March/April 2023

by nature nordic

Espresso House Group CEO

Anssi Thureson on strategic growth, the importance of staff satisfaction, and why first impressions always count.

Why technology matters

The next evolution of digital acceptance

Imminent deforestation laws

What it means for your business

Instant revival

A new sensory analysis protocol to help expand instant consumption

Disaster plan

How the Caribbean and Central America are prepared to manage risk

www.gcrmag.com

COVER STORY

IN THIS ISSUE

FEATURES

8 NORDIC BY NATURE

Espresso House Group CEO Anssi Thureson on the next phase of the company’s evolution, and discovering new geographies to expand

12 TIME TO ACT

What the European Regulation on deforestation-free supply chains means for the global coffee industry

17 WHAT’S THE RISK?

How insurance programs are helping producers in the Caribbean and Central America manage disaster risk with greater security

21 MAXIMISING SCREEN TIME

Eversys unveils its new digital signage and customisation services to provide added value to customers

25 A SOLUBLE SOLUTION

Flavourtech explains how its Rotating Disc Column is helping roasters meet the demand for soluble coffee offerings

38 MILESTONE MOMENT

Buencafé General Director

Cristina Madriñán on celebrating the company’s 50th anniversary and how it has stayed relevant in the global coffee industry

40 A GREEN ATTITUDE

Rancilio Group explains its renewed commitment to sustainability with a new development model

32 AIM HIGH, THINK GLOBAL

Why a partnership with Highpresso is key to positioning a brand into the marketplace of tomorrow

Neuhaus Neotec on the launch of its next generation of roller grinders, the SPECTRUM grinder series,

34 ENTER ARTIFICIAL INTELLIGENCE

How Cropster aims to enrich the industry by deploying the use of AI into its product suite to interpret data and provide actionable insights

36 STRAIGHT TO THE SOURCE

Almacena Platform discusses its sustainable and transparent approach to connecting the specialty coffee supply chain

LAST WORD

58

The Coffee Science Foundation is launching a new research project to determine where the sweetness in coffee really comes

“I SEE A VERY STRONG INTERRELATION BETWEEN PEOPLE WHO FEEL VALUED AND DELIVER QUALITY TO OUR GUESTS, AND A SUSTAINABLE BUSINESS LONGTERM.”

MAN, VS MACHINE

Technology is moving at a pace I can’t compete with. Recently, when I went to the self-service check-out counter at the Uniqlo clothing store, my items of clothing tallied up automatically without scanning or touching a thing, thanks to Radio Frequency Identification technology. It easily reduced my transaction time and streamlined my checkout process. Bonus.

However, when I wanted to contact my local bank after hours, I was encouraged to use a web chat service to make my inquiry, and was greeted by a “bot”. After failing to classify nor correctly respond to my question, it asked if I wanted to speak with a human. “Yes” was my resounding response.

To me, there is still immense value in the human skill, but in this ever-changing world, the advances of technology will soon become unstoppable.

In the global coffee world, we already have contactless payment, high-tech robot arms pouring lattes, automated processes, and telemetry services. Their ability is proven, and information deemed powerful, however, it’s what you do with it next that matters most.

This exact consideration is the specialty of Adam Carr, Founder and Managing Director of Highpresso, a strategic management consultant. This edition, Carr talks about understanding the value of the information and implementing change in businesses to get the most from new technology.

WMF Professional Coffee machines is doing just that. It is exploring how to combine robotics technology with its coffee machines to produce innovative and comprehensive solutions.

Cropster’s Roasting Intelligence program

uses smart prediction capabilities to anticipate the roast outcome and provides roasters with advice on how to prevent defects in real-time, and make pre-emptive decisions to ensure maximum coffee quality and minimum wastage.

And Coles Express in Australia is actively using Eversys’ telemetry system to digitally activate new coffee products overnight to more than 800 coffee machines across multisite chain locations – a feat not physically possible at the same speed.

As you’ll see this edition, there are many companies thinking broadly about how technology can be used to our advantage, and help customers become more efficient, agile, and empowered. Quite simply, it’s the future.

It’s been predicted that AI technology alone will create 97 million new jobs by 2025, and we’re already seeing it’s integration in coffee. I wonder that’s next?

This month’s cover story, Espresso House Group, was an early adopter of digital services. As CEO Anssi Thureson discusses in our “digital” conversation, as long as his employees are connected and communicating – online or physically via a simple smile and wave – it means everybody understands the purpose and culture of Espresso House and can work together towards a common goal. And that’s what being connected is all about.

CHIEF OPERATING OFFICER

Christine Clancy christine.clancy@primecreative.com.au

EDITOR

Sarah Baker sarah.baker@primecreative.com.au

JOURNALIST

Hayley Ralph hayley.ralph@primecreative.com.au

Isak Ivanovic isak.ivanovic@primecreative.com.au

ART DIRECTOR/DESIGN

Daz Woolley

HEAD OF DESIGN

Blake Storey blake.storey@primecreative.com.au

DESIGN PRODUCTION MANAGER

Michelle Weston michelle.weston@primecreative.com.au

BUSINESS DEVELOPMENT AND MARKETING ACCOUNT MANAGER

Adele Haywood adele.haywood@primecreative.com.au

CLIENT SUCCESS

Ben Griffiths ben.griffiths@primecreative.com.au

PHOTOGRAPHY

PMAGI AB Foto & Film

CONTRIBUTORS

Gordon Feller HEAD OFFICE

Prime Creative Pty Ltd 379 Docklands Drive, Docklands, Victoria 3008 p: +61 3 9690 8766 f: +61 3 9682 0044 enquiries@primecreative.com.au www.gcrmag.com

SUBSCRIPTIONS

+61 3 9690 8766 subscriptions@primecreative.com.au

Global Coffee Report Magazine is available by subscription from the publisher. The rights of refusal are reserved by the publisher

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

Sarah Baker Editor, Global Coffee ReportGlobal Coffee Report is owned and published by Prime Creative Media. All material in Global Coffee Report Magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Global Coffee Report are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

The new Mytico line brings excellence to life in every detail. Gamechanging coffee solutions that deliver impeccable Italian design on the outside and Franke’s Swiss quality on the inside. Go BeyondTraditional and unlock more potential for your coffee business with Mytico. Stand out from competition and convince customers to come back for more.

NEWS DRIP BY DRIP

Food, Agricultural, and Environmental Sciences at The Ohio State University in Columbus, Ohio.

See page 58.

ASIA PACIFIC

In November 2022, the Partnership for Central America, World Bank, and the United Nation’s World Food Programme launched a Disaster Risk Insurance and Finance in Central America Consortium. The consortium aims to identify and support climaterelated agricultural insurance solutions for up to two million smallholder farmers in Guatemala, El Salvador, and Honduras, to increase food security and financial resilience.

See page 17.

Cropster Coffee is using technology to connect producers with the global market and build long-term relationships with buyers. Its Roasting Intelligence AI is one such program that uses smart prediction capabilities to anticipate the roast outcome. It measures data variables such as heat mass and roast temperature. It provides roasters with advice on how to prevent defects in real-time and make preemptive decisions to ensure maximum outputs and minimum wastage.

See page 34.

Buencafé is celebrating 50 years of transforming the future of coffee, reinvesting its profits into improving coffee growers’ quality of life,

impact is a result of Buencafé producing 24 million cups of Colombian coffee daily, exporting to around 40 countries, reaching 60 markets, and delighting new consumers with 100 per cent Colombian coffee.

See page 38.

According to 2020 figures from Cecafé – the Council of Coffee Exporters of Brazil – and the Brazilian Instant Coffee Industry Association, Brazil produces 117,000 tonnes of soluble coffee each year. It exports 4.1 million bags of instant coffee per year, estimated to be worth US$600 million, and distributes 0.95 million bags to Brazil’s domestic market. In November 2022, it released a White Paper titled, ‘Quality Assessment of Instant Coffee: A Sensory Science Development’, proposing a new standardised methodology and sensory analysis protocol for instant coffee.

