Innovation

Investing in the Why the youth need coffee, and coffee needs the youth

The

Anton Mianovskyi of Gemini Espresso on saving his business from the destruction of war, putting Ukrainian coffee on the map, and why he believes his business can take on the world’s coffee giants.

www.gcrmag.com

in automation Technologies set to improve workflow and efficiency

evolving role of a roaster The reality of navigating a business post-pandemic

November/December 2022

thrive Determined TO

POWDER

GRINDERS

The machine can be con gured with up to four grinders, o ering the production and choice of four di erent types of beans.

MILK

In the 1-Step system, milk is frothed with air, ensuring optimal avour and texture.

Our engineers have designed an integrated powder unit that can hold up to 2kg.

Our engineers have designed an integrated powder unit that can hold up to 2kg.

10

DETERMINED TO THRIVE

Anton Mianovskyi of Gemini Espresso on why he believes his Ukrainian roasting business can take on the world’s coffee giants 14

INVESTING IN THE NEXT-GEN

The ICO Coffee Development Report explains why the youth need coffee, and coffee needs the youth 18 2030 AND BEYOND Nescafé unveils its sustainability plans for the next decade as it focuses on sustainable initiatives and growth in a transparent way 22 MORE THAN

JUST HOT AIR

Why Vietnamese coffee producer Tran Quang opted for an RFB roaster from Neuhaus Neotec 25

BUILDING MOMENTUM – AND MACHINES TOO

Eversys announces another factory expansion and explains the core drivers of growth 28 A

FITTING FINALE

MICE2022 unites the global coffee industry and maintains its title of largest dedicated coffee tradeshow in the Southern Hemisphere

MEET THE CHAMPS

Two new World Coffee Champions are crowned, making history for Taiwan and Australia

THE SUM OF ITS PARTS

Alcorn Café Engineering helps breathe new life into coffee equipment with bespoke parts and tailored solutions

THE EVOLVING ROLE OF A ROASTER

Vittoria Coffee on the reality of navigating a business post-pandemic

FEATURE

PIONEERING COFFEE TECHNOLOGY

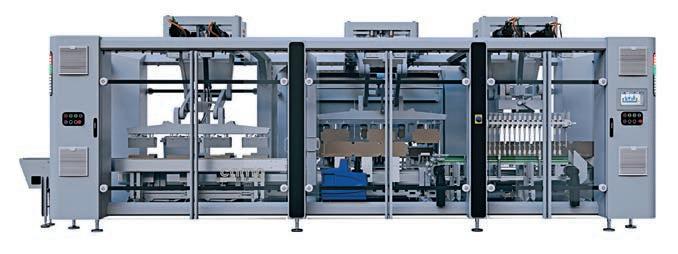

IMA Coffee discusses the launch of its IMA Coffee Lab featuring the latest processing and packaging technologies

BLUE SKYE THINKING

The Schaerer Coffee Skye is a modular and portable unit that fills a market gap for mid-level coffee machines

CAFÉ VARIETY ON-THE-GO

De’Longhi unveils the Eletta Explore at MICE, featuring two dedicated frothing technologies for hot and cold milk

SETTING THE TONE

How Tone has taken tankless water heater technology and elevated it to a whole new level with the Tone Touch 03 46 THE DIGITAL REVOLUTION WMF on becoming a total solutions provider thanks to the digitalisation and transformation of businesses 48 TELEMETRY

TRIUMPH

Vendon explains how its IoT telemetry and payments solutions help track and manage machine fleets remotely

WORD

E VEN BIGGER IMPACT

Swedish roaster Löfbergs Group has joined the European Coffee Federation to help improve sustainability at the farm level and across its European operations

CONTENTS November/December 2022

Anton Mianovskyi of Gemini Espresso on saving his business from the destruction of war, putting Ukrainian coffee on the map, and why he believes his business can take on the world’s coffee giants.

10

“WE ARE LIVING WITH THE SITUATION, BUT IT’S A SITUATION THAT DOESN’T JUST DISAPPEAR WITHIN ONE OR TWO MONTHS, SO WE MUST ADAPT AND TRY TO RETURN TO BUSINESS AND LIFE AS NORMAL.”

COVER STORY

FEATURES

28

44

58

LAST

REGULARS 04 EDITOR’S NOTE 06 NEWS DRIP BY DRIP 52 DIARY DASHBOARD 54 WHAT’S BREWING 56 MARKETPLACE IN

44 25 32

THIS ISSUE

34

36

AUTOMATION

38

40

42

NOVEMBER/DECEMBER 2022 | GCR 3

Anton Mianovskyi Gemini Espresso CEO

THE SHOW MUST GO ON

AS THE YEAR draws to an end, we find ourselves repeating the same mantra: “how fast did this year go? I can’t believe it. It’s nearly Christmas.” The sentiment may be the same, but compared to this time last year, many things have changed. We’re now free to move around without restrictions, mask rules have been removed from most flights and indoor settings, and the word ‘COVID’ is no longer dominating news broadcasts and conversations.

Instead, that job has been replaced with natural disasters, the Queen’s passing, tragedy, and war. For those impacted by the conflict in Ukraine, I can only imagine what an emotionally taxing and stressful year it’s been. Lives have been lost, livelihoods thrown into upheaval, and for companies such as Gemini Espresso, one of the largest coffee roasters in Ukraine, it’s forced the company to reconsider its operational base, growth potential in Ukraine, and the future of the business.

For many company CEOs, COVID tested their resilience and leadership while trying to stay a float, keep employees together, and adapt to the new normal. It was a new normal nobody wanted, and sadly for Ukraine companies, they are faced with the same dilemma.

Gemini Espresso CEO Anton Mianovskyi is surprisingly calm and measured when speaking to Global Coffee Report from Kyiv. He doesn’t flinch at the 24 warning alarms that ring throughout our interview, nor is he emotional. He’s calm, logical, and acutely aware of the challenging situation he finds himself in.

Mianovskyi could have easily chosen to cease operation under the circumstances, but it was never an option. It wasn’t an option for the company he’s watched evolve over the past 16 years. It was never any option for the 180-plus employees he’s responsible for. Rather, Gemini Espresso has stayed strong and operational

amongst the chaos. Mianovskyi moved the production facility away from danger, held a barista competition to uplift the youth of Ukraine when they needed to see fun instead of fighting, and the business has survived thanks to the support of the country’s largest petrol stations. He is the definition of a man who moves on and gets things done.

Another example of moving on was the 2022 Melbourne International Coffee Expo (MICE) which, after three years of postponements, finally opened the doors to more than 15,000 visitors who went to do business and network with new and existing customers in the Asia Pacific.

MICE was one of the biggest industry catch-ups in what can be now considered a post-COVID era. It was wonderful to replace virtual handshakes and mute buttons with face-to-face chats and physical embraces. After all, the global coffee industry is built on relationships, and events like MICE prove that no matter where you are in the world, coffee can bring us together.

In times of unrest, Mianovskyi reminds me of its power. “Just one delicious cup has the power to make you forget all your troubles in that one moment,” he says. “I just hope that one day the world returns to a normal situation, so we can just make coffee, not war.”

CHIEF OPERATING OFFICER

Christine Clancy christine.clancy@primecreative.com.au

EDITOR Sarah Baker sarah.baker@primecreative.com.au

JOURNALIST Hayley Ralph hayley.ralph@primecreative.com.au

ART DIRECTOR/DESIGN Daz Woolley

ART DIRECTOR Blake Storey blake.storey@primecreative.com.au

DESIGN PRODUCTION MANAGER

Michelle Weston michelle.weston@primecreative.com.au DESIGN Tom Anderson

BUSINESS DEVELOPMENT AND MARKETING ACCOUNT MANAGER Courtney Walker courtney.walker@primecreative.com.au

CLIENT SUCCESS Ben Griffiths ben.griffiths@primecreative.com.au

PHOTOGRAPHY

Brendan Hoffman, James Thomas Photography, Melbourne International Coffee Expo CONTRIBUTOR Paul Chai

HEAD OFFICE

Prime Creative Pty Ltd 379 Docklands Drive, Docklands, Victoria 3008 p: +61 3 9690 8766 f: +61 3 9682 0044 enquiries@primecreative.com.au www.gcrmag.com

SUBSCRIPTIONS +61 3 9690 8766 subscriptions@primecreative.com.au

Global Coffee Report Magazine is available by subscription from the publisher. The rights of refusal are reserved by the publisher.

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

Sarah Baker Editor, Global Coffee Report

Global Coffee Report is owned and published by Prime Creative Media. All material in Global Coffee Report Magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Global Coffee Report are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

4 GCR | NOVEMBER/DECEMBER 2022

EDITOR’S NOTE Global Coffee Report

NEWS DRIPBYDRIP

AFRICA

People between ages 15 and 34 years represent about a third of the 4.9 billion people living in coffee producing countries, and at least half of the labour force depending on the country’s demographic structure. One third of the 4.9 billion people who reside in coffee producing countries are between the ages of 15 and 34 years old, providing a significant pool of coffee producers and consumers. Africa is notably the region where there is the largest potential, as 70 per cent of young people in coffee producing countries reside in Africa.

