Executive Interview: GORICA

Global OEM Ranking List Market Report: Portugal Industry Voice: Brianza Plastica

Event Preview: NUFAM

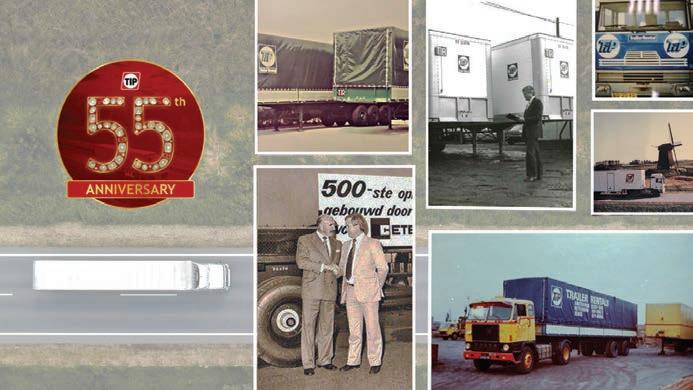

TIP Celebrates 55 Years

Executive Interview: GORICA

Global OEM Ranking List Market Report: Portugal Industry Voice: Brianza Plastica

Event Preview: NUFAM

TIP Celebrates 55 Years

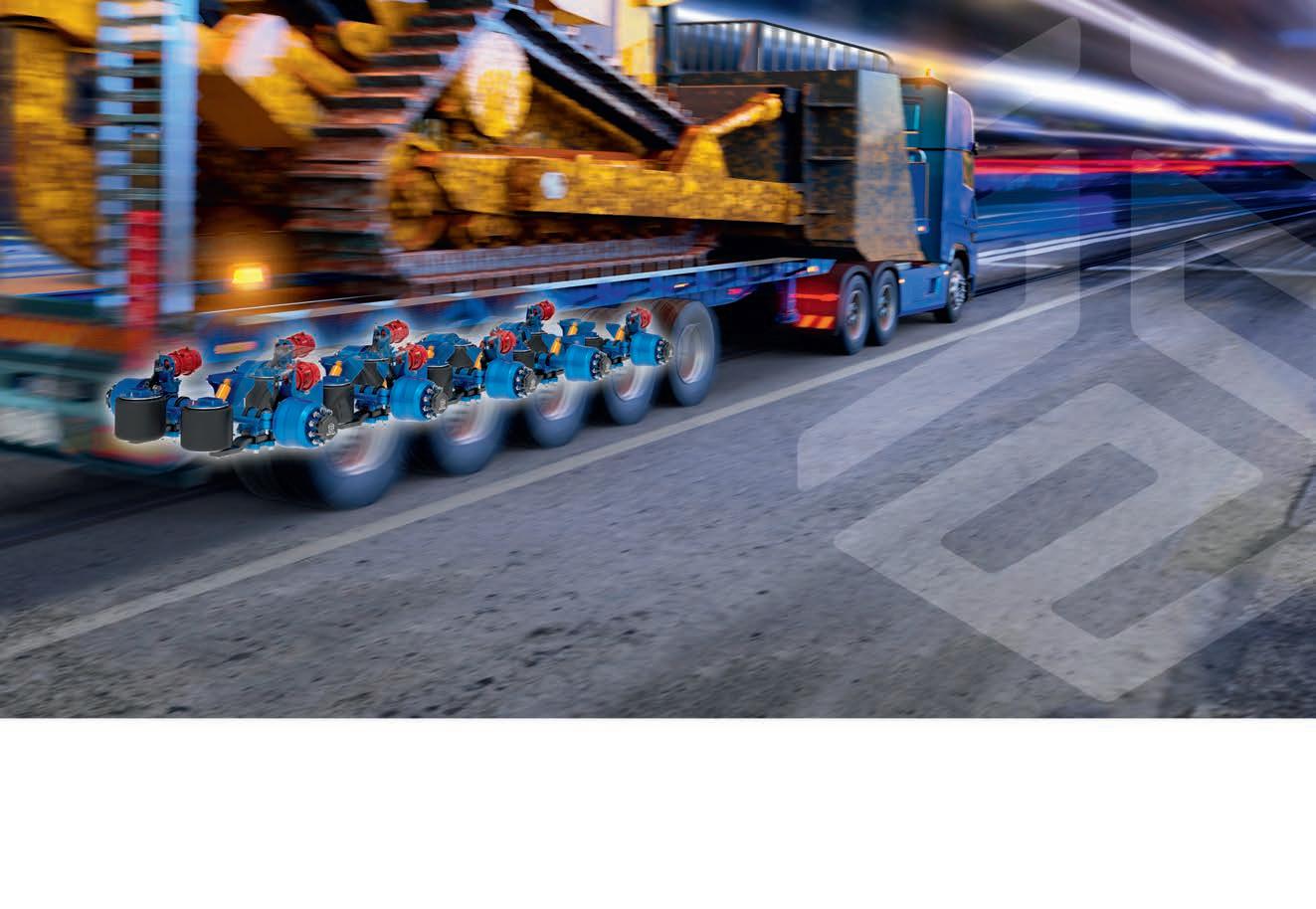

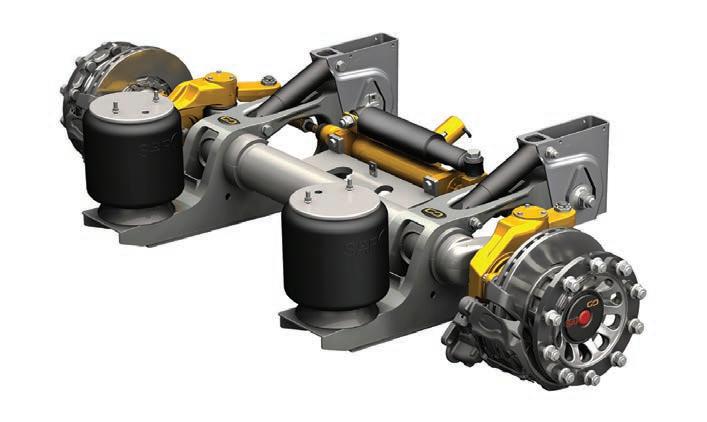

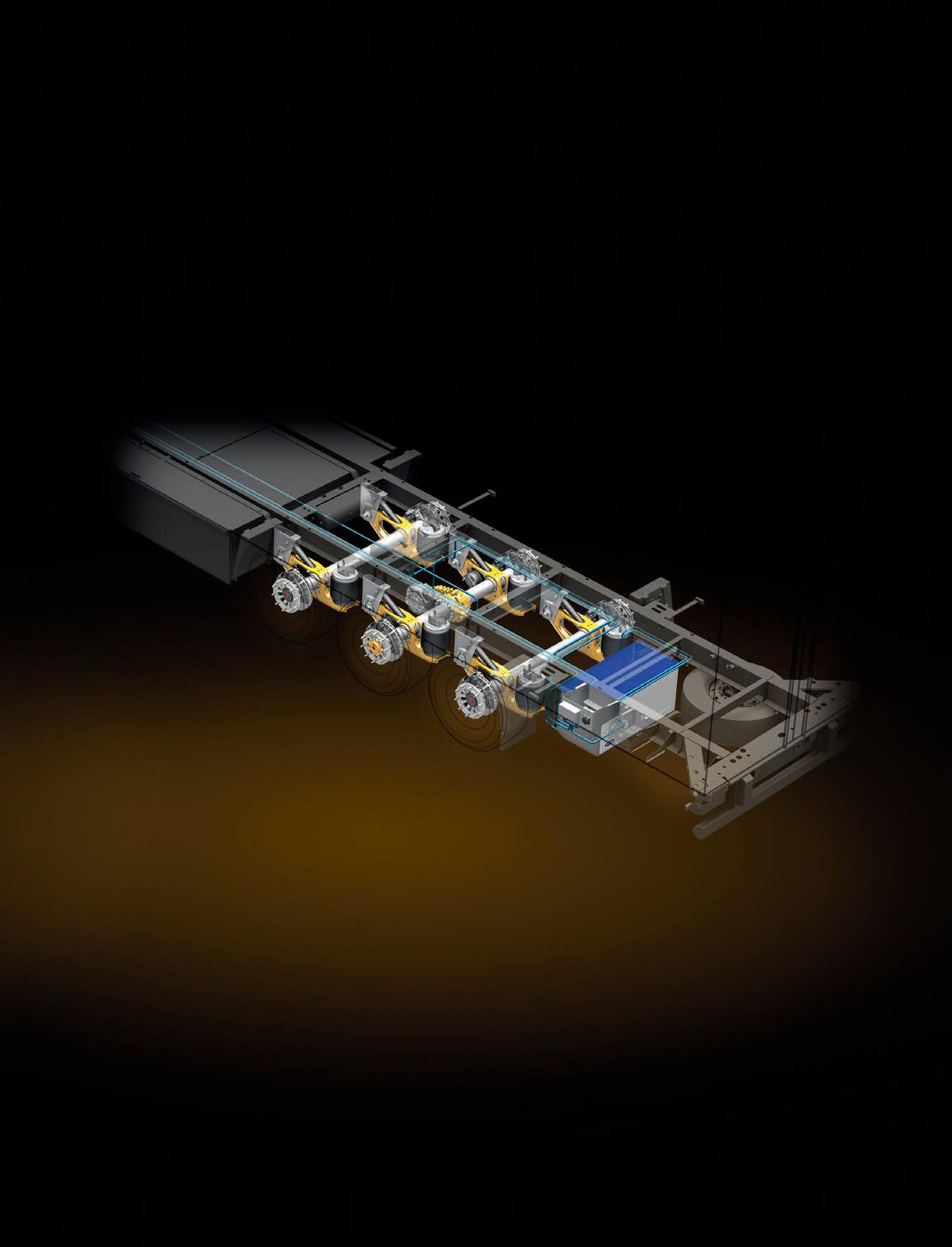

INDIVIDUAL RUNNING GEAR SOLUTIONS FOR SPECIAL TRANSPORT TASKS.

