May/June 2024 gcrmag.com

May/June 2024 gcrmag.com

Café William President and CEO

Rémi Tremblay on its goal to produce the most sustainable coffee GUATEMALA’S EMIGRATION GAME

Driving forces and action to preserve future coffee SUSTAINABLE SOLUTIONS Companies across the supply chain commit to do more 100-YEARS STRONG

Mahlkönig celebrates a century of innovation

28 Custom-fit cleaning

Cafetto reveals how its tableting process is unlike any other, and why its ‘no one size fits all’ mentality ensures a cleaning product for every coffee machine

31 Innovation for sustainability

The sustainability roadmap that secured Groupe SEB a place in the top 1 per cent of companies worldwide

44 Making headway

Thermoplan on its 50th anniversary and developing the first fully automatic machine to qualify for the WLAC

34 Savour the flavour

How to preserve coffee aromas using Flavourtech’s Integrated Extraction System

36 Brewing up a storm

Global Coffee Platform Brazil explains how chain to harmonise regenerative agriculture

Why coffee farmers are continuing to leave Guatemala, and its impact on the country’s

Eversys reveals how its machines suit the needs of Denmark’s evolving coffee culture

38 Seed to sip

Why UCC Europe’s Total Coffee Solution is the perfect fit for businesses of all sizes

40 Burr and beyond

Cimbali Group discusses the importance of quality grinder burrs and how its brands cater to every market segment agle evolution

Sustainability and technology unite in Victoria Arduino’s smartest and most

SUSTAINABILITY AND TRACEABILITY FEATURE

46 Partners in roasting

How Alps Coffee refined the art of roasting via a new partnership with IMA Petroncini

48 Bridging the gap

Neumann Kaffee Gruppe’s NKG Verified initiative exemplifies its commitment to sustainability

50 Tailoring sustainable solutions

Volcafe is on a mission to make the coffee industry more responsible and ensure sustainable profitability for its farmers

