The STIHL BGA 300 is the first battery backpack blower from STIHL. For professional applications in noise-sensitive areas. Ideal for efficient clearing of large areas, even with wet and heavy leaves. Petrol-performance blowing force with a battery leaf blower.

CEO

John Murphy

COO

Christine Clancy

Sales Director

Bradley Buchanan Editor

Tom Foster

tom.foster@primecreative.com.au

Advertising Sales Manager

Arron Reed

Arron.reed@primecreative.com.au

0466 923

Production Editor

Michelle Alder

michelle.alder@primecreative.com.au

Design Cat Zappia

Website landscapecontractor.com.au

Time for an upgrade?

Image: Bill Keefrey / adobe.stock.comIdon’t rate myself as very mechanically capable.

There are a few engines I know really well and I’m comfortable removing the top end and dealing with most of what I find. I can generally strip and clean a carby without too much grief – although ensuring the carby on my last Victa two-stroke was in exactly the right horizontal plane was a pain in the float chamber – and mostly I can puzzle my way through simple problems.

But lately I’m finding the complexity of modern internal combustion engines and mechanical systems a trial – not the basic fuel, spark and compression components. It’s the emission- and noise-control gear that have me scratching my head and wondering what the hell they do, how they do it and what effect my messing with them will have on the repair I’m trying to make.

But still, I have to admit there are plenty of

times I’m left struggling with what turns out to be childishly simple solutions.

My trusty old ride-on threw its chain recently, and while I correctly diagnosed the problem, doing something about it was a different matter. The drive chain had somehow wrapped itself around the upper drive sprocket and the whole mess was jammed like office workers on a Tokyo commuter train.

And it was locked solid.

I wriggled, rocked, swore and threw things. I removed the wheels – a task in itself when those rear wheels haven’t been off for a year or two – but all that showed me was; ‘Yep. That’s an unholy mess with no freeplay in any direction.’

As usual, the guys at the local mower shop patiently listened to my sobbing and wailing over the phone and then suggested, “Can you see the joining link?”

The joining link!

A couple of gentle taps with a punch and I had the chain in my hands, as compliant and willing to please as a Labrador wanting its tummy rubbed. After a clean and lube, it was back in place and I drove away, ready to get on with my mowing day.

When it was time to do around the trees and fenceline, I grabbed the push mower, made sure the battery was charged, and quietly moved off into the clean, open air.

There’s no doubt in my mind the future is electric, but on days like that one, I can see the future might be a great deal closer than we think.

Tom Foster Editor

Toro has appointed Semco Equipment Sales as a dealer for Toro commercial equipment.

Toro commercial equipment is supplied to sportsfields and sportsgrounds across the greater Sydney, Canberra, southern and parts of western New South Wales regions.

The appointment of Semco follows a review by Toro that indicated a new distribution model in the region was the best approach to serve its customers moving forward.

Toro said Semco had delivered close to three decades of service excellence across Australia, and had been associated with the Toro Australia brand in the construction, consumer and residential landscape contractor equipment markets since 2010.

The Toro commercial distribution appointment was also influenced by Semco’s 100 per cent Australian ownership and management. It has four well established centres for sales, parts and service across NSW and the ACT, supported by multiple mobile servicing units.

Ben Cavanagh, National Sales Manager - Equipment & Irrigation, Toro Australia, said, “Semco’s proven track record will ensure unwavering focus on the customer experience – from pre-sales engagement to post purchase support.

Toro Australia marks an exciting phase, both agreeing that this transition will benefit our customers in this region. Semco’s sterling reputation for integrity across all facets of the operations, coupled with its comprehensive parts and service support, underscores their genuine dedication to customer assistance,” he said.

The distribution transition commenced in early December 2023. A seamless customer experience is being guaranteed, with Mark McAllister of Toro commercial equipment moving from Toro Australia to Semco to ensure continuity and a familiar point of

Contact details and phone number remain unchanged.

Toro will progressively transfer the Toro commercial business across to Semco over coming months as Semco builds further capacity and infrastructure.

For further information phone Mark McAllister on 0434 692 404,Steve Zivkovich at Semco on 02 9833 6064 or Ben Cavanagh, Toro Australia, on 0417 200 216.

A ladder set up incorrectly can put you and other workers at risk of serious injury. Image: Yeongsik Im/adobe.stock.com

The Australian community has decided the cost to the nation of accidents, injuries and deaths in the workplace is no longer acceptable. Accordingly, all levels of government have instigated one of the most stringent sets of laws and regulations governing workplace health and safety in the world. Marc Worner would like to see injuries no longer a sorry part of the working week.

In landscaping and construction the top three accidents are: falls, overexertion (resulting in musculoskeletal injuries –sprains and strains), and being struck by objects. There are also many other risks we need to mitigate: dehydration; machinery and tools handling; lifting; violence; bullying; and harassment.

Fatalities highlight the potential danger of familiar equipment like ladders and how a fall, even from a low height, can result in serious injuries and even death.

Falls from ladders represent the most common form of accidents in our construction industry.

Ladders

A ladder set up incorrectly puts you and other workers at risk of serious injury. These are the key requirements for straight or extension ladders:

• Place the base of your ladder on a firm and level surface – make sure both feet are on

It takes more than a good toolbox meeting to create a safe work environment. This can be done by training workers, investigating accidents, and planning work to reduce risks. Image: Panumas / adobe.stock.com

the ground. Use leg levellers on uneven surfaces. On wet or unstable ground, brace the base to keep it in place

• Set up your ladder at the required angle –use the ‘4-to-1 Rule’: for every 1.2 metres up, place the base of your ladder 0.3

metres from the wall or upper support it rests against.

• Position and secure your ladder for safe access – if you’ll be getting off the top of your ladder to access your work area, your ladder’s side rails must extend at least one

Taking some time to focus on safety will help a company lower absenteeism Image: guitou60/adobe.stock.com

metre above the level or upper landing you are accessing. Tie off your ladder’s side rails at the top, and

• Place the top of your ladder against a stable surface – make sure both side rails are equally supported, unless your ladder is equipped with a single-support attachment. Now, checking your ladder is at the 4-to-1 angle: stand with your toes at the ladder’s base and extend your arms straight out. If your fingertips touch the rung nearest your shoulder level, your ladder should be at the 4-to-1 angle.

Good work, you’re safe!

Then there is the risk of a long duration of wage loss. There may be high health-care costs associated with workplace injuries, and ongoing serious medical conditions can result. These examples demonstrate the impact of

accidents and their ramifications:

• A young landscape apprentice fell from the roof of a house and became a paraplegic. It took three years for the Workers Compensation claim to settle. Meanwhile, the owner of the landscape company suffered a nervous breakdown that led to his early retirement and the close of his landscape business and the loss of six jobs.

• A worker was crushed and suffocated to death in a trench when the sides collapsed. There was no shoring erected. The employer was found guilty which caused the company to go into liquidation and for the owner and his wife to go bankrupt. The victim’s son, aged three at the time, will have to grow up fatherless whille his wife struggles to survive on welfare

• A worker was punched by a co-worker,

breaking his nose and fracturing his cheekbone. The co-worker was retrenched, found guilty of assault and the victim suffers ongoing medical problems that require his frequent absence from work

• A worker was installing a timber deck to an entertaining area when he fell one metre onto the concrete path below and fractured his spine in several places. The medical bills alone totalled nearly $280,000

• A landscaper was climbing a stepladder with a pneumatic nail gun, accidentally pressed the trigger; and it discharged two nails into his arm, severing some nerves. He had to be re-trained for another industry because of his subsequent disability, and

• During the mechanical removal of a tree stump, a natural gas line was ruptured, closing down operations for one day; but set back the landscape project by a week.

Taking some time to focus on safety will help a company lower absenteeism, maintain production, meet deadlines, stay within budget, improve work quality, and reduce musculoskeletal injuries like sprained ankles and strained backs.

The best way to reduce injuries and save money is to encourage positive attitudes toward health and safety in the workplace.

Show that you take safety seriously whether you are an employer or employee. It takes more than a good toolbox meeting to create a safe work environment. This can be done by training workers, investigating accidents, and planning work to reduce risks. It’s also good to instil a company culture which everyone is encouraged to:

• Embrace and promote safe work practices

• Set an excellent safety example for others, and

• Approach the boss or foreman at any time with safety problems and suggestions.

