SLEEPER BY SLEEPER:

SLEEPER BY SLEEPER:

When drilling in rock, you need a rig that can take on the tough ground conditions. Vermeer’s latest additions to the HDD market are two new intuitive compact rock drills; the D23x30DR S3 and the D40x55DR S3.

The new DR HDD range has the benefit of superior steering in extreme conditions. They are easy to use, versatile for both rock and clay drilling, and have a quieter noise level at the operator's ear, making them the perfect machines when minimal disruption in urban areas is required. Call Vermeer Australia today for further information.

Monkey Media Enterprises

ABN: 36 426 734 954

204/23–25 Gipps St

Collingwood VIC 3066

P: (03) 9988 4950

F: (03) 8456 6720

monkeymedia.com.au

info@monkeymedia.com.au infrastructuremagazine.com.au news@infrastructuremagazine.com.au

Editor Jessica Dickers

Journalists

Lauren Butler

Imogen Hartmann

Eliza Booth

National Media and Events Executives

Rima Munafo

Brett Thompson

Design Manager

Alejandro Molano

Designers

Jacqueline Buckmaster

Danielle Harris

Marketing Assistant

Stephanie Di Paola

Publisher Chris Bland

Managing Editor

Laura Harvey

Welcome to the last issue of Infrastructure magazine for 2020. It’s crazy to think that we have produced three out of four issues this year remotely and under lockdown in Melbourne due to the COVID-19 pandemic. The upcoming summer is looking cautiously brighter though, with the hope of continued eased restrictions around the country.

Throughout it all, Australia’s infrastructure industry has done a tremendous job in keeping critical assets working and in optimal condition, as well as progressing work on major construction projects. The recently released Federal Budget also shows the significant role infrastructure is set to have moving forward, with the government committing to major funding for transport and road safety projects around the country. You can read a full funding breakdown of the budget on page 14.

One of the biggest milestones the Infrastructure team has hit since our last edition was hosting the inaugural Critical Infrastructure Summit – a series of five Virtual Conferences that ran every Wednesday in September.

Like a lot of other businesses, we had to adapt quickly to the impact of COVID and move the Summit to an online format which allowed infrastructure professionals from around the country to tune in virtually to Critical Infrastructure: State of play; Construct 2020; Asset Management for Critical Infrastructure; Disaster Management; and The Future of Infrastructure

There were so many important discussions at these events and for those that attended, we hope you got a lot of value from our expert speakers. We have covered some of these throughout this issue of the magazine, including key takeaways

from the Summit (page 34), Tony Histon’s Disaster Management keynote presentation (page 70), and the machine learning and artificial intelligence panel from Asset Management for Critical Infrastructure (page 78).

We’ll be running the Critical Infrastructure Summit again in April 2021 so keep an eye on upcoming issues for more information on next year’s event.

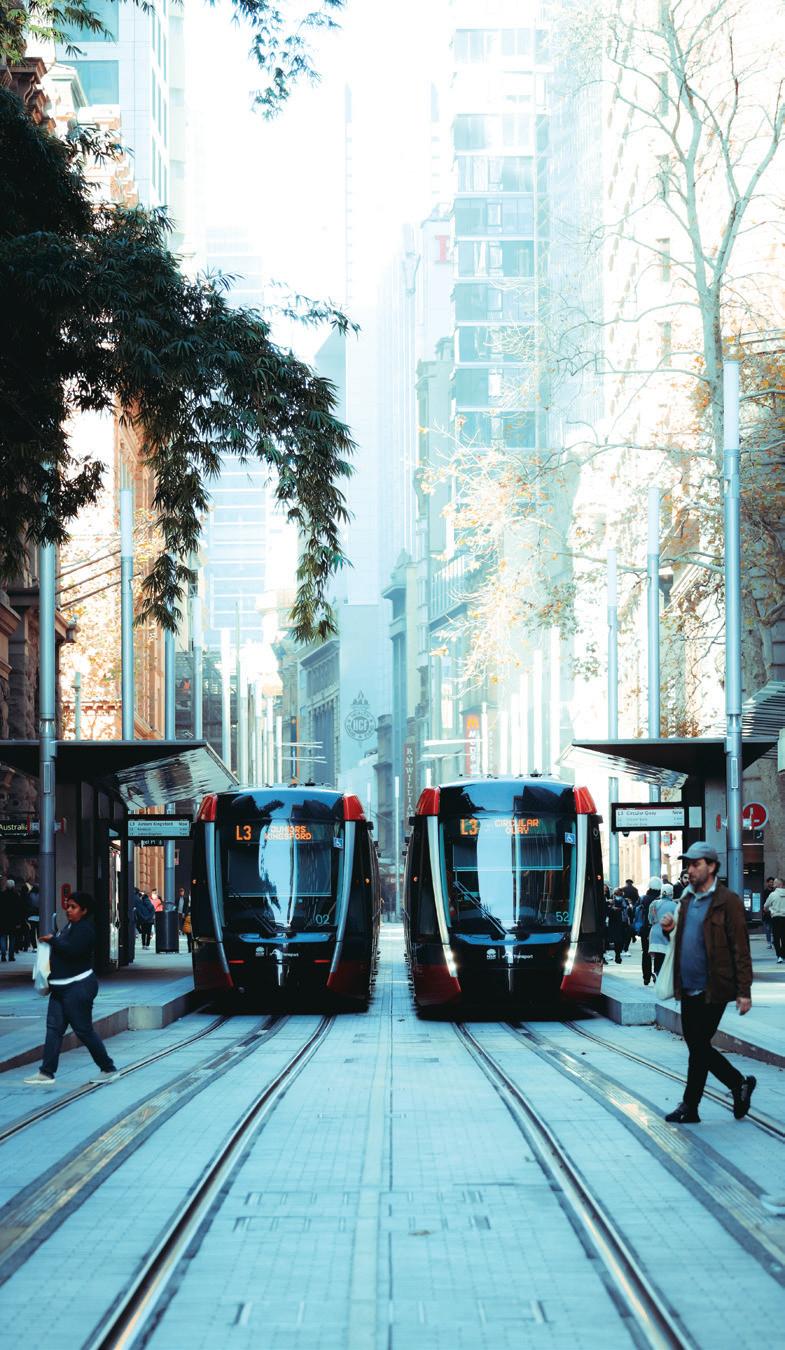

In addition to our Summit coverage, this edition also has a big focus on the rail sector as Infrastructure is a media partner for the AusRAIL Live and On Demand virtual event. As confirmed in the Federal Budget announcements, the rail sector will help drive infrastructureled economic recovery thanks to both new funding and the huge projects that are already underway.

Australasian Railway Association (ARA) Chief Executive Officer, Caroline Wilkie, recently said, “The flow on benefits of rail investment will be significant as new projects bring more jobs and sustainable infrastructure that will deliver community benefits for years to come.

“The future of rail in Australia will rely first on improvements to existing infrastructure, followed by the development of new, faster rail connections.”

We’re already seeing these rail projects progress in all states, making it an exciting time to be a rail professional.

As we wrap up the last few months of 2020, I’d love to hear your thoughts and predictions for 2021, as well as what topics you want to hear about.

Infrastructure is proud to be the voice of the industry, especially as we have navigated some uncharted waters this year, and we thank you for your continued support.

Jessica Dickers EditorDefend industrial networks at all levels.

Secure industrial networks with OT-IT integrated security.

Identify and mitigate system vulnerabilities in industrial networks before weaknesses are exploited by a cyberattack.

9 Build reliable and secure networks to maintain business operations

9 Integrate OT/IT perspective on network protection

9 Detect and mitigate cyberthreats for system integrity

9 Protect critical assets with tailor-made OT cybersecurity technologies

Connect with confidence.

Madison Technologies has been distributing Moxa’s reliable networking infrastructure Australia wide for more than 14 years. Our team is dedicated to ensuring our Moxa portfolio is fully supported with an extensive range held locally across our national supply chain, and a team of Moxa certificated sales and technical support engineers.

THE TEN PRINCIPLES FOR AUSTRALIA’S INFRASTRUCTURE-LED RECOVERY

In this excerpt from her keynote address at the Critical Infrastructure Summit 2020, Infrastructure Australia Chief Executive, Romilly Madew, outlines ten principles that should underpin the infrastructureled recovery from COVID-19.

GLOBAL INFRASTRUCTURE

WILL GLOBAL INFRASTRUCTURE BEND OR BREAK UNDER CLIMATE STRESS?

Infrastructure is the backbone of the global economy, connecting people, enhancing quality of life, and promoting health and safety. But climate change is revealing infrastructure vulnerabilities.

