September/October 2023

On the move

5 to go Co-Founder Radu Savopol on becoming a giant of the Romanian coffee industry, making brave choices, and the mathematics behind its rapid acceleration

Cold brew, hot success

Roasters transform a simple brew into a menu mainstay

The migration multiplier

Why the next generation of producers is at risk unless immediate action is taken

Building an empire

Allana Group on becoming one of the largest exporters in India

Single-serve solutions

Why customer demand is driving customisation and adaptations

www.gcrmag.com

COVER STORY

IN THIS ISSUE

FEATURES

10 COVER STORY

5 to go Co-Founder Radu Savopol on his strategic plan to target 1000 coffee shops in Romania over the next four years

15 COLD BREW, HOT SUCCESS

Why cold coffee beverages are dominating café sales with roasters investing in creative and quality-driven methods

21 THE GREAT HARVEST MIGRATION

Why origin migration will remain a threat to the next generation of coffee producers unless immediate action is taken

TECHNOLOGY PROFILES

27 THE EVERSYS ECOSYSTEM

How Eversys intends to use its three pillars of milks, beverage menus and IoT to drive performance

30 MAX EXTRACTION

Flavourtech discusses the continued growth of the Ready-to-Drink sector, and the future of flavour

32 WALK THE LINE

Franke Coffee Systems talks Mytico line through the eyes of a WBC finalist

34 BUILDING AN INDIAN EMPIRE

Allana explains how it became one of the largest coffee exporters in India

36 A TELEMETRY SOLUTION

Vendon supports premium coffee and machine operators with global IoT, telemetry, and payment solutions

38 KOREAN CALLING

Why Neumann Kaffee Gruppe is expanding in the Asia Pacific region

40 A NEW CHAPTER

Unic on why it’s determined to become the best in-class for both traditional and fully automatic coffee machines under the one brand

SINGLE SERVE

FEATURE

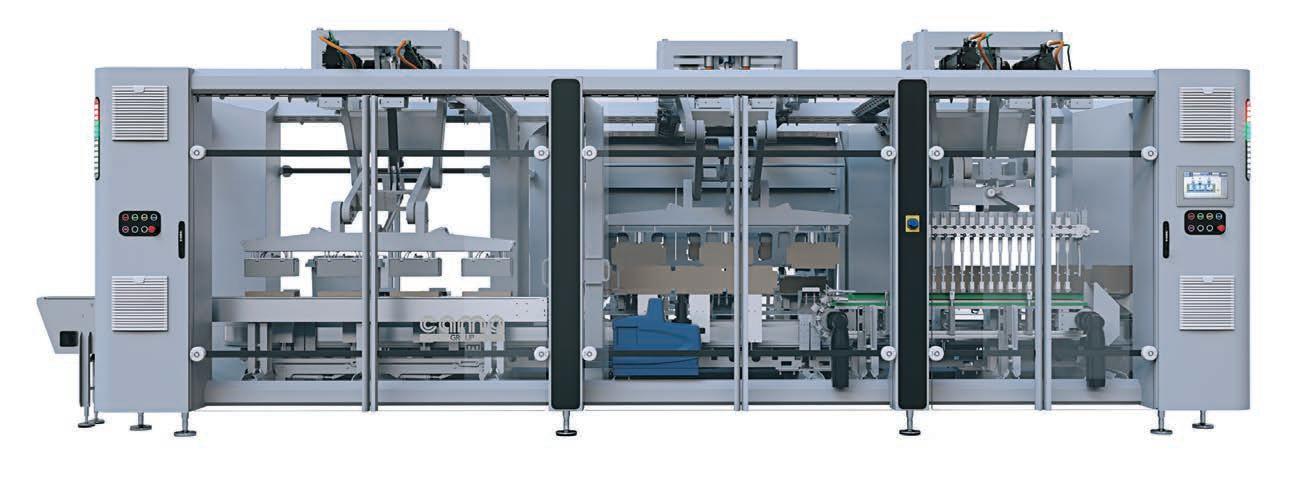

42 THE FULL PACKAGE

Cama Group discusses recent trends in the coffee packaging industry, and why all-in-one units are needed more than ever

44 CAPPAC CHRONICLES

Why Cappac has seen epic growth for its Nespressocompatible capsules

46 A COMPLETE CAPSULE APPROACH Modern Process Equipment Corporation

explains its complete plant systems for capsule manufacturing

48 FILLED WITH INNOVATION

IMA Coffee provides filling and sealing technologies for every type of capsule, and explains how its technological laboratories can be a valuable support

50 ALL IN ONE

Rychiger explains how its manufacturing operations offer a complete line of coffee capsule production

52 MILAN GETS SET TO HOST

The world’s reference exhibition for professional hospitality, out-of-home and retail gets set to take over Milan

LAST WORD

58 A DEGREE WITH A DIFFERENCE

Starbucks’ new sustainability learning and innovation lab scales solutions for the world’s most challenging social and environmental issues

REGULARS

04 EDITOR’S NOTE

06 NEWS DRIP BY DRIP

54 MARKETPLACE

“A LEADER SHOULD BE THE ONE TO BRING NEW PERSPECTIVES, TO INSPIRE AND MOTIVATE THEIR TEAM… A RELAXED ENVIRONMENT FAVOURS TRUST AND COURAGE TO EXPRESS BRAVE IDEAS AND DARING PROPOSALS.”

WALKING A FINE LINE

SOME

PROFESSIONS

HAVE

BECOME

extinct over the years due to the evolution of technology and a constantly changing world. The craftsmen that used to make horse carriages were replaced by automobiles and trains. Lamp lighters lit street lamps by hand each day before electricity, and switchboard operators connected callers before automated systems were introduced.

Coffee growing is an agricultural profession dating back to the 15th century. The method in which coffee beans are grown, picked and processed has evolved over the years. Mechanical harvesting is one such advancement, but for origin countries like Colombia where 90 per cent of coffee is grown on hilltops at high elevation, hand picking is dominant.

Now imagine if the profession became obsolete. Not because coffee growers were replaced by AI or robots, but because the next generation of growers had a better offer: the lure of city lights, less labour intensive work, and financial security. Who will be there to care for the coffee trees? Who will continue to pick the beans for an industry that once supported some 700,000 jobs, and a profession half a million families depended on? The mere thought provokes a reality that’s too real to comprehend, but it’s an obstacle that’s no longer a future prospect. It’s happening now.

According to the Migration Policy Institute, in 2022 there was a recordbreaking 2.4 million migrant apprehensions at the United States-Mexico border, with 43 per cent coming from Guatemala, Honduras and El Salvador where coffee is a prominent export.

The question of “why” is extensive and

complex, but as I discover in this edition, there’s no singular cause, and therefore no singular solution. Until I scratched the surface of this topic, I had no idea immigration lawyers marketed their services to help immigrants transition to the US, nor that there had been deaths at the border for those who attempted their escape in vain.

Glimmers of hope can be found in education and individuals who are passionate about advocating for a profession that their great-grandparents, grandparents and parents once did, and one they have fallen in love with, and hope their children will one day too.

Money does not guarantee happiness. Simply obtaining a good price for your coffee is not enough. What’s needed, is for producers to be part of the solution.

If we can begin to provide the support and structures needed to have producers stay in rural areas, nurturing a generational profession they enjoy and see themselves and their family doing for years to come, then maybe we can start to convert the thousands of migrants calling the US home in search of the “American dream”. Instead, let’s foster a dream where they stay in the fields growing coffee, are paid a good price, and are supported by their family and community. Right now, that dream is slipping away, and if we’re not careful, those bright city lights will become a permanent home away from the nautral beauty of origin.

CHIEF OPERATING OFFICER

Christine Clancy christine.clancy@primecreative.com.au

EDITOR

Sarah Baker sarah.baker@primecreative.com.au

JOURNALISTS

Hayley Ralph hayley.ralph@primecreative.com.au

Dominic Morrell dominic.morrell@primecreative.com.au

ART DIRECTOR/DESIGN

Daz Woolley

HEAD OF DESIGN

Blake Storey blake.storey@primecreative.com.au

DESIGN PRODUCTION MANAGER

Michelle Weston michelle.weston@primecreative.com.au

BUSINESS DEVELOPMENT AND MARKETING ACCOUNT MANAGER

Adele Haywood adele.haywood@primecreative.com.au

CLIENT SUCCESS

Ben Griffiths ben.griffiths@primecreative.com.au

PHOTOGRAPHY

Sorin Stana

HEAD OFFICE

Prime Creative Pty Ltd 379 Docklands Drive, Docklands, Victoria 3008 p: +61 3 9690 8766 f: +61 3 9682 0044 enquiries@primecreative.com.au www.gcrmag.com

SUBSCRIPTIONS

+61 3 9690 8766 subscriptions@primecreative.com.au

Global Coffee Report Magazine is available by subscription from the publisher. The rights of refusal are reserved by the publisher.

