Issue 21 November 2021 ROAD - RAIL - AIRPORT - PORT - URBAN - UTILITY The next generation of digital INFRASTRUCTURE WestConnex: Australia’s largest road project tunnels through BUILDING THE LONG-AWAITED MELBOURNE AIRPORT RAIL

Supporting Speak to us on (03) 8566 8312 or visit apn.net.au for more information. Internet that Moves with You WiFi Solutions for Remote Australia

1300 062 064 | polymaster.com.au See our range 25 YEAR DESIGN LIFE

Published by

Published by

Monkey Media Enterprises

ABN: 36 426 734 954

C/- The Commons, 36–38 Gipps St, Collingwood VIC 3066

P: (03) 9988 4950

F: (03) 8456 6720

monkeymedia.com.au info@monkeymedia.com.au infrastructuremagazine.com.au news@infrastructuremagazine.com.au

Editor Jessica Dickers

Journalists

April Shepherd

Lauren DeLorenzo

Annabelle Powell

Christopher Allan

National Media and Events Executives

Rima Munafo

Brett Thompson

Design Manager

Alejandro Molano

Designers

Jacqueline Buckmaster

Danielle Harris

Luke Martin

Publisher Chris Bland

Managing Editor

Laura Harvey

ISSN: 2206-7906

EDITOR’S WELCOME

We’re nearing the end of the year, and with vaccination rates climbing and roadmaps outlining plans for a restriction-free new year, thoughts are turning towards 2022 and beyond.

We’ve seen the release of several key future-planning documents recently, including Infrastructure Australia’s 2021 Australian Infrastructure Plan and Infrastructure Market Capacity Report, as well as calls for reform from across the sector.

This is a critical moment in Australia’s history; we’re dealing with the impacts of COVID-19, increases in cyber risks, and still rebuilding from floods and bushfires. The pipeline of infrastructure projects is one of the biggest the country has ever seen, so we need to have the skilled workforce and seamless procurement process to go with it.

Research shows that the infrastructure industry in Australia has low levels of productivity, a slow uptake of technology and is male-dominated, with construction having the second highest ranking gender pay gap.

Industry leaders are calling for reforms around infrastructure delivery to increase productivity, with changes needed to unlock key opportunities around embedding sustainability and resilience, supporting regional areas, and investing in technology and digital transformation.

Recent reports have found that there will come to a point in the next two to three years where the industry will be under pressure to meet demand. These reforms need to happen now and focus on collaboration between industry and government, to prepare for the future.

While these are heavy challenges, they also highlight that there are lots of opportunities for growth in the sector. We’ve made it a focus of this edition of the magazine to cover these important issues and get the insight from leaders who are at the forefront and pushing for change.

Infrastructure Australia explores its recent reports in-depth, the Civil Contractors Federation talks about the approach needed as the country starts to open up post-COVID, the National

Association of Women in Construction explains the widening gender pay gap and what needs to happen now, and the Australasian Railway Association outlines the procurement reform needed for rail construction. On the projects side of things, we also take a look at some of the biggest road and rail projects underway, including the Melbourne Airport Rail and WestConnex.

This edition also has a strong focus on digitisation, IoT and cloud communication as this is an area we believe has the most potential and opportunities right across the industry. Our recent event, the Critical Infrastructure: Digitisation Series, was held in October and featured two freeto-attend Virtual Conferences exploring how digital technologies are impacting infrastructure. Both conferences produced fascinating discussions on the future of digital including digital twins, robotics, AI, the Victorian Digital Asset Strategy, the Digital Territory Strategy, the Australian BIM Strategic Framework, 5G, cyber security, data privacy, the digital divide, and the NBN. We have lots of coverage on the event in this edition, but if you’d like to watch the recordings on-demand, you can register for free at www.critical-infrastructure.com.au/ watch-digitisation-on-demand/.

We’ll be running one more virtual event this year that will look at how best to plan your marketing for 2022. If you’re starting to think about your marketing strategy for next year and aren’t sure how to reach the infrastructure sector, join us for a free webinar on Thursday 25 November. You can register at https:// www.monkeymediaevents.com.au/b2bmarketing-in-2022/.

Fingers crossed we’ll be able to meet up offline at some industry events in the new year as I can’t wait to be able to discuss these industry challenges and opportunities with you in person in 2022.

Jessica Dickers Editor

Drop me a line at jessica.dickers@monkeymedia.net.au or feel free to call me on 03 9988 4950 to let me know what you think.

Don’t forget to follow Infrastructure magazine on social media – find us on LinkedIn, Twitter and YouTube.

2 November 2021 // Issue 21 www.infrastructuremagazine.com.au

Issue 21 November 2021 ROAD RAIL AIRPORT - PORT URBAN UTILITY The next generation of digital INFRASTRUCTURE WestConnex: Australia’s largest road project tunnels through BUILDING THE LONG-AWAITED MELBOURNE AIRPORT RAIL

your leading source of news for the local government sector

Council has been developed to keep you up-to-date with all of the latest news, discussions, innovation and projects in the local government sector.

Council is fully integrated across print and online, featuring a website updated daily with the latest industry news, a weekly e-newsletter delivered direct to your inbox, and a quarterly magazine that can be read in print and online.

Published by industry publishing experts Monkey Media, Council will arm community decision-makers with the critical information they need to deliver a better future for cities, towns and suburbs all over Australia.

www.councilmagazine.com.au info@councilmagazine.com.au

COUNCIL

MAGAZINE

HEAD TO THE WEBSITE TODAY to sign up for the FREE WEEKLY NEWSLETTER!

HEADING

FINDINGS FROM THE INFRASTRUCTURE MARKET CAPACITY REPORT

The Infrastructure Market Capacity report released by Infrastructure Australia in October lays out the opportunity and the challenges associated with Australia’s unprecedented infrastructure spend.

REOPENING AUSTRALIA AND THE NEED FOR A NATIONAL APPROACH

As Australia’s COVID-19 vaccination rates continue to rise, our focus increasingly turns to the need to re-open Australian businesses in an agreed and coordinated manner.

THE WIDENING GENDER PAY GAP IN CONSTRUCTION

HOW SMART BUILDINGS AND SMART GRIDS WORK TOGETHER TO REDUCE

BUILDING THE LONG-AWAITED MELBOURNE AIRPORT RAIL

The much talked about Melbourne Airport Rail project is becoming a reality, with progress being made towards making future travel to and from Melbourne Airport that much easier. INCLUSIVE

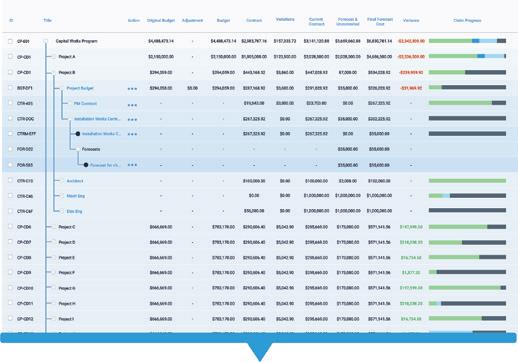

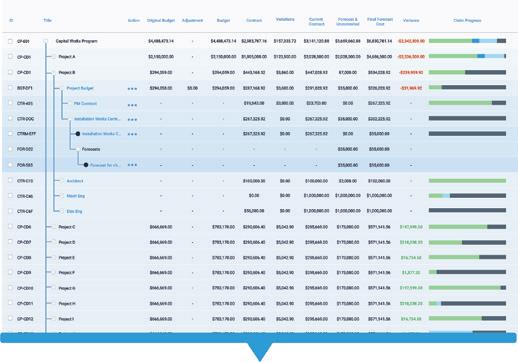

SPREADSHEETS ARE PUTTING YOUR PROJECT AND PORTFOLIO MANAGEMENT AT RISK

There’s no doubt that the entire construction industry – from owners to managers, contractors and suppliers – rely on spreadsheets. However, just because there is a critical mass of users, it doesn’t mean that spreadsheets should be used for the most important aspects of project and portfolio management.

THE NEXT GENERATION OF DIGITAL INFRASTRUCTURE

The world is changing at a rapid pace, with industries having to consider the critical infrastructure needed to sustain many generations to come. Dr Ian Oppermann, Chief Data Scientist for the NSW Government and Industry Professor at UTS, joined this year's Critical Infrastructure: Digitisation Series event program to discuss the new world of digital infrastructure, from 6G and safe data sharing, to all-encompassing IoT networks.

THREE STEPS TO LEVERAGING THE POWER OF YOUR DATA

SECURITY

KEY TAKEAWAYS: CYBER SECURITY AND DATA PRIVACY

As the Internet of Things (IoT) expands available datasets and smart technology is implemented in the utility and infrastructure sectors, the need for robust cyber security systems has never been greater. A panel at the recent Critical Infrastructure: Digitisation Series Virtual Conference invited industry leaders to discuss potential risks to these systems, the impact of new security legislation, and what asset owners should be doing to protect their infrastructure.

SECURING INDUSTRIAL INFRASTRUCTURE IS A JOURNEY

When we meet with industrial customers, we often hear some version of the following: “We’re digitising to improve our industrial processes, increase productivity and grow customer satisfaction, but now we’re worried about malware interrupting operations. What can we do?”