With our running gears and special axle solutions, there is nothing that can’t be transported. Your requirements motivate us to create new things. They inspire us to use our entire engineering expertise and decades of experience to develop innovative and reliable solutions together with you – customised for the type of vehicle and intended use.

The swing axle masters any heavy transport - even on critical ground and difficult terrain. It is part of our individual solutions that are uniquely powerful and resilient. Challenge us!

The knowledge it takes to become a leader is often found in mysterious places. For GORICA Group’s owner and Active Chairman, Ivan Fornazaric, it all started in the farming lands of socialist Yugoslavia. Far from the green fields and picturesque mountains of his youth, he reflects on his life and how it has shaped him into a powerful player in the Middle East’s trailer manufacturing industry.

34 MARKET REPORT

A look at the transport and logistics industry in Portugal.

56 BUILT TO ASK

Coldstores Group of Saudi Arabia talks robotics.

58 COMPANY PROFILE

TIP Group celebrates 55 years of operation.

60 INDUSTRY VOICE

Brianza Plastica makes big moves in the US.

70 SPECIAL REPORT

What you need to know about longer semi-trailers in Britain.

68 GLOBAL OEM RANKING LIST

Who are this year’s top 50 trailer builders?

36 NUFAM PREVIEW

See what the road transport industry has in store for the upcoming NUFAM trade fair in Germany.

46 GREEN LOGISTICS

Krone and BPW are contributing big time when it comes to achieving

“DUBAI ACCEPTS THAT WE ALL HAVE DIFFERENT BACKGROUNDS AND THAT IS WHAT MAKES THE SOCIETY STRONGER. THERE ARE ONLY FEW PLACES IN THE WORLD WHERE YOU CAN MAKE SUCH AMAZING CONNECTIONS WITH PEOPLE COMING FROM LITERALLY ALL ENDS OF THE GLOBE.”

04 EDITOR’S NOTE

76 EVENTS

78 MEGATRENDS

IAIN BANKS WAS A SCOTTISH author, a man of incredible imagination and exceptional talent with the written word. He leaves behind a vast body of work ripe for mainstream consumption. Most notably his Culture series of novels tackle larger-than-life ideas all with the genre trappings of action, adventure, intrigue and romance. While his space opera stories typically feature exotic aliens, advanced technologies and stunning locations, it is the worldbuilding, the lore, in which his omniscient narration indulges arguably a little too much perhaps. It’s fair to say that the Culture, a post-scarcity and utopian civilisation, is in essence a character in its own right. One can imagine an early draft of Consider Phlebas, the debut novel in a series of 10 books, may have waffled endlessly about the inner workings of this colossal galactic superpower. To some extent this is true. Fortunately, there is a plot, our daring characters are chasing the brain of a stateof-the-art starship, known as a Mind, which has fled imminent destruction. How far will our protagonists go to claim their prize? Read the book and find out, no spoilers here.

It’s easy to draw parallels between a science fiction page-turner published in

1987 and the state of international trailer manufacturing today. We’re seeing a surge of zero emission vehicles and smart trailers hit the road at a rapidly increasing rate which is not only exciting but also shaping how society – producers, consumers and everyone in between – behaves. Without being overly melodramatic we are in a sense moving closer to that utopia ideal by implementing modern and efficient road transport systems. Taking that idea further just look at how far we’ve come in the last five years from the development and rollout of electric axles to advances in telematics and smart systems where peripherals are talking to the Mind as it were of trucks and trailers. Sure, these vehicles are not reaching the stars yet but a little imagination, and a vision to simply do better than before, will see yesterday’s fiction become a reality. Back to Earth for a moment, this edition is jam-packed with great stories. There are NUFAM event previews, updates from leading trailer builders and component suppliers, and the soon-to-be-mostscrutinised editorial of the year, our annual Global OEM Ranking List.

CEO

John Murphy john.murphy@primecreative.com.au

COO

Christine Clancy christine.clancy@primecreative.com.au

INTERNATIONAL SALES

Ashley Blachford ashley.blachford@primecreative.com.au

MANAGING EDITOR

Luke Applebee luke.applebee@primecreative.com.au

JOURNALISTS

Peter White peter.white@primecreative.com.au

Louise Surette louise.surette@primecreative.com.au

DESIGN PRODUCTION COORDINATOR

Michelle Weston michelle.weston@primecreative.com.au

ART DIRECTOR

Blake Storey

DESIGN

Kerry Pert, Louis Romero

CLIENT SUCCESS MANAGER

Salma Kennedy salma.kennedy@primecreative.com.au

HEAD OFFICE

Prime Creative Pty Ltd 379 Docklands Drive Docklands VIC 3008 Australia p: +61 3 9690 8766 f: +61 3 9682 0044 enquiries@primecreative.com.au www.globaltrailermag.com

SUBSCRIPTIONS

+61 3 9690 8766 subscriptions@primecreative.com.au

Global Trailer is available by subscription from the publisher. The rights of refusal are reserved by the publisher.

ARTICLES

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

Global Trailer is owned by Prime Creative Media and published by John Murphy. All material in Global Trailer is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published.

The opinions expressed in Global Trailer are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

Follow us on twitter @Globaltrailer

NEW: KKS-U CONNECTOR RETROFITTABLE TO EXISTING TRAILERS

JOST KKS – push-button trailer coupling

#futurenow – Thanks to our revolutionary coupling system you can now change semitrailer quickly and safely out of the cab. Your start in the future of logistics. Ready to beam up?

Scan Global Logistics (SGL) continues to strengthen its foothold in Africa, opening its first office in Nairobi, Kenya. Already well-represented with offices in Togo, Benin, Mali, Cote d’Ivoire, Senegal and South Africa, the Danish company said this latest expansion is a pivotal part of its strategy to tap into the fastdeveloping African continent’s significant potential.

With the Standard Gauge Railway (SGR) opening, connecting coastal Mombasa with inland Nairobi, the improved road infrastructure over the last years, and Kenya’s advantageous location as the gateway for East Africa, SGL sees great potential by investing in the region. In close collaboration with their logistics colleagues in South and West Africa, the expansion to East Africa will provide SGL with a competitive geographical coverage to further support its large aid and relief and commercial cargo customers, the company said in a statement.

Asia-Pacific’s largest asset management company, ESR, has just completed construction on its first in-built cold storage facility in a cold chain industrial park in Sichuan, China.

As one of the earliest industrial zones in China, the park plays an important role as part of the Belt and Road initiative, focusing on the development of international supply chain, trade and intelligent manufacturing.

The multi-faceted cold storage facility’s first and second phase are 100 per cent tenanted to several domestic e-commerce companies.

“With the acceleration of e-commerce and resilient supply chain, demand for

modern and institutional-grade logistics facilities continues to grow,” said Jeffrey Shen, ESR co-founder and co-CEO. “We are proud that the project has been recognised by renowned e-commerce tenants in the country and we are committed to strengthening ESR’s cold chain development.”

cargo-partner has begun offering a new transport option as a supplement to the existing rail transport services on the Iron Silk Road in response to increased demand in China.

The Middle Corridor of the New Silk Road has become an increasingly viable alternative to air, sea and rail transport with cargo-partner adding it as a flexible China-Europe route choice. The first trip took place in early July and consisted of a temperature-controlled shipment of lithium batteries for an automotive customer.

By closely monitoring the changing local circumstances, cargo-partner can flexibly select the most favourable route

and border crossing for each individual shipment. Transit times vary depending on the origin and destination points and currently average 22 to 25 days.

In addition to the competitive transit times, the new transport option has the advantage of being able to move goods that cannot be shipped by air or rail.

CHINA

cargo-partner opened new offices and warehouses in key locations across China in recent months.

Highlights include a Pharmaceuticals & Healthcare Competence Center in Shanghai, a warehouse in Guangzhou in the south, and new offices in Nanjing in the east of the country and in Chongqing in central China.

The company promoted its extensive network at this year’s Transport Logistic event at the Shanghai New International Expo Centre which includes additions in Shanghai, Guangzhou, Chingqing and Nanjing.

“As a dynamic and rapidly evolving market, China presents immense

opportunities for the cargo-partner group,” said Luca Ferrara, CEO of cargopartner.

“Our new Pharma Center in Shanghai, our new warehouse in Guangzhou, and our new office facilities in Chongqing and Nanjing are further important puzzle pieces in our constantly growing network in China. Our strategic decision to establish a strong presence throughout China aligns perfectly with our longterm goals of improving our operational efficiency, fostering deeper relationships with our local partners and customers, and unlocking new opportunities for continued growth in the future.”

