, as well as other reusable options,” he said.

“The 100% recycled paper bags have been tested for use and we’re confident they can hold up to 6 kilos of goods. That includes everything you need to make spaghetti Bolognese or a family roast,” Swindells added.

The announcement follows Coles’ decision to remove single-use plastic

carry bags at checkouts in 2018, which saved approximately 14,000 tonnes of plastic from being produced each year.

between Australia and Indonesia.

“With the premium chocolate industry driving the work to identify and investing in opportunities across their value chain, we are confident that the partnership will lead to closer trade and investment, improved market access, and more inclusive economic growth.”

Rapid growth in the Indonesian premium chocolate industry over the last five years means it is highly suitable for investment.

Australia’s premium chocolate segment is also ripe for new opportunities, with similarly fast growth due to increased health consciousness and growing demand for a more diverse range of premium products.

“Research has shown that singleorigin cocoa beans from Indonesia exhibit the highest profile diversity in the world, reflecting the diverse agroclimatic conditions of the archipelago and advanced processing techniques applied by the premium

cocoa industry in Indonesia.

“This is part of the strength of our offering and we’re excited to work with Katalis to share the story of Indonesian people, culture, and flavours,” said Tissa Auliani, CEO, Pipiltin Cocoa.

the small and medium enterprises in Indonesia’s premium cocoa supply chain owned and led by women, new market opportunities will empower women entrepreneurs, smallholder cocoa producers, workers, farmers, and

VicReturn, the Scheme Co-ordinator of the new Victorian Container Deposit Scheme, has hit the ground running by appointing Jim Round as its inaugural CEO.

Round brings a wealth of experience to VicReturn. Most recently, he has held leadership roles at the Victorian Department of Jobs, Skills, Industry and Regions as Deputy Secretary and as the Chief of Planning and Governance at the Victoria 2026 Commonwealth Games Organising Committee.

Round has previously worked as an economic adviser to Prime Minister Gillard and as a Director in the Office of the Premier, the Hon. Dan Andrews MP.

VicReturn was announced by the Victorian Government last month as the Scheme Coordinator of the Victorian Container Deposit Scheme, CDS Vic, which commences on 1 November.

VicReturn is a not-for-profit entity with members comprising some of Australia’s leading beverage companies: Lion, Coca-Cola Europacific Partners and Asahi Beverages.

As Scheme Co-ordinator, VicReturn is responsible for managing the marketing of CDS Vic, running its financial operations and ensuring the

smooth operation of the Scheme.

Under Mr Round’s leadership, VicReturn will work closely with the Victorian Government and the three Network Operators to deliver a worldclass container deposit scheme for Victorians.

Vic CDS will provide benefits to households and community groups across the state while improving the environment and helping create a circular economy for beverage containers.

“We are delighted he has chosen to join VicReturn and look forward to benefitting from his extensive public sector and government experience,” said said Paul Klymenko, chair, VicReturn.

“His proven leadership abilities and track record of delivering results in demanding roles mean he is the right person to ensure CDS Vic achieves success in creating a circular economy for containers, reducing litter and creating opportunities for Victorian households and community groups to participate.”

“This scheme will cut container waste and create jobs and opportunities for Victorians. It’s a pleasure to be appointed CEO and I am looking forward to getting cracking,” added Round. F

DoorDash has partnered with leading sustainable packaging provider, BioPak to launch a new online shopping portal where merchants can enjoy exclusive pricing on sustainable packaging products, including DoorDash FSC™ certified bags.

T he partnership symbolises DoorDash’s commitment to helping merchants reduce environmental impact and meet their sustainability goals in an easy affordable way.

Merchants will now have access to a new one-stop shop where they can create an account on BioPak’s shopping portal using their DoorDash credentials and enjoy exclusive pricing when purchasing sustainable packaging products such as sugarcane containers and paper bags for their takeaway and delivery needs.

Leading the way in sustainable packaging solutions in Australia, New Zealand, Singapore, the UK and Europe, BioPak is on a mission to

create a world without waste where all product design, from raw material to

disposal, puts the environment first.

As a certified B Corp BioPak’s

plant-based, compostable packaging is the perfect solution for DoorDash merchants working to reduce waste and adhere to sustainability standards.

BioPak CEO Gary Smith says, “The partnership with DoorDash is an important step in our fight to achieve a Zero Waste future.

“At BioPak, we’re committed to disrupting the traditional packaging model and creating compostable solutions that can be adopted by businesses across Australia and APAC, changing consumer behaviours to adopt only circular economy solutions.”

Rebecca Burrows, DoorDash’s general manager for Australia, said that “DoorDash is committed to offering merchants affordable and sustainable packaging solutions whilst supporting them in their environmental ambitions. With over 30,000 merchants using the DoorDash platform in Australia we’re proud that the partnership will have a huge impact.”

Simply Cups, Australia’s largest paper cup recycling program, has been officially recognised as an Alternative Destination under the Australasian Recycling Label (ARL), giving consumers clear instructions

on how to recycle paper cups at one of the 1,500 cup collection locations in Australia.

Currently, paper cups, including coffee cups cannot be recycled in traditional kerbside recycling and as a

result, are sent to landfill.

The ARL provides guidance to consumers about which bin packaging should be placed in and includes an Alternative Destination option for specialised recycling programs, such as Simply Cups.

All paper cups – including coffee cups, soft drink cups, Slurpee cups, etc will soon be able to carry the ARL. Arrangements for this to happen will be finalised mid-late 2023.

Cups recycled through the Simply Cups program are given a second life in a variety of products made in Australia, including asphalt, lightweight concrete products and as a plasterboard substitute.

Recognition of the Simply Cups program as a valid recycling solution via the ARL Program is a great boost to the expansion of the ARL which is rapidly becoming the trusted guide to provide consumers with accurate

recycling instructions.

The ARL is an evidence-based label that provides easy-to-understand instructions about how to correctly dispose of all parts of a product’s packaging. The ARL ensures that when recycled correctly, materials can be reused again in the future.

The ARL is managed by the Australian Packaging Covenant Organisation (APCO) and requires recycling organisations to verify that their packaging is recyclable and demonstrate that there is a sufficient network of recycling points that are easily accessible to the majority of the population.

It also requires that the solution is available for all brands and types of coffee cups.

Closed Loop Environmental Solutions, who run the Simply Cups program is thrilled with the recognition of its cup recycling program under the ARL. F

The Ice Vodka product is unique in the world of spirits – the result of years of research & development (R&D) to perfect a proprietary cold vacuum distillation technique.

It is the first vodka to win a Double Gold for a cold vacuum distilled spirit, capping an exciting first 10 months of production for the distillery.

This year SFWSC received close to 6,000 entries from over 40 countries, which are then all blind tasted by a judging panel including some of the most respected, experienced experts in the industry.

“To have been recognised at such a prestigious level in the 2023 San Francisco World Spirits Competition is an honour to us all here at Banks and Bloom Distillery + Lab,” said executive director and Biochemist Elaine Darby.

As a small West Australian distillery in our first year of operation, utilising an innovative ‘cold distillation’ technique and rare Australian botanicals, we are thrilled that our Premium Ice Vodka has been recognised with a Double Gold.

Banks and Bloom Distillery + Lab announced that the Banks & Bloom Ice Vodka has been awarded DOUBLE GOLD

at the 2023 San Francisco World Spirits Competition (SFWSC); the most prestigious spirits competition in the world.

Out of these, Double Gold was awarded to only 500 products, including the Banks and Bloom Ice Vodka. Awarded to the entries that receive a Gold Medal rating by all members of the judging panel, Double Gold recipients are among the finest products in the world.

We see this as validation that concepts that began in our laboratory are now being recognised by an internationally respected judging panel and shared with the world of spirits.”

