3 minute read

FOOD SAFETY

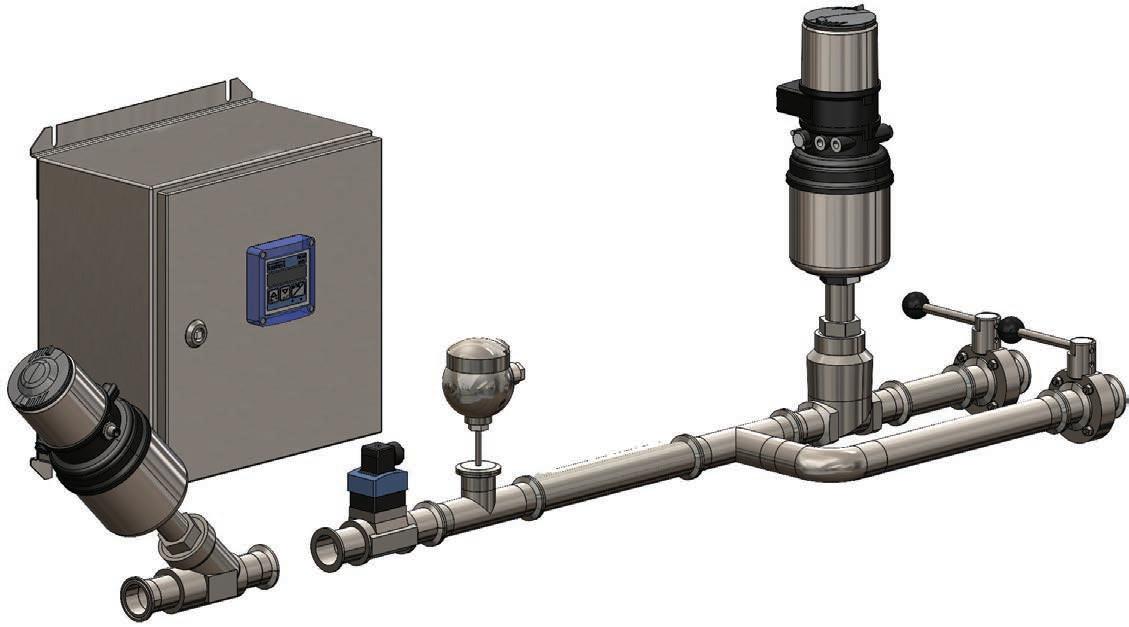

The water blending systems are flexible and can be applied to a range of processes in the industry.

Precise water blending system solutions from Bürkert

Fluid control experts from Bürkert know better than most the advantages of introducing water blending systems into the production process. Food and Beverage Industry News reports.

Water conditioning is an important process in many sectors, including food and beverage, chemicals and pharmaceuticals.

When it comes to blending water and maintaining a specific degree of water quality or a precise temperature, success depends on the exact measurement and dosing of the process water and make-up water.

Bürkert has developed a modular water blending solution with several options of transmitters and controllers that control and regulate the blending process precisely.

Bürkert’s Blending System can be adapted to a number of applications that support delivering a high quality of water to meet any legislation and standard.

Craft brewing offers two examples of where the Blending System solution can be applied. One is with temperature control to achieve the desired strike water temperature. The second is conductivity quality with blending and controlling two different qualities of water together to achieve the required output quality in manufacturing plants

The right water quality can only be achieved by selecting the right components.

Bürkert provides a best-fit solution, whether based on a standard solution or an individually customised system.

Depending on requirements, the piping, the process control, the sensor system and the control valves can either be pre-assembled or individually configured from individual components at Bürkert’s Systemhaus in Sydney.

The system is built around Bürkert’s Type 8619 multiCELL controller.

The multiCELL collects data from up to six sensors, allowing users to check the water temperature,

Bürkert’s range of water blending solutions guarantees batch quality every time.

Bürkert has developed a modular water blending solution that has precise measurement capabilities.

the pH value, the conductivity, the ORP value and the chlorine content at a glance.

The multi-channel transmitter can also perform a range of dosing, flow, level, pressure, and control functions.

Modularity in hardware and software offers high flexibility for adjusting it to the needs of the application, while sophisticated electronics and state-of-theart control algorithms ensure that optimum process control is maintained at all times with minimal operator intervention.

Bürkert’s batch controllers are also another addition to perform simple control tasks.

Depending on the individual design, the multiCELL is combined with hygienic butterfly valves, angle-seat valves, or modulating control valves, and various required instruments, such as conductivity and temperature sensors, hard-wired or connected via IO-Link.

A fitting example is the need in craft brewing to achieve the perfect strike water temperature consistently, a problem that is faced by many brewers in Australia.

The brewing has a lot of manual operations in place and the consistency of brewing batches can sometimes a problem.

In one such application Bürkert recently successfully completed, from a control system standpoint, the site PLC was full, with no I/O left to expand.

Rather than take the option of building and programming a completely new PLC and panel system, the company decided to hand over the water blending control tasks to a Bürkert Blending System, without affecting or requiring to expand the existing site’s PLC.

The multiCELL was able to perform all the control tasks and collect all the sensor signals including running PID control algorithms as a closed-loop, standalone control system, including the driving of digital and analogue signals to the process valves and instruments, and then hand this information back over to the PLC via a single digital signal using EtherNet/IP. The brewer only had to add an Ethernet switch to the existing PLC panel.

The Bürkert’s blending system consistently achieves the strike water temperature, guaranteeing every batch meets the quality and taste that head brewers are proud to call their own. F