Personal Protective Equipment (PPE) should always be used on site to protect against common workplace hazards such as noise, manual and mechanical injury.

Insurance makes more than good sense. There may be high health-care costs associated with workplace injuries.

Image: Studio Romantic/adobe.stock.com

It’s important to wear hearing protection when exposed to noisy equipment.

Image: Rawf8/adobe.stock.com

Workers should not be allowed to start without such equipment.

Think about having the right tools for the job. It’s not always easy to select hand tools to get the best outcome. Things which need to be considered include grip, handle size, grip surfaces, weight and triggers.

Landscapers are often exposed to on-thejob noise which can permanently damage hearing. It’s important to wear hearing protection when exposed to blowers, skid steers, air guns, angle grinders, chainsaws, circular saws, concrete saws, screw guns and drills.

The employer is responsible for providing hearing protection (earmuffs or earplugs).

TIP: As communication with co-workers may be critical, hearing protectors that do not block out too much sound should be worn, for example custom-moulded earplugs with vents.

Knowing what underground facilities are buried in or near a dig jobsite is essential if deadly, dangerous, or destructive accidents are to be avoided.

Users must lodge an enquiry online outlining where and when dig is planned. It needs to done at least one business day before starting work, and the address to go to is byda.com.au/.

The only battery system for professional needs

8 minutes charge

3000 life cycles

3.2 kW power

The Kress 8-minute CyberSystem™ is fast and powerful. Batteries, including the 660Wh backpack, get charged from 0 to 80% in as little as five minutes, or from 0 to 100% in just eight minutes.

Take charge of your future and end your reliance on petrol forever at Kress.com.

Dehydration is another risk which needs to be mitigated. Image: JU.STOCKER/adobe.stock.com

The purpose of occupational first aid is to provide workers with prompt, easily accessible and appropriate first aid treatment, and to keep a record of each treatment for any future reference or claim.

Depending on the job site, providing one or all of the following needs to be considered:

• Having someone with a Senior First Aid Certificate on site

• First Aid kits with the appropriate types and quantities of supplies should be available

• There needs to be an effective means of communication between first-aid attendants and workers who may need their help, and

• A record-keeping system should be in place.

Undertake a WHS (Work Health Safety) team meeting for each new job and carry out that toolbox meeting each week on that same job site because conditions do change. New team members or visitors to site should also be informed of all hazards and sign off your appropriate WHS sheet.

If you’ve read this and decided that to achieve the best outcomes for your business you need help, it’s at hand. There are numerous government agencies in each State able to provide information, and there’s the Federal government’s website safeworkaustralia.gov.au.

Consultants such as sesa.com.au can

create comprehensive solutions tailored to your business needs, and Pinnacle Safety and Training is a nationwide industry leader in the provision of WHS training for all staff. See pinnaclesafety.com.au.

All the hard work is taken from you when you purchase Construction/Subcontractor WHS Management Systems containing policies, procedures and processes set up as manuals for Queensland, NSW, Tasmania, NT, South Australia, and the ACT from safetyculture.com.au.

Must have

Insurance makes more than good sense. It’s the law. Employers must have Workers Compensation Insurance.

Workers are eligible for compensation benefits if they suffer a work-related injury or disease. Insurance brokers work for you, the client; and the benefits are reduced premiums. Landscape contractors, designers and horticulturalists have used industry brokers such as fitzpatrick.com. au for many years because the company tailors all insurances to individual business needs and is proactive when it comes to providing free advice as the laws change for each type of insurance and the appropriate level of cover.

Far better to be SAFE and never have to claim.

Your health comes first second and third!

The

Image: Nattawit/adobe.stock.com

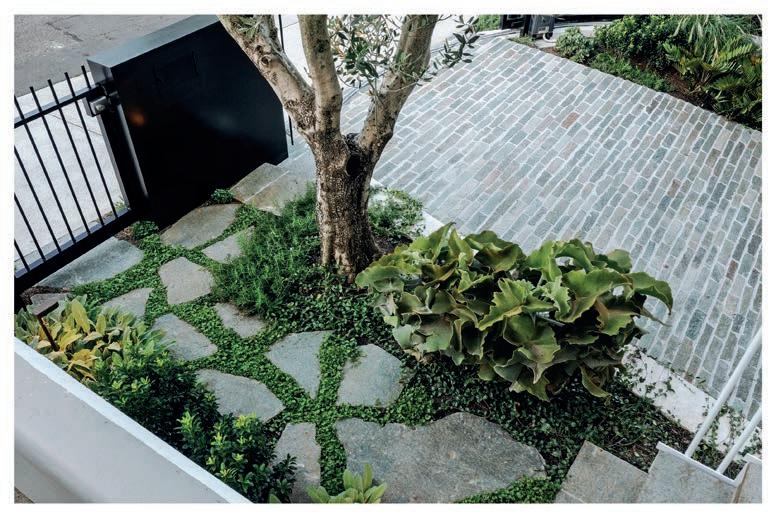

The aim of the site analysis is to ensure the renovation recognises, conserves, and enhances the characteristics that give places a valued identity and create a high-quality and distinctive landscape.

‘Old’ doesn’t mean ‘useless’. John Gabriele wants us to consider the value of old or used materials before automatically discarding them.

Everything has a finite life and that includes landscape installations which, by their very nature, are dynamic and under constant change due to the growth of plant material within them and the ongoing impact of time and climatic influences.

Landscapes and gardens are designed to engage users to interact with the landscape and its components and provide a sense of connection with nature that helps to shape and reshape our lives. While urban landscapes have become an instrumental part of modern-day living, there are those installations that have suffered over the course of time and no longer meet the functionality of the original design intent or reflect the modern narrative. Those landscape installations that are 20 years or 30 years old are now requiring a complete overhaul. They need the replacement of all components to bring them into line with modern urban design, or renovation to ensure they remain fit for purpose.

Whether it’s an urban residential

landscape or a utility landscape for public use, many older installations will at some stage require renovation to repair damaged hardscape components and remove certain components, including plant material, to allow for inclusion of more useable space. They may need a style change to meet modern lifestyle expectations.

Unfortunately, with the popularity of home renovation programs, there is a common belief that an old landscape should be ripped up holus-bolus and a completely new installation established.

Nothing could be further from the truth.

As with any approach to redesigning a space, a systematic method is required.

There are some basic steps to work through when dealing with a mature landscape before ripping up old paving or turning the first sod on a new planting. A complete site assessment should be the first step in the redesign process. Essential

starting points for good design go beyond the simple application and compliance with development controls. We need to analyse existing features of the site and look for interdependencies, opportunities, and constraints, as these will assist in the design of the new space. The aim of the site analysis is to ensure the renovation recognises, conserves, and enhances the characteristics that give places a valued identity and create a high-quality and distinctive landscape.

The typical considerations of a site analysis include:

• Aspect – determine the sun’s path and where shadows are cast throughout the day and over the year

• Wind – what is the dominant direction and where are the exposed areas of the site?

• Soil – what soil type is the landscape developed on? This will greatly influence any additional plant selection

• Topography – does the site have significant rises and falls? This can influence drainage

• Functional zones – are there zones

Transformed through evolution, the ultimate species delivers more power, productivity and precision than ever before.

within the landscape that serve a specific function: entertainment areas, play zones, water features?

• Views – are there existing views to be retained or views that require screening?

• Microclimate – what are the attributes of the space that differ from the surrounding areas climatic conditions? And,

• E xisting features – what hardscape features are currently in play? For instance, paving, retaining walls, pergolas, fencing, water features, decks, firepits, buildings and other structures.

A landscape SWOT analysis should follow on from the site analysis to assist in determining which aspects of the site may be retained and those features that may require removal or modification. It will assist in setting the objectives of the scope of works to be undertaken. Examples of what could be considered in a landscape SWOT analysis follow.

Strengths:

What hardscape features are currently in play? For instance, water features.

Image: Martin/adobe.stock.com

Weaknesses:

• Poor drainage on south-east corner of site from compacted soil.