See page 14.

ASIA PACIFIC

Vietnamese roaster Tran Quang’s roasting facility has become a showcase plant in Ho Chi Minh City, featuring Neuhaus Neotec’s RFB batch roaster, known for its innovative hot-air roasting system. This

technology doesn’t require multiple moving parts in the roasting chamber, just the air to move the beans and to heat up the coffee.

See page 22.

A record 15,056 attendees visited the Melbourne International Coffee Expo from 27 to 30 September 2022 with 15 per cent international attendees from 75 countries. The attendance figure is the highest of any MICE expo since the event’s inception in 2012, with an increase of 25 per cent of visitor numbers since the 2019 event.

See page 28.

Shih Yuan Hsu (Sherry) won the World Brewers Cup in Melbourne at MICE. In her open service, Yuan Hsu used an OREA Brewer V3, and a flat bottom brewing dripper made of polycarbonate, to preserve the core temperature. Melbourne’s own Anthony Douglas of Axil Coffee Roasters won the World Barista Championship. Douglas used an Anaerobic Natural Sidra coffee from Huila, Colombia, produced by Nestor Lasso at his farm, El Diviso.

Douglas is the first Australian to win the title in seven years after Sasa Sestic. See page 32.

Alcorn Café Engineering (ACE) sends bespoke machine parts the world over so that business owners can extend the longevity of their coffee equipment. One of ACE’s most popular products is its shot timer, called the ShureShot with three fully programmable outputs and Kronos touchpad. In addition to retrofitting machines, it repairs espresso machine control boards, offers repair services, and more.

See page 34.

Vittoria Coffee says coffee pricing is the number one issue impacting coffee roasters at the moment, currently at US$0.64 cents at time of print. Vittoria Coffee has used the past two years to expand its offering into the retail sector, and launched into the instant market for the first time in its 75-year history. See page 36.

EUROPE

Before the Ukraine war broke out, Gemini Espresso roasted about 250 tonnes of coffee per month, making it “one of the top five largest coffee

15,056

NEWS In brief

25

The record number of attendees who visited the 2022 Melbourne International Coffee Expo from 75 countries.

14

The next generation can play a crucial role at each step of the coffee global value chain.

6 GCR | NOVEMBER/DECEMBER 2022

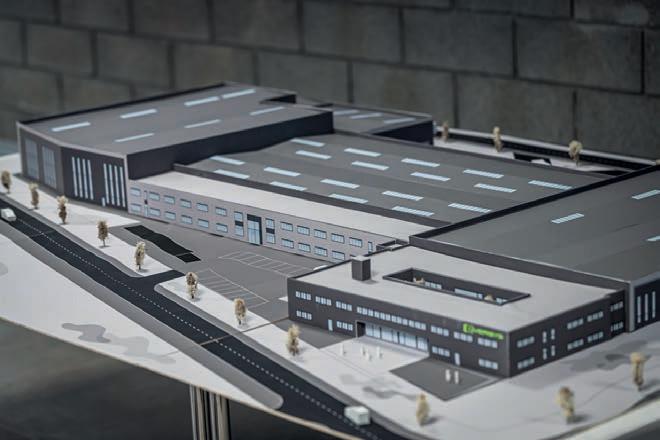

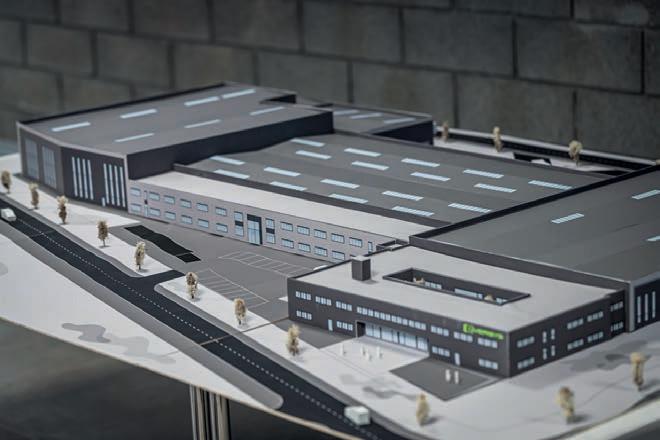

Eversys’ new factory will feature production and warehouse space, and significantly more room for stock.

roasters in Ukraine”, according to CEO Anton Mianovskyi. With the future of Ukraine so unpredictable, and an estimated 7.2 million Ukrainians relocated outside of the country according to UN Refugee Agency UNHCR, Mianovskyi has opened a second Gemini Espresso commercial office and sales division in Warsaw, Poland, and is planning on starting roasting production here in 2023.

See page 10.

Every year, Nescafé supports around 100,000 coffee farmers and buys more than 800,000 metric tons of green coffee – that’s more than 13 million bags from more than 20 countries. To ensure the coffee is sourced responsibly, Nestlé has released the Nescafé Plan 2030, a renewed strategy to help make coffee farming more sustainable. Nestlé is investing more than US$1 billion in the project, supported by Nestlé’s regenerative agriculture financing, to follow its commitment to accelerate the transition to a regenerative food system and ambition to achieve zero net greenhouse gas emissions.

See page 18.

Eversys will expand its 7500-squaremetre facility by two-and-a-half times to about 18,000 square metres. The project represents an investment of around US$25 million, with the aim of completion by the end of 2023. Eversys has already created around 60 new jobs in 2022, bringing its current total number of Sierre-based workers to 220.

See page 25.

The IMA Coffee Lab is a unique centre open to all customers and coffee processing companies seeking professional advice and innovative solutions. It houses a fully functioning pilot plant covering all handling, processing, and packaging stages. Located at the IMA Coffee Petroncini facility between Bologna and Ferrara in northern Italy, the Coffee Lab covers 3000 square metres and will be the

starting point for new products and research and development solutions.

See page 38.

Schaerer’s new Coffee Skye automated coffee machine is one of the most portable units the Swiss manufacturer has produced, with slim dimensions and integrated 4.9-litre water tank. This model covers demand for mid-level output between the Schaerer Coffee Club and the powerful Schaerer Coffee Soul 10 and 12.

See page 40.

The De’Longhi Eletta Explore coffee machine grinds, doses and brews with accuracy. Once the beans are added, an integrated grinder and brew unit work together to extract the espresso in line with the pre-selected recipe from a choice of 42 customisable recipe options. It features two dedicated carafes, one each for hot and cold milk frothing.

See page 42.

The Touch 03 is Tone’s latest commercial coffee and tea brewing equipment and an automated, urn-free drip brewer. It is one of the world’s first boilerless coffee brewers with temperature consistency of up to 99 per cent. It uses an electronic heating system that takes a few seconds to heat water to 98°C and currently saves 1.3 tonnes of carbon pollution annually.

See page 44.

WMF’s solution concepts make full use of the technological possibilities of digitisation, and enable completely new business models in the international coffee market. WMF has around 130,000 connected machines sending data to its cloud, and offers the WMF CoffeeConnect Portal to customers to provide a real-time overview of machine performance.

See page 46.

Previously operating under Draugiem Group and now a part of the multinational technology company Azkoyen Group, Latvia-based Vendon has grown to be a leader in providing service for vending and coffee machine businesses in more than 80 countries globally. Part of Vendon’s diverse payment options is contactless payments to help increase business sales, and reduce operational costs. It has also developed the loyalty and payment platform QuickPik to increase customer convenience.

See page 48.

Swedish roaster Löfbergs Group has joined the European Coffee Federation to help improve sustainability at the farm level and across its European operations. The Karlstad-based company joins other global roasters already part of the ECF including illycaffè, Jacobs Douwe Egberts, Lavazza, Nestlé, Starbucks EMEA, and Tchibo.

See page 58.

70%

The number of young people in coffee producing countries residing in Africa, according to the International Coffee Organization’s 2021 Coffee Development Report.

46

8 GCR | NOVEMBER/DECEMBER 2022 NEWS In brief

WMF offers digital solutions, such as concepts where the coffee machine communicates over an interface with a robotic arm

when your coffee makes your guests feel at home.

There is nothing better than waking up with a delicious coffee after a good night’s sleep. Our fully automatic coffee machines are easy to use, even as a self-service station for your guests. They deliver consistently high incup quality, so your guests can enjoy the perfect coffee experience to complement their pleasant stay. Because the better the coffee tastes, the more you will make your guests feel at home.