INDUSTRY INSIGHTS

STIMULUS FOR INFRASTRUCTURE: THE MARSHMALLOW EXPERIMENT OF SOCIETIES

With infrastructure set to lead a post-COVID economic recovery, Dr Naderpajouh from RMIT looks at the role of developing new infrastructure systems to face challenges and compares the current situation to the famous ‘marshmallow experiment’.

BECOMING AN INNOVATIVE AUSTRALIAN TRENCHLESS TECHNOLOGY CONTRACTOR

HEALTHY HEADS: IMPROVING MENTAL HEALTH IN THE LOGISTICS INDUSTRY

KEY TAKEAWAYS FROM THE CRITICAL INFRASTRUCTURE SUMMIT

BOOKING ACCOMMODATION FOR YOUR UPCOMING INFRASTRUCTURE PROJECT

AUSTRALIA’S BIGGEST RAIL INFRASTRUCTURE PROJECTS

There’s a lot happening in the rail infrastructure space across Australia. From expansions and new metros, to rail linking suburbs and new stations – the rail sector is continuing to boom. With the number of projects running concurrently, we’ve taken a look at some of the biggest rail projects around Australia and their progress to date.

HOW THE RAIL INDUSTRY IS DRIVING A POST-COVID ECONOMY

DIGITALLY ENABLED ASSETS: INFRASTRUCTURE MANAGEMENT FOR THE 20S

USING VULCANISED RUBBER IN TRACK DAMPING SYSTEMS

LEADERSHIP IN THE RAIL INDUSTRY

IoT & CLOUD COMMUNICATION

WHAT’S IN STORE FOR THE FUTURE OF INFRASTRUCTURE?

HOW TO SEAMLESSLY INTEGRATE AUDIO AND VISUAL PASSENGER INFORMATION

RECREATING SOUTH EAST QUEENSLAND IN THE DIGITAL WORLD

THE CIRCULAR ECONOMY IS HERE AND IT'S A BIG OPPORTUNITY

ACCESSING INFRASTRUCTURE SUSTAINABILITY DATA

NORTHCONNEX: MISSING LINK

A GAME CHANGER FOR SYDNEY

Road planners have talked about “missing links” for decades. Like that other cliché to describe big infrastructure – “game changer” – it can sound impressive but mean very little to motorists stuck in traffic. But if there ever was a motorway you could confidently call both a “missing link” and a “game changer”, it’s NorthConnex, which will connect Sydney’s M1 and M2 via 9km twin motorway tunnels.

SETTING THE STANDARD FOR SODIUM SILICATE STORAGE

METRO TUNNEL’S ADVANCE WORK PAYS OFF

DISASTER MANAGEMENT

A NEW PARADIGM FOR MANAGING INFRASTRUCTURE DURING DISASTERS

CONTACT HARALD – THE PLATINUM STANDARD CONTACT TRACING SOLUTION FOR YOUR COVID-SAFE PLAN

MACHINE LEARNING

CHALLENGING TIME FOR AUSTRALIA’S AIRPORTS MACHINE LEARNING AND AI CHANGING THE GAME

THREE SHORTLISTED TO BUILD WESTERN

INTERNATIONAL AIRPORT

PROJECTS ADDED TO THE INFRASTRUCTURE PRIORITY LIST

FEDERAL BUDGET BREAKDOWN – $7.5 BILLION FOR TRANSPORT INFRASTRUCTURE AROUND THE COUNTRY

Lisa is a circular economy and zero-carbon business transformation leader. She has been successfully advising industry and governments in developing new policy frameworks and regulations that bring about market change to enable the circular zero-carbon economy over the past 14 years. This work has covered the energy, water, waste and mobility sectors in the UK and Australia. Lisa established and led the Open Cities Alliance, a peak industry association with unique membership from government to private sector and research organisations. In Australia, Lisa initiated and established the Australian Solar Thermal Association (AUSTELA), advised electric mobility providers, and worked with Flow Systems from a startup sustainable water utility to its major role in shaping a new sustainable water and now multi-utility market.

Transport for NSW Project Director, NorthConnex

One of Australia’s most experienced construction professionals, Pat has enjoyed an outstanding 42-year career in the construction industry. His previous work experience includes the Sydney Harbour Tunnel, Eastern Distributor, M5 East and Cross City Tunnel.

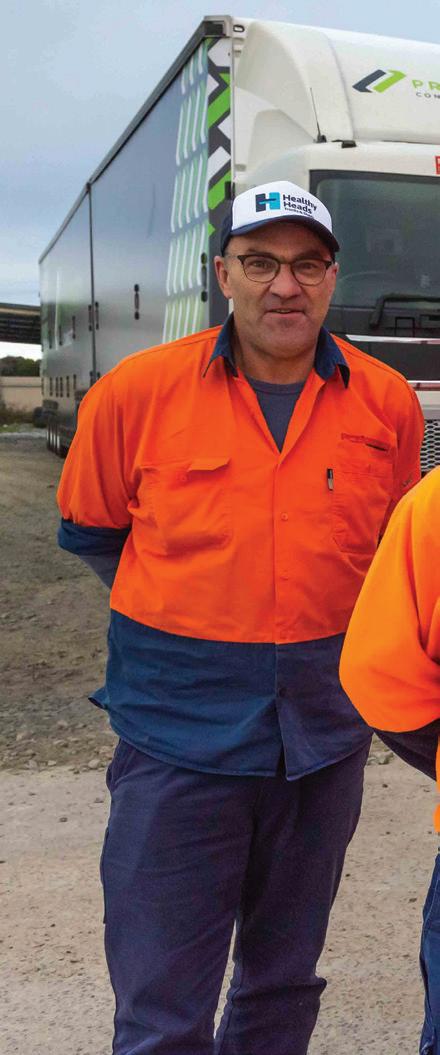

Lachlan BensonInterim CEO Chief Executive Officer, Healthy Heads in Trucks & Sheds Foundation

Lachlan is also the Managing Director of consultancy Blue Arcadia and sits as a Non-Executive Director on a number of industry related boards including the iMOVE Cooperative Research Centre into freight mobility. He has previously been the interim CEO of the Australian Logistics Council, as well as five years as Executive General Manager of Logistics at Sydney Ports Corporation where he oversaw the highly successful Port Botany Landside Improvement Strategy. This built on extensive experience in supply chain management issues gained in other senior logistics roles including as NSW and QLD State Manager for grain exporter AWB Limited, as a Senior Policy Advisor for ports and freight within the NSW Department of Transport and as Manager of the Transport Logistics & Infrastructure Group at Informa Australia.

CEO, Australian Airports Association (AAA)

James Goodwin was appointed Chief Executive Officer of the AAA in June 2020. Prior to this, James was the Chief Executive of Australia’s leading vehicle safety advocate, the Australasian New Car Assessment Program (ANCAP) since 2015. Before joining ANCAP, James held the position of Director – Government Relations & Communications at the Australian Automobile Association and also held a highprofile senior community and corporate affairs position at AirServices Australia. A former journalist and news presenter, James worked for major network news outlets in Sydney and Canberra including several years in the Parliamentary Press Gallery.

CEO, Infrastructure Australia

Romilly is responsible for overseeing Infrastructure Australia’s critical role in helping governments prioritise projects and reforms that best serve our communities. Before joining Infrastructure Australia, she was CEO of Green Building Council of Australia (GBCA) for 13 years. In acknowledgment of her contribution to Australia’s sustainable building movement, Romilly was awarded an Order of Australia in 2019. She is currently a Commissioner for the Northern Territory Economic Reconstruction Commission, Member of Placemaking NSW Advisory Committee, and Independent Chair of the Currawong State Park Advisory Board (NSW). She has sat on numerous Federal Government panels including the Cities Reference Group, National Sustainability Council, Climate Futures Independent Expert Group and the National Urban Policy Forum.

Transmission & Distribution Lead, Accenture Asia Pacific, Middle East & Africa

Tony leads Accenture’s Transmission and Distribution Practice in Asia Pacific, Africa and the Middle East. Over the last 20 years, he has helped utility businesses across Asia Pacific deliver resilient energy infrastructure and systems. Tony develops Accenture’s capability, research and offerings to digitally enable network operations, field work and asset investments. Tony holds an Executive MBA from the AGSM, a Masters in Engineering Science, a Bachelor of Electrical Engineering with Honours and electrical trade certifications.

Three parties have been shortlisted to build Western Sydney International (NancyBird Walton) Airport’s passenger terminal in a major step for the project.

The three shortlisted parties are:

♦ Lendlease CPB Joint Venture (a joint venture between Lendlease Building and CPB Contractors)

♦ Multiplex Constructions

♦ Watpac Construction

Western Sydney Airport CEO, Simon Hickey, said the integrated international and domestic passenger terminal will offer passengers and their families a stress-free travel experience.