Opportunities:

• Sloping topography provides for good surface-water run-off

Opportunities:

• Mature tree provides protection to existing understorey planting, summer shade and winter sun (deciduous trees) to property north side

• Soil pH and texture class provides for a wide selection of plants to be cultivated, and

• Surrounding buildings provide wind protection.

• Maximise level changes and incorporate steps and retaining walls.

Threats:

• Loss of privacy from overlooking buildings

• Neighbouring vegetation restricting direct light to garden beds.

A well-defined SWOT analysis of any site will assist in identifying the strengths of the site, such as unique features, understanding

the weaknesses which may include lack of features, poor quality, lack of structural integrity, or other disadvantages. By assessing these factors, landscapers can develop a comprehensive understanding of what is necessary for the successful renovation of the site.

The beauty of working with an established landscape is that there will inevitably be some mature plants that form the basic structure of the planting as a focal point and provide an opportunity for a change in design to utilise the structure and framework that mature plants provide. Removal of mature plants from a landscape, particularly residential landscapes, can be a costly mistake. It is estimated that the removal of mature plantings can reduce the value of a property by up to 10 per cent, and in some instances even higher. Bear in mind that not all landscapes will contain plant material that is worthy of retention and there will be instances where replacement with a more appropriate species is warranted.

Hence the importance of a detailed SWOT analysis.

Retaining plant material in an existing landscape may cause some inconvenience to other stages of construction. Plant protection zones may be required to prevent mechanical damage to established tree trunks and root zones, and machinery and equipment access may be compromised to some degree and require reconfiguration to allow for the construction to proceed with minimal disruption to efficiency.

Apart from the obvious materials that have long been used in landscapes, from recycled materials such as timbers, masonry and aggregates, there are many other options for material reuse that won’t necessarily give the impression of being old or second hand,

which is a common criticism of reused or recycled products. Many products that have been recycled or repurposed may not even form part of the visual landscape to a great extent. This is evident when it comes to growing media substrates derived from recycled materials, some of which may be retained from the original site. Significant cost savings can be achieved through retaining loose materials and reusing them. It may require some modification to meet required standards, but the savings are more than just monetary: it is demonstrative of good environmental stewardship.

The benefits of retaining existing materials within a landscape avoids the costs associated with demolition, transportation,

and disposal of materials to landfill. Masonry components in landscapes are a case in point. They can be acid washed or cleaned with high-pressure water to breathe new life into them with little effort, thereby extending their life in an existing installation.

Materials used in landscapes are often seen as having a linear lifecycle, ie: they are produced from virgin materials and have a useable life expectancy. They move through the lifecycle once and then are disposed of.

If we look at materials differently in terms of their lifecycle being circular rather than linear, materials can be reused, recycled, or repurposed. This paradigm shift in thinking results in a more sustained approach to business practices.

Opportunity also exists for the

reclamation and reuse of site materials within any size construction site with thoughtful planning prior to site excavation and demolition activities. Effective incorporation of reused, recycled, or repurposed materials in landscapes requires considered planning and an integrated approach to landscape design. Collaboration is needed between designers, suppliers, and construction contractors to encourage adaptive resource management across all sectors of the landscape construction industry.

The use of recycled, reused, and repurposed materials in construction is setting the standard for more sustainable ecological landscape design. The time is right to consider the option to renovate, not detonate.

Green spaces that create inviting environments for residents, guests or customers are crucial whether you manage sporting fields, golf courses, parklands, facilities or private property.

Achieving the desired results is simple with Husqvarna by your side, and now with new EPOS technology it’s even easier to experience outstanding results, reliability and lower emissions. With virtual boundaries, the possibilities are endless.

For rapid growers like Leyland Cypress (x cuppressocyparis leylandii) planting 200mm - 300mm pot sizes is good. Larger plants will look more impressive in the beginning, but the younger ones will soon catch up. Image: dbvirago/adobe.stock.com

Jonathan Garner continues sharing his expertise on planting. This issue the focus is on hedges and screening plants.

Autumn at last!

I love autumn. Plants love autumn.

The warmish soil, cooler air temperatures and reducing daylight hours tell our green friends the time for rest is soon, and milder air temperatures encourage healthy root growth. Planting in Autumn will hold plants in good stead for exceptional performance in Spring.

Always aim to plant your advanced stock in Autumn. It’s a far more forgiving time. If you happen to miss a vital watering event, the tree will pardon you. If you must plant advanced stock during Spring and Summer, please factor in the extra resources necessary to ensure healthy establishment and the best long-term outcome.

We discussed general planting practices last issue, so this time I thought we’d cover a situation that benefits from adjusting our approach.

The aesthetic and functional advantages of growing hedges and screens within the

garden are numerous. These plantings should be best considered long-term assets within the landscape. Given the major intention of all hedges, be they large types for screening, windbreaks, privacy and aesthetic back drops, or low types to define borders, accentuate features, edge pathways and provide visual continuity, it’s paramount we invest our time and knowledge in ensuring the hedgerow remains healthy and grows in a consistent manner. Excluding steep grades and situations where access to the same amount of sunlight throughout the hedgerow is variable, if you select the appropriate plant for the location and follow these steps success is sure to follow. Consistent growth rates require consistent inputs.

1. Set out

Measure and mark the hedge line using stakes and a stringline to ensure a straight and uniformed row.

If you’re planting along an existing fence line or a narrow strip like the side of a house,

dig your trench and set your plants closer to the fence or structure. Aim to locate the plants as far back from the path as possible. By setting the trunk of the hedge closer to the wall or fence, you’ll have more space for the dense branch network to develop with less incidences of woody branches being located where the foliage should be.

2. Excavate

Dig a trench along the marked line. Obviously the depth and width of the trench will depend on what pot size is being planted. With rapid growers like Sweet Viburnum (V. odoratissimum), Leyland Cypress (x cuppressocyparis leylandii), non-invasive bamboos such as Slender Weavers Bamboo (Bambusa textilis) and so forth, I’m a fan of planting 200mm - 300mm pot sizes. Larger plants will obviously look more impressive in the beginning, but the younger ones will soon catch up and are likely to exceed the performance of the larger and more expensive models. If you excavate too much,

firm up the backfilled soil with your boots. You definitely don’t want hedging plants to sink.

The root flare needs to be sitting around 75mm higher than the surrounding ground level. Most importantly, the wider the trench the better opportunity to determine or discover hinderances that may affect consistencies in growth rates. Elements such as boulders, compacted layers, variations in soil textures, buried stumps and so on will all govern how consistent and successful the hedgerow will perform. By creating a trench system we’re preparing and providing identical soil conditions for the entire hedgerow. Most importantly, the trench approach encourages the roots of each plant to grow left and right towards their neighbouring relatives. In time the thousands of fine roots will grow into larger roots which eventually graft together to become one entire root system. The hedge row will essentially become one resilient plant where resources are shared equally through the hedge. You will notice that in time, growth rates will be consistent throughout the entire row.

Gaps in Buxus look crap, so plant densely and aim to use 150mm pot sizes. Image: OLAYOLA/adobe.stock.com

If you are relying on pressure-compensated drip irrigation, install the line so the spaced emitters are in direct contact with each root ball but not too close to the root flare. Image: Alin/adobe.stock.com

Desired eventual heights of the hedge will dictate the spacing.

Excluding bamboo varieties, If I’m growing a three-metre-tall hedge, I space most plants 600mm apart. Conversely, If I’m planting Leyland cypress as a 10-metre-tall screen, I’ll space them 90cm apart. With low hedges such as Buxus, I’m a fan of planting 150mm

pot sizes at six per metre or 200mm pots at five per metre. Planting 150mm pot sizes ensures you should eventually have no gaps along the base of your hedge. Planting 200mm pot-sized Buxus encourages gaps along the bottom of the hedge as the plants are already forming a vase shape. Gaps in Buxus look crap, so plant densely and aim to use 150mm models.

The aesthetic and functional advantages of growing hedges and screens within the garden are numerous.

Image: Александр Беспалый/adobe.stock.com

With closer spacing and the eventual shared root system, you will achieve a dense screen that can cope with occasional plant losses within the row. (Although this shouldn’t happen).