See page 46.

The Coffee Science Foundation is launching a research project to determine where the sweetness in coffee comes from after discovering it does not come from sugars in the bean. The project began in December 2022 in collaboration with the Specialty Coffee Association and Flavor Research and Education Center in the College of

Flavourtech’s Rotating Disc Column (RDC) is helping roasters meet the demand for soluble coffee. The RDC allows a continuous flow of coffee slurry for high temperature extraction. The slurry is exposed to temperatures of between 150° to 180°C for just 20 minutes to enable further hydrolysis to take place. The end result is a premium RTD or soluble product in terms of quality and enhanced aroma at the end of the line.

See page 25.

Highpresso is an innovation and strategic management consultant that helps clients grow their brand by implementing new technologies and utilising data-driven strategies in a way that suits their vision. Since 2016, Highpresso has delivered a range of services to market, including competitor analysis and product benchmarking for dairy products, sustainability programs and strategy to government bodies, and product development for a new generation of coffee machines.

See page 32.

US$8.6 million

The amount Espresso House is investing in the salaries of its coffee shop employees this year, in order to be competitive in the market and show appreciation to staff.

Last year, a record 15,056 attendees visited the Melbourne International Coffee Expo over four days at the Melbourne Convention and Exhibition Centre, with 15 per cent international attendees from 71 countries. This year, the expo will celebrate its 10th birthday from 17 to 19 August, featuring more than 200 exhibitors showcasing the latest and greatest in coffee, equipment, and services.

See page 50.

EUROPE

Espresso House Group CEO Anssi Thureson has helped grow Espresso House from 160 shops in 2015 into one of the leading premium coffee shop brands, operating more than 500 coffee shops across Sweden, Norway, Denmark, Finland, and Germany. It’s next stage of growth will be franchise operations and looking for partners to expand its presence in Germany, Poland, Switzerland, Austria, and one day, Asia.

In 2022, Espresso House exceeded pre-COVID 2019 sales figures by 15 to 20 per cent.

See page 8.

The European Parliament and the European Council of the European Union provisionally agreed on a new regulation on 5 December 2022 to ensure supply chains remain free from processes and products that cause deforestation. Industry groups had been involved in the development of the Regulation since 2019. Further drive to the initiative was undertaken at the COP26 climate conference in Glasgow in November 2021, when the European Union, along with more than 140 other countries, pledged to halt deforestation by 2030. According to the European Commission, the hope is that this new regulation will stop a significant share of global deforestation and forest degradation, and reduce greenhouse gas emissions and biodiversity loss.

See page 12.

services on its models to expand the screen’s visual experience. Coles Express in Australia uses this added value feature on each of its 800-plus Eversys Cameo coffee machines installed. It has seen consistent doubledigit growth across its coffee product sales since installing the Eversys Cameo machines throughout 2020/21.

See page 21.

WMF Professional Coffee Machines is supplying robotics technology in self-service cafés Coffeebanhada and Rossum Café. According to WMF, the fully automatic WMF 5000 S+ was the best machine for the job in both cafés due to its high performance of up to 250 cups per day, variety of coffee specialties available, and the flexible technical integration capability into upstream and downstream customer systems.

See page 29.

Business-to-business agricultural marketplace Almacena Platform is digitalising the coffee supply chain to increase farmers’ income and create new brands. Currently, Almacena Platform has more than 160 cooperatives with over 300,000 farmers that supply 12 per cent of the African coffee supply registered on its platform. It facilitates sales to 11 European countries.

See page 36.

capable of balancing economic, financial, environmental, and social interests. Since 2020, Rancilio Group headquarters have been powered by 100 per cent renewable energy sources, using 70 per cent solar power, 10 per cent hydroelectric power, 7 per cent wind power, and 13 per cent from other renewable energy sources.

See page 40.

Neuhaus Neotec is launching the next generation of roller grinders, the SPECTRUM grinder series, at the Interpack trade fair from 4 to 10 May in Düsseldorf, Germany. The first machine of the new series, the SPECTRUM 102, will have a roll length of 1000 millimetres and two grinding sections. Neuhaus Neotec says this size is one of the most sold models thanks to its capacity.

See page 42.

Brambati is using a heat recovery system that significantly enhances the efficiency of its coffee production plants. The system is based on an air and water heat exchanger which allows a stream of water to be heated by a stream of hot air. It allows for the recovery of about 450 kilowatts of thermal power, equivalent to saving about 45 normal cubic metres of natural gas in a 300-kilogram batch roaster.

See page 44.

100%

The number of Buencafé’s profits that benefit 540,000 Colombian coffee growing families, contributing to the sustainability of the coffee industry in Colombia, the third largest coffeeproducing country in the world.

nordic

by nature

While few CEOs would understand the labour and knowledge required to uphold the standards set to employees, each quarter Espresso House Group CEO Anssi Thureson visits one of the company’s designated coffee shops to immerse himself behind the coffee machine.

“The leadership team make important decisions, but we also need to understand the effect of our operations and decision-making,” Thureson tells GlobalCoffeeReport

“We call it ‘out of office Friday’. You learn so much from the experience. It’s a great way to meet colleagues, connect with our guests directly, listen to their needs, and understand what they want.”

After a long career working in the retail and grocery market in Finland, Thureson applied for an interview with Swedish-born Espresso House, not having heard of the company.

“Two hours before the interview in Stockholm, I decided to visit a few Espresso House shops to get a taste for the brand. I was stressed I wouldn’t be able to find one. All of a sudden, I saw Espresso House coffee shops on every corner,” Thureson says.

“I remember a girl in her early twenties waving to me. She said, ‘god morgon, do you want coffee?’ Her big smile was telling me there was something unique in the feeling and experience of Espresso House. There weren’t too many other people in Stockholm Central Station smiling at seven o’clock in the morning. I was lucky to have such a good first impression of the brand, and it’s the feeling we chase over and over in our business.”

When Thureson was appointed company CEO in May 2022, taking over the position from long-serving employee John Nylén, the former Chief Operating Officer spent his first 100 days travelling and meeting with 330 coffee shop managers.

“I base my leadership on listening. It’s not always about wisdom. It’s really fascinating to work with young people. They really want to express themselves, to be heard, and they are really fast learners,” Thureson says. “After my first 100 days, I realised what an extremely strong culture at Espresso House we have, and what amazing people we have working for us.”

As such, a long-term strategy for Espresso House is to offer competitive salaries to coffee shop employees, which this year will be an investment of around US$8.6 million.

“I want to show appreciation to our people. They are the heart of our business. I see a very strong interrelation between people who feel valued and deliver quality to our guests, and a sustainable business long term,” Thureson says. “When our people grow, our business grows. If they are happy, then we have succeeded in delivering the right work conditions, which we hope develops into a role as a master barista, senior baristas, assistant managers, and other layers of growth. I see so much joy when our people develop.”

Approximately 30 per cent of Espresso House office staff have taken the opportunity to invest in the company, which Thureson says is a key driver in company culture and employees’ sense of belonging.

EXPANDING THE ESPRESSO HOUSE CULTURE

Espresso House is part of the world’s largest coffee family, JAB Holding BV. When Thureson started work at Espresso House in 2015, the company had 160 shops, mainly across Sweden. He soon discovered that part of his role as country manager would be to share the business with the rest of the world. Espresso House has now grown into one of the leading premium coffee shop brands, operating more than 500 coffee shops across Sweden, Norway, Denmark, Finland, and Germany.

“We work in five different markets with five different languages and currencies. We have done a lot of transformation in our processes and communication to become a more professional company. We have been extremely proud of the fact we operate our shops by ourselves, but the next stage of our growth journey is to give our brand to future partners,” Thureson says.

