Bourgault

Bourgault

WITH A FULL 8 YEAR WARRANTY AS STANDARD*

PLUS, THE MAXAM AGRIXTRA RANGE DELIVERS MINIMAL SOIL COMPACTION, A COMFORTABLE RIDE AND IMPROVED TRACTION WHICH SURPASSES ALL AGRICULTURAL TYRE EXPECTATIONS. WHEN PACKAGED WITH ONE OF THE BEST WARRANTIES IN THE INDUSTRY, THE AGRIXTRA DELIVERS THE PERFORMANCE YOUR FARM DESERVES!

25

31

Image: CEA

52

35

47

55

28

38

42

44

58

51

Earlier this month, I had the pleasure of attending my first field day of 2024 at Wimmera.

After several years working in this industry, I have thoroughly enjoyed every opportunity to attend one of these events and set a goal for the new year of getting out to some field days which I had not previously visited.

Wimmera was one of these, although coverage of this event has of course featured in Farms & Farm Machinery before.

Plenty of excellent machinery was on display and there is an extensive wrap-up in this edition of the magazine.

What struck me most was that no matter where you go in Australia, there is always such a positive energy during the field days and this energy extends to the surrounding towns before and after each day.

Events season is starting to ramp up, and an upcoming highlight on the calendar is next month’s inaugural FutureAg Expo in Melbourne.

Powered by the organisers of major European event Agritechnica, this promises something different for the Australian agricultural community and we have previewed this event – along with a couple of the exhibitors.

Our cover story this month concentrates on Bourgault.

The Canadian manufacturer is celebrating 50 years in operation, and we delve into the importance of the Australian market to the company, highlighted by a new product designed for local farmers.

CJD Equipment is another company

which recently reached the half-century, with coverage of their milestone celebrations in Perth.

We also profile several companies and the products they offer – specifically Sawquip, Jetland Loading Ramps and Muck Runner – to help introduce readers to what is available across the scope of agricultural products.

Plenty of new products have been released from the likes of TYM and Strautmann (both of which are distributed locally by Inlon), Brisbane Mini Excavator Sales and Case IH.

This edition also highlights Dieci’s Cotton Pro telehandler, Antonio Carraro’s SRX tractor range and plenty of industry news.

There is also a deep dive into how a farming group upgraded to a whole fleet of JCB Fastrac based on operator demand, plus how a Victorian government grant is helping a farm invest in electric machinery.

Agriculture is a diverse industry and this edition shows the full scope of what is

Sturt

investing more than $50 million into agricultural research projects and facilities – focusing on sustainable energy, animal health, agricultural technology and soil health

Building on the university’s existing investments in agricultural research, more than $50 million has been put into projects which the university says could revolutionise the industry.

The investments will be facilitated through Charles Sturt University’s Agrisciences Research and Business Park (AgriPark) and key industry partners.

“These investments mark a significant step towards realising the vision of a more sustainable, innovative and resilient Australian agriculture sector,” Charles Sturt University vice-chancellor Renée Leon says.

One of the most invasive Australian weeds is being touted as a potential economic crop, with benefits for agriculture and other industries

“By collaborating with sector-leading partners like Telstra, NAB, Food Agility CRC and others, Charles Sturt is able to better leverage our researchers’ cutting-edge innovations to serve the needs of primary producers and the industry as a whole.”

Of the new investments, the money will be split into four key areas.

Firstly, $22 million will be invested over three years for projects at the Global Digital Farm, which is an integrated digital learning and research environment. It works within a full scale, commercial, mixed farm operation.

Another $20 million will also be invested

The prickly paddy melon weed costs the agricultural industry approximately $100 million a year in cattle deaths, lost grain yields and control measures – but now it could be turned into an economic crop, according to the University of South Australia (UniSA).

University researchers have found that this weed has the potential to be a source of urease enzymes, used to create bio cement and prevent soil erosion.

50 native plants and weeds were screened in a study which looked at finding a cheaper and more environmentally friendly source for bulk production of urease enzymes to strengthen soil.

UniSA says of the weeds tested, paddy melon ticked all the boxes and was almost as effective as soybean enzymes, which are more expensive and used primarily for food.

After crushing the seeds and extracting enzymes in a liquid form, they were freeze-dried to create a powdered high-concentration cementation agent, UniSA says.

“Using this technique, we cut down the cementation time from one week to six hours,” UniSA geotechnical engineer Mizanur Rahman says.

Individual plants can yield 50 or more paddy melons, each containing up to 200 viable seeds.

over three years for various projects in the university’s Renewables in Agriculture program, including bringing the first hydrogen tractor to Australia.

There will be $10 million invested across various projects in the Cool Soils Initiative, which supports farmers in exploring their practices to improve the health of their soil, increase their yield, and reduce on-farm greenhouse gas emissions.

This program will also be expanded into Western Australia for the first time.

Rounding out the investments, $8 million will go towards a circularity Centre of Excellence being developed in Wagga Wagga.

“We know that climate change is impacting the profitability and productivity of farms around the country,” Federal agriculture, fisheries and forestry minister Murray Watt says.

“It’s fantastic to see more serious investment to help advance the development of technology to help farmers reduce their emissions.”

Taking into consideration the time taken to harvest, extract the seeds and turn them into a powder, the UniSA researchers estimate a 75 per cent saving compared to lab-grade enzyme production costs.

According to UniSA, plant-based urease enzymes are becoming a popular alternative to cement, lime or artificial soil binders because they are natural and not damaging to the environment.

“Compared to the production of commercial enzymes, paddy melon enzymes are cheaper, more sustainable, and more efficient than other enzymes used to cement and stabilise soils,” Rahman says.

“Not only have we found a natural alternative to other commercial enzymes, but we could solve a very expensive problem for the agricultural industry by harvesting these weeds, reducing the availability of seeds for spreading, preserving biodiversity and growing paddy melon as a commercial crop.”

UniSA says these findings could also benefit the construction, forestry and mining industries.

“I believe we have found a win-win solution that helps not only farmers, but also offers a natural cementation option for several industries,” Rahman says.

Scientists have achieved a breakthrough in molecular plant pathology, allowing for new genetic strategies to protect crops from disease

Australia’s national science agency, the Commonwealth Scientific and Industrial Research Organisation (CSIRO), has developed a rapid-gene screening platform.

This can identify avirulence (Avr) effector genes in organisms which cause plant diseases, known as plant pathogens.

According to CSIRO, rust pathogens reduce agricultural productivity and are a

Australia’s dairy trade has slowly changed in recent years, as export volumes have fallen while imports have spiked, Rabobank says in a new report

threat to global food security, leading to annual crop losses of US$1 billion worldwide.

“Our advanced screening technology represents a technological leap forward in our ability to study the processes that give plants enduring resistance to disease, enabling new genetic strategies to safeguard crop production and disease management in Australia and abroad,” project co-lead Peter Dodds says.

The trade profile for Australian dairy is in a transitional period driven by a range of factors, Rabobank says in its ‘Australian Dairy Sector Outlook: Slowing trading places’ report.

Dairy imports are expected to increase in Australia’s domestic supply chain into the future to accommodate the local milk production decline, the agribank says.

“Since the most recent production high in 2020-21, more than 700 million litres of milk have been lost from the supply chain,” report author and RaboResearch senior data analyst Michael Harvey says.

Tomasz/stock.adobe.com

“This method enables high-throughput screening of complex genetic libraries in a plant’s cellular environment at an unprecedented speed. This enhances the ability to select more disease-resistant crops and aids efforts in pathogen surveillance.

“We have been able to identify several new fungal Avr effector genes in the wheat stem rust pathogen, reducing the time from years or even decades to mere months.”

Effector genes in plant pathogens, like rust fungus, encode proteins that suppress plant immune responses, CSIRO says, If the plant recognises these pathogen proteins, they can activate plant defence mechanisms and stop widespread infection.

Thomas Vanhercke, who also co-led the project, says that while this study examined Avr genes in a rust fungus which affects wheat, the same technique can be applied to other crops and pathogens.

Imports are expected grow further in the near future due to the country’s reduced milk production and the lower costs of overseas products, the bank says.

