ALAN

TUDGE TALKS POPULATION AND CONGESTION BUSTING

POWER PROCESSING

THE NEW HG6800TX OFFERS HIGH HORSEPOWER IN A COMPACT GRINDER WITH UNMATCHED MOBILITY AND PRODUCTIVITY

Built for high volume land-clearing and pipeline right-of-way operations, the new HG6800TX horizontal grinder raises the bar when it comes to horsepower versus footprint. Packing 708 kW of CAT® power in a 41,731 kg tracked frame, it features an infeed designed specifically for larger materials like whole trees and large stumps. This new grinder tames terrain and powers through tough materials like no other. Contact your local Vermeer team to learn more

AS AUSTRALIAN INFRASTRUCTURE PROGRESSES, WE’RE PROUD TO PARTNER WITH THE CONTRACTORS THAT ARE LEADING THE WAY FORWARD.

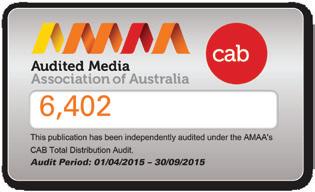

8,313

Published by

Monkey Media Enterprises

ABN: 36 426 734 954 PO Box 1763

Preston South VIC 3072

P: (03) 9988 4950

F: (03) 8456 6720

monkeymedia.com.au info@monkeymedia.com.au infrastructuremagazine.com.au news@infrastructuremagazine.com.au

Editor Jessica Dickers

Assistant Editor

Claire Gaynor

Journalists

Elisa Iannunzio

Lauren Butler

Daniel Johnson

Digital Marketing Manager

Sam Penny

Business Development Manager

Rima Munafo

Marketing Assistants

Helena Brace

Melissa Charalambous

Senior Designer

Alejandro Molano

Designer

Aileen Ng

Publisher Chris Bland

Managing Editor

Laura Harvey

AEDITOR’S WELCOME

ll states and territories recorded positive population growth in 2018 with Victoria recording the highest growth rate of 2.2 per cent. With this continued increase, it’s no surprise the sector’s had a lot of major project announcements lately (particularly in Victoria in the lead up to the state election), as well as contracts and funding awarded, to try to mange the strain on assets and consequences such as congestion.

There is a lot happening in the rail sector, from ongoing construction on the Sydney and Melbourne Metro’s, to several announcements in Melbourne including a rail link to the airport, and a suburban rail link connecting outer suburbs and bypassing the CBD. The Inland Rail Project also continues to ramp up and award contracts for different sections of the project.

What all of these major rail projects have in common is their goal to increase capacity, whether that is reducing the pressure of commuter growth in major cities, or allowing Australia’s freight network to meet demand. Aside from creating more rail lines and stations, the benefits of technologies are also being realised through initiatives like the ARA’s smart rail route map. There is always going to be a balance between building new assets and optimising existing infrastructure and it’s a line that the sector is still trying to perfect.

Regardless of the best way forward, these major projects are exciting and creating more opportunities for the industry. The challenge will be in making sure we have the capabilities and resources to meet this demand. I think technology is an important factor in this, and the benefits of new technologies and use of data featured prominently in discussions at the Asset Management for Critical Infrastructure 2018 Conference, which ran from 12–13 September in Sydney.

The event, created by Infrastructure Magazine, brought together asset owners and managers in the infrastructure and utility space for two days of debate about the most pressing challenges and opportunities in asset

management. We’re extremely proud of the delegate feedback we’ve received about the event, with attendees finding real value from the high level keynote presentations and dedicated streams including rail, corrosion, energy infrastructure and trenchless.

If you missed out on attending, you can see the coverage of the event throughout this issue and keep an eye out on our digital channels for announcements about the 2019 conference.

Another sector focusing on investment to keep up with increased demand is airports. While airports in our capital cities are getting a lot of attention, it’s important that funding also looks at regional airports to increase connections between our states.

I’m looking forward to meeting more of you and discussing these ideas at the Australian Airports Association National Conference, and several other industry shows before the end of the year including AusRail

Due to increasing demand, connectivity is key, not only connecting regional passengers to major cities, but connecting the overall sector – rail links between airports and city centres, freight lines from ports, improved roads surrounding airports. It’s important to create this interoperability as all these new projects can’t operate effectively in isolation.

Bringing together the various assets allows the industry to have a more holistic view of infrastructure and is key to the sector’s future success. We then need to be looking at what the industry can do in regards to maintenance, new technologies, or new projects to facilitate this.

Also, in this edition, we talk to Minister for Cities, Urban Infrastructure and Population, Alan Tudge, and delve a little deeper into issues such as population growth, increased congestion and some of the biggest projects currently impacting the sector.

I hope you enjoy this issue and we’ll see you again in the new year.

Jessica Dickers Editor

INDUSTRY INSIGHT

OPTIMISING THE INFRASTRUCTURE WE ALREADY HAVE

It would appear beyond dispute that infrastructure will be at the centre of almost all our major investments as a nation for a generation to come. Not only is the efcient use of infrastructure crucial to our economic growth, but it also lies at the heart of our day-to-day lives and quality of life in the form of transport, health, education, telecommunication, water and energy services.

ALAN TUDGE:

THE CONGESTION - BUSTING MINISTER

In late August, the Federal Government was turned upside down, with former Prime Minister Malcolm Turnbull ousted from the top job, and Scott Morrison taking over the leadership position. With a new Prime Minister came a fresh Cabinet, and Federal Member for Aston, Alan Tudge, became the new Minister for Cities, Urban Infrastructure and Population, with population a new addition to the portfolio. Here is Infrastructure Magazine’s exclusive interview with the new minister, finding out his vision for the sector, key projects and how the industry can overcome current challenges.

AUSRAIL

AIRPORT INVESTMENT DRIVING GROWTH AND COMMUNITY CONNECTION

Those of us who work in the infrastructure sector understand that, at its core, efective infrastructure must be about economic and community connection. For airports, the connection they provide is becoming an ever-growing part of how we live our lives — and how we support our economic growth.

IMPROVING ROADS BY DESIGN AT AUSTRALIA’S GATEWAY

$300 MILLION AIRPORT EXPANSION TAKES OFF IN THE NT

LAND CLEARING

KEEPING COSTS DOWN FOR SOLAR FARM DEVELOPMENT AND MAINTENANCE

Solar power is becoming an integral part of Australia’s energy mix, with the Australian PV Institute confirming that in mid-2018 there was 35GW of solar farms in the planning and development pipeline. As solar farms span across a vast area, land clearing activities need to take place to ensure the area is clear. Ongoing maintenance of the land is also important as uncontrolled undergrowth can cause the panels to be damaged. Both land clearing and regular maintenance activities are required with the right equipment. INDUSTRY

GPS AND 3D MACHINE CONTROL REDUCING DOWNTIME

Brendan Walsh and his team at Ground Technique have been working on a 20-lot Tran Civil development in Diamond Creek, Victoria. This project is on a large sloping block that is very undulating and requires a substantial amount of cut and fill. To complete this project, Mr Walsh installed the Topcon 3D GPS+ machine control from Position Partners on his Hitachi Zaxis 13-ton excavator.

CIVIL CONSTRUCTION TRENDS TO WATCH OUT FOR

THE AUSSIE INVENTION TRANSFORMING WORKSITE SAFETY

PROTECTING AGAINST BRIDGE CORROSION

The $620 million Darlington Upgrade Project in Adelaide went through a rigorous design and construction process to ensure it was protected against corrosion and degradation. Here, the Australasian Corrosion Association outlines some of the corrosion mitigation work that was undertaken for this project. WHY ALL PROJECT MANAGERS SHOULD BE DESIGNING AGAINST CORROSION

BUILDING DISASTER RESILIENCE INTO OUR CRITICAL INFRASTRUCTURE

NSW residents and businesses are set to benefit from a new strategy that will help keep the lights on, water running and transport moving, even when dealing with disasters. THE BIGGEST ISSUES IN ASSET MANAGEMENT IN

THE ARGUMENT FOR FULLY INTEGRATED CONNECTED MULTIMODAL TRANSPORT

Driverless vehicles seem like they could belong in a distant world, but in reality, there is no doubt that we are moving towards a future where vehicles will be self-driving.

