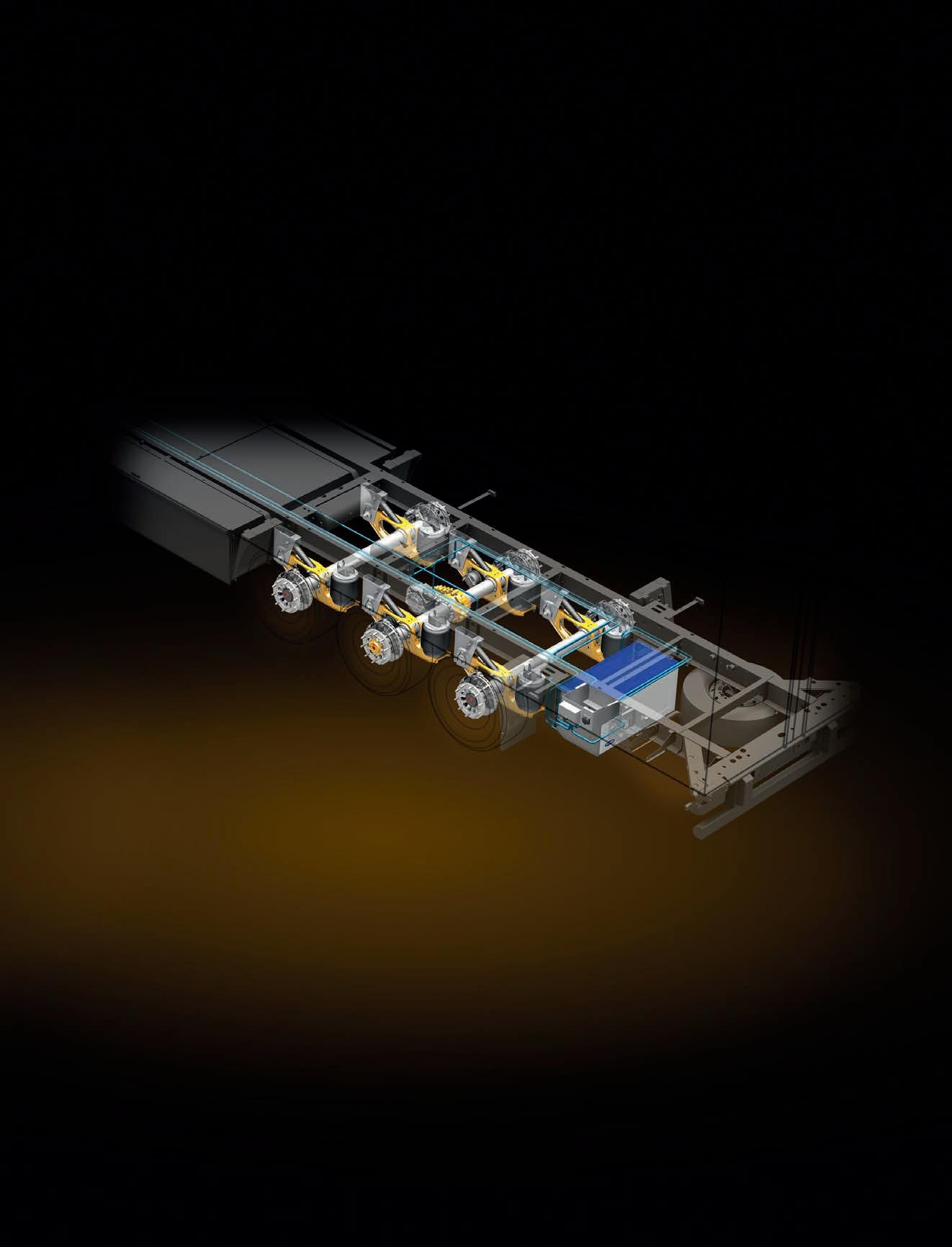

INDIVIDUAL RUNNING GEAR SOLUTIONS FOR SPECIAL TRANSPORT TASKS.

With our running gears and special axle solutions, there is nothing that can’t be transported. Your requirements motivate us to create new things. They inspire us to use our entire engineering expertise and decades of experience to develop innovative and reliable solutions together with you – customised for the type of vehicle and intended use.

The vehicle concepts for low-loaders are as varied as the transportation tasks. The use of air-sprung modules with rigid and steering axles is just one solution from our uniquely wide range of running gear systems for low-loaders. Challenge us!

24 MARKET REPORT

A look at the impact food loss within the cold chain is making on the industry and the planet.

46 SPECIAL REPORT: ECO-DRIVING

Research shows that eco-driving –driving in a way that reduces emissions – can have an impact on both the environment and the bottom line.

50 SPECIAL REPORT: TRUCK PARKING

It’s a problem spanning the globe – nding secure truck and trailer parking.

54 EVENT REVIEW

is year’s Heavy Duty A ermarket Week event in Grapevine, Texas broke attendance records.

28 MATERIALS & COMPONENTS

See the latest R&D innovation from Brianza Plastica.

30 BRAKING TECHNOLOGY

With a history spanning 70 years, SAE-SMB Industries’ strength comes from its engineering innovations.

34 LOW LOADERS & HEAVY HAULAGE

Kässbohrer has a manufacturing facility dedicated to low bed trailers.

38 BUILT TO TASK

Quality materials and specialised manufacturing makes these o erings a standout.

Honouring tradition and still looking towards growth and innovation can be a ne balance for any company. For Brazil’s Randoncorp, that balance has been reached with a recent rebranding, encompassing the profound changes the trailer builder has undergone and marking the beginning of a new stage.

“RANDONCORP HAS UNDERGONE PROFOUND TRANSFORMATION IN RECENT YEARS. WE ARE A TRADITIONAL COMPANY ORIGINATING FROM A FAMILY BUSINESS AND HONOURING ITS OWN

34

04 EDITOR’S NOTE

What does ESG or Environment, Social and Governance mean to you? Is it planting trees and frolicking in the garden once a month?

Singing the praises of a humanitarian movement that happens to be on-trend right now? Supporting an awareness campaign for better public relations but not actually making a meaningful contribution to the cause? Well, it could be but not really.

So, the United Nations is pushing a joint objective for the international community –17 Sustainable Development Goals (SDGs) ranging from ending poverty to promoting sustainable economic growth to taking urgent action to combat climate change and its impacts. ese are to be implemented from 2016 to 2030. To achieve such ambitious goals a framework is required to support it hence the emergence of ESG which champions core values for companies, nancial institutions and shareholders around the world to consider and apply where appropriate. at makes ESG a di cult proposition to follow especially when there are so many factors in the mix. Simply put, ESG is a way to measure a company’s long-term impact on society and the environment. is can take so many forms like paving the way for a more sustainable waste management supply and value chain or implementing practices that genuinely boost health and safety all the while openly reporting on it to ensure transparency with

the mission and the outcomes.

For the road transport industry and more broadly manufacturing, a clear focus for many businesses would naturally be decarbonisation or at least working towards minimising carbon emissions. Scope 1 emissions are physically direct; Scope 2 emissions are generally indirect greenhouse gas emissions associated with the purchased supply of energy; and Scope 3 emissions are again indirect, but these are typically generated from within the wider economy via other businesses.

Last year Brambles, an Australian supply chain logistics company, reported outstanding performance across its ESG assessments which tied into a circular business model. In particular, the organisation adapted to changes in sustainability reporting and disclosure by introducing and adopting ISSB standards to empower decision-making with investors and stakeholders. Similarly, Swedish furniture specialist, IKEA, has transitioned to a circular economy and invested in electric vehicles over the past few years. e business has invested in its people, forecasting challenges ahead for livelihoods and human rights.

As ESG shapes the world, I wonder what it will look like in 2030?

CEO

John Murphy john.murphy@primecreative.com.au

COO

Christine Clancy christine.clancy@primecreative.com.au

INTERNATIONAL SALES

Ashley Blachford ashley.blachford@primecreative.com.au

MANAGING EDITOR

Luke Applebee luke.applebee@primecreative.com.au

JOURNALISTS

Louise Surette louise.surette@primecreative.com.au

Peter White peter.white@primecreative.com.au

DESIGN PRODUCTION COORDINATOR

Michelle Weston michelle.weston@primecreative.com.au

ART DIRECTOR

Blake Storey

DESIGN

Kerry Pert, Blake Storey

CLIENT SUCCESS MANAGER

Salma Kennedy salma.kennedy@primecreative.com.au

COVER

Image: NAZ Industries

HEAD OFFICE

Prime Creative Pty Ltd 379 Docklands Drive Docklands VIC 3008 Australia +61 3 9690 8766

enquiries@primecreative.com.au www.globaltrailermag.com

SUBSCRIPTIONS

+61 3 9690 8766

subscriptions@primecreative.com.au

Global Trailer is available by subscription from the publisher. e rights of refusal are reserved by the publisher.