“To win Double Gold in our first year of operation is something we feel incredibly proud of and it’s really just the tip of the iceberg,” added managing director Trent Carroll. F

Purpose-built by Charter Hall, the new Equipment Services and Point-of-Sale facility at Richlands will drive business efficiencies and deliver a range of sustainability benefits.

Leading beverages company, CocaCola Europacific Partners (CCEP) Australia, has officially opened a brand-new, $40 million warehouse facility in Richlands, Queensland, in partnership with Charter Hall.

Located at 262 Orchard Road, the new building is CCEP’s first 5 Star Green Star rated property in its Australia property portfolio and reflects the company’s continued investment in more efficient and sustainable infrastructure.

Comprising 8,791 square metres and strategically positioned adjacent to CCEP’s existing Production and Distribution Centre at 260 Orchard Road, the new site has enabled the relocation of the company’s

Equipment Services division and Point-of-Sale warehouse, previously based at Rocklea.

The new site features a 233-kilowatt solar power system, while water-efficiency is supported

by a 100,000-litre water tank that enables reuse of water for amenities and gardens.

The building also utilises low-pollutant materials which help to provide CCEP employees

with an improved, indoor working environment, including better air quality, daylighting, and thermal comfort supported by cutting edge climate control. Efficient LED lights and motion sensors are also used throughout.

Weather resilience also formed an important part of the brief to Charter Hall with a strong focus on creating a building design capable of tolerating future climate-related events such as extreme rainfall and floods, helping to minimise disruptions and ensure continuity of CCEP’s high service levels.

CCEP Australia is proud to employ more than 3,500 people. The new Richlands warehouse is one of 20 CCEP-managed sites in the state, with the company’s property footprint spanning as far north as Cairns. CCEP has operations in every state and territory across the country. F

Combilift is the perfect fit for the grocery trade industry. Safely handle goods in narrow aisles, and minimise double handling with our multidirectional forklifts, articulated reach trucks and pedestrian forklifts.

Contact Us Today

To find out how Combilift can help you unlock every inch of your storage space

combilift.com

Bedford, Leyton Property and Leyton Funds are partnering to create a state-of-the-art advanced manufacturing hub in Adelaide’s north expected to be worth over $45 million once complete.

The joint venture partners have unveiled plans for what is believed will be Australia’s largest social enterprise site, offering employment opportunities to people of all abilities.

The development will be located on what is expected to be one of South Australia’s largest commercial greenfield development sites on Main North Road in Salisbury South.

It will specialise in the advanced manufacture of furniture and the supply of components to the commercial joinery and construction industry.

“The investment will significantly increase Bedford’s manufacturing capability to deliver a world class commercial product to the market. This will include an investment in the latest automation and robotics technology,”

said Bedford COO Social Enterprises Sam Hunter.

Adjacent to the new advanced manufacturing facility will be a firstclass Food and Beverage hub with hospitality retail offerings including:

• Commercial kitchen

• Beverage production facilities

• Public entertainment area

The hub will be home to Bedford’s first social enterprise called Cultivate Food & Beverage, which recently opened its first site in Brooklyn Park.

This social enterprise has a unique offering, delivering a full supply chain solution to medium and large size food and beverage producers with a national footprint.

Approximately 100 jobs are expected to be created during construction.

The centre will provide ongoing employment for more than 200 people when complete.

Bedford CEO Myron Mann

said that. pending council approval, construction was expected to begin later this year and be completed by 2025.

“This investment in our future will enable us to grow, innovate, and manufacture at scale while remaning true to our purpose,” he said.

Bedford’s investment forms part of its five-year masterplan.

Iconic NSW beer, Tooheys, has unveiled a bold new look for its range of beers, with an overhaul of the brand’s packaging, designed by

creative agency Weave.

This packing revitalisation has given the beer brand a fresh, modern look, while simultaneously reflecting its rich

history and enduring commitment to brewing great, refreshing beer.

As the first major update to Tooheys core packaging since 2015, leading beverage company Lion says the contemporary new appearance showcases Tooheys’ core brand assets, whilst still nodding to the brand’s rich 154 year history.

“Tooheys is a brand that has over a century and a half of stories under its belt – so there is a challenge in moving too far away from the past and our rich legacy,” said Chris Allan, head of Core Beer Marketing at Lion Australia.

“We feel the new packaging pays tribute to our proud heritage as well as modernising in a way that allows the core brand assets to shine.”

Tooheys Extra Dry required a different approach since it has always

Bedford’s investment forms part of its five-year masterplan announced in November 2022.

Bedford engaged property advisory firm Broadway Property to source and secure the site and guide the joint venture partnership arrangements. F

been slightly different to the rest of the trademark and it is a clear-bottled, even more refreshing variant.

The established date has been replaced with a product descriptor and finished with the recognisable white diagonal slash that has been a defining element of the beer since its invention in 1994.

The stag has been used to connect the Extra Dry product name with the Tooheys wordmark, elevated above the stag.

A sleek, colour-refresh has also been applied to the product label for Tooheys Old, replacing the previous maroon logo to its original all-black colour scheme, complementing the refreshing Dark Ale.

The new modern design has been rolled out across the entire Tooheys portfolio, including Tooheys Old, Tooheys New and Tooheys Extra Dry.

Little Creatures has announced the transformation of The Camfield, Australia’s largest pub, into a Little Creatures microbrewery, marking the beer’s second outpost in Western Australia.

In partnership with Three Pound Group, the venue promises to offer exclusive brews and the perfect night out for beer enthusiasts, friends and family.

The Camfield will host old favourites like the Little Creatures’ iconic OG Pale Ale, as well as the first of The Camfield brewed, limited-release beers, Backyard Ale, an All-Australian IPA, and a new permanent Draught Ale that celebrates the partnership.

New brews will be developed and brewed every few months too, only available at The Camfield and Three Pound Group venues.

“Little Creatures is proud to be opening its second outpost in Western Australia, twenty-three years on since opening the doors to its first brewery in Fremantle,” said Little Creatures Head

Brewer, Russ Gosling.

“We’ve put a lot of effort into creating a space that is both inviting and exciting for locals and visitors alike, and we can’t wait to share it with everyone.”

Little Creatures has been an icon of Western Australia and craft beer since 2000 and is loved around the country.

Lion are investing significantly behind the brand which sees Little Creatures Page 1 already brewing at The Camfield located microbrewery ahead of the official launch on 5 May, taking over from Bevy Brewing Co which will now cease production.

“The Camfield has been pouring

Little Creatures on tap since we opened the doors in 2018 and are honoured to be its second home in WA,” said Tim Mclernon, general manager, Three Pound Group.

Little Creatures currently has two breweries, one in Fremantle and one in Geelong where its range of products are manufactured.

The first Fremantle brewery was built on the site of an old crocodile farm in 2000 by a group of friends looking to capitalise on the growing popularity of pale ale beers.

These include it’s limited releases, such as Stou King, and its more well known products such as Pipsqueak, and Pale Ale.

Since its inception Little Creatures has had a strong focus on supporting the local community and source all of its ingredients locally.

On top of this, the company routinely assists local charities and community initiatives, as well as hiring local. F

access by demonstrating to our trading partners Australia’s commitment to, and confidence in our biosecurity system.

“Domestic and international trade is essential to the horticulture industry,” he said.

“By working with some of the country’s top scientists, the process for reaching market access agreements will be made easier.

a $9.5M injection into pest and disease risk management measures for safe trade.

While Aussie produce is renowned for having stringent biosecurity practices along all stages of the production and supply chains, State and Territories have differing phytosanitary, or pest and disease management, requirements for inter-state trade.