I oT SENSOR NETWORKS CREATING SMART CITIES

Contributors

Alan Tudge

Minister for Cities, Urban Infrastructure and Population

Alan Tudge is the Federal Member for Aston in the Australian Parliament and the Minister for Cities, Urban Infrastructure and Population. He was first elected in 2010 and, prior to his present portfolio, was the Minister for Citizenship and Multicultural Affairs with responsibility for skilled migration, visa processing, pathways to citizenship and multicultural affairs; Minister for Human Services (where he introduced the cashless welfare card); and Parliamentary Secretary to the Prime Minister.

Before entering parliament, Alan spent most of his career in business including with the Boston Consulting Group in Australia and the United States, and worked as a senior adviser to the Foreign Minister and Education Minister. He holds a law degree and arts degree from Melbourne University and an MBA from Harvard University.

Sue MCCarrey

Chief Executive, Office of the National Rail Safety Regulator (ONRSR)

Sue McCarrey has been in the position of Australia’s National Rail Safety Regulator since December 2014. In addition to guiding the ONRSR through a critical phase in its evolution, Sue oversees the nation’s standalone Rail Safety National Law, and works with industry to ensure a safe rail system for the community and to deliver the social and economic benefits flagged by the national transport reforms.

Prior to joining the ONRSR, Sue enjoyed a distinguished career in the Western Australian public sector where she led a review of port authority governance, metropolitan transport planning and the regional freight transport plan in her role as Deputy Director General – Policy Planning and Investment with the Western Australian Department of Transport. Sue established a framework for a statewide transport investment program in order to provide the government with a whole of transport view of investment priorities based on planning needs. Under her leadership, the ONRSR has matured into a fully-formed national operation that is continuing with its vision for a safe, efficient and prosperous Australian rail industry.

Dr John Stone

Senior Lecturer in Transport Planning, Urban Planning Program, Faculty of Architecture, Building and Planning at University of Melbourne

John is a Senior Lecturer in Transport Planning at the University of Melbourne. He has been an active researcher, teacher and advocate in Australian urban transport politics for 30 years and has contributed to many government and community policy processes. His research focuses on comparative analysis of the political, institutional and technical dimensions of urban transport policy and system performance in cities in Australia, Canada and German-speaking Europe to understand how better decisions can be made in Australian cities.

Contributors

Caroline Wilkie CEO, Australian Airports Association

Caroline Wilkie has been CEO of the Australian Airports Association since 2011. The AAA represents all major regular passenger transport airports in Australia as well as council airports. The membership spans from councils with grass strip runways to Australia’s major gateways. The AAA also represents a further 140 corporate members. The AAA is engaged in research, developing industry publications, education, advocacy and major industry events. Caroline has a Masters of Public Affairs and more than 15 years’ experience in Association Management.

Philip Davies

Chairman, SMART Advisory Council, University of Wollongong

Philip Davies recently retired as the Chief Executive of Infrastructure Australia. He is a Partner with Deloitte and chairs both the SMART Advisory Council and the Australian Logistics Council.

He is a Chartered Professional Engineer and Fellow of the Australian Institute of Company Directors, with over 25 years of global infrastructure experience. His roles have involved shaping policy, delivering nationally significant infrastructure projects and leading reform.

Philip has also held various board positions in commercial and public life for more than three decades including as Deputy Chair of the Committee for Sydney and as a board member of Infrastructure Partnerships Australia.

During his time leading Infrastructure Australia, he provided independent expert advice to all levels of government on infrastructure, including advocating for reforms on key issues such as the means of funding, financing, delivering and operating infrastructure, and how to better plan and utilise infrastructure networks.

Danny Broad

CEO, Australasian Railway Association (ARA)

As Chief Executive Officer of the Australasian Railway Association (ARA) — the peak body for rail in Australia and New Zealand — Danny is responsible for all facets of the Association’s activities, including policy and advocacy, membership growth, and the implementation of the ARA’s strategic vision. Danny maintains strong professional relationships with key stakeholders and decision influencers while placing ARA members’ needs front and centre. Danny’s extensive knowledge and passion for the rail industry, coupled with his business acumen, provides the ARA with trusted and highly respected leadership.

During his career, Danny has advanced from behind the drawing board in a structural design capacity, through to project management and general management in the power, civil, construction and rail industries having worked on numerous major infrastructure projects across Australia.

GOVERNMENT ANNOUNCES

NEW FUTURE TRANSPO RT OFFICE

The Federal Government will establish a new Office of Future Transport Technologies to help prepare for the arrival of automated vehicles and other transport innovations.

Deputy Prime Minister and Minister for Infrastructure, Transport and Regional Development, Michael McCormack, said the initiative was made possible through a $9.7 million investment by the Liberals and Nationals Government.

Mr McCormack said the new office would enhance the Federal Government’s strategic leadership role to coordinate more cohesively with other governments and agencies to implement future transport technologies in Australia more successfully and responsibly.

He said the development and uptake of automated vehicle technologies and associated applications would also be managed with a continued focus on improving transport and road safety outcomes.

“Automated vehicles are on the verge of becoming commercially available here and the Australian Government is taking proactive steps to manage the associated challenges and opportunities within that evolving and future transport landscape,” Mr McCormack said.

Mr McCormack said Australian governments and industry needed to collaborate effectively in order to develop the right policy, regulation and infrastructure to adapt to future technology use.

“Getting Australians home sooner and safer is a core focus

of our government and the emergence of automated vehicles represents a significant opportunity to realise safety and productivity benefits while supporting Australian industry and innovation.

“The Australian future transport and mobility industry is expected to generate more than $16 billion in revenue by 2025.

“While representing an emerging business opportunity for the national economy, these technologies also have great potential to reduce the $27 billion cost of road crashes in Australia each year.

“These advances can also help to reduce the significant social impacts that road deaths and injuries have on families and the wider community.”

Mr McCormack said he wanted to ensure these new technologies are deployed in a manner which improves safety, productivity, accessibility and liveability for Australians in both urban and regional areas.

“This new Australian Government $9.7 million investment will ensure the regulatory settings are workable and nationally consistent, that they fit with emerging United Nations regulatory developments and are consistent with related Commonwealth policies and laws; including those relating to privacy and data use.

“While some of this work has already started, we will see the Office of Future Transport Technologies ramping up over the next few months to coordinate Australia’s responses to the challenges ahead.”

scanning

With TIMMS*, indoor maps and models covering thousands of square metres of space can be mapped in minutes and entire buildings mapped in a day.

The TIMMS provides both LiDAR and spherical video of a facility and produces fast and accurate geo-located maps, enabling Taylors to translate environments into visual 2D & 3D layouts.

Our experience in scanning using TIMMS is revolutionising the way we understand, operate and improve our built environments. This has proven successful in mapping data around:

• Airports

• Hospitals

• Schools & Universities

• Shopping Centres

• Tunnels, Carparks & Basements

• Warehouses & Industrial Facilities

• Offce Buildings & High-rises

• Event Spaces & Exhibition Centres

We can create 3D reality models in a variety of formats to provide a solution to suit the end user’s requirements.

* TIMMS: Trimble Indoor Mobile Mapping System

www.taylorsds.com.au Contact us today:

The $1 billion Rail Infrastructure Alliance (RIA) works package will build two entrances at each end of the Metro Tunnel in Kensington and South Yarra, as well as a new platform at West Footscray.

A consortium comprising John Holland, CPB Contractors and AECOM will deliver the RIA Package, in partnership with Rail Projects Victoria and Metro Trains Melbourne.