4 November 2021 // Issue 21 www.infrastructuremagazine.com.au

THE CARBON FOOTPRINT SHARED 2032 OLYMPIC GAMES DREAM – LONG-TERM LEGACY REQUIRES GENUINE COLLABORATION 18 20 22 24 26 46 50 38 40 44 A WORD FROM INFRASTRUCTURE AUSTRALIA INDUSTRY INSIGHTS RAIL IoT & CLOUD COMMUNICATION

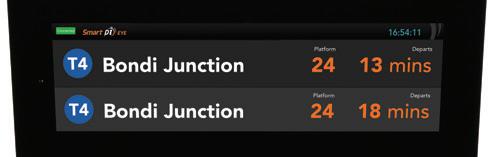

DESIGN OF PUBLIC INFORMATION SYSTEMS THE PROCUREMENT REFORM NEEDED FOR RAIL CONSTRUCTION THE CHANGING FACE OF RAIL 28 32 34 36 28

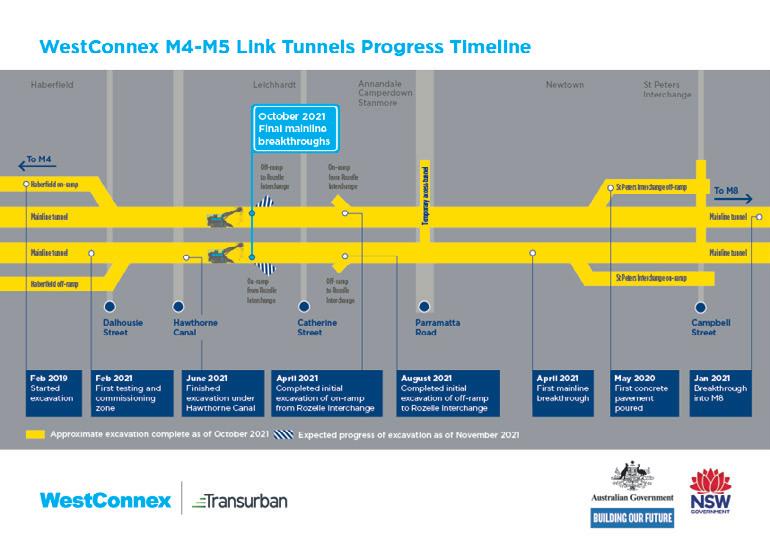

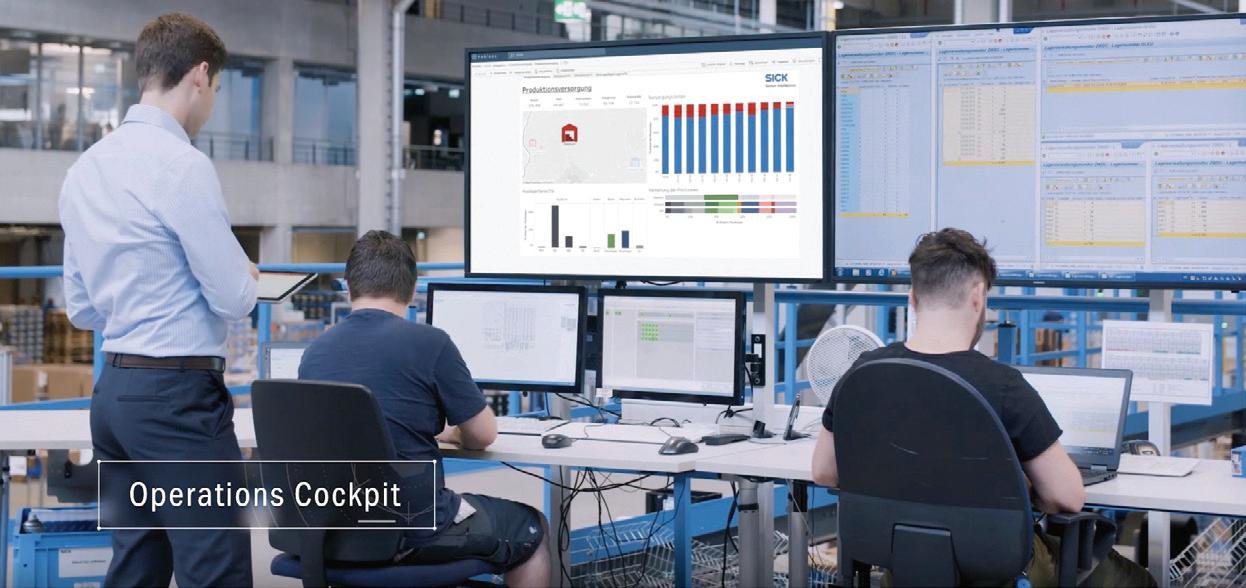

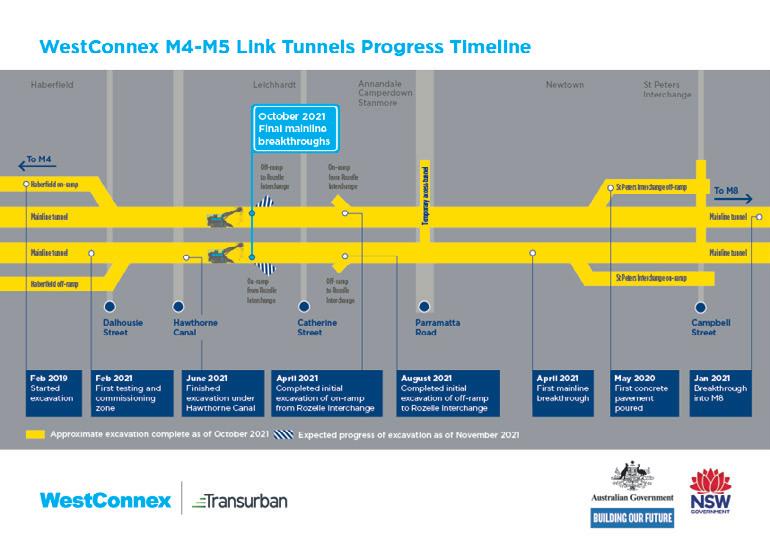

AUSTRALIA’S LARGEST ROAD INFRASTRUCTURE PROJECT TUNNELS THROUGH

Sydney’s WestConnex project has just marked a significant tunnelling milestone and is now moving into its next exciting phase.

THE UNSEEN MACHINES BEHIND OUR BIGGEST INFRASTRUCTURE PROJECTS

IMPROVING INFRASTRUCTURE RESILIENCE TO BUSHFIRES

CSIRO’s Bushfire Adaptation research leader, Justin Leonard, explains how Australia’s national science agency, CSIRO, is working with industry to tackle a major threat to critical infrastructure –bushfires.

RETURNING TO THE OFFICE: HOW SAFE WILL IT BE?

A MENTAL HEALTH AND WELLBEING ROADMAP FOR SUPPLY CHAIN WORKERS

The global pandemic has unquestionably placed immense pressure on the supply chain sector, and no more so than on the people working on the frontline.

REGULARS

MAKING THE MOST OF STRATEGIC PARTNERSHIPS IN RENEWABLE ENERGY

When the ground is shifting or the going is tough, joining forces can make a lot of sense. The booming Australian renewable energy market is a changing and challenging environment, but it also offers enormous opportunity for developers and investors willing to work together for mutual benefit.

8 VIC CONSTRUCTION SECTOR HIT HARD BY LOCKDOWNS, RESTRICTIONS AND MANDATES

9 ARTC ANNOUNCES MAJOR INLAND RAIL COLLABORATIVE AGREEMENT

10 THREE COMPANIES SHORTLISTED FOR NSW COFFS BYPASS CONSTRUCTION

12 FRAMEWORK TO REOPEN AUSTRALIAN AIRPORTS ANNOUNCED

12 CONTRACT AWARDED FOR $1.18 BILLION WARRINGAH FREEWAY UPGRADE

14 WHAT THE INDUSTRY IS SAYING ABOUT DIGITAL AND CLOUD INFRASTRUCTURE 16 KEEPING YOU

5 www.infrastructuremagazine.com.au November 2021 // Issue 21 CONTENTS

2 EDITOR’S WELCOME 6 CONTRIBUTORS 68 ADVERTISERS’ INDEX 68 FEATURES SCHEDULE NEWS

POWERED ON 52 56 60 62 64 66 TUNNELS DISASTER MANAGEMENT FUNDING / INVESTMENT

HEADING

Kristine Scheul

National Chair, the National Association of Women in Construction (NAWIC)

Kristine has been a member of the National Association of Women in Construction (NAWIC) for almost 15 years and is the current NAWIC National Chair. She is passionate about supporting women in the construction industry and has a long history in construction law. Kristine is also currently the Executive Branch Manager at Transport Canberra City Services.

Byline

Preamble

FChris Melham CEO,

FChris Melham CEO,

Civil Contractors Federation (National)

Chris has accumulated over 30 years of experience as an industry advocate within the not-for-profit industry association sector. He has represented a number of industries at state, federal and international levels, and currently represents Australia's civil construction industry as Chief Executive Officer of Civil Contractors Federation National (CCF).

In his capacity as the CCF National CEO, Chris also sits on a number of high level Federal Government Advisory Committees representing the interests of CCF, including: Australian Government Security of Payments Working Group; Australian Taxation Office Fuel Schemes Advisory Group; National Heavy Vehicle Regulator Industry Reference Forum; Standards Australia Council; and the Australian Construction Industry Redundancy Trust Fund.

Naomi Frauenfelder Chief Executive Officer,

Healthy Heads in Trucks & Sheds

Naomi is Healthy Heads in Trucks & Sheds’ inaugural CEO, having previously been Executive Director of the TrackSAFE Foundation – an Australian rail industry not-for-profit that addresses suicide on the rail network, and the resultant trauma caused to train drivers and other frontline staff.

Naomi has spent her career to date honing her passion for working nationally to unite industries behind significant causes such as mental health, providing individuals and organisations with the resources they need to face challenges head-on, creating cultures of care and support.

6 November 2021 // Issue 21 www.infrastructuremagazine.com.au INFRASTRUCTURE

Contributors

Contributors

Catherine Baxter

Chief Operating Officer, Metro Trains Melbourne, and Chief Executive Officer, Metro Academy

Catherine leads a team of dedicated and passionate people who are focussed on ensuring that Metro delivers on its promise to the travelling public of Melbourne. She has extensive experience and expertise in rail operations, having previously held executive roles in large national ASX-listed businesses including Aurizon, UGL, and Boral. With 30 years of experience in rail, she ensures a strong focus on safe and disciplined operations.

