CHALLENGE US!

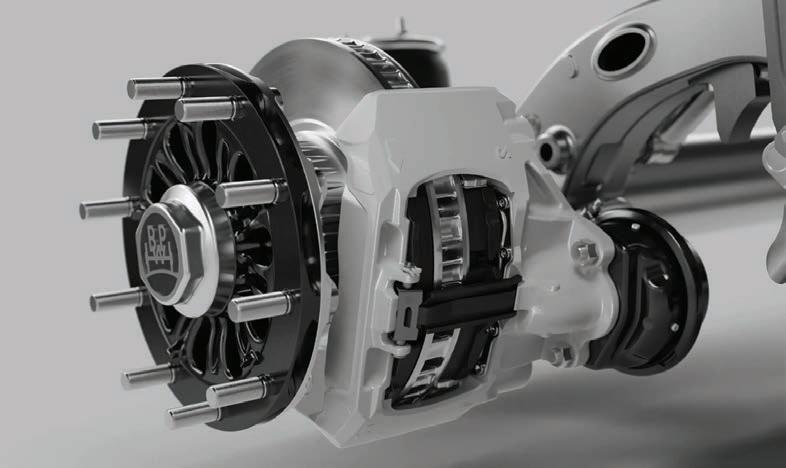

With our running gears and special axle solutions, there is nothing that can’t be transported. Your requirements motivate us to create new things. They inspire us to use our entire engineering expertise and decades of experience to develop innovative and reliable solutions together with you – customised for the type of vehicle and intended use.

The swing axle masters any heavy transport - even on critical ground and difficult terrain. It is part of our individual solutions that are uniquely powerful and resilient. Challenge us!

INDIVIDUAL RUNNING GEAR SOLUTIONS FOR SPECIAL TRANSPORT TASKS. MORE

34

IN THIS ISSUE

BUSINESS

34 MARKET REPORT

From its ancient roots, transport has been a defining aspect to Saudi Arabia’s economic and cultural fabric.

50 INDUSTRY VOICE

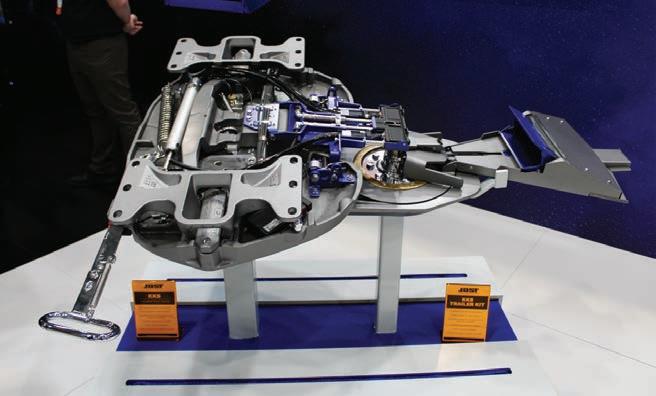

JOST CEO, Joachim Dürr, reflected on JOST’s dominant global market position which led the KKS’ arrival down under.

52 BUILT TO ASK

Valk Welding helps Australian trailer builder, MaxiTRANS, with its growth ambition.

54 EXECUTIVE PROFILE

An exclusive interview with SAFHolland Middle East Managing Director, Jean Khoury.

GAME CHANGER

CIMC Vehicles proves to be a powerful world leader in the international trailer manufacturing scene with its commitment to state-of-the-art technology, driven in part by an entrepreneurial spirit that is capitalising on new opportunities, particularly in electrification and the final mile.

”OVER THE PAST 20 YEARS, WE HAVE CONSISTENTLY PURSUED INNOVATION, INCREASING OUR INVESTMENT IN GLOBAL, ADVANCED TECHNOLOGIES AND INTRODUCING AND INCUBATING ADVANCED RESEARCH AND DEVELOPMENT METHODS AND MANUFACTURING TECHNOLOGIES.”

CIMC Vehicles CEO and President, David Li

56 EVENT REVIEW

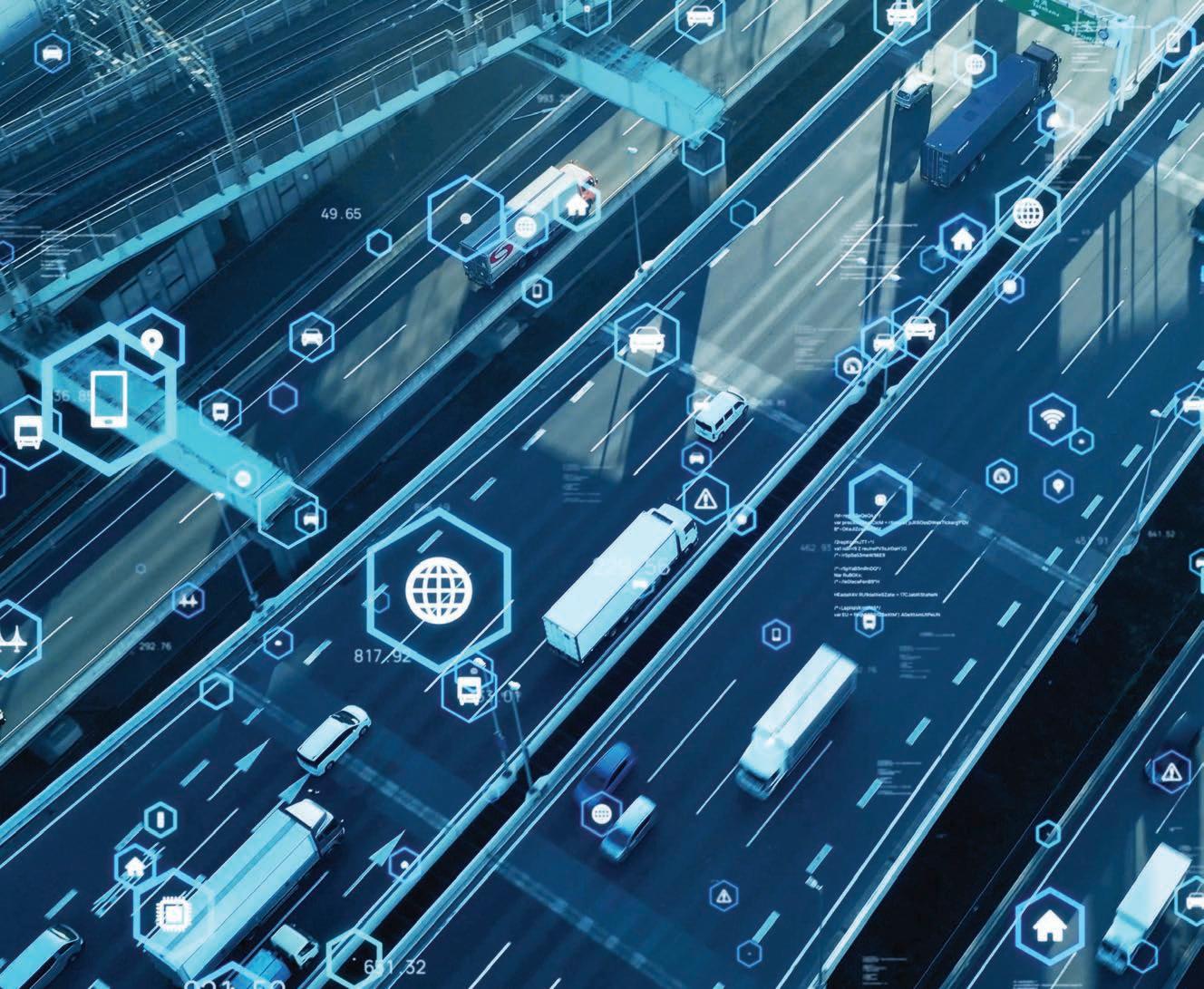

More than 75,000 visitors from more than 120 countries attended this year’s Transport Logistic event in Munich to see innovation in transport across all modes.

FEATURES

40 REFRIGERATED TRANSPORT TECHNOLOGY

See what GORICA and Brianza Plastica bring to the cold chain transportation market.

46 BODY HARDWARE, EXTRUSIONS AND LIGHTS

A showcase of technologies from SAFHolland and Lucidity Group.

65 SPECIAL REPORT

By 2024, vehicles purchased for transport use in California will have to start transitioning to zero-emissions, just the first of various regulations set to unfold over the next 20 years.

HELD TO ACCOUNT

IT IS A PRIVILEGE TO USE THIS publication as a means to dive deep into industry issues and ask pertinent questions. Earlier this year a US organisation criticised a government agency’s regulation on what is essentially a phased-in transition toward zero emission commercial vehicles. There was a lot of noise about ‘forcing’ carriers to invest in new technologies and our editorial team investigated claims from a number of sources about the pros and cons. Read our special report on the subject and please let us know what you think of this situation.