52 Sustainable problem solving

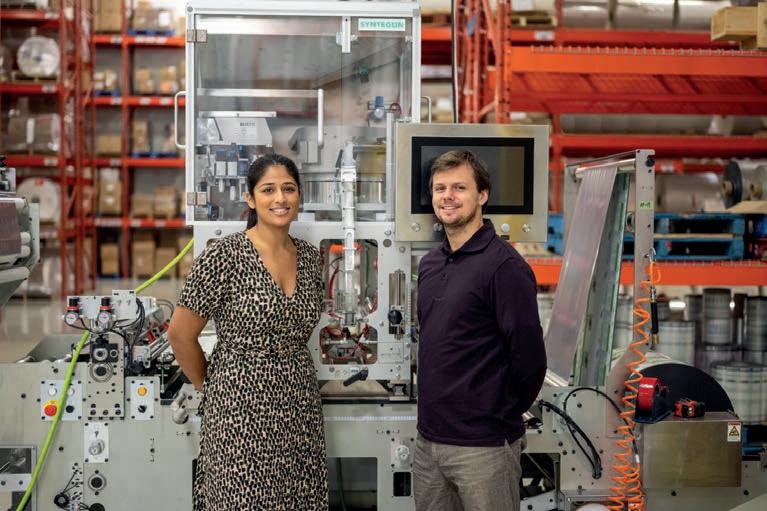

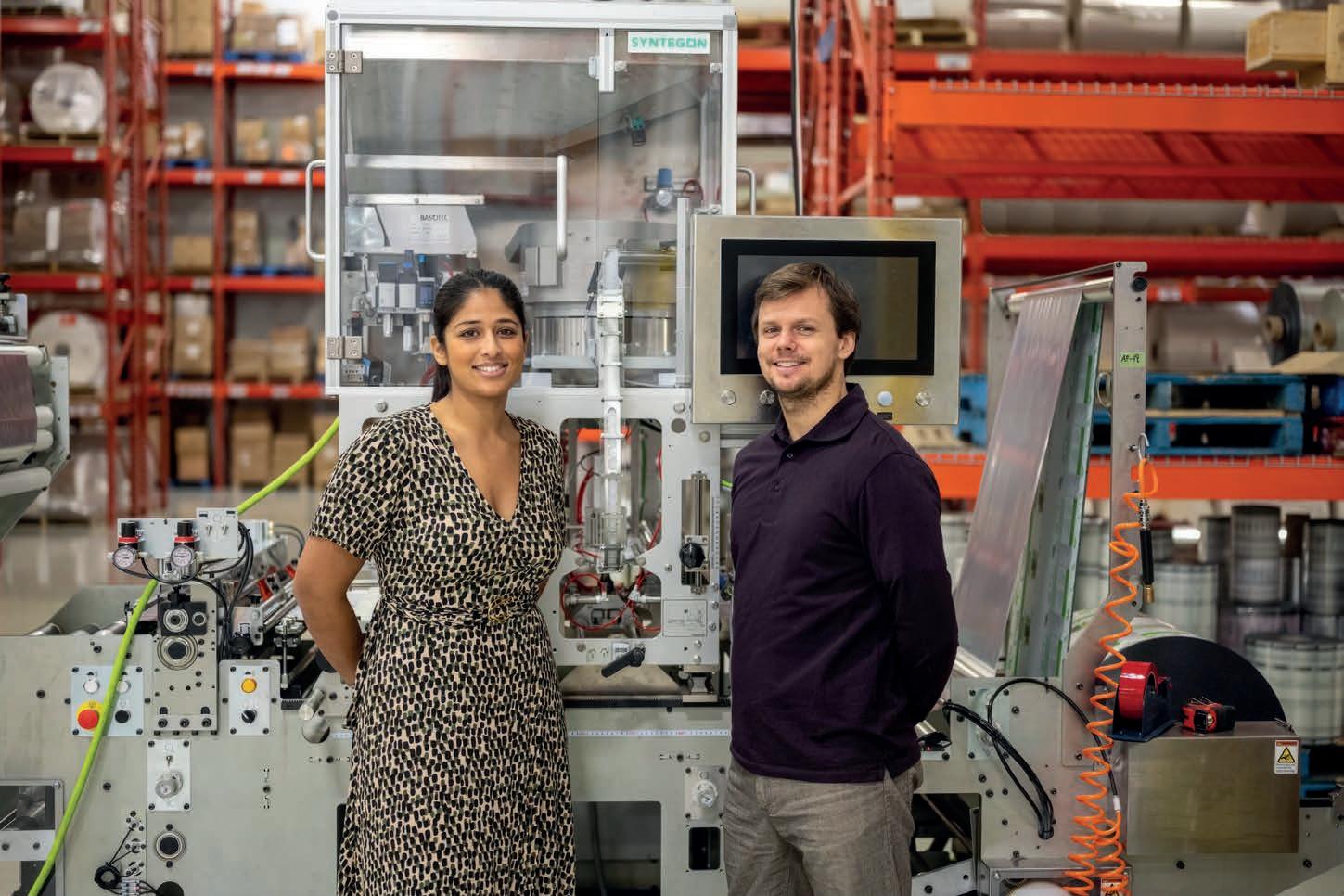

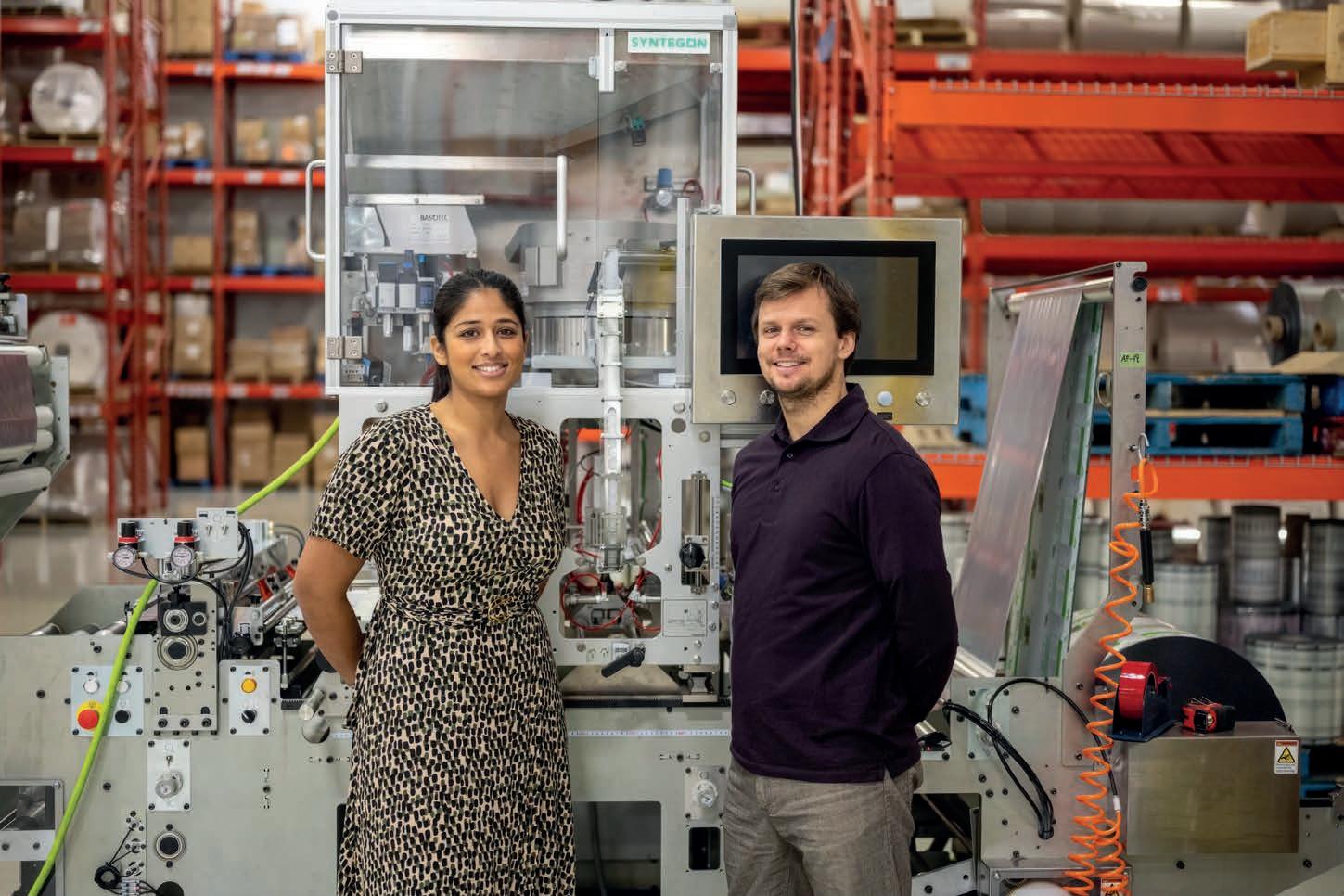

Syntegon describes how its sustainable packaging solution ensures coffee beans remain fresh

58 A sign of the times

The Specialty Coffee Association undertakes the first major overhaul of its membership program in decades

04 Editor’s note

06 News in brief

54 Marketplace

56 Diary Dashboard

that you can choose your friends but you can’t choose your family, however, for the past 13 years, I couldn’t be more grateful that my global coffee family chose me.

As a young 22-year-old journalist ready to make my mark on the media world, I never imagined I would have a career as an international coffee journalist. I always thought I’d be a news writer or a foreign correspondent, and in an unconventional way, I have done both these things, and more.

When I applied to work for Prime Creative Media, I was denied the editor role of an adventure sports magazine, and instead asked what I knew about coffee, to which I replied, “not much”. I took on a role as a junior journalist, working on Australian coffee trade publication BeanScene, until Global Coffee Report was established in 2011 as a way to further support the growth and evolution of the international coffee community, and the many businesses within it. The publication was in its infancy, and so was I.

I made it my mission to submerge myself in everything and anything to do with coffee, and learn from leaders and experts around me. Coffee quickly became an industry that welcomed me with open arms, and one I have come to adore.

Over the years, I have interviewed thousands of people across the global coffee supply chain, setting my alarm clock almost as many times to connect with various international time zones. I have spoken with growth-driven CEOs, passionate manufacturers and engineers, game-changing scientists and agronomists, and producers who continue to push through the barriers to sustain the world with a product we are all obsessed with.

No matter the location or cultural difference, coffee is the universal language that connects us all. What’s been fascinating to see, is how this understated yet complex agricultural product has become the epicentre of communities, the

gateway to livelihoods, and the foundation of careers for thousands of people.

I’ve been fortunate to see this firsthand: watching Brazilian farmers eagerly anticipate their score in a Cup of Excellence competition, Honduran producers hold my hand with gratitude for bringing awareness to their smallholder family farm, and at the other end of the chain, listening to the tales of elderly baristas who have dedicated their lives to serving espresso in the historical coffee houses of Milan.

I cherish the places I’ve been, the experiences I’ve shared, and the friendships I’ve made along the way. Coffee is the business of people, and above all, it’s the people in this industry I value most.

It’s fair to say my work has become my passion, and coffee has become my family. But just like all families change and extend, so must I, as I begin the next phase of my career as Publisher of Prime Creative Media. I will be responsible for the development of its many industry publications, and extend my family, branch by branch. In doing so, I hand over the honour of Global Coffee Report Editor to a talented writer who will no doubt embrace this wonderful industry as I have.

I want to thank you, dear reader, for your support over the past 13 years. Thank you for believing in the value of print media, trusting me with your articles, and allowing me to share them with care and passion over the past 74 editions of Global Coffee Report I have had the privilege to produce. It has been my honour to be your storyteller.

Coffee is my past, present, and will always remain my future. I take comfort knowing that I now have extended family across the globe, and I look forward to connecting over a coffee together, one day soon. GCR

Sarah Baker Editor, Global Coffee Report

Sarah Baker Editor, Global Coffee Report

CHIEF OPERATING OFFICER

Christine Clancy christine.clancy@primecreative.com.au

MANAGING EDITOR

Sarah Baker sarah.baker@primecreative.com.au

EDITOR

Kathryn Lewis kathryn.lewis@primecreative.com.au

JOURNALIST

Hayley Ralph hayley.ralph@primecreative.com.au

ART DIRECTOR/DESIGN

Daz Woolley daz.woolley@primecreative.com.au

HEAD OF DESIGN

Blake Storey blake.storey@primecreative.com.au

BUSINESS DEVELOPMENT AND MARKETING ACCOUNT MANAGER

Adele Haywood adele.haywood@primecreative.com.au

CLIENT SUCCESS

Ben Griffiths ben.griffiths@primecreative.com.au

PHOTOGRAPHY

Dominic Blewett Photography, Alps Coffee’s Florian Andergassen CONTRIBUTOR

Dominic Morrell

HEAD OFFICE

Prime Creative Pty Ltd 379 Docklands Drive, Docklands, Victoria 3008 p: +61 3 9690 8766 f: +61 3 9682 0044 enquiries@primecreative.com.au gcrmag.com

SUBSCRIPTIONS

+61 3 9690 8766

subscriptions@primecreative.com.au

Global Coffee Report Magazine is available by subscription from the publisher. The rights of refusal are reserved by the publisher.

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

Global Coffee Report is owned and published by Prime Creative Media. All material in Global Coffee Report Magazine is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Global Coffee Report are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

The low height of our Mytico coffee machine encourages your baristas to engage with customers while crafting their perfect coffee beverage. And when it’s easy to connect, additional sales come naturally.

Discover more at mytico.franke.coffee

Canadian roaster Café William has invested US$47 million in a new facility in Sherbrooke, Quebec, with US$20 million of the total plant dedicated to technologies to improve energy efficiency and eliminate the use of fossil energies. One hundred per cent of the plant itself is powered by renewable energy. The roaster has partnered with Neuhaus Neotec to install the RFB 300, using electricity from hydropower as its heat source instead of natural gas. Café William estimates it will avoid about 730 tonnes of carbon dioxide emissions annually.

See page 10.

Global Coffee Platform Brazil hosted a field day in São Paulo to promote regenerative agriculture practices. The meeting brought together 70 people from 43 institutions, including national and international exporters, co-operatives, associations, class entities, state rural extension bodies, and certification organisers. The interactive field day was targeted at GCP members and partners’ technicians and agronomists.

See page 17.

According to the United Nations International Organization for Migration 2021 report, Guatemala has reported mass labour shortages in the coffee sector, with 353,504 people leaving the country in 2021 alone. This exodus of coffee farmers could have a devastating effect on the country’s economy, as well as the world’s supply of quality coffee. According to non-profit agricultural research organisation World Coffee Research, Guatemala produced 3,441,000 bags of coffee from 2019 to 2021, compared to 3,553,000 bags from 2009 to 2011.

See page 20.

As of December 2023, sustainability initiative NKG Verified is available in 10 countries and has impacted more than 30,000 farmers in Mexico, Honduras, Colombia, Brazil, Peru, India, Vietnam, Indonesia, Kenya, and Uganda. NKG will continue to expand its supply chains, and is currently preparing to establish new NKG Verified supply chains in Costa Rica and Tanzania.

See page 48.

The SCA will introduce a new membership model focused on providing value and connectivity to its growing international community. Its updated member portal will serve as a centralised hub for members to access a wide range of resources, tools, and information tailored to their needs. Going forward, associate membership will be a free tier that lowers the barrier to entry, making it more accessible for individuals and companies to join and explore the benefits of SCA membership.

See page 58.

Cafetto manufactures and distributes more than 30 tablet products. This includes its Tevo Mini and Maxi Espresso Machine Cleaning Tablets to remove coffee oils, grounds, and stains, and improve the taste and aroma of espresso once the machine is cleaned. Cafetto’s objective is to provide an effective cleaning solution that doesn’t lose its efficiency within fast-paced environments, such as a café that requires thorough cleaning in a timely manner.

See page 28.

The ready to drink (RTD) market has been a focal point for Flavourtech for more than two decades. According to Flavourtech Global Sales Manager Paul Ahn, it started in 2000 when a customer requested an automated, continuous, and inline process that would allow the desirable notes of roasted coffee beans to be

25

transferred from the raw material to the final extract.

See page 34.

After 100 years in business, Mahlkönig is now one of the most recognised in the coffee scene. From its first product has followed some of the world’s most iconic grinders, including the EK43 released in 1990, which many believe marked a pivotal moment in coffee grinding history.

See page 25.

In January 2024, sustainability assessment platform EcoVadis awarded Groupe SEB a Platinum rating, its highest level of recognition which places the company in the top 1 per cent of companies assessed worldwide. According to Groupe SEB, EcoVadis is the most widely used sustainable assessment with over 100,000 companies evaluated across 200 industries and in more than 175 countries.