Catherine is currently the CEO of Metro’s Registered Training Organisation the Metro Academy. She is also a Fellow of CPA Australia, and member of CITL Chartered Institute Transport and Logistics, an Associate Fellow of ANZ Institute of Managers and Leaders, and a member of the Australian Institute of Company Directors. She is also leading Metro through a yearly Annual Performance Improvement Plan (APIP).

Priscilla Radice

Chief Executive Officer, Infrastructure Association of Queensland (IAQ)

Priscilla is a dynamic senior leader and a trusted business advisor on change management and leadership, and is a well-regarded project director in port development, transport and logistics, and city strategy sectors.

Before her role with IAQ, Priscilla was a Principal at Arup. In her role as Head of Strategy for Transport & Resources Asia Pacific, she was responsible for setting the overall strategic business direction, winning numerous Project Director roles and rolling out a sector restructure, which resulted in outstanding revenue uplift and an empowered client centric leadership team.

Prior to Arup, Priscilla was Head of Strategic Projects at the Port of Brisbane and has held various executive positions in economic development and city shaping roles in other capital and regional cities in Australia.

Dr Ian Oppermann

Chief Data Scientist, NSW Government

In addition to his role within the Department of Customer Service, Ian is also an Industry Professor at the University of Technology Sydney, and was previously the CEO of the NSW Data Analytics Centre.

Ian has nearly 30 years of experience in the ICT sector. He has held senior management roles in Europe and Australia as Director for Radio Access Performance at Nokia, Global Head of Sales Partnering (network software) at Nokia Siemens Networks, and then Divisional Chief and Flagship Director at CSIRO. He is considered a thought leader in the area of the Digital Economy and has contributed to six books and co-authored more than 120 papers.

7 www.infrastructuremagazine.com.au November 2021 // Issue 21 INFRASTRUCTURE

VIC CONSTRUCTION SECTOR HIT HARD BY LOCKDOWNS, RESTRICTIONS AND MANDATES

Victoria’s construction industry has faced numerous challenges and changes in the later half of 2021, with workplace restrictions, vaccine mandates, site shutdowns and violent protests taking its toll on the essential sector.

In August, the Victorian Government announced a lockdown extension and tougher restrictions for Melbourne’s sixth lockdown, including additional restrictions for the construction industry as the COVID-19 Delta variant cases rose.

The new restrictions stated that large-scale construction sites would be limited to 25 per cent for site capacity or five workers per site, whichever is greater, with small-scale construction sites allowed five workers per site.

Following on from the August restrictions, the Victorian Government launched a COVID compliance blitz in September to target the spread of the virus in the construction sector and ensure that sites could remain open. This included mandates on vaccines – including the requirement for workers to show evidence to their employer of having had one dose of the COVID-19 vaccine before they return to site on 5 October.

Construction sites were identified as a major source of transmission, and the four-week blitz saw a ‘zero tolerance’ approach, applying fines and prohibition notices in response to any serious non-compliance.

The restrictions and vaccine mandates introduced by the Victorian Government were met with backlash from a small percentage of the wider construction industry, with more than 500 protesters gathering outside the Construction, Forestry, Maritime, Mining and Energy Union (CFMEU) office on Monday 20 September. Bottles and crates were thrown at officials,

prompting police to use rubber bullets and tear gas to disperse the crowd.

A two-week shutdown was announced just hours after the protests and came into effect from 11.59pm that same day.

Protests continued for several days, beginning in Melbourne’s city centre and spreading to other Melbourne landmarks throughout the week, including the city’s war memorial and the West Gate Bridge.

Victorian Premier, Daniel Andrews, said at the time, “There is no excuse for the terrible behaviour we have seen in our city over the last two days. We know vaccinations are our only ticket out of this pandemic. There is no other way.”

In early October, the Victorian construction sector reopened, following the release of the State Government’s Construction Sector Roadmap, which detailed the steps to reopening the industry in line with public health recommendations.

The shutdown eased at 11:59pm on 4 October, with new restrictions detailing that in order to work onsite, all workers must carry an Authorised Worker Permit and must have had at least one vaccine dose.

Additionally, every construction site in Victoria would be required to have a designated fully trained COVID Marshal to ensure compliance with the Chief Health Officer‘s directions. Subject to continued high levels of compliance by the industry, workforce caps will progressively increase. Once the 70 per cent double dose milestone has been reached, largescale construction can return to 100 per cent of its workforce.

Caps will be removed when Victoria reaches its 80 per cent target, and in addition, all onsite workers must be fully vaccinated by 13 November.

NEWS

ARTC ANNOUNCES MAJOR INLAND RAIL COLLABORATIVE AGREEMENT

The Australian Rail Track Corporation (ARTC) has secured a collaborative framework agreement with Freight Connect (a consortium including Laing O’Rourke and FKG Group) for the delivery of Inland Rail civil works in Northern New South Wales and Southern Queensland.

The agreement will focus on an approximately 85km section between North Star in New South Wales and Whetstone in Queensland as well as a separate 14km package south of Moree called Narrabri to North Star Phase Two.

ARTC Inland Rail Interim Chief Executive, Rebecca Pickering, said the announcement was the culmination of months of work by ARTC and was a crucial part of the project as it delivered the ‘missing link’ between the two states where no previous rail line existed.

“Inland Rail is a fast freight backbone that will transform how goods are moved around Australia – it’s also a catalyst for regional employment and economic opportunity,” Ms Pickering said.

“Both sides of the border will benefit significantly from Inland Rail, with more than 11,800 direct and indirect jobs in Queensland and 7,500 in New South Wales expected at the peak of construction in 2023-24.

“We’ve already committed 641 contracts to businesses in Queensland and 657 in New South Wales worth more than $1.95 billion across the two states, and this agreement will create even more economic stimulus as the country recovers from the impacts of the pandemic.”

A 50-50 joint venture between ACCIONA and CPB Contractors Joint Venture (ACACPB JV) has also been appointed as the preferred proponents to work with ARTC on the Southern Civil Works Program.

“ACACPB JV will initially be working with ARTC to review reference design and develop construction plans and methodologies ahead of the development of a fully-costed proposal for the first of the works packages next year,” Ms Pickering said.

For information on Inland Rail tenders and market opportunities visit the suppliers webpage or register your interest on the ICN Gateway.

DON’ T JUST WATERPROOF. FUTURE PROOF.

Fosroc offers

solution.

9 NEWS LIQUID APPLIED TORCH APPLIED SHEET MEMBRANE

proof. AU 1800 812 864 fosroc.com.au NZ 0800 657 156 fosroc.co.nz

your project

Combined with our concrete repair mortars, grouts, sealants, industrial and surface treatments, we can provide you with a tailored construction solution. Fosroc. Future

* Fosroc and the Fosroc logo are trade marks of Fosroc International Limited, used under license. www.infrastructuremagazine.com.au November 2021 // Issue 21

THREE COMPANIES SHORTLISTED FOR NSW COFFS BYPASS CONSTRUCTION

The Coffs Harbour bypass has released a shortlist of companies invited to tender for construction of the project.

CPB Webuild Joint Venture, Acciona Seymour Whyte Joint Venture and Gamuda Ferrovial Joint Venture have been selected to take part in the tender process, which will be finalised by the end of 2021, with the successful contractor to be announced mid-2022.

New South Wales Deputy Premier and Minister for Regional Transport and Roads, Paul Toole, said this is a significant step towards a project that will transform the region.

“This will be the biggest infrastructure project in Coffs Harbour’s history, removing more than 12,000 vehicles a day from the centre of town, bypassing 12 sets of lights and saving around eleven minutes in travel time,” Mr Toole said.

Federal Member for Cowper, Pat Conaghan, said the bypass will deliver an economic boost to the region, creating about 12,000 jobs during construction.

“Not only will locals get work, but they’ll also get valuable training and experience that will be transferable to many careers or business ventures,” Mr Conaghan said.

State Member for Coffs Harbour, Gurmesh Singh, said the project is also having flow-on effects for the regional economy.

“We’ve signed up 13 local builders to carry out work on a range of at-home noise treatments, including seals to windows and doors, reglazing with acoustic glass, installation of air conditioning, acoustic insulation, or relining of exposed walls,” Mr Singh said.

“More than 30 local businesses have also been engaged for the preliminary work now taking place, and there will be more opportunities for local suppliers as work progresses.”

Three tunnels will be built for the bypass at Roberts Hill, Shephards Lane and Gatelys Road, delivering safer and quicker journeys for the thousands of locals, tourists and freight operators who use this route daily.

PEDESTRIAN & VEHICLE DETECTION

10 November 2021 // Issue 21 www.infrastructuremagazine.com.au NEWS AGD SYSTEMS PTY LTD. Unit 17/15 Valediction Road. Kings Park NSW 2148 Australia T : 02 9653 9934 E : sales@agd-systems.com.au W : agd-systems.com.au

You can’t manage what you can’t see

We know you’re running a complex operation, with multiple teams across distributed sites. There’s every likelihood that you’ve got inefficient practices and duplication of effort, leading to potential time and budget blow outs, or even putting lives at risk.

Get a 360° view of your site

PerspioTM links your operational tools with plant, equipment, labour and material data from the site into one simple view. So you can better manage your risk on site, in real time. Your sites will be more efficient, have better safety outcomes and be more environmentally responsible.

Learn how PerspioTM can help streamline your operations

Inauro.io/construction

efficiency,

. IN THE KNOW Take control of your site inauro.io/construction Operational Data 3rd Party Data Field Data

Get real-time visibility of your site with PerspioTM. More

greater uptime

FRAMEWORK TO REOPEN AUSTRALIAN AIRPORTS ANNOUNCED

The Australian Government announced a reopening framework for Australia’s international airports, with quarantine arrangements to ease and passenger caps to be lifted from November.

Australian Airports Association (AAA) Chief Executive, James Goodwin, said airports would be ready to welcome back increasing numbers of Australians from overseas.

“This is a positive step in the right direction to allow more vaccinated Australians to return home and others to reconnect with family overseas, and comes just in time for Christmas,” Mr Goodwin said.

“Airports will be critical to ensuring the challenging logistics associated with resuming international travel will be successfully managed.