ARTICLES

All articles submitted for publication become the property of the publisher. e Editor reserves the right to adjust any article to conform with the magazine format.

COPYRIGHT

Global Trailer is owned by Prime Creative Media and published by John Murphy. All material in Global Trailer is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher. e Editor welcomes contributions but reserves the right to accept or reject any material. While every e ort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. e opinions expressed in Global Trailer are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

Follow us on twitter @Globaltrailer

#futurenow – Thanks to our revolutionary coupling system you can now change semitrailer quickly and safely out of the cab. Your start in the future of logistics. Ready to beam up?

American AIT Worldwide Logistics has announced it has acquired Global Transport Solutions Group (GTS), an international freight forwarder specialising in time-critical marine spare parts logistics.

Headquartered in the Netherlands, GTS and its more than 600 employees across 16 locations serve 2,000 ports around the world.

The company’s business is divided into two sub-brands: Marinetrans offering ‘door-to-deck’ spare parts logistics for ship owners and managers, and Best Global Logistics, providing time-critical solutions and general forwarding for other industries, including life sciences shippers.

Mexico City has joined a pledge to decarbonise freight transport and improve air quality.

The city, where 58 per cent of greenhouse emissions come from transport, joined a climate pledge, in collaboration with C40 Cities, a global network of 100 mayors in leading cities united in confronting the climate crisis. Dubbed the Laneshift Initiative, the city will collaborate with the Environment Ministry to accelerate the development of electric vehicle (EV) infrastructure and the deployment of EV heavy-duty trucks to reduce emissions.

According to C40, in 2021, an estimated 4.4 thousand deaths could be attributed to air pollution in Mexico City.

Canadian company, Metro Supply Chain, has completed its SCI Group

acquisition, adding 3,000 employees to its team.

Together, Metro Supply Chain and SCI, a Canadian third-party logistics company, now manage close to two million sqms of space, operating out of more than 175 sites across North America and the United Kingdom. The acquisition bolsters Metro Supply Chain’s e-commerce offering and opens up in-demand vertical sector capabilities such as technology and healthcare.

J.B. Hunt Transport Services Inc. has entered into a multi-year intermodal service agreement with American retail company Walmart.

The contract will see the transport and logistics company, one of the largest in North America, purchase Walmart’s intermodal assets including its container and chassis fleets. specialises in domestic and international freight movement that offers shipping options, including ocean, transloading, temperature-

controlled and expedited capabilities. It has had a long-standing relationship with Walmart.

Röhlig Logistics has expanded its global network with a new subsidiary in Toronto, Canada.

“Canada is the world’s tenth largest economy, relying heavily on its abundant natural resources,” said CEO Sea Freight, Air Freight, Contract Logistics & Sales, Hylton Gray.

“Moreover, the nation boasts a thriving services sector, a well-established manufacturing industry and a steadfast dedication to fostering innovation and technological advancements.”

Röhlig has appointed Jan Dreyer as General Manager for Canada.

Dreyer was, most recently, Regional Vice President Central Canada at Kühne+Nagel.

DHL is connecting customers on Earth with space through lunar deliveries, partnering with space technology

company Astrobotic.

The Astrobotic Peregrine Lunar Lander, part of NASA’s Commercial Lunar Payload Services initiative, launched from Cape Canaveral, Florida. Aboard the mission were DHL MoonBoxes, specially designed capsules filled with mementos from people worldwide. The collaboration marks one of the first commercial missions to the moon. The mission is aiming to continue to provide a cost-effective means for customers, including scientific, commercial, and governmental organisations, to send their payloads to the moon.

Canada’s TFI International has announced the acquisition of Hercules Forwarding, a less-than-truckload (LTL) carrier specialising in intra-US and US-to-Canada cross-border transportation. Founded in 1985, Hercules is familyowned with US headquarters in Vernon, California and Canadian headquarters in New Westminster, British Columbia. Hercules has a 31-terminal network and operates more than 210 trucks, close to 600 trailers and approximately 75 containers, generating more than US $100 million in annual revenues.

Representatives from various American commercial trailer manufacturers have agreed to form a Dealer Advisory Council, helping bring electric trailers to the commercial trucking market. Electric trailer company, Range Energy, has spearheaded the initiative which has encouraged OEMs, including Doggett Freightliner, North American Trailer and Great Dane, to bring experience in trailer sales and new technologies to the group. Range Energy’s electric trailers can be attached to any electric or diesel-powered truck, reducing emissions and promoting sustainability.

Kuehne+Nagel has released details of a new contract logistics fulfilment centre in Piscataway, New Jersey which will support a fashion customer. It will be strategically positioned close to John F. Kennedy International airport and Port Elizabeth, as well as an existing Kuehne+Nagel luxury retail brand facility. The facility will offer 5,000 sqm of space and integrate automation and robotics

for picking and putaway, enhancing efficiency in the fulfilment process. It will open in late-April 2024, and brings approximately 50 new job opportunities to the area.

The first fully electric sets of semi-trailers and trucks are now in operation in Latin America, transporting ore in Chile.

The historic milestone is the result of a partnership between Brazilian semitrailer manufacturer, Randon, and Chilean mining company SQM which produces lithium.

The units are from the Hybrid R line, built with an e-Sys electric auxiliary traction system, which acts on the recovery of energy generated during descent and braking movements. These movement can generate up to 207 hp of additional power to contribute to traction on climbs and overtaking.

Brazil-based trailer builder, Librelato, has unveiled its updated industrial plant, highlighting a new manufacturing layout. Located in the city of Criciúma, Brazil, the factory has undergone a complete

renovation at an investment of $15 million BRL (more than $3 million USD) as it looked to optimise its processes by expanding its production line to meet growing demand.

The Criciúma factory builds products specifically for open cargo applications, including a line of bulk carriers and container ships.

Randoncorp has released its 2023 figures which have resulted in the highest EBITDA in its history.

With a net revenue of 10.9 billion BRL (2.91 billion USD), the company said in a statement that these results demonstrate the resilience of Randoncorp’s business model which has overcome the current complex truck market.

Its EBITDA, 1.6 billion BRL at a margin of 14.4 per cent, is 0.9 percentage points higher than the previous year. In addition, revenues of $466.7 million USD were recorded for the foreign market, which represents an increase of 6.9 per cent in the annual comparison, despite the drop in demand in Latin America and the effects of the macroeconomic scenario in Argentina.

A state of the art, upgraded and fully integrated global manufacturing centre of trailer systems and On/Off highway systems. Expertly designed and engineered with worldwide accessibility, offering you private label and OEM manufacturing solutions.

Drawing upon decades of expertise spanning Asia, Australia, US, and in Europe, Fuwa stands as a global manufacturing powerhouse, unrivalled as the foremost network of specialists in truck and trailer components across the globe.

UK-based global event organiser Clarion Events has selected Kuehne+Nagel as its official global logistics partner.

The purpose-led partnership will focus on reducing the carbon footprint of exhibitions and setting new standards for the events industry.

Clarion Events organises more than a hundred exhibitions around the world, with about one million people visiting its events each year. Kuehne+Nagel will be the exclusive onsite handling provider for those events, which includes storage, lifting services, customs support, traffic management and international freight forwarding.

The delivery of Krone vehicles in southwest Germany will now take place using combined transport. The new method involves using an exclusive block train travelling once or twice a week and allowing up to 32 semi-trailers to be transported each trip.

This sustainable logistics solution was made possible by the construction of a new loading facility in the town of Werlte by Emsländische Eisenbahn GmbH. Meanwhile, working with Austrian service provider, Vega International Car Transport, allowed for the development of special low-floor wagons, making it possible to load

vehicles up to 4 metres high.

Toll Global Forwarding has announced it is expanding into Poland with the opening of two branches strategically located in Poznan and Krakow.

Establishing a direct presence in Poland creates more value for local businesses which will benefit from Toll’s global network as well as Poland’s access to Eastern European and Baltic companies, Toll said in a statement.

Toll has 16,000 employees with 500 sites in 27 markets, and a forwarding network that spans 50 countries.

CEVA Logistics has signed a new multiyear contract to continue providing all logistics services for Scuderia Ferrari’s cars and equipment during Grand Prix events.

This year’s Formula 1 World Championship which, for the first time, will include 24 events worldwide, starts on 2 March in Bahrain, ending on 8 December in Abu Dhabi.