“The advantage of designing a new airport from the ground up is taking a fresh, new approach, learning from the global experiences of airports, passengers and airlines,” Mr Hickey said.

“As well as looking at what makes the world’s best airports work so well, we gained insights from our airline MOU partners that helped us design a terminal that will make catching a plane fast and easy.”

The terminal precinct will include a public plaza, retail and dining options, and will be connected to the new M12 Motorway and Sydney Metro – Western Sydney Airport train service.

Mr Hickey said sustainability was a key consideration in the terminal design and will take advantage of natural sunlight and air flows to reduce energy use and create a healthier, more comfortable environment.

The design of Western Sydney International’s passenger terminal is ongoing, and is said to be finalised when the winning contractor is appointed in mid-2021. Terminal construction is due to begin by the end of 2021.

The first stage of Western Sydney International is on track to open in 2026, and will cater for up to ten million passengers a year.

The full line-up of sought after John Deere construction equipment is now available across Australia, supported by trusted and reliable sales and service from AFGRI Equipment and RDO Equipment. They know what it takes to support production-class machines and each is armed with advanced machine monitoring, remote diagnostic capability and world-class parts availability. It’s a New Day and a New Deere.

Infrastructure Australia has added two projects from NSW and ACT to the Infrastructure Priority List, to support the national infrastructure-led COVID recovery.

The construction of Parkes Bypass on the NSW Newell Highway and the upgrade of Canberra’s Commonwealth Avenue Bridge have both been named Priority Projects. Infrastructure Australia Chief Executive, Romilly Madew, said, “With the addition of two new Priority Projects – Parkes Bypass and Commonwealth Avenue Bridge – the Infrastructure Priority List now showcases more than $65 billion worth of nationallysignificant investment opportunities for governments at all levels to choose from.”

The NSW Government’s proposed $172 million Parkes Bypass project involves construction of a 10.5km bypass along the Newell Highway, including bridges over existing railway lines, connections to the Parkes Special Activation Precinct and upgrades to local roads.

Connecting Melbourne and Brisbane, the Newell Highway is a vital freight corridor for consumer, manufacturing and agricultural goods.

The existing highway runs directly through the Parkes town centre, which contributes to congestion and safety risks in the town and limits the ability of high performance freight vehicles to use the corridor.

The Parkes Bypass is expected to help remove heavy vehicle traffic from the town and improve connectivity between local producers and the Parkes Special Activation Precinct, which is being established to leverage the Inland Rail project.

Proposed by the Federal Government, the $124.9 million upgrade to Commonwealth Avenue Bridge will deliver critical safety improvements to an iconic and critical part of Canberra’s transport infrastructure.

The proposal includes structural upgrades to meet modern safety requirements and accommodate the increasing number of vehicles and active transport users travelling on the bridge.

The bridge forms part of the corridor for the planned extension of the Canberra Metro light rail network, which would be assessed under a separate business case.

•Reduce rattle gun use

•Eliminate hot works

•Faster turn-around

•Better productivity

•Fits conventional bolts

•No special tools

Waterjet cutting is a process of precision cutting that utilises high pressure water.

We can process a wide array of materials. Heavy gauge plate, thin sheet stock and composite materials (i.e. carbon fibre, phenolics etc.). It is not uncommon for 6+ inch aluminium and titanium to be cut on waterjets to near final shapes. Edge quality of the parts can vary depending on customer requirements.

We can process anything from a very rough cut for hog-outs, to a very fine edge for precision, finished parts:

Cut up to 6 m x 3 m (20 ft x 10 ft)

Thickness up to 254 mm (10 in)

Improved yield and less waste material

Supplied close to net shape reducing customer machine time

Shorter lead times

Zero heat effected zone

Processing of customer supplied materials

Anew feature roof is being installed for Sydney’s Central Station, as part of the Sydney Metro construction works, creating a new landmark for the city.

Minister for Transport and Roads, Andrew Constance, said the roof over the Northern Concourse is nearly two thirds complete, after workers installed the steel girders, affectionately known as the “hockey sticks”, and cassette roof sections.

“The 80m-long and 40m-wide roof extends from the northern end of

Platform 8 to Platform 16, and will sit more than 16m aboveground to enable natural light to filter into the station,” Mr Constance said.

“More than 500 workers are currently delivering the Sydney Metro works at Central, with more than 5,000 working across the Sydney Metro City and Southwest project.”

The roof structure was manufactured and pre-assembled in the Hunter Valley town of Kurri Kurri, before large sections were transported to Sydney in the middle of the night.

Key highlights about the roof installation include:

♦ 58 cassette sections being installed, each weighing around five tonnes

♦ Largest cassettes are 16m long and 4.5m wide

♦ Eight girders being installed, each weighing 30 tonnes

♦ Longest girders are near the Station Master’s Office, measuring 21m long

♦ 21,000 square metres of existing canopy was demolished for the new roof

♦ Roof has perforated aluminium cladding panels, 21 distinctive diamond-shape skylights, lighting and speakers

Sections of the roof will be progressively installed over the Northern Concourse until the end of 2020, with the Central Walk expected to be open to commuters in 2022. Sydney Metro construction will continue with metro rail services through the city expected to start in 2024.

Absafe Group supplies a comprehensive range of products and services focused on safety and flexibility, with high levels of customisation. As the National Distribution and Service Agent for Sky Climber, Absafe excels in providing the right solution for your access requirements.

The Sky Climber Swing Stage System allows infrastructure workers to set up in any location where wire ropes can be hung, providing extremely flexible and efficient access to structures of any height.

Its modular design and articulation capabilities allow it to fit into all locations.

As the Swing Stage requires fewer parts to access the same working area as a scaffold, it is considerably faster to install and a more cost-effective option for getting tradesmen to the right point, at the right time.

The Alpha series has often been referred to as the most premium hoists in the powered suspended access business. With superior engineering design, they boast a unique traction mechanism which allows wire rope to enter without friction and then squeezes the rope with equally distributed pressure over 360° to attain the lifting traction.

Sky Climber Swing Stages provide significant value through improved efficiency and the reduction of risks, project duration, and disturbances to daily operations. It is suitable to be implemented on new commercial construction, heavy industrial works, maintenance, big projects, and anything in between. The Alpha hoist motors are robust, reliable and safe.

As the primary Australian distributor, reseller, and master service agent of Sky Climber Swing Stage equipment and Alpha hoists, Absafe provides businesses with the opportunity to purchase these products for themselves, saving a considerable amount of money compared to the cost of renting for lengthy projects.

Absafe works closely with companies to develop custom designs to suit each specific scope of work, and provides engineered design and on-site training to guarantee safety, reliability and the perfect match for your task.

Coupled with a highly efficient planetary gearbox, this combination has been a true success in meeting users’ needs. This series is offered in many variations to fit the needs of any project.

If you are having issues with access or are in need of quality safe swing staging, please contact Matthew Van Brink on 0431 299 157 or matt.vanbrink@absafe.com.au. Absafe Group is here to help.

The highly anticipated 2020-21 Federal Budget was released on 6 October and featured significant funding for Australia’s infrastructure industry, including a $7.5 billion investment in transport infrastructure around the country as part of the Federal Government’s COVID-19 economic recovery plan.

Since the start of the COVID-19 pandemic, the government has committed to invest an additional $14 billion in new and accelerated infrastructure projects over the next four years. These projects will support a further 40,000 jobs during their construction.

Some of the key infrastructure funding announcements from the budget include:

♦ $7.5 billion for transport infrastructure

♦ Funding for ‘shovel-ready projects’ including $2 billion for road safety initiatives and $1 billion for the Local Roads and Community Infrastructure Program

♦ Additional $4.5 billion investment in nbn co

♦ An investment of $2 billion for new projects under the National Water Infrastructure Development Fund. This more than doubles the fund to a total of $3.5 billion. Key funding in this includes: $325 million for Wyangala Dam and $242 million for the Dungowan Dam project

♦ Infrastructure Australia has received additional funding in the 2020-21 Federal Budget to provide reform and investment advice in support of the infrastructure-led COVID recovery

♦ An additional $1.2 billion to support Australian businesses to employ 100,000 new apprentices or trainees as part of the COVID-19 economic recovery plan. Businesses who take on a new Australian apprentice will be eligible for a 50 per cent wage subsidy, regardless of geographic location, occupation, industry or business size

The funding builds on a series of infrastructure investments from the Commonwealth in response to the COVID-19 pandemic, which now totals more than $11.3 billion. Prime Minister, Scott Morrison, said the Federal Budget would deliver funding for infrastructure, which supports the government’s JobMaker plan.