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

Editor, Global Coffee ReportGlobal Coffee Report is owned and published by Prime Creative Media. All material in Global Coffee Report Magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Global Coffee Report are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

Excellence in the cup

Beyond expectations

A full new experience

Designed for efficiency and serviceability

ASIA PACIFIC

Flavourtech Global Sales Manager

Paul Ahn says ready-to-drink beverage sales are growing at a significant rate. In response, Flavourtech, a global technology manufacturer specialising in aroma recovery, extraction and evaporation solutions, has worked towards incorporating more automation and innovation into its systems, as seen in its Integrated Extraction System and Spinning Cone Column.

See page 30.

AMERICAS

Cold coffee accounts for more than half of Starbucks’ beverage sales. In the US, cold beverages account for 76 per cent of beverage sales at companyoperated locations.

US roaster Blue Bottle Coffee says interest in cold coffee has been growing at a steady rate and has become a menu mainstay, and Saudi Arabian roaster Camel Step producing a Nitro Cold Brew product line in 10,000-can batches using water, 100 per cent Arabica coffee, and nitrogen.

In the United Kingdom at Blank Street coffee shops, cold brew sales accounted for less than 1 per cent in 2022. It now accounts for 30 per cent of the entire business.

See page 15.

According to the Migration Policy Institute, in 2022 there was a record-breaking 2.4 million migrant apprehensions at the United StatesMexico border, with 43 per cent coming from Guatemala, Honduras and El Salvador where coffee is a prominent export.

Due to a 10 per cent increase in droughts throughout Honduras, the Honduras Technical Unit of Food

apprehensions will also increase by 90 per cent.

See page 21.

MPE’s innovations in single-serve coffee capsule production for preserving aroma and flavour are available to coffee capsule producers around the globe. President Daniel Ephraim says MPE’s degassing silo technology employs a variety of tubes and channels inside a silo to solve two of the biggest problems facing coffee capsule production.

See page 46.

Starbucks is building on its more than 10-year partnership with Arizona State University to develop an environmental education lab at Hacienda Alsacia, the company’s global agronomy headquarters for research and development in Costa Rica. The lab will serve as a hub for hands-on and virtual learning opportunities for Starbucks employees, students, researchers, and industry leaders to expand the capabilities and collaboration needed to cultivate positive social and environmental change beyond coffee, including climate adaption and agricultural economics.

See page 58.

Allana Group received such uptake for its coffee that in 1982, it decided to diversify into coffee exports and create the Coffee Division, based in Bangalore. The divisional office is situated in the heart of the city in close proximity to the Coffee Board of India. According to Allana CEO Ratnakar Mishra, Allana has held the distinction of being India’s leading exporter of green coffee for a number of years consecutively, with exports in the range of 24,000 to 30,000 tonnes per annum.

See page 34.

48.7 per cent

5 to go’s market share as the largest branded coffee chain in Romania.

Experience the perfect fusion of traditional craftsmanship and modern automation. Designed in Italy and made in Switzerland, Mytico offers an unparalleled coffee experience. Our attention to the smallest detail ensures that you can prepare a delicious cup of coffee every time.

Discover more at mytico.franke.coffee

Establishing Neumann Kaffee Gruppe (NKG) Korea is an important next step in Neumann Gruppe’s evolution. NKG Korea will offer all types of coffees from commercial mainstream to specialty qualities. NG Chief Operating Officer Ruben Scholz says NKG’s global network of 60 companies in 27 countries and more than 3200 highly skilled employees makes the green coffee service group particularly strong and flexible in responding to changes.

See page 38.

EUROPE

Five to go opens an average of 13 locations monthly, with the company’s transition into a franchise model key to helping reach approximately 500 coffee shops. The brand is tracking 150 store openings this year, with 64 opened as of August. Co-Founder Radu Savopol says the Romanian brand is on track to have reach 1000 cafés over the next four years.

See page 10.

To demonstrate how Eversys is catering to the needs of customers in various markets, different Internet of Things technology partners will rotate on the Eversys stand at HostMilano in October to share their Application Programming Interface solutions. It includes Bibe Coffee, Sm Vend, Specter, and Iovent.

See page 27.

Franke Coffee Systems has released a new product category, BeyondTraditional, and unveiled a new Mytico range that celebrates the modern needs of today’s coffee shop operators. Its Mytico Due machine has a daily capacity output of 300 cups, while Mytico Vario contains a higher daily capacity output of 360 cups. The Mytico product line is currently available in Europe and the Middle East and launched in Asia-Pacific in Q3 of 2023. See page 32.

Latvia-based multi-service tool provider Vendon is determined to make the daily operations of coffee businesses easier with useful tools and solutions, provided by reliable telemetry data. Vendon’s goal is to provide advanced telemetry solutions and revolutionise the coffee-making process, empowering operators to create the perfect drink recipe of the best quality.

See page 36.

Until 2019, Electrolux Professional was part of Electrolux home appliances. In 2019, the company's shareholders decided to spin-off Electrolux Professional to accelerate its growth. Using the expertise of Electrolux Professional, Unic’s logo underwent a refresh, as did the design of its machines, starting with the Tango XP series of fully automatic coffee machines: the Tango XP Duo, Tango XP Solo, and Compact models, which will be on display at HostMilano in addition to Unic’s Traditional Classic line.

See page 40.

Cama Group is beginning to experiment with how its flagship capsule packaging monoblock IF 318 machine can cooperate with more sustainable materials. In response to constant customer changes and to provide an alternate to traditional side-loading technology, Cama Group has also released its All-in-One machine, an evolution of its monoblock model, specifically for the coffee industry to pack all possible formats

See page 42.

Dutch manufacturer Cappac’s vision for a greener future extends to using a minimum of 80 per cent recycled material, and achieving carbon neutral Nespresso-compatible capsules by early 2024. The company actively engages in recycling efforts, such as one it conducts with the community of Blokker in the northwest of the Netherlands. Last year, it reclaimed and recycled more than 40

million capsules alone.

See page 44.

IMA Coffee has strengthened its commitment to reduce the environmental impact along the coffee production chain in collaboration with OpenLab, IMA Group’s network of technological laboratories and testing areas. This commitment applies through adapting filling and sealing technology to the new packaging materials and testing alternative processes to preserve the resources and minimise the packaging waste.

See page 48.

Rychiger acquired packaging machine manufacturer Nuspark in September 2019, now known as Rychiger Canada. The opportunity to acquire Nuspark has helped enlarge Rychiger’s footprint in the North American market for other branches. It now offers customers single-serve capsule machinery in one complete production line.

See page 50.

To date, some 1826 exhibitors are registered for biennial expo HostMilano 2023, representing 40 per cent international from 50 countries. According to HostMilano, recent Future Market Insights research estimates that, for food service equipment alone, the value of the global market will reach US$44 billion this year, and will achieve US$76 billion in 2032 thanks to a compound annual growth rate of +5.6 per cent.

See page 52.

51 million

The number of international migrants the United States hosts worldwide

On the move

5 TO GO CO-FOUNDER RADU SAVOPOL ON BECOMING A ROMANIAN COFFEE GIANT, MAKING BRAVE CHOICES, AND THE MATHEMATICS BEHIND ITS RAPID ACCELERATION.

By Sarah Baker

By Sarah Baker

or years, Radu Savopol was used to getting home at 6am as the owner of nightclubs and restaurants. These days, the role is reversed as he wakes at the crack of dawn to begin his day managing one of Romania’s largest coffee chains.

“Moving into the coffee industry was one of the biggest bets I’ve taken in my life. I had to trust my feelings and my vision to create 5 to go, the brand, and the business where all my Hospitality, Restaurant and Catering (HoReCa) expertise came together with my inherited passion for art and architecture,” says Co-Founder Savopol.