Whether you agree, disagree or are indifferent to the matter, we are keen to learn more as sustainability and the uptake of new technologies is rapidly becoming the norm. The likes of CEVA Logistics proudly declared at this year’s Transport Logistic event in Munich, Germany, that it is committed to growing its electric vehicle fleet to more than 1,450 units over the next three years and other transport and logistics companies are following suit. More recently, Schmitz Cargobull delivered an all-electric trailer to a fleet in Romania and there are so many other incredible innovations in the pipeline. Meanwhile, take a look at what is happening on Britain’s roads. At the time

of writing there were about 3,000 Longer Semi-Trailers (LSTs) using that freight network and that is expected to increase following new legislation. These heavy goods vehicles are typically up to 2.05 metres longer than the current standard semi-trailers on UK roads (15.65 metres instead of 13.6 metres). Important to note these are not the road trains permitted in some other countries or the 25.25-metre designs found in some EU countries. Also, new guidance on the approval and intended use of these vehicles has been released for transport operators which is fantastic. There are concerns about the impact it may have on infrastructure, though, and there are other voices that are vocal about safety risks to cyclists and pedestrians however you only need to consider the economic and tangible benefits of leveraging efficient road transport technologies to realise that this will lead to reductions in emissions and fuel and help to minimise the environmental impact with fewer truck movements required for freight tasks.

CEO

John Murphy john.murphy@primecreative.com.au

COO

Christine Clancy christine.clancy@primecreative.com.au

INTERNATIONAL SALES

Ashley Blachford ashley.blachford@primecreative.com.au

MANAGING EDITOR

Luke Applebee luke.applebee@primecreative.com.au

JOURNALISTS

Peter White peter.white@primecreative.com.au

Louise Surette louise.surette@primecreative.com.au

DESIGN PRODUCTION COORDINATOR

Michelle Weston michelle.weston@primecreative.com.au

ART DIRECTOR

Blake Storey DESIGN

Kerry Pert, Louis Romero

CLIENT SUCCESS MANAGER

Salma Kennedy salma.kennedy@primecreative.com.au

HEAD OFFICE

Prime Creative Pty Ltd

379 Docklands Drive Docklands VIC 3008 Australia p: +61 3 9690 8766 f: +61 3 9682 0044 enquiries@primecreative.com.au www.globaltrailermag.com

SUBSCRIPTIONS

+61 3 9690 8766 subscriptions@primecreative.com.au

Global Trailer is available by subscription from the publisher. The rights of refusal are reserved by the publisher.

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

Global Trailer is owned by Prime Creative Media and published by John Murphy. All material in Global Trailer is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published.

The opinions expressed in Global Trailer are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

Follow us on twitter @Globaltrailer

OUT OF THIS WORLD

JOST KKS – push-button trailer coupling

#futurenow – Thanks to our revolutionary coupling system you can now change semitrailer quickly and safely out of the cab. Your start in the future of logistics. Ready to beam up?

NEWS INTERNATIONAL

AFRICA & ASIA

SOUTH AFRICA

Truck body and trailer manufacturer, Serco, was tasked with building three mobile clinics to boost local health services.

Truck rental and logistics company, Spartan Truck Hire, specified Serco for the project.

These clinics will be used by Shout-ItNow in areas where there is little or no access to medical care and attention in South Africa.

The deal was funded by PEPFAR – the United States’ President’s Emergency Plan for AIDS Relief – which is the largest commitment by any nation to address a single disease with its activities focusing on expanding access to HIV prevention, treatment and care interventions.

Shout-It-Now is a proudly South African organisation which aims to empower youth to have bold conversations about sex and relationships through innovative approaches to reach communities with free sexual and reproductive health services.

Shout-It-Now works in partnership with the SA Department of Health and is funded by PEPFAR through the Centres for Disease Control and Prevention and Grand Challenges Canada.

The three mobile clinics needed to be fitted with all the equipment necessary for the efficient and all-round functioning of a modern health care provider.

Serco built the 9.5m insulated truck bodies with provisions to accommodate the required equipment which was fitted and installed in co-operation with a variety of local suppliers.

Features in and on the vehicles include cubicles to cater for a variety of patients day or night, air conditioning, electric power supply (solar and

generator backup), Wi-Fi, TV, ablutions, a kitchenette, furniture, and storage compartments in the belly of the chassis with full livery on the boxes. The clinics are already in use and according to the Fleet Director of Spartan Truck Hire, Shailesh Koobair, the client is very satisfied with the vehicles which have more than exceeded their operational expectations.

Koobair said Spartan Truck Hire has been a customer of Serco’s over many years. “We are very happy with the service and quality of the products we have received from Serco and will continue to use them as our needs require.”

Spartan Truck Hire, which has been in business in South Africa for more than 40 years, and has more than 2,000 vehicles in its fleet. It operates in Johannesburg, Cape Town, Pretoria and Durban.

CHINA

Global transport and logistics company, Freja, is opening a new office in Shenzhen, China, as it continues to expand its service offerings in air freight, sea freight, project forwarding and e-commerce.

This will be the fourth office, with others located in Shanghai, Qingdao and Guangzhou.

“The opening of the new office is a natural step in our development, and it will support us in better fulfilling our customers’ needs,” said Freja China Managing Director, Leo Hu. “After a slow economic recovery due to Covid-19 and years of political uncertainty, we want to strengthen today’s supply chains by expanding our business.”

The Danish company said the new office will allow it to improve transportation speed and its cargo size range.

CHINA

Kuehne + Nagel is expanding into the area of animal healthcare logistics, addressing a growing need in greater China.

The global transport company has partnered with Elanco Animal Health, an American animal pharmaceutical company, to open two dedicated fulfilment centres in Chengdu, West China.

The new facilities comprise a 3,000-square-metre manufacturing

GROUPED. FOR SUCCESS.

NEWS INTERNATIONAL

ASIA & EUROPE

warehouse and a 12,000-square-metre distribution centre for finished products. “As an animal healthcare customer, Elanco relies on the highest quality standards,” said Marcello Ferrari, Global Vice President Customer Development Healthcare and Contract Logistics. “With our HealthChain label, we ensure that our customers’ trust is a core element of our strategic Roadmap 2026.” To streamline the process and satisfy the stringent standards on healthcare products administration, Kuehne + Nagel has implemented a state-of-the-art warehouse management system and computerised validation program for the project.

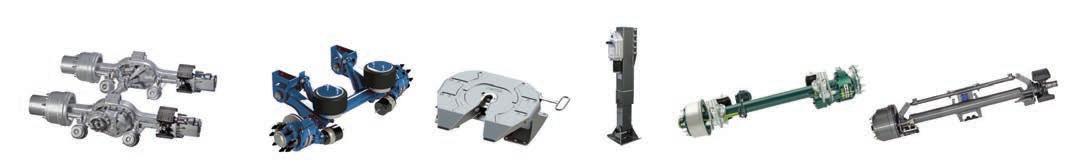

Combining decades of experience gathered in Asia, Australia, Europe and the US, global manufacturing powerhouse Fuwa has forged the strongest network of truck trailer component specialists in the world. Merging local expertise with world-leading manufacturing prowess and an irrevocable commitment to innovation, our entire range of axles, suspension systems, landing legs, couplings, king pins, fifth wheels and ball races have been designed for one goal only -- to guarantee your success. Join the Group. Join the Revolution.

transportation project is an important symbol of the transformation to green and low-carbon development, conforms to the development trend of high efficiency and low energy consumption and also conforms to the development requirements of high-standard economic and trade rules,” said Jin Shaojing, Director of Shanghai Huangpu District Commission of Commerce.

SINGAPORE

FUWA ENGINEERING

p: +65 68631806

CHINA

“In addition, it conforms to the Chinesestyle modernisation, pushes the industry to move towards high-end, optimises the modern logistics system, and steadily promotes the high-quality development goal of energy conservation and carbon reduction.”

making significance.”

SINGAPORE

Following its win at the top of the World Bank’s Logistics Performance Index (LPI), Singapore will host its first multimodal logistics trade fair.

Set for 1-3 November this year, the event will focus on logistics, mobility, IT and supply chain management.

AUSTRALIA

FUWA HEAVY INDUSTRIES

p: +86 750 5966333

Dylan Lu, Vice President of Elanco in China, said China is the second largest market for Elanco, after the United States.

“Thanks to Kuehne + Nagel, we managed to consolidate our existing facilities and upgrade our supply chain operation to the next level.”

CHINA

International logistics provider, Yusen Logistics, recently launched a new hydrogen-powered transport service. On 28 March, the Yusen Logistics Hydrogen Transport Launch Ceremony was successfully held at YL-CN Kunshan Huaqiao Logistics Centre.

During the event, Yusen Logistics showed all guests its new hydrogen fuel cell truck and the prospects of the hydrogen transportation business. With environmental issues being one of the most urgent and critical areas at present, the launch of the truck was a crucial step in Yusen Logistics’ ESG practice.

“Yusen Logistics’ hydrogen

Yusen Logistics China President and CEO, Tomoo Moriya, said the project is just the beginning of the company’s sustainable development.

“In the future, Yusen Logistics will continue to promote initiatives based on long-term sustainable development prospects in line with our brand promise and we are willing to work with all partners to promote sustainable social development,” he said.

In March this year, Yusen Logistics joined the Green and Low-Carbon Development Branch of Shanghai Foreign Investment Association as a founding member.

“Carbon reduction in road transportation is the key to the low carbon transition in the transportation sector, in which carbon emissions from trucks play a pivotal role,” said Huang Feng, President of Shanghai Foreign Investment Association.