In 2023 CEVA was able to organise a world-first rail transport service to deliver Scuderia Ferrari’s equipment between three North American Grand Prix, which reduced the carbon footprint by 90 per cent compared to air transport, and by 32 percent compared to road transport alone.

TIP Group has announced it is supporting logistics company DS Smith with a substantial supply of trucks and trailers as part of its fleet renewal initiative.

The paper, packaging and recycling

logistics specialists have received 61 Volvo FM 460 Globetrotter 6×2 tractor units and 26 Lawrence David pillarless curtainsider trailers on a long-term leasing arrangement.

TIP worked with the fleet team at DS Smith to determine the optimal specifications to best suit the its needs. That operation will see paper reels transported from its paper mill across the UK to customers, with return journeys transporting bailed fibre back to the mill for recycling into paper reels.

DB Schenker started the year with new

leadership announcements, beginning with appointing Niklas Wilmking to the Global Board of Management for Contract Logistics and Supply Chain Management.

Wilmking has a PhD in logistics and has been with DB Schenker for more than 20 years, holding several management positions. He’s had key roles in Germany and Asia, with his last role being CEO for Asia Pacific.

Meanwhile, the global logistics company has appointed Vishal Sharma to replace Wilmking as CEO for Asia Pacific, moving from his position as CEO for the company’s Cluster Greater China.

The CEO of Girteka Transport has left his desk and taken to the open road, driving a fully loaded truck through Europe and delivering cargo to customers.

Mindaugas Paulauskas wanted to understand what it meant to be a driver and what their day truly entailed.

Joined by an experienced Girteka driver, he is navigating his way around Europe, documenting lessons learned to bridge the gap between management and the driving community.

His journey kicked off in Šiauliai, Lithuania and is continuing across Europe.

He hopes to be able to have a closer look at the trucks, trailers and technologies that make driving and delivering easier and smoother, but also wants to create awareness of today’s road transportation situation — the rising issue of professional driver shortages.

The European Parliament Transport Committee (TRAN) has voted on the revision of EU rules on vehicle weights. The text, adopted at the meeting, retains incentives regarding weight allowance and adds derogations for zero-emission vehicle combinations. Following the voting carefully, the World Road Transport Association (IRU) said it welcomed the decision to allow up to six additional tonnes for zero-emission vehicle combinations as well as the 12.5 tonne allowance on the drive axle. This, the organisation explains, compensates for load capacity losses due to the weight of zeroemission technology, such as batteries.

SAF-Holland has acquired Italy-based axle and suspension system specialists,

Tecma Srl.

Tecma develop and manufacture customer-specific axle systems and suspensions for special vehicles and heavy-duty applications, which are developed in close cooperation with vehicle manufacturers according to customer requirements.

The company currently employs about 60 people and operates a development and production site in Verona, Italy.

For many years there has been a close partnership between Tecma Srl and IMS Group Benelux, which was acquired by SAF-Holland in January 2024.

Tiger Trailers will provide 38 rigid box vans to Britain’s largest bakery brand, joining its nationwide fleet of vehicles delivering fresh bread across the country.

British bakery, Warburtons, had unique operational requirements, looking for a bespoke, intelligent and ergonomic design to help with its deliveries to more than 18,500 stores daily.

Built on 14-tonne DAF chassis from local firm Lancashire DAF, each rigid is fitted with Warburtons’ racking along its sides, along with adjustable

centre aisle load bars to suit its loading requirements.

Trailer manufacturer Schwarzmüller Group has appointed a new CEO. Sole owner and Chairwoman of the supervisory board, Beate Paletar, announced Wolfgang Muhri will head the Austrian-based company. His appointment completes the three-person management team whose members will ensure that the Schwarzmüller continues to flex its muscles internationally, despite the currently challenging environment, the company said in a statement.

Joining Muhri on the management board will be CFO Daniela Lorenzer and CSO Maik Spindler, both relatively new to their roles.

Food logistics company, NewCold, is expanding in its home country.

A new automated warehouse is already under construction in Dinteloord in the Netherlands and NewCold has recently acquired a family-owned cold storage facility in Kruiningen.

Since its formation in 2012, NewCold has grown from having warehouses in Germany and France to 15 in several countries on three continents, including the United States, the United Kingdom and Australia. It is moving into new markets, with expansion to India and Canada already announced.

“NewCold has earned its reputation for innovation. We are growing because we deliver high-level service consistently, using automation and proprietary software to cut loading times, costs, and carbon footprints,” Hage said.

CMA CGM Group have announced the purchase of Bolloré Logistics at a price tag of 4.850 billion (Euro).

This is CMA CGM’s largest acquisition since its creation in 1978 and constitutes a major step group’s logistics development strategy, complementing its historical maritime transport line of business.

Bolloré Logistics achieved, in 2022, a turnover of 7.1 billion (Euro), transported 710,000 TEUs of ocean freight and 390,000 tons of air freight, along with a storage capacity of 900,000 m2. Its 14,000 employees will all join CMA CGM.

JOST has announced it will be partnering with the European Truck Racing Association.

The German company, a specialist in the production of systems, components and technology for commercial vehicles, will feature heavily during the European truck racing calendar. Throughout the racing calendar,

JOST will be featured within the paddock, showcasing its products.

In addition, the company will deliver workshop sessions in its known “Truck Stop” format during various events throughout the season which kicks off at the end of May in Misano, Italy and finishes in Spain in October.

TIP Group has announced it will partner

with a container transport company, launching a 12-month pilot project which will see the replacement of traditional diesel gensets on container chassis.

Tip, and Danish Ancotrans, are hoping the electric powered gensets will mark a significant leap forward in sustainable transportation solutions.

Featuring a lightweight battery system, the project is aiming for a minimum autonomous runtime of 20 hours. This innovation not only enhances sustainability by reducing greenhouse gas emissions, but also contributes to creating cleaner and quieter cities, the company said.

LC3 Transport has become among the first fleets in Italy to have emission free refrigerated trailers, with a Schmitz Cargobull delivery.

The electric S.KOe COOL semi-trailers are now in operation, working in collaboration with Lidl Italia, a supermarket chain with more than 730

shops across the country.

The refrigerated trailers are part of LC3’s sustainable fleet, as the company focuses on achieving the goal of zero emissions by 2050.

The fleet’s tractor units run on BIO-LNG, an environmentally friendly fuel that reduces CO2 emissions, and it has a growing fleet of liquified natural gas vehicles.

Owner-managed company, Röhlig

Logistics, achieved a strong result in the 2023 financial year, which it says is thanks to the acquisition of new

customers and the corresponding increase in orders.

The company earned an EBIT of about 20 million (EUR) in 2023, to which all of the core business areas – sea freight, air freight and contract logistics –contributed. The gross profit generated in the 2023 financial year totalled around 222 million (EUR). The core markets of Australia, New Zealand, South Africa and the United Arab Emirates made a particular contribution to this. The country organisations in Mexico, Italy and France also recorded very positive developments, the company said.

Poland DHL Group has opened a combined sorting and distribution centre in Poland that is prepared to handle a million parcels daily.

The centre, located near Poznan, Poland, was a joint project between DHL eCommerce, Post & Parcel Germany and DHL Freight, and is designed to deliver faster lead times to customers.

With an investment of about 180 million (Euro), the new facility spans an area of 32,000 sqm and features 3,000 metres of conveyor belts and a sorting capacity of 45,000 parcels per hour.

Logistics company Röhlig has officially opened its newly expanded warehouse facilities in Malaysia.

The refurbished space, located just outside Kuala Lumpur, is one of four new warehouses opened between 2020 and 2023, increasing the company’s capacity by more than tenfold and having access to more than 20,000 square metres of warehouse space.

The facility is positioned close to the country’s major transit hubs and is one of the few warehouses in the area offering both bonded and non-bonded storage all under one roof. It’s equipped with support cross-docking, local/regional distribution, pick-and-pack and assembly. It is also Good Distribution Practice for Medical Devices certified, and able to handle a range of cargo.

Carrier Transicold is providing transport refrigeration units, connected cold chain solutions and training to help cold chain development in East Africa.

The initiative is part of an agreement with the Africa Centre of Excellence for Sustainable Cooling and Cold Chain (ACES).

An inauguration ceremony for the ACES facility took place in Kigali, Rwanda, which included the Rwanda Minister of the Environment, Dr. Jeanne d’Arc Mujawamariya and David Hill, DirectorGeneral Environment, Rural and Marine, UK Government.