“When I first decided to take a step into the coffee industry, I attended the 2015 HostMilano expo. At that stage, I had just opened six or seven shops. I remember going through the expo and seeing everything the industry had to offer. It was like being a kid at Disneyland. It was an amazing atmosphere. Nobody knew who I was or what 5 to go was. Fast forward to this year’s HostMilano [in October] and I’ve already got a lot of invitations, private meetings, and events to attend. The experience couldn’t be more contrast.”

Savopol established 5 to go in 2015 with then 20-year-old business partner Lucian Bădilă after mapping out their business plan on a café napkin. Savopol describes his role as the “mathematician mind” while Bădilă is the “ultimate salesperson”, a complementing partnership that has so far proven successful.

They were excited to bring the coffee-to-go concept to Romania after observing its fast uptake and ease of implementation in other countries. Up to that point, Savopol says Romanians enjoyed traditional Turkish coffee amongst a landscape “dominated by very poor-quality coffee from vending machines”.

“There was no well-developed coffee culture back then. Even now, there is a lot of room for improvement,” Savopol tells Global Coffee Report. “We wanted to come up with a business model that responded to the modern consumer [who is] constantly on the move, who needs quality and tasteful products at an optimal price and a simplified purchase process, and a brand to resonate with. And we succeeded.”

In order to get closer to customers and respond to a need it detected, 5 to go espresso-based drinks were first priced at 5 Romanian leu (about USD$1.10) with a goal to deliver “simple, fast and efficient” coffee. That price point has changed for the first time in six years due to rising inflation and operational costs, however, Savopol says the company still aims to offer customers quality products at a fair price, and customers have remained loyal.

The brand started with a small coffee shop out of a garage in the old centre of Bucharest, but Savopol’s plans were big from the beginning.

“MOVING INTO THE COFFEE INDUSTRY WAS ONE OF THE BIGGEST BETS I’VE TAKEN IN MY LIFE.”

Radu Savopol5 to go Co-Founder Images: Sorin Stana

“From the first 5 to go coffee shop, which was no more than 12-square-meters in size, the pace of development has accelerated. At the end of 2022, we reached almost 450 stores nationwide, and each month we break our records and set new benchmarks,” Savopol says.

“It’s been an amazing journey. It’s only natural for a brand to be proud of its accomplishments, but we are 100 per cent entitled to be proud for reaching a strong position in the HoReCa segment in Romania in record time, and an outstanding 90 per cent brand notoriety in our country.”

Five to go opens an average of 13 locations monthly, with the company’s transition into a franchise model key to helping reach approximately 500 coffee shops. Around 420 of those venues fall under the brand’s ‘classic concept’, with others representing ‘coffee corners’ thanks to partnerships with retail and local businesses including Carrefour, Donuterie, and more.

“[As of August 2023] we are the largest branded coffee chain in Romania, with a market share of 48.7 per cent, and the largest chain of cafés in Eastern Europe, but also the most accessed franchise in Romania. We already have operations in France, Belgium, Great Britain, and Hungary and we are still targeting important international markets such as Spain, Germany, Poland, Republic of Moldova,” Savopol says.

“Each venue is strategic. I don’t just open one location internationally. It has to be accompanied by 10 to 20 locations and needs one to two years to really access its validity and market position.”

The biggest challenge as the company scales, Savopol notes, is how to transfer his business know-how and vision to his 235 franchise partners who contribute to winning the trust of tens of thousands of consumers each day.

“Ensuring all our partners embrace our vision and remain happy is very important. I try to visit each store after it opens and spend up to an hour building a connection with the franchisee partner,” he says.

In July 2023, 5 to go announced the opening of a flagship store in the historical centre of Brașov. Savopol says regional development is an important strategic pillar for the brand.

by reaching a total of 1000 cafés in Romania in the next four years,” he says.

To do that, the brand will track 150 store openings this year, with 64 opened as of August. The rest, Savopol says, is mathematics.

“Romania has a population of 20 million people and it’s a population that enjoys its coffee,” he says.

“Our growth strategy is not very complicated. We look at a map, we analyse the population numbers of each city, and how many high schools and hospitals there are in the area, then introduce a 5 to go store. Our brand becomes a meeting point for a city, a place for friends, parents, and children to gather.”

A key reason for its consistent growth, Savopol says, is the fact it’s a Romanian business that started from scratch and has a commitment to quality and diversity of products backed by a consolidated team.

“Our brand is more than a product customers appreciate. It is an experience provider, defined by the barista who we continuously train to be a source of information and inspiration for

to go’s coffee, a blend of Arabica from Cerrado, Brazil, and varieties from the high plains of Colombia. About 160 tonnes of coffee is roasted each year thanks to Bristot Coffee, with the aim to be roasting 200 tonnes by end of year. Savopol says the rate of uptake is strong, with venues averaging 33 kilograms of coffee per month, compared to 20 kilograms per month in 2015 when 5 to go launched.

“The taste of coffee is among our top values, and it cannot be found anywhere else because it is a distinctive blend with an intense, fullbodied, creamy aroma, created especially for 5 to go,” Savopol says.

“But certainly, [our customers] want more than a coffee. They want a tasting experience and an environment that’s comfortable, social, and has a good energy. We are trying to always exceed their expectations.”

Meeting those expectations is something Savopol takes seriously and is why the brand launched its own specialty coffee brand called Lucky Cats, available in-store and

in retail markets.

“Staying flexible and focused on the market’s current needs is a must. For instance, 5 to go is a global brand with a presence in the hospitality industry, but also with an accelerated growth in retail,” he says.

“I strongly believe that nowadays, the only constant is change. What we can all notice is that people’s passion for quality is constantly growing, and this also applies to coffee drinkers. We have a younger coffee audience. We try to keep up with them and their preferences, and to surprise them with innovations, from the launch of new ranges and products to creative campaigns and special offers.”

The last few years haven’t been easy for Romania’s HoReCa industry. The restrictions of COVID-19 resulted in large periods of uncertainty, while the war in neighbouring Ukraine forced the brand to adapt and make location and portfolio changes. Savopol says 5 to go has come through the other side thanks to making brave choices, which included being one of the first coffee brands to open additional cafés after lockdown.

“We used those difficult times constructively and worked more on strategy improvement, but what mattered the most, was that Lucian, I, and the entire team can rely on each other and completely trust our business model, so we were confident that together we can come back strong, no matter how difficult the situation,” he says.

“A leader should be the one to bring new perspectives, to inspire and motivate their team. Positivity and patience are very important. Because a relaxed environment favours trust and courage to express brave ideas and daring proposals.”

Those daring proposals include increased regional and international expansion where 5 to go intends to constantly increase turnover and market share. By the end of the 2023 financial year it had exceeded its estimated turnover by 5 per cent and is experiencing a 55 per cent increase on last year’s results.

In January 2023, it was estimated that more than 1.65 million customers drink at least one coffee in 5 to go’s network per month, and that 72 per cent of the Romanians have heard of the brand.

“In 10 years’ time, I hope every single person in Romania will know about 5 to go and I hope [our portfolio] numbers will make us proud even internationally,” Savopol says.

“Coffee has changed my life in so many ways. What I appreciate most, is my team and their success. Sometimes, I go to visit a 5 to go shop and sit there with my laptop and listen to the client’s interaction with the barista. For me, seeing customers come to our shop every, and happy, is the best reward.”

Cold brew, hot success

COLD COFFEE BEVERAGES ARE DOMINATING CAFÉ SALES WITH MANY INTERNATIONAL ROASTERS INVESTING IN CREATIVE AND QUALITY-DRIVEN METHODS THAT ARE TRANSFORMING THE SIMPLE BREW INTO A MENU MAINSTAY.

hen Australian-trained barista Jai Lott moved to New York in 2015, he’d been working in the specialty coffee industry for five years. He recalled seeing cold brew on Stumptown Coffee’s menu, but he’d never heard of it. When he joined the Bluestone Lane team as its Coffee Director later that year however, cold brew was “definitely an established thing”.