In March 2023, cargo-partner announced the launch of a new Pharmaceuticals & Healthcare Competence Center in Shanghai. China is one of the world’s main producers of pharmaceuticals and healthcare products, as well as an increasingly important consumer market for this type of products. The new Pharma Competence Center now serves as an operational hub for exporters and importers who require GDP-compliant transport solutions for medicinal products. cargo-partner’s on-site experts can provide not only temperaturecontrolled air and ocean freight services, but also temperature-controlled trucking for the first and last mile.

In addition to cargo-partner’s existing warehouse facilities in Shanghai, Chengdu, Kunshan and Hong Kong with a total of 22,000 square metres of storage space, the logistics provider has opened a new warehouse in Guangzhou as of 1 March 2023.

Guangzhou is an important logistics gateway in Southern China, and contract logistics is one of the main focus areas of cargo-partner’s strategy for China

in 2023. This is why cargo-partner has recently opened its first warehouse in Guangzhou, which is scheduled to be expanded in 2024 to meet the strong market demand. While the majority of cargo-partner’s customers in Guangzhou are currently from the high tech industry, the local team plans to expand its capabilities in the e-commerce, industrial and consumer goods sectors in the near future.

In April 2023, cargo-partner celebrated the relocation of its Chongqing office to a larger, more modern facility. Thanks to its ideal geographic location and welldeveloped infrastructure, Chongqing is a key transport and logistics hub in central China. Its airports rank among the top 10 in China for year-round throughput, and the city’s port is the largest in the Upper Yangtze region. Moreover, the Chongqing-Duisburg connection is a cornerstone of the growing transEurasian railway network. The new office in Chongqing is just one aspect of cargo-partner’s strategic expansion and will support the local team in serving customers across the region with a full range of logistics solutions.

To further strengthen its local network, cargo-partner recently opened a new customer service and sales office in Nanjing. The new office is one of several cargo-partner offices in the Yangtze River Delta region, where the logistics provider offers a wide range of air freight, sea freight, land transport, contract logistics and value added services. Nanjing is a major logistics gateway in eastern China, situated at the confluence of several key logistics hubs, including Nanjing Lukou International Airport, Nanjing Port as well as important railway hubs connected to the main railway networks.

Since the opening of cargo-partner’s first office in China in 2004, the international transport and logistics provider has continuously expanded its network of offices and warehouses in the country. Today, the company is represented with 380 employees across 16 offices in

Transport and logistics company, Toll Group, has opened a new freight forwarding branch in Changsha, China. Located near major cities such as Guangzhou, Shenzhen, and Xiamen, the branch will strengthen Toll’s presence in China’s central region.

According to a Toll Group spokesperson, the new branch will also cater to its customers’ needs, while solidifying Toll’s commitment to delivering exceptional logistics solutions in the region.

“Our Changsha branch is of strategic importance, located in one of the largest cities in central China with a population of over 10 million,” the spokesperson said. With a 2021 Gross Domestic Product (GDP) of ¥1.3 billion CNY (approx. €168.2 million), Toll said the region’s strong industrial development offers abundant opportunities for export and import businesses.

Toll entered the Chinese market in 1995, beginning operations in South China through a joint venture.

As a fully owned foreign entity, Toll began to merge and streamline its extensive network of logistics distribution centres, cross-dock and depot facilities to 21 strategically located distribution centres across China. Toll now operates in Beijing, Shanghai, Guangzhou, Qingdao, Wuhan, Urumuji and other key Chinese cities to service over 50 customers.

With decades of expertise acquired across Asia, Australia, Europe, and the US, Fuwais a global manufacturing powerhouse that has established itself as the premier network of truck and trailer component specialists worldwide.

We bring together local expertise, world-leading manufacturing prowess, and an unwavering commitment to innovation. Our comprehensive range of axles, suspension systems, landing legs, couplings, king pins, fifth wheels, and ball races is meticulously designed with one goal in mind to

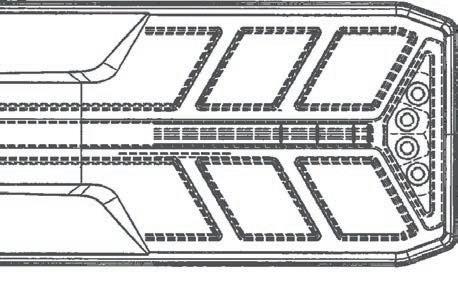

Hämmerle Spezialtransporte – a fleet headquartered in Hard, Austria – has invested in Kässbohrer trailers.

Hämmerle Spezialtransporte, which operates in the construction industry, has taken delivery of the K.SPA M. This purchase bolsters a fleet mix of 20 trucks and 45 trailers that are used to transport bridge structures, crane systems, precast concrete projects, laminated wood beam structures, furnished room boxes for hotel facilities, laser and CNC machines and more around Europe.

Hämmerle deploys heavy duty vehicles including low beds, low loaders and HD platforms.

Reinhard Hämmerle, General Manager of Hämmerle Spezialtransporte and Faruk Karakılıç, Area Sales Manager for Kässbohrer, were present for the delivery ceremony at the Kässbohrer ULM Production Facility.

Reinhard Hämmerle, General Manager of Hämmerle Spezialtransporte, said: “We are excited to establish with Kässbohrer and integrate the Kässbohrer K.SPA

M into our fleet. Offering a complete solution for the transfer of various large loads, K.SPA M presents one of the best examples of heavy-duty engineering.

“The K.SPA M’s extendable chassis and sliding platform features will greatly enhance our operational flexibility, allowing us to efficiently transport even the most challenging loads across Europe.

“Hämmerle Spezialtransporte is aware of Kässbohrer’s wide product range and quality, especially in the standard vehicle segment. Kässbohrer provides its customers with the advantage of robust, lightweight, ease and speed in their operational work with its products specially developed for heavy transport and compatible with tough road conditions.

“We are prepared to establish a longterm partnership with Kässbohrer, and this investment is the first step in that direction. We strengthened our fleet with Kässbohrer vehicles and established a successful business partnership, we believe that our successful co-operation with Kässbohrer will continue in the coming years.”

Karakılıç also delivered a statement and provided details about the K.SPA M vehicle.

“As Kässbohrer, we are happy to offer vehicles that provides flexible and safe transportation solutions for heavy, long, flat and ballast loads thanks to its extendable, strong and flat chassis, variable container positioning combinations and different load safety options such as Code XL certified front panel which is resistant up to 22,5 ton longitudinal loads,” he said.

“Hämmerle Spezialtransporte choice Kässbohrer K.SPA M, an extendable heavy duty platform developed by

Kässbohrer in three- and four-axle versions, is available in different height options that can be coupled with mega and standard trucks.

“We will continue our innovative approach to meet the needs of our customers, and we believe our partnership with Hämmerle Spezialtransporte will continue for many years.”

Czech Republic-based global logistics company, Rhenus, has been given the distinction of owning the most sustainable industrial building in the country.

The business site beat out more than 100 other projects to claim the certification from BREEME, a third-party sustainability standards assessor. The modern building, which measures 14,000 square metres, is found south of Prague Airport, with the company using it as a transhipment point and warehouse.

The site achieved 92.1 per cent in the overall assessment, based on its economic and ecological benefits, including its environmentally friendly components such as LED lighting, energy-efficient heating and cooling systems, and sustainable energy.

Rhenus provides a broad range of logistics services at the site, including warehousing, transportation, customs clearance and other value-added services such as packaging and labelling.

“We’re creating more efficient and faster loading and unloading times through the cross-docking area, which measures 6,500 square metres, and through 24/7 loading operations using stand-by trailers,” said Markus Menzel, Managing Director of Rhenus Czech Republic.

German logistics company, Dachser, is expanding activities in Finland with a new logistics centre in Pirkkala, in the south of the country.

Expected to open in the northern summer of 2024, the new general cargo facility will be located at TamperePirkkala Airport, covering an area of around 5,000 square metres.

The region is an important economic area in Finland, and the largest inland centre within the Nordic countries. The new centre will offer local businesses access to Dachser’s dense European overland transport network, the company said in a statement.

Dachser has been active in Finland since 2014, and is already represented with a logistics centre in Kerava, in the Helsinki metropolitan area, which opened in 2019. In Vantaa, Lahti and Tampere, Dachser also has locations specialising in air and sea freight.

Trailer builder, Kässbohrer, has inked a deal with Roos Spedition, with the freight forwarding company acquiring a Kässbohrer Chemical Substance Tanker K.STC 30.

Roos Spedition’s focus is the international transport of liquid chemicals and hazardous goods ,with a fleet of more than 300 chemical tankers.

The K.STC vehicle is the lightest chemical tanker on the market with tare weight of 6,500 kg. Depending on the climate, it comes with several insulation options, including glass wool insulation, stainless steel, aluminium, glass reinforced plastic or fibreglass reinforced polymer. It can also be configured with several volume options, compartments and different

discharge placements.

“We consider this investment as the beginning of our long-term cooperation with our valued customer Roos and we believe our partnership will continue for many years,” said Kässbohrer Area Sales Manager Germany for Kässbohrer, Faruk Karakılıç.