This investment, being delivered

Australia’s national science agency, will work closely with Australia’s domestic biosecurity regulators to strengthen our science-backed approach to managing phytosanitary risks, making it easier for growers to conduct safe cross-border trade.

Hort Innovation chief executive officer Brett Fifield said the program would also facilitate international market

“Improved risk science tools can support biosecurity measures that may be more cost effective and less time prohibitive for growers without compromising our already great reputation for delivering quality, safe produce.”

As part of the four-year effort, researchers will work closely with State and Federal Governments to develop and refine a fit-for-purpose ‘toolkit’ that can be used to improve state-level decisionmaking about biosecurity risks and how these are best managed.

Anew campaign supporting one of Australia’s largest providers of food relief, Foodbank, has launched in Woolworths supermarkets.

From 26 April 2023 until 16 May 2023, donations from customers and brands of participating products including Arnott’s, Sanitarium, Dolmio, Vetta, SPC, Pauls and Kraft Heinz will help Foodbank provide meals to Australians in need, with a goal of raising enough funds to provide 1 million meals.

Customers will be able to donate to Foodbank during the first two weeks of the campaign by rounding up their shop in store, or can choose to donate their Rewards dollars directly to Foodbank via the Everyday Rewards app.

Foodbank is facing increased demand for support, with its latest Foodbank Hunger Report 2022 revealing over 2 million households

across Australia have experienced food insecurity in the last twelve months. The day-to-day reality of food insecurity they’re seeing differs greatly between households, and on a typical day there are over 306,000 households in Australia receiving assistance from food relief organisations.

“We are seeing more and more Australians reaching out for help. These are people with jobs, double incomes,

Foodbank for more than 20 years.

Throughout this time, over 46 million meals have been given to people in need from the resources and donations provided by Woolworths,

A love of family, and heritage, helped give rise to Granddad Jack’s. An Australian distillery piling up global acclaim for its Gold Coast produced spirits. Adam McCleery writes.

For David Ridden, founder and owner of Granddad Jack’s distillery, every aspect of the company is a love letter to his own grandfather, David Goulding AKA Granddad Jack.

The craft distillery is run by the Ridden family, with Ridden’s son Luke taking on the role of head distiller. And in just a few short years Luke, and some of Granddad Jack’s products, have gained acclaim and awards from across the world.

I had a close relationship with my grandfather, who was born on the 11th of June 1919 and grew up in a hard time,” said Ridden.

“I sat with him several times and he told me stories about his life and at his 90th birthday my mum and her two sisters wrote a this is your life story book for him and ever since then I really wanted to tell his life story.

“The story of someone who grew up in a time when it was tough to survive.”

This connection and love for his grandfather has always stuck with Ridden, in a deep way, and it has informed everything about Granddad Jack’s.

“After selling a former business I wanted to do something to tell my grandfather’s story and it just seemed like a distillery would be the best place to tell that story. My grandad loved whiskey and drank it every day and lived to be 93-years old,” said Ridden.

“My grandfather was all about supporting the local neighbourhood, so for us it was important that the distillery kept that alive.”

Opening the first Granddad Jack’s distillery on the Gold Coast meant Ridden needed a distiller. His son Luke, a 20-year-old mechanic at the time, put up his hand and when the distillery opened in August 2018 Luke become the youngest commercial distiller in the country.

“Before open the distillery we didn’t know anything about the process,” said Ridden.

“ We didn’t have huge expectations of what it would become, but today it has become much more than we

ever anticipated.”

W hen we decided to build a distillery in November 2017, we had

no idea what we needed, said Ridden. Luke, much like his father, knew the importance of what they were

trying to achieve and immediately flew to Tasmania to get some firsthand knowledge about distilling, before taking things one step further. Demonstrating the commitment which helped him, and Granddad Jack’s become global award winners.

“From there things gathered momentum and we realised the commercial commitment, so we got more serious than we were thinking,” said Ridden.

Ridden and Luke both had an affinity with craft distilleries out of the USA because many had built brands on neighbourhood recognition and storytelling, two tenants of Granddad Jack’s.

“ They are passionate about being small and true to their neighbourhoods,” said Ridden.

“We had two objectives, to find out what we needed to build a distillery and to find somebody that we could entice to come to Australia to teach Luke how to be a commercial distiller faster than anyone had done it before.

“We visited 40 distilleries across California and New York state, and while in a San Diego distillery with a distiller called Trent Dalton, thought we had found that person.

“He is an incredible distiller and storyteller and although he wouldn’t take up the opportunity, he knew someone who fit the bill as well as he did.”

R idden and Luke were introduced to Blake Heffernan who now is the head distiller at Old Harbor Distillery in San Diego.

“ That’s where things all really got going,” said Ridden.

Ridden flew Blake to Australia to spend time teaching Luke everything he needed to know about the distilling process, knowledge which normally takes years to learn.

“He helped teach Luke everything he needed to know to become the

award-winning distiller that he is today,” said Ridden.

“The number of awards he has won locally and around the world is amazing. Best coffee liqueur twice, we were in the top four gin producers in the world in 2022 at the IWSC awards.

“Without Blake, there is no doubt we wouldn’t be producing the quality spirits and have won the awards and acclaim that we have in just five years.

Luke, and Ridden, were already making waves from the very start of the distillery coming into operation.

“When we opened, Luke was only 21 and was the youngest commercial distiller in the country,” said Ridden.

“And we were the fastest distillery to have ever opened in Australia. We opened in eight months from when we took possession at the building, and I’m not sure if that’s been beat since. Now I think about it, it’s been beaten by us, we open our Brisbane distillery in just five months and three weeks, said Ridden.

“There is no way starting on your own with no input would lead to this level of success. Blake spent hours a day with Luke helping produce and

showing Luke every step of the process.”

“Our first ever whiskey release won two gold medals in world whiskey competition for the packaging and label design, a book with the bottle of whiskey hidden inside and leather label,” said Ridden.

“Everything we do is to encourage people to take the time to sit down and taste the whiskey and feel a part of the whole process, a part of our family.

That is a special part of our brand that not everyone can have.”

The book Ridden mentions is related to the first five whiskies released by the distillery, all of which were paired with a hand-crafted book telling the story of Ridden’s grandfather and how his legacy informs everything Granddad Jack’s does.

“That book was 100 per cent hand crafted by the last remaining

“After selling a former business I wanted to do something to tell my grandfather’s story and it just seemed like a distillery would be the best place to tell that story. My grandad loved whiskey and drank it every day and lived to be 93-years old.”Luke Ridden was Australia’s youngest distiller when he took up the role at the family run business. Granddad Jack’s inspiration was Ridden’s grandfather, David Goulding, an inspiration which is a part of everything the business does.

book maker on the gold coast,” added Ridden.

This is a great example of the attention to detail Granddad Jack’s puts into its premium offerings. Never losing site of its roots and goals.

For example, Granddad Jack’s is distilled as a craft level to retain its premium quality while not moving away from the true heart of the company’s brand and storytelling.

“I think that is the number one thing, a lot of people ask what we do, we are storytellers who just happen to make world class spirits,” said Ridden.

“We have been super lucky that we’ve been able to make this world class spirit and have that story. The essence of our business is 100 per cent the story.”

T his goes into every aspect of the company.

“Every spirit has a name from my grandad’s life story,” said Ridden.

“You see photos of him, captions and little sayings he had everywhere in our distilleries and bars, everything we do has that element.

“We don’t design something new or put something in the distillery that he wouldn’t have approved of.”

An example of how the success of Granddad Jack’s hasn’t muddied the message for Ridden and the rest of the team, is their emphasis on

quality over quantity.

“We release only small batch whiskey because we only age in 100 and 50 litre barrels and we don’t blend,” he said.