Australia has had a long history of being a dairy exporter but has seen a slow decline in recent years, the bank says.

The report states 8.129 billion litres of milk were produced in 2022-23, marking the third consecutive year of decline in milk production. Harvey says 2022-23 also saw the nation’s milk supply available for manufacturing fall to its lowest level since the 1990s.

Over the last decade Australia has seen its dairy imports spike, with the annual dairy import volume in liquid milk equivalent doubling, Rabobank says.

“In 2023, Australia imported more than 1.4 billion litres of dairy product in liquid milk equivalents, excluding caseins,” Harvey says.

“A large proportion of the import mix is bulk and ingredients – particularly butter and skim milk powder – as domestic manufacturing of these products has declined. But more imported dairy products are also appearing on retail market shelves.”

“For the calendar year 2023, dairy export volumes were down with double digits across most products, with the largest declines in liquid milk (down 41 per cent year on year) and butter (down 52 per cent),” Harvey says.

Despite the reduction in milk production and export volumes, Australia still ranks as the fifth largest dairy exporter in the world – with four per cent of global trade, the report says.

Australia has a secure availability of local-origin dairy product, Harvey says.

“With ongoing support from retailers to source locally where possible, Australian-origin dairy products will remain readily available to consumers,” he says.

“At times the pricing point for local product may trigger ‘sticker shock’ for consumers.”

Expanding milk solid imports may help Australian consumers, as more cost-effective imported ingredients reduce raw material costs for food manufacturers – keeping consumer prices more affordable for packaged foods with dairy ingredients, Harvey says.

Sundew Professional Solutions has developed an insecticide spray to help tackle Australia’s fire ant problem – damaging crops and livestock

The next steps in Australia’s response to varroa mite have been agreed, following last year’s decision that eradication was not possible

ANTagonistPRO polymer insecticide spray will be able to help farmers, horticulturalists and landholders fearing damage to crops and livestock caused by red fire ants.

Fire ants have the capability to cost the Australian economy billions of dollars per year if left unchecked here, according to the National Fire Ant Eradication Program.

Australia’s Invasive Species Council says that if left unchecked, the pest could form colonies in 95 per cent of mainland Australia and most of Tasmania.

Sundew’s insecticide spray can also be used where fire ants are already present.

“Prevention and treatment are especially important at this time of the year, as autumn approaches, when the highly invasive and mobile ants become more active while the soil is warm and the days are milder,” Sundew CEO David Priddy says.

“These aggressive ants are the ultimate hitchhiker – they will move around on vehicles and even floodwaters.”

Sundew says ANTagonistPRO is Australia’s only approved spray treatment that can be applied rapidly over large surface areas by tractors, utes, quad bikes, and other farm vehicles equipped with boom sprays.

Using spray applications will target large

The varroa mite National Management Group (NMG) has agreed on a new plan to deal with the ongoing threat.

Varroa mite – also known as Varroa Destructor – has been described as the most serious threat to honey bees globally and was first detected in Australia in 2022.

Initially detected in New South Wales, it was successfully removed from that state before later returning, leading authorities to accept that full eradication was no longer possible.

The NMG met last month and endorsed a National Response V4, which incorporated a transition to management.

Activities in the management plan are to:

- ensure an orderly stand-down of emergency response operational activities in NSW and Victoria; - slow the spread of Varroa Destructor; - bu ild industry resilience to the pest; - provide management options including Integrated Pest Management recommendations and chemical control options; and

- support pollination security.

The Australian Honey Bee Industry Council (AHBIC) successfully advocated for exceptional circumstances to be applied in the plan, which allowed for the timeframe to be doubled from the usual 12 months to 24 months.

areas quicker, at cheaper cost and be more effective than other methods, Priddy says.

ANTagonistPRO is complemented by Sundew’s SAS PRO rapid response direct nest treatment to kill individual nests.

Sundew says its new spray is also weatherproof, doesn’t need to be reapplied once dry and will last up to six months on treated surfaces.

Sundew says its spray is the only red imported fire ant (RIFA)-approved concentrate product for applying to vehicles, earthmoving equipment, recreational vehicles, shipping containers, contractor and transport vehicles, as well as agricultural equipment – reducing the risk that RIFA can be moved from property to property.

“This treatment can be applied to large areas to massively reduce time, costs, and physical effort required compared with the slower baiting and spearing methods originally approved by the Queensland Department of Agriculture and Fisheries..

“We believe this method is a big step forward in countering what may well become a national issue if left unchecked. We have already got the runs on the board from working with professional pest controllers. We believe the message needs to be heard more widely and sooner rather than later.”

AHBIC describes this as a “big win” for the industry.

“This extension will allow critical activities like extension across all jurisdictions to continue over a longer period,” AHBIC says.

“This will ensure all beekeepers have the opportunity access the resources as needed.”

The management group also lowered the agreed upper cost of the response to a maximum of $100 million, of which a significant amount of will be spent on education.

“The development of national education materials and rollout of non-accredited workshop training will commence for a period of 12 months,” AHBIC says .

“This will include face to face training events across all jurisdictions for all beekeepers, online learning, webinars, factsheets and video resources.”

Mandatory hive monitoring and reporting every 16 weeks remains in place for beekeepers across New South Wales.

There remain two Varroa mite control zones in New South Wales – the suppression and management zones

Beekeepers must notify the NSW Department of Primary Industries if they wish to move bees from the management to suppression zone.

Australian farmers are making strategic decisions to better position their business, in the face of climate change uncertainty

Recent research undertaken by a Charles Darwin University (CDU) PhD student has found farmers are coming up with new strategies to tackle climate change – such as planting crops at different times.

The university says impacts of extreme climate events including heat waves, drought, flooding and rainfall are causing disruptions to global systems of farming and food production.

“The uncertainty of climate change is a significant challenge which is prompting Australian famers to think differently to ensure business success, particularly in extreme environments,” PhD student David McKenzie says.

As part of his research, McKenzie spoke

have responded to the impacts of climate change on their farming business.

“Farmers saw massive rainfalls that would last for one month, then they wouldn’t see rain for four to five months at a time, so they needed to change the way they grazed in order to harvest the rainfall,” he says.

“The farmers adapted their processes to better accommodate growing crops in the non-growing season rainfall episodes and intense hot dry season rainfall events outside the usual growing period.”

To counteract the increasing regularity of fires, heatwaves and flooding, McKenzie says farmers altered the scale of their farm, were flexible with crop and animal

against changing climate was also important to farmers, the PhD student says.

“The farmers I interviewed had a range of different strategies and forms of financial reserves to support them during the times when the climate is challenging,” McKenzie says

“For example, one farmer sells stock to provide equity, another has money invested with a financial advisor in a farm management deposit, while others reinvest profits back into the farm.

“Overall, what is clear from this research is that farm businesses need to be innovative, strategically positioned and managed to keep in step with the adaptive demands of evolving climate change.”

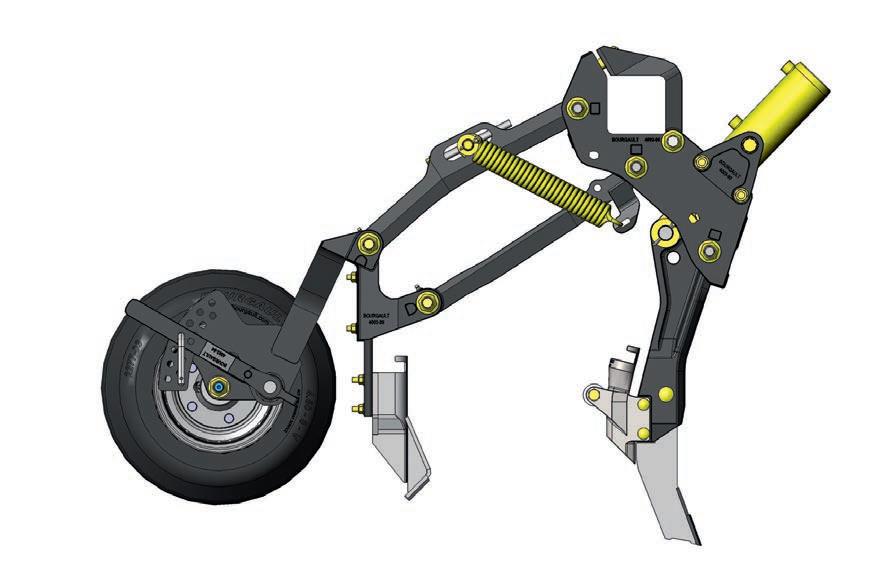

Bourgault knows about the word big.

