Training Taking

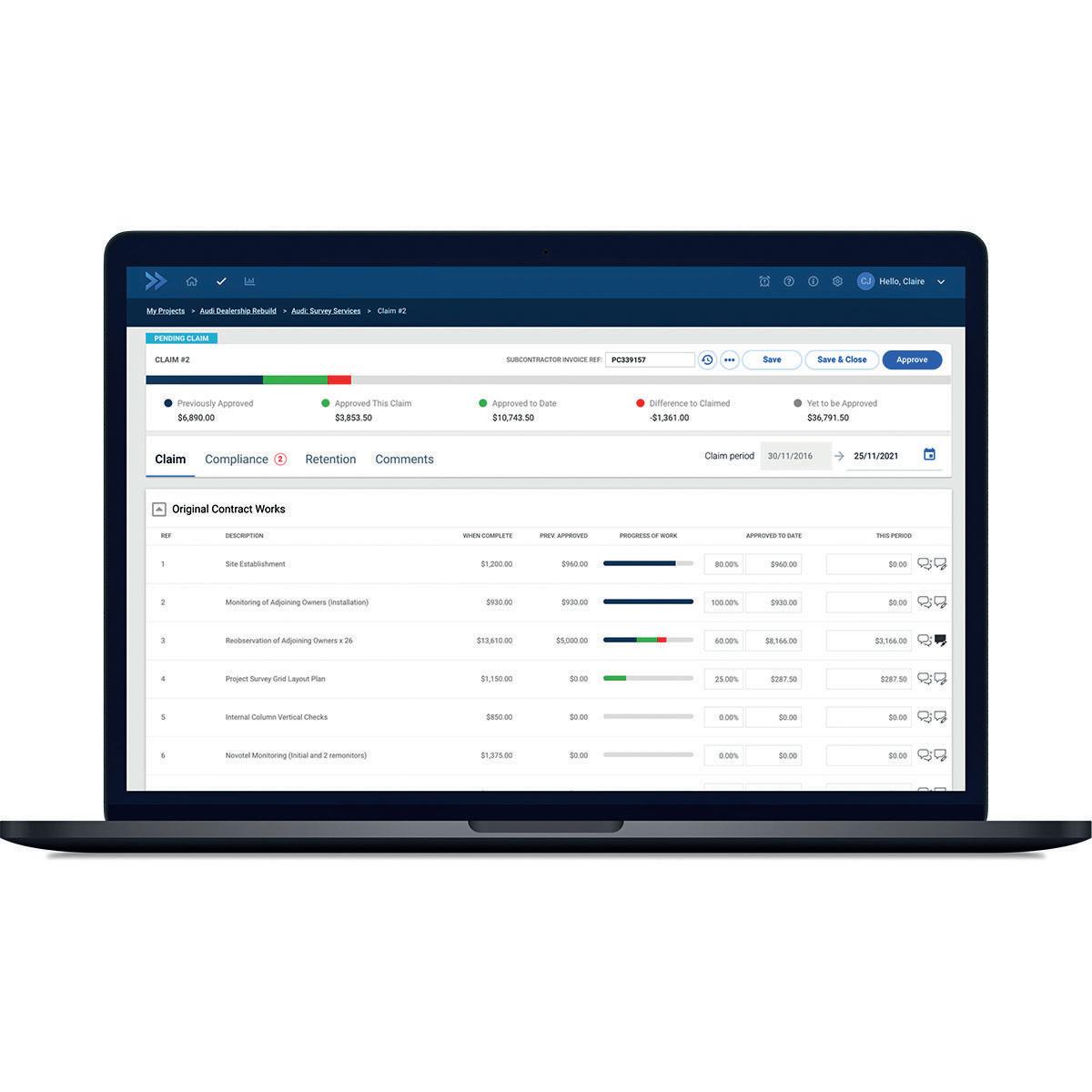

The easy way to submit and assess progress payments

Many construction businesses use spreadsheets to manage, submit and approve progress claims. But this is time-consuming and error-ridden, potentially leading to payment delays, failure to comply with regulatory obligations, and causing friction between main contractors and subcontractors. There’s a much better way.

Payapps is the cloud-based collaboration tool that makes submitting and approving payment claims easier and faster than ever before. Payapps helps main contractors and subcontractors work better together to make progress claims and approvals simple and seamless, with a single, accurate and transparent view of every contract from project start to finish.

Ditch the spreadsheets today. Learn more at payapps.com/insideconstruction

Area9 Lyceum builds 21st century skills and competencies through one of the world’s first fourdimensional learning platforms, Area9 Rhapsode.

Dr. Gretchen Gagel catches up with Gabrielle Trainor, Chair of the Construction Industry Culture Taskforce (CICT), to discuss sustainable construction.

Project Manager for Multiplex drives positive change, managing complex and unique projects around NSW.

Bitumen and Asphalt Production Foreperson for Downer seizes opportunities.

NAWIC champions women in construction.

ACA boasts new era for construction.

An insight into Advanced Precast’s success.

FIA’s advocacy success.

Lentune’s Supplier Invoice Automation enables a streamlined, cloud-based workflow for construction businesses.

Mad Cat Constructions deploys a suite of Trimble solutions on their small machines.

The Green Building Council of Australia leads the sustainable transformation of the built environment through their Green Star rating system and key pillars.

Makinex launches Hybrid Power Systems to generate clean power on construction sites, reducing diesel consumption and improving power efficiency.

Construction software company Payapps is taking action to create a more sustainable future for the construction industry, achieving Climate Active carbon neutral certification in Australia.

McConnell Dowell look for new ways to reduce their carbon footprint, led by the company’s Executive General Manager of Health, Safety, Environment and Quality.

38

Earth Friendly Concrete develops absolute zero cement concrete technology that works through ordinary concrete supply chains.

42 Eliminating material waste with Matrak Matrak software simplifies the complexities of material tracking and presents huge potential in tracking emissions resulting from the use of materials.

Blackwoods’ assess, inform, equip model provides end-toend safety solutions.

Following the successful launch of our first print magazine, we’re pleased to bring to you the October 2022 edition of Inside Construction, filled with the latest news and insights into the construction industry. This month we delve into ‘Green Construction’ and showcase the industry leaders forging positive change in the sustainability space.

Rising material costs, fewer skilled workers and a series of supply chain disruptions all pose challenges for the industry, and yet we’re seeing an immense push for change - from both industry organisations and the private sector, to develop a more sustainable built environment in Australia.

The developing trends and techniques in built sustainability are reshaping the industry for the better and are fundamental to the future of construction.

This month, we hear from some of the leading construction companies doing their part for the environment. We’re seeing an increase in the use of sustainable construction materials in current and planned builds, resulting in lower carbon emissions. Products like Wagners Earth Friendly Concrete, a zero cement geopolymer concrete, can reduce a projects carbon footprint by up to 80 per cent when compared to ordinary concrete.

In the sustainable technology space, Makinex has developed Hybrid Power Systems to generate clean and efficient power on construction sites, reducing site diesel consumption by over 90 per cent.

New technologies are being used to reduce material waste and reordering. Last year alone, Matrak’s solution to material tracking saved around 30 shipping containers of materials in over 180 projects.

Construction businesses are also pivoting their operations to align with the initiatives of organisations like the Green Building Council of Australia (GBCA), which we can proudly announce as an official Inside Construction media partner.

Our team has worked closely with the GBCA to present this month’s ‘Green Construction’ feature, sharing the latest facts, trends and figures of sustainability in the built environment.

It’s not just construction companies that are vital to the sustainable future of the industry, but also the workers on the ground. Australia’s construction workers are the drivers of positive change, including women like Gabrielle Trainor, Chair of the Construction Industry Culture Taskforce, who is pushing for the adoption of a Sustainability Culture Standard across the industry.

Organisations, like the National Association of Women in Construction (NAWIC), are striving to help champion and empower women, like Gabrielle, in the construction industry to reach their full potential.

The Inside Construction team is thrilled to share news of an official media partnership with NAWIC. Our partnership aims to empower women in construction and forge a brighter future for the industry.

We hope you enjoy the read.

John Murphy

Christine Clancy

Sarah Baker sarah.baker@primecreative.com.au

Ashley Grogan ashley.grogan@primecreative.com.au

Brad Buchanan bradley.buchanan@primecreative.com.au

Daz Woolley

Art Director

Blake Storey blake.storey@primecreative.com.au

Michelle Weston michelle.weston@primecreative.com.au

Adele Haywood adele.haywood@primecreative.com.au p: +61 0403 500 544

Glenn Delaney glenn.delaney@primecreative.com.au

Marcus Walters

Head Office

Prime Creative Pty Ltd 379 Docklands Drive, Docklands, Victoria 3008 Australia p: +61 3 9690 8766 f: +61 3 9682 0044 enquiries@primecreative.com.au www.insideconstruction.com.au

+61 3 9690 8766 subscriptions@primecreative.com.au

Inside Construction is available by subscription from the publisher.

The rights of refusal are reserved by the publisher

All articles submitted for publication become the property of the publisher. The Editor reserves the right to adjust any article to conform with the magazine format.

Inside Construction is owned by Prime Creative Media and published by John Murphy.

All material in Inside Construction is copyright and no part may be reproduced or copied in any form or by any means (graphic, electronic or mechanical including information and retrieval systems) without written permission of the publisher.

The Editor welcomes contributions but reserves the right to accept or reject any material. While every effort has been made to ensure the accuracy of information, Prime Creative Media will not accept responsibility for errors or omissions or for any consequences arising from reliance on information published. The opinions expressed in Inside Construction are not necessarily the opinions of, or endorsed by the publisher unless otherwise stated.