Thousands of passengers on the Sunbury, Cranbourne and Pakenham lines will pass through the entrances each hour, before heading underground into twin nine-kilometre tunnels onboard High Capacity Metro Trains.

Victorian Minister for Public Transport, Jacinta Allan, said the Metro Tunnel will completely transform Melbourne’s rail network, delivering a turn-up-and-go train system that will compare favorably with the great cities of the world.

“The Metro Tunnel will see more trains running across Melbourne’s rail network – improving reliability and slashing travel times to some of the city’s key employment, education, health and tourism destinations.”

Turnbacks will be built at West

Footscray and Hawksburn stations, allowing services to start and end at these stations during timetabled peak periods for the first time, instead of travelling further down the line.

Public spaces near the eastern tunnel entrance, including South Yarra Siding Reserve, will also be rejuvenated as part of these works before being returned to the local community once tunnel entrance works are complete.

The Metro Tunnel will help reduce delays, cancellations, waiting times and overcrowding across the metropolitan network by giving Melbourne’s three busiest lines (Cranbourne, Pakenham, Sunbury) a new underground pathway through the city, thereby freeing up space in the City Loop for the benefit of other train lines.

The Metro Tunnel will create capacity for an additional 504,000 peak passengers each week across the network.

Around 1000 people will work on the RIA package, including almost 100 apprentices, trainees and engineering cadets. The majority of RIA works are expected to be finished in line with the completion of the tunnels and stations, ready for opening by the end of 2025.

RAIL ALLIANCE TO BUILD TWIN METRO TUNNEL ENTRANCES

ARTC SEEKS PARTNER FOR INLAND RAIL PROJECT

The ARTC has opened a Registration of Interest process and is seeking a Public Private Partnership (PPP) to build a section of the Inland Rail Project in Queensland.

Inland Rail Chief Executive Officer, Richard Wankmuller, said the ARTC is continuing to gauge market appetite for the once-in-a-generation opportunity to deliver the Inland Rail PPP section from Gowrie near Toowoomba to Kagaru near Brisbane.

This partner will deliver the most technically-challenging section of the Inland Rail comprising approximately 130km of dual gauge rail, significant earthworks and complicated tunnels and bridges through the Toowoomba, Little Liverpool and Teviot ranges.

“Private sector involvement in the design, build, finance and maintenance of the PPP section of the Inland Rail programme is critical,” Mr Wankmuller said.

“There is leadership in the private sector that will deliver

“The PPP enables ARTC to access major Australian and multi-national builders and engineers to harness innovative design solutions and more efficient construction methodologies."

Mr Wankmuller said the Registration of Interest process was

NEW CHAIR FOR PO RTS AUSTRALIA

Ports Australia’s Board of Directors have appointed a new chair, filling the vacancy left by previous chair, Paul Weedon.

The Board has elected Grant Gilfillan to the position.

Mr Gilfillan is the Chief Executive of the Port Authority of NSW and a previous President and Chair of the International Association of Ports and Harbours.

Mr Gilfillan said he was looking forward to leading the organisation during an exciting time for the industry.

“We have seen a lot of changes over the last couple of years and there are plenty more on the horizon for the Australian Port sector and for the nation’s freight and supply chain as a whole.

“A strong voice like Ports Australia is crucial during these times to achieve the best results for the country’s ports to optimise trade and efficiencies to and from the port gate.

“I look forward to working with the management team at Ports Australia to realise the current projects the organisation is working on and plan for the future of the sector.”

Ports Australia’s Chief Executive, Mike Gallacher, also said he was looking forward to working closer with Grant as the organisation achieved key milestones.

“As Deputy Chair and with his experience throughout the sector Grant has been a valuable resource for the organisation, I am looking forward to him exercising that experience further in his role as chair.

“This organisation has plenty to offer both our membership and wider Australia and we are working hard to realise this potential.”

Grant has previously worked in Africa, the Middle East and Europe as a Senior Vice President, Managing Director and General Manager for DP World. Prior to this he served as Director of Operations for P&O Ports, Australia and New Zealand and as Managing Director of CSX World Terminals in Australia.

Grant was appointed to the Chair of the Australian Cruise Association in September 2017 and is currently serving as a Director on the Board of Lyttelton Port Company in Christchurch, New Zealand.

Department of Agriculture and Water Resources

Call for tenders $1.5 billion for water efficiency projects

The Australian Government’s Murray–Darling Basin Water Infrastructure Program is funding projects across the Basin to recover water for the environment.

Projects

We’re seeking tenders for water efficiency projects over $1 million, including:

• urban e.g. upgrading urban water infrastructure

• industrial e.g. upgrading processing facilities

• off-farm e.g. channel lining

• metering e.g. installing or replacing water meters

• on-farm projects in Qld, SA and ACT.

Delivery Partners

We’re also seeking tenders from organisations that will work with water rights holders to develop and deliver water saving projects.

All projects under $1 million must apply through a Delivery Partner, including on-farm projects in Qld, SA and the ACT.

How it works

Successful funding recipients must transfer an agreed volume of saved water to the Commonwealth. Funding of up to 1 75 times the market value of the saved water will be available for each project.

How to apply

You can apply through a series of rolling tenders.

The next two tender rounds close at 3 pm on 10 December 2018 and 25 January 2019

For more information and to access the tender documents, visit agriculture.gov.au/waterefficiency

Email procurementhelpdesk@ agriculture.gov.au for assistance.

ADDITIONAL $5 BILLION FUNDING FOR MELBOURNE AIRPO RT RAIL LINK

The consortium AirRail Melbourne, consisting of IFM Investors, Melbourne Airport, Metro Trains Australia and Southern Cross Station, will contribute $5 billion to the Melbourne Airport Rail Link Project.

This funding matches the $5 billion provided by the State Government and $5 billion from the Federal Government, bringing the current total to $15 billion.

The Consortium will be ready to break ground two years earlier than currently planned, provide a 20-minute trip between the airport and city, and benefit regional Victorians.

Australasian Railway Association (ARA) CEO, Danny Broad, said the essential project has sat on the shelf for long enough and it’s time for it to proceed.

“The Victorian Government has said the door is open for private infrastructure funding and after debating for more than 50 years, AirRail Melbourne has a solution on the table that needs to go ahead,” Mr Broad said.

“Melbourne’s population is set to double and the city’s livability will only be maintained with continued investment in infrastructure projects like this.

“The consortium ticks all the boxes, financial security with IFM Investors, MTA’s local and international rail experience and is book-ended with the Melbourne Airport and Southern Cross Station.

“Rail is proven to have far-reaching benefits and AirRail Melbourne will be no different, benefitting regional Victoria with additional capacity for the regions and creating jobs during construction and operation.

“Rail in Australia is booming, with unprecedented investment nationally. The AirRail Melbourne super train will secure Melbourne’s future livability,” Mr Broad said.

27km of new track and twin rail tunnels will form AirRail Melbourne. The project will support 12,000 jobs each year during construction and stimulate 13,000 jobs in Melbourne’s west and Victoria’s regional areas. The service will operate 24 hours per day and reduce regional travel time into the city by ten minutes.

Registrations of Interest (ROI) are also open for providers to help deliver the project. The ROI process, led by Rail Projects Victoria, will help government assess which organisations have the experience and capability to help bring the project to fruition, as well as gauging potential interest from private sector investors and operators.

The search includes designers, engineers, rail systems providers, rolling stock providers, investors, financiers, developers and other rail infrastructure providers. The full Business Case is currently being developed in partnership with the Commonwealth Government.

NORTHCONNEX TUNNELLING COMPLETE

Tunnelling for the NorthConnex, Australia’s longest and deepest road tunnel, is now complete.

NSW Minister for Transport and Infrastructure, Andrew Constance, said tunnelling started back in mid-2016 when the project’s first road header entered the ground at West Pennant Hills.

“Fast forward two years, 14 breakthroughs, 2.4 million cubic metres of spoil and the twin nine-kilometre tunnels are ready to be paved,” Mr Constance said.