Losses within an established hedgerow are usually due to initial planting errors and irrigation or drainage inconsistencies. If you’re maintaining consistent resources through the hedge and you find a dead plant, check out the root flare. The death will likely be collar rot disease. This is from soil or decayed plant material accumulating around the trunk. Stop and think about the unnatural conditions we create when growing a hedge with woody plants. Nowhere in nature do you see an identical row of tightly clipped plants with foliage extending from the upper tips down to the soil level. Keep in mind the dense foliage close to the ground keeps the most sensitive section of the woody plant, its root flare, in conditions much like a dungeon. It’s dark, it’s damp, air movement is restricted and the millions of micro-organisms hungry to decay the falling leaves around the trunk are eagerly looking for anything woody (like root flares) to revert back to compost. This is

the reason I plant above the soil level. Always keep the root flare as dry as you can!

Drench your root balls as usual, remove the pots, place them out, tease the roots, obey your spacing, and ensure the majority of the lateral branches are facing left and right to maximise points of growth between each plant. Aim for the root flare to be 75mm above soil level, gently backfill, create the ring or a long mound of soil to retain water, mulch, and commence your establishment watering regime.

5. Irrigation

If you are relying on pressure-compensated drip irrigation, install the line so an emitter is in direct contact with each root ball but not too close to the root flare. Double up with your drip line with one line on each side of the hedge so each root ball has its own emitter. Create the situation where the drip line can be moved away from the trunks as the hedge matures. Program the system so it delivers sufficient water.

Let’s do a quick sum now and we’ll discuss

irritation later this year.

One emitter delivers two litres per hour. As a 200mm pot is 4.5 litres, we need to provide around one-third of the pot volume of water every event. This equates to 1.35 litres or 44 minutes of run time per event.

Don’t forget the frequency of this duration will be reduced as the weeks go on.

6. Training and pruning

Branch density close to the trunk is vital.

Pruning can commence once the plants have established. Depending on the season, location and species, approximately 12 to 18 weeks after planting, I prune the plant back by one- to two-thirds. This encourages a flush of growth close to the trunk. Once this growth recovers to the original size of the plant it’s time to start tip pruning. This can be done several times during the growing season, depending on the growth rate of your chosen plants. It’s often done in spring and early summer when the plants are actively growing. Having a dense branch network close to the trunk or stems will make for a durable, healthy and long-lived hedgerow.

The Honda Buffalo range are the contractor’s choice!

Assembled in Australia and built tough to withstand all environments and conditions.

HRU19 Buffalo Premium

HRU196 Buffalo Pro

19” Cast Aluminium Deck Honda GCV170 Engine Engine Brake

19” Cast Aluminium Deck Honda GXV160 Engine Engine Brake

HRU196 Buffalo Pro

19” Cast Aluminium Deck

GXV160 Engine Blade Brake

HRU216M3 Buffalo Pro

21” Cast Aluminium Deck Honda GXV160 Engine Blade Brake Self-Propelled 3 Speed Gearbox

The HRU Aluminium Deck is durable and built tough to protect the engine and resist rust and corrosion. Outstanding performance thanks to the open rear chute designed to cut and catch wet grass.

Honda engines are tried and tested in the demanding conditions. Made from high quality materials and purpose-built components that ensure reliable long-term use

The Honda HRU Mower range is assembled right here in Melbourne, Victoria. Honda are committed to the local manufacture of our products using Australian & overseas materials.

The Milwaukee MX FUEL™ Plate Compactor eliminates the headaches associated with petrol-powered light equipment while delivering the power and run-time users expect.

Images: Milwaukee

Reliable, ergonomic, and productive compaction.

One of the many new additions to the MX FUEL™ Equipment System*, the Milwaukee MX FUEL™ Plate Compactor eliminates the headaches associated with petrol-powered light equipment while delivering the power and run-time users expect.

Critical to job-site preparation, compaction increases ground density by removing air, increasing the ground’s strength, stability, and load-bearing capacity.

Ideal for compacting flatwork, foundations, and utility trenches, the MX FUEL™ Plate Compactor hits hard and travels fast without sacrificing compaction performance. The MX FUEL™ Plate Compactor has fast travel speeds, keeping users productive on the job regardless of the compaction material such as crushed rock and stone, road base, asphalt, or even patio pavers.

Plate Compactor provides instant power with no petrol headaches, requires no regular maintenance, and produces less noise and

The battery-powered plate compactor has the ability to go in both forward and reverse directions.

go in both forward and reverse directions, giving users greater control, while accessible push buttons on the handle control direction,

stand-by, and multiple speeds for precision manoeuvrability around forms.

The handle can easily fold down, creating a smaller footprint for safer transportation around the job site and more efficient storage, whether storing under shelving or in the bed of a truck.

The MX FUEL™ Plate Compactor has the run-time to get the job done. When paired with the MX FUEL™ REDLITHIUM™ FORGE™ 12.0Ah Battery, the plate compactor delivers up to 35 minutes of continuous runtime, or approximately 464 square metres of compaction per charge. The new MX FUEL™ Super Charger provides fast charging speeds for increased productivity and efficiency on the job site, charging the REDLITHIUM™ FORGE™ 12.0Ah Battery Pack in only 65 minutes to 100 per cent charge. The battery pack and new MX FUEL™ Super Charger are COOL-CYCLE™ capable, an Active Cooling System that provides high-speed cooling for less downtime, allowing users to stay productive when swapping batteries.

Accessible push buttons on the handle control direction, stand-by, and multiple speeds for precision manoeuvrability around forms.

Productive on the job regardless of the compaction material such as crushed rock and stone, road base, asphalt, or even patio pavers.

As an added benefit, ONE-KEY™**, provides the ability to track the plate compactor with community tracking and alerts, complete inventory management, and industry-leading smart equipment technology to secure the user’s investment.

Milwaukee Tool remains unwavering in its commitment to delivering disruptive innovation by working alongside trade professionals to identify challenges and provide solutions that are unparalleled in enhancing job site safety and productivity. With solutions that cover the concrete pour to finish process, Milwaukee Tool’s MX FUEL™ Equipment System is safe, reliable, and productive, going beyond the limitations of petrol and corded solutions.

For more information about the MX FUEL™ Equipment System, or to book a demo on site, please visit milwaukeetool.com.au/ system/mx-fuel/

MX FUEL™ Plate Compactor (tool only) (MXFPC50-0)

• Battery type: Lithium-ion

• Battery system: MX FUEL™

• Plate width: 19.7”

• Plate length: 22.6”

• Height (handle folded): 23”

• Weight (tool only): 150lbs

• Travel speed (ft/m): 86ft/m

• Compaction area: 9850sq.ft/hour

• Amplitude: 0.09”

• Centrifugal force: 3600lb/f

As long as there is an unimpeded sky view to ensure optimal technical conditions, Husqvarna’s sophisticated satellite technology, Husqvarna EPOS™, delivers centimetre-level accuracy in seconds.

Images: Husqvarna

Husqvarna’s EPOS™ (Exact Positioning Operating System) is a breakthrough technology for a new series of robotic lawn mowers which allows operation without boundary wires.

The satellite-based technology enables the mowers to work within virtual boundaries, making it an easy and flexible solution. It’s perfect for football pitches, golf courses, city parks, company real estates – and all other places that deal with changing circumstances and needs.

Also, the absence of physical boundary wires means problem-free aerating, scarifying and turf repair.

Once the Automower® is onsite and the reference station has been installed all you need is a smart phone and the Automower® Connect app.

Virtual boundaries can be created and set for the robotic mower using the phone in one or several work areas. As long as there is an unimpeded sky view to ensure optimal technical conditions, Husqvarna’s sophisticated satellite technology, Husqvarna EPOS™, delivers centimetre-level accuracy in seconds.

Combined with the reference station, the robotic mower can safely and efficiently mow any grass area.

Once a selection has been made from Husqvarna’s range of robotic lawn mowers you simply download the EPOS™ app for professionals or the Automower® Connect app for residential home owners, and you’re off to a great start.

The system consists of three parts: a charging station; a robotic mower; and a reference station.