“In New York, you could set your calendar so that on the first day of spring, every coffee shop would flip to selling iced coffee and cold brew, like clockwork. Then, when the first leaf falls, it would flip back to hot beverages, like muscle memory. Now it’s different. Cold coffee represents a good third, if not half of our business the whole year round. It doesn’t change,” says Lott, now Blank Street Vice President of Product and Customer Experience. “There’s something about New York specifically that’s really embraced the cold brew movement that I find really interesting.”

“As the specialty industry in the United States has bloomed into the beast that it is now, there’s demand for quality, and like everything in coffee, as everyone’s gotten better and better and pushed each other to produce the best cold brew, it’s gotten pretty competitive.”

Strong competition and curiosity has led to industry bodies diving further into the science and research behind cold coffee. In June 2022, the National Coffee Association (NCA) USA released a first-of-its kind safety guide for retailers of cold brew coffee, with NCA President and CEO William “Bill” Murray commenting in a press statement that “cold brew coffee has seen explosive growth since NCA began

tracking it in our exclusive consumer research, and is now the third most popular method of brewing coffee”.

In November 2022, the Coffee Science Foundation alongside the Specialty Coffee Association (SCA) announced a new publication from its Cold Brew Extraction research project, with the study finding floral flavour to be a higher sensory attribute in cold brewed coffee. The results substantiated the general belief that cold brew is less sour, per descriptive analysis, but not necessarily less acidic chemically.

“Historically, there hasn’t been much research dedicated to cold brew, so it’s great to see scientific data that will further our understanding about how cold brew differs from traditional heat-brewed coffee,” said SCA Board of Directors member, Julia Leach, in a press statement.

STARBUCKS COLD BREW STRENGTH

One such company that has helped spread awareness of cold beverages is Starbucks, which first introduced cold brew to its menu in the summer of 2016. It now offers a range of cold coffee beverages including Iced Coffee, Cold Brew, Nitro, Iced Espresso, and more.

In the US, Starbucks launched the White Chocolate Macadamia Cream Cold Brew in time for the US summer on 9 May. While in Asia, customers enjoy unique and locally relevant cold coffee beverages like the Okayama Peach Apple Cold Brew, and Belgium Chocolate Nitro Cold Brew.

Currently, cold coffee beverages accounts for more than half of Starbucks beverage sales. In the US, they account for 76 per cent of beverage sales at company-operated locations.

In a Starbucks 2022 Investor Day transcript, Brady Brewer, Starbucks Chief Marketing Officer and Executive Vice President said cold coffee beverages are more frequently customised, and customers are increasingly adding modifiers like cold foam.

“They commanding a premium price, they’re driving our sales, and they are among our highest margin products. And they are also more frequently customised,” Brewer said.

“When you think about that elevated handcrafted experience at Starbucks, cold, customised, plant-based beverages is where it’s at.”

In response to the growing popularity of handcrafted cold foam on Starbucks beverages, the coffee company is introducing portable cold foamer machines to its stores, which were designed and created thanks to its barista partners.

“This investment in equipment improves the partner experience by allowing partners to conveniently make cold foam at any station behind the bar, no matter where they are crafting beverages,” Brewer said.

BLUE BOTTLE AND BEYOND

For US roaster Blue Bottle Coffee, cold coffee beverages are served every day, year-round, on café menus. “Quality and innovation have always been a part of Blue Bottle’s journey, and we continue to let curiosity guide our exploration in cold coffee. Our ongoing exploration of cold coffee beverages for our

its cold brew blend, cold brew single origin, and New Orleans-Style Iced Coffee (NOLA). It also serves its seasonal beverages iced to meet guest demands.

“Knowing there is a strong interest in cold beverages, we also look for opportunities to offer products for guests to enjoy coffee outside of our cafés cold,” Brewer says, pointing to Blue Bottle Coffee’s Craft Instant Espresso and limited-edition Exceedingly Rare Costa Rica whole bean coffee, as examples.

“Both are delicious hot, but we believe they’re event better when enjoyed cold,” Brewer says.

This year, Blue Bottle Coffee also released its Cold Blend No. 1, a seasonal whole bean coffee that it designed “to shine brightest when sipped cold”. Additionally, it offers ready-to-drink options for guests with its single origin cold brew cans, and NOLA cartons, providing customers with more ways to enjoy cold coffee wherever they may be.

This extends to Blue Bottle Coffee’s Samra Origins Craft Instant Coffee. Customers can simply combine one teaspoon (four grams) of one single-serve sachet with one-ounce hot water, stir, and add ice and six-to-eight ounces of cold water for a tasting profile of floral and fruit notes.

“Cold coffee has become an income driver for businesses due to the increasing demand of consumers,” Brewer says. “There are several reasons why demand for cold coffee has increased. For some, a preference for cold coffee may be a matter of taste, but it’s also versatile and refreshing. Additionally, many guests get cold coffee in the morning but it’s an option they gravitate towards during afternoons when looking for a refreshing pick-me-up later in the day.”

As such, and given the interest around cold coffee, Brewer says innovation in the cold coffee space will only continue.

“Despite constant innovation in indulgent cold coffee beverages, there is still opportunity for advancement of the cold coffee experience in the pure coffee space. For Blue Bottle, we will continue to explore cold coffee as part of our dedication to crafting the perfect cup of coffee for our guests,” Brewer says.

ONE STEP FURTHER

Saudi Arabian roaster Camel Step first started producing cold brew in-house in 2017 using manual brew tools. It noticed huge customer uptake in the country’s hot climate, before other market players and cafés followed suit.

“Saudi Arabians considers coffee a major representation of their cultural activities. They drink light-roasted coffee and enjoy coffee on average three times per day: morning, noon and night,” says Mohammed Alfaify, Head of Partners Management at Camel Step Co.

After a while of producing cold brew batches, Camel Step noticed a need for more consistent product preparation as it scaled its stores, with the product having an initial three-day maximum shelf life. As such, the company decided to invest in RTD canned products.

“We looked to other countries to see what opportunities were available because in Saudi Arabia, the main RTD ingredient was a coffee powder, not ground coffee, and flavour additives. Our goal was to produce a healthy and organic product to the market,” Alfaify says.

To create its own RTD cold brew product, the Camel Step team determined three key characteristics it needed to perfect: preparation, extraction, and filtration.

While the preparation was deemed easy enough, Alfaify says working through five stages of filtration to achieve 0.2 microns of particle size proved the challenge to achieving the desired “silky, smooth, light, juicy coffee profile with a sweetness of floral and fruitiness”.

“We changed the cartridge filters every batch, which is expensive but necessary to ensure the consistency level of the flavours in each batch,” Alfaify says.

“We tried many different coffee origins including Ethiopia and Colombia, honey processed, natural, and different ratios, but what was most beautiful for us, was the Colombian, fermented natural processed coffee named La Milagrosa, a direct traded coffee from Chalo farm. It tends to be heavier bodied and more floral. It’s a profile lots of people in Saudi Arabia like.”

The result is Camel Step’s Nitro Cold Brew product line that was launched in 2022. The production line produces 10,000-can batches. The 250-millilitre cans contain just three ingredients: water, 100 per cent Arabica coffee, and nitrogen. Nitrogen gas is added before the coffee cans are filled, with additional liquid nitrogen used during

Lott says he’d like to think Blank Street has “changed the way Londoners think about coffee”, noting other larger coffee chains including Pret a Manager and Costa Coffee launched their own cold brew products a month later.

Lott says after working on the perfect concentrate ratio for cold brew, developing an entire category and menu around the top-seller was the next stage of product innovation.

“During the nine months we took to develop the concentrate with the right roast profile and extraction refinement, we questioned how to use cold brew as a product, an ingredient more than an end-state product. I started thinking about it as if it were espresso and what could we do,” Lott says. “I haven’t been this excited about innovation in the coffee space in recent memory.”

The result, albeit a little serendipitous, Lott says, was a dedicated cold brew menu that resulted after two hours with 45 drink options using Blank Street’s signature cold brew shot as a base.

“It was proven by our numbers that all our customers consistently love and are loyal to cold brew as a final beverage, but we questioned what else we could do with it,” Lott says.

The result was a final menu catered to different beverage personas: a cold brew cortado – two and a half times the caffeine of a double espresso with four ounces of milk; Shaken Brown Sugar Cold brew –a sweet, delicious ‘treat day’ drink that marries the molasse of the brown sugar and cold brew; Shaken Chai Cold Brew – devoted to dirty chai drinkers; and Grapefruit Spritz Cold Brew – a clean, refreshing and surprisingly well paired combination that ticks a lot of boxes according to Lott.