ACES is a first-of-its-kind, one-stop hub for technical assistance and knowledge transfer for the cold chain. By mid-2024, the facility will include a technology testing and demonstration centre, a fully equipped refrigeration and data

telematics training facility, classrooms, a conference centre and a 200-hectare smart farm.

A.P. Moller-Maersk has opened an integrated cold chain facility in New Zealand with the aim of allowing larger quantities of imported and exported goods to flow through the country.

Maersk has operated in New Zealand for 27 years but, at approximately $140-150 million NZD, this facility in Hamilton is the company’s biggest infrastructure investment in the country to date. The new facility offers customers end-to-end supply chain management including import, export and crossdocking services. It enables the exchanging of goods between transport

modes, such as rail and truck.

Logistics company, CEVA, has opened a facility in Sydney, Australia, the first warehouse to be opened in a new industrial park.

The new 34,000 sqm warehouse, in the Aspect Industrial Estate, is strategically located in close proximity to the Western Sydney Airport and has access to key transportation routes.

As part of the CMA CGM Group, CEVA aims to achieve net zero by 2050, and after two years of planning, the Kemps Creek distribution warehouse is built to

specifications that prioritise sustainability and technology in its operations.

Solar panels have been installed for an 830kW photovoltaic system with battery, as well as translucent roof sheeting, LED lighting, electric vehicle charging points and rainwater harvesting to help water conservation.

Team Global Express has unveiled Australia’s largest logistics electric vehicle fleet.

The logistics company has received 43 out of 60 electric trucks at its depot in Bungarribee, which will roll out across

the streets of Western Sydney. It will take possession of 36 Volvo eFLs and 24 Daimler Fuso eCanters in total to facilitate the five-year trial.

Over the last 12 months, Team Global Express has turned its facility into ‘The Depot of the Future,’ to house the vital infrastructure required to service the electric vehicles. The depot upgrade included the construction of charging infrastructure and a battery storage system, which uses 400kws of solar energy from on-site panels. The installed 1MW battery energy storage system will enhance the depot’s renewable power capacity and reduce grid power reliance.

HONOURING TRADITION AND STILL LOOKING TOWARDS GROWTH AND INNOVATION CAN BE A FINE BALANCE FOR ANY COMPANY. FOR BRAZIL’S RANDONCORP, THAT BALANCE HAS BEEN REACHED WITH A RECENT REBRANDING, ENCOMPASSING THE PROFOUND CHANGES THE TRAILER BUILDER HAS UNDERGONE AND MARKING THE BEGINNING OF A NEW STAGE.

It’s been a meteoric rise. Going from a tool manufacturing workshop in the 1940s to a company that is now among one of the largest manufacturers of semi-trailers in the world is an impressive feat.

By all accounts, however, the biggest changes for Randoncorp have taken place more recently and have buoyed the company to solidify its legacy and pledge a commitment to the future.

It makes sense then that the company’s rebrand has only recently taken place. e new name has been billed as a tribute to its legacy, but also as a way to build a new identity that re ects the path of the future.

Previously known as Empresas Randon, the company, which is made up of ve di erent verticals with its OEM making up 35 per cent of revenue, chose to change its name to Randoncorp last year.

“ is was a strategic and necessary step,” said Randoncorp CEO, Sérgio L. Carvalho. “Randoncorp has undergone profound transformation in recent years. We are a traditional company originating from a family business and honouring its own legacy. But at the same time, we are very youthful.”

Carvalho goes on to explain that it isn’t just the company that has changed, so has its business model – becoming much more resilient as it faces the future.

“We have advanced in the development of disruptive technologies, acquired and created industrial units, grown and expanded our global presence.”

In many ways the name change isn’t just a recognition but a coming of age, spurred by the fact that it is hitting record consolidated net revenue – reaching 11.2 billion BRL ($2.3 billion USD) in 2022.

e Randon OEM has a signi cant presence in the markets of Chile, Paraguay, Uruguay, Argentina, Colombia and also in the North American market. To these countries it exports platforms, bulk carriers, tippers and tankers, mainly to customers transporting bulk cargo, industrialised cargo, containers, transporting minerals in general and transporting fuels. In Brazil, it supplies mainly to agribusiness and mining, industry, civil construction and petrochemical segments. To serve these markets, its highlighted products are the tipper, the bulk carrier, the carbon tanker, the sider (tipper) and the general cargo van.

e company’s headquarters is in Caxias do Sul, found in Brazil’s southern, mountainous region. Active in ve complimentary business verticals, Randoncorp o ers a complete line of equipment for the land freight transport services from road implements to rail cars.

A publicly traded company, it is present in more than 120 countries on ve continents.

Its emphasis is on industrial parks and distribution centres in the Americas, Europe and Asia, as well as assembly units in Africa and is made up of more than 16,000 employees.

e company says its growth is supported by three di erent pillars – acquisitions, diversi cation (whether in terms of portfolios, markets or geographies) and mobility innovation.

“Our legacy drives us to seize opportunities to build something even bigger and better for the future,” Carvalho said. “In the last ve years we have quadrupled our revenue. is outcome is the result of a solid growth strategy that relies on the commitment of our teams, and today we are proud to place ourselves more and more as a global reference in the mobility segment.”

• OEM (Randon)

• Motion Control (Frasle Mobility)

• Auto Parts (Castertech, Suspensys, Master, Jost Brazil)

• Financial and Digital Services (Rands)

• Advanced Technology (Auttom, CTR, Nione)

What is proving to work well is the diversi cation of Randoncorp’s products and services that results in solid synergy of operations that can meet global mobility challenges.

“We have a strategic position in the development of innovative and disruptive technologies in electri cation, nanotechnology and composite materials, as well as industrial automation solutions and digital and nancial services for the transport and logistics sector,” Carvalho explained.

Looking to more recent gures, Randoncorp recorded in the year, revenue of 10.9 billion BRL.

Consolidated EBITDA reached 1.5 billion BRL in the year, which represents an increase of 4.3 per cent compared to 2022. e EBITDA margin was 14.5 per cent in 2023. Considering the complex and competitive market context, with a decrease in volumes and revenues associated with the truck market and a challenging international scenario, leadership is pleased with these numbers proving the company is able to overcome challenges thanks to its diversi cation.

Foreign market gures are also showing solid global achievements. e revenues that bring together the values of exports with sales made by units located outside Brazil, totalled, in 2023, 466.7 million USD, 6.9 per cent higher than 2022, favoured by the increase in revenues from operations US and UK.

Not a company to shy away from a market challenge or a complicated consumer need, Randoncorp sees innovation as the way to come up with creative solutions and sees it as a duty to invest.

In 2023 it invested 193 BRL million in research and development, completing 60 projects and registering 126 patents. Focusing on trends in the automotive industry, Randoncorp encourages scienti c research and the search for new technological solutions by supporting the Instituto Hercílio Randon, the rst Brazilian science and technology institution focused on the automotive sector.

e company recently opened an e-plant dedicated to the production of e-Sys, an electric auxiliary traction system with axles, batteries and an intelligent management algorithm, an unprecedented development made entirely by Randoncorp.

It has also recently announced the full acquisition of Auttom, a reference in industrial automation and robotics. e aim is to reinforce the synergy of the business verticals and enhance the development of automation solutions for the market.

Randoncorp has also made advancements in nanotechnology with NIONE, which patented a nanostructured additive for coatings that increases corrosion resistance and can double the useful life of automotive components exposed to extreme weather conditions. Nanotechnology also appears in the formulation of cast products, providing great lightness and durability to fundamental components of heavy transport.

Other innovative projects the company have recently launched:

• A photovoltaic plant with 2,400 solar panels to supply activities in Caxias do Sul – the rst Brazilian plant is part of a series of global initiatives that focus on the generation of renewable energy.

• Randon Smart, a telemetry system that manages semi-trailer eets o ering controls and actions for tracking semi-trailers with real-time date generation.

• Composs, a line of composite materials products, which replace metallic components and result in products with superior performance. Weight reduction, which can exceed 60 per cent, is one of the main advantages.

• Randon Solar, a refrigerated truck with energy control and management. It is equipped with exible photovoltaic panels on the sides and roof to capture solar energy, saving an estimated 1.800 litres of diesel per year.

What’s new

Randon’s NEW R range of trailers is creating a buzz within the industry, with a series of technologies and solutions that deal with

modularity, electromobility, sustainability and embedded intelligence. Unprecedented modular manufacturing technology enables a 70 per cent decrease in weld usage, reduced operating costs, and simpli ed maintenance.

A semi-trailer from the NEW R Line can be up to 1.0 tonnes lighter than similar ones on the market, depending on the model, resulting in increased safety, pro tability and environmental gains.