“We have been working closely with state and territory governments to invest in the infrastructure that is ready to go and can help rebuild our economy and create more jobs,” the Prime Minister said.

“This investment through the budget will boost the national economy and is part of our plan to support an estimated 30,000 direct and indirect jobs across the nation.”

The 2020-21 Federal Budget includes funding for key transport infrastructure projects across the country. Here is the state-by-state breakdown:

Federal Budget funding: $2.7 billion

Expected jobs created: 8,000 direct and indirect jobs across the state

Total federal infrastructure funding for COVID-19 recovery: $5 billion+

Key transport infrastructure investments for New South Wales include:

♦ $560 million for the Singleton Bypass on the New England Highway

♦ $360 million for the Newcastle Inner City Bypass between Rankin Park and Jesmond

♦ $120 million for the Prospect Highway Upgrade

♦ $491 million for the Coffs Harbour Bypass (bringing the total federal contribution to $1.5 billion)

Federal Budget funding: $1.3 billion

Expected jobs created: 5,150 direct and indirect jobs across the state

Total federal infrastructure funding for COVID-19 recovery: $1.7 billion+

Key investments for Queensland include:

♦ $750 million for Stage 1 of the Coomera Connector (Coomera to Nerang)

♦ $112 million for the Centenary Bridge Upgrade in Brisbane

♦ $76 million for Stage 2 of the Riverway Drive Upgrade between Allambie Lane and Dunlop Street in Townsville

♦ $42 million for the Mt Lindesay Highway Upgrade between Johanna Street and South Street in Jimboomba

Federal Budget funding: $1.1 billion

Expected jobs created: 3,850 direct and indirect jobs across the state

Total federal infrastructure funding for COVID-19 recovery: $1.6 billion+

Key investments for Victoria include:

♦ $320 million for the Shepparton Rail Line Upgrade

♦ $208 million for Stage 2 of the Warrnambool Rail Line Upgrade

♦ $292 million for the Barwon Heads Road Upgrade

♦ $85 million to upgrade Hall Road in Cranbourne

Federal Budget funding: $1.1 billion

Expected jobs created: 6,800 direct and indirect jobs across the state

Total federal infrastructure funding for COVID-19 recovery: ~$1.3 billion

Key investments for WA include:

♦ $88 million for the Reid Highway Interchange with West Swan Road

♦ $70 million for the Roe Highway Widening and Abernethy Road Upgrade

♦ $16 million to undertake sealing of priority sections of the Goldfields Highway between Wiluna and Meekatharra

♦ $16 million to undertake upgrades on the BroomeCape Leveque Road and associated community access roads

Federal Budget funding: $625 million

Expected jobs created: 2,600 direct and indirect jobs across the state

Total federal infrastructure funding for COVID-19 recovery: $785 million+

Key transport infrastructure investments for South Australia include:

♦ $200 million for the Hahndorf Township Improvements and Access Upgrade

♦ $136 million for Stage 2 of the Main South Road Duplication between Aldinga and Sellicks Beach

♦ $100 million for the Strzelecki Track Upgrade

Federal Budget funding: $360 million

Expected jobs created: 2,200

Total federal infrastructure funding for COVID-19 recovery: $410 million+

Key transport infrastructure investments for Tasmania include:

♦ $150 million for the Midway Point Causeway (including McGees Bridge) and Sorell Causeway as part of the Hobart to Sorell Roads of Strategic Importance corridor

♦ $65 million to upgrade the Tasman Bridge

Federal Budget funding: $190 million

Expected jobs created: 1,050 direct and indirect jobs across the territory

Total federal infrastructure funding for COVID-19 recovery: $240 million+

Key investments for the Northern Territory include:

♦ $120 million to upgrade the Carpentaria Highway

♦ $47 million for National Network Highway Upgrades

AUSTRALIAN CAPITAL TERRITORY

Federal Budget funding: $155 million

Expected jobs created: 400 direct and indirect jobs across the state

Total federal infrastructure funding for COVID-19 recovery: $180 million+

Key transport infrastructure investments for the ACT include:

♦ $88 million for the Molonglo River Bridge

♦ $50 million for a South West Corridor upgrade package

An additional $2 billion over 18 months will be directed towards road safety initiatives, continuing efforts to reduce road trauma in Australia. This funding will be under a new Road Safety Program to deliver an estimated 3,000km of lifesaving road improvements and support thousands of jobs right across the country.

The program will deliver works such as new shoulder sealing, rumble strips to alert drivers they are moving out of their lane, median treatments to prevent head-on collisions, and barriers to prevent run-off-road crashes and protect against roadside hazards.

The program will be delivered in three, six-month tranches and on a ‘use it or lose it’ basis. Funds that states and territories do not spend will be re-allocated to those that can, with jurisdictions required to provide road safety data as a key condition of funding.

To monitor and evaluate its progress in this area, the Federal Government is also investing $5.5 million to establish a National Road Safety Data Hub. The Data Hub will establish the first nationally-available road safety data collection to assess the effectiveness of road safety efforts by all Australian governments in the move towards the nationally-agreed target of zero fatalities and serious injuries by 2050.

An additional $1 billion will also be allocated for local governments to enhance local road infrastructure through the Local Roads and Community Infrastructure Program. This will also be on a ‘use it or lose it’ basis.

This builds on the Federal Government’s initial $500 million announced in May 2020. This investment, together with the new Road Safety Program, will support around 10,000 jobs over the life of the projects.

According to Safe Work Australia, in the past two years more than 230 Australians were killed at work, with almost half of this number being employees in the transport, postal, warehousing and construction sectors. What these figures don’t account for though are the near misses and injuries sustained by workers. Technology can help make these incidents more preventable.

Temporary traffic controllers are critical to managing the safe passage of vehicles through road work sites. Traffic control workers, whether working on busy highways, country roads or large private sites, are putting their lives at risk every day to keep others safe.

The number of speeding vehicles, distracted drivers and heavy machinery they deal with on a daily basis can be up to 10,000 vehicles over an eight-hour period. For this reason, it is important for traffic controllers to be able to carry out their duties in a safe environment by removing them from the roadside where possible.

Traditionally STOP/SLOW signs are used by workers to control traffic, but this requires controllers to be next to, or directly on, the road. These signs can be dangerous for a number of reasons: the first being that traffic controllers are directly in the line of fire of incoming traffic; and secondly, they can be difficult to see from a distance in large vehicles.

STOP/SLOW signs can expose traffic controllers to speeding or careless drivers. Relocating the operator from busy roadways removes the greatest risk of injury or death.

The best way to remove workers from harm’s way without compromising a job’s effectiveness is to use a portable traffic light. The PTL Portable Traffic Signal System (PTSS) uses smart and innovative technology to enhance visibility, making it safe and efficient for traffic control operators. Controllers can easily control the temporary traffic lights with a Handheld Remote Control (HRC) at a safe distance from traffic.

After using the PTL system a Traffic Control Manager said, “Keeping my workers safe is the most important thing to me. That’s why I love using PTL. They are simple and easy to learn and make it that much safer for me, my team and the other workers we are protecting.

“This happens not just by removing us from the roadside, but out of the sun, where possible, so we are able to stay alert to manage the traffic in the safest and most efficient way we can.”

With transport authorities all over the country campaigning for more regulations and awareness for safety around traffic controllers, implementing a portable traffic signal is a simple and definitive way to reduce the risks surrounding the work of traffic controllers.

While these devices can require an upfront investment, you can’t put a price on the safety and life of a person.

Madison Technologies’ Portable Traffic Light system is ITS Approved in Queensland and Western Australia, with more states to come. If you would like more information on the PTL, please visit portabletrafficlight.com.au

Portable Traffic Light is the next generation portable traffic signal system, that’s built to last.

9 Portable lightweight design for quick set-up 9 Removes traffic controller/operator from vehicle path 9 Lightweight Hand Remote Controller with backlit low power LCD display 9 Lithium LiFePO4 battery run time of 20+ hours

Highly stable tripod that’s adjustable to suit any terrain

Designed and manufactured in Australia

Connect with confidence.

Madison Technologies is Australia’s and New Zealand’s well-connected supplier of reliable commercial and industrial communications technology products. We deliver comprehensive solutions for our customers’ complex industrial and commercial connectivity challenges. We provide all the products you need in one place, with a streamlined supply chain, responsive team, a comprehensive distribution network, and technical support and training. Contact our team to learn more.