The Brown Sugar Cold Brew turned out to be a best seller, with chai and cortado tied in second place. While cold brew is arguably more expensive when measured by ounce, Lott says Blank Street can charge a small premium because the product is harder to produce, twice the caffeine level, and offers

more theatre to the customer. To ensure cold brew operation and workflow was streamlined in Blank Street venues, Lott says the preparation needed to be no more than seven steps in 70 seconds.

“When creating new formulas, I evaluate drinks through the “milk crate” exercise. Hypothetically, a barista should be able to stand in a milk crate while making a drink. When they have to run around or move all over the place to make a single drink, it starts to affect barista morale,” Lott says.

Lott adds that cold brew is entering an exciting period of creativity among the international coffee community, and for someone who’s “innovation obsessed”, he’s determined to continue pushing the envelope to see how he can continue to make drinks better and better.

“We’ve definitely gone all in on cold brew,” Lott says. “We pushed espresso so far through automation, making blends better and sourcing better, and espresso hasn’t hit its ceiling, but I feel like I have this weird playground to enjoy. Anything that was ever done with espresso in the past, in the cold space, has already validated that it can be done with cold brew too.”

GCR Blank Street says cold brew drinks represent 30 per cent of its UK stores’ coffee orders.

The great harvest migration

ORIGIN MIGRATION IS IMPACTING EVERYONE ACROSS THE COFFEE SUPPLY CHAIN AND WILL REMAIN A THREAT TO THE NEXT GENERATION OF COFFEE PRODUCERS UNLESS IMMEDIATE ACTION IS TAKEN.

hen Olga Alvarado left her Honduran home and son at 18 years old to move to the United States, she did so with the intention to earn enough money to buy a coffee plot in Honduras and provide a better future for her son.

In an interview Alvarado shared with Fairtrade International, she said the situation when she left Honduras was “very difficult” because of low coffee prices. Alvarado stayed in the US eight years to save enough money to buy six acres (about four hectares) of land. She returned to Honduras in 2015 and joined the Coaquil coffee cooperative in the Masaguara area. Today, Alvarado is one of the 760,000 smallholder coffee farmers that are part of Fairtrade.

“My hope for my children is to get them ahead, that they would be professionals, that they don’t migrate to another country,” Alvarado tells Fairtrade International. “[I] teach them what I am learning, so that in the future they can do what I am doing now.”

Alvarado’s case is one of thousands, with about half of the members of the Coaquil cooperative having previously migrated to the US.

According to the Migration Policy Institute, in 2022 there was a record-breaking 2.4 million migrant apprehensions at the United States-Mexico border, with 43 per cent coming from Guatemala, Honduras and El Salvador where coffee is a prominent export.

Significant arrivals were also felt by Brazilians, Ecuadorians, and Haitians, with arrivals representing a 37 per cent increase compared to 2021 figures.

“During this season’s harvest, Central America reported mass labour shortages, higher costs, and fleeing youth from coffee communities. Some cooperatives have seen 10 to 15 community members disappear in a matter of weeks, all of whom were former coffee pickers,” says Lauren Jones of the University of California, Berkeley, studying a bachelor of science in environmental economics and policy.

“While we may see short-term impacts on labour during harvest season, the drivers and resulting implications of migration on coffee are interconnected with climate change, food

insecurity, low wages, and insufficient income. In addition, it is one of the main causes of next generation farmers leaving their communities.”

Jones says additional historic drivers of migration for coffee farming communities include poverty, violence, inequality, water insecurity, natural disasters, political instability, family ties in destination countries, and lack of access to work. In recent years however, climate change, the COVID-19 pandemic, and low coffee prices have contributed to worsened living and farming conditions.

The U.S. Department of Homeland Security, Instituto Hondureño de Café, says a drop in coffee prices from US$1.60 to US$1.40 would estimate a 22 per cent increase in migration in a non-coffee producing municipality and 120 per cent increase in migration in a coffee producing municipality. It also predicts a 5 per cent decrease in coffee prices would result in a further 14,400 more Honduran migrants, where currently one million people depend on coffee to sustain their livelihoods.

The National Institute of Migration in Honduras says approximately 400 people intersect irregular border crossings between Nicaragua and Honduras on a daily basis.

Due to a 10 per cent increase in droughts throughout Honduras, the Honduras Technical Unit of Food Security and Nutrition predicts migrant apprehensions will also increase by 90 per cent.

A Mixed Migrant Centre survey of 212 migrants in August 2020 responded that the pandemic had resulted in a lost income, reduced access to work, increased stress, lack of mobility and reduced access to basic goods.

STRATEGY AND STRUCTURE

Blanca María Castro, International Women’s Coffee Alliance (IWCA) Chapter Relations Manager says while the economic price challenges of coffee production are a significant contributor to harvest migration, it is not the primary cause.

“Receiving a good price for coffee without structure does not mean it will change the situation. Suppose that a small producer of one year, one crop, receives good money for their coffee, they won’t invest. They will most probably hire a coyote to bring their kids to the [United] States. If they can, they would do that immediately. They will use that money to move,” Castro says.

What the market needs to understand, Castro adds, is that the right economic structures need to be in place, with human development programs and projects that allow businesses to be sustainable.

“There needs to be a plan and structure where farmers can ensure not only their kids, but their grandkids, can follow the farming profession and take care of the land. It’s not a matter of buyers and the roasters paying more. Yes, that can be done. But we need to create awareness and say, ‘hey, this is a red flag, what’s going on?’ If the governments or entities are not really involved and not really putting their heads together and doing something about it, it won’t change. We need to raise our voices and make some noise. It’s not a matter of money. It’s about creating structure,” Castro says.

She notes that issue stems back to a lack of leadership, security, and structure in Central American governments, with drug trafficking difficult to control. Castro says the situation is not gender specific. Rather, it’s an issue impacting whole generations of families, and those countries directly near the United States.

“They are promised the American dream. The opportunities of work in the US are real. I’m in Texas right now. If I look out to the people on the street, I see people repairing roofs or doing work on the streets, most of them are Latinos,” Castro says.

The other type of prevalent immigration is that of producers moving from rural areas to urban areas, which is also affecting production.

“A lack of governmental structure is also involved in this scenario. What are they doing to entice kids to stay in the rural area and get the support they need for education and technical access? All they need is to really fall in love with their ancestor’s coffee, and not dream about being a lawyer or doctor, or impossible dreams,” Castro says.

“Coffee farming is so vulnerable. It can be wonderful one year, and messy the next. The biological behaviour of coffee plants has shown that one year could produce high yields of cherries, and the next it doesn’t, not to mention climate change effects.”

For Castro, all these factors equate to a reality she’s genuinely concerned about.

“We all depend on agriculture, and coffee brings a lot of money into the market, so I don’t know why Latin American governments are not investing and creating the structures and develop better programs for improving rural activities and making the agricultural sector better as a whole, not just for coffee,” she says.

Brazil Specialty Coffee Association Executive Director Vinicius Estrela says rural migration to urban

environments in Brazil, is common, as is migration from the less developed north and northeast regions of the country to the more developed south and southeast regions.

“This does not affect only coffee, of course. Youth from coffee producing areas often move to larger cities seeking better opportunities,” Estrela says.

He adds that the impact of harvest migration is a sad reality for the lost potential of coffee varietals.

“When people abandon coffee for economic reasons, we lose much in terms of the diversity of terroirs that produce the various sensory profiles that captivate coffee lovers around the world,” Estrela says.

“Ultimately, responsibility lies with the consumer voting with his or her money for a sustainable, equitable supply chain to guarantee availability of high-quality coffees from diverse origins into the future.”

Thankfully, Estrela says the world’s largest producer of coffee has more registered coffee producers today, than ever before.

“According to the National Coffee Council, there are over 330,000 coffee farmers in the country, 78 per cent being small producers, and coffee is responsible for 8.4 million direct and indirect jobs in 1983 municipalities,” he says.

“That said, we are indeed concerned about the coffee producers of the future. The succession of coffee farms to the next generation is a frequent topic of discussion.”

What’s needed, Estrela says, is consumer education.

“Lack of attention or care at any point [in the coffee chain] can ruin everything. But it all starts with the hard work of the coffee producer in the fields. Without the producer, the rest of the value chain falls apart,” he says.