Recently, it’s introduced to the market the Sider Modular NEW R in a new version that has a modular chassis with standardised components and con gurations that allow multiple combinations of the nal product. Being one tonne lighter than the previous version, the Sider Modular NEW R enables greater net load gain, positively impacting conveyor pro tability and operating costs.

e Hybrid R line, equipped with e-Sys technology can, depending on the application, loading condition and road condition, save up to 25 per cent on fuel, allow for less wear and tear on components and contribute to lower emissions of gases and waste into the environment.

e Randoncorp expansion strategy is supported by a vision of the future, says Carvalho and the company has already strengthened its global positioning. At the beginning of 2023, it consolidated its global strategy steps with the acquisition of the North American semitrailer manufacturer Hercules, entering its OEM vertical into the North American market. Meanwhile, the acquisition of the operations of AML Juratek in the United Kingdom serves the European a ermarket.

The future, according to Carvalho, is looking bright.

In March, the company released its guidance for 2024, projecting consolidated net revenue between 11.5 billion BRL and 12.5 billion BRL, with an estimated revenue in the foreign market between 420 million USD and 480 million USD. Regarding the EBITDA margin, the projected range was between 14 per cent and 16 per cent at the end of the twelve months of the year.

In 2024, Randoncorp will launch Caldeira Verde, a project looking to operate the

boilers of Frasle Mobility – a multinational company focused on the a ermarket and part of Randoncorp – with biomass replacing natural gas. e project, worth 17 million BRL, will reduce greenhouse gas emissions by 60 per cent, which represents 20 per cent achievement of the target stipulated in Randoncorp’s ESG commitments.

“We are con dent in our expansion strategy, diversi cation of segments and products, and internationalisation to continue growing in a resilient way,” Carvalho said. “We are optimistic with caution.”

www.randoncorp.com

The circulating eet of trailers and semitrailers in Brazil already exceeds 1 million units, with the majority – more than 800 thousand vehicles – being used by cargo transport companies, followed by selfemployed drivers and cooperatives.

Currently, according to data from the National Land Transport Agency, the average age of the national eet of towed cargo vehicles is 11 and a half years, being 18.2 years (for independent transporters), 9.8 years (in transport companies load) and 13.3 years for cooperatives.

In recent years, the Brazilian trailer market has undergone a transformation due to the possibilities of forming combinations of cargo vehicles, which has made the national standard one of the most competitive in the world in terms of gross and net weight transported.

Currently, the majority of the volume of trailers demanded by the market is intended for the formation of trains with up to nine axles that allow the transport of a Total Gross Combined Weight (PBTC) of 74 tonnes, which requires a special transit authorization.

Recent changes to the law have allowed the unrestricted transit of trains with up to 58.5 tonnes of PBTC, which include four-axle trailer con gurations or more traditional seven-axle trains, called bitrens [interlink semi-trailers] (57 tonnes). Furthermore, the controlled use of 91-tonne trains for the transport of sugar cane was authorized under a more restricted license.

GLOBAL FOOD LOSS HAS NOW BECOME SUCH AN IMPORTANT ISSUE THAT GOVERNMENT BODIES AND THE COLD CHAIN’S BIGGEST PLAYERS HAVE BEEN FORCED TO ACT BUT IS IT TRULY ENOUGH.

The gures are staggering when broken down. An estimated 14 per cent of total food produced for human consumption is lost even before it reaches consumers. Add in food waste at the consumer level, and the gure climbs to close to 30 per cent.

In fact, the lack of e ective refrigeration throughout the food supply chain contributes about 526 million tonnes of food going to waste every year. According to the United Nations, this is enough food to feed around one billion people in the world. is is at the same time that there are currently an estimated 850 million people in the world who don’t eat enough.

Estimates suggest that ine ciencies within the cold chain speci cally contribute to about nine

per cent of food spoilage in developed countries, while this number can be signi cantly higher in developing regions with less infrastructure.

Food loss isn’t just about losing the sustenance and nutrients the food supplies, there are also other losses. Seeds and water for growing are squandered (it’s estimated that about half the water used to produce food in the US alone goes to waste), as is fuel for transport, electricity for storage and labour.

Food waste is also a signi cant factor in climate change. As food goes to the land ll and rots, it produces methane, a potent greenhouse gas. is makes reducing food waste necessary to ghting climate change with it accounting for approximately 16 per cent of all greenhouse gases. According to the United Nations Food and Agriculture Organisation, the production and transportation of food that is wasted accounts for 8.0 per cent of global greenhouse emissions.

In February this year, the European Parliament in Brussels hosted a round table event – Advancing Food Loss Technologies and Policies – organised in collaboration by Trane Technologies and sustainable development institute, Competere.

e focus of the event was food loss during transport and the waste that occurs along the global cold chain.

Discussions reiterated the fact that a big part of improving food loss is better cold chain management, ensuring that products are kept at suitable and uninterrupted temperature conditions all the way from harvest to plate.

e answers on how exactly to do that were a bit more elusive.

According to research collected by Competere, a signi cant portion of food loss can

be attributed to production processes and failure to comply with sustainability and conservation standards. Looking at the fruit and vegetable sectors, for example, the research institute detected losses close to 50 per cent of total production.

“ is is where supply chain industries – from harvesting, to transport, to nal distribution – must take a step forward,” Competere said.

Trane Technologies, a global manufacturer specialising in temperature control systems for transportation, and the parent company to well-known refrigerated transport company, ermo King, has long been at the forefront of sustainability commitments.

“It is shocking that almost the 30 per cent of food is lost or wasted, much of which happens during transport,” said the president of Trane Technologies’ ermo King EMEA, Claudio Zanframundo. “Having an e cient and sustainable cold chain makes a big di erence in reducing food waste and putting food on tables across the world. at’s why it’s vital that policy makers and industry leaders connect regularly so we can move the needle on this important issue.”

Trane Technologies is advancing its 2030 Sustainability Commitments, including the Gigaton Challenge - a pledge to reduce customer greenhouse gas emissions by 1 billion metric tons. is reduction equates to two per cent of the world’s annual emissions – or, the annual emissions of Italy, France and the UK combined. e company has also pledged to be net-zero by 2050 and is the rst in the industry to have near and long-term emission reduction targets.

ere are at least now new EU rules when it comes to food waste. In February members of the European Parliament (MEP) adopted proposals to better prevent and reduce waste across the European Union. is included higher 2030 targets to cut down on food waste with a revision to the Waste Framework Directive.

MEPs want to increase the binding waste reduction targets proposed by the Commission to at least 20 per cent in food processing and manufacturing (instead of 10 per cent) and to 40 per cent per capita in retail, restaurants, food services and households (instead of 30 per cent), in comparison to the annual average generated between 2020 and 2022. EU countries would need to ensure that these targets are achieved at national level by 31 December 2030.

MEPs also want the Commission to evaluate the possibility and make appropriate legislative proposals to introduce higher targets for 2035 (at least 30 per cent and 50 per cent respectively).

“We provide focused solutions to reduce food waste, such as promoting ‘ugly’ fruits and veggies,

According to the International Food and Agriculture Organisation, in sub-Saharan Africa, 30-40 per cent of total production is lost before it reaches the market, due to problems ranging from spillage to lack of proper postharvest storage, processing or transportation facilities.

On the plus side, however, widespread adoption of mechanisation, post-harvest technologies such as cold storage, and other infrastructure investments have reduced downstream postharvest losses to about 10 per cent.

Solar Freeze, for example, is an agri-tech company in Kenya that provides smallholder farmers with mobile cold storage units powered by solar to help reduce post-harvest losses. Farmers using the refrigerated units powered by solar are moving away from diesel-powered generators for cold storage, hence reducing the environmental impact. The cold chain innovations around decentralised renewable energy (DRE) are paramount in Africa and Asia given that access and connection to electricity in rural areas, where food is produced, is still a luxury.

In Kenya, an estimated 40 to 50 percent of food is lost or wasted throughout the entire food chain as it goes from farm to fork—twice the global average. In 2017, $1.5 billion USD worth of food went to waste—tossed out or left to rot—according to the country’s National Bureau of Statistics, resulting in lost earnings for farmers and others. In Nigeria, 45 per cent of postharvest output spoils due to the unavailability of cold storage, resulting in a 25 per cent loss of income for the country’s 93 million small farmers.

keeping an eye on unfair market practices, clarifying date labelling and donating unsold-but-consumable food,” said Polish MEP and Rapporteur for the committee, Anna Zalewska.

e full house is scheduled to vote on its position during the northern spring’s plenary session. e le will be followed up by the new Parliament a er the European elections in June.