In this excerpt from her keynote address at the Critical Infrastructure Summit 2020, Infrastructure Australia Chief Executive, Romilly Madew, outlines ten principles that should underpin the infrastructure-led recovery from COVID-19.

by Romilly Madew, Chief Executive, Infrastructure Australia

by Romilly Madew, Chief Executive, Infrastructure Australia

Australia’s infrastructure sector will be critical as we navigate the rolling series of crises facing our country – drought, flood, bushfires and COVID-19 – as well as the long-term transformation of the economy and the ‘new normal’ of record investment highlighted in Infrastructure Australia’s 2019 Australian Infrastructure Audit

Before the pandemic, over 20 per cent of Australia’s GDP could be attributed to our infrastructure sectors. Given the significant economic contribution of the sector, we should be proud that during COVID-19, the industry has proven that it can be resilient and agile in dealing with a fast-changing landscape.

In addition to infrastructure-led stimulus and recovery plans announced by the Australian Government and numerous state and territory governments, we are seeing a reprioritisation of projects and a greater focus on investments that will deliver the greatest economic benefits.

We have seen an increased focus on resilience, a key theme from the 2019 Australian Infrastructure Audit and our 2020 updates to the Infrastructure Priority List, as well as greater collaboration across the public and private sector as we together work to streamline and fast-track approval processes.

Since the beginning of the dual health and economic crises, Infrastructure Australia has been working closely with the Australian Government, infrastructure bodies in the states and territories, and industry on policy advice to guide the COVID-19 response.

Working collaboratively with our colleagues in the states and territories, our focus has been on improving our ability to move quickly to identify investments that will boost productivity, keep the economy growing and help create jobs.

We are advocating for a staged infrastructure recovery response, beginning with protecting and maintaining the existing pipeline of projects. Mobilising new projects both small and large is the second phase, with industry reform also to be considered as part of Australia’s long-term recovery response.

To support this staged approach and ensure infrastructure can play its role in driving the recovery, we have worked closely with Building Queensland, Infrastructure NSW, Infrastructure SA, Infrastructure Victoria, Infrastructure WA and Infrastructure Tasmania, as well as our counterparts in the NT and ACT.

Together we have established a set of principles that should underpin Australia’s infrastructure-led recovery from COVID-19:

1. Build confidence in the sector and the future project pipeline: support the timeliness of the existing pipeline, address constraints across the sector and prepare for future disruption by accelerating infrastructure planning and approvals, finance and procurement, delivery, maintenance, and renewal.

2. Select projects and reforms that deliver lasting benefits: projects should offer more than short-term stimulus by enhancing productivity, improving sustainability, building resilience, or encouraging innovation.

3. Provide a staged and proportionate response: with the response commensurate to the location and scale of impact on the sector, as well as the appropriate time-scale of interventions.

4. Target intervention: for the regions and industry sectors experiencing the greatest impacts, and with the greatest capacity to benefit from a response, such as building, tourism and retail.

5. Coordinate action across industry and jurisdictions: the industry is interconnected and the capacity of the market finite, so an infrastructure response must be equally

coordinated across all three levels of government, regional development frameworks, and responses to climate and other disasters.

6. Reduce time to market and accelerate delivery: maintain rigour while facilitating timely decision-making, planning approval and funding decisions. Align decision-making frameworks and fast-track approvals within agreed programs or project pipelines.

7. Build industry capacity and capability: through leadership development, building skills and capability, supporting innovation and exchanging experience across the public and private sectors.

8. Increase collaboration and openness in contracting: engage industry early and openly on scope, budget and timing, in return for transparent contracting, supporting industry sustainability. Facilitate reasonable commercial outcomes and provide a foundation for lasting reform.

9. Address the funding challenge and amplify private investment: public funding and reform should unlock private investment or innovation, multiplying the dollar for dollar impact.

10. Remove supply chain bottlenecks: infrastructure supports supply chain efficiency, while benefiting from its effectiveness. Regulation and pricing should be reviewed to ensure it is flexible and outcome focused.

In developing these principles with our colleagues in the states and territories, our aim has been to support a balanced approach to rebuilding right across the nation and the transformation of the economy to the ‘new normal’.

Australia’s response to COVID-19 should progress policy priorities by enabling the long-term sustainability of the sector, building community resilience and transforming the economy. Alongside the State Infrastructure Strategies, the Australian Infrastructure Plan due for release in 2021, will provide a template for this reform.

Jonathan Woetzel, Mekala Krishnan – McKinsey Global Institute; Dickon Pinner, Hamid Samandari, Hauke Engel, Brodie Boland, Peter Cooper, and Byron Ruby – McKinsey & Company

Infrastructure is the backbone of the global economy, connecting people, enhancing quality of life, and promoting health and safety. But climate change is revealing infrastructure vulnerabilities.

When Hurricane Sandy struck the eastern seaboard of the United States in October 2012, subways, airports and roads were flooded, causing transportation to grind to a halt. Millions lost power, some for days or weeks, shutting down businesses and creating public safety issues. In addition to winds knocking out a quarter of mobile phone towers in the Northeast, the loss of electricity forced many towers offline after depleting their emergency batteries. $11 billion gallons of sewage flowed into rivers, bays and coastal waters because severe inundation overwhelmed municipal wastewater systems.

In total, the storm caused about $70 billion in damages. But despite being one of the costliest and most destructive storms on record, this event was not an aberration. Nine of the costliest mainland US hurricanes on record have occurred in the past 15 years. Going forward, climate change is expected to further intensify these risks.

Infrastructure usually involves large investments in assets that are designed to operate over the long term. For example, coal-fired plants are designed for 40 to 50 years, and hydropower dams and large geotechnical structures for up to 100 years. To date, the design of these facilities typically has assumed a future climate that is much the same as today’s. However, a changing climate and the resulting more extreme weather events mean those climate bands are becoming outdated, leaving infrastructure operating outside of its tolerance levels. This can present direct threats to the assets, as well as significant knock-on effects for those relying on the services those assets deliver.

HOW FOUR GLOBAL INFRASTRUCTURE SYSTEMS ARE IMPACTED BY CLIMATE CHANGE

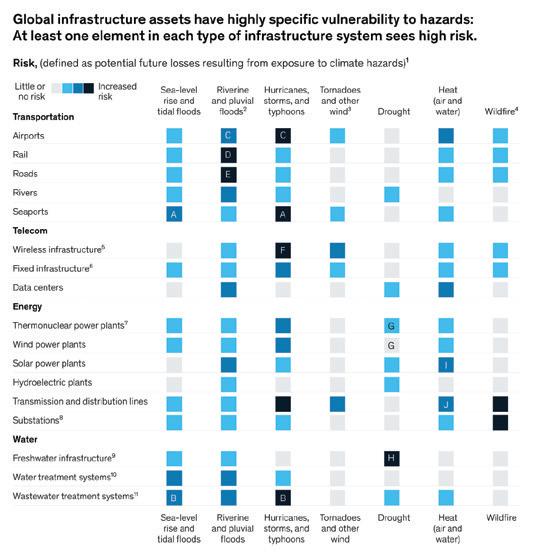

This article examines four critical infrastructure systems –the electric power grid, transportation, telecommunications, and water storage, treatment, and purification – to determine how vulnerable global infrastructure is to a changing climate.

In the four major infrastructure classes, we identify a total of 17 types of assets to evaluate against seven global climate hazards: tidal flooding amplified by sea level rise, riverine and pluvial flooding, hurricanes/typhoons and storms, tornadoes and other wind events, drought, heat (temperature increases in both air and water), and wildfires. Each type of infrastructure system has specific elements vulnerable to specific climate hazards. We map those hazard infrastructure intersections where risks will most be exacerbated by climate change.

Overall, we find that climate change could increasingly disrupt critical systems, increase operating costs, exacerbate the infrastructure funding gap, and create substantial spillover effects on societies and economies1. We find that there is a range of unique vulnerabilities of different types of infrastructure assets to different categories of climate hazards. Few assets will be left completely untouched.

In certain countries, heat-related power outages could increase in severity and may push the grid to cascading failure. Aircraft could also be grounded more frequently as both planes and airports cross heat-related thresholds.

Understanding these differences is crucial for successful planning. To that end, we have produced a heat map that explores the risk of potential future interruptions from typical exposure to climate hazards by 2030 (Exhibit 1).

Our analysis reveals two different sets of risks involving infrastructure: direct (for example, a power plant goes offline because it floods) and indirect (for example, a power plant cannot transmit power because the power transmission lines have gone down). A typical asset’s direct risk is estimated in our heat map analysis. But direct vulnerabilities are only half the story. Risk is further exacerbated by the vulnerabilities of a specific infrastructure asset to failures in the infrastructure systems within which that asset is embedded.