Federal Member for Berowra, Julian Leeser, said the project has been an enormous one.

“Around 2,550,000 cubic metres of spoil has been excavated across all sites almost 300,000 cubic metres of shotcrete and concrete has been poured,” Mr Leeser said.

Federal Minister for Cities, Urban Infrastructure and Population, Alan Tudge, said the $3 billion project would transform NSW, and boost the national and NSW economies.

“NorthConnex will bust congestion and provide more reliable and efficient journeys for freight,” Mr Tudge said.

NSW Premier, Gladys Berejiklian, said the NSW Government was investing record amounts in public transport projects and is delivering vital missing motorway links.

“For too long the clogged Pennant Hills Road has been a headache for locals and a bottleneck for trucks delivering goods around our State,” Ms Berejiklian said.

“NorthConnex will remove 5,000 trucks a day from Pennant Hills Road, bypass 21 sets of traffic lights and save drivers up to 15 minutes in travel time.”

A total of 9 roadheaders and one surface miner remain on site and over 900,000 cubic metres of spoil has been delivered to Hornsby Quarry. The average daily peak workforce is up to 1,700 workers on site, while 11,500 people have been inducted to the project; it is estimated 15,000 in total will be inducted. A total of $16 million has been spent to date with Indigenous businesses and 182 apprentices have completed Certificate III Civil Construction through the NCXHub.

INFRASTRUCTURE SUSTAINABILITY AWARD WINNERS

The Infrastructure Sustainability Council of Australia (ISCA) awarded six sustainability awards at its annual conference, recognising excellence in organisational, individual and project leadership in the industry.

Rebecca Miller, Climate Risk and Resilience consultant at AECOM, took out the IS Individual Leadership Award which recognises the individual who best exhibits the most outstanding performance, leadership and greatest contribution to advancing infrastructure sustainability in Australasia.

Rebecca’s extensive work to understand how the infrastructure sector can best address the diverse and challenging range of acute shocks and chronic stresses that threaten to undermine our cities and communities warranted her consideration for the ISCA Individual Leadership in Infrastructure Sustainability Award.

Sydney Metro’s Sustainability Engineer, Laura Pritchard, took home ISCA’s new award category, the IS Emerging Individual Leader – recognising potential

future leaders aged 30 years or younger. In her acceptance speech, Laura recognised the female leaders in the industry and encouraged them to keep on leading and mentoring as “the next generation of women and men benefit from them as role models.”

Laura was nominated because she goes above and beyond in driving innovation including partnership with Social Traders, research into low carbon concrete and research into modern slavery, which triggered a program gap analysis on sustainable procurement being undertaken.

For its championship of sustainability both internally and externally, to other infrastructure agencies, and being the first to register for an ISv2.0 planning rating, Main Roads WA was awarded the IS Organisational Leadership Award. This award recognises the organisation that exhibits the most outstanding performance, leadership and greatest contribution to advancing infrastructure sustainability in Australasia.

Level Crossing Removal Authority’s ‘Training for the Future’ program won the IS Innovation and Impact Award, which celebrates the infrastructure project demonstrating the most impressive implementation of innovation.

Training for The Future (TFTF) is an innovative Victorian Government skills and industry development program creating a sustainable and inclusive talent and supply chain pipeline for major rail infrastructure projects in Victoria. Capitalising on the infrastructure boom to maximise impact for prosperity, people and planet, the program was created in response to the impending labour requirements and opportunity for economic inclusion of our most disadvantaged communities.

The project awarded the highest design IS score in the past year, winning the IS Outstanding Achievement Award for Design, was Melbourne’s Metro Tunnel – Early Works.

Winning the IS Outstanding Achievement for As Built went to the Level Crossing Removal ProjectBayswater Alliance.

OTTA SEALS:

THE UNDERUTILISED TOOL IN PAVEMENT PRESERVATION?

Improving asset management can often come from new or improved technology not just enhanced processing and reporting of data sets.

One such instance where adopting and adapting technology has proved to be a winner, has been in the central NSW regional Shire of Narrandera.

Relatively unknown in Australia, otta seals are a low-volume, low-cost road treatment used predominantly in South Africa. Put simply, graded gravel/crushed rock is placed on a relatively thick film of soft bitumen, and then rolled.

They have become attractive to some Australian councils who seek greater sustainability, combined with a view that a number of current standards, if applied directly, would lead to excessive cost and overuse of scarce premium materials ultimately leading to inefficient asset management.

The Narrandera Shire Council has 300km of sealed roads and 800km

of unsealed roads, but the unsealed roads only serve about ten per cent of the population. The significance of the savings from introducing adapted technology is made clear by referencing against their annual rate revenue, where to reseal the sprayed seal network on a ten-year return cycle (as recommended by Austroads and ARRB) the annual reseal budget would be in the order of 20 per cent of the annual rate revenue. If they were to re-sheet the unsealed network at a five-year interval as recommended, the annual re-sheet budget would be about 90 per cent of the annual rate revenue.

Council has realised considerable lifecycle cost savings with otta seals for local roads with low traffic volumes due to the use of less-tightly specified materials and a longer period between maintenance interventions.

Narrandera Shire Council completed about 65km of otta seal in last four years, 20km of new otta seal in 2017/2018 alone. Importantly, they have customised the process of otta seals to suit the Australian environment, including amending gradation of stone, percentage of cutter and rolling regime and signage after application.

For more information contact the Manager of Works, Narrandera Shire Council, or Kym Neaylon, Executive Manager (Professional Development), CPEE at kym@pavementeducation.edu.au.

The Centre for Pavement Engineering Education (CPEE) is dedicated to road and pavement engineering education, and because of this dedication regularly provides training in regional centres and the more remote parts of Australia far from capital cities.

WHEN A ROAD TRAIN IS A SEWAGE TREATMENT PLANT

Treating sewage in remote locations requires robust systems that have little maintenance requirements and flexibility of fabrication.

Hydroflux has been reviewing customer feedback from one of its well-established products and finding comments such as “it’s robust”, “it never fails”, “it is simple and effective” and “it just keeps rolling along” made them reconsider how it is referred to.

Back in the 1960s, when the system was developed and when marketing was not quite as swanky as it is today, a methodical assortment of numbers and letters was often sufficient to identify a product.

With over 150 of these somewhat unbranded systems operating for many years in various remote areas worldwide, in 2017 Hydroflux Epco decided to establish the RoadTRAIN® brand.

EFFECTIVE SEWAGE TREATMENT FOR REMOTE AREAS

The Hydroflux Epco RoadTRAIN® is undeniably the most robust sewage treatment plant available in the market, as it is a prefabricated on-site sewage

treatment system specifically designed for use in remote locations where simplicity is essential.

It is designed to meet the demands of isolated communities, mining and construction camps, and even resorts for the complete purification of domestic sewage to a quality that allows discharge to local water courses, irrigation or reuse.

These plug and play micro sewage treatment plants are available in three different sewage treatment process options and two modes of fabrication.

OVERCOMING LOGISTICAL ISSUES

It is the flexibility of fabrication methods that continue to be a deciding factor when considering alternatives. Remote locations will often have accessibility problems and having any equipment delivered greater than the size of a shipping container can present challenges.

In these cases, the preference is to supply the “bolted and assemble

on site” design which is flat packed in 20 containers suitable for shipping anywhere in the world. Comprehensive assembly details are supplied along with all components down to nuts, bolts and washers. Installation can often be conducted inexpensively using local trades with everyday tools.

If logistics is not an issue, the RoadTRAIN® can be supplied as a completely welded and assembled system that requires minimal installation works.

The most commonly used RoadTRAIN® is based on the extended aeration activated sludge process, although rotating biological contactors are also popular. RoadTRAIN's® membrane bioreactors have been used in some of the most sensitive areas.

Whichever RoadTRAIN® process is preferred, the performance combined with the fact that they are so simple to operate and require very little maintenance make them ideal for treating sewage in any remote location.