“It is important airports are involved in co-designing any new arrangements required as we begin this process and look forward to working closely with government agencies on these details.”

Mr Goodwin said work is needed now on the next phase of the framework where airports can welcome back international

tourists and other important cohorts such as business people, students and skilled workers.

“There needs to be a focus on bringing back international travellers to assist in returning our economy, particularly the tourism sector, back to its full strength,” Mr Goodwin said.

“We welcome the development of safe travel zones where quarantine will not be required with nations such as New Zealand and we look forward to having other highly-vaccinated nations included as part of these pilot programs.”

Brisbane Airport Corporation (BAC) welcomed the announcement of the framework, with BAC CEO, Gert-Jan de Graaff, saying the framework, including seven-day home quarantine for returning vaccinated travellers, was a sensible and safe approach that would ease pressure on the hotel quarantine system, and provided a ray of hope for families, as well as thousands of businesses that rely on inbound visitation.

“I can’t wait to see our international terminal retailers opening their doors again after nearly two years,” Mr de Graaff said.

CONTRACT AWARDED FOR $1.18 BILLION WARRINGAH FREEWAY UPGRADE

A$1.8 billion design and construction contract for New South Wales’ Warringah Freeway upgrade has been awarded.

The project will be jointly delivered by CPB Contractors and Downer EDI Works.

New South Wales Minister for Transport and Roads, Andrew Constance, said the upgrade will reduce congestion and simplify the complex road corridor, which is used by up to 250,000 vehicles each day.

“This crucial upgrade will make the Warringah Freeway more efficient and reliable for the drivers who use it every day, and will pave the way for the future Western Harbour Tunnel and Beaches Link,” Mr Constance said.

“More than 15,000 jobs will be created during construction of the entire Western Harbour Tunnel and Beaches Link program, with about 600 direct jobs created for the Warringah Freeway upgrade.”

Early works are already underway, with the main work to start early next year. Construction is expected to take approximately five years to complete, subject to the detailed design and construction program.

The Warringah Freeway upgrade includes:

♦ Upgrade 4km of the Warringah Freeway, between High Street at North Sydney and Willoughby Road at Naremburn, to reduce the amount of merging required, and improve safety and traffic flow

♦ Improve interchanges with Falcon Street at Cammeray and High Street at North Sydney, including a new northbound on-ramp at High Street which will ease pressure on the existing ramp at Berry Street

♦ Connections to the future Western Harbour Tunnel and Beaches Link

♦ Improved public transport links, with a continuous southbound bus lane from Miller Street to the Sydney Harbour Bridge

♦ Around 2.5km of new and upgraded cycleways and pedestrian paths, integrated with public transport networks, including the future Victoria Cross metro station at North Sydney

NEWS

CONCEPTUALISE YOUR NEXT PROJECT WITH HIGH RESOLUTION 3D

DESIGN I CONSTRUCT I OPERATE I MAINTAIN I EVOLVE

GO TO STORE

WHAT THE INDUSTRY IS SAYING ABOUT

DIGITAL AND CLOUD INFRASTRUCTURE

Industry leaders came together virtually in October for the Critical Infrastructure: Digitisation Series – two free-to-attend Virtual Conferences on 5 and 7 October exploring how digital technologies are impacting infrastructure. Here are the highlights from the conference.

The Critical Infrastructure: Digitisation Series was the latest event to be held under the highly successful Critical Infrastructure Summit umbrella, and took a deep dive into two sides of digital transformation: the digital technologies that are being employed in the design and construction of infrastructure; and the infrastructure being built to enable Australia’s digital transformation.

Created and run by Monkey Media – the publishers of Infrastructure, Utility, Energy, Council and Pump Industry magazines – the event saw more than 650 infrastructure professionals registered over the two days.

The conferences included:

easily enable high-value outcomes, from live condition monitoring and bushfire mitigation, to customer analysis and risk-based maintenance planning. Because Snowflake is built for ease of use, speed of development, and hands-off maintenance, Snowflake’s customers report dramatic reductions in time to value and total cost of their data projects, and we appreciate their insights and input into the event.

IMPLEMENTING DIGITAL IN PHYSICAL ASSETS

♦ Digital Infrastructure: Implementing digital in physical assets – 5 October

♦ Cloud Infrastructure: The systems behind the new virtual economy – 7 October

With speakers from the Federal Government, NT Infrastructure Commission, NSW Government, Office of Projects Victoria, UNSW Canberra, PwC, Digital Twinning Australia, Cross River Rail, Australasian BIM Advisory Board, IoT Alliance Australia, Infrastructure Australia, Queensland AI Hub, and nbn Co – there were in-depth discussions across both conferences. These conferences wouldn’t have been possible without the support of the sponsors – Series Partner Everbridge, Session Partner Snowflake, and Sponsor Hexagon.

The Snowflake Data Cloud is being used across the utilities sector to quickly and easily digitalise both business and operational technologies. By collapsing data silos into Snowflake’s data platform, utility businesses are able to quickly and

Conference 1 explored how technology can help deliver a more profitable, resilient infrastructure industry and a better built environment. It looked at how tools and technology like BIM, big data and analytics are changing how infrastructure is planned, designed, built and managed.

Wayne Patterson, Director of Spatial Operations, Spatial Services, NSW Department of Customer Service, kicked off the event with his keynote presentation on the NSW Spatial Digital Twin.

Wayne has led the team that developed the ground-breaking NSW Spatial Digital Twin, a 4D (3D+time) Foundation Spatial Data Framework. The NSW Spatial Digital Twin is helping the NSW Government with infrastructure asset planning and management, integration with land use planning, data collaboration, and sharing.

Wayne also gave delegates a live demonstration of the digital twin, showcasing what it is capable of and how it can be used to best advantage. It was a fantastic session, combining a look at what the wider industry is doing, with the advancements happening in NSW and a first-hand demonstration of the digital twin in action.

Our second speaker was Sue Keay, CEO of the Queensland AI Hub. Sue was formerly a Research Director for CyberPhysical Systems at CSIRO’s Data61, and the Chief Operating Officer for the Australian Centre for Robotic Vision. She delivered a fascinating presentation outlining how robotics and automation are being implemented in the critical infrastructure sector, and the opportunities available.

14 NEWS

We then had an industry panel looking at digital asset strategies around Australia, featuring three infrastructure leaders. The panellists were: Luke Belfield, Acting Victorian Chief Engineer, Office of Projects Victoria; Louise McCormick, Interim Infrastructure Commissioner of the Northern Territory, NT Infrastructure Commission; and Andrew Curthoys, Digital Relationship Manager, Information Management & Technology, Cross River Rail, and Chair, Australasian BIM Advisory Board.

In his role at the Office of Projects Victoria, Luke shared his insights into the Victorian Digital Asset Strategy and how this has supported the state’s huge pipeline of transport mega-projects. Louise explored how the NT is implementing digital technologies through the Digital Territory Strategy. While Andrew discussed both the approach to BIM that the Australian BIM Strategic Framework recommends to government to ensure consistency, as well as his role at Cross River Rail and how the project has been implementing technologies in its construction.

It was a great discussion that covered where Australia's critical infrastructure sits when it comes to digitisation, the biggest challenges to the implementation of digital technologies, and where are the biggest opportunities that perhaps aren’t being focused on enough. This was in addition to questions sent through by delegates, who were able to participate in the panel and ask their burning digital questions to the three speakers.

Then, Genéne Kleppe, Chief Executive Officer, Digital Twinning Australia, closed the day with a frank look at how asset owners should actually be digitising their physical assets. Genéne said whether your innovation is seeking sustainability or disruption, digitising critical infrastructure requires getting out of the weeds. Digitising value propositions exist, with roadmaps abound and the simplicity of what you need to do will surprise you.

THE SYSTEMS BEHIND THE NEW VIRTUAL ECONOMY

While the first event was all about implementing digital technologies in physical assets, the second day of the Digitisation Series focused more on the digital infrastructure that has become indispensable to the functioning of society. This session looked at topics including 5G and the digital economy, data privacy and cyber security, the digital divide between regional and metropolitan Australia, and a look at the NBN rollout.

We were lucky enough to start the conference with a recorded presentation from the Hon. Paul Fletcher MP, Minister for Communications, Urban Infrastructure, Cities and the Arts, Federal Government.

Minister Fletcher discussed 5G, connectivity and the digital economy and gave several great examples of projects and initiatives already underway across the infrastructure industry that demonstrate 5G capabilities, including autonomous vehicles.

Dr. Ian Oppermann, Chief Data Scientist, NSW Government, then delivered an in-depth presentation on the future of the infrastructure sector and the opportunities in digital. He touched on data sharing and the next generation of digital infrastructure. We covered Ian’s presentation in more detail in the article on page 40.

Day two also included an industry panel session, this time looking at an important topic when it comes to digital and cloud infrastructure: cyber security.

Panellists included:

♦ Robert Di Pietro – Partner, National Lead for Critical Infrastructure & Operational Technology, PwC Australia Cyber Security

♦ Elena Sitnikova – Critical Infrastructure Protection, Research Leader, UNSW Canberra at the Australian Defence Force Academy (ADFA)

♦ Frank Zeichner – CEO, IoT Alliance Australia

These three speakers have a wealth of cyber and critical infrastructure experience between them which made this a must-watch panel for anyone working in infrastructure. We have also deep dived into the key takeaways from this panel in an article on page 46.

Peter Colacino, Chief of Policy and Research at Infrastructure Australia, then joined us to talk about the digital divide between regional and metropolitan Australia, and the opportunities there are to increase digital access around the country. While discussions on digital infrastructure can sometimes focus on the technical systems, we can’t have a discussion about the next phase of digital infrastructure when parts of the country still don’t have equal access to these services.

Peter has led the delivery of the landmark 2019 Australian Infrastructure Audit, and the recently released 2021 Australian Infrastructure Plan and Infrastructure Market Capacity Report, so he was able to explore this topic within the context of the current challenges and opportunities in the sector.