“Yusen Logistics launched its hydrogen energy transportation business in a timely manner to help logistics customers easily achieve the goal of ‘zero carbon emissions’ which is of epoch-

EUROPE

FUWA K-HITCH

p: +61 3 9369 0000

khitch.com.au

“Singapore is the gateway to the greater Southeast Asia region and the most dynamic and exciting hotspot for transport and logistics right now,” said Stefan Rummel, CEO of Messe München, the organiser of the event.

“Many global companies are already active here, and many more want to come to reap the rewards of the attractive conditions.”

The LPI ranking gave Singapore the best scores in the quality of logistics services, competence, and infrastructure categories. With its favourable geographical location on the Strait of Malacca, the city-state is home to one of the world’s most important transhipment hubs.

AUSTRIA

Geis Group has gained a 66 per cent stake in Austrian transport and logistics company, Quehenberger.

The German transport solutions business is taking over the shares retrospectively as of 1 January 2023. The remaining 34 per cent is held by the previous majority owner, Christian Fürstaller, who will continue to run the company as CEO and retain all its workforce. Their combined service offering ranges from road freight transport and contract logistics to air and sea freight.

Geis Group’s managing partners Hans-

VALX International p: +31 (0)88

GROUPED FOR .

NEWS INTERNATIONAL

EUROPE

Wolfgang Geis and Jochen Gris said in a joint statement that they will now focus on organic growth and use synergies to expand the business with plans to create a presence in central and south-eastern Europe.

With a total of more than 10,000 employees at approximately 200 locations in 13 countries the group of companies is hoping to become a leading logistics player in its markets. The company said customers will benefit from this partnership as they will now get access to a much larger network that stretches from Luxembourg to the Black Seas and from the Baltic Sea to the Mediterranean.

Branches in Russia, Belarus, Kazakhstan and Ukraine were excluded from the takeover. These companies were spun off from the Augustin Quehenberger Group into a separate holding company, CF Logistics, in 2022.

AUSTRIA

German transport and logistics company, a. hartrodt, has expanded its European network by opening an office in Austria. Previously, the company had serviced Austrian customers from Germany, the Czech Republic or Slovakia.

“With our own local office, negotiations are easier,” said Christine Mair, who will head up the new office and plans to hire a sales expert and up to three operational employees. This is in line with a. hartrodt’s European sales strategy of investing in locations and regional specialists.

Mair said she wants to develop competitive solutions for the Austrian market which has a population of nine million and a strong base of small and medium-sized enterprises with strong

export industries.

a. hartrodt has more than 100 locations and 2,000 employees around the world.

BRITAIN

New government laws allowing Longer Semi-Trailers (LSTs) on Britain roads has sparked debate as to whether the decision is safe or necessary. There are currently 3,000 of these longer semi-trailers on the road but they are expected to increase with the new legislation, which comes into effect at the end of May.

The Department for Transport (DfT), which has been trialling the trucks since 2011, has stated they are safe and will ultimately help businesses become more productive and drastically reduce carbon dioxide emissions.

LSTs are a type of Heavy Goods Vehicle (HGV) trailer up to 2.05 metres longer than the current standard semi-trailers on UK roads – 15.65 metres instead of 13.6 metres. These are not the road trains permitted in some other countries or the 25.25 metres designs in use in some EU countries.

The total weight of the LST, the goods and the prime mover, according to DfT, must still be within the UK domestic weight limit of 44 tonnes. They must pass the turning circle test applied to the existing 13.6 metre trailers, for which the LSTs require a steered rear axle. Fully loaded LSTs can move the same volume of goods using fewer journeys than current trailers, for little change in fuel use per mile, while reducing overall emissions, congestion, and collision risk. LSTs complement other approaches to freight carbon reduction, such as modal shift, increasing engine efficiency, and the use of electric vehicles, but LSTs

can be implemented without the need for further significant technological and infrastructure development.

Road safety advocates, however, have voiced concern that the 18.55m-long trailers could pose a danger to cyclists and pedestrians because of their increased tail swing.

Tail swing is the movement of the rear of a truck as it turns and can increase its area, depending on the length of the trailer and the weight of the load.

According to the DfT, the new trailer rule is set to result in £1.4 billion of economic benefits and take one standard-size trailer off the road for every 12 trips. It estimates the vehicles will save 70,000 tonnes of carbon dioxide from being released into the atmosphere over 11 years.

Furthermore, the trial demonstrated that, with appropriate operational management, LSTs can be operated safely and deliver up to a 13 to 14 per cent reduction in real world emissions, with an average saving of 8.0 to 9.0 per cent across the whole trial. The trial also carried out route modelling and specialist analysis of the impact of LSTs on vulnerable road user groups. Following demonstration of consistent trial safety and emissions performance, DfT has introduced regulations to permit LSTs to be used widely across Britain. The Campaign for Better Transport, however, has argued that the new size will pose a safety risk and possibly damage current infrastructure. It maintains that the government should be focusing its efforts on increasing train transport as opposed to larger trucks.

According to the European Rail Freight Forward coalition, every freight train emits 80 to 100 per cent less CO2, than

NEWS INTERNATIONAL

EUROPE

a freight truck and replaces 50 trucks at a time.

EU

New commercial vehicle registrations are going gangbusters across the European Union (EU).

For Q1 2023, new truck sales reached 86,455 units, up 19.4 per cent compared to Q1 2022.

All member states except Denmark (-8.9 per cent) recorded substantial growth, including the four largest markets: Germany (+20.9 per cent), France (+12.4 per cent), Poland (+19.1 per cent) and Italy (+9.5 per cent).

As for the fuel types of new trucks, 96.1 per cent are diesel, 1.1 per cent are electrically chargeable and 2.7 per cent are ‘other’.

“Diesel trucks remained the top choice for buyers in the EU, representing 96.1 per cent of all new registrations in the first quarter of 2023,” the European Automobile Manufacturer’s Association (ACEA) said in a statement.

“New diesel truck registrations increased by 19.4 per cent, with most member states reporting double- or triple-digit gains. Having recorded a remarkable 408.5 per cent growth, electrically chargeable vehicles now represent 1.1 per cent of all EU trucks, with 939 units.” ACEA is a Brussels-based trade association of the 14 major car, van, truck and bus producers in Europe.

The ACEA commercial vehicle members are DAF Trucks, Daimler Truck, Ford Trucks, IVECO Group, MAN Truck & Bus, Scania, Volkswagen Commercial Vehicle and Volvo Group.

GERMANY

Ulrich Steenken will assume the role of

Chief Financial Officer (CFO) at global logistics service provider, Leschaco, headquartered in Bremen, Germany. In Steenken, the company has chosen an internationally experienced finance manager with proven industry expertise, who thus completes the management board.

After studying business administration at the University of Cologne, Germany, the graduate business economist started his professional career as a commercial controller at Trans-O-Flex, Weinheim, Germany. He then moved to Kuehne & Nagel Inc., New York City, USA, where he assumed responsibility as Regional Controller Latin America. This was followed by key positions in financial management at Rohde & Liesenfeld International GmbH & CO KG, Hamburg, Germany (part of the Geodis Group since 2008) and Paul Günther Logistik AG. Hamburg, Germany. In 2008 he moved to the Geodis Group, an international logistics service provider, where he most recently held the position of CFO at Geodis FF Germany GmbH & Co KG, Hamburg, Germany. Before joining the Leschaco Group, Ulrich Steenken was the managing director of Confion Consulting GbR.

In his role as CFO, Ulrich Steenken will be responsible for the financial management of the Leschaco Group as a member of the Management Board and will work closely with Constantin Conrad, Chief Executive Officer (CEO) of the group to drive the growth plans of the familyowned company and the strategic to achieve goals.

“We welcome Ulrich Steenken as CFO on the Leschaco Management Board and look forward to working together to achieve our future goals,” said Conrad.

“We are convinced that his leadership experience and specialist knowledge will be of great value for the growth and success of our company will be.”

In addition to CEO Conrad, members of the Management Board of the Leschaco Group are Oliver Oestreich (Chief Operating Officer), Nils Fahrenholz (Incoming Chief Operating Officer) and Steffen Küpper (Chief People and Culture Officer).

GERMANY

Schmitz Cargobull subsidiary, Cargobull Parts & Services GmbH, has appointed a new Director for Parts and Sales.

Christian Renfordt has accepted the role and has been working in the automotive aftermarket space since 2002. He will be responsible for sales, product management and pricing of international spare parts.

Renfordt has already put a number of initiatives in place to ensure efficient spare parts logistics, in addition to expanding the product and service portfolio with attractive pricing. “Quality spare parts, easy identification of spare parts and high availability are important for our customers,” he said. “In the event of a repair, the trailer must be back on the road quickly. Because only a running trailer is successful and profitable.”

Cargobull Parts & Services GmbH is a wholly owned subsidiary of Schmitz Cargobull AG. In the aftersales area, it takes care of all the needs of customers and their vehicles throughout Europe.

FINLAND

Speed Oy has taken delivery of 20 Kässbohrer non-extendable light container chassis K.SHG L vehicles

www.flatlaminates.com

We stand right in the middle of every project realization.

Close to you since 1962

HIGH QUALITY GRP FOR COMMERCIAL VEHICLES.

NEWS INTERNATIONAL

EUROPE

specially developed for its Nordic operations.

The container chassis are linked via dolly and are operated as A-double combination.