The driver uses a mobile phone and the app to set up the installation and set virtual boundaries. The boundaries define work areas and stay-out zones, and are set by guiding the mower around the areas via the app. Boundary lengths are unlimited, allowing complex shapes for maximum flexibility. There are no physical wires to break or maintain, and different worksites with different names can be kept in either app and selected with a touch of the phone screen. And if a site changes, with a new fence or garden, for instance, the mower boundaries can be modified with a click of the app.

It’s a low-noise, no-direct-emissions set up ideally suited to professional propertymaintenance and landscaping contractors.

Using your smart phone, you’re able to activate and de-activate stay-out zones, and

thanks to the Husqvarna Fleet Services™ digital management tool, you’ll always know where the mower is, how much you’ve used it and when it needs to be serviced or replaced – and much more. All this updated information, easily accessible on your phone or tablet, helps ensure a hassle-free and productive business.

See the EPOS™ system in action and Husqvarna’s range of robotic mowers here:

Here are three examples from Husqvarna’s EPOS™ range:

• The 550 EPOS™ handles all types of lawns and manages steep slopes up to 45 per cent (24°) with perfect cutting results – even in rainy conditions. Remote Object Detection enables higher mowing speed and area capacity. Robust, thorough construction provides durability and reliability

• CEORA™ is a professional-level autonomous mowing solution that is easy to use and has a very large area capacity – there are two models of CEORA™ available, with a working capacity up to 75,000m2 . It’s also low in noise and direct-emissions-free when in use.

• Husqvarna Automower® 450X NERA is a high-performing robotic lawn mower, ideal for domestic use on lawns up to 5000m². Wireless installation via the Automower® Connect app and the Husqvarna EPOS™ Plug-in Kit results in customisable lawn maintenance by virtual boundaries – and no risk of wire breakage.

The ultimate in manoeuvrability and stability for on slopes of up to 25 degrees. Images: Cub Cadet

Make

he Cub Cadet PRO Z Series was built with the commercial user in mind.

Maintenance-free spindles and EFI engine options amp up productivity, while a fully welded frame and commercial-grade decks are engineered to stand up to tough demands for years to come.

Add it to your crew and see the PRO Z difference for yourself.

Key features include:

• The ultimate in manoeuvrability –responsive steering gives a fast and professional cut as well as providing the

ultimate in manoeuvrability to cover acres up to 10 per cent faster than comparable lap bar units and delivers true zero-turn handling for less overlap and straighter, better presented lines

• Superior steep terrain handling – Cub Cadet’s Synchro-Steer™ with four-wheel steering helps eliminate turf damage, increases productivity, and delivers unmatched stability on slopes up to 25°

• Power and efficiency – Efficient Kohler EFI engines on Pro Z 148 and 154 models provide increased torque and can deliver

up to 25 per cent in fuel savings when compared to an equivalent carburettor engine, while powerful Kawasaki engines, ranging from 27HP to 35HP, are standard on Pro Z 500, 700 and 900 Series models.

Heavy-duty air filter and air-filtration systems ensure a longer engine life to keep cutting with confidence year after year.

Commercial-grade transmissions also allow cutting large areas efficiently, with forward speeds of up to 22kph and mowing of up to 10 acres per hour

• Heavy-duty construction – fully fabricated,

triple-plated steel decks with top and bottom reinforcements power through the rigours of a job, day in and day out, and decks range from 48" and 54" in the PRO Z 100 S Series. and up to 72" in the range. A three-position, easy adjust ROPS (Rollover Protection System) offers added protection for tough, hilly terrains for peace of mind, and Cub Cadet’s Triple Guard™ Corrosion Defense E-Coat Paint System delivers automotive-grade corrosion resistance against wear and tear. This defense system ensures protection of the machine’s painted surfaces, such as the chassis and deck, for years of reliable performance and an ongoing professional appearance.

• Warranty – the PRO Z 100 S Series Commercial Warranty is two years on the unit and three years on the engine, while the PRO Z 500 S/PRO Z 700 S/PRO Z 900 S Series offer three years on the unit and three years on the engine

• Ultimate Comfort – an adjustable steering column will suit all types of operators, and a roomy operator station, intuitive panel, and easy deck lift help reduce fatigue. Plus, high-back comfort seats with armrests with dial suspension and seatbelt come standard across the range, all helping to minimise operator fatigue.

To see more detail on the entire Cub Cadet range, log on to cubcadet.com.au.

“ “

An adjustable steering column will suit all types of operators.

High-back comfort seats with arm rests for all-day comfort and standard ROPS gives added peace of mind.

Designed for the commercial landscaper. Images: Greenworks

Turn heads and make the competition jealous with performance, intelligence and innovative independence that they’ll wish they had. Here’s a couple of great GREENWORKS® mowers that’ll do that and more.

GREENWORKS 25" self-propelled lawnmower

The muscle of this mower flexes with its heavy duty 25" heavy-duty steel deck and with more intelligent power than any of its 160cc comparable petrol competitors. The 25" cut delivers superior cut quality with premium blade speed, ranging between 4000rpm and 4500rpm.

This mower features dual, counter-rotating mulching blades for the best quality cut, providing a 30 per cent better cut quality, and the large 25" deck gives the user a 20 per cent quicker cut time compared to 21" competitors. Runtime is a sure thing, up to 90 minutes on a single charge, with the dual battery ports and the powerfully tough

Designed to be quiet, at only 79dB, you can mow your lawns when the petrol guys can’t.

commercial grade motor allowing effortless manoeuverability, giving increased traction up hills and slopes, and cutting through the thickest challenges with ease. It also provides a higher lift for the best cut in any condition.

The single-lever height adjustment quickly raises or lowers the deck for different grass conditions, with seven positions for precise mowing, and the handle adjusts for the user’s height and folds down for easy storage.

Designed to be quiet, at only 79dB, mow your lawns when the petrol guys can’t. Forget the petrol, oil, sparkplug, fuel filter, and air filter. Enjoy fume- and emission-free mowing.

Features include:

• 160cc petrol-powered equivalent

• 25" commercial-grade 14-gauge steel deck

• Mow up to 1.5 acres on a single charge

• Commercial-grade brushless motor

• Two-in-1 cutting system

• Seven-position height-adjustment system

• Dual port system provides more power and doubles runtime, and

• Recommended retail: $1349 (skin only).

Featuring some of the best modern technological advances in outdoor power equipment, the GREENWORKS® 82V 30 self-propelled lawnmower is equipped with two independently controlled hub wheel motors and twin dual brushless cutting motors delivering more power than 200cc petrol mowers. The ETS (Easy Turn System) drive system automatically adjusts the power to compensate for sloped conditions and effortless control.

Runtime is a sure thing, up to 90 minutes on a single charge.

Constant power and torque is directed to the hub motors, providing faster cutting speeds and more torque than petrol units. It is also the first push lawnmower to have a reverse function to easily power out of tight areas.

Petrol units lack the technology to adapt to grass conditions on the fly and are limited to only 3600rpm on average, leading to uncut grass, clumping and inefficient bag collection. With independent brushless motors, GREENWORKS® mowers achieve higher blade-tip speeds and automatically increase power to maintain consistency throughout the cut. Our intelligent mowers never bog down, even in the tallest, thickest and wettest grass.

Designed for the commercial landscaper, the 82V 30” lawnmower boasts an extralarge grass bag that carries 12 per cent more clippings than comparable units, and has independently controlled wheels for optimised traction. It also includes a smart LCD screen that provides the status of the

lawnmower (battery status, speed control, blade speed and error codes), and a tri-port powerhead that holds three batteries for continuous runtime.

• 224cc petrol-powered equivalent

• 30" commercial-grade 12-gauge steel deck

• Mow up to two acres on a single charge

• Tri-port powerhead holds up to three batteries to deliver superior runtime

• Independently controlled wheel motors for optimised traction and manoeuverability

• High-visibility LED light for navigating in low-light conditions

• Dual sealed motors provide up to 16,000ft/ min blade-tip speed for best cutting performance

• $2999 (skin only).

Dual, counter-rotating mulching blades provide 30 per cent better cut quality.