See page 31.

US$7.7 million

The amount Café William has generated in Fairtrade Premiums for investment in co-operative operations, services to farmers, and community projects.

NKG Verified is our program for traceable and sustainable green coffee supplies. It provides clear and ongoing visibility into supply chains, ensuring that all – to the farm level – comply with specific social, environmental and economic criteria that are confirmed by third-party auditors.

NKG Verified is recognized by the Global Coffee Platform (GCP) as Coffee Sustainability Reference Code equivalent, 2nd party assurance.

Danish Barista Champion Fritz Storm has experienced the evolution of the Scandinavian coffee industry firsthand. The region produced six of the first seven World Barista Champions, including Storm. However, he felt the knowledge gap between coffee professionals and consumers was widening, which inspired him to establish Coffee by Storm in 2013. See page 36.

While Japanese company UCC launched the first canned coffee product in 1969 and opened its first directly managed coffee plantation in Blue Mountains, Jamaica, in 1981, it wasn’t until 2012 that it established UCC Europe to tap into the continent’s rapidly expanding coffee industry. Over the past 90 years, the company has expanded across the whole value chain ‘from seed to sip’, with a global network of coffee farms, roasteries, and manufacturing plants.

See page 38.

In 2019, Cimbali Group acquired Keber, an Italian manufacturer with 30 years of experience designing, developing, and producing steel burrs. Also taking over its production plant in Dolo, Venice, the acquisition has enabled Cimbali Group to have more control over its equipment parts.

See page 40.

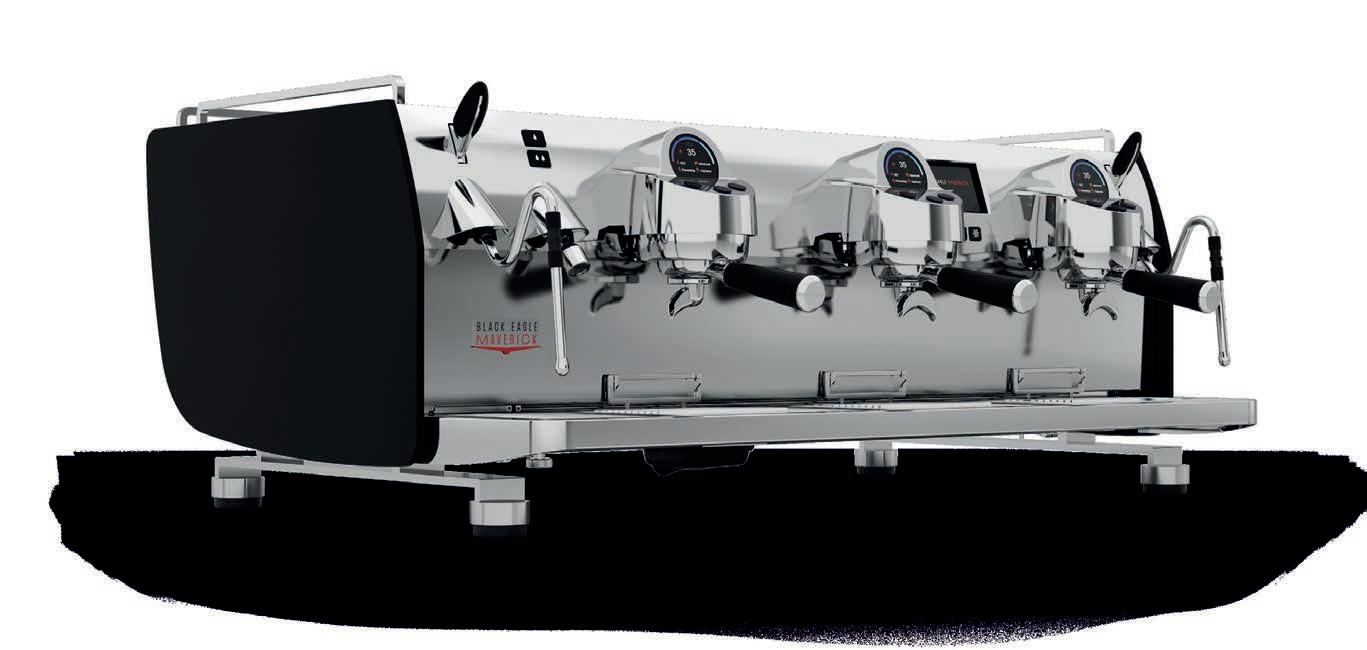

The Black Eagle Maverick espresso machine uses 37 per cent less energy than previous Victoria Arduino models. Improved electronics and Proportional Integral Derivative mean the machine can control the heating elements with greater

For Flavourtech, the RTD market has been a focal point for over two decades. Image: Flavourtech.

speed and efficiency while maintaining a consistent temperature.

See page 42.

Thermoplan has constructed its fifth production plant named unique. Located at its headquarters in Weggis, Switzerland, and spanning almost 14,000 square metres, the plant’s name reflects the company’s openness to embracing new technologies.

See page 44.

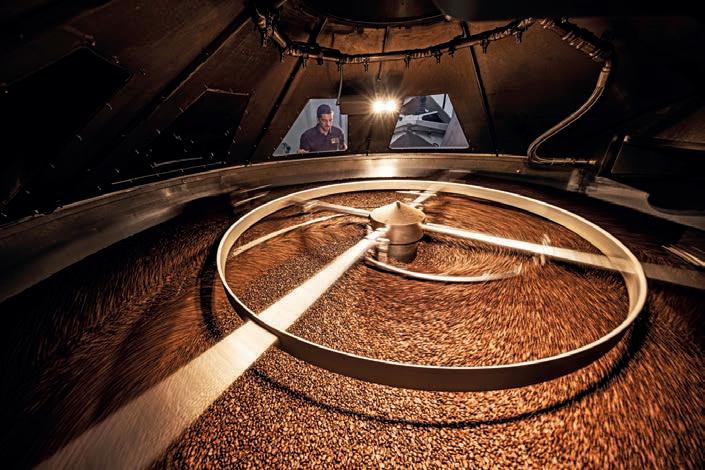

IMA Petroncini’s TMR Series is comprised of modular drum roasters, with a capacity to roast from 1000 to 3600 kilograms per hour. The TMR 720 model can roast up to 720 kilograms per batch. It has

been specially designed for industrial productions that require high profitability and repeatability of the roasting process.

See page 46.

Volcafe is currently running more than 70 projects at origin that aim to not only increase farmer profitability but also introduce regenerative farming practices. Coffee cultivation is deeply affected by climate change and these projects intend to combat it by promoting a variety of initiatives, which range from introducing shade trees and promoting income diversity to building solar dryers.

52

See page 50.

Syntegon has provided valve sealing and application technology for more than 40 years. It first created technology for its own production-line machines for the coffee industry, and progressed to stand-alone application machines that can be integrated into machinery from other companies.

See page 52.

59 per cent

The percentage of Guatemalans living below the poverty line, according to The United States Agency for International Development.

Café William President and CEO Rémi Tremblay on its goal to produce the most sustainable coffee, and why installing an industrial-scale electric roaster is essential to helping achieve its mission.

THERE ARE SOME companies that talk about sustainability like a checklist and others that turn words into action. For Canadian coffee roaster Café William, the term is far from a greenwashing ploy or company value. It’s a way of life.

When, back in 2000, the company reflected on the type of business it wanted to become, it was determined to have a place in the global coffee market, but was adamant it didn’t want to increase its impact on the environment in order to get there.

“We felt that we needed to do something. Over the past couple of years in Canada, we’ve had extreme weather conditions, very high temperatures, and lots of forest fires. Last year in Quebec, the fires burned an area 10 times greater than the average number of hectares burned over the past decade,” Tremblay tells Global Coffee Report.

“We felt a moral obligation [to act], not just because we’re a company that wants to grow. We decided we wanted to reduce the carbon footprint of our operations. We also wanted to have a broader positive impact on our people and improve their [living] conditions. By growing the company, we knew we could have a better impact and involvement in our community, and the countries we buy our coffee from.”

Its first commitment came in the

BY SARAH BAKERsustainable sourcing of its coffee. Ninety per cent of branded Café William coffee sold is Fairtrade and organic certified. Tremblay cites the roaster as one of “the most important importers of Fairtrade coffee in Canada” thanks to more than two million kilograms of certified roasted coffee sold in Canada and the United States in 2022.

Since joining Fairtrade in 2000, Café William’s own brand and private label business has generated more than US$7.7 million in Fairtrade Premiums for investment in co-operative operations, services to farmers, and community projects.

Next came a commitment to greener transportation. On 15 December 2023, Café William transported its coffee via a zero-emissions sailboat from Santa Marta in Colombia to Quebec in Canada.

Tremblay admits it was a “crazy idea”, but four containers holding approximately 160,000 pounds or 72,000 kilograms of green coffee was a way to prove windpowered sea transportation is a viable method. The journey took about a month, which Tremblay says is no longer than some traditional cargo shipments that make multiple port stops and spend valuable time loading and offloading containers. He notes it is more expensive than regular container shipment, however, is a price he believes businesses can absorb and should be willing to pay.