“My grandfather sipped away at whiskey like a traditional old boy, for me it’s about sitting and sipping and for us we make sure our whiskey is always premium and tells the story about not

just what was in the bottle but the whole process. Drinking less but better is what we believe in,” said Ridden.

Ridden said they don’t just provide customers with whiskey, but with an experience, something to savour.

On top of keeping the whiskey program limited to 50 and 100 litre non-blended barrels is the environment they are in. Which Ridden said helps

create a smooth end product.

“We don’t put our barrels in a false environment, the air pressure and humidity is different on the gold coast and our barrel room never gets below 10 degrees all year round and in summer its closer to 40 degrees,” he said.

“ With the combination of small barrels and the environment we age our whiskey in, creates an amazingly smooth whiskey.”

And based upon the feedback of their customer base, the smoothness of the drop goes a long way to reinforcing premium status, while also encouraging the whiskey to be consumed in the right way.

“The feedback we get is that it’s not only smooth, but you never want to drink it all because when its’ gone, it’s gone,” said Ridden.

“We have been lucky to produce something that isn’t just a whiskey, but an experience. When you buy our whiskey it’s a 100 per cent experience.

“From the packaging to the bottle. It’s not just here is your bottle and go. We give our customers something to savour.”

W hile whiskey is at the core of Granddad Jack’s, the company also produces gin, vodka, coffee liqueur, and other specially limited lines as part of its growing range of products.

“Ultimately, for us, small batch super premium is core to our being.”

And Ridden says this is a concept that Granddad Jack’s company will never abandon. F

Australian flexible packaging specialists, Favourite Packaging, innovate the next generation of packaging and put emphasis on clients, customers, and the market. Food & Beverage Industry News reports.

most innovative and reliable providers of raw materials and semi-finished products.

“Favourite Packaging are also on the constant search for the latest innovations that support our mantra to be at or ahead of the market’s requirements,” said Yates.

Favourite Packaging’s office, staff and logistics operations are based in Beresfield, an ideal location to service Australia.

Over many years, they have made logistics, warehousing, and delivery management a speciality and hence, each customer benefits by having access to innovative materials, competitive pricing, warehouse efficiencies and reliable delivery.

solutions for their clients.

This includes knowing their market, cooperating to optimise the materials, printing, types of packaging and supply schedules and, staying close to customers so adjustments, changes and innovations can be crafted.

Apart from this unique cluster of strengths, Favourite Packaging provides great modern and innovative products.

Pouches have become more and more popular for a wide variety of foods, perishables, coffee, powders, liquids, bread, baked products, and pet foods.

Recently Food & Beverage Industry News caught up with Justin Yates, managing director at Australia’s Favourite Packaging who have been supplying flexible and industrial packaging since the mid 1980’s.

Their specialities include flexible packaging for foods, perishables, coffee, powders, baked products, bread, liquids, pet foods and pallet wrap.

Their products include pouches, printed re-wind, bread bags, oven bags and the thinner, lighter Nano stretch pallet wrap.

Favourite Packaging can supply all of these in either traditional or new recyclable materials. But their products are just the beginning of their strong points.

T he first thing that struck me while talking with Yates was his understanding that packaging not only must efficiently contain and preserve contents but must also project the brand and play a part in selling the content “off the shelf and into the trolley”.

To be an excellent flexible packaging solutions provider, Yates and Favourite Packaging must know and understand the demands of the

end users and consumers.

Among other initiatives, a few years ago Favourite Packaging joined the Australian Packaging Covenant (APCO).

“Through APCO and other research avenues, Favourite Packaging are at the forefront of appreciating what’s required to meet the 2025 national packaging targets, the significant influence consumers have on ethical packaging and what viable options in materials are available,” said Yates.

For example, Favourite Packaging has already researched and now provides recyclable options in their printed rewind, pouches, and stretch wrap.

Research and innovation are constantly being carried out in other forms of flexible packaging that will meet shelf-life requirements, the consumer’s demands, and conform to 2025 national packaging targets.

The second standout point about Favourite Packaging is their well refined supply chain management, including sources, scheduling, transport, inventory, and delivery.

Over the years Yates has established strong supply lines with some of the

The third standout about Favourite Packaging is their dedication to customising flexible packaging

Favourite Packaging cooperate with their clients and provide many types of pouches such as stand-up, side gusseted, quad seal, box, or flat bottom, flat or pillow. Closures include heat seal tear notch, press seal, slider

zipper seal, one-way valves, rippa-zippa seal.

For the high volume, high frequency production runs, Favourite Packaging provide printed rewind. Benefits come from economies of scale, transport, store, and inventory costs.

They supply printed rewind film for cakes, muffins, sausage rolls, pies, chips, nuts, confectionary, dried fruit, pasta, and similar products that are individually wrapped or packaged in quantities. Their printed rewind film rolls are supplied in laminations of LDPE, HDPE, PET, BOPP & CPP for flow wrapped or Vertical Form Fill.

Specifically for bread and baked products, Favourite Packaging supply specialised pre-formed bread bags, including wicketed bread bags as well as micro perforated oven or micro-wave friendly packaging.

“For pies and sausage rolls, we supply special material with an airhole perforation so they can be cooked without having to come out of the packaging,” said Yates.

Yates said their pouches, bags and printed rewind have the option to come in recyclable material.

This material provides the right protection to preserve shelf life, meets the criteria for recyclable flexible packaging while contributing to improving your brand image. Consumers can discard the packaging through recycling processes, thus contributing to the circular economy.

By changing to recyclable flexible packaging, the carbon footprint of your package can potentially be reduced around 60 per cent.

To loop back to what Yates had mentioned earlier about their packaging ‘standing out on the shelf’, Favourite Packaging pride themselves on cooperating with clients to ensure printing and design is optimised to match the brand’s essence.

Most printing is done through the Gravure method, as this is optimised for large runs.

“But we also do digital printing, which allows us to supply short runs; ideal for trials, smaller orders or quick turnarounds,” he said.

Yates also mentioned Favourite Packaging also supply the next generation in pallet wrapping.

“Our Nano33 Stretch Wrap is much thinner yet stronger, more flexible and more durable and hence provides better load control and is more cost efficient and helps our clients attain ethical and social outcomes,” he said.

The Nano33 stretch wrap comes in 100 per cent recyclable material and is also available in 30 per cent recycled material.

“If they are using 100 tonnes of plastic on pallets each year, then you can get an easy 30 per cent reduction on that material with this solution,” said Yates. F

To learn more about Favourite Packaging’s flexible packaging solutions visit www.favouritepackaging.com.au

Eliminating animal products is not limited to strict vegetarians or vegans. Flexitarians, too, are reducing their intake of animal-based foods and this is having an effect on the dairy industry. Krones breaks down what this means for the industry. Food & Beverage Industry News reports.

Just ten years ago, plant-based drinks were still a niche product found mostly in organic grocery stores.

Today, they’ve made their way into every supermarket, without exception – and they’re filling the shelves with an increasingly colorful array of products.

According to Global Data, average growth rates for the milk and milk alternatives market as a whole will be around three per cent each year between 2020 and 2025.

Meanwhile, plant-based drinks are forecast to grow by seven per cent annually, far faster than the market overall.

Europe and North America are lending especially strong momentum to this vigorous trend.

A simple comparison of the figures from 2020 with the estimates for 2025 shows dramatic growth in both regions: 21 per cent in Europe and even 36 per cent in North America.

By contrast, dairy drinks are

expected to grow by only four and one per cent in these regions, respectively.

“Plant-based drinks will become an equal alternative to dairy in the medium term,” said Stefan Höller, head of Product Management Processing Unit at Krones.