While transitioning to electric equipment is appealing for many reasons, the upfront cost is often a deterrent for landscape and mowing contractors. But ‘going electric’ is not just better for the environment, but better for your bottom line, too. Leveraging the Total Cost of Ownership (TCO) framework, which factors upfront costs in addition to the ongoing running and maintenance costs, helps build a practical business case to guide investment decisions.

TCO refers to the total cost of ownership of capital equipment, such as a commercial ride-on mower. It factors in all expenses related to owning and using the vehicle throughout its entire lifespan. TCO covers purchase, maintenance, fuel or running costs, replacement, and disposal costs.

Regardless of the scale of the operation and how the budget is structured, considering TCO for the entire life cycle – from purchase to ongoing operation and maintenance – supports a favourable business case for an electric fleet.

Case study: Delta FM

Delta FM is the facilities maintenance arm of Compass Group, which employs 30,000 people in Australia.

sustainability goals.

“We were looking at changing over to battery products by 2025.

switch to electric by comparing costs and looking at the total cost of ownership over a five-year period and taking depreciation

into account. After creating a lifecycle cost analysis sheet, Nick quickly discovered that over the five years, EcoTeq’s Rival mower would be $23,500 ahead of its dieselpowered counterpart even with the higher initial outlay to purchase the electric mower.

“We worked out that with the running and maintenance costs, we’d be saving $15.57 per hour with the electric Rival mower,” Nick outlined. “On average, our diesel mowers use 7.2 litres per hour. That’s $13.86 per hour. Multiply that figure by 16 hours and that’s a cost of $222 in diesel per week. And how much better is it to not be pumping all that diesel pollution into the air?”

“We didn’t need to budget for any infrastructure modifications, either. We didn’t have to install 3-phase or anything like that. We bolted an external charger to the wall which plugs into a regular socket,” Nick pointed out.

The less obvious cost benefits of going electric

While maintenance and running costs take centre stage in a TCO analysis, there are other factors often overlooked in the calculations:

1. Increased operational hours: noise complaints are a constant challenge, especially in residential areas. The quiet operation of electric mowers allows operators to work extended hours for enhanced productivity.

2. Reduced operator strain and injury: regular and frequent exposure to high levels of vibration – such as those produced by diesel mowers – can lead to permanent stain or even injury. Reduced exposure to vibration equals reduced downtime due to injury and minimises the risk of compensation claims.

3. Less downtime: electric equipment is seriously easy to maintain. With no internal combustion engine and no hydraulics, there are fewer points of failure, meaning greater uptime and productivity.

4. Greater operational efficiency: electric mowers deliver up to 30 per cent faster ground coverage through all grass conditions.

Let the numbers talk:

EcoTeq’s TCO Calculator

EcoTeq has developed an independently reviewed and easy-tofollow calculator to understand the TCO of electric and ICE mowers. Factoring maintenance costs, fuel costs, running costs, operational hours, and machine performance and output, realistic figures for your business case are available in just a few clicks.

Request a no-obligation TCO consultation to discover the long-term savings of ‘going electric’. Contact EcoTeq on 1800 100 150 or visit ecoteq.com.au.

Regardless of the scale of the operation and how the budget is structured, considering TCO for the entire life cycle supports a favourable business case for an electric fleet.

Backed by a comprehensive warranty and extensive specialist network, the Masport Contractor Mower series is designed for commercial operation and built to last. Images: Masport

The commercial-grade Masport Contractor® lawnmowers series come with the ability to catch, mulch, or rear discharge the grass clippings, while the use of high-quality materials provides extra durability and reliability. Additionally, the self-propelled models are equipped with commercial-grade three-speed transmission built for long-lasting performance.

Powered by a choice of three engines, the Masport Contractor mower fleet features the Briggs & Stratton 190cc OHV Series 850, used on both the heavy-duty steel self-propelled and aluminium push mower models. Additionally, a Kawasaki 179cc OHV Series FJ 180V and a Honda 160cc OHV Series GXV160 engine options are also available on the heavy-duty steel self-propelled models. The Hondapowered mower is specifically designed for commercial mowing, offering the additional feature of Blade Brake Clutch, allowing you to

Self-propelled models are equipped with a commercial-grade three-speed transmission built for long-lasting performance.

disengage the rotation of the blades without stopping the engine or losing drive.

The 3-in-1 functionality of the Contractor mowers support catch, mulch, or reardischarge options when cutting grass. This allows recycling of the grass in a variety of

ways, either feeding those nutrients back into the lawn, spreading the cut grass evenly or removing from the garden for a cleaner finish.

The robust chassis construction with front bumper guard provides protection to the cutting chassis, front axle and engine.

Professional grade, heavy-duty wheels and reinforced handles contribute to the mower’s long life.

Masport’s famous Quadcut 4 swing-back blade cutting system makes for superior catching due to increased airflow. The reardischarge chute steel flap is designed for safe discharge of grass when mowing without a catcher.

For the self-propelled models, a commercial three-speed transmission provides the perfect speed-to-job ratio demanded by contractors and homeowners with large yards.

A three-position handle height adjuster, a soft-grip handle and an ergonomic start position ensure an easier mow. The large, 80-litre catcher also allows for longer mowing and reduced running costs, while the mulch feature allows for recycling the cut grass.

Backed by a comprehensive warranty and extensive specialist network, the Masport Contractor Mower series is designed for

Honda understands the importance of a contractor having the right tools for the right job, which is why Honda stands in a class of its own when it comes to investing in the right mower for your business. The Honda Buffalo range includes some of Honda’s most advanced lawnmowers, assembled in Australia and built tough to withstand and handle harsh environments and conditions.

Contractors who own a Honda can mow with confidence knowing they will produce the perfect Honda finish while having outstanding warranty protection and the support of Honda’s 400+ nationwide dealer network.

Visit your local Honda dealer today or find out more at honda.com.au.

The HRU19 Buffalo Premium features the best cutting and mulching performance seen on a Honda mower. Featuring a GCV170 four-stroke engine, 19” cast aluminium deck, and weighing only 31kg means it is easy on the arms so you can go harder for longer. The 54-litre polymer catcher means less stopping and more mowing, with the swing-back blade cutting system delivering a beautiful professional finish while improving the quality of your customers lawn.

HRU196

Built tough like the rest of the Honda Buffalo range, the HRU196 Buffalo Pro offers the options of an engine brake and blade brake push mower. Also featuring a 54-litre polymer catcher and 19” cast aluminium deck, the HRU196 Buffalo Pro is powered by a GXV160 four-stroke engine and will handle all environments with its cast-iron bore and ultimate engine durability.

The HRU196 Blade Brake features technology that stops the mower blades within three seconds of the operator releasing the handle, while the engine continues to run. Perfect for safely clearing away any obstacles, emptying the catcher, or taking a quick break without having to restart the engine.

HRU216 Buffalo Pro

The HRU216 Buffalo Pro is the mower of choice for those big jobs! This beauty features a GXV160 four-stroke engine with self-propelled operating three-speed gearbox that allows you to vary the speed as you go, making a massive difference when mowing large lawns. Also featuring the same Blade Blake technology as the HRU196, along with premium power and torque, ensuring you have best-in-market quality.

Best known for its high-quality compact earthmoving and construction machines, Bobcat now has a range of zero-turn mowers. Landscape Contractor Magazine spoke to a couple of very happy new owners.

Bobcat of Australia is offering six zero turns in its current range: the ZT2000, ZT3000, ZT3500, ZT6000, ZT6100 and ZT7000. The first two are offered for residential use while the ZT3500 is marked ‘entry-level commercial’. The last three are commercial.

ZT2000

The ZT2000 is the perfect zero-turn mower for those who want durability and a professional cut at an affordable price. Equipment includes a Kawasaki FR series engine for powerful, pro-grade performance, and innovative HydroGear ZT-2800 hydrostatic transaxles which deliver smooth and simple operation with heavy-duty output torque and ground speeds up to around 11kph.

A 1.5” x 2.5” steel-tubed frame is lightweight and rugged, and the 42”, 48” or 52” TufDeck cutting system has durable, steel-fabricated spindle assemblies to handle the toughest jobs, while a high-backed spring suspension seat keeps the driver comfortable.

An impact-resistant, 3.8-gallon fuel capacity keeps the machine at work.