“It’s a big step. It means that we want to start a franchise operation. We do have some franchise operators in small pockets of the market, but we want to expand that and discover new geographies to grow in the future.”

Espresso House is already negotiating with several partners in Germany, where Thureson says it would be a natural fit to expand its current presence, in addition to Poland, Switzerland, Austria, and one day, Asia.

When Espresso House Founder Charles Asker opened the first Espresso House shop in 1996 in

ESPRESSO HOUSE GROUP CEO ANSSI THURESON ON STRATEGIC GROWTH, THE IMPORTANCE OF STAFF SATISFACTION, AND WHY FIRST IMPRESSIONS ALWAYS COUNT.Image: Espresso House Group

Lund, a small city in the Southern part of Sweden, his ambition, Thureson says, was to operate 100 shops.

“People told him it wouldn’t happen, that it was already a lot to handle just one shop. But as of last year, Espresso House broke a great milestone – 500 shops. Of course, the next milestone is to hit 1000

“We know we can achieve that goal if we grow at a fast pace with our franchise partners and continue our organic growth. I also believe our unique Nordic values of being humble and sustainable, have allowed the company in the past few months, to focus more on becoming better instead of becoming bigger.”

Thureson acknowledges the challenge will be “scattered” competition from other coffee chains and many boutique roasters in the Nordic region. However, in the German market already, Espresso House’s newest addition, results have been “exceptionally good”.

“There are not too many players that offer what makes us unique – specialty coffee and baked goods from our premium quality bakery in Arlöv [just outside Malmö in Sweden]. Not too many companies have succeeded in combing these two elements. You either succeed with one or the other, but we have both,” Thureson says.

“Entering a new market is like education, you start small and grow steadily. We conduct a thorough food analysis to see what assortment of products will work well. The breakfast behaviour in the Nordics is quite unique, with focaccias and bagels, but in Germany, they love their salty pretzel in the morning with a good coffee, so of course we need to fulfil their needs.”

Espresso House’s cinnamon roll is its top seller, even in Germany. Thureson notes the company still uses Founder Charles’ grandmother’s old mud cake recipe. “That’s one recipe we probably won’t touch,” he says.

TRADITIONS AND TRIUMPHS

Aiding the growth of Espresso House is the company’s committing to the digital space, which it has pioneered since 2014 with the launch of its My Espresso House loyalty program.

In Sweden, Thureson says almost half of customers pay for their order via the Espresso House app or

Anssi Thureson

Anssi Thureson

CEO, Espresso House Group

by using its digital loyalty program. He says the digital transformation was counter-intuitive of the COVID era, whereby the company had already educated its customers to use contactless payment.

Espresso House’s latest innovation, at oneand-a-half years in the making, is a subscription model that enables customers to make monthly payments, “just like a streaming subscription”.

For Espresso House employees, in addition to an internal Espresso House Academy, a digital training platform is used to maintain consistency across all markets. A digital Barista Pulse system also encourages staff to rate their shift with different versions of smiling emojis. For instance, if a barista rates their shift as stressful because they were understaffed on a busy Saturday, the company can monitor operations and implement better planning.

“It’s important that we are a flat organisation so that people feel we are doing this together. It also gives the leadership team strong access to our people and a direct form of communication,” Thureson says.

“I believe that when we are connected with

“I WANT TO SHOW APPRECIATION TO OUR PEOPLE. THEY ARE THE HEART OF OUR BUSINESS. WHEN OUR PEOPLE GROW, OUR BUSINESS GROWS.”Image: Espresso House Group Espresso House has a designated in-house architect to recreate the Nordic look and feel of its shops.

our people, and everybody knows the purpose and meaning of Espresso House, then we can create a fantastic and fun business.”

Part of that ethos includes a sustainable roadmap. In 2021, Espresso House started mapping its carbon footprint according to the Greenhouse Gas Protocol. This year, it aims to work towards setting science-based emission reduction targets in line with the Science Based Target Initiative’s recommendations and criteria.

“We are proud of our long-standing producer relationships of 20 to 25 years. We have full transparency from bean to cup, and we understand that a company of our size needs to invest in certifications,” Thureson says.

In 2021, Espresso House bought coffee from 10 different countries, and brewed more than nine million cups of specially graded coffee.

All of Espresso House’s coffee is roasted in its Länna-based factory, just outside Sweden’s capital of Stockholm, where it produces 800 tonnes of coffee annually. Thureson says the volume is attributed to its growth in multi-channels and distribution of products to grocers and on-demand coffee stations.

In 2022, Espresso House exceeded pre-COVID 2019 sales figures by 15 to 20 per cent. It also won the Allegra Award 2022 for Best Coffee Chain in the Nordic Region.

Also on the rise is Espresso House’s 43 converted coffee shops, formerly of Balzac Coffee which it acquired in 2017. The transformation has resulted in a 20 to 30 per cent sales increase.

To see the results for himself, Thureson tells Global Coffee Report his next ‘out of office Friday’ is booked for March.

“I’m not the world’s best latte artist, but I can pour a heart, or a tulip,” he says. “We have t-shirts that say: ‘Sorry if I can’t get up to speed because we’re out of office.’ We really do try to be as humble as possible and bring a great energy to the team. Hopefully our colleagues won’t be scared by having their boss jump behind the coffee machine.” GCR

Time to act

WHAT THE EUROPEAN REGULATION ON DEFORESTATION-FREE SUPPLY CHAINS MEANS FOR THE GLOBAL COFFEE INDUSTRY AND WHY THERE’S NO TURNING BACK.

hen the European Parliament and the European Council of the European Union provisionally agreed on a new regulation on 5 December 2022 to ensure supply chains remain free from processes and products that cause deforestation, it was a strong signal to the world that it is determined to address global deforestation.

“Today’s political agreement on the EU’s deforestation law marks an important turning point in the global fight against deforestation,” said Frans Timmermans, Executive Vice-President for the European Green Deal in a press statement.

“Combatting deforestation is an urgent task for this generation, and a great legacy to leave behind for the next.”

Virginijus Sinkevičius, Commissioner for Environment, Oceans and Fisheries added that to succeed, it would “build efficient and close cooperation with both consumer and producer countries to ensure a smooth process”.

Industry groups had been involved in the development of the Regulation since 2019. Further drive to the initiative was undertaken at the COP26 climate conference in Glasgow in November 2021, when the European Union, along with more than 140 other countries, pledged to halt deforestation by 2030.

Once adopted and applied, the new law will ensure that goods such as coffee, palm oil, cattle, soy, cocoa, timber, and rubber, that are placed on the EU market, will no longer contribute to deforestation and forest degradation in the EU and elsewhere in the world.

These commodities were chosen on the basis of a thorough impact assessment identifying them as “the main driver of deforestation” due to agriculture expansion.

According to the European Commission, the hope is that this new regulation will stop a significant share of global deforestation and forest degradation and reduce greenhouse gas emissions and biodiversity loss.

The Intergovernmental Panel on Climate Change estimates that 23 per cent of total anthropogenic greenhouse gas emissions between 2007 to 2016 come from agriculture, forestry, and other land uses.

The Food and Agriculture Organization of the United Nations estimates that 420 million hectares of forest were lost to deforestation between 1990 and 2020, and that the world lost around 178 million hectares of forest cover in the same period of time, which is an area triple the size of France. It’s for these reasons and many others, that the time has come to act.

THE BLACK AND WHITE

Given that the EU accounts for one third of world coffee consumption, virtually all of which is imported, says Anthony Woolich, regulatory partner at HFW lawyers, and a member of the City of London Law Society’s Committee on Commercial Law, this new Regulation will have “wide-reaching impacts across the industry”.

“Brazil and Vietnam together account for over half of the EU’s coffee imports,” he says.