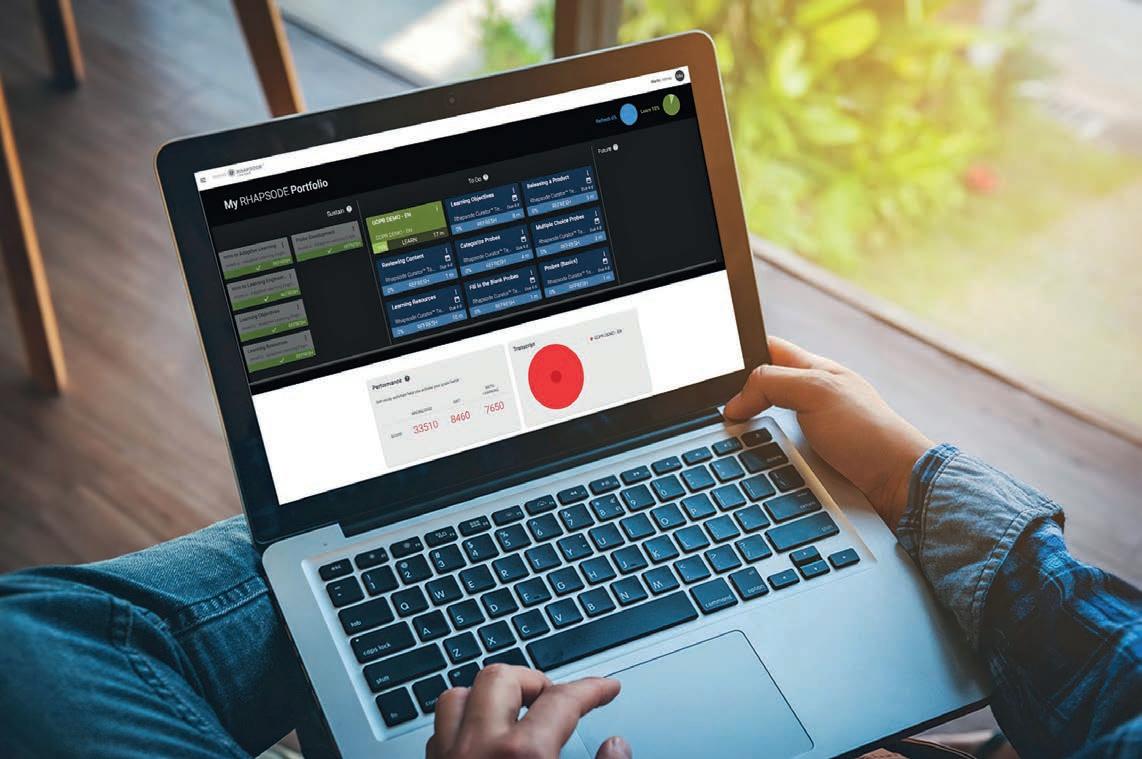

One of Australia’s leading contractors, John Holland, has seen the benefits of a new health and safety learning platform – Area9 Lyceum’s Rhapsode – saving the company more than 12,000 hours in training time.

Rhapsode uses an AI algorithm built on the experience of more than one billion data points to support each learner exactly as a personal teacher would, but at scale. The platform measures and assesses the learner as they move through the content, filling the gaps in critical safety knowledge that standard e-learning fails to deliver.

More than 30,000 million learners worldwide use Area9 Lyceum’s learning platform, which delivers truly personalised training.

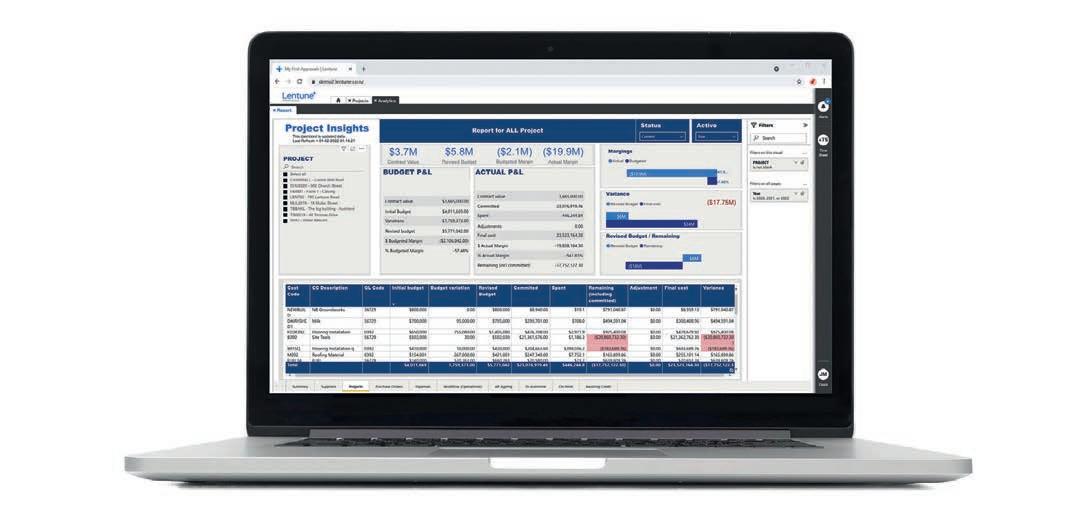

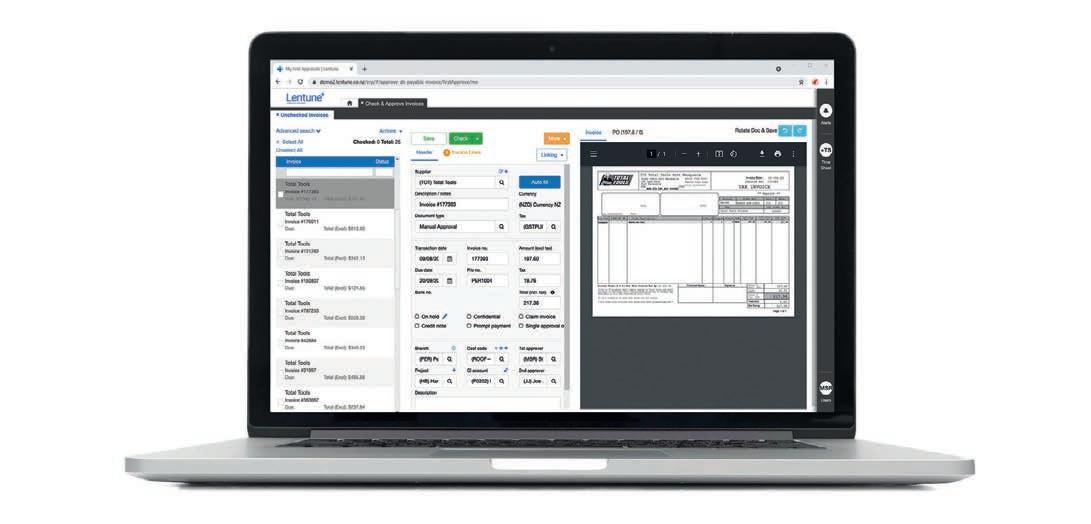

This month we caught up with Jono Bonifant, Director & CEO of Lentune, to explore the company’s Supplier Invoice Automation software.

The first of Lentune’s now suite of construction management products, Supplier Invoice Automation enables a streamlined, cloud-based workflow for construction businesses. The smart accounts payable software greatly reduces supplier invoice processing, provides a real-time picture of each invoice, and gives the user greater control over their cost management.

One company reaping the benefits of Lentune is construction machine and equipment supplier, Wacker Neuson who has seen the time required to process, approve, and store supplier invoices reduced by over 50%.

Bonifant and Matthew Watson, Finance Manager, Wacker Neuson look into the advantages of moving away from manual handling and data entry. Pages 18-20.

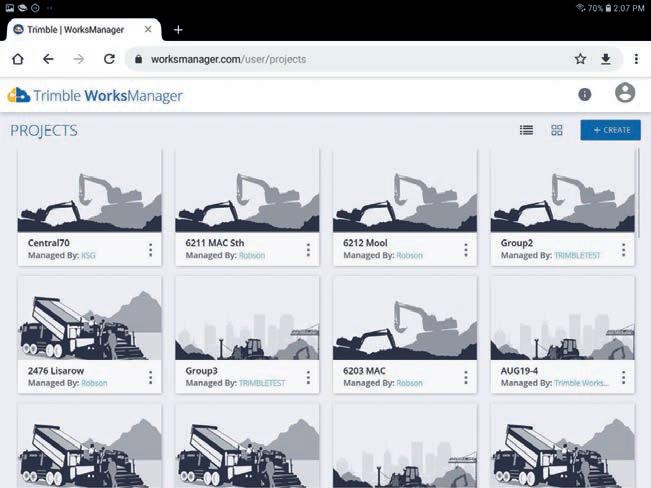

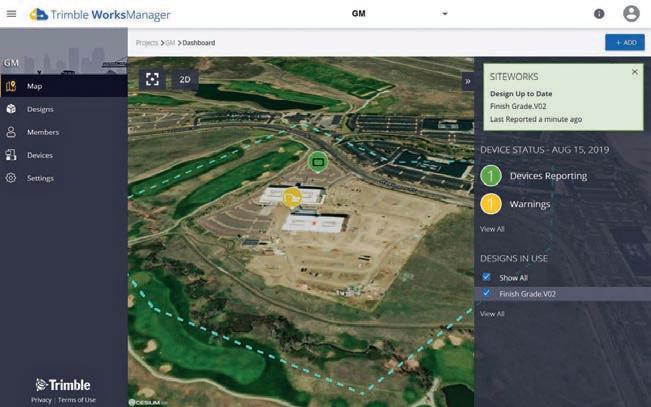

Australian civil and commercial contractor, Mad Cat Constructions has deployed a suite of Trimble solutions on their small machines.