Anyone who has ever used the Canadian manufacturer’s machinery knows it is designed to handle the biggest jobs, its 9000 I Air Carts with 45,000L-plus capacities being one prominent example of this.

Its latest addition to the Australian market – the 4420 DKD deep knife drill – is further evidence of this fact, being capable of comfortably working at depths of around six inches (15cm).

Combine all of this with the fact Bourgault is celebrating its 50th anniversary in 2024 and it becomes clear that not only are the manufacturer’s machines big, but this year is too.

Founded in the Canadian province of Saskatchewan in 1974, the company’s growth journey features Australia at the forefront – making the celebration one

Bourgault Australia is preparing for its new deep knife drill to reach full production, but it is far from the only big thing on the company’s radar

which Bourgault believes local customers should feel part of.

Australia was the first overseas market to which Bourgault expanded in the late 1990s and these shores remain crucial to the manufacturer’s success, being a frequent testing ground during the research and development processes of new products.

This has led to instances of products being developed for the unique demands and harsh environments of the Australian market, of which the 4420 DKD is a recent example.

Announced by Bourgault late last year, and first shown to the public at field days during the spring of 2023, the 4420 DKD is about to step up to full production in the coming months.

One of the biggest changes of the 4420 DKD compared to previous drills produced

by Bourgault lies in the name – deep knife drill – with the latest unit having a new generation frame with an all new opener with independent fertiliser knife and seed closer.

The front fertiliser knife works to a considerable depth, being optimised for depths of 12cm to 16.5cm below the surface according to Bourgault, and is followed by a seed placing closer that is parallel with a packing wheel.

Bourgault’s Western Australian operations manager Ben Bulley says customers who have already used the 4420 DKD have relayed positive feedback in several areas.

“The main positive feedback relates to seed placement and good germination of the planted crop, and we believe that comes from some of the design features of the deep knife opener,” he says.

“It holds well in the ground, so it has a good shattering effect of the subsoil. This helps to bring moisture up that may be down in the subsoil and it also helps the roots to establish and find any moisture that is collected there from any rainfall.

“Our packer wheel has quite a good high packing ability and is adjustable so you can tailor it to suit the conditions.

“What that does is firm the seed bed and just pushes a little bit of soil closely in around the seed, squeezing some of that air out of the soil – so you get good seed-soil contact.

“Once you get that, the seed will germinate well and resist disease, helps resist drought, and you get an early strike, quick germination, and you can see the crop coming up out of the ground quite rapidly.”

The 4420 DKD also has a heavy duty

forward shank with on-the-go adjustable hydraulic breakout between 68kg and 450kg, plus a 16mm wide knife point.

A heavy-duty rear frame and robust frame construction can accommodate drill-mounted liquid tanks.

Ben says the ability to carry up to 5,000L of liquid on board is important, particularly in markets such as Western Australia where he is noticing increased uptake of liquid fertilisers.

The 4420 DKD also has a ground-following 1:1 contour ratio, easy packing pressure adjustment with a cordless impact driver and easy depth adjustment with a simple handle and pin.

Large tyres, a steerable front axle and floating hitch ensure optimal depth control and superior tracking.

Another significant benefit is the ability

for both sizes – which have 12m and 18m working widths – to fold up to just 5.5m for transport.

It is a product specifically designed for Australian farmers which has undergone plenty of testing to ensure it will be the ideal fit.

“We completed the field trials and prototyping last seeding season, and since then we’ve imported and received the first limited production run of factory production machines,” Ben says.

“We’re in the process of building those now to ship out to some customers that have purchased and Bourgault will also be running some of these machines as demonstrators through this season.

“It’s still early days and the quantities

are quite limited. There are several reasons for that, but it’s mainly to do with production.

“Once it goes from prototyping to a production machine, you only want to produce around a dozen or so machines in that first run, just to make sure everything fits together properly the way it should.

“Everything is positive though and we’re looking forward to getting these machines

back into the field and operating again.

“The next production run is in June this year and that’s when the company will be ramping up the machine to go into full production.

“There are two production runs slated for 2024, and we’ll have shipments coming in through the year, ready for customers for 2025.”

Bourgault’s 4420 DKD is a step up – or down, to be geometrically accurate – from previous drills, and is in keeping with the company’s broader philosophy of producing big machines.

This is particularly true when considering the 9000 I Series of Air Carts, which Bourgault says are the largest in the world.

The manufacturer’s biggest model in this range – the 91300 – offers a capacity of 45,810L split across four tanks, allowing broadacre farmers to seed for longer without needing to refill.

The next two models down, the 9950 and 9650 – which still have impressive capacities of 33,470L and 22,900L respectively – are both available as leading or trailing air carts.

This feature means the L9950 is the largest leading air cart on the market, Bourgault says.

Individual weigh scales across the 9000 I Series models allow users to ensure a precise amount of seed is being released, while also highlighting the fact these carts are packed with technology to ensure easy and efficient usage.

Numerous tyre options are available across the range to minimise ground compaction – an important issue with heavy machinery – and help ensure a consistent germination.

All of this is occurring at a milestone time for Bourgault, which celebrates a halfcentury in business in 2024.

As part of this, all machines being delivered throughout the year will have a 50th anniversary decal on them.

“The company is very proud of its history and it has a lot of long term employees,” Ben says.

“A lot of employees have been with the company for 20 or 30 years and you get a lot of loyalty and consistency through that.”

Bourgault Australia was founded in 1997 and Ben believes this long history Down Under, plus Australia’s importance to Bour gault globally, are reasons to celebrate the company’s milestone.

“Australia is the first overseas market that Bourgault ventured into and it’s still a very key and important market,” he says.

“This is also part of the reason why they’ve been willing to develop the 4420 Drill for us. That was developed for Australia and they did it because this market is important.”

Bourgault Australia has full distribution centres on both sides of the country – locat ed in Perth and Albury – with company staff and a full stock of spare parts for its products at each.

Bourgault’s full Australian product range and dealer network can be viewed at www.bourgault.com/en-au

A Fremantle business is positioning to be the world’s largest grower of Asparagopsis, seeking investment as it finalises talks with Indonesian growers

Asparagopsis, a seaweed which can help reduce methane emissions from cows when turned into a feed supplement, is attracting interest and investment worldwide.

Currently growing seaweed on 32 hectares of sea floor in Western Australia’s Cockburn Sound, Fremantle Seaweed sits in a zone where both cold water and tropical Asparagopsis can grow.

Fremantle Seaweed says it is in advanced discussions with Indonesian growers to form a joint venture to be the largest supplier to access the Chinese and US cattle and dairy markets.

This, plus an expansion of Australia’s North West coast, could make Fremantle Seaweed the largest asparagopsis marine grower in Australia and put it up there with the biggest in the world, the company says.

The business was co-founded by Fremantle locals, forming mining electrician Chris de Cuyper and agricultural industry veteran Mick Holland, and the business was granted $4 million by the WA government to pursue investment in WA.

To support its planned expansion, Fremantle Seaweed has launched a digital campaign with crowd sourced funding house Birchal, to target people who want to invest in sustainable business.

“It’s an unusual investment tactic to run a digital campaign, but we are younger ourselves so invested in digital photography and telling our story through capturing everything we do,” de Cuyper says.

“We have done extensive research on

Prime Creative Media, the publisher of Farms & Farm Machinery, is Australia’s first publisher to send paper wrapped magazines at scale, in partnership with its printing and mailing supplier FSG.

FSG owner Michael Murphy and Prime Creative Media COO Christine Clancy, at the mailout from Australia’s first paperwrapping mailing machine. Image: Prime Creative Media

Based in Victoria, FSG purchased the country’s first ever paper-wrapping mailing machine in January this year.