This trip “tested the waters”, reducing approximately 50 per cent or one tonne of carbon dioxide emissions compared to Café William’s current cargo shipments. But something “much bigger” is in the works. In addition to having invested in the construction of a cargo sailboat in Costa Rica, Café William will partner with Towt, a French sail cargo company to transport one million kilograms (or 50 containers) of green coffee from Colombia and Central America to Quebec City in the second half of 2024. Tremblay says this mission will see Café William become the first roaster to transport coffee from port to factory, roastery to customer, using practically no fossil fuels.

From this endeavour, Tremblay hopes to make one, if not two, annual sailboat shipments of coffee to demonstrate “this legitimate business model”.

To accompany its sustainable ethos, Café William has invested in green packaging that diverts 8.5 tonnes of plastic from landfill annually. It invested US$47 million in a new facility in Sherbrooke, Quebec, with US$20 million of the total plant dedicated to technologies to improve energy efficiency and eliminate the use of fossil energies. One hundred per cent of the plant itself is powered by renewable energy. And two Tesla Semi electric trucks, due for delivery this year, will also encourage greener ground transport, and reduce

dependence on fossil fuels.

Given that coffee has one of the most important ecological footprints, Tremblay says the next logical step for Café William was to commit to hydroelectricity roasting.

“Our choice to partner with Neuhaus Neotec was made with the confidence that the company wanted to invest and take on the crazy project with us. They convinced

us, and they delivered on their promise,” Tremblay says. “We’re blessed to have found the right partner in Neuhaus Neotec. They did an amazing job.”

After initial trials in December 2023, the Neuhaus Neotec RFB 300 industrial-scale electric roaster, which Tremblay calls “the big monster” due to its size and capacity, was running seamlessly at full capacity

from the end of January. After initial hesitation on how the company would monitor roasting curves, times, and handle heat modulation, his mind was soon put at ease.

The RFB 300 uses electricity from hydropower as its heat source instead of natural gas. It has an hourly output of three to 3.5 tonnes of green coffee, and requires a maximum power supply of one megawatt.

Café William estimates the company will avoid about 730 tonnes of carbon dioxide emissions annually.

“It is a great sense of pride to be roasting with hydroelectricity in Quebec, and producing coffee with a smaller carbon footprint. Nobody does that on a commercial scale,” Tremblay says.

Considered “the world’s first industrialscale roaster”, Tremblay says being first is never easy, but in doing so, he hopes that Café William is setting a new standard for the global coffee industry.

“We invested more than US$2 million before knowing if it would actually work, but my partners and I were optimistic, and our roastery proves it does. It’s performing as well as natural gas. We’re really happy. We turned the gas source off two months

“I think there’s a lot of big players out there that should be inspired to switch to electric roasting. It’s our duty to reduce the usage of fossil fuels, and we’re on our way.”

There’s no going back. Café William

We really felt like we needed to do something that would make a positive impact

Rémi Tremblay PRESIDENT AND CEO CAFÉ WILLIAM

will now take the time to optimise cycle times and coffee batches to match recipe profiles. The new roaster, described as “solid, sophisticated, and very reliable”, is built to run. It has the potential to operate 24 hours, seven days a week, and given the brand’s growth trajectory and readiness for new business, this may happen sooner rather than later.

“We have room in our facility to add two more roasters. We can double the size of the plant if we want. We have the land. We have the capacity. We have room for growth,” Tremblay says. “We now have the potential to become the biggest roaster in Canada.”

Tremblay believes Café William is in the top five of the country’s largest roasters, with the brand experiencing the most growth in the retail market in 2023.

“We’re still far from the big players, but we’re working hard to get there. We more than doubled the business in five years. I think if we work well, we’ll do that even faster in the next couple of years. We’re exceeding 15 million pounds of roasted coffee on a yearly basis, so I think we can reach 30 to 40 million pounds in the next four to five years,” he says.

Café William, or Café William Spartivento as it was formerly known, was established as a retail brand under the banner of parent company Vittoria Coffee in 1988, before undergoing a name change and brand realignment in 1995, unveiling

what Tremblay describes as “Café William 2.0”. For the past 30 years, Vittoria Coffee has held a stronghold in the Canadian foodservice industry.

Tremblay hopes Café William will one day experience the same growth. It aims to expand the brand throughout Canada, with distribution to 1500 stores already, including five major retailers in Quebec, and Costco outlets nationwide. Tremblay plans to take on the US in 2025, starting with the north-eastern region.

“[The US] is definitely a competitive market. There are many shelves in the grocery stores. Even in Canada, we’re fighting against big players, but we have a unique offering, especially with our Sustainable Series,” Tremblay says.

“From the start, we’ve said we want to create the best blends compared to any other coffee on the shelves in Canada, and I think we’ve been able to do that. We offer sustainable, high-quality coffee at a very competitive price that’s accessible to consumers.”

Tremblay says the majority of its Sustainable Series coffees have the potential to be transported via sailboat from South and Central America, becoming Café William’s most sustainable coffee on the shelf.

This is the ultimate company goal. While it’s not there yet, Tremblay says “we’re pretty close”. On the day of this interview with Global Coffee Report, Café William

had just received notification it had become B Corp certified. Tremblay says this recognition for its high standards of social and environmental performance sets the foundation for the company’s future, and shows the world it is serious about its sustainable efforts.

“We want to build a company that is going to outlast us. Serge Picard, Jonathan Haley (Café William Owners), and I are part of a generation that’s getting older, and we really felt like we needed to do something that would make a positive impact. It’s a big motivator for why we’re in business. Making money is healthy, but it can’t be the only purpose. We’re not just thinking beyond the cup, we’re acting beyond the cup,” Tremblay says.

“If other roasters feel the appeal to follow our tracks and start roasting with electricity, and get rid of fossil fuel, we will be proud of our influence and accomplishment.”

Tremblay credits the initial success of the company to a collaborative effort of Café William’s partners, including Picard. He says respect and teamwork have been an integral part of the company’s growth, as has its agility and entrepreneurial spirit.

“We’re proud of what we’ve accomplished and the product we’ve created. I’m confident in the capacity of our team, and that we can deliver on the goals we set out to achieve,” Tremblay says. “This is just the start.” GCR

THERMOPLAN‘S BLACK&WHITE4 FAMILY –YOUR ULTIMATE COFFEE COMPANION

Experience the unparalleled versatility and exceptional benefits of our Black&White4 fully automatic coffee machines:

• Perfect milk foam every time

• Innovative modular system

• Customizable features to suit your preferences

• Intuitive interface for simple operation

• Effortless cleaning for maximum convenience

• ThermoplanConnect for digital excellence

Elevate your coffee experience with the Black&White4 Family and discover a new standard of perfection!

We create outstanding coffee experiences for the most dynamic businesses in foodservice, hospitality and retail.

Global

Coffee Platform Brazil

technical consultants Eduardo Sampaio and Eduardo Matavelli explain how it aims to harmonise the concepts and practices of regenerative agriculture.

THE IMPACT of climate change and the global cost of living crisis is threatening the future of coffee farming. In order to protect coffee –and those who produce it – Global Coffee Platform (GCP) says it’s time to rethink the system by implementing regenerative agriculture.

“Currently, we are trying to combine the chemical, biological, and physical aspects of regenerative agriculture in a way that producers can understand, adopt, and implement, and in turn increase soil and yield performance,” says Eduardo Sampaio, GCP Brazil Technical Consultant.

These aspects of regenerative agriculture prioritise soil management, biodiversity, ecosystem services, and economic resilience in order to mitigate climate change and build resilient livelihoods and prosperous farmers.

In order to harmonise the concepts of regenerative agriculture, GCP Brazil is working with its governance system and other stakeholders in the supply chain, including GCP members, partners, certifications, coffee entities, rural extension services, technicians, and research bodies. The process began with the Brazil Working Group (BWG), a technical group that discusses and proposes solutions within the governance. The goal is to evolve

conventional agriculture, focusing on the reduction of water use and other inputs, and prevention of land degradation to improve soil, biodiversity, climate resilience, and water resources while making farming more productive and profitable.

“GCP is active on the ground through national platforms in six producing countries, and many have identified that their production systems need to be reconsidered or intensified. This is due to the lack of enabling environments, as well as access to technical systems or long-term commercial relationships,” Sampaio says.

GCP, a multi-stakeholder membership association, is dedicated to advancing farmer livelihoods, and creating a thriving coffee sector for generations to come. It aims to act collectively on local priorities and critical issues, scale local sustainability programs, and grow the global market for sustainable coffee.

Practice makes perfect Sampaio says in order to generate sustainable production results in Brazil, a more moderated approach to farming is needed compared to what has been implemented over the past 50 years.

“We need to intensify efforts to deepen the root systems of the coffee trees and improve soil fertility to combat climate

change. The rational use of nitrogen, administration of micro-organisms, and integrated pest management are additional ways we can improve agricultural practices. This is what GCP Brazil is focused on promoting,” he says.

According to GCP Brazil, regenerative practices such as good soil coverage and crop integration are key factors of profitability for maximum production and increased living income for farmers. Integrating other crops and trees in coffee farms creates a micro-climate that increases biodiversity, enriches soils, reduces erosion and water pollution, and improves carbon storage. Improved soil health, cultivating crops intercropped with coffee, such as banana, avocado, and beekeeping, also bring social benefits through increased productivity and income.