A partnership between BPW’s idem telematics and data solutions company, CO3, is looking to offer a new tailored connection that enables fast and easy integration and onboarding. idem telematics provides fleet management solutions and now, with the help of CO3, aims to streamline the connectivity process and facilitate data exchange between companies and software systems.

The alliance will benefit idem’s customers and partners, allowing them to leverage the power of CO3’s data marketplace. In addition, by using idem’s technology as the backbone of their feet management solutions, OEMs can now effortlessly participate in the CO3 data marketplace, helping them provide their customers with access to advanced data capabilities.

Meanwhile CO3 customers will have access to advanced data from idem telematics at higher quality and ping rates, ensuring real-time insights and improved decision-making capabilities.

“By combining the strengths of CO3 and idem telematics, we can deliver a seamless experience for fleet managers, OEMs, and CO3 customers, unlocking the full potential of data-driven insights for improved operational efficiency and business growth,” said Managing Director at idem telematics, Jens Zeller.

The city of Hamburg’s position as a logistics hub in the North Sea and Baltic region will be strengthened thanks to a minority shareholding deal involving China’s COSCO Shipping Ports (CSPL), Hafen Hamburg (HHLA) has announced. HHLA and CSPL have agreed to a minority shareholding deal which will see CSPL provided with a 24.99 per cent share in HHLA’s Container Terminal Tollerort.

The terminal in the Port of Hamburg, Germany’s biggest seaport, will now be developed into a preferred handling location for CSPL, where freight flows between Asia and Europe will be concentrated.

In a statement, HHLA refuted claims that the entire port would be sold to China or that the deal was unfair:

“The cooperation between HHLA and CSPL does not create any one-sided dependencies.

“On the contrary: it strengthens supply chains, secures jobs and enables value creation in Germany. Smoothly functioning logistics are a basic requirement for global trade flows and prosperity.”

In order to meet new challenges, Krone has appointed Dr Tono Nasch as an additional member of the Krone Group Supervisory Board.

With its new member, the Board, chaired by Bernard Krone, aims to strategically tackle issues including electrification, automation, sustainability and digitisation.

Dr Nasch is managing partner of ISP, a family-owned business in Salzbergen, Germany that tests fuels and lubricants.

Close to you since 1962

We stand right in the middle of every project realization.

HIGH QUALITY GRP FOR COMMERCIAL VEHICLES.

He brings with him his knowledge of automated testing technology and electromobility, the Krone said in a statement.

“Dr Nasch’s experience is the perfect complement to the existing competencies of the members of our Supervisory Board,” Bernard Krone said. “We are looking forward to making use of his expertise to forge ahead with growth and innovative power in our group of companies.”

TIP Group has received the first solarpowered refrigerated trailer from Finnish company, Valoe.

Equipped with Valoe’s solar system, the trailer is now being operated by transport company, Frigoscandia, to serve transport in unbroken cold chains utilising solar power.

In January 2023, TIP and Valoe signed a €20 million, three-year-agreement for equipping hundreds of trailers by the end of 2025.

Now, the first solar-power refrigerated trailer is on the road.

The trailer was handed to TIP on 20 June, which will now drive along the Scandinavian roads thanks to Frigoscandia.

Three more trailers with this specific technology will also be joining TIP’s fleet in the coming months.

During this trial, the trailers will collect crucial and valuable information on the solar system, allowing Valoe to further optimise its system.

The pilot trailer has vehicle-integrated solar panels which produce enough electricity required for the cooling system, without polluting.

The solar panel are based on conductive

backsheet and meet EU lead-free criteria pursuant to the RoHS Directive. Additionally, the durable and lightweight modules are mounted on an aluminium fastening and cooling element which makes the modules easy to install and replace.

TIP Group VP Sales and Marketing, Rogier Laan, said a cleaner world is an important goal for TIP, which it is now striving for together with Valoe.

“We play an important role in the industry and strive to reduce the impact on the climate,” he said.

“We aim to significantly reduce the CO2 emissions and diesel consumption of refrigeration units in our current fleet –for example, by integrating solar power systems onto the trailers.

“In new refrigerated trailers, we can refrain from using diesel altogether and be at the cutting edge in implementing more environmentally friendly technology in the transport sector.”

TIP Group has announced a milestone in its Nordic business expansion.

The transport and logistics solutions provider has successfully acquired three companies that will substantially boost its operations in the region.

The acquired companies are LAST og TANK AS in Norway, Savon Rekkahuolto Oy in Finland and the truck business of EURO-Leasing A/S in Denmark.

“With these important acquisitions TIP has achieved another milestone in our expansion in Europe,” said TIP Group President and CEO, Bob Fast.

“It increases our footprint in the Nordics, allowing us to increase the supply, availability, maintenance and repair of trucks and trailers in Norway,

Finland and Denmark and expands and diversifies our customer base.”

LAST og TANK AS is a truck and trailer workshop providing service for all types of work across multiple brands and asset types. They have been in operation since 1995. Located in the south-east of Norway, approximately 20km from Oslo, the workshop covers two major highways in a region with significant infrastructure development projects. Combining high volume of heavy vehicles due to the regional rail and highway projects along with a large population of regional customers, this acquisition is a great opportunity for TIP Group to increase activity in multiple types of heavy assets, as well as gaining new leasing and rental customers. This acquisition brings the total number of workshops in Norway to four.

Savon Rekkahuolto Oy is a truck and trailer maintenance and repair business which also performs body builds and specialised vehicle projects. It is an authorised service partner for Iveco, DAF and MAN and has been in operation since 2014 with two workshops (Varkaus and Mikkeli). The area covers major industries and heavy transport volume, providing us with great opportunities to grow the existing business. Broadening TIP’s network with two locations in the eastern part of Finland will enable it to strengthen service levels for existing clients. This acquisition brings the total number of workshops in Finland to five. TIP Group has successfully closed a deal with EURO-Leasing A/S to acquire their truck business, following the earlier acquisition of their trailer business. This acquisition adds a fleet of approximately 300 young trucks, from the manufacturer MAN to TIP’s portfolio.

TIP is committed to ensuring the seamless continuation of business for all customers and suppliers of the three acquired companies.

According to Christian Petersen, TIP Vice President Nordics: “These acquisitions further solidify TIP’s growth trajectory in the Nordics, building upon the previous acquisition of the trailer business of EURO-Leasing A/S in Denmark and the workshop business of Släp & Kaross in Sweden. TIP is working closely with the acquired companies to facilitate smooth and effortless transitions and we warmly welcome all our new employees to the TIP family.”

More than 200 female managers and leaders in logistics gathered to discuss leadership and the future of the industry at Poland’s largest women in logistics event.

CEVA Logistics partnered with this year’s Women in Logistics Forum, the largest platform for women managers and leaders in the Polish logistics sector. The community of the Forum gathers more than 800 women leaders who represent multinational and national 3PL providers, in-house logistics departments and service providers for industry and trading companies. This unique women’s business platform enables women to exchange knowledge and experiences, support each other and be part of a public debate touching on the most important issues in the Polish business market.

This year’s Forum meeting was held in Warsaw where nearly 220 women leaders gathered to discuss their perspectives on today’s logistics and best practices of women in leadership

in logistics under the event theme, Excellence Together.

CEVA Logistics Air Product Head, Northeast and Southeast Europe, Ewa Wlodarczyk, shared her expert insights at the event in Warsaw.

“Supply chains are huge, complex and dynamic environments where cooperation and communication are crucial aspects,” she said.

“Women intuitively have these skills and thrive in this kind of environment. Most women in leadership roles see their key challenge and opportunity in building an organisational culture based on excellent cooperation.

“In today’s business world, women must join forces to develop new competencies and share our achievements. Continuous development will play a more important role in leadership than ever before. I define leadership as resilience to pressure, boldness to pursue the impossible and the ability to solve complex problems.”

Germany-based company, MBS Logistics, will open a new office in Switzerland as

part of its global growth plans. Located at Zurich Airport, the new branch, set to open in July, will offer services for air, sea and road freight as well as specialise in the delivery of urgent shipments which guarantees offers within 15 minutes of request receipt.

“Entering the Swiss market is a strategic step that corresponds to our growth goals,” said MBS Logistics CEO, Joerg Roehl.

“I am confident that with our practical, customer-oriented approach we will increase MBS’s market share in Switzerland and establish ourselves as a reliable partner for logistics solutions here as well.”

Chairman of the Board of Directors. “His appointment will ensure the continued development of Kuehne + Nagel as the global market leader in sea logistics.”

A New Zealand national will join Kuehne + Nagel’s Management Board. The Swiss company announced Michael Aldwell will assume responsibility, as

of this October, from long-standing executive, Horst Joachim Schact, who will continue to work in an advisory role supporting sustainability programs Aldwell began his career with Kuehne + Nagel in Auckland in 2008 and has international leadership experience in Asia Pacific, the Middle East and the Americas, most recently as Head of the Northeast region of the US.

“We are very pleased to appoint Michael Aldwell, a proven executive from within our own ranks,” said Dr Joerg Wolle, Chairman of the Board of Directors.

“His appointment will ensure the continued development of Kuehne +

Nagel as the global market leader in sea logistics.”

Swiss transport and logistics company, Friderici Holding, announced it has acquired the Gattoni Garage in Monthey, Switzerland.