For some however, this simply isn’t enough.

“Today the Parliament acknowledged the need for more ambitious action on food waste, but the targets agreed fall short of addressing the magnitude of the challenge and honouring international commitments,” said the Policy O cer for Circular Economy & Waste at the European Environmental Bureau, Fynn Hauschke. “At the same time, the Parliament failed to meaningfully take on food losses and waste at primary production. e agreement is a missed opportunity to cut greenhouse gas emissions and improve food security and biodiversity.”

Not just a focus in Europe, late last year the US announced a $10 million investment to launch USAID’s Food Loss and Waste Accelerator.

rough Feed the Future, the US government’s agship food security initiative, the Accelerator will support partner country policies and collaborate with businesses to reduce food loss and waste to help ensure that more food can make it o the farm and into the homes of those who need it most.

With a focus on nutritious value chains and businesses led by women and youth, USAID’s Food Loss and Waste Accelerator will provide co- nancing for micro, small, and medium enterprises through the Feed the Future Market Systems and Partnerships’ Food Loss and Waste Partnership Facility. is, the US Agency for International Development said, will enable businesses to invest in climate-smart practices such as sustainable cold chain, community composting, and business models that intentionally minimise production waste and post-harvest losses. Working with partner governments, the Accelerator will provide support for policies that address food loss and waste, including identi cation of points along commodity chains where food is being lost or wasted.

Cold chain technology is aimed at reducing consumer waste at the source by allowing growers and manufacturers to track the temperature of a product throughout its

distribution journey.

e technology allows suppliers access to what was previously a major blind spot—the journey from farm to store inside a delivery truck—so they can spot temperature change trends and create solutions to help extend the life of their products.

To save on fuel, delivery drivers will o en put their trucks into an economy mode, which raises or lowers the truck’s temperature during their trip.

ose spikes and shocks can cause the products to deteriorate at an accelerated rate.

When this happens, those products might be rejected by the receiver and labelled as waste, decline quickly on the shelf or be thrown away shortly a er purchase.

Global refrigeration company Carrier has come up with a solution through its Lynx Digital Ecosystem, developed in partnership with Amazon Web Services.

It leverages advanced data analytics, IoT and machine learning to optimise the cold chain, creating a system that is healthier, safer, sustainable and intelligent.

Lynx automates key processes and delivers real-time visibility and insights throughout the

cargo’s journey, helping optimise cold chain operations, decrease energy use and enhance outcomes with reduced costs, delays, cargo loss and spoilage in transit.

e Lynx application will intelligently monitor connected refrigeration systems from anywhere in the world, providing vital information through a centralised data stream and improved visibility for asset owners, producers, drivers, eet managers and retailers on the products being transported and the delivery modes transporting them.

In 2022, Carrier began collaborating with the United Nations World Food Program (WFP), to help advance cold chain development and training in West Africa.

WFP agreed to work with global corporations, including Carrier, to build a worldclass Transport Training Centre in Accra, Ghana, aimed at enhancing transport and logistics capacities across the region.

Since January 2023, the Transport Training Centre has trained nearly 200 participants from WFP, the private sector and non-governmental organisations across West Africa.

“Collaborative e orts between the public and private sectors can drive transformational cold chain development and growth,” said Tim White, President, Refrigeration, Carrier.

“We’re pleased to partner with WFP to make a meaningful di erence across Africa, as the potential bene ts of these collective e orts are far reaching and can positively impact the cold chain from farmers and manufacturers to consumers with wide-reaching bene ts.” Carrier supports and contributes to the project by providing equipment and tools and by developing training programs on best practices, operation and maintenance of transport refrigeration equipment.

www.globaltrailermag.com

WITH A SUBSTANTIAL INVESTMENT PUT INTO A NEW RESEARCH AND DEVELOPMENT LABORATORY, BRIANZA PLASTICA HAS SUCCESSFULLY CREATED AN EXCITING RANGE OF FIRE-RESISTANT PRODUCTS.

Acompany ethos of constant evolution has kept Italy’s Brianza Plastica on the cutting edge of product development and its most recent release is proof of that.

A er more than 60 years of experience in the production of berglass laminates in sheets and rolls, the company decided to expand with a new research and development laboratory.

ree times bigger than its predecessor and with a signi cant increase in sta , it is here that the Brianza team were able to develop an entire range of grp at laminates that are completely re-resistant and compliant with international re rating standards.

e Elyplan Fire Performance range can be put on vehicles both horizontally or vertically, and are expected to be most useful when it comes to commercial transport. A er careful research and analysis, in partnership with its clients, Brianza Plastica developed the R118 and B476 range of grp at laminates. ese products combine all the main properties

of the Elyplan range, such as atness and tight dimensional tolerances, with the ame-retardant requirements of the automotive and building new e-mobility markets.

In particular, the Elyplan Fire Performance R118 is a range of grp products compliant with the United Nations Economic Commission for Europe’s regulation R118, annexes 6,7 and 8. anks to this compliance, Brianza Plastica’s re performance laminates can be placed on vehicles such as buses, private or public transport.

Brianza Plastica’s Elyplan Fire Performance grp laminates are also compliant with the British Standard Norm BS 476 part 7, which regulates the re test on building materials and structures. anks to this norm, the grp at laminates are appropriate for the construction of stables or small prefabricated houses, as they provide added assurance about the overall safety of the building in case of re.

Due to the increasing demand of the market, the range has obtained two important European certi cates in the re-resistant norms’ framework –D-s2, d0 and B-s1, d0. With this in mind, Brianza Plastica is able to produce Elyplan Fire Performance laminates in a thickness of 1.5 mm and 2.00 mm. is product is mostly placed on commercial vehicles, speci cally those transporting hazardous materials such as explosives, ammunition or chemicals.

All of these new developments couldn’t have occurred without the research labs that o er modern equipment, allowing fundamental testing. One of the core sections is the instrumental laboratory where analysis equipment such as a dynamometer,

Xenotest, viscometer, optical microscope and re testing apparatus allows for precise tests and analysis, including the characterisation of the nished products.

The other important area is the chemical laboratory, where Brianza Plastica sta carry out the main product formulation activities by simulating the production process and analysing both incoming raw materials and the nished products.

e company said this new lab and instruments couldn’t have come at a better time, explaining that worldwide re rating standards have increased in the past few years within both the construction and transportation industries.

Brianza Plastica was founded in 1962, established as a manufacturer of berglass laminates for the industrial and commercial sectors and has continued to expand its production, operating mainly in the construction sector.

Important know-how and expertise acquired over the years and the demand for grp laminates with better characteristics, have made its berglass laminates suitable for recreational and temperaturecontrolled vehicles.

Between 2006 and 2008, the company built two

new production facilities equipped with discontinuous laminating technologies and expanded the main production site of Carate Brianza, Italy, with the introduction of a new continuous laminating production line.

Brianza Plastica is currently one of the main European manufacturers of berglass laminates in sheets and rolls and also the only company able to o er at laminates made with two production technologies— continuous hot laminating and discontinuous cold laminating. In 2014, it opened the commercial-logistics centre of Elkhart, Indiana to serve the entire US market and to strengthen its presence in that territory.

In summer 2016 a third production site for discontinuous grp laminates was established in Rovigo, Italy, together with a new continuous plant in Carate Brianza. ese productive investments increased the production capacity by 40 per cent.

At the beginning of 2019, the new chemical laboratory was inaugurated, almost tripling the previous surface area, and signi cantly improving the equipment used to carry out most of the chemical-physical tests, on both raw materials and nished products.

Today Brianza Plastica supplies berglass laminates which are able to satisfy all market requirements. With its four production sites dedicated to berglass laminates, the group is in a position to o er a comprehensive service to the sector for the next few years.

WITH A HISTORY SPANNING 70 YEARS, SAE-SMB INDUSTRIES HAS MANAGED TO MAINTAIN A PARTNERSHIP OF TRUST WITH ITS HISTORIC SUPPLIERS, BUT ITS TRUE STRENGTH COMES FROM ITS ENGINEERING INNOVATIONS.

SAE-SMB’s engineering aptitude has solid historical roots. Its story begins in 1947 when three technicians specialising in mechanical engineering began the production of axles for industrial vehicles.

e new company, Société Ardennaise d’Essieux, (SAE) grew rapidly due to the know-how of its three creators. Over the years, SAE has become a leader in the production of industrial axles in the French market, gaining a prestigious position on the European market, due to the quality and reliability of its products.