“Unless we can ensure that people can proudly say they are coffee producers in their regions, that it’s not just an economically viable activity, but rewarding, something their children want to carry on, we face a future in which coffee is overwhelmingly dominated by a few big players offering less diverse, less interesting coffees at higher prices.”

Outside of immigration movement is a rising market of business immigration into the US, according

Law Office in Portland and Miami.

“Since COVID-19 and change in administration overall [in the US], in the past three years we have seen an increase in business and investor immigration in general,” Batrakova says.

“Our clients are businesses and individual business people who often come to the US to open start-ups or new affiliate offices, trying to make a living in the US.

“They call [the US] a land of opportunities for a reason and probably it’s the ability to make a living

here and succeed, as well as the quality of life.”

The Batrakova Law Office has represented many clients in the coffee industry in the past 18 years who want to immigrate to the US, most recently a Guatemalan coffee producer and roaster in Portland. On average, the fee for an individual going through the employment migration process can be upwards from US$8000, for either an E-2 treaty investor visa or an L-1A intracompany transferee visa.

“I’m originally myself from the former Soviet Union. I think my ability to empathise with the clients because I understand what the process is like, I’ve been through it myself, makes me passionate about immigration law. And of course, I love to strategise with businesses and individuals on their ability to come to the US and start their life here,” Batrakova says.

HOPE AND CHANGE WILL COME

Before producers question leaving their farming communities, IWCA Colombia Executive Director Lina Maria Granados Uribe says empowerment, education and awareness is needed, especially for female producers who, over the country’s 57 years of conflict, have seen their husbands killed, kidnapped or disappear, forcing them to stay in fields and maintain coffee crops.

“That’s why 30 per cent of the coffee growers in Colombia are women. It’s not that common in other countries,” Uribe says.

“Already people from the FARC (Revolutionary Armed Forces of Colombia) and other violent parts of the country are focused on growing coffee, not cocaine. So for us as Colombians, coffee is a positive solution to our conflict.”

Uribe is a fourth-generation coffee producer in Quindío. She is the first in her family to speak English, obtain a Master of Business Administration, and “really believe” that coffee is more than the picking, harvesting, and selling of green beans.

Once Uribe finished her university degree in 2016, she returned to the Central Andes, far from the capital city of Bogota in Colombia where 50,000 people live. In Colombia, 95 per cent of coffee grown comes from small producers who own one to five hectares of coffee, with 5 per cent large roasters who make up 95 per cent of the country’s coffee production.

Of the cooperative Uribe is part of, only 10 per cent of 101,500 members are under 30, with the average age 65. If no action is taken to motivate the next generation, Uribe says the cooperative

will disappear in 20 years’ time. As such, it was always her intention to stay in the coffee fields and use her education to help her community. Uribe and IWCA Vice President Ana Maria Donneys started the IWCA Colombia Chapter, and begun working with to empower women to stay in the coffee fields.

“Women are perfectly capable of running a coffee farm, and coffee can open doors and opportunities,” Uribe says.

One of the first projects Uribe undertook on her return was to find direct trade relationships for Colombian coffee due to the number of farmers who struggle with free market prices where “the prices are going nowhere”.

“We are working on having direct relationships with the consumer. It’s the only thing that can help us to stay in their business,” she says.

“At this moment, our numbers are in red because picking and operational costs are more expensive, and market prices are going down. There will be challenging times over the next two years, however my dad told me the other day, ‘this is not the first time I’ve had hard times, but I love my job.’”

Like Castro, Uribe says the solution to reduce producer migration is not about increasing coffee prices or having consumers pay more. It’s about helping young people fall in love with the business of coffee, and ensuring producers and consumers are staying close to one another.

“My purpose is to be the bridge between the consumers in the consuming countries and the producers here so that we can get a ‘bigger slice of the cake’ and not see it taken by the middleman. Our main goal is to give opportunities to small and medium-sized producers to go direct to coffee shops, little roasters, and for people in consuming countries to know our history, our families, and all the effort and people involved behind a cup of coffee. We have to start being conscious about the people behind it, because consumers really do have the power in their hands when they make their buying decision,” Uribe says.

In the five or so years since the IWCA Colombia chapter started, Uribe says she’s amazed at the change she’s witnessing in her producing region. More women are involved in production with their families, promoting themselves, making agreements, becoming baristas and Q graders, and even requesting English classes for the rural town to better connect with the world.

“We are planting a little seed for people to measure their actions and success to help improve their lives. Coffee has to be a trap for young people to stay in the fields. They need to know they are part of a global community, that they belong to something, and coffee can open the doors to that sense of belonging,” she says.

Uribe is under no pretention that the challenges ahead are large. But when people question why she stays farming, amongst the mosquitos, rain and daily obstacles, passion overrides.

“I am really proud to tell people that my family are coffee growers, and that I am a grower myself,” she says. “When I become a mum one day, I will teach the same love for coffee as the generations of my family’s coffee farmers have to me, because this is how we preserve the profession.” GCR

Make it smarter

Making a mark in coffee encapsulation and packaging

Global Co ee Report is the leading business magazine covering the international co ee industry. In-depth features explore on-the-ground developments at origin, co ee pricing issues, technology updates, research breakthroughs and much more.

www.gcrmag.com/subscribe

UNLIMITED ONLINE CONTENT

The Eversys Ecosystem

EVERSYS EXPLAINS HOW IT WILL USE ITS THREE PILLARS OF MILKS, BEVERAGE MENUS, AND IOT TO DRIVE PERFORMANCE, NOW AND INTO THE FUTURE.

hen it came to deciphering the direction of Eversys’ presence at the HostMilano exhibition in October, it was a strategic decision in line with market shifts and customer needs.

“One of the first fundamental goals in exhibiting at HostMilano is to show to the market that our super traditional machines can deliver the exact same in-cup quality as traditional espresso machines. Next, we want to celebrate Eversys’ modularity and how the machines have been designed to make the life of a technician as easy as possible. The third fundamental goal is to celebrate innovation,” says Eversys Marketing Director Andre Eiermann.

“HostMilano is where we showcase to the commercial universe and large roasters and companies how we can drive their performance even more by looking at current key trends in our industry.”

The three trends the Swiss manufacturer identifies are dairy and dairy alternatives, innovative hot and cold beverages, and the advantageous possibilities of connectivity and software-assisted features.

Eiermann estimates that 80 per cent of all coffee beverages served globally are milk-based. As such, Eversys has three dedicated options to cater to all dairy and dairy-alternative needs: its 2-Step, 1-Step

“It’s about flexibility and showing to our key commercial partners that anyone can perfect dairy and

“Our technology has the ability to own the dairy milk alternative space, and to demonstrate this, Eversys will feature two machines on its stand at Host: one texturing dairy milk, the other, dairy alternatives, to

To demonstrate its flexibility and adaptation to Asian beverage innovations, Eversys will also create

Renowned latte art professionals will rotate and present their texturing prowess and what’s possible

HostMilano visitors to see how they can leverage their menus and embrace coffee as an ingredient for desserts, as well as alcoholic and non-alcoholic beverages.

“We want to inspire people and stimulate new items, and thanks to two baristas and mixology specialists from Switzerland and China, they will demonstrate four crafted recipes and mixed coffee beverages,” he says.

To celebrate the future of innovation, Eversys’ tech team will provide on-site training at HostMilano. Eiermann says this is a clear sign to the market that investing in Eversys is not a oneoff investment, but about working in partnership to harness potential even further, from after sales support to technical expertise.

The tech team will also officially unveil the Légacy espresso machine, and demonstrate its capabilities including the latest precision grinding module. Users can configure up to four grinders

to produce and choose between four different types of beans. To put this to the test, Eiermann will serve 30 espresso tonics and 30 affogatos on the new Légacy machine while talking to the crowd to indicate how baristas can unleash their creativity while maintaining efficiency.

“The idea is to show the audience how the role of the barista has transformed from simply making coffee to becoming a creative expert in coffee and coffee-based beverages, with a major focus on customer service as well as innovation,” Eiermann says.

The Eversys exhibition stand will also feature an open corner where it will host Internet of Things (IoT) technology partners to present their Application Programming Interface (API) solutions.