These dependencies can spread risk. We find that each system (for example, energy and water) has at least one severely vulnerable element. Because of the interdependency of these infrastructure systems, the high-risk assets may represent critical points of failure for the entire system, causing operational losses for all other assets in the chain and knock-on effects for a broader set of institutions and individuals.

The power grid is highly vulnerable to climate risk from both acute and chronic impacts, amplified by fragile components and relatively low redundancy. The effects of climate-related hazards on the power grid are already apparent. Higher temperatures lower generation efficiency, increase losses in transmission and distribution, decrease the lifetime of key equipment including power transformers, boost peak demand, and force certain thermoelectric plants offline. Day to day, these pressures cause rising operating costs and reduced asset life. In rare cases, these stressors can overwhelm the grid and lead to load shedding and blackouts.

Instances and associated costs of disruptions to the power

grid are likely to rise as temperatures increase. As average heat levels increase, so does the frequency of extreme heat events and the duration of less severe periods of higher than average heat that cause efficiency losses. Hot periods will be hotter than systems are used to, increasing the degree of failure and thus the associated recovery times, lost revenues, and repair costs.

Transportation infrastructure is widely distributed, interconnected, and can be affected by relatively minimal climate hazards, resulting in significant societal impacts. For example, extreme heat is already disrupting global air travel. In July 2017, approximately 50 flights were grounded for physical and regulatory reasons when temperatures in Phoenix, Arizona, skyrocketed to 48° Celsius.

We analysed the effect of extreme heat on global air travel. Assuming regional aircraft are largely similar to today’s and keeping the number of regional flights constant to isolate climate impact, if no adaptation measures are taken (for example, lengthening runways or improving aircraft technology), this translates into about 200 to 900 flights grounded per year by 2030 and about 500 to 2,200 flights by 2050. This could directly affect about 16,000 to 75,000 passengers per year in 2030 and about 40,000 to 185,000 passengers per year in 2050, up from an estimated 4,000 to 8,000 today (these events are not currently systematically recorded) from extreme heat.

More or fewer passengers may be affected depending on whether heat waves strike on heavier travel days (when flights are fuller) and how long the heat conditions persist. Air transportation delays cost the US economy $4 billion USD (approximately $5.6 billion AUD) in 2007, with most direct costs falling on passengers.

Water supply systems can also experience long-lasting outages from acute shocks like hurricanes and flooding. Two weeks after Hurricane Katrina in 2005, 70 per cent of affected drinking water facilities were still offline. Flooding can also result in long recovery periods. Effects are more dramatic in the developing world, where contamination of drinking water is common, and cholera and E. coli frequently cause widespread diarrhea outbreaks in the aftermath of floods. Water treatment systems, however, such as desalination plants, could be increasingly used to limit the impacts of drought.

Wastewater systems also suffer as a result of climate shocks. During drought, sewers can have inadequate flow, resulting in blockages and the inability to process human waste. Blockages lead to the possibility of sewerage systems bursting in the middle of urban areas. But the biggest threat to wastewater systems is flooding, particularly during hurricanes. Similar but more gradual wastewater overflows are also happening because of chronic stresses.

A fast-growing sector, telecommunications infrastructure has more agility and redundancy, yet as the world’s dependence on the communications network increases, climate risks will also grow. High winds or trees can topple cell phone towers and telephone poles, blow down telephone lines and base stations, and knock microwave receivers out of alignment. Aboveground cabling is more at risk than buried lines of support and pole failures, damage from debris and falling objects (such as trees), and breakage from tension caused by extreme wind speeds.

Flooding and hurricanes are the biggest global threats. In 2015–16, floods in the United Kingdom inundated a number of key telecom assets, cutting off thousands of homes, businesses and critical public services such as the police. Hurricanes Irma and Maria caused devastation to telecom infrastructure in the Caribbean, with over 90 per cent of mobile sites destroyed in Puerto Rico, St Martin, Dominica, Antigua and Barbuda. These threats interfere with the system just when it is needed most for disaster recovery.

Infrastructure is expected to bear the brunt of anticipated climate change adaptation costs, typically estimated to be between 60 and 80 per cent of total climate change adaptation spending globally, which could average $150 billion to $450 billion USD per year on infrastructure in 2050.

However, most estimates of the cost of adaptation relative to current assets are small compared with the scale of infrastructure investment. Estimates vary significantly, but consensus puts adaptation spending for new assets at about one to two per cent of total infrastructure spending a year.

Adaptation should be tailored to the specific hazard and infrastructure risks. However, opportunities exist for adaptation that are relevant for all infrastructure sectors. Examples of ways to adapt current and future infrastructure to climate risks can be considered, including by:

♦ Reducing exposure through transparency

♦ Accelerating investment in resilience

♦ Mobilising capital to fund adaptation

How global infrastructure evolves over the next 50 years may be a major determinant of the impact of climate change on civilisation. More money will need to be spent both on and in support of infrastructure, and in new ways. Building slightly higher walls, metaphorically or literally, may not be the best solution. And the risks extend beyond infrastructure.

A failure to adapt by not taking climate change into account in the design, construction and maintenance of infrastructure assets will not only cause costs to owners and operators, but will leave entire communities exposed and vulnerable. Adaptation can deliver a strong return both by reducing costs from climate-related damage to infrastructure itself and by avoiding significant knock-on effects in wider society.

¹Climate science makes extensive use of scenarios ranging from lower (Representative Concentration Pathway 2.6) to higher (RCP 8.5) CO2 concentrations. In our analysis, we have chosen to focus on RCP 8.5 because the higher-emission scenario it portrays enables us to assess physical risk in the absence of further decarbonisation. (We also choose a sea level rise scenario for one of our cases that is consistent with the RCP 8.5 trajectory). Such an “inherent risk” assessment allows us to understand the magnitude of the challenge and highlight the case for action. For a detailed description of the reason for this choice, visit McKinsey.com/climaterisk

by Dr Nader Naderpajouh, Senior Lecturer, RMIT University

by Dr Nader Naderpajouh, Senior Lecturer, RMIT University

With infrastructure set to lead a post-COVID economic recovery, Dr Naderpajouh from RMIT looks at the role of developing new infrastructure systems to face challenges and compares the current situation to the famous ‘marshmallow experiment’.

Increasingly we hear about economic recovery in response to the COVID-19 pandemic and its consequent recession.

The recovery revolves around stimulus packages at the global level such as the economic stimulus plan by the European Commission, at the country level such as the US or Australian Governments’ stimulus packages, or at the local level such as the economic recovery package by the City of Melbourne. Within the response mechanisms there is often encouraging news about the focus on infrastructure.

The focus on infrastructure is remarkable news, as infrastructure systems tend to be neglected in comparison to other competing priorities. There is an old saying that nobody thinks about infrastructure systems such as sewerage or utility networks until they stop working. In this context, we should be pleased that there is a potential for investment in infrastructure and politicians, corporations and communities can play a role in pushing infrastructure to the top of the agenda on any fiscal discussion including the stimulus package.

However, news of infrastructure investment within such stimulus packages often point to short-term economic gains such as employment and productivity impacts (productivity often referring to GDP). This should always be taken with a grain of salt.

A primary purpose of infrastructure systems is to serve the needs of communities and societies in the long term. They are often capital-intensive projects that have a substantial impact on societies and lock us in for decades. Therefore, we should be very cautious and ensure that short-term economic gains such as employment and productivity do not jeopardise the selection of alternative infrastructure systems.

The selection of alternative infrastructure systems and prioritising investment is a complex process involving a range of criteria. Theoretically, the core of a decision-making process is cost-benefit analysis that is also practically driven by the power relation between the proponents of the projects. While the majority of cases include social and environmental criteria in addition to economic and technical criteria, historical trends suggest that market driven criteria often dictate the final selection of alternative infrastructure systems.

Therefore, in cases such as economic recovery, there is a need to give greater weight to social and environmental criteria. This is because investment in infrastructure is already providing market driven gains of economic recovery.

The temptation to sacrifice long-term quality of life driven by well-planned infrastructure versus short-term economic gains is hard for societies to resist. The case of selecting infrastructure systems for economic recovery post-pandemic is similar to the marshmallow test.

The marshmallow test is a famous social science experiment on delayed gratification that was first conducted at Stanford University in the 1970s. In the study, children were put into a room by themselves with one marshmallow on a table in front of them. The children were told that once the researcher left the room they could either eat the one marshmallow straight away, or wait a period of time until the researcher got back, and then they could instead have two marshmallows.

Organisations facing the urge of snapping back are sitting behind the desk and can’t take their eyes from the potential stimulus package in front of them. But the communities who collectively weigh their decisions and consider the long-term

implications for resilience and quality of life, will also enjoy the long-term benefits of the service of infrastructure that is designed to be fit for the communities’ needs and new environmental realities.