Friderici said it was a major milestone, allowing the company to strengthen its market position and expands products and services.

Established in 1964 in an industrial zone of Monthey, the truck maintenance business’s owner Roland Gattoni decided to sell at the age of eighty.

Friderici Holding has been in operation since 1880 and today focuses on specialist transport operations, both national and international, as well as lifting, handling and warehousing.

Global transport and logistics company, Kuehne + Nagel, has reported first half financial results that are greater to the comparable figures of the pre-pandemic period.

Net turnover for the first six months of 2023 was 12.7 billion CHF (approx. €13.3 billion), EBIT was approximately 1.1 billion CHF (approx. €1.2 billion) with earnings of

860 million CHF (approx. €900.2 million). The conversion rate, which describes the ratio of EBIT to gross profit of the Group, remained at a high level of 24 per cent.

“Kuehne + Nagel coped well with the transition from the exceptional economic situation shaped by the pandemic,” said CEO, Stefan Paul. “In a weakened economic environment, Sea and Contract Logistics gained market share and kept earnings stable. In contrast, volumes in Air Logistics declined broadly in line with the market.”

Its strategic plan, according to the company, is unchanged with a focus on high-quality logistics services and an extraordinary customer orientation.

Transport and logistics company, Transfera, over the past decade has has grown from a team of 17 to 420 people. It celebrates many achievements including the construction of one of the largest and modern logistics centres (TLC1) in Serbia and the region, regional and global business expansion, the opening of 20 branches throughout Serbia and securing revenue of approximately 100 million euros in 2022. “The achieved results are just the beginning of big plans and goals that will mark the future era of Transfera’s business,” it said in a statement.

A haulage firm has taken delivery of two fixed-roof curtainsider semi-trailers only four months from being ordered. Stoke-based Reid Freight Services, which transports goods across the UK and overseas, has hailed the efficiency of Schmitz Cargobull’s new manufacturing operation in Manchester for turning the

order around so quickly.

“We needed two new curtainsiders quite urgently due to high demand,” said Chad Smith, Transport Contracts Manager at Reid Freight Services.

“We waited less than four months from the order to delivery, which was very impressive given the current production delays impacting the transport industry.”

The curtainsiders are the first Schmitz Cargobull semi-trailers to join the company’s fleet and will be used for general haulage and the company’s work supporting the rail industry.

“The new trailers look fantastic. With a payload capacity of up to 26 tonnes and side loading height of up to 3,100mm, they will definitely improve the efficiency of our business,” said Smith.

The new S.CS fixed-roof trailers comply with DIN EN 12642 Code XL load security regulations and feature a bulkhead specific for the British market. Officially opened in March, the manufacturing facility is producing trailers specially developed for the UK and Irish markets.

The UK Government is encouraging young people to take up careers in the logistics sector with £300,000 (approx. €348,731) of funding as part of the next phase of a campaign.

Following a highly successful first year, the Department for Transport (DfT) will continue to invest in the industryled Generation Logistics campaign to improve recruitment and retention of a skilled and diverse workforce in the logistics sector.

Doing this, DfT said, will vitally support the UK’s supply chain resilience as well as help grow the economy across the country.

The campaign’s second year will now primarily focus on raising the profile of logistics in schools and colleges by supporting educators with resources and materials – driving a new generation of talented individuals to pursue rewarding career paths in the sector.

According to DfT, the first year of the campaign contributed to a more diverse and stable workforce across the

record time.

logistics sector by raising awareness and improving perceptions.

“The first year of government funding has had a positive impact, showcasing the diversity of career opportunities in this vital sector,” said Transport Secretary, Mark Harper.

“That is why we are pleased to announce additional year two funding to further build resilience in the sector.

“We continue to work closely with industry leaders, like CILT (UK) and Logistics UK, to fully understand the needs of the industry and this is yet another step we are taking to grow the economy and support industry across the UK.”

In total, DfT has invested £645,000 (approx. €749,851). This includes £345,000 (approx. €401,083) in year one and now £300,000 (approx. €348,731) in the second year.

As in year one, DfT’s year two investment will be supplemented by industry sponsorship from leading companies and trade associations.

Transmec Group is extending its range of supply chain solutions after opening a state-of-the-art cross-dock warehouse at London Gateway Logistics Park. Providing a new home for its London

branch, the 15,329-square-metre hub has racking for almost 30,000 pallets and is 50 per cent larger than the branch’s previous base at West Thurrock.

Transmec provides a wide range of transport, logistics and customs services for clients in multiple sectors, including manufacturing, fashion, leisure, pharmaceutical, automotive and food. The relocation to DP World’s London Gateway Logistics Park is designed to support growth plans by increasing services for existing clients while attracting new customers based in the UK, EU and globally.

“The move will enable us to grow by

building on our existing strengths,” said Transmec UK General Manager, Imran Mohammed.

“We intend to make the most of the new warehouse’s excellent facilities while also taking full advantage of London Gateway’s superb road, sea and rail connections.

“To support the international rail terminal and deep-sea port we’ll be providing complementary services from customs clearance to container shunting and devanning.”

An approved ETSF (External Temporary Storage Facility), Transmec’s warehouse is ideally located for managing imports and exports.

In-house customs clearance expertise includes IPAFFS compliance for food imports for which temperature-controlled storage is available.

Distribution using Transmec’s own fleet of vehicles ranges from last-mile services to central London to domestic and EUwide collection and delivery.

The London branch will continue to link closely with the Transmec Group

including 30 across Europe and North Africa, and further UK warehouses at Redditch, Worcester and Bradford.

Logistics company, Kinaxia, has secured a five-year contract to provide all domestic linehaul and trunking services for home delivery specialist ArrowXL, which delivers more than two million customer orders a year for retailers, e-commerce companies and manufacturers.

“We are excited to be extending our relationship with ArrowXL and welcoming new drivers into the Kinaxia family,” said Richard Smith, Managing Director of Kinaxia’s primary sector business.

“The arrangement reinforces our nationwide capabilities in the primary sector and creates growth opportunities across a wide area of the UK, as well as enabling us to offer more flexibility to our existing customers.”

MBBA Logistics is taking delivery of 13

The company transports goods from ports including Tilbury, London Gateway, Purfleet and Felixstowe, so Krone trailers, which are designed for harsh seaport environments, were a considered choice. All models, according to Krone, have a cathodic dip coating followed by powder coating, providing resistance to stone chipping and weathering. For MBBA, the new trailers will replace older units, but also accommodate winning new and improved contracts from its client base.

The Krone Box Liner trailers have a flat chassis configuration for 20′, 30′, 40′ and 45′ containers. They are designed to be durable and versatile and tailored to British requirements, with a 10-year guarantee against corrosion perforation. Krone trailers are manufactured in Germany, with Krone UK providing nationwide product support, parts supply and aftersales care throughout Britain and Ireland.

An event transportation specialist has added an additional 20 S.BO EXPRESS trailers from Schmitz Cargobull to its business.

Stagefreight’s latest order will bolster the company’s 134-strong trailer fleet, including 15 S.BO EXPRESS dry freight boxes sourced from Schmitz Cargobull over the past year.

Stagefreight Director, Ian Uttley, said the trailers are ideally suited for the firm’s work transporting event, staging and audio-visual equipment for theatre, TV, films and music tours as well as conferences and exhibitions held across the UK, Europe and further afield.

“We do everything from the Royal Ballet to Peppa Pig and have delivered musical

instruments and equipment to European venues for big bands such as Coldplay and Metallica,” he said.

“We have supplied equipment for events staged in places as far as Marrakech, the Canary Islands and even the Arctic Circle.

“The S.BO EXPRESS is a fantastically robust trailer that will serve us well for many years. It’s also easy to repair and parts are readily available. The whole package from Schmitz Cargobull really works for us.”

For the Leeds-based company, which also runs a fleet of 63 trucks, major benefits of the S.BO EXPRESS are the

wide range of load-securing options and the TrailerConnect telematics system. Unpalletised freight can be secured by means of three rows of flush-mounted load-securing rails. Load-securing protection beams can be suspended as required, whilst lashing eyes, with a pulling force of up to two tonnes, provide flexible load-securing points. “When travelling long distances, we always look to maximise capacity, loading them as much as we can,” said Uttley. “The trailers offer plenty of good tie-off points and load securing rails to ensure the stability of goods in transport.”

With an internal body height of 2,900mm, the S.BO EXPRESS features a FERROPLAST structure, protecting the goods from the weather and minimising the risk of theft, and LED light strips to provide more safety when loading and unloading. Certified to DIN EN 12642 code XL, the trailer also includes corrosion-resistant aluminium rear doors.

With more than 25 years’ experience in event transportation, Stagefreight has recently diversified into refrigerated transport and general haulage, including food logistics and essential supply chain services.

Sean Kenney assumed the role of CEO for Hyundai Translead on 1 July 2023. He succeeds Bongjae Lee who served a seven-year term with the business and will transition to take a leadership role at Hyundai Glovis in Korea.

Kenney joined the company in 2020 as Chief Sales Officer. The OEM said he has played a pivotal role in shaping the company’s strategic direction and success.

“With extensive years of experience in the transportation industry, he has consistently demonstrated exceptional leadership, deep industry expertise, and a strong commitment to customer satisfaction,” Hyundai Translead said in a statement.