European Commission’s spokesperson for the environment, Adalbert Jahnz, says companies placing relevant commodities and products on the EU market will be required to put in place and implement due diligence systems to ensure that only deforestation-free – produced on land that was not subject to deforestation after 31 December 2020 – and legal products, according to the laws of the country of origin, are allowed on the EU market.

While the regulation is an opportunity to enhance trade in deforestation-free products and boost opportunities for sustainable actors around the globe, Jahnz says traders and roasters buying direct will have to go through three key steps as part of their due diligence systems:

1. C ollect information on the commodity, quantity, supplier, country of production, evidence of legal harvest, etc.

2. Use the information gathered under the first step to analyse and evaluate the risk of noncompliant products entering the supply chain.

For example, on the plots of land used for producing the commodities.

3. Take adequate and proportionate mitigation measures in case you find risk under step two, to make sure that the risk becomes negligible.

The Regulation is not expected to enter into force until mid-2023. Large companies will have a further 18 months before they have to comply with the Regulation’s requirements, while small and medium-sized enterprises will have 24 months.

NO EASY FEAT

Jahnz says a key and challenging requirement for companies will be obtaining geographic coordinates of the plots of land where the coffee they place on the market, was produced.

“Using geolocation coordinates is the simplest and most cost-effective way of obtaining the necessary geographic information for EU Member States’ competent authorities to be in a position to check whether products and commodities are deforestation-free,” Jahnz says.

He says information on the plot of land or farm where the commodity has been produced allows for the use of satellite images – widely available and free-to-use digital tools – to check whether a product or commodity is compliant or not with the deforestation-free requirement of the proposal.

HFW’s Woolich says that it’s important not to understate the challenges involved in ensuring traceability, adding that the requirements under the Regulation to provide precise geographic coordinates are “very specific”.

“Furthermore, the mixing of coffee from different farms will create a risk that coffee produced on deforested land could be introduced. It is expected that satellite imagery will be used to monitor deforestation patterns,” Woolich says. “It is also worth noting that it will be incumbent on those seeking to sell coffee in the EU, rather than the farmer, to prove that it is not produced on deforested land. This still leaves a big challenge of tracing a coffee harvest back to a particular plot of land, especially in a

lines foR

supply chain with multiple levels between the farmer and the importer.”

Carolin Ehrensperger, Head of Sustainable Business Unit of Neumann Gruppe GmbH in Hamburg, Germany, the holding company of Neumann Kaffee Gruppe, says currently, for conventional coffee, however, this level of traceability does not exist. While satellite images are widely available, tools that reliably detect deforestation are not.

“At the moment, no coffee map exists that would tell us where coffee was grown before the cut-off of 31 December 2020, and no tool that would reliably detect coffee or deforestation as defined by the EU regulation. This means even with high quality geolocation data on farms, deforestation events can’t be detected with certainty,” she says.

“The most widely used tool, Global Forest Watch, relies on tree cover loss, not deforestation. This leads to many false positives requiring costly manual checking of information including on the ground visits. Systems are especially bad at identifying agroforestry systems and renovation is often tracked as deforestation. Even for more advanced algorithms, that come at a cost, reliably detecting deforestation in the tropics remains challenging.”

Given that coffee is still often grown in remote and difficult areas to access, Ehrensperger says that for many farmers, especially if they produce small volumes, it is still more efficient to sell their coffee to a middleman passing by, instead of spending hours or even days travelling to the next purchasing point by an exporter.

“Beyond this issue of traceability, farmers don’t necessarily have access to technology to map their farms’ geolocations. Boundaries and ownership may also not be clearly defined. Aspects on data protection remain open, as well as what a plot of land is according to national laws. National solutions to this issue may arise.”

While there may be a few grey areas to overcome, Ehrensperger says roasters will be obliged to undertake due diligence under the regulation.

“Operators and traders, including roasters, will be held accountable in case deforestation was detected on the plots where their coffee came from. Sanctions include confiscation of the coffee and can lead to penalties of at least 4 per cent of turnover, as well as temporary exclusion from trading/selling in the EU,” she says.

TRACEABILITY: THE PRICE WE PAY

Compliance with the regulation will make coffee exports into the EU more costly. The Impact Assessment backing the proposal estimates that the costs of compliance for companies are significantly lower than the expected benefits. However, guaranteed expenses include the cost of geolocation data, the expense of information sharing systems and traceability and monitoring systems at origin.

“Depending on how easy it will be to shift the coffee from the origin to other markets, these costs will be forwarded to buyers’ increasing prices or will have to be subsumed by producers locally, reducing

the price they receive for coffee even further and making alternatives to coffee more attractive – a threat to attractiveness for coffee farming further contributing to concentration in the industry we’ve seen for decades,” Ehrensperger says.

HFW’s Woolich says the countries which will find the new regulations challenging are those where the industry is dominated by smallholder farmers rather than large, mechanised farms, with better access to technology and resources.

“Brazilian agriculture is dominated by these larger farms, for whom compliance will be easier than countries whose coffee industries are mostly made up of smallholders, such as Vietnam, Colombia and East African countries,” Woolich says. “Because the EU is such a large market for coffee, representing approximately 50 per cent of worldwide coffee imports, there are only limited opportunities for producers to shift to supplying non-EU countries. So, Brazil, which is already the world’s largest coffee producer, is likely to become even more prominent globally.”

Vinicius Estrela, Brazil Specialty Coffee Association (BSCA) Executive Director says smallholders may struggle with additional costs to ensure traceability and monitoring in the coffee value chain, but that Brazil is in a strong position to adapt to the changes.

“Brazil represents a low risk level as a coffee origin, considering the main producing areas [has been] consolidated for decades. Also, Brazilians are subject to the federal forest code, one of the most advanced ones in the world,” Estrela says.

Ehrensperger adds that indirectly, a shift in trade patterns may occur, depending on the complexity of the value chain and farm structure.

“More advanced economies are at advantage to ship to the EU, while coffee from less advanced economies, with less structured supply chains and countries with higher deforestation rates, will be shipped elsewhere,” she says.

“Proofing a non-negligible risk and implementing mitigation measures is also easier in closer supply chains with long-standing relations. This model is currently seldom practised by larger roasters, as their key focus is on keeping the taste the same every year and prices stable, which may require shifting in origins/regions due to climatic conditions.”

ONE STEP FORWARD

The good news is, that for all commodities, there are already producers and operators who have best practices in place that ensure deforestation-free supply chains and many countries have traceability systems. They are models others can learn from, such as Nestlé who has already pledged to eliminate deforestation from its coffee supply chains by 2025. Meanwhile, for those which have taken little to no action to date, there is work to be done.

European Commission’s Jahnz says there is a strong EU commitment to step up its engagement with partner countries, consumer, and producer countries to address deforestation and forest degradation.

“Partnerships and cooperation mechanisms by the EU and its Member States will support countries to address deforestation and forest degradation where a specific need has been detected, and where there is a demand to cooperate,” he says. “For instance, to facilitate compliance with the Regulation for companies/smallholders, or to help partner countries meet their international commitments on halting deforestation, such as under the Glasgow Declaration or the Sustainable Development Goals.” GCR

What’s the risk?

HOW INSURANCE PROGRAMS ARE HELPING PRODUCERS IN THE CARIBBEAN AND CENTRAL AMERICA MANAGE DISASTER RISK WITH GREATER SECURITY.

conomic and natural hazards continue to be a threat to the Caribbean. The region is highly exposed to a range of natural hazards, from volcanic eruptions to earthquakes and hurricanes, floods to drought. It not only damages infrastructure stock, it destroys agricultural production. Over the years, such hazards have caused severe damage to economies and livelihoods in the region.

According to the Nobel Peace Prize-winning Intergovernmental Panel on Climate Change, an intergovernmental body of the United Nations, climate change brings more frequent and intense, unusual, and extreme weather events.