Founded in 1992, Speed Oy offers unit transports and delivers containers from all container ports in Finland. Together with its offices in Vuosaari Harbour, Helsinki; in Mussalo Harbour, Kotka; in Port of Rauma and in Hollola, Lahti area, Speed Oy supports shipping companies, their agents, Finnish import and export companies and forwarding agencies. With its new Kässbohrer non-extendable K.SHG L container chassis vehicles specially engineered to provide ease of manoeuvrability for longer trailer combinations compliant with Nordic regulations, Speed Oy will increase operational efficiency and allow higher payload and lower fuel consumption.

Tuomo Vallas, General Manager of Speed Oy, Matti Virtanen, Sales Director of Vak Oy and Mehmet Önen, Head of Key Account Management of Kässbohrer, attended the delivery ceremony and detailed their newly established partnership.

Vallas said: “As Speed Oy, we already know Kässbohrer container chassis vehicles. We preferred Kässbohrer vehicles as we trust their quality and robustness.

“The Kässbohrer Light Container Chassis offers to carry more weight without sacrificing its strength and durability. The Kässbohrer K. SHG L was redeveloped for meeting the flexibility need of our operations with the option to carry 40′. We operate our container chassis linked via dolly for A-double combination. With our new container chassis, we get one of the lightest combinations,

allowing higher payload and lower fuel consumption.

“The support from sales and after-sales teams makes it easy and efficient to work with Kässbohrer.”

Önen also shared his thoughts about the valuable cooperation.

“As Kässbohrer, our main priority is to make developments to satisfy our customers’ operational needs by presenting the highest number of options to meet their unmet operational needs,” he said.

“Designed specifically for our customer Speed Oy’s Nordic operations, our robust Lightweight Container Chassis K.SHG L with higher payload capacity is very durable, longest, and lightweight, enabling our customers to achieve maximum efficiency in their operations. K.SHG L enables lower fuel consumption with a light chassis design.

“Speed Oy operates by combining two container chassis via dolly reaching A-double combination. We have engineered our chassis to be easily manoeuvred on existing roads, the finest example of design and engineering excellence. Speed Oy safely operates Kässbohrer A-double combinations.

“As Kässbohrer, we meet the operational needs of our partners with our competent sales and after-sales support. We are very glad to build a partnership with Speed Oy. We will continue to develop our partnership with Speed Oy through our high-quality vehicles and the services we offer them.”

GERMANY

Equipment specialist, SAF-Holland SE, has started the financial year better than expected.

It generated sales of €480.4 million

in the first quarter – 29.9 per cent above the previous year’s level, and significantly above market expectation. SAF-Holland said solid organic growth combined with efficiency improvements in production-related areas and cost savings in administrative functions led to an increase in adjusted EBIT of 84.6 per cent.

The preliminary result, before income tax, increased to €28.6 million and was also above market expectations.

The outlook for 2023, according to the company, is an expectation of sales tending around the upper end of the range.

After suffering a recent cyber-attack, the company temporarily lost sales of €40 million, of which approximately €15 million was attributed to the first quarter of 2023 and a greater effect occurring in the second quarter.

It continues to expect to recover the majority of lost revenue over the course of the second and third quarters of 2023, although there was a one-time expense in the low single-digit million-euro range for IT security and consulting services.

UK

Cold chain carrier, P&S Logistics, has taken delivery of a rigid truck fitted with a Schmitz Cargobull M.KO COOL box body.

The bespoke vehicle was designed and built over the course of 15 months – a process that owner-operator Phillip Hudson describes as a labour of love. Hudson embarked on the upgrade of the 26-tonne vehicle with the aim of maximising the flexibility of his Middlesex-based European food distribution operations.

Built by Schmitz Cargobull in Lithuania,

EUROPE

the refrigerated box body M.KO COOL was shipped to the UK and equipped with Carrier Transicold’s Supra 1150 MT (multi-temperature) unit and ECO-DRIVE power module. It was fitted with a tail-lift sourced from Germany, with additional truck specifications including Kelsa light bars, safety cameras and interior equipment. The rigid was finished with a hand-painted livery, in original designs to reflect different aspects of the business.

Hudson also operates a Schmitz Cargobull drawbar reefer, equipped with a Carrier Transicold Supra 1050 unit. The ECO-DRIVE is able to run both the truck fridge and the trailer cooling unit electrically off the truck engine’s power take-off.

The drawbar was built to the same high specification as the rigid truck, featuring Schmitz Cargobull’s proven Ferroplast side panels, which are stronger yet thinner than Glass-Reinforced Plastic (GRP) bodywork – helping to increase the loading aperture inside the body.

“What I have is very rare,” said Hudson. “I wanted to create something highlyspecced which stands out from the crowd that I can use for the long-term. With the technology fitted, the truck and drawbar meet all the regulations, which has future-proofed my business.”

This box body has three different temperature zones for ambient, chilled and frozen goods.

“If I have work that only requires a 26-tonne truck, or there are weight restrictions, I can just park the drawbar,” said Hudson. “The bespoke, mechanically operated tail-lift also enables easy and quick loading and unloading of pallets by electric pump trucks.”

Used primarily to transport Slovakian food, the rigid has been liveried with

the country’s flag, with the cab painted with images of London where Hudson was born. The rear doors, designed with Hudson’s Polish wife in mind, feature the Wawel Dragon from Polish folklore as well as the country’s flag.

P&S Logistics’ relationship with Schmitz Cargobull dates back more than five years. The company first supplied Hudson with a rigid reefer in 2016 to help him expand his business operations.

LITHUANIA

Parcel delivery company, Venipak, has purchased an e-commerce wholesaler which represents the likes of LEGO, L’Oreal, Disney and Mattel.

The acquisition of Strengholt Entertainment BV, which was more than a year in the making, and is expected to form the basis for the expansion of Venipak’s e-fulfilment arm in Europe and the expansion of its air freight services across Europe, Asia and the Americas. The company’s business model will also change with its logistics now complemented by whole-sale channels for e-commerce.

Nerijus Raudonis, Venipak Group founder, said the company plans to set up 200 e-fulfilment centres in Europe where it will distribute goods. Plans are also underway to include Chinese and American branches in the wholesale trade.

According to the company, while Strengholt had a wide range of products, a developed IT infrastructure and a network of partners, they didn’t have an international model to bring their products closer to customers, to reach them faster.

“We will fill this gap in Europe and connect it to the Asian and US markets,”

said Venipak General Manager, Justas Šablinskas.

“Almost none of the e-commerce businesses operating in the Baltics have the kind of service that we will receive from Amazon, so as intermediaries, we will open up new business development opportunities for our customers.”

Venipak currently operates in the Baltic states, Poland and China. It provides parcel delivery, e-fulfilment and air freight with 251 self-service parcel delivery terminals in Lithuania and 201 in Latvia. In Estonia, the network of self-service parcel delivery terminals is currently being rolled out and two thirds of the planned 151 are already operational.

NORWAY

Danx has made a strategic alliance with Tromsø Budbil Sentral (TBS), the largest courier company in Norway, to ensure it can service hard-to-reach areas in the north of the country.

Danx, a spare part logistics and delivery specialist in the Nordic region and the Baltics, is hoping the investment will offer resource support while benefitting from TBS’s well-established local customer network, which stretches from Narvik to Kirkenes, in northern Norway. “By joining forces, we strengthen our offering to northern Norway, expand our network, and progress the Danx Carousel group’s ambition to become the European leader for time-critical in-night logistics,” said Danx Managing Director, Ole Larsen. “We’re looking forward to working with the TBS team to further develop their network, solution, and sector offering which will bring about more success together in the future.”

The new venture represents a significant

EUROPE

development for Danx, enabling it to provide its customers with a pre7am delivery service of regular and temperature-controlled goods to remote destinations.

Frank Riise, Managing Director of TBS, will continue to head up the courier service’s operations as it joins Danx. This development comes after Danx’s recent joint venture with Polish logistics specialist, ILS, which has boosted Danx’s time-critical and in-night logistics solutions in Eastern Europe.

ROMANIA

Germany-based container carrier,

Hapag-Lloyd, has opened a new office in Romania.

Strategically situated, Romania offers Hapag-Lloyd direct access to Central, Eastern and Northwestern European countries via the Danube-Black Sea Canal.

With the port of Constanta, it will also provide an important hub port for container traffic in the Black Sea region. Located in Bucharest, Senior Managing Director Region South Europe, Juan Pablo Richards, said the new office will allow Hapag-Lloyd to take advantage of the region’s growth opportunities.

Perfectly effective

“Romania is an attractive growth market with an important port and good hinterland connection via road and rail,” he said.

“This new office in the capital Bucharest aligns with our strategy to grow in key markets.

“We are very pleased to open an own office in this strategically significant location, which will allow us to serve our customers even better in the Black Sea area and beyond.”

According to Hapag-Lloyd, Romania has reached one of the highest growth rates of all EU members in recent years and has garnered sizeable investments from

Transport temperatured goods more cost-effectively with the S.KO COOL reefer. The innovative insulation system FERROPLAST® together with the efficient S.CU cooling unit and the smart TrailerConnect® telematics system ensure optimized and reliable transportation. Also available fully electric as S.KOe COOL. More Information:EUROPE

multinational corporations and other EU countries alike.