Imported from UK supplier Norpak, the machine’s ability to wrap publications in paper will eliminate plastic wrapping for several Prime Creative Media titles, including Farms & Farm Machinery.

“It’s the evolution of the mailing industry to abolish the use of single-use plastics in mailing magazines,” says Michael Murphy, owner and director of FSG Mailing.

“This follows the government’s move to get disposable plastics out of our Australian systems.”

Up until this technology was in place, the only alternative option to plastics for publishers was paper envelopes.

Murphy says this was cost prohibitive for many clients, because the price of producing and printing the envelopes was high, in addition to labour of either hand inserting magazines into the envelopes, or using expensive equipment to insert into the envelopes and seal them - adding a significant increase to mailing costs.

our investment competitors and there is nothing to equal it.

“We thought using this was the best way to reach younger investors who consume their news across social media, to have exposure to our story.”

The news comes as Adelaide-based CH4 Global celebrates being named a one of America’s Top Green Tech Companies by Time Magazine.

CH4, ,which has an administrative head office based in Nevada, was among 250 companies selected by the magazine.

The distinction comes just weeks after CH4 Global completed the first commercial deliveries of its Methane Tamer cattle feed supplement to a feedlot at Warnertown, south of Port Pirie.

Mailing houses like FSG have experimented over the years with bioplastics, and recyclable plastics, but Murphy says the technology never quite worked out.

Murphy came across this technology through his supplier UK company Norpak, who previously supplied his plastic wrapping machine.

An additional environmental benefit to the machine is that because the addresses are printed directly onto the paper wrapping, it eliminates the need for flysheets – the paper that lists the addresses and is placed onto a magazine.

This improves efficiency, as it limits the printing and transportation of flysheets.

It also means that only a small amount of more paper is being used in with the new system, once the paper used in flysheet printing is taken into account.

This also opens up a vast array of options in using recycled and sustainable paper products.

Prime Creative Media COO Christine Clancy was on site at FSG in Bayswater to witness the first publications being sent out in paper-wrapping.

“It’s such an honour to watch history in the making, to see our publications make this first step in reducing single use plastics in our environment,” Clancy says.

energy, innovative machinery, supply chains, biosecurity, agtech and smart farms, and the human connection.

The conference program includes keynotes from founder of agritech start-up Goterra and 2023 ACT Australian of the Year Olympia Yarger, plus chief scientist for the Food Agility Cooperative Research

Agribusiness researcher Mark Fletcher will provide practical insights on developing farmgate strategies, while DataFarming’s Tim Neale will share the transition to digital agronomy. Farmo founder Nick Seymour will explore key insights around the barriers to adoption in agtech on the Expert Stage within the exhibition.

Thanks to a new partnership, the National Farmers’ Federation will also bring a wealth of expertise and experience to

Melbourne will host the FutureAg Expo in April.

Image: Marvin / stock.adobe.com

FutureAg Expo, exploring sustainable practices, trade strategies, the impact of climate change on agriculture and discuss key policy areas impacting the industry.

“The conference is an opportunity to connect and collaborate with our industry’s leaders, innovators and professionals, addressing the challenges, opportunities and insights which will advance Australian agriculture now and in the future,” Nissen says.

FutureAg Expo will be held across three days between Wednesday 17 April and Friday 19 April 2024 at Melbourne Showgrounds, Ascot Vale, Victoria.

To register or for more information on FutureAg Expo 2024, including exhibitor and sponsorship opportunities, visit www.futureagexpo.com.au

JSG Industrial Systems will use the FutureAg expo to remind customers how lubrication and fire suppression equipment can improve daily operations on a farm

As FutureAg provides a snapshot at what the next generation of Australian agriculture will look like, it is important to remember every aspect of the farming process and the need to consider maintenance.

Machines will evolve, as will the technology powering them, but the importance of lubrication and fire suppression will remain constants.

This is the core business of expo exhibitor JSG Industrial Systems, which will be showcasing its product range under the theme of “adding value to the crop cycle”.

Lubrication

Providing an extensive range of lubrication systems is an area of expertise for JSG, which can offer its customers everything from basic and manual setups for small farm equipment through to fully automated systems for large-scale broadacre machinery.

This variety will be on display at FutureAg, with JSG’s experienced team able to guide potential customers through the most suitable options available, depending on their specific requirements.

Regardless of a machine’s size, the importance of regular lubrication is fundamental, as JSG’s lubrication product sales manager Branco Zivic previously told Farms & Farm Machinery.

“What we’re trying to introduce is the idea that regular greasing or periodically greasing a machine is better than doing it once a day,” he said.

“Small amounts of grease, but often, is better than a one-off situation once a day.

“It’s also important that farmers keep introducing new technologies or systems that can benefit greater productivity and

reliability of their equipment,” Zivic added.

“If we can provide them a product that would reduce labour and increase productivity, then they’re a lot better off.”

Much of JSG’s lubrication product range bears the SKF Lincoln brand name.

A newly launched product is the SKF Lincoln compact lubrication pump series (CLP). Lightweight, simple and easy to use pump with a compact design, it is suitable for small progressive lubrication systems.

Among these options is the CLP Basic and Basic Plus, designed to be both reliable and affordable for the more simple lubrication tasks.

It offers reliable functionality and easy maintenance and can be controlled by an external lubrication controller or the machine control system. Using the SKF eLube app allows users to determine lubricant levels and pump functions remotely.

There is no need to stop the machine or physically access the pump to check lubricant levels and this can save time and also reduce the risk of accidents.

By adding an automated CLP system, farmers have the dual benefits of both reduced maintenance at the end of a long working day, and an easier and more cost-effective regular machine service.

Another of JSG’s most recent additions is the automated electric cartridge pump (AECP), which only hit the local market late last year.

Designed to provide simplicity and compactness for machines such as small tractors and telehandlers, the AECP can

be placed directly on to the machine.

It lubricates progressively throughout the day while the machine is in motion, with the only ongoing requirement being to replace the empty grease cartridge.

JSG’s larger-scale systems also provide real-time data and predictive maintenance alerts, optimising a farmer’s lubrication schedules for maximum efficiency.

Fire suppression

Australian farmers regularly work in extreme heat and remote environments, where a small fire caused by mechanical failure or overheating can quickly become a major problem.

It is for this reason JSG says that equipping machinery with its fire suppression systems is vital.

“These are designed to detect and suppress fires quickly, safeguarding equipment, crops and operator safety,” JSG says.

“These systems are not only critical for preventing immediate fire dangers but are also crucial for maintaining continuous farming operations and essential for sustaining agricultural productivity.”

JSG offers fire suppression systems from Muster, which can be broadly split into the Muster Foam Based System and Muster TUFF system.

If excessive heat or flames are detected within the engine bay while a machine is operating, the Muster fire suppression sensors will immediately discharge an environmentally-responsible firefighting foam solution.

The TUFF system – which stands for

Transferrable Unit for Fire Fighting – is easily attached or positioned on mobile equipment or the back of a support vehicle. This is a flexible unit designed to provide more power, and is available in three sizes (38L, 66L and 110L) and two different pressure capacities (700kPa and 1,370kPa).

Ideally suited to the agricultural market, it works off nitrogen pressure and comes with a 15m retractable hose reel.

This means fires which may have quickly spread around the machine can be swiftly and effectively dealt with.

To learn more about what JSG Industrial Systems can offer, visit www. jsgindustrial.com or visit them at Stand 82 at next month’s FutureAg.

In the six years after he started working on his family dairy farm in 1984, Tom Paltridge saw a significant expansion of the herd.

But the larger herd meant dairy effluent was starting to become a problem – the natural cow by-product that, if not managed properly, can have negative impacts on the environment.

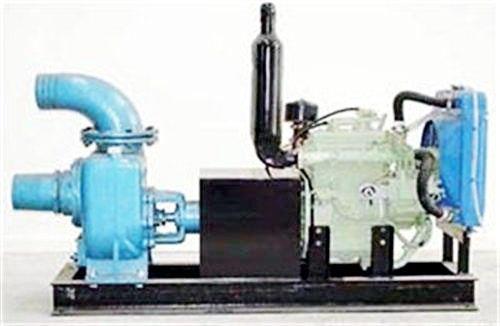

An EPA designed effluent system, consisting of a weeping wall, underground pipes, a manure pump and a travelling irrigator, meant they were constantly reactive to blockages.