Mad Cat Constructions Director and Project Administrator Trevor Reynolds turned to Trimble dealer, SITECH Construction Systems, for a solution after identifying challenges around small machine productivity.

John Holland users are taking 20-30 minutes less to complete Rhapsode courses than previous approaches and John Holland estimates that Rhapsode has saved the company 12,800 hours to date, closed gaps in critical health and safety knowledge, and is enabling improvement in the company’s approach to critical health and safety risk management.

Dr. Khurram Jamil, President –Strategic Initiatives for Area9 Lyceum and Martin Smith, Group General Manager Health, Sustainability and Climate, John Holland share the benefits of Rhapsode and its innovative learning formula. Pages 13-17.

The Mad Cat fleet is now equipped with the latest in Trimble technology. Reynolds, along with Shane Wright, Account Manager, SITECH, describe how the introduction of Trimble Solutions has saved Mad Cat time and money, increased employee satisfaction and improved safety on site. Pages 22-25.

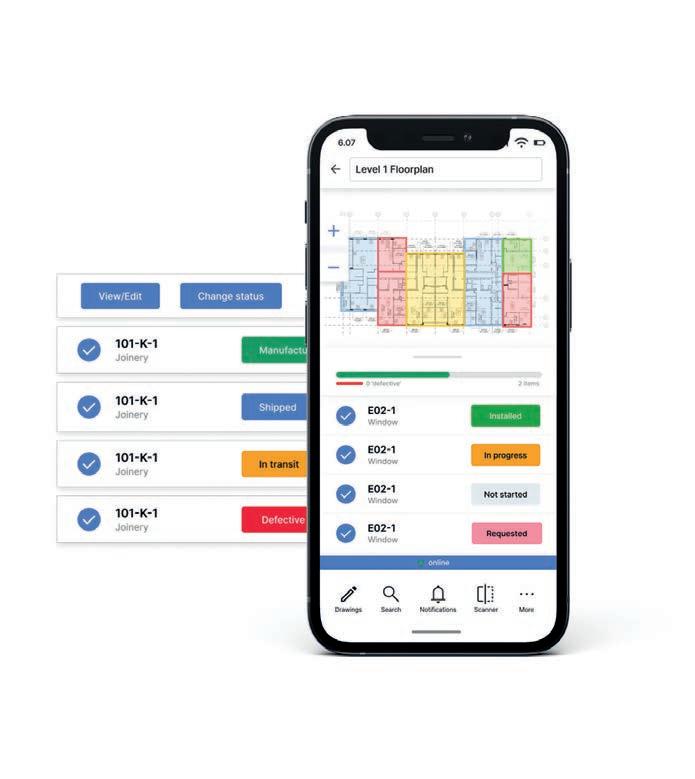

Founded by brothers Shane and Brett Hodgkins, Matrak is changing the way construction teams manage their projects.

The Hodgkins brothers, Shane CEO and Brett CTO, developed Matrak as an end-to-end material tracking

platform to simplify and support the complexities of tracking and managing materials.

Last year alone, the Matrak team estimated they saved around 30 shipping containers of materials in over 180 projects. Hutchinson Builders are one of the companies seeing the sizeable value of the Matrak platform.

Shane, Brett and Jacob Baldacchino, Façade Manager at Hutchinson Builders look into the Matrak platform, its huge potential in tracking emissions resulting from the use of materials, and its capability in eliminating the need for material reorders. Pages 42-43.

Blackwoods invests time and expertise in their customers, an approach that resulted in a quality solution to worker safety on the West Gate Tunnel Project (WGTP).

In November 2020, construction was underway at the West Gate Tunnel Project (WGTP). As with all Tier 1 construction companies, health and safety is a core value and WGTP (CPB Contractors) were looking at an effective engineering solution to control Silica dust exposure whilst undertaking jackhammering activities. They turned to Blackwoods who delivered a retrofit dust suppression system.

Blackwoods’ Terry Meachen, Major Projects Manager and Drew Dauncey, Technical Safety Specialist recount the WGTP and their solution to improve safety on site. Pages 44-45.

Simplify the complexities of construction supply chains with the leading material tracking platform.

Contact us today at www.matrak.com/demo

The Green Building Council of Australia (GBCA) was formed with a purpose to lead the sustainable transformation of the built environment.

This month the team at Inside Construction has worked closely with the Green Building Council of Australia to highlight the fantastic work companies are doing in the ‘Green Construction’ space.

GBCA CEO Davina Rooney has worked in the construction industry for over 20 years and is advocating for more conversation and action around sustainability in the construction industry. The GBCA is leading the way for change through four key pillars – rate, educate, advocate, and collaborate.

Rooney presents the top opportunities for construction companies to reduce their carbon footprint in today’s environment.

Makinex has launched Hybrid Power System’s (HPS), a system that uses solar and battery technology to generate clean power on construction sites. The fundamental goal of the product is to reduce diesel consumption by over 90%, with one recent customer reducing their diesel consumption by 99% over a 3-month summer period using the system.

The HPS product, over its development cycle, has morphed into

the company’s recent launch of a subbrand – Makinex Renewables. Makinex Managing Director Paul Weaver details the advantages of clean power, reducing diesel consumption and the company’s passion for renewable products.

Construction software company Payapps is taking action to create a more sustainable future for the construction industry, achieving Climate Active carbon neutral certification in Australia in 2021.

Their mission to develop and provide software to make life easier for its users has reduced the need for paper globally in over 30,000 construction companies, saving approximately 20 tonnes in paper each year.

Jessica Widdicombe, Senior Finance Manager at Payapps, has been with Payapps for 4 years and led the process for the company to achieve Climate Active carbon neutral certification.

Widdicombe encourages other construction companies to be a part of the carbon neutral journey.

McConnell Dowell employees are constantly looking for new and innovative ways to reduce their impact on the world around them. Leading the charge is Samantha Johnson, the company’s Executive General Manager of Health, Safety, Environment.

Evidenced by the company’s large portfolio of sustainably managed

projects around the globe, the Port Kembla Gas Terminal - Marine Works project is a perfect example of McConnell Dowell’s commitment to reducing, or eliminating where possible, negative environmental and social impacts.

Johnson delves into several projects completed and underway by McConnell Dowell, their mission to reduce their carbon footprint and the sustainable solutions the company has adopted across their operations.

Wagners Earth Friendly Concrete (EFC) has been reducing the carbon footprint in the built environment with their geopolymer concrete. Over the past 10 years, with over $20 million dollars of their own investment, Wagners EFC developed a zero-cement concrete technology that works through ordinary concrete supply chains, proven globally in commercial construction and infrastructure projects.

The company has now established a market in London, securing several partners in the UK to set up EFC producers in multiple locations – one being the High Speed 2 (HS2) project.

Talking about the project, Jason Zafiriadis, Wagners EFC’s Chief Commercial Officer explains the huge carbon emissions EFC can save compared to traditional cement made concretes.

Dr. Gretchen Gagel caught up with Gabrielle Trainor, Chair of the Construction Industry Culture Taskforce (CICT) this month, to discuss sustainable construction and the Culture Standard being adopted across the construction industry in Australia. Trainor joined the CICT in 2020 and is a key driver of the new Culture Standard initiative, developed by the NSW and Victorian Governments, and the Australian Constructors’ Association, together with other industry leaders and researchers. Trainor is a non-executive director and advisor whose experience covers over 25 years on boards in the public and private sectors.

Jade Nicholson , Project Manager with Multiplex Constructions, has worked on a range of projects including the Charles Perkins Centre at The University of Sydney Camperdown and M&L Hospitality’s redevelopment of 161 Sussex Street, Sydney. More recently Nicholson worked on a commercial building, with the purpose of the project to bring together 10 displaced entities in the healthcare system and deliver a purpose-built building which focused on collaboration. Nicholson is now delivering a high school in Mosman for School Infrastructure, with her team using new technologies such as a new digital materials handling booking system.

Emily Jennings, Bitumen and Asphalt Production Foreperson for Downer started with the company in 2017, seizing opportunities for career growth every step of the way. Depending on what her team has on for the day, Jennings could be doing anything from blending bitumen, operating the asphalt plant, loading sprayers and bulkers with bitumen, or driving a loader, forklift, HR truck or bobcat. She has helped manufacture and deliver high specification bitumen to Ayres Rock and Alice Springs airports, and continues to work on a range of projects including the Darwin Rail Terminal as well as upgrades to Darwin and Tindal Airports.