In Central America’s coffee producing regions, natural disasters tend to hurt the poor and vulnerable most, exacerbating already high risks encountered by smallholder farmers, and reducing the productive agricultural potential in extensive areas of Central America. Despite significant vulnerability to climate risks, millions of agricultural producers in the Caribbean and Central America are largely uninsured, according to the United Nation’s World Food Programme (WFP).

In response, disaster risk management has evolved over the past decade, with multiple types of insurance programs aiming to support the coffee sector.

A UNITED FRONT

Ministers from all Central American countries plan to collectively manage disaster risk under the umbrella of the Caribbean Community and Common Market, the oldest surviving integration movement in the developing world that groups 20 countries, 15 member states, and five associate members.

Collaborative action from governments has already seen programs evolve to help coffee growers and roasters mitigate disaster risk in

Central America with insurance and finance solutions. In November 2022, the Partnership for Central America, World Bank (WB), and the WFP launched a Disaster Risk Insurance and Finance in Central America Consortium (DRIFCA). The consortium aims to identify and support climate-related agricultural insurance solutions for up to two million smallholder farmers in Guatemala, El Salvador, and Honduras, to increase food security and financial resilience.

“Insurance mechanisms that pay out directly to farmers and other vulnerable populations provide an important livelihood safety net around the world,” says Mark Lopes, Chief Operating Officer of Partnership for Central America.

Guatemala, Honduras and El Salvador are also vulnerable to the impact of strong hurricanes. In 2020, hurricanes Eta and Lota left a trail of devastation. In October 2022, hurricane Julia caused the loss of crops that form staple foods of the Central American populations, where according to WFP, approximately one million people are already severely food insecure.

Will Warshauer, CEO of United States-based non-profit TechnoServe, adds that the September 2022 Puerto Rican Hurricane Fiona was a recent example of how essential disaster insurance is for smallholder farmers.

“In our market-based approach to improving farmer incomes for the long-term, TechnoServe knows firsthand how disaster risk insurance promotes food security, protects business investment, and helps farmers fight poverty,” Warshauer says.

Michel Kerf, World Bank’s Director for Central America and the Dominican Republic, is responsible for enhancing the financial resilience of smallholder farmers and vulnerable households affected by severe and frequent climate-related disasters in northern Central America.

“Our global and regional experience has demonstrated the value of strong partnerships between the public and private sectors to design and implement effective disaster risk financing solutions,” Kerf says.

The WB is not alone in its efforts. According to WFP’s Regional Director for Latin America and the Caribbean, micro-insurance is an innovative way smallholders can effectively manage risks and reduce vulnerabilities so they can transition to sustainable food and nutrition security.

A FUTURE OF THREATS

Eric Brenner, Program Coordinator at the Texas A&M University Coffee Center in the Unites States, says coffee farmers face three major threats: low prices, pests and diseases, and climate change.

“We have now reached a point where all three threats have converged into an interconnected and complex ecosystem that when changes occur in any of these three distinct environments, [it] will trigger Brenner says even though threats are different in nature, they cannot be treated as independent events. To make matters worse, the logistical disruption created by the global pandemic added what he calls

“a new layer of challenges for the coffee industry” exacerbating the vulnerability of coffee farmers. The challenge, however, is finding solutions that are feasible and sustainable.

Historically, low coffee prices reduce a coffee farmer’s ability to obtain supplies, whether it be fertiliser, fungicides, or pesticides. As a result, a farmer’s ability to combat pests like coffee berry borer and diseases like coffee leaf rust, are also reduced significantly.

“A farmer is now in a situation that is also [worsened] by climate change because some of these pests and diseases proliferate as a result of higher temperatures and erratic rainfall patterns where you have areas of extreme wet conditions or long periods of drought,” Brenner says.

“In the case of coffee berry borer, higher temperatures not only increase the population of this pest but also reduce the gestation period causing an explosion in the population in a shorter period of time. As a result of coffee berry borer and the coffee leaf rust infestations, the quality of the coffee greatly decreases which translates into lower prices paid to the coffee farmer, creating a continuous cycle of poverty, and decreased livelihoods.”

Brenner says understanding the link between each threat, and how they relate to each other through cause-and-effect mechanisms, is pivotal, because it serves as the foundation that will help support the creation and implementation of educational and training programs for coffee farmers.

Due to the unpredictable nature of coffee farming, any coffee insurance program or sovereign disaster risk financing will help safeguard against sudden macroeconomic shocks that negatively impact fiscal performance, and in turn, economic development. As such, Brenner says is it “extremely relevant”, yet in order for any program to be effective, understanding the complexity and correlation of threats will be extremely important for its long-term sustainability.

In 2007, Central America’s Finance Ministers created the Caribbean Catastrophe Risk Insurance Facility (CCRIF) to provide cost-effective and fastdisbursing liquidity. It has become an efficient way to finance a liquidity gap arising in the immediate aftermath of disaster. CCRIF pools Caribbeanwide country-level risks into a central, more diversified risk portfolio, offering lower premiums for participating national governments.

CCRIF limits the financial impact of

catastrophic hurricanes, earthquakes, and excess rainfall events by quickly providing short-term liquidity when a parametric insurance policy is triggered.

In 2022, CCRIF made four payouts totalling US$15.2 million to three of its member governments during October for hydrometeorological events associated with the 2022 Hurricane Season.

To support CCRIF, Evaluación de Riesgos Naturales and Risk Engineering and Design, a risk management specialist, formed a consortium to provide risk management, financial planning services, and catastrophe modelling services while coordinating reinsurance placement for CCRIF.

“Since its inception in 2007, CCRIF has made a total of 56 payouts to 16 of its member governments, totalling approximately US$245 million – all paid within 14 days of the disaster event. Based on the assessment of the use of payouts, these funds have supported over 3.5 million persons in the Caribbean and Central America, following natural disasters, providing them with food, medication, and water,” says Isaac Anthony, CCRIF’s CEO.

Payouts also have been used to support the rehabilitation of critical economic infrastructure, such as roads and bridges in the rebuilding of schools and other social infrastructure.

The US$40 million payout to Haiti following the 2021 earthquake is the largest payout CCRIF has made since 2007.

“In the face of a changing climate, parametric insurance is a must-have tool for governments in the Caribbean and Central America. CCRIF has been in the business of providing parametric insurance for the last 15 years and we continue to be encouraged that we are able to support our members to have access to quick liquidity after a natural disaster, to begin recovery efforts and to support the most vulnerable in their populations,” Anthony says.

The CRIF’s member governments purchased US$1.2 billion in coverage for catastrophe risk insurance for 2022/23 against climate-related and seismic hazards. The renewal focused on tropical cyclones, excess rainfall and earthquakes, and the fisheries sector.

For the earthquake, tropical cyclone and excess rainfall policies, members ceded over US$1.2 billion in coverage – an increase of 10 per cent over the previous year. Thirteen governments increased their coverage compared with the 2021/22 policy year. The renewal and demand for increased coverage by members illustrates

that countries continue to recognise the importance of financially protecting their economies against natural disasters.

Raul Salazar, Chief of the Regional Office for the Americas and the Caribbean at the United Nation’s Office for Disaster Risk Reduction, says “more stagnant weather patterns are expected”.

In order to reduce disaster risks and losses, Salazar and his UN teams are building what he calls “multi-hazard, multi-sectoral and multi-actor preventative and anticipatory approaches” which integrate disaster, climate, and crisis risk management.

“This will strengthen the resilience of people, their agricultural livelihoods, and the ecosystems they depend on in a sustainable manner. Multi-hazard early warning systems are required now, more than ever, to anticipate and mitigate the interconnected, cascading and mutually aggravating nature of risks and their impacts across sectors and systems, including agri-food systems,” he says.

Salazar is focused on “informing agricultural planning and investment”, and “speeding up” the implementation of prevention, preparedness, and anticipatory action measures, such as insurance. He says successful multi-hazard early warning systems leverage the knowledge and expertise of a diverse pool of expertise, including local, traditional, and indigenous communities, to effectively monitor, identify, communicate alerts ahead of disasters, and undertake appropriate measures.