And, as the application of effluent was restricted to paddocks close to the dairy, these were constantly overloaded with nitrates due to high application rates.

Frustrated by what he saw as a waste of nutrients, Tom invented his own way to transport the effluent further by converting an old fuel truck.

He would pump the effluent directly into the fuel tank and then gravity feed the effluent out the back of the tank via six-inch pipe dropping onto a plough disc – a very rudimentary splash plate – 1000 litres at a time.

When he showed his invention to a visiting Irish farmer, the Irishman smiled and said we have tankers to do that job.

So, knowing that UK and European farmers had been spreading effluent on pastures for many years, Paltridge started looking for a workable and beneficial solution to manage the effluent produced on his dairy farm.

While on exchange in the United Kingdom in 1996, Paltridge attended a field day where he met Philippe Pichon – who had a stand for his family’s machinery manufacturing business, Pichon Industries.

Pichon’s business was family owned at the time and based out of France – selling vacuum tankers for sucking up and spreading dairy and intensive animal farm effluent, back onto paddocks.

Key to Paltridge’s dairy effluent prob-

into Australia – starting his own business Muck Runner Pty Ltd.

“That encounter in the UK was the beginning of a life-long friendship between Phillippe and I, and a close relationship between Muck Runner and Pichon Industries,” Paltridge says.

Based out of Mount Gambier, South Australia, Muck Runner still sells Pichon machinery to farmers and contractors all over Australia.

The Pichon range focuses on muck

slurry tankers and solid spreaders.

Paltridge says all of these machines specialise in effluent handling – which can be manure from cows as well as the water that is used to keep yards clean.

According to Paltridge, effluent is a widely unused resource in Australia, but he has been using Pichon machines for many years to put effluent nutrients back on paddocks – assisting in growing pastures.

“The beauty of these Pichon machines is that the farmer already owns the product, and the nutrients are in the effluent, we can then use the machine to get those nutrients out to the paddock to grow the grass,” he says.

“And because they are mobile, we can use the tanker or spreader to target the paddocks that may be deficient in organic matter.”

Pichon speciality

Muck Runner solely focuses on the Pichon brand, importing these machines either for stock or for specific customer orders.

Based out of France, Pichon makes galvanised tankers, solid manure spreaders, slurry stirrers and tanker attachments for applying the effluent, such as trailing shoes, drip hose booms, and tine or disc injectors – handling dairy effluent and effluent from intensive husbandry overseas.

machines together ourselves, we know our way around them,” Paltridge says.

Tankers range in size from 5,000 to 20,700 litres, while solid spreaders range in capacity from 10 to 24 cubic metres.

The Pichon tankers, one of Muck Runner’s key product focuses, are used to suck up and transport manure and wash down water that runs into holding pits or ponds on dairies, piggeries and other intensive animal husbandry operations.

What ends up in the pit or pond is a wonderful organic fertiliser full of nutrients.

Paltridge explains the businesses’ vacuum tankers product as a pressure vessel.

“Being a system that uses vacuum, the air is sucked out of the tanker and then atmospheric pressure forces effluent in,” he says.

“When we go to the paddock, we pump air back into the tanker and that forces the product out.”

The benefit of this is that the Pichon tanker is only pumping air, not the effluent – leading to less problems such as blockages of pumps.

There are also no moving parts coming into contact with effluent.

Muck Runner assembles the imported machines on-site in its Mount Gambier workshop and provides them Australia-wide, with the Northern Territory and Canberra being the only two places the product hasn’t been sold to yet.

Having this knowledge of the machines, Paltridge can be an effective problem-solver for clients – working out most issues with just a phone call.

Paltridge believes the Pichon machines are unmatched for quality, performance and longevity.

All machines are hot dip galvanised at 480 degrees, with up to 8mm thick steel on bigger models, have stainless steel valves, bolts and fittings and oversized axles.

Such features make for a machine that will last for generations and is a great return on investment.

“I use the same machinery on my farm as the ones we sell for Muck Runner,” he says.

In fact, the very first tanker Muck Runner brought to Australia is still in use after nearly 30 years.

It had been in use weekly on Paltridge’s farm but has recently been sold to another farm to continue its service, as Paltridge has now upgraded to a 20,700 litre tanker.

He currently removes four loads a week from his effluent pit for his 400-cow herd.

“That first tanker is still going after 30 years and is as effective as it was the day it was built,” he says.

Muck Runner’s most recent sale has been

shoe attachment.

This attachment goes on the rear of the tanker and places effluent directly on top of the ground, underneath the leaf of the grass.

Paltridge says this tanker is hot-dipped galvanised to protect the 8mm thick steel from the corrosive effects of effluent – giving the machine a long lifespan.

The tanker has been fitted with a 14,000-litre/minute vacuum pump and has a plunger arm auto filler with turbo –allowing the driver to suck effluent from pits or ponds without getting out the tractor or dragging heavy hoses around.

With touch screen control and an electronic flow meter, operators can control the amount of effluent spread.

Recently, there has been increased interest using attachments such as trailing shoes and injectors to go on the Pichon tankers.

Paltridge explains that in doing so, effluent can be applied under the leaf of a plant, but still on top of the ground –therefore giving better utilisation of the business’ product.

“We want the poop back out on the paddocks, because that’s when it’s making us money!”

For more information on Muck Runner’s Pichon products visit www.muckrunner.com.au or call Tom Paltridge on 0419 851 543.

The

Sawquip’s extensive range of Australian made saws means both farmers and rural contractors can find a product to handle their unique needs

Any product that is many times faster than the traditional alternative, easy to operate and which eases the physical burden on farmers is ticking multiple boxes.

All of these benefits are what Sawquip says its range of towable firewood bench saws offers to customers.

Due to celebrate its 20th anniversary in business next year, Sawquip is in a position of experience to know the benefits of its Australian-manufactured products and the importance of local backup.

Sawquip’s technical sales manager Troy Pilcher cites the firewood bench saws as being the most popular product among the farmers in the company’s customer base, while the excavator saw range is the most sought-after by rural contractors.

Farmers and rural contractors are a significant portion of Sawquip’s clientele, according to Pilcher, along with arborists and civil contractors, plus land clearing and tree-care companies.

Pilcher says there are several key areas that customers are drawn to across all industries and which have helped Sawquip to develop and progress over almost two decades in business.

“We’ve developed a competency in large tungsten circular saws, which is one of the things we specialise in,” he says.

“Over the last 20 years, we have a lot of experience in dealing with circuit blades in different applications, cutting timber, vegetation and different materials.

“The range we’re doing at the moment is primarily timber focused, but one of the things that gives us a bit of a difference is

Sawquip’s towable firewood bench saws can be separated into three distinguishing characteristics.

There are two models which are motor-driven – the SBS30 and SBS36 – and both of these also have an electric-start equivalent.

The other model – PTOSBS36 – connects to a tractor via three-point linkage and is driven by the PTO.

The main difference between the SBS30 and SBS36 is the cut capacity.

The SBS36 has a 900mm tungsten-tipped blade compared to the 750mm tungsten-tipped blade on the SBS30, which gives the SBS36 a larger cut capacity of 355mm compared to 280mm.

Another standard feature across Sawquip’s towable bench saw range is concealed rollers, which bolster both its safety and efficiency by ensuring logs glide effortlessly across the bench saw and reduce both friction and the risk of jams.

Pilcher says there are three main rea-

sons why farmers are drawn to Sawquip’s towable bench saws.

“They are very portable, so farmers can take it around to any paddocks where they have timber to chop up or dead Iimbs that have fallen,” he says.

“The second thing is it’s quite quick, probably three to five times faster than using a chainsaw and you don’t have the maintenance involved.

“A third thing is that it saves your back bending over like with chainsaws, which particularly helps a lot of farmers that are middle to older generation.”