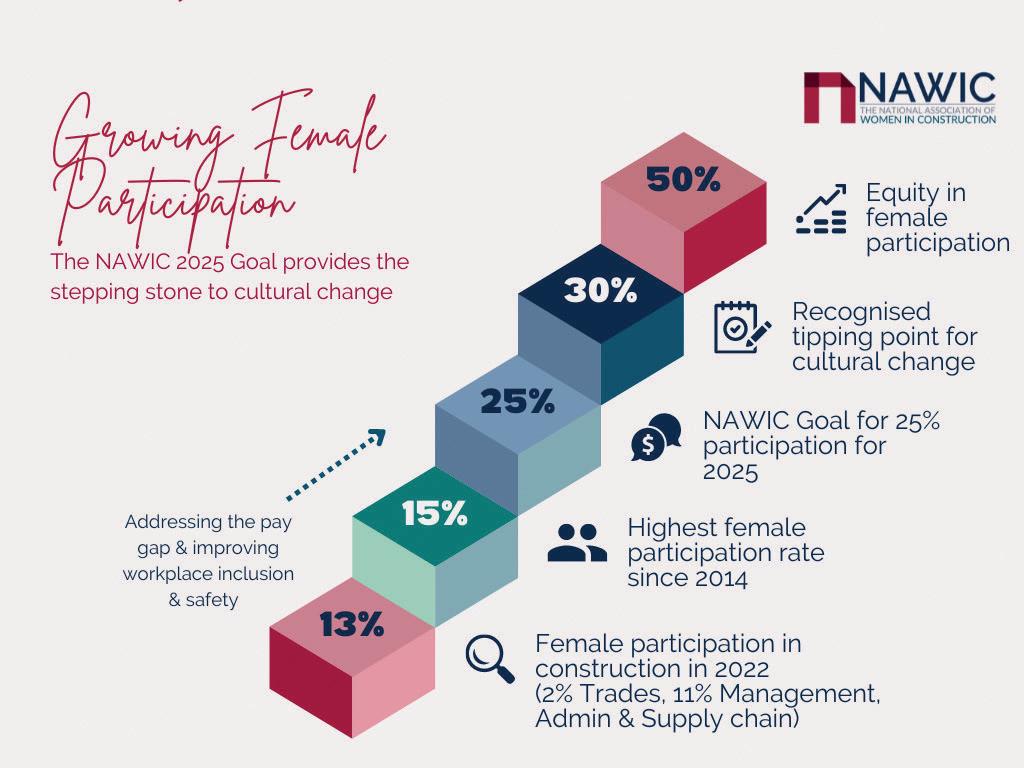

The National Association of Women in Construction (NAWIC) has come on board as an official media partner of Inside Construction

NAWIC’S vision is to create an equitable construction industry where women fully participate and their core policy is to achieve 25% female participation in the construction industry, by 2025 (#25by2025).

The organisation provides a forum for its over 7,000 individual members and over 150 corporate members to meet and exchange information, ideas and solutions.

Members have an opportunity to expand personal and business networks, maintain awareness of industry developments, improve skills and knowledge, and contribute to other women in the construction industry.

Lauren Fahey, NAWIC’s General Manager, introduces the organisation, their goals, and shares the latest data from their member survey conducted earlier this year to highlight the need for industry action.

Jon Davies, CEO Australian Constructors Association (ACA) represented the construction sector at this year’s 2022 Jobs and Skills Summit. He took the opportunity to put construction on the nation’s radar and to emphasise the need for change.

The CEO’s message was simple – ‘change will only happen if government, industry and unions leave behind the baggage of history’.

Speaking under the banner of creating safer, fairer and more productive workplaces, Davies outlined the importance of the construction industry to the Australian economy.

The ACA’s idea for the Summit was a new ratings initiative called the Future Australian Infrastructure Rating – FAIR. Essentially, FAIR would rate government funded projects on how well they performed against key reform areas such as improved productivity. The FAIR initiative could be included in the next iteration of the National Partnership Agreement as a requirement for all federally funded projects.

Joining the National Precast Concrete Association Australia (National Precast) in 2015, Advanced Precast has seen consistent growth over its almost 40 years in business.

As an effort to showcase the important work being undertaken by the precast concrete industry around Australia, Inside Construction interviewed Brett Foster, Operations Manager, Advanced Precast.

Advanced Precast joined National Precast after identifying the advantages of being around a network of likeminded people.

The company was established in Melbourne in 1985 and today employs 160 people comprising construction workers, engineers, detailers and administrative staff. Since those early years, the company has grown to become one of Australia’s market leaders in the field of precast concrete within the building sector.

The Formwork Industry Association (FIA) has successfully advocated the reinstatement of the Certificate III in Formwork/Falsework until 31 December 2023.

Following extensive campaigning at both federal and state level by the FIA, the Australian Skills Quality Authority (ASQA) agreed to extend the transition period of CPC31511 - Certificate III in Formwork/Falsework.

The decision extends the transition period for ASQA registered training organisations, to continue training assessment and issue Australian Qualifications Framework (AQF) certification.

The FIA is also currently piloting a new Safe Formworker program and negotiating a new education pathway with governments, which includes a new Certificate III in Formwork with a focus on infrastructure, and a pathway for accessible learning with accredited and unaccredited training, as well as ‘recognition of prior learning’ (RPL) for mature and existing workers.

Area9 Lyceum builds 21st century skills and competencies through one of the world’s first four-dimensional learning platforms, Area9 Rhapsode™

In the construction sector, the safety and wellbeing of its employees is paramount. One of Australia’s leading construction contractors, John Holland, has seen the benefits of a new health and safety learning platform - Area9 Lyceum’s Rhapsode.

Dr. Khurram Jamil, President – Strategic Initiatives for Area9 Lyceum, says Rhapsode according to estimates from John Holland, has saved them more than 12,000 hours in training time and delivered more effective targeted training to its employees.

“Founded by physicians and computer scientists, and headquartered in Copenhagen and Boston, Area9 Lyceum combines more than 20 years of research into human factors and cognition,” says Khurram

“With cutting-edge computer science and artificial intelligence (AI), we transform learning outcomes for millions of learners and businesses like John Holland.”

“Across construction, mining, manufacturing, health care, finance and corporate education, Area9 Lyceum brings scientific rigor to transform learning outcomes at scale globally.”

John Holland employs over 5,300 staff and more than 1,300 contractors working on projects across Australia and New Zealand. After years of predominantly classroom training, the company included international adaptive e-learning provider, Area9 Lyceum, to its blended approach to learning following successful trials in early 2020.

Speaking of Rhapsode Martin Smith, Group General Manager Health, Sustainability and Climate, John Holland says, “The personal approach for each learner was found to reinforce their journey, as opposed to the traditional ‘one size fits all training’.”

Higher-quality data enabled the business to measure the effectiveness of the training at individual, group, and site level.

Khurram says many current e-learning platforms provide a ‘one size fits all’ approach, not taking into account individual learning needs.

“We have profound insight into the way individuals learn, and how their needs

change over time. Every learner is unique – Rhapsode delivers truly personalised learning at scale, cutting training time in half, guaranteeing proficiency, and making lasting impacts on careers and business outcomes,” he says.

“With more than 30 million learners having used Area9’s methodology, it is based on peer-reviewed scientific research about what works in learning, combined with empirical evidence collected over many years.”

John Holland has worked with Area9 Lyceum to complete the development of 15 health and safety courses based on John Hollands safety-critical procedures and started to move its key health and safety technical training, and non-technical learning, into Area9 Lyceum’s adaptive learning platform.

The company has also committed to providing its training courses to a range of

John Holland employs over 5,300 staff and more than 1,300 contractors working on projects across Australia and New Zealand.

“Across construction, utilities, mining, manufacturing, health care, finance and corporate education, Area9 Lyceum brings scientific rigor to transform learning outcomes at scale globally with over 30 million learners.”

John Holland’s leadership recognised the value of personalised training and made the decision to move all safety critical procedural courses to Rhapsode.

John Holland’s leadership recognised the value of personalised training and made the decision to move all safety critical procedural courses to Rhapsode.

John Holland’s leadership recognised the value of personalised training and made the decision to move all health and safety critical procedural courses to Rhapsode. 15 procedural health and safety courses have so far been delivered and they have been adapted to support specific projects John Holland is delivering, including the Metro Tunnel project underway in Melbourne.

“By taking a scientific approach, Rhapsode knows how to measure the impact of training, and how to dynamically reorient the learner when appropriate as they work through the course content,” says Khurram.

“By adapting moment-by-moment and over longer periods of learning, this allows the learner to speed through things they already understand and zero in on what matters for this learner, short term as well as long term.

“Rhapsode supports individual needs, measures confidence, and improves the engagement and learning experience for each

The Rhapsode software allows global management requirement courses to be tailored to both subcontractors and leaders, and to refine the focus of the learning objectives and outcomes.

“The results from a full year of integrating our health and safety critical procedural courses into Rhapsode have been excellent - all key metrics have been exceeded by this partnership,” says Martin.

Rhapsode uses an AI algorithm built on the experience of more than one billion data points to support each learner exactly as a personal teacher would, but at scale. The platform measures and assesses the learner as they move through the content, filling the gaps in critical safety knowledge that standard e-learning fails to deliver.

The software is particularly adept at measuring levels of ‘unconscious incompetence’ – the ‘I don’t know what I don’t know’ - where a learner is not aware that they lack knowledge about a task they are undertaking, or believe they are carrying out activities and tasks in accordance with procedures even though they are not.

In the context of construction health and safety, this poses a significant risk both to the individual and the surrounding workforce. However, Rhapsode reporting shows that the

average level of ‘unconscious incompetence’ for people completing the course is reduced from 25% to less than 1%, significantly increasing the learners understanding of the procedural content in task planning and execution..

“The difference in this platform is the AI ability to move each learner to a higher level of understanding,” says Martin.

“This has a significant and positive impact on health and safety risk management as Rhapsode helps each learner understand their learning gaps.”

The Rhapsode software has identified thousands of significant gaps in the competencies of learners. “But the key to the success of this innovative platform is the elimination of the gaps and each person reaching 100% proficiency on the content. This is a very different outcome to the standard compliance ‘tick and flick’ e-learning,” says Martin.

“We now have detailed data from individuals, works sites, subcontractors, and across the organisation that shows the elimination of these knowledge gaps and the positive impact this can have on the management of critical safety risks,” says Martin.