Discover more at coffee.franke.com

Discover more

thrive Determined TO

By Sarah Baker

By Sarah Baker

ANTON MIANOVSKYI OF GEMINI ESPRESSO ON SAVING HIS BUSINESS FROM THE DESTRUCTION OF WAR, PUTTING UKRAINIAN COFFEE ON THE MAP, AND WHY HE BELIEVES HIS BUSINESS CAN TAKE ON THE WORLD’S COFFEE GIANTS.

STORY

10 GCR | NOVEMBER/DECEMBER 2022

Images: Brendan Hoffman

COVER

Gemini Espresso

hroughout Global Coffee Report’s interview with Gemini Espresso CEO Anton Mianovskyi from his office in Kyiv, a total of 24 alarms ring out, indicating a potential threat of missile attack.

“Every time [the alarm] goes off, you’re nervous. You wait. Maybe a rocket will drop from the sky nearby. It’s normal,” says Mianovskyi, assuring that he’s in a safe place.

Mianovskyi says he’s never experienced such a roller coaster of emotions as he has in these past eight months.

He describes January 2022 as “the best” start to the year. He was on a work trip to Mexico for three weeks before celebrating his wedding anniversary with his wife in Paris. On their return, they took their children skiing in Andorra in the Pyrenees mountains. It was an enjoyable time. Family life was good. Business was good, but in the space of 24 hours, everything changed.

“We returned to Ukraine from Andorra on one of the last flights to Boryspil on 24 February at midnight. We arrived at our flat at 1pm, went to sleep and woke up four-and-a-half hours later because we heard a loud blow. Our apartment is on the 24th floor, and a rocket had passed by our window. The next two to three hours were really hard. For the first time in my life, I didn’t know what I should do,” Mianovskyi tells Global Coffee Report

“I explained to my children what was happening, then took my car and went to the petrol station. I saw the rockets but my mind was not comprehending what I was seeing. I couldn’t accept that this was 21 century Central Europe.”

Mianovskyi decided to move his family to a safer place. He took his wife, kids, sister, dogs, cats, and drove to his parent’s house in a small village 45 kilometres east from Kyiv. Over the next four days they watched Russian troops move into Kyiv’s city district.

Mianovskyi had a responsibility to keep his family safe, but he also had a responsibility to look after 180 employees who rang him asking, “do we go to work? What should we do?”

Mianovskyi found a government program online with relocation strategies to help large companies move their production facility. “We are one of the biggest coffee roasters in Ukraine. Our factory is huge at 2500-square-metres, and we were facing the challenge of moving it all,” Mianovskyi says.

The list of equipment included one 250-kilogram IMF roaster, a Giesen roaster, and five different packaging lines, which can package more than 15 to 20 tonnes per day of ground, whole bean, and Japanese drip line filter coffee.

“When we started preparations for the move, the fighting between the Ukrainian and Russian armies was very close to our factory, no more than two or three kilometres away. The government-arranged service to help us move said: ‘sorry guys, we can’t provide trucks with drivers any more. It’s too dangerous’,” Mianovskyi says.

Instead, he paid a commercial delivery company “huge money”, almost five times the normal rate, to transport 23, 20-tonne trucks to Chernivtsi in the western corner Ukraine, bordering Poland, Hungary, and Romania.

Mianovskyi stresses that the move was not just about moving factory equipment but relocating the families of his employees and accommodating them in apartments, hotels and houses with their possessions and pets. “The company paid for everything,” Mianovskyi says. “The most important thing in our business, is our people. We are one big family.”

Mianovskyi had only viewed the new factory space online. On arrival, he realised the available space was on the second floor of the building. Desperate for a solution, he rang some restaurant partners who suggested a location in Lviv, which was known to hold events, such as Ukraine’s annual coffee festival. With festivals unlikely to be held in the immediate future, the space became Gemini Espresso’s new home. With room to spare, Mianovskyi invited other small coffee roasters to co-habit the space. At one stage, six different roasting companies operated from this one place.

Out of the experience, those six roasters create a coffee brand together titled “roasted in Ukraine”, which Gemini Espresso is looking to push into the international arena.

“WE ARE LIVING WITH THE SITUATION, BUT IT’S A SITUATION THAT DOESN’T JUST DISAPPEAR WITHIN ONE OR TWO MONTHS, SO WE MUST ADAPT AND TRY TO RETURN TO BUSINESS AND LIFE AS NORMAL.”

NOVEMBER/DECEMBER 2022 | GCR 11

Anton Mianovskyi CEO, Gemini Espresso

“In normal life we would compete, but every time when we have coffee festivals, coffee championships, or in hard times such as war, we are friends, and that’s what I love about the Ukrainian coffee community,” Mianovskyi says. “The collaborative brand represents Ukrainians still working together. We want to show the international community just how strong businesses are in Ukraine.”

Pre-war, Gemini Espresso roasted about 250 tonnes of coffee per month, making it “one of the top five largest coffee roasters in Ukraine”, according to Mianovskyi. Given the current situation, however, he says it’s hard to know who among the top five, is on top. Now, Gemini Espresso roasts between 170 to 180 tonnes of coffee per month, but Mianovskyi hopes volume can soon return to the level it was once.

With the future of Ukraine so unpredictable, and an estimated 7.2 million Ukrainians relocated outside of the country according to UN Refugee Agency UNHCR, Mianovskyi has opened a second Gemini Espresso commercial office and sales division in Warsaw, Poland, and is planning on starting roasting production here in 2023.

“Poland isn’t the same market as Ukraine, but it’s people and their drinking habits are very similar so it’s easy to integrate our business, and Poland is a good location to start connections in the European Union,” he says.

Mianovskyi now splits his time between the two cities, spending one month in Poznañ, Poland, where his family now resides, and another month in Kyiv, to give Gemini Espresso the best chance to recover, and thrive.

“We are living with the situation, but it’s a situation that doesn’t just disappear within one or two months, so we must adapt and try to return to business and life as normal,” Mianovskyi says, acknowledging that coffee is part of the daily ritual that can help retain that normalcy.

“One nice, delicious cup of coffee can help us forget about all our problems, just for that moment,” he says.

DESTINED TO LEAD

Mianovskyi started working at Gemini Espresso 16 years ago, at 21 years of age. After working as a barman in nightclubs, he joined Gemini Espresso as Regional Manager for four years. Mianovskyi climbed his way up the ranks, taking on the role of Area Manager, then Chief of Sales and Commercial Director, before being appointed CEO in 2020.

“I may have only known one company all my life, but I treat it like my company,” Mianovskyi says.

The company started with just 15 employees and the understanding that importing Italian coffee products was the best solution to deliver customers with a quality product.

“In our country, Lavazza coffee is very famous in Soviet history. It’s considered the number one brand because it’s the first commercial Italian coffee to be available in the Soviet Union market. The older generation of 50 years and older only know Lavazza coffee,” he says.

After the Ukrainian Revolution in 2014 under the leadership of President Viktor Yanukovych, Mianovskyi says “something changed in Ukrainian people”. They started buying Ukrainian products, such as Ukrainian alcohol, and accepting that buying premium, Ukrainian-made products supported the local economy.

“They started realising that compared to the quality of European products, the quality of local products was no less, if not the same. And in the case of Ukrainian-roasted coffee, it’s even better because it is fresh,” he says. “People saw a difference in taste, and they preferred it.”

As such, since 2014, Mianovskyi says Ukrainian coffee businesses have been fast growing. Participation in Specialty Coffee Association education has increased, as has the number of young professionals competing in the national coffee championships, of which Gemini supplies equipment to support the next generation of talent.

“There’s a greater understanding between specialty and commercial grade coffee in the Ukrainian people. If you presented a bad cup of coffee to someone on the street, they wouldn’t drink it,” he says.

This movement has excelled over the past five years, with many more young specialty

12 GCR | NOVEMBER/DECEMBER 2022 COVER STORY Gemini Espresso

coffee roasters emerging. To cater to the country’s varying levels of coffee preferences, Gemini Espresso produces 70 different products across three different market segments: commercial-grade, mid-level, and specialty.

Gemini is company’s largest and most popular brand, which Mianovskyi describes as “a powerful, strong, medium-roasted commercial brand”. Gemini Espresso’s acquisition of Italian brand Ducale Caffe offers a commercial-grade offering, and its newest specialty coffee brand YoCo – short for ‘Your Coffee’ – launched just four months before the war began. Gemini Espresso sources its beans directly from origin such as Africa and Central America, and from Swiss trading company ECOM.

“The key to buying specialty coffee, is to buy something special, something expensive, and something that tastes different. We have explored new lots and coffees with fermentation techniques that we’re bringing back to Ukraine, coffee that no-one else in the country has,” Mianovskyi says.

He says this specialty arm of the business will never be about large volumes, but rather is a side of the business that’s “good for the soul”, with the hope to one day buy a washing station and visit more origin countries.

“If we grow at the level I hope we can, I might even buy a small farm, and build a small house to live in with my wife, kids, and stare at the mountains,” he says with excitement. “That would be really nice.”