ZT3000

The ZT3000 has dependable Kawasaki FT series engine matched with a commercialgrade transmission, and Hydro- Gear ZT-3100 hydrostatic transaxles provide reliability and speed to tackle turf faster.

The unit’s constructed with a lightweight, durable, 1.5” x 2.5” steel tubed frame, and the 48”, 52” or 61” TufDeck Pro cutting system features professional-grade, castaluminum or steel-fabricated spindles for maximum durability and high-quality results.

Convenient maintenance and all-day mowing comfort combine with a powerful Kawasaki FX series engine and durable Hydro-Gear ZT-3400 hydrostatic transaxles to give the ZT3500 superior all-day performance.

Other features include:

• Professional-grade, cast-aluminum or steel-fabricated spindle assemblies

• 23” drive tyres

• Optimal user comfort

• Dual fuel tanks, and

• Quick ground speeds.

Mark Hardes spends his weekdays slashing roadsides near Singleton in NSW. On weekends he’s a gun for hire, looking after lawns for some very fastidious property owners. His recent move to a ZT2000 has made a big impact on his lawn-maintenance work.

Is Mark happy with his new Bobcat?

“Mate! I love it,” he grinned.

“The build’s excellent. It’s all solid steel, which I was quite amazed with, ’cos when I first searched online I thought it was a pressed deck. But when I finally went and had a look, it has a fabricated steel deck.”

And it’s not just the quality of the build which impressed Mark.

“It’s knocked that much time off my work,” he continued. “I was using a 48” before I bought this 52” Bobcat, and it was taking between four and five hours to do one lawn.

The Bobcat’s knocked my time down to three hours.”

We pointed out the ZT2000 was a residential mower, but Mark wouldn’t hear about quibbles like that. As far as he’s concerned, the Bobcat is more than capable of doing the work he asks of it.

And not only do the work, but do it well.

“Quite a few of the lawns I do are three- or four-acre lawns. Most of them are manicured. The owners want their lawns looking nice –neat and tidy. The Bobcat leaves no wheel marks on any of their lawns,” he said, clearly in awe.

Mick Duncan’s close proximity to Bobcat dealer Clark Equipment prompted him to drop in and check out the new zero turns when he was shopping for a new mower to

keep his commercial property in good shape. Mike’s work history meant he knew what to look for.

“I went and looked at all the different mowers,” he explained. “I’m an ex-mechanic, so I probably over-analysed everything, but the Bobcats looked really well built. What other brands describe as their commercial spec tends to be entry-level spec on Bobcats. Bobcat’s chassis are a lot bigger and the frames look more solid.

“The other thing I wanted was a machine that had the ROPS on it, and I wanted a machine which could take a sun canopy as well.

“That was actually a bit of a consideration. That, and the 3500 has a serviceable transmission and a commercial motor.”

Is Mike happy with his choice of a ZT3500?

“Honestly, it’s unbelievable.

“Foot-long Kikuyu grass…it just mows through it and chucks it out, no problem.

“The old mower used to throw grass just outside of the chute. Any time you got in the big stuff it’d just block up and stall. I don’t know how many belts and clutches I broke on that thing. But the Bobcat throws grass a couple of metres out!” he said, amazed at the Bobcat’s performance, “And it spreads the clippings really evenly.”

Bobcat’s zero-turn mowers are obviously every bit as good as all the machinery in the Bobcat range. For lawn-care professionals and property-maintenance contractors that means excellent ROI.

Find out more about entire Bobcat range at bobcatofaustralia.com.au.

Zero exhaust emissions and notably reduced noise levels make the L25 Electric a perfect choice for within natural or sensitive surroundings. Images: Volvo CE

Volvo Construction Equipment has stepped up its focus towards sustainability and environmental responsibility.

The L25 wheel loader is a five-tonne wheel loader featuring a 40kWh, Lithium-ion 48V battery. This innovative power source underscores Volvo’s commitment to environmental sustainability and elevates operational efficiency.

“The L25 employs a dual electric motor concept for optimal energy efficiency,” explained Reid Gibson, Product Manager – Electric and Sustainable Technologies at CJD Equipment. “One electric motor is exclusively allocated for the working hydraulics and steering, with a peak power

of 32kW. Meanwhile, the second electric motor is dedicated solely to the driveline, directly linked to the rear axle via the gearbox.

“This configuration guarantees peak efficiency in the drivetrain, with the electric motor in the driveline delivering a maximum power of 36kW.”

The L25 is well-suited for transporting substantial loads or materials, featuring a 1.2m3 standard bucket, forklift, grapple,

or material handling arm. Its zero exhaust emissions and notably reduced noise levels make it a perfect choice for tasks near livestock or within natural surroundings.

“Due to the machine’s zero emissions, the L25 also operates seamlessly in indoor environments and emission-restricted zones, giving operators a choice for a cleaner, quieter work environment,” said Reid.

Its compact design further enhances its versatility, making it perfect for navigating confined, narrow spaces, and the L25

supports various Volvo attachments, providing adaptability for multiple tasks.

“The Volvo L25 also comes with a twoyear/2000-hour warranty with genuine Volvo parts, and the battery and electric components are covered for five years or 5000 hours, whichever occurs first,” added Reid.

The powertrain design of the L25 electric model imparts superior responsiveness and controllability compared to traditional diesel machines. Propelled by the electric motor intricately linked to the gearbox and rear axle, the electric system facilitates instantaneous torque control. This feature enables the loader to achieve maximum power output without the delay associated with waiting for RPM to build.

Furthermore, the electric powertrain is inherently more straightforward than its diesel counterpart. Characterised by fewer moving parts and a transmission system that efficiently modulates power and torque, this streamlined design translates to a more rapid and direct response. The reduction in transmission lag and throttle-response time enhances operational efficiency and elevates overall performance.

With impressive high lifting and breakout forces and superior roll-back and dump angles, the L25 electric loader stands out as an ideal machine for various bucket applications.

With impressive high lifting and breakout forces and superior roll-back and dump angles, the L25 electric loader stands out as an ideal machine for various bucket applications. Its robust, rigid planetary axles, featuring 100 per cent mechanical differential locks on both front and rear axles, offer maximum traction and contribute to minimal tyre wear.

Further augmenting its off-road capabilities and stability is the articulatingoscillating centre joint, making the L25 electric loader exceptionally well-suited for navigating confined and narrow spaces. This combination of features positions the L25 electric loader as a versatile and high-performing solution across various applications.

Streamlined maintenance

The maintenance of Volvo electric machinery is a primary advantage attributable to the inherently maintenancefree nature of the machine’s electrical components, batteries, and motors. In the case of the L25 Electric, its fully electric driveline significantly reduces the use of hydraulic oil by half, eliminating the necessity for engine maintenance.

traditional engines, such as engine oil, oil filters, and diesel particulate filters.

“Across the Volvo electric range, there is a significant reduction in maintenance costs vs diesel equivalent models. The Volvo L25 Electric Wheel Loader distinguishes itself with easily accessible lubrication and

explained Reid.

To facilitate machine monitoring, a new and improved Human-Machine Interface (HMI) has been implemented, allowing operators to navigate seamlessly through machine information and settings. These advancements underscore L25 Electric’s

commitment to streamlined operations and reduced maintenance demands.

The Volvo L25 Electric has a 40kWh LithiumIon 48V battery and an onboard charging system using a Type 2 automotive standard inlet.

The L25 onboard charger provides efficient charging capabilities. This charger comes with a charging cable, plug, and adapters,

ensuring seamless integration into various charging setups. With these charging accessories, operators can easily maintain the machine’s power levels, enhancing productivity on the job site.

“The onboard charge enables the machine to charge from 0 to 100 per cent in under six hours,” stated Reid.

The battery in the L25 loader allows fast charging at any State Of Charge (SOC), and it is theft-protected. It can charge from a wall

socket or wall box, and for applications requiring faster charging, optional fast offboard chargers are available for indoor and outdoor use.

Introducing Volvo’s electric motors in the L25 marks a significant shift in operational dynamics, notably in noise reduction and enhanced comfort. According to Reid, electric motors significantly reduce noise levels compared to traditional diesel engines. This improvement is complimented by a revamped hydraulic pump and the relocation of the main control valve, collectively contributing to a quieter operational environment.