Martin says courses at John Holland are taking 20-30 minutes less to complete than previous approaches. The AI-based solution can determine an individual’s proficiency profile around the course content and support each learner personally, so it moves quickly through the areas with high competency and spends more time on learning and content across areas where there are gaps.

For John Holland users, the average time to health and safety proficiency has been halved across all courses. John Holland estimates that Rhapsode has saved the company 12,800 hours to date, closed gaps in critical health and safety knowledge, and is enabling improvement in the company’s approach to critical health and safety risk management.

Keeping the focused educational content to areas where learner knowledge is low also helps maintain learner focus. “It deters them from glazing over the content they assume they already know, even if they do not,” says Martin.

“Because the adaptive learning platform tells the learner that they need more information

on a topic before delving into that educational content, the learner recognises that all the information being provided is information they require and do not fully understand already.”

Khurram says Area9 Lyceum’s approach is to work closely with businesses to support their needs and requirements including with direct employees, new starters, and subcontractors.

“Rhapsode AI algorithm allows each learner to engage in a personalised learning journey through the course to achieve 100% proficiency, a key difference to standard e-learning proven across millions of people in a wide range of industries,” says Khurram.

For company’s looking to replace their current training or learning processes with Rhapsode, Khurram says the process is straight forward.

“Our partnerships start with small starter projects working closely with the subject matter experts in the business to build a course to be used across a number of employees,” he says.

“This is an efficient and effective way to assess the value of adaptive learning for the company which is integrated into their existing LMS allowing single sign on for employees.”

“From this pilot we continue to work with organisations in building more courses, supporting improvements in competency, saving time, engaging employees and enhancing business outcomes.”

“By taking a scientific approach, Rhapsode knows how to measure the impact of training, and how to dynamically reorient the learner when appropriate as they work through the course content.”

Jono Bonifant joined software solutions provider Lentune in 2014, and together with Lentune founder Matthew Reid, has transformed the supplier invoice process in construction with Invoice Automation software.

Jono Bonifant is the Director & CEO of Lentune, and for the past six years has partnered with Lentune’s Founder, Director & Software Architect Matthew Reid to simplify and refine the supplier invoice process in construction.

When Jono joined Lentune as Commercial Manager in 2014 he and Matthew noted businesses lacked insight around their invoice processes and identified the demand for a streamlined solution. “We started looking at the construction industry and discovered many companies were still tied to a lot of paper, and the painstaking task of data entry, when it came to supplier invoices,” says Bonifant.

“During a build, contractors can be inundated with invoices from their suppliers which, without automated invoicing, takes a lot of time for their accounts team to enter the data and process the information.”

Bonifant and the Lentune team then set about their goal to develop a project management system around the financials

of construction, and the Supplier Invoice Automation module was born.

The first of Lentune’s now suite of construction management products, Supplier Invoice Automation enables a streamlined, cloud-based workflow for construction businesses. The smart accounts payable software greatly reduces supplier invoice processing, provides a real-time picture of each invoice and gives the user greater control over their cost management.

Bonifant says the software was created out of a large focus to eliminate the use of paper to improve sustainability, but first and foremost was developed to remove the need for data entry to improve productivity on site.

“It takes around 75% of an administration team’s time to enter and process invoicing data. By removing data entry from the invoicing process, productivity improves significantly,” says Bonifant.

“The traditional invoicing workflow generally starts with an invoice arriving which is then printed off and, at some point, passed to the

boss for sign-off. The last thing that happens is the invoice is put into a financial system, with the whole process sometimes taking up to eight weeks.”

Bonifant says through Lentune technology all invoicing information is found in one platform and is available in a visible and accurate format as soon as the document is received from the supplier. It can give you a running total of project spend and if used with the Lentune app to create purchase orders, Lentune can tell you the total committed costs before project invoices have come in. By using Lentune software which has been developed specifically for construction, it can empower construction professionals to control and manage their job costing efficiently.

One company reaping the benefits of Lentune is construction machine and equipment supplier, Wacker Neuson. Prior to installing Lentune, the business had a manual paper-based supplier payments system.

Matthew Watson, Finance Manager, Wacker Neuson says the manual system wasn’t efficient and relied on lots of manual handling and data entry. “Our system also didn’t meet our lean objectives nor our environmental goals of reducing waste, including paper waste, where possible,” says Watson.

“Wacker Neuson offer zero-emission battery technology in many of our products and we take this ethos right through our business.

“Lentune helped us automate our accounts payable system. We moved away from manual handling and data entry onto Lentune’s digital cloud-based software. We find the optical character recognition functions within Lentune fantastic. This functionality really helps cut down data entry and drive efficiencies.”

Watson says their workforce is now able to process invoices more quickly since moving to the all-digital accounts payable model.

“We measure efficiency by the number of keystrokes required to enter, approve and process an invoice. Lentune, with its optical character recognition technology and improved user interfaces, has helped us reduce keystrokes to enter a supplier invoice by 75%,” says Watson.

“Lentune also has a great document storage feature which really helps with documenting the vendor invoice approval process.”

According to Watson Lentune has helped Wacker Neuson reduce the time required to process, approve and store supplier invoices by over 50%.

The construction industry is currently facing challenges from inflationary material costs to an increasing skilled labour shortage, but we’re seeing more businesses tackle these challenges with the adoption of new technologies and systems.

“Ultimately if your business doesn’t have good systems in place, it can result in staff that are swamped with paper trying to keep up with the running of their projects, and customers who are worried about cost blowouts. You should also consider the reputation that will come from the downfall of these things going wrong,” says Bonifant.

“By adopting a solution that gives accurate and timely information to everyone in the business, it can improve employee wellbeing and help retain staff in the current competitive construction environment.”

During the beginning of the Covid pandemic, the need to be able to complete a job away from the office increased sharply and continues to do so. It accelerated the conversation around mobile working solutions and systems that allow construction professionals to work on the move.

Constructors need information on the go, out in the field and they need to be able to complete the job away from the office. Mobile working has become more than commonplace, it’s the new norm. Bonifant says the best way to manage a project on the go is with cloud-based software.

“Having systems that are mobile and user friendly is paramount to a quality solution. Our cloud-based system allows the user to access all supplier invoices anywhere there is an internet connection with the click of a button,” says Bonifant.

Simplifying operations, Lentune’s Invoice Automation system breaks workflow down into three simple stages.

The check stage allows the administrator or accounts team to do their due diligence and ensure the data captured by the system is accurate. The system generates a visual PDF of the supplier invoice based on the data which can then be reviewed in seconds, checked in and delegated to the appropriate person.

“Lentune helped us automate our accounts payable system. We moved away from manual handling and data entry onto Lentune’s digital cloudbased software.”

Invoice pricing can be checked against agreed supplier pricing before invoice approval.

Once the first stage is complete it provides visibility for the rest of the workforce to see what costs have been assigned to each project. Supplier invoices then move into the approval stage where team members approve the invoices that have been assigned to them.

Following approval, the third stage is processing. Lentune picks up any approved invoices and automatically sends them to the business’s accounts package to be paid. To further simplify the process Lentune can integrate with the business’ existing

Bonifant says delegated authority is also an important feature of the invoicing system. “We all want to give our team ownership to do their role well, but we also want to make sure we’re not giving them control over things outside of their responsibilities,” says Bonifant.

“Delegated authority is a powerful tool for making sure people stay on task and only have authority over the tasks assigned to them. Lentune allows the administrator to select who in their business has the authority to view, amend and approve supplier invoices.”

“The user can be specific around who can approve invoices on what job and to what level. It gives them a lot of control around how they structure their business.”

From a dedicated dashboard, Lentune gives the administrator full visibility and oversight regarding the supplier invoices that need to be processed. They can see who in their team has invoices assigned to them that haven’t been actioned, how many and what the value

“In terms of chasing things up, Lentune does the grunt work for you. Accounts teams have the information in front of them rather than having to sift through loads of data to see what invoices are still outstanding,” says Bonifant.

Lentune also provides the user with immediate access to back costing information and historical invoicing, ensuring accurate

The outdated manual systems of shuffling through piles of paper and data entry are quickly becoming a thing of the past. Lentune’s Invoice Automation software can save time and effort for everyone in the

solar and battery technology to generate and store reliable, clean power without the need to be connected to an overhead power network.

is a combination of highly efficient solar panels, high-capacity battery storage and a backup generator that ensures 24/7, environmentally friendly power.

HPS is the only solution in the world that goes wherever you need it. Simply transport to your site and within moments, clean and constant power is at the ready.

The HPS system is a game-changer for any site that needs to be maintained. It removes the dependency on generator power, lowering refuelling and servicing costs.

Australian civil and commercial contractor, Mad Cat Constructions has deployed a suite of Trimble solutions on their small machines. Its fleet is now equipped with the latest technology, including the Trimble Earthworks Grade Control Platform and Trimble WorksManager Software.

Mad Cat Constructions (VIC) PTY LTD, established by Trevor Reynolds and Jim Knight, is a civil contractor based in Warragul, Australia. Mad Cat operates a large fleet of specialist machinery and attachments to facilitate civil and commercial projects for road corporations, councils, developers and large construction companies.

Effectively use machine control on small machines to gain productivity advantages.

• Trimble Earthworks Grade Control Platform.

• Trimble WorksManager Software.

• Trimble Siteworks Positioning System.

• Improved productivity.

• Greater accuracy.

• Safer jobsite.

• Less waste.

• Increased profits.

Mad Cat Constructions employs an experienced team and manages a large fleet of specialty machinery and attachments to facilitate a range of projects, from road and bridge construction to demolition and erosion control around Victoria.