“Because one thing is clear: It won’t be possible to feed all of the world’s population with animal-based foods alone in the long term,”

In an effort to slow climate change and at the same time ensure that people have access to clean drinking water and enough food, policymakers, companies, and private individuals are looking for root causes in many areas of life and business.

Debates often quickly home in on livestock farming because it requires a great deal of water and land area and creates relatively high levels of greenhouse gas emissions.

For that reason, many people are consciously switching to plant-based

alternatives, whose production entails (sometimes significantly) lower water consumption.

Many people have no choice but to seek alternatives to milk for health reasons. Between 66 and 75 per cent of adults worldwide (the exact number varies by source) cannot properly digest dairy.

That’s because lactase production in the intestines either drops off substantially or stops altogether with age.

But there are dramatic regional differences here: Europeans are said to have developed the ability to produce the enzyme lactase as adults, as part of their evolution.

I n Asia and Africa, on the other hand, it is quite common to be intolerant of cow’s milk.

According to Euromonitor, some 85 per cent of the populations there lack the enzyme and lactose intolerance is

therefore considered entirely normal.

As a result, plant-based alternatives have long been established in those markets.

The trend on supermarket shelves has long been toward offering extensive selection.

But when it comes to milk, there’s not much scope for variation besides fat content and perhaps an organic label.

While there is no question that almond, soy, and oat are the most popular types, the pallet of plant-based drinks is much, much wider than that.

Rice, cashew, hazelnut, pea, coconut..., the possibilities seem endless. But plant-based drinks offer variety not only in terms of their raw materials but also in their nutrient profiles.

They bring us full circle to more conscious nutrition.

For example, soy beverages contain large amounts of phytonutrients and

unsaturated fats, almond “mylk” is rich in fiber and vitamin E, and oat drinks deliver fiber and antioxidants.

Many makers of these products also fortify them with calcium and B vitamins to achieve a micronutrient profile similar to cow’s milk.

When it comes to frothing, most milk alternatives can now hold their own against cow’s milk in terms of texture. And it’s no wonder, since there are so many possibilities for influencing the final consistency during the production process.

Filling these products, which may be made from myriad plant sources including soy, oats, spelt, buckwheat, rice, almonds, or other nuts, involves exactly the same technology as dairy milk. Producing them is a different matter entirely.

The process technology makes all the difference.

The main production steps for all milk alternatives are essentially the same: The grains or nuts are milled

(either wet or dry) and then filtered or separated before any additional ingredients such as plant oils are blended in.

To make the products shelf-stable, they are heat-treated and homogenized, after which they are filled aseptically.

The individual process steps will be quite different depending on the input materials used – whether they are fresh or dried and whether they are whole nuts or grains, meals or flours.

The first differences emerge at the milling stage: While cereals are usually ground to flour, to which water must be added, materials with higher fat content, such as almonds and peanuts, grind to a highly viscous paste.

The milling process itself will vary depending on the raw materials used: The deciding factors here include whether the inputs are dried or fresh, peeled/hulled or whole, that is, with the skins or hulls still on.

Some raw materials will be roasted prior to milling. Almonds, for example, are roasted to reduce undesirable constituents such as benzaldehyde.

To make further processing easier, many raw materials (including soy, hazelnuts, rice, almonds, and peanuts) are first soaked in water. This step can also help remove unwanted constituents or impurities.

A blanching step may also be added in order to improve the microbiological profile and reduce certain original enzymes. Here, the raw material is briefly heated in water and then immediately cooled.

In the case of cereals, the starch

components must first be broken down using hydrolysis.

Because the starch is separated into dextrins, this step influences the viscosity of the product by preventing gelatinization.

The process also affects the product’s sweetness since the dextrins are separated into the sugars maltose and glucose.

Unwanted constituents can then be removed or deactivated by subsequent heating of the liquid: For instance, heating can deactivate the lipoxygenase enzymes in soybeans, which are responsible for the typical “beany” flavor.

Both soy and cereals have relatively high fiber content. In order to produce a milk alternative that goes down smoothly, insoluble fibers must be removed in either a decanter centrifuge or a

filtration process. Such a process is not necessary for almonds.

The remaining solids can be dried and pressed and made available to animal feed producers or other users. Some beverage producers of non-dairy drinks collect these fiber residues and feed them back into the manufacturing process for a second extraction to increase yields.

Depending on the raw material used, the protein, fat, mineral, or vitamin content will be higher or lower.

Thus, makers of plant-based drinks might add plant oils (such as sunflower), vitamins or minerals, or even salt, sugar, or stabilizers to the product.

Subhead: Heat treatment and homogenization

To make the finished product shelf-stable, heat treatment and homogenization are done before filling. Since most products on the market are shelf-stable and sold at room temperature, they undergo ultra-hightemperature (UHT) pasteurization.

Subsequent high-pressure homogenization ensures that any remaining particles are reduced in size, for instance so that fats remain in suspension and do not separate out.

Since plant-based products resemble milk not only in terms of appearance but also in their sensitivity, aseptic filling is necessary to ensure a long shelf life. For this purpose, Krones offers the Contipure AseptBloc DN – proven technology with which to fill plantbased drinks aseptically and reliably. F

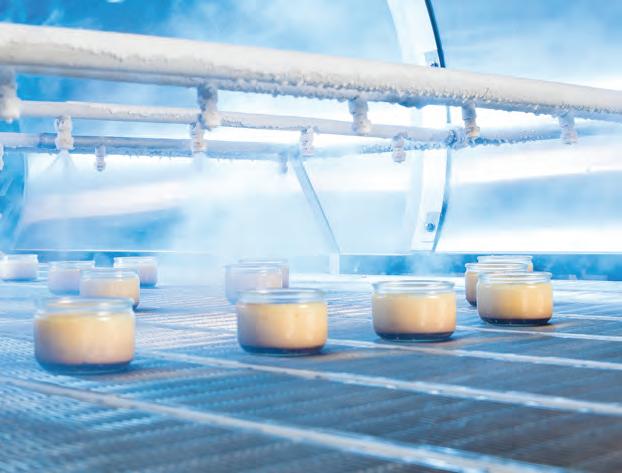

Tetra Pak, experts in food processing, provide product diversity with its Tetra Pak High Shear Mixer across multiple sectors including dairy, beverages, and prepared foods. Adam McCleery writes.

Tetra Pak has a particular focus on developing solutions and technologies such as its highly efficient High Shear Mixer, which improves on traditional products while continuing to innovate on new methods.

Any food manufacturer or producer knows the importance of mixing in the production process and through technological innovation, Tetra Pak continues to help its customers get this important step right every time.

Processing key components sales manager for Tetra Pak Oceania, Andrew McCullagh, said the innovative design of the Tetra Pak High Shear Mixer makes it a valuable asset across multiple sectors of the food and beverage industry.

“The versatile range of products that can be produced on the Tetra Pak High Shear Mixer is one of its strengths. The same machine has the ability to

make hummus, dips, sauces, and soups, as well as other cold emulsions such as mayonnaise.”

Mixing ingredients the correct way is critical for food and beverage producers, whether that involves dissolving, emulsifying, dispersing powders or liquids, and incorporating solids.

Tetra Pak has spent three decades continually innovating its product offerings to improve this process.

As a result, the company has a wide range of High Shear Mixers that give a manufacturer or producer greater control over the mixing process ensuring a better, more consistent product.

Every detail of the mixing process can be fine-tuned to achieve the quality characteristics you want your product to have. Once you have achieved the desired result for your product, the control on the mixer can replicate that same process

every time,” said McCullagh.

Some of the more prominent features of the Tetra Pak High Shear Mixer, include product diversity, is its ability to increase productivity and output.