The difference is that unlike the kids in the marshmallow test that just need to wait to get their reward, organisations need to work hard to refine their selections. Here are my five suggestions for the way forward.

1. There is a need to give extra weight to quality of life, liveability and resilience criteria in the selection of alternative infrastructure for investment, especially focusing on the priorities such as social equality. This is especially important as the infrastructure projects within the stimulus package are already satisfying economic needs of creating jobs and increasing productivity, therefore, they need to have higher focus on social and environmental criteria and less on market criteria to offset the high bias to market.

2. These times are perfect windows for innovation. For example, we could have a proportion of the projects to be prioritised based on a different set of criteria (purely social and resilience oriented), and assign a certain proportion of the stimulus package to the projects that are prioritised in this separate list.

3. We can encourage communities to develop shovelready projects, and invest in efforts to engage them in the development of projects. Major corporations and political parties use the post shock times very efficiently to drive their preferences. Communities can learn and can be assisted financially and technically to engage in the development and selection of their infrastructure systems through the stimulus package. This is the perfect time for community-driven projects, the ones that are often pushed back in normal situations. If a community needed an infrastructure system and had constantly faced challenges such as lack of budget, now they should vehemently pursue the stimulus package for their long due infrastructure needs.

4. Another major point is the diversification of the economy, which will be based on diversification of related infrastructure. The stimulus package should target infrastructure systems that we do not fund in normal situations to diversify the economy.

5. Maintenance and future-proofing of existing infrastructure is also very important. This is especially true given that they are not prioritised compared to new projects in normal situations because there is no ribbon cutting involved.

Considering all of these recommendations, the most important point is to make sure no processes and regulations are overlooked, and all the checks and balances in the processes are followed. In the volatile environment of the new normal, we cannot afford low-quality infrastructure that is not well planned.

We must learn from Australia’s history of building defects, such as the combustible cladding issue and the poor execution of apartments, to ensure necessary processes are followed and that we do not compromise our long-term quality of life with solely focusing on short-term market driven economic benefits.

This is a perfect time for community driven projects, and part of stimulus can help communities define their needs

Vermeer is a pioneer of trenchless technology – one of the broad range of complementary technologies offered by the company for underground service installations. Here, Aaron Forbes, Director of Versatile Services Australia (VSA), explores what Vermeer Australia means to an innovative trenchless technology contractor.

We started in early 2018 with the aim of filling a need for a modern underground utility specialist focused on smaller, more technically challenging projects. Two years later, we have a staff of 12 and have expanded beyond our Perth base into the Sydney market, with NBN installation and maintenance being an important part of our work.

I’ve been in the industry for 20 years, working my way up from an offsider position to a plant operator, then site management and construction management until becoming a director of a Horizontal Directional Drill (HDD) company.

I was trained on a Vermeer 7x11A and 16x20 15 years ago, and I’ve worked with Vermeer Australia ever since as I had great experiences with it early on. As I moved into management roles, I got to appreciate the team that supports Vermeer equipment more, so it’s a combination of the equipment itself and the company that supports it.

Vermeer Australia has the traditional sales and support values of a company that has been working with Australian contractors – both large and small – for 30 years. This capability has been further extended with Vermeer Australia now a fully owned part of the RDO Australia Group – one of the largest specialist equipment dealer organisations in the world.

Our D24x40DR was a good reliable machine for the work we did at the time, but we needed a bigger machine for the Sydney work which is mostly hard rock and limestone. The results have been consistently outstanding; we often rack out the drill in solid rock without complications, racking out up to 250m a day, many times in complete rock conditions. Our operators love how easily it handles difficult conditions, particularly the D40x55DR’s automated system which has made getting through the sandstone on the Sydney jobs a breeze. Its reliability and strength in the inner rod system is incomparable to any other drill manufacture.

We are currently focusing on tightening our internal gears so we may expand outward. This refers to both an increase in manpower but also machinery. We hope to continue to expand our network of Vermeer drills and other machinery on an ongoing basis. With the high volume of work we are seeing begin to appear in WA, our next step for this goal would be to attain some more heavy duty Vermeer drills to match our Sydney capacity.

We’ve enjoyed good support from Vermeer, whether in Perth or in Sydney. As someone who has worked in all ranks within the drilling industry, I can confidently recommend Vermeer to any and all users. Yellow iron all day, every day!

For more information on Vermeer’s products and services, please visit vermeeraustralia.com.au

The need for a national mental health body for the freight and logistics sector has reached a critical point. Infrastructure spoke to mental health and wellness initiative, Healthy Heads in Trucks & Sheds, Interim CEO, Lachlan Benson, about the goals of the organisation and what can be done to improve mental health outcomes for workers in freight and logistics.

Alot of time, effort and finances are invested in minimising and eradicating workplace accidents. However, there is often an aspect of workplace safety that is overlooked – mental health and wellness. One industry that is especially susceptible to poor workplace mental health is the freight and logistics sector.

Realising the critical need for improved workplace mental health in the freight

and logistics industry, national initiative Healthy Heads in Trucks & Sheds is looking to raise awareness and improve the lives of workers across the whole sector.

Healthy Heads in Trucks & Sheds is the national body responsible for the promotion and management of improved mental health and well-being

outcomes for the freight and logistics sector. From truck drivers and delivery drivers, to warehouses and head offices, Healthy Heads is working with industry to create conversations, provide support and improve the mental health and well-being of workers to ensure they are happy and healthy.

“The aim of Healthy Heads in Trucks & Sheds is to deliver a single national mental health plan to road transport and logistics industries,” Mr Benson said.

“The principal object of the foundation is to promote the prevention and control of mental health issues in truck drivers, distribution centres, warehouse staff, and other road industry participants, as well as to support healthier options around diet, exercise and individual well-being.”

The Healthy Heads in Trucks & Sheds initiative was officially launched on 18 August 2020, marking two years of preparation work that involved raising awareness, creating support systems and national industry initiatives.

“It began as a working group, and then a steering committee of the major transport logistics industry players and their customers,” Mr Benson said.

“It’s been driven very heavily by those founding members, particularly Woolworths, Coles, Linfox, Toll, Qube, Ron Finemore Transport and Australia Post, all of whom have had senior representatives involved in the process since day one to tackle the issue of mental health, which they saw as a challenge, not only in their own businesses, but across the sector as a whole,” Mr Benson said.

Statistics show that mental health in this industry is a major issue, not just for individual workers, but also companies both large and small.

Mr Benson said that factors such as long hours, shift work, contact work, fatigue, isolation, traumatic critical incidents, and being away from friends and family for extended periods of time, all contribute to poor mental health outcomes.

“If you look at the statistics across the sector, we’re at a point where almost one in two workers in the sector will experience a mental health issue. Of those, close to 40 per cent of them will say that that issue was caused, or exacerbated by work.”

Furthermore, Mr Benson said that surveys indicate that over 13 per cent of truck drivers have been diagnosed with depression, meaning there are tens of thousands of drivers across the country struggling with potentially fatal mental health issues.

“What we are seeing is that drivers who have depression are seven times more likely to be involved in a crash. But even when you look at the well-being piece, the leading cause of death in this industry is heart attack, heart disease and suicide. These are significant issues.

“In fact, when looking at the major statistics from the Super industry around the sector, you’ll find that mental health is the second highest disability claim consistently,” Mr Benson said.

With the COVID-19 pandemic forcing numerous sectors to slow down and even shut up shop for months, the exact opposite is happening in the freight and logistics sector. As panic buying swept the nation at the beginning of the lockdowns in Australia, and more people requiring home delivery as retail outlets closed, the demand for goods has risen exponentially. This has caused a massive strain on workers and resources across the sector and resulted in heavier workloads than ever before.

“It has undoubtedly been a very tough period for the freight logistics sector, very tough,” Mr Benson said.

“This has placed incredible stress on supply chains, because at the same time as everyone was being asked to stay at home, we were asking the people in our sector to keep working, and to work above and beyond to keep supply chains functioning.

“It was effectively like the equivalent of Christmas day every day.”

The lockdowns have been especially difficult on truck drivers who are facing a number of unique challenges and restrictive rules, causing even more isolation and concern than usual. Mr Benson said that what many people didn’t realise is that when businesses closed, truck stops also closed, which prevented drivers across the nation from accessing these integral safe spaces.

“That’s the lifeline to keeping those guys on the road and actually their only place of social interaction on those deliveries. To either talk to someone behind a counter, or over a cup of coffee next to their truck,” Mr Benson explained.

“So we actually increased the pressure on them by initially shutting those facilities, and took away their support mechanisms. Fortunately, that decision was reversed very quickly.