Since its inception in 1995, the company has invested in advanced technology to streamline operations, and drive productivity and quality. After identifying challenges around small machine productivity, Mad Cat Constructions Director and Project Administrator Trevor Reynolds says the team turned to local Trimble dealer, SITECH Construction Systems, for a solution.

“Our teams were spending too much time interpreting and working off 2D plans. We also had no connectivity between the office and the field,” says Reynolds.

“We needed a streamlined solution to improve the efficiency and productivity of our small machines, so we approached SITECH Construction Systems.”

“Our fleet – which includes excavators,

graders and skid steers with various blades and scoops – is now equipped with the Trimble Earthworks Grade Control Platform.

In the background, Trimble WorksManager Software wirelessly transfers data such as 3D designs to the Earthworks systems on the construction site along with the Trimble Siteworks Positioning Systems.”

Mad Cat Constructions deployed Trimble Siteworks Positioning System (SPS) integrated with Trimble WorksManager Software. The SPS system makes use of Real-Time Kinematic positioning (RTK) to capture accurate points of plus or minus 10-20mm, without the surveyor having to manually level the pole.

Shane Wright, Account Manager, SITECH says the Earthworks Grade Control Platform and SPS Rovers receive RTK corrections via the internet with the Trimble Internet Base Station Service (IBSS).

“IBSS allows you to get highly accurate Global Navigation Satellite System (GNSS) positioning for site positioning or machine control,” says Wright.

The Trimble Earthworks Grade Control Platform was installed on the Kubota machine at Super Groups before being delivered on site.

The SPS base station receives GNSS data from satellites, the data is then processed by the base station into RTK data before being sent to Trimble WorksManager – Trimble’s cloud base software. WorksManager then sends the RTK corrections data via the internet to the Earthworks Grade Control machines and SPS rovers to ensure accurate positioning onsite.

Wright says Mad Cat Constructions also use WorksManager for data transfer. “Traditionally with machine systems, the surveyor would have to use a USB stick, plug it in to a computer to download the designs, then walk out to the machine and plug it into the control box and download the design data” he says.

“WorksManager removes that manual process, and transfers all data via the cloud, directly to the machines.”

Mad Cat Constructions operators can now upload their design into the WorksManager software, allocate the machines they want the design to go to, and the chosen machine pulls that design from the cloud.

“It’s a streamlined process that removes the need for manually carrying and collecting data,” Wright adds.

On the machine control side of the business,

Trimble Earthworks Grade Control Platform allows operators to view 3D models of a site, overlaid onto existing ground – and allows users to access cut/fill information, slope data and other bench points, and reference points in context.

Mad Cat Constructions is using the Trimble Earthworks Grade Control Platform, Trimble’s latest offering in machine control systems. The Grade Control Platform allows operators to view 3D models of a site. The model is overlaid onto existing ground and users can access cut/fill information, slope data and other bench points, and reference points in context.

Operators especially like the Trimble Earthworks ‘Autos’, or automatics mode, which automates the boom and bucket operation while the operator controls the stick for consistent, high accuracy finished grade in much less time.

Just recently, Mad Cat began construction on a large subdivision project in Victoria. The project scope included all civil works, from initial bulk earthworks and utility installs through to completed roads and footpaths. During planning for the project, crews wondered if the same technology-enabled

advantages gained on big machines could be realised on small machines for things like drainage, power and communications trenching, and footpath preparation.

The Mad Cat team knew that a Kubota U55-4, a 5-ton tight tail swing excavator powered by Kubota’s 47.6 HP direct injection engine, would be ideal for activities in narrow space. They needed grade control software – and automatics – to further drive operator productivity.

Working with SITECH, and the team at Victoria-based Kubota dealer Supergroups, Mad Cat installed Trimble Earthworks with automatics on the U55-4, one of the smallest machines the system has been used on.

“As we are running other equipment already with Trimble Earthworks and automatics, it was very easy to implement with a few adjustments – we basically put it straight to work,” says Reynolds.

“We simply upload the prepared project design using Trimble WorksManager into the cloud and the machine loads the files and away we go.”

While Mad Cat has not yet calculated the exact return on investment, Reynolds says, “It’s a no brainer.”

He points to one example of laying electrical tape over power conduits. “We don’t need to mark out trench locations, mark the depth or have someone measuring,” he says.

“We don’t have to worry about locating other services nearby.

“The operator just gets in and digs to the correct depth and position.

“Another benefit is the ability to deliver perfectly in-line trenches for utilities to the specified depth with no over digging. The accuracy reduces spoil that has to be removed from the site and requires less time to dig and verify depths.”

Reynolds says the introduction of Trimble Solutions has saved time and money, increased employee satisfaction and improved safety on site.

Bottom line, he concludes, “There are fewer people involved in the same activity and we’re more accurate. Having the Trimble Earthworks Grade Control Platform, Trimble WorksManager Software and Trimble Siteworks Positioning System has been a game changer.”

This month the team at Inside Construction has worked closely with the Green Building Council of Australia to highlight the fantastic work companies are doing in the ‘Green Construction’ space.

The Australian construction industry continues to charge forward despite global supply chain pressures, labour shortages and cost inflations. Nationally, there are a plethora of projects in the pipeline and, as the industry continues to see rapid growth, we’re seeing an increase in construction companies looking to pivot their operations to more sustainable models.

from embodied carbon and 28%of emissions come from the building and construction sector globally.

These staggering statistics have seen a surge in conversation and action around sustainability in our industry and organisations like the GBCA are leading the way for change.

“Buildings have about 40% of the global carbon budget, they use about 50% of global materials, and they’re fundamentally important to our health and wellbeing.”

In 2002 the Green Building Council of Australia (GBCA) was formed with a purpose to lead the sustainable transformation of the built environment. GBCA CEO Davina Rooney has worked in the construction industry for over 20 years, and says she’s seen sustainability strategies have gone from being a ‘nice to have’, to something that’s at the top of the industry’s agenda.

“Buildings have about 40% of the global carbon budget, they use about 50% of global materials, and they’re fundamentally important to our health and wellbeing,” says Rooney.

“This year the GBCA celebrates our 20th anniversary. Over the past decade we have seen the construction industry make huge strides in creating a more sustainable built environment, but we still have a long way to go.”

According to the 2021 report from the Clean Energy Finance Corporation, Australian buildings and infrastructure: Opportunities for cutting embodied carbon, up to 10% of national greenhouse gas emissions come

Rooney says they do this through four key pillars – rate, educate, advocate and collaborate.

“We rate buildings, which is to set the standard for best practice through our rating system GreenStar. We educate by working with industry, running conferences, training and thought leadership series on the latest sustainability topics. We advocate, partnering with government to set strong standards and sensibly transition innovative ideas into regulation,” she says.

“To bring all this together, we collaborate with industry. We now have over 600 members who we work with to make positive change happen and deliver new models, and ways of working, at scale in the built environment.”

Many people and businesses don’t know how integral Green Construction is to climate change says Rooney. The decisions we make throughout the life of a build can have enormous impacts on the future of construction.

“There’s no reason why all new buildings shouldn’t be designed to be net zero, highly efficient, powered by renewables and fossil

fuel free – the technology to support the transition exists now,” says Rooney.

“The next huge focus for the sector is the materials that we all use. This is what we call the hard to abate part of the sector. Our partners in manufacturing are doing amazing work, but one of the big roles of construction companies is to create a business case for change.

“I was speaking to one of the big manufacturers in the last week and their low carbon concrete range has caused their market share to quadruple in the last year. That’s because of key construction companies looking for more sustainable options.”

Pushing for sustainable alternatives in the construction industry has been a big focus for the GBCA since their inception, but Rooney says working with the industry to take innovative ideas to scale across every project is paramount.

The GBCA’s Green Star rating system is recognised internationally and is one of the largest and most comprehensive of its kind in

companies for sustainable incentives on their projects.

“Over 55-million-sqm’s of building space and over 40% of CBD office space in Australia is Green Star certified. What we find is there’s an enormous amount of area for improvement in this space as we work with our partners,” says Rooney.

“The key opportunity here is for all of us to take sustainability and try and deliver it in every project, every day.”

In the past few years, we’ve seen a green rush of people putting in designs to the highest construction standards, with a focus on delivering buildings that are decarbonised for the future.

Sustainable and environmentally friendly construction is increasingly becoming of top importance to everyone in the supply chain, from clients and constructors to materials suppliers and sub-contractors.

“The only way to achieve a 40% reduction in embodied carbon by 2030 is by everyone in the industry working together,” says Rooney.

“Whether it’s using more sustainable products or reducing waste during a build, Green Construction is critical to creating a prosperous future for our nation.”

carbon by 2030 is by everyone in the industry working together.”

Davina Rooney, CEO, Green Building Council of Australia.

Inventing and designing efficiencydriven products for over 15 years, Makinex has launched a system that uses solar and battery technology to generate clean power on construction sites.

For over 15 years Makinex has been identifying inefficiencies in the construction sector, and inventing products to make contractors more efficient, safe and profitable.

Ingrained in Makinex’s culture is a passion for challenging conventional methods of work, and after identifying the need for a more sustainable power solution on site, the team invented the Hybrid Power System (HPS).

The Makinex team saw the opportunity to create the HPS product 4 years ago, with a core competency of providing clean power to construction sites and reduce diesel consumption.

Makinex Managing Director Paul Weaver says that over time the product has morphed into a range of Hybrid Power Systems from 10kVA, up to 90kVA.

“The fundamental goal of the product is to reduce diesel consumption by over 90%, particularly in remote site locations,” says Weaver.