OPTIMISING THE INFRASTRUCTURE WE ALREADY HAVE

by Philip Davies, Chairman, SMART Advisory Council, University of Wollongong

by Philip Davies, Chairman, SMART Advisory Council, University of Wollongong

It would appear beyond dispute that infrastructure will be at the centre of almost all our major investments as a nation for a generation to come. Not only is the efcient use of infrastructure crucial to our economic growth, but it also lies at the heart of our day-to-day lives and quality of life in the form of transport, health, education, telecommunication, water and energy services.

Earlier this year, Infrastructure Australia launched Future Cities: planning for our growing population, a report that identified the choices we have to make as we face very significant population growth.

In the next 30 years, Australia will be home to 36 million people, most of whom will be centred in our largest cities — Sydney, Melbourne, Brisbane and Perth.

There are many obvious economic advantages to this, but the speed and magnitude of the coming change means we now need a smarter, and far more sophisticated, systematic and integrated approach to the way we plan our cities.

While Infrastructure Australia has identified a $55 billion pipeline of nationally significant priority projects, with an additional $25 billion now under delivery, the bigger opportunity — though often ignored — is how we optimise the use of our existing infrastructure.

USING DATA TO MAKE THE MOST OUT OF CURRENT INFRASTRUCTURE

Part of the problem here is political. Too much of our planning is project led and short term, dictated by political objectives rather than long-term need. New infrastructure projects win elections where finding ways to optimise infrastructure is hard to translate in media opportunities and political capital.

The irony here is that improving services and reliability, without the significant expense and inconvenience of building new infrastructure from scratch, is exactly what voters care about most.

So the question is, how do we optimise the infrastructure that we already have?

A decade ago, there may have been a good argument to say that this was a question too complex to address. These days, however, this is no longer the case.

We now have access to far more data and much more sophisticated analytical tools thanks to the

advances in sensors, the Internet of Things and the increasing use of data collection systems in the design and implementation of infrastructure.

Our ability to optimise infrastructure services through the use of data lies at the heart of the mission of the SMART Infrastructure Facility at the University of Wollongong, where I have recently taken up the role of advisory council chair.

Researchers at the facility are already pushing the boundaries of infrastructure optimisation and creating smart solutions to make our cities more liveable, despite the demands of increasing population.

APPLYING STRATEGIES IN AUSTRALIA AND OVERSEAS

One example of this is the work done with MTR, one of the world’s largest providers of mass transit systems in global cities including Melbourne, Hong Kong and Stockholm.

For the past two years, SMART has been helping devise information systems to support and enhance MTR’s “learning organisation” strategy.

The aim is to foster in-house innovation by promoting creative thinking amongst its employees, through knowledge sharing, as well as collective assessment and maturation of innovative ideas.

After an initial in-depth review of existing cultural and technological obstacles, SMART designed information systems aiming to enhance the effective implementation of the strategy. These tools include an online, crowd-sourced and automated assessment system of innovative ideas posted by MTR staff based on meta-moderation principles.

This system allows for a fast, fair and anonymous maturing and ranking process that doesn’t require the costly assignment of specific human resources to the task. This system can easily be transferred to a wide range of organisations that want to unleash the collective creativity of their staff.

Further away, SMART is collaborating with CSIRO-Chile and local partners to address acute water management issues in the Atacama Desert, one of the driest places on earth. SMART

has developed an interactive model of groundwater access and management in order to reach a consensual agreement on sustainable water rights allocation amongst farmers, mine operators and water companies.

Closer to home, SMART is currently collaborating with Liverpool City Council in Sydney to support its ambitious city centre renewal through the use of smart sensing technology. Researchers have already developed a ‘smart visual sensor’ using IoT technology as part of their Digital Living Lab that automatically processes street footage and sends only data points of pedestrian or vehicular mobility patterns, avoiding privacy issues usually associated with video surveillance of public spaces.

Furthermore, this technology can be easily retrofitted onto existing CCTV networks and complemented by other ubiquitous data sources such as mobile device connections.

SMART was established in 2011 and has ambitious plans for growth over the next five years, fuelled by a combination of a rapidly growing capability, and the growing needs of governments and infrastructure owners.

Never has the need been greater for smarter use of existing infrastructure to meet unprecedented population growth over the coming decades.

For more information on SMART and its projects, visit smart.uow.edu.au

ALAN TUDGE: THE CONGESTION - BUSTING MINISTER

In late August, the Federal Government was turned upside down, with former Prime Minister Malcolm Turnbull ousted from the top job, and Scott Morrison taking over the leadership position. With a new Prime Minister came a fresh Cabinet, and Federal Member for Aston, Alan Tudge, became the new Minister for Cities, Urban Infrastructure and Population, with population a new addition to the portfolio. Here is Infrastructure Magazine’s exclusive interview with the new minister, finding out his vision for the sector, key projects and how the industry can overcome current challenges.

FIRSTLY, CONGRATULATIONS ON YOUR APPOINTMENT TO THE PORTFOLIO OF CITIES, URBAN INFRASTRUCTURE AND POPULATION; WHAT ARE YOUR MAIN GOALS FOR THIS PORTFOLIO IN THE FUTURE?

Thank you. Infrastructure investment has been a core priority of the Coalition Government over the last five years. With more than $75 billion in funding and financing committed to new and upgraded infrastructure over the next decade, the Coalition is a major player in public infrastructure investment. We have also been a policy leader. We have overhauled the way the Commonwealth invests in major infrastructure, including restructuring Infrastructure Australia to be a truly independent advisor to governments, implementing more innovative financing and project delivery structures which are driving greater efficiency. We have initiated the successful City Deal model and established a 10-year rolling pipeline of upcoming investments to provide certainty to the market and the community.

However, there is more work to be done in this space. In particular, all levels of government must work together to make our cities function better. Our cities are vibrant, cosmopolitan and economic powerhouses. I want to maintain this vibrancy and economic growth, and I will be working closely with my state and territory counterparts to deliver the investments and the reforms needed to support our urban centres. Our existing City Deals are already returning benefits to the people of Townsville, Launceston and Western Sydney. I am committed to building on the success of these deals to help Darwin, Geelong, Hobart and Perth capitalise on the opportunities created by the next round of City Deals. In our largest cities, the supply of transport infrastructure

has struggled to keep up with the demand of growing populations. It is well accepted that governments have been playing catch-up with their urban infrastructure programs over the last decade, particularly on our congested road and rail networks. Our existing urban infrastructure commitments, such as our $2.33 billion investment in Perth METRONET and our $1.255 billion commitment to upgrade the M1 between Gold Coast and Brisbane, are helping. Our challenge is to keep our focus on long-term solutions to our congestion crisis, including cleaning up pinch points to make existing networks more efficient, as well as improving connections to orbital and regional centres to help spread demand.

Finally, an important expansion of the portfolio has been taking on population policy, alongside cities and infrastructure policy. These three policy areas are inherently interconnected, and opportunities to further integrate the government’s policy settings will ensure we can make our cities even better places to live, work and play.

YOU MENTIONED THE AREA OF POPULATION HAS BEEN ADDED TO THIS PORTFOLIO; WHAT IS THE MAIN AIM OF THIS ADDITION AND HOW WILL POPULATION IMPACT FUTURE INFRASTRUCTURE INVESTMENT AND PLANNING?

The Prime Minister, Scott Morrison, created the new portfolio which merged population policy with urban infrastructure and cities policy. It made a lot of sense to combine these three areas as they are so interconnected. Population growth, for example, is the major reason for building more infrastructure, while our big capitals are where most of the growth is occurring. If we get these three levers right, then our cities will be even better places to live.

In 2002, Australia’s population was projected to increase by 2.5 million by 2017. In reality, it increased by five million — double the projected growth. In Melbourne, the increase was more severe over the same period. The city increased by 1.2 million people, compared to the expected 400,000 – three times what was projected.