“Supporting growers through a sustainable environment (technical assistance, technology, credit, growers’ organisation, logistics, and market access) is crucial to preserve and promote resilient crops with adaptation capabilities and high productivity,” says Sampaio.

In 2023, GCP Brazil launched the Living Income Study in Brazilian Coffee Production as part of its Collective Action Initiative on Social Well-Being. The study demonstrated growers of different sizes and

regions in Brazil were able to reach a living income from coffee growing.

“The findings show that once growers have access to an enabling environment, they are able to earn a living income. These conclusions, however, cannot be extrapolated to all coffee growers in Brazil, as the study concentrated on a specific population in the main producing coffee regions,” Sampaio says.

GCP Brazil is using the study findings to focus on increasing climate resilience, incorporating sustainable regenerative agriculture practices among growers to decrease the impact of climate change. The organisation is also using the findings to address the enabling environment in regions where it is not yet developed, or where it does not reach most growers.

“Through the focused collective action of GCP members and the initiative partners, we are able to provide the coffee sector with critical viable learnings and insights on living income as milestone towards farmer prosperity, while at the same time ensuring sustainable practices for coffee production,” says Sampaio.

Hands-on experience

Prioritising regenerative agriculture knowledge-sharing and training across Brazil’s coffee production chain is a meaningful step towards GCP’s goal to advance farmer prosperity.

This was the motivation behind the field day that took place on 21 February at APROD, the Association of Mountain Coffee Producers of Divinolândia in São Paulo. Here, members and partners undertook a hands-on session in regenerative agriculture practices, promoting best practice and sector alignment.

“The event focused on the experiences of small farmers in the region who have

embraced regenerative agriculture as a transformative approach. Technical lectures and stimulating discussions provided a comprehensive and inspiring landscape for all attendees,” Sampaio says.

During the field day, attendees had the opportunity to talk to family producers about the opportunities and challenges they face. This was complemented with technical lectures by experts and a round table discussion on how to increase the number of producers adopting regenerative agriculture practices effectively. Teotonio Soares de Carvalho from the Federal University of Lavras, commonly known as UFLA, and Guilherme Chaer of the Brazilian Agricultural Research

Corporation, known as Embrapa, led the discussion panel.

The meeting brought together 70 people from 43 institutions, including national and international exporters, cooperatives, associations, class entities, state rural extension bodies, and certification organisers. The interactive field day was targeted at GCP members and partners’ technicians and agronomists that are new to the concept.

“GCP member organisations and institutions already working on regenerative agriculture, or those that have included it in their strategies, also participated in the knowledge sharing and alignment of best practices on the topic,” says Sampaio.

United in the belief that coffee sustainability is a shared responsibility, GCP members and GCP’s Network of Country Platforms, including Brazil, are working together to achieve transformational change in prosperity for one million coffee farmers by 2030. The field day forms part of GCP Brazil’s harmonising efforts for coffee sustainability in the sector, which will contribute to GCP’s 2030 goal.

Eduardo Matavelli, Technical Coordinator of GCP Brazil, says regenerative agriculture is a topic that needs to be discussed more frequently with rural producers.

“GCP Brazil prioritising this topic in alignment with various actors in the coffee production chain is fantastic, because it enables everyone’s involvement and gives strength to the actions we develop. It also promotes broad involvement and leads to more robust actions in GCP’s 2030 goal,” says Matavelli.

Matavelli says Brazilian coffee grower Daniela Bertolin presents an example of a producer who uses regenerative agriculture solutions for small mountain farmers, where the difficulty of farming is greater due to the growing conditions and high cost.

“I truly believe if all key players, including coffee farmers, organisations, governments, coffee traders, roasters, and consumers work together, we can achieve our common vision of a sustainable and more regenerative coffee sector,” he says.

The last of the four meetings to harmonise the concepts of regenerative agriculture was held on 4 April in Campinas, São Paolo. During the meeting, GCP

Brazil steered participants through seven fundamental elements and practices of the implementation of regenerative agriculture. At each step of the process, technical experts on the subject were invited to contribute with their knowledge.

“We have also compiled knowledge on, and various proposals of, regenerative agriculture from different entities and organisations,” Matavelli says.

The collective concept for regenerative agriculture will be presented to the National Advisory Board (strategic body of GCP Brazil’s governance) for validation.

Matavelli says the next steps are to closely monitor the implementation of these agricultural practices through demonstrations that consider multiple realities on the ground. These will be installed in different coffee regions of Brazil. He says the idea is for these units to serve as models for other coffee producers to learn and replicate the practices.

“We also have an application called CSC App for monitoring indicators of regenerative agriculture and agricultural practices being implemented by growers

in the field, which is available to GCP members,” says Matavelli.

Despite the success of the field days and workshops, Matavelli says farmer prosperity is a journey that can’t be undertaken alone.

“To this end, we invite all stakeholders to continue supporting us in GCP’s 2030 goal as we accelerate ambitions and aim to create a long-lasting impact on the coffee value chain,” he says. GCR

The field day brought together 70 people from 43 institutions, including national and international exporters.

Guatemalan

coffee farmers have been emigrating for decades in search of a better life outside the country. GCR examines the roots of the issue, and what can be done to preserve the country’s future coffee production.

OVER THE PAST DECADE, the Guatemalan coffee industry has had to navigate a series of devastating hurdles. From the catastrophic outbreak of coffee leaf rust (Hemileia Vastatrix) in 2016 which saw smallholder farmers on average lose 71 per cent of their crop according to a study by the University of Maryland*, to the COVID-19 pandemic which caused great disruption to the global coffee supply chain, these monumental challenges left many of the country’s coffee farmers without an income.

Some of these farmers simply gave up the profession and left the country in search of a better life, escalating what was already a huge emigration issue in South America’s coffee-growing nations. According to a 2021 report by the United Nations International Organization for Migration, Guatemala has reported mass labour

shortages in the coffee sector, with 353,504 people leaving the country in 2021 alone.

Another factor contributing to the issue is a lack of adequate financial support for the country’s agricultural industry. The United States Agency for International Development reports that 59 per cent of Guatemalans live below the poverty line, and 77 per cent of this population sector intends to migrate in search of economic opportunity.

This mass exodus of coffee farmers could have a devastating effect on the country’s economy, as well as the world’s supply of coffee. According to non-profit agricultural research organisation World Coffee Research, Guatemala produced 3,441,000 bags of coffee from 2019 to 2021, compared to 3,553,000 bags from 2009 to 2011.

Juan Pablo Cassasco de Groote works with the U.S. Embassy in Guatemala

as an immigration expert. He says the migration crisis is worsening as the country experiences an increase of legal and illegal emigration.

“Guatemalan workers are highly regarded as reliable workers in the United States, therefore are drawn to better working conditions, even under perilous conditions towards the north,” says Cassasco de Groote.

“There have been a number of systemic issues in Guatemala, including a lack of rule of law, constant corruption, and a lack of proper education, that have led to a vicious cycle for society.”

This cycle, according to him, is the reason Guatemala receives less foreign investment compared to neighbouring countries. He adds that Guatemala could have great potential as an exporter of goods if given the right opportunity to succeed.

“Guatemala is an agricultural country with agricultural tradition,” he says. “It is rich in natural resources, and it has a hard-working population that is driven to obtain better opportunities.”

Despite this, Cassasco de Groote says there is reason for hope in solving these issues. Bernardo Arévalo assumed the Guatemalan presidency in January 2024, which Cassasco de Groote says could signal the end of corruption in the country.

“Change must come from inside the country before we can accept foreign help,” he says. “As a society, we need to come together and agree on a common group to develop our economy in order to reduce emigration.”

Building from within World Neighbors, a US-based international development organisation committed to promoting financial literacy to underdeveloped regions around the world, has worked with Guatemalan farmers since the 1980s.

“We are under pressure to convince these farmers that they can, in fact, make it on

their own,” says World Neighbors CEO Kate Schecter.

“We’re looking to get each farmer to be self-sufficient to the point where they don’t even need us anymore. We don’t bring donations, goods, or equipment, but instead we help them raise money in their own communities.”

Part of World Neighbors’ work in Guatemala is encouraging coffee farmers to diversify their crops.

“We’ve seen that coffee growers don’t want to be totally dependent on coffee,”

Schecter says. “These other crops can be either for personal consumption or for sale, for example chickens are a small and profitable business.”

Beyond the farm, Schecter says it’s important to consider living quality when convincing farmers to stay.

“Some of the communities we work in are not on the grid for water or electricity, so we make sure our farmers have access to these necessities,” she says. “A lot of farmers who stay in their communities do so because they have nice homes that they’ve invested in, with clean water and working stoves for cooking.”

Farmers are able to afford such necessities through a series of financial programs that World Neighbors has implemented in the community.

“We have created savings and credit groups, where we teach the farmers how to best manage their money,” Schecter says.

“The farmers who end up saving and starting small businesses eventually become the ones that train and teach new members of the groups to impart some of this knowledge. What we’ve seen in Guatemala is that some farmers are saving up so much money that they need to form a community bank or a cooperative.”

While World Neighbors has seen noticeable improvement among the Guatemalan farming community, the migration issue hasn’t gone away, particularly among men looking to pursue a better lifestyle.

“This is why we are focused on empowering women to make money from farming,” she says. “Guatemala is still a very traditional society, and women do not have much political power, and

they are often the ones left behind in the poorer communities.”