Over the past 15 years, Gemini Espresso has also grown its network of coffee equipment, now considered the largest distributor of coffee machines in Ukraine, according to Mianovskyi. It sells equipment from 12 international brands and despite a high volume of businesses closing in Ukraine, Gemini Espresso is still selling equipment to new coffee shop customers in Kyiv.

Mianovskyi says coffee shops were the first things to return post-COVID lockdown, and drive-thru and coffee-to-go outlets remain the most popular method of consumption, largely because they stayed open during the pandemic and current conflict.

Thankfully for Gemini Espresso, it’s largest clientele has always been the country’s biggest petrol stations and coffee chains, accounting for the majority of Gemini’s 18,795 clients and partners in Ukraine and abroad. Mianovskyi says one petrol station brand in particular operates around 460 venues, and another has about 260 petrol stations, each with coffee options available.

“These are our number one clientele. It’s a really good market for us. In Ukraine, petrol stations chains are the safest segments because they’re always open. One popular petrol station brews about 100 kilograms of coffee per month. It’s a huge volume,” Mianovskyi says.

For its retail offering, Gemini Espresso distributes its product through B2B wholesaler Metro Cash & Carry, and national supermarket chains.

The rising costs of green beans, and dropping Ukrainian currency means price rises have to be reflected in Gemini Espresso’s product, however for now, it’s experiencing “good commercial results, just not huge profit”.

Mianovskyi has a clear vision of where wants to take the company. His goal is to hold the number one position in the Ukrainian market. Then, it must grow its presence in Europe, and abroad, to which it already has export contracts in Saudi Arabia, Oman, and Kazakhstan.

“I don’t think a lot of European companies take the quality of Ukrainian coffee companies seriously, but I want to show that quality Ukrainian businesses can be one of the strongest players in the coffee market, and we can compete with the likes of large European brands and coffee companies, such as Lavazza, Segafredo or JDE Peets,” he says.

“We want to show the international coffee community that Ukrainian coffee businesses are still operating and are heading in a good direction.”

Mianovskyi is confident that distribution will increase when the war ends, and that his business will have a prosperous future. He acknowledges that his life, and the direction of the business has forever changed, but is determined to move forward.

“I hope that one day the world returns to a normal situation, so we can just make coffee, not war,” he says. GCR

NOVEMBER/DECEMBER 2022 | GCR 13

Stirring sustainable success

NESTLÉ HAS UNVEILED THE NESCAFÉ PLAN 2030 TO HELP DRIVE REGENERATIVE AGRICULTURE, REDUCE GREENHOUSE GAS EMISSIONS, AND IMPROVE FARMER LIVELIHOODS.

very year, Nescafé supports around 100,000 coffee farmers and buys more than 800,000 metric tons of green coffee – that’s more than 13 million bags from more than 20 countries.

This carefully measured feat would not be possible without the Nescafé Plan, a global sustainability initiative launched in 2010 to expand responsible sourcing.

Now, Nestlé’s Head of Green Coffee Development Marcelo Burity tells Global Coffee Report that Nestlé has released the Nescafé Plan 2030, a renewed strategy to help make coffee farming more sustainable.

“We are building on a 10-year track record of the existing Nescafé Plan and accelerating our efforts to help make coffee farming of Nescafé more sustainable,” Burity says.

“The Nescafé Plan 2030 will help farmers transition to regenerative agriculture to simultaneously help improve their income and mitigate their environmental impact. This will help farmers become more resilient and much better prepared to tackle risks like climate change.”

Nestlé is investing more than US$1 billion by 2030 in the Nescafé Plan 2030. It is supported by Nestlé’s regenerative agriculture financing, following its commitment to accelerate the transition to a regenerative food system and ambition to achieve zero net greenhouse gas emissions.

In a company webinar held in October, David Rennie, Head of Nestlé Coffee Brands, told the audience that climate-change is shifting temperatures and weather patterns, which is impacting farming around the globe, and coffee is no exception.

“Climate change is putting coffee-growing areas under pressure due to rising temperatures, severe droughts, and flooding. Building on the existing Nescafé Plan, we’re fast-tracking our

work to help tackle climate change and address social and economic challenges in the Nescafé value chains,” says Rennie.

According to the Inter-American Development Bank, rising temperatures will reduce the area suitable for growing coffee by up to 50 per cent by 2050. At the same time, around 125 million people depend on coffee for their livelihoods, according to the Fairtrade Foundation. Data from Technoserve estimates that 80 per cent of coffee-farming families live at or below the poverty line. Action is needed to ensure the long-term sustainability of coffee.

“We need to act now to ensure the longterm sustainability of coffee. And Nescafé, a brand that touches the lives of hundreds of millions of people, is ideally placed for that,” Rennie says.

Burity adds that regenerative agriculture, a conservation and rehabilitation approach to farming, is one method that holds the key

18 GCR | NOVEMBER/DECEMBER 2022 INDUSTRY PROFILE Nestlé

Nescafé will provide farmers with regenerative agriculture practices such as high-yielding coffee plantlets.

to such long-term sustainability. Its approach to farming aims to improve soil health and fertility, as well as protect water resources and biodiversity. Healthier soils are more resilient to the impacts of climate change and can increase yields, helping to improve farmers’ livelihoods. To make the transition, Nescafé will provide farmers with training, technical assistance, and high-yielding coffee plantlets.

“Some of the regenerative practices that will be applied specifically to coffee include planting cover crops to help protect the soil. It also helps add biomass to the soil, which can increase soil organic matter and thus soil carbon sequestration,” Burity says.

“Nescafé will stimulate farmers to incorporate organic fertilisers to contribute to soil fertility, which is essential for good soil health, and increase the use of agroforestry and intercropping to preserve biodiversity. The company will also facilitate pruning of existing coffee trees or replacing them with disease and climate-change resistant varieties, which will help rejuvenate coffee plots and increase yields for farmers.”

Nescafé will work with coffee farmers

Nescafé will facilitate pruning of existing coffee trees, which will help rejuvenate coffee plots.

Nescafé will facilitate pruning of existing coffee trees, which will help rejuvenate coffee plots.

to test, learn, and assess the effectiveness of multiple regenerative agriculture practices. To do this, Nestlé has developed a framework which includes a definition of regenerative agriculture, regenerative agriculture practices and key performance indicators, based on a holistic approach.

“Regenerative agriculture is an enabler to deliver lower emissions and higher farmer incomes,” Burity says.

The roasting giant will focus on seven key origins from where the company sources 90 per cent of its coffee: Brazil, Vietnam, Mexico, Colombia, Côte d’Ivoire, Indonesia and Honduras.

Philipp Navratil, Head of Nestlé’s Coffee Strategic Business Unit, told the webinar audience that as one of the world’s leading coffee brands, Nescafé aims to have a real impact on coffee farming globally.

“We want coffee farmers to thrive as much as we want coffee to have a positive impact on the environment. Our actions can help drive change throughout the coffee industry,” says Navratil.

“Nescafé has a long history of supporting thousands of farmers across the globe, and I’ve had the privilege to visit many coffee farmers. I’ve always felt humbled by their dedication and hard work, but also their social and economic challenges. But with being the world’s largest coffee brand also comes the responsibility to act and to lead the sustainable developments for the benefits of coffee farmers and the coffee industry at large.”

Navratil says regenerative agriculture is one such sustainable development that contributes to drawing down carbon dioxide from the atmosphere and reducing greenhouse gas emissions. It’s for this reason it forms a key part of Nescafé’s Zero Net roadmap, a commitment to halve greenhouse gas emissions by 2030 and reach zero net greenhouse gas emissions by 2050. It will work with farmers, suppliers, and partners to help protect agricultural lands, enhance biodiversity and help prevent deforestation. The brand also intends to help farmers plant more than 20 million

trees at or near their coffee farms.

The Nescafé Plan 10-year achievements include the implementation of impact assessment of field programs in partnership with the Rainforest Alliance across 14 countries, and achieving a 46 per cent reduction in greenhouse gas emissions in soluble coffee factories per tonne of product. Nescafé has also reached 53 per cent less water withdrawal in soluble coffee factories per tonne of product.

The company is committed to supporting farmers who take on the risks and costs associated with the move to regenerative agriculture. It will provide programs that aim to accelerate the transition to regenerative and resilient agriculture, starting with pilots in Mexico, Côte d’Ivoire and Indonesia, where Nescafé will trial a financial support scheme for smallholders and learn the best approach for each country.

“These could include measures such as conditional cash incentives for adopting regenerative agriculture practices, income

20 GCR | NOVEMBER/DECEMBER 2022 INDUSTRY PROFILE Nestlé

The Nescafé Plan 2030 aims to help make coffee farming more sustainable.

protection using weather insurance and greater access to credit lines for farmers,” says Burity.

The brand aims to achieve 100 per cent responsibly sourced coffee by 2025, 20 per cent of coffee sourced from regenerative agricultural methods by 2025, and 50 per cent by 2030.