At the same time, smaller urban areas are hungry for more people to support local growth. High-quality public infrastructure is essential to support the ambitions of these cities and regional centres, and to attract the workers they need.

Our City Deals are already taking steps to better integrate our infrastructure investment decisions with local land use planning. Ultimately, our national population settings and how growth is distributed will be the key driver of Australia’s future public infrastructure needs. Integrating these policies into the portfolio recognises that population trends are at the heart of infrastructure investment decisions, particularly for our urban areas. Conversely, it also ensures that planning for appropriate levels of infrastructure investment is embedded into our population strategies.

WHAT DO YOU THINK ARE THE BIGGEST CHALLENGES CURRENTLY FACING THE INFRASTRUCTURE SECTOR?

Transport congestion is already costing the Australian economy up to $25 billion per year and this is estimated to rise to $40 billion by 2030. Every day commuters across the country are stuck in traffic, spending hours on the road each week, which they could be spending at home with their families. Many of the trains have reached crush capacity, if there is a train line at all.

While expenditure on public infrastructure has increased markedly — greatly assisted by the Federal Coalition in the last five years — due to the time it takes to deliver new projects, urban transport networks in our largest cities have simply not kept pace with the demand of a fast growing population. Solving the growing congestion crisis in our big cities will mean delivering the right urban infrastructure, ahead of need. This includes all levels of government identifying network deficiencies early, setting out long-term, predictable plans for investment, and working together to better integrate transport investment with urban and demographic planning.

At the same time, we also need to have sufficient capacity and skills in the market to build the infrastructure projects the country needs. The Australian Government’s 10 year, $75 billion infrastructure investment is supporting the construction market and sustaining Australian employment. Recent unemployment figures confirm this with Australia recording the lowest unemployment rate since 2011 at 5.0 per cent. More importantly, a pipeline of priority projects announced in the 2018–19 budget is responding to the call for greater certainty in the construction market, delivering long-term confidence and enabling forward planning. The pipeline includes programs and projects across all states

and territories, in urban and regional areas, and of varying scale and scope, thereby providing opportunities for industry participants of different size and capacity.

WHAT WOULD YOU SAY ARE SOME OF THESE MAIN INFRASTRUCTURE PROJECTS THAT WILL HAVE THE BIGGEST IMPACT ON THE INFRASTRUCTURE SECTOR AND AUSTRALIANS?

Our investment agenda is delivering the upgrades to transport networks that Australia needs. This means investing in packages of works which can reshape our cities and major transport corridors, such as the continuation of works on the Bruce and Pacific Highways that are modernising our key freight corridors. It also means combining our investments with reforms to help generate new economic and social opportunities, such as through our City Deal model. Nowhere is this approach more apparent than through our investment in the Western Sydney Airport and supporting infrastructure.

As the Prime Minister has said, Western Sydney Airport is the biggest game changer for Sydney since the Harbour Bridge. By itself, it is the largest civil engineering project underway in Australia but it’s also part of a wider package of infrastructure investment in the surrounding region — including the North-South Rail Link and the road upgrades through the Western Sydney Infrastructure Plan.

When it opens in 2026, this full-service airport will be well connected to Sydney’s transport network and to the world. The Australian and New South Wales Governments have jointly committed to deliver the first stage of a North-South Rail Link from St Marys to the Badgerys Creek Aerotropolis via the new airport with a joint objective of having rail connected to the airport in time for its opening. Work is already well underway on the jointly delivered business case for this rail line. In addition, our governments are investing $3.6 billion in roads near the airport as part of the Western Sydney Infrastructure Plan. A Development Authority is also being established under the Western Sydney City Deal to encourage development and jobs around the aerotropolis in knowledge intensive industries. Through this massive program of infrastructure investment, we are transforming the Western Sydney region into a new, third city for Sydney with the airport at its centre.

Western Sydney Airport will keep Sydney, New South Wales and Australia open for business. A key benefit is the jobs generation. Unlike many other types of infrastructure, the airport will support more jobs during operations than in construction. This means long-term job opportunities for the Western Sydney community — and the economic benefits of the airport will not only be felt locally. Western Sydney Airport will support tourism and high-value freight, while businesses located at the nearby aerotropolis will benefit from 24-hour access to global markets.

PRIME MINISTER, SCOTT MORRISON, CALLED YOU THE "MINISTER FOR CONGESTION BUSTING" – HOW ARE YOU PLANNING TO REDUCE THE LEVEL OF CONGESTION IN AUSTRALIA’S MAJOR CITIES?

There are three main points to our congestion-busting plan:

1. A massive boost in infrastructure expenditure to build the major intracity road and rail networks and address local congestion pinch-points

2. Easing the population pressure off the three big cities and more rapidly grow the smaller states and regions.

3. Building a better population planning framework. I outlined the Coalition direction in my speech to the Menzies Research Centre in early October:

The Congestion Challenge: More Infrastructure and Stronger Population Planning to get better Cities. Our plan will build on the work the Coalition has undertaken for the past five years.

The Coalition lifted expenditure as soon as we came to office, including funding to deliver key intracity spines over the next decade. We are already delivering major, city-shaping upgrades like WestConnex, which will allow commuters to bypass 52 traffic lights and cut travel times between Parramatta and the city by 40 minutes. But we are also investing in planning for the next round of intracity spines, such as the Western Sydney rail line and the North East Link in Victoria.

In particular, we recognise that passenger rail remains the most efficient way to move large numbers of people in peak periods and we have committed almost $9.4 billion to upgrade our passenger rail networks over the next decade. We are also investing in freight rail upgrades, such as our $400 million commitment to upgrade Port Botany rail line in Sydney, to help get freight vehicles off the roads in some of the most congested corridors.

In the immediate term, the government is also alleviating high-priority local pinch-points across our major cities. While getting major infrastructure links right is critical for our cities’ long-term sustainability, it is often local pinch-points that cause the greatest delays for commuters now.

The government has been investing in congestion-busting packages in Melbourne, Sydney and Perth, and at Budget 2018 we set aside a further billion dollars to address urban congestion. This additional allocation will focus on our most congested urban networks, with works identified through a robust, data-driven process to get the best value out

of our investments for commuters. We will make further announcements about these priority works early next year.

Beyond direct investment, I would also like to see pressure taken off our largest cities by supporting the growth and prosperity of our smaller states and our regions. Even as our largest cities face the challenges of rapid population growth, other areas are crying out for more people. Settling even a small proportion of new migrants to these smaller states and regional Australia can make a big difference to both these centres and to our crowded east coast capitals.

To help this transition, we are looking at our national population settings, including working on measures to have more new arrivals go to the smaller states and regions, and require them to be there for a least a few years. We are also supporting better transport connections between major urban centres and their regional orbitals.

WHAT TYPES OF INFRASTRUCTURE INVESTMENT WOULD SUPPORT A VISION FOR MORE DECENTRALISED CITIES?

An important first step to decentralisation is to better link up orbital population centres near our major cities, such as Gold Coast or Geelong, as well as across our regional towns. Better transport links bring down the time and cost of getting from affordable secondary cities to the employment markets in larger cities. In turn, the greater dispersion of population to our orbitals helps drive local economic activity in these smaller cities, making them increasingly attractive places to live and work even aside from their connection to the nearby capital city.

Through Budget 2018, the government has committed funding to deliver the next round of connecting infrastructure to orbitals. For example, we have committed $1.225 billion towards four projects to upgrade the M1 Pacific Motorway to improve congestion, safety and travel times for the thousands of commuters who travel on the Pacific Motorway to major metropolitan employment centres in Brisbane. Beyond just looking at the closest orbital cities, we are also investing $1.75 billion through a Regional Rail Revival package to cut the travel times for thousands of people travelling daily from regional Victoria to Melbourne for work.

We are also working with the states and the private sector to plan for longer-term infrastructure upgrades to support interregional travel, including through our $20 million Fast Rail Business Case investment. Under this commitment, the

government is funding three business cases which look at long-term faster rail solutions to support urban, regional and rural development.