Closing out the conference was John Parkin, Chief Engineering Officer at nbn Co, who gave a fantastic update into the NBN rollout and what’s next. Missed the Critical Infrastructure: Digitisation Series Event?

You can still watch the panel session, or any of the other presentations on demand. Register for free at www.critical-infrastructure.com.au/watch-digitisation-on-demand/.

15 NEWS www.infrastructuremagazine.com.au November 2021 // Issue 21

KEEPING YOU POWERED ON

Widely used in infrastructure settings that require uninterrupted and high levels of power, generators are a critical part of getting the job done.

From the initial investment, it’s important to regularly maintain your generator. A structured maintenance approach ensures that your generator’s performance is maximised whilst extending its life span.

In addition to specialist generator technicians conducting services, there are routine checks that you can do to keep your power running. Each day (or weekly for standby) do a walk around inspection which includes:

♦ Ensure fastenings, fixings and connections are secure

♦ Check the condition and tension of fan and charging alternator belts

♦ Ensure fan and exhaust guards are in place and secure

♦ All filter caps are in place

♦ Check for leaks – coolant, oil and fuel

♦ All pipes are secure and in good condition

♦ Fuel, oil and coolant levels are correct

♦ All hoses are in good condition and connections secure

♦ Battery terminals are tight and electrolyte level is correct

♦ Control panel does not indicate any errors

Idle standby generators require an additional operational check every two weeks by running the generator for five minutes, and every month another run for one to two hours on 50 per cent load, in addition to draining the water and sediment from the fuel tank and tank bund area.

AllightSykes is the exclusive distributor of FG Wilson diesel generators in Australia with its range spanning 11kVA-1ph through to 1650kVA-3ph.

For your generator to continuously perform at an optimum level, a regular service schedule is recommended. AllightSykes 24/7 specialist generator technicians can perform three monthly, six monthly and 12 monthly scheduled services, including the option of an Extended Service Contract covering replacement costs and labour.

• Pre-award audits of manufacturers, subcontractors and suppliers

• Experienced, certified and qualified inspectors

• Verification of manufacturing and testing in accordance with AS standards

• Surveillance inspections throughout the entire manufacturing process

• Individual inspection and test of completed equipment

• Pre-delivery and ship loading inspections

• ISO 9001-2015 QMS certified company

November 2021 // Issue 21 www.infrastructuremagazine.com.au

NEWS // SPONSORED EDITORIAL

Quality Verification of Railway Locomotives, Wagons, Steel Rails & Track Turn-Outs

Quality Technical Services LLC Shanghai Operations Office Contact: Frederik Ford Mobile: +86-13501790361 www.qtsinspect.com For more information, please visit allightsykes.com or get in touch at service@allightsykes.com. 16

TOUGH EQUIPMENT SUPPORTING CRITICAL INFRASTRUCTURE

As the original equipment manufacturer of Allight towers and Sykes pumps in Australia, and the only distributor of Perkins engines and FG Wilson generators, AllightSykes works with our customers throughout the entire product life cycle from concept to aftersales care.

We maintain a strong local Australian footprint with two well established manufacturing facilities and five service branches. Our Australian made products are distributed throughout the world, and because we design and manufacture our own products, genuine parts are always avaialble.

AUSTRALIA | NEW ZEALAND | NORTH AMERICA | SOUTH AMERICA | DUBAI | ASIA | AFRICA allightsykes.com

FINDINGS FROM THE INFRASTRUCTURE MARKET CAPACITY REPORT

Tby Peter Colacino, Chief of Policy and Research, Infrastructure Australia

Tby Peter Colacino, Chief of Policy and Research, Infrastructure Australia

The Infrastructure Market Capacity report released by Infrastructure Australia in October lays out the opportunity and the challenges associated with Australia’s unprecedented infrastructure spend.

he commitment to infrastructure investment laid out by governments is a central component of our economic recovery roadmap to the COVID-19 pandemic, as well as laying the foundation for future economic growth.

Infrastructure Australia strongly supports this ambitious investment agenda to support productivity growth and lift Australia’s standard of living. However, this investment must also be matched with reform which requires both a maturing of the way we plan for and buy infrastructure, as well as how it is built, maintained and operated.

AN OPPORTUNITY FOR INDUSTRY TO GROW AND INVEST IN NEW CAPABILITY

The doubling of investment in major infrastructure over the next three years presents a significant opportunity for industry to grow and invest in new capability.

It also presents an opportunity for employment, with 105,000 jobs potentially unfilled in an industry that employs 182,000 people today.

However, the opportunity presented by the Market Capacity Program is the ability of industry to deliver this growth and move from a cycle of ‘infrastructure booms’ to a new normal of elevated activity, supported by a skilled workforce, an efficient and innovative industry, knowledgeable and capable public clients and mature, responsive decision-making, approval and commercial systems.

GLOBAL LEADERSHIP

Australia has a legacy as a global leader in infrastructure delivery and procurement model design.

Our model of Public Private Partnership has been exported globally, our mineral resource supply chains are some of the world’s most efficient and our electricity grid is the world’s largest.

However, our infrastructure sector – particularly the construction sub-sector – lags our international peers in the adoption of digital technology, supply chain development, workforce diversity, consideration of sustainability and the adoption of new delivery models.

If we are to deliver on the ambitious promise set out by the record $218 billion spend by 2025, the sector must modernise.

This modernisation would embrace new ways of working, seek out and adopt best practice and learn from others both here and abroad.

2021 AUSTRALIAN INFRASTRUCTURE PLAN

The 2021 Australian Infrastructure Plan, released in September, lays out the reform agenda to meet this challenge, and we have sought to balance the need to both deliver the infrastructure investment pipeline and support reform.

However, it is critical that action is taken in the short-term to align future project announcements and schedules to the capacity of the market in order to avoid cost escalation and improve value for money.

In order to deliver on the significant commitment to infrastructure spending, it will be necessary to fully engage the industry as a whole – the full spectrum of organisations, both large and small.

To better accommodate industry, procuring agencies will need to consider the size, risk profile, timing and packaging of infrastructure projects in order to ensure a competitive tender environment and to ensure that Australian businesses can fully participate in the sector.

We also need to lower barriers to entry to the market and increase the exportability of Australian capability through the adoption of international standards and approaches, including potentially contract suites like NEC or FIDIC.

THE REFORM OPPORTUNITY

Infrastructure is not a short-term proposition because major projects take years to deliver and operate for many decades. A poorly planned or delivered project can lock many years of inefficiency into the economy with far-reaching consequences. To overcome this challenge, reform is needed to improve front-end planning, develop procurement strategies to match

18 November 2021 // Issue 21 www.infrastructuremagazine.com.au A WORD FROM INFRASTRUCTURE AUSTRALIA

projects, understand the need to build sustainable market capacity and enhance due diligence to better manage risk and unlock efficiency.

All public infrastructure is delivered in partnership between industry and government, but the strength of these partnerships can vary.

At an industry level, trust needs to be strengthened between government, business and the community.

A transparent infrastructure pipeline partnered with wellplanned projects can unlock the capability for a step change in construction productivity.

Embracing new modern methods of construction and moving from a project-to-project approach to procurement, to a more sophisticated view of supply chains and networks, as well as utilising digital tools to enable change, is vital.

The building blocks of this approach are not new and the lessons of project challenges are painful to learn.

Over the next five years, more than 80 per cent of the future project pipeline by value is transport infrastructure, and on average three in four of those projects will be delivered over budget. It’s our hope that the lessons of poor project performance would be learnt once, and then shared.

In shifting to become a more mature client, government should invest in its own capability to overcome challenges in projects and commit to be model clients.

Many leaders are already delivering to world-class standards, however we must embrace the opportunity to share best practice, to support exemplar projects and encourage innovation.

There’s no need to reinvent the wheel – more widespread application and publishing of post completion reviews is a logical first step.

A SHARED CHALLENGE

The future of Australia’s infrastructure hinges on being affordable, meeting current and future needs, and maintaining access to the high-functioning industry that creates, operates and maintains it.

There is a legitimate but differing role for each level of government, which we articulate through the Implementation Pathway released alongside the 2021 Australian Infrastructure Plan.

With the vast majority of Australia’s infrastructure funded and delivered by states and territories, these governments must take a leadership role.

This demonstrates there is significant opportunity for local leadership – from individuals and local governments – to right-size approaches and demonstrate best practice.

And there’s a clear role for leadership from the Australian Government in identifying, supporting and encouraging meaningful change.

While there is an inescapable role for government in supporting reform – through best practice planning, contract reform and standardisation, embedding modern methods of construction at scale and supporting the digital transformation – reform can also be led by industry, as we have seen particularly around culture in NSW and Victoria.

This is not a challenge for governments alone, it’s a challenge for us all.

19 www.infrastructuremagazine.com.au November 2021 // Issue 21 A WORD FROM INFRASTRUCTURE AUSTRALIA

REOpENIN g AND THE NEED FOR A

by Chris Melham, Chief Executive Officer, Civil Contractors Federation National (CCF)

by Chris Melham, Chief Executive Officer, Civil Contractors Federation National (CCF)

As Australia’s COVID-19 vaccination rates continue to rise, our focus increasingly turns to the need to re-open Australian businesses in an agreed and coordinated manner.

As each day passes, industry edges closer to an environment where companies can get back to ‘business as usual’ as Australia transitions out of lockdown.

This process is being guided by the National Plan to transition Australia's National COVID Response, commonly known as the National Plan.

Jurisdictions signed up to this Plan earlier this year, and the expectation of industry is that it will now be implemented as per the agreement.

This four-phase National Plan transitions Australia from its pre-vaccination settings to postvaccination settings, and involves the implementation of different measures when the average vaccination rates across the nation have reached certain thresholds.

For example, phase three involves exempting vaccinated residents from

all domestic restrictions, and phase four involves minimising cases in the community without ongoing restrictions or lockdowns.

Despite governments agreeing to the four phase National Plan, which was based on the Doherty Institute’s findings, industry remains concerned that governments will not adhere to the National Plan as originally intended.