“Throughout his tenure as Chief Sales Officer, Kenney has guided Hyundai Translead through transformative initiatives, resulting in enhanced operational efficiency, expanded market

reach, and improved customer-centric solutions.

“His visionary approach and ability to identify emerging trends and opportunities have been instrumental in driving the company’s growth and solidifying its position in the industry.” Kenney said he is humbled to take on this new role.

“I am deeply committed to building upon our achievements and driving the company to even greater success with the entire Hyundai Translead team,” he said.

“We will continue to innovate, exceed customer expectations, and solidify our position as a leader in the trailer industry.”

Lee has expressed confidence in Kenney’s capabilities.

“Sean has been an instrumental leader, consistently demonstrating a remarkable agility to navigate complex challenges and drive transformative change,” said Lee.

“His passion, strategic acumen, and customer-oriented mindset make him the perfect fit for this role.

“I am confident that he will lead Hyundai Translead to new heights, spearheading innovation and shaping its future.”

Driver capacity models suggest the record declines in freight rates should be creating more jobs as it generates the creative destruction needed to set up the next cycle, according to the latest freight forecast from ACT Research.

The US Rate and Volume Outlook report says rebalancing is under way, although slower than expected, and demand is poised to gradually recover the from soft levels of the past five or six quarters.

“The preliminary Bureau of Labor Statistics data set, which we think gets closest to drivers, added 2.3k jobs in May, defying gravity for now,” said ACT Research Vice President and Senior Analyst, Tim Denoyer.

“We estimate another 12,400 total revocations of operating authority and 2,950 net revocations in May, bringing the total contraction in the industry since last October to over 15k fleets.”

Denoyer added that the spot market is continuing to rebalance with net revocations still at record rates and predicts that demand fundamentals are likely to improve from here.

American freight transportation company, XPO, has completed the expansion of its Salt Lake City service centre as part of its North American growth strategy.

The expansion adds 58 doors in the

growing Utah market, and expands the service centre’s yard, creating a more efficient workspace with capacity for greater traffic and freight.

“At XPO, we’re focused on adding capacity where it’s most effective in driving efficiency, growth and returns for our business,” said Dave Bates, COO of XPO.

“Our investment in the Salt Lake City facility will allow us not only to better serve our existing customers, but will support new business growth in a market that’s a major hub for freight.” The announcement marks a milestone in XPO’s plan to open 900 net new doors nationally by the first quarter of 2024.

US

SAF-Holland recently hosted an event for aftermarket industry leaders to celebrate the opening of its new distribution centre in northwest Cincinnati.

Replacing an older, smaller facility in Ohio, the new centre is designed to improve material flow, provide increased material storage space and features a dedicated area for kit assembly. The company hopes customers will see improved availability and reduced lead times.

“We were honoured to host many key leaders from the aftermarket service parts industry,” said SAF-Holland VP & GM –Aftermarket (Americas), Matt Wolfe.

“With this state-of-the-art facility, we can stock a broad product range, ensure appropriate stock levels for fast moving parts and increase our response time.”

US

FedEx has demonstrated continued momentum across the business through its financial year 2023 (FY23) and Q4 results.

FedEx’s operating margins for Q4 2023 were the strongest of the financial year as the company demonstrated strong expense management and executed drive initiatives. The quarter’s results, however, were negatively affected by continued demand weakness and cost inflation, partially offset by cost-reduction actions and US domestic package yield improvement.

FedEx Express operating results also declined due to lower global volumes, partially offset by decreased expenses and higher US domestic yields.

“FedEx Express continues to implement volume-related and structural cost-reduction actions, including further reductions

LIGHT IS THE NEW LARGE. BECAUSE WE CARE!

in flight hours and the early retirement of certain aircraft and related assets, to mitigate the negative effect of ongoing demand weakness,” a FedEx spokesperson said.

FedEx Ground operating results improved primarily due to higher revenue per package and cost-reduction actions. These factors were partially offset by lower package volume, higher infrastructure costs and increased other operating expenses.

FedEx Freight operating results declined primarily due to decreased shipments and lower weight per shipment, partially offset by improved revenue quality. Despite this, FedEx Freight is remaining focused on cost discipline, supported by a fourth round of furloughs to match staffing with demand and network optimisation from the planned permanent closure of 29 facilities.

For the full fiscal year, FedEx Corp. reported the following consolidated results:

• a revenue of $90.2 billion USD (approx. €82.7 billion);

• an operating income of $4.9 billion USD (approx. €4.5 billion);

• an operating margin of 5.4 per cent;

• a net income of $4 billion USD (approx. €3.6 billion); and

• diluted EPS of $15.48 USD (approx. €14.19).

“The solid close to the fiscal year demonstrates the significant progress Team FedEx has made in advancing our global transformation while adapting to the dynamic demand environment,” said FedEx Corp. President and CEO, Raj Subramaniam.

“FedEx is becoming a more flexible, efficient and data-driven organisation as we significantly lower our cost structure,

drive enhanced profitability, and deliver outstanding service for our customers.” Following these results, FedEx has announced an important step in its transformation journey. All FedEx Ground operations and personnel in Canada will transition to Federal Express Canada starting in April 2024.

According to FedEx, this transition will be seamless to customers, who can expect the same outstanding service they are currently receiving.

FedEx said the new streamlines structure will position the company to more efficiently address future growth opportunities in the Canadian market. FedEx is also reportedly making solid progress with Network 2.0, as the company has now announced optimisation plans to streamline pickupand-delivery operations across networks in 20 markets.

Librelato participated in one of the largest agribusiness fairs in Brazil, the Bahia Farm Show, between 6-10 June. The Bahia Farm Show has been held since 2004 and emerged with the aim of putting western Bahia on the radar of large companies, producers and entrepreneurs from different areas. Participating in fairs and events is one of the marketing practices that are part of Librelato’s strategic planning, with the objective of promoting the brand, exposing its products and services, listening closely to customers and

million BRL (approx. €6.5 million).

Librelato Northeast Region Commercial Consultant, Aloir Schickmann, said the company’s participation in the fair is significant and reaffirms the importance of agribusiness as a major driver of the company’s sales.

“Being in contact with customers in this segment motivates us to seek increasingly innovative solutions for this audience,” he says.

“It is worth remembering that some of Librelato’s main customers are in this segment, which reaffirms the importance of agribusiness to boost the

DB Schenker has announced its first foray into the battery metals mining industry.

Earlier this month DB Schenker was awarded a contract to provide comprehensive project construction freight forwarding and logistics services to Albemarle’s Kemerton Lithium Expansion Project (KEP) in Western Australia.

The engineering contractor will be Hatch Australia.

The Kemerton plant is located approximately 150 kilometres south of

near the Port of Bunbury and close to one of the world’s largest hard rock lithium deposits the Greenbushes mine. The work will be supported by the DB Schenker Project Control Tower office located in Perth, in conjunction with our global network of Project offices that are specialised and accustomed to the unique logistics service requirements of the industry.

DB Schenker is proud to be selected by Albemarle and Hatch to provide comprehensive international freight and logistics solution in support of this very important project.

working safely and efficiently, even on the most remote sites and mega projects in the world,” said DB Schenker VP Global Projects & Industry Solutions APAC, Frank Vogel.

Logistics company, DHL Supply Chain, has announced Brindha Pillay as its newest Chief Financial Officer for Australia and New Zealand.

She succeeds Craig Roberts who, after three decades, will be relocating to a DHL role overseeing Europe, the Middle East and Africa.

“It gives me great pleasure to pass the torch to Brindha, whose exceptional skills and dedication will undoubtedly drive continued success for DHL Supply Chain in ANZ,” said Roberts. “I’ve been working very closely with Brindha to ensure a smooth and successful transition.”

Pillay, who has worked for DHL for 15 years, started her DHL career as Australia’s finance manager.

German owner-managed company, Röhlig Logistics, has shared its expansion strategy, with plans to continue to open new facilities in Southeast Asia and Oceania.

The company says it is strategically advancing its contract logistics business and can currently boast 260,000 square metres of warehouse space in more than 15 countries. Its aim is to have representation in 40 warehouses worldwide by the end of 2023. “Most recently we have significantly expanded our capacity with new warehouses in Malaysia, Australia, South Africa and Singapore,” said Röhlig Logistics CEO – Sea Freight, Air Freight,

Contract Logistics & Sales, Hylton Gray. “This global presence across all continents allows us to ensure maximum reliability and flexibility even in times of volatile markets.”

Global supply chain solutions company, DP World, has announced it will commence operations at Indonesia’s Belawan New Container Terminal (BNCT), more than doubling its throughput capacity there.

The move, following an agreement with the Indonesia Investment Authority and government-owned port operator Pelindo, will strengthen the terminal’s position as a major trade and logistics

gateway, creating a direct link with the Malacca Strait, one of the world’s busiest shipping routes.

In addition to modernising maritime infrastructure, DP World will also work with its partners to connect other terminals and small ports on the Island of Sumatra to further realise it goal of reducing container logistics costs within Northern Sumatra.

“By investing in cutting-edge sustainable technologies, world-class training and the highest standards of health and safety, we aim to eliminate inefficiency and enable the flow of trade between Indonesia and the world,” said DP World Group Chairman, Sultan Ahmed Bin Sulayem.