UKRAINE

ÖBB Rail Car Group has plans underway to link its intermodal network, offering a connection between Kyiv and Vienna with stops in Budapest and Lviv. Working with Ukrainian Railways, the new connection will be the first regular, high-frequency intermodal link between Ukraine and the numerous hubs in Central Europe.

Rail freight has proven its systemic relevance in maintaining supply security during numerous international crises, said ÖBB CEO Andreas Matthä.

“The whole of Europe must grow closer together as far as rail freight transport is concerned. This is an important step in the right direction, for the economy, countries and the environment.”

Austrian ÖBB Rail Car Group has been supporting Ukraine with transport and logistics since March 2022, with more than two million tonnes of agricultural products alone, exported, equating to 100 trains per month.

The partnership, the company says, will bring advantages to customers including:

• Full access to Rail Cargo Group maritime, continental and Eurasian connections.

• Trucking service to any European destination.

• Fixed schedule and attractive transit times

• Weekly departures in both directions. In related news, transporting more goods by rail, according to ÖBB Rail Car Group, will see the EU succeed in meeting its climate targets.

“Achieving a 30 per cent share in the continental transport mix for freight

trains is possible – with the digitalisation and automation of rail transport,” said Dr Sigrid Nikutta, who is the new chair of the Rail Freight Forward initiative, a coalition of European rail freight companies.

Dr Nikutta, DB Board Member for Freight Transport and head of DB Cargo AG, has succeeded Dr Clemens Först, Board Spokesman of the ÖBB subsidiary Rail Cargo Group. Först has chaired the European rail freight initiative for five years, ever since it was founded. “Rail is in Europe’s DNA. With more than 260,000 kilometres of rail lines, Europe has the largest continental environmental network in the world,” said Dr Nikutta.

“Compared to road transport, each freight train emits 80 per cent to 100 per cent less CO2 and replaced more than 50 trucks at a time,” she said. The path to modernising rail freight infrastructure, according to Dr Nikutta, is a Herculean task that cannot be left to transport companies or the rules of the market alone.

“Investment in the rail system is worth it – it pays off for climate protection in Europe and the world,” said Dr Nikutta. “A strong Europe is more important than ever in the face of global challenges. And rail makes Europe strong – no other continent has such a dense network.”

At this year’s Transport Logistic trade show in Munich, the industry stood together.

Dr Nikutta said: “The goal of a 30 per cent modal share for climate-friendly rail freight transport can be achieved in just a few years. It can be done if there is support at European level for the huge task of expanding the network and upgrading to digital

standards in rail freight.

Freight trains generally receive a green signal at borders – 60 per cent of all trains cross at least one national border. Around 50,000 to 60,000 freight trains per week bring provisions to the continent, with its approximately 450 million people and their businesses and industries. Ten European rail freight corridors (RFCs) provide a backbone for the European economy.

POLAND

recently opened a new branch in Poland and this site is expected to take delivery of the new Curtain Master semi-trailers, which are XL certified, in Q2 2023. The XL certification ensures beverages, tyres and similar goods can be transported without additional protection or load restraint gear.

PNO is a Danish family-owned company, founded in 1975, that specialises in shortterm and long-term semi-trailer rental. It is also committed to transitioning its fleet to be more sustainable by providing customers with personalised transportation solutions guided by environmental best practice.

“We are a company that values close cooperation with well-established companies,” said PNO Poland Sales Director, Tomasz Milecki.

“We are pleased that Wielton has become our business partner, because we are committed to providing our customers only with proven products of the highest quality. Together with the Wielton manufacturer, we are guided by the same values. I believe that this is a promising start to a longer cooperation.”

In mid-April this year, representatives of the PNO Group and PNO Poland: Thomas Rimington, Chief Operating

EUROPE

Officer of PNO Group; Peter Hvidt Molin, Group Country Support; and Tomasz Milecki, Sales Director of PNO Poland had the opportunity to visit the production plants and the Quality Control Department located in Wieluń. This gave them an insight into the processes that are an integral part of production (e.g. anti-corrosion protection of the chassis by cataphoresis), and most

out the transaction.

“At Wielton, we are consistently pursuing a strategy based, among other things, on organic growth,” said Wielton Export Director, Jacek Stokowski.

“Our cooperation with PNO, which is one of the key European semi-trailer rental companies, gives us the prospect of entering the Scandinavian market and acquiring new customers.

are successfully increasing our market share in European countries and expanding our presence in foreign markets year by year.”

ROMANIA

The first all-electric Schmitz Cargobull S.KOe COOL semi-trailer was recently delivered to a fleet in Romania. Together with other representatives

NEWS INTERNATIONAL

EUROPE & MIDDLE EAST & NORTH AMERICA

Păun, General Manager at the transport company Blue River. During the event at the Schmitz Cargobull site in Ciorogarla, the advantages of the all-electric semitrailer were presented in detail and its functionality was demonstrated in practice.

“Blue River and Schmitz Cargobull have been business partners for many years and we are pleased to be able to provide Blue River with an efficient and sustainable vehicle for temperaturecontrolled transport in the form of the S.KOe all-electric refrigerated box trailer,” said Schacht.

Păun said: “For Blue River, the past year was a year of repositioning and bold decisions. We want to continue to drive forward the electrification of freight transport in Romania and thus act as a benchmark for the entire transport industry. The all-electric refrigerated box is part of this long-term sustainability strategy and we are pleased that Blue River is the first Romanian transporter to add this vehicle to its fleet.”

Schmitz Cargobull has been investing in research and development for sustainable and energy-efficient transport solutions for many years, making it one of the pioneers in innovation in the trailer industry.

“Our new all-electric S.KOe COOL semi-trailer is a clear demonstration of our commitment to sustainability and cutting-edge technology,” said Badea.

The all-electric S.KOe COOL semi-trailer is equipped with an all-electric cooling unit with integrated power electronics, a highvoltage battery and an axle generator, making it emission-free.

The electrified vehicle is also extremely quiet and thus enables delivery in urban areas in the early morning hours as well

as in the late evening. The electrically powered S.CU ep85 cooling unit is designed for emission-free cooling and heating of the load and offers a cooling capacity of up to 15,800 watts and a heating capacity of 10,500 watts. Batteries on the support winch replace the diesel tank and also offer the option of installing an additional pallet box with space for 36 pallets. The electrified Schmitz Cargobull trailer axle recuperates energy during braking, among other things, and thus extends the operating time of the refrigeration machine or reduces the recharging times of the battery via the power grid.

DUBAI

Emirati logistics and transportation company, Aramex, announced it has signed a joint venture agreement with the aim of enhancing the supply chain connectivity along key international trade routes.

Joining forces with AD Ports Group, the exclusive developer and regulator of ports and related infrastructure in Abu Dhabi, the venture will develop and operate a new non-vessel operating common carrier enterprise, in the hopes

of developing shipping connectivity across Middle Eastern, Indian and East and West African markets.

Aramex, who has a 49 per cent stake, will provide tailored solutions to freightforwarding industry players, servicing their ocean-bound container cargo. Its target is 10,000 containers in the shortterm with plans to increase the number of containers in the long term.

CANADA

Following 55 years of experience, strategic acquisitions, and a new website, Manac has strengthened its brand. The OEM in recent years has built a service centre in Moncton, Canada, developed new products and improved its service standards.

This new brand positioning is reported to focus on the human factor, cooperation and partnership as a growth driver with the new slogan ‘Together we go further’. This slogan, the OEM explained, symbolises Manac’s vision to be recognised as the industry’s preferred partner in North America and the company’s commitment to working closely with clients to cater to their everevolving needs.

NORTH AMERICA

“We literally go further thanks to the sturdiness, efficiency and durability of our trailers,” said Manac Vice President Sales and Marketing, Tom Ramsden.

“Concept-wise, we go further in terms of business, as we work together with our team members, clients and suppliers to generate synergies.”

To strengthen the reputation and equity of its numerous brands, Manac also created a consistent, scalable brand architecture that will help to onboard new brands in the context of potential future acquisitions. This architecture comprises a parent brand (Manac), sister brands (ABS and Peerless), as well as two types of sub-brands: the acquired child brands (Alutrec, Liddell, Cobra, and CPS) and the native brands (WING product line such as Darkwing).

This brand repositioning, Manac said, comes with a visual identity that puts the iconic flying moose at the forefront, focusing on the wings that carry us further. In addition, Manac has updated its image with a new, totally revamped website that is better suited for today’s market needs, where clients require increased transparency and concise, quickly accessible information. Clients can expect an improved user experience, thanks, in part, to increased ease of navigation, detailed product sheets, and a dedicated section for services such as repairs and liftgate installation.

US

National Association of Trailer Manufacturers (NATM) has appointed Alex Stowe as Executive Director. He has been acting as interim Executive Director since early November 2022.

Stowe joined NATM in 2021 as Technical Director. He has headed the compliance, technical and technology committees since that time. In these roles, Stowe has worked to further the Association’s mission to continuously advance trailer safety as well as the success of the trailer manufacturing industry.

“We are thrilled to have Alex leading the Association,” said NATM President, Marco Garcia.

“Our time working together in his past roles as Technical Director and Interim Director has proven to me that he is a highly valuable asset to our team and will work tirelessly on the Association’s mission to promote trailer safety for the industry.