Tiago Camiletti, a coffee farmer from Brazil, told the webinar audience that what the Nescafé Plan has achieved thus far, has proved to him and other coffee producers that it’s possible to produce more with less.

“It’s possible to have increased productivity while taking care of the health of the soil as well as nature,” Camiletti says.

“What I hope, for myself and the future of coffee production is that I can remain, in a sustainable way, in coffee farming, because as I always say, I am passionate about growing coffee. The income is a result of my work, but ultimately, I hope my children can continue

progress and assess the results of its field programs with coffee farmers through its Monitoring and Evaluation partnership with Rainforest Alliance.

“This will allow us to assess the evolution of adoption of regenerative agriculture practices and understand farmer household income. We are also working with partners such as the Sustainable Food Lab for farmer income measurement, PUR Project for agroforestry and the International Centre for Tropical Agriculture (CIAT) for regenerative agriculture, ensuring we have subject matter expertise embedded in the Nescafé Plan 2030,” says Burity.

He says that the field programs have positively impacted hundreds of thousands of farmers across many countries, and impact assessments carried out by Rainforest Alliance have shown optimistic results.

“In Mexico, productivity of farms has increased by 50 per cent since 2014, driven partly by renovating coffee farms with improved varieties. In Côte d’Ivoire, productivity of farms has increased by 10 per cent since 2015 partly by adopting pruning practices, and in Vietnam, farmers have lowered their cost of production by 15 per cent since 2014, using 70 per cent less water with more efficient irrigation techniques,” says Burity.

Despite the achievements of the Nescafe Plan 2030, Nestlé’s Navratil says sustainability is a journey that can’t be undertaken alone.

“To this end, we invite all stakeholders to continue supporting us in the Nescafé Plan 2030 as we accelerate ambitions and aim to create a long-lasting impact on the coffee value chain,” says Navratil.

“I truly believe if all key players including coffee farmers, organisations, governments, coffee traders, roasters and consumers work together, we can achieve our common vision of a sustainable

improved stainless steel KB/90 steam tap lock pin improved longevity stainless steel extension screw • replaces LM A.1.002

the original alternate sheer plate for EK43 was an ACE first and was made available in Aircraft Aluminium, Brass or Copper

Cafe Engineering Manufacturers of retrofit and custom engineered parts for the global espresso industry

ACE Kronos - designed and engineered in Australia for Australian conditions

Alcorn

More than just hot air

WHEN VIETNAMESE COFFEE PRODUCER TRAN QUANG WAS LOOKING TO BUILD A STATE-OF-THEART COFFEE PLANT, IT OPTED FOR AN RFB ROASTER FROM NEUHAUS NEOTEC.

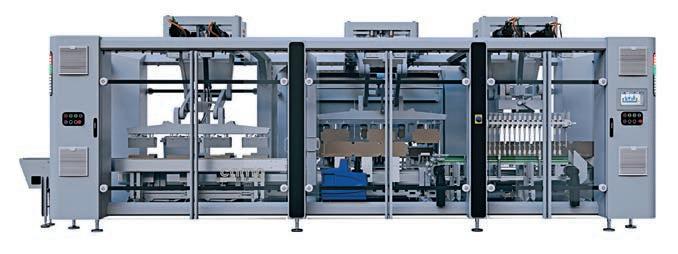

he Kahl Group in Germany is unique in that it can completely fit-out a new operation with all the coffee infrastructure from roasting to extraction. Vietnamese roaster Tran Quang recognised this one-stop shop advantage and engaged process engineering company Devex for the coffee extraction for three-in-one sachet products, and considered sister company Neuhaus Neotec to install its roaster and grinding section.

Lars Henkel, Head of Marketing for N euhaus Neotec, says the family-run Vietnamese company attached great importance to installing state-of-the-art technology that sets the highest standards in energy efficiency as well as product yield.

“This demand for the highest quality equipment and solutions runs like a thread through the entire concept of the factory,” Henkel says. “The owners also apply the same high standards to their social responsibility towards their employees making this plant a leader in the region.”

v

TECH PROFILE Neuhaus Neotec

22 GCR | NOVEMBER/DECEMBER 2022

The Neuhaus Neotec RFB roaster offers simple recipe control and production flexibility through fast implementation of the roasting parameters.

The facility has become a showcase plant in South-East Asia, including a viewing platform that allows visitors to see the coffee roasting plant in operation.

The RFB batch roaster is well known for its innovative hot-air roasting system. The coffee industry often talks about two types of roasters: drum and hot-air, but the competitive advantage with the RFB is that it is not a paddle roaster.

“All other roasters are paddle roasters and that means they need a paddle or an agitator to move the coffee beans around, and then they use contact heat to the roasting chamber or hot air to roast the beans. The RFB is the only technology where you don’t need all these moving parts in the roasting chamber, just the air to move the beans and to heat up the coffee,” Henkel says.

The absence of paddle is an advantage in a number of ways. Paddles produce abrasion on the beans and can detach fine particles that stick to the roasting chamber and are wasted, there i s also the matter of wear and tear, and parts.

The RFB moves the coffee out to the cooling chamber in the shortest time using gravity, which allows the shift of the quenching process from the roasting chamber to the cooling chamber. As a result, the material stress is significantly reduced and the roaster is able to start with the next roasting batch without time and energy consuming reheating times.

“The complete design of the RFB follows the intention to minimise material stress and to warranty for a maximum lifetime of the equipment,” Henkel says.

He points out that while the initial cost of an RFB can be slightly higher than traditional drum roasters, Tran Quang could see that it would make savings in the long term.

“The total costs are much lower because you have less energy consumption, less spare parts, less maintenance and less roasting loss, so these are the driving arguments for the instant roasters,” Henkel says.

Since the commissioning of the factory in Ho Chi Minh City, many domestic and foreign

have already enthusiastically inspected the plant, which the two sister companies are proud to call a showcase plant for the entire Asian region. GCR

For more information, visit www.neuhaus-neotec.com/de/

FOCUS ON THE DETAILS

Our unique RFB roasters are equipped with the newest and most innovative hot air roasting technologies. With our flexible roasting profiles we give our clients the possibility to optimize every detail of the roasting process for a perfect result.

WWW.NEUHAUS-NEOTEC.COM

“DEMAND FOR THE HIGHEST QUALITY EQUIPMENT AND SOLUTIONS RUNS LIKE A THREAD THROUGH THE ENTIRE CONCEPT.”

Lars Henkel Head of Marketing – Neuhaus Neotec

Global Coffee Report is the leading business magazine covering the international coffee industry. In-depth features explore on-the-ground developments at origin, coffee pricing issues, technology updates, research breakthroughs and much more.

UNLIMITED ONLINE CONTENT

www.gcrmag.com/subscribe YOUR COFFEE NEWS – WORLD WIDE

Building momentum – and machines too

EVERSYS ANNOUNCES ANOTHER FACTORY EXPANSION AND EXPLAINS THE CORE DRIVERS OF ITS GROWTH, INCLUDING THE SUCCESS OF ITS PRODUCT LINE, THE LAUNCH OF LÉGACY, AND A NEW STRATEGIC PARTNERSHIP.

It was just three years ago when Eversys opened its new production facility in Sierre, Switzerland. It was an achievement long in the making since the machine manufacturer’s inception in 2009 in Switzerland’s canton of Valais. It was recognition of Eversys’ market growth and ambition for future growth. What it never expected, however, was to outgrow this facility in such a short timeframe.

“When we were designing our first factory, it was important for us to have the possibility for an extension, a reserve, an option for additional land in the neighbourhood right next to us – that’s why we chose the place in Sierre where we are now. But we did not imagine our growth would happen so quickly,” says Eversys CEO, Martin Strehl.

Now that it has, Eversys will be expanding its production and office space, and organising the company’s logistics in a more efficient way.

“This will ease our production flow significantly. It’s more than what we already have: more production space, more warehouse space, and significantly more space for stock,” Strehl says.

Eversys’ existing 7500-square-metre facility will be extended by two-and-a-half times, to about 18,000 square metres. The land required for the expansion was made available thanks to the municipality of Sierre.

Strehl says the company received “very good support” from local political authorities in order to move production forward quickly.

The project represents an investment of around US$25 million, with the aim of completion by the end of 2023.

“Eversys has promising prospects. We feel comfortable in Sierre and well supported by

NOVEMBER/DECEMBER 2022 | GCR 25 INDUSTRY PROFILE Eversys

Eversys CEO Martin Strehl says the company is likely to break the US$100 million turnover mark for the first time.

The facility has become a showcase plant in South-East Asia, including a viewing platform that allows visitors to see the coffee roasting plant in operation.

The RFB batch roaster is well known for its innovative hot-air roasting system. The coffee industry often talks about two types of roasters: drum and hot-air, but the competitive advantage with the RFB is that it is not a paddle roaster.