“Since the beginning of Eversys, we’ve always been quite technology driven. Now, we want to show potential customers a bigger perspective of what it will mean to work with us,” says Stephan Zink, Eversys Software and Electronics Director.

AN IOT WORLD OF POSSIBILITIES

Previously, Zink says software solutions for Eversys customers were fairly standardised: use an interface and payment solution that is only accessible in the regions of Switzerland, Germany, Austria; use an API payment extension that connects to Bluetooth; or allow a customer to integrate their own API payment ecosystem.

“More and more, chain operators don’t only want to buy coffee machines that are isolated from a payment and telemetry solution. They want to integrate it into their ecosystem,” Zink says.

To demonstrate how Eversys is catering to the needs of customers in various markets, different IoT technology partners will rotate on the Eversys stand to share their API solutions. It includes Greek software company Bibe Coffee, and Latvian company Sm Vend, who both specialise in telemetry and payment solutions; Danish under-counter coffee solution and ordering company Specter, and German smart vending solution company Iovent, who offer turnkey operations with software and hardware for telemetry payment solutions.

“The payment world is becoming so complicated that we cannot alone create a keystone solution for each market, each country,” says Jonathan Besse, Eversys Research and Development Director. “We really want to make a custom fit for each country, and encourage our partners to work with us to develop tailor-made solutions, even if it means helping customers change their business model.

“It’s not about coffee consumption or technical ability. It’s about taking a customer-oriented approach

and really presenting a final solution to the customer. We want to see what problems we can solve for them.”

Such payment solutions could mean using the Alipay smart vending machine solution in China, integrating QR codes into the machine interface, or enabling tap-and-go transactions.

Eversys points to Irish coffee chain Frank and Honest under parent company Musgrave Group, who worked with Eversys in the past to develop payment solutions.

“We can really unleash full potential if we understand the needs of the key account, then develop the solution together, and that’s what we did with Frank and Honest. We understood their needs and said: ‘that’s possible, let’s develop it together’,” Besse says.

The end result involved using Eversys telemetry system to gather data from its machines to calculate the volume of coffee made per Frank and Honest location, and how much milk and sugar was used.

This information was then passed onto its logistics company to ensure enough stock was ordered at each store according to specific volume needs.

Another option is to combine Eversys’ telemetry system and integrate it with a company’s own payment portal and backend to present everything in one portal.

“Big companies have their own Enterprise Resource Planning (ERP) software system and they don’t necessarily want to use different systems in parallel. They want to combine the data and aggregate them, and have an overview at a glance. That’s the trend everywhere, integration. That’s when you have a solution that’s tailor made to your needs,” Zink says.

“We care about the last mile. We know how to bring the data from the machine to the backend using lots of sensors to measure and monitor. We bring all that data into ‘the cloud’, then it’s about the interface and combining different services where the possibilities are endless.”

For a long time, Besse says Eversys’ telemetry solutions represented pie charts and statistics for businesses to automatically measure and compare performance and KPIs, but what Eversys is focused on now, is how to optimise service from data available.

“We are different to other telemetry solutions out there in terms of the depth of data we offer. That’s where we are really strong. From the beginning, that was the focus. I’m convinced

it’s a strength we want to concentrate on in the future,” Basse says.

The future, Eiermann says, is thinking of Eversys beyond its coffee machine manufacturing abilities, and more as a solutions-oriented company that offers the strength of its mechanics, electronics, interface, cloud-based services, and IoT partnerships.

“We are opening up our ecosystem of solutions to our partners. We can’t do everything ourselves, so we believe in building strong partnerships with our clients. We are ready and open-minded to go to the next step together and create new and exciting solutions,” he says.

“No longer are we just talking about coffee making. We’re looking at the supply chain side of the business, using telemetry to analyse data, and going far beyond a simple cup of coffee. This is what our customers expect now. They are clearly emphasising in-cup quality, but they expect more than tasty coffee, and that’s what we can deliver thanks to the software side of our business. It really is a dealbreaker in today’s market.” GCR

For more information, visit www.eversys.com/en/

Max extraction

FLAVOURTECH TALKS TO GLOBAL COFFEE REPORT ABOUT THE CONTINUED GROWTH OF THE READY-TO-DRINK SECTOR, AND THE FUTURE OF FLAVOUR.

he desire for convenience and simplicity is growing in the beverage market for both manufacturers and consumers alike according to Flavourtech Global Sales Manager Paul Ahn. Ready to Drink (RTD) beverages have become a popular solution since their creation, and Ahn is confident their presence on market shelves is only set to continue.

“What we’re seeing worldwide is that RTD sales are still growing at a significant rate,” he says. “This is mainly due to the younger generations since they are looking for something convenient, but the convenience also has to be natural and healthy.”

Ahn says the rising popularity is also a result of younger generations moving away from fizzy beverages and more towards clean label products and healthy alternatives, many of which are RTD-produced.

“I’m glad that the younger generation is driving this so that we can get more natural products into the RTD space. Kudos to them for making this happen,” says Ahn.

Ahn says the increase of diversity among coffee flavourings has also played a role in RTD’s expansion. He says it was not long ago when coffee lovers were limited with their flavour options.

“In the tea market, we’ve seen fruit flavours come through for years, but now were seeing it in the coffee market as well,” he says.

In response to customer feedback, Flavourtech, a global technology manufacturer specialising in aroma recovery, extraction and evaporation solutions, has worked towards incorporating more automation into its systems.

“We implement safety and automation efforts so people working on the line are producing the best quality product in a consistent manner,” Ahn says.

This level of innovation can be seen with the Integrated Extraction System (IES), which Ahn says helps develop the richest, natural flavours.

“The IES is designed for the coffee and tea industry in the aim of producing the highest quality RTD beverage, full of the natural aroma from the raw material itself, the roasted coffee beans or tea leaves,” Ahn says.

“Before the IES, these natural, desirable aromas were typically lost or damaged through processes that were not designed to capture or maintain them. The result, as you can guess, is a RTD coffee or tea extract lacking flavour.”

Ahn says the system is a culmination of previous advancements in the flavour extraction field.

“Back in early 2000, one of our customers asked us for an automated, continuous and inline process that would allow a transfer of the desirable notes of the roasted beans from the raw material to the final extract,” says Ahn.

“Rather than forklift tanks around its factory which risked product inconsistency, the IES was a great leap

forward for this particular customer. It brought together the technologies necessary, such as the Slurry Preparation module, the Spinning Cone Column (SCC) and the Centritherm evaporator, combining all from the very start of the process to the end for a premium RTD extract full of natural aroma.”

Ahn says the result is product with more flavour and antioxidants, ensuring manufacturers have the upper hand over their competitors.

The success of the IES has allowed Flavourtech to develop alternate machines to better accommodate the specific needs of customers. One such example is a smaller version of the SCC.

“Going smaller can be a challenge for engineers,” Ahn says. “We’ve made changes by listening to our customers and what they want, so we built a smaller unit called the SCC100, which allows smaller runs to happen.

“Many of our customers worldwide have large production facilities producing large volumes of RTD consumed all around the globe. But we also see smaller, specialised customers who want to enter the market, and having a smaller system allows them to do that.”

Flavourtech released the Spinning Cone Column SCC100 in 2021. Ahn says the smaller design gives the RTD producer the ability to capture aroma from coffee or tea extract, and coming soon, from the slurry itself, or what Flavourtech describes as “a slurry capable SCC”.

“The engineers did a great job in redesigning the whole system from the ground up,” Ahn says.

“The slurry capable SCC used in the IES performs two tasks simultaneously. The first is what we call the aroma strip, where the volatile coffee or tea notes are captured and stored. The second is the brewing of the coffee or tea in 30 seconds as the slurry flows through the SCC. The spinning cones are the key here. They perform the aroma capture and extraction in this short time while producing a high quality extract.”

Both the IES and the SCC have taken lessons learned from flavour extraction systems used for other beverages in the tea and coffee industry.

“For example, you may have citrus or berry notes in the roasted coffee beans and tea leaves, but when they go through the extraction process, these delicate notes are either lost or damaged,” Ahn says.

“The IES process, on the other hand, captures these desirable notes upfront through the SCC, and at the same time, undergoes extraction to produce a premium coffee or tea extract.”

Flavourtech also remain committed to helping the environment, with sustainability a key feature of its SCC systems, which are used to minimise waste and recycle products for the benefit of the environment.