Makinex was founded in 2004. From humble beginnings in Sydney, NSW the company now has a presence in 14 countries, 50 employees, products carried by more than 4000 equipment hire and rental companies, and over 1000 reseller and OEMs.

The delivery of their latest product, the HPS, adds to their extensive offering of efficiencydriven solutions.

Weaver says the HPS is having success in remote site locations where typically they burn through a lot of diesel needing power for often 24 hours a day, seven days a week.

“Our system uses solar and battery technology to generate and store power without the need to be connected to an overhead electricity network, reducing diesel consumption on site and providing an efficient power source,” he says.

“We’ve made the generator component of the system the third wheel, designed to only kick in when the solar is not producing enough energy for the batteries to recharge.

“The system, manufactured here in Australia, has built in smarts that can be used by the customer to monitor and manage power. For example, if there’s a particular time of day that the noise levels need to be restricted, the system can be controlled so that the generator kicks in at certain times.

run for long enough to manage that without having the generator kick in.”

The functions in the system also allow the customer to monitor fuel consumption so they can get firsthand access, through their computers, of how much diesel they’re burning, and measures the reduction of carbon emissions.

When the HPS came about 4 years ago, Weaver says the conversation around carbon emissions wasn’t as strong as it is today. The increased price of diesel, which has been creeping up over the past year or two, has now put it at the front and centre of their customers’ minds.

“The third component that has contributed to the success of the product is tier one companies employing sustainability managers who are tasked with sourcing products like the HPS in the market,” says Weaver.

“I really enjoy dealing with people in the sustainability space. Though they’re not technically set up to understand the product to the level of an engineer or site manager, they’re the ones who are introducing our products to those key people in their business.

“We’re increasingly seeing with tenders the expectation of a green or environmental

benefit to what and how they’re building. Many companies are no longer prepared to accept a jet diesel generator on site that’s going to burn through 3, 4 or 5 litres of diesel an hour.”

The Makinex HPS delivers outcomes and results that help companies meet their sustainability goals. The system doesn’t rely on other energy sources or other elements of the process to come together, it can be commissioned on site in less than 5 minutes and supply instant power. In the main, the HPS delivers a great outcome for the environment, cost savings and efficiency.

A recent case study conducted by Makinex showcases the value of the system. One of their customers in northern NSW, using a 45kVA HPS, reduced their diesel consumption by 99% over a 3-month summer period. They used just 30 litres of diesel over the 3 months, unlike some traditional diesel-powered methods which can use that amount in just 6 hours.

“Our system provides a considerable financial benefit to the customer, and those that have bought or are hiring units currently are coming back for more,” says Weaver.

“We have now shifted our focus over to our supply chain and production. We’re investing more in that area so that we can fulfil the need that the market is creating for us, so that’s exciting in itself.

“The industry has a high expectation for quality products that last, so we often overengineer and over-design our products to ensure they’re reliable and of the highest quality.”

The HPS product, over its development cycle, has morphed into the company’s recent launch of a sub-brand – Makinex

Renewables – where they are designing and building sustainable and renewable technologies for the construction sector.

Weaver says there’s a few products in the pipeline that the market hasn’t seen yet that came about from conversations with their customers.

“We’ve been talking to our customers and asking questions around what they’re powering and how we can provide better products. It’s amazing how many ideas have come back to the table, and it allows us to

continue to develop great products in the renewables space,” he adds.

The continual pursuit of a better way is something that Makinex strives for and has been the catalyst for shifting the business to create sustainable, renewable products. The company has developed a reputation in the industry for bringing quality products to market, and their latest HPS is just the beginning of Makinex’s renewable

Energy levels and fuel consumption can be monitored, and noise levels can be controlled, making HPS intelligent and transparent.

As a continuous source of clean power, HPS excels in remote locations, eliminating diesel fuel dependence.

“Our system provides a considerable financial benefit to the customer, and those that have bought or are hiring units currently are coming back for more.”

Construction software company Payapps is taking action to create a more sustainable future for the construction industry, achieving Climate Active carbon neutral certification in Australia in 2021.

In 2021, the Payapps team made the decision to pursue carbon neutral certification through Climate Active, a partnership between Australian businesses and Government.

Achieving the certification later that year, the company has continued to put their best foot forward to improve their carbon footprint.

Payapps is a cloud-based collaboration tool for the construction industry, assisting contractors and subcontractors to simplify and expedite the payment approval process. Their mission to develop and provide software to make life easier for its users has reduced the need for paper globally in over 30,000 construction companies, saving approximately 20 tonnes in paper each year.

Founded in 2014 by Melbourne born Lincoln Easton, Payapps was developed to remove traditional, inefficient methods of managing progress claims. Easton found that many construction companies experienced friction when it came to managing progress claims and saw the potential for a Software as a Service (SaaS) platform focused on collaboration and efficiency.

Jessica Widdicombe, Senior Finance Manager at Payapps says the product has since become an efficient, sustainable, and globally recognised progress claims solution. “As well as improving efficiencies on construction sites, Payapps reduces the need

for paper helping our customers to achieve their goals in reducing their environmental impact,” she says.

Widdicombe has been with Payapps for 4 years and led the process for the company to achieve Climate Active carbon neutral certification.

“Our product is a clean technology by nature that helps reduce risks and promote efficiencies within the construction industry and so going carbon neutral ourselves presented as a logical next step,” says Widdicombe.

“Our leadership team is very passionate about sustainability, so when the opportunity arose to achieve a state of carbon neutrality, everyone was on board.”

Digitisation presents one of the greatest opportunities for the construction industry to achieve net zero emissions. With technologies like Payapps forging sustainable solutions for the industry, it’s becoming increasingly important for companies to be more receptive to adopting innovative technologies.

Although the Australian construction industry is slow-moving in the uptake of technology, technology-aided operations will one day become ubiquitous across the sector. Industry organisations like the Green Building Council of Australia are driving change in built sustainability, and green technology like Payapps is a major factor in driving this change.

“Many of our customers have key values around sustainability, and we want to support them by recognising Payapps can have a positive impact on their business and the environment,” says Widdicombe.

“We are able to show action, real intent, and commitment to carbon neutrality through our Climate Active certification. We aim to showcase the amazing benefits of technology in the sustainability space.”

The process to achieve carbon neutral certification, and maintain it each year, included a relatively small investment for a great initiative, Widdicombe says.

Payapps met the requirements of the Climate Active Carbon Neutral Standard by measuring their emissions, reducing where possible and offsetting remaining emissions.

“The first and biggest part of the process is calculating your carbon emissions. We had

help to get started from our major shareholder IFM Investors’ and an environmental consultant Pathzero, who guided us and helped us identify initiatives to achieve the certification. Pathzero’s SaaS solution enabled us to calculate our Greenhouse Gas (GHG) emissions, identify ways to reduce our impact, and look at ways to offset our emissions,” says Widdicombe.

The Payapps platform provides progress payment visibility across the supply chain, including subcontractors, and helps businesses involved in the process reduce their own carbon emissions. By reducing the need for paper, it also saves on the transportation, storage and archiving of documents, furthering its sustainability benefits right through the supply chain.

“We’re proud to be supporting our clients to become more sustainable by using the Payapps software and also playing our part here in the office,” says Widdicombe.

“We have introduced a number of initiatives to reduce our carbon footprint, including reducing our electricity consumption and waste, as well as recycling where possible. All Payapps employees are encouraged to do their part, whether it be reducing travel time or using efficient modes of transport.”

Payapps has also started an education process following their certification, largely for their Australia based employees, to provide their staff with everyday steps they can take to reduce their emissions.

“The education sessions are still in the early stages of development and we’ll continue to evolve them each year,” says Widdicombe.

According to the ACT Government’s ‘No Waste Paper and Cardboard factsheet 2022’ the average office worker uses approximately 50kg of paper, or 10,000 sheets of A4 paper, a year. Widdicombe says Payapps offices are almost paperless.

“We educate staff to look at the things we use day to day – like marketing materials, printed documents and electricity – and collaborate to find alternative, sustainable solutions,” she says.

Currently going through their second year of the certification process for the last financial year, Widdicombe says Payapps is continuing to be proactive in the sustainability space, always looking for ways to improve.

“Our headcount has doubled over the last 12 months, and the economy has opened back up. Our first year of certification is a low baseline to measure against considering everyone was in lockdown, so naturally our emissions will increase as the business grows, but we’re actively trying to reduce our emissions on a per employee basis moving forward.”

“Our goal is to continue to support industry pillars around sustainability and encourage other companies in construction to be a part of the carbon neutral journey.”

Payapps is an efficient, sustainable, and globally recognised progress claims solution.

“We have introduced a number of initiatives to reduce our carbon footprint, including reducing our electricity consumption and waste, as well as recycling where possible. All Payapps employees are encouraged to do their part, whether it be reducing travel time or using efficient modes of transport.”

Inside Construction weekly

is your

this

to

Throughout their global operations McConnell Dowell holistic approach to every project, embracing practices that help minimise environmental and social impacts.

Led by Samantha Johnson, the company’s Executive General Manager of Health, Safety, Environment and Quality (HSEQ), McConnell Dowell employees are constantly looking for new and innovative ways to reduce their impact on the world around them.

Johnson says in planning a project, the company looks into the impact that project could have on the environment and surrounding communities.

“In the planning phase, we put together an extensive plan to minimise the impact a

On the Eastland Port Wharf 7 Upgrade project in New Zealand, McConnell Dowell collaborated with their customer to innovate and deliver some outstanding sustainability outcomes.

we look at things like how we can reduce carbon, embrace the circular economy and minimise waste and pollution,” says Johnson.