These business cases will look at options that would significantly reduce travel times and improve access to affordable housing and employment opportunities outside the major capitals. My department is working closely with successful proponents to progress the three business cases and it is expected that they will be delivered to the government by mid-2019. At this time, the government will review the outcomes in detail and explore opportunities to take forward the projects in partnership with state governments and the private sector.

HOW SHOULD THE GOVERNMENT AND INDUSTRY BALANCE THE CONSTRUCTION OF NEW INFRASTRUCTURE WITH THE OPTIMISATION AND MAINTENANCE OF CURRENT INFRASTRUCTURE?

While most road and rail infrastructure is owned by the states, and sometimes operated by the private sector, the government strongly supports optimising the use of existing infrastructure.

The government’s Infrastructure Investment Program funds projects involving technological enhancements and improved operational practices to avoid delaying the need to implement more expensive construction solutions. As part of our standard project assessment processes, we check the extent to which the proposal has considered non-construction options, such as the use of technology to improve safety and capacity before investing in new infrastructure projects.

For example, we have funded a number of projects to install Intelligent Transport Systems to improve traffic flow and reduce accidents on busy or dangerous roads, such as on the Bruce Highway corridor between Brisbane and Caboolture.

THERE HAVE BEEN REPORTS OF THE INTENTION TO UNVEIL A NATIONAL POPULATION POLICY WHAT WILL THIS POLICY ENTAIL AND HOW DOES THE GOVERNMENT PLAN ON DEALING WITH RAPID POPULATION GROWTH?

The Coalition will be unveiling our population policy in due course and as mentioned, I delivered a speech to the Menzies Research Centre that outlined our direction. Our plan is to continue to invest in major infrastructure, take pressure off the big cities through decentralisation, and develop a better

planning framework with the states which better matches population growth with infrastructure spend.

The challenge for Australia is that our population growth is not evenly distributed. As I have outlined, we have very fast population growth in Melbourne, Sydney and South East Queensland. While the overall population of Australia has been growing at the rapid rate of 1.6 per cent per annum, our three large population centres have been some of the fastest growing cities in the world. Melbourne last year grew by 2.7 per cent, Sydney by 2.1 per cent and South East Queensland by 2.3 per cent. At the same time, we have the smaller states and many regional areas that have barely grown and crying out for more people.

South Australia, for example, grew by just over 10,000 people last year. Melbourne grew by 10,000 every 28 days. South Australian Premier, Stephen Marshall, however, wants to grow South Australia by another 15,000 people each year.

The same pattern is mirrored in many of the smaller states and territories. For example, the Northern Territory Chief Minister wants to grow Darwin faster. The Tasmanian Premier has indicated his desire to more rapidly grow his state.

Further, there are regional areas across Australia that simply cannot get people to do the work available. Three hours from Melbourne, in the beautiful seaside town of Warrnambool, they have unemployment of 3.8 per cent and businesses struggling to get workers. The recent headline of their local paper was “Wanted: 1000 workers!”. Other regional parts of the country are the same.

We need a more even distribution of growth across the country to support the smaller states and regions, while taking pressure off Melbourne, Sydney and South East Queensland.

THERE HAVE ALSO BEEN REPORTS OF POSSIBLE MEASURES ENCOURAGING NEW MIGRANTS TO MOVE TO REGIONAL AREAS WILL THIS BE SOMETHING INCLUDED IN A POPULATION POLICY?

While the government is looking closely at opportunities to support greater migration directly to regional areas and to the smaller capitals, this is not a radical idea. There are already a number of visa programs that support regional migration.

The success to expanding this approach will be matching the skills of new migrants with the skill shortages in rural and regional Australia. Currently, net overseas migration is heavily skewed towards our largest centres. While it

accounted for 64 per cent of our overall population growth in 2016-17, the figure is around 73 per cent for our biggest two cities. Hence, settling even a slightly larger number of new migrants to the smaller states and regions can take significant pressure off our big cities.

There are some constraints on this, of course. For example, 25 per cent of our annual migration intake is directly related to an employer sponsoring a person for a job where they cannot get an Australian. We do not want to jeopardise the growth of those sponsoring businesses, and hence the wealth of our nation. A further 30 per cent concerns family reunion; typically, an Aussie marrying a foreigner. We cannot send a person’s spouse to a different state.

So taking areas of constraint into account, we are working on measures to have more new arrivals go to the smaller states and regions, and require them to be there for at least a few years. In that time, the evidence suggests that many will make it their home for the long term. This will require close cooperation across different agencies, including with Regional Development Minister, Bridget Mckenzie, to ensure we get the settings right so that those smaller states and regions can benefit economically from population growth.

A further method for supporting regional growth (and taking pressure off our big capitals) is to better connect and integrate our orbital cities. Fast rail is an effective means of doing this, as has been noted by the Federal Parliament’s Joint Standing Committee on Infrastructure, Transport and Cities, led by John Alexander MP. If a person in Ballarat, for example,

can commute to Melbourne in 45 minutes rather than the present 75, then the opportunities for Ballarat’s growth would accelerate markedly.

We are presently investigating the potential for faster rail links between our big capitals and surrounding regional centres. Three detailed business cases are already underway and will be finalised mid next year — Newcastle to Sydney; Sunshine Coast to Brisbane; and Shepparton to Melbourne. Victorian Opposition Leader, Matthew Guy’s $19 billion commitment to fast rail from Melbourne to Geelong (32 minutes), to Ballarat (<45 minutes), to Bendigo (70 minutes), and to Traralgon (62 minutes), is consistent with our agenda. We would be pleased to work with him on his decentralisation plans should he be elected.

We can also more generally develop and support the growth of our regional centres and smaller capitals. We are doing this through several initiatives:

♦ Our public service decentralisation agenda led by Minister McKenzie. In May 2018, the government announced positions from five Commonwealth entities are to be moved with more to come

♦ Our City Deals to support growth of key regional centres and smaller capitals

♦ The $272 million Regional Growth Fund and $641 million Building Better Regions Fund

♦ The funding of large-scale road, rail and defence projects outside of the big capitals

With the technological revolution surging around the globe, businesses need to ensure they are in the best position possible to maximise the benefits and opportunities aforded by new and emerging technologies. Inherent in this is understanding the risks and obstacles that are likely to emerge in the context of a changing technological paradigm.

Nowhere is this more evident than in rail where there is, and will continue to be, significant change. This includes changes to how we move customers and freight in cities becoming more congested, how we move trains safely and efficiently around the network, and how we modernise the management of rail assets.

It has become exceedingly important to ensure the Australasian rail industry does more to keep pace and prepare for these changes.

INDUSTRY DEVELOPING

SMART RAIL ROUTE MAP

DIGITAL FRAMEWORK

In response, the rail industry is working together to develop a long-term strategic framework for digital and communication technologies. This commitment is embodied by the Smart Rail initiative, which aims to drive a coordinated industry focus to the adoption and deployment of telecommunications and technology initiatives within the industry.

Australasian Railway Association CEO, Danny Broad, said the Smart Rail Route Map is an industry-owned and industry-driven initiative, spearheaded by the ARA and the Rail Manufacturing Cooperative Research Centre (CRC), and delivered by Deakin University.

“It will help our industry to realise the vision of a national approach to rail technology, bringing economies of scale, supporting interoperability and many other efficiencies,” Mr Broad said.

“Defining industry goals, mapping the key challenges for the rail sector over the next 30 years relating to technology

disruption, and identifying focus area objectives and initiatives is critically important to putting rail on a stronger, more sustainable footing in the future.”

The $550,000 project ($200,000 in cash funding from Rail Manufacturing CRC and ARA, and $350,000 in in-kind contributions) will identify a long-term industry program to improve the rail industry's ability to adopt and keep pace with telecommunication and information-based technologies.

Smart Rail will focus on standardisation, integration and harmonisation over the next 30 years through the establishment of a common view of priorities, themes, timelines and actions.