The bench saw concept has been around farmers and timber cutters for decades, and Sawquip prides themselves on manufacturing the ultimate bench from years of industry knowledge and feedback to provide the most efficient and safest benches on the market.

Sawquip’s range of excavator log saws are the most popular with rural contractors, and are becoming a recognisable

attachment for efficient and precise processing of Australian hardwood timbers, like ironbark, box and gum species. This range is available in four different sizes suiting excavators from 3.5 tonnes to 30 tonnes.

The Logripper range provides contractors with the versatility to handle up to 800mm cuts with a 1,830mm tungsten-tipped blade.

These specifications relate to the topend X18, which is designed to handle the toughest jobs.

Between 180L and 200L of hydraulic flow per minute is required for the X18, and an excavator between 15-30 tonnes is recommended to run the powerful 880kg unit.

Sawquip’s next model down – the X15 – offers a 1,520mm blade and 650mm maximum cut, which then steps down to a 1,220mm blade and 510mm maximum cut on the X12 and a 900mm blade and 370mm maximum cut on the X09.

Each Logripper model can be fitted to any excavator with appropriate auxiliary

As machinery such as loaders and excavators increase in popularity on Australian farms, every logistical aspect of their daily operations needs to be considered.

One part of the equation – particularly for broadacre farms with long distances between where the machine may be needed – is safe transportation.

This is where Jetland Loading Ramps enters the conversation.

The Australian-owned company designs and sells high-quality ramps to handle everything from ATVs through to 42-tonne machinery, while also catering to non-farm specific needs such as wheelchair and walk ramps.

Jetland is experienced enough to know that while many farmers’ ramp needs are similar, a one size fits all approach is not always the answer.

One of Jetland’s points of difference is its ability to custom build ramps to any specification, depending on a customer’s requirements.

Jetland stands out through the ease with which customers can both purchase their ramp and have it delivered.

Jetland’s website is kept up to date with an extensive and detailed product selection and provides the ability to order online.

Crucially, if something is listed on the website, it means stock is available at Jetland’s warehouse in the Melbourne suburb of Mordialloc.

From there – Jetland promises free delivery Australia-wide to any commercial address with loading facilities, while also having a network of depots around the country where ramps can be delivered.

This represents a huge potential saving for customers in delivery costs, while also providing the confidence in knowing the locally built ramps will arrive quickly without delays in either manufacturing or overseas shipping.

Being able to get a product delivered anywhere within Australia for free – and quickly – would not count for much if the ramp itself was substandard.

This is not something Jetland ramp users need to consider though, with a wide variety of satisfied customers that are

not only farmers but also who represent industries as diverse as plumbing and removalists.

Jetland ramps are built strong and heavy-duty for Australian conditions, with four different series available to help customers decide what will best suit their needs.

The first of these, the A Series, is suitable for rubber track machines and is available with load capacities between 2 and 6 tonnes and in lengths between 2.5m and 4.5m.

The B Series is suitable for rubber track and rubber tyre machines. This is available in 2 to 6 tonne load capacities and 1.8m to 4.8m lengths.

Jetland’s C Series is also suitable for both rubber track and rubber tyre machines and comes in with 4 to 21 tonne load capacities and 2.5m to 4.5m lengths.

Jetland’s heaviest duty offering, the D Series, is suitable for steel track, rubber pads on steel, rubber track and rubber tyre machines, and is available in 2.5m to 4.5m lengths.

The D Series has recently been upgraded to support much heavier loads, a move

Images: Jetland.

which Jetland says highlights the company’s commitment to innovation.

Designed by Japanese engineers, the D Series now supports up to 42 tonnes, where it was previously only rated up to 21 tonnes.

Jetland says this makes it the first 42-tonne rated loading ramp available in Australia.

This is evidence of the variety offered by Jetland, while another aspect to consider is the machine wheelbase.

Jetland says it is important for customers to consider the machine wheelbase when evaluating their ramp loading capacity.

They should also choose a ramp with an internal width that is at least 5cm wider

than the wheels or tracks of the loaded machinery, the company says.

All Jetland ramps across the four series are built from super-strong aluminium, which helps to make them lightweight and portable.

Thorough safety systems and using high-quality raw material help to ensure a safe and reliable product, which also provides operators with confidence in carrying out secure loading and unloading of different types of machines.

Safety is a top priority when using loading ramps, and the Jetland team has put emphasis on ensuring their ramps not only meet but exceed safety standards.

The ramps feature anti-slip surfaces, ensuring maximum traction for vehicles and machinery during both loading and unloading.

They are also fitted with safety pins, ensuring the ramp remains securely in place during use.

Other features available across various Jetland models include a non-skid surface, flat rungs for smooth loading and heavy-duty raised tread on flat rungs.

All Jetland ramps are also backed up by a 12-month warranty, giving users additional peace of mind.

Jetland’s full range of ramps, and the delivery depot network, can be viewed online at www.jetlandramps.com.au

The ramps can comfortably handle a variety of heavy machinery

A Victorian government grant has enabled Duxton Dried Fruits to replace its petrol UTVs with electric units as the producer moves towards net zero emissions

As more private enterprises look to help reduce emissions across industry, one Victorian farm company is already reaping the benefits of government support.

Duxton Dried Fruits received a grant as part of the Victorian government’s $5 million Zero Emissions Vehicle Commercial Sector Innovation Fund, which has allowed for six petrol UTVs to be replaced with their electric equivalents.

Duxton has 540ha of dried grape vines in the Sunraysia region of north-western Victoria and currently produces about 30 per cent of Australia’s dried fruit harvest.

The grant has enabled Duxton to not only purchase six electric UTVs, but also install an on-site solar charging station for them.

The company is currently working with local educational organisations and other groups to develop a report into the machines, aiming to encourage greater user adoption of zero-emissions technology across the agricultural sector.

Duxton sustainability project officer Henry Young says this collaboration has

provided mutual benefits in terms of exposure, education and access to practical data.

“We’ve partnered with TAFE Victoria

and we’ve been working with our local TAFE provider SuniTAFE in Mildura,” he says.

“We’ve developed an educational

“In terms of the solar infrastructure, we’ve partnered with La Trobe University. They’re being fed the live data and they’re compiling a ‘pathway to adoption’ roadmap for the technology in the agricultural sector,” he adds.

“We’ve been working with the Mallee Regional Innovation Centre. They regularly put on grower workshops and field days and through them we’ve been able to showcase the technology and give it exposure to the local agricultural sector.

“This is a keystone project to demonstrate to our existing portfolios and the wider agricultural community of the way that solar can be adopted on a pathway to net zero.”

Duxton’s solar setup includes a rooftop-mounted solar array totalling 60kW, while a complementary battery system that stores 128kW hours of energy has also been installed.

Duxton used grant funds to engage a solar provider who designed a system which will account for all the company’s power usage and allow for the vineyard to reach net zero emissions.

The vineyard currently uses half a megawatt of electricity per year, Young says, while the solar system is designed to produce one megawatt of power per year.

The new electric vehicles have been “really well received” since being introcourse that our staff are completing that goes through maintenance procedures and operational procedures unique to high-voltage electric vehicles.

“We modelled it that with the increased electricity usage with the electric vehicles that the vineyard will be a net zero producer,” he says.

duced into Duxton Dried Fruits’ operations, according to Young, and operate seamlessly throughout the day before being charged overnight.

“There was a sense of anxiety with battery replacing internal combustion engines, but they have been absolutely faultless so far,” he says.

“The UTVs are integral to our day-today operations. All the machines are used daily by our staff.

“The various roles they fulfil include fuel and harvest support during the summer months, general yard duties, irrigation checks and currently they have been used widely for weed control.

“My favourite thing is probably the reduction in noise in the operator environment,” Young adds.

“They’re also considerably more powerful than the machines we’ve replaced,

and they have got a range of innovative features.”

Adopting new technology on farm often leads to benefits beyond initial expectations, and this has proven the case here for Young and the Duxton team.

“The solar system and battery have, in general, replaced us having a fuel bowser and fuel tank,” Young says.

“We’ve greatly saved on the complexity and labour savings of not having to organise fuel and have emergency run-ins to town, which is about 40km away, for supplies.”