“I look forward to continuing to advance NATM’s mission

NEWS INTERNATIONAL

NORTH AMERICA

of promoting trailer safety and overall success of the trailer manufacturing industry,” said Stowe. “Our Association is in an incredible position to continue to help our membership, and I am honoured to be able to serve as Executive Director.”

Stowe received his Juris Doctorate with a concentration in business transactions from the University of Nebraska College of Law. Prior to joining NATM as the Technical Director in the fall of 2021, Stowe was a Compliance Specialist Advisor overseeing HIPAA and privacy matters for an insurance company. He also spent time working in the college athletics realm for Creighton, Purdue, Ohio State, and his alma mater Nebraska. NATM has been dedicated to improving trailer safety and performance for more than 30 years. The Association represents manufacturers that produce light- and medium-duty trailers, supplier and service providers, trailer dealers and tow vehicle OEMs to the industry.

NATM seeks to promote safety awareness and provide a voice for trailer manufacturers and their suppliers when issues of trailer safety and regulation are considered by Congress and relevant government agencies.

Founded in 1987, the Association has grown to represent more than 1,000 companies belonging to the trailer industry.

NATM is dedicated to improving trailer safety. One way this is accomplished is through the mandatory Compliance Verification Program, requiring all trailer manufacturers to verify they have the manufacturing processes in place to build trailers that meet Federal Motor Vehicle Safety Standards (FMVSS) and industry best practices.

US

The Biden administration has announced it has ramped up its national logistics program in an effort to speed up delivery times and reduce consumer costs.

The Freight Logistics Optimization Works (FLOW) program now has 53 companies on board including FedEx Corp, United Parcel Service Inc and Maersk.

The US Transportation Department spent $1.5 million to create the program and is now asking for $5.3 million in the budget to continue the momentum.

The FLOW program was created to address supply chain issues by getting ports, truckers, shippers, retailers, wholesalers and other businesses to share information. These key stakeholders are working together with the Administration to develop a proofof-concept information exchange to ease supply chain congestion.

US Transportation Secretary, Pete Buttigieg, said the department will continue refining the program, seeking feedback from companies to make it more useful.

US

North American transport and logistics company, Hub Group, has reported its latest financial results.

The company reported net income of $62 million USD for Q1 2023 (Q1 2022: $88 million USD)

“Although we are in a softer demand environment the $1.2 billion of revenue we generated in the quarter is the second highest first quarter revenue in the history of our company,” said Hub Group President and CEO, Phil Yeager. “Our yield management, cost containment and operating efficiency initiatives resulted in operating income

margin of 6.8 per cent of revenue. “We continue to execute on our long-term strategy, investing in our core business and technology while diversifying our service offering. We remain focused on managing our costs and capital structure, while supporting our customers with great service and investing for growth to drive success in a variety of market conditions.”

First quarter 2023 results: Consolidated revenue for the first quarter of 2023 decreased to $1.2 billion USD as compared to $1.3 billion USD in first quarter 2022. Purchased transportation and warehousing costs declined as compared to prior year due to lower volumes, reductions in third-party carrier costs per load, and decreased use of third-party carriers for drayage, partially offset by higher equipment and rail costs. Salaries and benefits costs increased $9 million USD relative to prior year due to $28 million USD of incremental expense related to growth of our driver and warehouse employee headcount, partially offset by a $19 million USD reduction in office employee compensation due to lower headcount and lower incentive compensation expense.

General and administrative expense increased as compared to prior year due to higher rent expense and higher outside services expense primarily for IT software related to the acquisition of TAGG Logistics. Depreciation and amortisation expense increased as compared to prior year due to investments in our container and tractor fleets, as well as amortisation of intangible assets related to the acquisition of TAGG. Operating income for the quarter was $78 million USD (6.8 per cent of revenue) as compared to $115

NORTH AMERICA

million USD (8.9 per cent of revenue) in the prior year. EBITDA (non-GAAP) for the quarter was $124 million USD. The first quarter 2023 effective tax rate of 19.4 per cent benefitted primarily from a change in state apportionment methodology.

First quarter ITS Segment revenue was $709 million USD, as compared to $777 million USD in the prior year. Intermodal revenue per load for the quarter increased 3.0 per cent while volume decreased 12 per cent as compared to prior year.

Volume for the quarter was impacted by softer demand conditions as retailers’ inventory levels increased from the lows seen in 2021, which impacted demand for our services. Revenue for our Dedicated business line grew 5.0 per cent in the quarter. ITS operating income decreased to $49 million USD (7.0 per cent of revenue) as compared to $86 million USD (11.0 per cent of revenue) in the prior year due to lower volume, higher equipment costs and lower surcharges. These headwinds were partially offset by lower drayage costs as we increased the portion of drayage handled on our own fleet to 74 per cent in first quarter 2023 as compared to 58 per cent in the prior year, as well as an improvement in profitability at our Dedicated service line.

First quarter Logistics Segment revenue was $469 million USD, as compared to $541 million USD in the prior year. The decline in revenue was driven by lower revenue per load in our brokerage business line and lower managed transportation business line revenue, partially offset by revenue from TAGG.

First quarter operating income was 6.1 per cent of revenue as compared to 5.4

per cent last year. Operating income was unchanged at $29 million, as lower revenue was offset by lower purchased transportation costs and our yield management initiatives.

Capital expenditures for the first quarter of 2023 totalled $27 million USD. As of March 31, 2023, Hub Group had cash and cash equivalents of $343 million USD.

US

Retail corporation, Walmart, is committed to rapid online delivery and pickup. It has opened its first Market Fulfillment Center (MFC) in Arkansas in a bid to expand the use of its stores. Fulfilment through digitisation and connecting the store to supply chain assets end-to-end will, according to Walmart, will transform operations. The MFC utilises a proprietary storage and retrieval system which, according to Store Manager, Ryan Simpson, will enhance the customer experience with more accurate online fulfilment and also provide a runway to continue growing the business.

In related news, Walmart released its Q1 financial results.

Total revenue for the corporation was up 7.6 per cent at $152.3 billion USD, with operating income growing faster at 17.3 per cent at $0.9 billion USD. Walmart US E-commerce growth was 27 per cent which was led by pickup and delivery.

“We had a strong quarter,” said Walmart President and CEO, Doug McMillon. “We leveraged expenses, expanded operating margin, and grew profit ahead of sales. And a big thank you to our associates, who continue to step up and deliver for customers and members whenever and however they want to be served.”

US

Dorsey Trailer has exceeded its 2023 production goals following investments from its new owners.

In 2022, Dorsey set a production goal to produce 2,650 trailers but met demand by producing a total of 3,025 trailers (+14 per cent).

“We are very pleased with our production results,” said Trey Gary, CEO of the Elba, Alabama-based company. “We have been able to meet the increased demand for our durable trailers by expanding our production capacity, offering team incentives, and partnering with our employees for a more efficient workplace. We are confident that we will continue to meet the needs of our customers in the coming quarters.”

According to a TechSci report, the global semi-trailer market is projected to reach $37.05 Billion USD in 2023, growing at a CAGR of over 4.0 per cent during 2018-2023.

Dorsey Trailer is poised to meet that demand, offering a wide variety of truck trailers including steel and composite flatbeds, drop decks, extendable flatbeds and drop decks, open top or closed chip vans, and specialty trailers including beavertail and ramps, multi-axle, and oilfield trailers.

Dorsey Trailer’s success is due in part to its focus on customisation. Texas-based Superior Trailer Sales has worked with Dorsey Trailer for the past 12 years. “You are getting Tier 1 quality products at Tier 2 pricing when you buy from Dorsey,” said Superior Trailer Sales President, Benton Reynolds. “This is a company that is easy to work with and they are willing to customise.”

The company also places a priority on workplace incentives and

NEWS INTERNATIONAL

NORTH AMERICA & SOUTH AMERICA

employee compensation.

“Our employees have bought in on the idea of reaching production goals because they are seeing the benefits in each and every paycheck,” said Dorsey Trailer Assistant Vice President, Joseph Scott.

“Production bonuses and attendance bonuses were huge reasons for the increase in production for 2022.”

Scott added that Dorsey’s owners, Propst Companies, made an investment in new equipment.

He said Propst invested millions of dollars to ensure the workforce had the best equipment available. Improvements to the workplace environment have been cheered by employees. These incentives have paid off with increased morale and production.

Propst Companies purchased a majority ownership stake of Dorsey from Pitts Enterprises in 2019 and acquired the remaining ownership in April 2023. Since purchasing Dorsey Trailer, Propst, a diversified investment company with interests in real estate and a variety of other operating companies, has offered tremendous incentives to the Dorsey employees.

The Dorsey name has been engrained in the trailer manufacturing world since the early 1900s when Pete and Henry Dorsey opened a small machine shop to repair the power saws, boilers, and trucks of the booming timber business. By 1920, the little company was producing 25 to 30 logging units per day. The Dorsey company’s first commercial freight trailer was developed by 1930. By the end of the decade, truckers coast-tocoast were familiar with the Dorsey trade name.

“It’s quite the accomplishment to be

recognised as the fastest growing platform trailer manufacturer in the country, and truly, Dorsey is a treasure for Elba and an industry-driver for the rest of the state,” said Alabama Governor, Kay Ivey.

Dorsey is also a supporter of National Trailer Dealers Association (NTDA) programs and services. Gary served on the organisation’s Board of Directors from 2017–2020.