UN Secretary-General António Guterres agrees. In November 2022, after last year’s devastating flooding in Pakistan, Guterres launched an action plan to provide early warning systems within five years. On the International Day for Disaster Risk Reduction, he noted that it was “yet another reminder that real and concrete action on loss and damage must be global priority”.

“Extreme weather events will happen, but they do not need to become deadly disasters,” he said in a statement. GCR

STREAMLINE GROWTH IN 2023

Cropster Roast

Simplify the running of your roastery with solutions to produce exceptional coffees; including inventory management, profiling, quality control, cupping, and more.

Cropster Cafe

Empower your team to brew great coffee with tools to create recipes and handle task management, automatically log brews, and oversee quality control.

Maximising screen time

EVERSYS UNVEILS ITS NEW DIGITAL SIGNAGE AND CUSTOMISATION SERVICES TO PROVIDE ADDED VALUE TO CUSTOMERS SEEKING EDUCATIONAL OR BRANDED MARKETING OPPORTUNITIES.

n the early 2000s, small-body mobile handsets with keyboards were considered sleek and cutting-edge. Cars came equipped with knobs and dials, and the few early adopters of Global Positioning System accessories tinkered with their destination through pointers on unresponsive surfaces. Thanks to the digital age, a few things have changed.

This includes the evolution of interface displays as a result of a growing guild of graphic interface designers who have turned previously unexciting canvases into attractive, creative visual experiences.

Since its inception, Swiss espresso machine manufacturer Eversys has equipped its models with screens in order to be more intuitive, and aid customer and consumer satisfaction. The Eversys design and software teams are now taking a step further as they launch a new set of digital signage and customisation services to expand the screen’s visual experience.

Eversys Commercial and Marketing Director Christian Haueter says the intention behind the new Eversys Digital Services is to “genuinely empower” customers and “make marketers’ hearts beat strong”.

“We want to simplify and improve operations on machines in environments like convenience stores or quick service restaurants,” he says.

The new initiative will transform the interface on Eversys’ Légacy and Enigma lines to display digital screen signage. This can include screensavers or progress screens targeting a visual experience. It could feature video sequences, still or animated images or icons while idle or in production mode.

Similar to traditional digital signage on dedicated displays, this functionality aims to bring more value in locations where the coffee machine attracts customer attention and can be used to present information or promotions.

“We identified that screensavers could get the

attention of people passing by. The most interesting part is that while the [espresso] is being dispensed, that’s when you really have people’s attention. It is the ideal phase to display emotional experiences via videos or images,” says Stephan Zink, Software Director at Eversys.

discovered the benefits of this added value feature. Geoff Marks, Group Commercial Director of Tiger Coffee Oceania, an Eversys distributor in Australia and New Zealand, says the large national chain uses Eversys’ digital signage and customisation services on each of the 800-plus Eversys Cameo coffee machines installed.

“Each month, I receive an upload file from the Coles Express marketing team with between four to six images containing individual product promotions. It could be about an individual convenience food offering, a drink discount, or a coffee and chocolate promotion for AUD$4 (about US$2.70). We upload the promo images via the Eversys telemetry system, and they get pushed out nationally to all Coles Express coffee machines screens overnight on a selected day that Coles chooses,” Marks says.

“We program the images to appear on the touchscreen so that they all rotate while the customer’s coffee is dispensed.”

Coles Express has been using the Eversys digital signage system for the past two years, when it was first activated during 2021. Marks says the convenience chain is particularly impressed it can use the digital signage system to generate promotional material that can push sales and new revenue streams.

“For Coles Express, it’s about using the space provided and offering the real estate to key suppliers who might like to enhance their product promotion or work in combination with a mixed product offering. It’s a much better option than customers staring at a blank space for the duration of their coffee order,” Marks says.

Tiger Coffee can also use the Eversys telemetry system to digitally activate new coffee products across multisite chain locations.

“All telemetry updates are pushed overnight meaning activations for new products or price changes can happen instantaneously at all sites in the country. There is no way this change could be done manually in Australia to so many venues at once. It really does enhance the coffee equipment offering and give tremendous flexibility to Coles Express,” Marks says.

With Coles Express producing millions of coffee beverages each year, Marks says it is critical that the daily cleaning and servicing of Eversys machines is maintained to the highest standards.

“Using Eversys’ unique pull and push digital telemetry system allows all machines to program cleaning cycles and uphold regular preventative maintenance servicing,” he says.

“Our goal is to ensure Cameo C’2M machines are always working. Essentially, if we get contacted via the telemetry system there is an issue, we can make a change or an update remotely, without having a technician attend the site. We did this recently for a shop located more than 10 hours outside of Adelaide in South Australia. Fixing the issue remotely was a huge time and cost saving, and gave the venue instant access to sell products again.”

The end result, is extremely satisfied customers and a complete change in perception about the standard of coffee available at convenience locations operating Eversys machines.

“Coles has seen consistent double-digit growth across its coffee product sales since installing the Eversys Cameo machines throughout 2020/21 in comparison to outdated automatic machines used prior to June 2020. We are constantly monitoring the machines and their quality output. There truly is a consistent high value, coffee offering at every Coles Express nationally,” Marks says.

“The Eversys’ partnership and learnings over the past two years with Coles Express has really lifted the standard across its digital fleets internationally.”

Frank and Honest, a leading on-the-go coffee brand, has partnered with Eversys since 2016.

Sarah Grey, Operations Manager of Frank and Honest Coffee, says Eversys’ digital signage and telemetry system was part of the consideration process in choosing its coffee machine partner.

“The telemetry dashboard provides us with live machine information on key coffee quality metrics, such as ETC, cleaning stats, milk temperatures, aborts, and service information. The information is easily accessed and displayed in a user-friendly manner, highlighting trends and areas for action,” Grey says. “The data is also exportable to support the generation of offline reports. This data is core to supporting our field-based teams in driving standards with our stores. They use it as part of store visits and training

Frank and Honest Marketing Manager, Rosemary Walsh, adds that the digital screens on the Eversys’ Enigma machine provide a high-quality interface to display high-definition photography and videography, which can be customised to Frank and Honest’s brand needs.

“We can also tailor the message by site making it a powerful targeted marketing tool,” Walsh says.

Frank and Honest use the digital signage to communicate about its leadership in sustainability credentials to shoppers, social media channels and website, and to help launch a new digital loyalty app. It even incorporated a QR code to download the app, which has resulted in an estimated 35,000 downloads to date.

Frank and Honest has also used the Eversys digital screens in some of its university coffee sites for a graduate recruitment drive for Musgrave, the parent company Frank and Honest.

The scope of service focuses on preparing the signage material and the machines, and deploying content across a fleet of hundreds or thousands of installed devices. This means that content can be uploaded to an unlimited number of Eversys espresso machines within seconds without the need to go on-site.

“We assessed an icebreaker in Australia, and other clients are now contacting us to have the same. At the moment, customers must deliver their files to Eversys, and our staff uploads them. Up until now, we have created more than 460 screen files worldwide. But we want to go further and improve the process,” says Eversys’ Software Director Zink.

The software team is currently putting substantial efforts in projects to optimise operations with tailor-made selection screens, another valuable possibility offered by Eversys, mainly to self- or quick-service environments.

Eversys Digital Signage is only the starting point in the company’s digital evolution. The company wants to invest more into Internet of Things service offerings and explore future possibilities.

“The Eversys team is ready to inspire its customers with plenty of real-life references on enhanced visual experiences,” says Eversys Commercial and Marketing Director Haueter. We look forward to improving customised operator efficiency on Eversys displays – on top of delivering excellent coffee quality.” GCR

For more information, visit www.eversys.com/en/

FOCUS ON THE DETAILS

Our unique RFB roasters are equipped with the newest and most innovative roasting technologies. With our exible roasting pro les we give our clients the possibility to optimize every detail of the roasting process for a perfect result.