“All other roasters are paddle roasters and that means they need a paddle or an agitator to move the coffee beans around, and then they use contact heat to the roasting chamber or hot air to roast the beans. The RFB is the only technology where you don’t need all these moving parts in the roasting chamber, just the air to move the beans and to heat up the coffee,” Henkel says.

The absence of paddle is an advantage in a number of ways. Paddles produce abrasion on the beans and can detach fine particles that stick to the roasting chamber and are wasted, there i s also the matter of wear and tear, and parts.

The RFB moves the coffee out to the cooling chamber in the shortest time using gravity, which allows the shift of the quenching process from the roasting chamber to the cooling chamber. As a result, the material stress is significantly reduced and the roaster is able to start with the next roasting batch without time and energy consuming reheating times.

“The complete design of the RFB follows the intention to minimise material stress and to warranty for a maximum lifetime of the equipment,” Henkel says.

He points out that while the initial cost of an RFB can be slightly higher than traditional drum roasters, Tran Quang could see that it would make savings in the long term.

“The total costs are much lower because you have less energy consumption, less spare parts, less maintenance and less roasting loss, so these are the driving arguments for the instant roasters,” Henkel says.

Since the commissioning of the factory in Ho Chi Minh City, many domestic and foreign

have already enthusiastically inspected the plant, which the two sister companies are proud to call a showcase plant for the entire Asian region. GCR

For more information, visit www.neuhaus-neotec.com/de/

FOCUS ON THE DETAILS

Our unique RFB roasters are equipped with the newest and most innovative hot air roasting technologies. With our flexible roasting profiles we give our clients the possibility to optimize every detail of the roasting process for a perfect result.

WWW.NEUHAUS-NEOTEC.COM

“DEMAND FOR THE HIGHEST QUALITY EQUIPMENT AND SOLUTIONS RUNS LIKE A THREAD THROUGH THE ENTIRE CONCEPT.”

Lars Henkel Head of Marketing – Neuhaus Neotec

Perfetto, from hot to iced coffee.

NEW LatteCrema Cool Technology for Iced Coffee at home. De’Longhi’s new, exclusive and unique Cold Milk Foam Technology, perfectly mixes steam, milk and air to create creamy textured milk at a refreshingly cool temperature. Designed to balance sweetness and enable you to create iced coffees at home, with ease.

delonghi.com

LatteCrema Cool Coldmilkfoam technology

World united

RETURNED

he return of the 2022 Melbourne International Coffee Expo (MICE) was the biggest coffee family union the industry has seen since the height of the global pandemic.

A record 15,056 attendees visited the expo over four days from 27 to 30 September at the Melbourne Convention and Exhibition Centre (MCEC), with 15 per cent international attendees from 75 countries, indicating a strong return of overseas participation.

The attendance figure is the highest of any MICE expo since the event’s inception in 2012, with an increase of 25 per cent of visitor numbers since the 2019 event.

“Since the inception of MICE in 2012, it has been a destination to do business by connecting buyers and sellers under the one roof annually and forming client relationships. The expo was already the largest dedicated coffee expo in the Southern Hemisphere, and thanks to a return attendance after three years of postponement, we are proud to reinstate that title once again and announce the expo as being our highest attended ever,” says MICE Show Director Lauren Winterbottom.

WARM UP

To set the scene, national barista champions from across the globe descended on Melbourne the week leading into MICE, with many congregating at the Cafetto Barista Base camp to train ahead of the World Barista Championship (WBC), of which Cafetto is the qualified cleaning sponsor. On Monday 26 September, the inaugural CafeSmart Charity Golf Day took place at Latrobe Golf Course, uniting industry figures for a networking golf day. The sold-out event saw participants tee off for 18 holes, engage in an industry talk with guest speakers including La Marzocco UK and Ireland’s General Manager Paul Kelly, Sustainable Harvest’s David Griswold, and Eversys’ Director of Business Development and Marketing, Kamal Bengougam.

The event concluded with a live auction, in which about US$20,058 (AUD$30,836) was raised for CafeSmart training and employment programs for migrants and youth in Australia.

Golf participant and guest speaker Bengougam says as much as the day was a great networking opportunity there was a bigger message at play. “[It] reminded me that even in hardship, we

should remain generous and keep an eye out for those who may be less fortunate than we are,” he says.

That evening, a De’Longhi Melbourne Coffee Week (MCW) launch event began festivities before excitement set in and the countdown to MICE was just a few hours away.

THE BIG REVEAL

As the doors to the ninth edition of MICE opened, guests were met with a spectacular view of more than 170 exhibitors representing all sector of the global coffee supply chain. The eager exhibitors were ready to share the latest in machine innovation, experimental coffees, and product tastings.

At Roasters Marketplace, brews were running hot from Commonfolk Coffee Roasters, Black Vice Café & Roastery, Just Planet Coffee, Coffee Me Up, Merlo Coffee and Adore Estate.

Over on the WBC stage, visitors started filling the grandstands with competition underway, with the bellowing of the emcees providing an exciting ambiance.

For many international guests such as Eversys’ Bengougam from London, attending

MICE2022

AFTER THREE LONG YEARS, AND IT WAS WORTH THE WAIT WITH THE INTERNATIONAL COFFEE COMMUNITY WITNESSING THE REVIVAL OF THE AUSTRALIAN COFFEE SCENE.

MICE2022 hosted the World Barista and Brewers Cup for the second time in the event’s history.

28 GCR | NOVEMBER/DECEMBER 2022 EVENTS MICE2022

Images: Melbourne International Coffee Expo

MICE was a chance to meet people from all over the world and conduct meetings with friends not seen in years.

“It was as if time had stood still. People were smiling, sipping cups of espresso attentively, laughing…life as it used to be,” Bengougam says. “For Eversys, we had two partners with a great presence – Service Sphere and Tiger Coffee – exhibiting our machines. Our Super Traditional range caught the eye of visitors, led by the Shotmaster Pro that combines both market-leading performance, uncompromising in cup quality and eye-catching aesthetics.”

Bengougam says the exhibition was well attended and “business opportunities were alive”.

Over at the Vortx KleanAir Systems stand which displayed the Ecofilter, President Ron Kleist travelled from the United States and said the experience was “far better than I had dared imagine”.

“The quality of attendees and their deep knowledge of all-things coffee is a solid testimonial to the leadership position of Australia in the global specialty coffee community,” Kleist says.

“It was so wonderful to see so many coffee aficionados in one place at one time and enjoy being together in what seems like forever. Having the WBC and the World Brewers Cup at the same time added so much energy and excitement to the event. VortX will have a

much larger presence for MICE2023. Can’t wait to see friends old and new again.”

Brambati CEO Fabrizio Brambati travelled from Italy to display the KAR 15 roaster and 15-kilogram batch capacity, and says it was great to meeting existing and new Brambati clients.

“To participate to this exhibition is one of the signs of a return to normality. To meet all these people with whom to discuss of future projects instead of the pandemic situation was also a great achievement,” Brambati says.

Before we knew it, day one had ended, and it was time to celebrate with La Marzocco at Starward Whisky distillery.

BACK FOR MORE Day two of MICE started off with a sold-out city gathering of the International Women’s Coffee Alliance Australian ‘stronger together’ breakfast event, celebrating women who had forged successful careers.

Back at the MCEC, it was time to talk tech and explore new innovations.

Victoria Arduino displayed its new Black Eagle Maverick espresso machine, and brand-new PureBrew Filter Coffee, which the Australian coffee community appreciated.

“As Victoria Arduino, we also continued to support the best baristas worldwide with Mythos, the official grinder of the WBC. Mythos confirmed its positioning as the best-in-class grinder and we are proud to support the best competition in the world,” says Simonelli Group Marketing Manager Simona Giampieri.

Australian equipment distributor Coffee Works Express celebrated the Qualified Espresso Machine of the WBC, Tempesta, in addition to models from Slayer, Wega, Mazzer, and Astoria.

Rancilio continued the celebration of Italian manufacturing, presenting the RS1 espresso machine to the MICE masses.

“It provides cutting-edge brewing technology combined with Rancilio expertise and a unique workflow design. As a Specialty Coffee Association certified espresso machine, this validates its position in the market as an industry leader,” says Rancilio Australasia General Manager Paul O’Brien.

For first-time MICE participant Italian grinder manufacturer Eureka, Sales Director

A record 15,056 attendees visited MICE over four days.

NOVEMBER/DECEMBER 2022 | GCR 29

Fifteen per cent of guests to MICE2022 were international attendees from 75 countries.

Luca Nunzi says exhibiting was a unique opportunity to offer a direct Eureka experience to the many baristas and coffee shops owners of the Australian and southeast Asian market.

“And at the same time, [it was] a great moment of mutual enrichment, breathing firsthand the feelings and trends of a market so fascinating, and so unique,” Nunzi says. “We had many previews at our booth, representative of the last Eureka’s new generation of coffee grinders.”