“By the same token, when you look at environments around the border closures, there are different rules for borders, so it’s difficult for a transport operator because he’s obviously doing a job and delivering essential goods to people across the country. But in the back of his mind is the question, ‘Will I be able to get home again?’. That’s pretty tough for someone.”

Yet throughout the difficult circumstances and pressure on workers, Mr Benson said that the sector should

be recognised for its role in helping to keep the economy afloat and businesses open.

“It’s been a period of heightened pressure for the sector, but the sector should be equally commended for its efforts in keeping the economy open, and keeping the economy moving,” Mr Benson said.

The culmination of industry challenges, coupled with the added stress of the pandemic, has highlighted the drastic need for better mental health support of workers to not only save lives, but improve business outcomes for companies – leading to more jobs and happier workers.

In fact, Mr Benson said that it has been demonstrated that for every dollar that goes into mental health in the transport sector, there can be up to a $2.80 return. This can be seen through improved worker productivity, reduced sick leave and longer serving employees.

Mr Benson also said that as an industry it is integral for the larger companies to pitch in and help out the smaller-scale businesses who may be struggling to fund and implement health initiatives in their teams, creating a holistic approach to mental wellness across the sector.

“Those companies that have invested in mental health, which is typically the larger end of town where they have the resources to do so, have mental health programs. The challenge is that the majority of the industry, starting with single-owner drivers, through to mum and dad transport companies or warehouse companies, and family businesses, is where we need to get the most help, and that’s what Healthy Heads is about.

“This is about the big end of town

coming together to support the industry as a whole. We’re doing this for the whole industry. If we don’t look after the people in our sector, we’re not going to have people to drive our trucks or work in our warehouses.”

Mr Benson said the work of Healthy Heads is centred around three main pillars of action: training, standards and wellness. These three pillars inform initiatives with the aim of improving mental health and wellness across the sector including:

♦ Increasing and introducing more trained mental health care professionals at transport and freight facilities, including warehouses, distribution centers and truck stops

♦ Standardising policies and regulation at transport and logistics facilities, forming a cohesive and industry-wide standard of operations

♦ Focusing on the physical, dietary and overall mental wellness of individuals

However, Mr Benson said that the Healthy Heads initiative is only as strong as the support it receives from the industry. It is integral for companies to back the foundation and support the advancement of mental health programs that are available and accessible to all.

“This is an industry for industry solution, and we are only going to be successful if we have all of the industry behind us. We want to work with everyone, and to support all the excellent initiatives that are going on around mental health in the sector.

“What we need is for companies to reach out to Healthy Heads and get involved in the campaign, and to put their resources behind what we’re trying to achieve. We can’t do it on our own, we need the support and participation of the whole industry.”

If you, or someone you know, is experiencing a personal crisis, or needs someone to talk to, please reach out for help.

Lifeline: 13 11 14

Beyond Blue: 1300 22 4636 or beyondblue.org.au

Beyond Blue Coronavirus support service: 1800 512 348 or coronavirus. beyondblue.org.au

Headspace: 1800 650 890 or headspace.org.au

Suicide Call Back Service: 1300 659 467 or suicidecallbackservice.org.au

The inaugural Critical Infrastructure Summit featured five Virtual Conferences running every Wednesday in September, thousands of delegates tuning in, and a speaker lineup of leaders from across the infrastructure sector offering their expertise on current challenges, major construction projects, asset and disaster management, and future industry predictions.

It was a huge month, kicking off with Critical Infrastructure: State of play; then Construct 2020; Asset Management for Critical Infrastructure; Disaster Management; and wrapping up with The Future of Infrastructure.

Each Virtual Conference in the Summit had more than 1,000 people register and featured important discussions on the most pressing issues facing Australia’s infrastructure industry.

Romilly Madew, CEO of Infrastructure Australia (IA), opened the Summit with her keynote presentation outlining ten infrastructure principles IA has agreed upon with its counterparts in the states and territories as part of the postCOVID recovery. Romilly wrote an article to go alongside her presentation, which you can read on page 18 of this issue.

We also had Mark Crosweller AFSM, Head of National Resilience Taskforce at the Australian Strategic Policy Institute, share his expertise in developing resilience in an increasingly complex global environment. Delegate Scott Ryall said it was “one of the most thought-provoking presentations I

The last six months in infrastructure. Kirk Coningham, CEO, Australian Logistics Council; Marie Lam-Frendo, CEO, Global Infrastructure Hub; and Chris Melham, CEO, Civil Contractors Federation (National) created a fascinating discussion, not only around how their sectors have been impacted by COVID-19, but also at issues around skills, data and infrastructure funding.

Construct 2020 delivered fantastic insights into some of the country’s biggest infrastructure projects. The conference kicked off with welcome remarks from the Hon Michael McCormack MP, Deputy Prime Minister, and Minister for Infrastructure, Transport and Regional Development.

He said the government is accelerating works under the record $100 billion blueprint and he had some words for our delegates throughout the construction industry.

“Our national construction sector represents 8.4 per cent of Gross Domestic Product, supporting more than a million Aussie jobs. This means infrastructure will help lead us through the worst of this pandemic and into the light at the other end.

“You are all an integral part of this and the government thanks you for your commitment, your dedication to infrastructure development, especially at this tough time.

“Together we're doing two vital things, tackling the current downturn right now, but importantly, using this to build

Our keynote speaker Priscilla Radice, CEO, Infrastructure Association of Queensland, further built on the idea that we need a mix of “short run and long run projects; small spend and larger spend; local and regional; place-based and interregional projects – that together create a legacy.”

Priscilla gave a great exploration of Queensland’s role for infrastructure in revitalisation; including the future of its cities, the industry ecosystem, and new models for growth. After a higher level look at the pipeline and project funding, we then delved deep into some technical construction information on three of the biggest construction projects underway in Australia, across different sectors.

Tom McCormack, Chief Information Officer, Western Sydney Airport, outlined the construction task ahead for the Western Sydney Airport, and how the project will become Australia’s first smart airport.

Paul Thomas, Deputy Director of Tunnels and Stations, Rail Projects Victoria, gave delegates a closer look at the Melbourne Metro Tunnel project with an informative exploration of the current and future works.

Then Peter Engelen, GM Planning and Infrastructure, NSW Ports, closed the conference with a detailed analysis of construction works at NSW Ports, such as the on-dock rail at Port Botany.

Peter Seltsikas, Senior Manager, Asset Management at SA Water, gave delegates advice on how to develop strategic asset management plans in an uncertain future.

He explored concepts around connecting with customers, building capabilities, and resilience, but one of the fundamental takeaways was about really understanding how your assets are performing, something that SA Water is doing with the implementation of smart technology on its water main networks.

“Better understanding of asset performance will allow you to make the best decisions in an uncertain future,” Peter said.

Then, Matt Henson, Asset Management Systems Manager and Acting Lead for Asset Systems & Assurance at Jemena, gave us a detailed presentation on the interplay between asset management, risk management, resilience and change adaption.

We were also joined by Nicola Belcher, Director of Rail Assets, Projects and Compliance at the Victorian Department of Transport; Russell Riding, Automation Team Leader at Melbourne Water; and Bruce Thompson, Executive Director Spatial Services at the NSW Department of Customer Service, for the industry panel The role of machine learning, AI and digital twins in asset management. You can read some of the key discussion points from this panel on page 78.

Wrapping up the event was Bradley Hocking, Program Lead, Asset Management Systems at Shoal Group, who provided some great industry case studies looking at the work he’s done on an innovative Asset Management System Framework.

We were fortunate to have Tony Histon, Transmission & Distribution Lead, Accenture Asia Pacific, Middle East & Africa, deliver the keynote on achieving resilience through a new harsh reality, and then stick around for an extended Q&A session to give delegates the chance to join in on the conversation. Tony also delved deep into his presentation topic in the article on page 70.

Then we were joined by Mark Cannadine, Manager Business Resilience, ElectraNet SA; Victoria Chantra, Associate DirectorEnvironment, AECOM; and John Kilgour, CEO Civil Contractors Federation, Victoria, for the industry panel Preparing for the next disaster: how can we be ready for whatever is in store

John provided interesting insights on how the construction industry is coping with COVID-19; Victoria was able to speak to the importance of ensuring sustainability is embedded into the heart of the work we do to rebuild in the years to come; and Mark reflected that while there has been enormous change this year, it has brought opportunity. What we have learned this year, as organisations, is just how adaptable our people are.

Adrian Hart, Associate Director - Construction and Maintenance at BIS Oxford Economics, looked at future infrastructure opportunities and challenges. He said that over the next two years the sectors that will experience the strongest growth are transportation sectors including bridges, railways and roads.