“The NTDA appreciates the connections created by industry partners like Dorsey Trailer that help to not only create longlasting, mutually beneficial relationships, but that also help to elevate industry standards through their professionalism,” said NTDA President, Gwendolyn Brown.

US

Transport and logistics company, TFI International, is acquiring two LessThan Truckload (LTL) operations. It has completed the acquisition of Hot Line Freight Systems and has agreed to acquire Siemens Transportation Group (STG).

Founded in 1988, Hot Line is a specialised LTL provider based in Wisconsin. The company’s nearly 200 employees operate a network of 14 terminals (eight of which are owned), generating approximately $30 million USD (approx. €27.6 million) in annual revenues. With a strong focus on expedited one- to twoday LTL service across the Midwest as well as a nationwide over-theroad division concentrating on high-value and white glove freight, Hot Line is renowned for its exceptional customer service.

Hot Line’s Paul Burgmeier will continue to manage the business

as part of TFI’s Less-Than-Truckload segment, reporting to Executive VicePresident Rick Hashie.

Founded in 1962, the majority of STG’s operations are LTL, with a smaller portion of its business in truckload and flatbed. Based in Saskatoon, Saskatchewan, STG is a family-owned business providing a total supply chain solution spanning North America through its 15 terminals, including 11 in Canada and 4 in the US, generating annual revenues of approximately $150 million CAD (approx. €101.9 million).

STG’s Doug Siemens will continue to manage the business as part of TFI’s LessThan-Truckload segment, reporting to Executive Vice-President Chris Traikos. The transaction is subject to regulatory approval.

“We are pleased to be expanding our LTL footprint in both Canada and the US with these two LTL acquisitions,” said TFI International Chairman, President and CEO, Alain Bédard.

“STG’s impressive family-run approach has attracted a loyal customer base across diverse industries, and its compelling geographic presence and wellmaintained equipment strategically complement our growing network. Hot Line is another highly attractive acquisition with well-run operations and a strong presence in the midwestern US that will further bolster our LTL presence while allowing us to ramp its cross-border business. We are thrilled to welcome Doug, Paul and their impressive teams to our growing family of companies and look forward to watching both STG and Hot Line succeed under the TFI International umbrella.”

SOUTH AMERICA & OCEANIA

BRAZIL

The newly re-branded, Randoncorp, has reported a successful first quarter with a consolidated net revenue 7.3 per cent up from the same time last year.

The trailer and equipment manufacturer closed 2023’s first quarter with 2.7 billion BRL in consolidated net revenue, which it attributed to the company’s business diversification and its internationalisation strategy.

Consolidated EBITDA advanced 10.2 per cent when compared to 2022 first three months, reaching 442.2 million BRL.

Among the main factors that boosted these figures, the company said, was the increase in revenue from the foreign market, totalling $111 million USD, an increase of 11.1 per cent when compared to 2022’s first quarter.

“With growing revenues in hard currencies and in the aftermarket, investments in productivity and capturing synergies between our companies, we achieved a quarter with good results and margin expansion, even in a scenario of political and economic uncertainties,” said Randoncorp CEO,

Sérgio L. Carvalho.

In April, the company released its guidance for 2023, projecting consolidated net revenue between 10.5 billion BRL and 12 billion BRL, with an estimated revenue in the foreign market between 520 million USD and 570 million USD.

The company’s accelerated growth is also marked by its new corporate branding aimed to internationalise the company’s presence and provoke a visionary attitude grounded on investment in innovation.

Earlier this year, Randon Companies, announced a name change in what it called a strategic step towards its consolidation as a multinational company.

The new name – Randoncorp – is a tribute to the company’s legacy as it directs investments, strategies and innovation efforts towards a path of sustainable growth, the company announced.

“It is essential to build an identity that reflects this moment and the path we want to take from now on,” said Carvalho.

“The more we evolve, the more we commit ourselves to the environment, society and ethical and responsible governance.”

In addition to six plants located in Brazil, the company maintains a plant in Argentina and works with partners for the assembly of semi-trailers in several strategic global points in Central America and Africa.

BRAZIL

The 23rd Libreparts store has opened in Serra Gaúcha. This new store was inaugurated in the city of Caxias do Sul and is expected to support fleets as well as bolster the local economy.

Libreparts stores, according to Librelato, offer a wide variety of parts for trailers, including suspension, lighting and brake items, all with Librelato warranty. In addition to physical stores throughout Brazil, the brand has a virtual store for quick service, enhancing the user experience of Librelato products. Every detail of the Libreparts network is designed to optimise heavy vehicle uptime.

“By facilitating and streamlining the parts sales process, we increase business productivity and reduce vehicle downtime in case of maintenance,” Librelato said in a statement.

AUSTRALIA

Refrigerated truck rental business, Eurocold, is launching a Western Sydney expansion operation this month with plans to rapidly impact the New South Wales market.

The centrepoint of the operation is a 3,500 square metre site which will allow Eurocold to efficiently provide service to

NEWS INTERNATIONAL

the Sydney market with easy access to the Blue Mountains, Central Coast and Hunter Valley/Newcastle.

Eurocold Managing Director, Avraam Solomon, is planning to have 100 trucks on the road from the new facility by December this year and 150 by 30 June 2024.

Trucks will be available to rent or purchase from the opening day, with immediate delivery available.

Noting the changing face of the refrigerated truck market, Eurocold will apply its processes in providing rented trucks on a long-term basis.

The long-term rented trucks will be assembled in Brisbane and will be delivered as brand new machines. Short-term rentals, also available from day one, will offer customers unlimited kilometres.

Eurocold revealed the Sydney facility will

also perform on-site bodywork repairs on all manufacturers of refrigerated truck bodies including fibreglass, welding, hinges and seal repairs.

The new facility will help Eurocold establish a large footprint in Sydney, and will open the opportunity for further growth over the coming years, according to Solomon.

“We have intentions of growing quickly,” he said.

“We can do that by having trucks in the Sydney facility available for purchase and hire from day one.”

According to Solomon, Eurocold has also recruited local experts with deep industry experience, supported by the company’s national team.

“The team there are vastly experienced in their roles; they are local – so we’re committed to supporting Western Sydney – on top of that, the Sydney team

has the full support of our national team,” he said.

Solomon will be overseeing much of the operation first hand through personally being on-site during the launch phase. In March, Eurocold launched Revora – a sister brand that will assemble electric refrigerated trucks in Australia to “take customers on a journey towards zero emissions”.

Eurocold’s Sydney operation will take delivery of the Revora trucks as well as service that growing area of transport operations.

“The industry-leading processes that we’ve put in place over our years of operation allows us to hit the ground running and scale quickly, then with Revora coming online with the electric refrigerated trucks – we really have a broad offering for Sydney and New South Wales,” Solomon said.

OCEANIA

“We cannot wait to see the Eurocold brand being more prevalent in the Sydney market and helping operators move towards zero emissions with Revora.”

AUSTRALIA

Linfox has joined Transport Women Australia Limited (TWAL) as a Gold Partner to support its commitment to provide an inclusive, safe and diverse workplace.

Linfox will partner with TWAL to provide mentoring, host networking events and contribute to Government relations and advocacy activities.

Linfox Australia and New Zealand CEO, Mark Mazurek, said the company is serious about improving its female participation rate through increased opportunities and training.

“We are proud of the progress we have made, but recognise that we still have a long way to go before we achieve the diverse and inclusive workplace we aspire to,” he said.

“We continue to roll out unconscious bias and diversity and inclusion modules in our leadership training programs.

“We have also established reference groups and mentoring programs dedicated to influencing positive change.”

TWAL Chair, Jacquelene Brotherton, said TWAL was delighted for Linfox to join as a Gold Partner.

“We welcome the opportunity to strengthen the bond between our organisations and the benefits it will bring to both,” she said.

“Linfox has long supported increasing female participation in the transport industry.

“We look forward to the opportunity

to strengthen our leadership support and the additional benefits this partnership will bring to our advocacy for industry diversity and inclusion.”

NEW ZEALAND

TMC Trailers has been building trailers since 1948.

“We are incredibly proud to have reached this milestone and grateful for all of our loyal customers who have supported us along the way,” TMC Trailers said in a statement.

“We have come a long way since our humble beginnings, but our commitment to quality and customer satisfaction remains the same. Our team of skilled professionals work tirelessly to design, manufacture and deliver the best trailers in the business.

“We would like to take this opportunity to thank all of our staff, customers, and partners for their support over the years. We look forward to continuing to provide innovative and reliable trailers for many more years to come.”

TMC Trailers manufactures heavy transport equipment for operators in New Zealand and Australia. It specialises in curtainsiders, flat decks, skels, transporters, tippers and other custom designs.

The head office and manufacturing facility is based in Hornby, Christchurch. All production processes including computer assisted design, fabrication, abrasive blasting, painting and assembly are also performed in-house.

NEW ZEALAND

DHL Supply Chain has opened a new transport hub in Hamilton, New Zealand. This hub will further bolster final-mile delivery capabilities in under serviced areas outside of Auckland.

Fitted with state-of-the-art technology and equipment, the new facility will serve as a key logistics hub nationwide to better meet the needs and expectations of regional customers.

DHL Supply Chain New Zealand Managing Director, Matt Casbolt, was excited to announce the opening of the new transport hub in Hamilton.