Importantly, it will provide a basis for defining the rail industry direction, development initiatives and research programs and in effect, provide a framework through which next generation rail technologies can be integrated and supported in the Australasian rail environment.

PRIORITIES OF A SMART RAIL SYSTEM

The Deakin University project team, led by Professor Douglas Creighton from Deakin’s Institute for Intelligent Systems Research and Innovation, is providing expertise in systems mapping when workshopping, developing and modelling this project’s outputs.

The underlying strength of the project lies in the level of industry engagement on the development of strategy initiatives.

To date, the ARA and Deakin have held nine workshops, attracting close to 200 participants.

Some of the Smart Rail priorities include:

♦ Passenger rail safety, timeliness, convenience and valueadded services

♦ Freight customer cost-effective services and on-time delivery

♦ Harmonised and integrated public transport systems that enable seamless end-to-end journeys

♦ Cost-effective and efficient customer centric operations

♦ Smart asset management and maintenance

♦ Workforce digital and technological skills and competencies

♦ A national versus an independent approach

♦ Implications on the future customer experience and considerations for innovation and technology strategy and implementation

One of the most important issues that the Smart Rail project is focusing on is its rail culture and pertinacity to customise, which can restrict the adoption and implementation of these systems in line with the normal technology lifecycles.

A RENAISSANCE IN RAIL

The ARA’s work in this area is against the backdrop of a renaissance in rail.

Billions of dollars’ worth of investment has been committed over the next decade. This investment is needed, with Australia’s passenger and freight tasks expected to grow by 19 per cent and 26 per cent respectively by 2026.

“With more densely populated cities, and increased numbers of people and freight to move around our cities and through regional areas, it is critical that we as an industry have a common view of priorities, themes, timelines and actions so we can meet these challenges head on,” Mr Broad said.

The Smart Rail Route Map will be technology neutral, and communicated in a non-technical manner. The project outputs will be owned by the Australian rail industry and will be used to support the introduction of new technologies and services efficiently and cost effectively.

The ARA Board, which shapes the priorities and sets the policy directions of the ARA, is strongly supportive of the Smart Rail project. It recently agreed to an executive committee to guide the project’s long-term implementation following the project’s completion in late 2018.

The Smart Rail Route Map will be finalised and presented to industry in late 2018.

Smart Rail will be one of the topics for discussion at AusRail 2018 in Canberra on 27-28 November 2018. The Smart Rail: Technology of the Future panel will feature Paul Harris, Public Transport Victoria; Doug Creighton, Deakin University; Mark Smith, Transport for NSW; Stuart Thomson, Rail Manufacturing CRC; and Bonnie Ryan, GS1 Australia who will discuss how the project will provide a long-term strategic framework for digital and communication technologies in Australia.

A NEW ERA FOR RAIL NETWORK ACCESS PITS

In rail, unrestricted access to associated underground network infrastructure during installation is a key factor in a project’s success. Delivery of the Canberra Light Rail Project saw the introduction of Australia's first high strength modular access pit system capable of overcoming challenging dimensional restrictions and a highly accelerated schedule.

Stage One of the Canberra Light Rail Project is nearing completion, and includes the design and construction of a 12km light rail route spanning between Gungahlin to the city centre.

During installation of the Canberra Light Rail Project, project teams had to overcome restricted site access and limitations of the specified underground network access infrastructure. Having modular products that can be customised on site and adapted to project needs as they develop can greatly improve the flexibility of installation, reduce associated labour and plant costs, and eliminate challenges which otherwise cause significant delays.

The Canberra Light Rail Project had extensive project HV service footprint constraints which were mitigated by Cubis Systems, whose in-house design team developed the STAKKAbox™ ULTIMA Hybrid, an industry-first modular access pit system designed to meet the unique requirements of Australian rail networks.

FLEXIBLE DESIGN

additional custom Hybrid solutions provided to suit the large scope of works and changing installation requirements between all three project zones.

REDUCTION IN TIME AND COSTS

Time and cost savings are two of the most important considerations in any rail project and by using the ULTIMA Hybrid there was no need for specialist builders or heavy machinery resulting in no extensive traffic management or disruption, saving both time and associated labour costs.

The lightweight sections were rapidly installed on site, enabling two or more large custom pits to be fully assembled, including all connections and backfill, within one day by a small work crew. Modifications to the pits which accommodated the HV electrical conduits were easily completed using standard battery powered tools with the option to customise further as required.

The entire ULTIMA Hybrid assembly acted as an exoskeleton, consisting of an in-situ concrete base, the ULTIMA Connect pit system, ULTIMA beams and a three-part precast concrete encasement.

The design of the beams were engineered to deliver amplified lateral strength capabilities particularly for large access pits measuring two meters and above. All components were flat-packed for delivery, reducing freight and unloading costs.

For the Canberra Metro project, the STAKKAbox™ system was customised to three standardised pit sizes, with multiple

Cubis Systems specialise in the design and manufacture of innovative access pit and cable protection solutions, including modular, precast concrete and rotationally-moulded plastics, used in rail projects across the country. Cubis continues to push design limitations with its CABLEprotect RAILduct™ product, a HDPE moulded cable trough system typically five times faster than traditional concrete units, reducing total cost of installation and improving health and safety.

Watch the Canberra Metro Project video showcasing the STAKKAbox™ ULTIMA Hybrid by scanning the QR code. To find out more about Cubis’ extensive range of modular network access solutions, visit www.cubis-systems.com/au.

SUBURBAN RAIL LOOP

— HOW REALISTIC IS THE VISION?

by Dr John Stone, Senior Lecturer in Transport Planning, Urban Planning Program, Faculty of Architecture, Building and Planning at University of Melbourne, and Dr Crystal Legacy, Senior Lecturer in Urban Planning at the University of Melbourne

What should we make of the Andrews Government’s recent vision for a $50 billion suburban rail loop, which will link every major rail line in Melbourne and the new airport rail?

Clearly, the enthusiastic response from the public shows that the government has struck a chord. In fact, this new evidence showing that many people are desperate for an alternative to being stuck in traffic could be a game changer. Could we finally see an end to the accepted wisdom that the way to win an election is to promise a new road?

For infrastructure builders and planners, there is not yet much detail beyond the indicative budget and a timeline for construction of 30 years starting in 2022.

The government’s surprise announcement is backed by a short ‘strategic assessment’ and a video with a thumping soundtrack, both designed to set a vision ahead of more detailed planning work if the ALP is returned to government in November.

The basic project description was prepared by Development Victoria, supported by Rail Projects Victoria, with commercial and technical advice provided by PricewaterhouseCoopers and Aurecon.

The loop is proposed as a 90km arc with 13 stations from Cheltenham to Werribee, underground for the first stages from the Frankston Line to Box Hill, and Box Hill to the airport. Later stages envisage surface rail and tunnelling from the airport to Sunshine, and a final connection to Werribee. Travel time targets are 35 minutes from Broadmeadows to Monash, and 45 minutes from Cheltenham to the airport.

WHY IT’S NEEDED

The rail system was built in the 19th and 20th centuries so that people could work in the CBD and live in the suburbs. At first, people lived within walking distance of a station, but as the suburbs spread into the wedges between the radial lines, we have failed to develop networks of suburban buses and trams that cities like Toronto built to deliver people to the railway.

Now, in the 21st century, we need to catch up and give people in the suburbs an alternative that recognises public transport’s big challenge: crosstown travel.

Although most people live and work in the suburbs and come to the centre only occasionally, most travel is still within five to 10km of their homes. Local schools, health centres and shops need to be accessible by public transport. That’s the “20-minute city”, for which we need a good network of fast, direct buses that get us quickly to local destinations.

But we also need a mass transit system to connect good jobs, education and hospitals to the places where housing is affordable. Crosstown rail is a great way to provide the ‘mass transit’ part of the equation, because it will allow us to reach many more places without using so many valuable hours of the day.