This is of concern to the Civil Contractors Federation (CCF), the peak national voice for the civil construction industry, as it would have significant ramifications for businesses, the economy and Australian families.

IMPACT OF RESTRICTIONS

With civil construction investment providing an economic multiplier of 3:1, prolonged and unnecessary border closures would have a detrimental effect on the civil construction industry and the broader Australian economy.

Unnecessary or unwarranted restrictions would impact on the efficiency of the supply chain, affect the mobility of workers, and ultimately undermine business confidence.

It is therefore imperative that governments adhere to the National Plan as originally intended.

As part of the CCF’s role to advocate on behalf of the civil construction industry, I have written directly to the Prime Minister and Deputy Prime Minister to raise our concerns with the Government.

In the letter, I also acknowledge the important role suppression measures have played to minimise community transition when vaccination rates have been low, and the role CCF has played to actively communicate to industry the importance of vaccinations as a ‘pathway to work’.

November 2021 // Issue 21 www.infrastructuremagazine.com.au

20 INDUSTRY INSIGHTS

NATIONAL APPROACH AU sTRALIA

CONTINUING TO MINIMISE CASES

Our support for governments’ adherence to the National Plan takes into account modelling carried out by the Federal Treasury, estimating the direct economic costs of the COVID-19 management strategies modelled by the Doherty Institute.

Treasury did this through analysis of the direct impacts of activity restrictions and lockdowns used to manage the virus and contain outbreaks.

It found that, as vaccination rates rise, significantly less lockdowns and other restrictions will be required to continue to minimise cases of COVID-19, reducing the economic cost of managing the virus.

It also concluded that once 70 per cent of Australian adults aged 16+ are vaccinated, and assuming the spread of COVID-19 is minimised, outbreaks can be contained using only low-level restrictions. Once vaccination rates reach 70 per cent, lockdowns are unlikely to be required, significantly reducing the economic cost of managing COVID-19.

From a compliance perspective, the civil construction sector has adopted a

proactive and responsible approach to dealing with the impacts of COVID-19 over the last 18 months, and we are determined to continue this approach into the future.

Industry’s approach since the outbreak of the pandemic has been critical to supporting jobs and contributing to the economy during these difficult times.

THE CONSTRUCTION INDUSTRY IN 2021

In CCF’s recent report, Rebuilding Australia – A Plan for a Civil Infrastructure Led Recovery, it found that engineering construction activity was relatively insulated from domestic activity restrictions in 2020.

The lack of movement restrictions targeted towards construction workers has allowed pre-existing projects to progress steadily, and civil projects located outside of dense population centres have been geographically shielded from any direct impacts.

However, the report also points out that the industry is not entirely immune to the outbreak of COVID-19. Road engineering construction stalled

more than previously expected in 2020, which was attributed to some productivity losses due to social distancing guidelines and lockdowns, as well as far weaker than expected public works commencements.

CCF continues to reinforce to ministers and bureaucrats that civil worksites such as road and rail projects are typically very large and therefore workers can operate at safe and appropriate distances from one another.

Because of this, civil construction worksites have adjusted to the compliance requirements imposed on them by state and territory governments.

The proactive and responsible approach taken by industry in dealing with the impacts of COVID-19 through appropriate mitigation measures is consistent with the expectation of governments.

In return, industry expects governments to honour the spirit and letter of the National Plan to enable businesses to operate in a safe and responsible manner when vaccination targets are met.

www.infrastructuremagazine.com.au November 2021 // Issue 21 21 INDUSTRY INSIGHTS

The Civil Contractors Federation is the peak national representative body for the Australian civil construction industry, comprising over 1,900 civil construction companies across the construction supply chain.

THE WIDENING

GENDER PAY GAP

IN CONSTRUCTION

22 INDUSTRY INSIGHTS

Hby Kristine Scheul, National Chair, the National Association of Women in Construction (NAWIC)

Hby Kristine Scheul, National Chair, the National Association of Women in Construction (NAWIC)

In September, NAWIC proudly hosted its first National Forum which discussed solutions to the decreasing number of women entering and staying in the construction industry.

osted by the ABC’s Bright Ideas presenter, Paul Barclay, the forum discussion was based on ‘Finishing the unfinished business of abolishing gender bias from the Australian construction industry’.

I was personally honoured to be in the company of the panellists who were selected to contribute to this conversation – Dr Niki Vincent, Victorian Commissioner for Gender Equality, Professor Paula Gerber, and Andre Noonan, Acciona Geotech’s COO.

For NAWIC, this forum was the first step in a planned strategy that aims to bring together industry, government and most importantly, female stakeholders, to bring their collective thinking to solving one long-term problem at a time until gender equality throughout the industry has been achieved.

The number of barriers to attracting and retaining more women are well documented, but after 25 years of supporting the advancement of women in the construction industry, it is high time we collectively start promoting some solutions. I hope that forums such as this one will contribute to the solution and begin to create real change.

CONSTRUCTION HAS THE SECOND HIGHEST RANKING GENDER PAY GAP

One of the most prominent issues is that of the gender pay gap in the construction industry, which sadly, is continuously widening.

In Australia, Equal Pay Day is a date representing the additional days a female must work to earn the same amount as a male colleague. In 2021, this was 61 days, three more days than last year.

For women in Australia’s construction industry however, the gap is much wider, the second highest in Australia in fact, at 26.1 per cent, with women earning on average $36,361 p.a less*.

Essentially that means for many women working in construction, we must work at least another month before we catch up with our male colleagues. And like the national pay gap, the gap in construction is also widening – up one per cent from the year before.

So, what is it about the construction industry that causes it to have the second highest ranking gender pay gap and for that trend to go backwards instead of forwards?

Firstly, it is important to recognise that the gender pay gap is not the same as equal pay. Equal pay for equal work was enshrined in the Fair Work Act 2009 making it illegal to not provide equal pay to employees performing work of equal or comparable value. The gender pay gap is not just about equal wages, it measures women’s economic position compared with that of men, or more to the point, it measures the impact of both conscious and unconscious gender discrimination in the workforce.

For the construction industry, some reasons for the gap include discrimination in hiring, starting salaries, promotions and pay rises; undervaluing women’s competencies; the motherhood penalty impacting career progression and lack of workplace flexibility to accommodate caring and other responsibilities.

It is little wonder that the industry is finding it challenging to recruit women, and even if they do, having them stay. Why would women want to stay in an industry where it appears they are not valued as highly as their male colleagues?

ADVOCATE FOR CHANGE

Through the development of our Strategic Plan, NAWIC is seeking to break down why our industry is finding it so difficult to increase the number of women participating in the industry, and then assist women and industry to resolve those issues holding them back.

We recognise that in most instances, the discrimination experienced by women is not intentional, but equally, not actively seeking to do something about it has the same effect.

However, recognising that there is an issue in the construction industry is one thing, actively working out what to do about it is another. Through the forum’s ongoing discussion, we not only want to identify what the specific barriers are to the construction industry, but we also want to solve them, in turn creating an industry where women get to fully participate and achieve recognition of their value.

NAWIC now plans to leverage the outcomes of the discussion, advocate for the changes necessary, and work with each of the participants, whether on the panel or listening in, about what to do next.

At the very least, we want to see a change in the WGEA scorecard on the gender pay gap. At a minimum, it will be a positive step towards achieving our goal of 25 per cent women in construction by 2025.

*ABS Statistics.

Additional figures from Workplace Gender Equality Agency’s Gender Equality Scorecard

The scorecard is an analysis of information collected from its own annual census of participating companies. The report card, released in November 2020, calculated the average gender pay gap across all industries from participating companies who have more than 100 employees.

Last year, the scorecard revealed an average gender pay gap for base salaries of 15 per cent across private sector industries. That increased to 20.1 per cent if the calculation was based on total remuneration packages, which included bonuses, commissions and other entitlements.

www.infrastructuremagazine.com.au November 2021 // Issue 21

23 INDUSTRY INSIGHTS

HOW SMART BUILDINGS AND SMART GRIDS WORK TOGETHER TO REDUCE THE CARBON FOOTPRINT

Building and construction activities are a major cause of carbon emissions. According to the Global Status Report, building and construction combined account for 36 per cent of global final energy use and 39 per cent of energyrelated carbon dioxide (CO2) emissions when upstream power generation is included.

For some time, businesses and governments have worked to reduce the impact of the built environment. For example, the Federal Government introduced the National Australian Built Environment Rating System (NABERS) more than 20 years ago – a national rating system that measures the environmental performance of buildings, measuring energy efficiency, water usage, waste management and the indoor environment quality of a building or tenancy and its impact on the environment.

GREATER OPPORTUNITIES TO DECARBONISE

Andrew McCluskey, Siemens Australia’s Country Business Unit Head for Smart Infrastructure Regional Solutions & Service, said that the digitalisation of energy and smart building technology is offering building owners greater opportunities to decarbonise. Integrated hardware and software are providing building operators better opportunities to see what is happening internally, and interact with the energy systems they are connected to in new ways.

“Siemens is also implementing its own decarbonisation strategy with a commitment to become carbon neutral by 2030,” Mr McCluskey said.

“This involves several key concepts around the changing low carbon and energy efficient landscape, and how the grid and smart buildings are starting to work together in new, connected ways.”

SUSTAINABLE URBAN PRECINCTS PROGRAM

Siemens played an instrumental role in the ambitious sustainability program undertaken by RMIT, to reduce its energy and water use and carbon emissions by 25 per cent. The $128 million program started in 2014 and at the time was the largest Sustainable Urban Precincts Program in the Southern Hemisphere.

The program was implemented across RMIT’s three Melbourne campuses, with Siemens responsible for the City Campus, which is made up of 90 buildings across two city blocks.

The project’s aim was to reduce electricity use over eight years by an estimated 239 million kW, which is enough electricity to power 7,000 houses for six years. This is equivalent to a 30,000 tonne reduction in greenhouse gas emissions – the same as planting an area the size of Melbourne CBD with 128,000 trees annually.