International transport and logistics company, Mainfreight, has released its 2023 annual report.

In financial year 2023 (FY23), Mainfreight reported a total revenue of $5.7 billion NZD (approx. €3.2 billion) –an 8.8 per cent increase from the year prior.

Profit Before Tax (PBT) was recorded at $587.4 million NZD (approx. €275.6 million) and net profit at $426.5 million NZD (approx. €241.2 million) – both a 20 per cent increase year-on-year (YOY).

Among the results, Mainfreight

achieved a record after tax profit for the year ending March 2023.

“An increase of $71 million over the previous year is very satisfactory and is a huge credit to the global Mainfreight family,” said Mainfreight founder and Chairman, Bruce Plested.

“These past two years have seen Mainfreight generate ever increasing revenue and profits because of a very volatile and difficult congested freight network.

“This volatility has grown our business and provided opportunity not experienced before in. our lifetime.” Mainfreight Australia reported a

revenue of $1.4 billion AUD – a 20.6 per cent increase from $1.2 billion the year prior.

PBT was 27.3 per cent higher than FY23 at $136.8 million AUD.

Mainfreight Group Managing Director, Don Braid, said Australia was the company’s best performing region.

“Our Australian team took advantage of increased freight volume across all key three business units,” he said.

“The continued industry consolidation of the express pallet transport segment is providing opportunities, as is the increasing customer requirements for greater levels of service.”

Recycling & waste management have manifold tasks: the same holds true for the solution of Hüffermann Transport Systems! We have played an active role in the development of modern swap bodies logistics. Benefit from the innovative system of the market leader! hueffermann.de

THE KNOWLEDGE IT TAKES TO BECOME A LEADER IS OFTEN FOUND IN MYSTERIOUS PLACES. FOR GORICA GROUP’S OWNER AND ACTIVE CHAIRMAN, IVAN FORNAZARIC, IT ALL STARTED IN THE FARMING LANDS OF SOCIALIST YUGOSLAVIA. FAR FROM THE GREEN FIELDS AND PICTURESQUE MOUNTAINS OF HIS YOUTH, HE REFLECTS ON HIS LIFE AND HOW IT HAS SHAPED HIM INTO A POWERFUL PLAYER IN THE MIDDLE EAST’S TRAILER MANUFACTURING INDUSTRY.

Post-war socialist Yugoslavia was not typically a place where someone could discover their passion for entrepreneurship or learn to embrace innovation, but Ivan Fornazaric considers himself lucky to have grown up with parents who believed in the rewards of progress and were willing to take big risks to get them.

Fornazaric’s father was a farmer at a time when the government was keeping a sharp eye on the goings on of the working class, ensuring no one was individually benefiting from business growth

or private enterprise. Not deterred, he became the first in the family’s province to own modern agricultural equipment.

“My father was the furthest example of a typical farmer,” said Fornazaric.

“He was a confident man and I learned from him that confidence comes from within by putting plans to action. He was always a go-getter in his work.”

That lesson has helped Fornazaric weather the storms that come with both enterprise and

international strife to build the one of the largest manufacturers of truck bodies, trailers, semi-trailers in the United Arab Emirates.

But there is another aspect to his success – he loves trucks and trailers and has vivid recollections of taking vehicles apart as a child, studying and then rebuilding them.

“My best memory is when my brother Aleksander and I built a go-cart using a scooter engine,” he said. “Boy, did we have a blast speeding on that scooter around the farmlands.”

Fornazaric’s interest in all things mechanical saw him attend an engineering boarding high school. He secured an internship at a national trailer company where he was able to work during the summer holidays, moving across different production lines. While earning a commerce degree, he continued to work for the company as a technician designing tipping trailers.

When the company started to look for markets to export to, he put his hand up and was selected to join the export department. Along with a senior colleague, he became responsible for the Middle East.

“My first business trip was to Syria and Lebanon, which at the time was facing civil war, but fast forward some years later and I secured an opportunity to represent the company in Kuwait.”

That was 1987 and it was also when his Middle East journey truly began.

Fornazaric’s time in Kuwait wasn’t lengthy. By 1990 he had been forced out because of the Iraqi invasion and subsequent Persian Gulf War. He had to decide whether to return to his homeland and search for a new job or stay in the Middle East and set up his own company. The problem was Eastern Europe, at the time, was proving to be turbulent as well.

He decided to make the United Arab Emirates his home and his move to Dubai was a welcoming experience for him and his family as they were among many foreigners and Kuwaitis taking refuge there. It looked nothing like it does now, he recalls.

“Back then, it was not uncommon to have camels crossing the road, and there weren’t any skyline towers of course,” he says adding that at the time, his children, Luka and Andreja, loved riding dirt bikes in the desert behind the compound where they lived.

It was in Dubai that he set out on his own establishing GORICA and continuing to sell trailers in the Gulf region.

His first company GOTRADE LLC, which is the predecessor to GORICA, and today’s trading arm of GORICA, was formed in 1990, just before the breakup of Yugoslavia which saw his home become, in part, an independent Slovenia.

“There were opportunities but huge risks as well,” he said – crediting Dubai for offering a positive and open business climate. “Partly it was being in the right place at the right time, but it was also because of the person I had become, and my drive to set something up on my own.”

The organisation moved quickly from importing trailers into the UAE to assembling them and then finally, complete manufacturing, opening a facility in Jebel Ali Industrial Area in 1998.

however, he says, made the company stronger and able to adapt to any situation thrown at it.

“These are all parts of the world where I was physically located and doing business,” he said. “Not only did we survive as a company, but I would say that we even grew during these times. One must accept that challenges happen, but you have to take and accept them, and with some luck they become opportunities.”

Setting up a home, life and business in a foreign country would presumably be fraught with cultural challenges but Fornazaric says Dubai has long been open and tolerant to all cultures and ethnic backgrounds.

“Dubai accepts that we all have different backgrounds and that is what makes the society

all ends of the globe.”

Adding to that is the fact that Dubai was, and still is, very much open for global business which he says is thanks to the foresight of the country’s leaders who have created a welcoming environment for investment.

Reflecting on the past few decades, a few milestones stand out to Fornazaric. The first and foremost was the establishment of GORICA’s independent trailer manufacturing in the UAE in 1998, followed by the purchase of the Krone factory assets in Demark and their relocation to Dubai. Over the years GORICA has opened sales and service, manufacturing companies in the

many, including hard work, dedication, focus on quality and after sales service, staying true to the brand without compromise and especially staying humble,” he said.

This philosophy has helped them weather economic storms over the decades. Fornazaric describes the turbulence as a rollercoaster with a steady stream of downturns and rebounds, some of which have been wholly unique to the region. He sees the rollercoaster ride as resilience-building.

“We need to understand that the Middle East and Africa, where we mainly operate, are very fragile economies,” he said. “If we compare this to the US, UK, the EU and other developed economies, this is what gives us the edge. We are used to acting very quickly because we have become accustomed to such rollercoaster situations.”

For someone who is known for being hands on in the business, the most recent company change is a personal one – hiring its first CEO. Fornazaric will take on a new role as ‘Active Chairman’.

In his mid-sixties now, he says his day looks slightly different to what it did when he was 35, but he still goes into the office every day. “I travel a little more, and occasionally spend a random day here and there on the golf course, but my thoughts are always with the business, and I love it.”

Hiring the CEO, Martin Kolman, who was formerly the Vice President of transport manufacturing company Hyva, is part of what Fornazaric considers to be ambitious growth plans for GORICA over the next five to ten years.

“We need to take the company and the group to a next level, and I know that more minds that think differently is the way forward to great things,” he said.

Domen Bocker, GORICA’s General Manager of Sales and Marketing, agrees. He said the company is fully focused on investing in new opportunities which include expanding its market reach across Africa and the Commonwealth of Independent State (CIS) countries, as well as institutional partners such as the UN, UNICEF and the Red Cross.

“We are developing new products and re-engineering some existing ones to fit different markets and clients,” he said adding that GORICA’s green program, which focuses on electric, solar and hydrogen technologies, is also a top priority.

For Fornazaric, achieving those goals has a lot to do with continuing to learn from the past. Politically, he still keeps a watchful eye, knowing with experience how to navigate situations.

“We are of course concerned with the civil war in Sudan and the situation in Ethiopia, and we hope Iraq will come back strong and stable, but our surroundings have taught us to pivot and remain agile and understand that the there is no constant,” he says. “We must always be prepared to make changes as the environment around us changes.”

Fornazaric said he is proud of the products that the GORICA brand design and manufacture and is excited about what the future holds for the company.

“My work feeds me with energy, interest, and the urge to build the business further. I am truly passionate about Trailers.”

www.goricagroup.com

FROM ITS RICH NAVAL HISTORY, WHICH MADE IT ONCE ONE OF THE WEALTHIEST COUNTRIES IN EUROPE, TO UNPRECEDENTED SOCIAL AND ECONOMIC UNREST, PORTUGAL IS STILL FINDING ITS PLACE IN THE EUROPEAN UNION. WHILE IT ISN’T ALL SMOOTH SAILING, THERE IS HOPE ON THE HORIZON.

Essentially, strikes have spread to almost every sector within the working class and recent figures may give an indication as to why.