Reid noted, “The reduced noise levels allow for easier communication on worksites and lead to a more comfortable and safe work environment.”

Moreover, the transition to electric power offers additional benefits beyond noise reduction. Notably, the absence of diesel engines reduces vibrations, addressing operator-fatigue concerns, particularly during extended operating periods.

Additionally, integrating innovative features such as the electric park brake with hill-hold functionality demonstrates Volvo’s dedication to advancing safety standards, particularly in challenging terrain.

The introduction of the Electric Machine Management App further augments operational efficiency by providing real-time insights into charging status, battery level and machine location.

In an era where reducing carbon footprints and embracing clean-energy solutions are paramount, Volvo’s innovative electric wheel loader emerges, setting new standards for efficiency, performance, and environmental stewardship.

For many years, CJD Equipment and Volvo CE have been supplying premium construction equipment tailored to the specific needs of Australia’s diverse industries. Their collaboration over 30 years has ensured the delivery of high productivity, fuel efficiency, and safety solutions, enabling machines to operate at peak performance.

CJD Equipment boasts an extensive national support network, guaranteeing comprehensive assistance regardless of location or time. For further details, please reach out to your local CJD branch at 1300 139 804 or visit cjd.com.au.

Unleash the future of farming with the revolutionary L25 Electric compact wheel loader from Volvo.

Zero exhaust emissions from use

Significantly lower noise levels

The Volvo L25 Electric delivers all the performance you would expect from a wheel loader in this size class, but with less noise and zero emissions. The integrated on-board charger allows the machine to charge from 0 to 100% in under 6 hours. Fast charging solutions are also available for both indoor and outdoor use.

Reduced energy costs

Premium warranty coverage

Hitachi’s commitment to delivering reliable and durable machines is evident in the robust ZW80-5B. Image: Hitachi CM

Designed and built with an emphasis on the environment, operator comfort and safety, the ZW80-5B wheel

loaders have been developed to perfection.

Hitachi Construction Machinery Australia Pty Ltd (HCA) has added a compact ZW80-5B wheel loader to its fleet.

“The strategic decision to introduce the compact ZW80-5B to the Australian market was driven by a thorough analysis of the evolving needs within the landscaping, agricultural and construction industries. Recognising the demand for a versatile and efficient solution, we aimed to provide customers with a compact yet powerful option,” stated David Gallina, HCA’s Product Manager of Wheel Loaders and BELL equipment.

Weighing in at 5465kgs, the ZW80 starts off strong with a robust 2.9lt diesel engine and hydrostatic drive, featuring a standard manually locking differential. Equipped to handle a Hook-On 0.9m3 GP bucket, the ZW80-5B boasts a 36.8kN breakout force,

ensuring the strength to efficiently scoop full loads. Additionally, with a top speed of 34kmph, it offers the speed required to move these loads swiftly.

With operator comfort and safety at the forefront, the ZW80 is equipped with a floor-to-ceiling tinted-glass front window, providing a 360° unobstructed view to the rear, along with LED working lights (front and rear). Sliding side windows and lock-back doors enable flow-through air ventilation, ensuring both the machine and the operator can maintain maximum productivity throughout the year.

The walk-through design provides convenient access from either the right or left, featuring safety handrails and large steps mounted on both sides. Daily maintenance is simplified with the wide-open engine cover and low-profile

counterweight. With a sound-insulated design, low-noise engine, and rubbermounted enclosure frame and hydraulics, it creates a secure and quiet work environment.

The loader’s adjustable suspension seat cushions against shocks and vibrations while providing an extra-wide seatbelt that adjusts for an exceptionally comfortable fit.

An oscillating axle allows handling irregular terrain and ensures a smooth ride and stable load-carrying capability, while a wrap-around counterweight creates a low centre of gravity, enhancing stability during both loading and travel.

Hitachi’s commitment to delivering reliable and durable machines is evident in the robust support structures and the use of large pins and bearings in the ZW80’s centre-pin area. The side-by-side

arrangement of the aluminium radiator and oil cooler allows for convenient access during routine maintenance and cleaning.

The HST control system facilitates easy manoeuvring between work modes and ensures a seamless transition between speed changes, providing smooth startups on slopes and excellent traction across all speed ranges.

The new auto-mode feature automatically engages and disengages the engine based on the machine’s travel speed, preventing unnecessary pitching and saving fuel. This is especially helpful during lighter work when frequent on-and-off cycles occur. The new Eco Mode reduces engine RPMs when full power is not required.

The ZW80 is the smallest machine in Hitachi’s wheel loader line to incorporate Eco Mode, cutting fuel consumption by approximately 10 per cent when full power is not necessary.

The ZW80’s controls incorporate a comprehensive set of audible and visual service alerts. The differential-lock switch is conveniently located alongside the

joystick, offering easy access to a power boost on demand. While the inching pedal enables the machine to decelerate while keeping the engine at higher RPMs and ensures positive braking at the bottom of the pedal stroke.

Tailored for demanding environments, the ZW80 is built with a focus on robust performance, making it well-suited for the challenges encountered in agricultural, landscaping, and construction industries. Equipped with a hook-type quick coupler as a standard feature, it enables effortless attachment switching directly from the cab. This functionality facilitates swift and smooth replacement of various working tools and buckets, enhancing efficiency in tasks across diverse applications.

In addition to providing adaptability across a range of industries, the ZW80 demonstrates HCA’s dedication to delivering innovative and personalised solutions to customers throughout diverse sectors in Australia. The Hitachi ZW80 ensures you receive all the essential features of a compact wheel loader and more!

Visit hitachicm.com.au for further details or call your nearest Hitachi dealer to organise a test drive today; 1300HITACHI.

Anything but ordinary.

Images: Wacker Neuson

Built to outlast, outwork and outdo

Wacker Neuson has a range of mini loaders, skid steers and compact track loaders that are the ideal fit for a variety of applications.

Today’s generation of Wacker Neuson mini loaders, skid steer and compact track loaders is anything but ordinary.

Designed and engineered to handle the tough stuff, these machines will exceed your expectations. All machines offer the latest in design and industry-leading service accessibility.

If you need to lift material to greater heights, the vertical-lift units give you a competitive edge when loading trucks and material bins. Our class-leading hinge pin height on vertical lift units offers maximum loading and unloading capabilities. The variable-speed cooling fan increases efficiency, improves fuel economy and assists in cold starts. An intuitively designed, high-visibility

cabin includes angled pedals and foot bed. In addition, conveniently located switches help reduce operator fatigue. A wide door offers easy access with no restrictive lap bar. Controls ensure operators with a variety of machine experience can efficiently work with the loaders. The best service access is provided with a cabin that fully tips forward with the arms down.

Versatility comes standard with every Wacker Neuson loader. The universal skidsteer attachment plate enables attachments to be switched out easily, accomplishing more in less time. Category-leading hydraulic horsepower is standard.

Wacker Neuson has created a cabin environment with operator comfort and convenience in mind. Access in and out

is easy, with the medium frame range there’s no restrictive lap bar and controls are intuitively placed. Selectable ElectricHydraulic options (ISO/H-Pattern) on certain models ensure operators with a variety of experience can efficiently operate these machines. Additionally, these machines offer the only one-piece pod-style cab that fully tilts forward with arms down, providing complete access to all maintenance components.

Wacker Neuson’s compact track loaders (ST models) include a selection of engine horsepower and radial or vertical lift machines. The Wacker Neuson range of compact track loaders and skid steer loaders need to be seen to believe how good they are.

Has the power and performance to take on the toughest jobs. Powered by 55kW regeneration-free T4F engine, and available with High Flow hydraulics, the SW21 maximises the performance of your hydraulic attachments.

auxiliary flow for improved performance with high-flow attachment applications like cold planning and brush clearing. Contact your local dealer for specific products and services for your landscaping or construction requirements.

Scan the QR code to view the full range of Wacker Neuson products

COMPACT TRACK LOADER ST31

Matches the compact size of a medium frame with lift capacity of larger loaders. The vertical lift arm, 3.2-metre lift height and 55kW regeneration-free engine make the ST31 an accomplished material

COMPACT TRACK LOADER ST11