FIND YOUR FUTURE.

Hghpresso

Global Coffee Consultants

Let us help you cement your place as a global leader in the coffee industry

ith many coffee roasters seeing the growth of the instant and ready-todrink (RTD) market and thinking about expanding their product portfolio, Paul Ahn, Sales Manager at global technology manufacturer Flavourtech, says it’s a natural progression to provide a higher quality product.

“Coffee roasters take such pride in their work. To them, it is both an art and science in producing roasted beans full of flavour,” Ahn says. “We are seeing the rise of specialty instant coffee, and as the demand increases, so must production. We can help here by providing a means to do so on a commercial scale and with consistency.”

Ahn says convenience and quality will continue to be driving forces for the coffee industry in 2023, and it will be joined by a continuation towards more natural and healthy products.

A soluble solution

“We will continue to help our customers adapt quickly to the changes and help them grow with demand. Our systems are all about capturing the natural flavours from the product itself through a gentle yet efficient process,” he says.

Ahn says Flavourtech, an aroma recovery and extraction specialist, is able to cater for this demand thanks in part to its Rotating Disc Column (RDC).

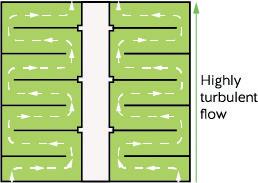

“The RDC is a continuous extraction device operating closely to plug flow (an idealised flow without any mixing in the axial direction but perfectly in the radial direction). Its function is to hold a slurry flow of solids in liquid for a specified residence time and at a specified temperature so that the transfer of soluble components from the solid particles to the liquid extract is maximised,” says Ahn.

Inside the RDC is a central, vertical drive shaft. Attached to the shaft is a series of rotating baffles. Between each adjacent pair of rotating baffles is a stationary baffle. Slurry is pushed from the bottom of the RDC up through the column, ensuring identical extraction time and consistency.

The RDC can be inserted into Flavourtech’s Integrated Extraction System (IES), a continuous, automated processing line that allows customers to produce premium aromas, extracts, and concentrates for RTD coffee and tea products, as well as soluble coffee and flavour industries.

“This allows a continuous flow of coffee slurry for high temperature extraction. The slurry is exposed to temperatures of between 150° to 195°C for just 20 minutes to enable further hydrolysis to take place. The end result is a premium RTD or soluble product in terms of quality and enhanced aroma at the end of the line. In a traditional process, extraction cells are set at high temperatures and pressure that could last for three to four hours instead of 20 minutes,” Ahn says.

FLAVOURTECH EXPLAINS HOW ITS ROTATING DISC COLUMN IS HELPING ROASTERS MEET THE DEMAND FOR SOLUBLE COFFEE OFFERINGS.

The internal volume of the RDC is determined by the desired product flow rate and holding time and is tailored to customer requirements.

“The RDC allows temperature, pressure, and residence time to be controlled precisely to obtain near identical conditions for all parts of the mixture being processed, ensuring consistency in processing and ultimately, contributing to a superior end product,” says Ahn.

“In contrast to batch tank processing, the RDC’s continuous and automated process means a superior product of higher quality and with consistency.”

Ahn says there are many benefits to this extraction process that allows the manufacturer to capture the unique roast and ground flavours of coffee beans.

“The RDC’s unique design ensures the materials flowing through it are maintained in a continuous, dynamic state, preventing settling and the formation of static pockets,” he says. “The risk of burning and the formation of undesirable burnt notes are greatly reduced as the RDC offers precise control of temperature and with a reduced residence time during the extraction process.”

He says the RDC is ideal as a continuous coffee extraction tank, feeding the extract to the next stage of a process.

“Typically, extraction is conducted batch-wise in large static tanks or cells and so requires a much larger footprint in the factory,” says Ahn.

Normally in the coffee industry, Ahn says flavour is recovered following the high temperature soluble solids extraction process by which point many of coffee’s desirable flavours have already been lost.

“Based on Flavourtech’s 40 years of experience in the flavour industry, we know that the best natural aroma comes from processing the raw material directly in our Spinning Cone Column (SCC), prior to the product being subjected to high temperatures,” he says.

As a result, Flavourtech designed the RDC to allow for high temperature extraction of coffee slurry post SCC aroma capture.

“In Flavourtech’s extraction process, the coffee slurry is first processed through the SCC to capture the natural fresh roast and ground notes. It is then sent to the RDC for extraction of the soluble solids. This means all the fresh coffee notes are preserved and can be added back later in the process to produce instant coffee that smells and tastes like it was freshly brewed,” says Ahn.

Flavourtech originally designed the RDC in the early 2000s with instant coffee producers in mind. The consumption habits of soluble coffee recently, however, would radically shift during the recent pandemic event.

“The demand for soluble coffee has gone up due to more people choosing to work from home,” he says. “Though, they are seeking better quality coffee in terms of flavours, something that is close to the flavours of freshly brewed coffee. We now see a category called ‘specialty instant coffee’ rise quickly.”

The final step in the soluble coffee process is to concentrate the extract before spray or freeze drying the product. Ahn says Flavourtech’s evaporation technique is unique in that the liquid remains in its Centritherm evaporator with a residence time of just one second with low operating temperatures, eliminating the production of burnt flavours in the final product.

“The whole process is continuous, automated, and designed to provide a premium product. With the IES, customers can produce a consistent product, day in day out, with minimal fuss and labour, and maximum flavour that is more in line with the flavour of a freshly brewed espresso,” Ahn says. GCR

For more information, visit www.flavourtech.com

Barista bot

WMF PROFESSIONAL COFFEE MACHINES IS SUPPORTING A NEW WAY TO ENJOY COFFEE WITH ROBOTICS TECHNOLOGY IN SELF-SERVICE CAFÉS.

obotics technology is increasingly becoming a firm feature in the hospitality sector. There are ‘robochefs’ in the kitchen, robot-supported self-service cafés, and to WMF Professional Coffee Machines, it’s just the beginning.

“The greatest potential of digitisation lies in making communication between guests, service staff and coffee machines as efficient and convenient as possible through networking and automation,” says Benjamin Thurner, Vice President Digital at WMF Professional Coffee Machines.

“Businesses must consider the trends of modern customer experience such as contactless payments, fast communication and interaction channels, and customer individualisation. These aspects can be implemented efficiently and impressively with robotics concepts.”

To cater for this growing demand, WMF has partnered with South Korean coffee chain Coffeebanhada and Slovak start-up Rossum Café to supply their coffee machines and provide technological expertise.

“High-performance WMF 5000 S+ coffee machines are operated by high-tech robot arms in both Coffeebanhada and Rossum Café, which not only prepare the desired coffee specialties quickly and simply, but also provide a unique show effect for guests – a very special coffee experience,” says Thurner.

Since Coffeebanhada was founded in 2011, the café has focused on modern self-service concepts. In 2017, it presented a self-developed robot barista called Episode Marco, which is used in the café’s unmanned branches. Known as ‘smart cafés’, these Coffeebanhada venues account for about a quarter of more than 600 locations Coffeebanhada operates.

Coffeebanhada has combined Episode Marco with WMF automation since the collaboration began

in January 2021 through WMF’s local trading partner Dooree Corporation. Since January 2022, Coffeebanhada had equipped 85 smart cafés with WMF 5000 S+ machines.

“At Coffeebanhada, the first step was to examine how the Episode Marco robot could best connect to a fully automatic coffee machine. WMF engineers focused primarily on connectivity and interface programming, as both cashless payment methods via smartphone and credit card and additional devices were to be connected,” says Thurner.