Inflation in Portugal 2022 exceeded records, with a rise of 7.8 per cent and the forecast for this year stands at 5.4 per cent, numbers not seen in the last 30 years. Meanwhile, food prices increased 20 per cent over the past year and house prices rose 18.7 per cent. Rents increased by more than 35 per cent in major cities like Lisbon and Porto.

Like so many countries around the globe, Portugal is currently in the grips of economic and social turbulence. The country has been swept up in the wave of strikes by workers across Europe over the last nine months, joining the likes of France, Italy, Germany and Spain, where scores of protests across major cities continue to break out as citizens seek better wages and improved living conditions that they believe should match current inflation rates. So, what does that mean for a nation that sits in a precarious economic position at the best of times, and will it turn to its strengths to find a way through?

Strikes have ramped up over this northern summer, particularly within the transportation industry, disrupting holidaymakers in both Portugal and across the continent. This past January more than 150,000 people took to the streets of Lisbon – the largest gathering since the toppling of the far-right Salazar regime in 1974. In February and March, Portuguese railway workers paralysed hundreds of trains, while an ongoing strike by civil servants has forced the delay of more than 21,000 trials and legal proceedings. A call to action was declared on 28 June, referred

Many are blaming price increases on recent policy changes that have encouraged young workers who left the country to return, as well as the 16,000 so-called “digital nomads” who currently live in Portugal and work remotely but earn much more than the national average.

Portugal may now be one of the poorest countries in Europe, but it wasn’t always that way.

At a time when its colonial empire included Asia, Africa and South America, it boasted great wealth but without domestic investment, its gains slowly dwindled. Some experts blame the country’s failure to industrialise as quickly as other jurisdictions as part of the reason they didn’t prosper, while others suggest it was the number of political crises over recent centuries, including a civil war.

It was in the mid-1970s, after the Portuguese revolution, that the country’s economy broke away completely from its overseas assets and in 1986 joined the European Economic Community.

Today Portugal’s economy is dominated mainly by manufacturing and is heavily reliant on tourism dollars. Its poor productivity compared to other EU countries reflects its low investment in new technologies and, historically, high levels of bureaucracy that have limited entrepreneurship. In addition, the share of low-skilled workers is one of the highest in Europe –46 per cent in 2017 compared to 17 per cent in the EU, according to the International Monetary Fund.

Finding its way out of economic crisis is something even the country’s President, Marcelo Rebelo de Sousa is expecting may take some time. He told journalists earlier this year that unemployment figures (currently at 6.5 per cent, up half a percentage point over last year) signals that development is slow. He did, however, point out that Portugal isn’t alone in its struggle.

“Even major European powers like Germany are experiencing slow progress, he said.

“Therefore, I would say, always with caution, that the exit from the crisis period – which comes from the past, the pandemic aggravated it, and the war also aggravated it, it has many factors – is an exit that may take a little longer than some expected.”

Despite this, Rebelo de Sousa considers the fact that, in 2022, the Portuguese economy grew by 6.7 per cent in gross domestic product as good news.

“Now, we already know that in 2023 such growth is not possible and, therefore, we will see exactly what

the economy’s evolution will be. I belong neither to the pessimists nor to the raving optimists, and therefore I like to be in a very quiet and very realistic and intermediate position,” he said. But economists are clear, despite tough times for workers, Portugal’s economy will recover, pointing out that it bounced back relatively well after COVID. Recent economic reports from the National Statistics Institute give mixed reviews. As mentioned, Portugal’s economy grew 6.7 per cent in 2022, its strongest pace in 35 years thanks in part to tourism and domestic demand, however, inflation put the brakes on the fourth quarter with the GDP growing just 2.7 per cent between October and December, compared to 4.3 per cent in the previous three months.

According to the most recent figures from the European Commission on Economy and Finance, Portugal’s economic growth will pick up in the second half of this year. Inflation is projected to moderate, although wage adjustments amid the high unemployment rates are expected to keep pressure on prices of services. After narrowing to 0.4 per cent of GDP in 2022, Portugal’s general government deficit is forecast to improve to 0.1 per cent of GDP in 2023 and 2024. In annual average terms, unemployment is forecast at 6.5 per cent in 2023 and 6.3 per cent in 2024 amid a moderate increase in employment and wages. Overall, inflation is forecast at 5.1 per cent in 2023 and 2.7 per cent in 2024.

The future of Portugal is still bright with a number of factors on its side. According to Ernst & Young, the country is gaining ground as an investment destination in Europe and capturing higher quality investment that “prove Portugal’s success in transitioning to a more innovative and knowledge-intensive economy.”

Another benefit, according to experts, is the fact that it has one of the highest percentages of English-speakers in the world (among non-native English-speaking countries), a huge advantage in the business world.

The World Travel and Tourism Council predicted last year that the travel and tourism sector in Portugal would drive the national economic recovery beginning this year, and could even surpass pre-pandemic levels.

There are also signs that the government is beginning to do more to encourage foreign investment, especially by attracting high-tech companies and reduce bureaucracy.

www.globaltrailermag.com

Promising a vast array of exhibitions, programs and presentations, NUFAM this year is expected to have a heavy focus on technology and the future of mobility concepts.

Running from 21-24 September in Karlsruhe, it is Germany’s most comprehensive trade fair of its kind. Exhibitors will include leading commercial vehicle manufacturers and dealers, representing all classes, bodies, trailers and semi-trailers, as well as accessories. Along with vehicles, there will be a focus on a variety of other sectors. Among them will be:

• Dig ital services and telematics - Leading companies will present their latest solutions for efficient applications and business processes including navigation, camera systems, data archiving, tachographs, GPS and cold-chain monitoring.

• Interior technology – Technical systems inside the vehicle can play an important role in safe transportation. Solutions include truck lighting, load securing systems and interior fixtures and fittings.

• Alternative vehicles and fuel – Along with mainstream vehicles, there will be the opportunity to view and discuss electric mobility, natural gas, hybrid drives and LPG technology, as well as self-driving vehicles.

• Maintenance – All the tools and equipment needed to keep commercial vehicles in tip top shape with be on show. This will include exhaust purification, hydraulic ramps and platforms, paint shops, washing systems, body repair and truck tools.

• Tyres and wheels – Covering all types of motor vehicles, a variety of manufacturers and suppliers will be on hand with wheels and tyres, as well as carcasses, tubes and truck rims.

• Services – Along with products, a range of relevant transport and logistic services and their affiliated experts will be available. They will include truck financing, leasing, rental, fleet services, fuel and service cards and driving schools.

WITH 450 EXPECTED EXHIBITORS, NUFAM – GERMANY’S LEADING COMMERCIAL VEHICLE TRADE FAIR –IS SHAPING UP TO BE THE BIGGEST ONE YET.

As an event preview and a taste of what topics will be highlighted at the four-day event, a media day was held in June. Along with sharing information about the event, a panel of industry experts discussed alternative transport options for the future. The debate touched on the topic

of the high cost of alternative vehicles and their fuel sources, the need for research and the urgency in developing new, practical solutions. The fair is being held daily from 10am to 6pm at the Karlsruhe Trade Fair Centre from 21-24 September.

www.nufam.de

Transport temperatured goods more cost-effectively with the S.KO COOL reefer. The innovative insulation system FERROPLAST® together with the efficient S.CU cooling unit and the smart TrailerConnect® telematics system ensure optimized and reliable transportation. Also available fully electric as S.KOe COOL. More Information: www.cargobull.com

JOST MAKES THE CHALLENGING JOB OF A TRUCK DRIVER EASIER. AT NUFAM 2023, TAKING PLACE IN KARLSRUHE FROM 21 TO 24 SEPTEMBER, JOST WILL PRESENT THE LATEST SAFETY TECHNOLOGY AND SMART ASSISTANCE SYSTEMS.

On the exhibition stand in the hall and outside the international audience will experience live demonstrations of the automatic coupling system KKS, as well as innovative new products and tried and tested solutions. Special product highlights are the unique King Pin Finder assistance system and the ZGA with TRIDEC EF-S.

The KKS enables drivers to couple and uncouple semi-trailers via remote control without leaving the driver’s cabin, automatically, safely and quickly. The driver is guided through the entire coupling process, with sensor technology providing live information on the KKS remote control throughout every step of the process. For example, the support plate sensor indicates that the trailer plate is touching and the position of the king pin is also monitored by sensors. Climbing out of the cabin to manually open the fifth wheel, cranking down the landing gear and manually connecting the spiral cable, air and brake connections are all a thing of the past for drivers. Time, comfort and safety gains are made possible with just

one product.

At the NUFAM JOST will present another innovation of the KKS – the KKS-U Connector: With the KKS-U Connector, existing fleets can be retrofitted with a KKS system without much effort, as it is simply and quickly mounted to the underside of the semi-trailer The KKS-U connector controls all the mechanical, electrical, and pneumatic connections between the truck and trailer, eliminating the need for vulnerable air, electrics and ABS/EBS spiral lines. Alongside the exhibit at the stand, there will also be live demonstrations. Visitors can have a look at the automatic coupling process every day in the outside area.

JOST King Pin Finder: new assistance system

One of JOST’s new products that will be presented in Karlsruhe is the King Pin Finder, a camera integrated