SAE became trademark of reference for axles and “turnkey” suspensions both mechanical and pneumatic, particularly appreciated by the manufacturers of special trailers, low loaders, tankers, dump and forestry trailers.

Meanwhile SMB was founded in the 1970s and was the exclusive supplier of axles and suspensions for all trailers of the General Trailers group (Fruehauf, Benalu, Trailor) and Titan,

In 2006, the two companies, SAE and SMB, merged and then nally in 2013 the ADR Group, the world’s leading agricultural axles, purchased the company and injected more than €8 million.

In 2018, launching new markets, SAE-SMB Industries established itself in the Middle East and a year later, in its race for international development, it moved into the strategic Asian market with entities in India and China.

Over the years, much of its success can be attributed to an ambitious program of investment in research and development resulting in both quality products as well as valuable technical support.

Here are some of SAE-SMB’s o erings:

Today, most trucks have disc brakes, therefore the use of the same braking system on the trailer gives uniformity to the behaviour of the road train, improving the feeling of safety of the driver and his driving comfort. e new design for 22.5” o set wheels is the focus of the whole experience in this eld.

Easily adaptable to every kind of construction, SAE SMB’s focus on the needs of special

SAE-SMB Industries is headquartered in France.

transport is well expressed by the axle with brake 330x160, 11 tonnes capacity and compatibility with 17,5” wheels. e small 300x100 axle braking with 5.5 tonne capacity, is a project targeted for toll-free transport in Germany. e top of the range is the new C1, 14 tonne axle capacity with outboard drum for easy maintenance.

Self steering axles

Tyre wear is reduced on trailers and semi-trailers tted with self-steering axles, the handling of the truck and its fuel economy is improved. With the self-steering axles, remould tyres can be used with improved safety.

As the heart of technological innovation, research is enhanced with the support and experience of many people, from scientists to the operators. In testing, axles and suspensions are tested both for the structural e ectiveness and brake e ciency.

Certi ed performance

SAE SMB axles meet the ECE-R13 requirements, and their characteristics are recognised both in Europe and in most of the industrialised countries throughout the world.

www.sae-smb.com

THE ARTIFICIAL INTELLIGENCE REVOLUTION IN TRANSPORTATION IS MAKING HUGE STRIDES AND TRAILERS HAVE NOT BEEN IGNORED. THIS IS HOW TRAILERS AND AI ARE WORKING TOGETHER TO REDUCE OPERATING COSTS.

Whether it is recognising its optimum load or checking critical components and issuing warnings, trailers and arti cial intelligence are joining forces more and more.

e new iC Plus running gear generation from BPW is using intelligent algorithms to analyse braking performance, something that has been saving testing and downtime in the UK for a number of years. It’s now rolling out across Europe for the rst time.

e BPW Group has been steadily driving forward digital networking for drivers, freight and vehicles so transport companies can achieve greater e ciency with their trailer eets.

“Together with idem telematics, BPW has created a new generation of running gear that makes both The

vehicle operation and the entire transport process more economical,” said Product Manager at BPW, Caren Freudenberg. “Rolling data analysis saves the eet operator unnecessary visits to the workshop and maximises vehicle availability.”

At BPW, trailer running gear has long been created as a digital twin. Digital DNA opens up e ciency gains along the entire life cycle – from design and assembly to driving operations, maintenance and repair.

Now, with the new iC Plus running gear generation, which comes with telematics hardware as standard, BPW is creating the basis for the introduction of arti cial intelligence into the trailer.

BPW is leveraging arti cial intelligence to optimise preventative maintenance capabilities for eet operators.

Intelligent algorithms detect data patterns in the running gear that can, for example, indicate the need for maintenance of critical components. is also includes the brakes, with iC Plus informing the driver, eet manager and dispatcher when the brakes need to be checked in the workshop. Causes can include a defective air hose, a sluggish brake calliper or a weakening spring on the cylinder.

Either way, typical maintenance and repair tasks are recognised by arti cial intelligence before expensive breakdowns or even accidents can occur.

What makes the system standout however is that BPW doesn’t need separate sensors to analyse the braking performance, accessing the data collected in the EBS instead.

In addition to the brake lining wear sensors, the AI interprets the need for maintenance and repair in a di erentiated manner in context. is means that temporary reaction patterns – triggered by a severe pothole, for example – are ltered out.

“All information relating to utilisation, operation, driver and vehicle performance is available to the eet operator at any time at the click of a mouse via the cargo eet 3 telematics portal from idem telematics,” said Freudenberg. “ e open-system platform also enables controlled, secure data exchange with external applications, such as transport management or ERP systems. Transport today couldn’t be smarter or more e cient.”

Brake lining wear measurement is also tried and tested with iC Plus. It works with a sensor which gives the eet manager su cient exibility to plan a workshop visit to change the brake lining.

e digital maintenance management system from BPW and idem telematics also integrates statutory inspection regulations, maintenance instructions for BPW axles and vehicle status and fault messages. It documents maintenance work down to the last detail – creating a digital vehicle le without any paper, hole punches or folders.

Brake performance measurement has already proven its worth in the UK, where closemeshed brake checks for trailers are required by law.

For years AI has been saving eet operators expensive downtimes on the brake test stand. With the iC Plus running gear generation, BPW will be introducing its innovation to the rest of Europe.

www.bpw.de

WHETHER IT IS A LOW BED, LOW BED PLATFORM OR A LOW LOADER, KÄSSBOHRER HAS A MANUFACTURING FACILITY DEDICATED TO THESE TRAILERS AND QUALITY PROCESSES AND PREMIUM MATERIALS ARE KEY.

Kässbohrer’s robust, long vehicle life and high functionality low bed trailers are among the top two choices of European heavy haulage transportation Operational since 2019, the dedicated low bed facility in Adapazari, Turkey has one of Europe’s highest annual production capacity of 2,500 low beds in double shi s. Operating with Industry 4.0 principles, it is equipped with latching cranes complete with RIFD tracking, automated surface preparation and paint cabins, as well as metalisation facilities for partial and full metallisation of the vehicles for longest product life.

Because of this, Kässbohrer can o er long vehicle life and high functionality, in xed, extendable, jumbo, hydraulic low bed, low loader and low bed platform series.

Kässbohrer is constantly developing its product range. is includes extensions (including single, double and lateral extensions), steering type, number of axles, main dimensions such as platform length, width, and height as, well as hydraulic gooseneck options.

K.SLL 2

e K.SLL 2 has been reengineered with innovated processes and components to o er the lowest low loader to accommodate the maximum height on heavy-haulage transportation. It has a ground clearance of only 100mm, allowing for the highest abnormal goods to be safely transported without the need for special permits.

With two axles, it comes with detachable gooseneck shortening loading operations of bulky goods while enhancing operational safety with front-loading capability.

With its special pool length of 6.810mm and kingpin capacity of up to 24 tonnes, the K.SLL 2 provides exible transportation of tall and heavy goods with no requirement for additional permission.

Extendable by a maximum 5.550mm, it is equipped with hydraulic axles of 12 tonne capacity each with a turning angle of 42°, to provide maximum maneuverability under the toughest road conditions.

With its strong chassis and robust construction, the K.SLL 2 is designed for the reliable and on-time transport of heavy haulage and abnormal goods.

K.SLH series

e K.SLH series is engineered for the extreme heavy-haulage transportation, delivering peak performance even at the ercest road conditions. It is designed to comfortably transport all goods in the below-55-tonne category, by optimal weight distribution, hydraulic steering axles and hydraulically adjustable neck.

e series comes in three to six-axle con gurations with single or double extension options that are easily maneuverable by progressive hydraulic steering, wireless remote

steering control and auto-alignment systems.

K.SLH 4

e K.SLH 4, an extendable, hydraulically steered low bed with four axles, transcends the limits of engineering with its high manoeuvrability even on the narrowest curves in rural areas.

With up to 6.200mm extendable, strong, and at chassis the K.SLH 4 provides exible and safe transportation for high and heavy loads. To minimise the defects, the manometers located on the gooseneck and easy-to-access installation, enables diagnosis of the breakdowns.

e automated central lubrication system is specially designed to minimise the maintenance cost in long-term usage. It o ers multifunctional and exible transportation capability with various lashing rings with 8-to-13.44 tonne capacity, 4 x 2 rows of vertical pillar pockets and pillar pockets on side raves.

www.kaessbohrer.com

Strenx® performance steel can meet the challenges facing the transport industry, which is constantly looking for ways to increase payload and improve fuel efficiency. Strenx® is a high-strength structural steel with extremely consistent properties, making it perfect for designing trailer chassis and other transportation products that are stronger, lighter and safer. That’s why we call it performance steel.