One female farmer working to make a difference is Olga Marina. Her farm, based in Chucte Centro in the municipality of Olopa, Chiquimula, primarily grows coffee of the Anacafé 14 variety, but has expanded to include a smaller domestic garden to grow vegetables for her family. World Neighbors has helped Marina by providing training, seeds for coffee seedlings, and compost bins to ensure the farm remains self-sufficient moving forward.

Marina thinks the migration issue comes down to the lack of benefits some farmers believe they are entitled to, particularly in regard to their coffee crops.

“Some have as little as one cuerda (0.1 hectare) of land dedicated to coffee, while the largest small farmers have up to 10 cuerdas (one hectare),” she says. “Coffee crop production can vary considerably from year to year, which means income is not constant, and harvest only comes once a year.”

Marina adds the work of World Neighbors is crucial in providing financial education to the local community in order

to incentivise farmers to stay in Guatemala.

“It is essential to raise financial awareness among families and to create local job opportunities,” she says. “Support for technical assistance, access to funding, training in sustainable agriculture practices, and access to water and sanitation are all required to create the conditions for wellbeing and prosperity in communities.”

According to Marina, smallholder farmers rely heavily on the success of each harvesting period to stay afloat. However, the wages coffee farmers receive for each harvest is approximately US$8 per quintal (100 kilograms), making it difficult for them to cover family expenses let alone reinvest in their farms.

“Farmers cannot afford to cover the whole coffee production process,” says Marina. “For some, the only option is to turn to large high-interest loans from local lenders.”

Marina says labour shortages have become a primary concern for larger farms, with farmers having to pay higher wages in order to secure workers.

“This situation also creates internal migration, bringing farmers from other regions or even neighbouring countries

such as Honduras or El Salvador,” she says. While Marina understands the issues many local farmers face, she has made the decision to remain in Guatemala and continue to farm coffee. She has learned from the experiences of others that the grass is not always greener outside of the country, especially for struggling farmers.

“I have witnessed the difficulties faced by those who emigrate to the United States, especially when it comes to the wellbeing of their children,” she says.

Because of this, Marina has stayed committed to providing her children with a proper education in Guatemala.

“My eldest daughter is studying to become an accountant, and my second daughter is progressing in her primary education. It is important for me to be with them to support their educational journey and help achieve their goals and aspirations,” she says.

Marina suggests awards for coffee producing from large roasters should be focused on smaller coffee farmers, as she says they might otherwise become disenfranchised to commit to coffee.

“Often, awards and prizes are left in

the hands of intermediaries, who enjoy it for themselves, depriving us of our merit and benefits,” she says. “It would be very valuable for roasters to consider implementing programs such as insurance for coffee producers, which would help us mitigate the negative impacts of climate change and ensure the stability of our farms.”

A fair price

Marina is not the only Guatemalan local aware of the lack of assistance.

Asociación de Cooperación al Desarrollo Integral de Huehuetenango (Acodihue) was founded in 1996 with the support of the Guatemalan government and the European Union. Its mission is to provide assistance and services to producers to help maintain quality coffee while developing social and economic programs that benefit farmers and their communities.

Acodihue Co-director Felix Camposeco has been a part of the coffee industry his whole life. His parents were coffee producers, and he has worked with Acodihue for over a decade. Camposeco

“Often, people think of Fairtrade as an organisation that keeps and maintains a certain minimum price, but for small producers it’s a way of life,” he says.

He adds that most coffee farms in the

country are Fairtrade certified, which has proven to be a disadvantage in the global market. Fairtrade products often cost more because they have a minimum price that helps farmers cover production costs.

“A lot of companies are looking for coffee that is of poorer quality which can be sold at a lower cost,” he says.

Camposeco says it is crucial for coffee roasters to consider their product beyond the profit. He urges others to look at the “black drink of energy” as a representation of an entire community of hardworking people.

“Behind that cup of coffee, there’s a family getting up at 6am every morning and putting in a lot of effort to make their crops sustainable,” he says.

“They are dedicating their lives to uphold the country’s coffee culture and to give you that boost of energy in the morning. We need to have these people producing coffee, because if they don’t, they might have to abandon the crop altogether.” GCR

* The impact of coffee leaf rust on migration by smallholder coffee farmers in Guatemala. (Dupre et al, 2022).

At Volcafe, we work across green coffee value chains, forging strong relationships with coffee growers through trade and technical support, running processing plants and facilities, and handling transport logistics.

We hold a key position in the global coffee supply chain linking farmers in the field with roasters in the market. We’ve earned a reputation as a go-to partner for sustainability projects that deliver on-the-ground impacts while also achieving the aims of our customers.

We understand our role in responsible sourcing and are actively driving change in our industry. We work with internationally recognised standards – including our own Volcafe RS Standard – to offer a wide range of responsibly sourced coffees.

Working with over 45,000 farmers in 11 coffee origin countries, our farmer support programme Volcafe Way provides training, guidance, and support to help coffee growers build sustainable profitability and a better future at their farms.

Mahlkönig has a history of producing some of the industry’s most iconic grinders. To mark its centenary, CEO Dr Marcel Lehmann looks back on the brand’s milestone moments and ahead to its bright future.

IN 1924, the bustling harbour city of Hamburg, Germany, was one of the world’s busiest commerce hubs, trading luxury goods such as wine, tobacco, carpets, and tea. Among its most popular imports was coffee, which arrived from producers around the globe to be processed and roasted in the city. It was during this formative moment of the burgeoning European coffee scene that Mahlkönig was born, first as Stawert Mühlenbau GmbH & Co. KG.

On 13 December that year, Mahlkönig was registered officially as a trademark and embarked on its mission ‘to elevate the coffee experience through uncompromising quality and innovation’. Unlike many other grinder manufacturers that were established in the early 20th century, it made grinders for the food industry from day one, quickly becoming a trusted name.

Fast-forward 100 years and the brand is now one of the most recognised in the coffee scene. From Mahlkönig’s first products has followed some of the world’s most iconic grinders, including the EK43, released in 1990, which many believe marked a pivotal moment in coffee grinding history.

Dr Marcel Lehmann, CEO of Hemro Group, of which Mahlkönig is a flagship brand, is extremely proud of how far it has come since its humble origins in Hamburg.

“We are a global team of innovators and coffee lovers, with colleagues coming from

all around the world with expertise in research, technology, product development, purchasing, production, marketing, and sales. It’s this diversity that enables us to develop and build the best coffee grinder for every field of application,” says Lehmann.

“Mahlkönig grinders have become epochal, they have their own fanbase. Sometimes it staggers me that almost 200,000 people choose to follow our brand on Instagram to see pictures of grinders. People in this industry are so passionate about their craft.”

This success didn’t happen overnight, of course. Years of innovation and industrychanging products have paved the way for international stardom.

“Mahlkönig has always been about innovation. When its first grinders were launched in the 1920s, the brand was ahead of its time and laid the foundations for the EK 0 W1 BN in the 1950s, and then all the other Mahlkönig grinders that have continued to spearhead advancement in the industry,” he says.

Arguably one of its biggest milestones was the release of the EK43, which is now the world’s most sold professional coffee grinder. While it was celebrated by baristas for its advanced accuracy when preparing filter coffee, it wasn’t until Matt Perger used the grinder in his routine at the 2013 World Barista Championship that its popularity for crafting espresso skyrocketed and it

became a must-have item in coffee shops around the world.

According to Lehmann, by this point Mahlkönig was already playing a pivotal role in the specialty coffee scene through its sponsorship of the World Barista Championship (from 2009 to 2021) and its

As tastes evolved and technology advanced, the company adapted, continuously pushing the boundaries of what was possible in coffee grinding.

“You can see throughout the product launches over the years that our goal has always been on convenience, making it easier for the barista to create the perfect cup of coffee,” he says.

Alongside convenience, Mahlkönig has also focused on precision and reliability. Every grinder goes through rigorous grinding testing and systematic particlesize analyses before it leaves the Mahlkönig factory to ensure every single machine is up to scratch.

Much of the company’s success is attributed to its team of industry experts, who have always strived for innovation in the sector and have built a brand baristas know and trust.

“Mahlkönig stands for reliability and trust, and our team embody this. We have colleagues in our factory in Hamburg celebrating their fortieth anniversary at the company this year,” says Lehmann.

“It is this reliable and dedicated team that we value the most at Mahlkönig. We appreciate this strong commitment of all our colleagues as the most precious source of inspiration and strong basis for continued success.”

Lehmann believes the brand is now firmly in its technological era, in which research and design advances are focused on streamlining workflow, keeping quality consistent, and utilising smart systems.

“We are now transforming our products from being standalone coffee grinders to integrated products, which help baristas

ease workflow by connecting the grinder to the coffee machine. For example, this means if there is something outside of range on the grinder, the user will now be able to see that on the dashboard,” he says.

Rather than being hindered by its heritage, Mahlkönig leverages its legacy and reputation while embracing modernisation. Many of its workforce at its factories and headquarters in Europe have been with the company for decades, passing down their wisdom to new recruits.

“Mahlkönig may have been around for a century, but we manage Hemro Group like it’s a start up. Alongside our experienced team we welcome young people who are often full of novel ideas, and we love working with baristas who are usually younger. We’re not afraid of trying new things. We are ambitious to change,” say Lehmann.