The program replaced 2,000 fixtures and had a target to reduce water use by an estimated 68 million litres. Impressively, the targets were achieved four years ahead of schedule.

As part of the project, a Distributed Energy System was implemented, encompassing new HV infrastructure as well as two cogeneration systems. Also included was Siemens’ building management system (Desigo) and Siemens software to monitor and analyse energy consumption and savings.

Siemens likes to call the way forward the ‘grid interactive’ building which incorporates newer and smarter technologies.

THREE STAGES TO BECOMING A GRID INTERACTIVE BUILDING

From Siemens’ perspective there are three stages a company can take to become a grid interactive building:

1. Load management: this is where all electricity loads within a building’s footprint are managed whilst using automation and enhanced algorithms to predict or suggest more energy efficient actions

2. Optimisation within the building or campus: this is bringing together a portfolio of many buildings to have a centralised management view, which in turn leads to better decision making

3. Demand flexibility: this is about understanding the total loads along with internal patterns and needs, and once understood, it can start looking at a future where it interacts and optimises the grid at a building level

It is clear the building sector has the potential for significant improvement. Vital to this is expert support from specialist companies that understand buildings; so it can prioritise the right actions across the business and manage the risks around project implementation, performance and finance.

November 2021 // Issue 21 www.infrastructuremagazine.com.au

24 INDUSTRY INSIGHTS // SPONSORED EDITORIAL

For more information, go to siemens.com.au

NO PULL START NO MIXING PETROL & OIL NO ENGINE MAINTENANCE BOOK NOW AVAILABLE AT A UTHORISED A GENT BOOK A TEST DRIVE WITH A MILWAUKEE SPECIALIST ARN-1932

SHARED 2032 OLYMPIC GAMES DREAM –

LONG-TERM LEGACY REQUIRES GENUINE COLLABORATION

26 INDUSTRY INSIGHTS

Tby Priscilla Radice, CEO, Infrastructure Association of

Tby Priscilla Radice, CEO, Infrastructure Association of

The 2032 Olympic and Paralympic Games are a once-ina-century opportunity for Queensland and are strongly supported by the infrastructure industry.

he Infrastructure Association of Queensland Inc (IAQ) recognises the coordinated effort to achieve the successful bid and the tremendous effort ahead to deliver the best Games for athletes, spectators and respondents, while delivering on legacy.

South East Queensland has the longest delivery runway of any Games, but we cannot afford to be complacent and squander this time advantage.

Aside from the tremendous benefits that will flow from the event itself, the Games are the catalyst needed to activate planning and delivery of the critical infrastructure our growing state needs to stay connected and maintain equitable living in the 21st century and beyond.

Leadership, cohesion, ambition and a united vision will be key to success over the eleven-year journey, and industry involvement will help create a united delivery and legacy-focused team with a nonpartisan focus. The private sector will contribute to, and enable, more innovation and greater funding.

PLANNING FOR BEYOND THE GAMES

We need to be bold in our thinking with a focus on 2052, not just 2032! The Games can act as a significant springboard to deliver sustainable, affordable, and inclusive connectivity to all Queenslanders.

IAQ is advocating for the creation of ambitious targets beyond 2032 and mapping out how the Games will help deliver foundational infrastructure for the needs of all Queenslanders in areas like energy, water, mobility, digital, health and education.

The 2032 Games are not the end goal, they are a positive catalyst to galvanise action and bring people together to act collectively. Society can rally around this global sporting event – an extraordinary event that brings out the very best in people.

The Games is also a transformational catalyst for all three levels of government to collaborate on an agreed program and governance framework for ten years, hand in hand with the private sector.

Leaders acting collectively to genuinely collaborate and agree to a long term plan might be the greatest legacy of all. In turn, this transparency and agreed vision will build business confidence, attract significant new investment, boost economic productivity, enhance our global brand and bring more investors and visitors to the whole of Queensland.

Queensland has all the essential ingredients to lead the way into a new future globally, building a green sustainable economy that supports thriving communities.

The changes to the International Olympic Committee’s (IOC) approach means we can plan and deliver longterm development needed for a growing South East Queensland, not just specifically for the Games.

Delivering for growth is a critical factor, and recent modelling by the Austrian Institute of Economic Research highlights it’s the investment in the infrastructure, especially connectivity infrastructure like transport and digital, that drives the biggest economic boost.

COLLABORATION WITH INDUSTRY

IAQ supports a targeted dialogue and planning process which confirms infrastructure priorities that are aligned with the state's long-term planning and allows us to think big and act fast.

By involving industry, we can embrace multiple contributions to deliver outstanding outcomes for all involved, working collectively to draw upon experience and find new ways to deliver the Games safer, faster, at a lower cost, more sustainably, and with liveability and legacy at its heart.

The challenges of sourcing the workers with the skills and capacity to deliver cannot be underestimated. Joined up strategic workforce planning focused on the health and wellbeing of workers needs to start now.

IAQ’s view is that legacy will be achieved if Queensland sets ambitious targets, and we hold ourselves to account for delivering on them, beyond the Games themselves. For example, the Games gives us the ability to trigger the delivery of critical infrastructure ahead of population growth and shift the dial

towards a clean and green economy such as:

♦ 45 minute SEQ – public and active transport infrastructure to enable quicker connectivity and improved liveability, including faster interregional passenger rail to integrate with the existing Cross River Rail and Brisbane Metro projects

♦ Whole-of-system energy and water grid planning that leverages technologies and is planned in conjunction with major changes and risks such as future of mobility shifts and climate change

♦ Appropriate, accessible and sustainable accommodation solutions, delivering innovative facilities and funding models which can help deliver affordable housing for every Queenslander

♦ Equitable and globally competitive access to telecommunications and data infrastructure, following on from recent critical work such as the Sunshine Coast International Broadband Submarine Cable

♦ Improved health outcomes with competition venues and programs as identified by government, which will support an active and healthy Queensland for many generations to come

♦ Sustainable placemaking and community activation opportunities

♦ Accelerating digital take up and designing a delivery model that supports a sustainable and diverse infrastructure industry to ensure we can deliver value for money outcomes

♦ Leveraging the long-term pipeline certainty to build skills and capacity, diversify the industry and attract new talent such as female participation and overseas skilled migrants

♦ Embedding Circular Economy principles

♦ Catalysing investment and innovation in the manufacturing sector

Working together is key to a successful outcome – we have a deadline, and the eyes of the world are watching. Let’s think big and go for Gold!