Front

Rear

Front

O road low bed

DUE TO THE UNIQUE NATURE OF ITS MARKET CULTURE, OPERATIONAL DEMANDS AND ROAD REGULATIONS, GORICA’S LOW BED SEMI-TRAILERS ARE A VASTLY IMPORTANT OFFERING, REQUIRING SPECIFIC DESIGN ATTENTION.

By its own admission, Dubai-based GORICA Group’s low bed semi-trailer product portfolio is one of its most important.

Speci c conditions, including the desert, mean, typically, the low beds are tailor-made to the customers’ speci cations. at being said, they can be generally categorised into two types – front and rear loaders.

e front loaders have a hydraulically powered front gooseneck which allows special equipment with low clearance, such as trenchers and cranes, to be easily loaded. ey have a payload ranging from 80 to 130 tonnes.

e rear loaders, which are more popular, o er exibility for various types of construction projects and heavy haulage. ey tend to range from a 50- to 100-tonne payload and include various types of rear ramps including single, double or full width ramps.

e low bed portfolio also comes in di erent axle con gurations where mechanical under slung suspension is used, or in some cases, air suspension.

ere are di erent axle capacities, from 12 tonnes per axle, up to 20 tonnes and when it comes to four or more axles, GORICA can o er force steering solutions allowing smooth operations, especially when space is restricted.

Finally for special heavy haulage and speci c

industries, GORICA o ers low bed semi-trailers with hydraulically operated axles with a self-steering function, suitable for skilled operators.

According to GORICA’s General Manager, Sales and Marketing, Domen Bockor, the vibrant trailer market in the Middle East is fuelled by so-called ‘mega and giga projects’ in the construction industry, such as new urban development, Neom, and the Red Sea project, a planned tourism location in Saudi Arabia, as well as numerous activities within the oil and gas sector.

All of these factors make low bed semi-trailers, in various con gurations, a hot commodity.

“Currently our order intake and deliveries are above average with very upwards positive trends for the remainder of 2024 and 2025,” Bockor said. “We do also see a trend of higher capacity low bed semi-trailers being required due to the huge sizes of the projects in Middle East.”

Beside the local, United Arab Emirates market, GORICA have leading market share in low bed semi-trailer international markets such as the Kingdom of Saudi Arabia, Oman and Qatar. It also supplies Iraq and the African continent.

“Export markets are becoming increasingly important due to demand and require technical speci cations to ‘get the job done,’” Bockor said.

One of GORICA’s latest developments is o road, multi-axle ( ve and six) low bed semitrailers. e ve-axle low bed trailer has air suspension, super single tyres and two force steering axles for so top-sand haulage with payload of more than 70 tonnes. e six-axle low bed trailer comes with hydraulically steered axles and is the reference for o road, so top-sand heavy haulage. Both products are part of GORICA Group’s development strategy focused to widen its product portfolio.

e GORICA low bed semi-trailer program stands out for its value, with the best total cost of ownership in the industry, said Bockor.

“We o er durability, exibility of operations, high level of customisation and by far the best re-sale value in the region,” he said, adding that this is compounded by the company’s competitive delivery times and a ersales support service.

“A er sales and timely spare part support is the key in this sector as most of the projects are based on milestones and deadlines.”

www.goricagroup.com

DESPITE TEMPERATURES AS LOW AS -40°C , SAF-HOLLAND SENT ITS EXPERT TEAM TO THE FROZEN SWEDISH NORTH TO PUT ITS MECHANICAL AND DIGITAL TRUCK AND TRAILER COMPONENTS TO THE ULTIMATE TEST.

It is an environment not for the faint hearted. Ice and snow as far as the eye can see and frigid temperatures. But SAF-HOLLAND engineers dug deep, knowing the results from these extreme conditions would be crucial.

Located within the Arctic Circle, the Colmis Proving Ground in Arjeplog, Sweden, is the ideal location for vehicle cold condition testing. It has more than 50 multipurpose tracks, covering both frozen lakes and land courses, allowing manufacturers to test every aspect of winter driving.

Even in extreme environments, drivers and eet operators must be able to rely on their vehicles to be constantly roadworthy and safe, said Vice President of Research and Development at SAF-HOLLAND, Sebastian Quick. “ e in uence of challenging weather can have a massive in uence on product robustness, functionality and the interaction of coordinated mechanical parts, electronic components and sensor systems,” he said. “Systems developed at the factory ‘under laboratory conditions’ o en behave very di erently in practical tests due to propulsive forces, roll movements, heavy loads, and other in uences. In winter conditions, correct functioning of axles and brakes is particularly crucial for avoiding failures and accidents.”

e testing involved new and updated developments, as well as the SAF TRAKr electric

trailer axle, the automatic SAF TIRE PILOT I.Q. tyre-in ating system, the HALDEX EB+ 4.0 electronic trailer braking system and other safetyrelated components.

e truck involved in the testing mastered the challenging manoeuvres at the icy proving ground, covering more than 3,000 km in a total of 40 hours.

“Our chassis-related modules and systems are used worldwide, in very di erent conditions,” Quick said. “Safety and accident prevention are our top priority during product development. e ndings from the cold test will directly in uence the development and continuous improvement of our products.”

e cooperation within the SAF-HOLLAND group of companies and products was tantamount to the testing’s success, he added. “During projects like these, we bene t from the positive synergy e ects in the group of companies. at drives joint research and results in optimally coordinated products.”

Among the developments and systems SAFHOLLAND tested and which de ed the cold weather were:

SAF TRAKr

e electric axle converts the kinetic energy of the vehicle into electrical energy. For example, during braking or thrust phases, to generate electricity for auxiliary consuming units such as heating and cooling systems or tail li s.

SAF TIRE PILOT I.Q.

e digital tyre pressure assistant monitors the pressure in trailer tyres. If too much pressure is lost, the system automatically tops up the tyre and sends a noti cation to the driver in the cab.

For close to 40 years, Colmis proving ground has witnessed the constant development of the automotive industry and its winter testing activity.

Found in the arctic circle, it is just under 1000 km from Stockholm, Sweden.

It o ers a range of multipurpose tracks with a combined distance of 700 km found on rough terrain, frozen lakes, hills and in tight circles.

There is even a specially prepared ‘slush track’ to test vehicles in slushy conditions. Services also include cold chambers, workshops and even accommodation for the testers.

HALDEX EB+ 4.0

e electronic trailer braking system has a modular design that can be individually con gured. It serves as a platform for di erent product families: EBS, ABS with roll-over control and as a conventional ABS for trailers.

HALDEX ILAS-E

e li axle valves provide electrically controlled li ing and lowering of one or several li ing axles for air suspension systems.

HALDEX Safe Parking Trailer Emergency Module (TEM)

e system automatically activates the parking brake to provide more safety during hitching and unhitching of trailers, preventing uncontrolled movements and minimising vehicle damage and accidents.

www.safholland.com

NOW AVAILABLE IN THE UK AND IRELAND, SCHMITZ CARGOBULL’S EMISSION-FREE BOX BODY SOLUTION FOR TEMPERATURECONTROLLED TRANSPORT IS ON THE MOVE.

An all-electric box body trailer.

Schmitz Cargobull has o cially launched its all-electric box body semi-trailer – the S.KOe COOL – in the UK and Ireland.

e trailer manufacturer has developed the reefer semi-trailer with e-axle generator to help operators meet increasingly strict emissions regulations.

“ e S.KOe COOL is the perfect choice for businesses who are leading the charge towards a cleaner and greener transport sector,” said Managing Director Schmitz Cargobull UK & Ireland, Colin Maher. “We are delighted to be able to introduce the fully electric semi-trailer across the UK & Ireland, providing our customers with a truly sustainable solution for their temperaturecontrolled operations.”

e S.KOe COOL is equipped with the fully electric S.CU ep85 cooling unit with integrated power electronics, a battery system and an electric generator axle, enabling 100 per cent emissionsfree operation. It is also quiet, ideal for early-morning and late-evening deliveries in urban areas.

Introduced at an event in Birmingham, England, the S.KOe COOL was unveiled alongside other Schmitz Cargobull products ideally suited to the retail sector, including its M.KO refrigerated truck body and the S.KO CITY box body semi-trailer.

Already in operation for more than 50 customers across Europe, last year the S.KOe COOL achieved overall vehicle type approval by the German Federal Motor Transport Authority a er meeting statutory safety, environmental and production requirements of the EU – making Schmitz Cargobull the rst manufacturer to gain approval for a fully-electric refrigerated semi-trailer with an e-axle.