“This is the latest addition to our twoyear transport network development strategy, following on from the establishment of our Whangarei, Tauranga, and Hawkes Bay transport hubs,” he said.

“With the addition of our new Hamilton hub and existing network, we are proud to now provide last mile and line haul services to customers in regions and key markets that represent over 50 per cent of the country’s GDP.

“Our goal is to continue delivering an exceptional transport service to our customers, enabled by great people, a strong network presence, and partnering with the best transport service providers.”

The new hub will service customers across all sectors that require a high service standard in deliveries, including consumer goods, life sciences, healthcare, engineering and IT sectors. DHL’s investment in regional areas is aiming to enhance the resilience of supply chains in New Zealand. As part of this investment, DHL plans to open further hubs later this year and into 2024.

CHANGER GAME

CIMC VEHICLES PROVES TO BE A POWERFUL WORLD LEADER IN THE INTERNATIONAL TRAILER MANUFACTURING SCENE WITH ITS COMMITMENT TO STATE-OF-THE-ART TECHNOLOGY, DRIVEN IN PART BY AN ENTREPRENEURIAL SPIRIT THAT IS CAPITALISING ON NEW OPPORTUNITIES, PARTICULARLY IN ELECTRIFICATION AND THE FINAL MILE.

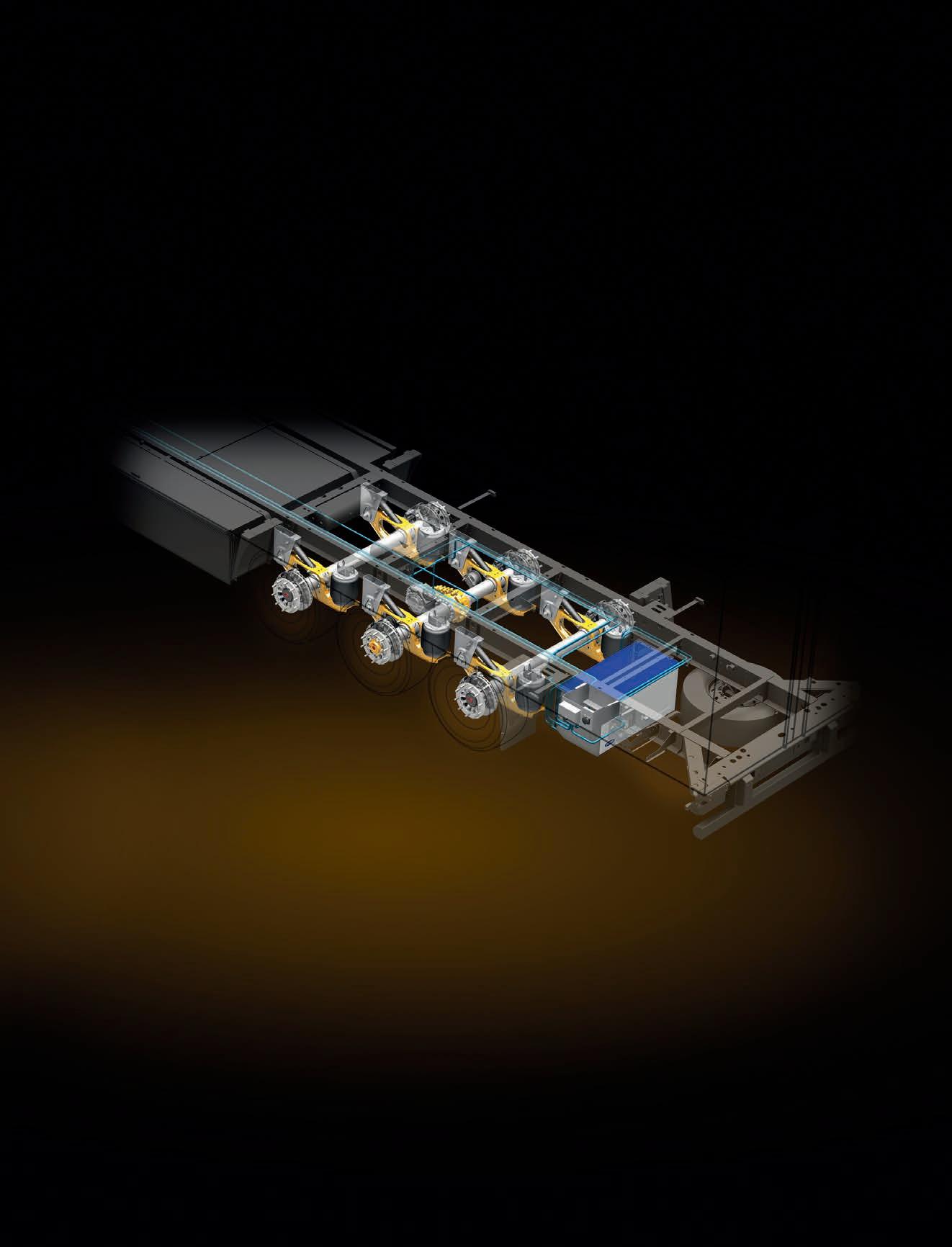

The Chinese economy is transitioning from high-speed growth to high-quality development. CIMC Vehicles, as a result, is seizing this opportunity to launch a third venture. By adopting a new development philosophy, it continues to build its Light Tower manufacturing network and drive intensive growth through innovation and expanding its business scope. The OEM is also accelerating its exploration of new energy sources and removing barriers in the supply chain to achieve high-quality development.

David Li, CIMC Vehicles CEO and President, said that starting the third venture, in a sense, is a structure driven by dual wheels.

“On the one hand, it focuses on our existing businesses, firmly adhering to the theme of ‘structural reform of production organisations’,” he said. “We aim to make them stronger, better, more efficient and more globally extended. On the other hand, it explores prospects in the field of new energy.”

Specifically, CIMC Vehicles’ strategic initiatives are as follows:

First is the ‘Star-chained Manufacturing Network’. Simply put, it is an upgraded version of the

Light Tower plants, which connects all Light Tower production lines or Light Tower plants digitally. This constitutes the ‘Star-chained Manufacturing Network’, supporting the business philosophy of ‘Intercontinental Operation, Local Manufacturing’. The OEM is expediting the structural reform of its semi-trailer production organisation, focusing on building business groups, and striving to achieve the vision of high-quality industry integration, innovative distribution models and continuous improvements in market share and value.

Second, regarding the launch of the ‘North America Compass’ plan, the OEM aims to reshape the production organisation of North American

chassis trailers and refrigerated semi-trailers, promote sales of intermodal transportation product portfolios and actively establish a new development pattern of sharing sales networks and channels in North America. This should result in steady market share growth and enable new growth opportunities in the European market.

Third, CIMC Vehicles is accelerating the growth of its Champion Tanker Business Group. Seizing the recovery opportunity in the heavy-duty truck market, the OEM has improved its order delivery. By enhancing the division of labour and collaboration among its LTP production centres, the business can improve production efficiency and establish additional business growth.

Fourth, the OEM is promoting the ‘Light Tower Manufacturing Network’ to support the plan to start a business for the third time. CIMC Vehicles has already built and invested in 24 Light Tower production lines

worldwide, covering a full range of semi-trailers, various types of tankers, and truck bodies for specialty vehicles. Yet, the utilisation rate of these product lines has not been fully maximised according to Li. It limited their capabilities to support overseas and cross-regional operations flexibly. Since 2022, CIMC Vehicles has been preparing an upgraded version of the Light Tower plants, namely the ‘Light Tower Manufacturing Network’. In 2023, leveraging a national unified market, CIMC Vehicle will network and digitalise the Light Tower production lines of Champion Tanker Business Group, TB Business Group and the business group of semitrailer in China.

Fifth, CIMC Vehicles is constructing a new management infrastructure for digitalisation to support the plan to start a business for the third time. The OEM will further optimise the ‘Accounting 2022’ process, focusing on improving the quality of overseas enterprise reports. It will iterate the ‘Money 2021’ process to build the CIMC Vehicles Group’s treasury system and explore the launch of an electronic settlement platform for related transactions. Also, the OEM will initiate the digital upgrade of the ‘Budget 2020’ process to establish a digital ‘data middle platform’. Moreover, CIMC Vehicles has iterated the ‘Performance 2020’ process to optimise the KPI management system further.

Sixth, the OEM is advancing ‘Organisational Development 2023’. By promoting the iteration and upgrade of its executive team, CIMC Vehicles aims to build an operational Leadership Triangle for intercontinental operation to start a business for the third time. This, in turn, will

gradually upgrade the governance structure of the listed company and implement long-term incentive mechanisms.

“Regarding new energy, as the commercial vehicle industry accelerates its transition towards new energy and intelligence trends, CIMC Vehicles, in line with the trend of electrification and intelligence in the automotive industry, expedites innovation and exploration in the field of new energy,” said Li. “We focus on the R&D of new energy products, enhancing our leading advantages in lightweight, intelligence and adaptability. We define a new integrated product for integrated tractor-trailers and promote the standardisation and serialisation of various technological modules. Through strong cooperation with prime mover manufacturers, we accelerate the market penetration of new energy products.”

CIMC Vehicles will actively respond to market trends and will show great courage to tackle any challenge head-on, make the best efforts and demonstrate the entrepreneurial spirit of the third venture.