The convenience factor is significant and when time equals money, the financial impact of this is also beneficial.

Young acknowledges while there is a financial outlay for farms to invest in the full electric setup, it was a “no-brainer” for Duxton and is a decision the company expects will yield long-term benefits.

“The machines from a pricing standpoint are on par with what’s out there in the market already in terms of internal combustion engines,” he says.

“There is a significant

solar and battery setup, but that is offset by the greatly reduced operating costs of not having petrol in the system.

“Each business is unique, and you will

having a solar and battery system is a no-brainer.”

A large-scale cropping operation continues to thrive thanks to its fleet of JCB Fastrac 8330 tractors

When operators are fighting over the opportunity to drive one particular tractor, you know the manufacturer is doing something right.

For staff at Willaroo, a 15,000ha farm owned by Warakirri Cropping, the tractor in demand was a JCB Fastrac 8330 iCON.

“Our operators were fighting over who was going to drive the Fastrac. You spend a full day on that and you’ve still got a spring in your step when you get off it, but on the other one you had a bit of a sore

back by the end of the day,” Willaroo farm manager Matt West says.

Willaroo is located southwest of the Queensland border town of Goondiwindi, but its 15,000 arable hectares are on the New South Wales side of the border.

Cropping the likes of wheat, barley and chickpeas, it is a large-scale operation that requires multiple tractors.

Spending their days towing the likes of trailed sprayers, linkage spreaders and chaser bins, it is imperative that the

tractors selected by Willaroo are both efficient and comfortable.

It has therefore been music to operator’s ears – and relief to their backs – that the JCB fleet has been expanded.

Operators now have the choice of one Fastrac 8330 Series 4, an 8330 Series 5 and an 8330 iCON.

JCB’s Fastrac range has proven to be a clear winner for Willaroo’s operators, which West believes is down to two main factors.

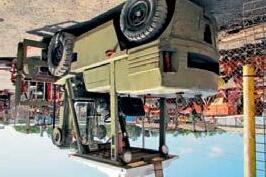

Images: CEA.

“First of all, it’s the comfort,” he says.

“They’re such a smooth tractor in the paddock and the efficiencies gained from the spreading side are significant.

“We’ve been able to spread in the paddock at a higher speed and have operators sit in the seat and be comfortable.

“The tractor seems to cruise across the paddock quite nicely. They’re very smooth and efficient, having that added speed to get jobs done a bit quicker.”

Having previously run a Fastrac alongside another manufacturer’s tractor, prompting the anecdote about operators competing to be inside JCB’s machine, West is able to recognise the reduced fatigue experienced by operators.

As is often the case with Australian farmers, it was a word-of-mouth recommendation that began West’s association with JCB tractors.

It only took one experience for him to realise the potential it could have for Willarroo.

“There was a guy running one in Goondwindi on a spreader, and I went and had a look at it and just had a chat to him,” West says.

“I then went to a field day at (local dealer) WJ Matthews and did a demo on one. We were pulling a trailing spreader and I was

heading sideways across the tram lines.

“We were doing 30km/h and the spreader behind us was bouncing around crazy, but we were sitting in the tractor and it was just gliding across the paddock.

“That was probably the biggest selling point for me, just how smooth this thing was and how much I could improve my spreading efficiencies going forward.”

Fastrac tractors have been part of JCB’s

range since 1991 and have naturally been refined and improved over time.

The 8330 is the manufacturer’s highest horsepower offering that provides up to 348hp (260kW) in power.

A major recent development has been the addition of the iCON concept, which is a new technology-packed control system designed to elevate the user experience.

“The iCON is definitely a step above the

other series tractors,” West says.

“Bringing that technology into the machine has made a big difference, especially with the ISOBUS compatibility and being able to bring that into the separate screens.

“It’s a big improvement and we’re quite impressed with the iCON.”

The first JCB Fastrac 8330 iCON hit Australian farms in late 2022 and boasts the manufacturer’s new electronics infrastructure suite.

Improved ISOBUS connectivity is a critical element of the iCON concept, as is JCB’s new armrest console and 30cm touchscreen display.

Swiping right on the touchscreen brings up a more detailed running screen that includes settings for up to six front and rear spool valves, plus a remote camera view, an ISOBUS 2 Universal Terminal screen and satellite guidance and precision farming options.

This ability to control attachments such as the spreader, sprayer and chaser bin more easily was cited by West as the biggest advantage of the iCON series.

Adding a completely new control system has been a major upgrade, but JCB’s 8330 Fastrac was already a popular tractor – hence why Willaroo already had two in its fleet.

In addition to the powerful 348hp (260kW) engine that produces 1,450Nm of

traction and therefore stability.

West described the JCB’s speed across the paddock as an advantage over other tractors, and the numbers back this up.

JCB lists the Fastrac 8330’s top speed as being 70km/h, allowing it to move quickly between jobs on large-scale farms such as Willaroo, while a modified Fastrac also set a record for the world’s fastest tractor in 2019.

For West, his initial experience with both the tractor and local dealer WJ Matthews was nothing but positive – and this has continued to be the case.

Any farmer knows even the best plans can go awry, and even the most reliable machines have occasional issues, but the way JCB have handled these have al-

“We’ve had JCB come and train some of the staff through the new tractor and (national Fastrac product manager) Andrew Hacker has been out on the farm too.

“Warranty has probably been a big thing for me too. With any issues that we have had, WJ Matthews and JCB have really bent over backwards for us.

“Nothing has been too much of a drama, they’re willing to listen and help with any issues. With other tractor manufacturers or other companies that we deal with for some of our other gear, we would have been stuffed being down a tractor at harvest.

“I can’t praise them enough for that.”

The Fastrac is a staple of JCB’s tractor offering

JCB’s Fastrac being demonstrated in New South Wales

The Fastrac is a staple of JCB’s tractor offering

JCB’s Fastrac being demonstrated in New South Wales

Inlon has hit the ground running to start 2024, bringing new TYM tractors to Australia while welcoming upgrades to Strautmann feed mixers

An official launch event for new utility cabin tractor models TYM T68 and T78 was held at the main office of Australian distributor Inlon earlier this year.

In addition to the new tractors, TYM dealers from across Australia also got

TS25 and T2900HST compact tractors.

Three representatives from TYM Korea travelled to Australia as part of a factory delegation and learned more about the local market.

“After the inevitable ‘pandemic lull’ in

up for lost time, with four new models released in the last six months and two more to come in 2024,” Inlon’s sales and marketing manager Gary Surman says.

“It was an opportunity for the delegation to speak with dealers and hear about the great customer experiences, new product ideas and needs of the Australian market.”

The TYM TS25 and T2900 ROPS tractors are described by Surman as being “welcome additions to the compact tractor market”.

Both offer auto throttle and HST simplifying operation, while their heavy-duty front axle, longer wheelbase and large industrial front and rear tyres give extra stability when lifting and loading.

TYM’s other additions - the new TYM T68 and T78 cabin tractors - are powered by the German-built Deutz TCD 2.9L turbo diesel intercooled engine, which is fuel efficient, reliable and powerful, with a dual dry-element air cleaner for Australia’s dusty conditions.

The four-cylinder engine produces an impressive 67hp and 75hp respectively and only 2200 engine rpm for optimal fuel efficiency.

“Importantly, the electronic engine governor holds the set engine rpm, under varying loads, delivering the maximum power of the engine when required, without rpm droops or spikes,” Surman says.

“This is ideal for PTO work, as the PTO speed is maintained without loss of rpm up to the maximum power rating.

“In comparison, an engine with a mechanical governor experiences rpm droops and spikes as the load varies in operation.”

Power shuttle transmission for the TYM T68 is 24-speed, with 18 speeds under 10km/h and 16 speed, with 11 speeds under 10km/h for the T78.”

Distributed Australia-wide by Inlon, the TYM T68 tractor loader package starts from $74,900 while the TS25 starts from $20,713 (tractor only).

The TYM range can be viewed online at www.tym.ag/931.

Mixer innovation

Strautmann, another brand represented in Australia by Inlon, has continued its innovation and development of its feed

Now in its fourth generation, Strautmann has introduced its new Intensive Mix System (IMS) auger.