The EK Omnia, the brand’s new release, encapsulates its innovative outlook. Inspired by the EK43, the new grinder is the company’s latest leap in coffee grinding innovation, combining leading technology with the quality and consistency the EK is known and loved for.

the next level,” he says.

To mark the milestone anniversary, Lehmann and the Mahlkönig team invited industry friends to celebrate at the Mahlkönig 100 Year Event at the Specialty Coffee Expo in Chicago in April. The celebration featured a gallery of images from the company’s 100-year history, as well as live music and drinks.

“As we celebrate our 100th anniversary, we honour the countless individuals who

our dedicated employees to our loyal customers, partners, and everyone in the coffee scene and beyond who love our products,” says Lehmann.

“Together, we have built a legacy that already spans 100 years, rooted in a shared passion for exceptional coffee.” GCR

For more information, visit mahlkoenig.com

Cafetto explains why its tableting process is unlike any other and how its ‘no one size fits all’ mentality ensures it has a cleaning product suited for every coffee machine.

LIKE MOST high-volume machinery, coffee equipment requires frequent cleaning to perform at its best. To help café owners and baristas keep on top of this, global cleaning specialist Cafetto has developed an extensive tablet range which covers traditional machines, automatic machines, and milk-system cleaning.

“Cafetto manufactures and distributes over 30 tablet products, such as our Tevo Mini and Maxi Espresso Machine Cleaning Tablets, to remove coffee oils, grounds and stains, and improve the taste and aroma of espresso once the machine is cleaned,” says Cafetto Research and Development Manager Daniel Knowles.

“Our tablets span a variety of shapes, diameters, and weights. The different varieties are specifically suited to the application, machine type, and cleaning purpose.”

Cafetto’s objective is to provide an effective cleaning solution that doesn’t lose its efficacy within fast-paced environments, such as a café that requires thorough cleaning in a timely manner.

“We wanted to provide a sustainable solution, so we created low-water content products that reduce transport emissions due to the reduced weight. These products

also had to be applicable across many machines and environments,” Knowles says.

“The solution was pre-weighed, preportioned tablets, with simple instructions for use that cater to all user-experience levels. Each product comes with straightforward instructions and easyto-follow pictograms, so all the customer needs to do to use the right tablet on the right machine to create the right results.”

Despite the tablets’ ease of use, Knowles says the science behind them is quite complex.

“Essentially, they’re a blend of minerals, biodegradable detergents, and binders, with the ratios of these ingredients depending on the final application of the cleaning. Tablets are made by compressing a powder under large amounts of force to cause the specialised particles to fracture and mechanically interlock with one another. This mechanism helps provide the tablets’ dissolution characteristics,” he says.

According to Cafetto, the dissolution time in the cleaning cycle is an important factor to ensure it removes built-up coffee oils and residue.

“Cleaning cycles can vary in length, and the dissolution profile is modelled to this. If the cleaning cycle is short, the tablet

must dissolve quickly to allow the cleaning actives to function correctly. On a longer cleaning cycle, the dissolution period can release the cleaning actives over time. This comes down to a tailored dissolution profile for the tablet, effervescence, and disintegration-based dissolution,” says Knowles.

“For example, Cafetto’s S15 Espresso Machine Cleaning Tablets are formulated to dissolve in automatic cleaning cycles to provide optimal cleaning performance.”

According to Knowles, Cafetto’s unique tablet formulation is inspired by pharmaceutical and homecare technologies.

“It’s a cross-pollination of industry technologies,” he says. “We are very specific about what we do, with a ‘no one size fits all’ mentality. Each of our tablet products is made to respect the unique needs and complexities of each machine type.”

The tablet manufacturing process is finalised by sealing the products in plastic jars or blister packaging.

“The rationale behind the blister packs is to provide a cleaning experience that’s completely touch free, along with the peace of mind that the product is protected in tamper-proof packaging. It’s designed to

make the cleaning process even easier from start to finish,” Knowles says.

Knowles says being a trusted brand and significant contributor to the global coffee industry has allowed Cafetto to share its knowledge on the importance of cleaning products in the production of excellent coffee.

“We want our customers to have faith in what Cafetto does and know we maintain close communication and reputable service to support our customers’ journey with us,” Knowles says.

“We are always looking ahead for ways to support our growth. That’s just part of Cafetto’s DNA, and our commitment to the industry that has supported us in return for many years.”

The Cafetto team is committed to continuous improvements and solutions as it grows. Knowles says he has confidence in its plans and processes to tackle whatever comes next.

the stigma that these types of products are more expensive and less effective than their traditional counterparts.

“We will always monitor and act promptly on any discrepancies to control what we can deliver to customers and distributors. We’re currently focused on adding to our sustainable business practices and making

“Cafetto has always been environmentally conscious. We decided very early in the business’ life to not only produce traditional products but also include an organic range,” Knowles says.

market trends, then find a way to deliver. Doing so has led to successful product development, improvements, and longlasting relationships.” GCR

For more information, visit

Fully electric roasting on large scale production isn’t a vision anymore. In 2024 we have brought the world’s first large scaled electric RFB roaster with a capacity of 3 ton/h successfully into operation. And the well-known flexibility of RFB roasting technology has not been compromised. However, you do not necessarily have to choose one technology. The hybrid technology from Neuhaus Neotec allows both gas and electric operation and can therefore be individually adapted to your local conditions. So choose the optimum solution for you and we will deliver it.

Sustainability Manager Ayca Ozol explains how Groupe SEB’s professional coffee machine unit is committed to creating a more sustainable future.

IN NOVEMBER 2023, sustainability assessment platform EcoVadis awarded Groupe SEB a Platinum rating, its highest level of recognition which places it in the top 1 per cent of companies assessed worldwide.

“Since it is the most widely used sustainable assessment with over 100,000 companies evaluated across 200 industries and in more than 175 countries, it is a very important accomplishment for us,” says Groupe SEB Professional BU Sustainability Manager Ayca Ozol.

For Groupe SEB, this recognition comes from a series of initiatives that have taken place within the company. Its professional coffee machine unit, which includes brands WMF, Schaerer, Curtis, and La San Marco, continuously evolves its operations to ensure sustainability is a vital component.

“We design our products to be part of the circular economy to contribute to carbon neutrality,” says Ozol. “We prioritise quality to extend the life of our products and promote the use of recycled materials and recycling.

“Additionally, we formulate eco roadmaps

to control the greenhouse gas (GHG) emissions across our whole value chain.”

This includes use of eco design, eco manufacturing, and eco logistics to contribute carbon neutrality in every phase of the products’ lifecycles.

Ozol says the professional coffee machines across the portfolio adhere to Groupe SEB’s sustainability framework.

“All our sustainability efforts are anchored in the Group’s comprehensive roadmap, which is formulated in accordance with the most demanding international standards,” she says. This includes the Global Compact, Carbon Disclosure Project, the Science Based Targets initiative (SBTi), and Ecovadis.

The company prioritises two main factors when assessing the lifespan of its products: quality and repairability. These characteristics are considered when new machines from the Group’s coffee brands WMF Professional Coffee Machines, Schaerer, and Curtis are designed and constructed at its plants in Geislingen in Germany, Zuchwil in Switzerland, and Montebello in California, United States.

“Every single machine undergoes an

extensive quality assurance process at every stage of development and production before leaving the factory with a 100 per cent final inspection, which even extends to detailed data analysis after delivery to customers,” says Ozol.

“We also ensure the quality of our stainless-steel components by producing the vast majority of our sheet metals and grinding discs in our plant in Geislingen. This robust management plays an essential part in the longevity of the machines and the quality of the coffee that our customers can offer.”

Ozol says Groupe SEB’s professional coffee machines are at the cutting edge of innovation, not only in finding new ways to create high-quality beverages, but also in ensuring its partners are supported in sustainable practices.

“Milk, coffee, and water are not only the most important ingredients of a coffee, they also account for the lion’s share of the carbon emissions of an average recipe alongside the energy use of preparation,” she says. “We are committed to developing innovative technologies

that help our customers use our machines more efficiently.”

These new innovations are focused on the heating, boiler insulation, and cleaning processes within the machines, with each element designed to minimise milk, coffee, and water waste. Among these innovations are the WMF Dynamic Milk and Schaerer Best Foam systems.

“These systems, together with the WMF 2-Milk-Solution and Schaerer Twin Milk, allow the same machine to offer different milk alternatives, which facilitates the use of plant-based milk,” says Ozol. “The Best Foam and Dynamic Milk systems allow this key ingredient to be frothed in line with the highest taste and texture expectations, while using air to increase milk yield.

“Machines from WMF and Schaerer also integrate patented technology which ensures constant monitoring of the brewing process and the amount of coffee grounds to maintain consistent taste, and therefore increase the efficient use of coffee.”

To increase boiler efficiency, users of WMF and Schaerer machines can select Eco Mode, which reduces the boiler’s temperature.

“This mode is especially useful for machines that are only used during peak times and then remain in standby mode for longer periods, with tailored timing choices available for the highest possible energy savings,” says Ozol.

WMF and Schaerer machines also include fully automatic cleaning systems through the WMF AutoClean and Schaerer ProCare.

“Both systems guarantee the highest standards of hygiene, but also keep an eye on the consumption of cleaning agents, energy, and water,” she says.

Groupe SEB Professional Coffee Machine Unit also designs recyclable products by prioritising sustainable materials while emphasising easy disassembly. For example, around 39 per cent of the materials used in the WMF 1500 S+ automatic coffee machine are recycled, based on figures

from a university-run sustainability management survey.