“WMF project managers were able to draw on digital expertise and experience from comparable projects, such as Cafe X, the first robot equipped by our machines about 10 years ago, or MyAppCafé, one of the first autonomous coffee stations with a robot barista to be made in Germany.”

coffee machines and robot baristas, together with connected ice machines, now supply

Coffeebanhada guests with coffee around the clock that reflects the preferences of the South Korean market, such as Caffé Americano, Caffé Latte or Caffé Mocha.

“[The robots] are the centre of attention, showcasing that these futuristic self-service cafés are real customer magnets, even without personnel,” Thurner says.

Rossum Café in Slovakia has also used WMF’s high-performance machines since its first autonomous coffee bars were established in 2020 thanks to a relationship through WMF’s local partners in the Czech Republic.

“Like at Coffeebanhada, Rossum Café uses a high-tech robot arm to prepare delicious beverages with a WMF 5000 S+ professional coffee machine. Here too, the locations are unmanned and rely consistently on cashless payment options,” Thurner says.

“However, Rossum Café locations are not cafés in the classic sense, but self-contained coffee stations which can be compared to small kiosks. Due to their compact design and small footprint, they are easy to set up in busy places such as shopping malls, railway stations or airports, where they attract travellers and other customers with impressive technology and sophisticated design that serve them efficiently with fresh coffee.”

Thurner says the WMF 5000 S+ coffee machine was chosen because of its extensive configuration and customisation options.

“In both Coffeebanhada and Rossum Café, the fully automatic WMF 5000 S+ was the best machine for the job due to its high performance of up to 250 cups per day, variety of coffee specialties available, and the flexible technical integration capability into upstream and downstream customer systems,” he says.

Thurner adds that the WMF 5000 S+ machines were used in the first autonomous Rossum Café coffee bars but have since been individually modified for optimum customer experience.

“To allow the robot to activate these correctly, a remote API software interface was implemented and individually adapted,” he says.

WMF coffee machines have different networking options – both locally via a direct connection between the coffee machine and the control computer or robot, or via the cloud.

“After all, seamlessly combining robotics technology with coffee machines to produce innovative and comprehensive solutions is one of the core competencies of the developers at WMF,” Thurner says.

WMF believes digitisation is an innovation driver of the future, both in terms of business and customer loyalty and experience.

“From a customer’s perspective, the focus is clearly on efficiency and cost benefits, as well as lack of human resources. Particularly when we look at the shortage of skilled workers and employees that is prevalent in many industries, the digitisation of processes is crucial,” says Thurner.

“On the one hand, this relates to recurring work processes that have so far been performed manually. On the other hand, it involves the automation of data flows.”

According to Thurner, in many businesses today, company-relevant information is still managed in separate data silos, the consolidation of which causes high time and cost expenditures.

“If we look at the external view, or the customer and their enjoyment experience, digitisation allows completely new offerings, especially in the self-service area or contactless ordering and payment. The ultimate goal is always sustainable customer loyalty through positive experiences. This is why we have a clear focus on digitisation and view it as the right path for the future,” he says.

Thurner also believes ongoing digitisation will intensify the customer’s need to have access to information and services at all times.

“The desire for round-the-clock availability will further displace concepts like classic opening hours. Self-service solutions will benefit hugely from this development, above all unmanned stores but also robotic cafés with an experience factor,” he says.

“Another driver for increasingly digitised hospitality is the rising expectation of product quality. The demand for digital touchpoints, mobile payment offers, and the convenient integration of customer loyalty programs along the customer journey are a clear expression of this.” GCR

For more information, visit www.wmf-coffeemachines.com

Aim High, think global

IN AN ERA WHEN COMPETITION IS HIGH AND INFORMATION IS KEY TO UNLOCKING BUSINESS SUCCESS, A PARTNERSHIP WITH CONSULTANT HIGHPRESSO IS KEY TO POSITIONING BRANDS INTO THE MARKETPLACE OF TOMORROW.

hen clients approach Highpresso for the first time with an idea of what they’d like to conceive, quite often they aren’t sure how to achieve it. What they soon learn from working closely with the innovation and strategic management consultant, is that there are many opportunities to grow their brand by implementing new technologies and utilising data-driven strategies in a way that suits their vision.

“We assist clients on their innovation journey, all the way from building strategy and implementation roadmaps, to executing strategy, and commercialising novel processes and products,” says Highpresso Founder and Managing Director Adam Carr.

“What we like doing best is understanding the unique value proposition a company offers to its customers, and working alongside marketing, operations and research and product development to craft solutions and products that engage the marketplace of tomorrow.”

Since 2016, Highpresso has delivered a range of services to market, including competitor analysis and product benchmarking for dairy products, sustainability programs and strategy to government bodies, and product development for a new generation of coffee machines.

What binds all projects together, is the requirement to innovate in a way that is scalable and meaningful for each brand.

Highpresso has worked with many future-focused clients across multiple countries. It works with equipment manufacturers in Europe and the United Kingdom, distributors in Australia and the United

States, and global quick service restaurants and local government bodies to add vision and value to their portfolios. It has also developed contract manufacturing solutions for roasters and small distilleries.

“Some of the work we’re doing currently includes developing onboarding processes and implementation execution using telemetry systems, building new grinding and extraction systems for the domestic market, and assisting global manufacturers with product development and delivery,” Carr says. “We’ve also been assisting Australian government bodies in building scalable carbon reduction programs with a focus on building value for cafés, while tracking their carbon footprint reduction.

“We are building the future with clients who want to innovate and sustainably scale their innovations.”

Adaptation is Highpresso’s forte. The company predicts significant industry changes in the domestic and commercial markets over the next five years, and wants to help businesses adapt and thrive.

One such method is through modernising systems and processes at a café level through telemetry. Carr says there are multiple products on the market that can monitor how well a café is extracting coffee, and technology that shows users in-depth time-resolved data on every shot.

But how can this be integrated with existing systems and processes? What does a business need to change see the benefits of the new technologies? Carr says understanding the value of the information and implementing change in businesses to get the most from new technology is what Highpresso strives to deliver.

“It’s worth distinguishing between information and data. One can have an awful lot of data and still not have any information available to help understand what the next steps should be. The person with the most doesn’t necessarily win,” he says.

“That said, an awful lot of information can be gleaned from the right kind of data. A simple shot tracker can be used to count shots, forecast filter, and grinder burr changes.”

Accumulate this data in the right way, and one can start to visualise seasonality trends, the impact of different times of day to quality of service, even the way a simple blend tweak will impact the service life of a grinder fleet. Data can also be used to see when an operator is busy or not, which facilitates a better relationship with the customer by not interrupting during demanding hours.

“Understanding these trends, and eventually being able to forecast them, can change the way one does business. Opportunities begin to present themselves, such as remote training services, asset management and facilitating sale subscriptions to wholesale based on real-time feedback,” Carr says.

Highpresso is working with businesses to rollout such technologies and help them see the value on a broad scale.

“We want businesses to capture the right data, feed the right information back to the relevant stakeholders, and help build out further capability that technologies can enable,” Carr says.

While telemetry and automated tools can be highly effective if adopted appropriately, Carr says its value is determined by what each brand prioritises, and how the tool is implemented. And that’s where Highpresso is ready to help.

For example, if a roaster is focused primarily on quality, but has a desire to grow sales, Highpresso will help design a pathway focused on rapid expansion, but one that doesn’t compromise on taste.

“Being able to scale-up this quality is difficult without either having an army of trainers, or a way of measuring that quality remotely, processing the data, and succinctly reporting that back to the stakeholders in the business,” Carr says.

He says while roasters are well versed in this former method, Highpresso is well versed in the latter, which Carr believes is the more scalable approach.

“Our team is connected to a global network of manufacturers, engineers, and suppliers. We partner with global operators that we trust to deliver high quality outcomes, no matter the country,” he says.

“We believe we can connect like-minded partners to deliver an innovation portfolio tailored to each roaster and manufacturer that wants to make a true impact on the future.”