Strautmann pioneered the develop-

agitates, lifts and loosens feed material, for a faster mixing time, uniformity and lower power requirements. With the new IMS, Strautmann has increased the number

of steps, making them smaller and more frequent.

The steps now occur every 60 degrees of auger angle rather than the previous 90 degrees, which the manufacturer says accelerates the mixing process while using less power and reducing wear on the auger.

Strautmann also has a patented knife adjustment system, and this means the IMS auger can be adapted to specific feed components that need increased cutting in the mixing process, such as straw and complete round bales.

The knives are available in two lengths and their working angle can be set according to whether an aggressive cutting action or mixing is needed.

A mix of knife types and angles can be arranged along the auger flight.

A special mounting position is available for the top auger knife which enables it to more aggressively and quickly break up complete bales that are loaded into the bowl.

“The stepped design gives fast, low horsepower mixing because the steps lift and loosen the fodder as it mixes, creating a uniform feed ration without over processing,” Strautmann product manager for feed mixing technology Andreas Haggeney says.

“Tests comparing traditional pure smooth spiral augers with the stepped flight auger have showed considerably reduced power consumption with the stepped design.”

The German-built product has performed strongly on Australian farms for over 30 years and is set to go to a new level thanks to the latest upgrades.

Strautmann offers a wide variety of Verti-Mix models with capacities

whole herd will benefit from optimum nutrition.

Uniformly mixed feed provides better weight gain, fertility and improved feed

Strautmann’s new IMS auger

Strautmann’s Verti-Mix is distributed in Australia by Inlon, and the full range can be viewed at www.inlon.ag/932.

The Cotton Pro 70.10 telehandler is another example of Dieci’s commitment to industry-specific solutions for Australian farmers

Dieci’s philosophy has always been to not only provide versatile telehandlers, but also industry-specific models that suit the unique needs of certain operators.

One such example lies in the Italian manufacturer’s Cotton Pro 70.10.

Carrying around large bales of cotton is heavy work and requires a telehandler with grunt, which is why the Cotton Pro has a 7,000kg maximum lift capacity and a 9.65m maximum lifting height.

As a 12-tonne unit, the Cotton Pro not only weighs in heavier than Dieci’s popular all-rounder, the Agri Plus 40.7, but also its other specialised telehandlers such as the Poultry Pro and Piggery Pro.

The Cotton Pro 70.10 also exceeds these units in terms of its reach and capacity as well, showing it can comfortably handle the big jobs required by cotton producers such as combining bales of raw cotton or spearing hay bales.

All Dieci telehandlers are made in the same region of Italy as Ferrari but are also engineered locally to ensure the end product is perfectly suited to Australia’s tough conditions.

One example of an Australian-specific

addition on the Cotton Pro is the tropical cooling pack, which is added exclusively to local units in recognition of the extra heat faced Down Under.

This is designed to shield the intercooler from cotton, debris and dust, while heat shields around the exhaust pipes help

The engine’s cooling system also utilises a reversible fan to blow any dust and fibres away from the radiator.

A 125hp (93kW) FPT Tier 3 engine powers the unit, which has a 130L per minute hydraulic flow rate. Dieci’s Cotton Pro is available in three steering options includ-

The Cotton Pro’s hydraulically operated telescopic boom is equipped with sideshift that allows the carriage to be shifted from side to side to tightly pack loads.

This means users can move a bale from the front to either the left or right in small increments without needing to move the whole machine. Such a feature adds versatility and ease to an operator’s day, and D ieci has ensured they can do so while also being comfortable.

An Australian-designed air condition ing system is installed in the third-generation cabin, as are a luxurious air seat, excellent thermal and sound insulation and 360-degree views that boost both safety and convenience.

There is continuous oil function on hydraulic sockets, hydrostatic transmission with variable flow pump, plus a patented compensation cylinder inside the lifting ram to ensure the load on the boom is balanced at all times.

Dieci’s telehandlers – including the Cotton Pro – can be customised with a wide array of attachments such as forks, buckets and clamps to ensure they can

perfectly handle whichever tasks a farmer needs done.

“Dieci has dedicated its efforts to ongoing research in cutting-edge technologies within the agricultural, industrial, mining and construction sectors,” Dieci Australia CEO Pat Italiano says.

“The aim is to manufacture fit for purpose telehandlers that are not only

innovative but also prioritise the operator’s needs. This commitment to quality is reinforced by delivering exceptional after-sales support and service across the country.”

The Cotton Pro, along with all Dieci telehandlers, can be viewed online at www.dieciaustralia.com.au

Antonio Carraro’s philosophy has always been to provide solutions to unique challenges faced by farmers.

The Italian manufacturer’s tractors might not be the enormous broadacre beasts aiming to tackle jobs requiring several hundred horsepower, but that is not what they are claiming to be.

Instead, the tractors are focused on the needs of its core market – the horticulture sector – where space is tight and every centimetre counts.

Antonio Carraro’s tractors meet these needs in several ways – by being low enough to fit under branches and narrow enough to fit in between tight rows.

It is this latter factor for which the SRX range of tractors is known, and which Antonio Carraro Australia’s national sales manager Marco Corra says is becoming increasingly popular.

“There are more and more vineyards that are planting narrower rows around that 1.2m distance, particularly in Western Australia as well as in Victoria,” he says.

“When people are adding new lines and new vines into their already-set-up

vineyards, they tend to do it as narrow as possible, while allowing the machines to

“We want to let people know that they can really push their rows as much as 1.2m

There are two main models in Antonio Carraro’s SRX range, the 90hp SRX9800, and the 110hp SRX8900.

While it has evolved over time, the SRX range has been part of Antonio Carraro’s offering for over 60 years.

The larger of the SRX tractors also offers a pressurised cabin for operators which features air-conditioning and sound buffering, but which also remains low enough to be ideal for farmers in horticulture environments.

While the SRX range is designed to be compact and operate in tight spaces, it is certainly not undersized in terms of power or capability.

In addition to the 90hp and 110hp outputs, both tractors have a PTO shaft and 2,400kg lift capacity, meaning they can be used with a variety of attachments.

It is in its attachment capabilities that one of Antonio Carraro’s most unique features comes into its own.

The tractors are reversible, meaning a quick rotation of the turret which houses the driving system allows operators to operate the SRX in the opposite direction - effectively turning a rear implement into a front one and increasing both versatility and visibility.

This feature, Corra believes, contributes to an important part of the winemaking

process and ensures the best quality product - something both farmers and consumers can surely agree upon the importance of.

“Even just when it comes to pruning or de-leafing, you can do the job according to each tree rather than just setting the bar at a certain height and cutting each tree the same,” Corra says.

“The fact you have the reversibility on the tractor means you can adjust your attachment according to the need of each plant rather than each row.

“That benefits the grapes that you’re going to pick from that particular tree and then the wine. It’s all the domino effect of making the best wine really.”

Beyond just winemakers, the SRX is also popular with growers of berries such as blackberries and blueberries.

This is because of the fragility these particular fruits have, Corra says, and their tendency to fall off the tree as soon as they are touched by any machine.

The tractors have an oscillating chassis of 15 degrees, thanks to the manufacturer’s patented Actio, which increases stability and traction.

In addition to offering the Actio, the SRX range has articulation in the centre of the tractor, which removes the need for front steering wheels and therefore pushes the

front wheels closer to the bonnet, thus achieving the narrowest of tractors.

This helps to create a tight turning circle and can be a gamechanger for farmers with only narrow distances at the end of the row to manoeuvre into the next row.

The SRX being articulated means operators can rely on the rear wheels following the path set by the front wheels.

Corra contrasts this setup with that of a car, where the fixed axle creates a different dynamic when turning.

“With a car, for example, where you are fixed and the chassis doesn’t bend in the centre, the rear wheels don’t follow the front wheels and they actually cut the corner a little bit when you turn,” he says.

“With the articulated tractor, you’re following the exact same passage that your front wheels are, so it becomes as a peace of mind that if you are out of the row with your front wheels, you are 100 per cent sure that you’re not going to knock down any tree.