Eureka presented the Mignon Libra, equipped with a new instant grind weighing technology; and the Atom Excellence, a new ultra-compact solution with endurance and premium usability. It also showcased the Prometheus grinder, considered a “perfect synthesis between design and innovation, technology and style”, and the winner of the MICE Ancillary Electrical Equipment 2022 Product Innovation Award.

For many brands, MICE was the first opportunity products had been physically presented to market in years, and for others like Probat, it was a chance to present new innovation.

“The great desire to meet again in person was truly remarkable about this year’s MICE, reflected not only by the crowds of visitors in the aisles but especially at the Probat booth,” says Probat’s Iris Gerlach. “Here, attendees took an equal interest both in the UG22 drum roaster and the electrically powered Sample Roaster. Whereas the former attracted great attention, due to its unmistakable individuality in particular, the Sample Roaster sparked ample discussions revolving around Probat’s manifold and ambitious approaches to decarbonising the coffee industry.”

Hemro Group displayed its Mahlkönig Grind by Weight E65s and E80S models. In addition, Hemro Group Head of Sales Asia Pacific Ross Quail says MICE was a special opportunity for Australians to support local barista Anthony Douglas, and for the industry to gather again.

“I’d have to say overall that it was great to be amongst the nation’s coffee people,” Quail says.

On the World Brewers Cup (WBrC) competition stage, competition got underway on day two, with fans marvelling at the presentations and finesse of the brewing techniques.

That evening, UCC coffee invited customers to its new roastery opening where guests marvelled at the capacity of the facility. De’Longhi MCW events also continued this evening, with the Single O World(ish) Parachute Championship and Cafe Imports ‘Where are we now’ events taking place. All registration fees for De’Longhi MCW were donated to MICE official Charity Partner StreetSmart, working to fight homelessness.

THE HALFWAY POINT

Day three of MICE was an opportunity to refuel with plenty of coffee options at Roaster’s Alley, including Australian specialty roasters Toby’s Estate, St Ali, Mocopan, and Veneziano Coffee Roasters.

Over in Origin Alley, it was a chance to celebrate the producers and traders who had travelled from across the globe to present their coffees from South America and Africa, East Timor, Papua New Guinea and Panama. Cuppings were a plenty on the Minas Hill stand, in addition to InterAmerican, and FTA, with guests lucky to meet some of the farmers that grew the very coffee they were tasting.

That afternoon, the Semi Finalists of the WBC and WBrC were announced, more social events continued. That night, the Victoria Arduino Lab got bustling with a Pure Brew party with the 2017 World Coffee in Good Spirits Champion Martin Hudak.

THE FINALE

With tiring feet and weary eyes, one last energy injection was needed to conclude MICE in the best way possible. Last laps around the show floor continued to reveal new products, and the afternoon celebrated the best of them in the MICE2022 Product Innovation Awards.

The LaCimbali M200 won the award for

Franke Coffee Systems displayed its Specialty Beverage Station SB1200 at MICE.

30 GCR | NOVEMBER/DECEMBER 2022 EVENTS MICE2022

The Victoria Arduino E1 Prima features a unique insulation mechanism to reduce heat dispersion and energy consumption.

Coffee Preparation Equipment.

“It is with great happiness that the Service Sphere team celebrate the Product Innovation Award for The La Cimbali M200. The winning of this award is recognition of the evolution of high-quality coffee output, blended with wellconsidered design and barista ergonomics,” says Service Sphere Director Maurizio Marcocci.

The Compass from Nucleus Coffee Tools was awarded the Product Innovation Award for Coffee Accessories, Weber Workshops’ Unifilter portafilter won the People’s Choice award, and Eureka Grinders’ Prometheus grinder won the Ancillary Electrical Equipment award, in what Eureka’s Ballocci describes as “the cherry on the top” for its first direct participation in MICE.

Attention then turned to the WBrC competition stage where Shih Yuan Hsu (Sherry) of Taiwan was crowned the 2022 Champion. Then it was the WBC’s turn. With the grandstands full and the home crowd anxiously waiting, the top six finalists

what was the biggest MICE Melbourne, and world, had ever seen.

The celebrations continued long into the night, thanks to St Ali who hosted the official After Party, where a new champion was toasted, and a successful MICE

came to an end.

Australia’s Anthony Douglas of Axil Coffee Roasters stood side-by-side with the United States’ Morgan Eckroth. It was a moment resembling the same situation in 2013, when Melbourne last hosted the WBC – Australia’s Matthew Perger placed runner-up to America’s Pete Licata. This time, the placings reversed, and Douglas was crowned the 2022 World Barista Champion. It was a fairy-tale ending to MICE2022 – a Melbourne world champion, at a Melbourne-hosted event, in

officially

Rancilio presented the SCA-certified RS1 espresso machine at MICE2022.

Meet the Champs

2022 WORLD BARISTA CHAMPION — A NTHONY DOUGLAS

Anthony Douglas of Axil Coffee Roasters has written the history books. When he was crowned 2022 World Barista Champion on the last day of the Melbourne International Coffee Expo, he became the first Melbourne barista to win the World Barista Championship (WBC) and the first to win the title at a homerun event.

“I feel incredibly proud to be named this year’s world champion and am honoured to represent Australia, and more specifically Melbourne, on the world stage. I couldn’t have done it without the unwavering support and commitment of the team at Axil who have been by my side inspiring me for the past nine years,” says Douglas.

Douglas is the first Australian to win the title in seven years when Sasa Sestic won in 2015.

“It’s such an honour to win the World Barista Championship, something I don’t take for granted,” he says.

Morgan Eckroth of the United States placed runner up, Claire Wallace of the United Kingdom placed third, Takayuki Ishitani of Japan placed fourth, Benjamin Put of Canada placed fifth, and Patrick Rolf of Sweden placed sixth in the Finals round.

Axil Coffee Roasters’ Founder, David Makin, a two-time Australian Barista Champion, was Anthony’s mentor. Jack Simpson was his coach, and Matt Crowley, both from Axil Coffee Roasters, helped coach and roast Douglas’ coffee.

His routine focused on the theme of ‘trust’, building layers of trust with his judges, and

ultimately between the barista and consumer in an informative and fun way.

Competing against 47 world-class competitors from around the globe, Douglas used an Anaerobic Natural Sidra coffee from Huila, Colombia, produced by Nestor Lasso at his farm, El Diviso. The coffee was fermented for 80 hours anaerobically prior to drying as a natural, resulting in intense purple and red fruit characteristics such as cherry and blackberry, and an acidity and tannin quality reminiscent of red wine. The coffee was roasted with a higher airflow with a low finish temperature post-first crack, but a longer development of 24 per cent.

To streamline his technique and extraction, Douglas used the ‘Weiss distribution technique’. This uses a series of pins to evenly distribute the coffee top to bottom and achieve higher extraction yields.

The final key decision was Douglas’ choice of milk. He explored ‘cryodesiccation’, a method of turning the liquid in milk into a vapour and concentrating the milk solids including proteins,

Anthony Douglas wins the World Barista Championship, and Shih Yuan Hsu (Sherry) wins the World Brewers Cup.

32 GCR | NOVEMBER/DECEMBER 2022 EVENTS WCC2022

Anthony Douglas pours his winning signature drink in the WBC final.

For his signature drink, Douglas paired a Colombian honey for complex sweetness, a lactofermented passionfruit syrup to elevate the fruit notes, hibiscus cold brew tea to add complexity to the red wine tannins, and a ‘cryodesiccated’ date syrup to increase texture and intensity in the drink.

“Working in the coffee industry for the past 12 years has taught me that making great coffee is all about consistency and pushing the boundaries of what has been done before. I’m ecstatic that I could show that to the judges and that I got to be surrounded by others as passionate about coffee as I am,” Douglas says.

2022 WORLD BREWERS CUP CHAMPION — SHIH YUAN HSU

Shih Yuan Hsu (Sherry) took on 30 other national Brewers Cup representatives from 28 to 30 September at the Melbourne International Coffee Expo and was the last woman standing when emcee Hide Izaki called her name in front of a packed crowd and global livestream audience.

“I’m still feeling nervous, the reality hasn’t set in yet. But I really enjoyed the stage and had a lot of fun. I’m still in shock,” Yuan Hsu tells Global Coffee Report.

Elika Liftee from United States placed runner up, and Elysia Tan from Singapore placed third in the competition. Tomas Taussig from Czech Republic placed fourth, Jhon Christhoper from Indonesia placed fifth, and Simen Andersen from Norway placed sixth.

Yuan Hsu has worked in the coffee industry for six years and currently works as a barista at Coffee Lover’s Planet in Hsinchu, Taiwan.

Yuan Hsu competed in the 2019 and 2020 Taiwan Brewers Cup, placing fifth overall in the 2019 World Brewers Cup.