“It has a patented dynamic shear feature which allows powerful mixing but also the ability to be gentle on the product when you need to,” said McCullagh.

“ That flexibility allows it to work across a range of operations that some of these products need.

“For example, sometimes you need a smooth texture for products like hummus and other plant-based spreads, and sometimes you need to gently mix in some flavour. This allows you to do both easily.

“The machine has heating and cooling integrated within the mixer including direct steam injection. It also

has vacuum capability, so you are able to introduce powders, liquids and other ingredients without having to open the vessel.”

“ When the powders come in via vacuum, they instantly disperse into the high shear mixing head. If you compare this to a kitchen blender, instead of pouring product in the top where it can clump up and float around you are injecting it at the mixing head, ensuring effective mixing right away.”

“There’s also our patented double sharp agitator which allows you to make high viscosity products and still have effective mixing,” said McCullagh.

“Customers can add on ingredients handling options like a bin lifter which is useful for large fruit or particles that can’t draw in under vacuum, or bulk powder tipping stations with dust extraction.”

The Tetra Pak High Shear Mixer provides additional protection against a breakdown of the emulsifying process, which is a known pain point for food producers.

“ You must be controlled in forming the emulsion and you don’t want to break it. The perfect mayonnaise texture occurs when the oil droplet size is reduced but then the mixing intensity must reduce to preserve the texture. This technology provides better control and the ability to do it at pace,” said McCullagh.

T his added protection against emulsification breakdown, McCullagh said, was a key feature in research and development of the Tetra Pak High Shear Mixer.

All the features needed to make mayonnaise also translates to other products like hummus, dips, soups and sauces.

Customers can use the Tetra Pak High Shear Mixer to create new products or improve their current product offering with the ability to produce faster, at a higher capacity, or with less equipment or steps than they do now. Or for products they currently make; they can do it faster, at higher capacity, or with less equipment or steps than they do now.”

Tetra Pak holds local workshops to give potential users added insight into

the benefits of the Tetra Pak High Shear Mixer, along with the best ways to use it.

“The key purpose of the workshops is to help customers understand what the equipment is, and how it can help them” said McCullagh.

“Seeing and touching the equipment and end products leads to a better understanding of the capabilities and opportunities for customer operations.

In addition to the local workshops, Tetra Pak has product development centres across the globe in 9 locations which are available for product development trials. Allowing customers to determine the right process and equipment without having the cost of full-scale production batches.

The Tetra Pak High Shear Mixer, along with the broad range of technologies from the company, gives greater product offerings and the flexibility to address specific production needs. From batch mixing to recirculation mixing and continuous mixing.

This also applies to the beverage sector, from plant-based drinks and smoothies to iced tea, sports drinks, and still drinks. As well as prepared foods like puddings and custards, infant formula, hummus, fruit preparations and jams, mayonnaise, and cold emulsion mixing, tomato products, soups, sauces, and more.

These features, along with others, are all evidence of the continued innovation and improvement of products at Tetra Pak, which aims to help customers produce quality products of the same standard, every time.

Tetra Pak has built a strong reputation for helping increase productivity and output for customers and the Tetra Pak High Shear Mixer is another example of this capability. F

www.ams-ic.com.au

AMS have been suppliers of instrumentation and calibration equipment to all industries since 1973 representing some of the world’s leading manufacturers of the equipment in their field.

Due to inflationary factors the material costs of construction are skyrocketing and delays in projects are only compounding the rise in costs. Food & Beverage Industry News reports. writes.

The construction sector has been making headlines for various reasons in recent times, however, at a base level, inflationary pressures continue to drive up the costs associated with projects, especially when they are delayed.

Rob Blythman, general manager at Total Construction, said the current economic climate was having a huge impact on the building sector, especially with regards to projects moving forward.

Normally, Blythman said, a client of Total Construction works with the company to determine a figure for the cost of a project before moving into the next stage. However, the uncertainty of market influences and already rising costs has upset the process.

“A lot of clients now are rethinking their business plans which is not detrimental but more of a delaying in the process. The issue is the longer the delays, the more it will cost,” said Blythman.

“

Some clients go through the Early Contractor Involvement process with us, which is meant to rationalise down the design, dotting the I’s, and crossing the T’s, to get a rock-solid price before moving ahead,” he said.

“We start that off with a cost plan and give the client a number before going into the ECI process, which might take

eight to 12 weeks to do and by the end the cost has gone up exponentially.

“So, all the savings eked out through value engineering are swallowed up by the inflationary factors in the marketplace.”

The ECI model is designed to allow builders to get involved in the planning of a project, and even start on some aspects of the job before the design has been completed.

In the current climate where any delays in the project are resulting in uncertain costings, early involvement is encouraged by Total Construction, and without delays once it is underway.

Blythman, while understanding the concerns, reiterated that delaying the project with hopes of costs coming down has proven to be a fruitless enterprise that ultimately leads to greater costs.

“And by that point many clients have already leased land or space, they are too deep in and committed,” he said.

This means the company paying for the construction project will inevitably find itself between a rock and a hard place. Which is why Blythman is adamant the fewer delays, the better.

“Speed is of the essence; you must stay ahead of the inflationary curve. At one-point costs were going up at about five per cent a week. It’s gone up 30 per cent over the last 12 months alone,”

he said.

“It really skyrocketed. And now there’s the double whammy of resource shortages which is leading to those prices going up. So, it’s not just material costs but the costs of labour too.

“The tradespeople available to do the work are still as busy as ever because they are in huge demand and can pick and choose their jobs.”

The market fluctuations and uncertainty has also led to changes in the ways clients approach companies like Total Construction.

“We’ve weathered the storm as a company,” said Blythman.

“And from a client’s perspective they’ve got to be nervous about builders at the moment.

“We’ve even had projects where clients have wanted to see our books before they engage with us.

“That will become more common moving forward, banks would demand that but now it’s the clients themselves.”

Another area where Blythman said he would like to see changes made is with bank guarantees.

“We are pushing hard to do away with bank guarantees. It’s crazy that to win or start a project we have to pay the client, that is what the bank guarantee is,” he said.

“It isn’t realistic in the current

climate for the builder to wear the risk of price rises, material changes, and resource requirements.

“As a company it’s our job to manage that but to expect us to wear any unforeseen changes is not viable. And if we put in the expected increases, or the ones we think will appear, you won’t win the project.

“What’s important to understand is there’s no point in getting a build at the cheapest price possible and then never having it completed because the builder has been bankrupted.”

Blythman said the benefits of contacting the contractor on an ECI model presented more certainty in an uncertain time.

“You might zero a price down, but it will be eaten away by increases while waiting,” he said.

“Which means it’s critical to get the design right, get the price, and then decide whether to go forward.

“That does cost money but locking in a budget and then going to the builder won’t get you what you need.”

The overarching message from Total Construction is that in the current uncertain climate, cost changes are a strong possibility. Meaning, the sooner a project is started and completed the less risk of unforeseen price rises in any one area, or across the board. F

Australia’s most trusted and proven trade event dedicated to food production, manufacturing and distribution.

Returning this year on 23-26 July 2023 at the Melbourne Convention & Exhibition Centre, foodpro provides the first opportunity for the industry to reconnect face-to-face, make big business deals and explore ways to create an efficient future for manufacturing.

Showcasing the latest packaging and processing solutions, foodpro’s expansive exhibition floor brings the entire food manufacturing supply chain under one roof. With a range of new features, dedicated zone areas and networking functions on offer, you can’t afford to miss out.

23-26 JUL 2023

MELBOURNE CONVENTION & EXHIBITION CENTRE

foodproexh.com

Scan the QR code to register

Angel Yeast, a specialist yeast extract supplier, is bringing nutritional yeast protein to a market seeking more protein options. Food & Beverage Industry News reports.