www.infrastructuremagazine.com.au November 2021 // Issue 21

Queensland Inc (IAQ) 27 INDUSTRY INSIGHTS

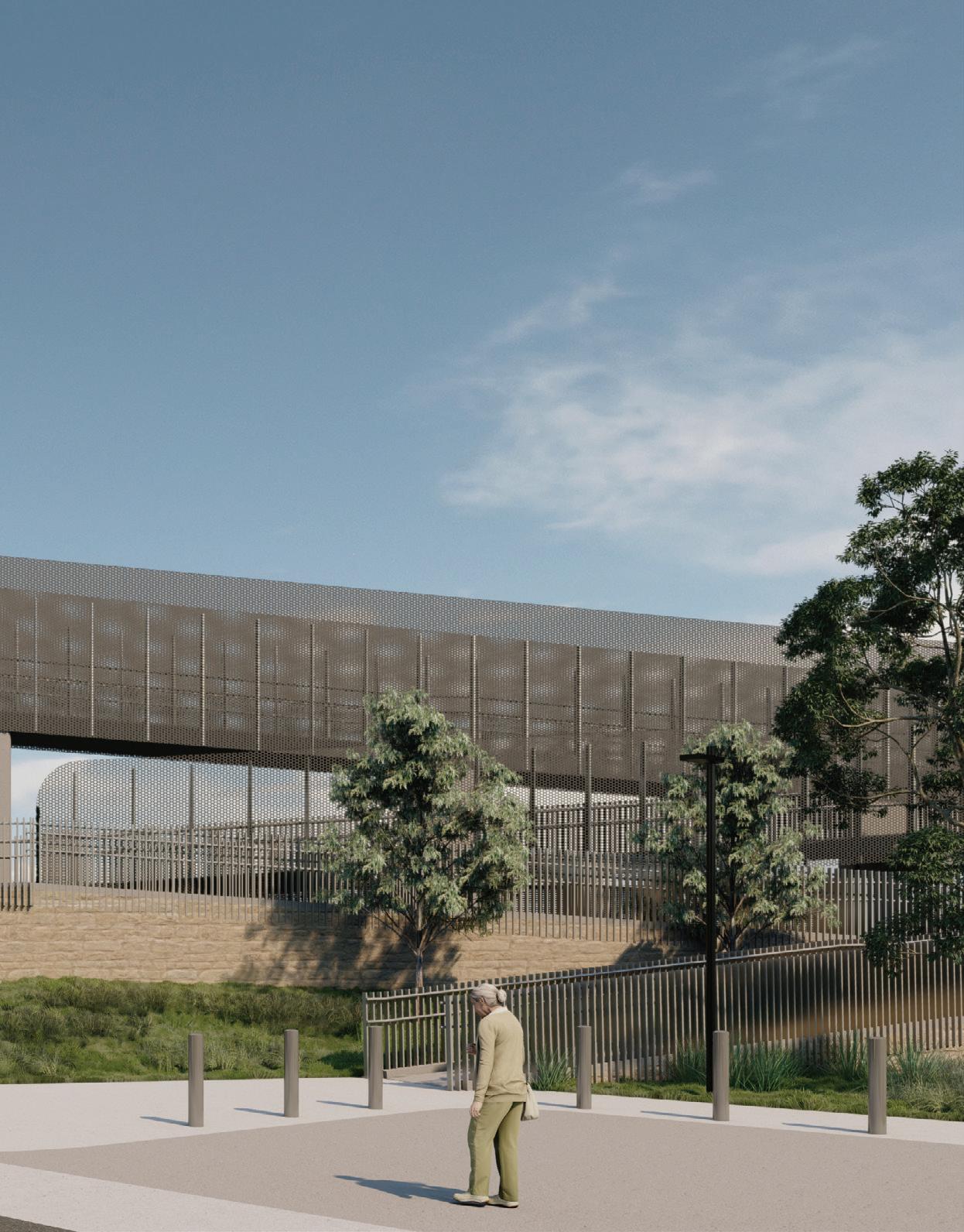

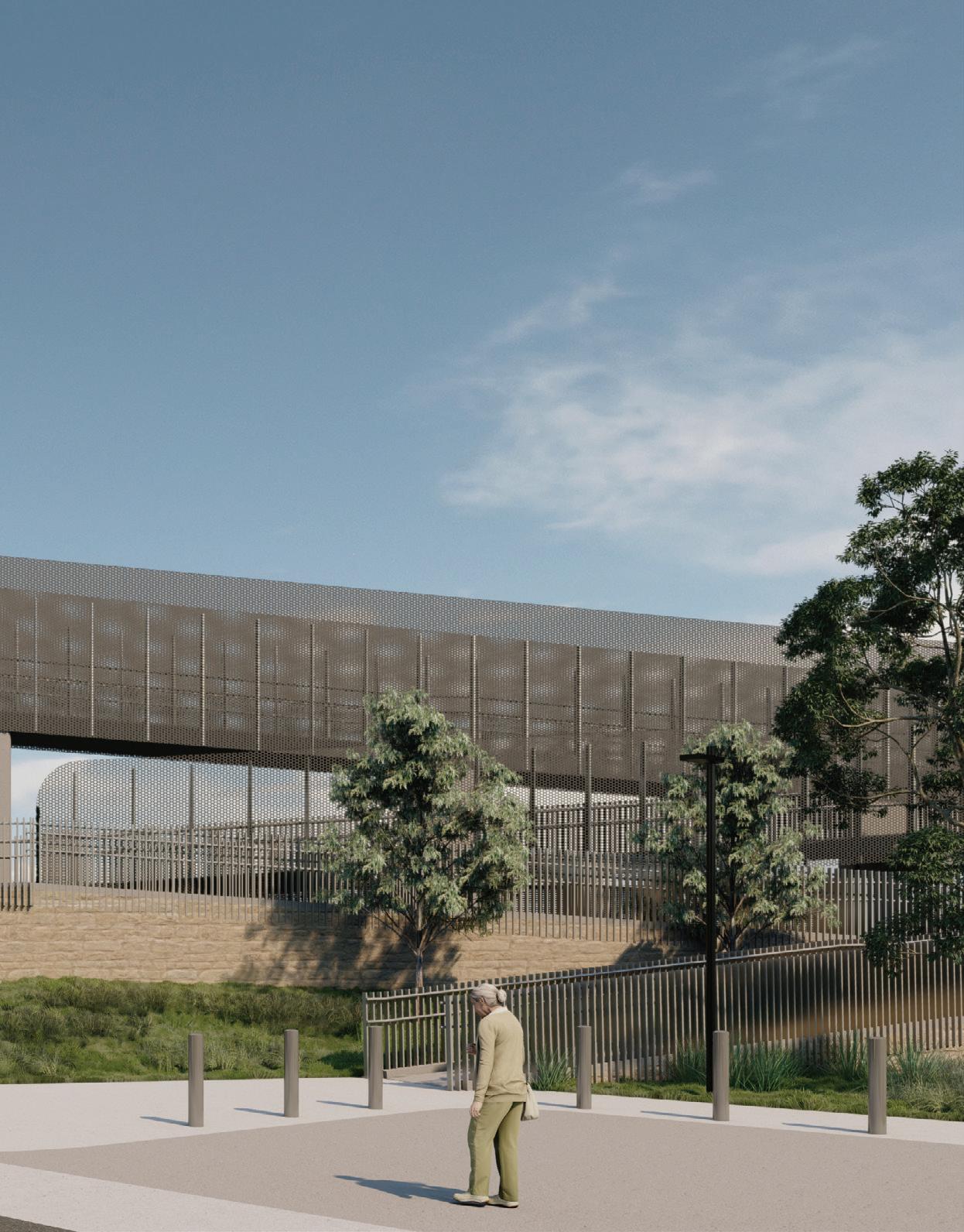

BUILDING THE LONG-AWAITED MELBOURNE AIRPORT RAIL

November 2021 // Issue 21 www.infrastructuremagazine.com.au 28 RAIL

Melbourne Airport Rail will provide much more than just a new rail link to Melbourne Airport, with other upgrades proposed including a new, accessible shared-use overpass over the rail line in Sunshine North.

The

much talked about Melbourne Airport Rail project is becoming a reality, with progress being made towards making future travel to and from Melbourne Airport that much easier.

The project has been decades in the making. In fact, planning for a rail connection to the airport predates the construction of Melbourne Airport itself in 1970.

By the end of this decade, there will be a rail connection to Melbourne Airport for the first time.

The project involves laying around 13km of track between Melbourne Airport and Sunshine Station in Melbourne’s west, and adjacent to the existing Albion-Jacana freight corridor. A new rail bridge to cross the Maribyrnong River will be built alongside the existing heritage bridge.

A series of new above-ground structures will include elevated viaducts and shared use overpasses. Substations will also be built to provide the extra power for trains that will run on the line. There will also be structural

modifications and strengthening works at Calder Freeway, Fullarton Road, Western Ring Road, Keilor Park Drive and McIntyre Road.

Noise walls, signalling equipment and overhead line equipment will be installed along the route.

After reaching Sunshine, Melbourne Airport Rail will connect into the heart of Melbourne’s CBD via the new Metro Tunnel.

Rail Projects Victoria’s Ben Ryan, the Project Director for Melbourne Airport Rail, said the route was chosen for its far-reaching connectivity benefits for the metro, regional and Melbourne Airport trains that will pass through Sunshine Station for all travellers.

“The Sunshine route will provide superior connections to more areas of Melbourne compared with other options assessed, through its integration with the Metro Tunnel and an upgraded Sunshine interchange,” Mr Ryan said.

“Among a number of other benefits, it also allows us to deliver the project to Victorians earlier.”

In 2018, it was predicted that 67 million passengers would travel through Melbourne Airport by 2038. Melbourne Airport Rail aims to both cater to this demand and reduce congestion on roads towards the airport.

Planning and delivery of Melbourne Airport Rail is being overseen by Rail Projects Victoria (RPV), which is also assisting in the delivery of other major rail infrastructure projects such as the Metro Tunnel, Sunbury Line Upgrade, Regional Rail Revival and Geelong Fast Rail.

Melbourne Airport Rail is being made a reality through a joint commitment from the Federal and Victorian Governments, each contributing $5 billion towards the project for a total of $10 billion committed funding.

www.infrastructuremagazine.com.au November 2021 // Issue 21 29 RAIL

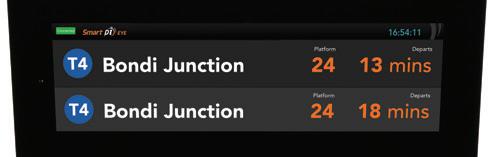

TURN-UP-AND-GO SERVICE AND OTHER BENEFITS

When operational, Melbourne Airport Rail will provide a ‘turn-up-and-go’ style service, enabling trains every ten minutes, with a journey to Melbourne’s CBD taking around 30 minutes.

With links into the new Metro Tunnel, direct airport access will be provided to 30 stations, including Sunshine, Footscray, the five new underground Metro Tunnel stations, and stations along the Cranbourne and Pakenham lines in Melbourne’s south-east.

The project will also integrate into the broader metro and regional rail network across the state. Across Victoria, most commuters – even those in regional areas – will need to make only one interchange during their trip to or from the airport.

“By using the Metro Tunnel infrastructure and the Sunshine route, we can connect the airport to key employment areas across metropolitan Melbourne and regional Victoria, either directly or with only one interchange,” Mr Ryan said.

Travellers will also benefit from the use of the new fleet of High-Capacity Metro Trains (HCMTs) on Melbourne Airport Rail. These HCMTs have more carriages, better accessibility features, more hand-holds and more space than other models currently on Melbourne’s metropolitan train network.

Although the rail link itself is the focal point of Melbourne Airport Rail, Mr Ryan said there are other benefits included in the project scope.

“We’re also making major improvements to Sunshine Station, such as a second concourse with better accessibility features, escalators and lifts,” Mr Ryan said.

The combination of the Metro Tunnel, Airport Rail and Geelong Fast Rail will deliver a 'turn-up-and-go-style' service for Sunshine and easy connections to Victoria’s western regions, Southern Cross via Footscray and Melbourne’s CBD through the Metro Tunnel.

The project will also provide new or upgraded pedestrian and cycling connections, and other rail infrastructure upgrades such as new signalling and power systems along the route.

In the short-term, there will also be support for up to 8,000 direct and indirect jobs during Melbourne Airport Rail’s construction, including engineers and planners, construction workers, and local suppliers who will help shape the project.

PROGRESS TO DATE AND CONTRACTS TO CONFIRM

Engagement with the community and key stakeholders has been a continuous process, helping refine the project’s scope, design and planning approvals.

Mr Ryan said there has been a significant response from the community to date surrounding the project.

“Overall, lots of people are happy that the project is on its way – more than 90 per cent of people agreed or strongly agreed that the project will benefit the broader Victorian community,” Mr Ryan said.

“But the people who live and work along the corridor care a lot about their communities, so we have received, and continue to receive, a lot of important local feedback on what they value about their communities.

“Since late 2020, more than 3,000 people have visited our virtual engagement room and we’ve had in excess of 2,500 responses to surveys.”

The COVID-19 pandemic has changed the way the project team performed these community engagements. But the team adapted to conduct engagement both online and face-to-face, subject to the COVID-19 health advice at the time.

In early 2021, concept designs for an elevated rail bridge over the Maribyrnong River and elevated twin tracks between Sunshine and the Albion Junction were released by the Victorian Government (seen in Infrastructure magazine, Issue 19).