“In the 2019 World Brewers Cup, my compulsory service wasn’t very good, so this time I used a syphon brewing method, which is more efficient and consistent. This time, for my open service

I used an OREA Brewer V3, a flat bottom brewing dripper made of polycarbonate, which preserves the core temperature inside, to ensure I received a higher score,” she says.

Yuan Hsu used a natural Geisha from Finca Mikava Coffee in Colombia, located 2000 metres above sea level.

“The coffee cherries undergo a carbonic maceration process with a special strain of yeast and are slow-dried with frequent agitation, bringing a clean cup,” she says.

Yuan Hsu used a light roasting profile to make the aroma and flavour more sophisticated and bring out a fruity sweetness, with tasting notes of “peach, orange, berries, and pineapple”.

For her routine, Yuan Hsu used 14 grams of coffee, inputting 200 grams of water. Using a ratio of 1:14, 50 grams of water are added every 30 seconds, a total of four times.

“I would like to thank my company UCC Coffee Taiwan, who helped me a lot, and made me feel like I’m not alone. Without all of you, I couldn’t have done so well,” Yuan Hsu says. GCR

The sum of its parts

ALCORN CAFÉ ENGINEERING HAS BEEN HELPING BREATHE NEW LIFE INTO OLD ESPRESSO MACHINES, GRINDERS AND ROASTERS WITH ITS BESPOKE PARTS AND TAILORED SOLUTIONS.

Sean Alcorn from Alcorn Café Engineering (ACE) has built his company on finding unique solutions to problems that can arise with a variety of coffee equipment, from espresso machines to grinders and roasters.

Starting as a repair business, ACE has transformed into a business that sends bespoke machine parts the world over so that business owners can extend the longevity of their coffee equipment.

“We design and engineer improved parts for the specialty coffee industry,” says Alcorn. “We find the Achilles heel in a particular

machine and, if we can we develop a better part, then hopefully it gives the roaster or the café owner greater longevity, and that’s what we are known for. I’m proud of the fact that I can count the number of breakdowns our customers have had over the past few years on one hand.”

Alcorn points out that it is just not just the down time or the cost to fix the problem that concerns café operators when a coffee machine ceases to function, it’s the loss of coffee sales plus the loss of the food revenue in many businesses.

“Despite the fact that this industry loves loyalty, if the machine is down on that day and a customer walks down the road and the barista happens to be better on the day, then that customer is gone simply because the machine was out of order,” Alcorn says.

Alcorn Café Engineering has a broad understanding of a range of coffee machines, and it can often spot issues that manufacturers may not be aware of.

Alcorn tells the story of a machine that would never fill the steam boiler due to the reliance on mains pressure. The machine had a steam pressure of 1.45 bar and by simply opening the tap at the handwashing sink, the pressure at the machine immediately fell to 1.15 bar. As the machine was relying mains pressure, ACE added a pump and a motor to resolve the problem. In subsequent versions of the machine, the machine manufacturer added a fill boost pump as an option at time of order once it became aware of the issue.

Alcorn says while coffee machine manufacturers are quick to highlight the benefits of using original parts, ACE has created a following with some devoted fans of its bespoke parts.

One of ACE’s most popular products is its shot timer. The shot timer generally picks up a signal from the machine’s solenoid valve so when the valve opens, it times the shot that is being brewed.

“Time is important in the extraction of a good espresso. At the time, we knew most machines came without a shot timer, so we went and developed our first one and we called it the ShureShot. What started as a simple shot timer like many projects, was moulded by customer needs. The

A sheer plate for EK43 grinders help protect the motor from damage.

34 GCR | NOVEMBER/DECEMBER 2022

PROFILE

The ACE Kronos Touchpad is designed and developed in Australia.

TECH

Alcorn Cafe Engineering

ShureShot has three fully programmable outputs and we can drive the brew valve, the pump, and a bypass valve,” Alcorn says. “The displays can be programmed green, indicating the ideal shot range was achieved, or red, providing the user an indication that the shot was out of range. This tool is particularly ideal for training and education for new staff.”

This solution was not for everyone however, and ACE has since moved on to more basic shot timers. Alcorn says there are certain areas of the coffee industry that have a cult-like love of the ShureShots, so much so that ACE has recently filled an order for several ShureShots and is wondering if they might be making a comeback.

Another popular part is ACE’s Kronos touchpad that sells particularly well in Australia. The touchpads were designed and developed in Australia by ACE and are a direct replacement for keypads in many other traditional machines.

“Customers were looking for a more reliable solution. We made our enclosure from a more temperature resilient material and added eight machined brass inserts for screwing our supplied stainless steel machine screws into metal, rather than self tappers into plastic – which are prone to premature breakages. Then, customers were telling us that they loved the feel of the touchpad,” Alcorn

says. “I had never thought about it but our keypads had a much nicer tactile feel than a lot of other manufacturers. They just work well and they don’t miss a beat.

“They are Australian made and we just applied for the official Australian Made label this year, and we now have that on the shot timers, too.”

Alcorn learned his skills in the Australian air conditioning industry and was trained as a refrigeration and air conditioning technician at his family business.

He is now keen for ACE to “fly the flag” on Australian products because the Australian coffee industry is well respected globally, and so is ACE. Alcorn says the reason the company’s parts have such a solid reputation in the US market is because of their longevity.

“They like the idea that our parts last longer because the repairers have to drive long distances to repair machines and they don’t want to have to come back too often,” he says.

ACE also repairs espresso machine control boards, in some cases completely rebuilding a thousand-dollar board for a fraction of the cost.

It was Alcorn’s knowledge of designing and manufacturing of control boards that led to ACE offering of a repair service.

“There is a view in certain parts of the industry that a repaired board is not as good as a new one but if I can design and make boards, we can certainly repair them,” Alcorn says.

The ACE Volumetric Board has connectors for shot timers or keypad cables, and is available for a variety of machines.

The company’s Instagram @aceservices highlights ACE’s variety of products from the ACE Shot Timer to custom machine switches and the ACE touchpads. They also have a collection of o-rings, valves, elements, and screws.

Alcorn continues to move away from simple repairs and into the design and manufacture of coffee machine parts, as well as some grander Australian-made design plans that are still under wraps.

For Alcorn, he says the satisfaction of his work is helping customers get the most out of their equipment.

“We are retrofitting machines that have been working for decades and they show no signs of stopping when you give them a bit of love and attention,” he says. “Sometimes it takes an outsider to see the problem and we come along and ACE it.” GCR

For more information, visit alcafe.com

A replacement DigiZone Board for Gen1 Synesso machines.

NOVEMBER/DECEMBER 2022 | GCR 35

An ACE steam tap shaft extension.

The evolving role of a roaster

VITTORIA FOOD & BEVERAGE MANAGING DIRECTOR ROLANDO

SCHIRATO TALKS ABOUT THE REALITY OF NAVIGATING A BUSINESS POST-PANDEMIC, TOP ISSUES IMPACTING ROASTERS, AND WHERE TO NEXT FOR THE THIRD-GENERATION COMPANY.

he global pandemic was a time of reflection, reinvention, and rejuvenation for many businesses. For some markets, it meant consolidation, and for others, it brought renewed attention to the value of being local, such as Vittoria Coffee, who has helped pioneer the development of Australia’s coffee industry since 1958.

“We remain a family business, 100 per cent privately owned, Australian owned, Australian roasted,” says Managing Director Rolando Schirato. “Sometimes there’s a perception that we’re a big multinational that operates offshore, but we’re proud to be family operated. We produce locally, we roast locally, we try to use local suppliers as much as possible.”

While the COVID-19 pandemic rattled a few businesses, for those that have seen growth and strong performance since, Schirato says there’s been little reprieve.

“I think everyone was hoping to have a bit of respite after COVID, but actually this year has probably been harder than the past two years,” Schirato tells Global Coffee Report.

“Coffee pricing is definitely the number one issue coffee roasters are facing at the moment. Coffee is priced in US dollars and they’re the highest they’ve been in over 10 years. We experienced the same situation about 12 years ago but that time, the United States dollar was pretty much at parity with the Australian Dollar, which helped us and many other Australian roasters. This time, we’re seeing coffee pricing at similar levels or higher combined with a weaker Australian dollar, currently at US$0.64 cents today (at time of interview). The combined effects of foreign exchange and rising coffee prices are the two biggest variables and impacts to any roaster’s bottom line.”

Prices are one thing, then add on freight increases, inflation, supply chain disruptions, and a whole raft of other headwinds right after COVID-19 where sales were affected. Thankfully,

Schirato says Vittoria Coffee has been lucky to bypass any major green bean shipment delays.

“We’ve been an importer of green beans since we started roasting in Australia 1958, so a strong supply chain is one of our core competencies. Like most Australian roasters importing green beans, we’re having to deal with missing shipping vessels and other disruptions. Collectively, this makes for tough conditions for coffee businesses,” Schirato says.