Many consumers are always looking for newer and better sources of protein and in recent years the consumer base has started to pivot away from protein supplementation due in large part to the limitations around plant-based sources, particularly for the many who demand natural, clean label ingredients.

The demand for protein, from a range of sources, also continues to grow as the global population does, with research showing a 5.3 per cent growth in the global protein market between 2017 and 2022s.

Here’s where yeast comes in.

The fact that yeast protein is a natural, clean label ingredient that doesn’t contain genetically modified organisms (GMO) is central to its appeal to consumers, based on the experience of those at Angel Yeast.

This is a major benefit when you see the figures showing over 50 per cent of respondents in the above-mentioned

study said they make their buying decisions based on wanting to eat cleaner and healthier.

A Food Supplements Europe survey of 13,200 people across 14 European countries found 67 per cent of people read the ingredient lists on supplement labels, and 56 per cent of people base their purchasing decisions on whether a product is labelled as organic, natural, or GMO.

This level of scrutiny is having an impact on market dynamics and is relevant as Europe leads the market for launches of clean label foods and beverages.

In terms of animal proteins, some of the key limitations relate to the rapid rise of veganism, vegetarianism, and flexitarianism.

A Smart Protein Project survey also found that almost 40 per cent of people planned to consume less meat, and 30 per cent of respondents were actively reducing

their dairy consumption. Meanwhile, people who consumed exclusively plant-based diets made up 7 per cent of the dataset and a further 30 per cent of people followed a flexitarian diet.

The figures seem to represent a barrier to the growth of products that include proteins derived from animals, and whey proteins which are the current ‘gold standard’.

Angel Yeast sought to solve this dilemma by researching and developing a protein source that is affordable, sustainable, eco-friendly, and as nutritious as animal protein.

One way the industry has responded to the concerns about animal proteins is through the extraction of proteins from soy, pea, hemp, rice, and other plants. Yet, plant proteins also have their own clean label problems.

Proteins such as wheat, soy, and pea use large swathes of land for cultivation, vary in cost and availability depending on the weather, and for some consumers raise concerns about heavy metals, pesticide residues, and GMOs.

Plant proteins also fall short of the amino acid content, digestibility, and protein synthesis capacity of whey, with research showing that they can’t match the composition and effects of animal proteins.

Across multiple studies, researchers have shown that plant-based proteins lack essential amino acids and leucine and may also be incompletely digested in the gut, leading to negative effects on metabolism and immune responses.

The limitations of animal and plantbased proteins has left many consumers, with evolving demands, without a large variety of choices.

For the large number of consumers who want healthy, clean label products

there have been two options: use animal proteins despite their concerns about the environment, animal welfare, and contamination; or use a plant-based protein with a suboptimal profile that has its own sustainability and health issues.

Now, consumers have a third option: yeast protein.

Nutritional yeast is often sold as a food product and marketed for its effect on the immune system and gut health.

This deactivated form of yeast has other important properties though. Angel Yeast is bringing those properties to the bodybuilding market with AngeoPro.

The microbial fermentation process used to make AngeoPro is both sustainable and scalable, unlike the crops grown for plant-based proteins, and delivers a reliable, guaranteed supply of protein regardless of variables such as the weather. Immediately addressing sustainability of production concerns.

The resulting yeast protein is natural, healthy, and has a neutral taste.

Yeast protein has nutritional benefits, too. Because it is a complete protein containing all essential amino acids, advocates of yeast protein argue it is the best substitute for plant and animal protein.

AngeoPro is also free from the allergen concerns associated with some plant proteins, such as soy, and can meet the demand for products with a clean label.

It is extracted from Saccharomyces cerevisiae, a species commonly known as brewer’s or baker’s yeast and has a similar digestibility value to whey protein.

Containing more than 70 per cent high quality protein, AngeoPro has a similar digestibility and leucine content to whey protein and, as a “slow protein,” it provides a slow and continuous supply of amino acids.

Thus, addressing some of the shortfalls in more traditional modes of protein mentioned above.

With a high content of protein of more than 80 per cent, Angel Yeast’s multifunctional protein addresses the limitations of existing animal and plantbased options.

The attributes, coupled to higher total BCAA content than whey protein, show AngeoPro is comparable to the gold standard animal protein and superior to plant-based proteins.

For bodybuilders, the attributes of AngeoPro translate into muscle gain, as Angel Yeast demonstrated in a doubleblind, randomized controlled trial in

Subjects in the study received 40g of AngeoPro, whey protein, or placebo a day and participated in a resistance training program that targeted major muscle groups for eight weeks.

In subjects with inadequate dietary protein intake, AngeoPro and whey protein significantly increased lean mass and muscle strength compared to placebo.

The yeast protein matched the gold standard, with the max bench press increasing by 5.78kg and 5.77kg, respectively, in the two active treatment arms. In the placebo group, the max bench press increased by 2.59kg.

The study provides clinical validation of AngeoPro, revealing the yeast protein to be as effective as the gold standard

adults.

The data differentiate AngeoPro from less effective forms of plant protein.

AngeoPro’s attributes support its use in products targeting the natural wellness market.

With its clean taste, yeast protein is used in high-protein bakery products, plant-based sauces, plant-based meat, beverages, and other foods and drinks aimed at people who want to naturally increase their muscles or are interested in nutritional value, digestion, absorption, amino acid score, and more.

A clinical trial of AngeoPro

indicated that the product is as effective as the gold standard animal protein at increasing muscle mass and strength in conjunction with exercise in older adults.

Also, the wide range of applications creates opportunities for brands across the food and beverage industry to target bodybuilders and other people who want to increase their consumption of protein.

By leveraging the benefits AngeoPro has over both animal and plant proteins, manufacturers can now provide natural, clean label products without compromising on muscle-enhancing performance.

Ultimately, Angel Yeast Protein is a sustainable, environmentally friendly, and nutritious food substance that provides an effective protein source and contributes to closing the protein gap.

The study’s results showed that yeast protein is a slow-digesting protein.

Slow-digesting proteins can provide a stable flow of amino acids to prevent muscle tissue breakdown.

The researchers found that the amino acids contained in yeast protein have characteristics that are unmatched by general vegetable proteins.

Angel Yeast Protein is a sustainable, environmentally friendly and nutritious food substance that provides an effective protein source and contributes to closing the protein gap. F