“At the end of the product life cycle, 89 per cent of the materials used can be directly reintegrated into the recycling process, according to calculations done by our recycling partner in Germany,” says Ozol.

“Our goal is to establish a uniformly defined recycling process for all our professional coffee machine brands around the world, which will increase our recycling rate in the coming years.”

To address repairability, the professional unit involves its in-house service teams from the very beginning of the development process, when they are taught how to best inspect, replace, and repair each machine.

“Service portfolio and product care systems help extend product lifespan, with reasonably priced spare parts available for eight years after the last serial production,” Ozol says. “A significant network of trained repairers ensures strong regional coverage for service availability.”

For professional coffee machines` international service network, which includes own service technicians across its 11 subsidiaries, as well as certified service partners worldwide, the company has introduced a range of digital tools. These aim to reduce both the total cost of ownership for customers, as well as the carbon footprint by minimising physical visits where possible and enhancing their efficiency when they do occur.

“The wide range of digital service tools includes remote service desktops, service monitoring, and remote software updates aiming to resolve service calls remotely whenever possible,” says Ozol. “Route optimisation using an AI dispatch engine will help ensure the most efficient technician schedules whenever an on-site customer visit is required.”

Ozol says its Van Stock Optimisation is another strategic approach in these efforts. This involves algorithm-based stock analysis for technicians’ vans to ensure the availability of spare parts and to minimise the numbers of second on-site visits.

new sustainability goals for 2024 to 2030, which will be made public in May.

“This approach also makes it possible to use smaller vans with a lower

“Our professional coffee machines will be fully integrated to this forthcoming ambition and will seamlessly adapt to the

For more information, visit wmf-coffeemachines.com and schaerer.com

The Schaerer ProCare system provides fully automatic cleaning.

The Schaerer ProCare system provides fully automatic cleaning.

TAroma recovery and extraction specialist Flavourtech on how to create a winning RTD beverage with the help of its Integrated Extraction System.

HE READY TO DRINK (RTD) market has been a focal point for Flavourtech for almost 25 years. According to Global Sales Manager Paul Ahn, the key to creating a great RTD beverage is producing a balanced and appealing flavour profile.

“A great RTD should showcase the natural characteristics of the coffee beans used, whether it’s fruity, chocolatey, or floral. The flavour should be well-rounded, without any off-notes or bitterness. These attributes contribute to the overall quality, taste, and consumer appeal,” he says.

Ahn believes an alluring aroma is also an integral part of any RTD coffee drink.

“The aroma should be inviting and aromatic, with hints of freshly brewed coffee or tea that evoke a sense of indulgence and satisfaction. The level of sweetness in RTD coffee or tea can vary based on consumer preferences or the intended target market, but it should be balanced and not overly sweet, complementing the coffee or tea’s natural flavours without overpowering them,” he says.

Flavourtech’s interest in continuous

RTD processing was sparked in 2000 when a customer requested an automated, inline process that would allow the desirable notes of roasted coffee beans to be transferred from the raw material to the final product in an efficient and safe working environment.

“We designed a system to capture the natural flavours of products, such as coffee, tea, fruits, and spices, which would normally be lost or damaged in traditional processing,” says Ahn.

“The Integrated Extraction System (IES) was a great leap forward as it brought together the technologies necessary to create a premium RTD extract full of natural aroma.”

The IES is a continuous, automated processing line that allows customers to produce premium aromas, extracts, and concentrates for RTD coffee products, as well as for soluble coffee and the flavour industry. To keep the aroma fresh, a Spinning Cone Column (SCC) within the IES performs two key tasks simultaneously.

“The first is what we call the aroma strip, where the volatile coffee flavours are

captured and stored. At the same time, the coffee is brewed for 30 seconds as the slurry flows through the SCC,” he says.

“The spinning cones perform the aroma capture and extraction in this short time while producing a high-quality coffee extract. The extract is then clarified and it’s ready for canning or bottling. Finally, the natural aroma captured upfront is added back to produce a full-flavoured RTD beverage.”

If concentration is required, Flavourtech’s Centritherm (CT) evaporator performs the task with a uniquely low temperature and a residence time on the heating surface of just one second.

“With such care provided to produce a high-quality extract, the last thing you want is an evaporator that may damage the product. The low operating temperature and short residence time of the CT equates to a high-quality concentrate, with the original aroma and colour still intact,” Ahn says.

Flavourtech’s Rotating Disc Column (RDC) can be added to the IES process if coffee hydrolysis is required.

“If the end target is instant coffee, a high temperature extraction unit achieving temperatures of 180 to 190°C will allow for further solids extraction in only 20 minutes. But, more importantly, the RDC high temperature extraction process comes after the aroma capture, so there is no loss or damage to the aroma that was previously captured,” says Ahn.

The IES has adjustable key parameters, such as temperatures of the different modules and steam pressures. These variables can be tailored to suit the specific requirements of coffee aroma and soluble solids extraction processes.

Ahn says this means the desired flavour profiles can be stored and easily recalled for future use.

“By incorporating these features and capabilities, the IES can be adjusted and optimised for both coffee and tea extraction processes, enabling manufacturers to produce high-quality beverages with consistency and efficiency,” he says.

Several key features of the system make it easy to operate from a technician’s point of view.

“This includes advanced automation that streamlines the extraction process, reduces manual intervention, and simplifies operation. The interface of the system is also intuitive and userfriendly, making it easy for technicians to navigate through different processes, set parameters, and monitor the extraction progress,” says Ahn.

The system is also designed with easy maintenance in mind, with accessible parts and clear instructions for routine upkeep. This reduces downtime and creates a smooth, safe, and efficient operation. To further streamline the process, Flavourtech provides comprehensive training and support, ensuring the necessary knowledge and skills to operate the system effectively are communicated to end users.

Flavourtech works closely with its RTD coffee customers to find the right solution for their business through a combination of consultation, customisation, and ongoing support.

“We begin with the initial consultation and identify key requirements and preferences, such as desired flavour profiles, production volumes, processing capabilities, and budget,” he says.

“Product trials, in one of Flavourtech’s pilot plants or on-site, assess the feasibility of different solutions, which involve testing various aroma profiles to achieve the desired tastes.”

Ahn says customers often seek ways to enhance the flavour profiles of their RTD products to meet consumer preferences and differentiate themselves in the market.

“We utilise our expertise in extraction technology to develop customised solutions that optimise aroma extraction from coffee beans while preserving the natural characteristics of the coffee,” he says.

To ensure every batch meets the same high-quality standards, Ahn says consistency is essential.

“Customers often request solutions to achieve consistent flavour, texture, and appearance across all products. Our technologies and processes enable precise control over extraction parameters, resulting in consistent product quality batch after batch,” he says.

“Overall, we work closely with our RTD customers to understand their unique needs and challenges.” GCR For more information, visit flavourtech.com

Barista

Champion Fritz Storm discusses his passion for sharing knowledge, and how Eversys machines suit the needs of Denmark’s evolving coffee culture.

WHEN DECIDING his next career move after becoming the third ever World Barista Champion in 2002, Fritz Storm didn’t follow the path many victors now take.

“A lot of the winners tend to do their own thing like running a café, but I knew from the beginning that wasn’t my goal,” he says.

A Denmark native, Storm has experienced the evolution of the Scandinavian coffee industry firsthand. The region produced six of the first seven World Barista Champions, including Storm. However, he felt the knowledge gap between coffee professionals

and consumers was widening, which inspired him to establish Coffee by Storm in 2013.

Its mission is to provide consultancy services to businesses across Denmark to guide them towards the right coffee, equipment, and service.

“We want to be the one stop solution for any business, big or small,” says Storm.

Coffee by Storm has provided an outlet for Storm to follow his passion for coffee education, and to show future champions the potential career opportunities outside of the café space.

Storm says coffee culture in Denmark has bloomed significantly throughout the company’s first decade.

“When we first started, coffee was just a black drink, and no one knew its capabilities,” he says. “What has changed the most in the past 10 years is the collective realisation that people don’t want to drink the same thing they’ve been drinking their whole lives, and they’re looking for new ways to enjoy coffee.”

When Storm was leading a barista camp in Shanghai alongside Japanese coffee icon Kentaro Maruyama in 2015, he decided to

check out the new machines on display at a nearby tradeshow. As the owner of Coffee by Storm, a complete coffee solutions company catering to the Danish market, he never missed the opportunity to add new kit to his catalogue.

“The e’4 machine from Eversys immediately caught my attention,” says Storm. “At the time, I didn’t know of any great super-automatic machines. Once Eversys told me about the e’4, I was eager to start working together.”

For Storm, it was the ability of Eversys machines to adjust to the desired parameters of the user that made him fall in love with the brand.

“Using these machines, I feel like I can take all the knowledge I have developed from manual machines and apply it to an Eversys machine,” he says. “As a barista, it works exactly how I want it to. I can dial in my recipes and the machine can recreate it automatically and consistently.”

As a World Barista Champion, Storm looks for consistency and quality in the products he uses, something he was particularly impressed by in Eversys machines’ espresso capabilities.

“This is incredibly important to what we do at Coffee by Storm, because our number one priority is producing the best in-cup taste,” he says. “To get this quality result, you need everything to be perfect, and that’s what Eversys provides.”