Together with its sustainable objectives, Ahn says Flavourtech has plenty of RTD-based projects on

Flavourtech specialises in aroma recovery and extraction in a number of beverages, including RTD tea and coffee.

“It’s all about providing a means to keep everything natural,” Ahn says. GCR

High quality, high reward

FRANKE COFFEE SYSTEMS BRAND AMBASSADOR WOJCIECH TYSLER DESCRIBES HOW THE MYTICO LINE MEETS THE END CONSUMERS’ NEEDS BY CREATING A CONSISTENT CUP OF COFFEE EVERY TIME.

ojciech Tysler is a 2021 World Barista Championship finalist. He’s worked in the hospitality industry for more than 17 years, has a wealth of industry knowledge and skills, and is what many would consider a credible source for finding a quality espresso machine. His passion for the perfect cup may have led him to Franke Coffee Systems, but the machine manufacturer’s new Mytico line is what influenced him to become the brand’s ambassador.

“When we’re talking about good coffee, we need good beans, good quality water at the right temperature, a good barista, and the right coffee machine. This is where the Mytico line comes in,” Tysler says.

Franke Coffee Systems’ new product category BeyondTraditional features its first product line Mytico, which Tysler believes is a one-of-a-kind machine.

“Franke’s innovative technologies paired with my barista skills are the perfect recipe to delight customers. Once set, Franke’s automatic coffee machines consistently create delicious coffee beverages. Baristas can focus on maintaining eye contact, offering a friendly smile, and engaging in small talk while signature coffee drinks are being prepared,” he says.

Franke Coffee Systems CEO Marco Zancolò says the BeyondTraditional product category “perfectly complements” the brand’s broad product portfolio of fully automatic coffee machines, while the new Mytico line unlocks even more potential for today’s coffee businesses.

“Different demands and segments require a flexible, modular system. This new product category shows our ability to constantly improve and adapt technologies and offer new products that meet the ever-changing needs of consumers,” Zancolò says.

The first two products in this product line, Mytico Due and Mytico Vario, include a large variability of beverage options on two eight-inch touchscreens. Tysler appreciates the programmable Barista Levers on both group heads, which give the user direct access to the most frequently used beverages or features.

“For example, if you pull the lever down you can set it up to produce a single espresso and pull the lever up to offer a double espresso,” he says.

Tysler says the patented Franke iQFlow extraction technology, available in both machines, allows baristas to control the flavour output while maintaining a consistent, high-quality coffee.

“iQFlow allows the user to personalise multiple flavour profiles and efficiently extracts the full aroma, flavour, and body from every roasted coffee bean, revolutionising the traditional extraction concept. This intelligent technology distils more flavour under constant, uniform pressure throughout the

entire extraction time, thus enabling consistent, individual taste profiles,” says Tysler.

“iQFlow is very precise with extraction time. What consumers look for in a good coffee is consistency, and the Mytico machines give you just that. Plus, when I start steaming milk on it, it’s absolutely amazing.”

Each machine has two coffee modules, allowing two operators to run the machine at once.

“With minimal effort and training required and a compact design that fits easily on your countertop at an ideal height for better customer interaction, Mytico maximises efficiency and effectiveness for a more streamlined service,” Zancolò says.

Zancolò says while the machine models look similar, the two possess distinct qualities.

“Mytico Due prioritises barista-quality service with a two-step preparation using fully automated or traditional steam wands and a modern design. Its automated operation and intuitive design, coupled with a low machine height, enable baristas to easily engage with customers,” he says.

The automatic machine has a daily capacity output of 300 cups. The Franke automatic cleaning system supports this volume by maintaining hygiene standards.

Mytico Vario, on the other hand, contains a higher daily capacity output of 360 cups. It features a simple configuration, automated operation, and

an integrated milk system. Different milk and milk alternatives can be prepared at the same time on both the left and right coffee module.

The integrated milk system helps reduce milk waste and opens up an additional beverage range, while the steam wand allows more variety with milk or plant-based alternatives.

“Franke’s FoamMaster technology provides the unique ability to pre-set a custom foam profile for each beverage and milk selection, allowing your customers to enjoy barista-style coffee at the touch of a button. Whether they choose hot coffee with milk or a milk alternative, light foam or more, every cup can be consistently executed to suit their preferences,” Zancolò says.

The machines come in six different Franke colours: Onyx, Cotton, Sand, Burgundy, Blueberry, and Basil. The range is intended to suit any environment, from a classic style restaurant to a modern coffee bar.

“Today’s consumers expect excellent coffee, as if prepared by a barista. Drinking a cup of coffee out-of-home is meant to be a memorable and enjoyable experience, yet the shortage of skilled staff in the industry has become a

concern on a worldwide scale. Thus, it is a challenge for owners of coffee businesses to consistently satisfy their customers’ demand for high-quality coffee experiences every single day, cup after cup,” says Zancolò.

“Franke’s new product category in professional coffee making, BeyondTraditional, is the perfect response to such challenges. It combines existing concepts and technologies with new trends and demands and brings to life solutions that go beyond industry standards. The first result of this new approach is the ground-breaking product line called Mytico.” GCR

For more information, visit mytico.franke.coffee

The Mytico line includes a variability of beverage options on two eight-inch touchscreens. The Mytico line creates consistent quality in every cup of coffee.Building an Indian empire

ALLANA EXPLAINS HOW IT BECAME ONE OF THE LARGEST COFFEE EXPORTERS IN INDIA AND CATERS TO THE NEEDS OF ALL TYPES OF BUYERS: SPECIALTY, SINGLE ESTATE, AND COMMERCIAL-GRADE COFFEE.

hen the Allana Group began trading in agricultural commodities in 1865, Founder Abdulla Allana and his family had no idea that the company would receive so much uptake that it would need a dedicated coffee division, nor that it would become one of the largest coffee exporters in India. But it did.

“Allana is a very entrepreneurial company. Despite earning a position of prestige in the Indian commodities market, the founding family allow us the freedom to input ideas, creating a stimulating working environment,” says Allanasons Director MP Devaiah.

“Through more than 158 years of inspired leadership, the Allana Group has emerged as a multi-product conglomerate of companies with wide-ranging interests. The company exports coffee, wheat, processed food, frozen buffalo and sheep meat, and is also making strides in the edible oils segment, along with a host of other products in the domestic market.”

After forming the subdivision, Allanasons, in 1973 to manufacture and supply processed food products, the company decided to diversify into coffee exports in 1982 and create the Coffee Division, based in Bangalore.

“The divisional office is situated in the heart of the city in close proximity to the Coffee Board of India. With the state of Karnataka producing 70 per cent of the coffee grown in the country, it is ideally located,” Devaiah says.

“Headed by a team of professionals well versed in the field and backed by the support of Allanasons, the Coffee Division soon made its presence felt, and found itself at the forefront of the industry.”

To complement this activity and gain control over the curing of the coffees sourced, Allanasons acquired its own curing factory in 1992.

“Gradually, this coffee curing unit, which was strategically located in Hassan in Karnataka and situated midway between the two major coffee growing districts of Chikkamagaluru and Coorg, became one of the hubs of activity in the industry,” says Devaiah.

“In turn, this required the expansion of the facilities and modernisation of the plant and machinery to meet the additional requirements of the Coffee Division. It also boasts an inhouse cup-tasting facility for evaluating the characteristics of coffee.”

Allanasons owns two large warehouses at the port cities of Cochin and Mangalore where cargo is unloaded prior to shipment, ensuring that all operations come under its effective control. The company exports all grades of washed and unwashed Arabicas and Robustas, and owns and operates a dedicated facility in Mangalore where coffee monsooning is carried out.

This is the 12- to 16-week process of spreading beans across the warehouse floor during India’s monsoon season, allowing the beans to absorb moisture, swell in size, change colour, and shed their acidity.

“We are a supplier of quality coffee known for fulfilling commitments on schedule,” says Devaiah.

“In recognition of the Coffee Division’s performance, the Coffee Board of India has

awarded Allanasons many accolades. Allanasons has won the APEDA Golden Export Trophy each year since 1992, reflecting its premier position in the export of agricultural products and processed foods. The Government of India has recognised Allana as a Premier Trading House, the highest achievable export performance recognition in the country.”