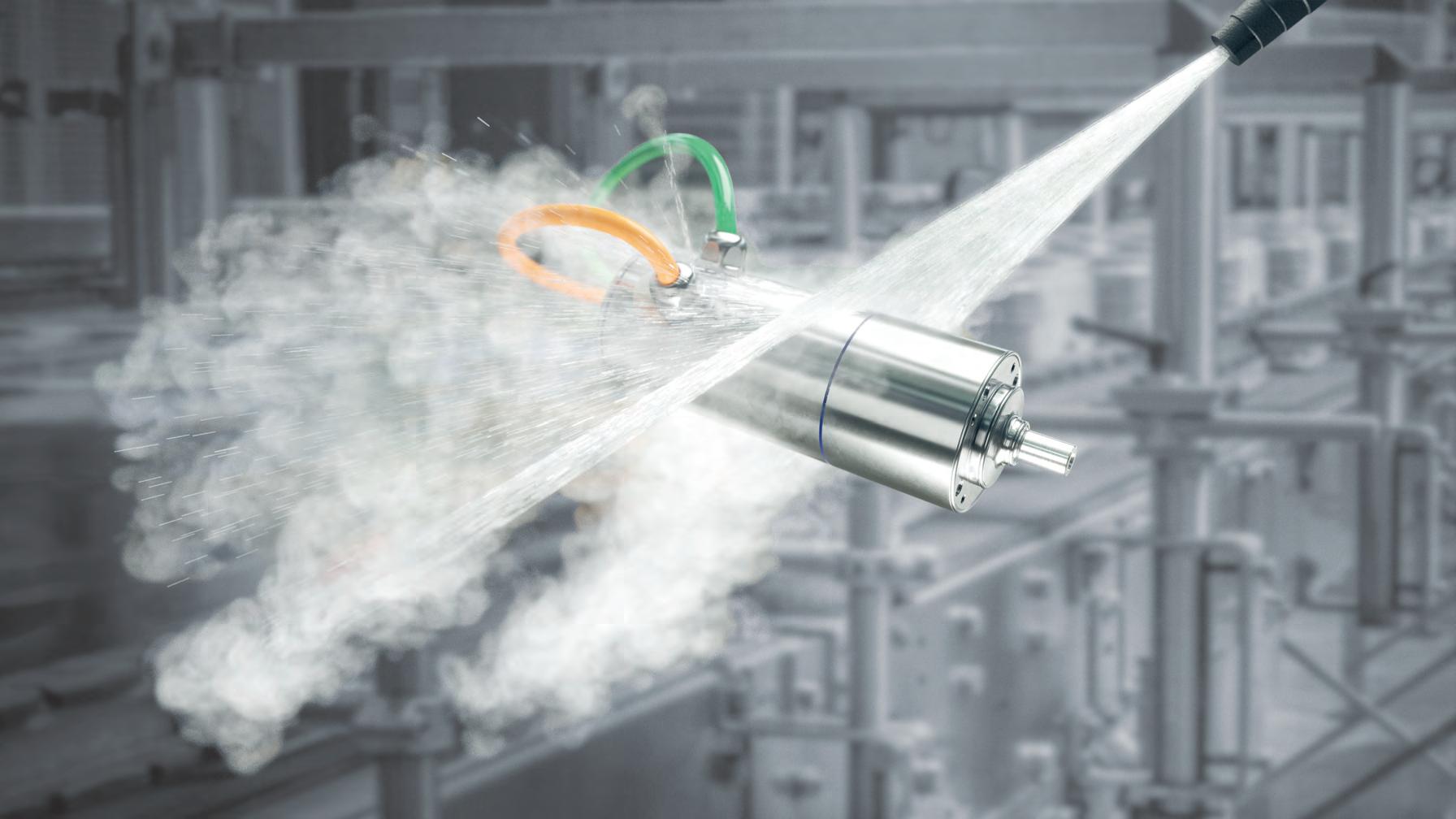

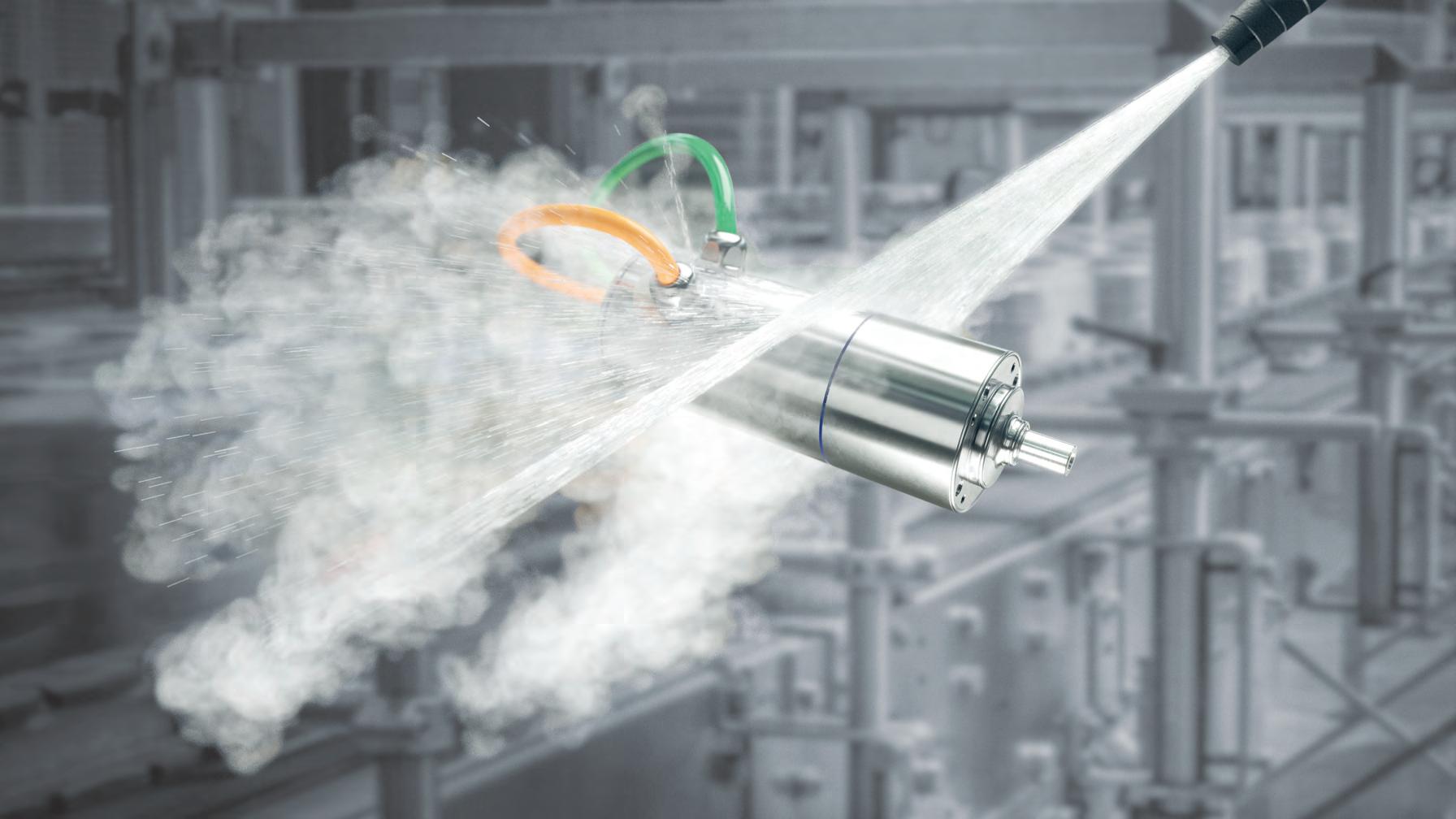

SEW-Eurodrive’s newest portfolio of stainless-steel gear motors are the perfect recipe for success, presenting strong reliability and hygiene to processing lines.

In the food-processing world there are many examples of conveyor lines brought to a halt by drive units that couldn’t handle the daily dose of highpressure washdowns and chemical cleaners.

This issue is one that SEW-Eurodrive continues to address with great success.

For example, a meat processing company and a client of SEW, invested in purpose-built, sealed mechatronic drives half a decade ago and since then have experienced the benefits.

The drive systems are still operating today, despite the harsh operating environment.

The longevity of the drive systems in this environment of constant washdowns and scrubbing is due to the fundamental design and fabrication of the units.

In a processing plant of this scale, supplying to both wholesale and retail outlets, the improved reliability and longer lifetime of the drives translate into significant savings.

It’s well-known that in food-

mentioned above, traditionally designed drive systems can be prone to damage from water ingress and frequent exposure to cleaning products.

This can lead to failures early in life, and it’s addressing this issue, and hygiene, where SEW thrives.

The solution used above was a Teflon coated piece, however, SEW now has a new portfolio of stainless-steel servo and gear motors which increases hygiene

This is because the property of stainless steel means the units, which are fully enclosed, hold up even better to the rigours of food and beverage manufacturing- where hygiene is critical.