“Our community and people are also of top importance to us here at McConnell Dowell. Our objective is to work with and for the community, keep everyone safe, embrace diversity and inclusion, and support and develop our people.”

Evidenced by the company’s large portfolio of sustainably managed projects around the globe, Johnson says the Port Kembla Gas Terminal - Marine Works project is a perfect example of McConnell Dowell’s commitment to reducing, or eliminating where possible, negative environmental and social impacts.

The NSW project involves the conversion of an abandoned coal terminal site to a gas import facility at Port Kembla to bring flexible additional energy supply to the eastern seaboard of Australia. “Driven by our engineering teams, we’ve been able to alter drilling work on the Port Kembla Project to save approximately 20,000 litres of diesel, which is around 54 tonnes of carbon emissions saved,” says Johnson.

“We’ve converted and removed several temporary works which has greatly reduced negative impacts on the marine environment,

which has in turn saved us steel and another 45 tonnes of carbon emissions.

“Similar to that we’re also completing the Eastland Port Wharf 7 Upgrade in New Zealand where again, by changing the piling design, the team has managed to save tonnes of carbon emissions as well as reduce the impact on the environment and community.”

McConnell Dowell was awarded the design and construct contract to rebuild Wharf 7 by Eastland Port in Gisborne, New Zealand in early 2022, following a successful six-month value engineering exercise.

The Wharf 7 contract is part of stage one of the $60 million Twin Berth Project which will enable the safe and simultaneous loading and unloading of up to two handymax, 180-200m long ships.

Using digital engineering and animation capabilities to refine the staging, McConnell Dowell’s engineering team has maximised value and sustainability on the Wharf 7 Project.

Speaking on the project, Johnson says, “Through a design refining process, we have been able to remove the need for 49,000 tonnes of hardfill by using 70% less steel and 50% fewer piles than the original design.”

“Social impacts have been reduced with

The Narre WarrenCranbourne Road Upgrade project is the fourth Major Road Projects Victoria (MRPV) contract awarded to McConnell Dowell. The others being the Echuca Moama Bridge, the Mordialloc Freeway, and the current Healesville - Koo Wee Rup Road Upgrade.

minimised disruption to port activities, and a drill and drive method to mitigate noise and vibration during piling.

“The marine environment, (Rua Koura (crayfish puerulus)) local ecology and seabed will be minimally affected due to the projects innovative design and construction strategy.”

Construction on the wharf began in April this year, with works expected to be completed in October 2023.

Johnson says more customers are now accessing loans that are purely dependent upon the plans being able to demonstrate a carbon zero or reduced environmental impact.

“We have combinations of customers who are using green finance, and their shareholders who are very interested in sustainability, and the environmental, social and governance (ESG) space,” says Johnson.

“Their shareholders are looking to invest in sustainable projects, and then we have our shareholders who are asking us to become more environmentally friendly and sustainable.”

“We have drivers coming from both sides. It’s great because then, when you add into the mix the advances in engineering, and all the technology that’s available now, it’s as though everything is coming together cohesively to allow us to achieve the best possible environmental and social outcomes.”

When McConnell Dowell tend for a project, Johnson says their teams working collaboratively with the client and the community are essential to environmental and social planning.

There may be a need for additional investment in innovative technologies or sustainable materials, or research and collaboration with the surrounding communities. The client needs to be able to see the value and outcomes that arise from their investment.

“Every project is different and has a different set of factors affecting what we’re going to construct. Whether we’re working towards reducing our carbon footprint or planning a project that benefits the community during and after construction, collaboration is key,” says Johnson.

“If we can see a different way of going about construction that’s going to have a much lower carbon footprint and be kinder to the

environment, then absolutely we’ll put that forward to the client.”

On the social side, Johnson and McConnell Dowell teams strive to make a positive contribution to the communities they work in through strong stakeholder engagement and consultation, providing local employment opportunities and seeking community feedback on every project.

The company also prides themselves on being proactive with social support and investment initiatives, such as supporting local Men’s Sheds, integrating Aboriginal artwork and working with local schools.

Recently, McConnell Dowell’s team on the Major Road Projects Victoria’s (MRPV) Narre Warren-Cranbourne Road Upgrade project held a working bee, hosting 10 student leaders from Cranbourne Primary School. Their team worked alongside the students to spread 15 cubic metres of mulch, refreshing garden beds across the school grounds.

Cranbourne Primary School Principal Lachlan Yeates says the working bee was a great learning experience for the students.

“We’re excited to be working with MRPV and McConnell Dowell to help support student leaders in becoming more environmentally aware,” Mr Yeates says.

“We greatly appreciate the time and resources volunteered by the project team to beautify the school grounds.”

In Victoria, government contracts require the contractor to use a certain portion of their spend on either local or social procurement. This can involve working with minority groups in the community, purchasing from social enterprises and providing employment for people from disadvantaged communities.

Johnson says regardless of whether there is a contractual requirement for local and social procurement, McConnell Dowell look to do it for every one of their projects. “It just makes sense,” says Johnson.

“There are huge benefits out of working with the community and working with some of the more diverse areas of the community. It brings about positive experiences and outcomes for our teams and the groups that we work with.”

“The local community tends to know if there are environmental hazards or areas of concern, so we’re committed to working with them from the outset of the project. That

“Our community and people are also of top importance to us here at McConnell Dowell. Our objective is to work with, and for, the community, keep everyone safe, embrace diversity and inclusion, and support and develop our people.”

can be right from the tender period when we haven’t even won a project yet, and it continues throughout the project’s lifecycle.”

In 2021, McConnell Dowell, in joint venture with Decmil, took out the Excellence in Environmental Outcomes Award at the Infrastructure Sustainability Council Gala Awards for their Mordialloc Freeway Project (MFP).

The MFP, a 9 km freeway link in Victoria, incorporates interchanges, bridges over wetlands and a shared user path. McConnell Dowell implemented a range of sustainability initiatives in response to waste crisis and shortage of quarry materials, creating what they call ‘Australia’s greenest freeway’.

“We were able to save thousands of tonnes of otherwise waste material to construct asphalt pavements, stormwater drainage pipes, noise walls and concrete reinforcing mesh, resulting in a 27% reduction in embodied energy,” says Johnson.

The MFP project team were able to divert 97% of construction waste from landfill, lay 321 tonnes of recycled road base and asphalt, and reuse 570 tonnes of plastic in 32,000 m2 of noise walls.

“We’re extremely proud of our effort in using innovative new technologies and processes to complete the MFP project to a high environmental standard,” says Johnson. Judges from the awards were equally

impressed with the project. One judge said, “The focus on reduced truck trips, local sourcing and recycling is a powerful way to improve industry practices.”

“The MFP demonstrates the potential cost benefits of improvised sustainability practices while supporting development and scale-up of local industry.”

As a global company, McConnell Dowell has a goal to reach carbon zero operations by 2050, but Johnson says they’re continuously striving to improve and kick ESG goals. Many of their goals are technology dependent and efforts to achieve those goals can be seen across their operations.

To improve their carbon footprint, McConnell Dowell is introducing solar generators instead of diesel-powered generators. “Whether it’s saving water or electricity, reusing and repurposing waste, or using less materials to achieve the same result, we’re always on the lookout for sustainable and environmentally friendly solutions,” says Johnson.

“Much of the plant we use is not currently available to either be electrical or hydrogen fuelled, so we have to wait for the technology to catch up. This doesn’t stop us from doing the best we can with the resources we have.”

Visit McConnell Dowell’s website for more on their projects and services at www.mcconnelldowell.com

“There are huge benefits out of working with the community and working with some of the more diverse areas of the community. It brings about positive experiences and outcomes for our teams and the groups that we work with.”McConnell Dowell, in joint venture, completed the Mordialloc Freeway Project (MFP) four weeks ahead of schedule in late 2021.

Established as an initiative of Australian construction materials company Wagners in 2010, Earth Friendly Concrete has since seen rapid growth, delivering sustainable geopolymer concrete across the globe.

Over the last 10 years, Earth Friendly Concrete® (EFC®), established by Wagners, has been reducing the carbon footprint in the built environment with their geopolymer concrete.

According to VDZ’s 2012 report –Decarbonisation Pathways for the Australian Cement and Concrete Sector – Australia consumes an annual per capita of approximately 450kg’s of cement. The report also states emissions from cement manufacturing accounted for 6-7% of global CO2 emissions in 2021.

The Wagners team saw the opportunity to play their part in reducing the impact construction has on the environment, developing an absolute zero cement solution to eliminate the climate impact of cement on the built environment.

Jason Zafiriadis, Wagners EFC’s Chief Commercial Officer says the decision to establish EFC came around the time there were talks of a carbon tax in Australia.

“EFC came from a real focus on understanding the bigger drivers of carbon emissions, and cement use was identified as an opportunity for change,” he says.

“If the cement industry was a country, it would be the third largest emitter of CO2

“To make a tonne of cement, you effectively need to bake two tonnes of lime, and a tonne of that gets released as CO2 into the atmosphere just through the chemical reaction, let alone all the energy you need to

Zafiriadis says Wagner’s aren’t afraid to take the hard road on things and solve the hard

The difficulty to create a cement free concrete was to make the product behave relatively like ordinary concrete in application. Over the past 10 years, with over $20 million dollars of their own investment, Wagners EFC developed a zero cement concrete technology that works through ordinary concrete supply chains, proven globally in commercial construction

“Our concrete can achieve around 80% of what you can achieve with ordinary concrete. We can achieve the full compressive strength range that ordinary concrete can deliver; we have better durability, which is important for